Patents

Literature

171 results about "Fatigue stress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

While the main symptoms of fatigue are a general feeling of weariness or being tired or drowsy, stress related fatigue is usually accompanied by other symptoms: Sore or aching muscles or feeling of muscle weakness. Headache. Moodiness, irritability or easily agitated. Dizziness and blurred vision.

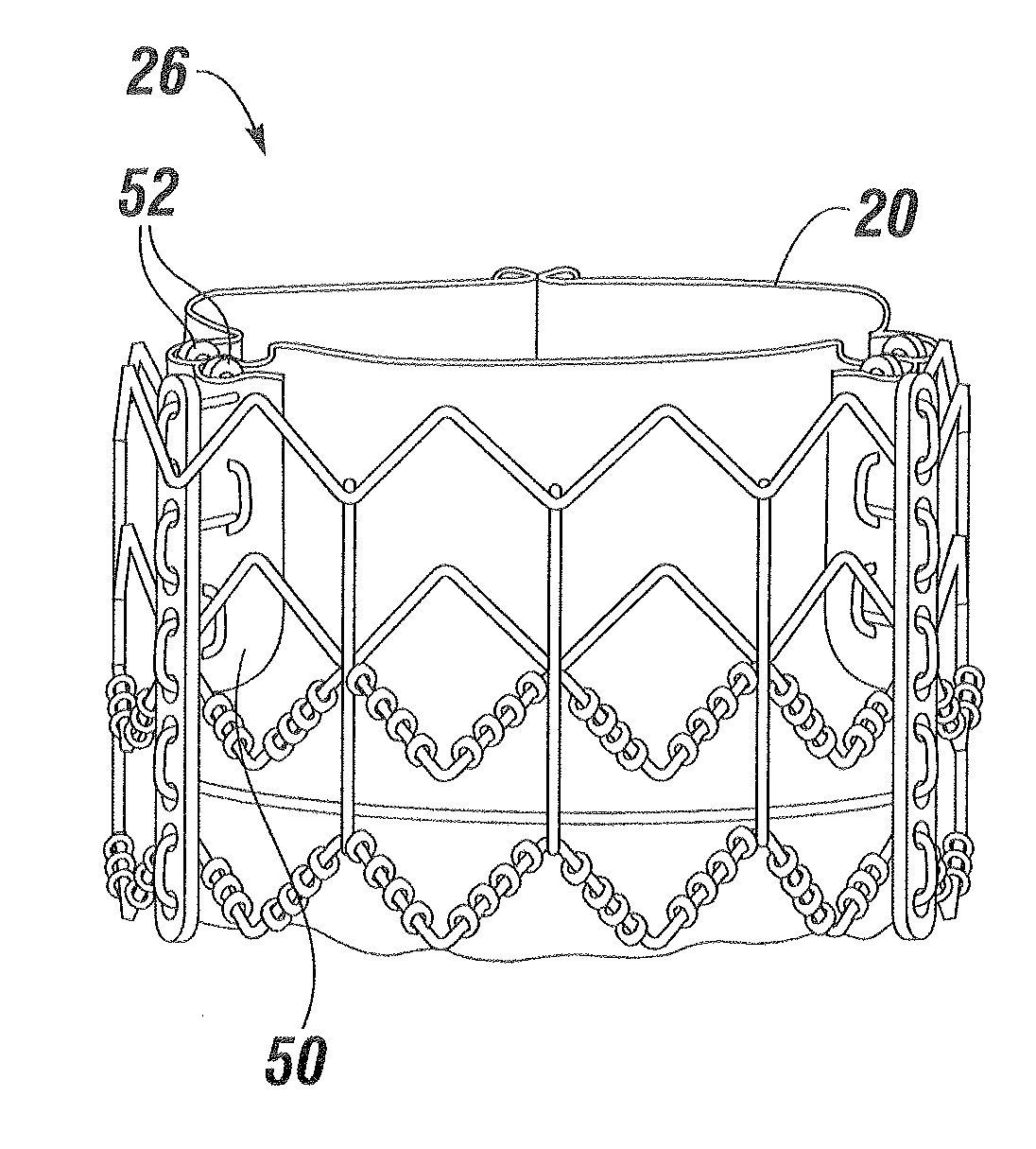

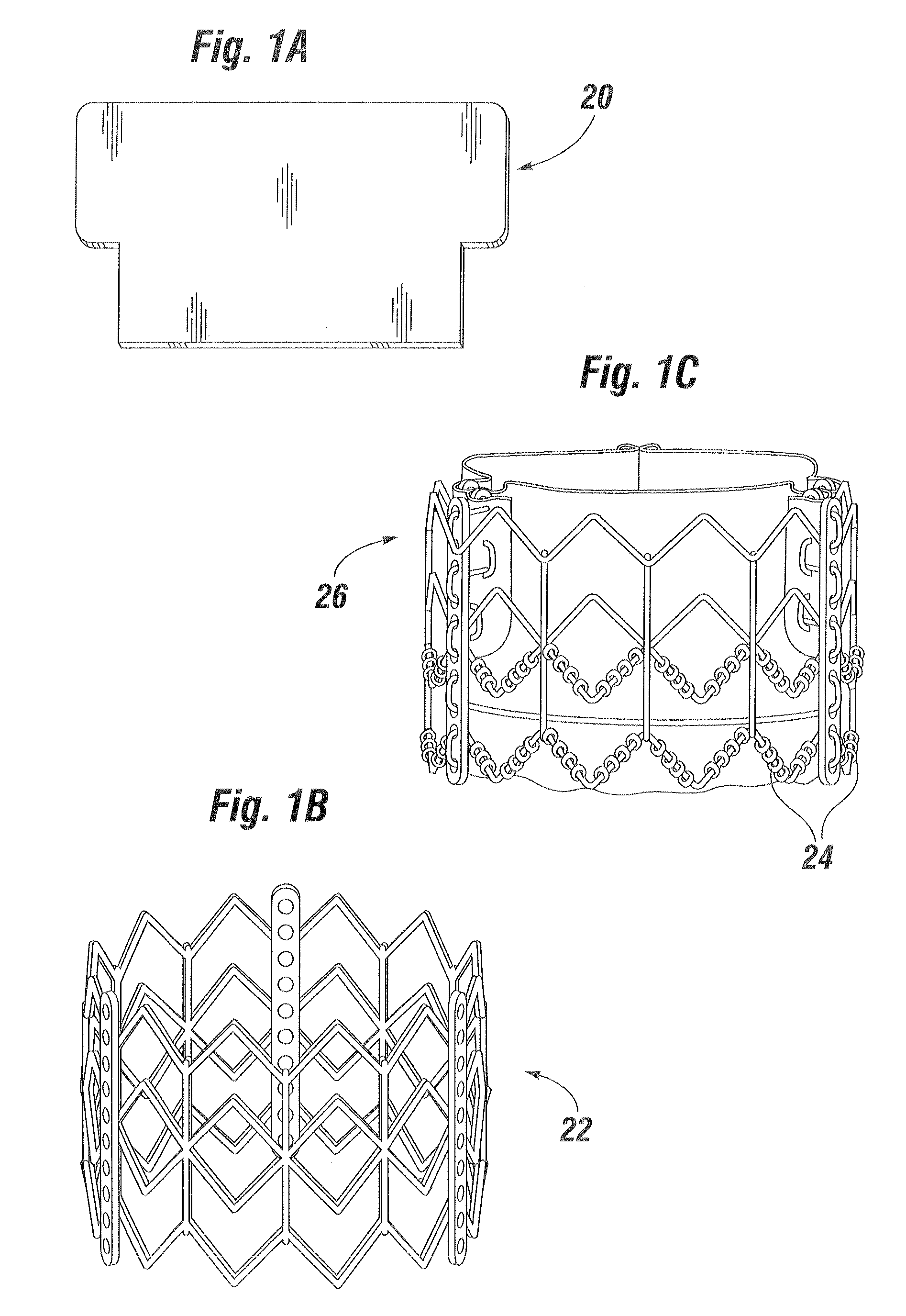

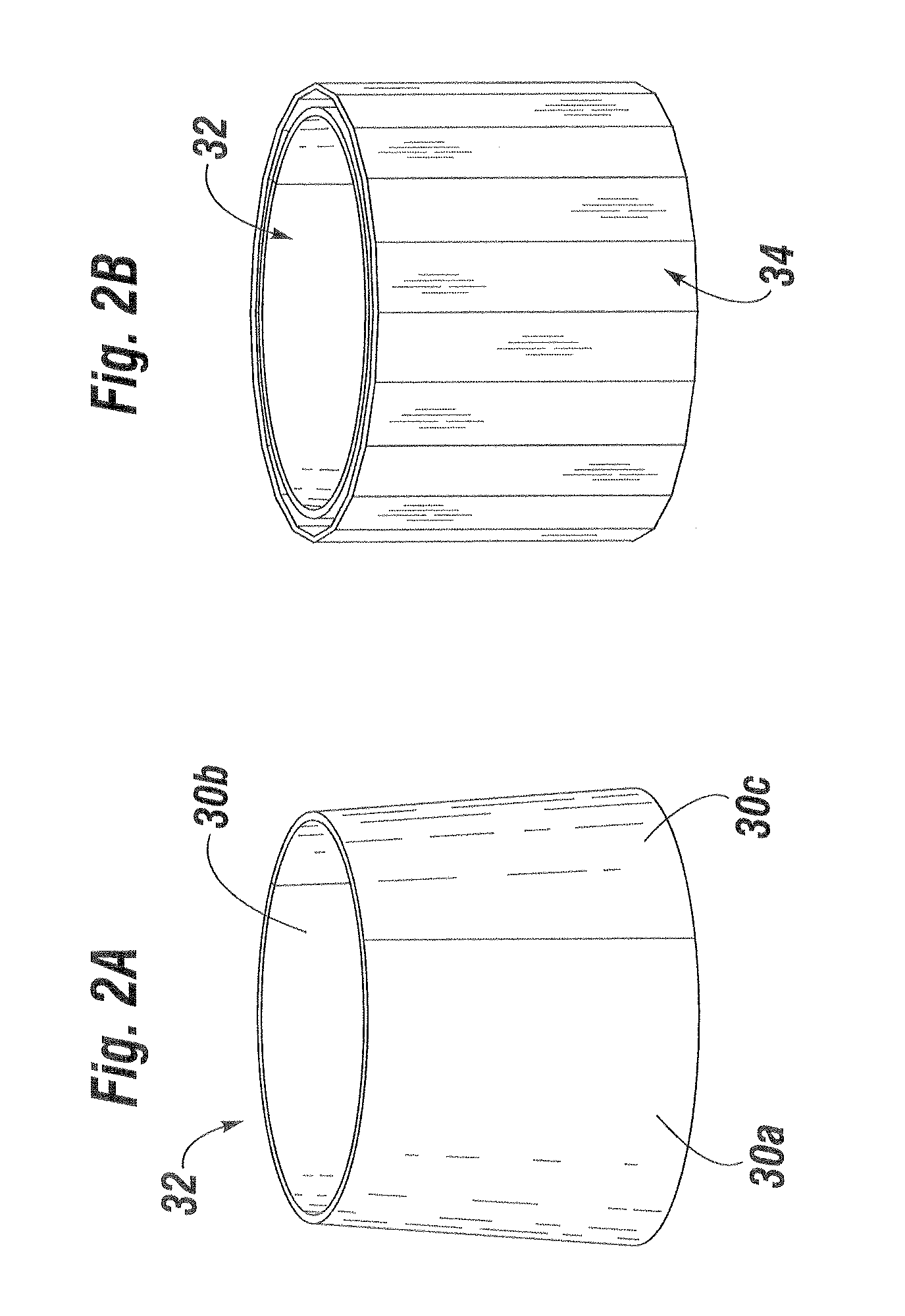

Virtual heart valve

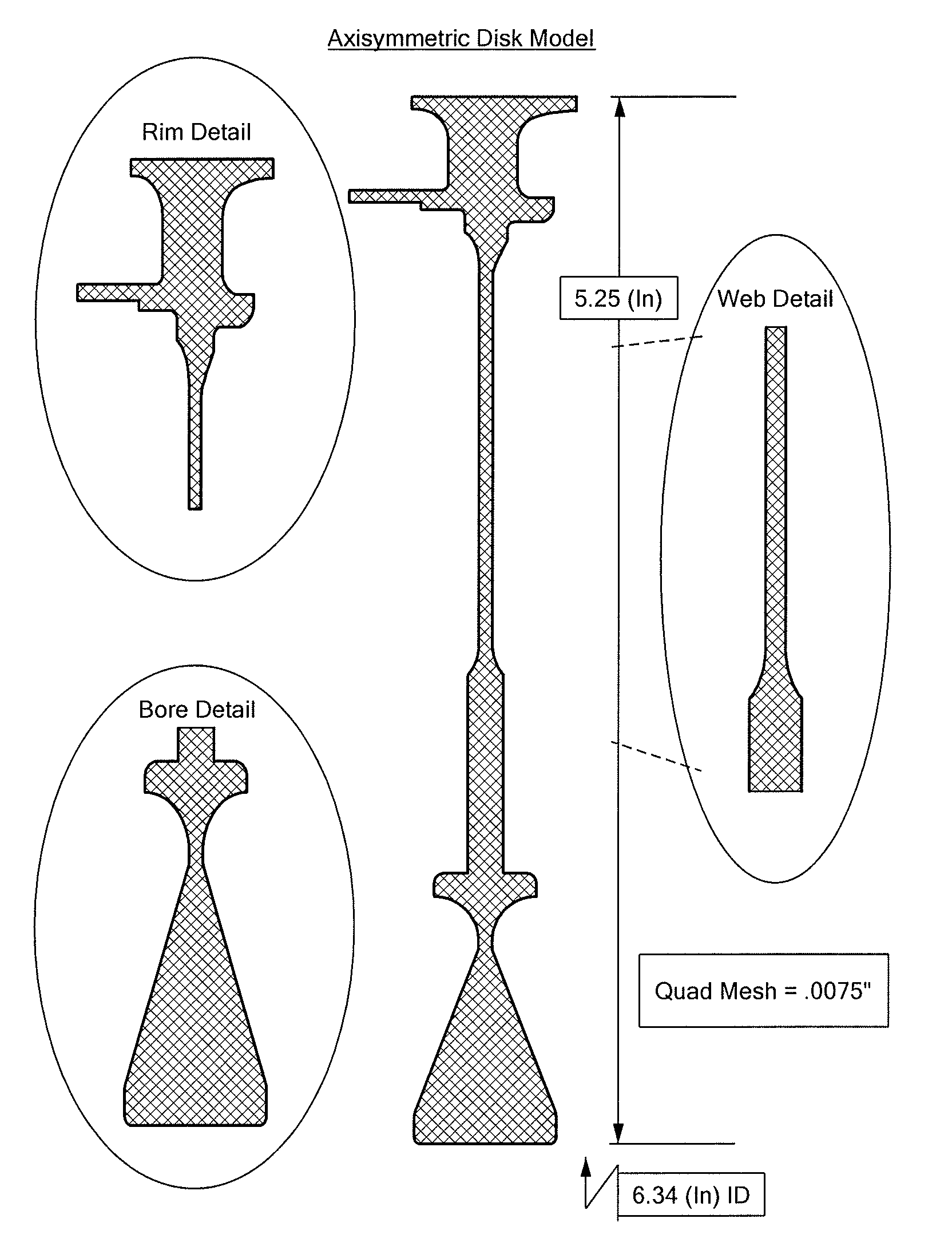

ActiveUS20070208550A1Accurate measurementFast formingHeart valvesAnalogue computers for chemical processesPrincipal stressStress level

A computational technique to construct a 3-D valve leaflet geometry. The invention pertains to methodology to construct a 3-D heart valve leaflet geometry using finite element analysis (FEA) to simulate the manual assembly process or, in other words, provide a virtual assembly process as an input to a subsequent simulated valve testing step. The simulated valves may be subjected to simulated cyclic valve opening and closings and the stress levels induced therein monitored. Simulated valve designs with lower principal stresses can then be selected for prototyping. Proposed valves can be subjected to cyclic fatigue stress testing under simulated physiologic conditions to study valve durability.

