Patents

Literature

266results about How to "Realize automatic filling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

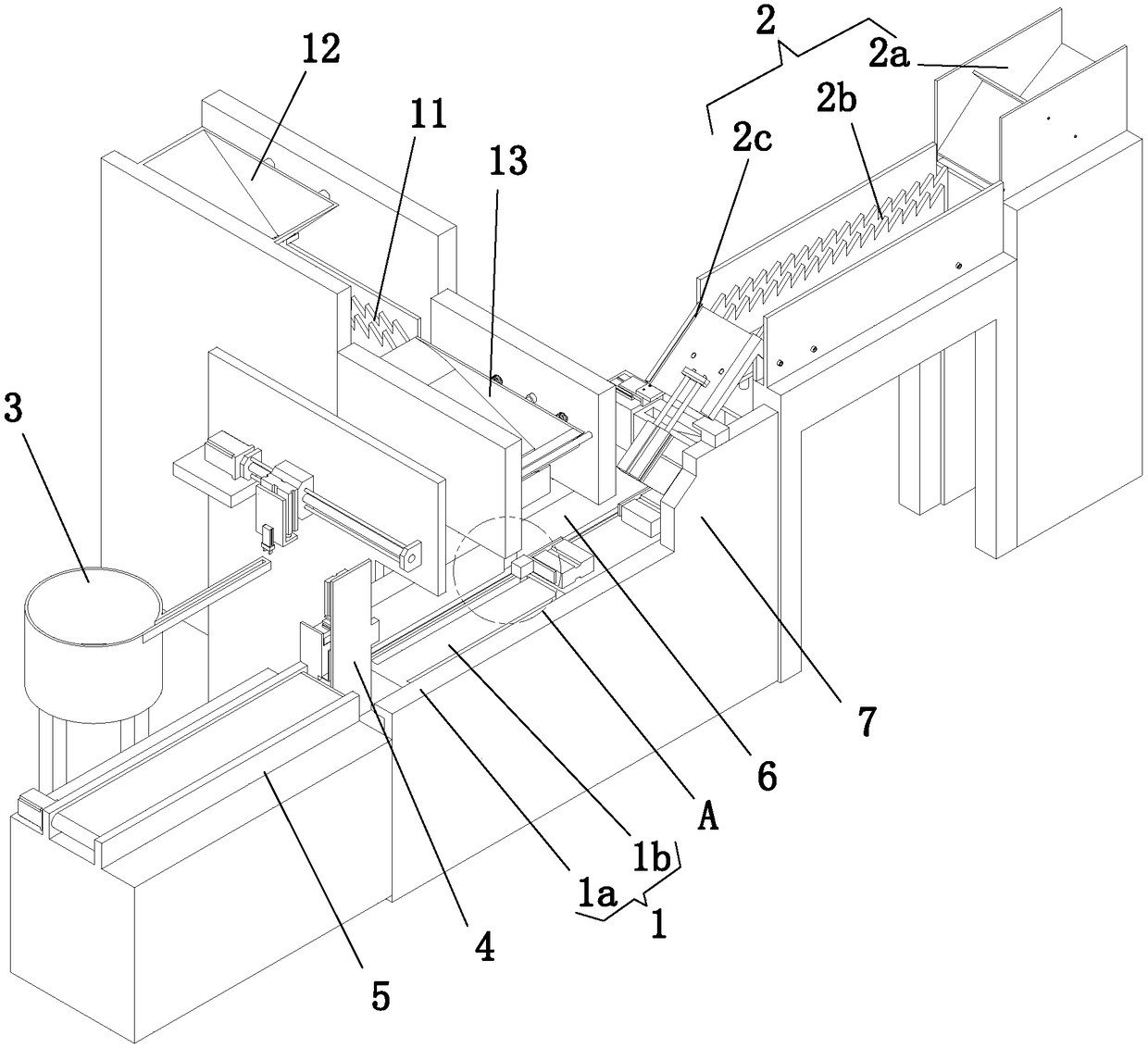

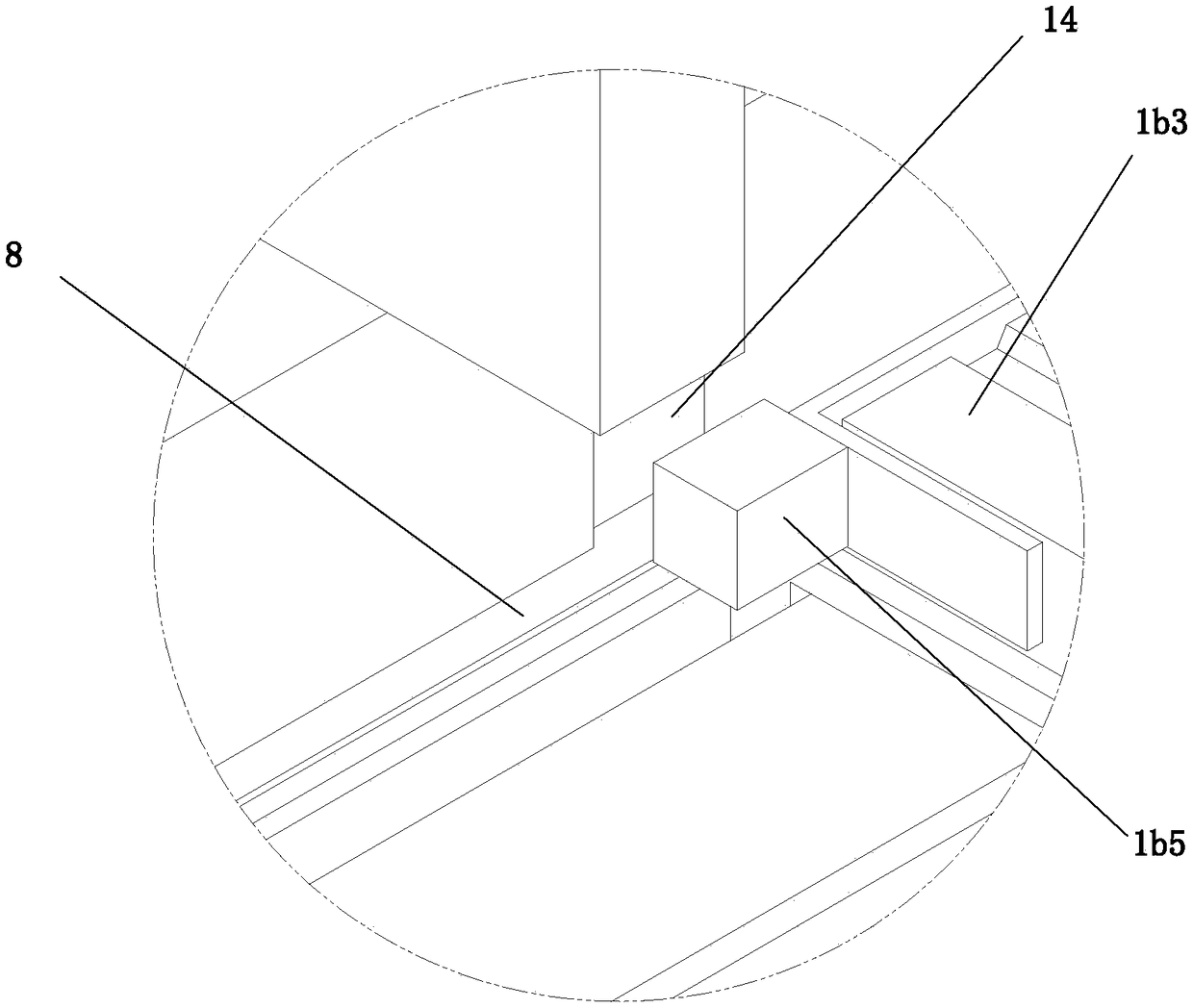

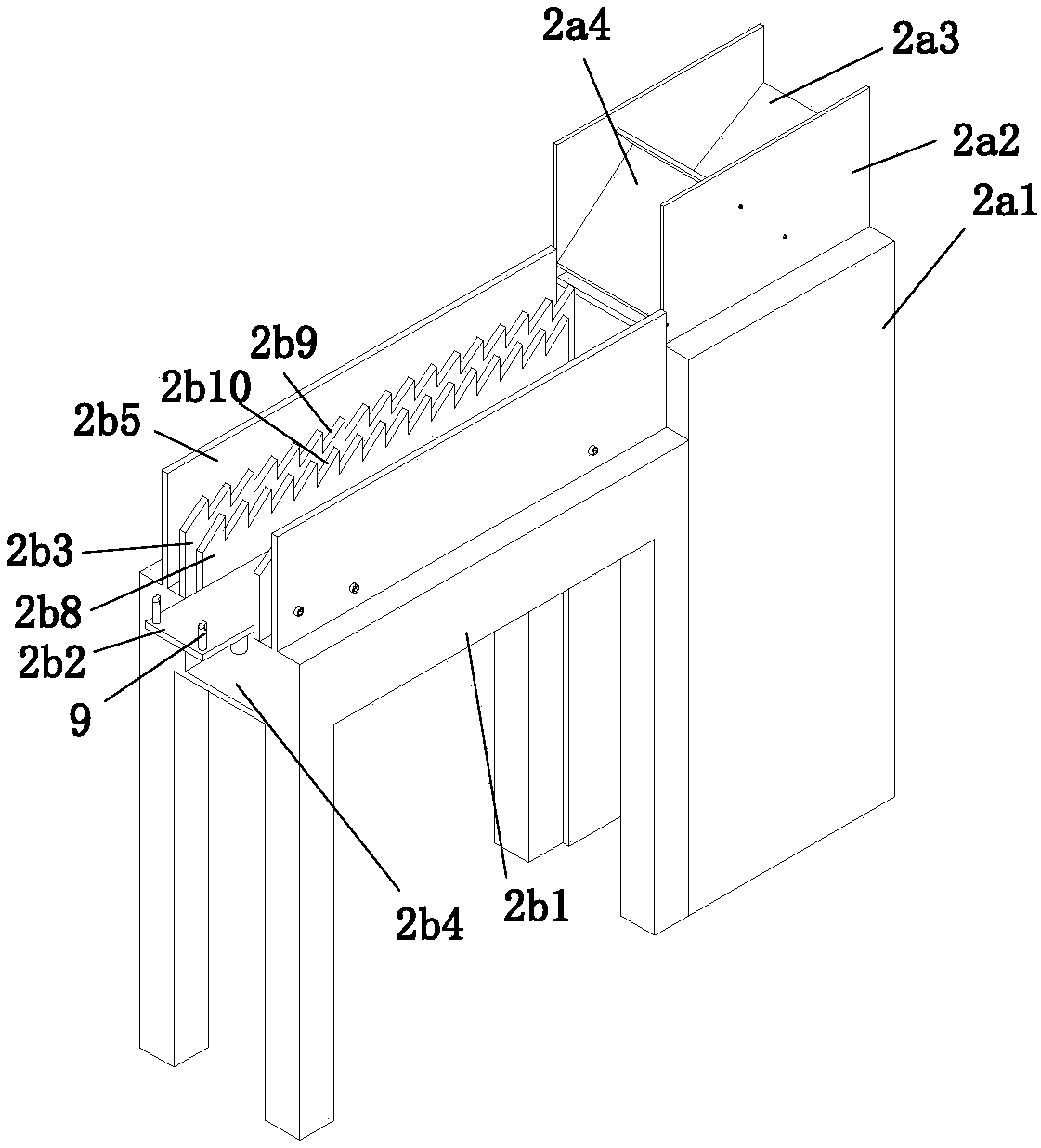

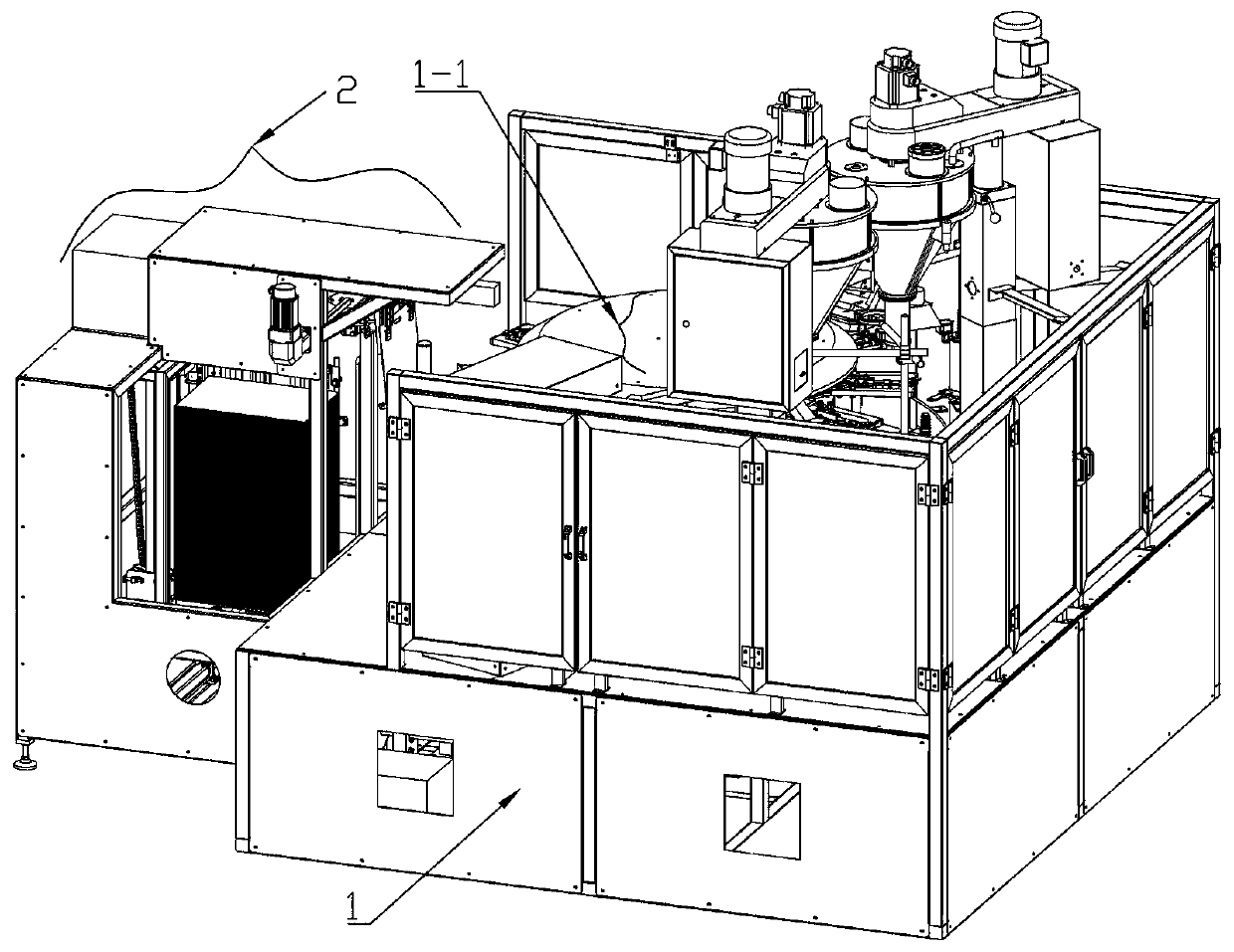

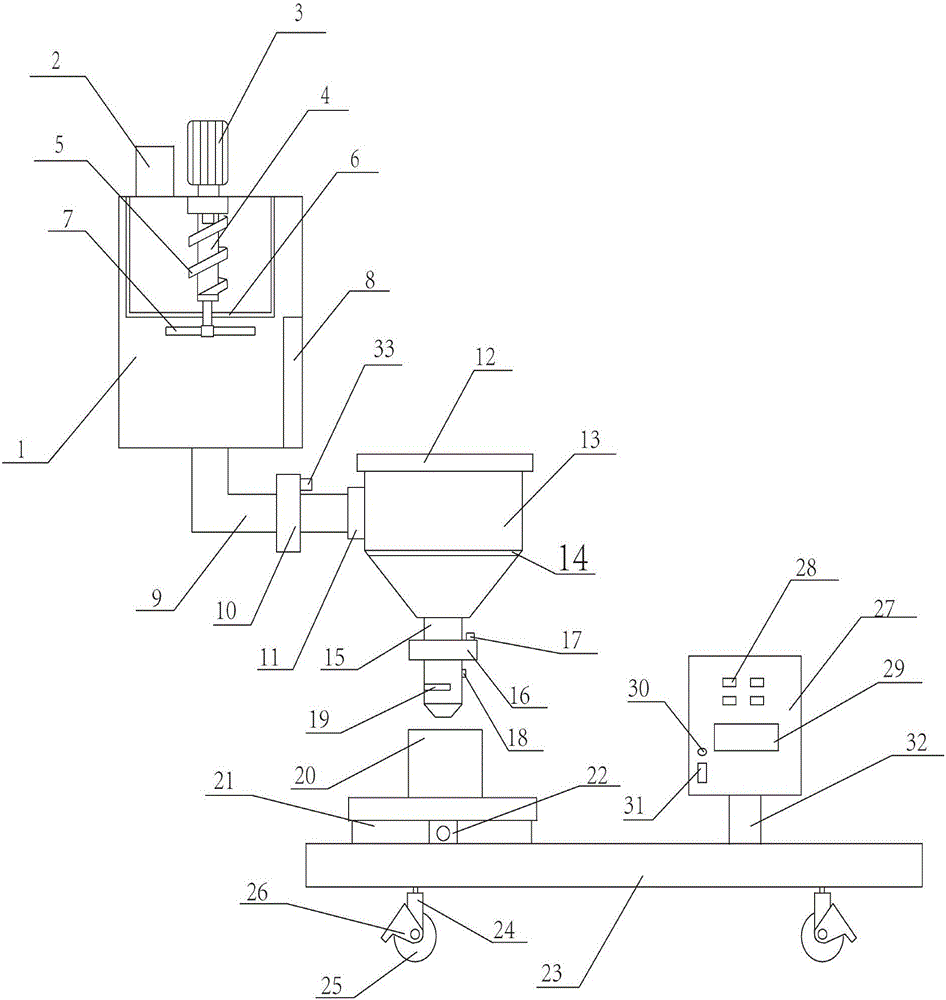

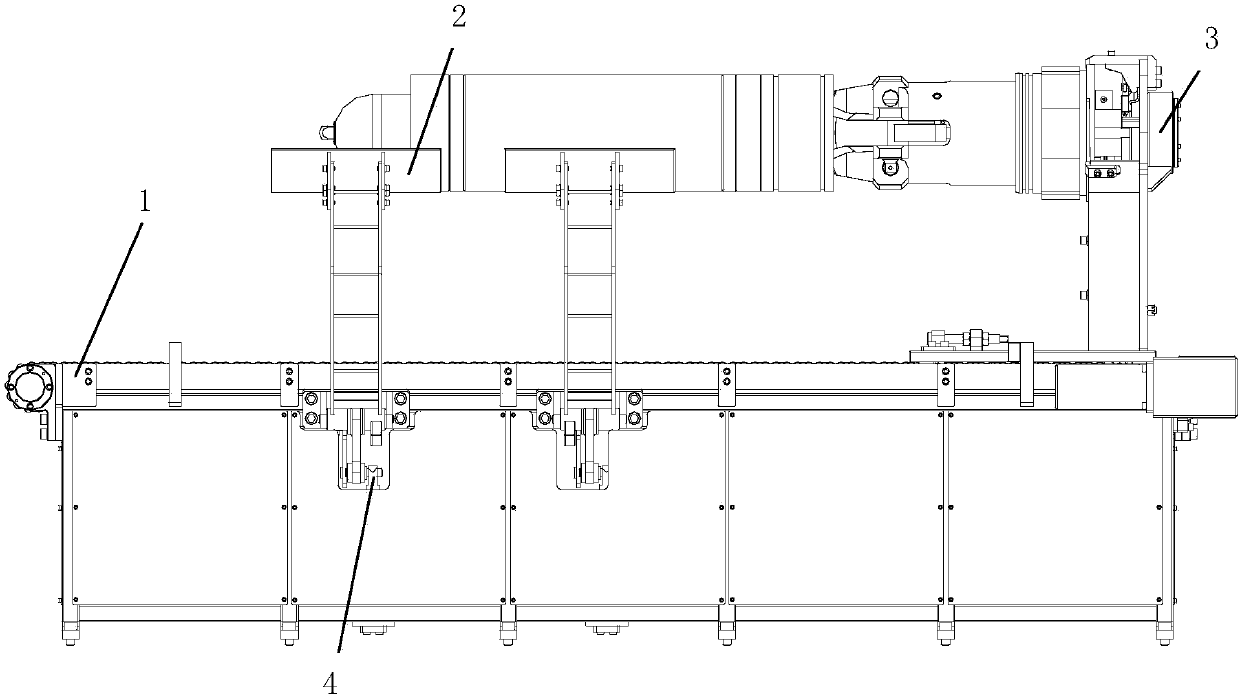

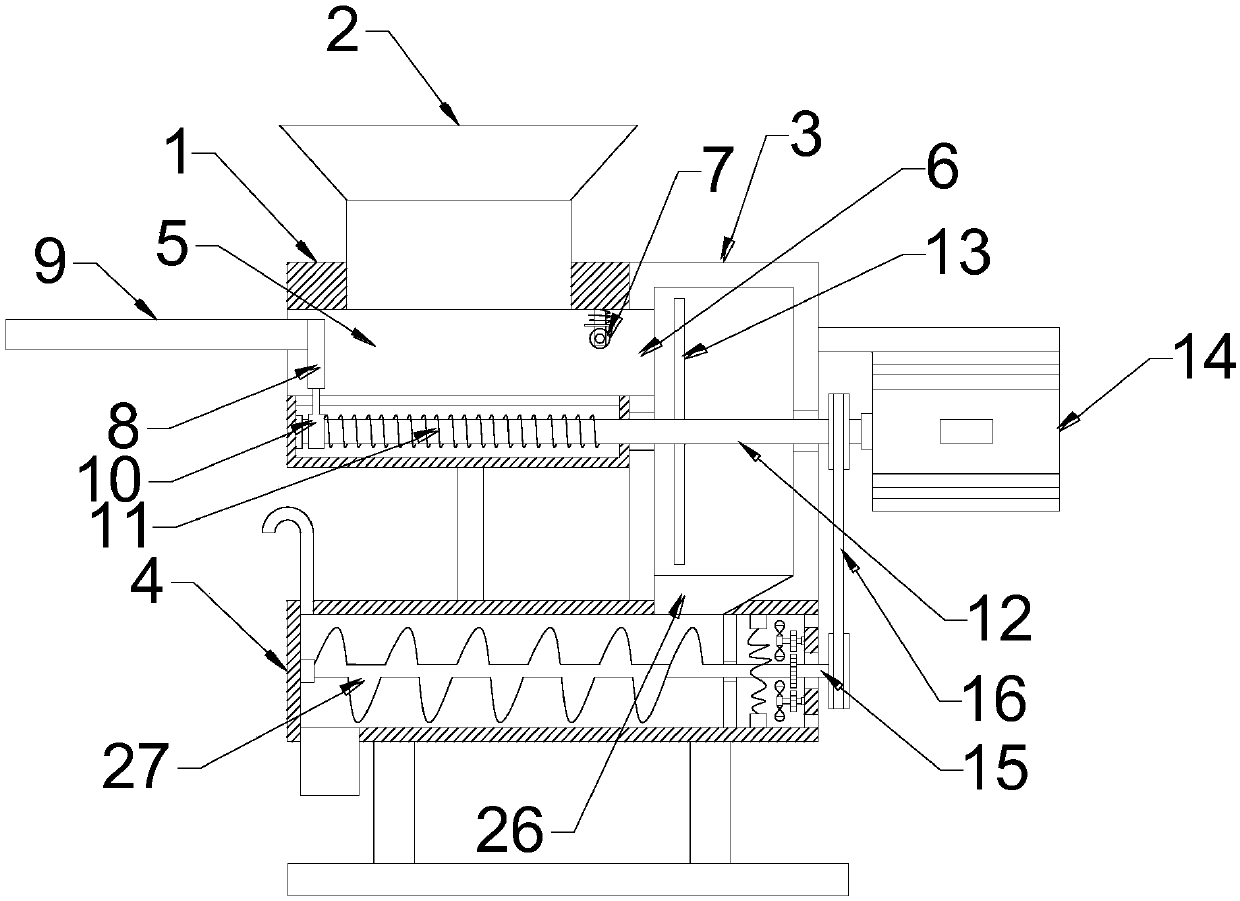

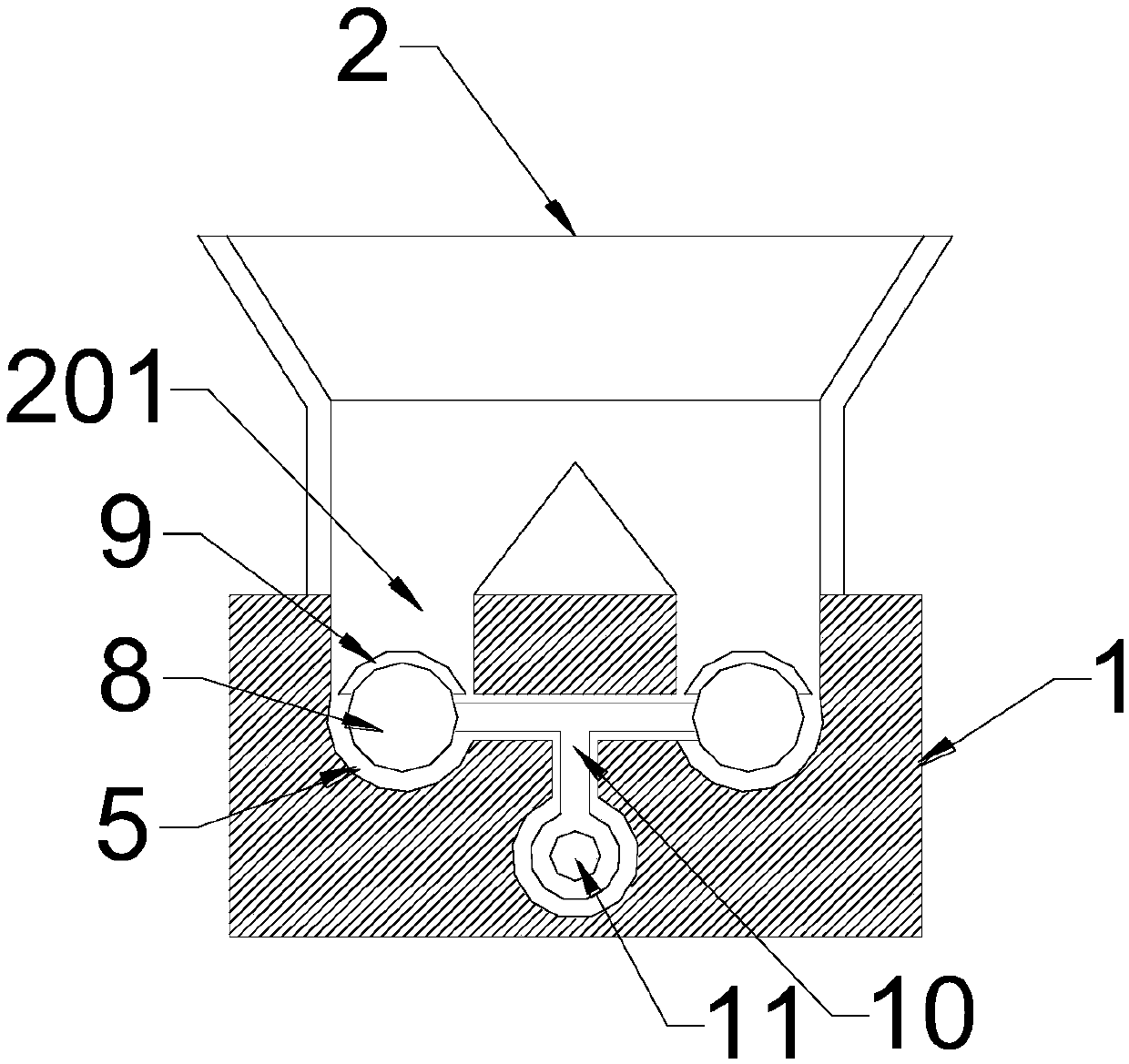

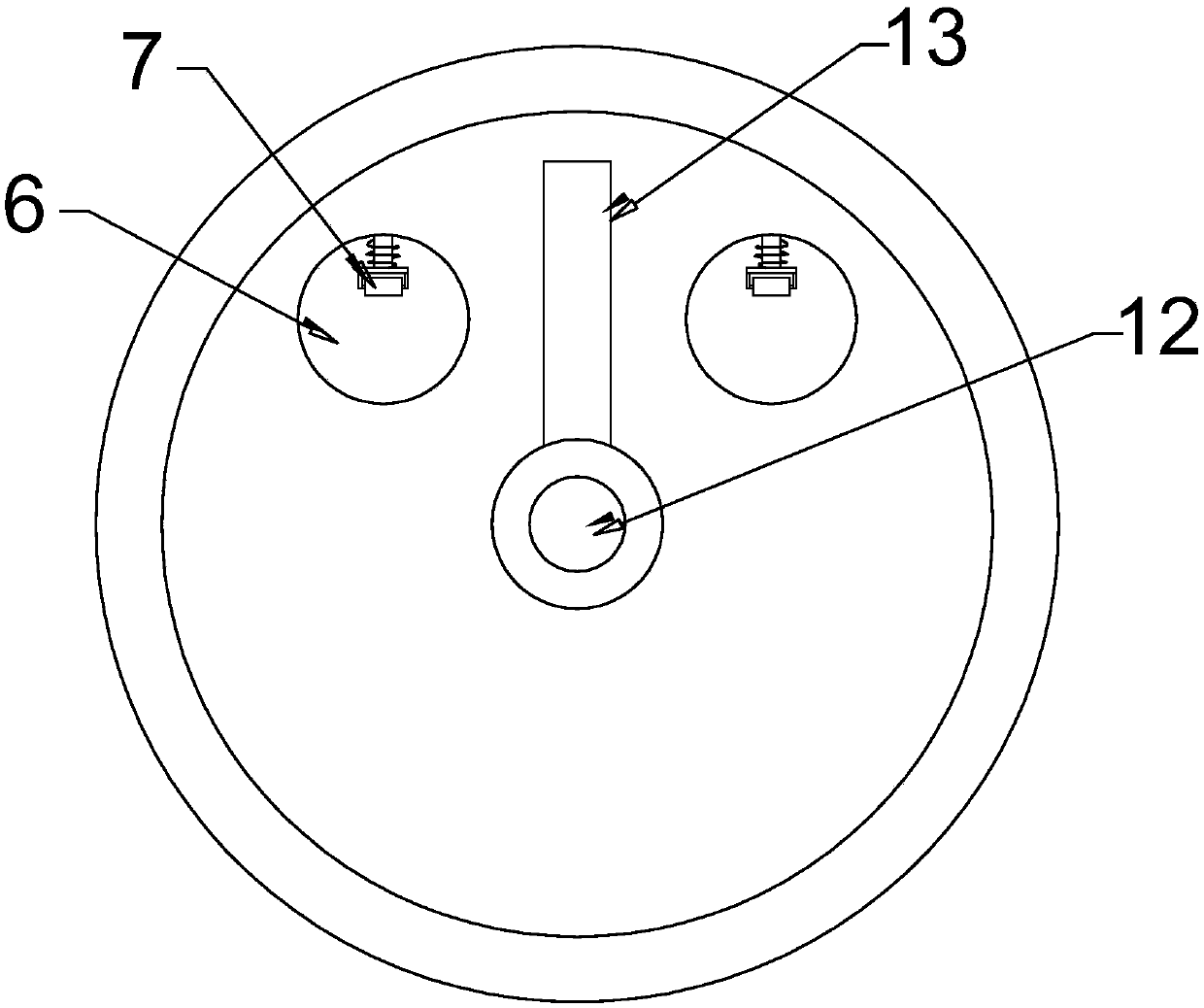

Full automatic pencil lead filling machine and filling technology thereof

ActiveCN108146687ARealize automatic fillingIncrease productivityRod-shaped articlesEngineeringMechanical engineering

