Patents

Literature

211results about How to "Change process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

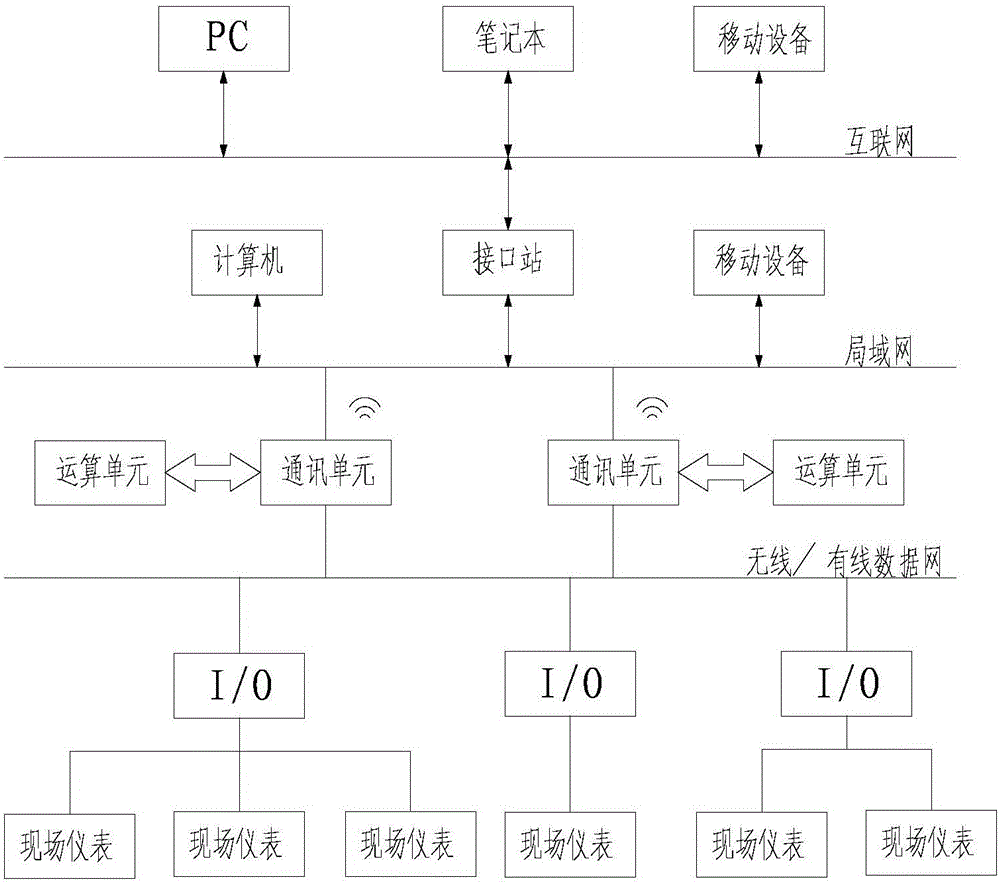

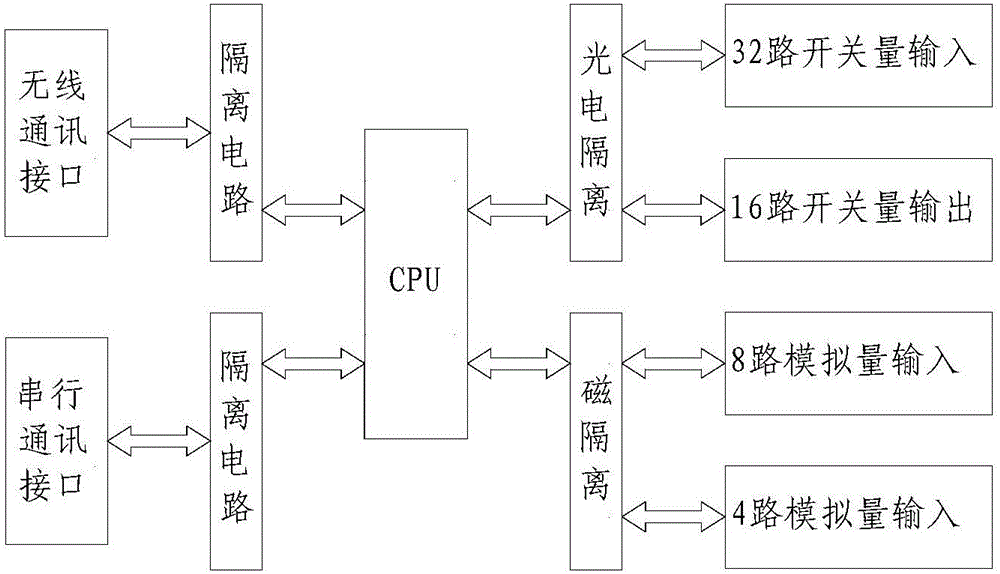

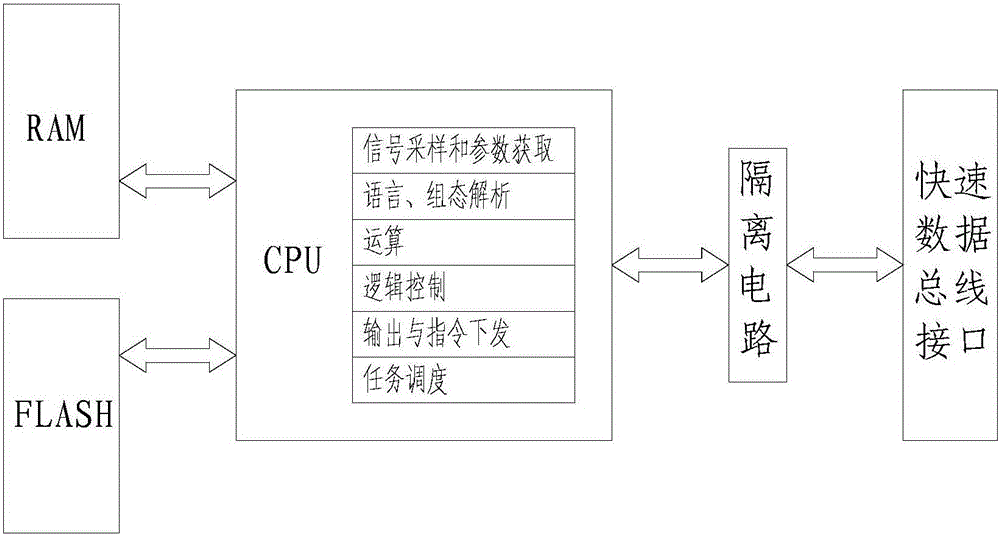

Distributed intelligent instrument control system based on Internet of things and method thereof

ActiveCN105824303ARealize production intelligenceIncrease productivityTotal factory controlProgramme total factory controlIndustrial PCLocal area network

The invention relates to a distributed intelligent instrument control system based on the Internet of Things, including an I / O (input / output) unit, a computing unit, a communication unit and a user terminal device, one end of the I / O (input / output) unit and a field instrument The other end of the I / O (input / output) unit realizes data interaction with the communication unit through the wireless network. The data bus is used between the communication unit and the calculation unit for data communication. Each calculation unit is equipped with a corresponding communication unit. Unit, to complete the transmission and forwarding tasks of signals, parameters, and instructions, the communication unit communicates with the user end equipment through the local area network, the user end equipment includes industrial computers and mobile devices, and the mobile devices include smart phones and Pads; the present invention is the same as the existing Compared with technology, it not only helps to realize intelligent production, improve production efficiency, and improve user experience, but also reduces costs, and helps to realize decentralized control and intelligent transformation of instruments.

Owner:上海颖电控制技术有限公司

Start-up method for ex-situ prevulcanization secondary activity center hydrogenation catalyst

ActiveCN103773436AChange processLess investmentHydrotreatment operations starting-upHydrocarbon oil crackingNaphthaEngineering

The invention discloses a start-up method for an ex-situ prevulcanization secondary activity center hydrogenation catalyst. After resistance to air loss of a device is qualified, circulating hydrogen compressor working load is adjusted to 0-20% of a maximum load, the catalyst reacts at a low temperature to release heat; when the bed layer temperature rise to 60-150 DEG C, start-up activation oil is introduced, the circulating hydrogen compressor working load is adjusted to 60-100% of the maximum load for wetting of the catalyst; the start-up activation oil is cycled in a reaction system closed path, the catalyst bed temperature is risen to 180 to 230 DEG C by heat exchange; a proper amount of olefin-enriched naphtha is added into the start-up activation oil, the catalyst bed temperature is risen to 300-380 DEG C to complete start-up activation. The start-up method, in the premise of no influence on the use properties of the secondary activity center hydrogenation catalyst, can better use the catalyst characteristics, reduce the device energy consumption, and reduce the device investment cost, and the start-up process can be simplified.

Owner:CHINA PETROLEUM & CHEM CORP +1

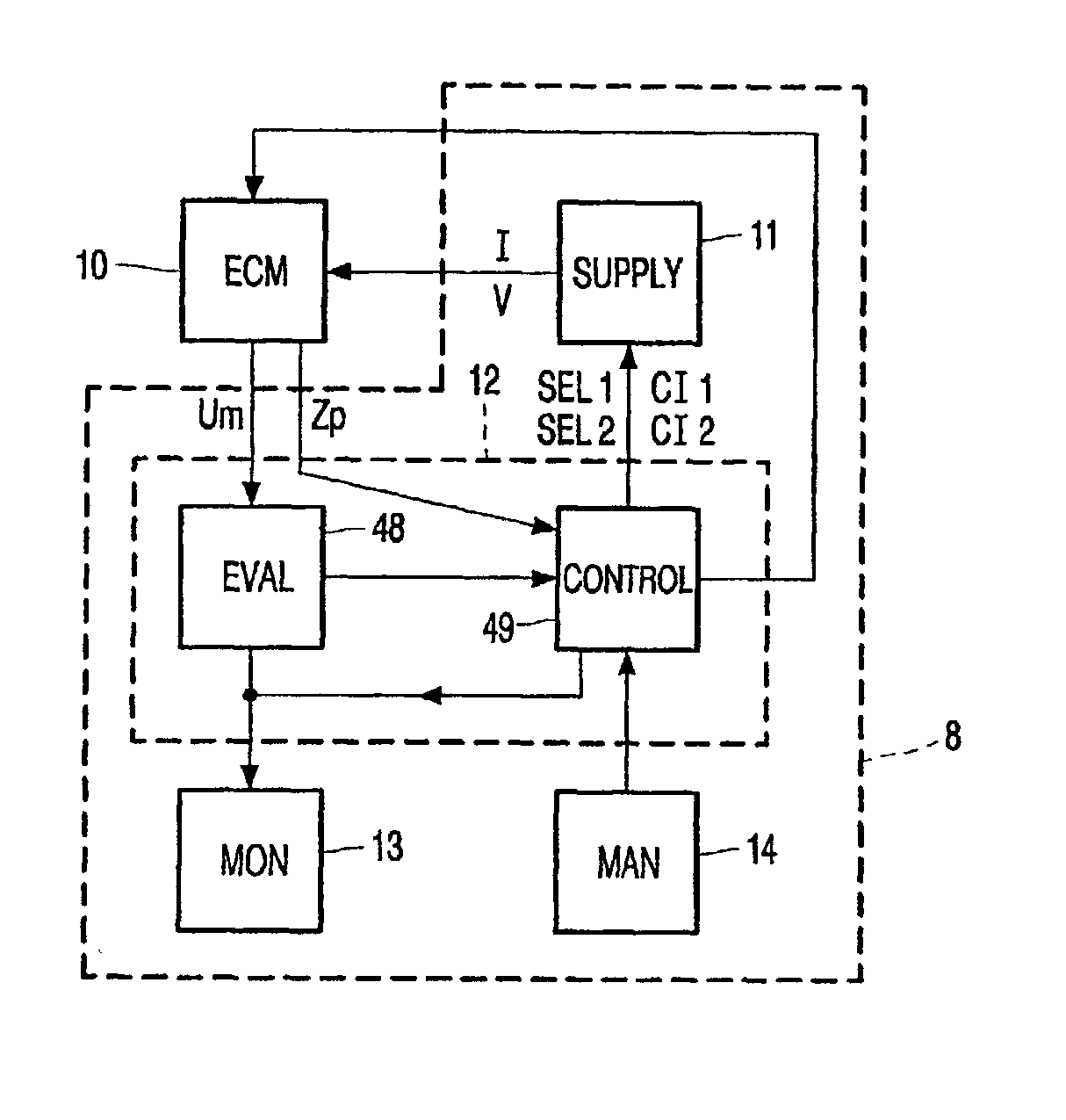

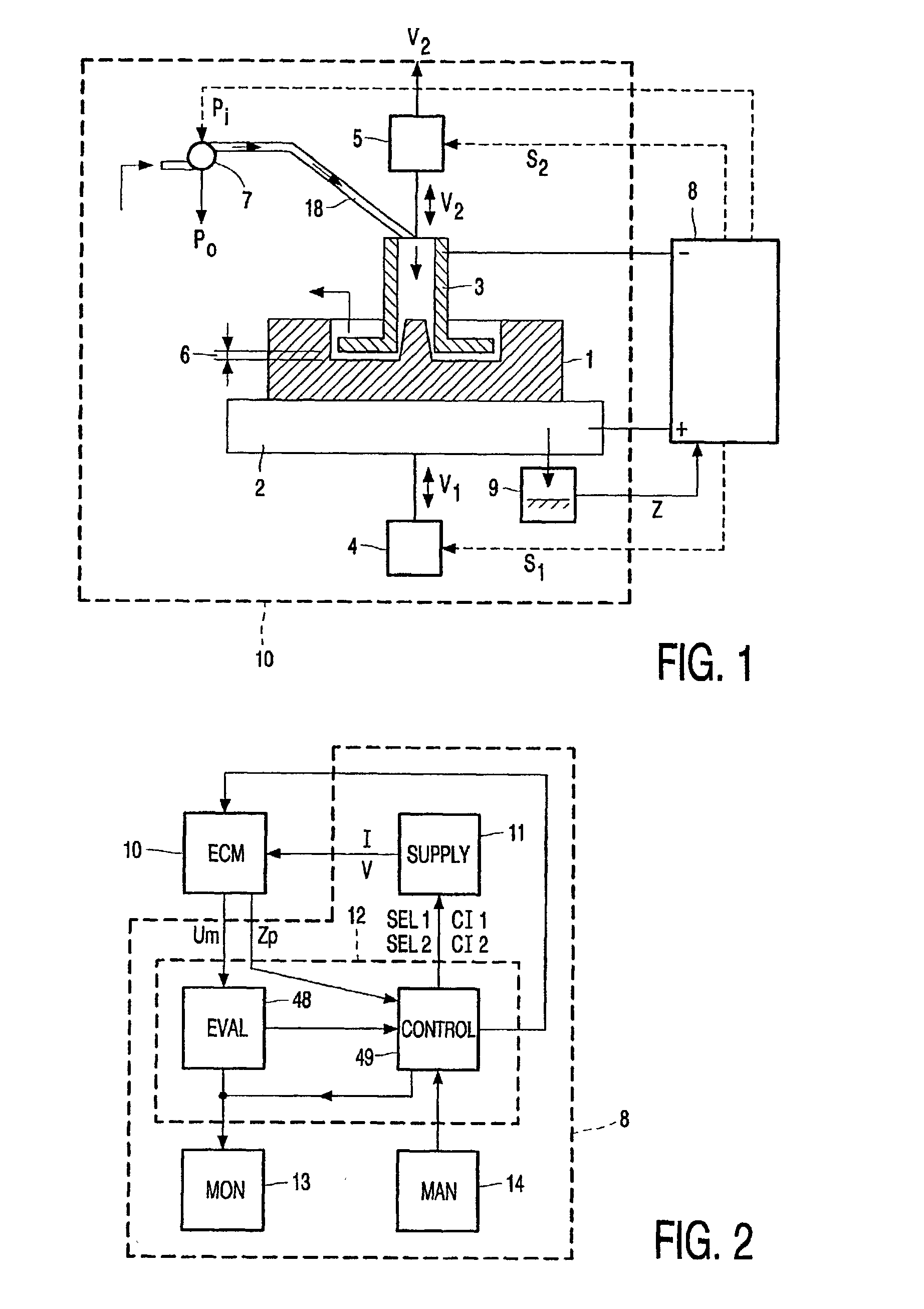

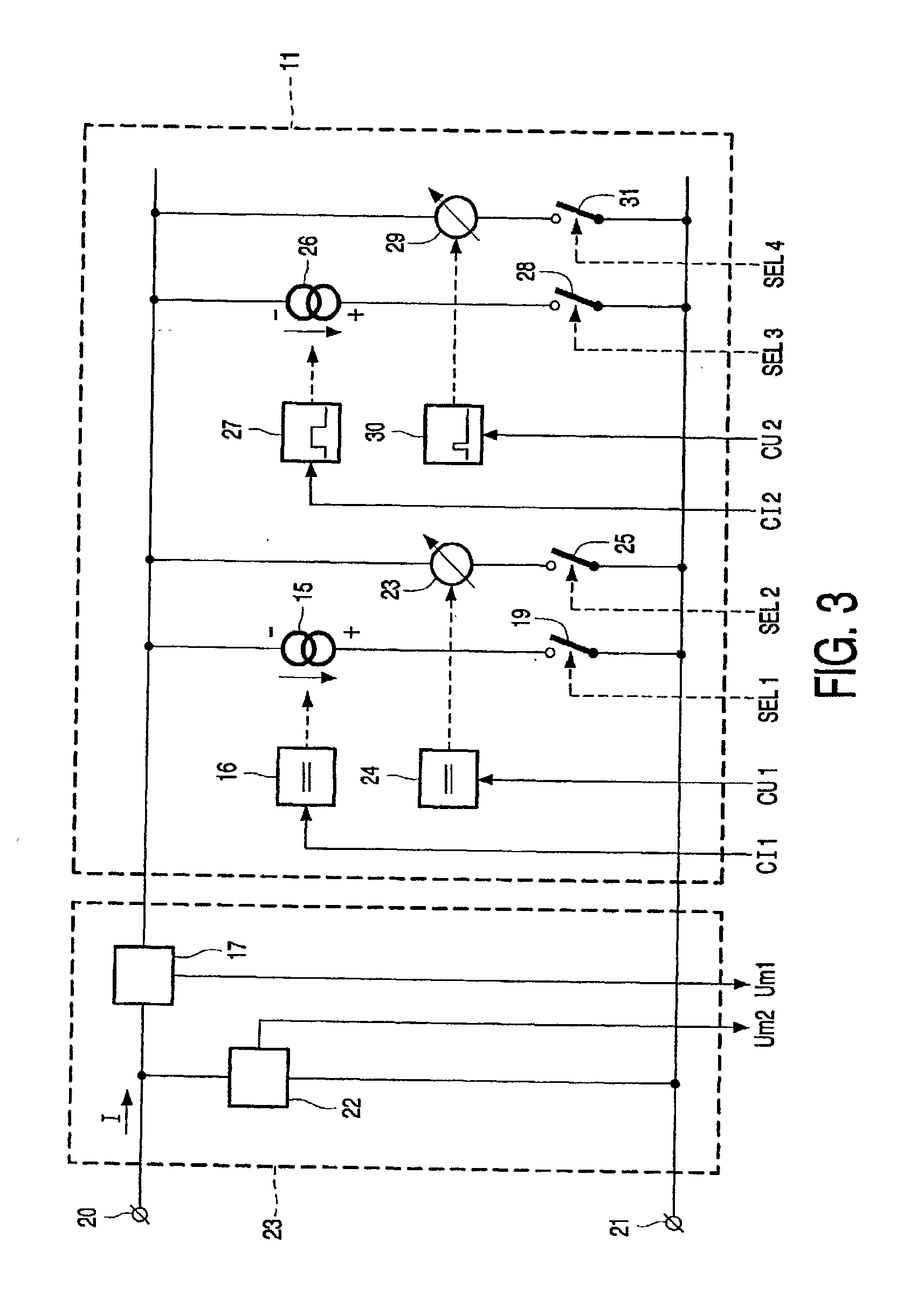

Method of controlling an electrochemical machining process

InactiveUS20020169516A1Improve machining accuracyAvoid large gapsMachining electric circuitsElectric circuitsElectrochemistryElectrochemical machining

A method of controlling a process of electrochemically machining an electrically conductive workpiece employing the spectral composition of the measured voltage within a predetermined measuring period such as induced by an applied current between the electrically conductive workpiece and an electrode tool. A process of electrochemically machining employing a material removing step with electric current supplied continuously and an a workpiece shaping step with electric current supplied intermittently. An advantageous embodiment employs extreme short pulses.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV +1

