Patents

Literature

40 results about "Friction & shear" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Friction usually, but not always, accompanies shear. Friction is the force of rubbing two surfaces against one another. Shear is a gravity force pushing down on the patient's body with resistance between the patient and the chair or bed.

Friction reducing devices

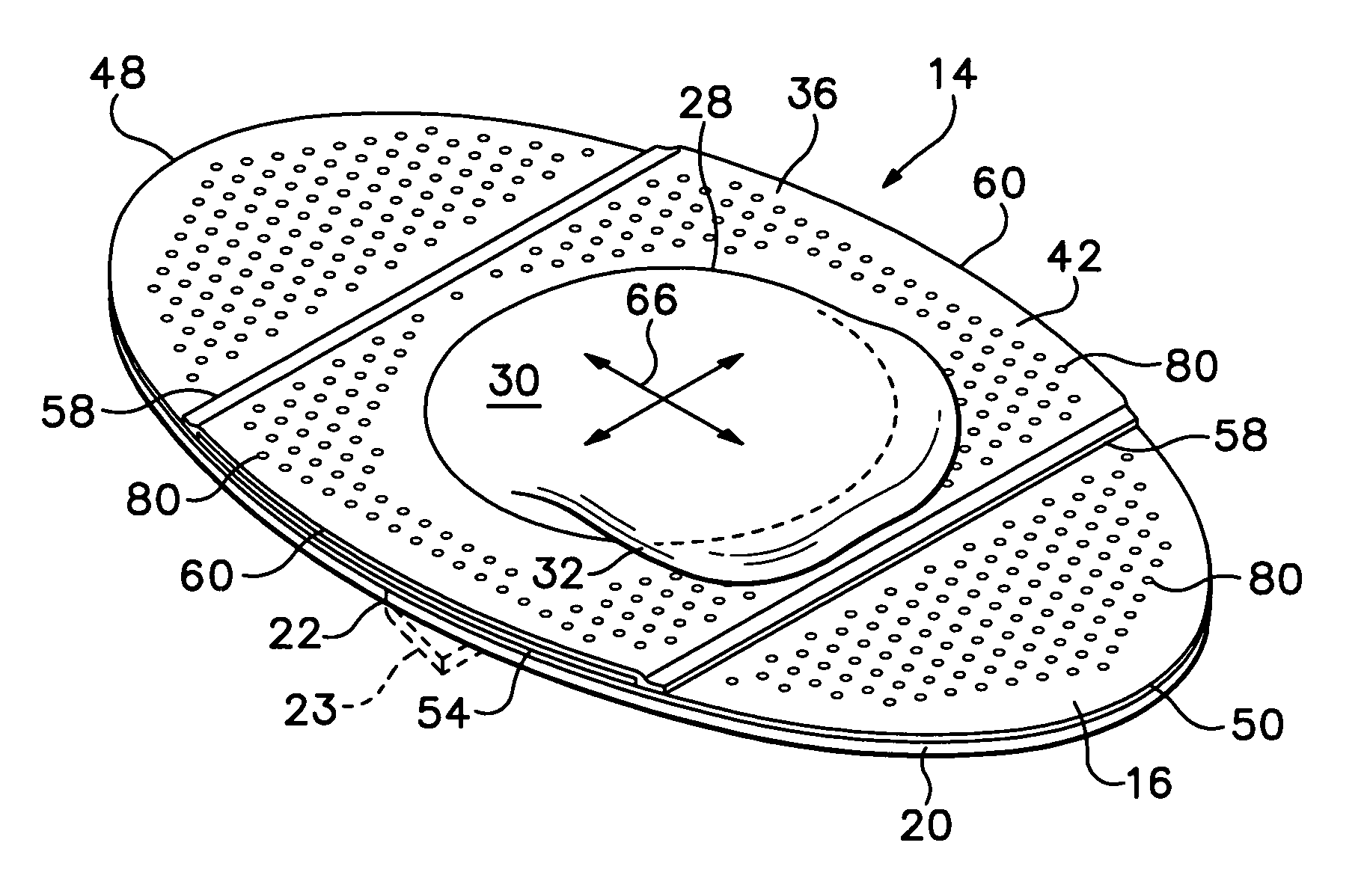

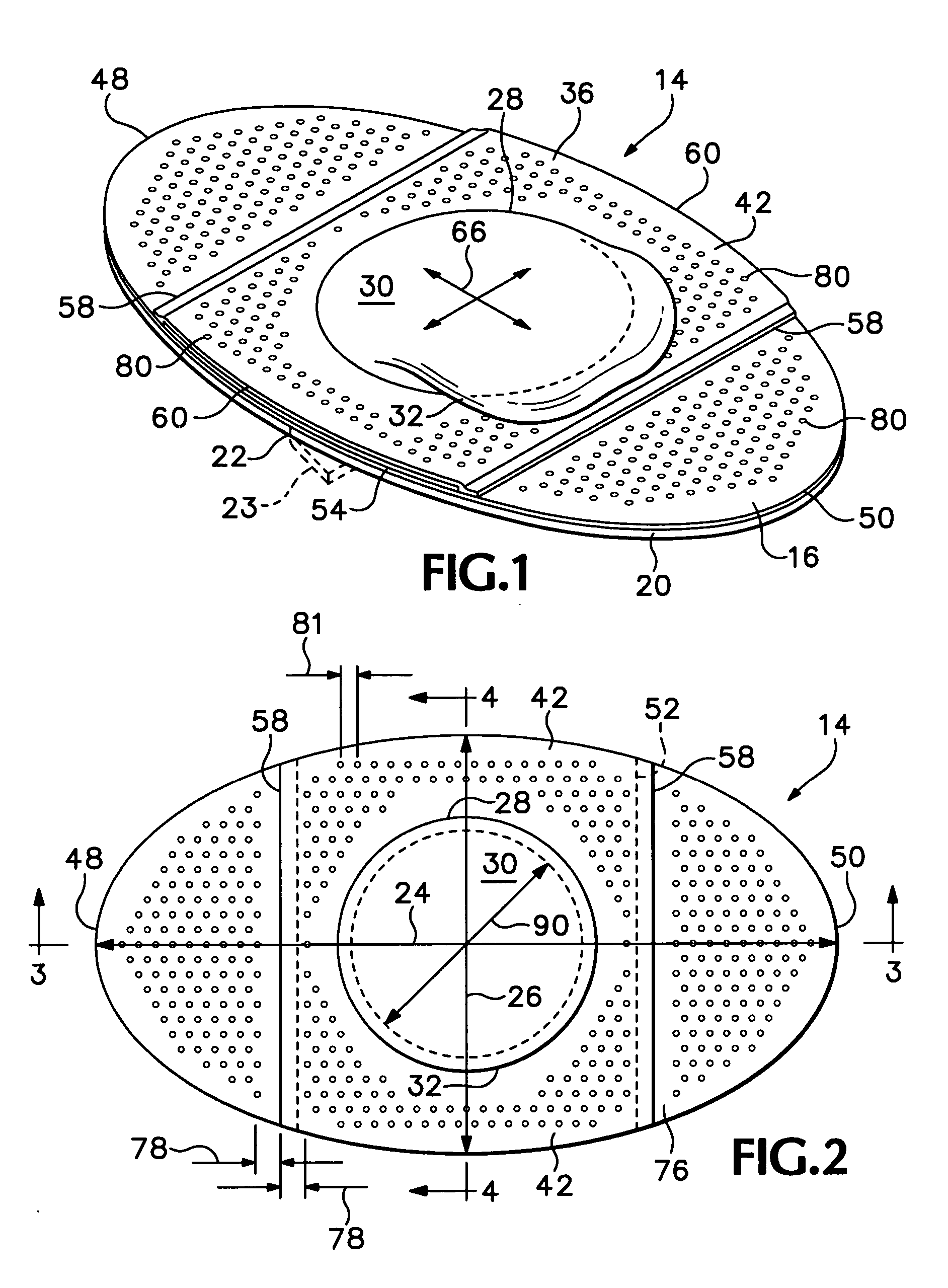

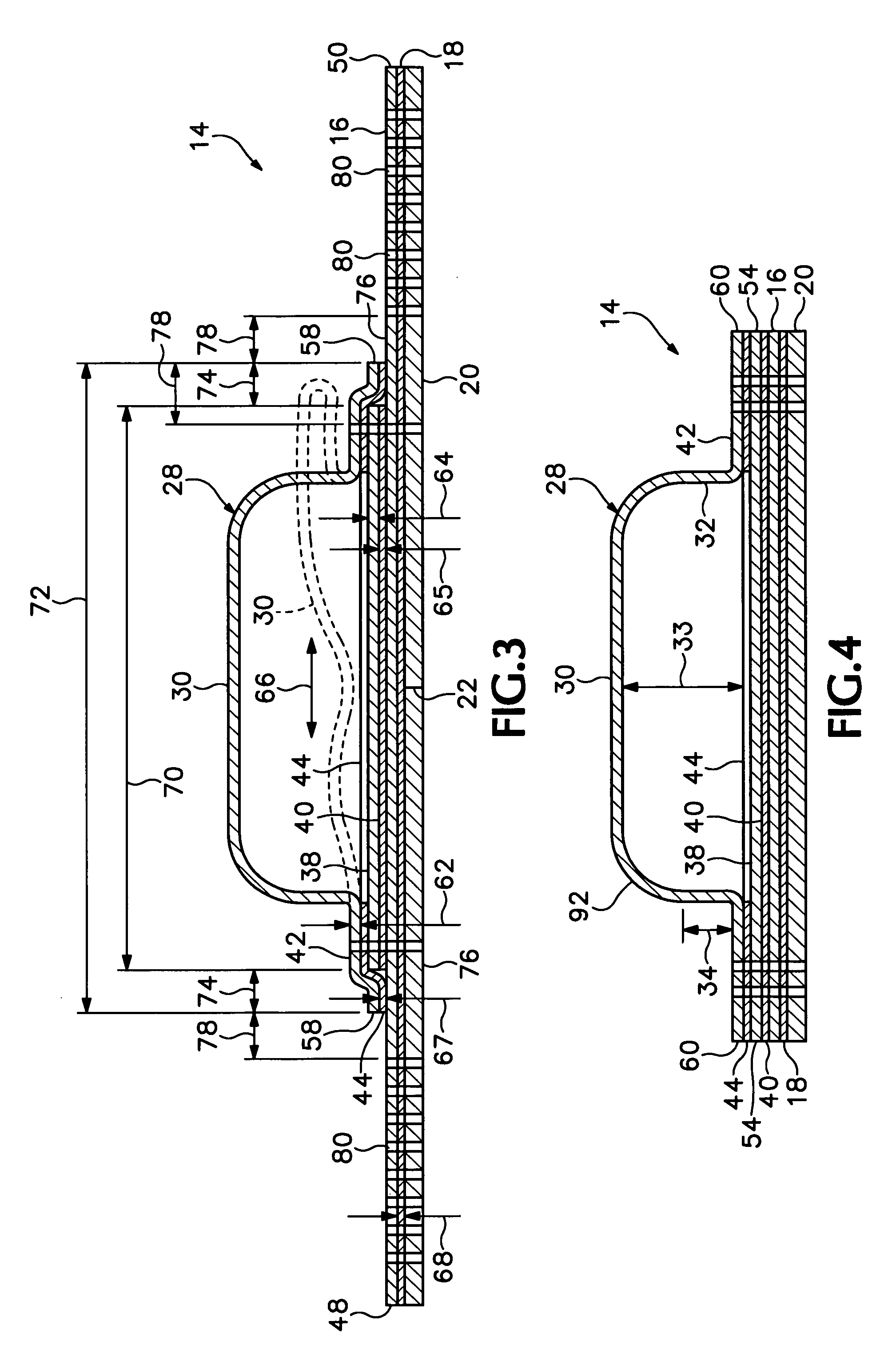

InactiveUS20070027423A1Overcomes shortcomingEnhance moisture and vapor transferFinger bandagesRestraining devicesSkin breakdownFriction & shear

Devices for reduction of damage from friction and for prevention and treatment of skin breakdown by relief of friction and shear forces. A friction reducing device may include a pair of thin membranes with low coefficients of friction with respect to each other, and of which one is free to slide through a limited distance along the other. A method of making one such device includes forming a dome in a flexible film and adhesively attaching a skirt surrounding the dome to a skin contact layer. Similar friction reducing devices may be incorporated in shoes, other clothing, or sports equipment or used to protect movable rods or cables.

Owner:ADVANCED WOUND SYST

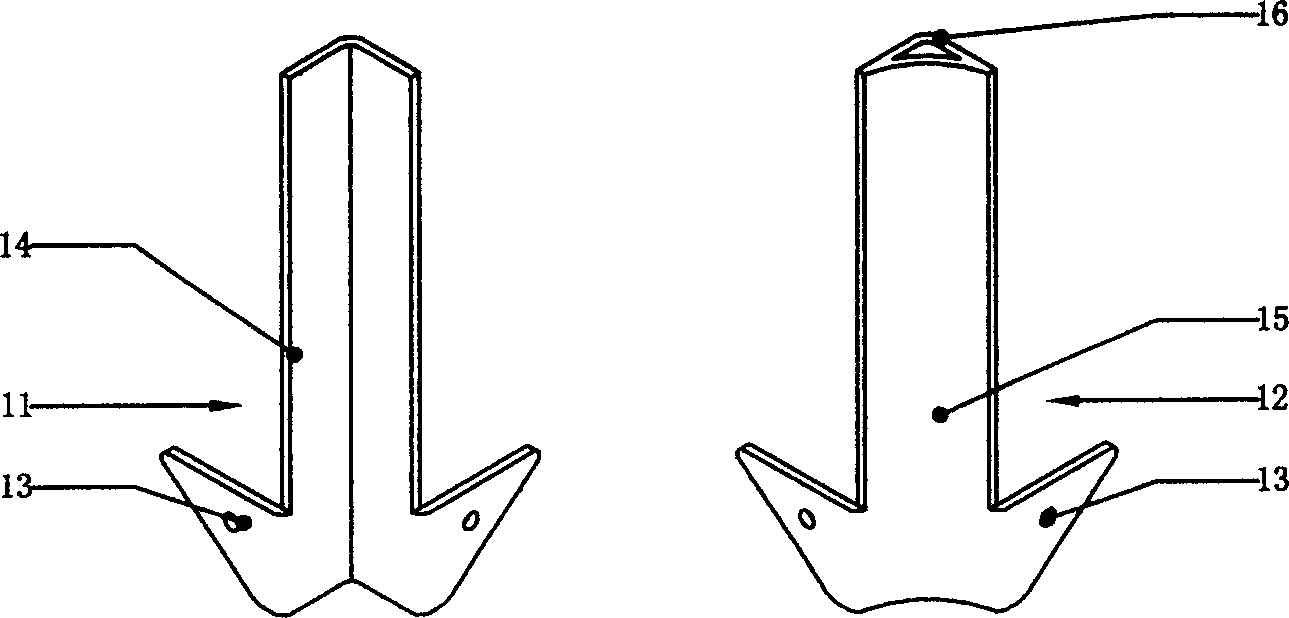

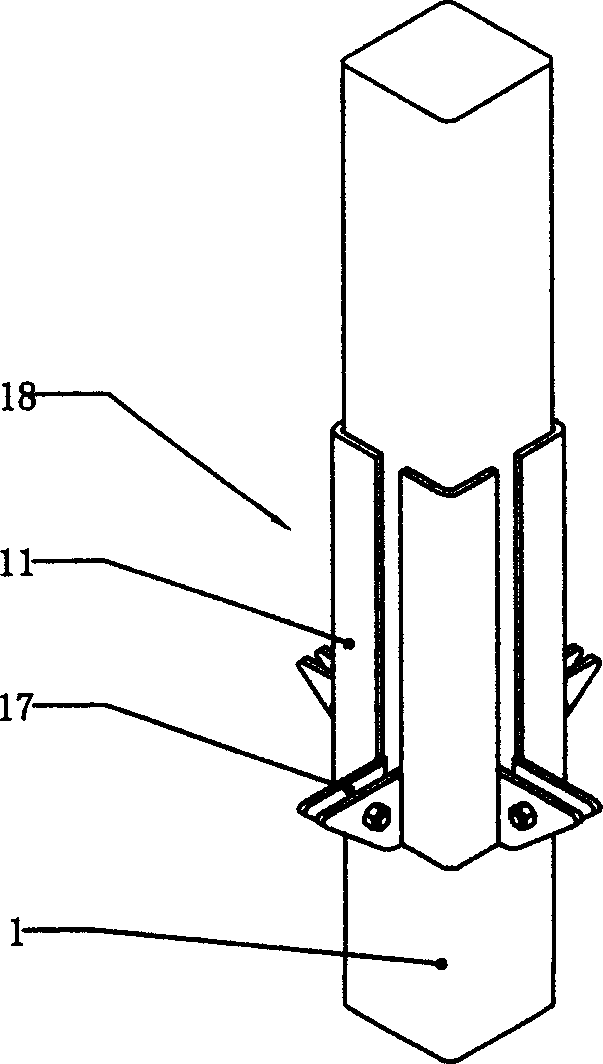

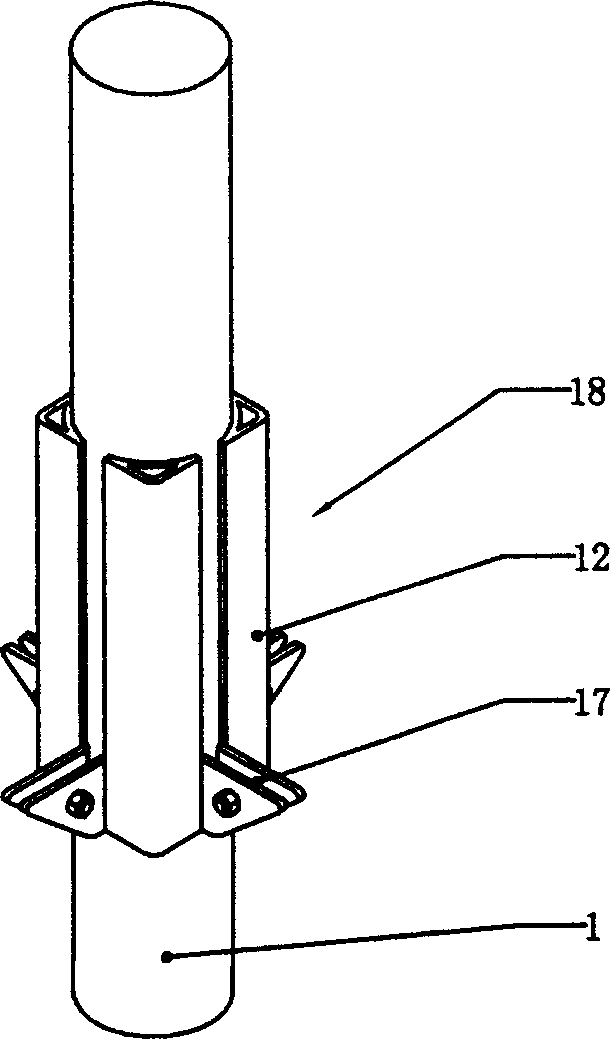

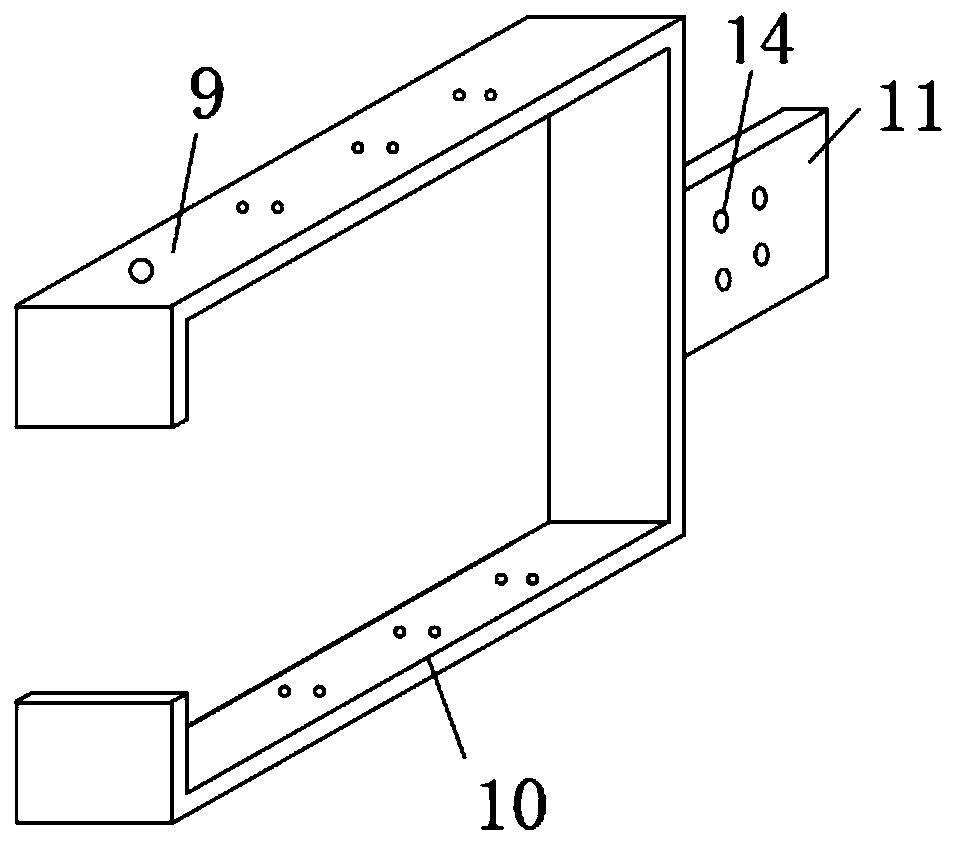

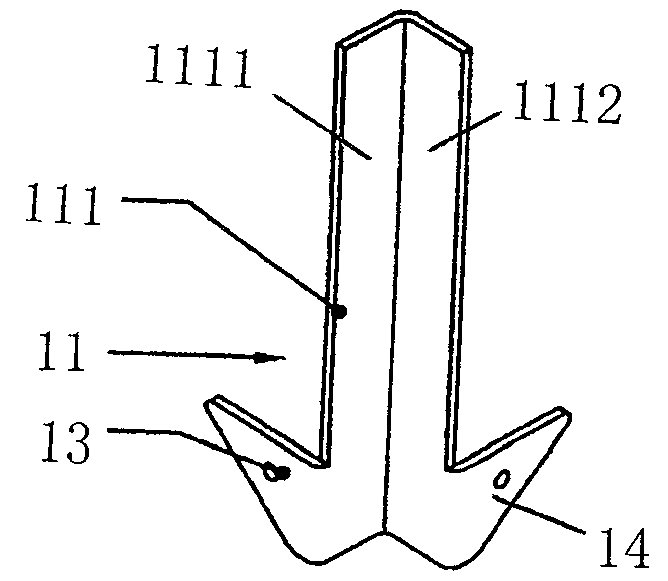

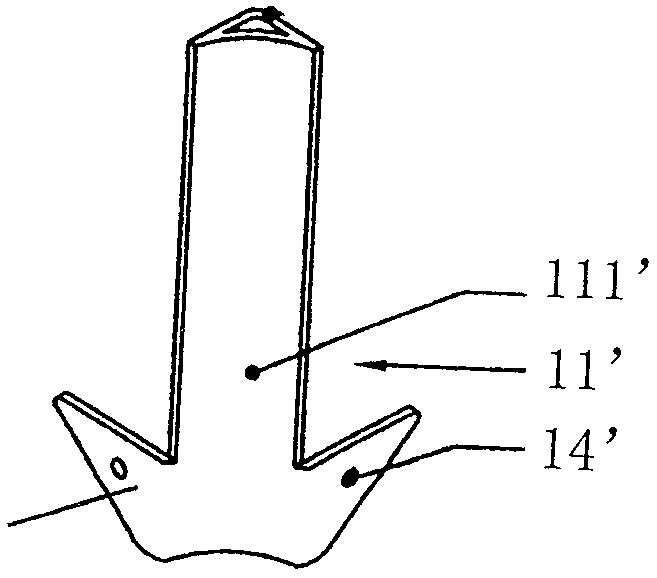

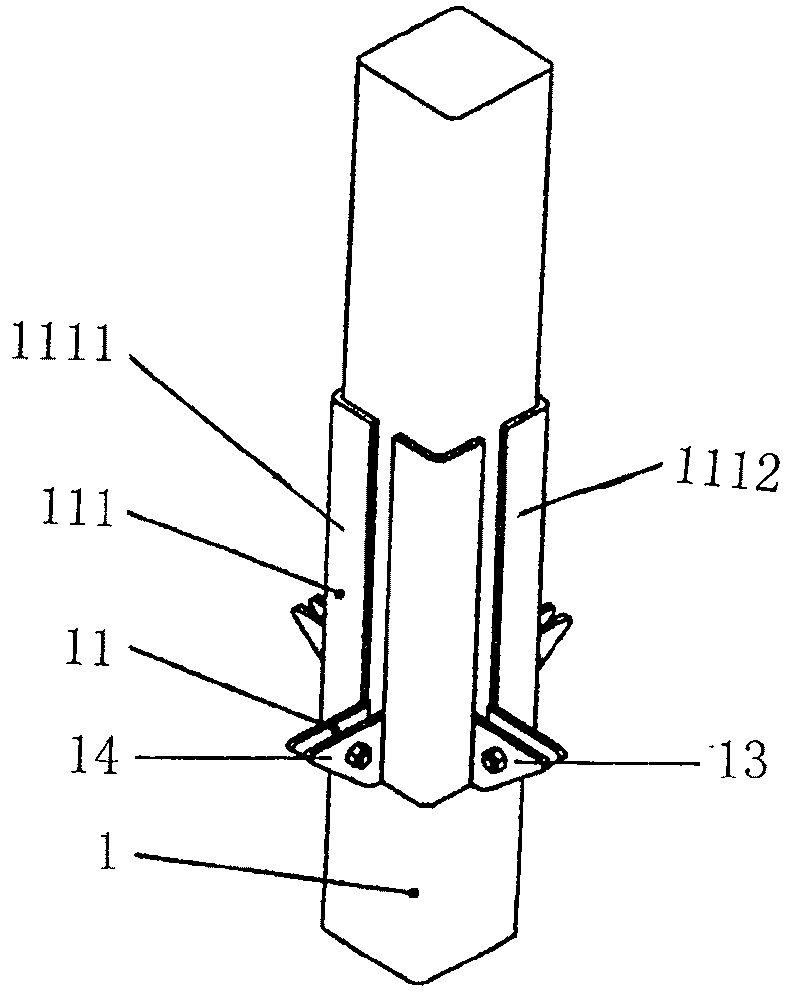

Butterfly type self locking connecting card with friction shear resisting board and construction steel frame node structure

InactiveCN1786362AIncreased load-bearing capacityEliminate damageBuilding constructionsFriction & shearSelf locking

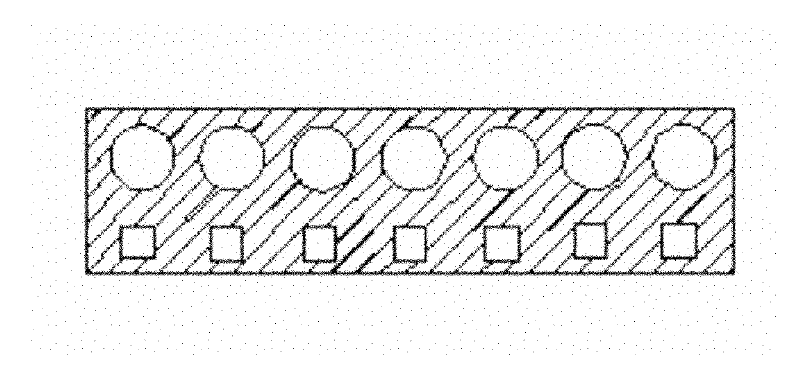

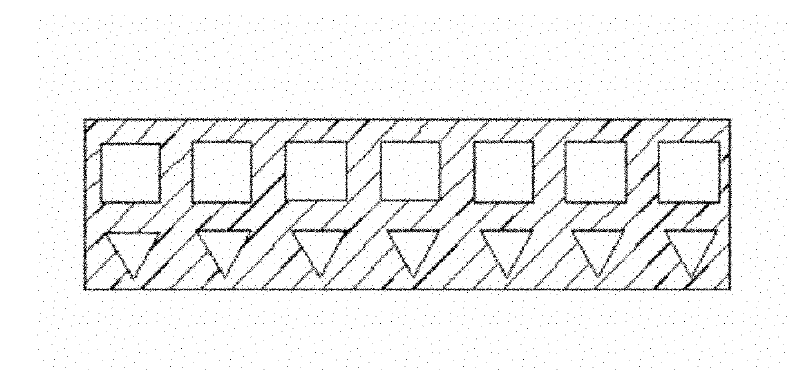

The invention relates to butterfly type self locking connecting card with friction shear resistant plate and building iron joint of framework structure. The friction shear resistant plate includes friction surface and shear resistant plate. Four friction shear resistant plates is formed square type node pillar to cooperate with hitch clevis. The connecting card includes card body. Both end of the card body are respectively set two card wings with door shape cross section. The card wing includes bearing plate, pretension plate, and self locking mounting plate. The self locking and pretension plate are set through holes. The invention utilizes the friction, and self locking principle, the friction shear resistant plate is gain the enlarged pressure and friction by butterfly type self locking connecting card to transfer to bearing force to act on node crossbeam to gain ideal joint intensity, stiffness, and bearing force.