Owner:EDWARDS LIFESCIENCES CORP

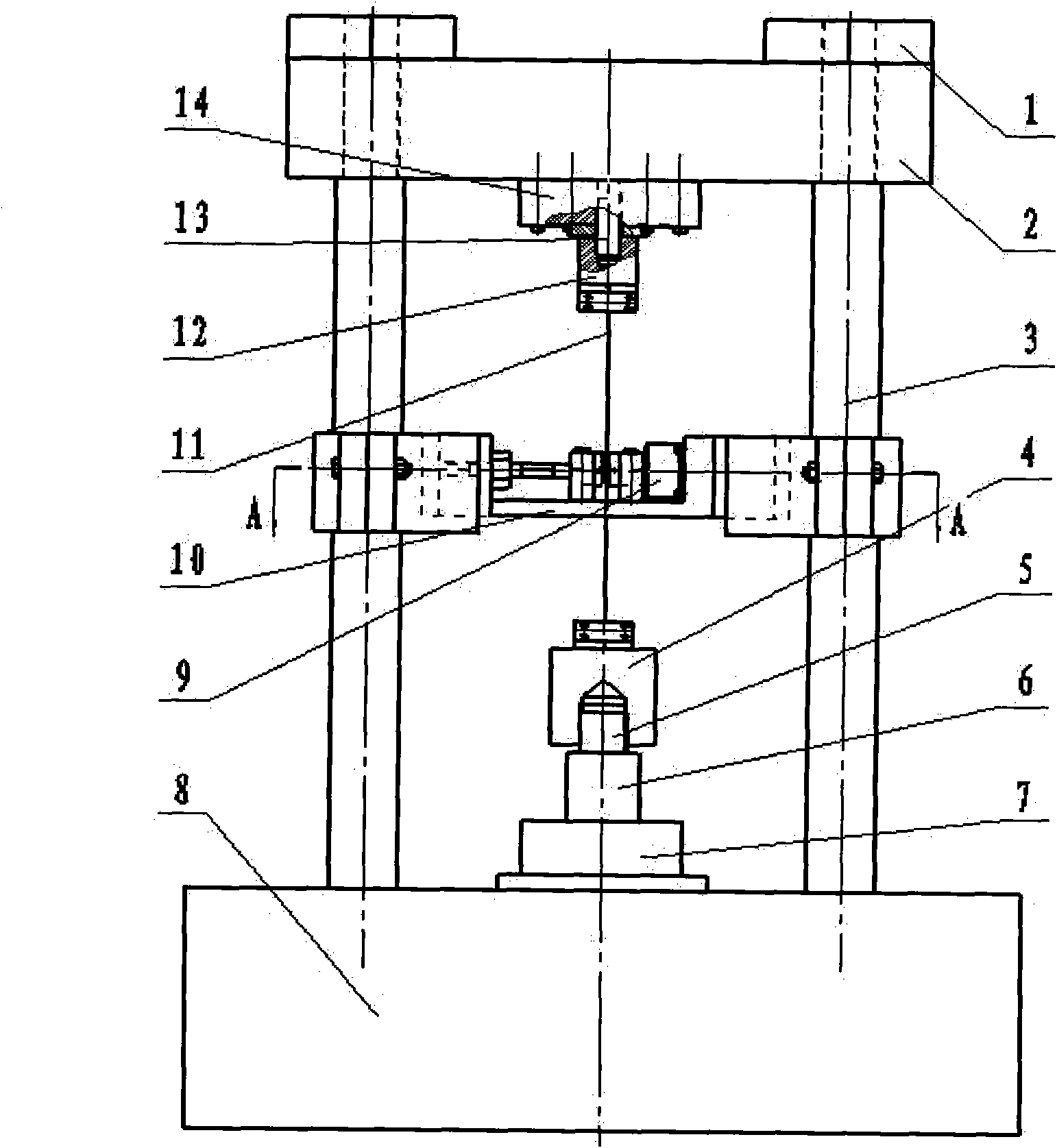

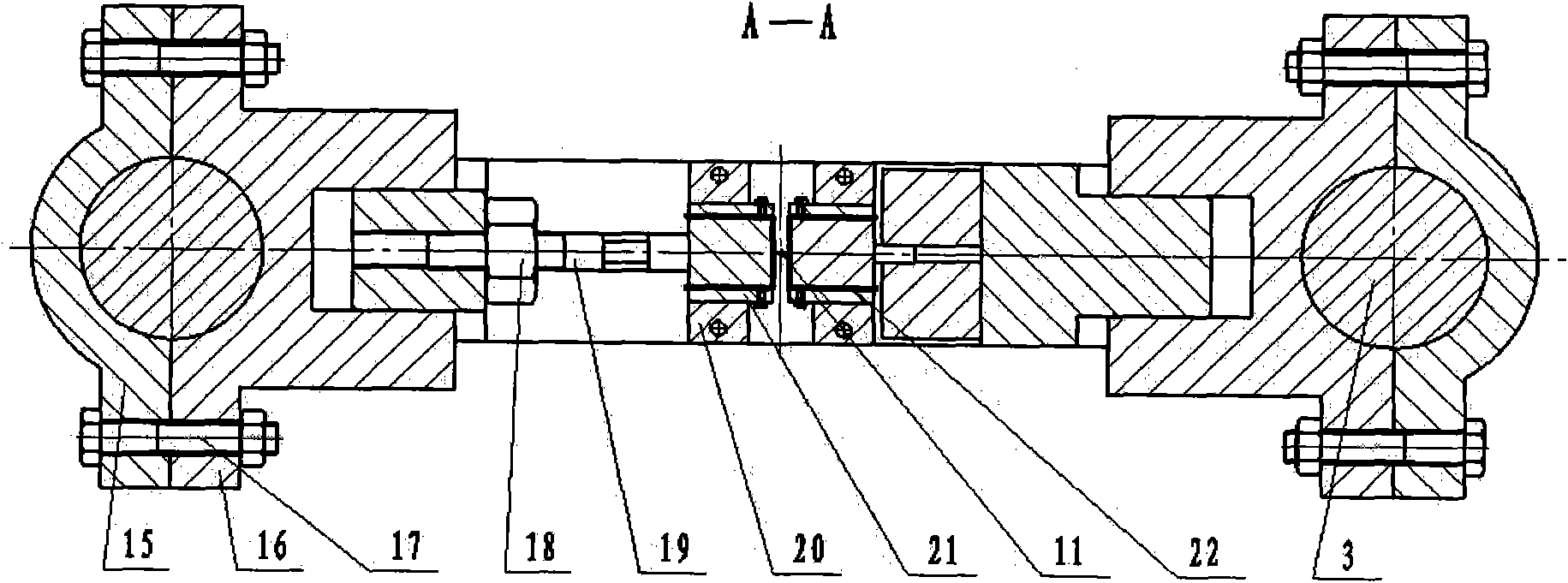

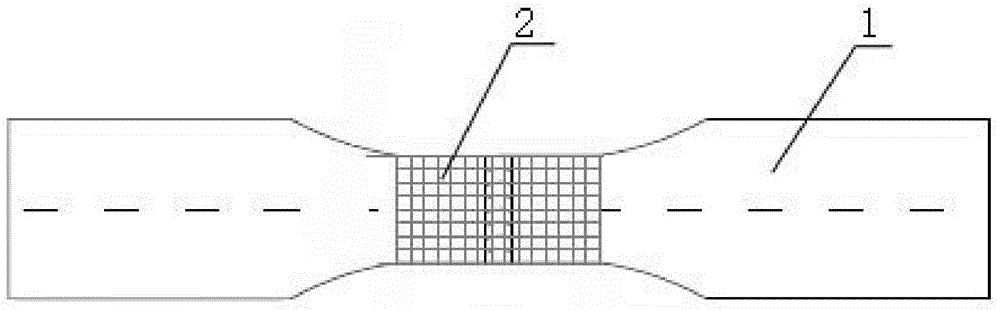

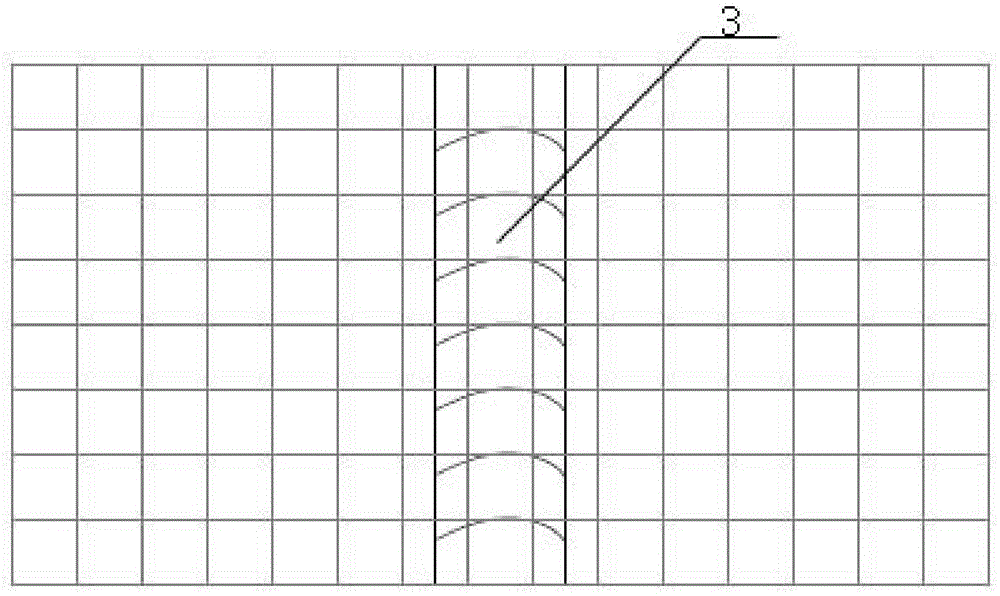

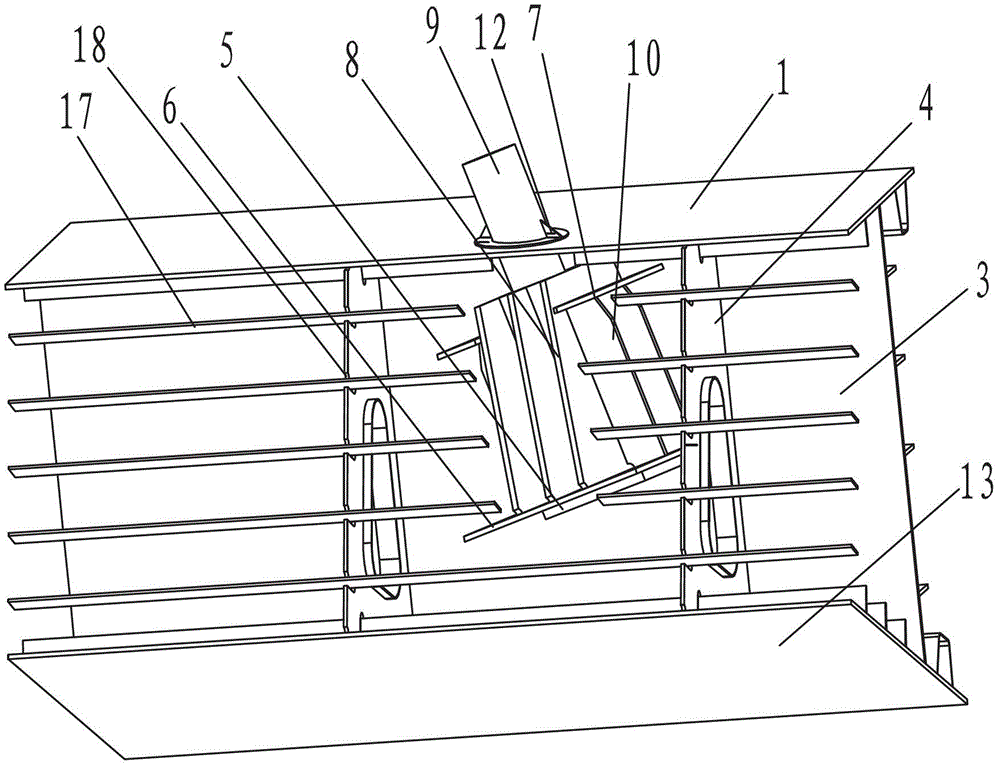

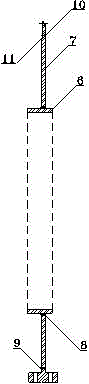

Steel wire fretting fatigue testing machine and method

InactiveCN101598647AEasy to controlEasy to measureMaterial strength using tensile/compressive forcesCompression deviceEngineering

The invention relates to a steel wire fretting fatigue testing machine and a method. The testing machine mainly comprises a horizontal loading device, an axial clamping device and an axial tensile compression device, wherein the horizontal loading device consists of a concave horizontal support saddle, a guiding support saddle, a wedged slide block, a loading steel wire, a pressure sensor, a loading rod and a locking nut; the axial clamping device consists of a spoke-type tensile compression sensor, a threaded rod connected with the spoke-type tensile compression sensor and an upper holding block fixed on the threaded rod; and the axial tensile compression device consists of an oil cylinder, a threaded rod connected with the piston of the oil cylinder and a lower holding block fixed on the threaded rod. The steel wire fretting fatigue testing machine has the advantages that by exerting horizontal set load on an axial steel wire through the horizontal loading device and by acting axial fatigue stress on a steel wire sample through the axial clamping device and the axial tensile compression device, the testing machine realizes fretting fatigue test of the coaction of fretting wear and axial fatigue stress of the steel wire sample; dynamic adjustment of the concave horizontal support saddle ensures that an axial fatigue steel wire does not generate bending stress; moreover, fluctuation ranges of both amplitude and frequency are wide and easy to control and measure by utilizing computer program.

Owner:CHINA UNIV OF MINING & TECH

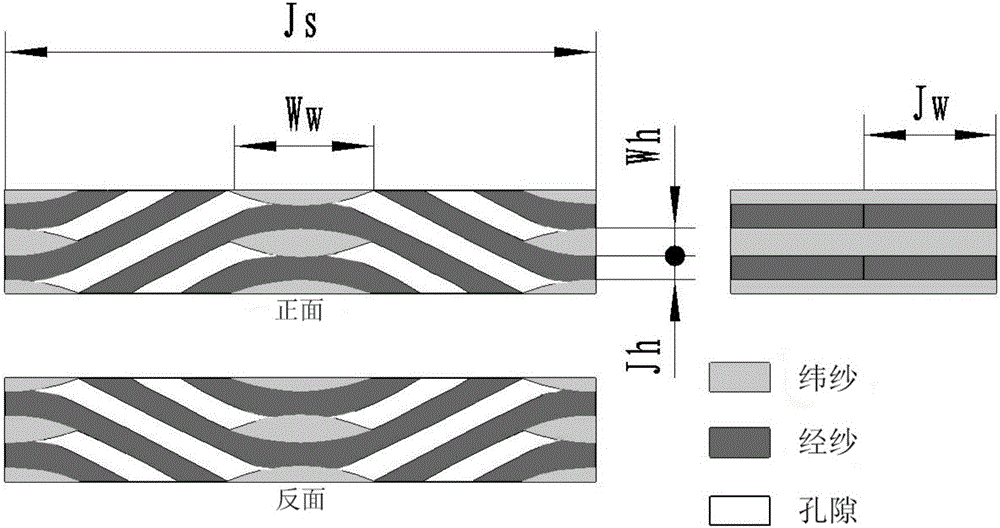

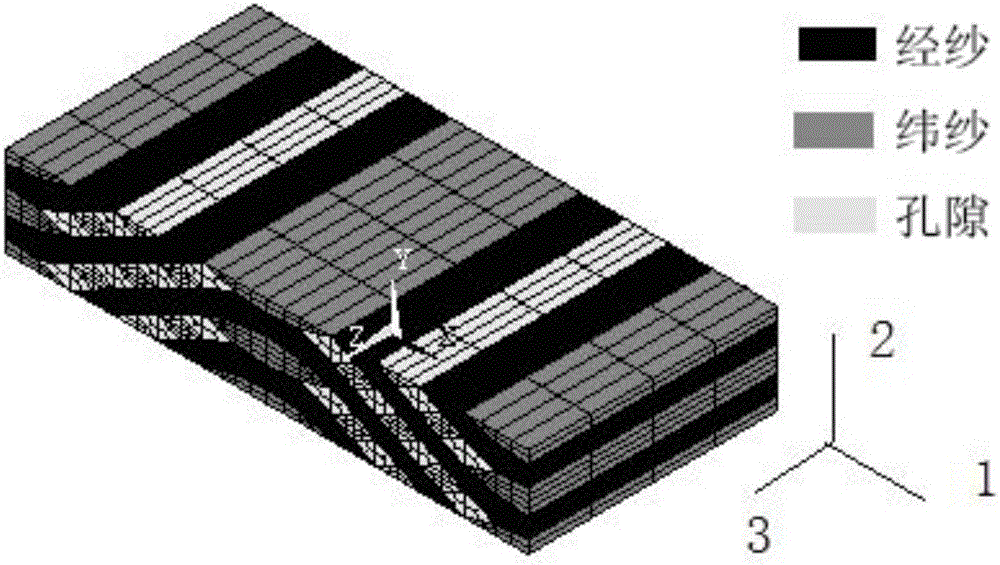

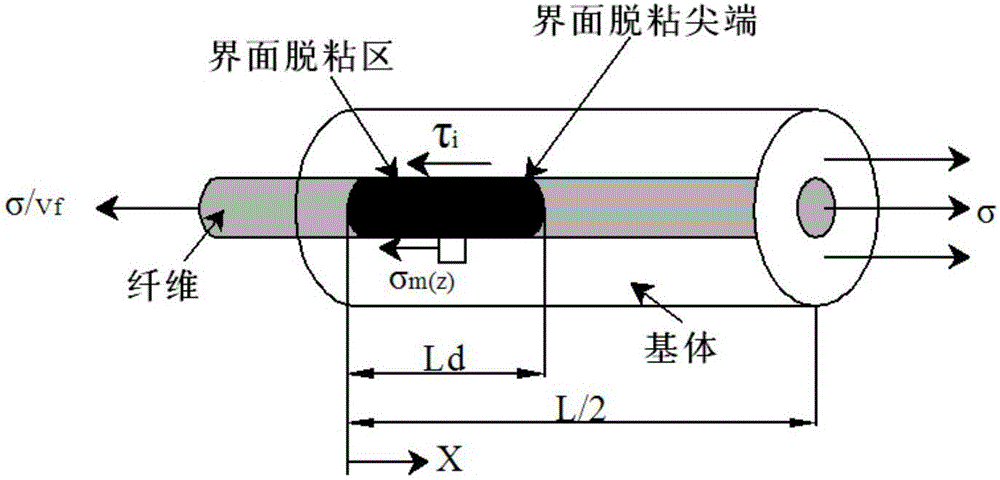

Complex braided structure ceramic matrix composite fatigue retardation behavior prediction method

InactiveCN105701312AFatigue Hysteresis Behavior PredictionDesign optimisation/simulationSpecial data processing applicationsStress–strain curveMaterials science

The invention discloses a complex braided structure ceramic matrix composite fatigue retardation behavior prediction method. The method comprises the steps of calculating a fatigue stress-strain curve under circulation with a microscale model to obtain the unit constitutive relation, substituting the unit constitutive relation into a unit cell model to conduct corresponding stiffness reduction on the unit cell model under different boundary conditions, and conducting statistics on the average stress and average strain of the unit cell model to obtain a unit cell scale fatigue retardation loop under the cycle number. By means of the multiscale model, the micro stress-strain field of a complex braided structure can be given, and therefore the fatigue retardation behavior of the material can be predicted precisely.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

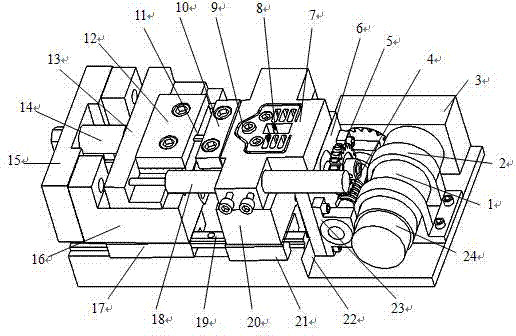

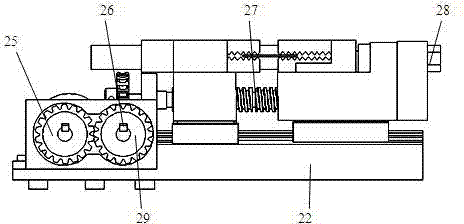

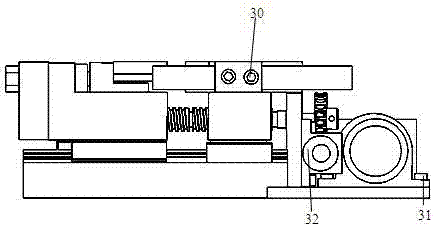

In-situ high-frequency fatigue material mechanical test platform under scanning electron microscope based on stretching/compressing mode

ActiveCN102331370AGood structural compatibilityImprove compatibilityMaterial strength using tensile/compressive forcesControl cellEngineering

The invention relates to an in-situ high-frequency fatigue material mechanical test platform under a scanning electron microscope based on a stretching / compressing mode and belongs to the field of machinery and electronics. The test platform comprises a precise loading unit, a precise motion conversion unit, a load / displacement signal acquisition and control unit, a high-frequency driving unit and a test piece clamping and connecting unit. The test platform provided by the invention has the advantages that the structure is compact, the test precision is high, the strain rate and the test frequency are controllable, an in-situ high-frequency test based on the stretching / compressing mode can be performed on a three-dimensional test piece aiming at centimeter-scale or above in characteristicdimension under the condition of observation of various imaging instruments, the on-line monitoring can be carried out on the microcosmic deformation, damage and breaking process of a material under a fatigue stress, and a novel test method for revealing microcosmic deformation behaviors and a damage system of the material is provided.