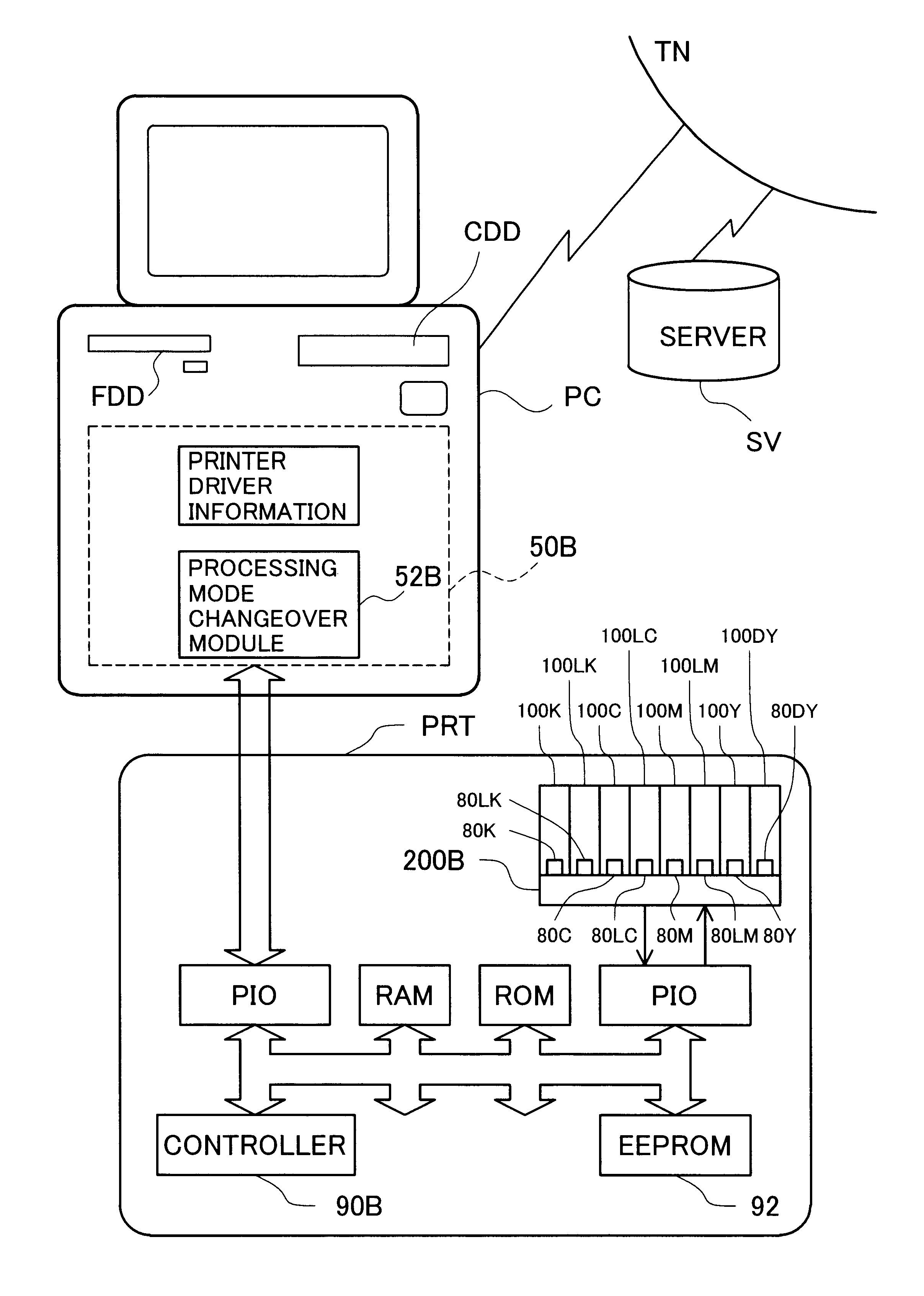

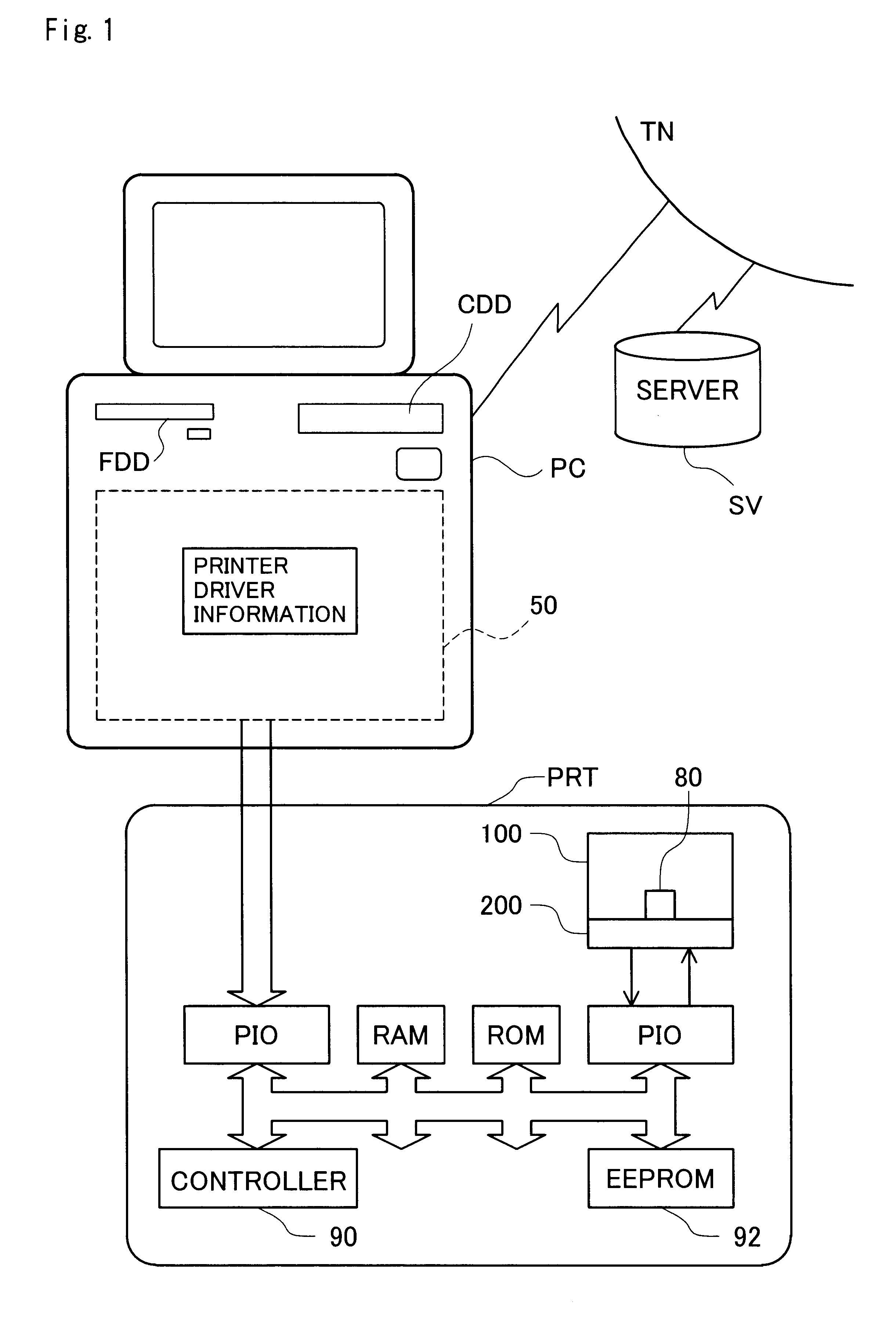

Judgement on compatibility between ink cartridges and printing apparatus

InactiveUS6655779B2Quality improvementImprove compatibilityOther printing apparatusEmbedded systemPrint processor

The object of the present invention is to provide a technique that flexibly determines compatibility of an ink cartridge with a printing apparatus with high accuracy.The ink cartridge has a storage element that stores therein compatible driver information, which is used to specify a printer driver compatible with the ink cartridge. The printing apparatus collates information of a selected printer driver with the compatible driver information and determines compatibility of the ink cartridge with the printer driver. The printer driver changes over the method of generating print data, based on the compatible driver information.

Owner:SEIKO EPSON CORP

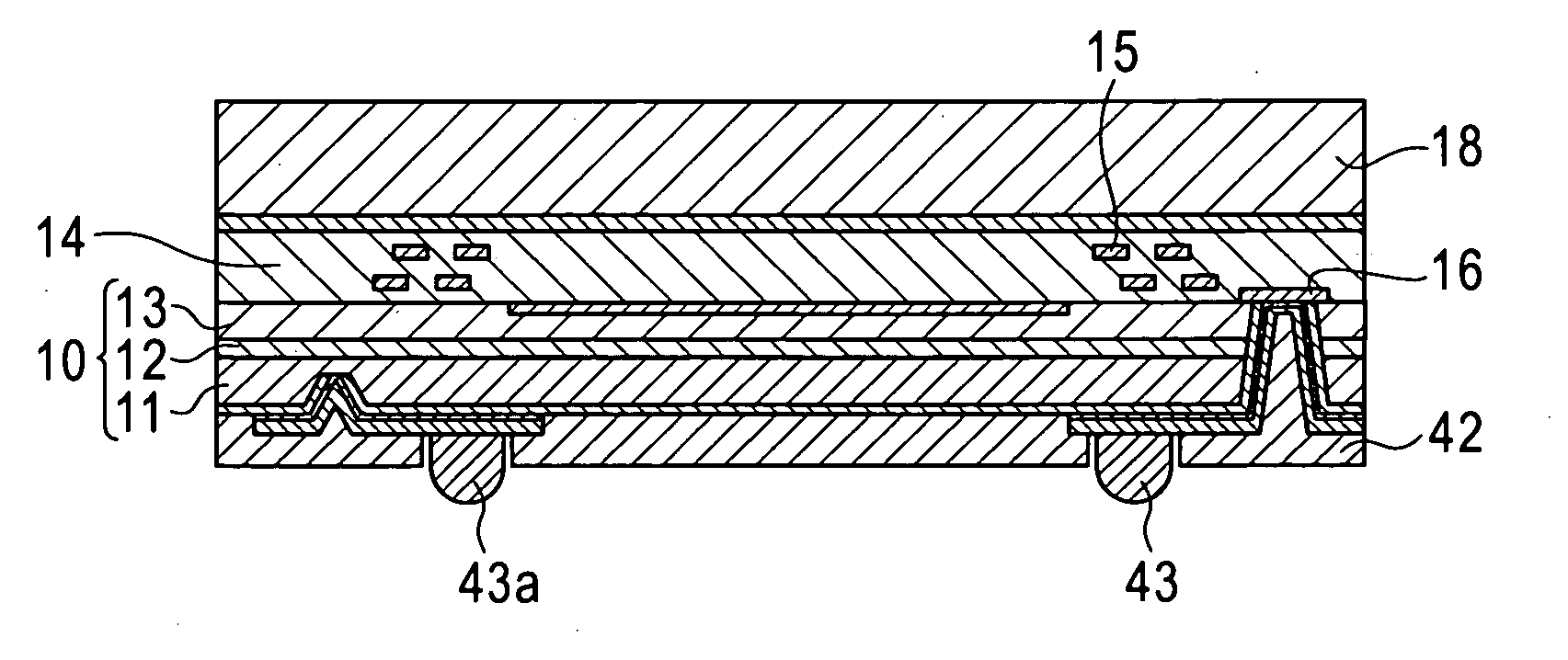

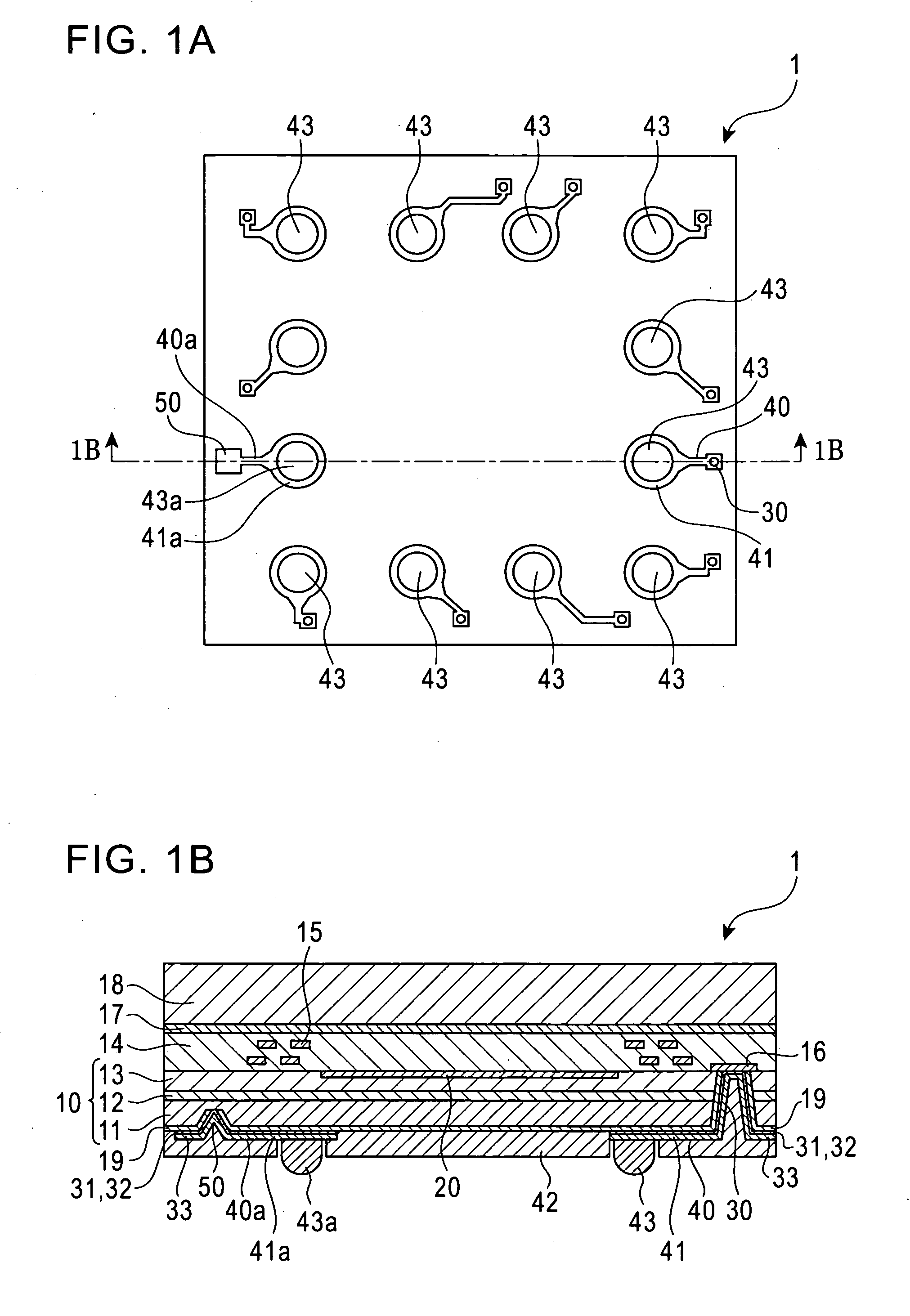

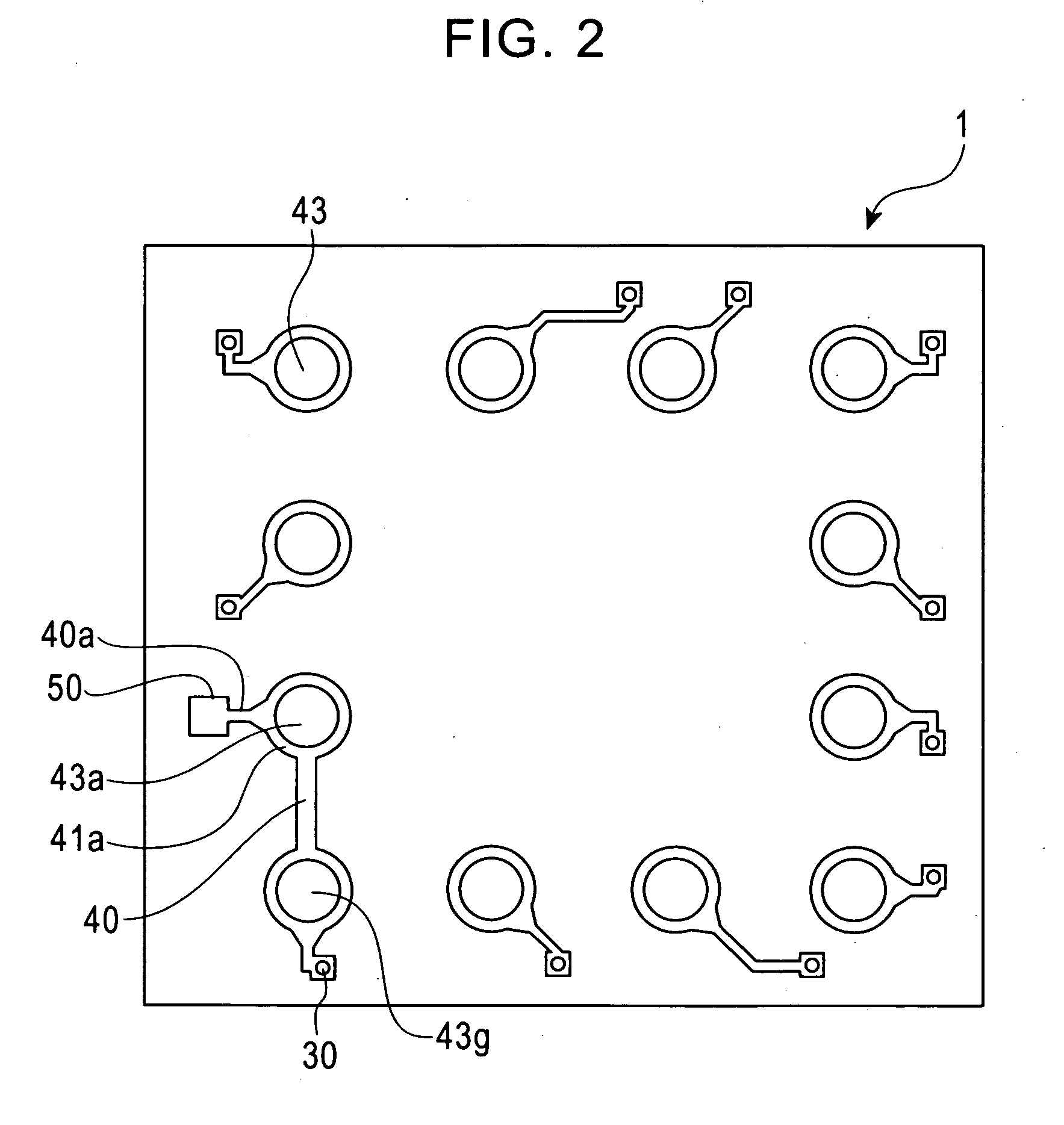

Semiconductor device and manufacturing method thereof

ActiveUS20100109114A1No improvement is obtainedNumber of manufacturing step of manufacturing is increasedSemiconductor/solid-state device detailsSolid-state devicesEngineeringSoi substrate

A semiconductor device manufacturing method includes etching a silicon on insulator (SOI) from its surface (i.e., semiconductor substrate layer) to form a first trench and a second trench. The first trench extends through the SOI substrate and reaches an electrode pad. The second trench terminates in the semiconductor substrate layer. The manufacturing method also includes forming an insulation film that covers the surface of the semiconductor substrate layer as well as the side walls and bottoms of the first and second trenches. The manufacturing method also includes removing the insulation film from the bottoms of the first and second trenches to expose the electrode pad from the first trench bottom and to expose the semiconductor substrate layer from the second trench bottom. The manufacturing method also includes forming a conductive film that covers the semiconductor substrate layer and the side walls and the bottoms of the first and second trenches to form a through via electrically connected to the electrode pad at the first trench bottom and to form a contact part electrically connected to the semiconductor substrate layer at the second trench bottom. The manufacturing method also includes patterning the conductive film on the semiconductor substrate layer to form the external electrodes and to form a potential fixing external electrode electrically connected to the contact part.

Owner:LAPIS SEMICON CO LTD

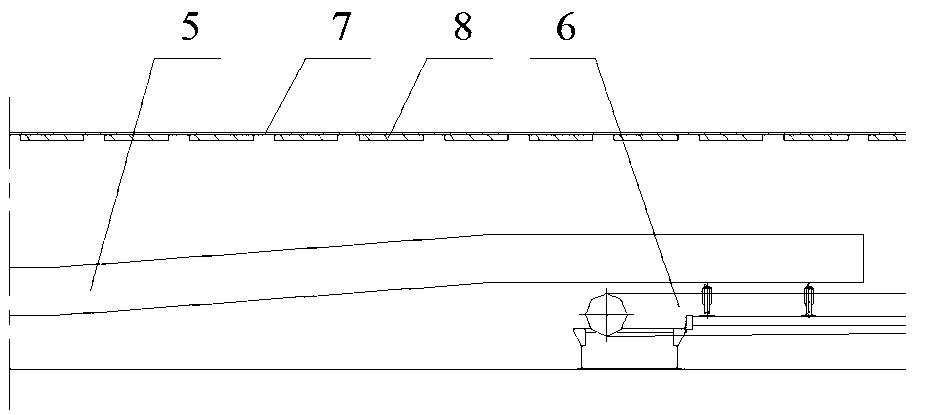

Supporting method for roadway fully-mechanized drivage operation without withdrawal of roadheader

InactiveCN103195457AImprove support qualityReasonable process designMine roof supportsAnchoring boltsProcess engineeringEngineering

The invention relates to a supporting method for a roadway fully-mechanized drivage operation without withdrawal of a roadheader, aiming to solve the problems of bad safe reliability and complex operating processes of conventional roadway fully-mechanized drivage operations with withdrawal of roadheaders. The supporting method includes providing temporary supporting for a new roof exposed in the roadway fully-mechanized drivage operation by an associated operation with the roadheader, and performing a supporting operation of laying metal nets and steel belts on a roadhead by a roadway drivage alternating supporting device; performing a permanent supporting operation of punching anchor rods on the roof and two sides of the roadway in a roadway zone behind the roadheader by a movable roof bolter supporting platform; and conveying coal cut by the roadheader through a bridge reversed loader and a belt conveyer. The process design is reasonable; supporting and moving is stable; a roadway empty operation is avoided; supporting is safe and reliable; the conventional operation method that the roadheader is needed to be withdrawn in each step and operation procedures are alternated frequently is changed, so that the roadheader can drivage continuously without being withdrawn. Synchronous mechanical operation of drivage and permanent supporting can be realized, and utilization rate and drivage efficiency of the roadheader can be increased remarkably.

Owner:LIAONING TIAN AN TECH CO LTD

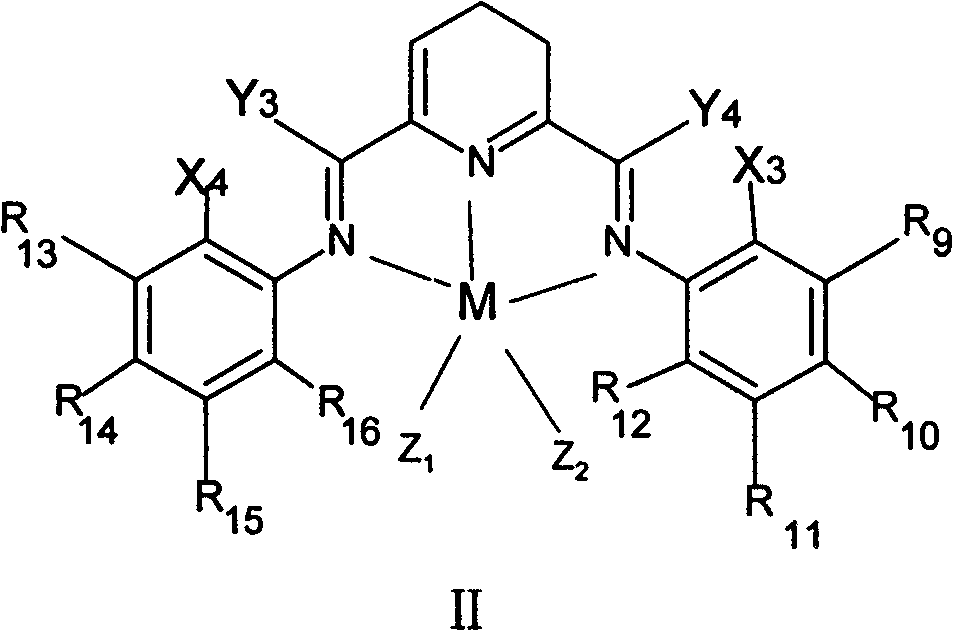

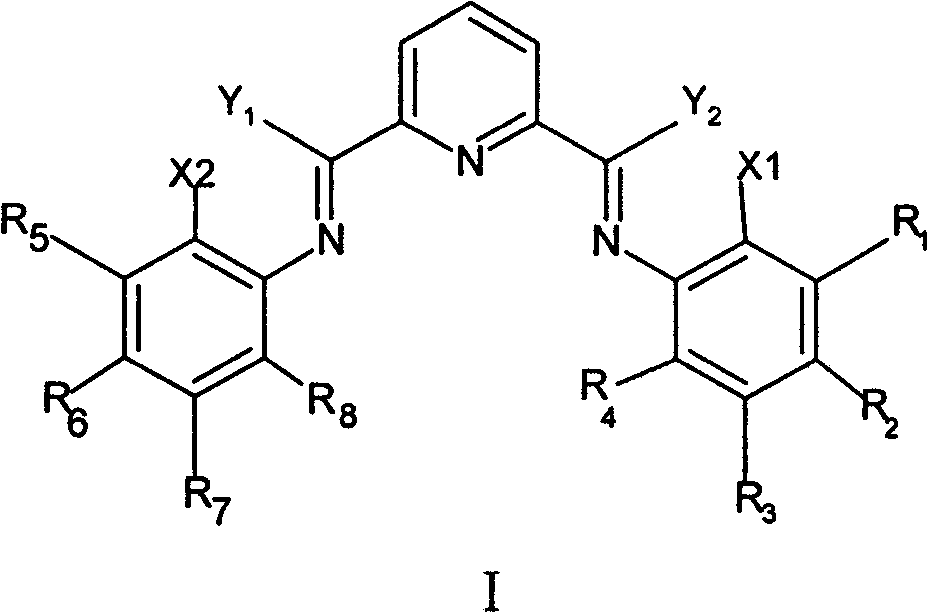

Method for preparing linear alpha-olefin

InactiveCN101906009AEasy to adjustChange typeHydrocarbonsHydrocarbon preparationDistillationMixed materials

The invention discloses a method for preparing linear alpha-olefin. The method comprises the following steps of: introducing catalytic solution and ethylene into a first reactor and reacting at the temperature of between 30 and 120 DEG C and under the pressure of 0.1 to 3 MPa for 1 to 40 min to prepare a first mixed material flow of first linear alpha-olefin, the ethylene and the catalytic solution; introducing the first mixed material flow and the ethylene into a second reactor and reacting at the temperature of between 40 and 90 DEG C and under the pressure of 0.5 to 4 MPa for 5 to 120 min to prepare a second mixed material flow of second linear alpha-olefin, the ethylene and the catalytic solution; performing gas-liquid separation on the second mixed material flow to obtain the ethylene and a liquid-phase product; cycling the separated ethylene to the first reactor or the second reactor for continuous reaction; and performing distillation separation on the liquid-phase product to prepare the linear alpha-olefin. The method has the advantages of mild reaction condition, simple operation and suitability for industrialized production.

