Patents

Literature

106 results about "Motor variable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In mathematics, a function of a motor variable is a function with arguments and values in the split-complex number plane, much as functions of a complex variable involve ordinary complex numbers. William Kingdon Clifford coined the term motor for a kinematic operator in his "Preliminary Sketch of Biquaternions" (1873). He used split-complex numbers for scalars in his split-biquaternions. Motor variable is used here in place of split-complex variable for euphony and tradition.

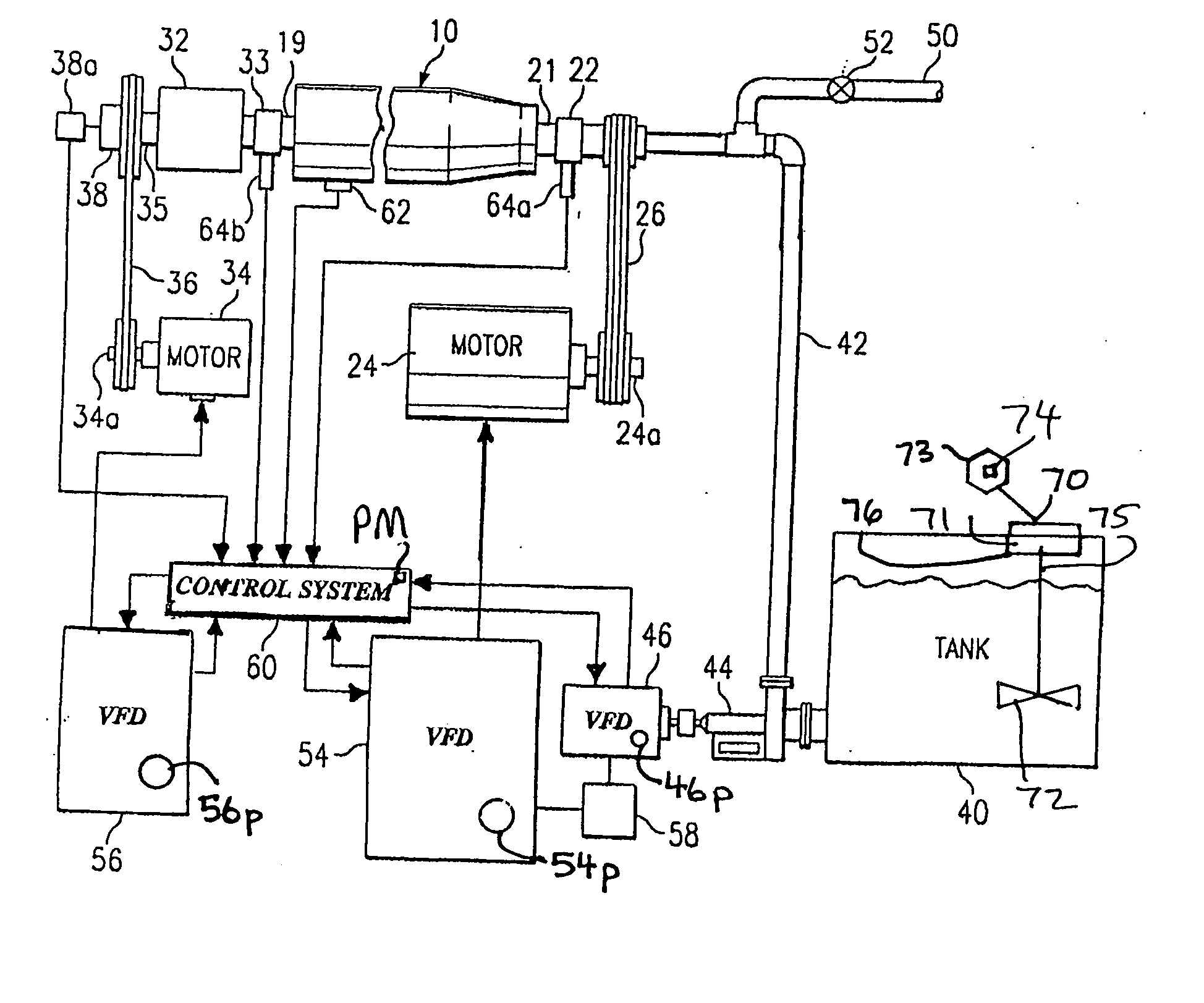

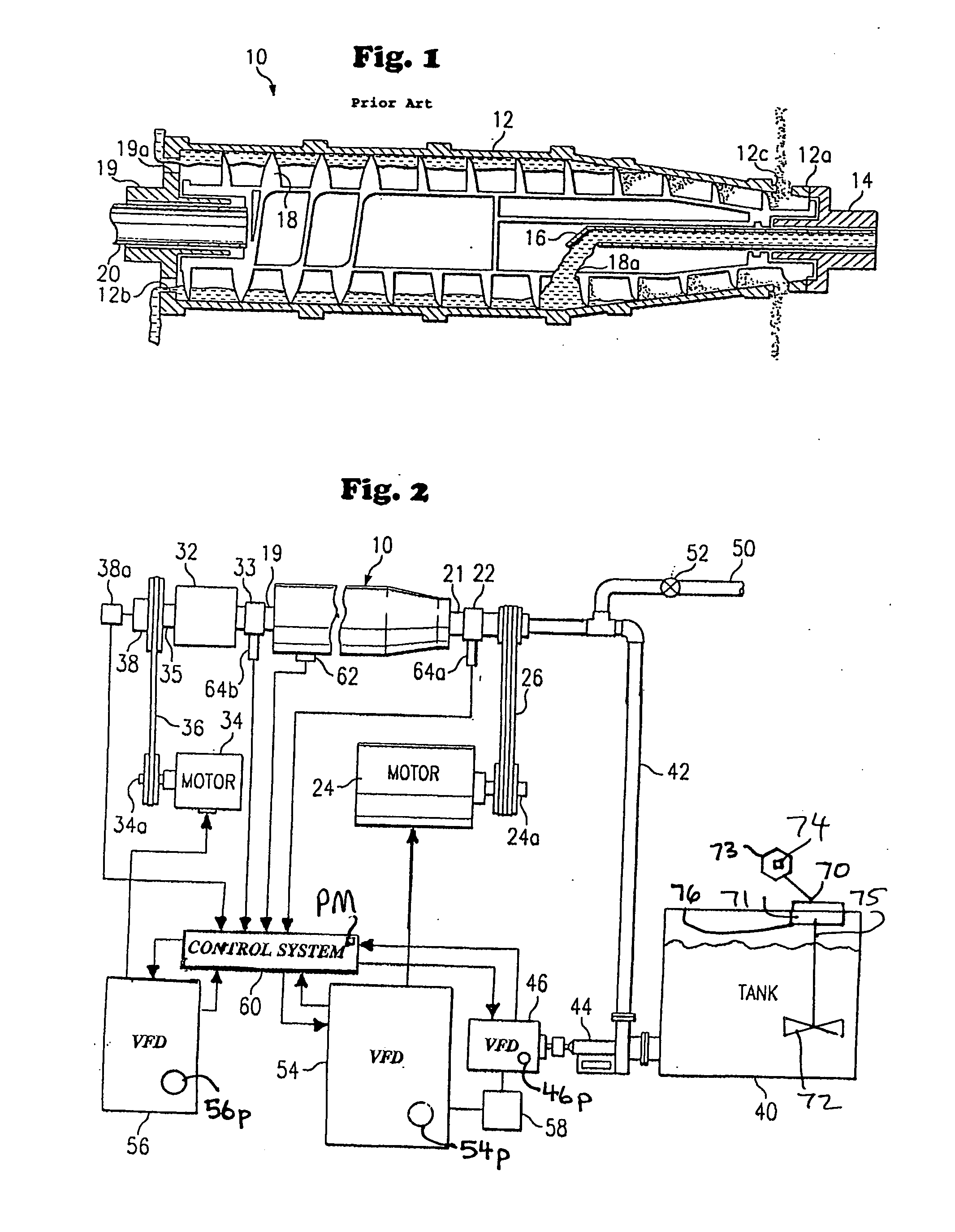

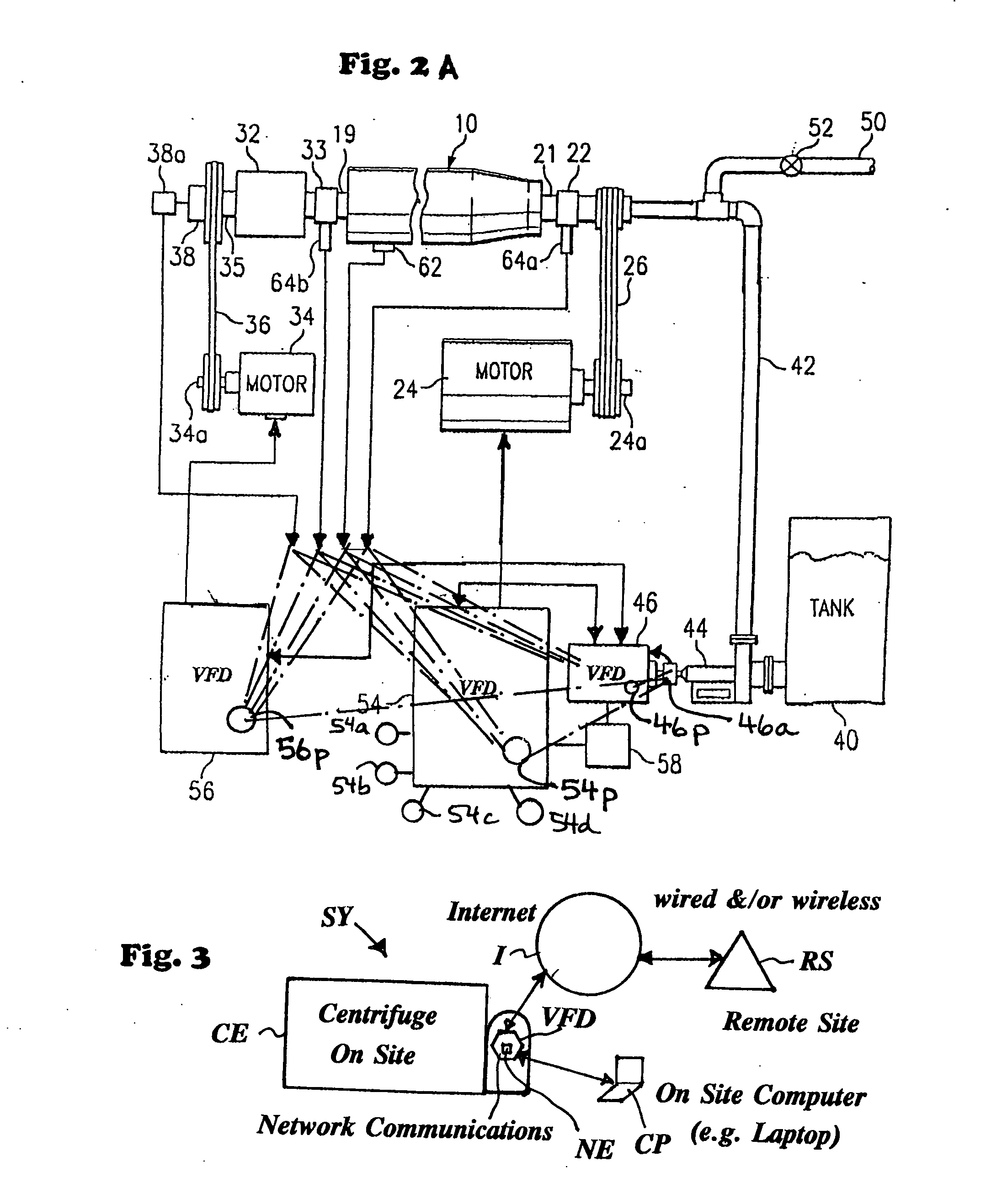

Controlled centrifuge systems

A centrifuge system for processing material, the centrifuge system including a housing, a bowl rotatably mounted within the housing, a bowl motor for rotating the bowl, a bowl motor variable frequency drive apparatus for providing power to the bowl motor, the bowl motor variable frequency drive apparatus including a bowl motor on-board controller for controlling the bowl motor variable frequency drive apparatus, a screw conveyor rotatably mounted within the housing, a screw motor for rotating the screw conveyor, a bowl motor variable frequency drive apparatus for providing power to the bowl motor, the bowl motor variable frequency drive apparatus including a bowl motor on-board controller for controlling the bowl motor variable frequency drive apparatus, and pump apparatus for pumping material to be processed into the bowl.

