Patents

Literature

291results about How to "Realize full automation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

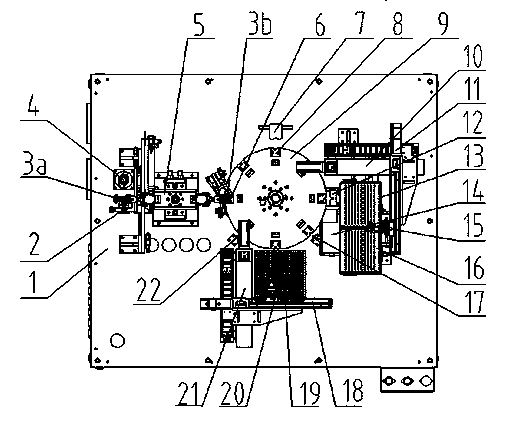

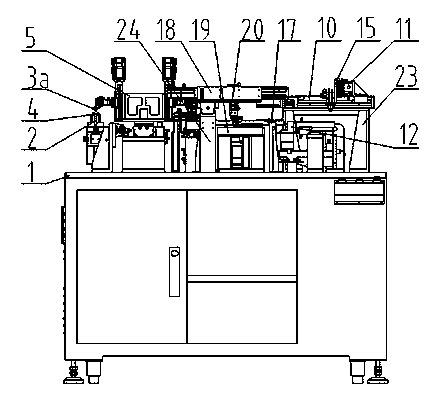

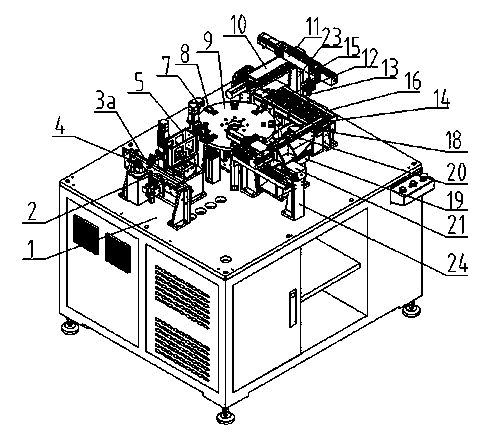

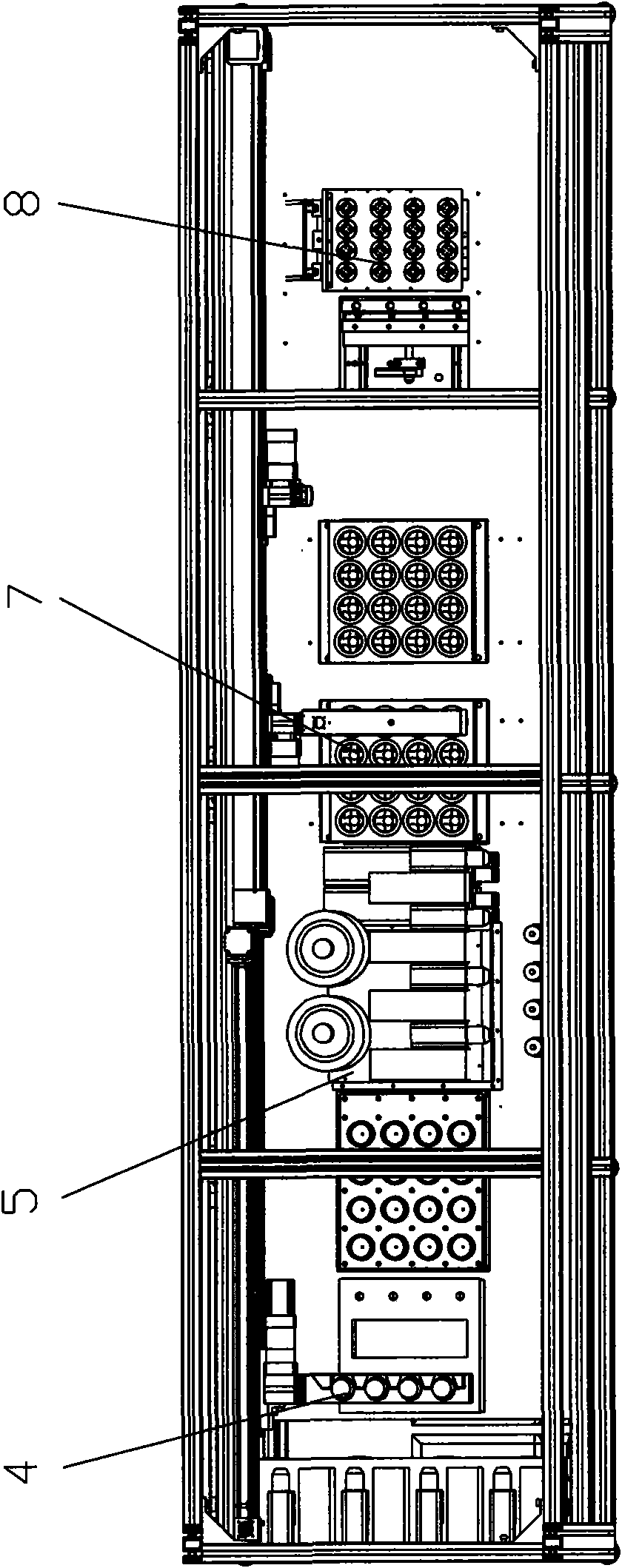

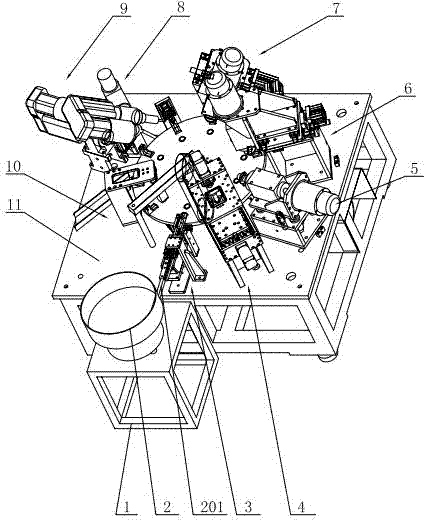

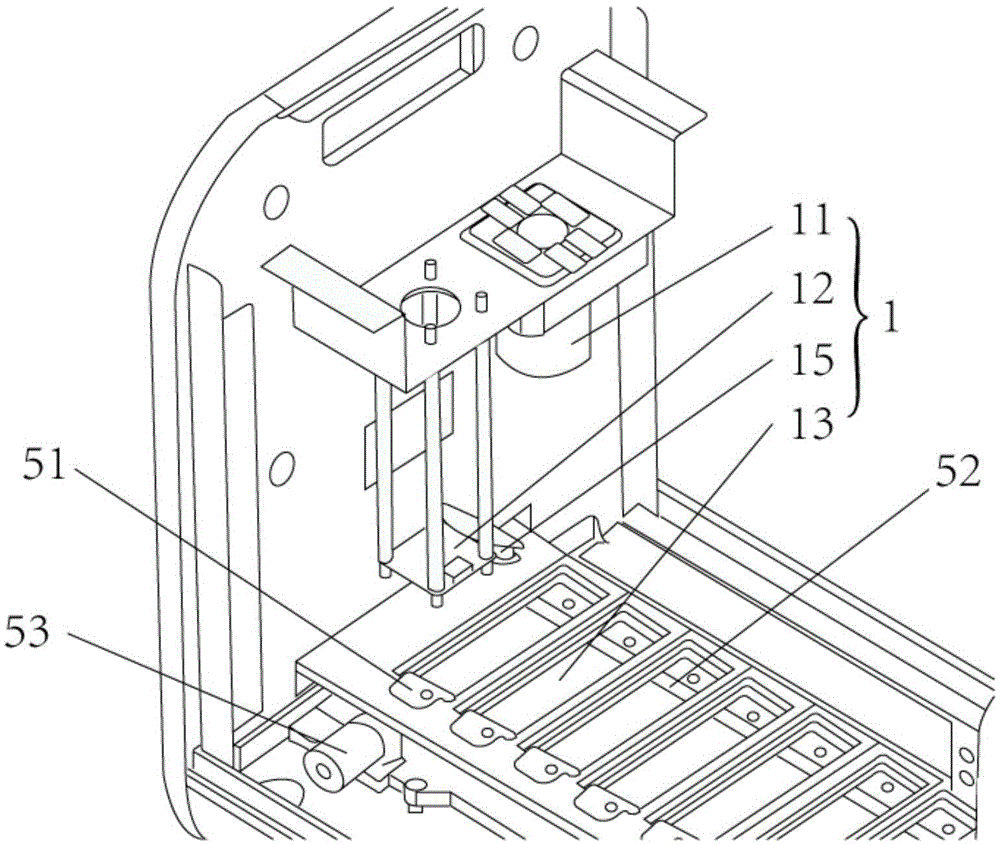

Optical sub-module detecting machine and detecting method

InactiveCN104280209ARealize full automationReduce labor costsOptical apparatus testingControl systemSemi automatic

The invention provides an optical sub-module detecting machine and detecting method. Through the detecting machine, optical sub-modules which include but are not limited to an optical transmitting sub-module and an optical receiving sub-module are fully automatically fed and detected, and good and bad products can be respectively discharged. The detecting machine comprises an optical fiber end face detecting and cleaning and optical fiber inserting and coupling mechanism, a full-automatic feeding mechanism, a feeding mechanism assembly, a discharging mechanism assembly, a high-accuracy station transferring mechanism (such as a rotating mechanism and a linear reciprocating conveying mechanism), a workbench, a control panel, a closed loop automatic detection control system, a human-machine conversion interface, a protecting cover and a fault alarming system. The optical sub-module detecting machine and detecting method make up for the blank in the field of full-automatic detection of optical sub-modules, and solve the problems that because of manual detection or semi-automatic detection, the detecting accuracy of parts to be detected is not high, the detecting efficiency is low, and the detecting cost is high.

Owner:WUHAN YIKE SIDE TECH

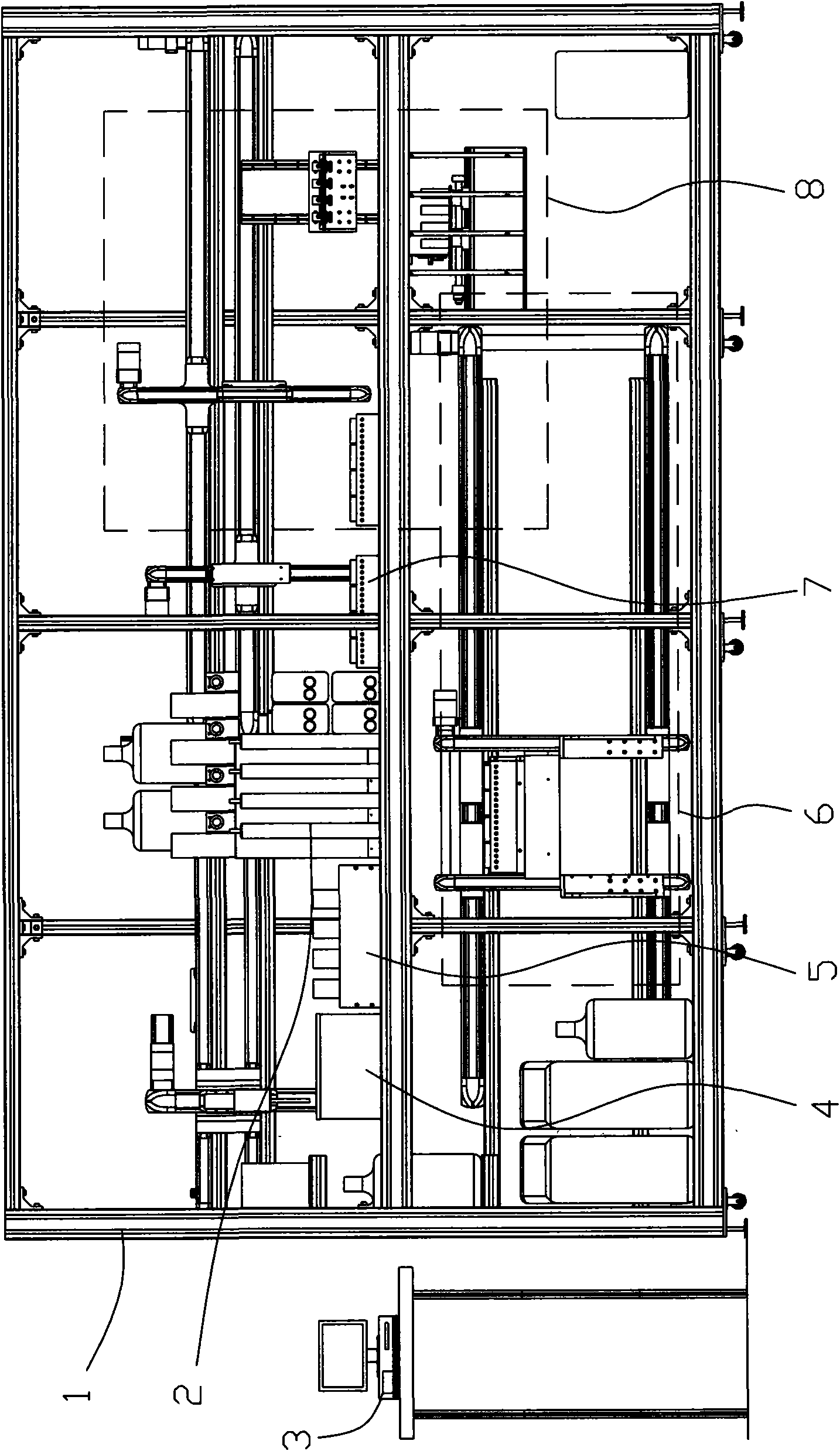

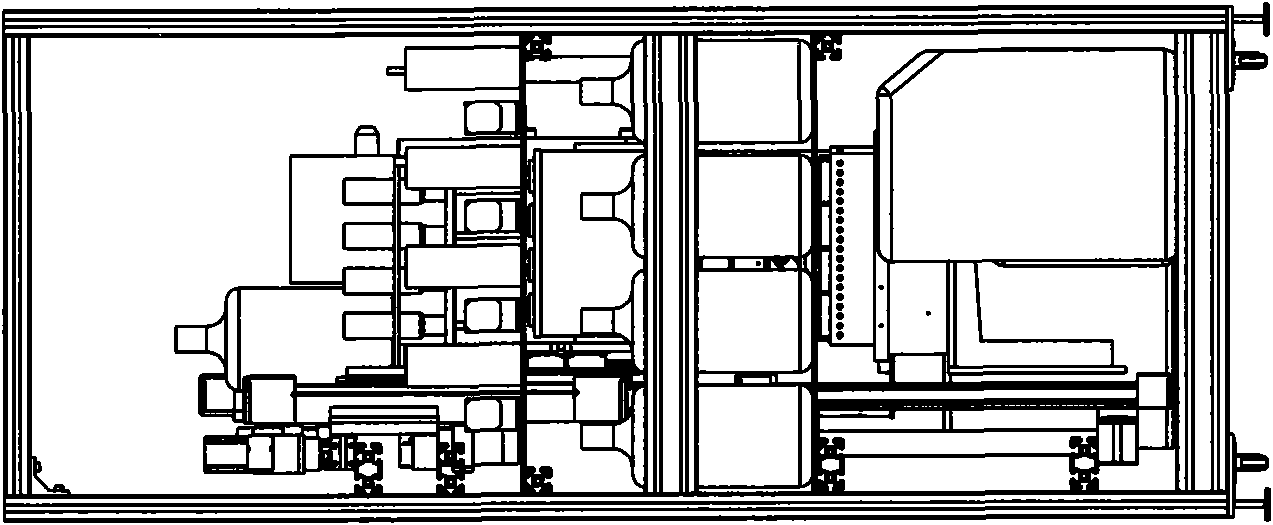

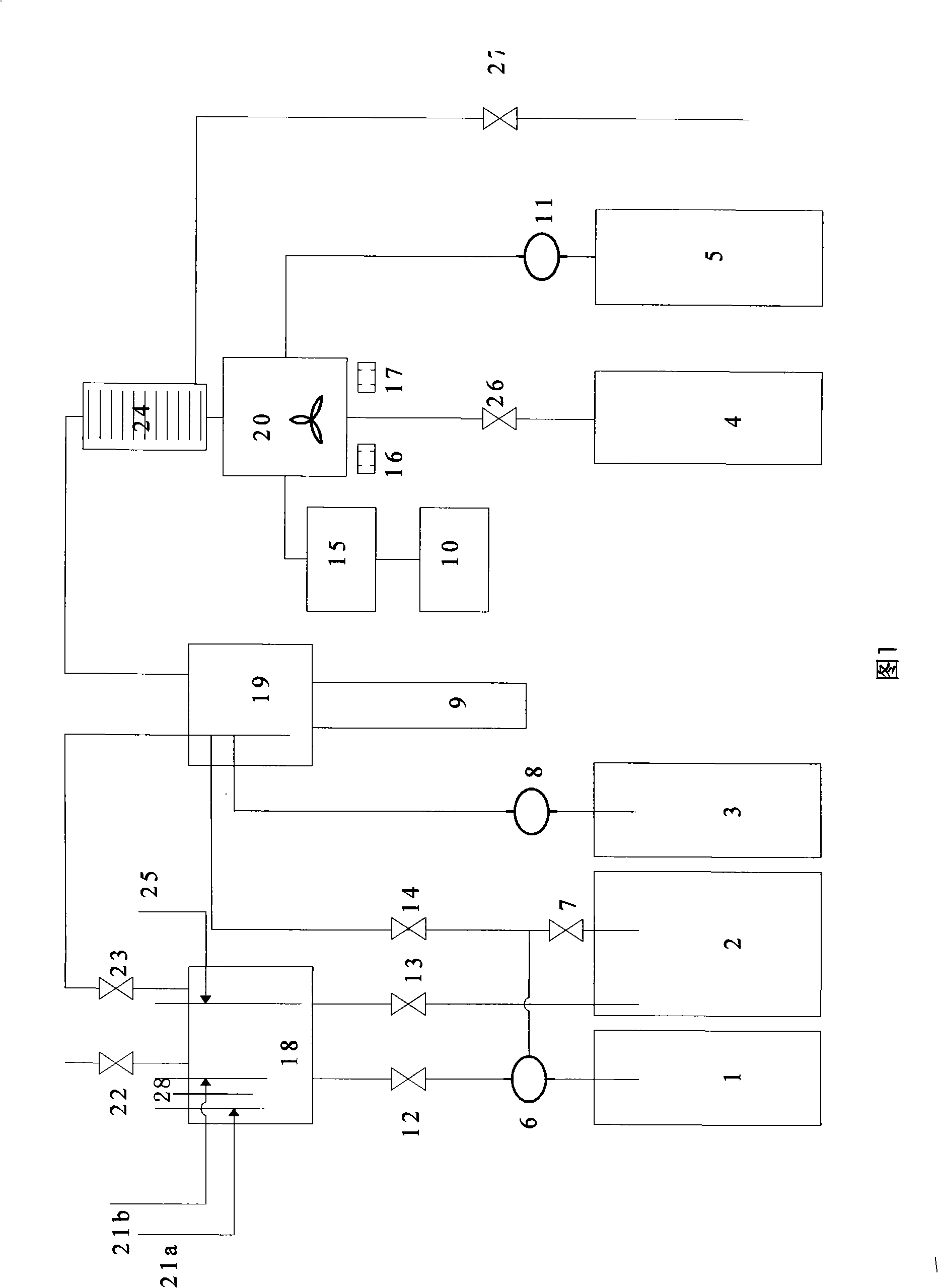

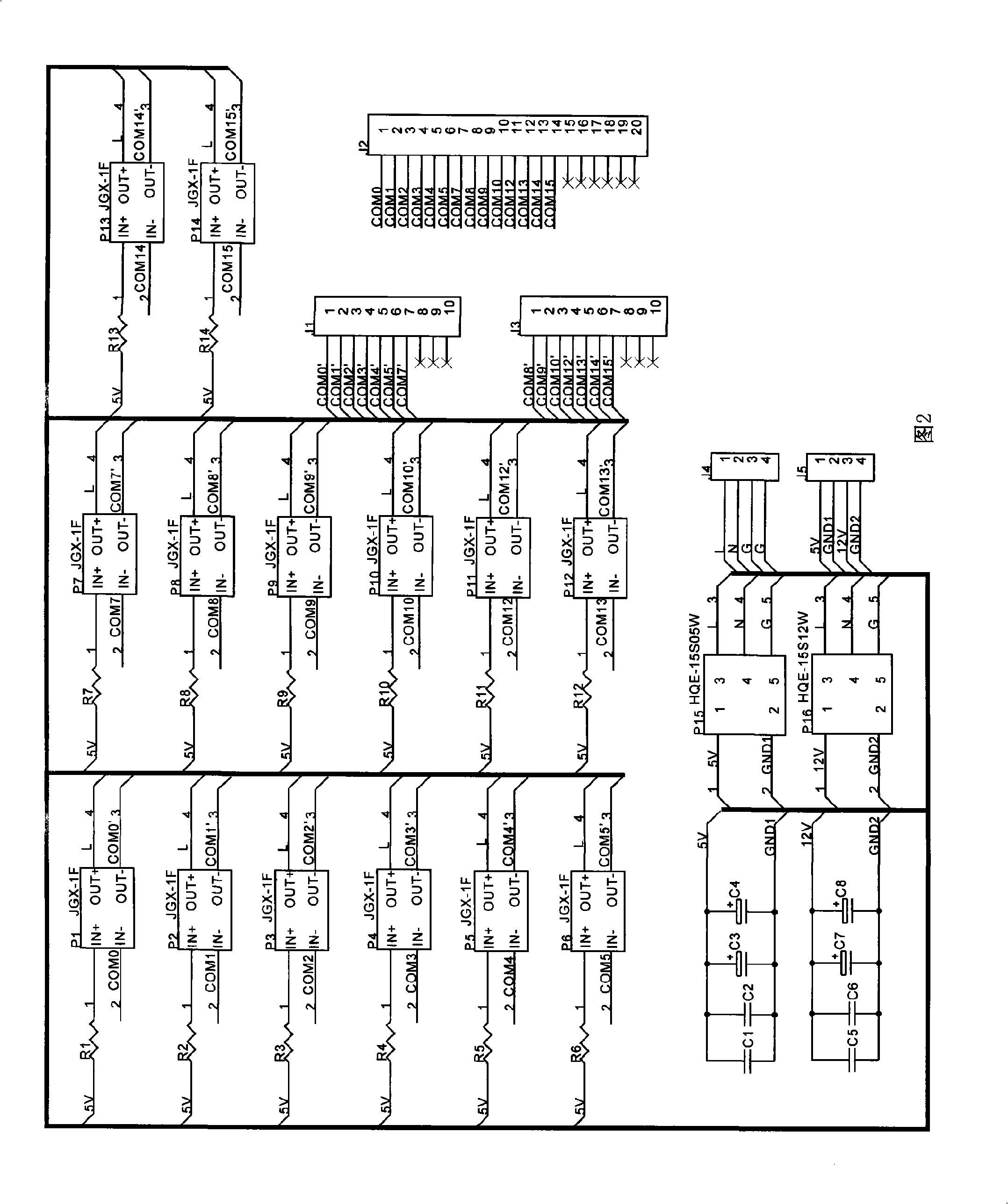

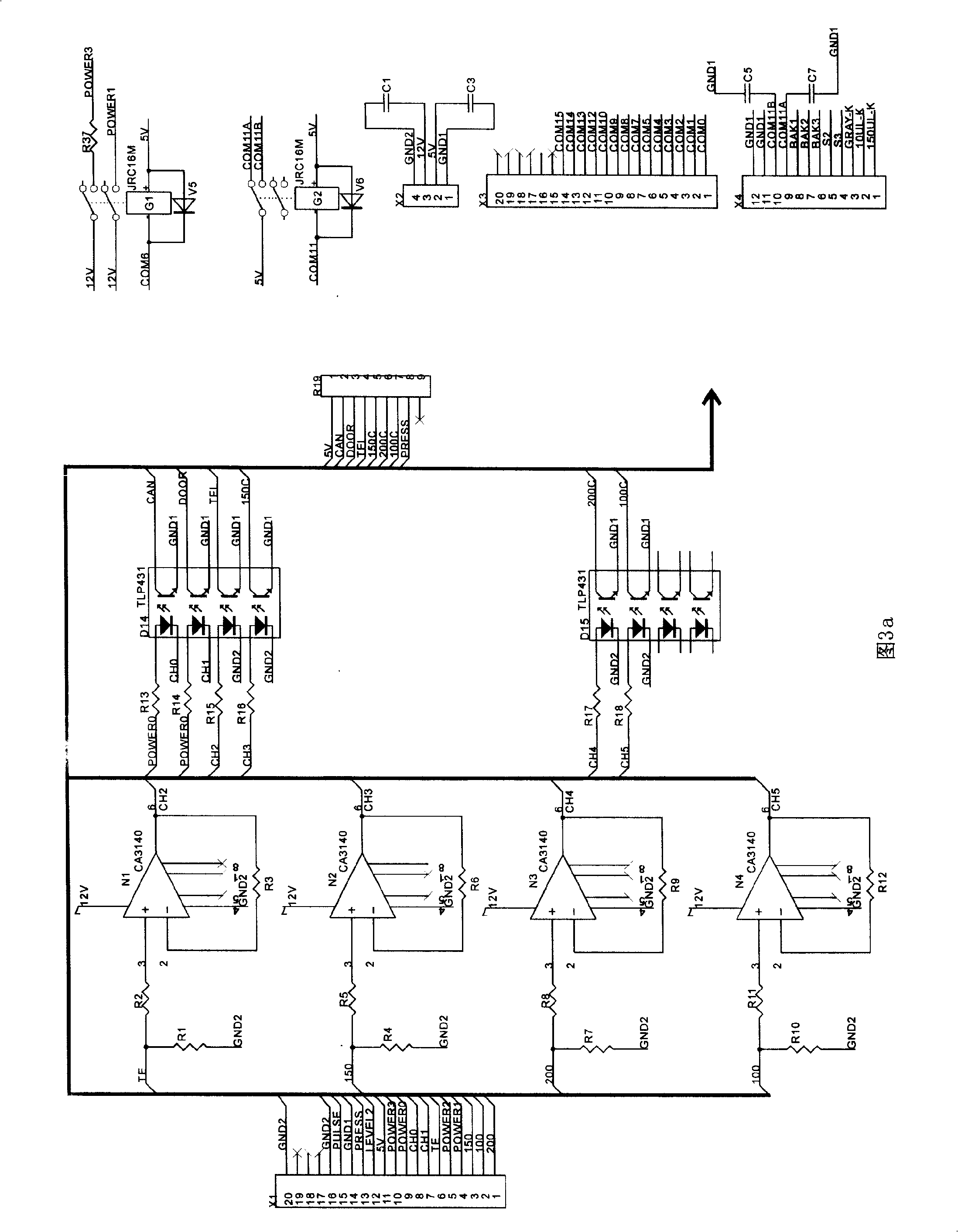

Full-automatic modular multi-sample intelligent processing system

InactiveCN101598739ARealize full automationIncrease throughputPreparing sample for investigationFiltrationNitrogen

The invention discloses a full-automatic modular multi-sample intelligent processing system, which comprises a liquid adding and homogenizing module, an automatic vacuuming and filtering module, an automatic nitrogen blowing and concentrating module, an automatic gelatum permeating and purifying module, an automatic slide phase extracting module, an automatic transmitting and heating module and an operation control module. Corresponding processing modules, experimental condition procedures and operation procedures are edited and selected by the operation control module according to the needs of different samples to be processed to carry out corresponding automatic processing. The full-automatic modular multi-sample intelligent processing system can synchronously process four samples, can continuously process fixteen samples, and carry out processing procedures of liquid adding, homogeneity extraction, filtration, gelatum purification, solid phase extraction, nitrogen blowing on the samples. The full-automatic modular food residual sample processing system realizes full automation of processing the samples, effectively improves the sample processing quantity, simplifies the operation process, improves the detection quality and improves the experimental safety.

