Patents

Literature

923results about How to "Uniform stress distribution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

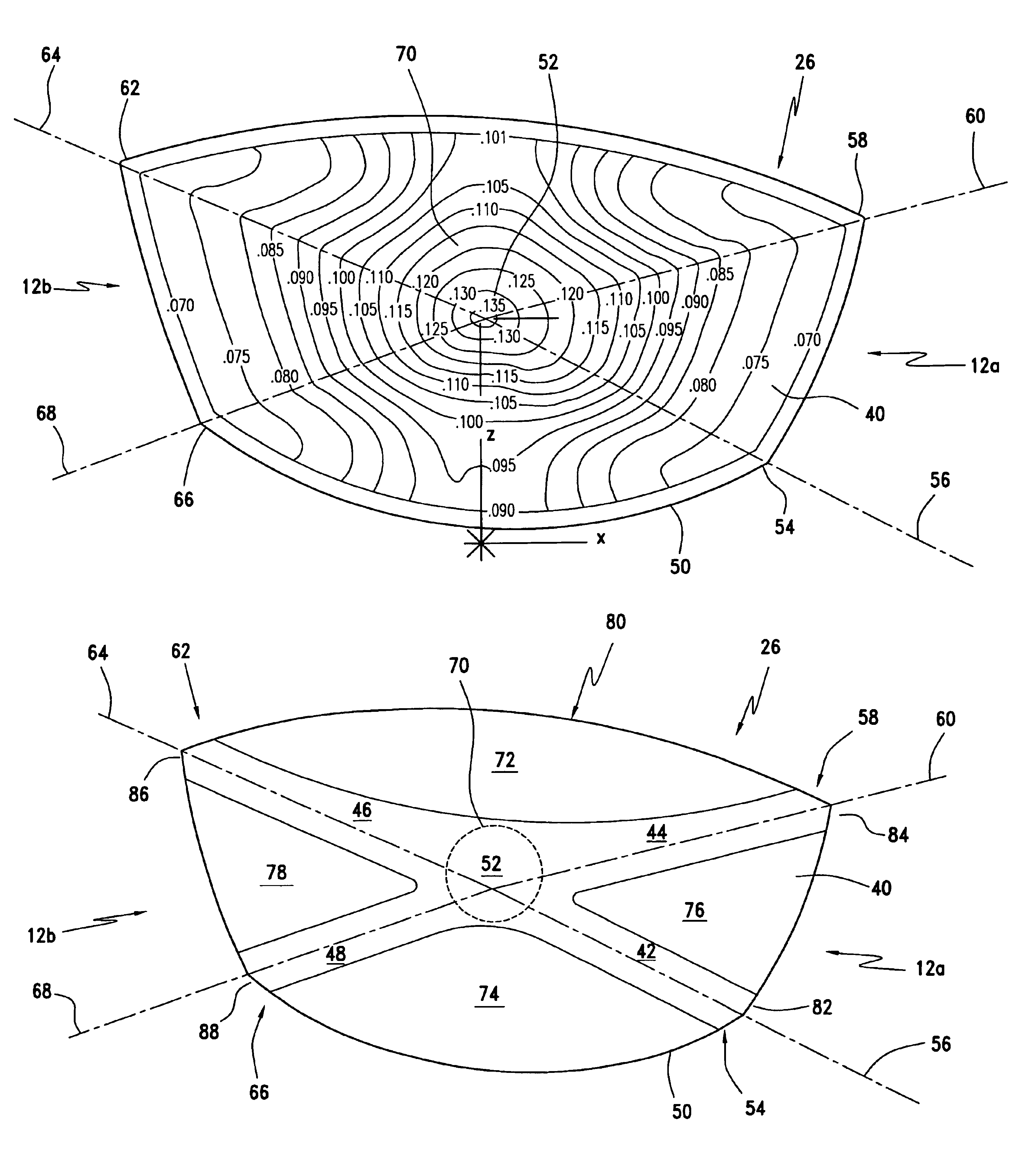

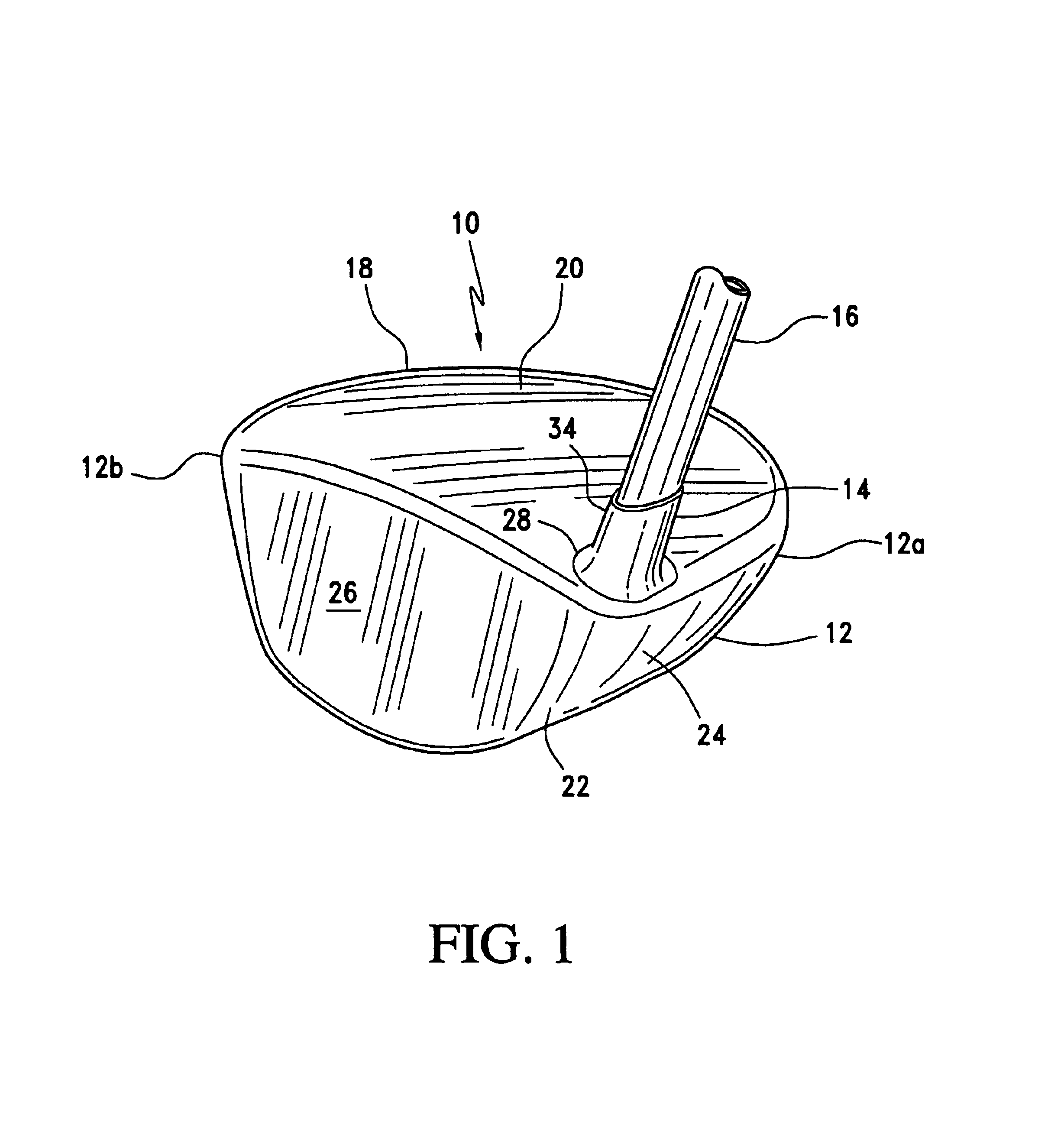

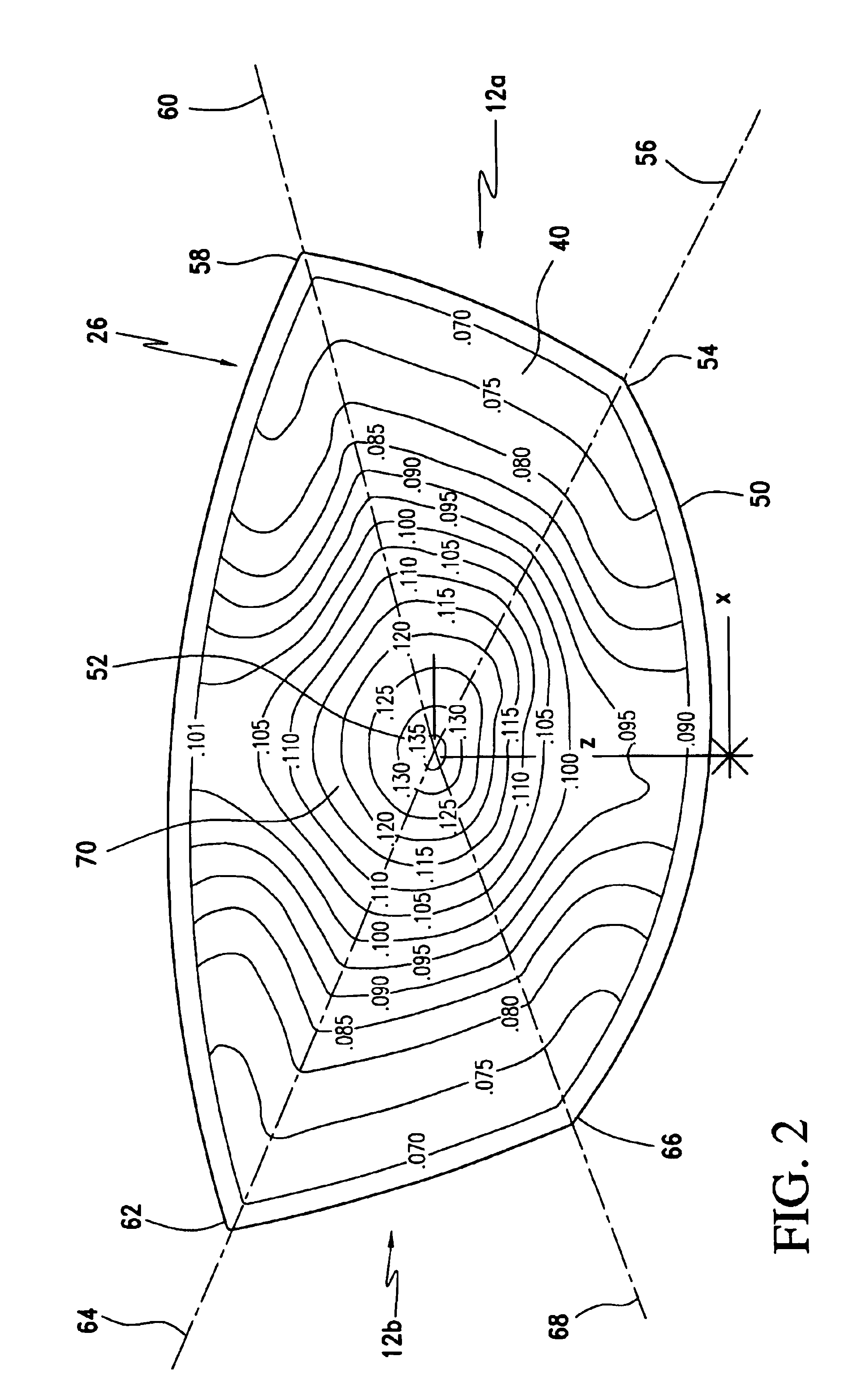

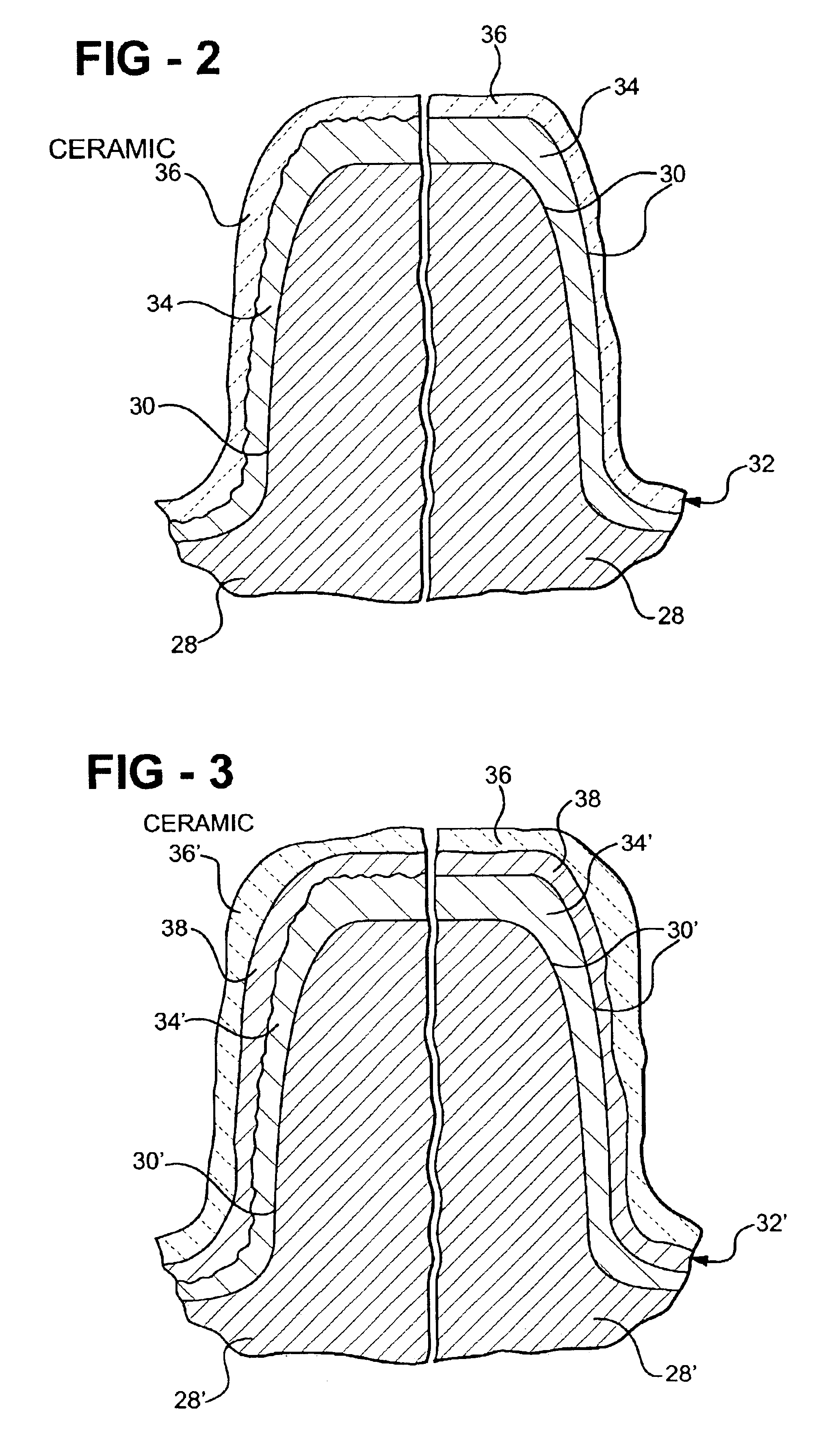

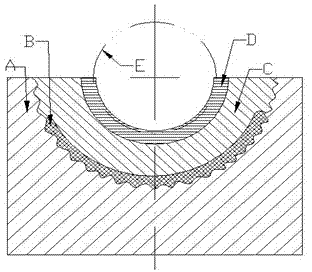

Golf club with diagonally reinforced contoured front wall

InactiveUS6926618B2Convenient lengthEfficient transferGolf clubsRacket sportsStress distributionFour quadrants

A golf club head composed of a forged metal material has a striking surface that is supported by diagonal stiffening regions that extend from a central region of the face toward the heel-sole quadrant, heel-crown quadrant, toe-crown quadrant, and toe-sole quadrants of the face. The diagonal stiffening regions are smoothly contoured to blend into the back surface of the face so as to avoid any stress concentrations. By extending the stiffening regions diagonally from the center of the club face to the four quadrants, a more uniform stress distribution can be obtained and therefore more uniform performance. Additionally, since the diagonal stiffening regions are greater in length than vertical or horizontal stiffening region could be made, the center of the face can deflect a greater amount without exceeding the yield strength of the material and, therefore, there is a more efficient transfer of energy from the club head to the ball.

Owner:KARSTEN MFG CORP

Micron nano material composite modified water-based adhesive

InactiveCN101210157ALow shrinkageImprove performanceMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesMicro nanoExtensibility

The invention relates to an aqueous binder which is compounded and modified by micro nano material. The modified aqueous binder of the invention adopts emulsion adhesive as matrix and micro-size and nano-size inorganic powder as modifier to prepare the compound and modified aqueous binder. The method of the invention can not only enhance the interface binding force of the aqueous binder, but also greatly improve the properties of water resistance, toughness and extensibility, leading comprehensive performance of the aqueous binder to be improved.

Owner:郑旷宇

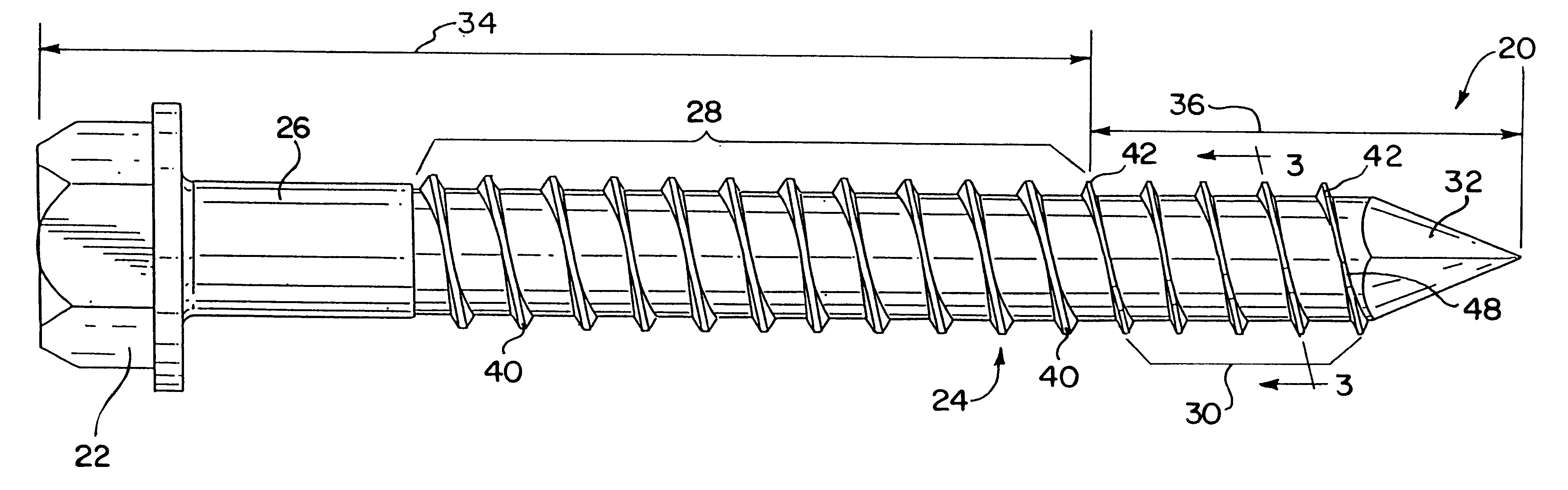

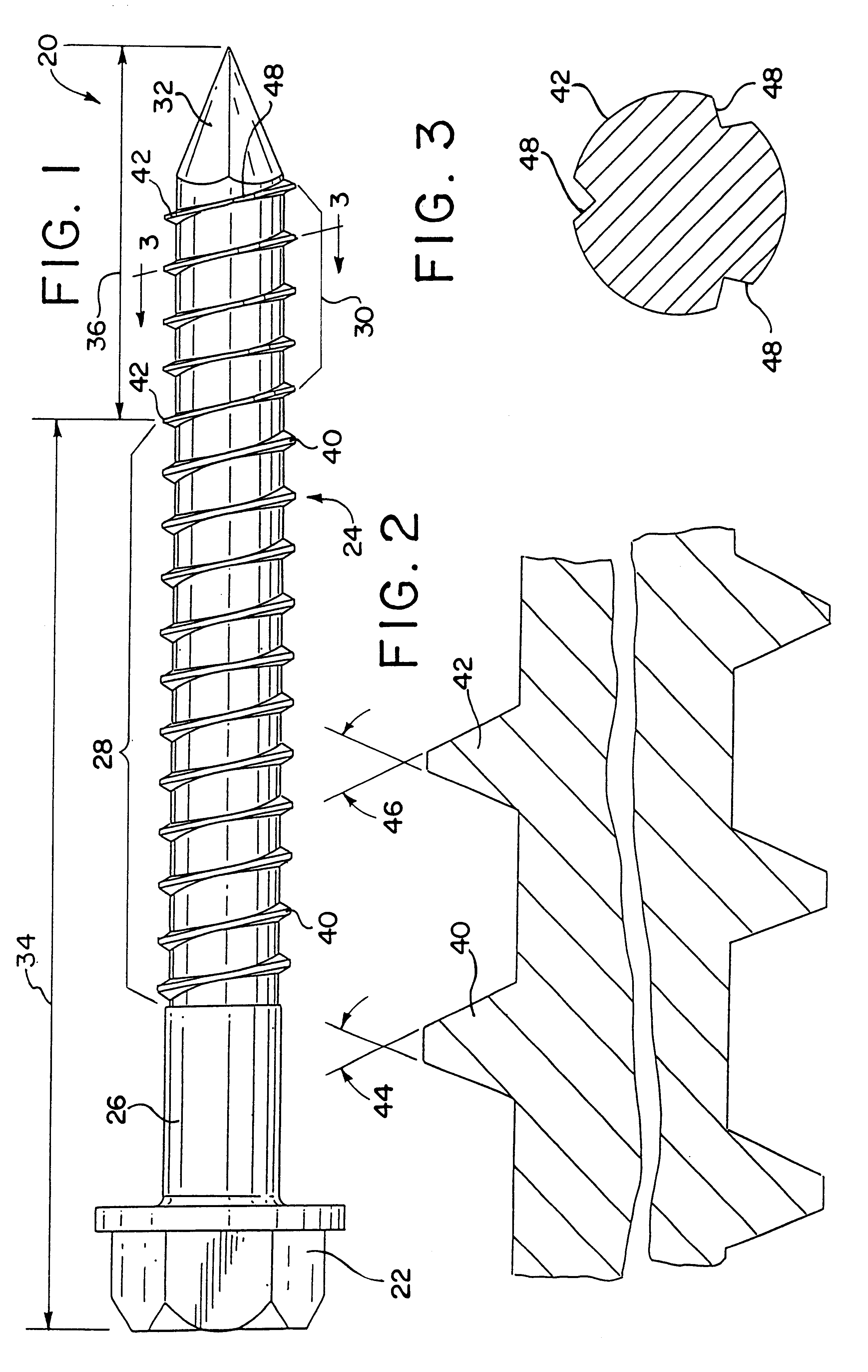

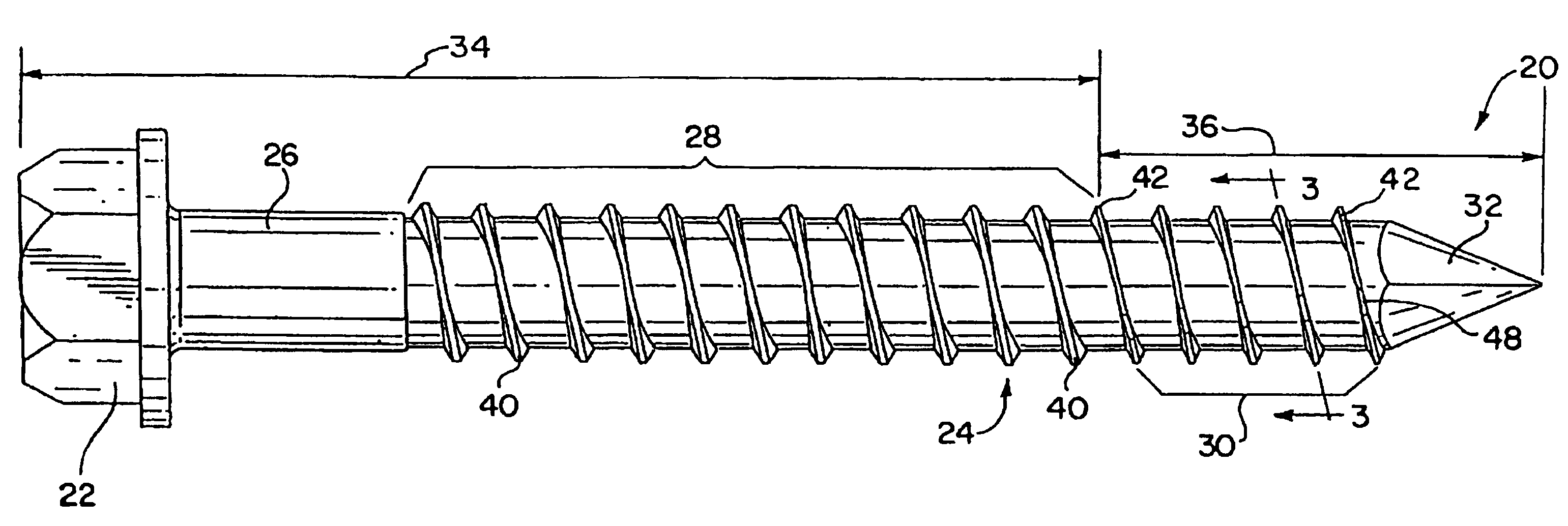

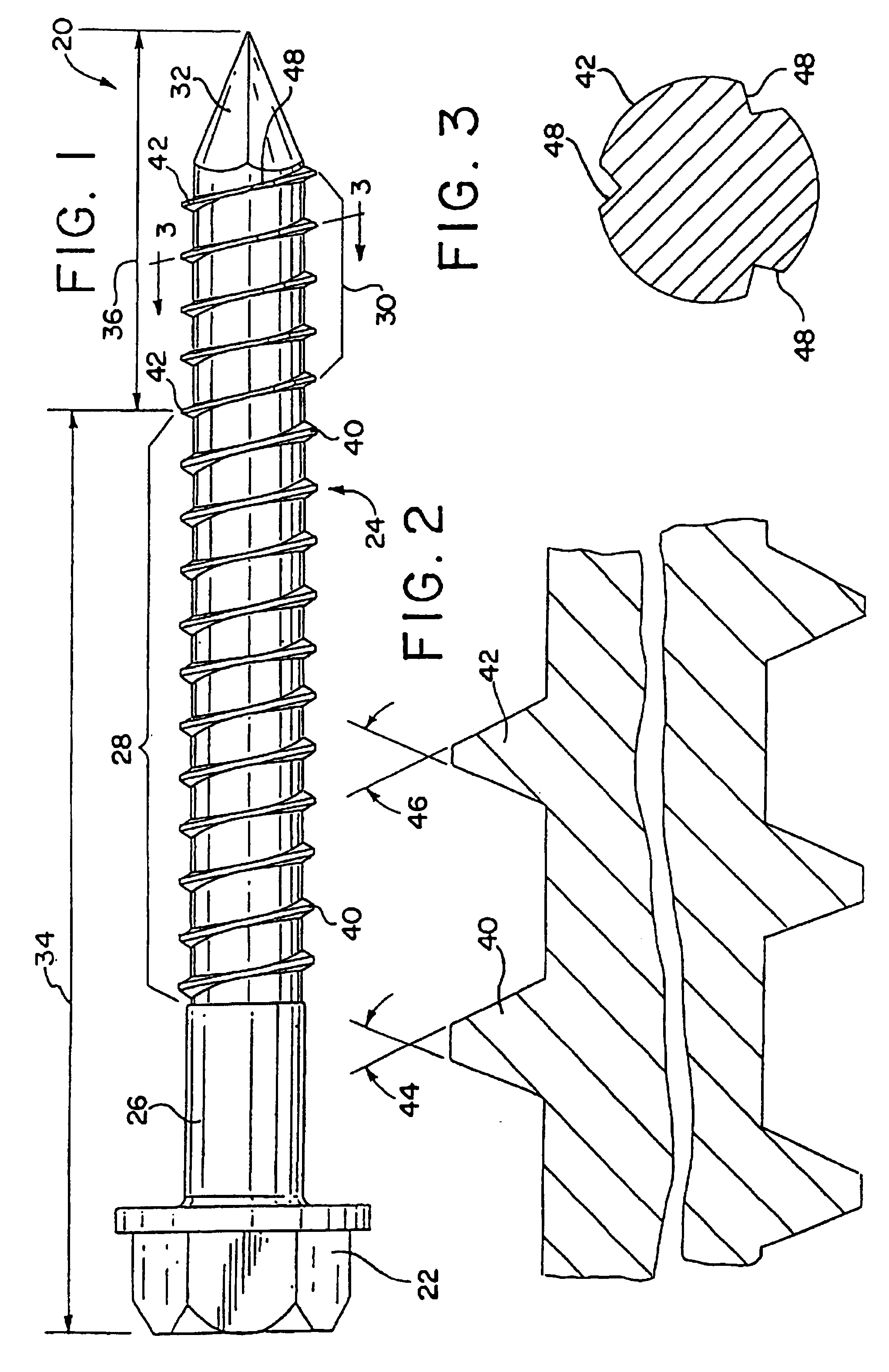

Masonry anchor device

An improved anchor device or fastening member which is particularly suited for use in the attachment of various fixtures and equipment to masonry, concrete, and other hard and / or friable substrates includes a head and a shank depending therefrom. The shank has a first threaded portion having a predetermined thread angle and a predetermined hardness, and a second threaded portion having a predetermined thread angle and a predetermined hardness. The first threaded portion is proximate to the head and the second threaded portion extends from the first threaded portion. The thread angle of the first threaded portion is different than the thread angle of the second threaded portion. In addition, the hardness of the first threaded portion is softer than the hardness of the second threaded portion. This provides for a more ductile anchorage when the fastening member is engaged with the substrate.

