Patents

Literature

123 results about "Roughneck" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Roughneck is a term for a person whose occupation is hard manual labor. The term applies across a number of industries, but is most commonly associated with the workers on a drilling rig. The ideal of the hard-working, tough roughneck has been adopted by several sports teams who use the phrase as part of their name or logo.

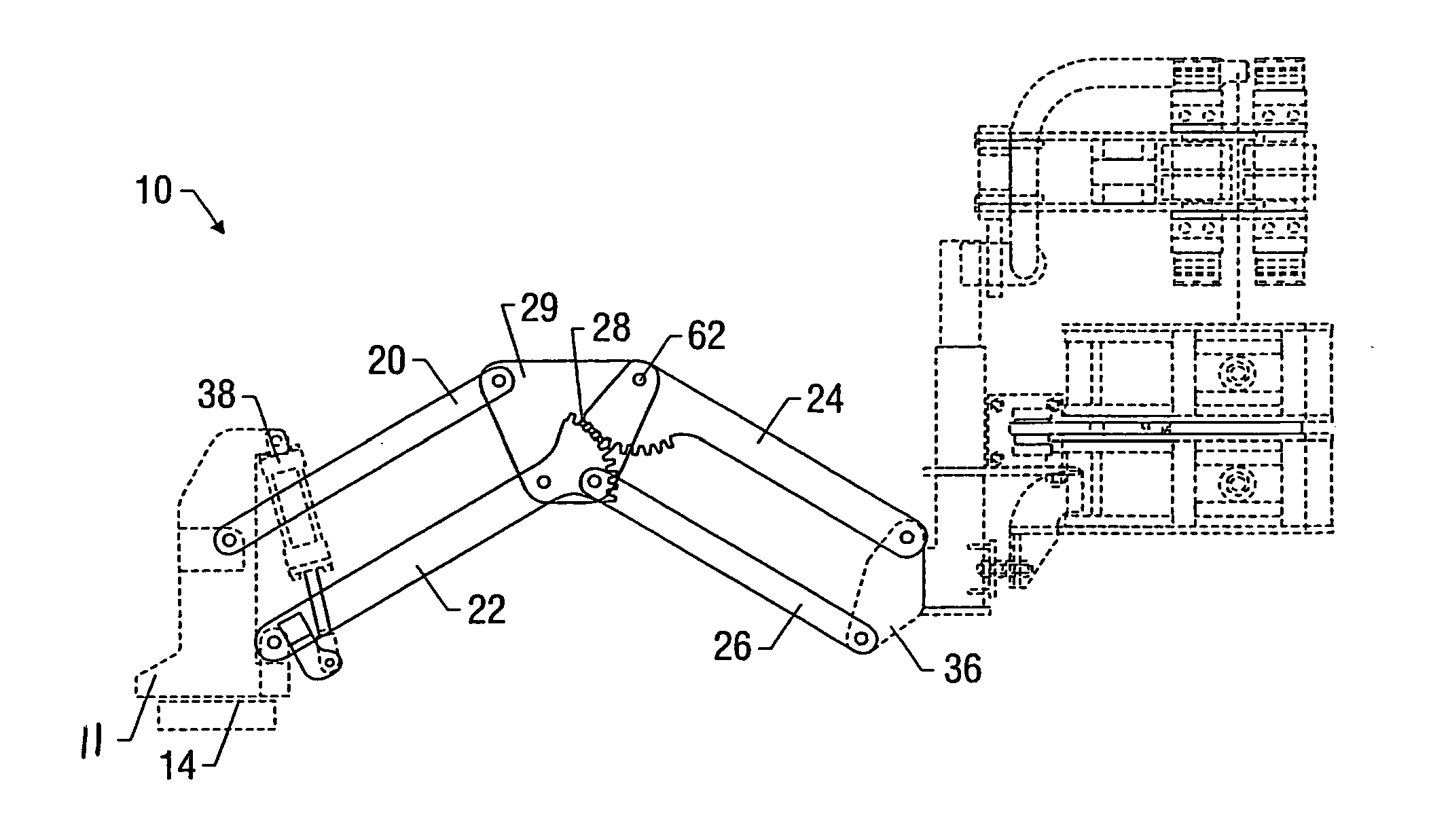

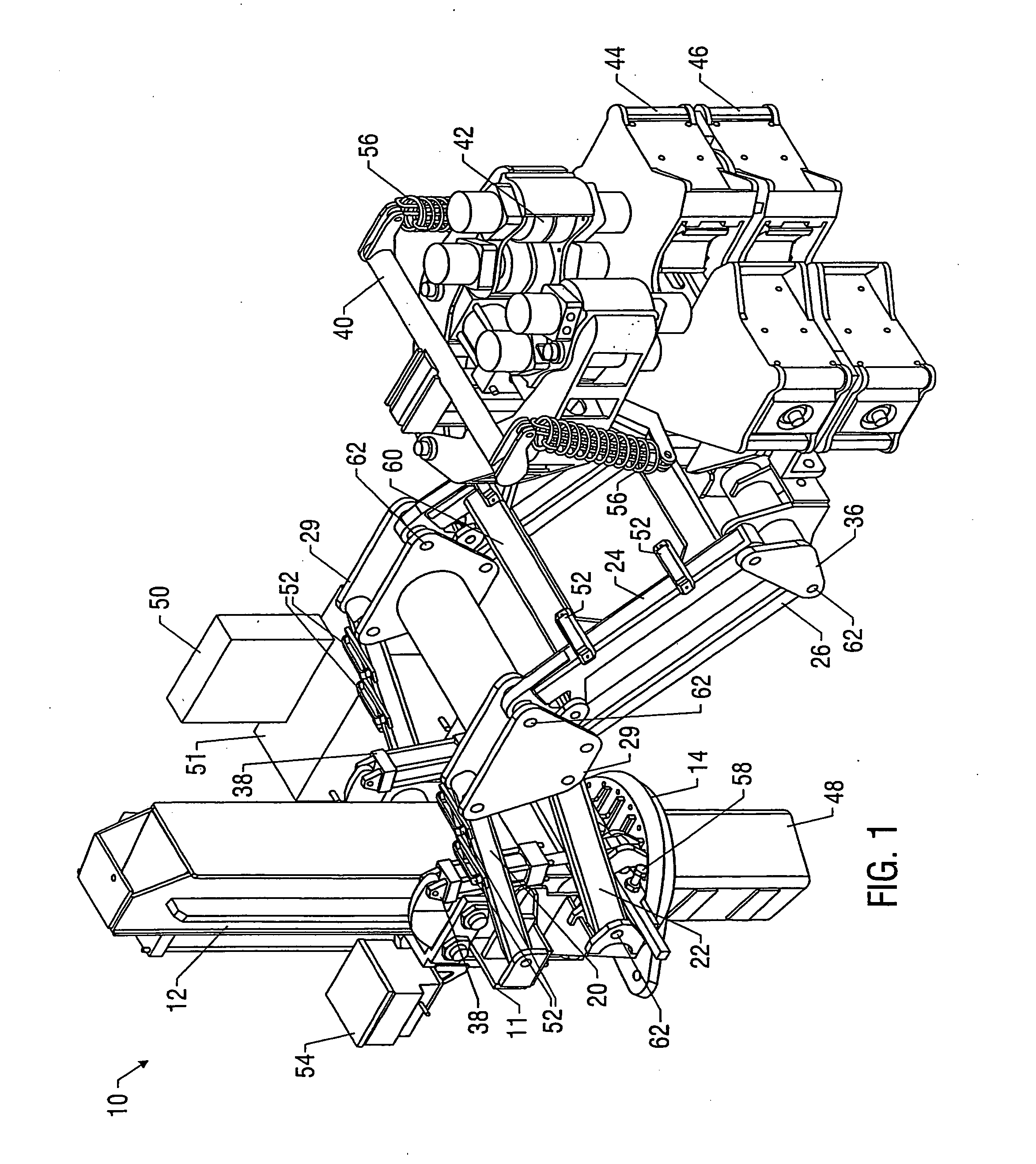

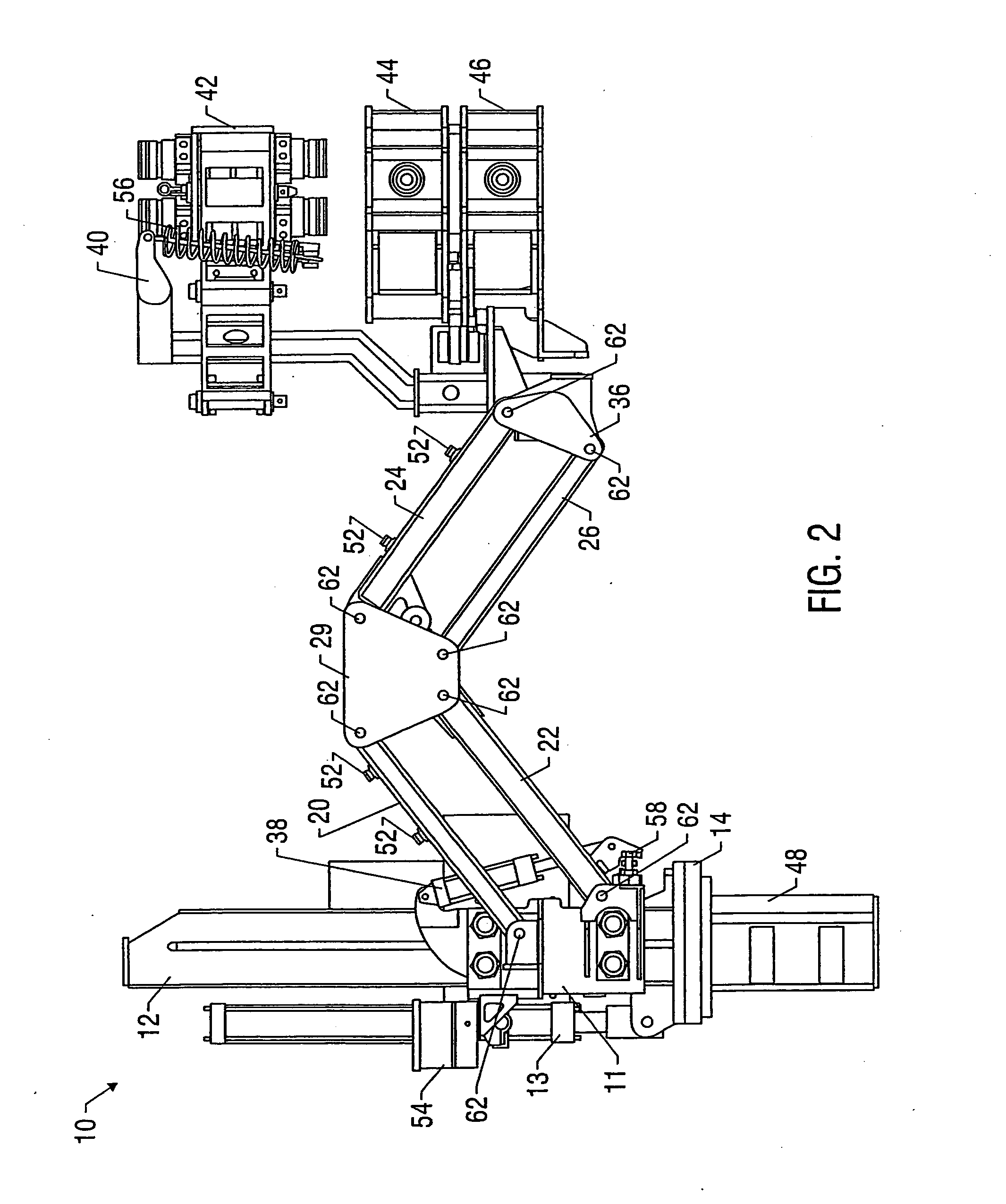

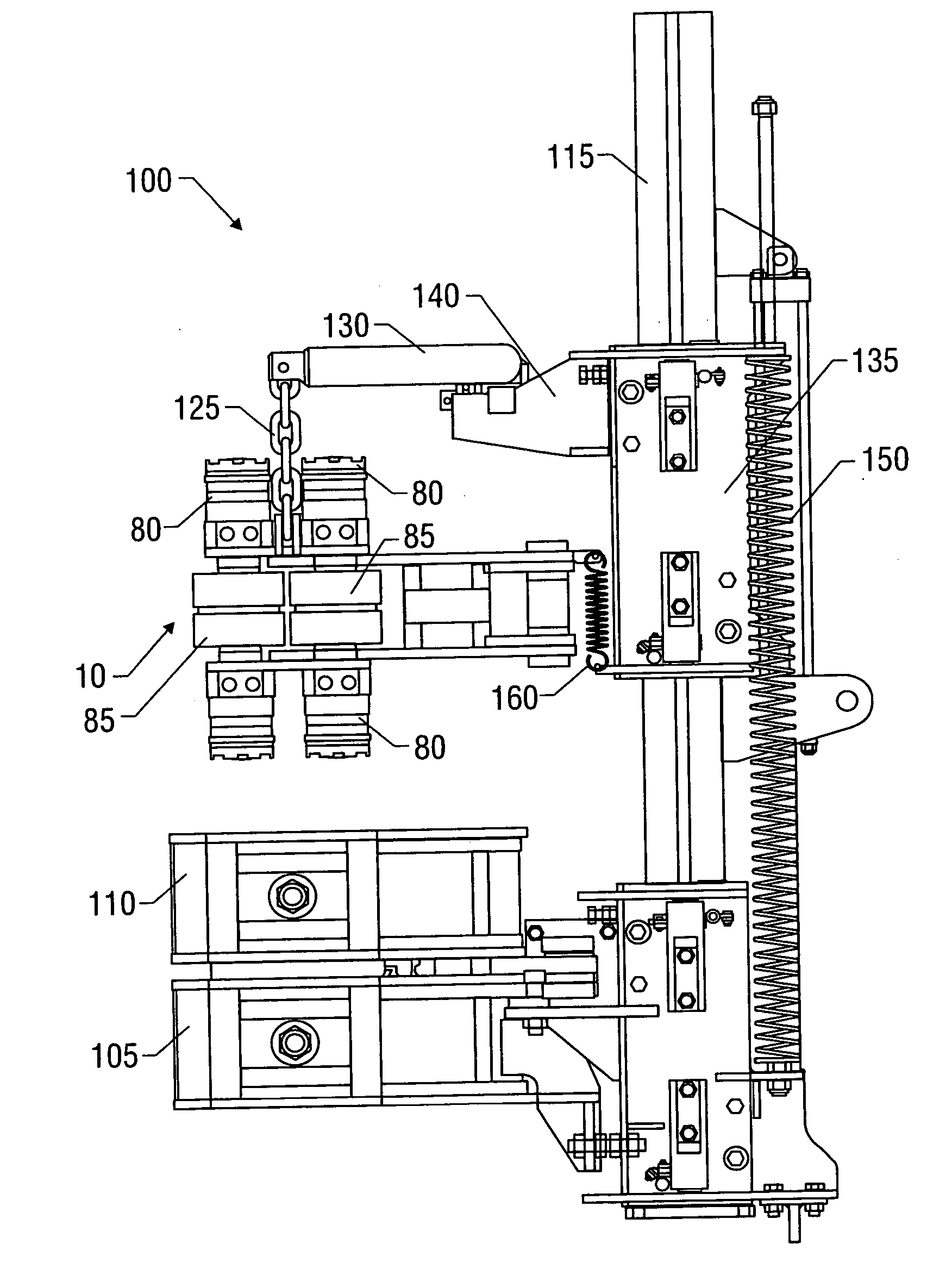

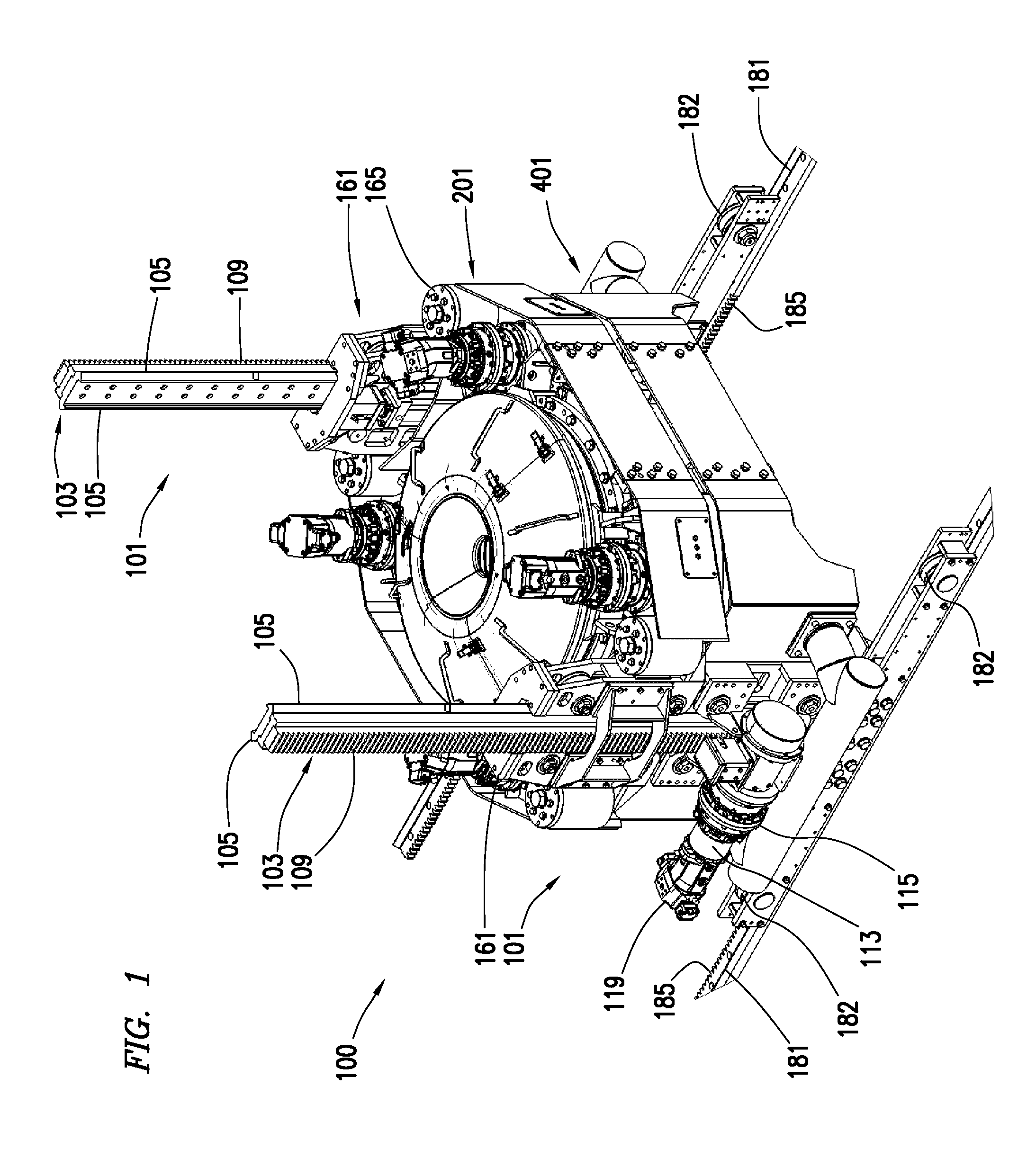

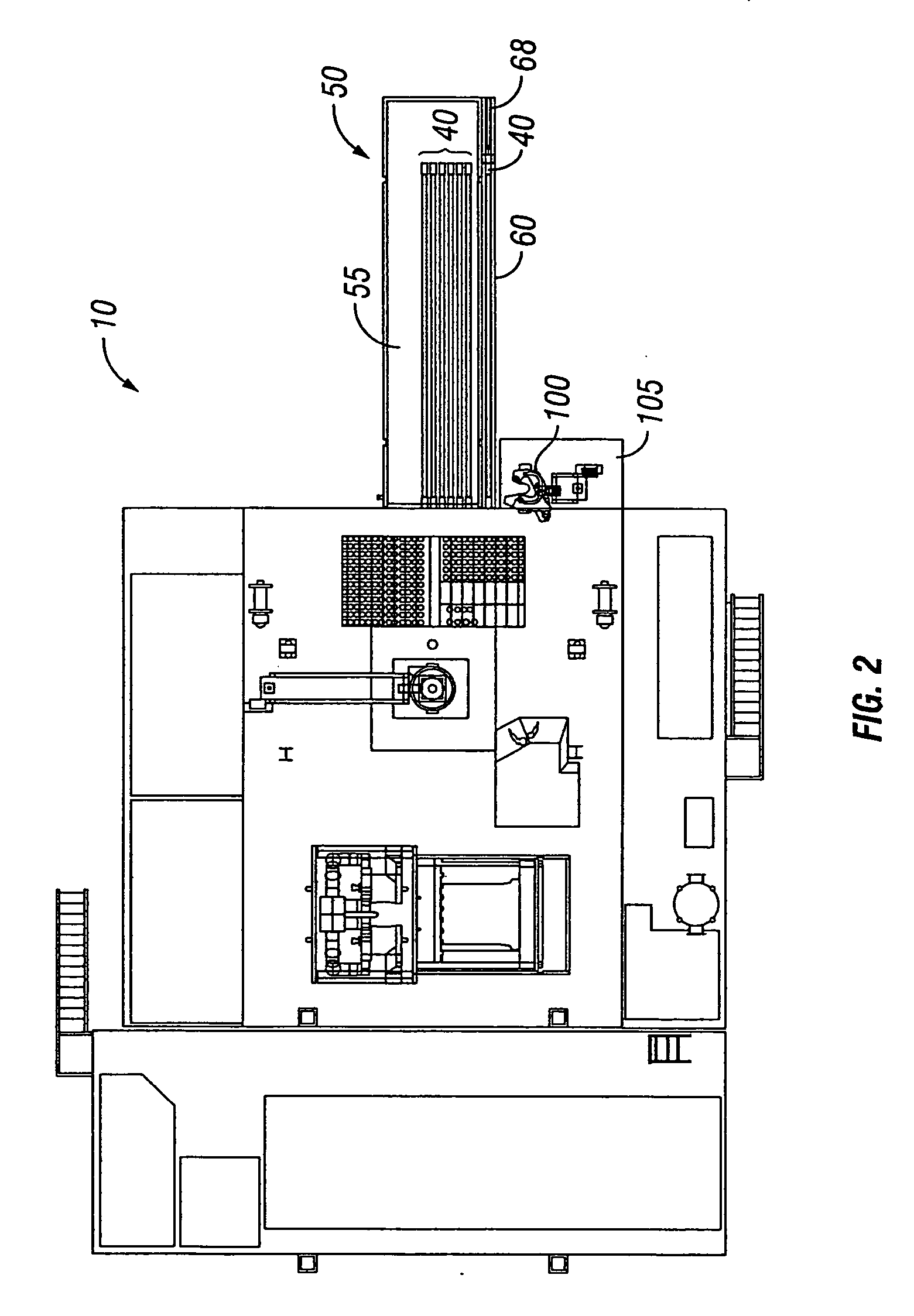

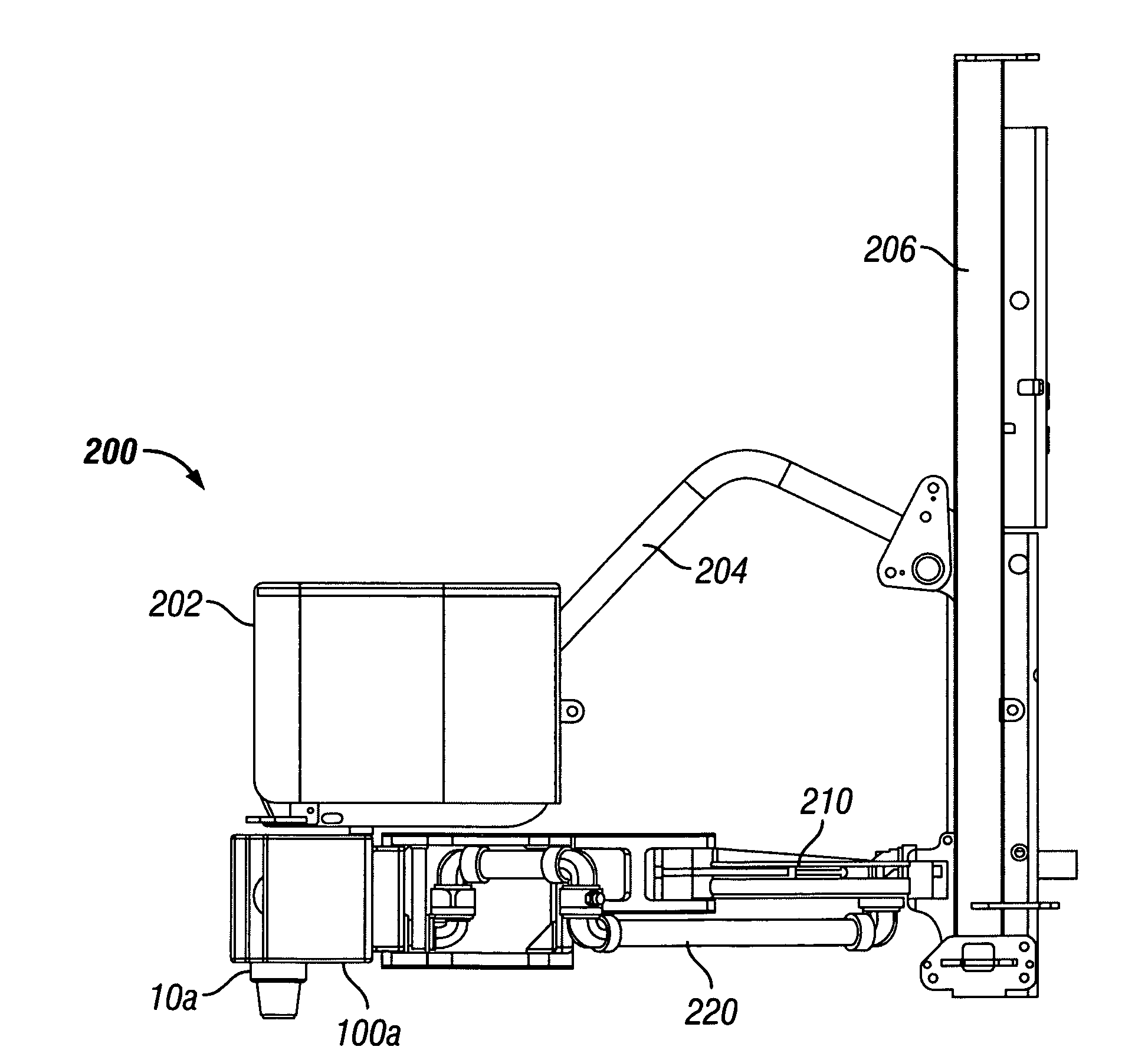

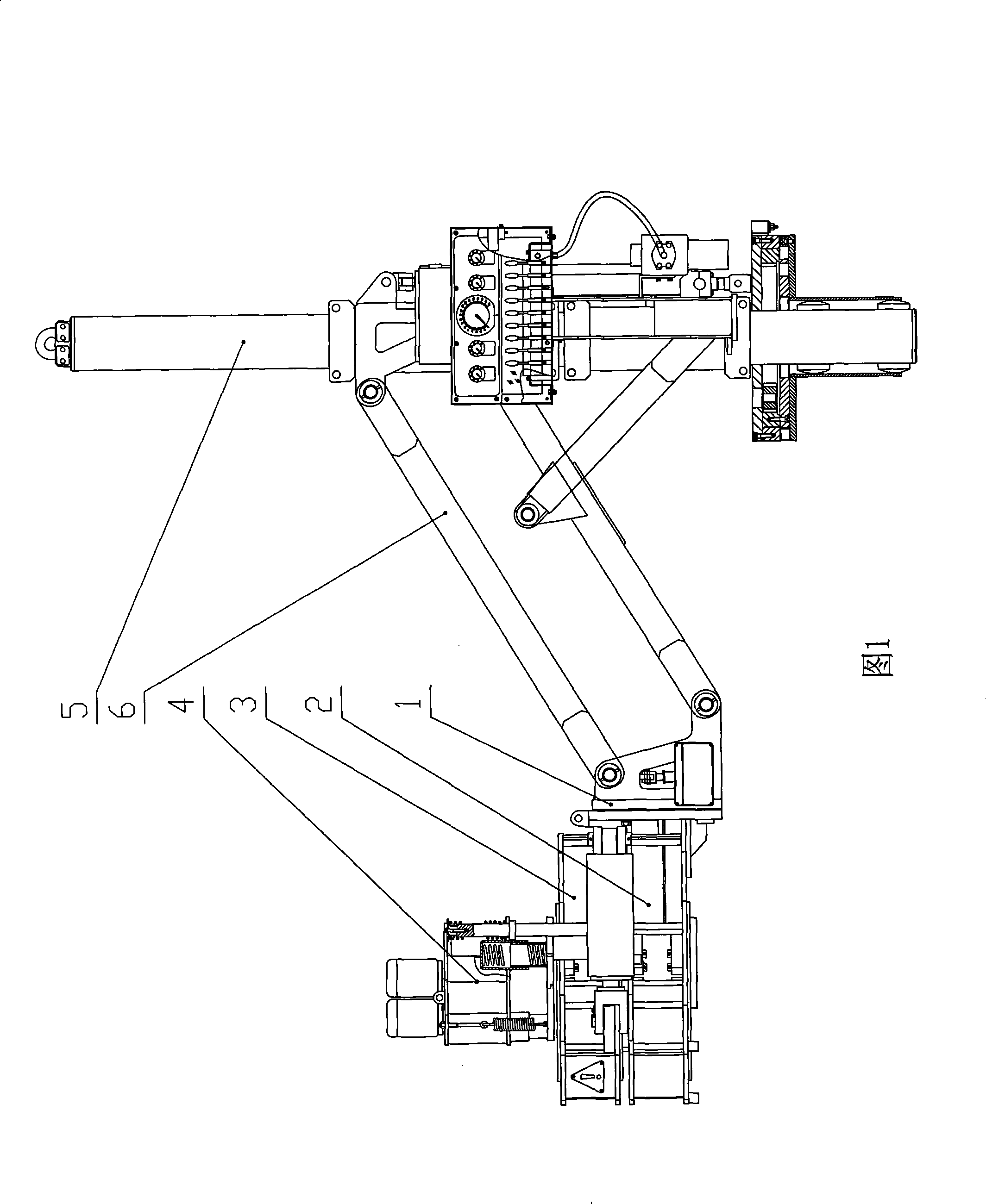

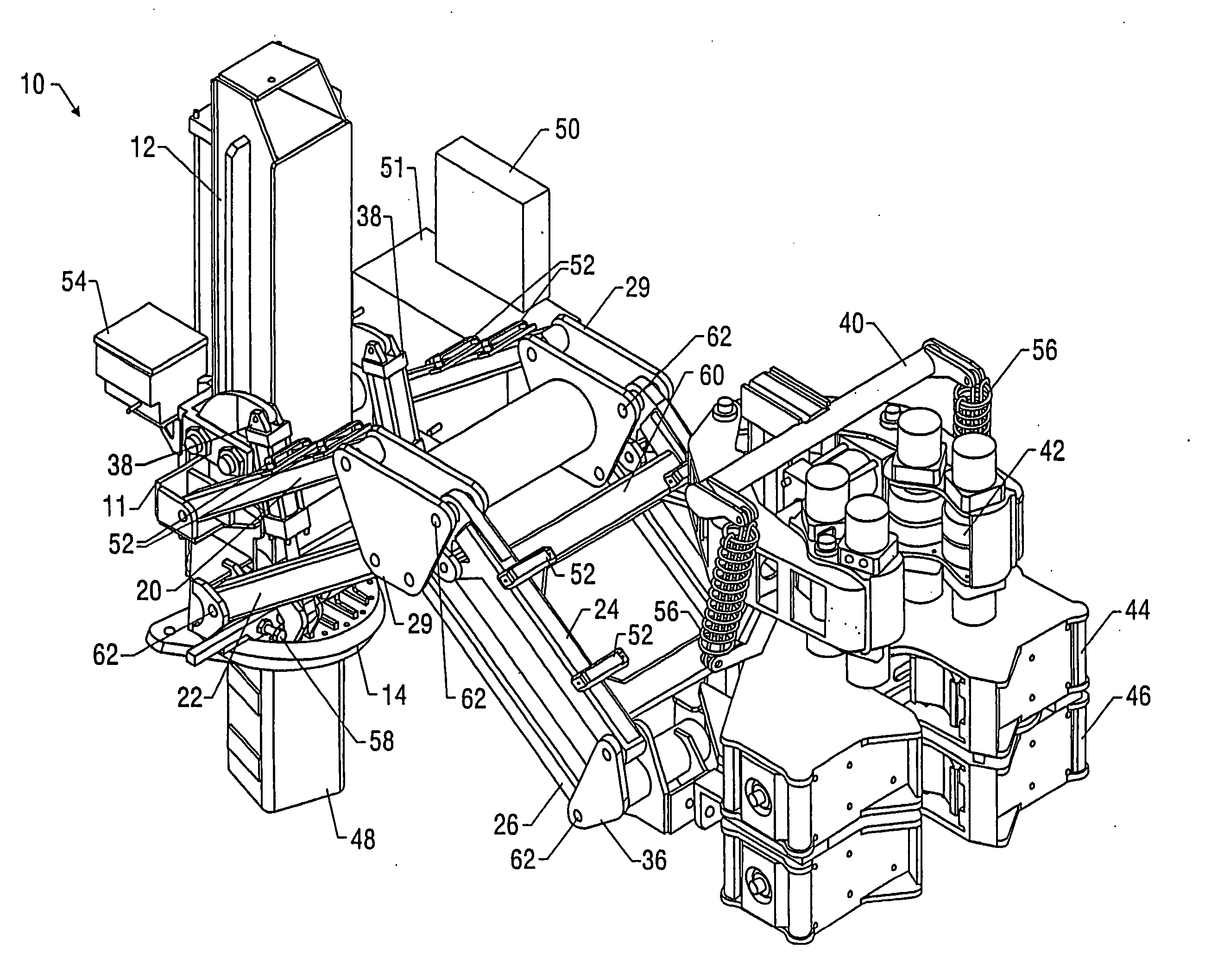

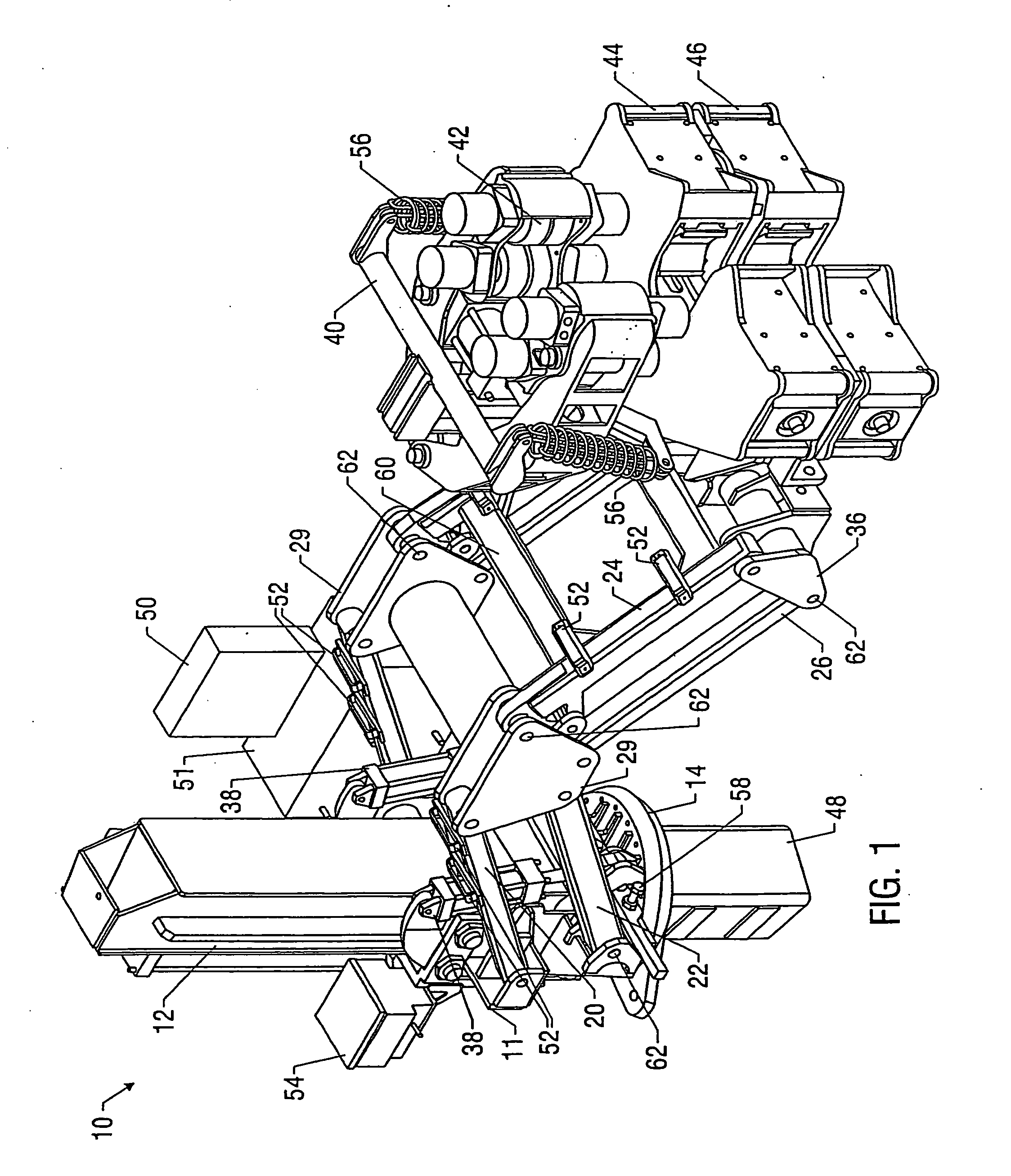

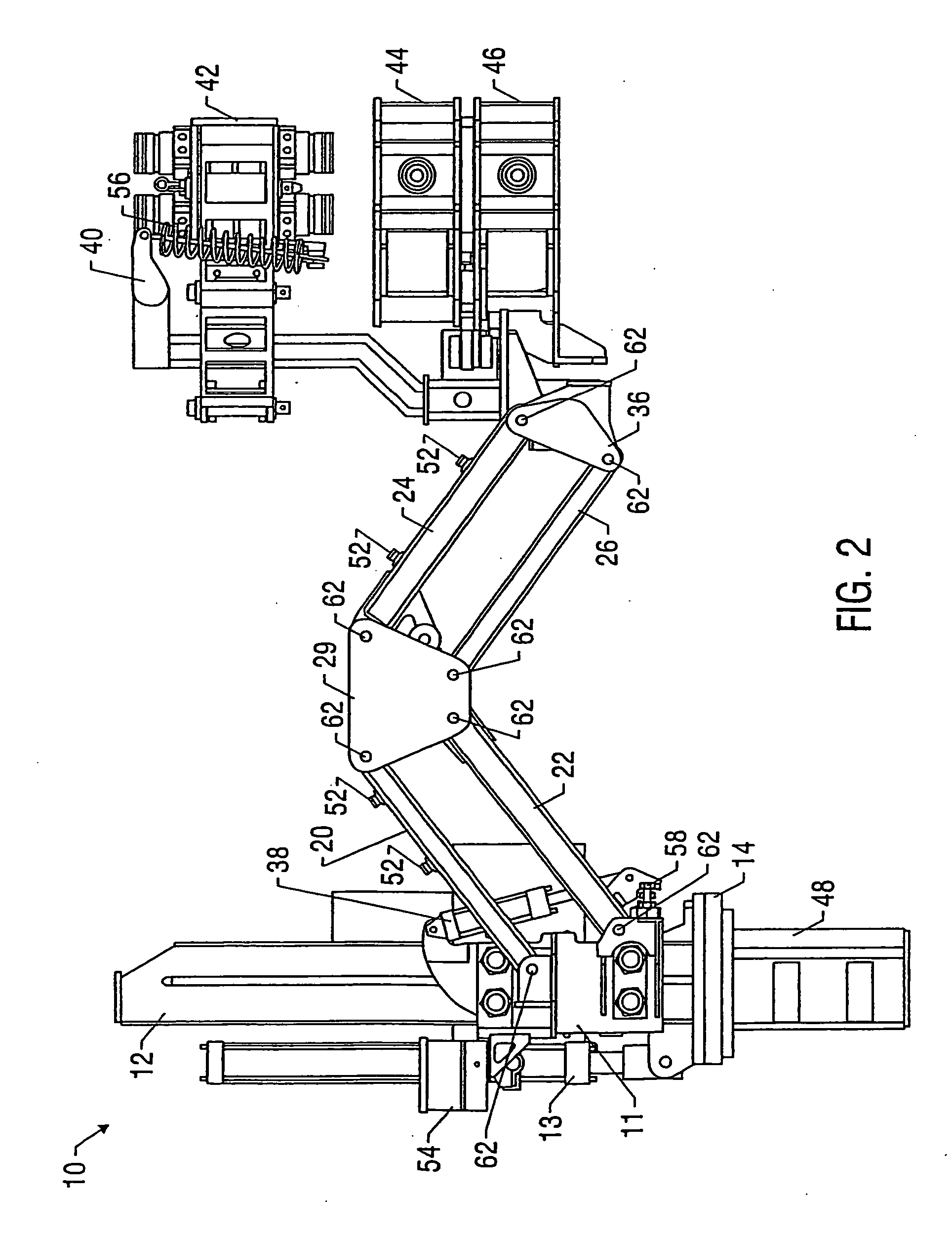

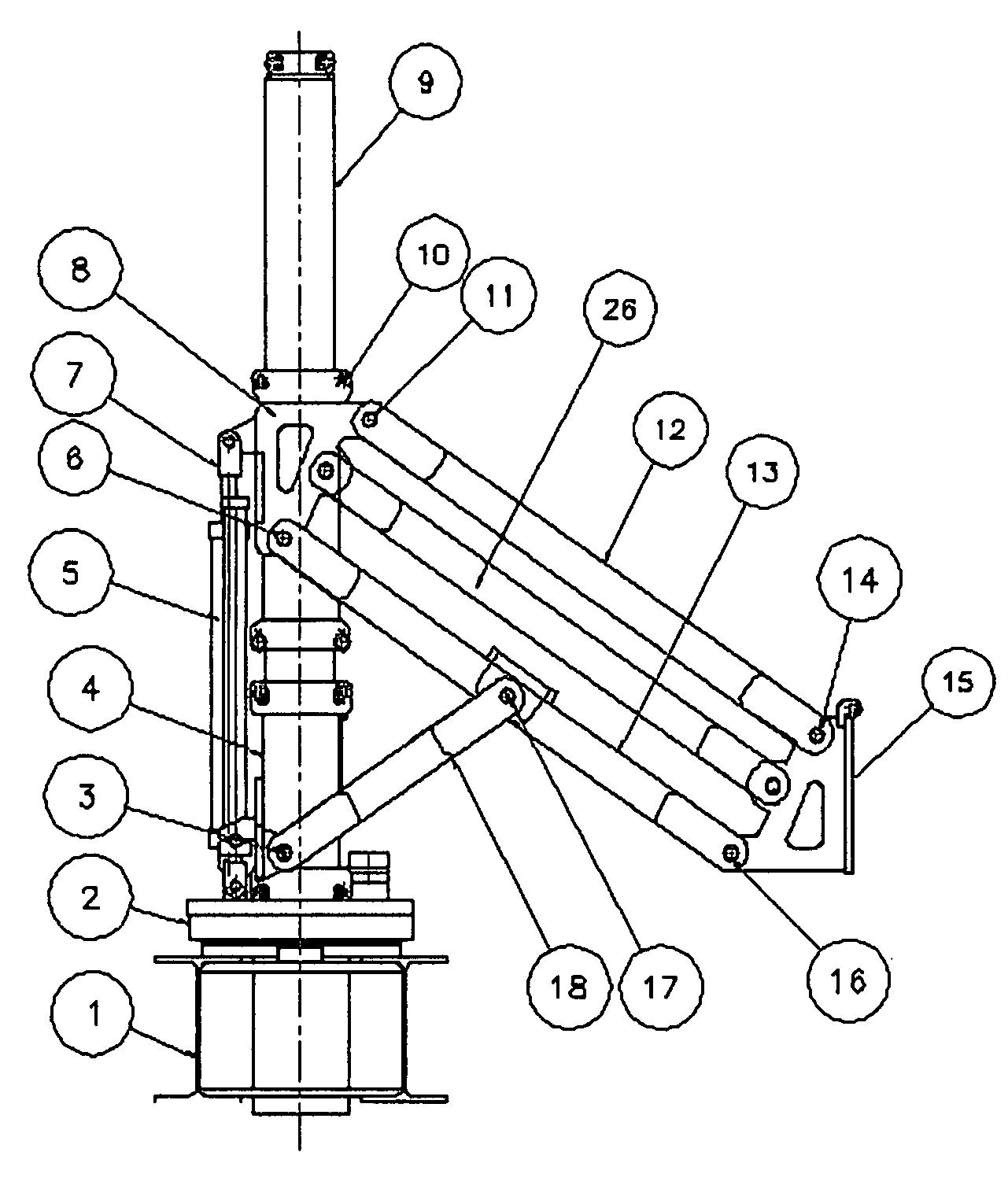

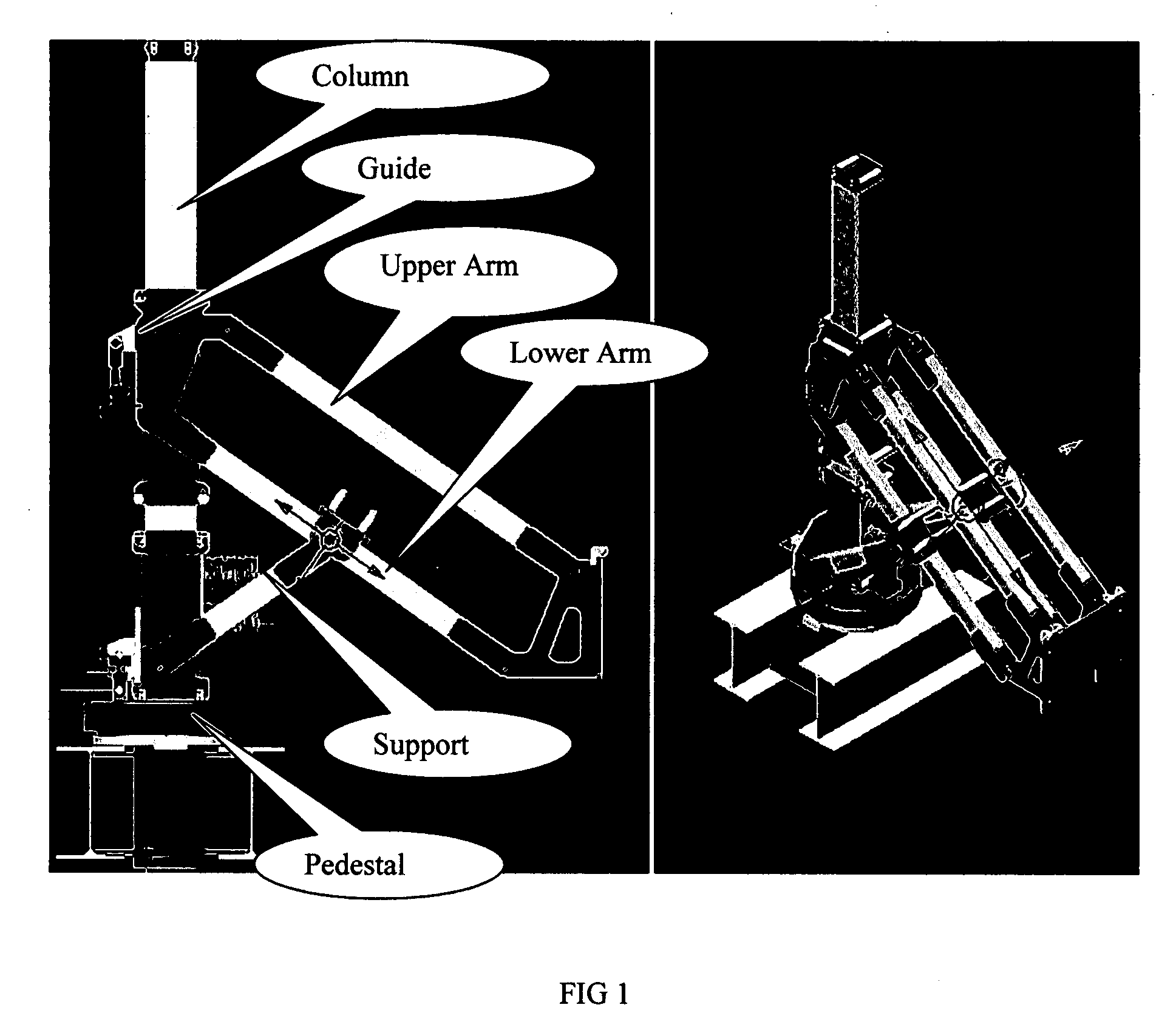

