Welded member fatigue stress and strain real-time non-contact type monitoring method

A welding component, non-contact technology, applied in the field of experimental mechanics, can solve problems such as fatigue, inconvenient contact sensors, stress and strain monitoring distribution rules, etc., and achieve the effect of high precision, powerful post-processing program, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

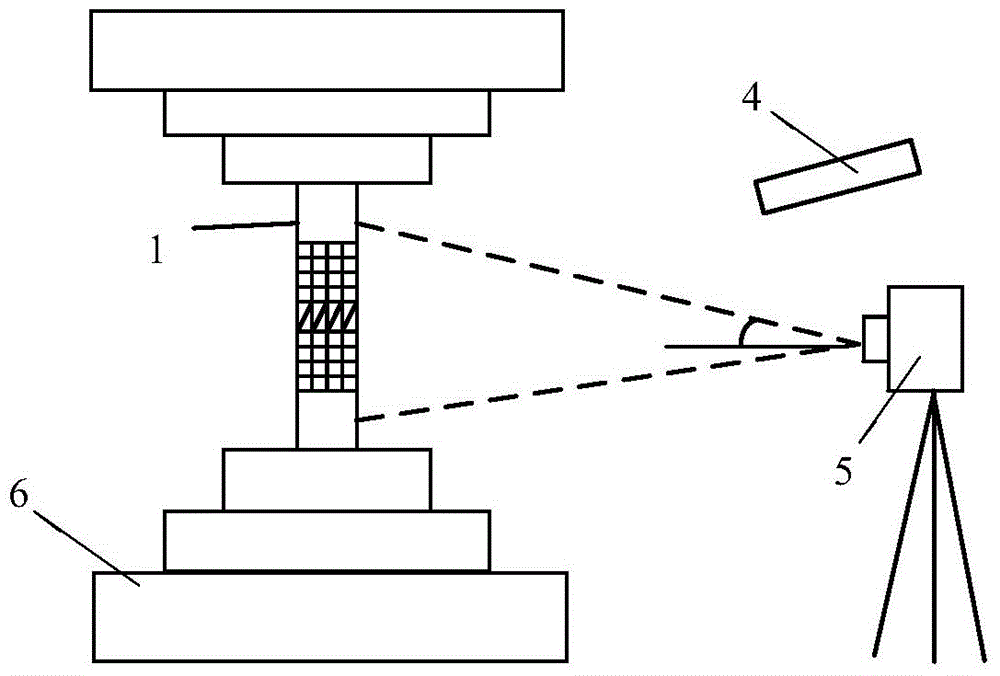

[0032]This embodiment is an experiment of monitoring the stress and strain in the weld area when the fatigue testing machine performs fatigue loading on the welded components.

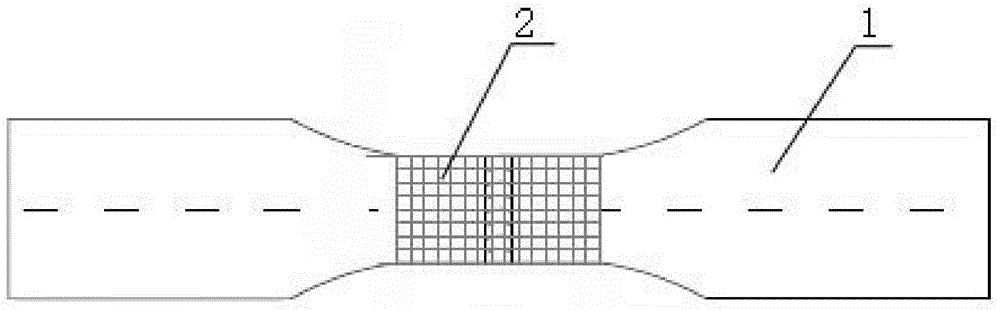

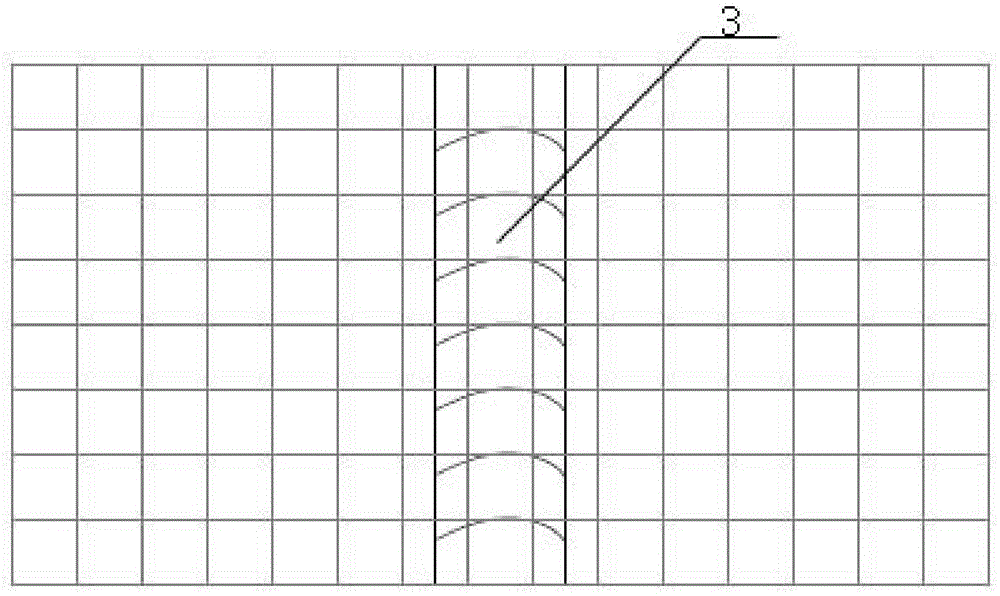

[0033] Such as figure 1 and figure 2 As shown, the steel used in this test is Q345B steel commonly used in construction, and its yield strength is 345Mpa. The standard test welded member 1 is made according to the requirements of relevant specifications. The welded component 1 includes the monitoring area 2. Since the stress at the weld plays a major role in controlling the welded component 1, the weld and its edge range are taken as the monitoring area 2. The monitoring area 2 includes the weld 3 and the edge of the weld, with a length of 75mm The width is 40mm, and a grid is drawn on the monitoring area 2. In order to facilitate the visual system of the monitoring device t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com