Method for preparing hollow polyaniline microspheres

A polyaniline, hollow technology, applied in the field of materials, can solve the problems of complicated operation and high cost, and achieve the effect of simple preparation method, low cost and avoiding transformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The embodiment of the present invention discloses a preparation method of polyaniline hollow microspheres, comprising:

[0030] Step a) mixing aniline with a molar ratio of 1:1.5 to 15 in a solvent and reacting it with an oxidizing agent, wherein the oxidizing agent is potassium ferricyanide, sodium ferricyanide, iron phosphate or copper sulfate;

[0031] Step b) drying the reaction product obtained in step a) to obtain polyaniline hollow microspheres.

[0032] According to the present invention, the molar ratio of the aniline to the oxidizing agent is preferably 1:2-10, more preferably 1:3-5. The reaction temperature in step a) is preferably -10-10°C, more preferably -5-10°C, most preferably -5-5°C. The reaction time is preferably 15 to 80 hours, more preferably 20 to 60 hours, most preferably 30 to 50 hours.

[0033] In the step a), the aniline with a molar ratio of 1:1.5 to 15 is mixed with an oxidant in a solvent, specifically:

[0034] Add aniline to water, stir...

Embodiment 1

[0046] Step 1. Add the aniline monomer into deionized water, and stir it electromagnetically for 3 hours to obtain a 0.2mol / L aniline aqueous dispersion;

[0047]Step 2, adding potassium ferricyanide into deionized water, stirring electromagnetically for 0.5 h to obtain a 0.6 mol / L potassium ferricyanide aqueous solution;

[0048] Step 3. At -5°C, the molar ratio of aniline to potassium ferricyanide is 1:3, mix the aniline aqueous dispersion with the potassium ferricyanide aqueous solution evenly, keep the temperature at -5°C, and place it still 28h, reaction;

[0049] Step 4, filtering the reaction product obtained in step 3, washing with water, methanol and deionized water successively until the filtrate is colorless;

[0050] Step 5, vacuum-drying the product obtained in Step 4 for 26 hours to obtain polyaniline hollow microspheres.