Owner:ZHEJIANG UNIV

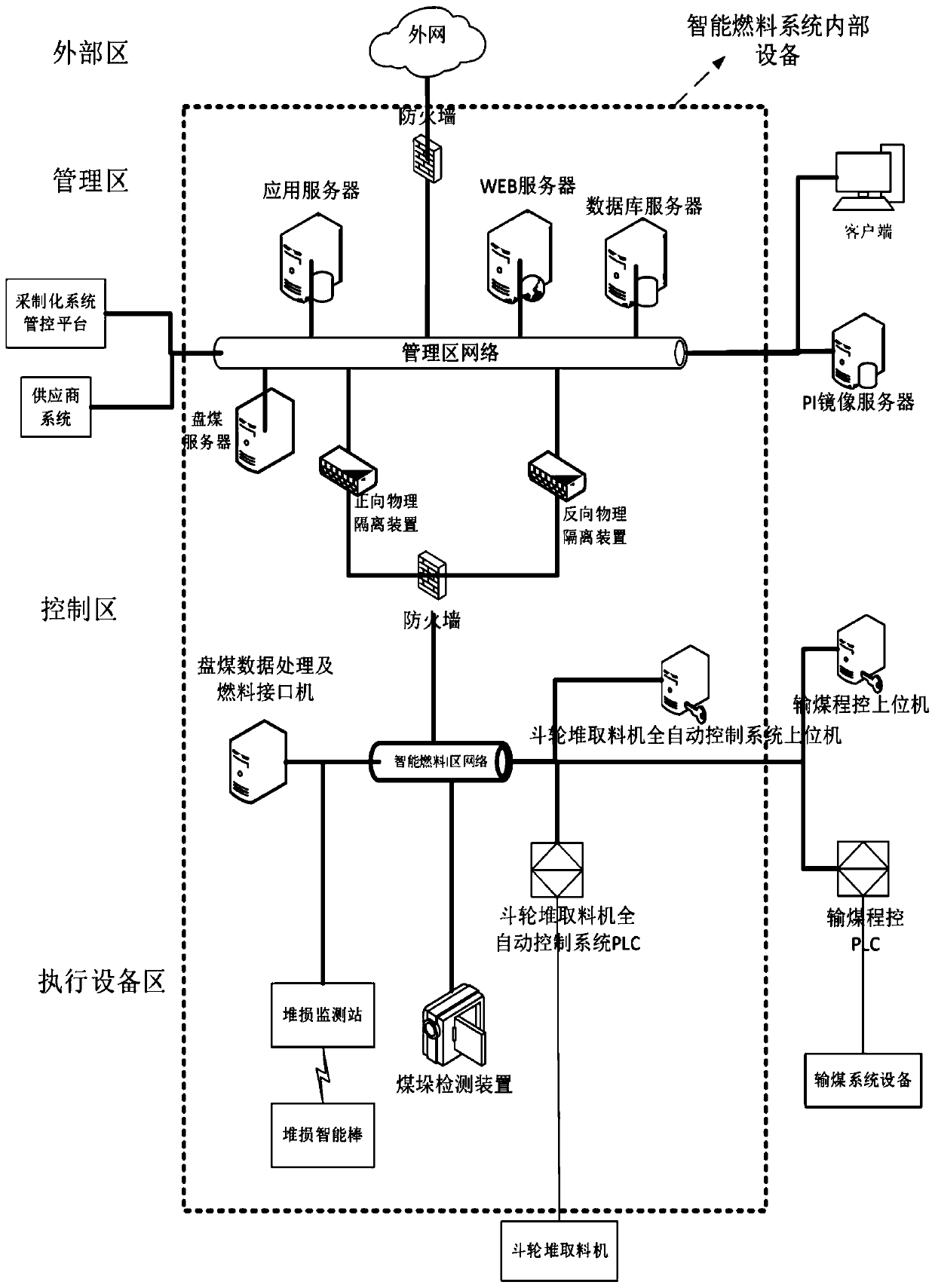

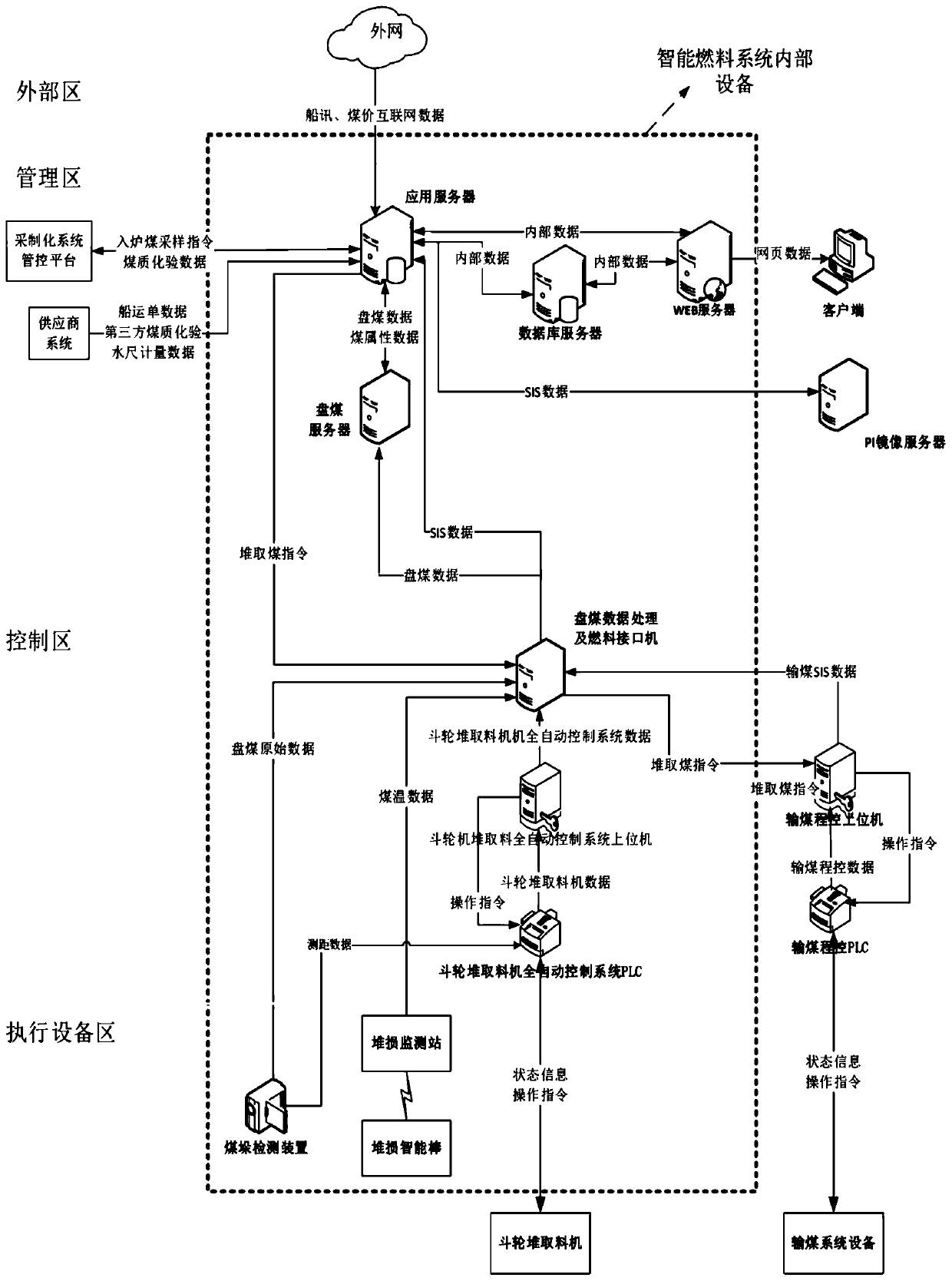

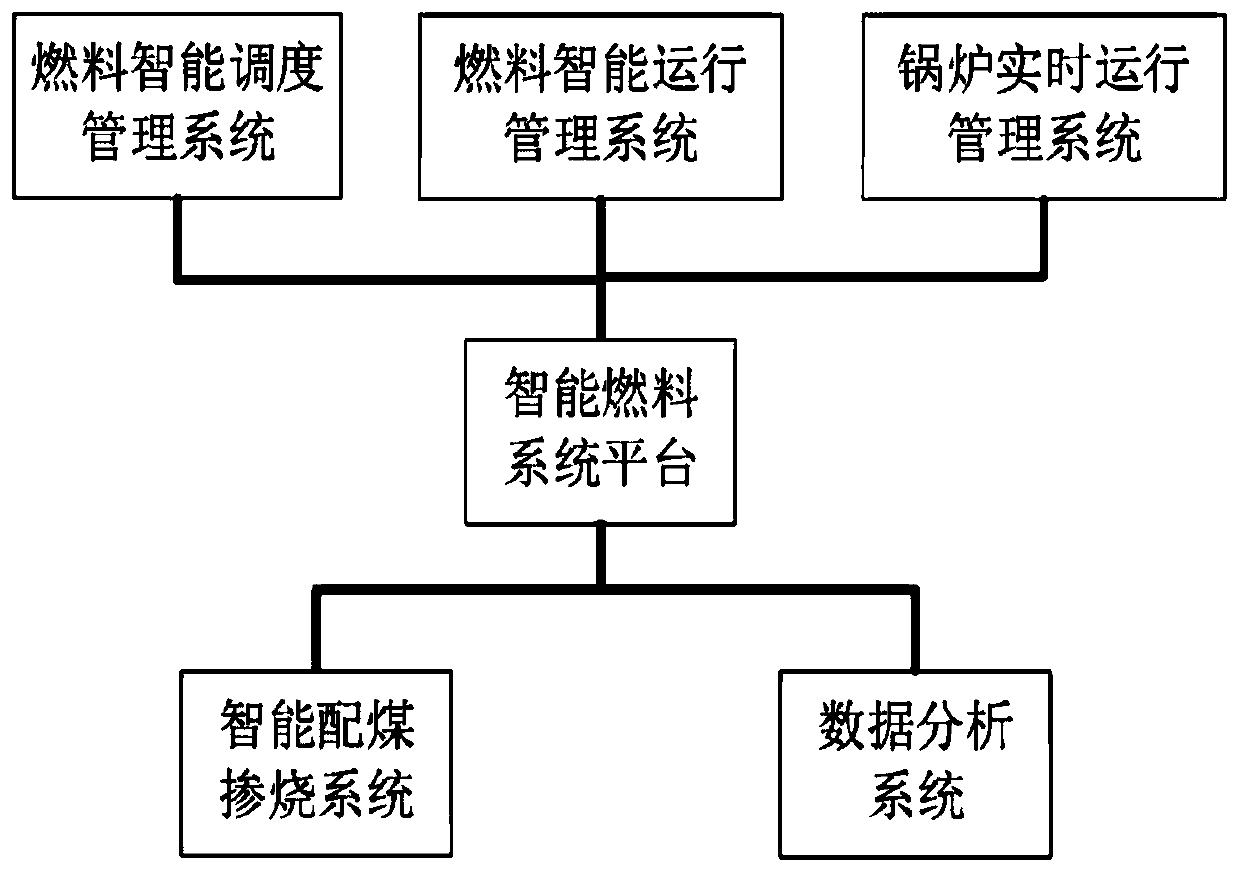

Real-time intelligent fuel system for water transport coal-fired power plant

InactiveCN109782726AAchieve integrationReal-time graspResourcesProgramme total factory controlAutomatic controlWater transport

The invention discloses a real-time intelligent fuel system for a water transport coal-fired power plant. The hardware equipment of the system includes a bucket wheel stacker-reclaimer automatic control system, a real-time coal check system, a coal temperature detecting device, a server, and the like; the hardware equipment of the system includes a system platform, an intelligent coal blending combustion system, a fuel intelligent dispatching management system, a fuel intelligent operation management system, a boiler real-time operation management system, a data analysis system and the like. Under the framework of an intelligent power plant, the data gaps of the whole process of fuel management are bridged through the fully automatic bucket wheel capable of accurate three-dimension positioning; intelligent coal stacking and in-boiler coal intelligent blending and combustion are realized through a combustion characteristic prediction-based intelligent coal blending technology; the automatic correlation of the types and quality of coal which is combusted real time in a boiler can be realized through a coal bunker intelligent layering technology; and an automatic coal blending technology, a plurality of metering devices used in a whole process, and an in-boiler coal type-based sampling technology are adopted to realize the intelligent balanced analysis of the coal quantity and coal quality in the whole process of fuel management.