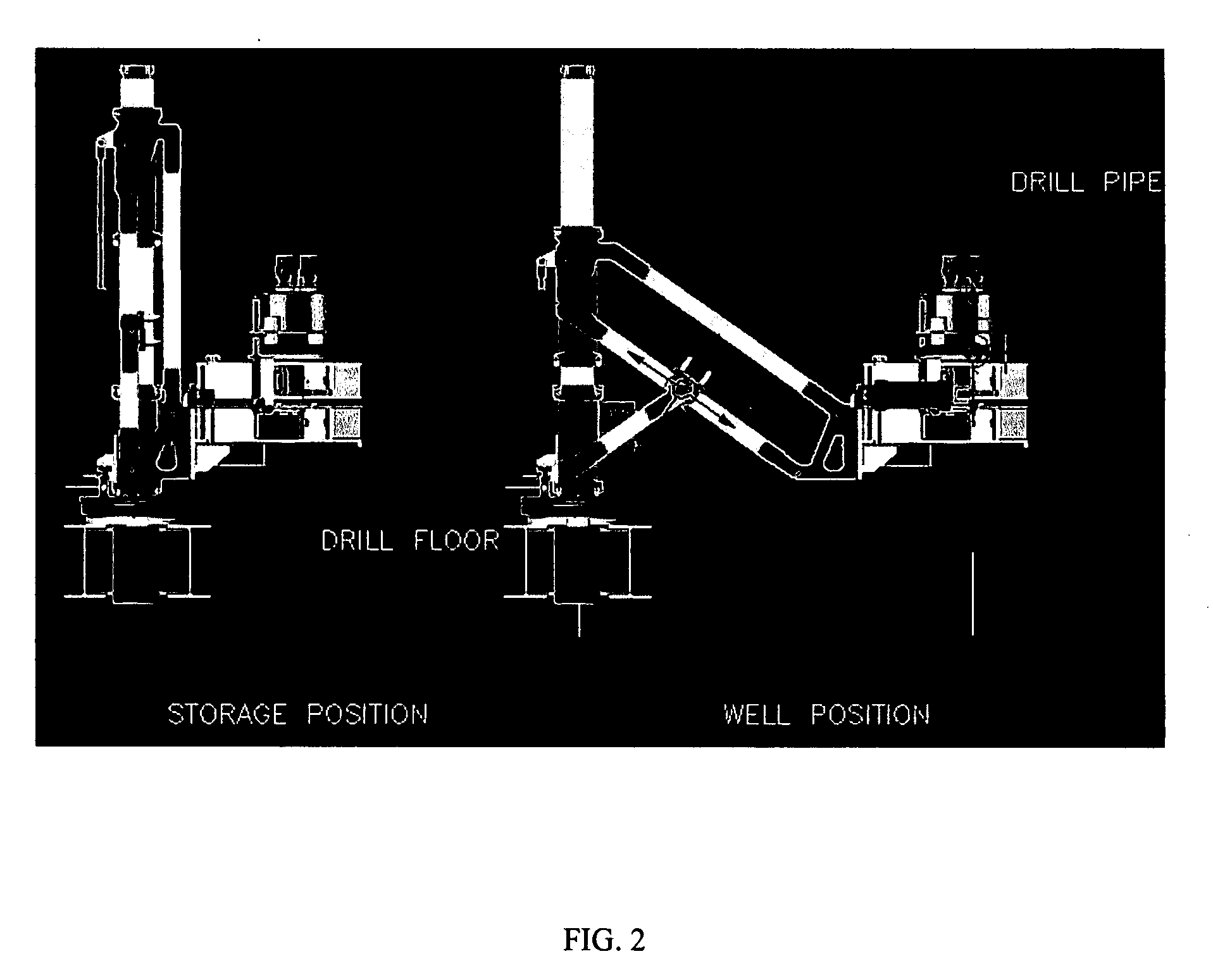

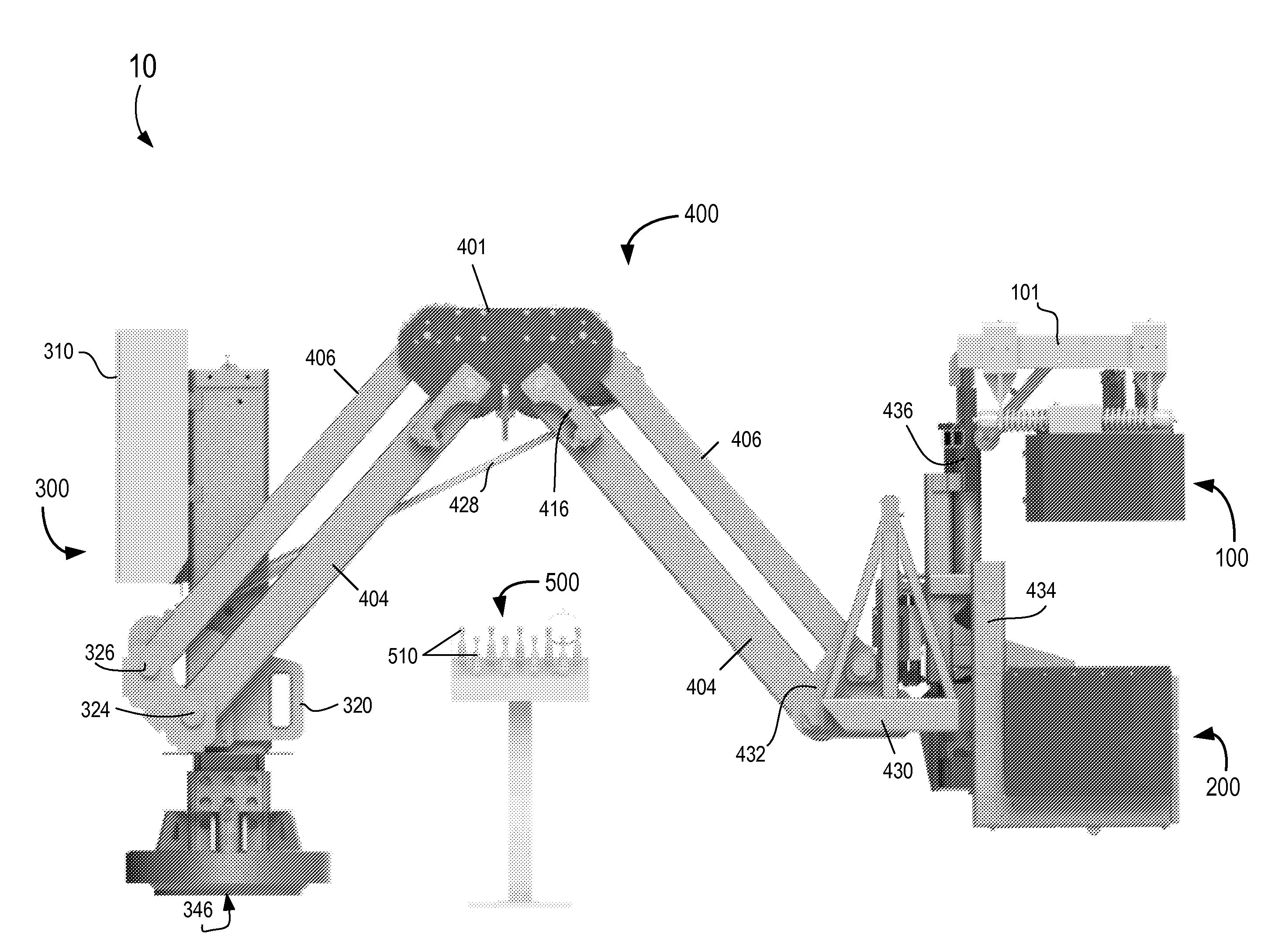

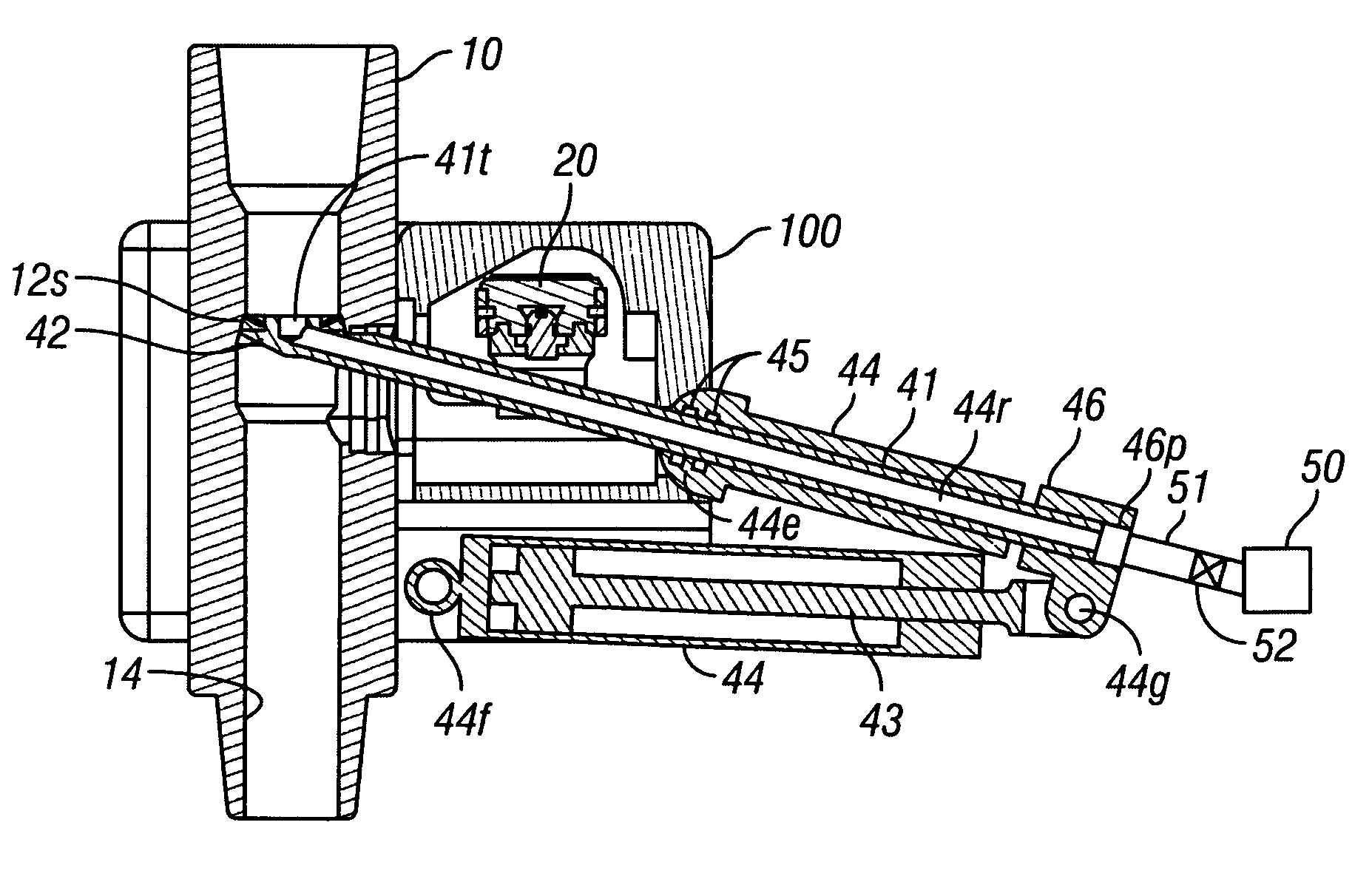

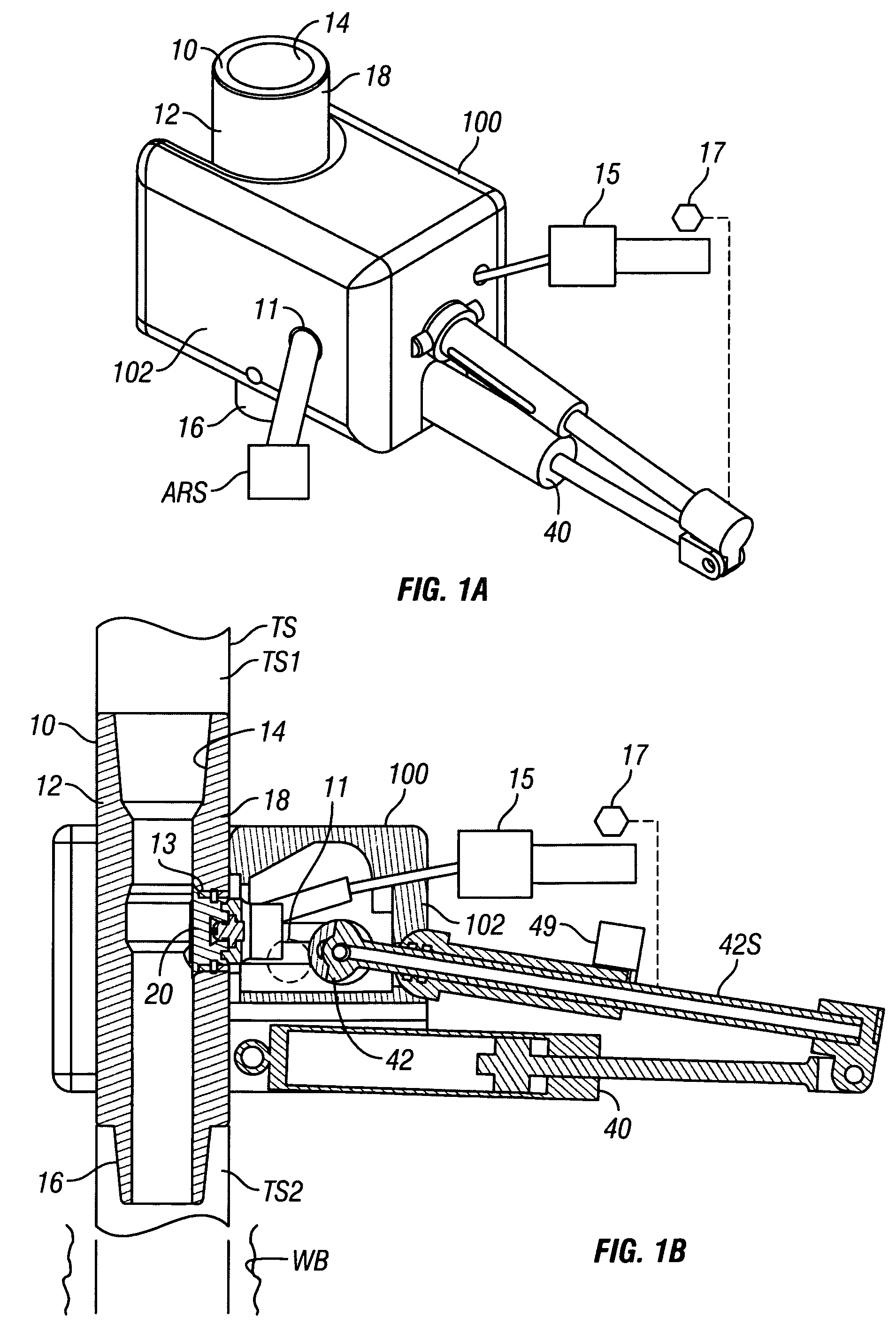

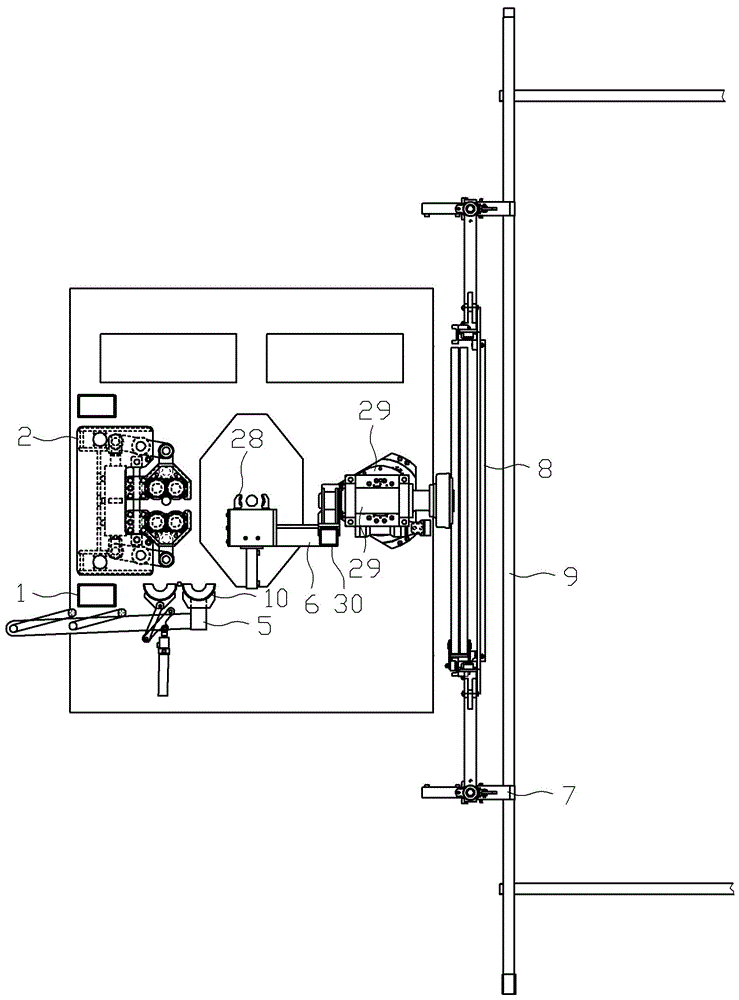

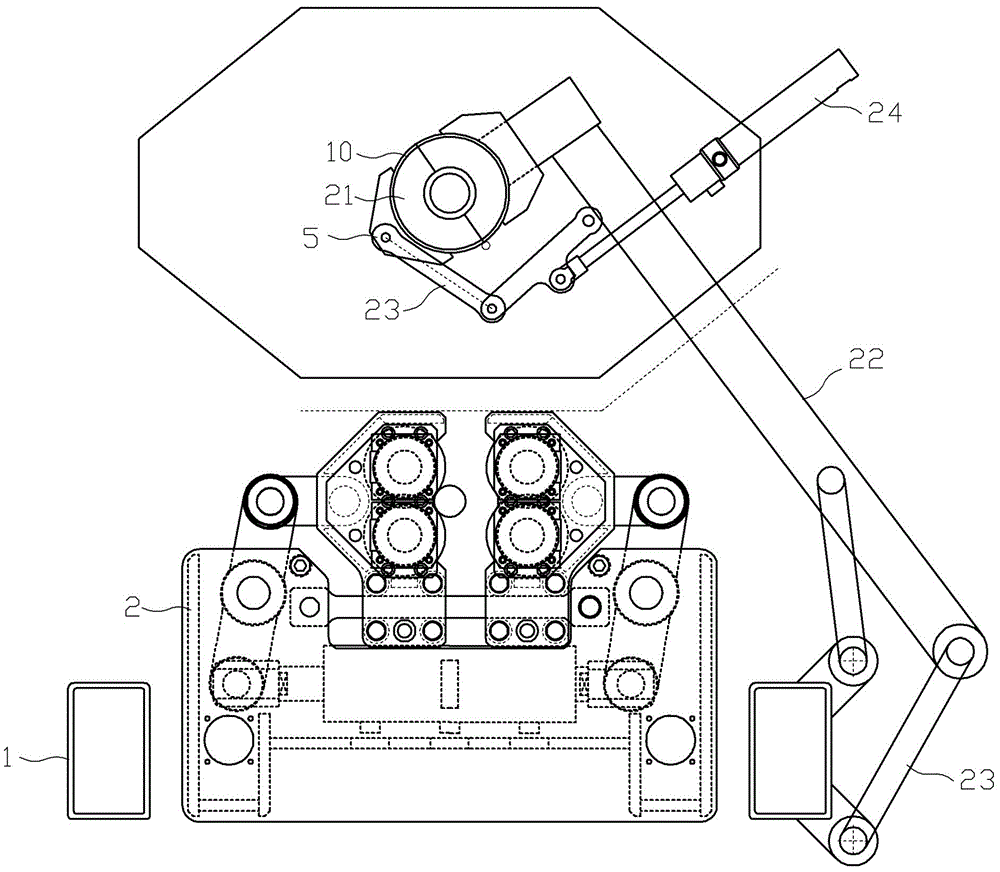

Automated arm for positioning of drilling tools such as an iron roughneck

The invention relates to an apparatus for moving an Iron Roughneck into position to allow making-up or breaking-out of threaded joints in a drill string. The apparatus may also be used to move other drilling equipment into position on the centerline of the well or at mouse holes. A self-balanced, dual synchronized parallelogram arm is utilized to accomplish the movement of the devices. Hydraulic or pneumatic cylinders are used for extension and retraction of the arm rather than to support the tool. The arm may hold the tool in any position without cylinder assistance. The linkage in the synchronized parallelogram may be accomplished by gears, links, slots, or rollers.