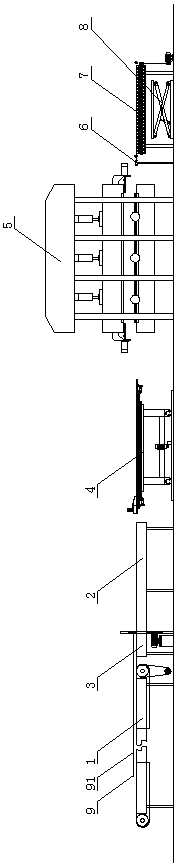

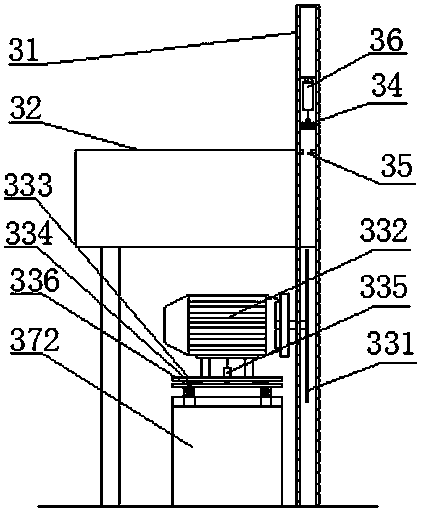

The invention relates to the field of pencil lead manufacturing, in particular to a full automatic pencil lead filling machine. The full automatic pencil lead filling machine comprises a pencil lead barrel charging and locating device, a conveying device, a pencil lead charging and locating device, a pencil lead barrel cover charging device, a press-fitting device and a finished product conveyingbelt; the pencil lead barrel charging and locating device, the conveying device and the finished product conveying belt are arranged in the conveying direction of the conveying device; the pencil leadcharging and locating device is perpendicular to the conveying device; the pencil lead barrel cover charging device is located on the side of the pencil lead charging and locating device; the conveying device comprises a first rack and a conveying mechanism; a mounting groove is formed in the top of the first rack; the conveying mechanism is fixed in the mounting groove; the press-fitting deviceis fixed in the mounting groove and is located between the conveying mechanism and the finished product conveying belt; a first supporting block and a second supporting block are arranged on the firstrack symmetrically; and a first slideway is arranged on one side, facing the second supporting block, of the first supporting block. Automatic filling of pencil leads is realized, the production efficiency is improved and the technology is simple and reliable.

Owner:陈信发

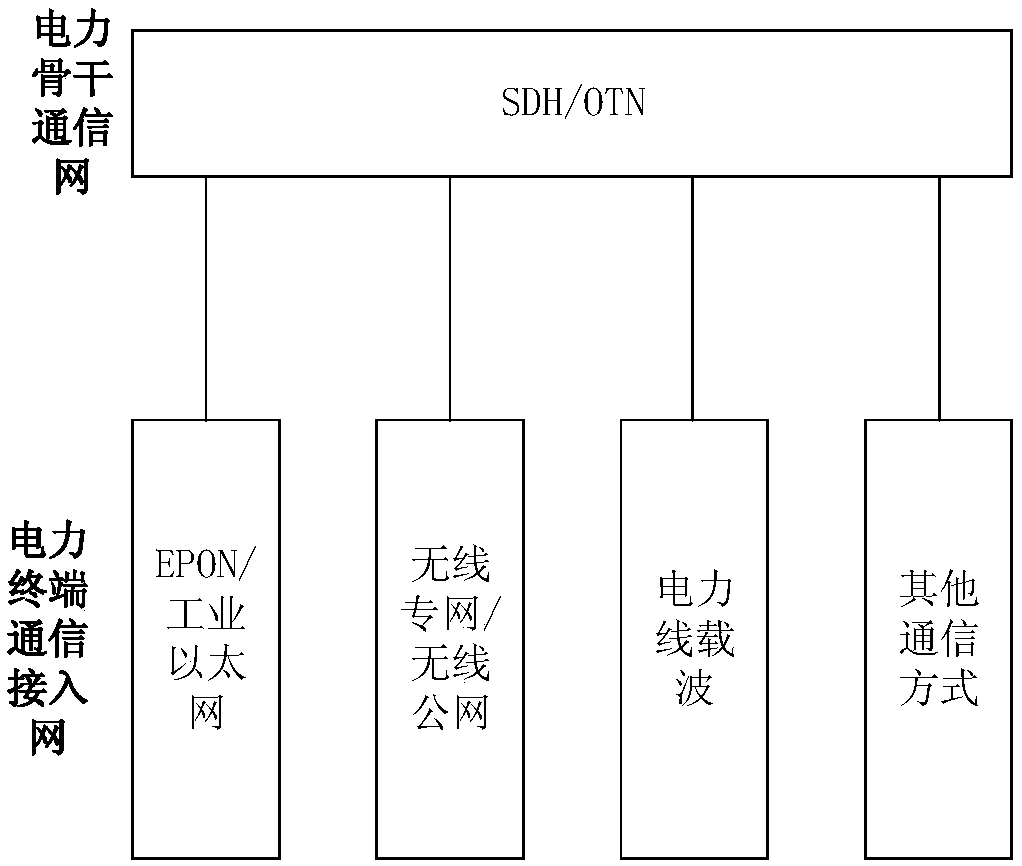

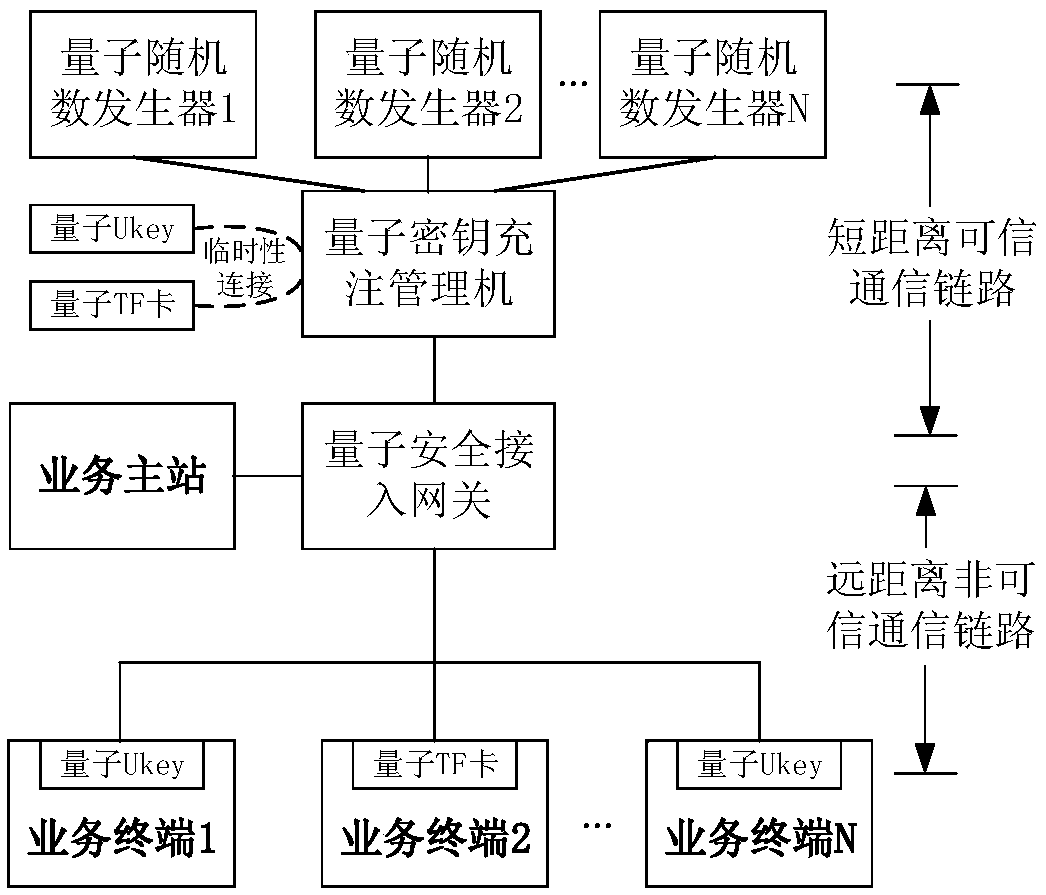

Automatic quantum key charging method and system adapting to electric power services

ActiveCN109412794AImprove the level of practicalityReduce construction costsKey distribution for secure communicationPrimary stationQuantum authentication

The invention discloses an automatic quantum key charging method and system adapting to electric power services. Quantum keys are divided into a quantum authentication key, a quantum encryption key and a quantum updating key according to a deployment structure for electric power service main station convergence and electric power service terminal access; the quantum authentication key is used foridentity authentication during communication interaction; the quantum encryption key is used for encryption and decryption of data during the communication interaction; and the quantum updating key isused to encrypt and decrypt a new quantum key in the communication interaction when used to update the quantum authentication key and the quantum encryption key and / or the quantum updating key. The quantum updating key updates the quantum authentication, encryption and / or updating keys, thereby realizing automatic charging and updating of the quantum keys.

Owner:南京南瑞网络安全技术有限公司 +2

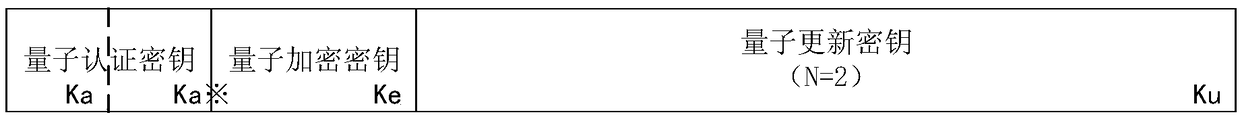

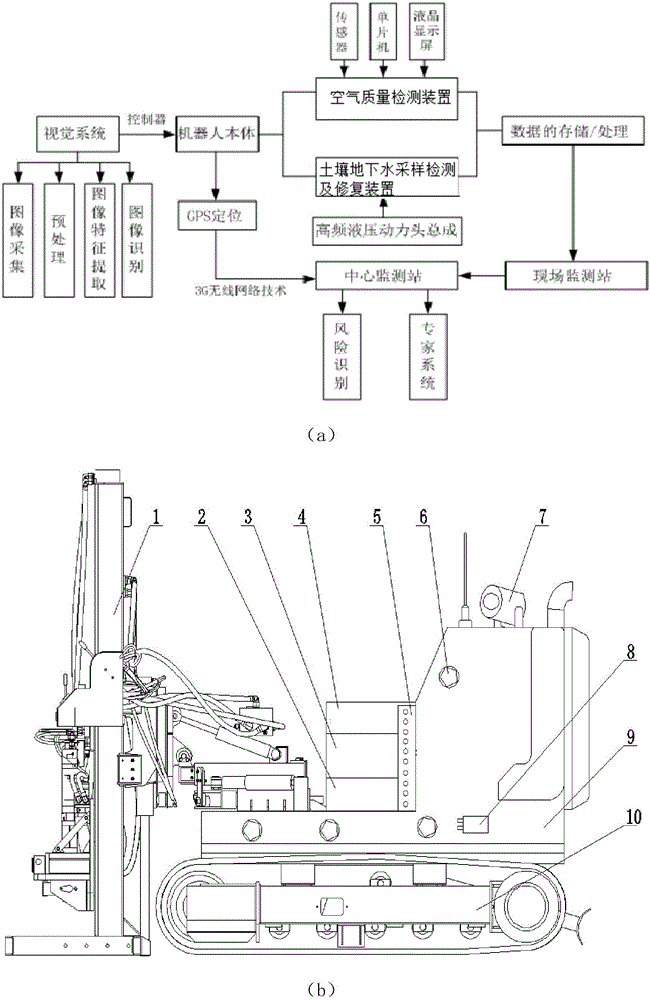

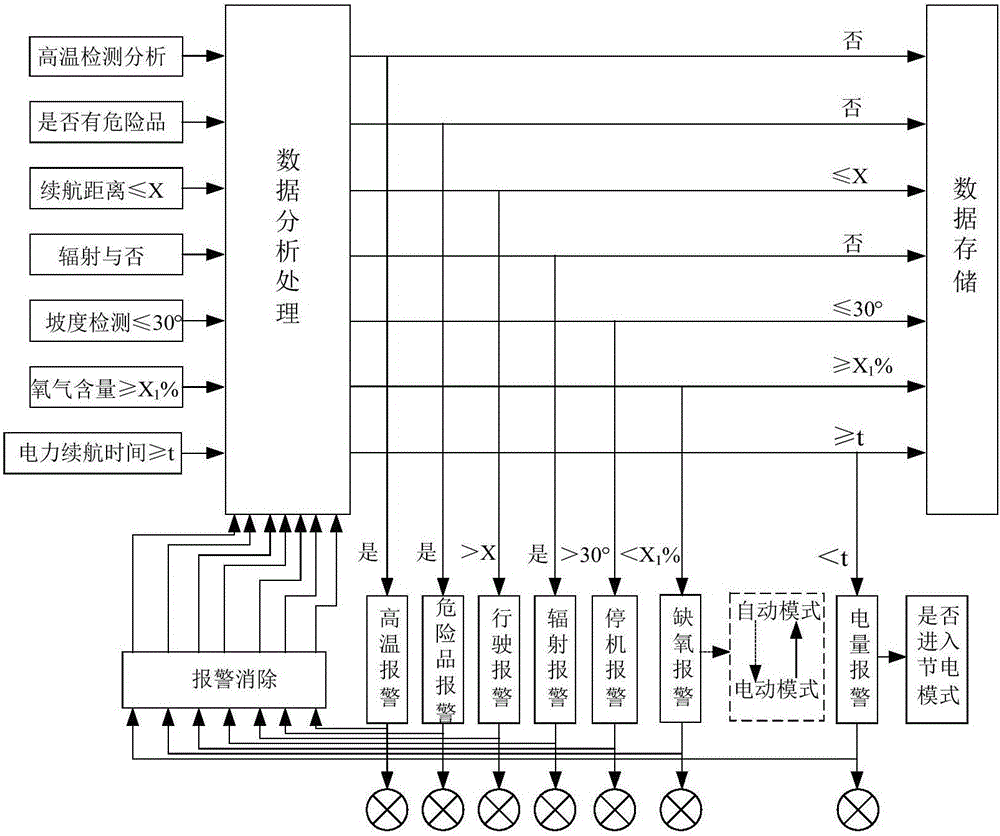

Engineering robot for environmental monitoring, environmental emergency handling and environmental remediation

ActiveCN105965547AStructural refinementGood integration effectManipulatorEnvironmental riskData processing

The invention provides an engineering robot for environmental monitoring, environmental emergency handling and environmental remediation. The engineering robot comprises a machine vision device, a self-alarm device, a remote control device, a GPS real-time positioning device, an air quality detection device, a soil underground water sampling detection and in-situ remediation device, a risk identification device, an environmental expert system, a data processing center, a robot body and a mobile device, wherein the machine vision device, the self-alarm device, the remote control device, the GPS real-time positioning device, the air quality detection device, the soil underground water sampling detection and in-situ remediation device, the risk identification device, the environmental expert system and the mobile device are all connected with the data processing center, and the soil underground water sampling detection and in-situ remediation device is further provided with an automatic drill stem filling device. The engineering robot integrates the multiple advanced technologies of soil underground water environmental risk detection and in-situ remediation, rapid environmental quality detection, machine vision, remote control, GPS real-time positioning, risk identification, the environmental expert system and the like, the structure is more simplified, and more comprehensive functions are achieved.

