Patents

Literature

105 results about "Physical Efforts" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Effort, in physical terms, is the amount of work involved in performing an activity; in general use it is also synonymous with Endeavor, which implies a deliberate exertion, and to use more energy than usual in an activity.

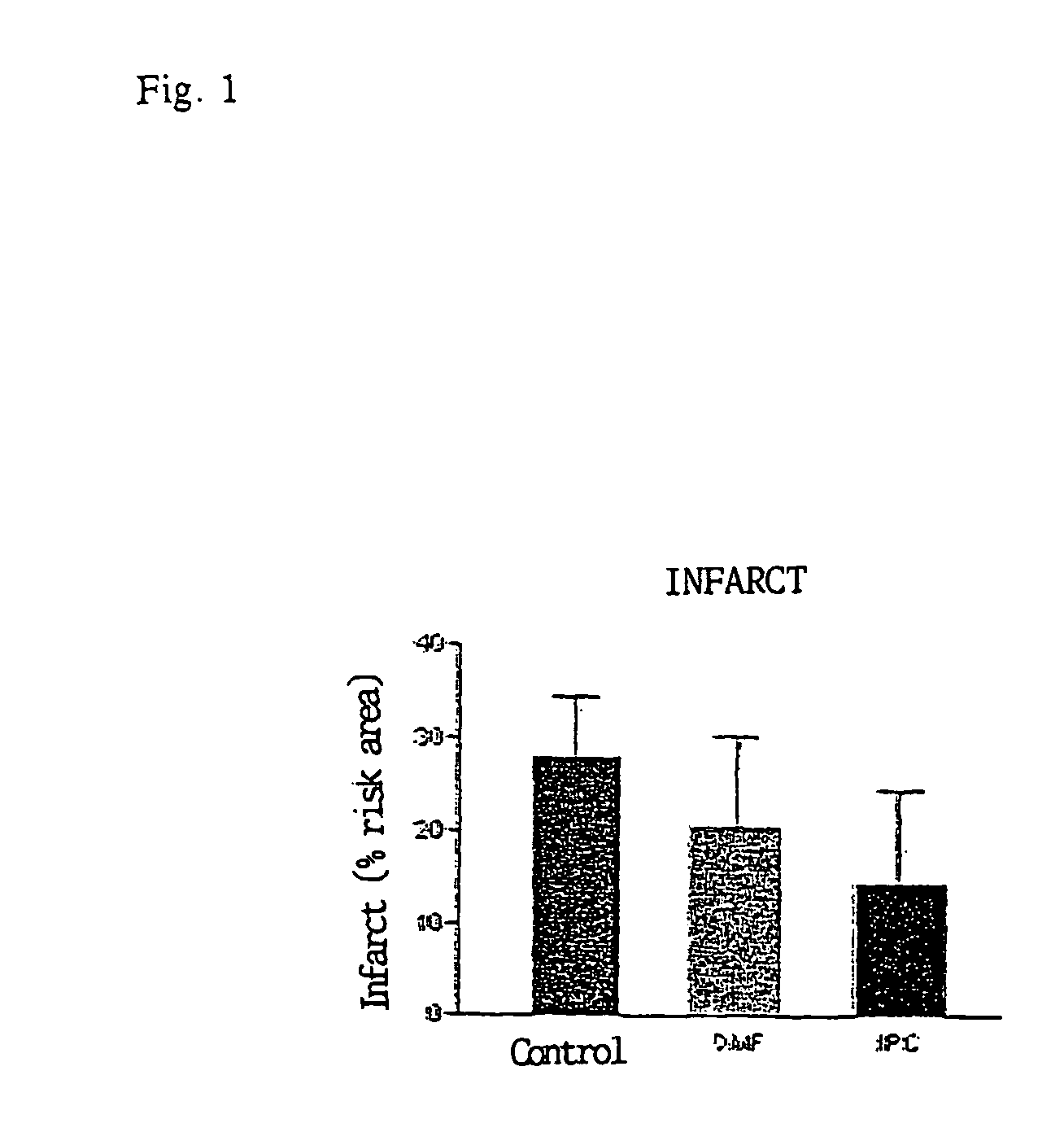

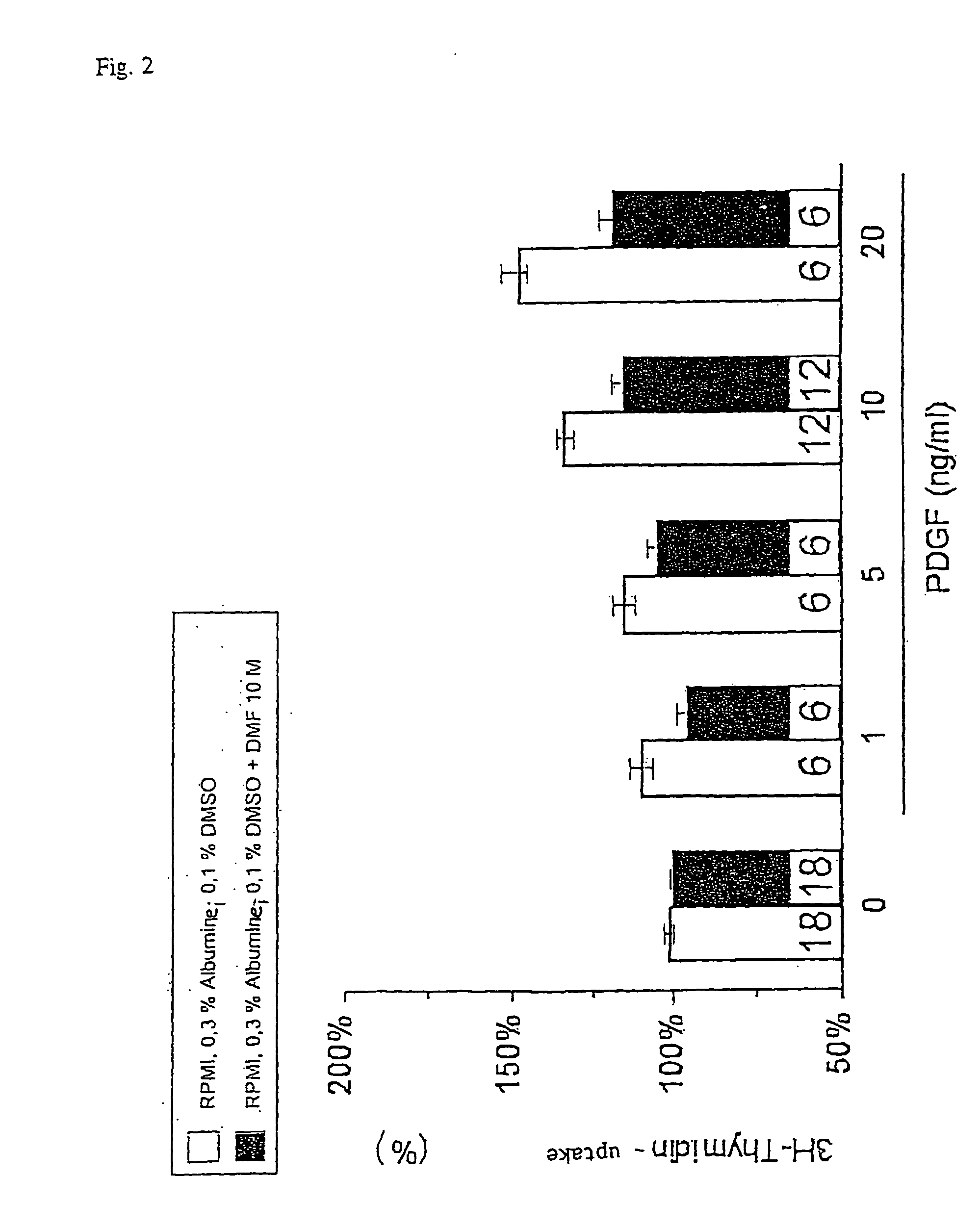

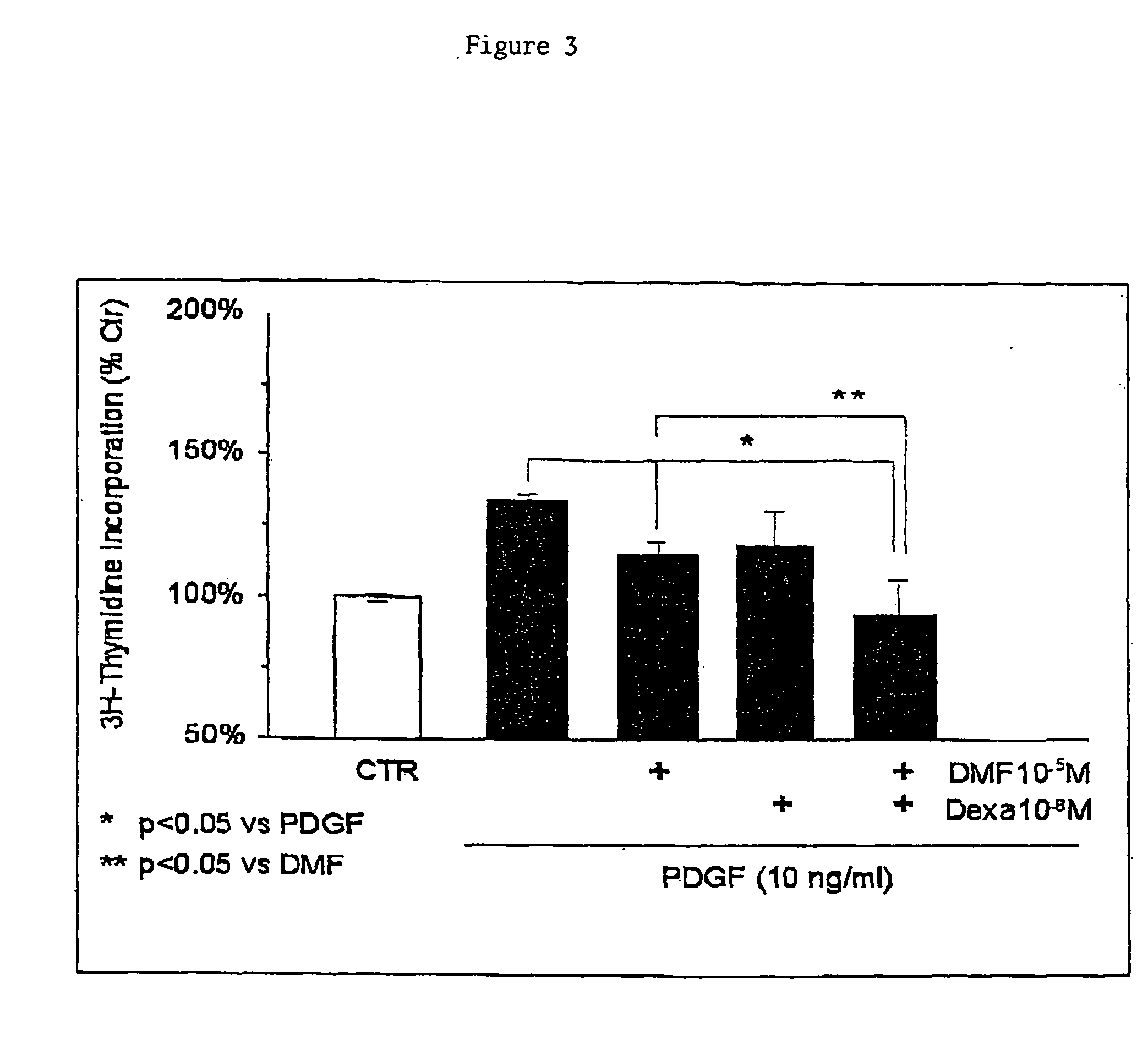

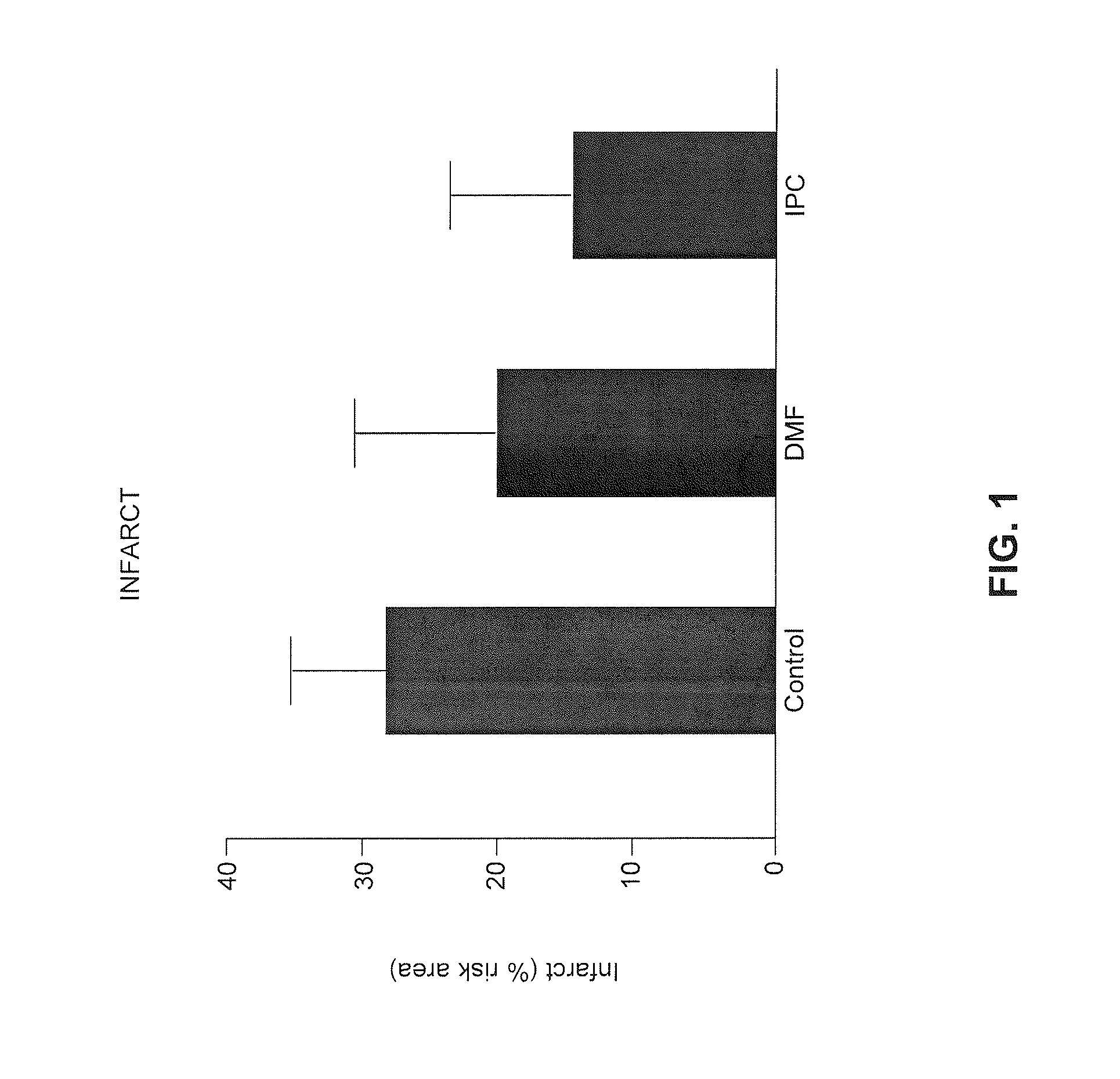

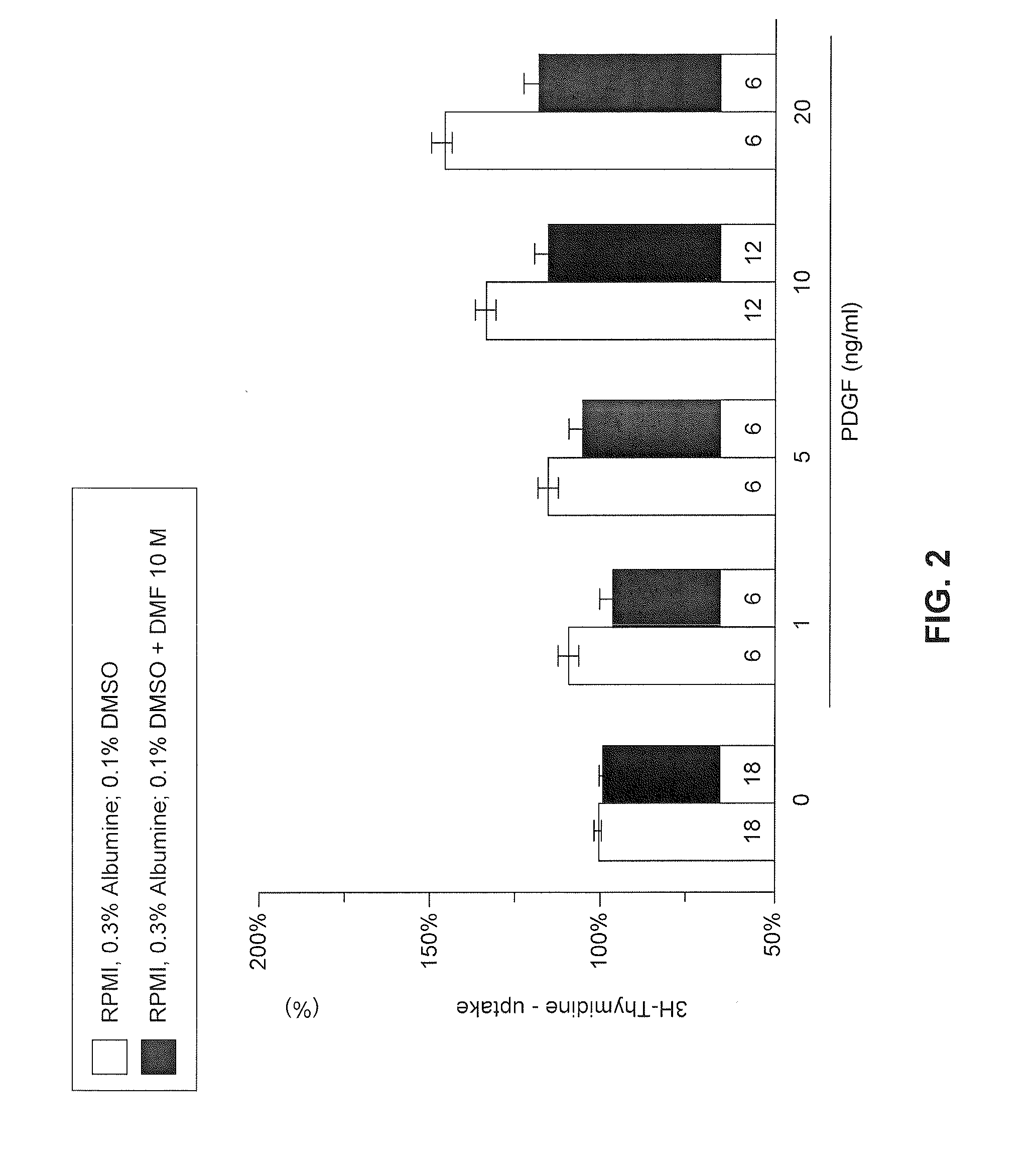

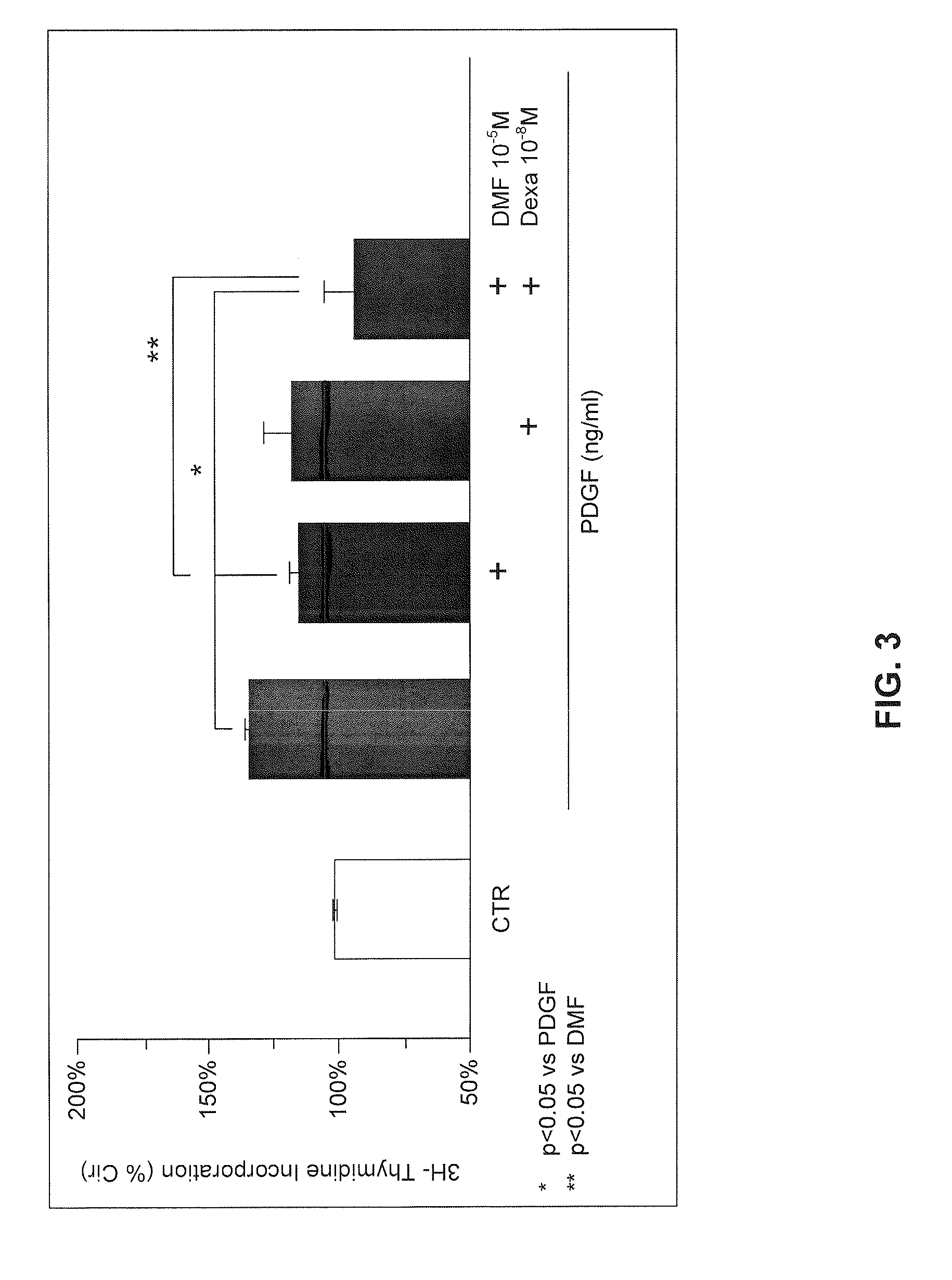

Use of fumaric acid derivatives for treating cardiac insufficiency, and asthma

According to a first aspect the invention relates to the use of fumaric acid derivatives selected from the group consisting of dialkyl fumarates, monoalkyl hydrogen fumarates, fumaric acid monoalkyl ester salts, fumaric acid monoamides, monoamido fumaric acid salts, fumaric acid diamides, monoalkyl monoamido fumarates, carbocyclic and oxacarbocyclic oligomers of these compounds and mixtures thereof for preparing a drug for the treatment or prevention of cardiac insufficiency, in particular left ventricular insufficiency, myocardial infarction and angina pectoris. According to a second aspect the invention relates to the use of fumaric acid derivatives, selected from the group consisting of dialkyl fumarates, monoalkyl hydrogen fumarates, fumaric acid monoalkyl ester salts, fumaric acid monoamides, monoamido fumaric acid salts, fumaric acid diamides, monoalkyl monoamido fumarates, carbocyclic and oxacarbocyclic oligomers of these compounds and mixtures thereof for preparing a drug for the treatment of asthma and chronic obstructive pulmonary diseases, especially asthma caused by allergies, infections, analgesics, job conditions or physical effort, mixed forms of asthma, or asthma cardiale.

Owner:FUMAPHAM AG

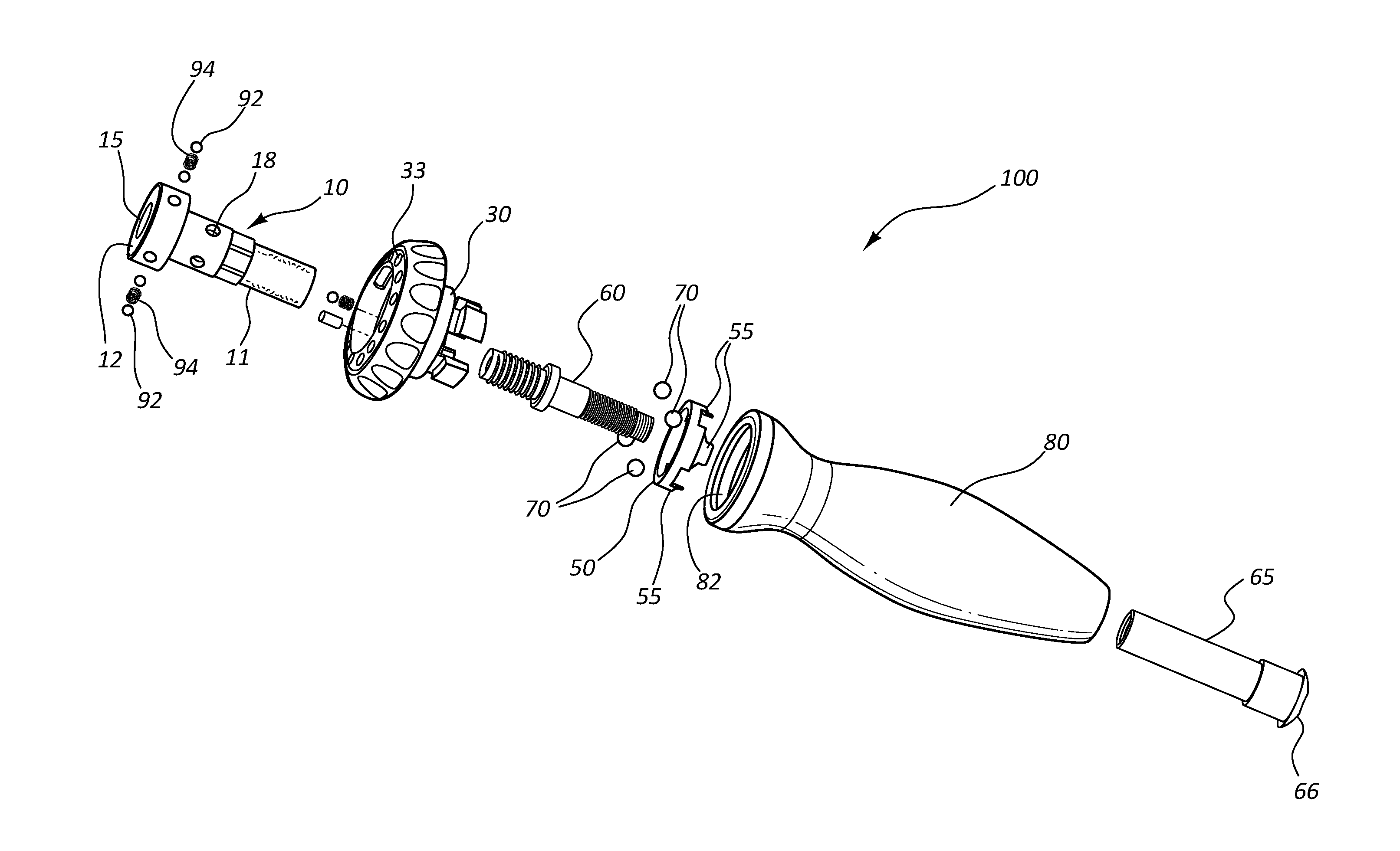

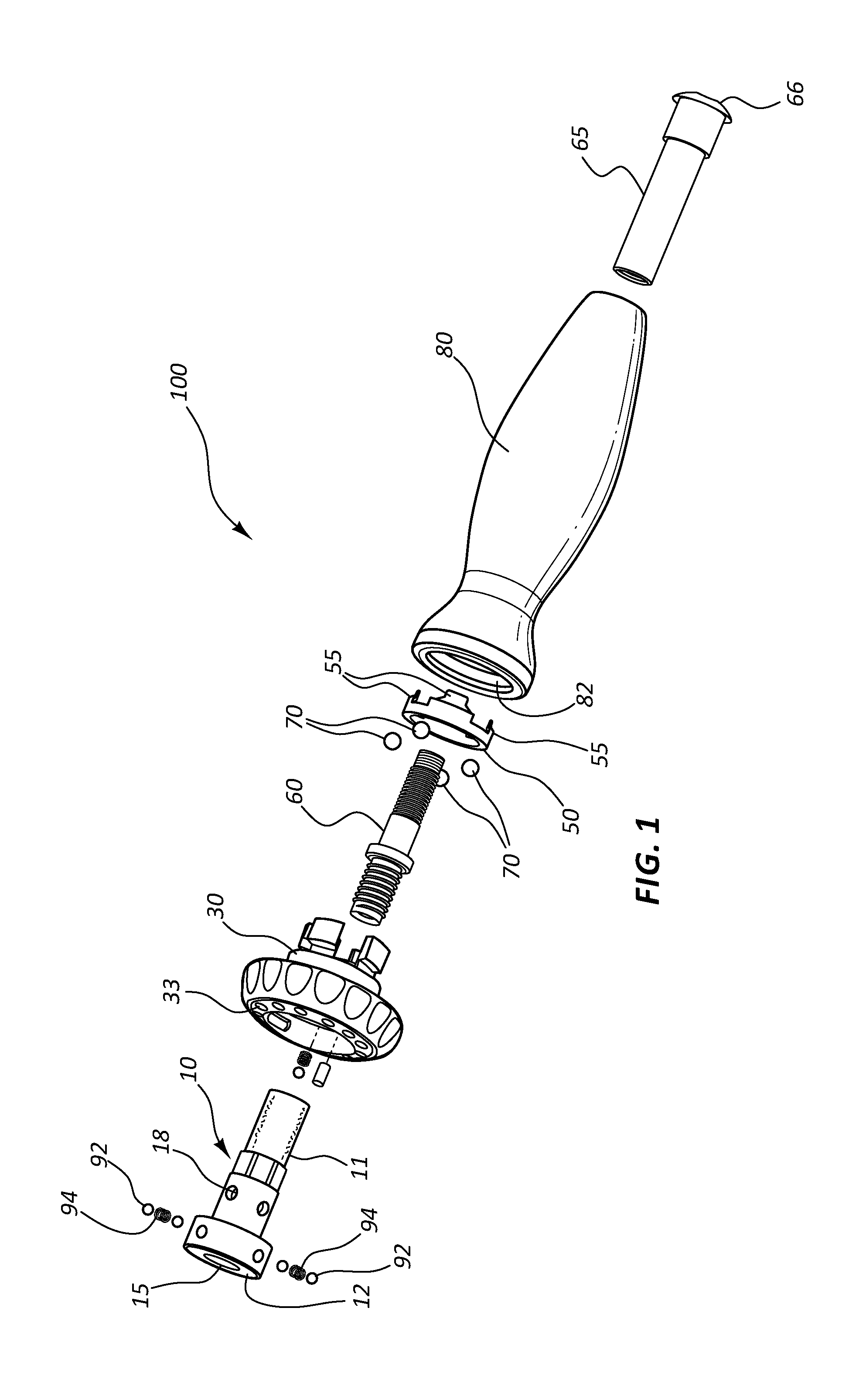

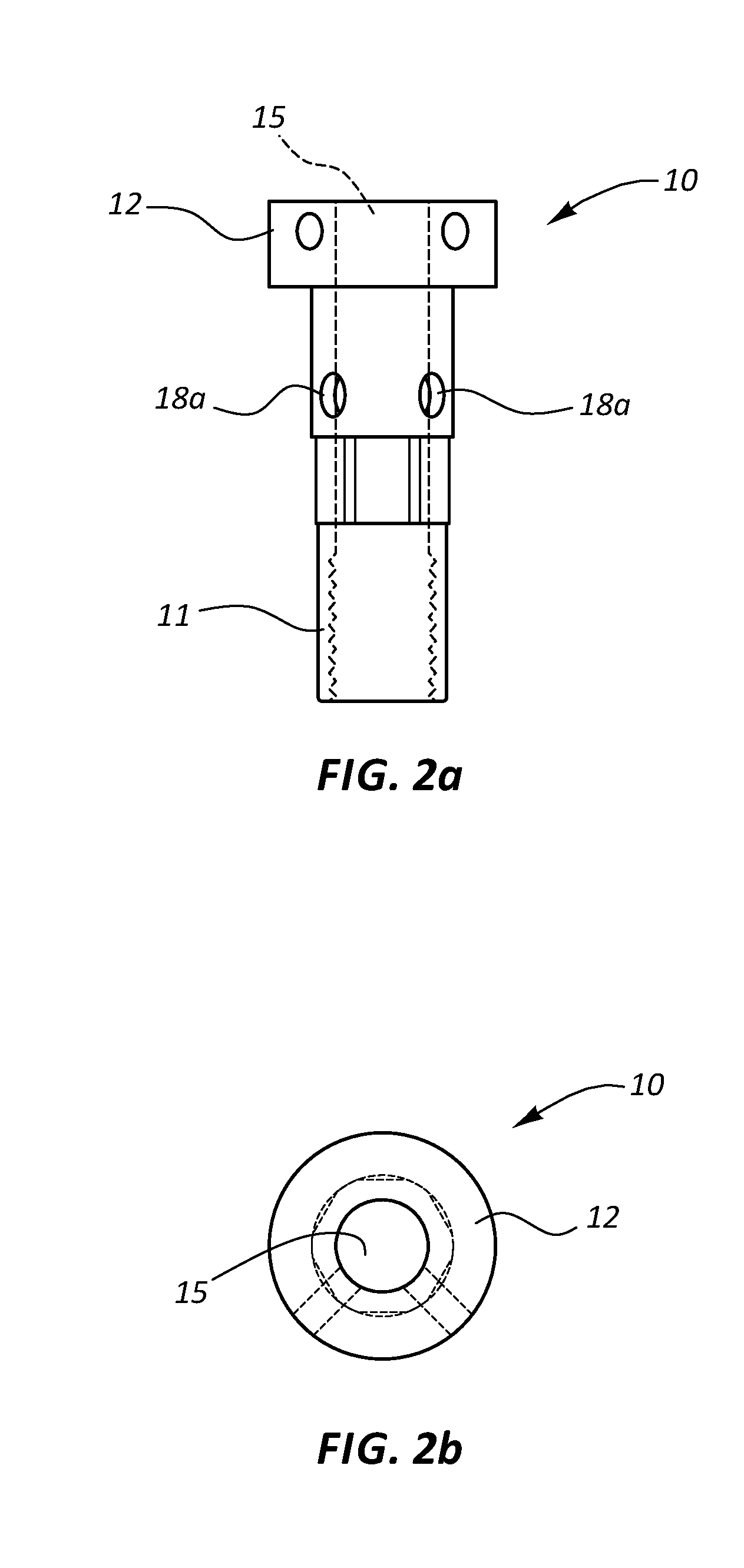

Surgical Instrument Adapter with Highly Secure Locking Shaft Mechanism

A highly secure instrument adapter includes a handle with an internal locking and release mechanism which does not use a pushing release and which requires little physical effort to lock and release, yet provides a stable and secure connection between an instrument and the handle. The locking mechanism is comprised an ergometric handle having an open handle cavity, a receiver having an internal threaded tubular body and a plurality of locking apertures, and a rotating collar having a limited range of rotation, a plurality of fingers that project outward from the flattened surface on a spacer structure, and a plurality of circular apertures placed alternately between said fingers.