Owner:ASIA FASTENING US

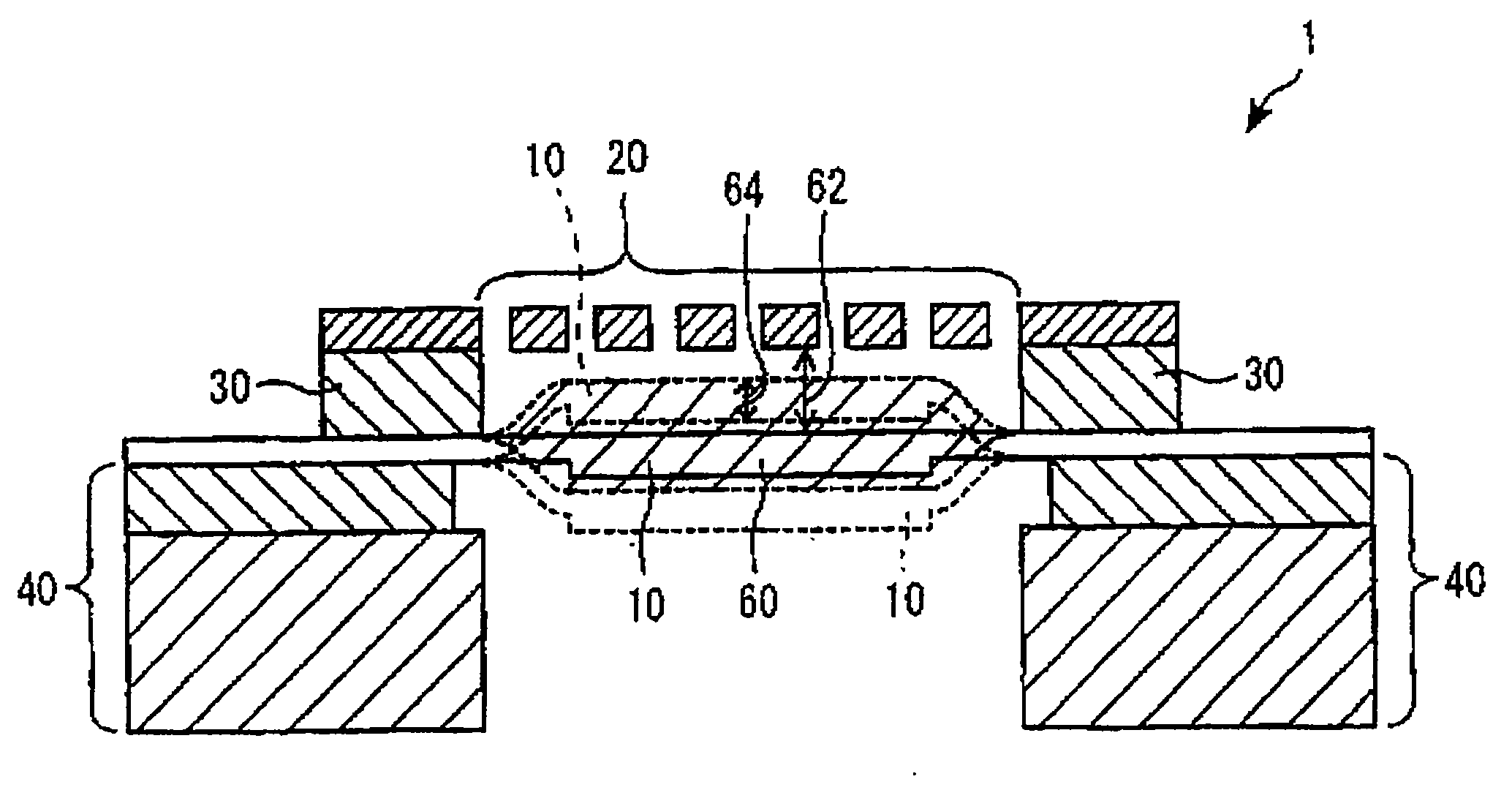

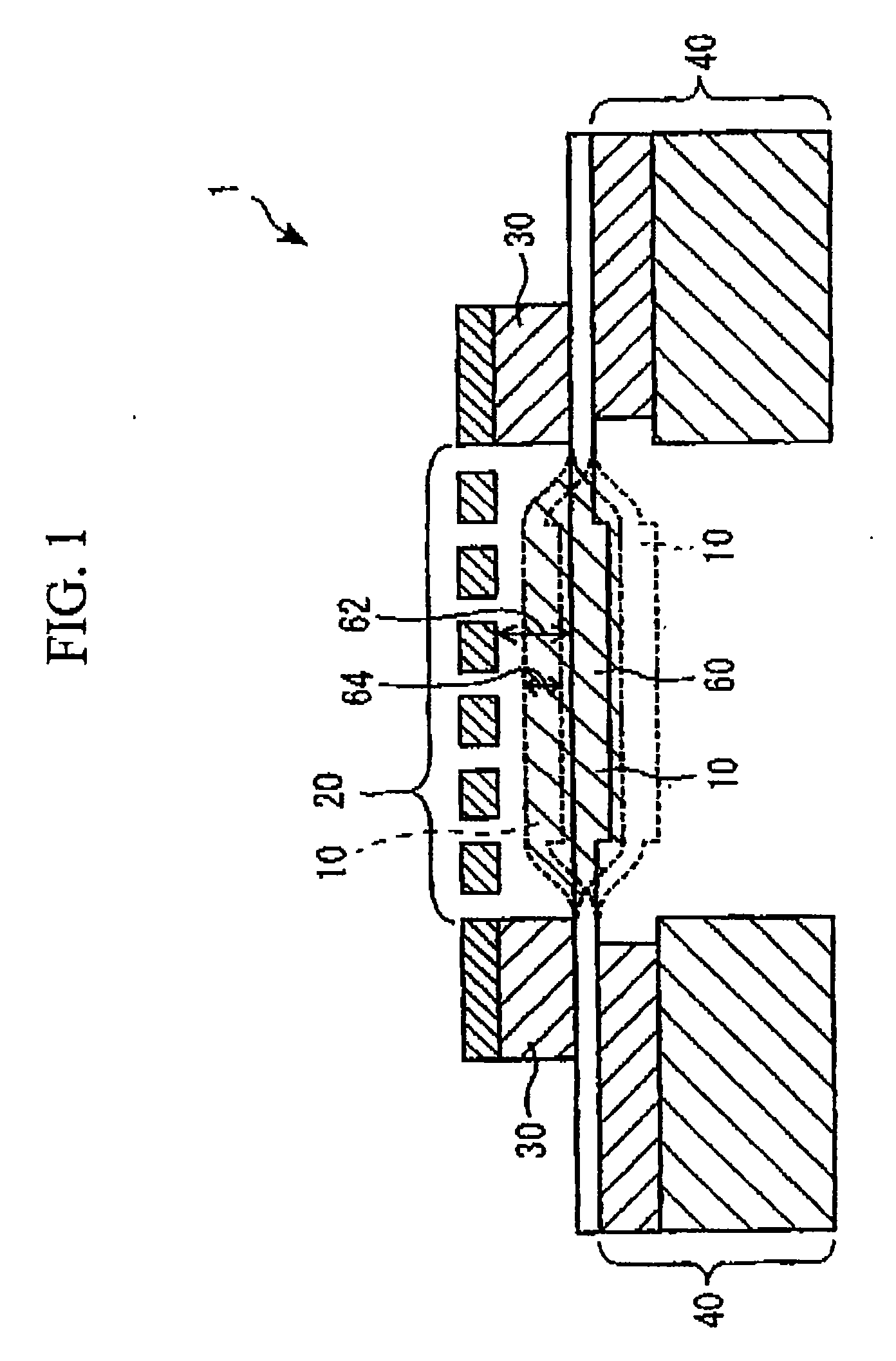

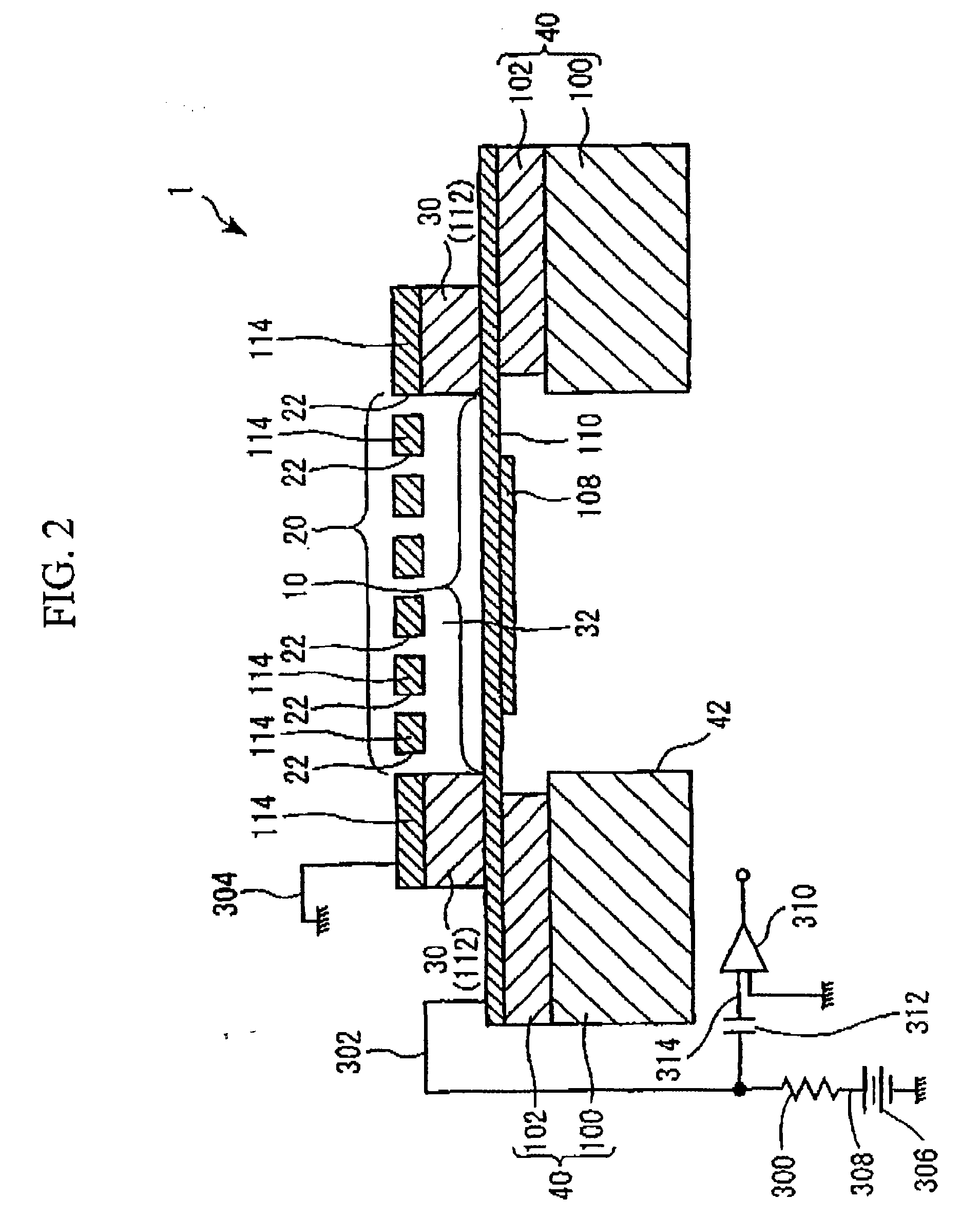

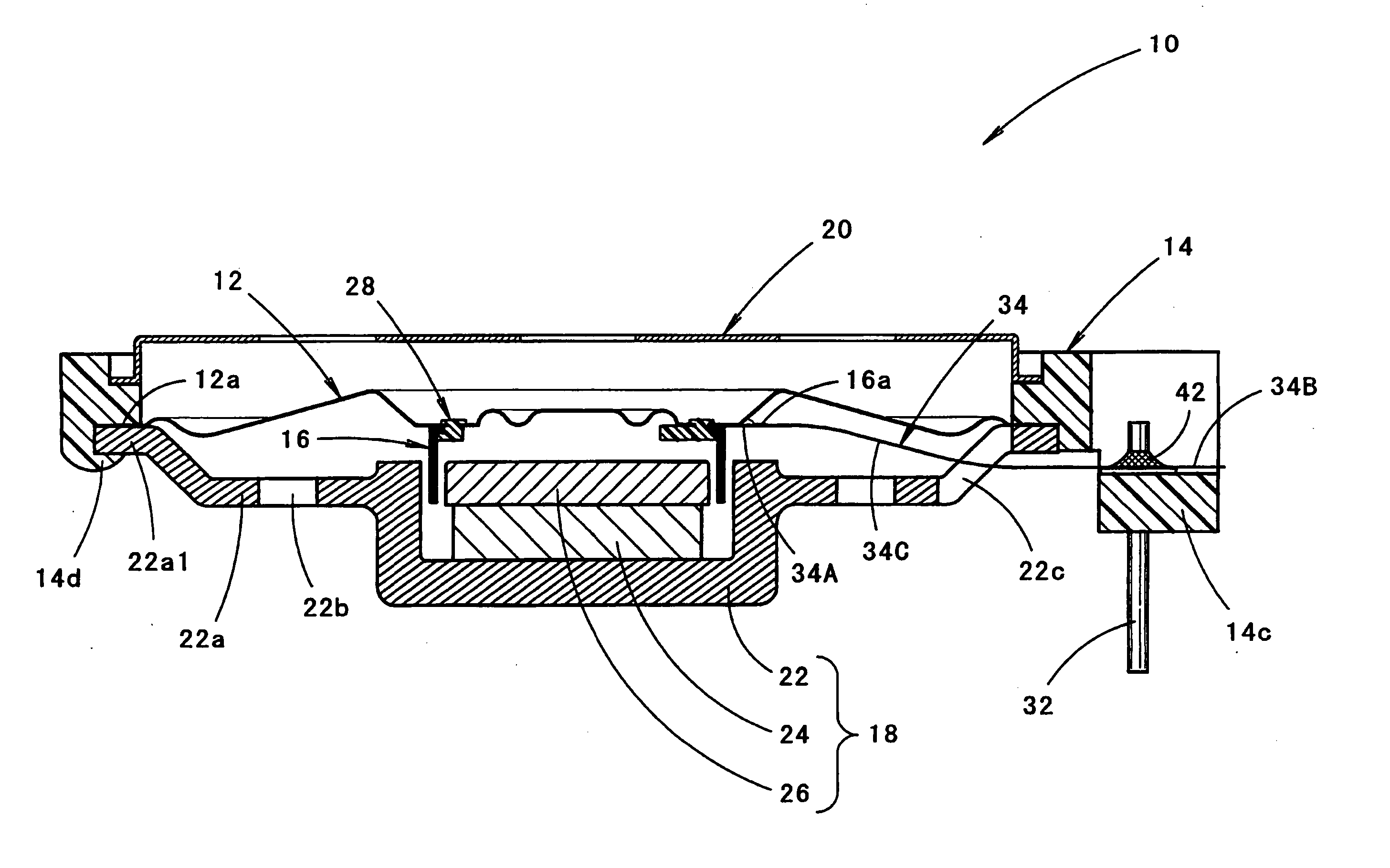

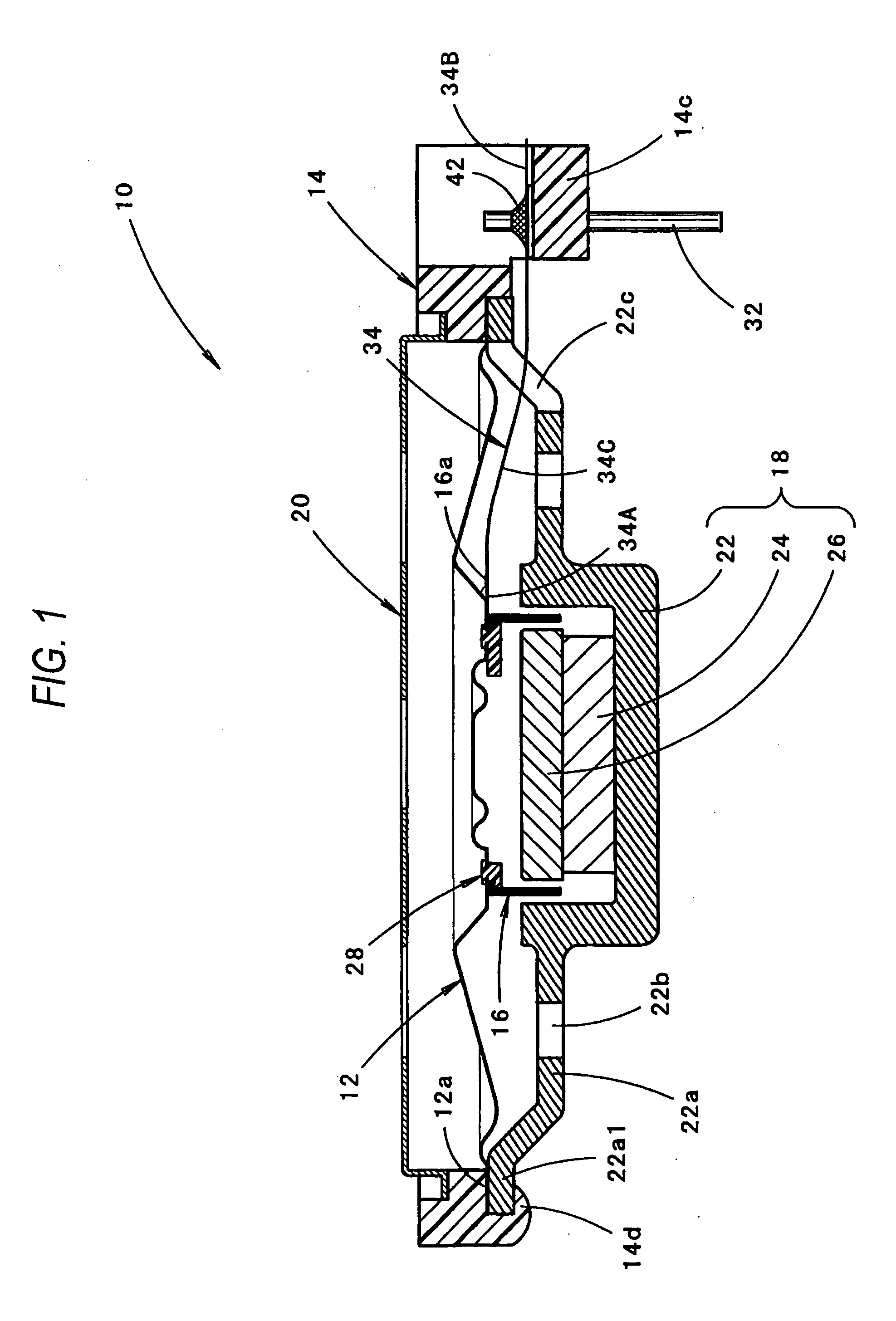

Capacitor microphone

InactiveUS20070058825A1Uniform stress distributionDegree of improvementPiezoelectric/electrostrictive microphonesSemiconductor electrostatic transducersCapacitanceEngineering

A capacitor microphone is constituted by a plate having a fixed electrode, a diaphragm including a center portion and at least one near-end portion that is fixed to the outer periphery, in which the center portion having a vibrating electrode, which is positioned relative to the fixed electrode and which vibrates in response to sound waves, is increased in rigidity in comparison with the near-end portion; and a spacer that is fixed to the plate and the near-end portion of the diaphragm and that has an air gap formed between the plate and the diaphragm. Alternatively, a diaphragm electrode is horizontally supported by extension arms extended from a circular plate thereof and is vertically held in a hanging state being apart from a fixed electrode with a controlled distance therebetween.