Owner:ZHEJIANG ZHENENG TECHN RES INST +1

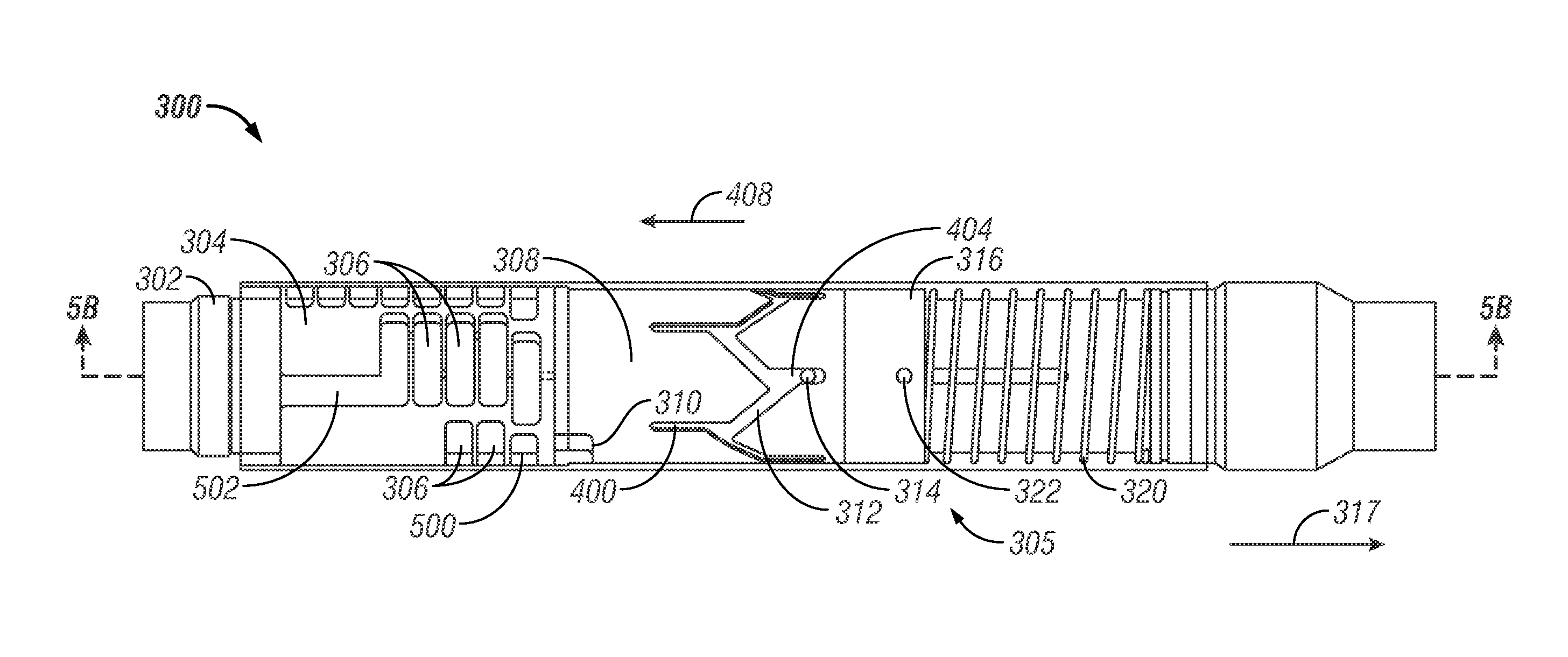

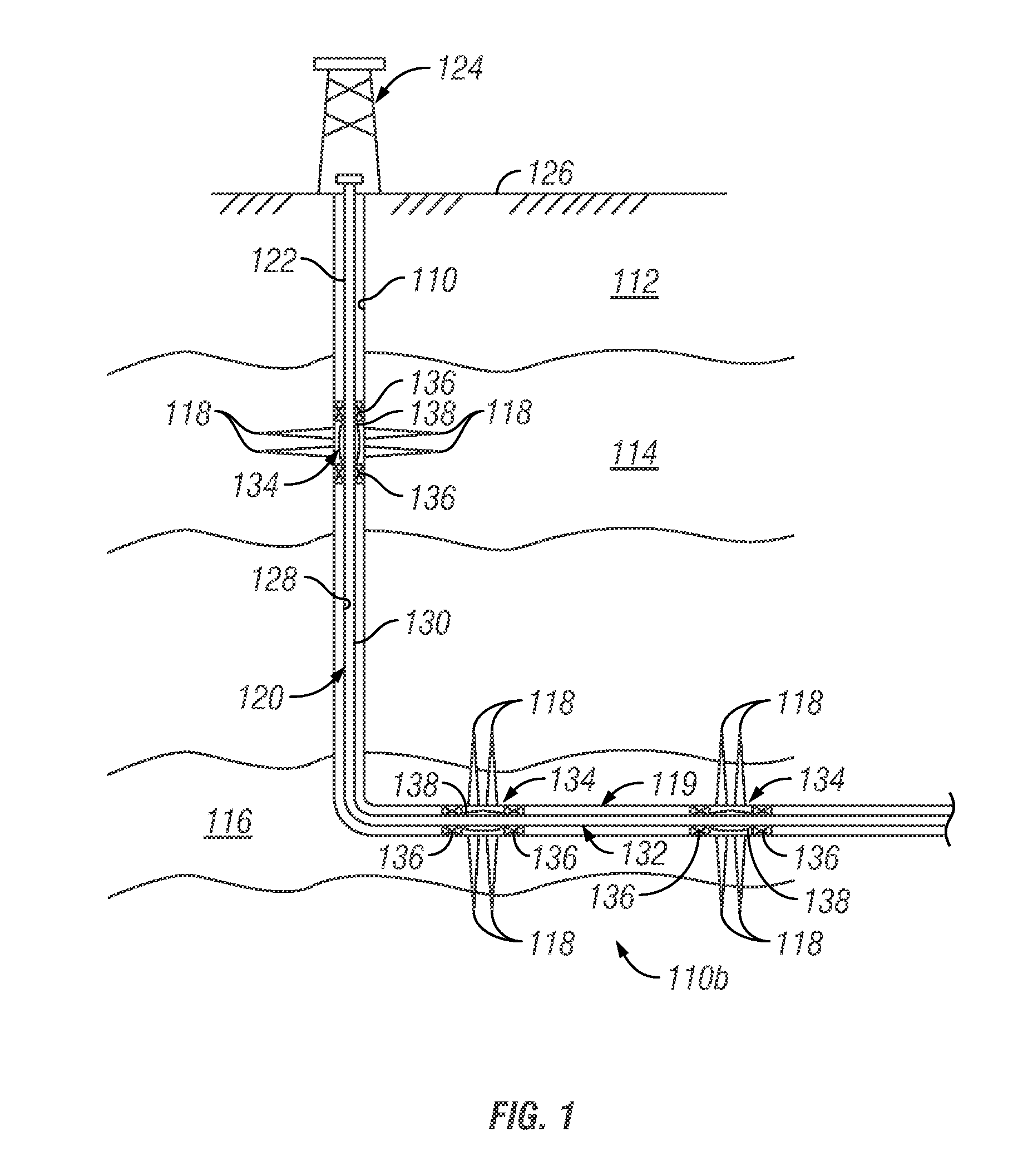

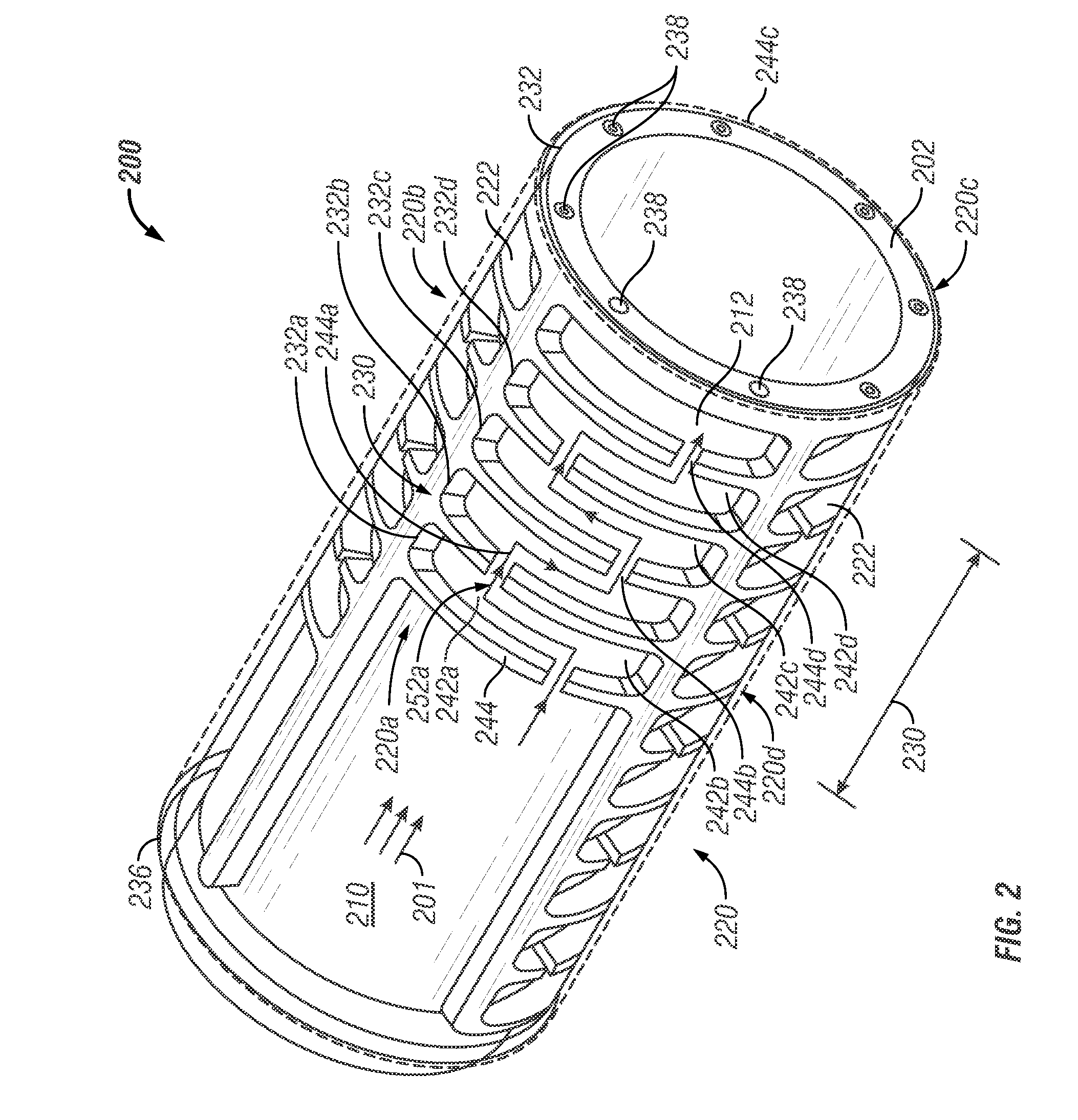

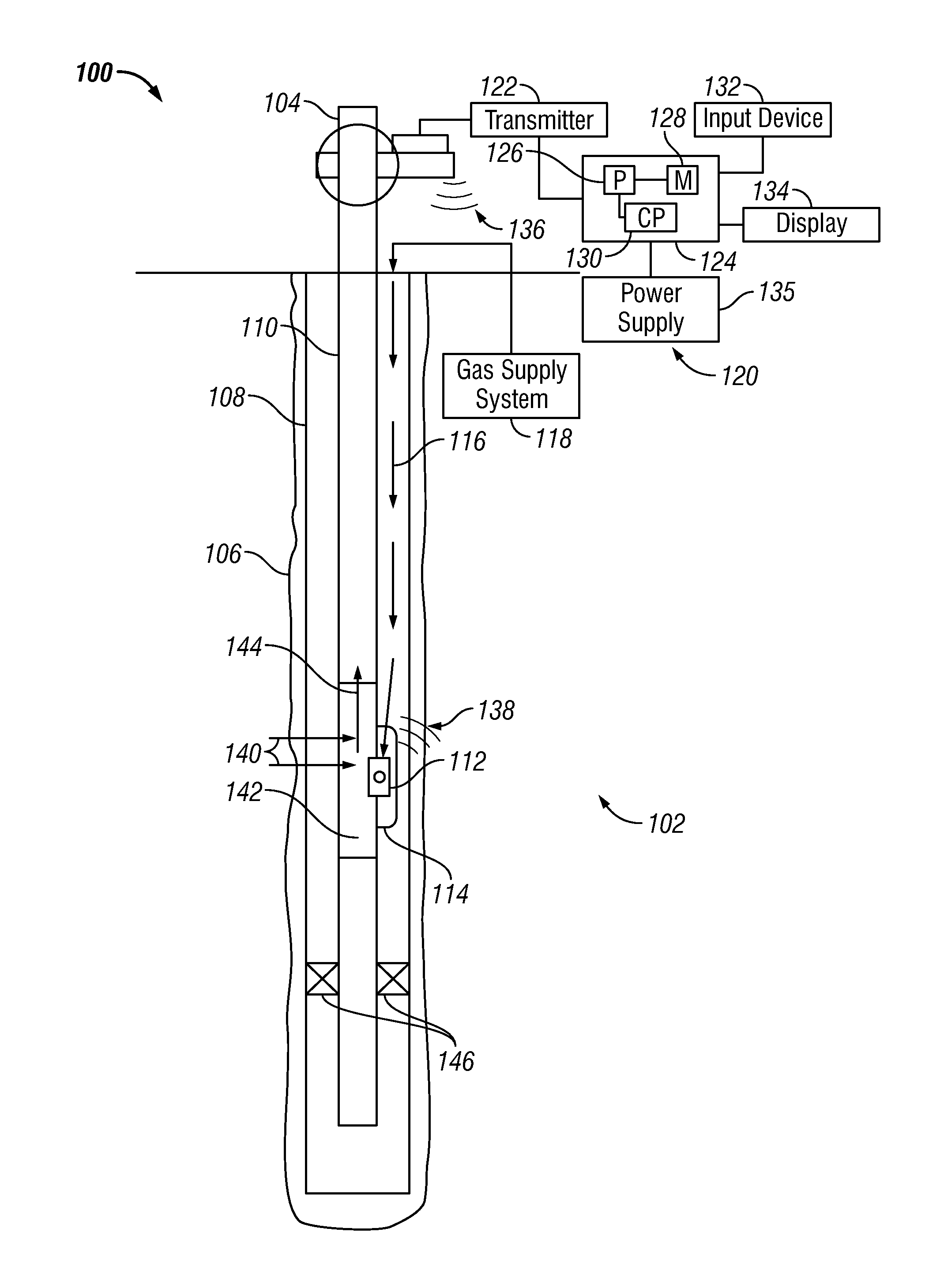

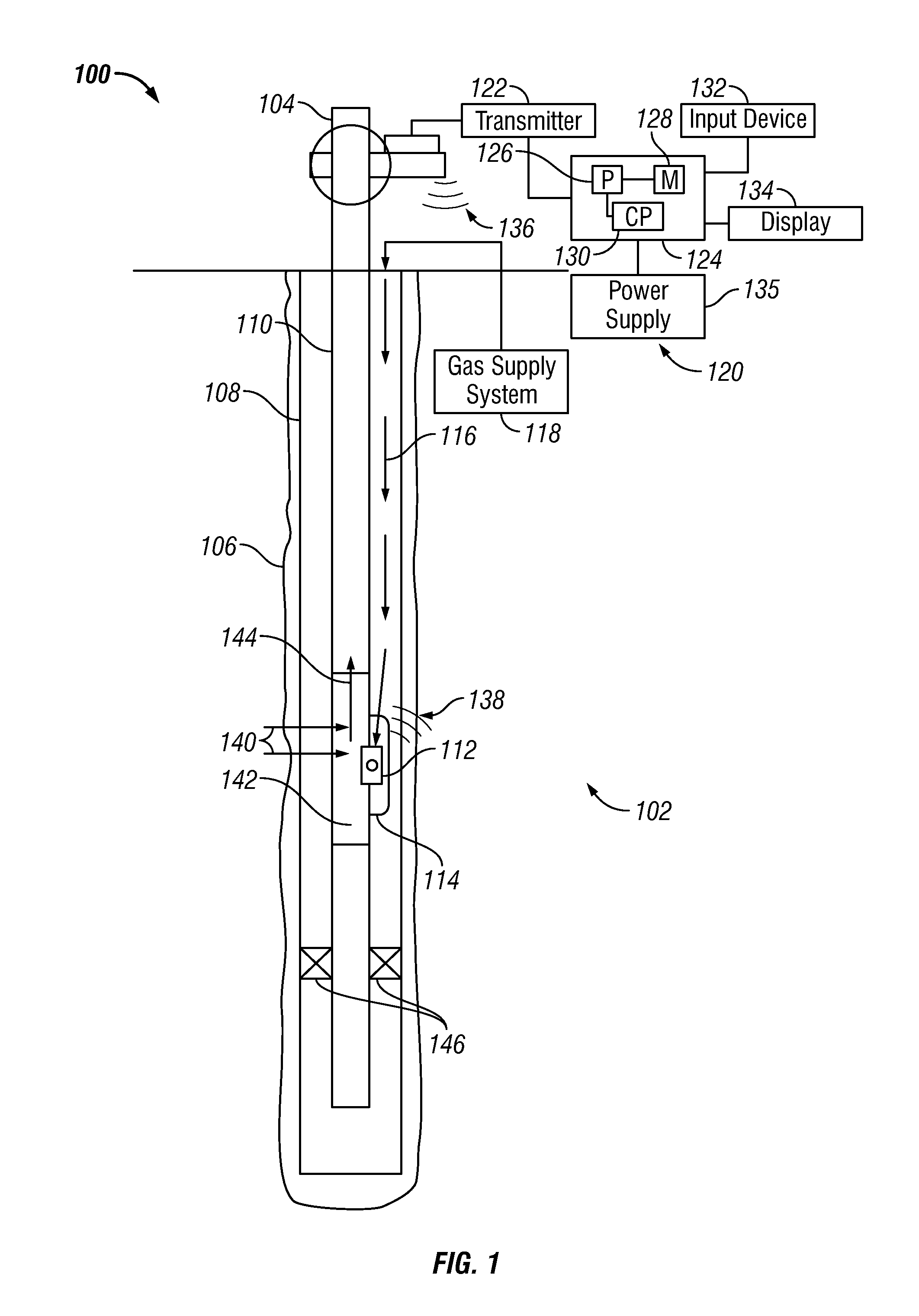

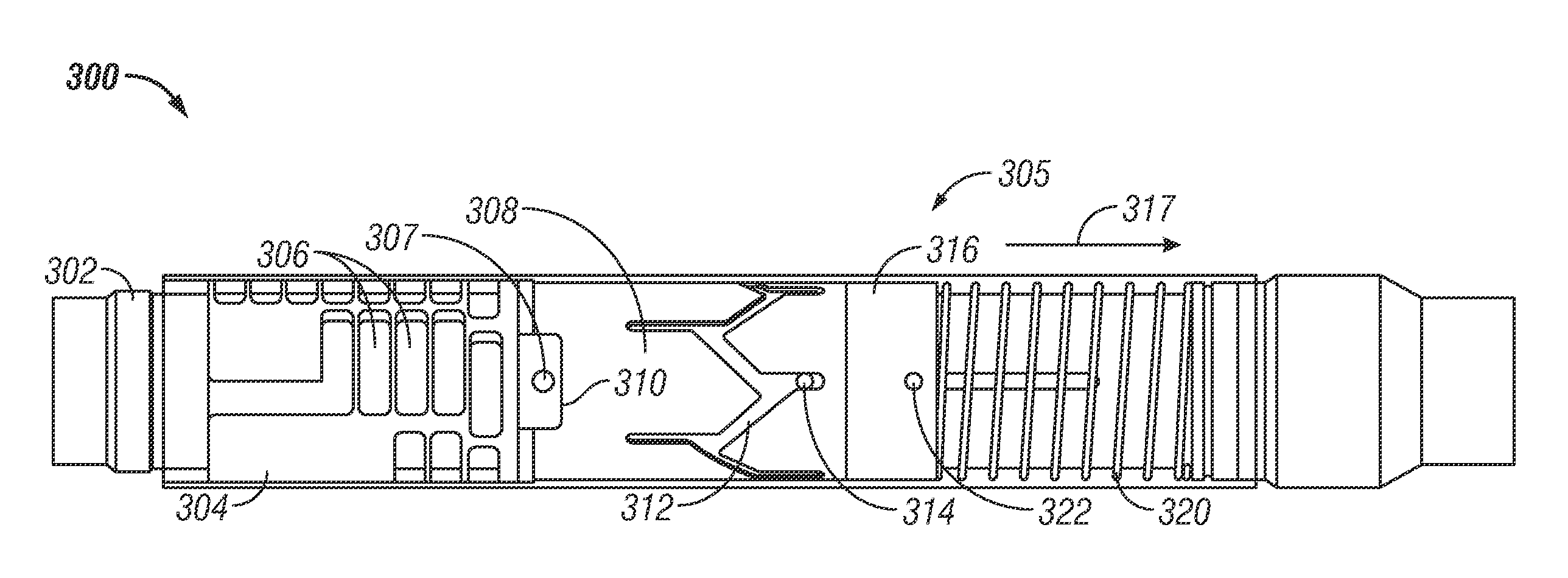

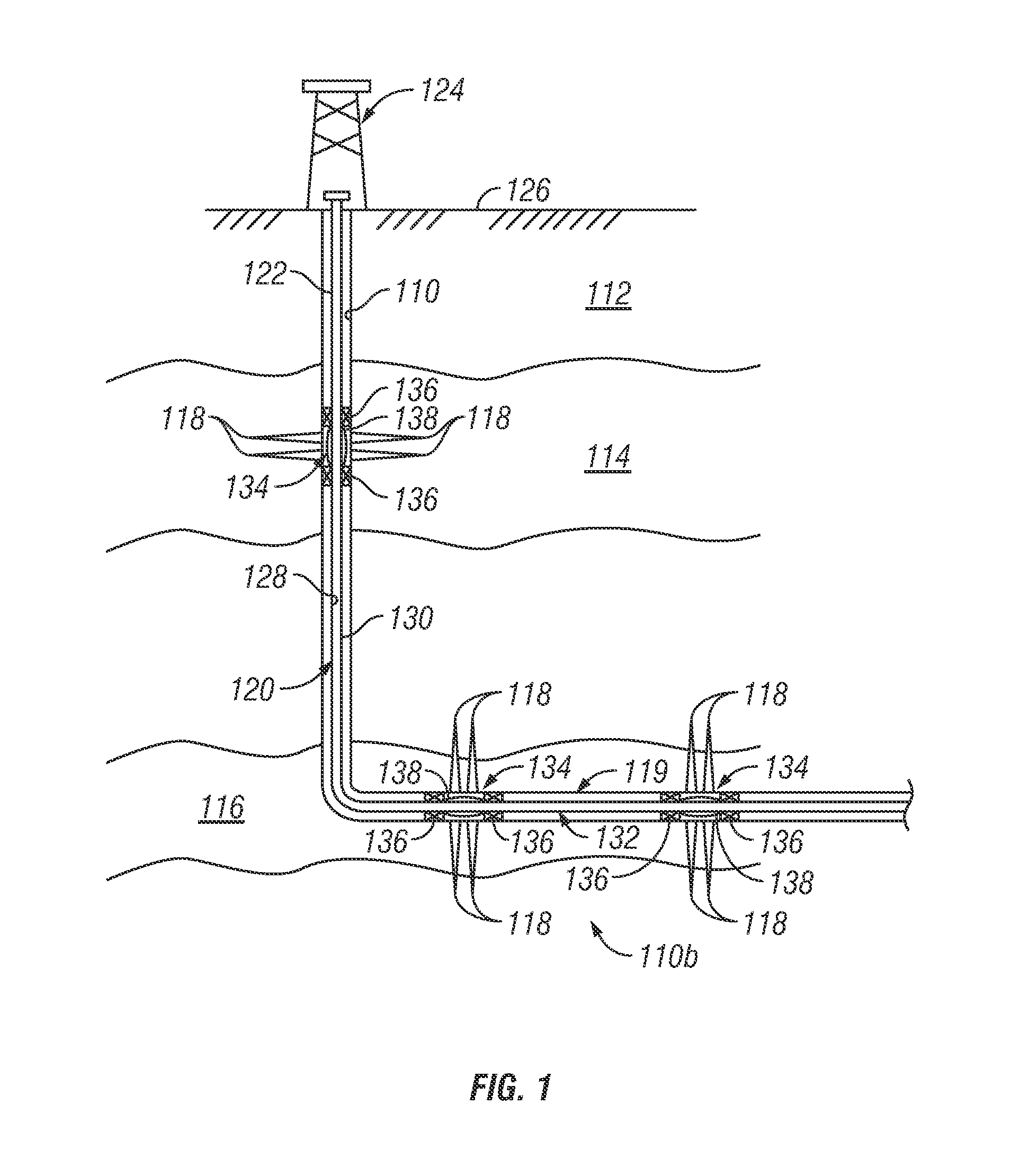

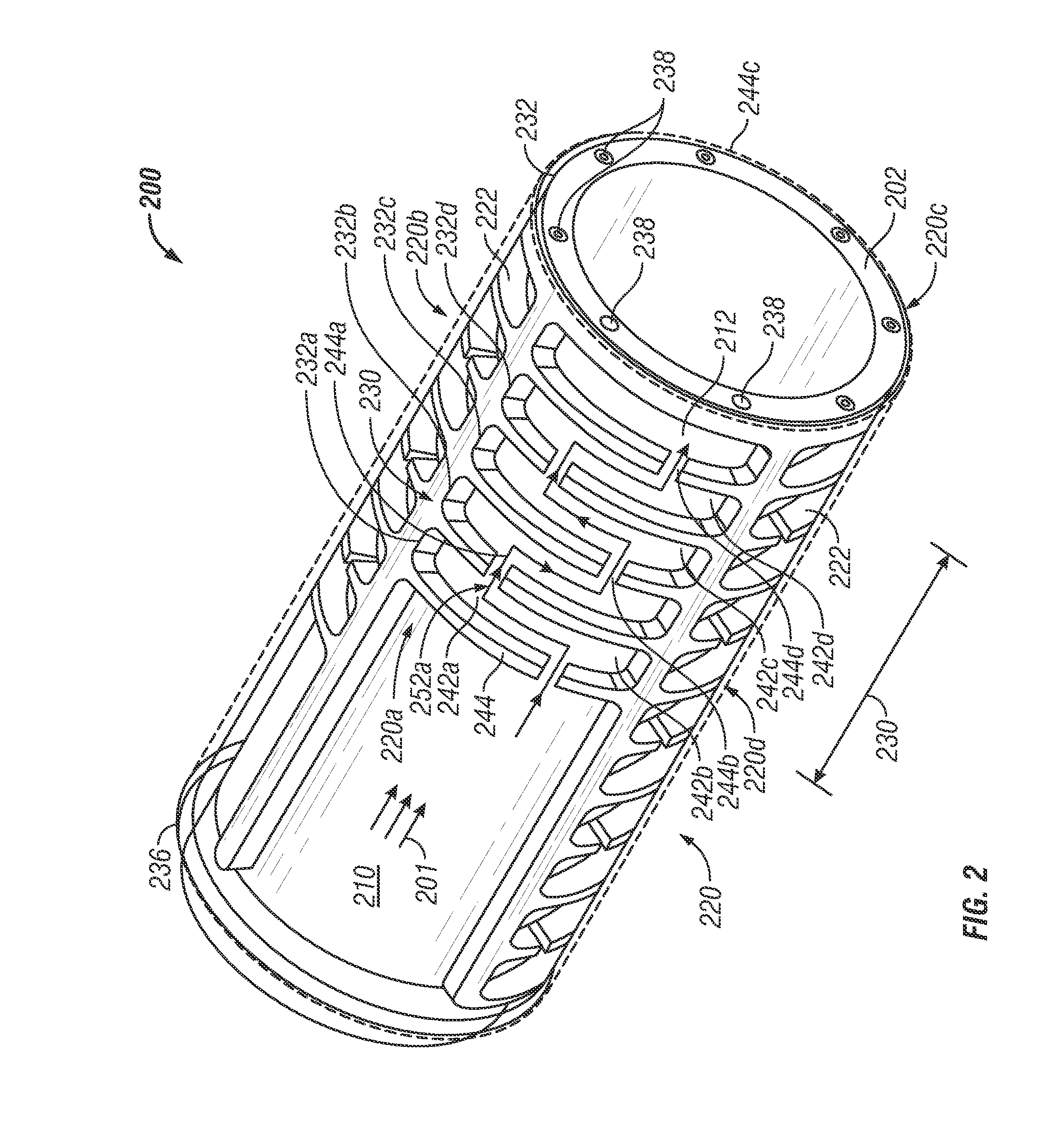

Downhole-Adjustable Flow Control Device for Controlling Flow of a Fluid Into a Wellbore

ActiveUS20110147007A1Change processFluid removalWell/borehole valve arrangementsStream flowEngineering

A flow control device is provided that in one embodiment includes a flow-through region configured to receive formation fluid at an inflow region and discharge the received fluid at an outflow region and a setting device configured to adjust the flow of the fluid through the flow-through region to a selected level. The setting device includes a coupling member configured to be coupled to an external latching device adapted to move the coupling member to cause the setting device to alter the flow of the fluid from the flow-through region to the selected level.