Owner:VARCO I P INC

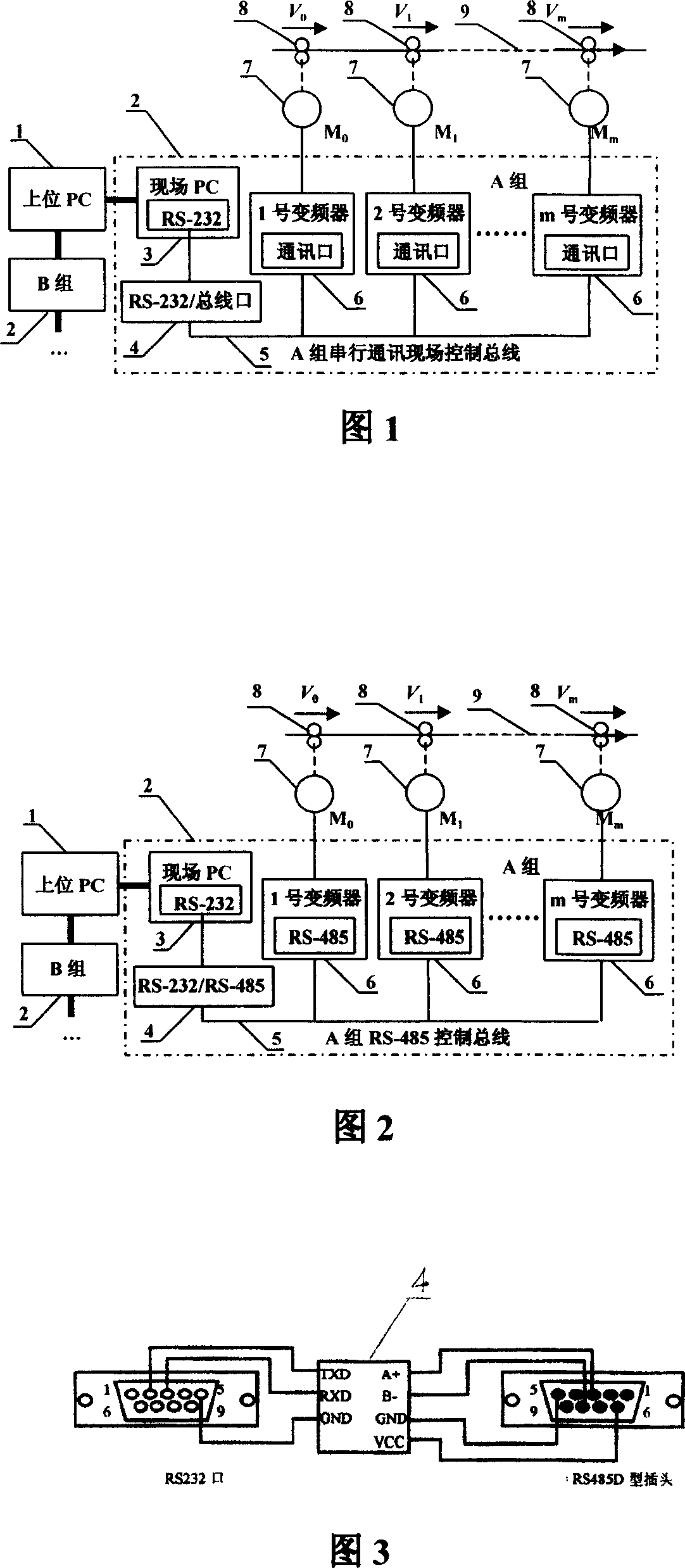

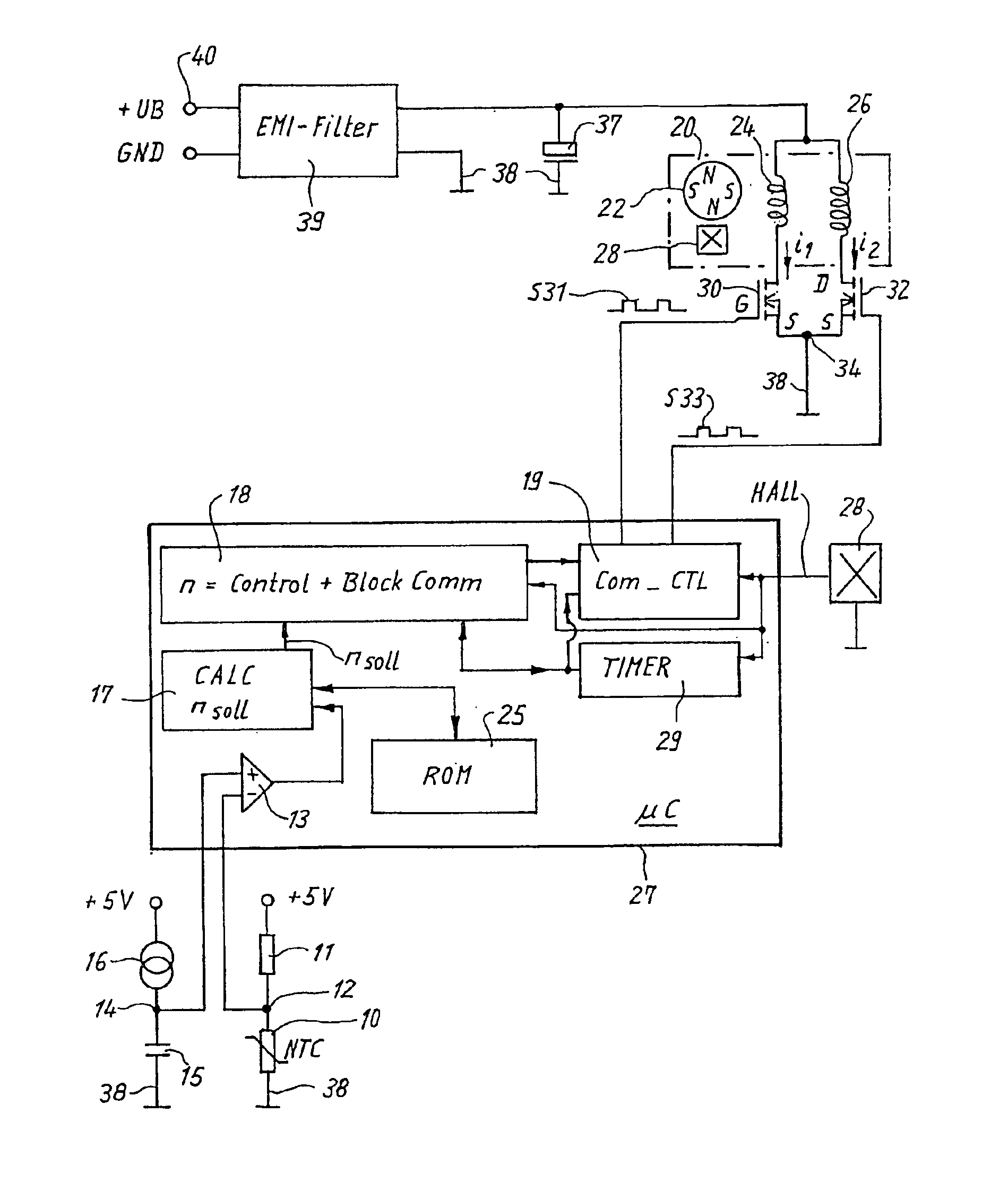

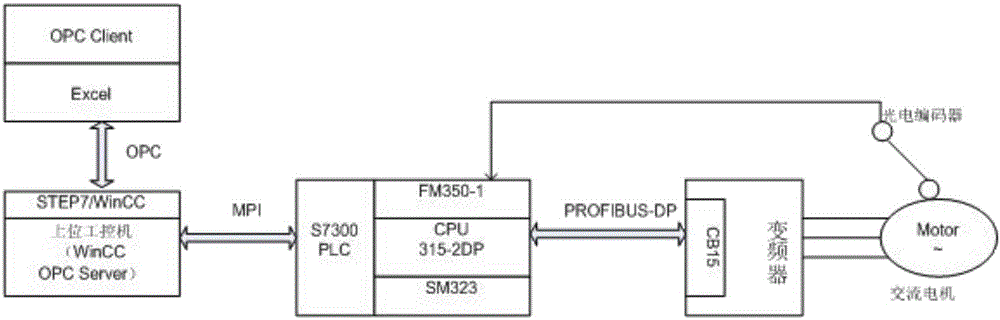

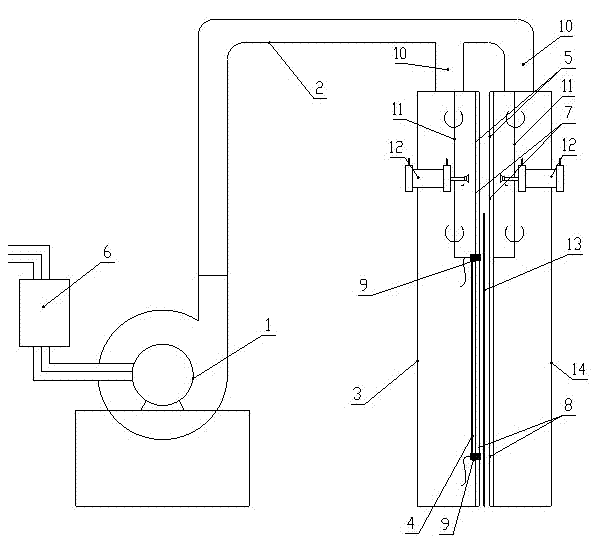

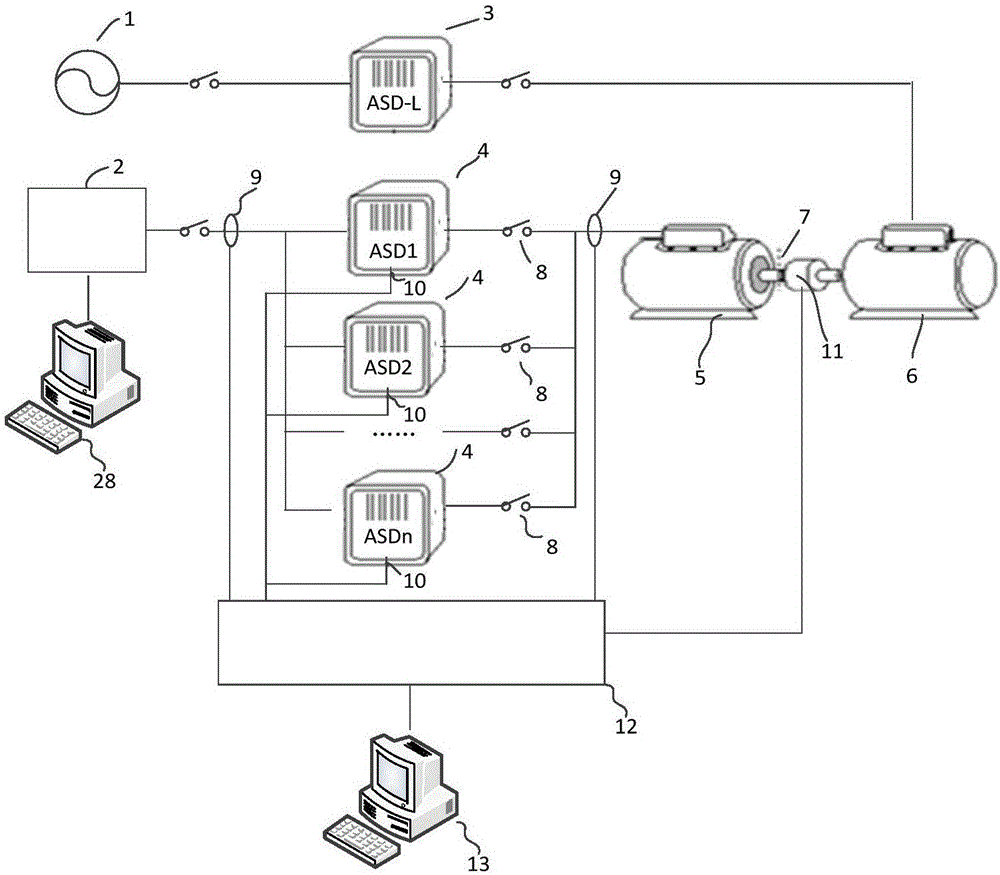

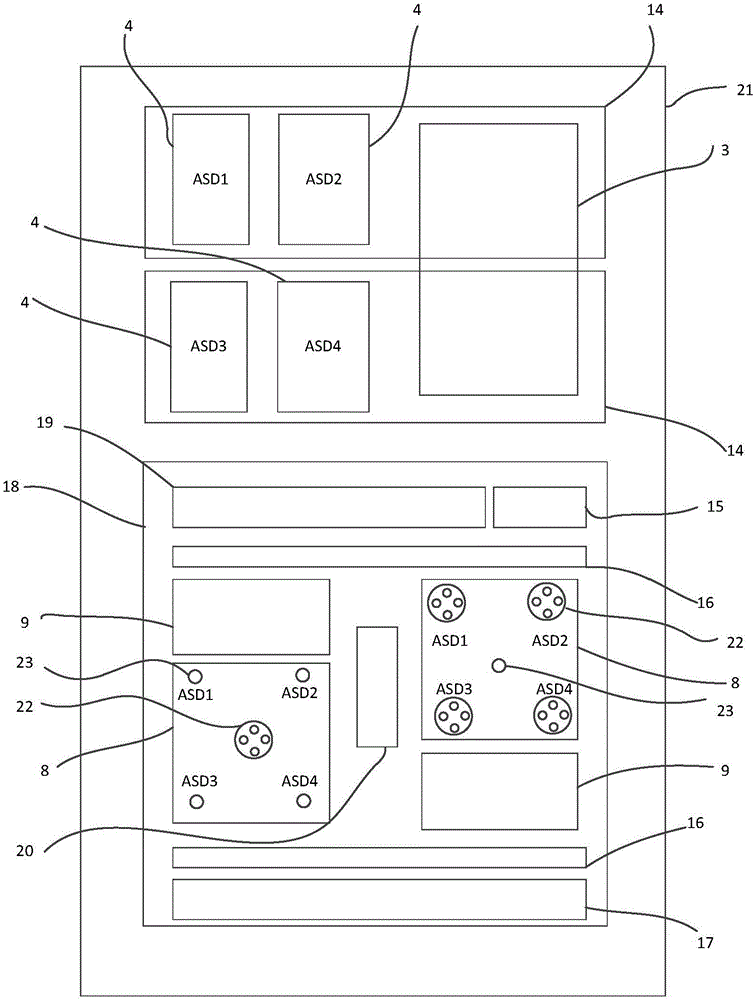

Computer control multiple motor variable frequency and speed regulating synchronous method and its central and distributing control system

InactiveCN101005258ASimple structureLow costAC motor controlComputer controlDistributed control systemMotor control

The invention discloses synchronization method for variable frequency speed control of multiple motors controlled by computer based on network, and relevant distributed control system (DCS). Through RS-232 / field control bus converter, and field control bus, PC carries out serial data communication to each frequency converter, as well as reading, calculating and rewriting operational characteristic parameters, and control parameters of each frequency converter. Thus, the method implements distributed control for synchronous operation of multiple motors, making linear speeds of multiple rollers equal or keep certain speed ratio so as to guarantee normal continuous processing. The invention simplifies system structure, reduces cost of equipment, raises reliability of system and level of control and management as well as saves energy etc.

Owner:HUNAN UNIV OF ARTS & SCI

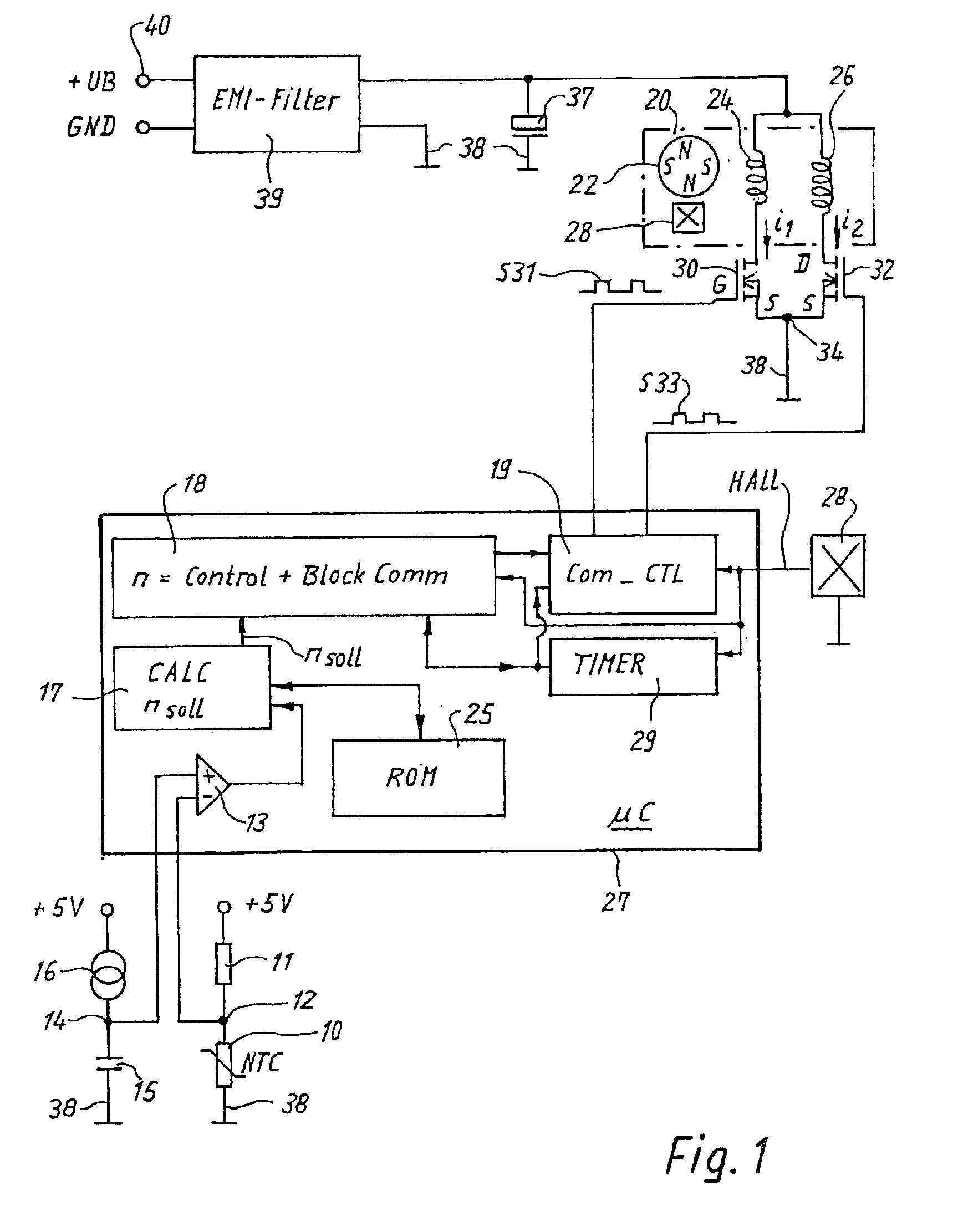

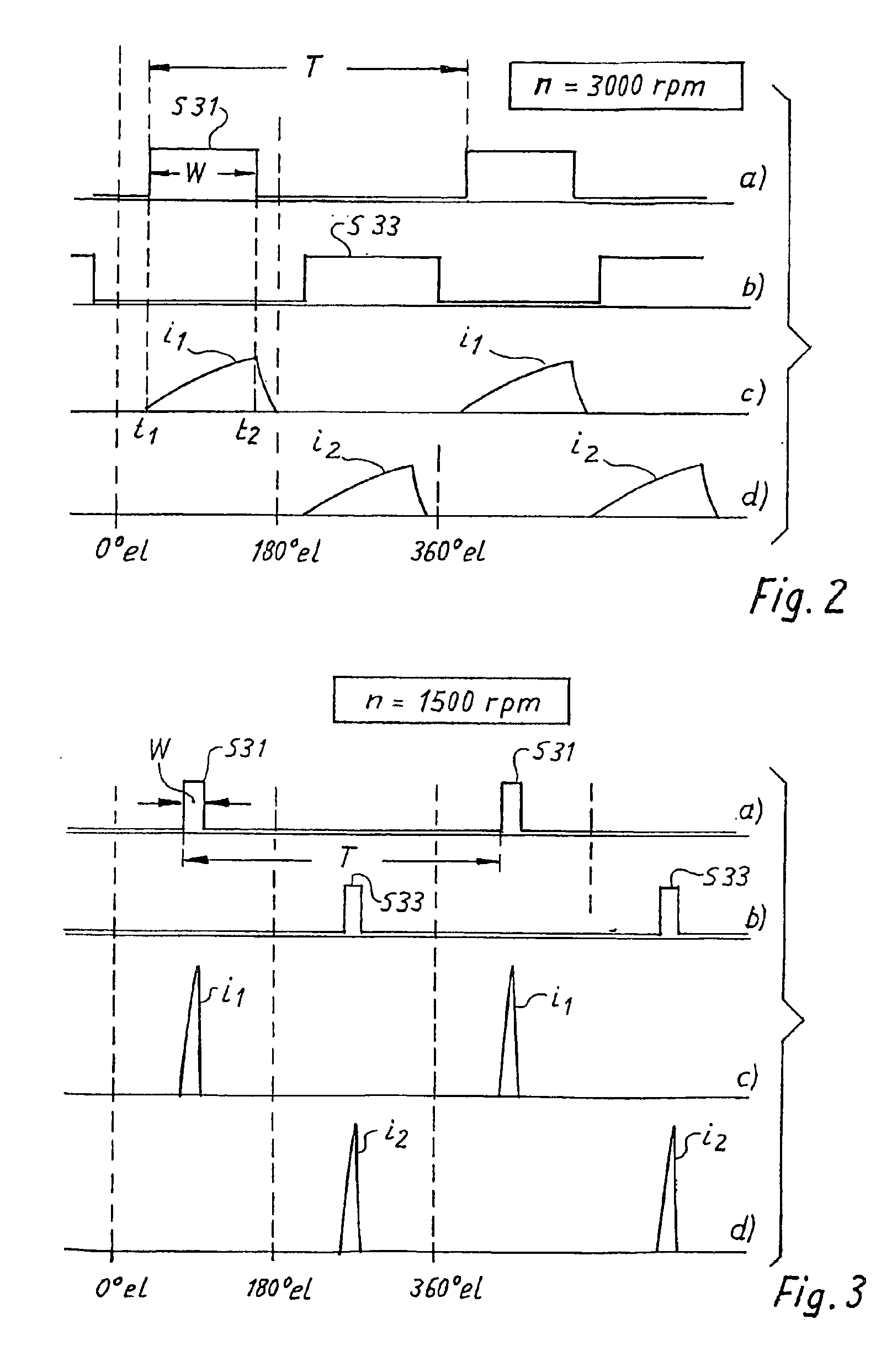

Method of controlling the commutation in an electronically commutated motor, and an electronically commutated motor for carrying out said method

InactiveUS6995534B2Improve efficiencyCurrent is limitedMotor/generator/converter stoppersAC motor controlPermanent magnet rotorCurrent limiting

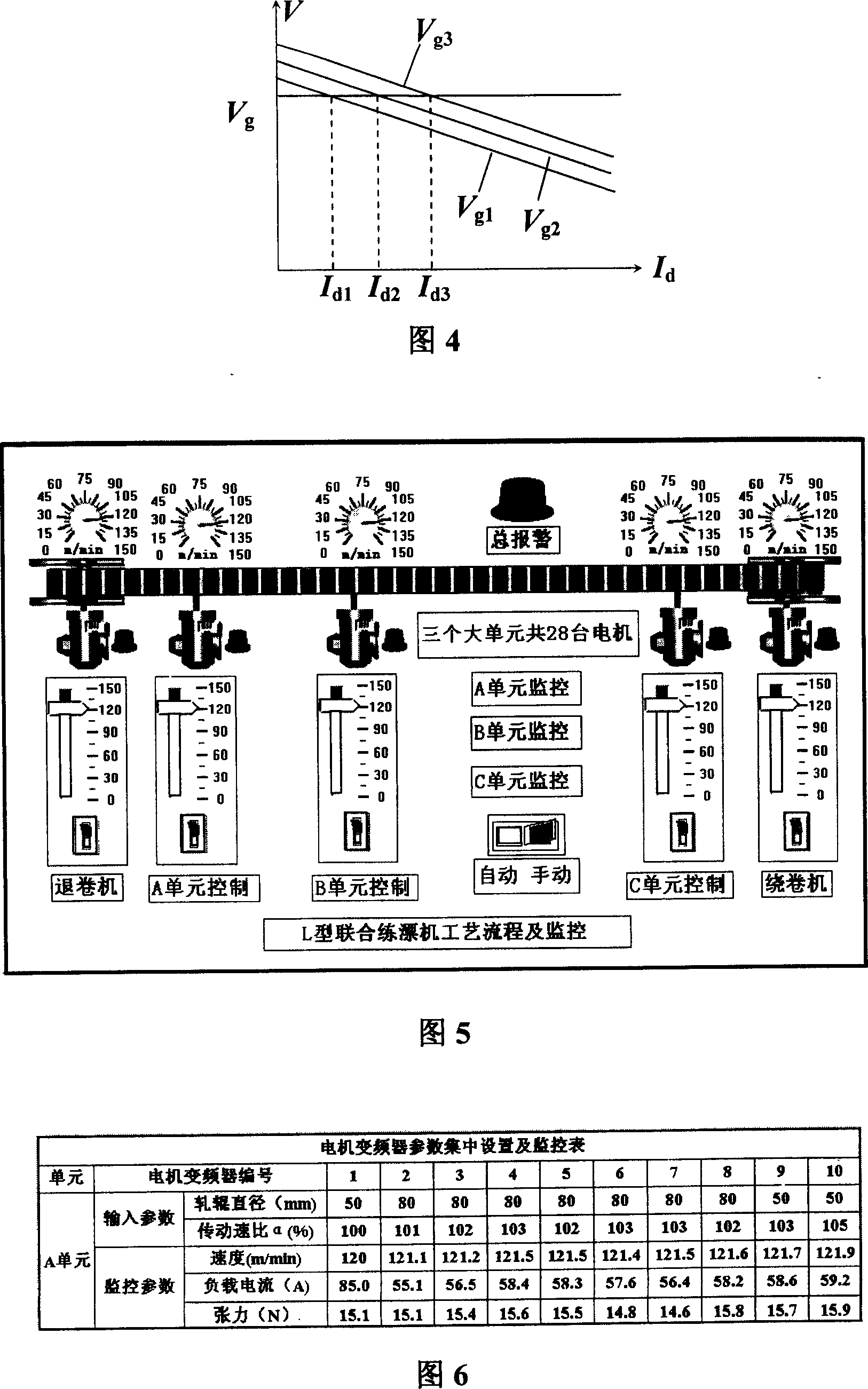

A method is disclosed for controlling the commutation in an electronically commutated motor (20) which comprises a stator having at least one phase (24, 26), and a permanent-magnet rotor (22), and with which a current limiter (36, 58) and a controller (18) for regulating a motor variable are associated. The current limiter (36, 58) serves to limit the current (I) in the at least one phase (24, 26) to a setpoint value. The regulation by means of the controller (18) is accomplished by modifying the distance in time (W) between switching on (t1) and switching off (t2) of the current (i1, i2) in the at least one phase. In this method, the setpoint value to which the current limiter limits the current (i1, i2) in the relevant phase is modifiable. It is modified substantially as a function of a ratio of two times (W / T), namely as a function of the ratio of the distance in time (W) between switching on (t1) and switching off (t2) of the current (i1, i2) in the relevant phase (24, 26) to the time period (T) required by the rotor, at the instantaneous rotation speed, to rotate through a specified rotation angle. A decrease in noise at low rotation speeds is thereby made possible.