Owner:YAMAHA CORP

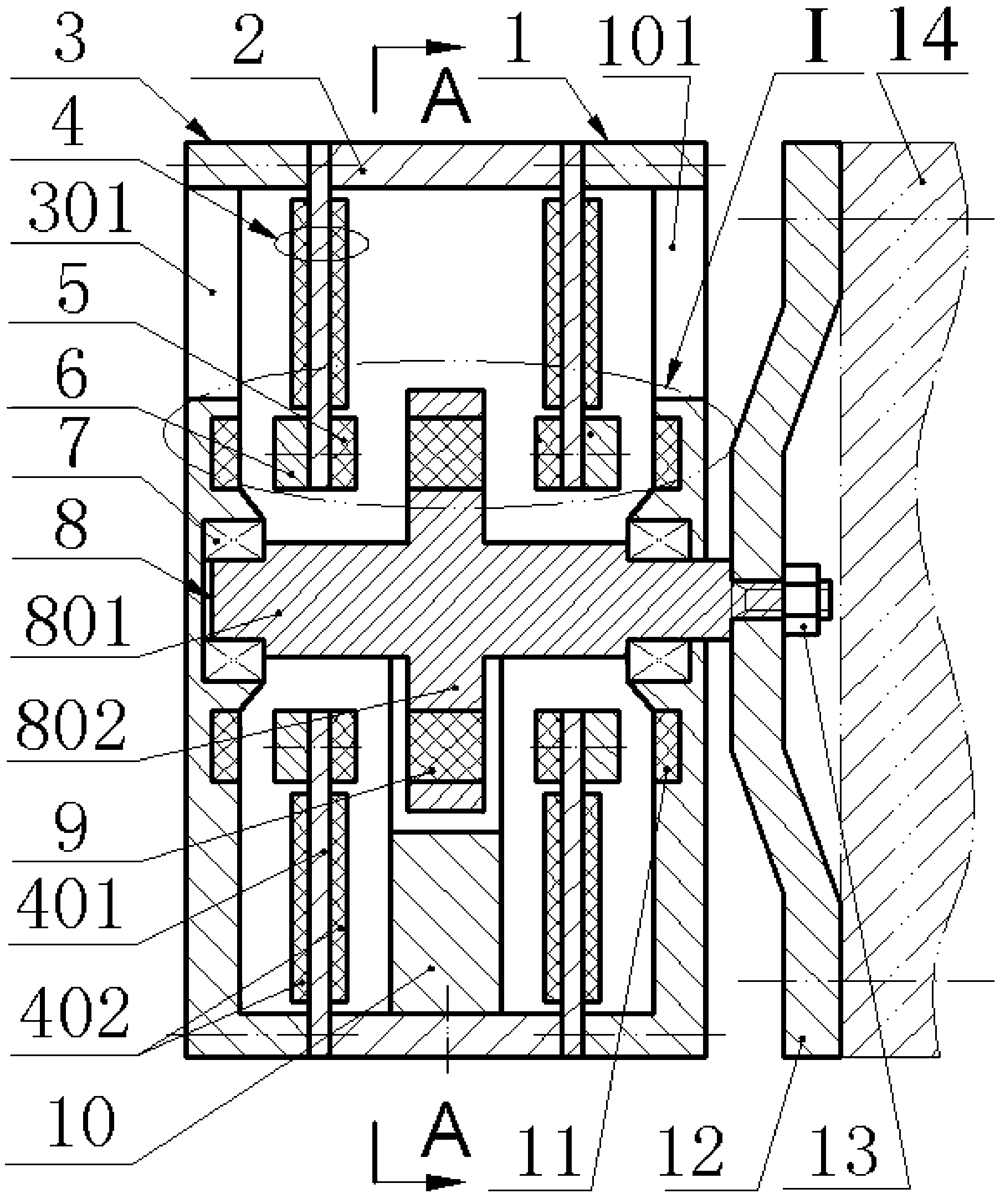

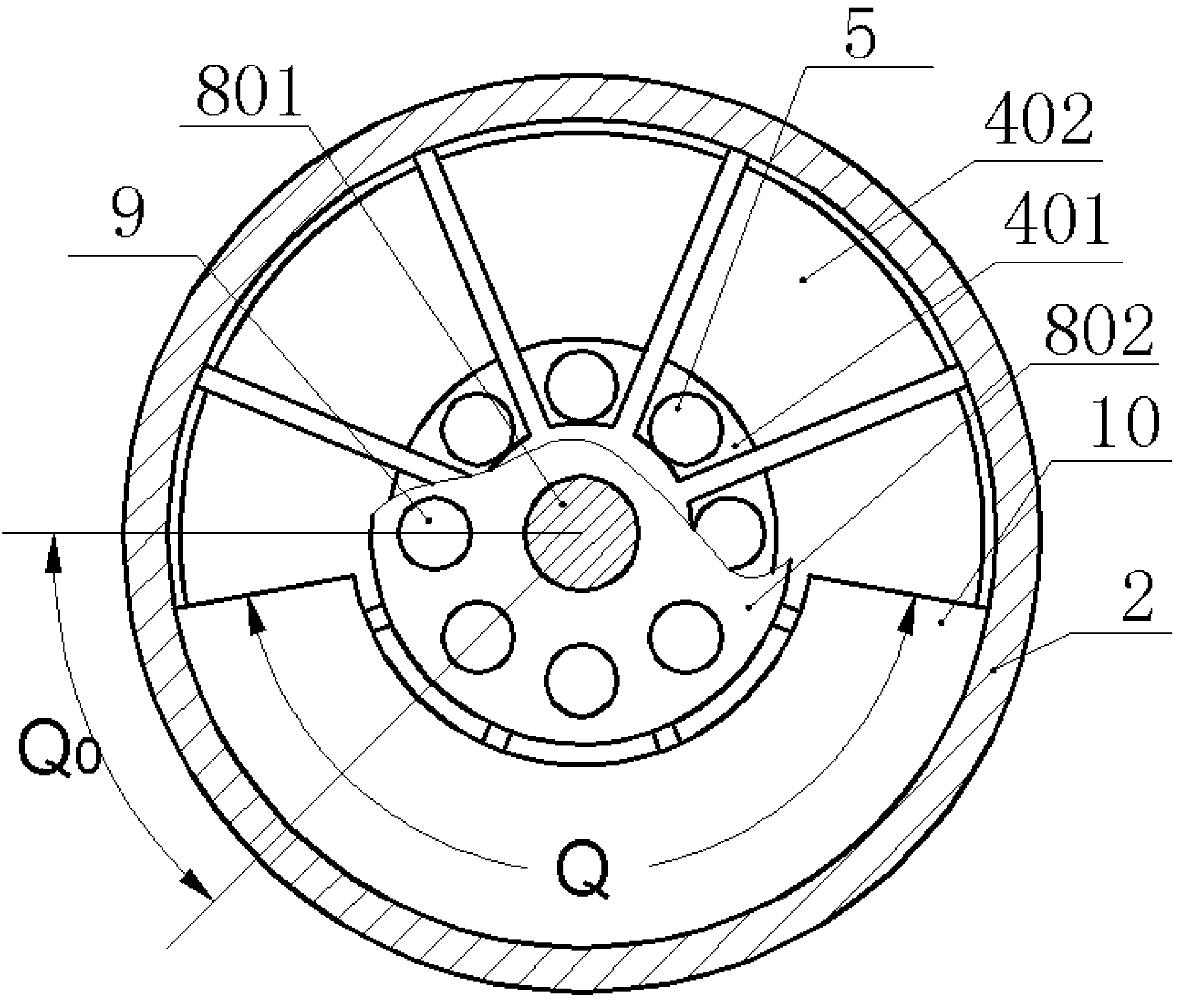

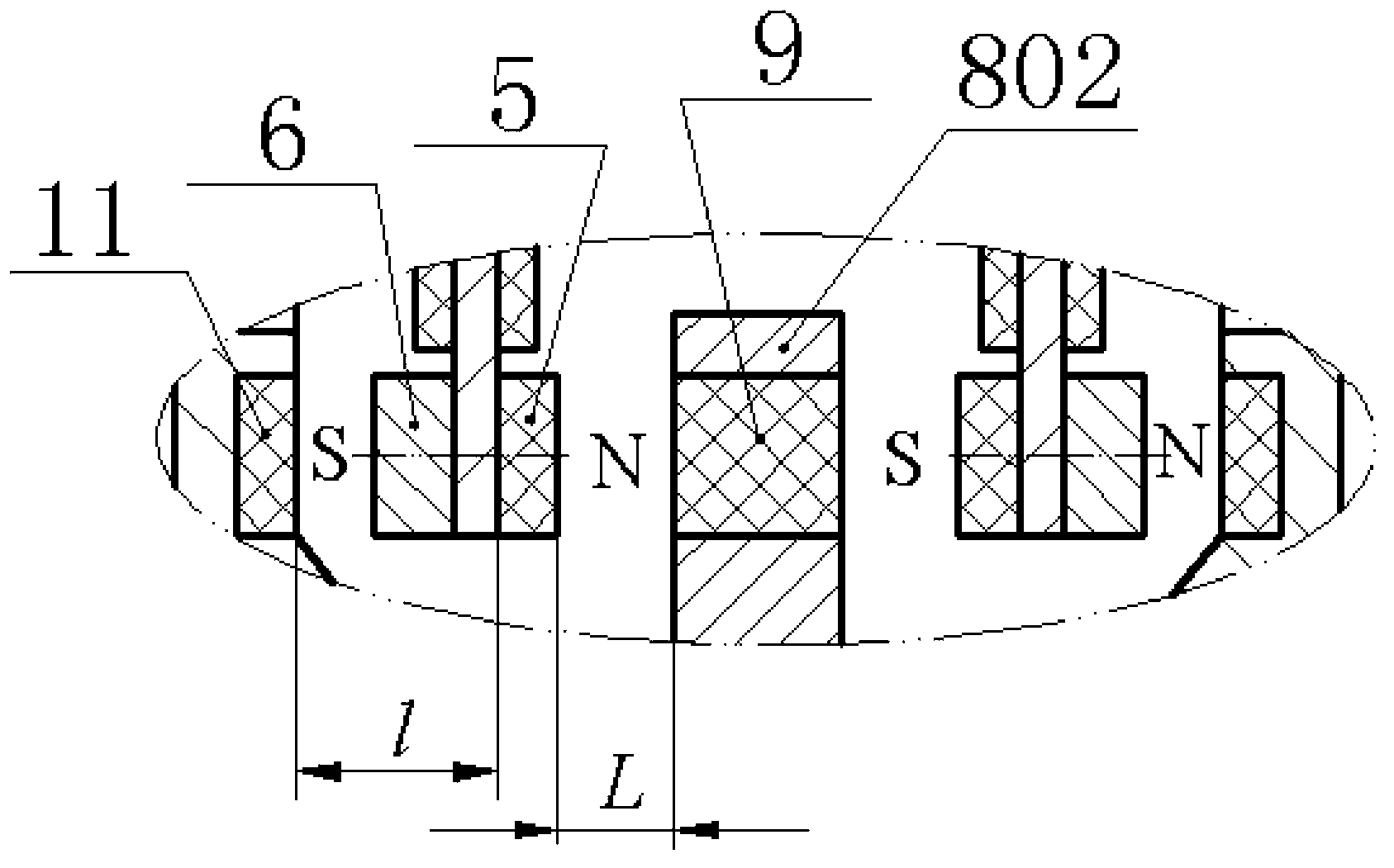

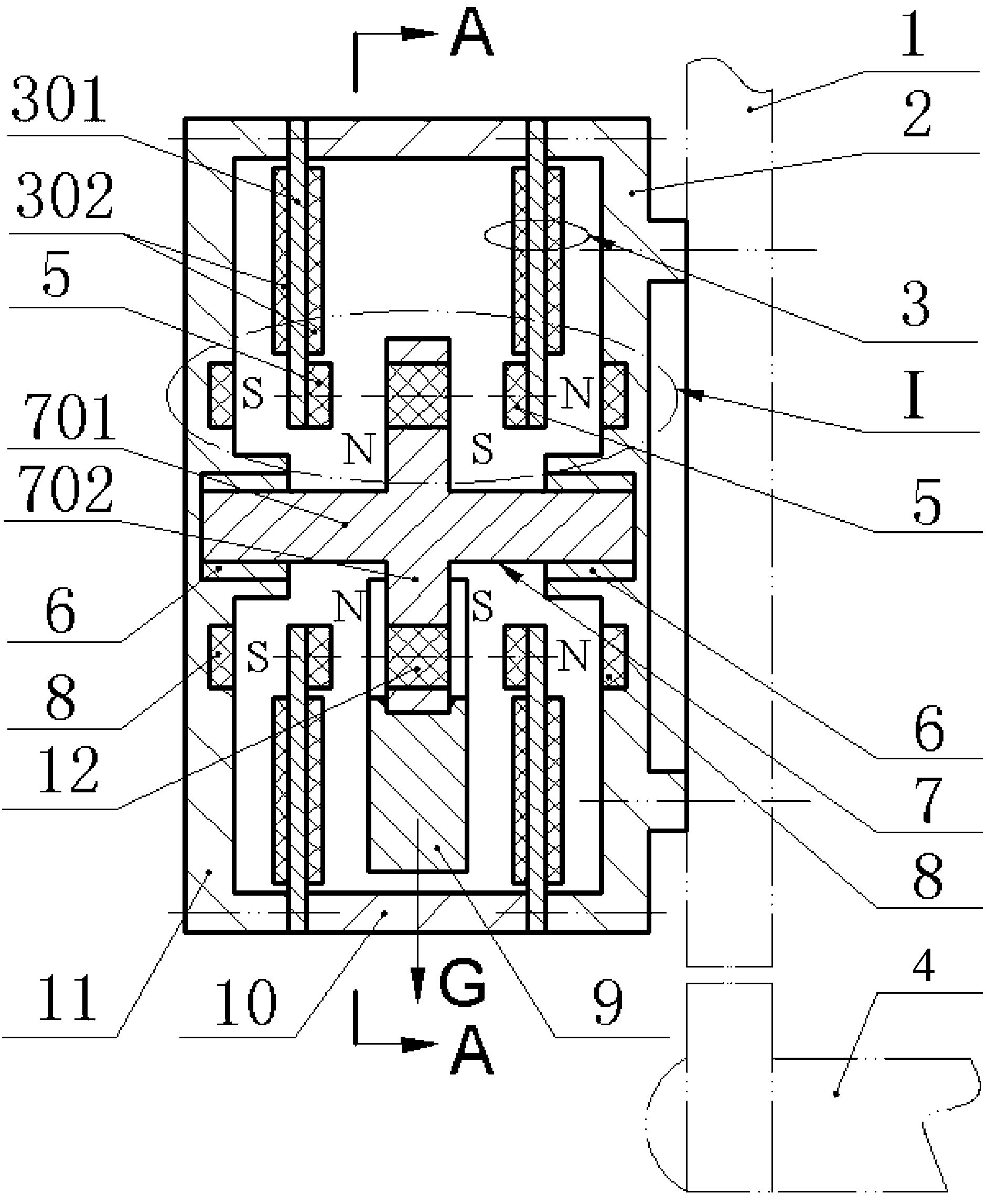

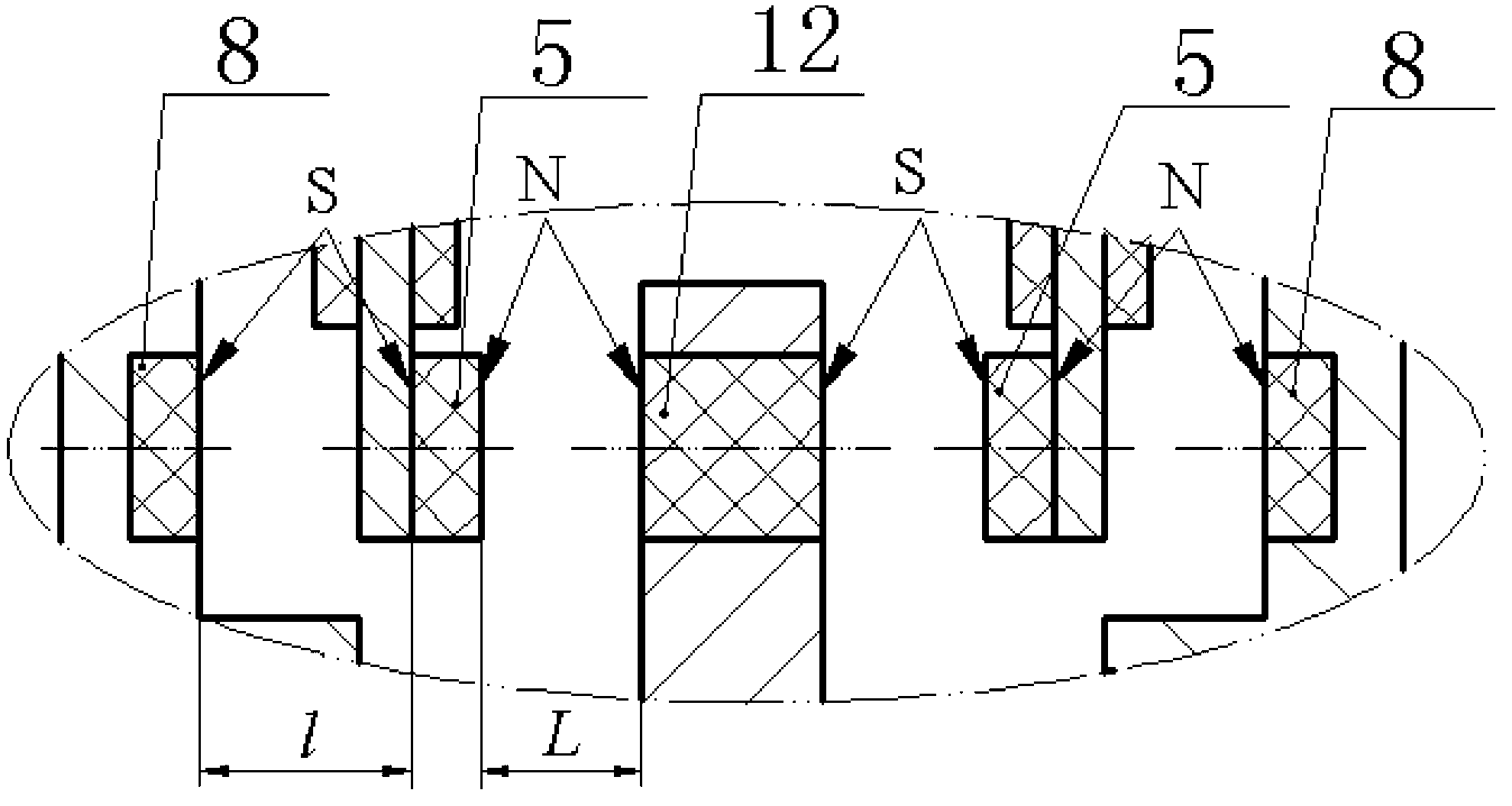

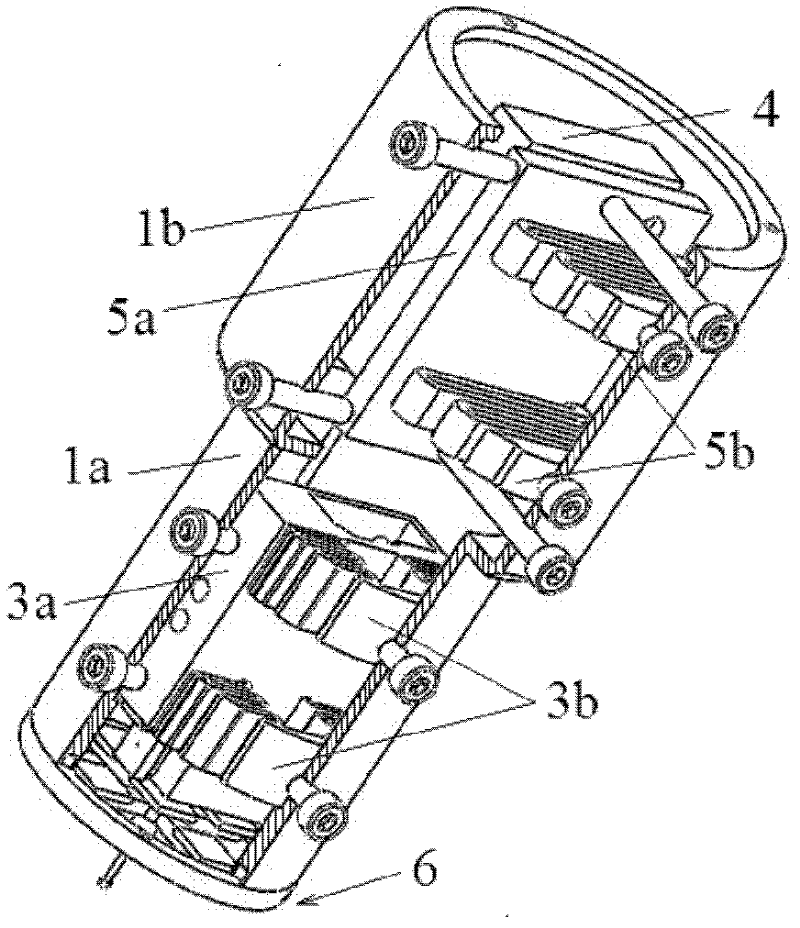

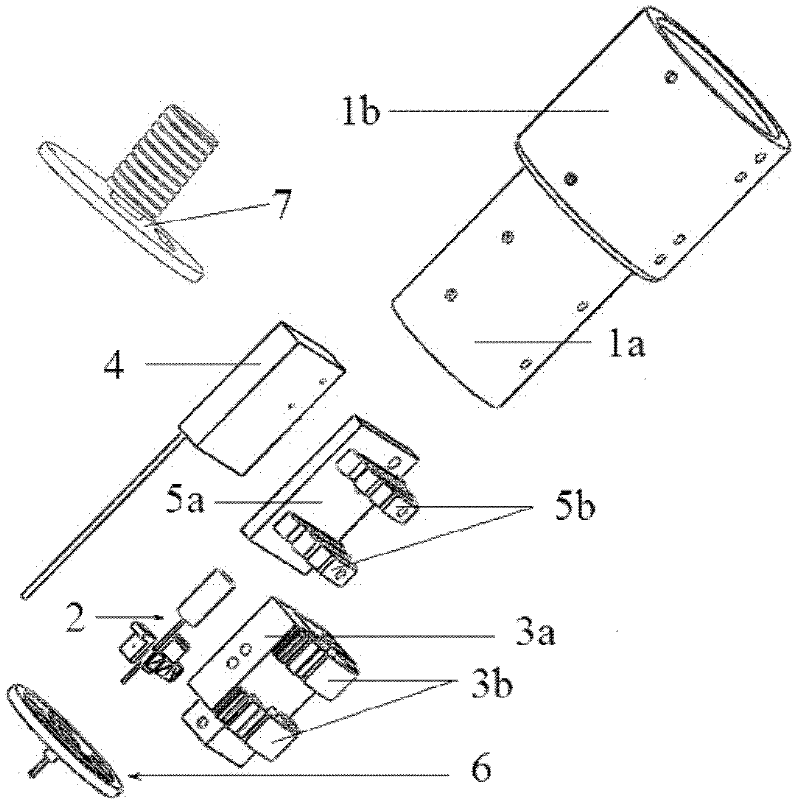

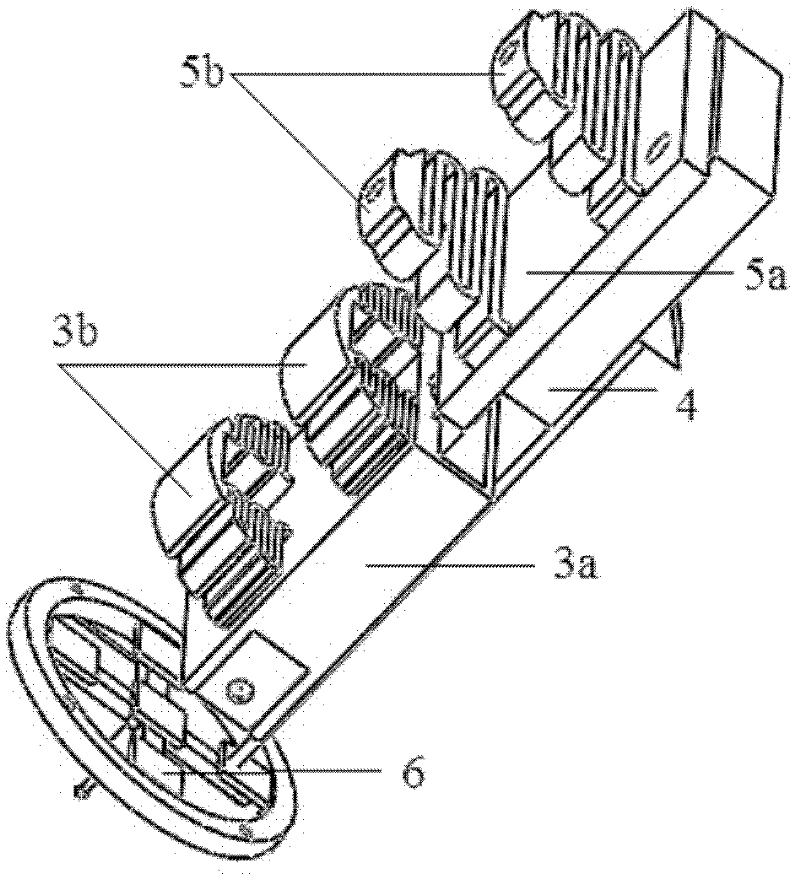

Shaft-end overhung piezoelectric cantilever beam electric generator

InactiveCN103259452AEffect of small axial bending deformationImprove reliabilityPiezoelectric/electrostriction/magnetostriction machinesNew energyEngineering

The invention relates to a shaft-end overhung piezoelectric cantilever beam electric generator, and belongs to the technical field of new energy resources and power generation. A left end cover and a right end cover are respectively installed at two ends of a shell body through screws. A semi-annular balancing weight is installed on the lower side of the interior of the shell body through a screw. The upper portion of the left end cover and the upper portion of the right end cover are respectively provided with a lightening hole. A magnet I and a bearing are embedded in the inner side of the bottom wall of the left end cover. A magnet I and a bearing are embedded in the inner side of bottom wall of the right end cover. A piezoelectric vibrator is arranged between the left end cover and the shell body in a compression joint mode. A piezoelectric vibrator is arranged between the right end cover and the shell body in a compression joint mode. A magnet II and a frequency-modulation mass block are installed at the free end of each piezoelectric vibrator. A rotating shaft of a rotor is installed on the left end cover and the right end cover through bearings. A connecting disc is installed at one end of the rotating shaft through a nut. A magnet III is embedded in a rotating disc of the rotor. The shaft-end overhung piezoelectric cantilever beam electric generator has the advantages that the piezoelectric vibrators are motivated for electric generation and external fixing and supporting are not needed; the shaft-end overhung piezoelectric cantilever beam electric generator is an integrated type individual component, so that the structure of a rotating body does not need to be changed, and the shaft-end overhung piezoelectric cantilever beam electric generator is convenient to install and maintain; the shaft-end overhung piezoelectric cantilever beam electric generator is high in reliability, strong in power generation capacity, and wide in velocity zone.

