Patents

Literature

714results about How to "Reduce physical labor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

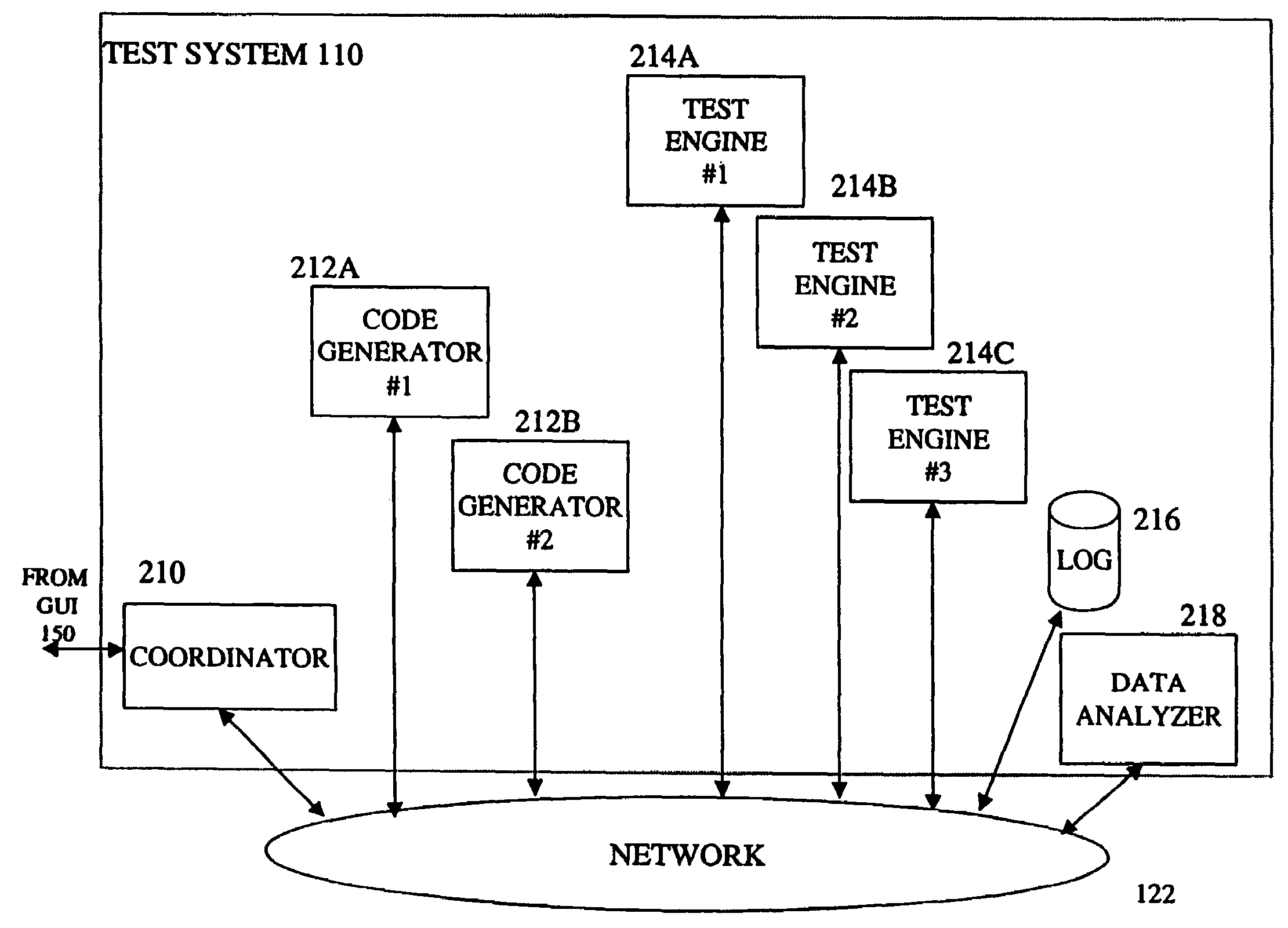

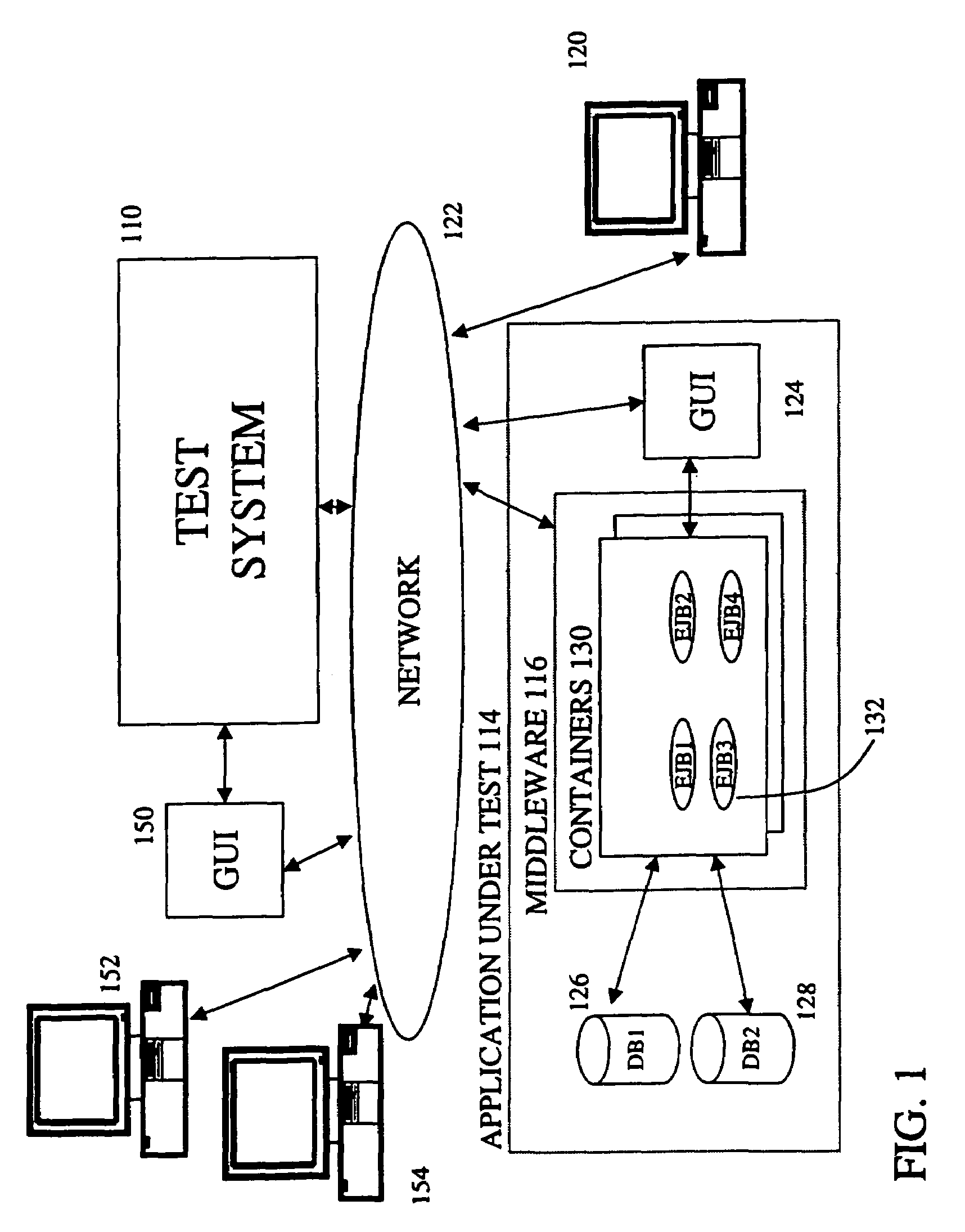

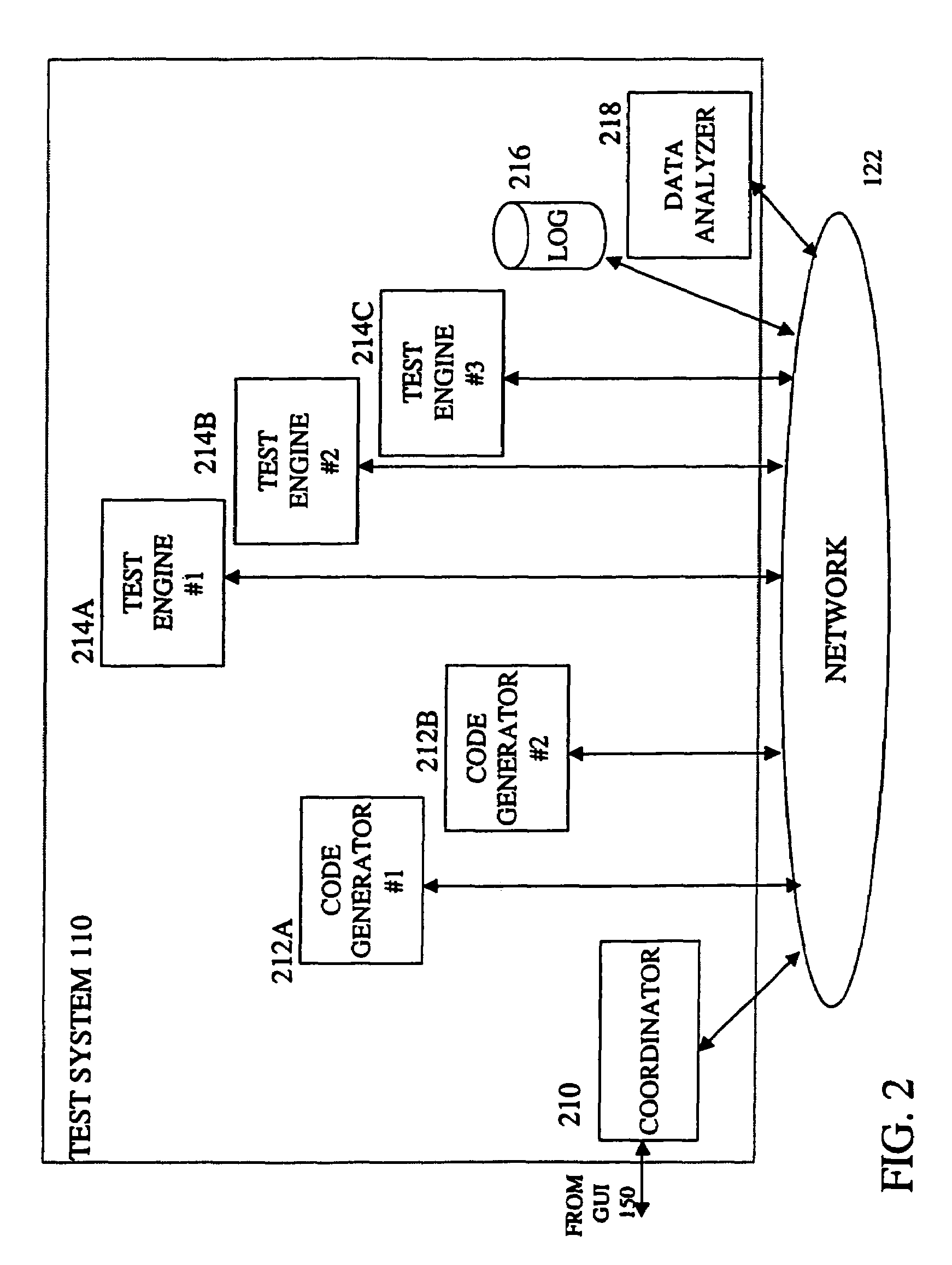

Test code generator, engine and analyzer for testing middleware applications

InactiveUS7000224B1Facilitate load based testing of N-tieredReduce physical laborElectronic circuit testingError detection/correctionProgramming languageData profiling

A system for testing middleware of applications in the N-tiered model. The test system contains test code generators, test engines to execute multiple copies of the test code and a data analyzer to analyze and present the results to a human user. The system is able to automatically generate test code to exercise components of the middleware using information about these components that would otherwise be available to the application under test. Multiple copies of the test code are executed in a synchronized fashion. Execution times of multiple events are recorded and then presented in one of several formats. With the system, an application developer can identify components that represent performance bottlenecks or can gather information on deployment properties of individual components that can be used to enhance the performance of the application under test.

Owner:ORACLE INT CORP

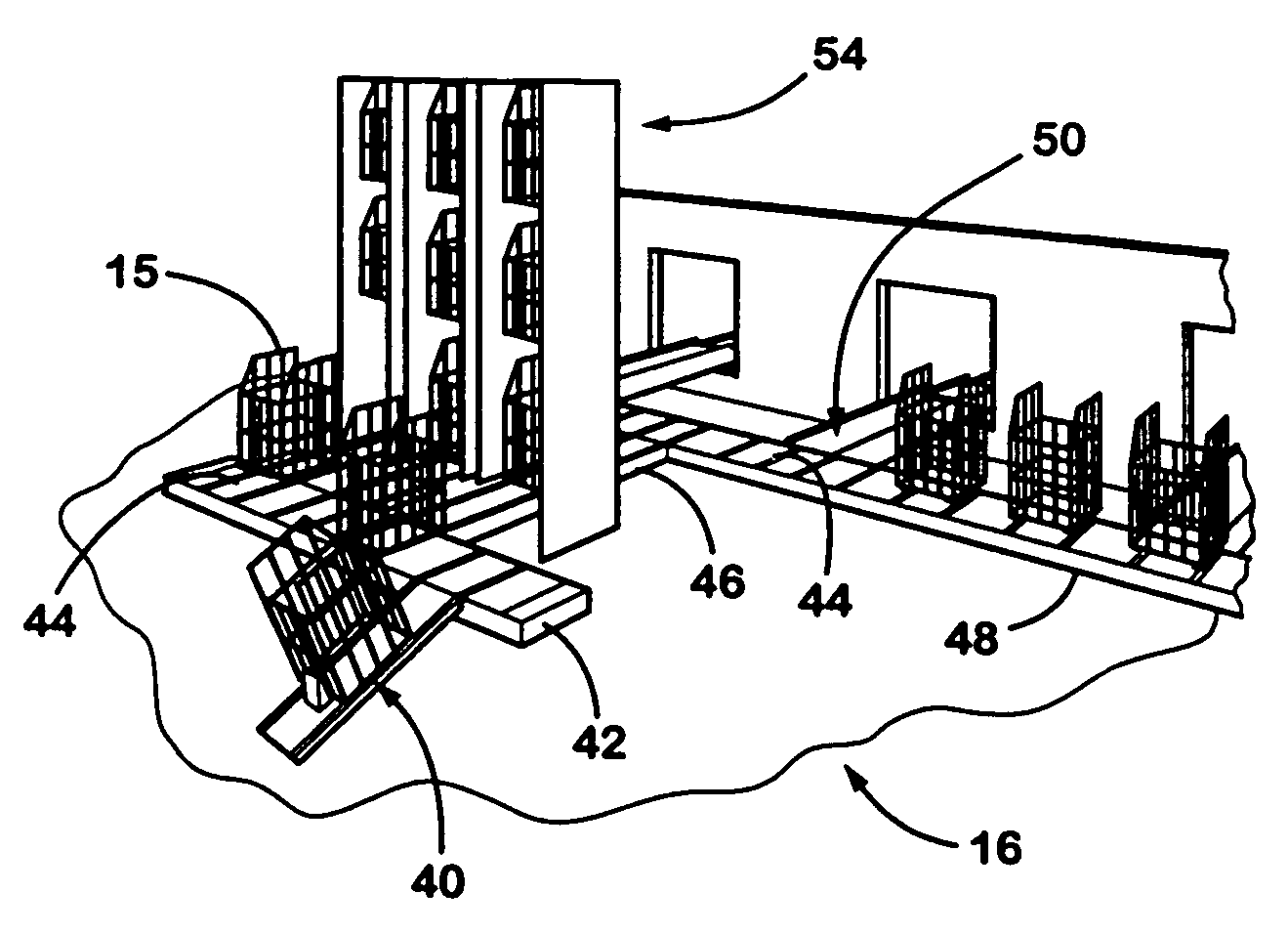

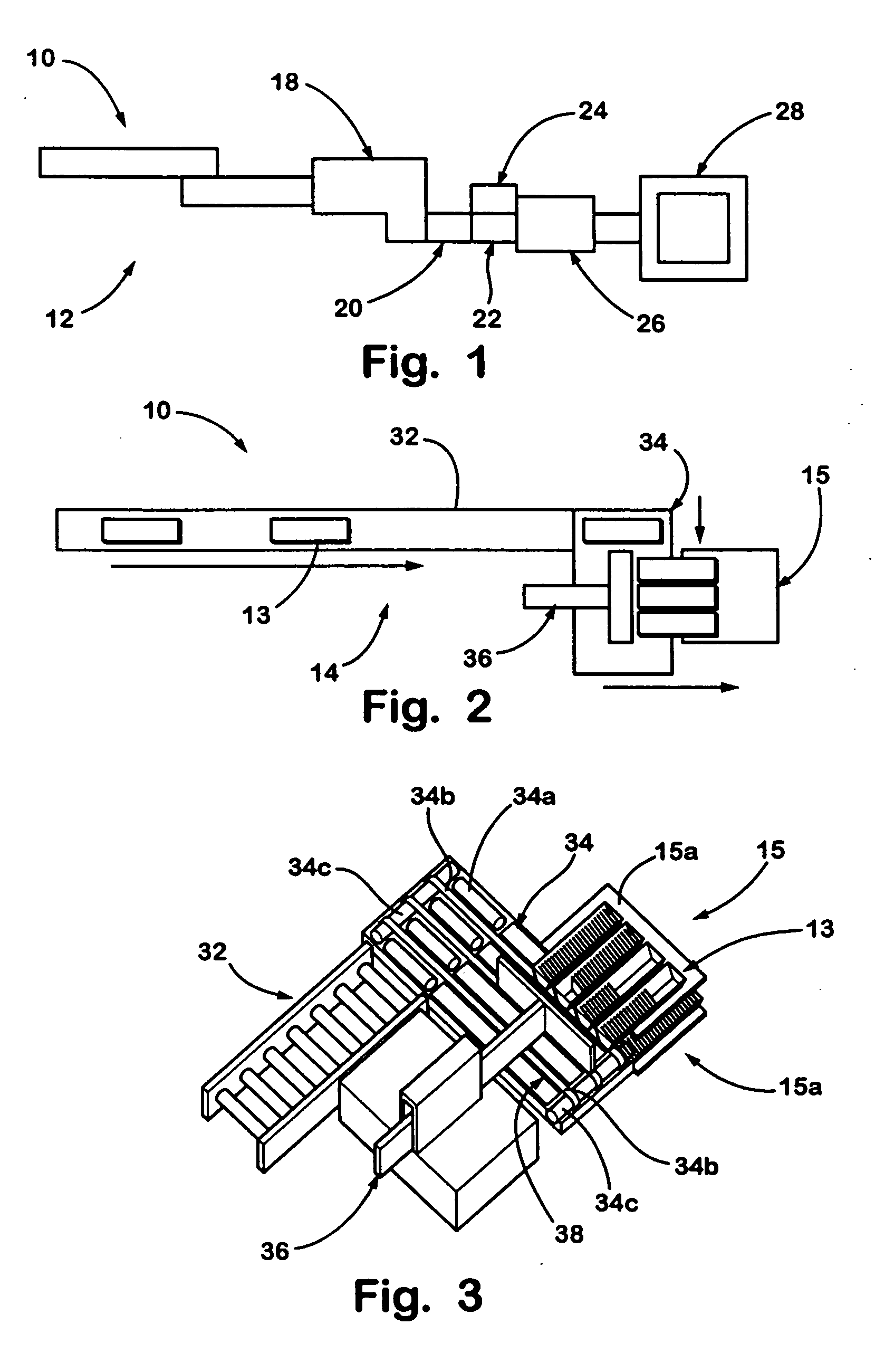

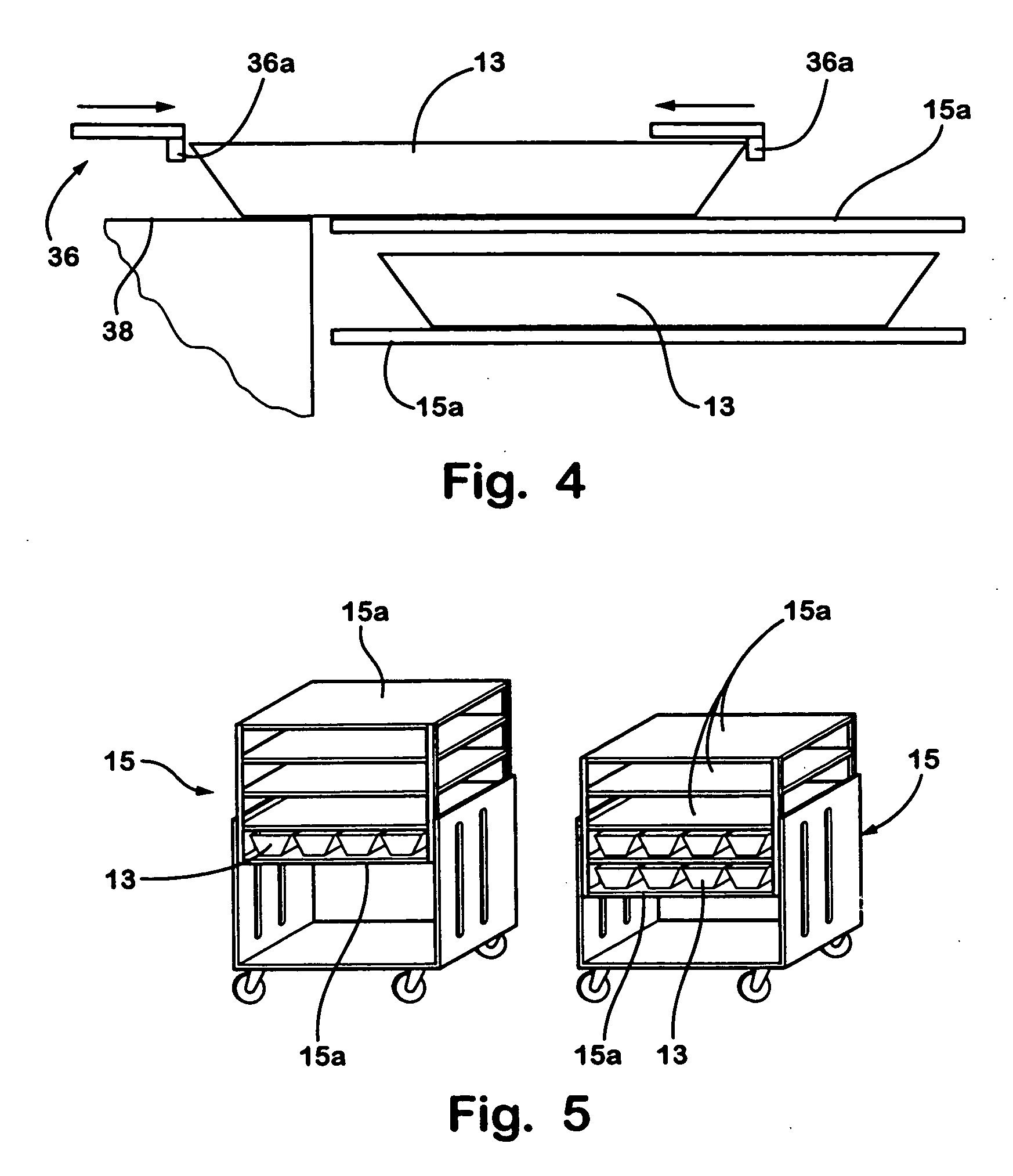

Mail container handling system

InactiveUS20050002772A1Reduce physical laborReduce laborPackagingStacking articlesHandling systemWaste management

A mail container and cart handling system includes a container inspection system, a container handling or loading / unloading system and / or a cart management or handling system. The container inspection system may destack trays and determine whether the trays are damaged and may discharge acceptable containers for use. The container loading / unloading system may receive trays of articles and may move the trays onto shelves of a cart, or may receive carts of trays and may remove trays from the shelves of the carts. The cart handling system may arrange carts at a loading or unloading area and may buffer the carts at the area to provide the carts in an arranged manner for loading carts into a trailer or the like or for receiving and moving carts into a facility.

Owner:RAPISTAN SYST ADVERTISING

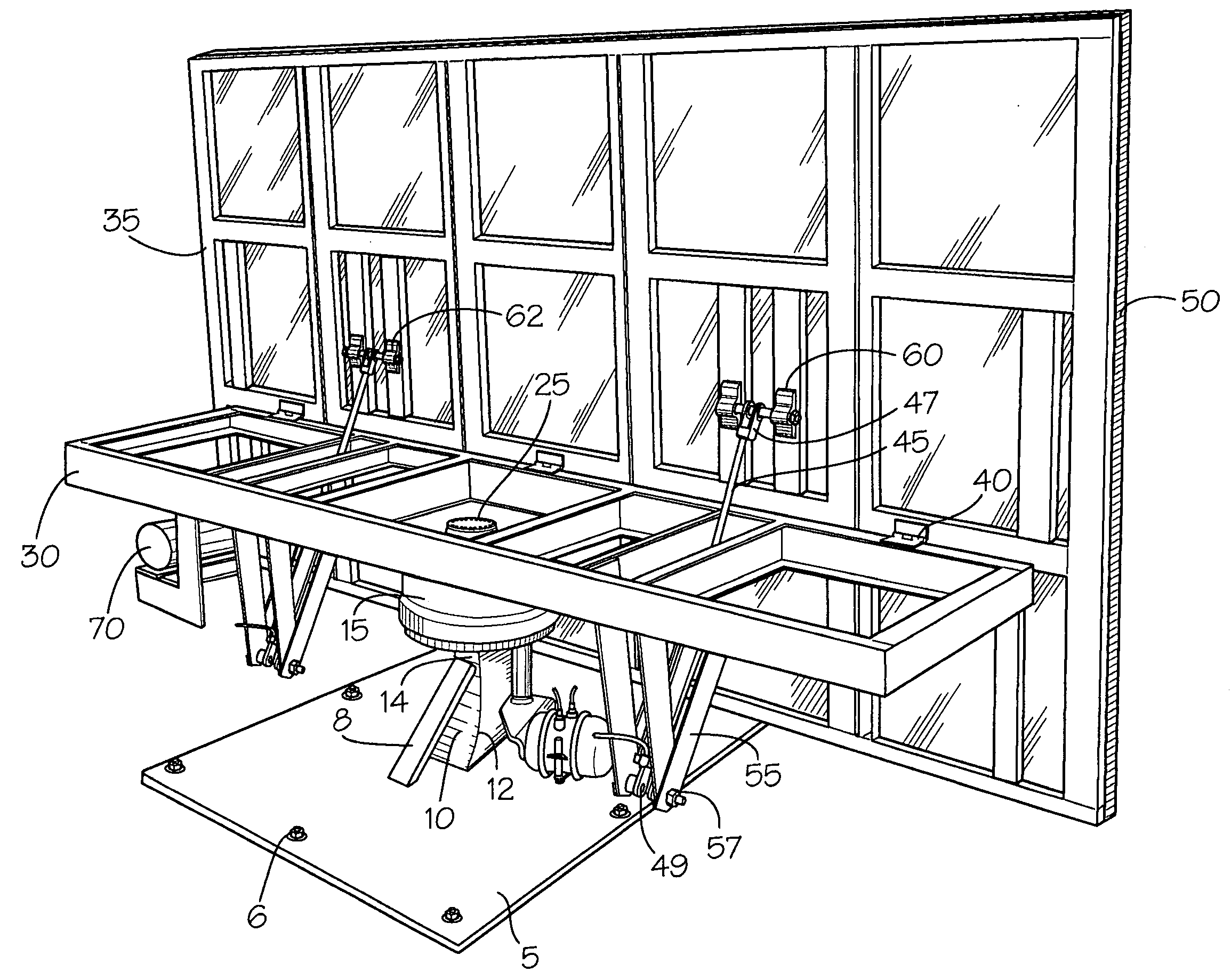

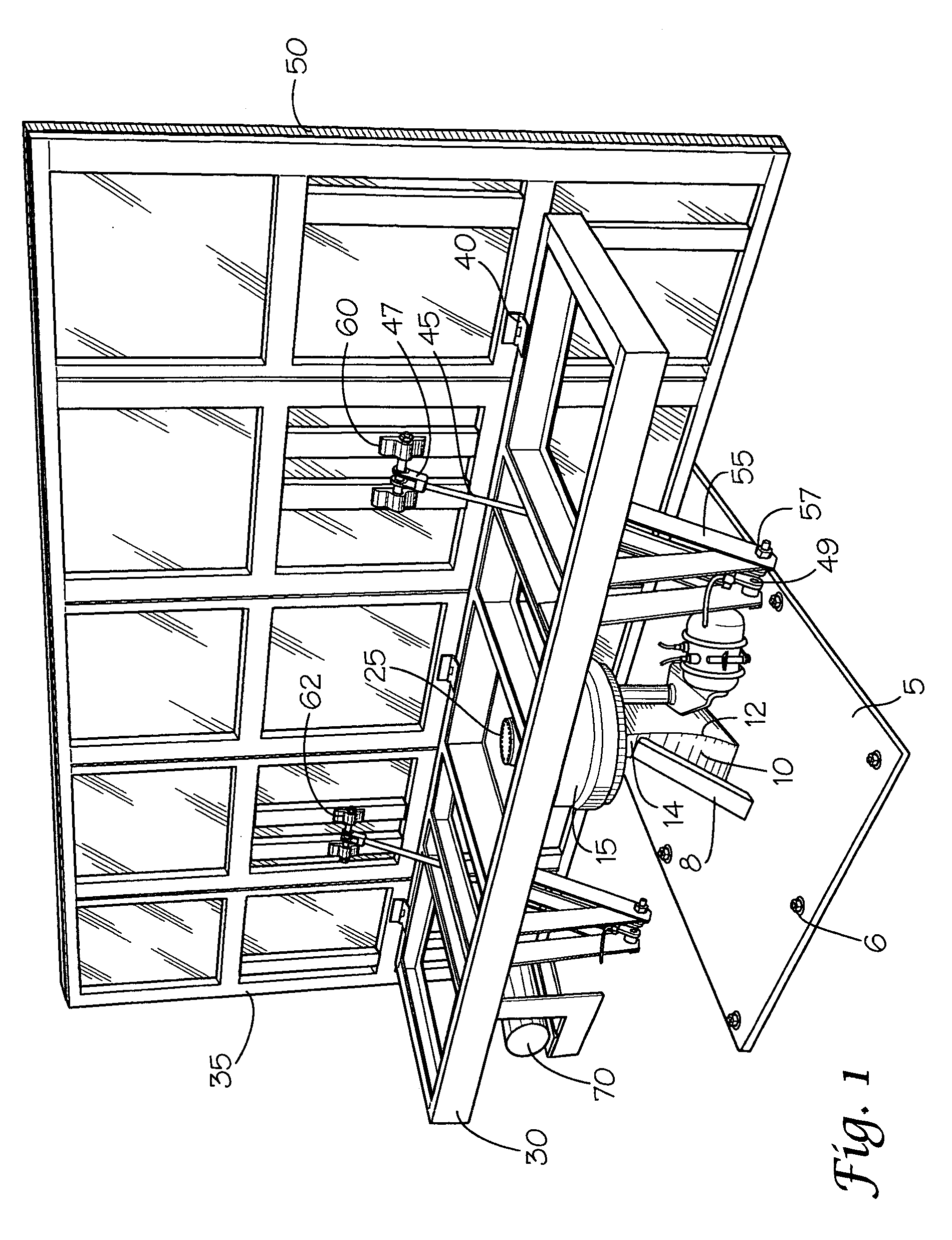

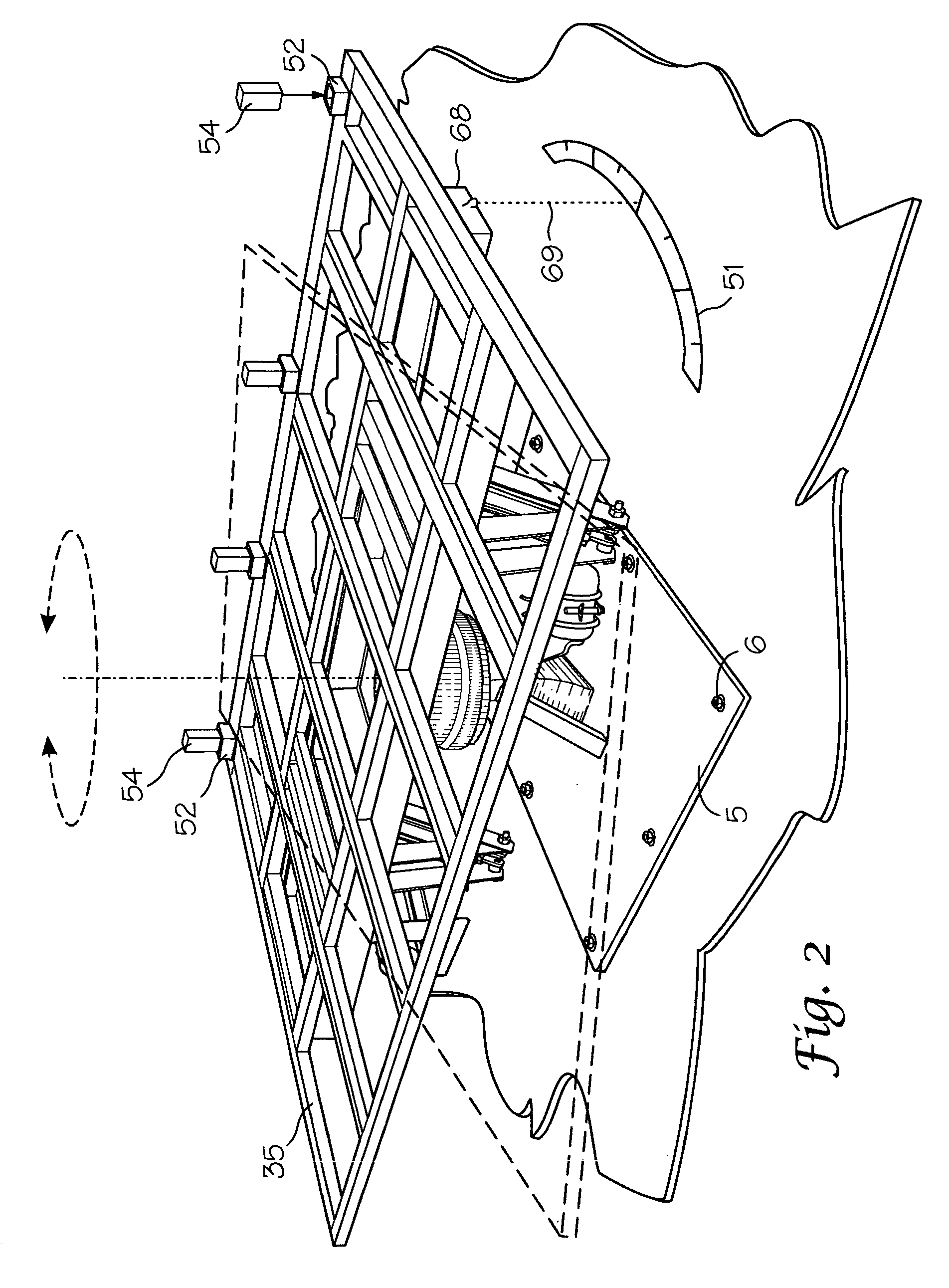

Cutting table for large stone work pieces

InactiveUS7025053B1Avoid problemsReduce physical laborMetal sawing devicesGrinding feed controlRotation around a fixed axisHinge angle

A cutting table for large stone work-pieces, such as marble includes an axel fixed to a base, and a spinning drum attached to the axel. A brake cooperates with the axel and the drum, either stopping or allowing the drum to rotate around the stationary axel. A mounting-plate attaches to the drum, and the mounting-plate attaches and supports a rectangular frame. On top of the frame, a surface-scaffold attaches by at least one hinge. The hinge, with the assistance of a lifting means, allows the scaffold to move from a position flat upon the frame to a position perpendicular to the frame. A work-surface for cutting large stone pieces attaches to and is supported by the scaffold. To manipulate a large stone work-piece, such as one of marble, a user positions the work-surface perpendicular to the frame and rests the work piece flush next to it. The user then lowers the lifting means, thereby rotating the work-surface and its juxtaposed work piece approximately ninety degrees to a position flat upon the frame. A user can freely rotate the work-surface and, with the assistance of the brake, lock the work surface in a desired position.