Owner:BAKER HUGHES INC

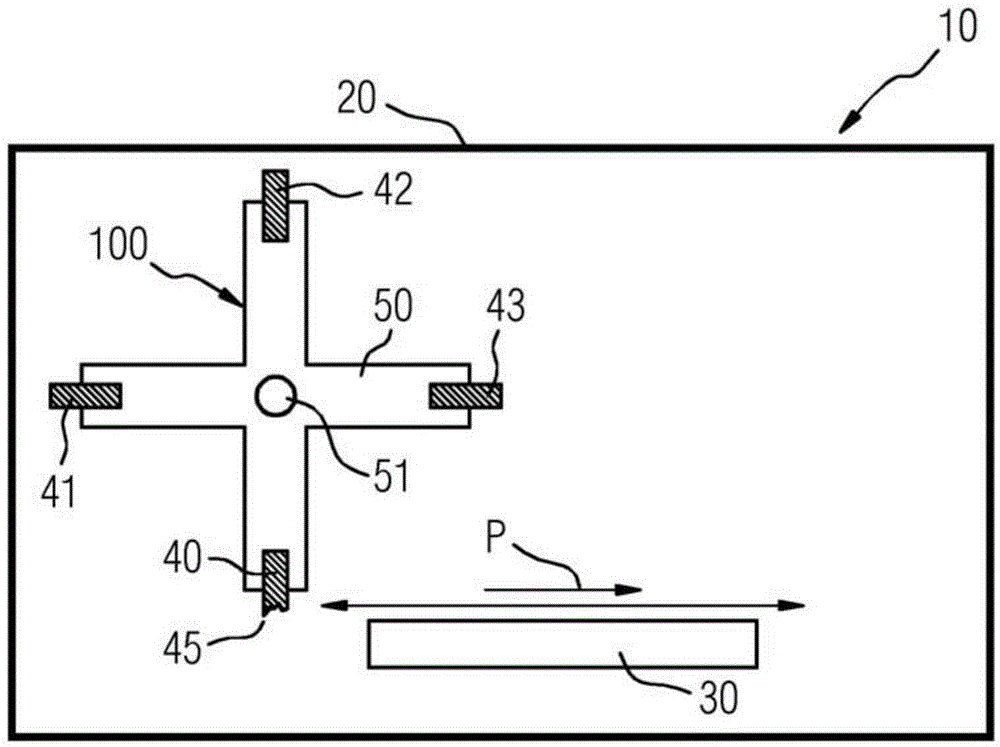

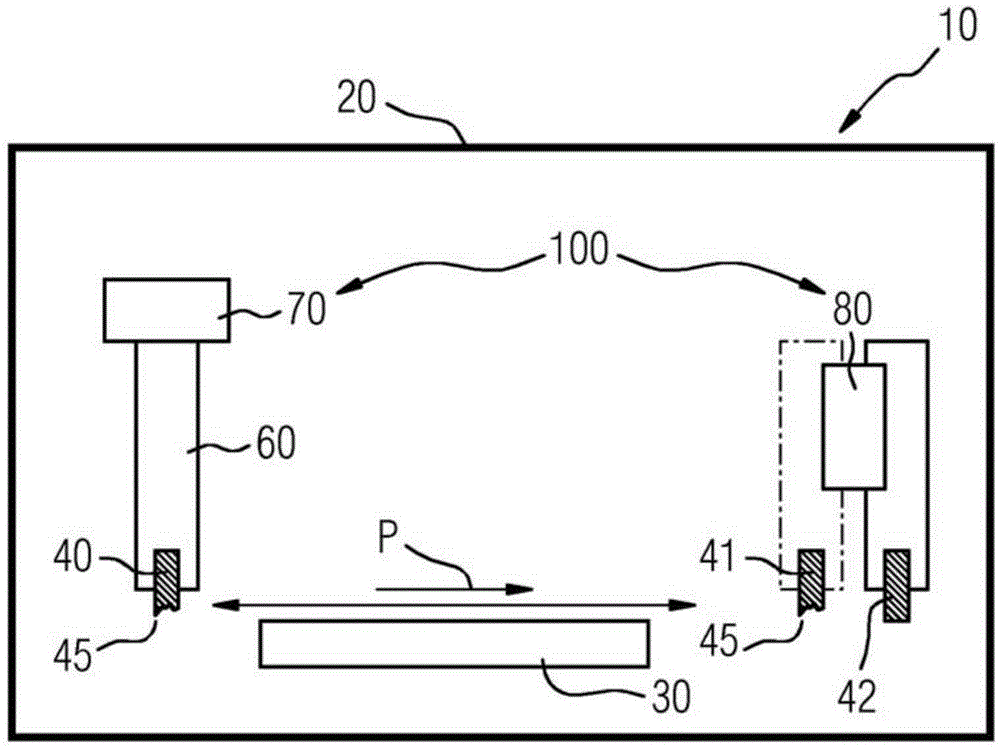

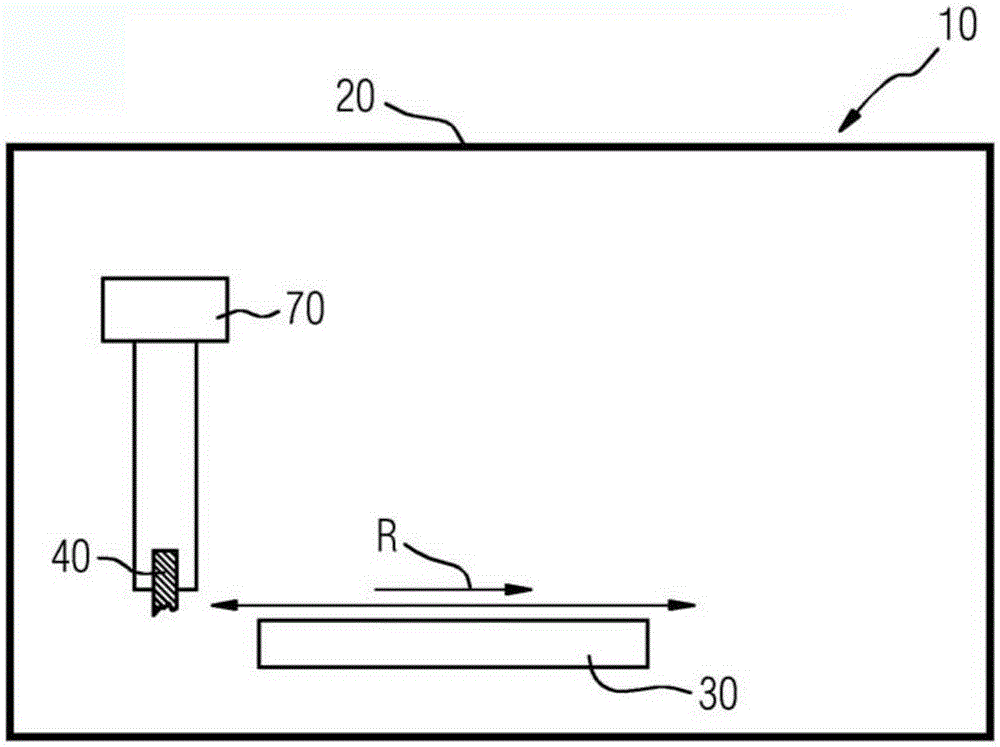

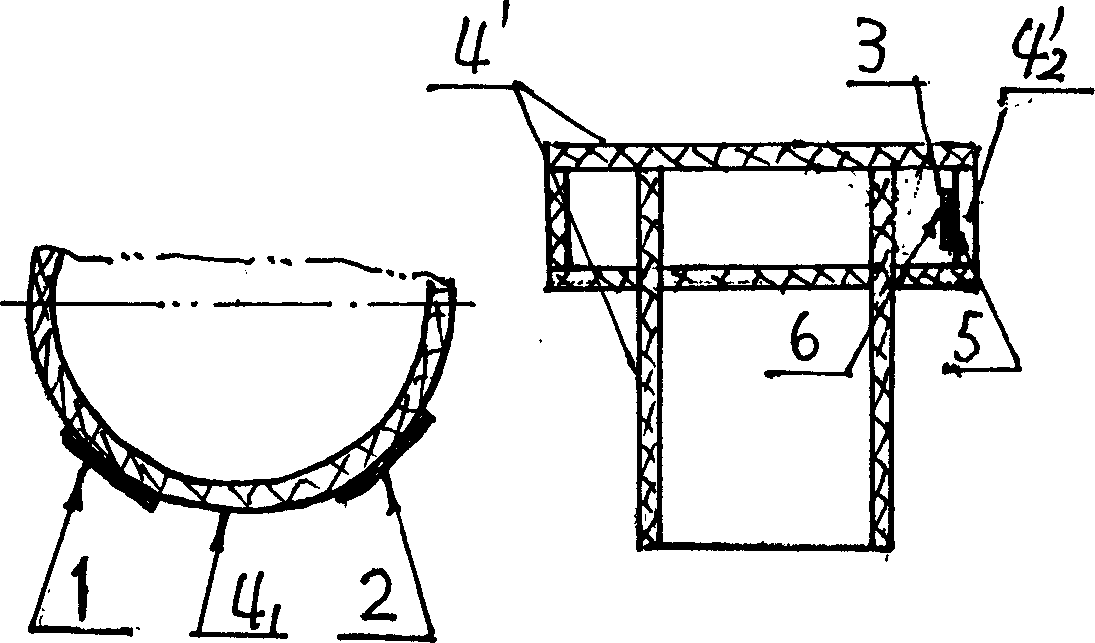

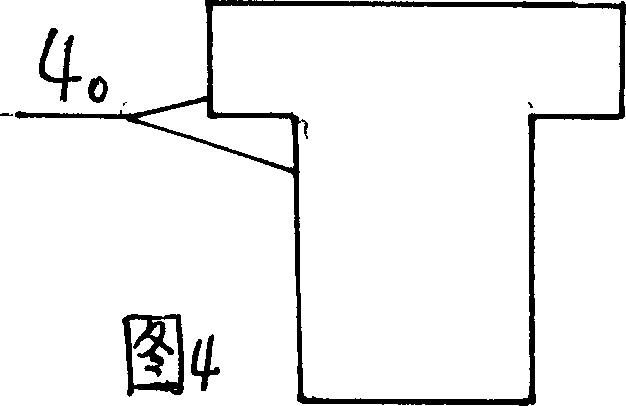

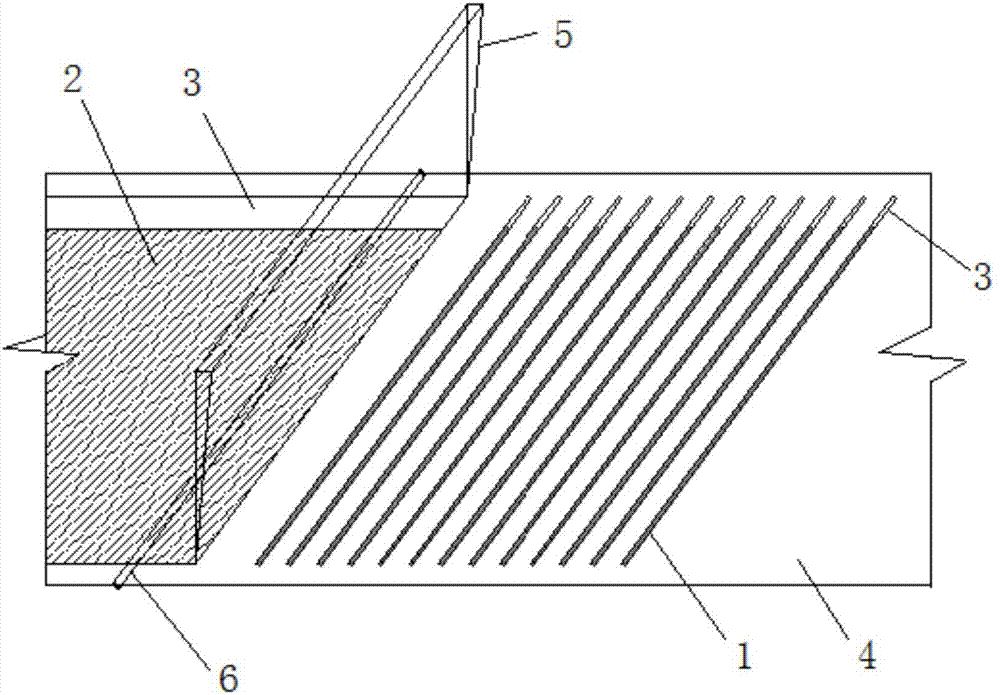

Arrangement for coating a powder

InactiveCN105408040AAchieve replacementPrevent openingAdditive manufacturing apparatusLiquid surface applicatorsMetal powderCoating

The invention relates to an arrangement (10) with a processing chamber (20), a coating platform (30) which can be found in the processing chamber (20), and a coating device with a coating element (40) which can be found in the processing chamber (20) for coating a powder, in particular a metal or ceramic powder. According to the invention, the arrangement (10) has an exchanging device (100) which is suited for exchanging at least one portion of the coating element (40) with another portion of the same coating element (40) or for exchanging the entire coating element (40) with another coating element (41, 42, 43) within the processing chamber (20) when the processing chamber (20) is closed. The exchanging device (100) can comprise a multiple head (50), in particular a pivoting head or a revolving head, an exchanging station (80), and / or a moving device (70) which allows a coating element (40) portion that is to be exchanged to be moved or pushed away. A part of the coating element (40) can also be rolled on a supply roller (230), and the coating element portion can be exchanged by unrolling the coating element from the supply roller (230). Together with the exchanging device (100), a wear determining device (300) is also preferably provided, said wear determining device being capable of measuring the wear of the coating element (40) and triggering an automatic coating element exchange or coating element portion exchange by means of the exchanging device (100).

Owner:SIEMENS AG

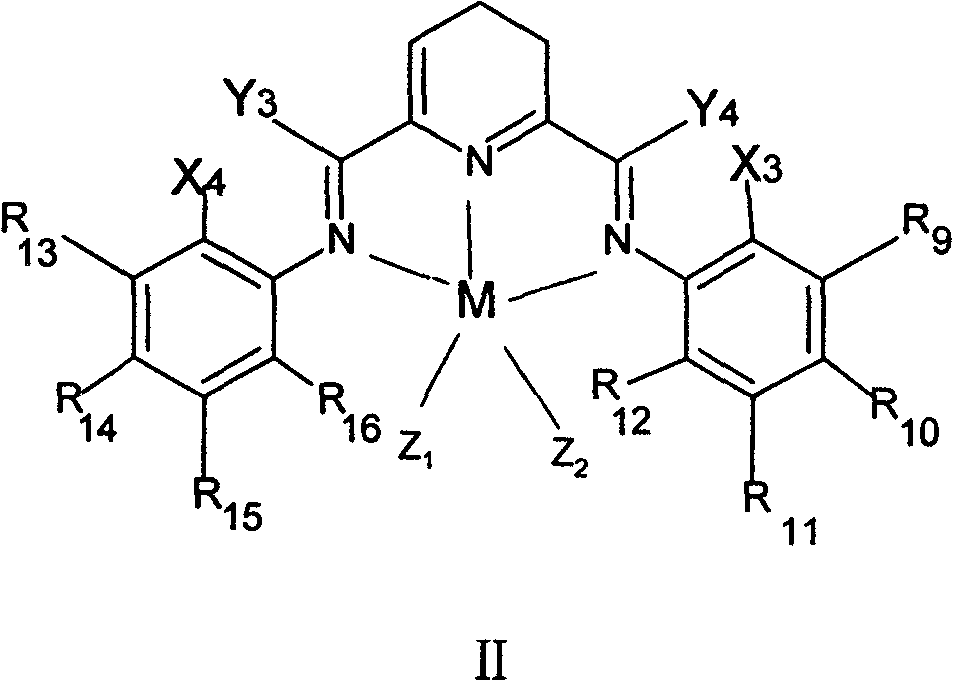

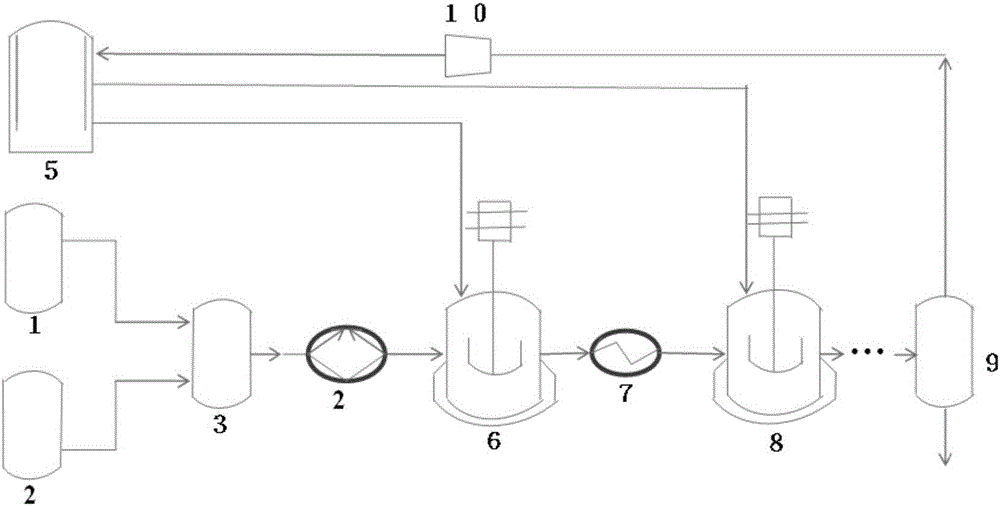

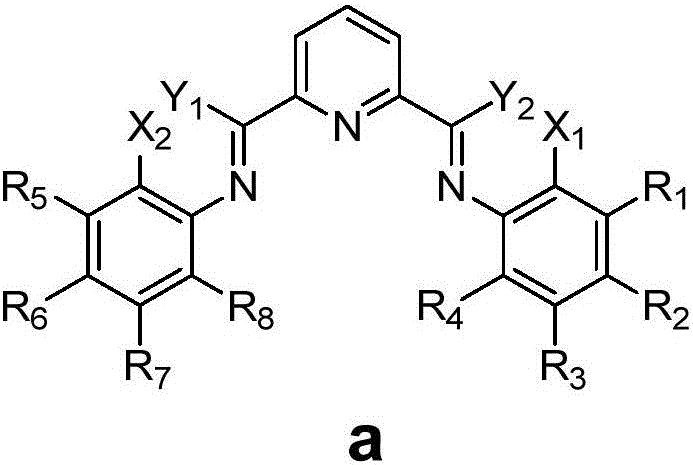

Ethylene oligomerization tanks-in-series technology

ActiveCN105693448ASolve the problem that the activity is too high and easy to overheatSmooth transitionHydrocarbon purification/separationCatalystsReaction temperatureEconomic benefits

The invention discloses an ethylene oligomerization tanks-in-series technology. A reaction medium, a promoter, an iron-based catalyst and a polyethylene wax inhibitor are introduced into a first reactor for pre-reaction at a low temperature, and the reaction materials are introduced into a second reactor after activity starts to be reduced; reaction temperature is increased to maintain high reaction activity for a long time; the reaction materials are sequentially introduced into an n reactor, and the temperature of the reactor is kept high (Tn-Tn-1>=10 DEG C); gas-liquid-solid separation and analysis are conducted on a product after reaction ends. By the adoption of the ethylene oligomerization tanks-in-series technology, catalyst deactivation due to temperature runaway caused by high reaction activity in the early stage of reaction can be effectively avoided, high catalyst activity is maintained for a long time, the catalysis efficiency of the catalyst is improved, and the yield of liquid-phase alpha-olefin is increased remarkably. The reaction technology is good for safety and stable operation of devices so that high economic benefits can be obtained.

Owner:ZHEJIANG UNIV

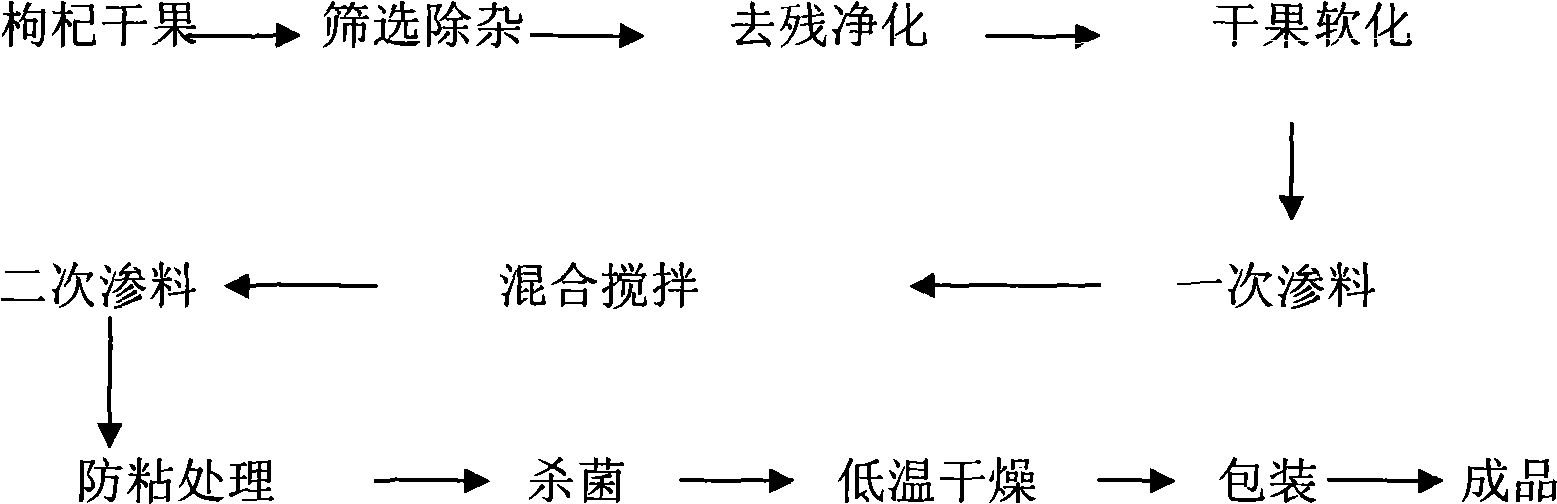

Medlar health-care preserved fruit and method of manufacturing the same

The present invention relates to a medlar health-care preserved fruit and a method of manufacturing the same, the product is composed of (by weight parts of raw material in finished product) 80 to 95% of medlar dried fruit, 2 to 15% of fruit juice, 0.3 to 5.0% of compatibility medicinal materials soaking juice, 0.1 to3.5% of citric acid, 0.1 to 1.0% of VC, the rest is pure water. The finished product is made by filtrating and edulcorating, purifying, dried fruit softening, stock leaked by medicament, mixing and agitating, stock leaked by fruit juice, antisticking process, sterilizing and low temperation drying of the medlar dried fruit.

Owner:宁夏沃福百瑞枸杞产业股份有限公司

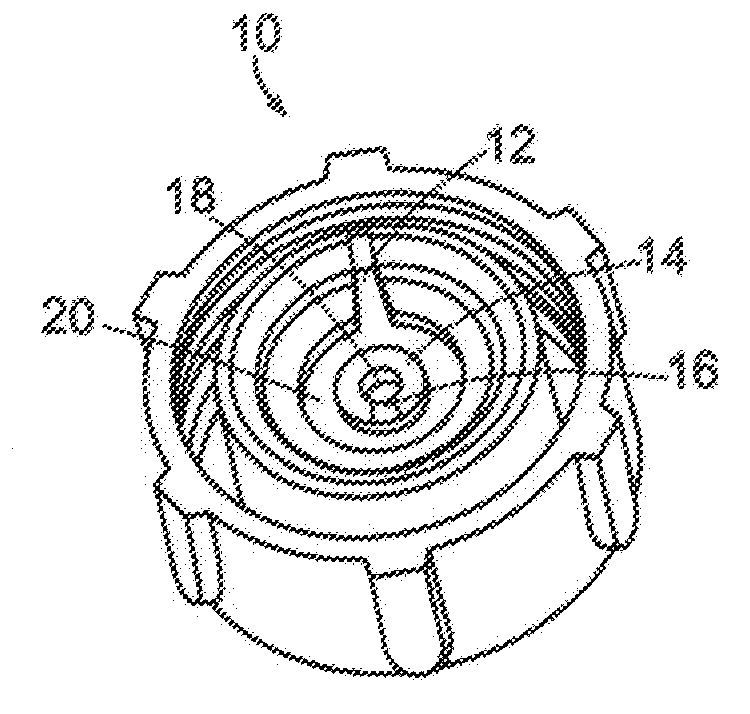

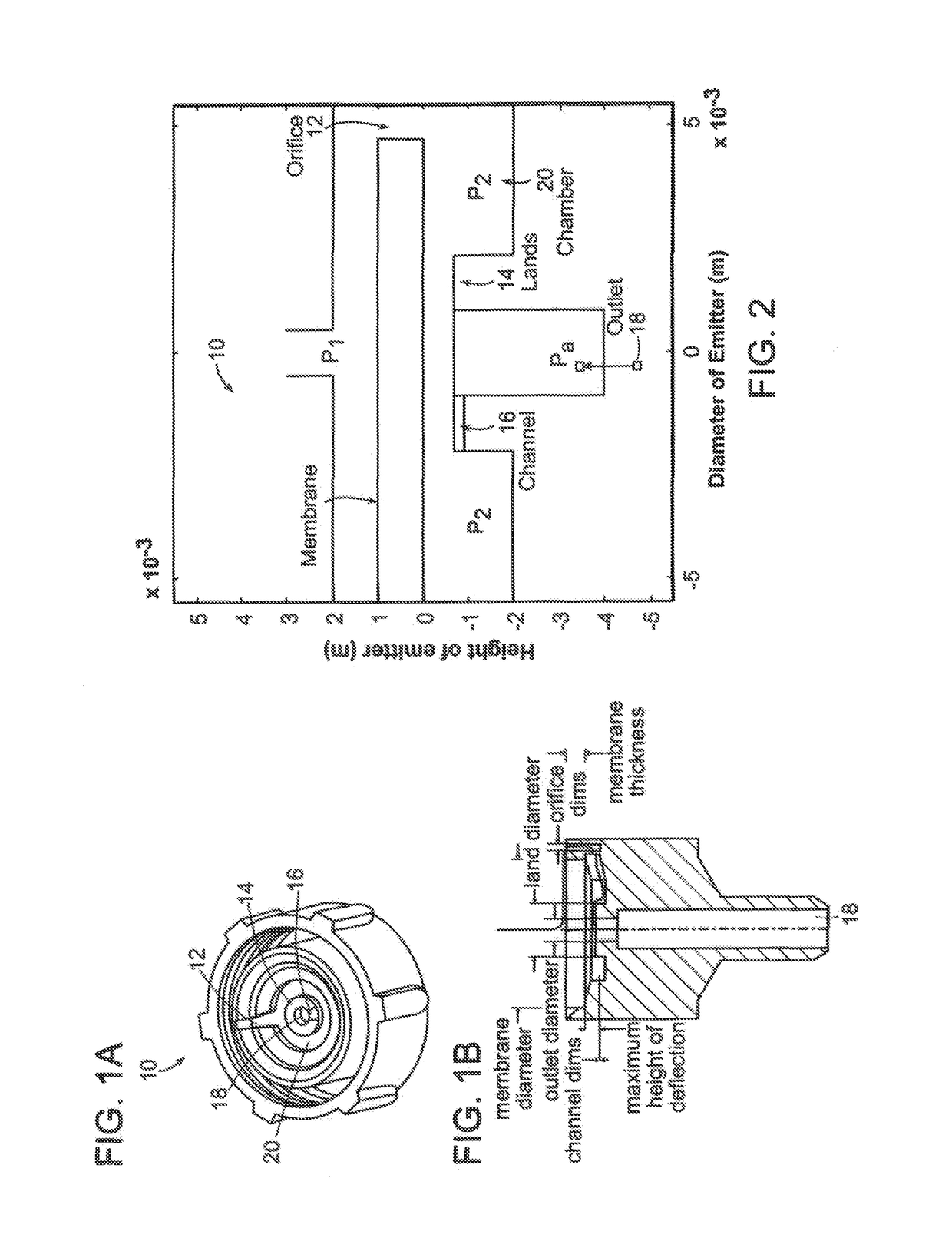

Pressure Compensating Emitter Having Very Low Activation Pressure and Large Operating Range

ActiveUS20170142916A1Change processConstant flowWatering devicesSpray nozzlesWorking rangeMembrane configuration

Owner:MASSACHUSETTS INST OF TECH

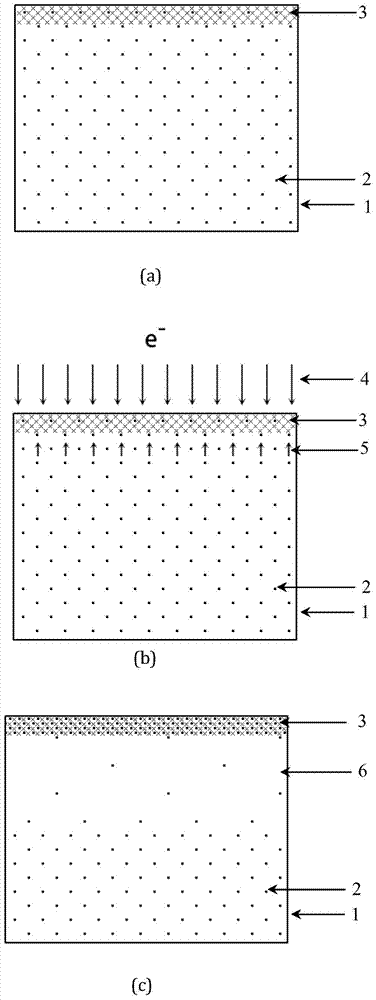

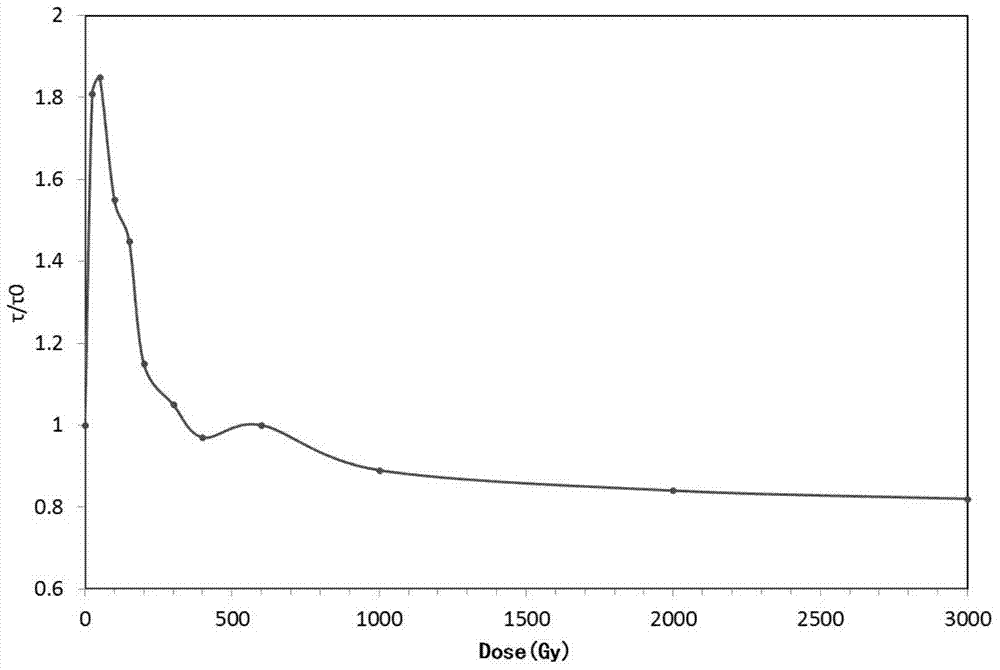

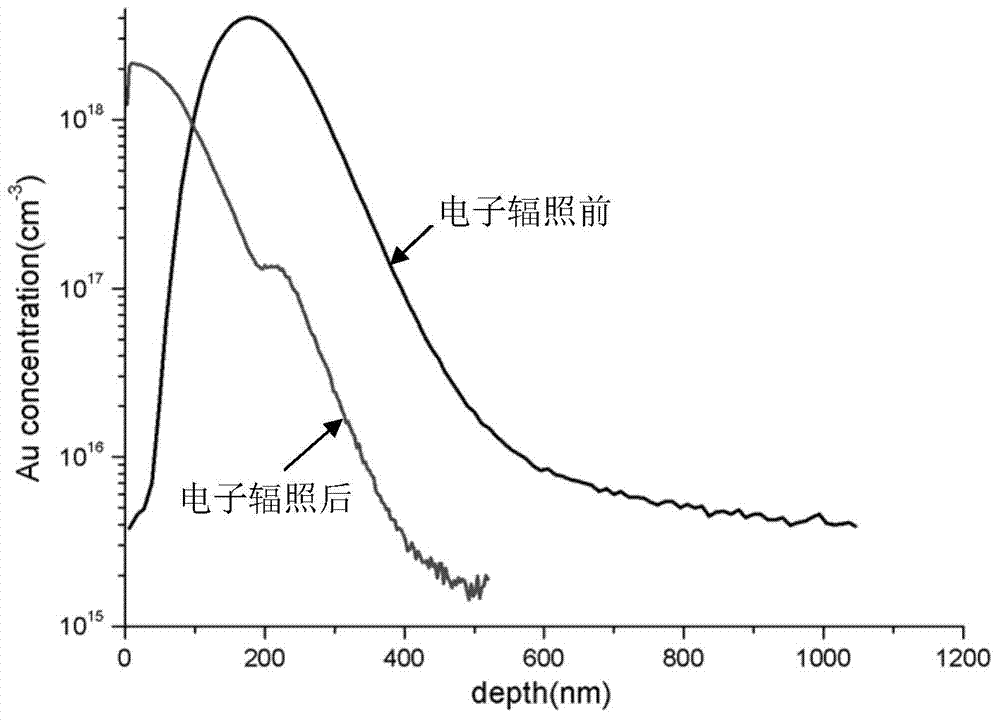

Method for removing transition metal impurities in silicon wafer or silicon device in sucking mode at indoor temperature

ActiveCN103794473AImprove radiation gettering effectChange structureSemiconductor/solid-state device manufacturingSemiconductor materialsSingle crystal

The invention discloses a method for removing transition metal impurities in a silicon wafer or silicon device in a sucking mode at the indoor temperature. Low-dose electron irradiation with the dose smaller than 5000 Gy is carried out on the silicon wafer or silicon device at the indoor temperature to enable the transition metal impurities in a to-be-cleaned area of the silicon wafer or an active area of the silicon device to be diffused to a nearby impurity sucking defect area, and therefore the concentration of the transition metal impurities in the to-be-cleaned area of the silicon wafer or the active area of the silicon device is lowered. Compared with an existing silicon material impurity sucking method, the method is implemented at the indoor temperature, and therefore the method can be used for silicon wafer or silicon device impurity sucking, is not limited to the single-crystal or polycrystalline silicon wafer and the silicon device, and is also suitable for other semiconductor materials such as germanium, and corresponding devices.