Owner:甘秀明

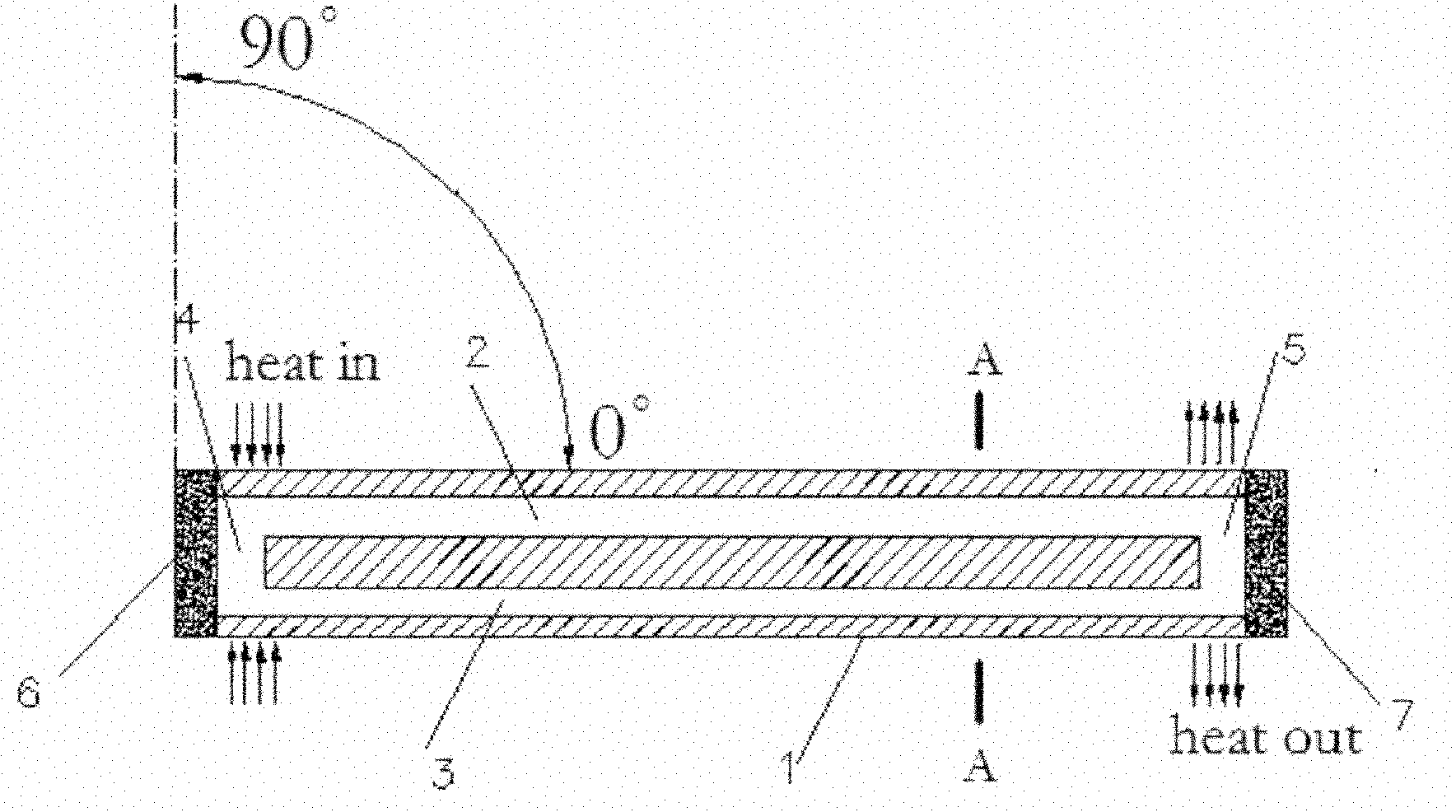

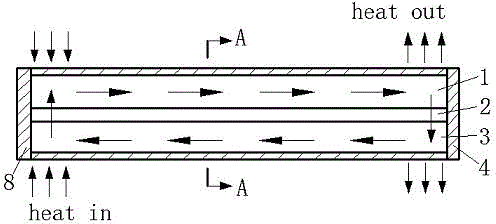

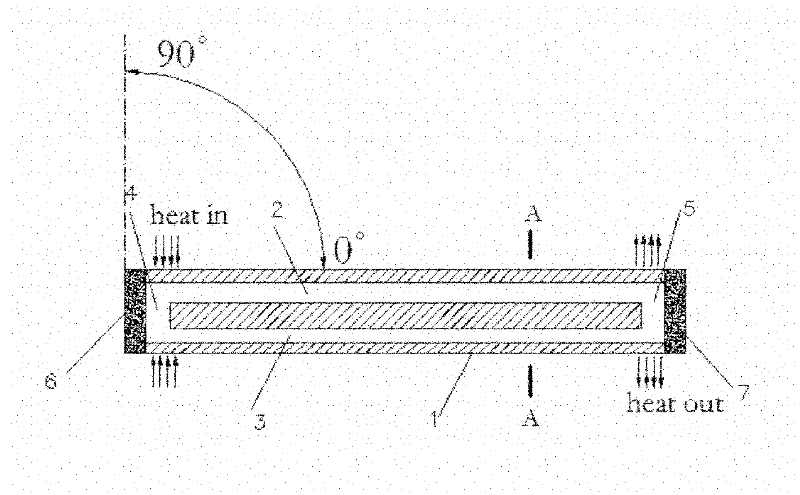

Plate type heat pipe with minitype circular channels

ActiveCN102135385AStable jobImprove heat transfer performanceIndirect heat exchangersFriction & shearHeat resistance

The invention relates to a plate type heat pipe with minitype circular channels. The interior of the plate type heat pipe is composed of a group or more than one group of minitype circular channels, wherein each circular channel comprises main channels and a connecting channel which is communicated with two ends of the main channels; the main channels are respectively an evaporation channel and a backflow channel; the connecting channel is respectively a liquid storage chamber and an evaporation chamber; the channels are filled with working media which play a role in phase change and heat transfer at a certain ratio, so that the efficient heat transfer of the heat pipe is realized; and welding, cold compression, hot compression or cementing are adopted for the sealing at each channel opening. The plate type heat pipe provided by the invention has the advantages of low heat resistance, high heat exchange efficiency, light weight, simple structure, high bearing capability and wide application, and ensures that the interface friction shearing force of vapor phase and liquid phase in the channels can be reduced maximally, thus being an efficient and practical novel heat pipe.

Owner:江乐新

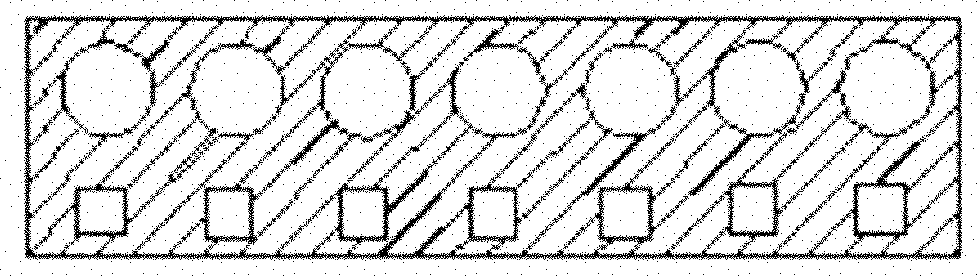

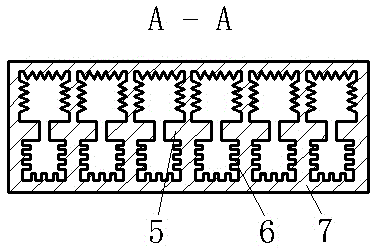

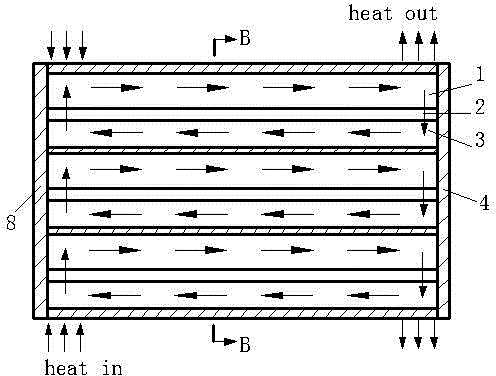

Plate type heat pipe with separation channels

ActiveCN104457359AImprove heat transfer performanceReduced frictional shearIndirect heat exchangersHeat resistanceFriction & shear

The invention relates to a plate type heat pipe with separation channels. According to the plate type heat pipe, one or more sets of separation channels are arranged in a plate type base body, one set of separation channels is composed of at least one evaporation channel and at least one condensation channel, the evaporation channels and the condensation channels are separated by reinforcing ribs, and capillary narrow clearances are formed in the reinforcing ribs. Working media with the phase-change heat transfer function are poured into the channels, and efficient heat transfer of the heat pipe is achieved. According to the plate type heat pipe, interface friction shear force of a vapor phase and a liquid phase in the work process of the heat pipe can be greatly reduced, and the novel plate type heat pipe has the obvious advantages of being low in heat resistance, high in heat exchange capacity, high in heat exchange efficiency, large in inclination range and the like, and is light, simple in structure, high in loading capacity, simple in manufacturing process, efficient, practical and low in cost.

Owner:长沙馨麓能源科技有限公司

Anti-flushing device of offshore wind power pile foundation

The invention discloses an anti-flushing device of an offshore wind power pile foundation. The anti-flushing device comprises an anti-flushing main body and a plurality of flexible elements; the flexible elements comprise fixed ends and energy dissipation ends; the flexible elements are fixed to the anti-flushing main body through the fixed ends; and the anti-flushing main body is fixed to a seabed. Compared with the prior art, according to the anti-flushing device of the offshore wind power pile foundation, through modes such as frictional resistance, impact, vortex, deflecting flow, diffusion and aeration between a water flow and fiber cloth strips, a rapid flow or a main flow is transformed into an evenly-diffused slow flow as soon as possible, and thus the effects of collision mixing and friction shear stress between energy dissipation and diffusion are achieved.

Owner:HUNAN INSTITUTE OF ENGINEERING

Double-acting type friction coefficient testing device and method

The invention discloses a double-acting type friction coefficient testing device and method, which belong to the technical field of material processing. The method comprises the following steps of: filling a blank in an extrusion cylinder during a test, introducing protective gas into a high-temperature heating furnace, and heating a working part to a preset temperature; implementing sinking strain of the blank through an extrusion rod so as to generate a certain pressure under the action of a lower power part; pushing down the extrusion cylinder through an upper pressing rod under the action of an upper power part, measuring a loading-process curve of the cylinder push process, and calculating the friction shear stress between the blank and the extrusion cylinder; directly contacting the upper pressing rod with an upper stopper top cover after the extrusion cylinder is completely separated from the blank, and compressing the blank by the upper power part, thus obtaining a stress-strain curve of the blank and flow stress sigma s under the deformation condition, and further obtaining the maximum shear stress value K of the material through the formula that K=0.577 sigma s; and calculating the friction coefficient m according to the constant-friction formula that tau=mK. The friction coefficient of compressional deformation can be tested at different temperatures and under different pressure conditions.

Owner:DALIAN JIAOTONG UNIVERSITY

Friction and shear combined type repairable metal damper

ActiveCN110080409AImprove energy consumptionAdjust the shock absorption capacityProtective buildings/sheltersShock proofingFriction & shearEngineering

The invention discloses a friction and shear combined type repairable metal damper which comprises a sliding guide rod and a protective shell arranged on the sliding guide rod in a sleeving mode. A friction board is arranged on the side face of the sliding guide rod, a plurality of sawteeth arranged in the vertical direction of the friction board are arranged on the friction board, a cover board is arranged on the side face of the protective shell, sawteeth meshed with the sawteeth of the friction board are arranged on the cover board, and a plurality of low-yield-point steel sheets are arranged between the protective shell and the sliding guide rod. The friction and shear combined type repairable metal damper has a good energy consumption effect, can achieve staged yield energy consumption, and is convenient to disassemble and high in repairability.

Owner:JIANGSU UNIV OF SCI & TECH

Novel fabricated composite shear wall structure with self-resetting function

PendingCN110241940AGuaranteed to be relatively staticAchieving the purpose of adaptive seismic responseWallsProtective buildings/sheltersFriction & shearEngineering

The invention provides a novel fabricated composite shear wall structure with a self-resetting function. The novel fabricated composite shear wall structure comprises a first pre-embedded body, a second pre-embedded body and a wall body, wherein the first pre-embedded body and the second pre-embedded body are both of U-shaped structures, the opening end of the second pre-embedded is inversely buckled in an opening slot of the first pre-embedded body, and the top plate of the second pre-embedded body is connected with the foundation end of the wall body; one ends of the joint of the first pre-embedded body and the second pre-embedded body are connected in a hinged mode, and the other ends of the joint of the first pre-embedded body and the second pre-embedded body are slidably connected; piezoelectric stacks are correspondingly arranged at the hinged joint and the sliding joint, and the piezoelectric stacks are connected with a controller; and the first pre-embedded body, the second pre-embedded body and the wall body are connected through a SMA-shaped memory alloy bundle. According to the novel fabricated composite shear wall structure, the voltage of the piezoelectric stacks are adjusted through the controller under different seismic load effects, thus the rotating friction force and the sliding friction force of the core region are adjusted, the purpose of self-adapting of the overall structure to seismic response is achieved, and real-time variable friction shear under the action of small and medium earthquakes is achieved; and under the action of rare earthquakes, a large amount of seismic energy is consumed.