Owner:ALTAMIRANO SILVANO

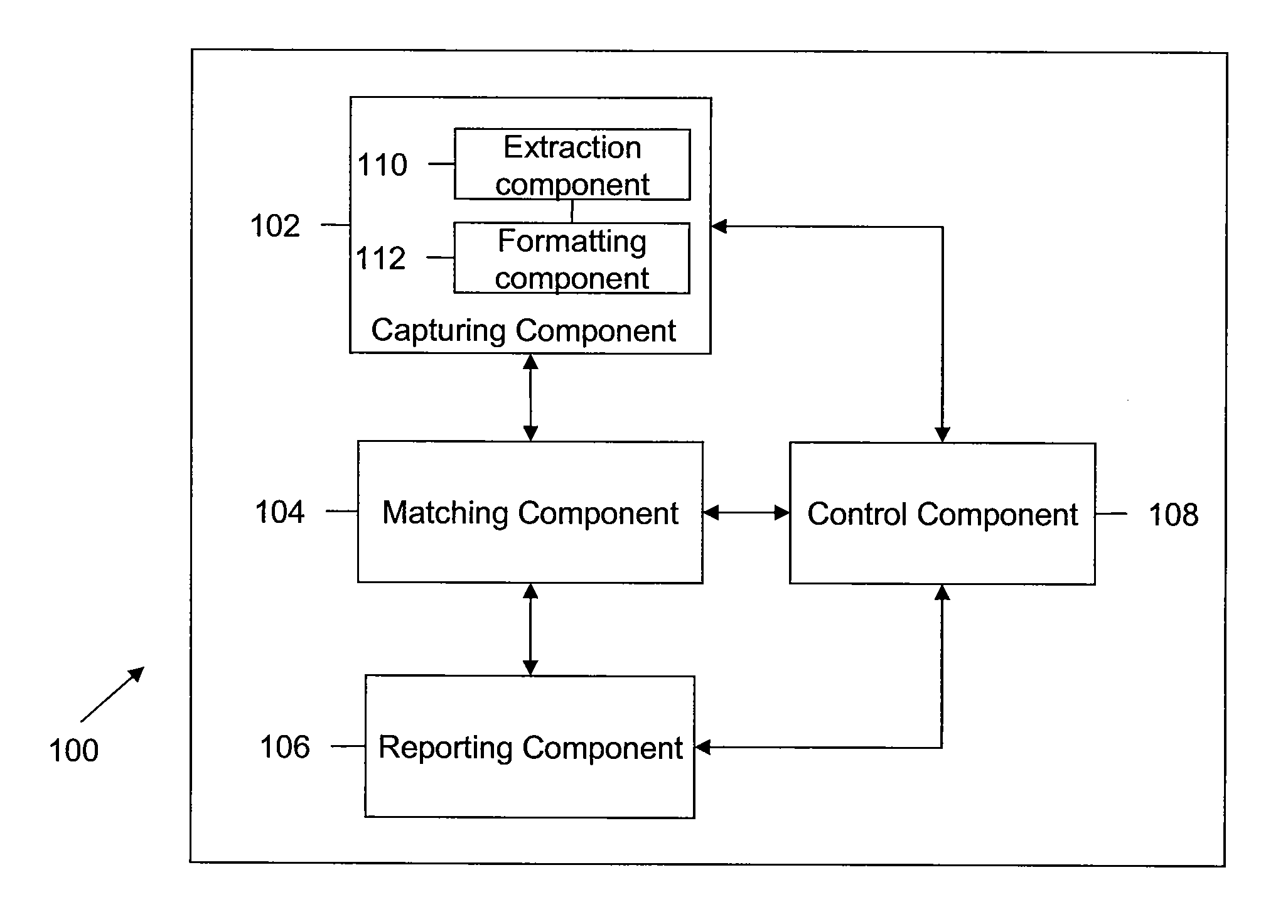

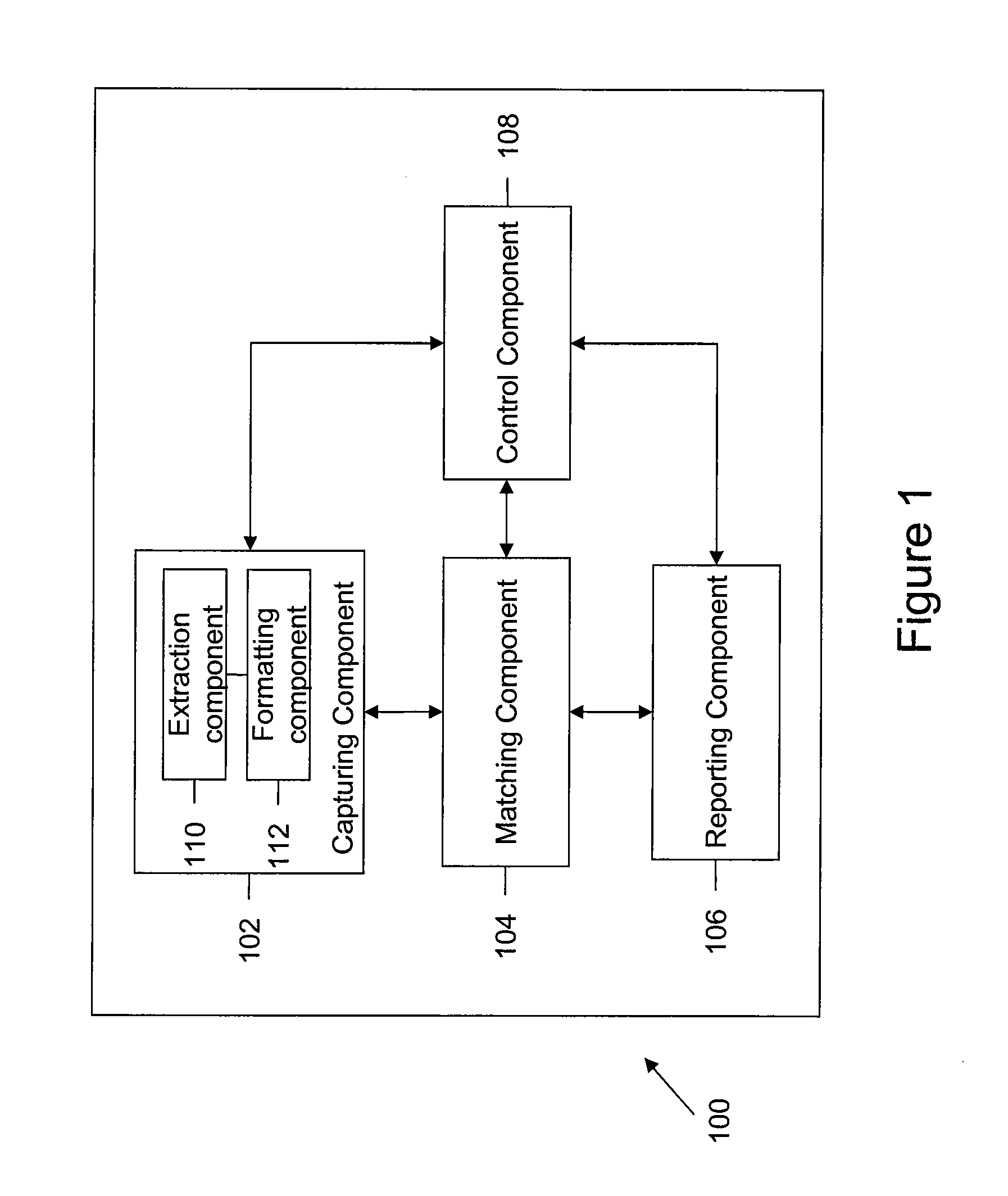

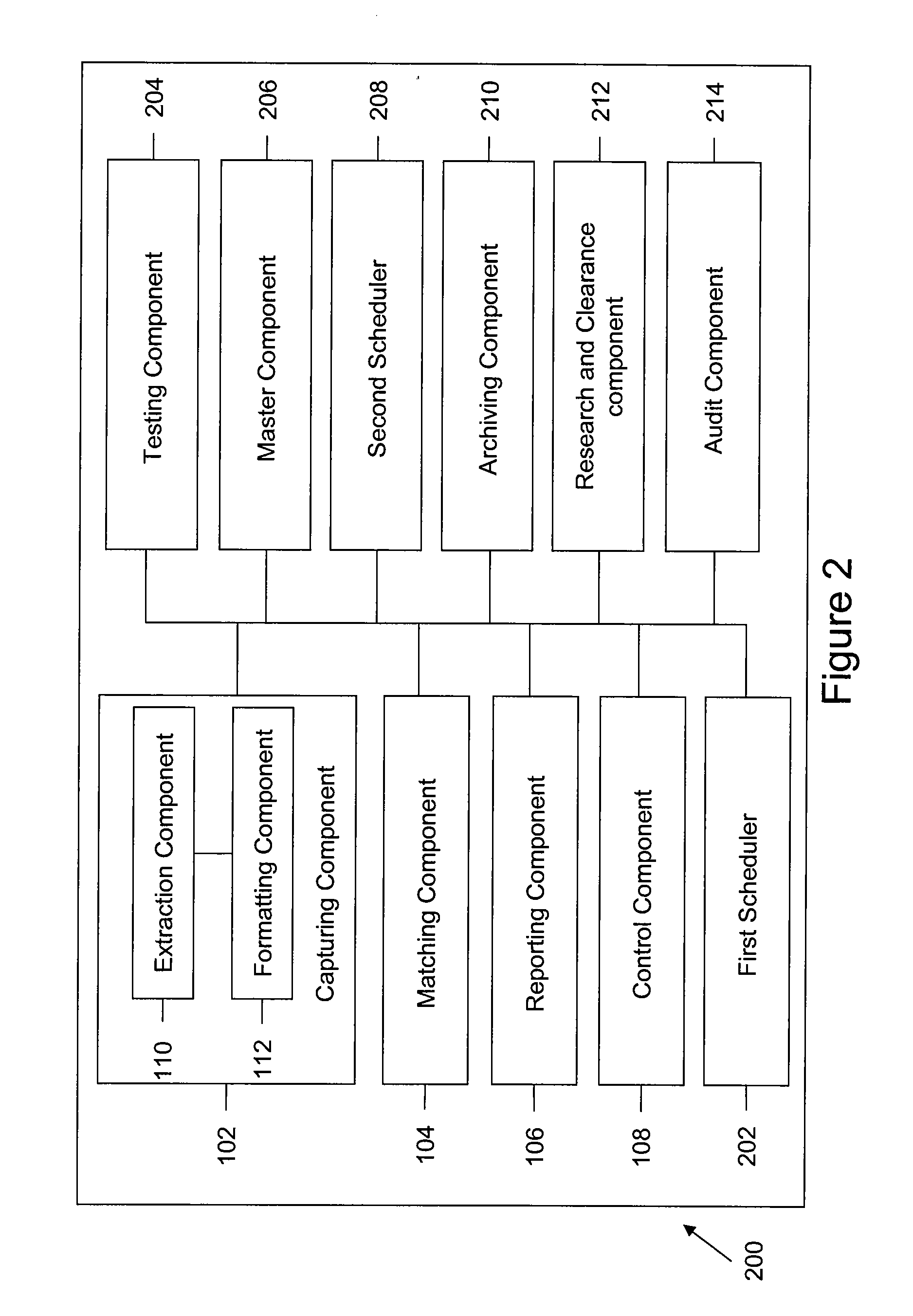

System and Method for Reconciling One or More Financial Transactions

InactiveUS20080103949A1Reduce effortProvide capabilityComplete banking machinesFinanceUser PrivilegeTransaction data

A system, method and computer program product for reconciling one or more financial transactions of one or more business units. The method includes capturing transaction data from the financial transactions using a first set of data logics. The capturing further includes extracting the transaction data from the financial transactions using import templates and transforming the extracted transaction data to a predefined format, using a first set of validations. The captured transaction data is then auto-matched with master data as reference, using one or more auto-match logics and a second set of validations. One or more reports are then generated on the auto-matched transaction data. The method further includes providing user privileges for controlling the capturing, the auto-matching, and the generation of the one or more reports according to a first predefined criterion.

Owner:LIBERTY PEAK VENTURES LLC

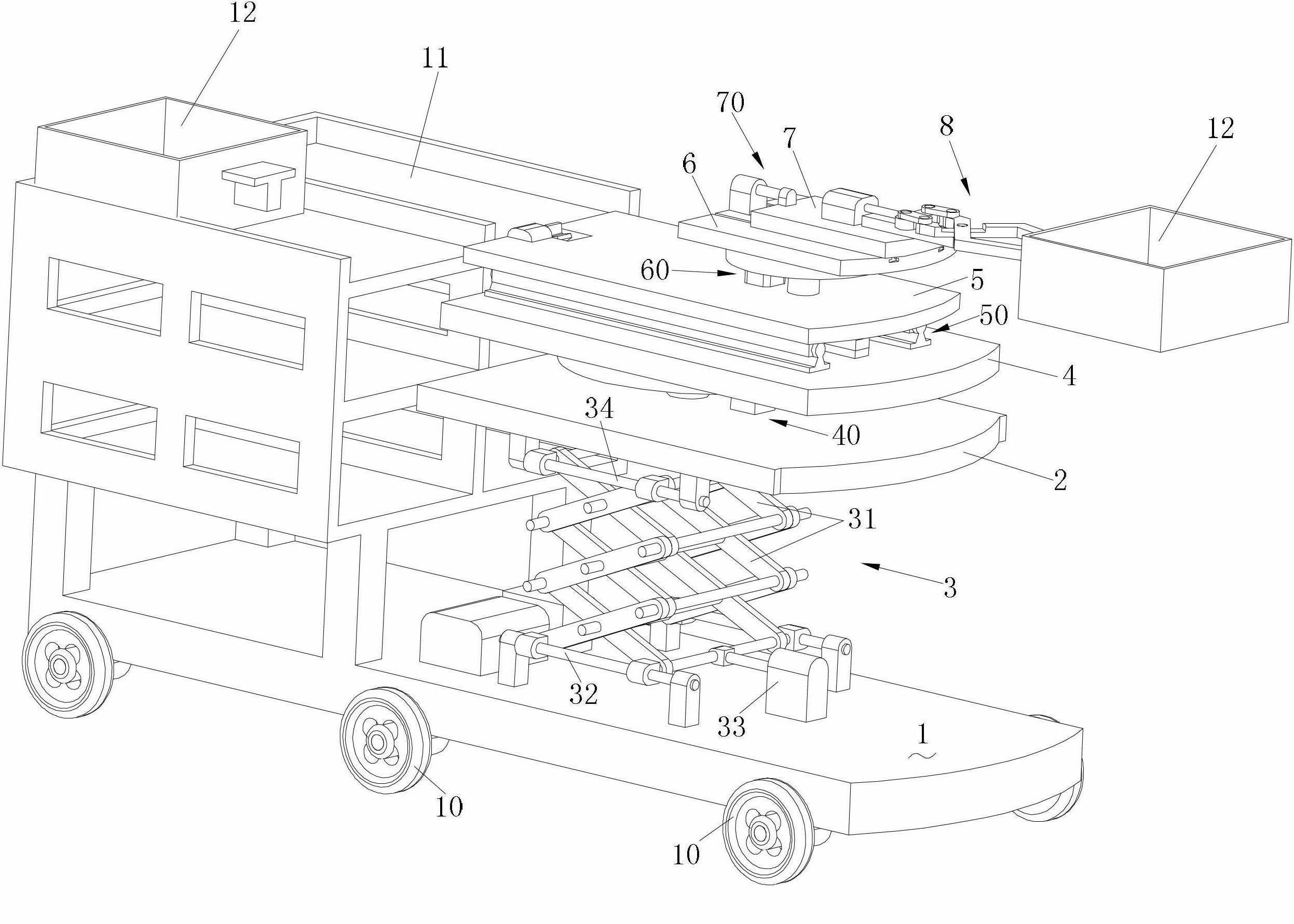

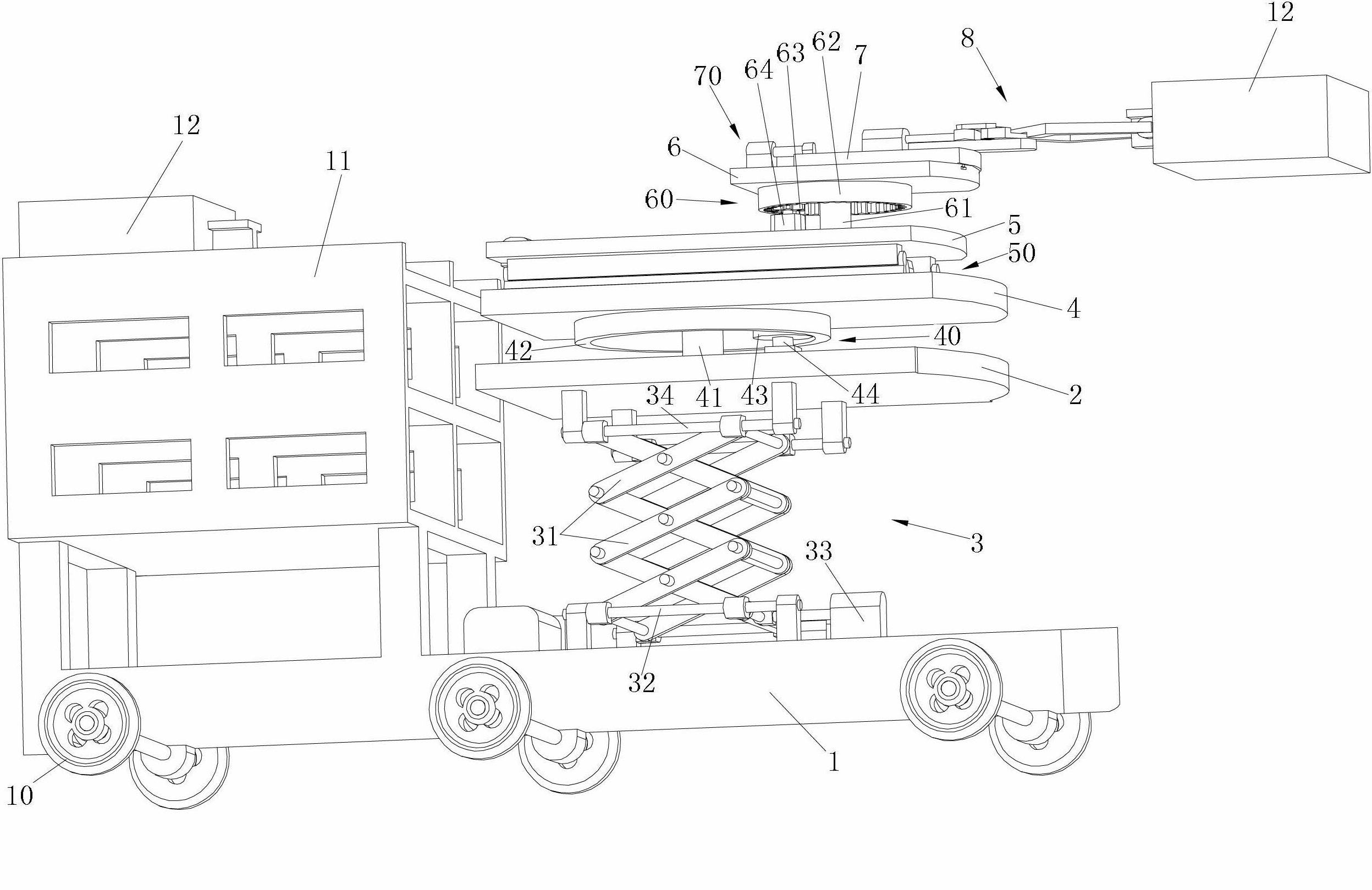

Rail type intelligent machine transporting truck

InactiveCN102658542AReduce physical laborIncrease the itineraryStorage devicesManipulatorVehicle frameTruck

The invention discloses a rail type intelligent machine transporting truck, comprising a frame, idler wheels located on the frame, a storage box located at the top of the frame, a supporting board, a lifting mechanism connected between the supporting board and the frame, a primary rotation board, a primary rotation mechanism connected between the primary rotation board and the supporting board, a primary translation board, a primary translation mechanism connected between the primary translation board and the primary rotation board, a secondary rotation board, a secondary rotation mechanism connected between the secondary rotation board and the primary translation board, a secondary translation board, a secondary translation mechanism connected between the secondary translation board and the secondary rotation board, and an executing mechanism connected on the secondary translation board, wherein a storage box is placed in the storage box. The rail type intelligent machine transporting truck provided by the invention replaces the conventional manual goods carrying manner, so that the human labor is reduced, and the production efficiency is improved. With the adoption of the two levels of rotation mechanisms and the two levels of translation mechanisms, the rail type intelligent machine transporting truck can expand the journey and increase the freedom degree. The rail type intelligent machine transporting truck can check more goods due to the vehicular storage box, so that the working efficiency is improved.

Owner:SHANGHAI DIANJI UNIV

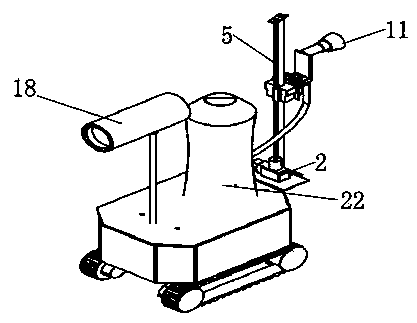

WiFi wireless control-based intelligent spraying robot

InactiveCN103676959APrecise control of walkingReduce direct contactTransmission systemsTarget-seeking controlWireless controlComputer module

The invention provides a WiFi wireless control-based intelligent spraying robot which comprises a video acquisition device, a mobile equipment terminal, a system control part and a spraying device, wherein the system control part comprises a dolly module, a WiFi module, a single-chip microcomputer module, a driver module and an obstacle avoidance module. The dolly module comprises a quad-driver track, an aluminium alloy body shell and two motors which are connected in parallel and are positioned at left and right sides of a dolly to drive the dolly. According to the WiFi wireless control-based intelligent spraying robot, a touch button of smartphone software is triggered to send a control instruction so as to accurately control the robot to walk along a right route and spray a crop. By the use of the spraying robot for spraying, pesticides are prevented from being directly contacted with human body during the spraying process, harm of pesticides to human is reduced, physical labor of spraying workers is minimized, and work efficiency is raised.

Owner:HECHI UNIV

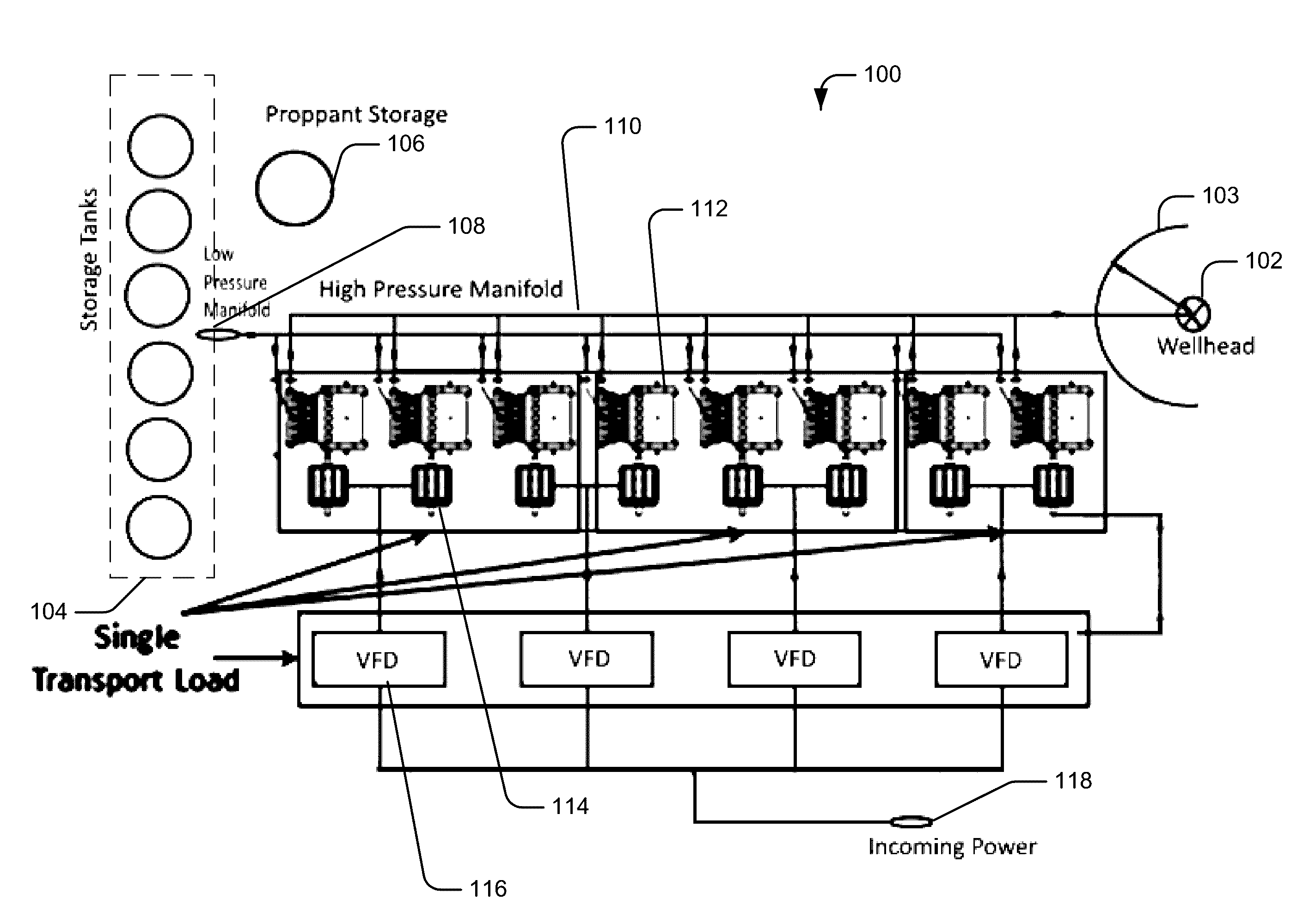

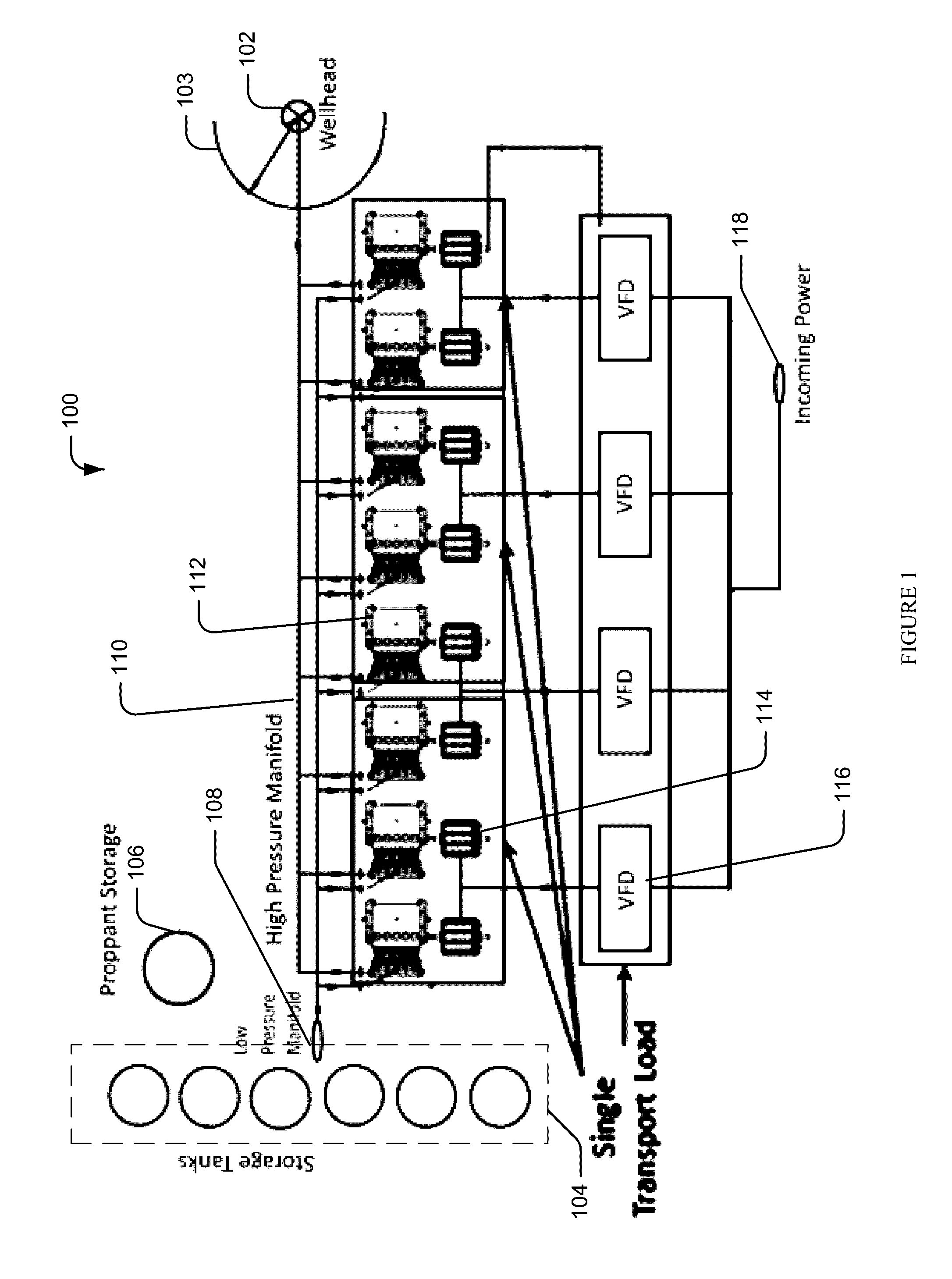

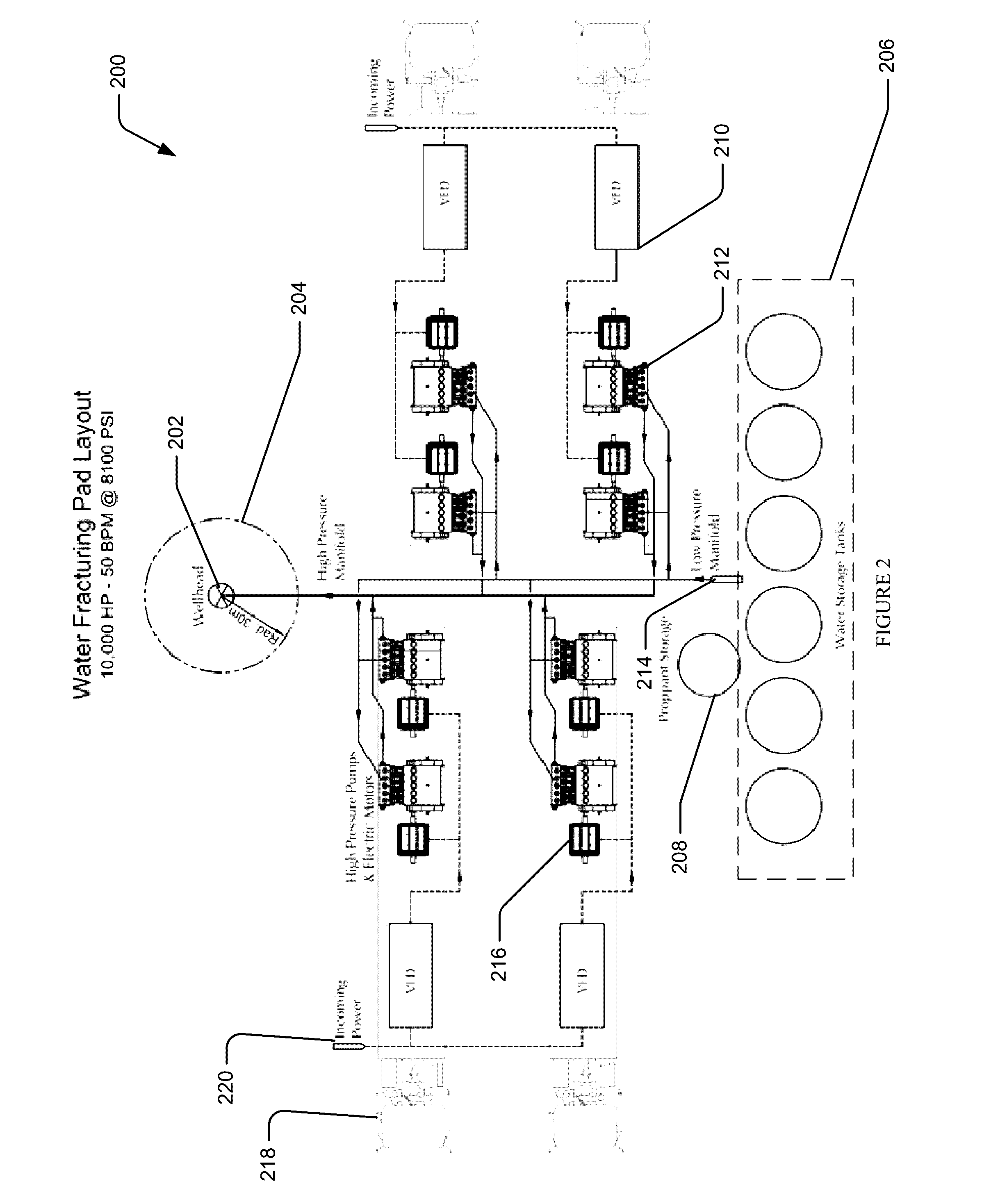

Fracturing system layouts

InactiveUS20160281484A1Reduce physical laborReduction and elimination of emissionChemical industryFluid removalFracturing fluidEngineering

Systems for stimulation of a formation include a variable frequency drive configured to receive and output medium voltage power and in communication with high pressure pump. A variable frequency drive actuates an electric motor associated with the high pressure pump, such that the pumps pressurizes a fracturing fluid, proppant, or combinations thereof for flowing the fracturing fluid, proppant, or combinations thereof into the formation.