Owner:BRADSHAW MEDICAL

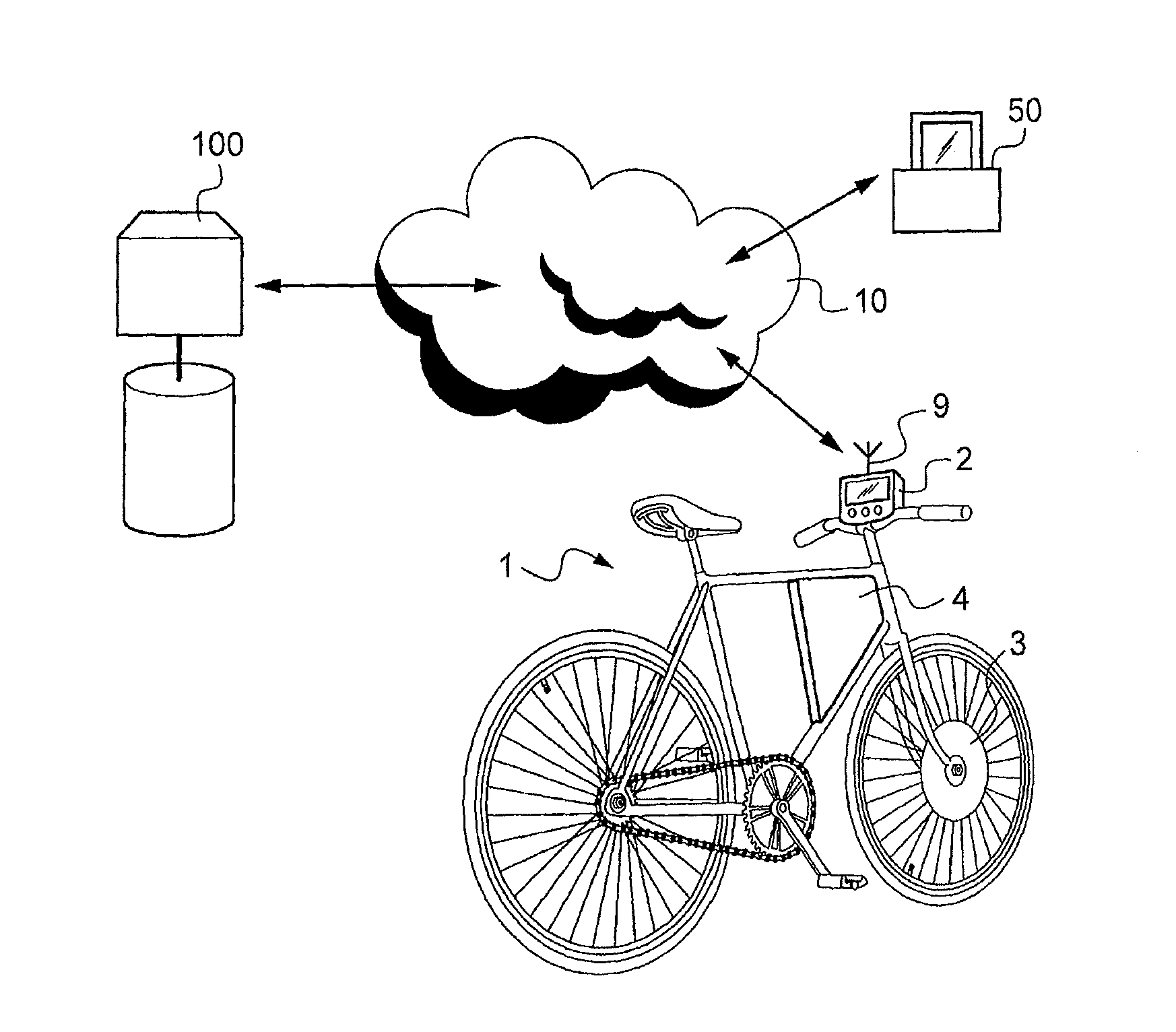

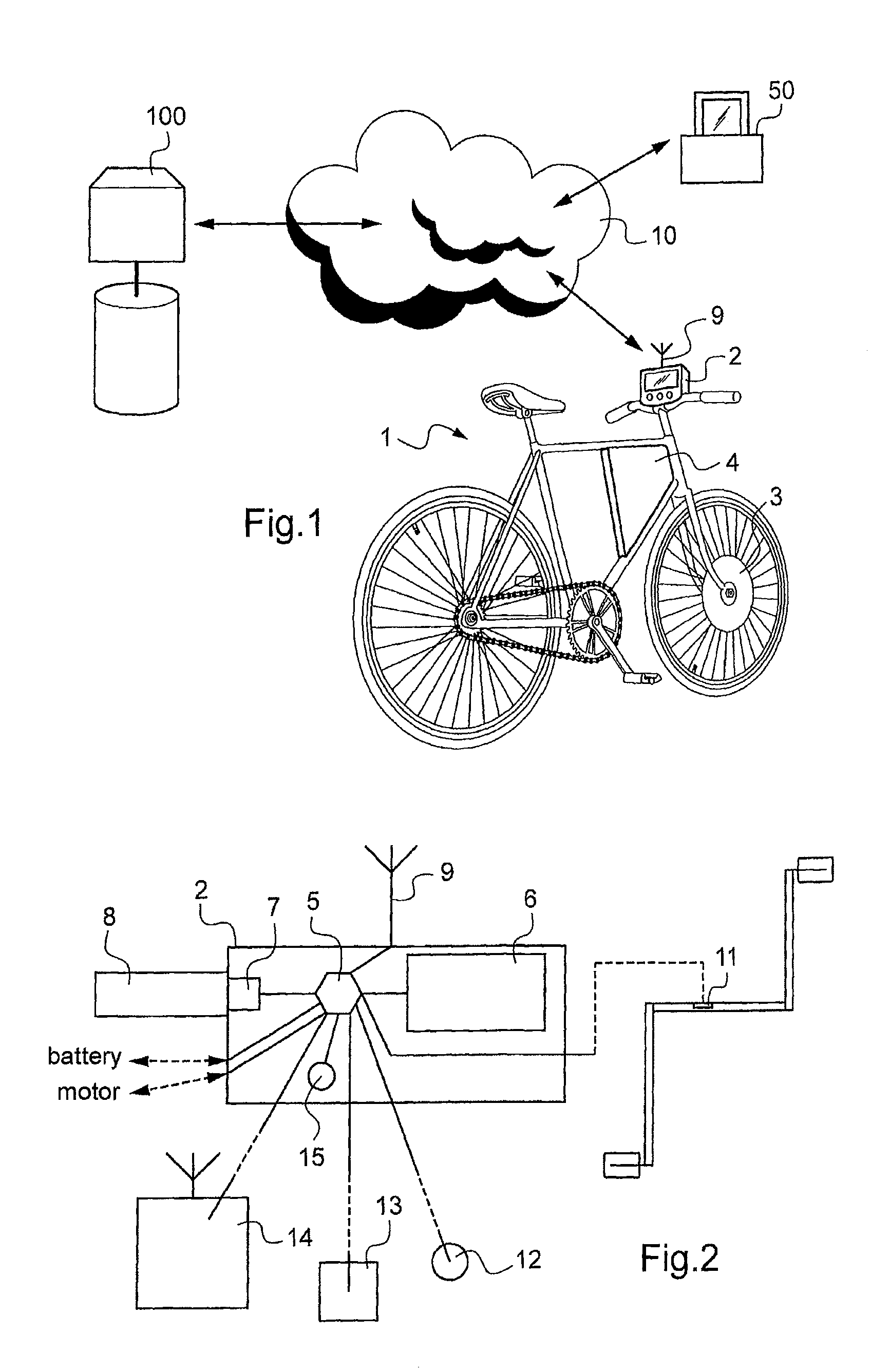

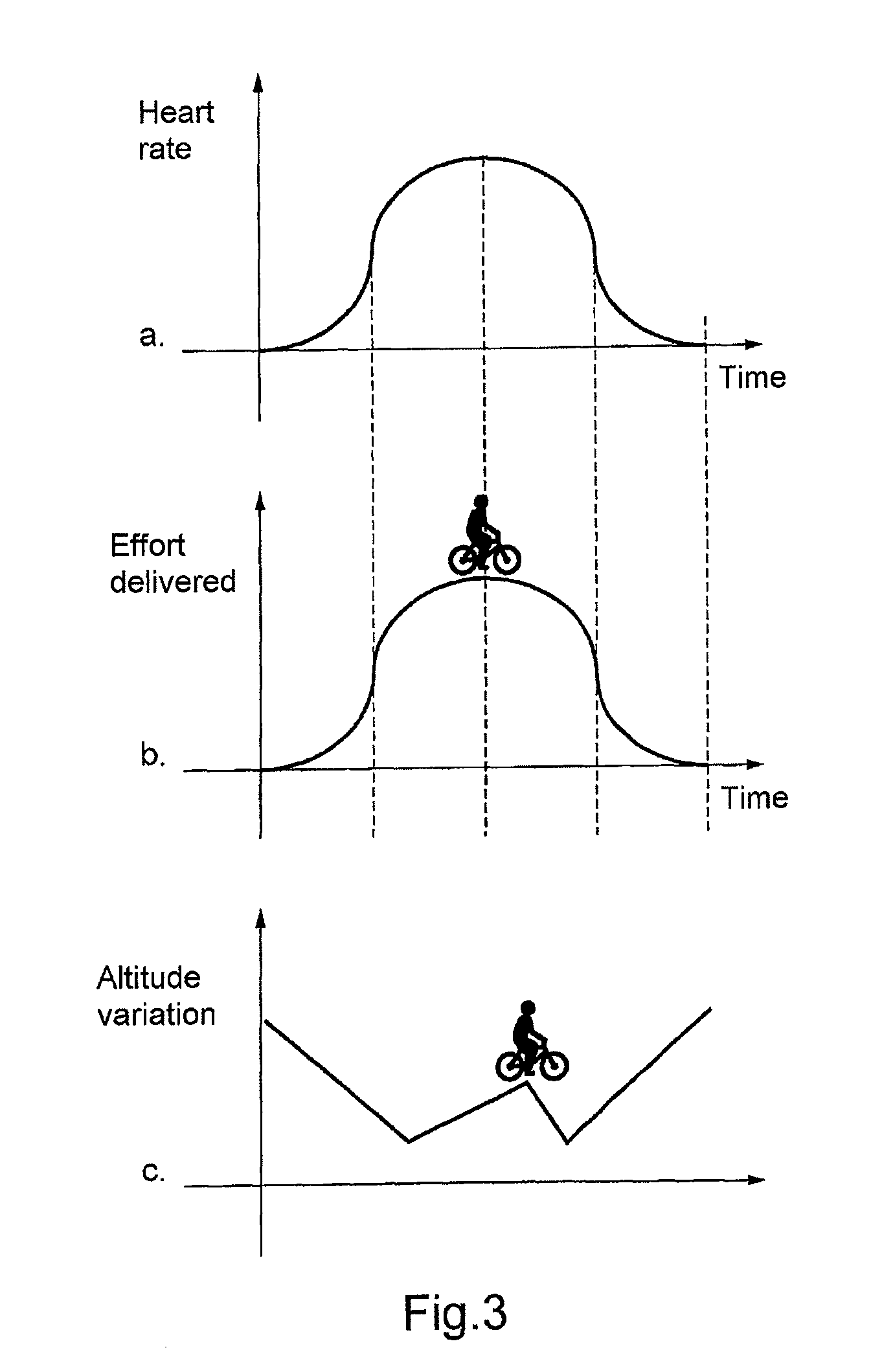

Method for managing the strain of a user of a human propulsion vehicle, and vehicle adapted for said method

InactiveUS20110254673A1Adapt to the environmentHealth effectsSpeed controllerAcoustic signalHuman powerControl unit

A method of managing physical effort expended by a user of a human-propelled vehicle provided with a control unit connected to an electric motor that is powered by a battery and that is arranged to take the place at least in part of the user for the purposes of propelling and of braking the vehicle, as a function of a program executed by the control unit in order to manage the physical effort expended by the user. A vehicle adapted to this method.

Owner:IMW PRODIONS

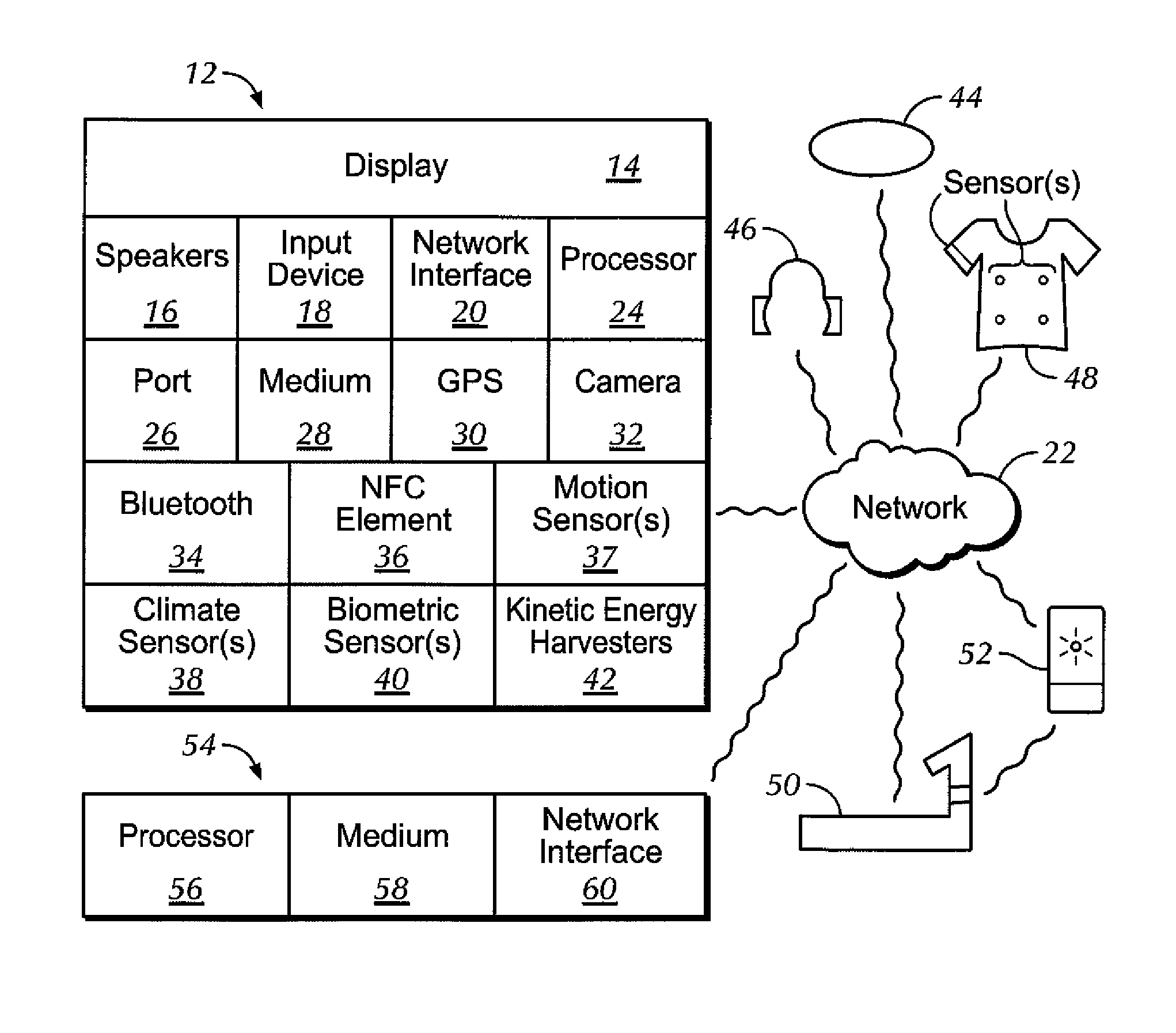

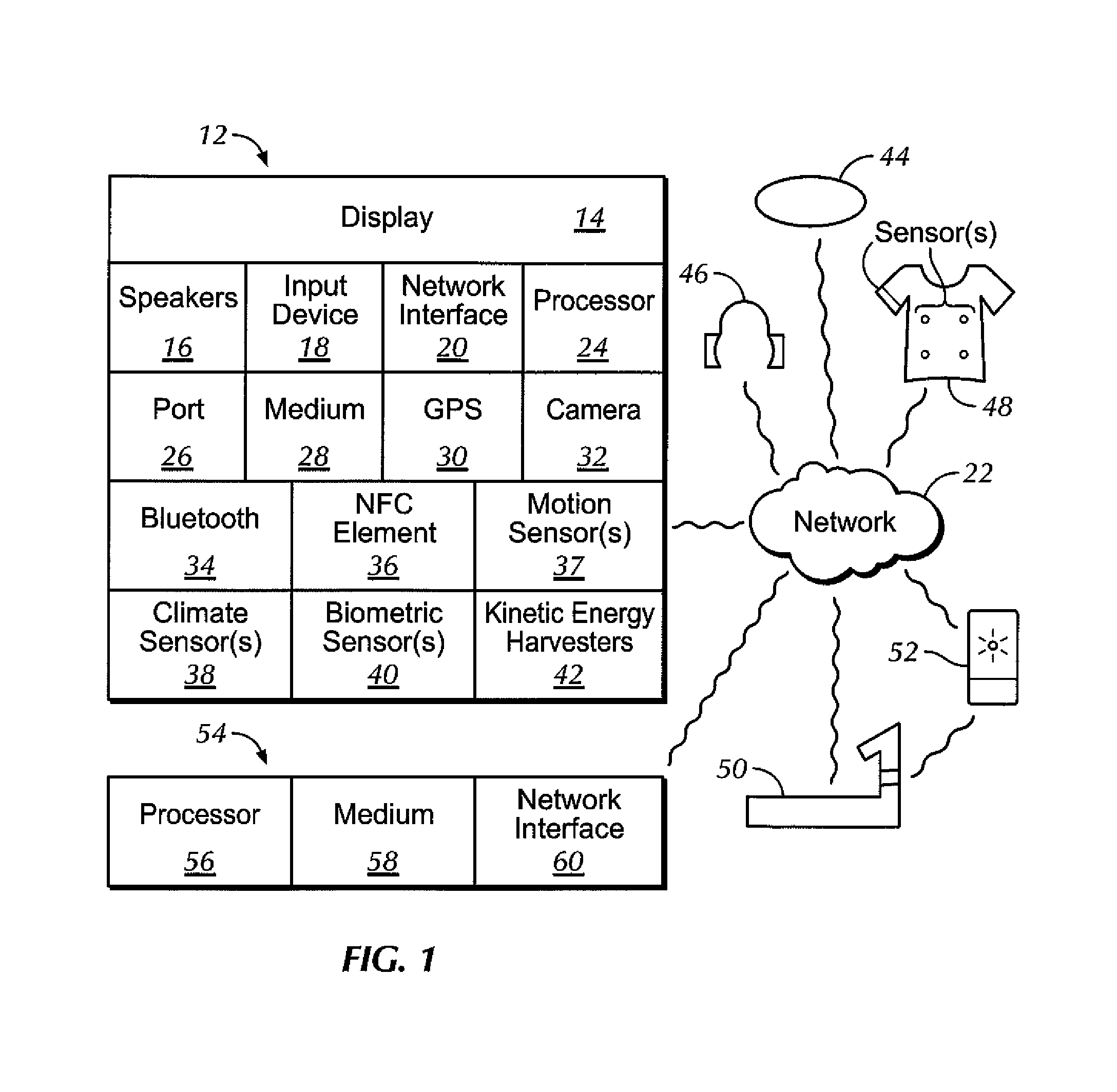

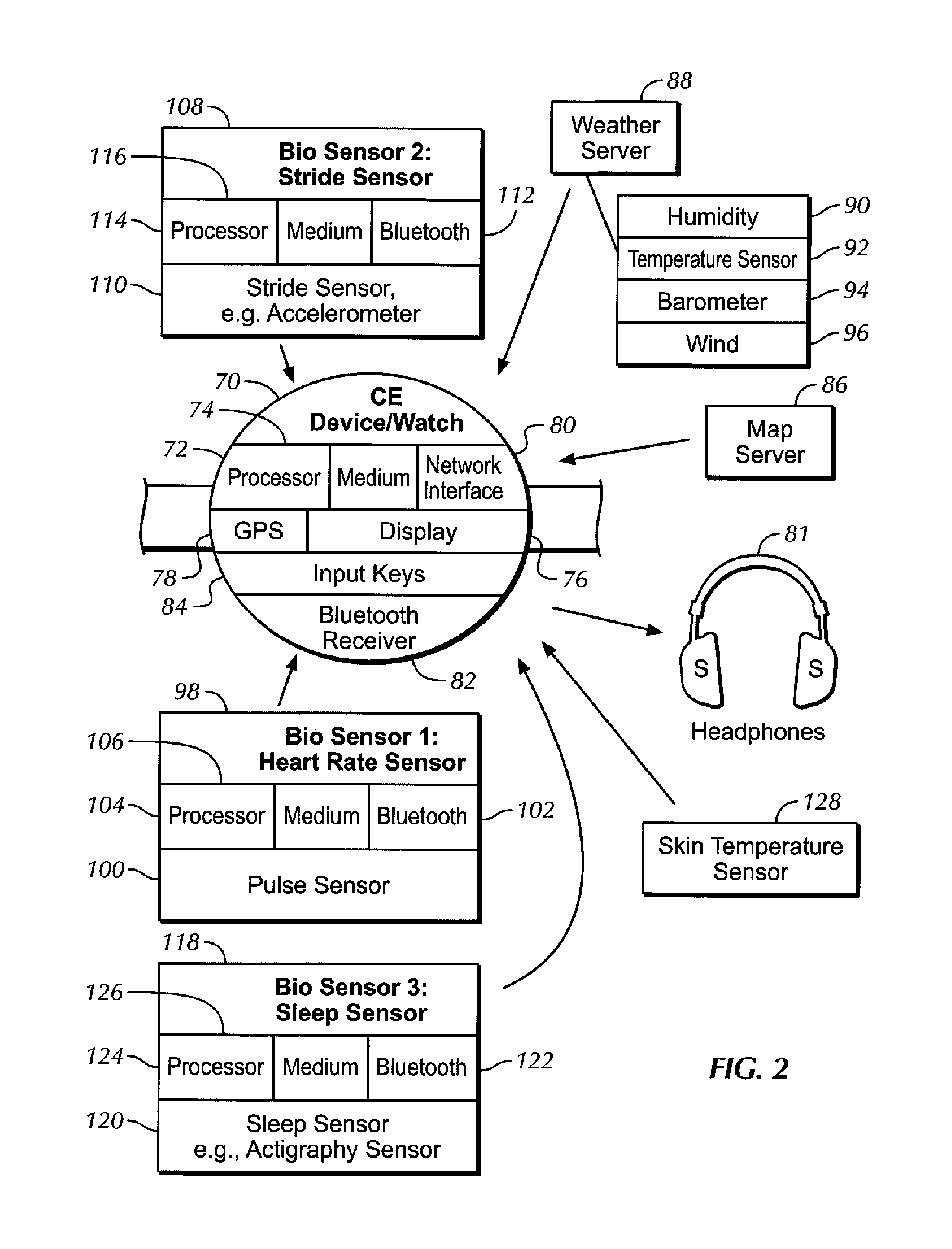

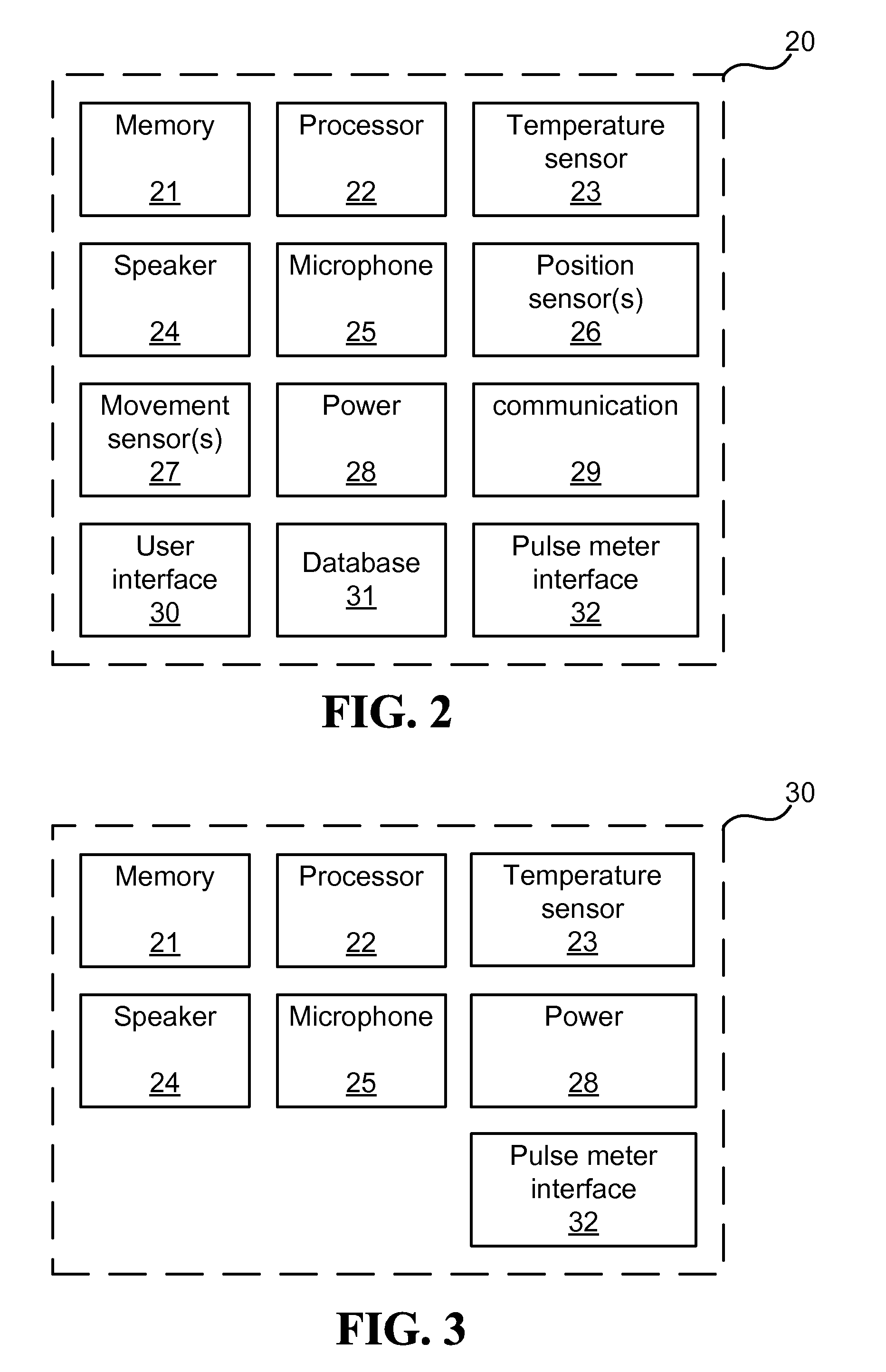

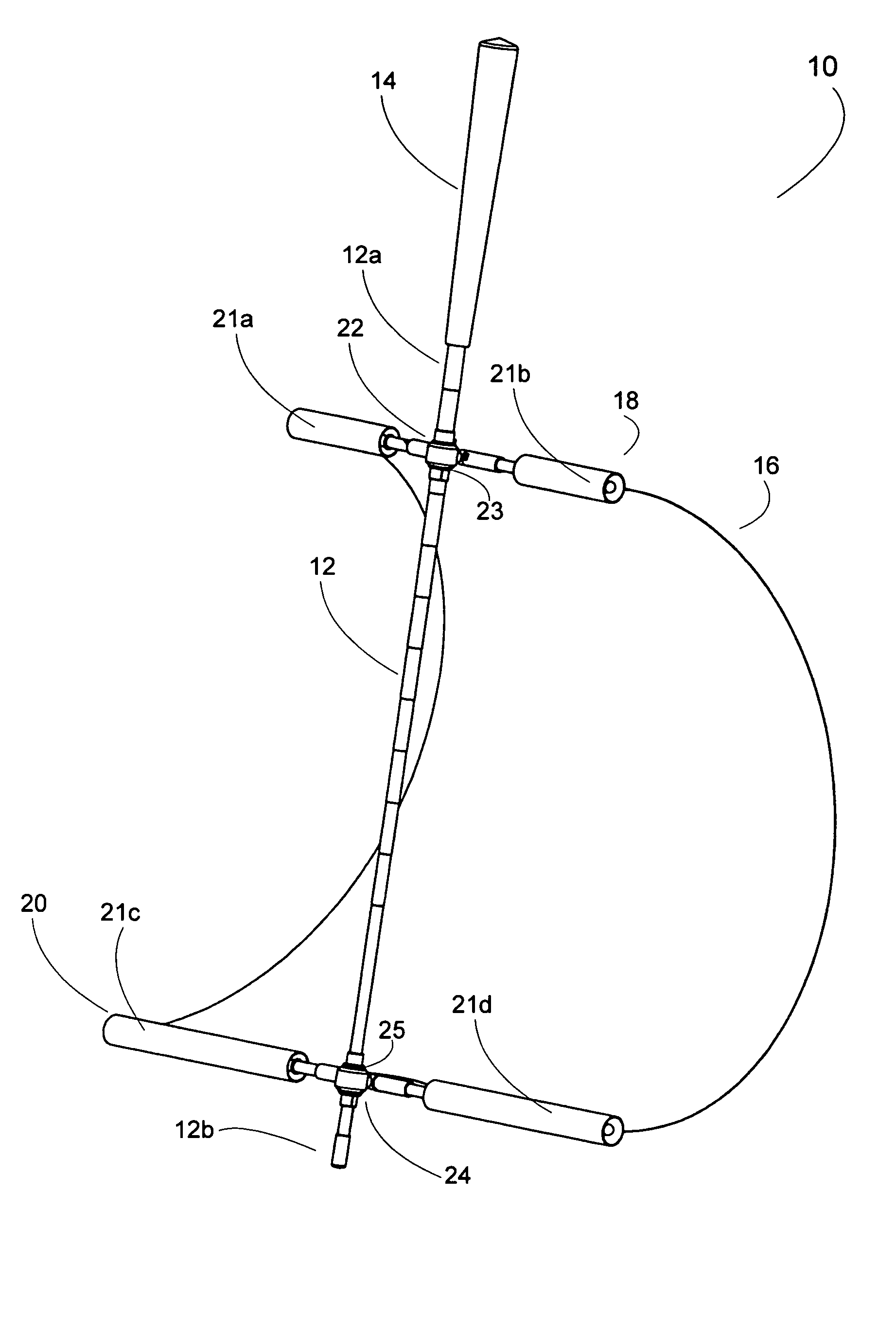

Combining data sources to provide accurate effort monitoring

ActiveUS8795138B1Indicator of true effortMore and qualificationPhysical therapies and activitiesDevices with sensorSmart systemComputer science

By combining data from different sensors (on fitness device, mobile smartphone, smart clothing, other devices or people in same location), an intelligent system provides a better indicator of an individual's physical effort, using rich data sources to enhance quantified metrics such as distance / pace / altitude gain, to provide a clearer picture of an individual's exercise and activity.

Owner:SONY CORP

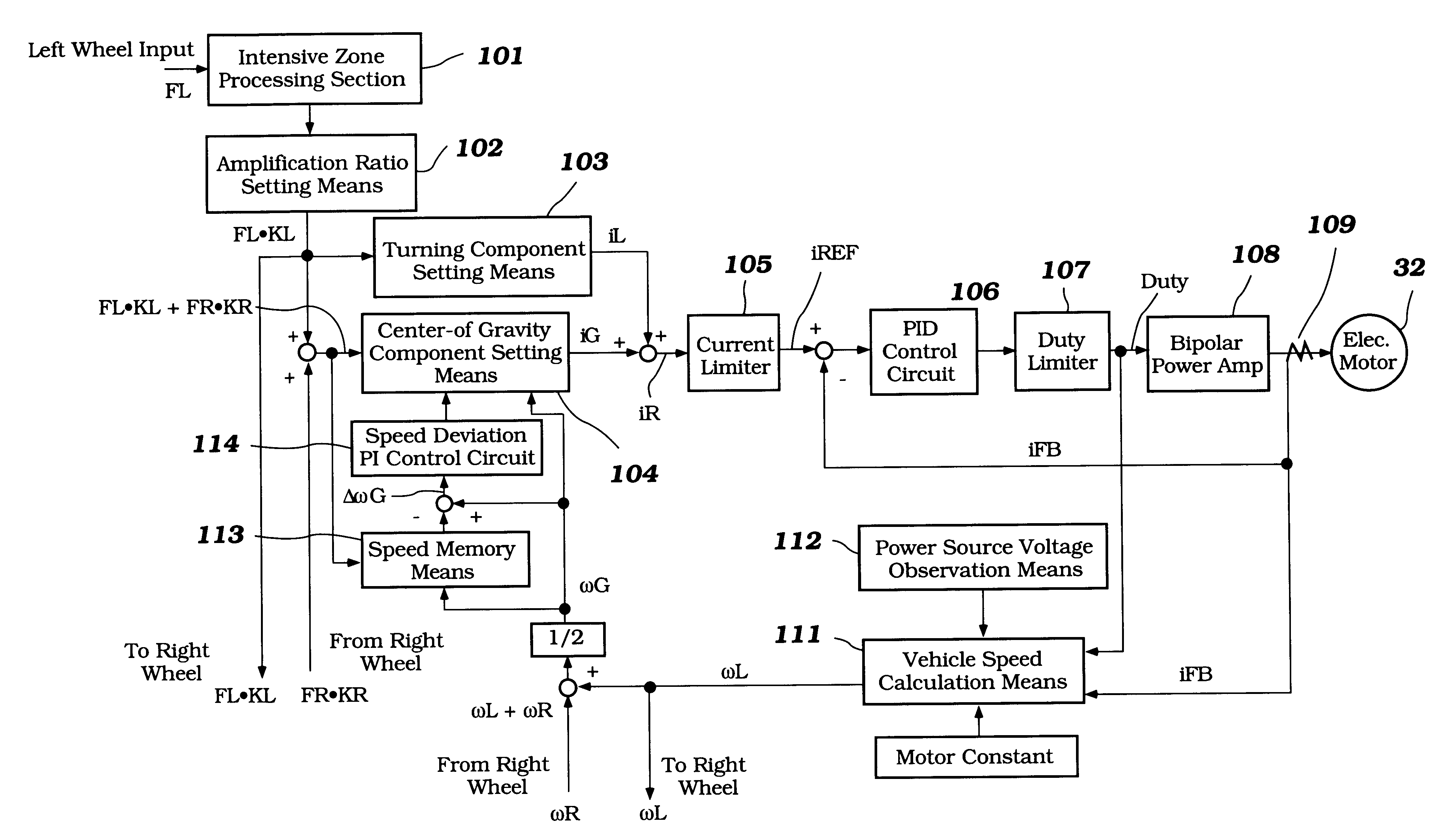

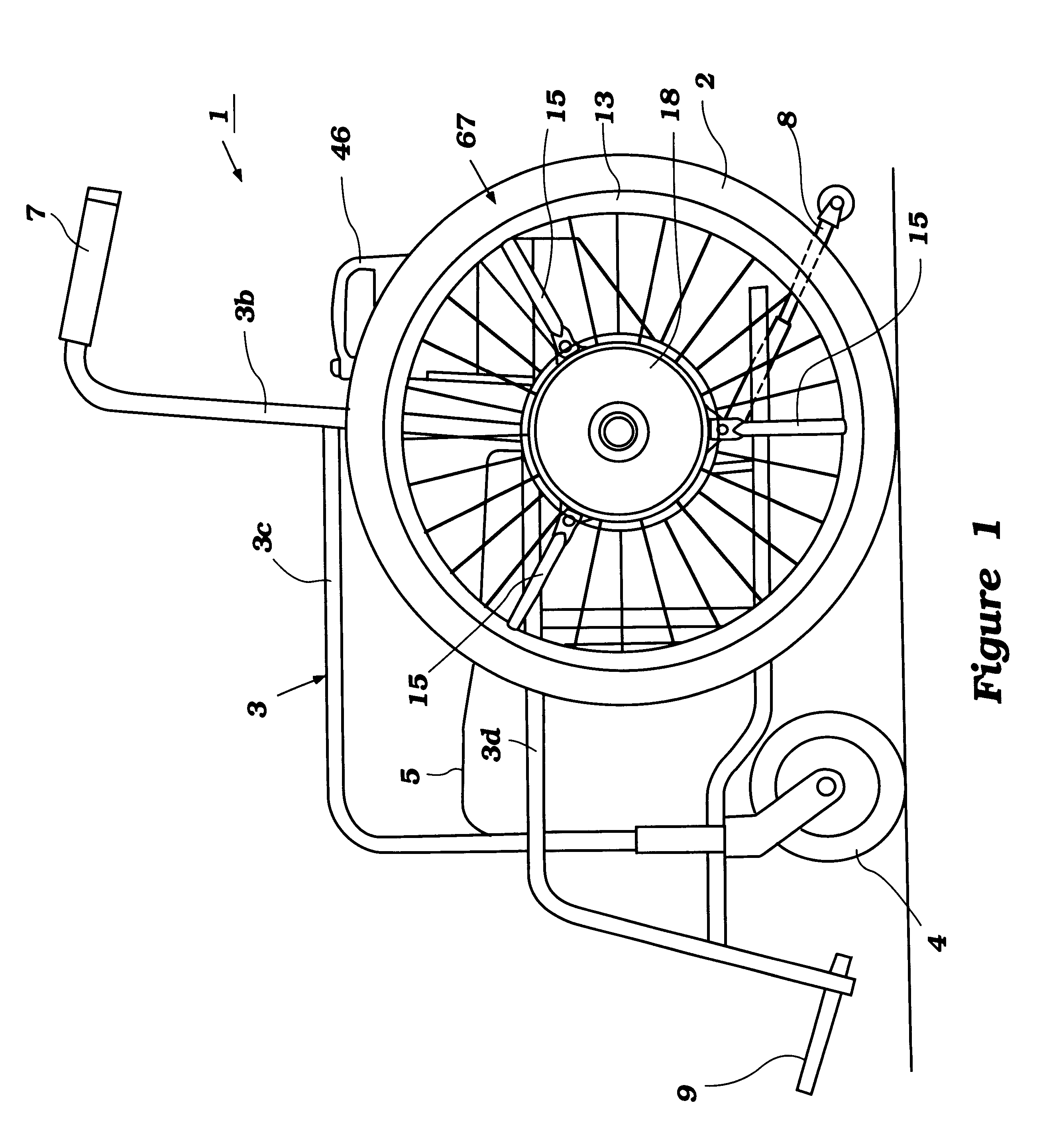

Wheel chair with auxiliary power

InactiveUS6230831B1Reduce physical exertionSmall amountMotor/generator/converter stoppersDC motor speed/torque controlUltrasound attenuationWheelchair

A power-assisted wheelchair (1) having an electric motor (32), a potentiometer (27) as means for detecting human power applied to wheels (2), and a controller (31) as means for controlling the electric motor (32) according to the detected human power so as to set the time-attenuation rate of the assist power to be greater as the human power is smaller, and to be smaller as the human power is greater.Therefore, the coasting amount of the wheelchair (1) for small indoor movements for example is restricted to a small value. As a result, small indoor movements with a small turning radius are made possible, a sufficient coasting amount is secured for an outdoor running. Therefore, along with the possibility of a comfortable running on a level road, a steep uphill running is made easy, and the physical effort of the rider is alleviated.

Owner:YAMAHA MOTOR CO LTD

Use of fumaric acid derivatives for treating cardiac insufficiency, and asthma

According to a first aspect the invention relates to the use of fumaric acid derivatives selected from the group consisting of dialkyl fumarates, monoalkyl hydrogen fumarates, fumaric acid monoalkyl ester salts, fumaric acid monoamides, monoamido fumaric acid salts, fumaric acid diamides, monoalkyl monoamido fumarates, carbocyclic and oxacarbocyclic oligomers of these compounds and mixtures thereof for preparing a drug for the treatment or prevention of cardiac insufficiency, in particular left ventricular insufficiency, myocardial infarction and angina pectoris.According to a second aspect the invention relates to the use of fumaric acid derivatives, selected from the group consisting of dialkyl fumarates, monoalkyl hydrogen fumarates, fumaric acid monoalkyl ester salts, fumaric acid monoamides, monoamido fumaric acid salts, fumaric acid diamides, monoalkyl monoamido fumarates, carbocyclic and oxacarbocyclic oligomers of these compounds and mixtures thereof for preparing a drug for the treatment of asthma and chronic obstructive pulmonary diseases, especially asthma caused by allergies, infections, analgesics, job conditions or physical effort, mixed forms of asthma, or asthma cardiale.

