Automatic loading method for parachute gas gun test missiles

An automatic loading and gas cannon technology, applied in ammunition supply, weapon accessories, offensive equipment, etc., can solve the problems of unable to test the launch mode of the ammunition, test failure, burning, etc., and achieve the effects of saving manpower, facilitating operation, and improving the degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings.

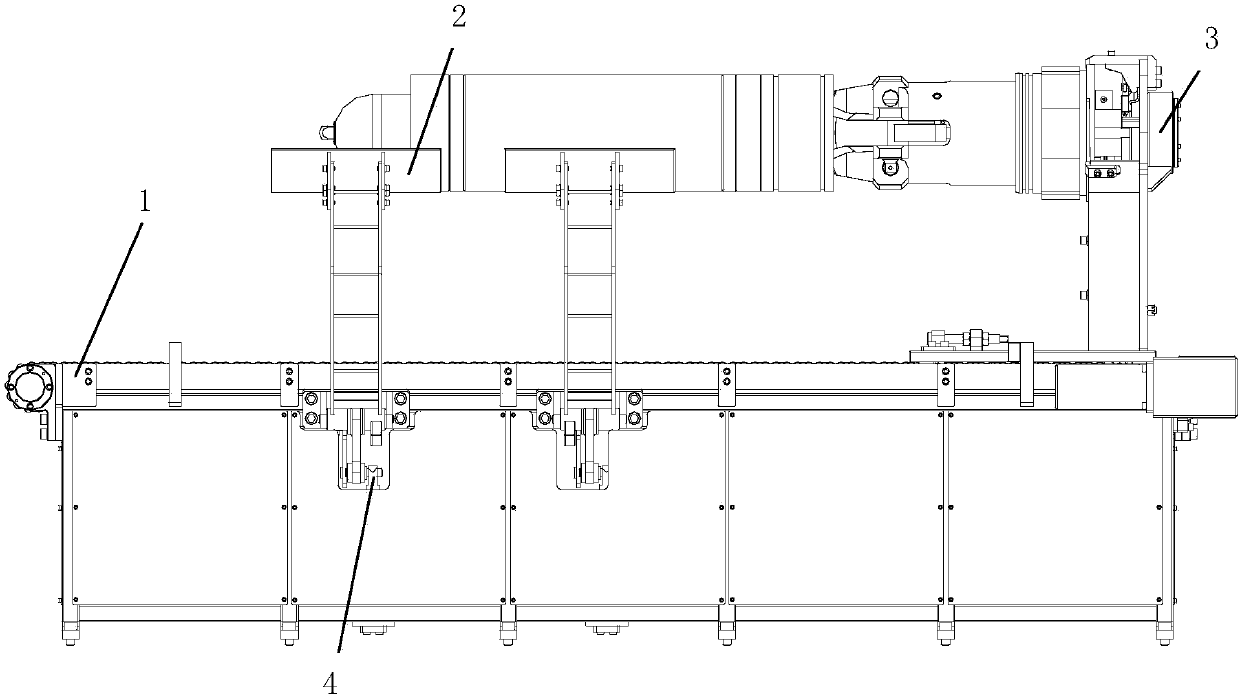

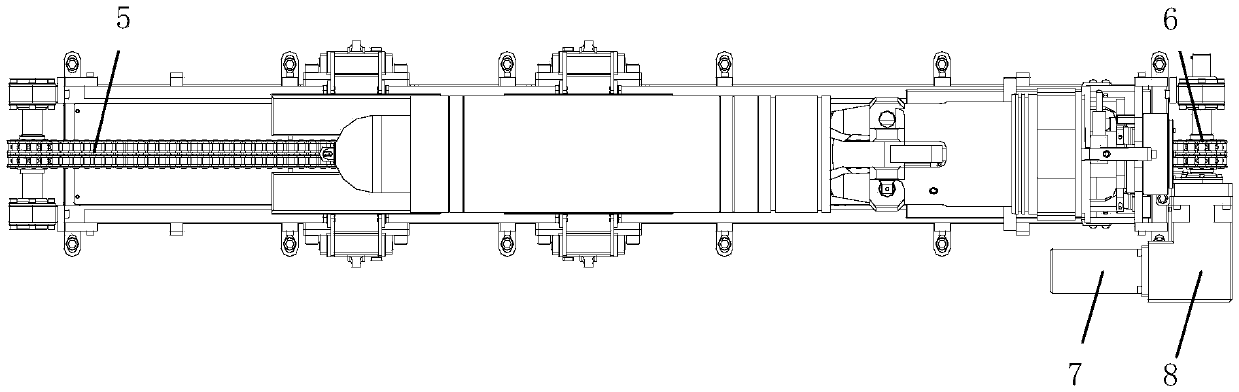

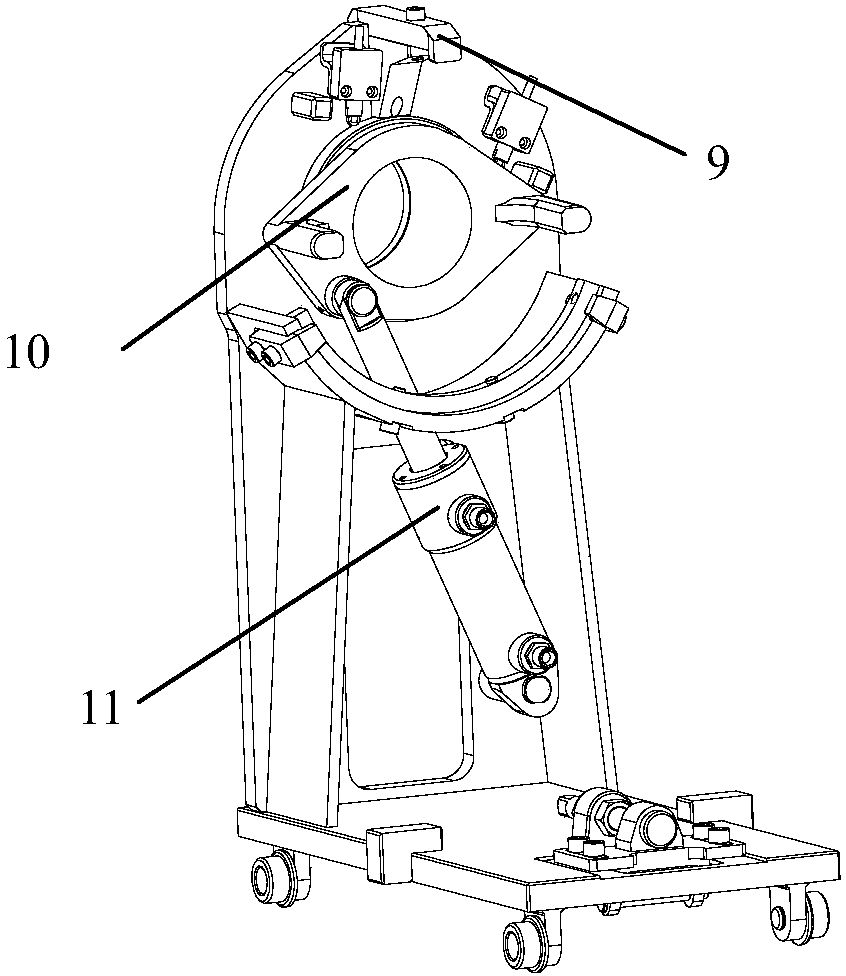

[0016] exist figure 1 , figure 2 Among them, the test bomb is placed on the support tray 2, and the breech block and the plug are connected with the bomb delivery vehicle 3. like image 3 As shown in the bomb delivery vehicle, the claw hook on the bomb delivery vehicle hooks the edge of the latch body, and the two pillars on the swivel sleeve 10 cooperate with the holes on the latch body to control the rotation of the latch body.

[0017] After the test bomb and the latch body are installed, the electrical control system gives a signal, the motor 7 drives the reducer 8, the reducer 8 drives the sprocket 6, the sprocket 6 drives the chain 5, the chain drives the bomb transporter 3, and the bomb transporter 3 Drive the latch body and the test bomb to move along the track on the bracket 1 to the direction of the gun bore. When the bomb delivery vehicle 3 mov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com