Real-time intelligent fuel system for water transport coal-fired power plant

A technology for fuel systems and coal-fired power plants, which is applied in comprehensive factory control, electrical program control, instruments, etc., and can solve problems such as automation, low level of intelligence, inability to upload real-time coal stacking operation data, and affecting boiler combustion effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

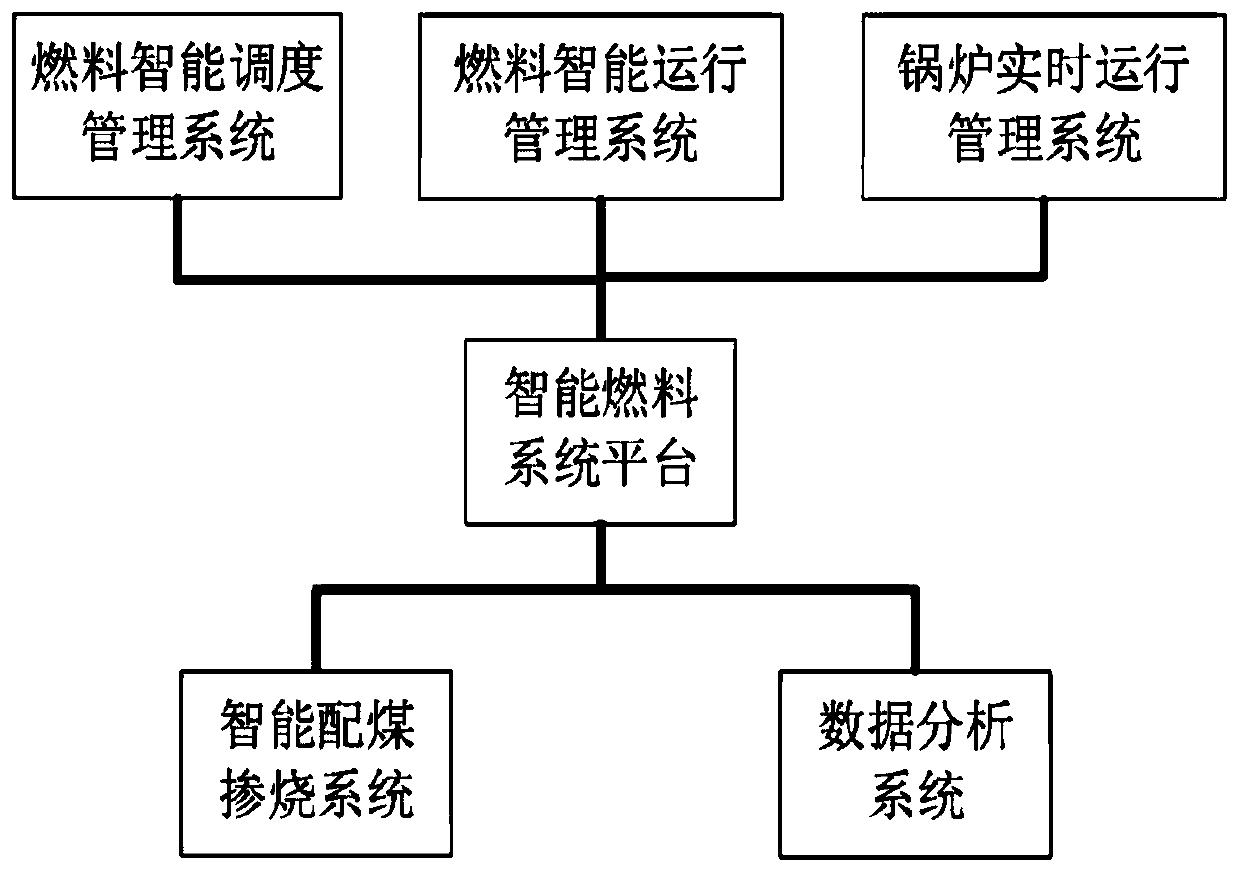

[0078] Embodiment 1: refer to Figure 1-8 . A real-time intelligent fuel system for a waterborne coal-fired power plant, including system equipment. The system equipment includes system equipment. The system equipment includes a bucket-wheel stacker-reclaimer automatic control system, a real-time coal storage system, a coal temperature detection device, and a server;

[0079] The automatic control system of the bucket wheel stacker and reclaimer realizes automatic addressing and automatic coal stacking and reclaiming operations through preset parameters, without manual intervention during the operation; the preset parameters and control instructions are passed through the coal handling program control system The delivery is automatically completed; the automatic control system of the bucket wheel stacker and reclaimer simultaneously obtains the sensory data of the bucket wheel stacker and reclaimer during the operation process, including the working mode of the bucket wheel st...