Owner:CHANGAN UNIV

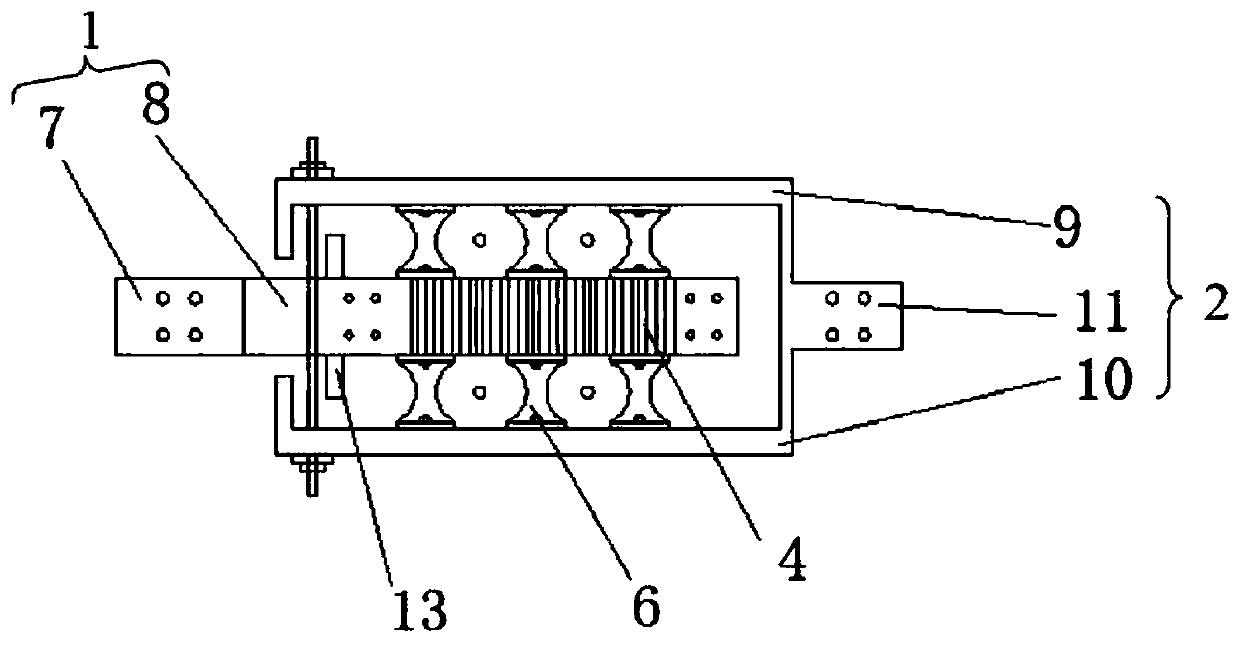

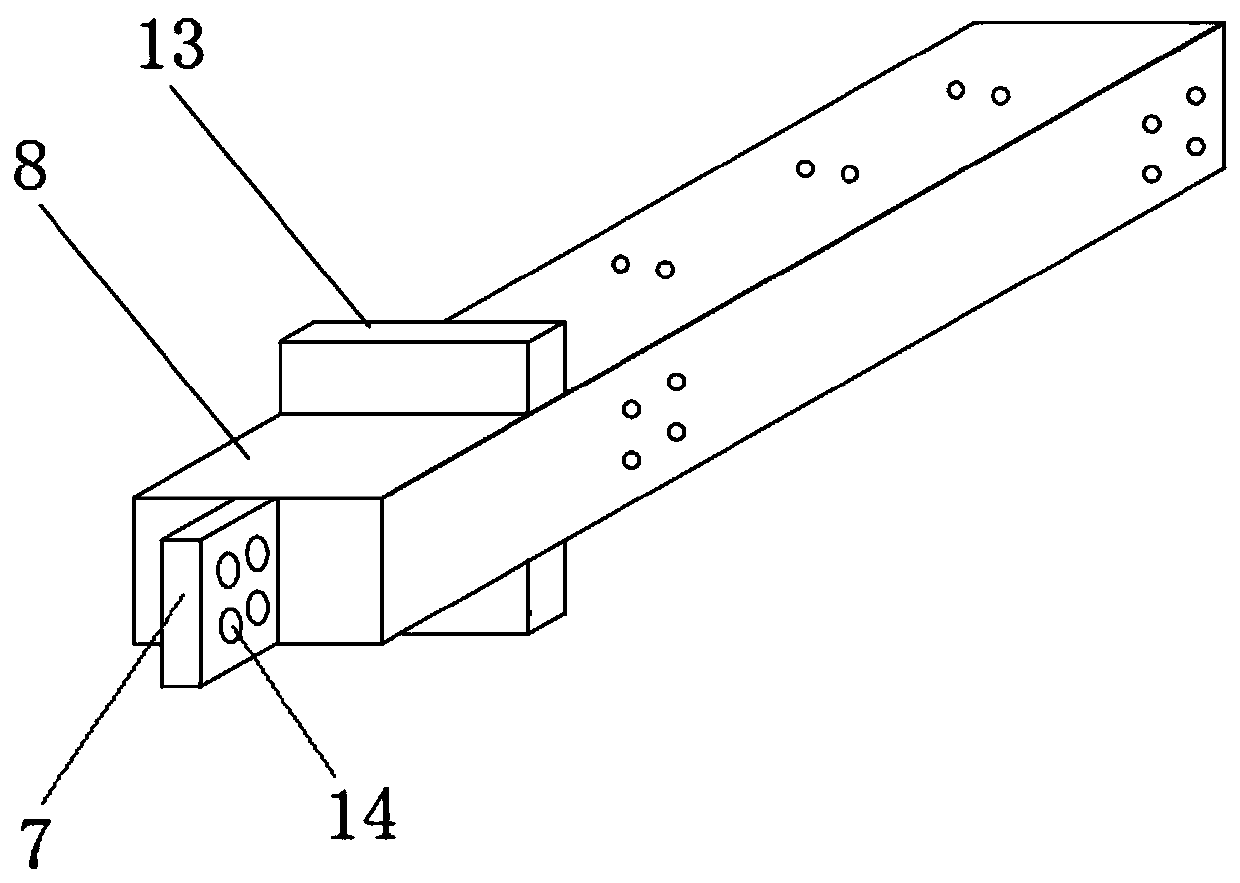

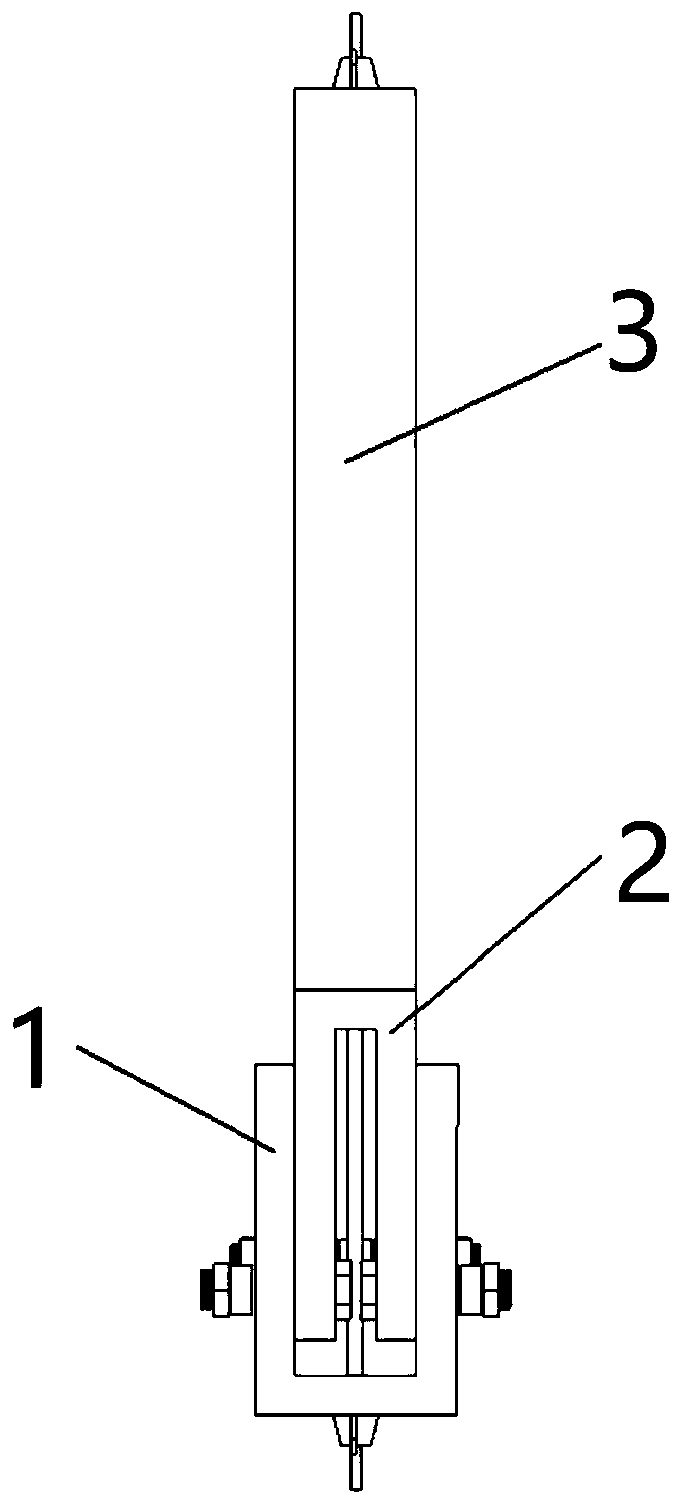

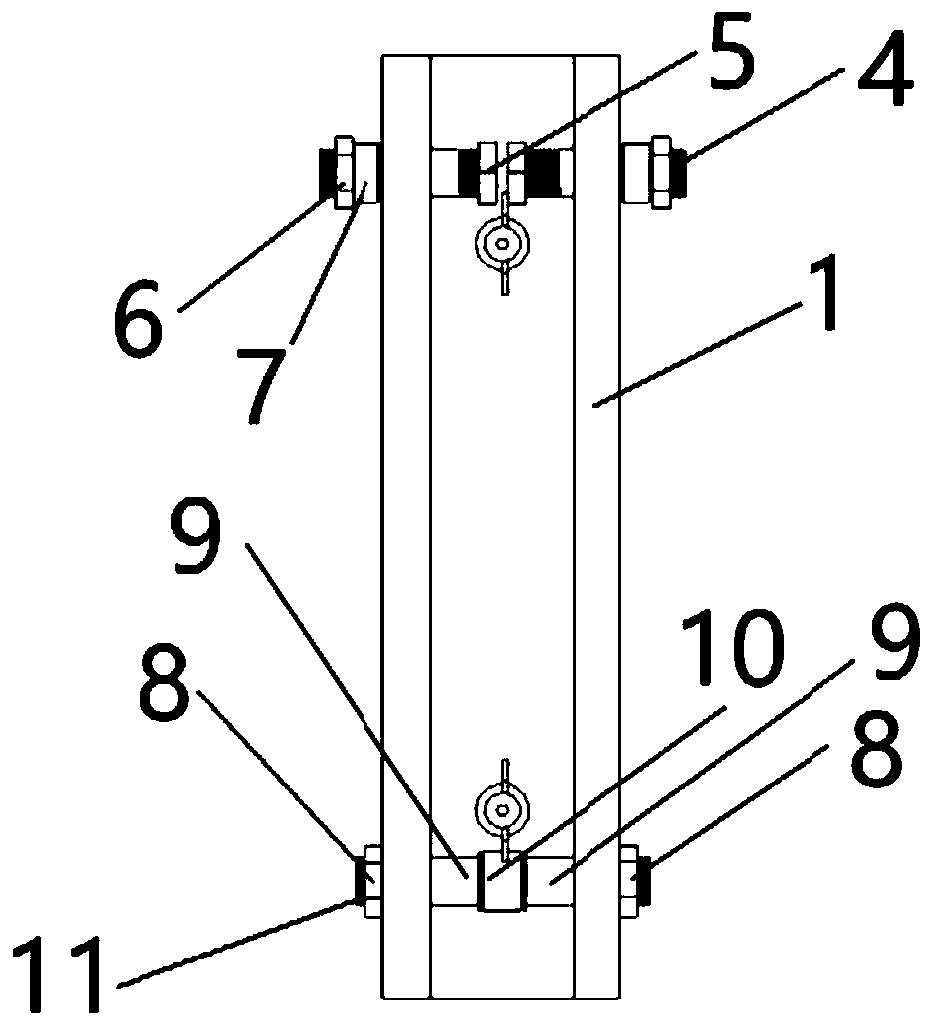

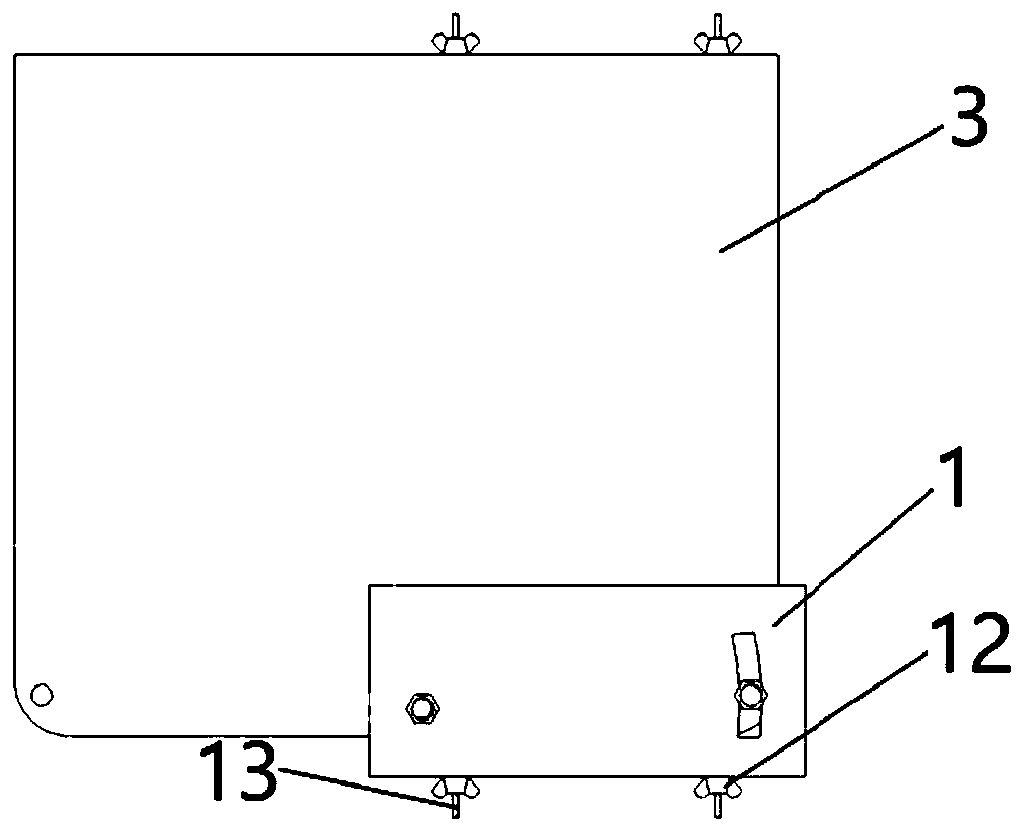

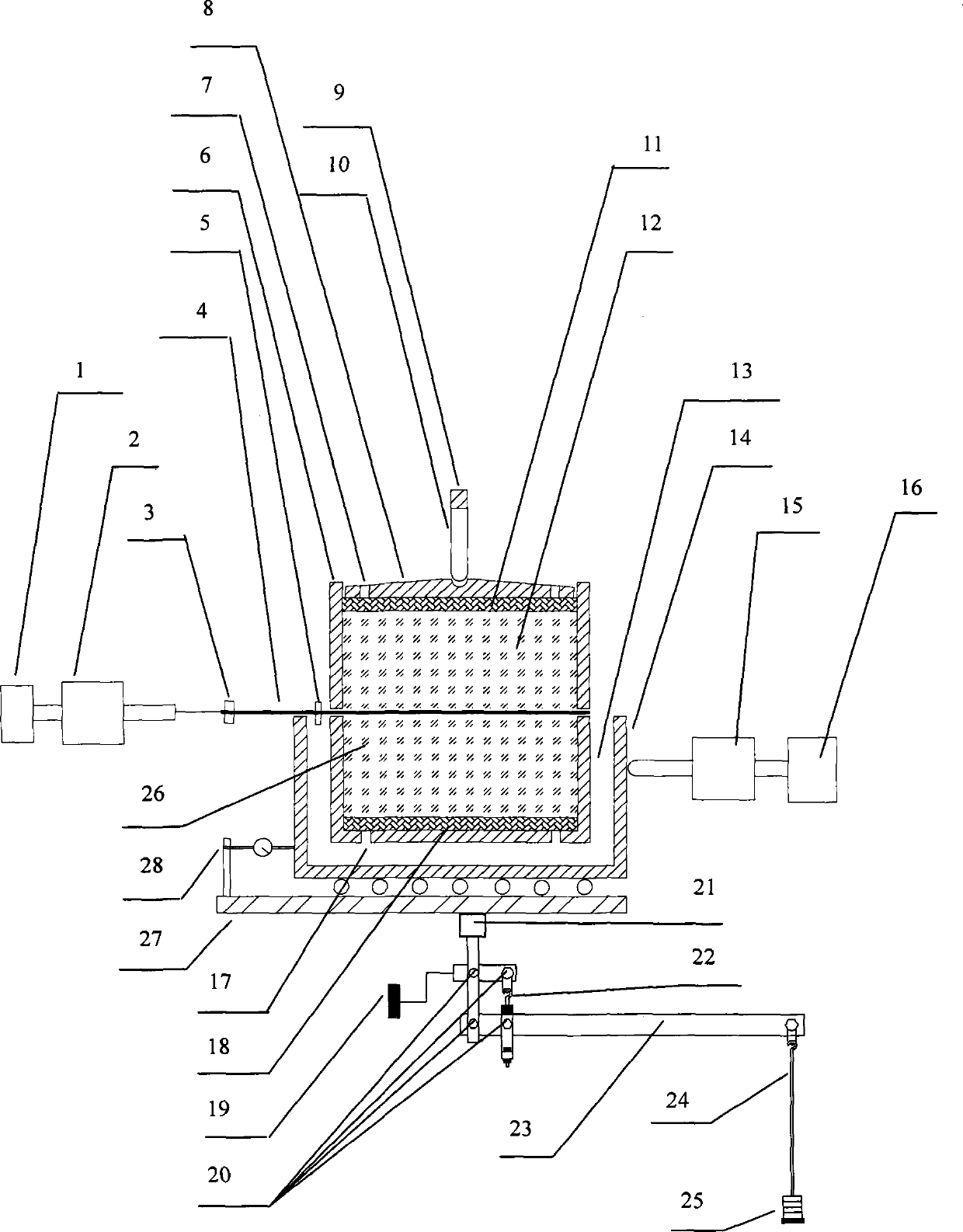

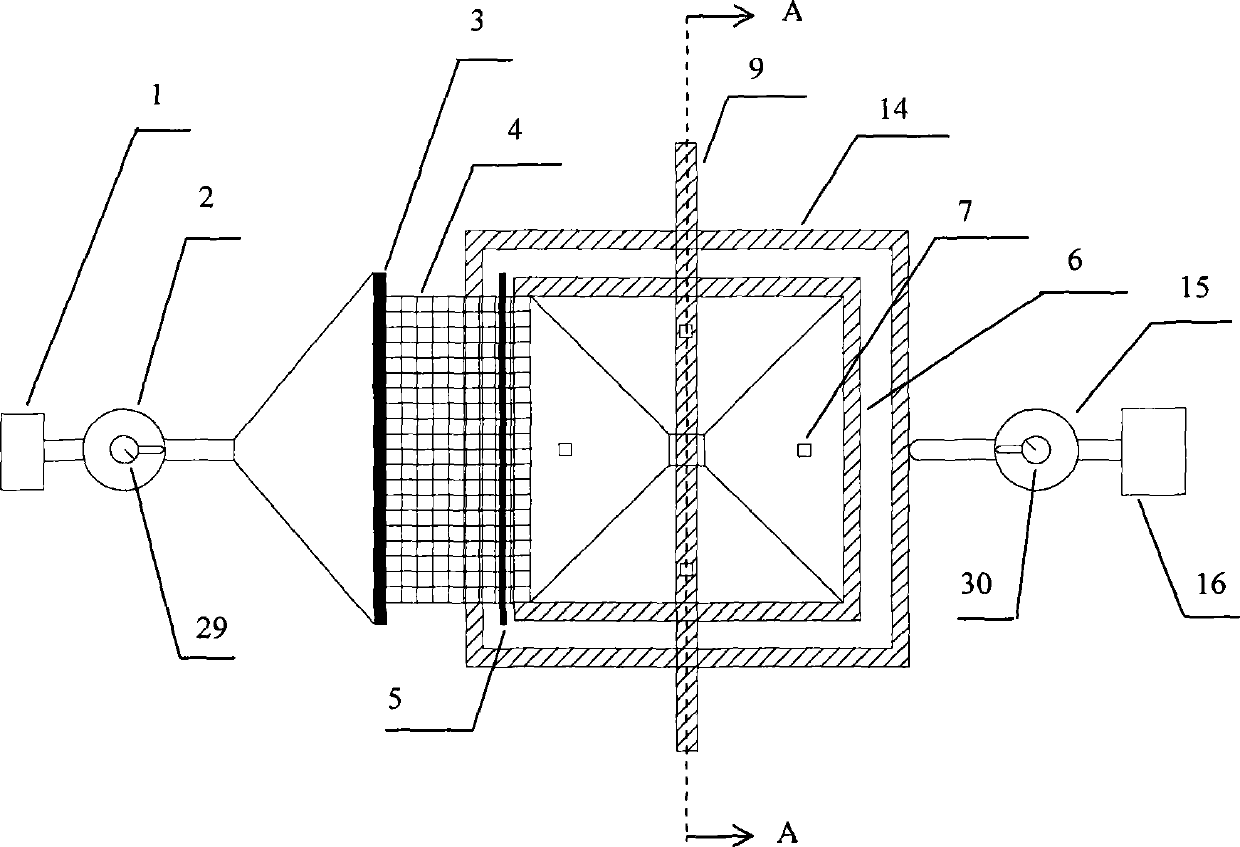

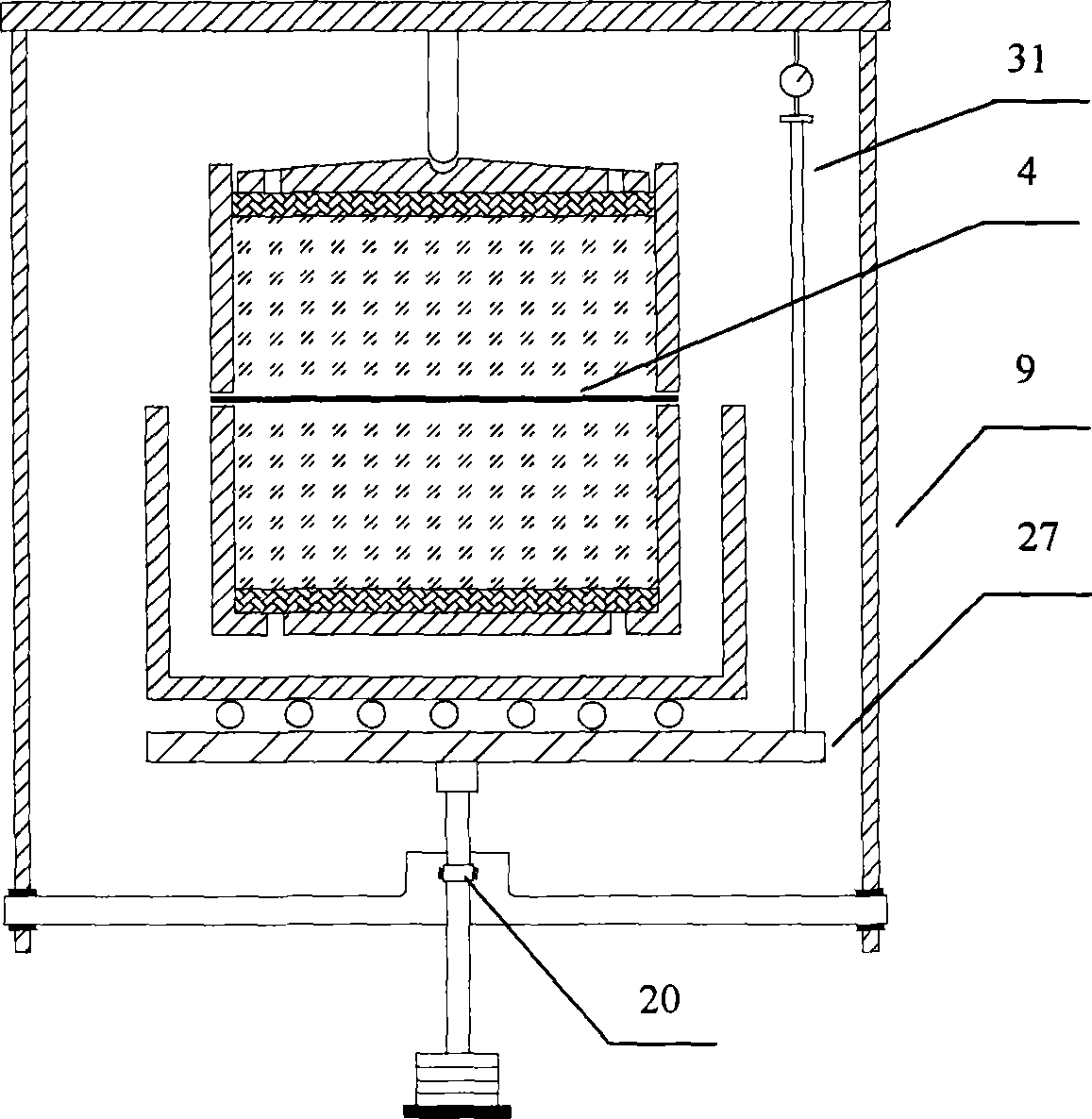

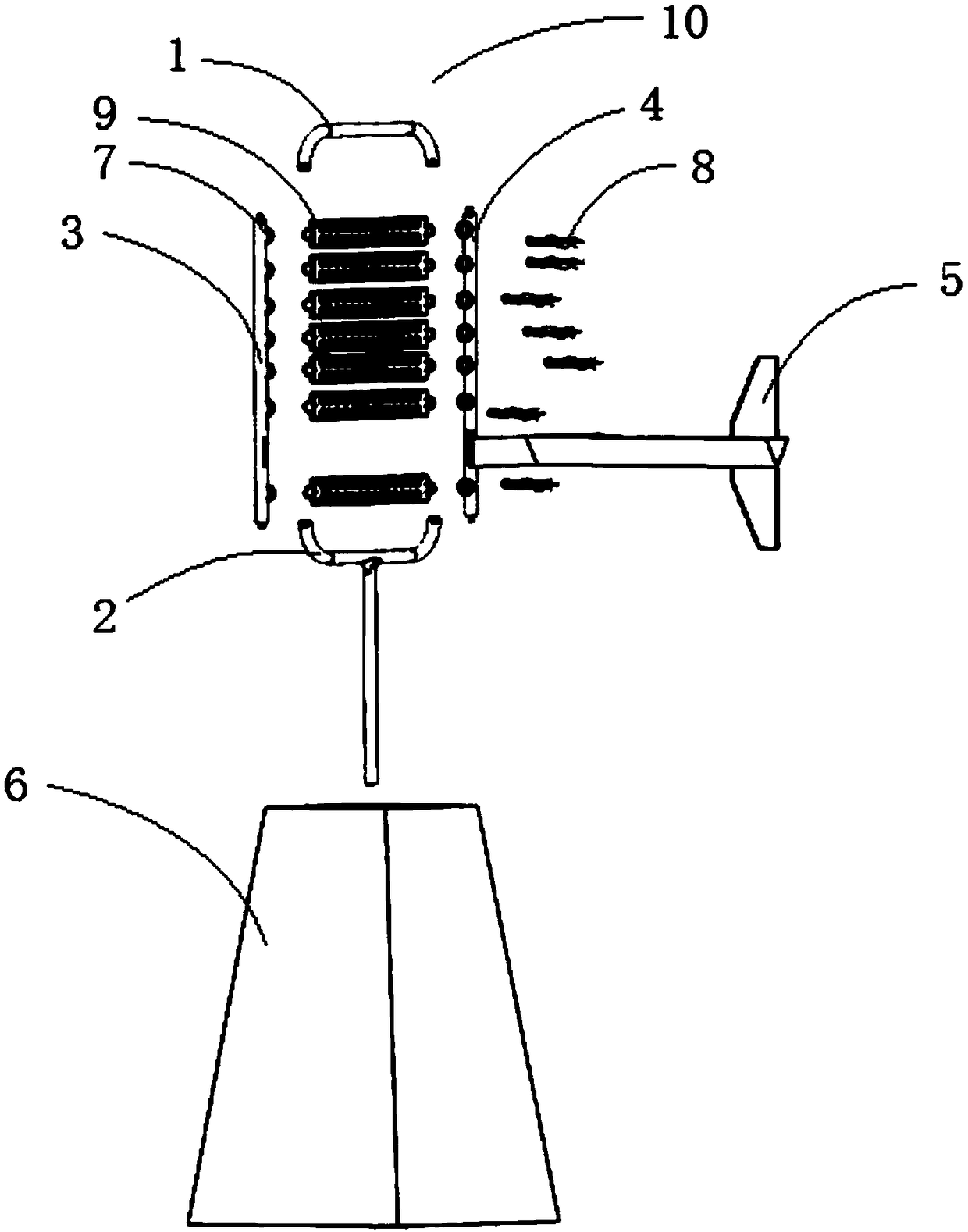

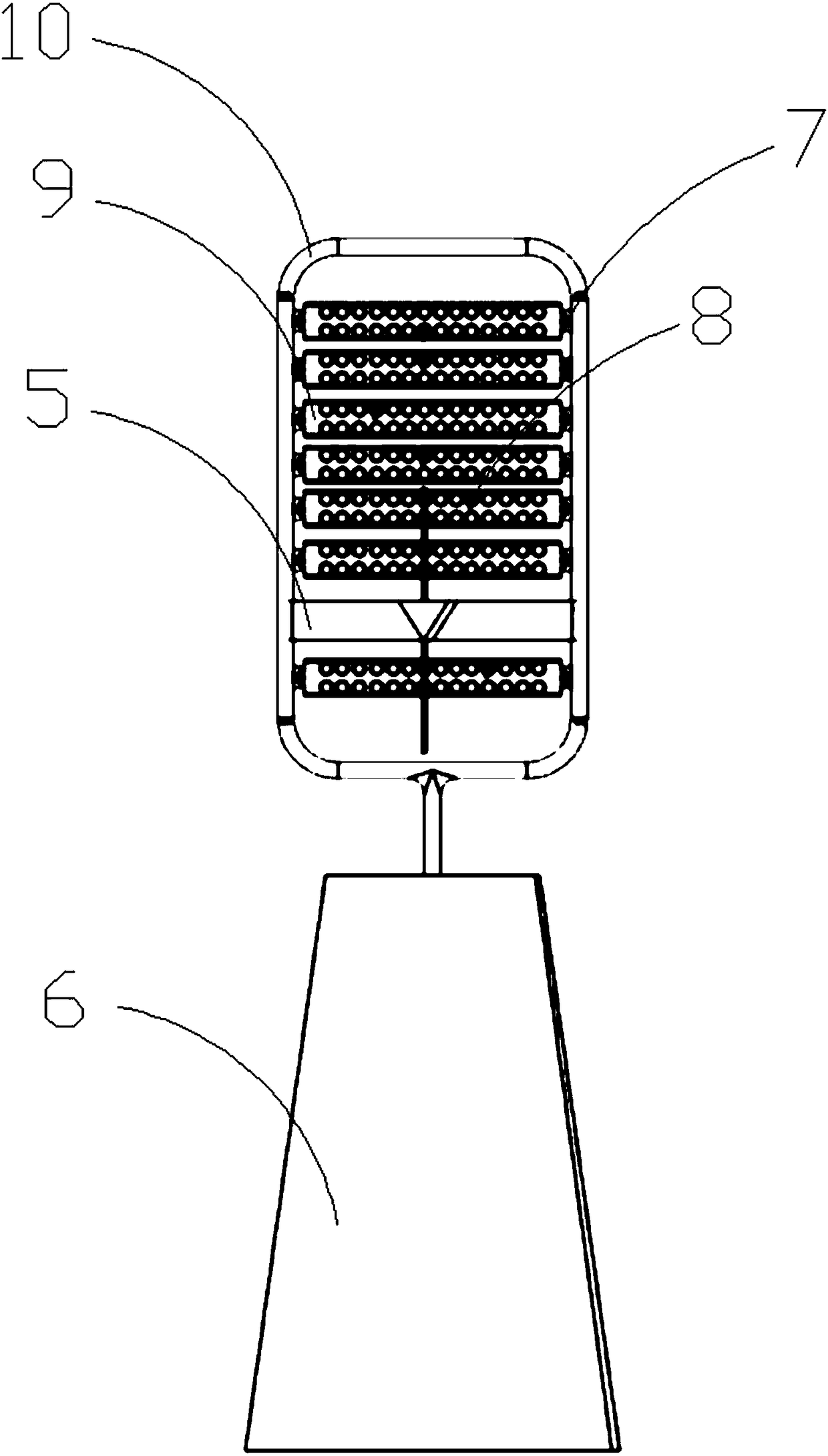

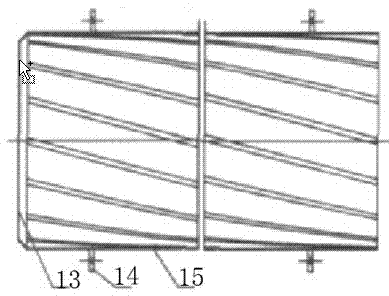

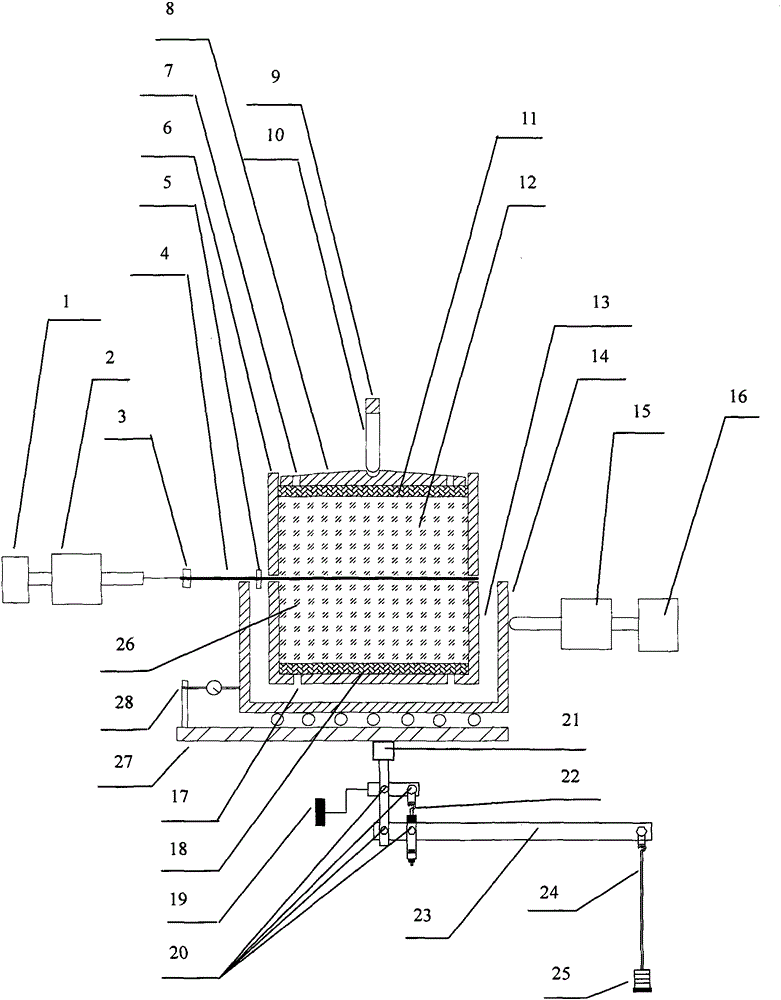

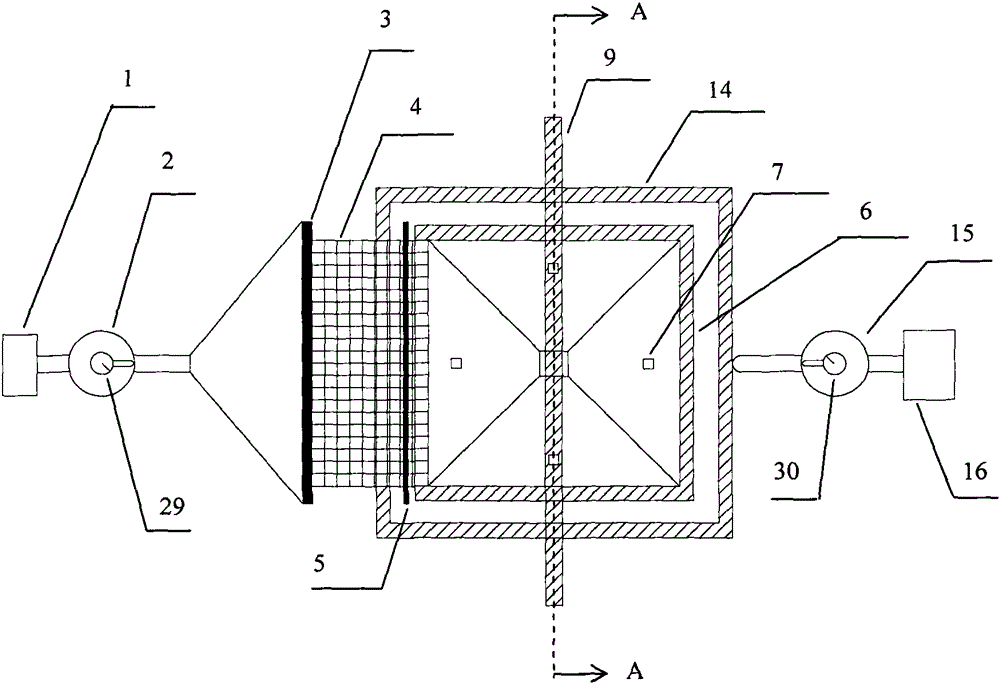

Anti-drawing and anti-friction testing method for geotextile of rock-soil body

InactiveCN103808570AHigh measurement accuracyEasy to useMaterial strength using tensile/compressive forcesMaterial strength using steady shearing forcesPorous mediumFriction & shear

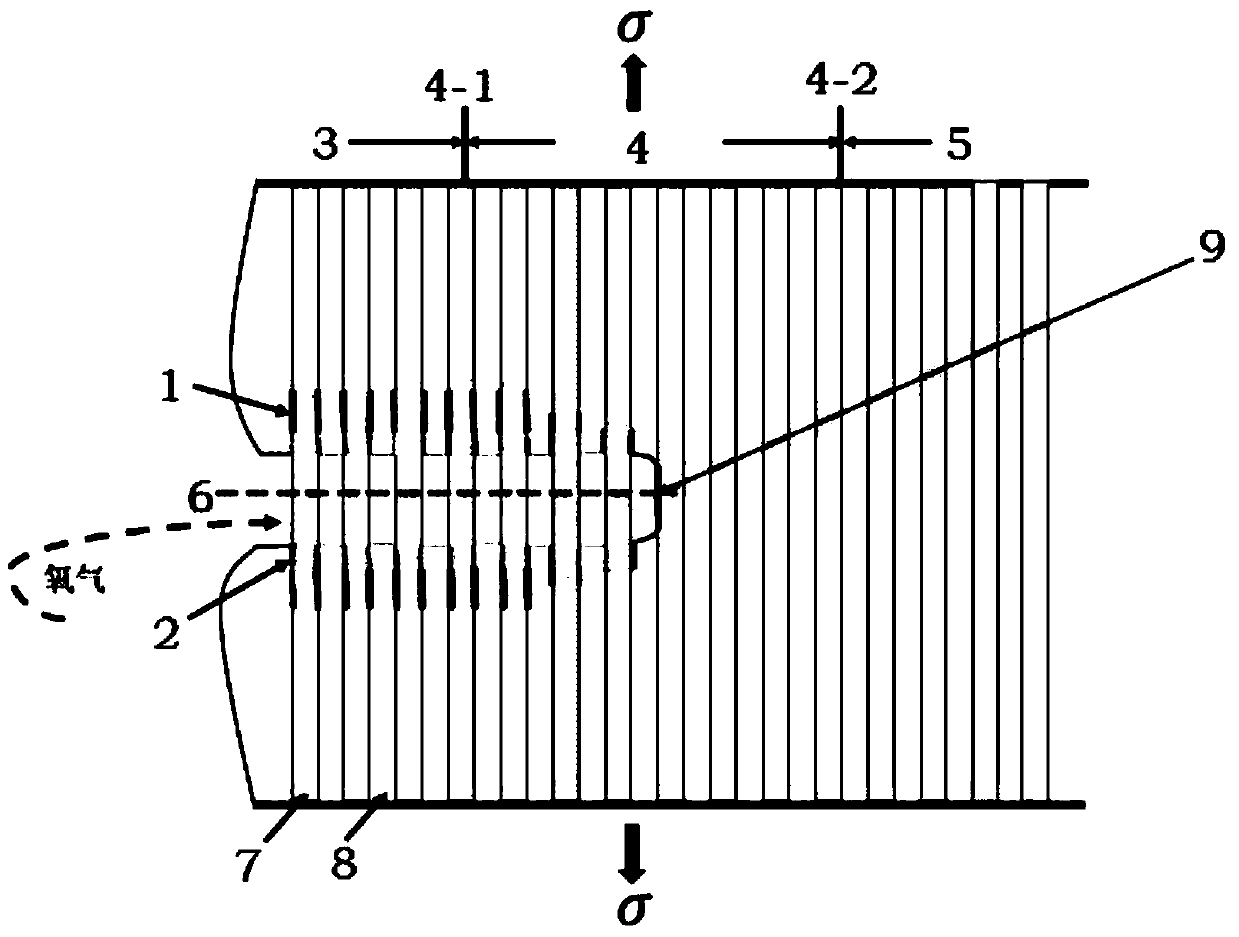

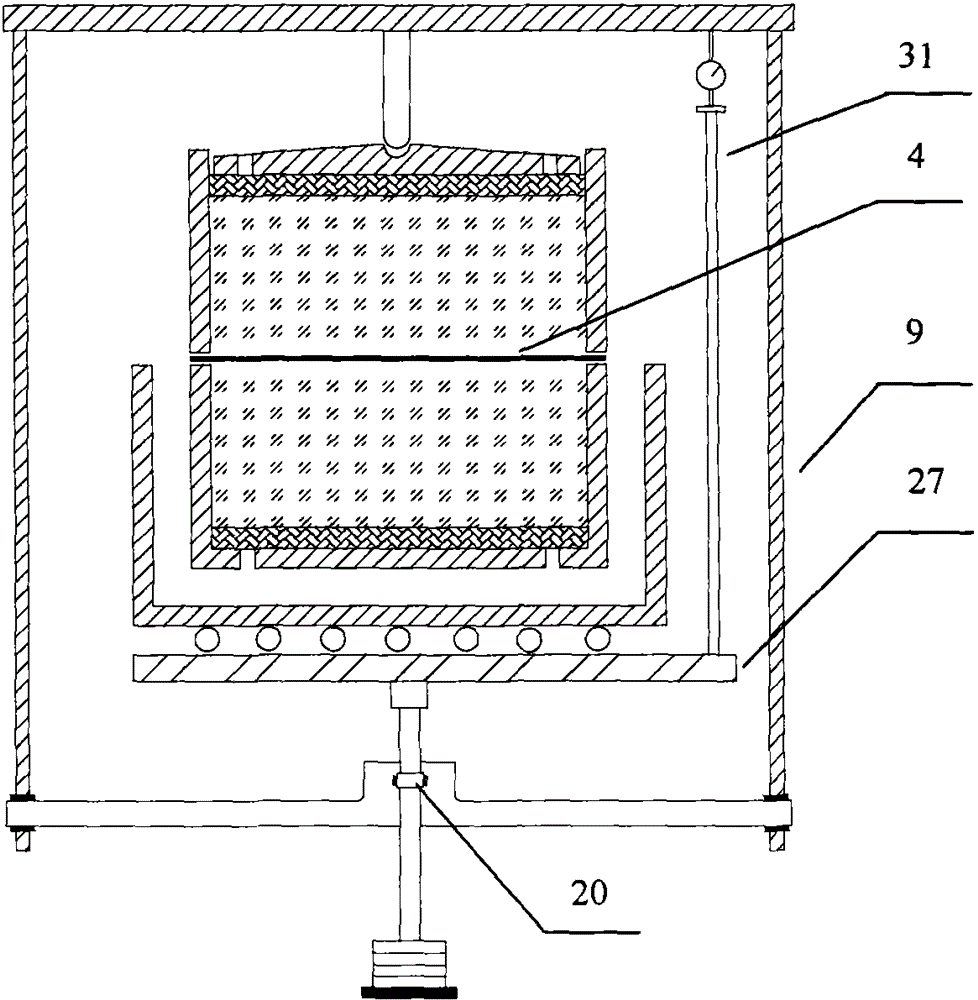

The invention provides an anti-drawing and anti-friction testing method for a geotextile of a rock-soil body. The method is characterized by adopting a testing device. The device comprises a drawing stepping motor (1), a drawing force measuring ring (2), an upper sample box (6), a pressurizing framework (9), a lower sample box (13), a lower base (14), a shearing force measuring ring (15), a shearing stepping motor (16), a pressurizing lever (23) and a weight (25). With the adoption of the device, an anti-drawing test and an anti-friction shearing test of the geotextile can be carried out and a force and deformation amount F-L curve is drawn; when an indication value of a drawing displacement meter (29) or a shearing displacement meter (28) is rebounded, the maximum value of the anti-drawing or anti-friction shearing strength of the geotextile (4) can be obtained. The method is simple and practical and is flexible to operate; the method can be used for test and experiment researches on anti-drawing and anti-shearing strength properties of the various geotextiles in various porous media.

