Expansion-type rotatable tail pipe hanger

A liner hanger and hanger technology, which is applied in wellbore/well parts, earthwork drilling, sealing/isolation, etc., can solve the complex structure of slip-type liner hanger, many construction safety hazards, and cementing problems. Quality is difficult to guarantee and other issues, to achieve the effect of improving the success rate of downloading, saving materials, and fewer parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

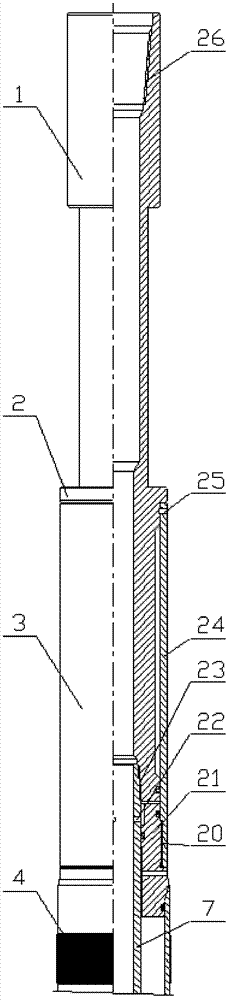

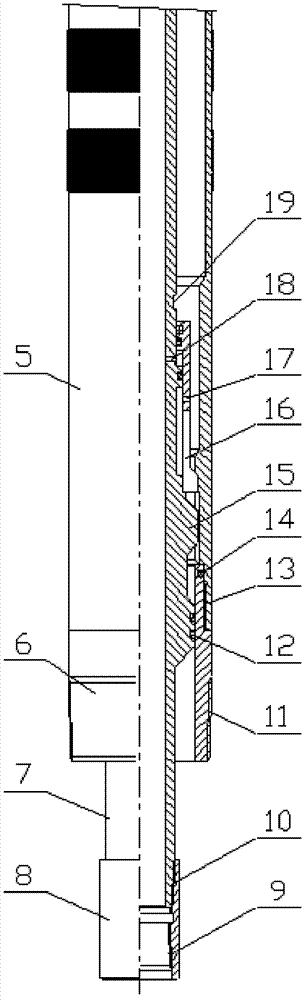

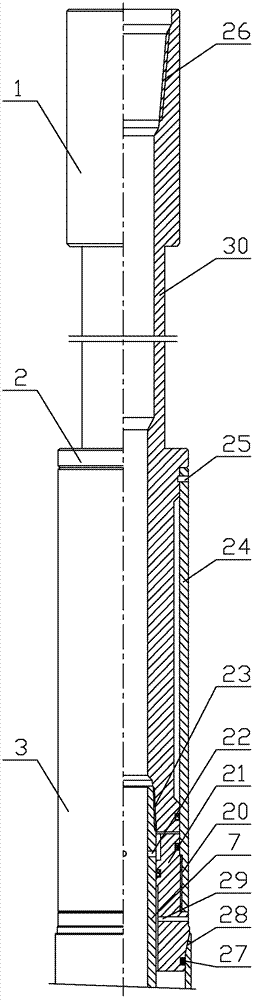

[0056] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0057] As shown in Figure 1, the lifting nipple 1, the central pipe 7 and the rubber plug nipple 8 are sequentially connected in series to form the assembly base of the hanger, wherein the upper end of the central pipe 7 is sleeved on the upper thread 23 on the outer surface. Inside the lower end of the lifting sub-joint 1, the lower end of the center pipe 7 is sleeved inside the upper end of the rubber plug sub-joint 8 through the lower thread 10 on the outer surface; the inner surface of the lower end of the rubber plug sub-joint 8 is designed with a rubber plug thread 9 for connecting Tail pipe rubber plug 40.

[0058] The expansion cone 21, the hanger body 5 and the conversion joint 6 are sequentially sleeved outside the central tube 7 between the lifting sub-joint 1 and the rubber plug sub-joint 8, that is, under the lifting sub-joint 1, the central tube...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com