Owner:NAT OILWELL DHT

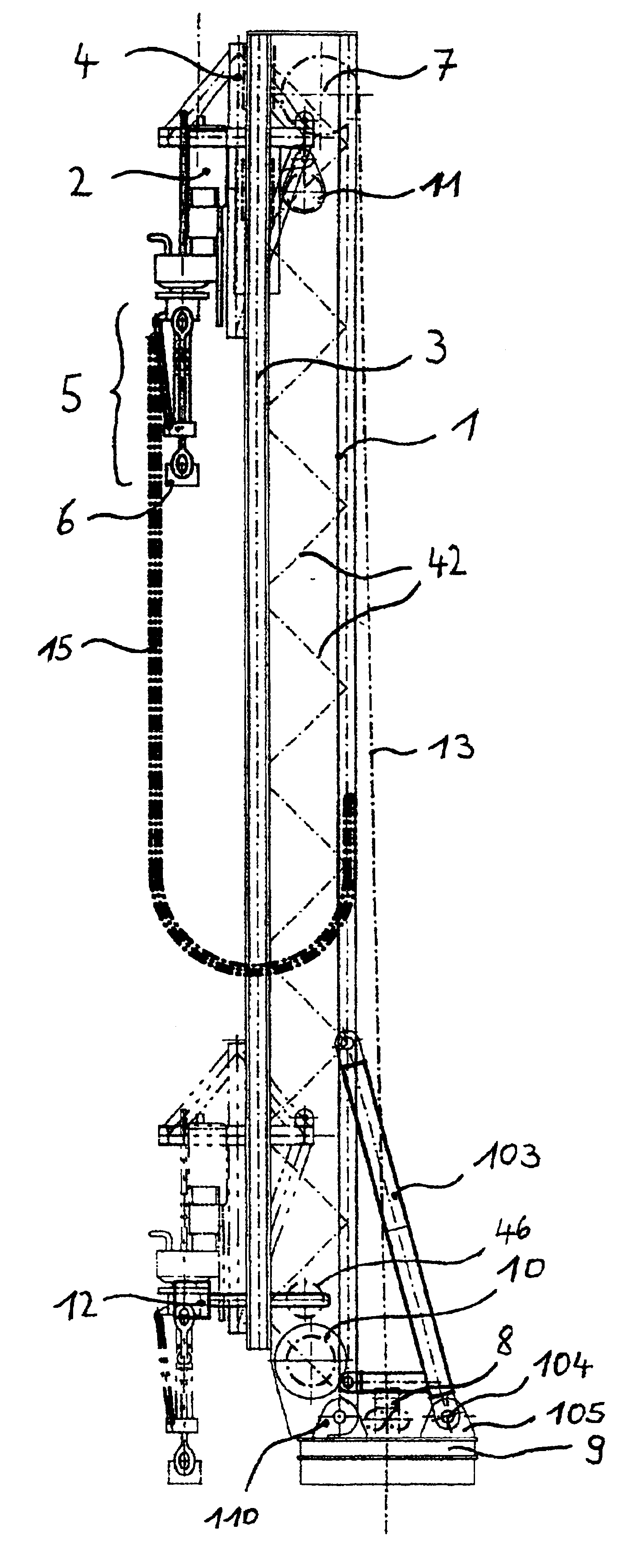

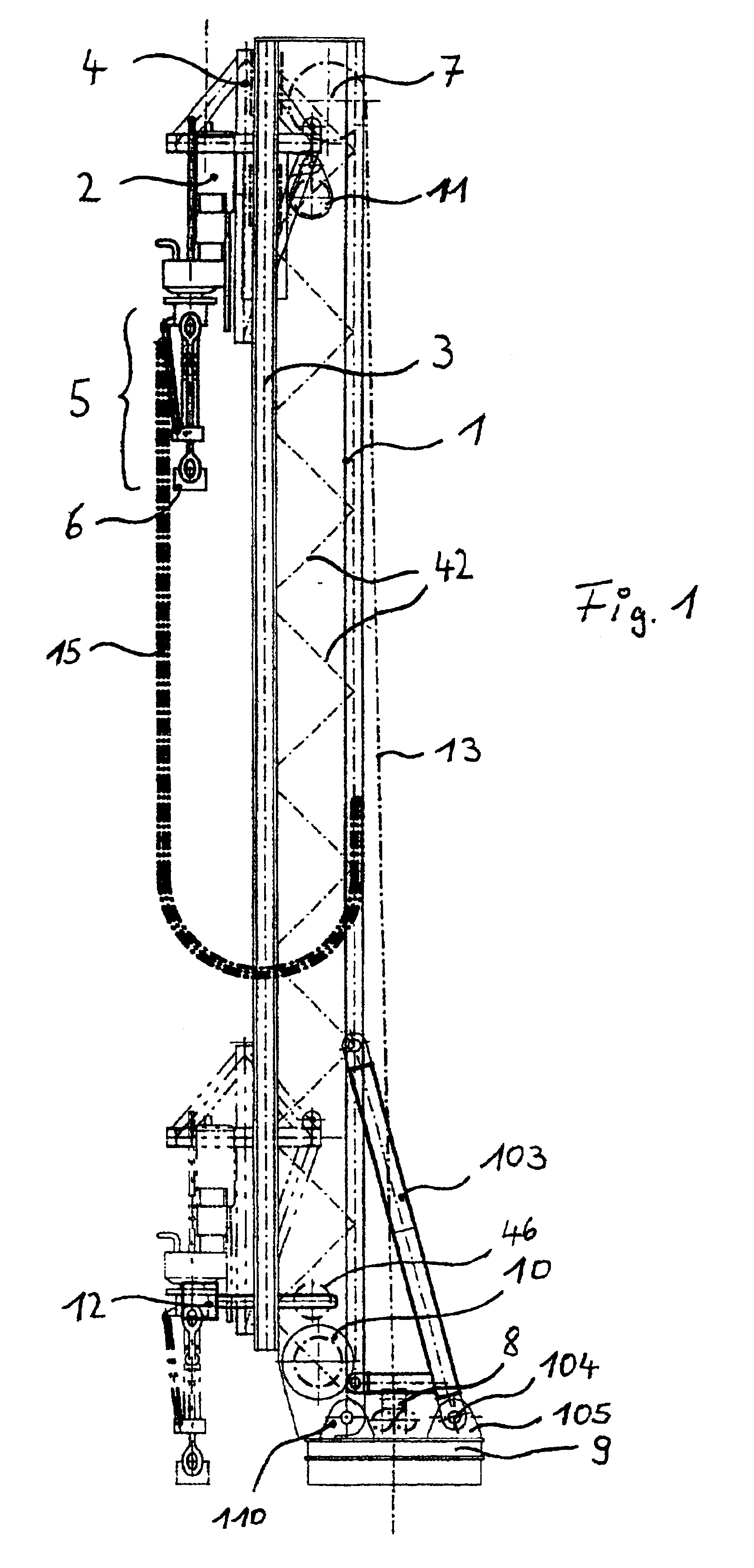

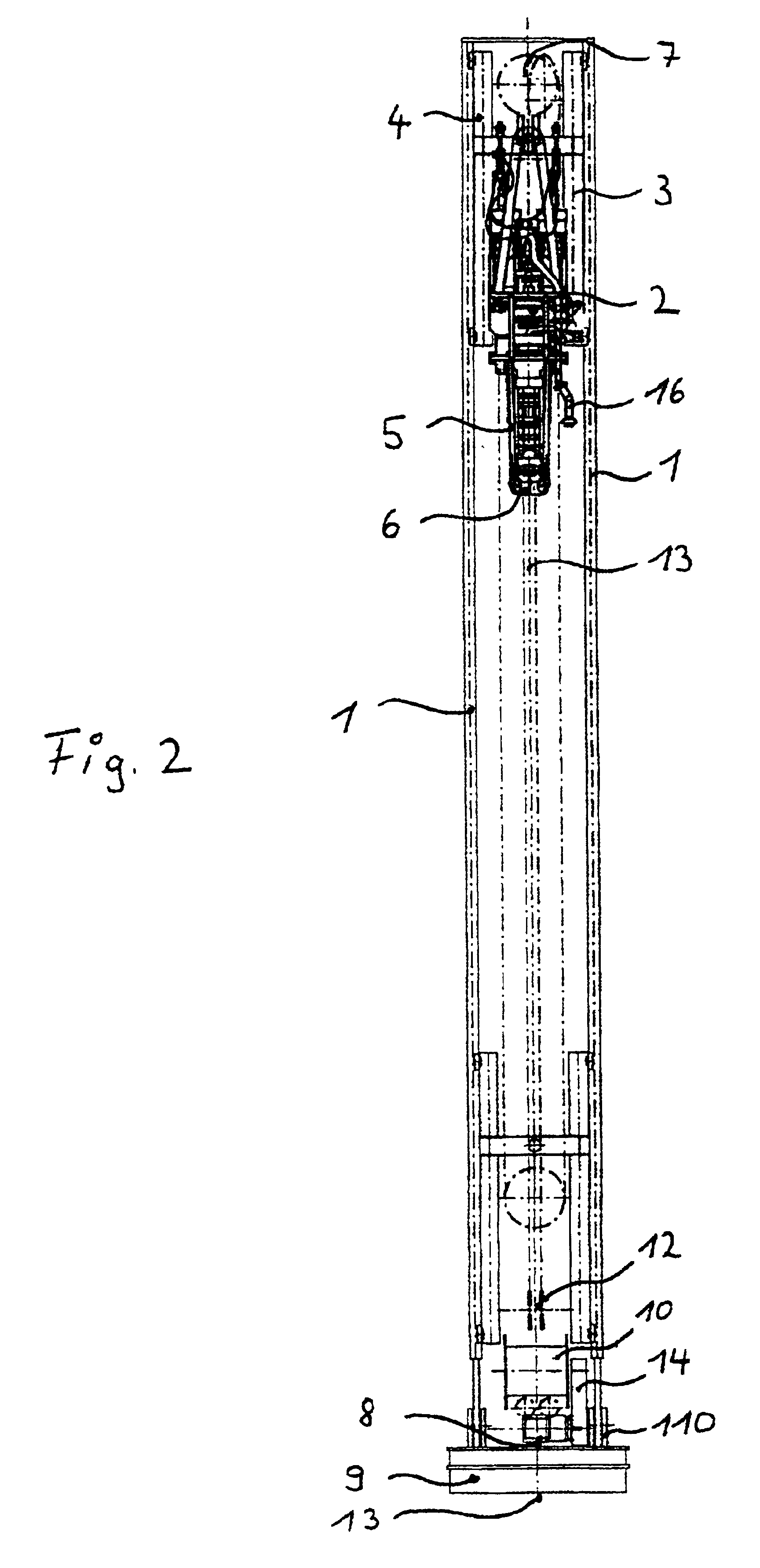

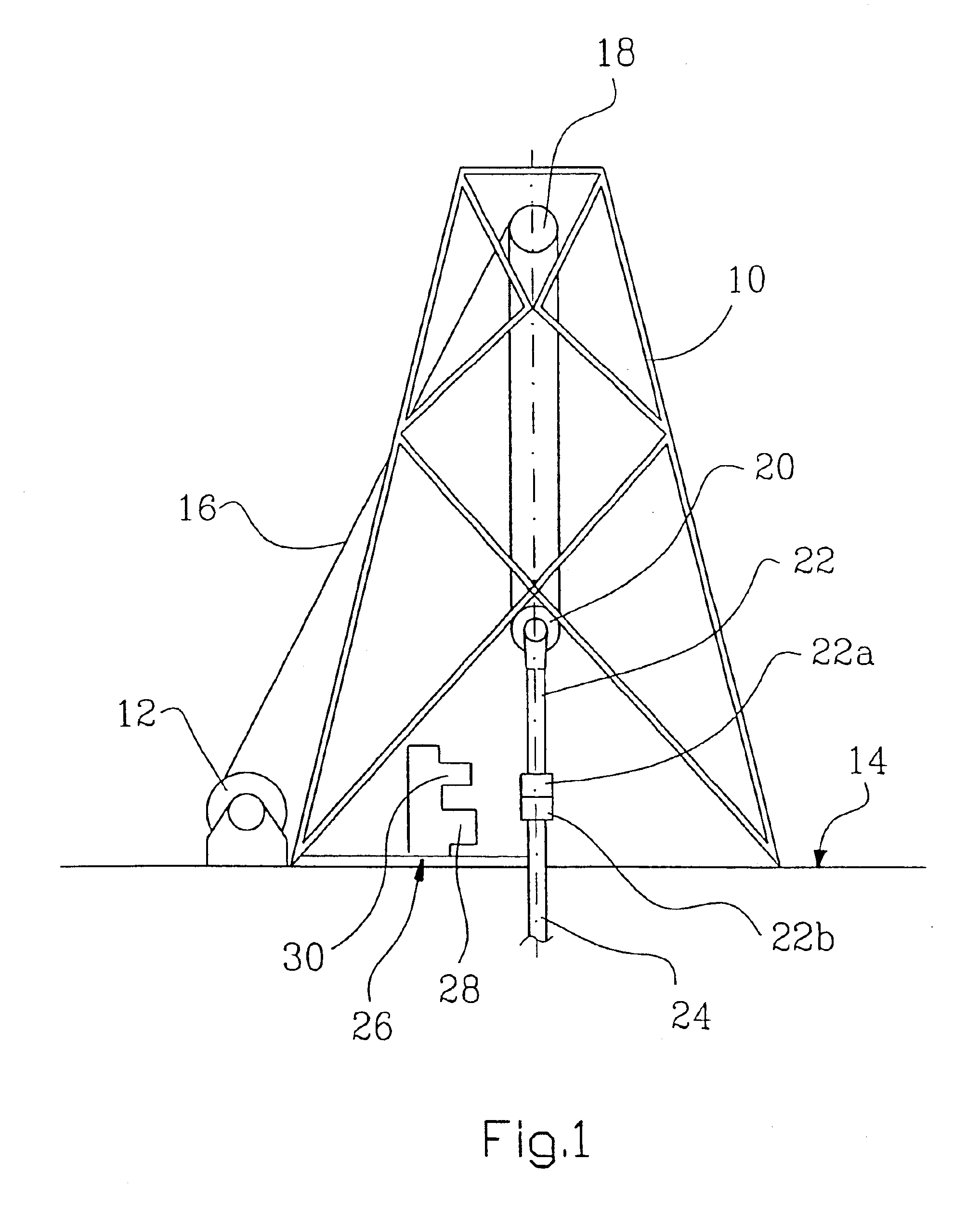

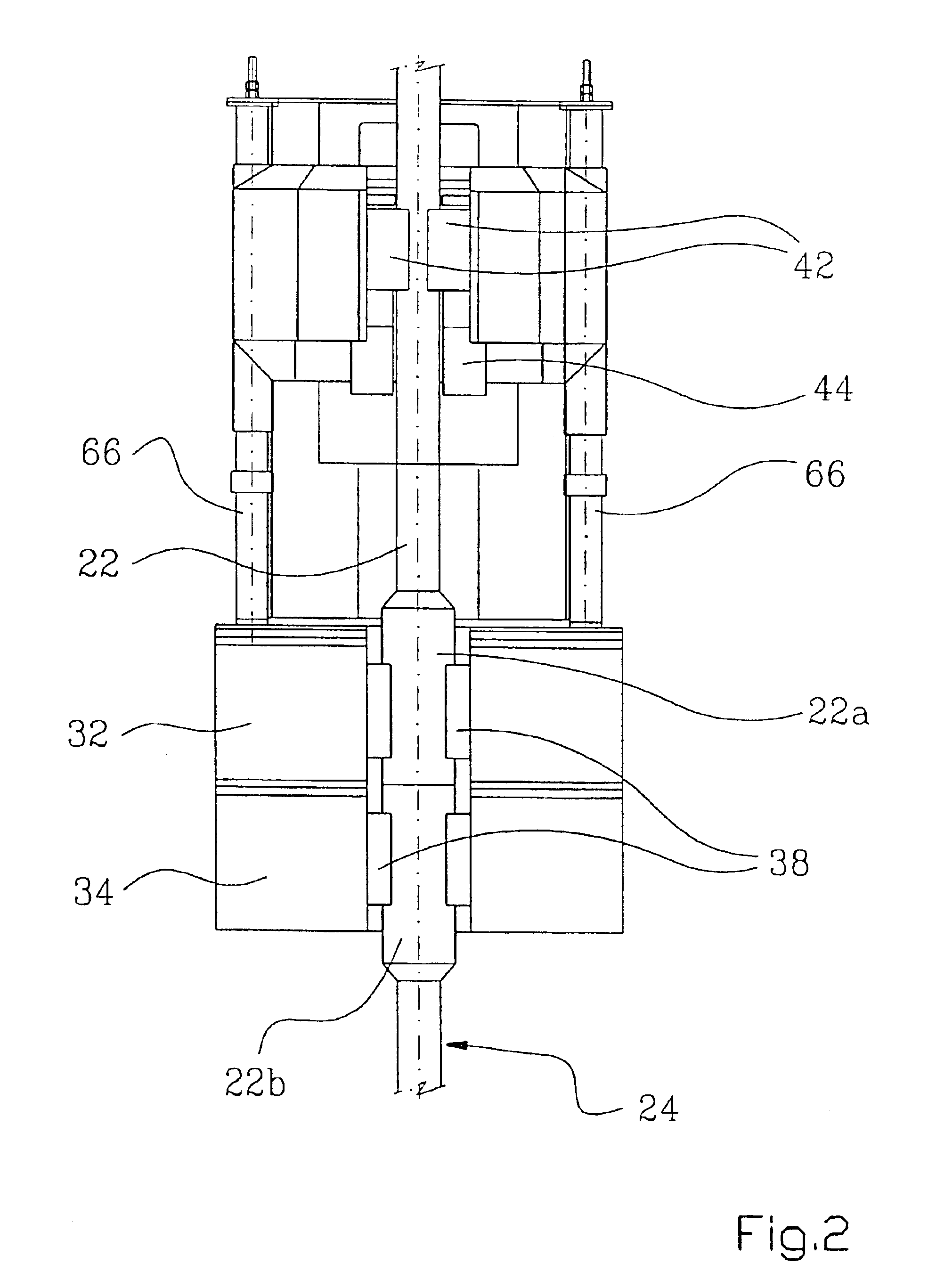

Drilling device and method for drilling a well

A drilling machine and drilling rig for exploratory drillings and producing wells, include a base mounting atop drive, and a multifunctional gripper for gripping drilling pipe from a stock and to be raised on the base for eventual positions positioning at a well center, an elevator being provided below the top drive. The base can be rotatably mounted and have a live ring at a base lower end region, the base being rotated to the pipe stock location and being rotatable to a well center as well. A drilling pipe upper end when raised on the base can be connected to the top drive, and an iron roughneck on a rig floor can be used to connect a pipe lower end to a pipe section in the well. Where two drilling machine are used, one can be used for actual drilling at the well center, and the second supplied with pipework for the operation.