Owner:BIOGEN INT

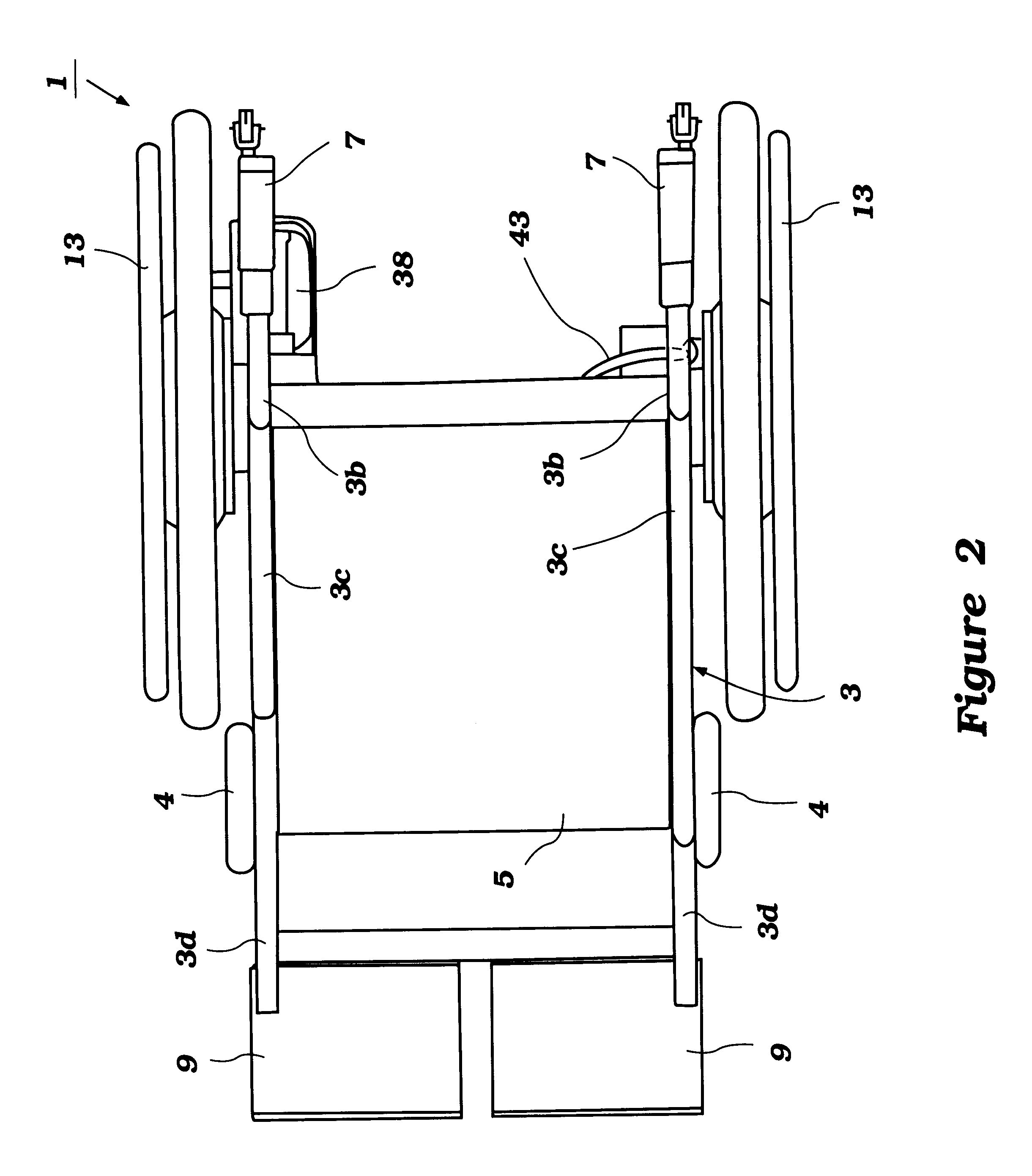

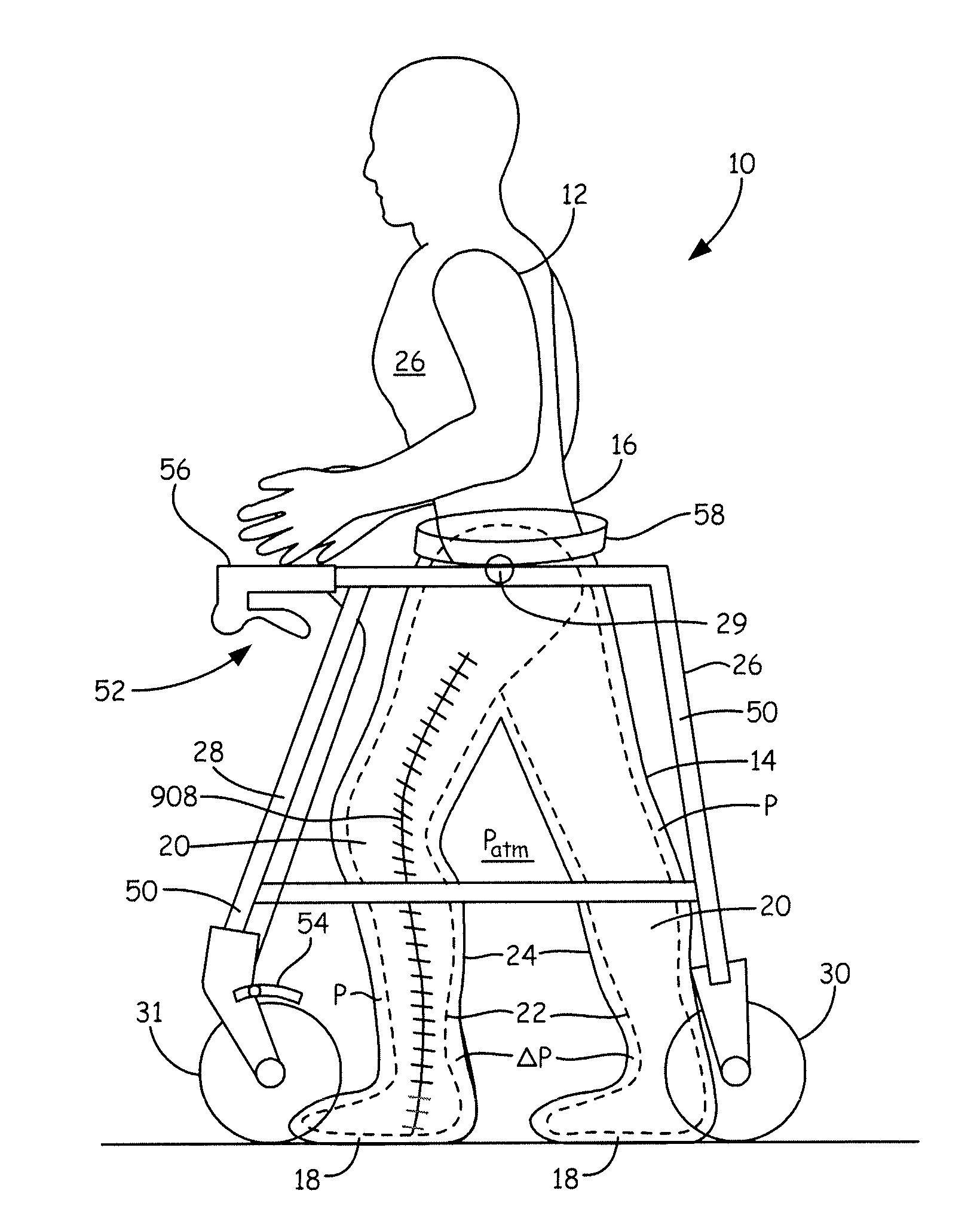

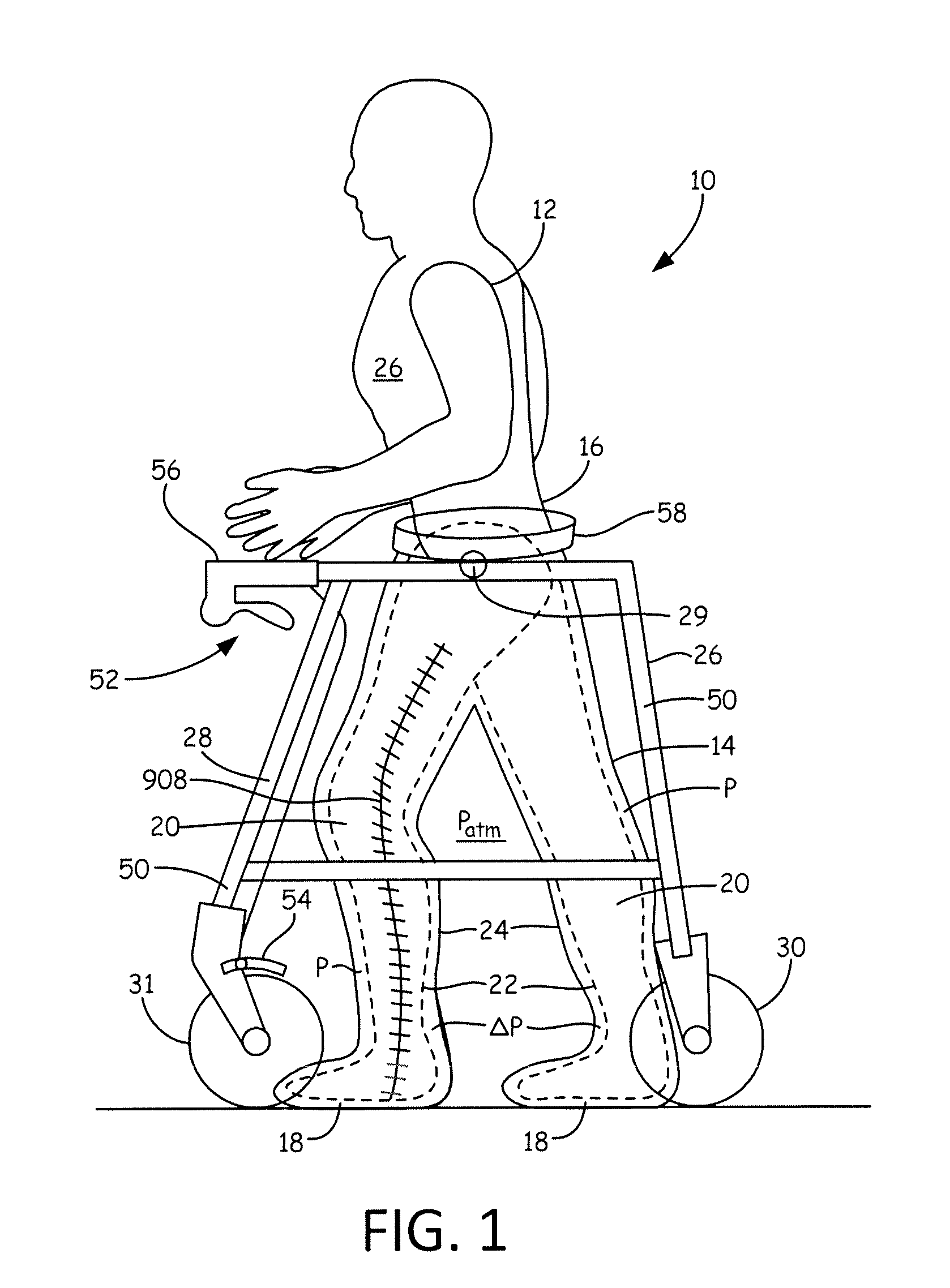

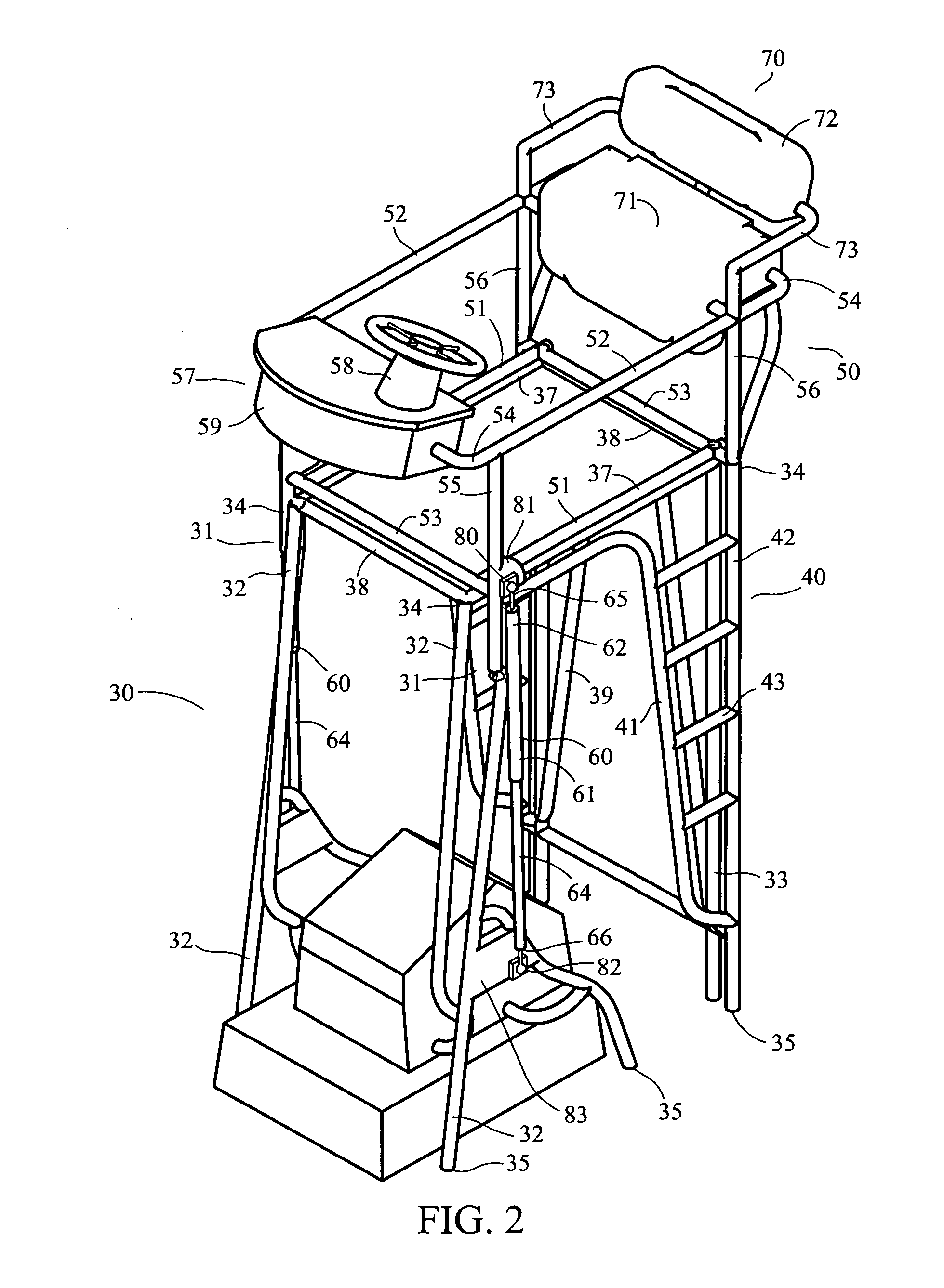

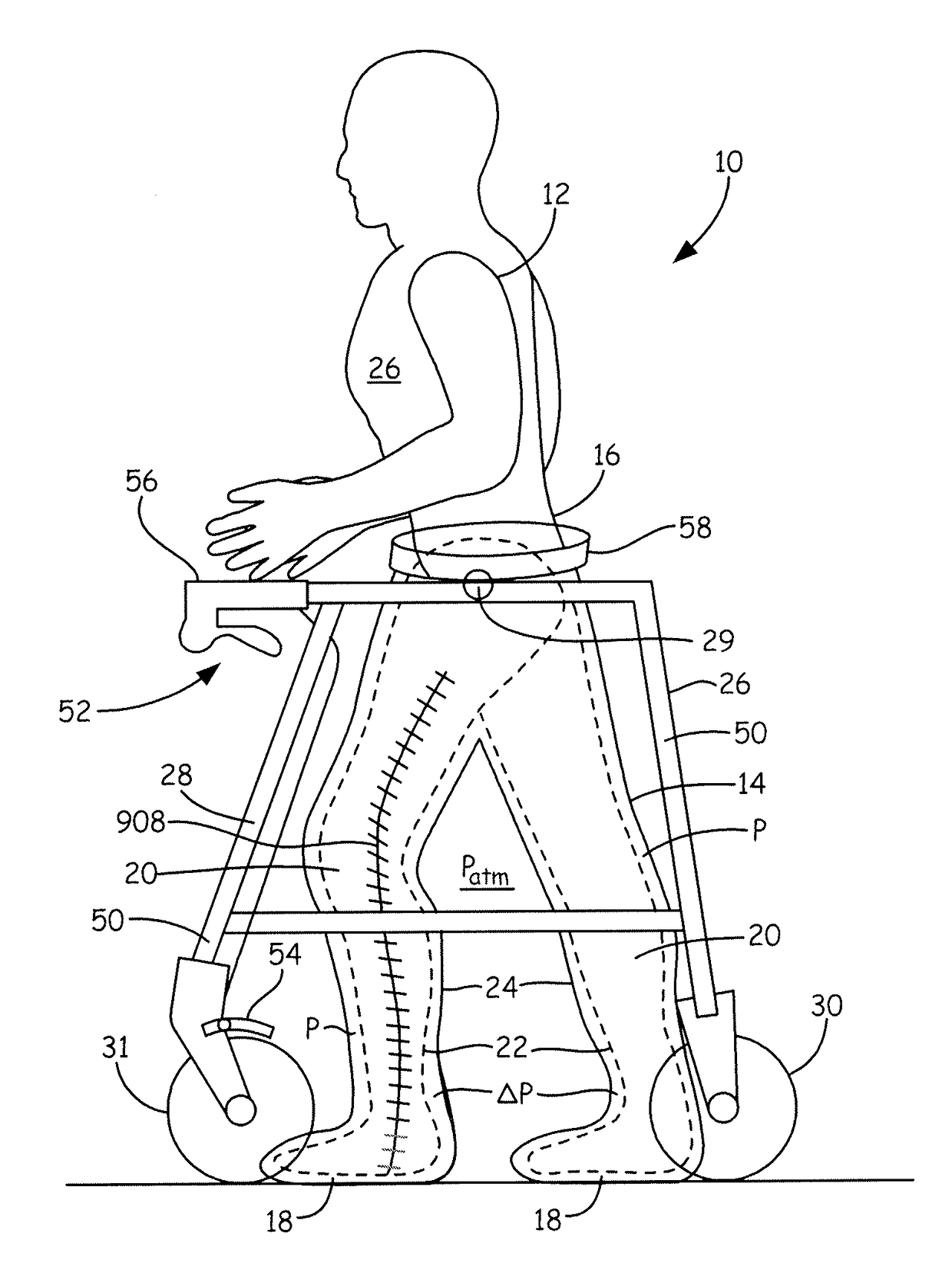

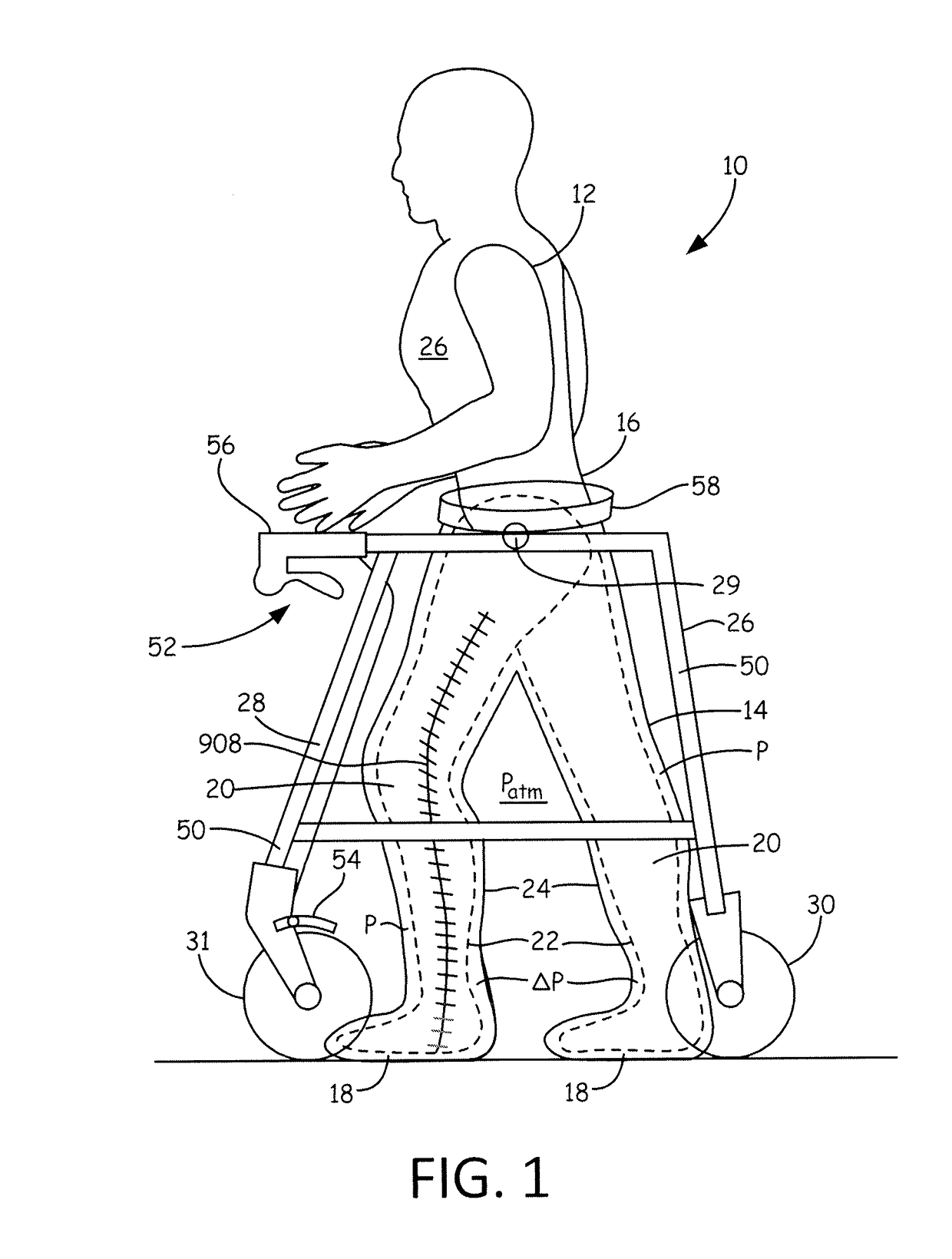

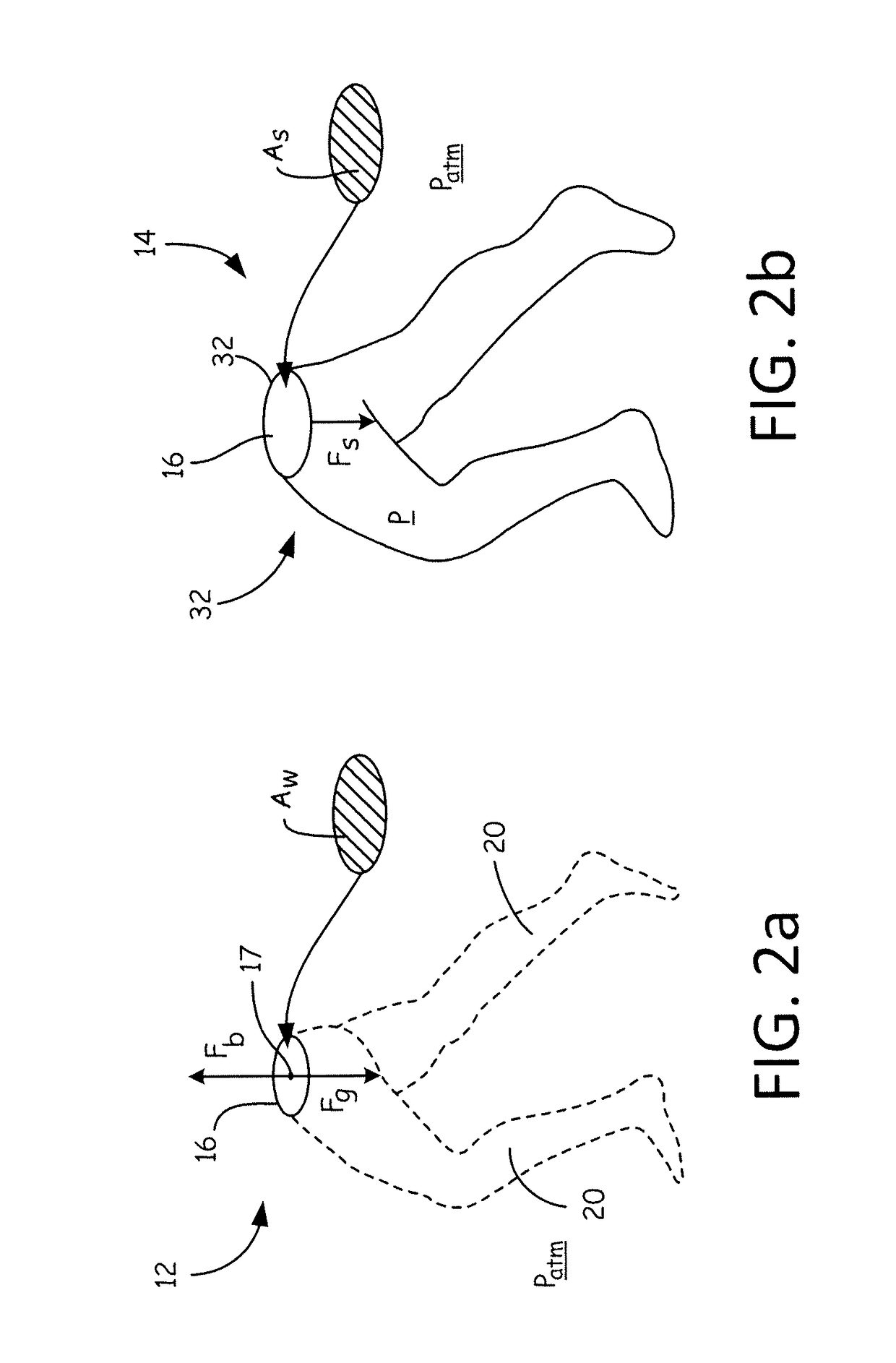

Body lift-assist walker device

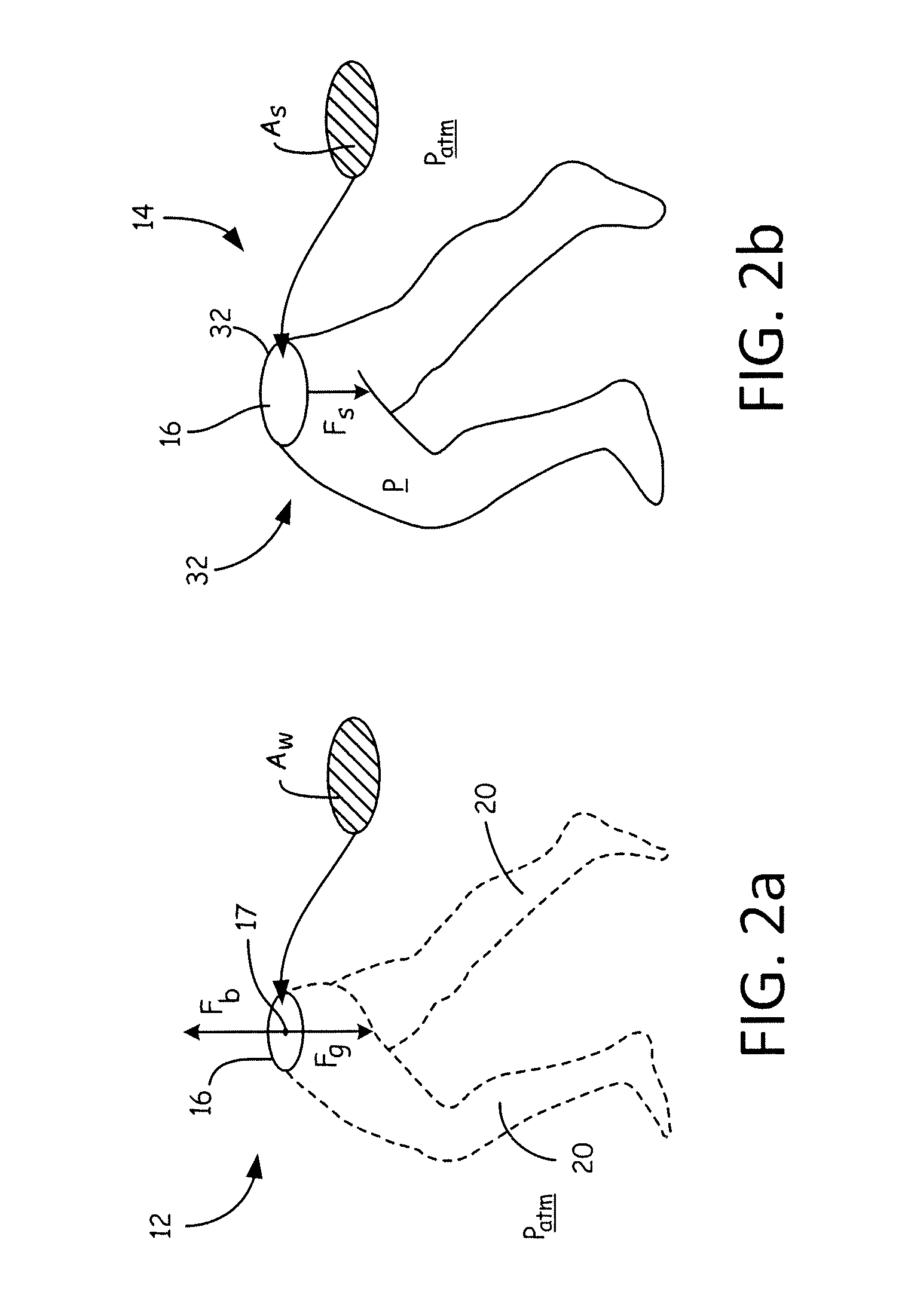

ActiveUS20160166454A1Minimal forceGood adhesionBlood stagnation preventionPneumatic massagePositive pressureDifferential pressure

The present invention provides a body lift-assist walker device for gait training is provided by the invention. The patient wears a pressurized body suit over all or a portion of his lower body, and the suit is attached to the walker device. A positive pressure or vacuum condition is applied to the interior of the suit, so that the differential pressure condition across the suit offloads a portion of the patient's body weight to the ground through the supportive walker device to make it easier for him to walk or run. The walker device also includes a lift-assisted body weight support device operated by a constant force mechanism like a pneumatic air cylinder that can lift the patient from a sitting position to a standing position with minimal physical effort. The device provides a portable and convenient system for persons undergoing physical therapy for treatment of gait or balance problems following an injury, stroke, or neurological disorder, or for use by elderly or disabled persons who have encounter difficulties in the sit-to-stand movement or walking.