Owner:CHINESE ACAD OF INSPECTION & QUARANTINE

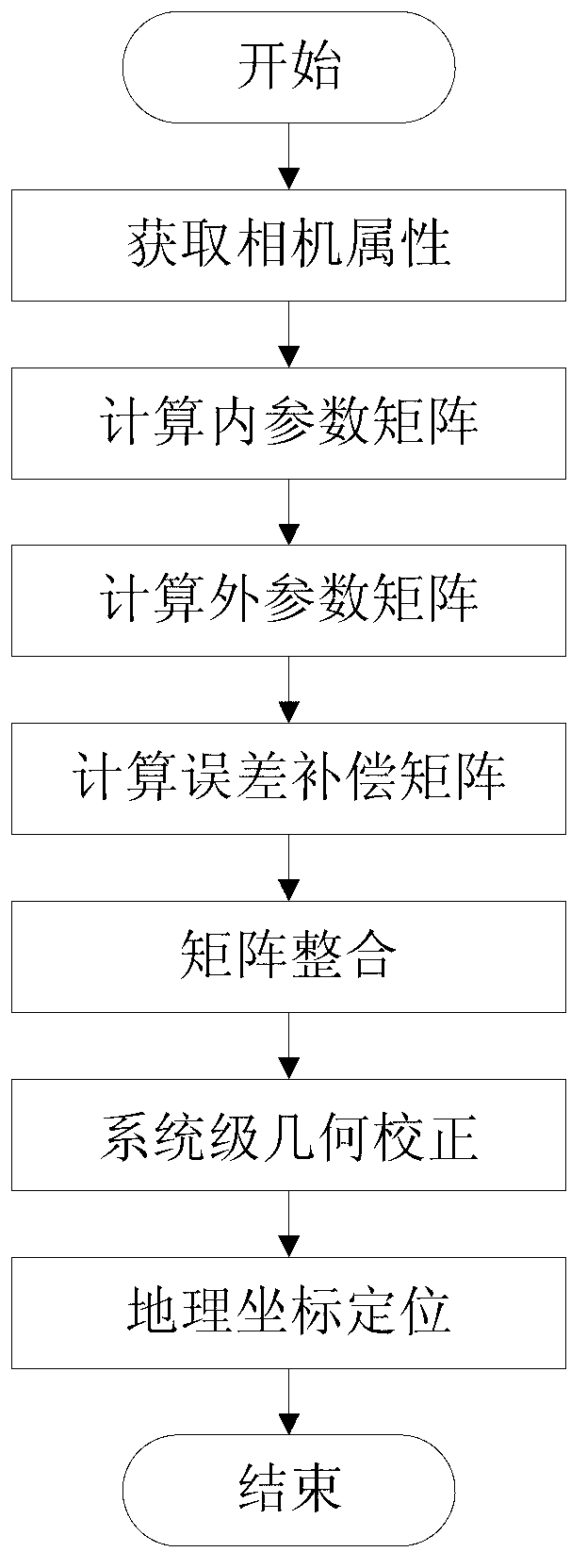

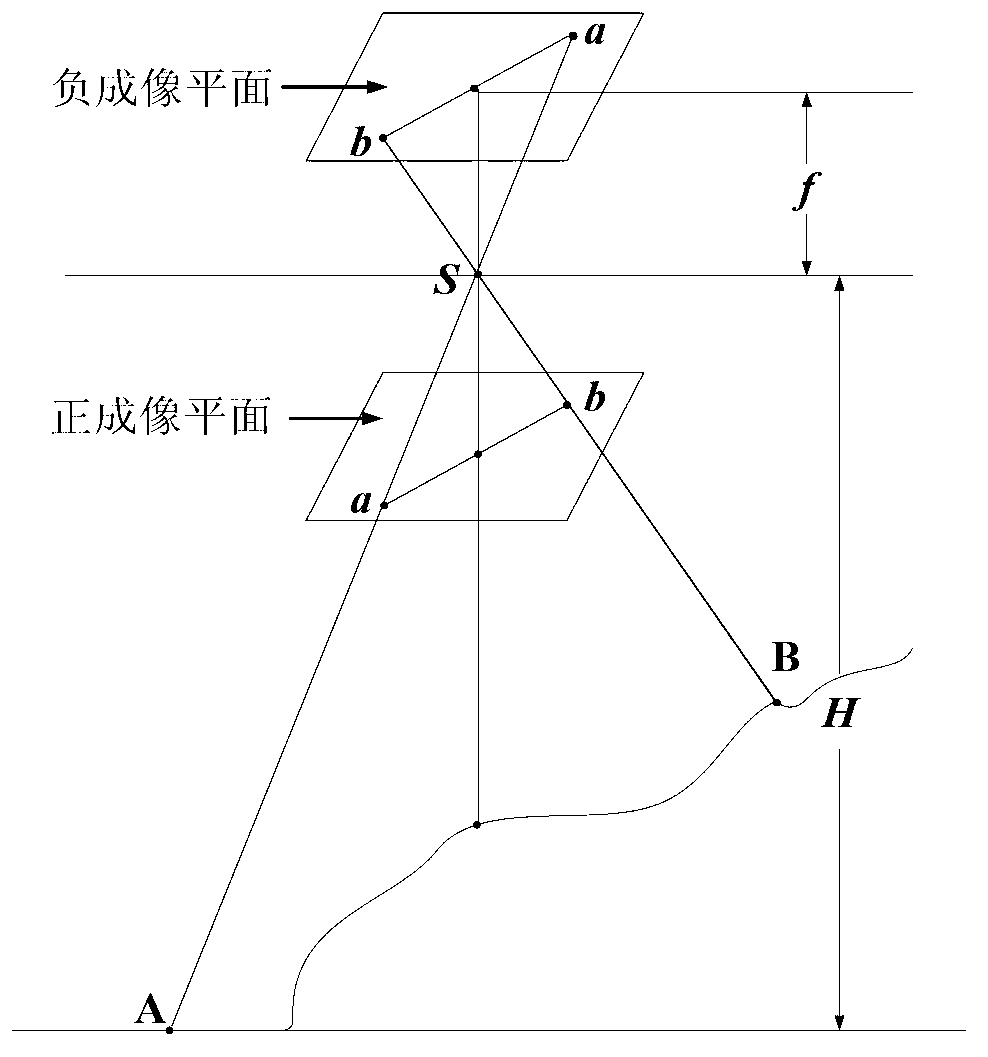

UAV high resolution image geometric correction method based on error compensation

ActiveCN103345737AHigh precisionRealize full automationImage analysisImage resolutionHigh resolution image

The invention discloses a UAV high resolution image geometric correction method based on error compensation. The UAV high resolution image geometric correction method based on the error compensation comprises the following steps that firstly, attribute parameters of an airborne camera are determined, and an internal parameter matrix Ain is calculated; secondly, external orientation parameters of remote-sensing images are obtained, and an external parameter matrix Aout is calculated; thirdly, on the basis of ground control points, an error compensation matrix Aerror_cmp is calculated; fourthly, correction matrixes are integrated; fifthly, on the basis of an overall situation transformation matrix A, geometric correction is conducted on the remote-sensing images; sixthly, geographical coordinates of the boundaries of the remote-sensing images are positioned. According to the UAV high resolution image geometric correction method based on the error compensation, factors causing geometric distortion of the remote-sensing images of an unmanned aerial vehicle are taken into consideration comprehensively, and accuracy of the UAV high resolution image geometric correction method is effectively improved through an error compensation mechanism. The UAV high resolution image geometric correction method based on the error compensation basically achieves automation of the whole course, certain parameter values can be used repeatedly once being calculated out, and work efficiency is improved greatly. According to the UAV high resolution image geometric correction method based on the error compensation, as height calibration parameters are brought in, geometric correction images of different types of resolution can be obtained according to requirements, and flexibility of the UAV high resolution image geometric correction method is improved.

Owner:北京北航天宇长鹰无人机科技有限公司

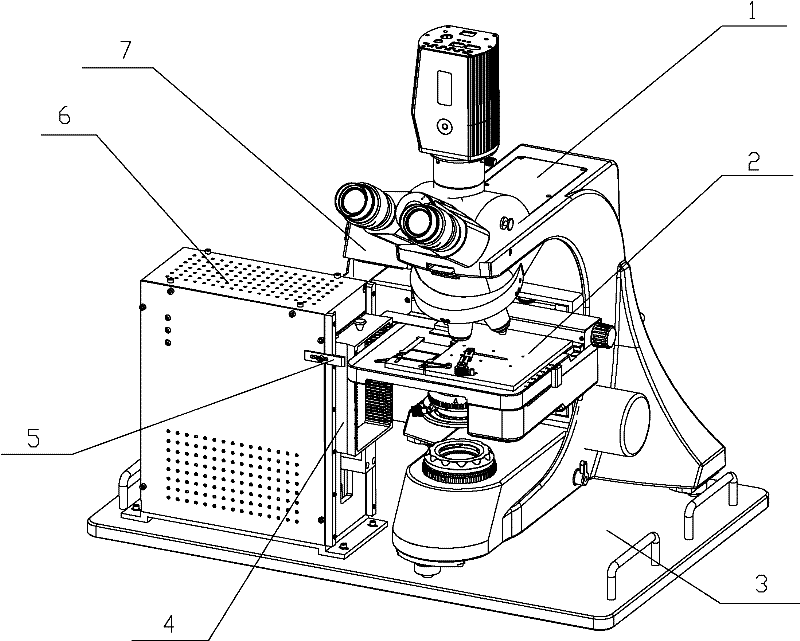

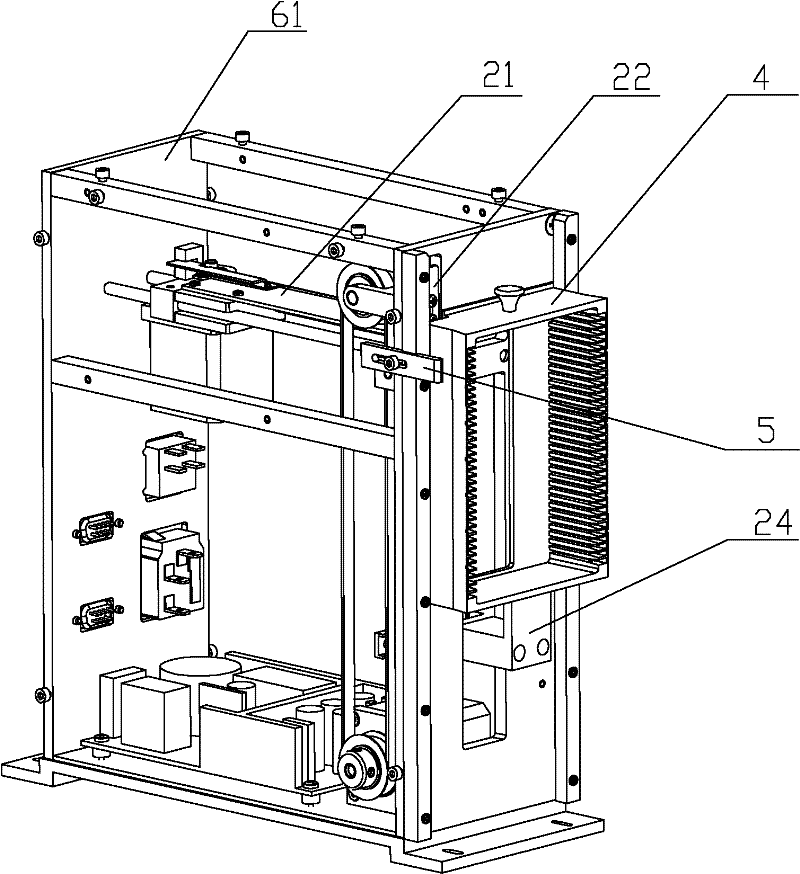

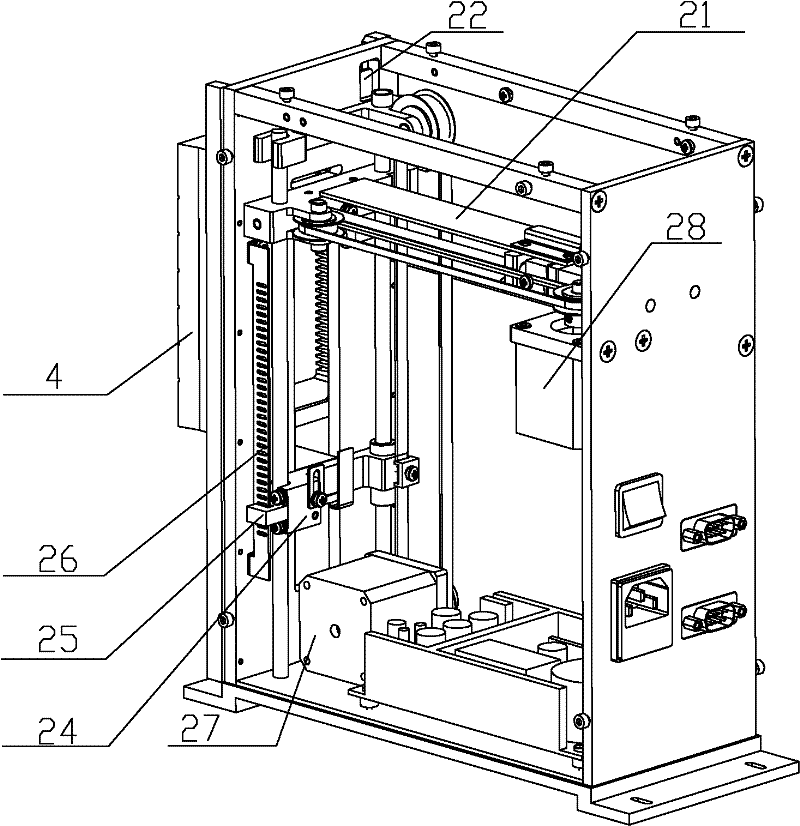

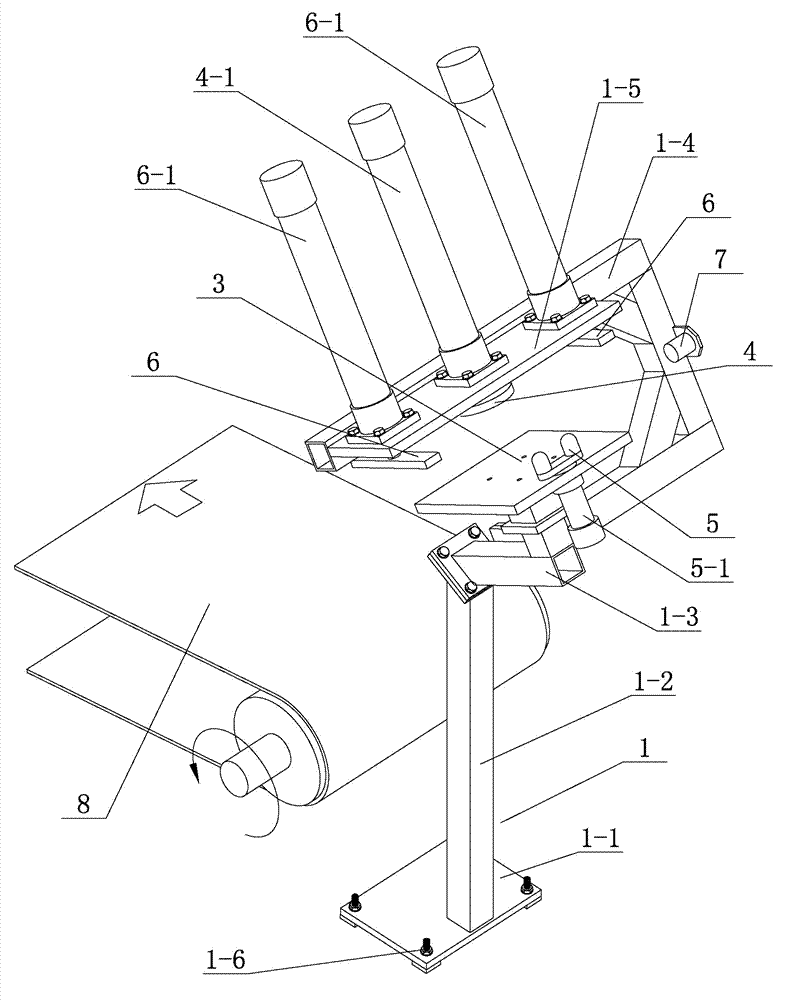

Microscope slice automatic feeding device

The invention discloses an automatic feed device for microscopic sections. The automatic feed device comprises a section feed device and a section-clamping device arranged on a microscope stage; the section feed device comprises a section box, a bracket, a section-pushing plate, a positioning detection device, a section sensing device and a hook dialing plate, wherein the section box is used for accommodating a plurality of sections, the bracket can drive the section box to lift, the section-pushing plate is used for pushing out sections from the rear part of the section box, the positioning detection device is used for accurately controlling the lifting of the section box, and the section sensing device can be used for detecting whether sections are in right positions in the section box; the section-clamping device comprises a section positioning groove, a section hook and a section-putback push plate, wherein the section positioning groove is used for accommodating sections, the section hook is used for locking sections entering the section positioning groove and cooperatively operating with the hook dialing plate, and the section-putback push plate is used for pushing sections from the section positioning groove back to the section box. The section feed device and the section-clamping device work correspondingly and cooperatively so as to jointly complete the operations of placing sections on a microscope and taking back sections from the microscope, thereby realizing the full automation of microscope operation, and achieving the effect that a microscope works normally in an unattended way within 24 hours.

Owner:MOTIC CHINA GRP CO LTD

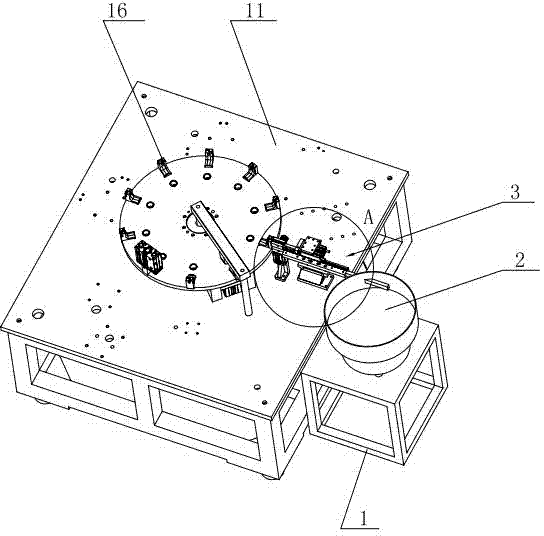

Lock cylinder automatic machining device

ActiveCN103495868ARealize the whole process of automatic conversationRealize full automationOther manufacturing equipments/toolsMetal working apparatusEngineeringMachining

The invention relates to a lock cylinder automatic machining device which comprises a first machine frame and a second machine frame, wherein a vibration material disc is arranged on the first machine frame, a rotation disc component is arranged on the second machine frame, a plurality of sets of locating dies are arranged in the circumferential direction of the rotation disc component and located on the second machine frame. The periphery of the rotation disc component is provided with a feeding unit, a drilling unit, a first groove milling unit, a second groove milling unit, a third groove milling unit, a first oblique hole machining unit, a second oblique hole machining unit and a discharging unit in the anticlockwise direction. A discharging pipe of the vibration material disc extends into the feeding unit, and the first machine frame is further provided with a locating unit. The lock cylinder automatic machining device has the advantages that the structure is simple, operation is simple and convenient, whole automation of the lock cylinder machining is achieved through all units, machining efficiency is good, quality is high, time and labor are saved, investment on enterprise labor resources is saved, production efficiency is greatly improved, and whole-journey automation of lock cylinder machining is achieved.