Owner:INST OF GEOLOGY & GEOPHYSICS CHINESE ACAD OF SCI

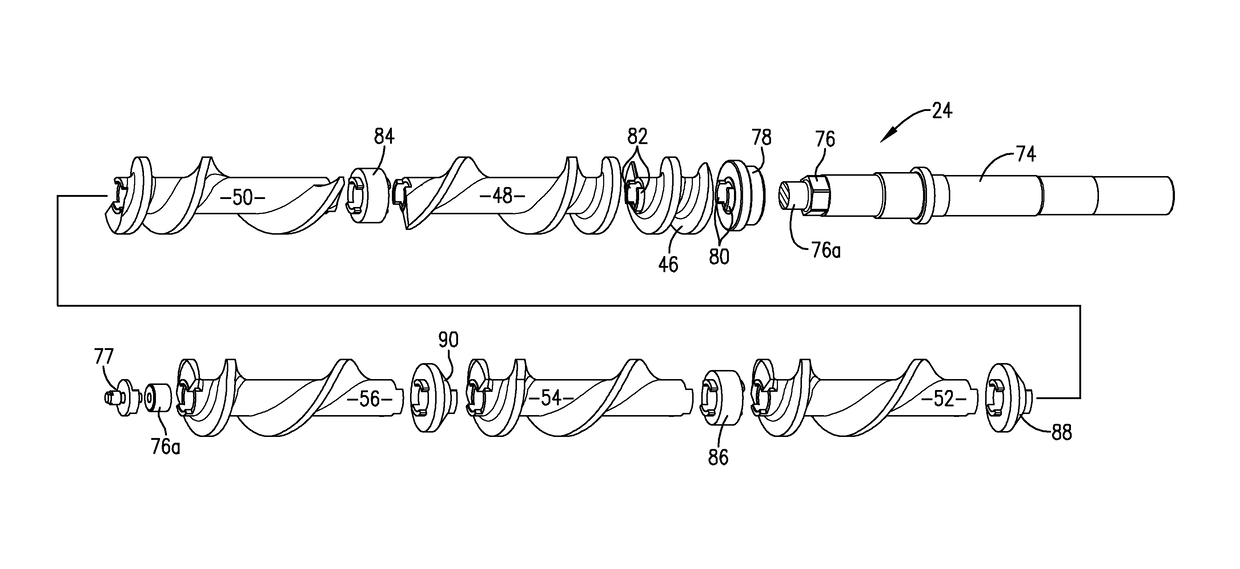

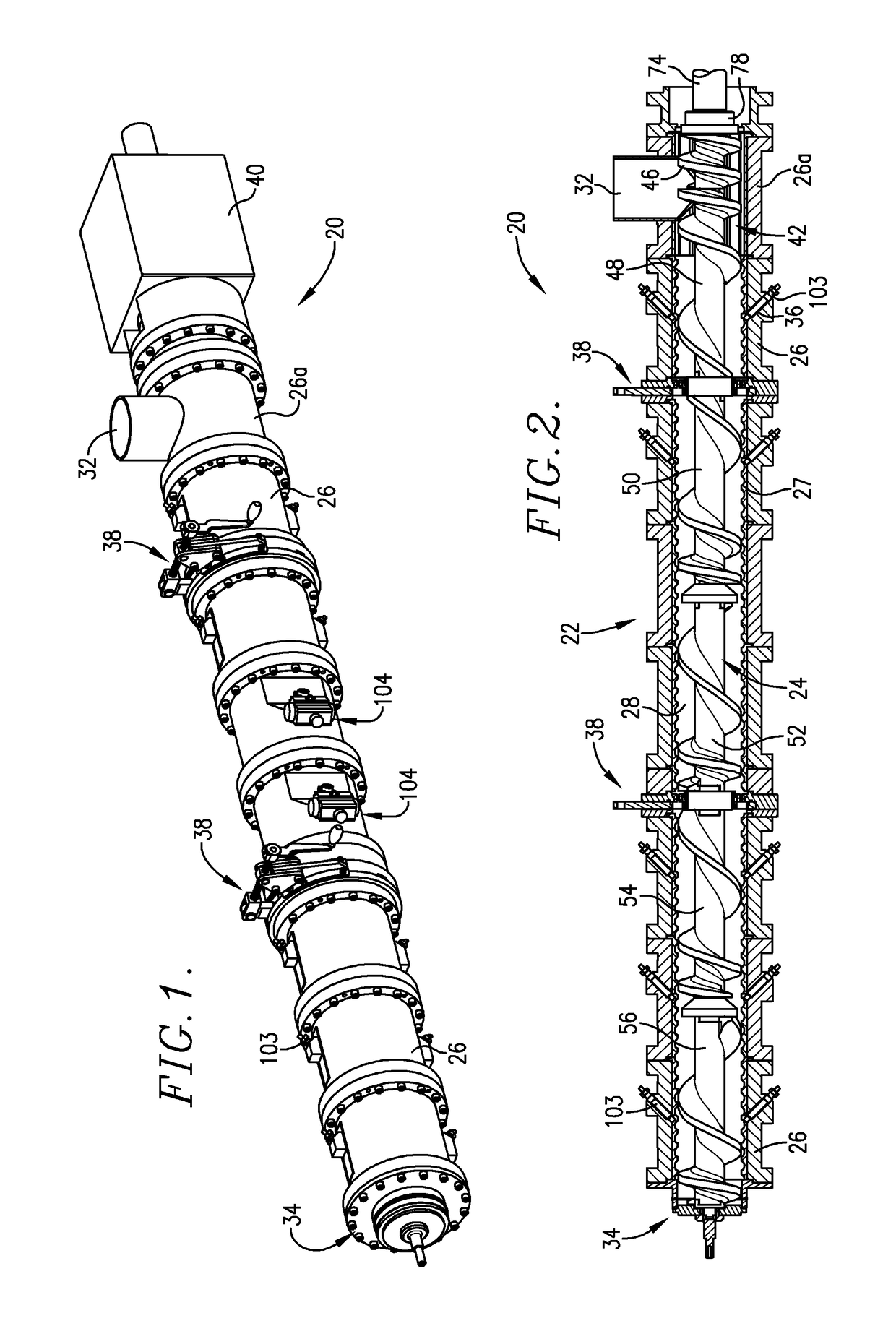

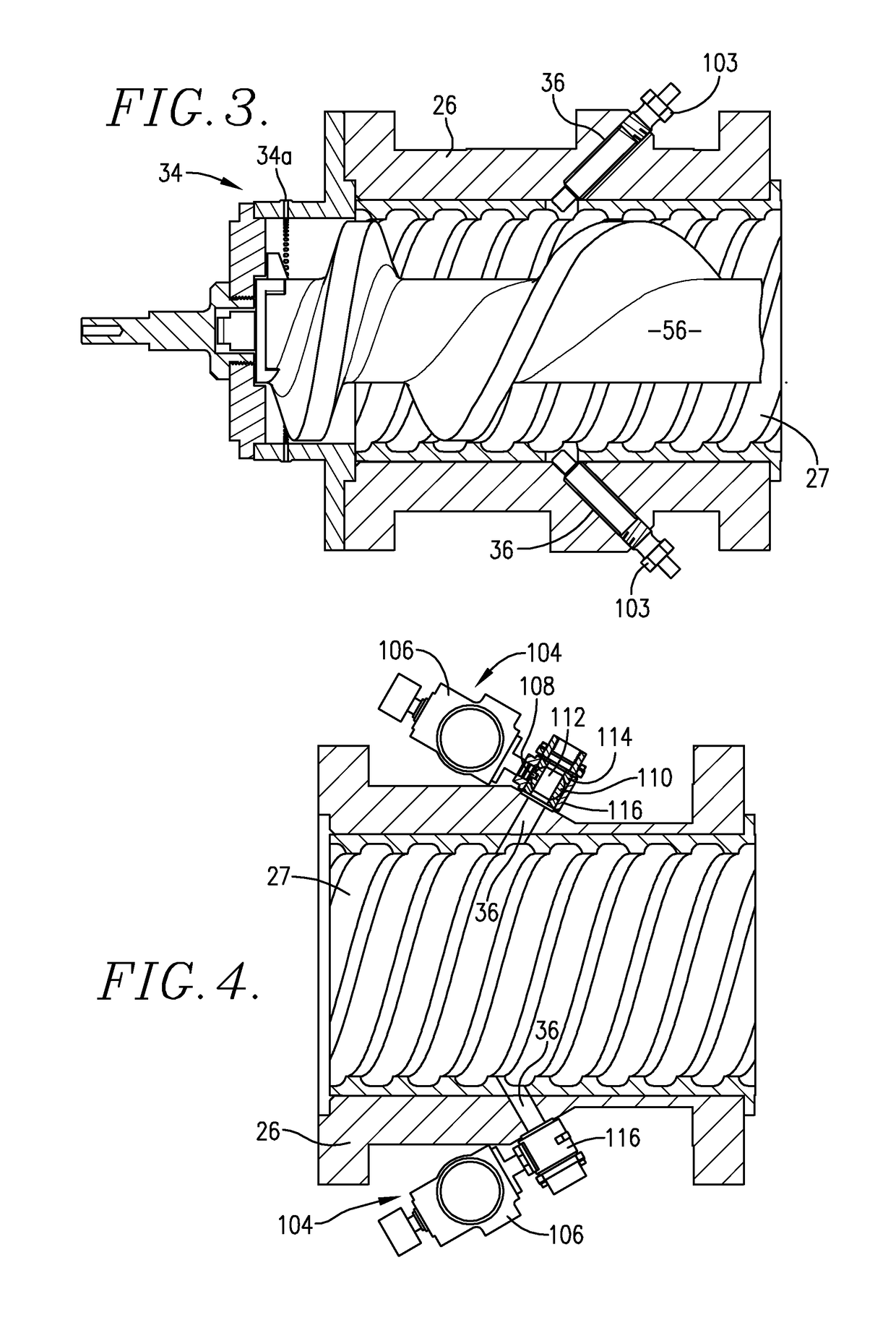

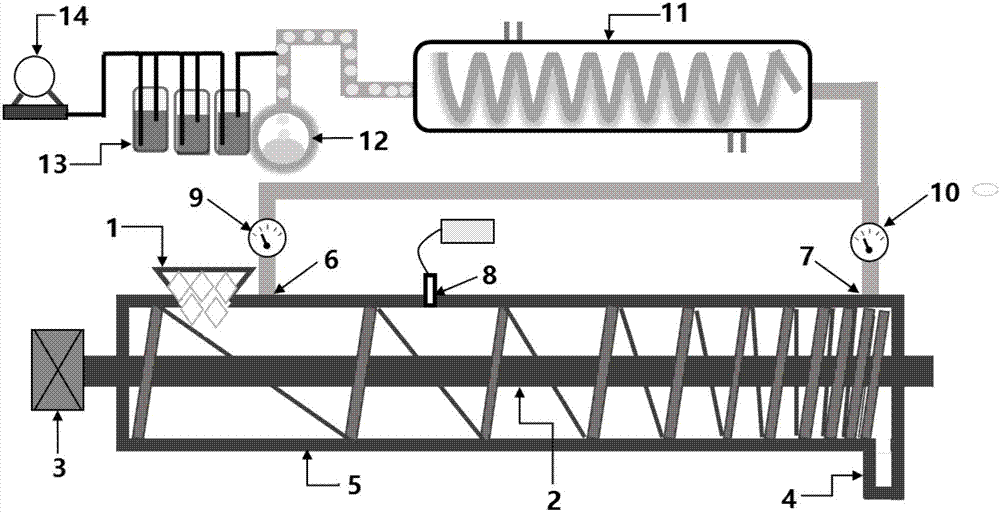

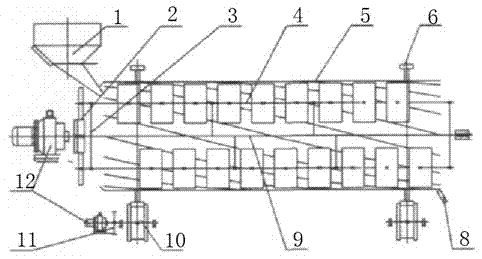

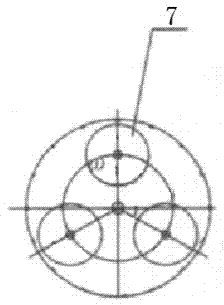

Method and apparatus for extrusion processing of high fiber content foods

InactiveUS9931603B2Improve the level ofReduce investmentFeeding-stuffFood processingProduction rateFriction & shear

An extruder (20) is specifically designed for the production of animal feed products (e.g., aquatic feeds) containing substantial quantities of low-cost fibrous materials, such as rice byproducts, at high production rates. The extruder (20) includes an elongated barrel (22) with a screw assembly (24) within the barrel and an endmost extrusion die assembly (34). The screw assembly (24) includes an inlet screw assembly (42) and a processing screw assembly (44). The assembly (44) includes screw components (50-56) of differential pitch to present a long pitch inlet section (64) and a tight pitch discharge section (68). Materials passing through the screw assembly (24) are successively subjected to high levels of steam injection (STE) followed by high levels of friction and shear (SME), so that the STE / SME ratio is at least about 6 / 1.

Owner:WENGER MANUFACTURING INC

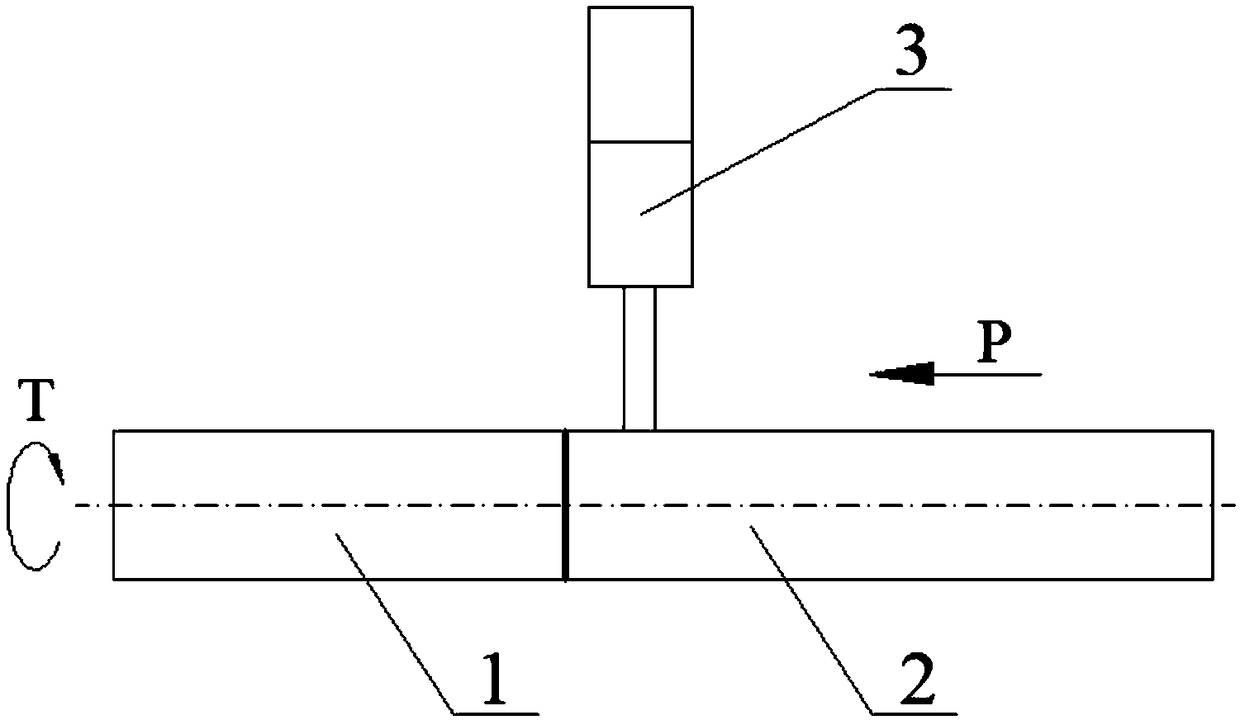

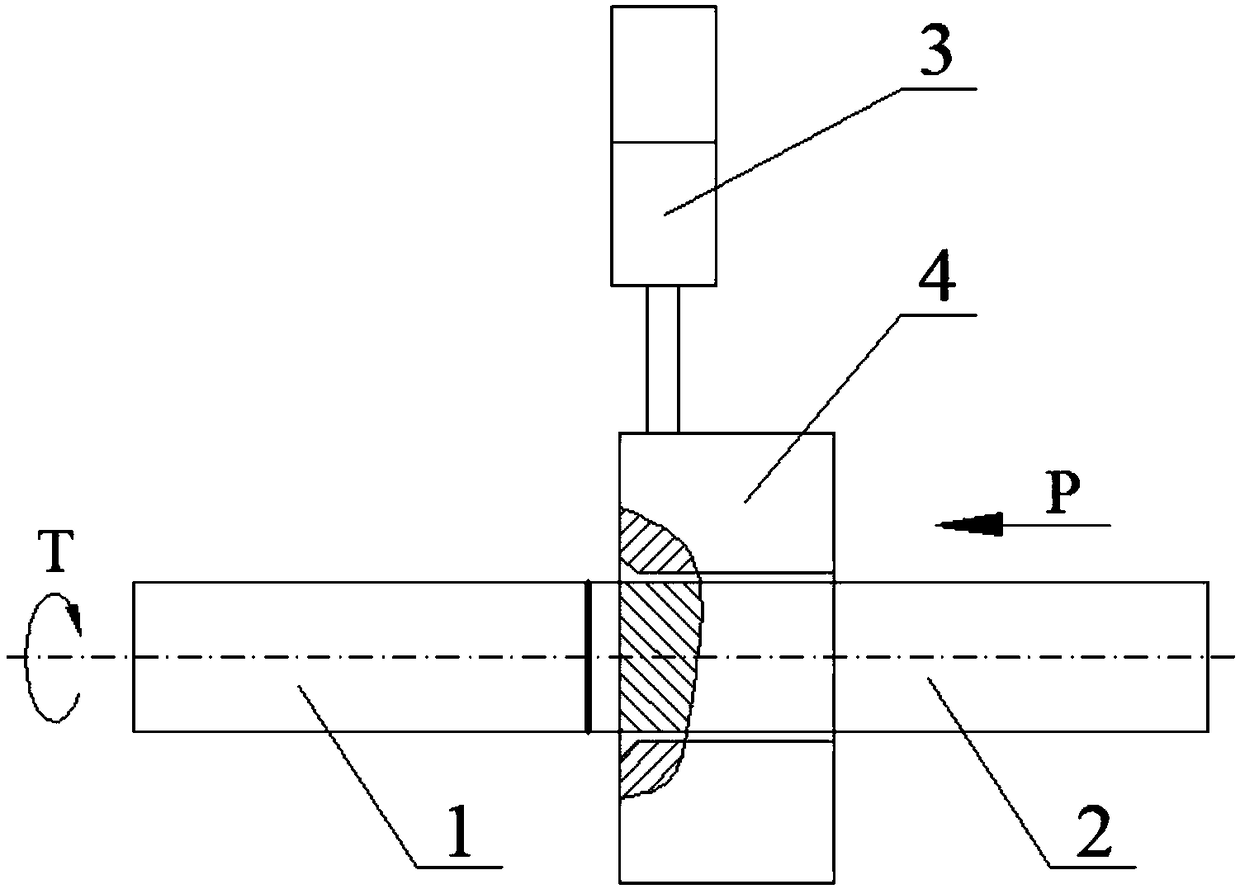

Ultrasonic vibration assisted friction welding method

InactiveCN109226956AReduce deformation resistanceHigh strengthNon-electric welding apparatusFriction weldingPositive pressure

The invention discloses an ultrasonic vibration auxiliary friction welding method, which is used for solving the technical problem of poor strength of a welding joint of the existing auxiliary friction welding method. The technical scheme is that in the process of rotating or linear friction welding, in addition to applying positive pressure and friction shearing force on the friction interface togenerate friction heat and plastic deformation, ultrasonic vibration is applied on the workpiece at the moving end, and the ultrasonic vibration transmitted to the friction interface can reduce the deformation resistance of high-temperature metal on the friction interface and promote the plastic deformation thereof, so that a larger plastic deformation amount can be generated even under a smallerfriction pressure, and finally the effective connection of workpieces at two sides is realized, and the strength of the friction welding joint is improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Fabricated recycled concrete composite shear wall structure

The invention provides a fabricated recycled concrete composite shear wall structure comprising a first pre-embedded body, a second pre-embedded body and a wall body. The first pre-embedded body and the second pre-embedded body are of U-shaped structures, the opening end of the second pre-embedded body is inversely buckled into an open slot of the first pre-embedded body, and a top plate of the second pre-embedded body is connected to the basic end of the wall body; one ends of connecting positions of the first pre-embedded body and the second pre-embedded body in hinged connection, and the other ends are slidably connected; and the hinged connection position and the sliding connection position are both provided with piezoelectric stacks, and the piezoelectric stacks are connected with a controller. In the fabricated recycled concrete composite shear wall structure, the controller is used for adjusting voltage applied to the piezoelectric stacks under different seismic load effects, the rotational friction and the sliding friction of a core region are adjusted, the purpose of self-adaption of the overall structure to seismic responses is achieved, and real-time variable-friction shear resistance under the small and medium seismic action is achieved; and under the rare occurrence earthquake effect, a large amount of seismic energy is consumed.