Owner:EBM PAPST ST GEORGEN & -

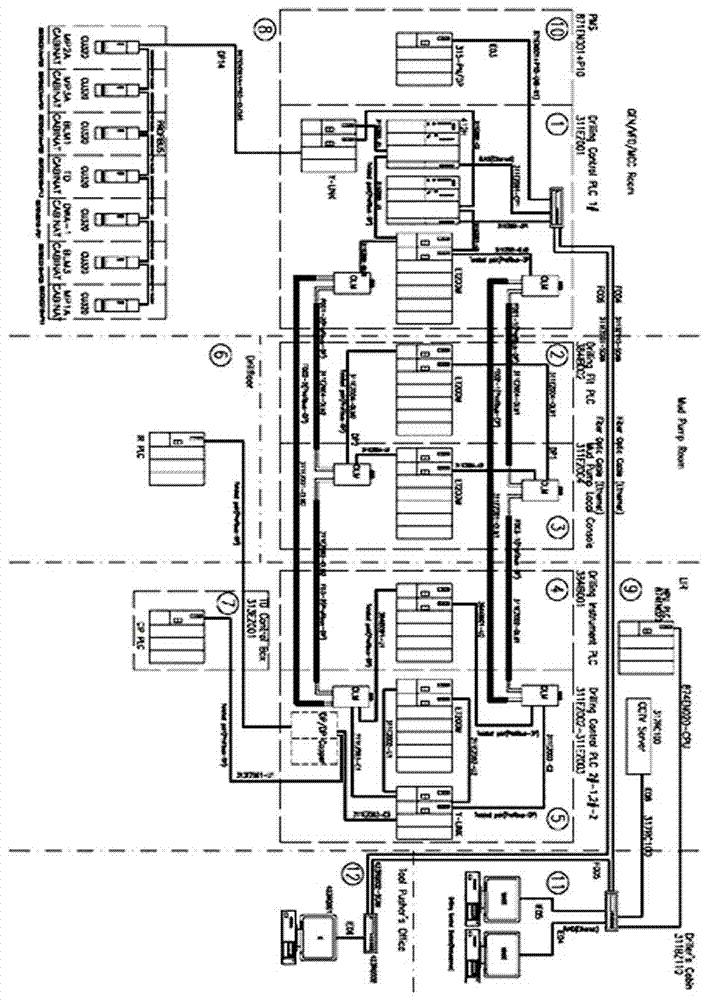

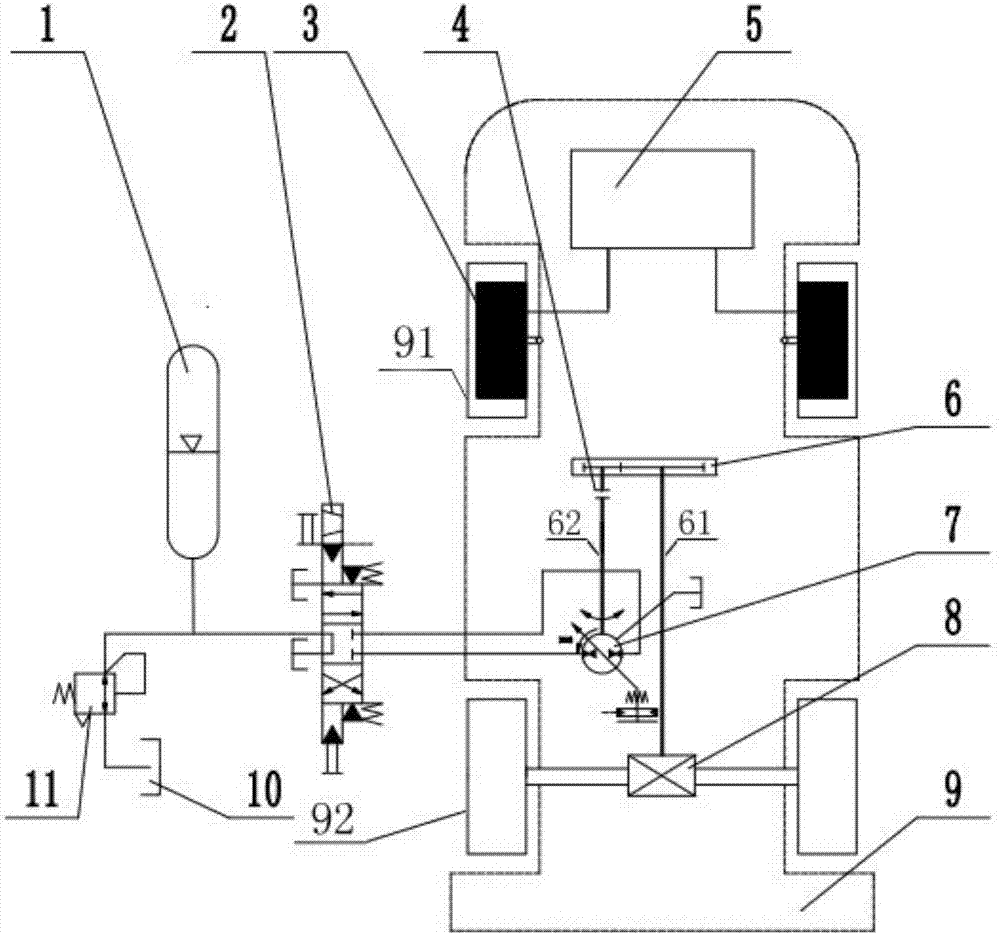

Drilling control and data collection system of self-elevating platform

InactiveCN103034212AHighly integratedImprove reliabilityTotal factory controlProgramme total factory controlTop driveRoughneck

The invention provides a drilling control and data collection system of a self-elevating platform. The drilling control and data collection system of the self-elevating platform is a control and data collection system based on a redundant programmable logic controller (PLC) and is characterized in that a main hull equipment drilling PLC, a mud pit PLC, a mud pump operating platform PLC, a drilling meter PLC and a drill floor control equipment PLC are respectively arranged in each area and are respectively conducted with a 412 H processor of a PLC main station. An iron roughneck PLC, a top drive PLC and a hydraulic power unit PLC are conducted with the 412 H processor, and a motor variable frequency controller is conducted with the 412 H processor through a CU 320 control unit. The 412 H processor is connected into a driller room switchboard through an Ethernet network through connection optical fiber, and a driller control industrial computer is conducted with the driller room switchboard through an Ethernet network. A generator controls the PLC to be directly conducted with the driller control industrial computer through the Ethernet network. The drilling control and data collection system of the self-elevating platform has the advantages of being high in integration level, good in reliability, strong in operability and the like, and meanwhile, driller control layout is reasonable and is controlled to display with equipment in a centralized mode, and operating is convenient.

Owner:海尔海斯(西安)控制技术有限公司

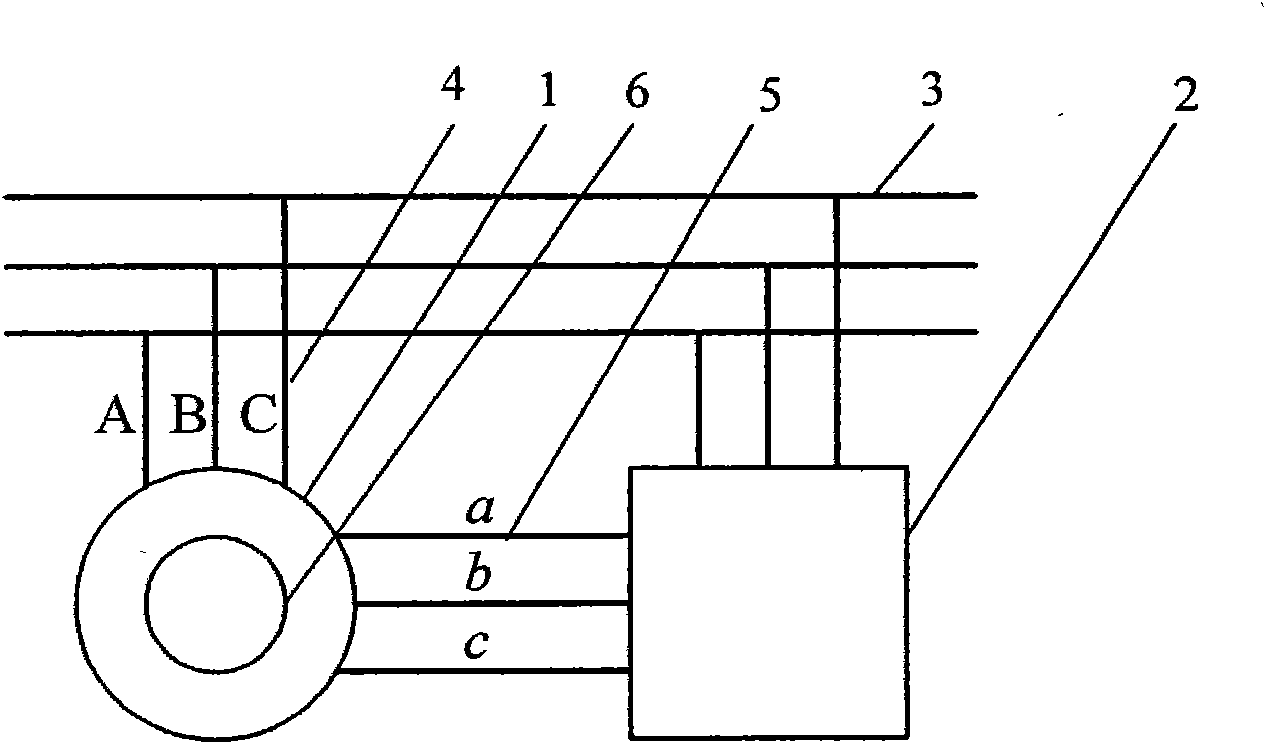

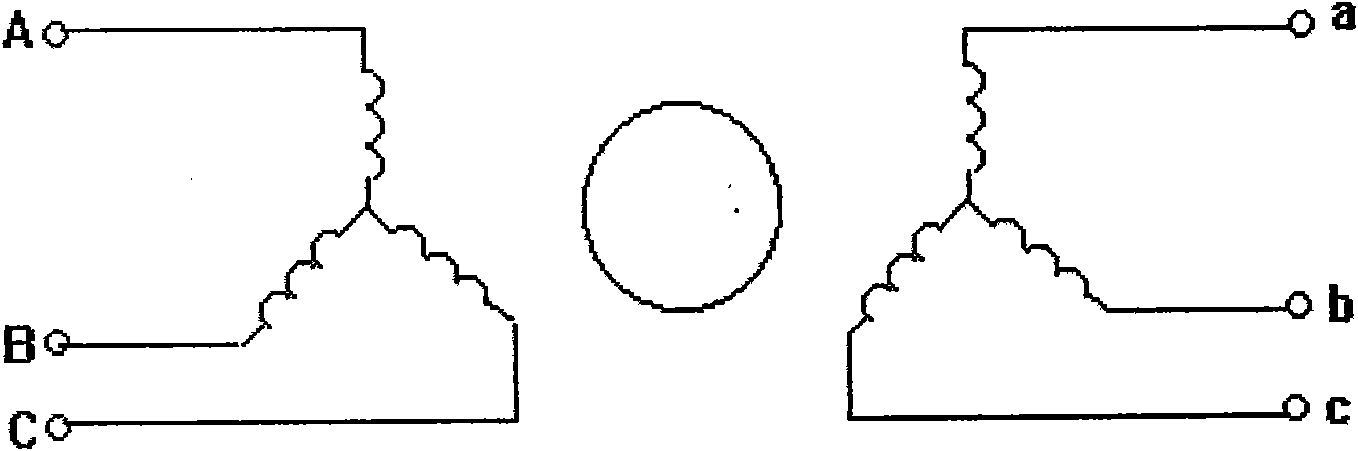

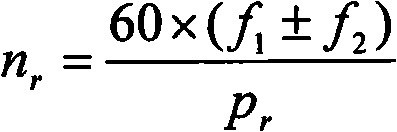

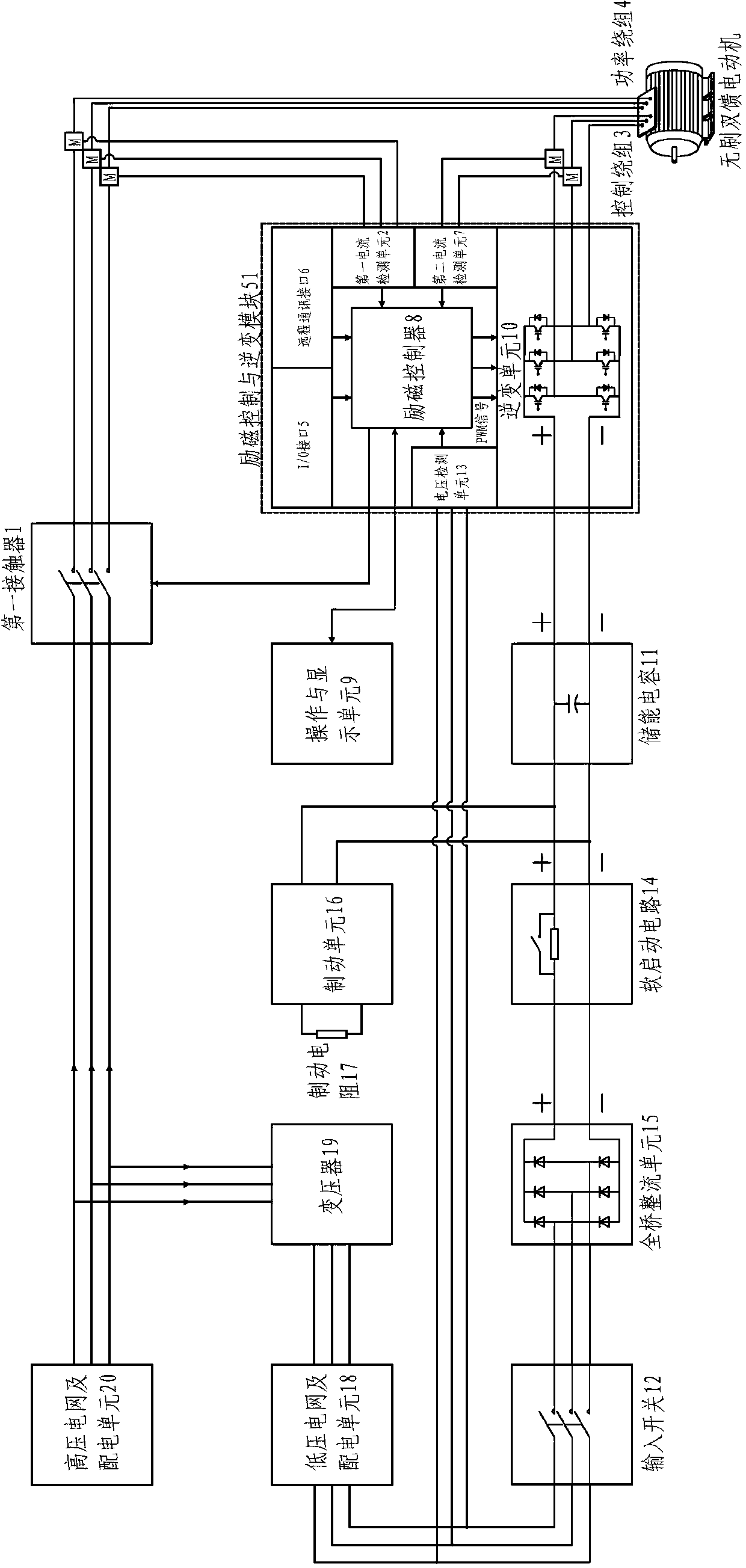

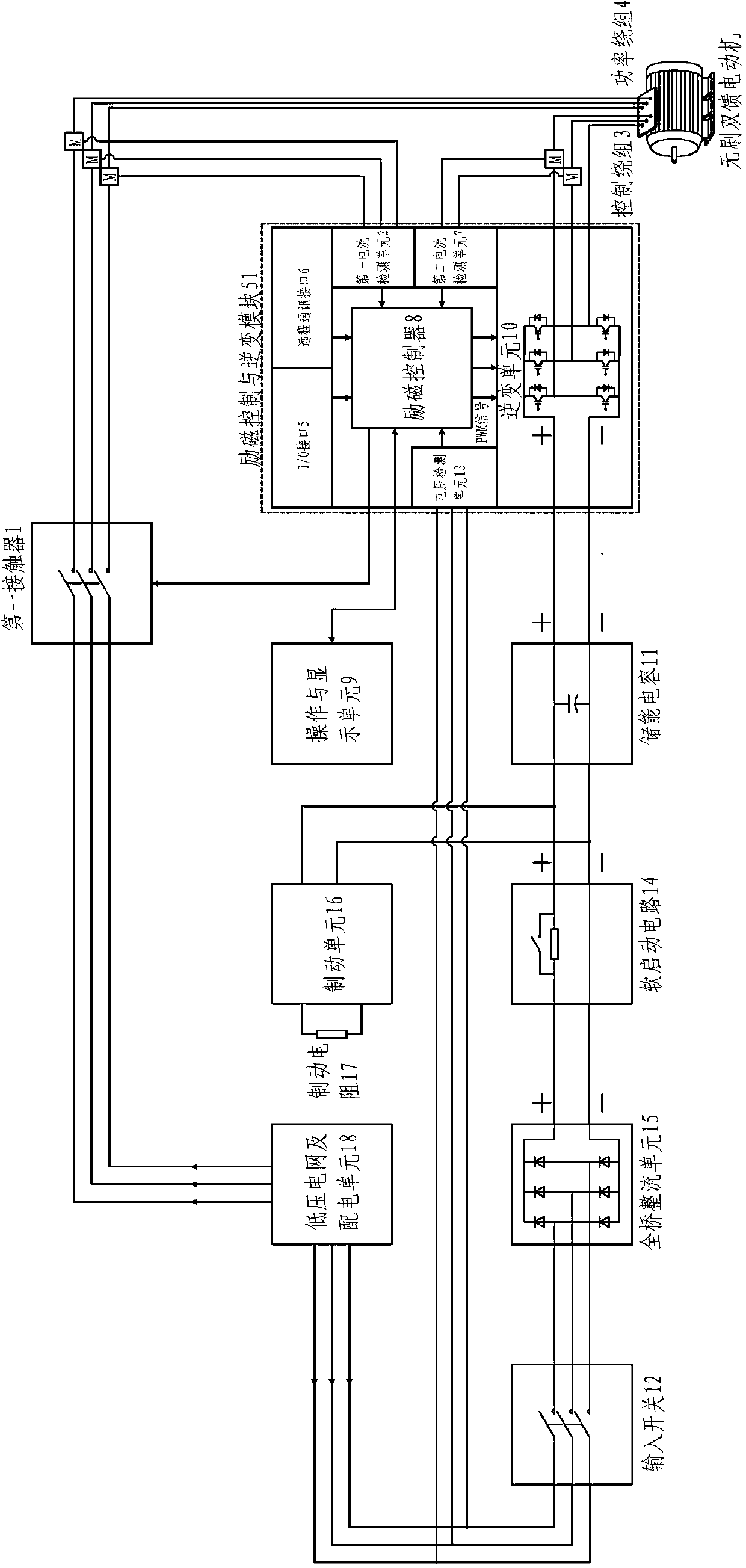

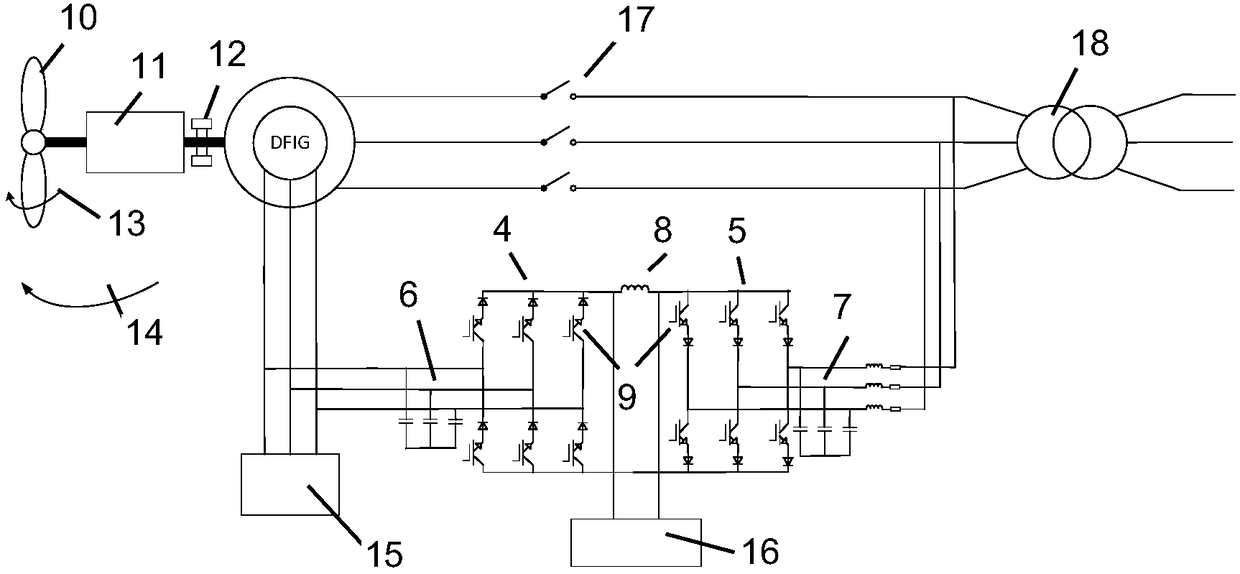

High-power brushless double-fed motor variable frequency speed control system and starting method thereof

