Battery-Powered and Logic-Controlled Gas Lift Valve for Use in Wells and Methods of Using and Making Same

a logic-controlled, gas-powered technology, applied in the direction of borehole/well accessories, non-positive displacement pumps, thin material handling, etc., can solve the problems of insufficient downhole pressure, excessive introduction of injected gas to the selected locations, and general imprecise valve settings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013]The present disclosure relates to apparatus and methods for controlling flow of formation fluids in a well. The present disclosure provides certain exemplary drawings to describe certain embodiments of the apparatus and methods that are to be considered exemplification of the principles described herein and are not intended to limit the concepts and disclosure to the illustrated and described embodiments.

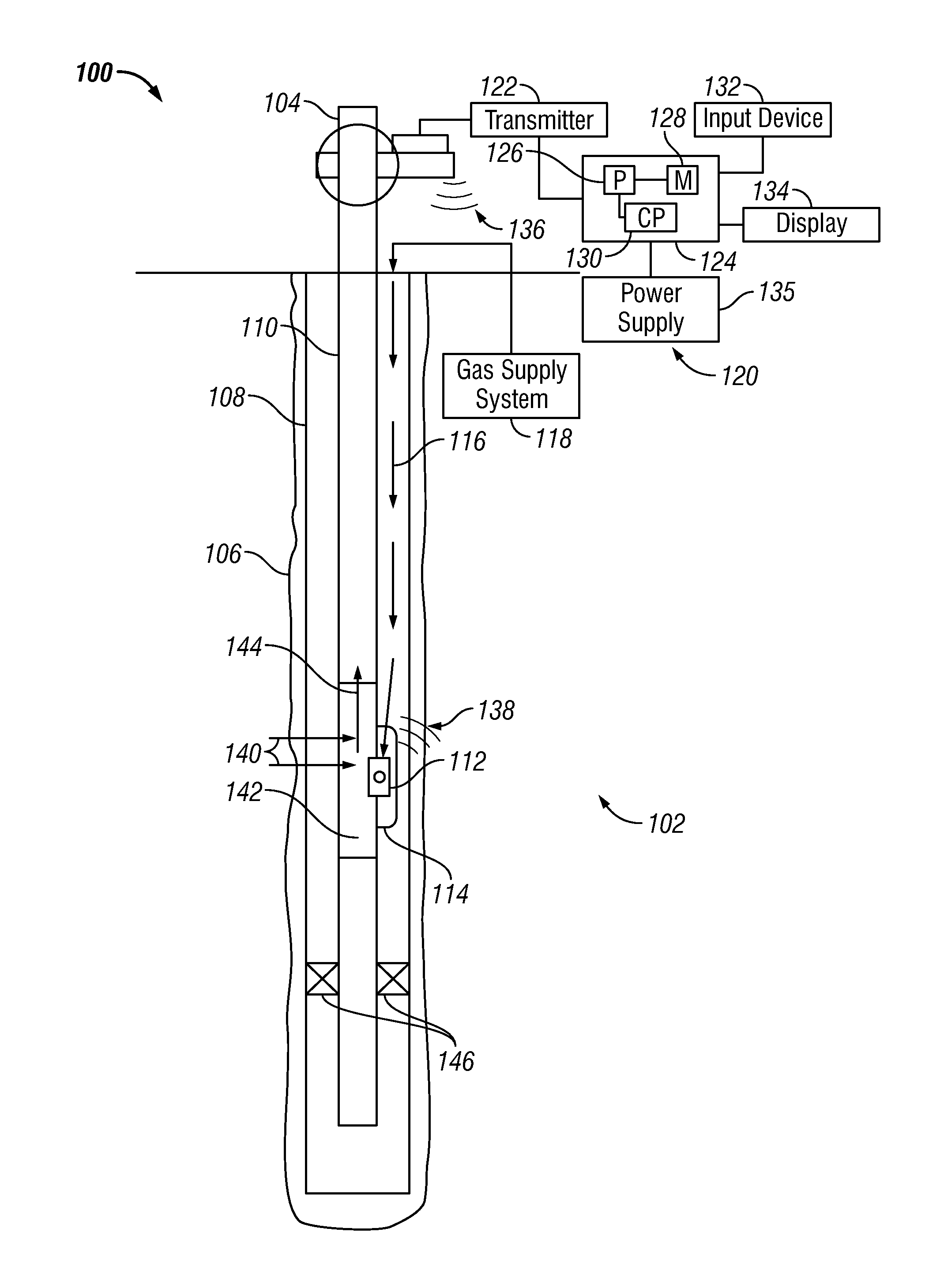

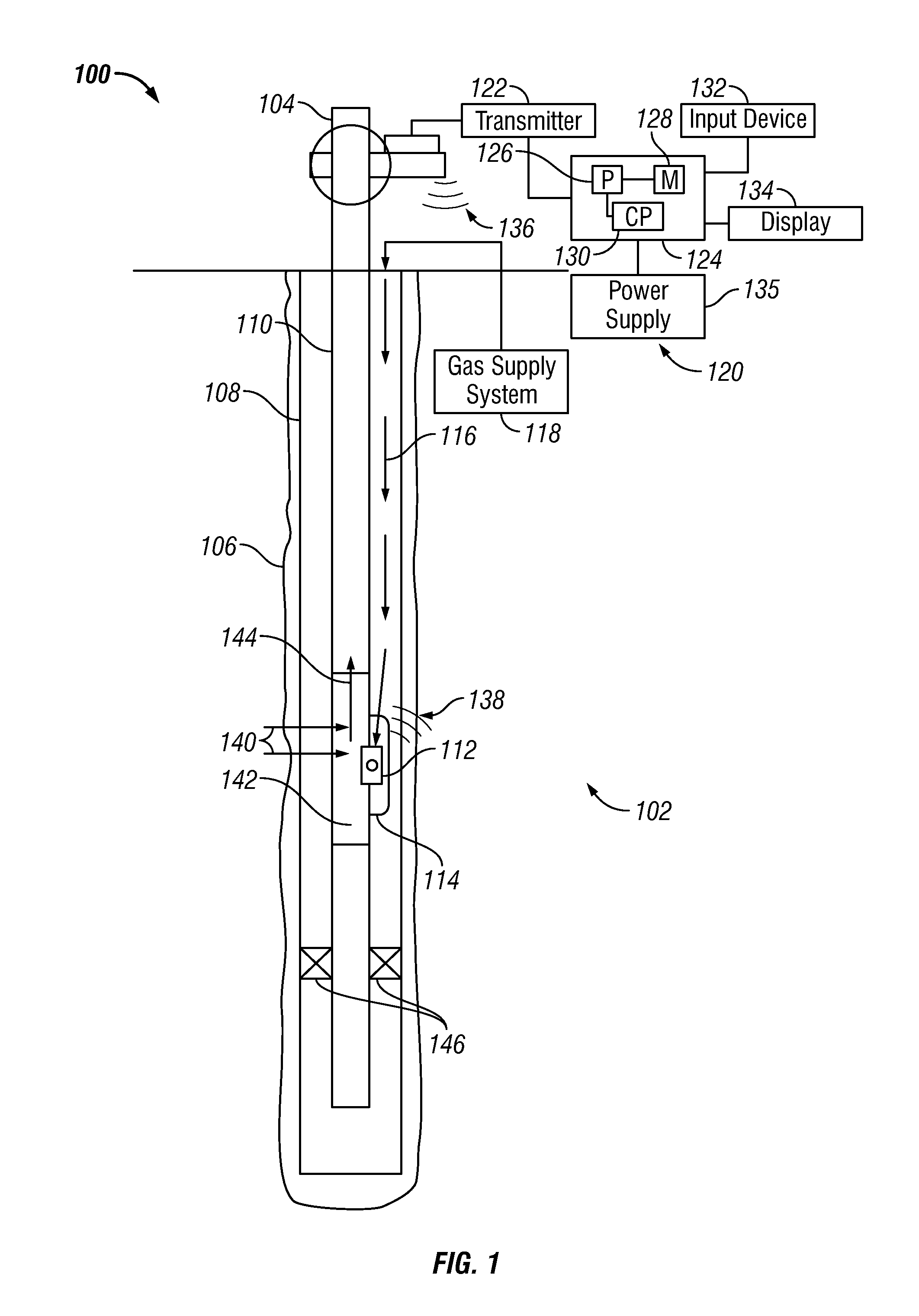

[0014]FIG. 1 is a schematic illustration of an embodiment of a wellbore system 100 configured to extract hydrocarbons from a formation. The wellbore system 100 includes a flow control system 102, wellhead 104, wellbore 106 and casing 108. The flow control system 102 is configured to enhance flow of formation fluid from a formation adjacent to the wellbore 106 as it flows through the casing 108 into a mandrel or base pipe 110. The flow control system 102 includes a flow control device 112 located in a side pocket 114 of the base pipe 110. As discussed below, the flow control de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com