Owner:BENTEC DRILLING & OILFIELD SYST

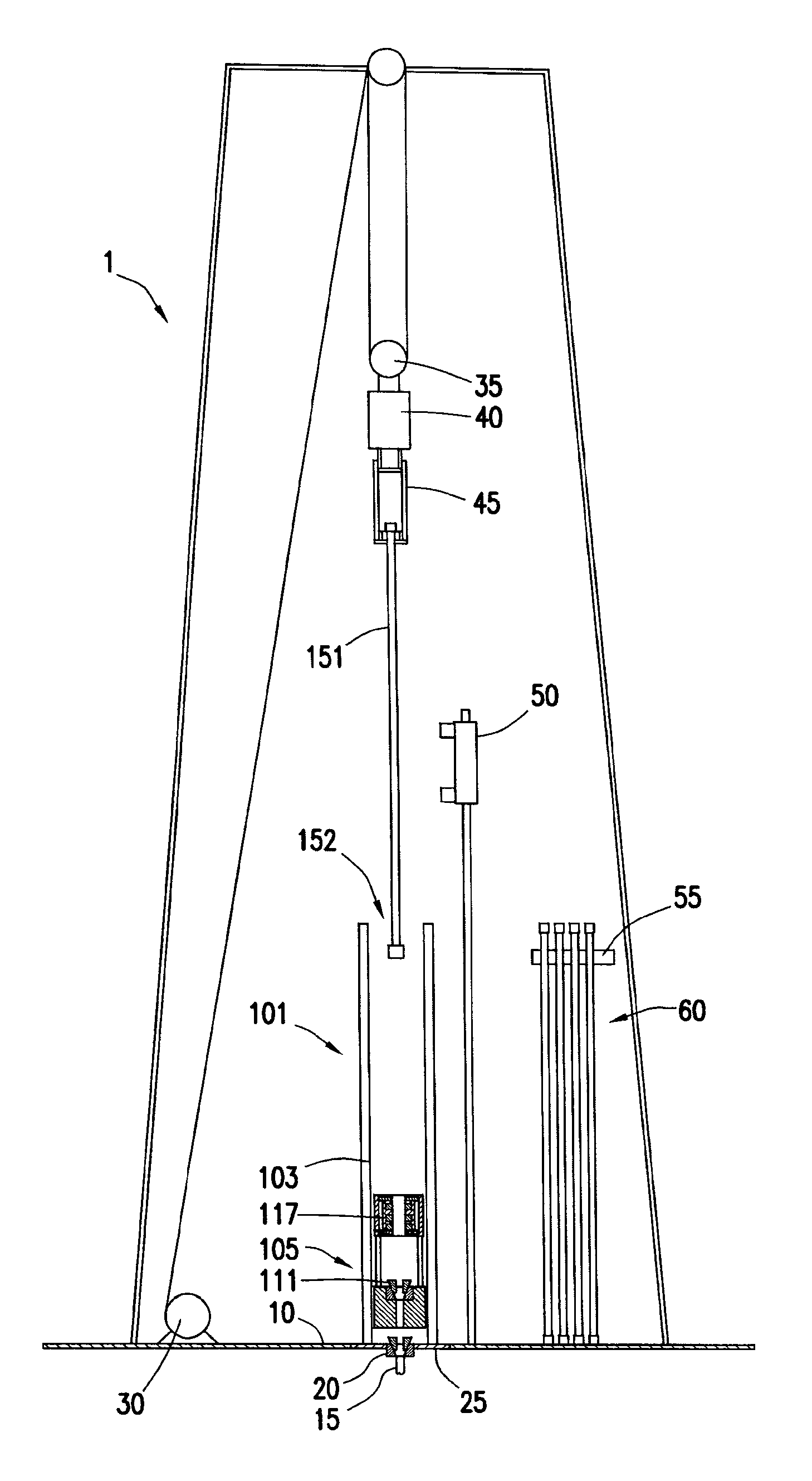

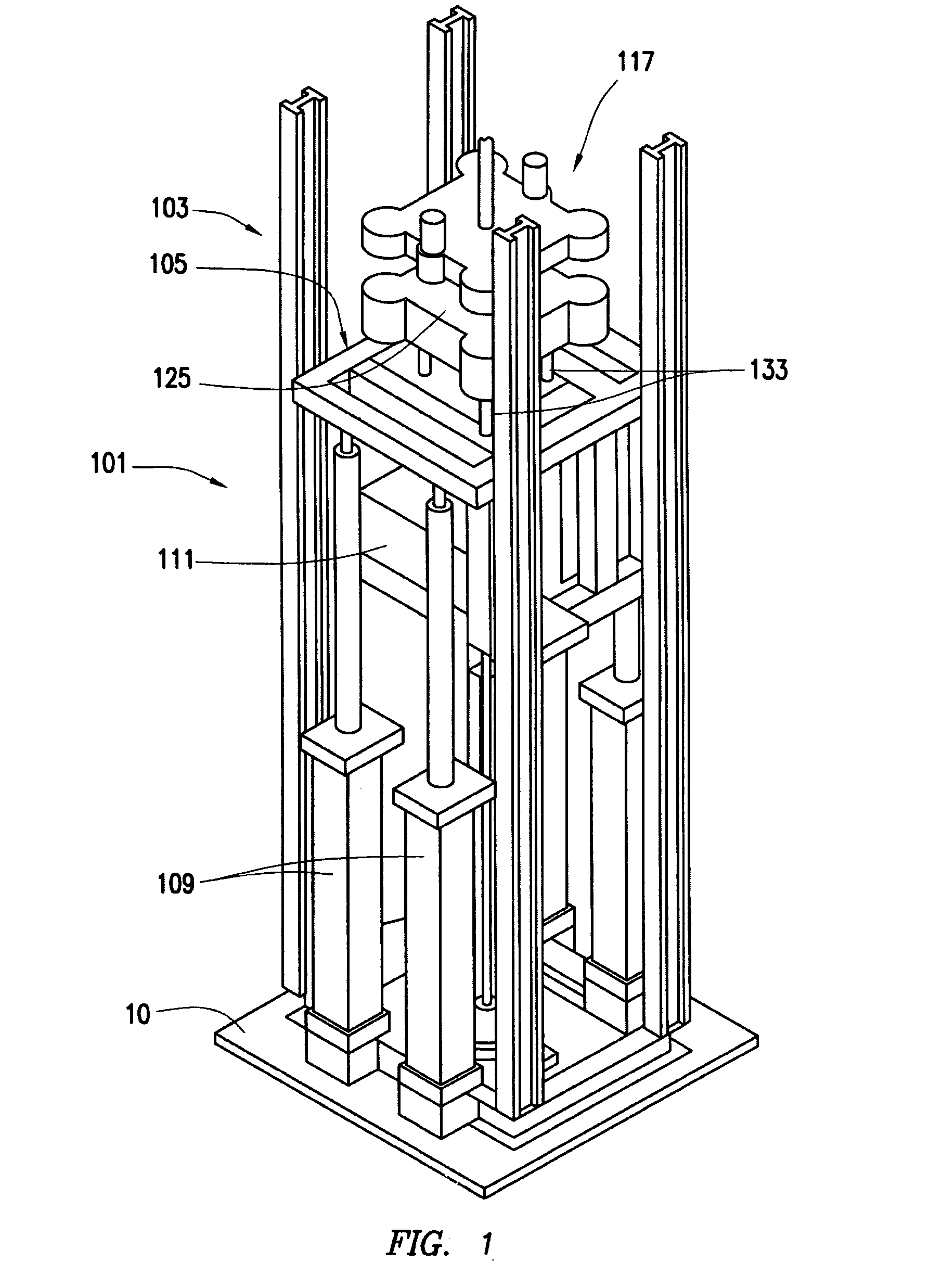

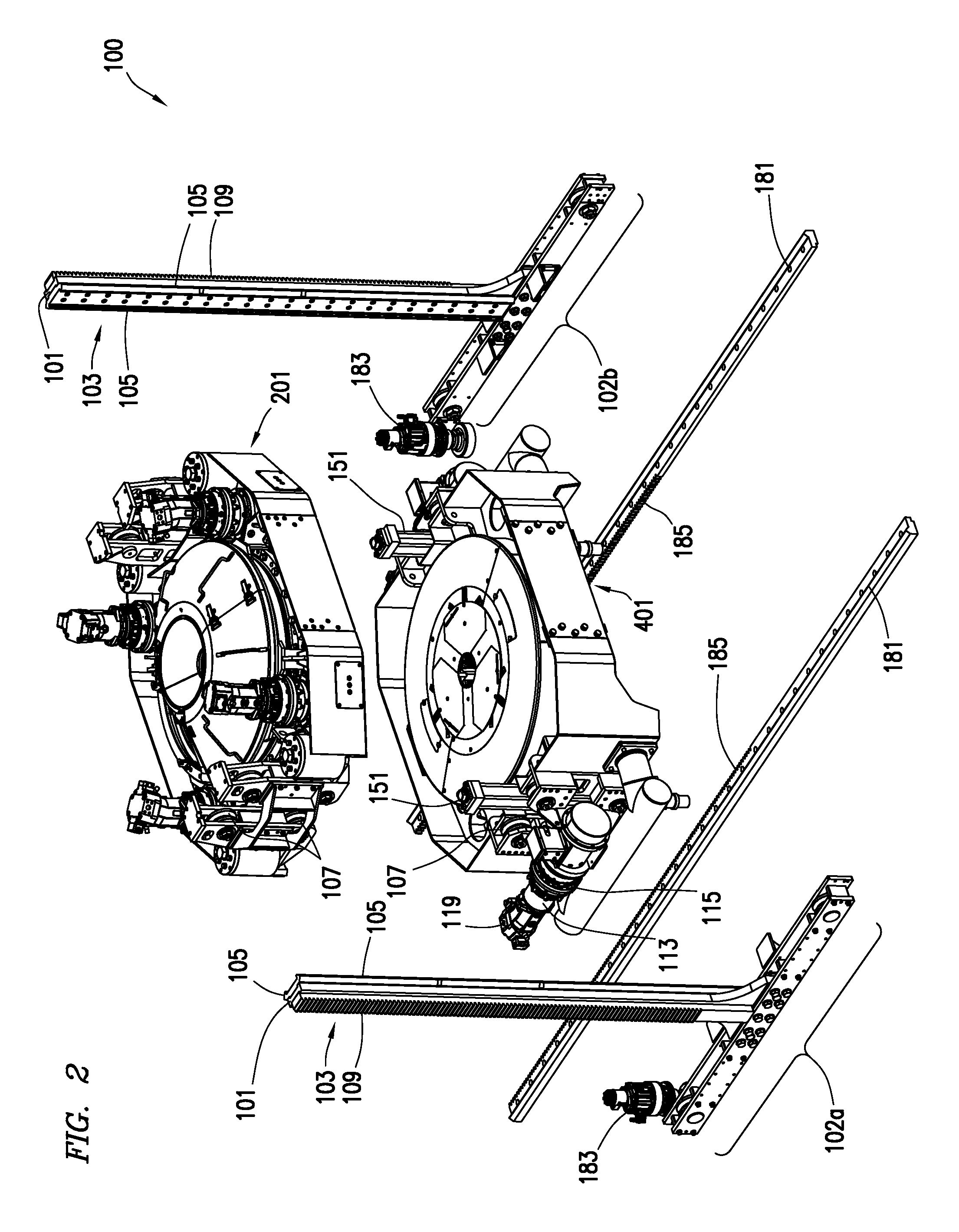

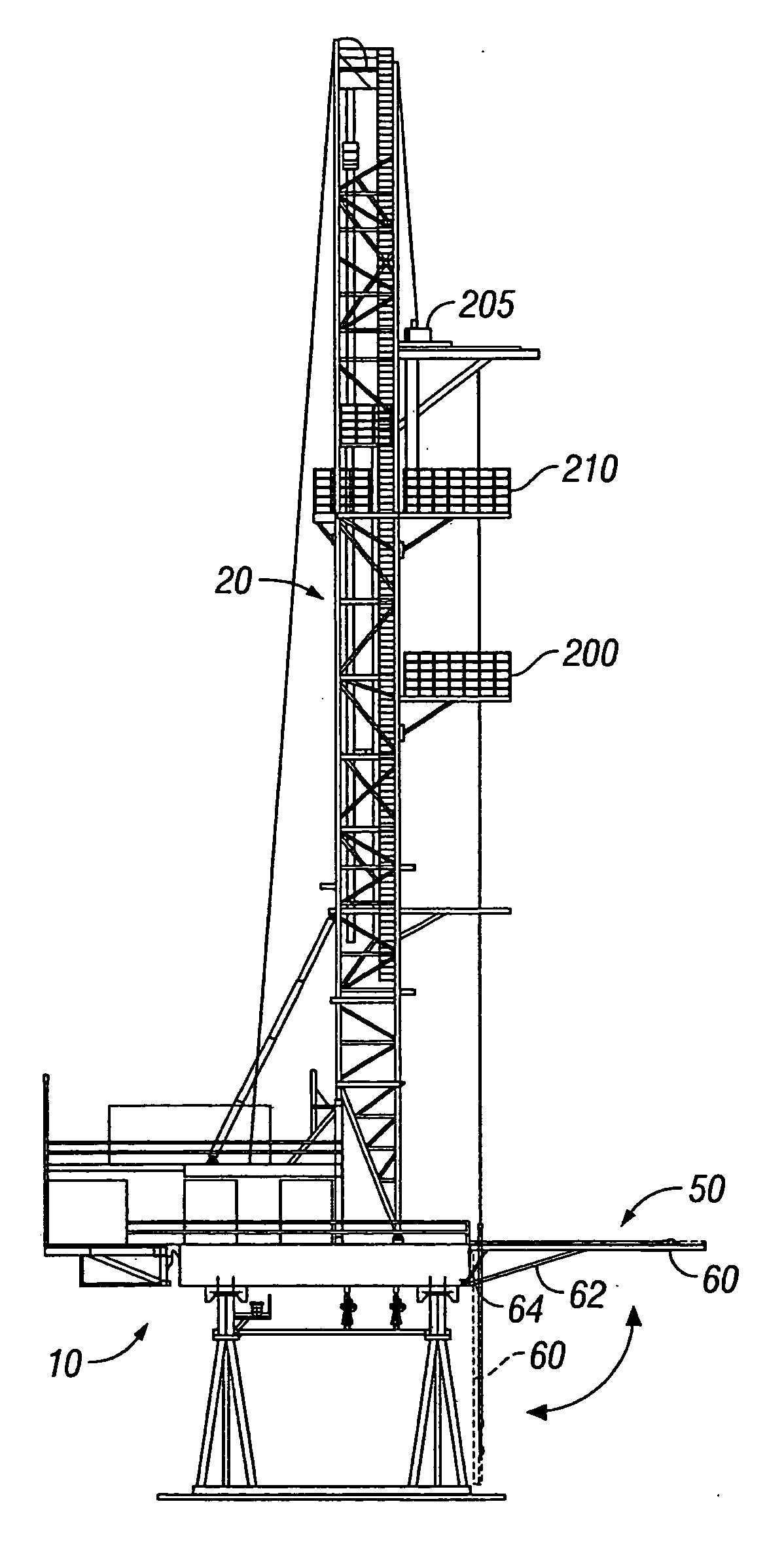

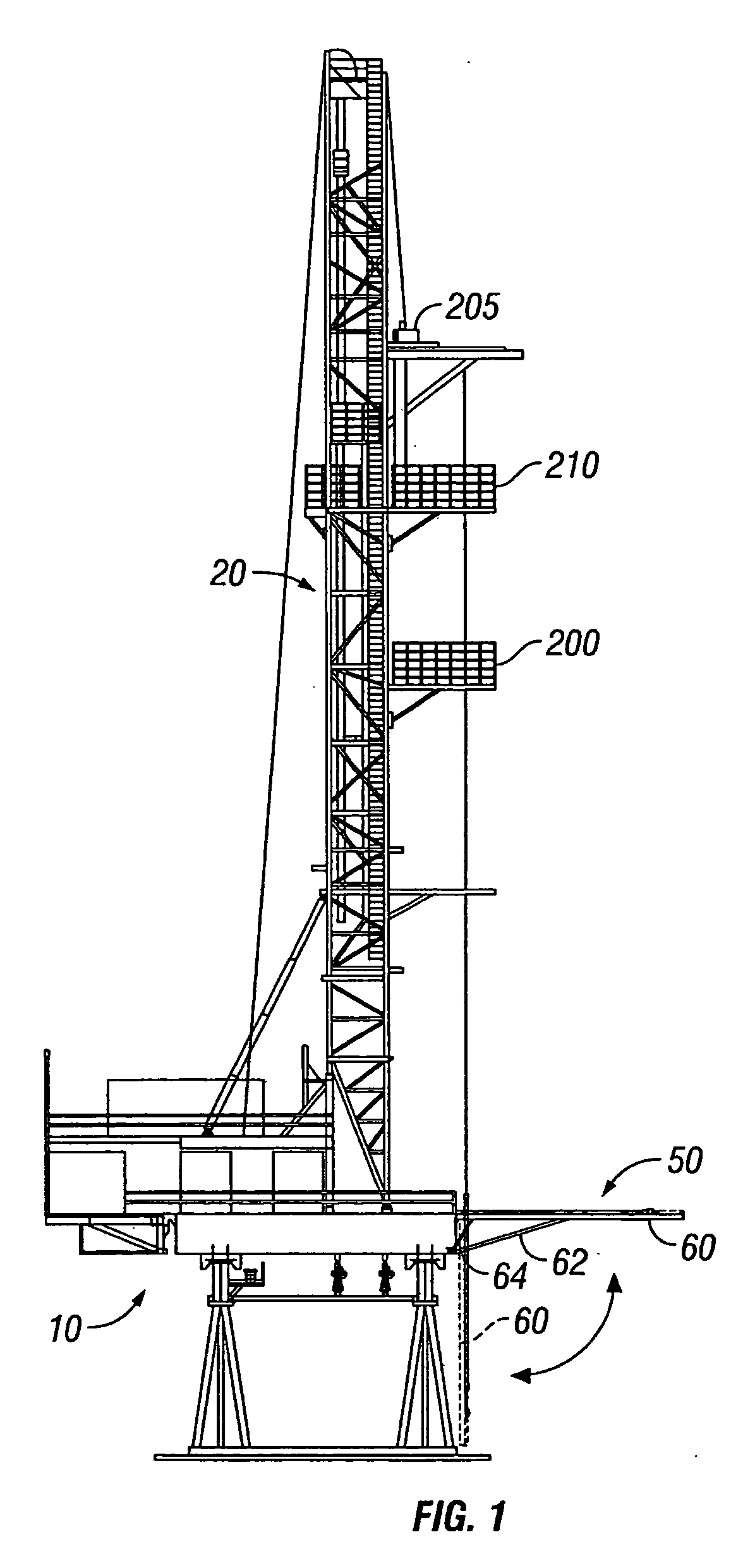

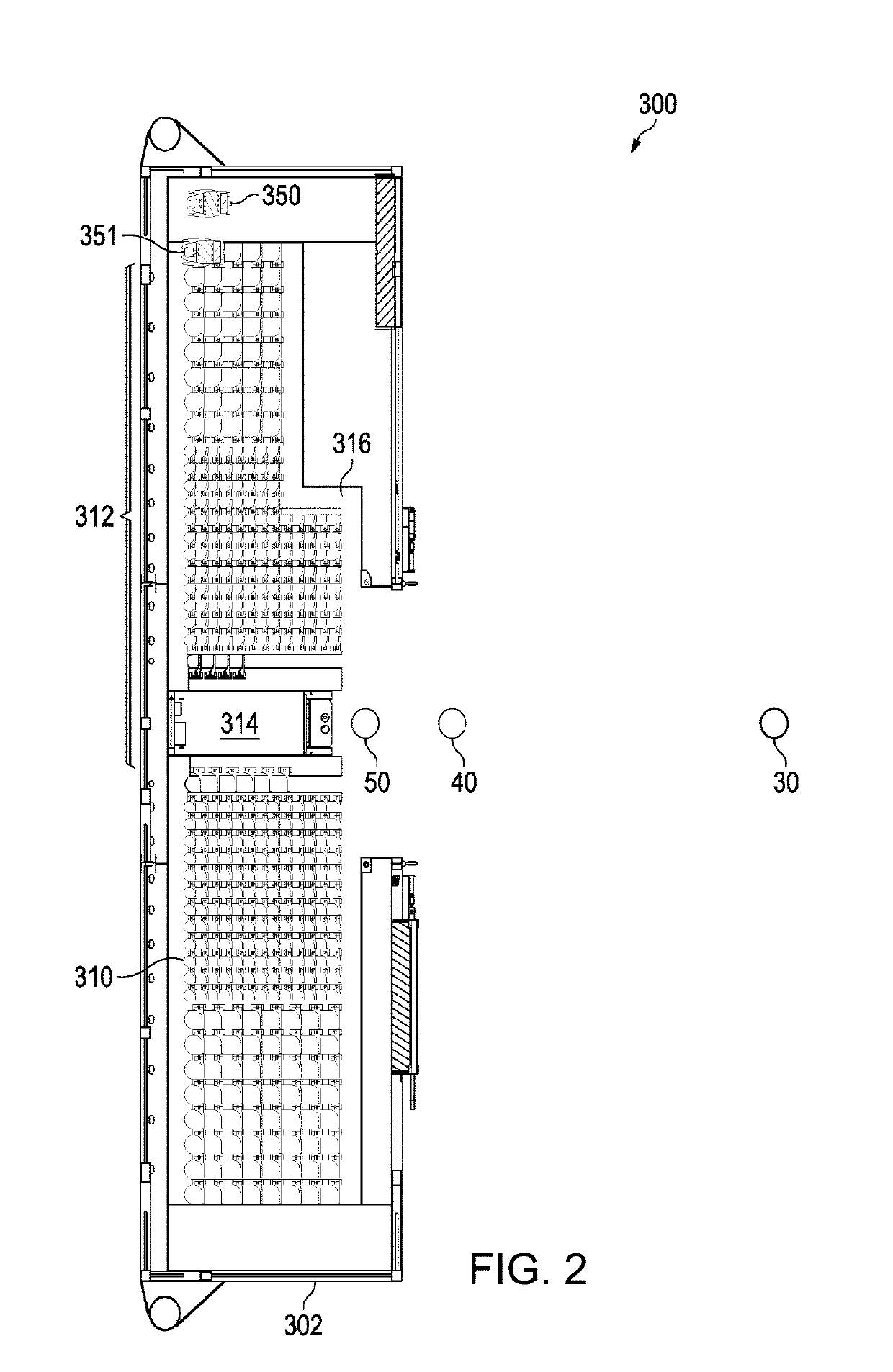

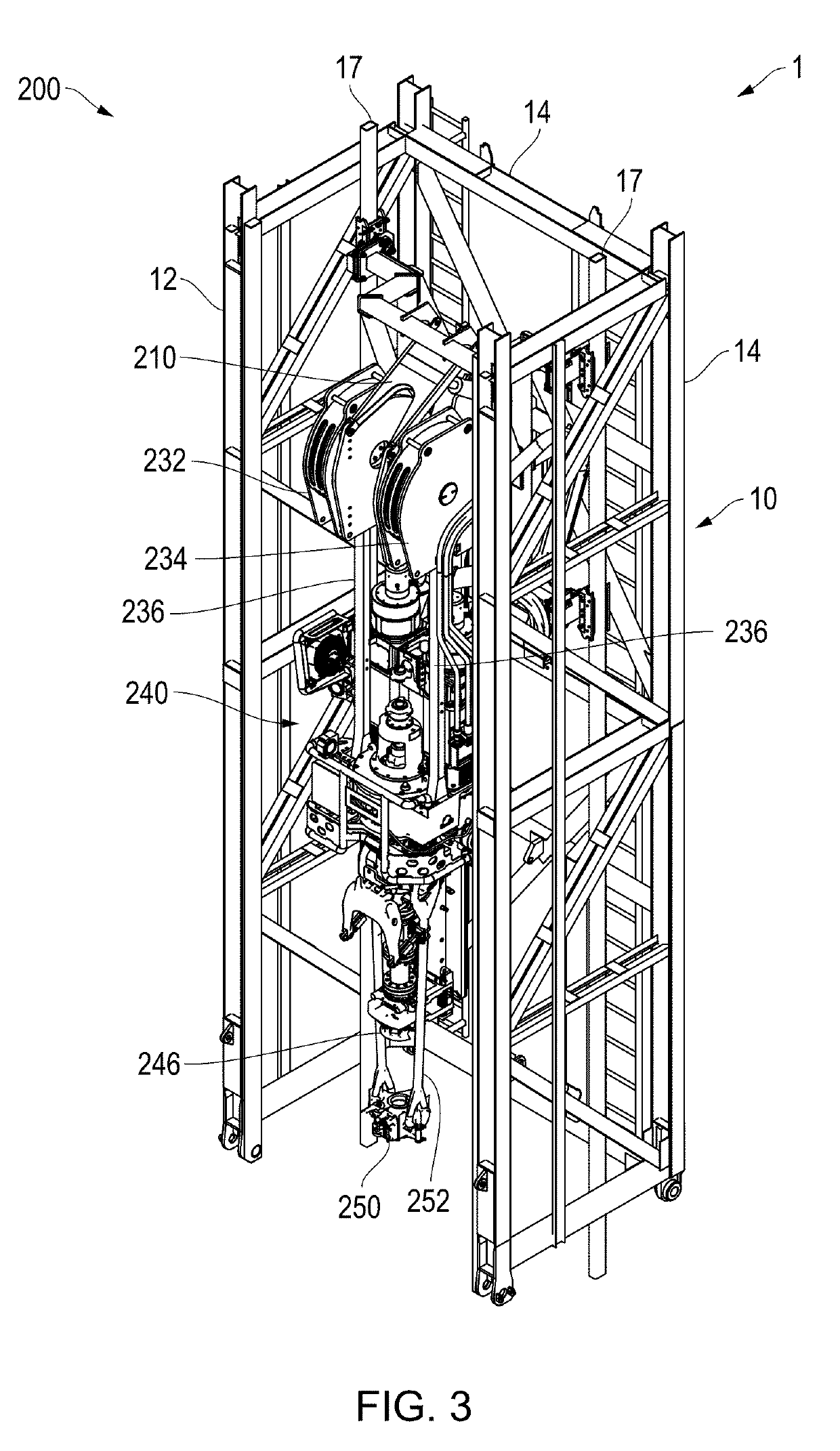

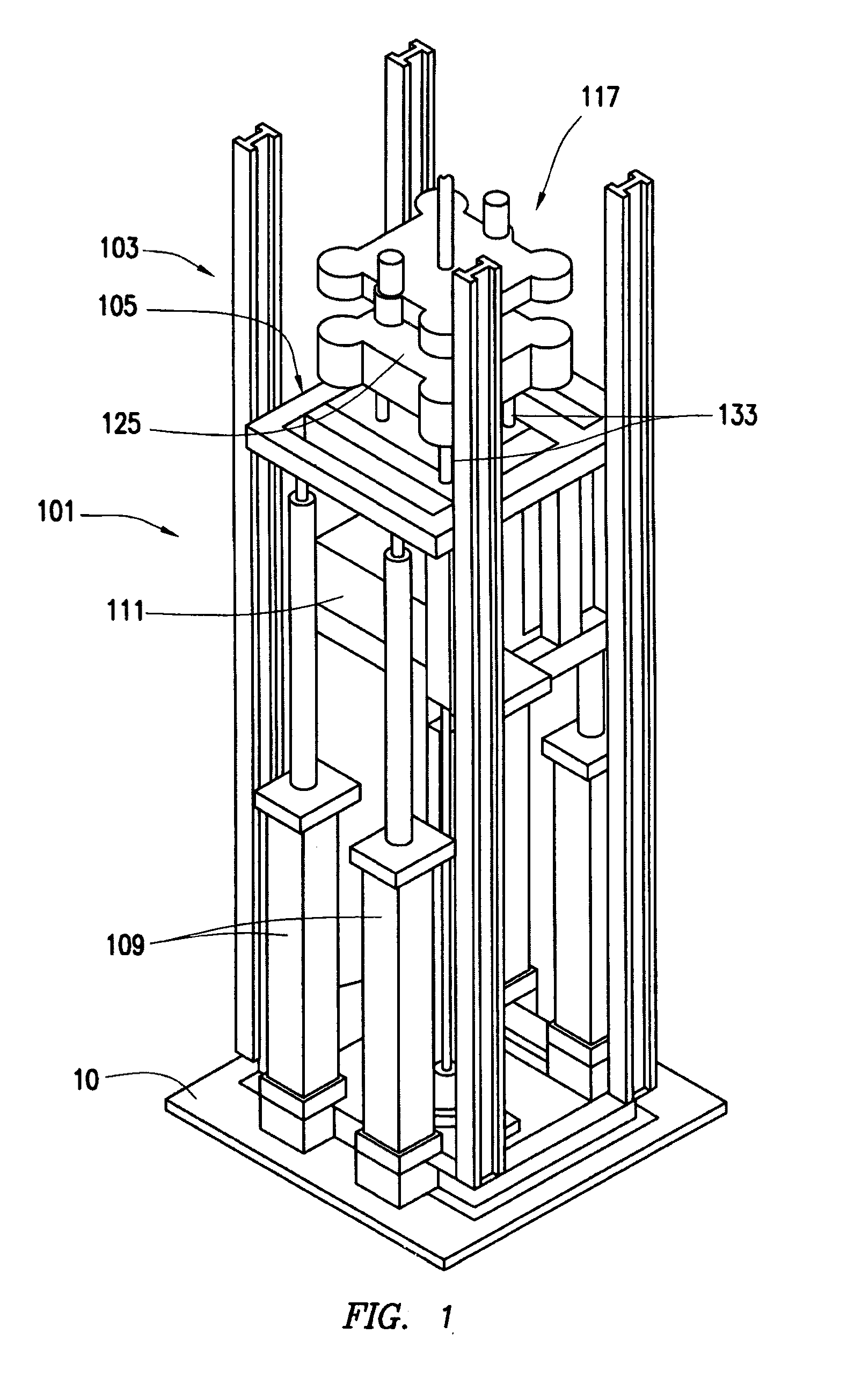

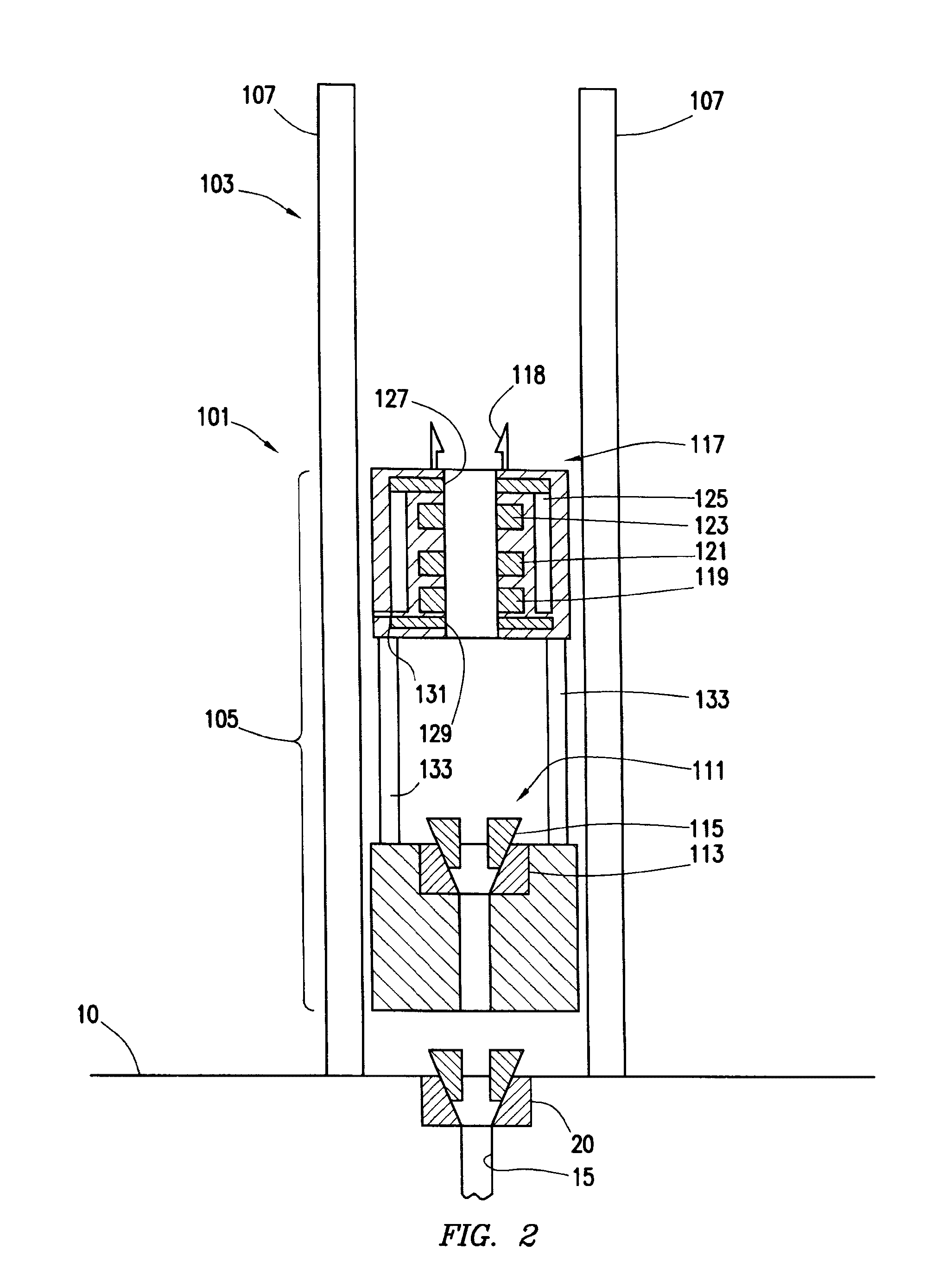

Automated pipe tripping apparatus and methods

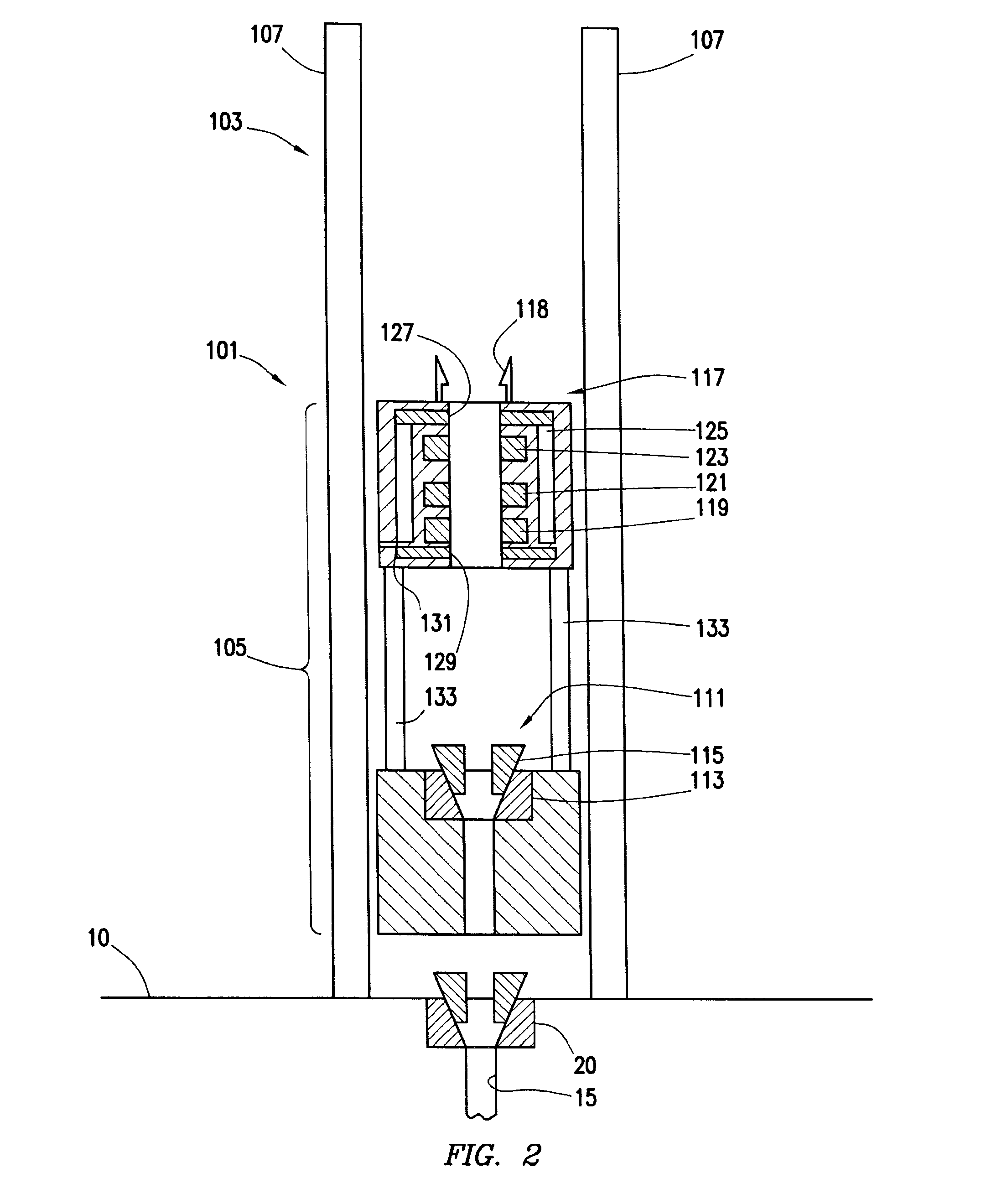

An automated pipe tripping apparatus includes an outer frame and an inner frame. The inner frame includes a tripping slips and iron roughneck. The automated pipe tripping apparatus may, in concert with an elevator and drawworks, trip in a tubular string in a continuous motion. The tripping slips and iron roughneck, along with the inner frame, may travel vertically within the outer frame. The weight of the tubular string is transferred between the tripping slips and the elevator. The iron roughneck may make up or break out threaded connections between tubular segments, the upper tubular segment supported by the elevator and the lower by the tripping slips. An automated pipe handling apparatus may remove or supply sections of pipe from or to the elevator. A control system may control both the automated pipe tripping apparatus and the elevator and drawworks.