Owner:ZHEJIANG NORMAL UNIVERSITY

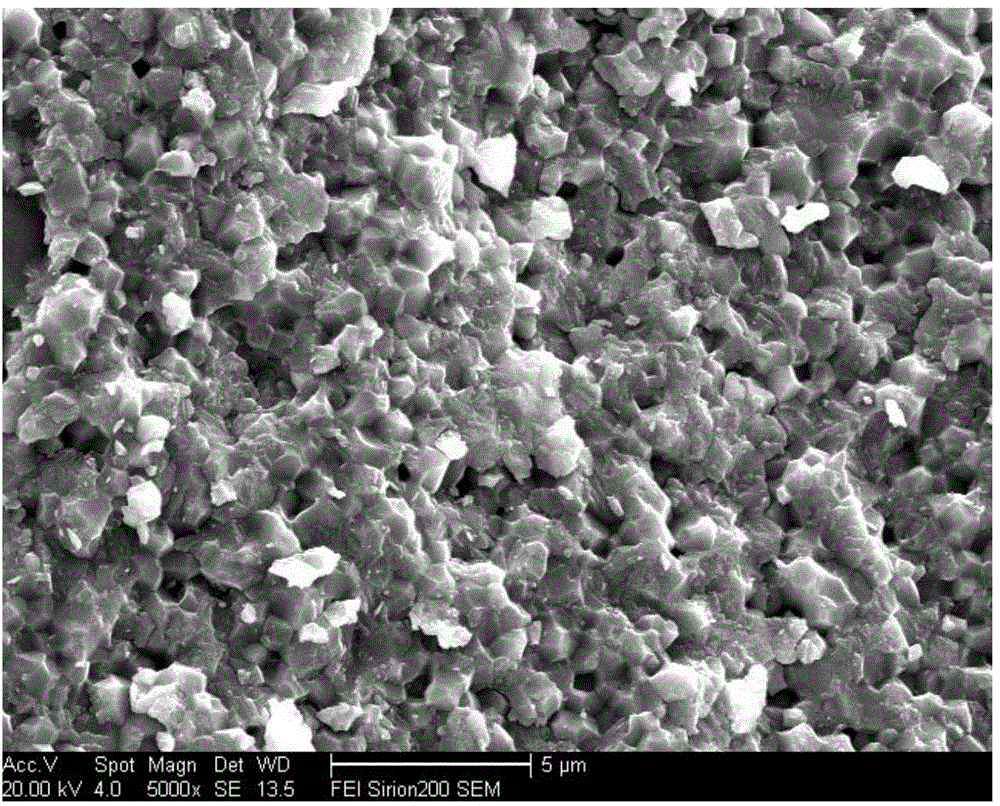

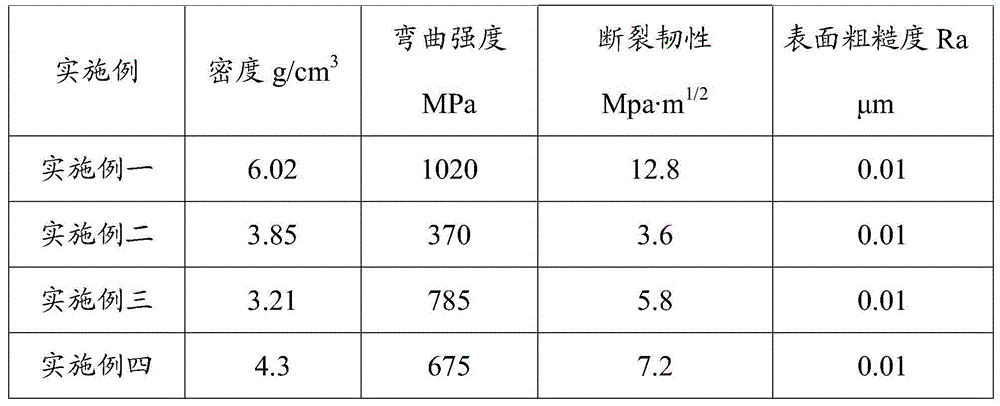

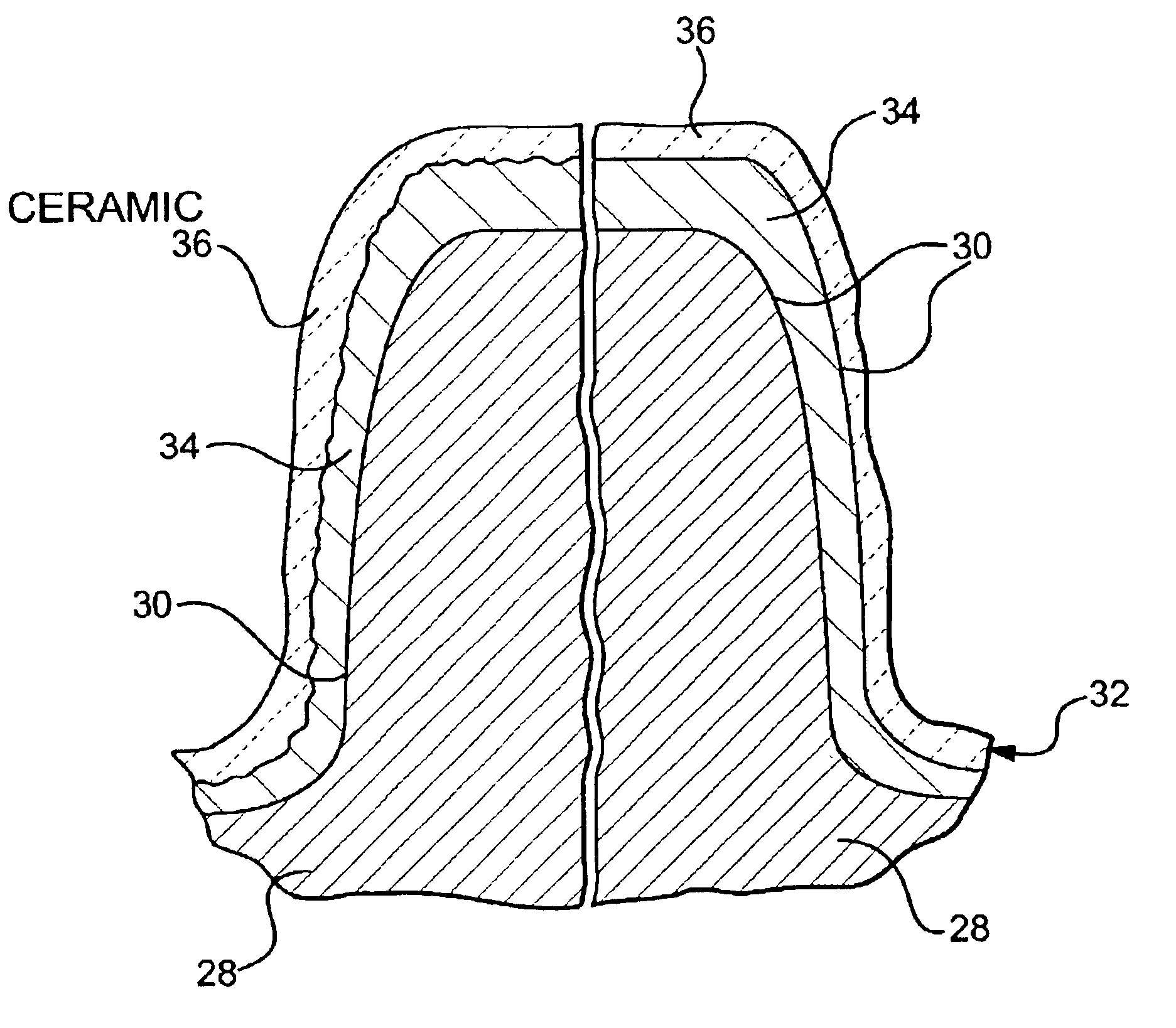

Ceramic mobile phone shell and preparation method thereof

The invention provides a preparation method of a ceramic mobile phone shell. The ceramic mobile phone shell is prepared by initiating the following raw materials with ultraviolet light and further sintering. The raw materials comprise ceramic powder, organic functional additives accounting for 2%-8% of the weight of ceramic powder and solvent accounting for 7%-18% of the weight of ceramic powder, wherein the organic functional additives comprise monomers, cross-linking agent and photoinitiator; the interior of the obtained ceramic mobile phone shell is of a crystal structure, the diameter ratio of maximum grains to minimum grains in the crystal structure is less than 5 and the average grain size is less than 5mu m. According to the ceramic mobile phone shell and the preparation method thereof provided by the embodiment of the invention, the problems of poor performances caused by non-uniform internal structure of a chip type mobile phone shell in the prior art and incapability of obtaining the ceramic mobile phone shell with good mechanical properties, large size and small thickness are solved.

Owner:ZHONGCAI HIGH NEW MATERIAL +1

Process for manufacturing high-strength bolt

The invention provides a process for manufacturing a high-strength (above) bolt. The process comprises the following steps: selecting a proper steel material, and cutting out a cylindrical blank with proper size; molding the head part and the rod part of the bolt by adopting cold extrusion technology; heating; manufacturing the rod part, including coarse grinding and fine grinding; detecting injury by magnetic powder; manufacturing screw; and performing surface mechanical reinforcement and corrosion resistance treatment. The process solves the technical problems of insufficient strength and fatigue fracture which are easily generated on the bolt existing in the prior art for manufacturing the high-strength bolt, and is a high-strength bolt manufacturing process capable of improving tensile and fatigue strength resistance of the bolt.

Owner:浙江裕泰汽车配件有限公司

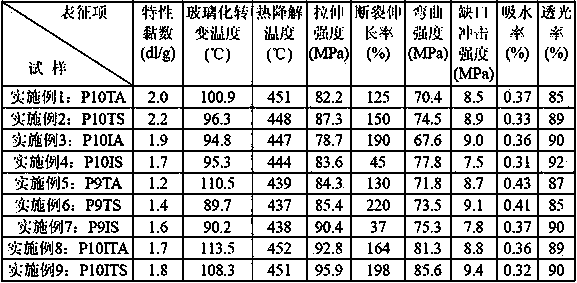

Semi-aromatic transparent polyamide material and preparation method thereof

The invention discloses a semi-aromatic transparent polyamide material and a preparation method thereof, belonging to the field of high-molecular materials. The material consists of a random copolymer of semi-aromatic amide salt and aliphatic amide salt and necessary auxiliaries; the intrinsic viscosity is 1.0-2.2dl / g, and the degree of crystallinity is less than 15%; the semi-aromatic amide salt is selected from amide salt 9T, amide salt 9I, amide salt 10T and amide salt 10I; and the aliphatic amide salt is selected from amide salt 610 and amide salt 1010. The preparation method comprises the following steps: adding the semi-aromatic amide salt, aliphatic amide salt and auxiliaries into a polymerization kettle; adding water which is 0.3-1.0 times the total mass of the semi-aromatic amide salt and aliphatic amide salt; in a protective gas atmosphere, stirring and heating to 160-210 DEG C within 1-2 hours, and performing constant-temperature pre-polymerization for 1-3 hours; heating to 240-300 DEG C, increasing pressure to 1-3MPa, and maintaining the pressure for reaction for 1-3 hours; slowly degassing to normal pressure within 1-4 hours; continuously stirring at constant temperature for 1-4 hours; and discharging after the reaction.

Owner:ZHENGZHOU UNIV

Masonry anchor device

An improved anchor device or fastening member which is particularly suited for use in the attachment of various fixtures and equipment to masonry, concrete, and other hard and / or friable substrates includes a head and a shank depending therefrom. The shank has a first threaded portion having a predetermined thread angle and a predetermined hardness, and a second threaded portion having a predetermined thread angle and a predetermined hardness. The first threaded portion is proximate to the head and the second threaded portion extends from the first threaded portion. The thread angle of the first threaded portion is different than the thread angle of the second threaded portion. In addition, the hardness of the first threaded portion is softer than the hardness of the second threaded portion. This provides for a more ductile anchorage when the fastening member is engaged with the substrate.

Owner:ASIA FASTENING US

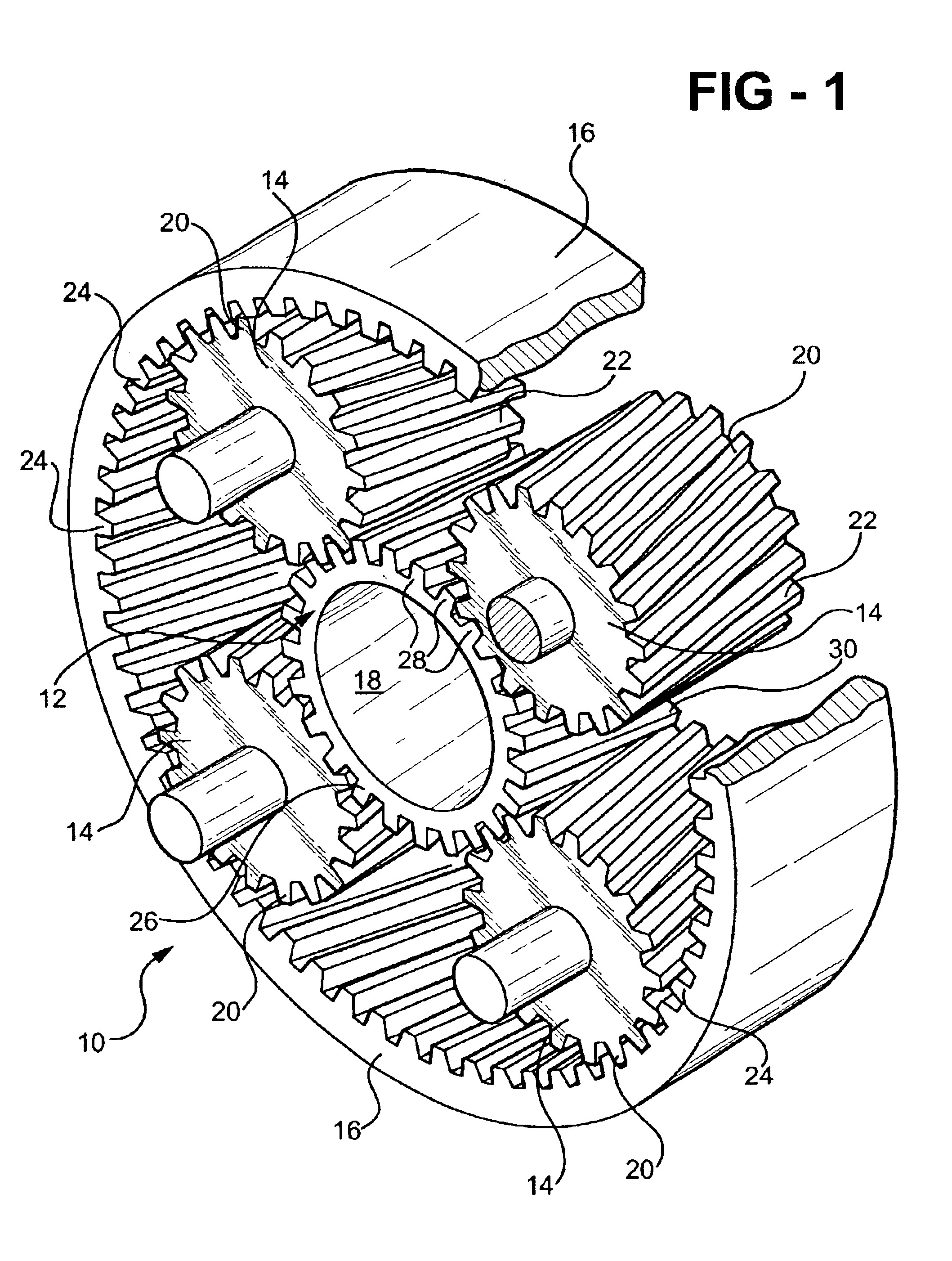

Planetary gearset with multi-layer coated sun gear

InactiveUS6846261B2Improve lubrication conditionsFlat surfaceMetal-working apparatusGear lubrication/coolingGear toothCoating

A planetary gearset includes a sun gear member having a sun gear body made of a steel material and an outer periphery with a plurality of teeth formed thereon. Each of the sun gear teeth has at least one mating surface for engaging mating surfaces on complementary teeth on at least one planet gear. A fatigue-resistant coating is applied to the mating surfaces of the sun gear teeth. The coating is harder and more abrasive than the mating surfaces of the planet gear teeth.

Owner:GENERAL MOTORS COMPANY

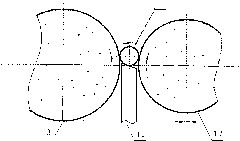

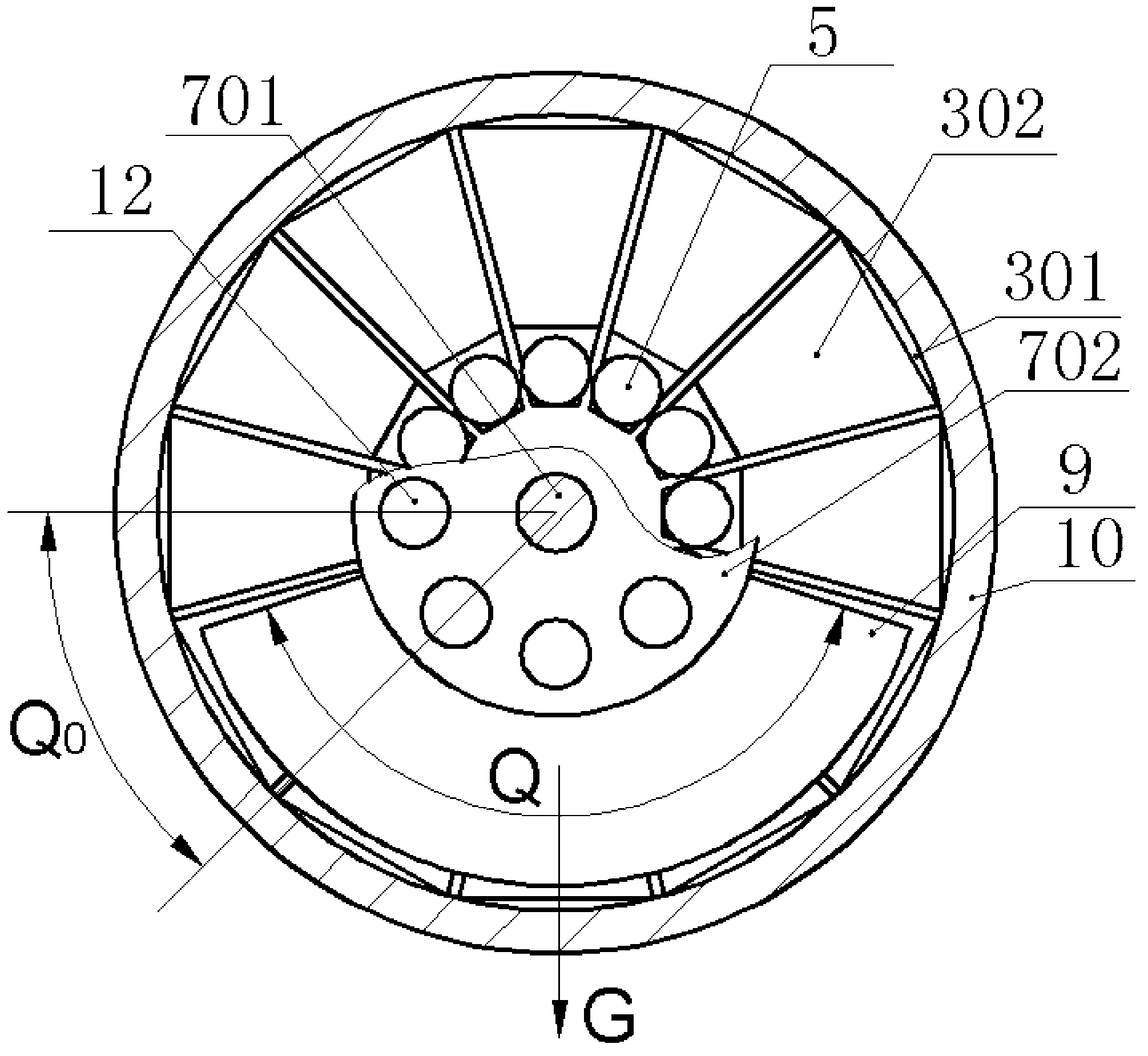

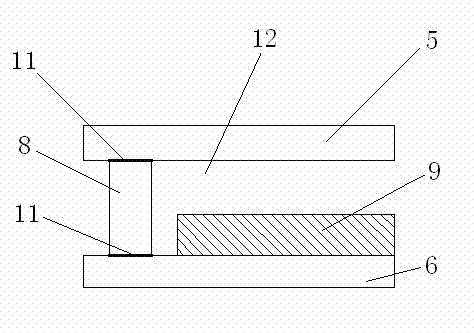

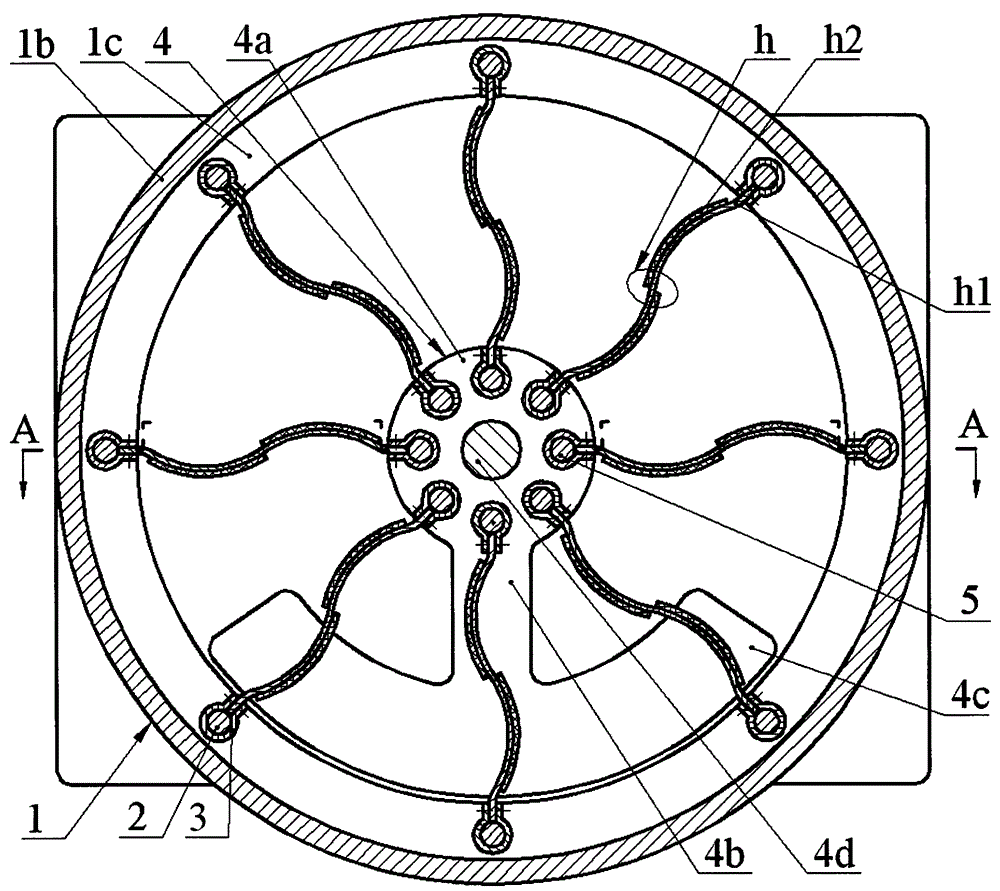

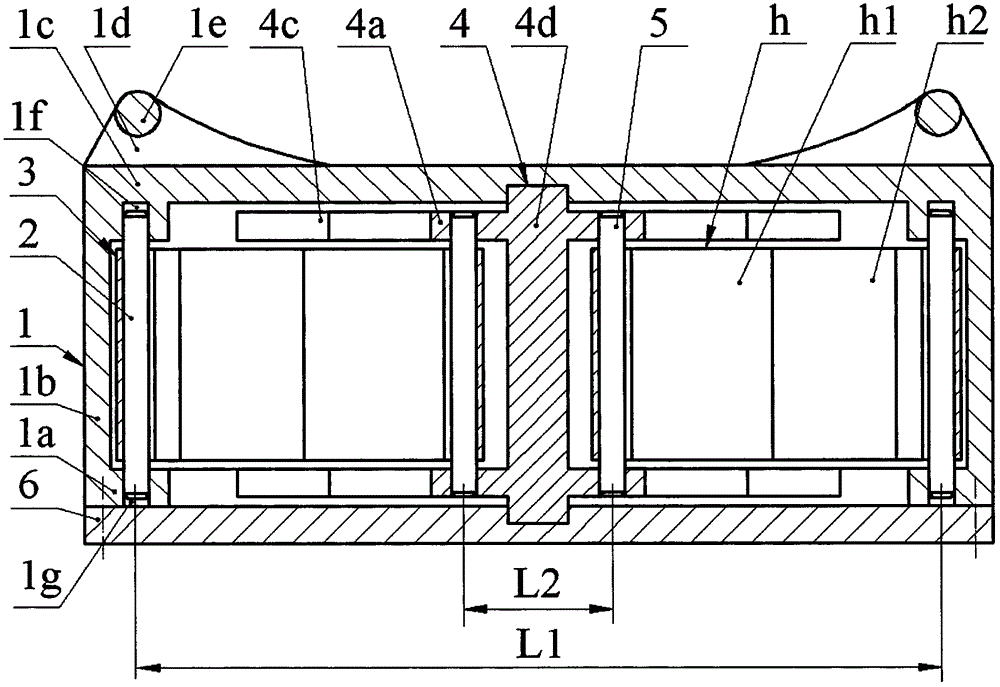

Piezoelectric cantilever beam generator for wind driven generator blade monitoring system

InactiveCN103259453AIncrease the effective areaUniform stress distributionPiezoelectric/electrostriction/magnetostriction machinesWind drivenNew energy

The invention relates to a piezoelectric cantilever beam generator for a wind driven generator blade monitoring system and belongs to the field of new energy resources and power technology. A left end cover and a right end cover are installed at two ends of a shell body through bolts. The bottom of the left end cover and the bottom of the right end cover are respectively provided with a first magnet and a shaft sleeve in an embedded mode. Piezoelectric vibrators are connected between the left end cover and the shell body and between the right end cover and the shell body in a pressed mode. A second magnet is installed at a free end of each piezoelectric vibrator. A rotary shaft of a driving disc is placed in the shaft sleeve which is embedded at the bottom of the left end cover and the shaft sleeve which is embedded at the bottom of the right end cover. A mass block is welded to the outer edge of a driving disc body and a third magnet is embedded in the outer edge driving disc body. The piezoelectric cantilever beam generator for the wind driven generator blade monitoring system has the advantages that relative rotation is generated between the magnet arranged on the driving disc and the magnets arranged on the piezoelectric vibrators, the piezoelectric vibrators are effectively driven, power is generated, and external fixed supporting is not required; the generator is an independent assembly, so that the structure of each blade does not need to be changed, and installation and maintenance are convenient; the generator is composed of the fan-shaped piezoelectric vibrators with the magnets with different masses, so that the piezoelectric cantilever beam generator for the wind driven generator blade monitoring system is high in reliability, strong in power generation capacity and wide in speed band.

Owner:ZHEJIANG NORMAL UNIVERSITY

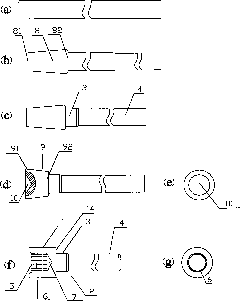

Elastic measuring head in three-dimensional micro-nano contact scanning probe

The invention discloses an elastic measuring head in a three-dimensional micro-nano contact scanning probe. The elastic measuring head is characterized in that: a cross suspension piece is arranged in the center of a fixed circular ring; a cantilever spring plate is connected to the arm end of each cantilever in the cross suspension piece, and the other end of each cantilever spring plate is connected with the fixed circular ring to form a suspension structure of the cross suspension piece in the fixed circular ring; on a side plane, towards the inside of a cylinder body, of the cross suspension piece, a center plane reflective mirror is arranged in the center of the cross suspension piece, and a cantilever plane reflective mirror is arranged on the arm end part of at least one cantilever which is positioned at the cross suspension piece; and on a side plate, towards the outside of the cylinder body, of the cross suspension piece, a scanning probe is fixedly arranged in the center of the cross suspension piece, and a measuring ball positioned at the foremost end of the scanning probe is fixedly arranged on the end part of the scanning probe. The elastic measuring head disclosed by the invention can obtain detection effects with wide measuring range, high accuracy, high sensitivity and small measured force.