Embodiment 2

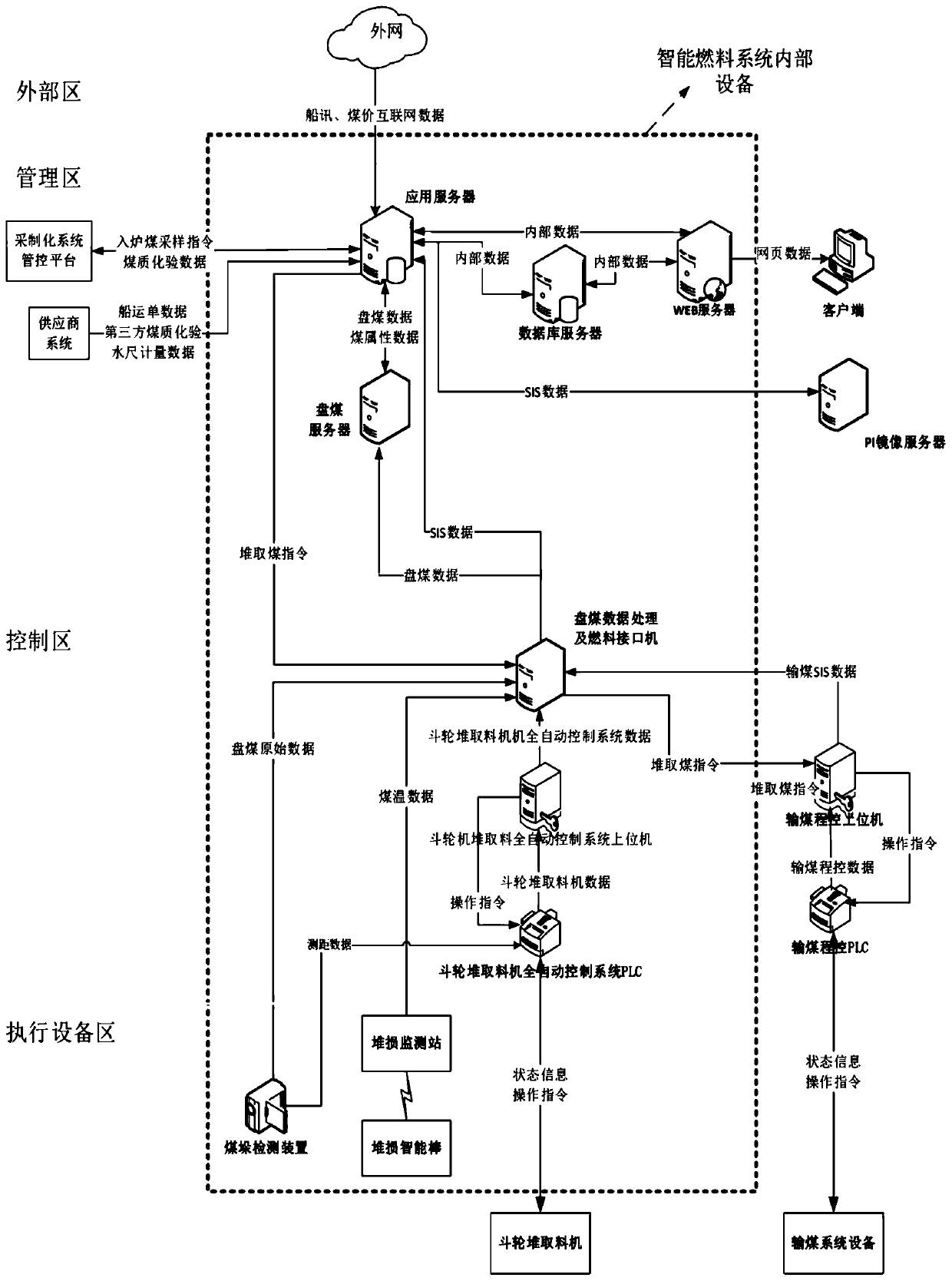

[0097] Embodiment 2: refer to Figure 1-8 . The first main function provided by this system is to integrate the real-time data information of all processes of coal combustion and coal handling equipment with the whole life cycle of coal transportation outside the factory and the circulation process in the factory as the main line.

[0098] The above-mentioned process data information includes shipping bill data, shipping news, incoming inspection data, incoming coal quantity, incoming coal quantity, coal yard inventory data, coal pile coal temperature data, incoming coal quality test data, coal conveying system equipment Operation data, unit operation data, coal bunker coal level data, coal feeder flow data, coal handling equipment power data, and plant weather data. The acceptance data of the factory includes water gauge measurement and third-party coal quality test data.

[0099] The above-mentioned coal handling equipment operation data includes ship unloader, coal handli...