Owner:ENSCO SERVICES LTD

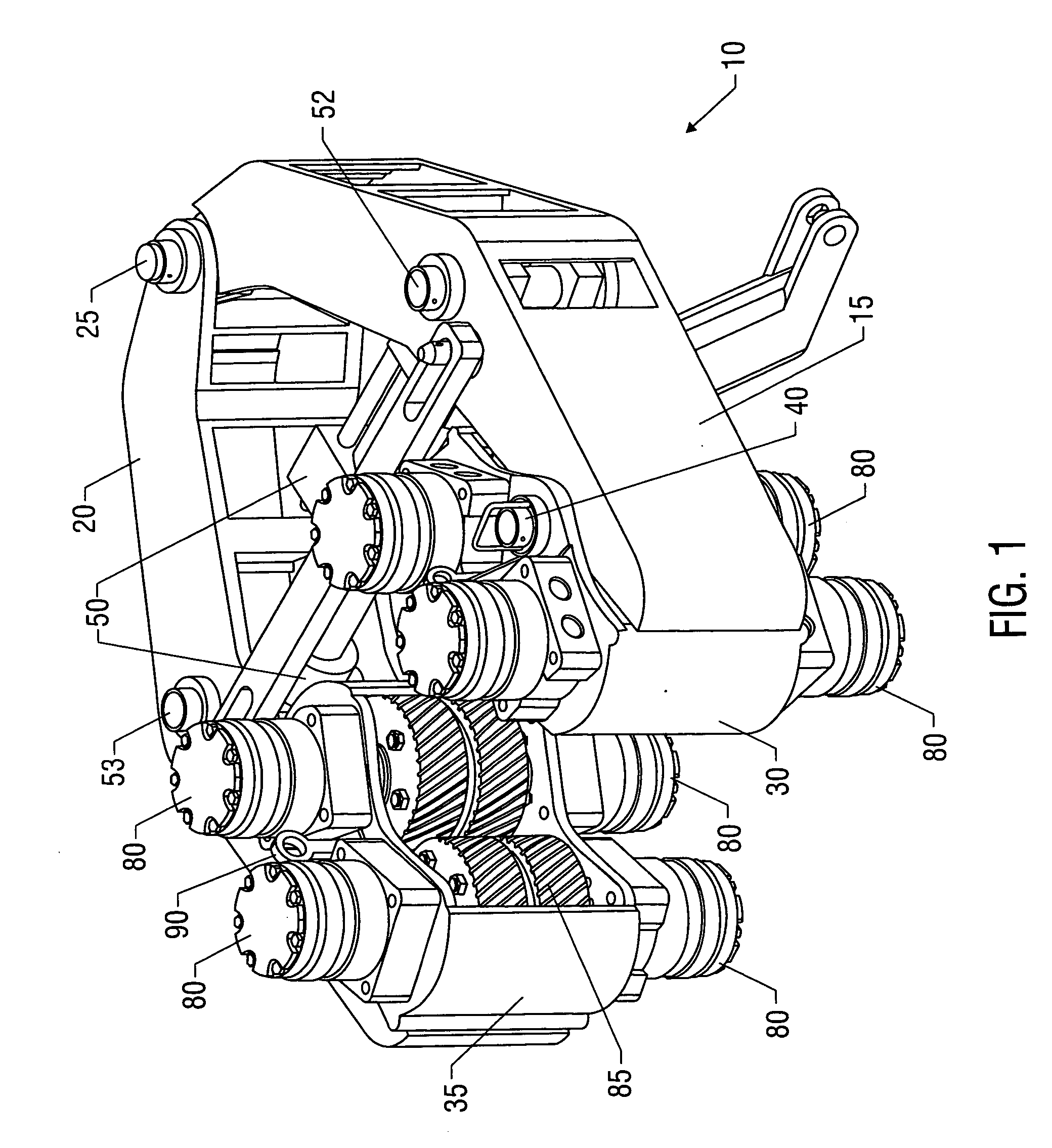

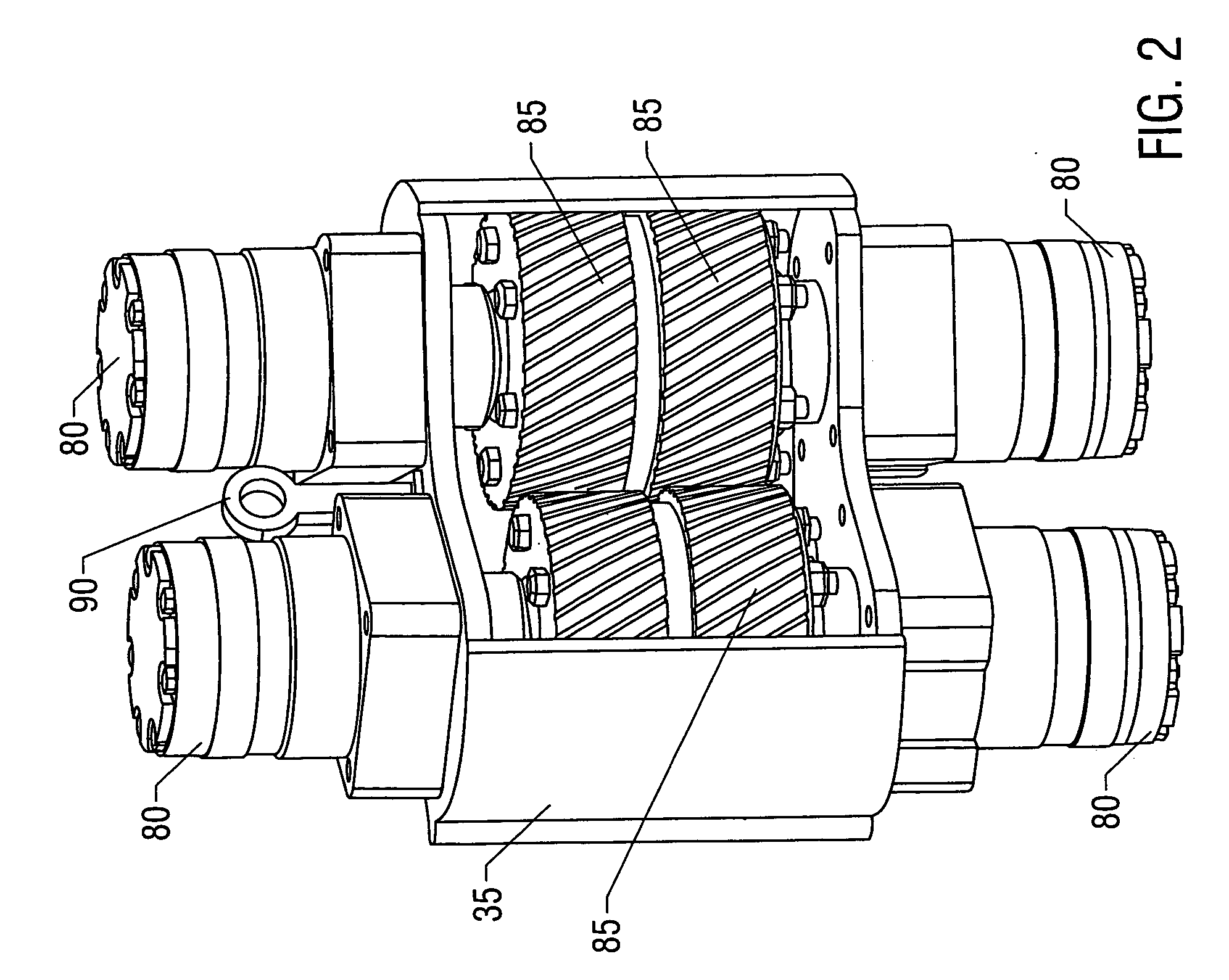

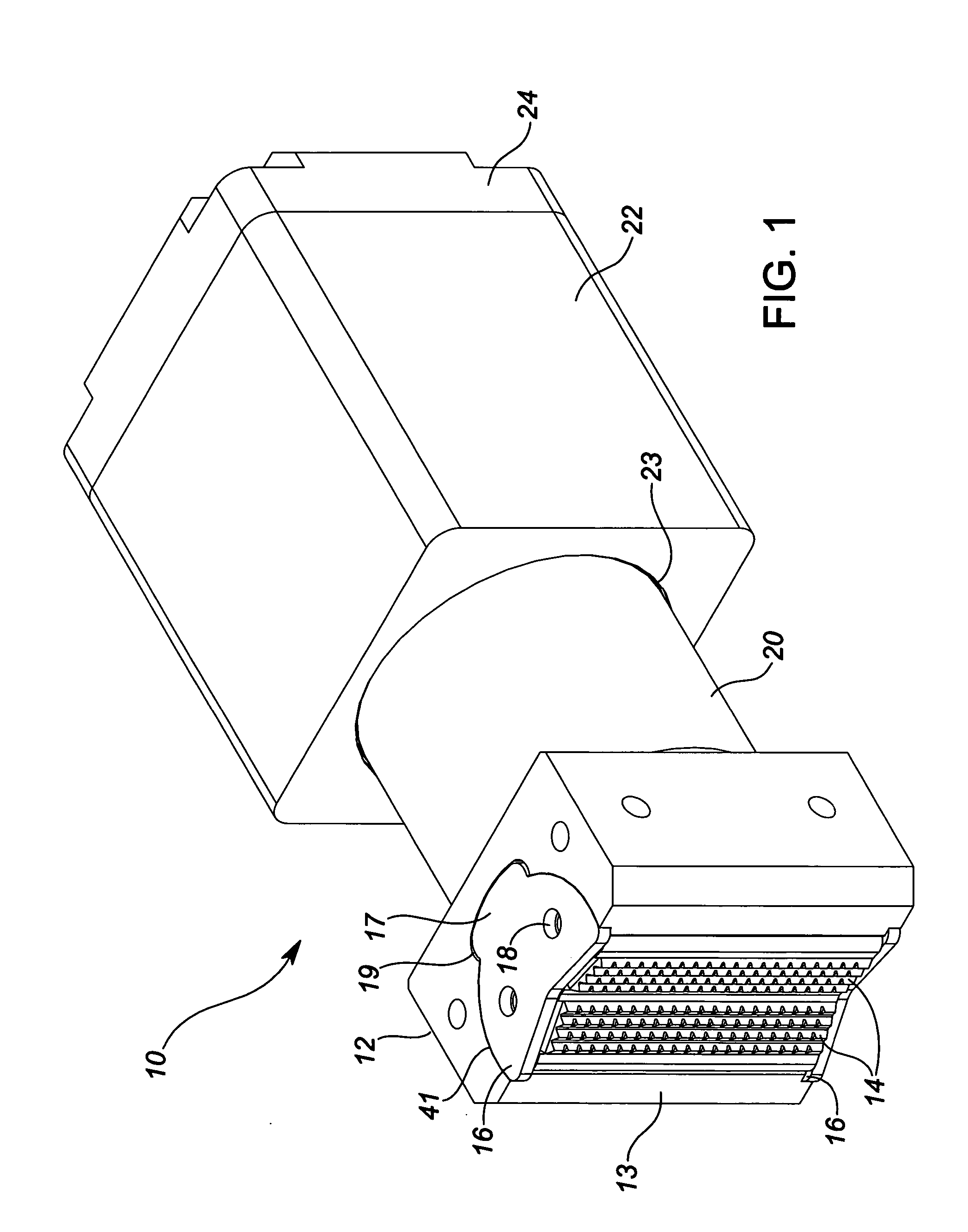

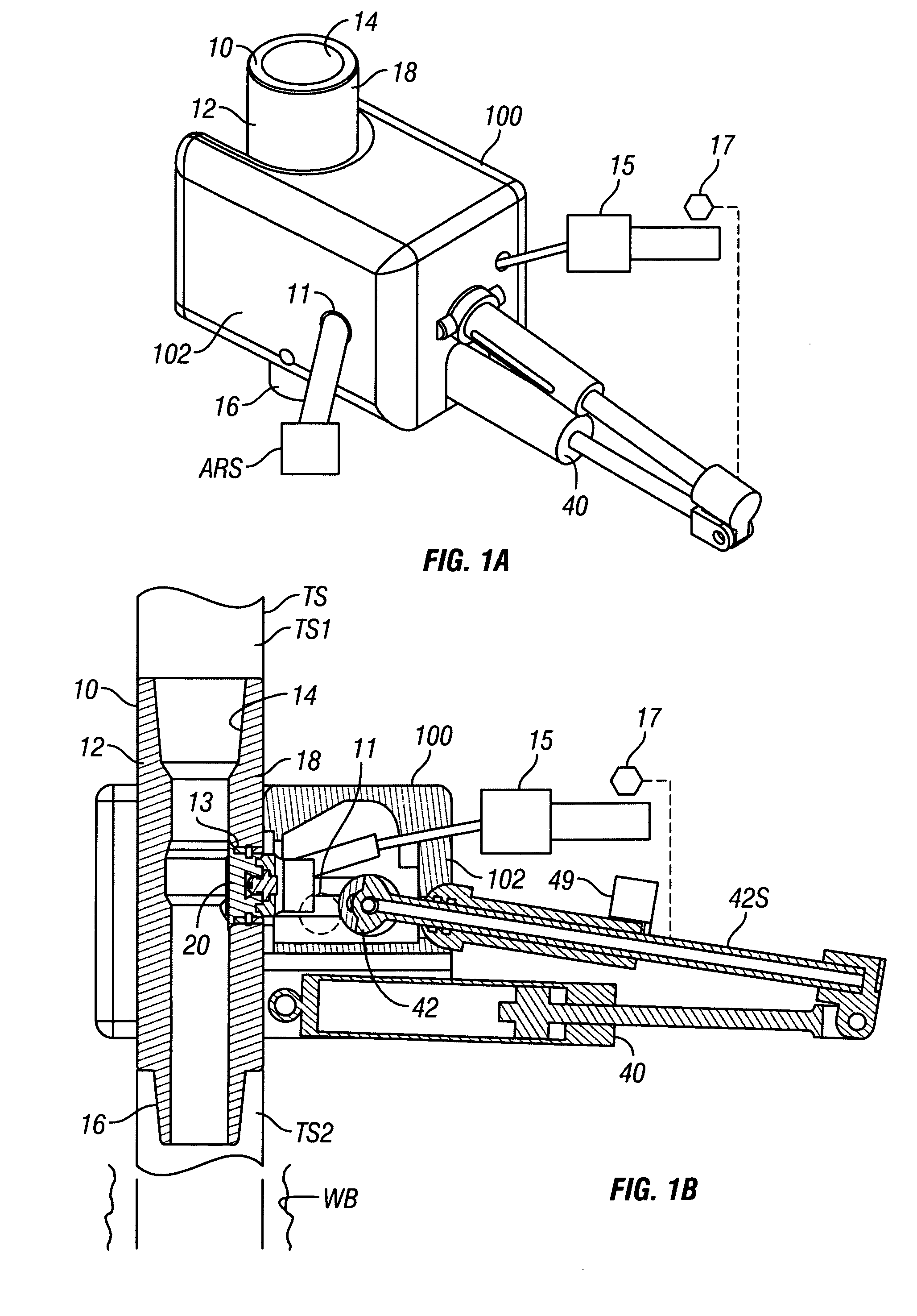

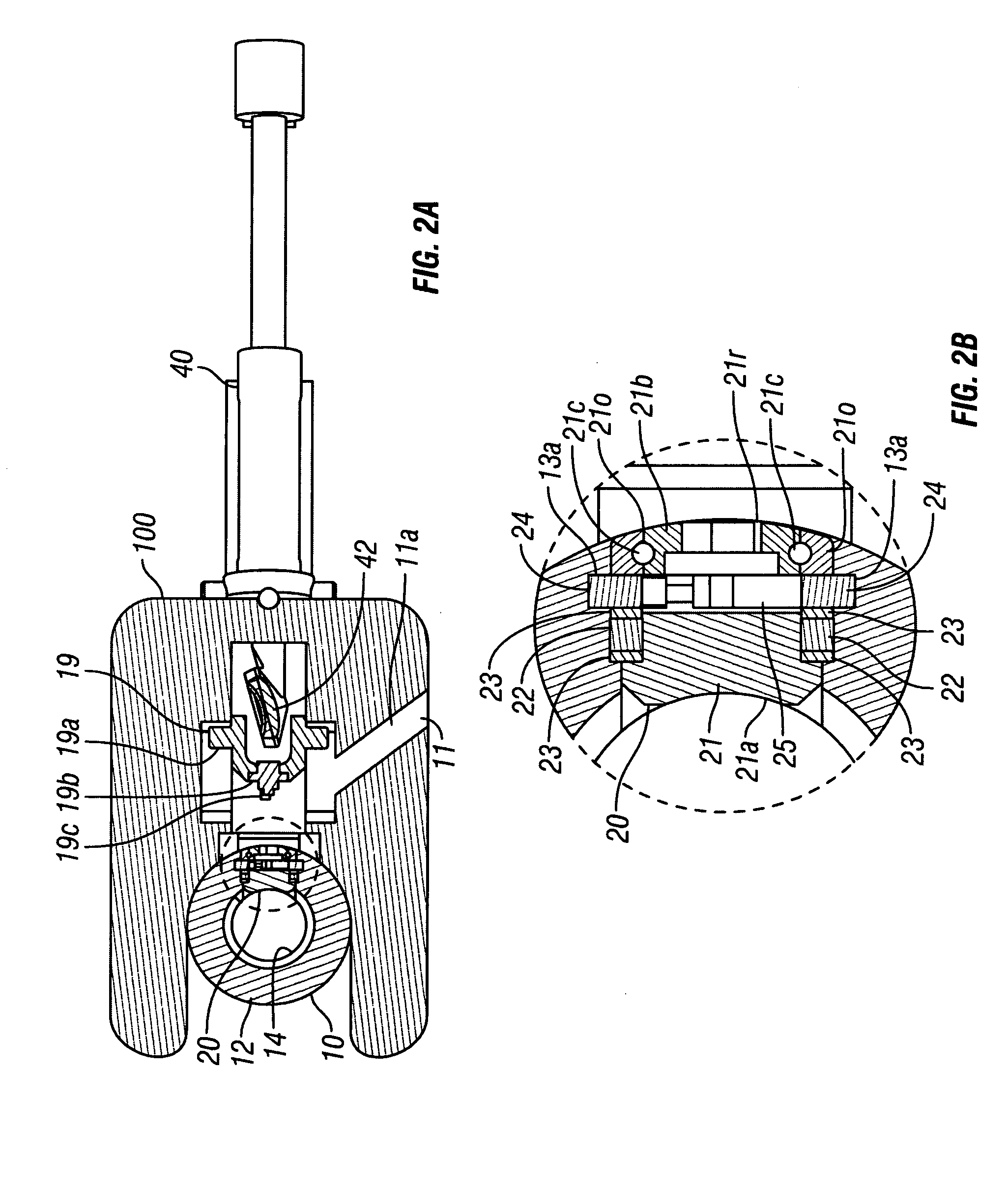

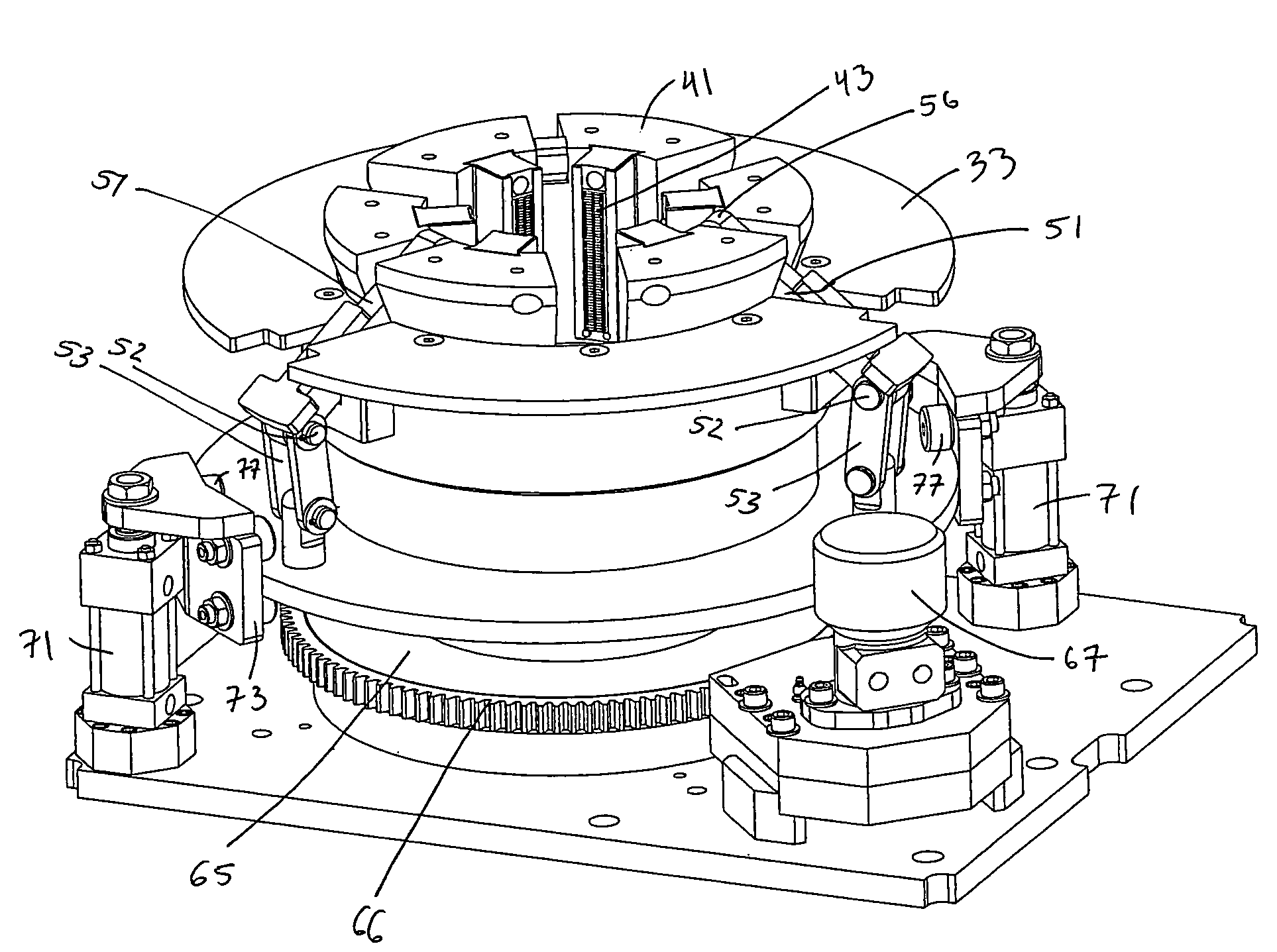

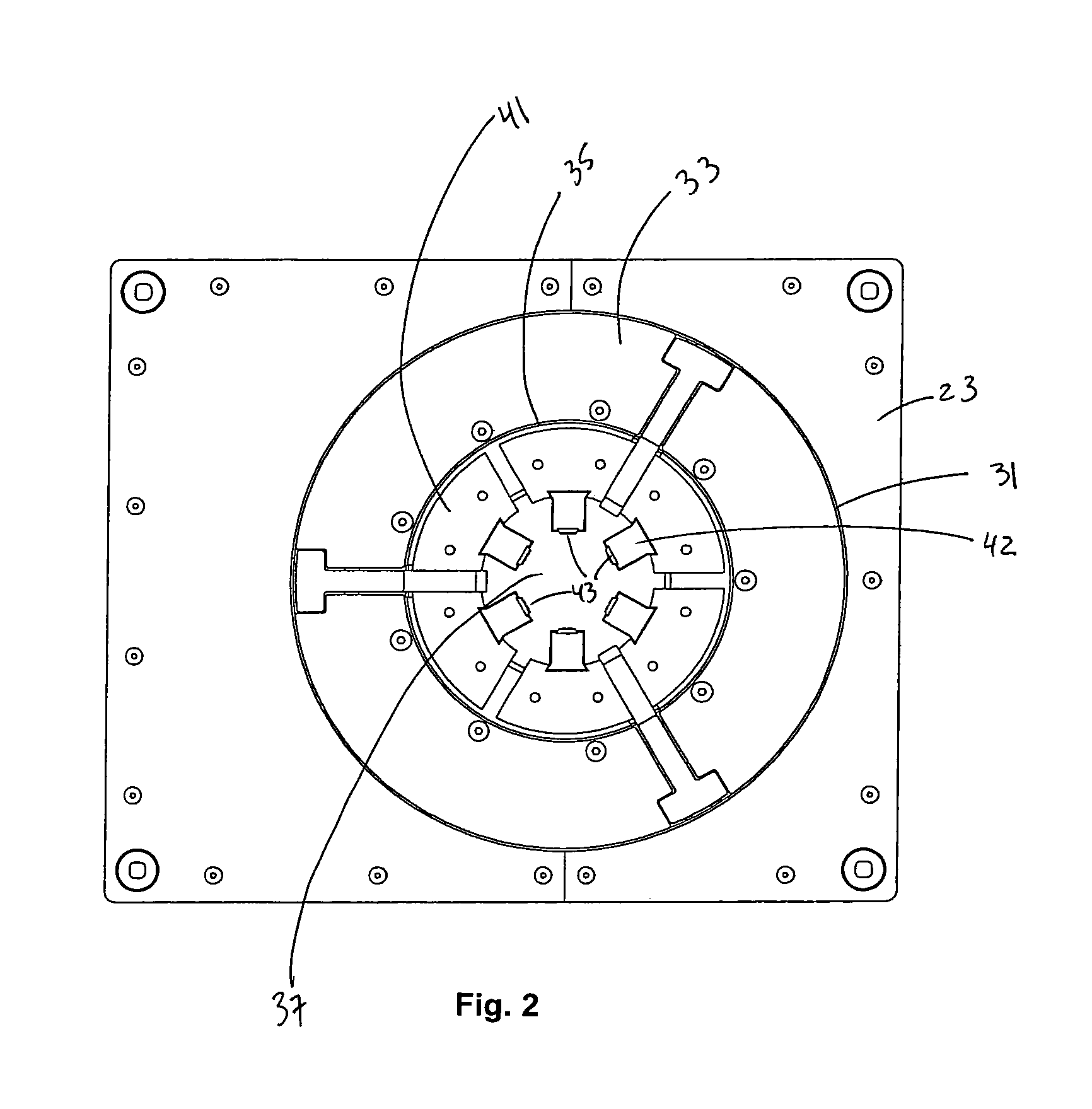

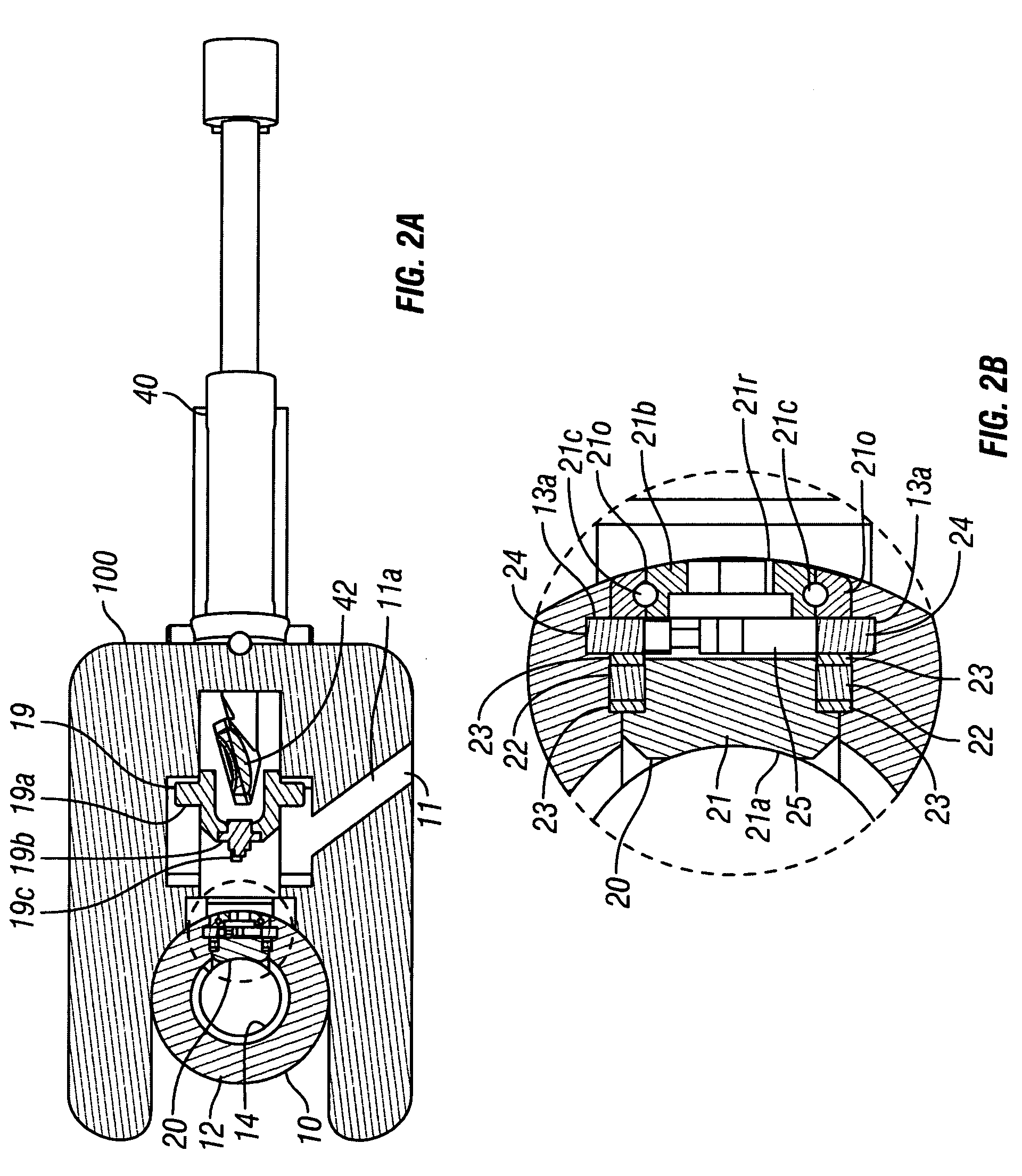

Drillpipe spinner

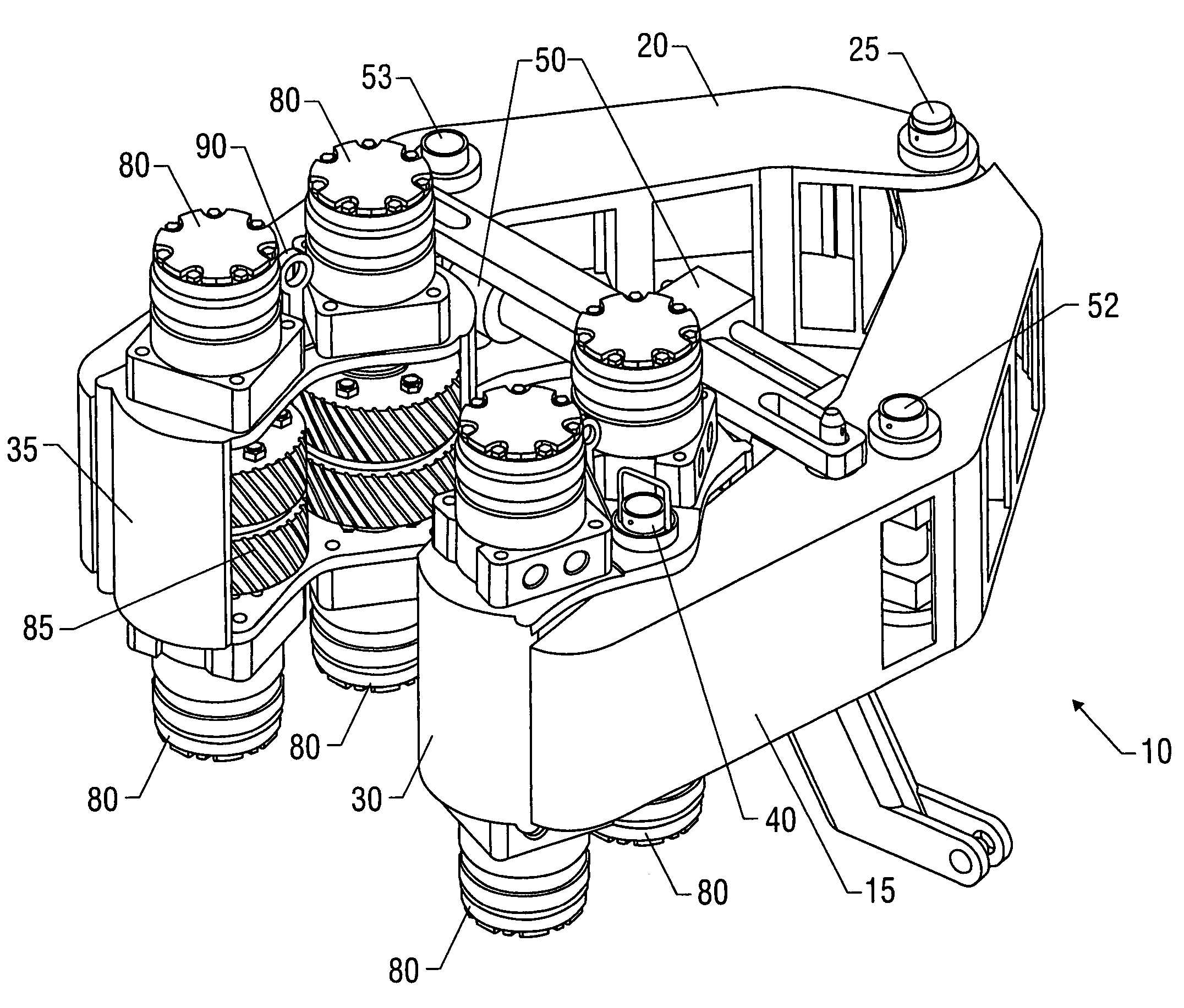

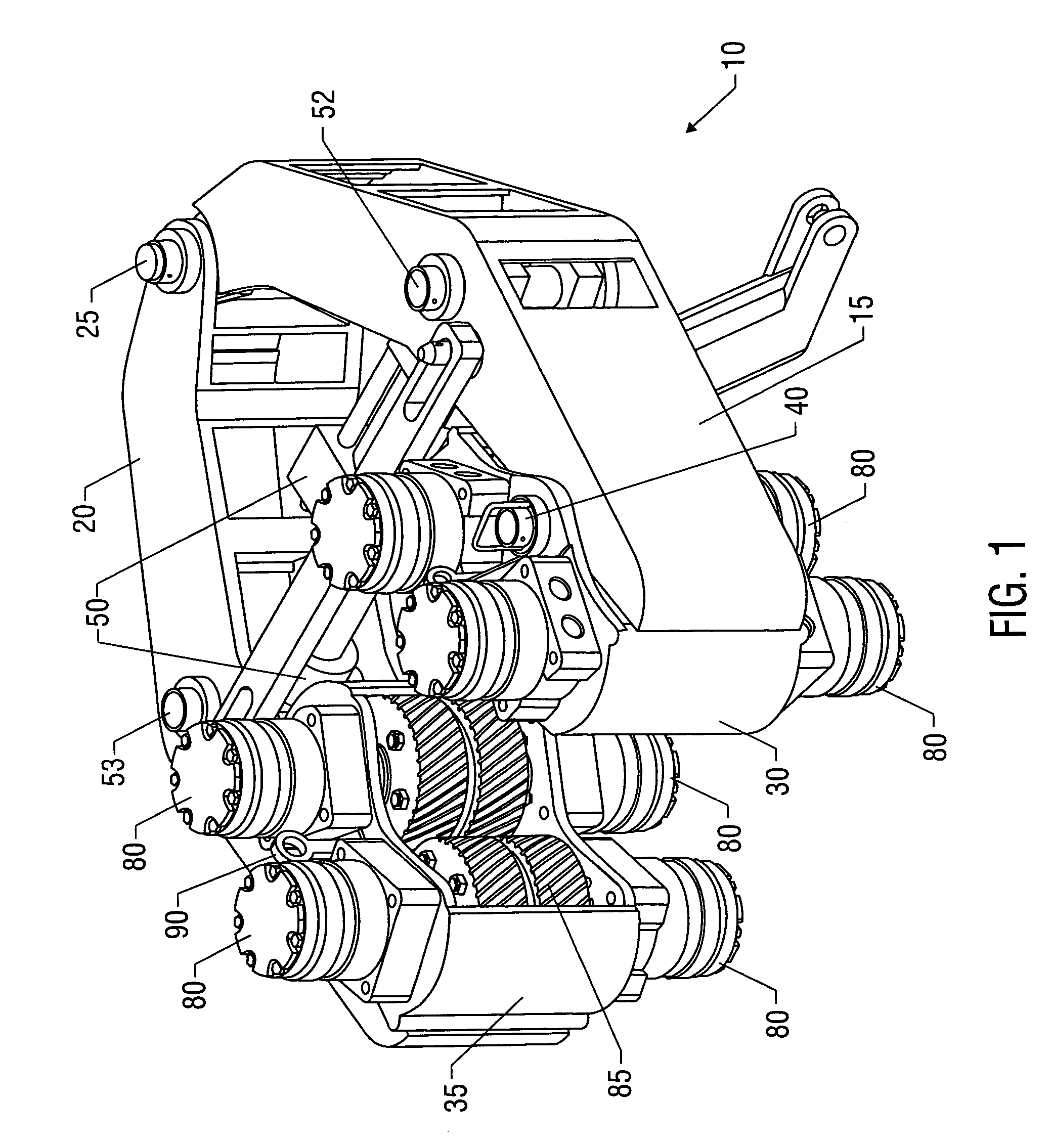

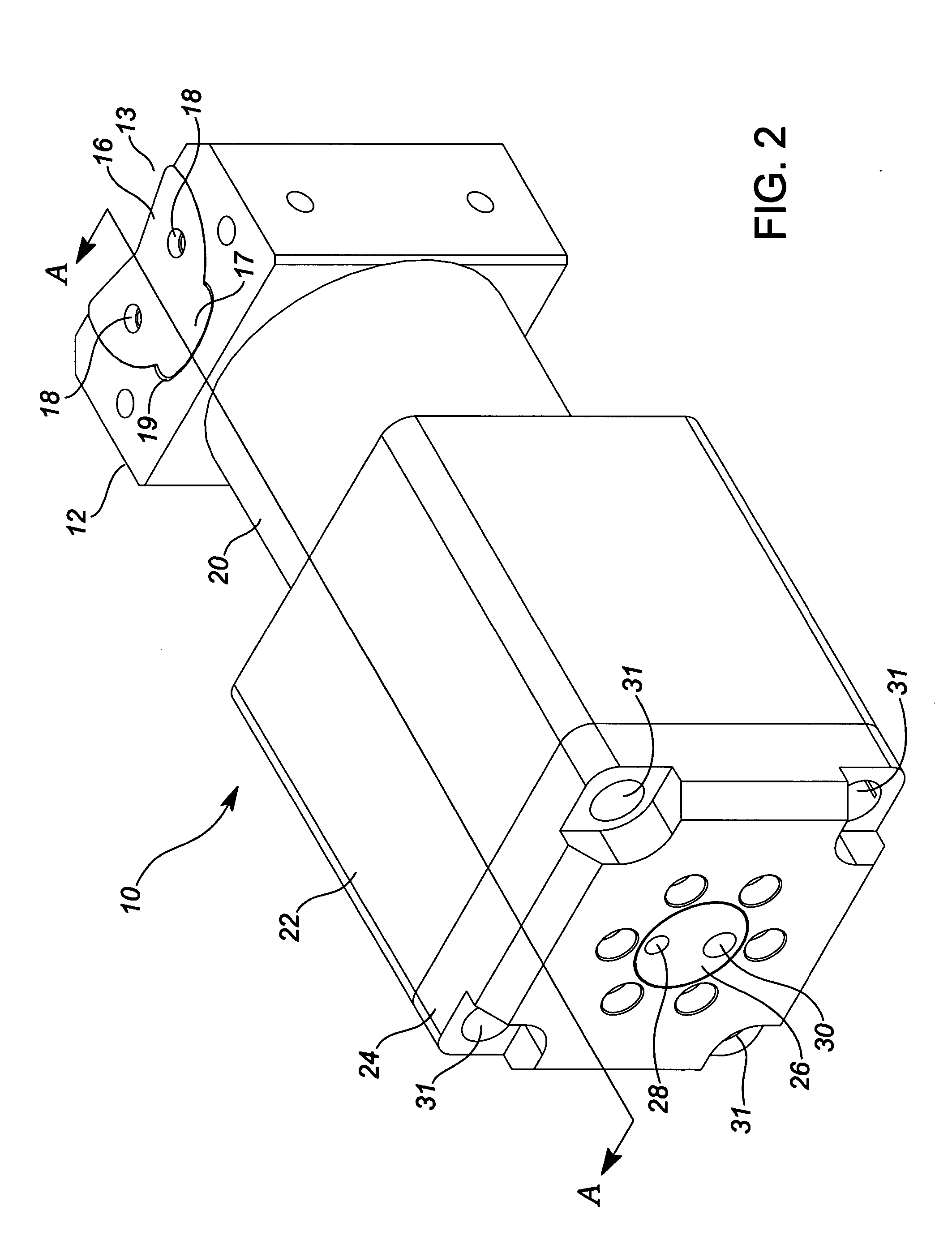

The invention relates to an improved drill pipe spinner. The improved spinner may be used as a stand-alone piece of pipe handling equipment or may be used in an Iron Roughneck. The spinner comprises a pair of clamping arms that are movable between an open position and a closed position, wherein in the closed position, the arms will clamp about a pipe to be made up or broken out and in the open position, the spinner may be moved away from or towards the pipe. The arms are preferably moved between the open and closed positions by a hydraulically actuated clamping cylinder. Attached to the distal ends of each arm is a roller bracket. The roller brackets are preferably attached to the clamping arms by a roller bracket pin. Each roller bracket includes a pair of drive roller assemblies, which together form the spinning unit. Each drive roller assembly preferably comprises a pair of drive rollers, with each roller rotated by a pair of hydraulic motors. If the rollers of the spinner have to be repaired, serviced or replaced, the arm brackets are easily removed by simply pulling the roller bracket pin and removing the roller bracket. A new roller bracket may then be picked up, aligned with and pinned to the arm by reinserting the roller bracket pin. The spinning unit can easily be removed and replaced on the rig floor by changing out the roller bracket.

Owner:NAT OILWELL DHT

Drillpipe spinner

The invention relates to an improved drill pipe spinner. The improved spinner may be used as a stand-alone piece of pipe handling equipment or may be used in an Iron Roughneck. The spinner comprises a pair of clamping arms that are movable between an open position and a closed position, wherein in the closed position, the arms will clamp about a pipe to be made up or broken out and in the open position, the spinner may be moved away from or towards the pipe. The arms are preferably moved between the open and closed positions by a hydraulically actuated clamping cylinder. Attached to the distal ends of each arm is a roller bracket. The roller brackets are preferably attached to the clamping arms by a roller bracket pin. Each roller bracket includes a pair of drive roller assemblies, which together form the spinning unit. Each drive roller assembly preferably comprises a pair of drive rollers, with each roller rotated by a pair of hydraulic motors. If the rollers of the spinner have to be repaired, serviced or replaced, the arm brackets are easily removed by simply pulling the roller bracket pin and removing the roller bracket. A new roller bracket may then be picked up, aligned with and pinned to the arm by reinserting the roller bracket pin. The spinning unit can easily be removed and replaced on the rig floor by changing out the roller bracket.

Owner:NAT OILWELL DHT

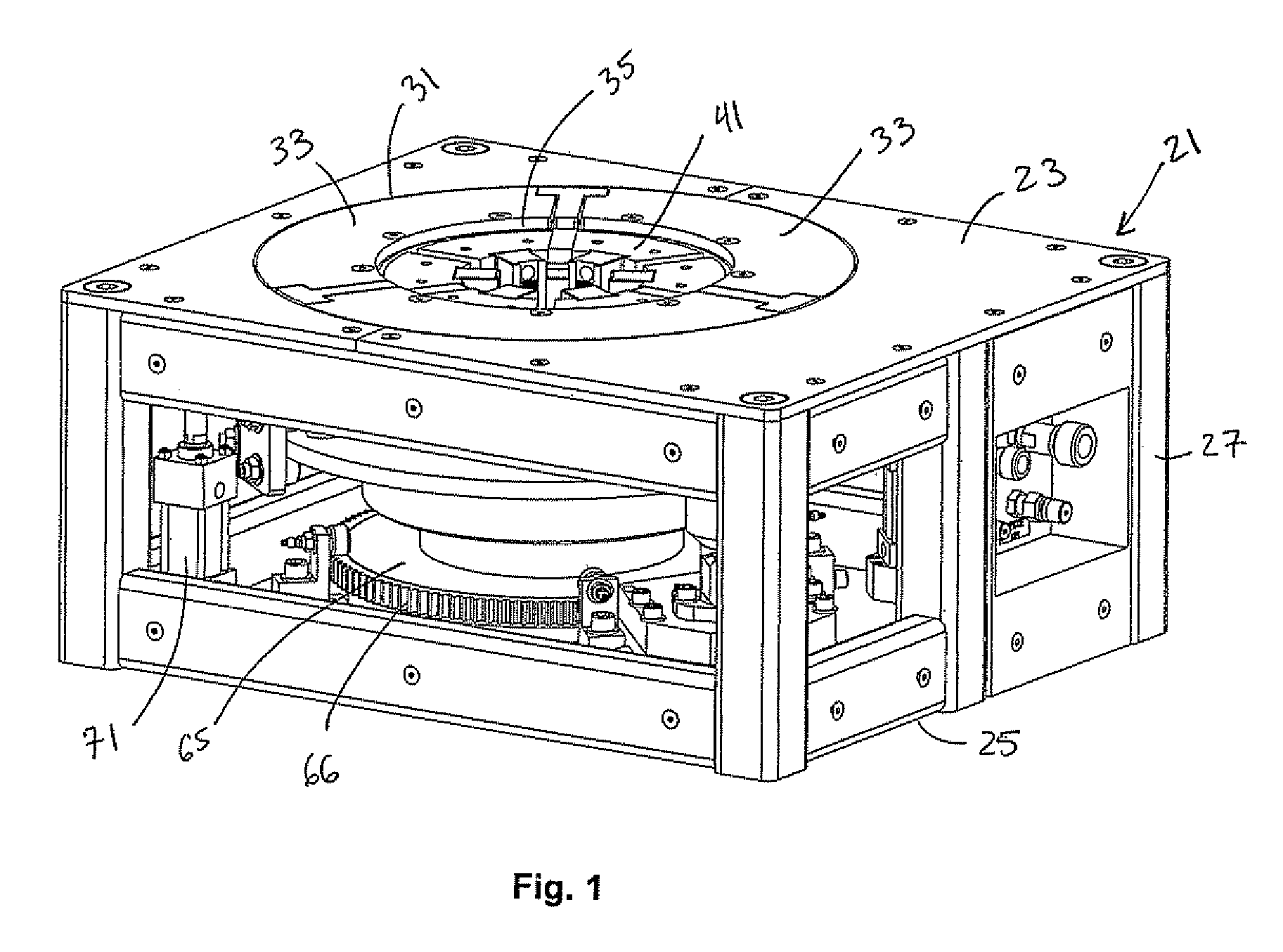

Automated roughneck

An automated roughneck may include a backup tong and a makeup tong. The makeup tong and backup tong may be selectively movable relative to one another. The makeup tong and backup tong may include spinner and gripper assemblies respectively adapted to make up and break out threaded connections. The automated roughneck may be configurable to be removable from the drill string in a lateral direction.

Owner:NABORS SERVICES

Pipe gripping ram

A ram is provided for use in the live and dead heads of an iron roughneck. The ram grips sections of pipe as connections are made or broken between the pipe sections. The ram includes a cylinder block having a bore and a fixed piston centered therein forming an annulus. An annular piston slides in and out of the cylinder block in the annulus. A tong mounted on the end of the end of the annular piston for gripping pipe includes a tong shoe and a tong die within the shoe. The tong die is capable of moving side-to-side within the shoe to self-center itself when gripping pipe. Pressurized gas or hydraulic fluid systems can be used to extend and retract the annular piston within the cylinder block.

Owner:LESKO GERALD

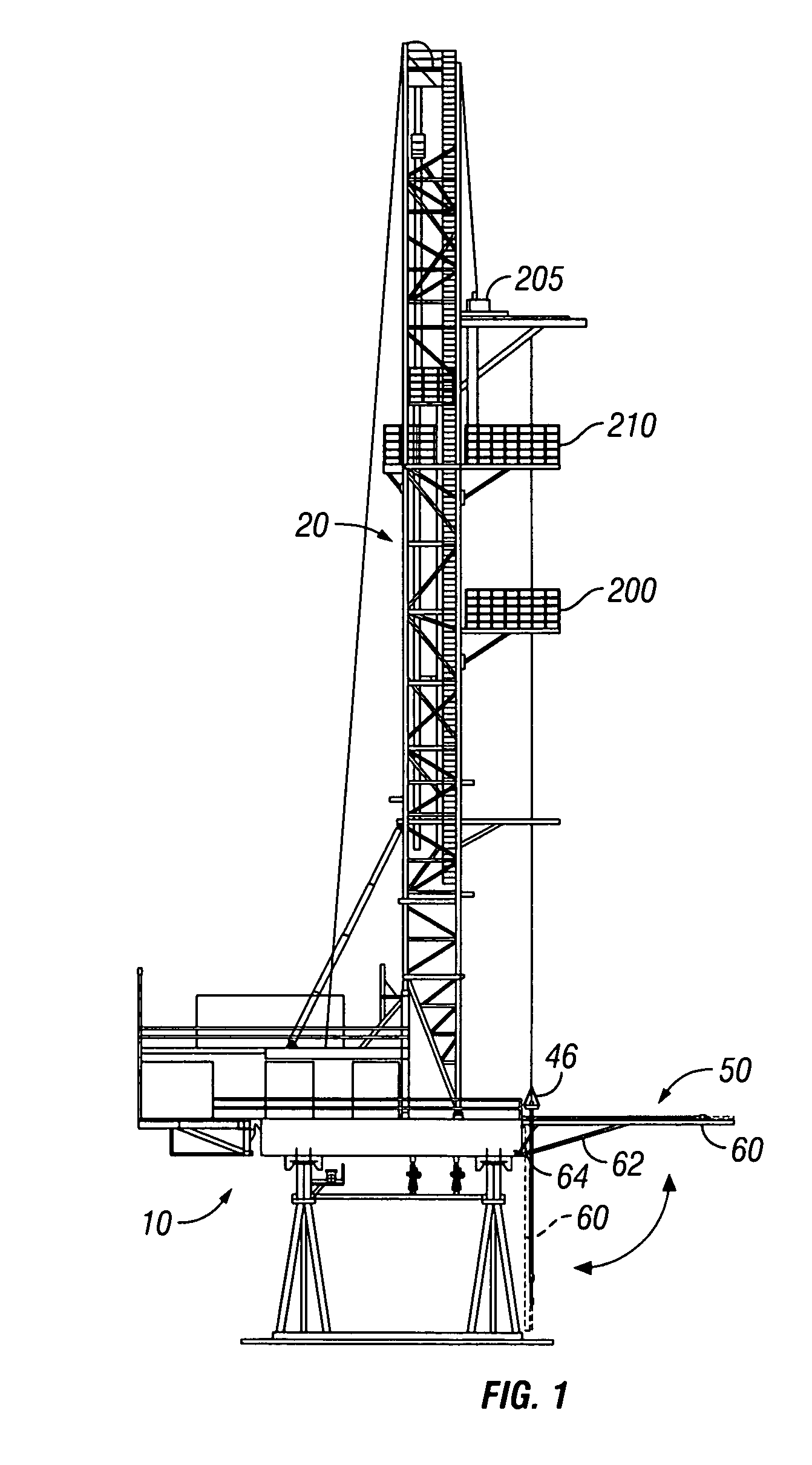

Pivoting pipe handler for off-line make up of drill pipe joints

An apparatus and method for use in the off-line make-up of drill pipe stands on drilling rigs used in the exploration and production of oil and gas reserves are disclosed. The disclosed invention is a pipe handling system in which a section of the V-door ramp attached to a drilling rig structure pivots to allow one or more joints of drill pipe to be placed in a vertical position. Through use of an off-line roughneck in conjunction with an off-line drill pipe elevator, the joints of drill pipe held in the vertical position via the pivoting pipe handler of the present invention can be connected together, connected to additional joints of drill pipe, and placed in a racking board to be stored until they are subsequently connected to the drill string. The use of the pivoting pipe handler of the present invention allows stands of drill pipe to be “made-up” without the need to interrupt drilling operations and, thus, significantly reduces the amount of time required to drill a borehole.

Owner:NAT OILWELL DHT

Drill pipe spinner device

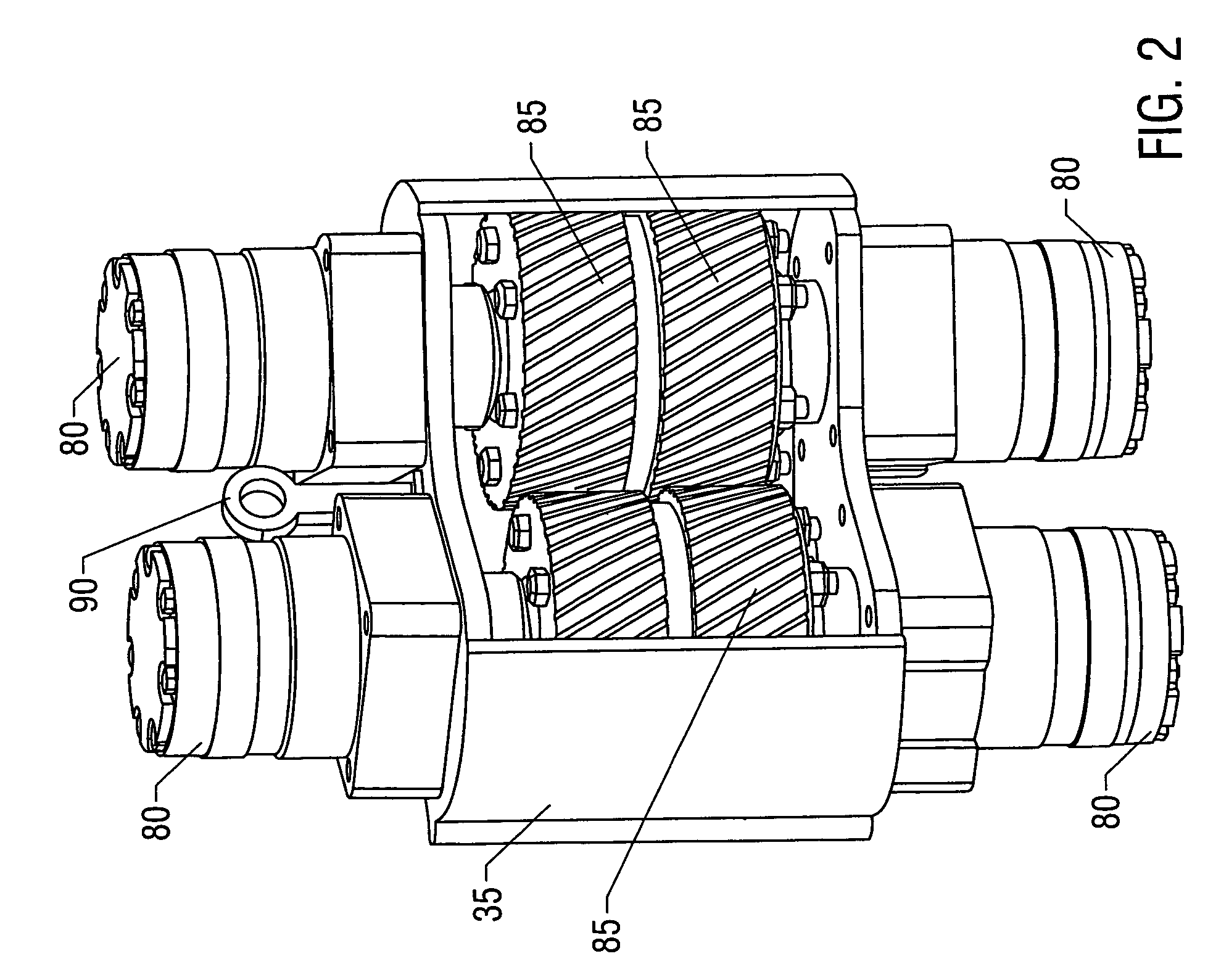

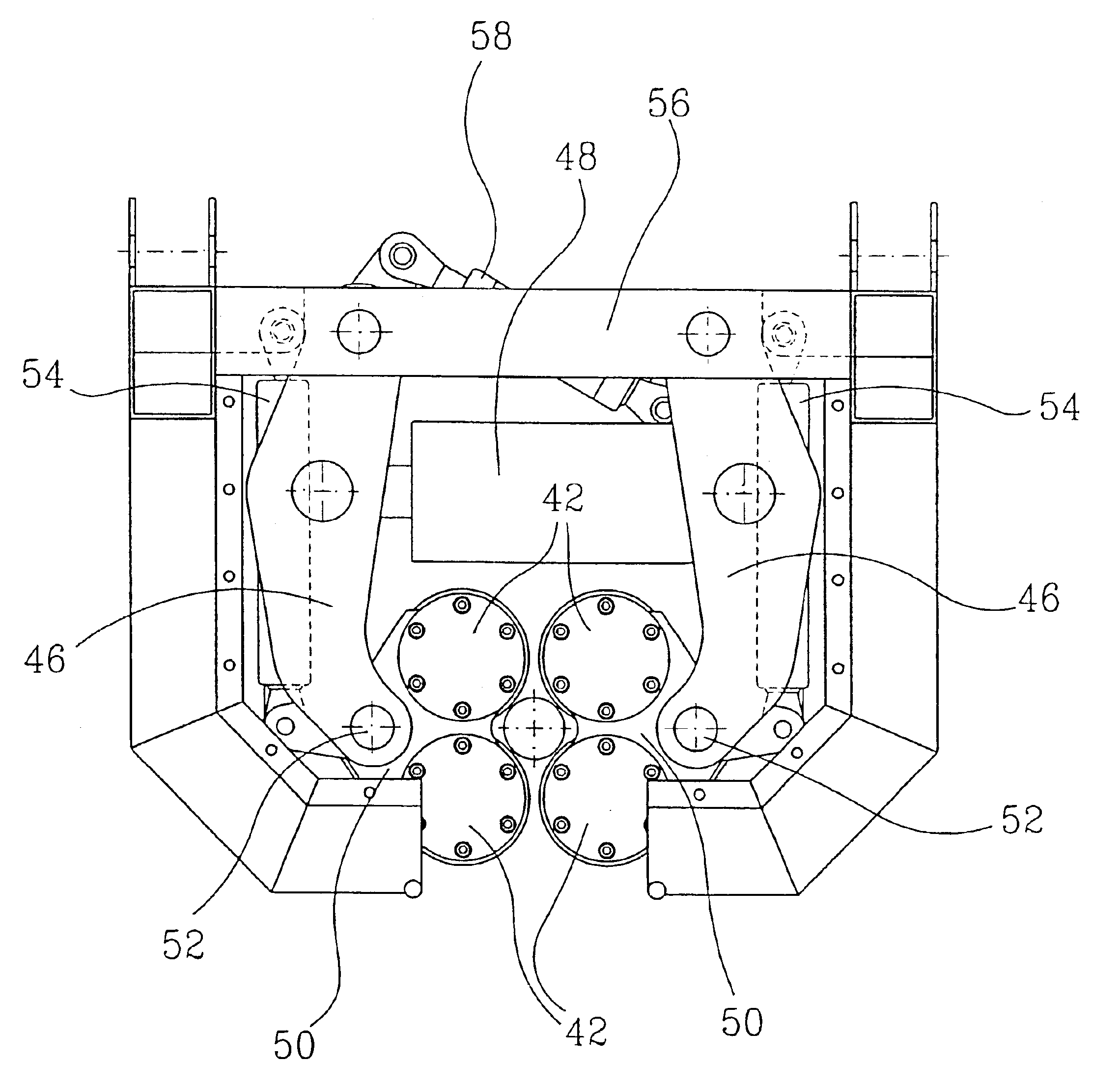

In spinner tongs, a so-called spinner (30), incorporated in an iron roughneck and thus serving to rotate a drill pipe during connection thereof to a drill string or during division of the drill string into individual pipes, the aim has been to reduce damage on the threaded connections (the pin-and-box joints) in the screwing / unscrewing operations. This is realised in an operation for the simultaneous centering and rotating of the drill pipe. Four spinner rollers (42) known in themselves, which are brought to bear on the drill pipe when surrounding it, are mounted according to the invention, preferably in pairs, at the outer ends of driven clamping arms (46), by bogies (50). At their opposite outer ends the clamping arms (46) are pivotally supported on a fixed frame part / structure (56) and are jointed to each other by means of a piston and cylinder (48) driven by pressure fluid and arranged to carry the clamping arms (46) towards and away from each other. For their forced centering the clamping arms (46) have a centering stay (58) arranged thereto, which is connected by its outer end to one clamping arm (46), and is connected by its other outer end to the other clamping arm (46). For the parallel displacement of the rollers (42), each bogie (50) has a parallel stay (54) arranged thereto, whose other end is supported on a fixed frame part / structure (56).

Owner:NAT OILWELL VARCO NORMAY AS

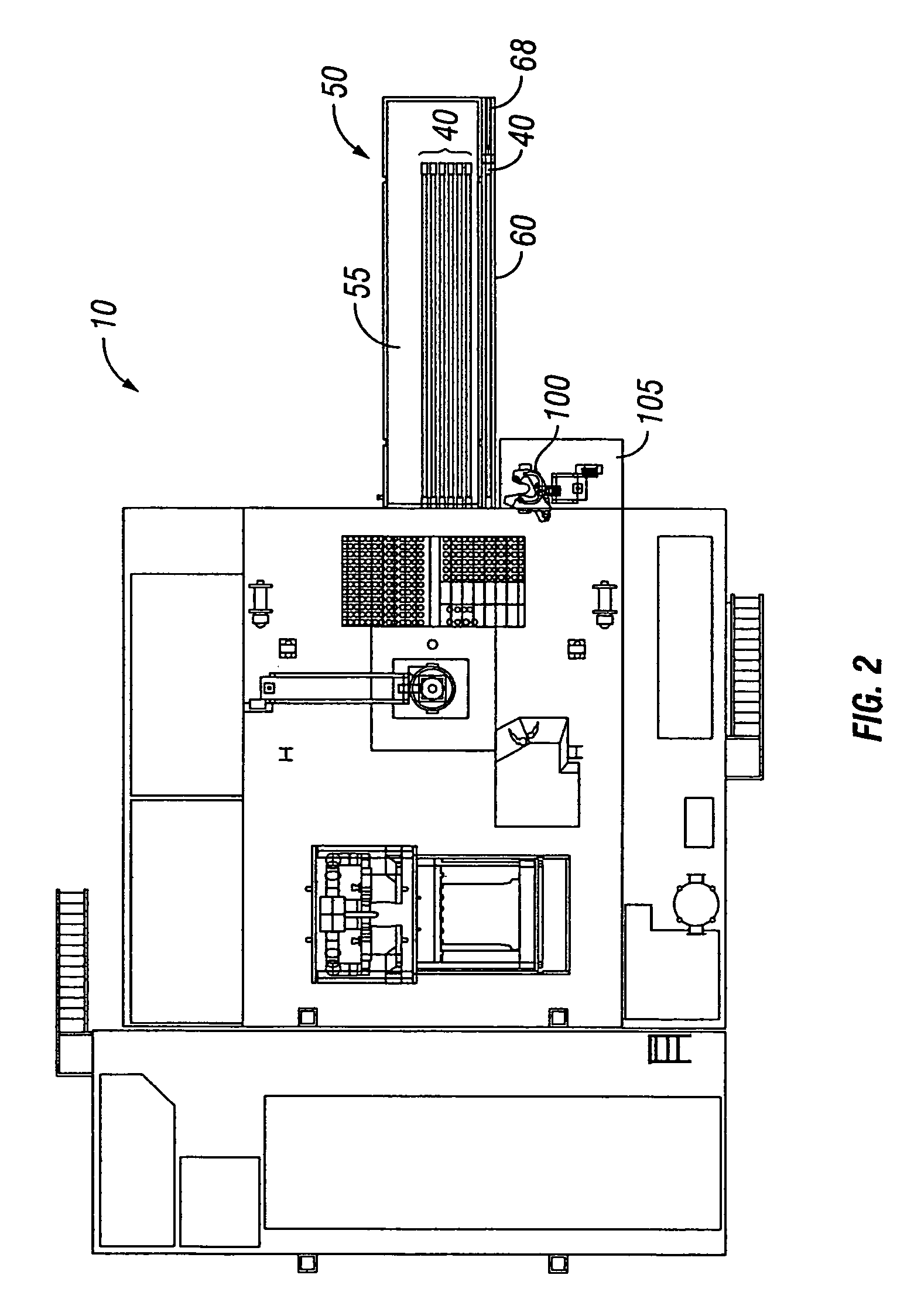

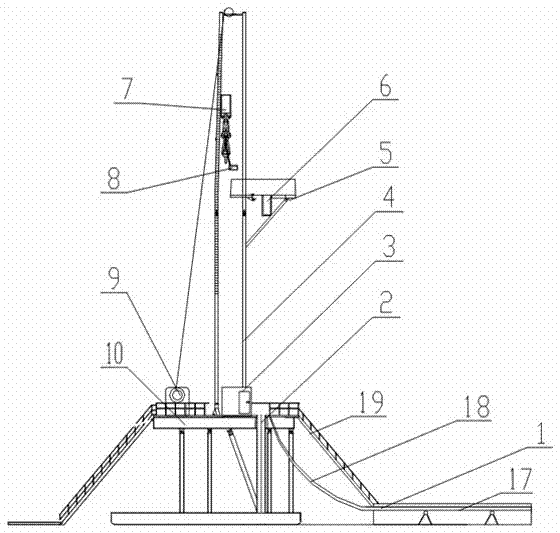

Drilling platform pipe racking system and method

InactiveCN101812977AIncrease productivityIncrease profitDrilling rodsDrilling casingsWell drillingRoughneck

The method disclose a drilling platform pipe racking system, which comprises a multi-station mouse hole, a derrick, a pipe grabbing mechanical hand and an iron roughneck, wherein the multi-station mouse hole at least provides two mouse hole-body drill stem insertion stations; a drill stem aligning device, a lifting cylinder, a drill steam buffer and a lifting pulley block are correspondingly arranged in the mouse hole body one to one; the pipe grabbing mechanical hand grabs drill stems in turn, puts the drill stems into the mouse hole body and joints the stems after the drill stems are pulled outside the mouse holes. The invention also discloses a method for racking pipes by the system. In the invention, a multi-station mouse hole structure providing at least two pipe racking stations is adopted, so two single pipes can be arranged in the mouse holes simultaneously; when the third single pipe is jointed, the third pipe can be directly connected with the rest single pipes; and thus, the production efficiency is greatly improved. Besides, the drill stem can be changed from a horizontal state into a vertical state by only one piece of equipment, namely the pipe holding mechanical hand, so the equipment use ratio is greatly improved, the space is saved and the equipment operation is simplified.