Owner:HEFEI UNIV OF TECH

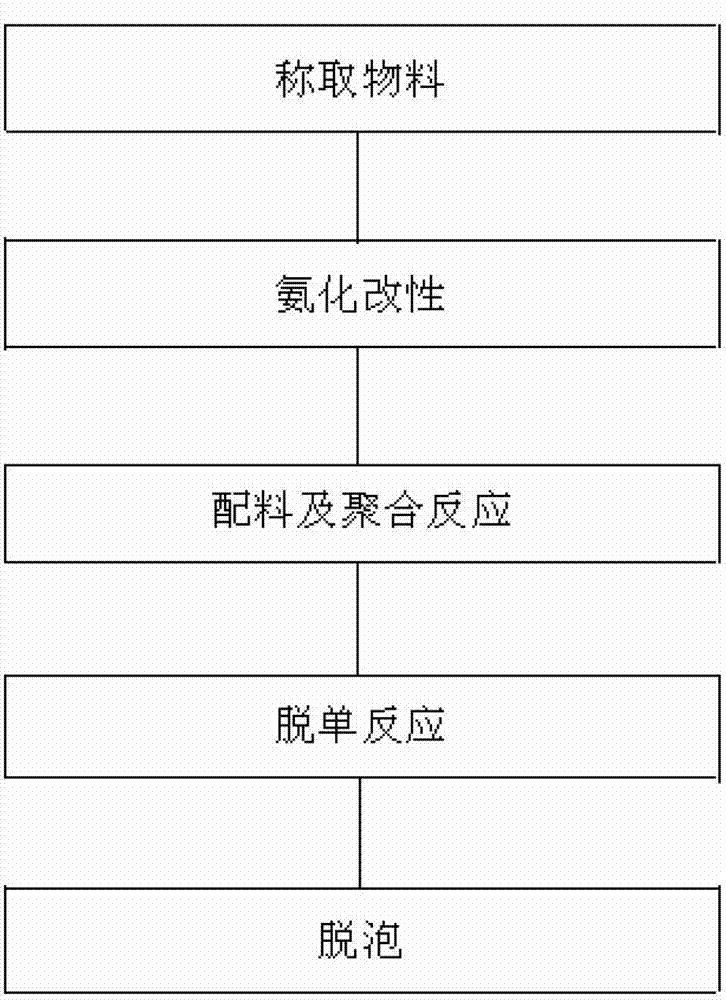

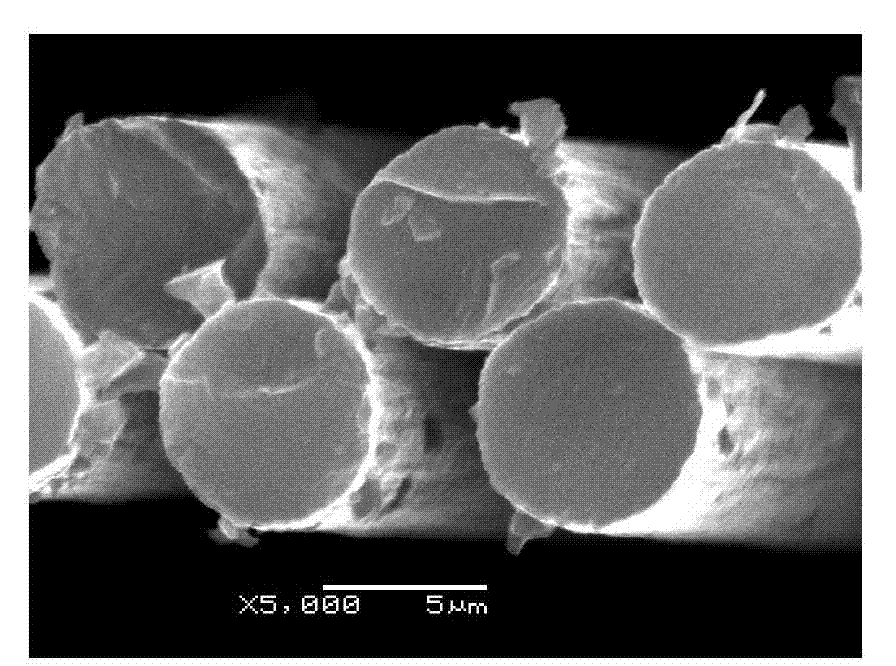

Multiple-ammoniation polyacrylonitrile-based carbon fiber spinning solution and preparation method thereof

ActiveCN102733011AImprove mechanical propertiesCollusion is strongFibre chemical featuresCarbon fibersAcrylonitrile

The invention discloses a multiple-ammoniation polyacrylonitrile-based carbon fiber spinning solution and a preparation method of the multiple-ammoniation polyacrylonitrile-based carbon fiber spinning solution. The preparation method comprises the steps of combining acrylonitrile, methyl acrylate, 2-acrylamide-2-methylpro panesulfonic acid and itaconic acid to be a polymer monomer, respectively and sufficiently dissolving the weighed solid monomer (itaconic acid) and an initiator (azodiisobutyronitrile) into a dimethyl sulfoxide solution; conducting ammoniation on the dimethyl sulfoxide solution of the itaconic acid by ammonia water; and sequentially adding all the materials into a polymerizing pot, adding the initiator (azodiisobutyronitrile) to conduct batch polymerization reaction, gathering, defoaming and filtering to obtain the multiple-ammoniation polyacrylonitrile-based carbon fiber spinning solution. According to the multiple-ammoniation polyacrylonitrile-based carbon fiber spinning solution and the preparation method, the comonomer structure of a multiple-copolymerization system is changed by the ammonia water, and dimethyl sulfoxide is taken as a solvent for homogeneous solution polymerization to prepare the polyacrylonitrile-based carbon fiber spinning solution, so that the hydrophily of the spinning solution is improved, and further, the high-performance fiber with high structure compacting degree, good mechanical property and high bonding strength is obtained.

Owner:XIAN KANGBEN MATERIAL

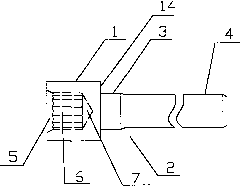

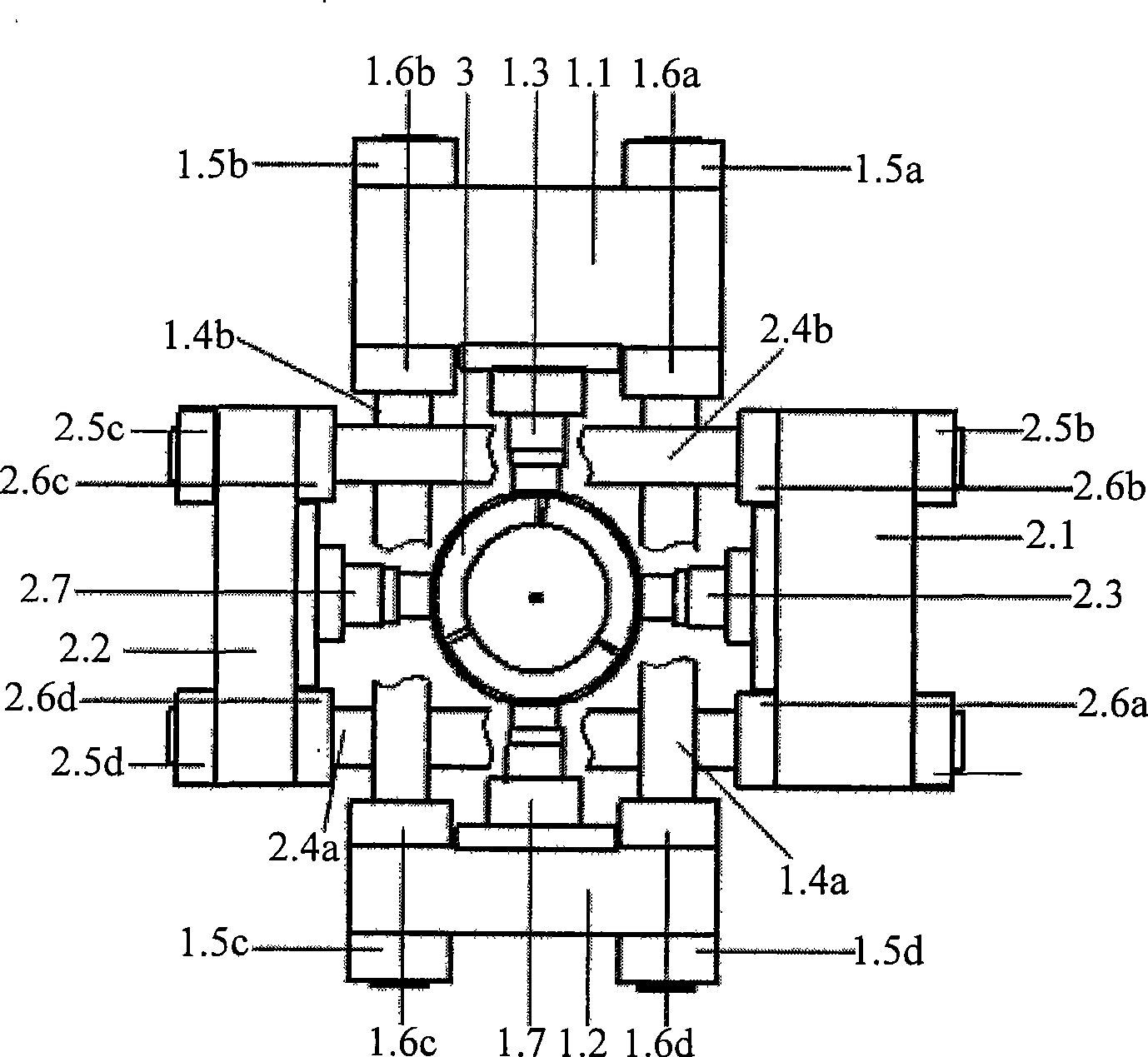

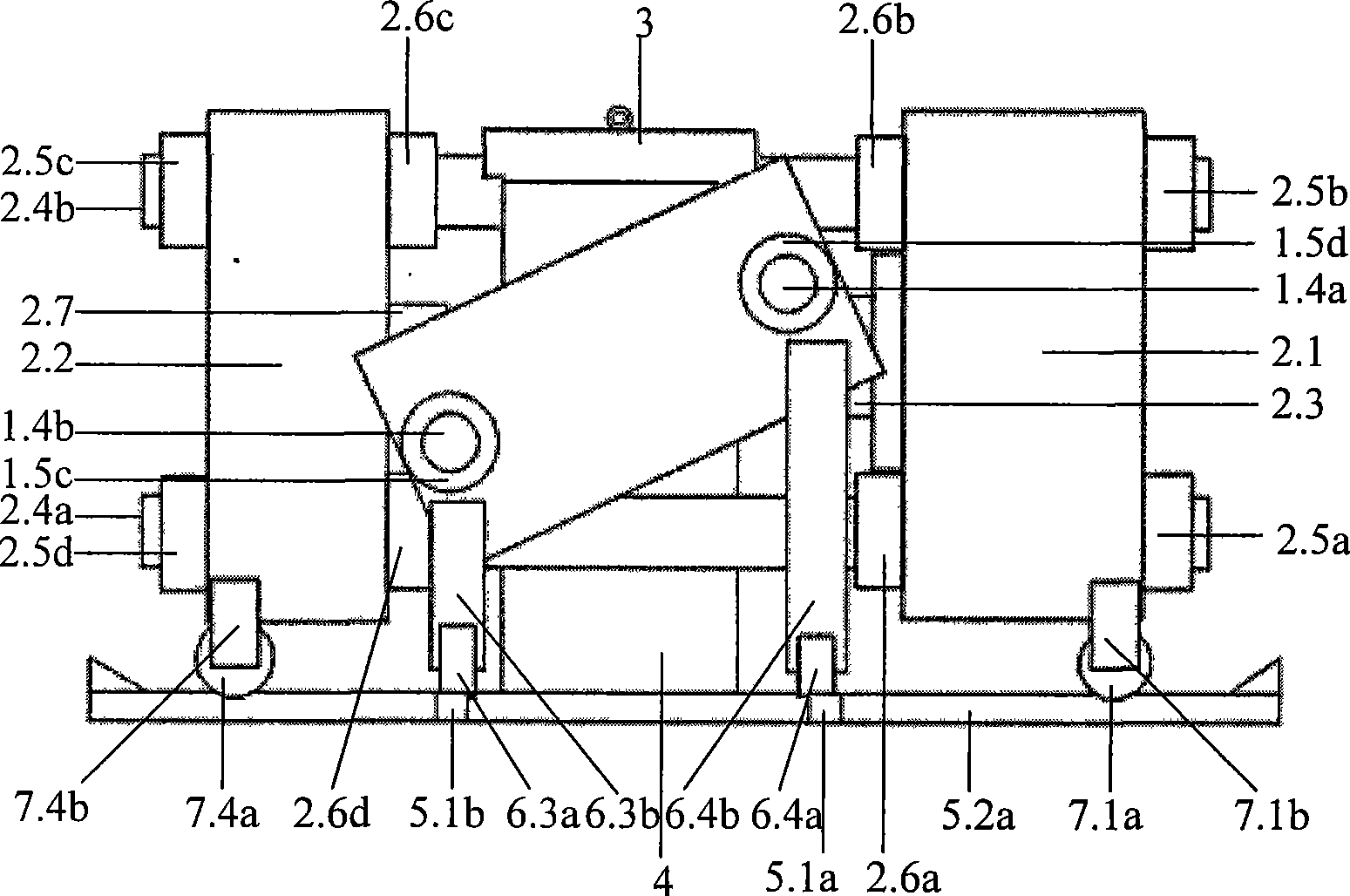

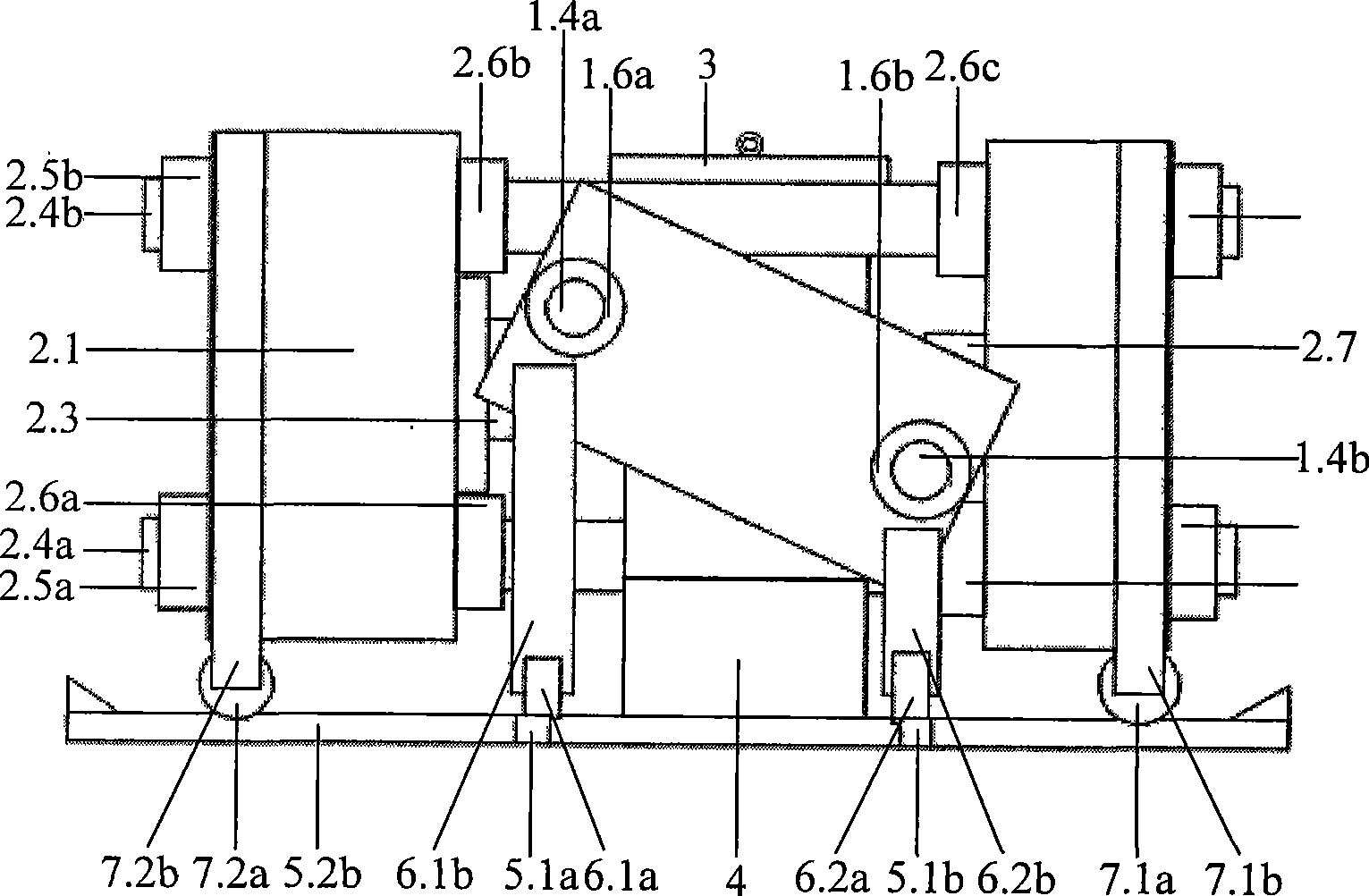

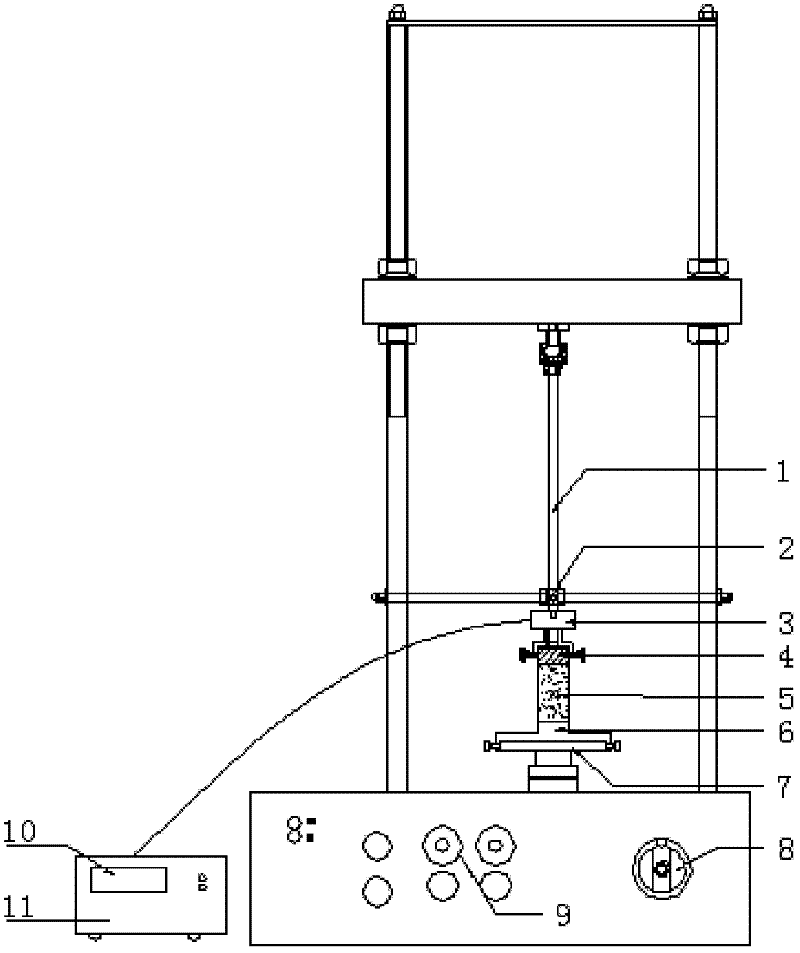

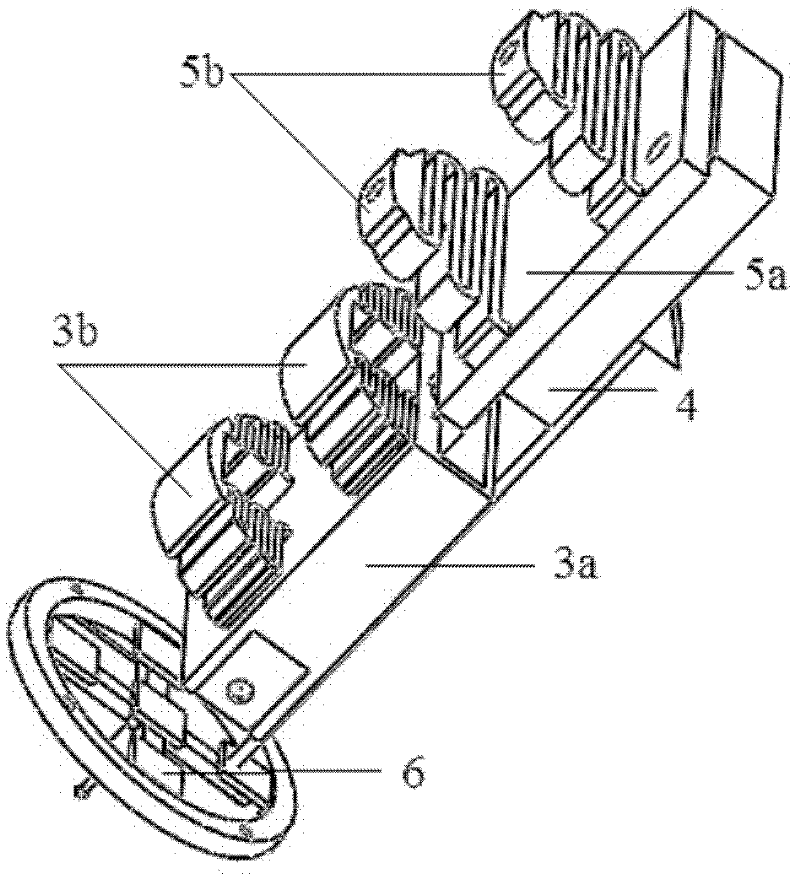

Slide transverse type symmetrical loading structure

InactiveCN101458192AUniform stress distributionSimple structureEarth material testingUsing mechanical meansTest sampleEngineering

The invention discloses a transverse sliding symmetrical loading structure which essentially consists of two sliding frames, a true triaxial pressure chamber, two groups of supports and two groups of slideways in the shape of an intersecting parallel. The two sliding frames are orthogonally and transversely arranged, on each of which is sequentially fixed with a main frame transom, a subframe transom, a pair of frame transverse columns, four pairs of cage nuts, a hydraulic jack and a counterforce base. The frame transverse columns are connected with the main frame transom and the subframe transom, external cage nuts and internal cage nuts fix the frame transverse columns, the main frame transom and the subframe transom, and the hydraulic jack and the counterforce base are respectively arranged inside the main frame transom and the subframe transom; the true triaxial pressure chamber is arranged in the center of the two sliding frames; the two sliding frames are arranged in the slideways through a group of corresponding supports and can freely move within a certain range. The structure can ensure the internal stress to be uniformly distributed in the test sample during loading, and has the advantages of convenient test sample loading and unloading, simple structure and relative low cost.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

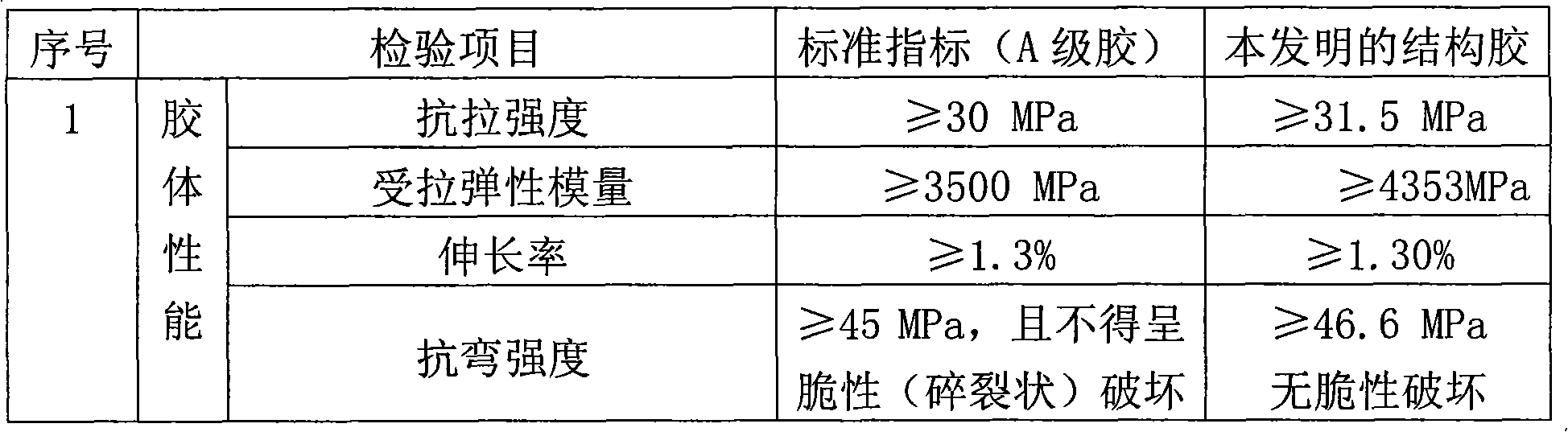

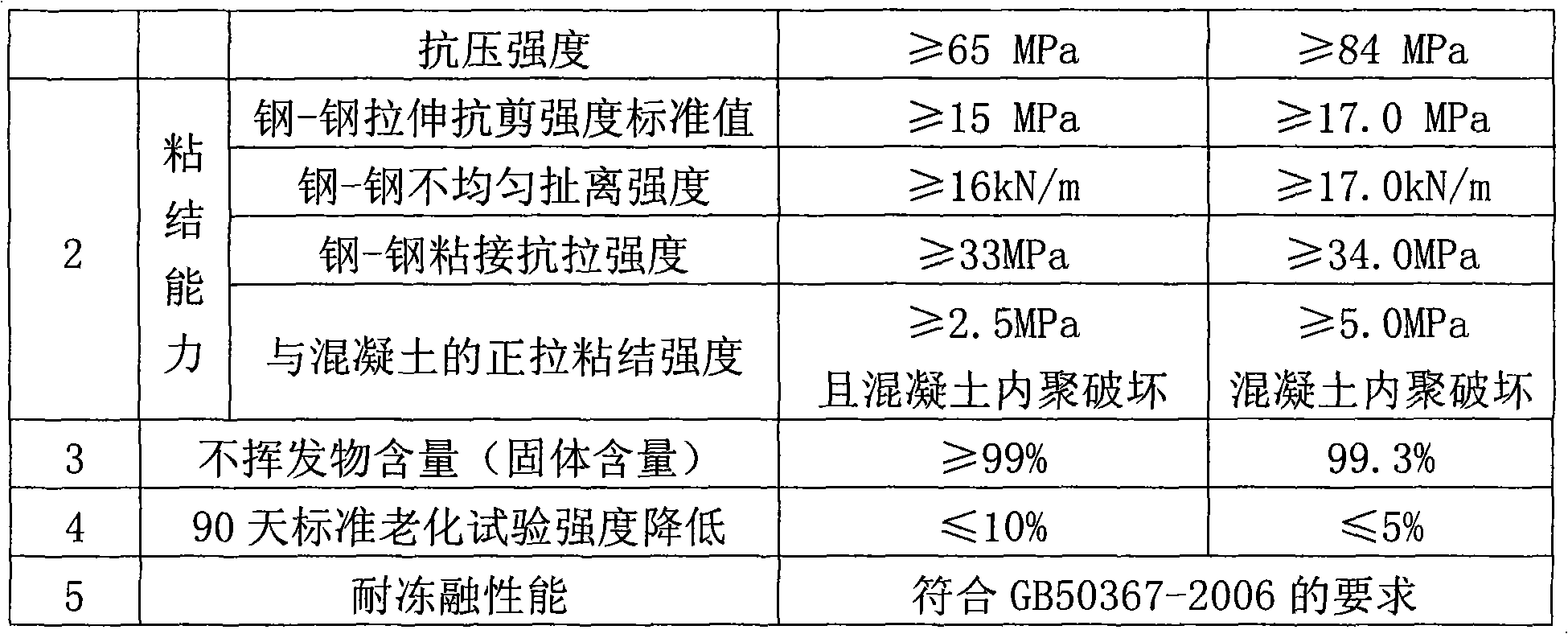

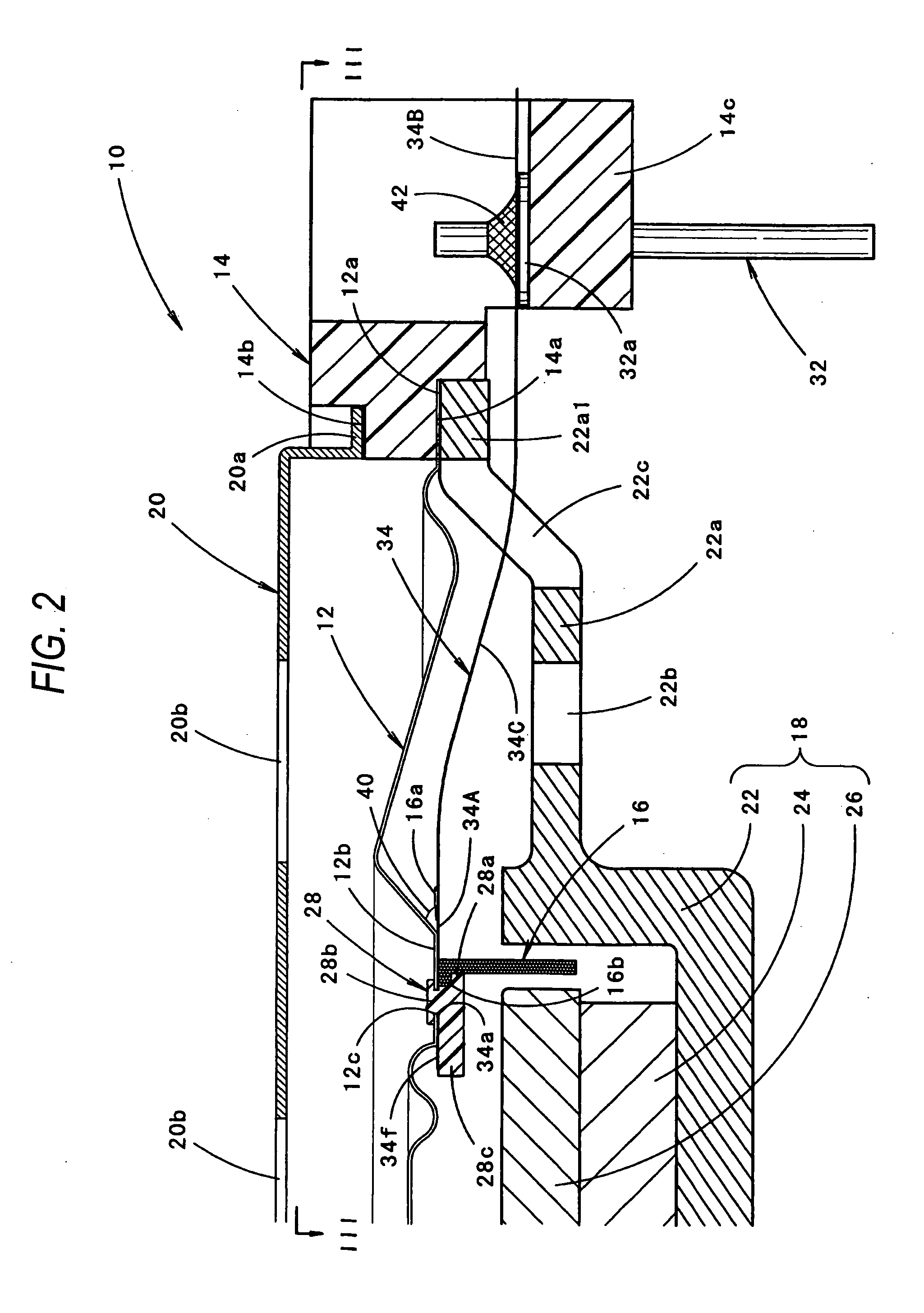

Structural adhesive for steel bonding

InactiveCN101921566AImprove adhesionIncreased mechanical toughnessNon-macromolecular adhesive additivesEpoxynovolac adhesivesEpoxyStress distribution

The invention discloses a structural adhesive for steel bonding, which comprises a component A and a component B of which the quality ratio is 100:(15-65), wherein the component A comprises epoxy resin, diluter, plasticizer, toughener and couplant; and the component B comprises modified polyamide resin, modified fatty amine and amino terminated polyether. The structural adhesive has the advantages of favorable bonding property, uniform stress distribution, high shearing strength and good mechanical toughness, has the characteristics of no flow after plate bonding, large anchorage withdrawal resistance and limit of harmful substances far below the national technical index, has the characteristics of high durability, convenient construction and stable strength, and can well soak the concrete and well bond the concrete and steel plates. The invention has high application and popularization values.