InactiveCN101621276ALow costAdjust power factor arbitrarilyAC motor controlSynchronous motors startersSpeed control systemPower factor

The invention relates to a variable frequency speed control system, in particular to a high-power brushless double-fed motor variable frequency speed control system and a starting method thereof. The variable frequency speed control system comprises a brushless double-fed motor and a variable frequency controller, wherein a stator power winding of the brushless double-fed motor is directly connected with a power frequency electric network; a stator control winding is connected with the variable frequency controller; the variable frequency controller is directly connected with the power frequency electric network; the stator power winding and the stator control winding are in star shape connection, and the pole numbers of the stator power winding is different from that of the stator control winding; and a rotor of the brushless double-fed motor is a magnetic resistance rotor. The variable frequency speed control system has the following advantages: the cost of the speed control system is greatly reduced, the power factors of the power winding can be adjusted at will, the starting process is smoother, and the variable frequency speed control system is more suitable for the requirements on load use of fans and water pumps.

Owner:SHENYANG POLYTECHNIC UNIV

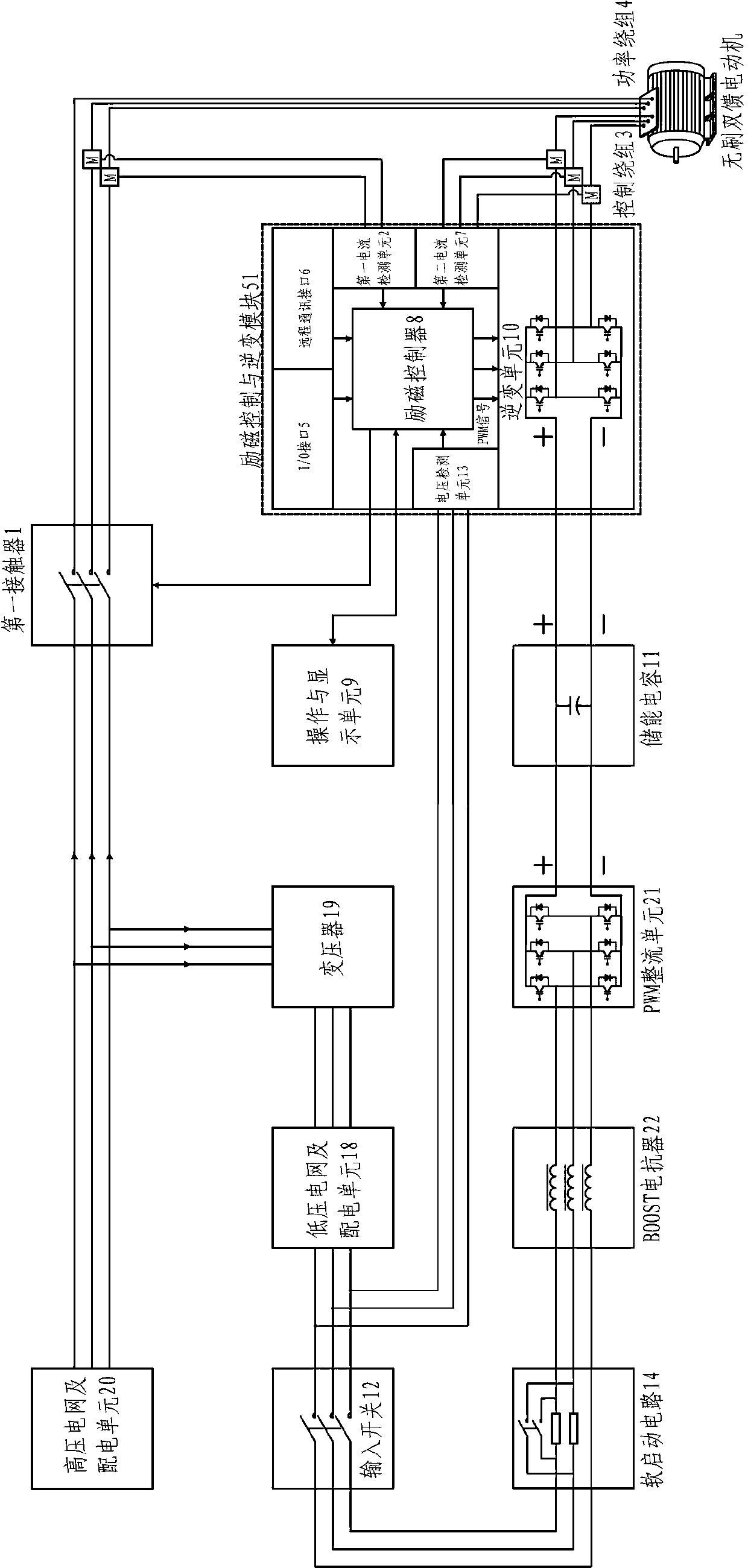

High-power brushless double fed motor variable frequency speed regulation system and control method

ActiveCN103138674AImprove reliabilityReduce manufacturing costAC motor controlSingle motor speed/torque controlCapacitanceEngineering

A high-power brushless double fed motor variable frequency speed regulation system comprises a power winding of the high-power brushless double fed motor and a control winding, a first contactor, an input power distribution unit, an entry switch, a soft start circuit, a alternating current or direct current rectifying unit, a energy-storage capacitor, an operation and display unit, and an excitation control and inverter module which is composed of a excitation controller, an inverter unit, a first current detection unit, a second current detection unit and a voltage detection unit. After the power winding is connected with the first contactor in series, the power winding is connected with the input power distribution unit, the entry switch, the alternating current or direct current rectifying unit, the energy-storage capacitor, and the inverter module, then the power winding is connected with the control winding. The soft start circuit is connected with a circuit between the alternating current or direct current rectifying unit and a three-phase output end of the entry switch in series or the soft start circuit is connected with a circuit between the alternating current or direct current rectifying unit and the energy-storage capacitor. Whole course frequency speed regulation of the brushless double fed motor can be achieved. The invention further comprises a fundamental control timing sequence and a method.

Owner:BEIJING SWORD ELECTRIC IND

Hydraulic control method of hydraulic motor rotating speed and device thereof

InactiveCN101398019AMeeting the Need for Adaptive CapabilitiesRequirement Realization of Adaptive CapabilitiesServomotor componentsServomotorsMaximum torqueControl valves

Owner:AVIC LIYUAN HYDRAULIC

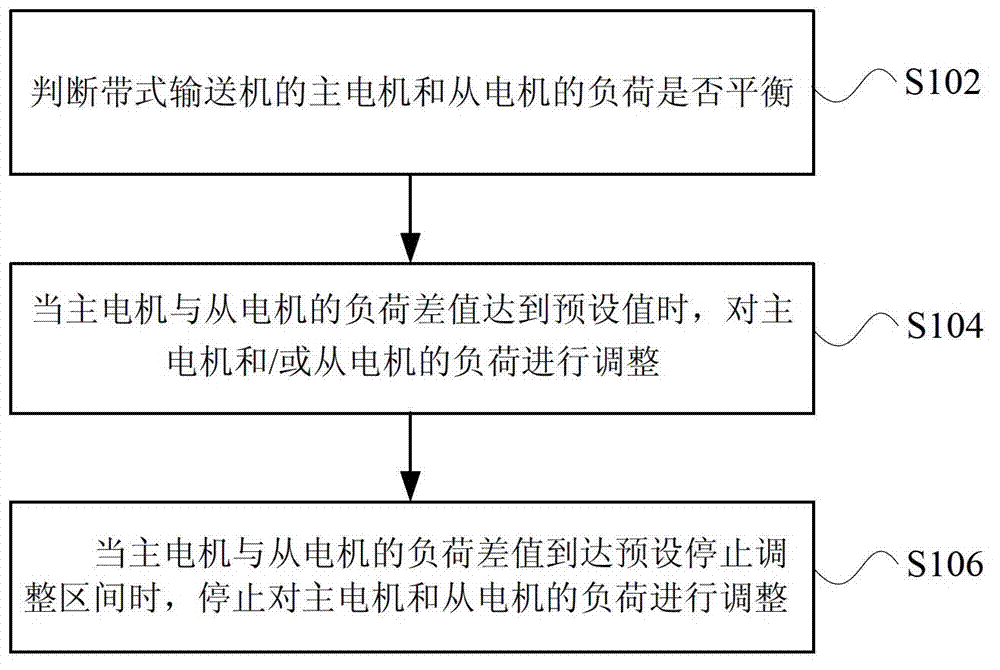

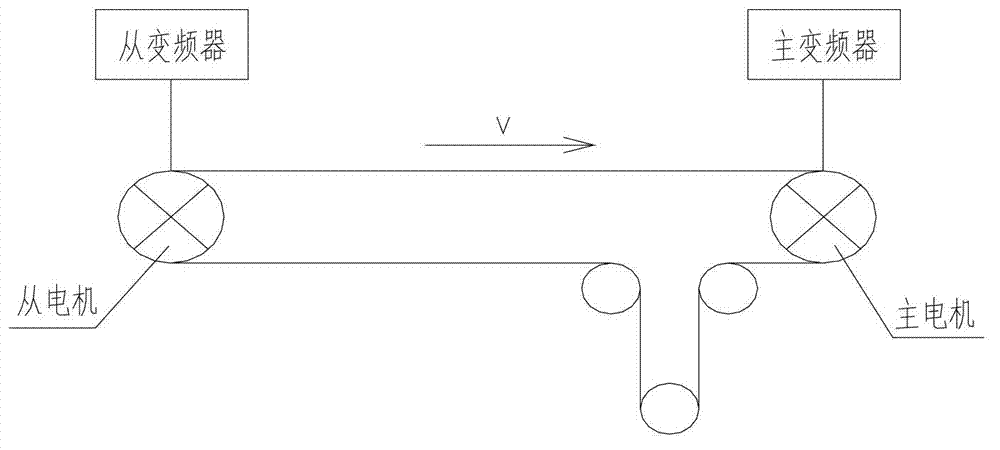

Method and device for controlling multi-motor variable-frequency drive of belt conveyor

InactiveCN102769417AGuaranteed uptimeMultiple dynamo-electric motors speed regulationMotor variableBelt conveyor

The invention provides a method and a device for controlling multi-motor variable-frequency drive of a belt conveyor. The method includes: judging whether load of a master motor and load of a slave motor of the belt conveyor to be balanced or not; and when a load difference value of the master motor and the slave motor exceeds a preset value, adjusting the load of the master motor and / or the slave motor, and when the load difference value of the master motor and the slave motor reaches a preset adjustment stop interval, stopping adjustment of the load of the master motor and / or the slave motor. By the method and the device, the belt conveyor can automatically adapt to load change conditions during operation by means of adjustment of unbalanced states of the master motor and the slave motor of the belt conveyor, so that stable operation of the belt conveyor is guaranteed.

Owner:ZOOMLION ENVIRONMENTAL IND CO LTD

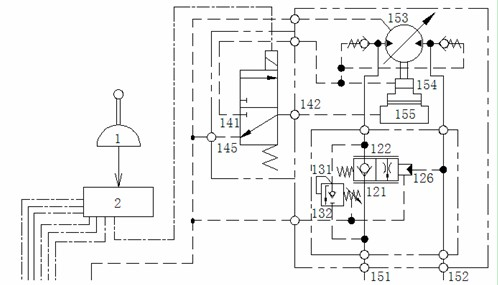

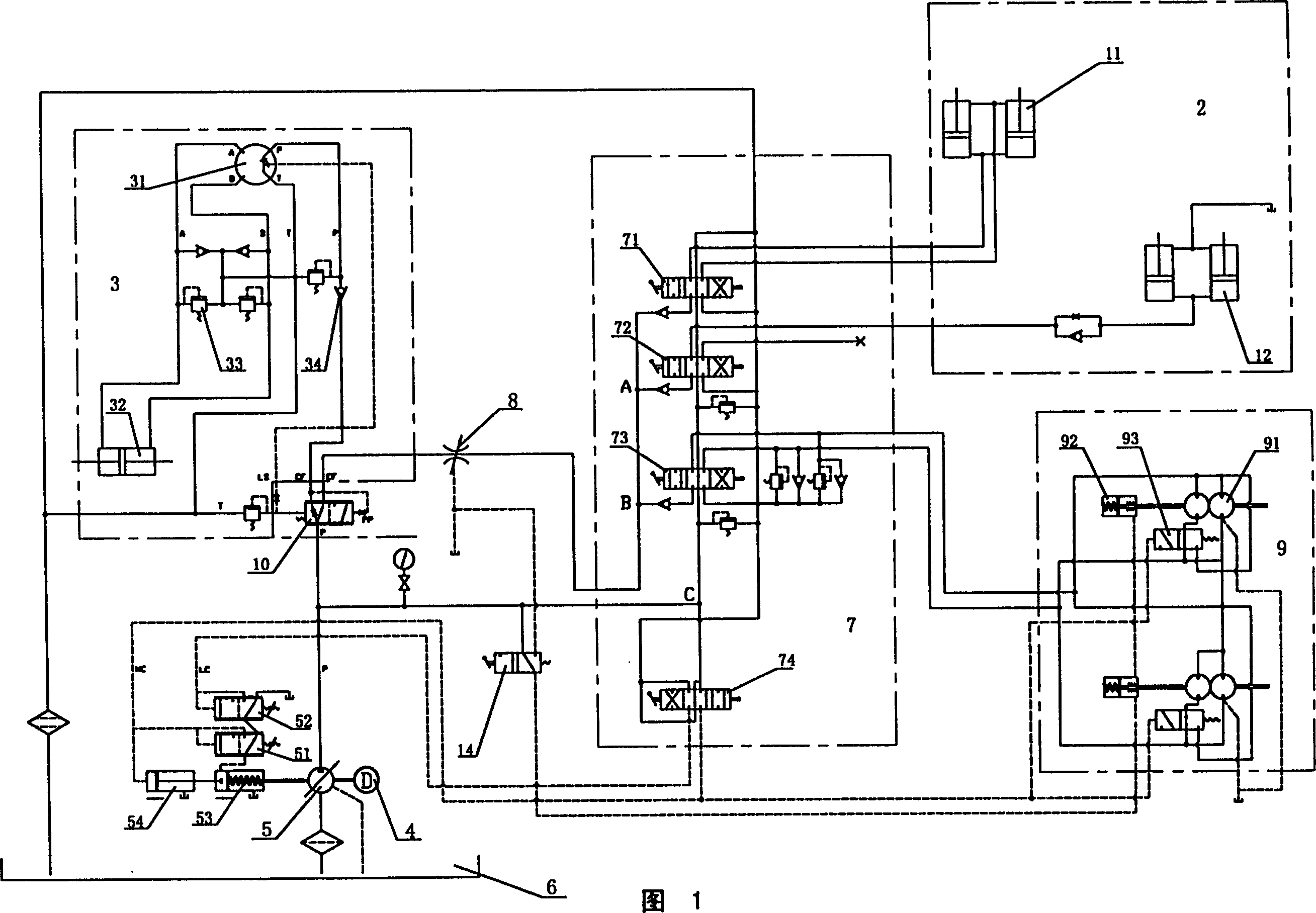

Crane hydraulic system for load sensitive ship

ActiveCN102030265ALow priceGuaranteed accuracyLoad-engaging elementsFluid-pressure actuator componentsElectricityControl system

The invention relates to a crane hydraulic system for a load sensitive ship, which comprises an electric proportional handle, a PLC main command controller, a control system and a power source, wherein the control system comprises an integrated electric liquid proportional reversing valve, an integrated two-way reducing valve, an integrated pressure stop valve, a load sensitive pilot control valve, a pressure sensor, a balance valve, a secondary overflow valve, a motor variable control valve and a two-stage electric control axial plunger variable motor that are connected through an oil pipeline; the power source comprises a load sensitive valve, an integrated electric control pressure stop valve, an axial plunger variable pump and a one-way valve that are connected through an oil pipeline; the PLC main command controller is respectively connected with the integrated electric liquid proportional reversing valve, the load sensitive pilot control valve, the pressure sensor, the motor variable control valve and the integrated electric control pressure stop valve through electric control signals; and the control system is connected with the power source through an oil pipeline. The invention can not only realize real-time control and higher accuracy, but also has stronger automation and better energy-saving effect.