Owner:东营市港城热力有限公司

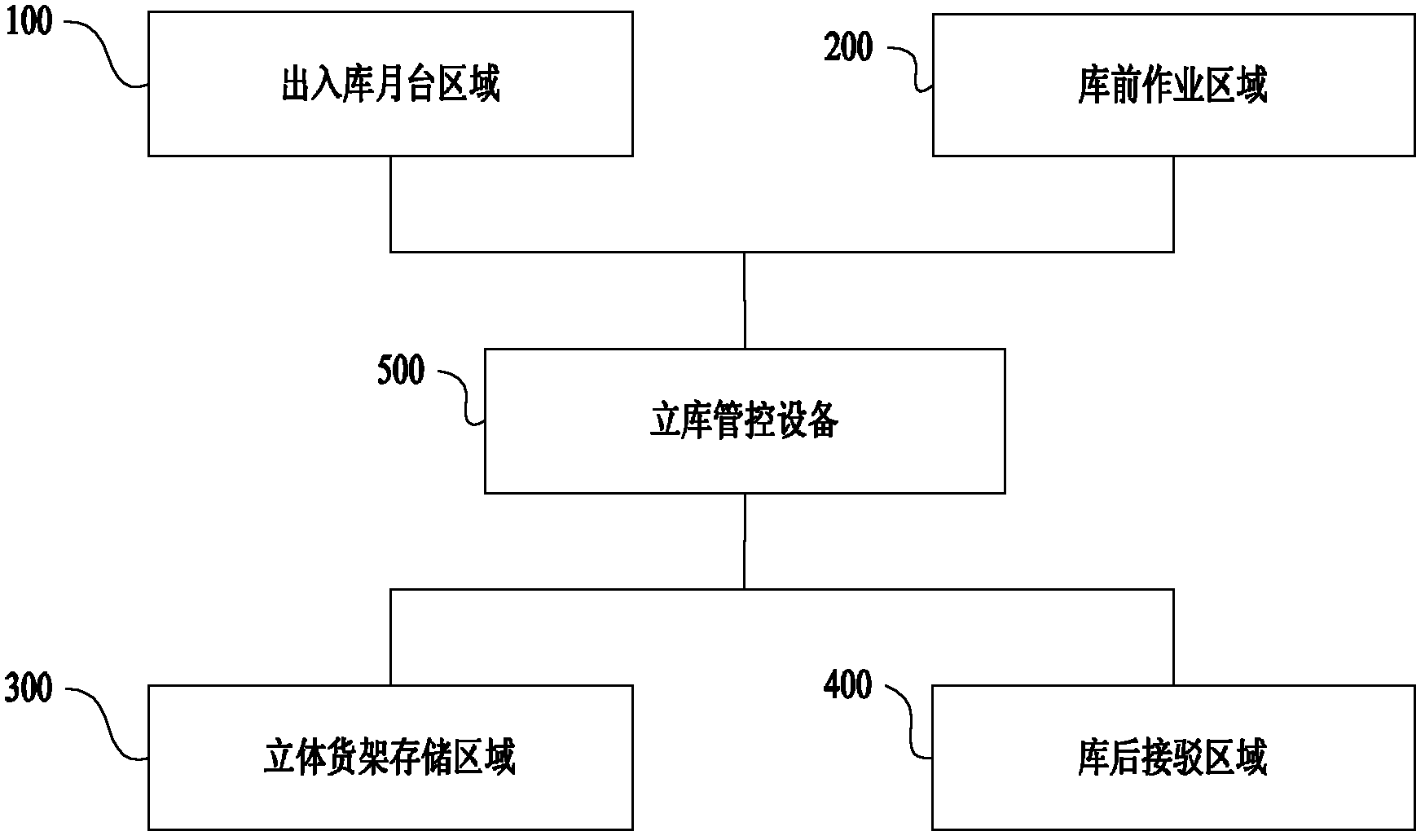

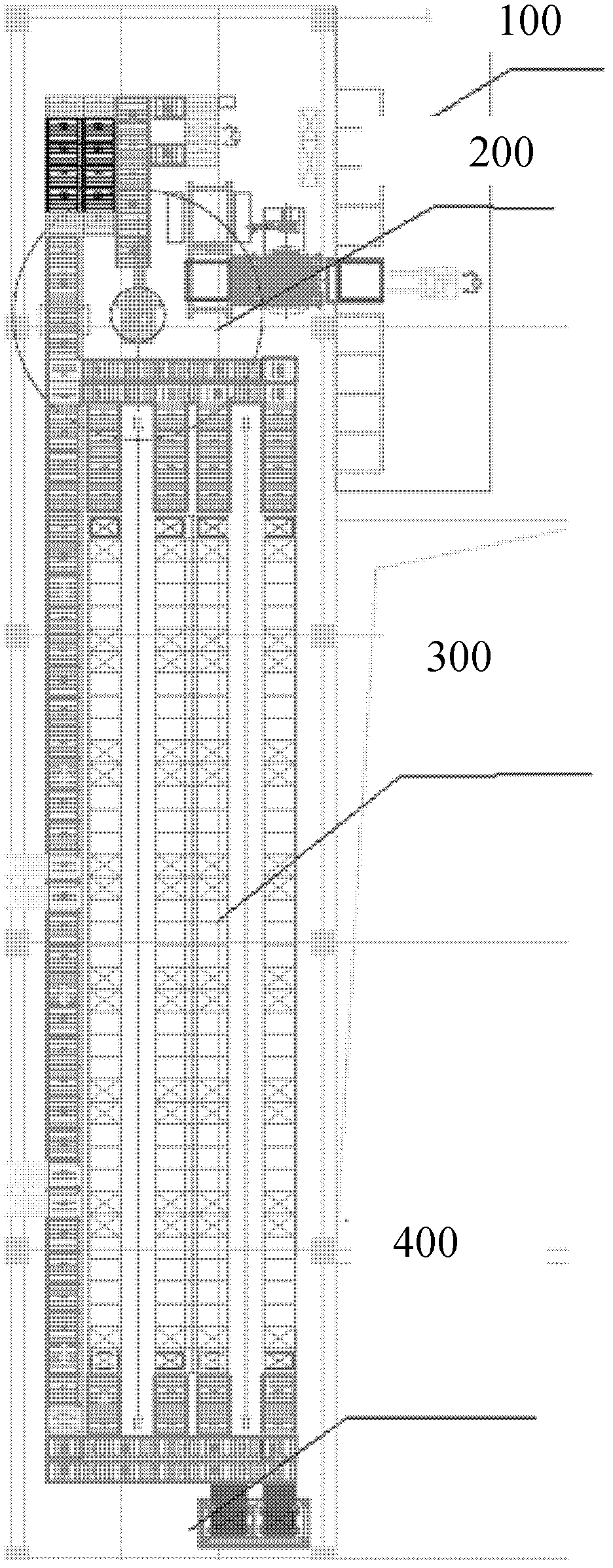

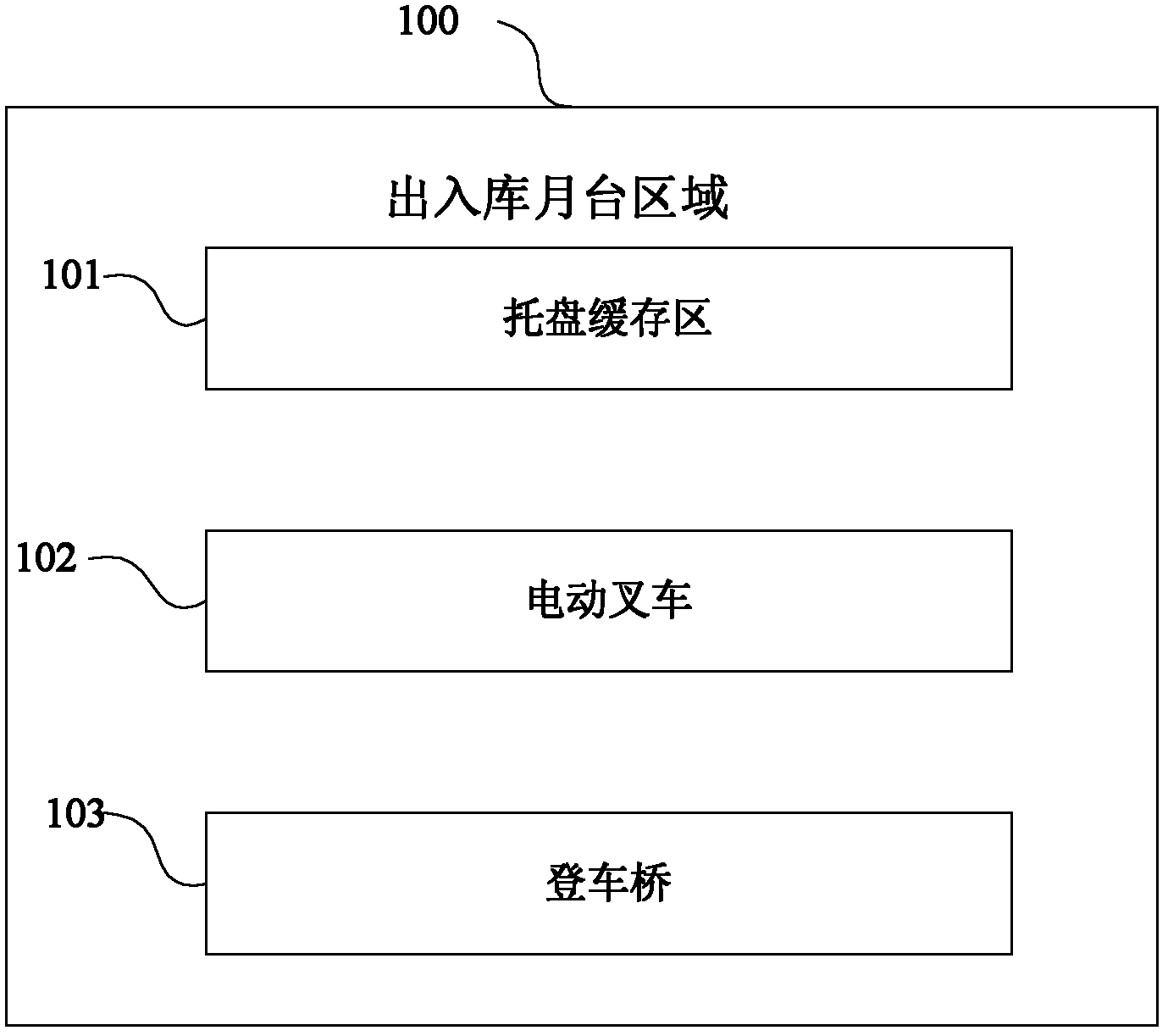

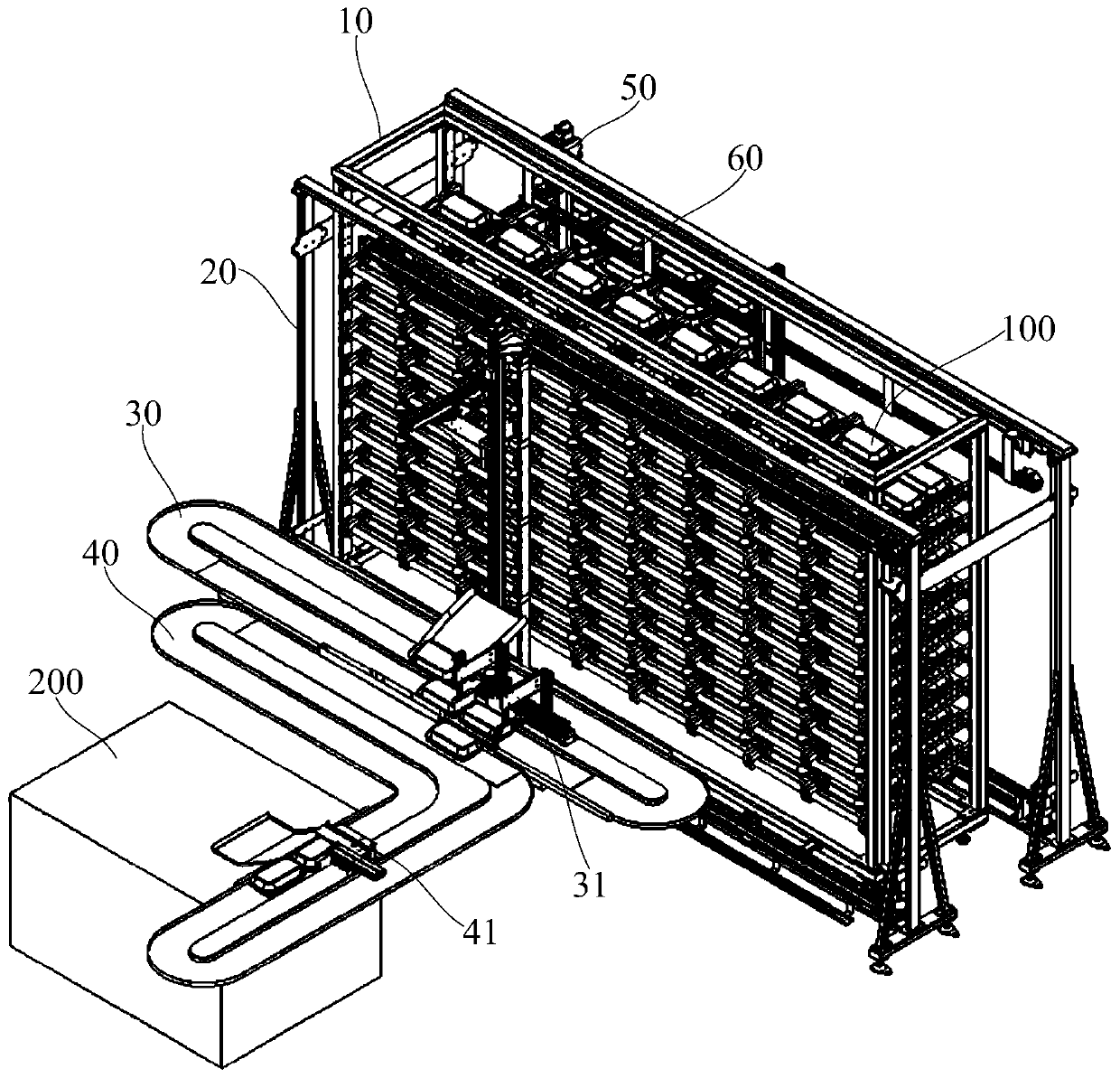

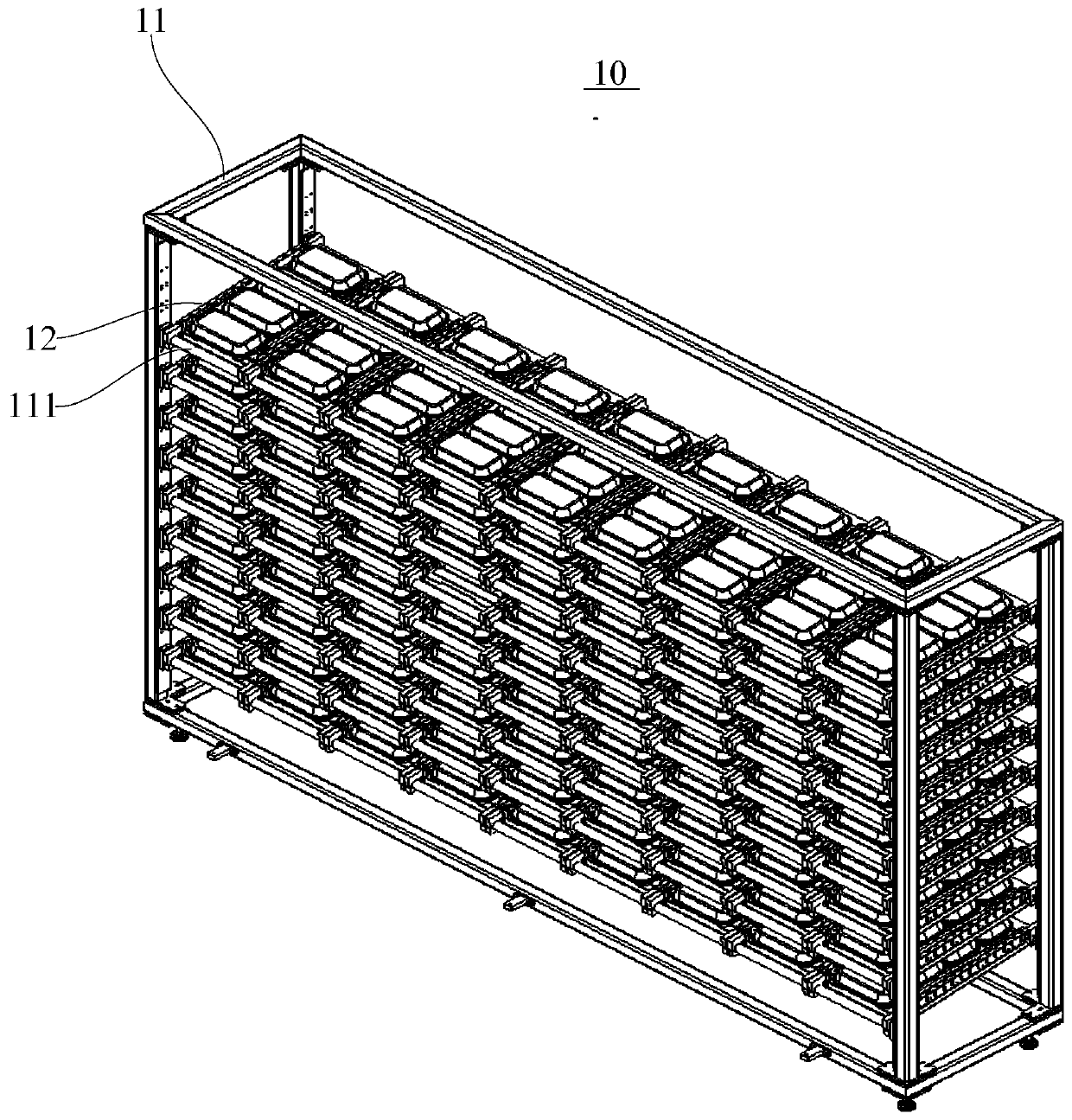

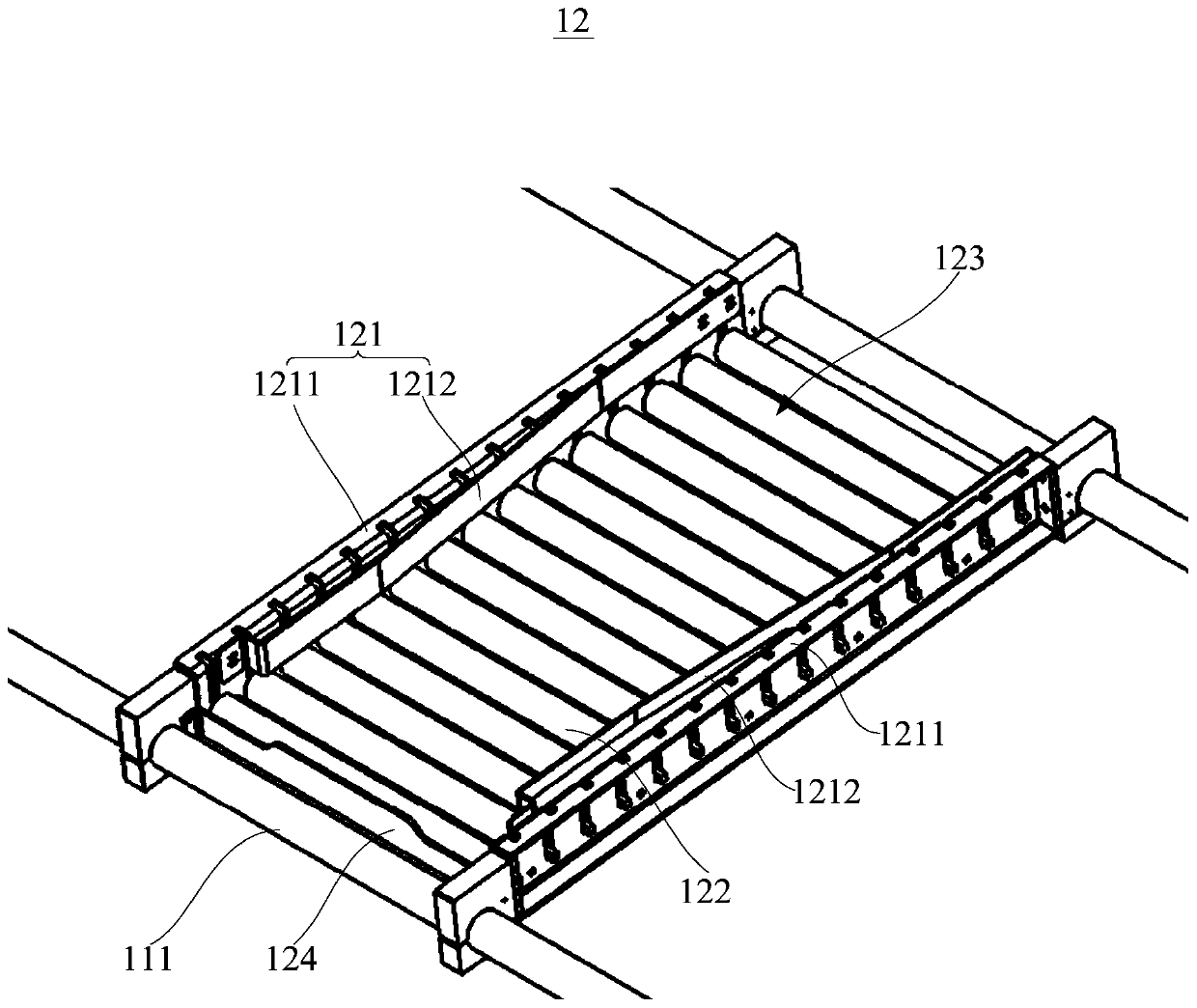

Intelligent stereoscopic storage system for electric energy metering device

An embodiment of the invention provides an intelligent stereoscopic storage system for an electric energy metering device. The intelligent stereoscopic storage system comprises a warehouse-out and warehouse-in platform area, a pre-warehousing operation area, a stereoscopic rack storage area, a post-warehousing connection area and stereoscopic warehouse control equipment, wherein the warehouse-out and warehouse-in platform area, the pre-warehousing operation area, the stereoscopic rack storage area and the post-warehousing connection area are respectively connected with the stereoscopic warehouse control equipment. By the aid of the warehouse-out and warehouse-in platform area, the pre-warehousing operation area, the stereoscopic rack storage area, the post-warehousing connection area and the stereoscopic warehouse control equipment in the intelligent stereoscopic storage system, automated storage of the electric energy metering device is realized, seamless butt joint of the intelligent stereoscopic storage system and an automated calibration assembly line is also realized, and human errors caused by manual storage and sorting are eliminated.

Owner:NORTH CHINA GRID MEASUREMENT CENT

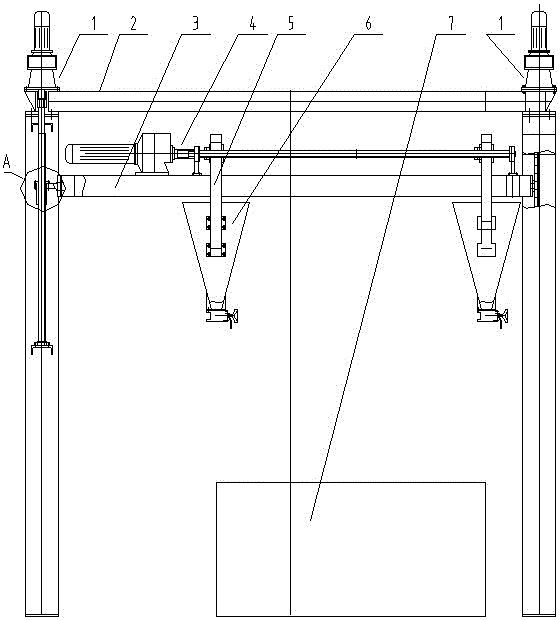

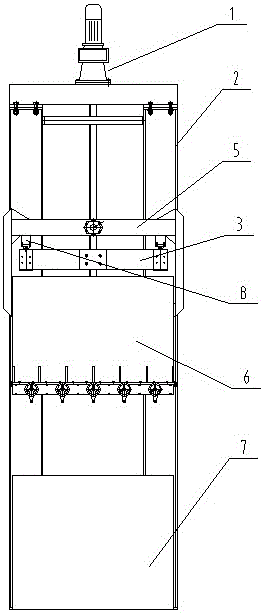

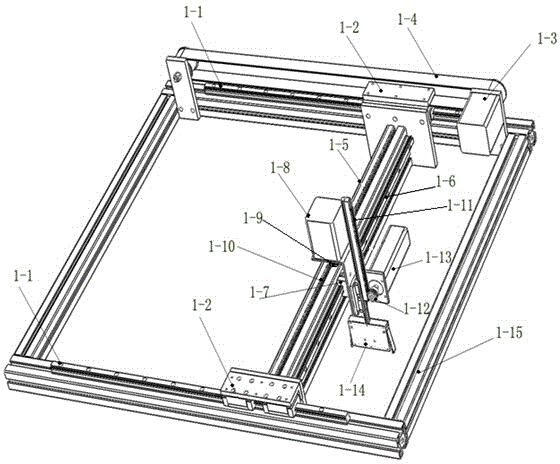

Full-automatic reciprocating sand sample preparing instrument

InactiveCN105092331APrecise control of horizontal movement speedAccurate control of horizontal movementPreparing sample for investigationProgrammable logic controllerElectric machinery

The invention relates to a full-automatic reciprocating sand sample preparing instrument which is characterized by comprising a rigid frame, wherein the rigid frame is fixedly connected with a vertical lifting system, a moving cross beam is fixedly connected with the vertical lifting system, a horizontal moving system is fixedly connected with the moving cross beam, a moving carriage is fixedly connected with the horizontal moving system, a funnel assembly is hoisted at the lower end of the moving carriage, distance measuring equipment is fixedly connected with the funnel assembly, a PLC (programmable logic controller) is fixedly connected with the rigid frame; the vertical lifting system, the horizontal moving system and the distance measuring equipment are respectively electrically connected with the PLC. According to the working process, sand in the funnel is subjected to sand rain scattering by virtue of a duckbill, the distance measuring equipment is used for monitoring the distance between the funnel assembly and the sand surface in real time, the horizontal moving system is used for driving the funnel assembly to move horizontally, a guide assembly is used for guiding for the moving carriage and the funnel assembly, the vertical lifting system is used for regulating height and controlling the falling distance of sand in sample preparation, and the PLC is used for controlling the operation of a speed control motor, thus realizing automation of the whole course of sample preparation of the system.