Owner:PROSTIM LABS

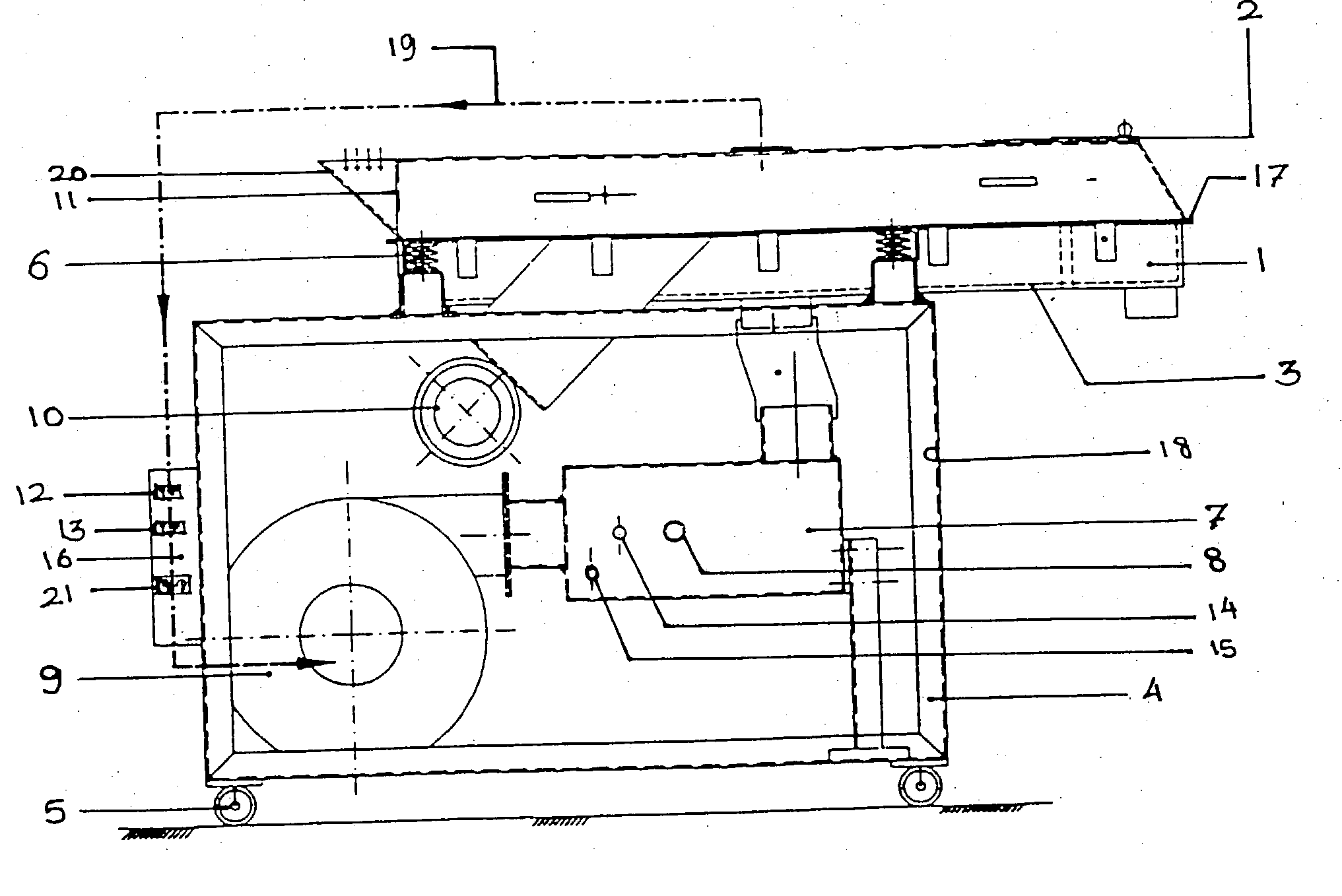

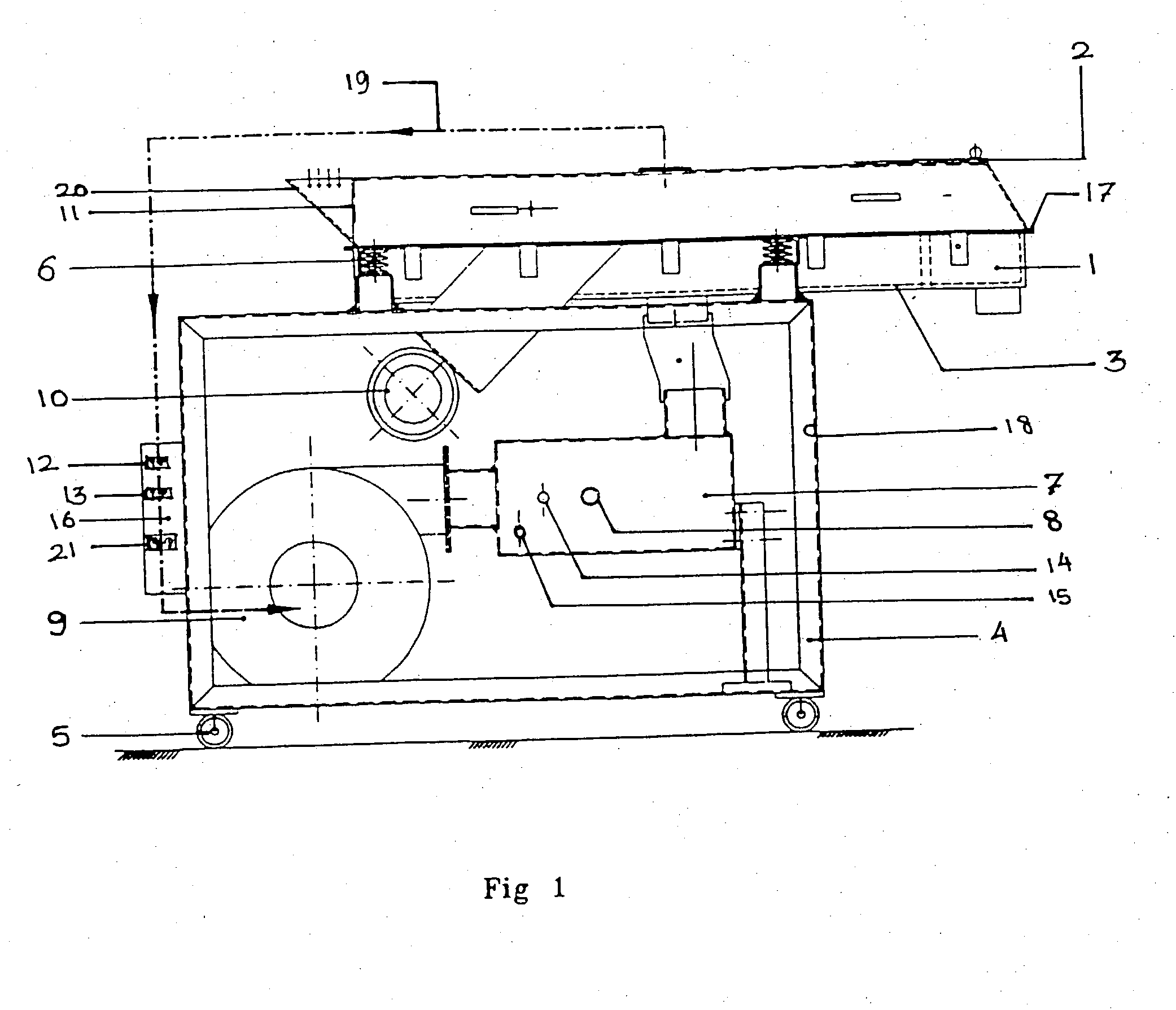

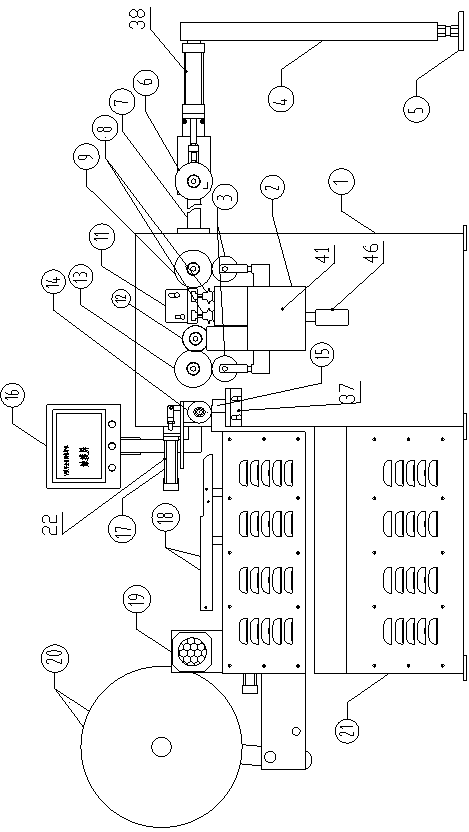

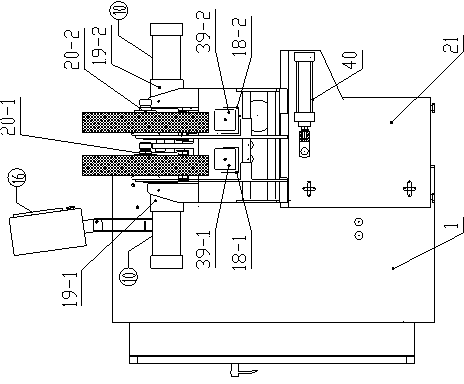

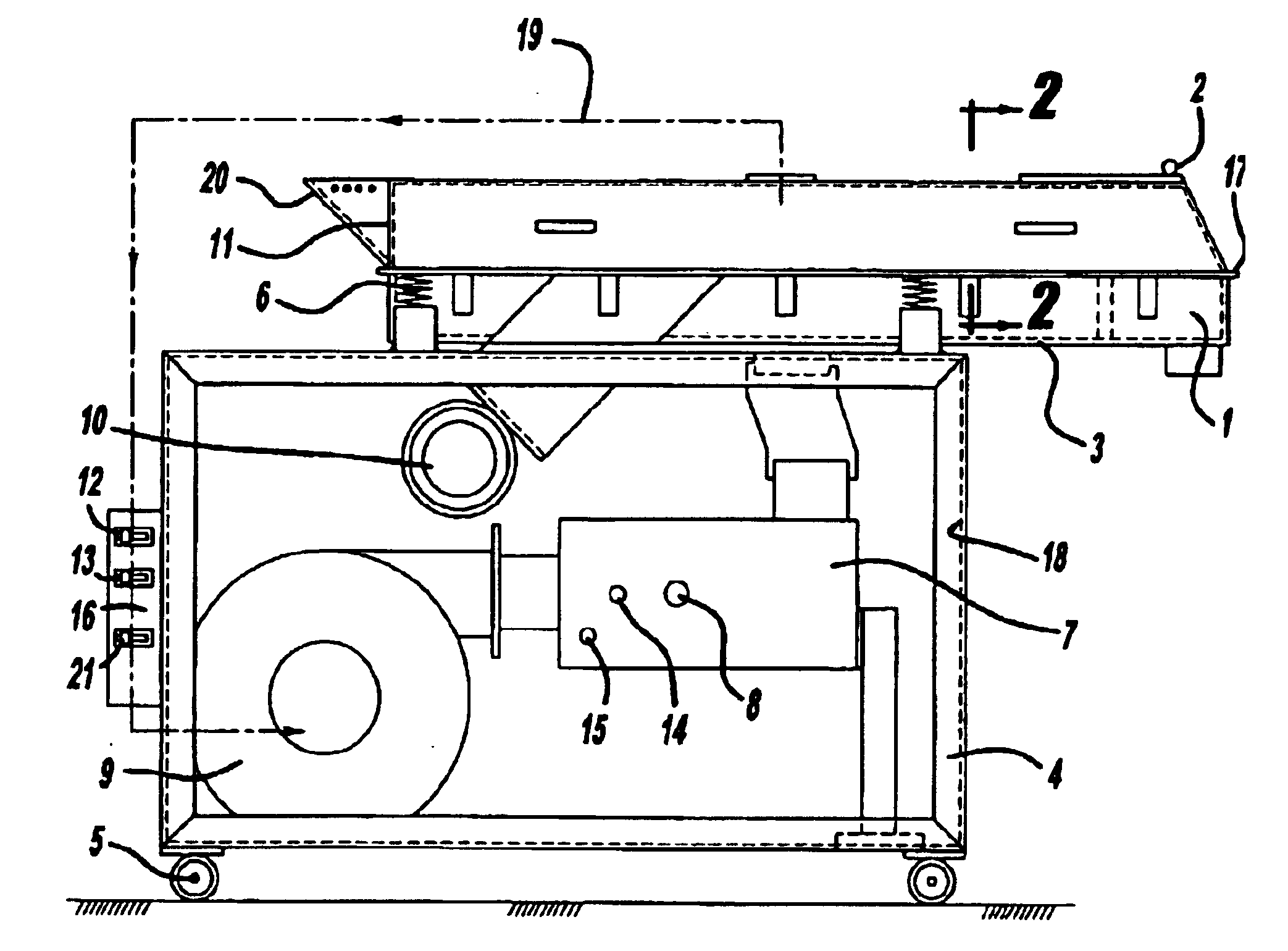

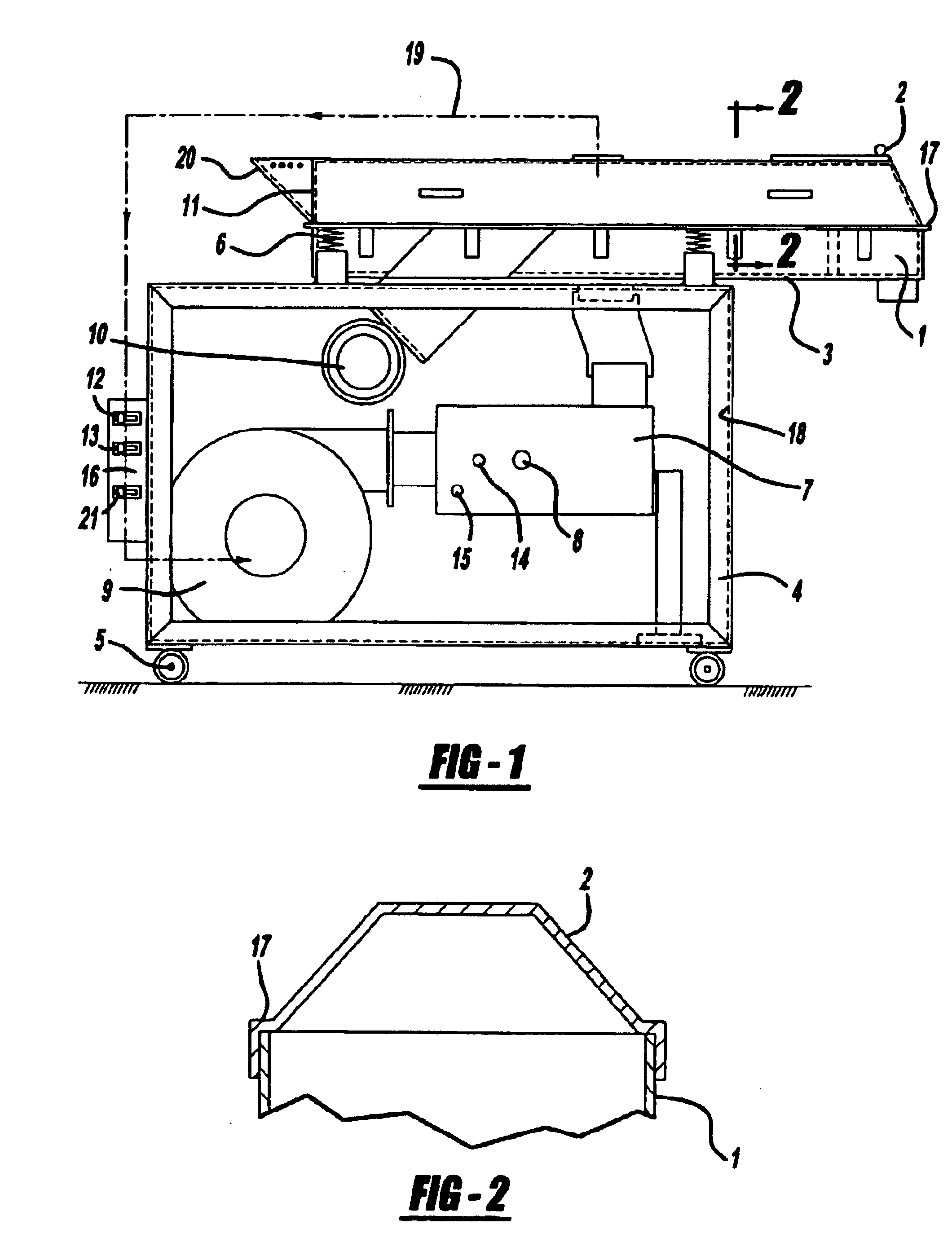

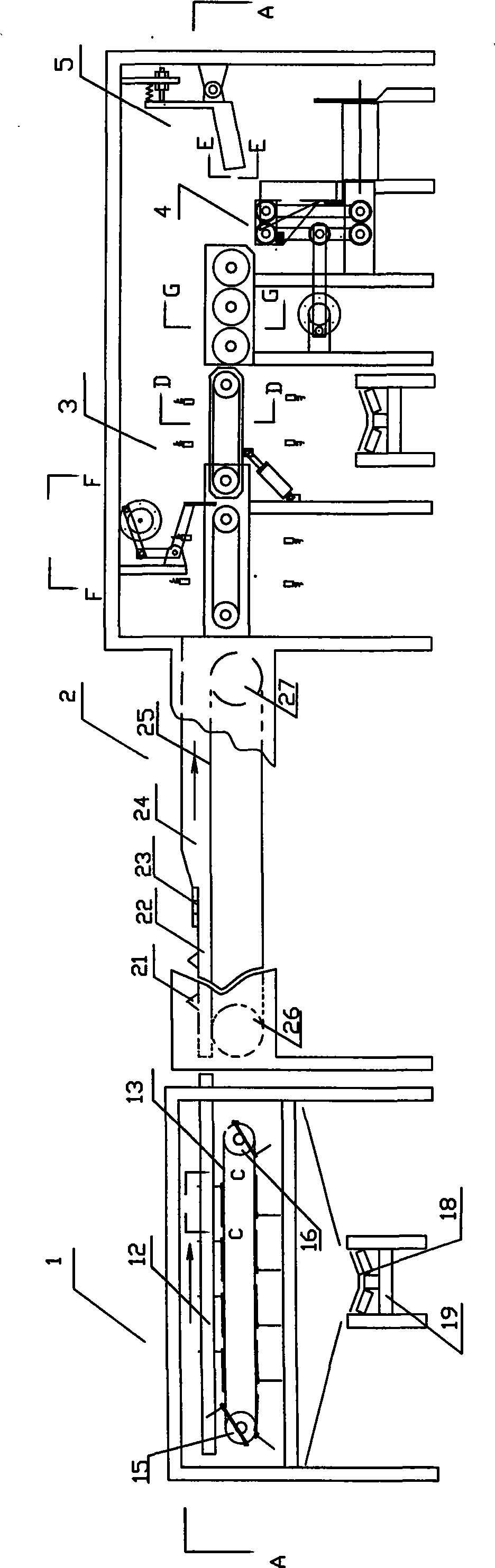

Continuous vibro fluidized bed roaster using flue gas

InactiveUS20040187709A1Reduction in human drudgeryClean and hygienic endGrain huskingGrain polishingCombustion chamberSolenoid valve

A continuous vibro fluidized bed roaster for roasting cereals, pulses, spices, oil seeds and ready-to-eat snack foods using flue gas, said roaster comprises of a main frame (4) which houses all the parts of the machine, the vibrating deck (1) is mounted on a set of coil springs (6) which is mounted on the main frame through screw fasteners, a perforated sieve (3) and a hood (2) are mounted on the vibrating deck (1) with rubber gasket (17) for sealing the hot air from leakage, a vibratory motor (10) is mounted on the feed end of the vibratory deck for imparting vibrations to the feed material, a vibratory feeder (11) is mounted on the feed side of the vibratory deck (1) for feeding the raw material in to the roaster through a hopper (20). A LPG burner (8) is fastened to the combustion chamber (7) using fasteners, a solenoid valve (14) mounted on the main frame (4) for regulating the LPG supply to the burner and also to close the LPG supply incase of electrical power failure with a signal for flame failure from the photo sensor (15), a blower (9) generates the air needed for the reducing the flue temperature is mounted at the end of the on the vibratory feeder (11) on to the main frame (4), a return duct (19) connects the hood (2) and the suction end of the blower (9), a temperature indicator is (21) is used for measuring the inlet temperature of the hot air admitted in to the roaster, an electrical panel (16) is mounted at the end of the main frame for housing all the required electrical controls and variable speed drive (13) for varying the residence time of travel of the raw material, a rheostat (12) for varying the feed rate of the raw material fed in to the vibrating deck, the roaster is covered by a set of covers (18) on all its sides, the complete machine is mounted on a set of castor wheels (5) for easy movement of the roaster to the required place, the materials of construction of the roaster are preferably of stainless steel but this shall not restrict the use of other materials as well.

Owner:COUNCIL OF SCI & IND RES

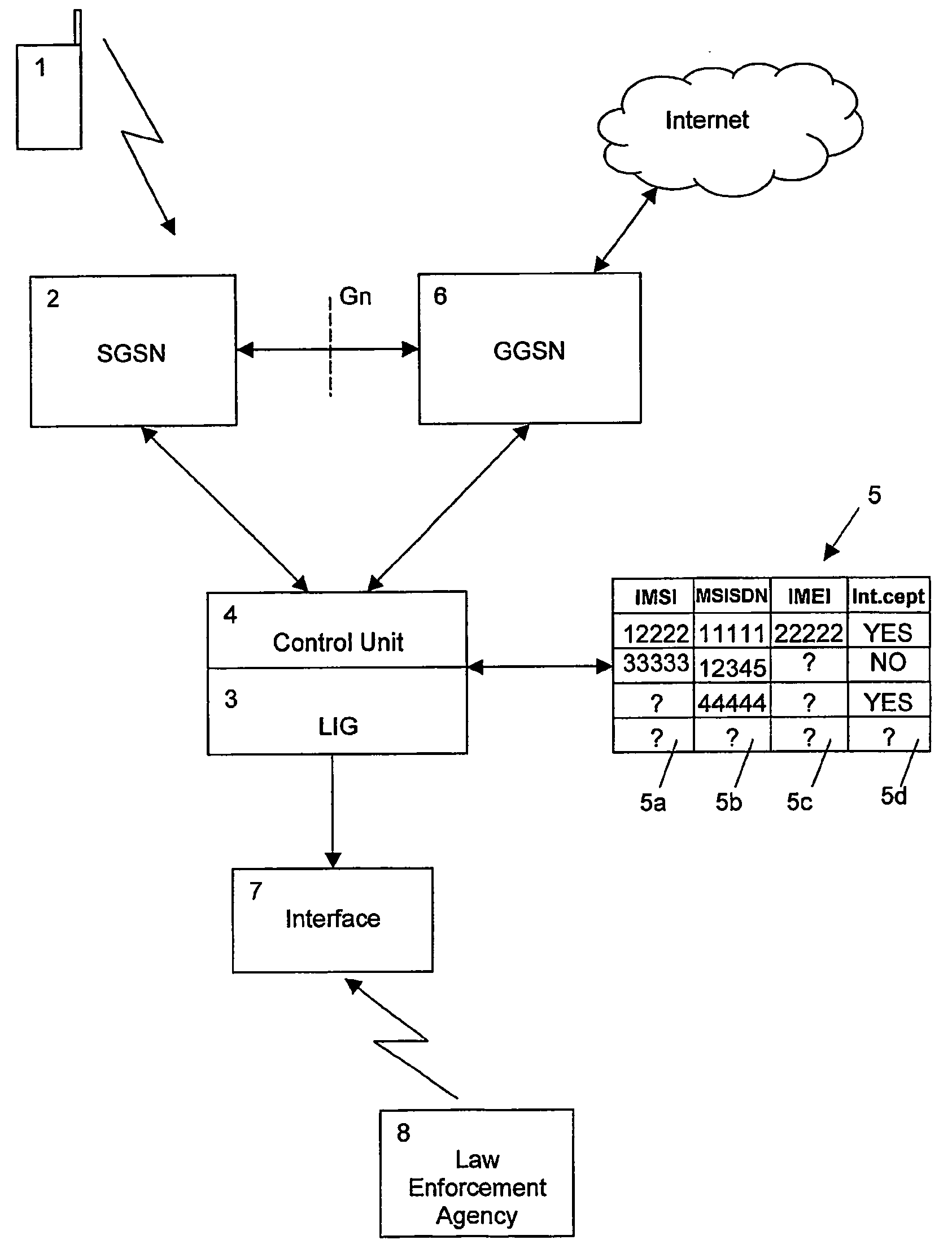

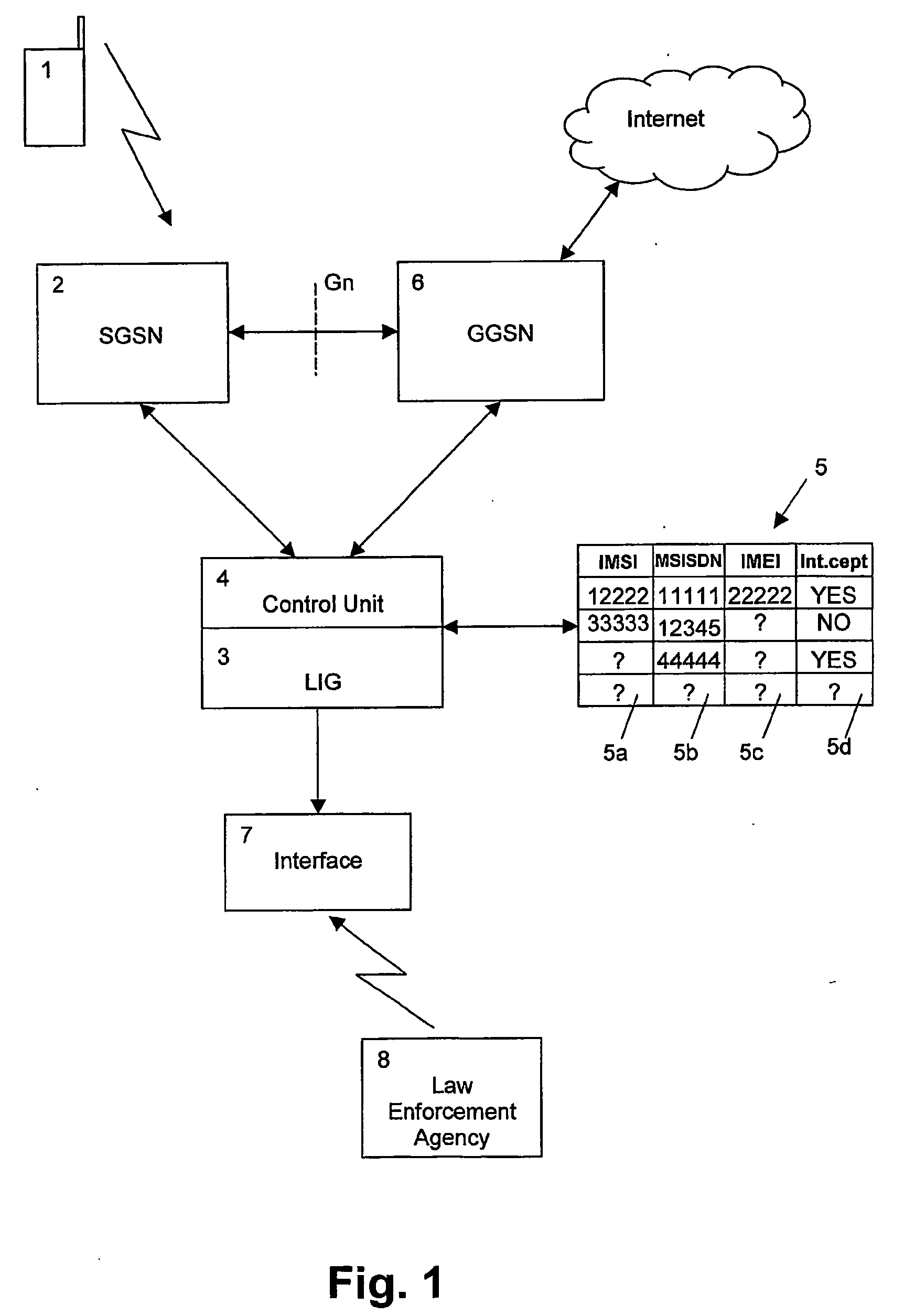

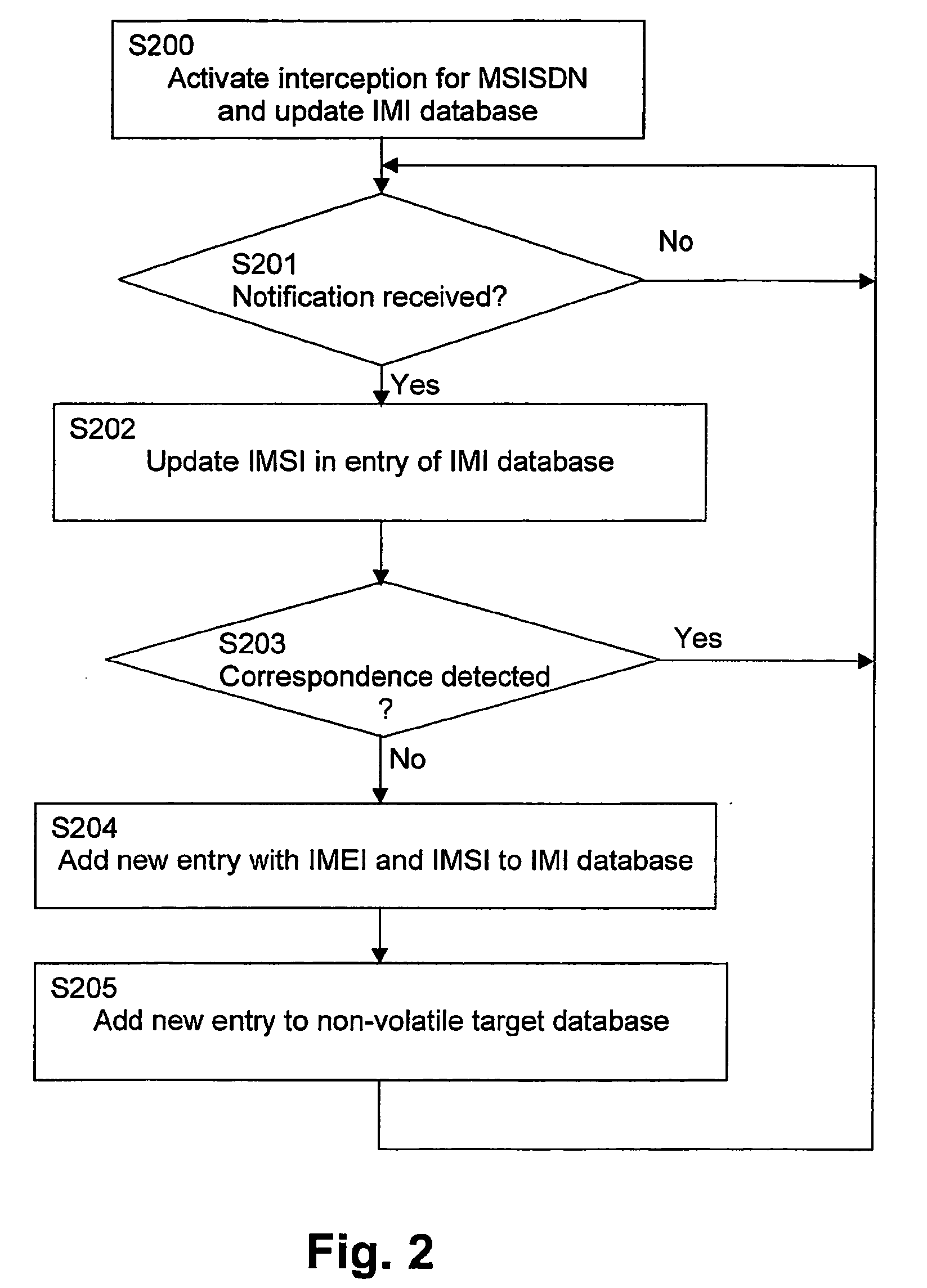

Infection-based monitoring of a party in a communication network

InactiveUS20050210127A1Increase coverageReduce physical laborSupervisory/monitoring/testing arrangementsMultiple digital computer combinationsData linkData bank

The present invention relates to a method and network device for monitoring a party in a communication network, wherein a link information linking at least two types of identifier data for identifying parties to be monitored is stored, and a correspondence between the stored link information of the monitor party and identifier data supplied from the communication network for the monitored party is checked. A new link information linking supplied non-matching identifier data to a stored other type of the at least two types of identifier data linked by the stored link information is added to the stored link information, to thereby provide an automatic Subscriber Identity Module (SIM) infecting feature. Thereby, no connections are missed as each new set of identifier data generates a new entry in the database.