Owner:LITE RUN

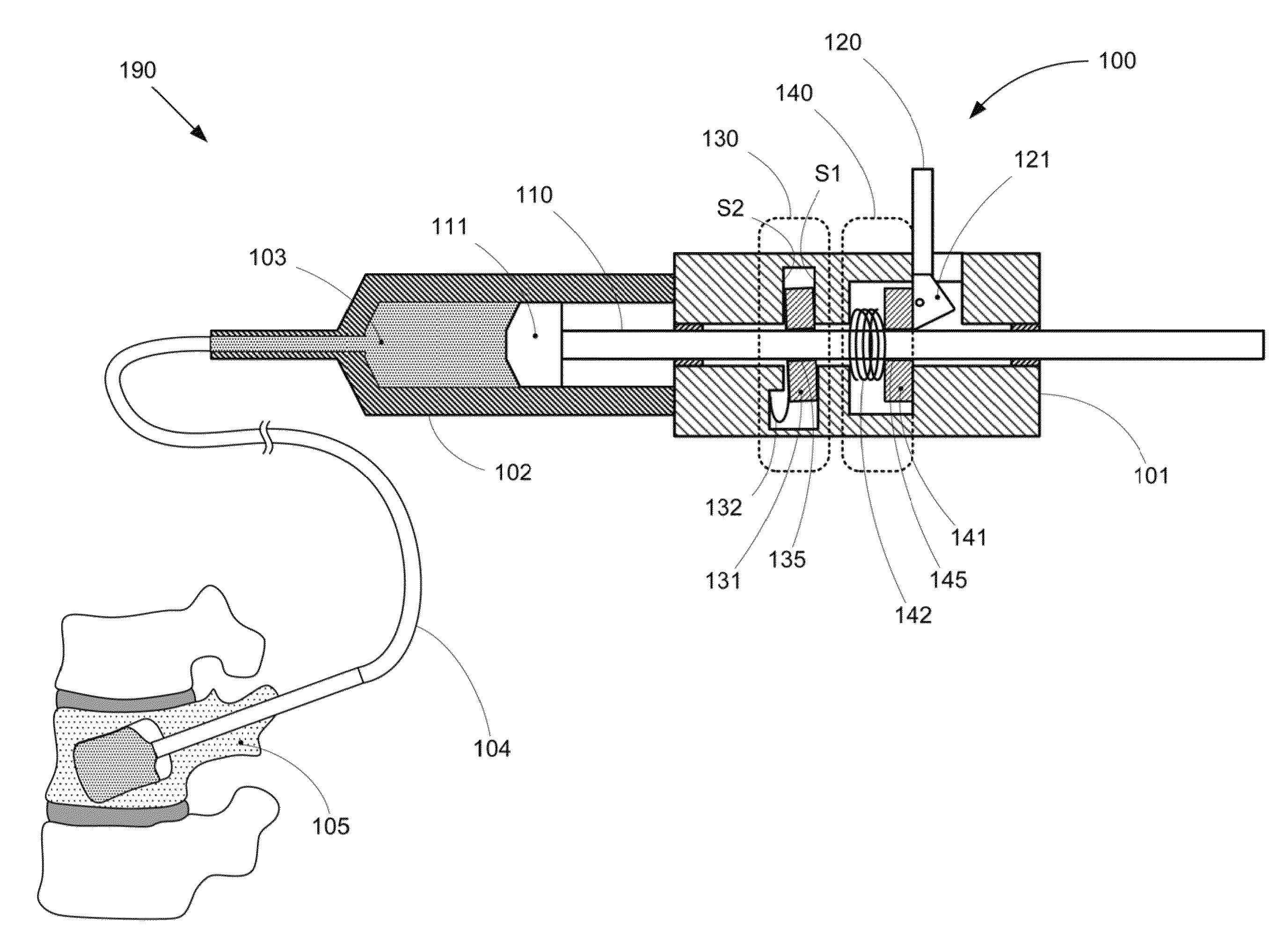

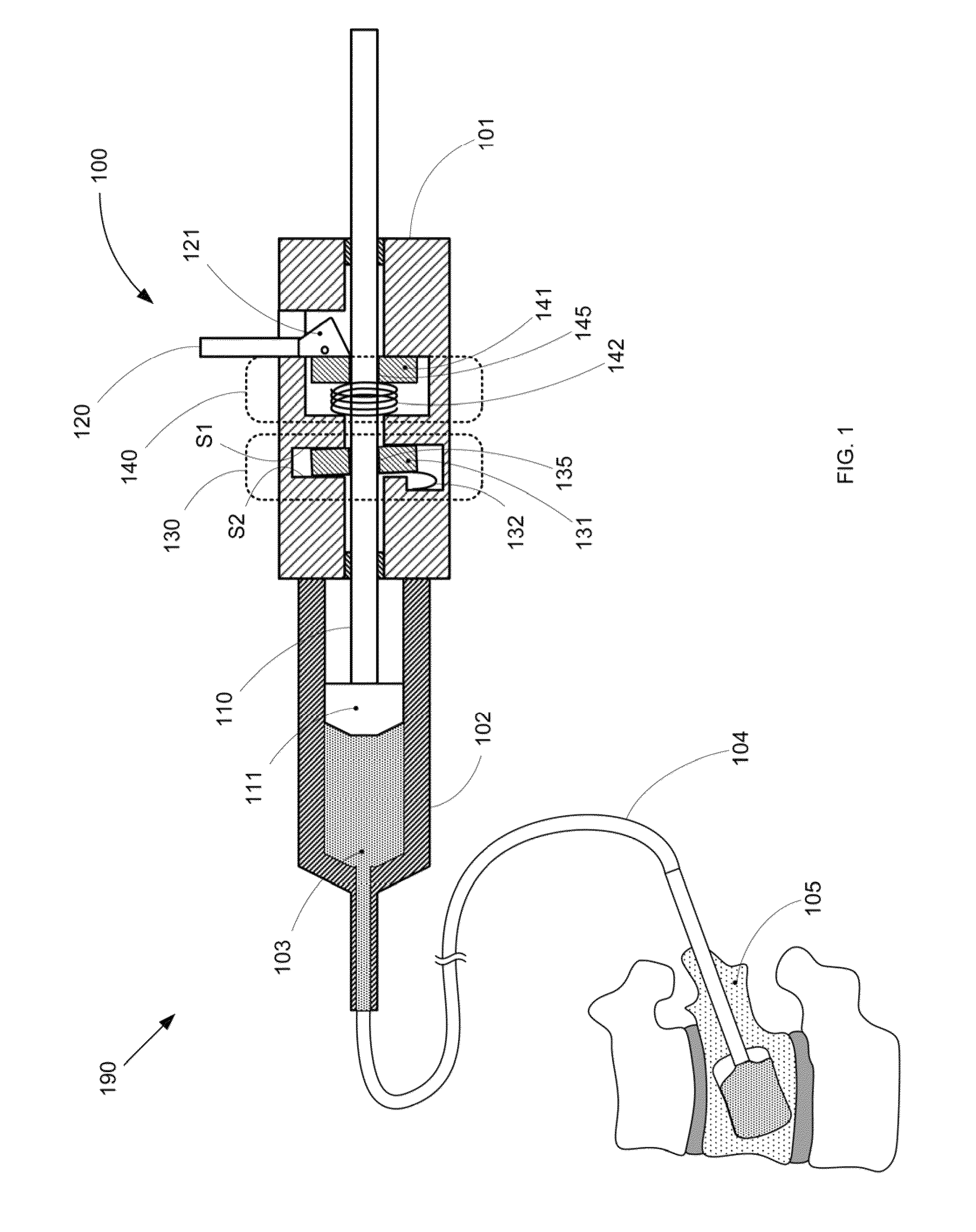

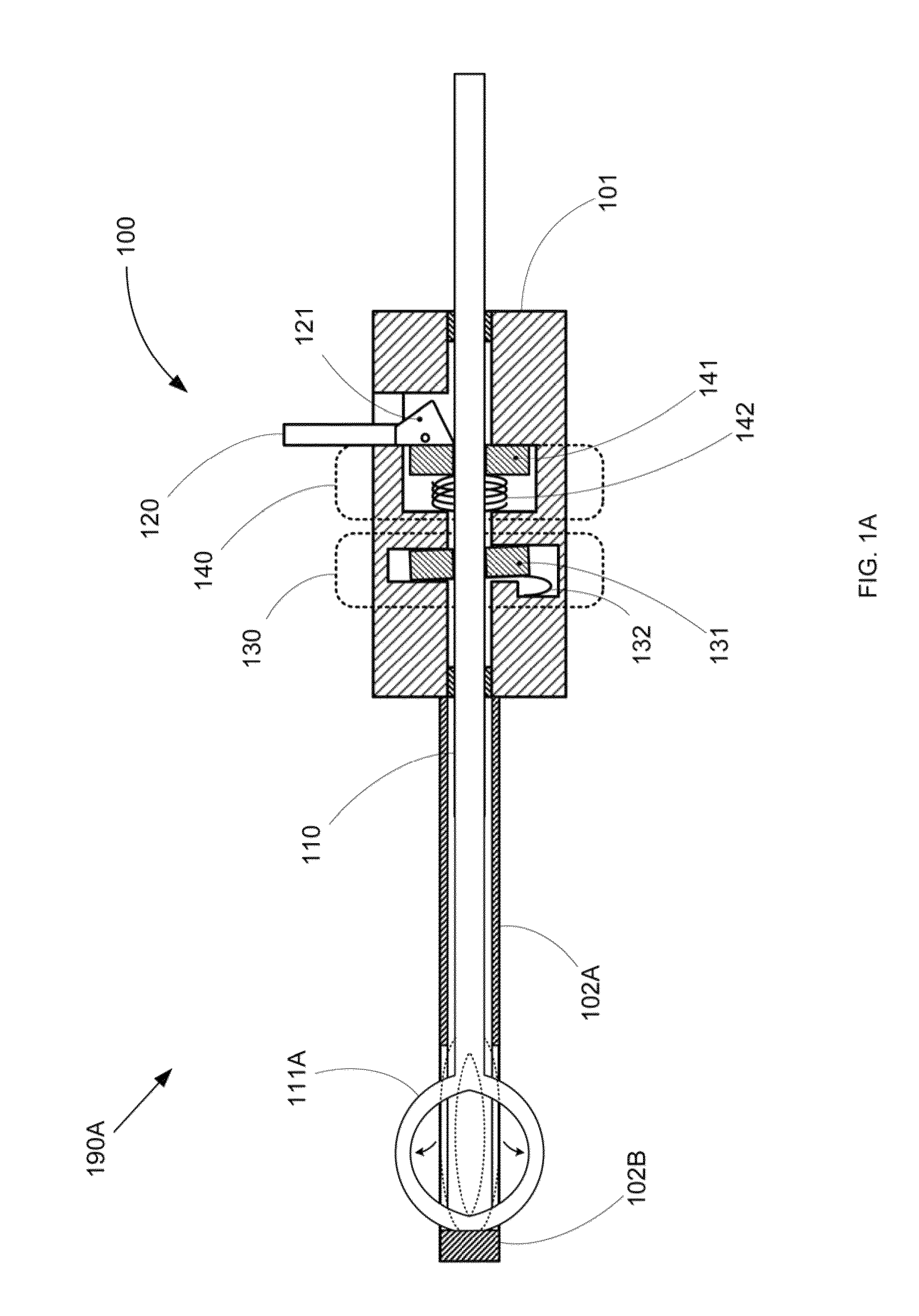

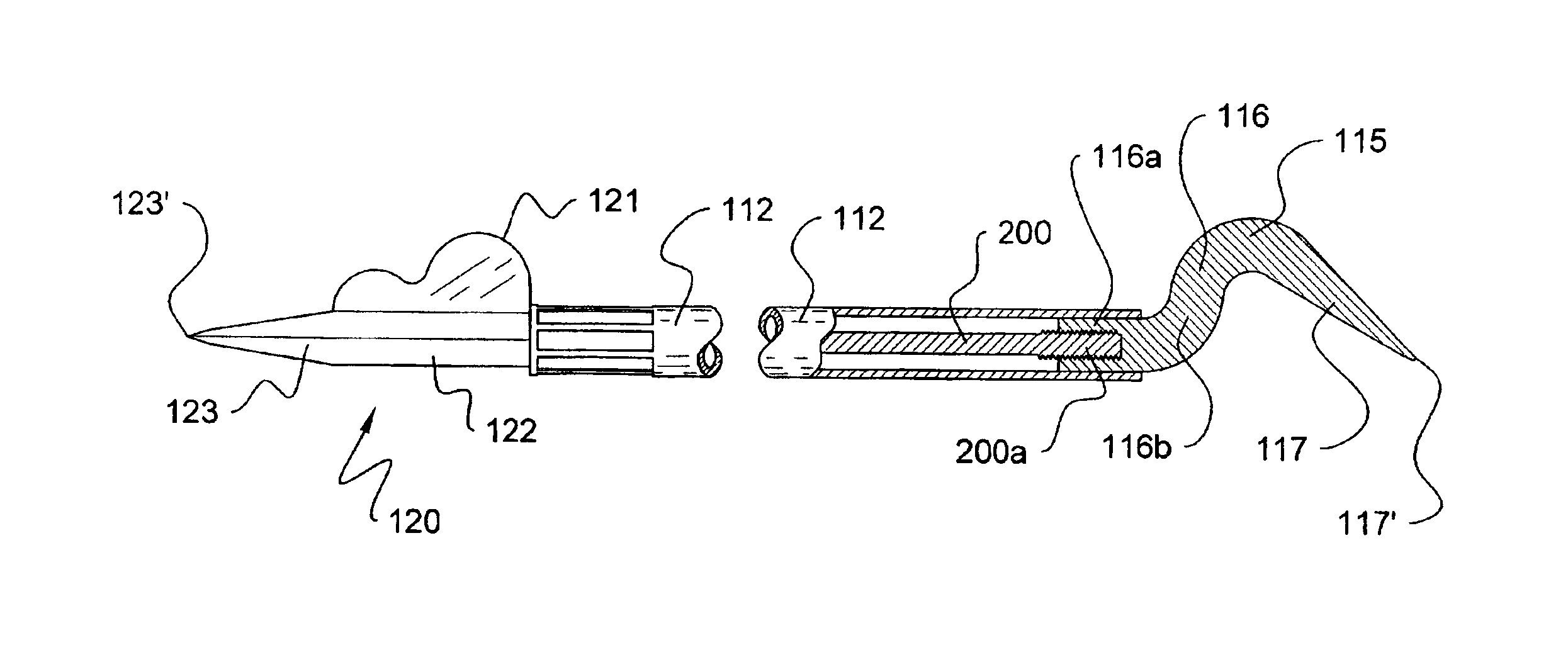

High pressure surgical system

An instrument for performing a medical procedure includes a drive shafts a holding clutch, a drive clutch, and an actuator. The holding clutch only allows advancement of the drive shaft, while the drive clutch transfers an advancement force from the actuator to the drive shaft. The dual clutch system allows a lever to be used as the actuator so that a user can generate large actuation forces manually (and optionally remotely) without significant physical effort. This capability can beneficially improve the usability and effectiveness of percutaneous surgical systems, such as those for vertebroplasty or kyphoplasty.

Owner:KYPHON

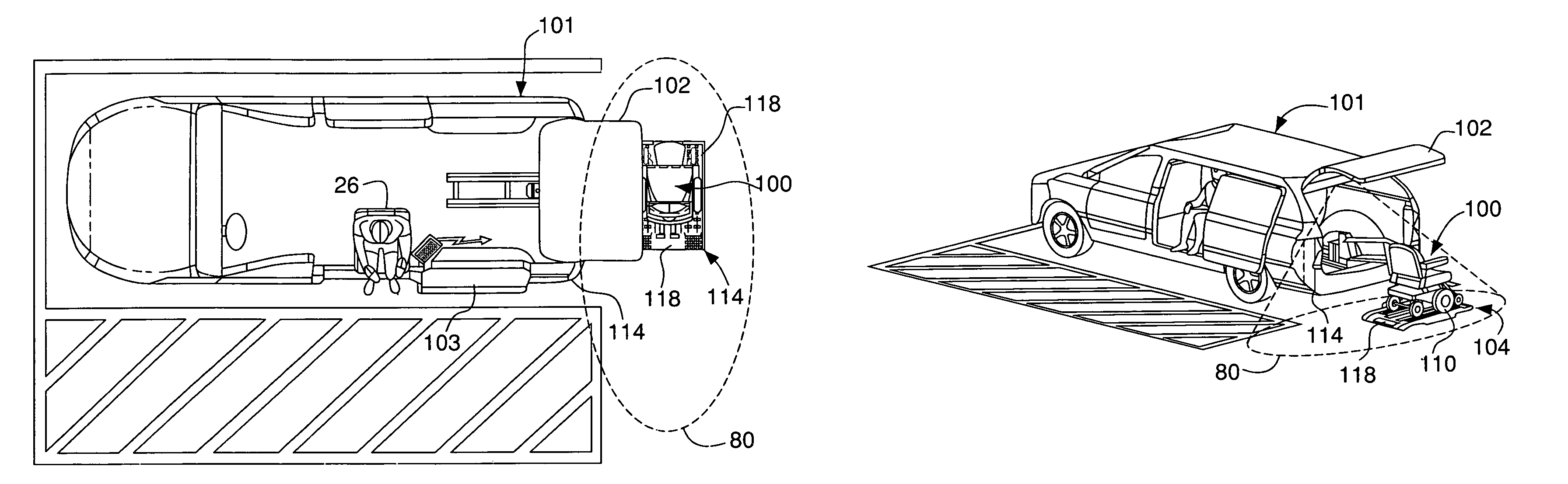

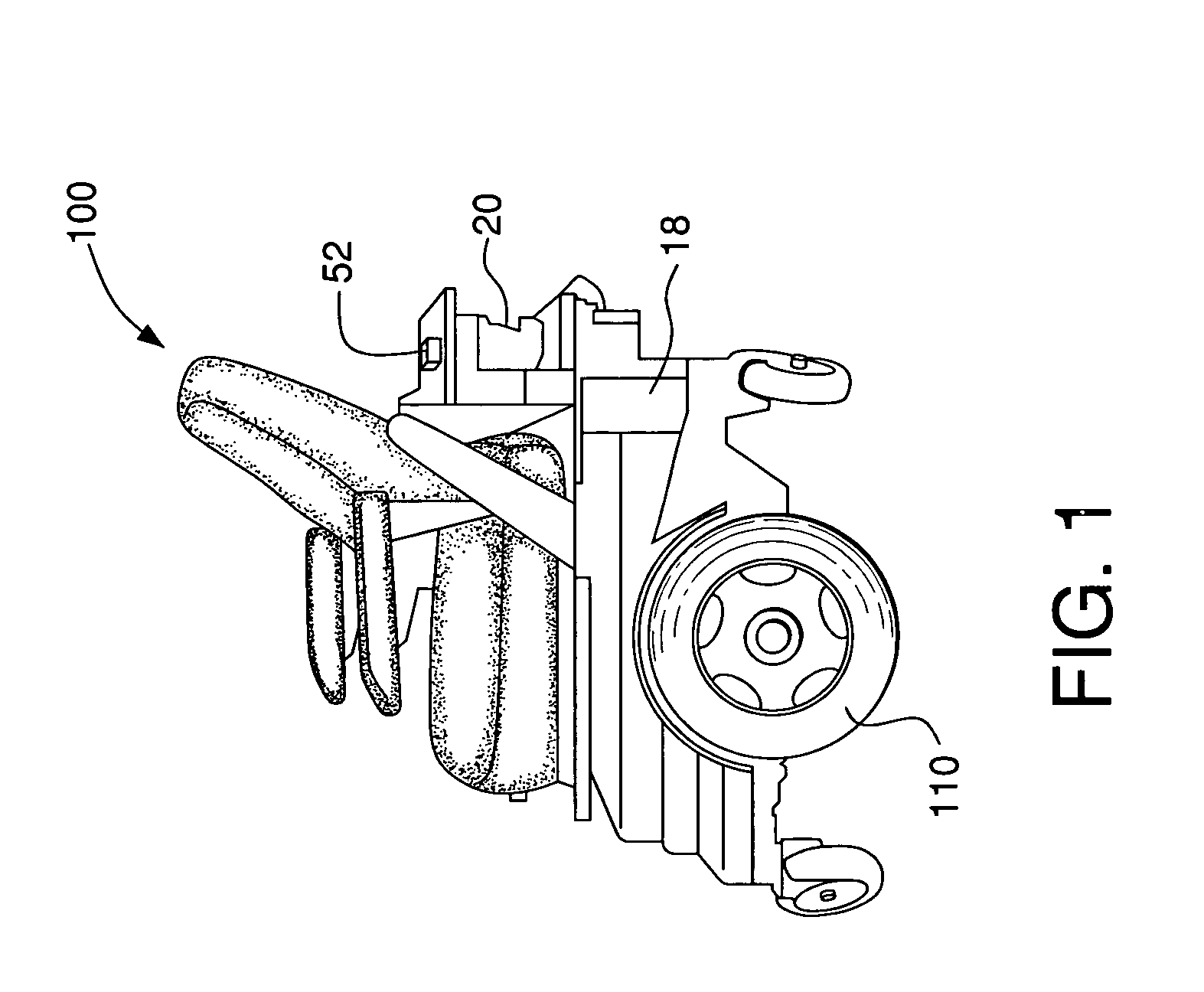

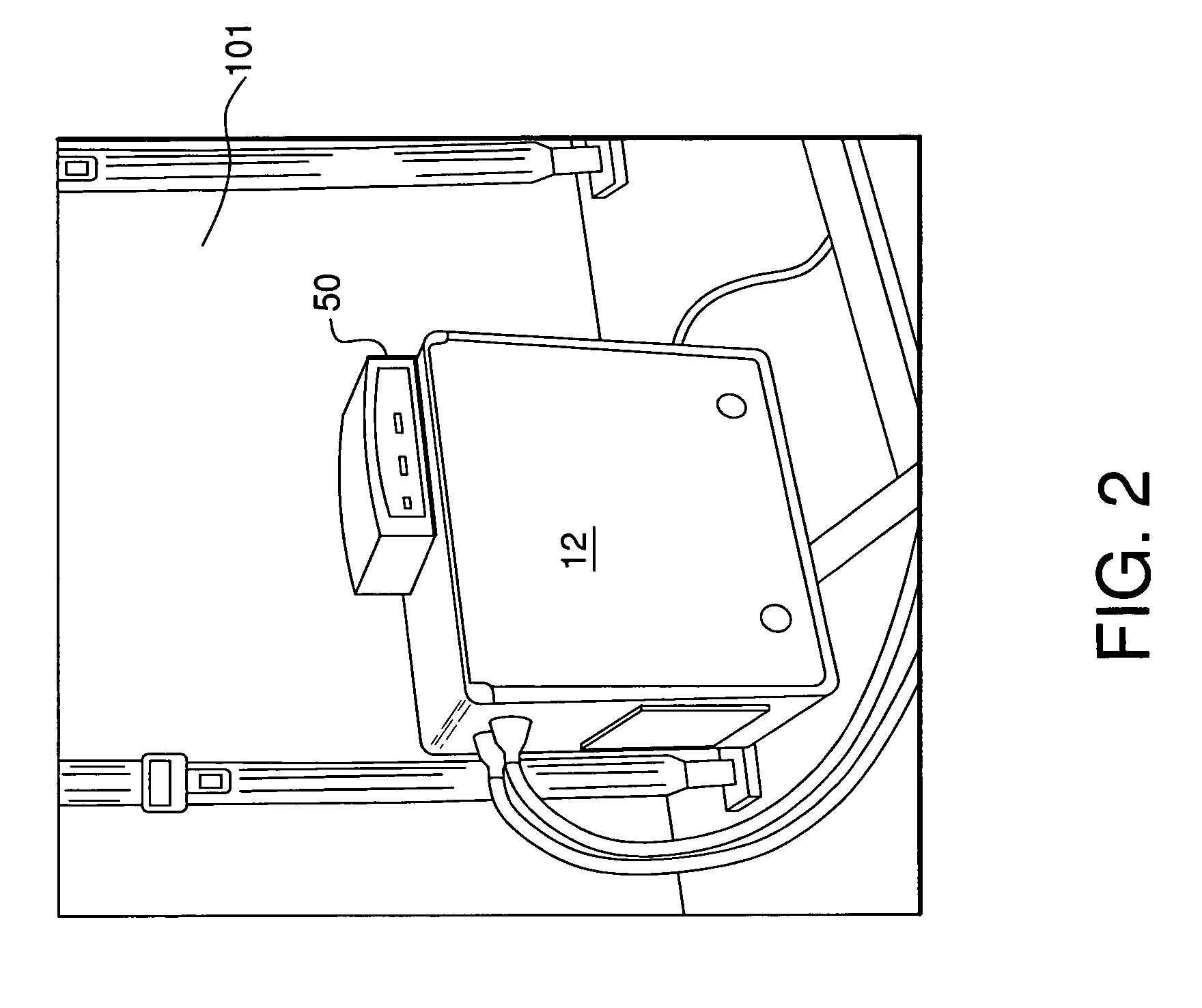

System for storing and retrieving a personal-transportation vehicle

InactiveUS7594556B1Minimal physical effortMinimal movementWheelchairs/patient conveyanceAutomatic initiationsMobile vehicleMotorized vehicle

A preferred embodiment of a system for automatically transferring a personal-transportation vehicle, such as a power chair, between a first and a second position proximate a motor vehicle such as a minivan is provided. The system can be used to transfer the personal-transportation vehicle between a first position on a lift and carrier assembly mounted on the motor vehicle, and a second position proximate a door of the motor vehicle, so that the user can transfer to and from the personal-transportation vehicle with minimal physical effort and movement. The system can generate guidance information for the personal-transportation vehicle based on position information generated by sensors located on one or both of the personal-transportation vehicle and the motor vehicle.

Owner:FS PARTNERS +1

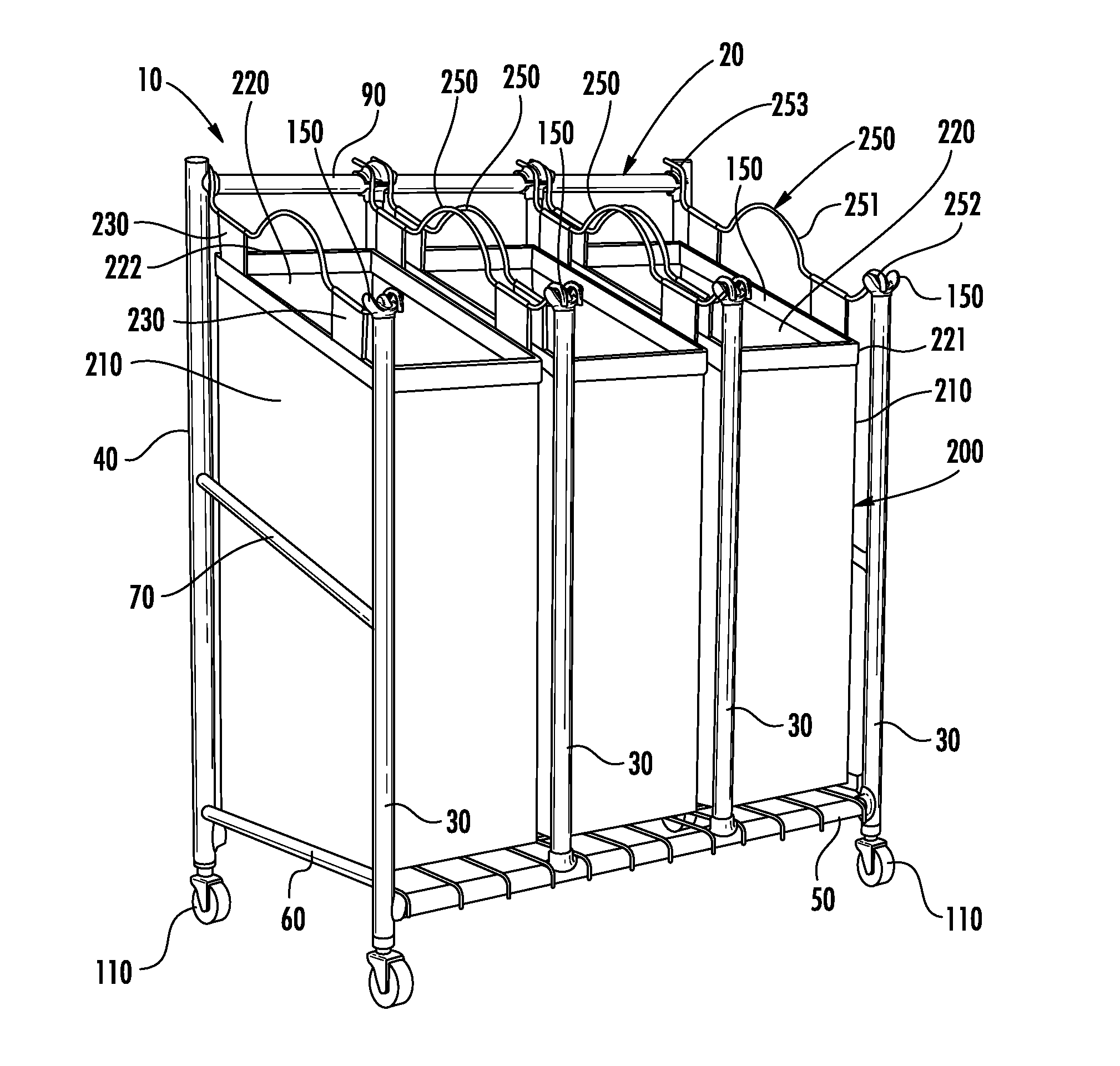

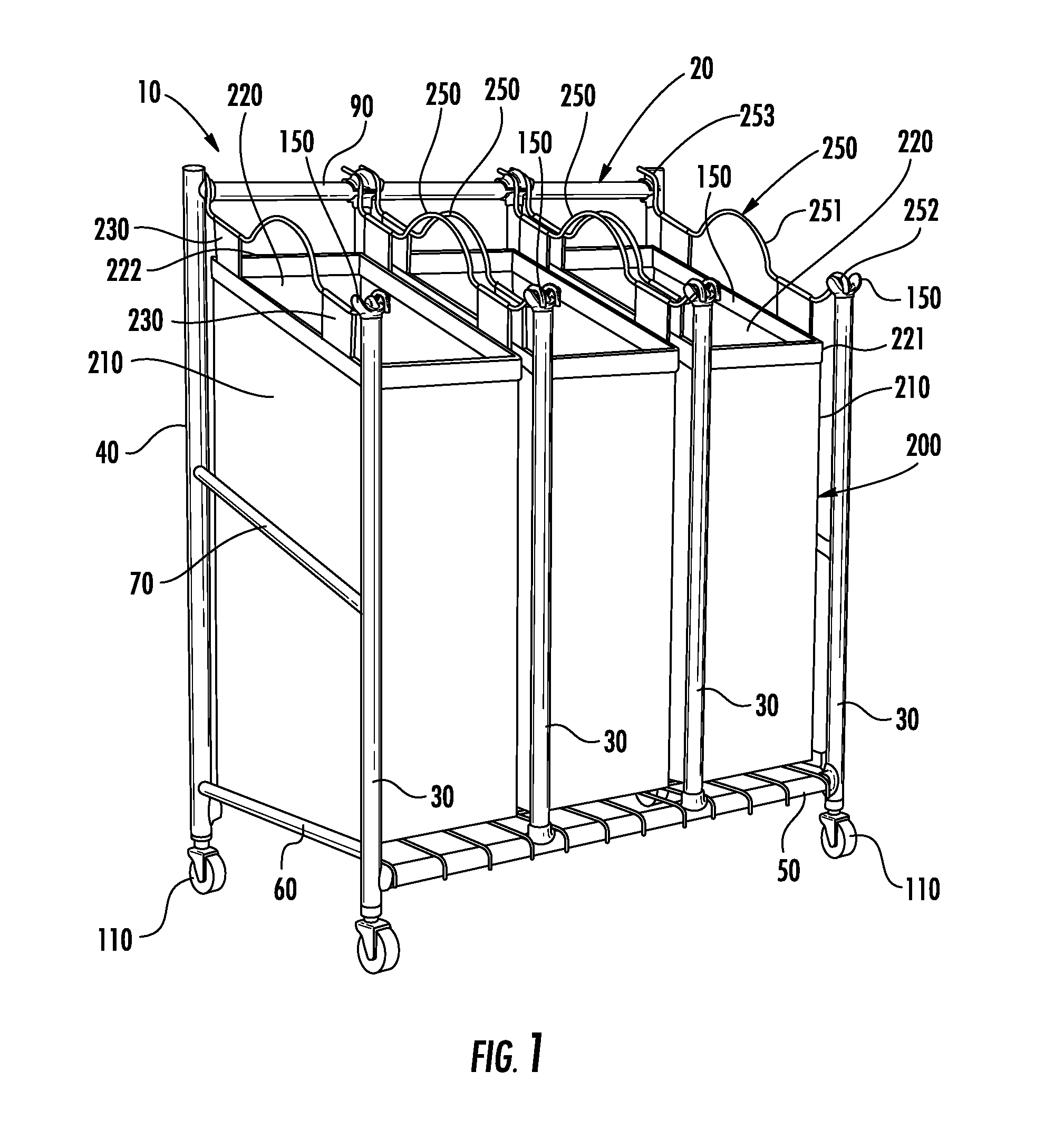

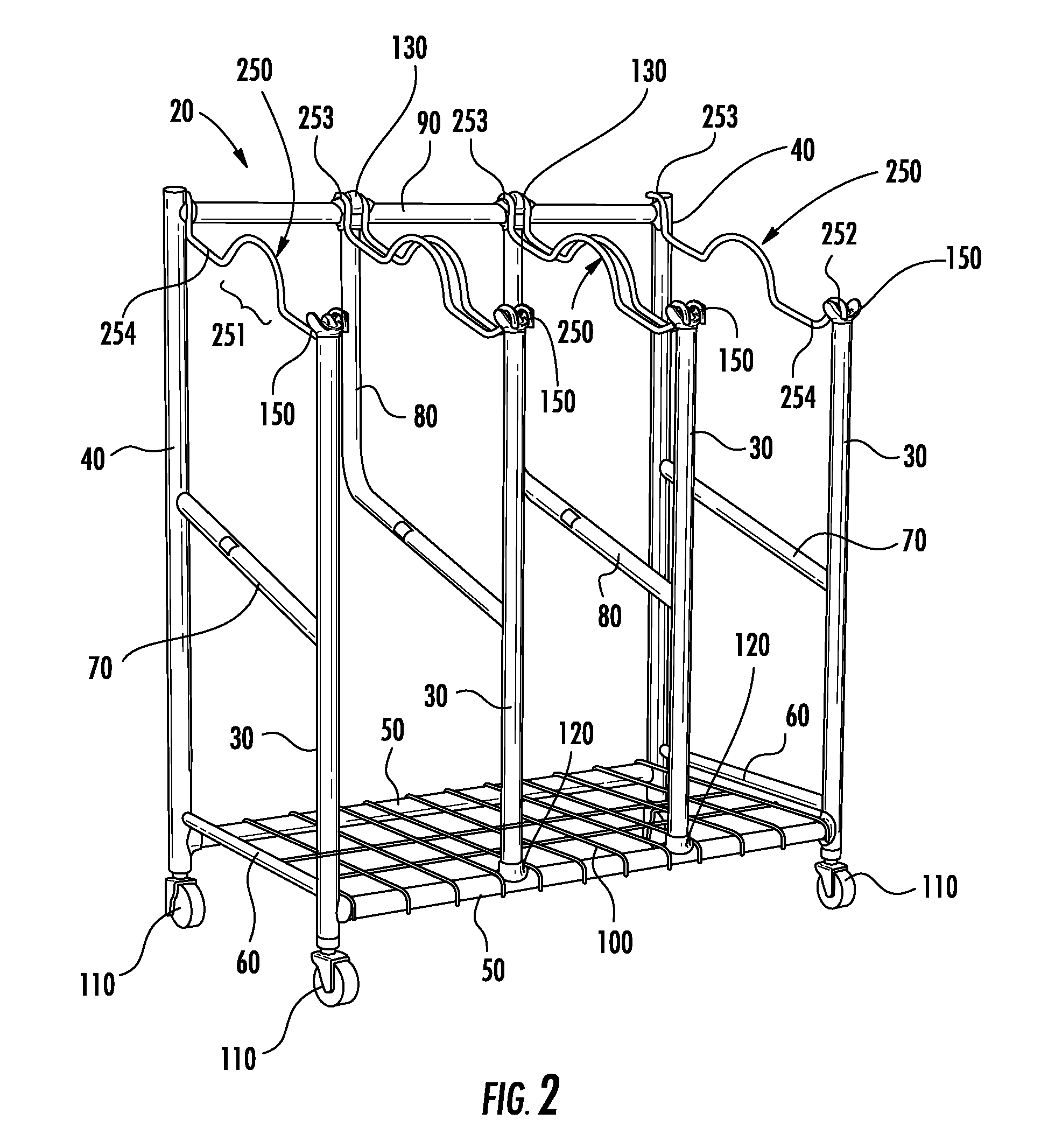

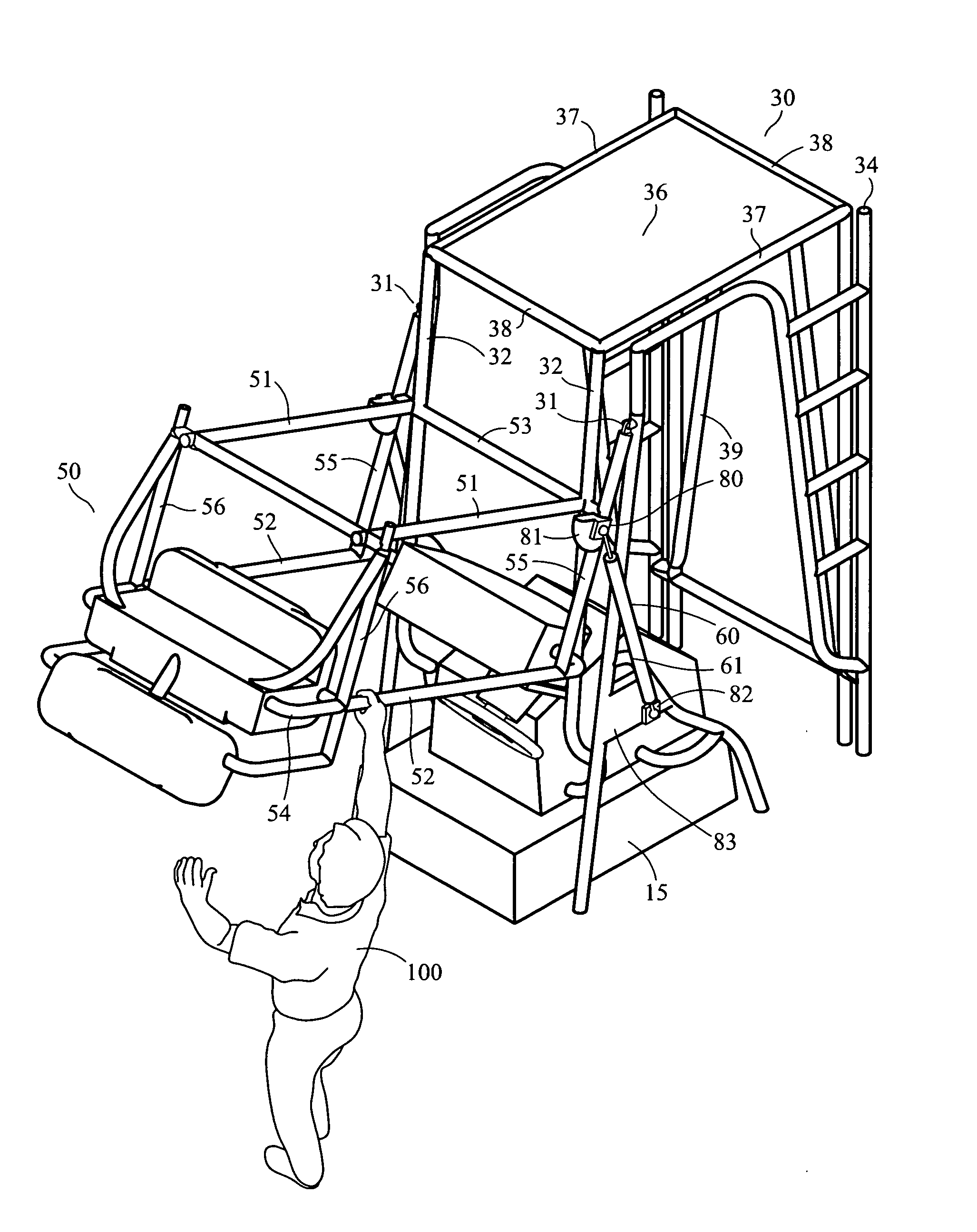

Laundry hampers and sorters with accessible front loading regions

InactiveUS8910813B1Overcomes shortcomingLess effortInternal framesLarge containersFront loadingEngineering

Laundry hampers and sorters are disclosed that are front loading, in that they permit removal and replacement of individual laundry bags without requiring the bags to be raised significantly in order to remove the laundry bags from a supporting frame. Removable laundry bags are supported, at least in part, by support members, such as front vertical posts having cupped or saddle-shaped supports disposed atop the vertical posts. As a result, the requirement for a top front horizontal bar of the frame is eliminated, permitting the laundry bags to be removed and replaced in position using a substantially horizontal direction of movement. This, in turn, provides ergonomic benefit, as significantly less physical effort is required to both remove and replace the laundry bags.