Owner:NANJING YIDESI ENVIRONMENTAL SCI & TECH CO LTD

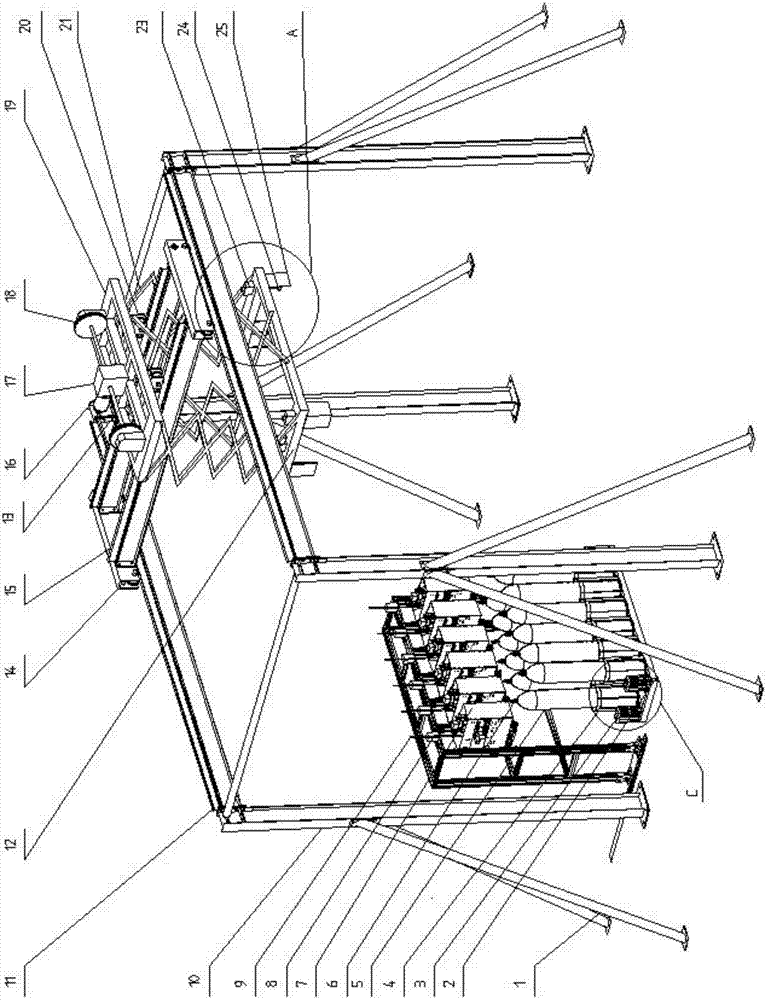

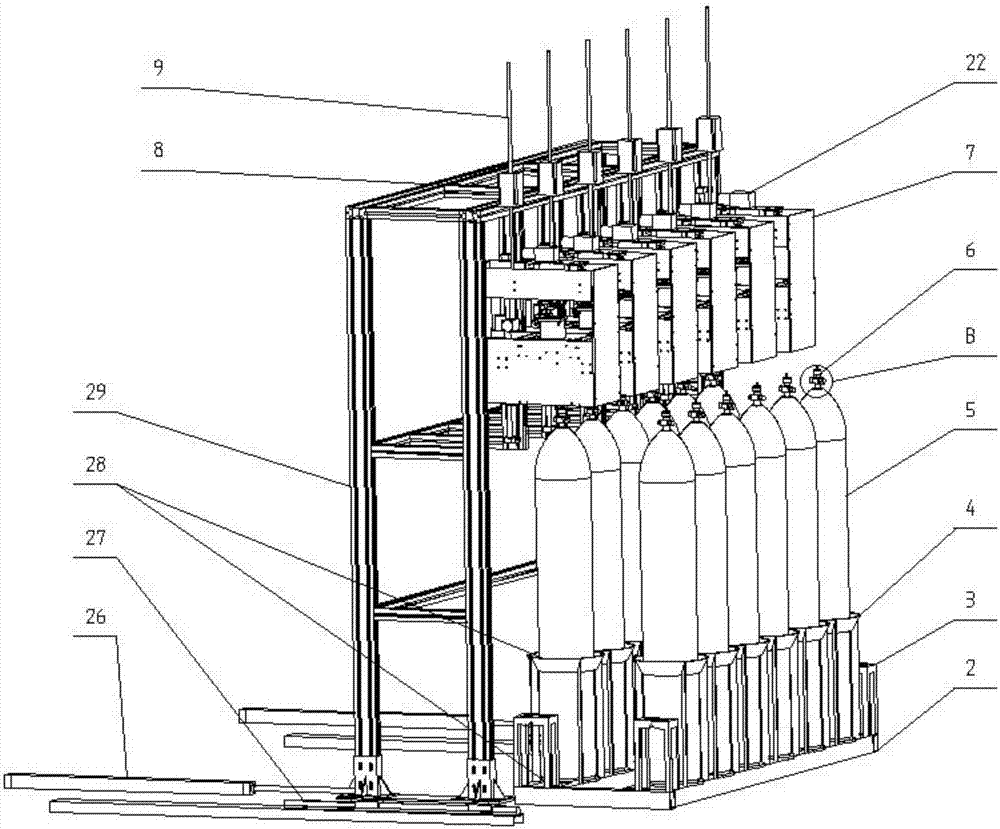

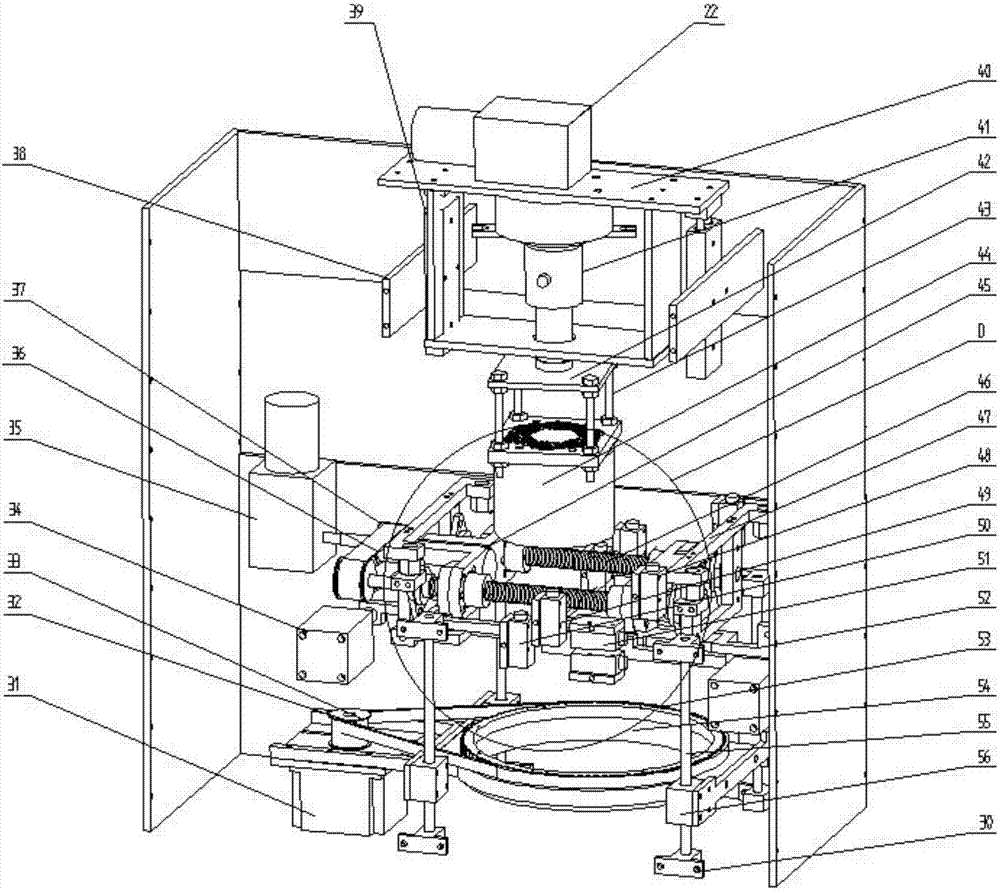

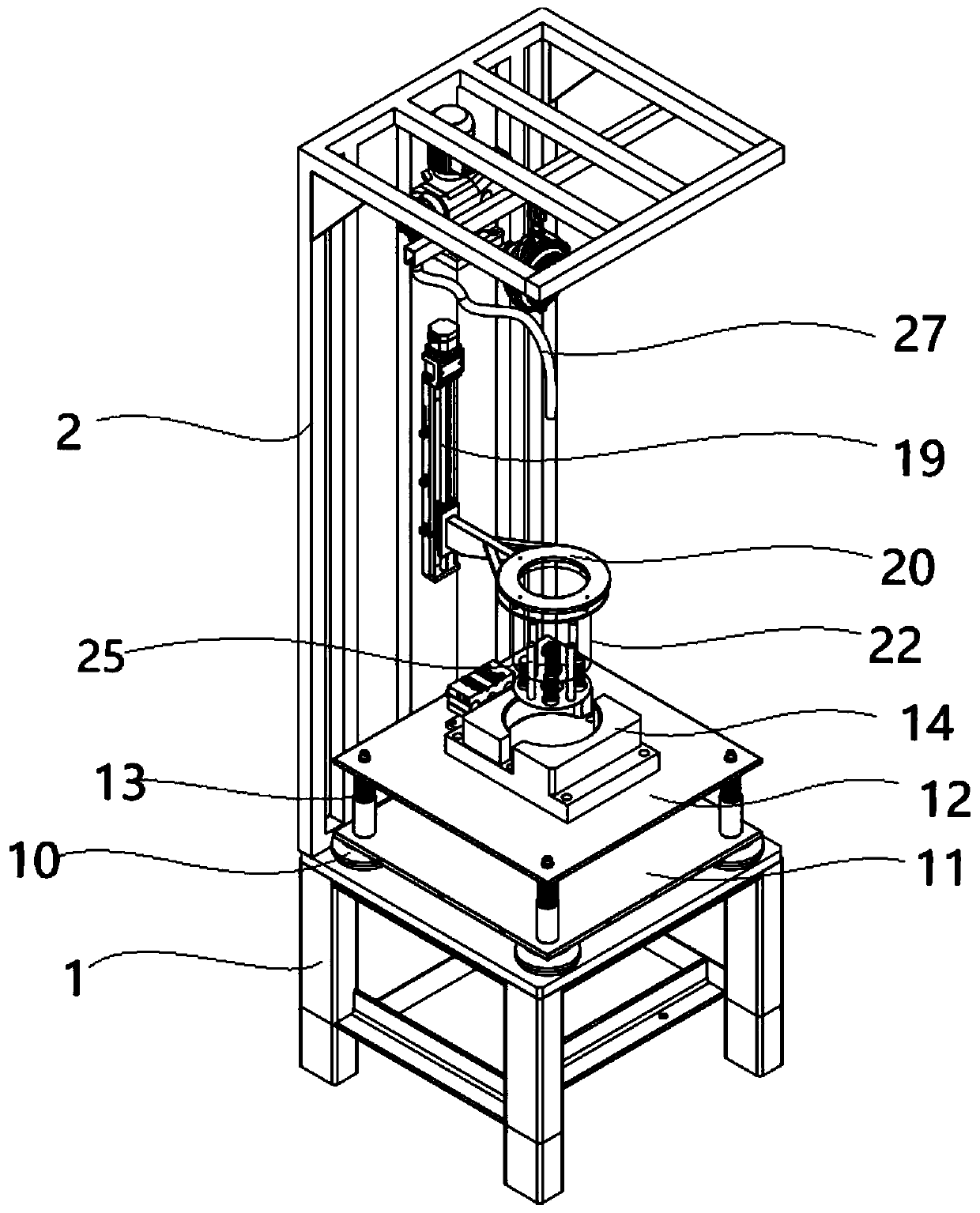

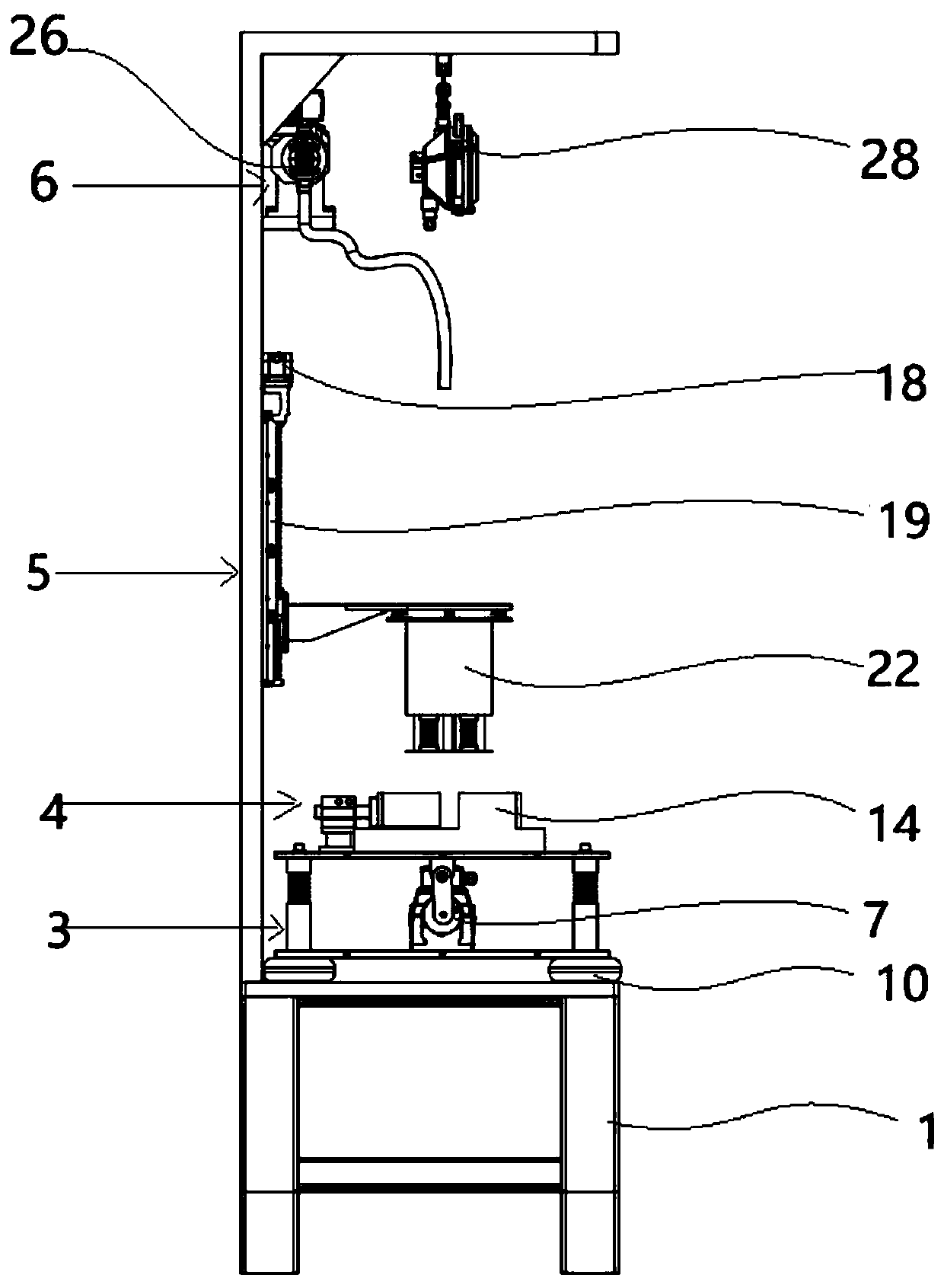

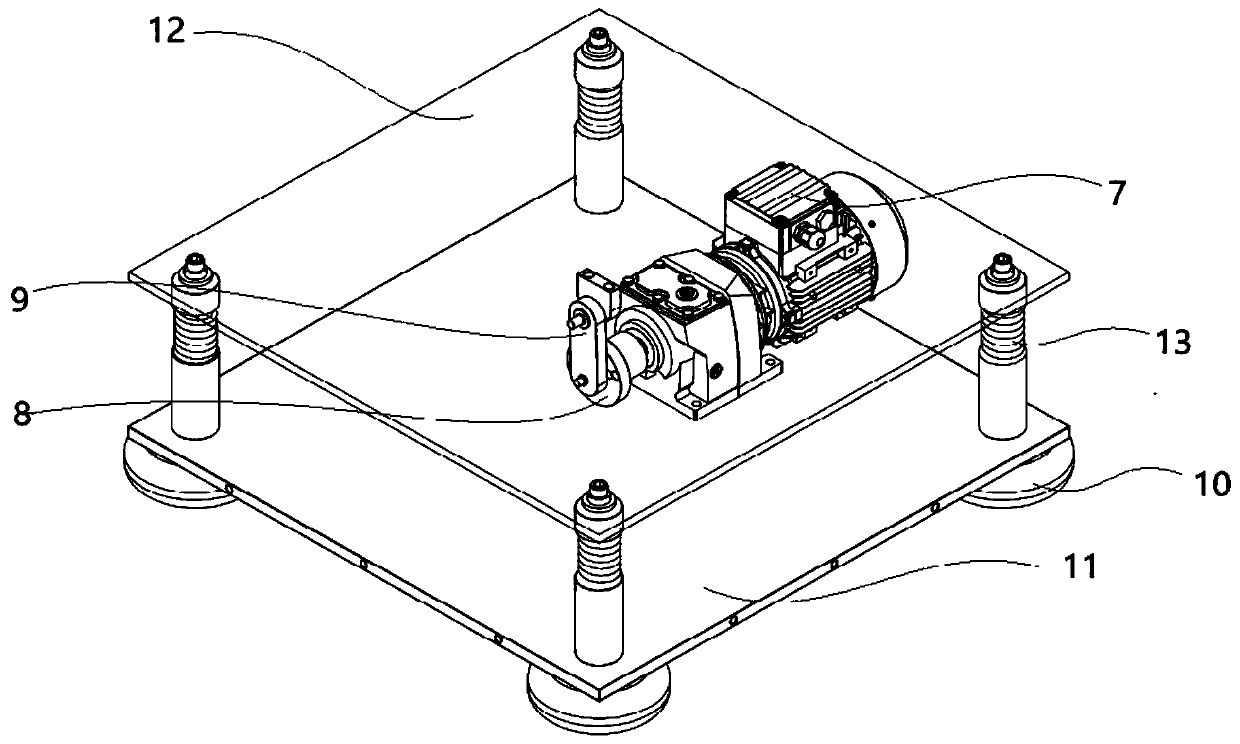

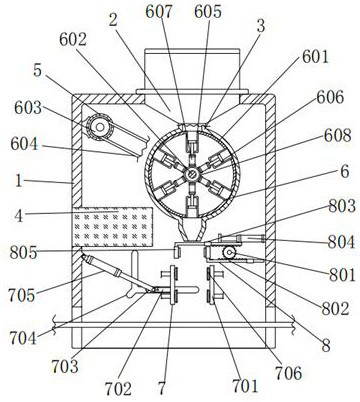

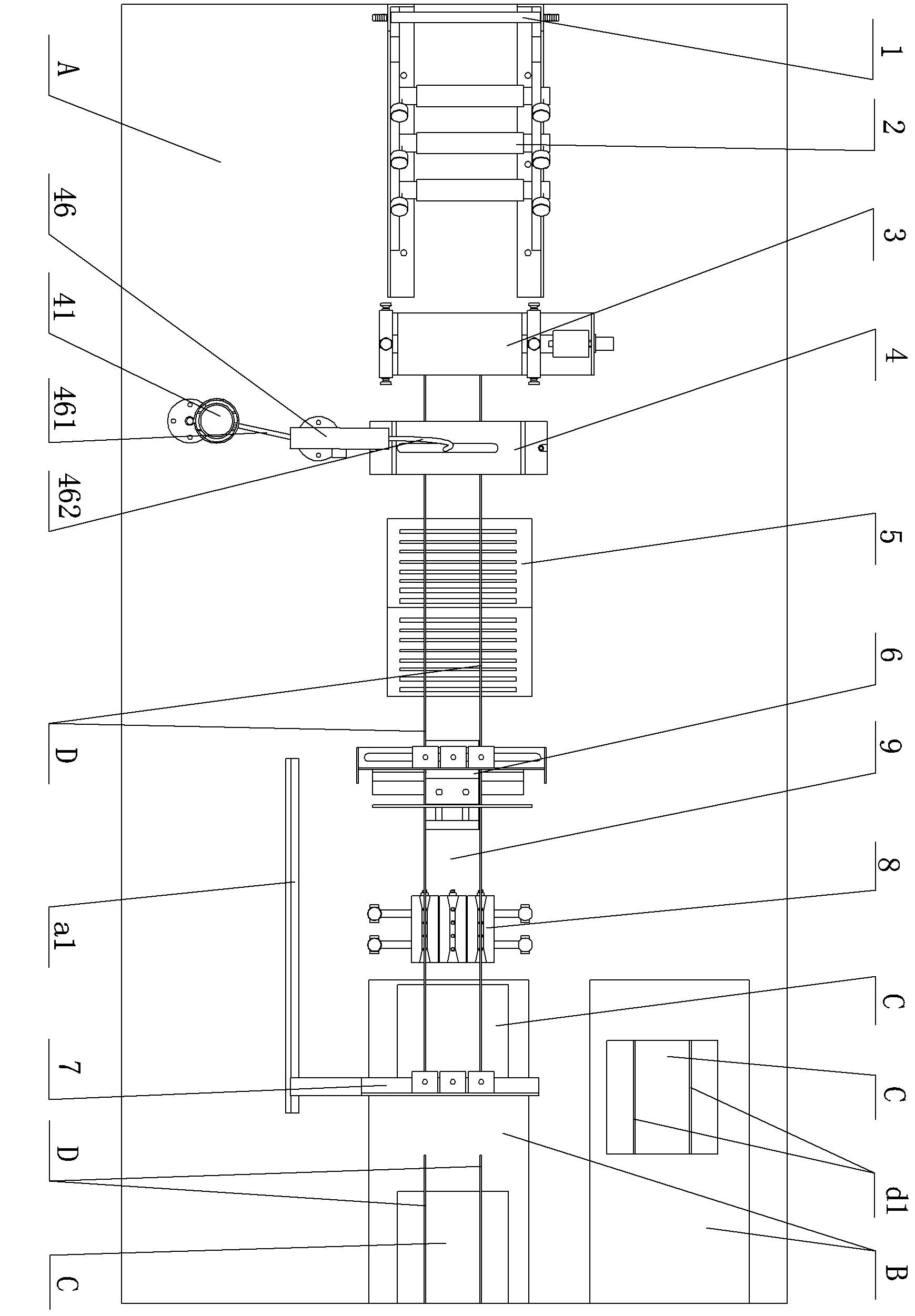

Automatic gas cylinder filling device and method

ActiveCN107237977AAvoid harmReduce labor intensityVessel mounting detailsContainer discharging methodsCylinder ValveProduct gas

The invention relates to an automatic gas cylinder filling device and method, and belongs to the technical field of methods and equipment for filling pressure containers with liquefied gas or solidified gas or compressed gas. The automatic gas cylinder filling device comprises a filling frame, a gas cylinder holding frame and a filling tank, wherein the filling frame is provided with a lifting driving mechanism with the lower end connected with the filling tank, and a cylinder valve opening-closing mechanism, a cylinder valve detection filling mechanism and a gas cylinder rotating mechanism are sequentially mounted in the filling tank from top to bottom. The automatic gas cylinder filling device further comprises a PLC which is connected with the lifting driving mechanism, the cylinder valve opening-closing mechanism, the cylinder valve detection filling mechanism and the gas cylinder rotating mechanism. PLC automatic configuration is adopted, automatic filling is achieved, filling staff are isolated in the gas filling process and are prevented from being injured when dangers happen during gas filling, the labor intensity of the staff is reduced, and labor is greatly saved.

Owner:济宁协力能源有限公司

Channel type automatic cigarette-sorting and -storing method and apparatus thereof

InactiveCN1843869AImprove flow and efficiencyReduce errorsStorage devicesAutomatic controlTraffic volume

The invention discloses a channel-type tobacco automatic classify storage method and relative device, which comprises: several layers and several tobacco storage channels (1). The whole process of feeding, storing and discharging are automatically controlled by computer (2). The invention can realize unattended operation of tobacco, to improve efficiency and flux, which replaces the disc unit with tobacco unit as transmission unit, to realize automatic tobacco feeding and selecting. And it can improve the safety of storehouse and reduce the labor intensity of worker.

Owner:GUIYANG PUTIAN LOGISTICS TECH

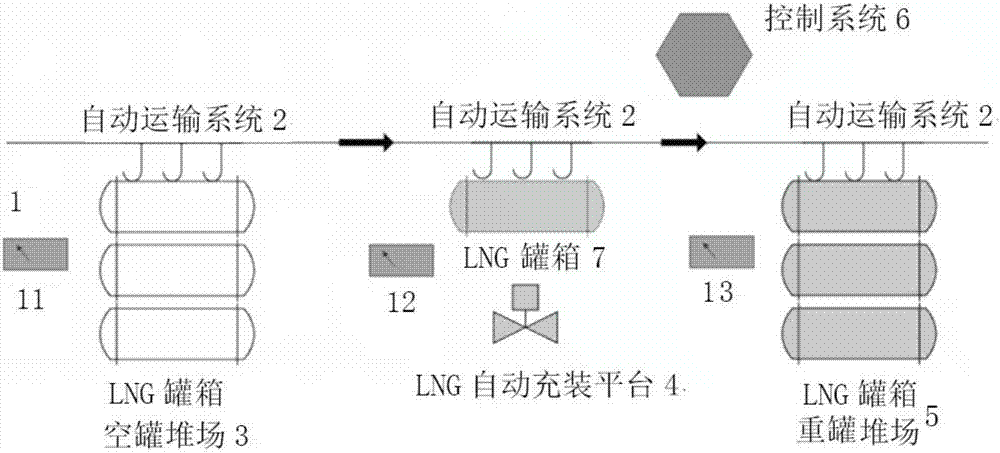

LNG tank box assembly line filling system

ActiveCN107479424AShorten filling timeRemove uncertaintyProgramme control in sequence/logic controllersMarine engineeringControl system

The invention relates to an LNG tank box assembly line filling system, and the system is characterized in that the system comprises a scanning and information recorder, an LNG tank box empty tank storage yard, an automatic conveying system, an LNG automatic filling platform, a control system and an LNG tank box refilling storage yard. The scanning and information recorder is used for obtaining the recognition information of an LNG tank box before filling, during filling and after filling. The automatic conveying system is connected with the LNG tank box empty tank storage yard, the LNG automatic filling platform and the LNG tank box refilling storage yard, and is used for conveying a to-be-filled LNG tank box to sequentially pass through the LNG tank box empty tank storage yard, the LNG automatic filling platform and the LNG tank box refilling storage yard. The LNG automatic filling platform is used for completing the filling of the LNG tank box. The control system is connected with the scanning and information recorder, the automatic conveying system and the LNG automatic filling platform. The system can achieve the automatic filling of the LNG tank box, and improves the filling efficiency and safety.

Owner:CHINA NAT OFFSHORE OIL CORP +1

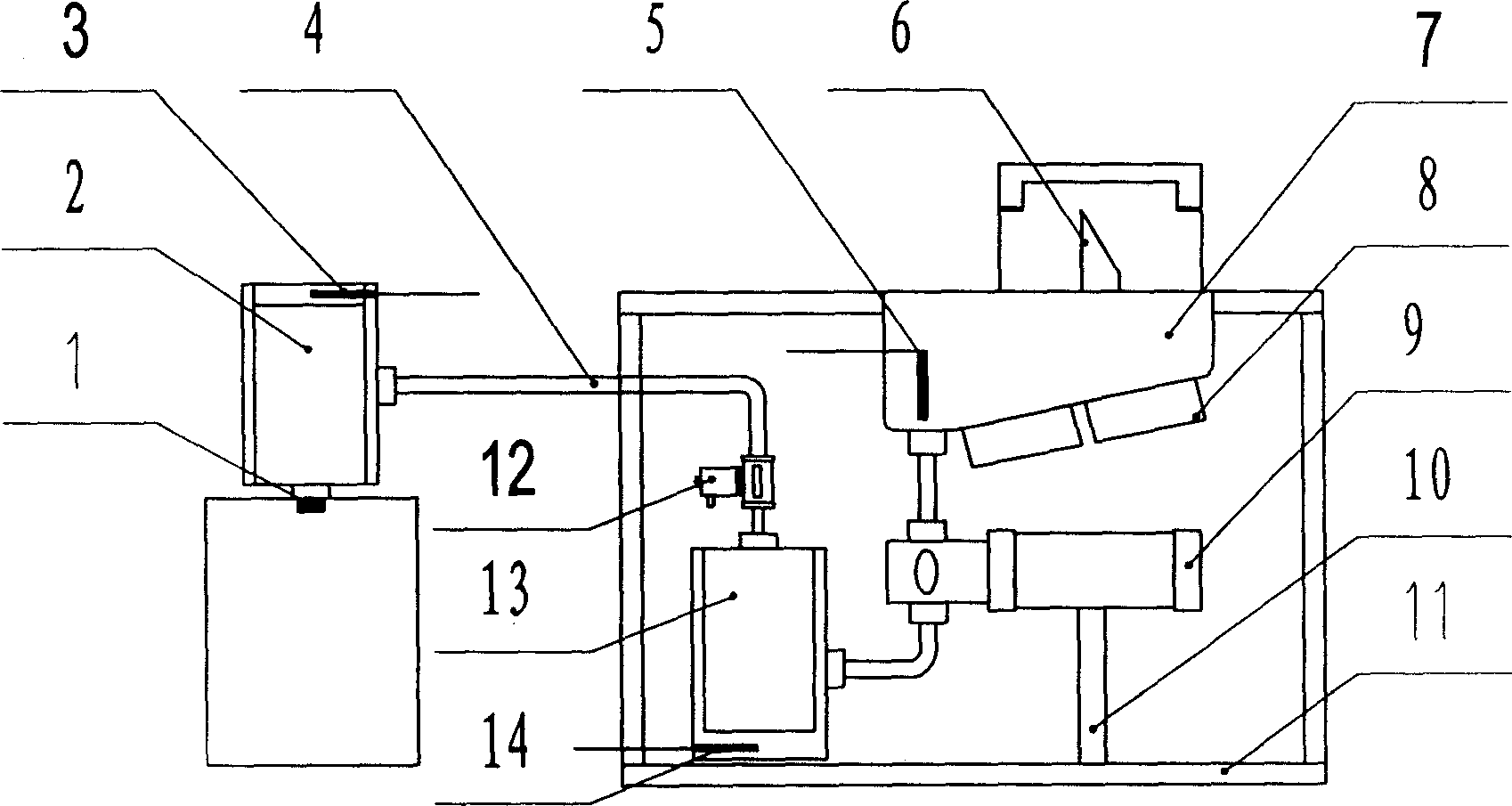

Hydrogen peroxide filling system of plasma sterilization device

InactiveCN1830491ASimple structureLow priceLavatory sanitoryDisinfectionPlasma sterilizationLiquid storage tank

A hydrogen peroxide filling system for the plasma sterilizer is composed of supporting frame, liquid storage tank, evaporator with nozzle, delivering pipeline between said liquid storage tank, and the high-precision metering pump with step motor, which is installed to said delivering pipeline.