Owner:天时海洋工程及石油装备研究院(青岛)有限公司

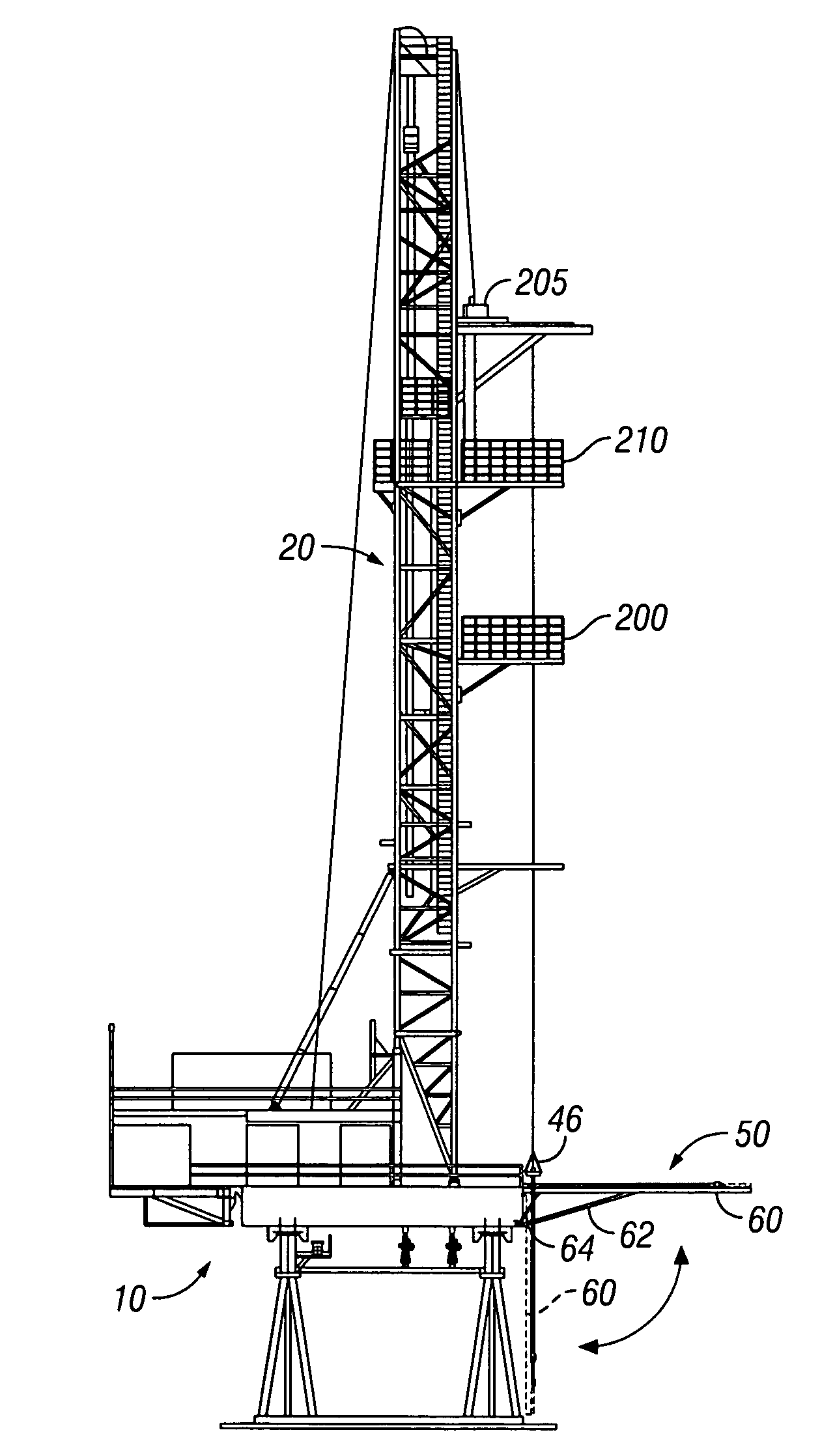

Pivoting pipe handler for off-line make up of drill pipe joints

An apparatus and method for use in the off-line make-up of drill pipe stands on drilling rigs used in the exploration and production of oil and gas reserves are disclosed. The disclosed invention is a pipe handling system in which a section of the V-door ramp attached to a drilling rig structure pivots to allow one or more joints of drill pipe to be placed in a vertical position. Through use of an off-line roughneck in conjunction with an off-line drill pipe elevator, the joints of drill pipe held in the vertical position via the pivoting pipe handler of the present invention can be connected together, connected to additional joints of drill pipe, and placed in a racking board to be stored until they are subsequently connected to the drill string. The use of the pivoting pipe handler of the present invention allows stands of drill pipe to be “made-up” without the need to interrupt drilling operations and, thus, significantly reduces the amount of time required to drill a borehole.

Owner:NAT OILWELL DHT

Wellbore continuous circulation systems

Systems and methods for continuously circulating fluid, e.g., drilling mud, through a wellbore tubular string, the systems in certain aspects including a sub positionable in fluid communication with the tubular string, the sub with a body, a plug releasably closing off a side opening of the body, and a closure apparatus for selectively closing off flow from the top of the sub into and through the body, while flow is permitted below the closure apparatus through the side opening down through the body into the tubular string; and, in certain aspects, such systems and methods including tubular manipulation apparatus, e.g. an iron roughneck and working with wellbore tubulars with the tubular manipulation apparatus. This abstract is provided to comply with the rules requiring an abstract which will allow a searcher or other reader to quickly ascertain the subject matter of the technical disclosure and is submitted with the understanding that it will not be used to interpret or limit the scope or meaning of the claims, 37 CFR 1.72(b).

Owner:NAT OILWELL VARCO LP

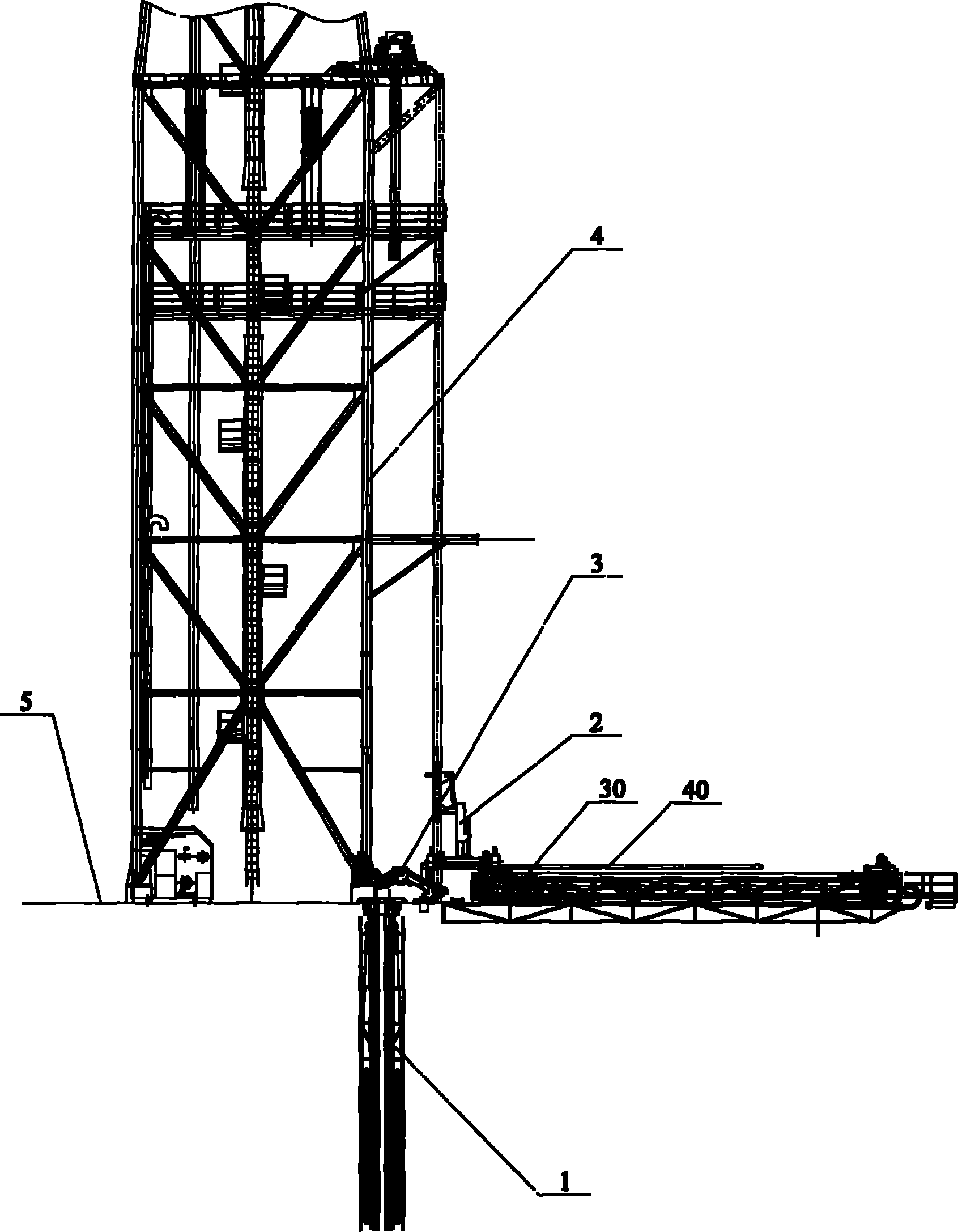

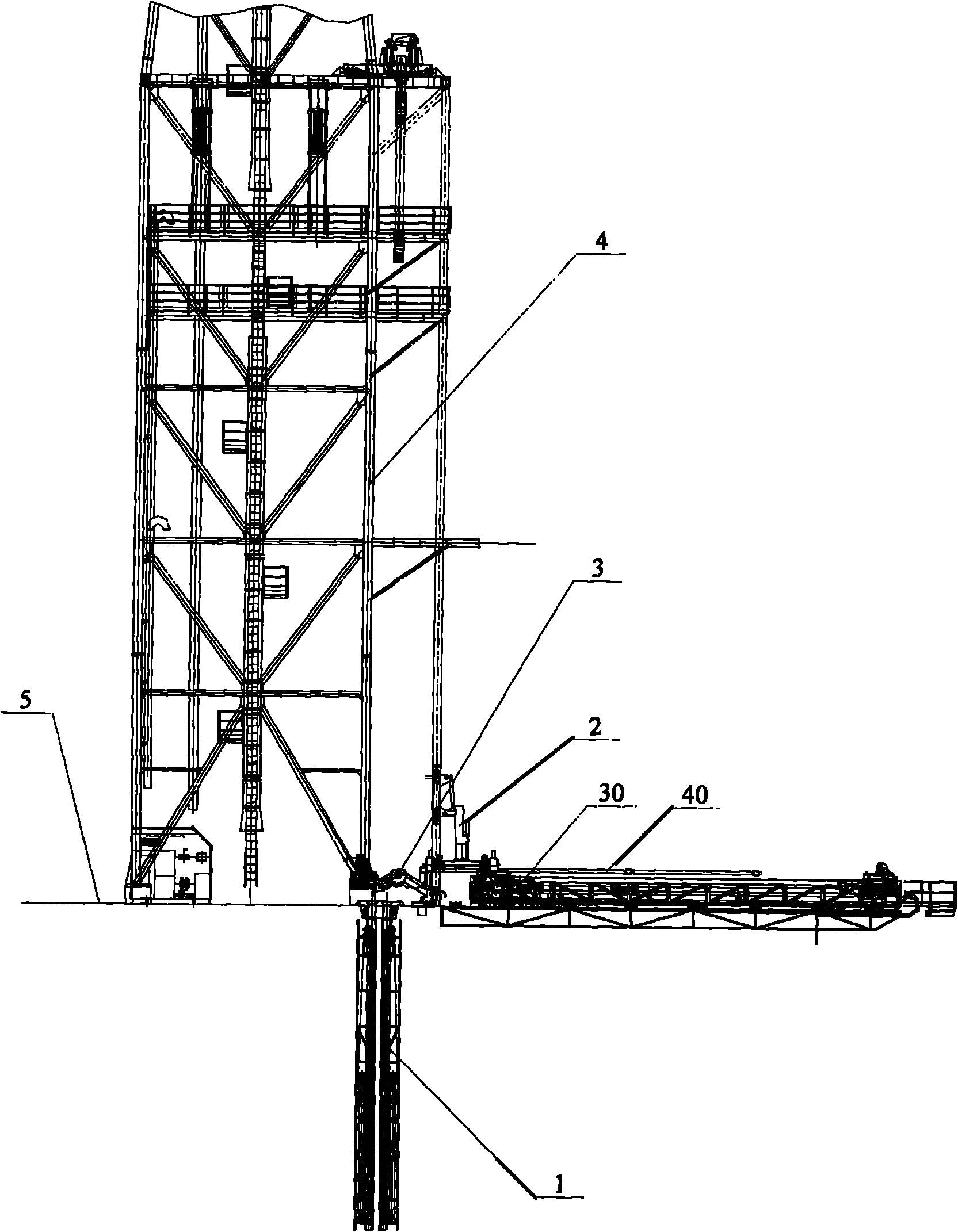

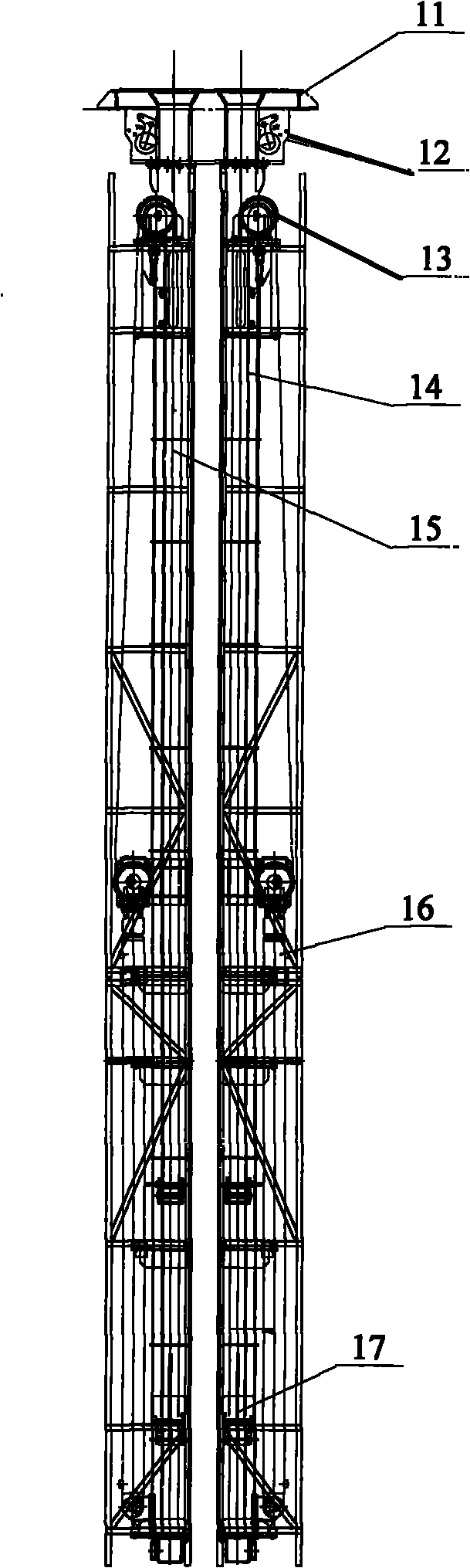

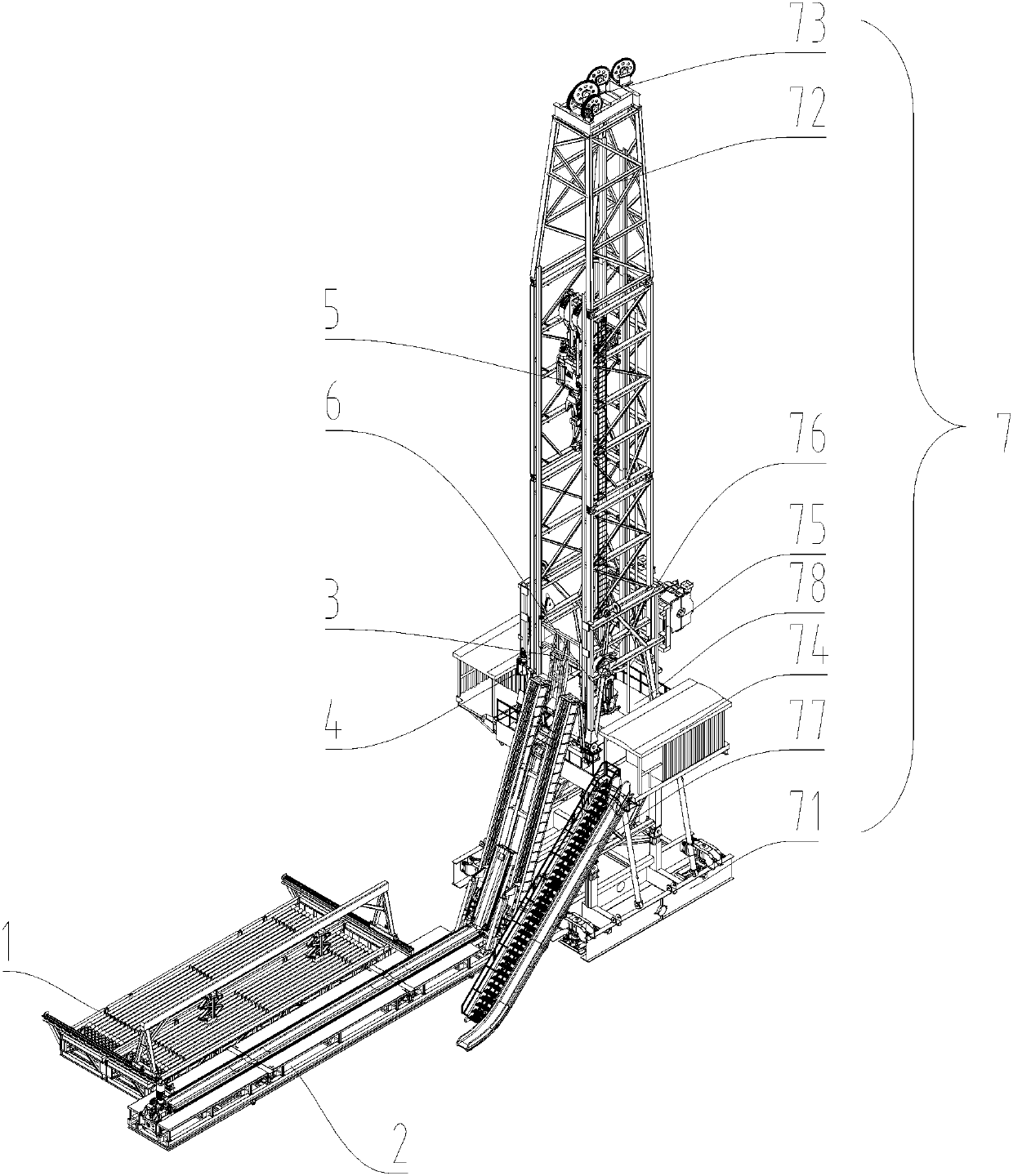

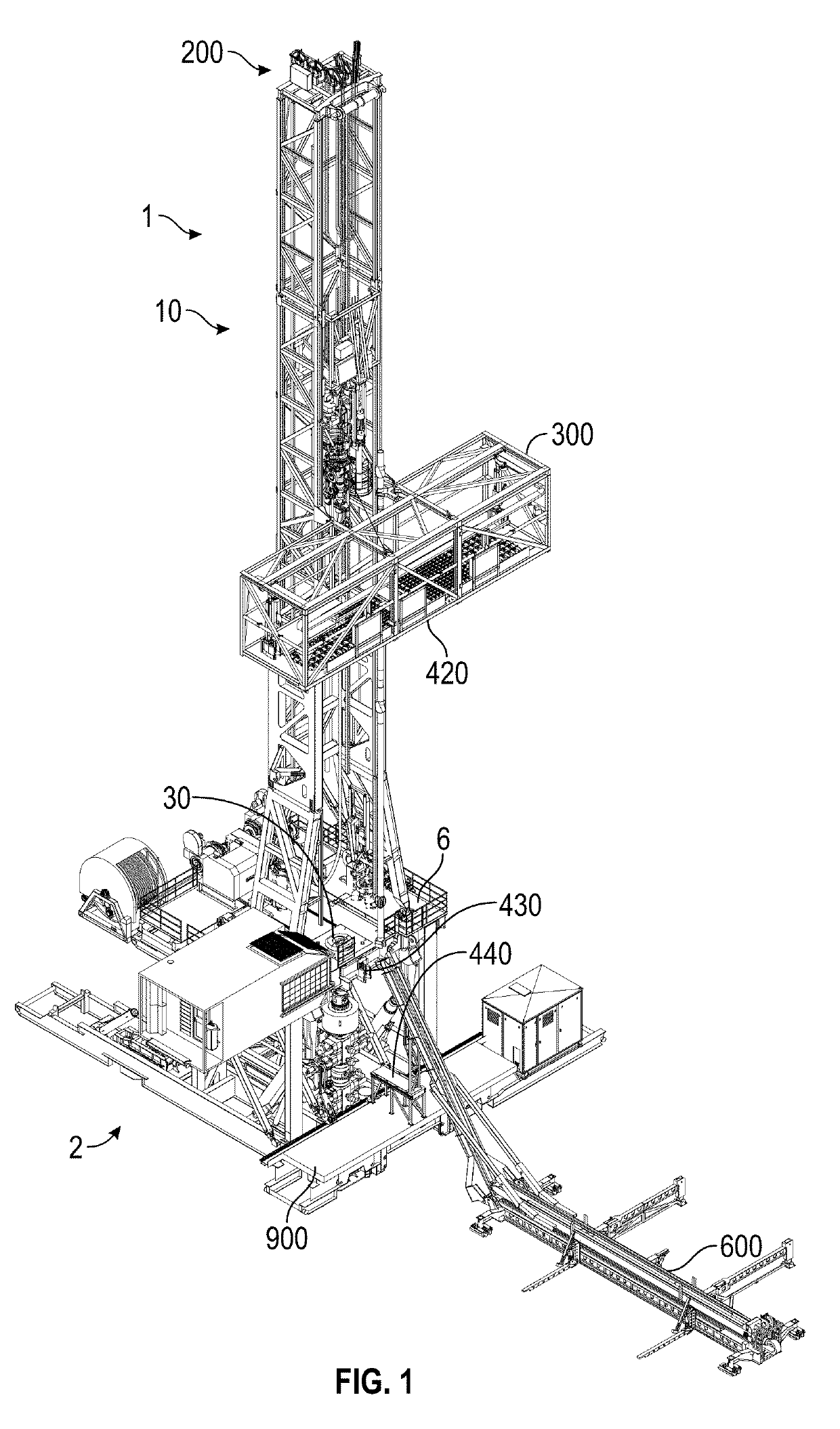

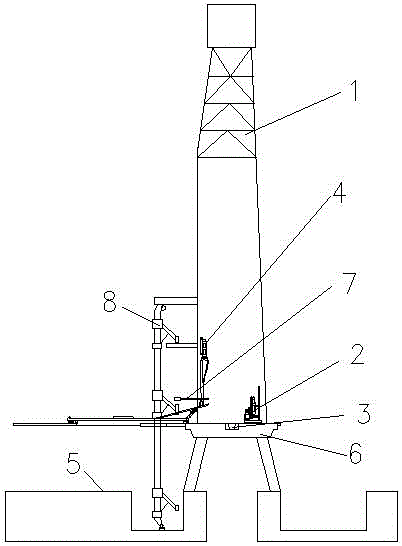

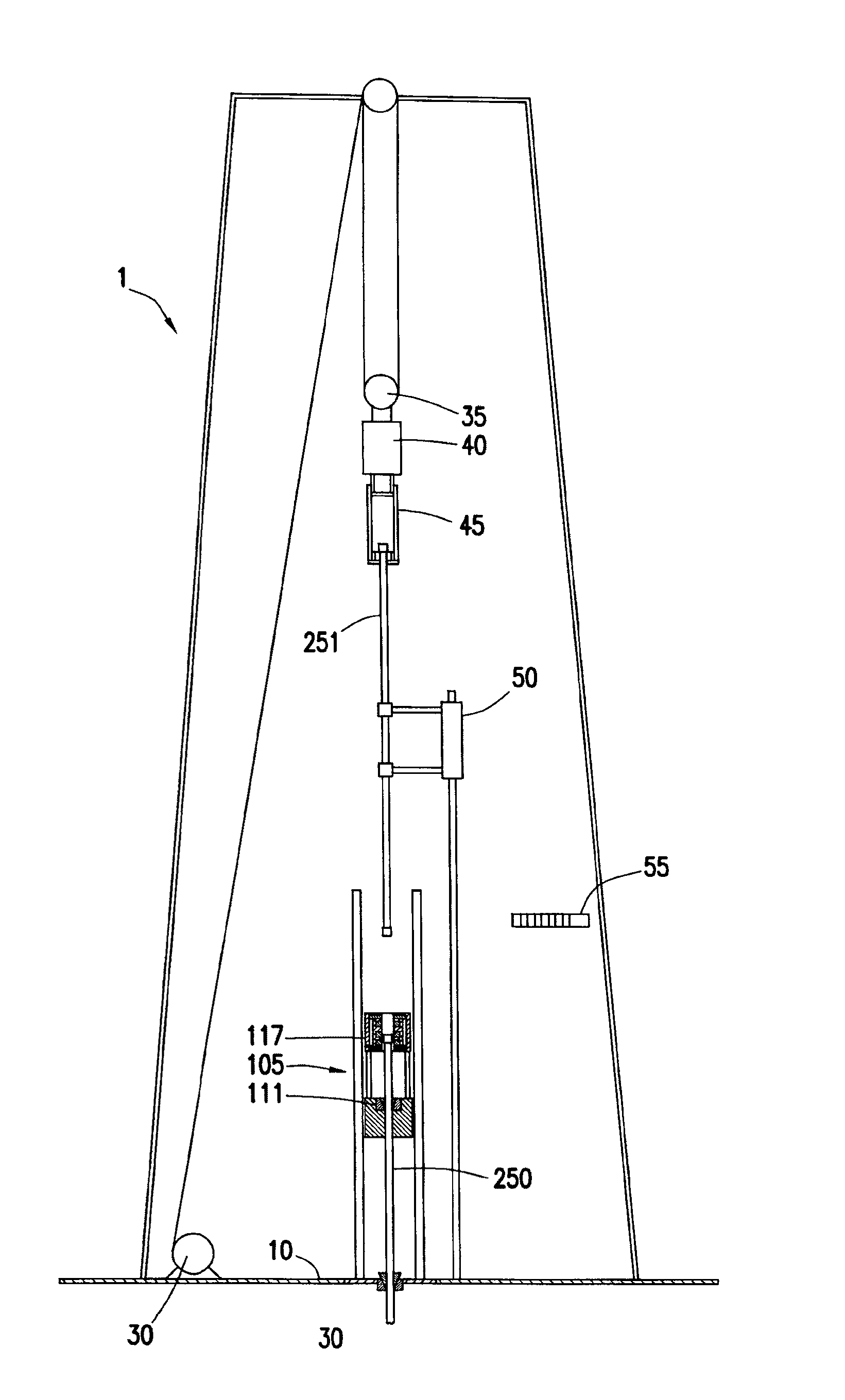

Automated drilling rig and method for moving and transporting pipe columns through automated drilling rig

PendingCN110043203AImprove work efficiencyLow running costDrilling rodsDrilling casingsRoughneckOil drilling

The invention relates to the field of oil drilling equipment, in particular to an automated drilling rig. The automated drilling rig comprises a derrick assembly fixedly connected with a foundation, atop driving assembly movably connected with the derrick assembly, and an iron roughneck fixedly connected with the derrick assembly; and the automated drilling rig further comprises a power pipe-arranging box fixedly connected with the foundation, a power catwalk fixedly connected with the foundation and the derrick assembly, a double-joint grabbing manipulator and a supporting manipulator, wherein the double-joint grabbing manipulator and the supporting manipulator are fixedly connected with the derrick assembly. The invention further discloses a pipe column moving and transporting method. The automated drilling rig occupies the small space and is simple in structure, the process is concise and easy to realize, the operation cost of the whole drilling rig is lowered, the working efficiency is improved, and the risk of safety incidents is lowered.

Owner:SICHUAN HONGHUA PETROLEUM EQUIP

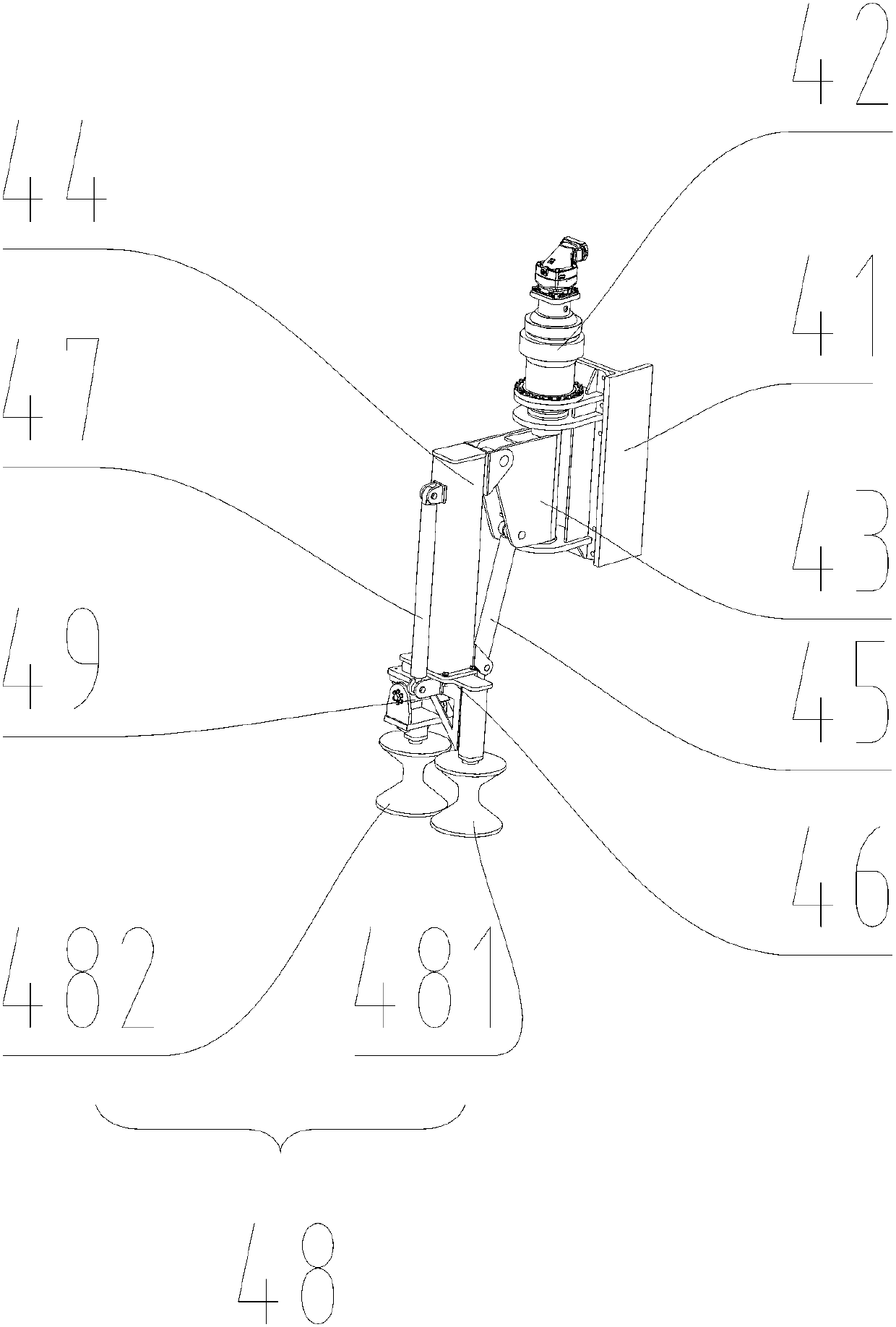

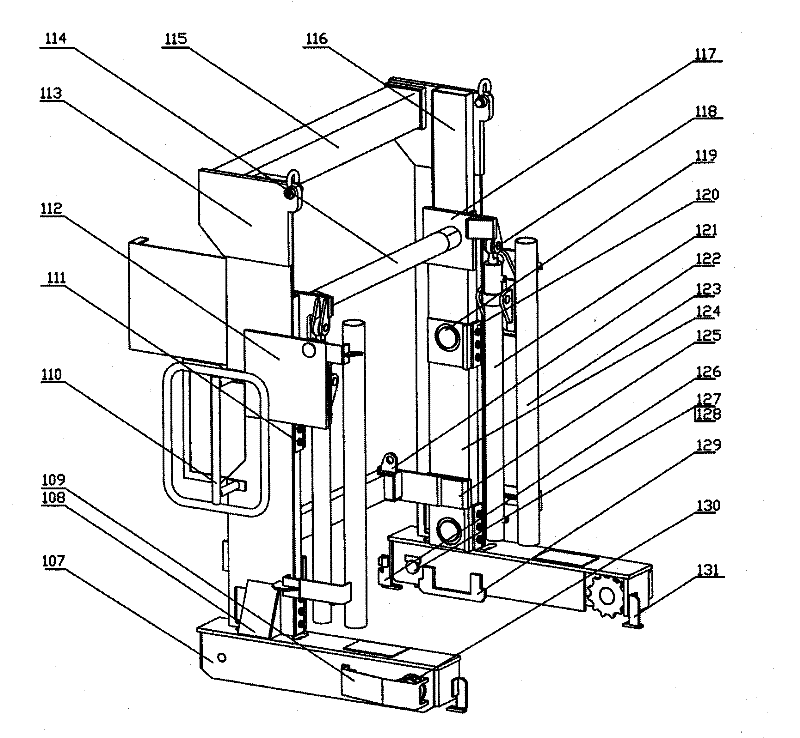

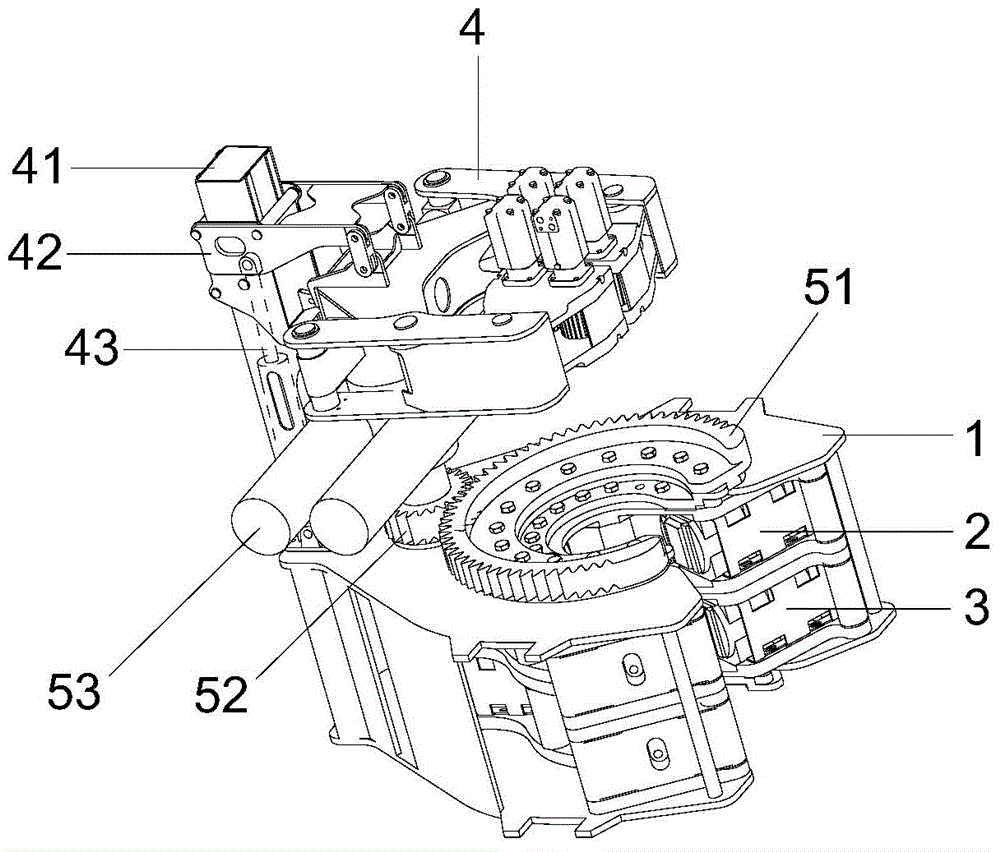

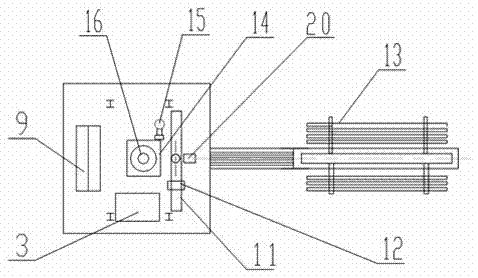

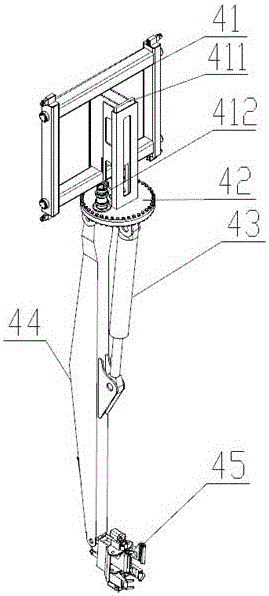

Iron driller

ActiveCN101397892AEasy to clipSolve operational problemsDrilling rodsDrilling casingsHydraulic cylinderRoughneck

The invention provides an iron roughneck, which relates to an assorted wellhead operation device of a petroleum drilling machine and aims at solving the problem of inconvenient operation in the prior art. The wellhead operation device comprises a tong head assembly, a support arm assembly and an electrohydraulic control system; the tong head assembly comprises a spinner assembly, a driving tong assembly and a driven tong assembly as well as a lifting mechanism and a swing mechanism. One end of the support arm assembly is movably connected on the lifting mechanism while the other end is movably connected with the swing mechanism. The swing mechanism is connected with the driving tong assembly and the driven tong assembly; the tong head assembly is arranged above the driving tong assembly and the driven tong assembly; the electrohydraulic control system consists of a hydraulic control system and an electronic control system; the swing mechanism, the lifting mechanism, the support arm assembly, the spinner assembly, the driving tong assembly and the driven tong assembly respectively contain respective hydraulic cylinder drive parts and the hydraulic cylinder drive parts of all the assembly are connected with and controlled by the hydraulic control system; and the electronic control system controls the hydraulic control system. The wellhead operation device is applicable to wellhead operation during petroleum drilling.