Owner:CHANGAN UNIV

A method for predicting the cracking stress of a steady-state matrix of a woven ceramic-based composite material by considering the environmental influence

PendingCN109598098ACracking Stress PredictionForecastingDesign optimisation/simulationStress distributionEnvironment effect

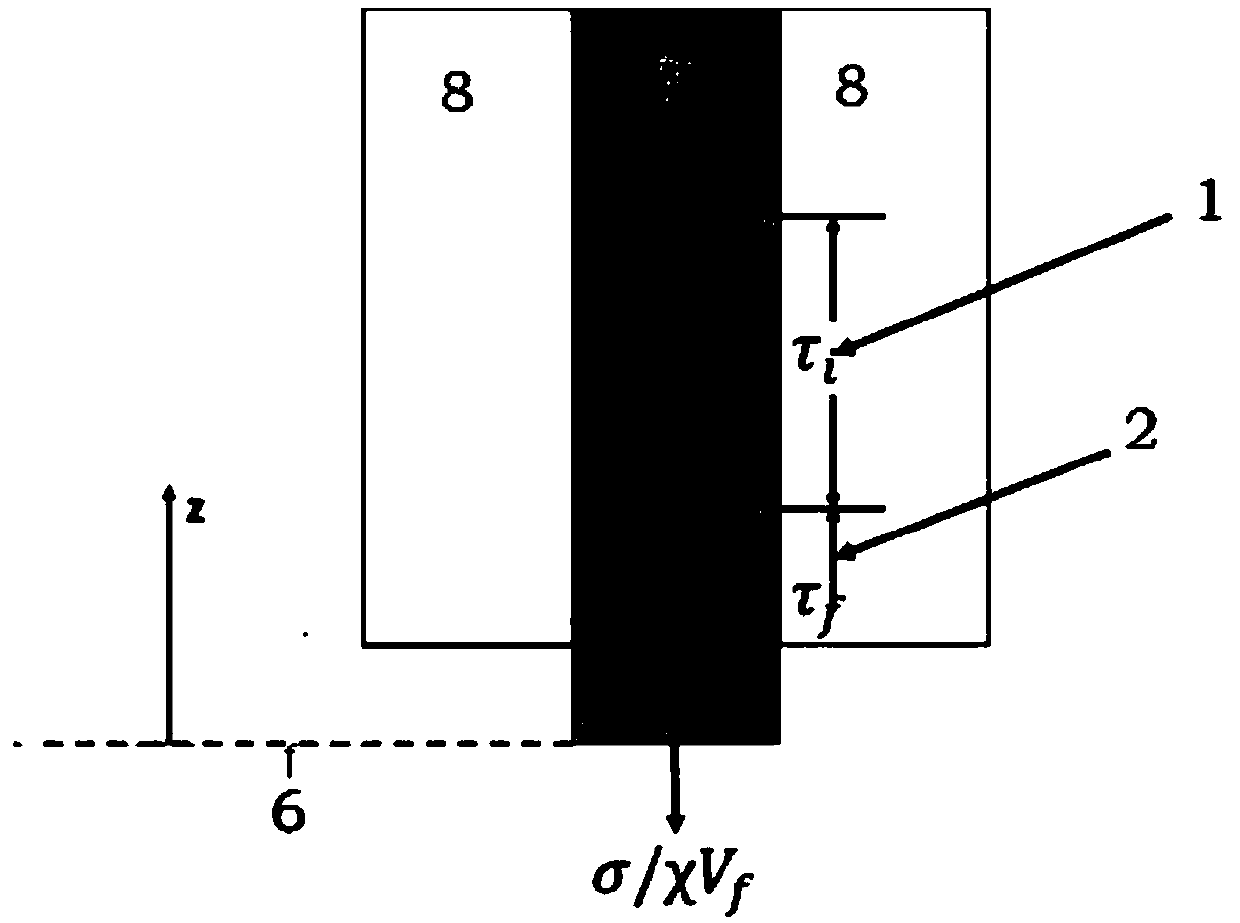

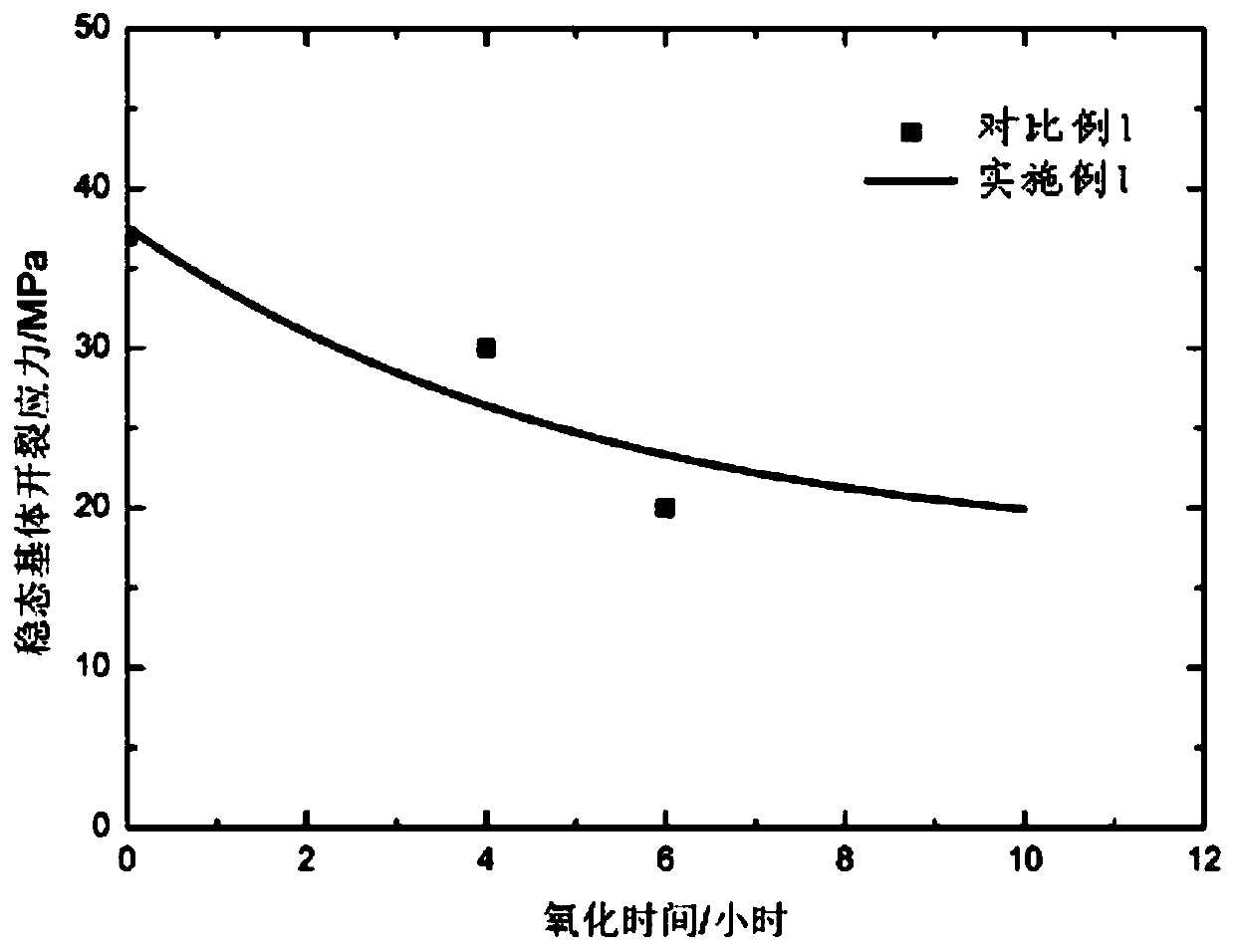

The invention belongs to the technical field of ceramic matrix composite steady-state matrix cracking stress prediction, and particularly relates to a method for predicting the cracking stress of a steady-state matrix of a woven ceramic-based composite material by considering the environmental influence. The invention provides a steady-state matrix cracking stress distribution equation, which is constructed and obtained by utilizing the length of a fiber / matrix interface oxidation area, and the fiber / matrix interface oxidation zone friction shear stress under the temperature condition and thefiber / matrix interface debonding zone friction shear stress under the temperature condition are constructed, so that the temperature and oxidation factors are included into a steady-state matrix cracking stress equation, and a basis is provided for accurately predicting the cracking stress of the steady-state matrix of the woven ceramic matrix composite material. Results of the embodiment show that the prediction method provided by the invention can predict the cracking stress of the woven ceramic-based composite material at different use temperatures.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

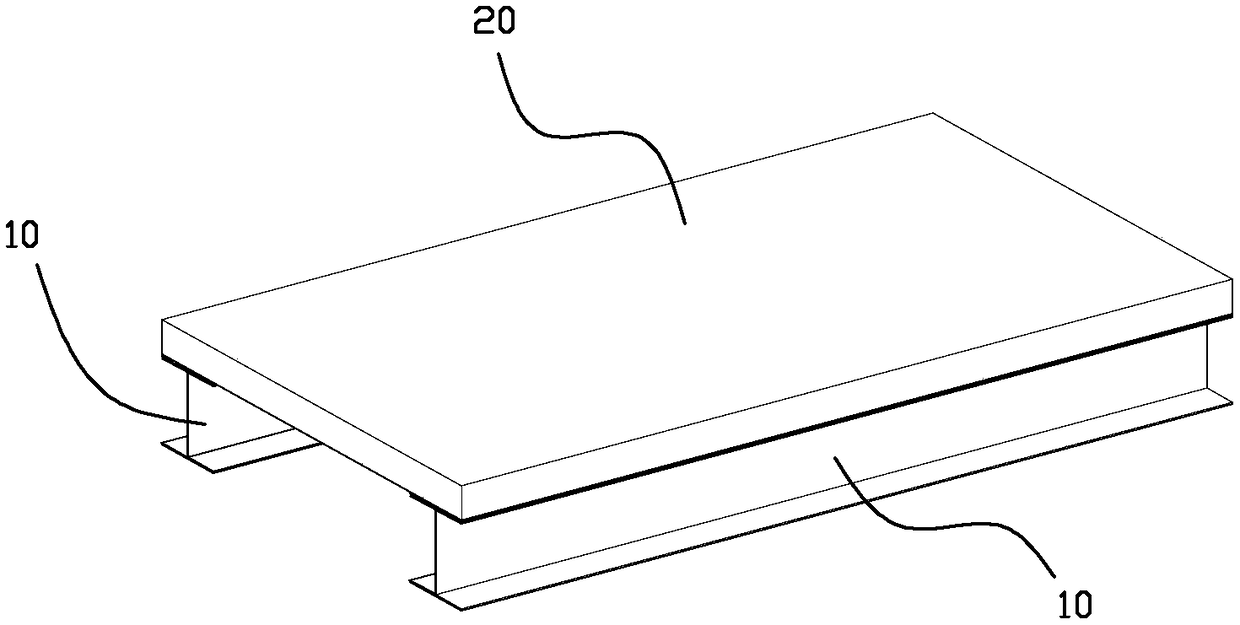

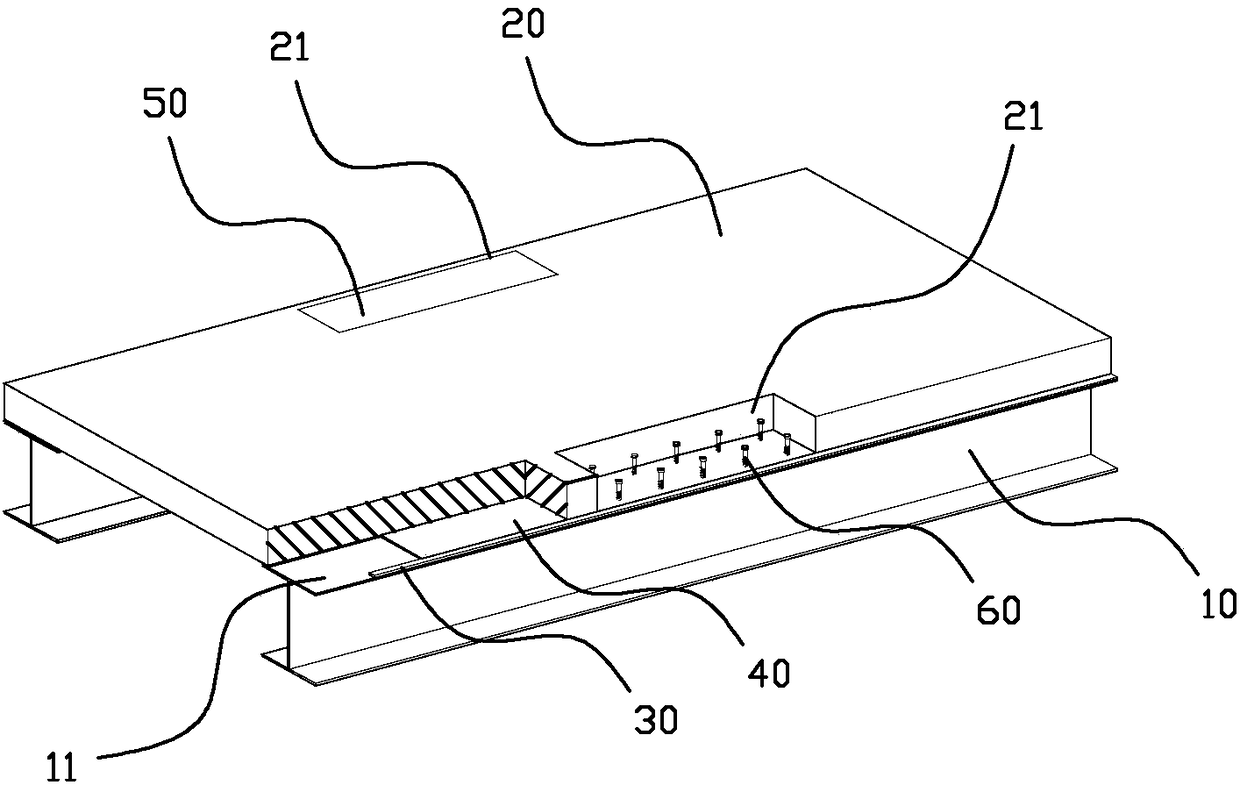

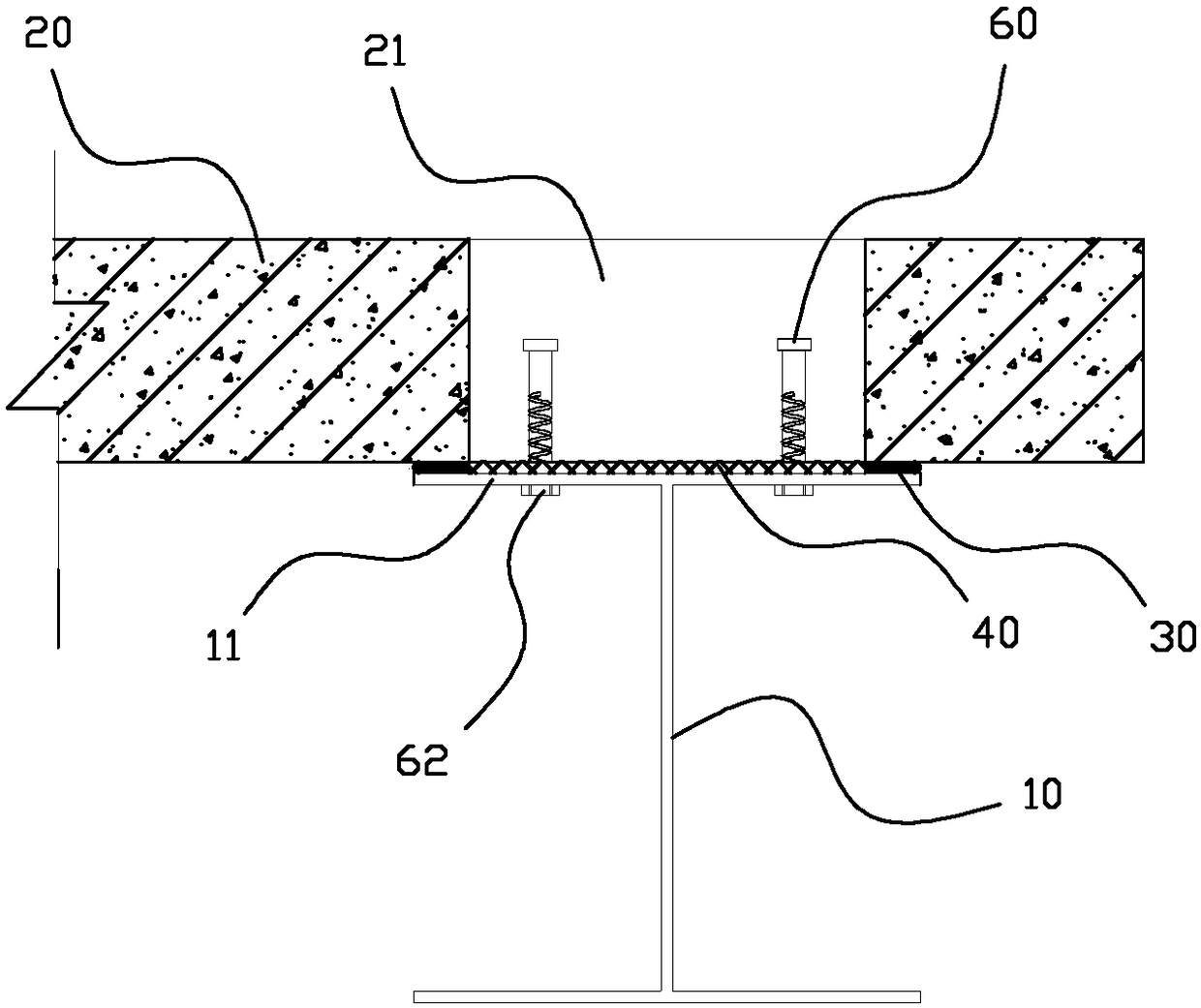

Steel-concrete composite beam structure with composite bonding anchorage shear-resistant joint and production method

PendingCN108330806AImprove fatigue lifeImprove the state of stressBridge structural detailsBridge erection/assemblyStress concentrationEpoxy

The invention relates to an interface pre-compression steel-concrete composite beam structure with a composite bonding anchorage shear-resistant joint and a production method thereof. The mode that anepoxy mortar layer and a shear resistance bolt are compositely connected is adopted, pre-tightening force is applied through the shear resistance bolt, thus the bonding interface of a concrete slab and a steel beam are in a pre-compaction state, and the concrete bridge deck slab and the steel beam are connected; meanwhile, friction shear resistance of the epoxy mortar shear-resistant connecting layer and the bonding interface can improve the stress state of bolt local stress concentration; and after the pre-tightening force is applied by the shear resistance bolt, the bonding surfaces of theepoxy mortar layer and the steel beam as well as the epoxy mortar layer and the prefabricated bridge deck slab are in a pre-compression state, in the bridge operating process, part of shear force between the concrete slab and the steel beam can be transmitted through the epoxy mortar layer, fatigue stress of the shear resistance bolt is reduced, the stress concentration phenomenon of the joint ofthe concrete slab and the bolt is avoided, and the fatigue life of the beam and bridge composite structure is prolonged.

Owner:HUAQIAO UNIVERSITY

Anti-scour device of offshore wind power pile foundation

The invention discloses an anti-scour device of an offshore wind power pile foundation. The anti-scour device comprises a support frame and at least one flexible element, wherein the flexible elementis detachably mounted on the support frame, a support table is mounted at the bottom of the support frame, the support frame rotates relative to the support table, and the support table is fixed on aseabed. Compared with the prior art, the anti-scour device of the offshore wind power pile foundation changes torrent or main flow into uniformly diffused slow flow as quick as possible through friction drag between water flow and fiber cloth strips, impact, vortex, overflow, diffusion, aerification and the like, so that the functions of collision mixing and friction shear stress of energy dissipation diffusion are realized.

Owner:湘潭永达机械制造股份有限公司

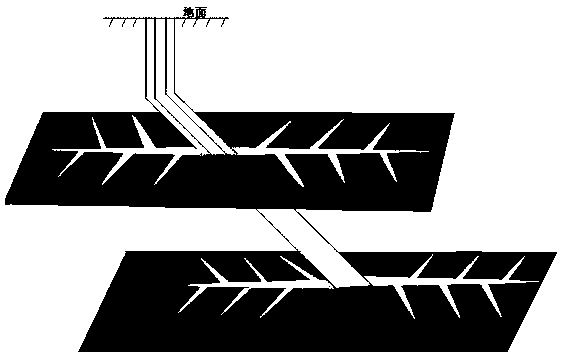

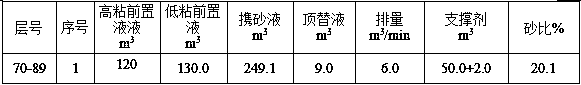

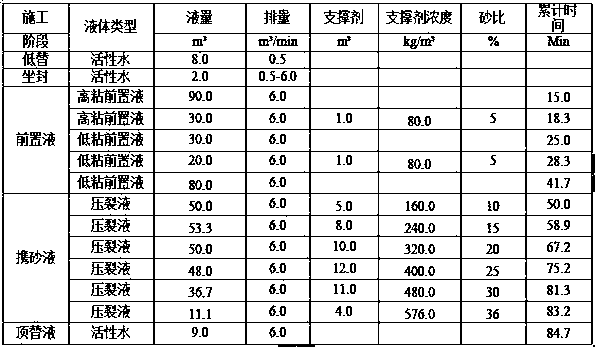

Single well multiple oil layer plane branch multi-crack fracturing technology

ActiveCN109356558AExpand the effective areaIncrease productionFluid removalDrilling compositionFriction & shearViscosity

The invention discloses a single well multiple oil layer plane branch multi-crack fracturing technology. High-viscosity ahead fluid and low-viscosity ahead fluid with different viscosities are adopted, the single well multiple oil layer plane branch multi-crack fracturing technology is divided into two segments and injected into the stratum, the front semi-segment is injected with mixing fluid ofthe high-viscosity ahead fluid and a high-efficient fluid loss agent, a plurality of cracks with half-length greater than or equal to 300 m of artificial cracks are fractured in the stratum to be usedas main cracks, then the low-viscosity ahead fluid is injected into a rear semi-segment, and fraction shear of the low-viscosity ahead fluid of the rear semi-segment and the main crack wall surfacesis used for building a plurality of branch cracks on the main crack wall surfaces, so that a complex artificial crack area is formed on a whole reservoir stratum; and fracture of a plurality reservoirs at the same time is realized.

Owner:SHAANXI YOUBANG PETROLEUM ENG TECH CO LTD

Device for producing oil by carrying out pyrolysis on polystyrene foam plastics

ActiveCN107151561ASmooth feedingEasy to produceCoke ovensLiquid hydrocarbon mixture productionRetention timeFriction & shear

The invention relates to a device for producing oil by carrying out pyrolysis on polystyrene foam plastics, belonging to the field of recycling of wastes. When the device is in use, the polystyrene foam plastics enters a screw extrusion device from a feeding port through a stock bin after being coarsely crushed, and heat is generated by means of extrusion and friction strain of a variable pitch screw, so that volume reduction of the polystyrene foam plastics is realized. An electromagnetic induction coil is wound on an external cavity of the outer wall of the device and can be used for enabling the variable pitch screw in the device to become an internal heat source for heating materials by means of self-heating. By adjusting the rotating speed of the screw, the polystyrene foam plastics can be enabled to maintain specific retention time in a specific area so as to be subjected to pyrolysis. Pyrolysis gas is discharged into a condenser pipe from a cavity under the condition of negative pressure and is then liquefied into oil, and exhaust gas of pyrolysis is absorbed by activated carbon, so that secondary pollution is reduced. The front end and the rear end of the device are respectively and externally connected with a vacuum pump, so that negative pressure and an oxygen-free environment are realized in a screw conveying device. The polystyrene foam plastics used by the device does not need to be cleaned, so that the production of cleaning waste water is effective reduced in a recycling process.

Owner:UNIV OF SCI & TECH BEIJING

Planetary rubbing type pea peeling machine

The planetary rubbing pea peeling machine can complete the peeling and separation of peas. The device mainly includes a feeding hopper, a planetary transmission, a planetary carrier, a planetary shaft, a drum, a roller, a rubbing roller, and a discharge port. Main shaft, idler, chain drive, driving device, in which the peas enter the inner cavity of the drum from the feed hopper, and under the action of the relative kneading motion of the rubbing roller and the drum, the peas sandwiched between the two are peeled due to friction and shear force , the peeled pea germ skin mixture is discharged from the discharge port; the planetary rubbing pea peeling machine has high working efficiency, convenient operation, simple structure, saves more labor resources, increases farmers' income, and reduces labor intensity of workers.

Owner:李晓波

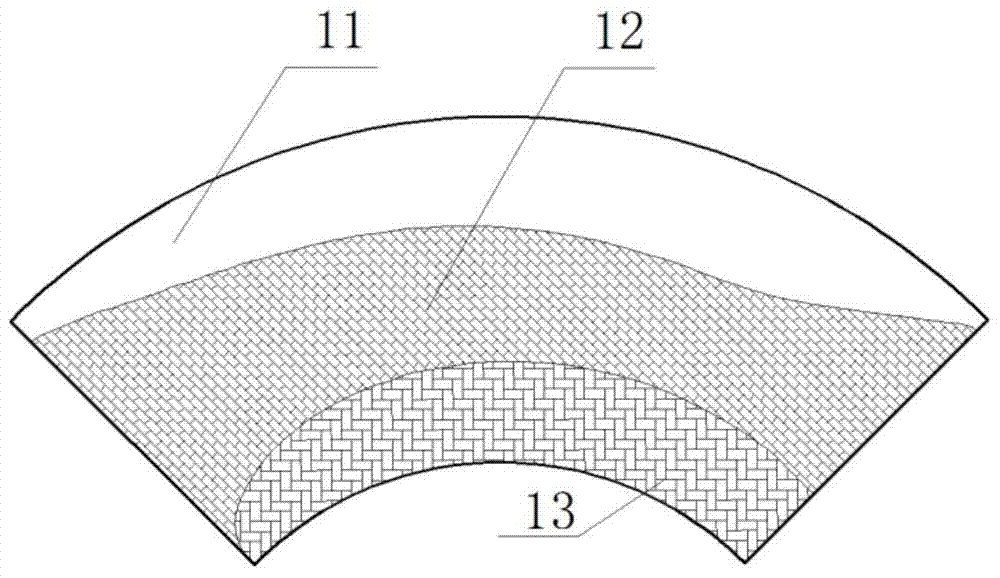

Wedge main friction plate made of high-temperature-resistant high-polymer composite and production method of wedge main friction plate

ActiveCN104802477AHigh decomposition temperatureImprove temperature resistanceSynthetic resin layered productsCarbon fibersAlkali free

The invention relates to a wedge main friction plate made of a high-temperature-resistant high-polymer composite. The wedge main friction plate comprises an enhancement layer and a wear-resistant layer, wherein the enhancement layer is prepared from 35-45 parts of copolymerized and modified resin and 55-65 parts of alkali-free glass cloth; the wear-resistant layer is prepared form 12-20 parts of sepiolite fibers, 5-15 parts of molybdenum disulfide, 10-15 parts of graphite, 1-5 parts of copper fibers, 1-5 parts of aramid fibers, 9-15 parts of carbon fibers, 3-8 parts of glass fibers, 5-10 parts of chromite ore powder, 5-10 parts of kaolin, 1-4 parts of titanium dioxide and 14-23 parts of copolymerized and modified resin; the copolymerized and modified resin is prepared from 1.0-1.7 parts of 4,4-diphenylmethylenebismaleimide and 0.6-1.2 parts of diallyl bisphenol A. The decomposition temperature of the friction plate which is under a partially larger friction shear stress working condition for a long time is greatly increased. The invention further provides a production method of the wedge main friction plate made of the high-temperature-resistant high-polymer composite.

Owner:HEBEI XINJI TENGYUE INDAL +1

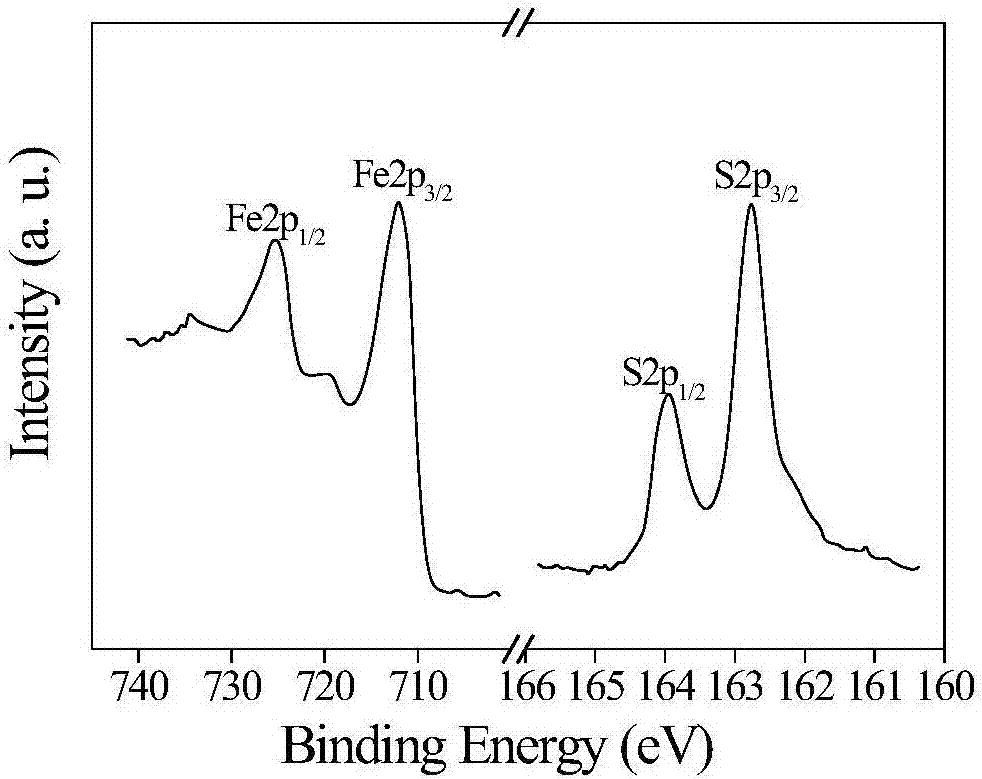

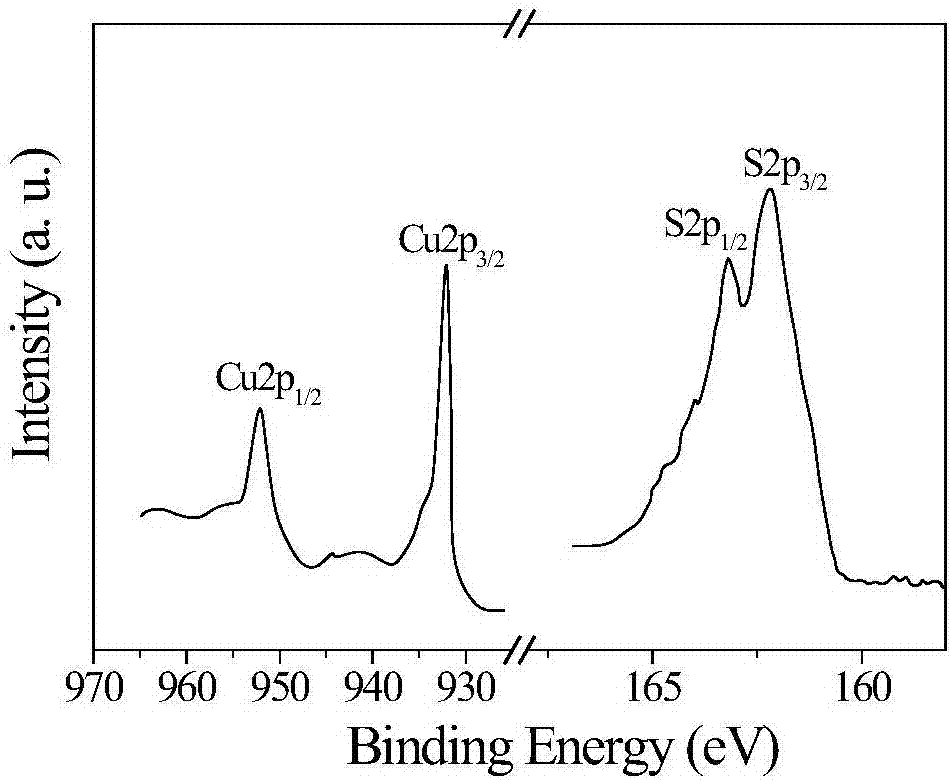

Method for lowering friction coefficient through surface filming performed in friction shear induced chemical reaction mode

ActiveCN107101084AReduce the temperature of the chemical reactionRapid anti-friction lubrication effectEngine lubricationChemical reactionFriction & shear

The invention discloses a method for lowering the friction coefficient through surface filming performed in a friction shear induced chemical reaction mode. Specifically, the method comprises the steps that in an ultrahigh vacuum environment, dialkyl disulfide is guided into a system, adheres to the surface of metal, and chemically reacts with the surface of the metal to form film through corresponding friction, and the friction coefficient is lowered. The method provided by the invention has good application and popularization prospects in lowing temperatures of certain chemical reactions, lowering the friction coefficient of the system and prolonging the service life of a friction pair.