Owner:NEATFREAK GRP

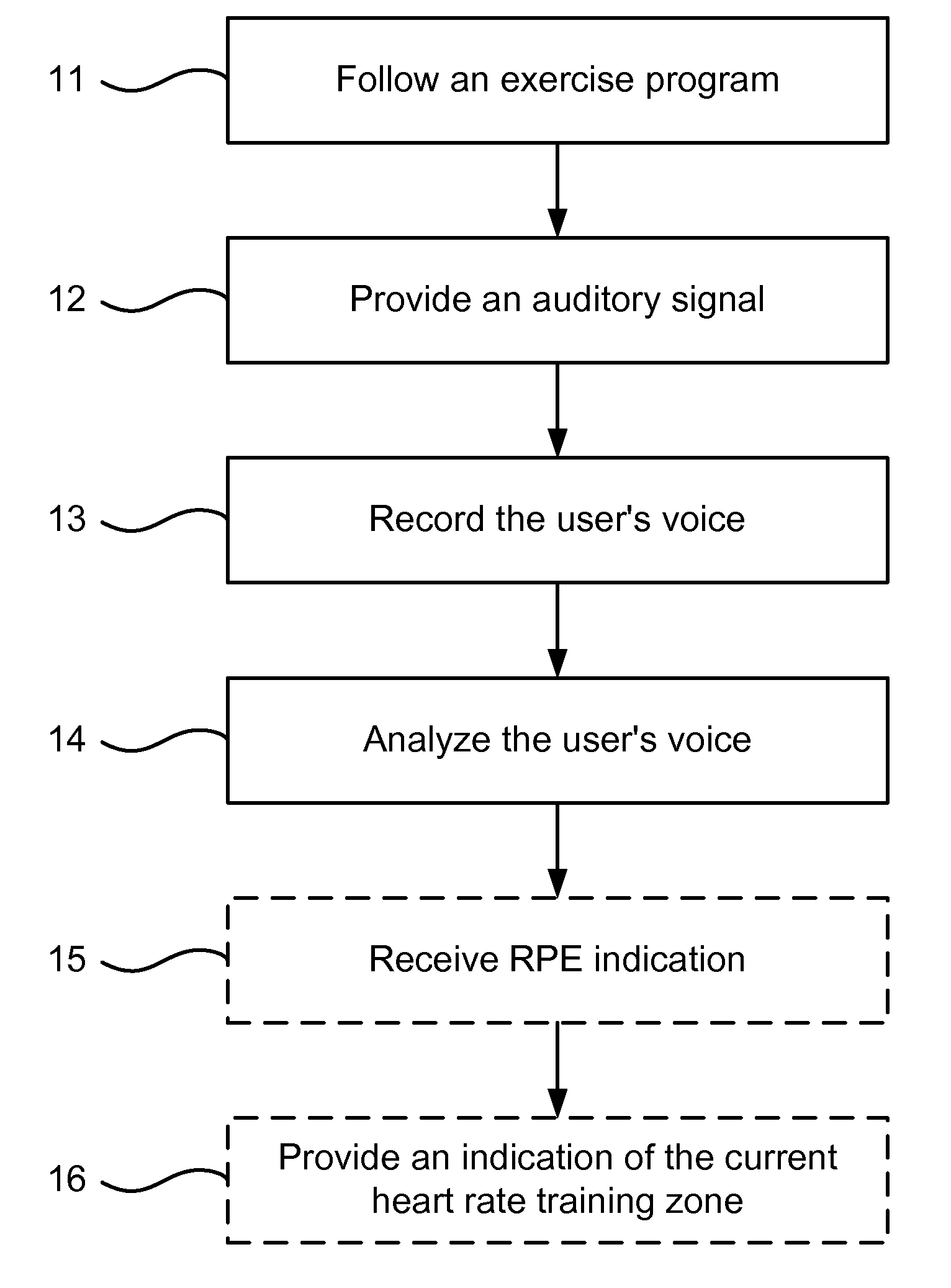

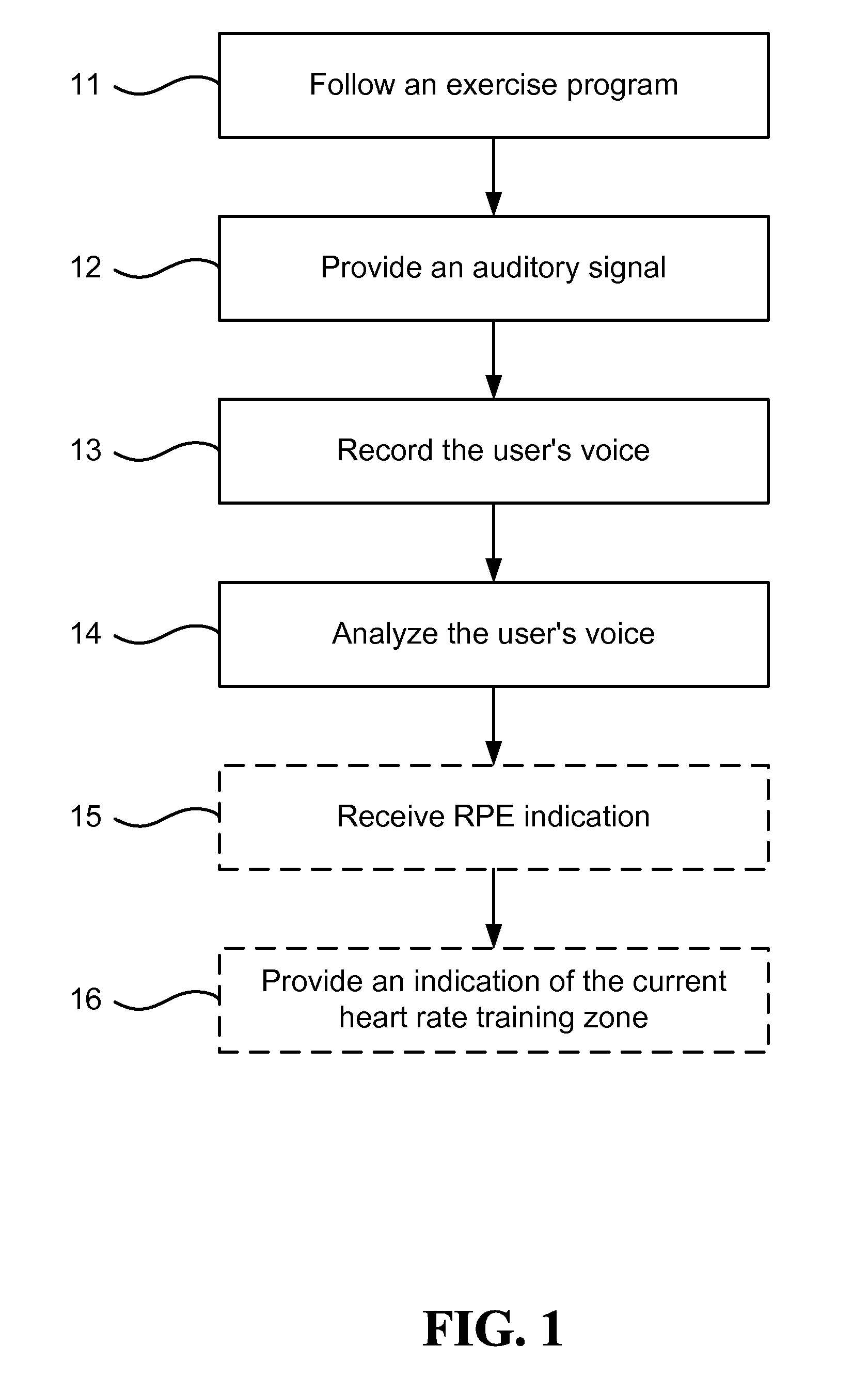

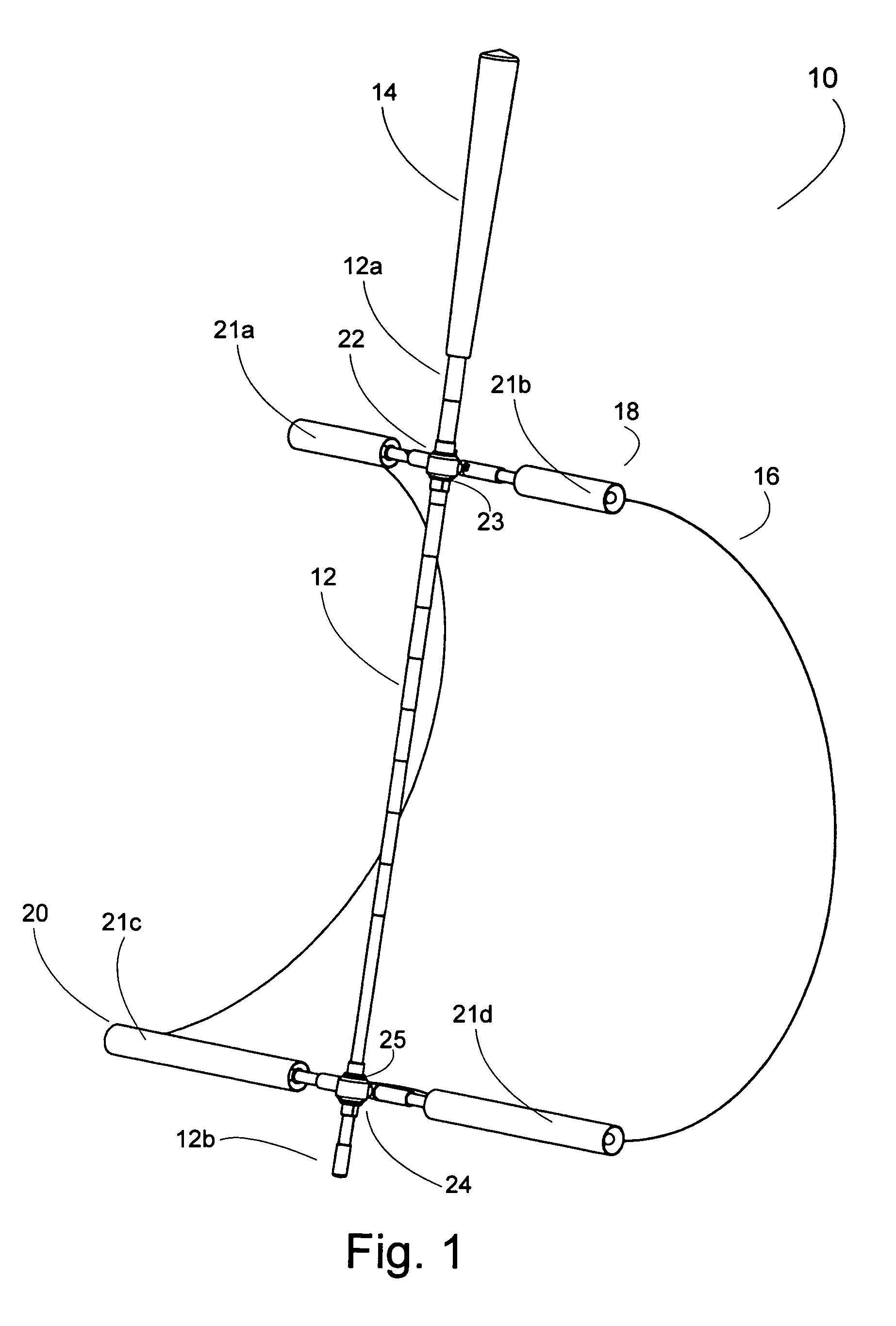

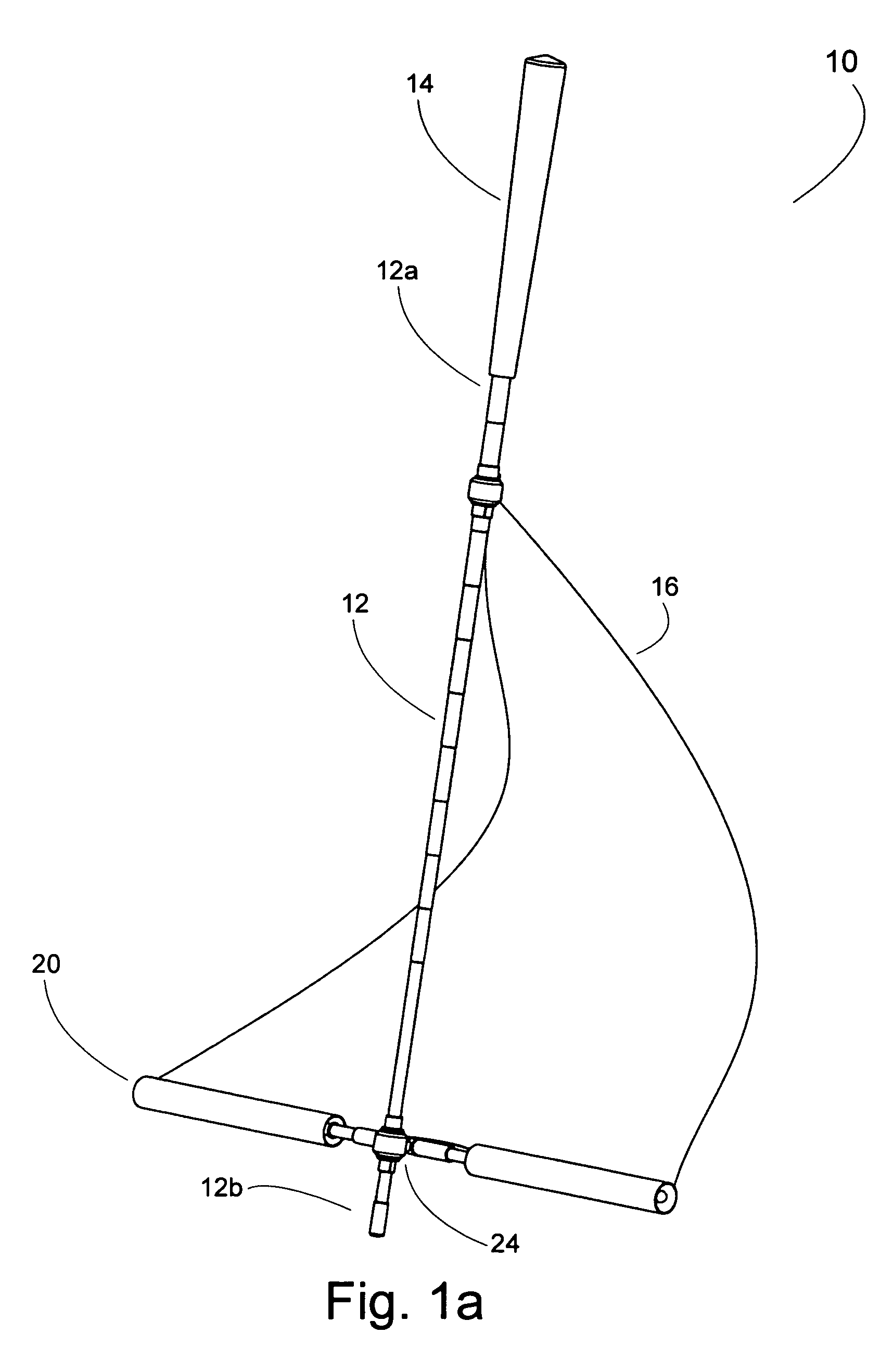

Methods and systems for computerized talk test

Methods and devices for executing a computerized talk test, comprising: following an exercise program; providing auditory signals from time to time; recording a user talking according to the auditory signals; analyzing the recordings to identify predefined properties; and providing an indication of the user's current heart rate training zone based on the analysis results. Other embodiments discuss a device configured to determine when a user approximately sustains a fixed level of physical effort and then execute a computerized talk test, and a device configured to identify a user's heart rate training zone based on identification of involuntary interruptions in the user's voice speech.

Owner:ACTIVE KNOWLEDGE

Physical conditioning aid for golfers

InactiveUS7384344B2Provide protectionImprove the immunityClubsSpace saving gamesPhysical conditioningEngineering

A physical conditioning device for golfers is provided. A weight is attached to the tip of a standard golf club shaft to provide strength training for a the backswing portion of a golf swing. A drag chute is attached to the shaft to add resistance to the downswing of the golf swing to prevent the user from simply allowing the weight of the club to cause the club to drop with little physical effort. This combination of weight and drag chute provides an enhanced conditioning effect.

Owner:AGUIRRE SERGIO

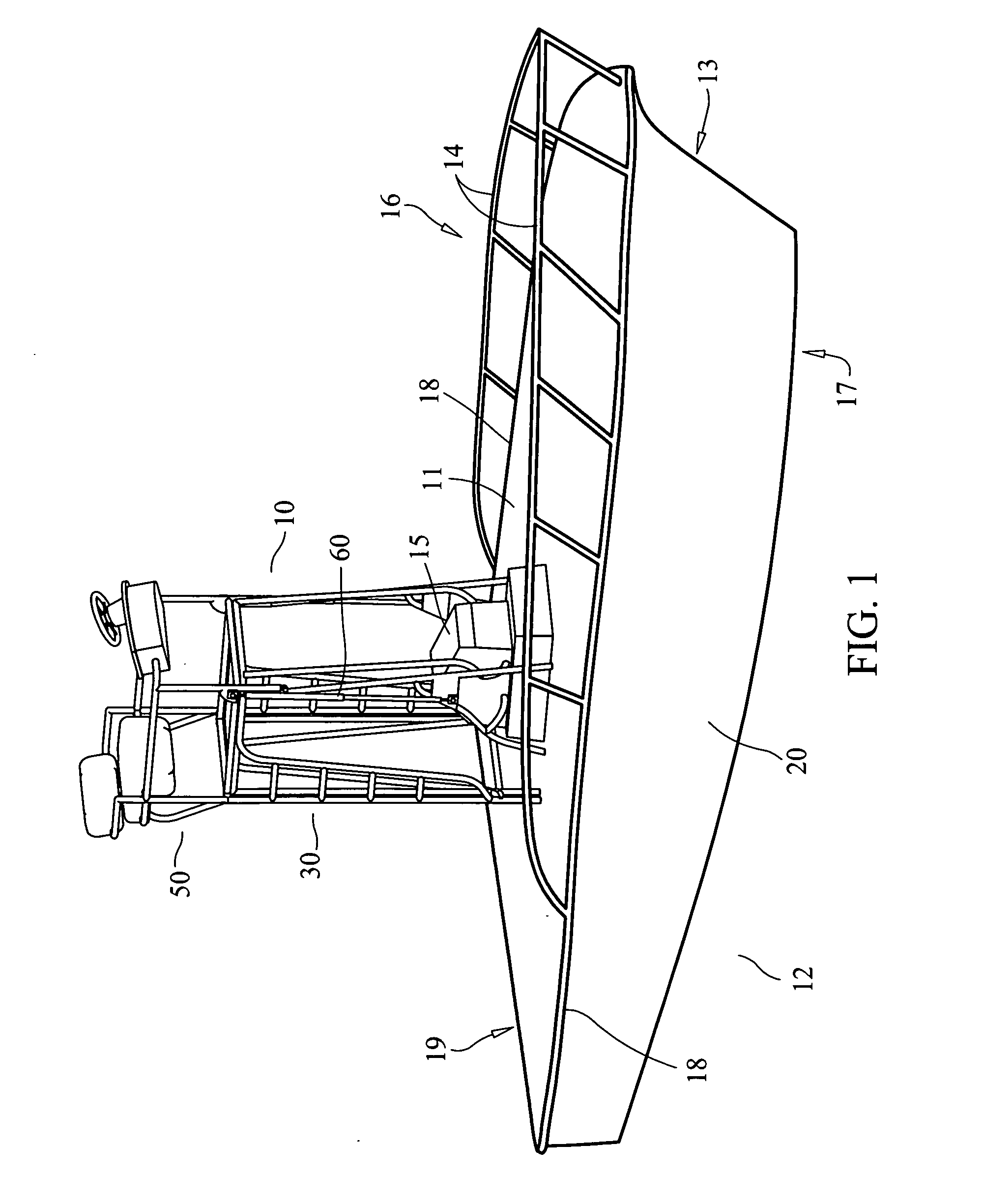

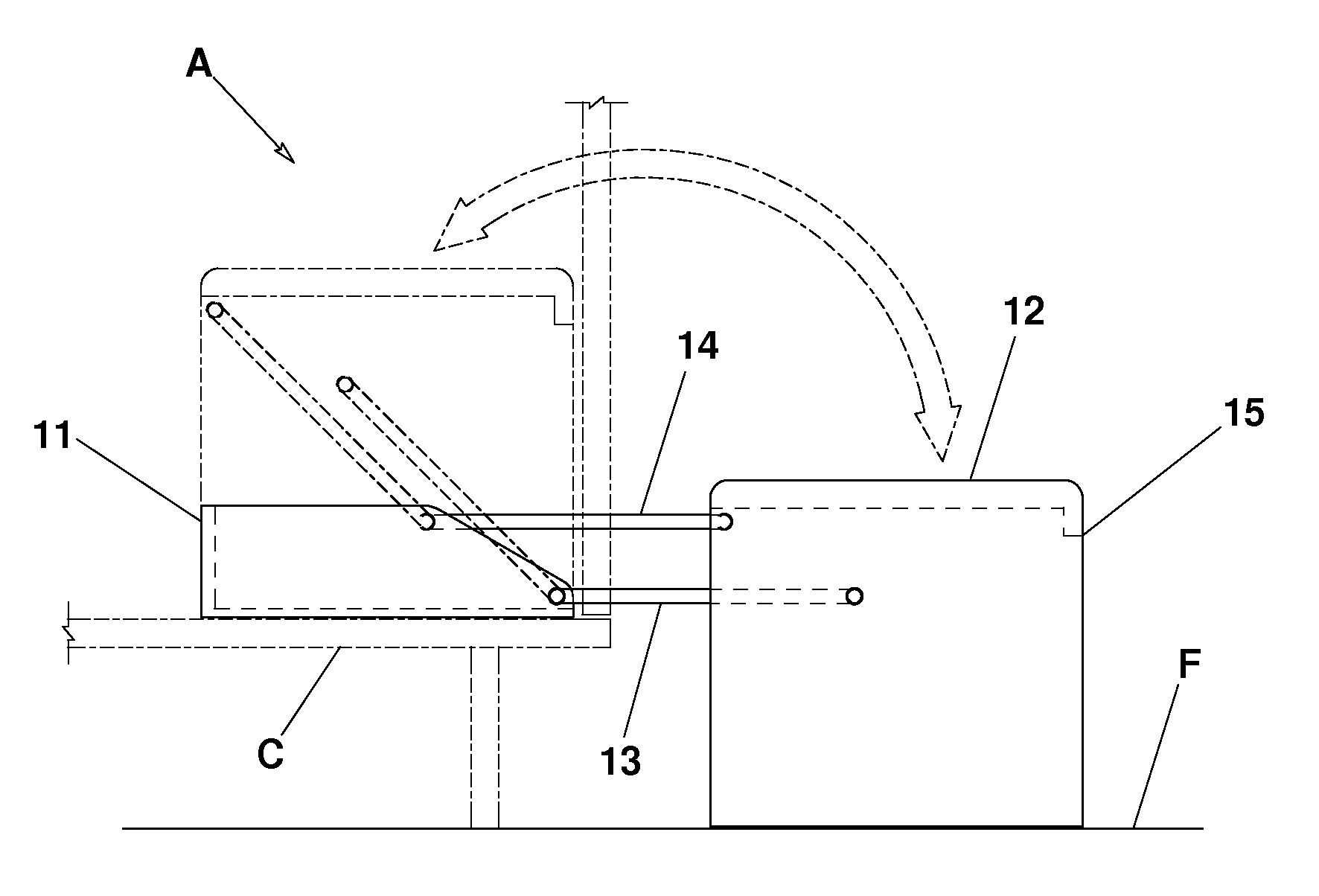

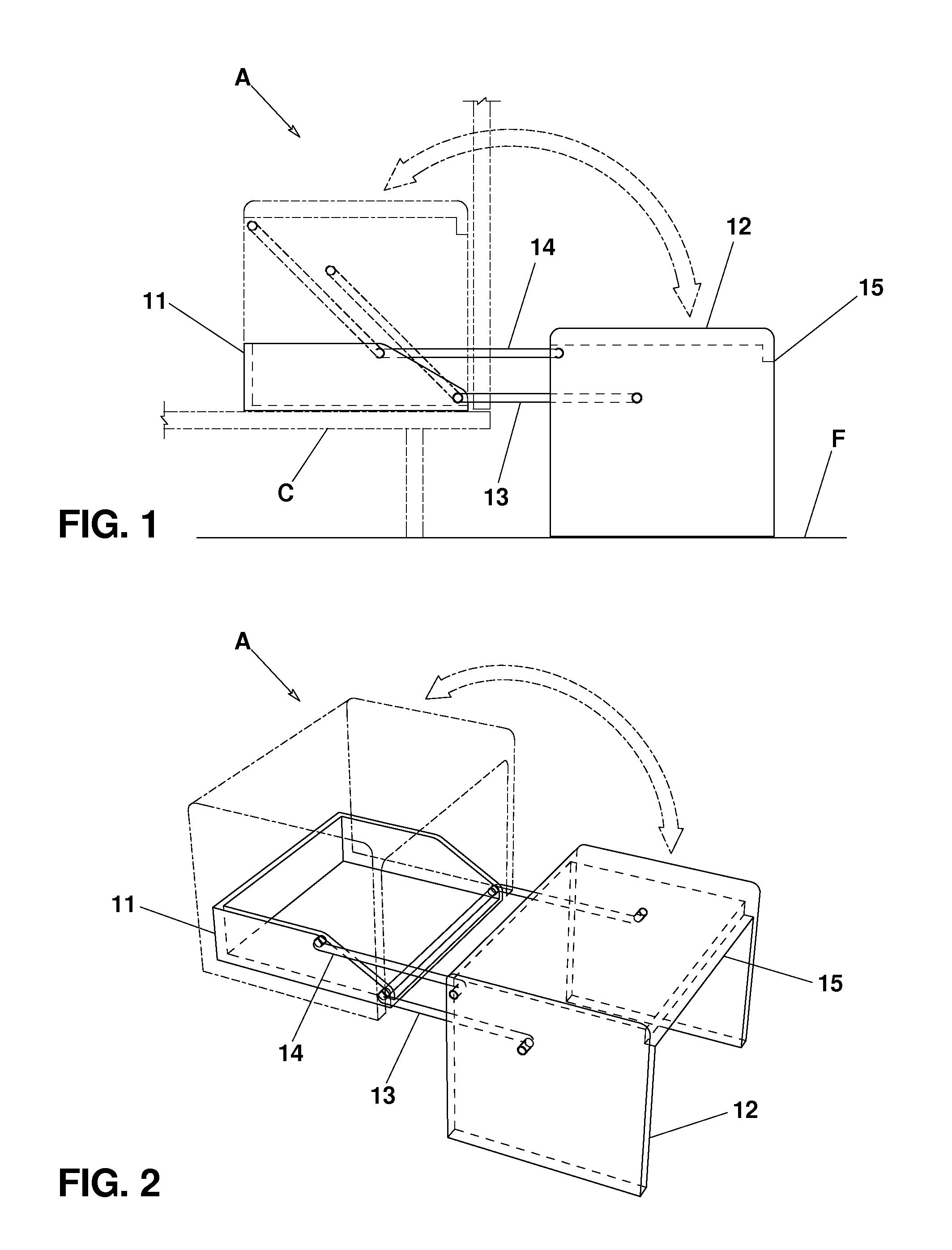

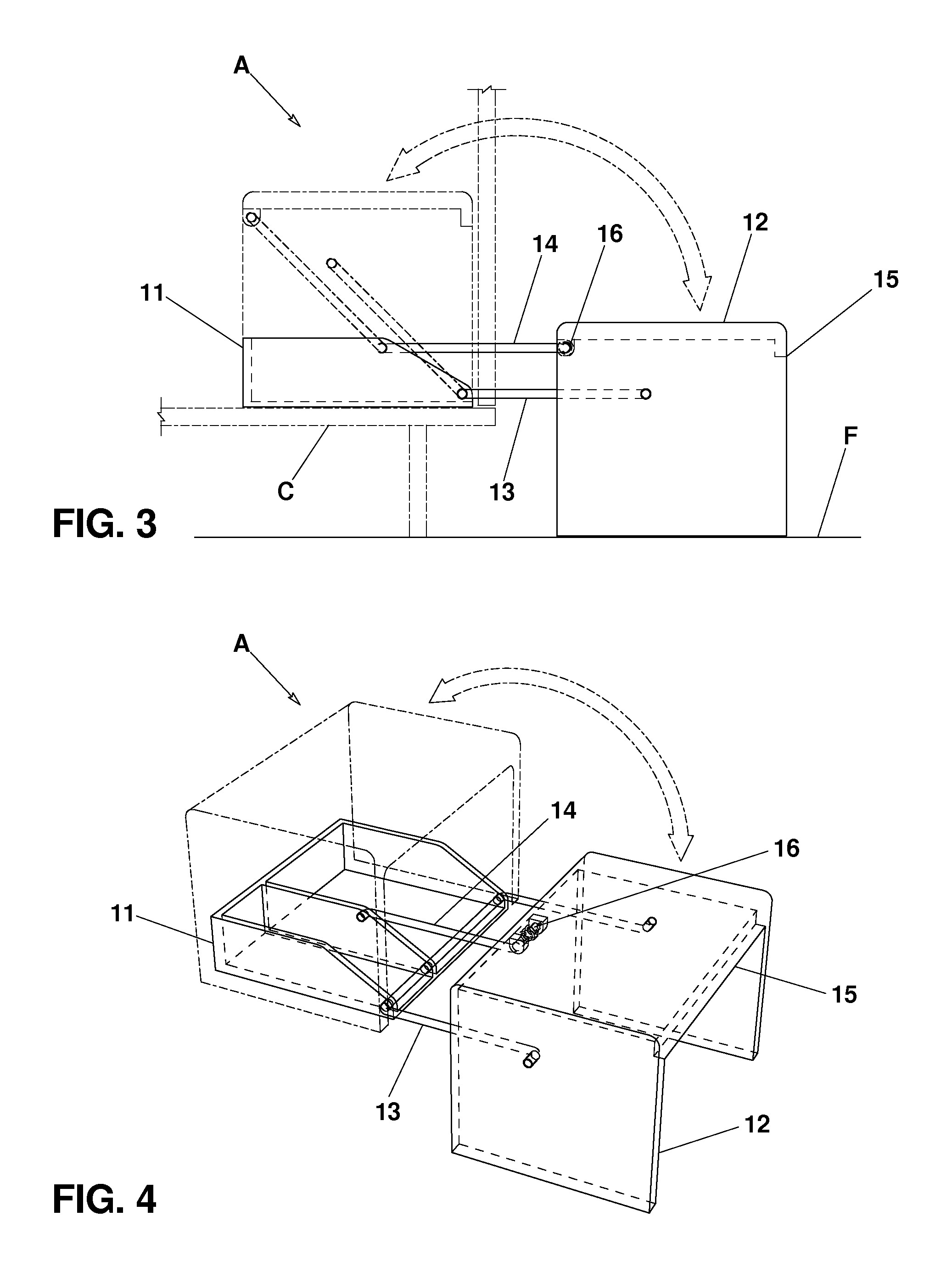

Marine folding tower

InactiveUS20090320738A1Less manual effortPromotes downward movementVessel partsFloating buildingsGas springEngineering

A system that will result in less physical effort in the lowering or raising of a marine folding tower, spotting station, driving station, fishing tower, or tuna tower. The system will be installed on a fishing boat, pleasure boat, or other marine vessel. The system comprises at least one gas spring, or hydraulic or electric ram or shock absorber of any size or style that attaches to both the upper frame assembly and lower frame assembly of the tower or other station.

Owner:BLUMBERG RYAN

Body lift-assist walker device

ActiveUS9649243B2Easier for him to walkGood adhesionBlood stagnation preventionPneumatic massageDifferential pressurePositive pressure

The present invention provides a body lift-assist walker device for gait training is provided by the invention. The patient wears a pressurized body suit over all or a portion of his lower body, and the suit is attached to the walker device. A positive pressure or vacuum condition is applied to the interior of the suit, so that the differential pressure condition across the suit offloads a portion of the patient's body weight to the ground through the supportive walker device to make it easier for him to walk or run. The walker device also includes a lift-assisted body weight support device operated by a constant force mechanism like a pneumatic air cylinder that can lift the patient from a sitting position to a standing position with minimal physical effort. The device provides a portable and convenient system for persons undergoing physical therapy for treatment of gait or balance problems following an injury, stroke, or neurological disorder, or for use by elderly or disabled persons who have encounter difficulties in the sit-to-stand movement or walking.

Owner:LITE RUN

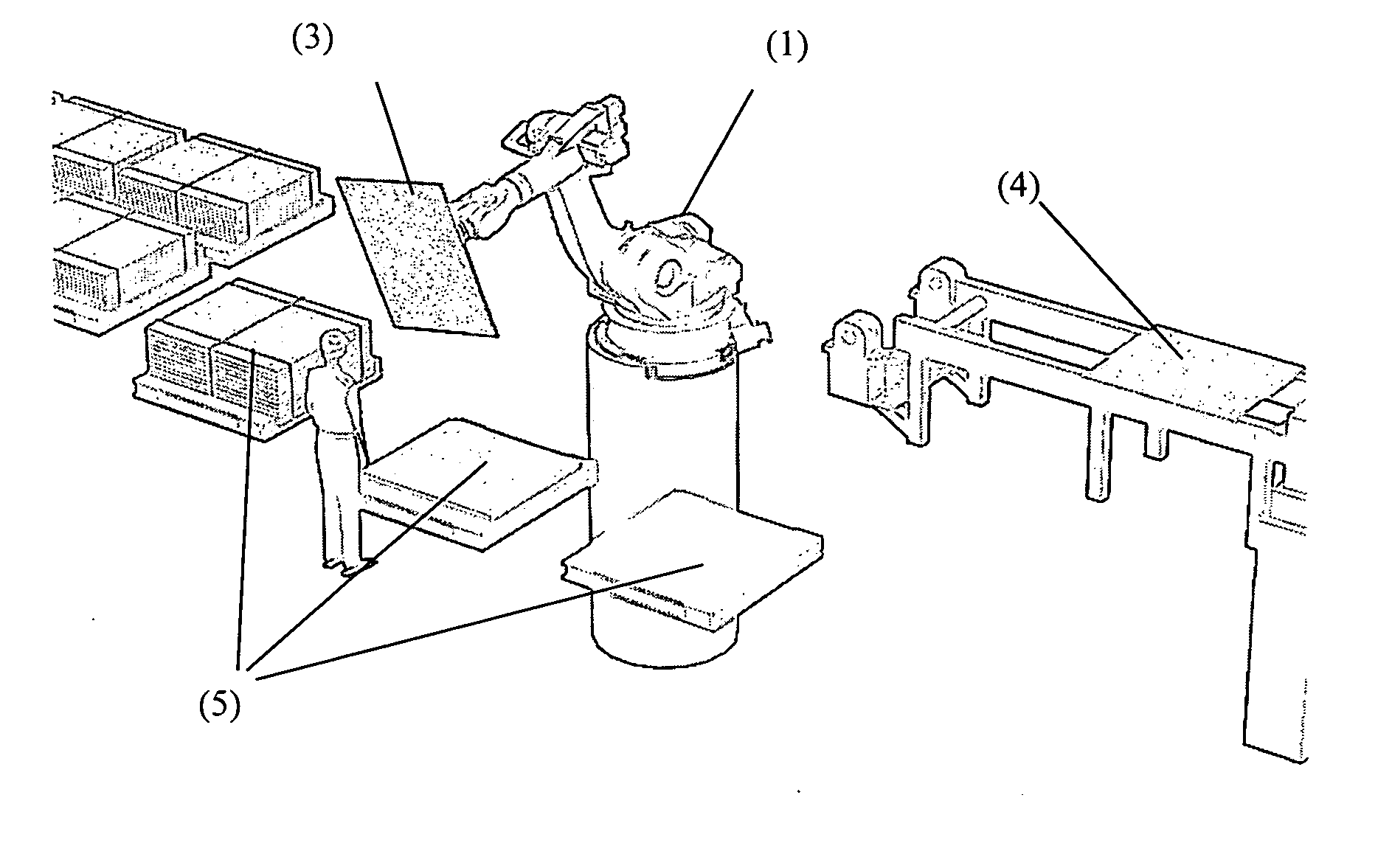

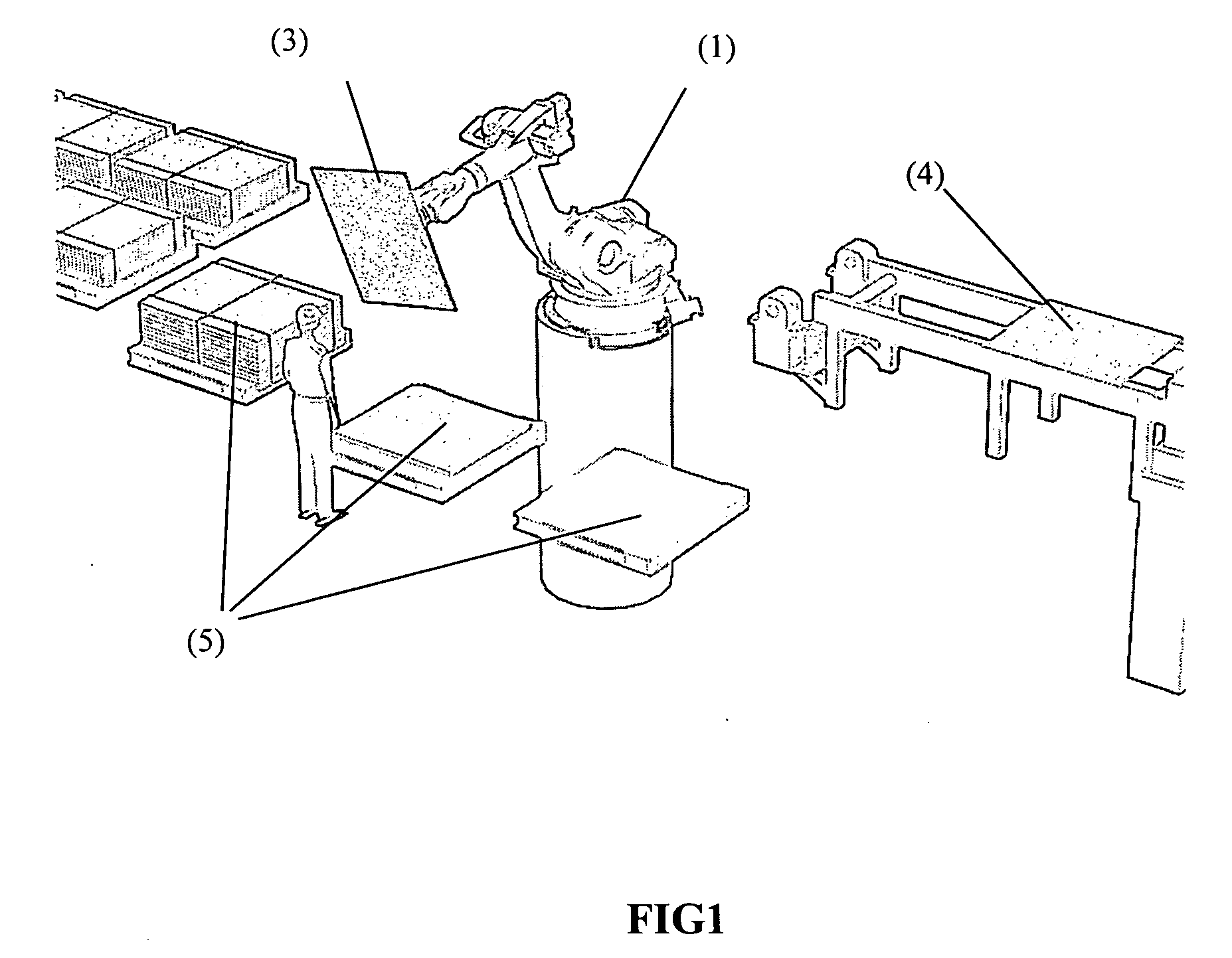

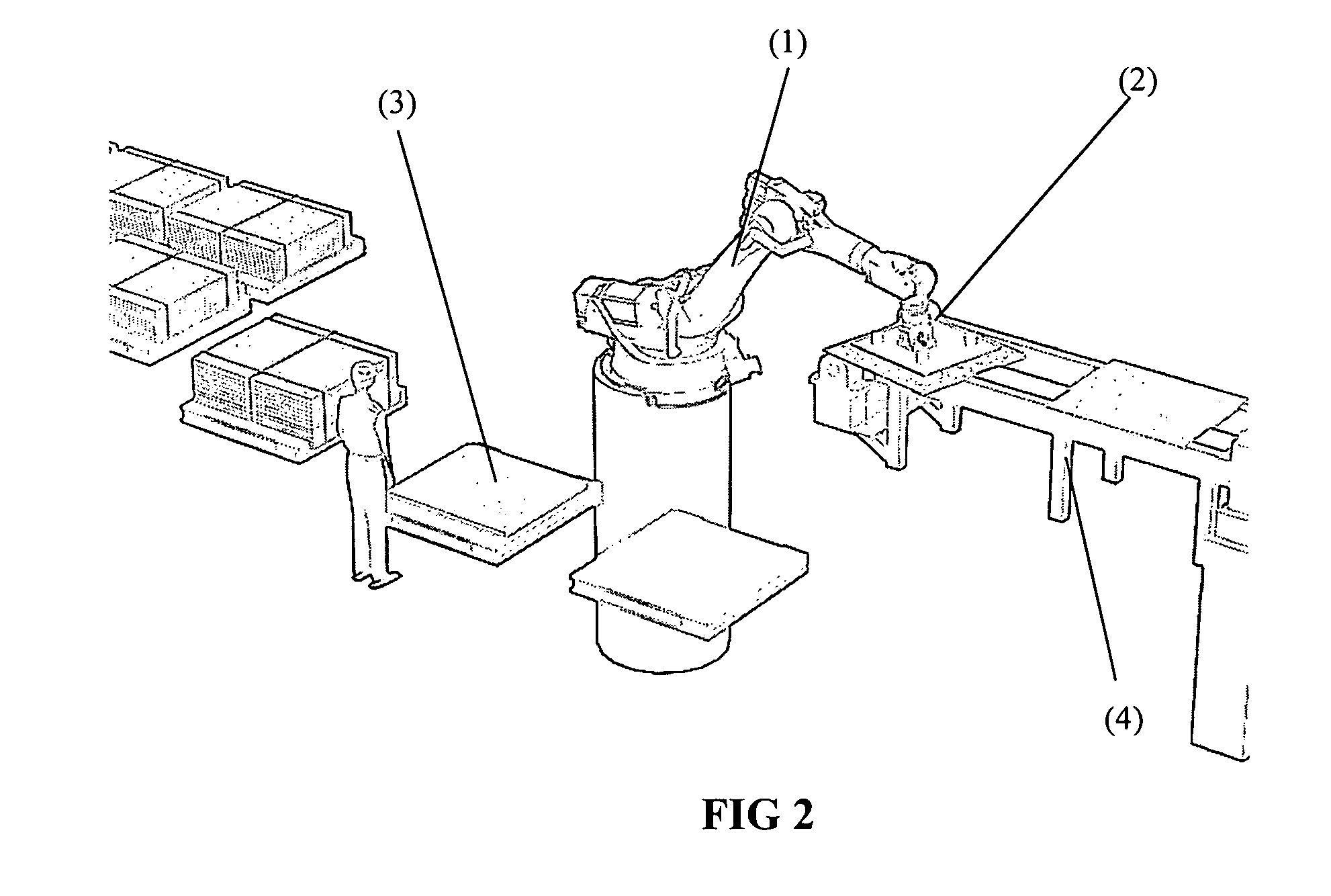

Robot system and method for cathode selection and handling procedures after the harvest