Owner:NOKIA TECHNOLOGLES OY

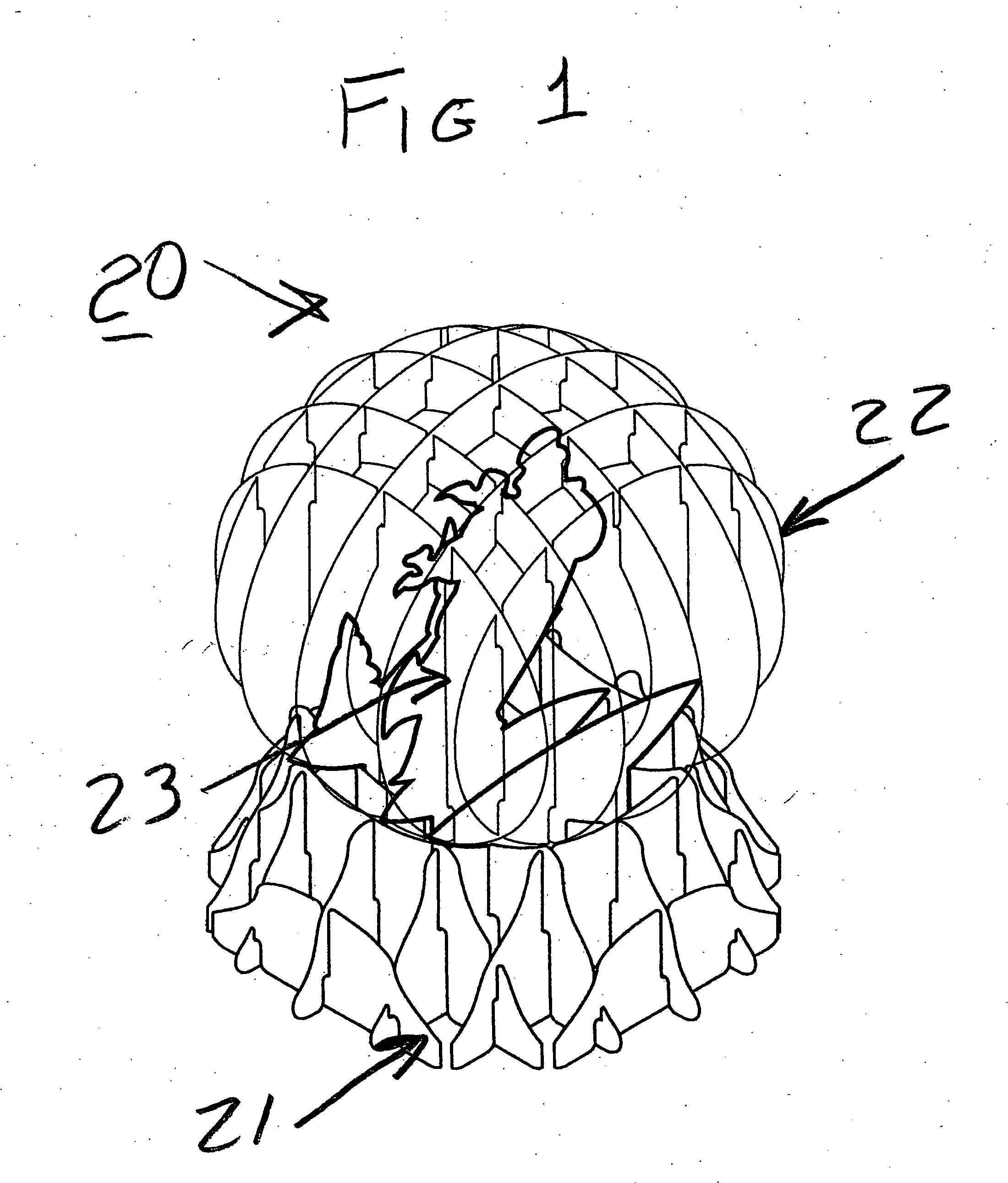

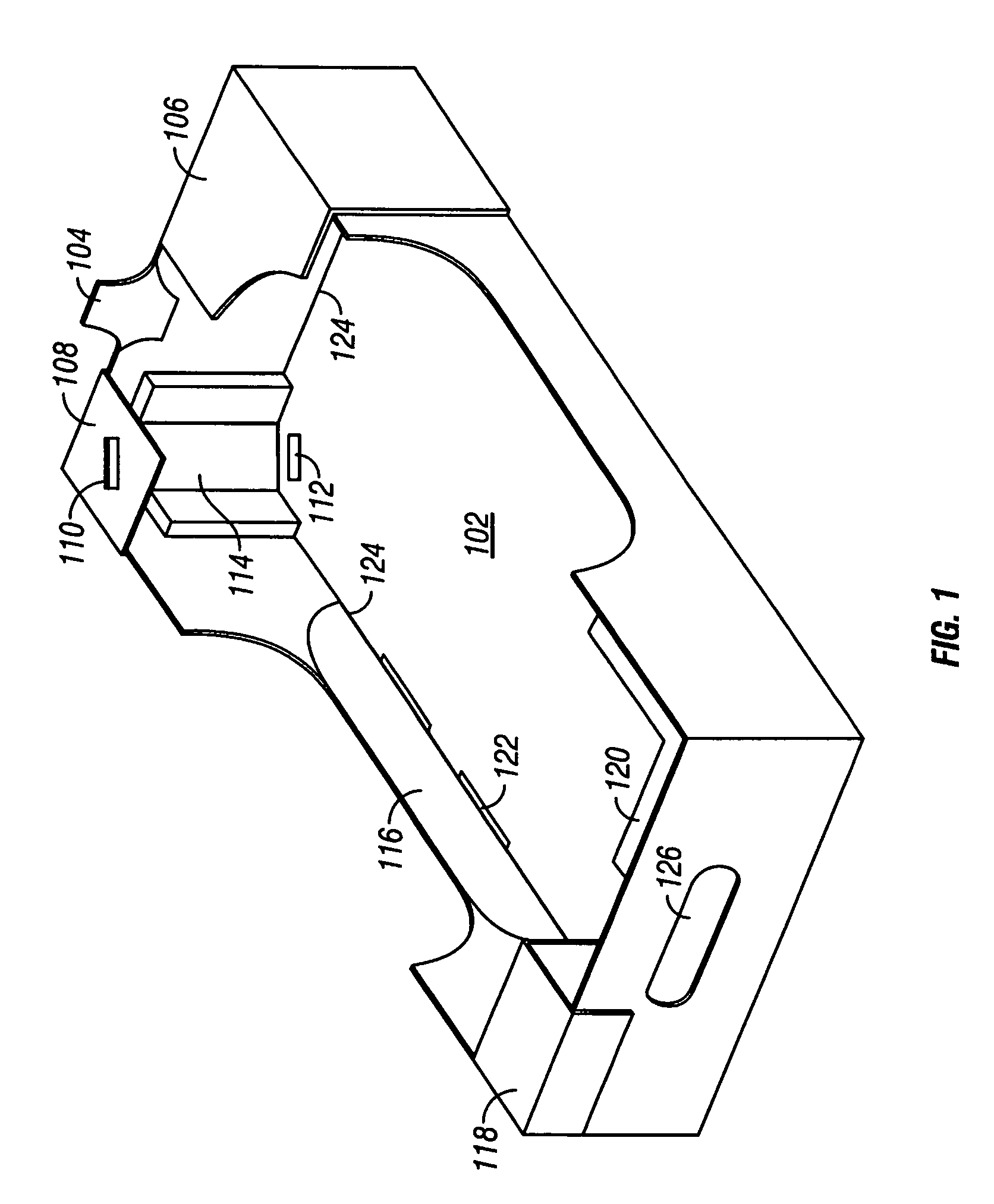

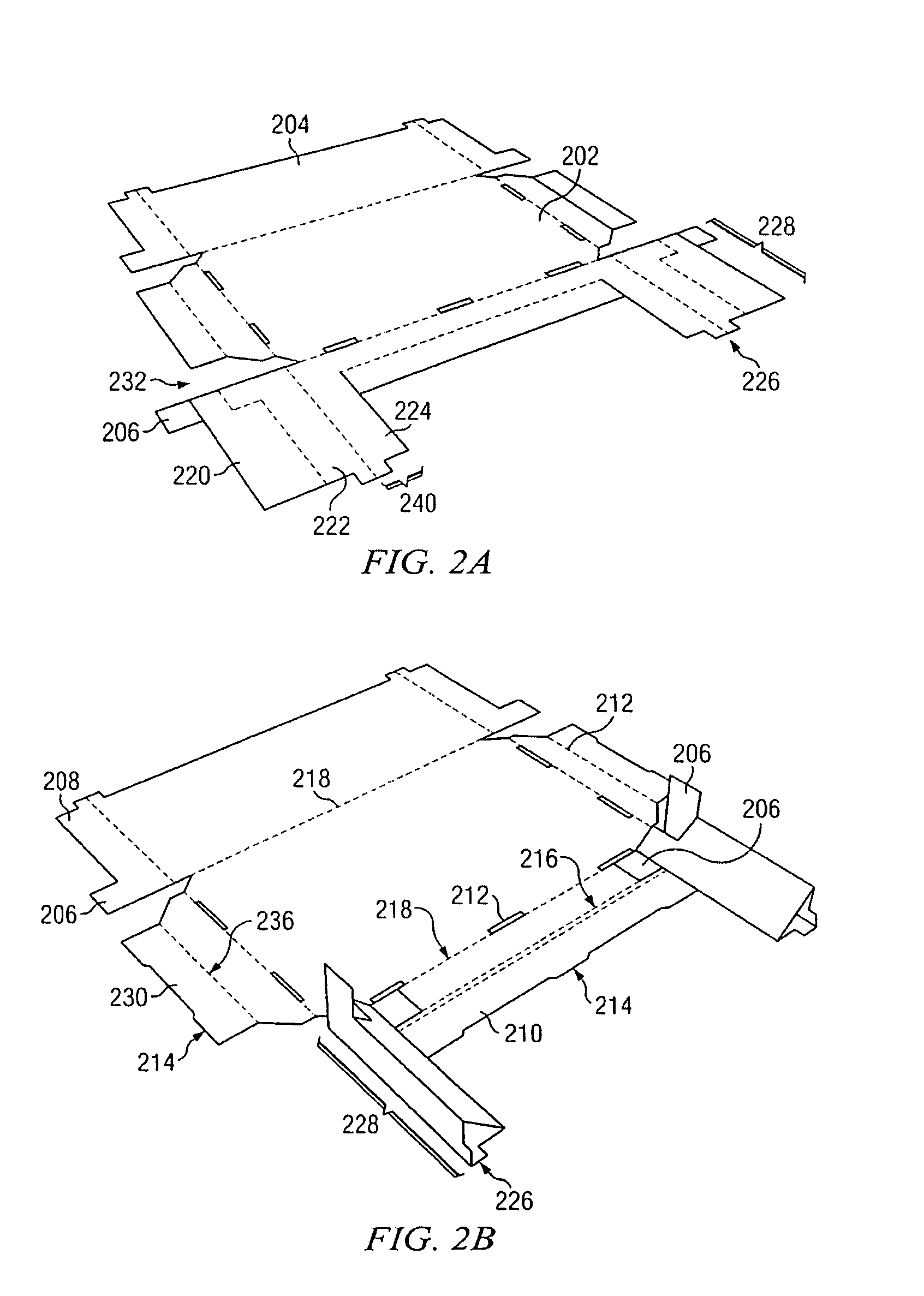

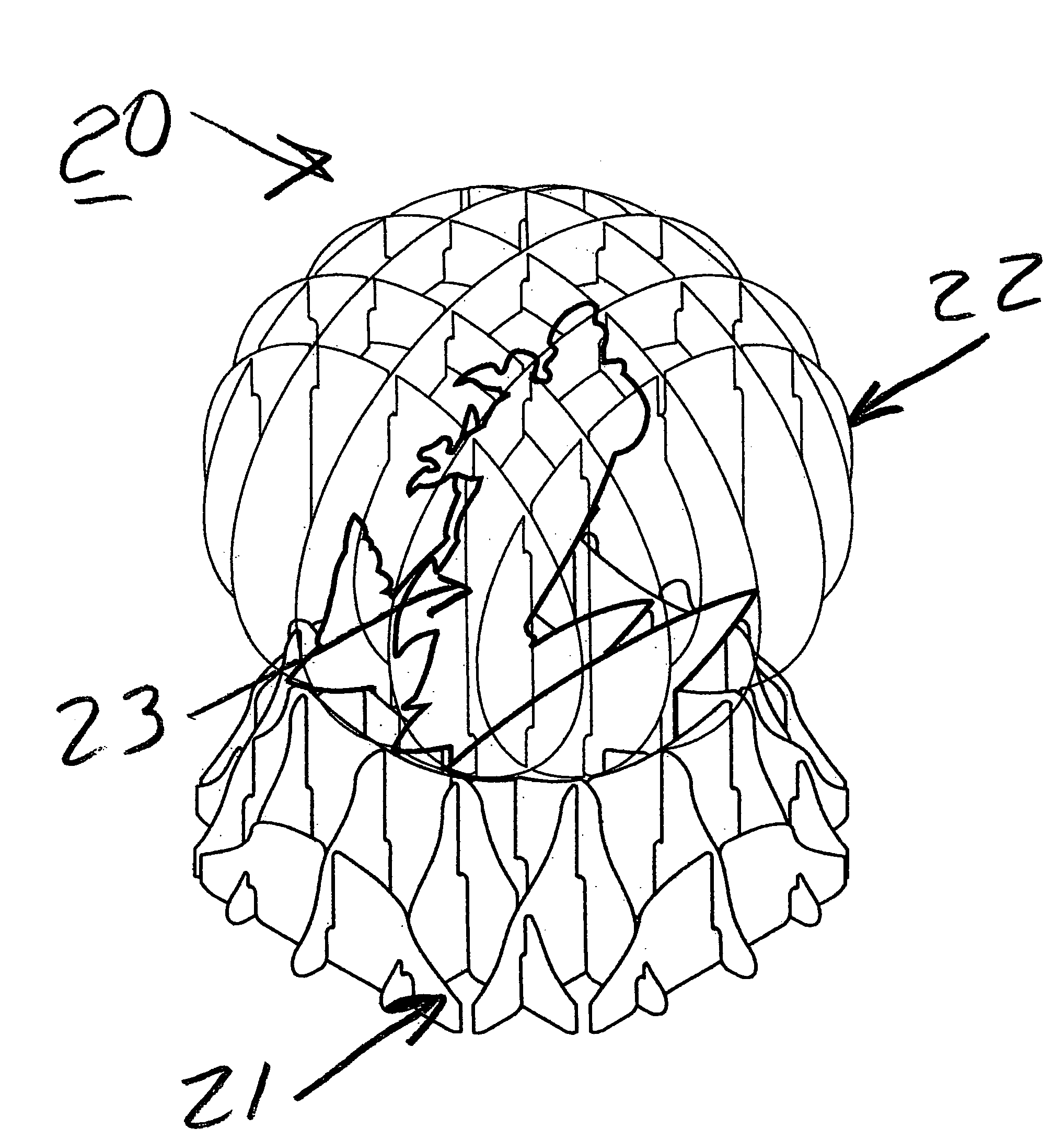

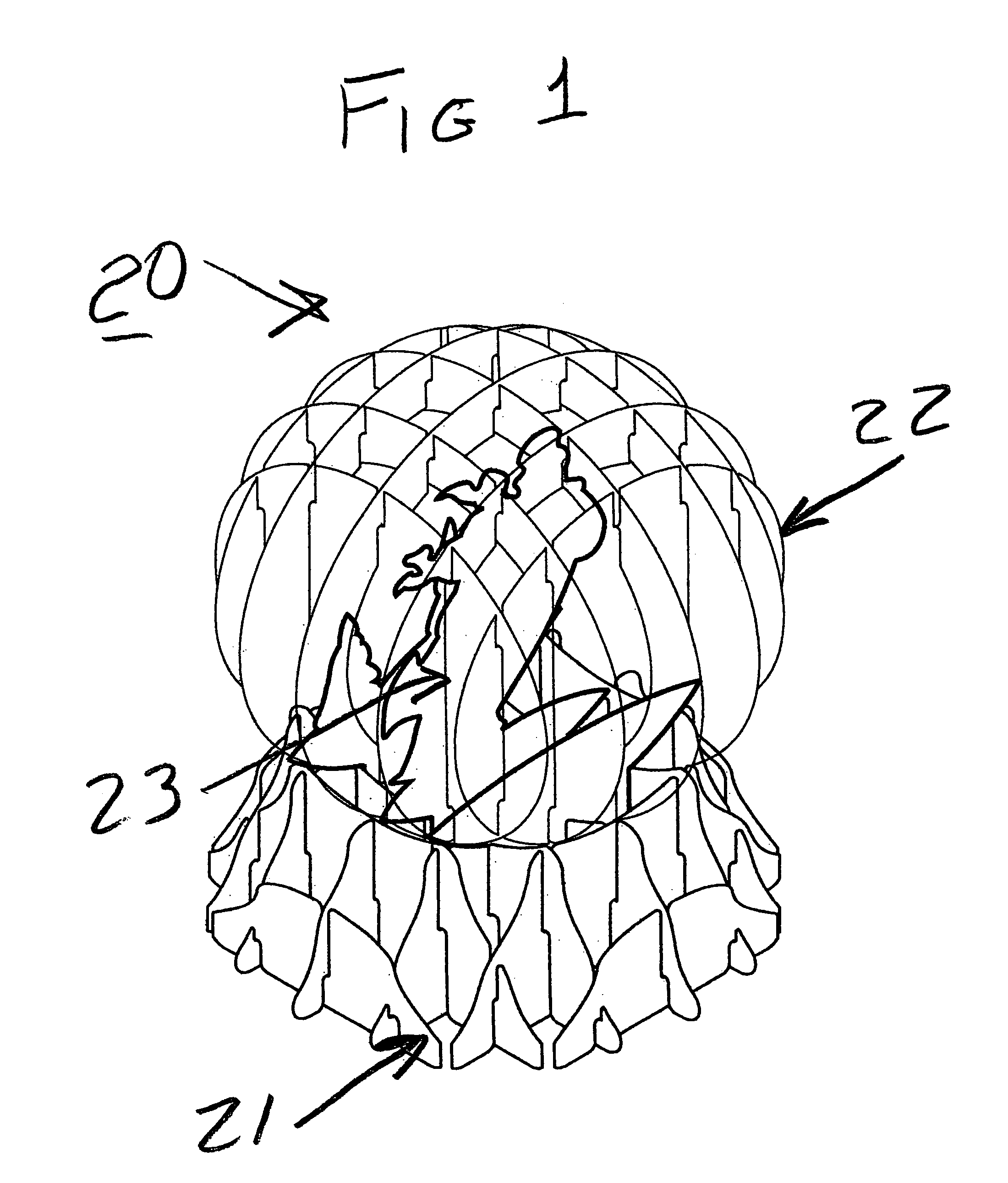

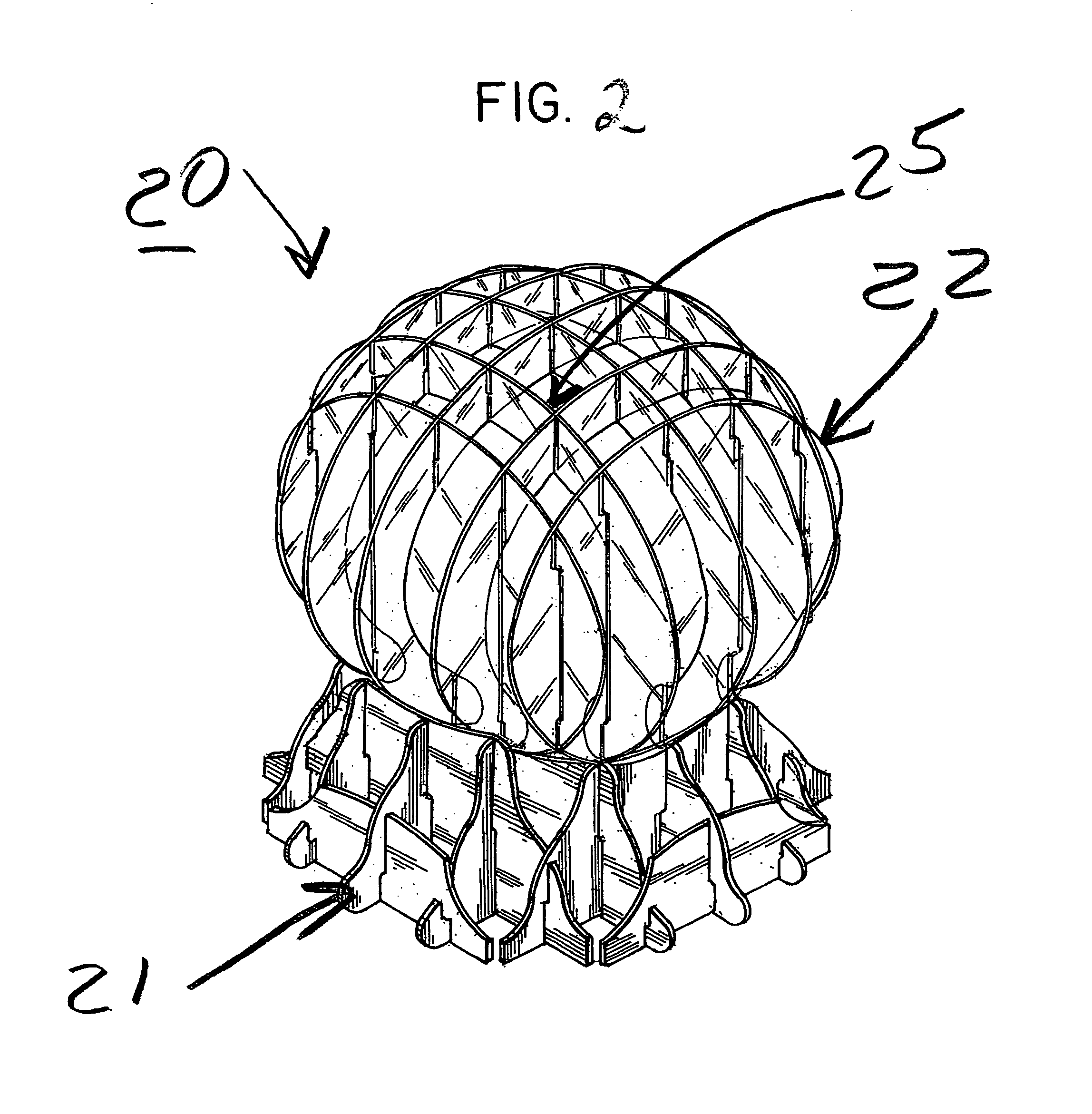

Foldable display system

ActiveUS20070017133A1Quickly and easily automatically erectedEasy and fast constructionOther printing matterBoardsGraphicsEngineering

By providing a housing member within which all of the required elements are pre-formed and constructed as a display system which enables any desired graphics to be inserted therein to form an integral part of the assembly, a unique, printed, visually exciting and interest generating foldable, three-dimensional display system is attained. In accordance with the present invention, the interest generating, foldable display system of the present invention is quickly and easily automatically erected from its flat, generally two-dimensional configuration into a three-dimensional display. Furthermore, the housing preferably comprises an enlarged internal cavity for receiving any desired display element. In this way, the display assembly is easily, and automatically converted from a two-dimensional, substantially flat configuration into a three-dimensional fully erected, interest generating, visually exciting display.

Owner:CROWELL CHRISTOPHER S

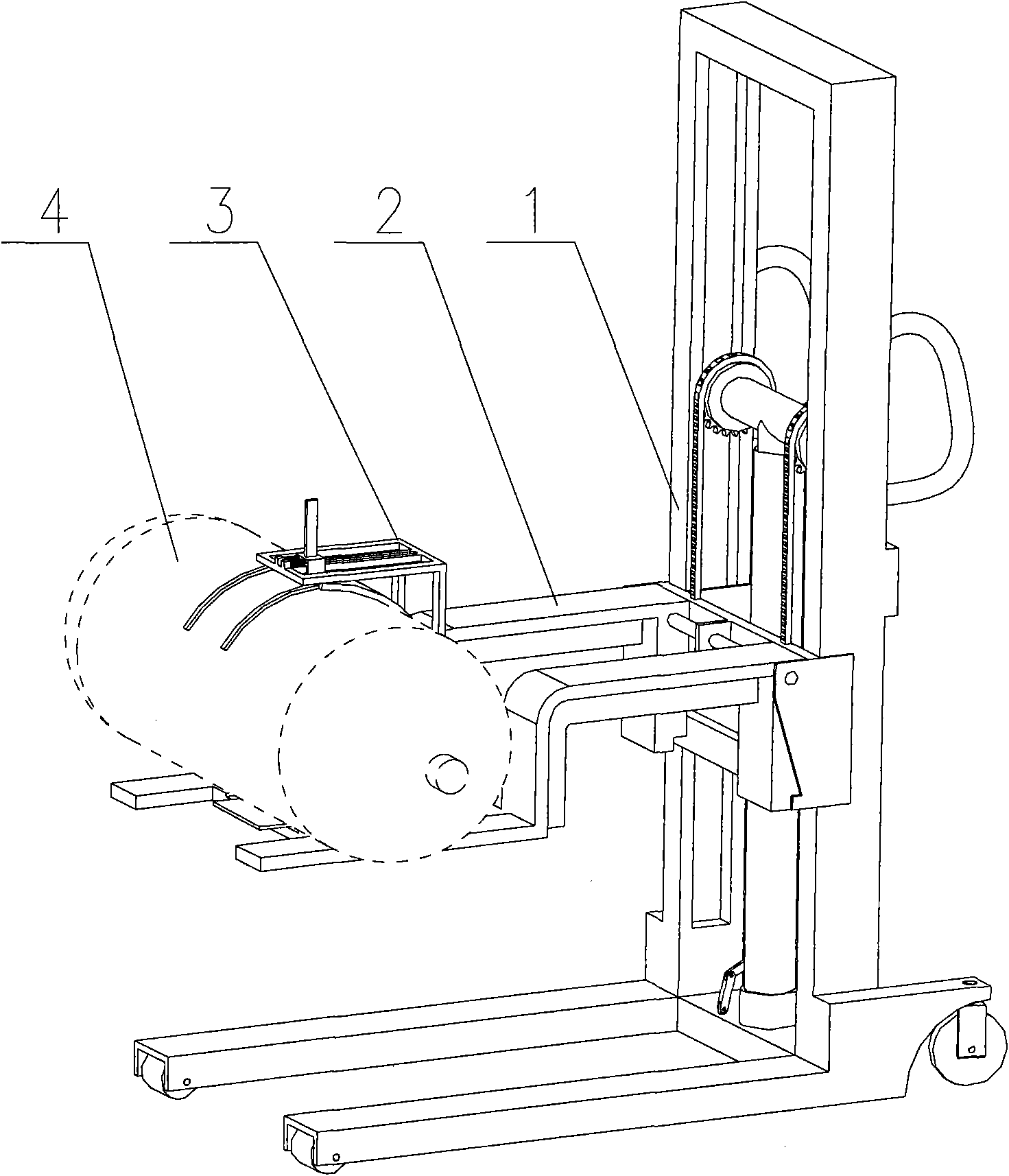

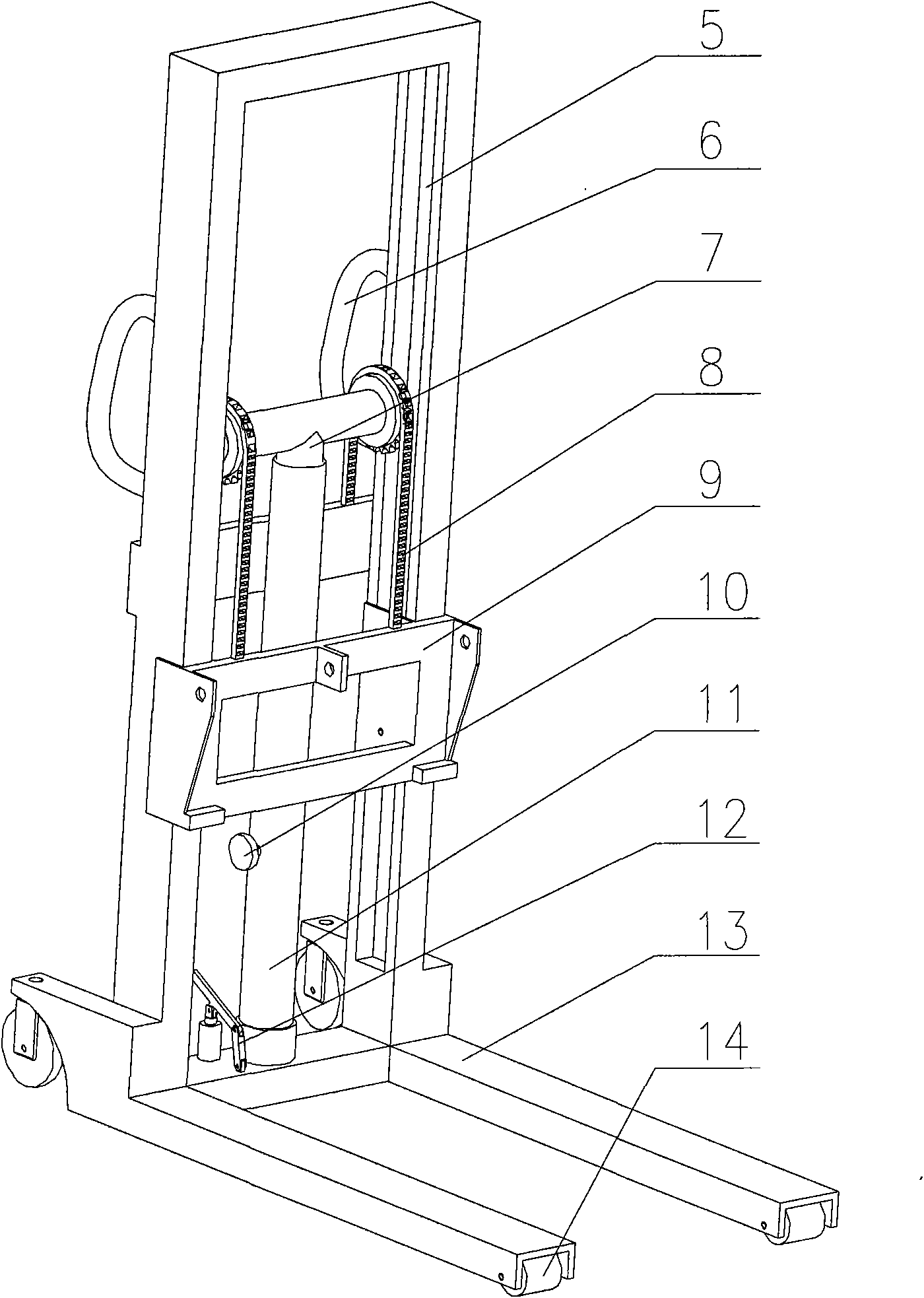

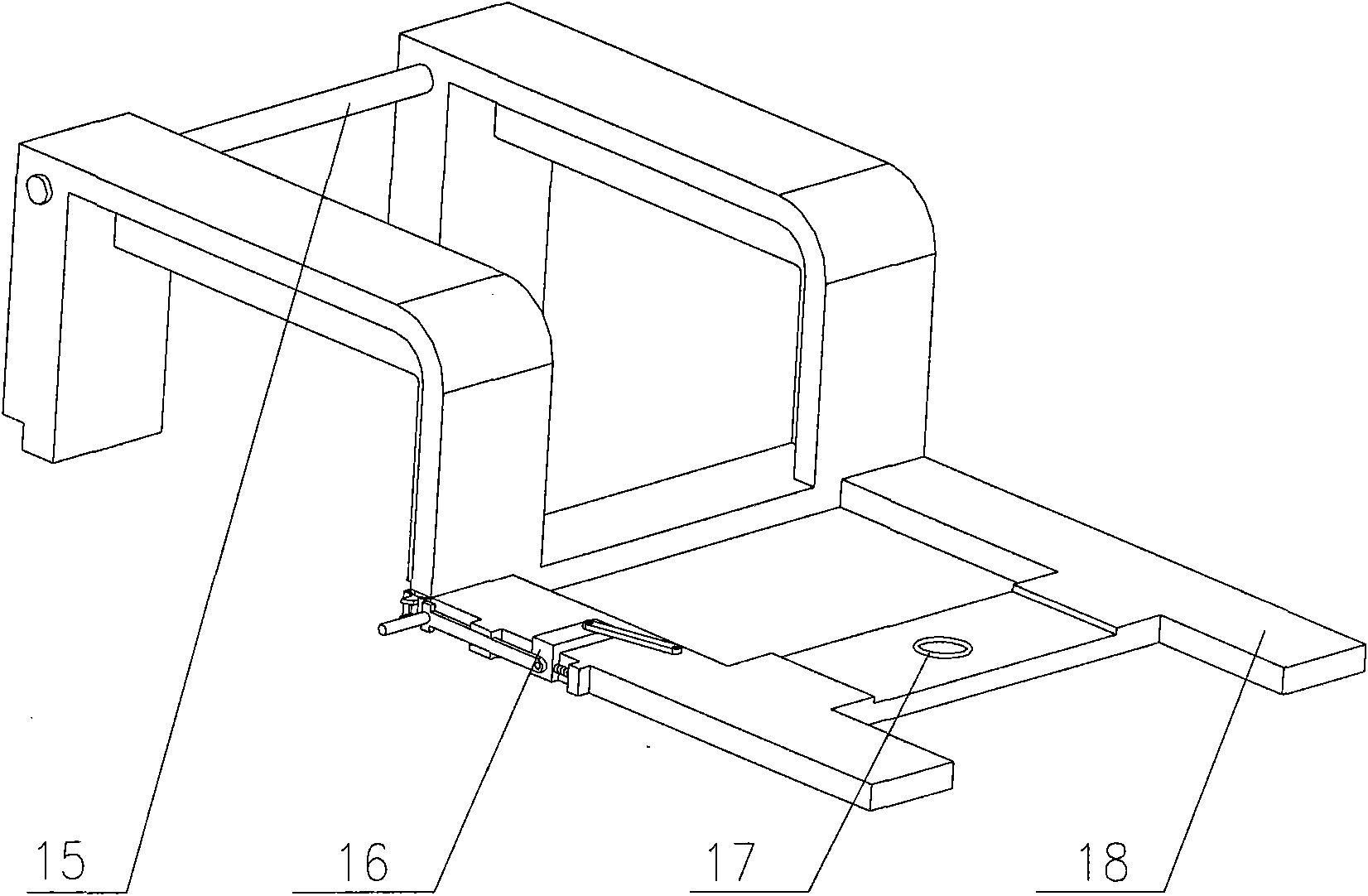

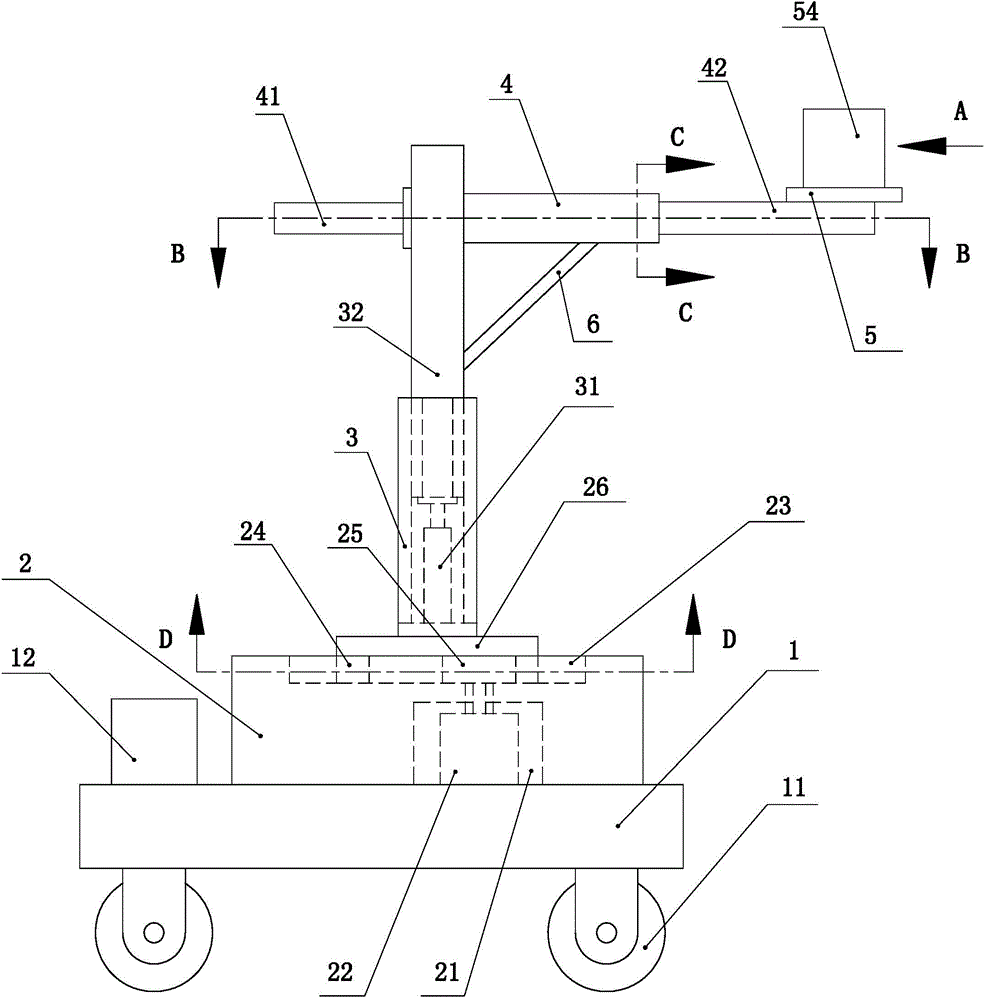

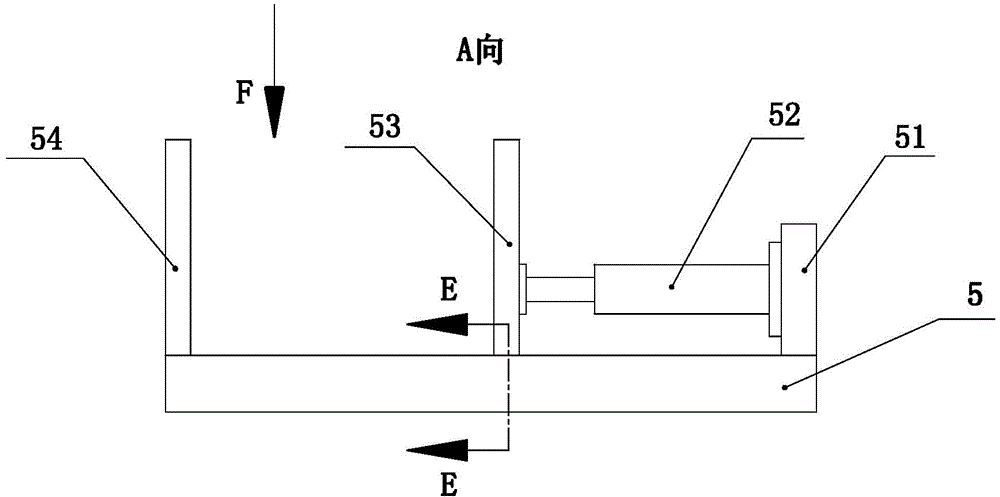

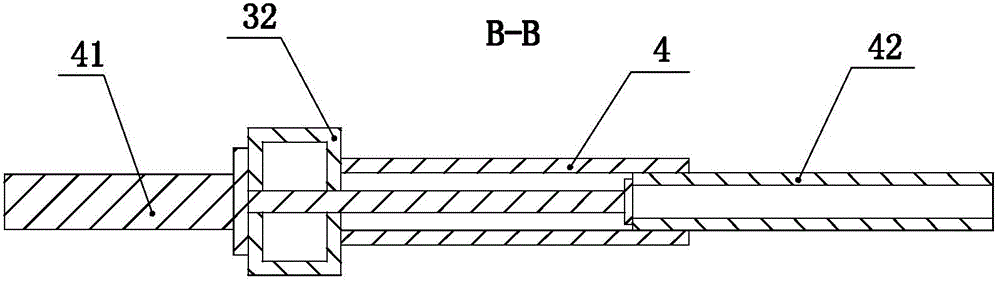

Vehicle CNG gas cylinder loading and unloading and carrying device and loading and unloading method

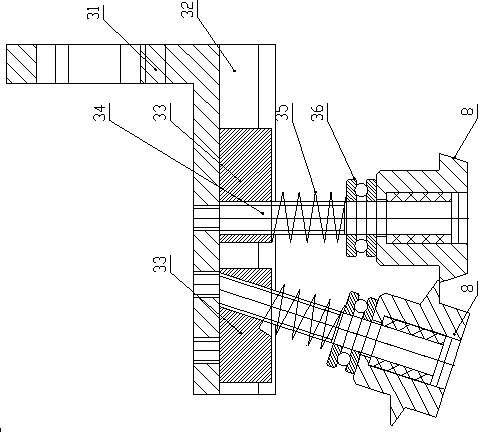

InactiveCN101913546AEffectively complete loading and unloading tasksReduce physical laborLifting devicesGas cylinderThrust bearing

The invention provides a vehicle CNG gas cylinder loading and unloading and carrying device, which mainly comprises three parts, namely a vehicle body, a supporting arm and a loading and unloading hand. The vehicle body is pushed by hands to move forwards and backwards; the supporting arm is designed into a step shape so as to adapt to the narrow space of an automobile trunk and a convex part on an edge of the vehicle; one end of the supporting arm is vertically connected with the vehicle body and can move up and down along the vehicle body, and the other end of the supporting arm mounts and supports the loading and unloading hand; the loading and unloading hand is arranged on a thrust bearing of the supporting arm and is provided with a clamping mechanism so as to grab the gas cylinder; and the loading and unloading hand can rotate on the supporting arm by controlling a rotary operating mechanism. The invention also provides a method for loading and unloading a vehicle CNG gas cylinder. After grabbing the gas cylinder, the loading and unloading hand can take the gas cylinder out of the automobile trunk or put the gas cylinder in the automobile trunk by horizontally advancing and retreating, vertically lifting, rotating and other actions. The vehicle CNG gas cylinder loading and unloading and carrying device has the advantages of solving the problem that the loading, unloadingand carrying of the gas cylinder is labor-consuming, avoiding dangers caused by fall-off of the gas cylinder due to careless manual operation, along with better popularization and application prospect.