Owner:SHINVA MEDICAL INSTR CO LTD

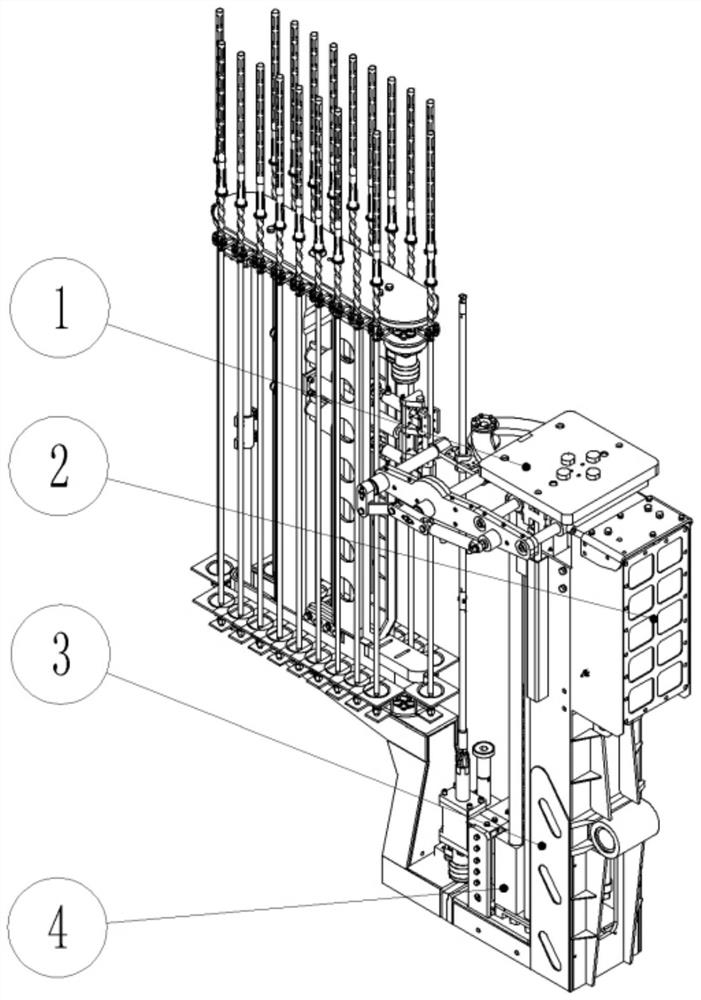

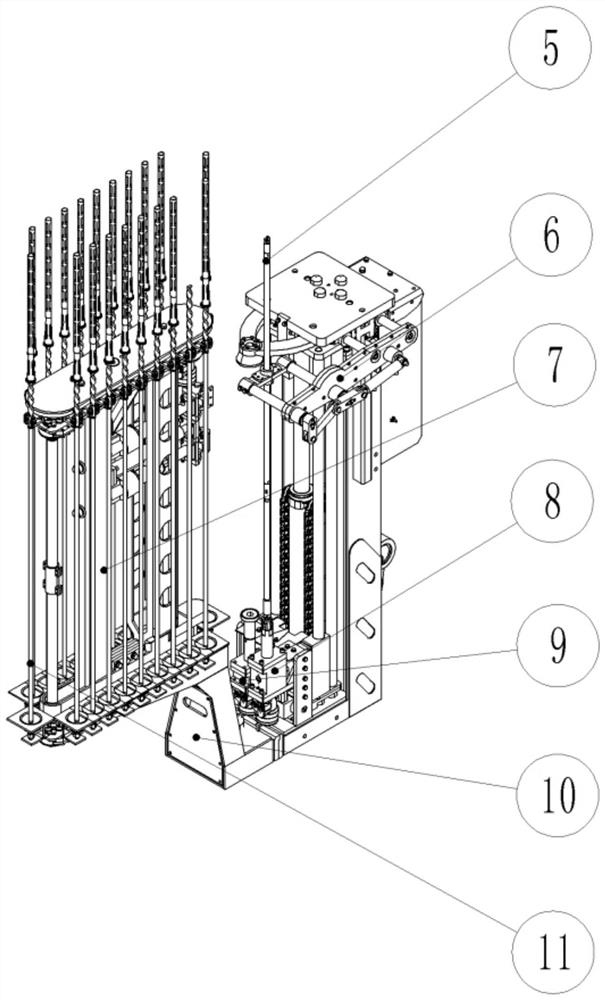

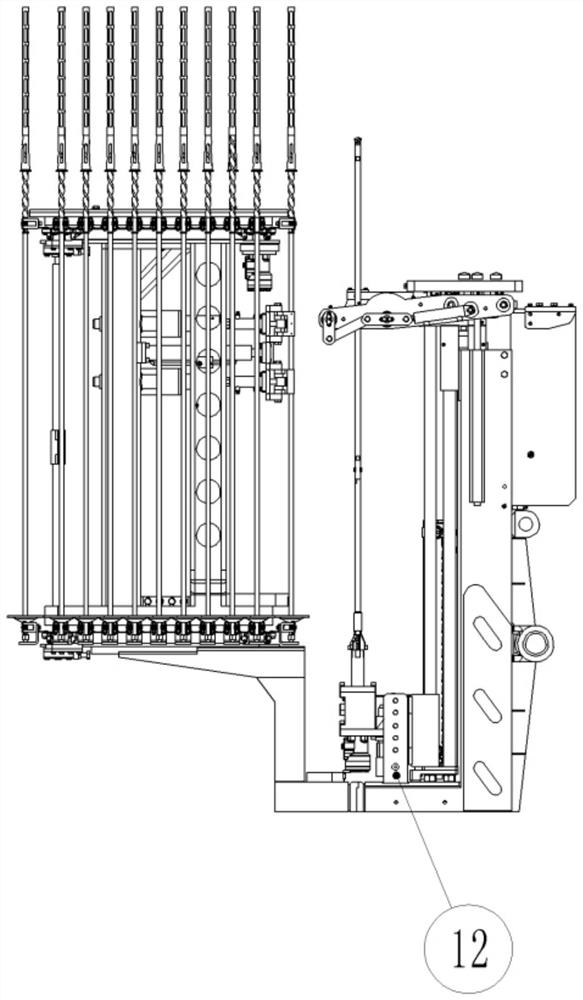

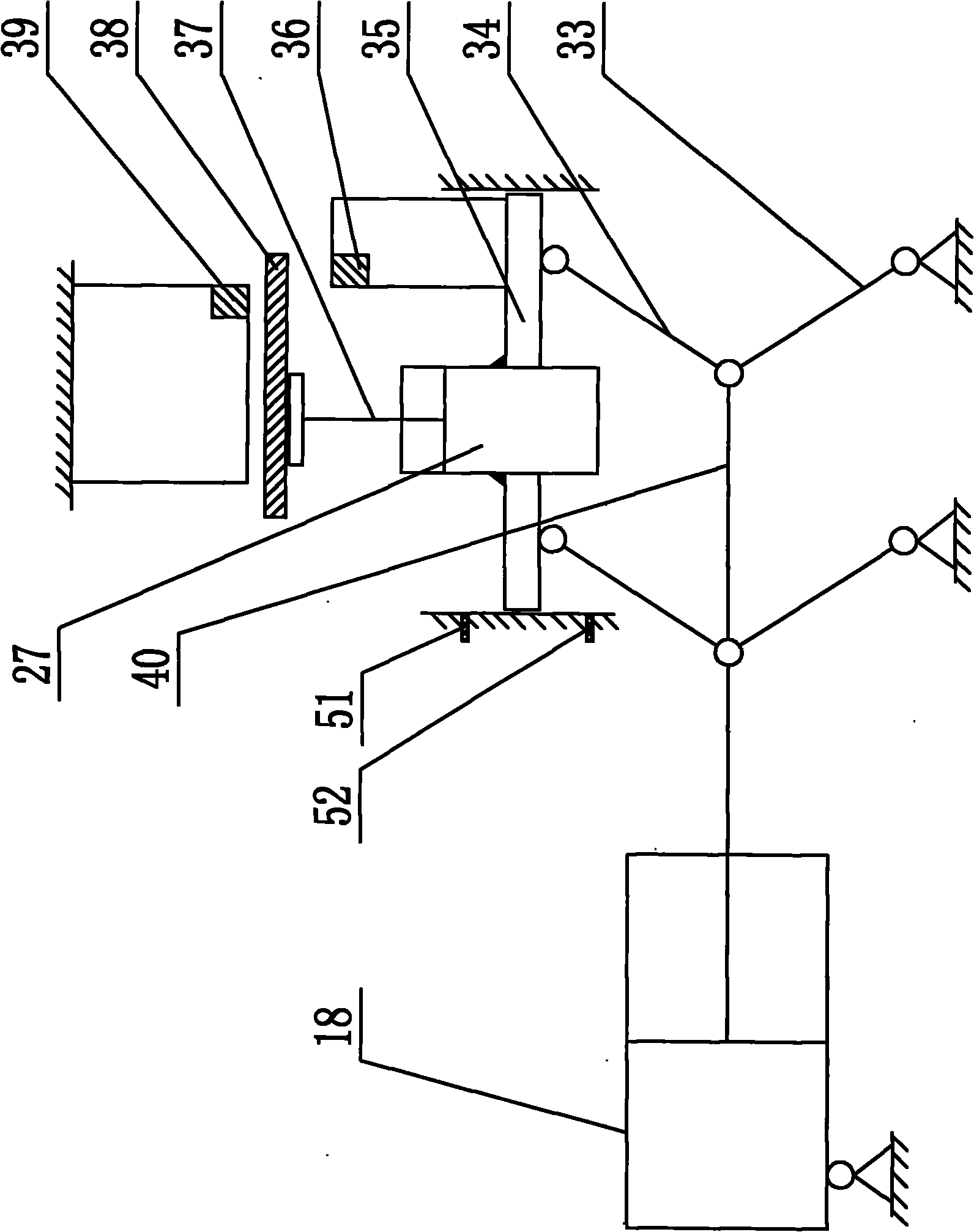

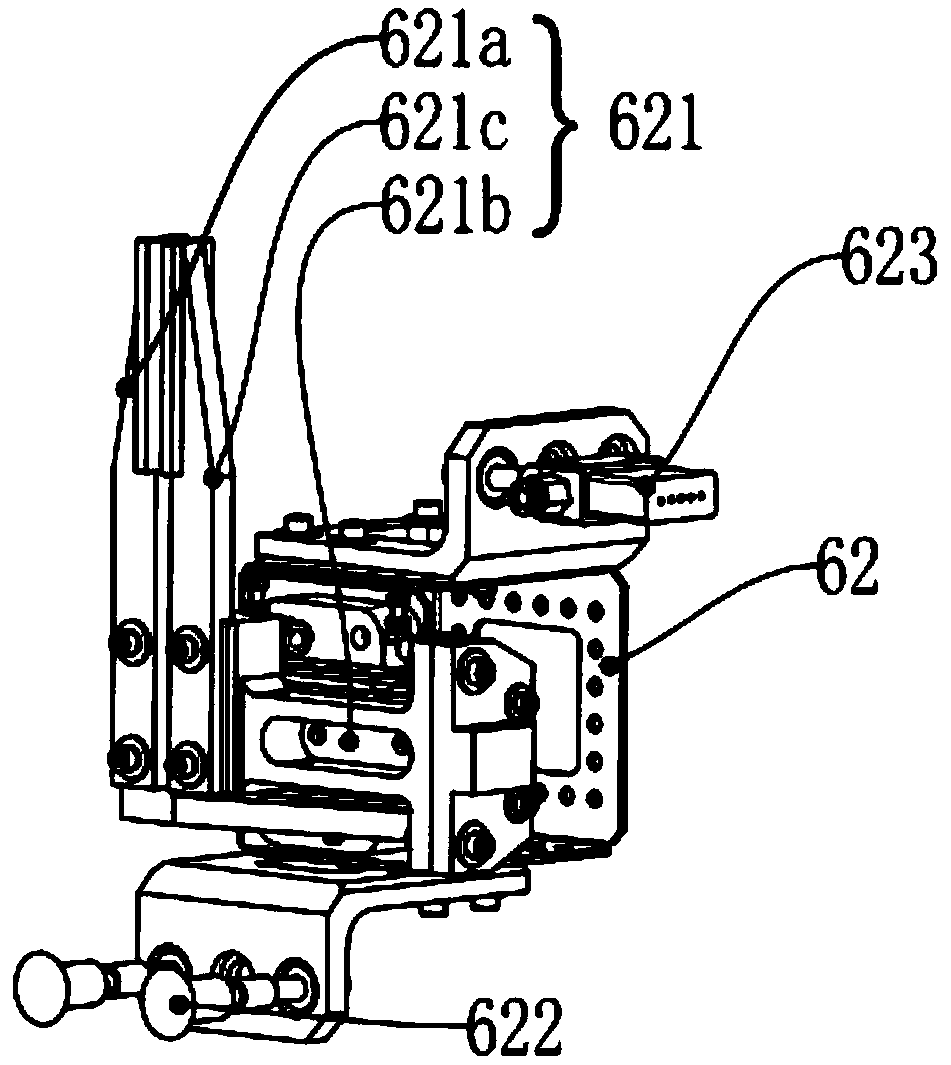

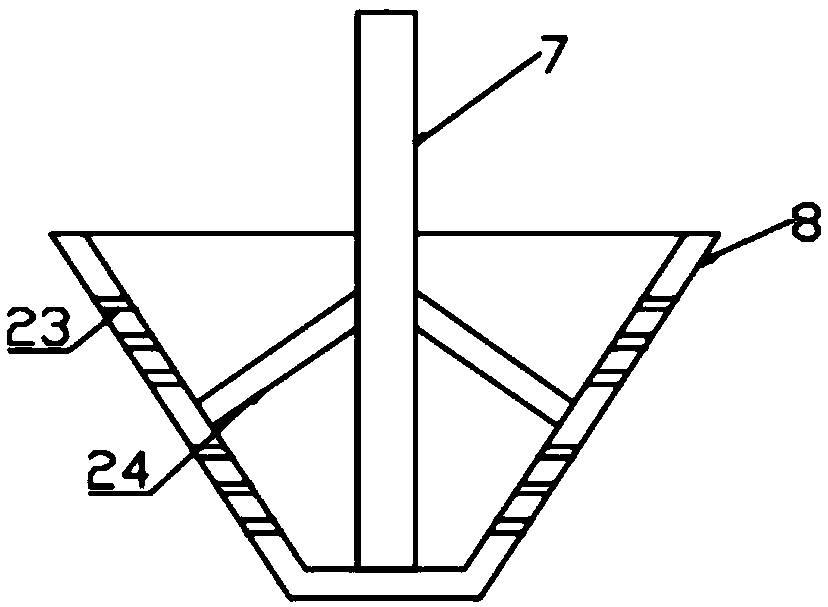

Full-automatic drill boom for anchor rod drill carriage

ActiveCN112112564ARealize automatic switchingRealize automatic fillingDerricks/mastsAnchoring boltsDrill pipeRock bolt

The invention discloses a full-automatic drill boom for an anchor rod drill carriage. The full-automatic drill boom comprises a speed-multiplying feeding mechanism, an anchor rod bin, a drill rod drill box, an anchor rod mounting drill box and a drill box transposer, wherein a plurality of anchor rods are arranged in the anchor rod bin, and after the anchor rods are driven to preset positions by chains, the anchor rods are grabbed by a manipulator and pushed to the anchor rod mounting drill box; and the anchor rod mounting drill box and the drill rod drill box are alternately connected with the speed-multiplying feeding mechanism through the drill box transposer, and the speed-multiplying feeding mechanism drives a drill rod and the anchor rods to push and retreat. The full-automatic drillboom has the advantages that the full-automatic work flow of automatic mounting of the drill boom, anchor rod replacement and automatic drilling is achieved, and efficiency and construction safety are increased.

Owner:LANG FANG JING LONG GRAND IND MACHINERY CO LTD

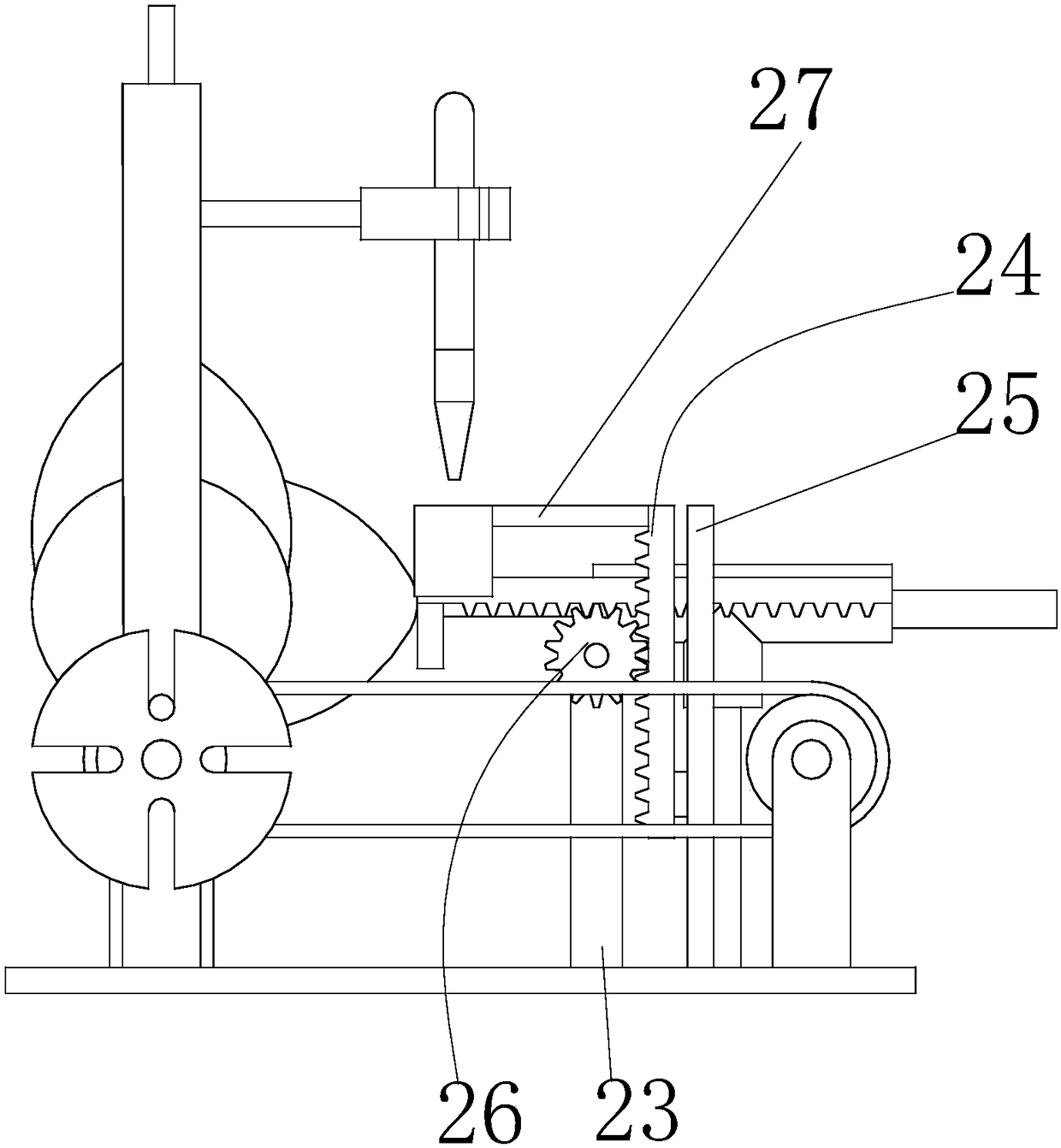

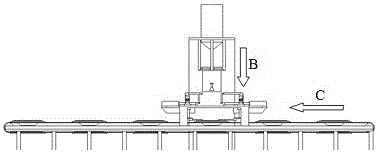

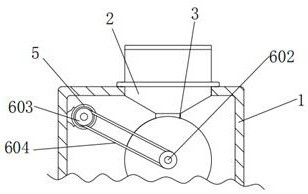

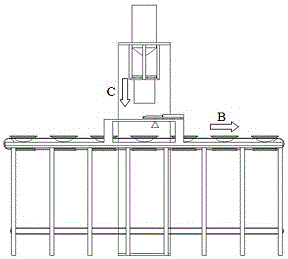

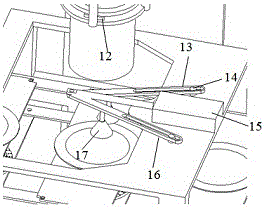

Correcting assembly line automatic filling machine

ActiveCN108423624ARealize automatic fillingHigh degree of automationLiquid bottlingAssembly lineEngineering

The invention relates to a correcting assembly line automatic filling machine. The correcting assembly line automatic filling machine comprises a bottom plate and a conveying belt, wherein the conveying belt is located above the bottom plate; belt wheels are connected to the left side and the right side of the conveying belt respectively, and each belt wheel is connected to a belt shaft which is arranged on the bottom plate through a bearing block; the belt shaft located on the left side is connected to a groove wheel, the arc surface of the groove wheel is uniformly provided with four interval grooves, a round wheel is arranged behind the groove wheel, the front end surface of the round wheel is provided with clamping pins matched with the interval grooves in an eccentric mode, the roundwheel is connected to a main shaft, the middle and upper portion of the main shaft is connected to a hanging bracket welded to the bottom plate through a bearing, and the rear portion of the main shaft is provided with a front cam and a rear cam respectively; and the rear end of the main shaft is connected to a motor. According to the correcting assembly line automatic filling machine, the automation degree is high, empty bottles can be subjected to intermittent horizontal conveying on the basis of the cooperation of the clamping pins and the interval grooves, springs are matched with the corresponding cam, so that each stopped empty bottle can be subjected to sequential position correction and automatic fresh milk filling, and the use is relatively convenient.