Owner:四川劳玛斯特高胜石油钻采设备有限公司

Automated arm for positioning of drilling tools such as an iron roughneck

Owner:NAT OILWELL DHT

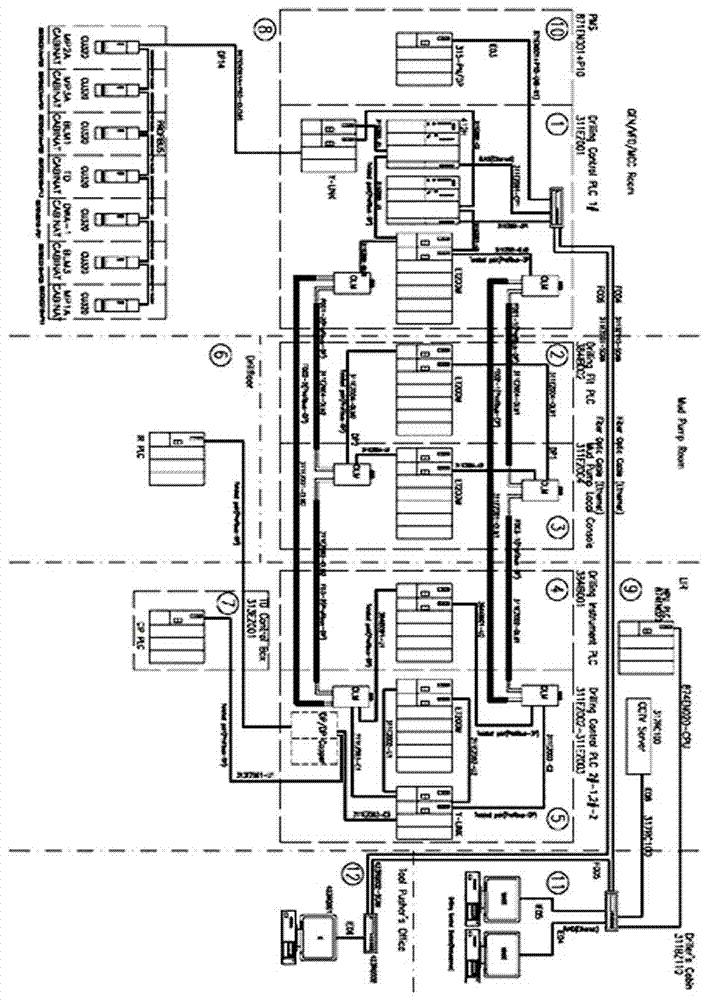

Drilling control and data collection system of self-elevating platform

InactiveCN103034212AHighly integratedImprove reliabilityTotal factory controlProgramme total factory controlTop driveRoughneck

The invention provides a drilling control and data collection system of a self-elevating platform. The drilling control and data collection system of the self-elevating platform is a control and data collection system based on a redundant programmable logic controller (PLC) and is characterized in that a main hull equipment drilling PLC, a mud pit PLC, a mud pump operating platform PLC, a drilling meter PLC and a drill floor control equipment PLC are respectively arranged in each area and are respectively conducted with a 412 H processor of a PLC main station. An iron roughneck PLC, a top drive PLC and a hydraulic power unit PLC are conducted with the 412 H processor, and a motor variable frequency controller is conducted with the 412 H processor through a CU 320 control unit. The 412 H processor is connected into a driller room switchboard through an Ethernet network through connection optical fiber, and a driller control industrial computer is conducted with the driller room switchboard through an Ethernet network. A generator controls the PLC to be directly conducted with the driller control industrial computer through the Ethernet network. The drilling control and data collection system of the self-elevating platform has the advantages of being high in integration level, good in reliability, strong in operability and the like, and meanwhile, driller control layout is reasonable and is controlled to display with equipment in a centralized mode, and operating is convenient.

Owner:海尔海斯(西安)控制技术有限公司

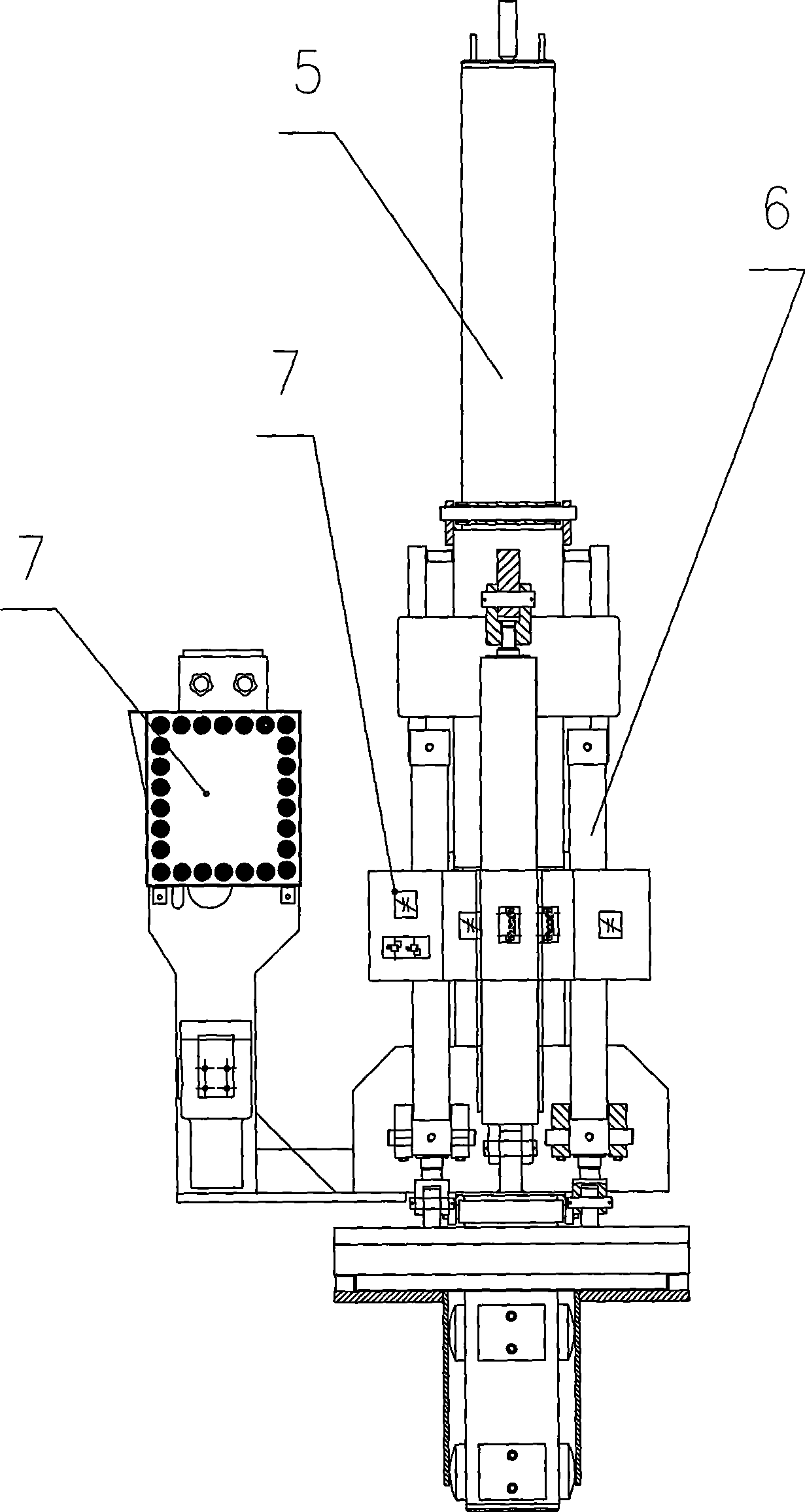

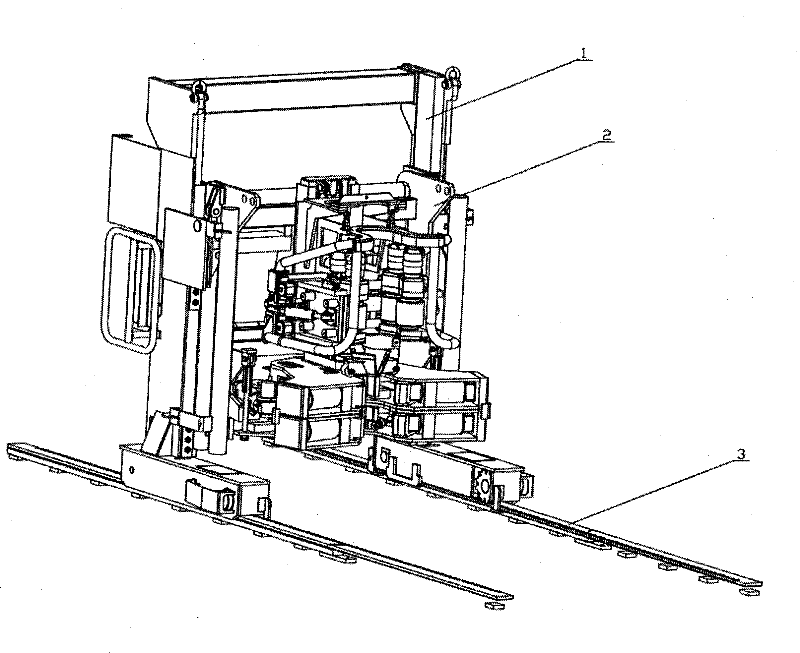

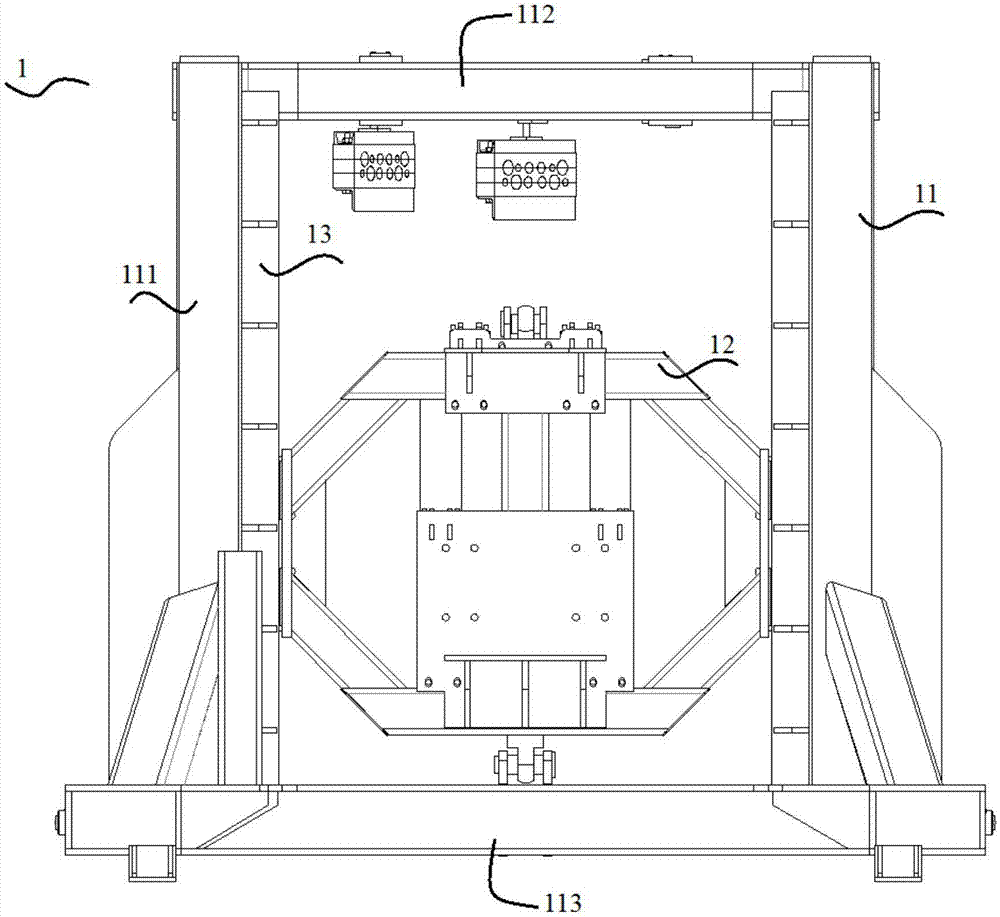

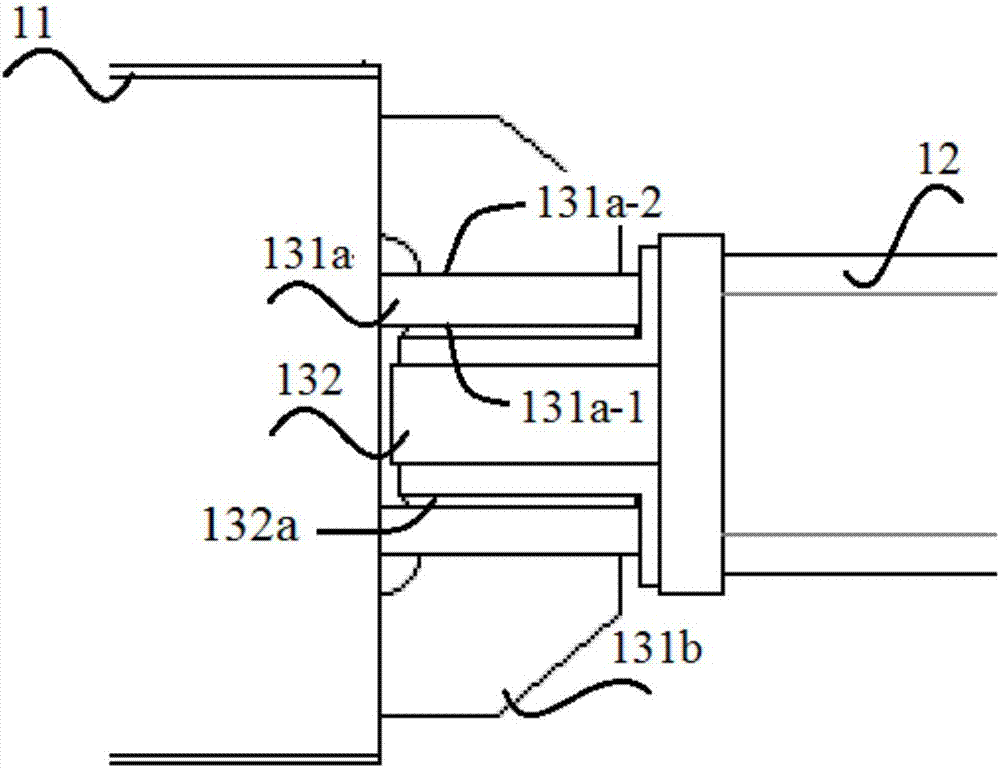

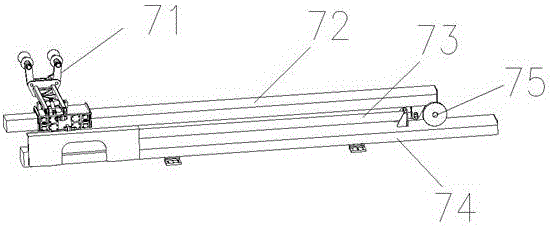

A floor rail type highly integrated intelligent iron driller

InactiveCN102287150AHigh degree of automationRealize full automationDrilling rodsDrilling casingsHydraulic motorHeadframe

The invention provides a floor rail type highly integrated intelligent iron roughneck, which integrates a lift car, a clamp head frame, a main back clamp and guide rails into a whole and consists of the lift car, the clamp head frame and the guide rails, wherein the lift car moves on the guide rails, the upper part of the clamp head frame is suspended and connected onto the lift car, in addition,the connection between the lift car and the lower part of the clamp head frame is realized through unscrewing, the lift car consists of a left side frame, a right side frame and a cross beam, the left side frame and the right side frame are respectively arranged on the two guide rails, the lift car drives a transmission gear to rotate through a lift car hydraulic motor for realizing the moving onthe guide rails. The floor rail type highly integrated intelligent iron roughneck can realize the application of a large-torque and wide-pipe-diameter-range rotary thread punching device and is applicable to the unscrewing on drill rods in any dimensions. The lift car, the clamp head frame, the main back clamp and the guide rails are integrated into a whole, so the weight of the whole equipment is greatly reduced, and the work efficiency is improved. The floor rail type highly integrated intelligent iron roughneck has the advantages that the automation degree is high, the full-process automatic operation of the work process can be realized, and the rotary thread punching operation of the whole site can be completed by one worker.

Owner:金华萨博思石油机械有限公司

Sequencing for pipe handling

ActiveUS20190106950A1Reduce disadvantagesReduce problemsDrilling rodsConstructionsTop drivePipe fitting

A method sequence for handling tubulars into or out of a wellbore, the method comprising: moving a tubular string into or out of a wellbore via a top drive; moving tubular stands to and from a setback position and a stand handoff position via a transfer bridge racker and a setback guide arm; moving tubular stands to and from the stand handoff position and a well center position via a tubular delivery arm and a lower stabilizing arm; building stands and breaking down stands offline via a mousehole and operating a roughneck on joints between the tubular stands and the tubular string.

Owner:SCHLUMBERGER TECH CORP

Articulated arm assembly

The invention of an articulated arm assembly described here is to carry and position a drilling related apparatus such as power tong, roughneck, drill sting, top drive, casing tong and any other applicable apparatus from the storage position to a working position such as well center or mouse hole. The combination of a parallelogram, a support arm, and a movable guide provides a simple means to move and position a drilling apparatus between a storage position to a desired working position such as a well center and to maintain the drilling apparatus at any desired position.

Owner:GE YAOGEN

Automated roughneck

An automated roughneck may include a backup tong and a makeup tong. The makeup tong and backup tong may be selectively movable relative to one another. The makeup tong and backup tong may include spinner and gripper assemblies respectively adapted to make up and break out threaded connections. The automated roughneck may be configurable to be removable from the drill string in a lateral direction.

Owner:NABORS SERVICES

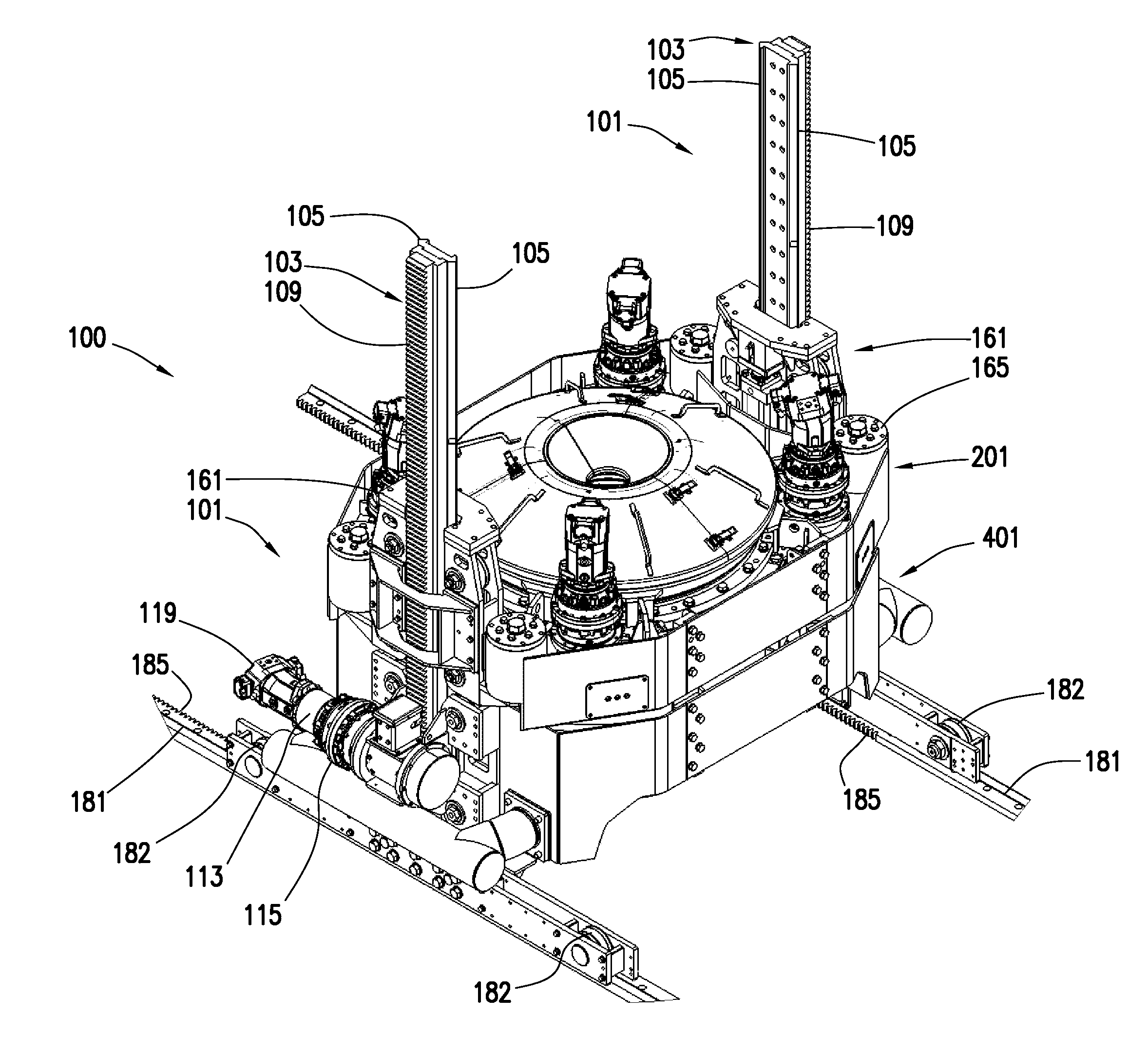

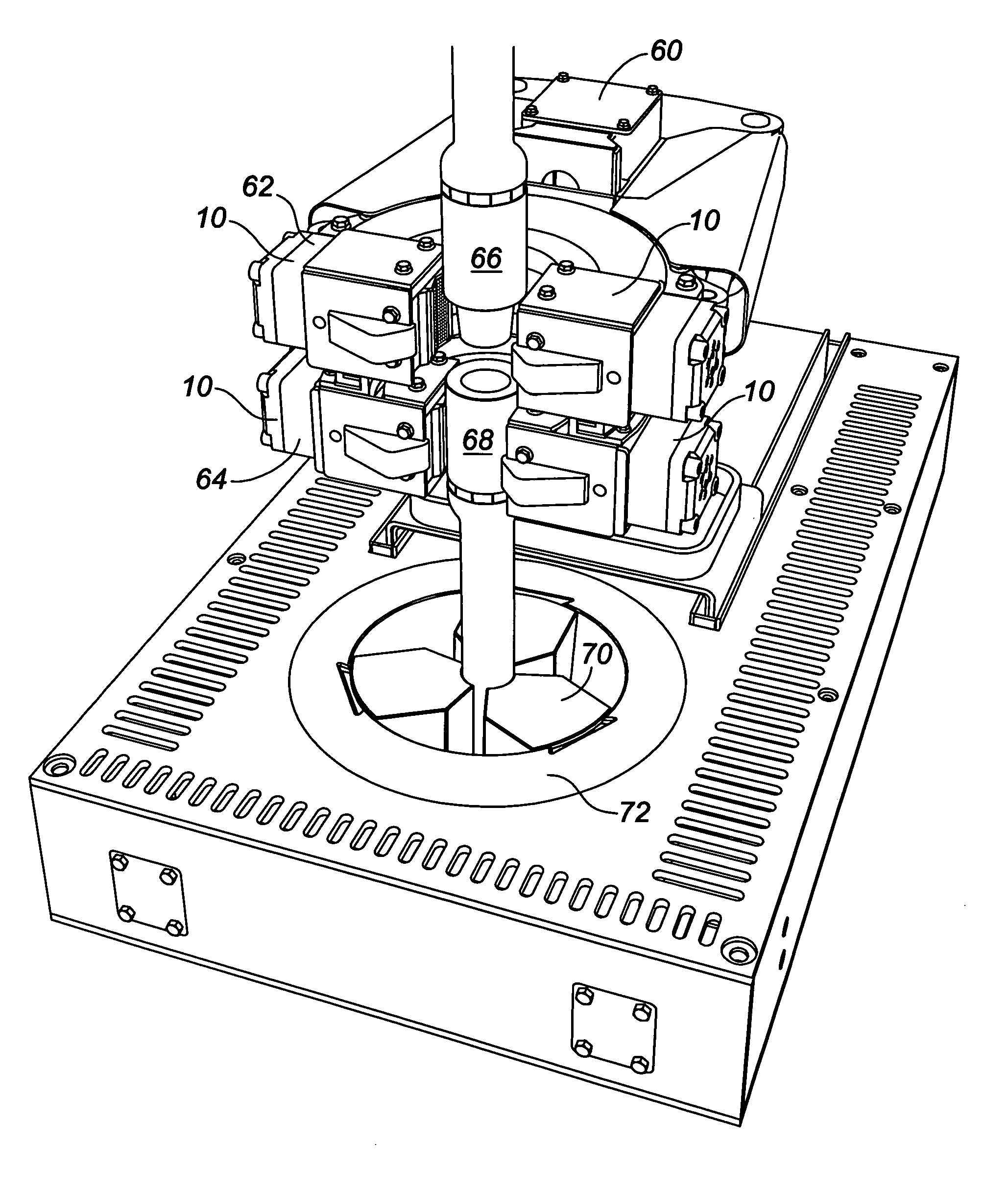

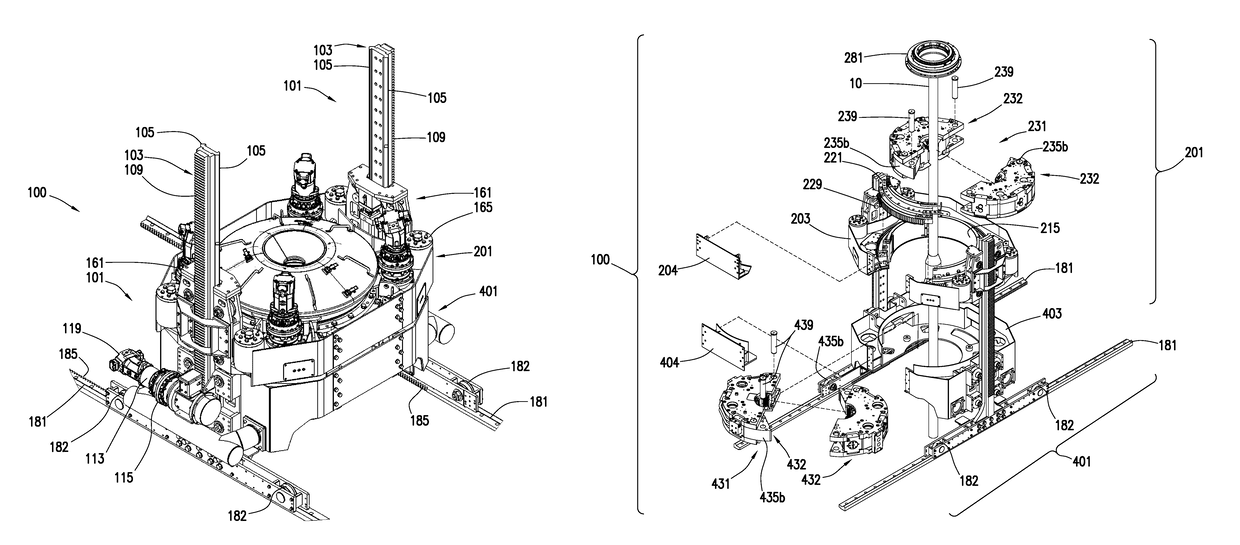

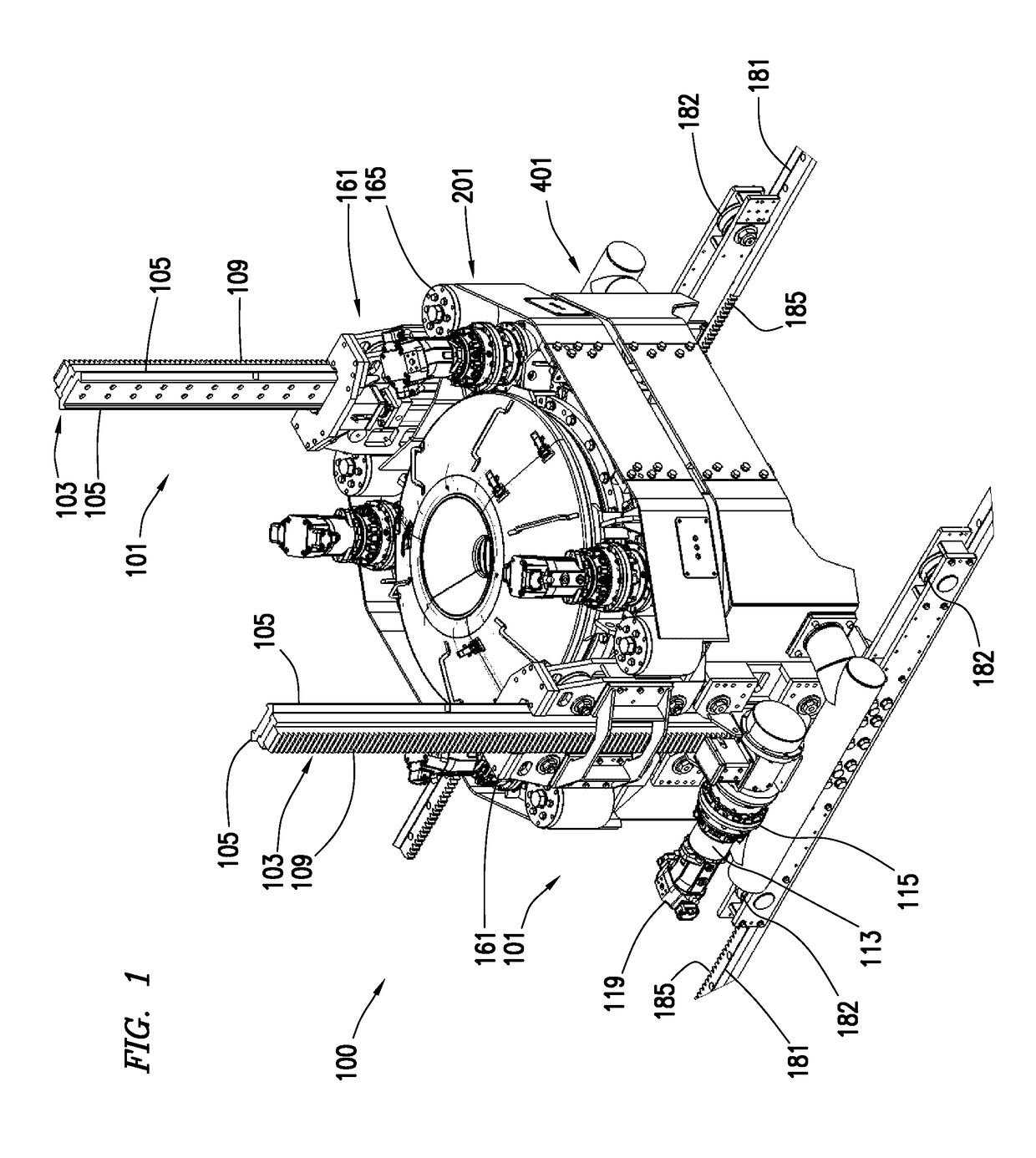

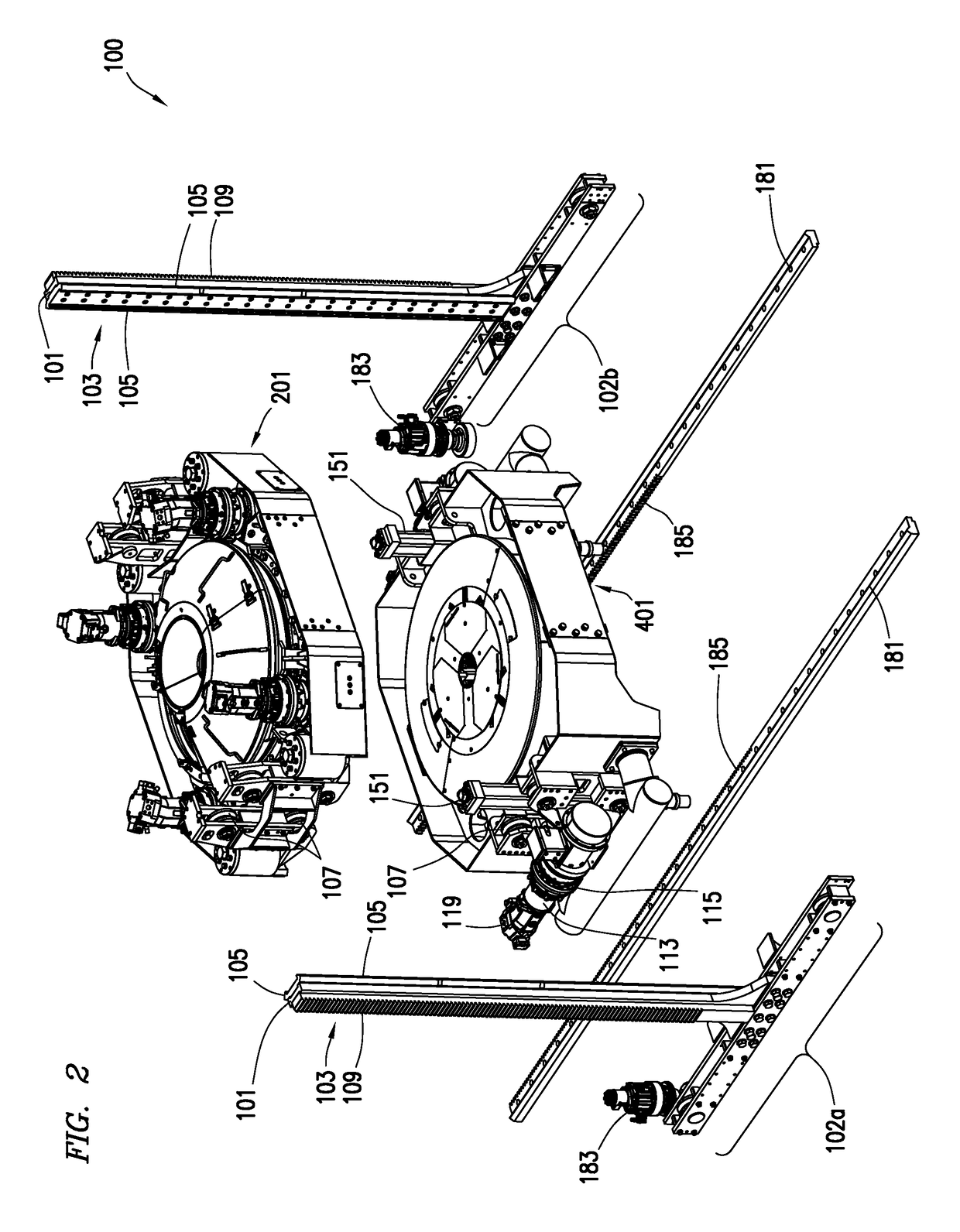

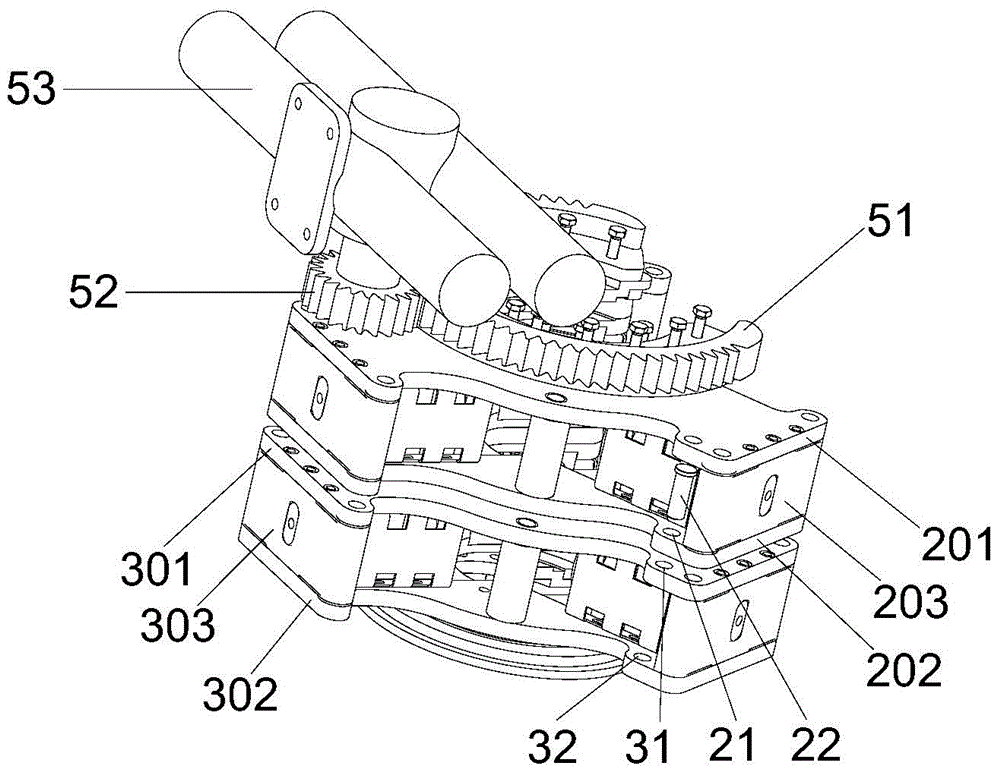

Low maintenance iron roughneck system with replaceable modular components thereof

An automated roughneck system is described which includes a base module, a removable spinner module for spinning pipe to connect or disconnect drill pipes at threaded interfaces, which automatically self-centers itself around a drill pipe and automatically adjusts to a varied range of drill pipe diameters, a removable torque module for torqueing drill pipe and which automatically self-centers itself around a drill pipe and automatically adjusts to a varied range of drill pipe diameters, an extension module including a first plurality of extension arms that extend between a central hub of the extension module and the base module, and a second plurality of extension arms that extend between the central hub and supporting structure that supports the spinner and torque modules thereon, with each of the base, extension, spinner, and torque modules being hydraulically powered, and being controlled by controls at the remote operator control console.