Owner:NORTHEAST DIANLI UNIVERSITY

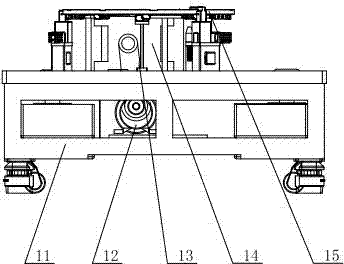

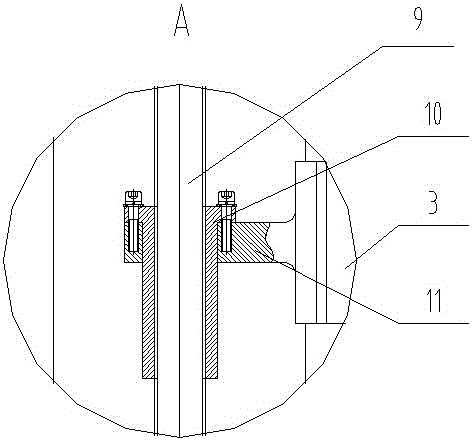

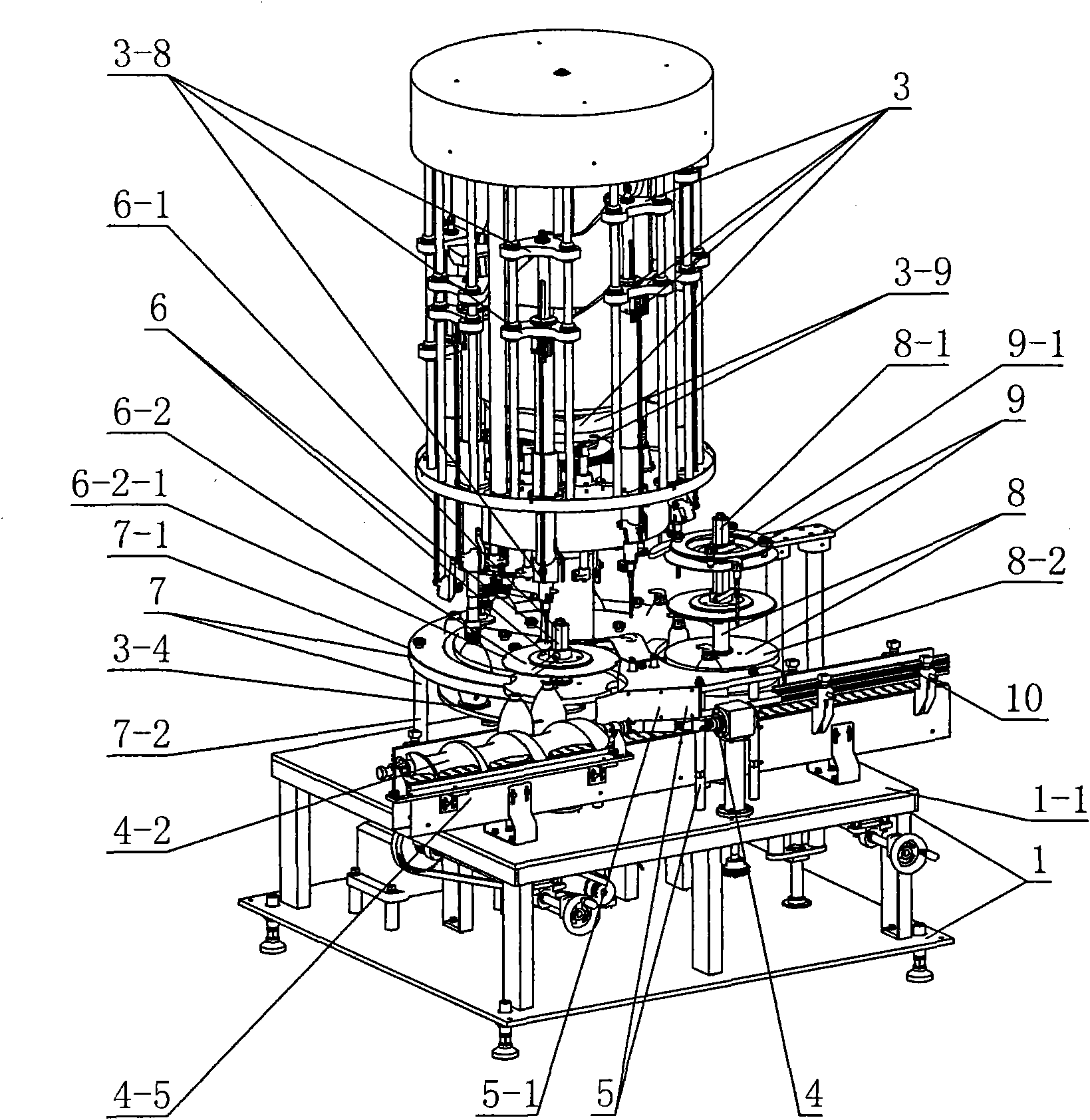

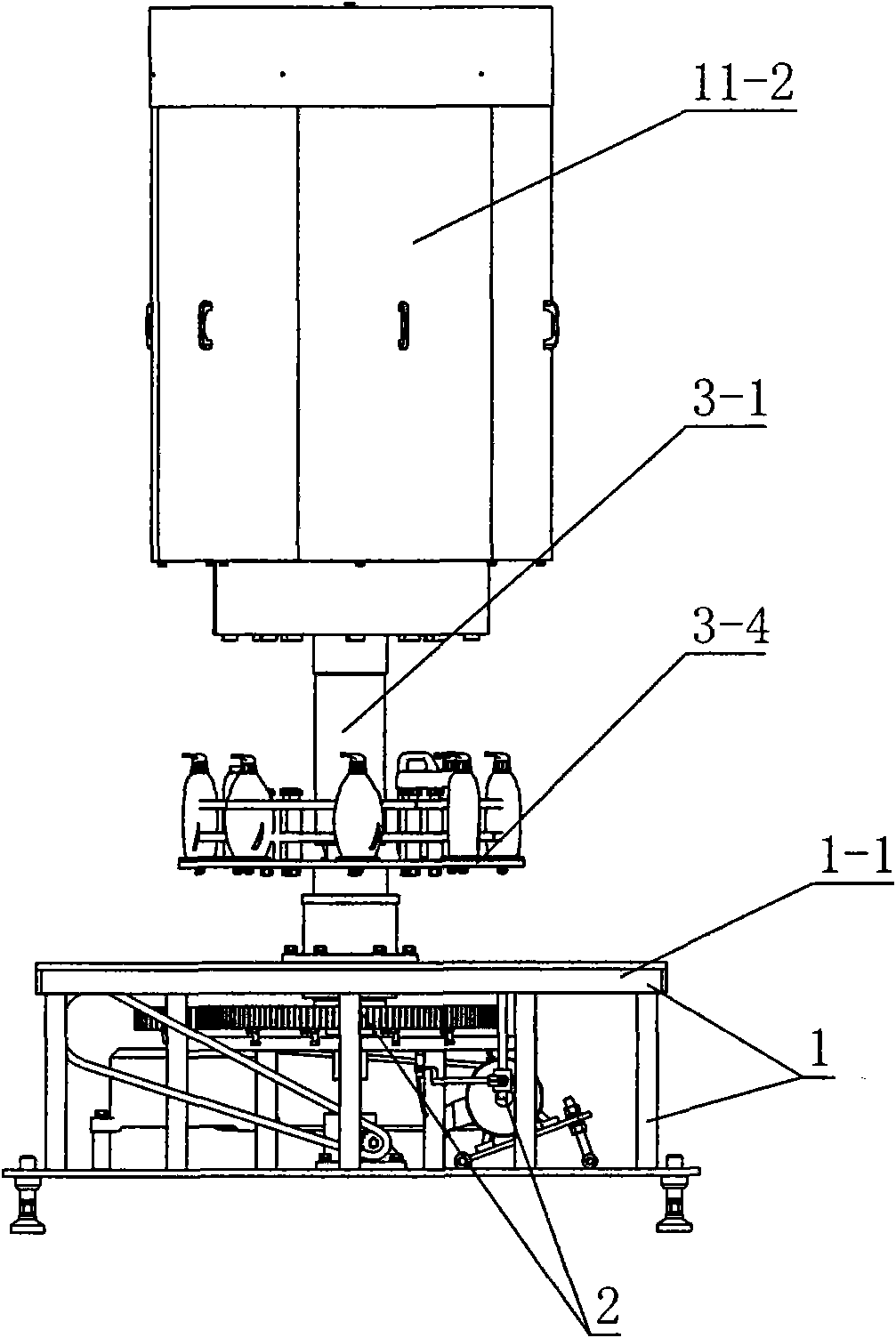

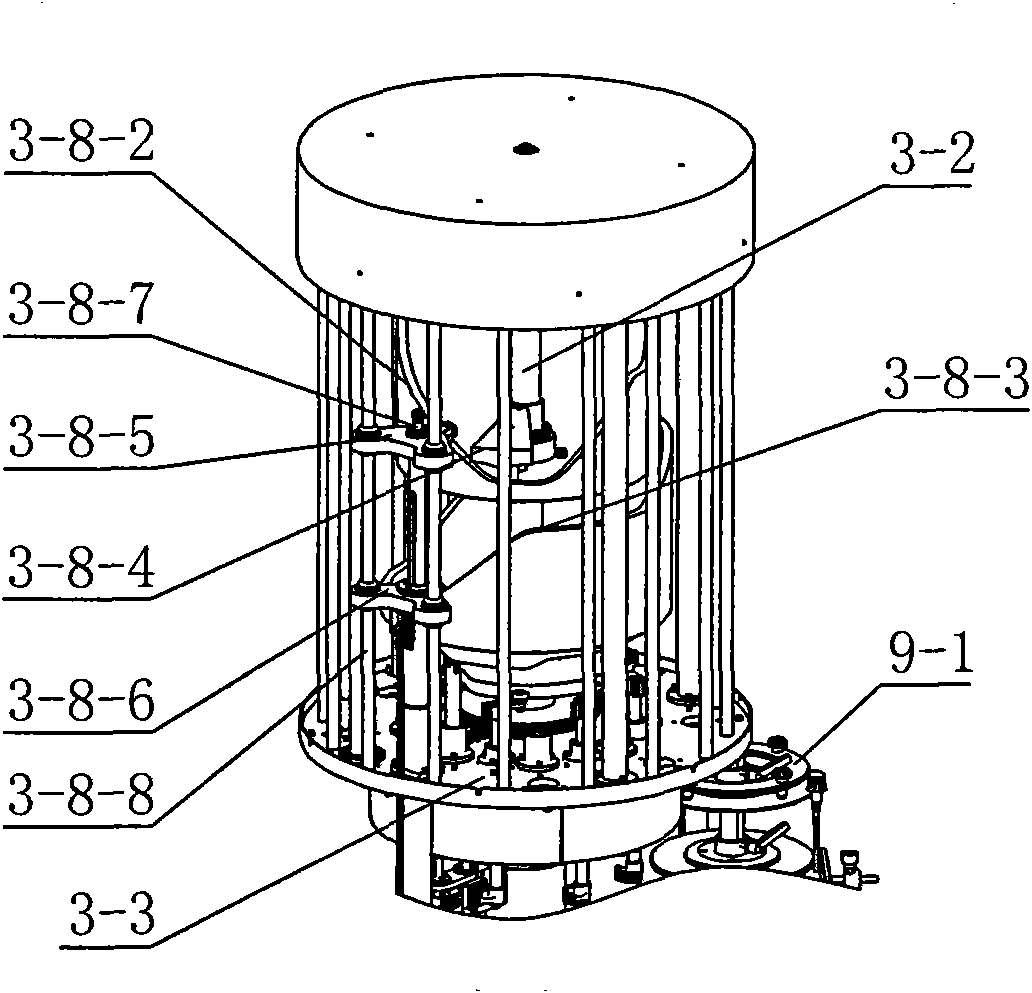

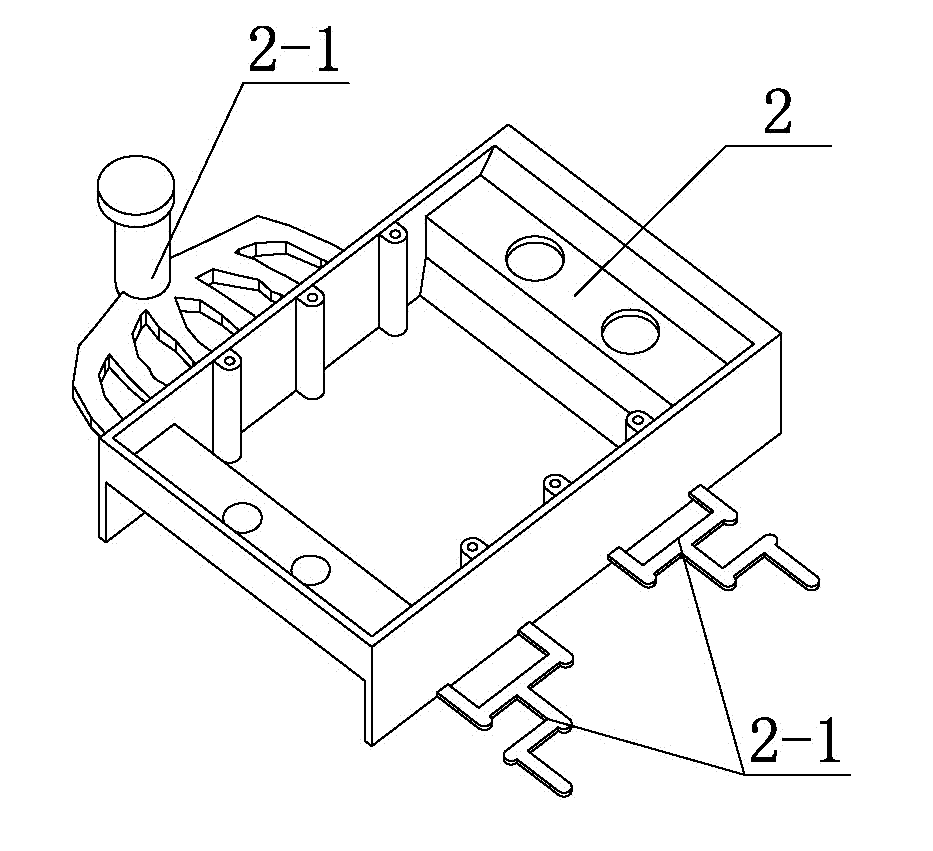

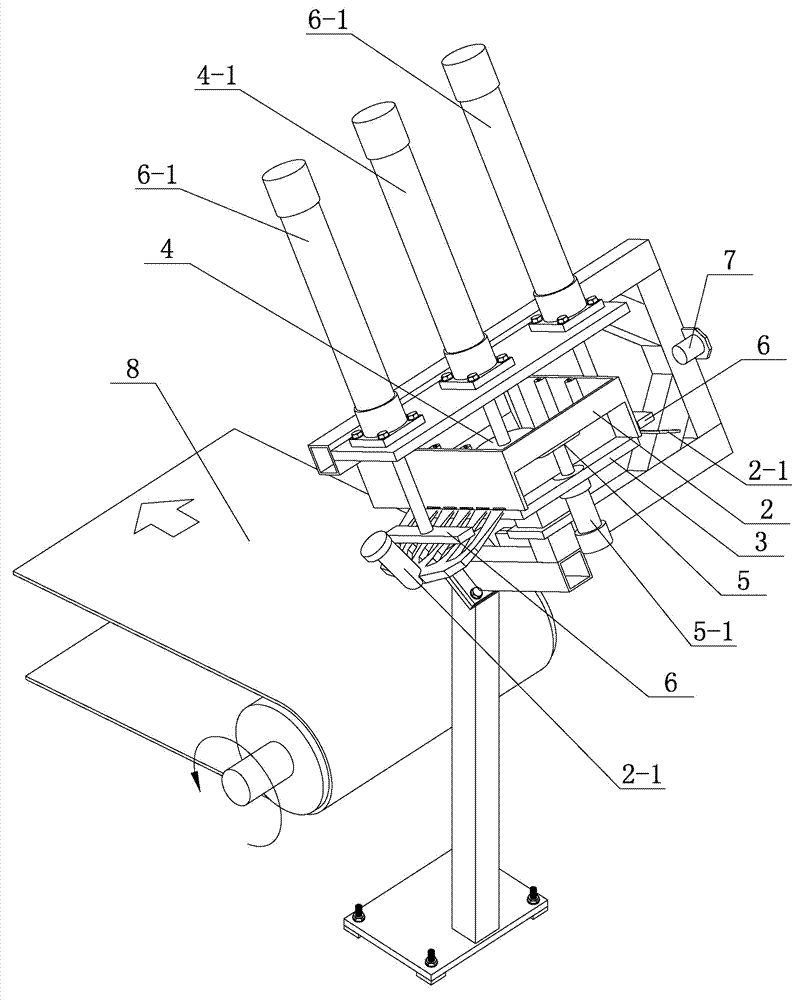

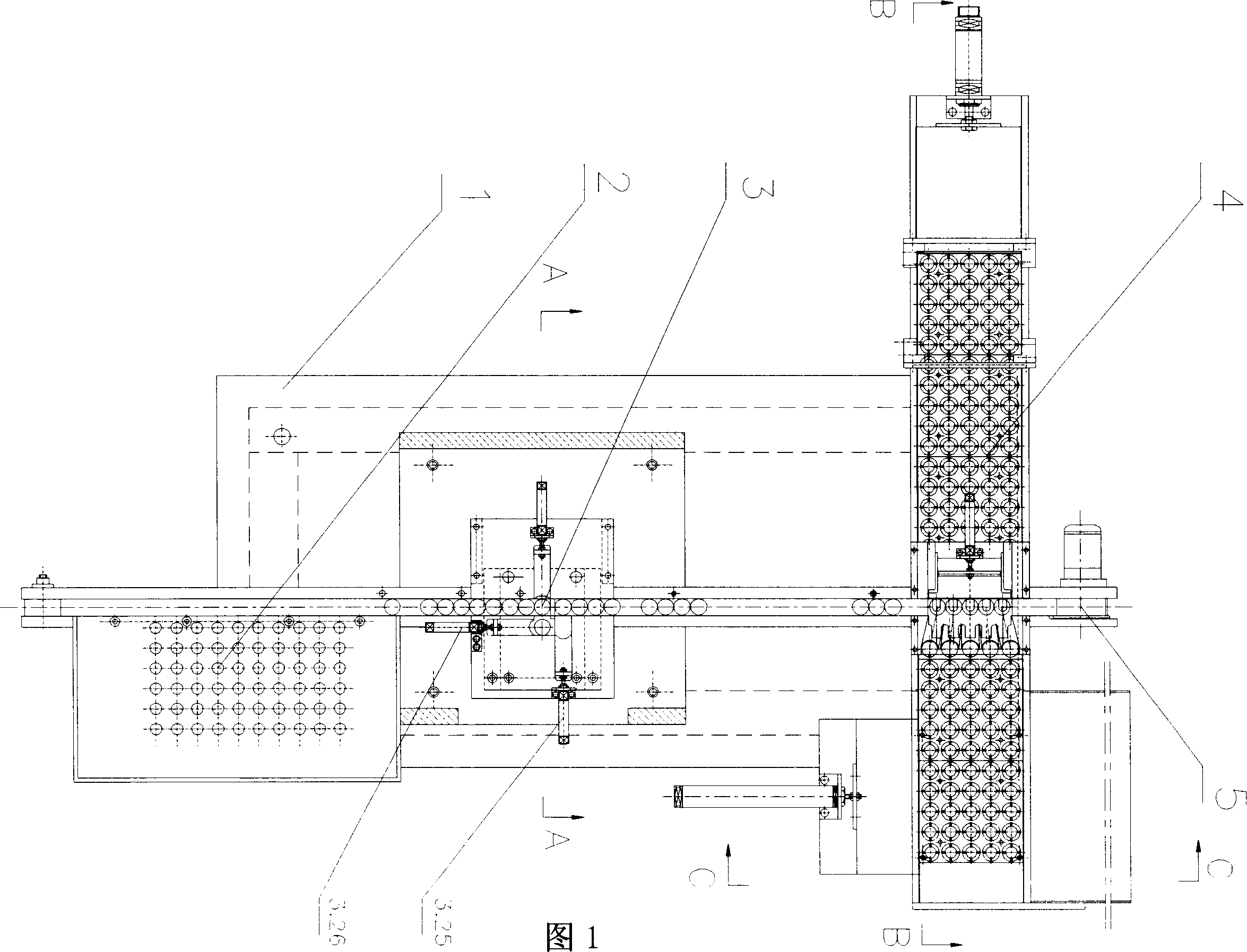

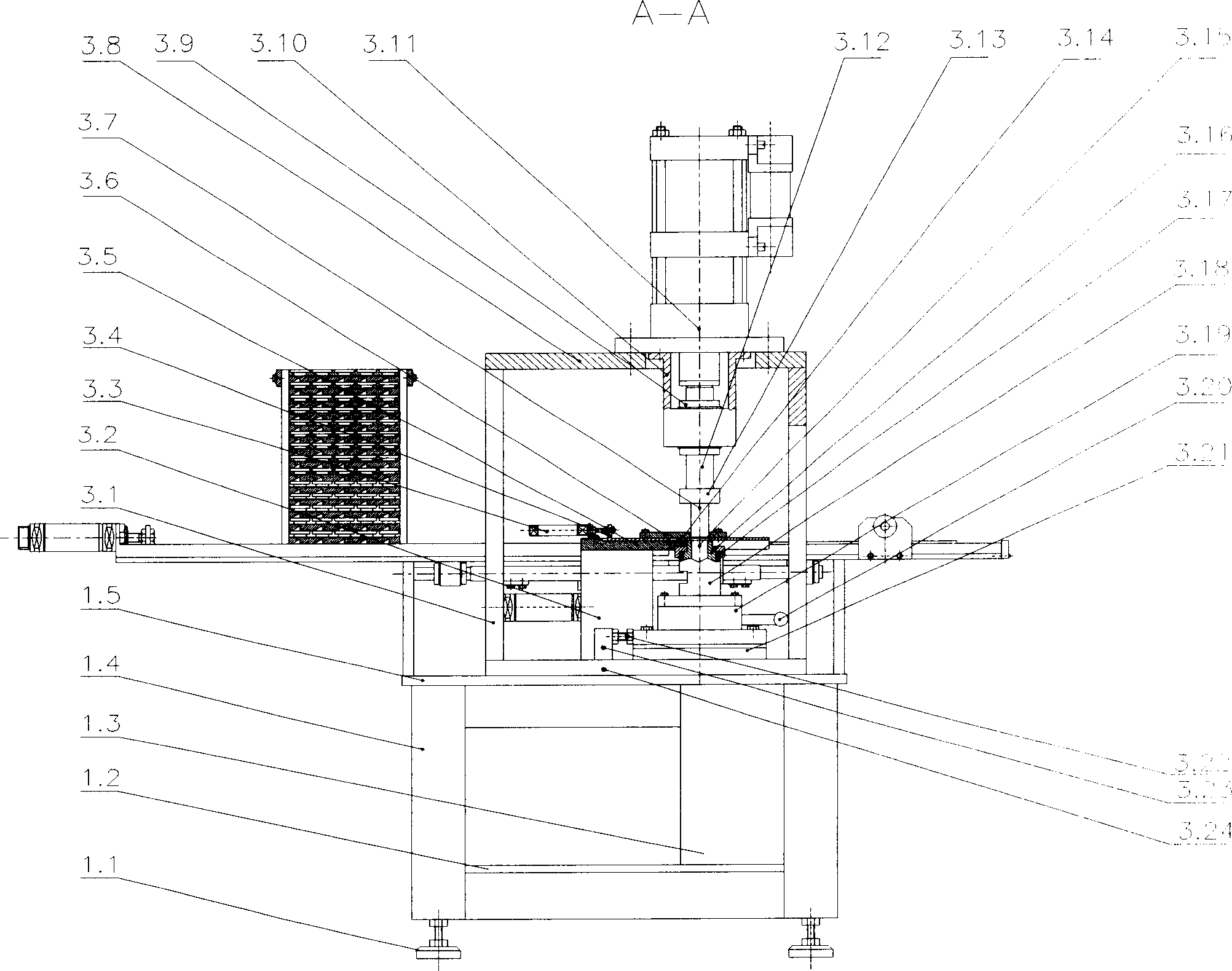

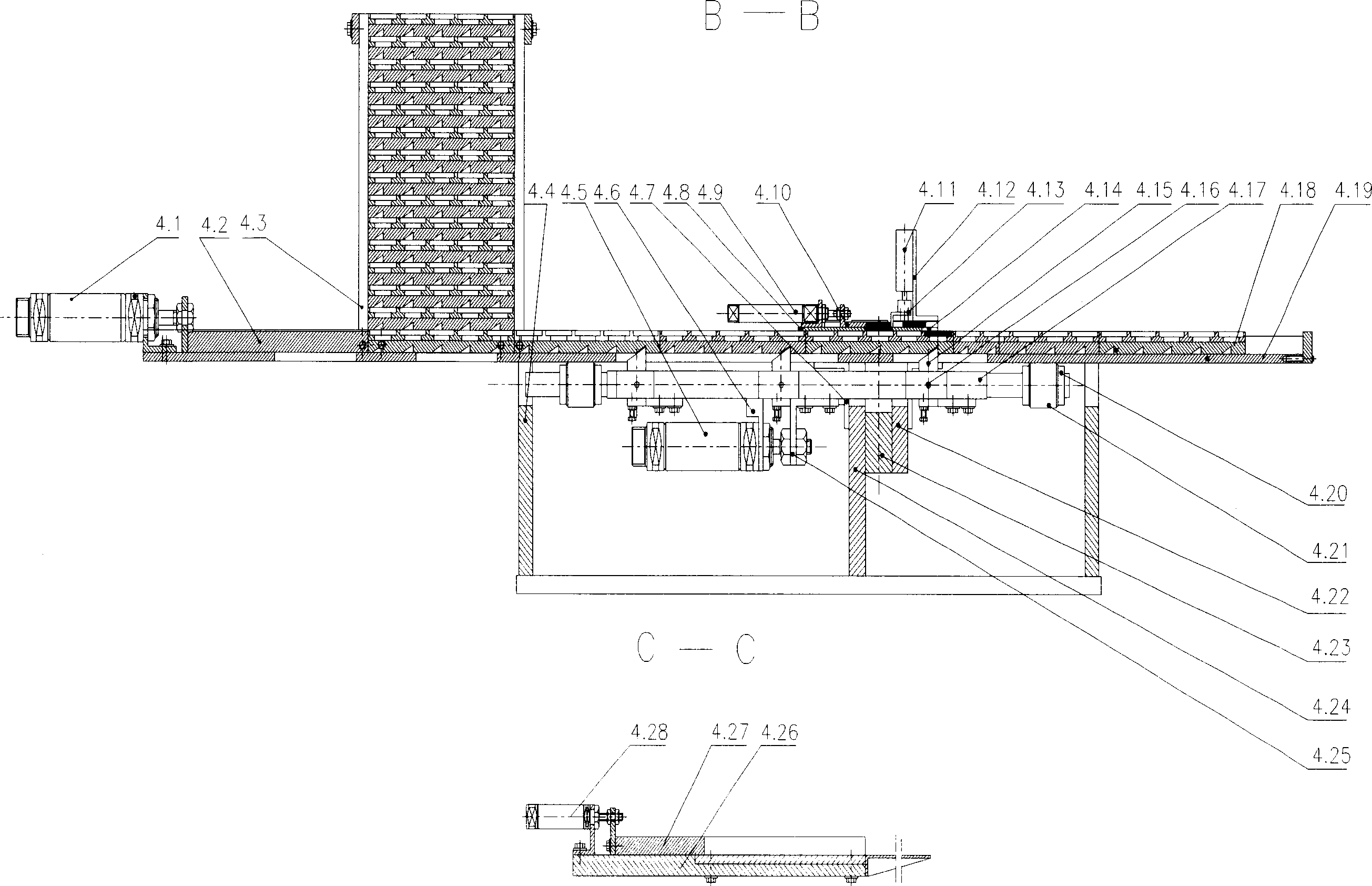

Full-automatic rotary capping machine

ActiveCN102336383ARealize automatic cappingCap screwing effect is goodCapsClosure using capsGear wheelEngineering

The invention relates to a packaging machine, in particular to a full-automatic rotary capping machine for capping a spraying pump bottle. The full-automatic rotary capping machine comprises a stand (1), a power driving device (2), a capping assembly (3), a bottle body supplying device (4), a bottle guiding device (5), a bottle feeding star wheel device (6), a bottle stopping device (7), a bottledischarging star wheel device (8), a cap supplying device (9) and a bottle outputting device (10), wherein the capping assembly (3) comprises a main shaft (3-1), an intermediate shaft (3-2), a rotarydisk (3-3), a bottle carrying plate (3-4), a clamping device (3-5), a capping disk (3-6), a gear wheel reversing and driving device (3-7), a cap grabbing device (3-8) and a capping assisting device (3-9); and the rotary disk (3-3) and the bottle carrying plate (3-4) are sleeved on the main shaft (3-1). The invention has the advantages of simple structure, high production efficiency, realization of automatically capping the spraying pump bottle and favorable capping effect.

Owner:CHANGZHOU HUITUO TECH

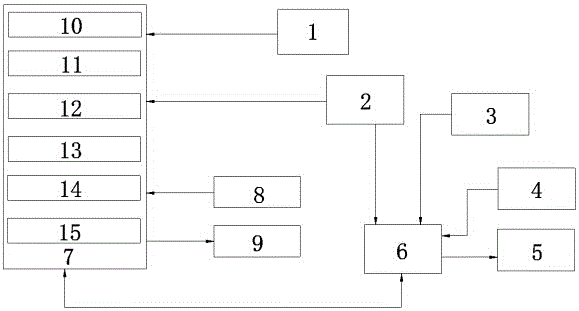

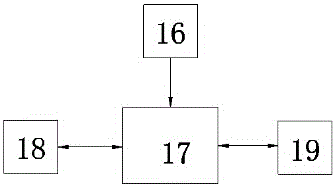

Unmanned surface vehicle navigation and control teleoperation platform

The invention discloses an unmanned surface vehicle navigation and control teleoperation platform, including a navigation radar, an automatic identification system, an attitude and heading reference system, a rotating speed and rudder angle sensor, a vehicle rudder control module, a yacht-mounted industrial control computer and a shore / mother ship control computer. The shore / mother ship control computer and the yacht-mounted industrial control computer are in bidirectional connection via TCP / IP or UDP protocols. The navigation radar and the automatic identification system are connected with the shore / mother ship control computer through an RS422 / 485 module. The automatic identification system, the attitude and heading reference system and the rotating speed and rudder angle sensor are connected to the yacht-mounted industrial control computer respectively. The yacht-mounted industrial control computer is connected with the rotating speed and rudder angle sensor through the vehicle rudder control module. The shore / mother ship control computer is connected with an engine telegraph and rudder order sensor based on a sliding resistor, and a rotating speed and rudder angle display module respectively. In the navigation guiding process, data can be traced and system parameters can be automatically identified by the radar, the collision risk between objects around the yacht and the unmanned surface vehicle can be timely analyzed, and the trial ship-operating avoidance scheme is provided.

Owner:NANTONG SHIPPING COLLEGE

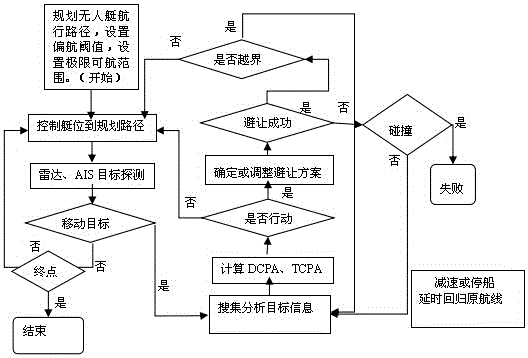

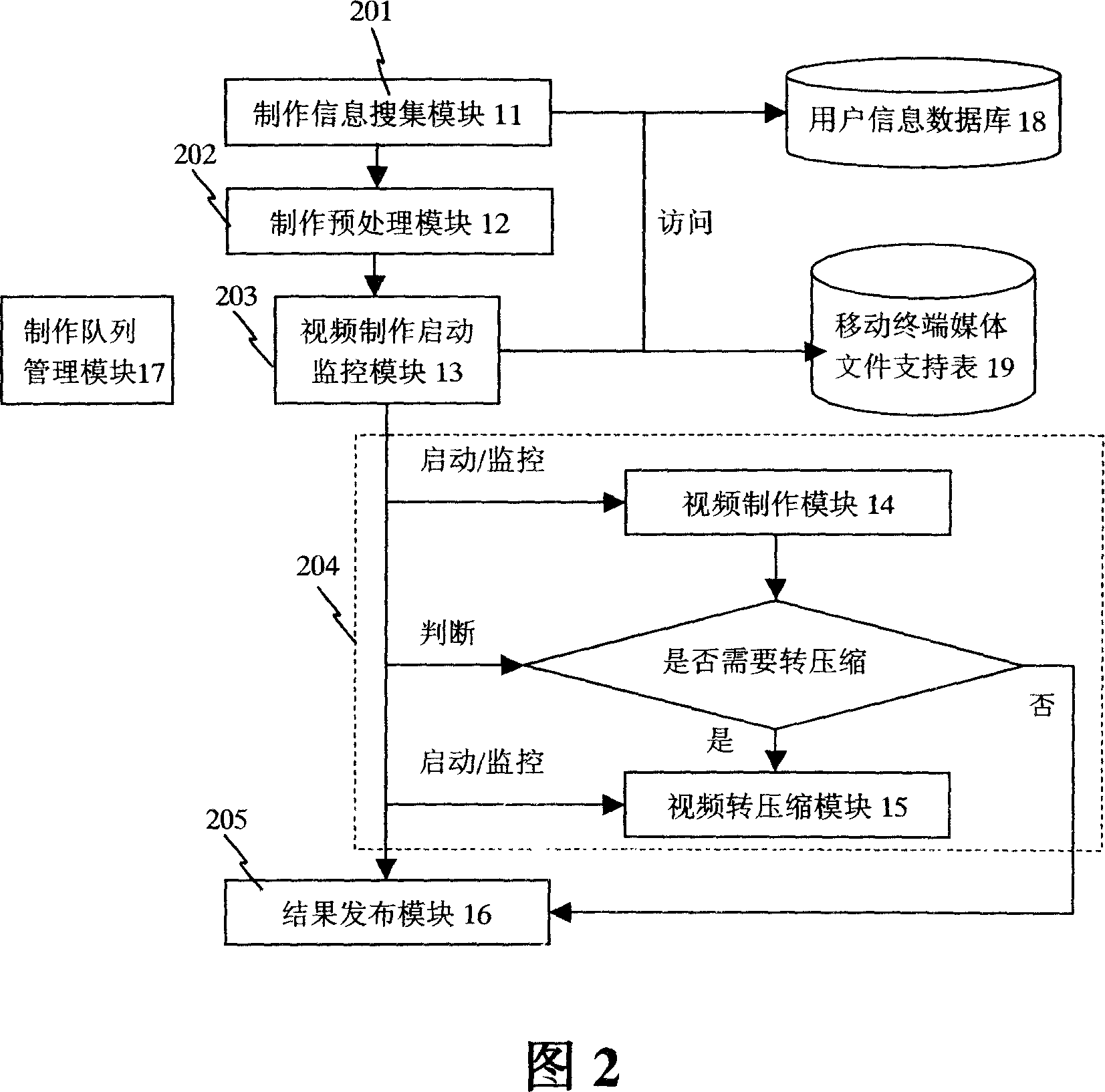

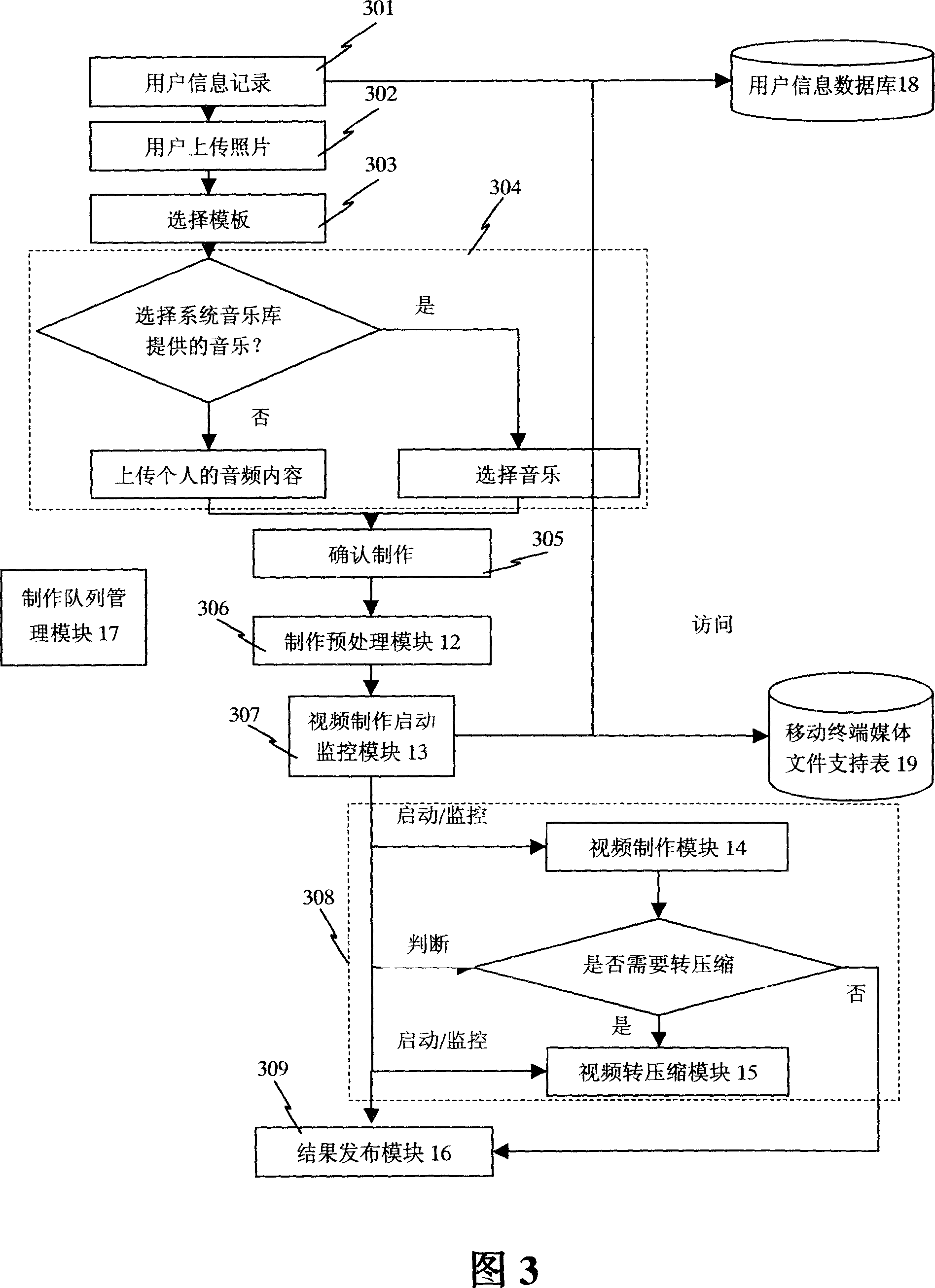

Method and system for automatic video production

InactiveCN1921612AShort processing timeRealize full automationAnalogue secracy/subscription systemsVideo productionInformation needs

The invention relates to an automatic video producing publish system and relative method. Wherein, said system comprises: producing information collecting module for obtaining the information needed to product video document to be stored in user information database; a video production start detecting module for accessing the user information database to obtain information with which to start the video producing module and accessing mobile terminal media document support list to obtain the format demand of video production, via said information and format demand to judge if the video document of video producing module needs compression; and a result publish module for publishing the video document without compression or publishing the video document that has been compressed. The invention can automatically produce video, to reduce the time and it can generate videos at different formats.