Owner:张家港杰德机械有限公司

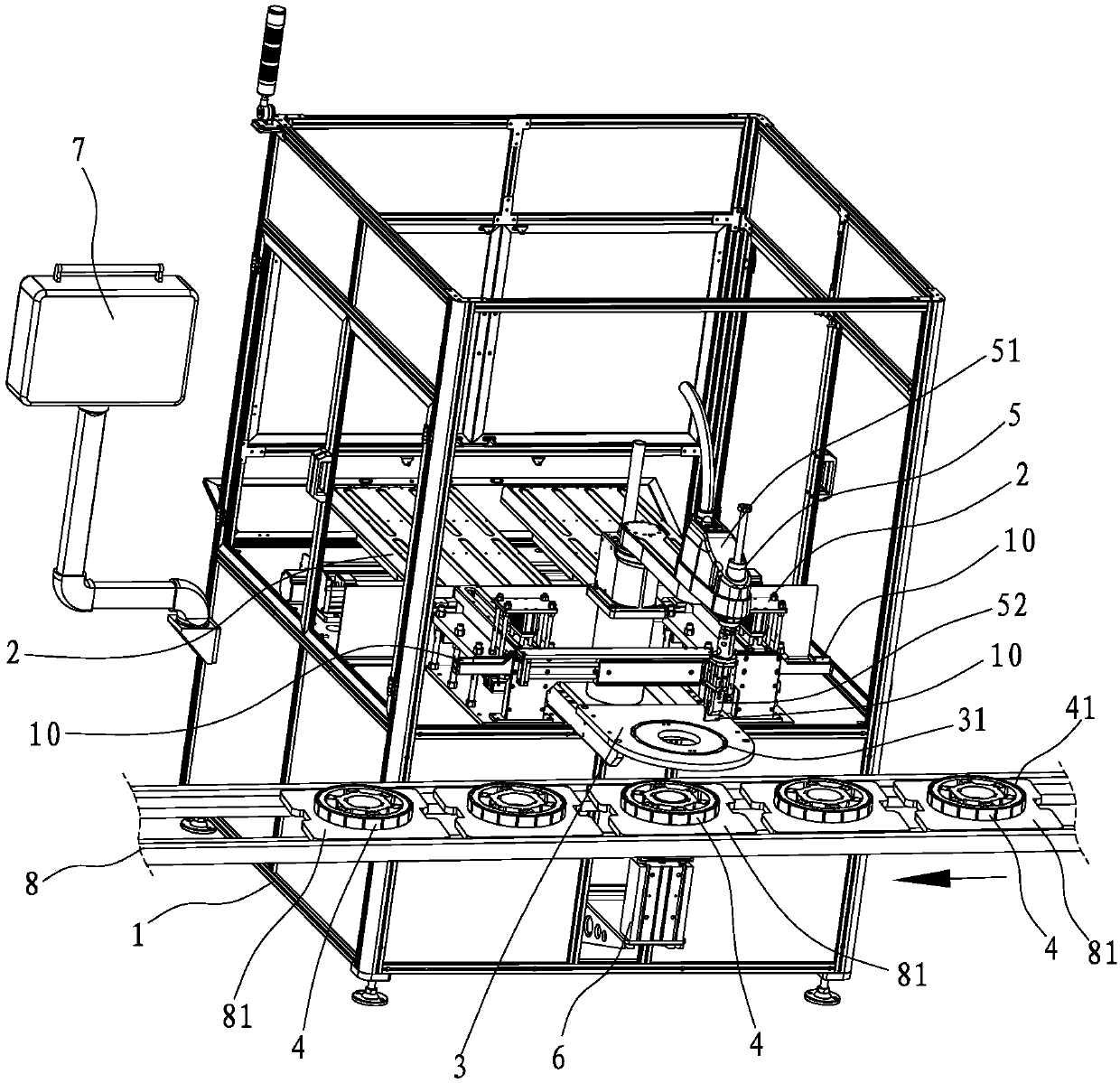

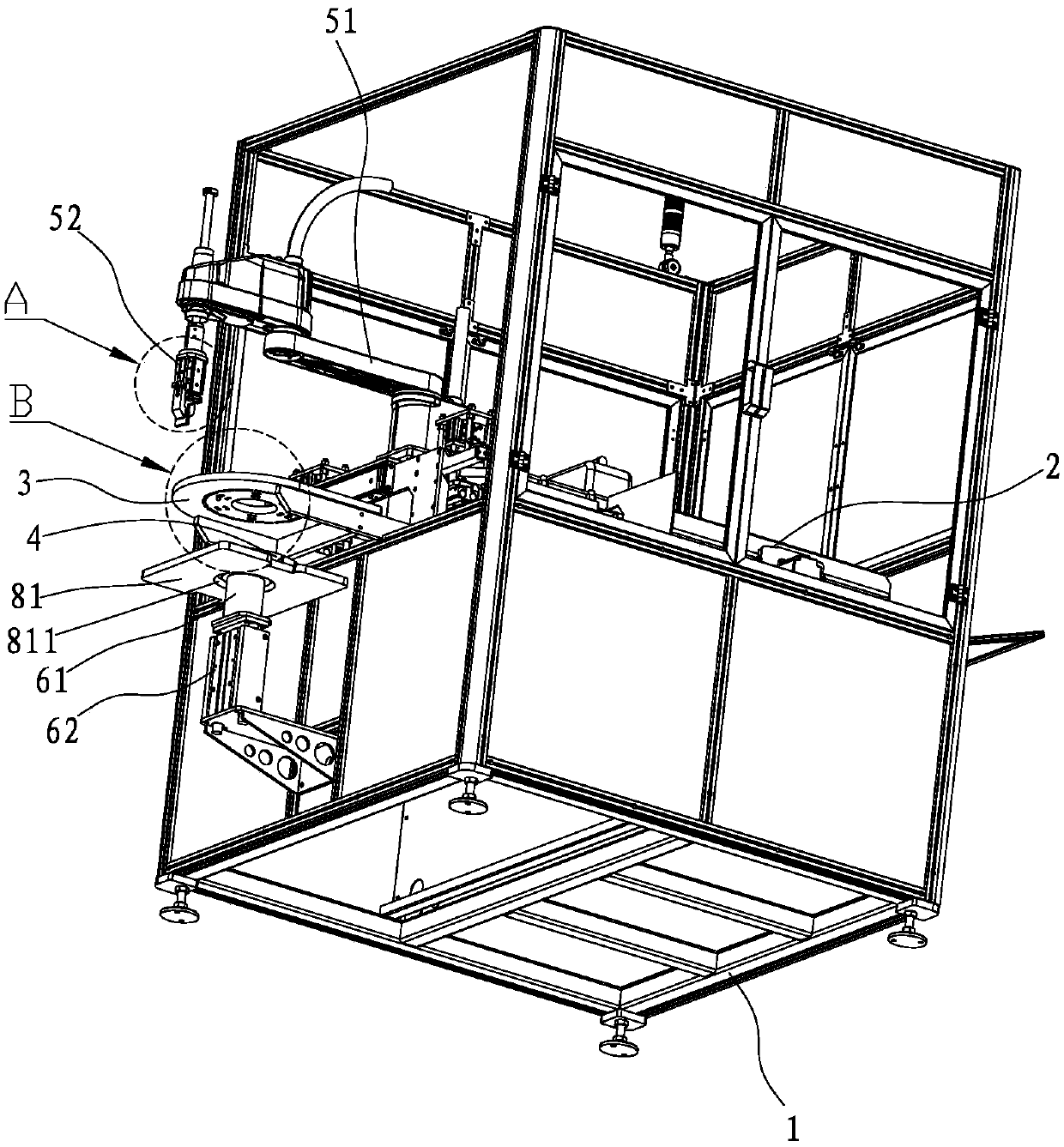

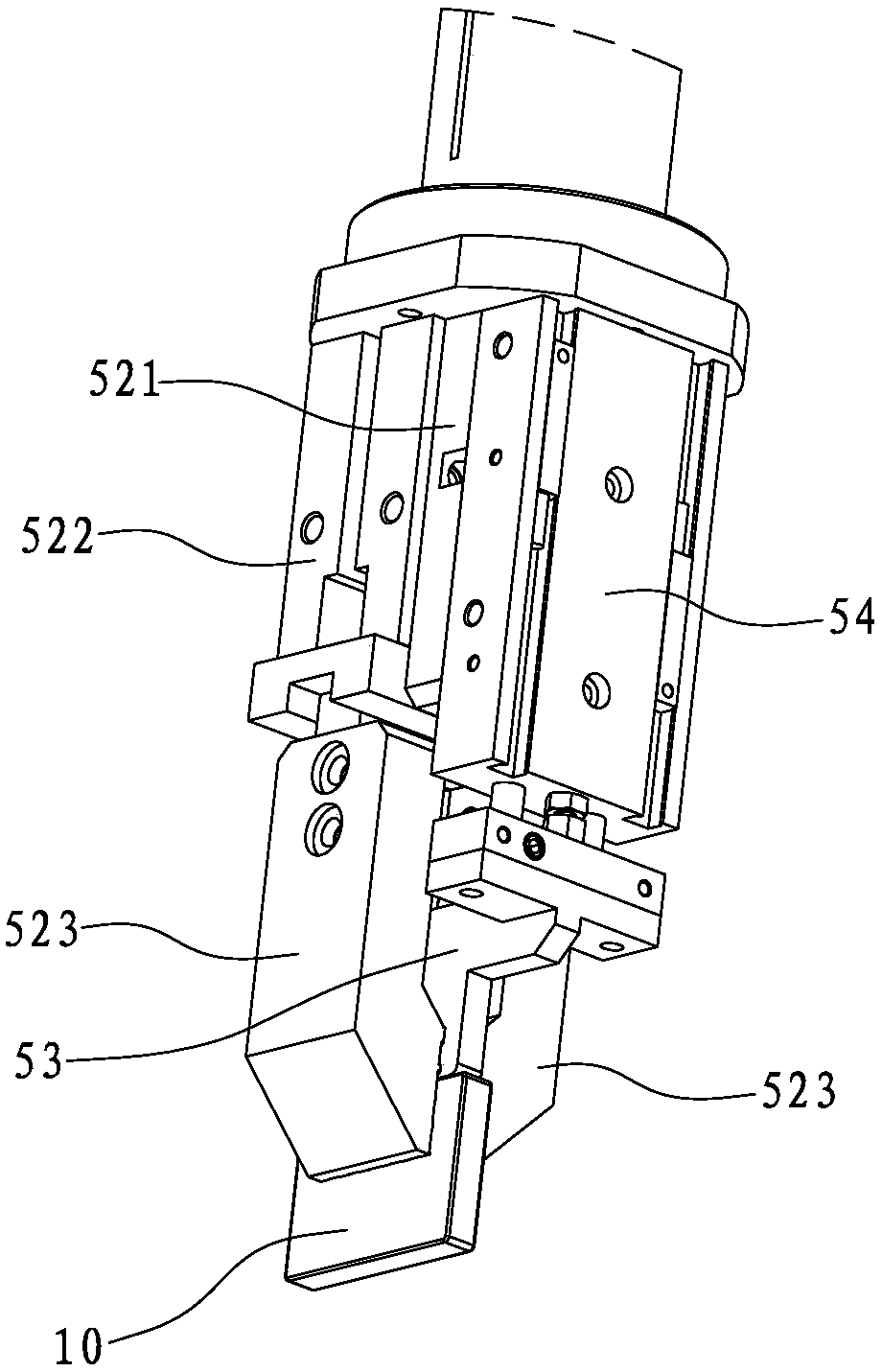

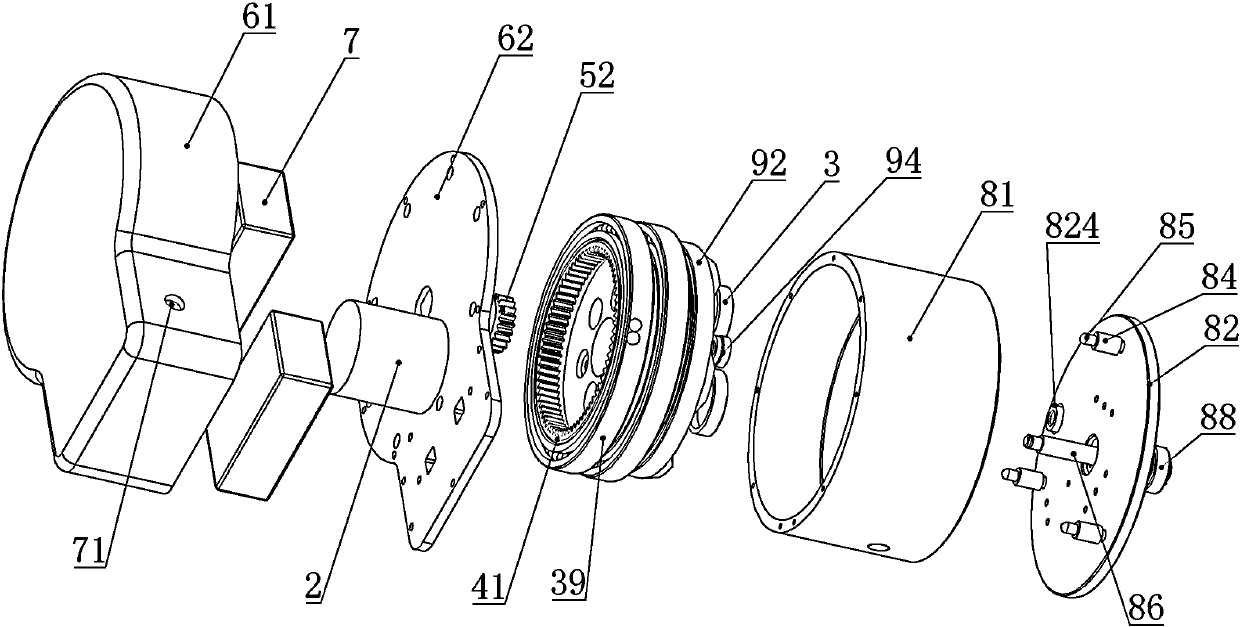

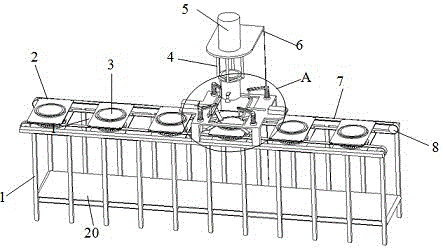

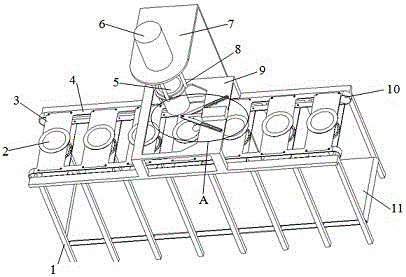

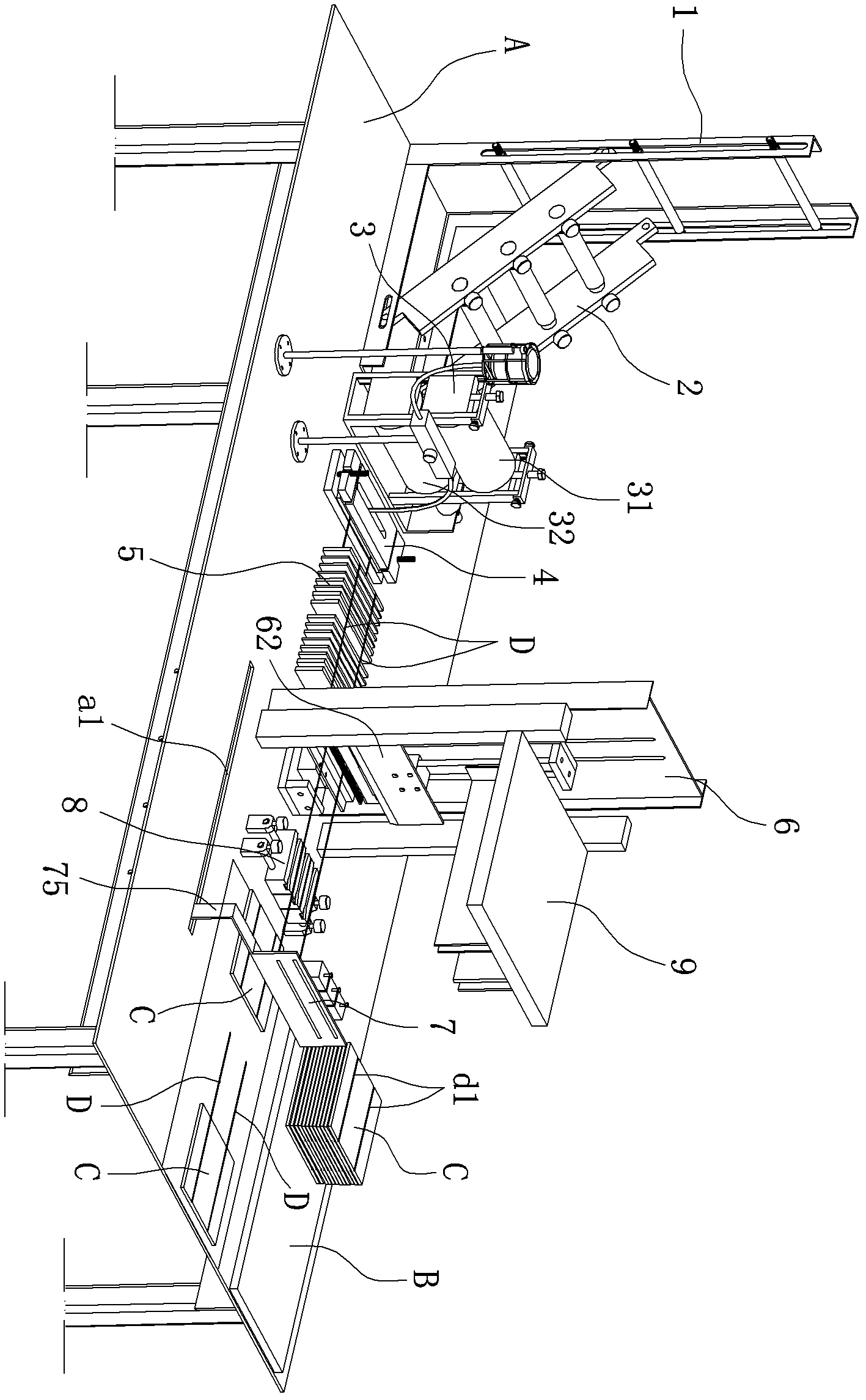

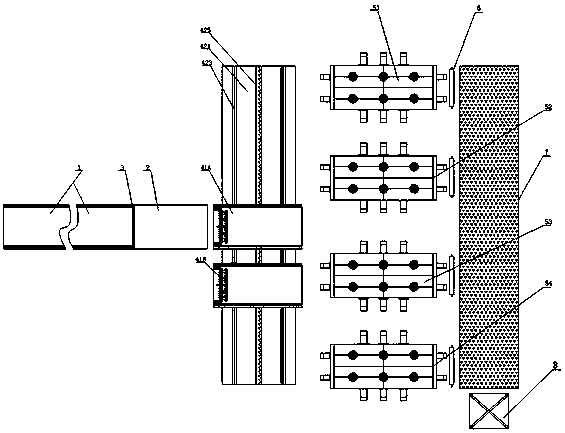

Automatic loading production line for magnetic steel sheets of motors

ActiveCN107863859ALabor savingIncrease productivityManufacturing stator/rotor bodiesManipulatorAssembly line

The invention discloses an automatic loading production line for the magnetic steel sheets of motors. The automatic loading production line includes a frame which is provided with a guide plate. The guide plate is provided with guide slots which correspond to the magnetic steel slots of a rotor core and are used for magnetic steel sheets to pass through. A jacking component used for jacking the rotor core towards the guide plate is arranged below the guide plate. An assembly line capable of conveying to-be-loaded rotor cores and delivering loaded rotor cores is arranged between the jacking component and the guide plate. A core tooling plate for placing a rotor core is arranged on the assembly line. The core tooling plate is provided with a jacking hole for the jacking component to pass through below the rotor core. The frame is provided with a feeding mechanism used for providing magnetic steel sheets. The frame is provided with a manipulator device which can clamp the magnetic steel sheets on the feeding device to the guide slots. The automatic loading production line for the magnetic steel sheets of motors further includes a control system used for controlling the movement of thefeeding mechanism, the jacking component, the manipulator device and the assembly line. The automatic loading production line for magnetic steel sheets of motors has a simple structure and high production efficiency.

Owner:GUANGDONG HANDSOME INTELLIGENT EQUIP CO LTD

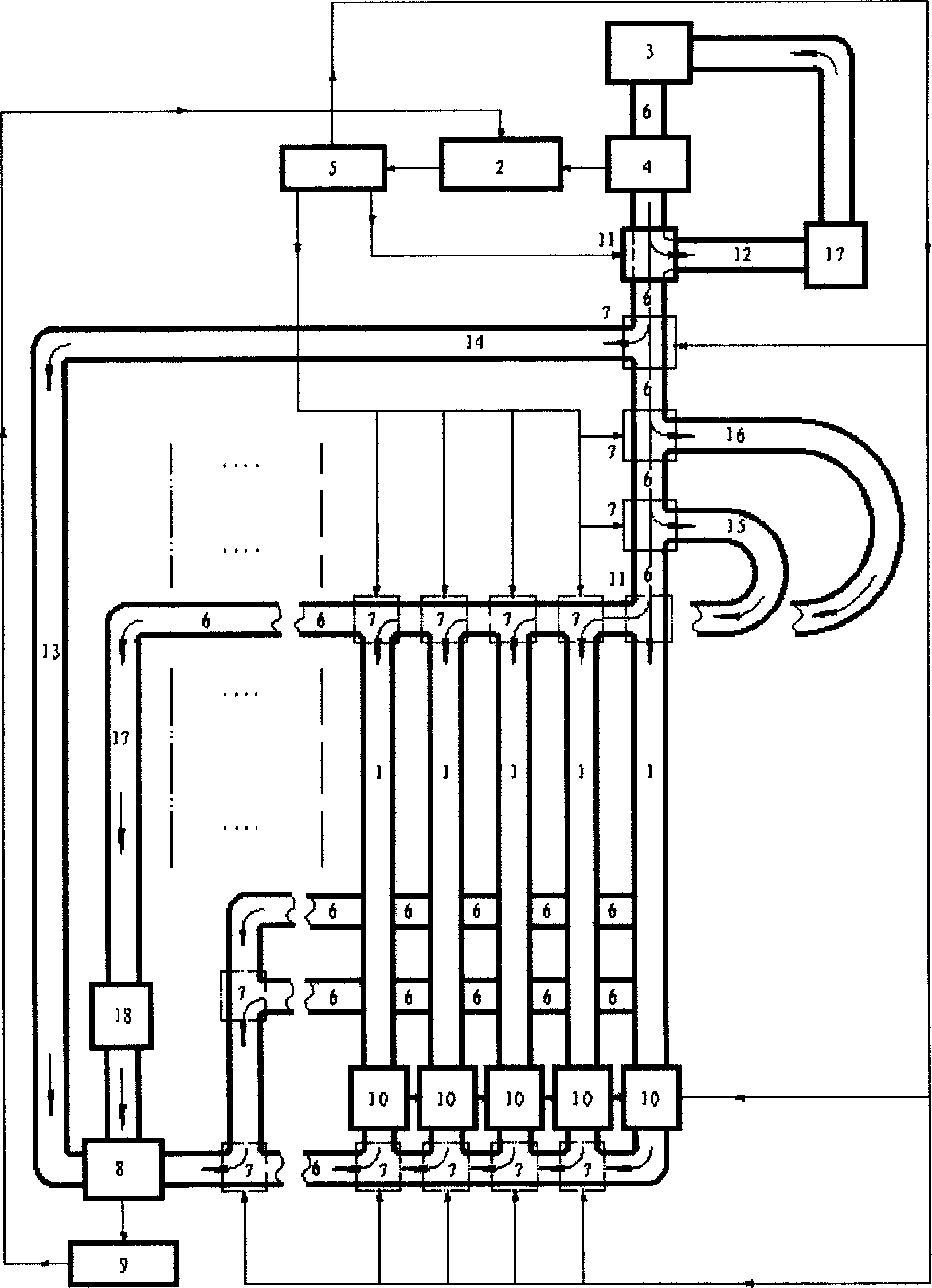

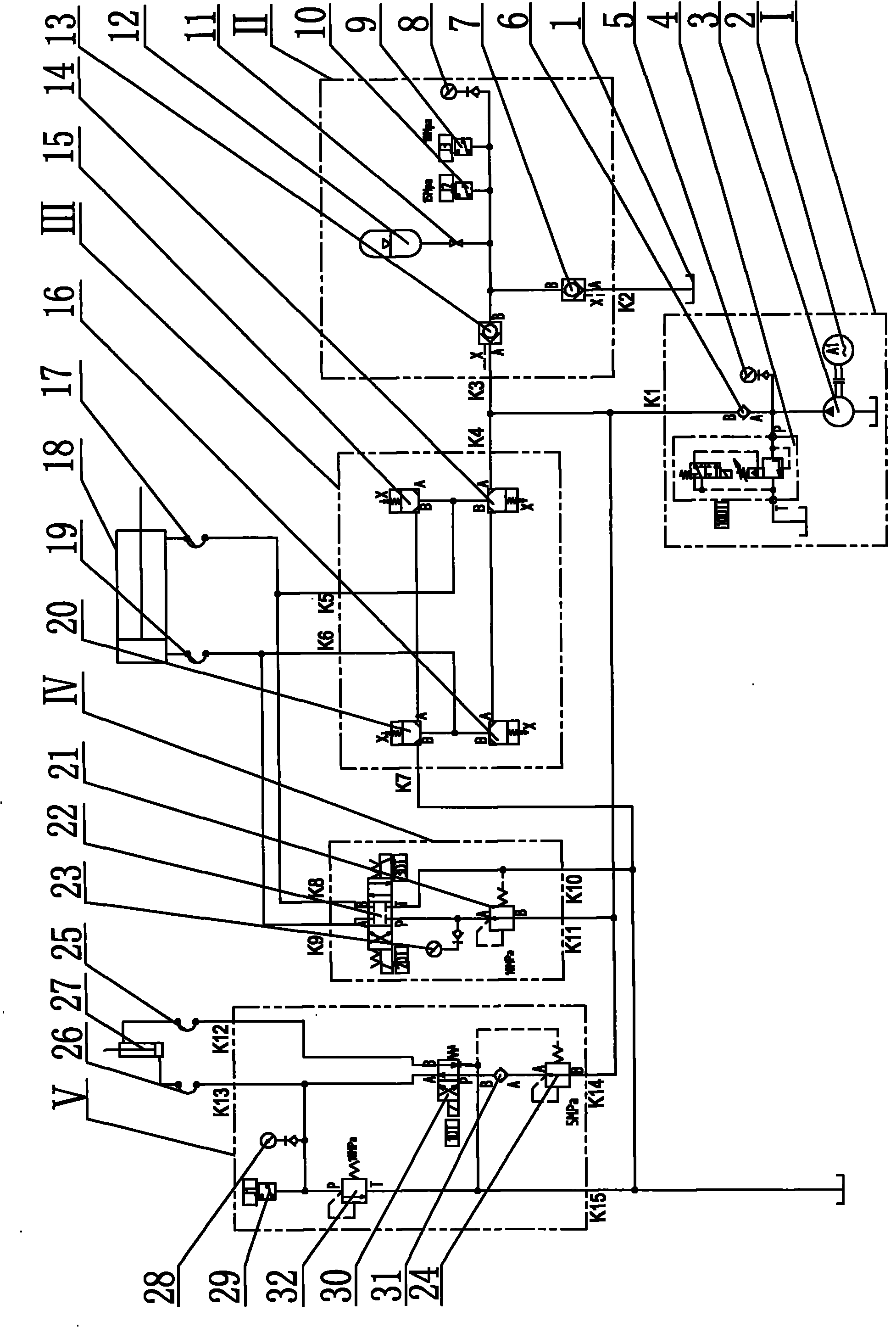

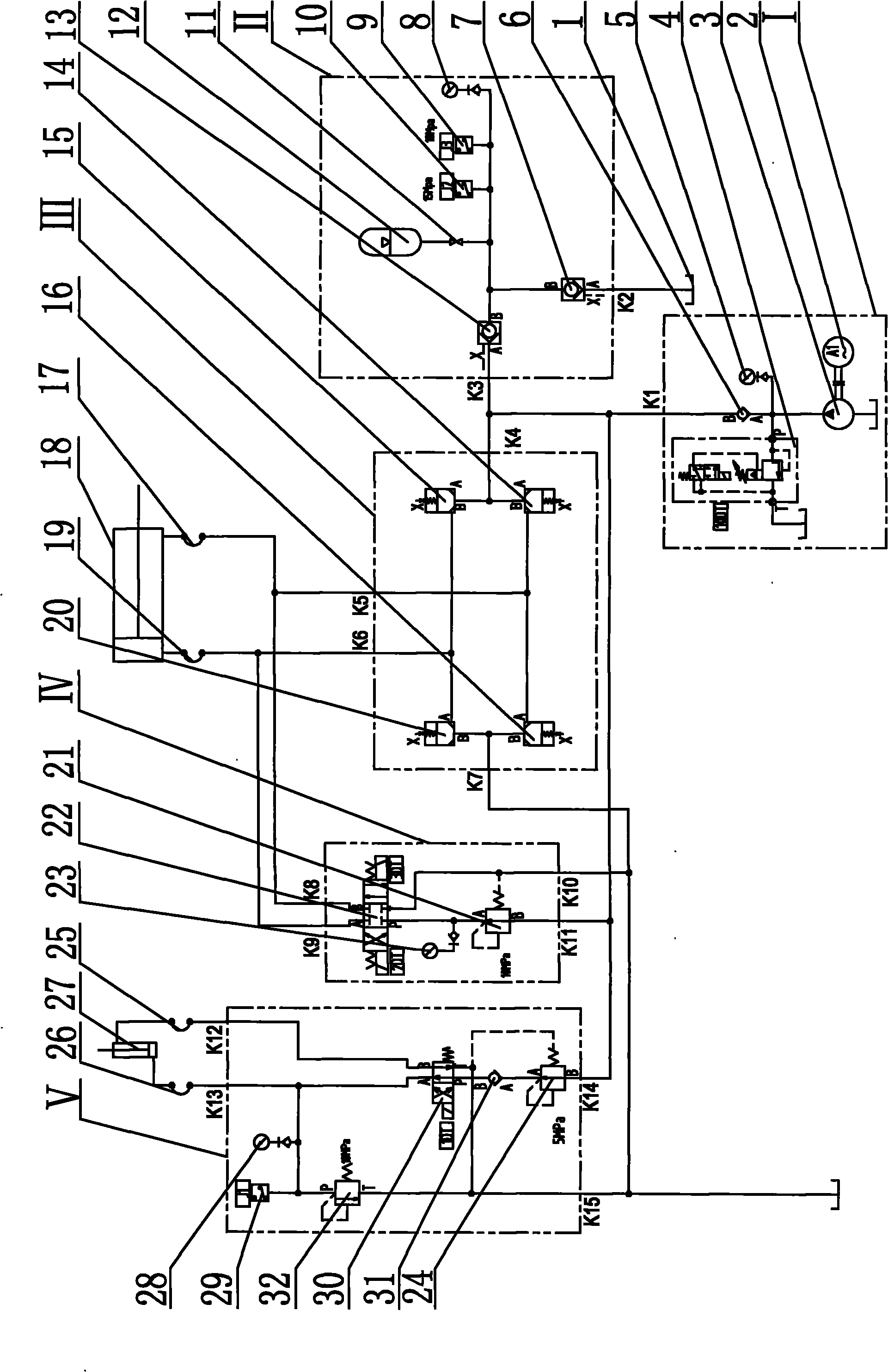

Hydraulic transmission loop of diagonal cutter shearing machine

InactiveCN101774042ASmall diameterAchieve regulationMechanical apparatusShearing machine accessoriesHigh pressureManufacturing line

The invention provides a hydraulic transmission loop of a diagonal cutter shearing machine, which belongs to the technical field of iron and steel sheet and plate processing. The invention is applicable to the hydraulic transmission of rolling production lines or experiment line shearing machines. The hydraulic transmission loop comprises a high-pressure pump source, an energy accumulator controller, a shearing oil cylinder controller, a shearing cutting edge regulation controller and a press plate oil cylinder controller, wherein a pressure oil opening K1 is respectively connected with a pressure oil opening K3, a pressure oil opening K4, a pressure oil opening K11 and a pressure oil opening K14, an oil return opening K2, an oil return opening K7, an oil return opening K10 and an oil return opening K15 are respectively connected with an oil tank, a work oil opening K6 is connected with the rod-free side of a shearing oil cylinder through a hydraulic rubber pipe, the work oil opening K5 is connected with the rod side of the shearing oil cylinder through a hydraulic rubber pipe, the work oil opening K9 is connected with the rod-free side of the shearing oil cylinder through a hydraulic rubber pipe, the work oil opening K8 is connected with the rod side of the shearing oil cylinder through a hydraulic rubber pipe, the work oil opening K13 is connected with the rod-free side of a press plate oil cylinder through a hydraulic rubber pipe, and the work oil opening K12 is connected with the rod side of the press plate oil cylinder through a hydraulic rubber pipe.

Owner:NORTHEASTERN UNIV

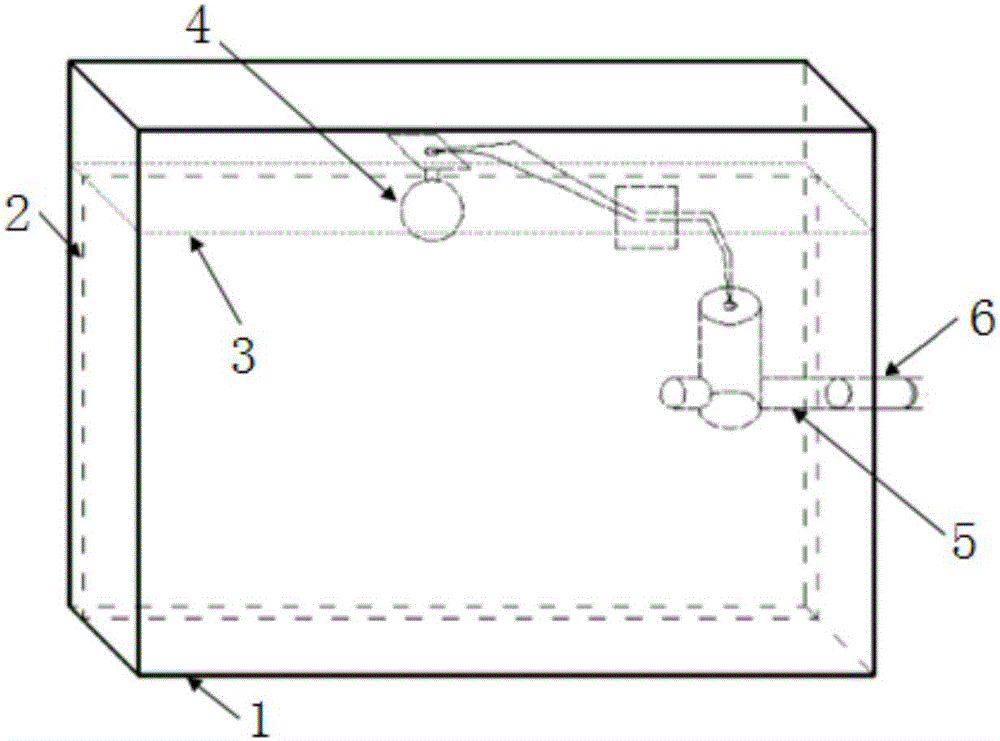

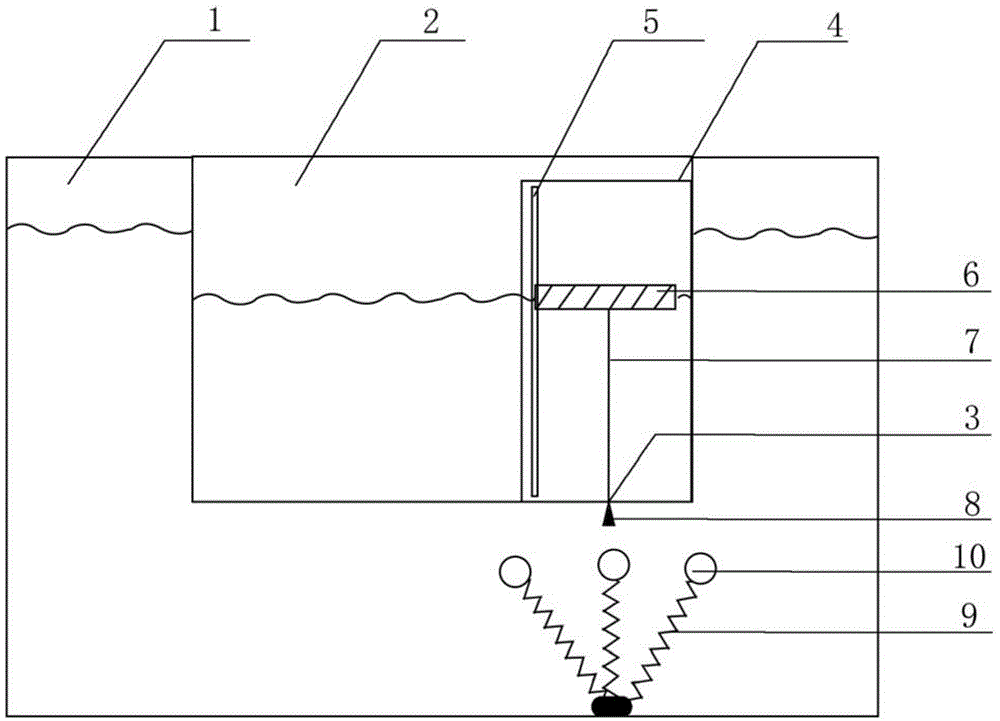

Immersed liquid-cooled server

The invention discloses an immersed liquid-cooled server. The immersed liquid-cooled server comprises a shell for accommodating a coolant, a server mainboard arranged in the shell, a liquid level sensor and an electronic valve, wherein the liquid level sensor is used for detecting the liquid level height of the coolant and adding the coolant through the electronic valve according to the liquid level height, and the electronic valve is arranged in a coolant delivery pipeline and connected with the liquid level sensor. The immersed liquid-cooled server is capable of detecting the liquid level of the coolant and adding the coolant automatically according to the liquid level height of the coolant.

Owner:SUGON DATAENERGYBEIJING CO LTD

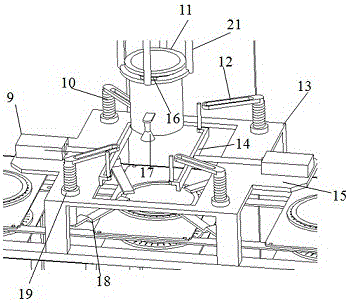

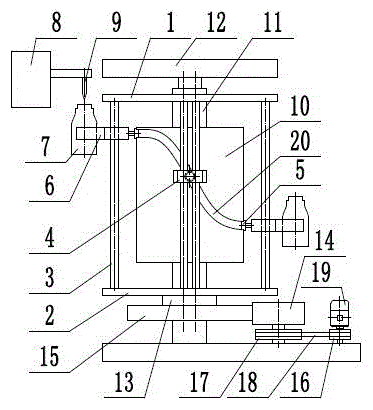

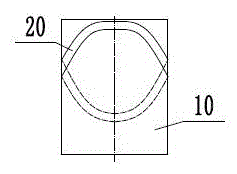

Drying agent automatic filling and vibration compacting device

ActiveCN111186599APrevent automated fillingPrevent functionSolid materialPackaging automatic controlEngineeringMechanical engineering

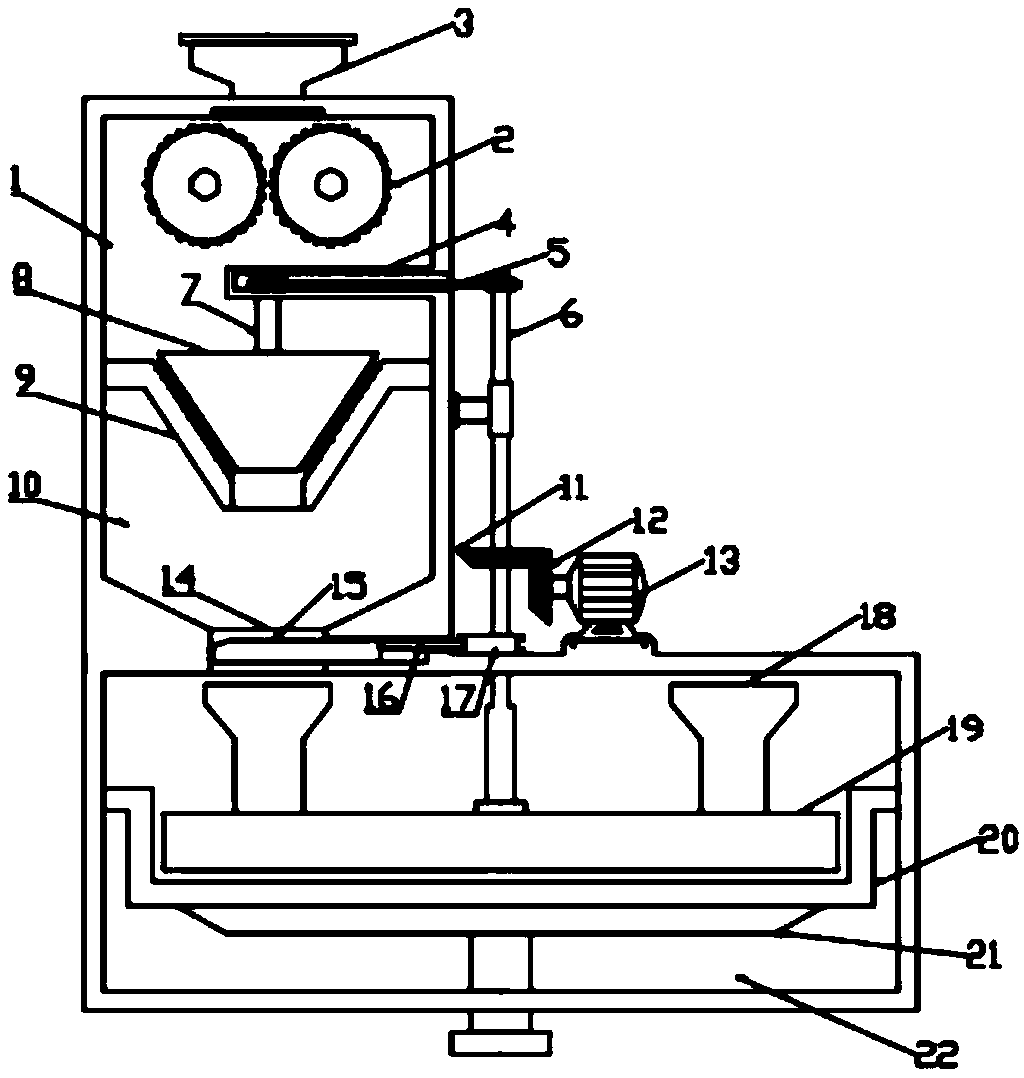

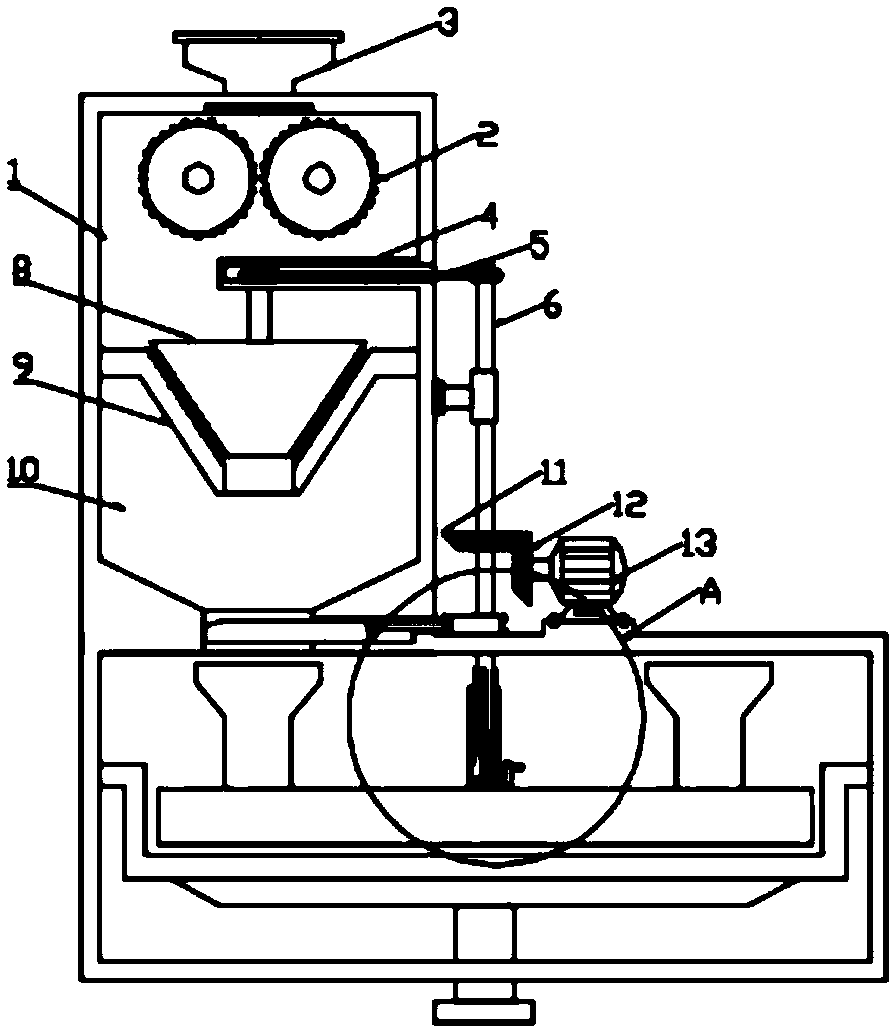

The invention relates to the technical field of drying agent filling, in particular to a drying agent automatic filling and vibration compacting device. The drying agent automatic filling and vibration compacting device comprises a machine body, a vibration mechanism, a positioning mechanism, a pressing compacting mechanism and a conveying mechanism; the machine body comprises a base and an uppersupporting frame, and the upper supporting frame is fixedly installed on the base; the vibration mechanism is fixedly installed on the base; the positioning mechanism is fixedly installed on the vibration mechanism; the pressing compacting mechanism is slidably arranged on the upper supporting frame; and the conveying mechanism is fixedly installed on the upper supporting frame and used for conveying a drying agent into a drying barrel. Through the drying agent automatic filling and vibration compacting device, the drying agent automatic filling and compacting functions are achieved at the same time, a traditional operation mode and technology process for drying agent filling are changed, when the device is used for drying agent filling, filling and vibrating are conducted synchronously, the drying agent assembling efficiency is improved, and in addition, the drying agent filling quality is precisely controlled.