Owner:PEKING UNIV

Plant tissue culture rooting and seedling exercising integrated cultivating device and cultivating method thereof

ActiveCN105123488ASave spaceShorten the timeAgriculture gas emission reductionCultivating equipmentsTemperature controlResource utilization

The invention discloses a plant tissue culture rooting and seedling exercising integrated cultivating device and a cultivating method thereof. The cultivating device comprises a plant cultivation system, an illumination system, a ventilation temperature-control system, a fluid supplying system, a CO2 supplying system and an environment control system. The plant cultivation system comprises a three-dimensional multi-layer cultivation frame and cultivation containers placed on the cultivation frame, each layer of multiple layers of the cultivation frame is provided with one cultivation container, and lifting seedling disc supports are arranged at the bottoms of the containers and used for suspending cultivation plants. The illumination system comprises lamp boxes, LED lamp tubes and fans, and the LED lamp tubes are arranged inside the lamp boxes and connected with the fans to be installed above the cultivation containers in an integrated mode without communication with the cultivation containers. On the premise of guaranteeing that space and time are saved, the cost is low, and the utilization rate of resources is high, the utilization rate of the resources and labor productivity are increased, the cultivation period is shortened, and the production cost is lowered.

Owner:上海离草科技有限公司

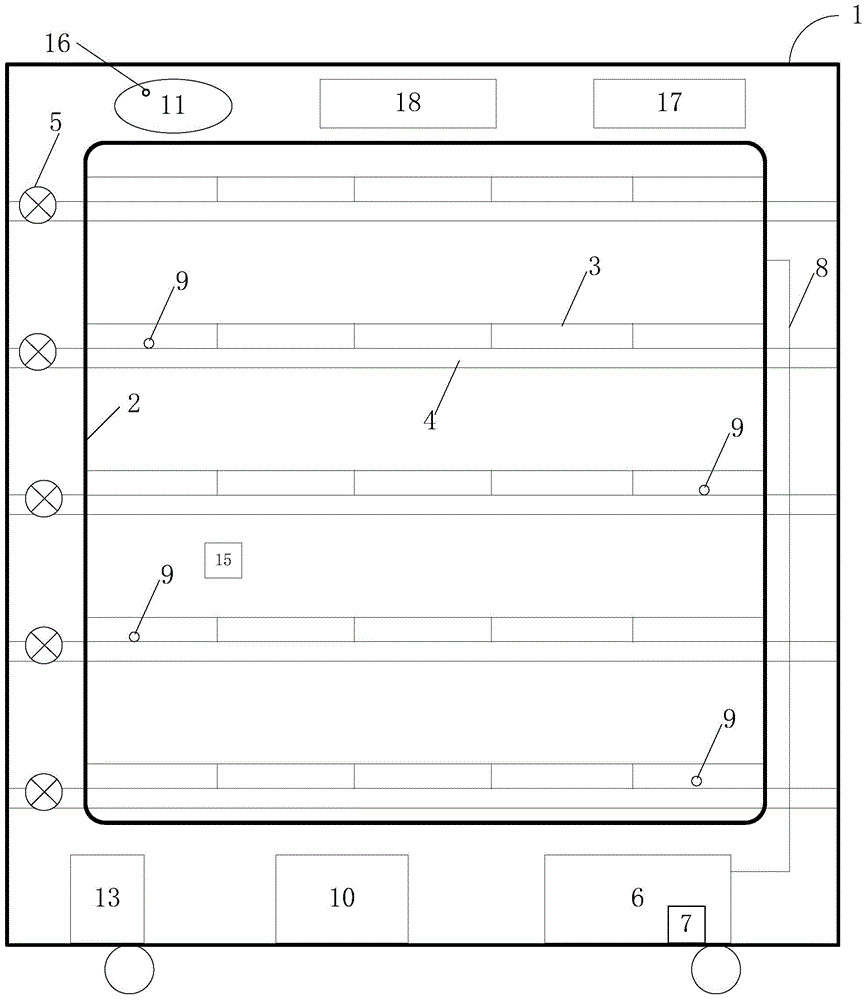

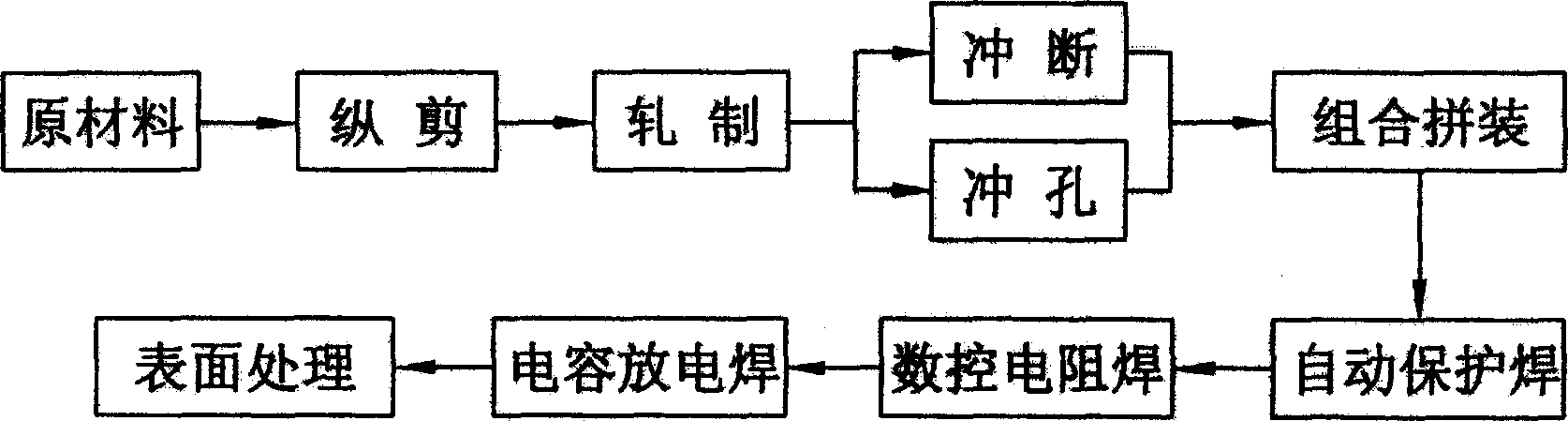

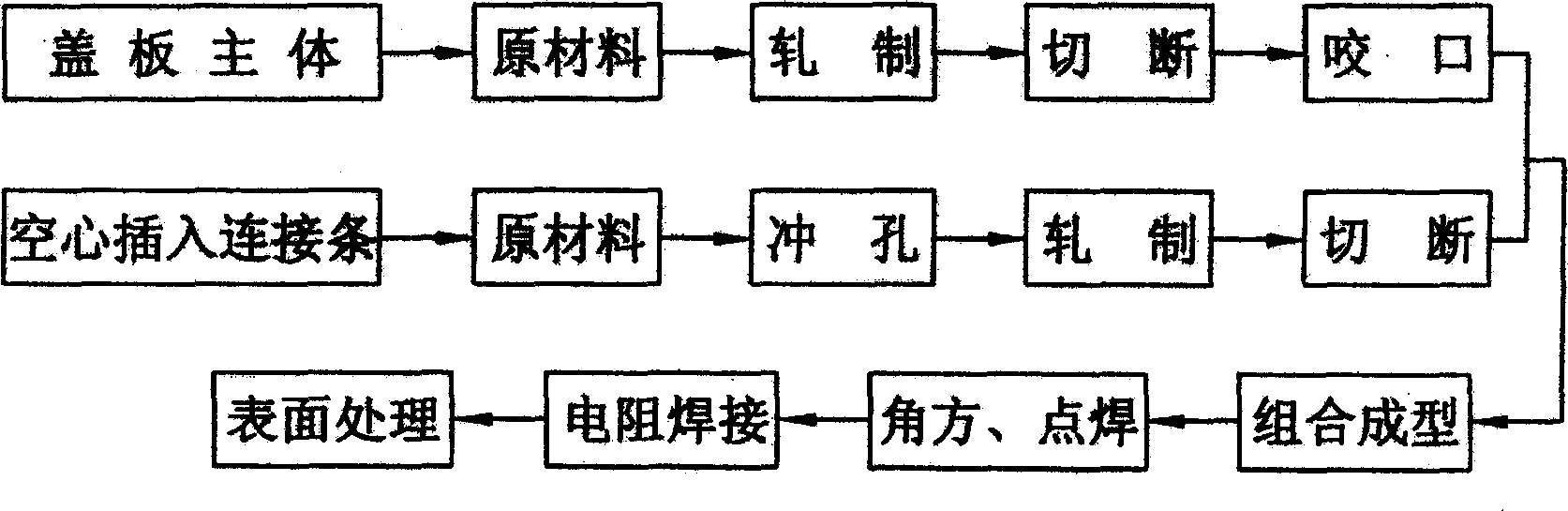

Manufacturing process for energy-saving light electric cable bridge structure

ActiveCN1584382AGuaranteed integrityHigh strengthPipe supportsElectrical resistance and conductanceCapacitance

An energy-saving production of electric cable bridge casings can reduce weight of products and costs, and improves performance of products while verifies functions of products. The casings consist of two parts, which are produced separately. Bridge bodies are produced by: cutting longitudinally, rolling, punching, assembling, and automatically welding. Radiation-cooled parts are produced by: rolling, cutting, holding-on, punching holes on inserted strips, rolling inserted strips for the upper pieces, cutting them, assembling, square-making, welding, and surface treating.

Owner:JIANGSU ONEQ ELECTRICAL APPLIANCE GRP

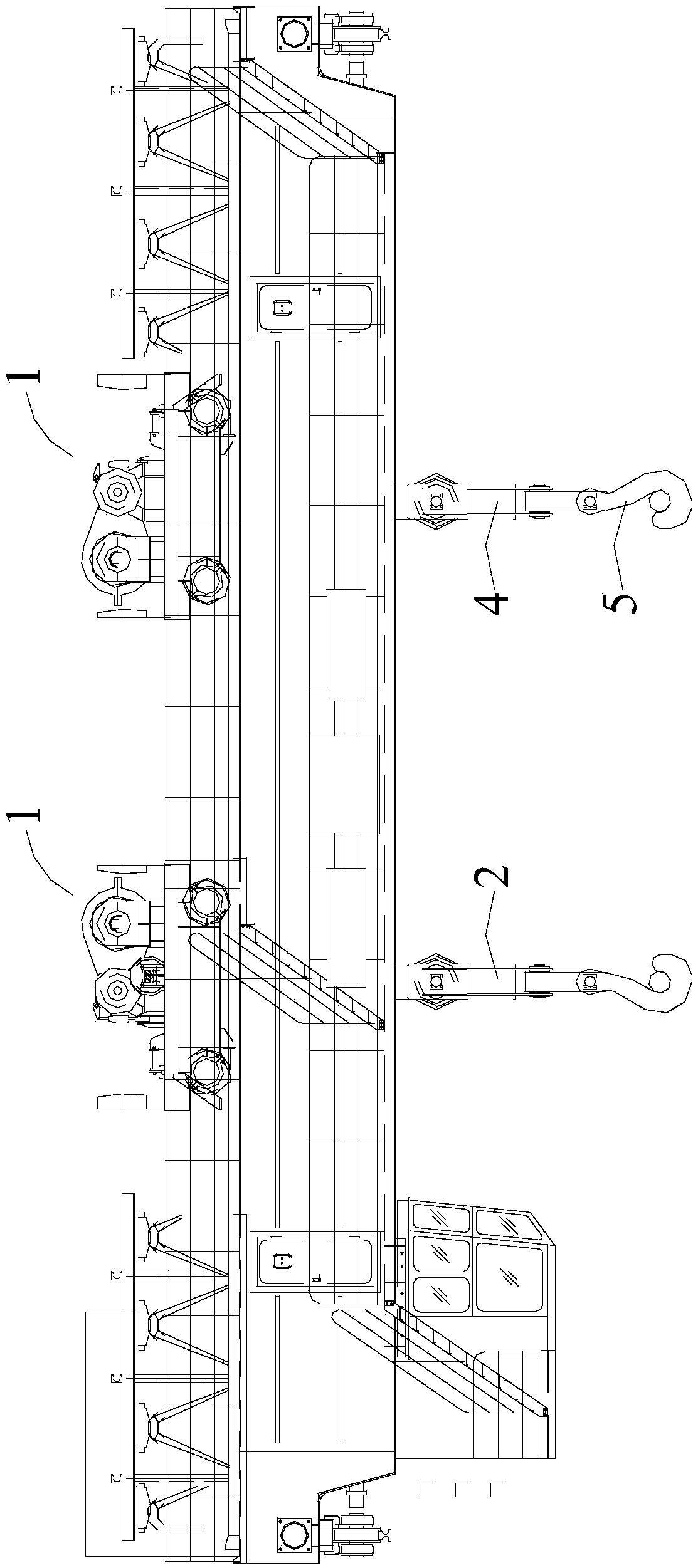

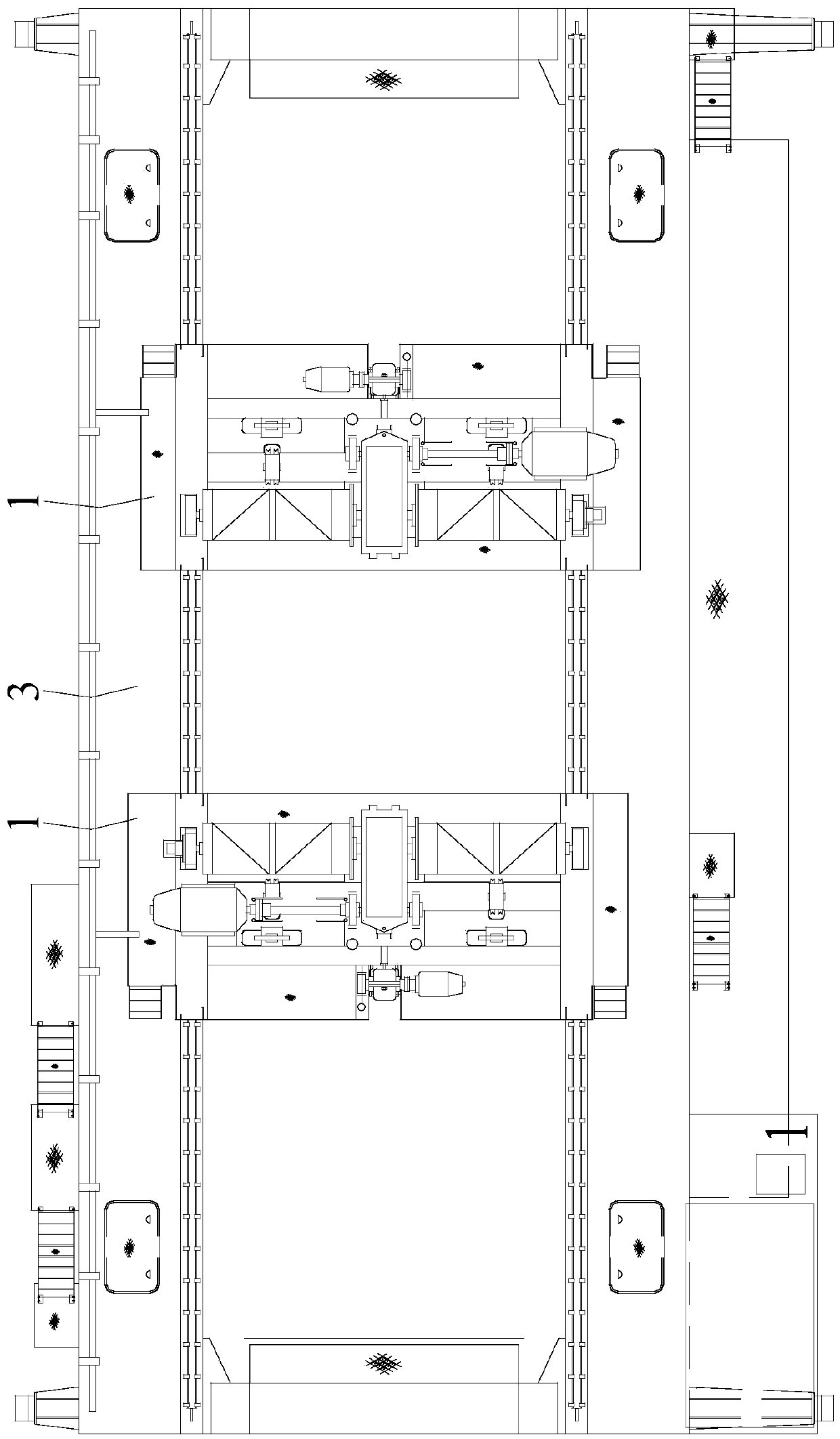

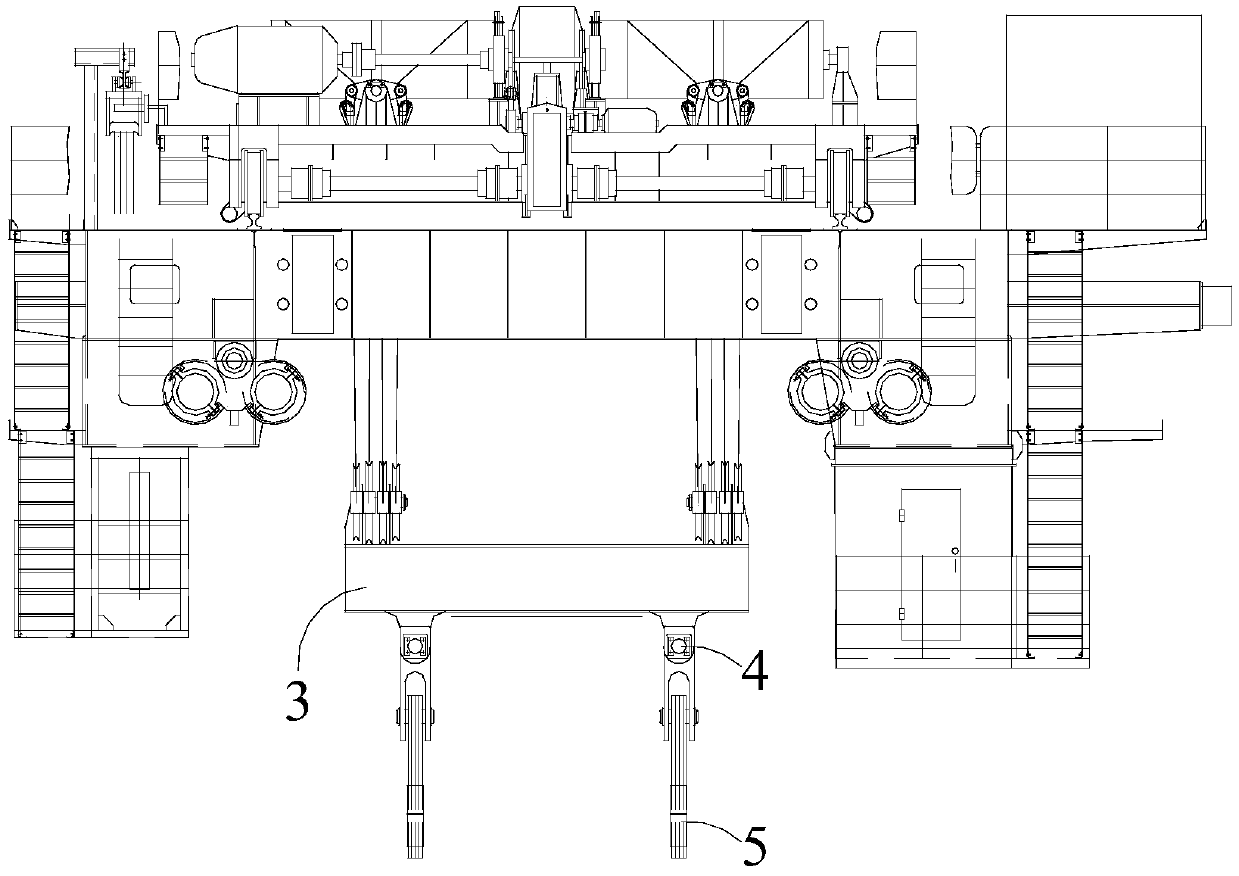

Lifting tool having four rotary lifting points and crane provided with lifting tool

Owner:TAIYUAN HEAVY IND

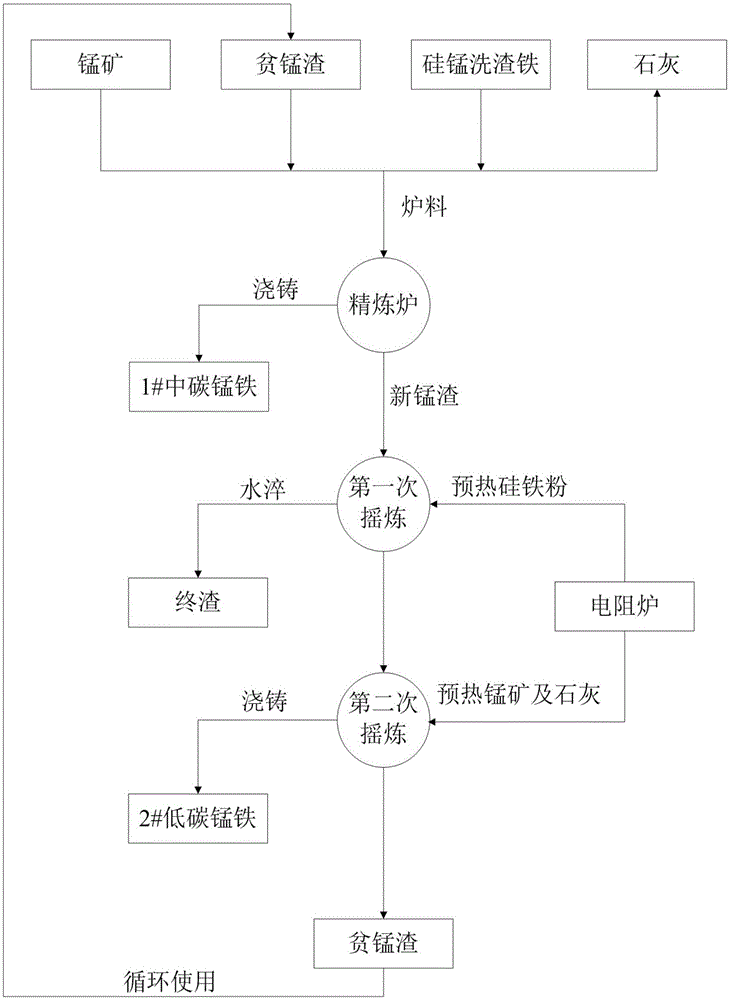

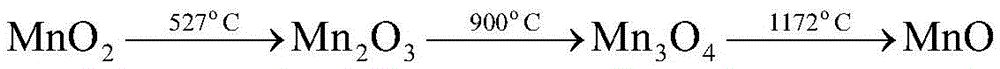

Method for refining low-carbon ferromanganese alloy through poor-manganese slag

The invention relates to a method for refining low-carbon ferromanganese alloy through poor-manganese slag. The method includes the steps that 1, silicomanganese slag washing iron, manganese ore and the poor-manganese slag are combined and added into a refining furnace as furnace charge, the manganese ore in the furnace charge is gradually decomposed and reduced under the high temperature condition, a primary smelted product is obtained, and after the primary smelted product is separated, liquid mid-carbon ferromanganese and new manganese slag are obtained; and 2, the new manganese slag and preheated ferrosilicon powder are combined and put into a shaking ladle for the first time of shaking smelting desilication, after final slag on the upper layer is removed, a proper amount of preheated manganese and lime are put into low-silicon manganese-silicon alloy liquid on the lower layer of the shaking ladle, the second time of shaking smelting desilication is carried out, the poor-manganese slag on the upper layer is recovered, and liquid which remains at the lower layer of the shaking ladle is liquid low-carbon ferromanganese. The method has the beneficial effects that a large quantity of energy is saved, production consumption is reduced, and meanwhile the productivity of the ferromanganese alloy is improved; production cost is greatly reduced, production benefits are greatly increased, waste is turned into wealth, cost is reduced, consumption is lowered, and profits are increased.