Owner:JILIN UNIV

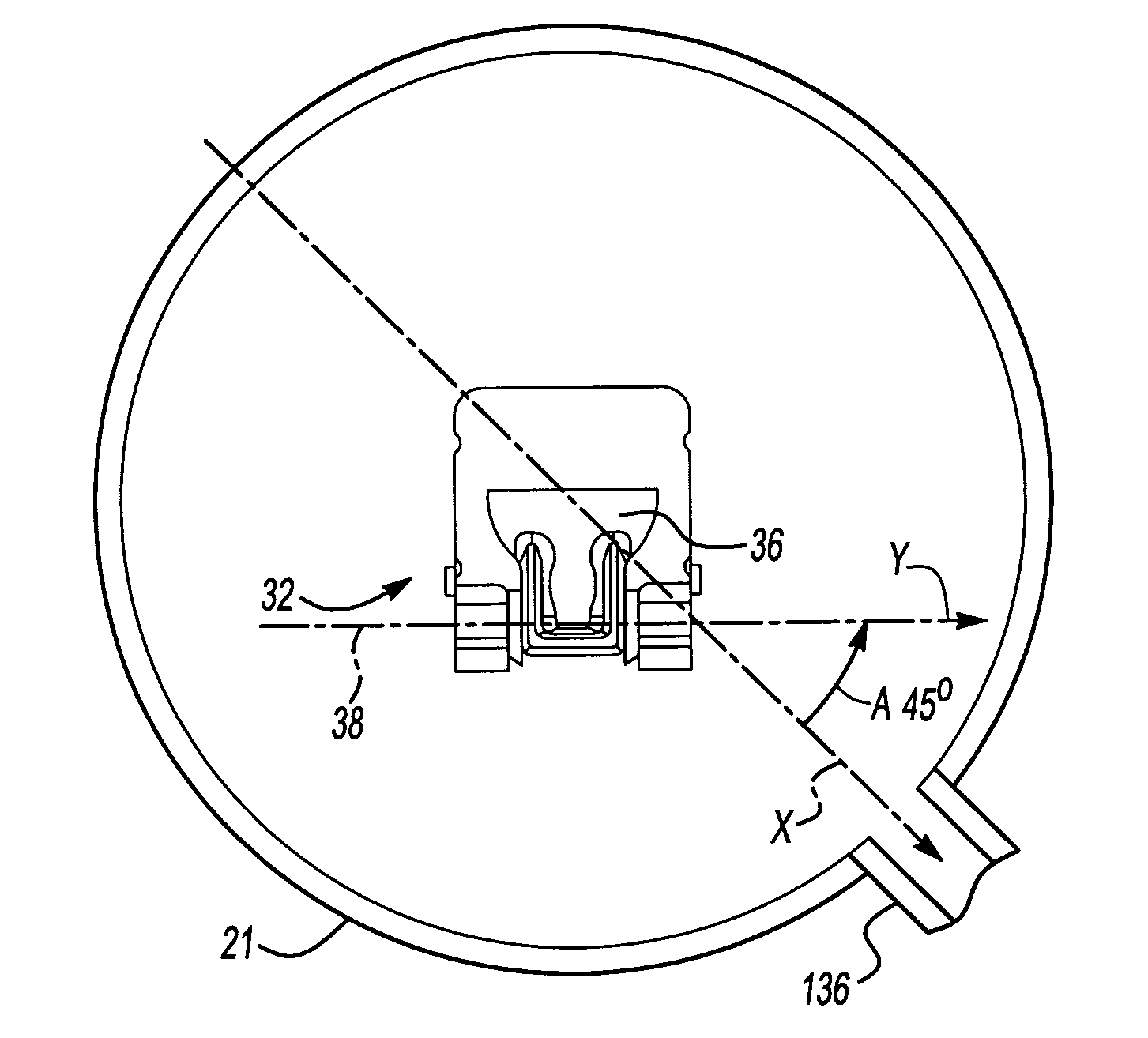

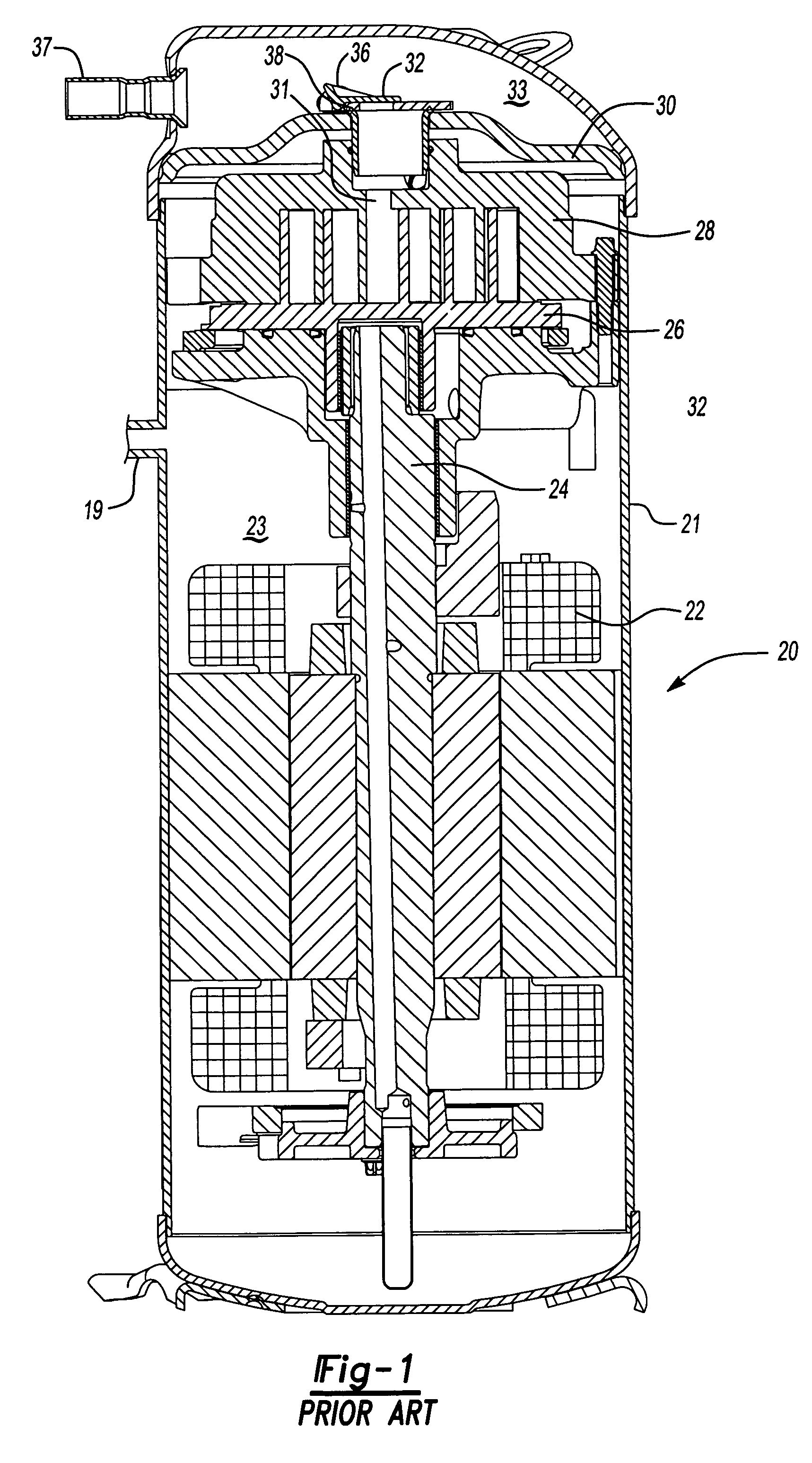

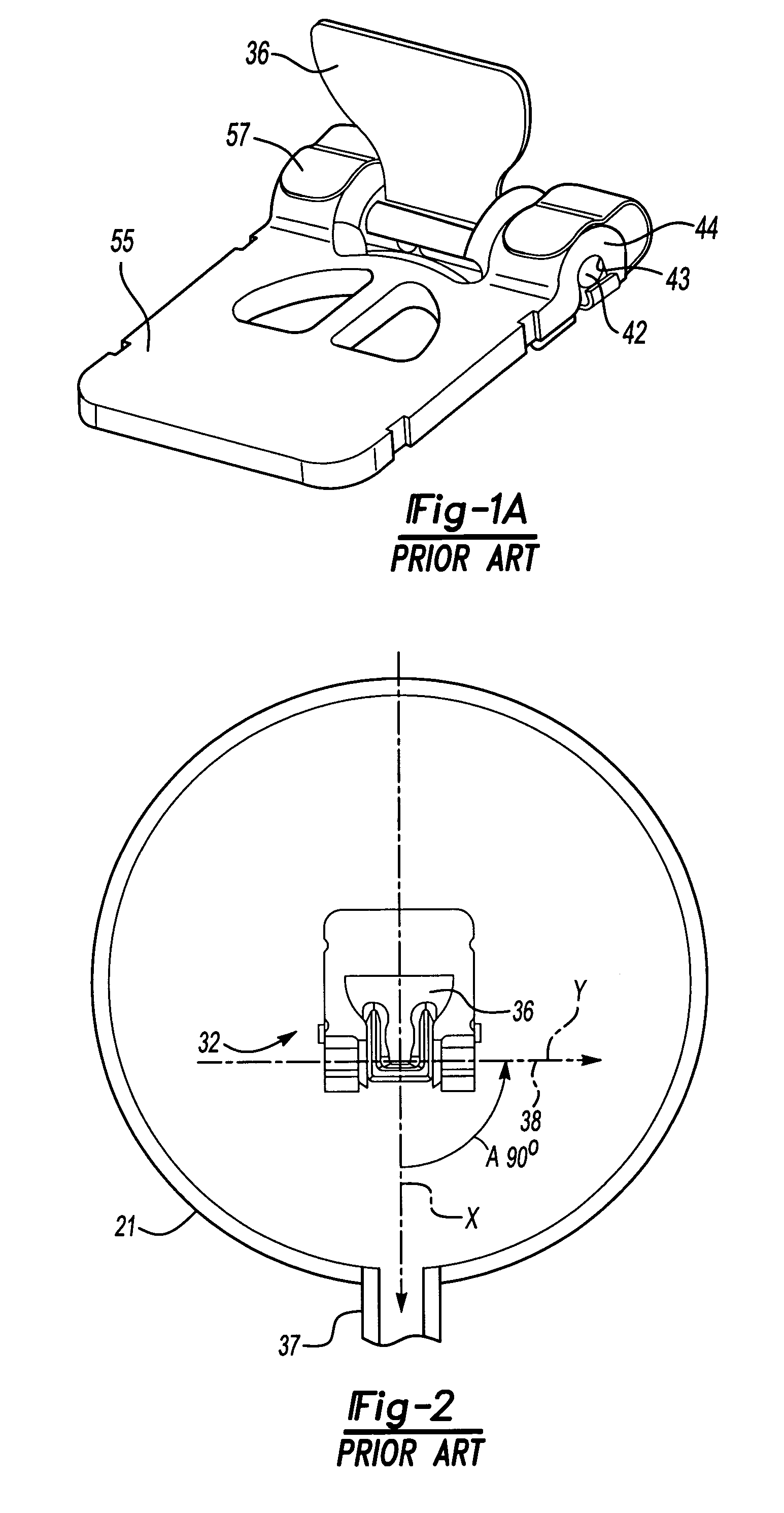

Compressor with check valve orientated at angle relative to discharge tube

InactiveUS7255542B2Reduce fatigue stressRaise checkRotary/oscillating piston combinations for elastic fluidsEngine of arcuate-engagement typeEngineeringCheck valve

A unique positioning of a discharge tube relative to a pivot axis of a check valve in a compressor reduces the wear and fatigue stresses on the pivoting check valve components. The tube is centered on an axis that is non-perpendicular to an axis that is parallel to the pivot axis of the check valve, and in one embodiment was at 45°. With the inventive positioning of the discharge tube relative to the pivot axis, the flow streamlines heading from the discharge port to the discharge tube are no loner normal to the flapper valve surface, and the amount of wear between moving valve components and fatigue stresses are reduced.

Owner:SCROLL TECH

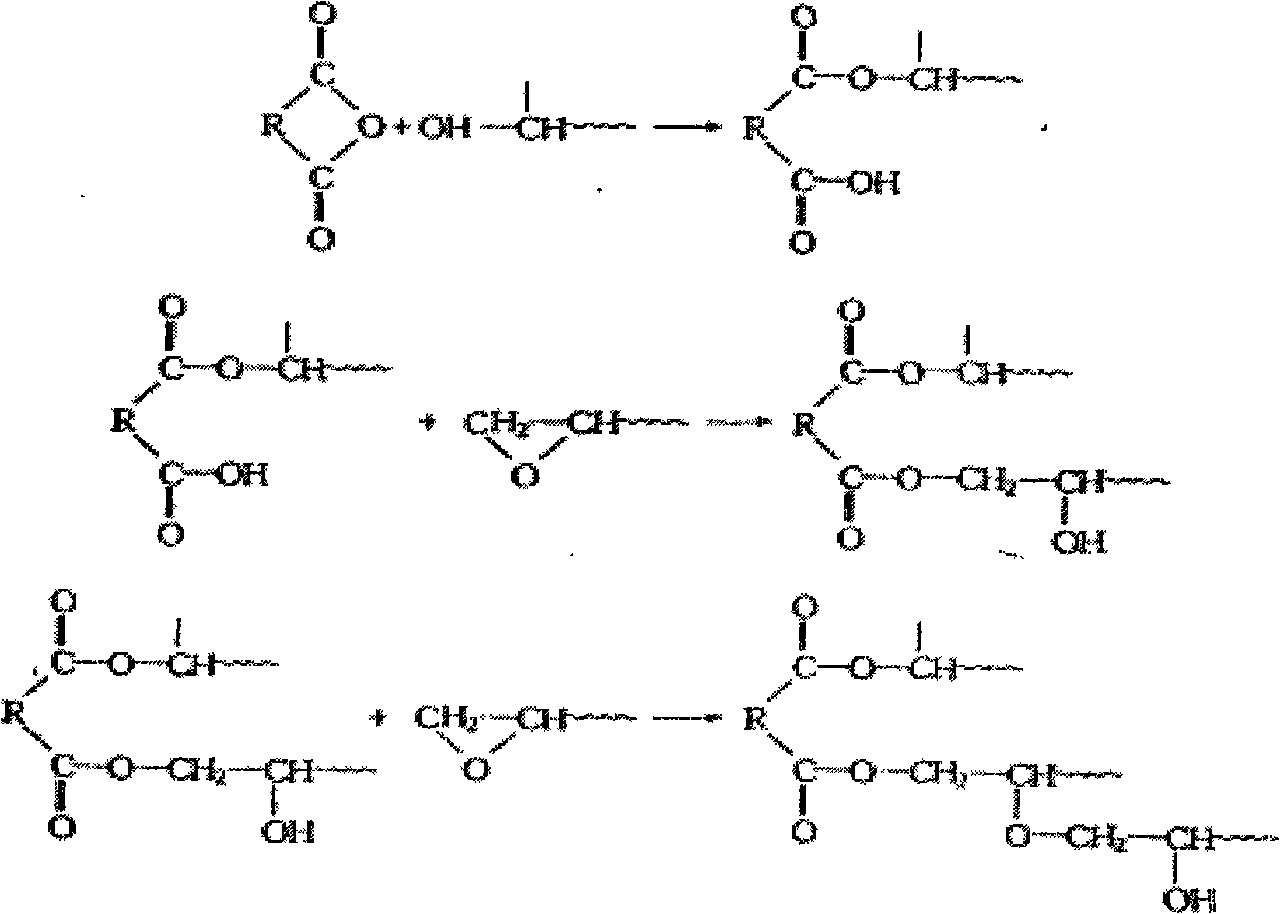

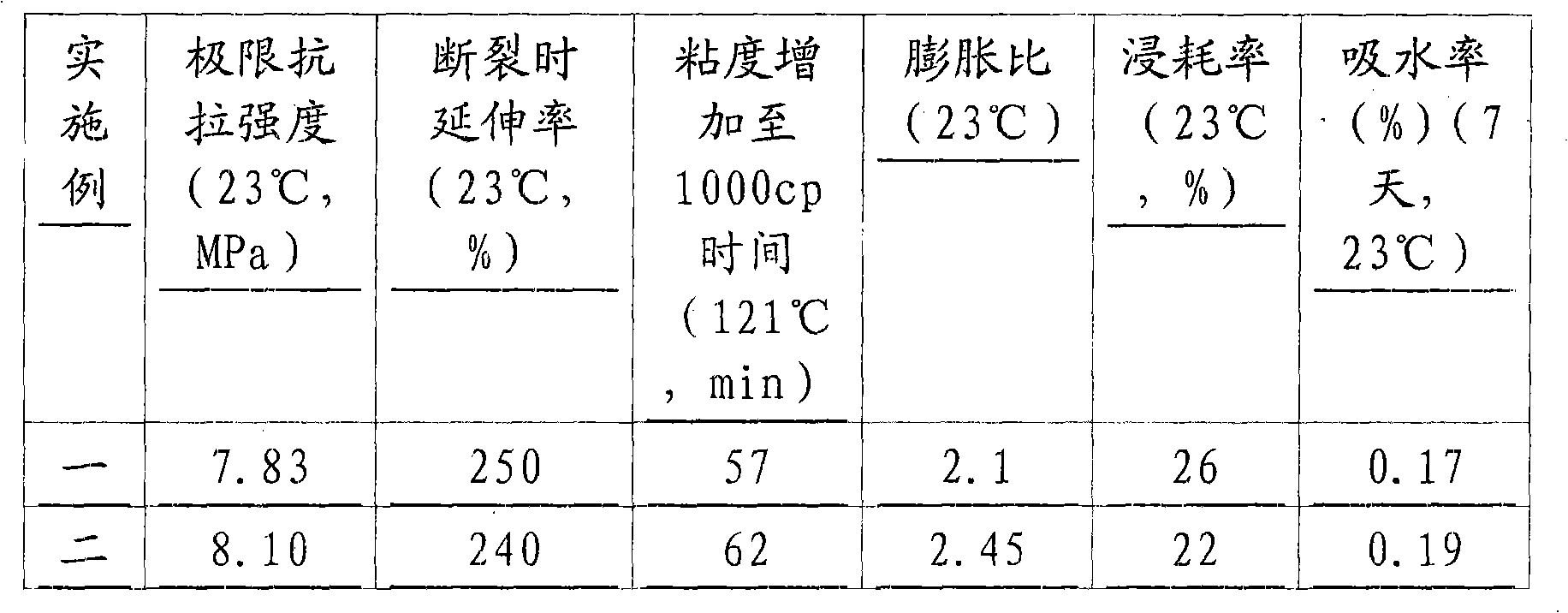

Preparation method of epoxy asphalt road surface materials

ActiveCN101634130AShorten closing timeHigh elongationRoads maintainenceBuilding insulationsEpoxyRoad surface

The invention relates to a preparation method of modified asphalt, in particular to modified asphalt which is used on the road surface, belonging to the technical field of chemical materials. The invention has the beneficial effects of easy operation, low cost, low energy consumption and short solidification time, thus shortening traffic closing time and being beneficial for rapid and smooth traffic. The epoxy asphalt road surface materials prepared by the method in the invention feature high elongation; the anti-fatigue life is 10 to 30 times of that of ordinary asphalt under the action of equal fatigue stress; the epoxy asphalt road surface materials have good deformation ability and durability, have dramatic effects in preventing tracking under high temperature, resisting cracks under low temperature and resisting water damage in the rainy season and have good anti-fatigue property.

Owner:江苏文昌新材料科技有限公司

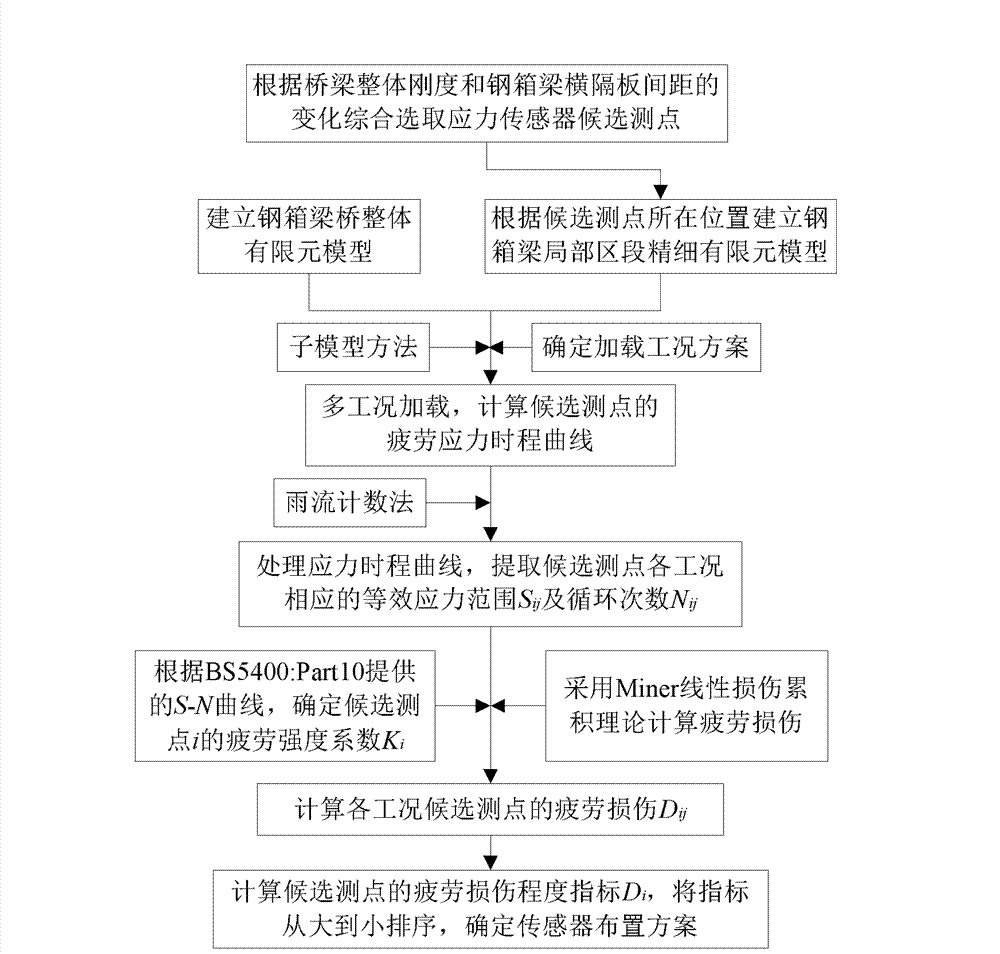

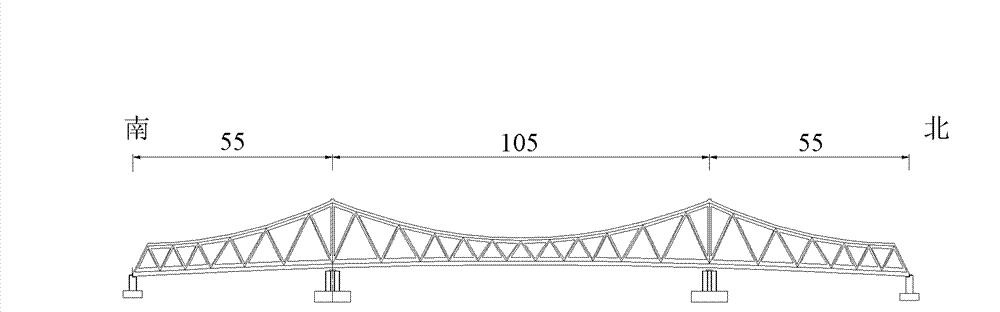

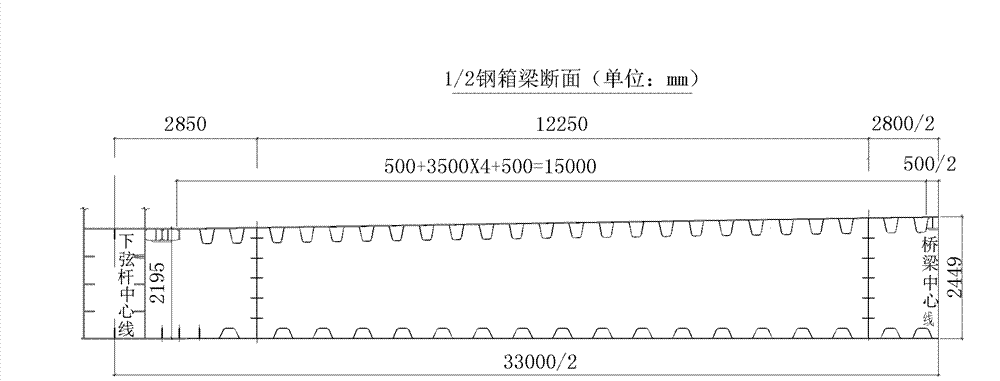

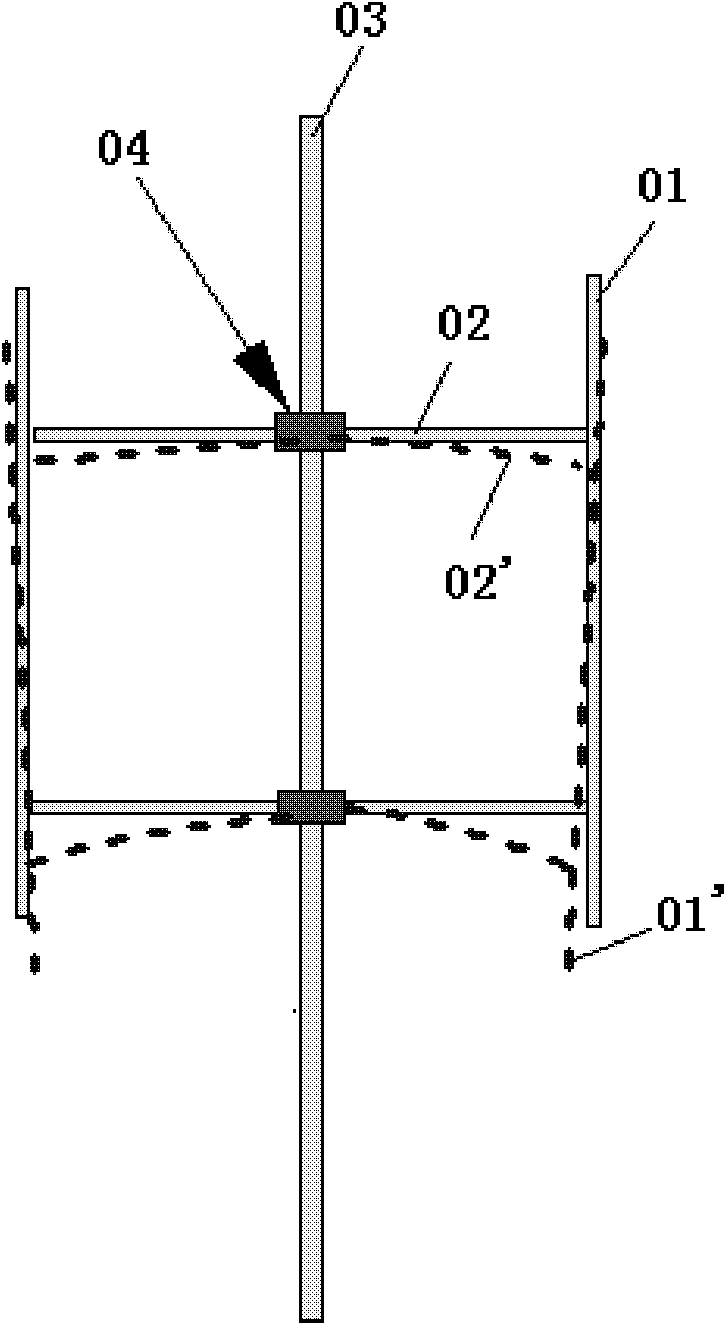

Arranging method of sensor for detecting fatigue stress of steel box girder bridge

The invention discloses an arranging method for a sensor for detecting fatigue stress of a steel box girder bridge based on a fatigue damage degree index, comprising the following steps: calculating fatigue stress of at a steel box girder candidate measure point area through the finite element model technology; constructing the fatigue damage degree index based on an S-N curve and a Miner linear damage accumulation theory provided by design specifications; and determining an arranging position of the sensor for detecting fatigue stress of the steel box girder bridge according to size of the fatigue damage degree index. The method provided by the invention effectively ensures analysis precision for fatigue stress of the steel box girder bridge by using the finite element model analysis technology, constructs the fatigue damage degree index of the steel box girder bridge on that basis, and provides reasonable evidence for selecting the arranging position of the sensor, so that subjectivity, empirical property and blindness for arranging the traditional steel box girder fatigue stress sensors are effectively overcome, and the method will be certainly applied and popularized widely.