Owner:CHINA THREE GORGES UNIV +1

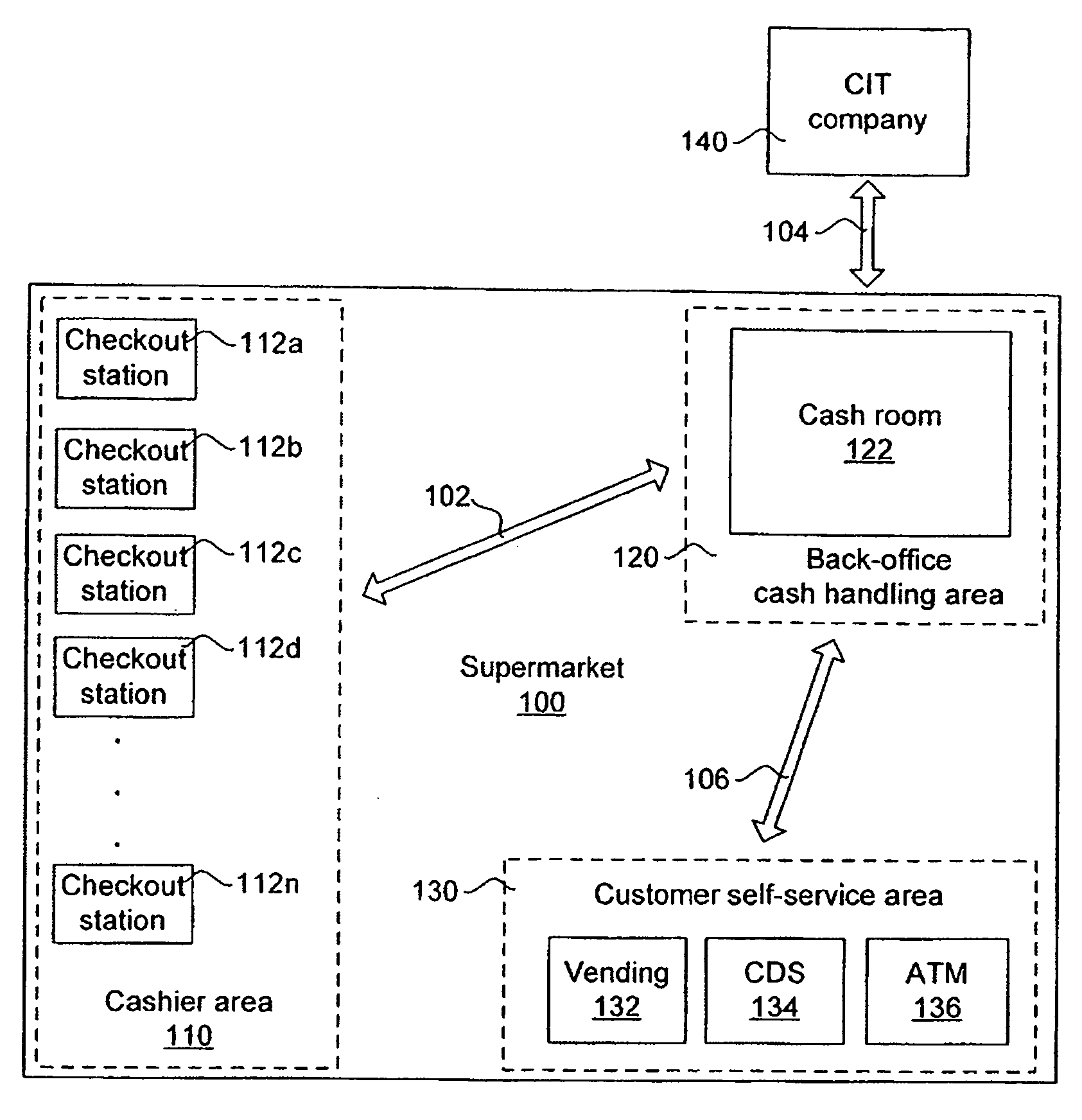

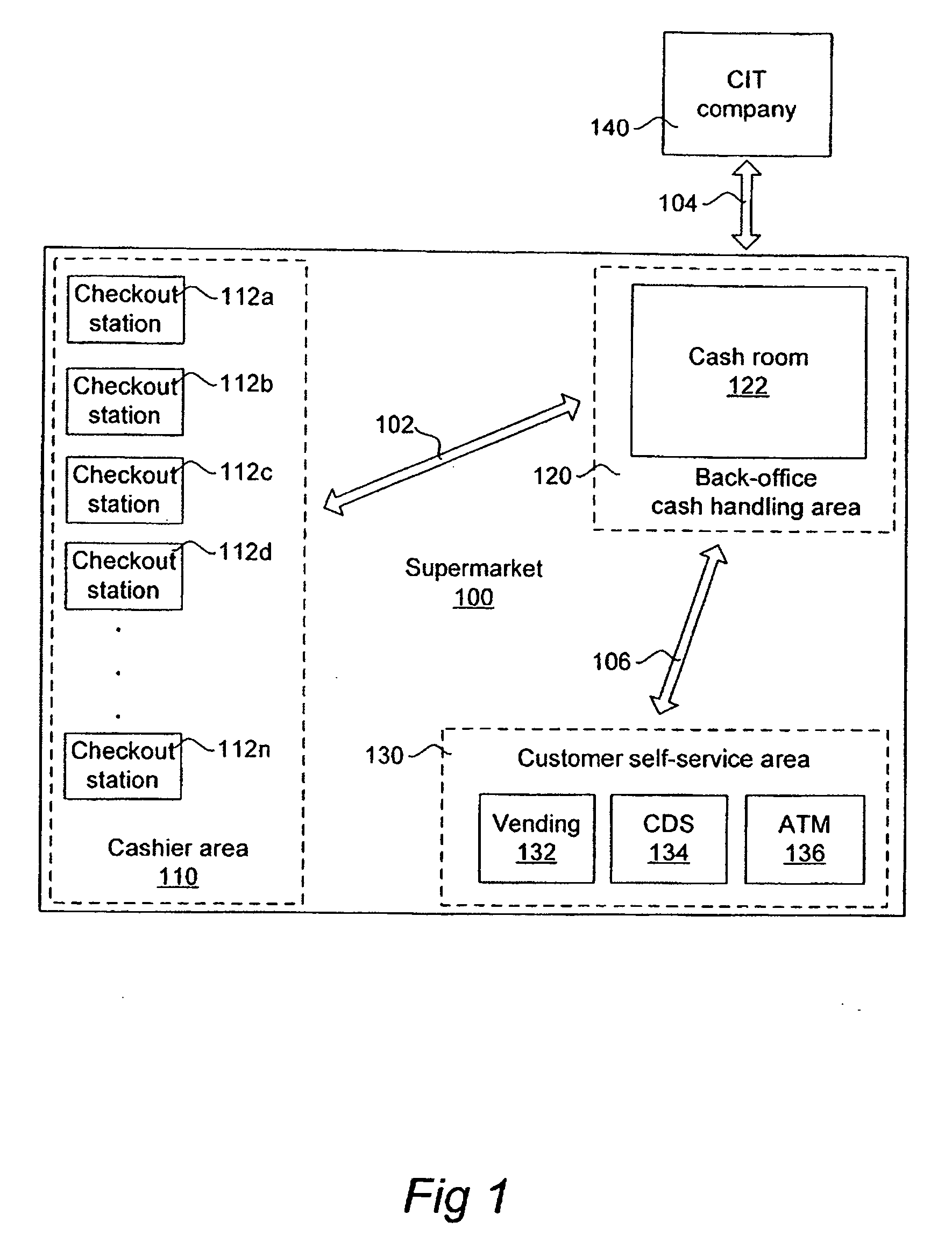

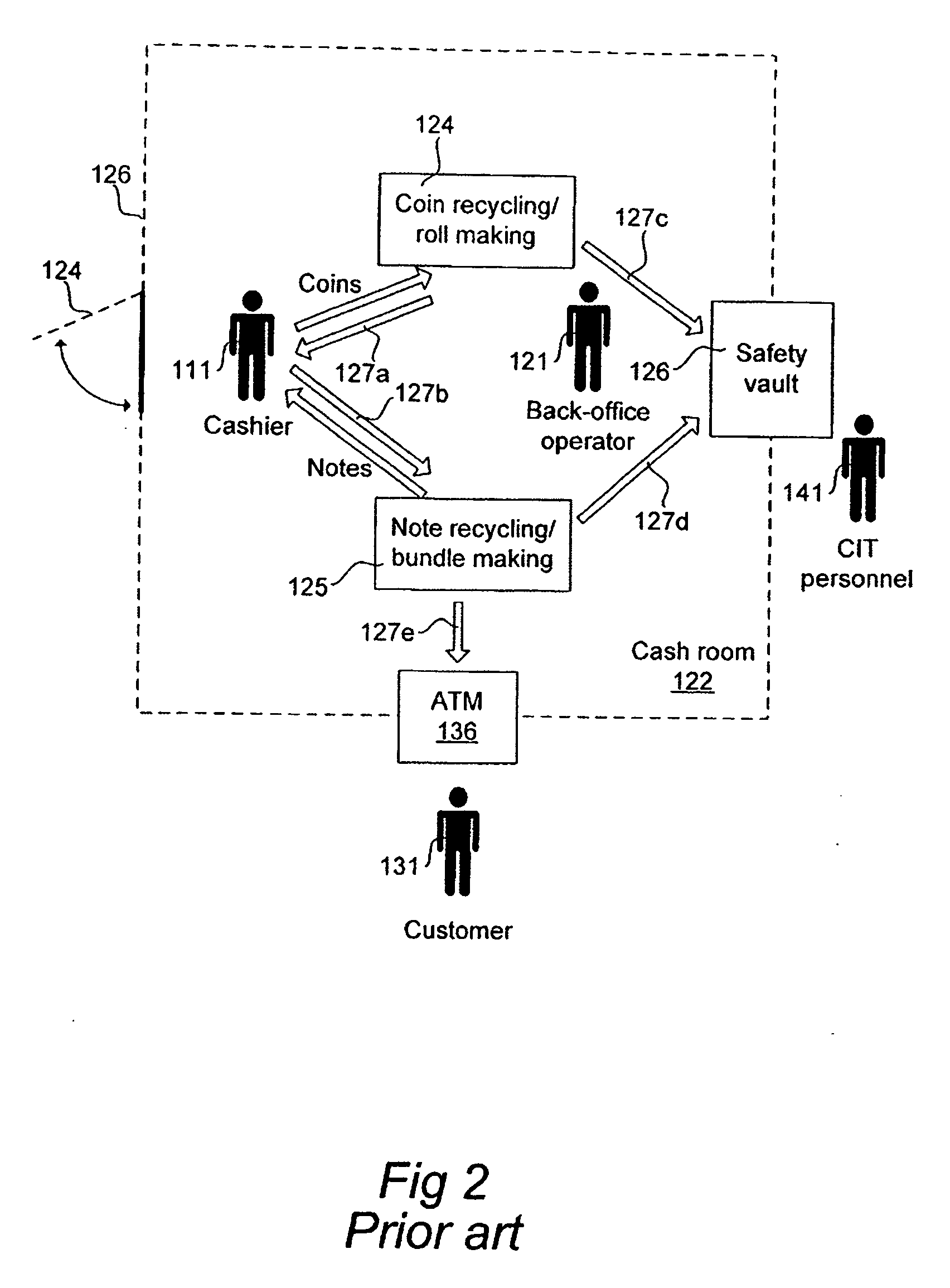

Cash recycling system having a cash receiving unit and a cash dispensing unit

InactiveUS20070151827A1High operational reliabilityImprove throughputComplete banking machinesCoin/currency accepting devicesEngineeringMechanical engineering

A cash recycling system is presented which has a cash receiving unit, the cash receiving unit has a cash input module, a cash processor, a cash output module, and a cash dispensing unit. The cash dispensing unit has a cash input module, a cash processor, and a cash output module. The cash input module of the cash receiving unit and the cash output module of the cash dispensing unit are accessible to a first type of user. The cash dispensing unit and the cash receiving unit are physically separate from and operative independently of each other. The cash output module of the cash receiving unit is adapted to supply cash, as processed by the cash processor, in a form which is sorted in denomination and therefore directly suitable for loading into the cash input module of the cash dispensing unit.

Owner:SCAN COIN IND AB

Hybrid shoppable pallet display

InactiveUS7637372B2Reduce physical laborMinimal laborOther accessoriesContainer/bottle contructionVisibilityDisplay device

Owner:FRITO LAY NORTH AMERICA INC

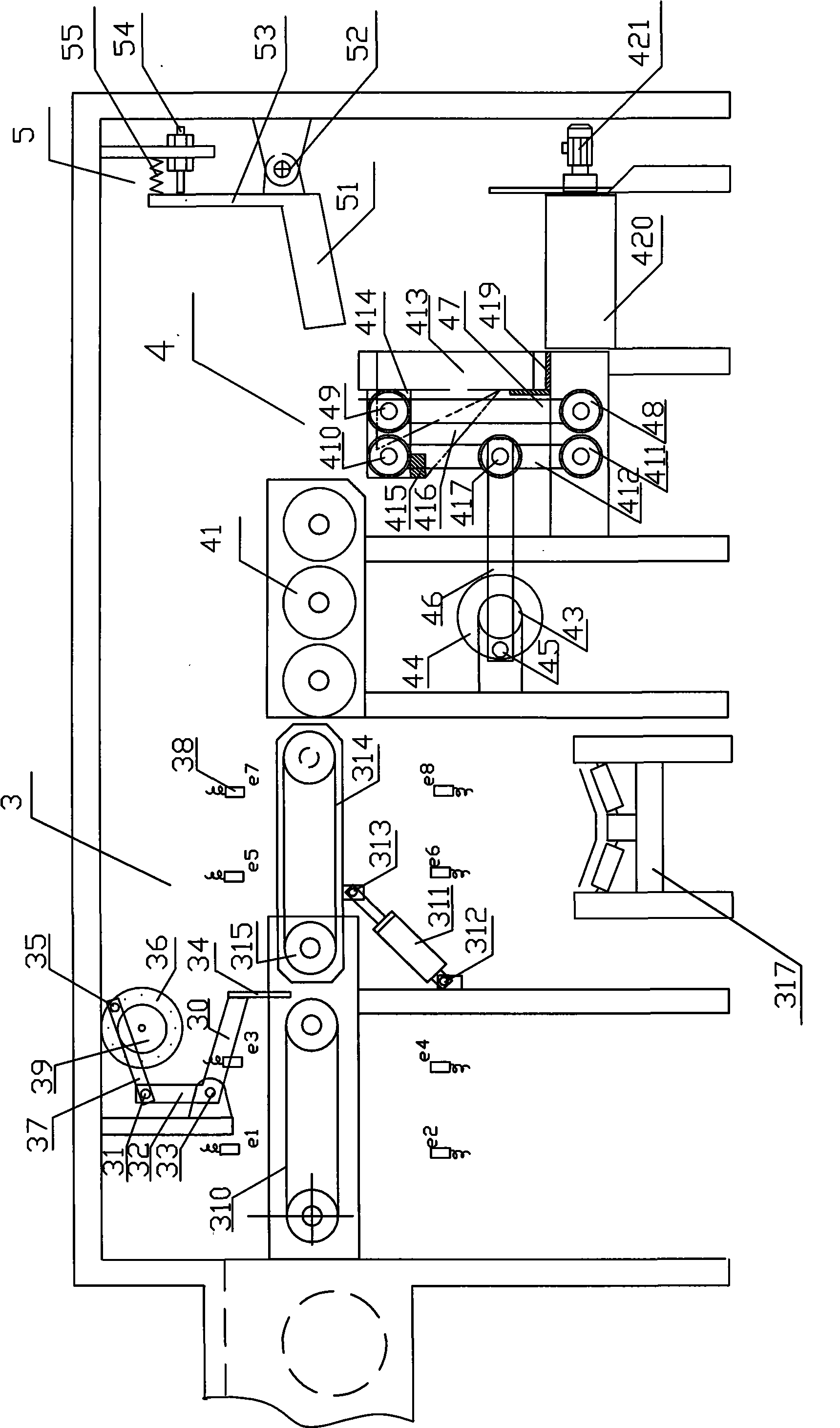

Digital full-automatic V-belt wrapping machine

InactiveCN103963327ANo difference in proficiencyReduce physical laborBeltsEngineeringMechanical engineering

The invention discloses a digital full-automatic V-belt wrapping machine which comprises a case; a feeding box is connected with the left side of the case; two cloth distribution scrolls, two guiding-open devices and two cloth guiding grooves are sequentially connected onto the feeding box from left to right; an automatic cut-off assembly and machine heads are sequentially connected onto the case from left to right; a tensioning assembly is connected with the right side of the case; the two cloth distribution scrolls, the two guiding-open devices and the two cloth guiding grooves are respectively arranged in parallel; the automatic cut-off assembly comprises a blade fixing seat, a long blade, a cut-off air cylinder and a disk blade; the long blade is fixedly connected onto the blade fixing seat; the disk blade is connected onto the cut-off air cylinder; the cut-off air cylinder is horizontally arranged; the limiting position of the disk blade in moving right is above the long blade. The digital full-automatic V-belt wrapping machine has the advantages that manual labor is reduced, the production efficiency is improved, the new worker training is eliminated, the proficiency and the working efficiency of new workers and veteran workers make no difference at all, and one worker can operate two machines when a long belt is processed.

Owner:要银安

A kind of method for preparing humic acid urea complex in aqueous medium

The invention provides a method for preparing a humic acid-urea complex in an aqueous medium, which comprises the following steps of: dissolving 20 to 400 parts of urea in 40 to 200 parts of water at the temperature of between 20 and 60DEG C; adding 40 to 200 pars of humic acid feed coal, heating to the temperature of between 40 and 100DEG C, and reacting for 5 to 30 minutes; adding 10 to 100 parts of phosphate, continuously stirring, reacting for 30 to 120 minutes, and performing solid-liquid separation; and evaporating and concentrating a solution to obtain concentrated liquor of the humic acid-urea complex, or drying to obtain a solid humic acid-urea complex. The method has the advantages that: the phosphate is used as an activator, and the extraction ratio of water-soluble humic acid is improved; the used humic acid feed coal is rich in resources, low in price and easily obtained; the production process has a simple and short flow, the equipment is easy and convenient to operate, reaction conditions are mild, pollutant emission is avoided in the production process, environmental pollution is avoided, and the method is suitable for large-scale industrial production; and the product has good water solubility and can effectively improve the fertilizer efficiency of urea and the utilization rate of nitrogen.

Owner:谭钧

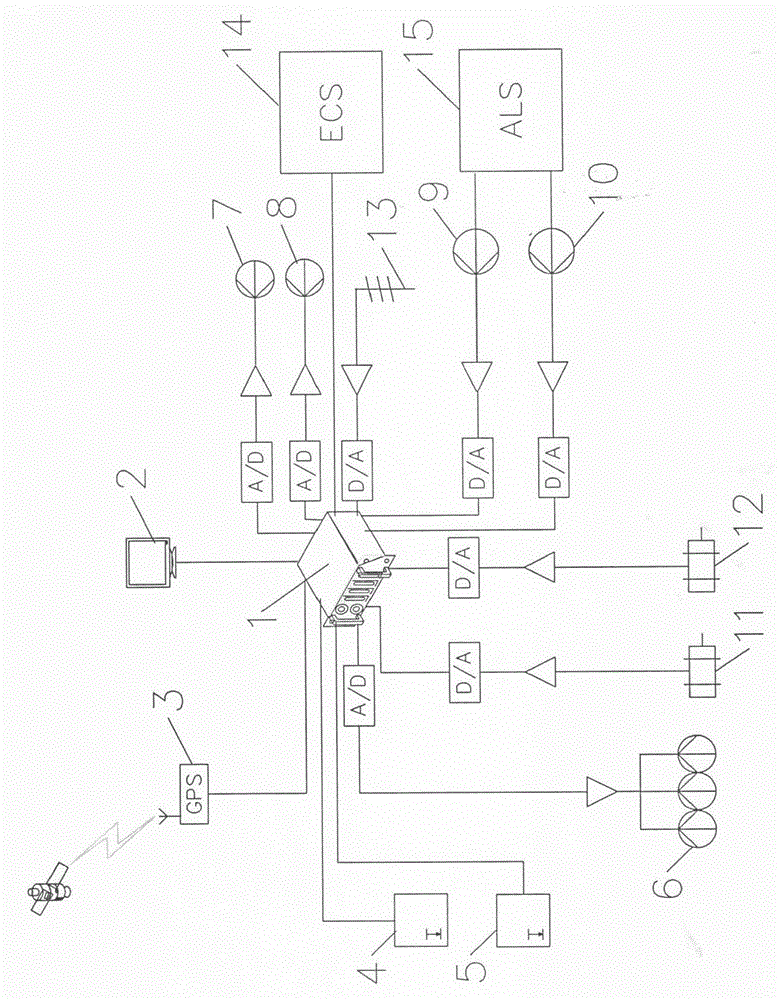

Automatic paving control system for paving machine

InactiveCN105178146AReduce inappropriatenessReduce physical laborRoads maintainenceLaser transmitterUltrasonic sensor

The invention discloses an automatic paving control system for a paving machine. The automatic paving control system for the paving machine comprises a paving machine automatic leveling system, a paving machine electric-control system, a longitudinal slope sensor, a transverse slope sensor, a scraper motor, a spiral distributing device motor and a vibrator. The automatic paving control system for the paving machine further comprises a center-control computer, a man-machine interaction device, a global positioning system (GPS), a data transmission system, a laser emitter, a laser scanner, an ultrasonic material level sensor, a speed sensor and an ultrasonic sensor. Relevant construction drawing technical parameters are input into the center-control computer, and the paving machine is controlled by the center-control computer through the data transmission system to complete the automatic paving process. The automatic paving control system for the paving machine is simple, convenient to use, applicable and capable of saving time and labor and greatly relieving labor intensity, automatic paving is achieved, inappropriateness of manual operation is reduced, manual misoperation is avoided, and accurate, continuous and standard automatic paving is achieved; high-efficiency, programmed, automatic and standard high-technology construction is completely achieved.

Owner:河南省路桥建设集团有限公司

Continuous vibro fluidized bed roaster using flue gas

InactiveUS6810794B2Reduction in human drudgeryClean and hygienic endGrain huskingGrain polishingFlue gasCoil spring

A continuous vibro fluidized bed roaster for roasting cereals, pulses, spices, oil seeds and ready-to-eat snack foods using flue gas, said roaster comprises of a main frame (4) which houses all the parts of the machine, the vibrating deck (1) is mounted on a set of coil springs (6) which is mounted on the main frame through screw fasteners, a perforated sieve (3) and a hood (2) are mounted on the vibrating deck (1) with rubber gasket (17) for sealing the hot air from leakage, a vibratory motor (10) is mounted on the feed end of the vibratory deck for imparting vibrations to the feed material, a vibratory feeder (11) is mounted on the feed side of the vibratory deck (1) for feeding the raw material in to the roaster through a hopper (20).

Owner:COUNCIL OF SCI & IND RES

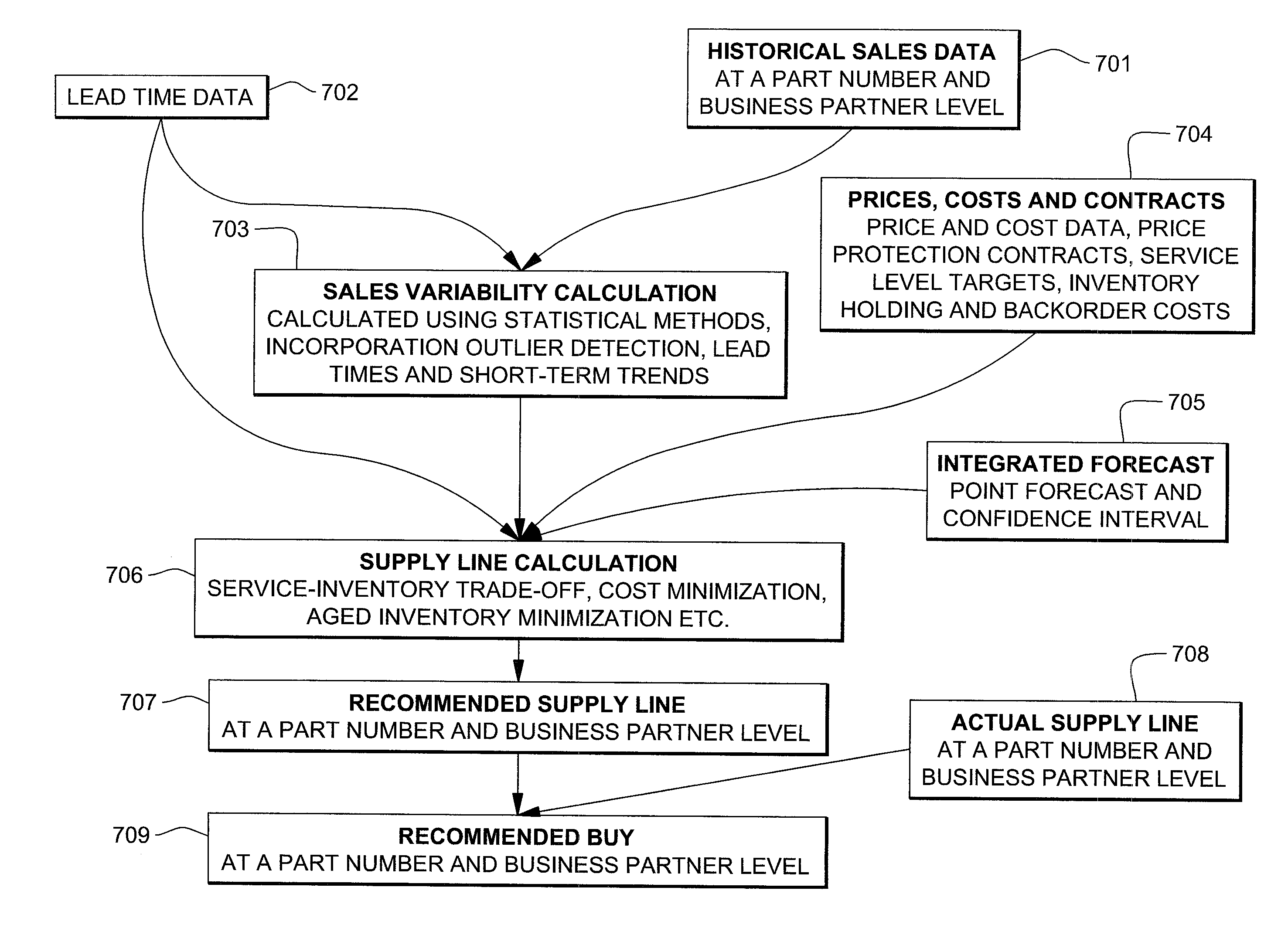

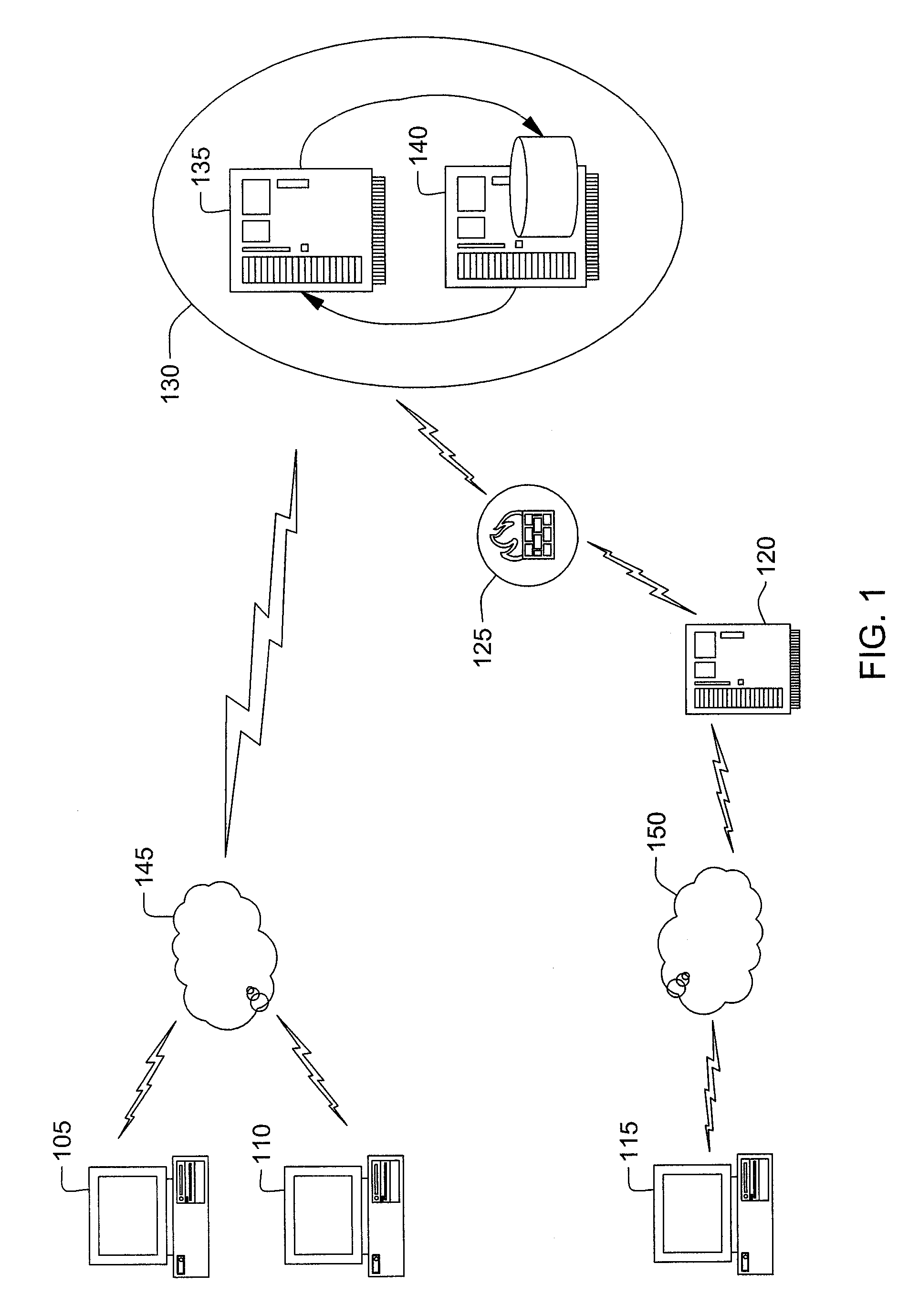

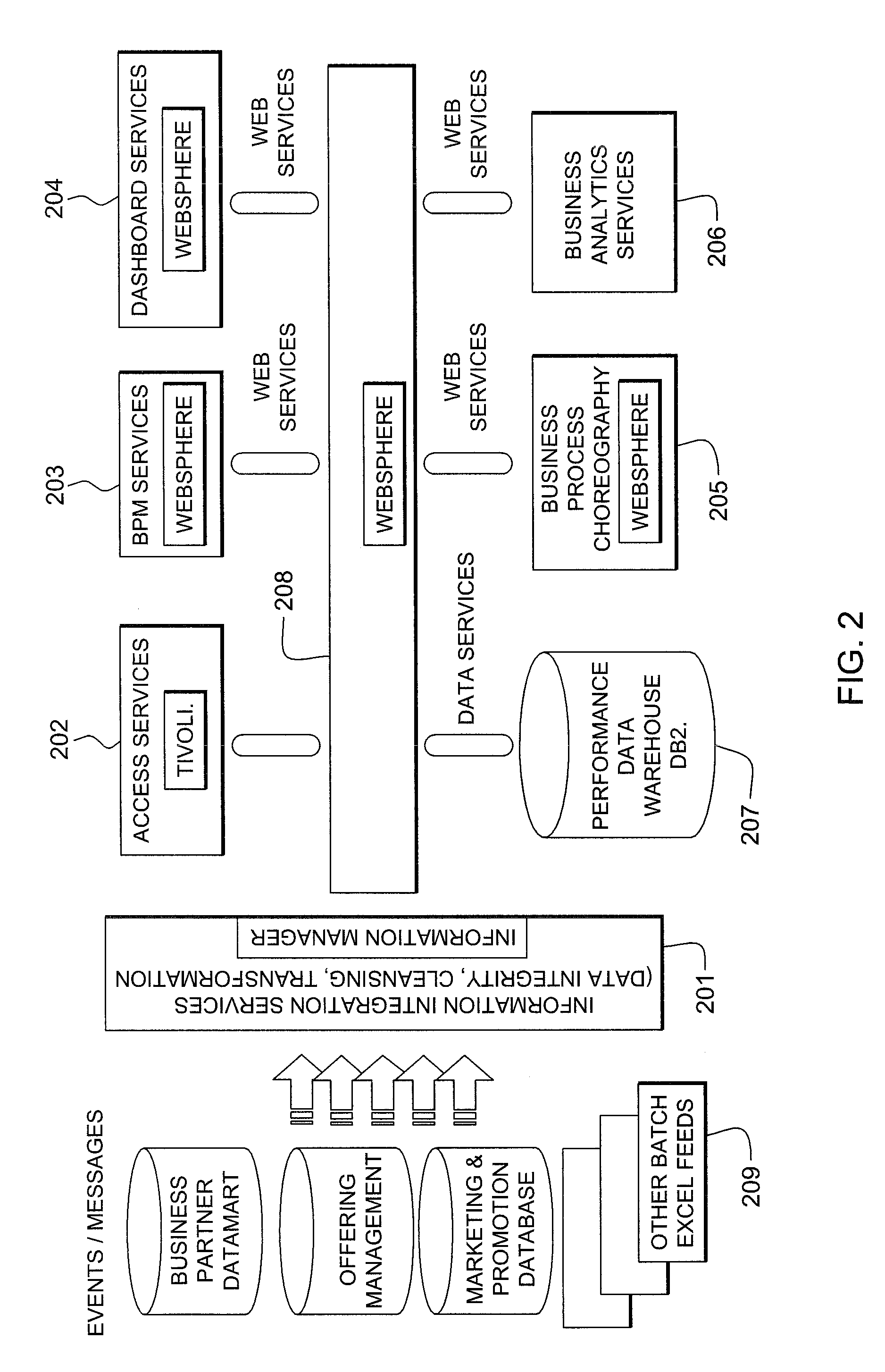

Business partner collaboration and buy analysis

InactiveUS20100121677A1Reduce demandMitigate supply imbalanceComplete banking machinesHand manipulated computer devicesPurchasingWorld Wide Web

The present invention provides a method, system and computer program product for implementing an automated inventory replenishment process between a manufacturer and a business partner. In one embodiment of the invention, a method is provided comprising the business partner purchasing and maintaining an inventory of goods from the manufacturer, and the manufacturer providing price protection to the business partner for the purchasing of the goods. This embodiment further comprises managing said inventory by using an automated process that takes into account said price protection for the purchasing of the goods.