Owner:RES INST OF HIGHWAY MINIST OF TRANSPORT +1

Electroacoustic transducer

InactiveUS20050254680A1Avoid stress concentrationUniform stress distributionPrinted circuitsCircuit lead arrangements/reliefStress concentrationTransducer

In an electroacoustic transducer, a pair of coil terminals elongating from a voice coil are electrically connected to a pair of terminal members attached to a frame via a flexible printed circuit board, respectively. According to the configuration, even in a case where an electroacoustic transducer is used at a high sound pressure, breakage of the coil terminals hardly occurs. In the flexible printed circuit board, the width of an intermediate portion is set to be smaller than the widths of an end portion on the side of the coil terminals and an end portion on the side of the terminal members. Therefore, the flexibility of the intermediate portion can be enhanced, whereby transmission of characteristic vibration of the flexible printed circuit board to a diaphragm, and stress concentration in the vicinity of the end portions are effectively suppressed.

Owner:STAR MICRONICS

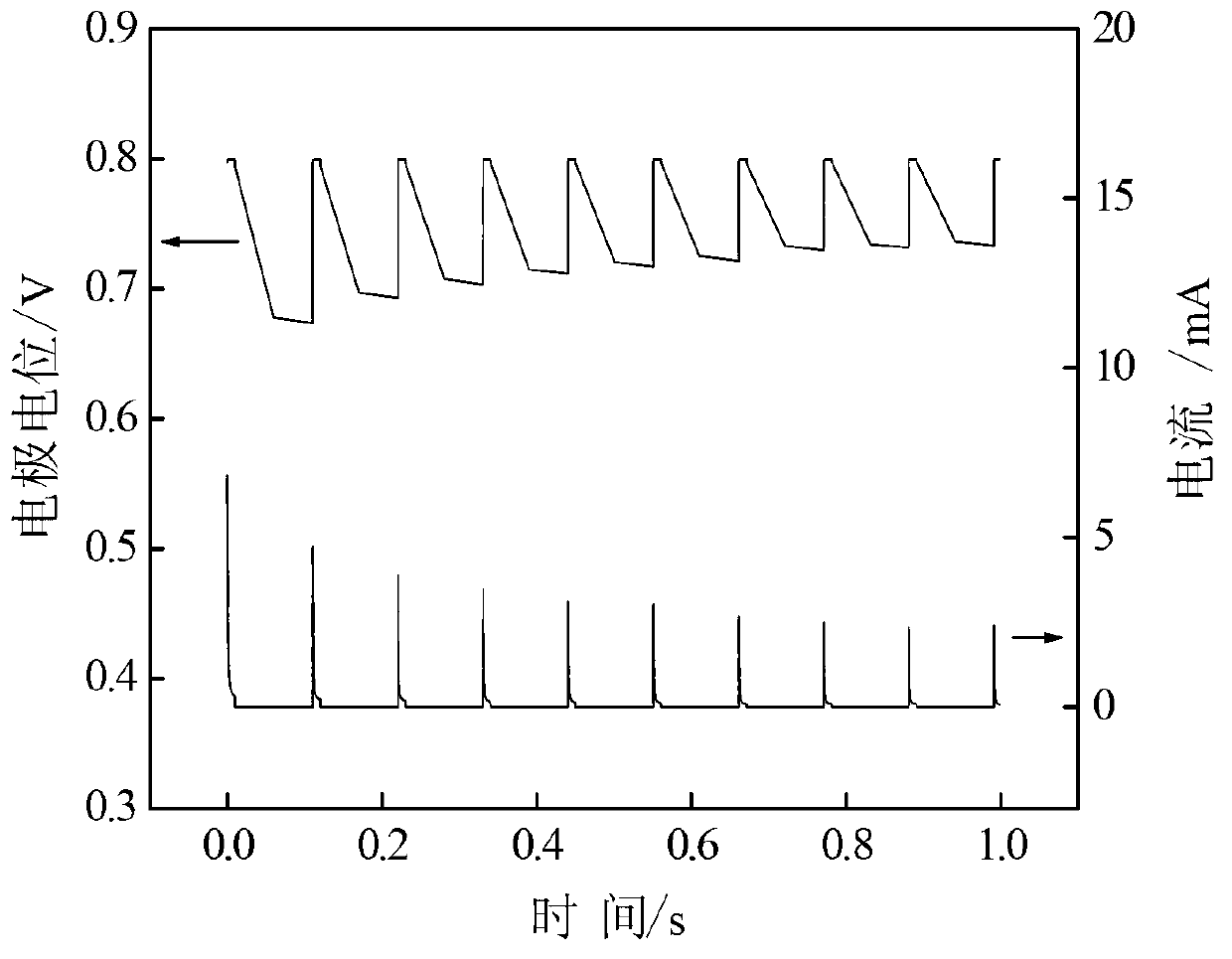

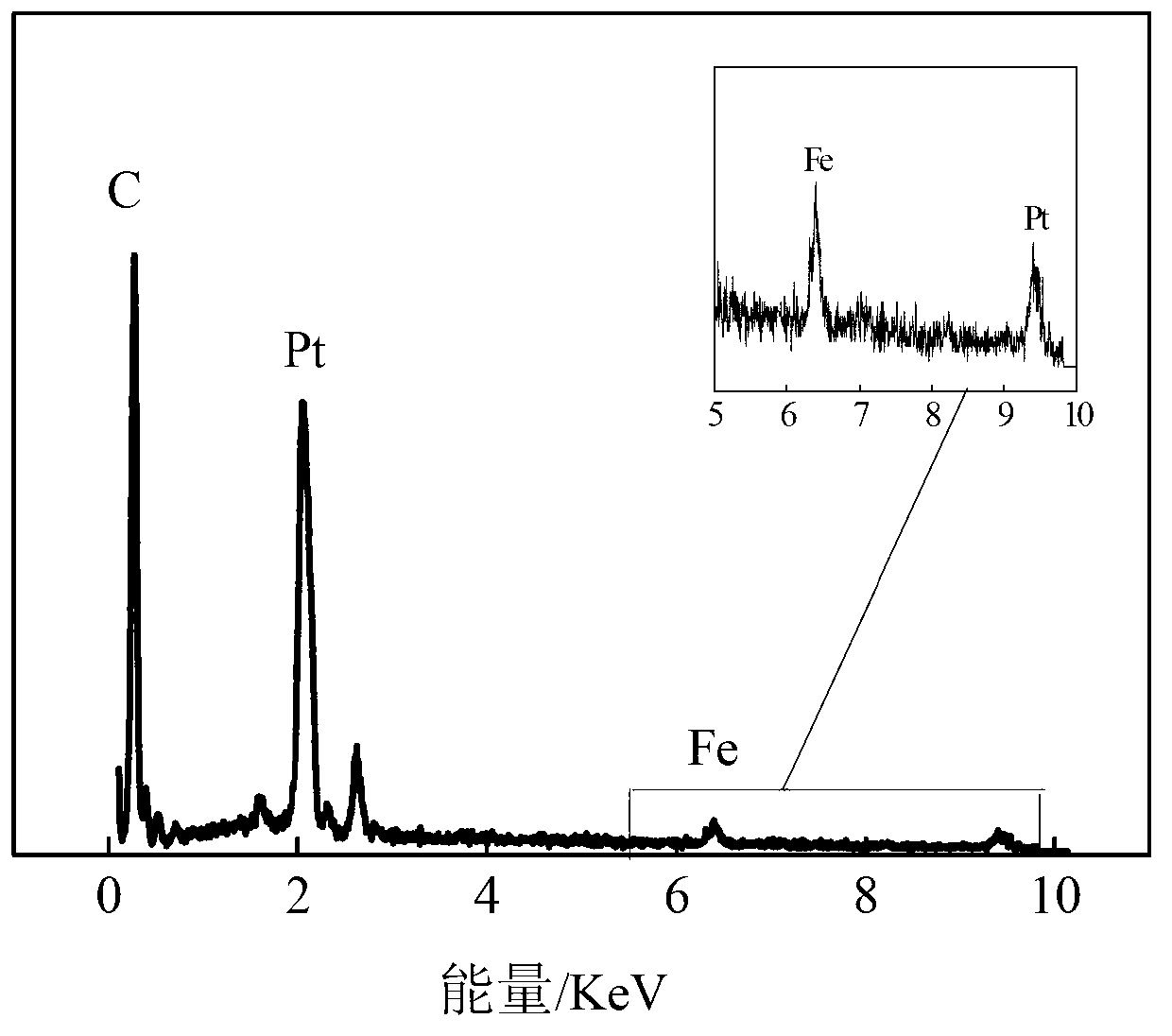

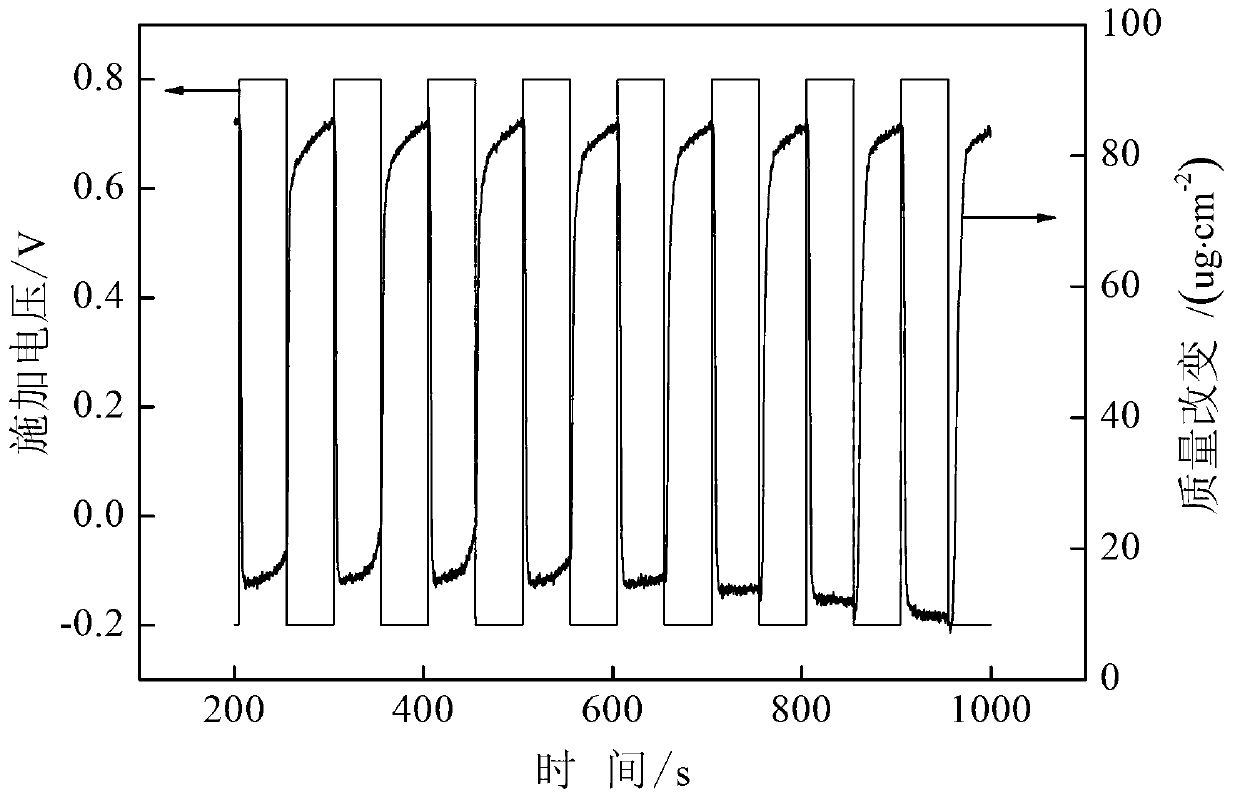

Preparation method of ion imprinted polymer film

ActiveCN103214689AEasy to operateMild preparation conditionsSemi-permeable membranesDispersed particle separationIn situ polymerizationRare earth ions

Belonging to the fields of electroactive functional polymer film material preparation and selective separation of ions, the invention relates to a preparation method of an ion imprinted polymer film. The invention is characterized by relating to a preparation method of an ion imprinted polymer film with an electronic control cation exchange function. The method includes: preparing a water solution of the monomer for polymer preparation, an electrolyte solution, a protonic acid solution, an imprinted ion solution and a doping ion solution, then mixing the five solutions, conducting in situ polymerization on a conductive substrate by a monopolar pulse electrodeposition method so as to synthesize imprinted ion removed ferricyanic group doped polymer film by one step. Being simple and fast to operate, the method provided in the invention needs no additional pickling step and can realize imprinted ion removal in situ. Also, the preparation conditions are mild and are easy to control. The ion imprinted polymer film prepared by the method has an electronic control cation exchange function, and can be used for selective removal of heavy metal ions in water or separation recycling of rare earth ions.

Owner:TAIYUAN UNIV OF TECH

Sandwich layer forging die and preparation method of forging die sandwich layer surfacing

ActiveCN104741499AExtended service lifeImprove performanceArc welding apparatusForging/hammering/pressing machinesSoft materialsHigh pressure

The invention discloses a sandwich layer forging die and a preparation method of forging die sandwich layer surfacing. The sandwich layer forging die is used for surfacing a layer of sandwich layer soft welding material which is better in plasticity and lower in yield strength than a cast steel substrate and a double-metal gradient surfacing material between the cast steel substrate and the double-metal gradient surfacing material; the preparation method of the forging die sandwich layer surfacing comprises the following steps of taking cast steel as the cast steel substrate, and welding a sandwich layer soft material on a substrate layer; surfacing a transition layer material on a substrate of a sandwich layer welded, welding and covering all sandwich materials to form a surfacing transition layer; welding a high-temperature wearing layer material; tempering to distress after the completion of the welding, and then mechanically processing to obtain a mould. The sandwich layer forging die provided by the invention is long service life and high in loading capacity of the cast steel substrate. According to the method provided by the invention, the critical bottleneck problems that the forging die is low in life and the die is high in manufacturing cost can be solved thoroughly, the die forging forming of various materials can be supported at high temperature and high pressure, and a brand new manufacturing method can be provided for forging die manufacturing.

Owner:CHONGQING UNIV +2

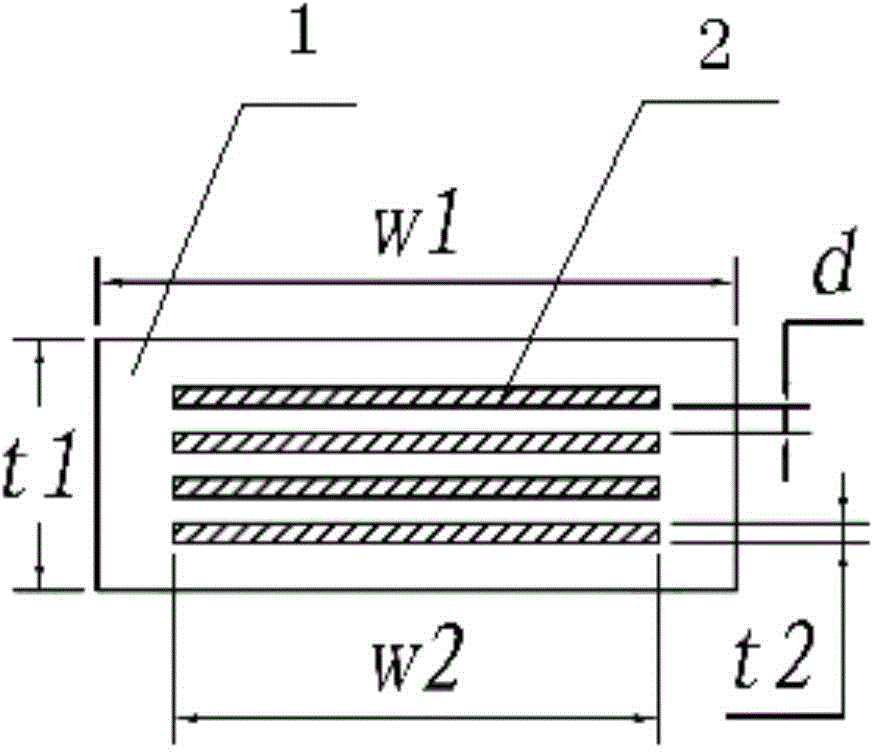

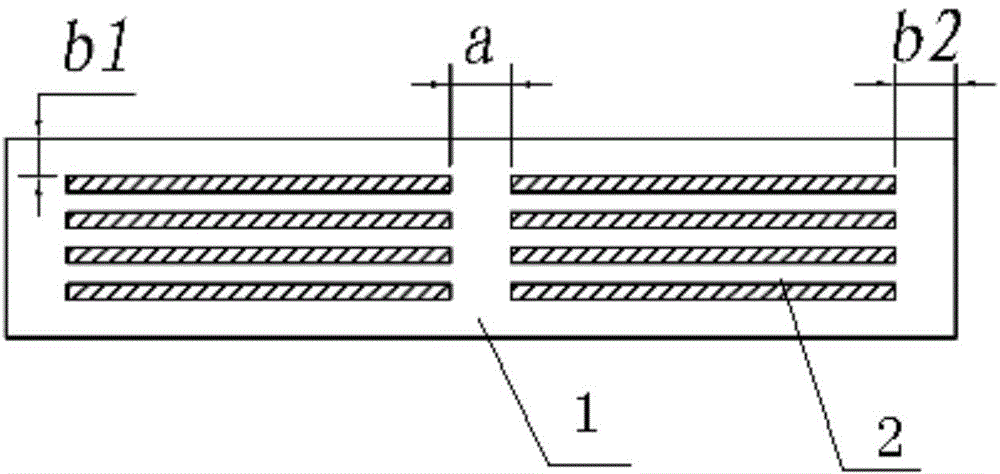

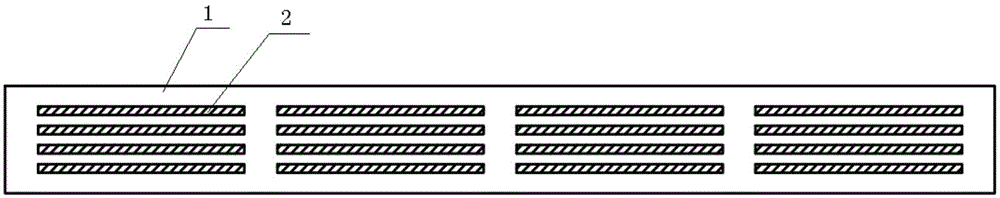

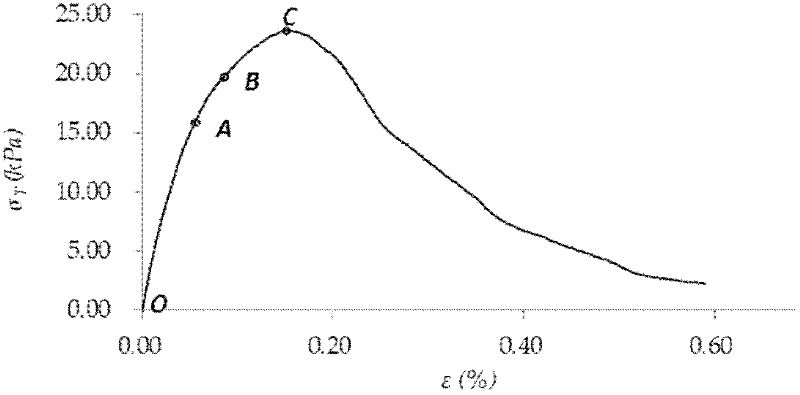

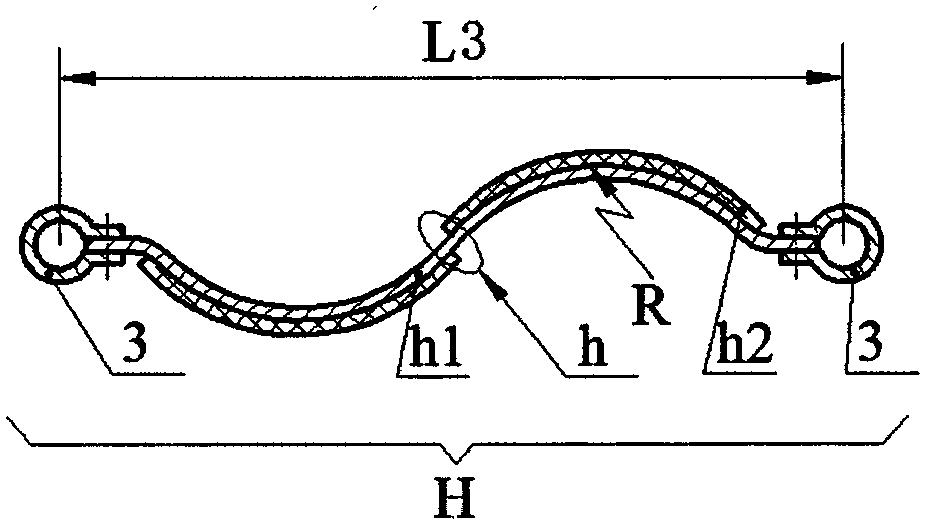

Dragging belt of composite materials

InactiveCN104528498AReduce the bending radius of curvatureEasy to bendRope making machinesElevatorsFiberThermoplastic polyurethane

The invention discloses a dragging belt of composite materials. The dragging belt is light in weight and good bending performance. The dragging belt comprises a plurality of inner bearing body layers and abrasion-resisting elastic bodies wrapped outside the inner bearing body layers. The inner bearing bodies are in a sheet shape which is continuous in the single length direction of the dragging belt. Each inner bearing body comprises a base body. A plurality of nonmetal non-twist continuous fiber monofilaments are arranged in the base bodies, the nonmetal non-twist continuous fiber monofilaments are not in contact, the base bodies of inner bearing body layers are made of thermosetting resin materials or thermoplastic resin materials, the abrasion-resisting elastic bodies are thermoplastic polyurethane or rubber elastic bodies. At least two inner bearing body layers are arranged in the thickness direction of the dragging belt. The thickness of the inner bearing body layers of the sheet-shaped structure of the dragging belt is small, under the premise that good bearing is achieved, bending curvature radius is greatly lowered, the obtained dragging belt is light in weight, high in intensity and easy to bend, abrasion resistance and whether resistance are achieved, anti-fatigue performance is achieved, service life is long, maintaining cost is low, and the dragging belt can be used for lifting of long-distance heavy objects.