Owner:SOUTHEAST UNIV

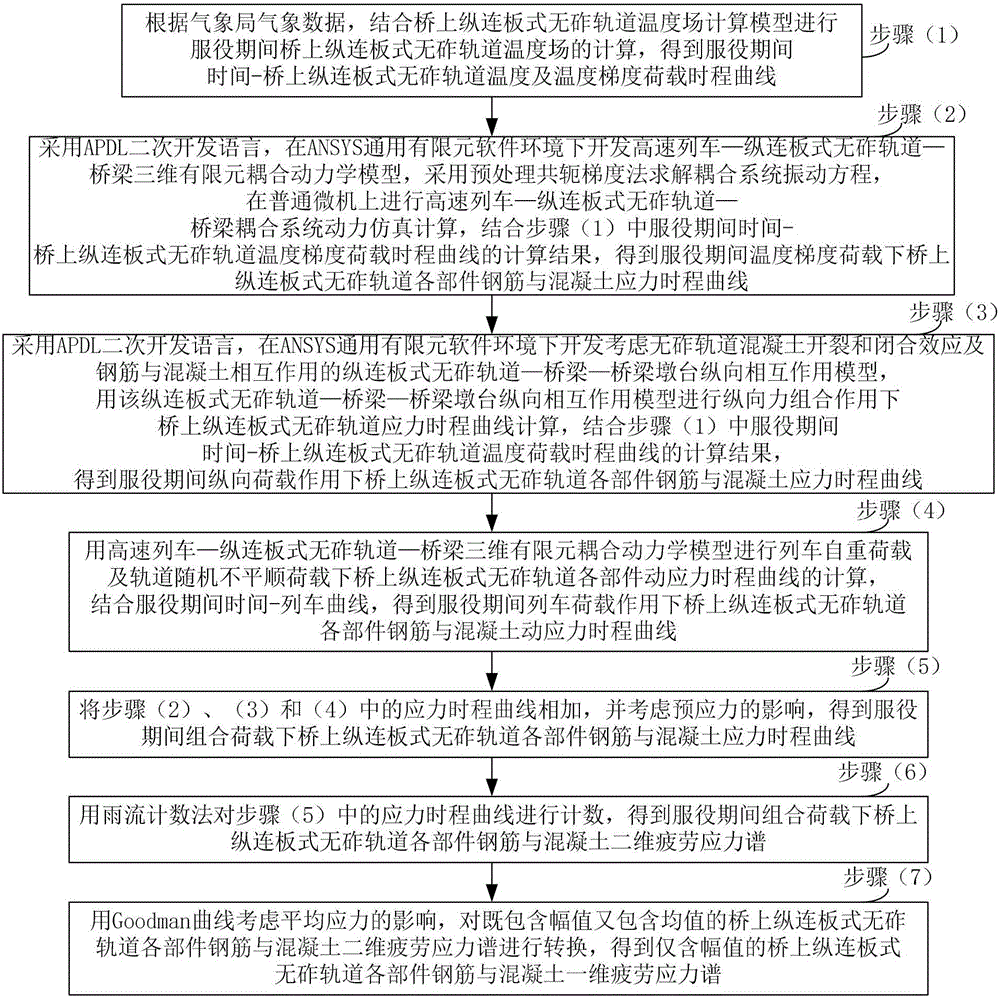

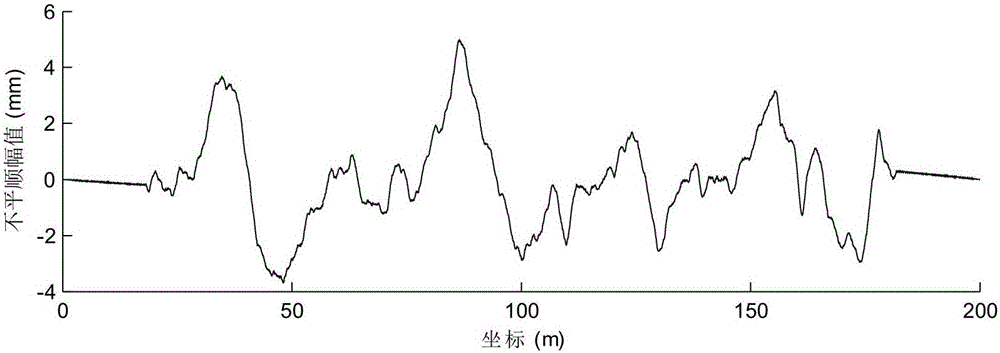

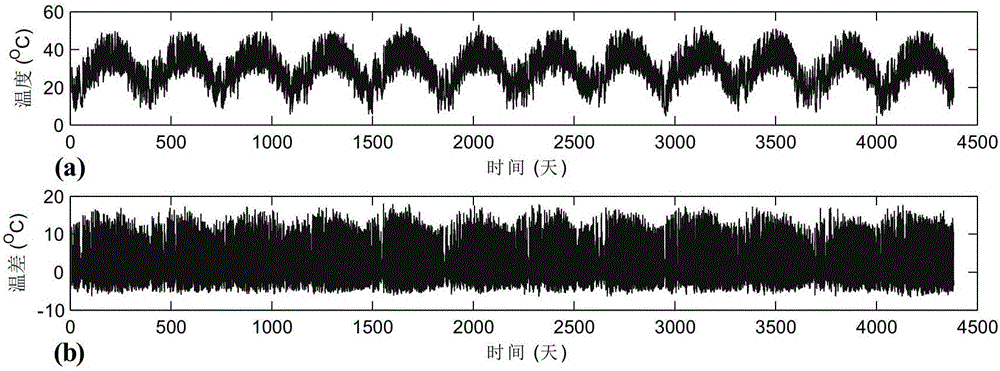

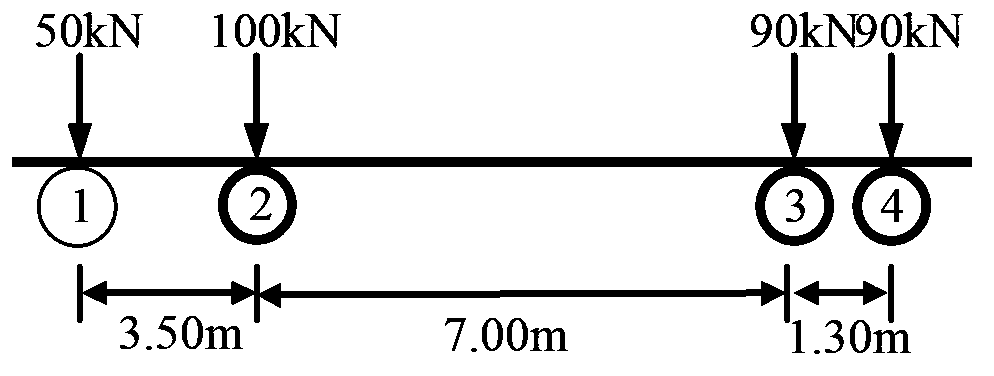

Fatigue stress spectrum analysis method and system of longitudinally connected ballastless track on bridge

ActiveCN106250604AImprove simulation accuracyDesign optimisation/simulationSpecial data processing applicationsDynamic modelsMechanical models

The invention discloses a fatigue stress spectrum analysis method and system of a longitudinally connected ballastless track on a bridge for improving the simulation accuracy of the fatigue stress spectrum of the longitudinally connected ballastless track on the bridge during service and providing important support for the fatigue design of the longitudinally connected ballastless track on the bridge. The method comprises the following steps: independently establishing a longitudinally connected ballastless track-bridge temperature field calculation model, a high speed train-longitudinally connected ballastless track-bridge three-dimensional finite element coupling dynamics model and a longitudinally connected ballastless track-bridge-bridge abutment longitudinal interaction model; utilizing the models to research the stress time travel curve and the fatigue stress spectrum of the longitudinally connected ballastless track on the bridge during the service under the composite actions of loads including a train vertical load, a train longitudinal load, a ballastless track concrete temperature load, a ballastless track concrete temperature gradient load, a ballastless track concrete contraction load, a ballastless track prestress load and the like. The mechanical model of the invention is finer, and a load model is more perfect.

Owner:浙江澎湃轨道科技有限公司

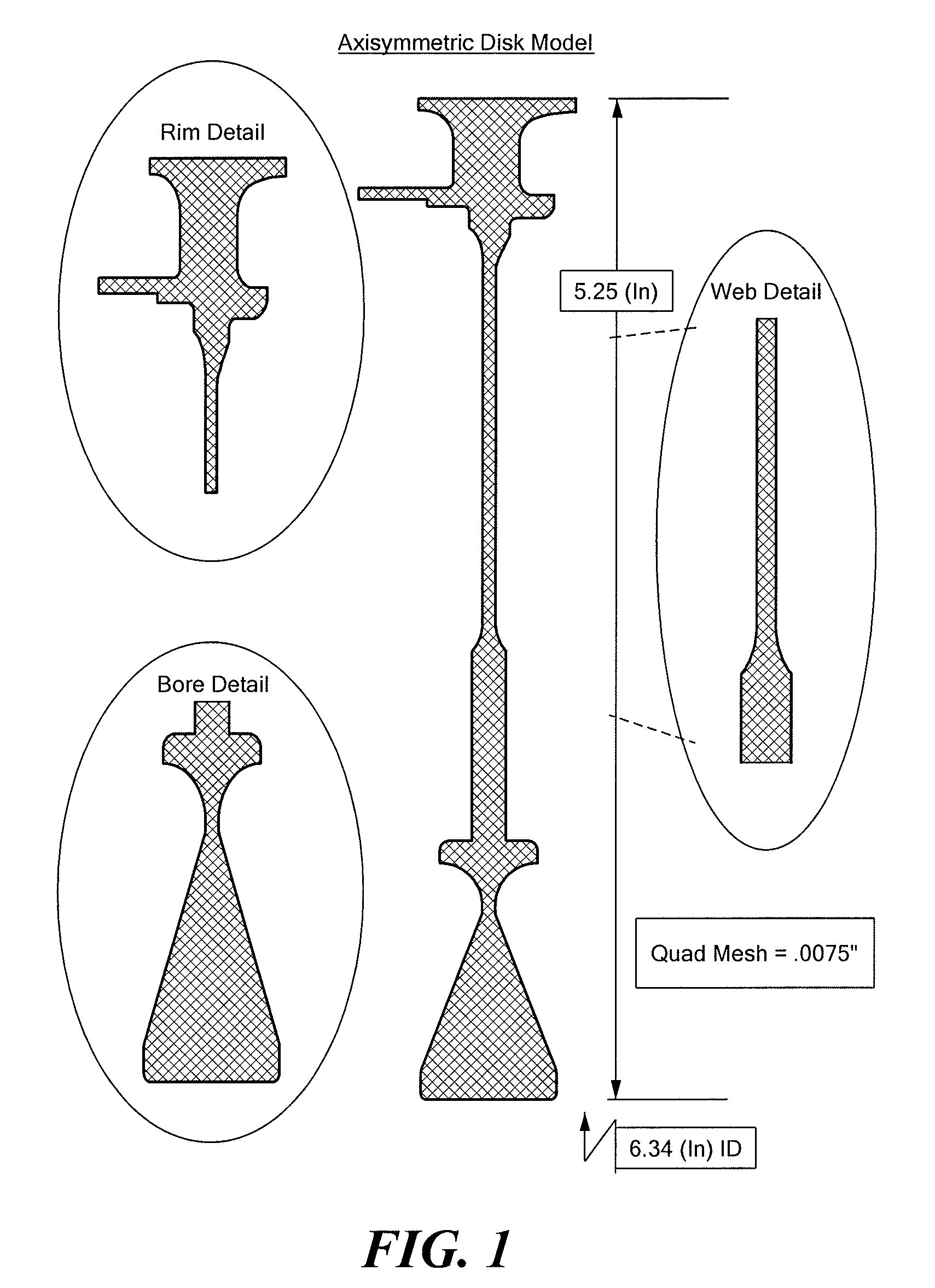

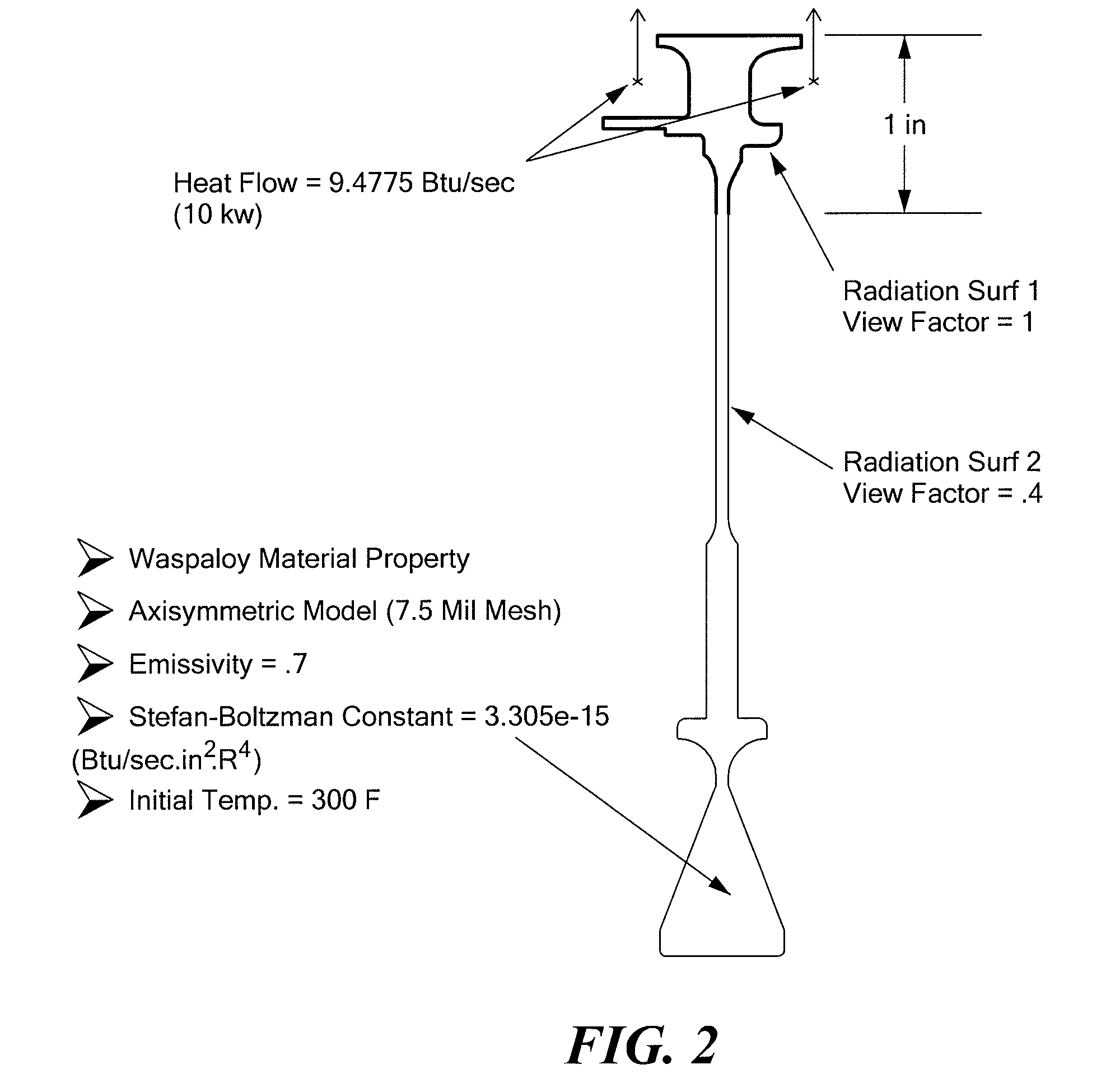

Systems and methods for producing thermal mechanical fatigue on gas turbine rotors in a spin test environment

InactiveUS20090316748A1Limit stray thermal radiationImprove heating efficiencyThermometer detailsMachine part testingRotation testEngineering

A test facility includes a heat source to thermally load a test object being mechanically loaded by rotation imposed by a spin test rig. The heat source can be a quartz lamp controlled to provide a thermal load with a differing phase than the mechanical load. Testing cycles can be run for the test object, with impingement cooling permitting the removal of the thermal load between cycles. The test facility emulates operating conditions in a gas turbine engine to impose realistic thermal and mechanical fatigue stress on the test component.

Owner:SCHENCK USA CORP

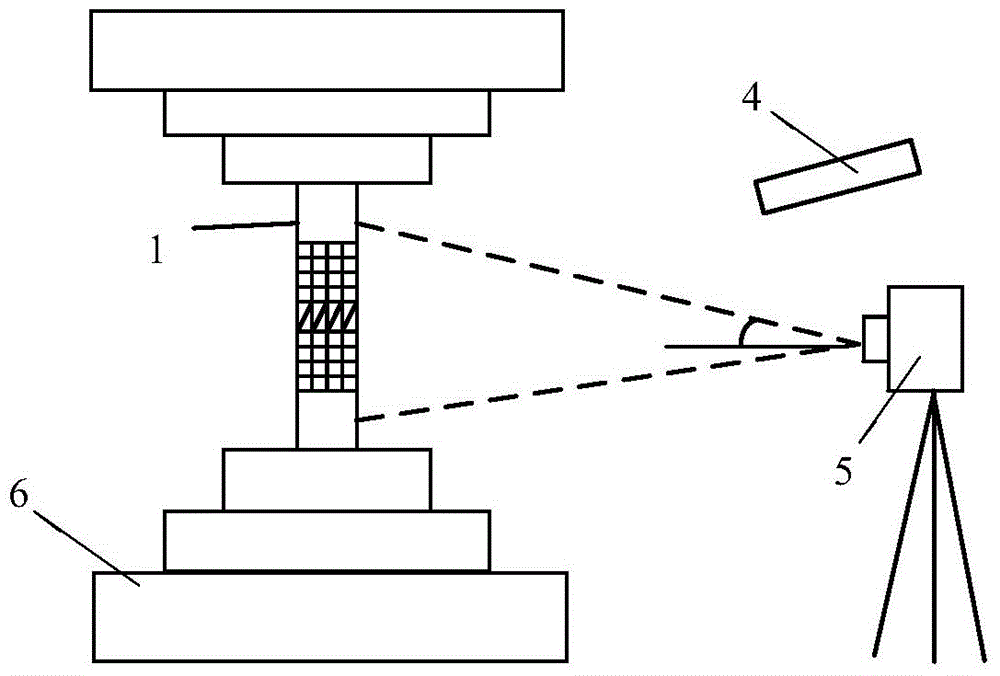

Welded member fatigue stress and strain real-time non-contact type monitoring method

InactiveCN104964886AAvoid conversionHigh precisionMaterial strength using repeated/pulsating forcesWeld seamStress–strain analysis

The present invention discloses a welded member fatigue stress and strain real-time non-contact type monitoring method. According to the method, the welded member welding seam and a certain surrounding area are subjected to grid division with a certain interval, each grid intersection point is adopted as an infinitesimal body as the stress and strain analysis unit, the feature information of the pixel points of all infinitesimal bodies in the area to be measured during the fatigue load acting process are extracted through a machine vision monitoring system when the fatigue load acts on the member, the collected member image is subjected to pixel point matching, the relation between the stress and strain change law and the image feature is established so as to obtain the feature change of the infinitesimal body during the fatigue load acting process, and finally the strain value and stress distribution law and the stress strain evolution law during the fatigue process are obtained. The method of the present invention is used for solving the monitoring problem of the stress and strain status distribution and evolution law of the welded member in the steel structure under the fatigue load acting.

Owner:SOUTHEAST UNIV

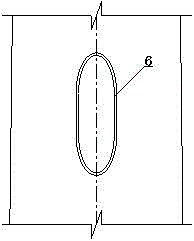

Prestressed anti-fatigue steel beams

InactiveCN102296751AIncreased design fatigue stress amplitudeIncreased fatigue stress amplitudeGirdersJoistsFatigue ProblemEngineering

The invention belongs to the technical field of civil engineering, and specifically relates to a prestressing anti-fatigue girder. The prestressing anti-fatigue girder comprises a top flange, a bottom flange, a web, a bearer stiffening plate and prestressing anchor slab, anchor holes, a high-strength prestressing steel strand, an anchoring stiffening plate, an anchor head, an arc plate, a bearer steel bracket and lateral movement proof cushion block. The prestressing steel strand is penetrated into anchor holes which are near to a tensile flange and are symmetrical on two sides of the web, and is anchored by the anchor head after stretch-draw, so as to generate a precompression on a girder tensile area. After prestressing relaxation, the prestressing steel strand has a pressure stress larger than amplitude of a self-weight stress and a fatigue tensile stress; and the girder bottom flange will not be subjected to tension under compound effects of deadweight and fatigue load. Therefore,a fatigue problem id solved. According to the invention, a design fatigue stress amplitude of the bottom flange is increased from a former one limited in an allowed fatigue stress amplitude to one approaching a design strength f, so as o substantially increase anti-fatigue capability and change a fatigue brittle failure to a ductility strength problem. An ultimate strength of the bottom flange isincreased by one time, so as to substantially increase material utilization rate of high-strength steel.