InactiveUS20070152616A1Programme-controlled manipulatorElectrolysis componentsRobotic systemsEngineering

As a final stage of the current copper production process, the cathodes are inspected and sampled to determine its quality. Based on the inspection and the sampling the cathodes are selected and arranged according to the different qualities. Currently the inspection and selection of the cathodes in the loading site is carried out manually, which means that the operators must inspect and manipulate one by one the cathodes produced by the plant which requires a high physical effort and a great amount of labor force. Due to the above, a robot system and method have been developed for the selection and manipulation of cathodes in the site. The robotic system is composed mainly of a robotic manipulator of at least 5 degrees of freedom, and a gripping mechanism which allows to take the cathodes from a feeding system located at one of its sides and take it through a predefined path arranging them in groups according to their quality, the decision as to which quality group each cathode goes is taken by a superior order which could be automatic or manual. The system additionally has different racks in which the robotic system groups the cathodes according to the quality. In this regard, most of the problems associated to the current operation are eliminated

Owner:MI ROBOTIC SOLUTIONS MIRS

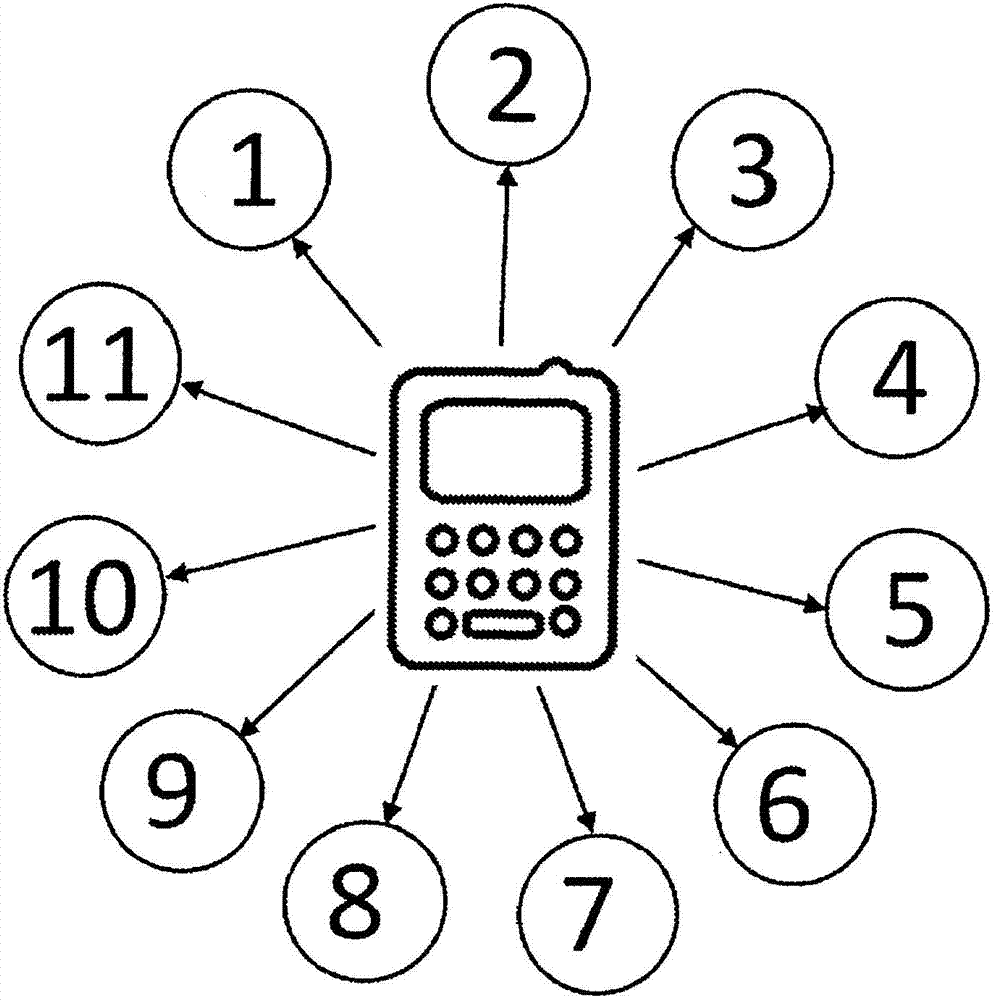

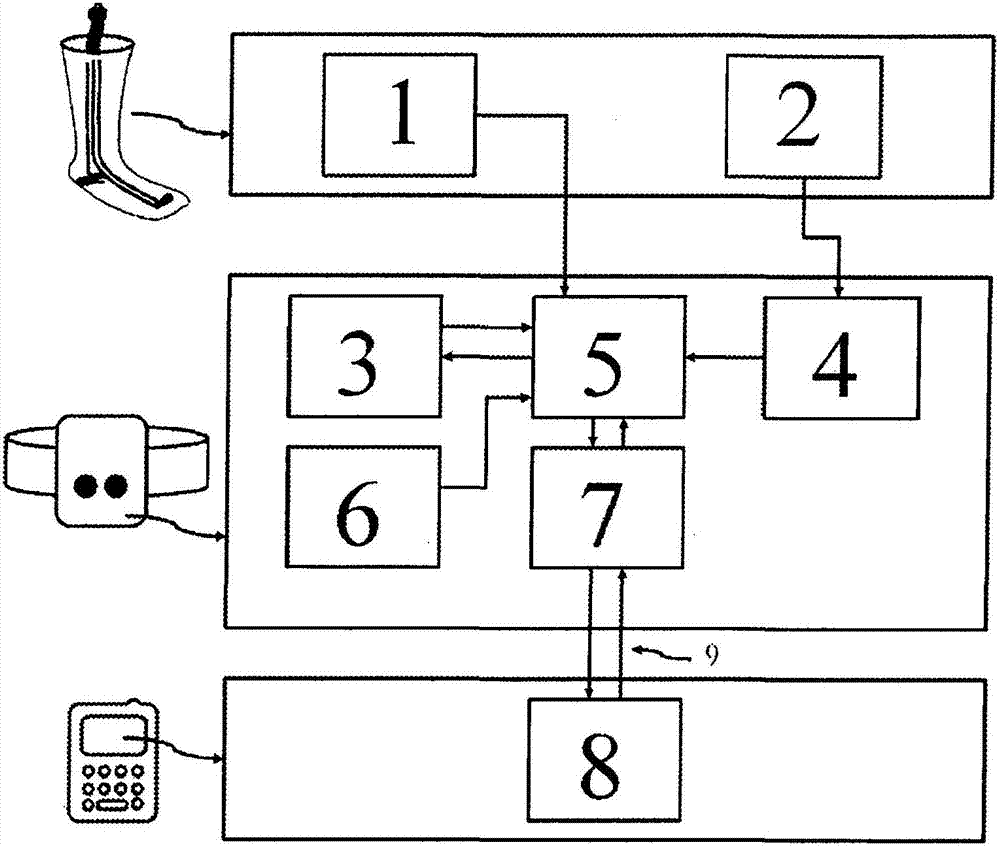

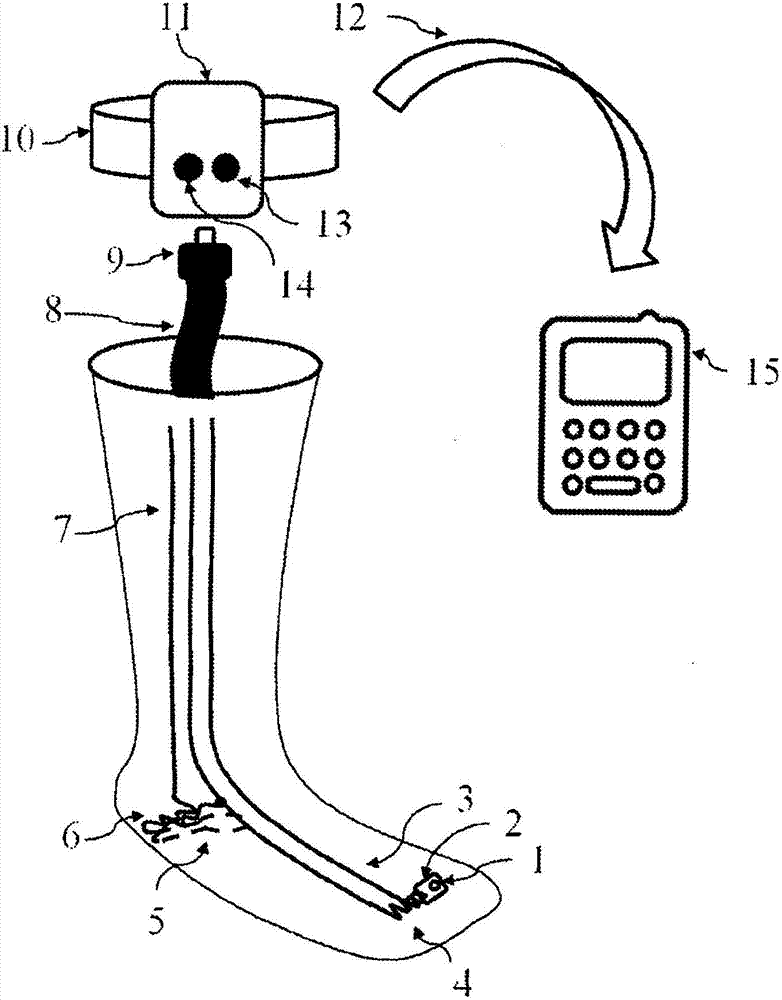

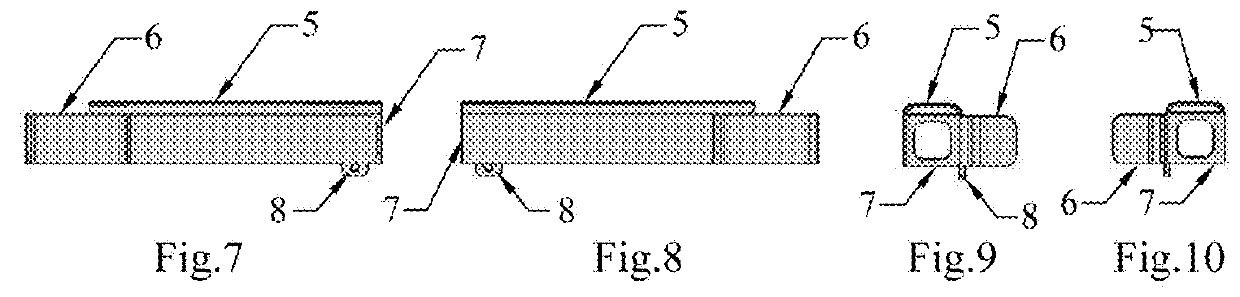

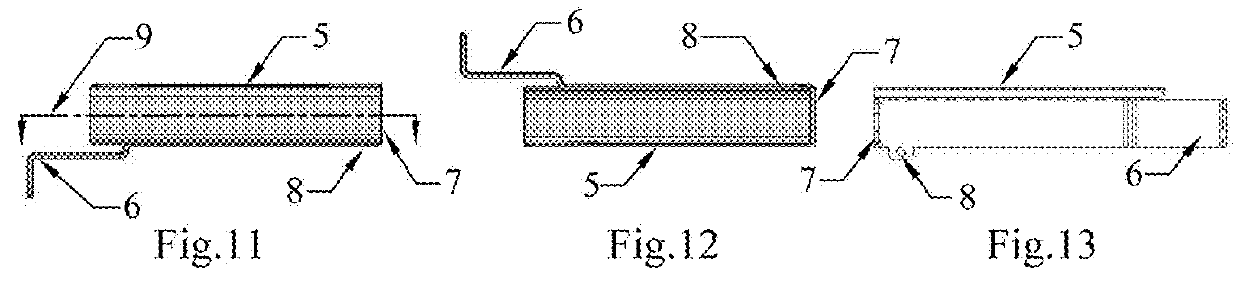

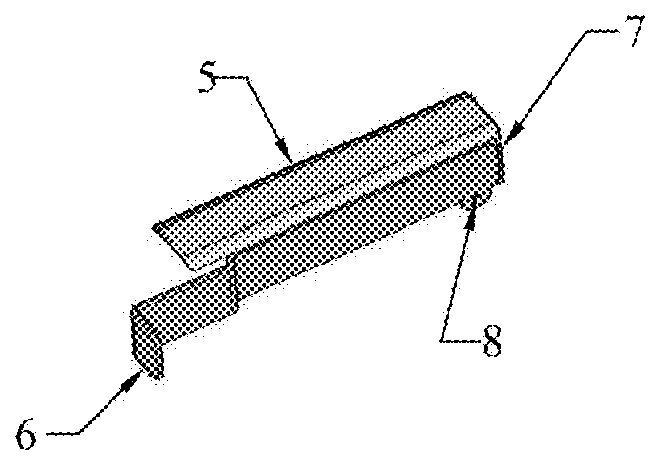

Sock for integrated biometric monitoring

The present invention relates to a sock with integrated biometric monitoring. The invention includes a biometric sensor system integrated into a sock with the ability to process and store the biometric data collected in order to provide useful information to the user, relating the user's biometric data to performance parameters of physical effort. The invention includes sensors integrated by means of suitable supports (2) in the textile structure of the sock, including sensors for temperature (1), heart beat and pressure (5) applied by the user's foot, for a processor (10, 11) with signaling means (13) and interaction means (14), which interprets and sends (12) the data to a mobile device (15) that stores the data and allows the display of the data.; The invention includes textile integration of biometric monitoring devices by means of conductive yarns (3, 4, 6, 7) knitted with the sock and connected to sensors, terminals (8, 9) and encapsulations.

Owner:FIORIMA

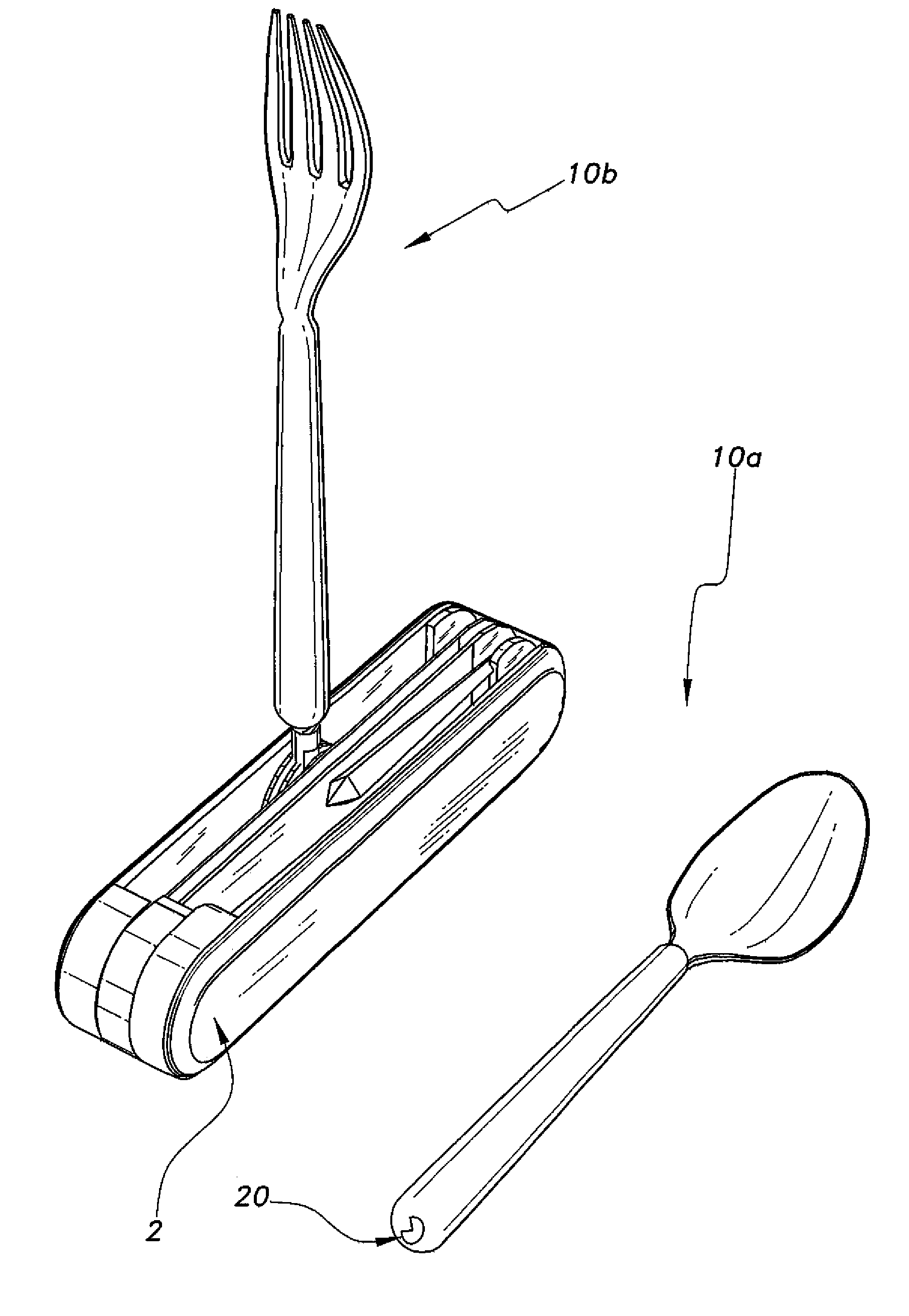

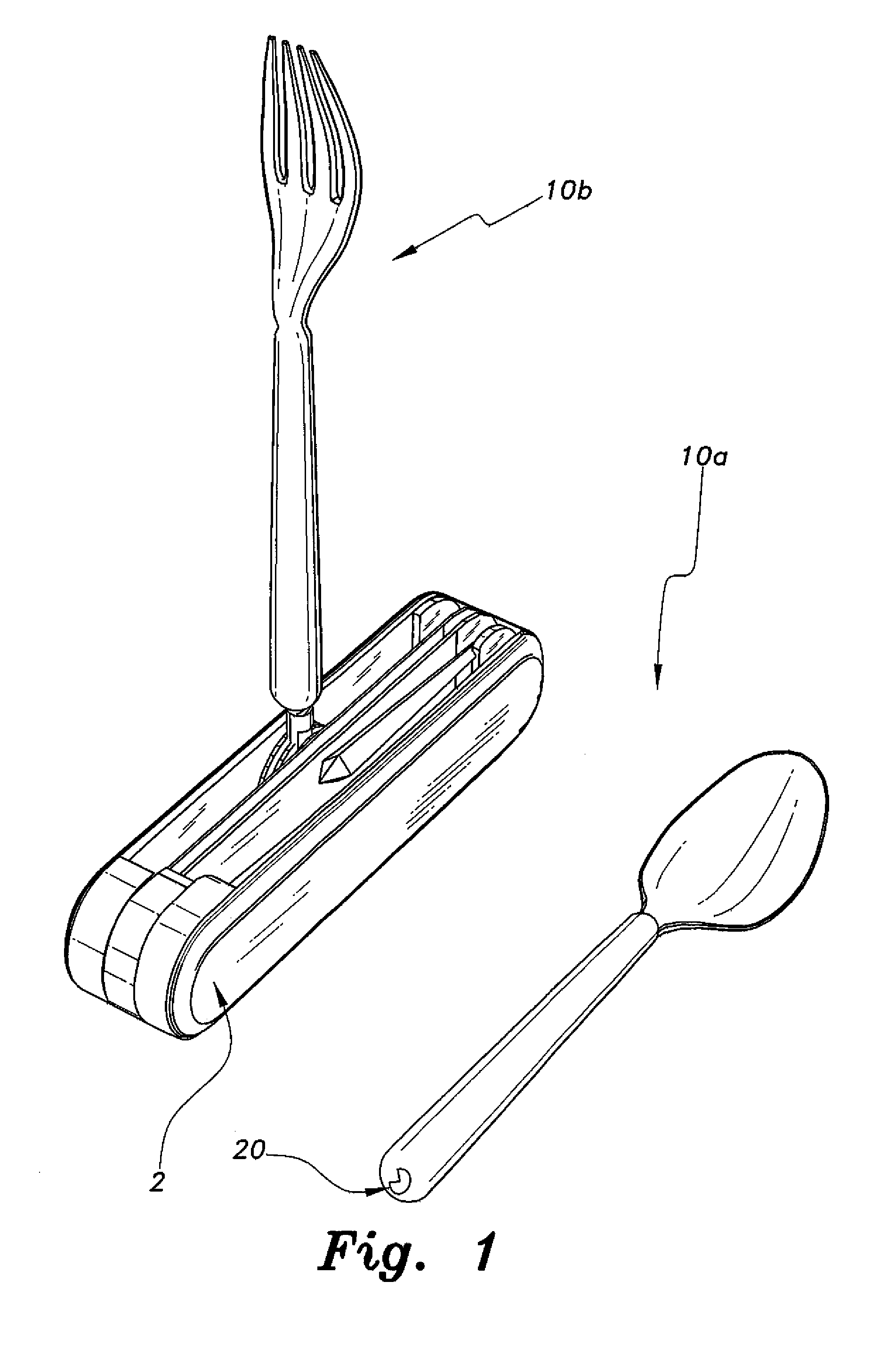

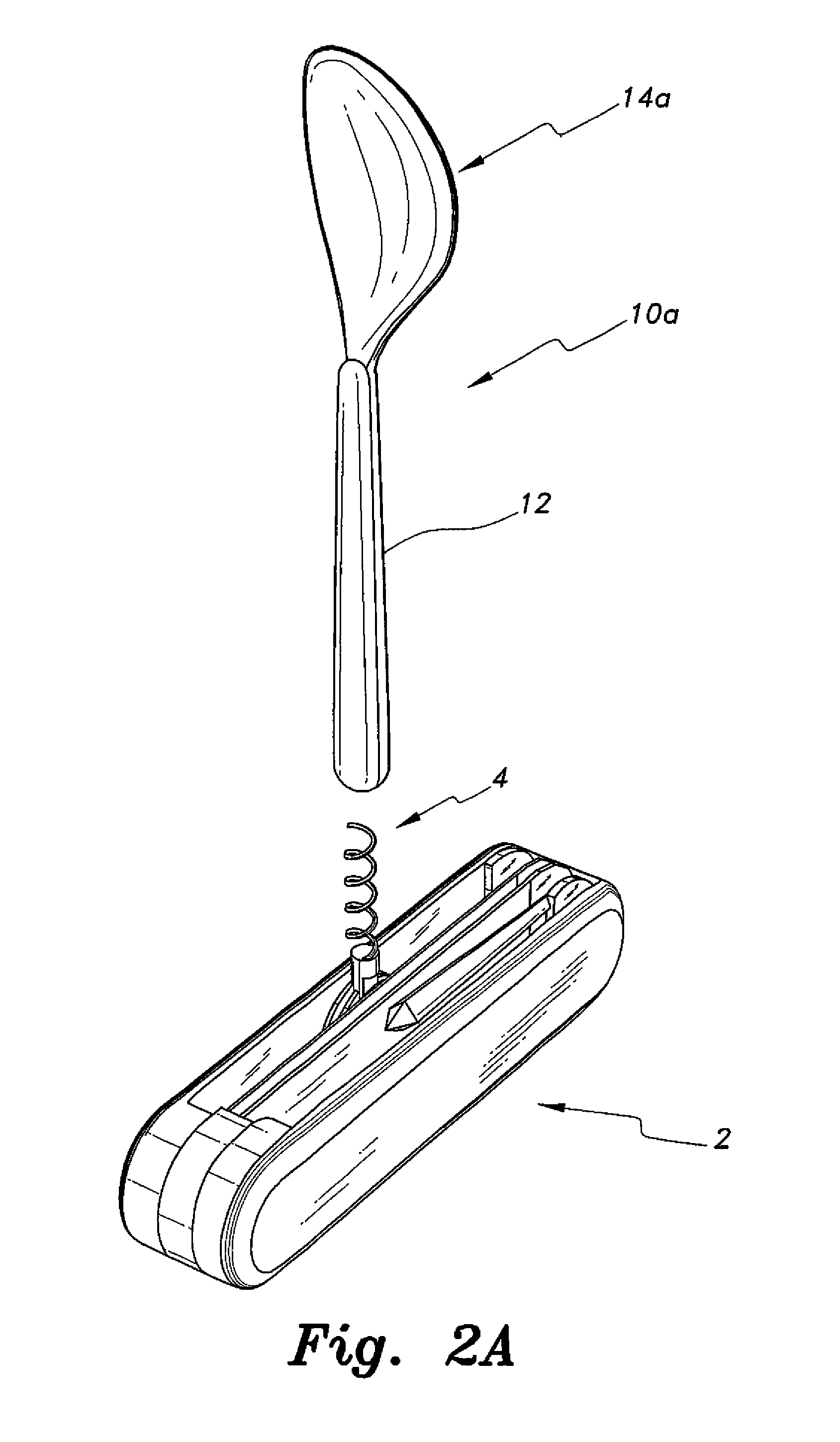

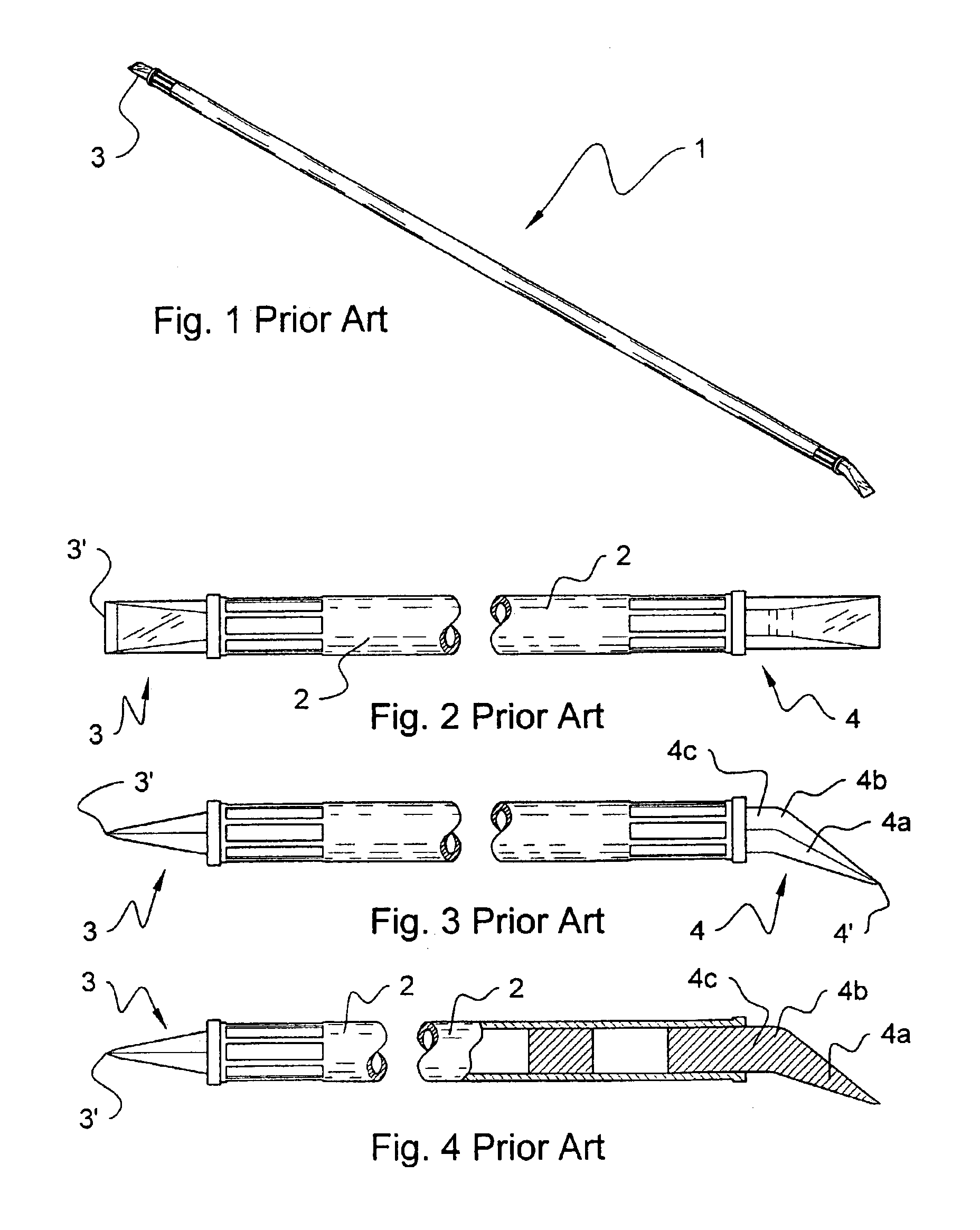

Utensil attachments for portable knife assembly

ActiveUS8635780B1Easy to operateMinimal effortPortable power-driven toolsKitchen equipmentEating UtensilsEngineering

The utensil attachments for a portable knife assembly include at least one utensil attachment having an elongate handle and a working section disposed at the distal end thereof. The working section can be in the shape of eating utensils, such as a spoon bowl or fork tines. An elongate, hollow connection socket is formed inside the handle and constructed to mount the utensil attachment to an existing corkscrew in the knife assembly. When assembled, the relatively large, elongate body of the knife assembly provides an easy to manipulate ergonomic handle requiring minimal physical effort from the disabled or those with limited motor control.

Owner:ABUL ABDULQADER HABEEB HUSSAIN

Retractable Step Stool/ Access Device

ActiveUS20130186709A1Quickly deployableQuickly retractableBathroom accessoriesStep stoolsStored energyEngineering

The present invention is for a step stool to be used by a child, diminutive person or an adult of average height to gain vertical reach. The retractable step stool / access device is positioned by one's foot between an elevated, retracted position or a lowered, deployed step accessible position. Internal stored energy mechanisms can be employed to ease some of the physical effort required, especially by a child or diminutive person, to complete the deployment / retraction cycle with either of their feet. In the raised, retracted position, the step stool is elevated from contact with the floor and clear of the standing area for general usage and allowing access for cleaning and maintenance of the floor.