Owner:萧学文

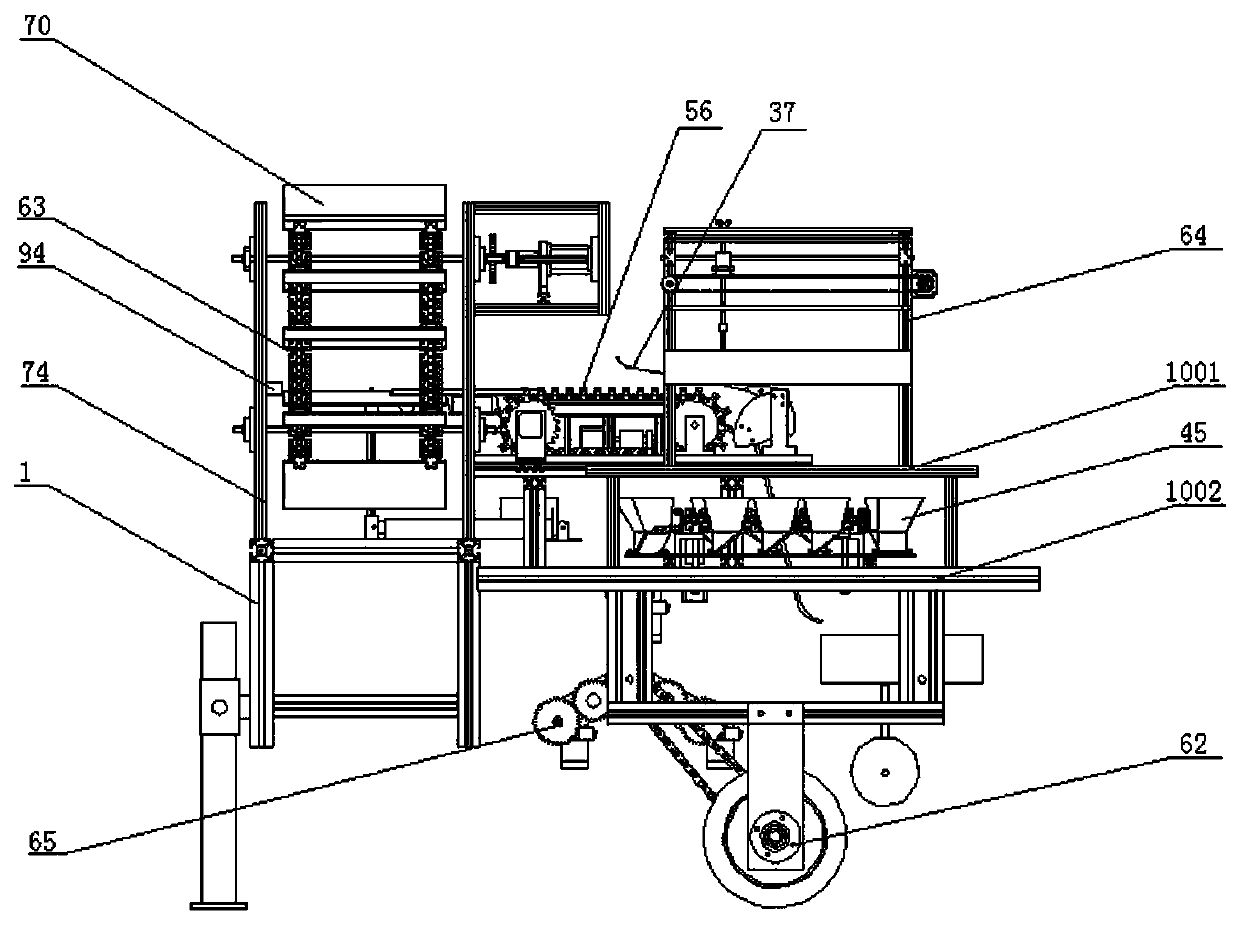

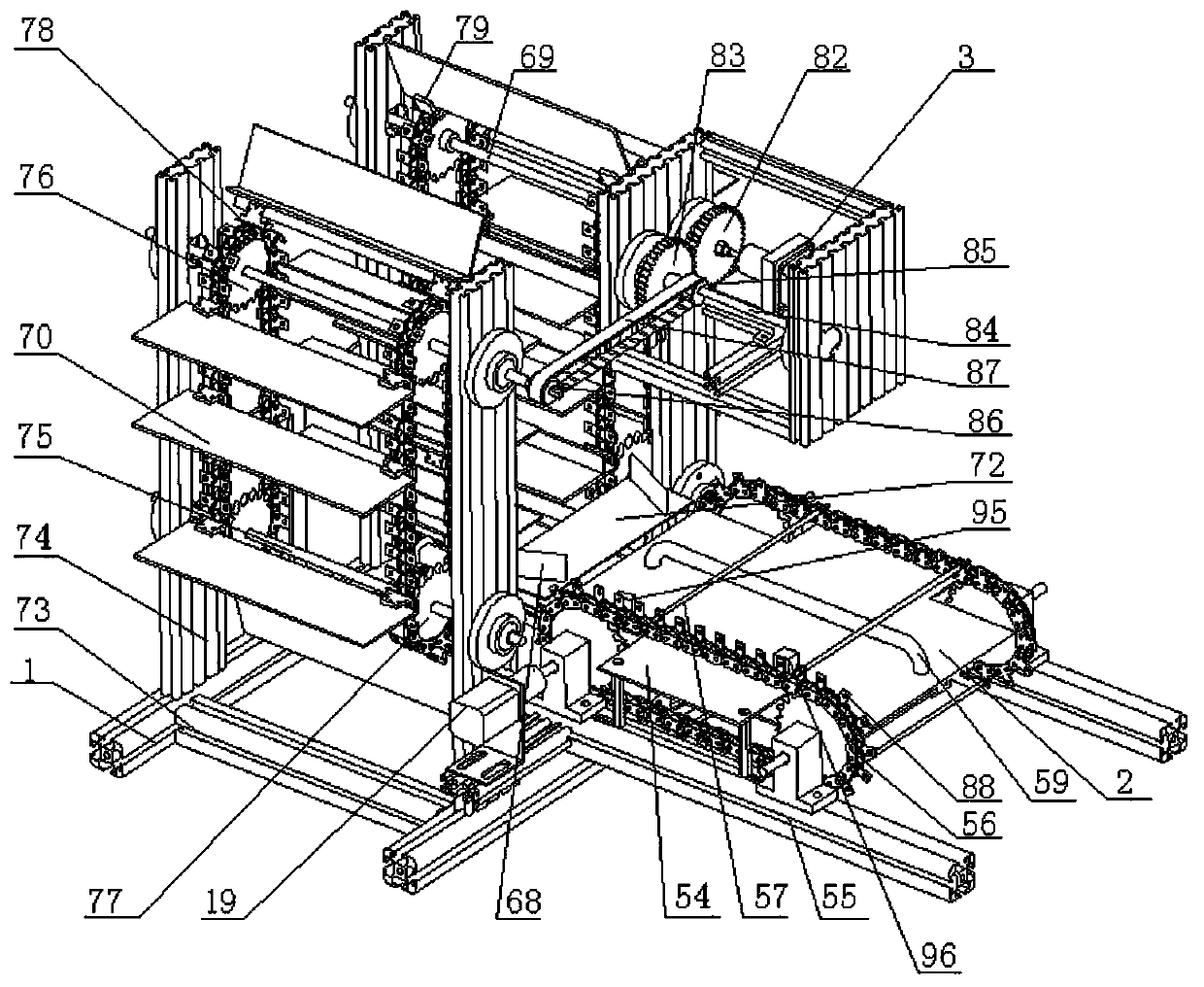

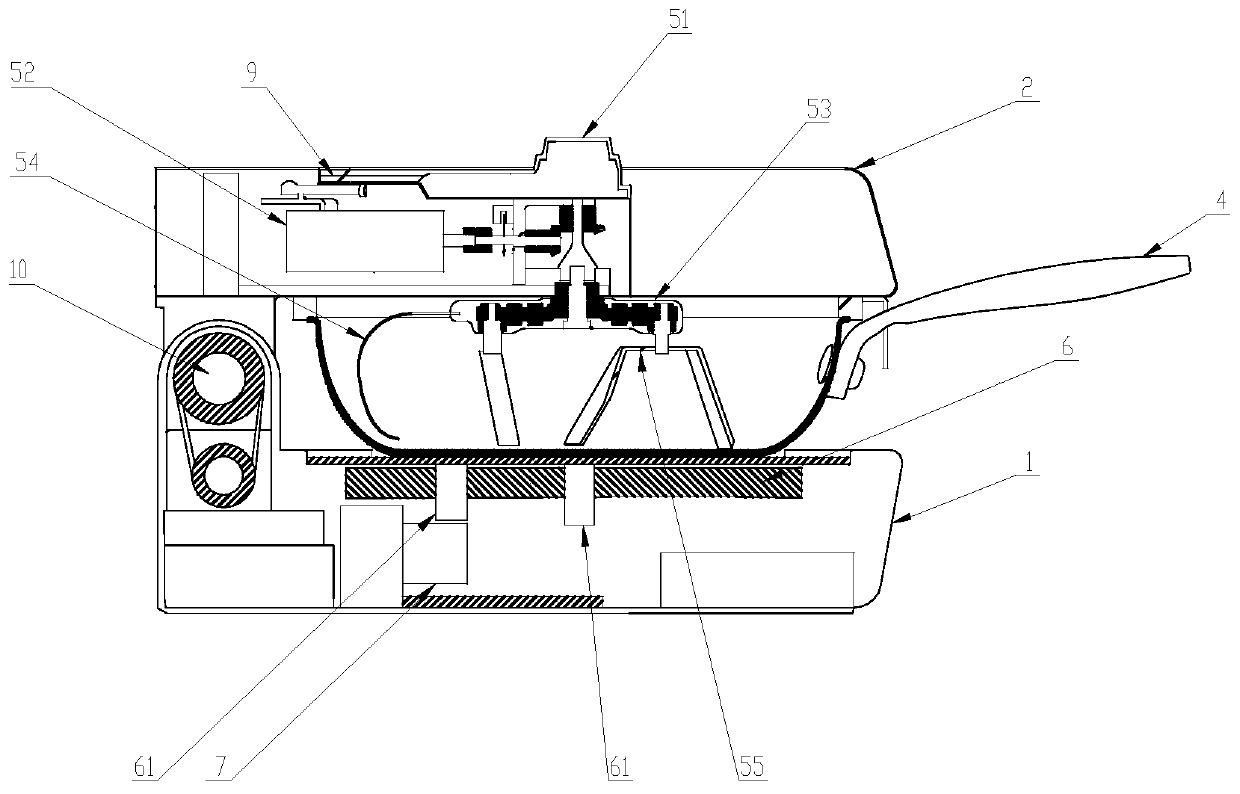

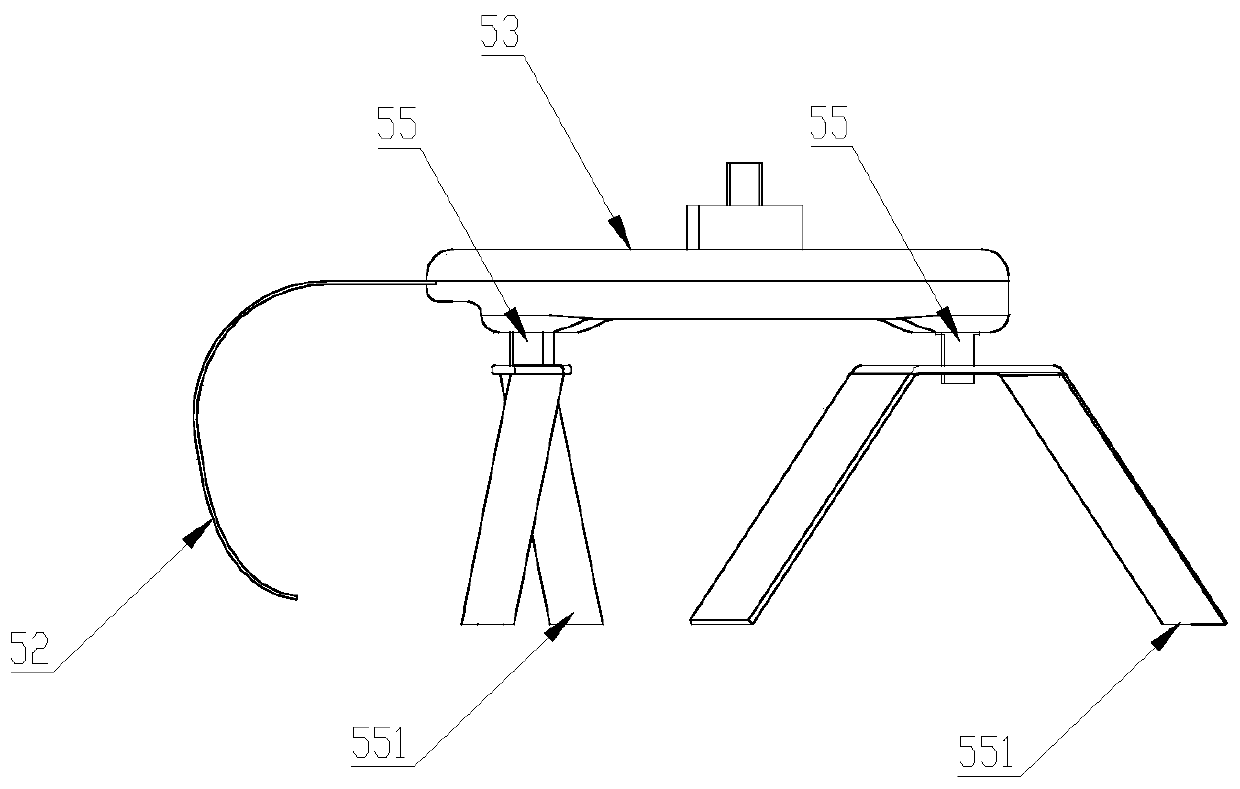

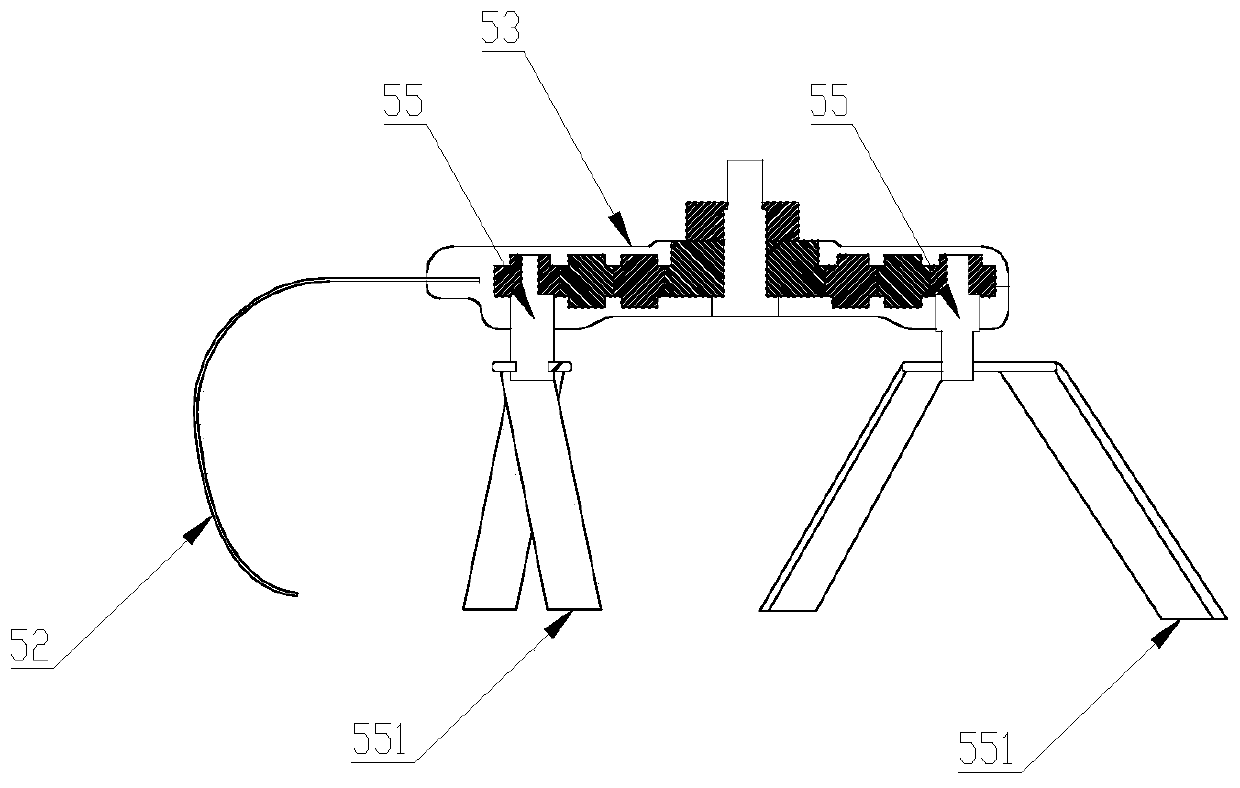

Full-automatic pot seedling transplanting machine

ActiveCN107667637AImprove battery lifeReduce volumeTransplantingMechanical engineeringFully automated

The invention discloses a full-automatic pot seedling transplanting machine which comprises a framework, a travel mechanism and a pot seedling transplanting device. The travel mechanism is arranged atthe bottom of the framework, the pot seedling transplanting device is arranged on the upper portion of the framework and comprises a seedling tray conveying mechanism, a seedling grabbing and releasing mechanism and a planting mechanism, the planting mechanism is used for transplanting pot seedlings into fields, and the seedling tray conveying mechanism comprises a perpendicular conveying mechanism, a horizontal conveying mechanism and a push mechanism; the seedling grabbing and releasing mechanism comprises an ejector pin mechanism, a seedling grabbing mechanism, a guide mechanism and a seedling releasing mechanism, the seedling grabbing mechanism is used for grabbing the pot seedlings ejected from the ejector pin mechanism and conveying the pot seedlings to the seedling releasing mechanism, and the seedling releasing mechanism is used for receiving the pot seedlings released by the seedling grabbing mechanism and conveying the pot seedlings to preset locations for planting the pot seedlings. The full-automatic pot seedling transplanting machine has the advantages that whole pot seedling conveying, grabbing, releasing and planting procedures can be automated by the integral full-automatic pot seedling transplanting machine during pot seedling transplanting.

Owner:HENAN UNIV OF SCI & TECH

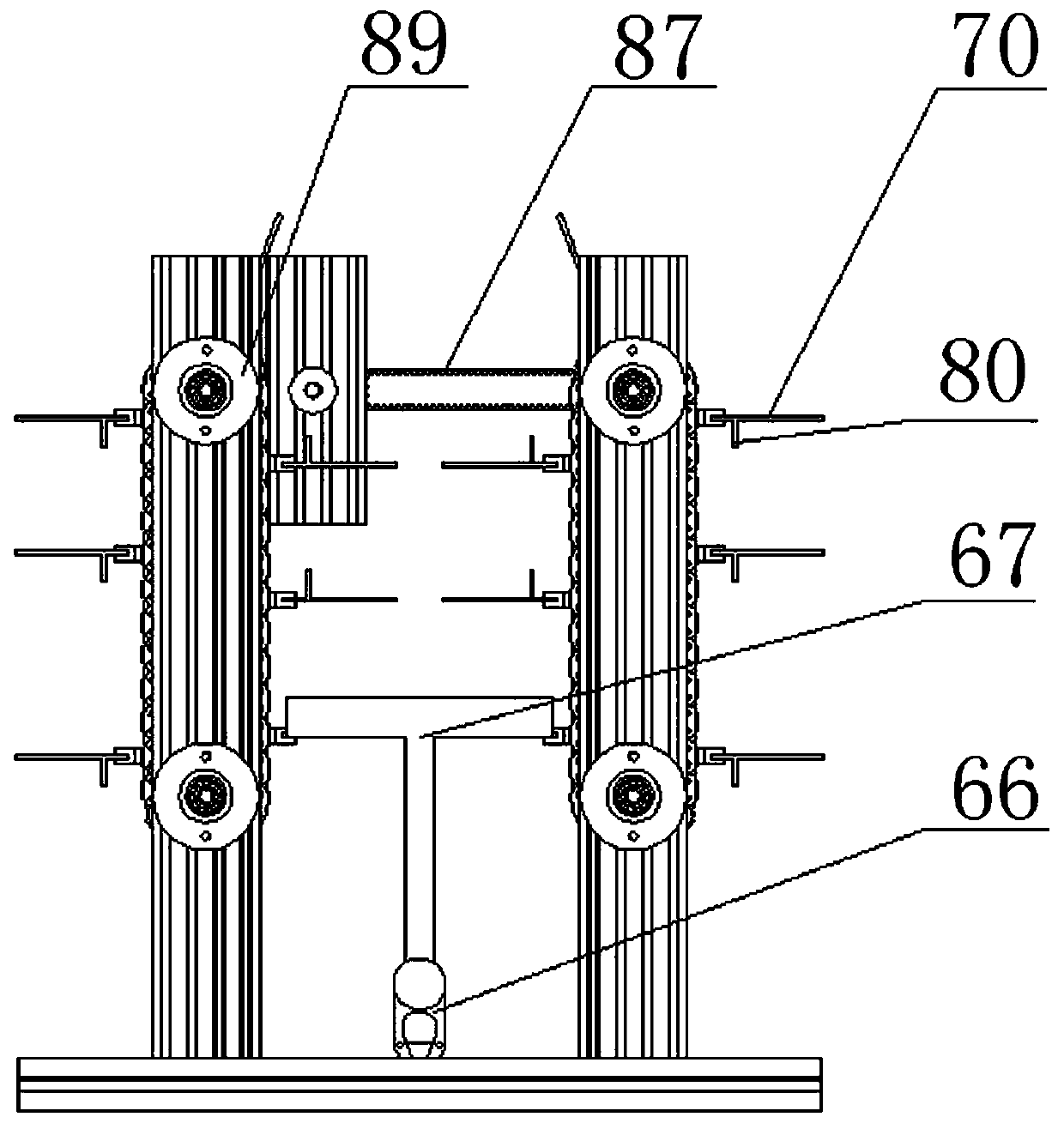

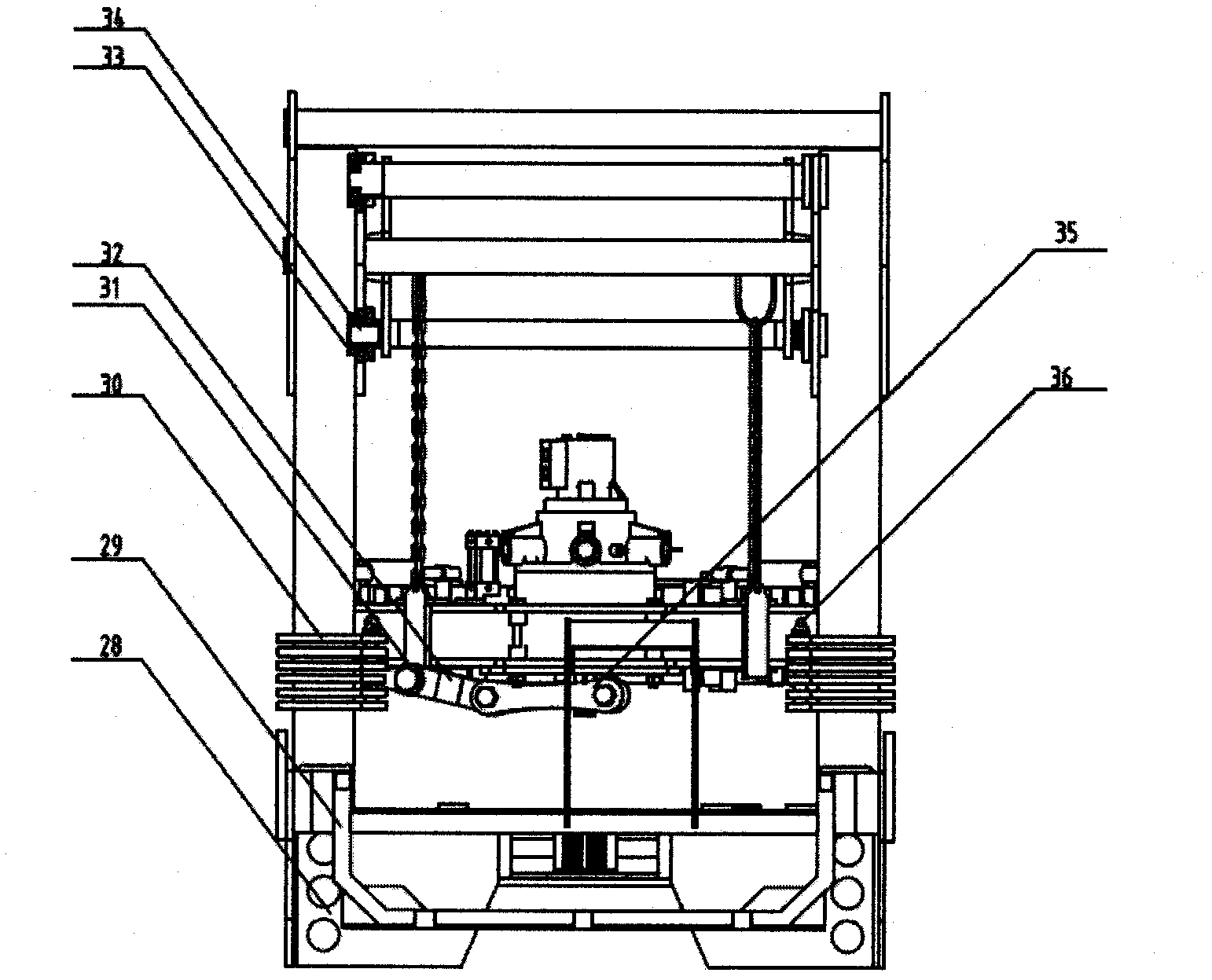

A floor rail type highly integrated intelligent iron driller

InactiveCN102287150AHigh degree of automationRealize full automationDrilling rodsDrilling casingsHydraulic motorHeadframe

The invention provides a floor rail type highly integrated intelligent iron roughneck, which integrates a lift car, a clamp head frame, a main back clamp and guide rails into a whole and consists of the lift car, the clamp head frame and the guide rails, wherein the lift car moves on the guide rails, the upper part of the clamp head frame is suspended and connected onto the lift car, in addition,the connection between the lift car and the lower part of the clamp head frame is realized through unscrewing, the lift car consists of a left side frame, a right side frame and a cross beam, the left side frame and the right side frame are respectively arranged on the two guide rails, the lift car drives a transmission gear to rotate through a lift car hydraulic motor for realizing the moving onthe guide rails. The floor rail type highly integrated intelligent iron roughneck can realize the application of a large-torque and wide-pipe-diameter-range rotary thread punching device and is applicable to the unscrewing on drill rods in any dimensions. The lift car, the clamp head frame, the main back clamp and the guide rails are integrated into a whole, so the weight of the whole equipment is greatly reduced, and the work efficiency is improved. The floor rail type highly integrated intelligent iron roughneck has the advantages that the automation degree is high, the full-process automatic operation of the work process can be realized, and the rotary thread punching operation of the whole site can be completed by one worker.