Owner:马人乐

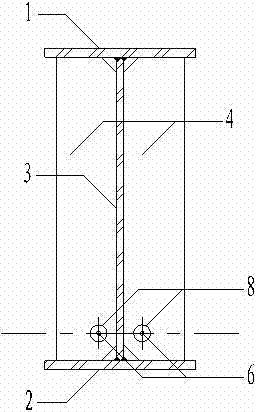

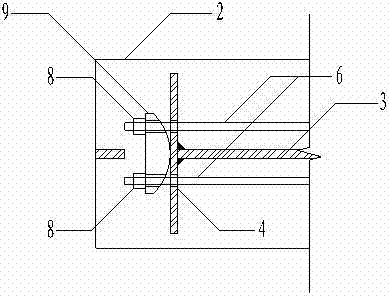

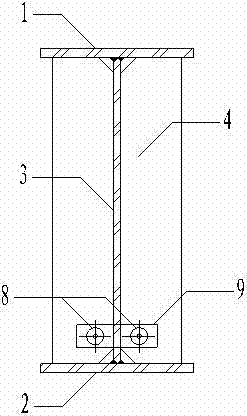

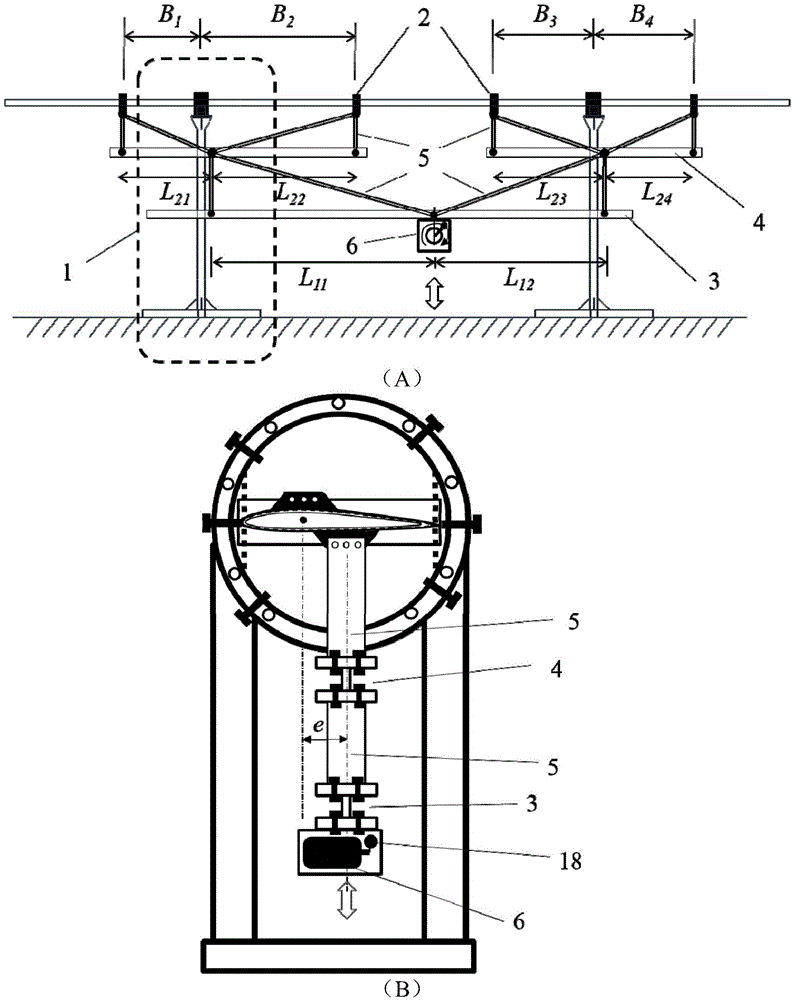

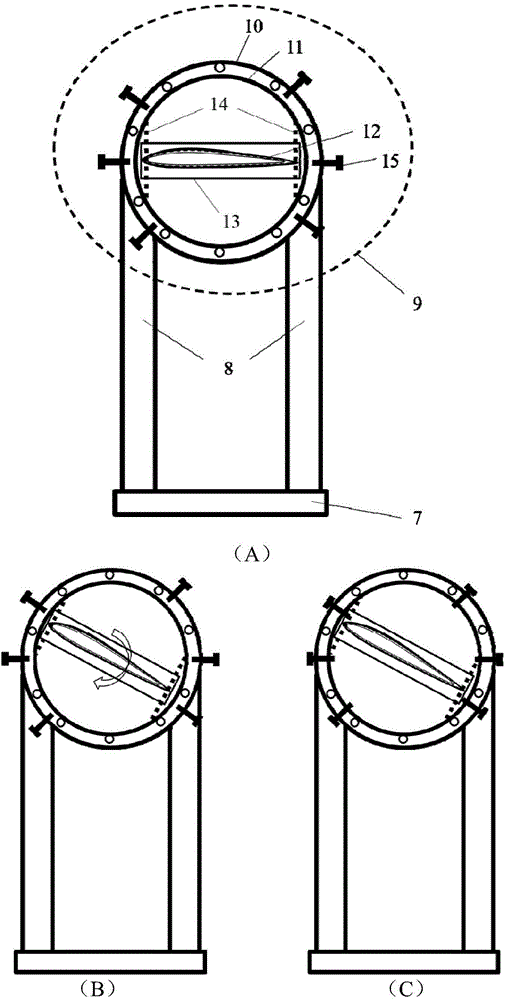

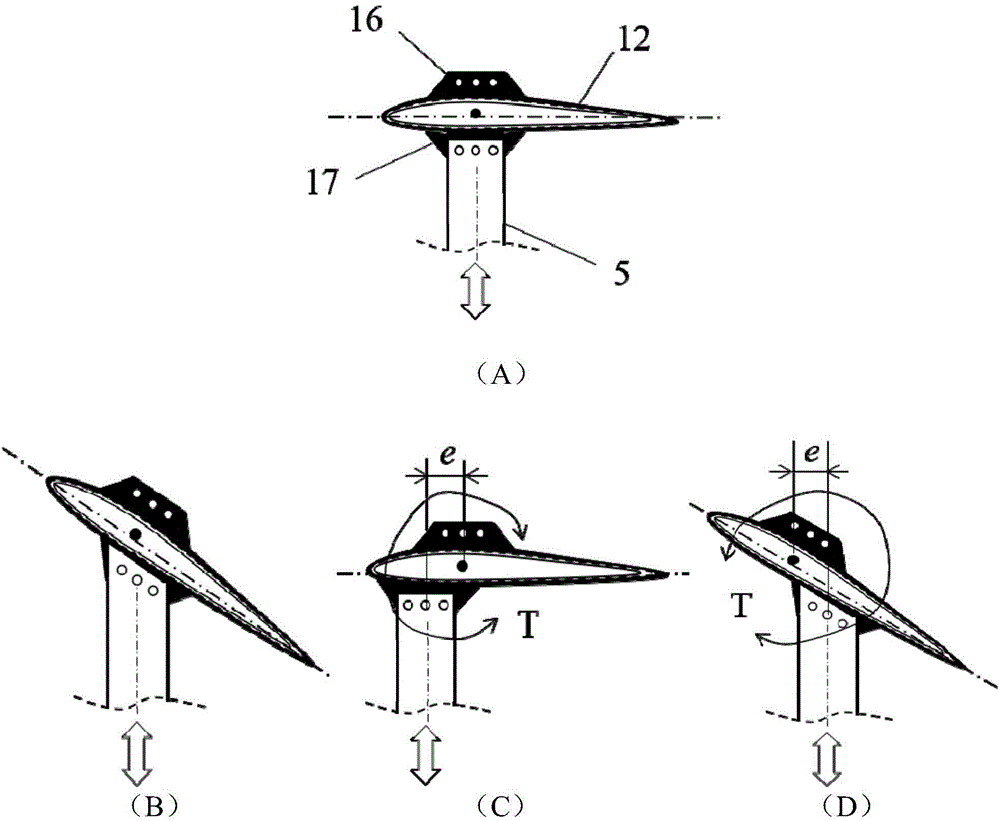

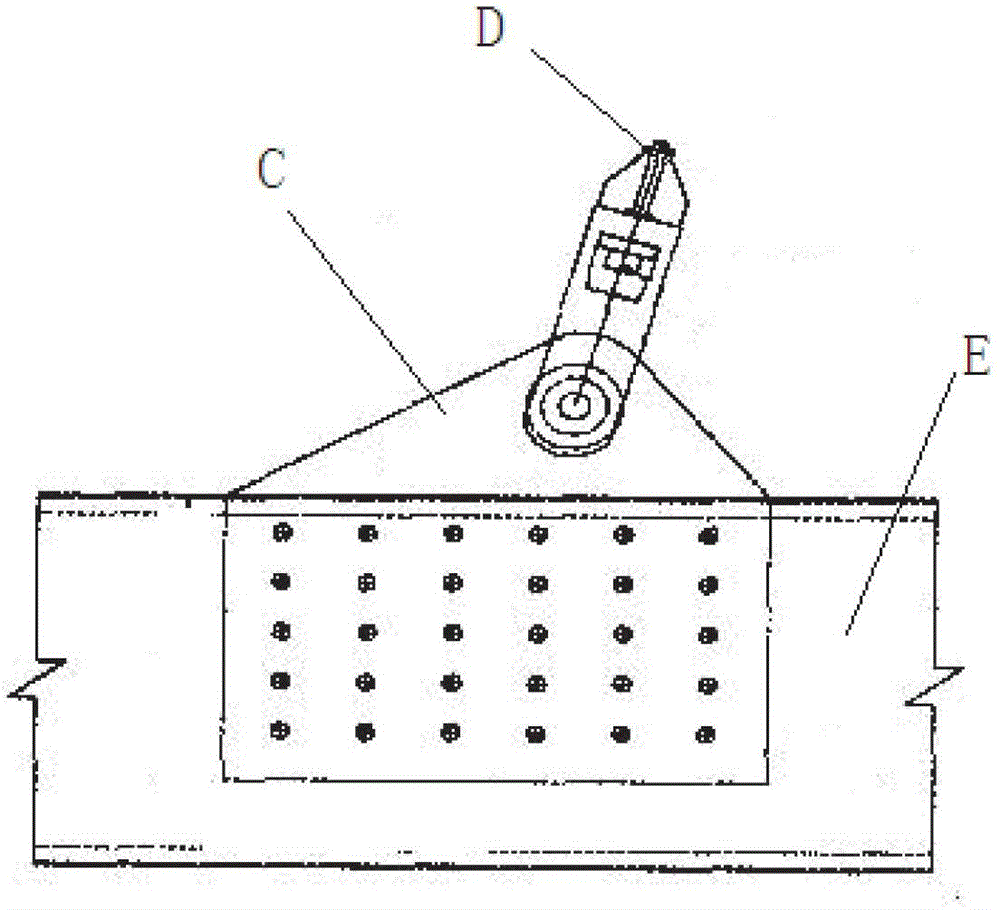

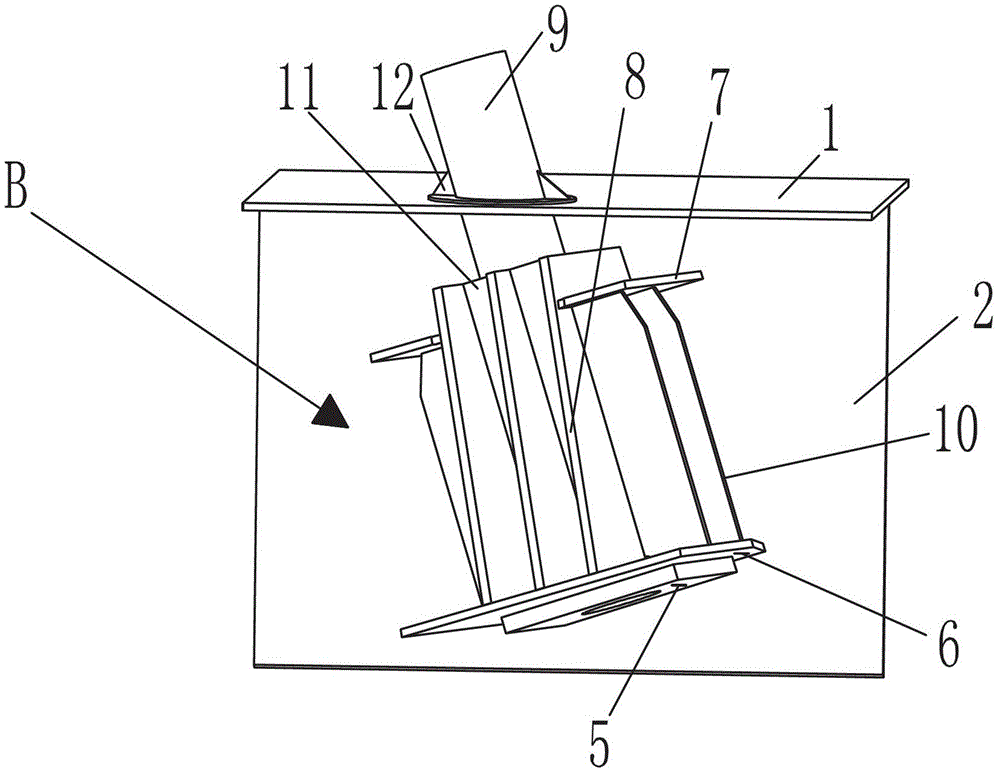

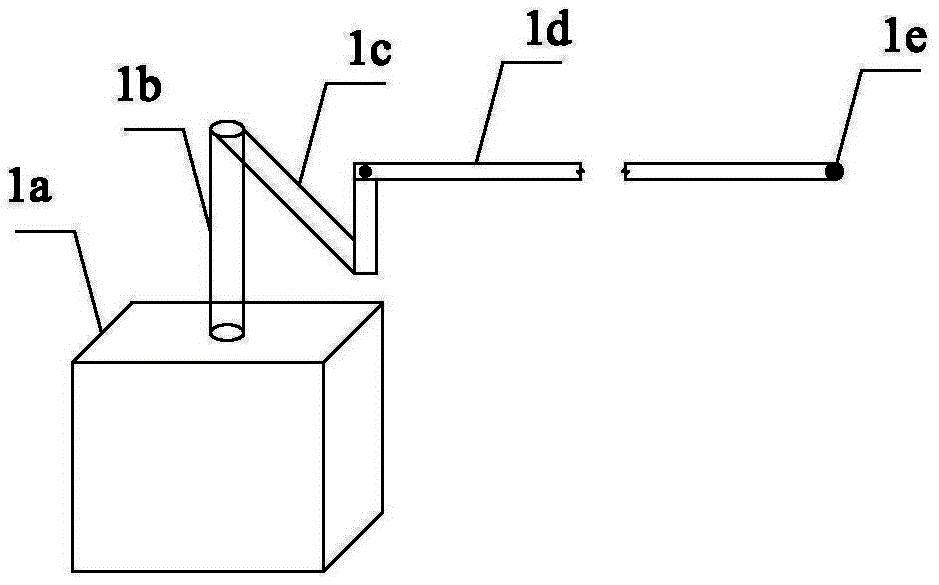

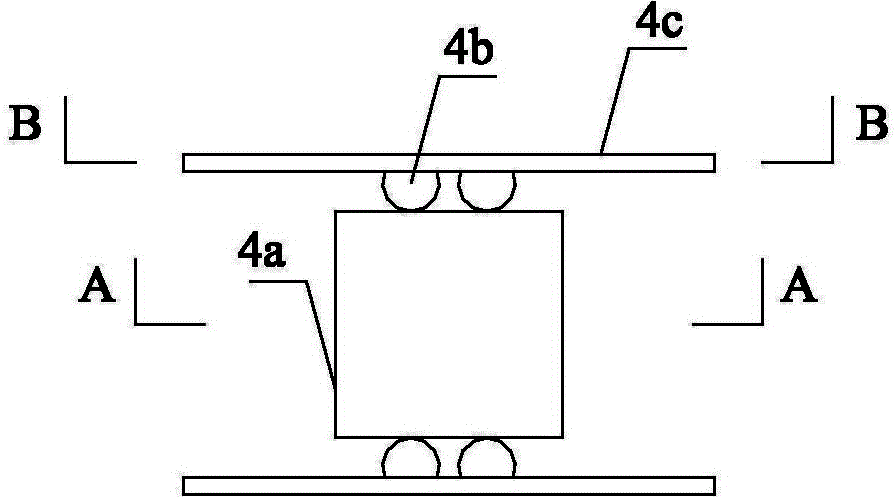

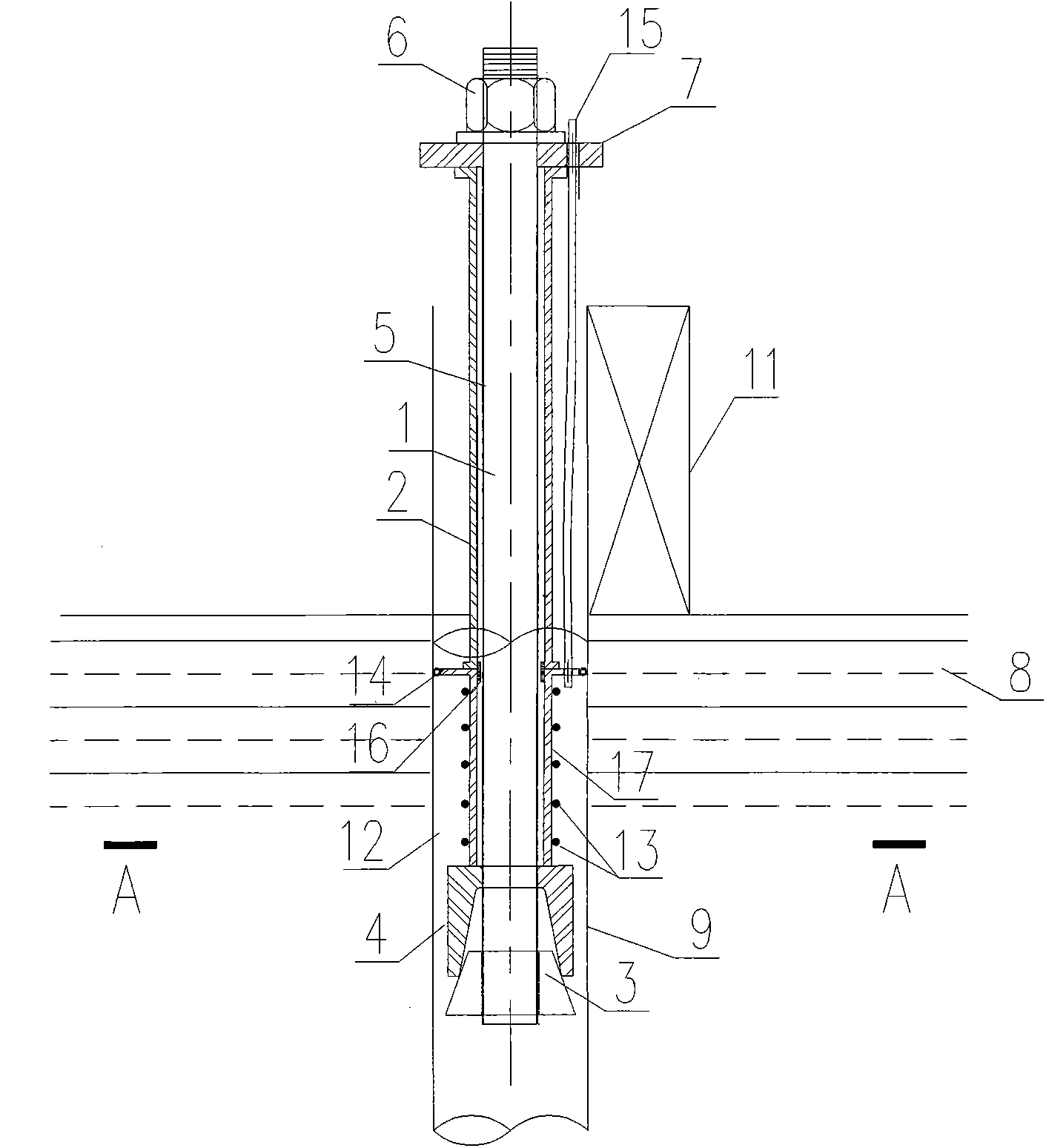

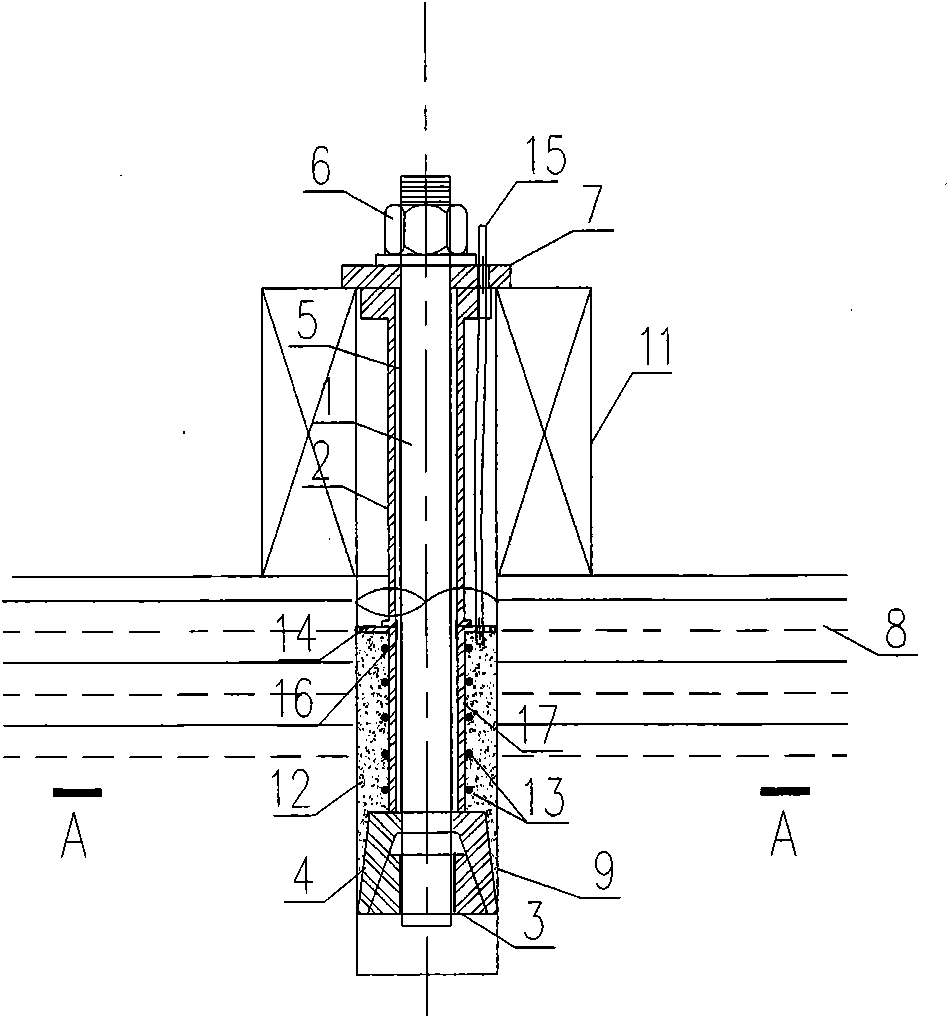

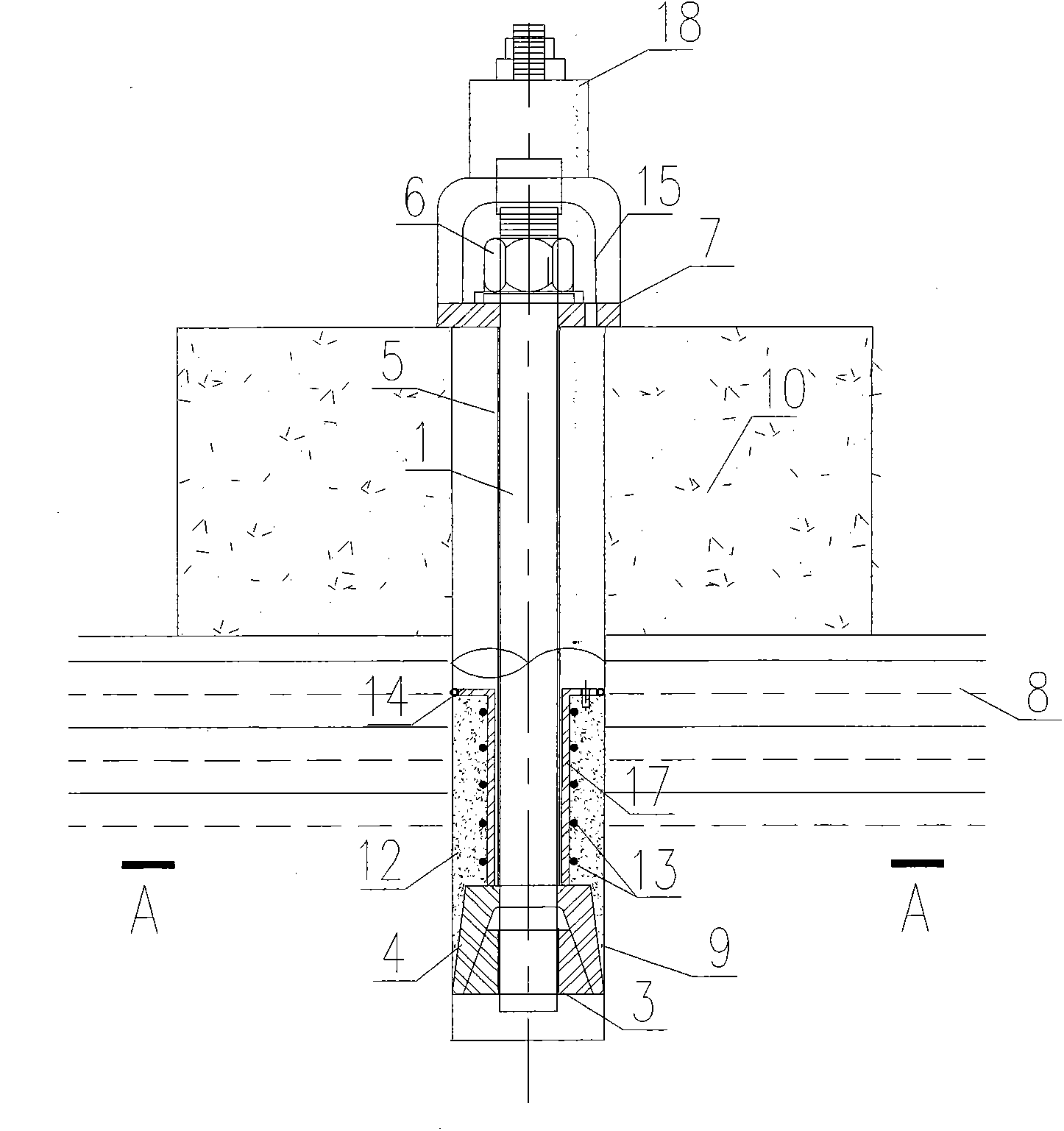

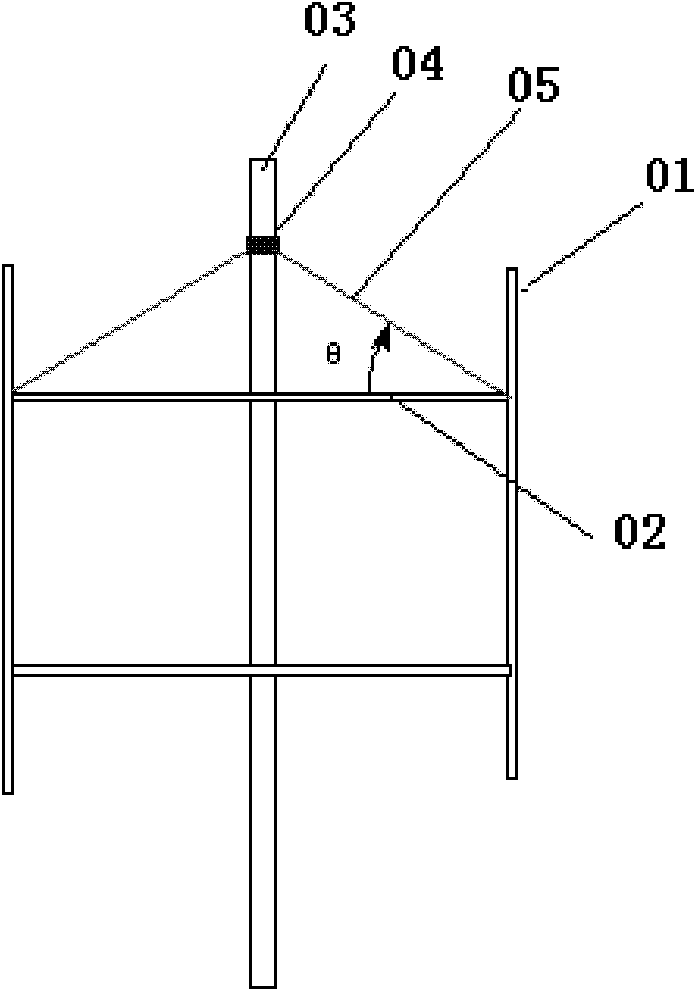

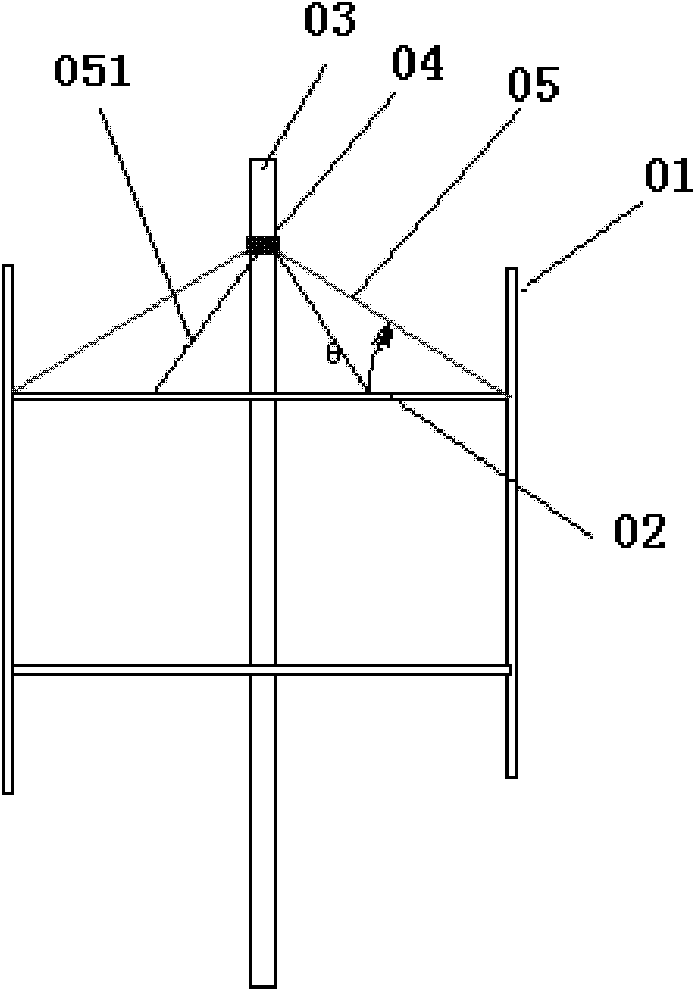

Device and method for testing structural fatigue of H-shaped vertical shaft wind turbine blade

ActiveCN104792516ATo reverse the realizationEvaluate fatigue structural performanceMachine part testingFatigue loadingStructural fatigue

The invention relates to a device and a method for testing the structural fatigue of an H-shaped vertical shaft wind turbine blade. The device comprises a support base component, a distribution beam, a loading hoop, a support connecting rod and an eccentric motor, wherein the distribution beam, the loading hoop and the support connecting rod are connected together by using bolts so as to form a whole load distribution system, so that the fatigue load which acts in an upper and lower reciprocation manner can be effectively conducted. When the device is used for experiment, the fatigue bending moment distribution of the blade under various working conditions can be simulated by adjusting the length L of the distribution beam and the position B of the loading hoop, and the fatigue stress state of the blade in axial torsion and multiple attack angles can be simulated by adjusting the structural modes of the support base component and the loading hoop; the strain distribution of the blade under the fatigue loaded condition can be measured, and furthermore, the fatigue structural property of the blade can be evaluated; by only exerting one external fatigue load to the device, combined fatigue loading modes such as bending, torsion and multiple attack angles of the blade can be achieved, and the device is simple and convenient to operate, accurate and reliable in result and relatively high in universality.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

Double-outrigger type cable beam anchoring structure of bridge steel box girder

ActiveCN102912721AImprove stress safetyImprove reliabilityBridge structural detailsStress concentrationSteel box girder

The invention discloses a double-outrigger type cable beam anchoring structure of a bridge steel box girder, comprising a steel box girder which is mainly formed by a top plate, a side plate, a side longitudinal web, a bottom plate and a transverse diaphragm plate. The double-outrigger type cable beam anchoring structure of the bridge steel box girder is characterized by also comprising an anchor box which is used for transferring the force of a stay cable to the steel box girder; a cable sleeve of the anchor box penetrates through the top plate; the body of the anchor box is located in the steel box girder; and two sides of the body of the anchor box are fixedly connected with the side plate and the side longitudinal web respectively. Through the double-outrigger type cable beam anchoring structure of the bridge steel box girder, the stress safety, the force transfer reliability and the fatigue resistance of the cable beam anchoring structure of the steel box girder are improved and the problem that the existing cable anchoring structures in common use have concentrated stress and overlarge local stress and fatigue stress is well overcome.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

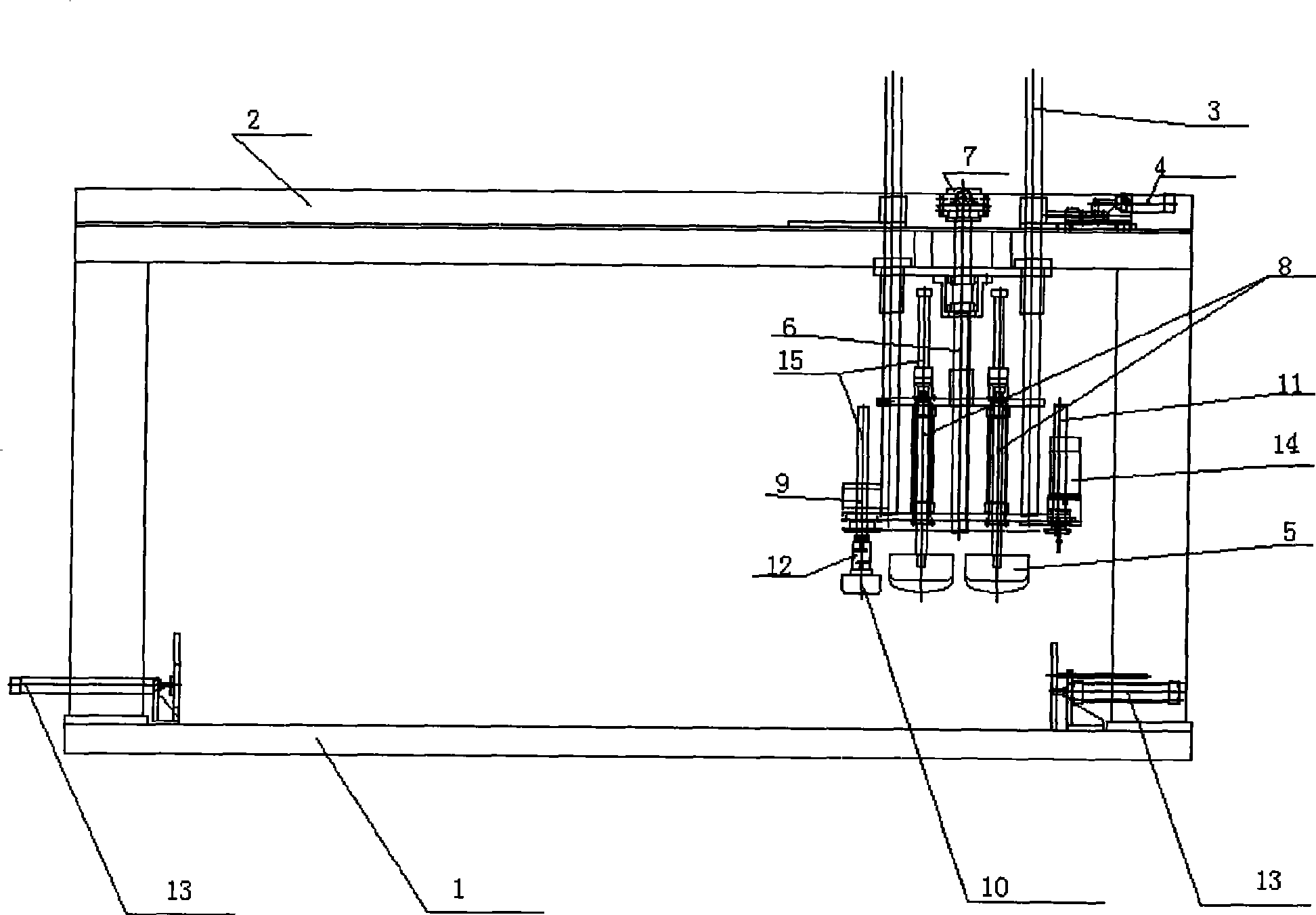

Testing machine for mattress durability

InactiveCN101446516AEasy to operateSave human effortElasticity measurementProduct inspectionEngineering