Owner:LOTEEM BEIJING RAIL TRANSIT TECH CO LTD

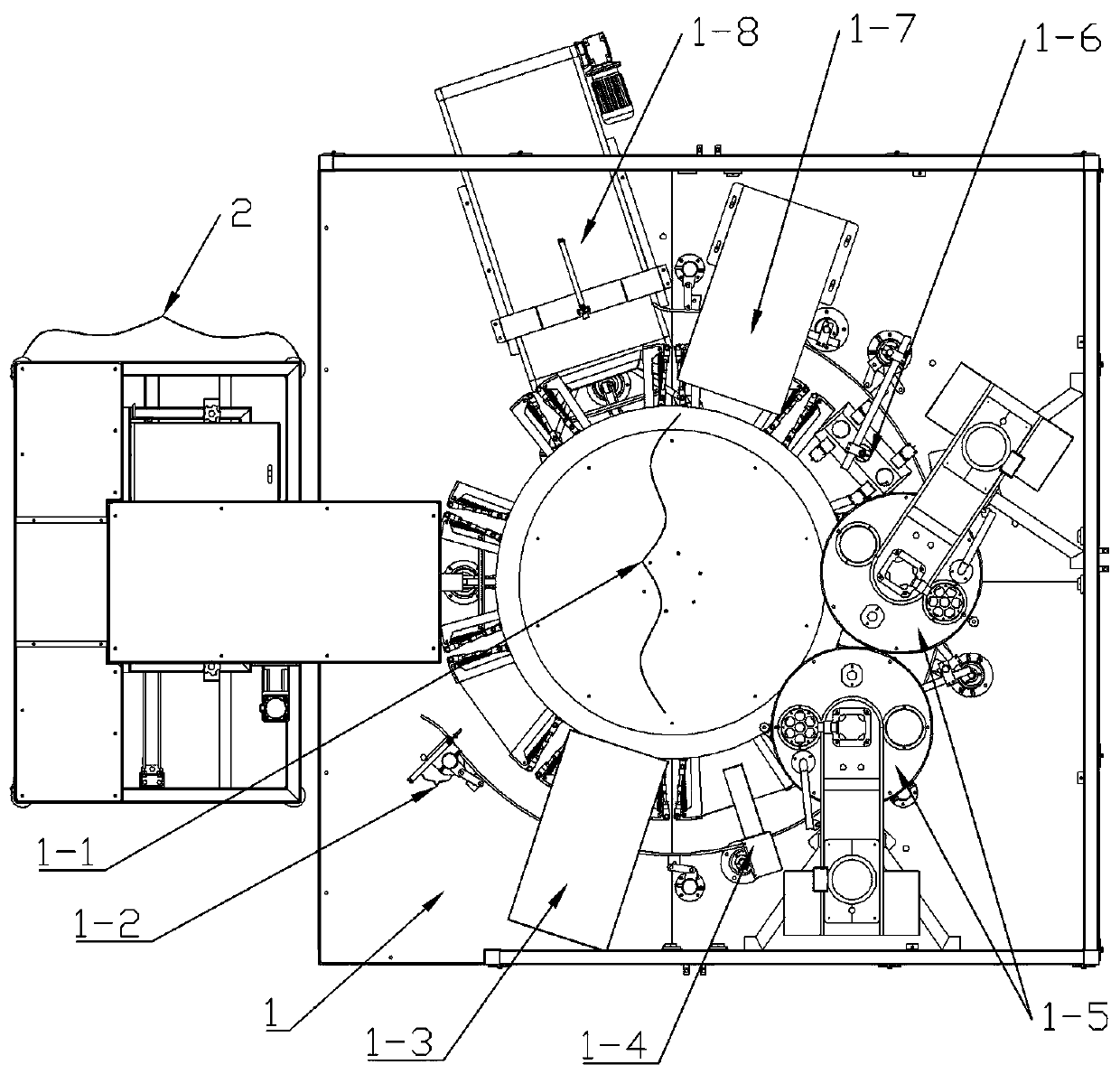

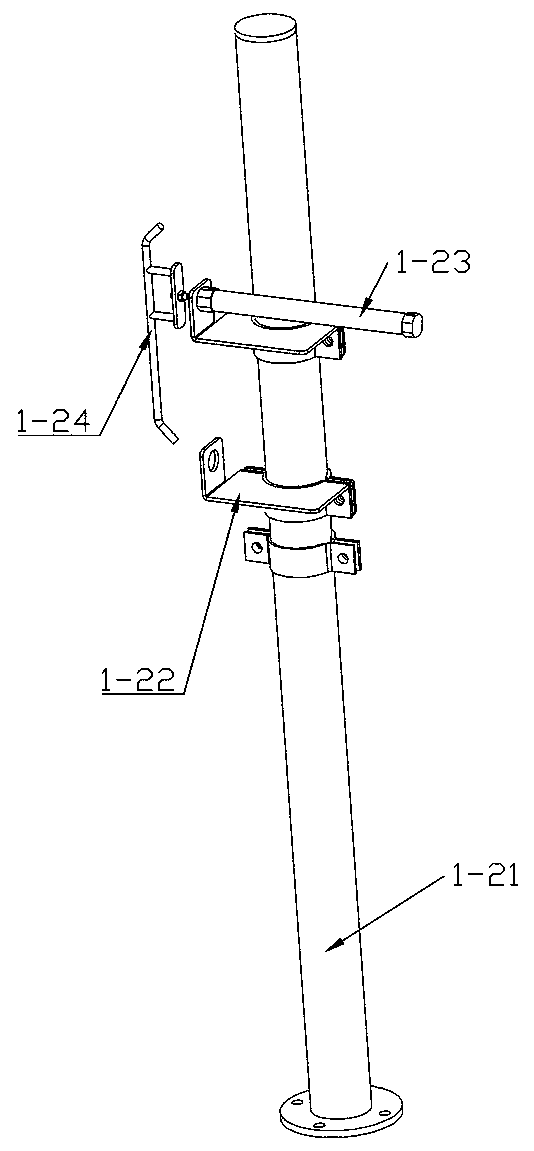

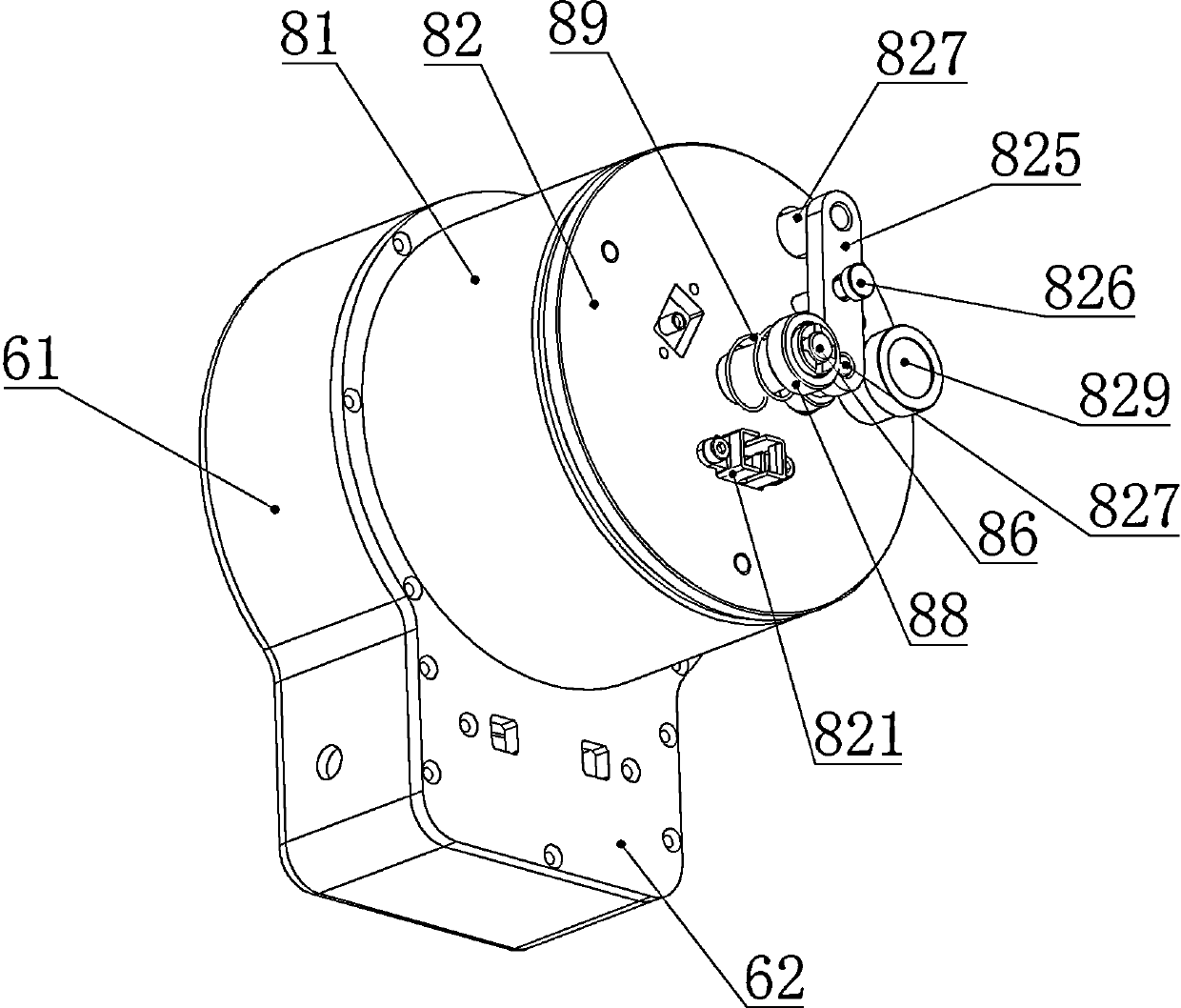

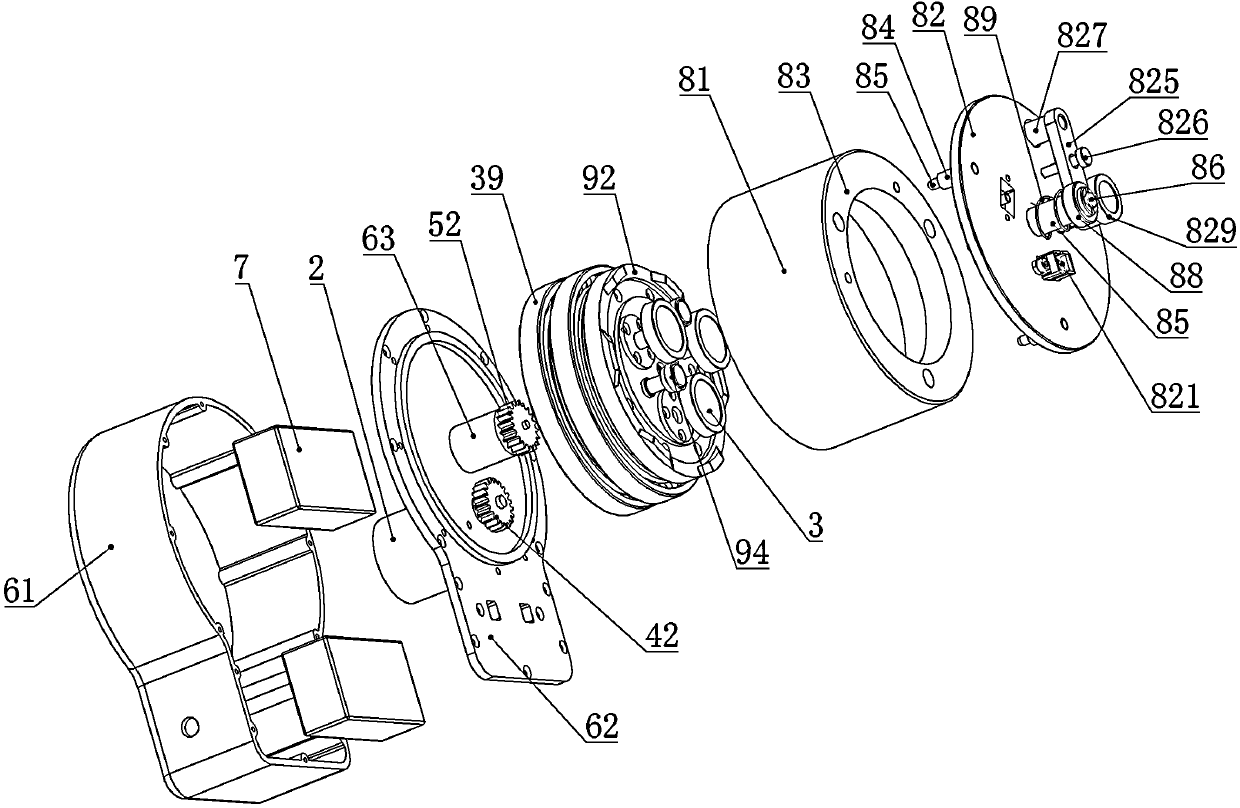

Ten-station flour packing machine

PendingCN110626554ACompact structureSmall footprintPackaging automatic controlEngineeringDust collector

The invention discloses a ten-station flour packing machine which comprises a working platform, a bag supplying mechanism, a packing bag detection mechanism, a bag opening mechanism, an opening detection mechanism, two filling machines, a dust collector, a sealing machine and an output conveyor belt. A center transposition mechanism is arranged at the center of the working platform. The packing bag detection mechanism, the bag opening mechanism, the opening detection mechanism, the filling machines, the dust collector, the sealing machine and the output conveyor belt are mounted on the workingplatform and are successively arranged around the center transposition mechanism. The bag supplying mechanism is located on one side of the working platform and faces a position between the packing bag detection mechanism and the output conveyor belt. A vacancy is reserved between the packing bag detection mechanism and the output conveyor belt. The ten-station flour packing machine is compact instructure and small in occupied space, and can achieve automatic filling. By arranging the two filling machines: one is used and the other is standby. When one of the filling machines fails, the other filling machine can be started immediately to replace the failed filling machine, and the failed filling machine is maintained specially during stop production for maintenance, so that normal production is not affected.

Owner:河南济开电器有限公司 +1

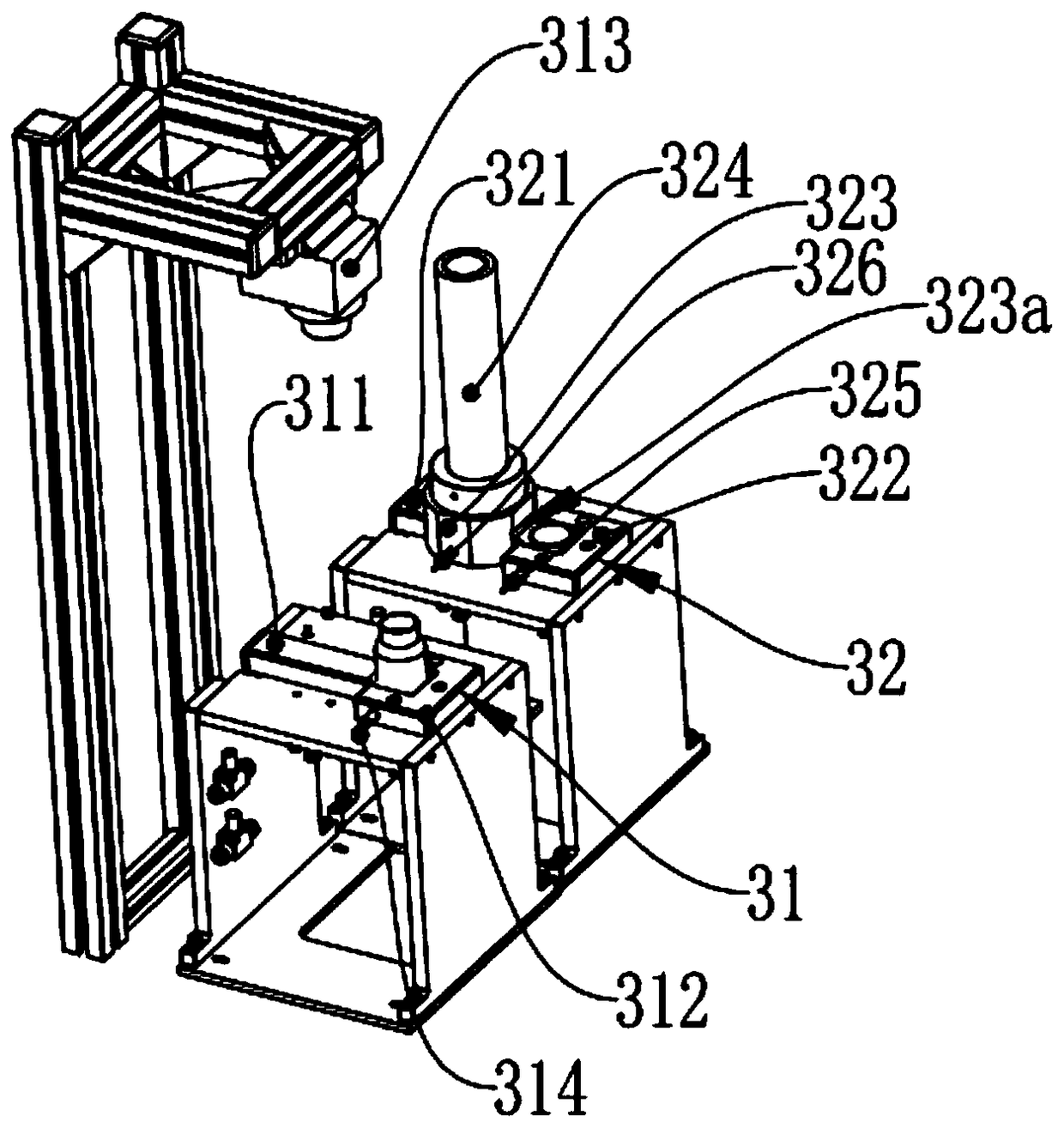

Optical fiber terminating device

ActiveCN103586766ARealize automatic fillingReduce difficultyLapping machinesWork carriersEngineeringOptical fiber cable

The invention discloses an optical fiber terminating device. According to the optical fiber terminating device, a clamp disk is vertically guided and assembled on a displacement tray, a fluid complementing hole is formed in the clamp disk above a displacement path, a fluid storage cavity is formed in a large-hole section of the fluid complementing hole, a pressing head which is assembled on the clamp disk in a limited mode is arranged at the upper portion of the fluid storage cavity, a driving pushing body and a driven pushing body are arranged between the clamp disk and the displacement tray, and the driving pushing body and the driven pushing body are in interval pushing fit to form an interval pushing mechanism. When a grinding disk and the fluid complementing hole are vertically opposite to each other, the driving pushing body and the driven pushing body are pushed to be matched, the clamp disk and the pressing head can move oppositely, the fluid storage cavity is compressed, grinding fluid stored in a cavity or sponge in the fluid storage cavity is complemented into a small-hole section of the fluid complementing hole by the pressing head, and then the grinding fluid is injected into the grinding disk through the small-hole section of the fluid complementing hole. Thus, the difficulty in choosing injection time and the injection positions is reduced, and the injection accuracy and the injection reliability are improved.