Owner:金华萨博思石油机械有限公司

Automatic sand blasting and spraying equipment

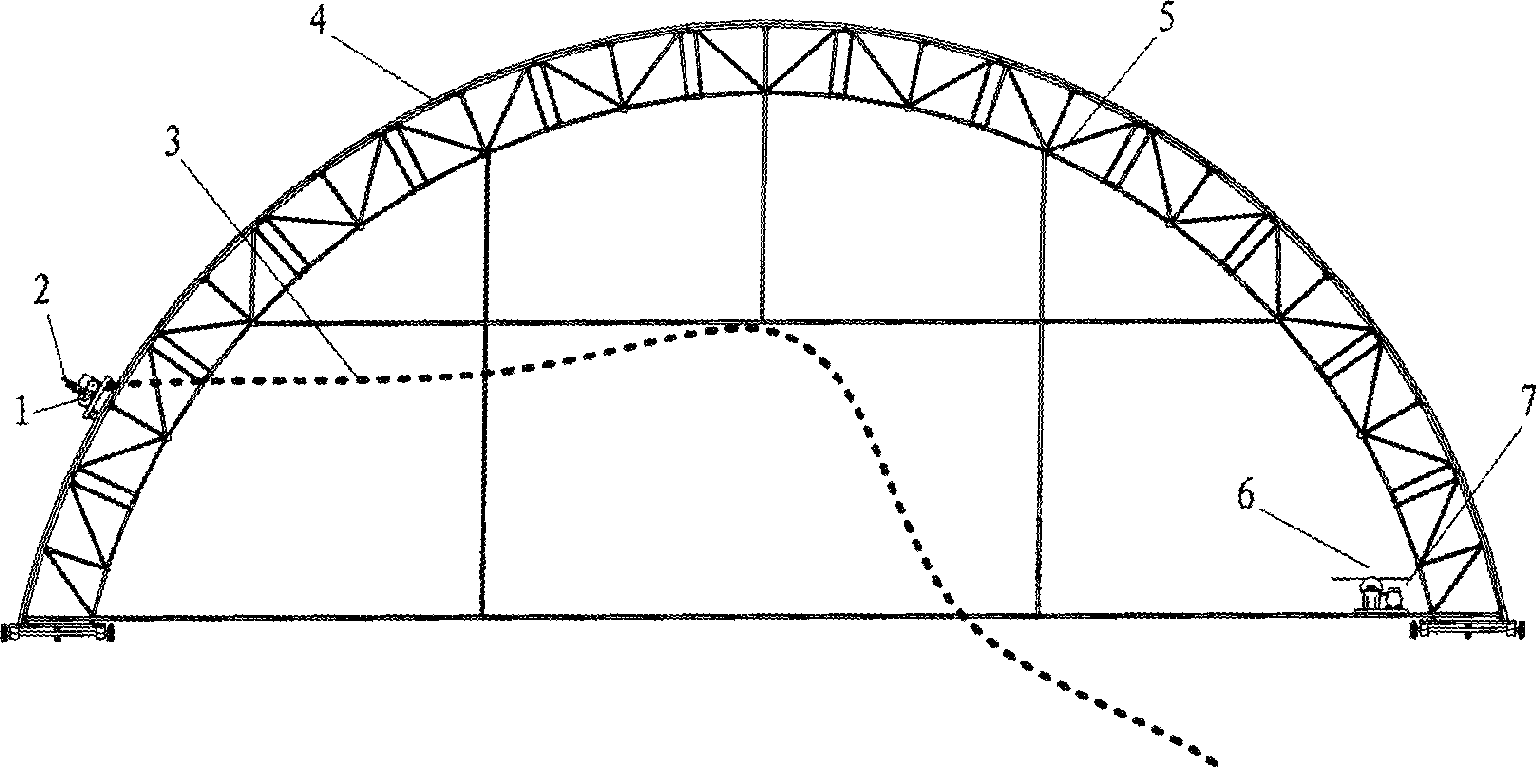

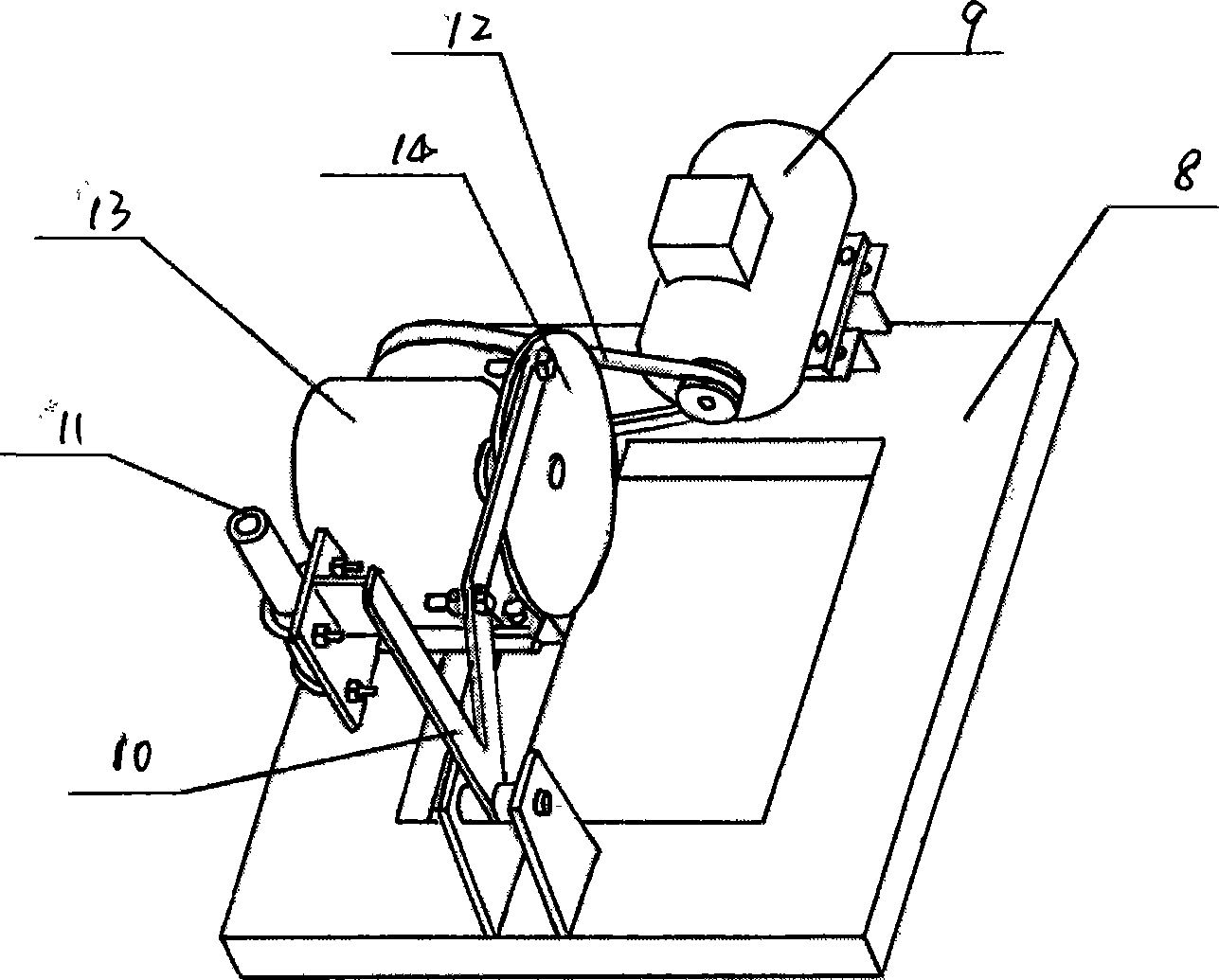

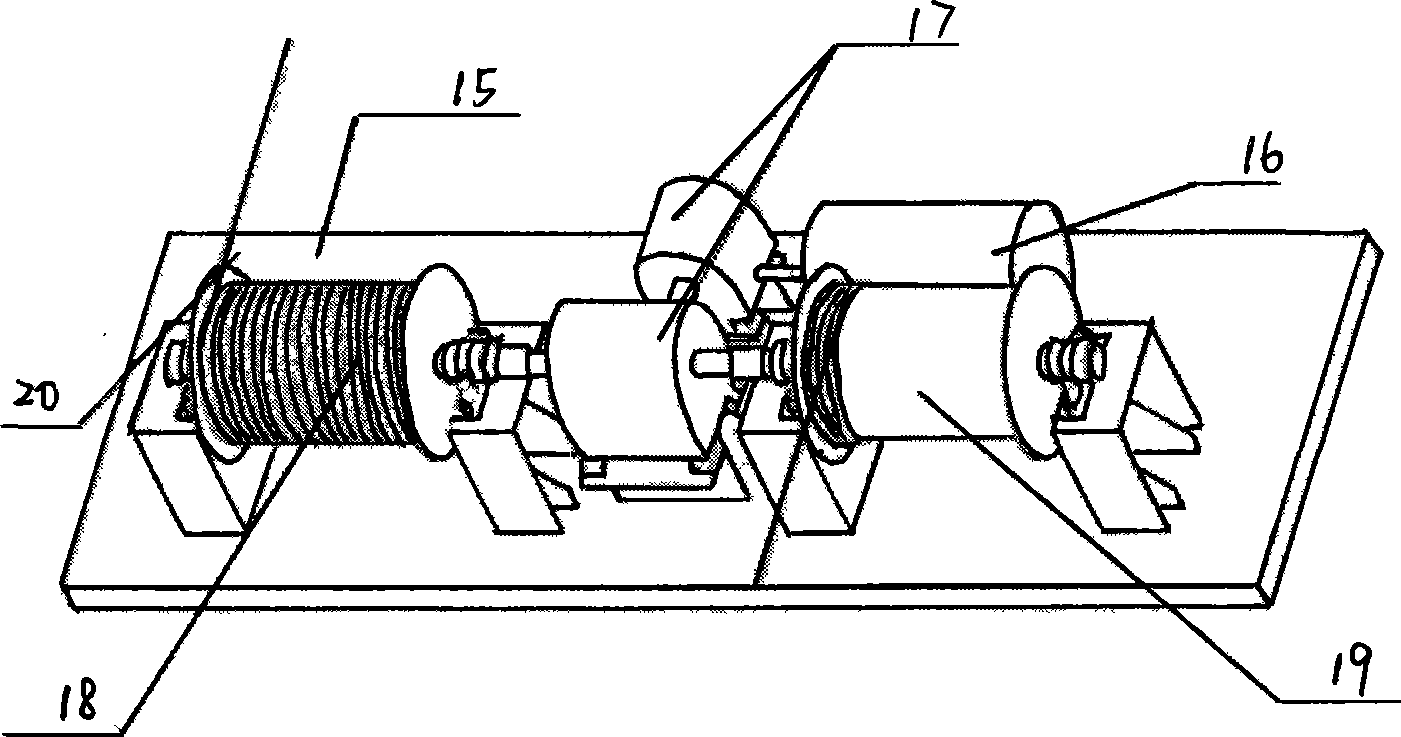

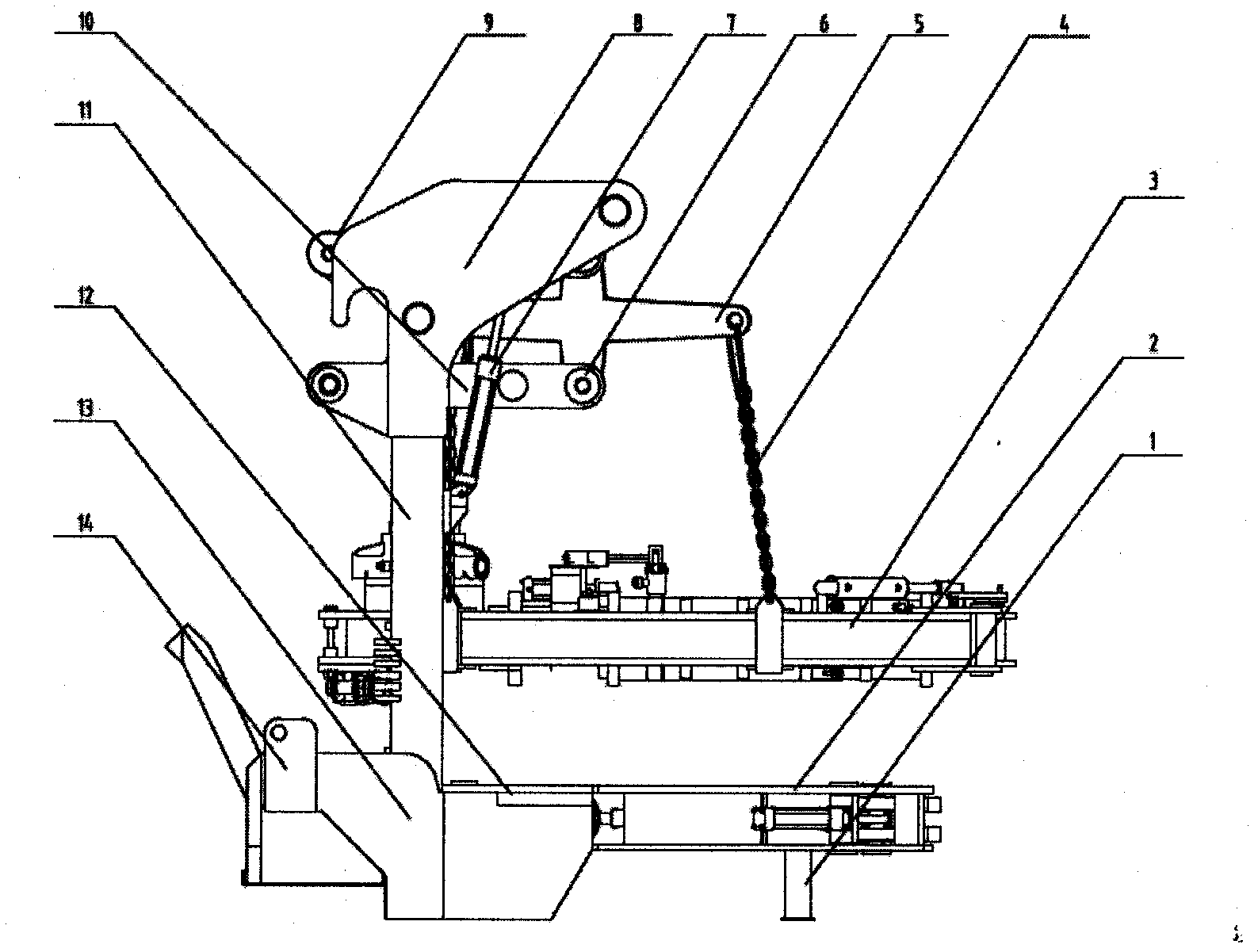

InactiveCN101456005ARealize full automationImprove work efficiencySpraying apparatusPretreated surfacesSand blastingEngineering

The invention provides an automatic sand blasting and rust removing and spraying device, which comprises a moving support having a moving mechanism and supporting rails, a spraying car connected with a conveyor tube, a driving device and a control device, wherein the moving support comprises an arch-shaped truss and the moving mechanism arranged at the bottom. The supporting rails are arranged above the arch-shaped truss. The control device and the driving device are arranged on the moving support and drive the spraying car to move to and fro on the supporting rails. The spraying car consists of a chassis, a spraying car motor, a transmission mechanism, a crank-rocker mechanism and a spray gun fixing seat for mounting a sand-blasting gun or a painting nozzle, wherein the spraying car motor is fixed on the chassis and is connected with one end of the transmission mechanism. The other end of the transmission mechanism is connected with the crank-rocker mechanism. The spray gun fixing seat is fixed at the end of the crank-rocker mechanism. The device adopts a PLC to control the whole process, realizes the automation of the whole process, improves the working efficiency greatly, better ensures construction safety and project quality, and reduces unnecessary damages.

Owner:TONGCHUANG KEXIN MATERIAL TECH CO LTD +1

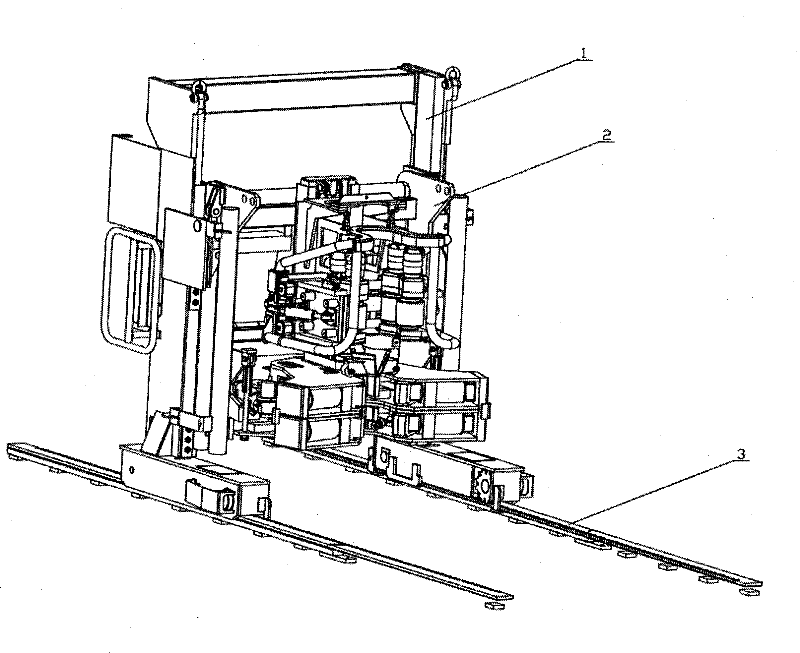

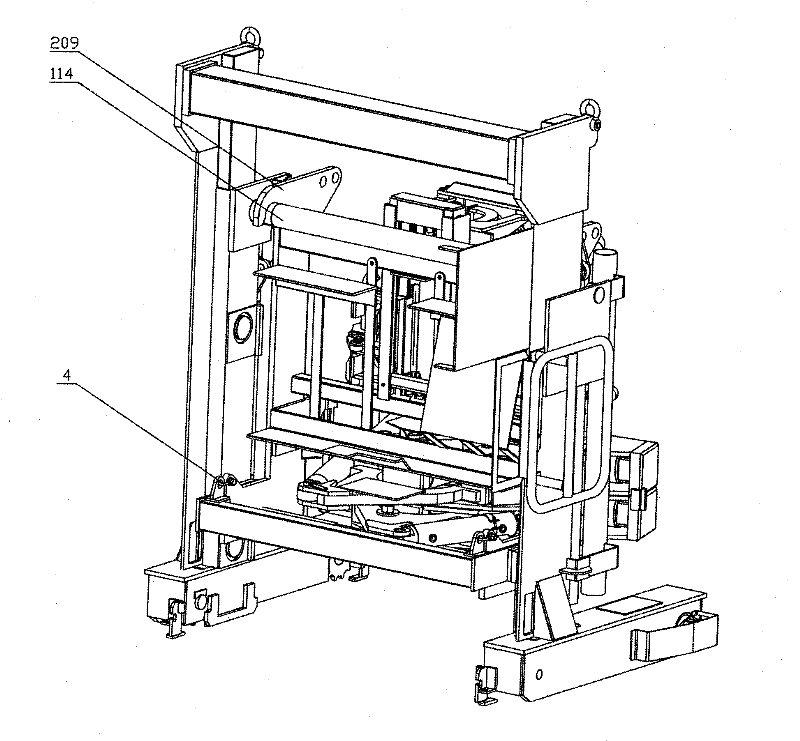

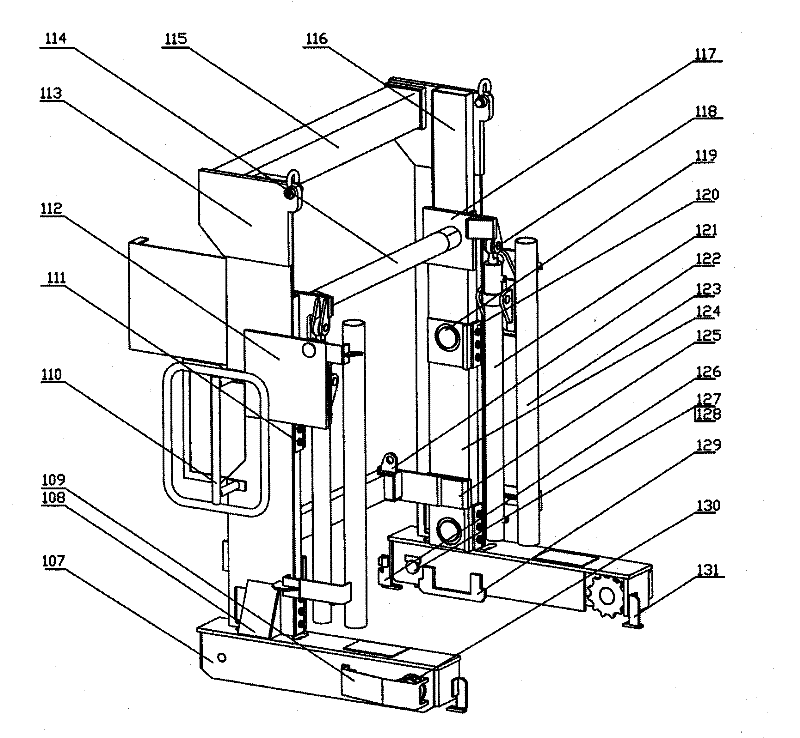

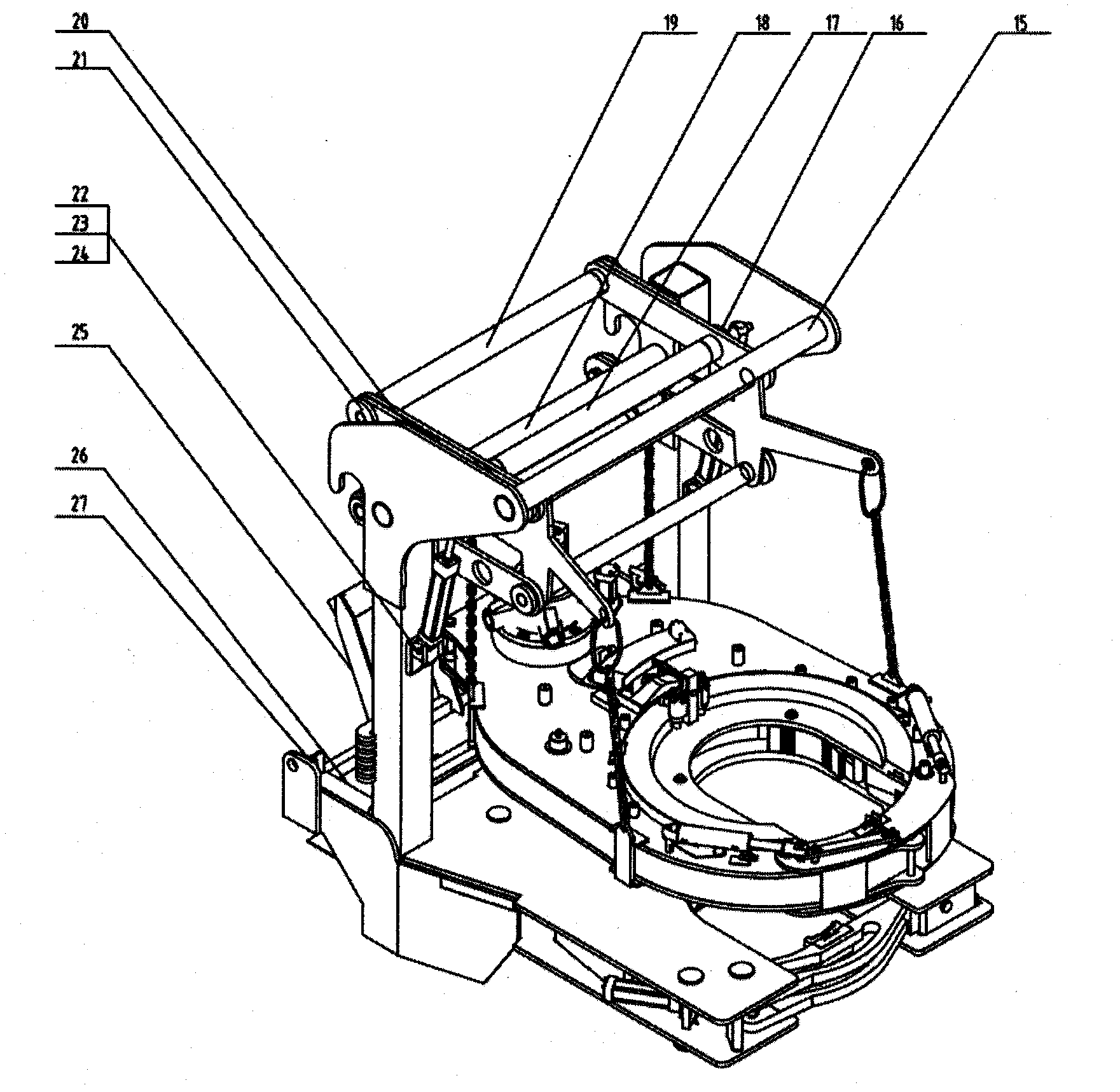

An Intelligent Casing Pliers with Back Tongs

InactiveCN102278083ARealize full automationReduce labor intensityDrilling rodsDrilling casingsEngineeringUltimate tensile strength

The invention provides intelligent casing tongs with back-up tongs, which comprises a main frame, a hanging frame, main tongs and back-up tongs, wherein the main tongs and the back-up tongs are connected on the main frame; the main tongs are suspended on the hanging frame through a chain, which is connected with the main frame; the back-up tongs are welded with the main frame and supported by two feet; the hanging frame is parallelogram-shaped; a rotary torque measuring device is mounted to the main frame; the main tongs achieve the effect of clamping a casing in a claw climbing manner; the back-up tongs are tightly clamped by three claws; and the claws are distributed in a mode of 120 degrees. The purpose of full-range automation of work of casing tongs is achieved, and the labor intensity of workers and accident incidence are reduced. The parallelogram-shaped hanging frame is adopted to ensure horizontal movement of power tongs. The tooth alignment process is centralized by adjusting a support cylinder. The back-up tongs improve the clamping force of the claws by use of a wedging mechanism. The back-up tongs are flexibly connected with the main tongs and can be detached to be used alone. The types of the claws are changed to fit different tube diameters, so as to increase the application range.

Owner:金华萨博思石油机械有限公司

Device and method for automatically removing sprue

The invention relates to a device and a method for automatically removing a sprue. The sprue is removed on an automatic production line, wherein the sprue is generated when a workpiece is cast. The device comprises a working table with an inclined angle, a workpiece chuck, a positioning head, a punching hammer and a grating sensor, wherein the grating sensor is used for detecting whether the workpiece is arranged on the working table; the workpiece is arranged on the working table by using a mechanical arm and is positioned on the working table by using the positioning head; the workpiece chuck is used for chucking the workpiece on the working table; the punching hammer is used for punching and removing the sprue of the workpiece; and the workpiece of which the sprue is removed is conveyed to a next working procedure by a conveyer belt. The device has the beneficial effects that a fracture surface is high in consistency after the sprue of a product is removed, thereby being beneficial for a follow-up machining procedure; a robot can be used for stabilizing and controlling an operation process; compared with a manual removing mode, the method has higher working efficiency and security; and the device for automatically removing the sprue is used, so that full-process automation of product machining is beneficially achieved.

Owner:ALTEAMS SUZHOU DIE CASTING ELECTRONICS TECH

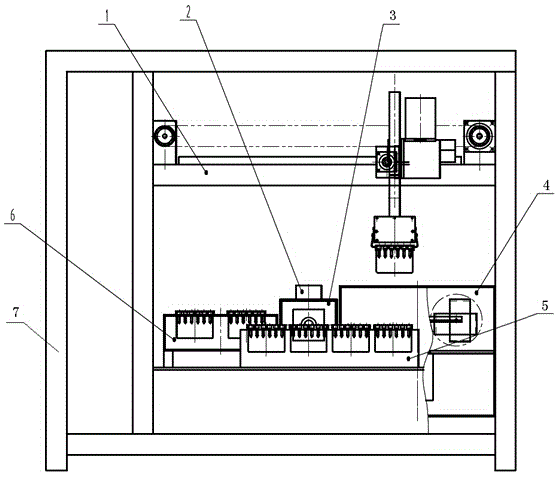

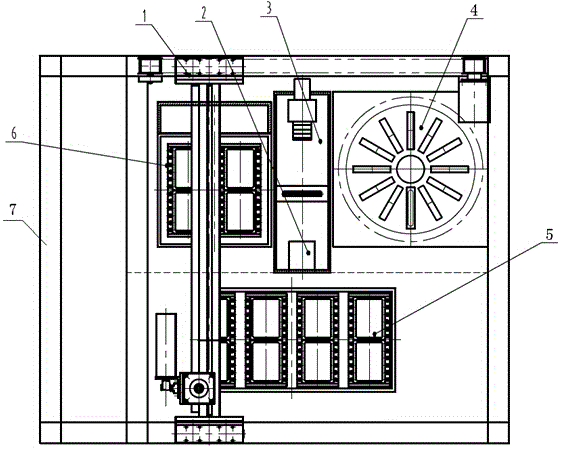

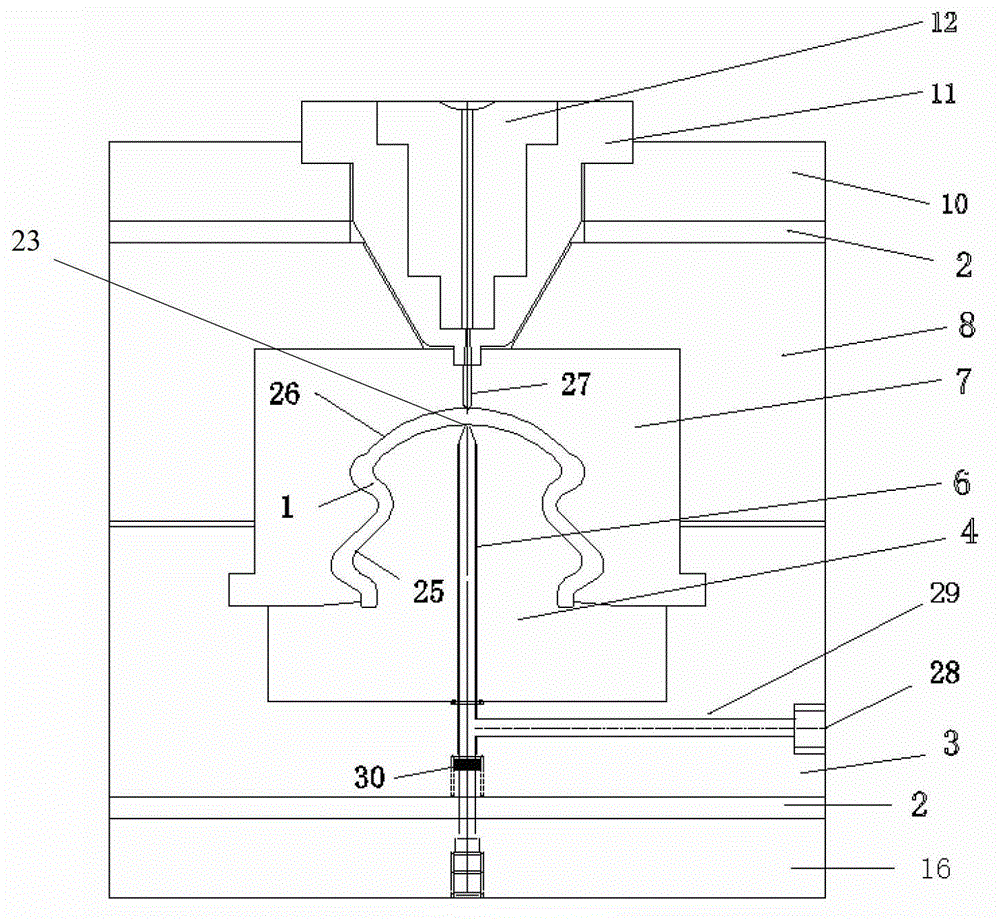

Full-automatic microcolumn gel card detection instrument

The invention provides a full-automatic microcolumn gel card detection instrument which comprises a controller, a centrifuge arranged on the upper end surface of a worktable, a box type image acquirer and a card box, wherein an incubator is also fixedly arranged on the upper end surface of the worktable; a three-coordinate card gripping mechanical hand controlled to move by the controller is arranged above the worktable, is connected with the worktable through a supporting column and is positioned above the centrifuge, the box type image acquirer, the card box and the incubator; a scanner is connected to the upper end surface of the box type image acquirer. According to the detection instrument, the three-dimensional motion and gripping operations in X, Y and Z directions can be performed through the three-coordinate card gripping mechanical hand, the full-automatic operations of capture of a microcolumn gel card from the card box after sampling, incubation, centrifuging, interpretation and returning of the card to the box are performed, and the detection efficiency and accuracy are improved.

Owner:合肥天一生物技术研究所有限责任公司

Catering automatic logistics line

PendingCN110498173ARealize full automationImprove work efficiencyConveyorsTable equipmentsLogistics managementEngineering

The invention relates to a catering automatic logistics line. The catering automatic logistics line comprises a storage goods shelf, a material taking mechanism, a screening rotation line and a conveying rotation line, wherein the material taking mechanism is used for clamping a material box at a designated position on the storage goods shelf, and feeding the material box to the screening rotationline; the screening rotation line is provided with a first material pushing mechanism capable of identifying information, and the first material pushing mechanism is used for identifying whether thematerial box is required by the conveying rotation line and pushing the screened material box to the conveying rotation line; and the conveying rotation line is provided with a second material pushingmechanism capable of identifying information, and the second pushing mechanism is used for identifying whether the material box on the conveying rotation line is required by a dining table and pushing the screened material box to the dining table. According to the catering automatic logistics line, the whole-process automation from storage to conveying can be realized, the working efficiency canbe effectively improved, and the labor cost is reduced.

