Continuous automation speedy driving technology for driving and anchoring

A technological and rapid technology, applied in mining equipment, tunnels, earthwork drilling and mining, etc., can solve the problems of poor stability of surrounding rock and low efficiency of fully mechanized excavation of roadways, etc., and achieve the effect of improving the construction environment and improving the efficiency of bolt digging construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Describe in detail below in conjunction with the specific implementation of the present invention:

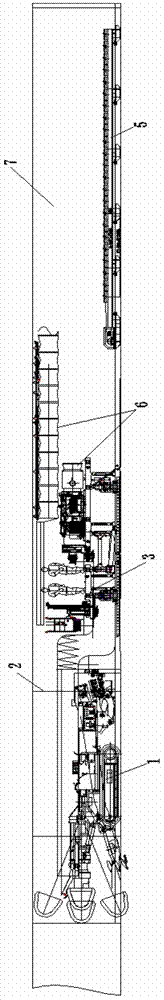

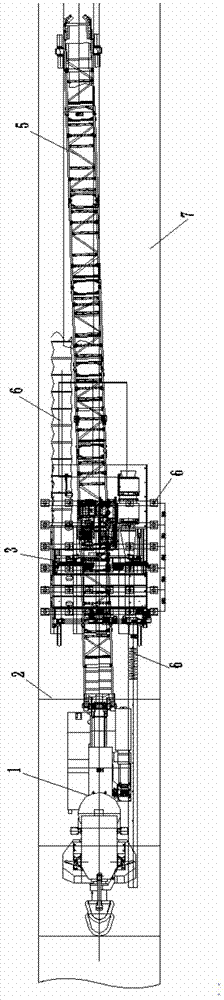

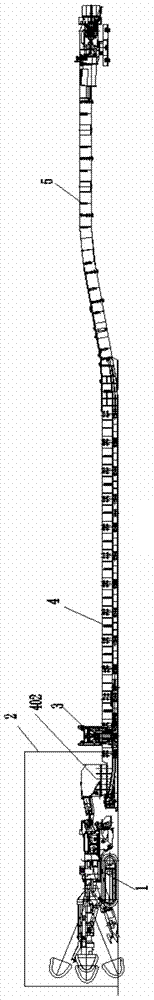

[0031] Such as figure 1 - As shown in -6, the continuous automatic and fast tunneling process of bolt digging of the present invention is based on the continuous support and self-moving type tunneling head support as the core, and adopts the roadheader 1, the airborne advanced drilling rig of the roadheader, the head support 2, and the rock bolt rig Device 3, reload conveying equipment 4 or belt conveyor 5, dust removal fan device 6. The roadheader 1, reloading conveying equipment 4 or belt conveyor 5 are arranged in the roadway 7 in sequence, the end support 2 is arranged on the roadheader 1, the end support 2 of the roadheader 1 works, and the air inlet of the dust removal wind device 6 is arranged in Roadway 7 ends; where:

[0032] 1. The advanced drilling rig mounted on the roadheader is to install the drilling rig on the forearm of the roadheader. The drilling pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com