Automatic SF6 gas charging system and method of GIS equipment

A technology of SF6 and equipment, applied in the field of SF6 gas automatic filling system, can solve the problems of DIS equipment safety hazards, waste of manpower and material resources, low reliability, etc., and achieve stable and reliable filling results, safe and reliable use, and improved efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

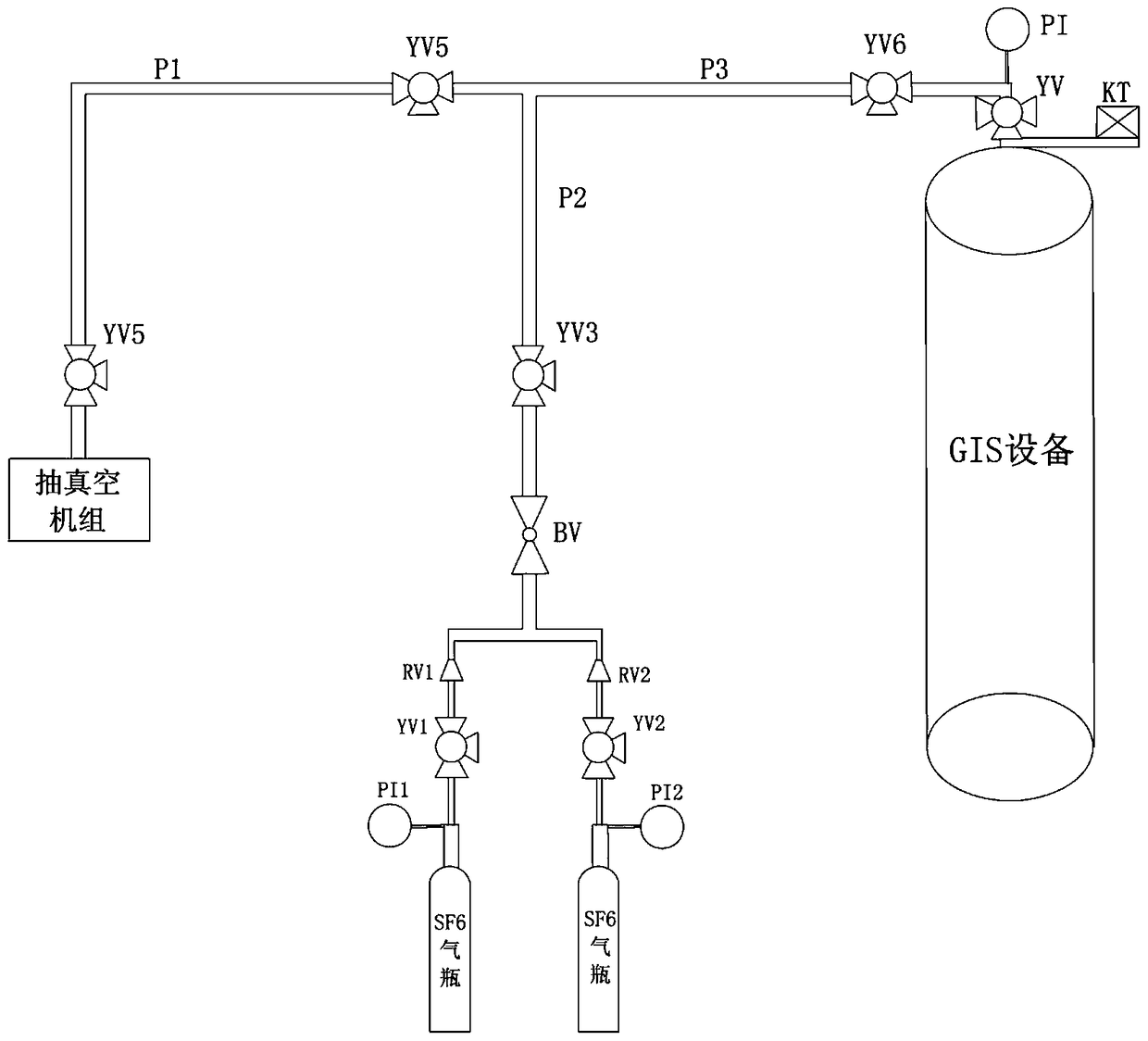

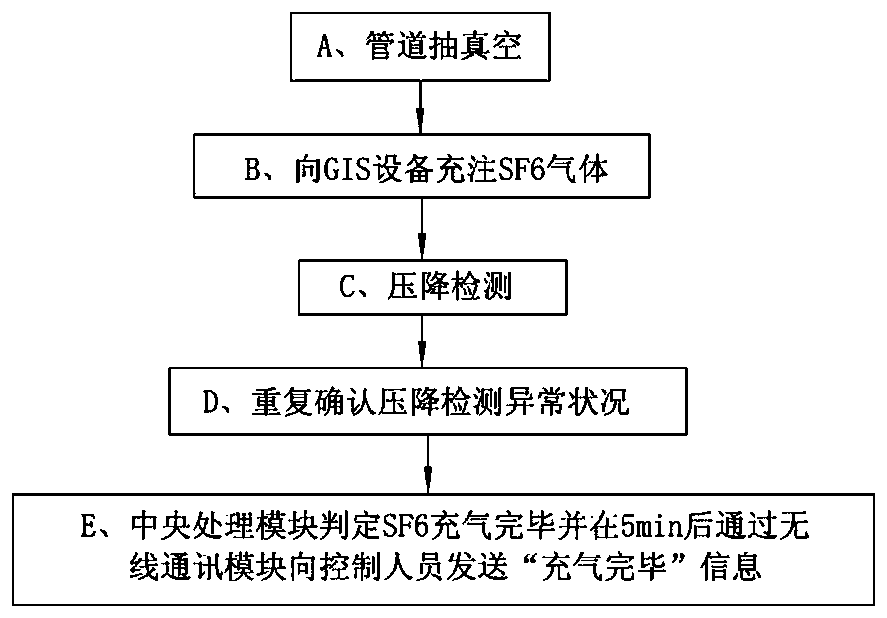

[0031] Such as figure 1 As shown, the present invention discloses a SF6 gas automatic filling system for GIS equipment, comprising an SF6 gas cylinder and a vacuum unit, the vacuum unit is connected to the gas chamber of the GIS equipment through the vacuum pipeline P1, and the SF6 gas cylinder is passed through the filling pipeline P2 is connected to the gas chamber of the GIS equipment. The GIS equipment is equipped with a density relay KT for detecting the SF6 gas density in the gas chamber, and also includes a central processing module, a wireless communication module and a charging control unit. The charging control unit includes the first solenoid valve YV1 , the third solenoid valve YV3, the fourth solenoid valve YV4, the sixth solenoid valve YV6 and the body electronic pressure gauge PI, the vacuuming pipeline P1 and the filling pipeline P2 are connected to the GIS equipment through the public pipeline, and the first solenoid valve YV1 is set at The gas outlet of the S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com