Owner:ZHENYUAN COUNTY HONGFENG NEW MATERIALS CO LTD

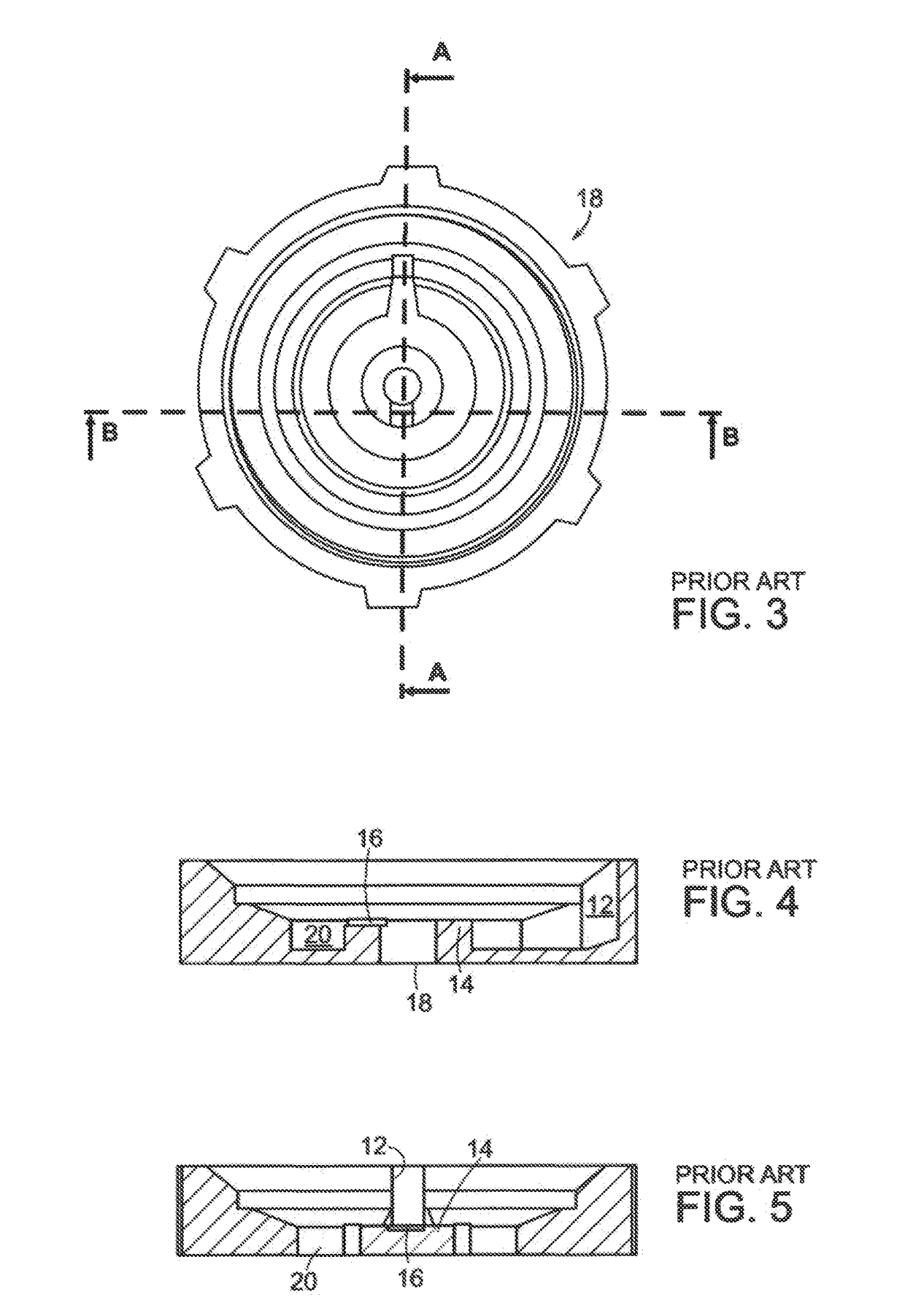

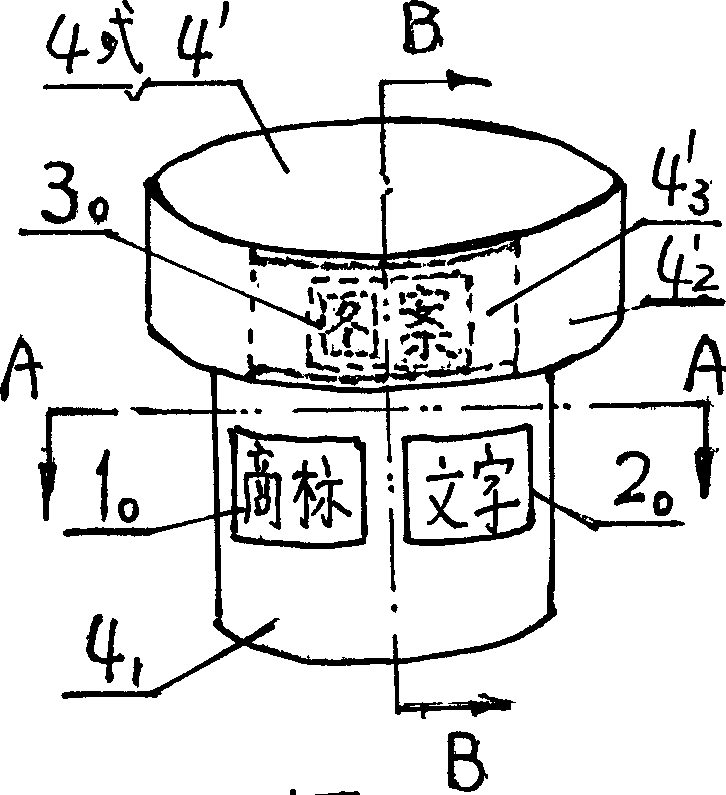

Anti-false bottle cap with thermo-color and invisible fluorescence display as well as mfg. and operation method

InactiveCN1431130AGood misalignment effectIncrease the difficulty of imitationCapsClosure capsFluorescenceUltraviolet

An antifraud bottle cap features that a thermo-allochroic ink and a fluorescent ink are used to print one or two markers on it, which are composed of trademark, pattern and characters. When it is heated, the colors of said marker can be changed or eliminated. When it is radiated by ultraviolet ray, the fluorescent marker can show. Its advantage is high antifraud effect.

Owner:邱忠明

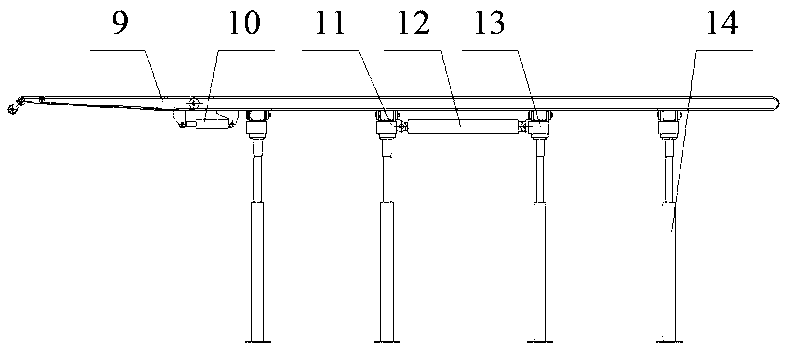

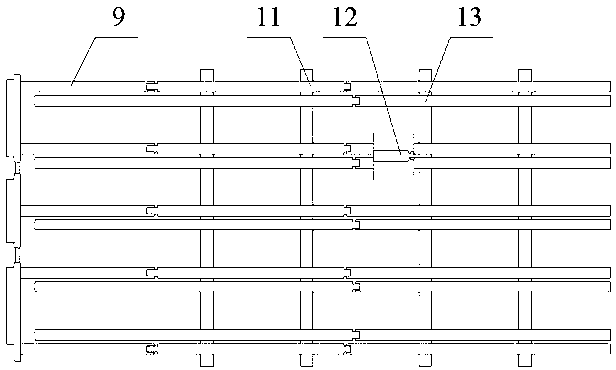

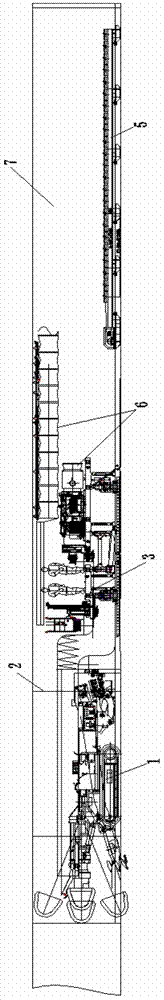

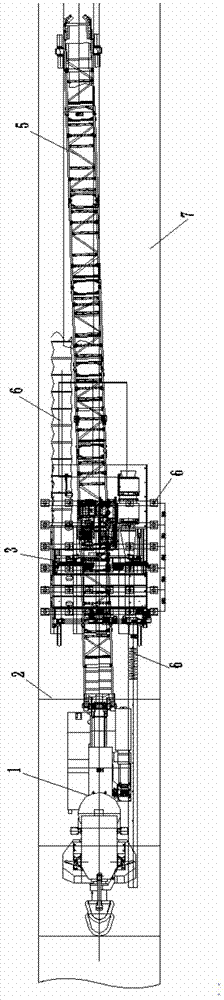

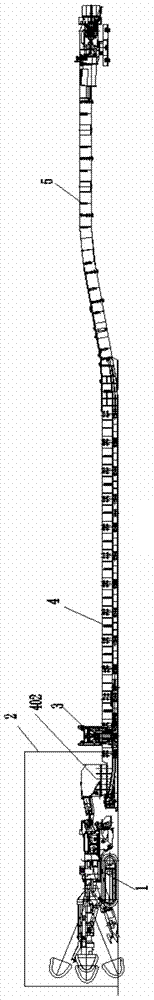

Continuous automation speedy driving technology for driving and anchoring

ActiveCN103899319ASolve the problem of low excavation efficiencyChange processTunnelsContinuous/uninterruptedEngineering

The invention relates to a continuous automatic speed driving technology for driving and anchoring. A driving machine, an advance drilling machine mounted on the driving machine, end supports, anchor rod drilling machine devices, a transferring conveying device or a belt conveyor and a dust removal fan device. The technology includes the operation processes of drilling, driving, supporting, anchoring, conveying and dust removal. Permanent support is divided into head-one support and rear support with the end supports as a boundary. According to the head-on support, the two head-on anchor rod drilling devices are used for the head-on support, at least two anchor rods are arranged in the gape between the end supports in each row in a drilled mode, the anchor rods only provide control and restraint for a top plate separation layer, and the end supports play a role in protection. When a next operation process cycle is performed, the rear support is constructed after part of remaining anchor rods and part of remaining anchor cables are completely lagged behind the end supports, and continuous operation is performed behind the end supports. The problem that comprehensive driving efficiency of a roadway poor in surrounding rock stability is low is solved, driving construction and anchoring construction can be in parallel operation, construction efficiency is improved, and meanwhile the construction environment of comprehensive driving and anchoring is improved.

Owner:山西潞安环保能源开发股份有限公司漳村煤矿

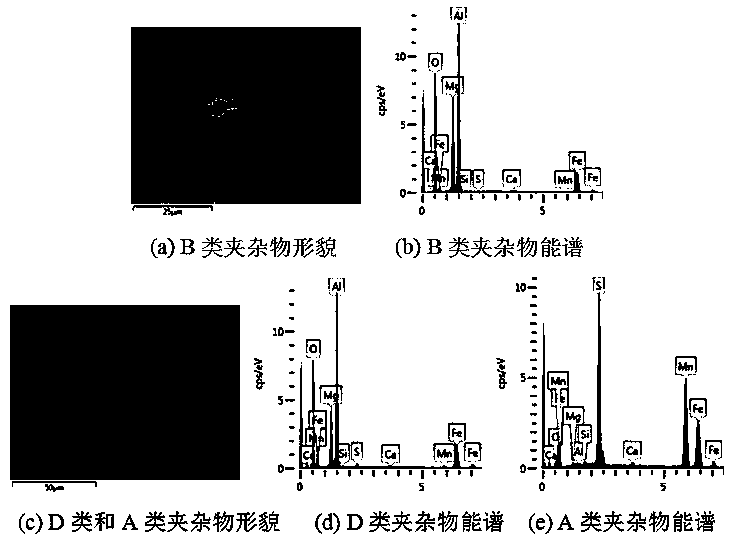

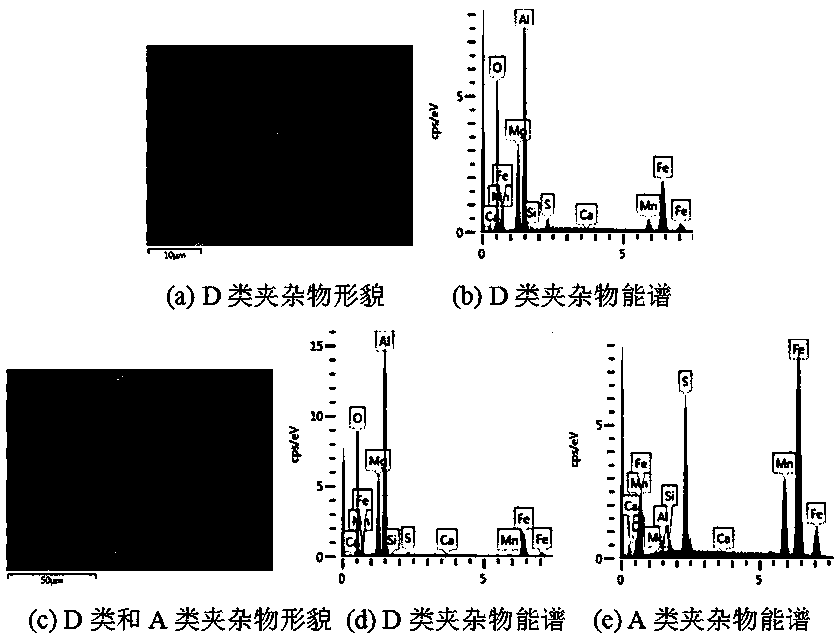

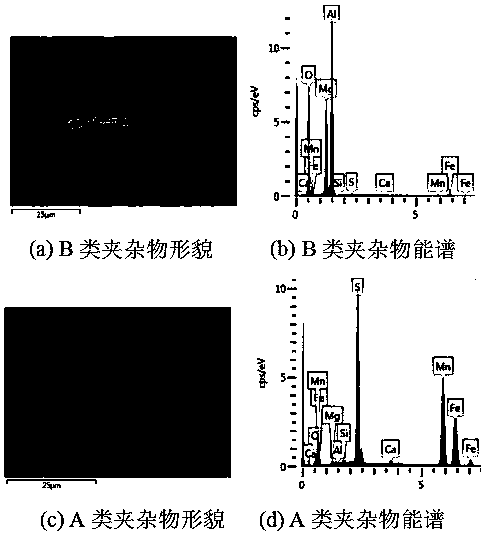

Smelting method of low-cost high-purity 60Si2Mn spring steel

PendingCN111485062AReduce manufacturing costReduce manufacturing costsManufacturing convertersProcess efficiency improvementCarbon alloySpring steel

The invention discloses a smelting method of low-cost high-purity 60Si2Mn spring steel. The method comprises the following process production steps of converter blowing adopting, LF ladle refining, RHvacuum treatment and casting by a curved spray continuous casting machine. In a converter tapping process, molten steel is subjected to aluminum strong deoxidation, recarburization, alloying and slagging, in a refining process, heating and composition fine-adjusting are conducted, staged bottom blowing stirring control, slag surface deoxidation and molten steel precipitation deoxidation are conducted, and the aluminum content is 0.030%-0.0.45% in a control process; the molten steel is subjected to vacuum treatment, and the molten steel is kept for 20-30min under the state of vacuum less thanor equal to 100pa; and the molten steel is left to stand soft blowing, and the curved spray continuous casting machine conducts protective casting. According to the method, through aluminum strong deoxidation of the molten steel at an initial stage, diffusion and precipitation deoxidation in a refining process, high aluminum content of the molten steel, high alkalinity refining slagging, and molten RH high vacuum circulation treatment, the high-purity 60Si2Mn spring steel can be obtained, and the production steps are few, a single precipitation deoxidation way is used, and the production costis low.

Owner:JIANGSU LIHUAI IRON AND STEEL CO LTD

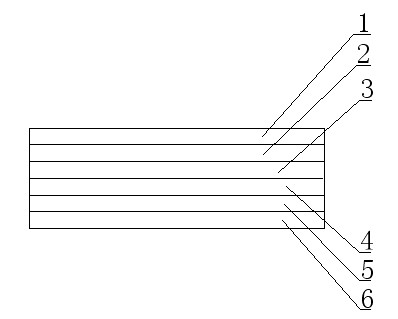

Weatherproof flexible veneer and manufacturing method thereof

InactiveCN102602085AGood flexibilityIncrease profitSynthetic resin layered productsLaminationSolid woodHot melt

The invention provides a weatherproof flexible veneer, which comprises a nonwoven fabric layer, a polyurethane (PUR) hot melt adhesive layer, a wood solid veneer layer, a water-based coloring layer, a PUR hot melt adhesive paint layer and an ultraviolet (UV) finish paint layer, wherein the nonwoven fabric layer is bonded with the solid wood veneer layer through the PUR hot melt adhesive layer, and the water-based coloring layer, the PUR hot melt adhesive paint layer and the UV-side paint layer are sequentially coated on the upper surface of the solid wood veneer layer. The weatherproof flexible veneer has good flexibility and does not crack and prevents the paint from peeling off after being bent for multiple times, the adopted synthesized materials can meet the international environment-friendly requirement, a traditional paint technical is changed, no pollution is led to an application environment, the utilization rate of the paint is high, the weatherproof flexible veneer is free from being delaminated at a high temperature and being embrittled at a low temperature, has excellent properties such as ultraviolet resistance, aging resistance and water resistance and can be made into a veneer synthesized material which can be continuously coiled, and the requirement on elongation and mass production of the material can be met.

Owner:ZHEJIANG LINYA

Method for producing liquid wood integral door

The invention discloses a method for producing a liquid wood integral door, which comprises the following steps of: 1) preparing liquid wood, namely (1) drying and grinding raw materials; (2) mixing the raw materials to obtain a mixture; and (3) generating the liquid wood, wherein the liquid wood comprises the following raw materials in part by weight: 100 parts of polyvinyl chloride, 40 parts of calcium carbonate, 60 parts of wood fiber powder, 4.5 parts of stabilizer, 8 parts of chlorinated polyethylene (CPE), 5 parts of acrylamide (ACR), 3 parts of H530, 0.5 part of polyethylene (PE) wax, 0.6 part of stearic acid, and 1 part of pigment; and 2) performing extrusion molding on the liquid wood at one time to obtain the integral door. In the method, the raw materials are molded at one time at a high temperature and under high pressure, do not contain formaldehyde, and are subjected to surface treatment by adopting thermal transfer technology; the integral door is free of paint, has no any toxic harmful gas and smell release in the production and use process, is environmental-friendly and has practicality.

Owner:杨华

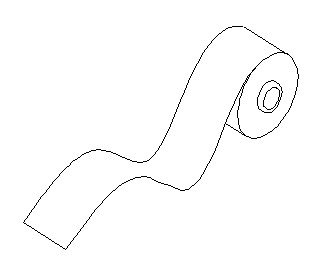

Ultrafine double-sided adhesive tape die cutting technology

InactiveCN106976127AEasy to useAvoid the problem of glue overflow and adhesionMetal working apparatusSurface layerEngineering

The invention provides an ultrafine double-sided adhesive tape die cutting technology. The ultrafine double-sided adhesive tape die cutting technology comprises the following steps that double-sided adhesive tape is provided, a heavy release film is attached to the bottom layer of the double-sided adhesive tape, the surface layer of the double-sided adhesive tape is provided with original release paper in an attached mode, and the whole double-sided adhesive tape is cut into a coil-shaped material strip; partial roller cutting is conducted on one side of the original release paper surface until a cutter arrives at the double-sided adhesive tape, the portion, located at the roller cutting position, of the double-sided adhesive tape and the portion, located at the roller cutting position, of the original release paper are torn away, and the heavy release film region is exposed and serves as a handle portion; the original release paper attached to the double-sided adhesive tape is torn away and replaced by a light release film; the material strip is inverted, the heavy release film surface is upwards placed to be processed through die cutting, cutoff is conducted until the cutter arrives at the double-sided adhesive tape layer, after first-time cutoff of the cutter is accomplished, the double-sided adhesive tape is driven by the material strip to backwards move by the width distance of the needed double-sided adhesive tape, cutting is conducted again, after second-time cutoff of the cutter is accomplished, the double-sided adhesive tape is driven by the material strip to backwards move by the spacing distance, cutting is conducted again, and the step is circularly conducted; and the double-sided adhesive tape width between the first-time cutoff operation and the second-time cutoff operation is reserved, and waste materials are torn away. The ultrafine double-sided adhesive tape die cutting technology achieves complete die cutting of the ultrafine double-sided adhesive tape, and avoids the adhesive overflowing adhesion phenomenon.

