Mechanical-hydraulic double-acting release rotary tail pipe hanger

A liner hanger, double-acting technology, used in wellbore/well components, sealing/packaging, earth-moving drilling, etc. Well quality and the effect of improving displacement efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

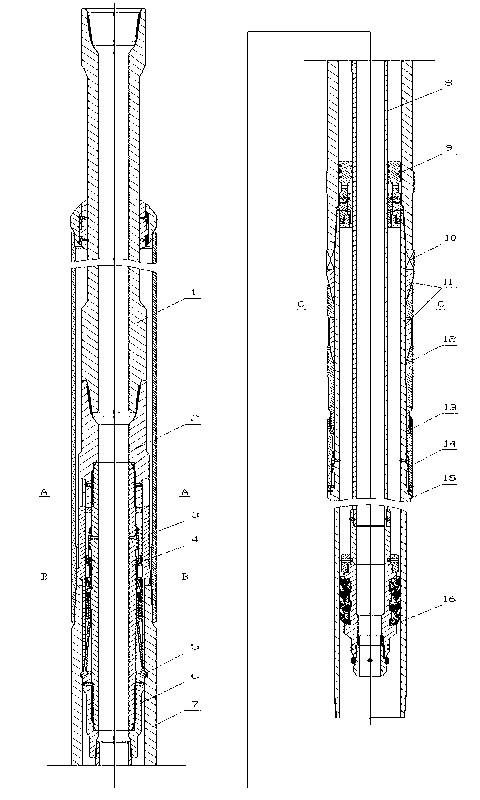

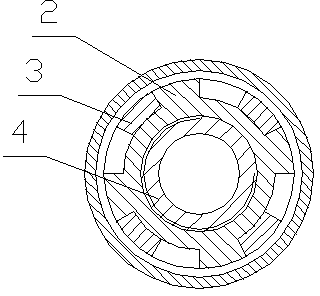

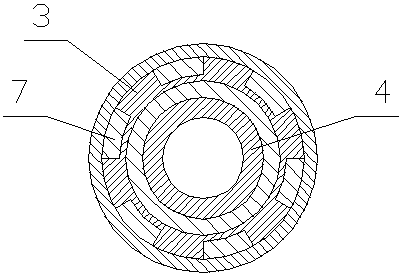

[0038] As a preferred embodiment of the present invention, the present invention mainly includes a short drill pipe 1, an upper joint 2, a torque cylinder 3, a double male joint 4, a claw block 5, a lower joint 6, a male and female joint 7, and a hand-discharging mechanism , sealing box 9, hollow rubber plug 16 and carrying mechanism. Wherein, the airtight box and the hand-losing mechanism can adopt the airtight box and the hand-losing mechanism in the prior art.

[0039] The upper joint 2 is engaged with the meshing teeth on the upper end of the torque cylinder 3 through the spline shaft, and the torque cylinder 3 is engaged with the meshing teeth on the upper end of the male and female joints 7 through the spline shaft, and the claw block 5 is fitted through the lower joint 6 The support is stuck in the inner groove of the male and female joints 7, and the sitting and hanging liquid cylinder 14, light-load bearing 13, conjoined double slips 12, conjoined double-cone 11, and he...

Embodiment 2

[0043] As the best embodiment of the present invention: the present invention mainly includes a short drill pipe 1, an upper joint 2, a torque cylinder 3, a double male joint 4, a claw block 5, a lower joint 6, a male and female joint 7, and a heavy-duty bearing 10. Conjoined double cone 11, conjoined double slips 12, sitting and hanging liquid cylinder 14, center pipe 15 and hollow rubber plug 16. The upper end of the short drill pipe 1 is provided with a drill pipe female thread to realize the connection with the drill pipe, and the lower end of the hanger is provided with a casing male thread to realize the connection with the liner. The claw block 5 is supported and stuck in the inner groove of the male and female joints 7 through the tapered surface support on the upper end of the lower joint 6, so as to realize carrying the tail pipe. The spline shaft on the upper joint 2 engages with the meshing teeth provided on the upper end of the torque cylinder 3, and the spline sh...

Embodiment 3

[0048] In yet another embodiment of the present invention, the hands-free cylinder 18 is arranged on the double male joint 4, and a cavity is left on the upper part, and the claw 21 is connected to the hands-free cylinder 18 through a connection mechanism and a hands-free control pin 19. The lower part of the elastic claw 21 is provided with an outward elastic claw block 5, and the elastic claw block 5 is supported in the groove of the male and female joint 7 through the conical surface support at the upper end of the lower joint 6, and the upper joint 2 passes through the flower. The key shaft is engaged with the meshing teeth at the upper end of the torque cylinder 3, and the meshing teeth at the lower end of the torque cylinder 3 are engaged with the meshing teeth at the upper end of the male and female joints 7. The conjoined double cone 11 and the conjoined double slips 12 are inserted into the Fitted together, the sitting and hanging liquid cylinder 14, light-load bearing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com