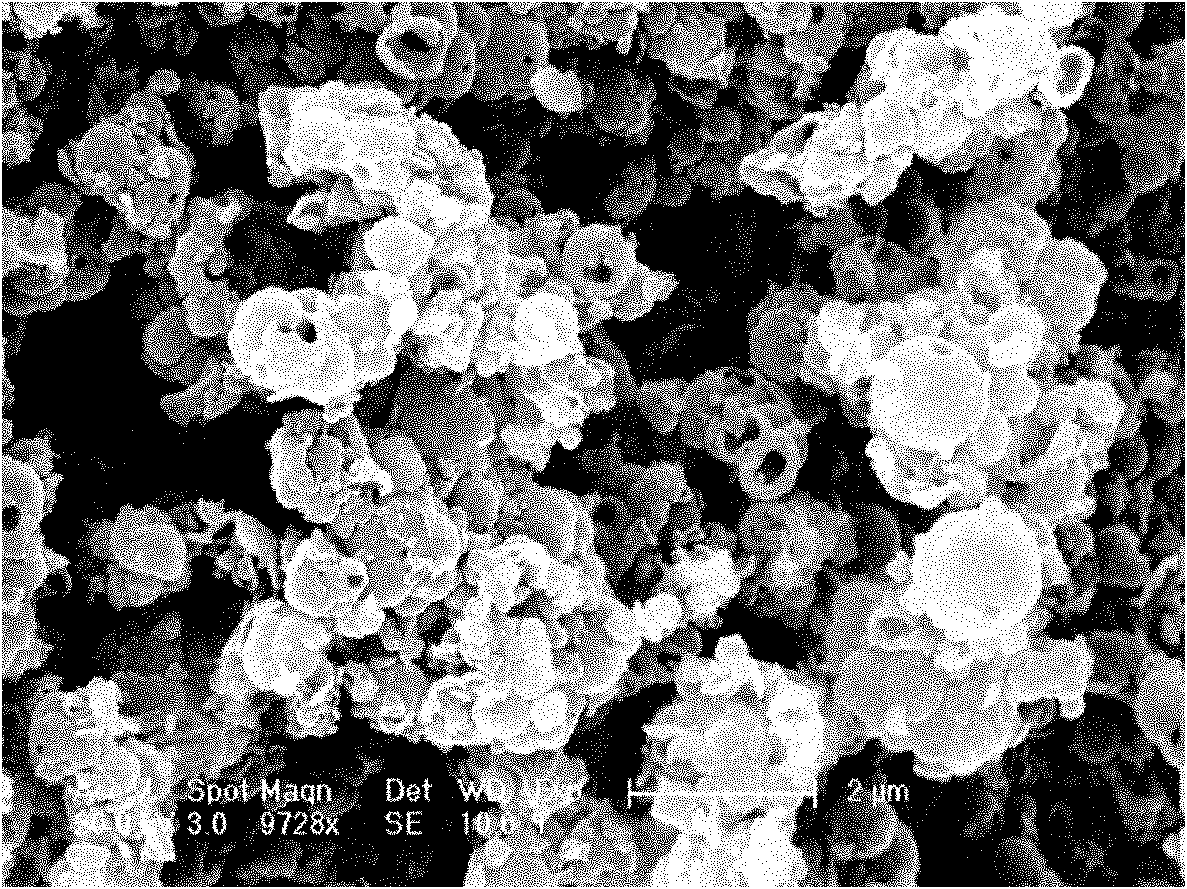

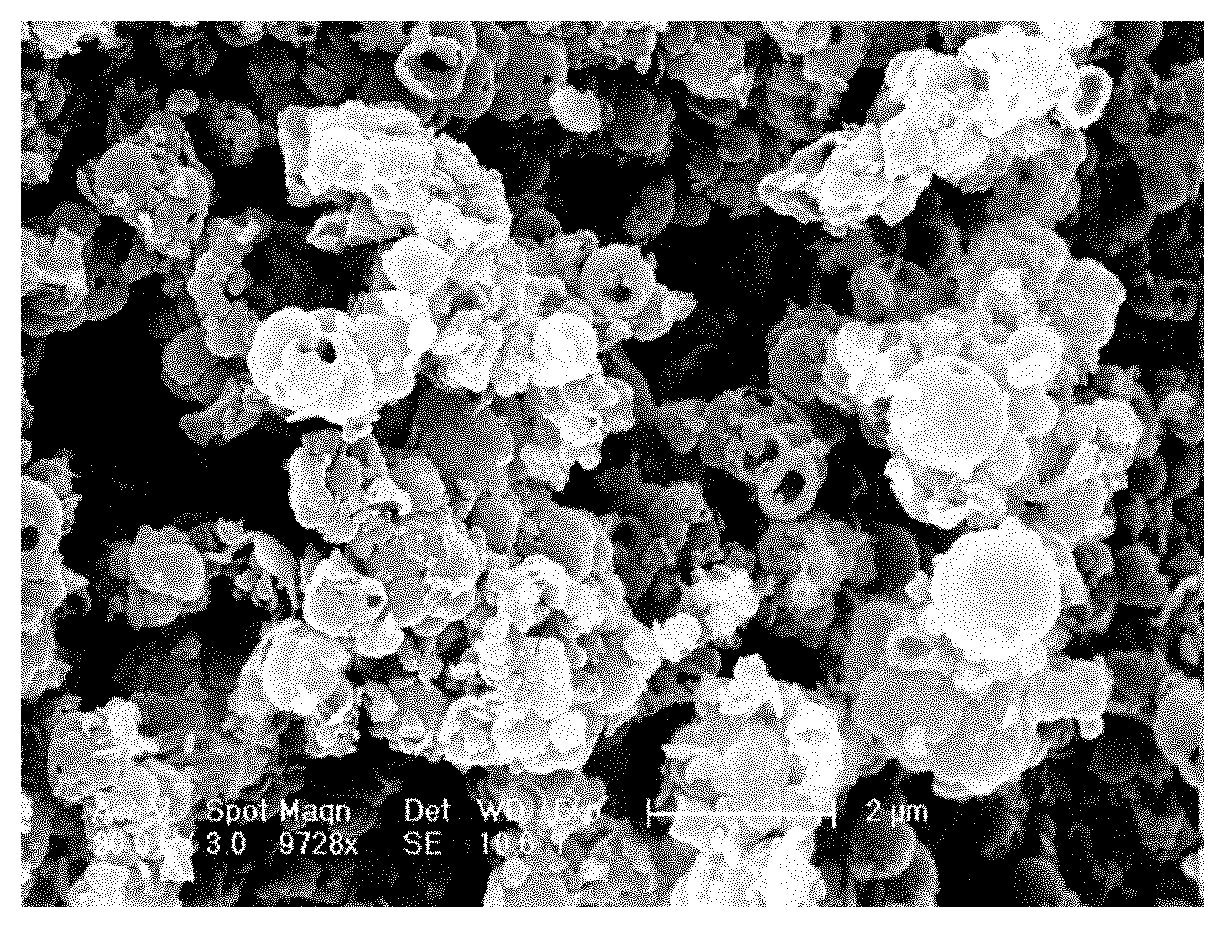

[0051] The polyaniline hollow microspheres prepared in this embodiment have a diameter of 180-480 nm and a wall thickness of 70-75 nm. fig...