Owner:WUHAN MARINE MACHINERY PLANT

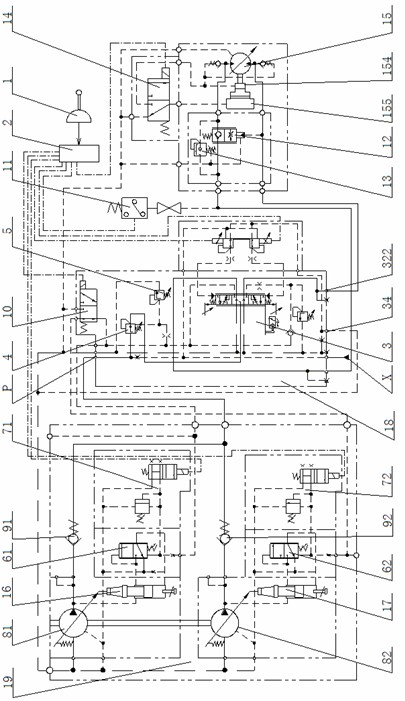

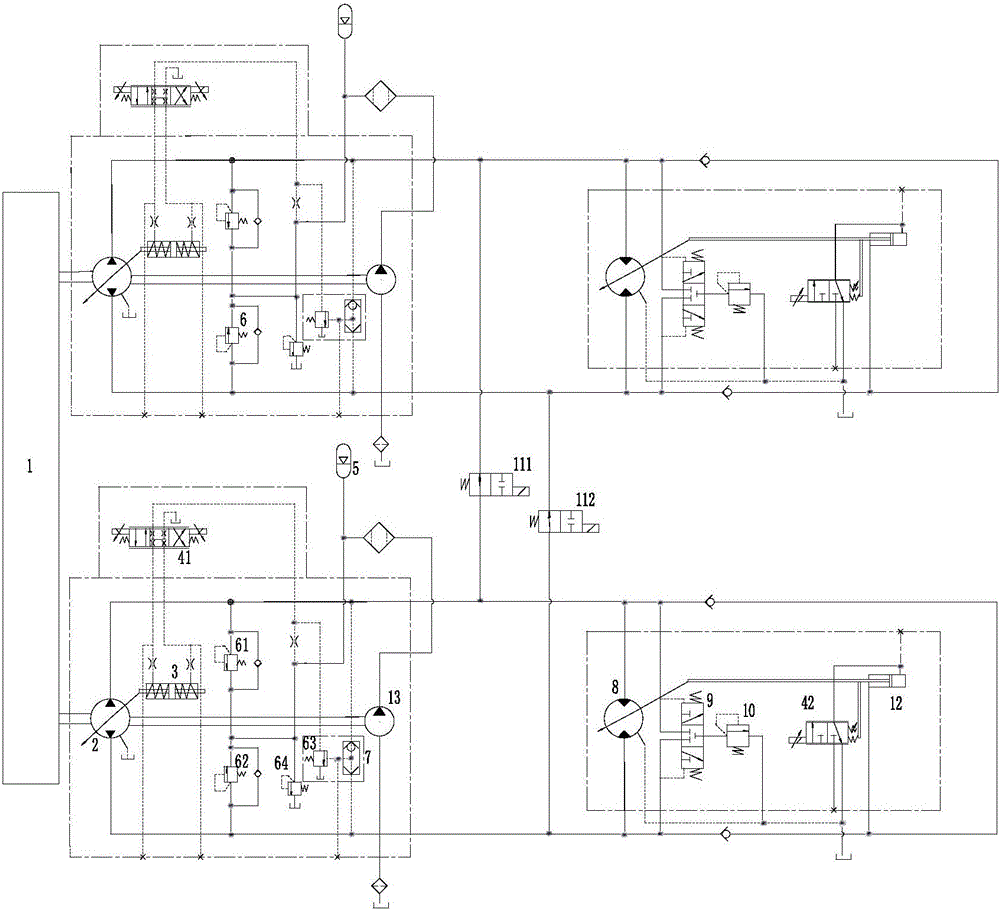

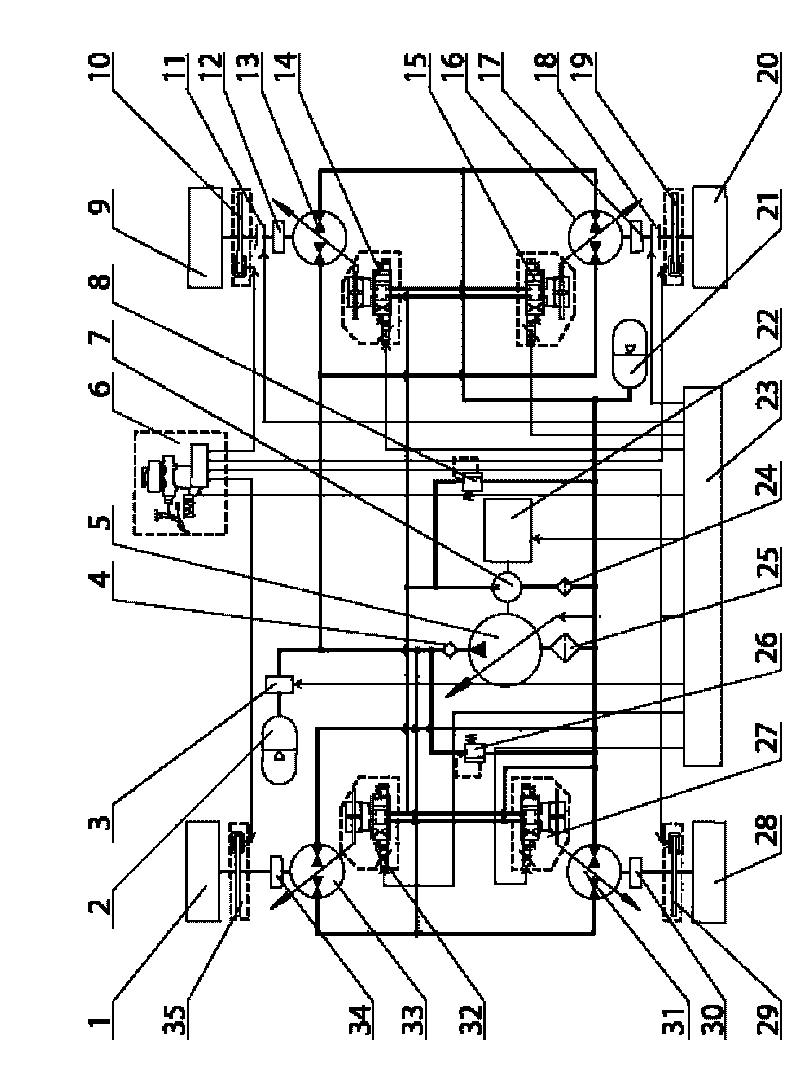

Land leveller traveling hydraulic driving system with parallel connection of double pumps and double motors

ActiveCN105971052ASimple structureEasy to operateSoil-shifting machines/dredgersHydraulic cylinderElectricity

The invention discloses a land leveller traveling hydraulic driving system with parallel connection of double pumps and double motors. The system comprises a transfer case, an oil tank, two single-pump single-motor closed hydraulic loops and a first two-position two-way solenoid valve as well as a second two-position two-way solenoid valve; the two single-pump single-motor closed hydraulic loops respectively comprise a traveling pump, a pump tilting tray control hydraulic cylinder, a first electric proportional valve, a second electric proportional valve, a first safety overflow valve, a second safety overflow valve, an overflow valve, an oil supplementing overflow valve, a shuttle valve, an oil supplementing pump, a flush valve, a motor variable control hydraulic cylinder and a traveling variable motor. The system is simple in structure and can realize stepless speed change, free veering and synchronous control.

Owner:GAOYUAN HIGHWAY MAINTENANCE TECH HENAN PROV

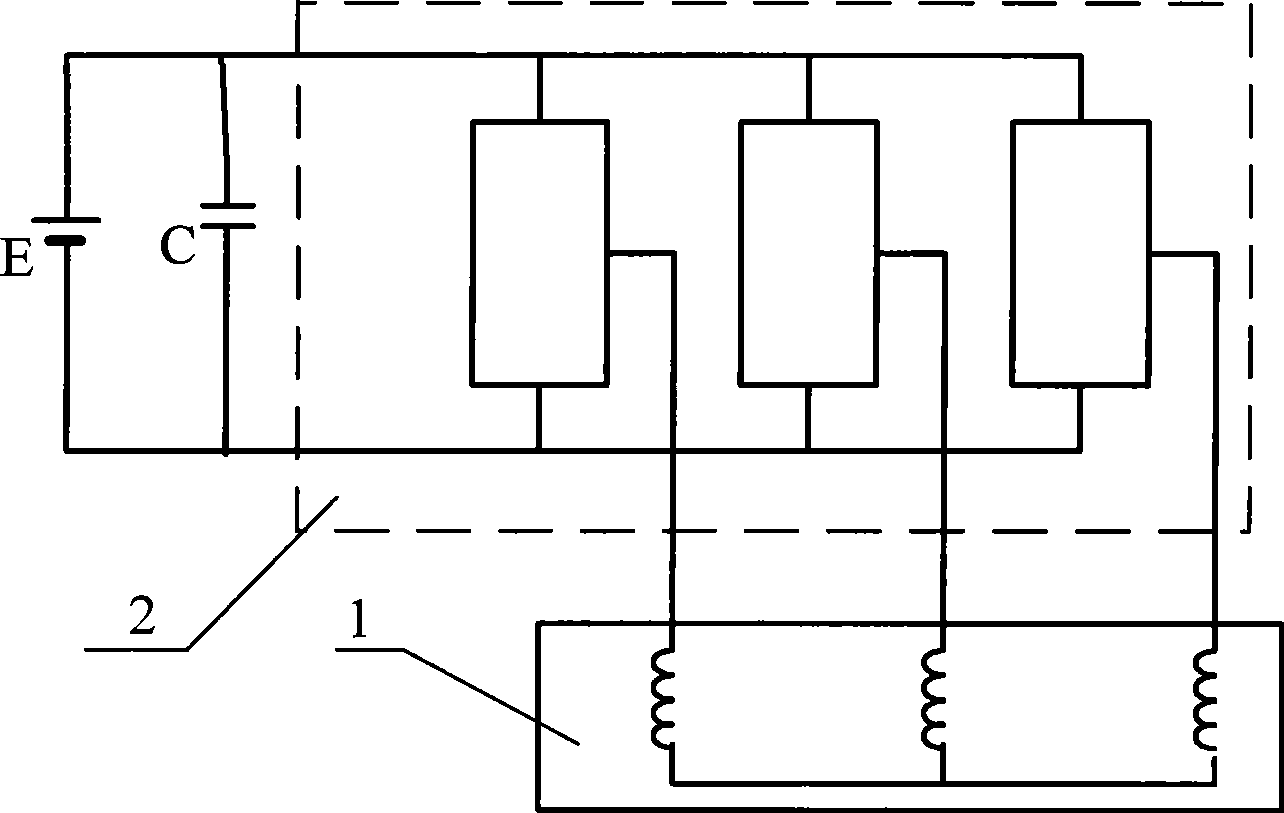

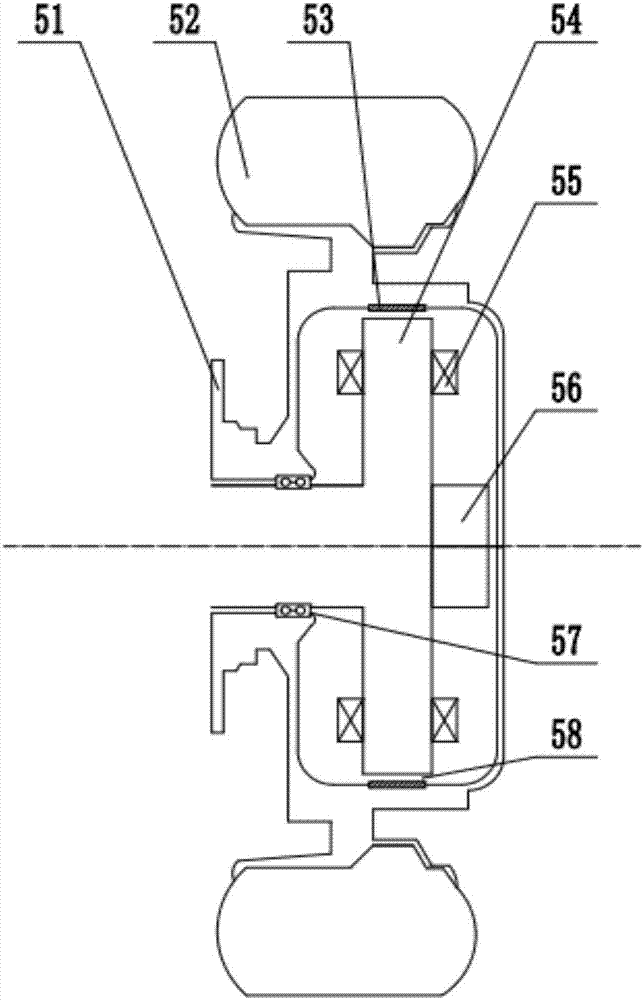

Frequency variable speed-adjusting device for both end power supplying multi-phase AC motor

The invention discloses a double-end-electrified multi-phase alternating current motor variable-frequency control device, which comprises a multi-phase alternating current motor, wherein the m head ends and the m tail ends of the stator winding of the multi-phase alternating current motor are led out to respectively connect with a multi-phase univertor, and the multi-phase univertor is formed by a direct current power supply, a filter capacitance, a multi-phase inverter and a variable-frequency controller, and the phase number m of the multi-phase alternating current motor is equal to that of the multi-phase inverter, wherein m>=5. The double-end-electrified multi-phase alternating current motor variable-frequency control device of the invention not only can realize large power by using a power electronic component with limited single-tube capacity in a larger range, but also has higher reliability as having redundancy on phase units and a system.

Owner:ZHEJIANG UNIV

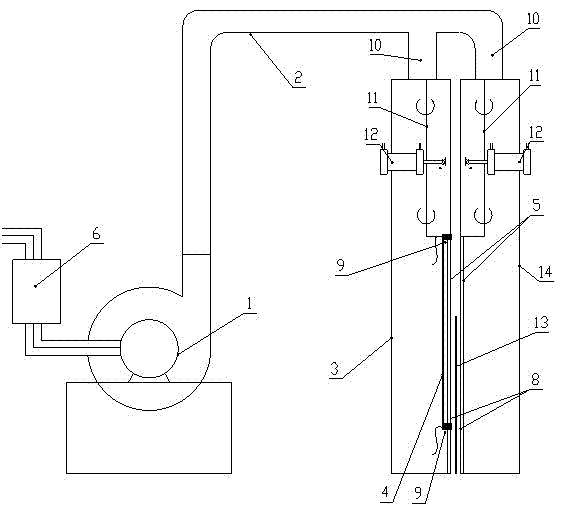

Driving system of wheel-drive type hydrostatic transmission hybrid vehicle

ActiveCN101722828AImprove stabilityEfficient use ofHybrid vehiclesGas pressure propulsion mountingDrive wheelControl power

The invention discloses a driving system of a wheel-drive type hydrostatic transmission hybrid vehicle, relates to the field of vehicle transmission, and aims to solve the problems that the driving torque of a driving wheel cannot be allocated reasonably and the structural layout is not flexible because the hydrostatic transmission hybrid vehicle uses an axle structure. A high-pressure hydraulic accumulator is connected with oil inlets of a constant-pressure variable pump and wheel hydraulic pumps / motors through an electromagnetic switching valve; the oil outlet of a fixed delivery pump is connected with oil inlets of wheel hydraulic pump / motor variable devices; a low-pressure hydraulic accumulator is connected with the oil outlets of the constant-pressure variable pump, the fixed delivery pump, the wheel hydraulic pumps / motors and wheel hydraulic pump / motor variable devices; the wheel hydraulic pump / motor variable devices control the wobble plates of the wheel hydraulic pumps / motors;and the wheel hydraulic pumps / motors are connected with input shafts of wheel reducers; a central controller controls power elements, the wheel hydraulic pump / motor variable devices, the electromagnetic switching valve, a wheel clutch, and a friction braking controller group which controls a friction brake. The maximum discharge capacity of the rear wheel hydraulic pump / motor is greater than thatat the front wheel hydraulic pump / motor; the reduction ratio of the rear wheel reducer is greater than that of the front wheel reducer. The driving system has the advantages of simplifying transmission, facilitating flexible layout, and being suitable for various vehicles.

Owner:哈尔滨工业大学高新技术开发总公司

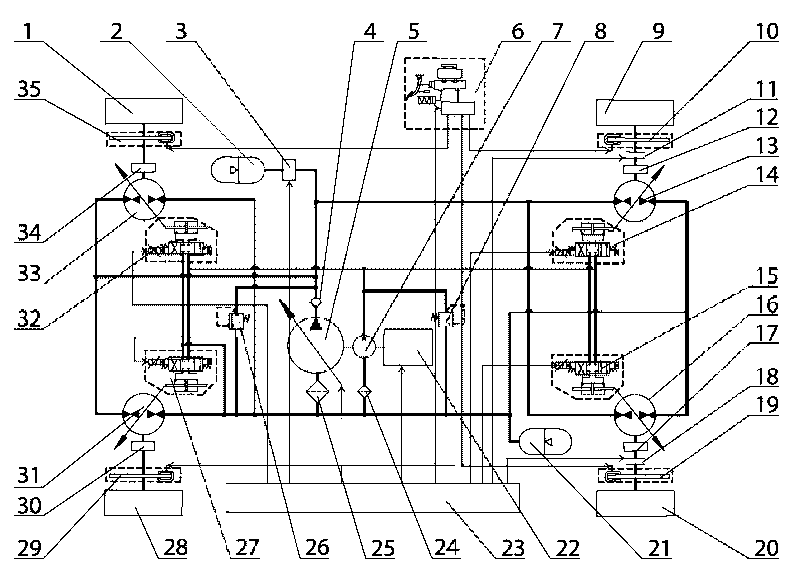

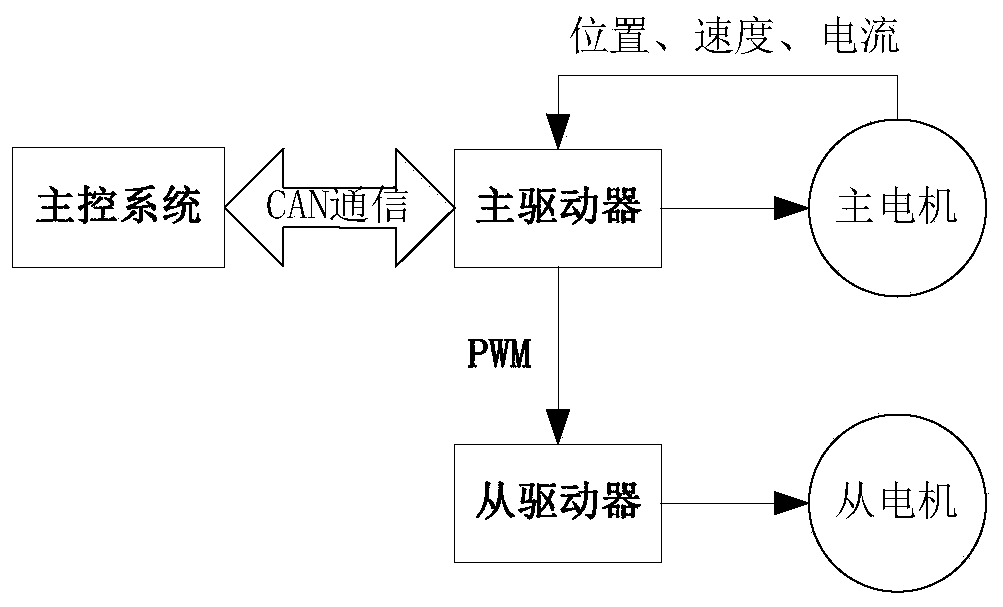

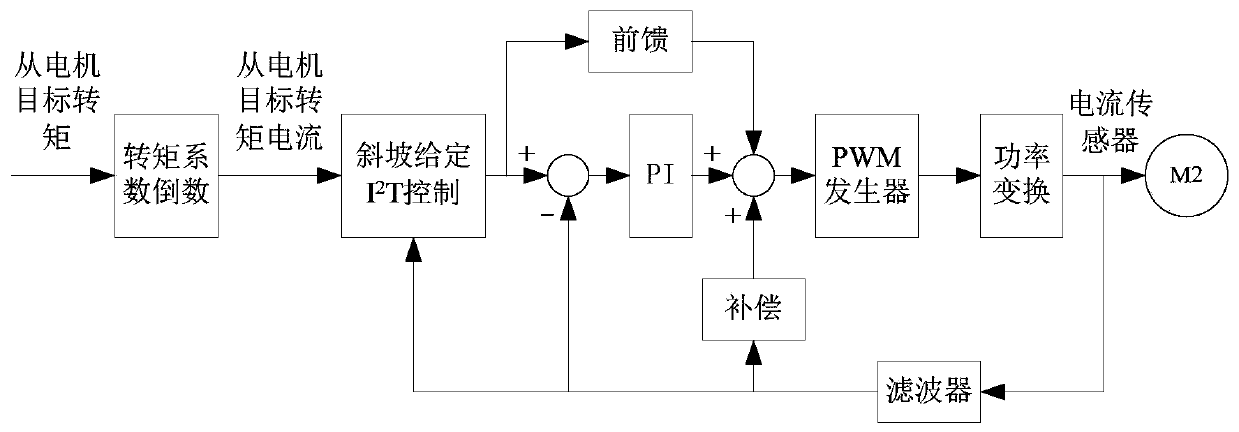

Method and device for controlling dual-motor variable-pitch system

InactiveCN110285017AGuaranteed to achieveRealize coordinated controlWind motor controlMachines/enginesMotor variableCoordinate control

The invention relates to a method and device for controlling a dual-motor variable-pitch system. The method comprises the steps that firstly, the current position of a paddle and the target position of the paddle are acquired, and a motor target rotating speed is calculated according to the difference value of the current position and the target position of the paddle; motor target torque is obtained according to the motor target rotating speed; then the motor target torque is distributed to a master motor and a slave motor, and master motor target torque current and slave motor target torque current are obtained; the master motor is controlled through the master motor target torque current, and the slave motor is controlled through the slave motor target torque current. According to the method, the master motor and the slave motor are controlled separately, one part of the motor target torque is output by the master motor, the other part of the motor target torque is output by the slave motor, coordination control over the master motor and the slave motor is achieved, and it is guaranteed that the paddle can reach the target position.