Owner:WHITE RALPH LAYNE

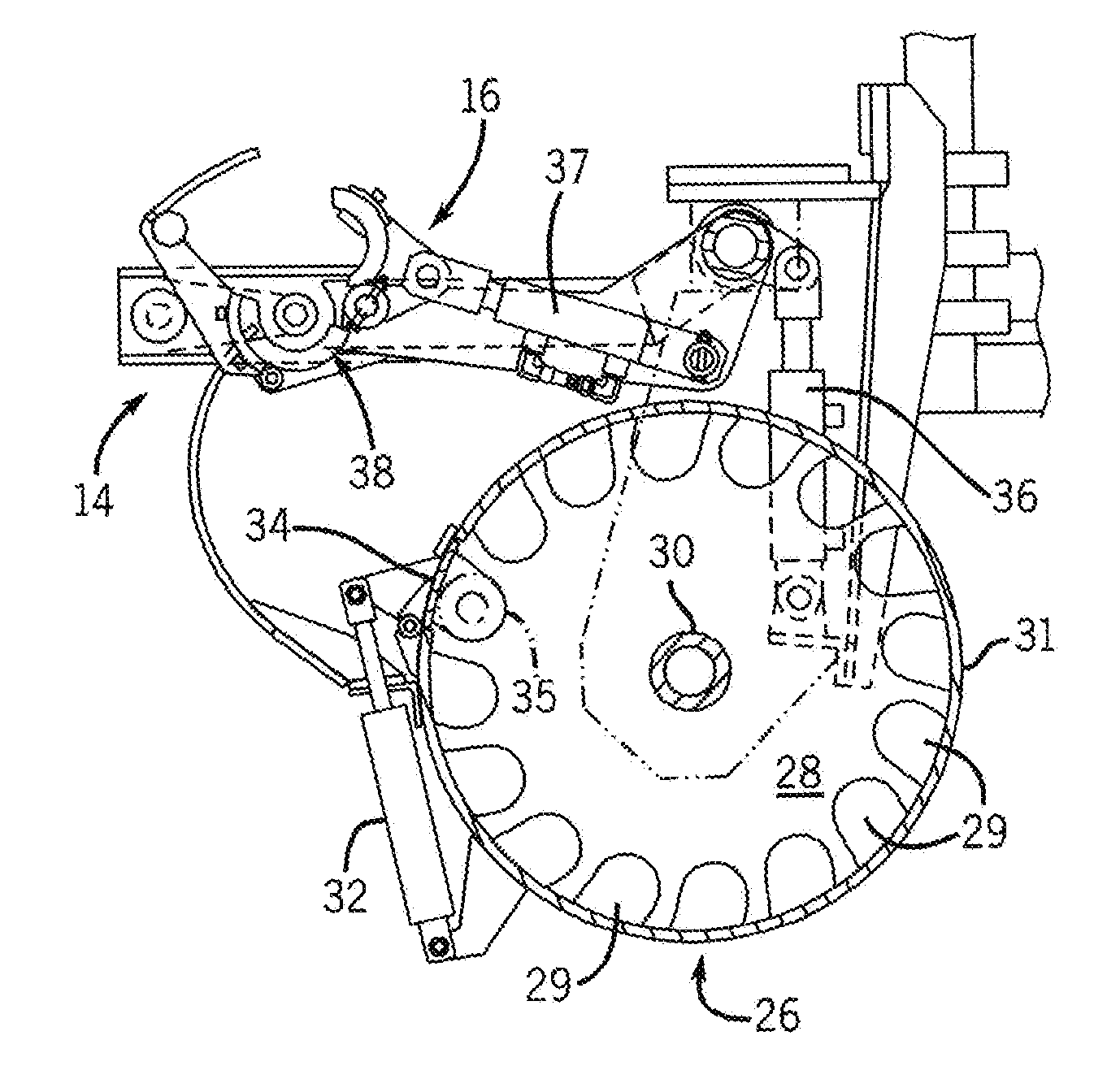

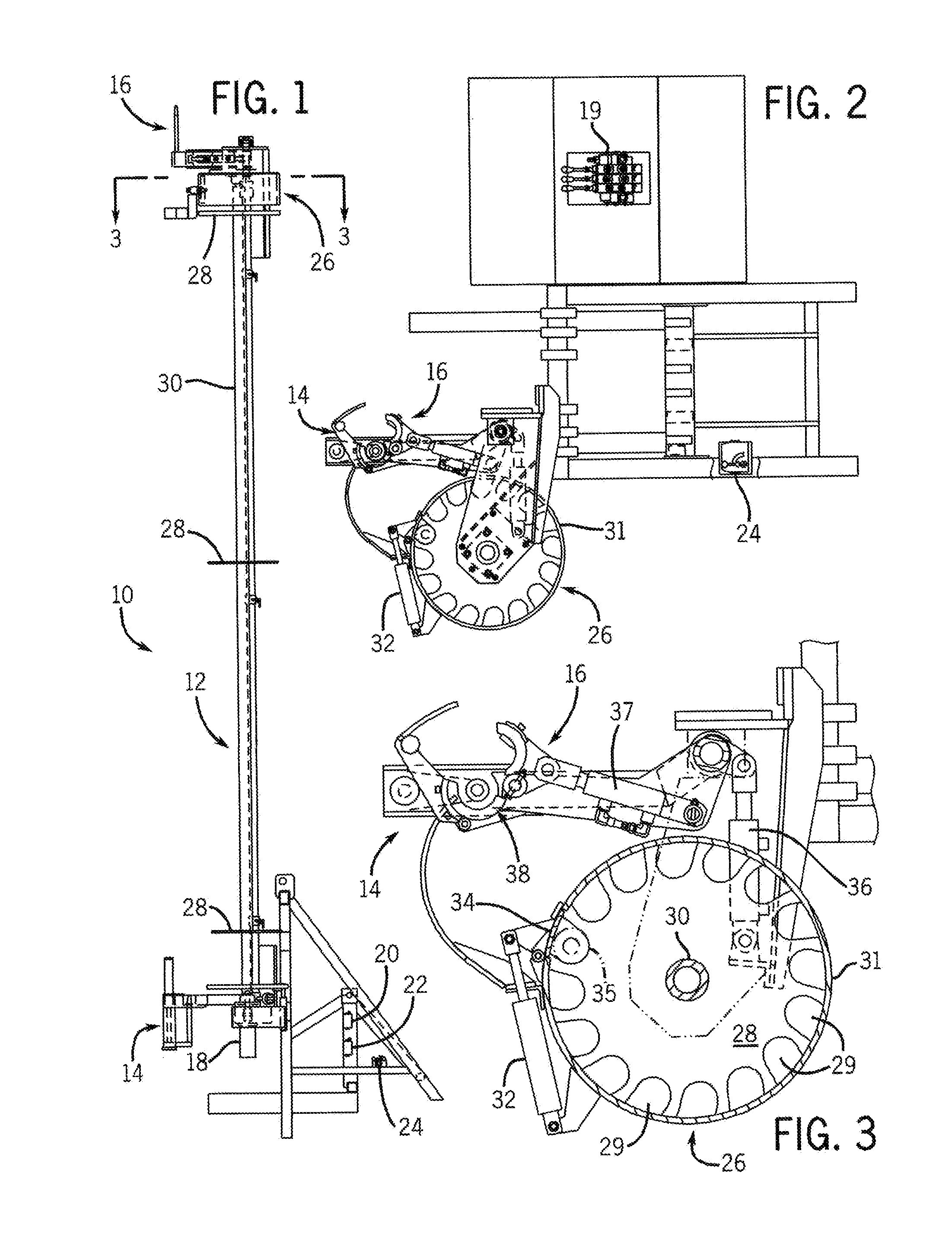

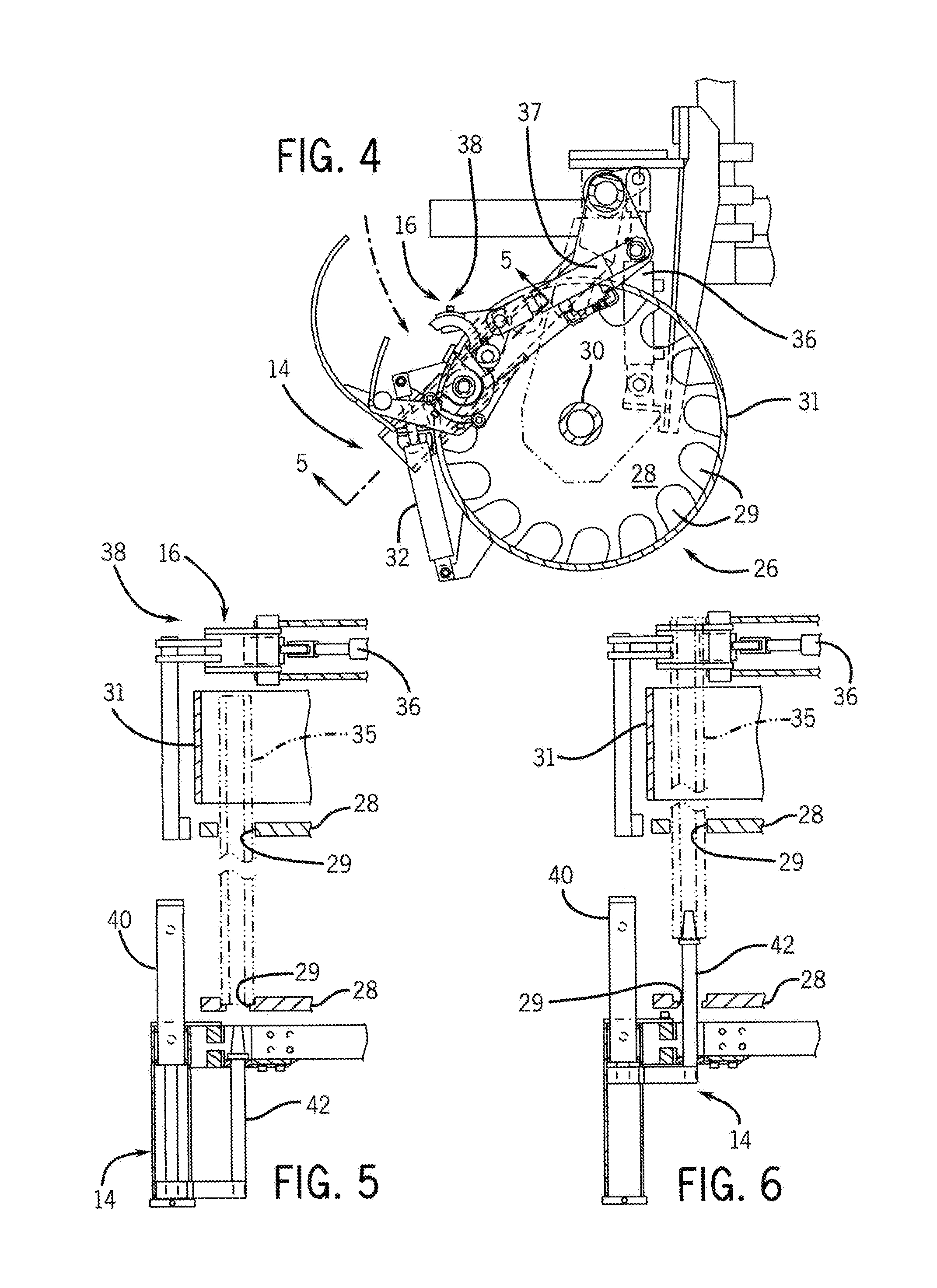

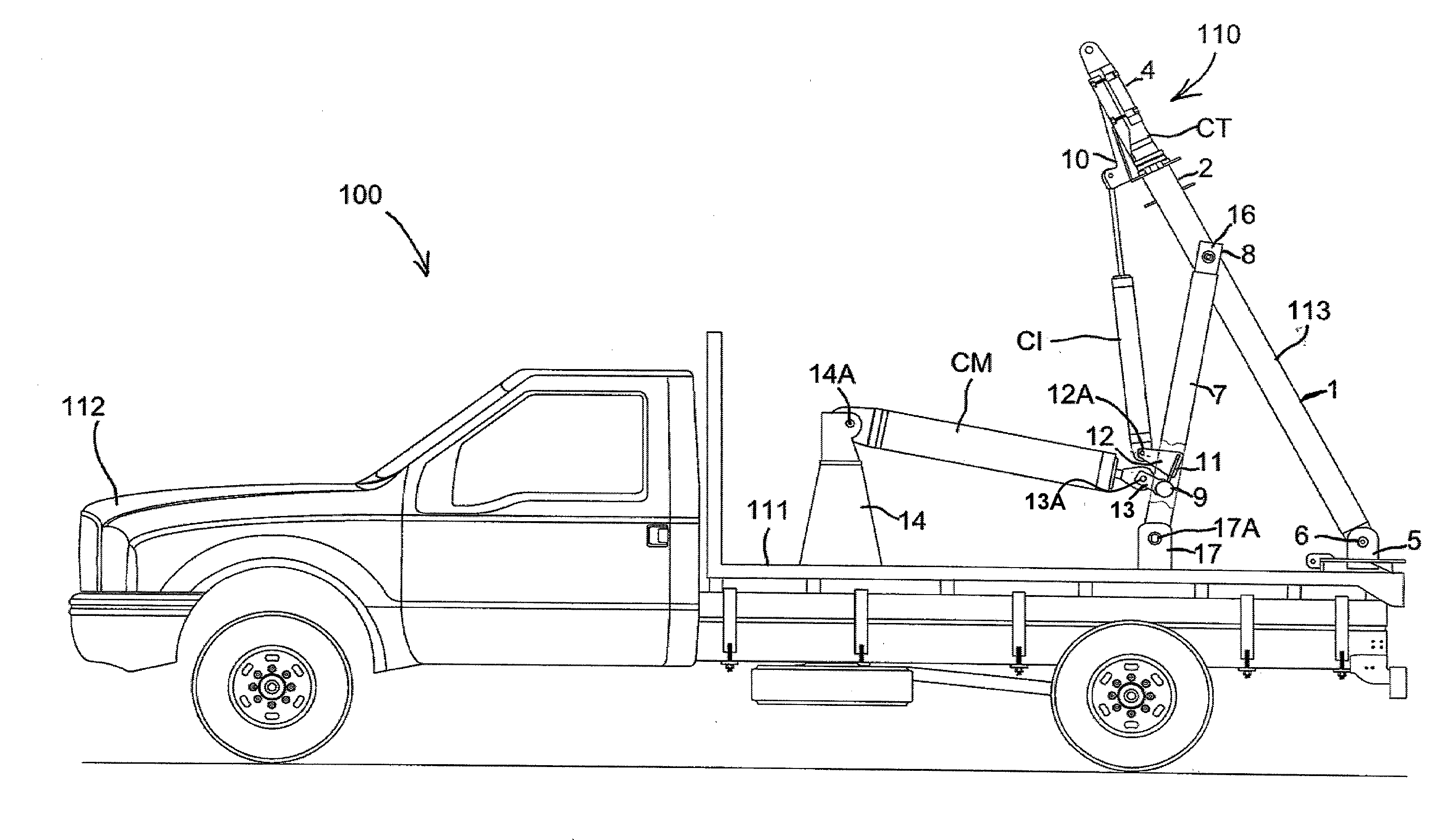

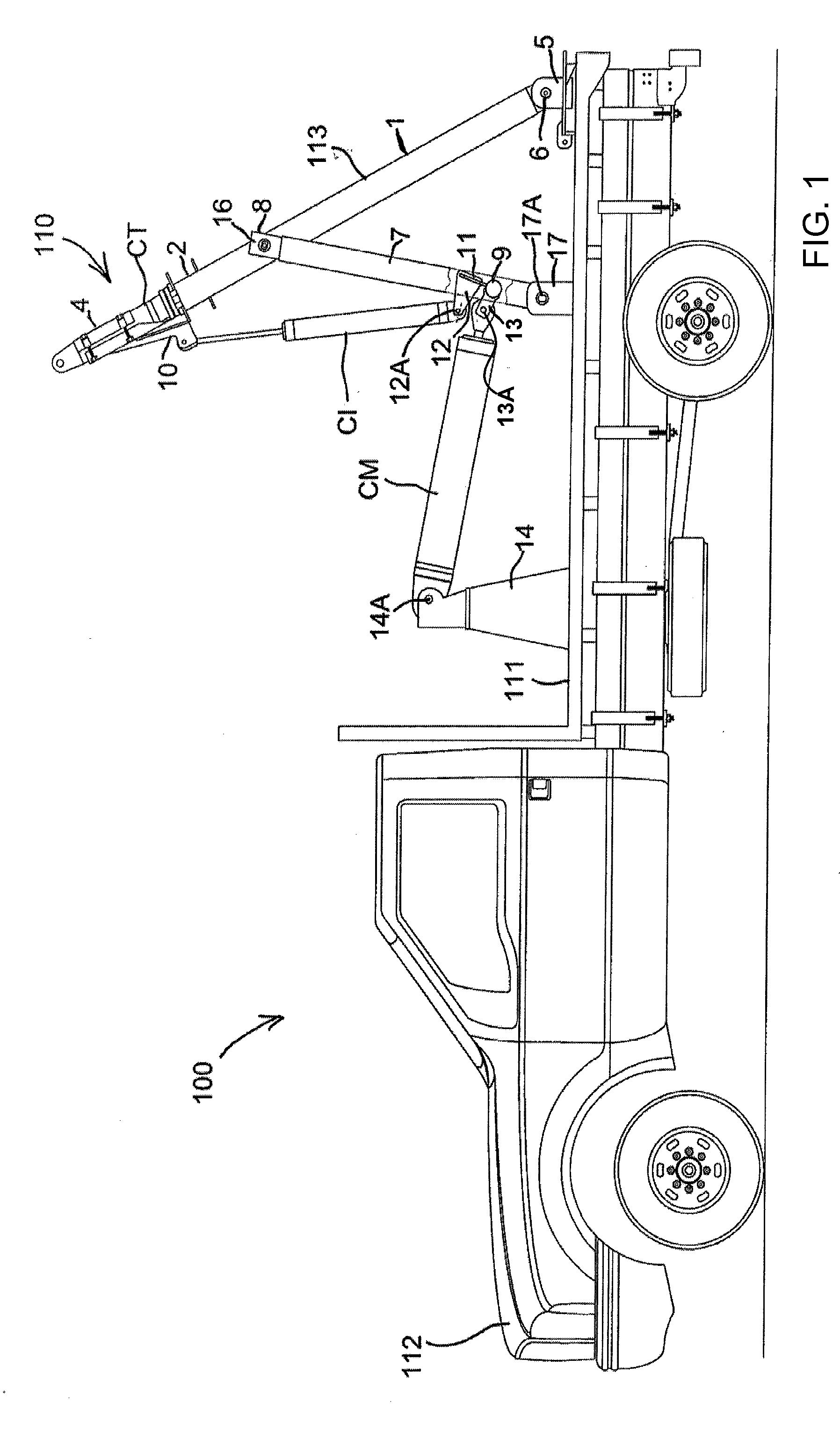

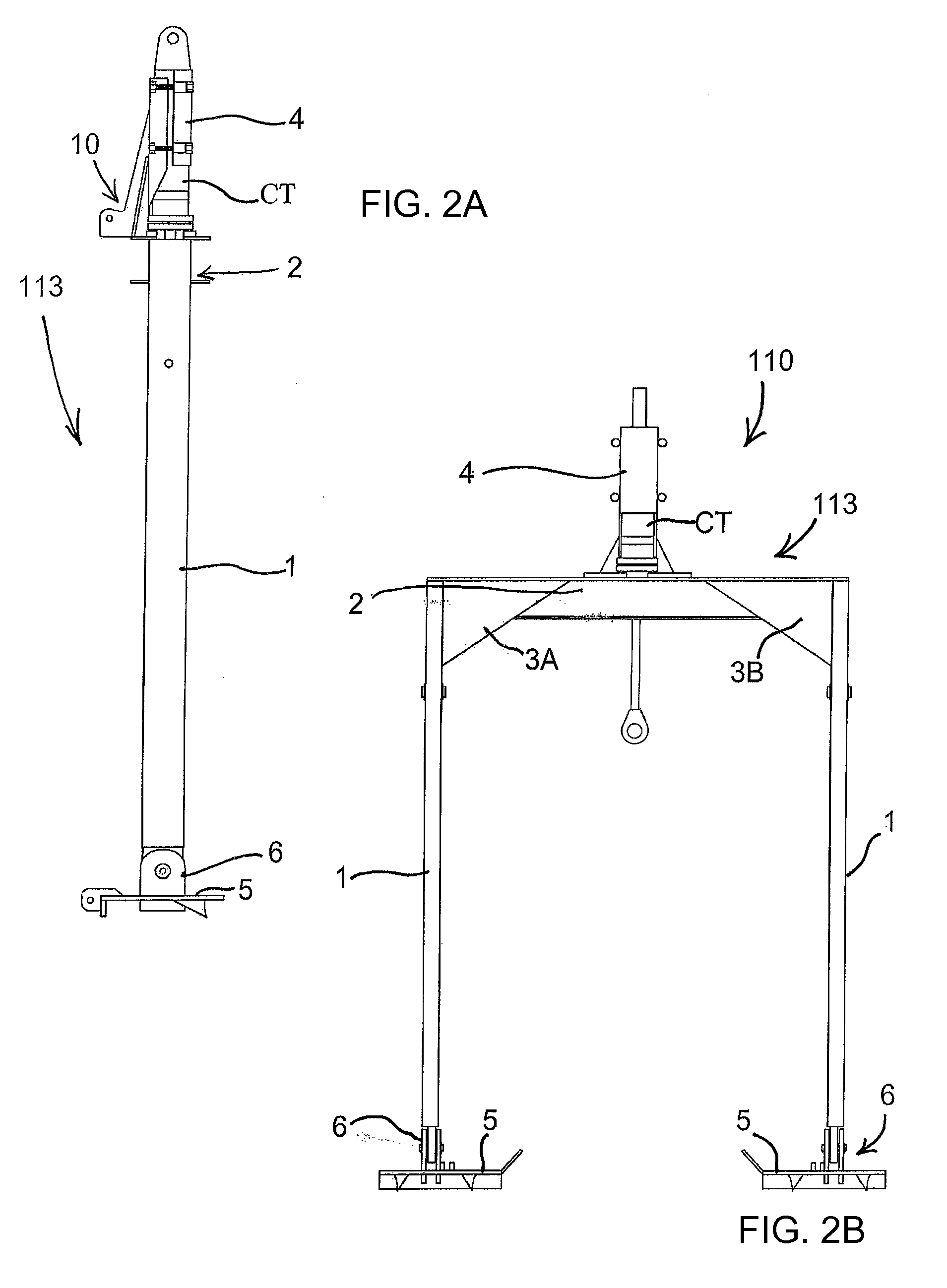

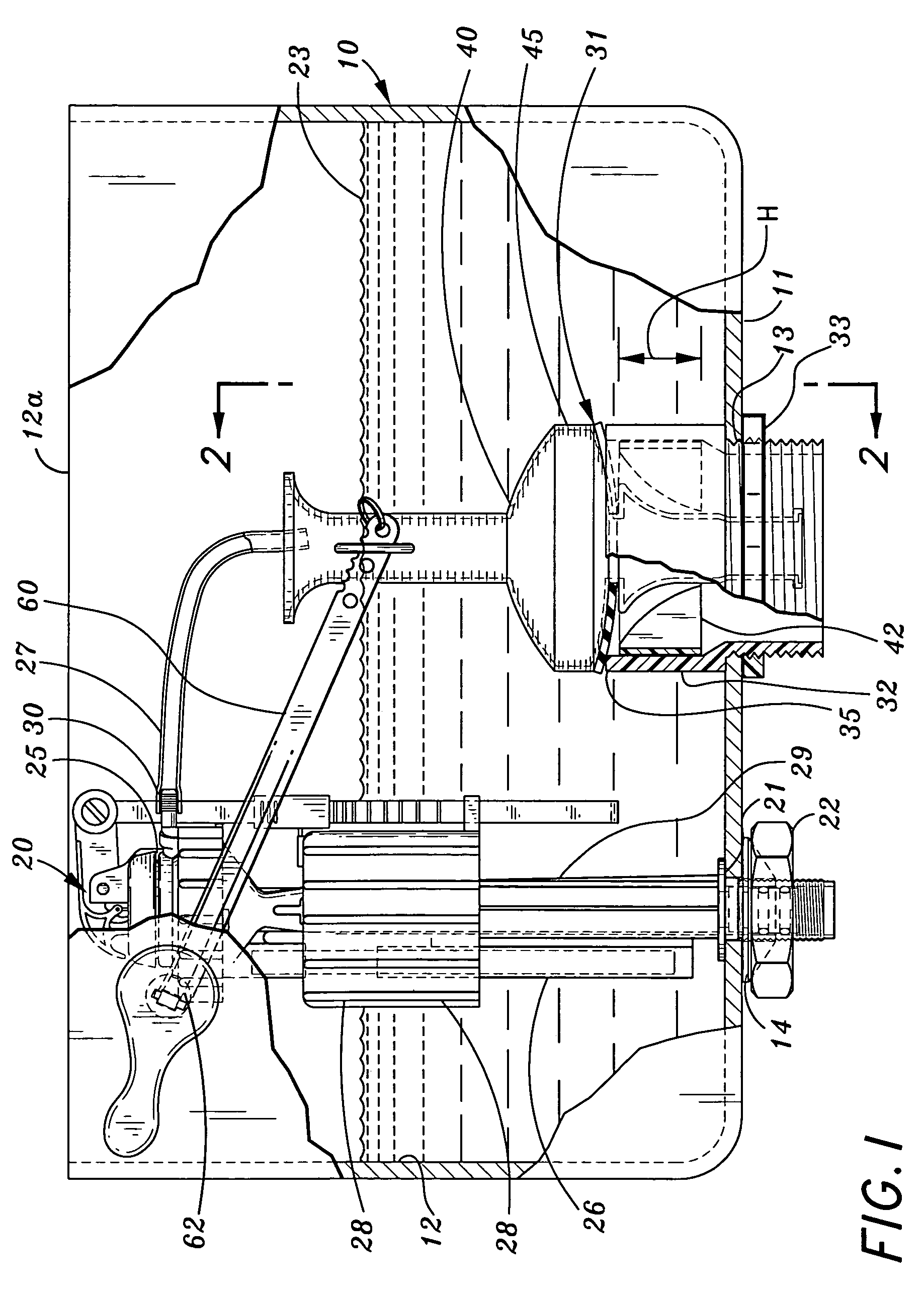

Pipe handling device

A pipe handling system reduces the amount of physical effort required for an operator to transfer steel rotary drilling pipe sections from a storage location to and from a rotary drive unit. The system utilizes an indexing arm which removes or adds the pipe sections from the storage location, placing them in the correct position to be attached to or removed from the rotary drive unit. The index arm, unlike other systems, can remove individual pipe sections to and from the storage location directly to the rotary drive unit's centerline of drilling position. This reduces both the number of physical moves required to complete the task and the amount of weight being transferred. The indexing arm is able to lift a pipe section from the storage location and place it below the rotary drive unit's centerline, then lower away from it without additional movement of the rotary drive unit itself.

Owner:KEJR

Toilet tank valve

Owner:ANTUNEZ BRUCE A

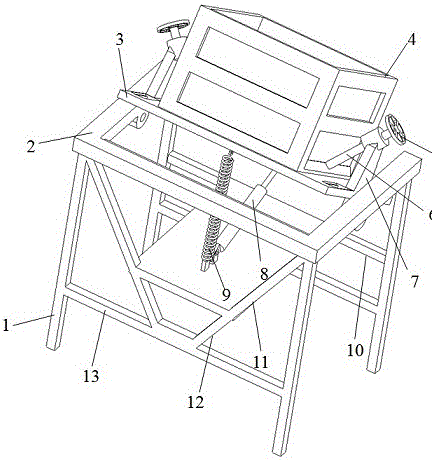

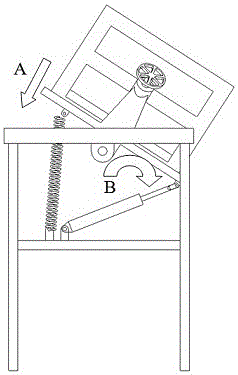

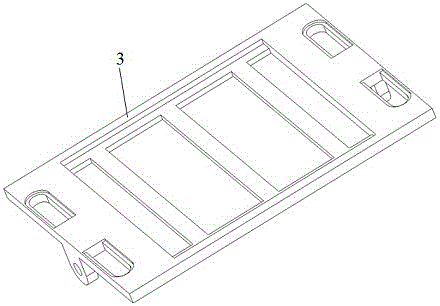

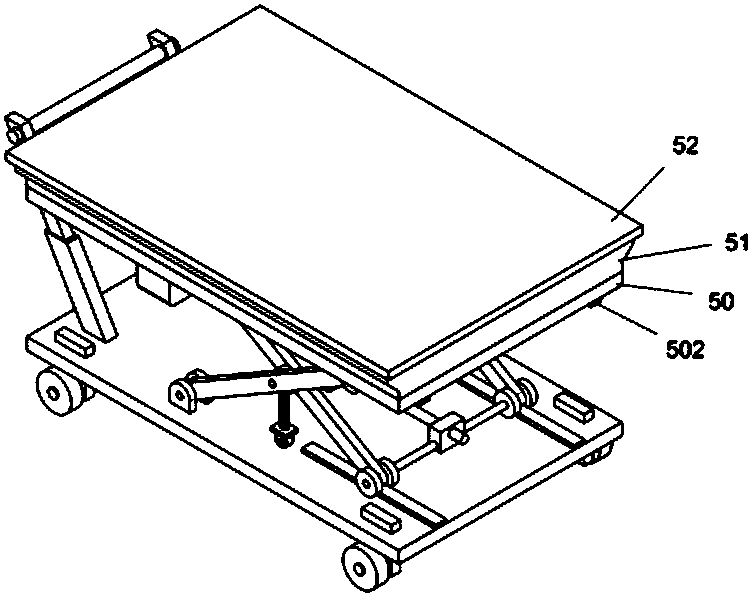

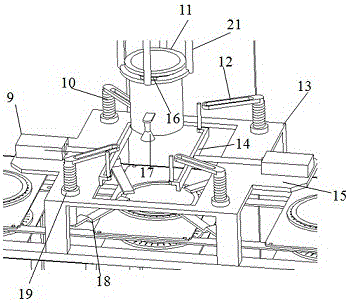

Coarse barium slag dumping overturning platform device

InactiveCN105905624ALow costShorten the production cycleBottle emptyingLoading/unloadingHydraulic cylinderPull force

The invention discloses a coarse barium slag dumping overturning platform device. The coarse barium slag dumping overturning platform device is characterized in that a piston rod of a hydraulic cylinder is in an extending state before the device works, and a returning spring is in match with the piston rod to act to enable an\ overturning platform to enter a horizontal state; roasted raw barium salt is dipped in a material tank and then the material tank\ is positioned on the overturning platform through a hoisting device; the material tank is fixed on the overturning platform through compressing wheels and compressing screws; as the piston rod of the hydraulic cylinder contracts, the overturning platform can be overturned\, wherein the overturning platform can be stably overturned under the effect of a pull force in the opposite direction of the returning spring\, and then the raw barium salt in the material tank falls down onto the ground; the overturning platform overturns to the horizontal position again, and then the material tank is removed through the hoisting device, and thus the device finishes the functional action. With the adoption of the device, the material in the material tank can be completely dumped in one time; in addition, a port of the material tank is nearly close to the ground when the downward overturning angle of the overturning platform meets the specified angle, so that little flying dust is generated when the material falls down onto the ground, and as a result, the working environment can be kept clean, and the physical effort of operators can be reduced.

Owner:GUANGXI LIANZHUANG SCI & TECH CO LTD

Mobile Testing Device and Method of Using the Device

InactiveUS20080184808A1Easily adjust to condition of testReduce the likelihood of injuryMaterial strength using tensile/compressive forcesHydraulic cylinderPhysical hard work

A mobile testing device is adjustable to perform different types of tension tests. The measuring device can conduct tests on components located on the ground or on elevated components. The measuring device can also carry out tensile strength tests on wire cables, slings, and other components. The measuring device can also be used to calibrate weight-indicating devices and instruments that indicate tensile strength. The positioning and movement of the gantry is achieved by using an assembly of hydraulic cylinders. Different working positions can thus be obtained and more than a trivial amount of physical effort is not required to operate the device.

Owner:PETROIL

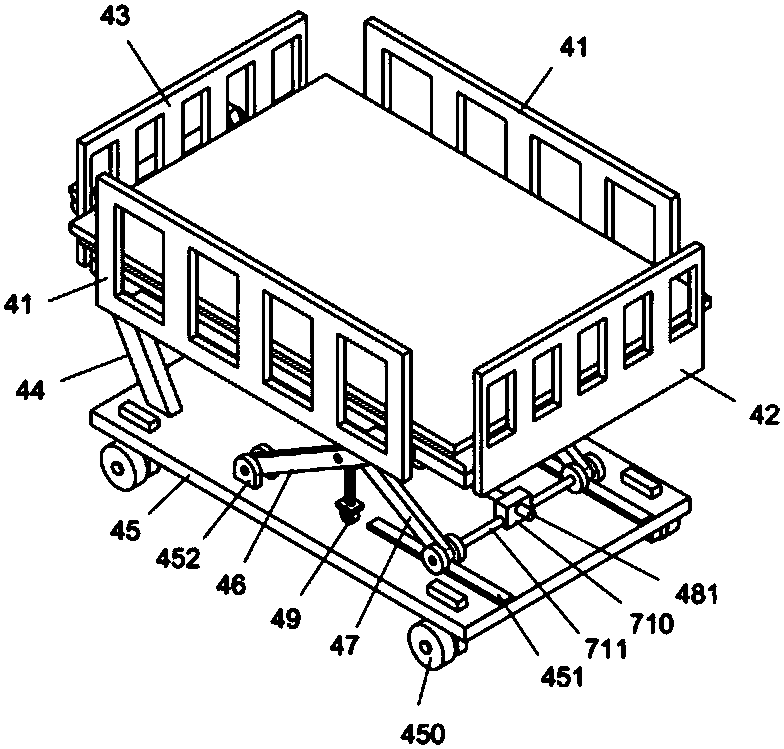

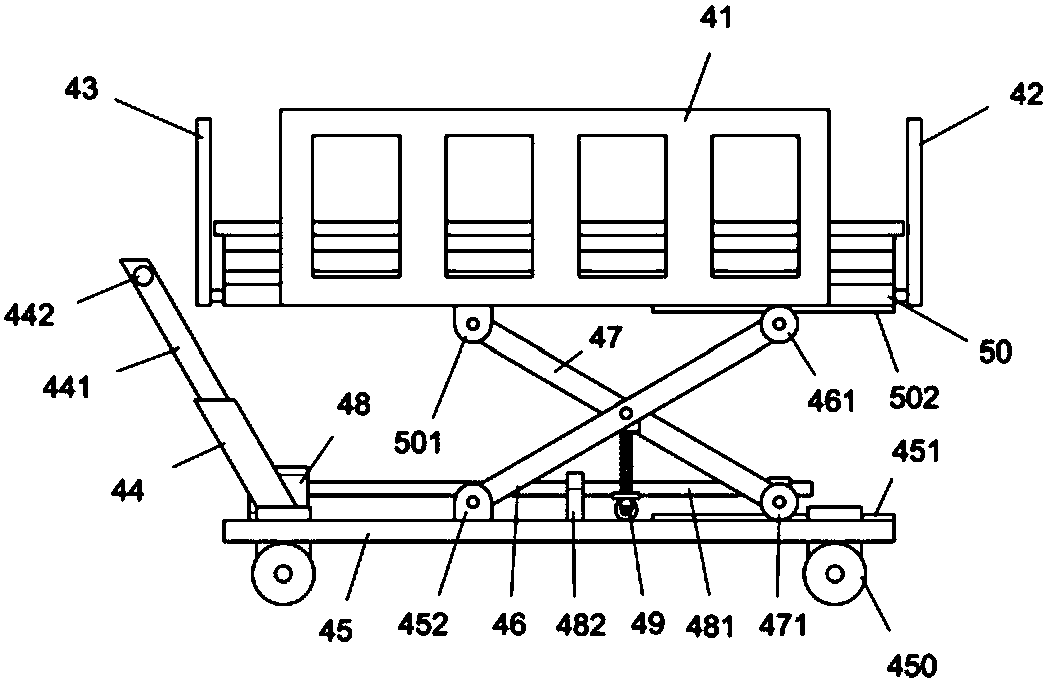

Turnover hospital bed for medical care

The invention discloses a turnover hospital bed for medical care. The turnover hospital bed comprises a base. The upper part of the base is provided with an elevating mechanism. The upper end of the elevating mechanism is fixedly connected with a bed body. A detachable bedside baffle, two side baffles and a bed end baffle. The elevating mechanism comprises a pair of cross-shaped shear forks installed between the base and the bed body. The pair of cross-shaped shear forks comprises a first shear fork and a second shear fork. The first shear fork is hinged onto the second shear fork through a pin roll. The lower end of the first shear fork is fixed by a first hinged seat fixed on the base. The upper end of the first shear fork is connected with a first pulley. The first pulley slides along an upper track fixed at the lower part of the bed body. A turning plate mechanism is arranged and capable of turning over leftwards or rightwards. During a body-turning operation process, a patient isautomatically driven to tilt and turn on his side at a certain angle. External force is offered when the patient is turned over by medical staff. The patient can turn over his body more conveniently.Physical efforts of medical staff are reduced.

Owner:DONGGUAN TIANHE ELECTROMECHANICAL DEV CO LTD

Scaling bar

A scaling bar for prying overhanging rocks from rocky wall structures. The scaling bar comprises an elongated tubular shaft and a first pick member attached to one end thereof, and, optionally, a second pick member attached to a second end thereof. At least one of the two pick members comprises an end portion closely fitted into engagement with the tubular shaft, a tip portion defining a substantially sharp leading edge for easier penetration in the rocky structure, and a cam element. The cam element comprises a first and a second leverage bulges, whereby by displacing the shaft, a lever is formed for dislodging unstable overhanging rocks with minimized physical effort from the workman. The second inner leverage bulge provides greater leverage to the tip portion than the first leverage bulge, but the size of the first leverage bulge is smaller, and can hence engage narrower clefts than the second leverage bulge. In use, a workman axially inserts the pick member of the scaling bar in a cleft adjacent to an unstable overhanging rock, and applies a transverse load by prying the unstable rock using the leverage provided by the first leverage bulge, hence widening the cleft. Subsequently, if necessary, the pick member is further axially driven into the cleft, and the workman again applies a transverse load to pry the rock away again using the leverage provided by the second leverage bulge. This procedure can be repeated so as to sink further into the rock bed, until the rock has been dislodged from its bed.

Owner:ATELIER DUSINAGE LAQUERRE & FILS

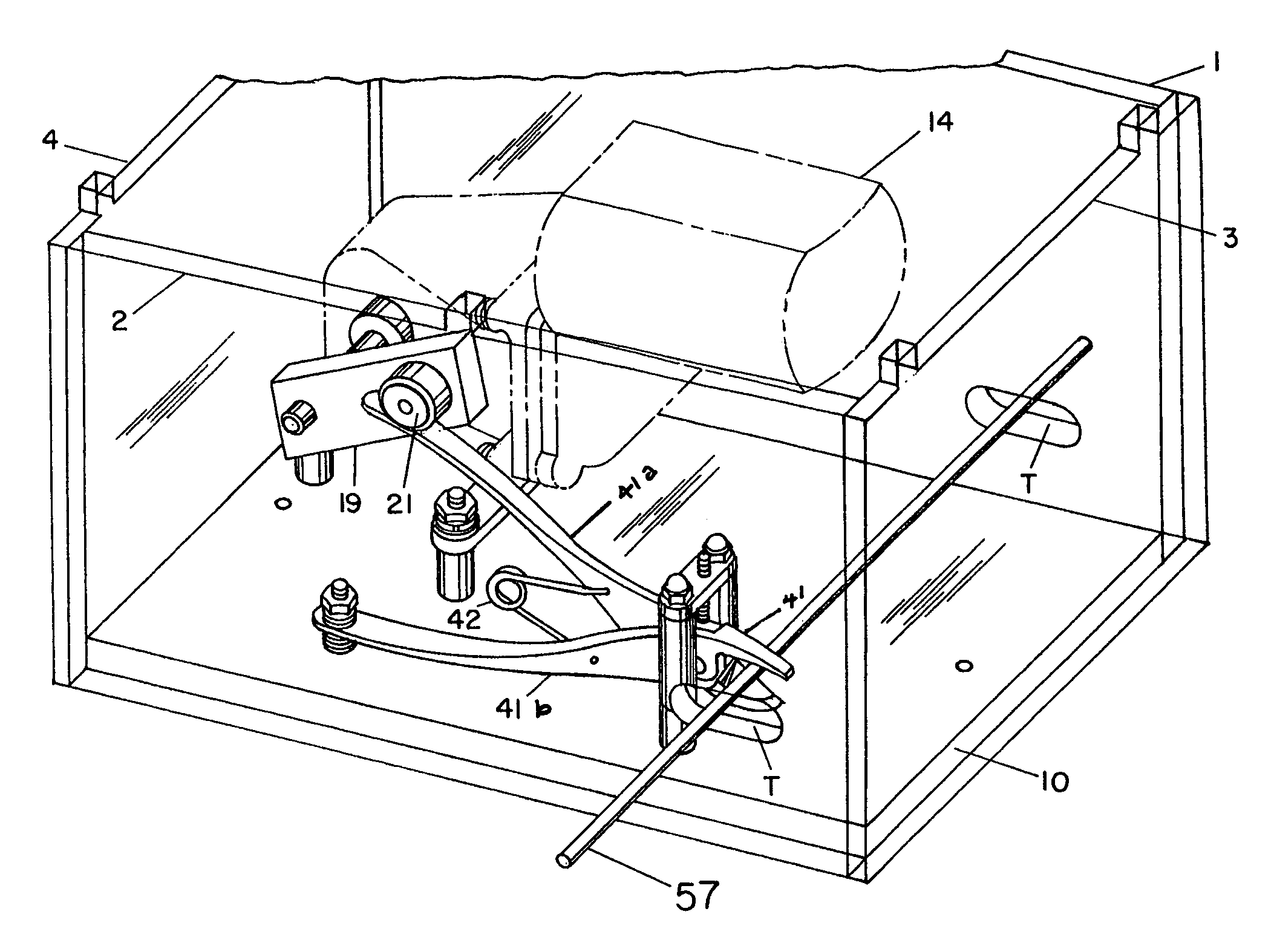

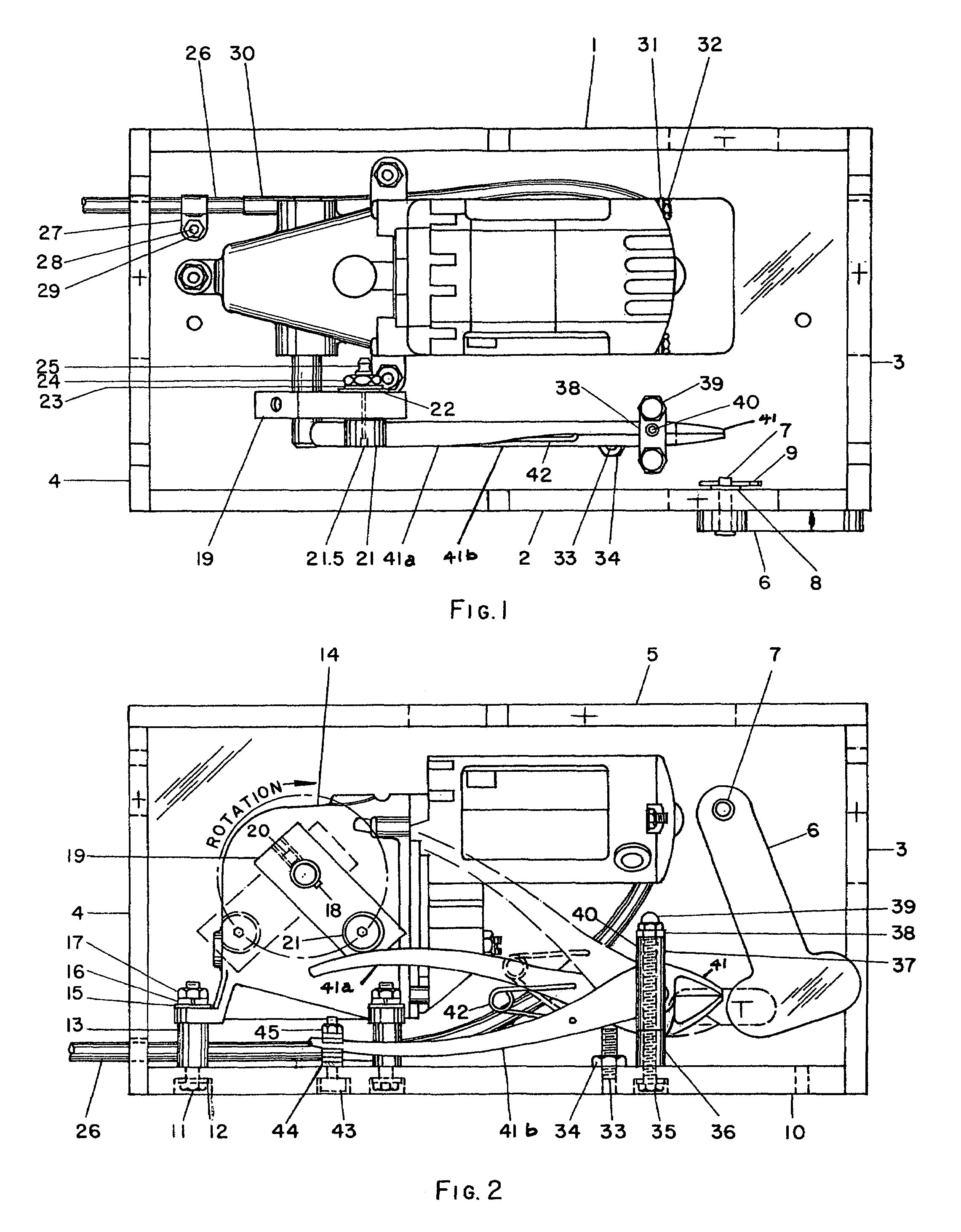

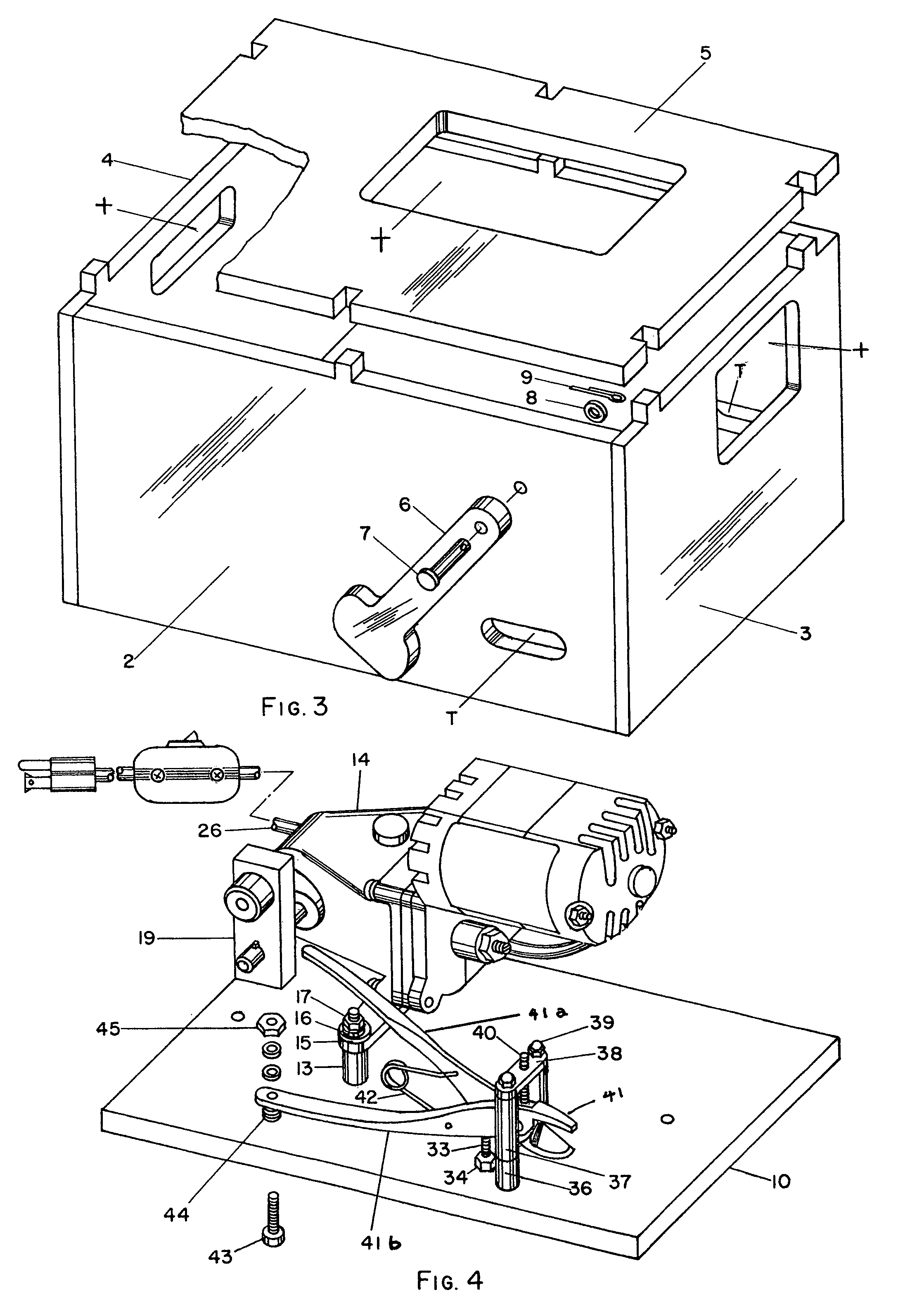

Wire cutter for artificial flower stems

Cutter suitable for artificial flower stems. Typically, plastic coated wire stems are cut with hand cutters to various lengths in preparing artificial floral arrangements. The invention requires far less physical effort by the operator than is required when using conventional wire cutters. In the preferred use of the preferred embodiment of the invention, an uncut stem is inserted crosswise through two elongated holes in the guard housing. When the cutter jaws open, the stem is pushed into the open jaws and is cut to a desired length from the flower end when the jaws close. In the preferred embodiment of the invention a gear reduction motor drives an arm and cam roller assembly. That cam roller forces the top handle of the cutter downward causing the jaws to close. As the cycle continues, the cam roller raises and a spring causes the jaws to open.