Owner:HENAN HUACHUANG COMM EQUIP

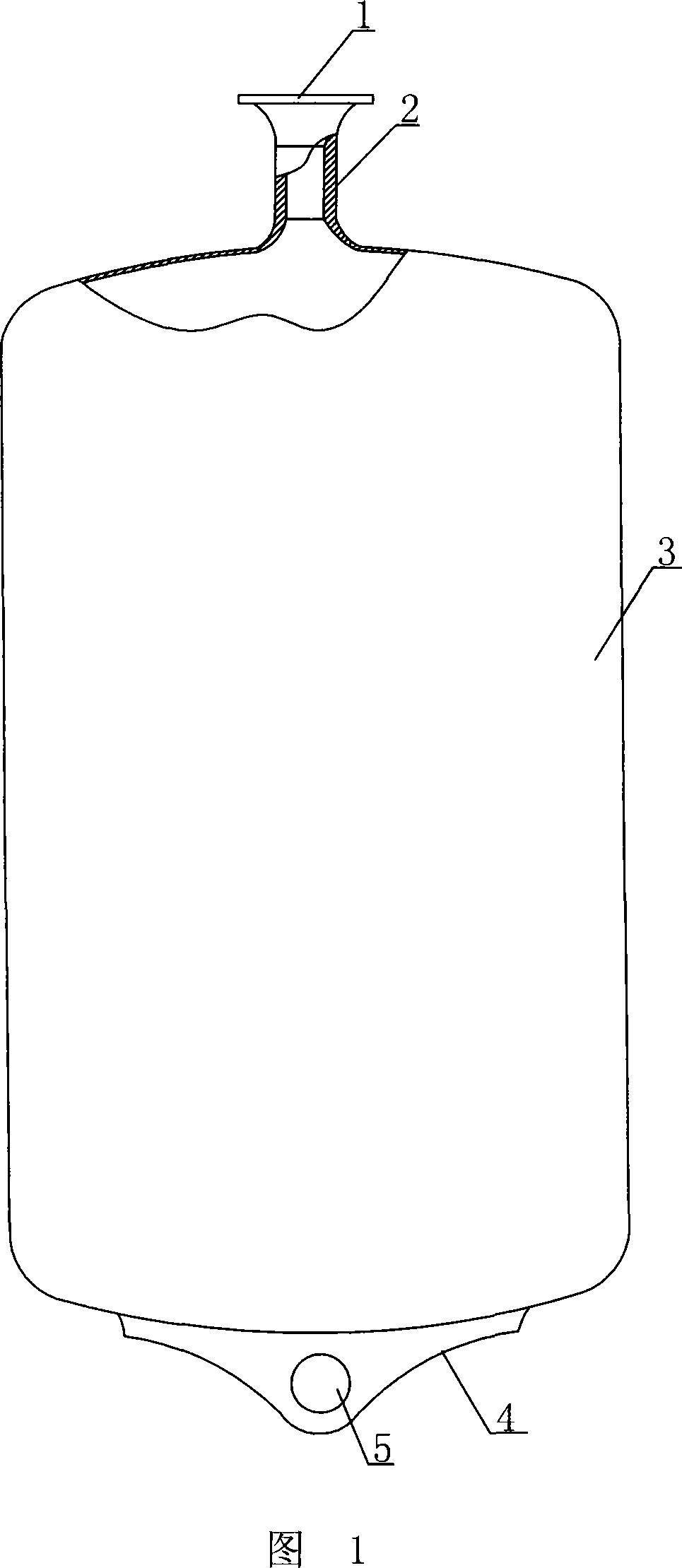

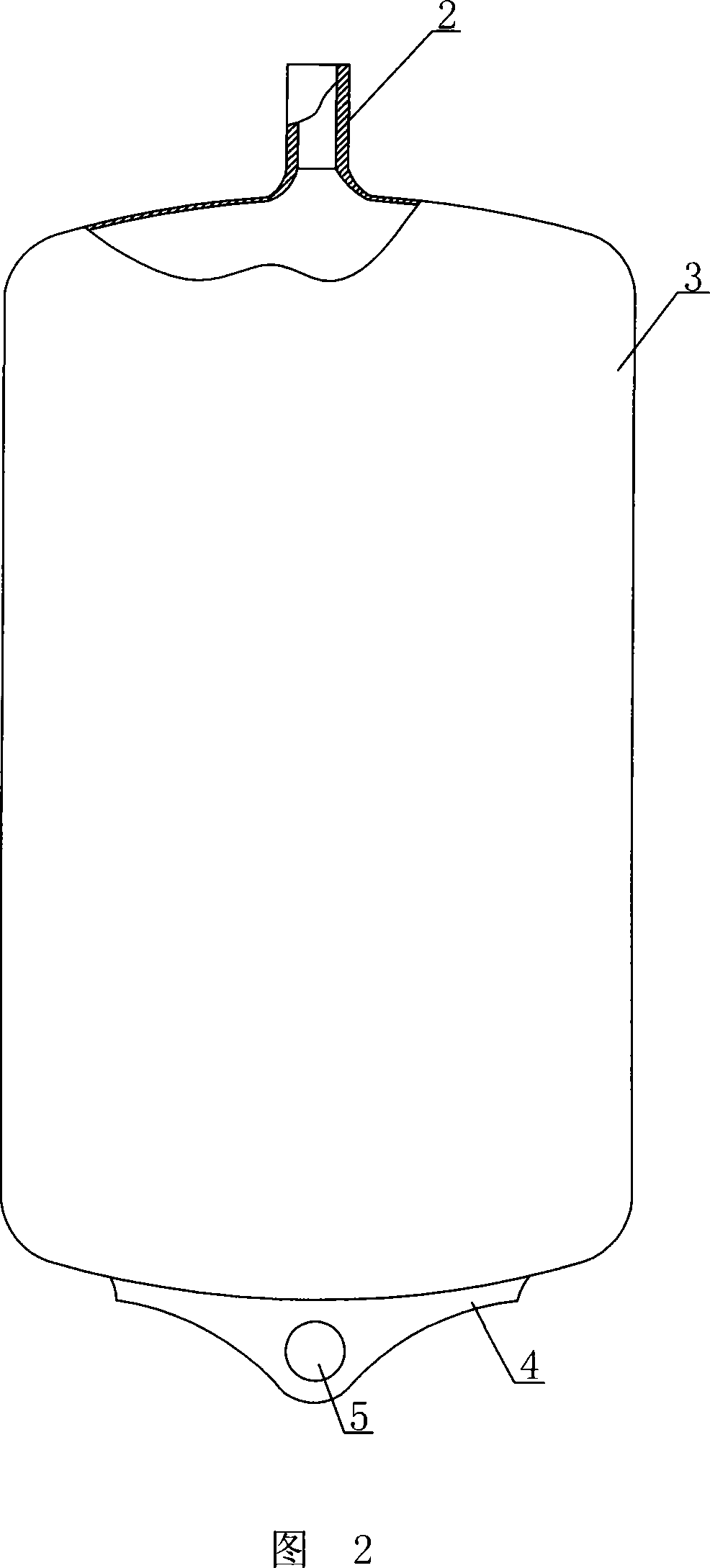

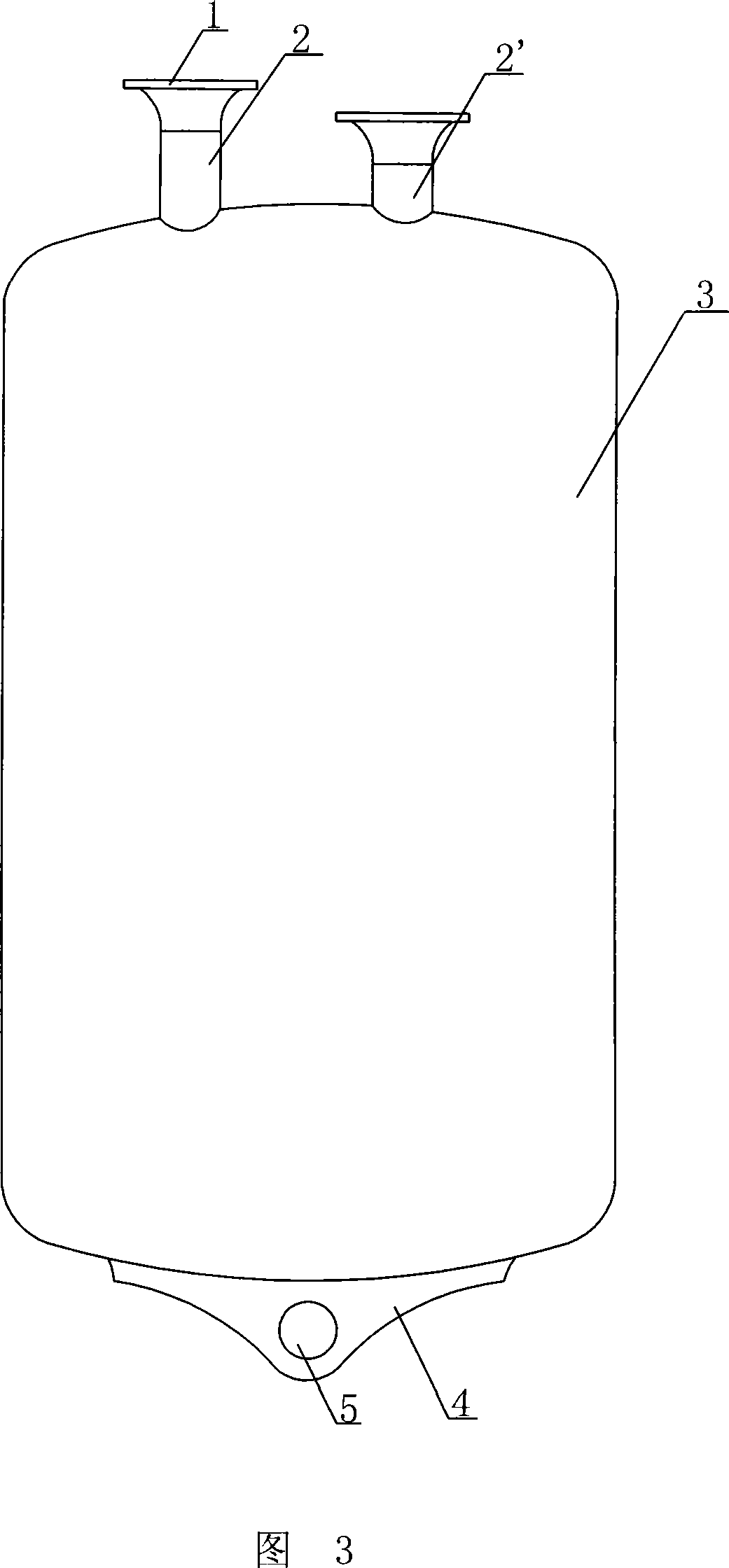

Blow molding medical bag and preparing method thereof

InactiveCN101229097APrevent leakageAvoid pollutionPharmaceutical containersMedical packagingBlow moldingBottle

The invention relates to a blow molding medical bag and a preparation method thereof. The blow molding medical bag includes a bag body. One end of the bag body is provided with a convex filling opening and the other end is provided with a lifting ring. The bag body, the filling opening and the lifting ring form an integral structure. The preparation method includes: taking medical polythene, medical polypropylene or medical modified-polypropylene as the raw materials and adopting a hollow blow molding method and a hollow blowing device to carry out one-time blow molding on the medical polythene, the medical polypropylene or the medical modified-polypropylene to acquire the blow molding medical bag. The blow molding medical bag has the advantages of reasonable structure, being convenient for mechanized filling and packaging, effectively preventing a loaded liquid from leaking and divulging. The invention can not only ensure the pollution free property during the filling and packaging processes, but also realize high speed manufacture with low cost, thus solving a plurality of defects existed in the existing perfusion bag of non PVC materials and polypropylene perfusion bottle. The preparation method can realize industrialized and mechanized manufacture and automatic filling and has the advantages of low cost and high output.

Owner:辽宁九洲龙跃药业有限公司

Warp sizing machine automatic stirring device

InactiveCN105332210ADoes not affect normal workRealize automatic fillingTextile treatment containersMixersMagnetic tension forceSlurry

The invention relates to the field of warp sizing machine machinery equipment and in particular relates to a warp sizing machine automatic stirring device comprising a slurry barrel. A slurry groove is embedded into the slurry barrel to reduce space occupation; a slurry supplying through holes is formed in the bottom of the slurry groove; a positioning frame is disposed in the slurry groove; the positioning frame and the slurry groove are communicated; a hollow-out structure with the height basically equal to the height of the positioning frame is mounted on the wall of the positioning frame; a buoyancy block is disposed in the positioning frame; the buoyancy block passes through the slurry supplying through hole to be connected with a valve via a connection rod; the buoyancy block floats up and down with the slurry liquid level in the positioning frame to control on-off of the slurry supplying through hole, so automatic slurry supply of the slurry groove can be achieved; and the warp sizing machine automatic stirring device is simply structured and no fault is caused. The magnetic structure is arranged on the valve; at least two springs are fixed on the bottom of the slurry barrel; a magnet is mounted on the top of each spring; when the slurry supplying through hole is blocked by the valve, the magnetic structure is balanced and each magnet is balanced; and when the slurry supplying through hole is unblocked by the valve, magnetic force size of each magnet by the magnetic structure changes, so each magnet is imbalanced and movements are caused and the slurry is stirred.

Owner:WUXI ANG YIDA MACHINERY

Impressed notch-huffing type barium sulfate crystal quantitative filling equipment

The invention discloses impressed notch-huffing type barium sulfate crystal quantitative filling equipment. Working personnel places a to-be-filled charging bag onto a soft plate, an impressed notch driving air cylinder and an electromagnet drive a pressing piece to rotate and move downwards, and thus the edge of the charging bag is fixed; then, a synchronous belt conveys the charging bag to the position under a weighing barrel, and during the period, barium sulfate crystals in a material supply tank fall into the weighing barrel till the measured value of a weight sensor reaches the specified value; meanwhile, after a blowing head sprays high-pressure gas, the charging bag is spread, then the barium sulfate crystals in the material supply tank fall into the charging bag, and the bottom of the charging bag makes contact with the conveying belt; and after filling is completed, the conveying belt conveys the charging bag to the process, and so far filling operation of one charging bag is completed. According to the impressed notch-huffing type barium sulfate crystal quantitative filling equipment, the barium sulfate crystals can be bagged; the efficiency is high; the action process is smooth; operation is automatically completed; and the physical effort of the operation personnel is reduced.

Owner:GUANGXI LIANZHUANG SCI & TECH CO LTD

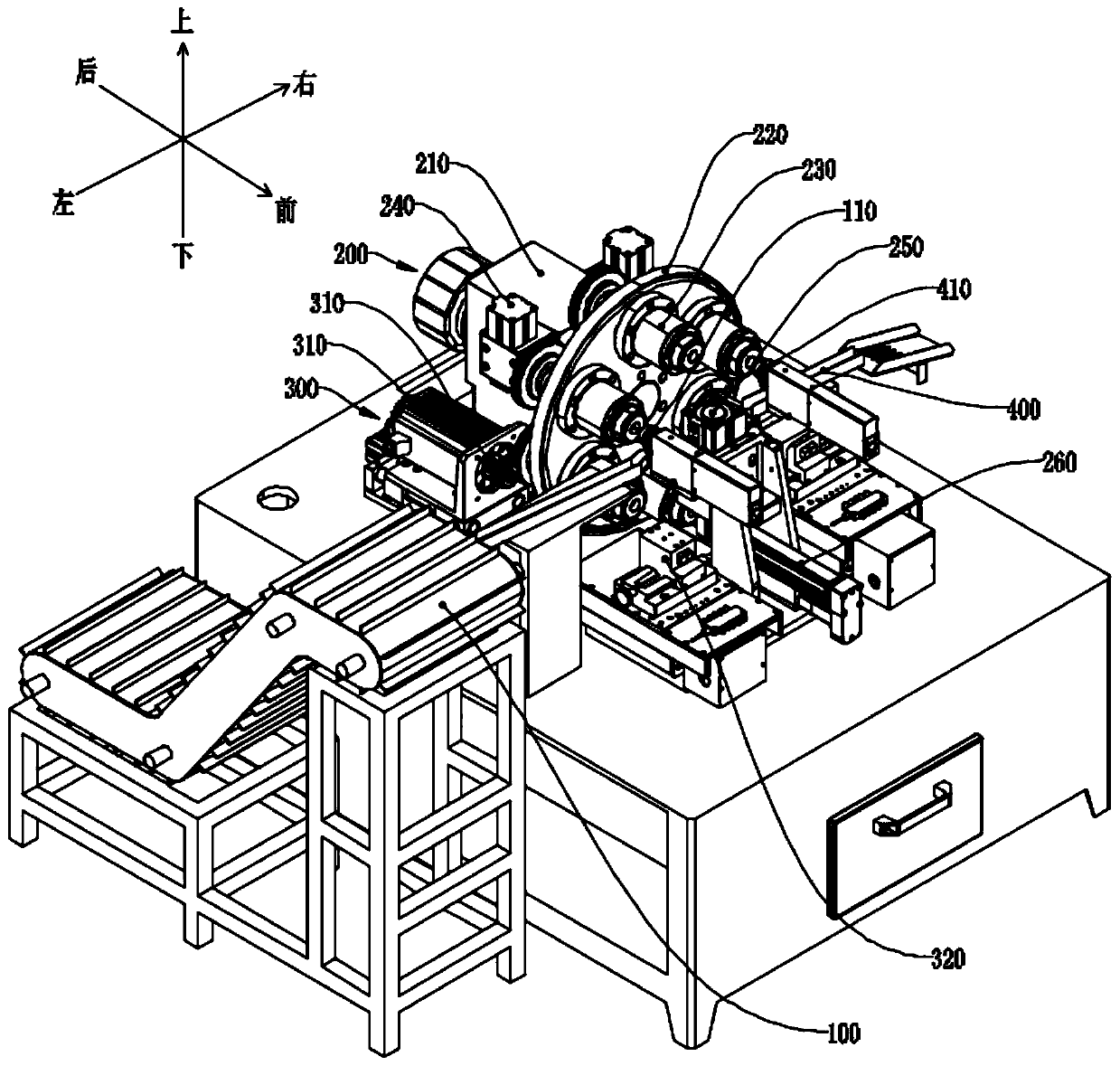

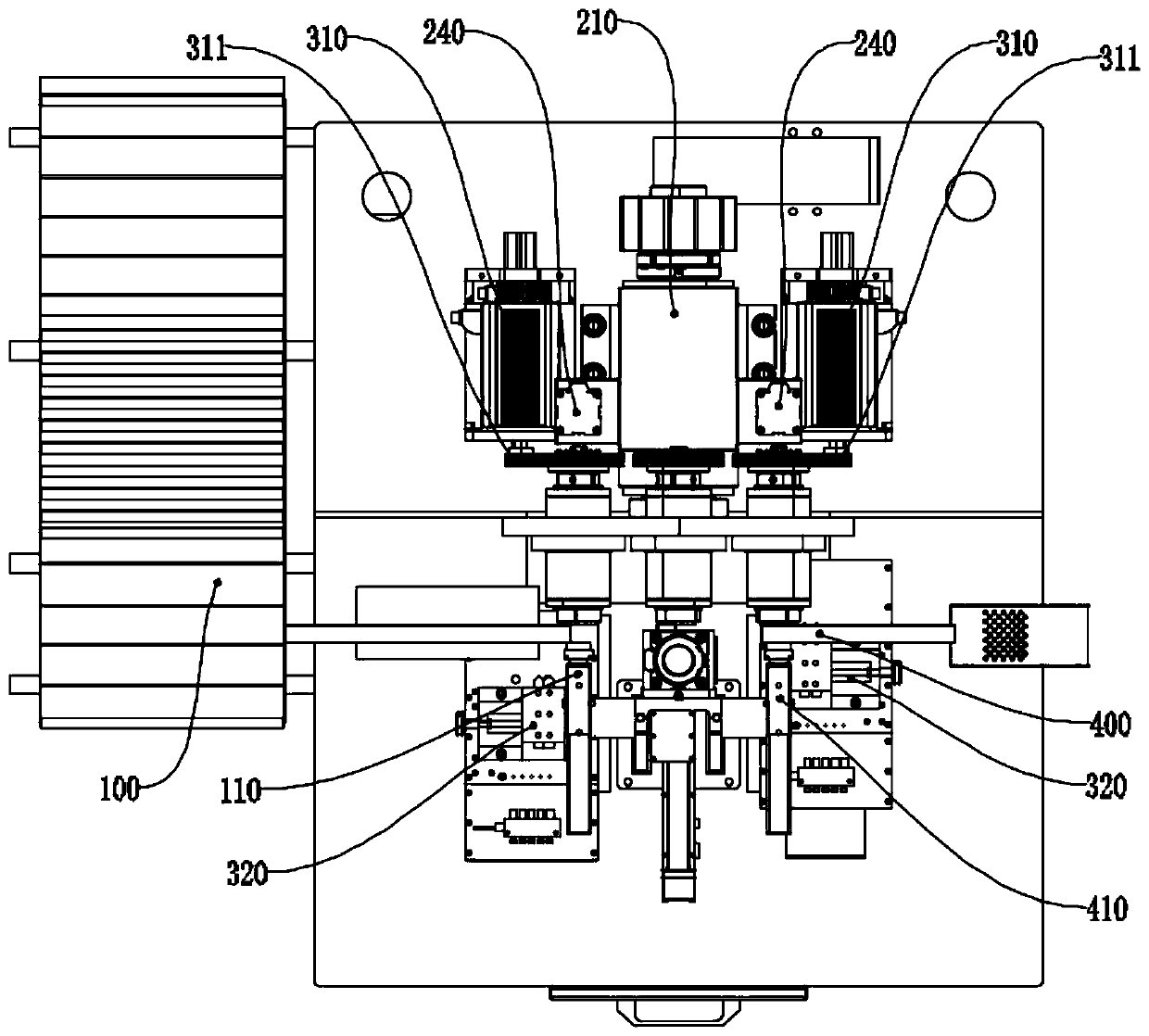

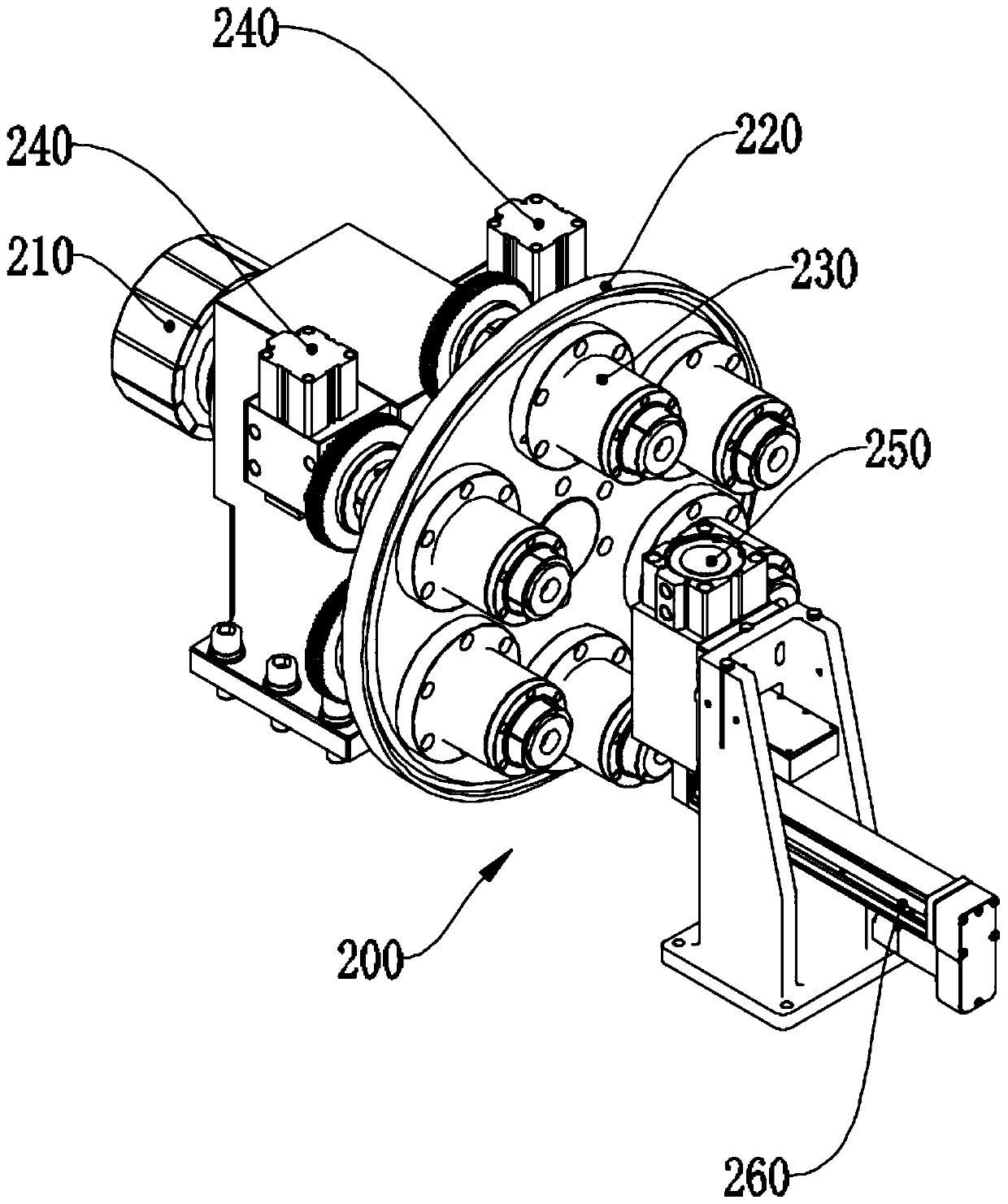

Fully-automatic double-sided chamfering machine

PendingCN110548935ARealize automatic fillingRealize automatic dischargeLarge fixed membersPositioning apparatusEngineeringFully automatic

The invention discloses a fully-automatic double-sided chamfering machine. The fully-automatic double-sided chamfering machine comprises a loading device, a reversing device, a cutting device and an unloading device, wherein the loading device comprises a loading grabbing assembly; the loading grabbing assembly is used for pushing a workpiece to a clamping end of the clamping assembly of the reversing device; the reversing device is used for workpiece reversing, and the cutting device is used for cutting the workpiece; and the unloading device comprises an unloading grabbing assembly which isused for grabbing the workpiece in the clamping end of the clamping assembly to the unloading region. The fully-automatic double-sided chamfering machine can realize automatic filling, automatic double-sided chamfering and automatic discharging of the whole processing process, does not need manual assistance in the whole workpiece double-sided chamfering process, is high in production efficiency and is simple in structure.

Owner:广东同慧智能装备有限公司

Intelligent food packaging equipment

InactiveCN112441274AImprove decentralization efficiencySave time at workWrapper twisting/gatheringSolid materialProcess engineeringFood packaging

The invention discloses intelligent food packaging equipment. The intelligent food packaging equipment comprises a machine body. An adjusting assembly is arranged in a discharging box. According to the intelligent food packaging equipment, through rotary connection of a grooved wheel and a belt and equal-distance distribution of vertical pipes, materials can be equally put down through rotation ofthe vertical pipes which are distributed annularly at equal intervals, then the material putting-down efficiency is improved, and the working time is saved. Meanwhile, the single-time putting-down amount of the vertical pipes can be adjusted according to use requirements, the putting-down precision is further improved, and the packaging effect is improved. A vertical plate on the left side can move along a sliding rail to adsorb a packaging bag through a suction cup, the packaging bag is driven to move reversely to abut against a vertical plate on the right side, the packaging bag is fixed toan outlet of a discharging box in an open state through adsorption of a suction cup on the opposite side, then automatic containing is achieved, and the automation degree is higher. A top opening ofthe packaging bag can be directly subjected to heat sealing after the packaging bag is contained. Multiple purposes are achieved through one machine, and the packaging convenience is further improved.

Owner:宋瑞伍

Filling equipment for heavy-duty water-based anticorrosive paint

InactiveCN106046902AImprove site utilizationReduce labor intensityBarrels/casks fillingRotary stirring mixersWork statusDrive motor

The invention aims to provide filling equipment for a heavy-duty water-based anticorrosive paint. The filling equipment comprises a stirring cavity, a feed pipe, a driving motor, a motor shaft, a stirring blade, a first filter screen, a stirring vane, a discharge pipe, a first flow control valve, a feed inlet, a sealed cover, a filling cavity, a second filter screen, a filling pipe, a second flow control valve, a second wireless valve controller, a liquid level sensor, a flowmeter, a paint bucket, a weighing platform, a bearing platform, an adapting piece, universal rollers, a control device, a control button, a display screen, a working state indicator light, a wireless transmitter, a supporting bar and a first wireless valve controller. The filling equipment is characterized in that the feed pipe is arranged at the upper end of the stirring cavity; the feed pipe and the stirring cavity are communicated with each other; and the motor shaft is arranged inside the stirring cavity. The invention has the following beneficial effects: automatic filling of the paint can be realized, and the filling equipment has advantages of saving manpower, raising filling accuracy and enhancing paint quality.

Owner:天津市津海特种涂料装饰有限公司

Barium sulfate crystal assembly line quantitative filling device

The invention discloses a barium sulfate crystal assembly line quantitative filling device. A material loading bag to be filled is placed on a flexible plate by an operator, the edge of a bag opening of the material loading bag is sucked by a pore machined in the flexible plate, and then the material loading bag is conveyed to the position under a weighing barrel through a conveying belt. Barium sulfate crystals in a material supply tank fall into the weighing barrel in the meantime until a measured value of a weight sensor reaches a designated value. Meanwhile, a piston rod of a jetting air cylinder pushes out a nozzle forwards, the material loading bag is opened after high-pressure gas is ejected by the nozzle, then the barium sulfate crystals in the weighing barrel fall into the material loading bag, and the bottom of the material loading bag makes contact with the conveying belt. After filling is completed, the material loading bag is conveyed to the next procedure through the conveying belt, and so far the filling operation of one material loading bag is completed through the barium sulfate crystal assembly line quantitative filling device. According to the barium sulfate crystal assembly line quantitative filling device, the barium sulfate crystals can be bagged, the efficiency is high, the action process of the device is smooth, the operation is completed automatically, and the physical output of the operator is reduced.

Owner:GUANGXI XIANGZHOU HUIZHI NANO SCI & TECH CO LTD

Liquid filling device

InactiveCN105084281AEasy to fillRealize automatic fillingLiquid bottlingGear wheelLiquid storage tank

The invention provides a liquid filling device and belongs to the technical field of liquid filling. The liquid filling device comprises four pairs of guide rods, sliding blocks and a cylindrical cam. A curved cam groove is formed in the outer side of the cylindrical cam. The pairs of guide rods are arranged between an upper rotary plate and a lower rotary plate at equal intervals in an equal-circumference mode and located on the outer side of the cylindrical cam. Each sliding block is arranged on the corresponding pair of guide rods and can slide up and down. An idler wheel is arranged on each sliding block in a rotatable mode and inserted in the curved cam groove of the cylindrical cam. A clamp is further installed on each sliding block. A liquid storage tank and the topmost end of the curved cam groove in the cylindrical cam are located on the same side. A rotary plate supporting shaft is coaxially arranged on the lower side of the lower rotary plate. A second gear is coaxially installed on the rotary plate supporting shaft. A first gear is engaged with the second gear. A first belt pulley is connected with a second belt pulley through a transfer belt. According to the liquid filling device, compound motion of continuous rotation and vertical movement of bottle bodies is achieved, automatic filling of liquid is achieved, and production efficiency is high.

Owner:周顺尧

Semi-automatic single welding machine for solar cell slices

ActiveCN102528203BRealize automatic fillingMeet product upgrade needsMetal working apparatusSoldering auxillary devicesCompression deviceSemi automatic

The invention relates to a semi-automatic single welding machine for solar cell slices, which comprises a rack, and is characterized in that: a welding strip fixing device, a welding strip alignment device, a feeding device, a flux coating device, a flux drying device, a welding strip cut-off device, and a welding strip traction device are sequentially arranged on the rack along the length direction, the welding strip cut-off device comprises a tool holder, a first compression device, a cutter and a welding head, and a chopping block is also arranged at the bottom of the tool holder; and the welding strip traction device comprises a second compression device capable of fixing welding strips, and a driving device capable of controlling the second compression device to move back and forth between a cut position and a welding position of each welding strip. According to the semi-automatic single welding machine for the solar cell slices, the fully manual operation is replaced to realize the semi-automatic single welding process for the solar cell slices, the overall structure is compact, the input cost is low, the working efficiency is improved, the labor is saved, the welding quality is ensured through the mechanized operation, and the needs of small and medium-sized photovoltaic enterprises for product upgrading can be better met. The semi-automatic single welding machine for the solar cell slices has broader market application prospects.