Owner:XUCHANG XUJI WIND POWER TECH +1

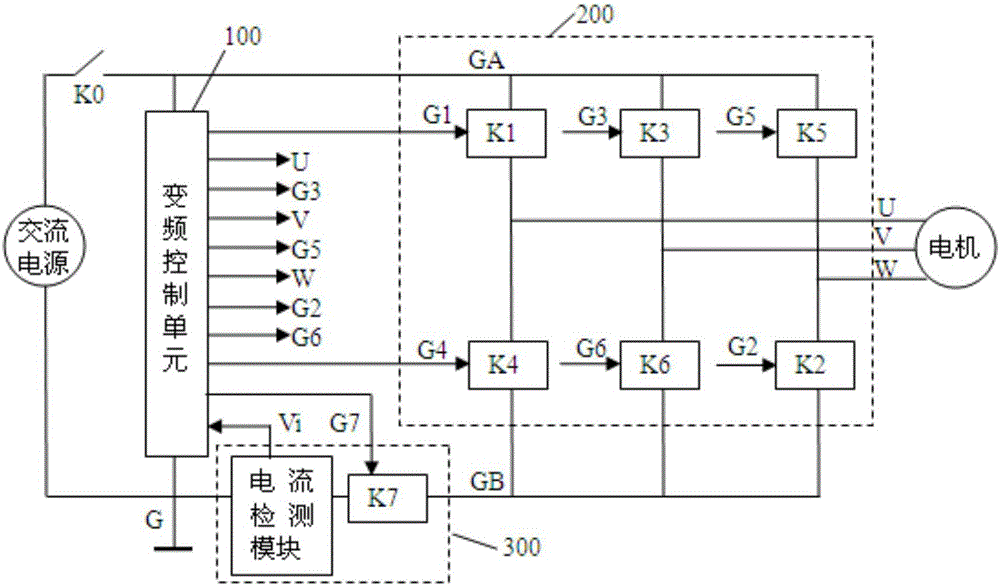

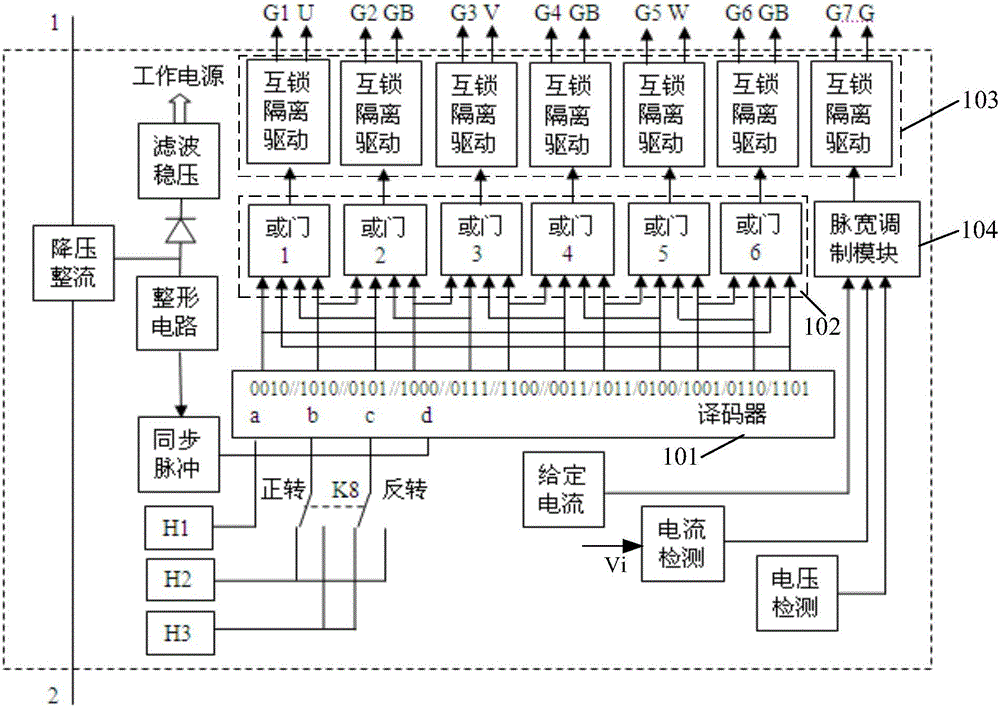

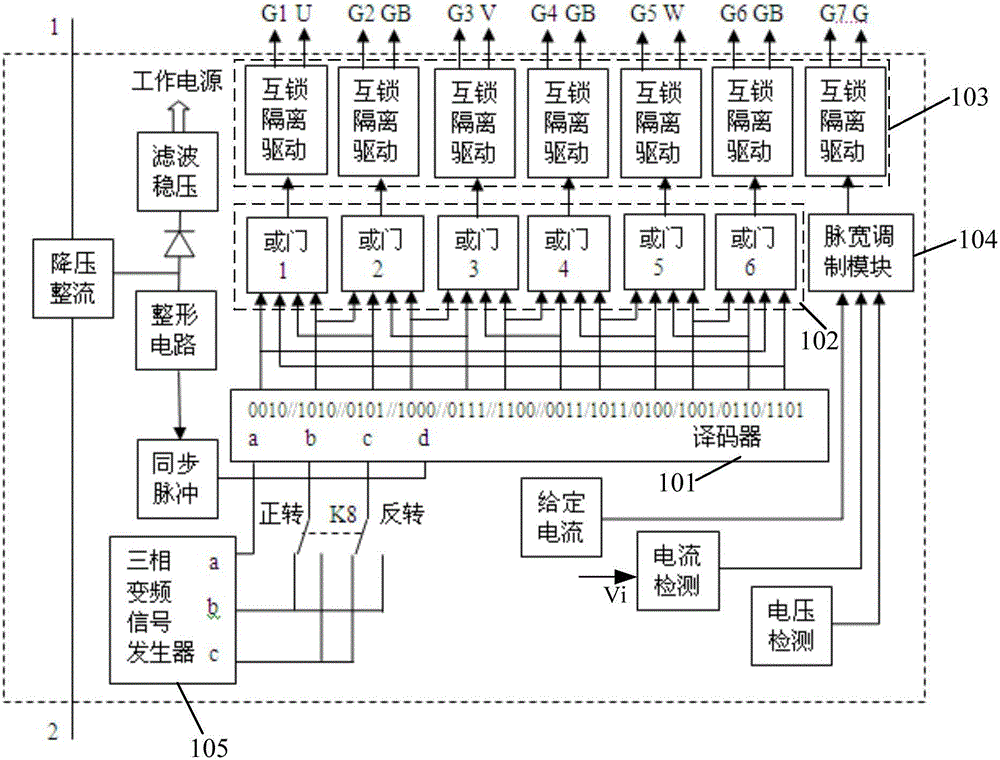

Motor starting and speed-regulation control circuit and driving control method thereof

ActiveCN106788000AAchieve normal startupThe overall structure is simple and reliableElectronic commutatorsStarter arrangementsDIACSilicon-controlled rectifier

The invention is suitable for the field of power electronics and electronic control and provides a motor variable-frequency starting and speed-regulation control circuit and a driving control method thereof. The circuit comprises a variable-frequency control unit for generating a triggering signal; a bidirectional switch unit used for controlling bidirectional gating according to the triggering signal to enable a single-phase power frequency AC power supply to be converted into a three-phase variable-frequency AC power supply and form a variable-speed motor rotating magnetic field to control motor starting and speed regulation; and a protection unit used for detecting motor current and controlling the motor current through pulse-width modulation chopping wave. The triggering signal controls each bidirectional silicon controlled rectifier to realize bidirectional conduction under the single-phase power frequency AC power supply, and the three-phase variable-frequency AC power and the variable-speed motor rotating magnetic field are generated in the selective conduction process through the bidirectional silicon controlled rectifier, thereby realizing motor starting and speed regulation. The motor starting and speed-regulation control circuit is simple and reliable in structure and low in cost, and expands use range of a three-phase permanent-magnet asynchronous motor.

Owner:深圳市斗索科技有限公司

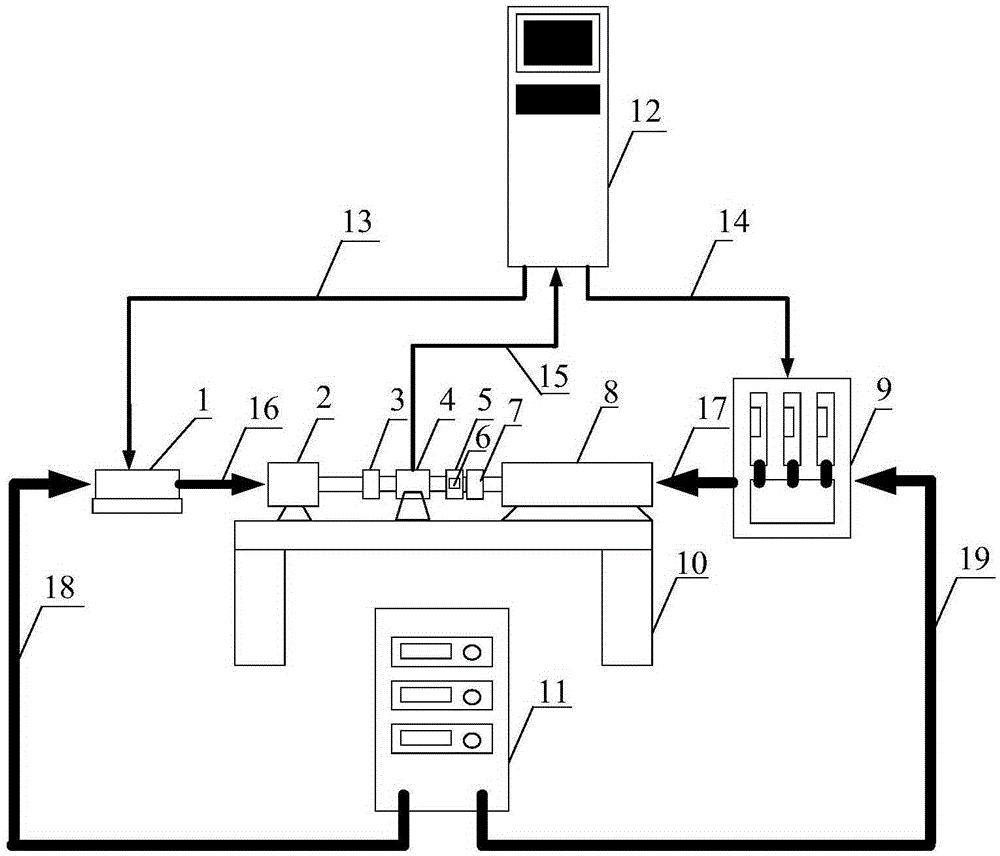

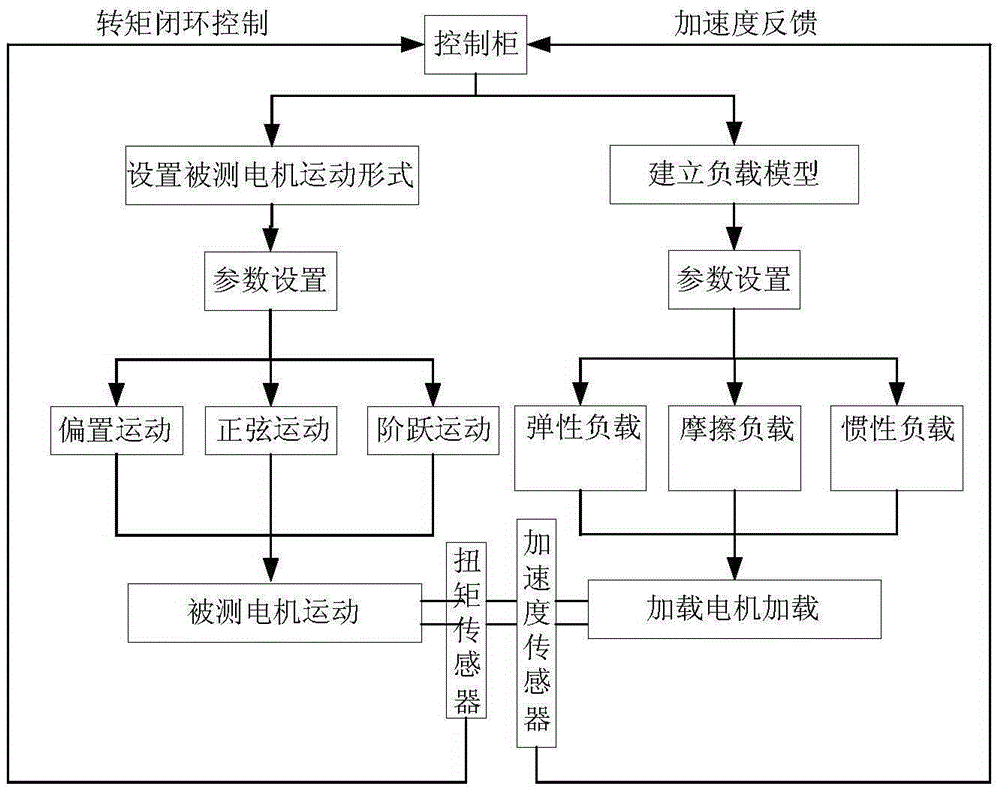

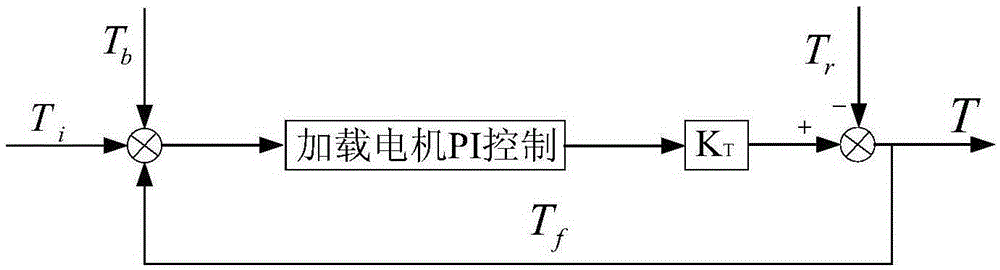

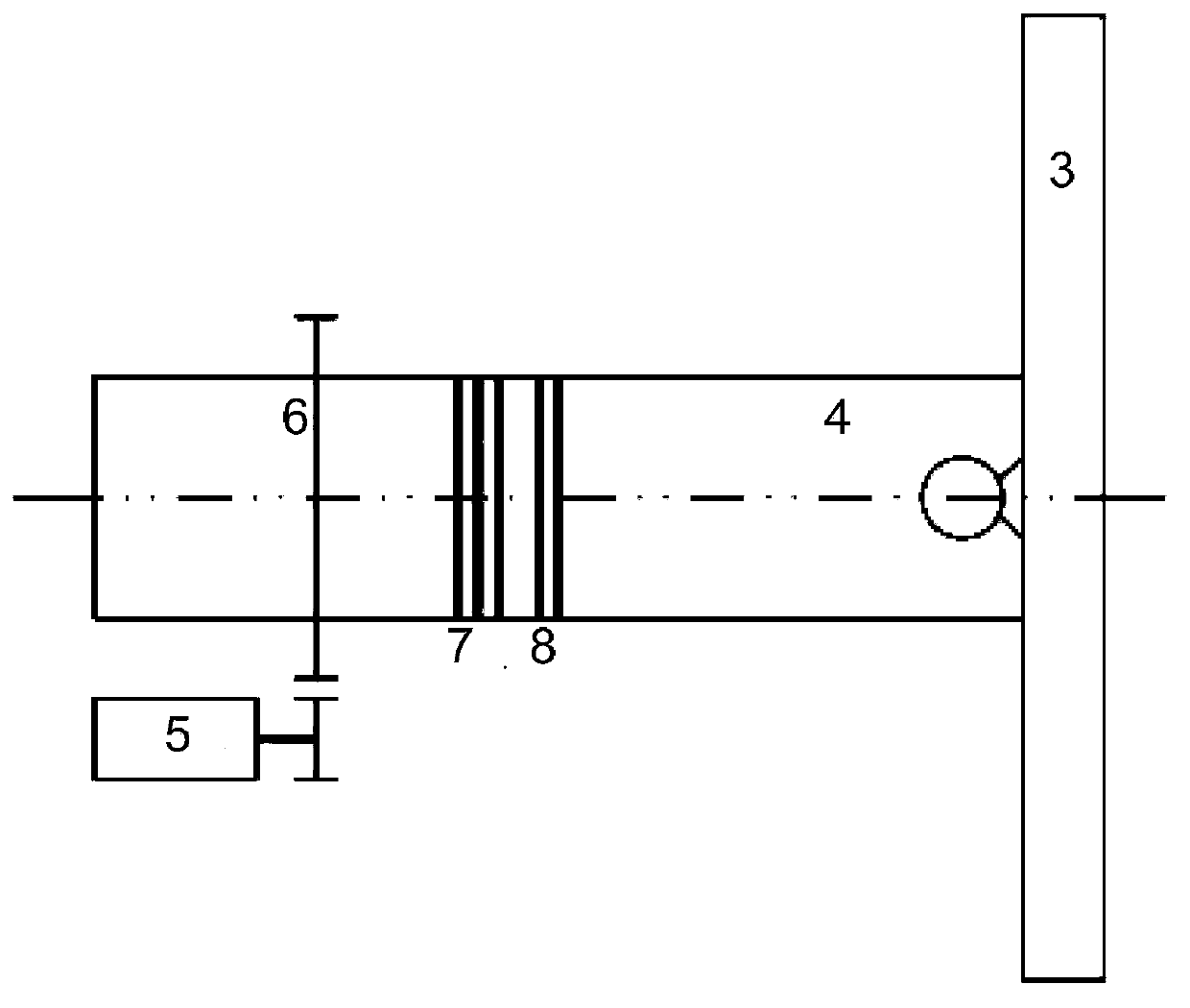

Spaceflight servo motor variable working condition dynamic loading system and spaceflight servo motor variable working condition dynamic loading method

InactiveCN106646220AEliminate the effects ofLoad accuratelyDynamo-electric machine testingMotor testingLoad torque

The invention belongs to the spaceflight servo motor testing field, to be specific, discloses a spaceflight servo motor variable working condition dynamic loading system and a spaceflight servo motor variable working condition dynamic loading method. The spaceflight servo motor variable working condition dynamic loading system comprises a tested motor driver, a tested motor, a first coupler, a torque sensor, a second coupler, an acceleration sensor, an electric slip ring, a loading motor, a loading driver, a direct current power supply, and a control cabinet. The spaceflight servo motor variable working condition dynamic loading method comprises steps that the control cabinet is used to set the motion form and the load parameter of the tested motor; the control cabinet is used to transmit a position instruction signal to the detected motor driver, and is used to control the motion form of the tested motor; during the variable working condition motion of the tested motor, the control cabinet is used to transmit a loading instruction signal to the loading motor driver; a deviation signal of loading torque and feedback torque is calculated by a PI control algorithm to acquire a loading control signal, which is transmitted to the loading motor driver, and then redundant force elimination is realized. The loading system and the loading method are used to eliminate the redundant force of the tested motor applied to the loading motor, and therefore the accuracy of the loading torque is guaranteed.