The invention relates to a testing machine for the durability of a mattress. The machine comprises a test table, a beam, a load device, and an electromagnetic valve, the beam stands on the test table, and the load device is fixed on the beam. The machine is characterized in that the machine further comprises a control device, a test device and a test piece position adjustment cylinder, wherein, the test piece position adjustment cylinder is arranged on the test table, the control device is connected with the load device, and the load device is connected with the test device. The control device controls cylinder working frequency through the electromagnetic valve, so as to adjust the load frequency of load units. The test device is fixed on the ledger plate at the bottom of the load device and in contact with the test piece through a round cushion block. The test device is driven by a motor and pulled by a guide post, the displacement of the test device is measured by a displacement instrument and the applied force is controlled by the strength sensor. The invention is used to test the ability of resisting fatigue stress and surface abrasion of the matters after certain times of to-and-fro pressurizing, has the advantages of simple operation, high efficiency and accurate measure, and belongs to the technical field of product inspection and tests.

Owner:KUNSHAN INNOVATION TESTING INSTR CO LTD

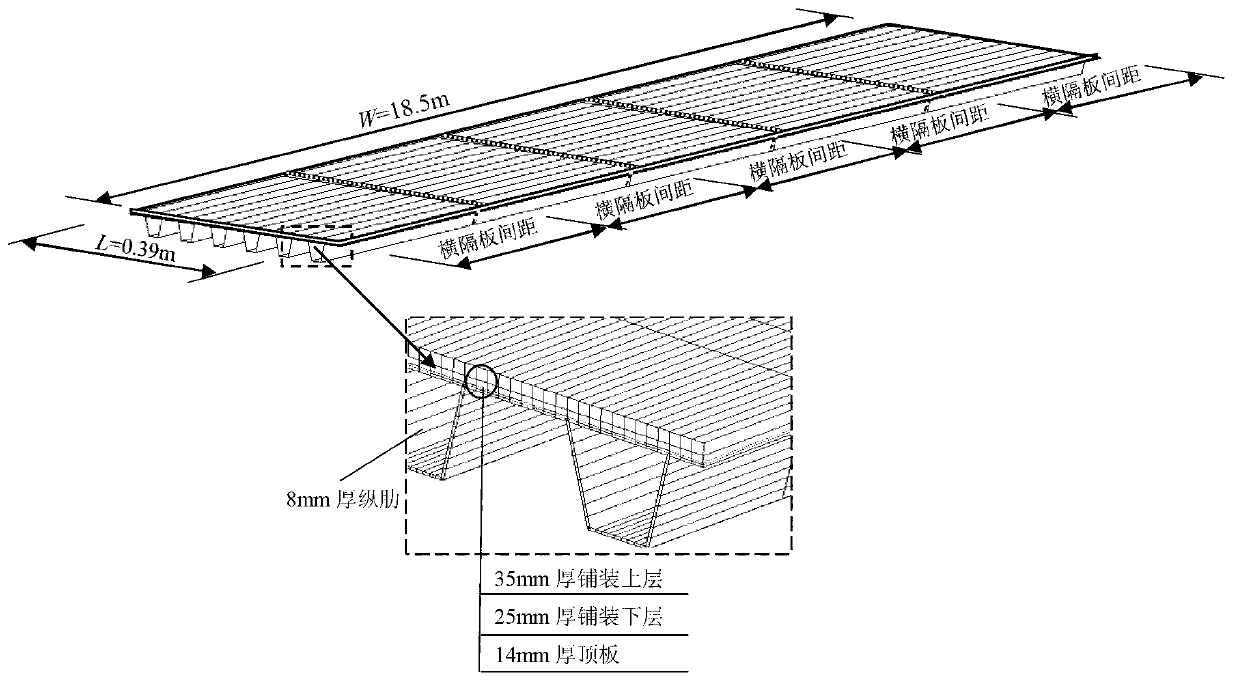

Method for calculating fatigue stress of steel bridge deck slab under combined action of vehicle load and temperature

InactiveCN103279588ARealize fatigue stress time history simulationAccurately reflect the change law of fatigue stressSpecial data processing applicationsBridge deckEngineering

The invention discloses a method for calculating the fatigue stress of a steel bridge deck slab under the combined action of a vehicle load and the temperature. The method includes the following steps: building a steel bridge deck slab-pavement layer integrated fatigue analysis model under the combined action of the vehicle load and the temperature, selecting a single standard fatigue vehicle, loading the integrated fatigue analysis model to the fatigue vehicle, calculating fatigue stress time history curves of welding details under predetermined working conditions, on the basis of the curve, building an analysis model for calculating the fatigue stress time history of the welding details under any working condition, and determining the fatigue stress time history of the welding details under the combined action of the vehicle load and the temperature. The calculation method can achieve simulation of the fatigue stress time history of the steel bridge deck slab during any time period, the simulating result can accurately reflect the change rule of the fatigue stress of the steel bridge deck slab in a real operation state, and the method fills the gap that no appropriate method for calculating the fatigue stress of the steel bridge deck slab under the combined action of the vehicle load and the temperature exists in the prior art.

Owner:SOUTHEAST UNIV

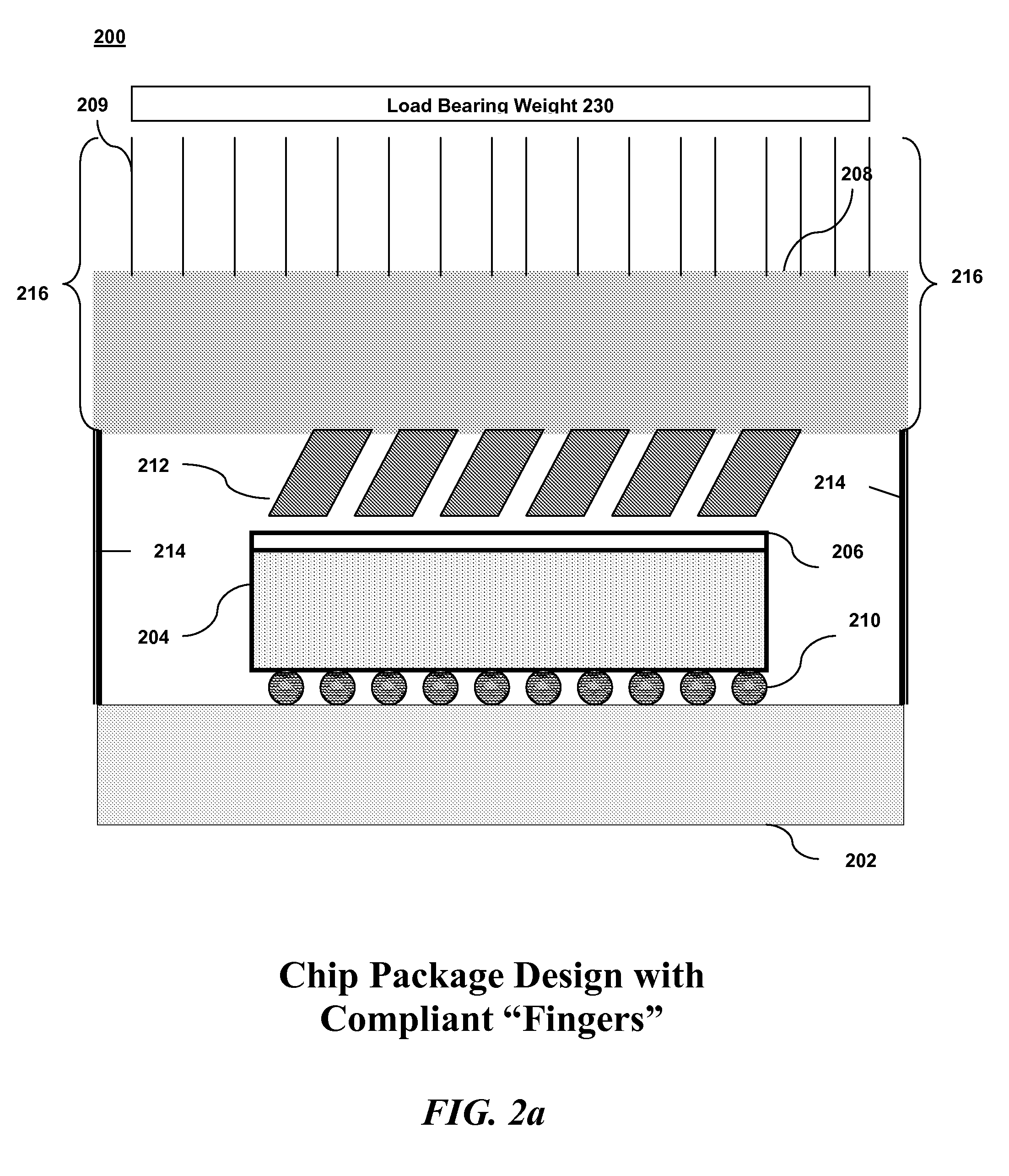

Heat Sink with Thermally Compliant Beams

ActiveUS20090039499A1High complianceImprove thermal conductivitySemiconductor/solid-state device detailsSolid-state devicesLight beamEngineering

A heat dissipating structure includes: a heat spreader; and a plurality of compliant beams attached to the heat spreader. The beams are formed of a high-conductive material such that a maximum stress of each beam is less than a fatigue stress of the high-conductive material; said beams are placed at an angle relative to a chip surface such that the beams are able to exert bending compliance in response to x, y, and z forces exerted upon them. The structure also includes a thermal material interface for bonding said structure to the chip surface. Both the heat spreader and the compliant beams can be machined from a copper block. An alternative heat dissipating structure includes compliant beams soldered to the chip surface.