Owner:GUANGDONG ATHENE ROBOTIC TECH CO LTD

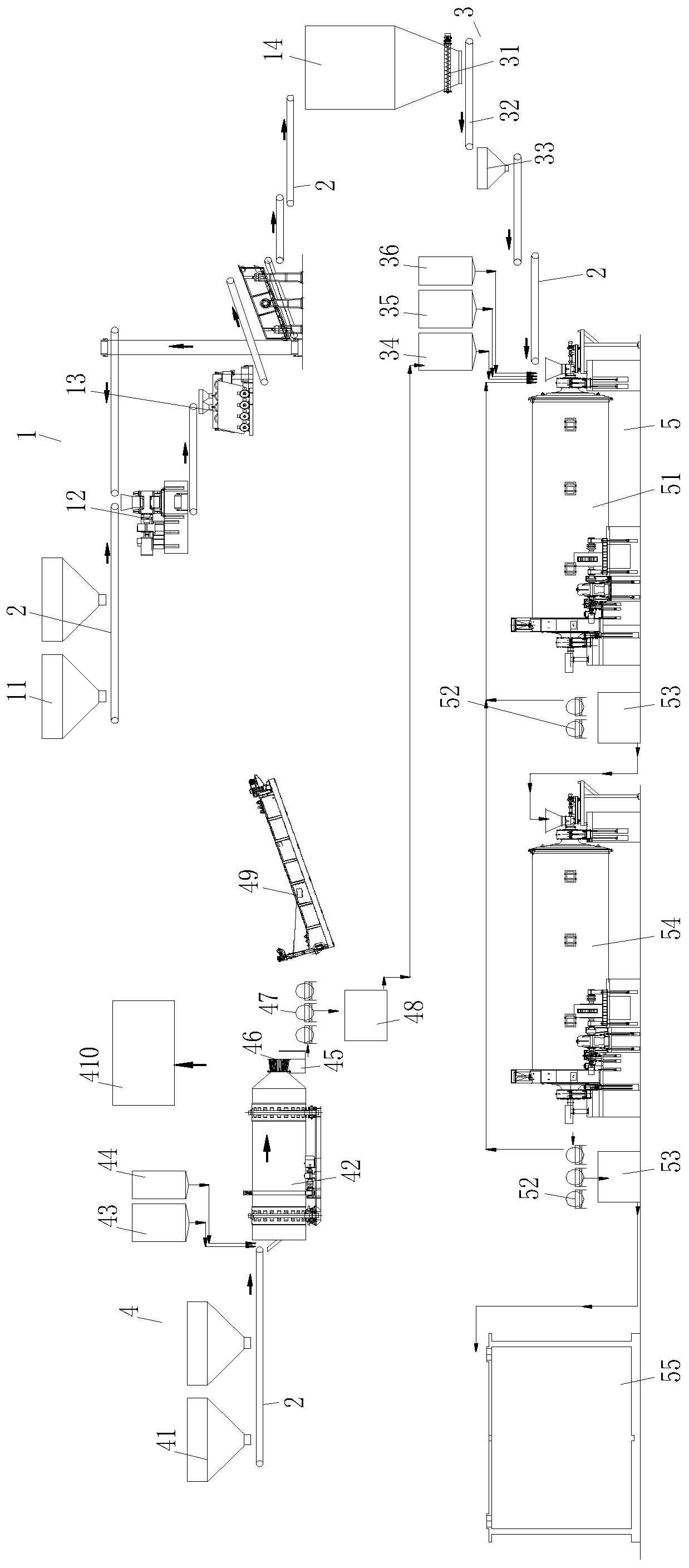

Intelligent wet powdering production technology for ceramic raw materials

InactiveCN110404657ARealize full automationIncrease production capacityGrain treatmentsNumerical controlProduction line

The invention relates to the technical field of ceramic raw material powdering and particularly relates to an intelligent wet powdering production line for ceramic raw materials. The intelligent wet powdering production line for ceramic raw materials comprises a raw material pre-crushing system, a belt conveying line, an automatic metering and batching system, a pug slurrying system and a continuous ball miller system. Transferring and conveying at the discharge end of the raw material pre-crushing system are carried out through a belt conveying line, the automatic metering and batching systemis located on the raw material pre-crushing system, the discharge end of the automatic metering and batching system is communicated with the feeding end of the pug slurrying system, and the other discharging end of the automatic metering and batching system is communicated with the continuous ball miller system. By means of the intelligent wet powdering production line for ceramic raw materials,the purposes of whole process automation, numerical control production and intelligent manufacturing of ceramic wet powdering technology are achieved, and thus the superior product rate and the production efficiency of ceramic products are improved; and besides, good mobility can be still ensured under the condition that the water content of slurry is low, and product defects are reduced.

Owner:广东鼎汇能科技股份有限公司

Automatic sealing loader for button cell

InactiveCN1801503ASimple structureAdvanced technologySmall-sized cells cases/jacketsPrimary cellsHuman–machine interfaceEngineering

The invention relates to an auto-sealing assembly machine for button cell, which comprises: a frame groupware, a feeding mechanism, a sealing mechanism, an assembly mechanism, a drive gear, a pneumatic control system, and an electric control system. It uses mechanical-electrical integration design scheme, monitors moment and state by sensors, controls actuators with PLC technology, feeds material with belt, and realizes complete automation. Wherein, the OS uses contact screen as human-machine interface for convenient interactive operation.

Owner:TIANJIN POLYTECHNIC UNIV

Intelligent cooking device and control method thereof

PendingCN110507156ARealize full automationHigh degree of intelligenceCooking vessel constructionsProcess engineeringCooking process

The invention provides an intelligent cooking device and a control method thereof. The cooking device comprises a base portion and an upper cover portion that can be turned over and opened, the base portion is an integration of a heating device for heating a pot body, and a liquid adding device for adding liquid into the pot body and a sensor for controlling temperature and power; the upper coverportion is an integration of a stirring device, a steam adjustment device, a food box and a film tearing device matching the food box; the entire cooking process is formulated by matching food proportion and distribution in the food box through a preset program, the entire device runs automatically, a user only needs to select and install the food box, select a corresponding dish and click to start, and then wait; and the participation steps of the user are maximally reduced, so that the user is completely liberated from the cooking process.

Owner:大连品上投资管理有限公司

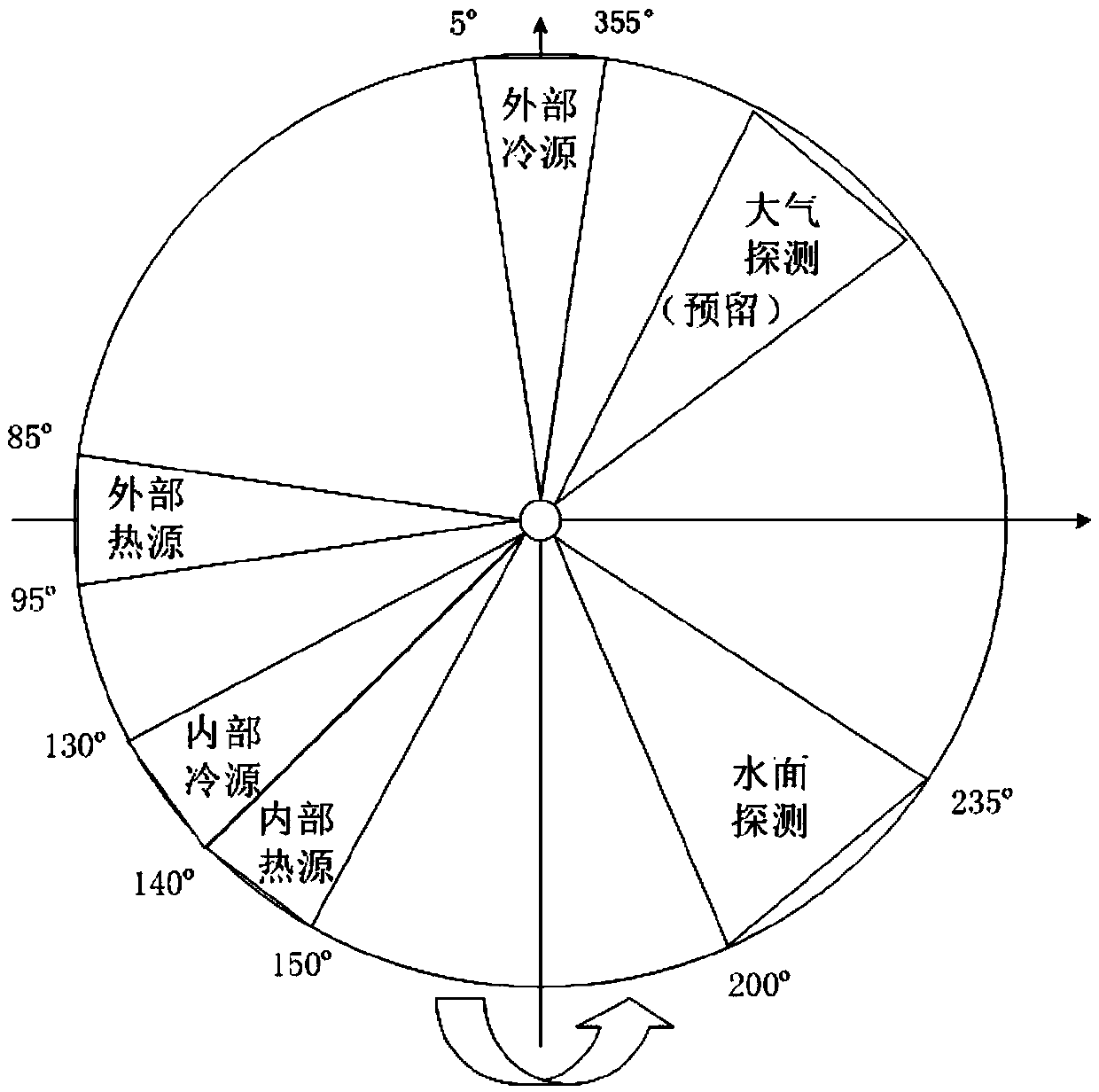

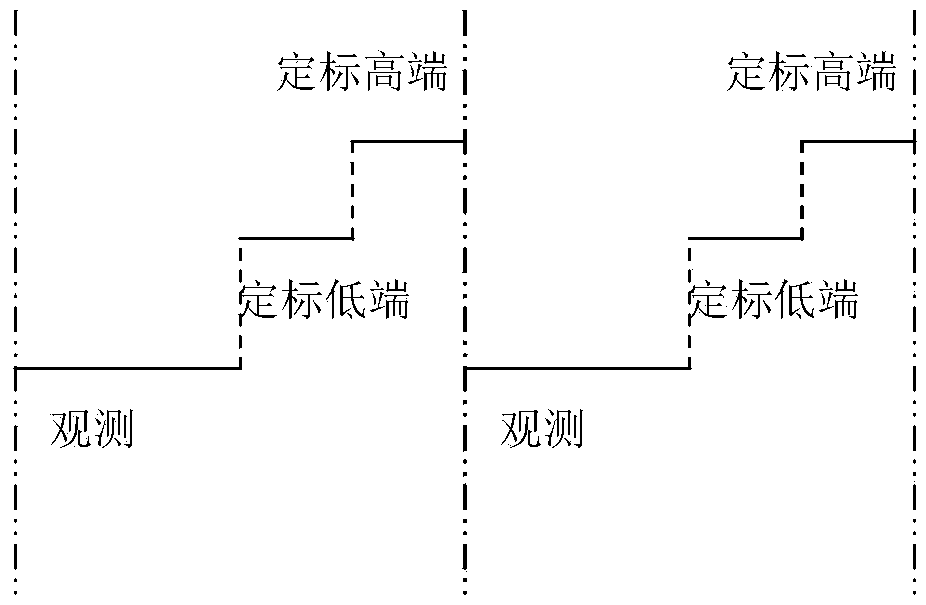

Four-point scaling device and method for microwave radiometer

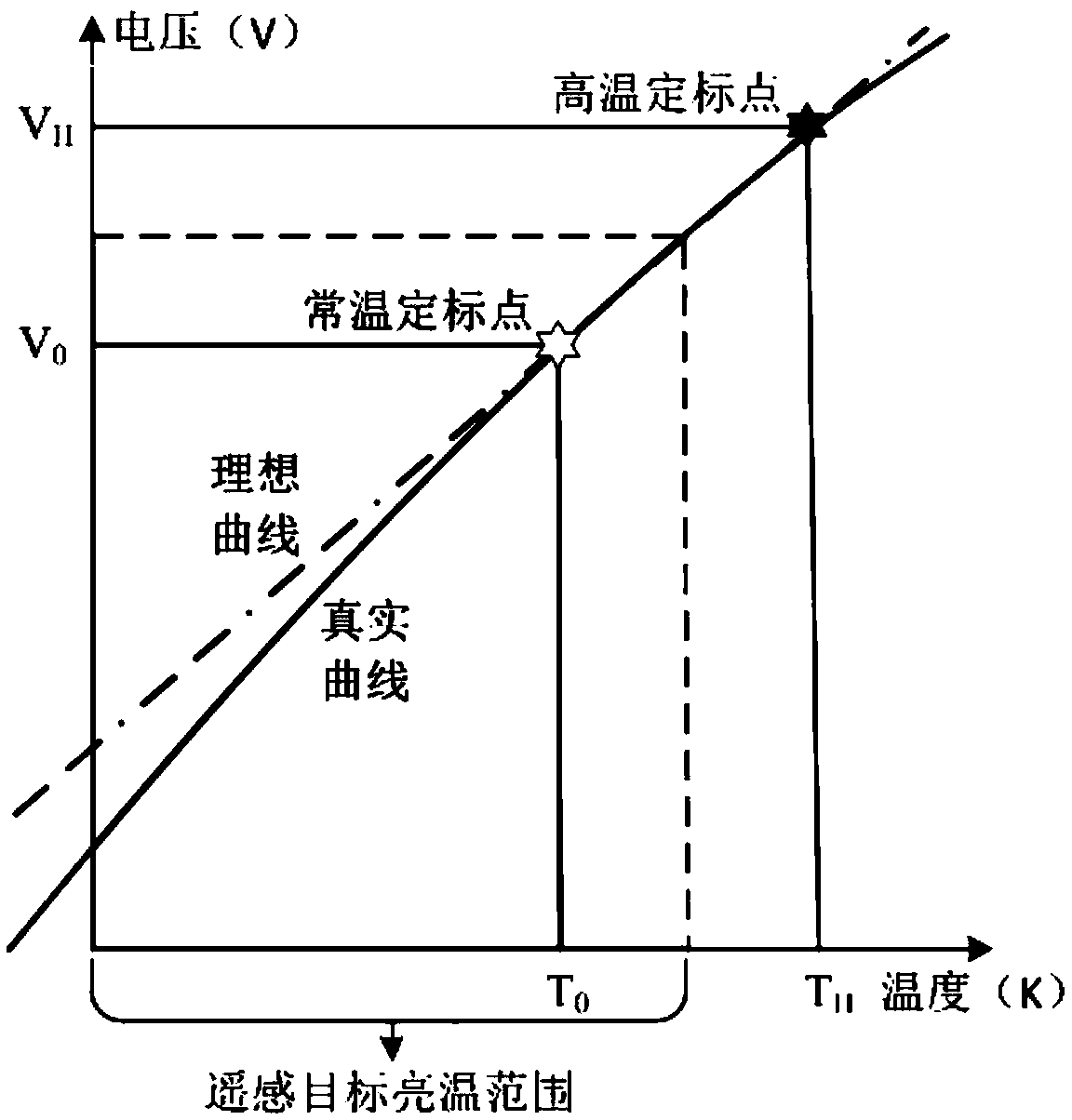

ActiveCN105372610AImproving the Calibration Accuracy of RadiometersImprove calibration accuracyElectrical measurementsCold airMicrowave radiometer

The invention provides a four-point scaling device and method for a microwave radiometer. A four-point scaling technology is used in the method, a high-temperature reference point and a normal-temperature reference point are arranged in the microwave radiometer to carry out internal scaling on a receiver of the microwave radiometer, and a normal-temperature scaling source and a cold air reference source are arranged outside the microwave radiometer to carry out external scaling on the whole microwave radiometer with an antenna. The device is provided with a special-purposed radiator scaling turntable, and reasonably distributes scaling and observation intervals of the microwave radiometer, so that real-time four-point scaling can be carried out on the microwave radiometer in each observation period, and a high-precision scaling result of the microwave radiometer can be obtained.

Owner:NAT SPACE SCI CENT CAS

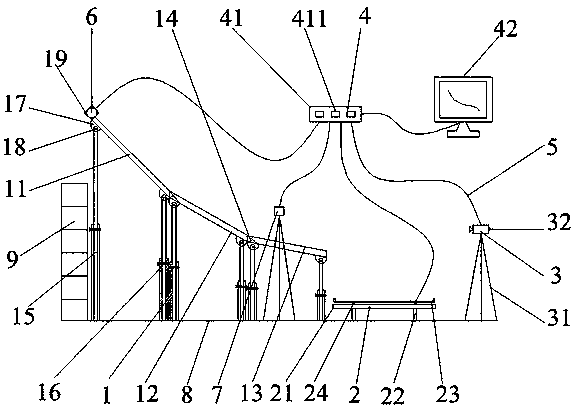

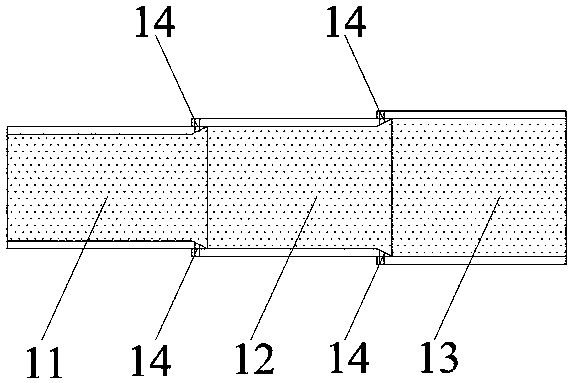

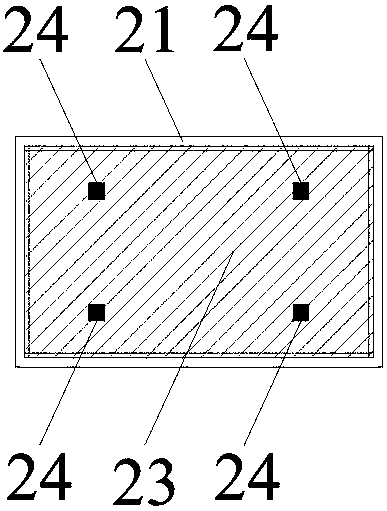

Analog test system for start, movement and impact of slope rolling stone

PendingCN107643158AStrong applicabilityStrong anti-interference abilityShock testingEngineeringRecording system

The invention discloses an analog test system for start, movement and impact of a slope rolling stone. The system is composed of a slope rolling stone slide model, a rolling stone impact test system,a first rolling stone motion recording system, a second rolling stone motion recording system, a test data processing system, a number of connecting lines and an experimental rolling stone. The sloperolling stone slide model, the rolling stone impact test system, the first rolling stone motion recording system, the second rolling stone motion recording system and the test data processing system are arranged on a worktable respectively, and the model and the systems are connected with the test data processing system through a number of connecting lines. According to the invention, the system can be applied to simulate the rolling stone movement on a slope type combining different slope grades; the slope rolling stone slide model has high applicability, can be reused to realize whole courseautomation and integration of rolling stone starting, movement recording, impact testing and data processing, has the advantages of constant monitoring and strong anti-human interference ability, andprovides a scientific basis for the prevention and control of rolling stones.

Owner:JILIN UNIV

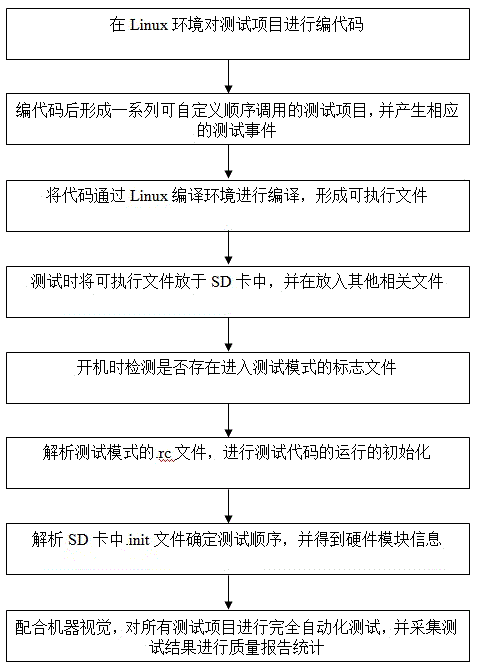

Method for automatically testing hardware module of intelligent displayer

ActiveCN104794032ARealize full automationSave human and material resourcesDetecting faulty computer hardwareMachine visionDisplay device

The invention relates to a method for automatically testing a hardware module of an intelligent displayer. The method comprises the steps of 1, encoding test items in a Linux environment; 2, forming a series of test items which can be called in a user-defined sequence after encoding, and generating corresponding test events; 3, compiling codes in a Linux compiling environment to form an executable file; 4, placing the executable file in an SD card during testing, and placing other relevant files; 5, detecting whether a logo file entering the test mode exists during starting; 6, analyzing a .rc file of the test mode, and initializing operation of test codes; 7, analyzing a .init file in the SD card to determine test sequence and obtain hardware module information; 8, conducting fully-automatic testing on all the test items based on machine vision, and acquiring test results for quality report statistics. According to the method, operation is easy, automatic testing of all the test items is achieved, and manual tracking and tracking are not needed during item testing.