Owner:BEIJING RES INST OF PRECISE MECHATRONICS CONTROLS +1

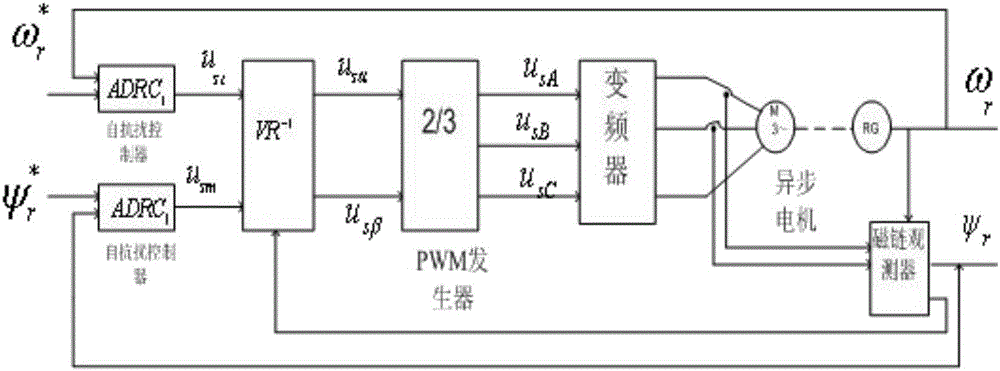

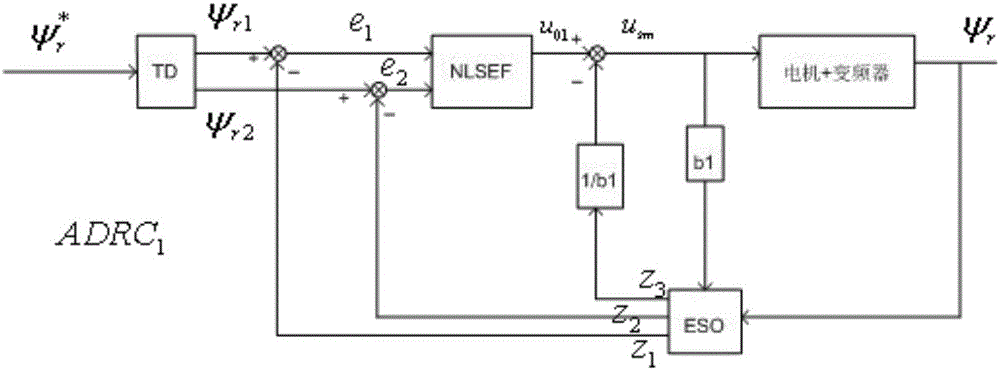

Method for controlling asynchronous motor variable-frequency speed control system based on active-disturbance-rejection controller

InactiveCN106208879AAddressing the impact of decoupling performanceSolve the rapidityElectronic commutation motor controlVector control systemsMathematical modelElectric power system

A method for controlling an asynchronous motor variable-frequency speed control system based on an active-disturbance-rejection controller belongs to the technical field of electric power system asynchronous motor variable-frequency speed control system, and comprises the following steps: step A, constructing a dynamic mathematical model of an asynchronous motor; step B, summarization of the active-disturbance-rejection controller; step C, designing an asynchronous motor control system based on the active-disturbance-rejection controller; and step D, simulated analysis. Beneficial effects of the present invention are: first, a defect of poor parameter robustness of a general vector control system is overcome, an effect of parameter time variable on vector control system decoupling performance and speediness and stability contradiction existed in the general vector control system are effectively solved; and second, the active-disturbance-rejection controller does not depend on a concrete mathematical model of a controlled system and has a strong disturbance rejection capability on internal and external disturbance. A simulation result indicates that the active-disturbance-rejection controller has uncertainty for a model and good robustness for noise measurement, and has a good dynamic property.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

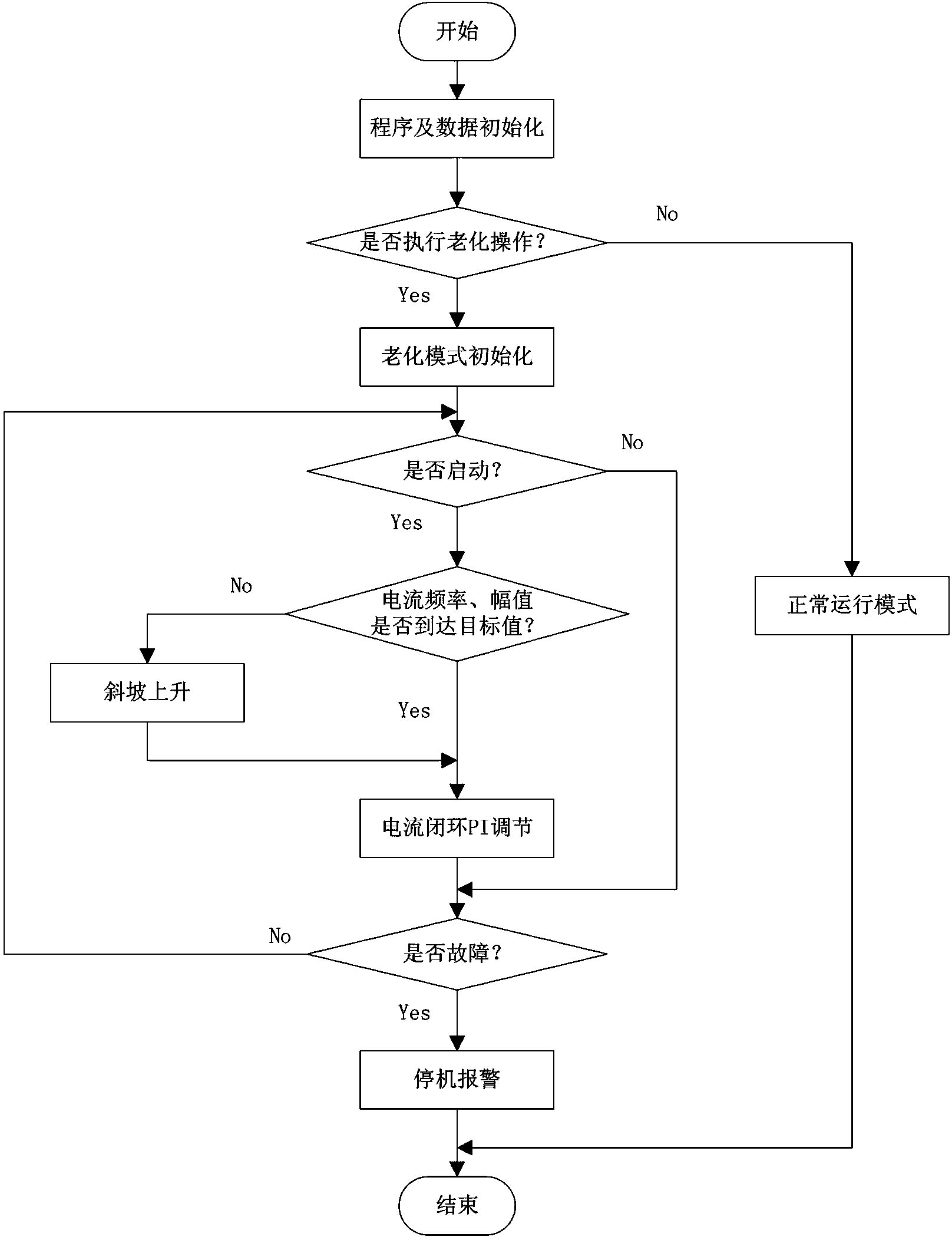

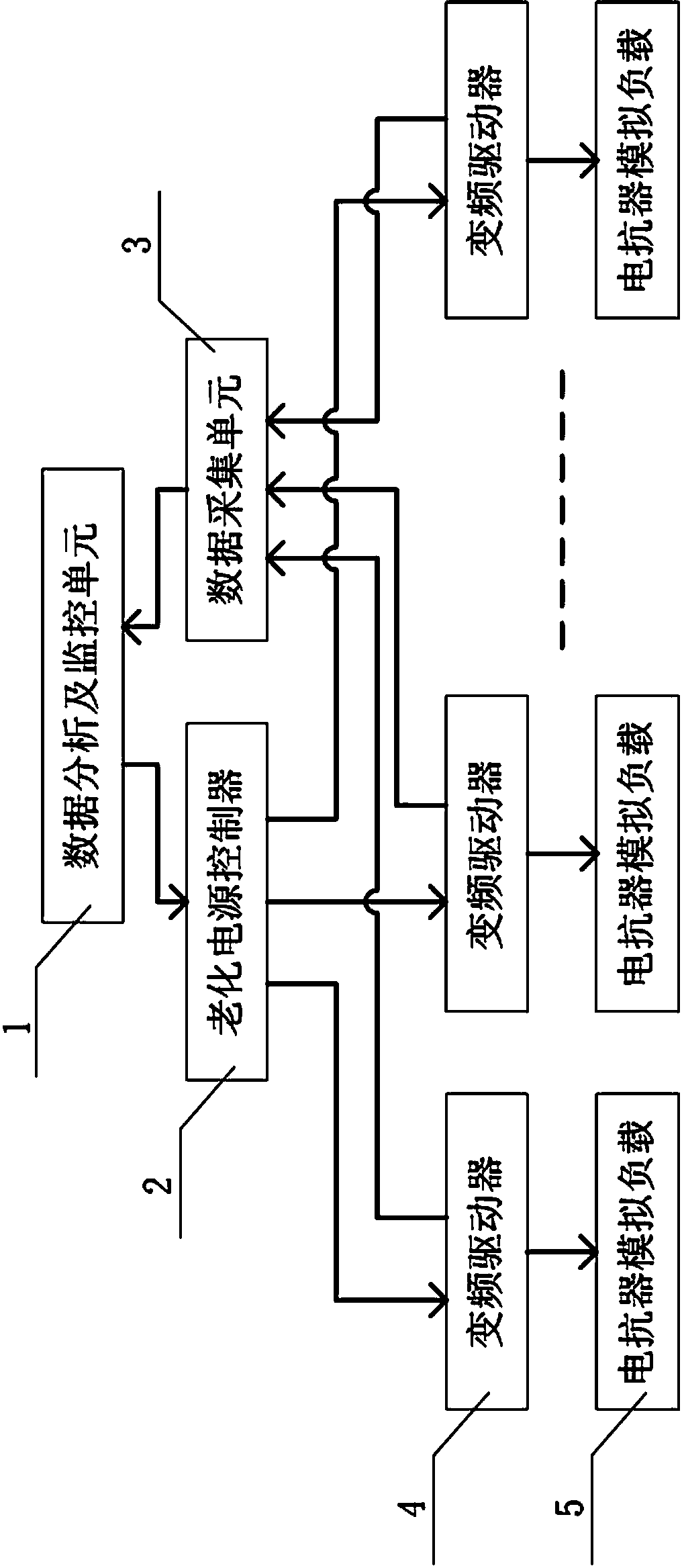

Motor variable-frequency driver aging test device and test method thereof

InactiveCN103412203AFully expose latent failuresConsumes less energyElectrical testingElectrical resistance and conductancePower controller

The invention relates to a motor variable-frequency driver aging test device and a test method thereof. The device comprises a data acquisition unit, an aging power supply controller, and a data analysis and monitoring unit, wherein the data acquisition unit is used for acquiring various data of a variable-frequency driver during the aging test process, the aging power supply controller used for controlling a power supply supplied to the variable-frequency driver and a load, the data analysis and monitoring unit is used for reading data of the data acquisition unit and sending control commands to the aging power supply controller, the load is an electric reactor analogue load, dotted terminals of the electric reactor analogue load are mutually connected, and the rest three taps of the electric reactor analogue are connected to a three-phase output end of the variable-frequency driver. The motor variable-frequency driver aging test device replaces a motor with an electric reactor to be served as the load of the motor variable-frequency driver, since the electric reactor is an inductive load, and the resistive component is small and the reactance component is large, thus the actual absorbed active power is very small, and most of reactive power is exchanged repeatedly between the driver and the electric reactor without being consumed.