Owner:HEFEI UNIV OF TECH

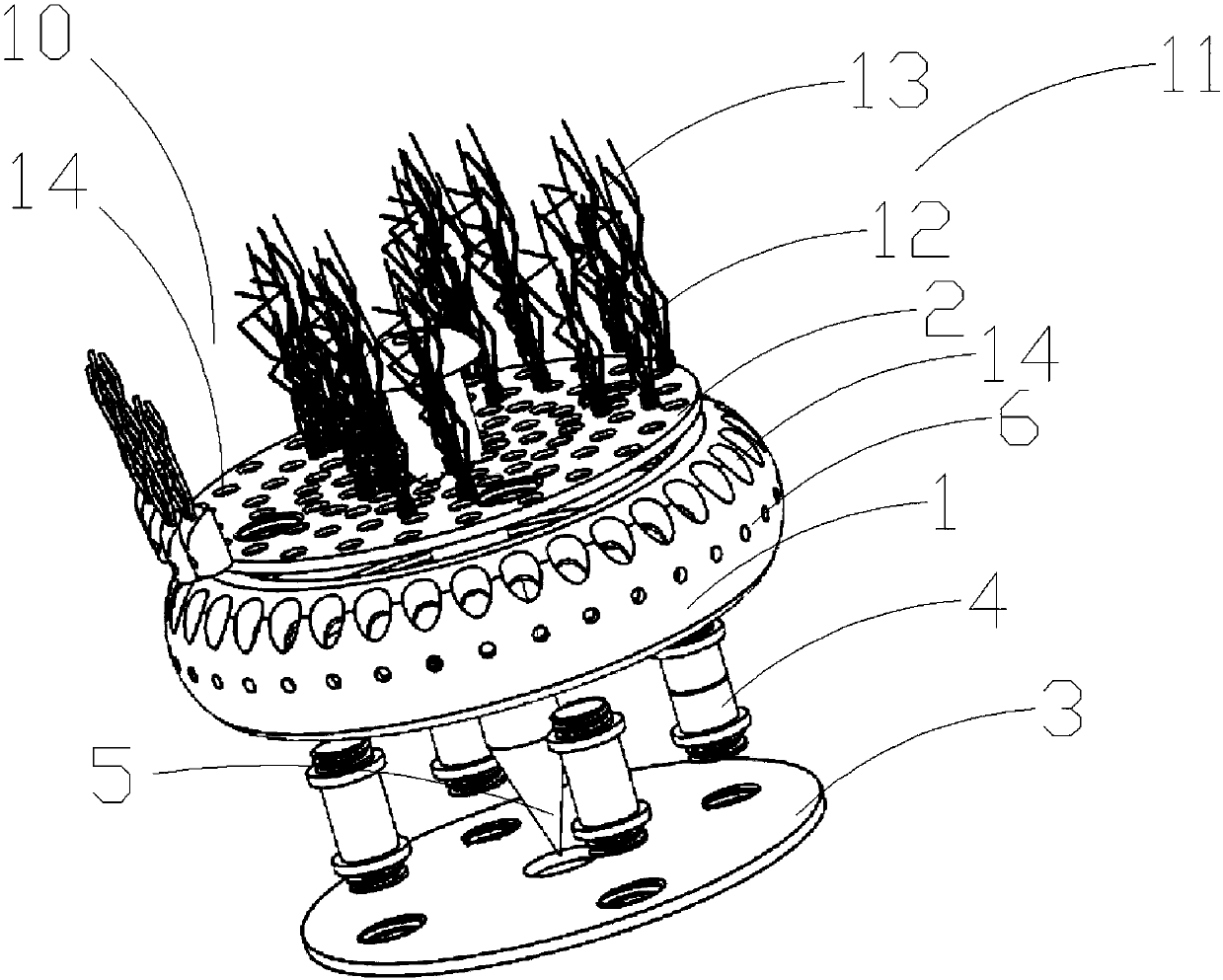

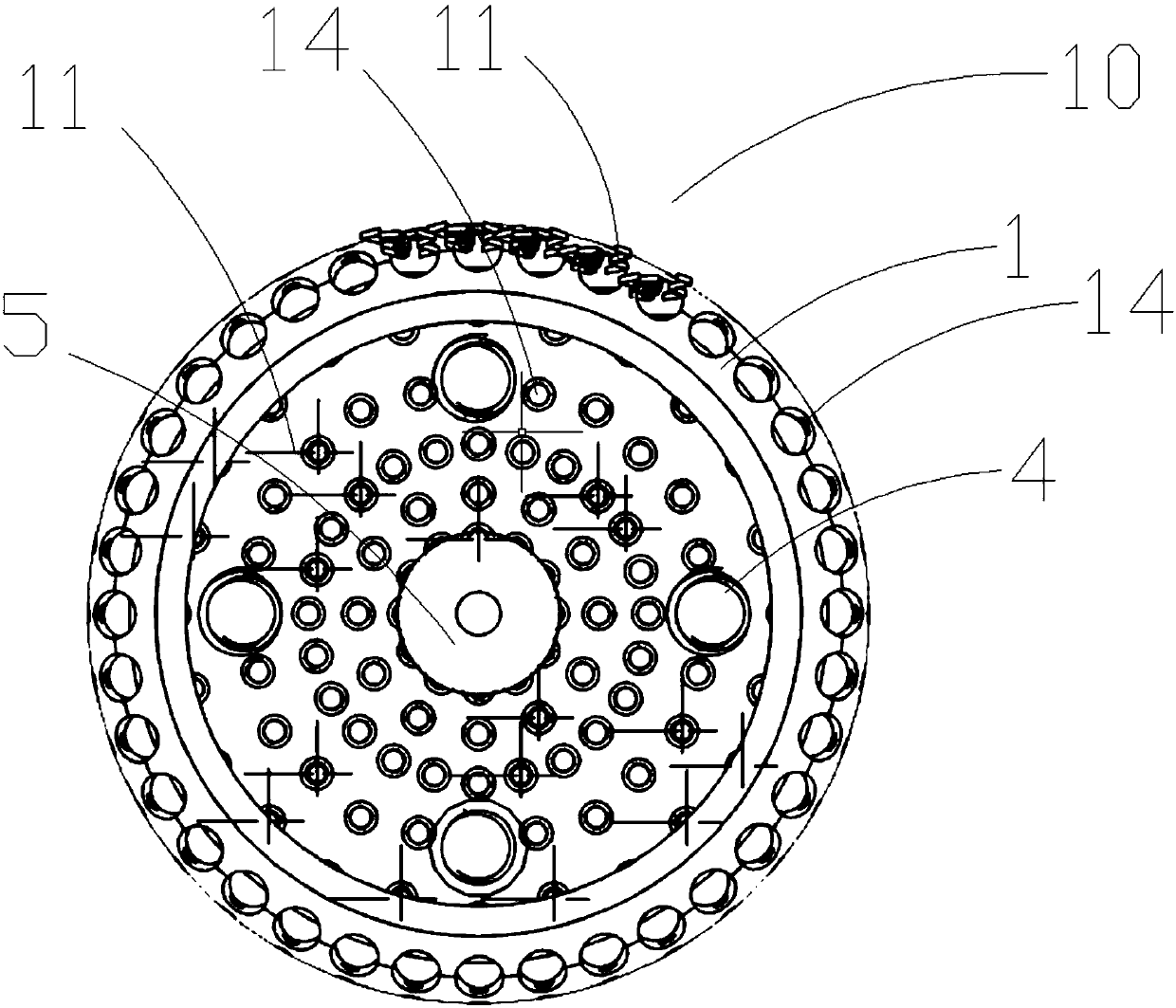

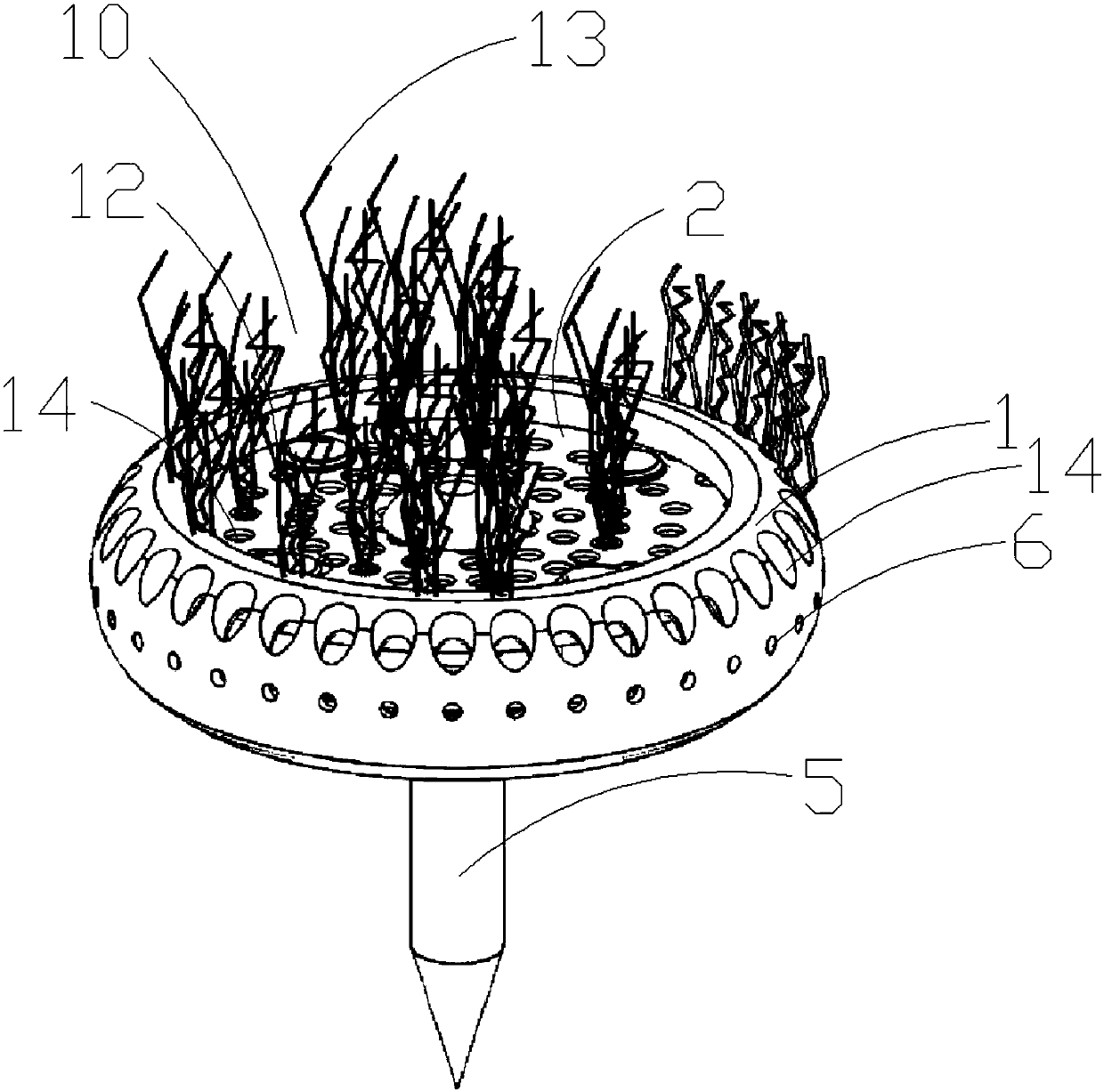

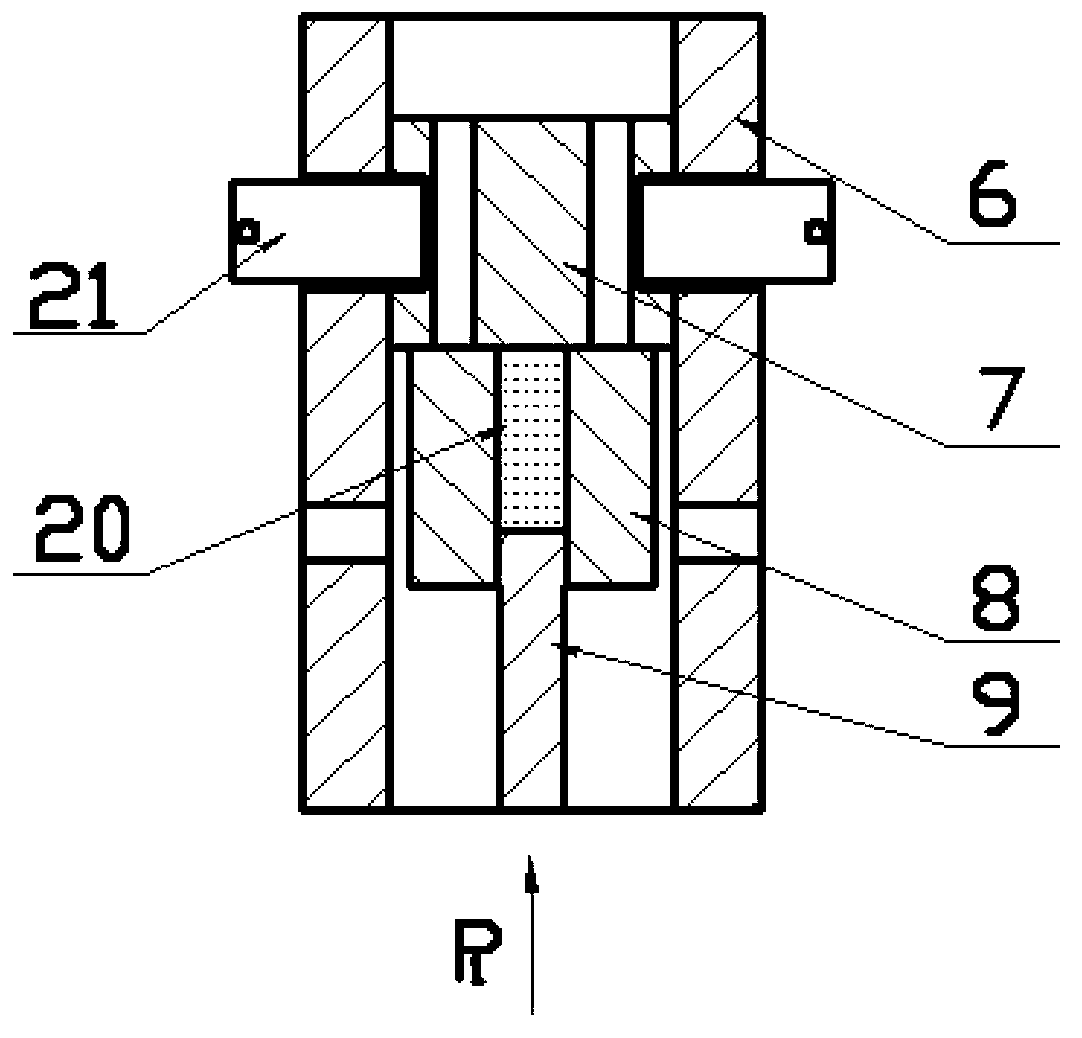

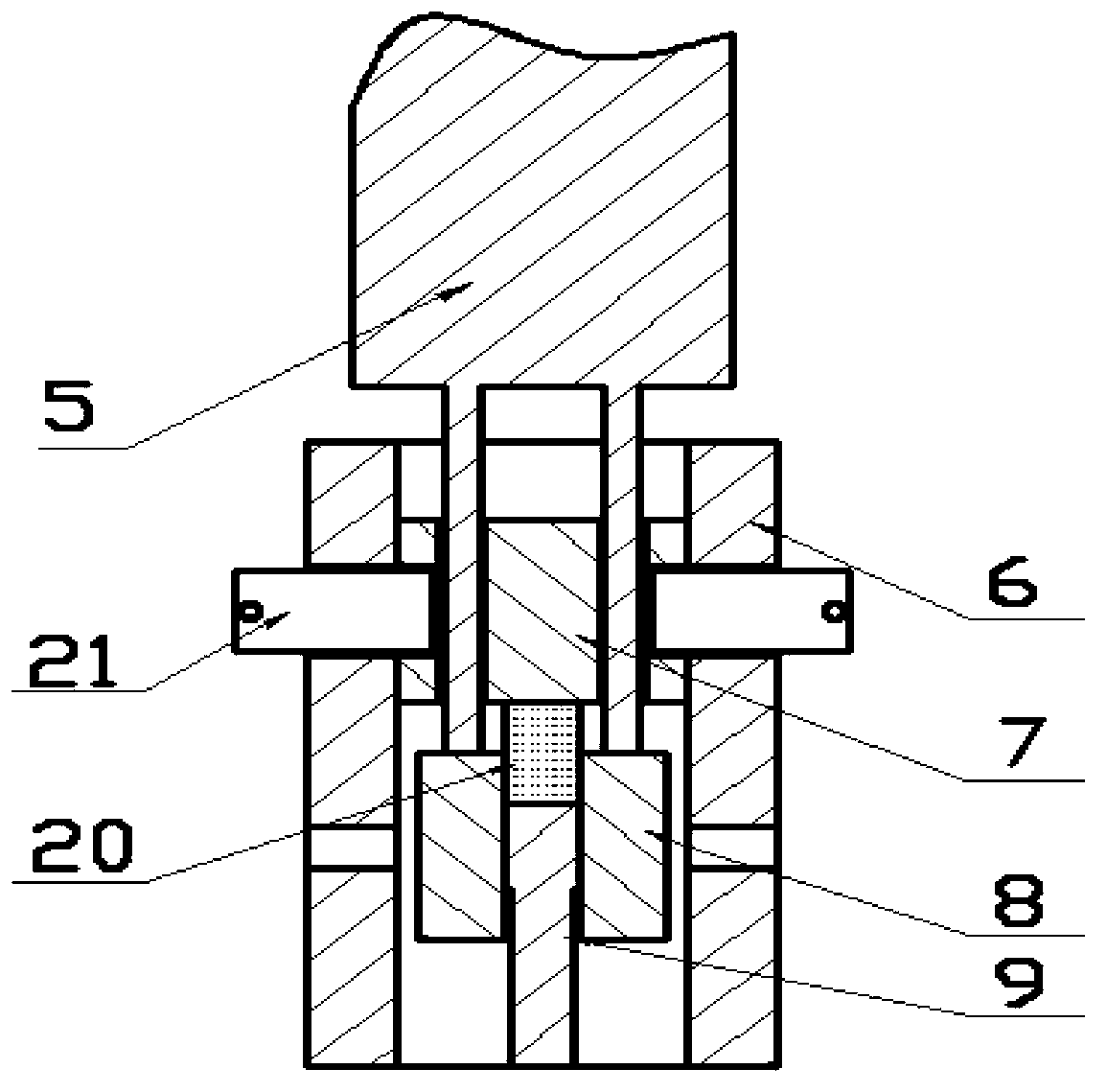

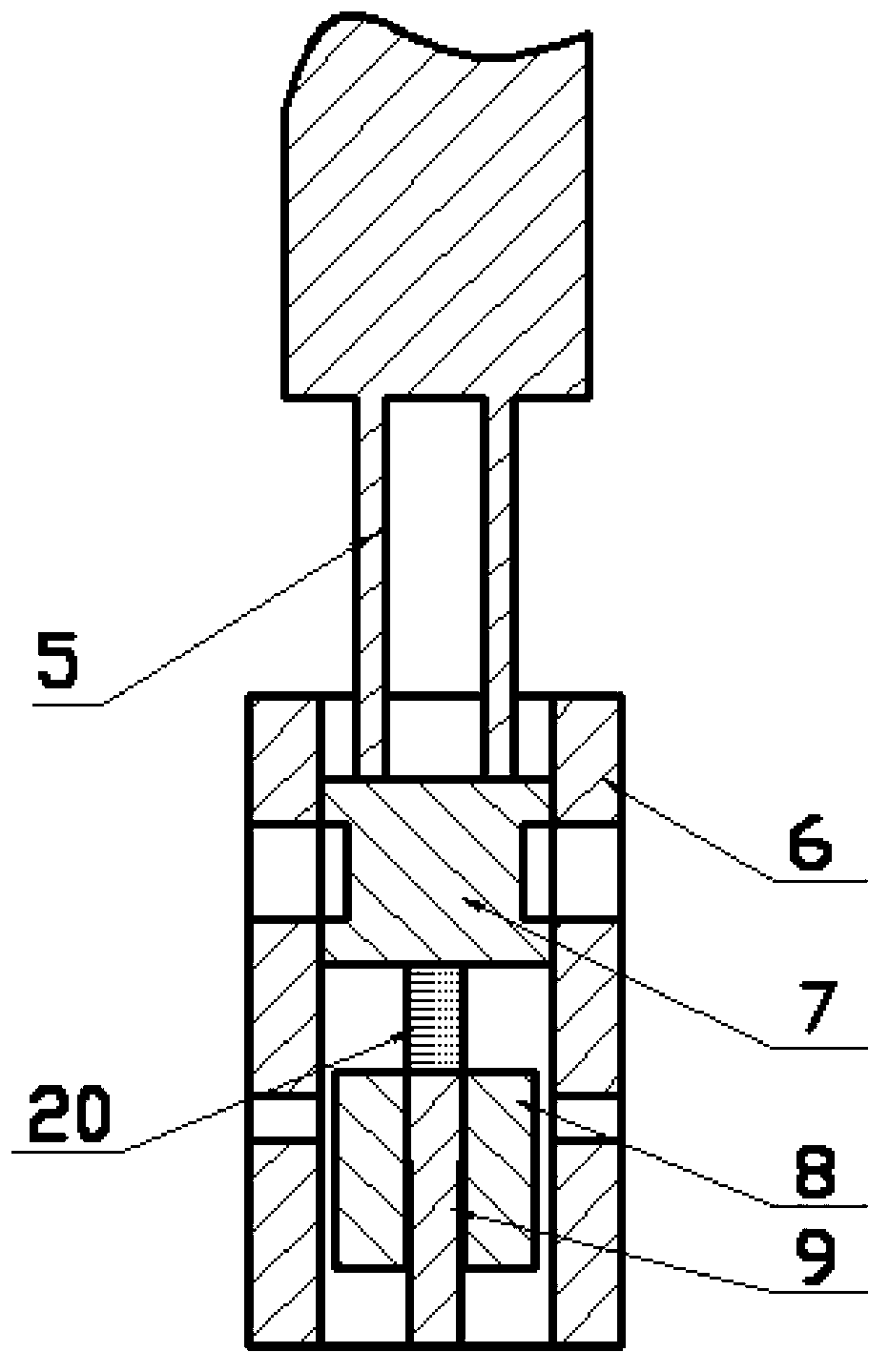

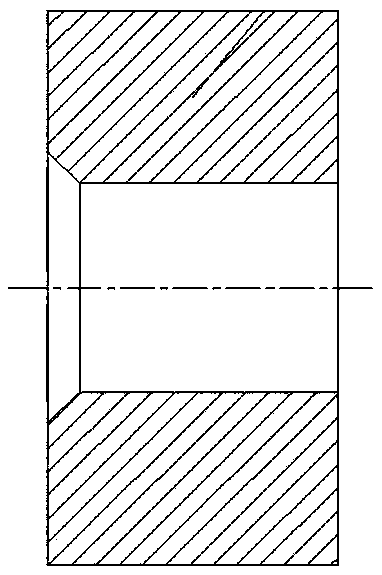

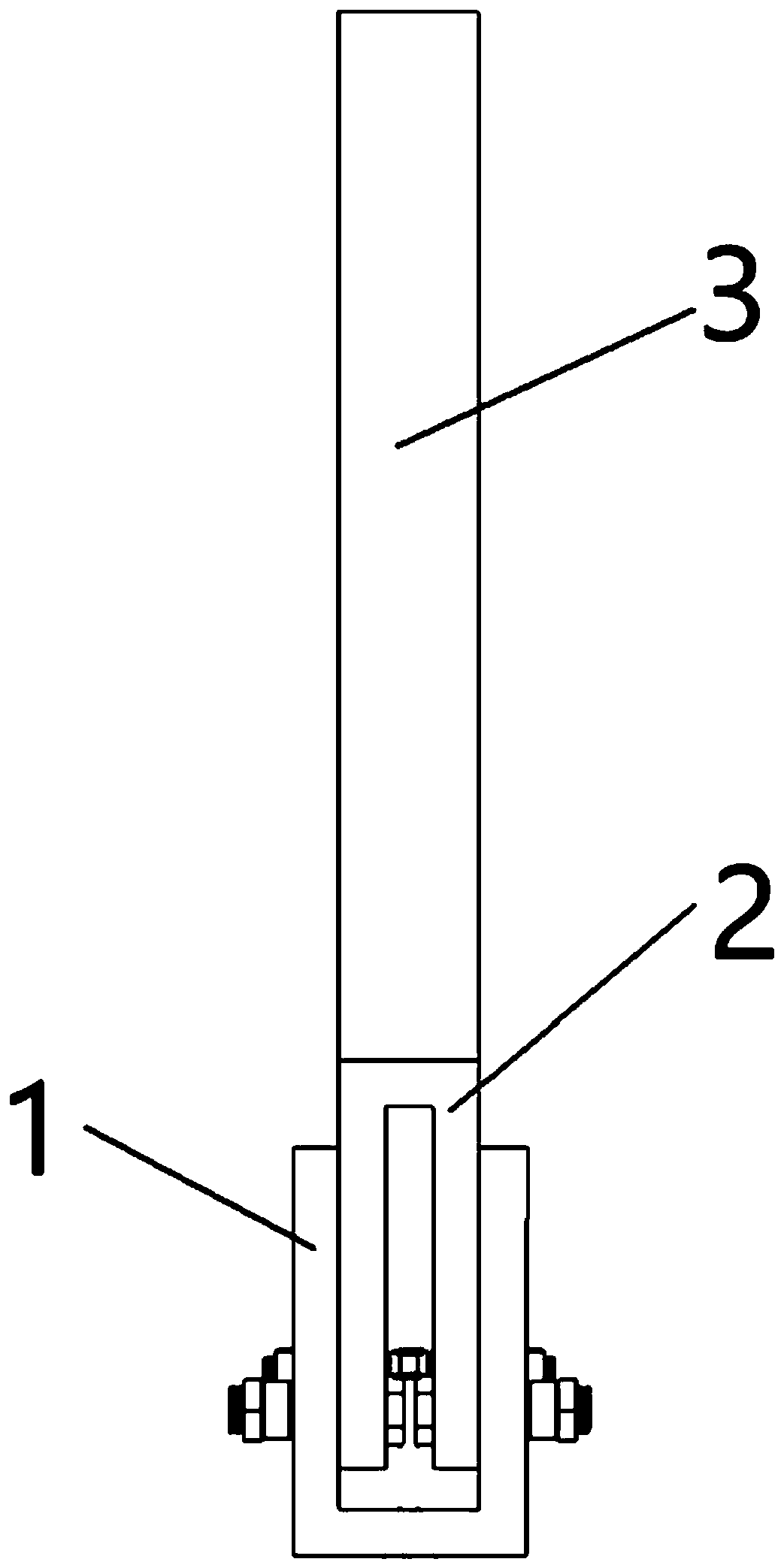

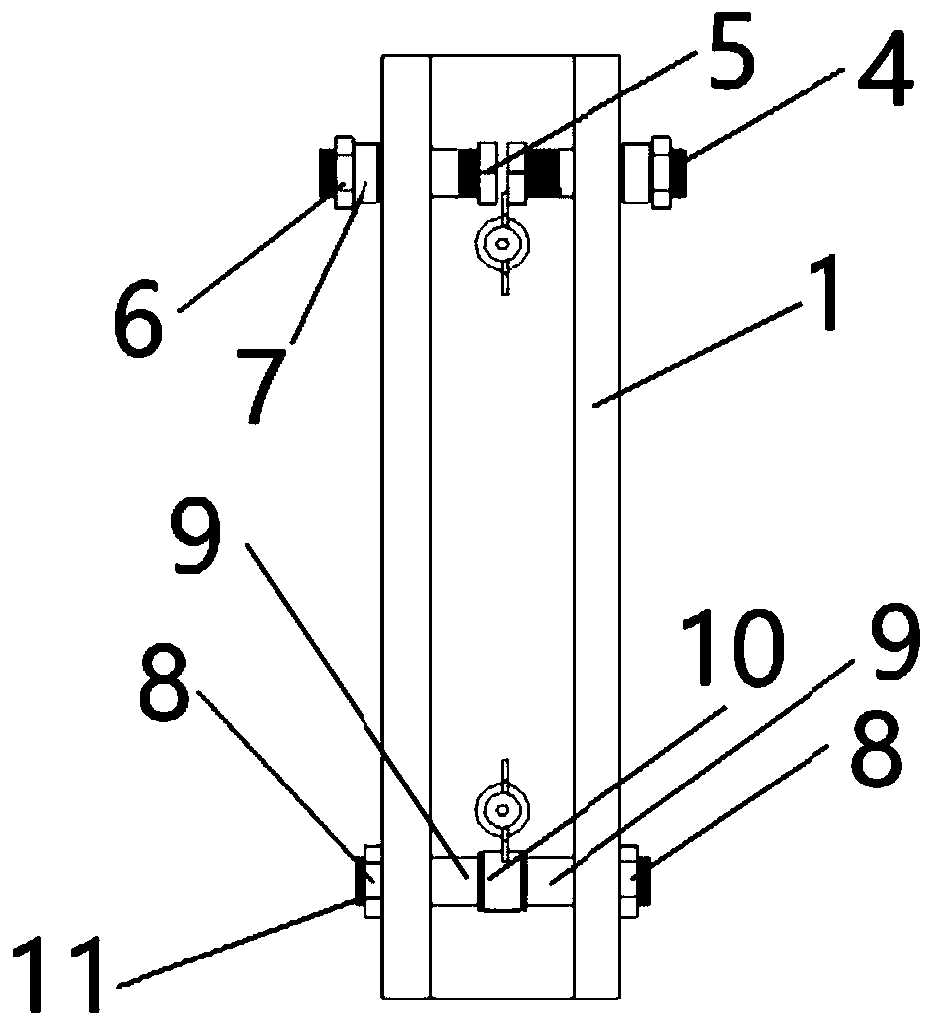

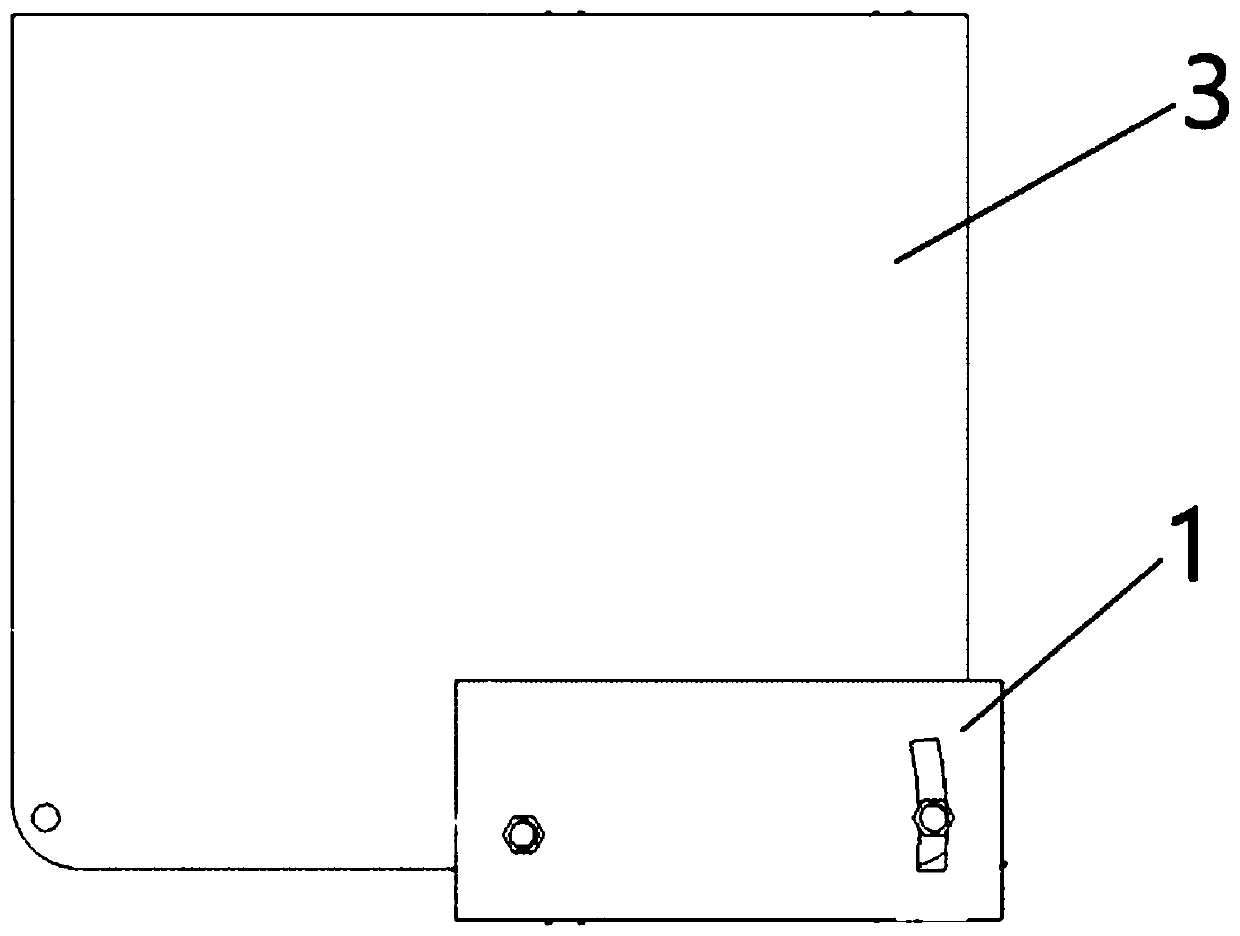

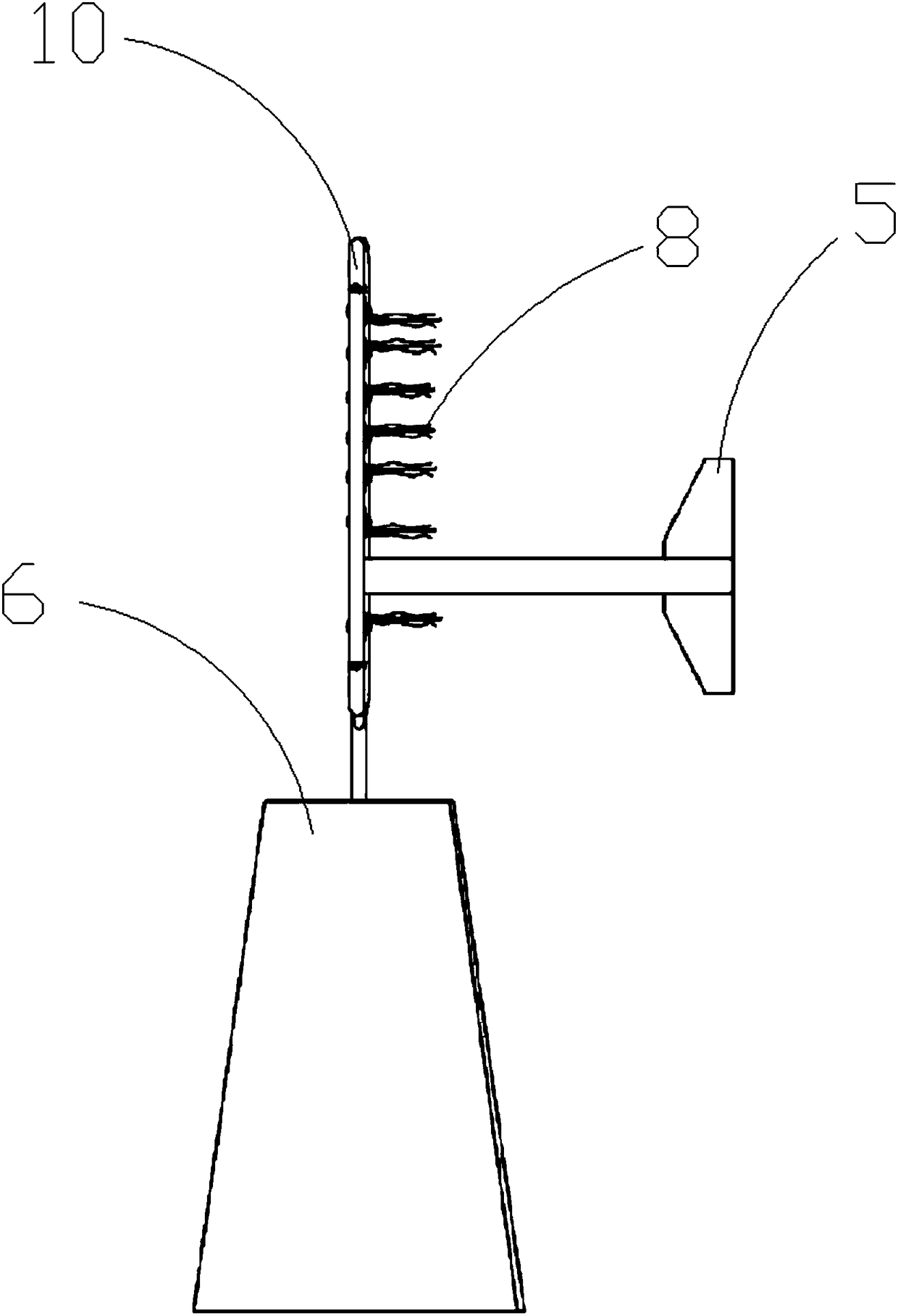

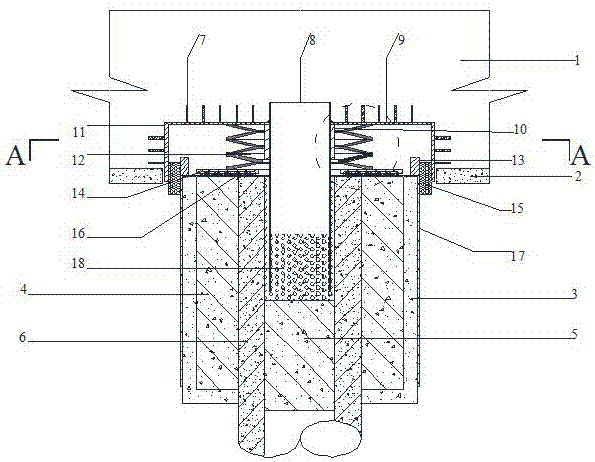

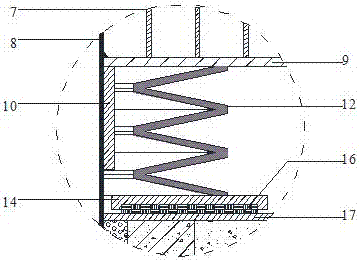

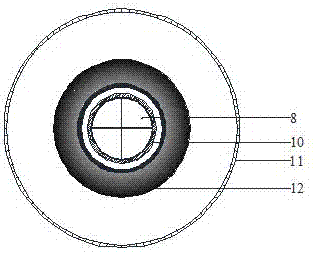

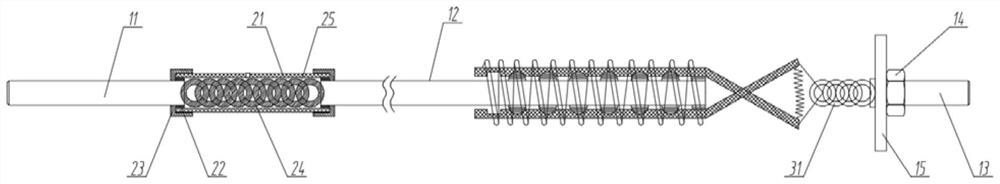

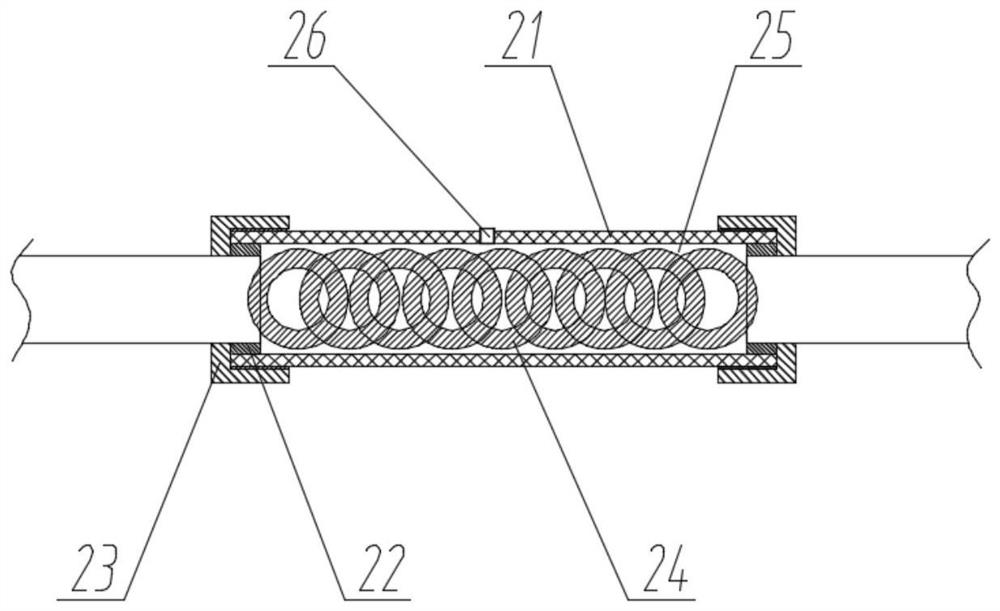

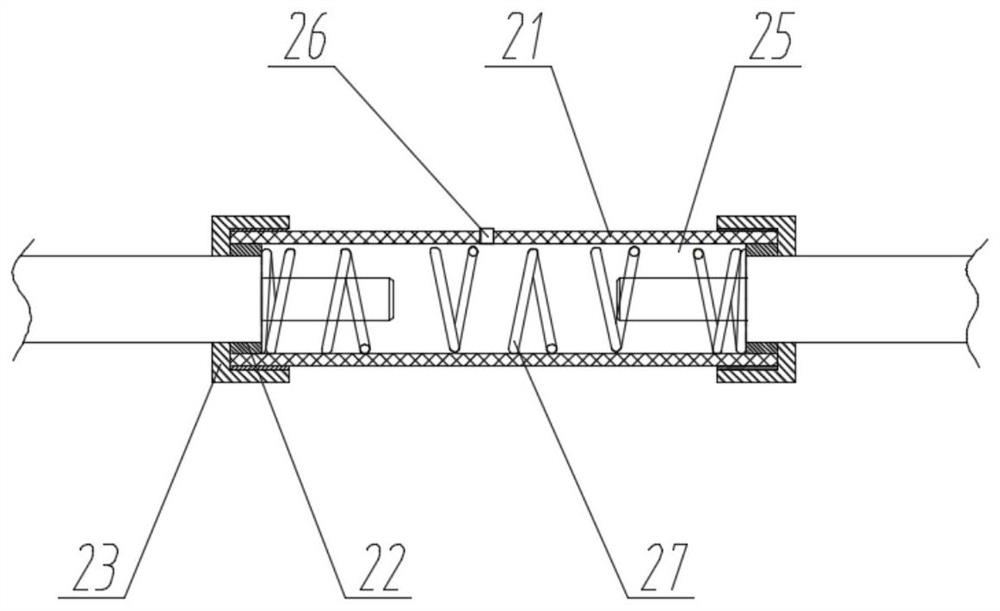

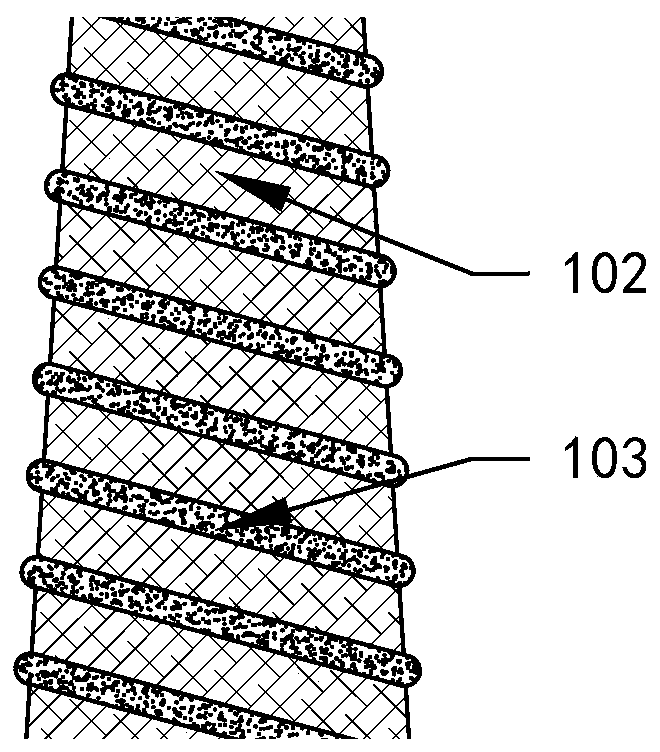

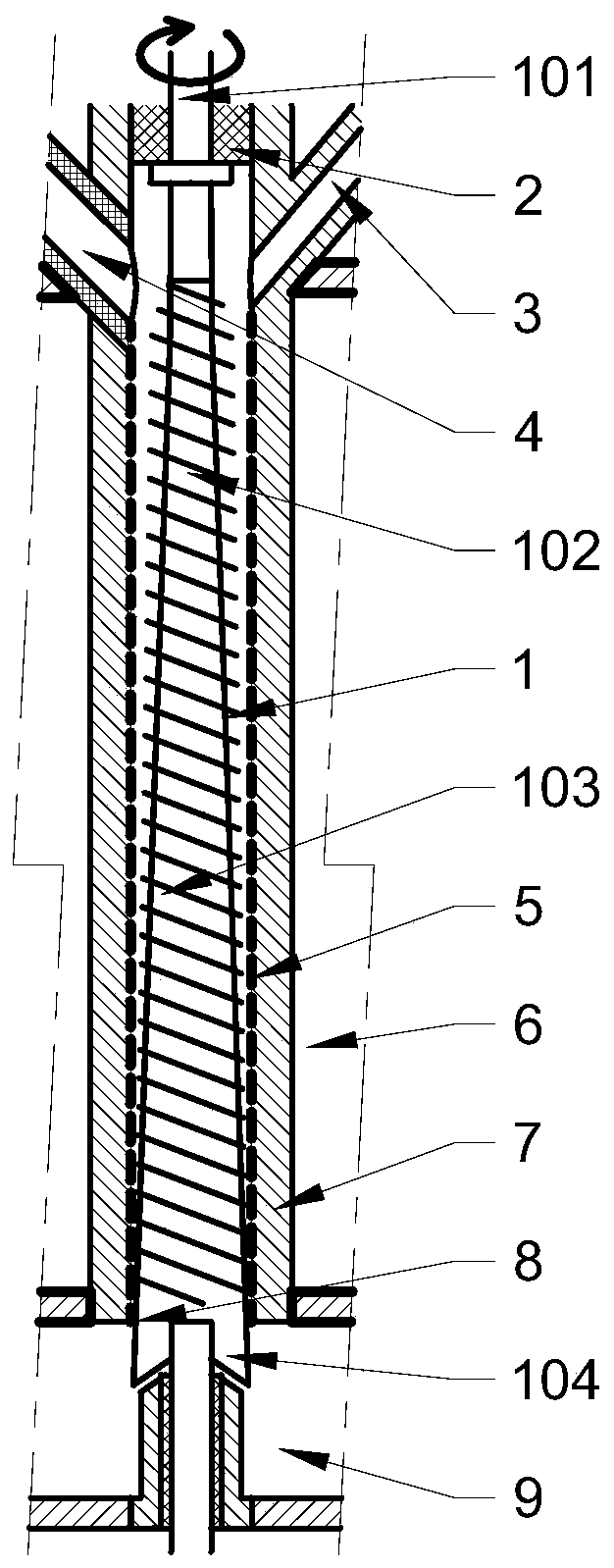

Pipe pile top friction-shearing type energy consumption connecting device and construction method thereof

ActiveCN107119677AEnhanced ductility and energy dissipation capacityAvoid prone to brittle failureProtective foundationBulkheads/pilesGlass ballFriction & shear

The invention discloses a pipe pile top friction-shearing type energy consumption connecting device and a construction method thereof. The device comprises an outer-layer steel cylinder, a center steel cylinder, a flexible steel pipe, an upper sealing plate, a lower sealing plate and a bottom sleeve; the flexible steel pipe penetrates through the center steel cylinder and extends into a pipe pile; a gap is filled with a glass ball and graphite mixture; an annular disc spring is arranged between the upper sealing plate and the lower sealing plate; a friction energy consumption pair and a limit retaining ring are arranged between the lower sealing plate and the top of the bottom sleeve; a connecting device is poured in a bottom groove of a bearing platform; the bottom sleeve is hooped on a pipe pile expansion head. Under an earthquake action, the shear deformation of the flexible steel pipe