Owner:TIANJIN GOLDSUN WIRE ROPE

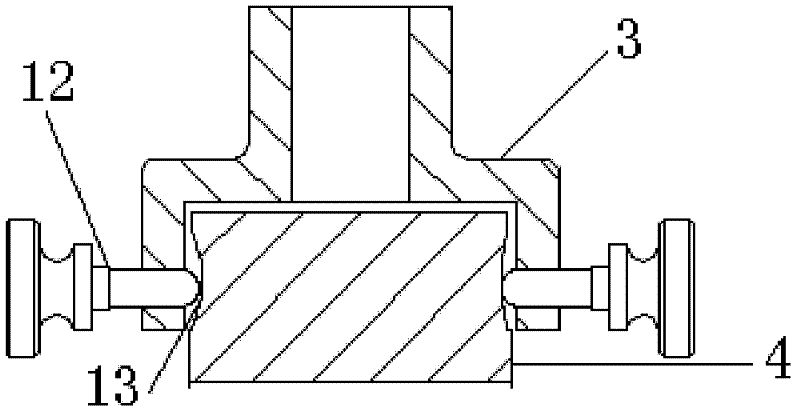

Clayey soil strain control type uniaxial extension meter

InactiveCN102252906AIngenious ideaUnique structureMaterial strength using tensile/compressive forcesStress distributionPull force

The invention discloses a clayey soil strain control type uniaxial extension meter. The uniaxial extension meter disclosed by the invention comprises a triaxial instrument, an extension system extending a specimen and a strain measuring system, wherein the extension system comprises a base capable of being lifted, a specimen cap and a connecting rod; the two ends of the specimen are respectively linked with the base and the specimen cap; the measuring system comprises a sensor and a digital display instrument; and the sensor measures a tensile force which is borne by the specimen and displaysthe tensile force through the digital display instrument. The uniaxial extension meter disclosed by the invention does not need to improve a conventional triaxial instrument, can carry out an extension test on specimens with different lengths, can overcome the defects of overlarge measuring force rigidity and over-small deformation of the original triaxial instrument, can improve extension stresstesting accuracy and stability and has the advantages of simplicity and convenience in operation and low cost; the extension test is carried out by adopting the extension meter disclosed by the invention; the stress distribution in the specimens is uniform; specimen damage occurs in the middle part of the specimens; and the extension stress and the extension deformation can be effectively measured, thereby searching the stress-strain relation of soil extension.

Owner:NANJING UNIV

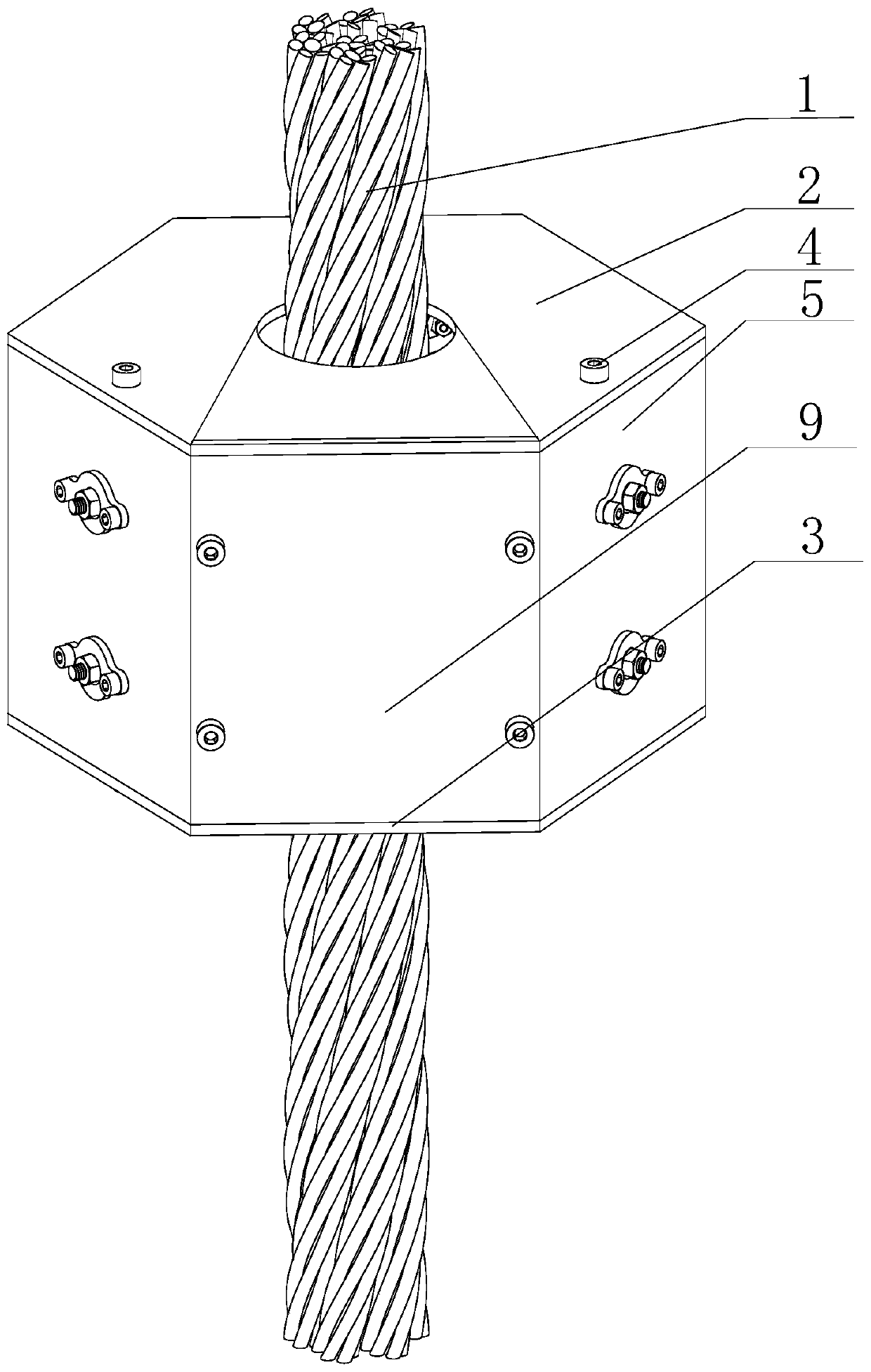

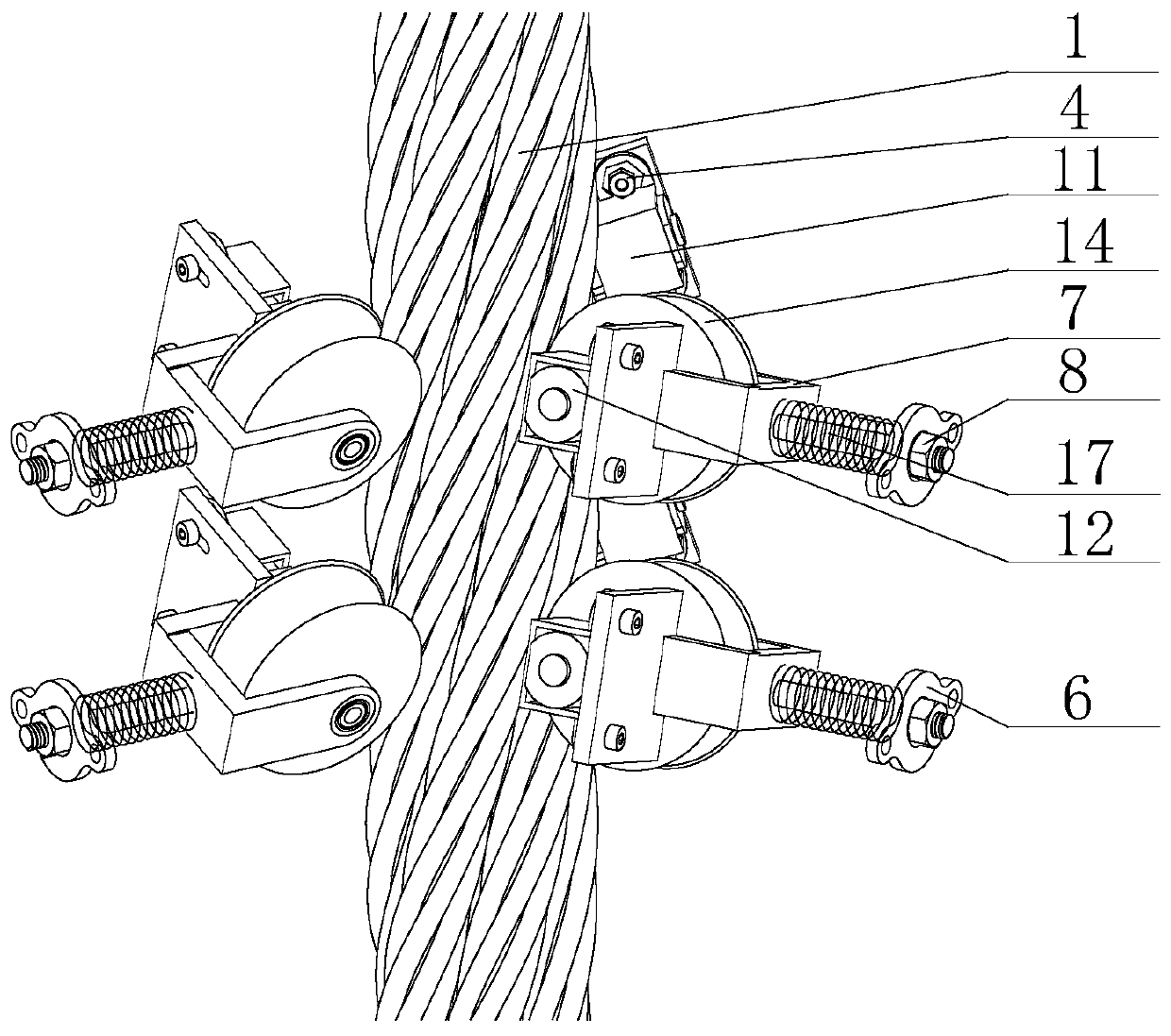

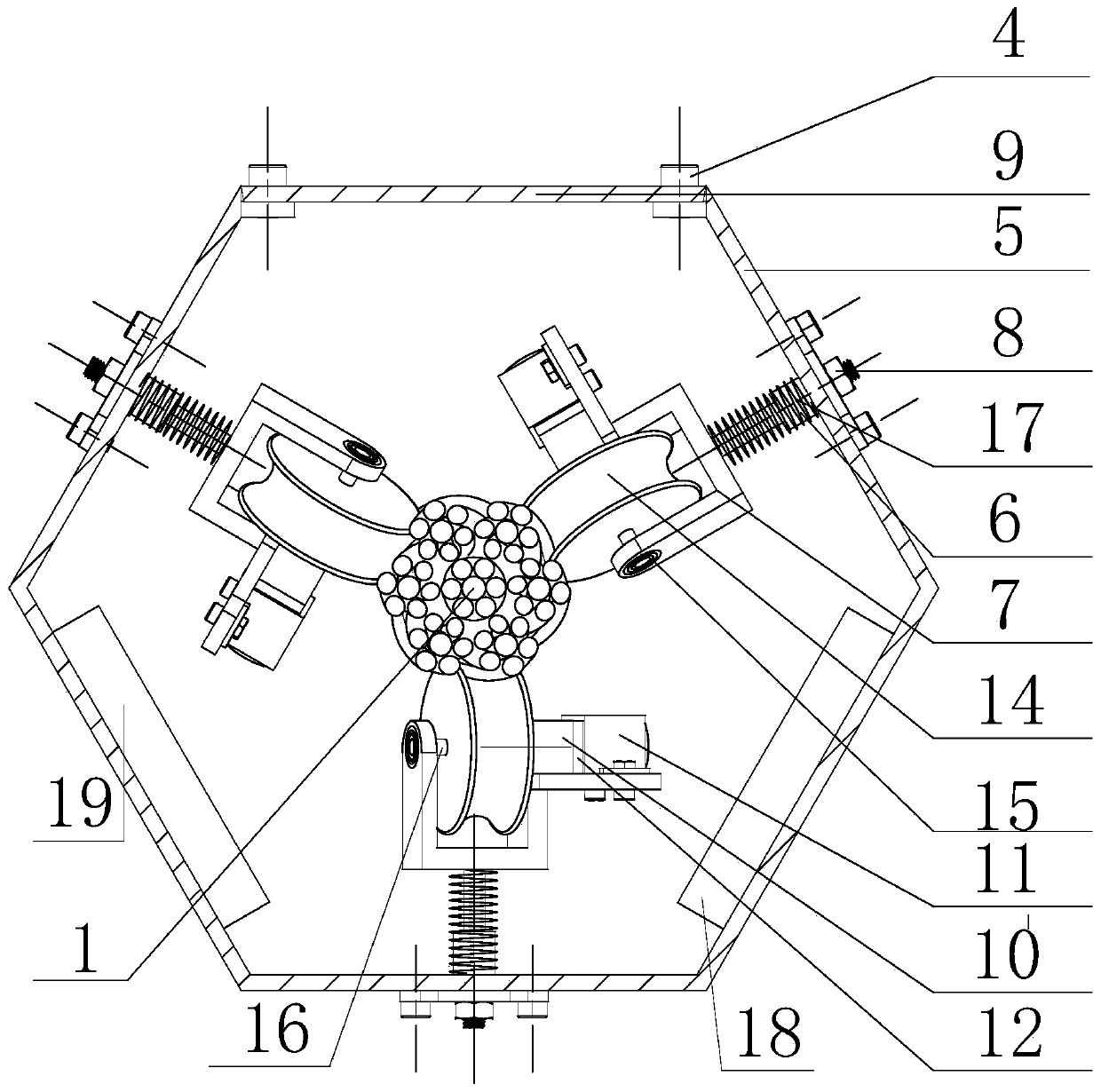

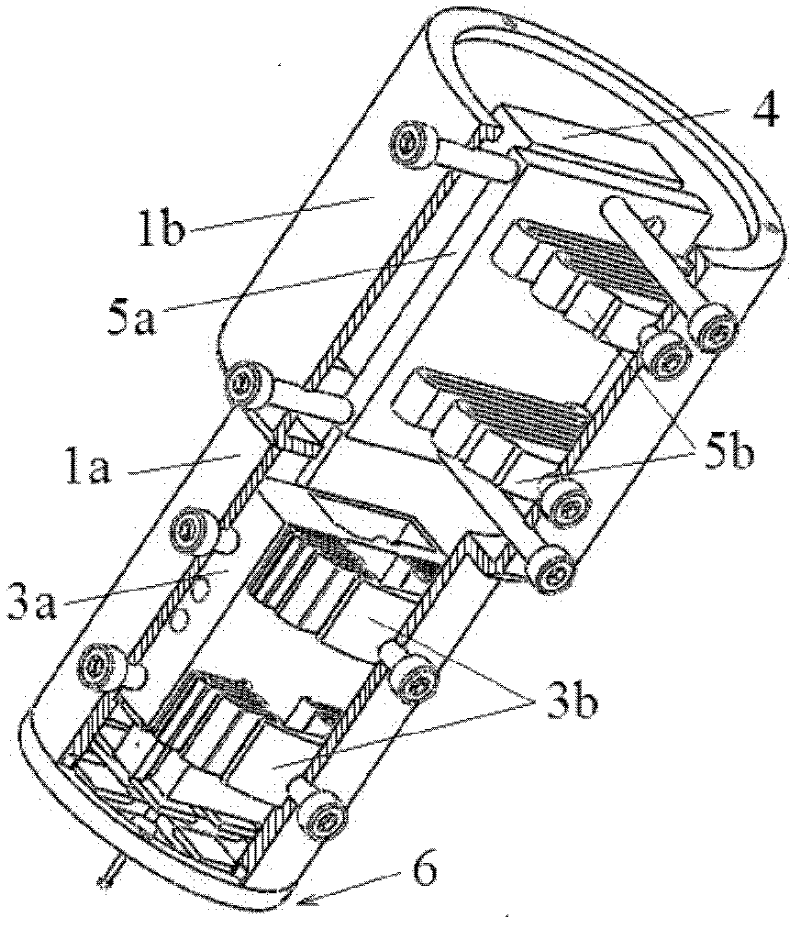

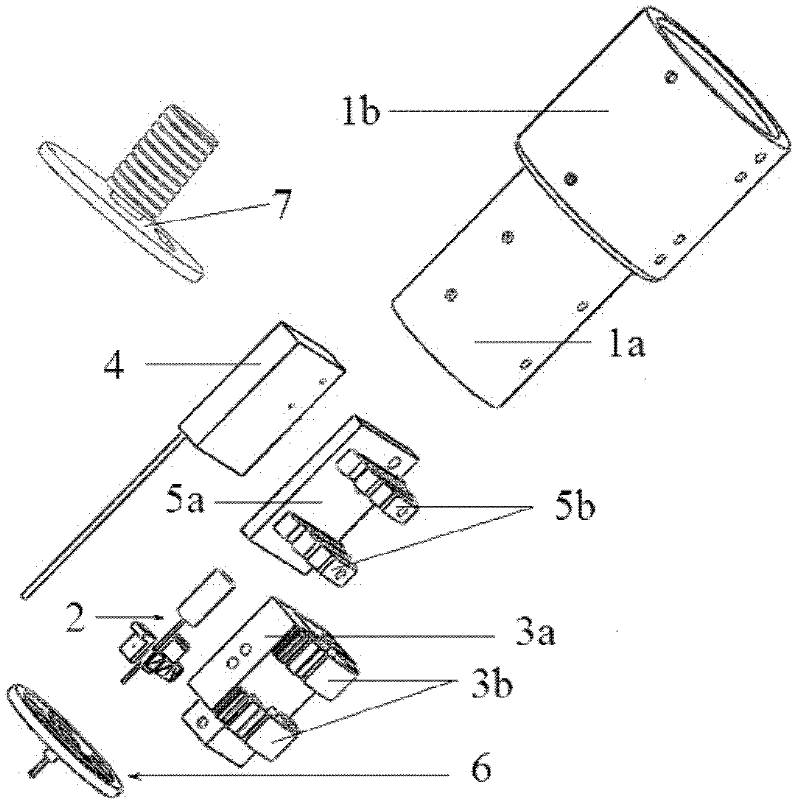

Steel wire rope twist direction climbing robot

The invention discloses a steel wire rope twist direction climbing robot. The steel wire rope twist direction climbing robot includes a plurality of modules, wherein climbing devices are arranged in outer shells of the modules, the climbing devices include tensioning supports, rolling wheels are mounted in tensioning supports, rubber sheets are arranged on the circumferences of the outer edges ofthe rolling wheels, shafts are arranged on the back sides of the tensioning supports, holes are formed in the outer shells close to the shafts, linear bearings are mounted at the positions of the holes, the shafts of the tensioning supports penetrate through the linear bearings and the holes, limiting anti-loose nuts are mounted on shafts outside the outer shells, and springs are further arrangedbetween the back sides of the tensioning supports and the inner walls of the outer shells. Compared with the prior art, the steel wire rope twist direction climbing robot can roll in the direction ofa spiral line twisted in a steel wire rope, the needed driving force is smaller and stable, and the bearing capacity is high; and the climbing robot can work under a special environment and can meet the requirement of anti-explosion; and the shafts of the tensioning supports move telescopically relative to the linear bearings, and the certain buffering obstacle crossing ability and the disturbanceresistant capacity are achieved.

Owner:CHINA UNIV OF MINING & TECH

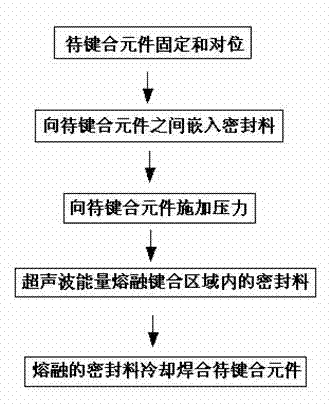

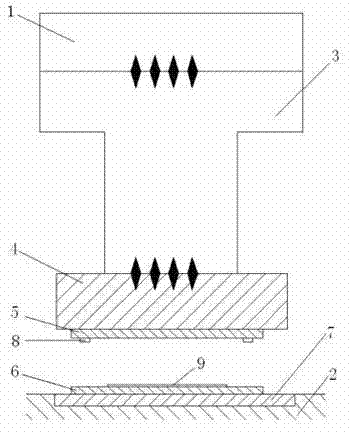

Ultrasonic bonding method and special ultrasonic welding machine used for optoelectronic device packaging

ActiveCN102225839ASolve the problem of hermetic packaging processImprove residual stress distribution stateSolid-state devicesSemiconductor/solid-state device manufacturingStress concentrationEngineering

The present invention discloses an ultrasonic bonding method and a special ultrasonic welding machine used for optoelectronic device packaging. The ultrasonic bonding method provided by the invention comprises the following steps of: fixing and precisely positioning the component to be welded, and applying an initial clamping force on the component to be welded, so that a glass sealing material is clamped by the component to be welded; and transferring the high-frequency vibration energy generated by an ultrasonic welding machine to the bonding surfaces through an energy guiding component, thus realizing the indeformable rapid welding package of the component to be welded. The special ultrasonic welding machine provided by the invention comprises an ultrasonic generator, a clamping component, the energy guiding component and a temperature control device. The ultrasonic bonding method and the special ultrasonic welding machine provided by the invention can accurately and precisely utilize energy, achieve the hermetic package of the component to be welded through energy transfer and transformation, significantly improve the residual stress distribution of the semiconductor optoelectronic device packaging layer, reduce stress concentration, guarantee the packaging quality of the semiconductor optoelectronic device and prolong the service life of the optoelectronic device, and canbe widely applied in the packaging of OLEDs (organic light emitting diodes), solar cells and other semiconductor optoelectronic devices.

Owner:SHANGHAI UNIV

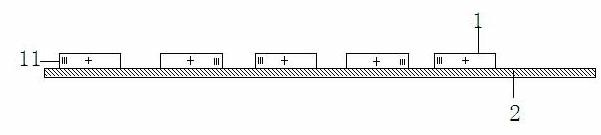

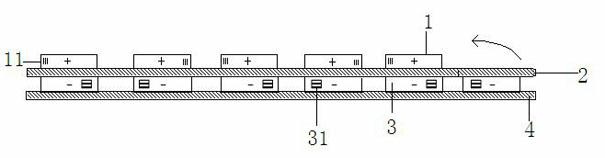

Lithium ion battery cell and preparation method thereof

InactiveCN102683742ALower internal impedanceReduce polarizationFinal product manufactureSecondary cellsInternal resistanceLithium-ion battery

The invention belongs to the technical field of lithium ion batteries, and in particular relates to a lithium ion battery cell which comprises at least two positive electrode plates, at least two negative electrode plates, a first wound membrane and a second wound membrane, wherein the positive electrode plates and the negative electrode plates are mutually overlapped, and the difference of the number of the positive electrode plates and the number of the negative electrode plates is one; the positive electrode plates are arranged at the same side of the first membrane; the negative electrode plates are arranged at the same side of the second membrane; and at the direction from the innermost circle to the outermost circle of the battery cell, the first membrane and the second membrane are alternatively arranged between the adjacent positive electrode plates and the negative electrode plates at intervals. Compared with the prior art, the lithium ion battery cell has the advantages that the parallel connection multiple layers of electrode plates provided by the invention can be used for reducing the internal resistance of the battery cell, thus the polarization is reduced, and the discharging platform is improved; the parallel connection of the electrode plates can be used for improving the high-multiplying-power charging and discharging capability of the battery cell; and because the electrode plates of the battery cell provided by the invention are stacked together, the internal structure is unified, the stress is distributed uniformly, the possibility of deformation is small. In addition, the invention also discloses a preparation method of the battery cell.

Owner:DONGGUAN AMPEREX TECH +1

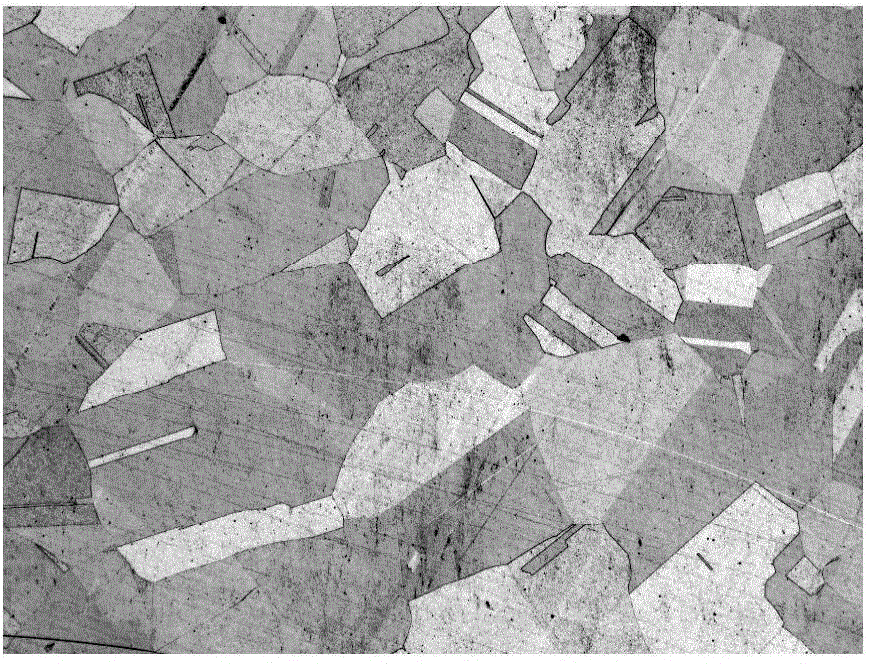

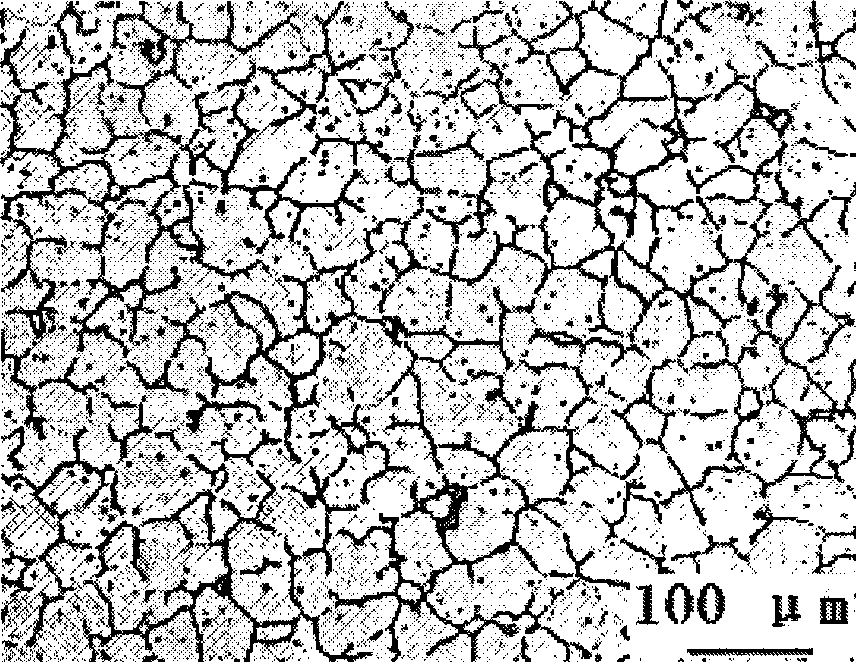

Deep overcooling treatment method for fine grain copper alloy shaped charge liner

The invention provides a preparation method of a fine grain copper alloy shaped charge liner. The preparation method of the fine grain copper alloy shaped charge liner comprises the following steps: carrying out compound cold extrusion plastic deformation, carrying out deep overcooling treatment, and carrying out recrystalization annealing, wherein the compound cold extrusion plastic deformation comprises the steps of putting a blank into a mould cavity of a preformed blank forming mould, carrying out forward extrusion forming to obtain a designed copper alloy preformed blank under the actions of three-dimensional compressive stress and deformation rate and then putting the preformed blank into a mould cavity of a shaped charge liner forming mould and gradually forming the shaped charge liner preformed blank by carrying out gradual-pass diameter-expanded extrusion plastic deformation, thus obtaining the shaped charge liner blank of a required shape structure; the deep overcooling treatment comprises the step of carrying out heat preservation on the shaped charged liner blank for 2-4 hours at the temperature ranging from -196 DEG C to 130 DEG C; and the recrystallization annealing comprises the step of carrying out heat preservation on the shaped charge liner (subjected to deep overcooling treatment) for 5-15 minutes at the temperature of 450-550 DEG C in a protective atmosphere, thus obtaining a shaped charge liner component. The preparation method of the fine grain copper alloy shaped charge liner has the advantages that strict requirements of the shaped charge liner on grain structure homogeneity, consistency of performance and stress state and distribution can be met, and quality of the shaped charge liner can be improved.

