Floor processing machine with tiltable finishing units

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

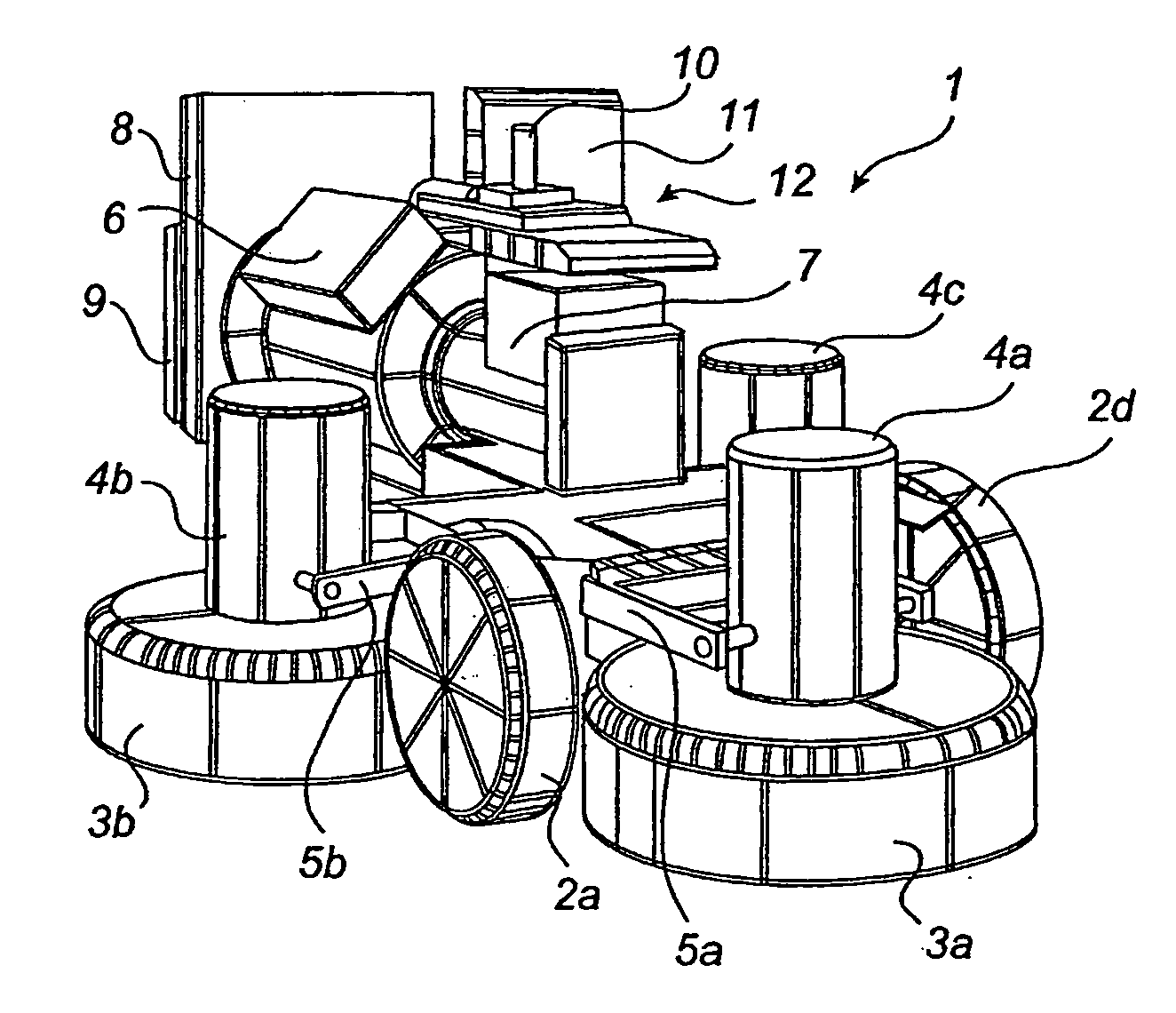

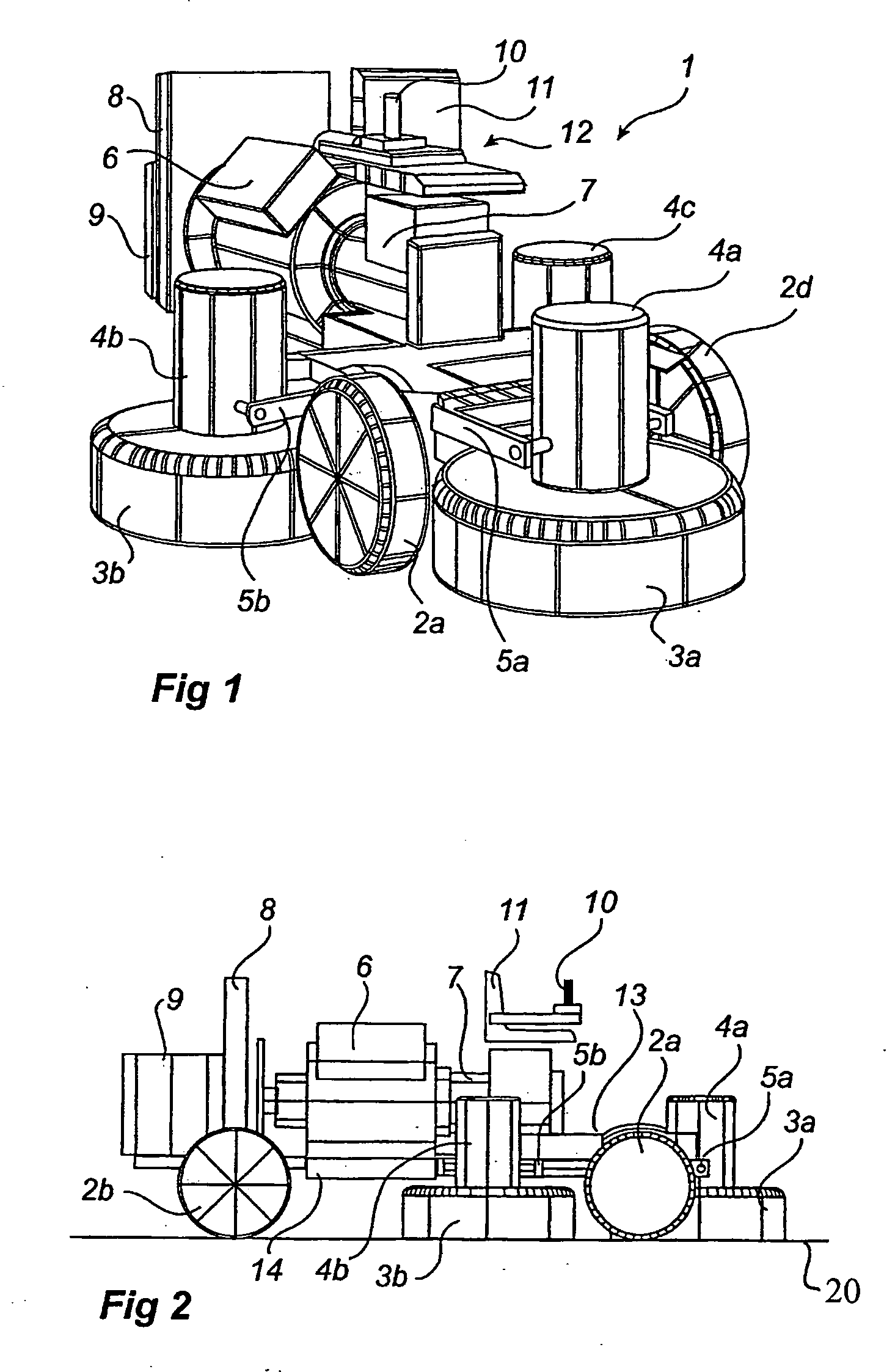

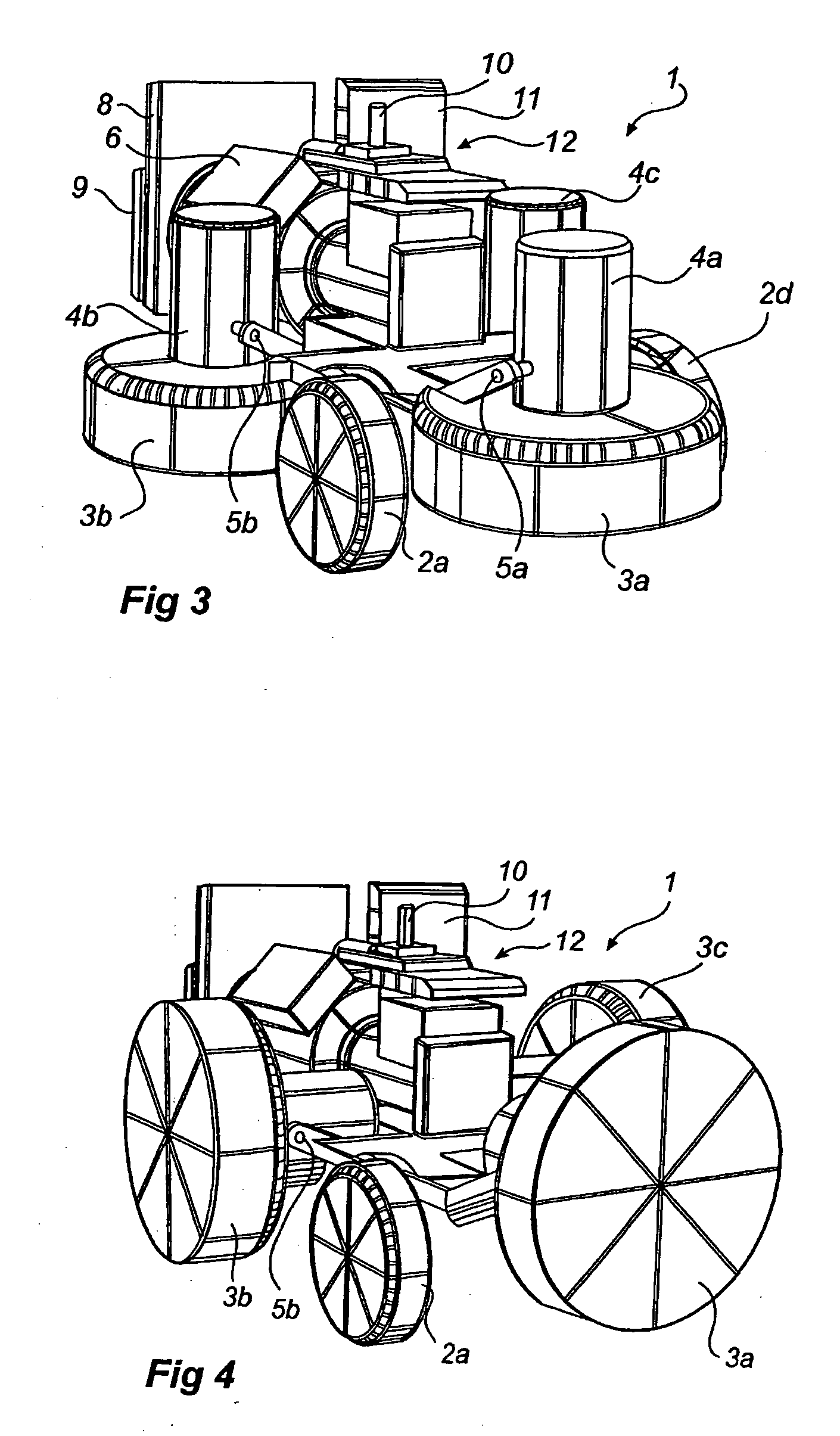

[0041]FIG. 1 shows a riding finishing machine 1, which comprises a frame 14 (FIG. 2), on which a set of wheels 2a, 2b, 2c, 2d is arranged, so that the finishing machine can travel on a base 20 (FIG. 2).

[0042]The frame 14 of the finishing machine is arranged to support essentially all parts of the finishing machine. The frame can be a substantially rigid frame element or bottom plate, or be hinged, for the purpose of, for instance, facilitating manoeuvring.

[0043]The set of wheels 2a, 2b, 2c, 2d serves to provide a two-dimensional supporting surface for the finishing machine 1 on the base 20 and can be designed in various ways, depending on which driving properties are required for the machine.

[0044]The frame also supports an engine 6. The engine dimension and the choice of compulsion force / fuel are determined based on the capacity required by the finishing machine 1. In one embodiment of the finishing machine 1, the engine can be a gas-driven or diesel-driven internal combustion engi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

| Weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com