Owner:IBM CORP

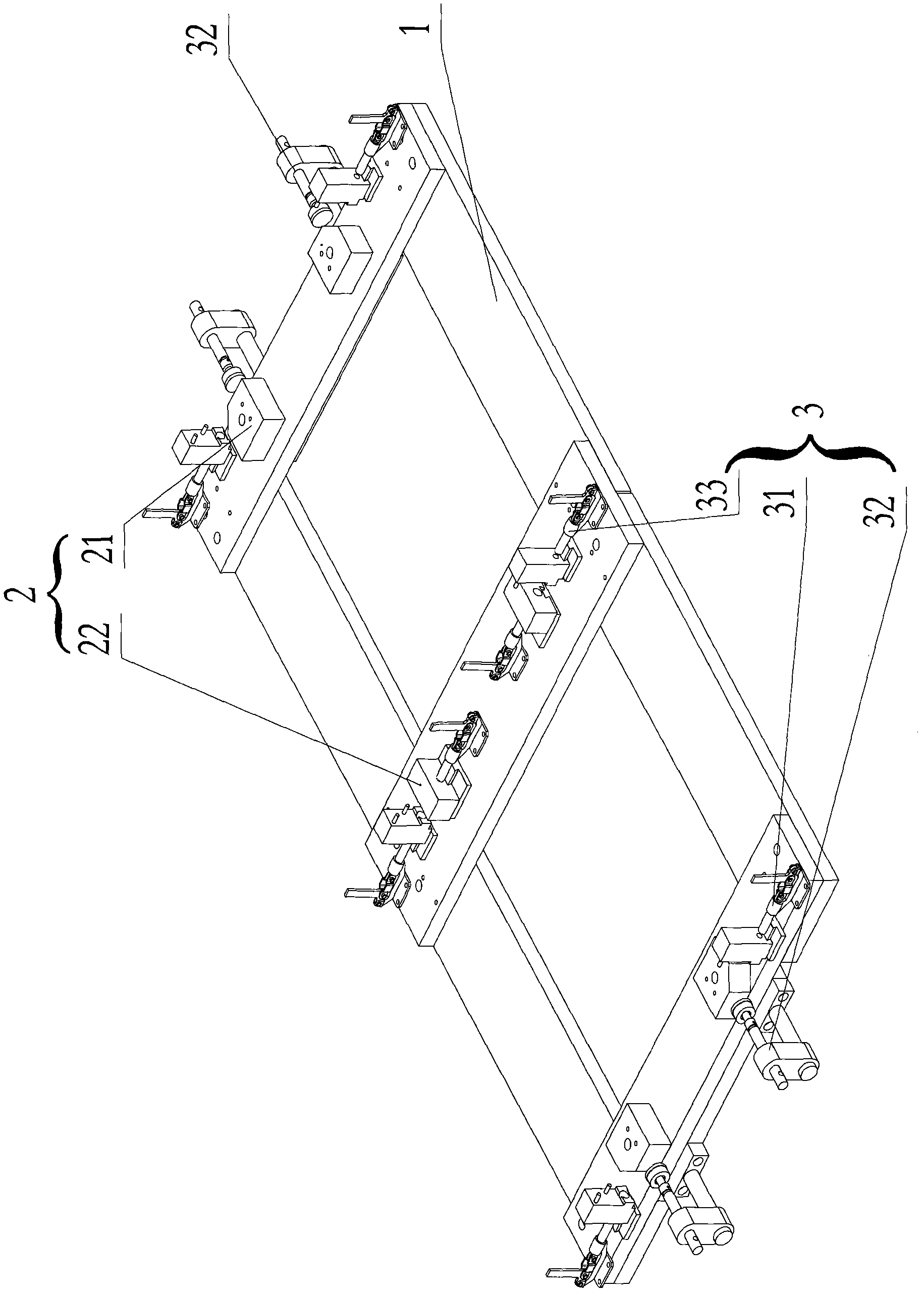

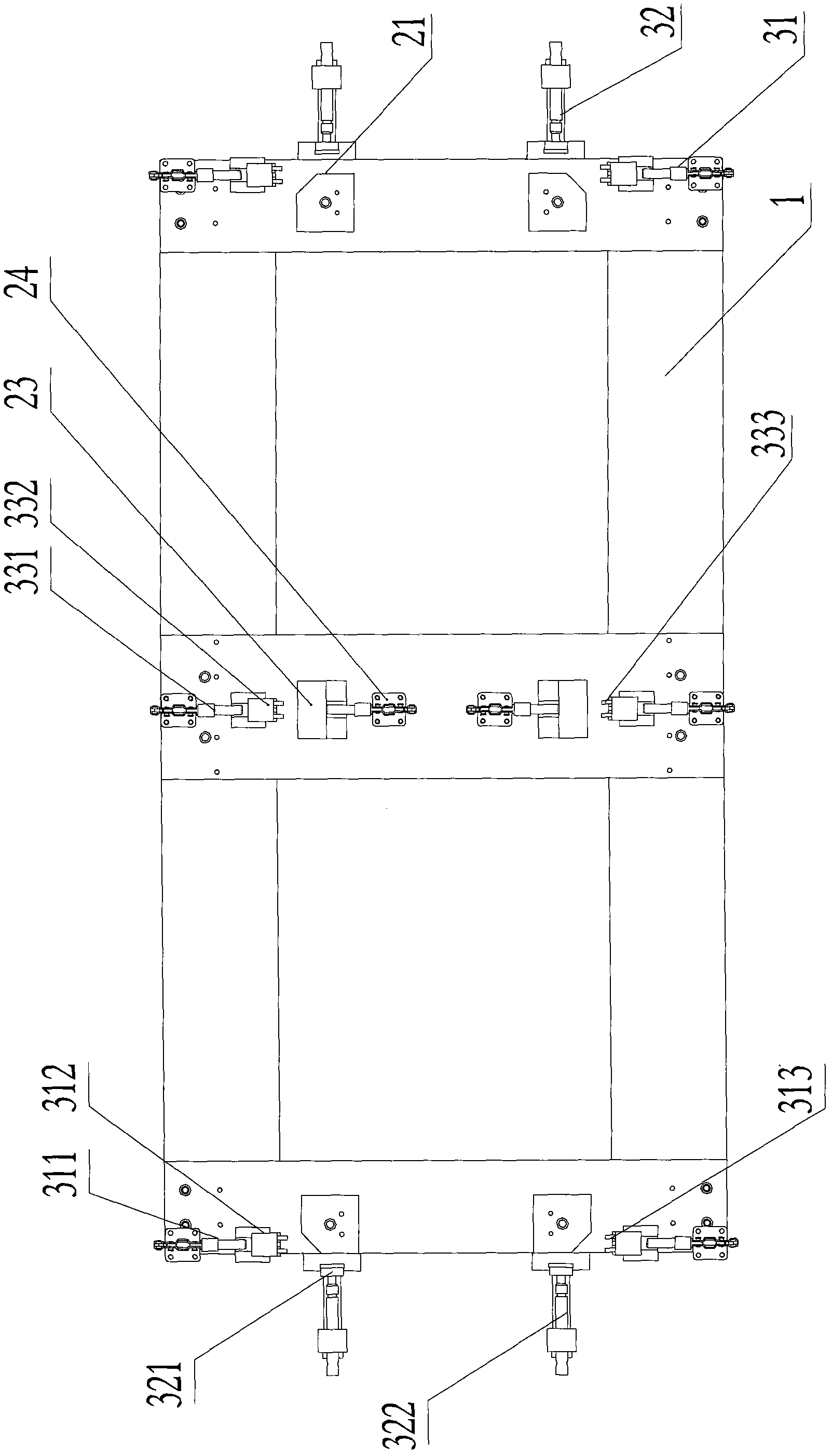

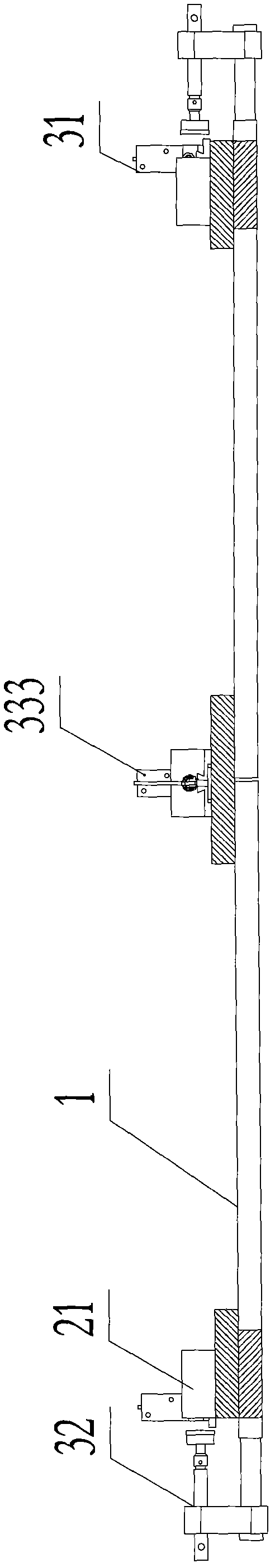

Welding tooling device for pillar frame of machine cabinet and assembly method of device

InactiveCN102029497AReduce physical laborControl or eliminate welding heat distortionWelding/cutting auxillary devicesAuxillary welding devicesInstabilityEngineering

The invention discloses a welding tooling device for a pillar frame of a machine cabinet and an assembly method of the device, wherein the device comprises a clamp body (1) and is characterized in that a positioning element (2) and a clamping device (3) are fixedly arranged on the clamp body, the positioning element (2) is used for horizontal position limitation of all parts of the pillar frame of the machine cabinet, and the clamping device (3) is matched with the positioning element (2) for clamping all the parts of the pillar frame of the machine cabinet in the horizontal direction. By adopting the device and the method disclosed by the invention, the physical labor of operation staff can be greatly reduced, and the assembly and welding efficiency can be improved; and the welding thermal deformation of a workpiece can be controlled or eliminated, and the instability of manual welding can be reduced.

Owner:Jiangsu Boamax Technologies Group Co Ltd

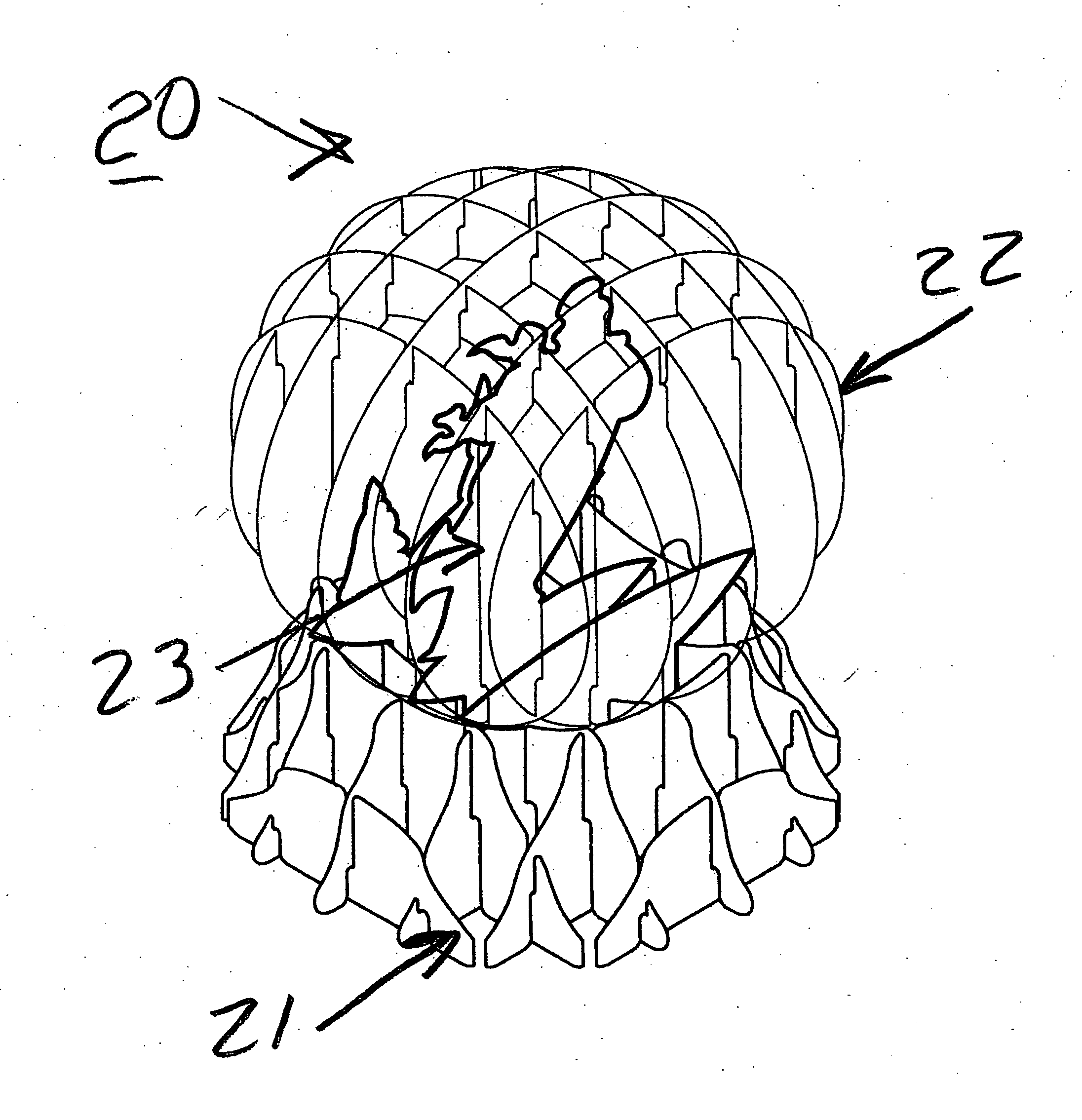

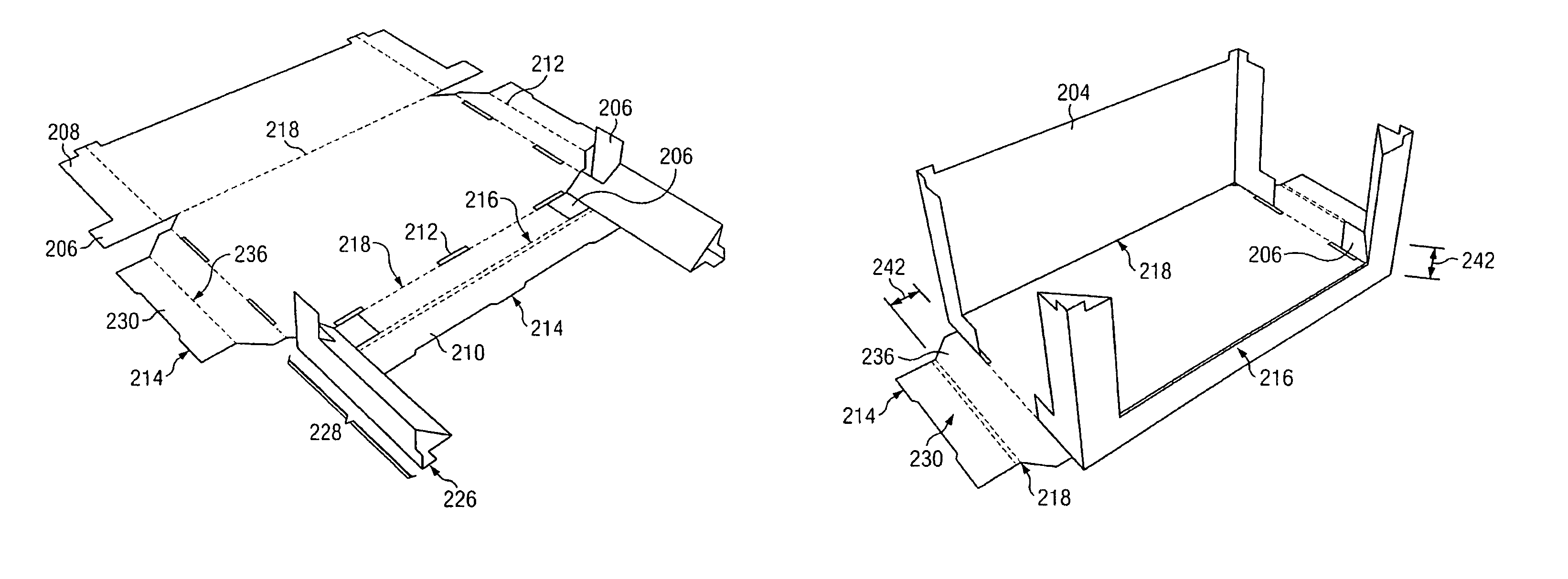

Three-dimensional folding graphics system

ActiveUS7490425B2Quickly and easily automatically erectedEasy and fast constructionOther printing matterBoardsGraphicsGraphic system

By providing a housing member within which all of the required elements are pre-formed and constructed as a display system which enables any desired graphics to be inserted therein to form an integral part of the assembly, a unique, printed, visually exciting and interest generating foldable, three-dimensional display system is attained. In accordance with the present invention, the interest generating, foldable display system of the present invention is quickly and easily automatically erected from its flat, generally two-dimensional configuration into a three-dimensional display. Furthermore, the housing preferably comprises an enlarged internal cavity for receiving any desired display element. In this way, the display assembly is easily, and automatically converted from a two-dimensional, substantially flat configuration into a three-dimensional fully erected, interest generating, visually exciting display.

Owner:CROWELL CHRISTOPHER S

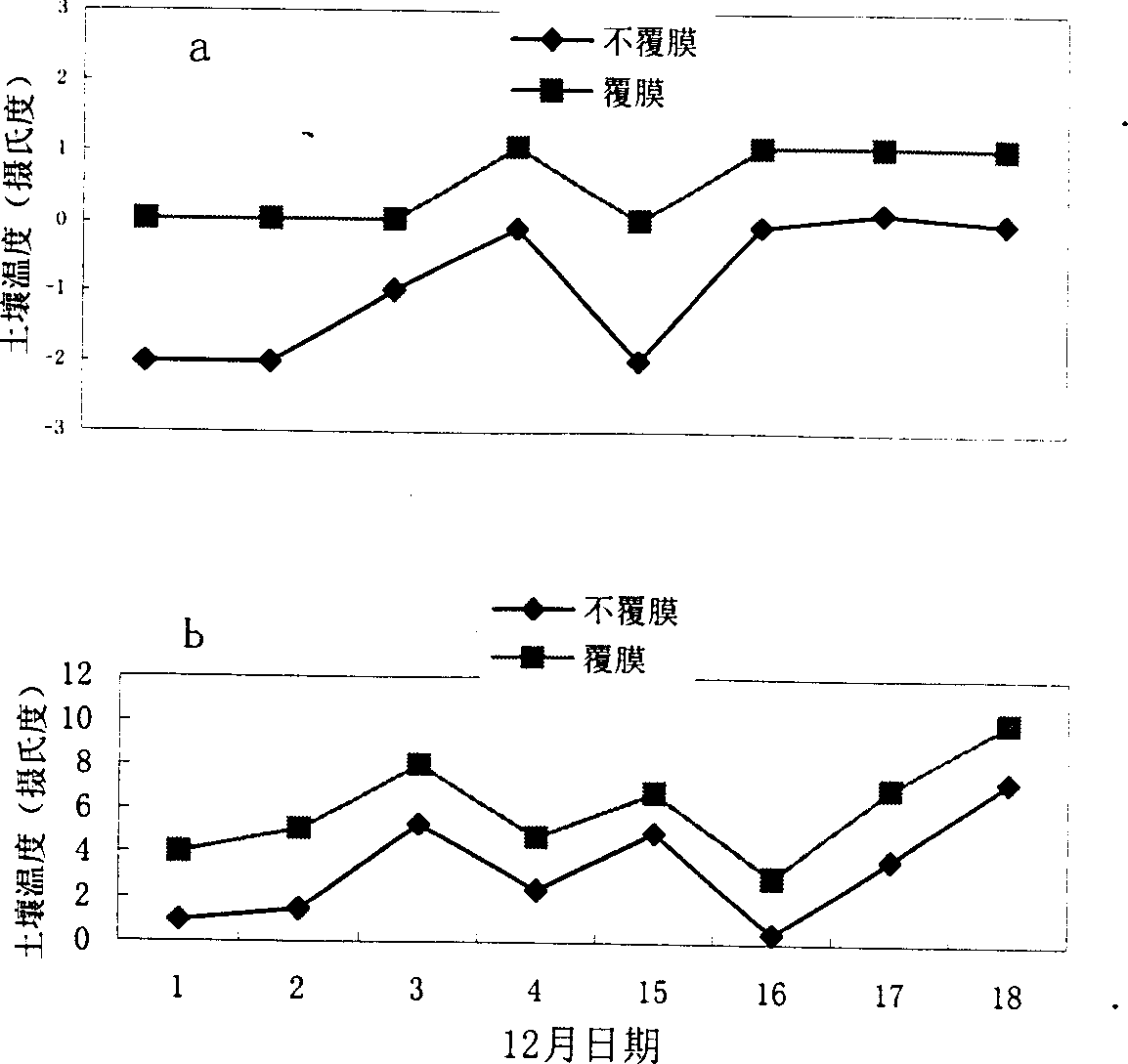

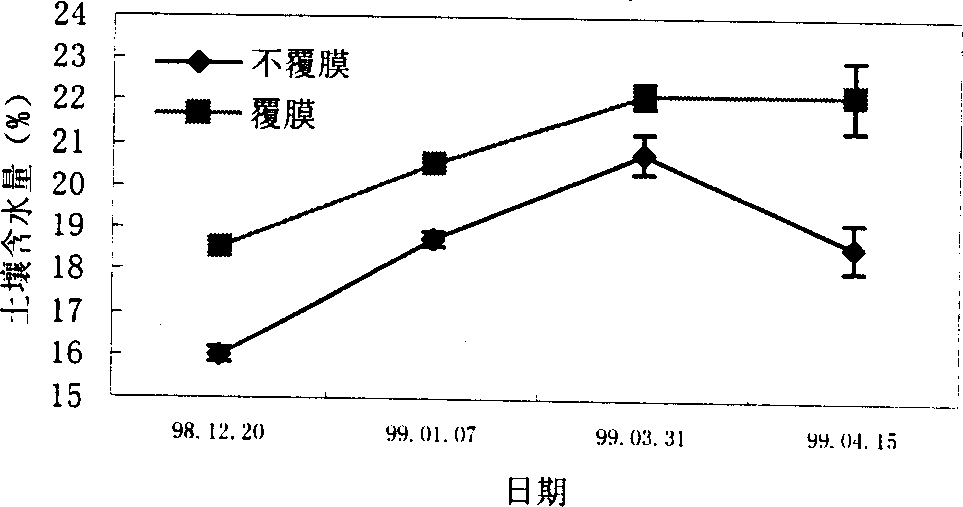

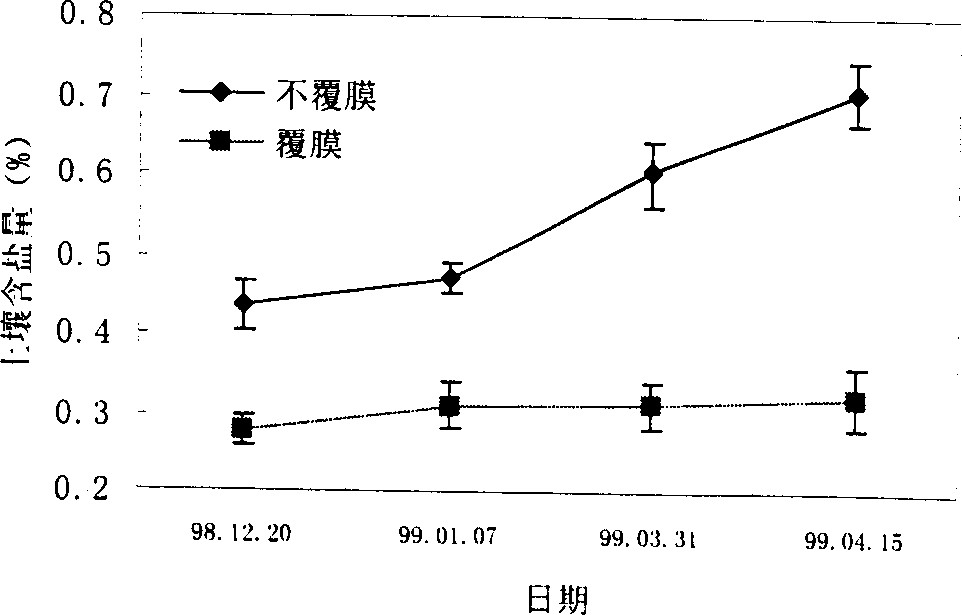

Wheat high yield cultivation technology in saline-alkali soil

InactiveCN1433671AInhibit salt returnKeep moisturePlantingFurrow making/coveringField cropAlkali soil

The high-yield cultivation technique of wheat in saline-alkali field includes the following measures: selecting salt-resistant fall wheat species seed, using organic fertilizer as main fertilizer andusing microelement fertilizer for saline-alkali field crops as auxiliary fertilizer, selecting DEkang 961 as cultivatino species, before sowing, in tenth-twentieth of October, adopting wild flooding irrigation method, watering, salt-pressing and making moisture, after 3-5 days ploughing under to great depth and making land preparation, then film-covering and hole sowing with 1-3 days, after reviving in spring and when the first new leaf is grown and second new leaf is only produced spraying 20% mepiquat chloride paclobutrazol microemulsion on foliage.

Owner:SHANDONG NORMAL UNIV

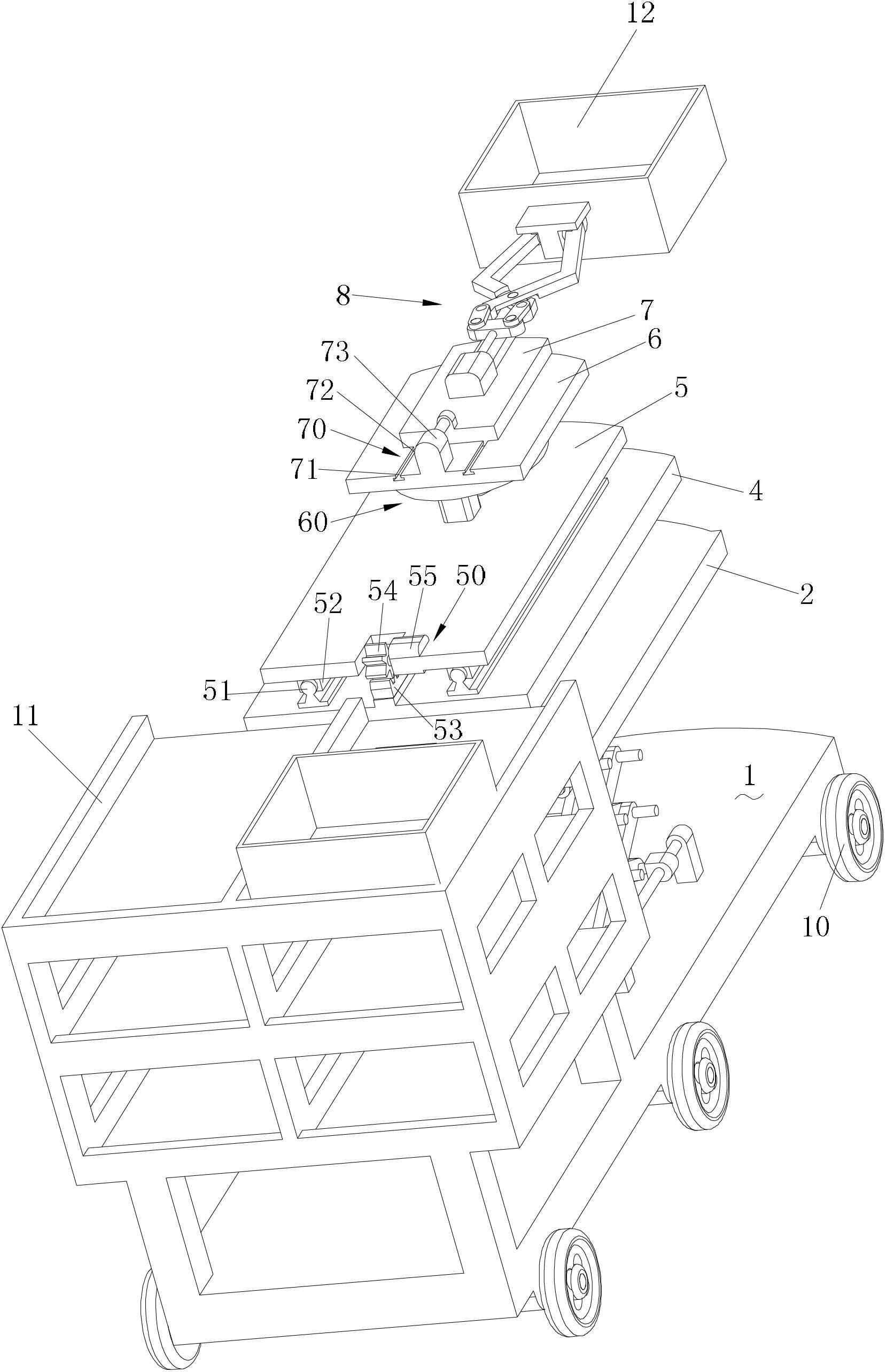

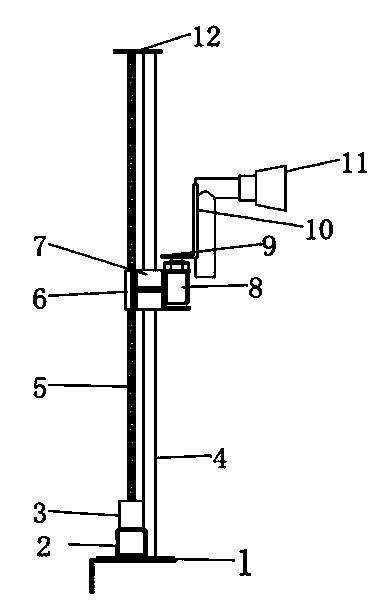

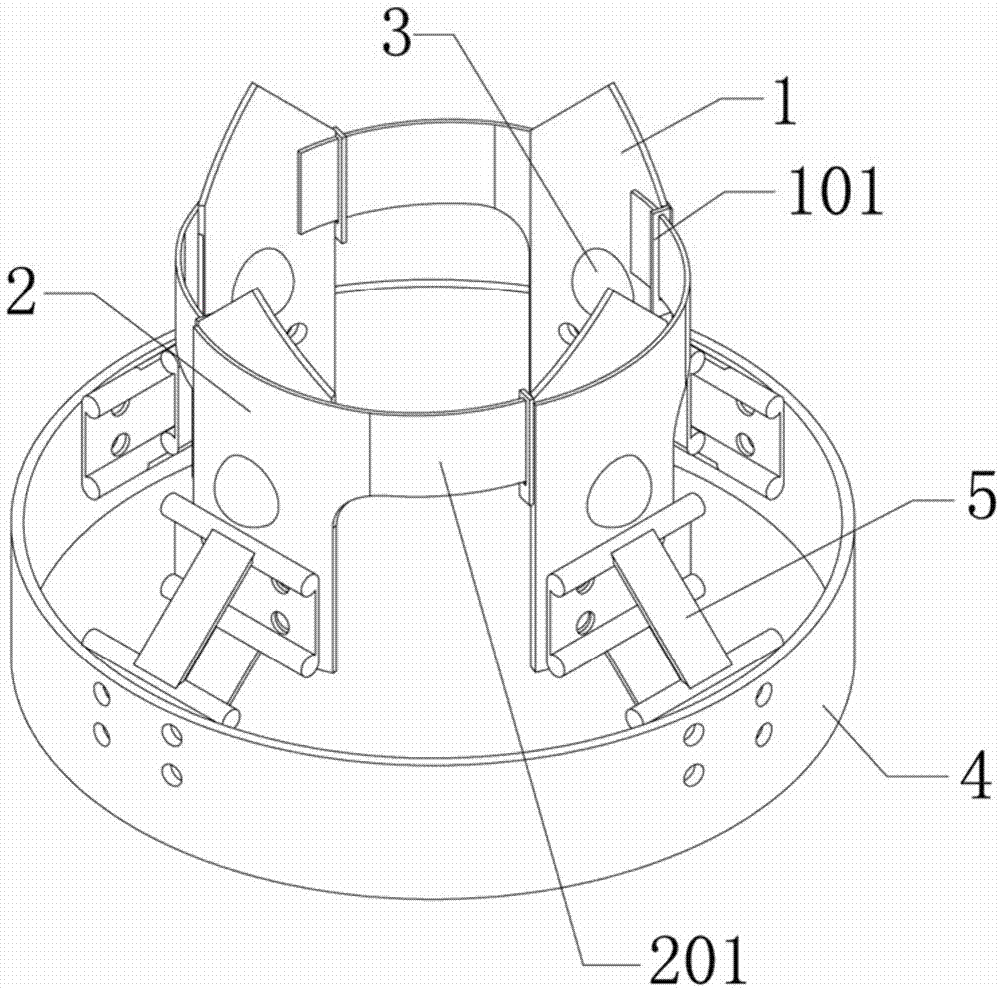

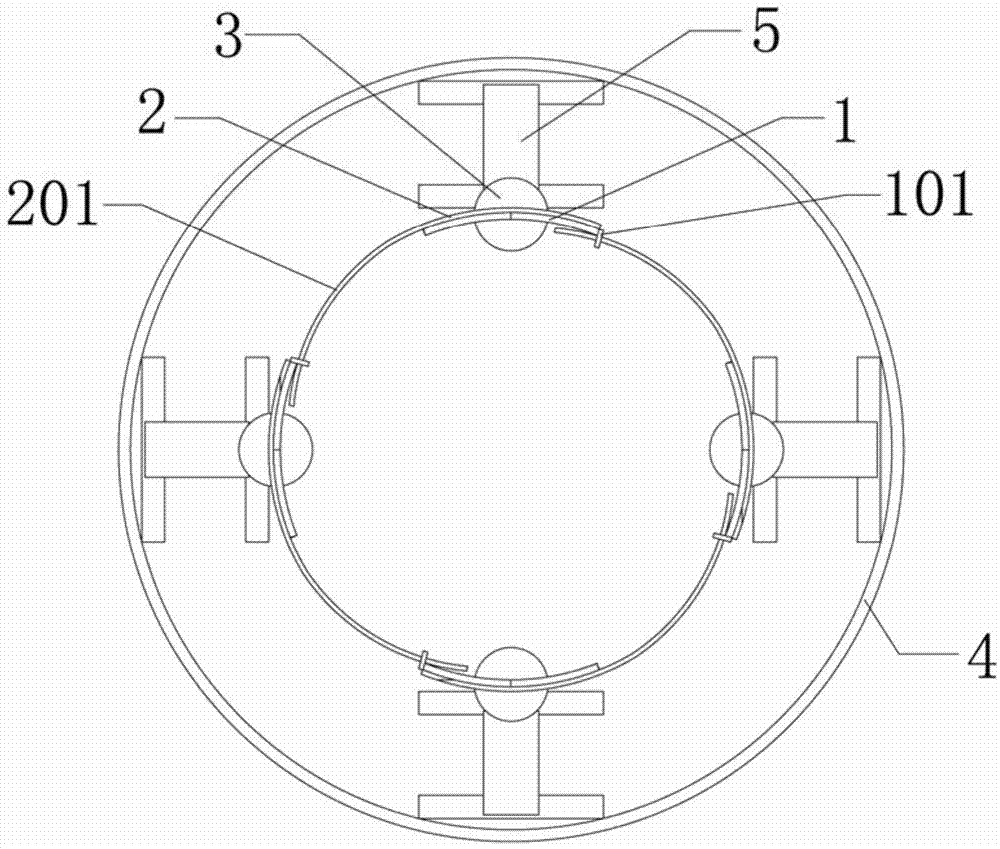

Current transformer mounting device

InactiveCN104084786AReduce physical laborImprove work efficiencyMetal working apparatusMechanical engineeringCurrent transformer

The invention relates to mounting of current transformers, in particular to a current transformer mounting device. The current transformer mounting device is used for solving the problems that physical exertion of workers is high and mounting efficiency is low according to an existing mounting mode. The current transformer mounting device is characterized in that a rotating assembly rotates to drive components on a rotary disc to rotate, a lifting assembly lifts to lift a cross arm and components on the cross arm, a stretching and retracting assembly stretches or retracts to drive a second sliding rod and components on the second sliding rod to stretch or retract, and through all the actions, a clamping assembly is fed to move to a proper working position; the clamping assembly lifts and clamps the current transformers, then the current transformers are mounted or demounted, and workers only need to screw or unscrew bolts. By means of the current transformer mounting device, physical labor of workers is greatly relieved, working efficiency is improved when the current transformers are mounted or demounted, and risks caused when workers directly carry the current transformers are avoided.

Owner:STATE GRID CORP OF CHINA +1

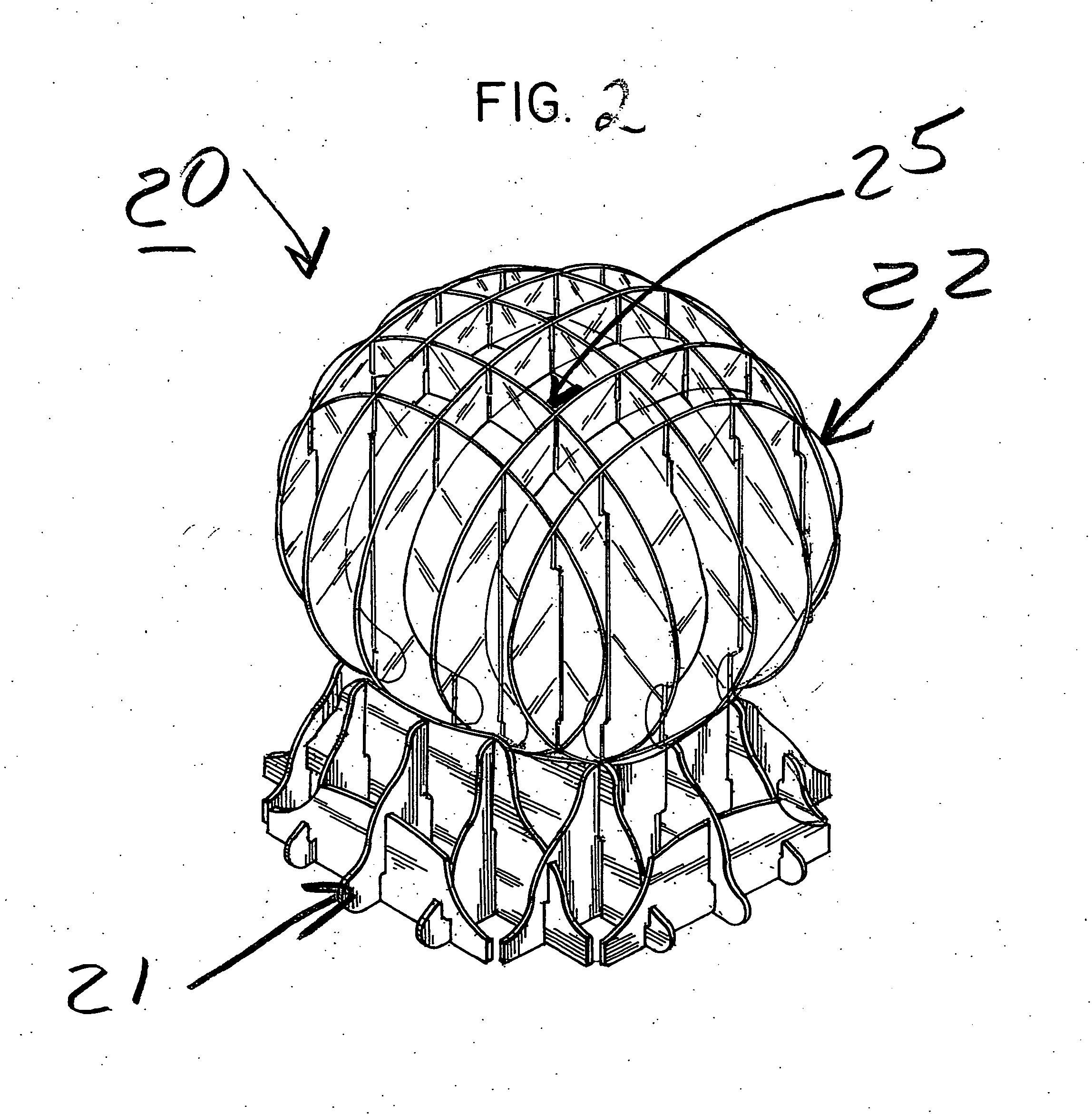

Inserting cutting type variable diameter banana shaft removing and combing cutter self-adaptive to diameter of banana spike rod

The invention discloses an inserting cutting type variable diameter banana shaft removing and combing cutter self-adaptive to the diameter of a banana spike rod. The cutter comprises hard combing blades, soft combing blades, universal ball bearings and a rack, wherein one side of each soft combing blade extends to form a cutter arm, and a limiting frame is arranged on each hard combing blade; the number of the hard combing blades and the number of the soft combing blades are plural, the body of one hard combing blade and the body of one soft combing blade are stacked to be combined into a combing blade set, a plurality of the hard combing blades and a plurality of the soft combing blades are combined into a plurality of combing blade sets arranged in the rack, the cutter arm of one combing blade set stretches into the limiting frame of the adjacent combing blade set, and the multiple combing blade sets are combined to form a circumferential cutting edge capable of wrapping the banana spike rod; each combing blade set is provided with one universal ball bearing, and a deformation structure is connected between each combing blade set and the rack. The cutter has the advantages of being light and small in overall structure, convenient to move, safe and labor-saving to operate, and suitable for mechanical banana combing.