Embodiment 3

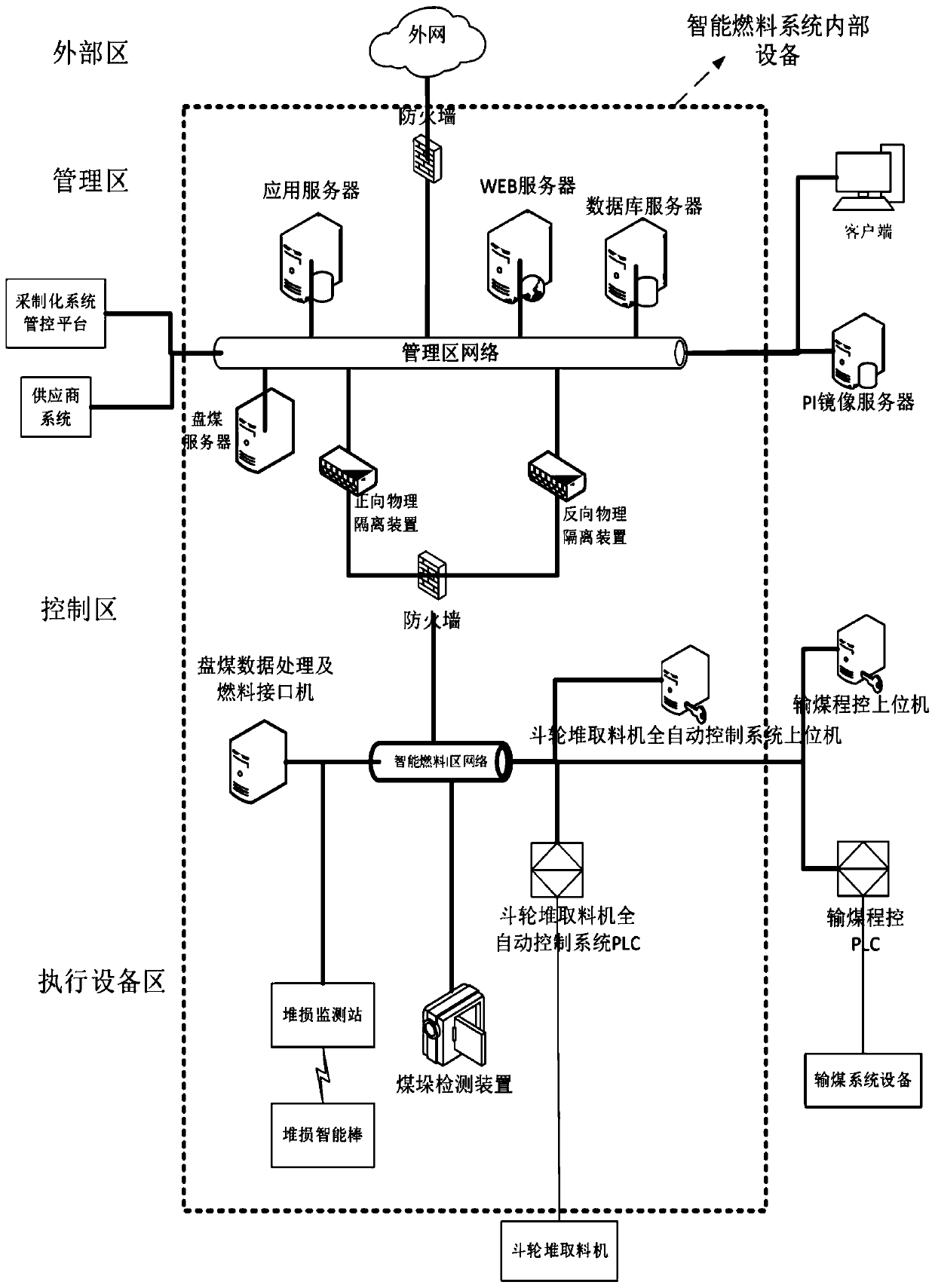

[0119] Embodiment 3: refer to Figure 1-8 . In order to better explain the working principle of the system, the composition of the system is described below, see figure 1 with figure 2 .

[0120] The system composition includes the internal equipment of the intelligent fuel system of the present invention and the existing systems of the power plant that are not part of the present invention but are closely related to the present invention.

[0121] The above-mentioned internal equipment of the intelligent fuel system refers to the equipment and systems newly added on the basis of the existing system of coal-fired power plants, including servers, network equipment, automatic control system of bucket wheel stacker and reclaimer, coal temperature monitoring device, etc.

[0122] The above servers include database server, application server, Web server, pan coal server, pan coal data processing and fuel interface server.

[0123] The above-mentioned database server adopts the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com