Embodiment 2

[0053] Step 1, adding aniline monomer into deionized water, ultrasonic treatment for 0.5h, to obtain 0.6mol / L aniline aqueous dispersion;

[0054] Step 2, adding potassium ferricyanide into deionized water, stirring electromagnetically for 2 hours to obtain a 3.0 mol / L potassium ferricyanide aqueous solution;

[0055] Step 3. At 10°C, mix the aniline aqueous dispersion with the potassium ferricyanide aqueous solution evenly according to the molar ratio of aniline and potassium ferricyanide as 1:5, keep the temperature at 10°C, and place it statically for 18 hours. reaction;

[0056] Step 4, filtering the reaction product obtained in step 3, washing with water, methanol and deionized water successively until the filtrate is colorless;

[0057] Step 5, vacuum drying the product obtained in step 4 for 36 hours to obtain polyaniline hollow microspheres.

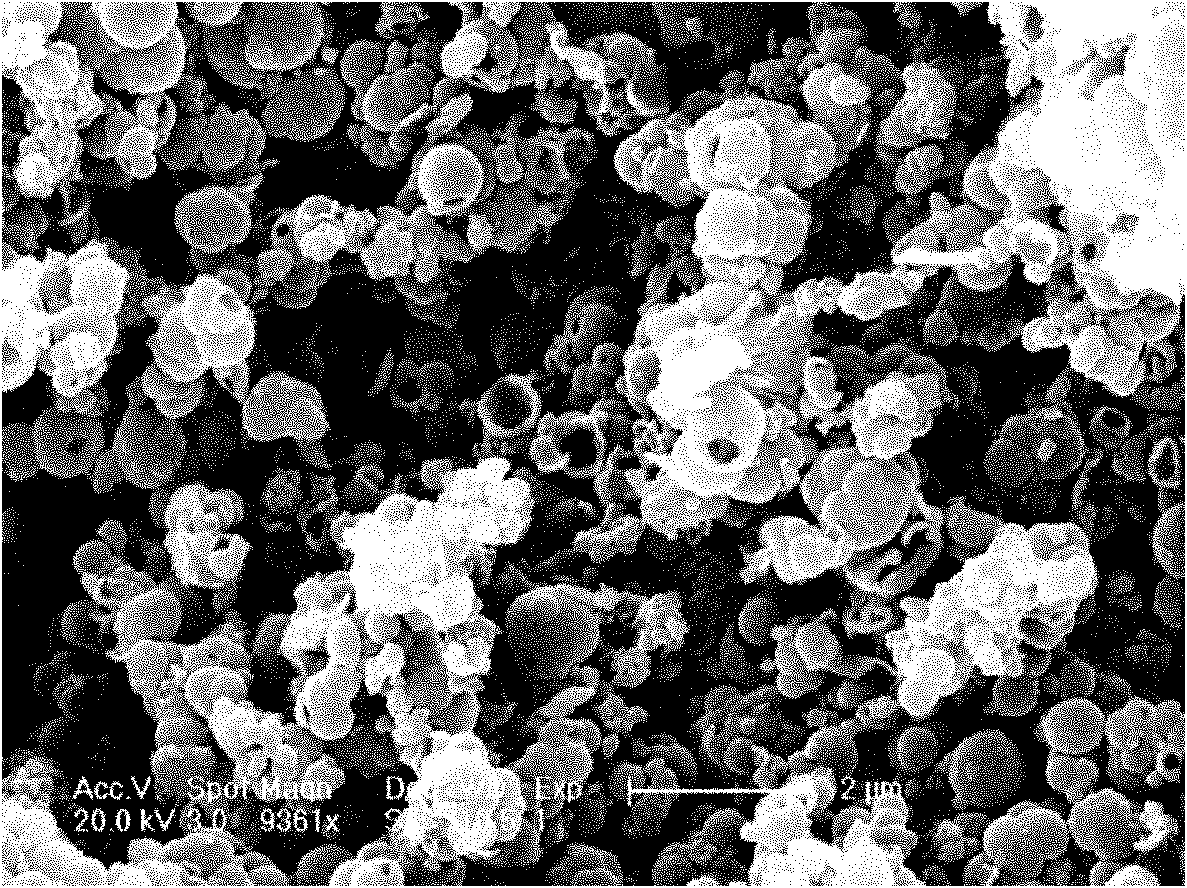

[0058] The polyaniline hollow microspheres prepared in this example have a diameter of 200-520 nm and a wall thickness of 75-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com