LNG tank box assembly line filling system

An assembly line and tank container technology, applied in the direction of electrical program control, sequence/logic controller program control, etc., can solve the problems of low manual operation efficiency, low degree of automation, low filling efficiency, etc., to improve filling efficiency and filling safety, reduce human error, and realize the effect of full automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in detail below in conjunction with the accompanying drawings. However, it should be understood that the accompanying drawings are provided only for better understanding of the present invention, and they should not be construed as limiting the present invention. In the description of the present invention, it should be understood that the terms "first", "second" and so on are only used for the purpose of description, and should not be understood as indicating or implying relative importance.

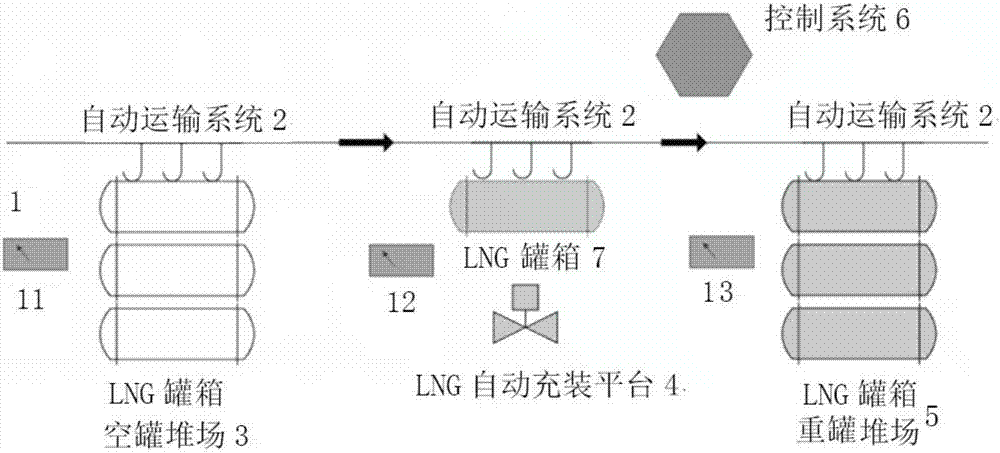

[0014] Such as figure 1 As shown, the LNG tank assembly line filling system provided by the present invention includes first to third scanners and information recorders, an automatic transportation system 2, an empty LNG tank storage yard 3, an automatic LNG filling platform 4, and an LNG tank Box heavy tank yard 5 and control system 6 .

[0015] The first to third scanning and information recorders 1 are used to obtain the ID information...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com