is caused, and meanwhile, a friction plate generates relative slippage, so that a pile top friction-shearing type horizontal energy consumption effect is realized; and the annular disc spring plays a vertical shock isolation role. Due to the arrangement of a multidimensional shock absorption connecting device between the pipe pile and the bearing plate, the delayed energy consumption capacity of a connecting node is improved, and the phenomenon that a pipe pile head easily generates brittle fracture under the action of an earthquake bending shear load is avoided.

Owner:TAIYUAN UNIV OF TECH

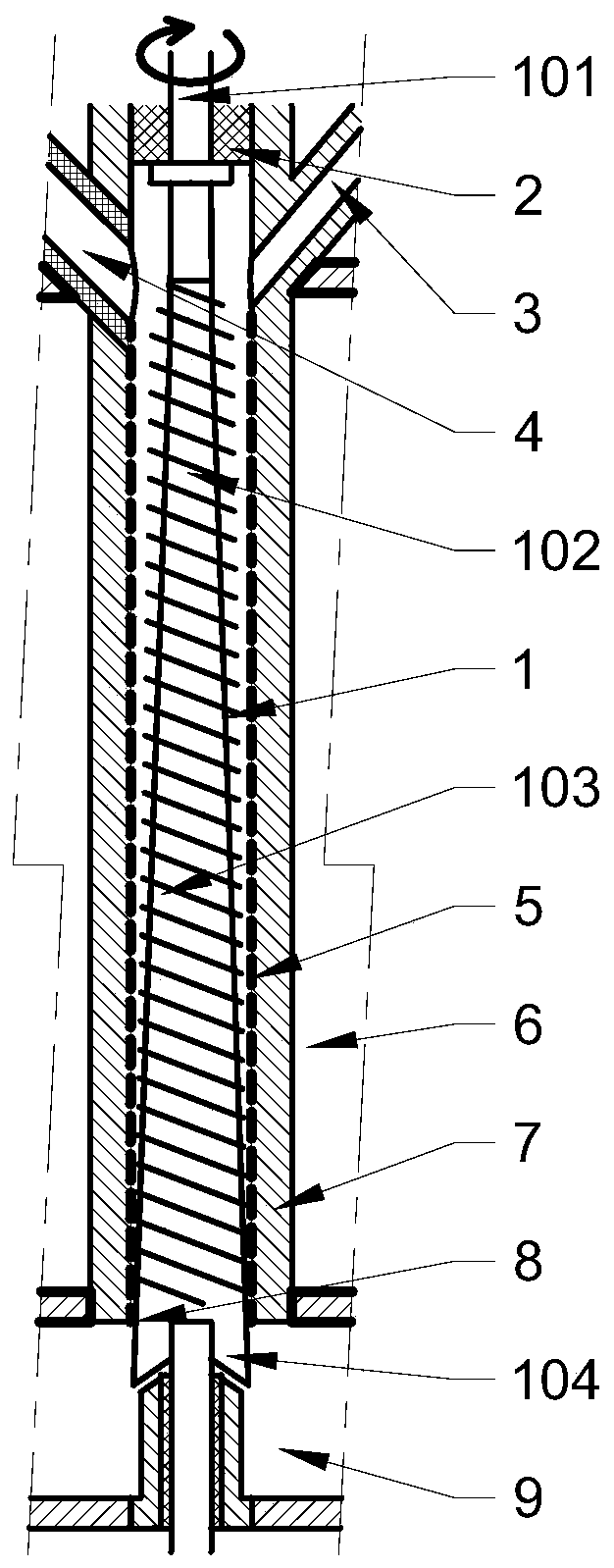

An Adaptive Friction Anti-Shear Large Deformation Bolt

ActiveCN113026739BStable supportAchieve clampingExcavationsBulkheads/pilesFriction & shearClassical mechanics

The invention discloses an adaptive frictional anti-shearing large deformation bolt, which comprises a bolt main body, a connection assembly and a casing assembly; the bolt main body includes a first rod body, a second rod body and a third rod body arranged left and right along the axis ; An anchor plate is installed on the third rod body, and a fastening nut is threaded; the first rod body and the second rod body are connected through a casing assembly, and the second rod body and the third rod body are connected through a connecting assembly; The assembly includes a support sleeve and a first adjustment assembly that expands left and right. The support sleeve is detachably set between the first rod body and the second rod body, and forms an inner cavity with the first rod body and the second rod body. The first adjustment assembly is located at In the inner cavity, the two ends are respectively fixedly connected with the first rod body and the second rod body. The self-adaptive frictional anti-shear large deformation bolt has simple structure and low cost, can effectively adapt to the shear deformation of rock mass, and plays a good supporting role on rock mass.