Owner:GLOBALFOUNDRIES US INC

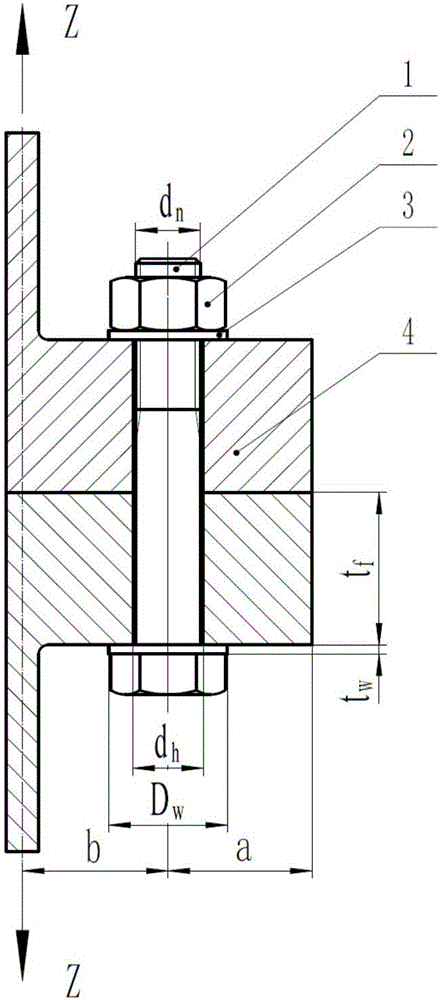

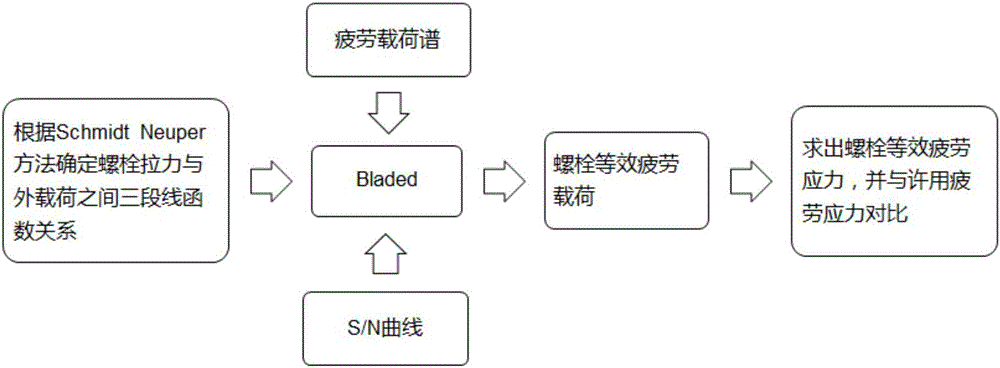

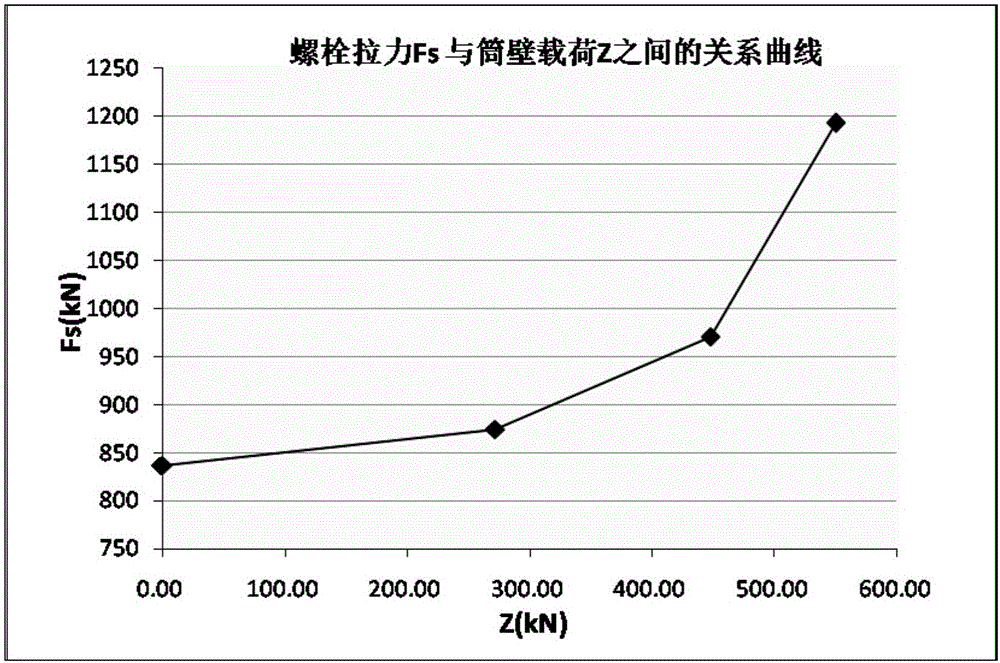

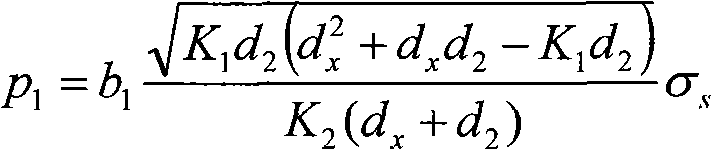

Calculating method for fatigue strength checking of L-type flange connecting bolt and device

InactiveCN106570326ARealize checkSimple processInformaticsSpecial data processing applicationsEngineeringTower

The invention relates to a calculating method for fatigue strength checking of an L-type flange connecting bolt and a device and belongs to the technical field of wind power generation. The method comprises following steps: first, calculating the three-section line relationship between external applied load and a screw bolt; second, obtaining equivalent fatigue load of the screw bolt according to the three-section line relationship in combination with time sequence load; then obtaining equivalent fatigue stress of the screw bolt according to the stress area of the screw bolt; then calculating allowable fatigue stress of the screw bolt according to the cycle number corresponding to the equivalent fatigue load of the screw bolt and the S / N curve of the screw bolt, and comparing the equivalent fatigue stress of the screw bolt with the allowable fatigue stress to check of the fatigue strength of the bolt. According to the method of the invention, the equivalent fatigue load is obtained according to the three-section line relation in combination with time sequence load; the process is simple and is easy to realize so as to increase the efficiency; the method can be applied in checking the fatigue strength of L-type flange screw bolts of blower fan towers; the method and device have wide application.

Owner:XUJI GRP +2

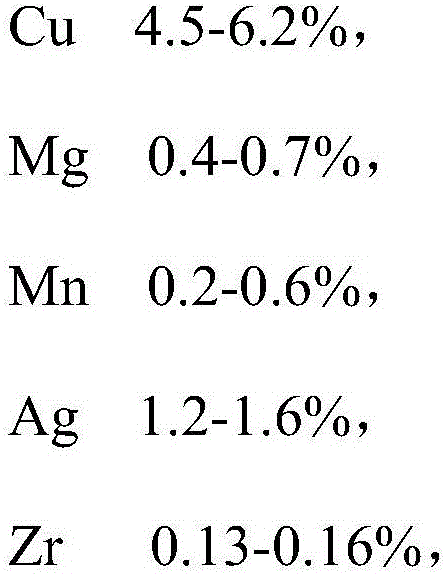

Reliability modeling method based on cumulative fatigue damage

ActiveCN107844663AImprove reliabilityImprove calculation accuracyGeometric CADDesign optimisation/simulationFatigue damageDamage tolerance

Owner:HARBIN INST OF TECH

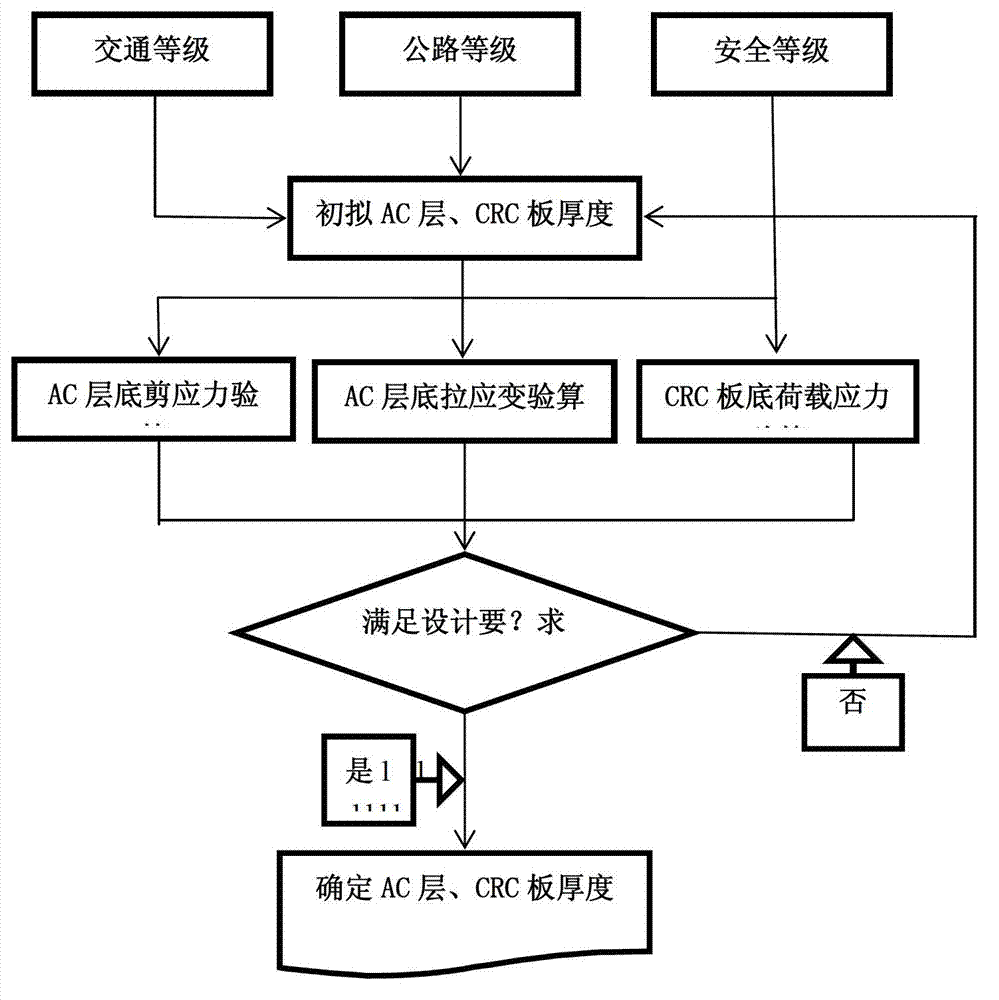

Method for designing long-life composite pavement structure of underground road

The invention relates to a method for designing a long-life composite pavement structure of an underground road. In order to provide the method for designing the long-life composite pavement structure of the underground road and achieve the purpose, a technical scheme adopted in the invention is as follows: the method for designing the long-life composite pavement structure of the underground road comprises the following steps: (1) searching and analyzing traffic parameters, determining traffic grade of the road and figuring out a cumulative action number of a standard axle load within a design reference period; (2) initially drafting a pavement structure, preliminarily drawing up structural parameters such as the thickness of an asphalt concrete (short for AC) layer and the thickness of a continuously reinforced concrete (short for CRC) plate according to a traffic quantity calculating result; (3) figuring out shearing strength and tensile strain at the bottom of the AC layer according to the structural parameters of the pavement structure and comparing and analyzing the shearing strength and the tensile strain of the AC layer with allowed shearing strength and allowed tensile strain; and (4) figuring out load fatigue stress at the bottom of the CRC plate and checking whether the parameter of the CRC plate satisfy design requirements or not. The method is mainly applied to road design.

Owner:TIANJIN MUNICIPAL ENG DESIGN & RES INST

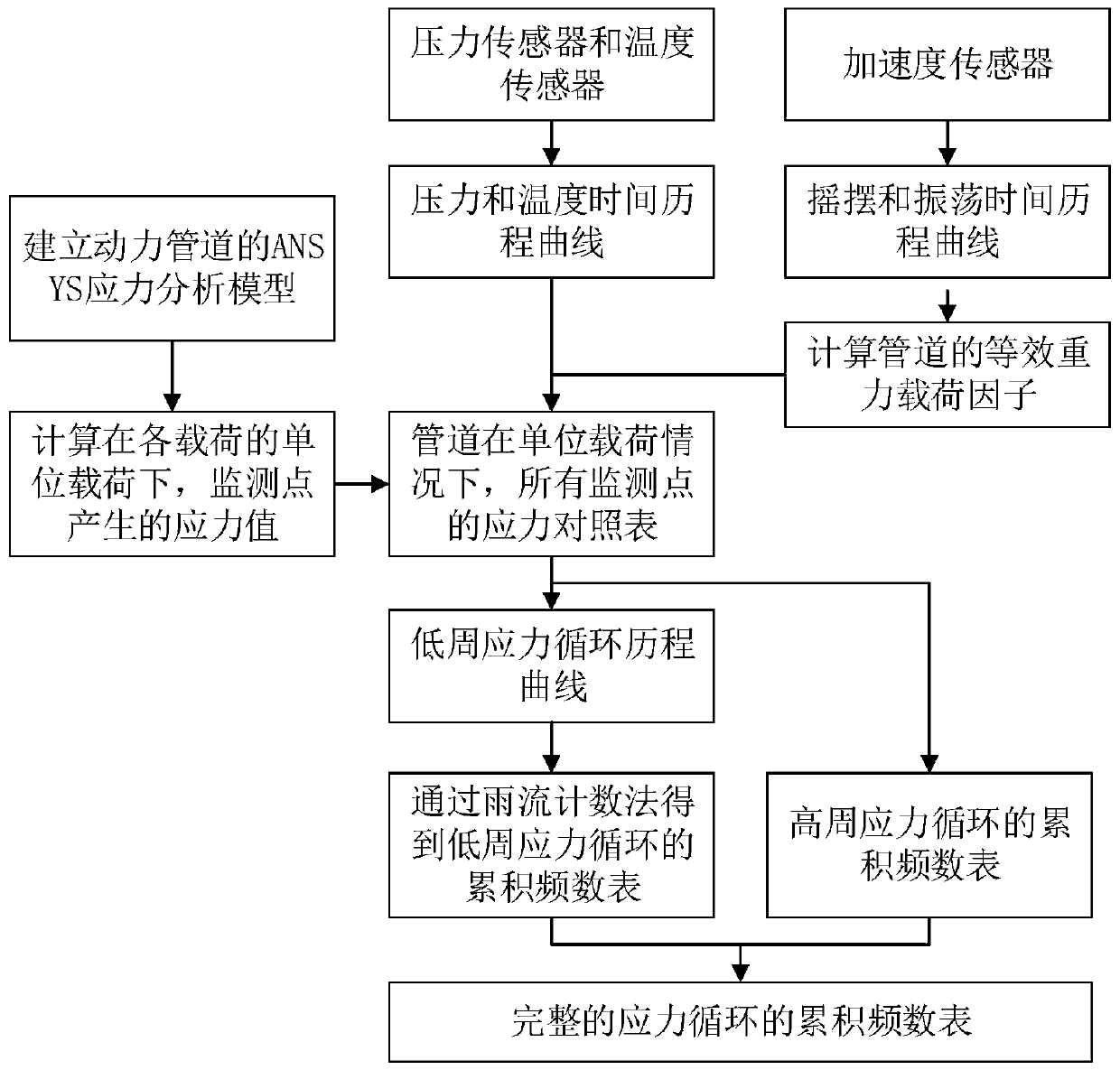

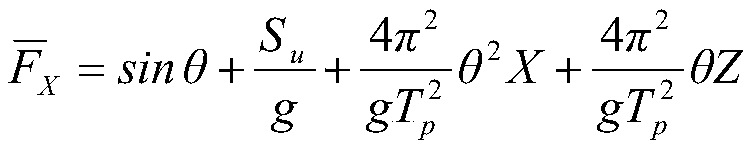

Method for monitoring fatigue stress of ship power pipeline

The invention discloses a method for monitoring the fatigue stress of a ship power pipeline, and relates to the technical field of safety control of the power pipeline. The method comprises the following steps: establishing a stress analysis model of the power pipeline, and generating a stress comparison table of all monitoring points of the pipeline under a unit load condition; obtaining a time history curve of low-period cycle load and high-period cycle load on the pipeline during a ship navigation process; calculating and drawing a cumulative frequency table of low-period stress cycles of the monitoring points; calculating an equivalent gravity load factor of the pipeline; calculating the cumulative frequency table of high-period stress cycles of the monitoring points; and merging the cumulative frequency table of the low-period stress cycles with the cumulative frequency table of the high-period stress cycles of the monitoring points to obtain a complete cumulative frequency tableof stress cycle, so as to complete the fatigue analysis and check of the monitoring points of the ship pipeline. By adopting the method disclosed by the invention, the setting of sensors can be reduced, the situation that the sensors are directly attached to dangerous points for measurement is avoided, and the stress monitoring of any area in the ship power pipeline is completed indirectly.

Owner:NO 719 RES INST CHINA SHIPBUILDING IND

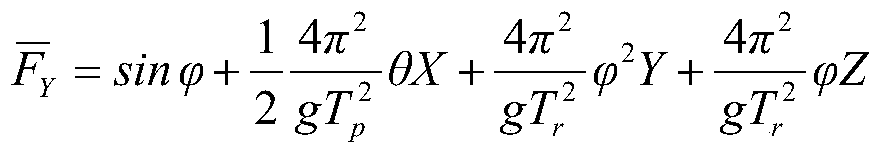

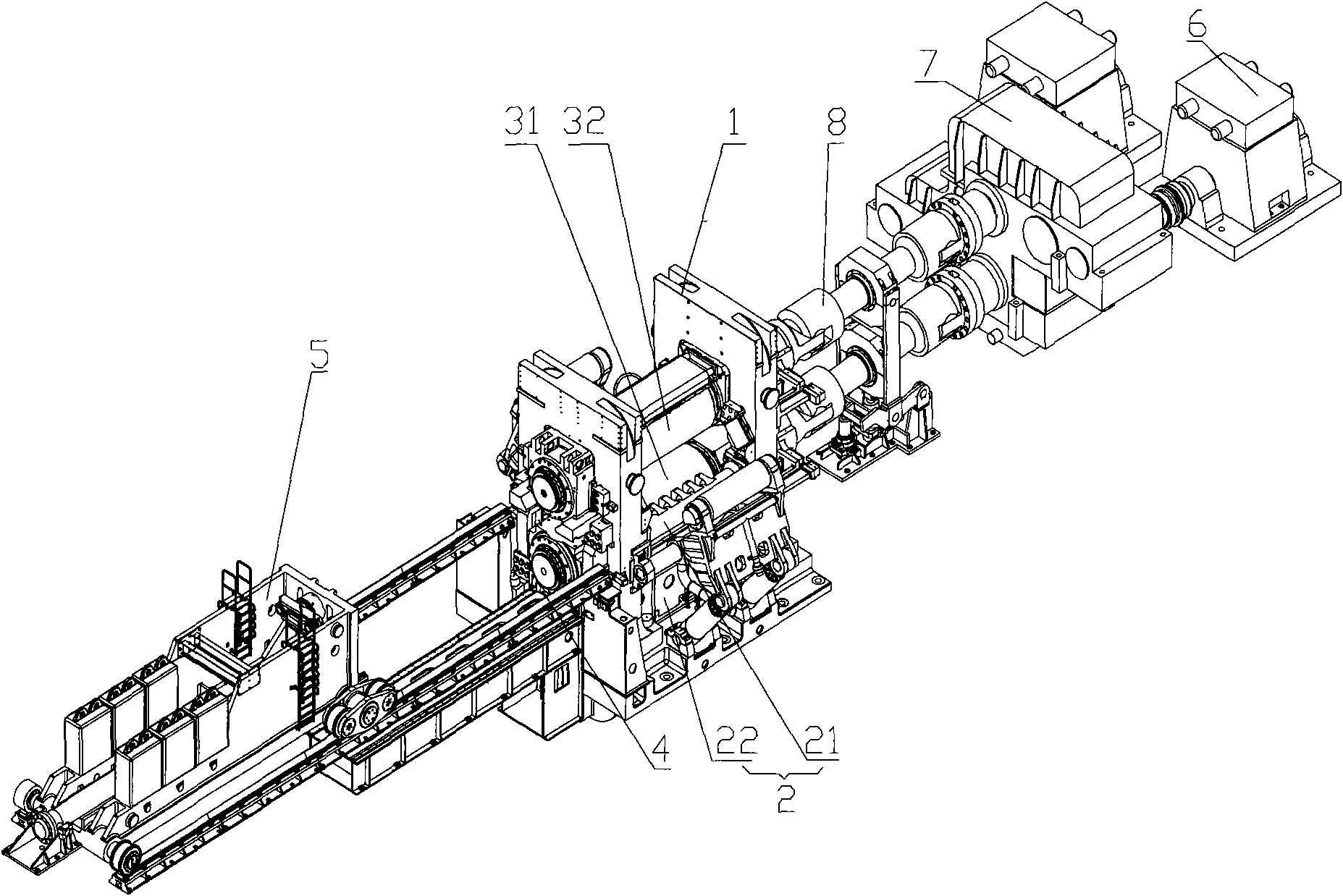

Multi-axial fatigue testing machine

ActiveCN104132857AChange the size of the forceMaterial strength using repeated/pulsating forcesStiffness coefficientEngineering

A multi-axial fatigue testing machine is disclosed. A drive unit is adopted to provide circulation power, and circulation force is transferred through a force transmission arm, a sliding device and a force transmission spring to a test piece such that the test piece is in a multi-axial fatigue stress state. By selecting the drive unit to connect bolt holes at different positions, multi-axial stress amplitude load applied on the test piece is adjusted; by replacing force transmission springs with different stiffness coefficients, stress amplitude load applied on the test piece is adjusted; and by changing moving displacement of a fixed device in a slide, different magnitudes of one-way initial stress or multi-way initial stress are applied. Therefore, the multi-axial fatigue testing machine can carry out a multi-axial fatigue test of a component by selecting reasonable magnitudes of stress amplitude and initial stress according to different force environments.

Owner:HOHAI UNIV

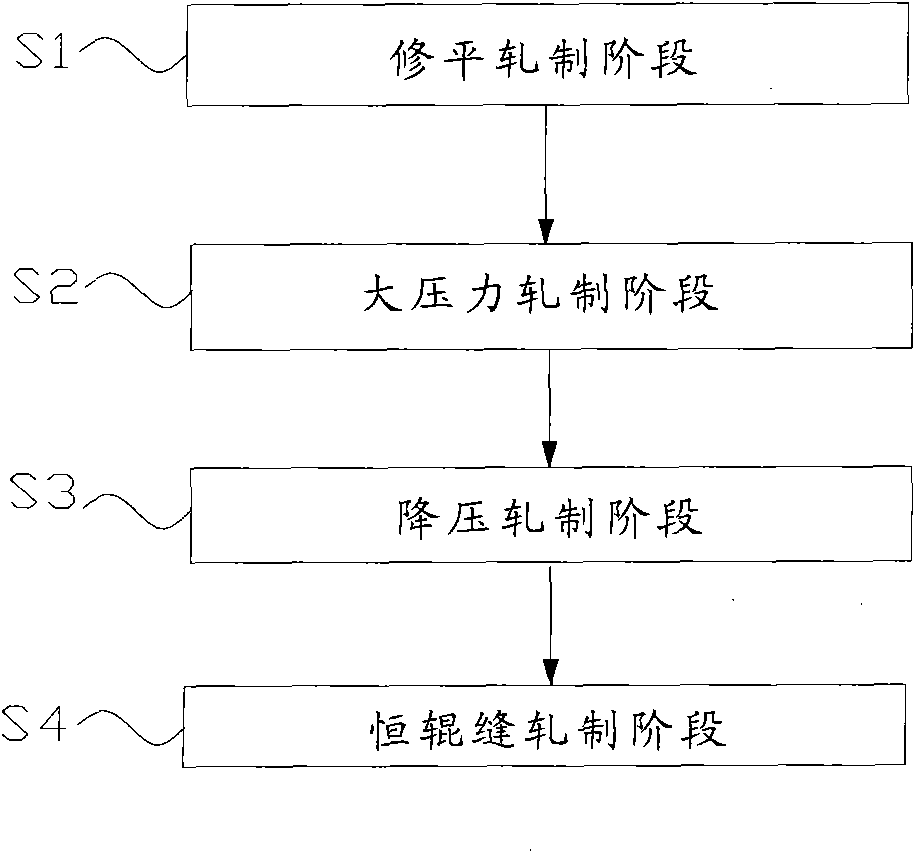

Shell course rolling technology and rolling equipment thereof

The invention discloses a shell course rolling method, which is characterized in that a first roller and a second roller respectively extrude the inner wall and the outer wall of the shell course. The core lies in that in the process of rolling, the first roller and the second roller are driven by driving devices to rotate. The invention also discloses shell course rolling equipment, comprising the first roller and the second roller; the first roller and the second roller are all drive rollers driven by the driving devices. The method and equipment discloses by the invention are used for rolling the shell course in a manner of double roller driving, thereby overcoming the defect of surface anti-fatigue stress on the inner wall of the shell course and improving the mechanical property of the finished shell course product.