Owner:SOUTH CHINA AGRI UNIV

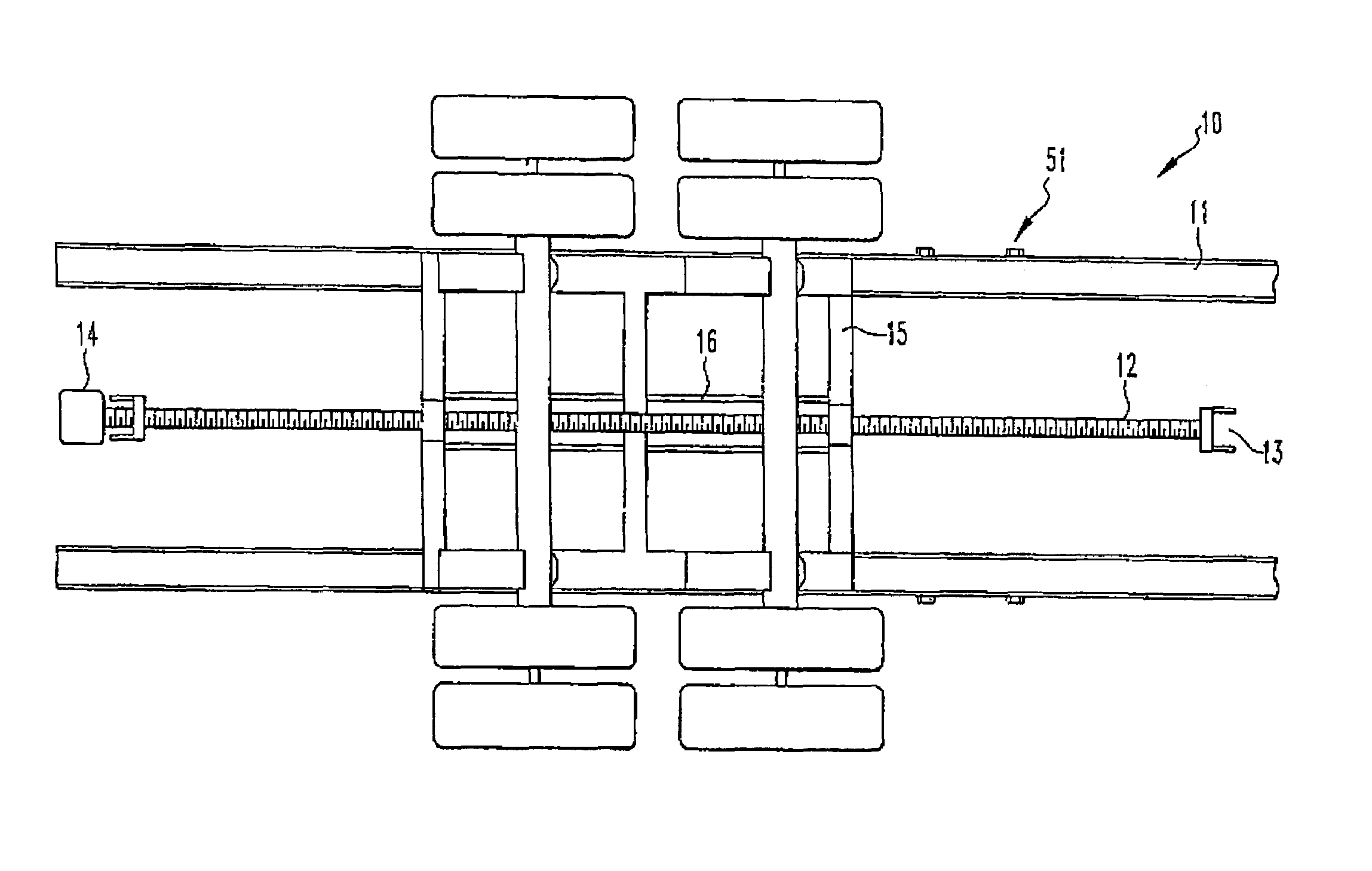

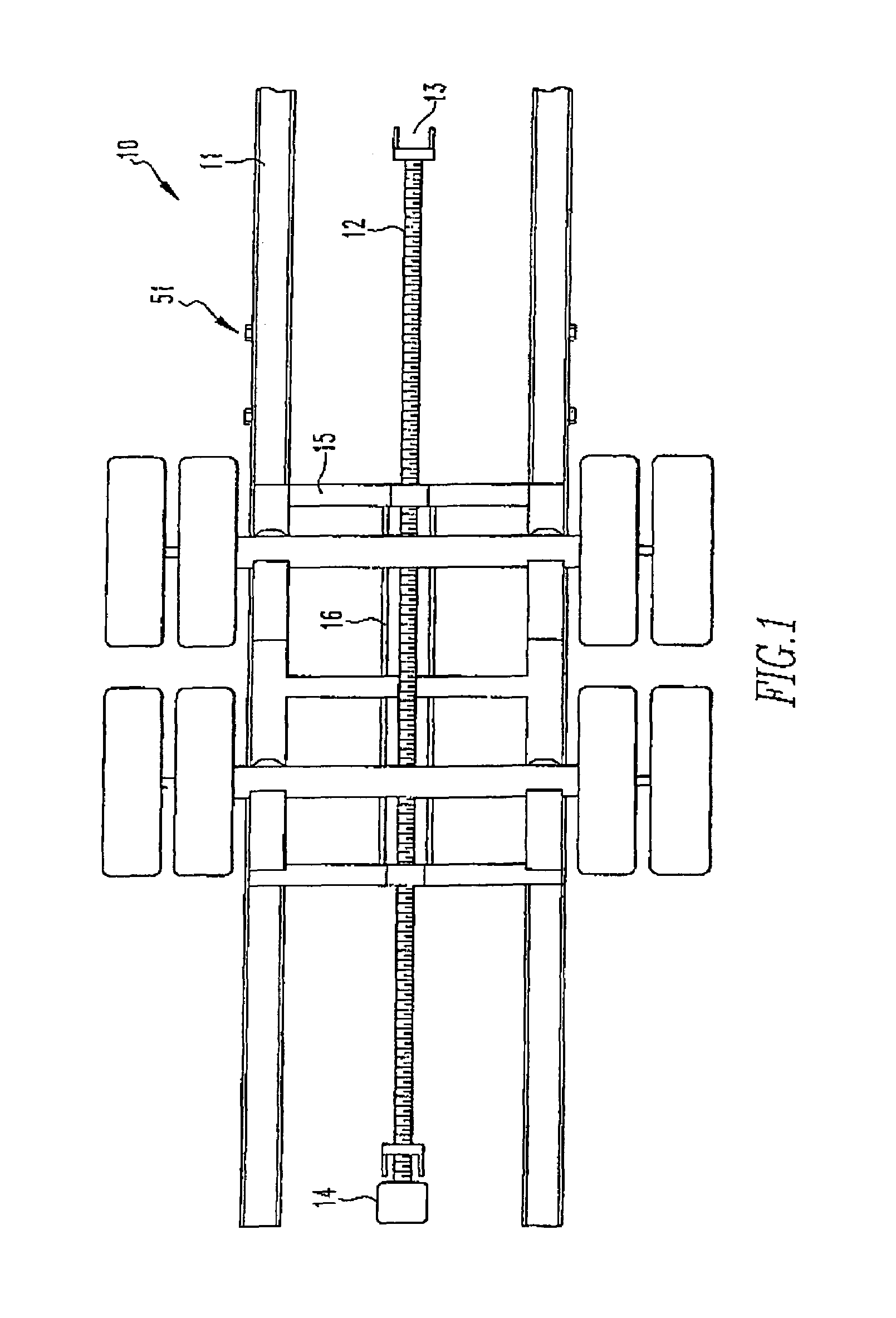

Weight redistribution in freight trucks

InactiveUS7410183B2Reduce physical laborMaximized road timeTractor-trailer combinationsTractorsWeight monitoringEngineering

Owner:ARCONIC INC

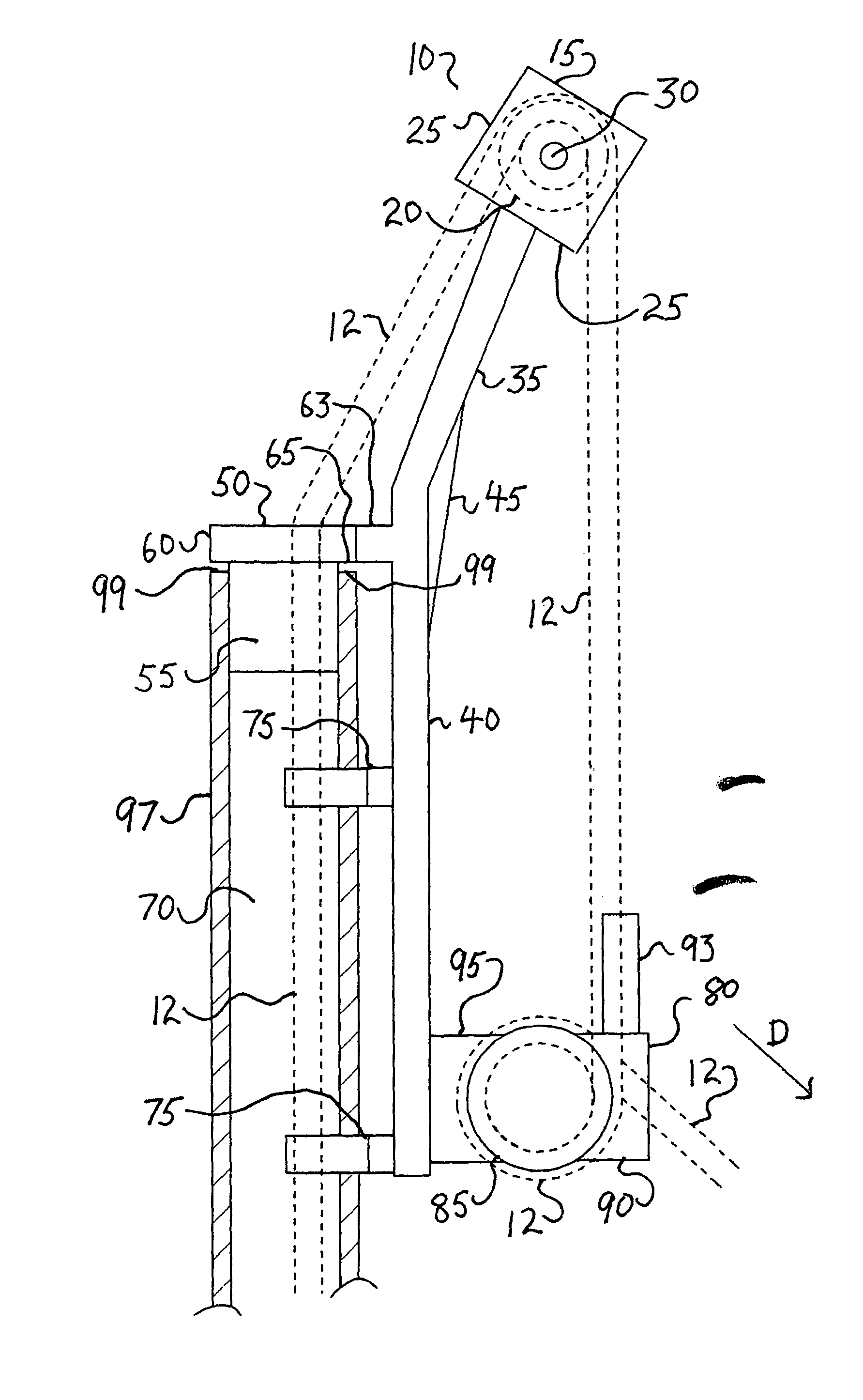

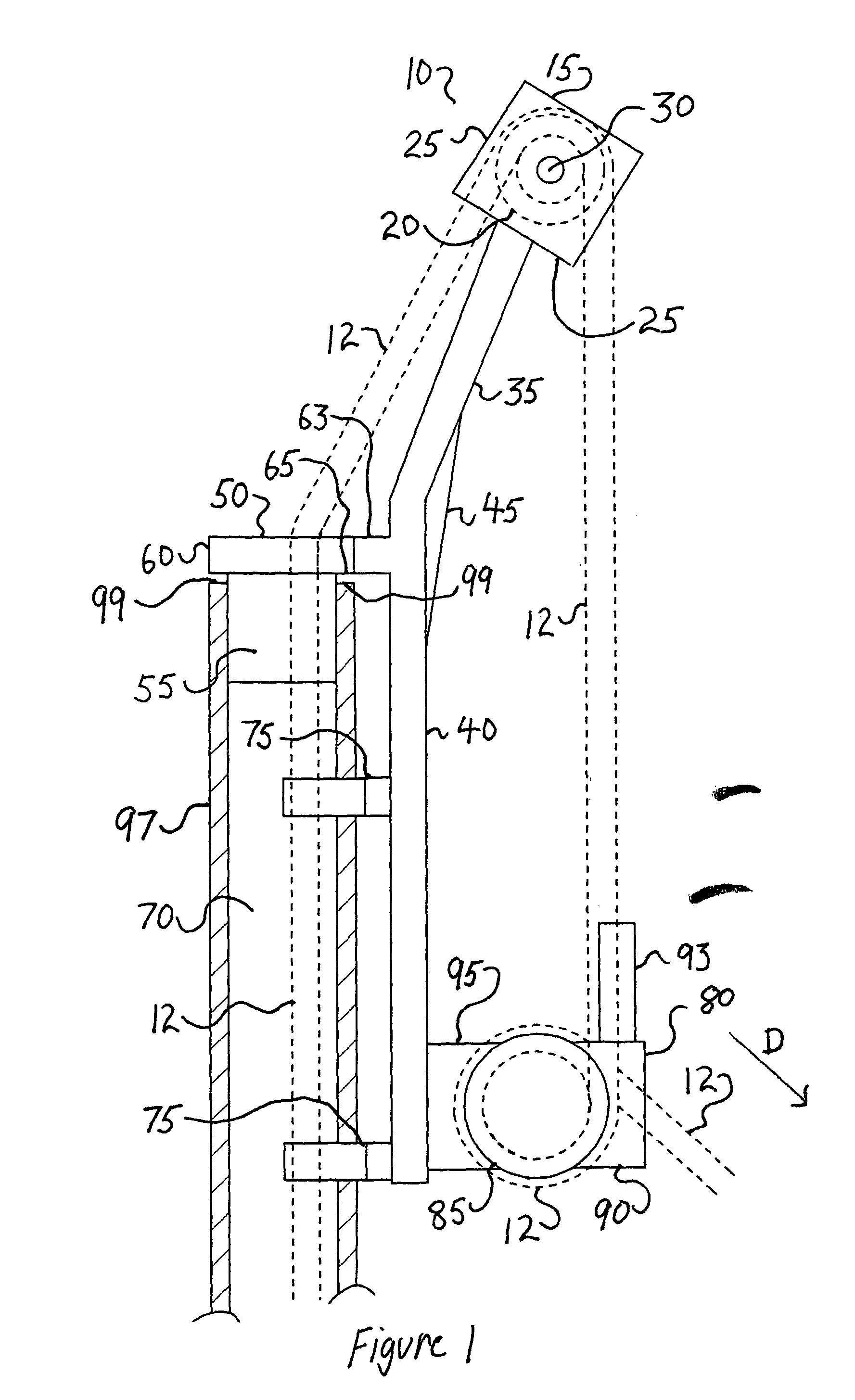

Machine for pulling wire through a conduit

ActiveUS7712726B1Reduce physical laborReduce laborWaterborne vesselsFilament handlingEngineeringMechanical engineering

A device for pulling wire through a conduit with sheave head, sheave head support boom, wire puller frame, conduit interface, and wire pull assembly. The wire pull assembly further comprises a capstan, a gear box having an input axle and an output axle, and a means to interface a power source to impart rotating force to the capstan.

Owner:JERNIGAN SCOTT ALAN

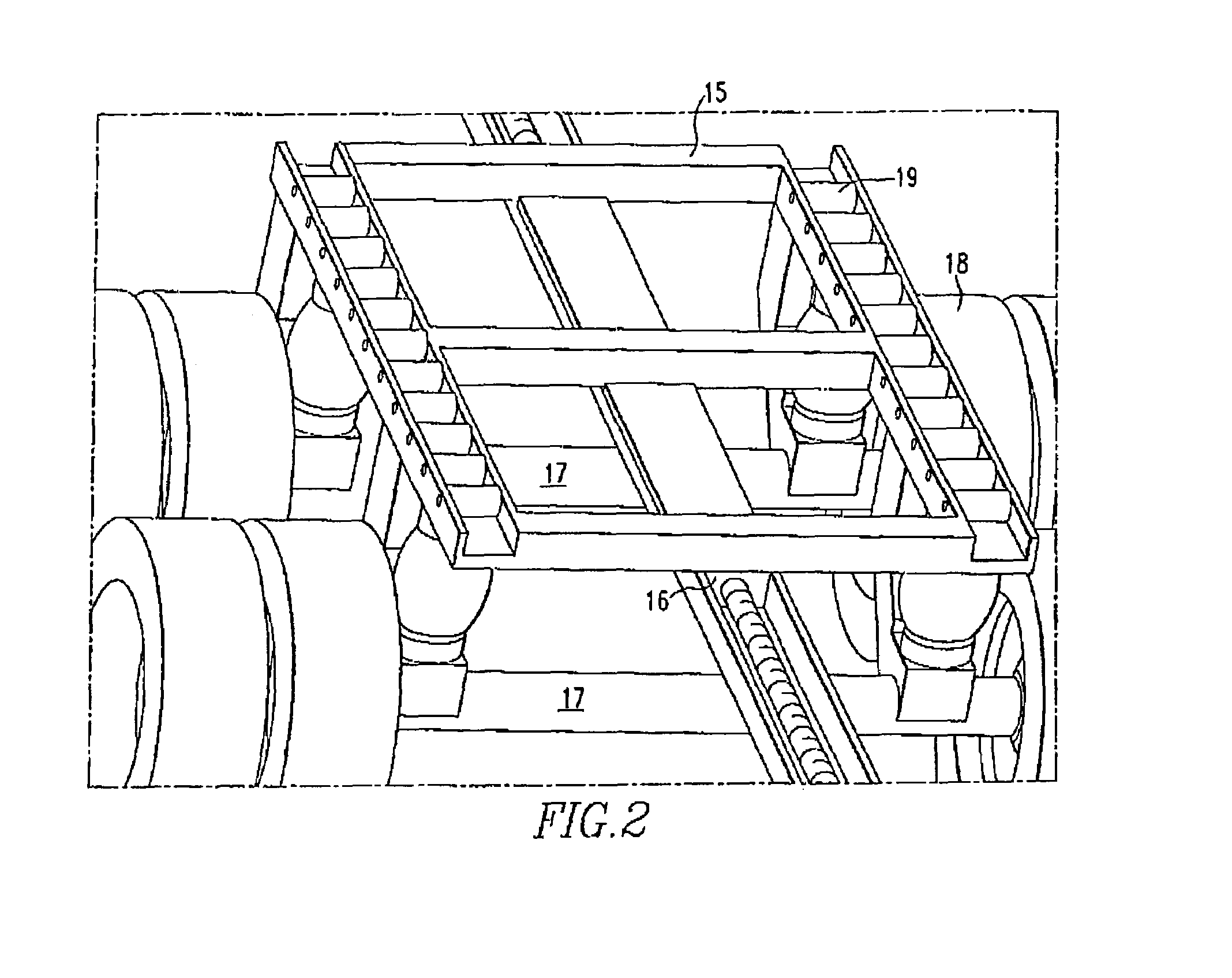

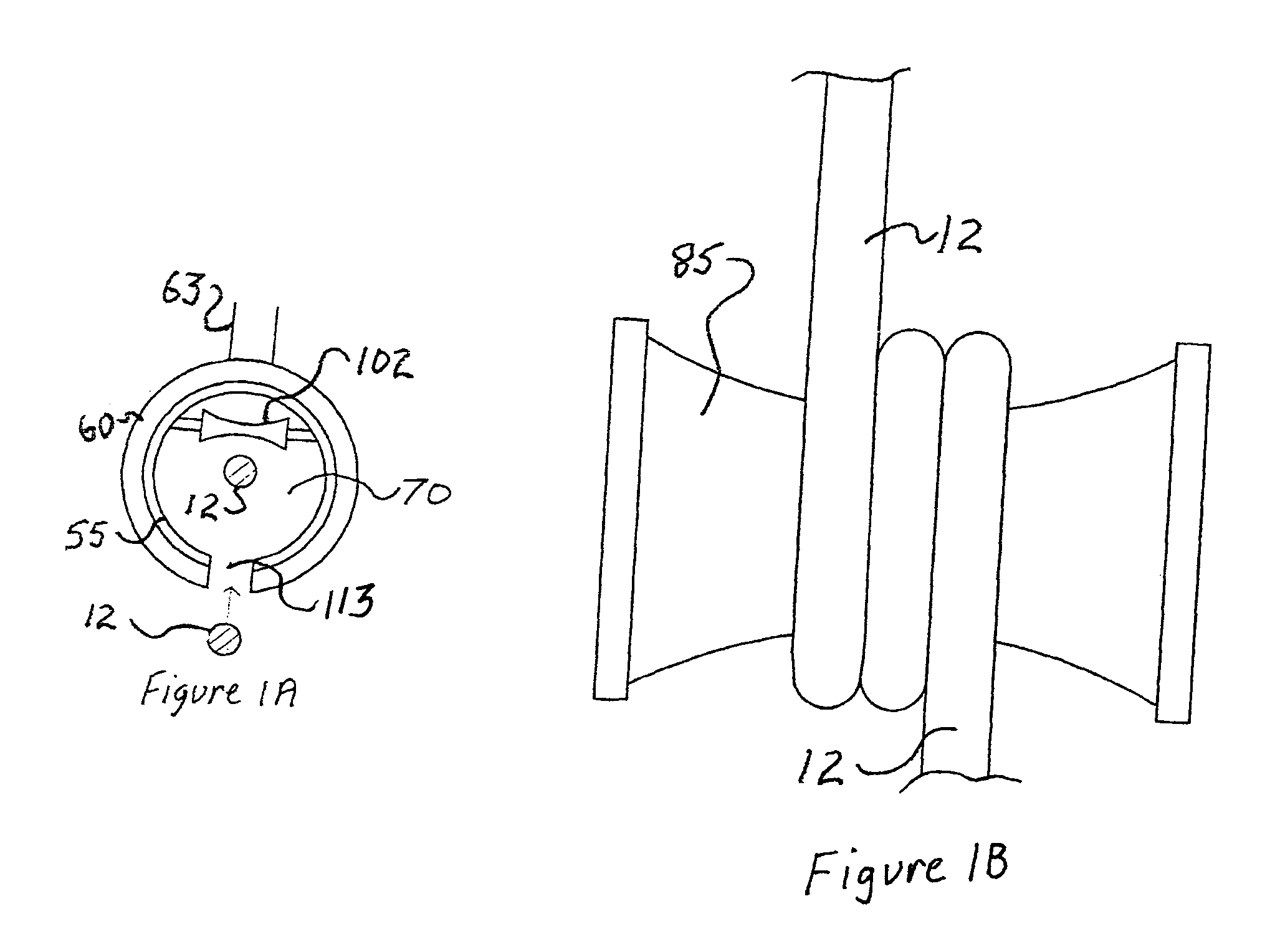

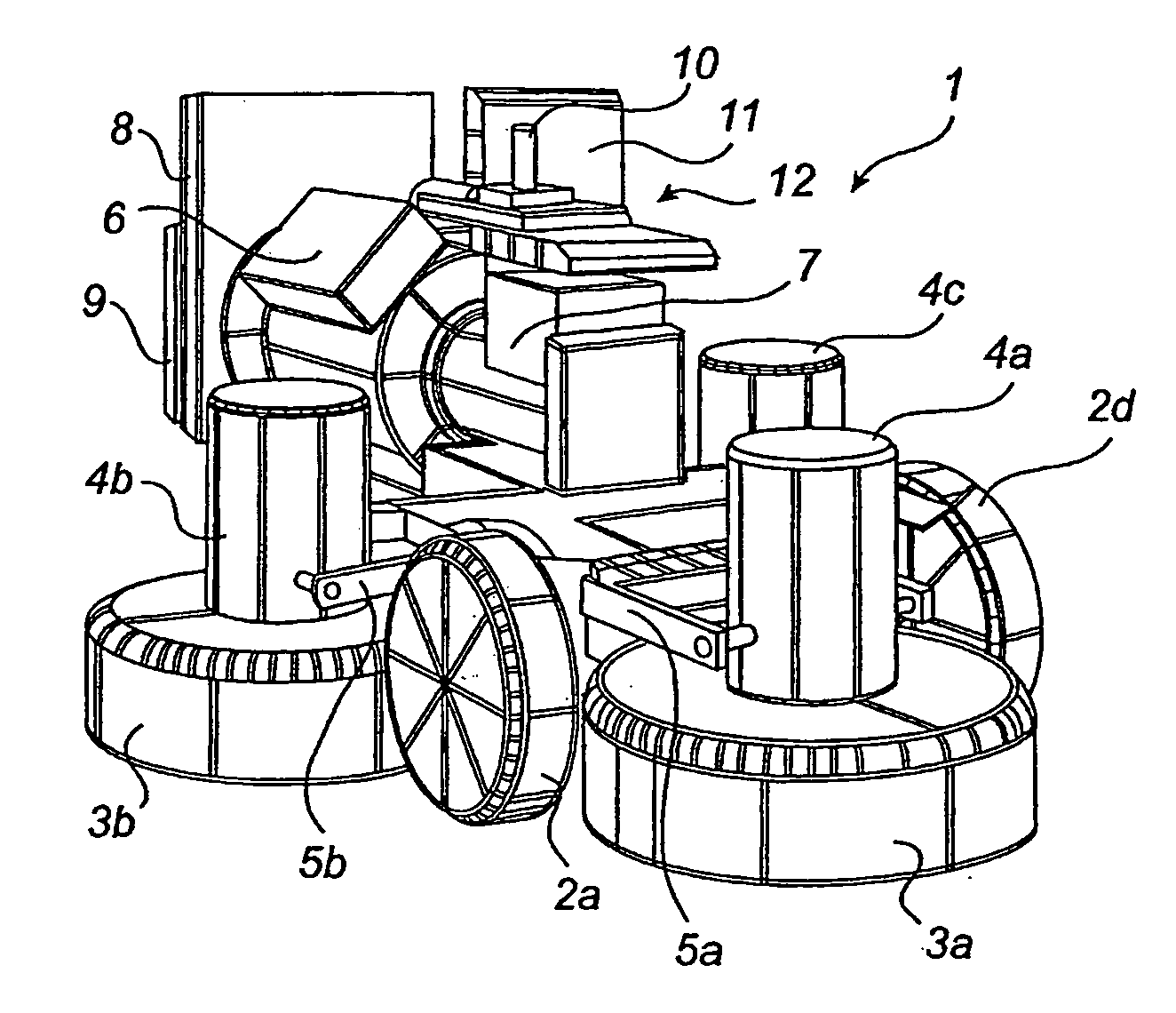

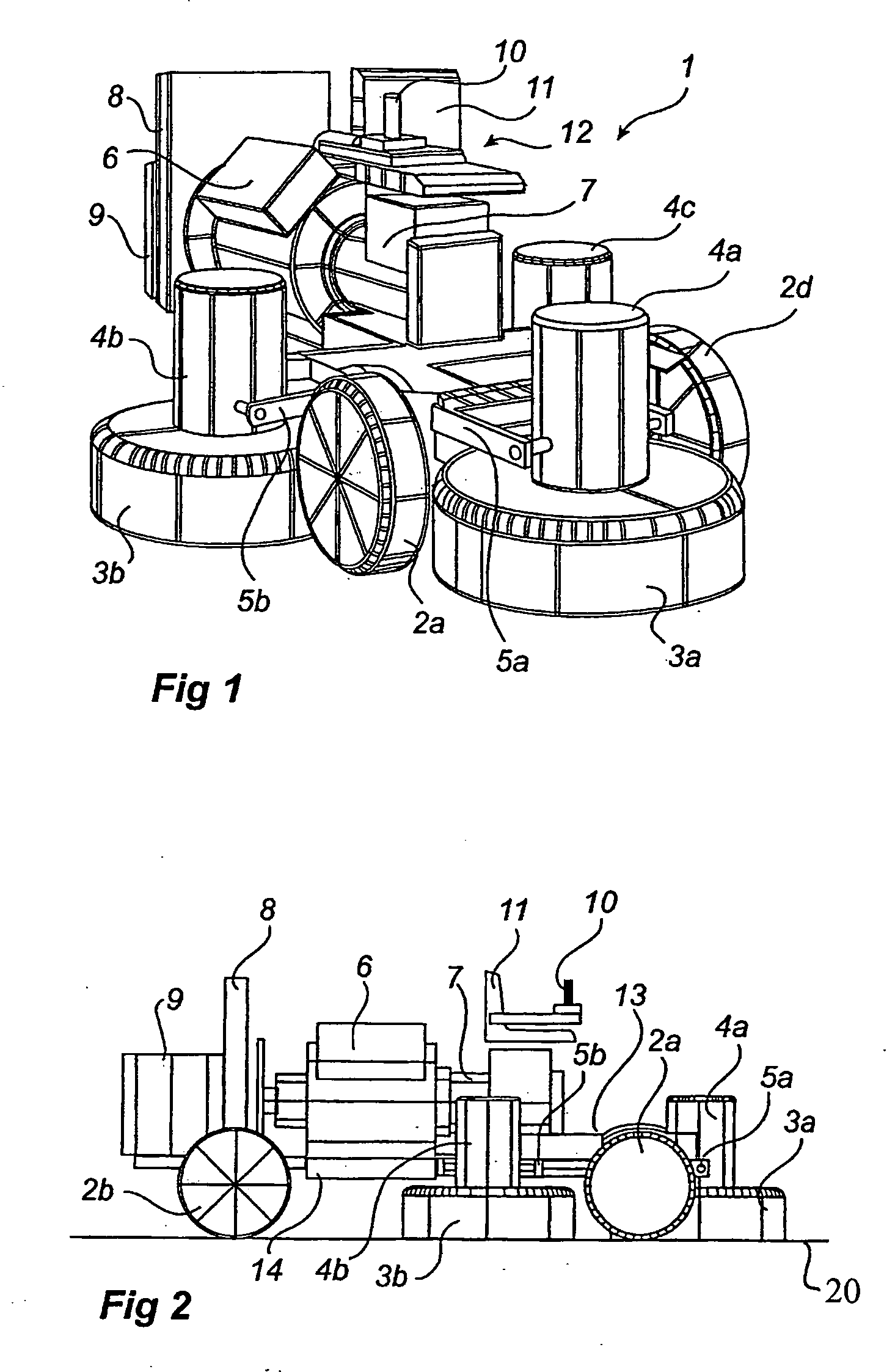

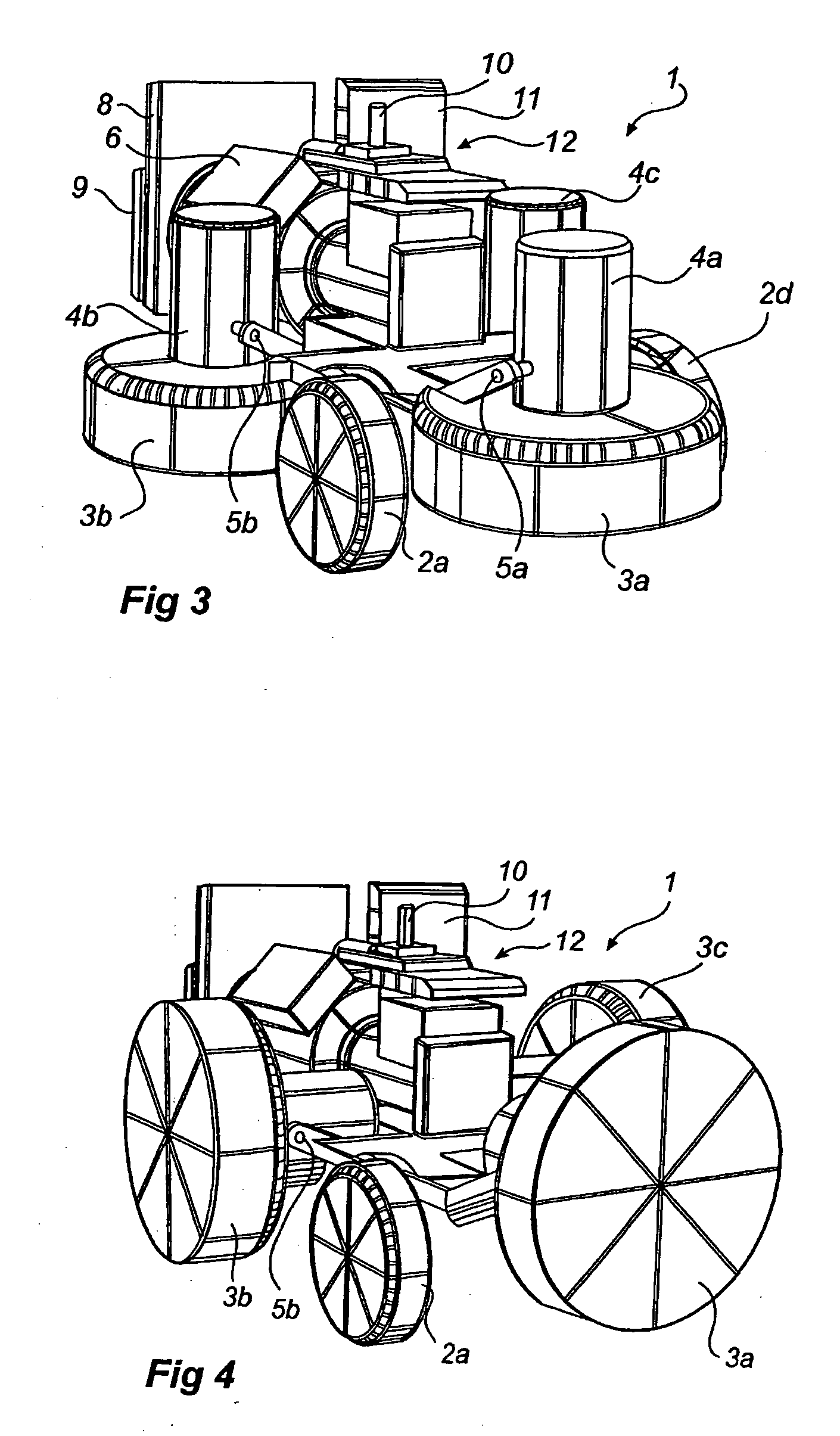

Floor processing machine with tiltable finishing units

InactiveUS20090023369A1Eliminate problemLow costPortable grinding machinesGrinding headsTerrazzoEngineering

A finishing machine (1) for finishing a work surface (20) which consists of a floor of terrazzo, marble, stone, concrete or the like, comprises at least two finishing units (3a, 4a; 3b, 4b; 3c, 4c, 300) which are supported by the frame (14, 100) of the finishing machine and which are arranged for grinding, polishing and / or machining of the work surface (20), and each machining unit comprises a motor (4a, 4b, 4c, 200) and a rotatably mounted working disc (41) driven by the motor. The finishing units (3a, 4a; 3b, 4b; 3c, 4c, 300) are individually tiltable relative to the frame (14, 100) about respective axes that are substantially parallel to the work surface (20).