Owner:昆山威斯泰电子技术有限公司

Tobacco stem pulping process for producing tobacco flake in method similar to papermaking

The tobacco stem pulping process for producing tobacco flake in method similar to papermaking includes: soaking tobacco stem in hot water of 40-70 deg.c for 1-2.5 hr to extract and solid-liquid separation to obtain solid tobacco stem and tobacco stem extracting liquid; beating tobacco stem fiber in conventional process with primary beating degree of 10-25 deg SR, secondary beating degree of 13-26 deg SR and final beating degree of 14-30 deg SR. The present invention has improved technological process and indexes and the tobacco flake has raised filling performance and capacity of lowering tar releasing amount of cigarette. The present invention can meet the requirement of industrial production and raise the utilization rate of tobacco flake.

Owner:CHINA TOBACCO HUNAN INDAL CORP

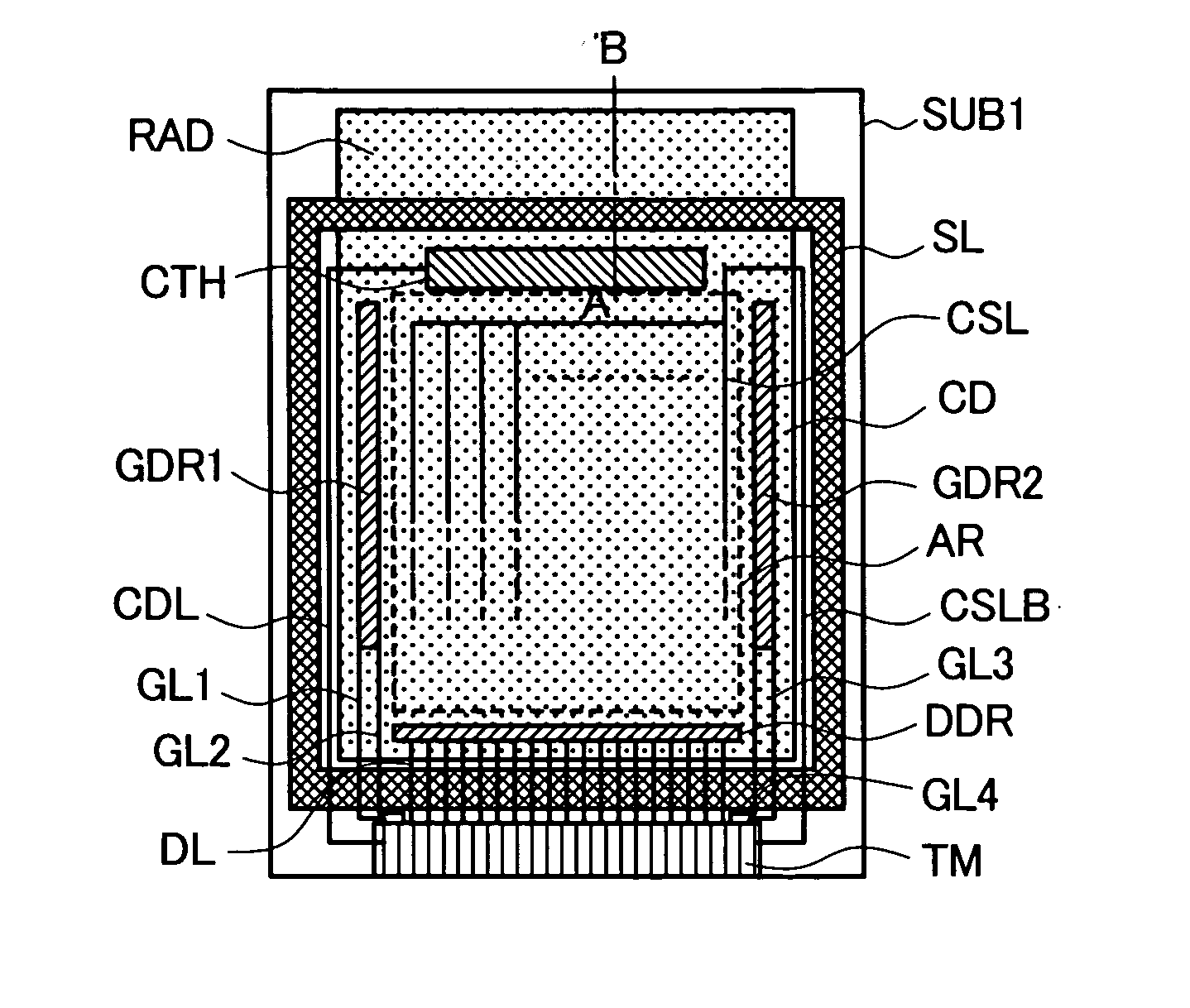

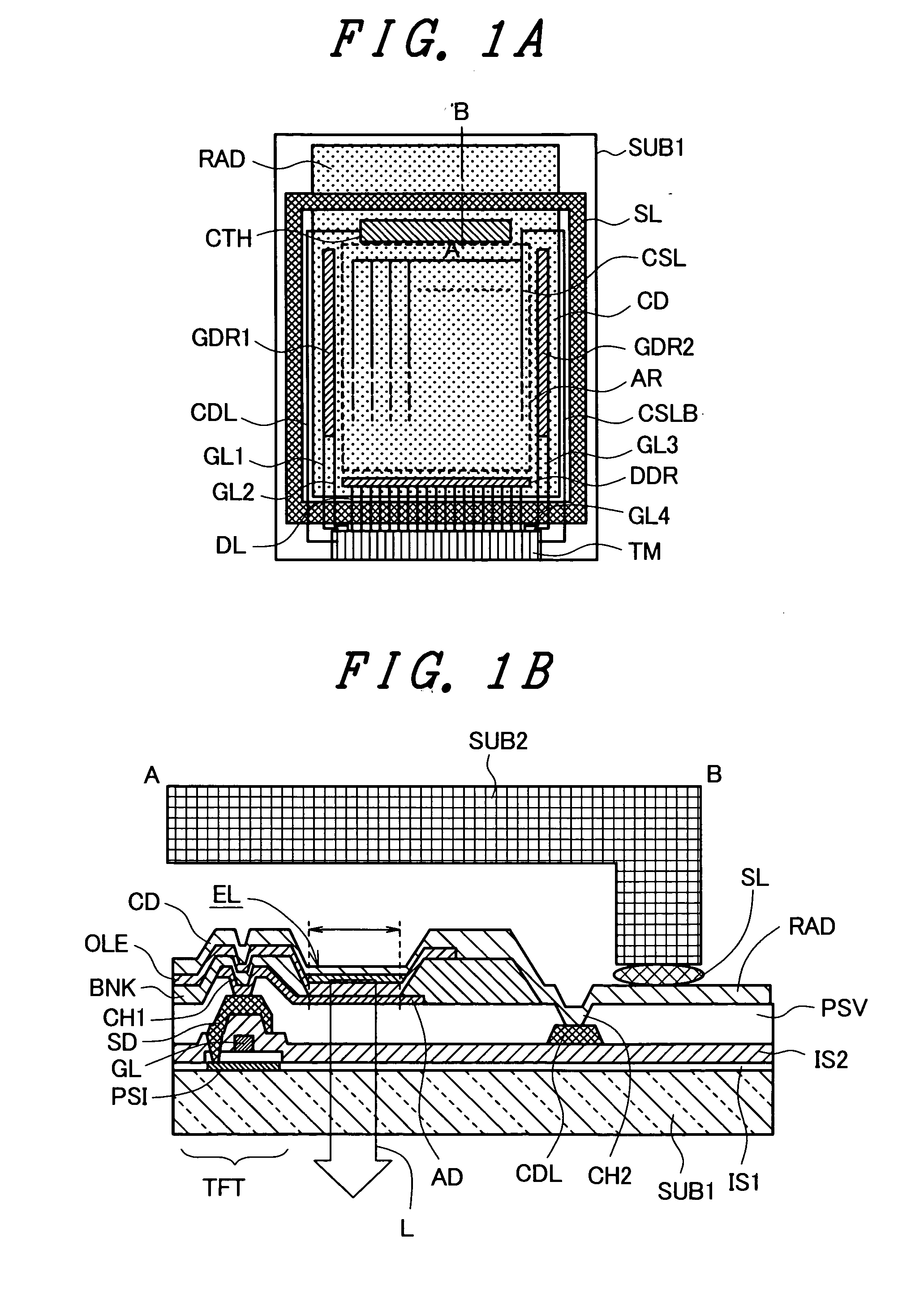

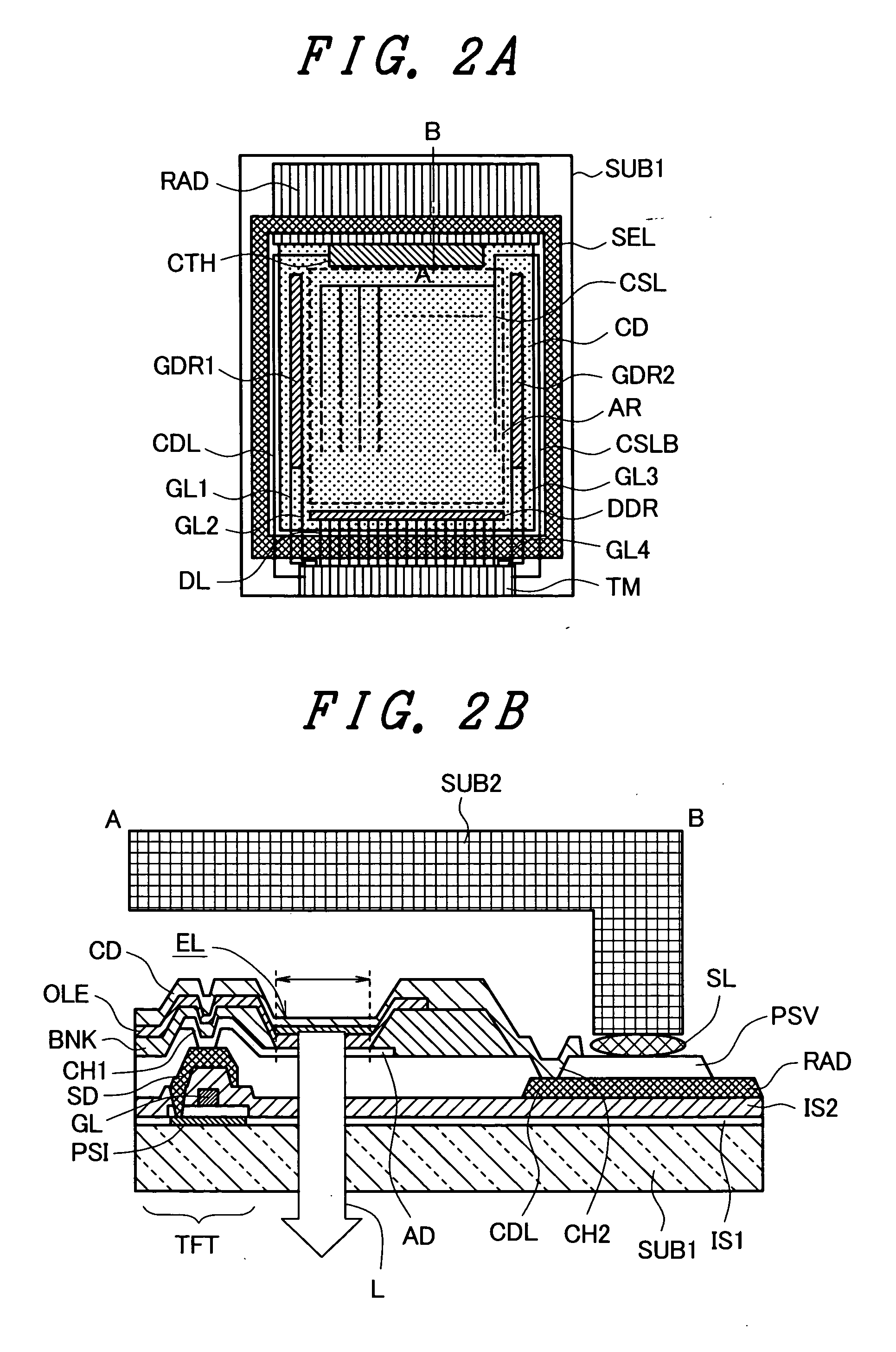

Organic light emitting display

ActiveUS20070045616A1Heat conduction distanceImprove radiation efficiencySolid-state devicesSemiconductor/solid-state device manufacturingLight emissionRadiation

An organic light emitting display provided according to the invention maintains light emission efficiency and elongates its lifetime by radiating heat generated from organic light emitting elements to the outside of an encapsulated area. In the organic light emitting display, a part of a cathode is extended to the outside of the encapsulated area of a main substrate to form a radiation section integrally with the cathode. Heat generated from organic light emitting elements is diffused and radiated from the radiation section so that the heat can be discharged therefrom.

Owner:SAMSUNG DISPLAY CO LTD +1

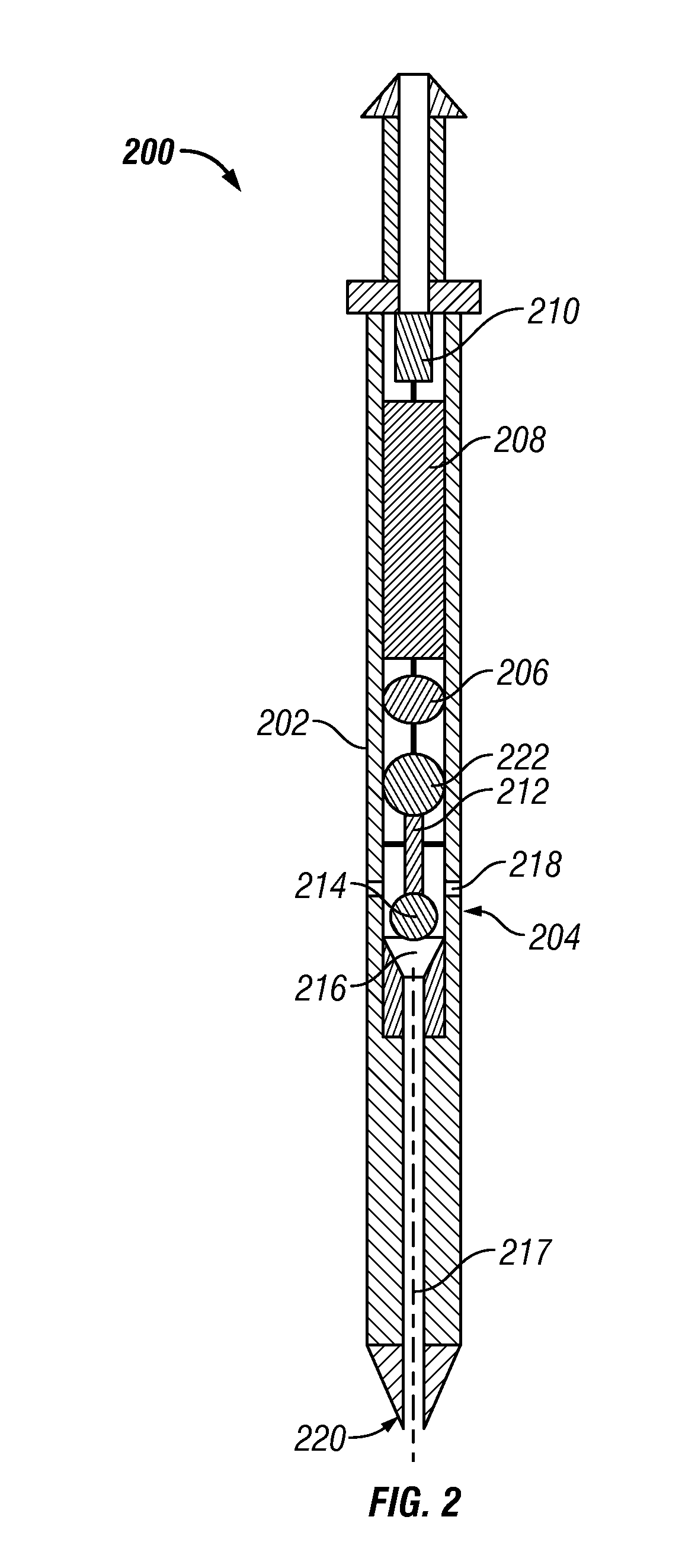

Battery-Powered and Logic-Controlled Gas Lift Valve for Use in Wells and Methods of Using and Making Same

A flow control device is provided that in one embodiment includes a flow-through region configured to receive formation fluid at an inflow region and discharge the received fluid at an outflow region and a setting device configured to adjust the flow of the fluid through the flow-through region to a selected level. The setting device includes a coupling member configured to be coupled to an external latching device adapted to move the coupling member to cause the setting device to alter the flow of the fluid from the flow-through region to the selected level.

Owner:BAKER HUGHES INC

Downhole-Adjustable Flow Control Device for Controlling Flow of a Fluid Into a Wellbore

ActiveUS20110147006A1Change processFluid removalWell/borehole valve arrangementsControl flowFormation fluid

A flow control device is provided that in one embodiment includes a flow-through region configured to receive formation fluid at an inflow region and discharge the received fluid at an outflow region and a setting device configured to adjust the flow of the fluid through the flow-through region to a selected level. The setting device includes a coupling member configured to be coupled to an external latching device adapted to move the coupling member to cause the setting device to alter the flow of the fluid from the flow-through region to the selected level.

Owner:BAKER HUGHES INC

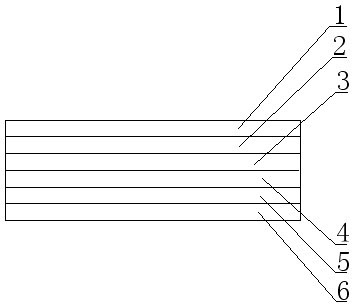

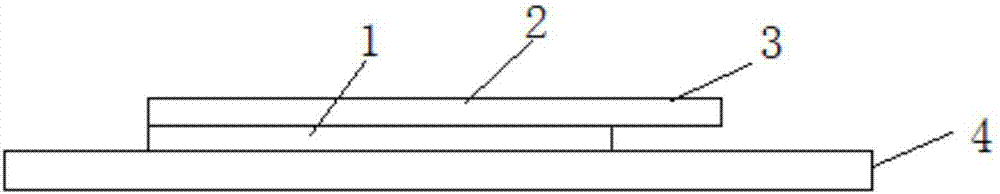

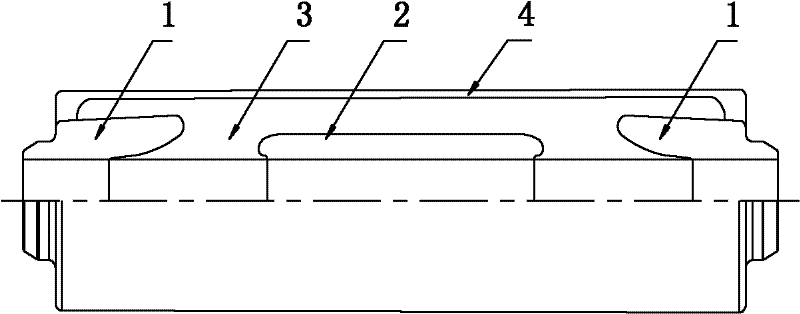

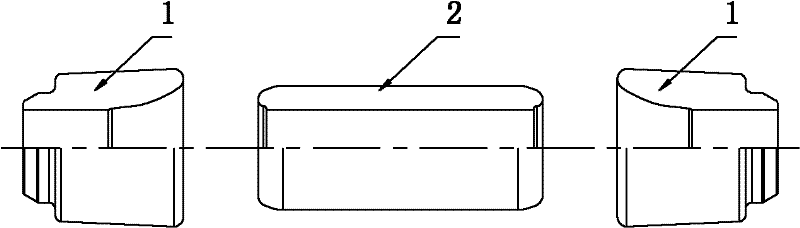

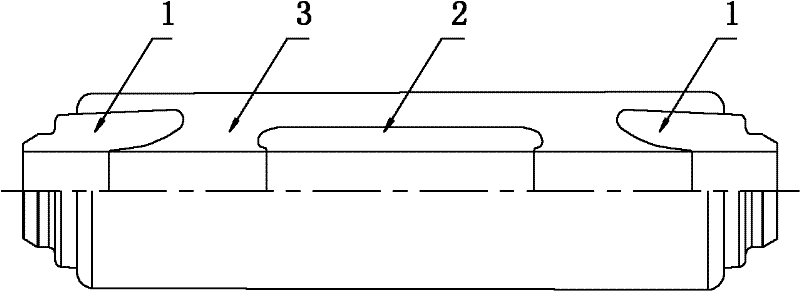

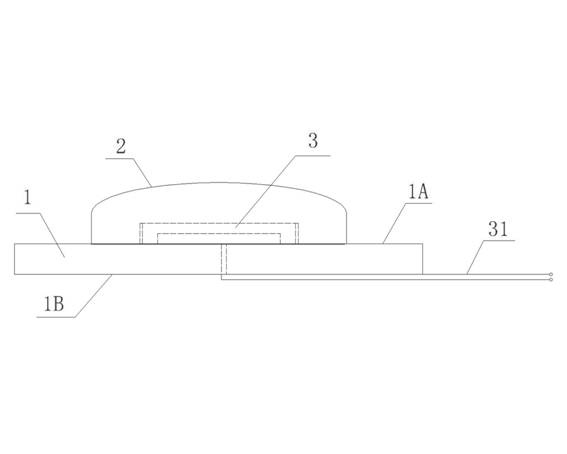

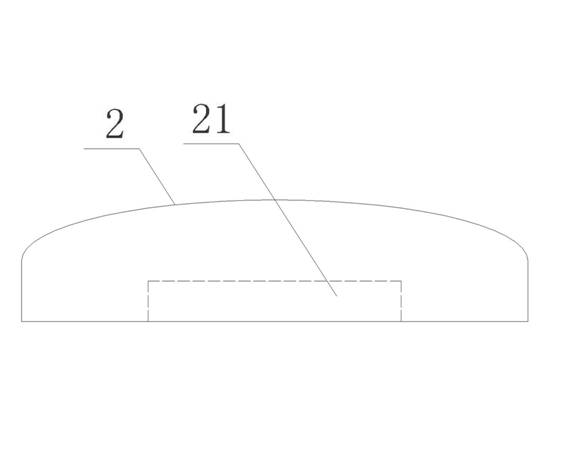

110KV intermediate head and production process thereof

ActiveCN102185274AImprove visibilityConvenient inspectionLine/current collector detailsCable junctionsEngineeringSilicon rubber

The invention provides an 110KV intermediate head and a production process thereof. The intermediate head comprises two stress cones (1), a screening tube (2), insulating layers (3) and outer screening layers (4), wherein the screening tube (2) is arranged between the two stress cones (1); the insulating layers (3) are filled between the screening tube (2) and the two stress cones (1); and the outer screening layers (4) are coated outside the insulating layers (3). The process of producing the 110KV intermediate head comprises three formations, that is, the first formation is the formation ofthe conductive stress cones and the screening tube; the second formation is the formation of the insulating layers: the formed stress cones and a formed stress tube are arranged in a mould during glue injection and then integrated after formation; and the third formation is the formation of outer conducting layers: all parts are integrated after formation to form the intermediate head. The formedinsulating layers of the intermediate head are made from transparent insulated rubbers, thus being high in visibility and being convenient to check.

Owner:江苏远航电缆附件有限公司

Warm moxibustion protector

InactiveCN102631287AAccurate temperatureImprove temperature stabilityDevices for heating/cooling reflex pointsElectrotherapyElectricityThermal insulation

The invention discloses a warm moxibustion protector comprising protection pads. Each protection pad is divided into an inner side surface and an outer side surface; at least one ceramic grain is fixedly arranged on the inner side surface of each protection pad, and a first groove is arranged on the bottom of each ceramic grain and is internally and fixedly provided with an electric heating element; the bottom of the ceramic grain is tightly adhered with the inner side surface of the protection pad; a power line of the electric heating element penetrates out of the inner side surface of the protection pad and then is connected with an external power supply or a controller; and a second groove is arranged to be adjacent to either side of the first groove and is internally and fixedly provided with a temperature detection element. The protector also can comprise a pneumatic massage mechanism. A plurality of connectors respectively connected with the protection pad can be arranged on the controller and can be used for controlling the moxibustion temperatures, the massage ways and the like of the protection pads, thereby forming a multifunctional warm moxibustion apparatus with functions of warm therapy, far infrared physiotherapy, moxibustion and massage therapy; and according to the warm moxibustion protector, a user can use the moxibustion apparatus conveniently and safely, the thermal insulation effect is good, the physiotherapy temperature is accurate and can be adjusted freely, the power consumption is less, and the warm moxibustion protector is low-carbon and environment-friendly.

Owner:SHANGHAI LITTER WINNER HEALTH TECH & EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com