Impressed notch-huffing type barium sulfate crystal quantitative filling equipment

A filling equipment and barium sulfate technology, applied in the field of solid particle filling devices, can solve the problems of low degree of automation and high labor intensity of operators, and achieve the effects of reducing participation, shortening production cycle, and ingenious design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

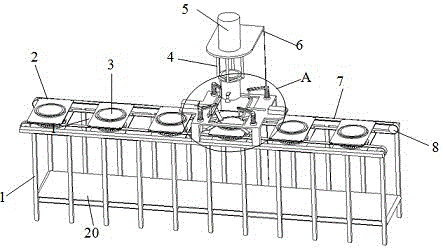

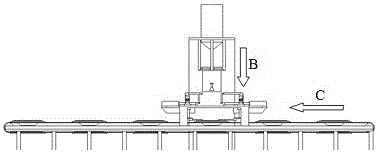

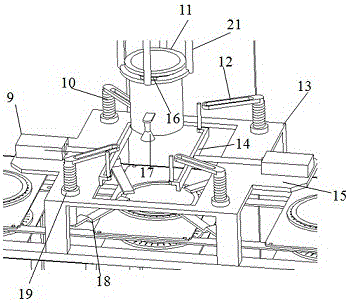

[0017] Compare below Figure 1 to Figure 3 To illustrate, before starting the device, the operator pours the barium sulfate crystals to be packed into the feed tank 5, then the barium sulfate crystals fall into the weighing cylinder 11, start the synchronous belt 7 and the conveyor belt 20, and the staff will pack the The material bag 3 is placed in the center of the soft board 2. The edge of the material bag 3 can cover the air holes around the center hole of the soft board 2. The pressing piece 18 presses the upper side of the edge of the material bag 3. Device, check whether the sequential movement of each part in the working process meets the work requirements, especially whether the air pressure of the blowing head 17 can smoothly open the filling bag 3, and the device has completed the preparation work so far.

[0018] When using this device for filling, the timing belt 7 and the conveyor belt 20 rotate at the same time, and the staff places the filling bag 3 to be fille...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com