Owner:HTC SWEDEN AB

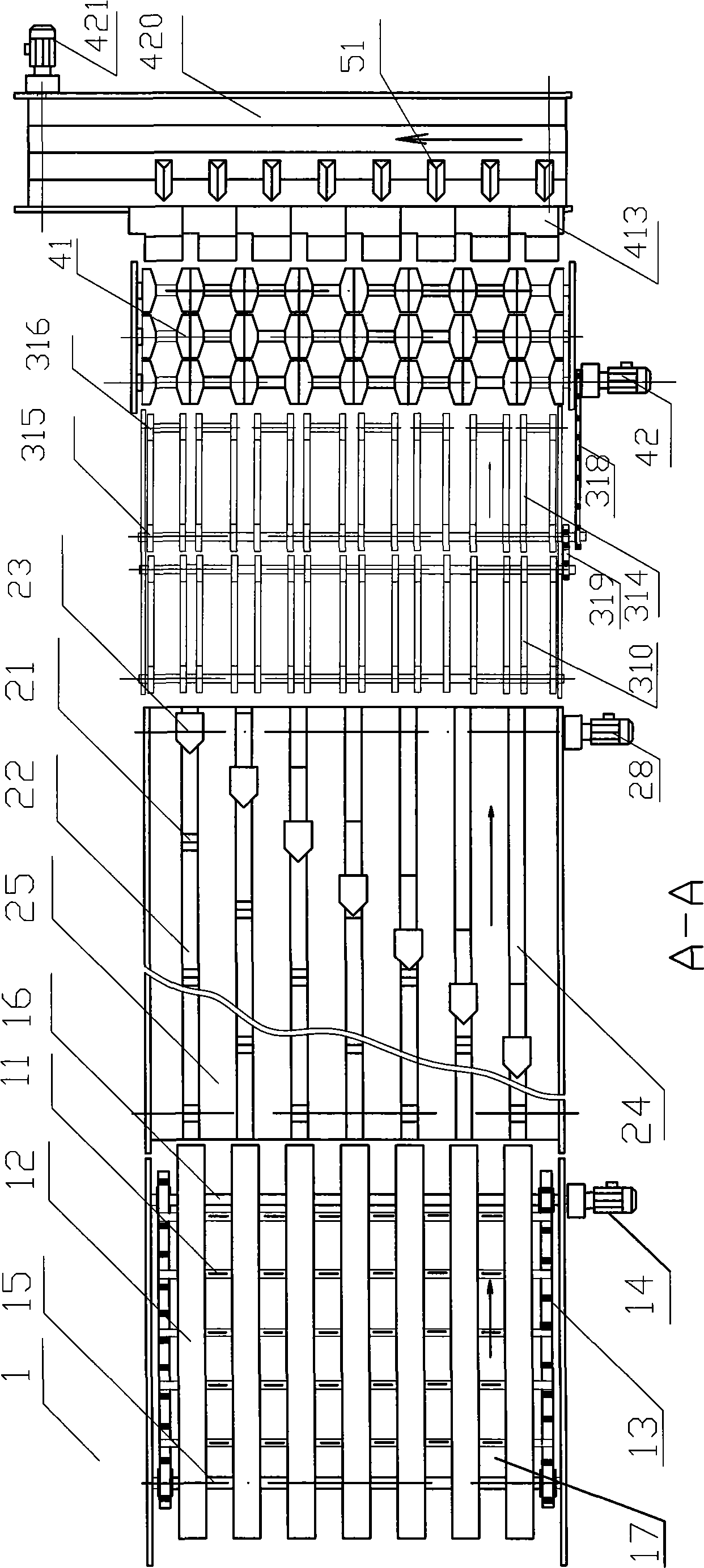

Beer bottle sorting machine

InactiveCN101519161AReduce physical laborReduce production laborControl devices for conveyorsMechanical conveyorsMicrocomputerAutomatic control

A beer bottle sorting machine comprises a conveying belt driven by a motor and a program automatic control system managed by a microcomputer, wherein the conveying belt is provided with a bottle sorting and conveying mechanism, a bottle separating and detecting mechanism, a defected bottle eliminating mechanism and a bottle standing or overturning standing mechanism. The invention automatically sorts scattered beer bottles on the conveying belt into a line to move forwards one by one, the scattered beer bottles stand one by one after the defected bottles are detected and eliminated one by one or stand after being overturned, and then are turned one by one to enter the next production stream line, the automatic operations are all completed by the program automatic control, therefore, the invention changes the manual labour into the automatic production line operation, can lighten the heavy labor of workers, and saves the production workers and the production cost in an enterprise.

Owner:周飞 +1

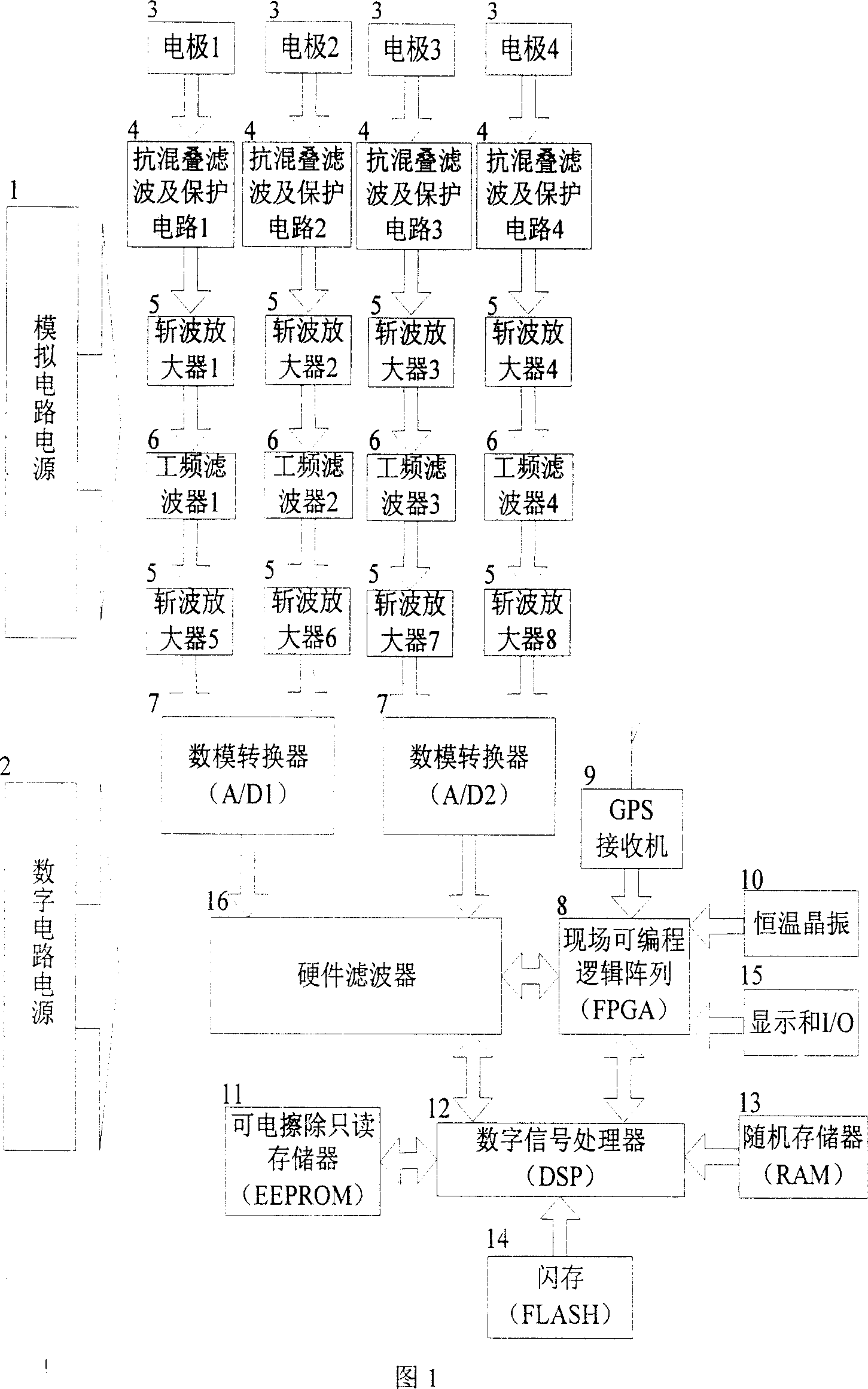

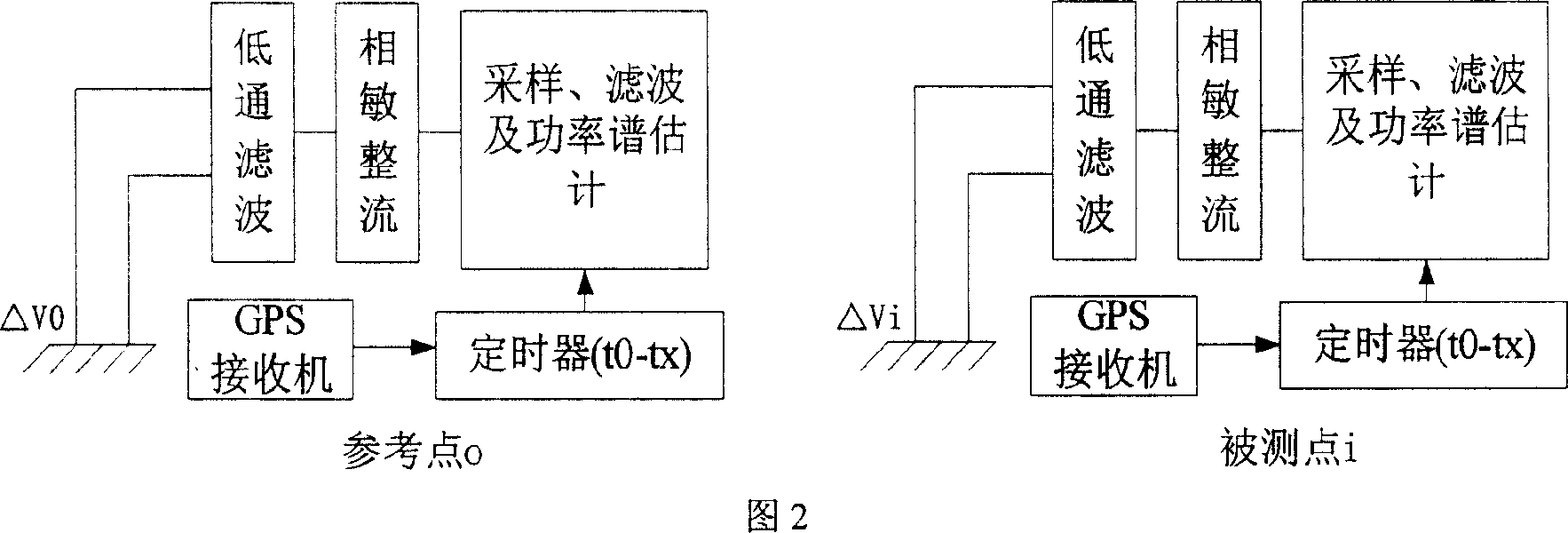

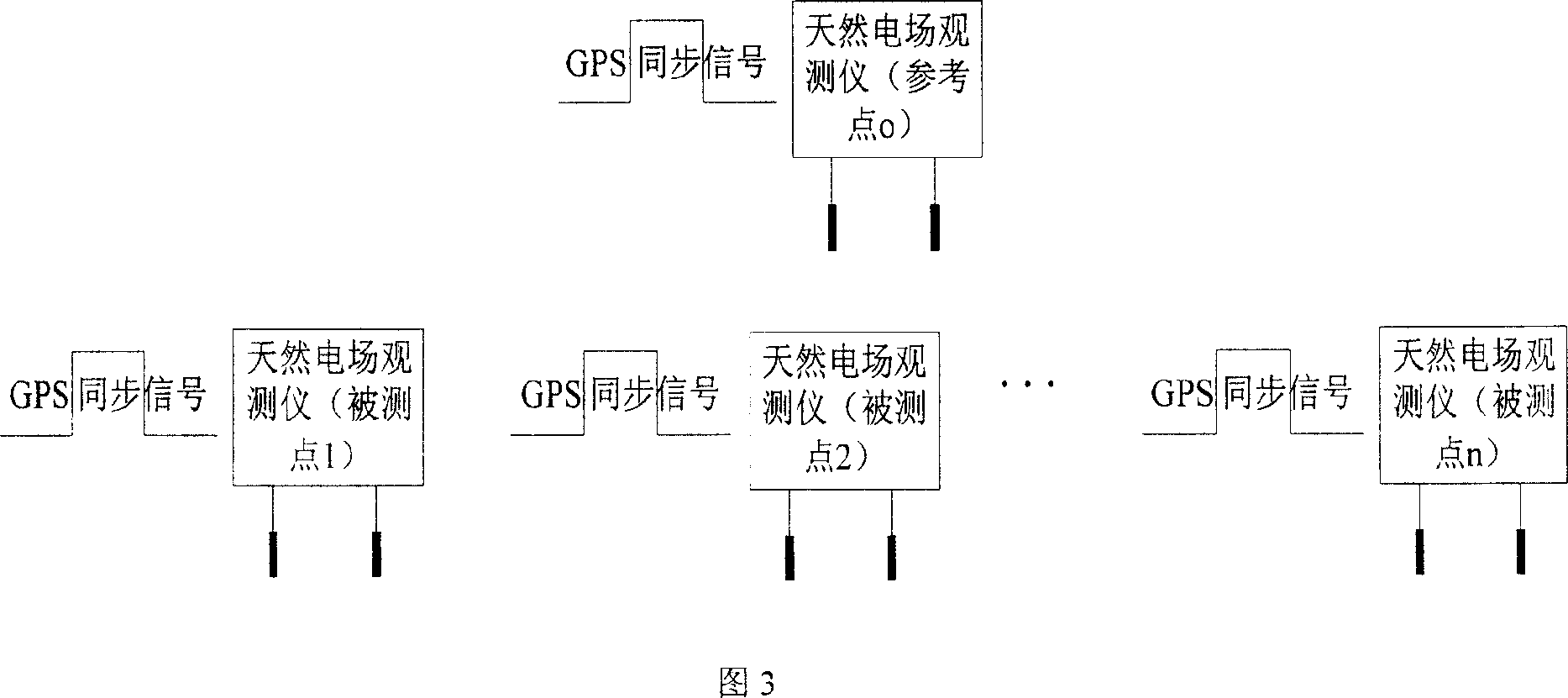

High precision measuring method for deep resource based on natural electric field idealization and detecting instrument

InactiveCN1945358AHigh precisionOvercoming the defect of low observation accuracyElectric/magnetic detectionProfile tracingDigital signal processing24-bit

The invention is about a method for idealistically measuring the deep source with a high precision based on the natural electric field and its device. It processes the digital signal by using DSP and FPGA based on the existing measuring principle of the natural electric field, and it adopts GPS device for synchronized measurements and digital integration and effective use of natural and artificial electric interference to achieve the idealized natural electric field measurement. There are four channels on the detector which can be connected to four pairs of electrodes, so the speed of measurement is increased. The hardware of the system consists of a simulation unit, an A / D conversion unit and a digital unit,in which, the simulation unit is mainly used to amply the input signal and filter the frequency interference, and the A / D conversion unit is used to convert the analog signals into digital signals by using the converter of 24-bit delta-Sigma A / Dconverter, and digital unit is used to process the converted signals including the digital signal filtering, power spectrum calculation and memory function.

Owner:张东来 +4

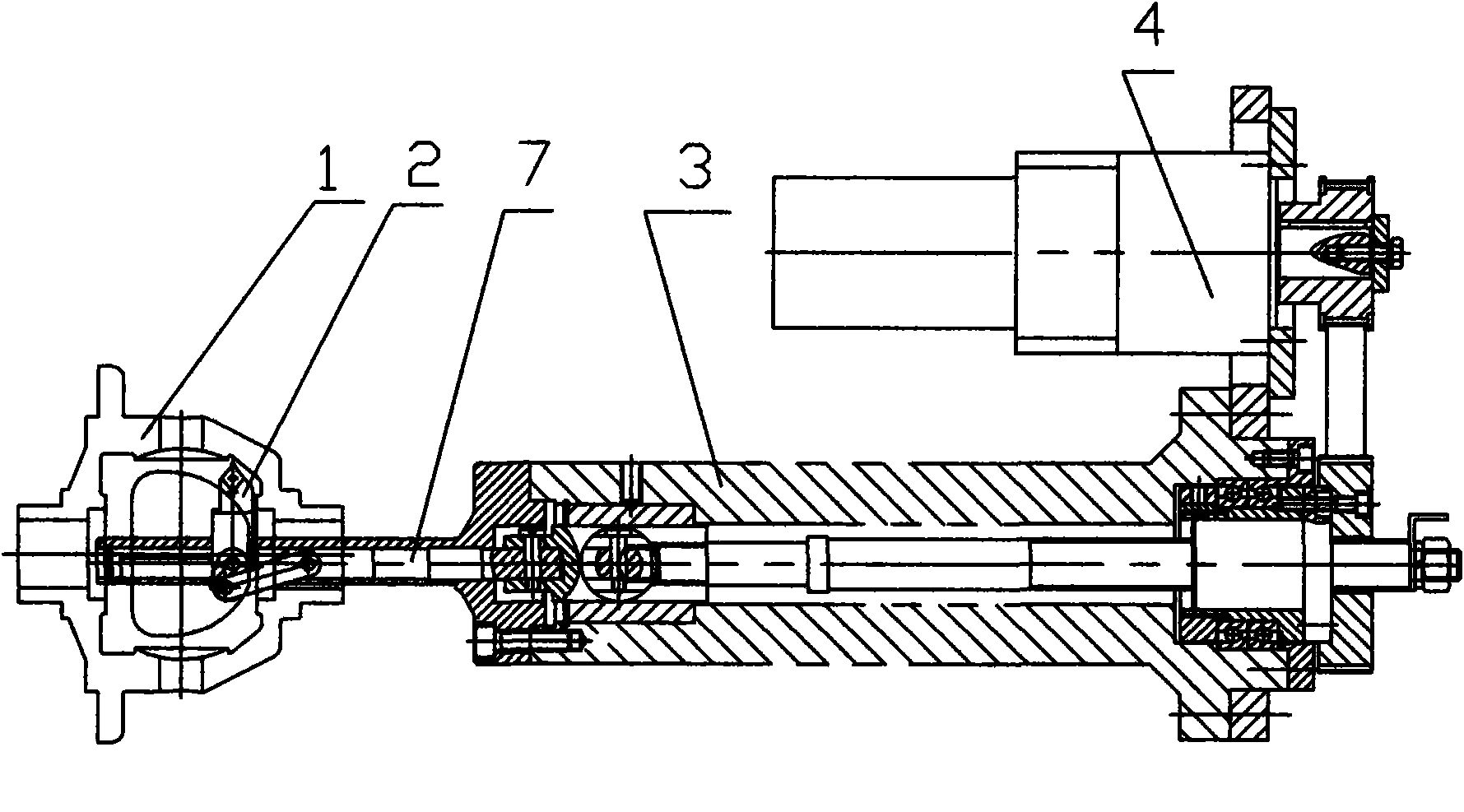

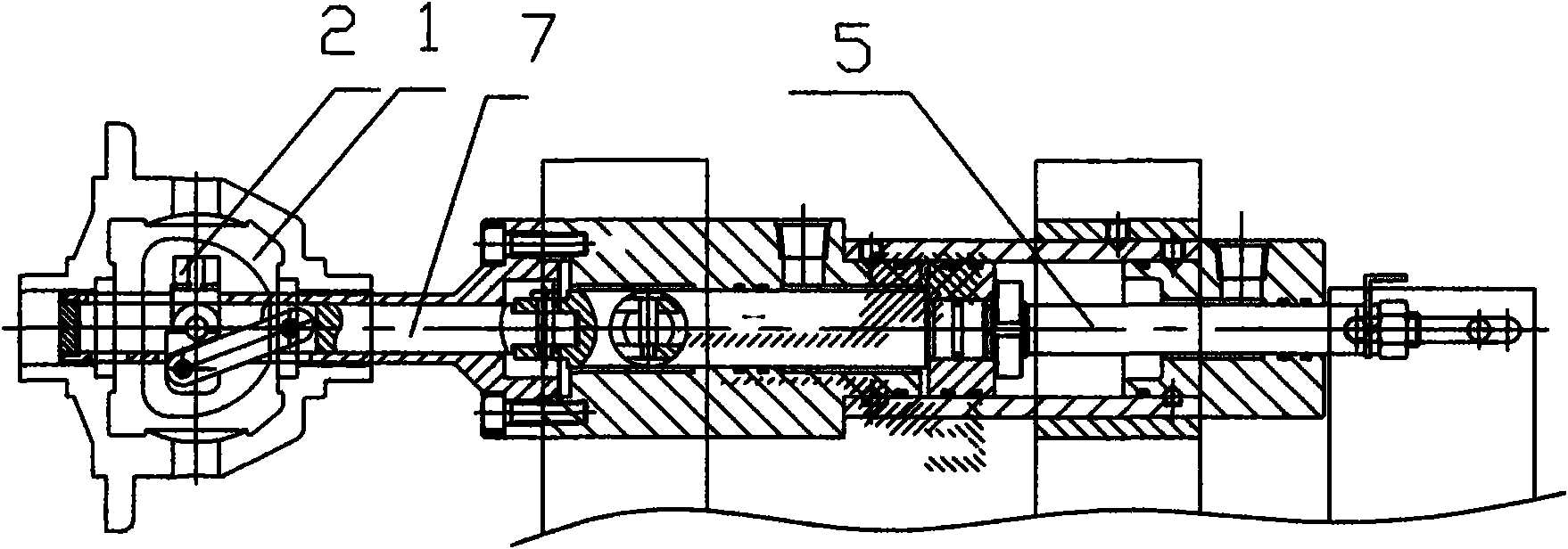

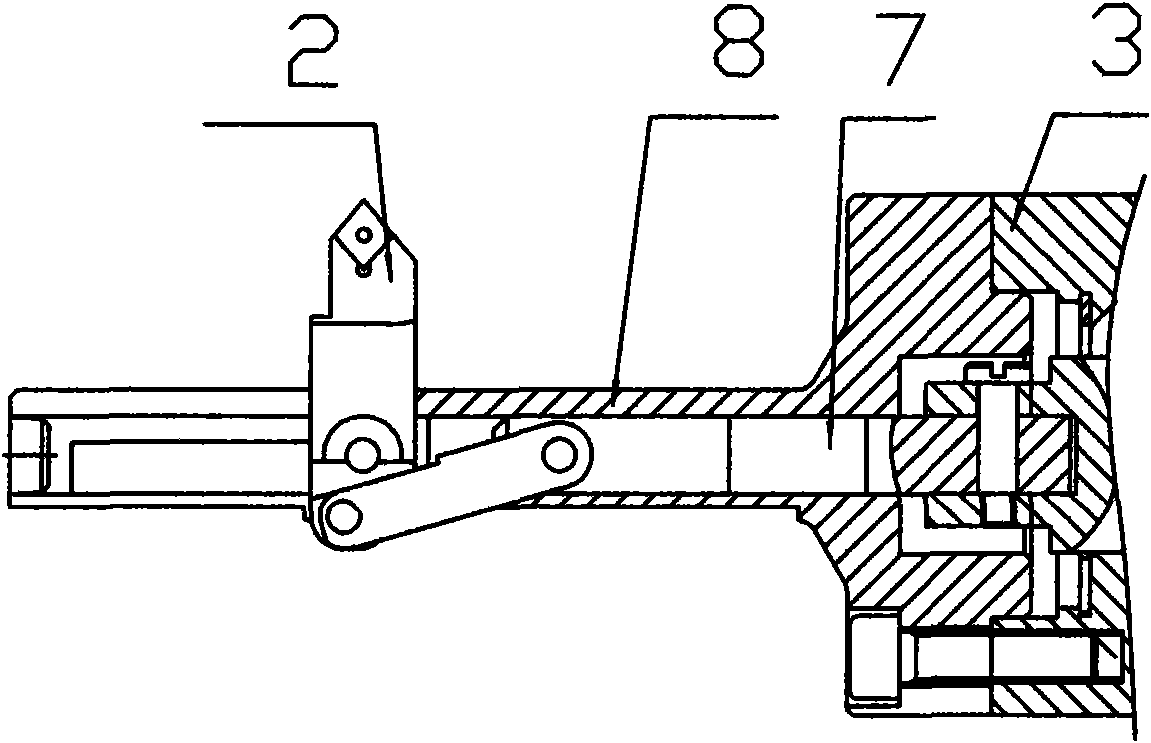

Processing technique capable of processing interior parts of integral differential mechanism casing by one step

InactiveCN101590533AHigh precisionEliminate positioning errorsFeeding apparatusTurning machinesPhysical hard workSlide plate

The invention relates to a processing technique capable of processing the interior parts of an integral differential mechanism casing by one step. The process adopts clamping once, and adopts a hydraulic power chuck, and a special claw is assembled to directly clamp the positioning surface of a workpiece; after the workpiece is clamped once, the inner sphere surface of the differential mechanism casing is firstly completed, and then the processing for key parts of two inner end surfaces and bearing hole working procedures are finished; a spherical surface machining cutter and a push rod are mounted in a cutter holder sleeve which is connected with an attachment, and the attachment is fixed on a machine tool sliding plate; the rear part of the push rod is connected with the connecting rod of a driving device; after entering into a processing part outside the cutter holder sleeve, the spherical surface machining cutter raises up under the action of the driving device to directly process the inner sphere surface of the differential mechanism casing; and the two inner end surfaces and the bearing hole of the differential mechanism are directly processed by an end surface scratching cutter without changing the clamping of the workpiece. The invention has the advantages of improving the machining precision and the production efficiency, saving the cost, lightening the labor intensity of an operator and improving the precision of the processed differential mechanism casing.

Owner:沈阳盛兴精益数控机械有限公司

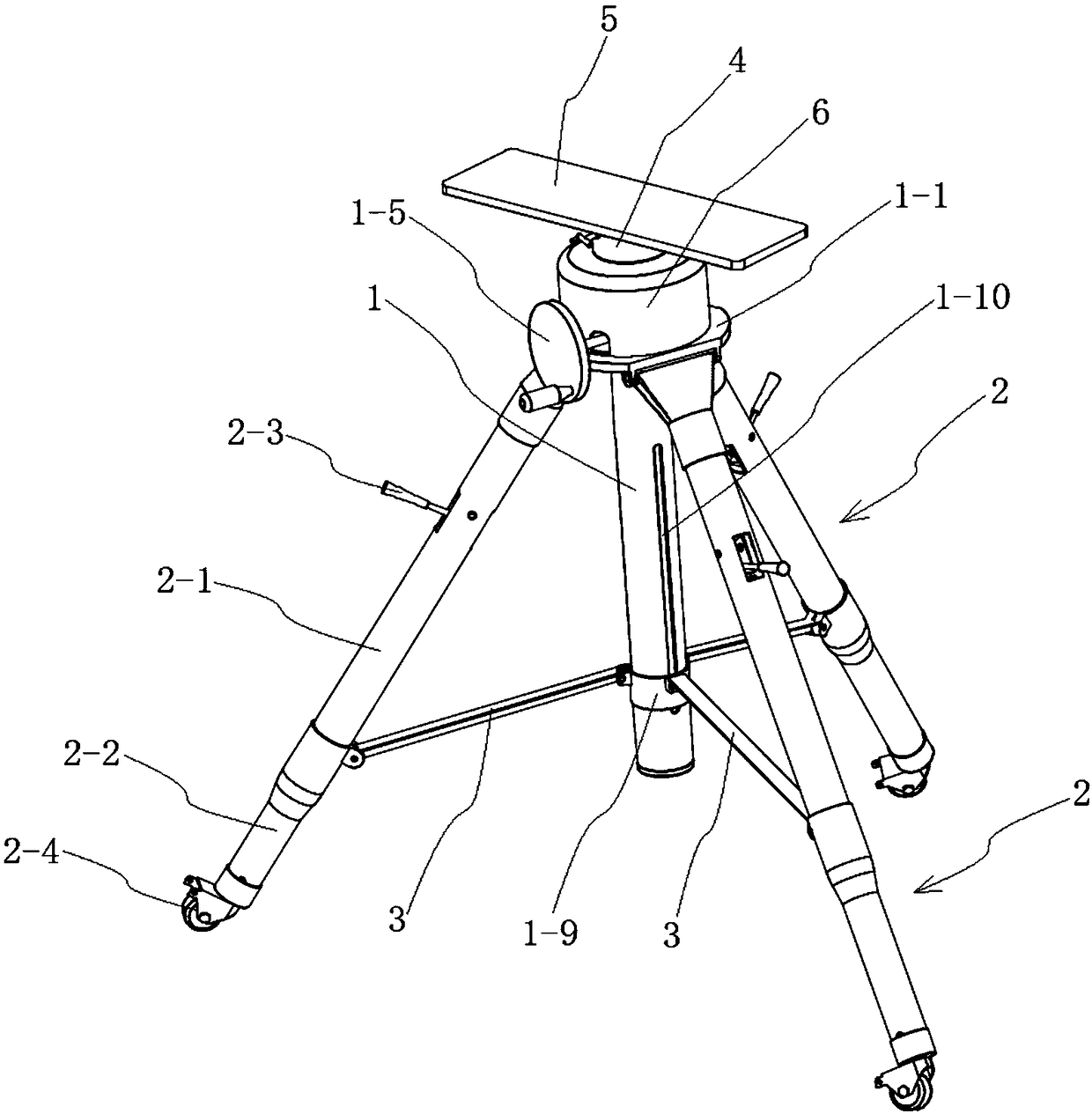

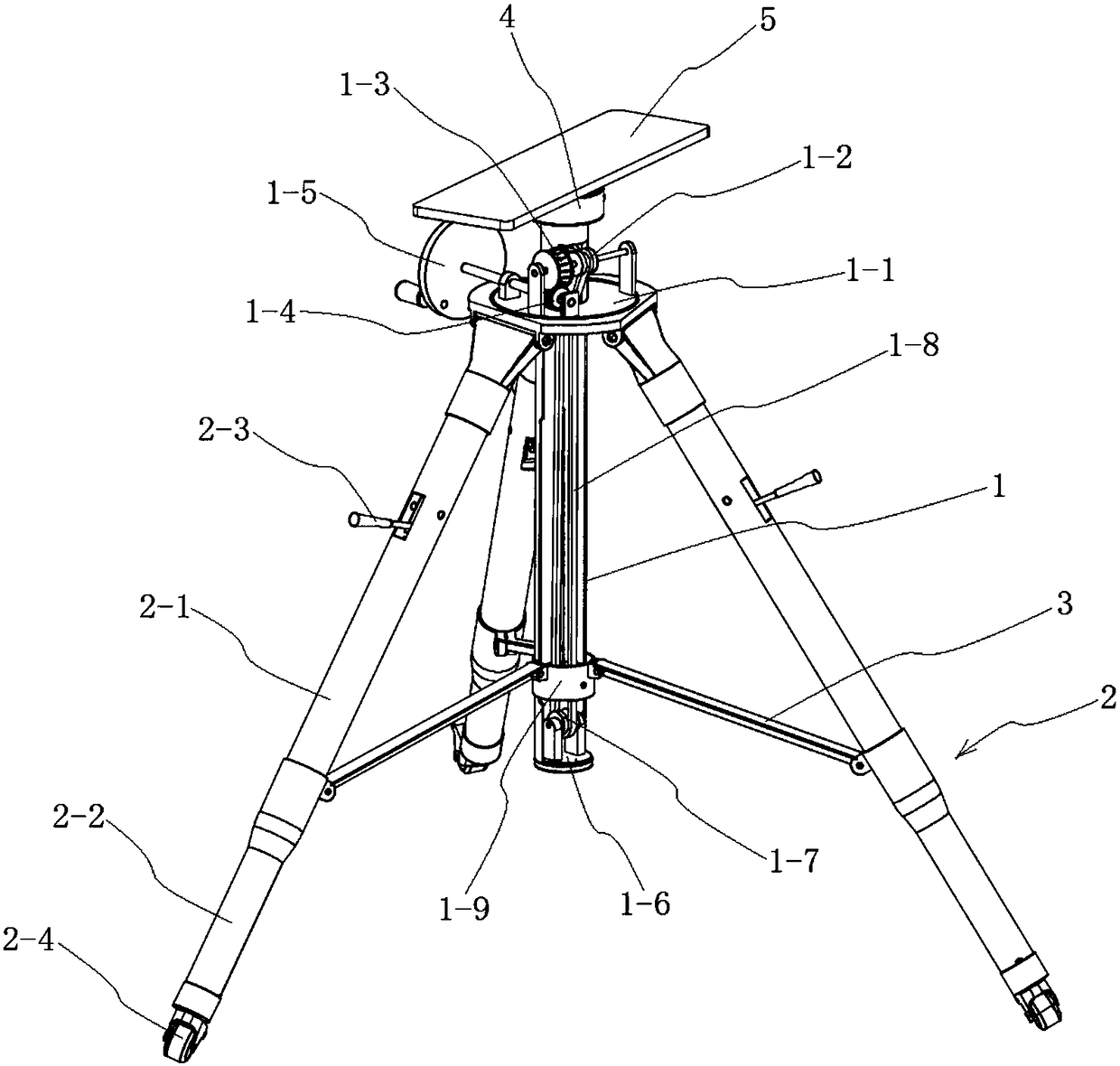

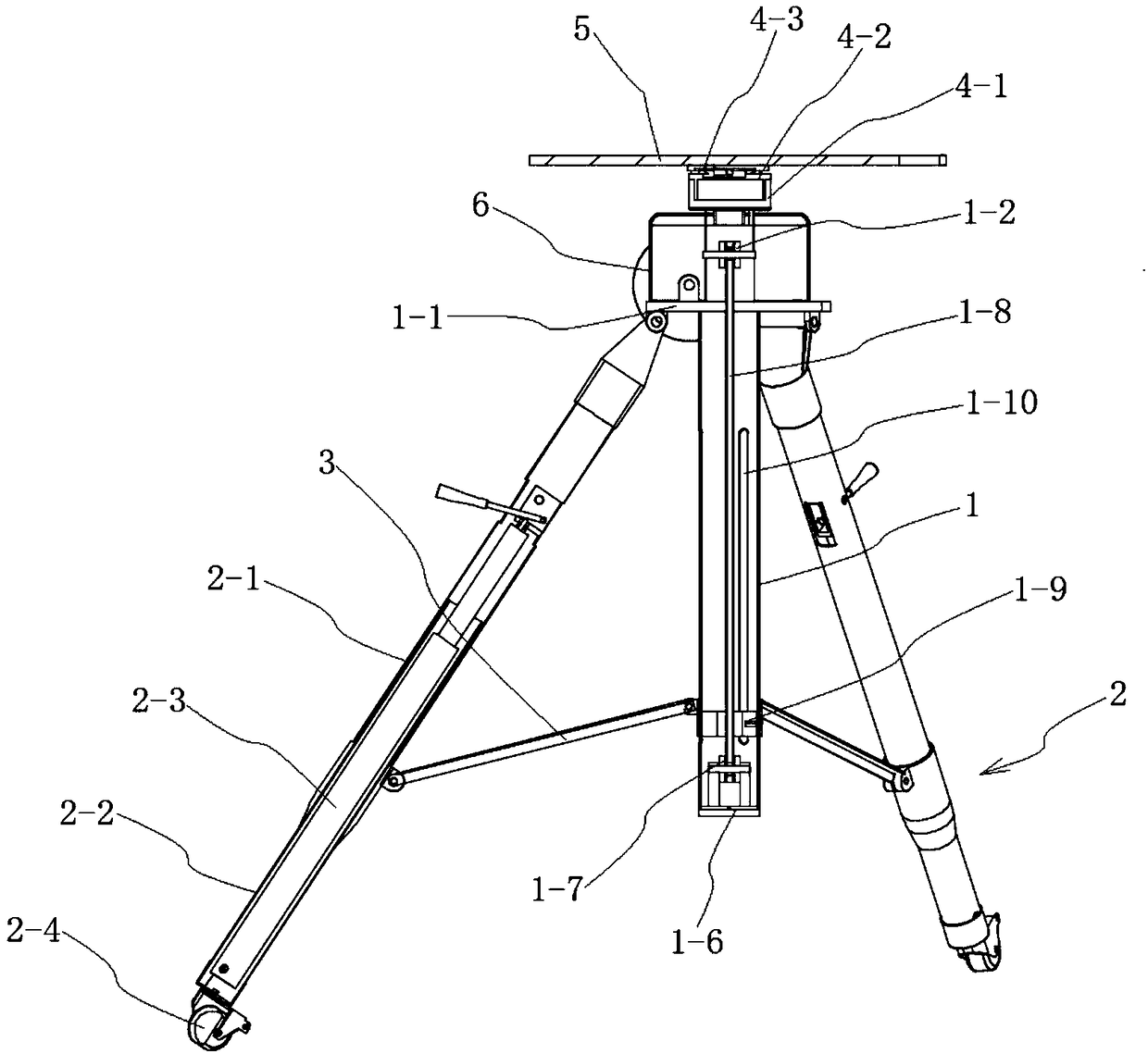

Tripod device convenient to operate and operation method thereof

ActiveCN108343825AEasy to adjustEasy to operateGearingStands/trestlesMechanical engineeringEngineering

Owner:CHANGZHOU INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com