Smelting method of low-cost high-purity 60Si2Mn spring steel

A smelting method and spring steel technology, applied in the field of alloy steel smelting, can solve the problems of high production cost, low molten steel cleanliness, and many process routes, and achieve the effects of reducing production and manufacturing costs, ensuring molten steel purity, and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

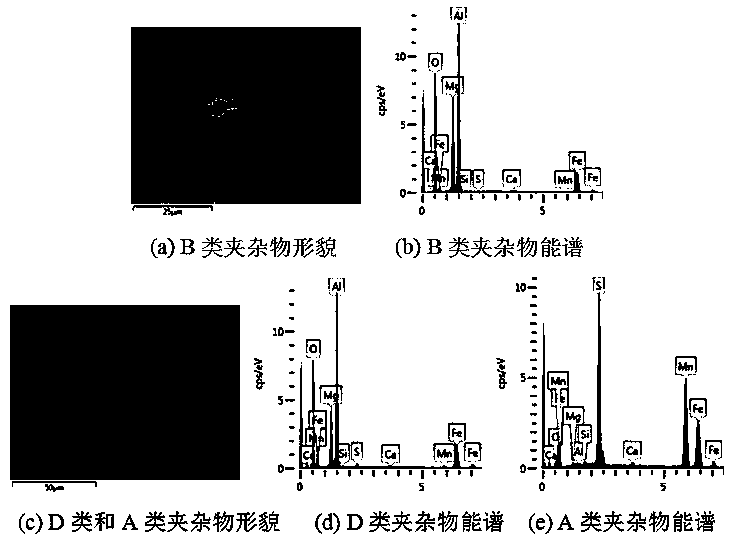

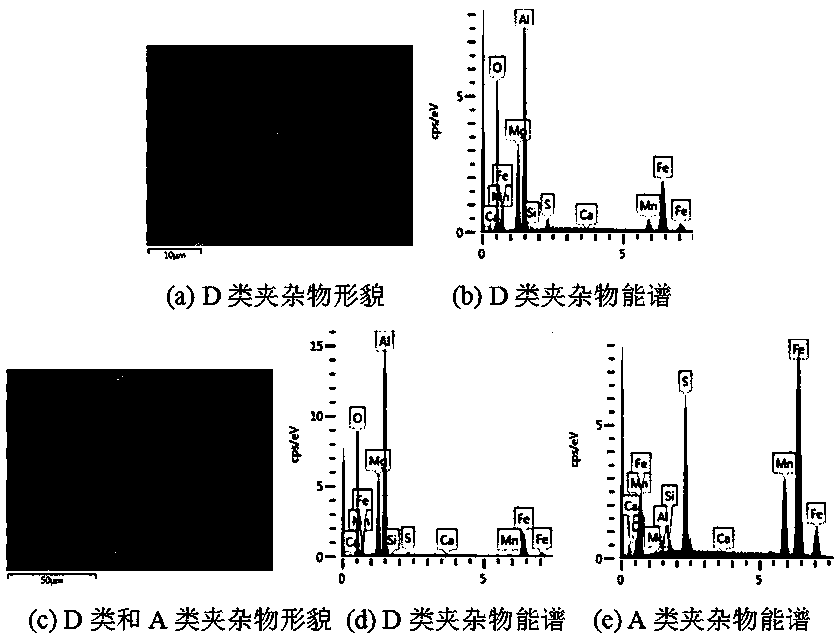

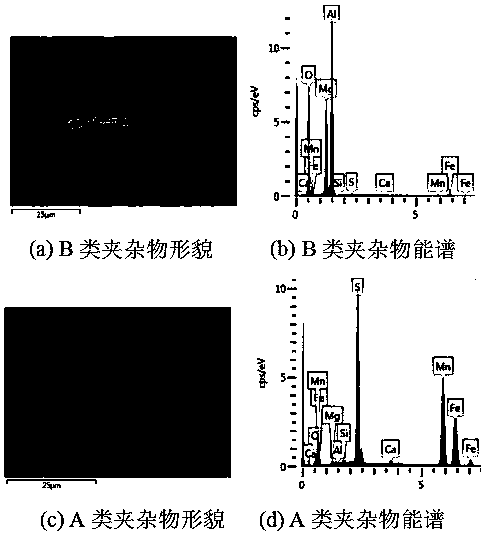

Image

Examples

Embodiment 1

[0036] 1) use w ([S])= 0.030% molten iron and ordinary steel scrap as raw materials, using top-bottom double-blown converter smelting, tapping volume 25t~35t, adding 0.5kg / t aluminum cake with a purity of 99.9% for molten steel precipitation deoxidation; adding aluminum cake for deoxidation After the end, use ordinary recarburizer, ordinary ferrosilicon alloy, silicon manganese, high carbon ferromanganese, ferrochrome alloy for preliminary alloying of molten steel; after alloying, before the end of tapping the molten steel, add 6.5kg / t.

[0037] Refining primary slag w (CaO) / w (SiO 2 )=5.5, w (Al 2 o 3 )= 25.3%; refined to the station w ([Al])=0.019%.

[0038]2) In the refining process of molten steel, the argon flow rate of bottom blowing and stirring is 400 NL / min to 600 NL / min when the temperature is raised in the early stage, the flow rate of argon gas is 200 NL / min to 300 NL / min when the temperature is raised in the middle stage of refining, and the flow of argo...

Embodiment 2

[0044] 1) use w ([S])= 0.020% molten iron and ordinary steel scrap as raw materials, using top-bottom double-blown converter smelting, tapping amount 25t~30t, adding 0.8kg / t aluminum cake with a purity of 99.9% for molten steel precipitation deoxidation; adding aluminum cake for deoxidation After the end, use ordinary carburizer, ordinary ferrosilicon alloy, silicon manganese, high carbon ferromanganese, and ferrochrome alloy for preliminary alloying of molten steel; after alloying, before the end of tapping the molten steel, add 5.5kg / t of lime and refining slag .

[0045] Refining primary slag w (CaO) / w (SiO 2 )=4.9, w (Al 2 o 3 )= 24.6%; refined to the station w ([Al])=0.029%.

[0046] 2) In the refining process of molten steel, the argon flow rate of bottom blowing and stirring is 300 NL / min to 450 NL / min when the temperature is raised in the early stage, and the flow rate of argon gas is 150 NL / min to 250 NL / min when the temperature is raised in the middle stage ...

Embodiment 3

[0052] 1) use w ([S])= 0.025% molten iron and ordinary steel scrap as raw materials, using top-bottom double-blown converter smelting, the steel output is 35t~40t, adding 1.0kg / t aluminum cake with a purity of 99.9% for precipitation deoxidation of molten steel; adding aluminum cake for deoxidation After the end, use ordinary recarburizers, ordinary ferrosilicon alloys, silicon manganese, high carbon ferromanganese, and ferrochrome alloys for preliminary alloying of molten steel; after alloying, before the end of tapping the molten steel, add 5.0kg / t of lime and refining slag .

[0053] Refining primary slag w (CaO) / w (SiO 2 )=4.2、 w (Al 2 o 3 )= 26.5%; refined to the station w ([Al])=0.035%.

[0054] 2) In the refining process of molten steel, the argon flow rate of bottom blowing and stirring is 450 NL / min to 500 NL / min when the temperature is raised in the early stage, and the flow rate of argon gas is 200 NL / min to 300 NL / min when the temperature is raised in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com