Owner:NO 59 RES INST OF CHINA ORDNANCE IND

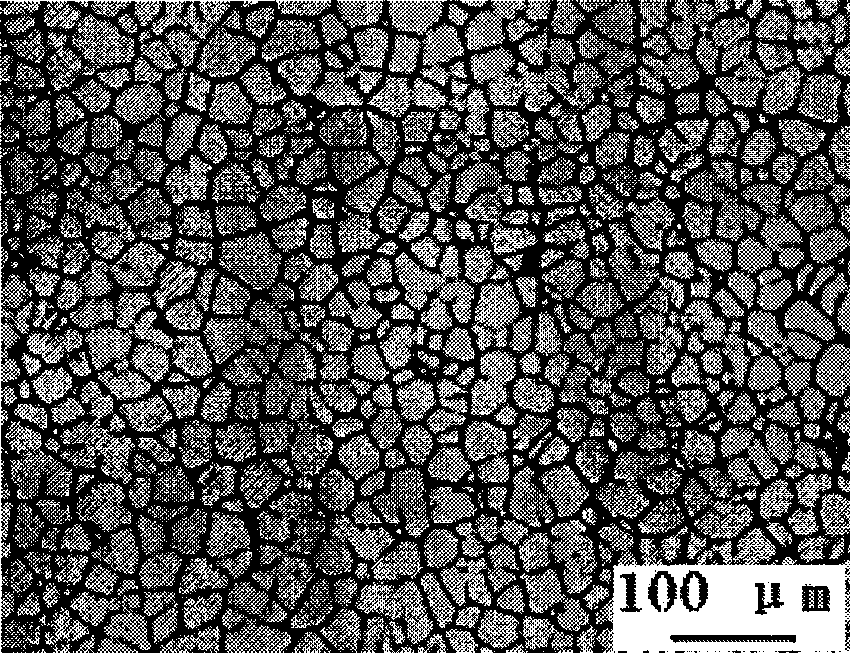

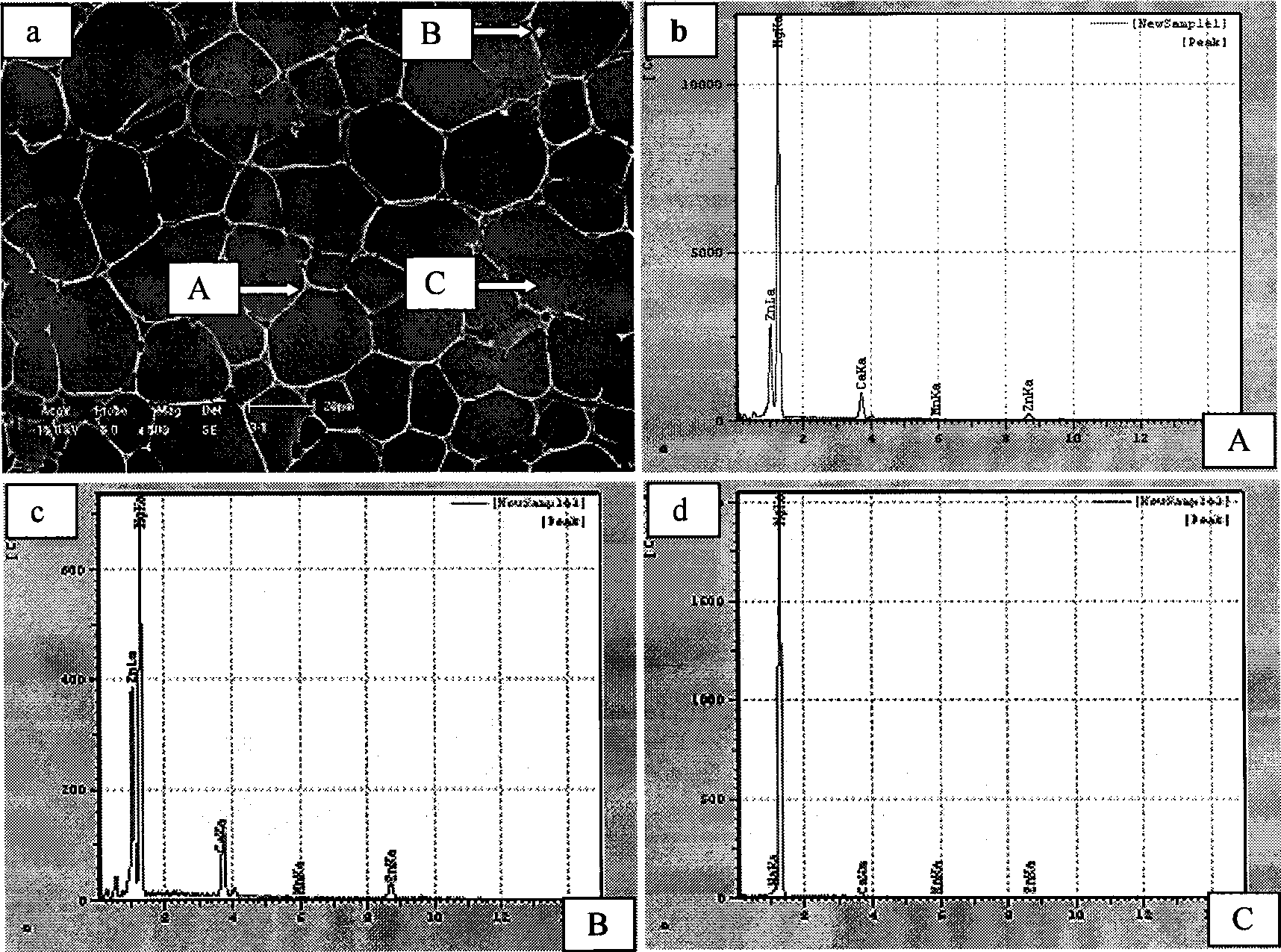

Preparation of nontoxic magnesium alloy material for biological implantation

The invention relates to a method for preparing a magnesium alloy material suitable for biological implantation, which comprises the following steps: preparing raw materials by the following chemical compositions in percentage by weight: 2.0 to 6.0 percent of Zn, 0.5 to 1.9 percent of Mn, 0.6 to 5.0 percent of Ca, less than or equal to 0.1 percent of total impurities, and the balance of Mg; or preparing the raw materials by the following chemical compositions in percentage by weight: 2.0 to 6.0 percent of Zn, 0.3 to 0.9 percent of Zr, 0.5 to 5.0 percent of Ca, less than or equal to 0.1 percent of total impurities, and the balance of Mg; preheating smelting equipment and adding the Mg into the raw materials; heating the mixture under the protection of argon gas with the flow rate of between 5 and 6 L / min and the pressure of 14 MPa; adding a fire retardant into the molten liquid when the temperature of the molten liquid reaches between 650 and 660 DEG C, raising the temperature of the molten liquid to between 700 and 720 DEG C, adding other alloy elements into the molten liquid respectively, and performing melting reaction; and stirring the mixture until the mixture is uniformly mixed after alloy is completely molten, keeping the mixture stand for 30 to 40 minutes, pressing a deslagging agent into the solution for deslagging, casting the alloy solution into a cast die after keeping the alloy solution for 10 to 20 minutes at the temperature of between 690 and 710 DEG C, and preparing a Mg-Mn series or Mg-Zr series biomedical magnesium alloy material ingot.

Owner:NORTHEASTERN UNIV

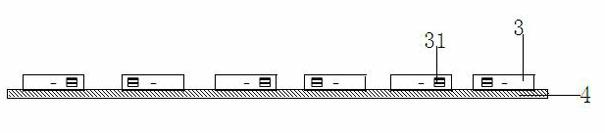

Piezoelectric generator excited by human motion

InactiveCN104485850AHigh mechanical reliabilityUniform stress distributionPiezoelectric/electrostriction/magnetostriction machinesTransducerHuman motion

The invention relates to a piezoelectric generator excited by human motion, and belongs to the field of power generation. A flange ring and a bottom wall are arranged at the two ends of the cylindrical wall of a shell. Two sets of side lugs are arranged on the outer side of the bottom wall, and a transverse bolt is arranged between two side lugs of each set. An end cover is arranged at the end of the flange ring, shaft holes are formed in the center of the end cover and the center of the bottom wall, and long pins are arranged in long pin holes in the flange ring and the bottom wall and sleeved with pin sleeves. The two ends of a main shaft of an exciter are arranged in the shaft holes in the end cover and the bottom wall respectively, swinging arms are arranged on flange plates on the two sides of the main shaft of the exciter, and swinging hammers are arranged at the ends of the swinging arms. Short pins are riveted in short pin holes in the flange plates and sleeved with pin sleeves. The pin sleeves which with the long pins and the short pins are sleeved are riveted to the two ends of a metal film, the metal film and a piezoelectric film adhering to the arc protrusion of the metal film form a piezoelectric vibrator, and the piezoelectric vibrator and the pin sleeves riveted to he two ends of the piezoelectric vibrator form a transducer. The piezoelectric generator has the advantages that the telescopic piezoelectric vibrator is hinged to the shell and the exciter and can collect the energy of the human motion, so that the piezoelectric generator has high reliability and power generation capacity.

Owner:ZHEJIANG NORMAL UNIVERSITY

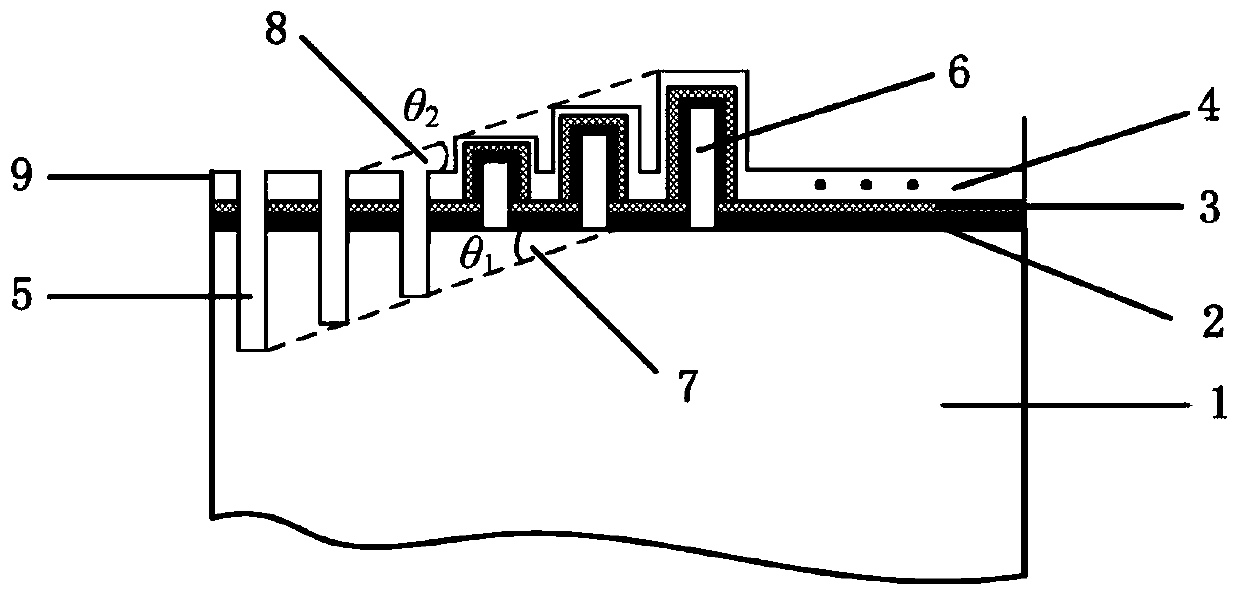

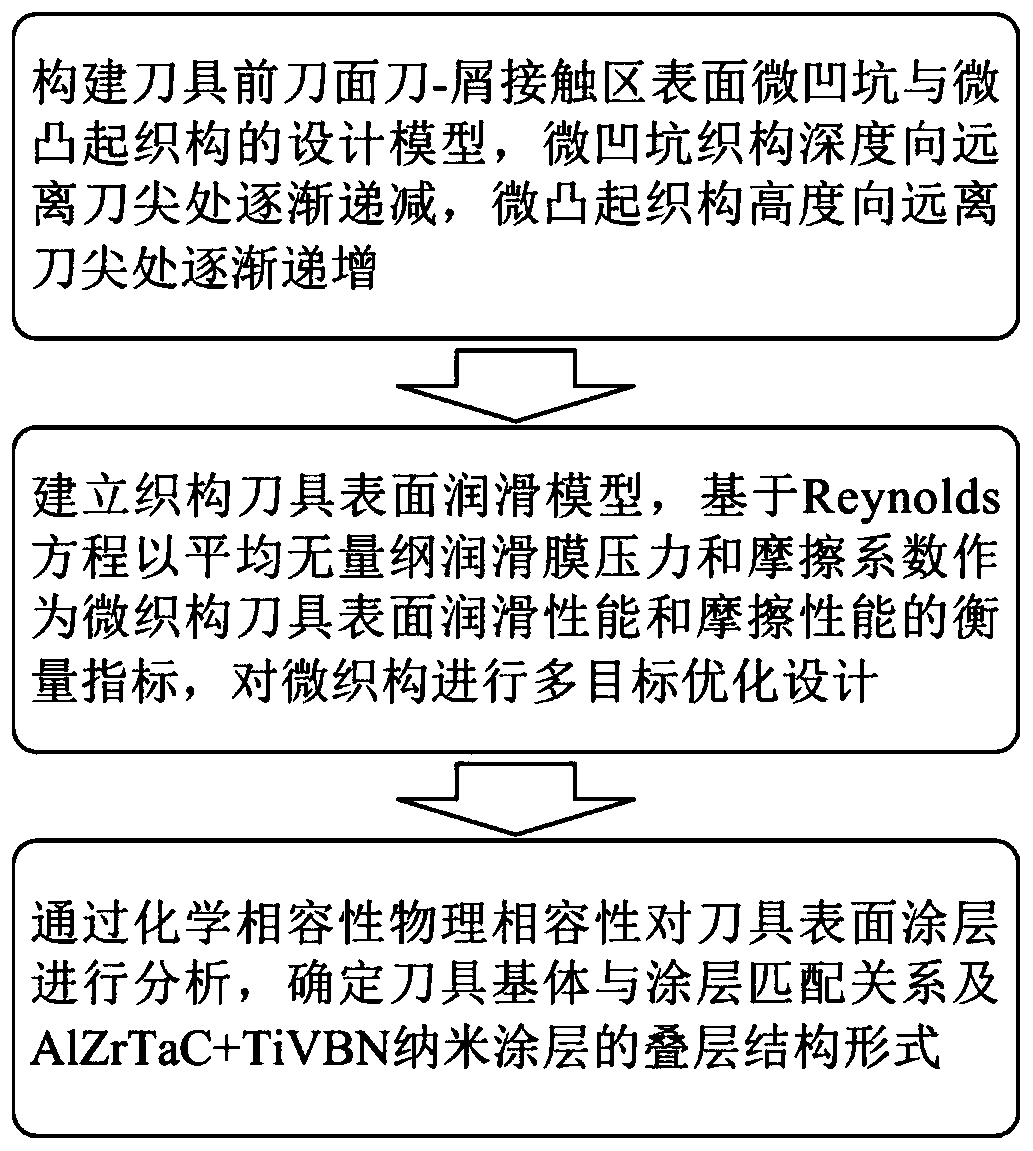

Bionic texture and coating layer cooperated anti-friction cutter and design method thereof

The invention discloses a bionic texture and coating layer cooperated anti-friction cutter and a design method thereof. The cutter adopts a basal body material of high-speed steel, hard alloys or ceramic; a bionic micro pit and micro projection composite texture is arranged in a cutter-chip contact area on the front cutter surface of the basal body material of the cutter; AlZrTaC+TiVBN alternate-distributed nanometer laminate coating layers are arranged on the surfaces of the texture and a basal body; the alternate laminate coating layers at least comprise single layers of 10 AlZrTaC layers and 10 TiVBN layers; and the thickness of the single layers of AlZrTaC and TiVBN is not bigger than100 nm. The design method of the cutter comprises the following steps: a design model of a micro texture on the surface of the cutter-chip contact area on the front cutter surface of the cutter is built; the oil film pressure and the friction coefficients of the cutter-chip contact interface are analyzed based on a Reynolds equation to optimize the geometric size of the micro texture and the depth or height gradual change dip angles theta 1 and theta 2; and through physical compatibility and chemical compatibility analysis, a laminate structural form of AlZrTaC+TiVBN coating layers is built. The cutter synthesizes the characteristics of the micro texture and the nanometer laminate coating layers, can reduce the friction and the wear of the cutter in the lubricating liquid cutting process, and can be widely applied to the cutting in the cutting liquid mode.

Owner:SOUTHEAST UNIV

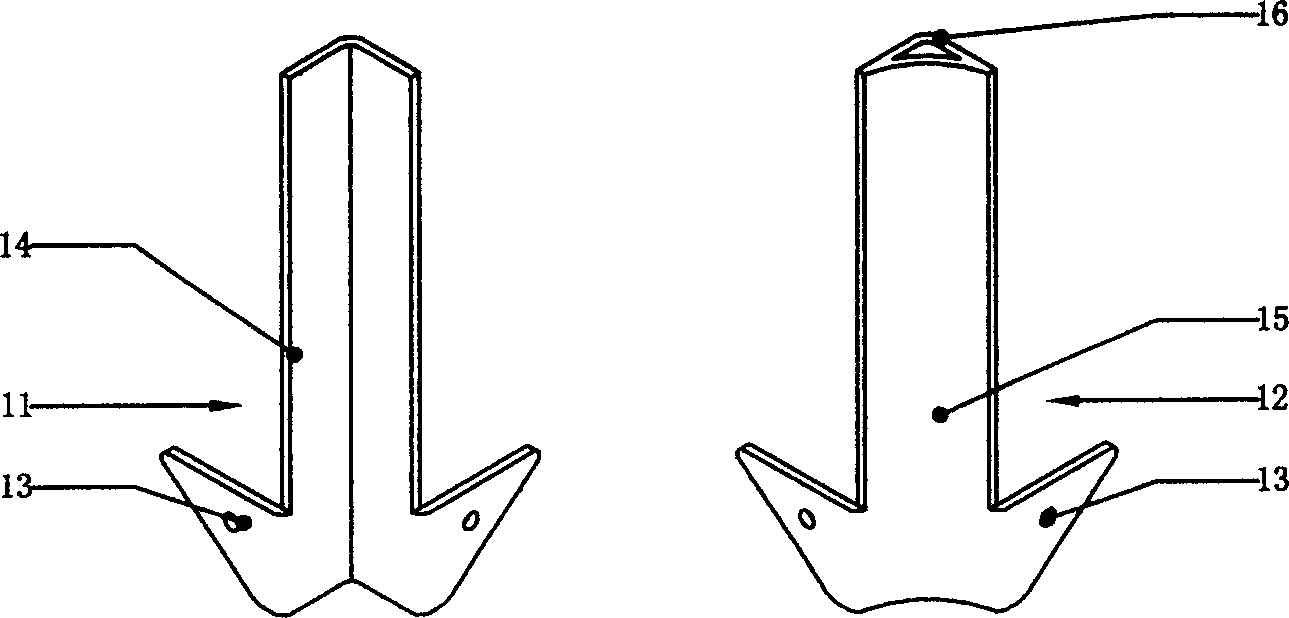

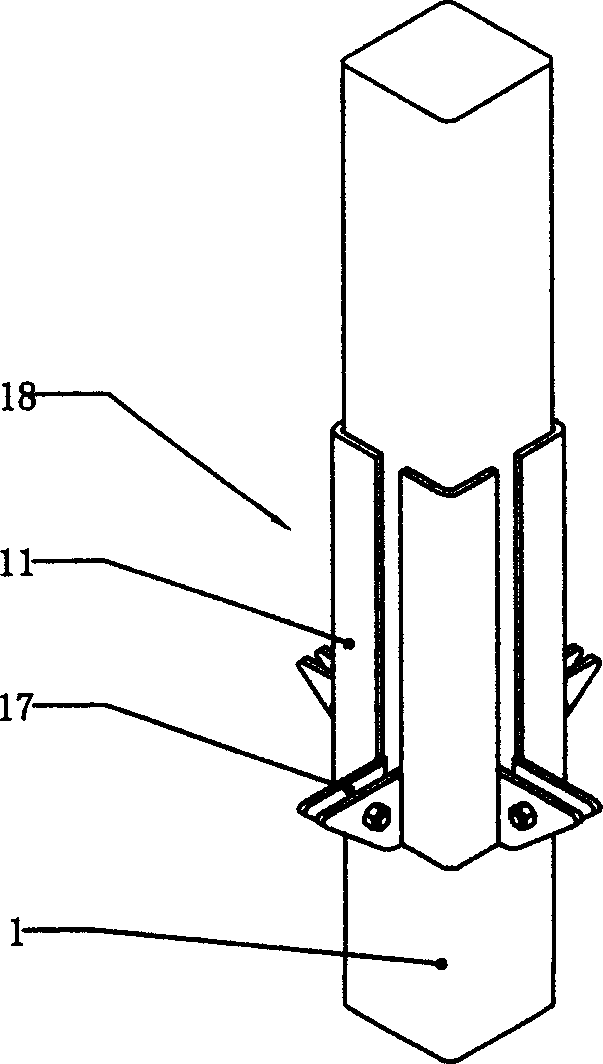

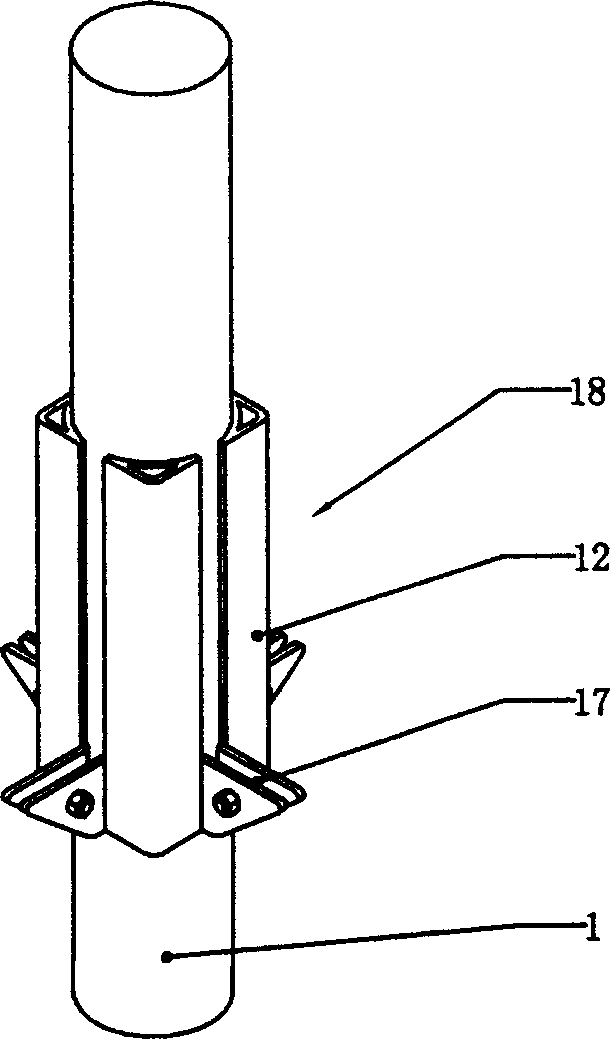

Butterfly type self locking connecting card with friction shear resisting board and construction steel frame node structure

InactiveCN1786362AIncreased load-bearing capacityEliminate damageBuilding constructionsFriction & shearSelf locking

The invention relates to butterfly type self locking connecting card with friction shear resistant plate and building iron joint of framework structure. The friction shear resistant plate includes friction surface and shear resistant plate. Four friction shear resistant plates is formed square type node pillar to cooperate with hitch clevis. The connecting card includes card body. Both end of the card body are respectively set two card wings with door shape cross section. The card wing includes bearing plate, pretension plate, and self locking mounting plate. The self locking and pretension plate are set through holes. The invention utilizes the friction, and self locking principle, the friction shear resistant plate is gain the enlarged pressure and friction by butterfly type self locking connecting card to transfer to bearing force to act on node crossbeam to gain ideal joint intensity, stiffness, and bearing force.

Owner:甘秀明

Three-dimensional micro nanometer contact scanning probe

The invention discloses a three-dimensional micro nanometer contact scanning probe, which is characterized in that in the front section of a cylinder, a Michelson interferometer is fixedly arranged in an installation box; in a rear section of the cylinder, a two-dimensional sensor is fixedly installed on an installation plate; a fixing ring is arranged at the front end of the front section of thecylinder, a cross suspension sheet is arranged in the center of the fixing ring, each cantilever of the cross suspension sheet is connected with the fixing ring through each cantilever spring sheet to form a suspension structure, a central planar reflection mirror and at least one cantilever planar reflection mirror are respectively positioned on the cross suspension sheet, emergent light of the Michelson interferometer is projected on the central planar reflection mirror, emergent light of the two-dimensional sensor is projected on the cantilever planar reflection mirror, and on one side plane of the cross suspension sheet towards the outside of the cylinder, the scanning probe is fixedly installed in the center of the cross suspension sheet. The three-line structured light machine vision width measurement method can acquire detection effects with large range, high accuracy, high flexibility and small measurement force.

Owner:HEFEI UNIV OF TECH

Method for preparing high-strength high-density isotropic graphite material

The invention provides a method for preparing a high-strength high-density isotropic graphite material. According to the method, pitch mesocarbon micro bead (MCMB) powder of which the D50 is larger than 20 micrometers, and the volatile content is less than 7 percent is taken as a raw material, and the high-strength high-density isotropic graphite material is prepared by adopting the self-sintering process that the raw material powder is added into an organic solvent of pitch, the solvent is removed, the powder is pressed, a green briquette is formed through isostatic compaction, roasting and carbonization are performed, and graphitization is performed. According to the method, an organic solvent method is utilized to disperse bitumastic cement, so as to realize the modification on MCMB powder with large size and low volatile matter, the original shapes and sizes of the MCMB particles are basically kept after modification, good self sinterability is realized, and the finally obtained graphite is fine and uniform in structure, high in density and excellent in mechanical property. The pitch of the dispersed and modified MCMB is distributed uniformly, the inner stress of the green briquette in the isostatic compaction step is more uniformly distributed, and balanced expansion and shrinkage in the working procedures of roasting and graphitization are realized, and therefore, a product is not liable to crack, and the yield reaches not less than 90 percent.

Owner:HUNAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com