Owner:GREENLEE WILFRED EARL

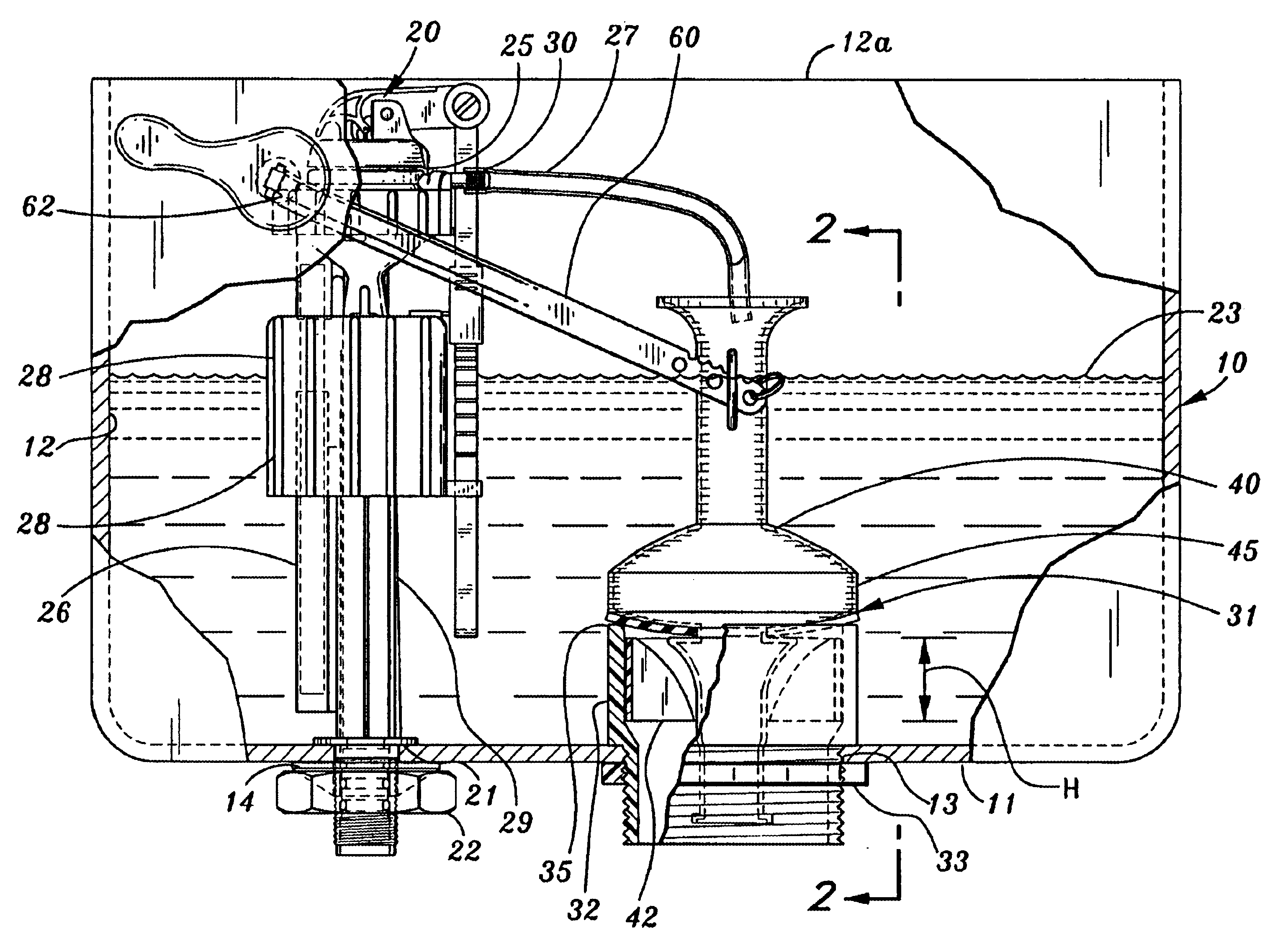

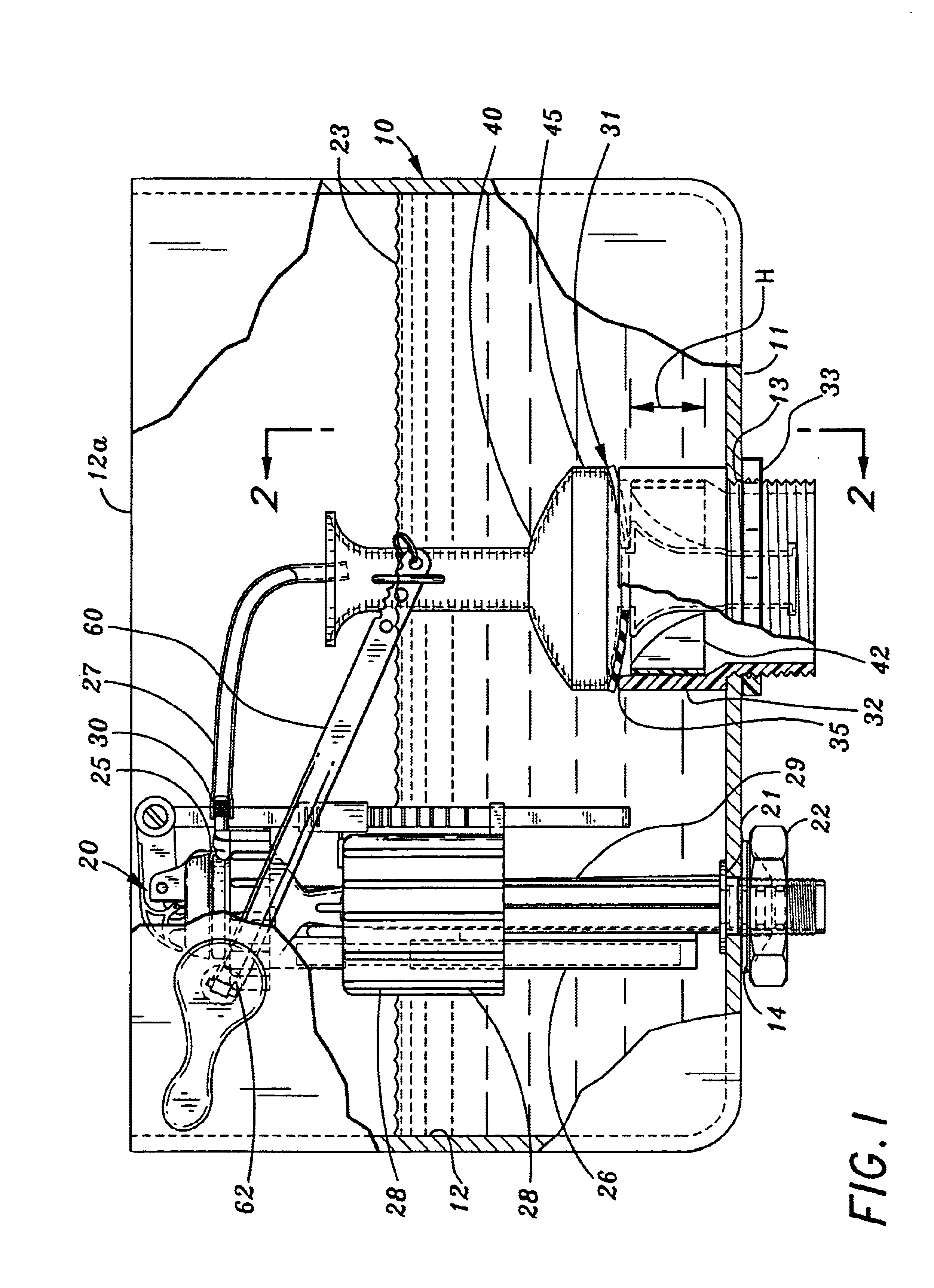

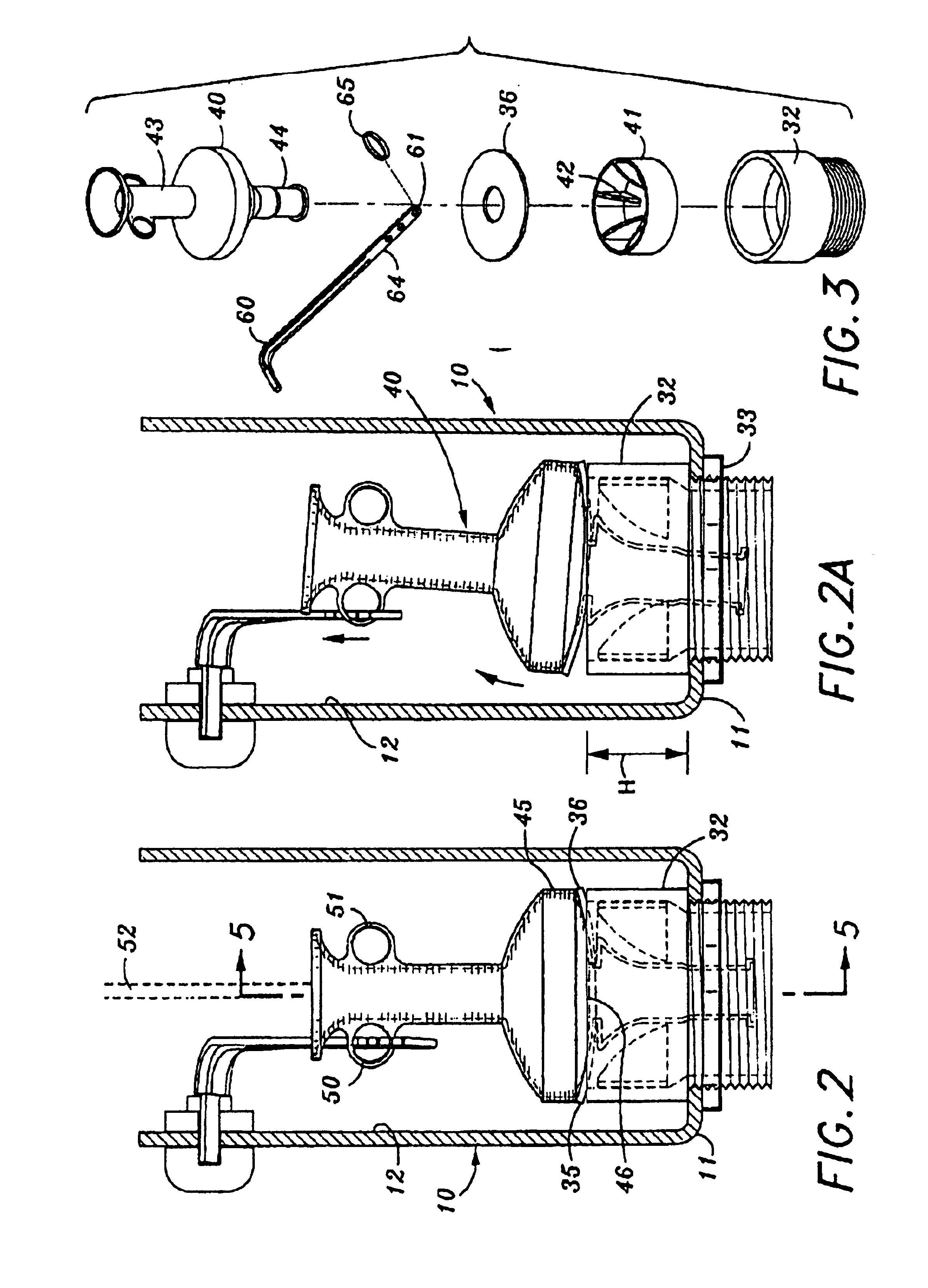

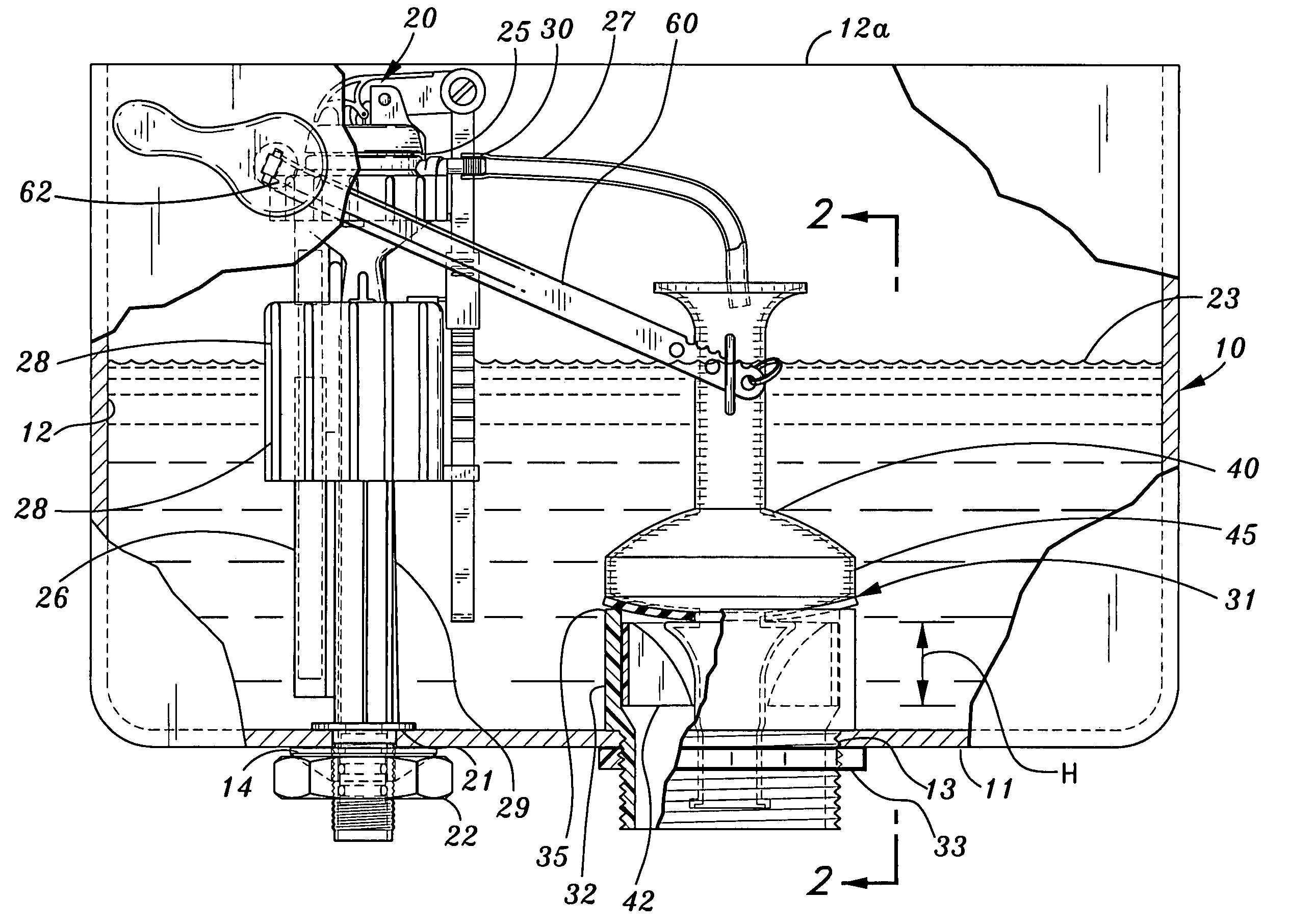

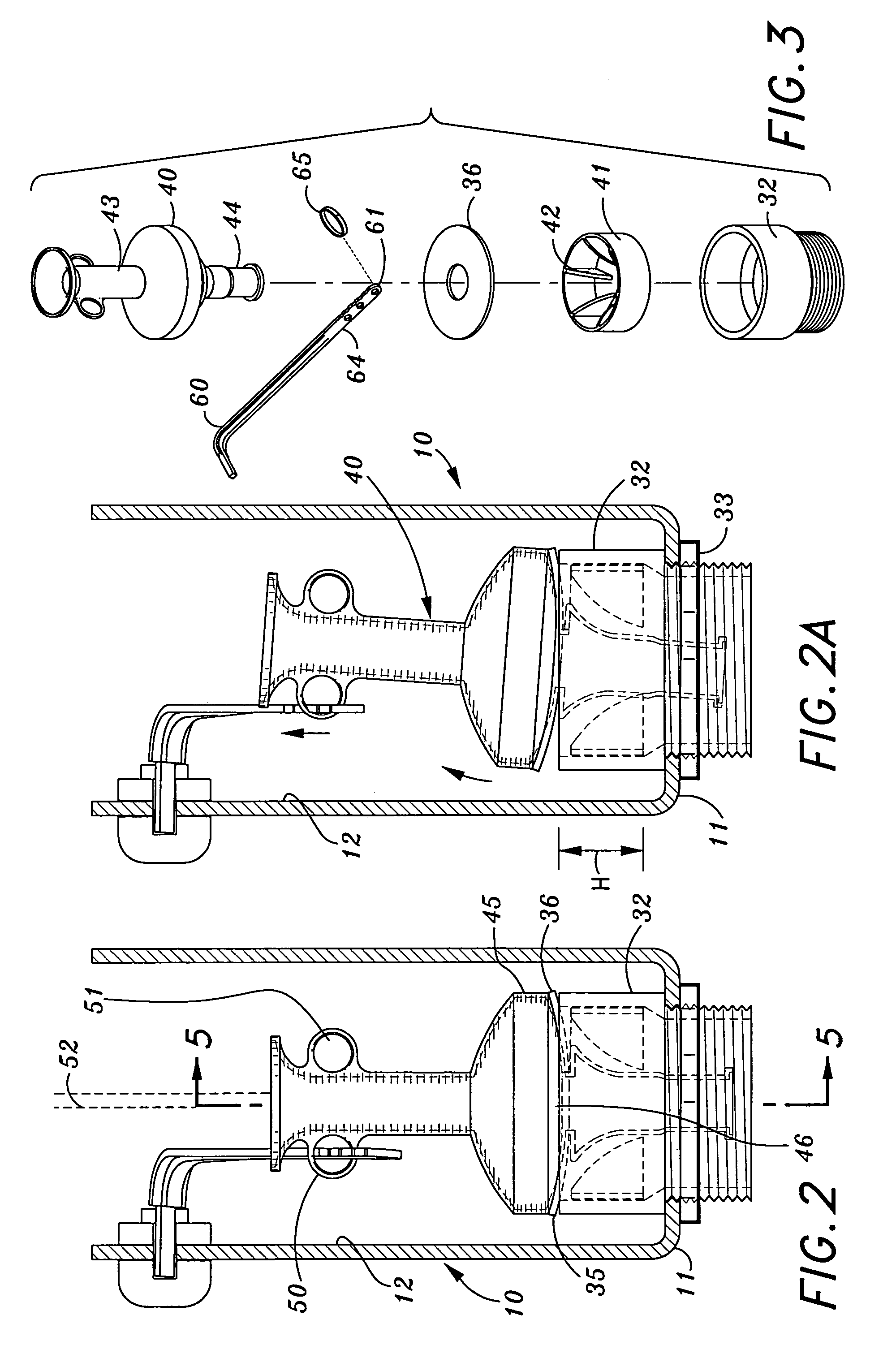

Toilet tank valve

InactiveUS7155751B2Reduce differential pressureLittle strengthFlushing devicesToiletPhysical Efforts

A hollow, open-ended closure for the tank valve which enables a large cross-section area of discharge port to be used, and which can pass bowl-refill water during the flushing sequence. It is especially useful as part of a valve in which it can be tilted to open the tank valve with reduced physical effort.

Owner:ANTUNEZ BRUCE A

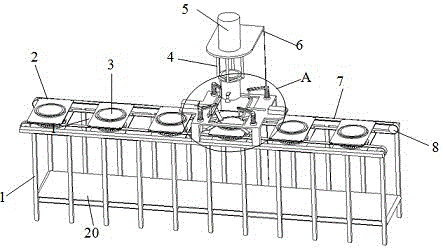

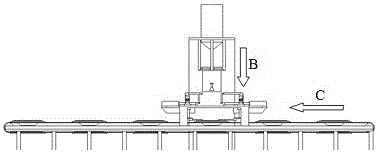

Impressed notch-huffing type barium sulfate crystal quantitative filling equipment

The invention discloses impressed notch-huffing type barium sulfate crystal quantitative filling equipment. Working personnel places a to-be-filled charging bag onto a soft plate, an impressed notch driving air cylinder and an electromagnet drive a pressing piece to rotate and move downwards, and thus the edge of the charging bag is fixed; then, a synchronous belt conveys the charging bag to the position under a weighing barrel, and during the period, barium sulfate crystals in a material supply tank fall into the weighing barrel till the measured value of a weight sensor reaches the specified value; meanwhile, after a blowing head sprays high-pressure gas, the charging bag is spread, then the barium sulfate crystals in the material supply tank fall into the charging bag, and the bottom of the charging bag makes contact with the conveying belt; and after filling is completed, the conveying belt conveys the charging bag to the process, and so far filling operation of one charging bag is completed. According to the impressed notch-huffing type barium sulfate crystal quantitative filling equipment, the barium sulfate crystals can be bagged; the efficiency is high; the action process is smooth; operation is automatically completed; and the physical effort of the operation personnel is reduced.

Owner:GUANGXI LIANZHUANG SCI & TECH CO LTD

Intelligent maintenance method of washing machine

InactiveCN103334261AShorten the timeReduce mental distressControl devices for washing apparatusTextiles and paperHotlineComputer terminal

The invention discloses an intelligent maintenance method for a washing machine. The intelligent maintenance method comprises the following steps that (1) when faults occur, the washing machine performs self detection, and begins reporting errors and generating corresponding fault signals after detection is finished; (2) the washing machine communicates with a mobile terminal and transmits the fault signals to the mobile terminal; (3) the mobile terminal detects corresponding fault types and fault maintenance methods according to the fault signal, wherein in the step (2), communication modes established between the washing machine and the mobile terminal comprise bluetooth, infrared and 3G (The 3rd Generation Telecommunication) network; in the step (3), fault maintenance methods output by the mobile terminal comprise a text-description-based maintenance method and a video-display-based maintenance method, when the fault maintenance methods output by the mobile terminal are difficult to implement, and the mobile terminal displays as initiatively calling manufacture service hotline. The intelligent maintenance method has the obvious advantages that a maintenance engineer does not need to spend a lot of time and physical effort in detecting faults, and the time consumption brought by browsing a maintenance handbook with numerous and diverse content is reduced.

Owner:NANJING LG PANDA APPLIANCES

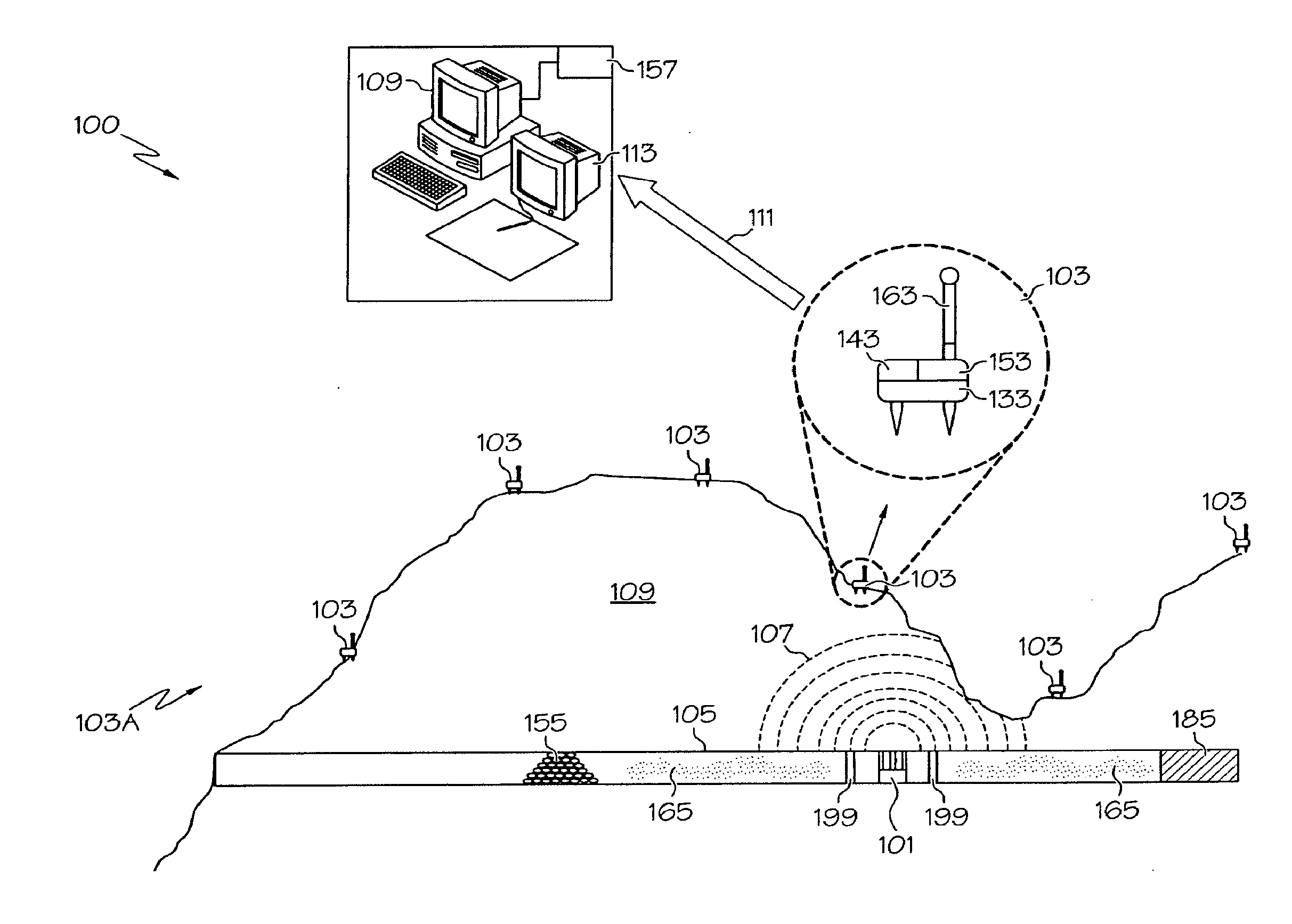

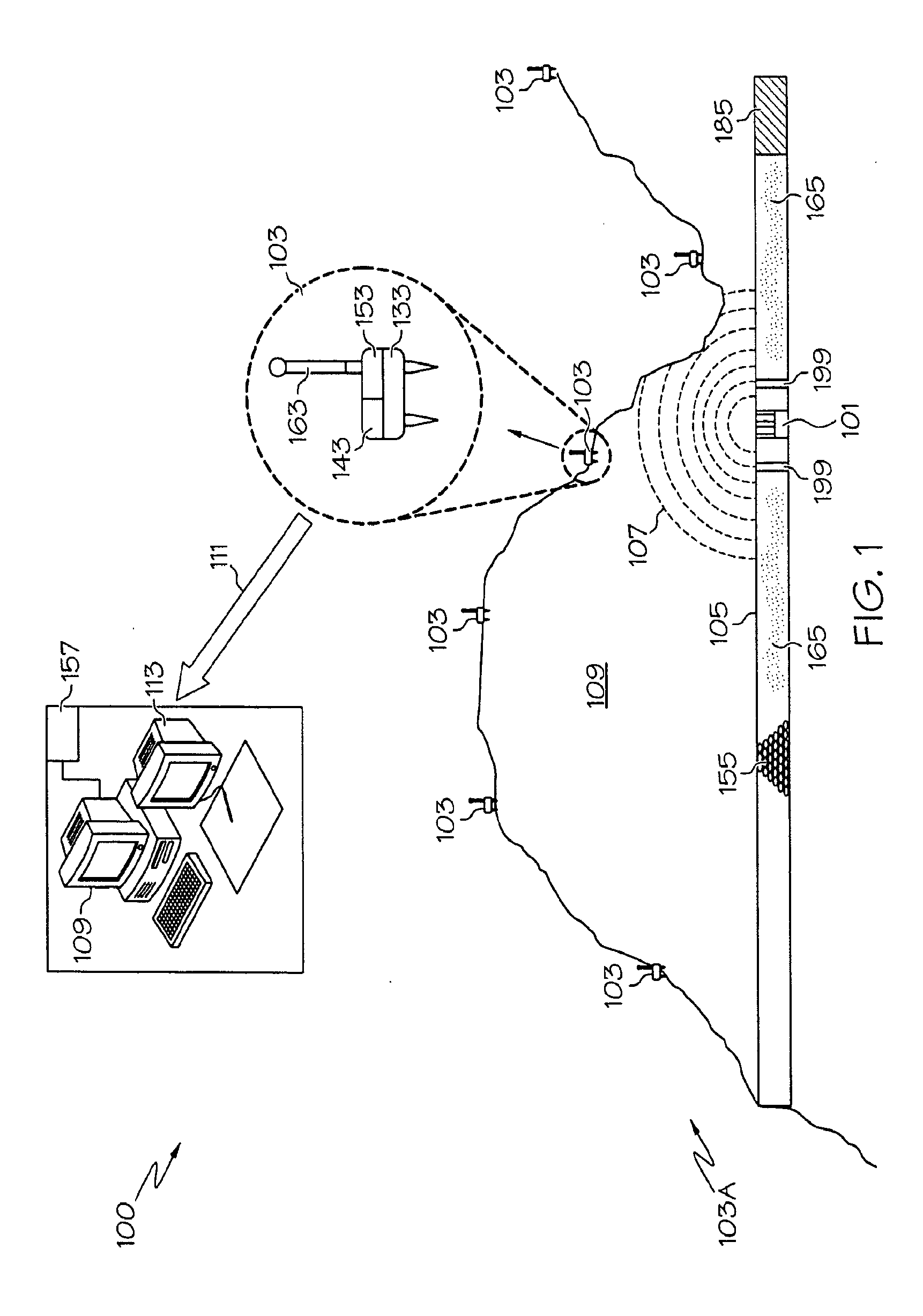

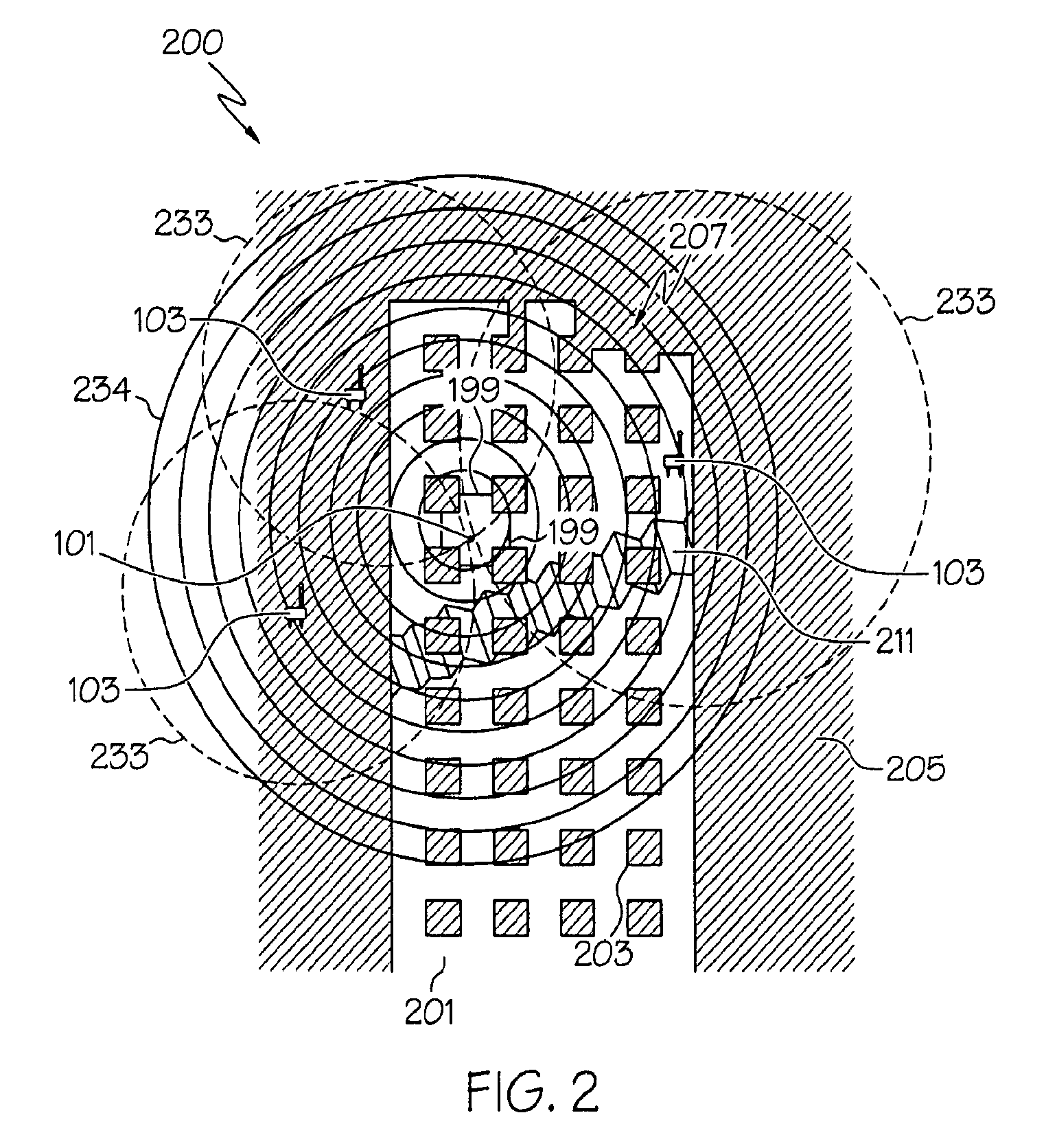

Miner acoustic communication and location system

ActiveUS20100135116A1Easy to operateEasy maintenanceSurveyMining devicesPhysical hard workEngineering

A miner communication and locating system is disclosed. Two technologies used in the system include a communicator, and a locator array that may be used with a computer. The communicator portion allows trapped miners to continually signal without physical effort that they have survived a cave-in or explosion in a direct, mechanical, and reliable manner. The locator array receives the communicator signal for use to accurately identify where the survivors are underground, and facilitate their rescue; a computer can be used to calculate the position of the communicator from information provided by a plurality of locators: global positioning system receivers may be used with the locator array.

Owner:BATTELLE MEMORIAL INST

Pistol loading assistant

The present invention relates generally to firearms and devices that allow a shooter to load an automatic pistol inside a locked holster. The problem of existing devices is that they do not allow to load a gun locked inside a holster and with one hand only. The present invention is intended to solve this problem. Pistol Loading Assistant—is a device in the form of an insert for a holster, allowing a shooter to load a pistol when it is in a holster in a locked position with a short move of one hand. A shooter moves pistol slide with device inside a locked holster and loads pistol with a cartridge. Charging hook of device covers safety lever of pistol from one side increasing safety. Device jointed with holster with locking cord and can provide convenient, easy and safe pistol loading with small physical efforts.

Owner:AKIMOV ANDREI FEDOROVICH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com