Owner:CHINA UNIV OF MINING & TECH

Cone mill roll biomass rapid catalytic pyrolysis reactor and pyrolysis method thereof

ActiveCN110003925ARapid condensationEfficient condensationBiofuelsLiquid hydrocarbon mixture productionCatalytic pyrolysisFriction & shear

The invention relates to a cone mill roll biomass rapid catalytic pyrolysis reactor and a pyrolysis method thereof. The pyrolysis reactor comprises a gas outlet, a feed inlet, a discharge hole, a conemill roll, a friction wall, a smoke flue, a closed shell, a carbon collection box and a sealing filler, wherein the cone mill roll consists of a cone roll body, a catalysis groove, a friction belt and a rotating shaft. Pretreated biomass particles suffer from the heating of the friction wall, and the surfaces of the pretreated biomass particles are rapidly warmed for a pyrolytic reaction; simultaneously, under the pushing extrusion of the friction belt, the materials suffer from the friction shearing action of the cone mill roll and the friction wall, the catalyst and heat can be sufficientlyfed into the interiors of the particles through surface residual carbon generated after the materials are constantly peeled and pyrolyzed, and efficient catalytic reaction is guaranteed; pyrolysis gas is rapidly condensed after gas-solid separation so as to obtain high-grade bio-oil fuel or bio-oil rich in specific high value-added products; and moreover, combustible gas and coke are colleted, high temperature flue gas is generated after combustion and is used for heating the shell, and a self-heating type pyrolysis process is realized.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

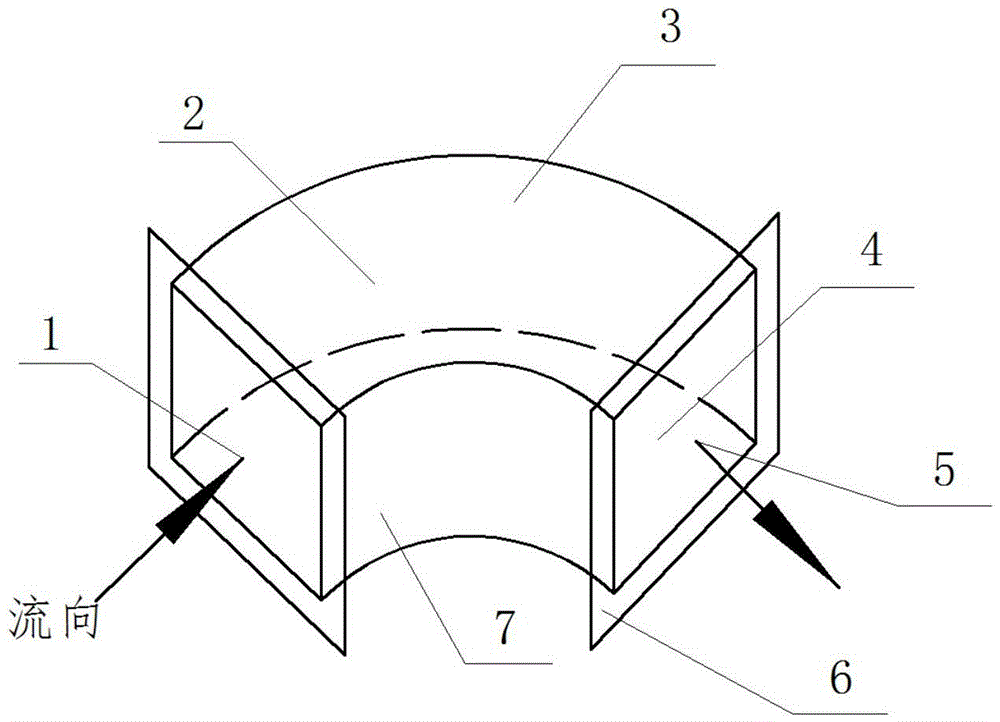

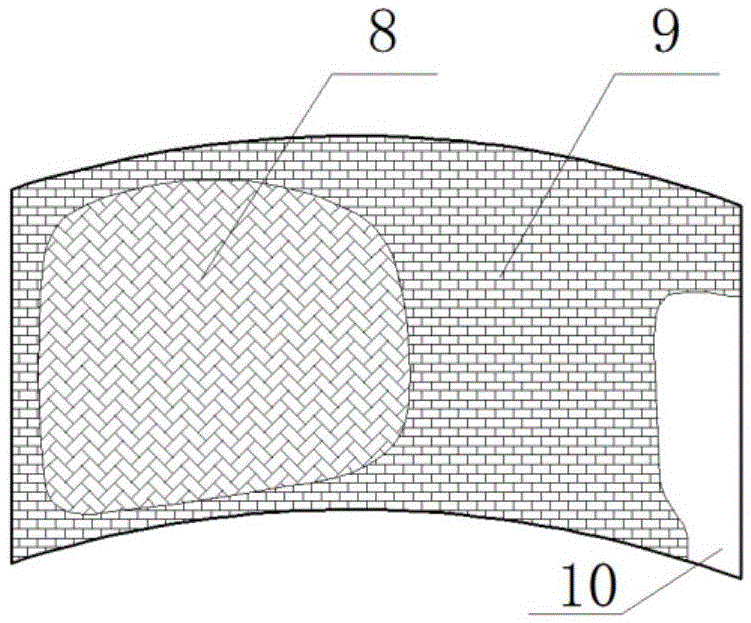

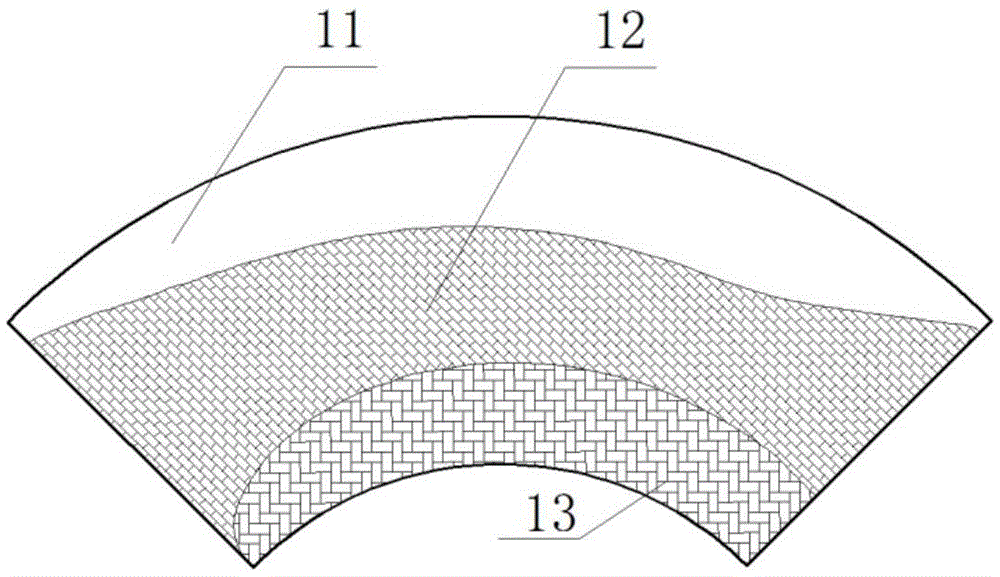

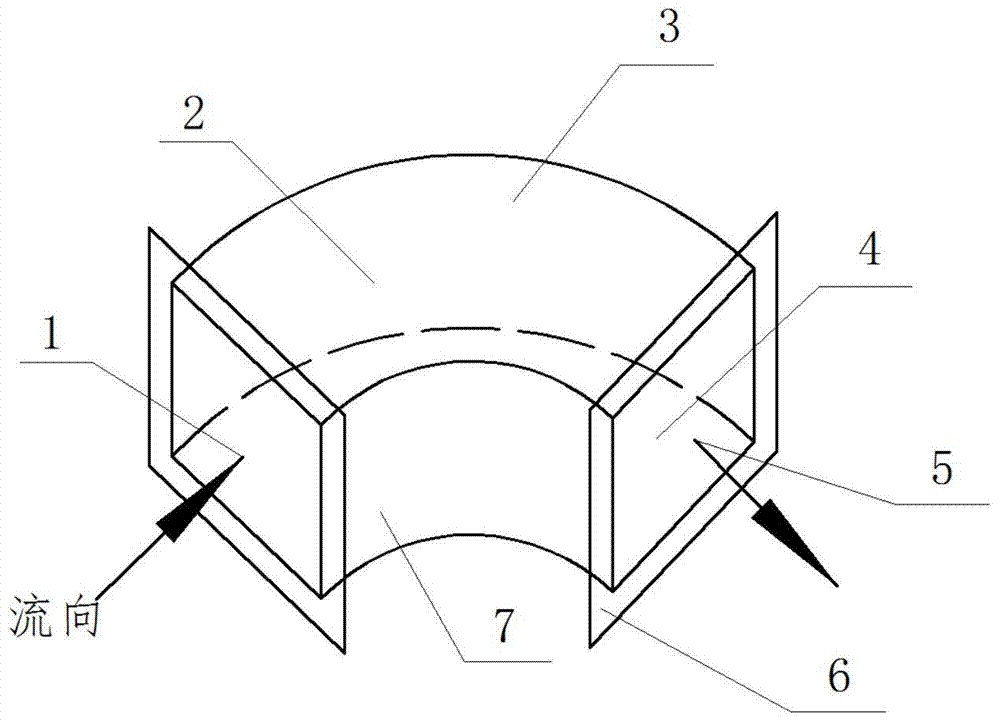

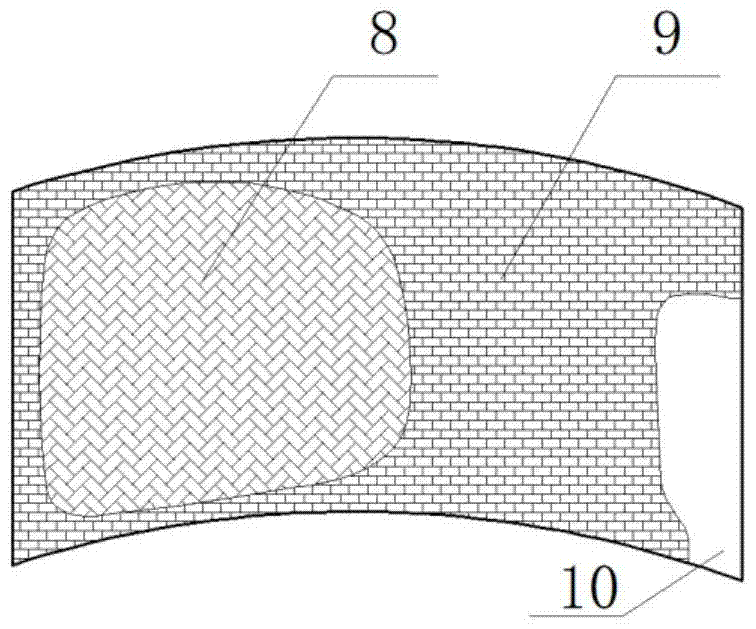

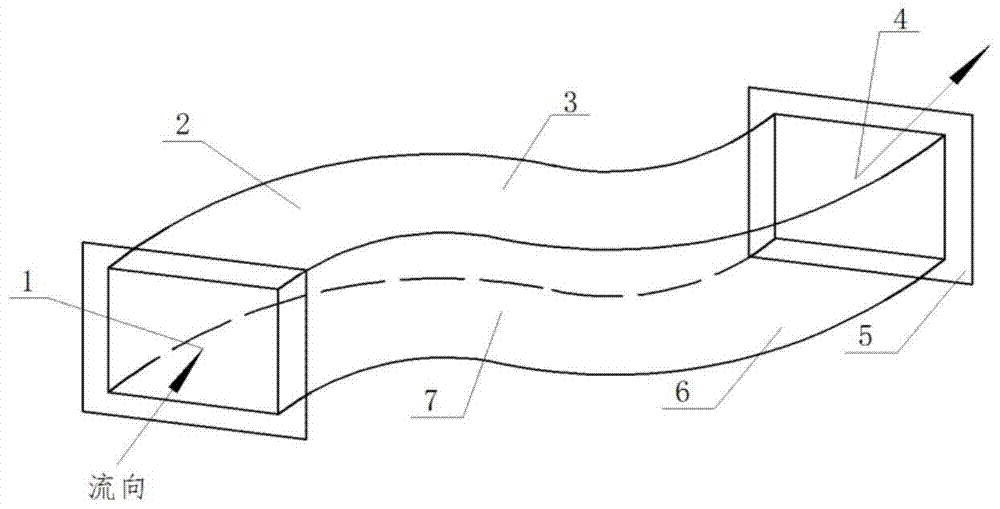

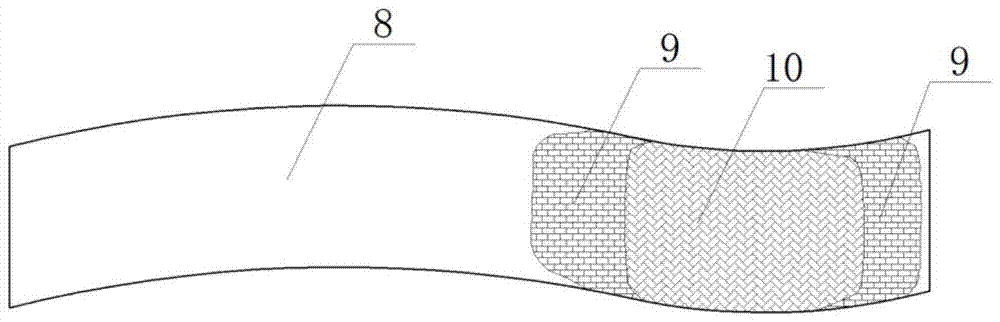

90-degree rectangular wear-resistant elbow and wear-resistant treatment method of elbow

ActiveCN105485460AAccurately locate the distribution of friction forceImprove grindingPipe protection against damage/wearSiphonsWear resistantFriction & shear

The invention discloses a 90-degree rectangular wear-resistant elbow and a wear-resistant treatment method of the elbow. The 90-degree rectangular wear-resistant elbow comprises an upper top plate, a lower bottom plate, an outer cambered surface and an inner cambered surface. A quarter of an arc-shaped pipe is obtained through the surrounding of the upper top plate, the lower bottom plate, the outer cambered surface and the inner cambered surface, which are taken as four sides. The upper top plate is the same as the lower bottom plate. The lower bottom plate and the inner cambered surface are both divided into high-friction areas, middle-friction areas and low-friction areas. Wear-resistant materials of different wear-resistance thicknesses are respectively arranged on the surfaces, which are positioned in the elbow, of the high-friction areas and the middle-friction areas. Different wear-resistant materials are adopted at parts with different friction shear forces, grinding a pipeline by a material during the pneumatic transmission process is effectively prevented, the wear resistance of different parts of the pipeline is enhanced according to the wear degrees of the different parts, and besides, the expensive material is saved, and the manufacturing cost of the elbow is reduced.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

A 90° rectangular wear-resistant elbow and its wear-resistant treatment method

ActiveCN105485460BAccurately locate the distribution of friction forceImprove grindingPipe protection against damage/wearSiphonsFriction & shearWear resistant

The invention discloses a 90° rectangular wear-resistant elbow and a wear-resistant treatment method for the elbow, comprising an upper top plate, a lower bottom plate, an outer arc surface and an inner arc surface; an upper top plate, a lower bottom plate, an outer arc surface and an inner arc surface A 1 / 4-circle arc tube is obtained by enclosing four surfaces; the upper top plate is the same as the lower bottom plate; the lower bottom plate and the inner arc surface are divided into high friction zone, medium friction zone and low friction zone; Wear-resistant materials with different wear-resistant thicknesses are respectively used on the surfaces of the high-friction area and the medium-friction area located inside the elbow. The present invention adopts different wear-resistant materials in the parts of different friction and shear forces, which can effectively resist the grinding of the pipeline by the material during the pneumatic conveying process, so that different parts of the pipeline can be strengthened according to the degree of grinding, and at the same time, expensive materials can be saved. Reduce the cost of the elbow.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Construction steel frame node structure

The invention relates to butterfly type self locking connecting card with friction shear resistant plate and building iron joint of framework structure. The friction shear resistant plate includes friction surface and shear resistant plate. Four friction shear resistant plates is formed square type node pillar to cooperate with hitch clevis. The connecting card includes card body. Both end of thecard body are respectively set two card wings with door shape cross section. The card wing includes bearing plate, pretension plate, and self locking mounting plate. The self locking and pretension plate are set through holes. The invention utilizes the friction, and self locking principle, the friction shear resistant plate is gain the enlarged pressure and friction by butterfly type self lockingconnecting card to transfer to bearing force to act on node crossbeam to gain ideal joint intensity, stiffness, and bearing force.

Owner:甘秀明

Plate type heat pipe with minitype circular channels

ActiveCN102135385BImprove heat transfer efficiencyAchieve separationIndirect heat exchangersHeat resistanceFriction & shear

The invention relates to a plate type heat pipe with minitype circular channels. The interior of the plate type heat pipe is composed of a group or more than one group of minitype circular channels, wherein each circular channel comprises main channels and a connecting channel which is communicated with two ends of the main channels; the main channels are respectively an evaporation channel and abackflow channel; the connecting channel is respectively a liquid storage chamber and an evaporation chamber; the channels are filled with working media which play a role in phase change and heat transfer at a certain ratio, so that the efficient heat transfer of the heat pipe is realized; and welding, cold compression, hot compression or cementing are adopted for the sealing at each channel opening. The plate type heat pipe provided by the invention has the advantages of low heat resistance, high heat exchange efficiency, light weight, simple structure, high bearing capability and wide application, and ensures that the interface friction shearing force of vapor phase and liquid phase in the channels can be reduced maximally, thus being an efficient and practical novel heat pipe.

Owner:江乐新

A method for testing the pull-out friction of geotextiles for rock and soil

InactiveCN103808570BHigh measurement accuracyEasy to useMaterial strength using tensile/compressive forcesMaterial strength using steady shearing forcesPorous mediumFriction & shear

The invention provides an anti-drawing and anti-friction testing method for a geotextile of a rock-soil body. The method is characterized by adopting a testing device. The device comprises a drawing stepping motor (1), a drawing force measuring ring (2), an upper sample box (6), a pressurizing framework (9), a lower sample box (13), a lower base (14), a shearing force measuring ring (15), a shearing stepping motor (16), a pressurizing lever (23) and a weight (25). With the adoption of the device, an anti-drawing test and an anti-friction shearing test of the geotextile can be carried out and a force and deformation amount F-L curve is drawn; when an indication value of a drawing displacement meter (29) or a shearing displacement meter (28) is rebounded, the maximum value of the anti-drawing or anti-friction shearing strength of the geotextile (4) can be obtained. The method is simple and practical and is flexible to operate; the method can be used for test and experiment researches on anti-drawing and anti-shearing strength properties of the various geotextiles in various porous media.

Owner:INST OF GEOLOGY & GEOPHYSICS CHINESE ACAD OF SCI

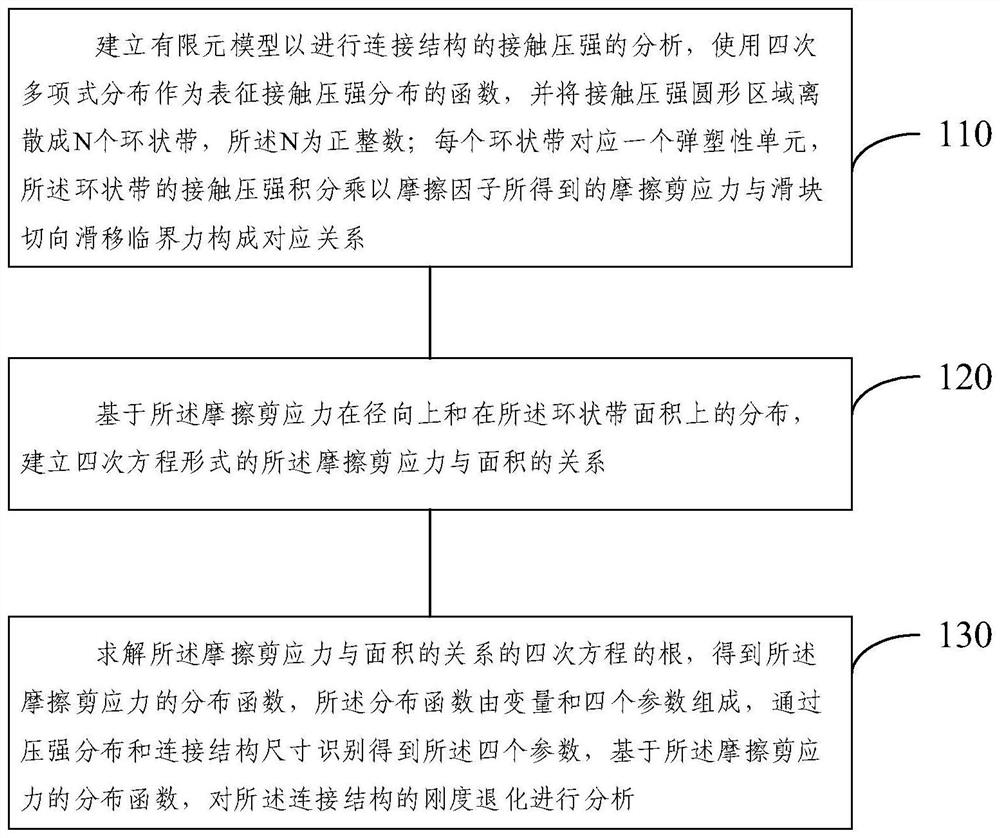

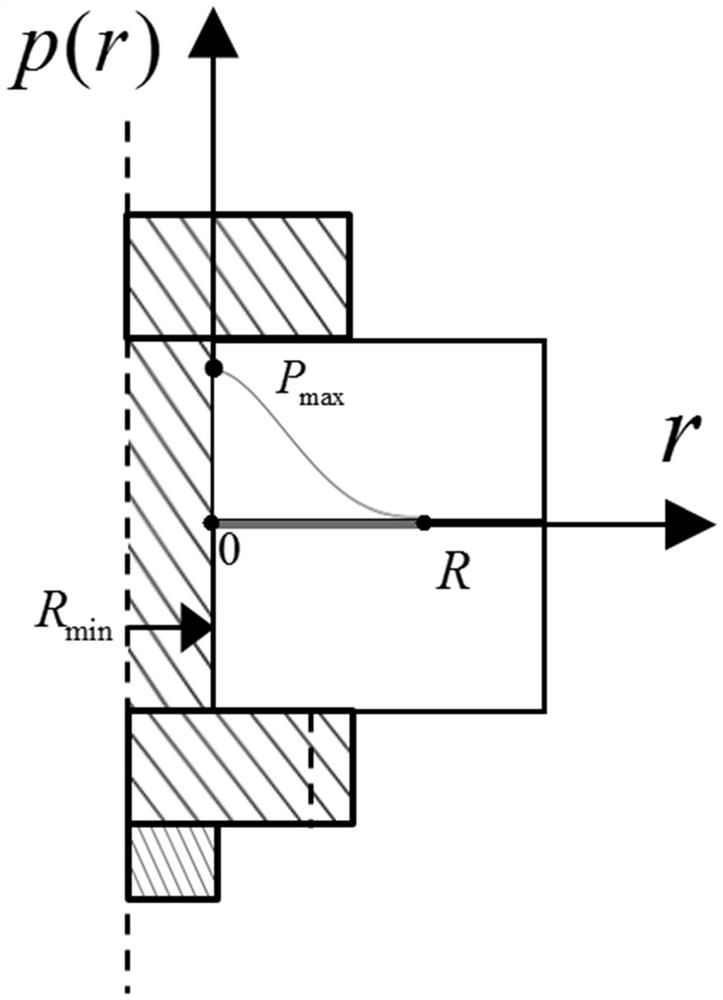

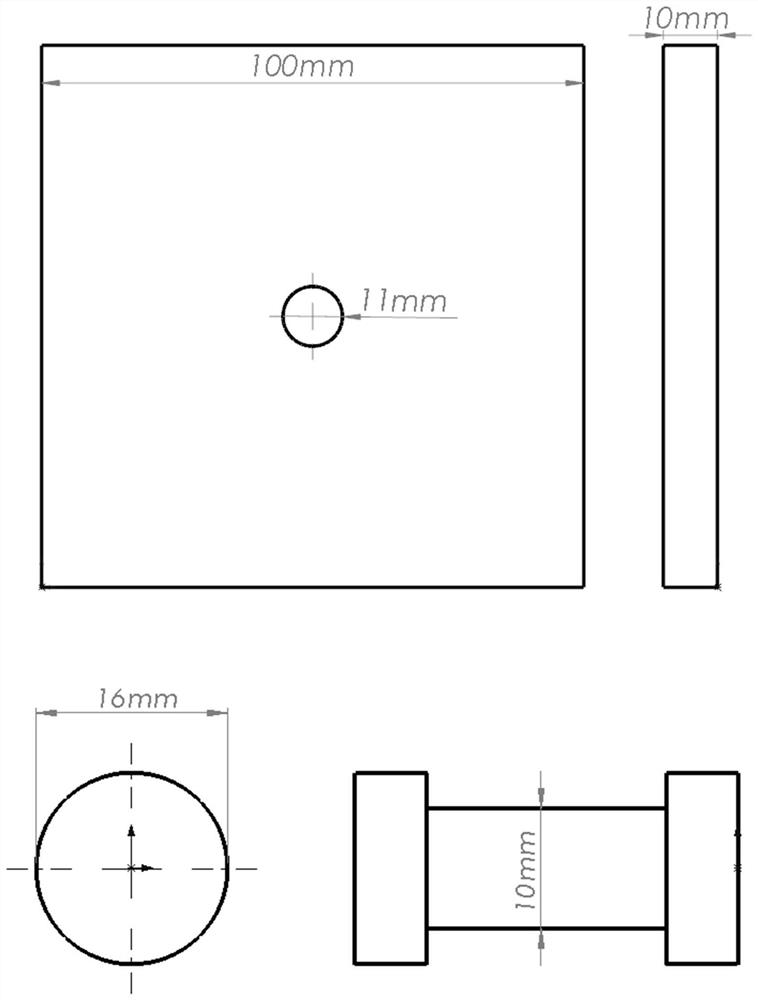

Connection structure rigidity degradation analysis method and device, electronic equipment and medium

The invention relates to a connection structure rigidity degradation analysis method and device, electronic equipment and a medium, and the method comprises the steps: using quartic polynomial distribution as a function for representing contact pressure distribution, and dispersing a contact pressure circular region into annular belts, wherein each annular belt corresponds to an elastic-plastic unit, and the friction shear stress obtained by multiplying the contact pressure integral of the annular belt by the friction factor and the tangential sliding critical force of the sliding block form a corresponding relation; establishing an equation of the relation between the friction shear stress and the area; and solving the root of the equation, and obtaining a distribution function of the friction shear stress, wherein the distribution function is composed of variables and four parameters, and the four parameters are obtained through pressure intensity distribution and connection structure size recognition. Through quartic polynomial pressure distribution fitting, the excellent performance of the quartic polynomial in representing the connection contact pressure distribution is verified. Based on the nonlinear distribution, a calculation method of a corresponding distribution function is provided, and a distribution function curve of the friction shear stress is obtained.

Owner:NAVAL UNIV OF ENG PLA

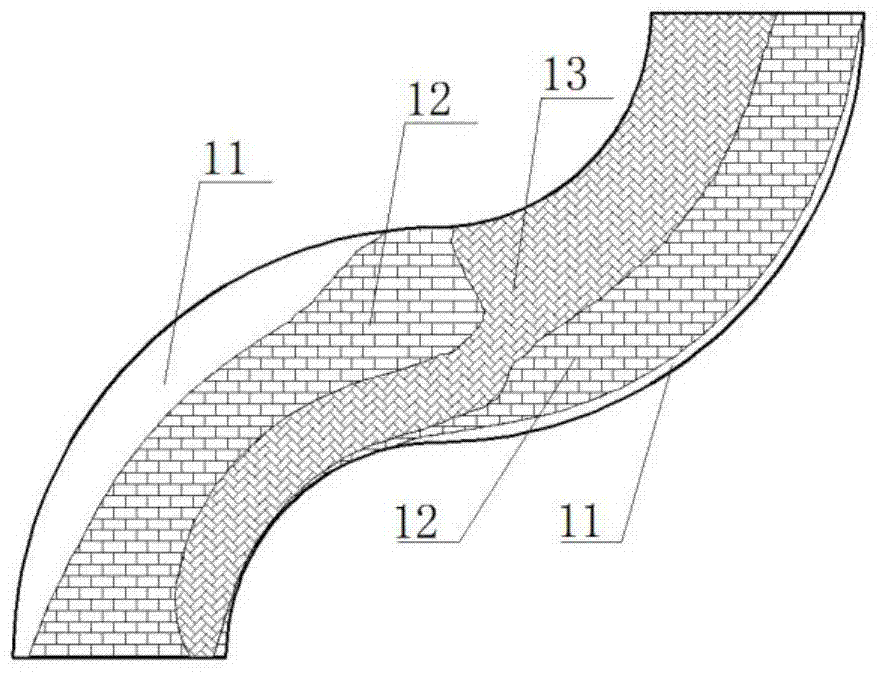

A wear-resistant S-shaped pipe elbow and a wear-resistant treatment method for the elbow

ActiveCN105485461BAccurately locate the distribution of friction forceImprove grindingSiphonsBendsFriction & shearWear resistant

The invention discloses an anti-abrasion S-shaped pipe elbow and a wear-resistant treatment method for the elbow, comprising an upper top plate, a lower bottom plate, an arc surface a and an arc surface b; an upper top plate, a lower bottom plate, an arc surface a and an arc surface b The S-shaped elbow is obtained as four side enclosures; the upper top plate is the same as the lower bottom plate; the arc surface a is the same as the arc surface b; the upper top plate, the lower bottom plate and the arc surface a are all divided into high friction zone and medium friction force Wear-resistant materials with different wear-resistant thicknesses are used on the surfaces of the high-friction area and the medium-friction area in the elbow respectively. The elbow adopts different wear-resistant materials in the parts of different friction and shear forces, which can effectively resist the grinding of the pipeline by the material in the process of pneumatic conveying, so that different parts of the pipeline can be strengthened according to the degree of grinding, and at the same time save expensive materials , reduce the cost of the elbow.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com