Sleeve assembly capable of improvinganti-shearing performance of anchor rod and anchor rod comprising sleeve assembly

A technology of bolts and sleeves, which is applied in the installation of bolts, mining equipment, earth-moving drilling, etc., can solve the problem of high support costs, affecting the effect of roadway support, roadway excavation construction speed, and roadway support safety is difficult to guarantee. and other problems to achieve the effect of improving the quality of support, reducing the physical labor of workers, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

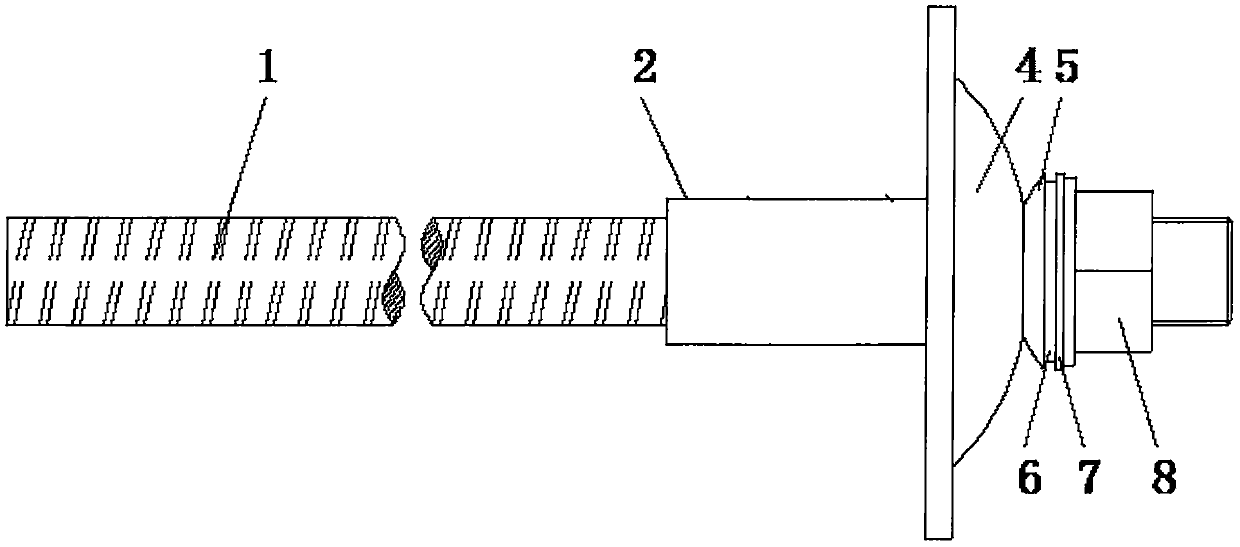

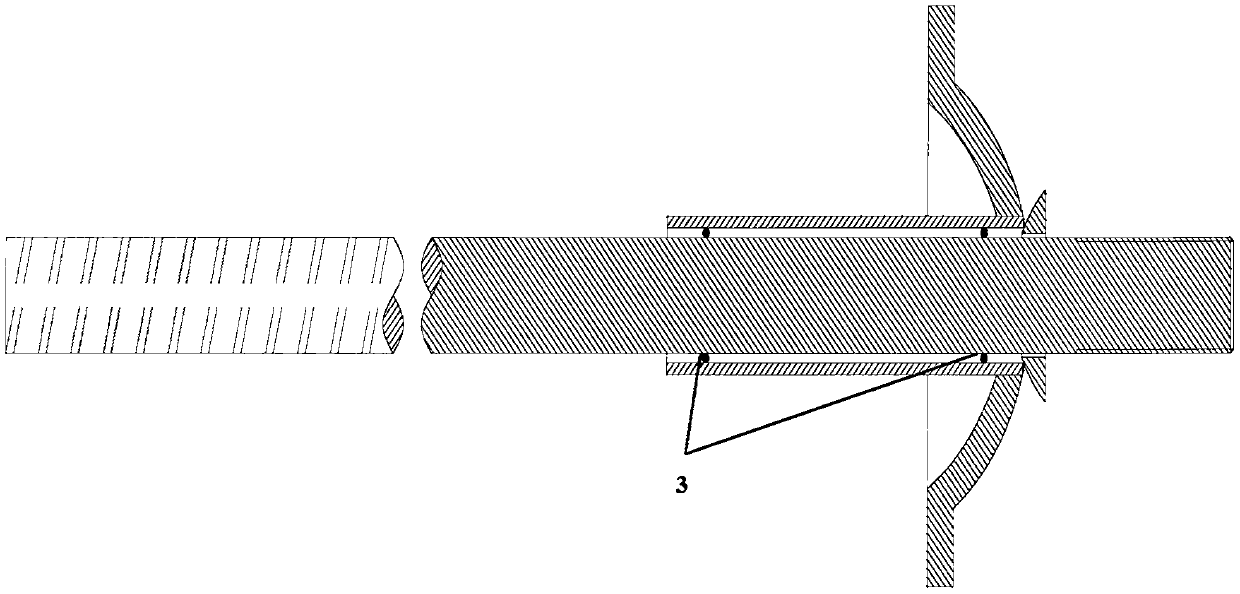

[0022] Example 1, such as Figure 1-Figure 2 As shown, a sleeve assembly for improving the shear resistance performance of the anchor rod, the sleeve assembly includes a sleeve 2, and the sleeve 2 is sleeved on the outside of the anchor rod body 1 and is located inside the tray 4 of the anchor rod end, an O-ring 3 for fixing the position of the sleeve 2 is set between the sleeve 2 and the anchor rod body 1; the sleeve assembly also includes a ball pad 5, a plastic Washer 6, iron gasket 7, the outer end of the iron gasket 7 is provided with a fixed damping nut 8.

[0023] As a preference, the length of the sleeve 2 is 100-1000mm, and the pipe wall of the sleeve 2 is 2.5-3mm; the inner diameter of the sleeve 2 is 6-8mm larger than the diameter of the bolt body 1, and the sleeve 2 The wire diameter of the inner O-ring 3 is 2.5mm.

[0024] As a preference, the specification model of the ball pad 5 is φ50mm×φ25mm×13mm.

[0025] An anchor with shear resistance, comprising an anch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com