Butterfly type self locking connecting card with friction shear resisting board and construction steel frame node structure

A node structure and connection card technology, which is applied in the direction of building construction and construction, can solve the problems of unsatisfactory three-dimensional cross-connection, failure to realize circular column connection, complex interface shape requirements, etc., and achieve good transmission, improved safety, The effect of little stress transmission disturbance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

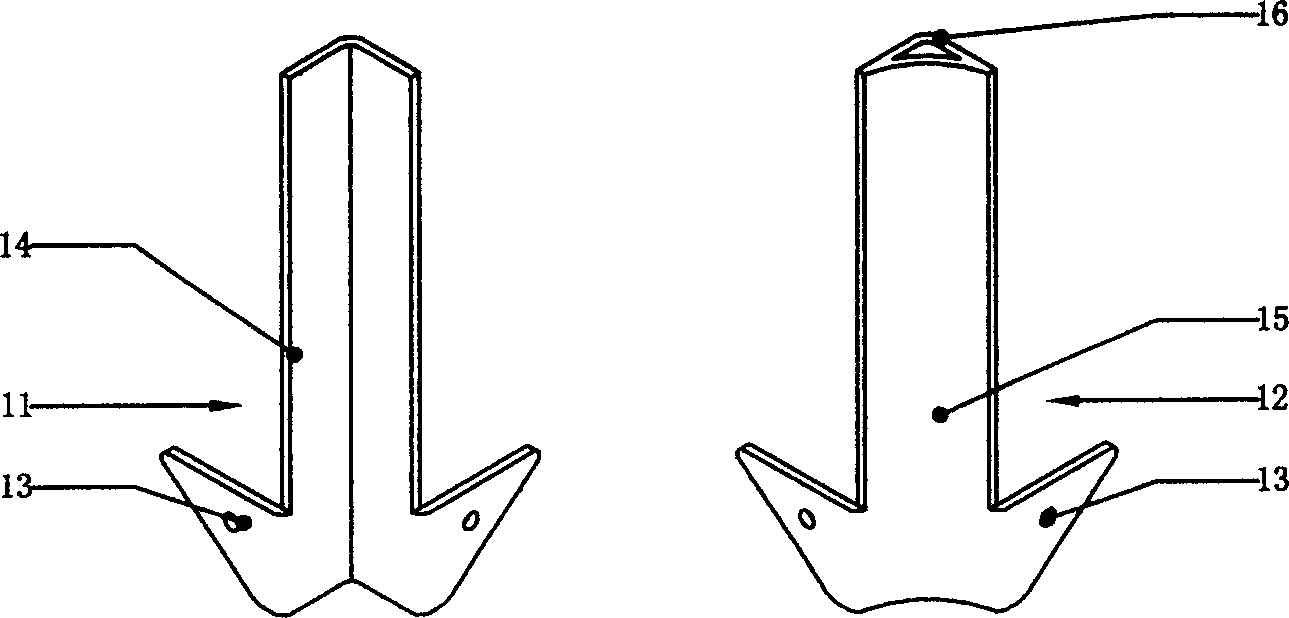

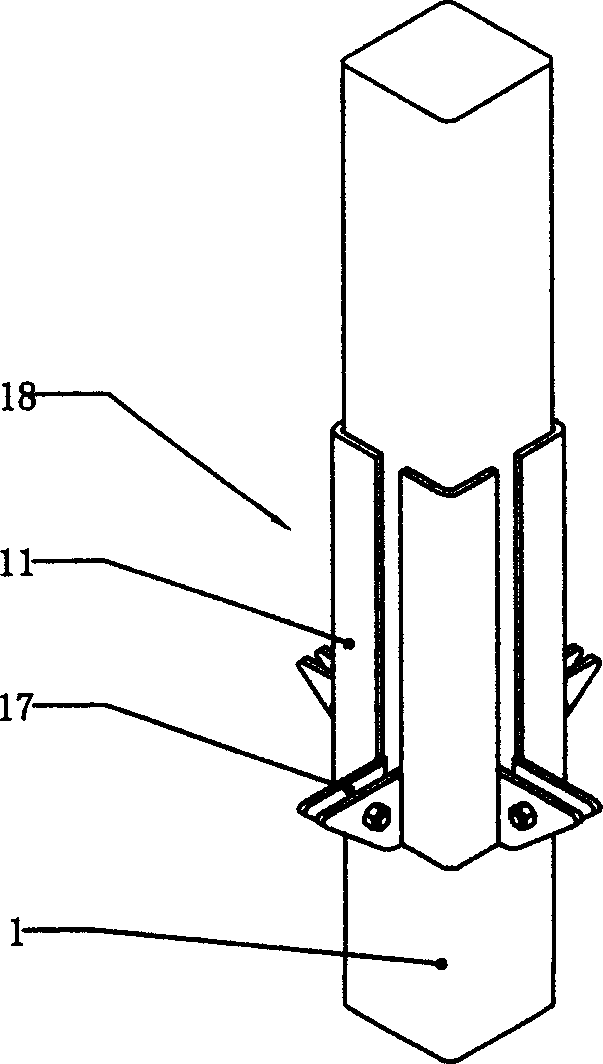

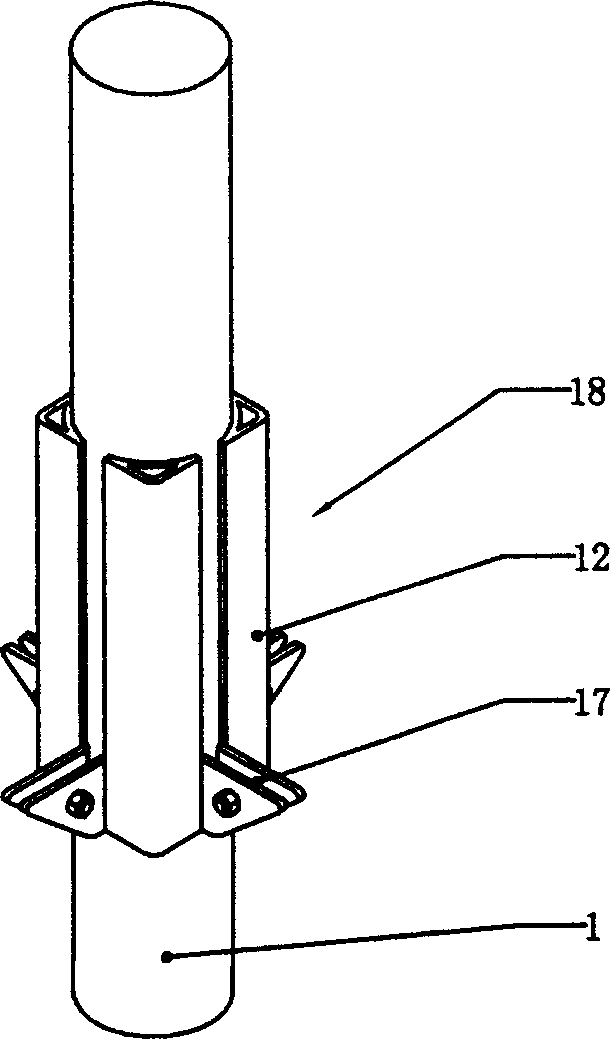

[0032] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 , The building steel frame node connection structure described in the present invention includes a vertical column 1, a beam 2, a connection clip 3 and a frictional shear plate 11 or 12 connecting the two. The V-shaped friction shear plate 11 includes a V-shaped friction plate 14. At the same end of the two outer surfaces of the V-shaped friction plate, there is a shear plate 13 perpendicular to the outer surface, with holes on it. The whole component is called V-shaped friction shear plate 11 . If it is matched with the cylinder, the inner side of the original structure called V-shaped friction shear plate 11 is connected with an arc-shaped friction plate with the same arc radius as the cylinder, which is called C-shaped friction plate 15, and the original V-shaped friction plate 14 is It is called friction support plate 16 . The C-type friction plate 15 with the friction support plate 16 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com