Owner:CHINA FIRST HEAVY IND +1

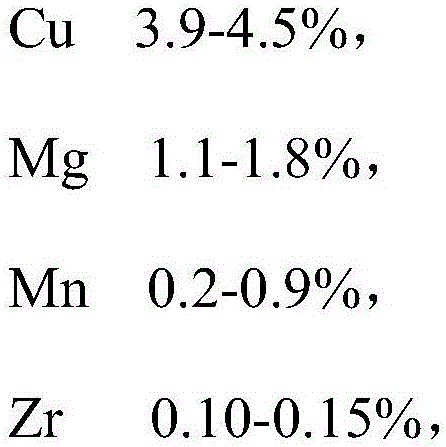

Method for improving damage tolerance performance of Al-Cu-Mg alloy

InactiveCN105734469AImproved resistance to fatigue damage toleranceImproved damage tolerance performanceFatigue damageCrazing

A method for improving the damage tolerance performance of an Al-Cu-Mg alloy is to carry out a solid solution + water quenching treatment on an Al-Cu-Mg alloy plate, and then perform a cold rolling pre-deformation treatment with a deformation amount of 6-15%, and then Perform aging treatment. The process of the invention is simple and reasonable, through cold rolling with small deformation amount after solid solution quenching, a certain compressive stress layer is generated on the surface of the plate, and the formation and expansion of cracks under the action of fatigue stress are effectively inhibited. With the natural aging treatment, the surface layer has a large density of dislocations due to the pre-deformation of cold rolling, which makes the alloy precipitate large-sized Cu-Mg atomic clusters during the natural aging process, and increases the Cu / Mg mass ratio of the clusters, so that The surface layer of the plate produces a large order strengthening effect and modulus strengthening effect; artificial aging treatment can cause the plate to precipitate a fine and dispersed second phase, and at the same time, the higher density dislocations on the surface can form a finer and dispersed second phase on the surface of the plate. Two phases, thereby hindering the formation and propagation of fatigue cracks in the surface area, and improving the fatigue resistance damage tolerance performance of the plate. This surface-hard-core-tough structure can effectively improve the damage tolerance performance of the plate, and is suitable for industrial applications.

Owner:CENT SOUTH UNIV

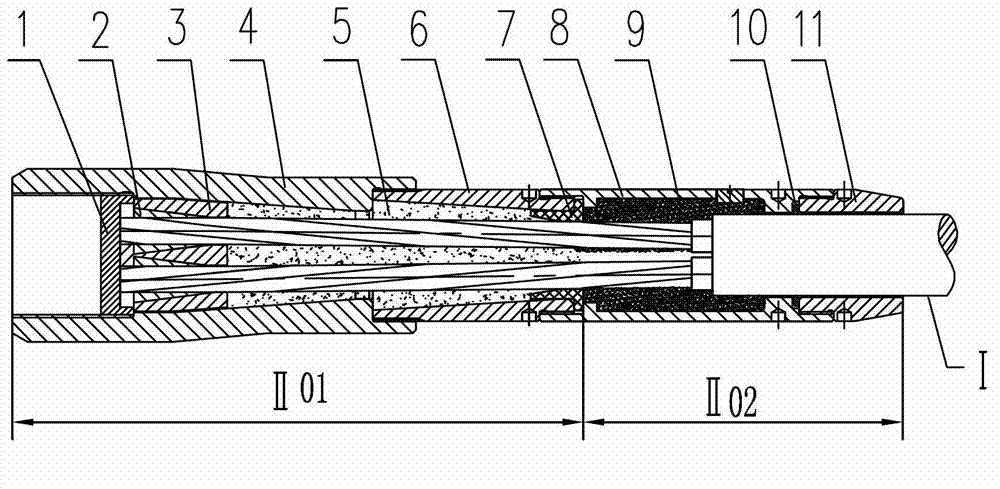

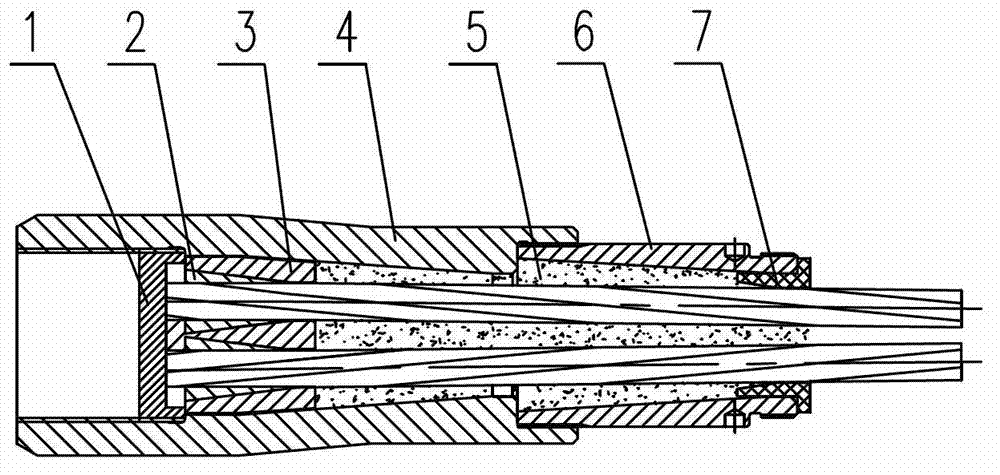

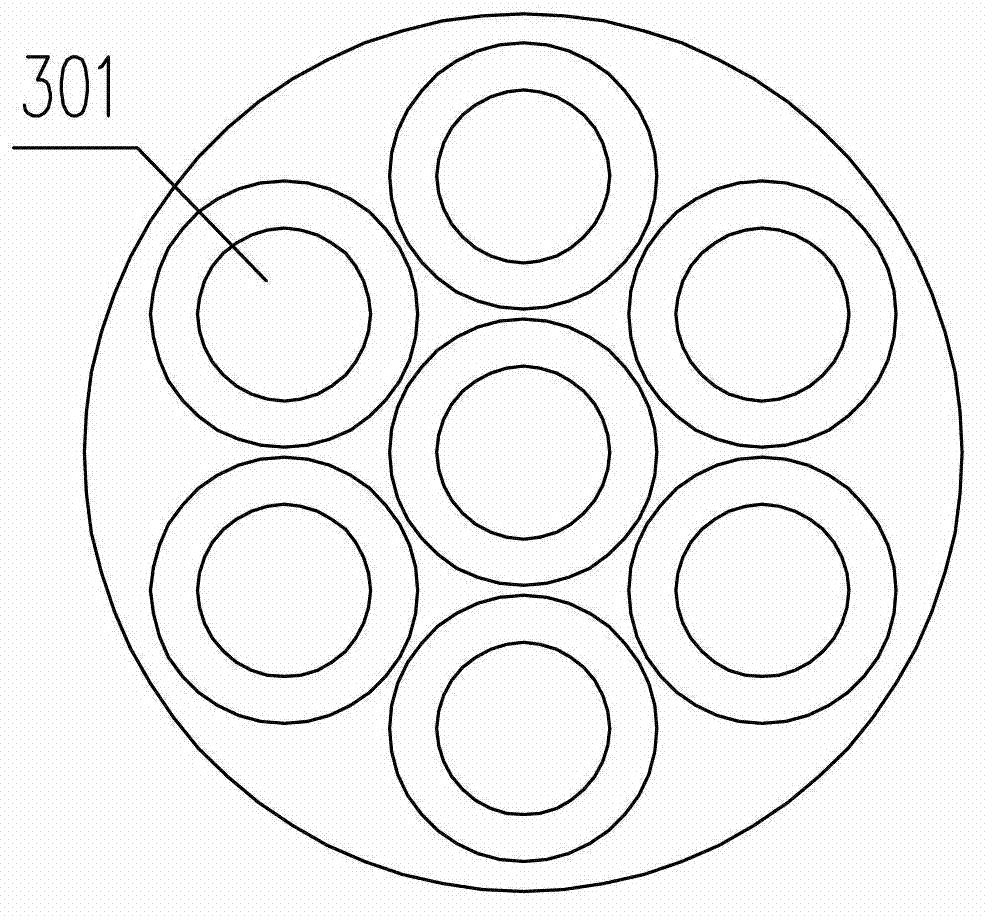

Composite strand tapered anchoring steel strand finished product cable and manufacture method thereof

InactiveCN103074851ASolve the problem of reliable clamping and anchoringGood anti-corrosion sealingBridge structural detailsShock resistanceEngineering

The invention discloses a composite strand tapered anchoring steel strand finished product cable, which comprises a cable body and two anchoring ends positioned on two ends of the cable body, wherein each anchoring end comprises an anchoring and clamping section and a sealing antiseptic section; each anchoring and clamping section comprises an end cover, a clamping piece, a wire splitting anchor plate, an anchor cup, an extension cylinder and a restriction ring; each wire splitting anchor plate is a cone with an external taper; the inner cavity of each anchor cup and the inner hole of each extension cylinder are both inner taper holes; each single steel strand of the steel strand finished product cable body is clamped on the wire splitting anchor plate by the camping piece; each wire splitting anchor plate is positioned in the inner taper hole of each anchor cup to be tightly cooperated with the inner taper hole of each anchor cup so as to form a positioning wedge-shaped anchoring structure; each extension cylinder is filled with epoxy iron sand to form a taper-shaped body which performs an auxiliary anchoring function on the steel strand finished product cable; and each sealing antiseptic section comprises a sealing cylinder, an O-shaped sealing ring and a gland. The finished cable has the advantages of high stress fatigue resistance, good shock resistance, reliable anchoring performance, compact anchorage structure and convenience in manufacture installation and anchorage change construction and is suitable for the bridge inhaul cable under the high-fatigue stress state.

Owner:LIUZHOU OVM MASCH CO LTD

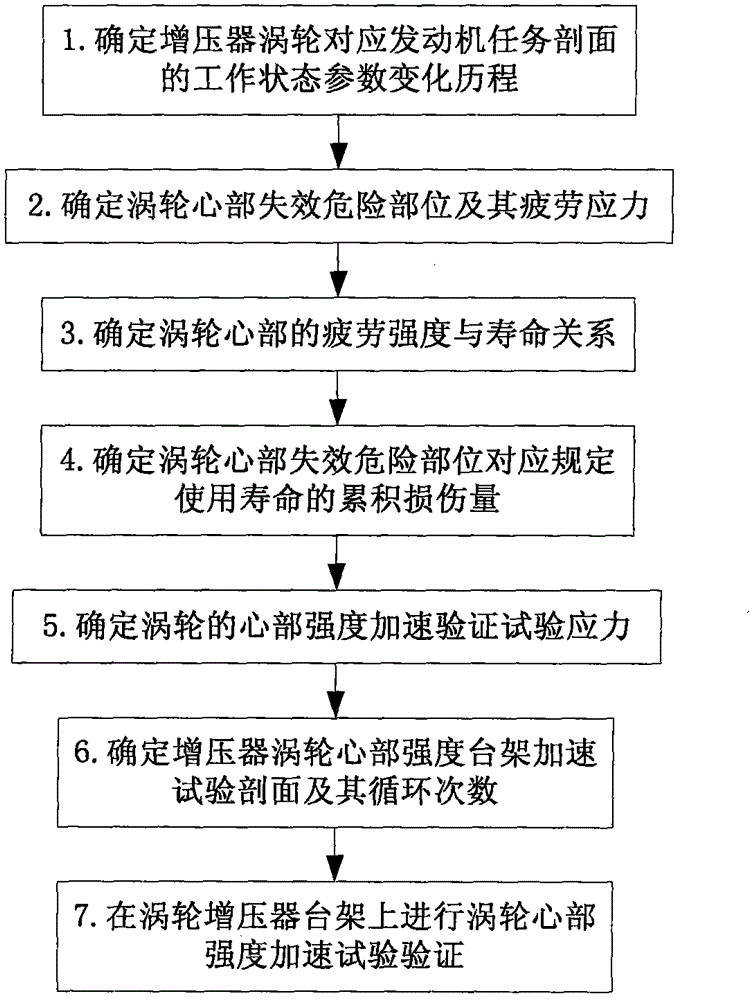

Acceleration test verification method for strength of center of supercharger turbine

ActiveCN104458236AImprove test verification efficiencyShorten test timeMachine part testingTest efficiencyState parameter

The invention relates to an acceleration test verification method for the strength of the center of a supercharger turbine. The acceleration test verification method includes the steps of firstly determining a working state parameter variation course of an engine mission section corresponding to the supercharger turbine, then determining the efficacy losing risk portion of the center of the turbine and the fatigue stress of the center of the turbine, determining the relationship between the fatigue strength of the center of the turbine and the service life by designing a turbine center strength simulation test sample piece and carrying out fatigue performance testing, determining the highest rotation speed of a turbine center strength acceleration test and corresponding acceleration test stress, compiling a turbine center strength rack acceleration test section, then determining the number of cycle times of a turbine center strength acceleration verification test section, and finally carrying out acceleration test verification on the strength of the center of the turbine on a turbine super test rack. test verification of the strength of the center of the supercharger turbine can be achieved on the test rack in a short period of test time, the test efficiency can be remarkably improved, the test time can be shortened, the test cost can be saved, and the scientific basis can be provided for reliability assessment and reasonable use of the supercharger turbine.

Owner:CHINA NORTH ENGINE INST TIANJIN

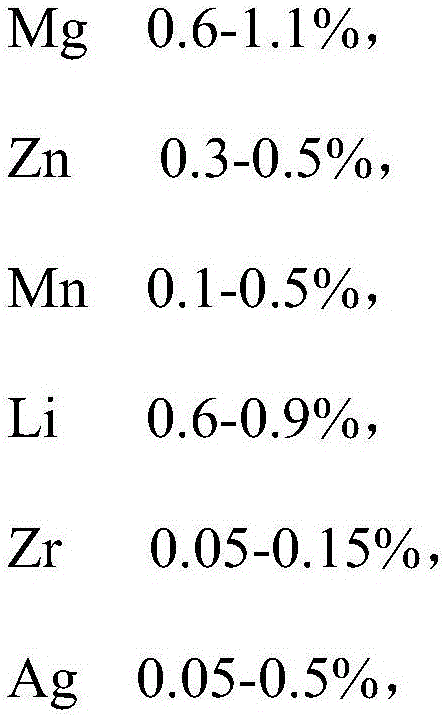

Method for predicting fatigue life of megawatt wind power generation composite material blade

PendingCN111125959AImproving the Simulation Accuracy of Fatigue Stress SpectrumImprove simulation accuracyGeometric CADDesign optimisation/simulationKinetic modelWind speed

The invention discloses a method for predicting the fatigue life of a megawatt wind power generation composite material blade. The method comprises the following steps: establishing a composite material temperature field calculation model; developing a blade-wind speed finite element coupling kinetic model; developing a wind speed-crack-notch interaction model; adding the stress time-history curves in the model to obtain a stress time-history curve of each part of the blade under the combined load; calculating the stress time-history curve by using a rain flow counting method to obtain a two-dimensional fatigue stress spectrum of each part of the blade under the combined load; and establishing an equal-amplitude fatigue median Sn-Sm-N curved surface, and estimating the fatigue life of theblade based on the two-dimensional fatigue stress spectrum according to a Miner linear fatigue cumulative damage criterion to obtain the fatigue life of the blade. The method has the characteristics of improving the fatigue life prediction precision of the wind power generation composite material blade, improving the engineering application value and the like.

Owner:通标标准技术服务(天津)有限公司

Prestressed sleeve self-lock anchor rod

InactiveCN104047287AEnsure three-way compressionImprove permeabilityFoundation repairBulkheads/pilesPull forceSeepage force

A prestressed sleeve self-lock anchor rod is characterized in that a fixing steel sleeve and a six-petal expansion self-lock head are welded, a threaded connection ring and the fixing steel sleeve are welded, a tool steel sleeve and the threaded connection ring are connected by threads, a prestressed pull rod penetrates, a thick cushion plate is additionally arranged on the upper end, an upper nut is screwed, and a truncated frustum extrusion head is additionally arranged at the lower end, then the whole set of anchor is formed; a thermal plastic sleeve sleeves an anchor rod and is sheathed on the whole anchor rod; the thermal plastic sleeve protects the prestressed pull rod from being rusted, enables the anchor rod to slide in concrete and is stable in anti-pulling performance; the fatigue stress amplitude of the anchor rod under the fatigue vibration pull force is about one fourth of a common anchor rod and is good in anti-fatigue performance. Rock holes are fully grouted to ensure that rock at the self-lock head is pressed from three directions, the strength is improved, the seepage force of grout is enhanced and the grout is greatly saved by designing seal rings, the applicable range of the anchor rod is enlarged by arranging the tool steel sleeve, and the economy aim for anchoring a deeper rock stratum can also be achieved.

Owner:JIANGSU JINHAI NEW ENERGY TECH +1

Tower drum doorframe gradually varied in thickness

InactiveCN104879280AReduce dosageReduce the amount of weldingWind motor componentsStress concentrationButt welding

The invention relates to a tower drum doorframe gradually varied in thickness. The tower drum doorframe gradually varied in thickness is shaped through integrated forging or casting, of a ring structure, and formed by sequentially connecting the doorframe upper end, the doorframe lower end and the arc doorframe middle together, and a smooth transition is adopted among the doorframe upper end, the doorframe lower end and the doorframe middle. The outer side wall of the tower drum doorframe gradually varied in thickness is connected with the side wall of a tower drum door opening. The outer wall of the tower drum doorframe gradually varied in thickness is of the same radian as the outer wall of a tower drum, and another smooth transition is adopted between the inner wall of the tower drum doorframe gradually varied in thickness and the inner wall of the tower drum. The thickness of the inner side wall of the tower drum doorframe is larger than the thickness of the outer side wall of the tower drum doorframe, and the tower drum doorframe gradually varied in thickness and the walls of the tower drum are connected through full penetration butt welding seams. Compared with annular reinforced doorframes usually used at present, the full penetration butt welding seams are used to connect the tower drum doorframe gradually varied in thickness with the walls of tower drum, stress concentration on the connecting welding seams is reduced, fatigue stress amplitude of the welding seams is reduced, fatigue resistance of the welding seams after being ground flush is high, and simultaneously the tower drum doorframe gradually varied in thickness can prevent the walls of the tower drum at the bottom of the tower drum doorframe gradually varied in thickness from being thickened, reduces welding quantity and welding deformation of the welding seams between the walls of the bottom tower drum, among the walls of the tower drum and the tower drum doorframe gradually varied in thickness, and among the walls of the tower drum and a flange at the bottom of the tower drum, improves economical efficiency of the tower drum, and reduces transportation difficulty. The tower drum doorframe gradually varied in thickness nearly has no effect on low order self-vibration characteristics of a wind turbine generator tower.

Owner:TONGJI UNIV

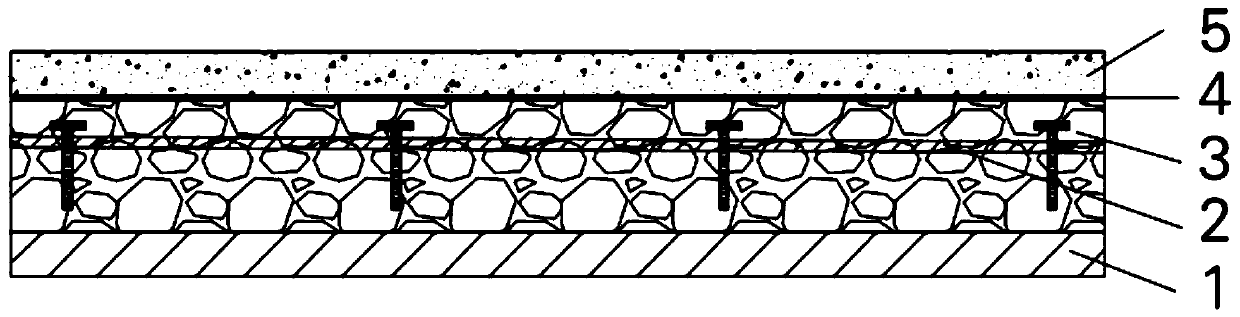

Steel bridge light pavement layer structure and paving method

InactiveCN110080087AReduce fatigue stressImprove local stiffnessBridge structural detailsBridge erection/assemblyBridge deckThin layer

The invention provides a steel bridge light pavement layer structure and a paving method and relates to the technical field of steel bridge paving. The fatigue stress of a bridge deck steel structurecan be effectively reduced, the local rigidity of a bridge deck system can be greatly enhanced, and the fatigue life of a steel bridge deck can be prolonged. The steel bridge light pavement layer structure comprises the steel bridge deck, a cement concrete layer, an adhesive layer and a multifunctional thin layer in sequence from bottom to top; the two adjacent layers are connected with each other; a reinforcement mesh is arranged in the cement concrete layer; the reinforcement mesh is fixedly connected with the steel bridge deck through a plurality of short bolt nails; the multifunctional thin layer is an open-graded or cut-off graded asphalt concrete thin layer; and the thickness of the multifunctional thin layer is 10-25 mm. The steel bridge light pavement layer structure provided by the technical scheme of the invention is suitable for steel bridge paving processes of new construction and bridge deck large and medium-sized repairing.

Owner:BEIJING ZHIHUATONG TECH CO LTD

Wind wheel cable-stayed structure of wind driven generator with vertical shaft

ActiveCN102086841AReduce aerodynamic dragSolving Weight Support IssuesFinal product manufactureRenewable energy generationWind drivenCable stayed

The invention discloses a wind wheel cable-stayed structure of a wind driven generator with a vertical shaft. The wind wheel cable-stayed structure comprises a stay cable and a cable-stayed bearing; the cable-stayed bearing is sleeved and fixed on a part positioned above an external rotor of the generator on a tower column; and one end of the stay cable is connected with the cable-stayed bearing,and the other end of the stay cable is connected with a blade or a supporting rod which is connected with the blade. By utilizing the wind wheel cable-stayed structure, the restriction of the power transmission path that the weights of the wind wheels are transmitted to the tower column through the generator for the traditional wind wheel support structure is broken through, and the weights of the wind wheels are directly transmitted on the tower column. The reasonable and effective support of the large wind wheels is convenient to realize, the design and manufacturing cost of the large wind wheel support structure can be lowered, the frictional resistance can be reduced, the power generation efficiency can be improved, the fatigue stress can be reduced, the service life of the wind driven generator can be prolonged, and the quiet running property of the wind wheels can be increased, and the vibration of the wind wheels can be reduced.

Owner:NAT WIND ENERGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com