Owner:宁波日林电子有限公司

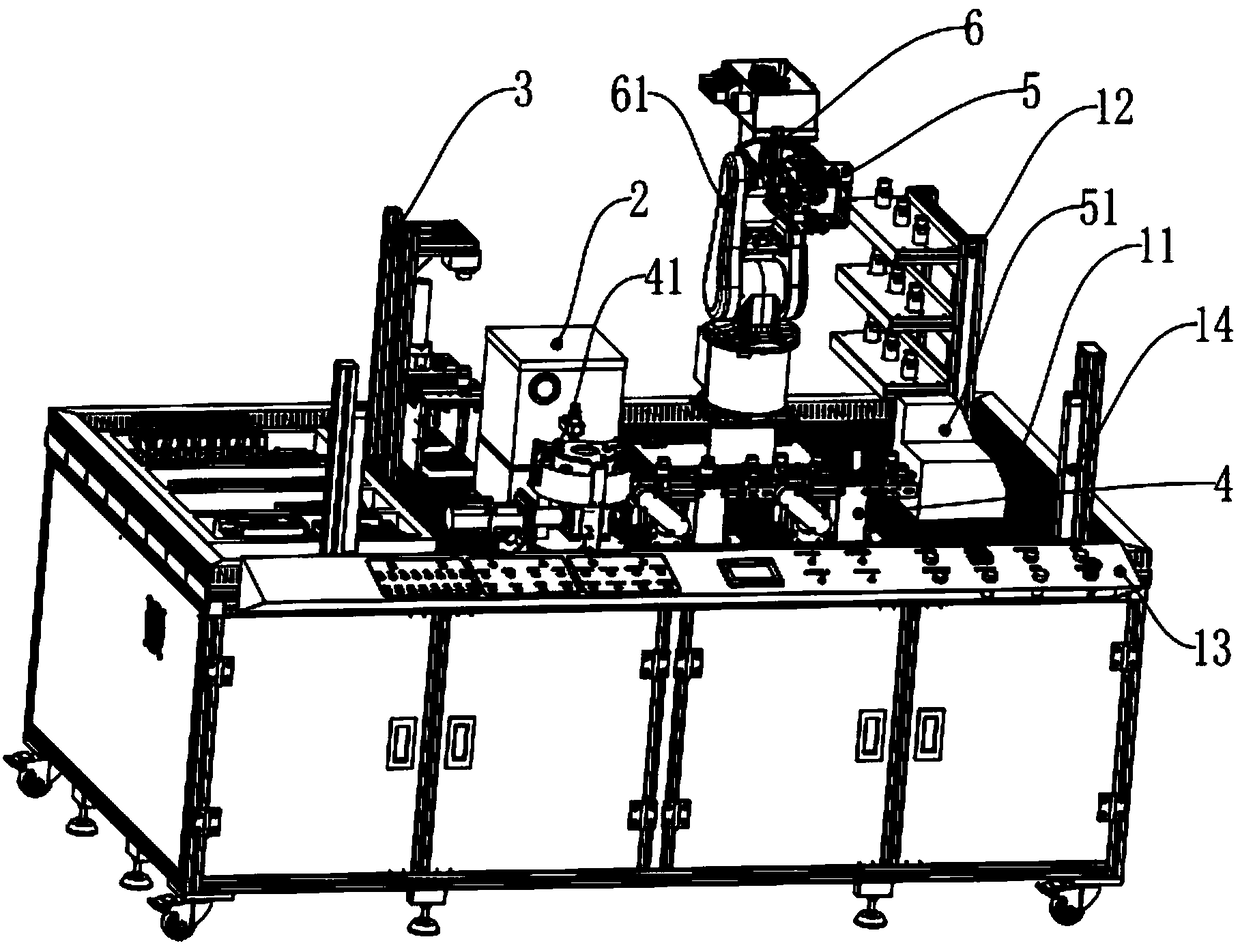

Automatic filling device for medicines and control method thereof

PendingCN109250673AEnsure safetyRealize fully automatic production fillingFlanged caps applicationBottle-handling machinesBiomedical engineeringMedicine bottles

The invention discloses an automatic filling device for medicines and a control method thereof, wherein the automatic filling device includes a machine base, a medicine filling box, a bottle cover installation mechanism, a medicine transmission device, a label sticking mechanism and a clamping structure. The clamping mechanism includes a mechanical arm and a medicine bottle clamp. The medicine bottle clamp is used for clamping a medicine bottle. The medicine filling box is used for filling the medicine bottle on the medicine transmission device. After the medicine filling box fills the medicine bottle, the medicine bottle is transmitted by the medicine transmission device, the bottle cover installation mechanism is used for installing a bottle cover to the medicine bottle; the label sticking mechanism is used for sticking a label on the medicine bottle. The functions of automatic medicine bottle filling, bottle cover installation and label sticking can be realized only through the single mechanical arm. The structure is simple, and the labor can be released; only one operator can operate and monitor the production process of the automatic filling device of the medicines, full automatic production filling is realized, and the safety of the production operator is ensured.

Owner:FOSHAN KINGPENG ROBOT TECH CO LTD

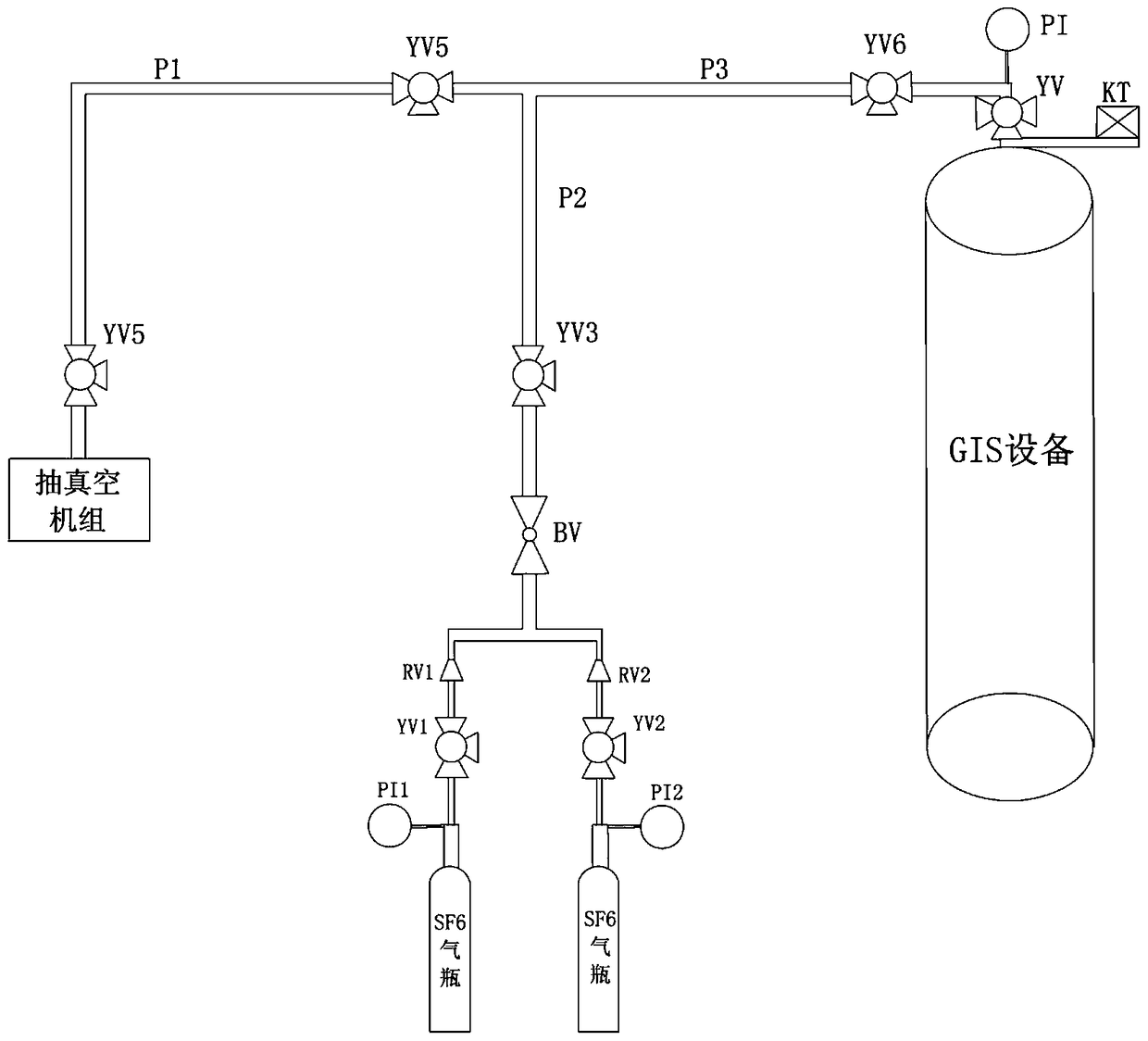

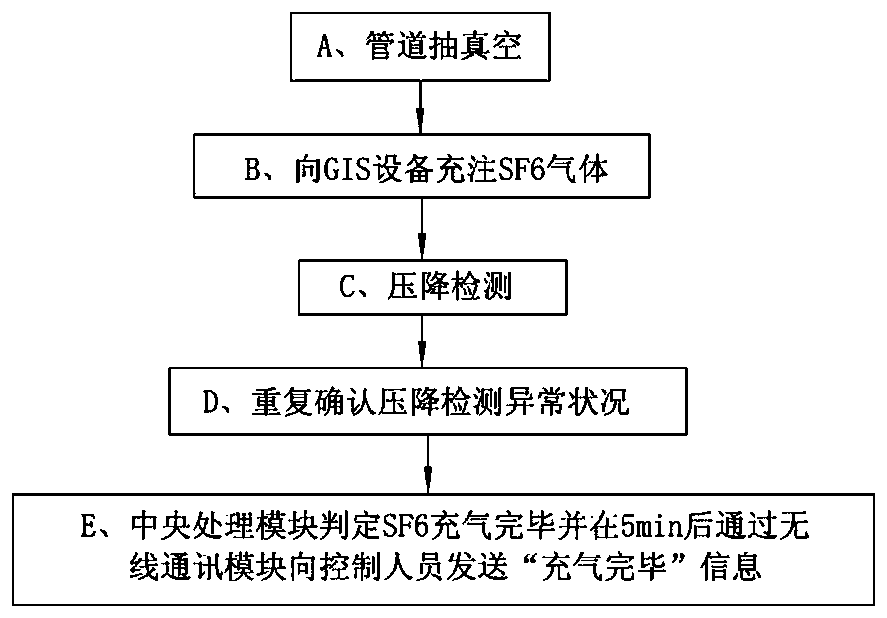

Automatic SF6 gas charging system and method of GIS equipment

PendingCN109386731AImprove stability and securityImprove work efficiencyVessel mounting detailsVessel geometry/arrangement/sizeCharge controlMaterial consumption

The invention discloses an automatic SF6 gas charging system and method of GIS equipment. The automatic charging system comprises a charging control unit, automatic charging of the GIS equipment is realized and charging conditions are monitored automatically, then the system stops automatically after charging is completed, labor and material consumption is reduced, furthermore, the working efficiency of SF6 gas charging in the GIS equipment is improved effectively, by cooperation of a density relay and a body electronic pressure gauge, whether an alarming contact and a latching contact of thedensity relay act reliably or not can be verified in the charging process through the monitoring result of the body electronic pressure gauge, a working process is simplified while it ensures that theGIS equipment is used safely and reliably, and the efficiency is improved indirectly; according to the automatic charging method, the GIS equipment is automatically charged with SF6 gas by successively carrying out pipe vacuumizing, SF6 gas charging and pressure drop detection operation, the process is simple, the method is convenient and speedy to control, the reliability of the charging processis ensured fully, and thus, the stable performance and safe and reliable use of the GIS equipment are ensured.

Owner:HENAN POWER TRANSMISSION & TRANSFORMATION CONSTR CO LTD +1

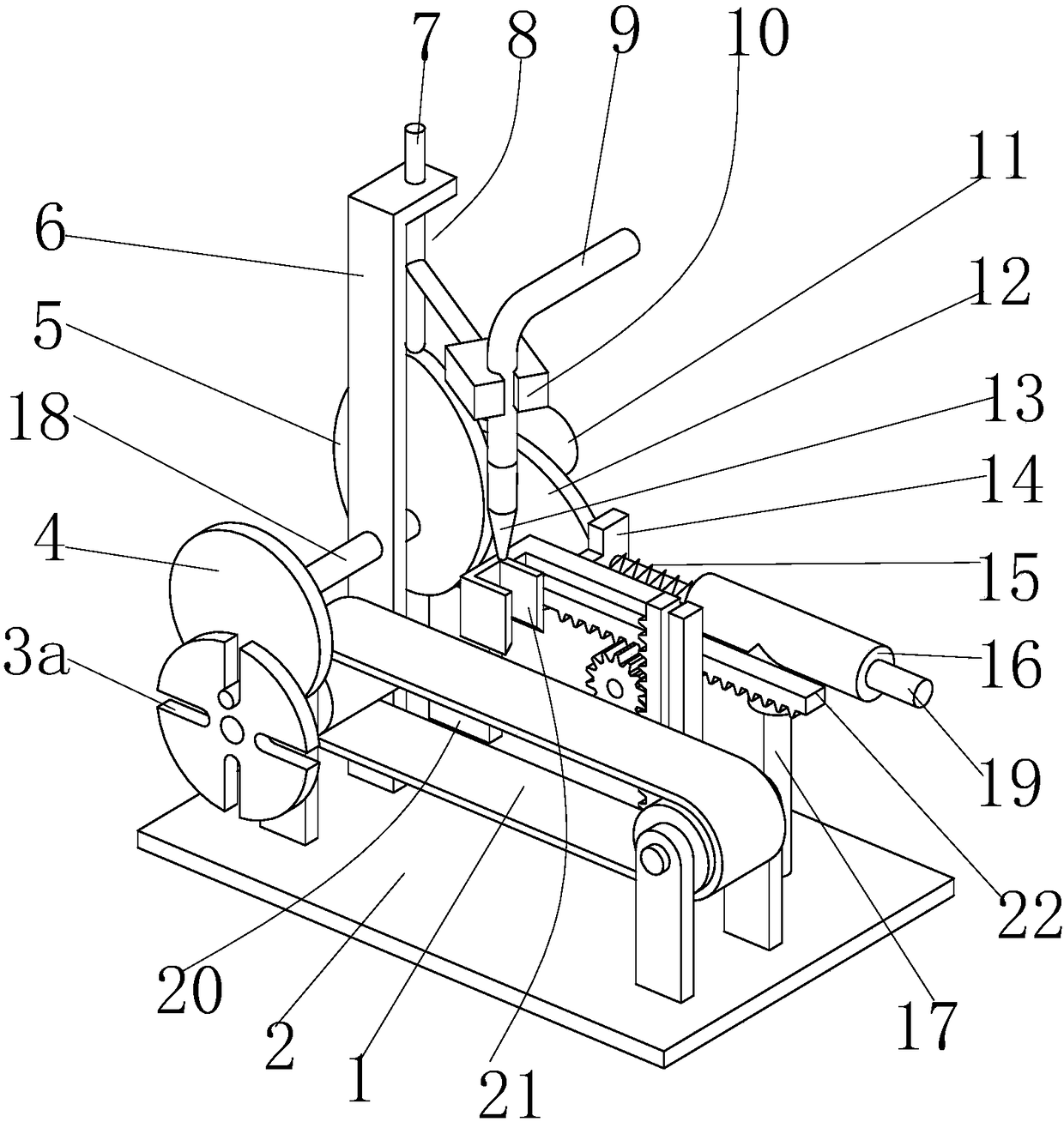

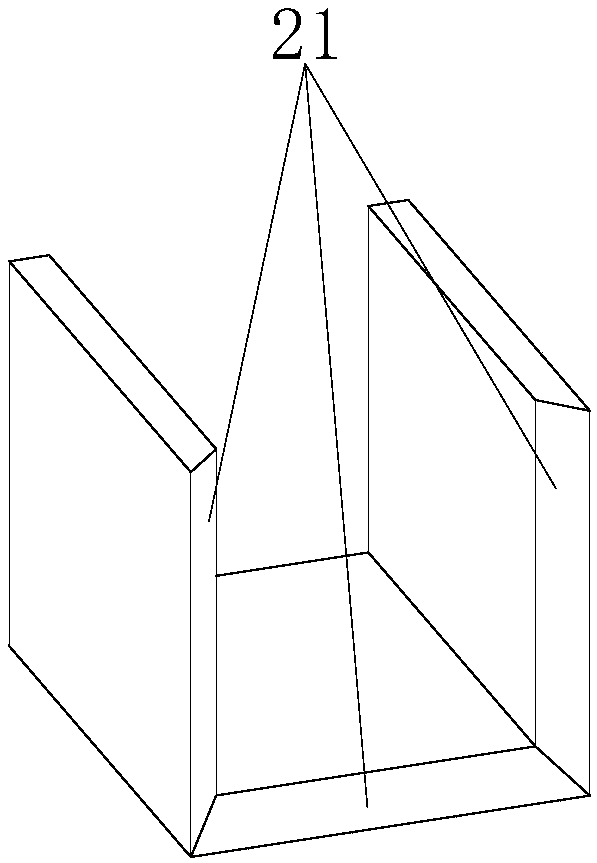

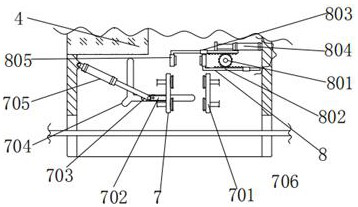

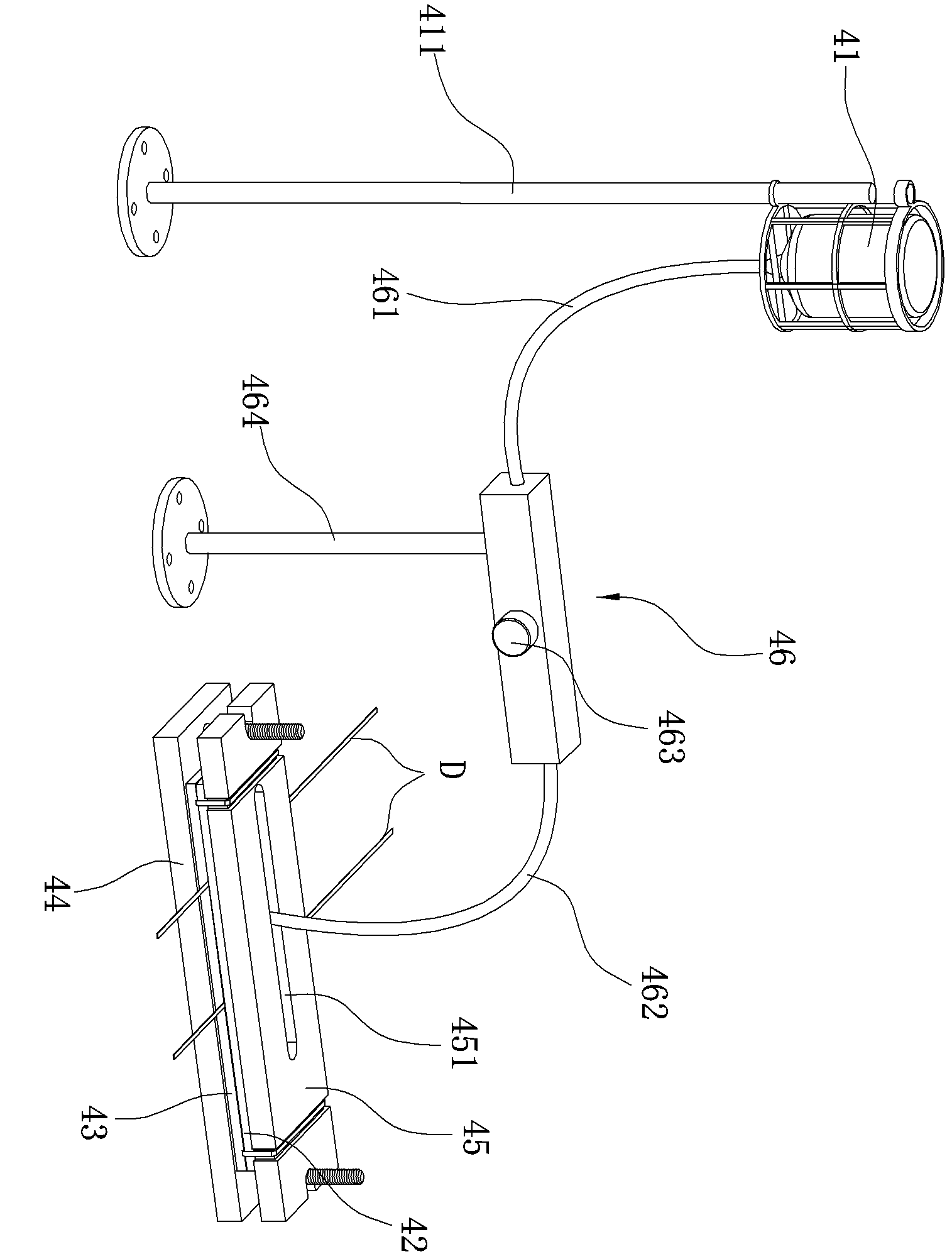

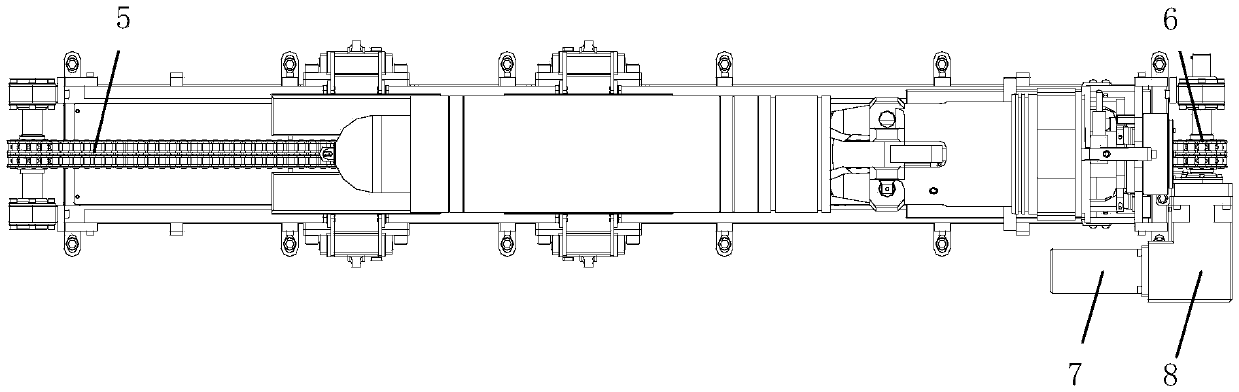

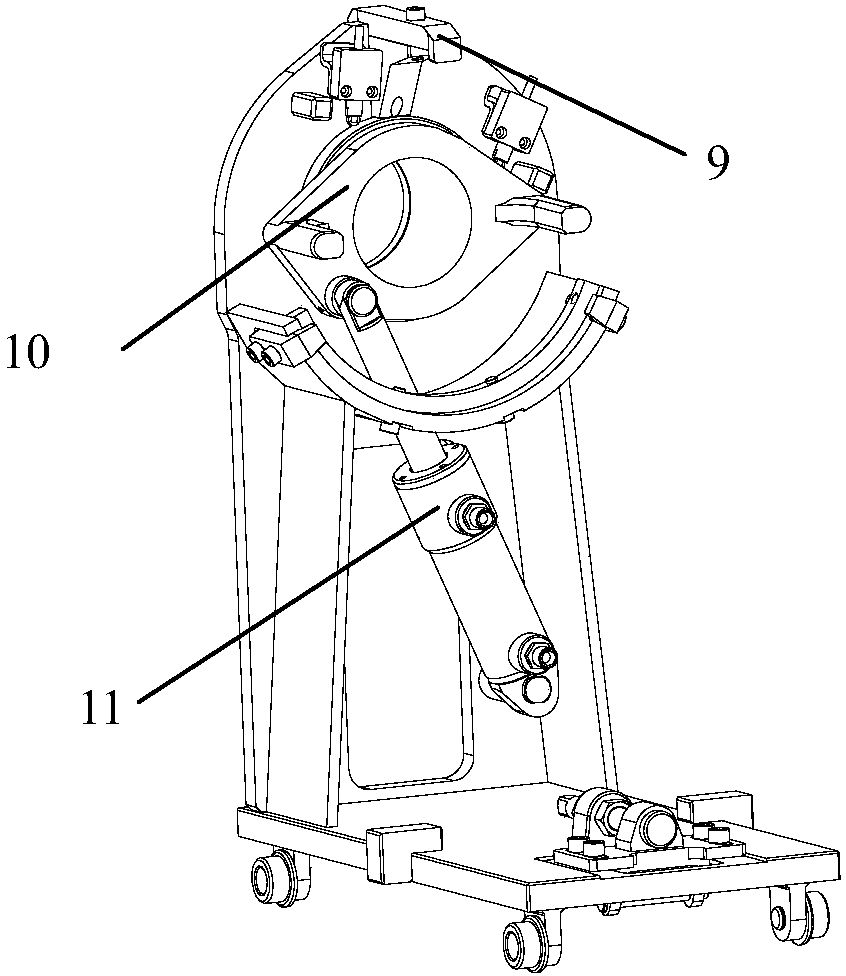

Automatic loading method for parachute gas gun test missiles

ActiveCN107941080ARealize automatic fillingHigh degree of automationAmmunition loadingReducerPetroleum engineering

The invention discloses an automatic loading method for parachute gas gun test missiles and belongs to the technical field of gas gun testing. According to the technical scheme, on the technology of manual loading of test missiles of an existing gas gun, it is designed that a support (1), missile trays (2), a missile conveying trolley (3), swinging disk oil cylinders (4), a chain (5), a chain wheel (6), a motor (7), a speed reducer (8), a claw hook (9), a rotating sleeve (10), a rotating oil cylinder (11) and other structures are included, and are assembled into the automatic loading method for the gas gun test missiles. The automatic loading method for the parachute gas gun test missiles has the beneficial effects that automatic loading of the test missiles is achieved, practicability isgood, operation is convenient and fast, and the testing efficiency is greatly improved.

Owner:AEROSPACE LIFE SUPPORT IND LTD

Automatic laminated wood board core processing method and device

ActiveCN107718181ARealize automatic precise cuttingRealize automatic fillingPlywood pressesLaminationHot pressManufacturing engineering

The invention discloses an automatic laminated wood board core processing device which comprises a board blank conveying assembly, a displacement adjusting mechanism, a hot-pressing unit and a finished product board conveying mechanism. The board blank conveying assembly comprises a conveying belt I, a loading platform and a cutting mechanism, the displacement adjusting mechanism comprises ferry trolleys, a ferry track and a pushing platform, the hot-pressing unit include two or more hot-pressing machines, and the hot-pressing machines use the conveying belt I as the axis and are longitudinally and symmetrically arranged at the tail end of the displacement adjusting mechanism. The finished product board conveying mechanism comprises a conveying belt II, a conveying pair roller set and a board blanking machine. Compared with the prior art, the automatic laminated wood board core processing device achieves automatic board blank loading through matched work of two ferry trolleys and fourhot-pressing machines, and fully utilizes the time difference of pressure maintaining in an instant pressing and alternative execution working mode. In addition, all the operations including board blank conveying, cutting, displacement and loading and finished product board recovery are automatic, and the working efficiency is greatly improved.

Owner:樊荣武

Medical nose department medicine powder grinding device

InactiveCN109433318ARealize the degree of grindingRealize automatic fillingGrain treatmentsCylindrical grindingMaterial storage

The invention discloses a medical nose department medicine powder grinding device. The device comprises a primary grinding cavity, a material storage cavity and a secondary grinding cavity; the primary grinding cavity is separated from the material storage cavity through a cylindrical grinding disc, a conical grinding roller is arranged on the inner side of a conical grinding disc, the conical grinding roller is of a hollow structure, an opening is formed in the upper end of the conical grinding roller, the conical grinding roller is fixedly connected with a rotating rod through a fixing rod fixed on the inner wall of the conical grinding roller, and the upper end of the rotating rod penetrates through the lower wall of a transmission cavity fixed on the inner wall of the primary grindingcavity and is connected with the transmission cavity in a rotating mode. According to the device, the design is novel, when the conical grinding roller arranged rotates, medicine powder on the inner side of the conical grinding roller enters the position between the conical grinding roller and the conical grinding disc through a centrifugal hole to realize grinding, the medicine powder is ground in a centrifugal manner, and automatic packing is realized; when a rotating shaft rotates, a baffle plate is driven by an eccentric wheel and a connecting rod to move in a reciprocating mode, thereforeintermittent discharging of the medicine powder in the material storage cavity is realized, so that the phenomenon that a large amount of medicine powder falls into the secondary grinding cavity at the same time so as to influence the grinding effect is avoided.

Owner:翟明伟

Apparatus integrating the medicinal materials slicing and drying function

InactiveCN108673605AImprove efficiencyHigh degree of automationDrying gas arrangementsDrying solid materialsResistance wireEngineering

The invention discloses a apparatus integrating the medicinal materials slicing and drying function, comprising a feeding plate, a feeding hopper, a crushing cylinder and a drying cylinder; The feeding plate is arranged with a front and rear symmetrical feeding slot, and the upper end of the feeding slot is connected with a feeding hopper; A pushing plate is nested in the feeding slot; a baffle isfixedly connected to the upper end of the pushing plate; a moving block is fixedly connected to the bottom of the pushing plate; the moving block runs through the screw rod; the screw rod is screwedwith the moving block. A feeding port is arranged on the right side of the feeding slot; a crushing cylinder is fixedly connected to the right side of the feeding plate; a cutting blade is arranged inthe crushing cylinder. According to the apparatus integrating the medicinal materials slicing and drying function, it is possible to realize automatic filling, improve the efficiency of slicing, andimprove the degree of automation by providing a pushing plate and a baffle driven by a screw rod and a feeding plate arranged with a feeding slot. In the apparatus integrating the medicinal materialsslicing and drying function, the slice is sliced and dried by providing a spiral blade roller and a resistance wire and a fan blade, which has better drying quality and higher drying efficiency, and integrates the drying function to improve the production efficiency.

Owner:贵港市申德机械设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com