Owner:FUZHOU UNIV

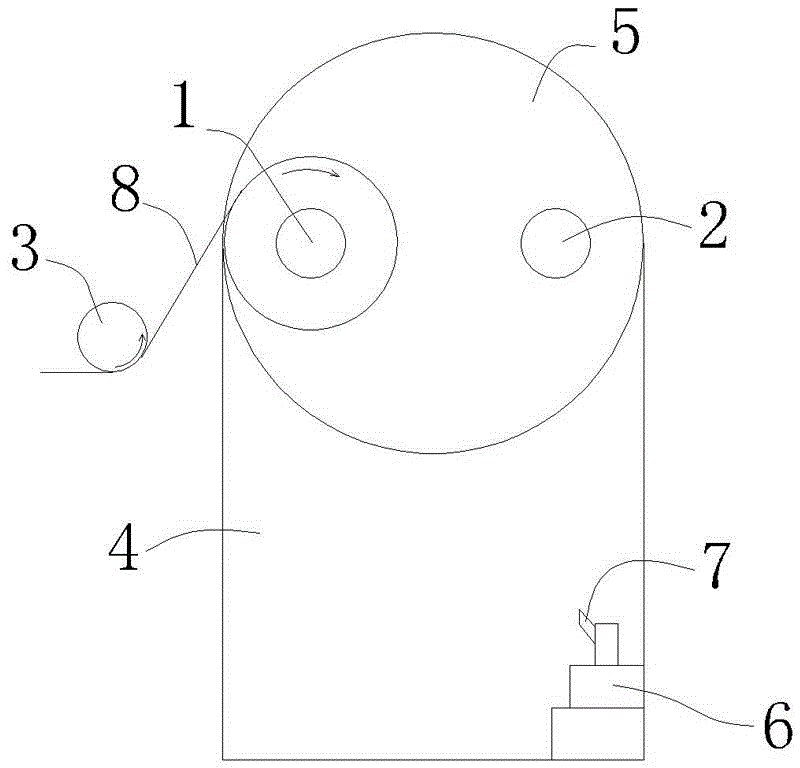

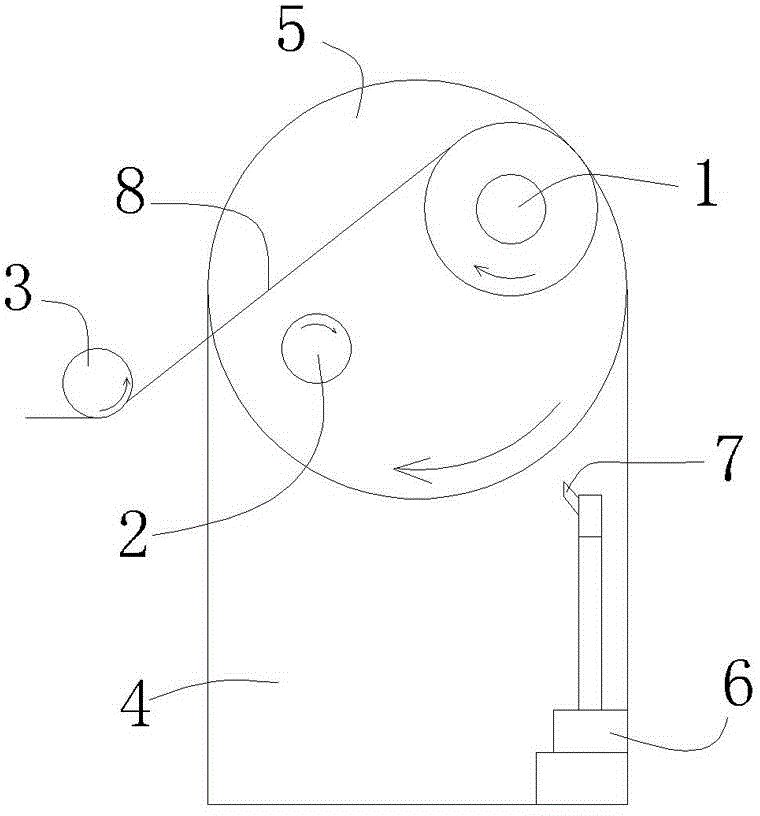

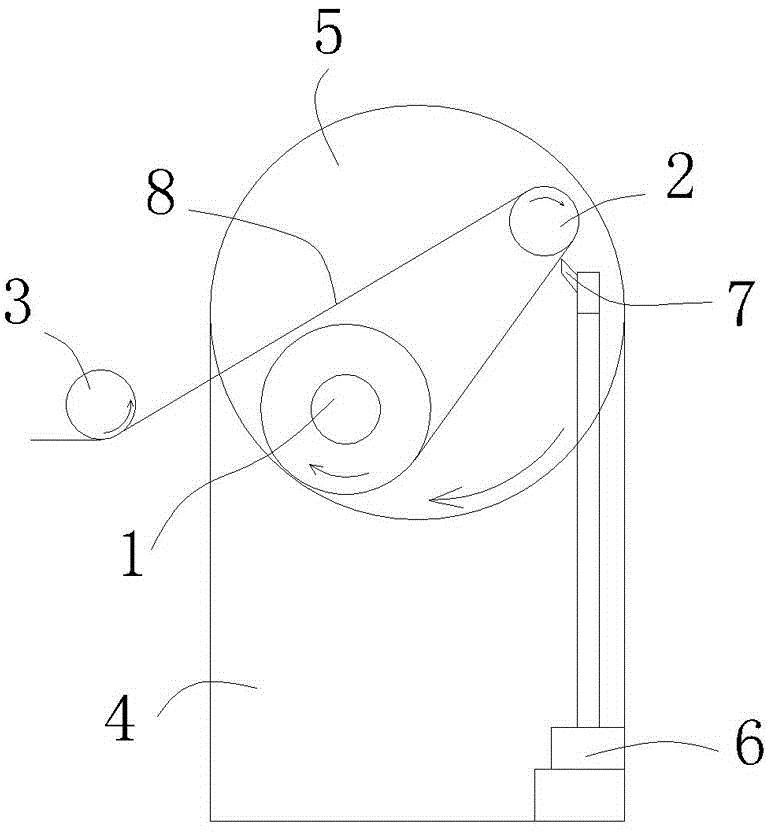

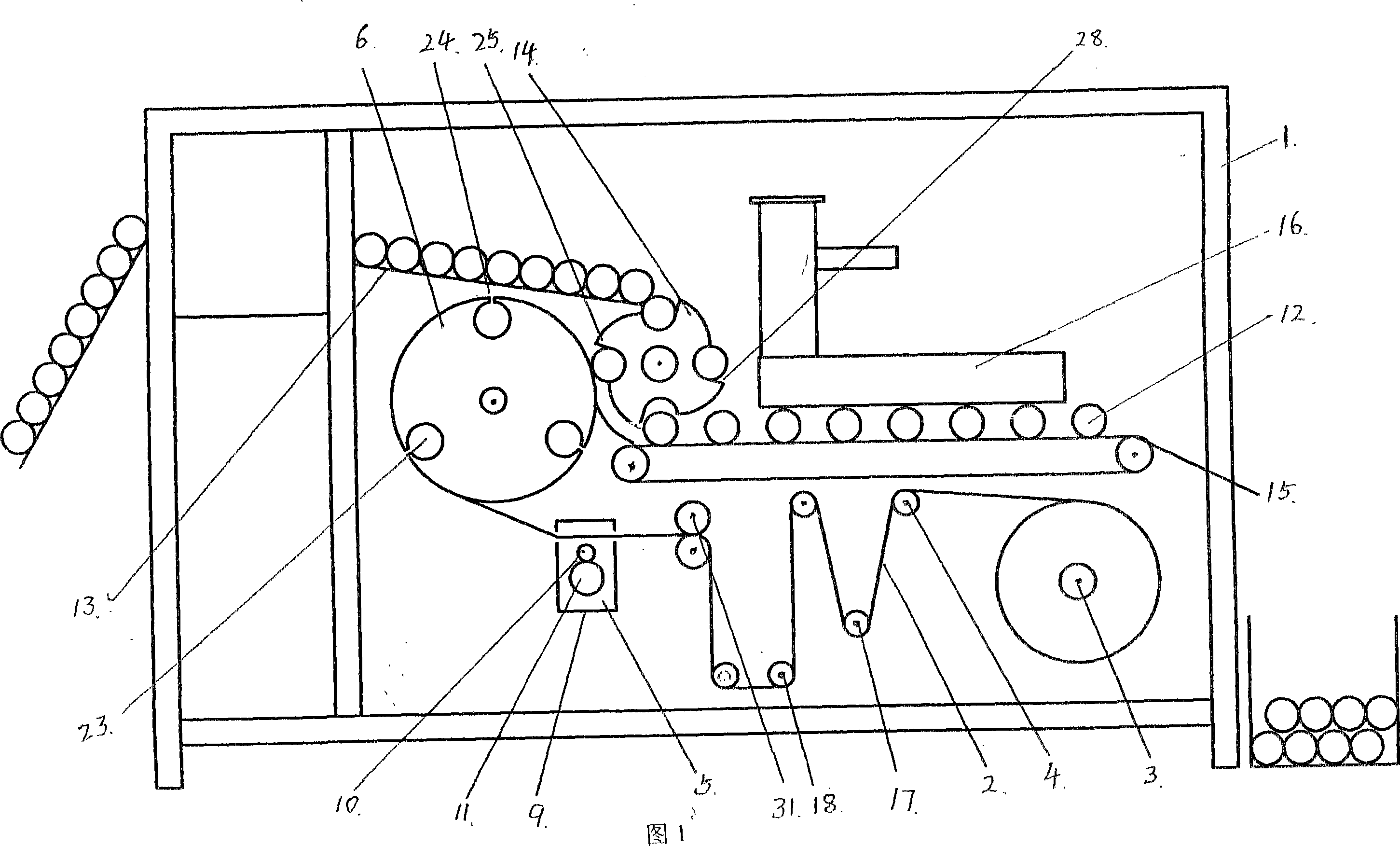

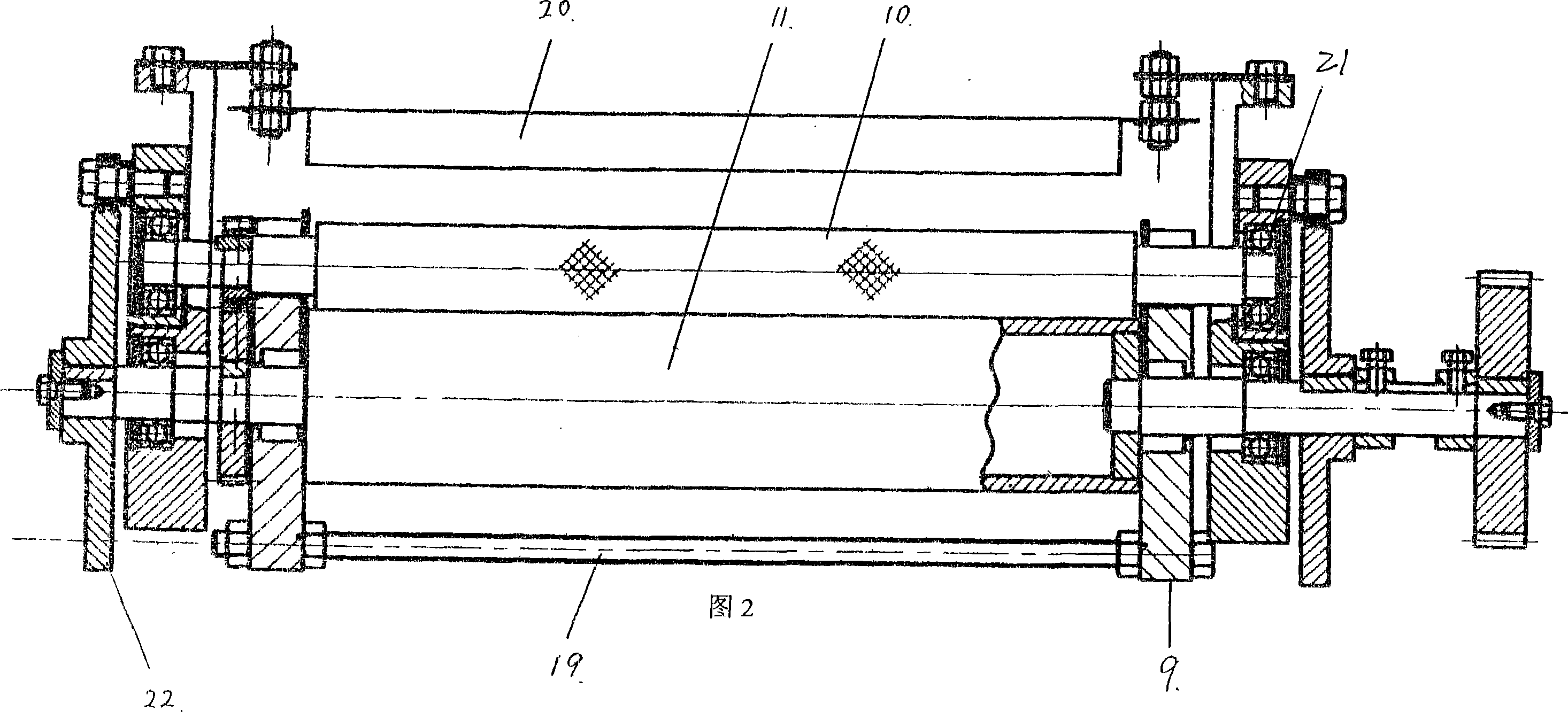

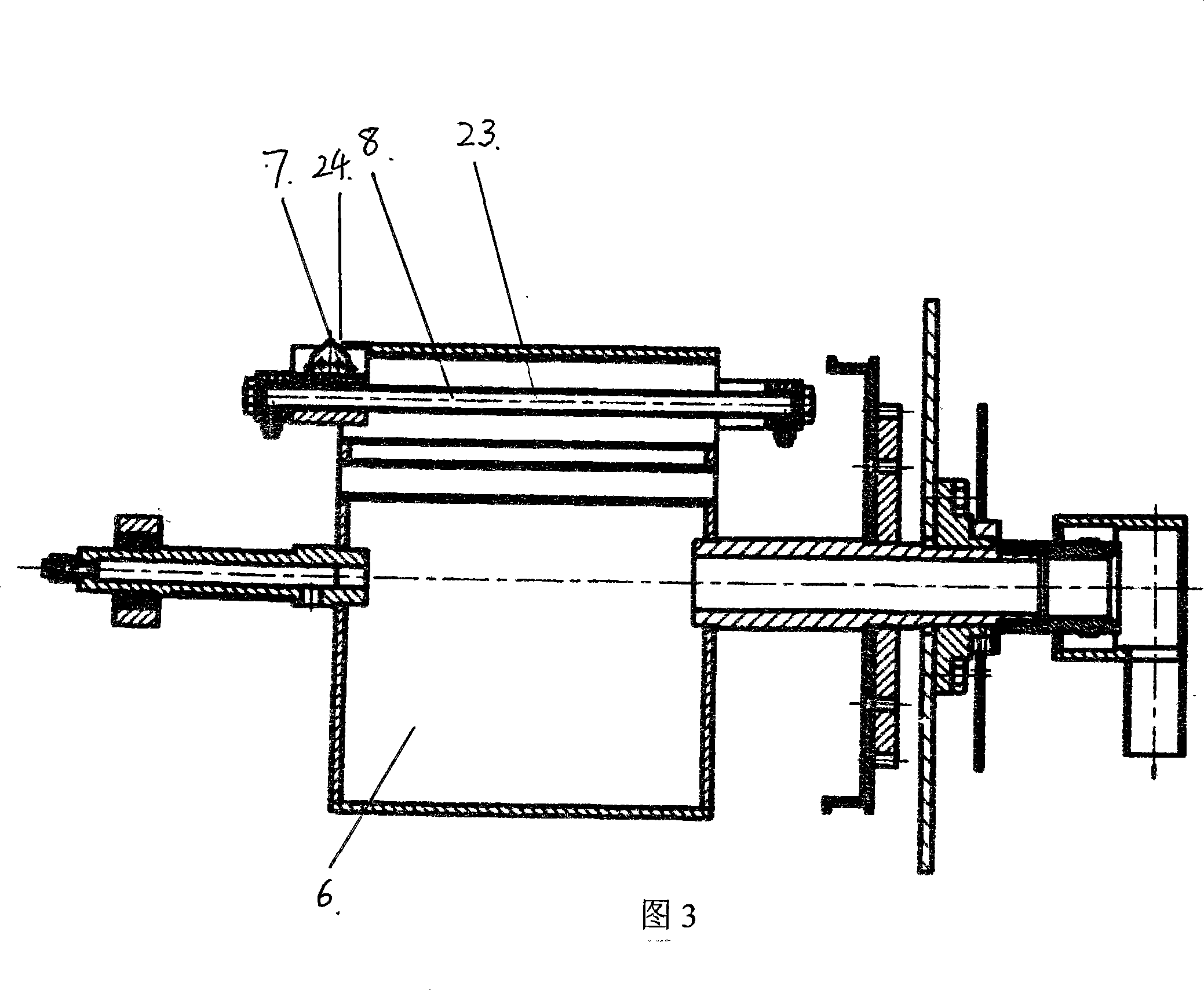

Film wind-up roll device

A film wind-up roll device comprises a guide roll rotating anticlockwise, a first wind-up roll rotating clockwise, a second wind-up roll which rotates clockwise and is parallel to the first wind-up roll, a cutter device and a support, wherein a converting roll which is capable of rotating in two directions and parallel to the first wind-up roll is arranged in the support, a rotary shaft is arranged in the middle of the converting roll, and the two ends of the rotary shaft are supported by the support; the first wind-up roll and the second wind-up roll are located in the converting roll, the two ends of the first wind-up roll are erected in the converting roll through first support shafts respectively and can be taken down, the two ends of the second wind-up roll are erected in the converting roll through second support shafts respectively and can be taken down, the cutter device comprises a lifting cylinder arranged in the support, a cutter is connected to the output end of the lifting cylinder, and the converting roll is provided with a hollowed-out portion allowing the cutter to penetrate therein. By the adoption of the device, full-process automation of rolling up and reel alternation of films is achieved, the success rate of rolling up is effectively increased, product loss is reduced, and product cost is reduced.

Owner:NINGBO DXC NEW MATERIAL TECH

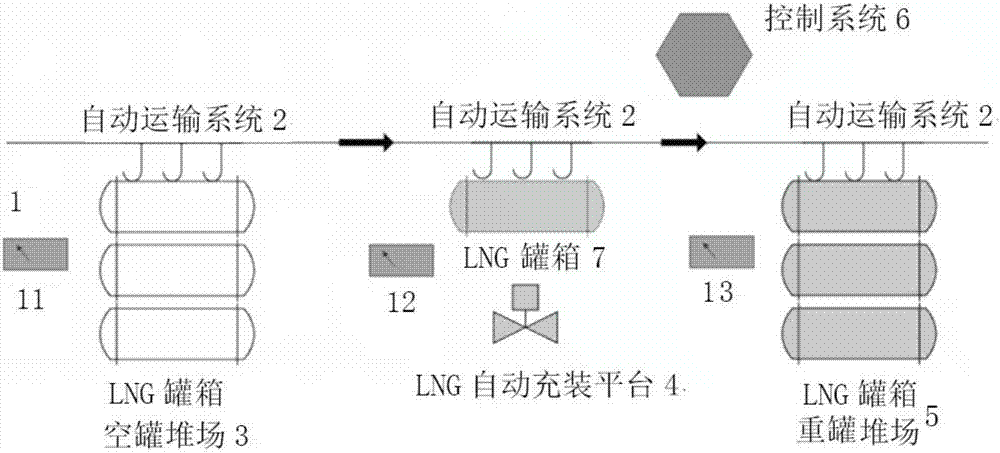

LNG tank box assembly line filling system

ActiveCN107479424AShorten filling timeRemove uncertaintyProgramme control in sequence/logic controllersMarine engineeringControl system

The invention relates to an LNG tank box assembly line filling system, and the system is characterized in that the system comprises a scanning and information recorder, an LNG tank box empty tank storage yard, an automatic conveying system, an LNG automatic filling platform, a control system and an LNG tank box refilling storage yard. The scanning and information recorder is used for obtaining the recognition information of an LNG tank box before filling, during filling and after filling. The automatic conveying system is connected with the LNG tank box empty tank storage yard, the LNG automatic filling platform and the LNG tank box refilling storage yard, and is used for conveying a to-be-filled LNG tank box to sequentially pass through the LNG tank box empty tank storage yard, the LNG automatic filling platform and the LNG tank box refilling storage yard. The LNG automatic filling platform is used for completing the filling of the LNG tank box. The control system is connected with the scanning and information recorder, the automatic conveying system and the LNG automatic filling platform. The system can achieve the automatic filling of the LNG tank box, and improves the filling efficiency and safety.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Horizontal labeler

InactiveCN101104449AGuaranteed continuityQuality improvementLabelling machinesLabelling short rigid containersEngineeringThermal contraction

The invention is a horizontal labeling machine for can body labeling operations, mainly composed of a can sending device, a label sending device and a thermal shrinkage device that are all arranged on a rack. The invention is characterized in that the label and the can body are horizontally conveyed; a label suction roller is provided with a cutter; a glue printer comprises a glue box, a glue-printing roller and a glue-hanging roller; the can sending device comprises a can storage box, a can shifter and a conveying belt; the can shifter is arranged on one side of the label suction roller; the can body of the can shifter is rotarily extruded with the label suction roller to finish labeling; the thermal contraction device adopts a thermal shrinkage apparatus for thermal shrinkage treatment on both ends of a labeled can body. Glue printing, label cutting, labeling and thermal shrinkage treatment are completed in the conveying process, so as to realize the full automation of horizontal labeling and ensure the labeling continuity. The invention is of fast conveying and high efficiency, which is widely applied to labeling operations on the external of various cylindrical cans and aerosol cans, as well as some plastic tags.

Owner:陈以忠

Computer full-automatic Kjeldahl determination device

ActiveCN101294914AReduce exposureRealize full automationMaterial analysis by observing effect on chemical indicatorDistillationEngineering

The invention discloses a computer fully automatic Kjeldahl nitrogen instrument which is provided with a device for distilling and titrating a detected sample after thermal decomposition and digestion. The device comprises a steam unit, a distillation unit, a condensation unit, an absorption unit and a titration unit. A steam furnace of the vapor unit is connected to the distillation unit through a steam blocking valve; an output tube of a buffering bottle of the distillation unit is connected with the condensation unit; an output tube of a condensation tube of the condensation unit is connected to the absorption unit; the output end of a titrator of the titration unit is connected to a titration cylinder of the absorption unit through a pipeline; and all the units of the device are sequentially connected through pipelines that communicate with each other, and controlled by a single chip control circuit. A safety door position sensor is installed on the safety door of the Kjeldahl Nitrogen instrument, and a digestion tube position sensor is arranged inside the safety door. The Kjeldahl nitrogen instrument has the advantages of simple structure, convenient operation and high detection accuracy, and can achieve the full automation of the protein inspection procedure.

Owner:洛阳朗诺电子科技有限公司

Method and device for manufacturing silicon rubber fire-cupping tool

InactiveCN103182763AIncrease productivityEasy and quick demouldingPneumatic massageDomestic articlesLiquid siliconNozzle

The invention discloses a method and a device for manufacturing a silicon rubber fire-cupping tool. The device comprises a nozzle, an internal mold core, a separable slide and a blowing and demolding device, wherein the slide comprises at least two separable slide blocks; a mold cavity for forming the silicon rubber fire-cupping tool is formed between the slide and the internal mold core; one end of the nozzle is connected with a channel for feeding the liquid silicon rubber raw material, while the other end is communicated with the mold cavity; and the blowing and demolding device is communicated with the mold cavity through a blowing hole opening which is arranged at the junction of the internal mold core and the mold cavity. The method takes the liquid silicon rubber as a raw material, and adopts the injected silicon rubber vulcanization molding technology to manufacture the silicon rubber fire-cupping tool with high elasticity, high transparency and complicated shape. The working procedures are simple and automated. The production efficiency is high, the demolding is simple and quick, and the device is not required to be dismantled or cleaned during the demolding process.

Owner:东莞市绿洲医疗器械有限公司

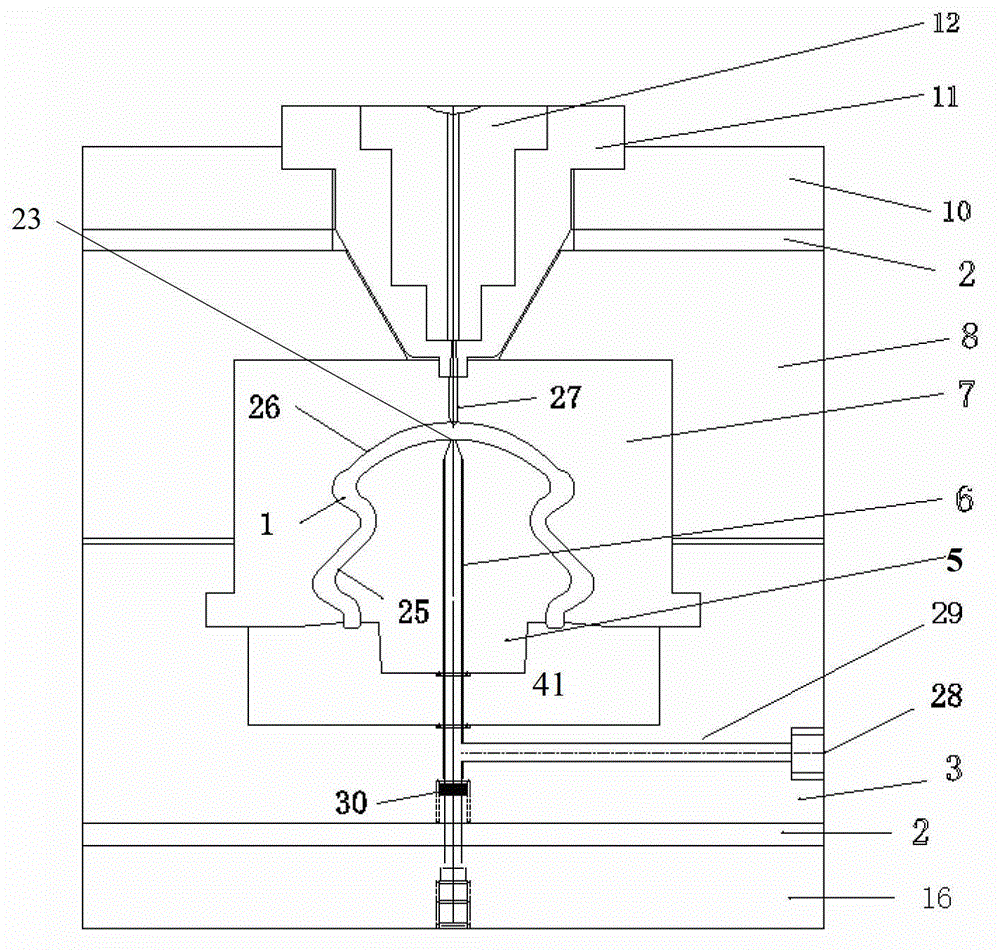

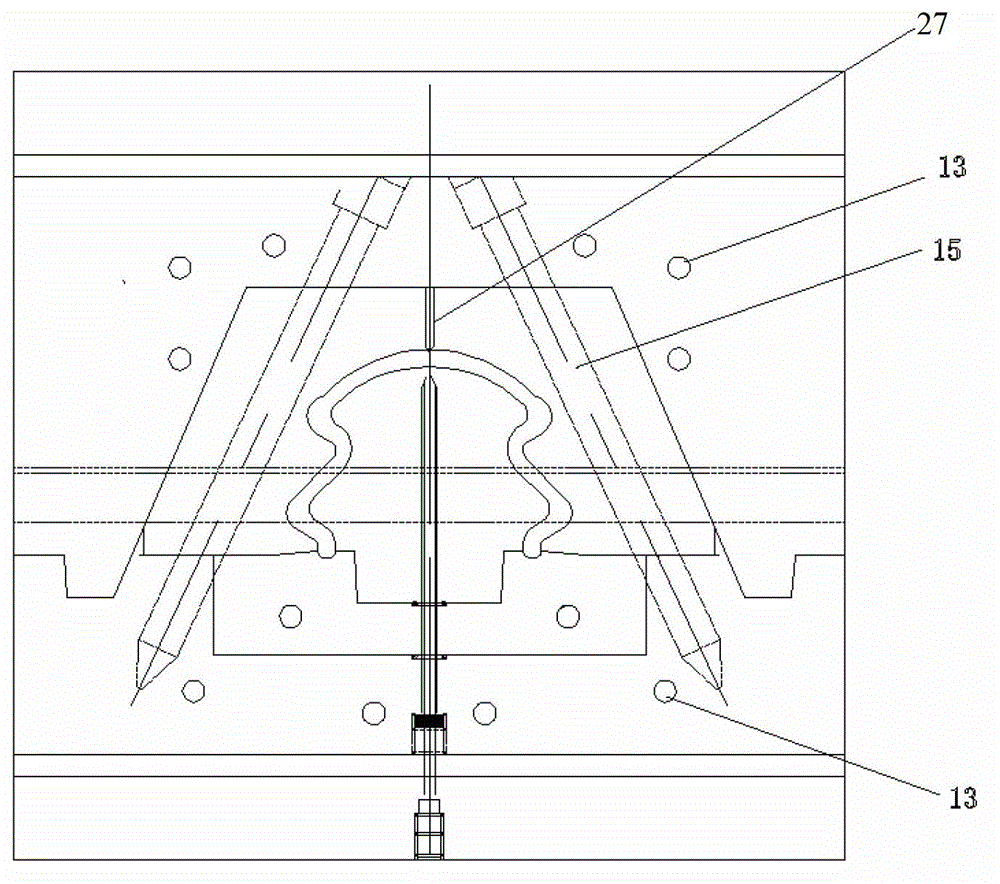

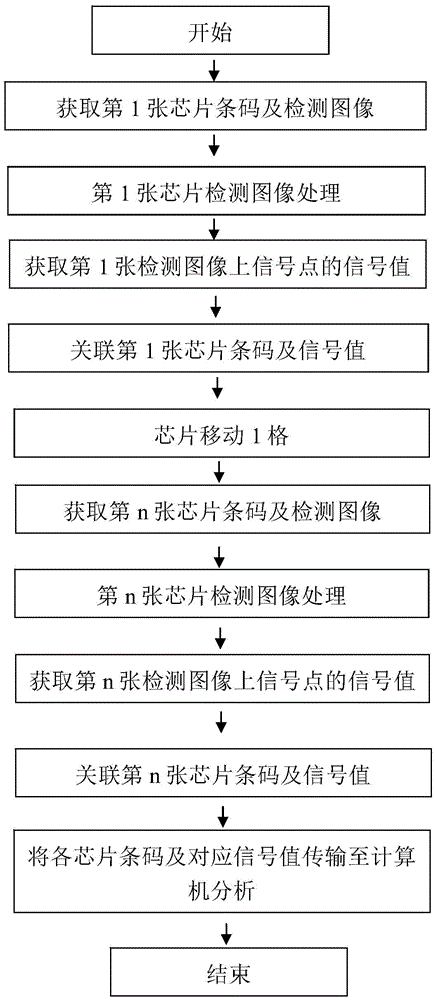

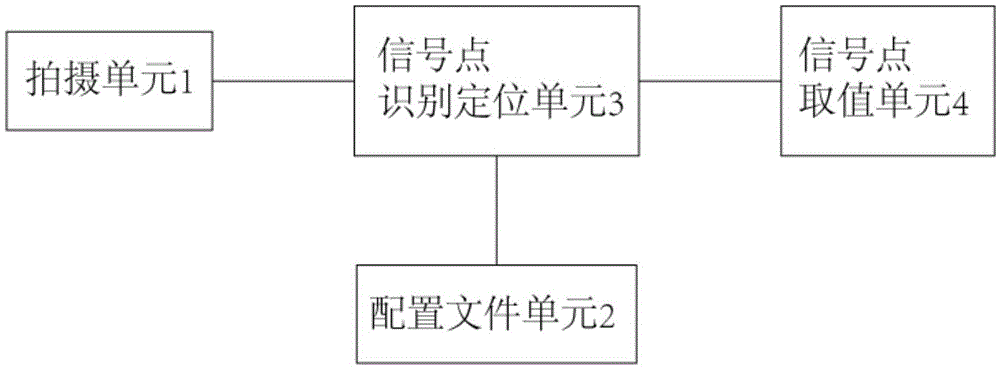

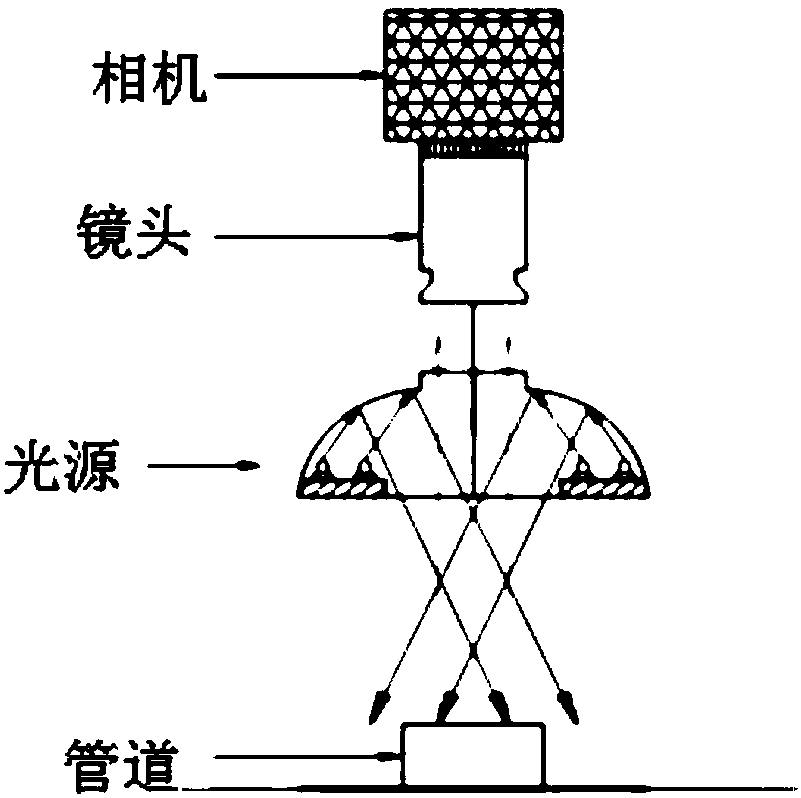

Method and device of continuously automatically reading transmission signals of multiple biochips

ActiveCN105590079AEnable high-throughput analysisImprove accuracySensing by electromagnetic radiationGlass chipBiochip

The invention provides a method of continuously automatically reading transmission signal values of multiple developing microarray biochips, and a reading instrument and a reading system for realizing the method. The reading method is characterized by comprising: (1) scanning a glass chip bar code to obtain chip bar code information; (2) placing the main camera used for shooting a chip image and the background light source used for main camera lighting on two sides of a glass chip; (3) identifying parameters according to the bar code information, chip images and signal points, automatically identifying and positioning the signal points, and automatically obtaining signal point coordinates; (4) automatically obtaining signal values of the signal points according to the obtained signal point coordinates; and (5) automatically continuously reading a plurality of chips (which can be chips of different types) through position movement.

Owner:SHANGHAI BAIO TECH

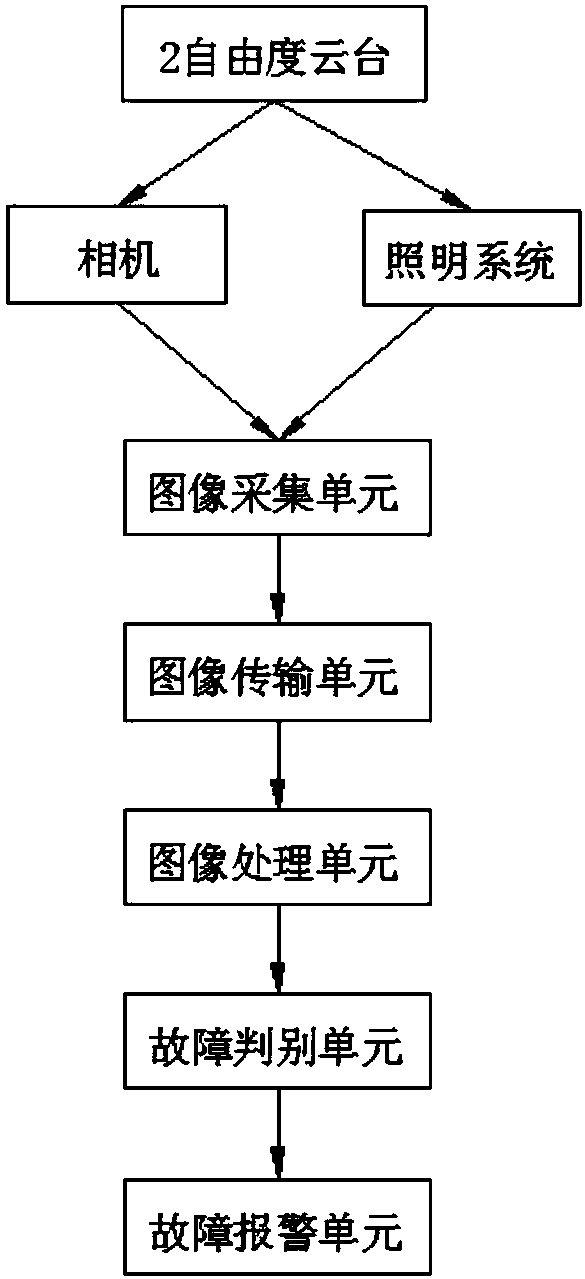

Machine vision detection method and system of boiler pipeline surface defect

ActiveCN107749058AEliminate salt and pepper noiseProtect Edge FeaturesImage enhancementImage analysisSample imageGenetic algorithm

The invention discloses a machine vision detection method and a system of a boiler pipeline surface defect. The method comprises the following steps of firstly, collecting a certain number of boiler pipeline surface images and taking as sample images; carrying out preprocessing, dimension reduction and characteristic merging on the images; then, using a genetic algorithm and a SMO algorithm to solve a classification hyperplane with highest accuracy; using the optimal classification hyperplane to determine a decision function; and then, through the decision function, carrying out real-time detection on the boiler pipeline surface images to be detected collected by an industrial camera. In the invention, a classification model is simple and reliable, a correct rate of defect identification is high; and compared with manual boiler surface defect detection, detection efficiency of machine vision detection is greatly increased.

Owner:CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com