Supporting method for roadway fully-mechanized drivage operation without withdrawal of roadheader

A technology of fully mechanized excavator and roadway, which is applied in the field of roadway fully mechanized excavation without retreating machine operation support, can solve the problems of poor safety and reliability, complicated operation process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

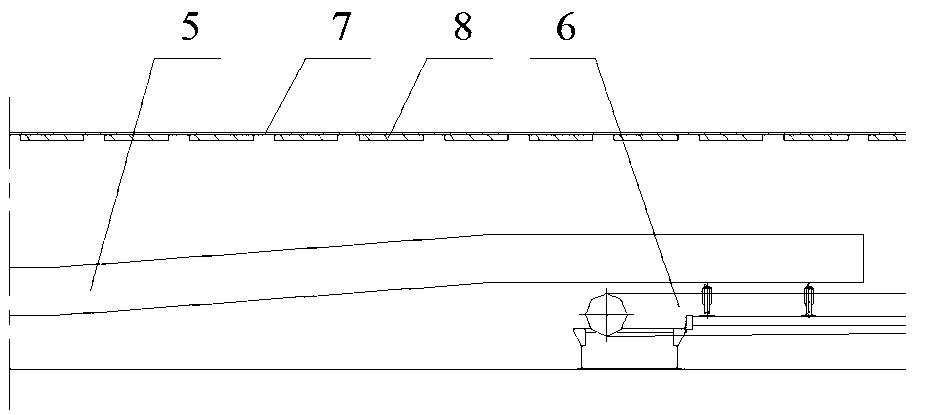

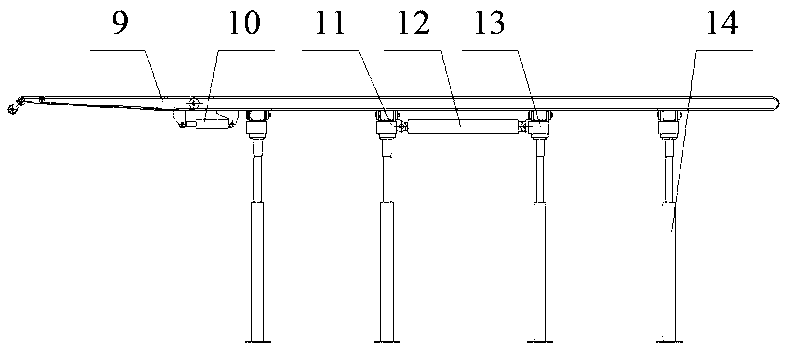

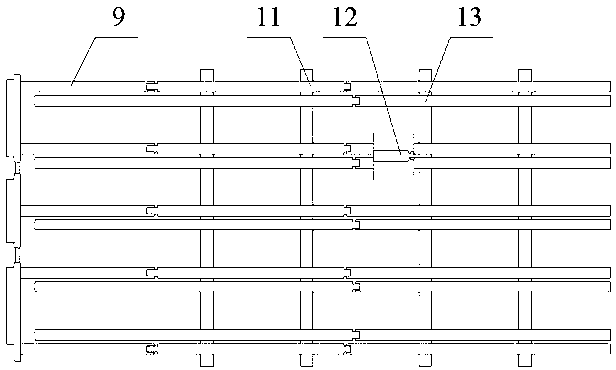

[0028] The specific operation steps of the present invention will be described in detail according to FIGS. 1 to 9 . The roadway fully-mechanized excavation non-returning machine operation support method includes performing supporting operations with the fully-mechanized excavator 2 for roadway excavation to realize temporary support for the newly exposed roof of the roadway fully-mechanized excavation operation, and using the roadway excavation staggered support device 1 ( The publication number is CN102654060A) for the support operation of laying the metal mesh 7 and the steel belt 8 at the front, and using the mobile bolter support platform 3 to perform roof and two gang bolting on the roadway area at the rear of the fully mechanized excavator 2 For the permanent support operation, use the bridge belt transfer machine 5 and the belt conveyor 6 to transport the coal cut by the fully mechanized excavator 2 out of the operation. Among them, the basic structure of roadway drivi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com