Owner:BERTELSEN JEFFREY LEE

Rail type iron roughneck

PendingCN106948775AExpand the scope of workImprove carrying capacityDrilling rodsDrilling casingsPipe fittingRoughneck

The invention relates to a rail type iron roughneck, which is used for performing screwing and / or unscrewing operation on an upper part pipe fitting and a lower part pipe fitting. The rail type iron roughneck is characterized by comprising a rail, a base, a spinning wrench and an upper unscrewing wrench, wherein the base can move forwards to the work position along the rail or can move backwards so as to be far away from the work position; the spinning wrench is arranged on the base; the upper unscrewing wrench is arranged on the base and is positioned under the spinning wrench. The iron roughneck related by the invention is the rail type iron roughneck. Compared with a cantilever type iron roughneck, the rail type iron roughneck breaks through the limitation of the cantilever length on the work range; the work range of the iron roughneck is obviously increased.

Owner:SHANGHAI ZHENHUA HEAVY IND

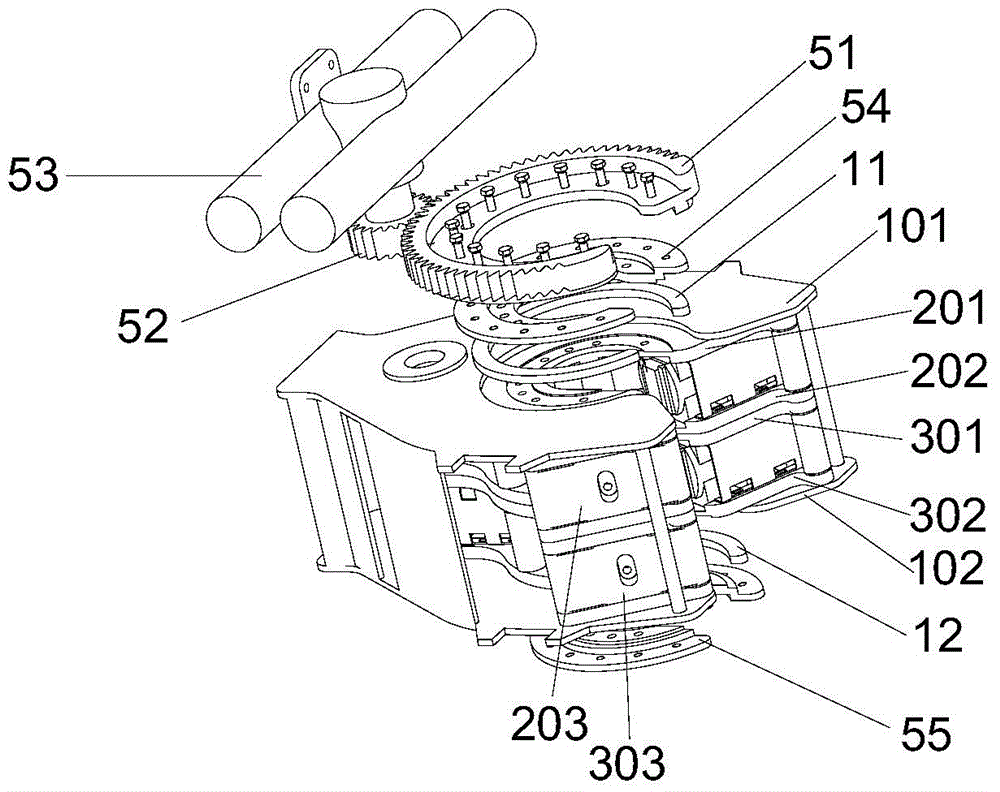

Petroleum drilling and production equipment, iron roughneck and clamp body

ActiveCN104895515ABuckle realizationBig make-up and breakout angleDrilling rodsDrilling casingsPunchingRoughneck

The invention discloses an iron roughneck clamp body. The iron roughneck clamp body comprises a rack, punching pliers, and a clamping clamp, the clamping pliers and the clamping clamp are arranged in the rack, a cover plate of the clamping pliers is provided with a gear ring along the circumferential direction of a clamp opening, the gear ring is engaged with a gear, and the gear is connected with a driving device. According to the iron roughneck clamp body, the punching torque is provided by the adoption of a transmission method of the gear and the gear ring, the punching of a pipe column is realized, compared with the method of applying the punching torque by the adoption of a punching oil cylinder in the prior art, the upper shacking angle is large, and the upper shackling efficiency is higher. The invention further discloses an iron roughneck and petroleum drilling and production equipment.

Owner:HUNAN SANY PETROLEUM TECH

Mouse hole support unit with rotatable or stationary operation

The present invention allows for the connection of multiple sections of drill pipe in a mouse hole by securing a given section of pipe in the hole and delivering a rotational force to secure that pipe section to another section of drill pipe placed above it over the mouse hole. In some embodiments, the rotational force may be provided by the support unit of the present invention. In alternative embodiments, the rotational force may be provided by an outside source such as an iron roughneck, with the support unit of the present invention holding the drill pipe section in a stationary position as such force is delivered. The unit then allows the connected pipe sections to be lowered and secured so the process can be repeated to connect multiple sections of drill pipe together in the mouse hole. The multiple sections of drill pipe may then be retrieved as a unit, and attached to the pipe string already being used to drill the well.

Owner:XTECH INDS

Petroleum drilling machine tubing string automatic processing system

The invention discloses a petroleum drilling machine tubing string automatic processing system. The petroleum drilling machine tubing string automatic processing system is mainly composed of a drill stand, a derrick, an automatic catwalk machine, a power rat hole, a rotary table, a drill stand manipulator, a power slip, an iron roughneck, a power elevator, a racking platform pipe-handling manipulator, a top drive, a winch and a driller integrated control system. After the petroleum drilling machine tubing string automatic processing system is matched to a petroleum drilling machine, automation of all tubing string operation processes of stand column connecting and stand column throwing, individual pipe connecting and individual pipe throwing, drilling, stand pipe storing and stand pipe fetching and the like during the drilling operation process is achieved. According to the invention, the automation degree of the drilling machine is increased, the problem that with respect to the existing drilling tubing string operation mode, many people need to cooperate with one another to work high above the ground, the labor intensity is large, the risk is high, and the efficiency is low is solved, and problems existing in the prior art that the power winch needs to be manually operated, the automatic catwalk machine is low in conveying efficiency and high in energy consumption are cvercome.

Owner:山东胜工检测技术有限公司 +1

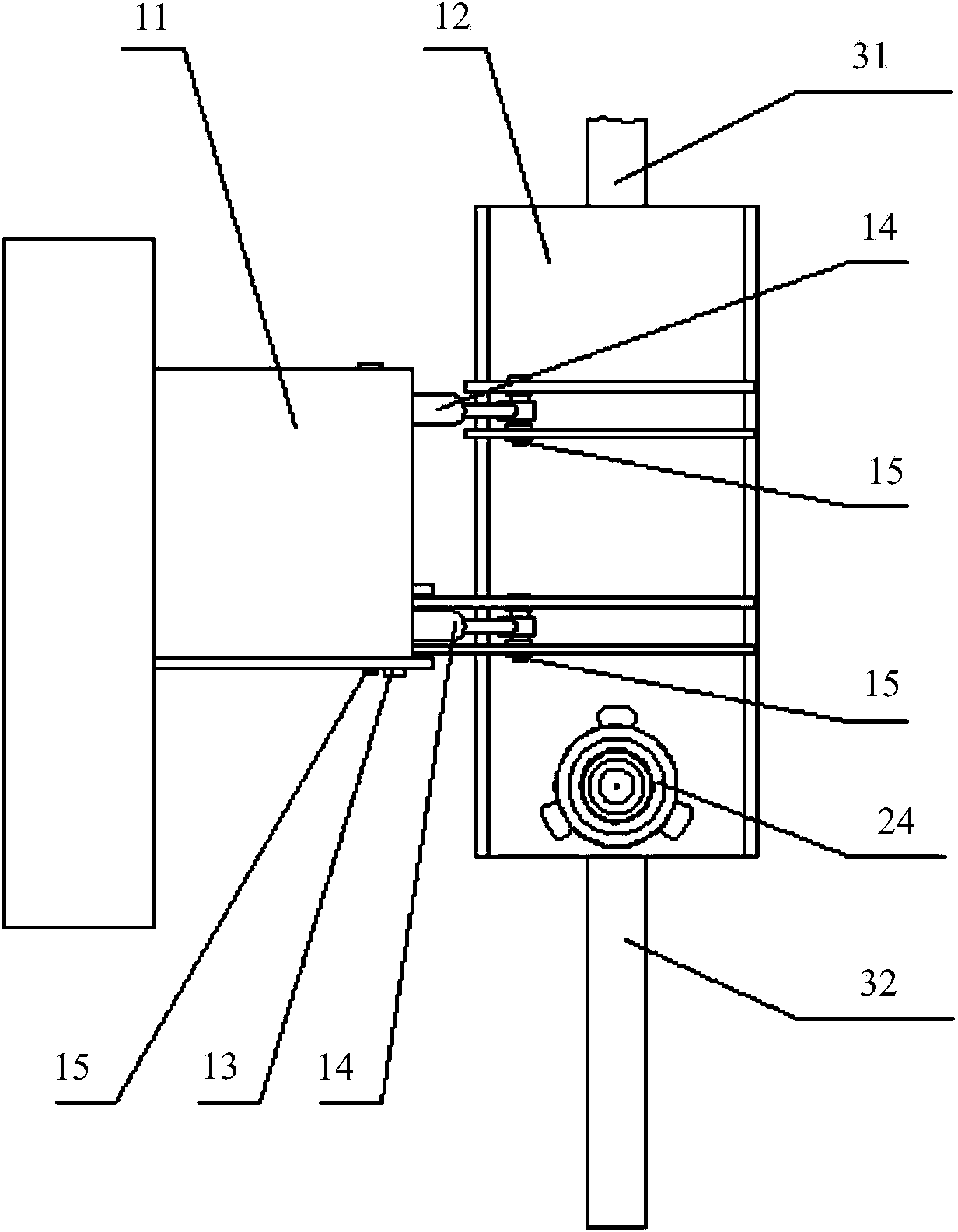

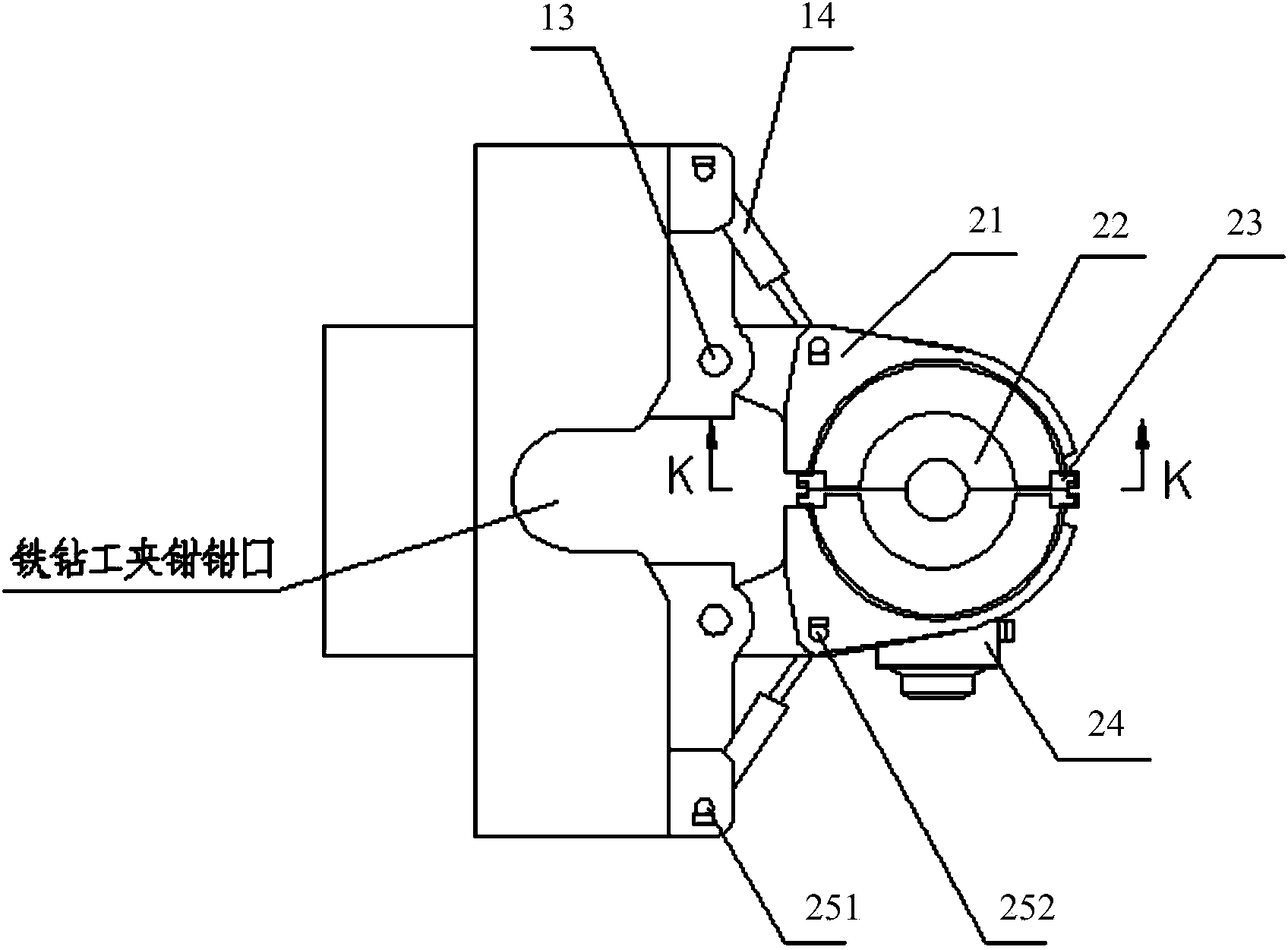

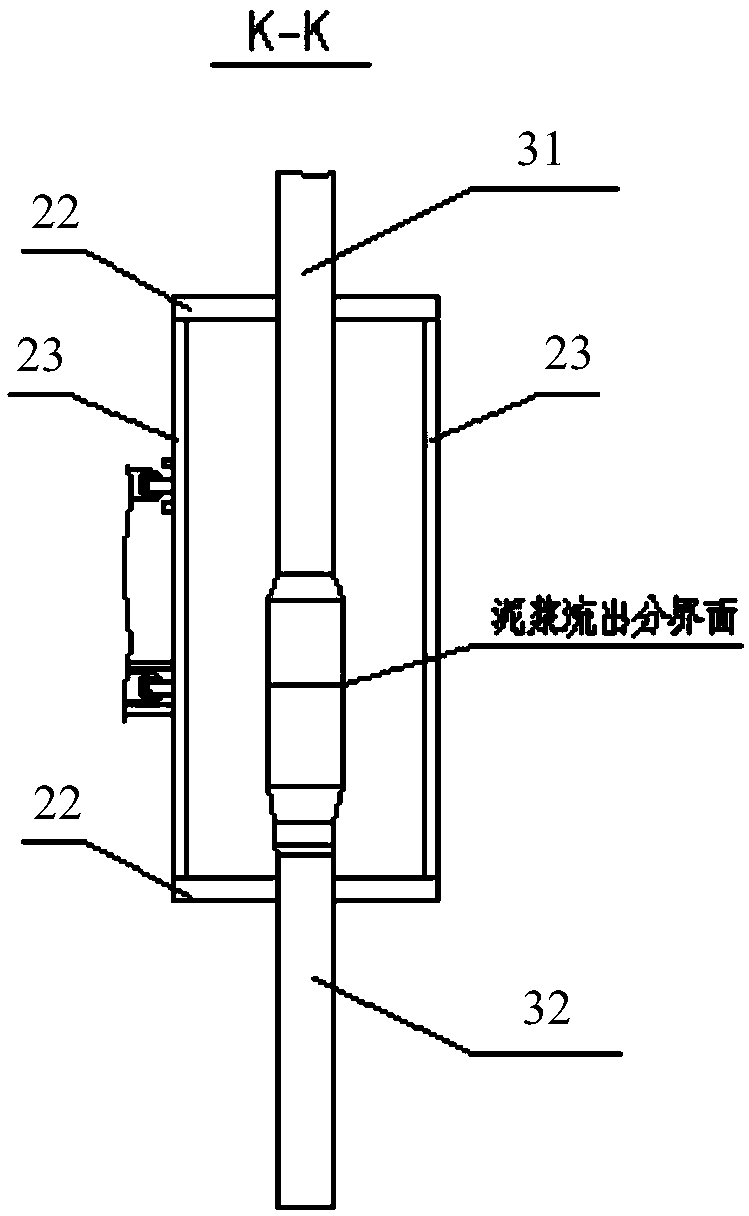

Composite iron roughneck and slurry blowout prevention box

ActiveCN103410459AShorten working timeImprove work efficiencyDrilling rodsDrilling casingsRoughneckEngineering

The invention provides a composite iron roughneck and slurry blowout prevention box which comprises an iron roughneck, a slurry blowout prevention box and two oil cylinders. The iron roughneck is provided with a clamp jaw, the box body of the slurry blowout prevention box comprises two half box bodies matched with each other, the two half box bodies are symmetrically arranged on the two sides of the front end of the clamp jaw of the iron roughneck and are connected with the two sides of the clamp jaw respectively through connecting pin shafts, the first ends of the oil cylinders are fixed to the two sides of the clamp jaw respectively through first oil cylinder pin shafts, the second ends of the oil cylinders are connected with the two half box bodies respectively through second oil cylinder pin shafts, and the two oil cylinders drive the two half box bodies to rotate around the corresponding connecting pin shafts to open to expose the clamp jaw, or to rotate to close for slurry collecting. The iron roughneck and the slurry blowout prevention box are integrated, the structure is greatly simplified, the total weight and the total occupied space of equipment are reduced, and more safe operation space is saved at a shaft mouth.

Owner:SHANGHAI ZHENHUA HEAVY IND

Marine drilling platform pipe processing system and stand pipe connecting and transporting method

ActiveCN106761487AReduce distortionEnsure safetyDrilling rodsDrilling casingsOperational costsRoughneck

The invention discloses a marine drilling platform pipe processing system and a stand pipe connecting and transporting method. The marine drilling platform pipe processing system comprises a derrick, an iron roughneck, a slip device and a pipe arranging device outside the derrick. The inside of the derrick is provided with a stand pipe connecting manipulator and a support manipulator, wherein the stand pipe connecting manipulator comprises a travelling block, a guide mechanism in the middle of the travelling block is provided with a rotating device, the bottom of the rotating device is connected with the top end of a mechanical arm through a hinge pin and connected with the base of a swing cylinder, and a clamping head is hinged to the bottom end of the mechanical arm. The marine drilling platform pipe processing system achieves gripping and vertical transportation of pipes, connection of stand pipes, and mutual transportation of the stand pipes among the outside and inside the derrick and the center of a wellhead; the stand pipes can keep a vertical state all the time during transportation, so that deformation of the stand pipes can be reduced, and the operational safety performance during transportation of the stand pipes can be guaranteed, energy consumption can be greatly reduced, and the operational cost of equipment can be saved.

Owner:LANZHOU LS PETROLEUM EQUIP ENG CO LTD

Automated pipe tripping apparatus and methods

An automated pipe tripping apparatus includes an outer frame and an inner frame. The inner frame includes a tripping slips and iron roughneck. The automated pipe tripping apparatus may, in concert with an elevator and drawworks, trip in a tubular string in a continuous motion. The tripping slips and iron roughneck, along with the inner frame, may travel vertically within the outer frame. The weight of the tubular string is transferred between the tripping slips and the elevator. The iron roughneck may make up or break out threaded connections between tubular segments, the upper tubular segment supported by the elevator and the lower by the tripping slips. An automated pipe handling apparatus may remove or supply sections of pipe from or to the elevator. A control system may control both the automated pipe tripping apparatus and the elevator and drawworks.

Owner:ENSCO SERVICES LTD

Wellbore continuous circulation systems and method

Systems and methods for continuously circulating fluid, e.g., drilling mud, through a wellbore tubular string, the systems in certain aspects including a sub positionable in fluid communication with the tubular string, the sub with a body, a plug releasably closing off a side opening of the body, and a closure apparatus for selectively closing off flow from the top of the sub into and through the body, while flow is permitted below the closure apparatus through the side opening down through the body into the tubular string; and, in certain aspects, such systems and methods including tubular manipulation apparatus, e.g. an iron roughneck and working with wellbore tubulars with the tubular manipulation apparatus.

Owner:NAT OILWELL VARCO LP

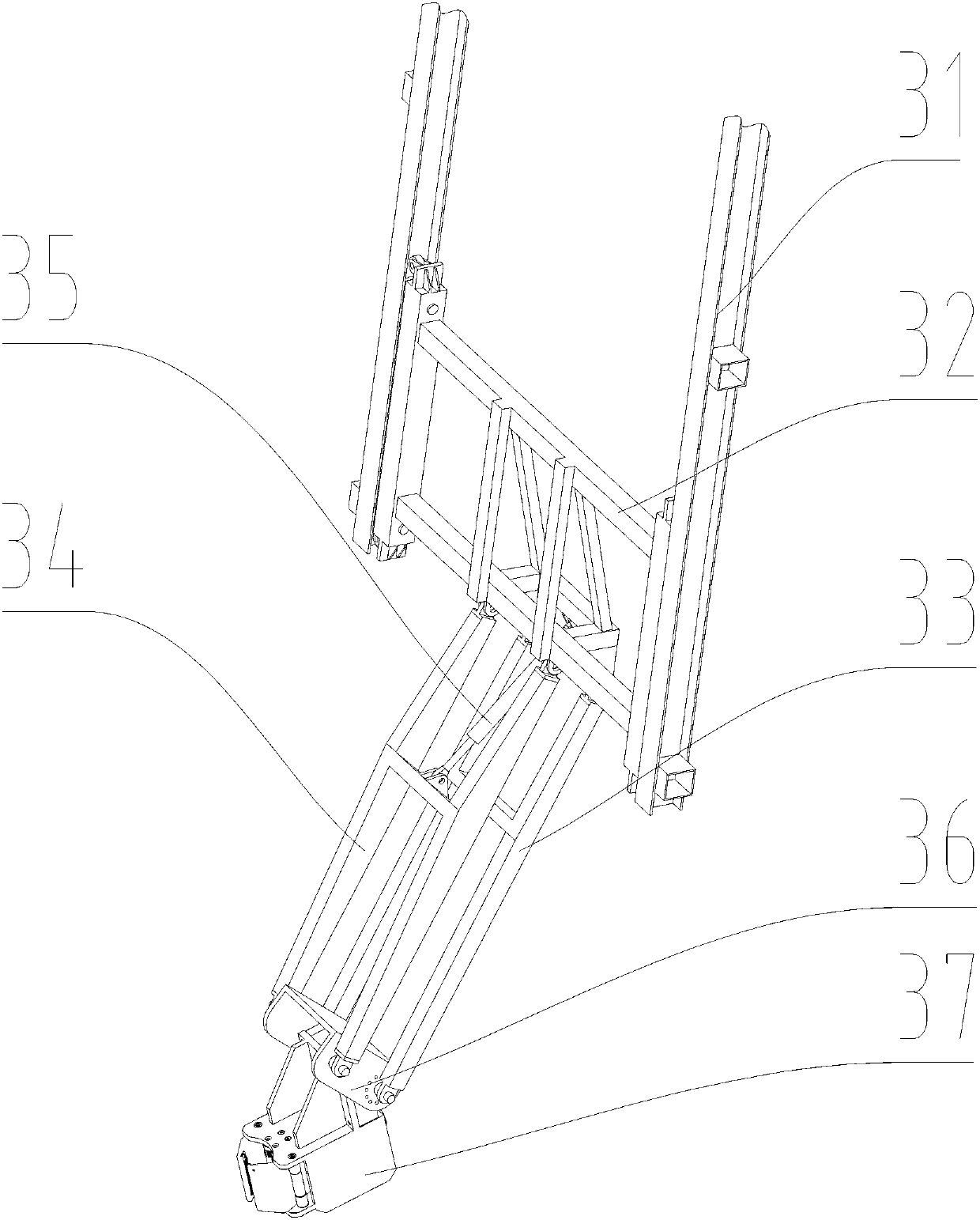

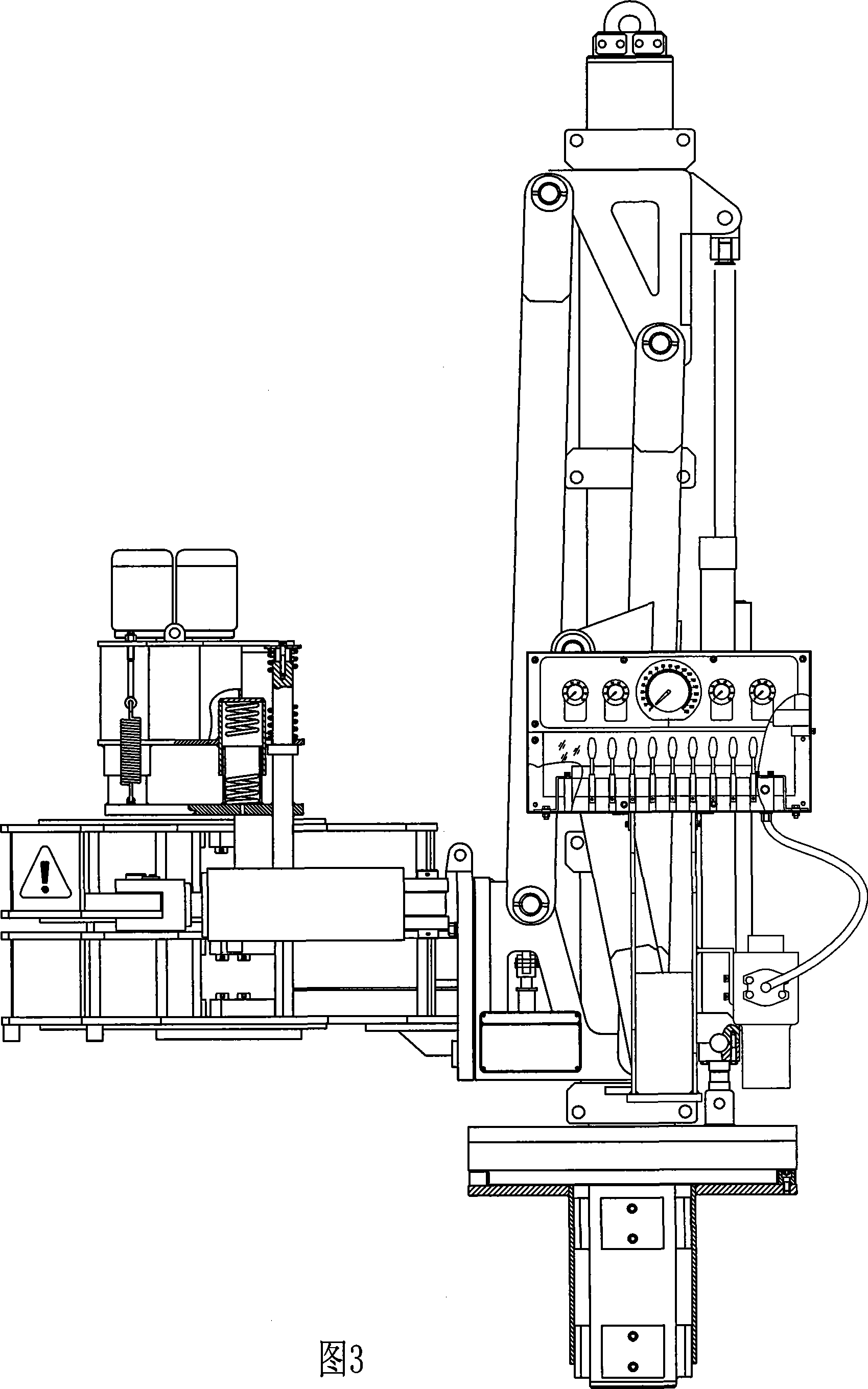

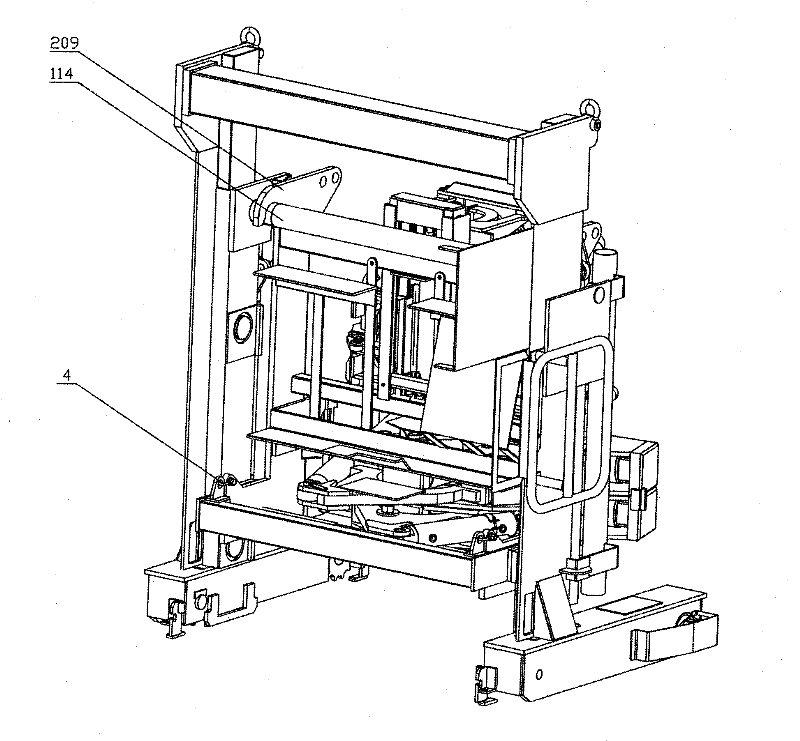

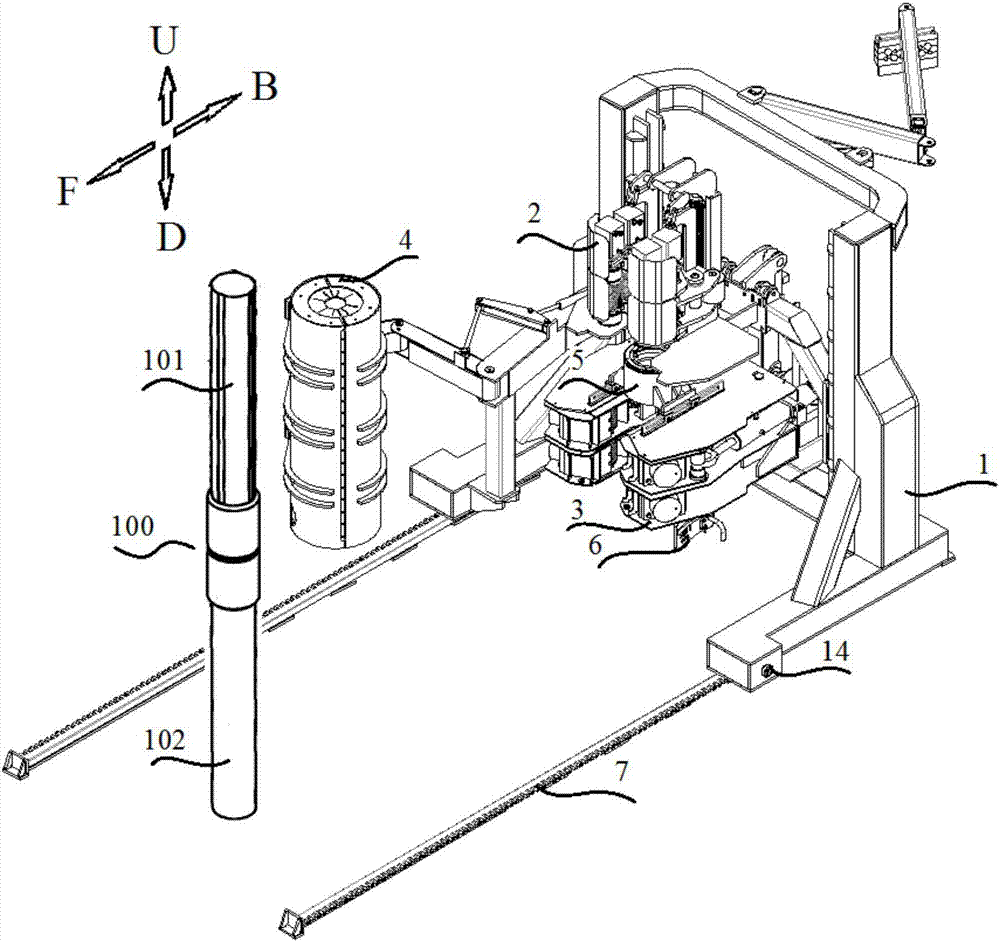

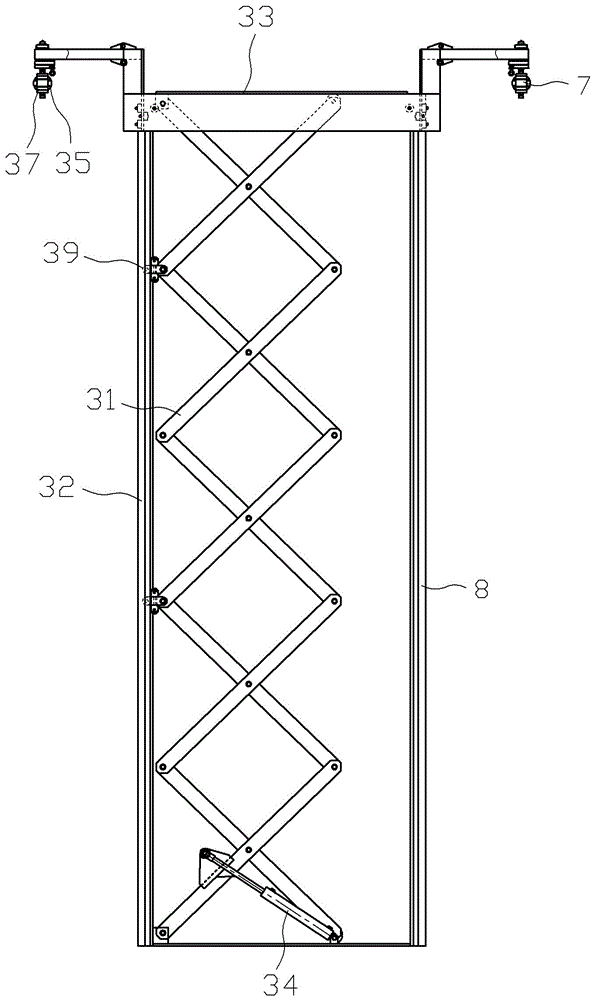

Intelligent tripping pipe system for under-pressure workover rig

ActiveCN106285513ARealize unmanned operationRealize intelligent operationDrilling rodsDrilling casingsRoughneckManipulator

The invention relates to petroleum machines, in particular to an intelligent tripping pipe system for an under-pressure workover rig. The under-pressure workover rig is provided with a rack (1), a tubular column lifting device and an iron roughneck device (2). The iron roughneck device (2) comprises a back-up wrench mechanism (3) and a spinning wrench mechanism (4), and further comprises a coupling detection part used for detecting the coupling positions of oil tubes, a residual liquid collecting device (5) used for collecting discharged oil tube residual liquid, a horizontal and vertical tube state conversion device (6) for the oil tubes, an oil tube lifting device (8) provided with a grabbing mechanical arm (7) and a control device used for controlling all the parts to act. The iron roughneck device (2) is fixed on a sliding table (11) capable of moving front and back in the horizontal direction. The intelligent tripping pipe system for the under-pressure workover rig has the advantages of being reasonable in structural design, convenient and reliable to use, high in positioning precision and high in automation degree.

Owner:牡丹江新辉石油机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com