Owner:FANS TECH ELECTRIC CO LTD

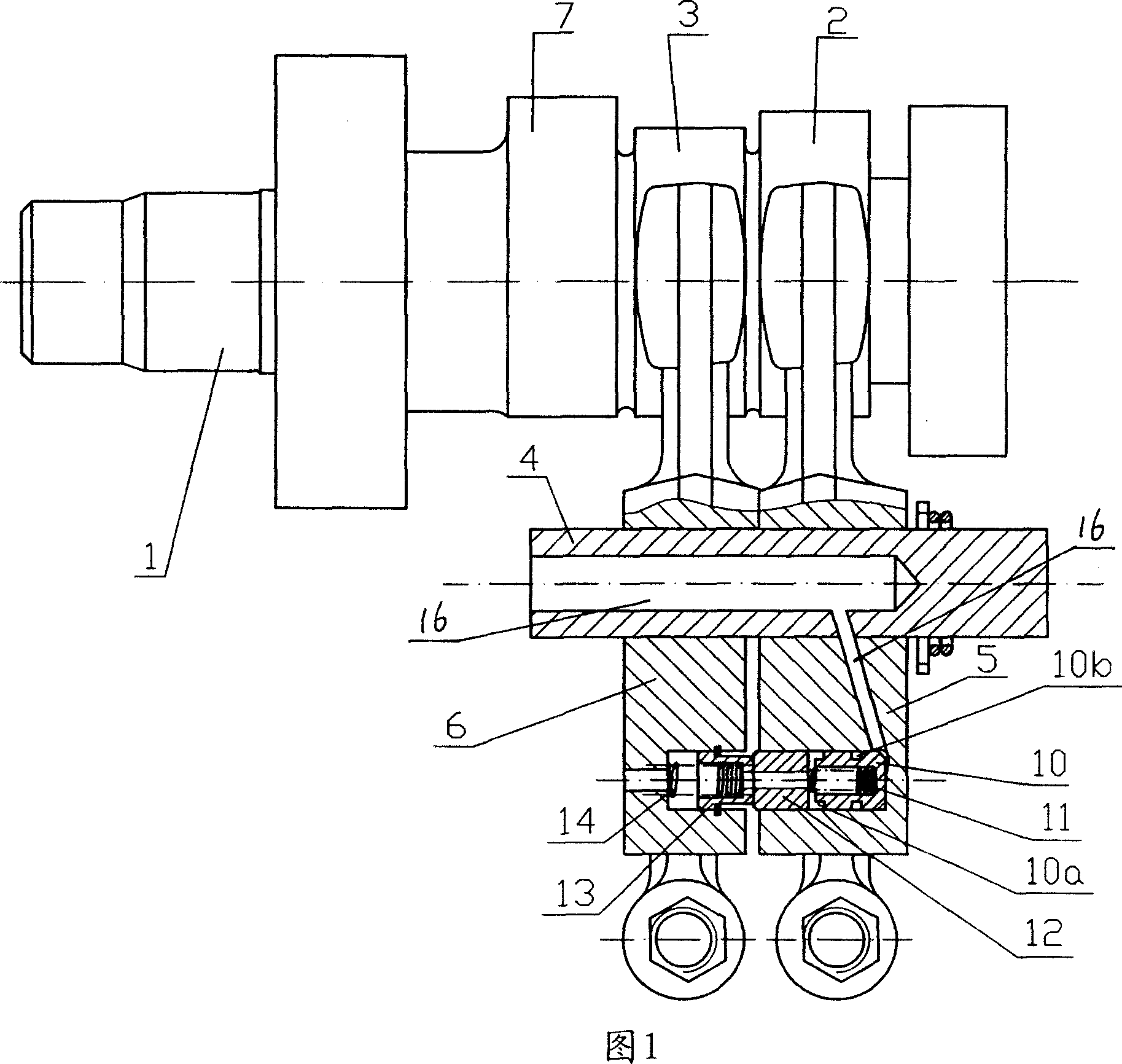

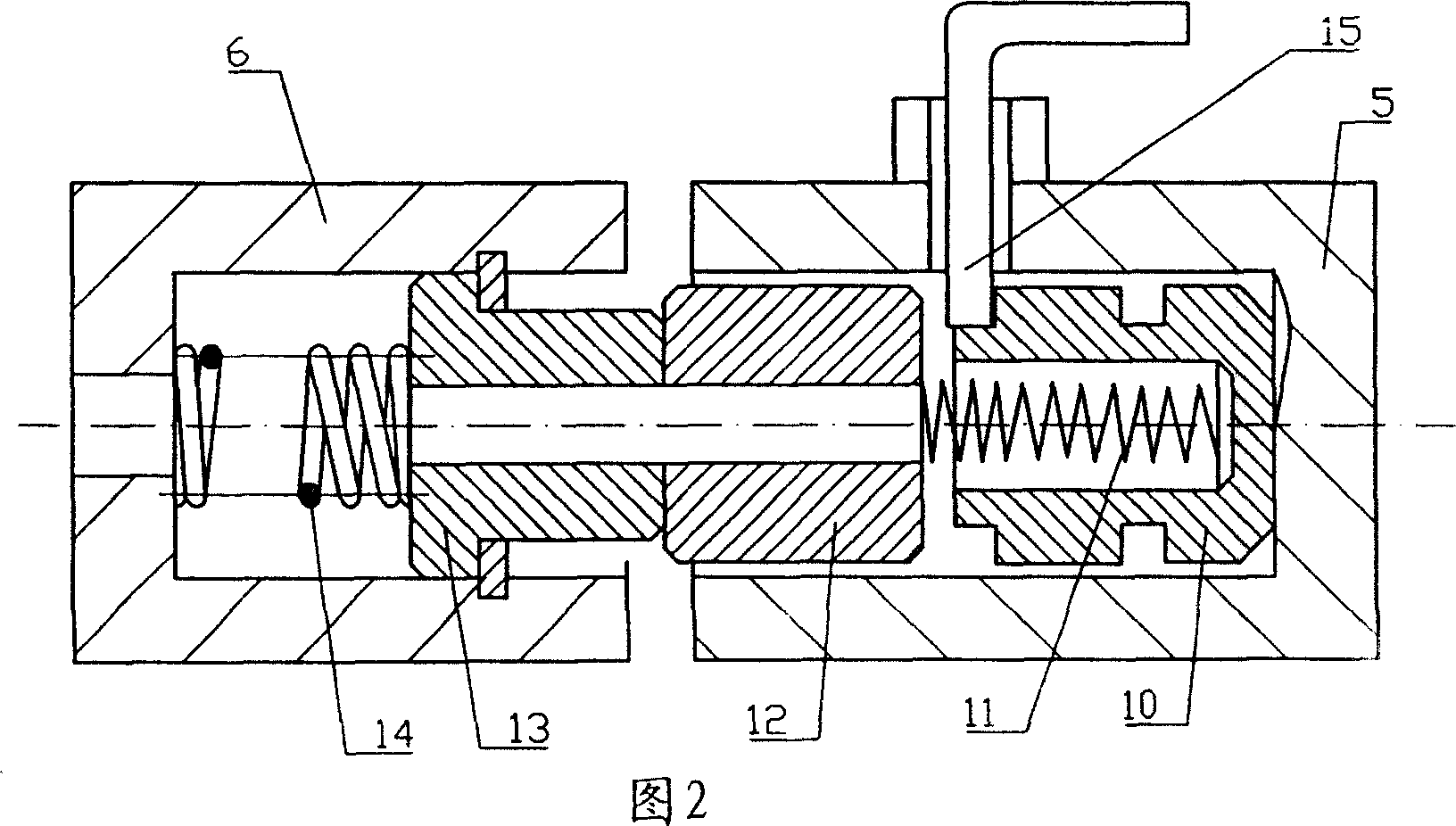

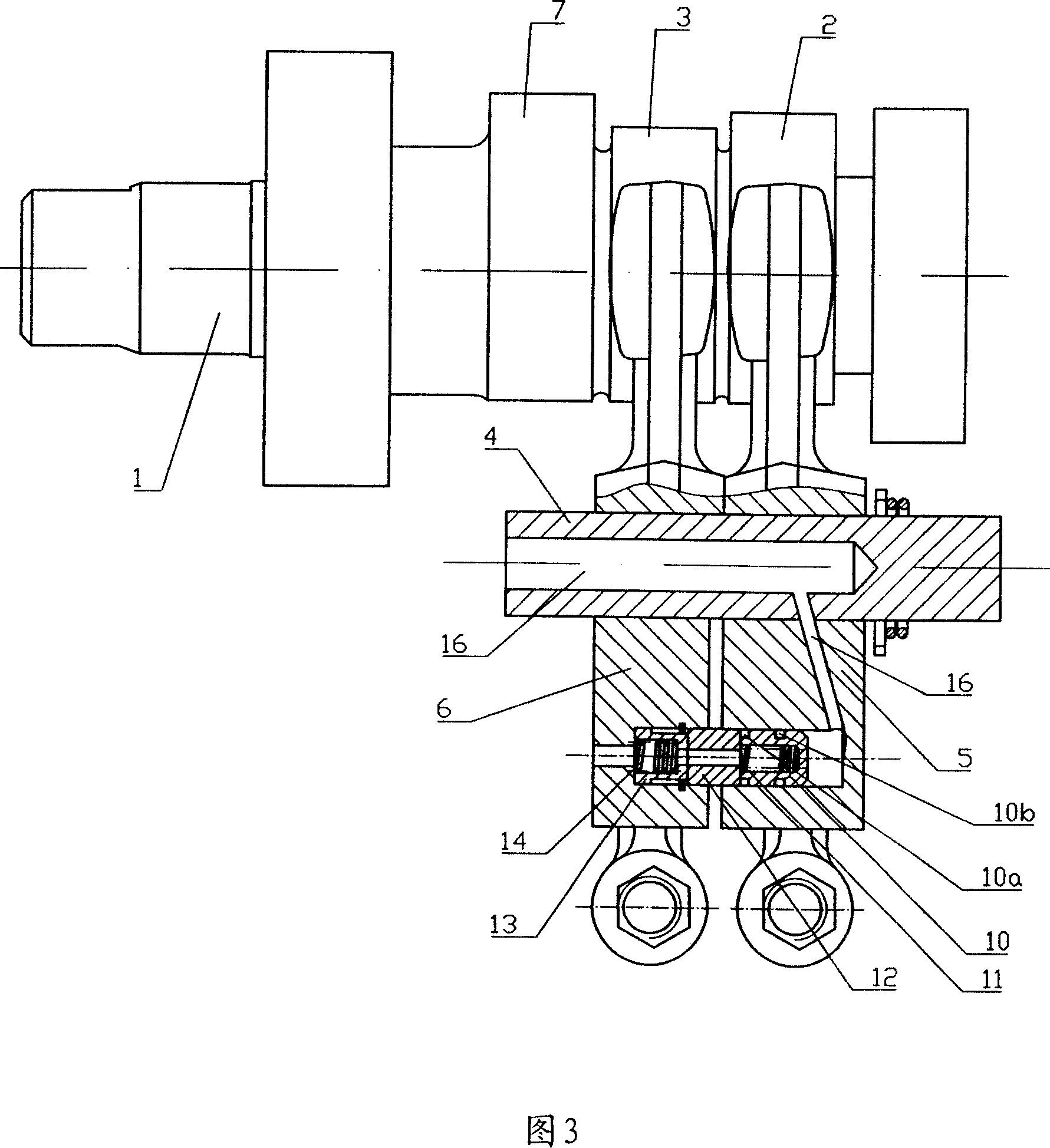

Three air valve motorcycle motor variable air inlet valve air distribution device

InactiveCN1948721AImprove powerImprove economyValve arrangementsMachines/enginesValve jobInlet valve

An admission device with the variable intake valve of the three-valve motorcycle engine is provided in the invention. The exhaust cam (7), the main inlet cam (2) and the inlet Idler (3) are on the camshaft (1), the line of the inlet Idler (3) is the entire round, its diameter is the same as the base diameter of the main inlet cam (2). The inlet rocker axis (4) has the major and the minor Inlet Rocker (5, 6). The clutch device composed of the initiative piston (10), the spacing spring (11), the switching piston (12), the blocking piston(13), the blocking Spring (14) and the lock sheet is between the major and the minor Inlet Rocker(5,6). According to the engine speed and load condition, the engine can switch between the single-intake valve and double-valve modes automatically. So it can increase the power, economy and emission characteristic in the whole speed and loading condition scope of the motorcycle. The whole structure is simple and contract, it has a small change to the original admission device.

Owner:CHONGQING UNIV

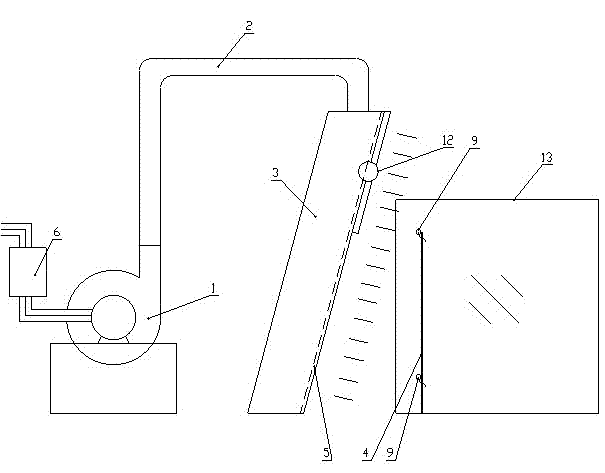

Fan device and method for glass drying

ActiveCN103758771ATo achieve the purpose of energy savingSave electricityDrying gas arrangementsPump controlInductorMotor variable

A fan device for glass drying comprises a fan, an air supply pipeline, an air outlet, an inductor device for detecting glass height, a motor variable frequency speed regulator for adjusting air quantity and a control device. The fan is connected with the air outlet through the air supply pipeline. The fan comprises a fan motor connected with the motor variable frequency speed regulator in a control mode. The air outlet is two long-strip-shaped holes arranged vertically in parallel and is divided into an upper air outlet and a lower air outlet according to the vertical position. An upper air outlet opening closing device used for controlling opening and closing of the upper air outlet is arranged at the position of the upper air outlet and comprises an air port baffle. The inductor device is located in front of the air outlet and comprises more than two inductors arranged from top to bottom, and the position of the inductor is matched with that of the air outlet. The inductor device, the motor variable frequency speed regulator and the upper air outlet opening closing device are connected with the control device in a control mode.

Owner:HENAN ANCAI HI-TECH +1

Vehicle hydraulic and hub motor combined braking energy recycling system

PendingCN107097764AOptimize layoutSimple mechanical structureBraking element arrangementsElectrodynamic brake systemsFour-way valveElectromagnetic clutch

Provided is a vehicle hydraulic and hub motor combined braking energy recycling system. A storage battery is connected with hub motors installed on front wheels. The hub motors are connected with an input shaft on a vehicle body through a suspension; a dynamic coupler is connected with a driving axle through a first transmission shaft. The dynamic coupler is connected with a secondary element pump / motor through a second transmission shaft. The second transmission shaft is provided with an electromagnetic clutch; the secondary element pump / motor is connected with a hydraulic oil tank through a pipeline; an energy storage device is connected with the secondary element pump / motor through a three-position four-way directional control valve, and the energy storage device and the three-position four-way directional control valve as well as the secondary element pump / motor and the three-position four-way directional control valve are both connected through hydraulic pipes; and a secondary element pump / motor variable pump is installed on the hydraulic oil tank through the hydraulic pipes.

Owner:ZHEJIANG UNIV OF TECH

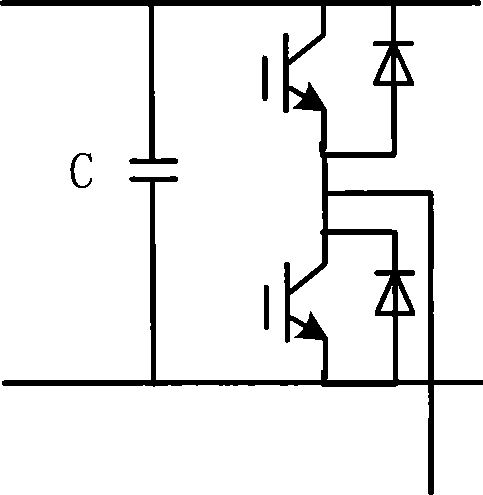

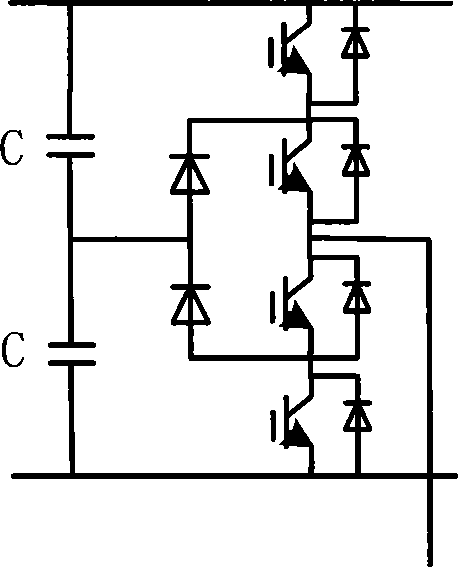

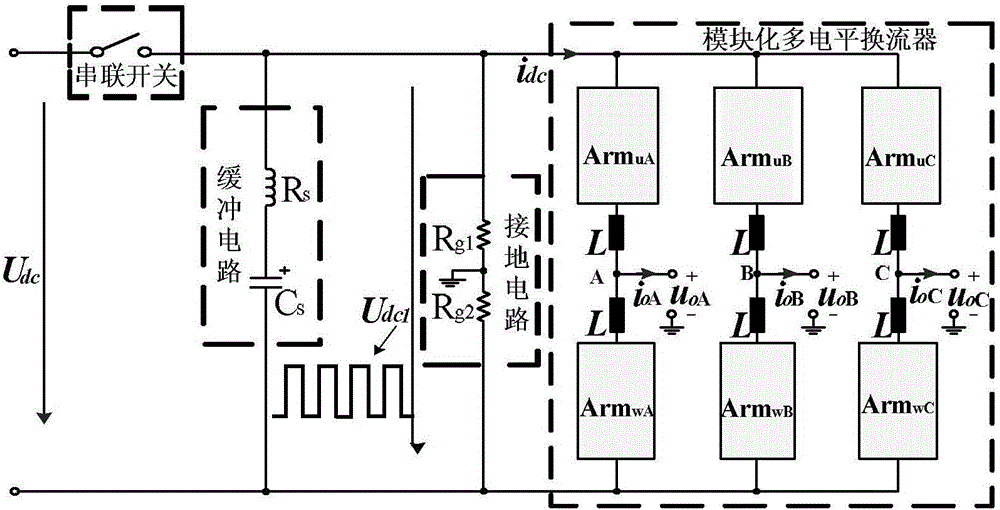

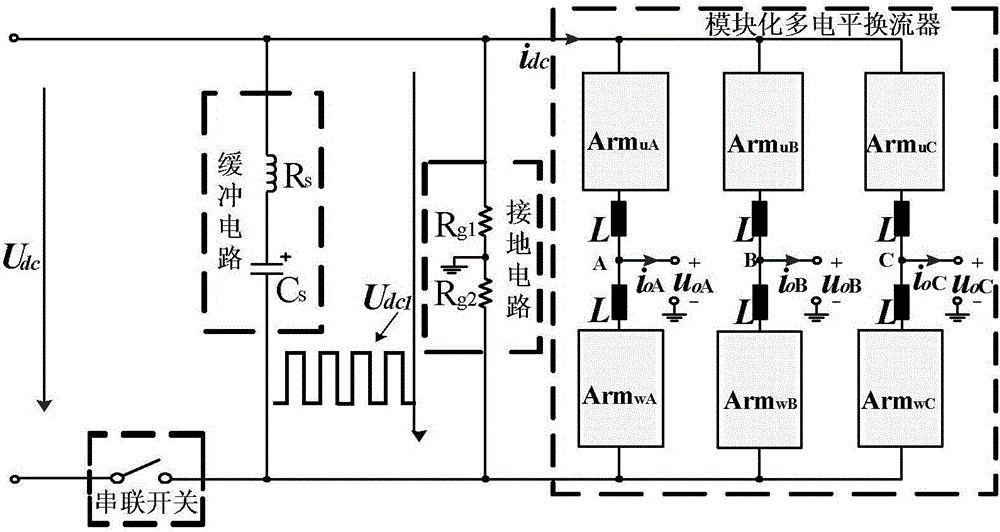

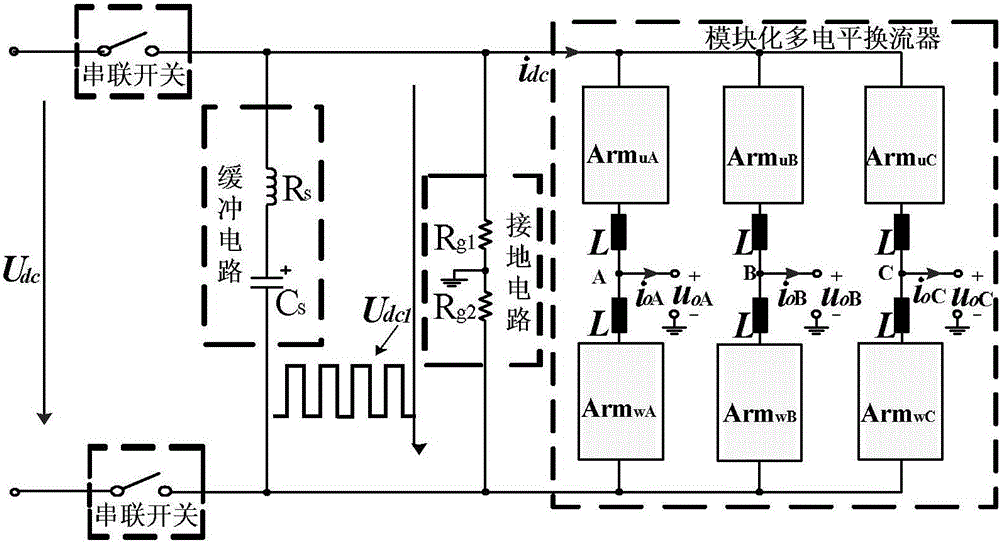

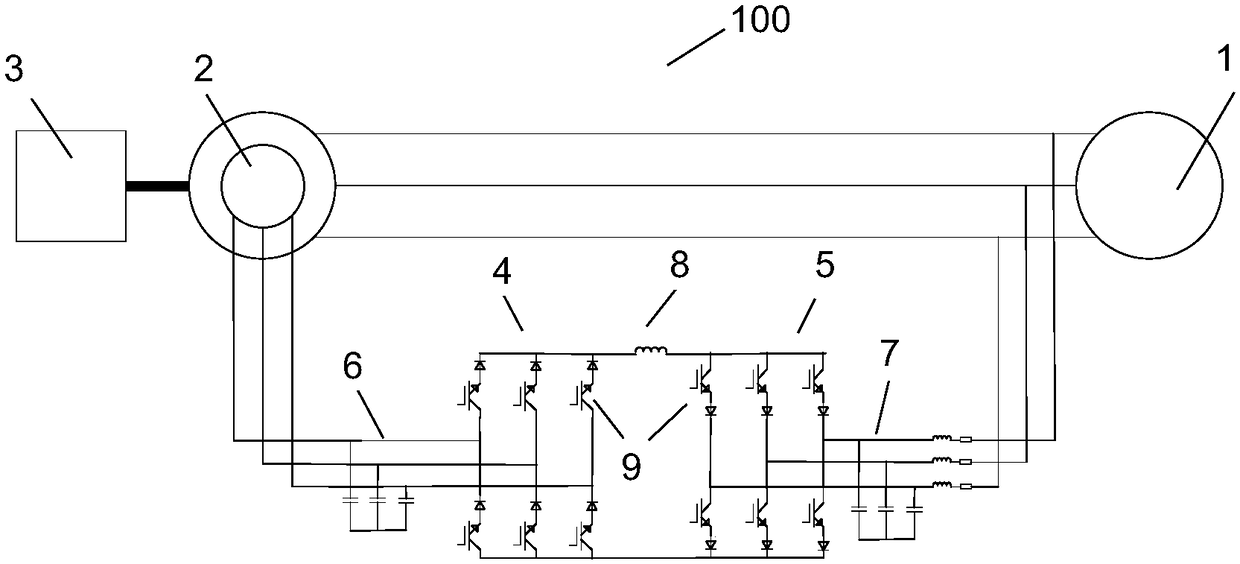

Hybrid modular multilevel converter suitable for low frequency operation and control method thereof

ActiveCN105915090ACausing a common mode voltageReduce capacitor voltage fluctuationsDc-ac conversion without reversalCapacitanceHybrid type

The invention provides a hybrid modular multilevel converter suitable for low frequency operation and a control method thereof, belongs to the field of power electronics, and aims at solving the problems of capacitor voltage fluctuation in low frequency operation of a MMC. The converter device comprises a series switch, a buffer circuit, a grounding circuit and the modular multilevel converter. The series switch is connected in series between a DC bus and the DC side of the modular multilevel converter. The buffer circuit and the grounding circuit are respectively connected in parallel at the DC side of the modular multilevel converter. The modular multilevel converter is composed of three-phase circuits. Each phase of circuit is comprises upper and lower bridge arms. Each bridge arm is formed by one electric inductor L and N submodules SM of the same structure through series connection. Each submodule SM comprises a half-bridge power unit and a capacitor C. The hybrid modular multilevel converter is used for high-voltage motor variable-frequency speed regulation.

Owner:HARBIN INST OF TECH

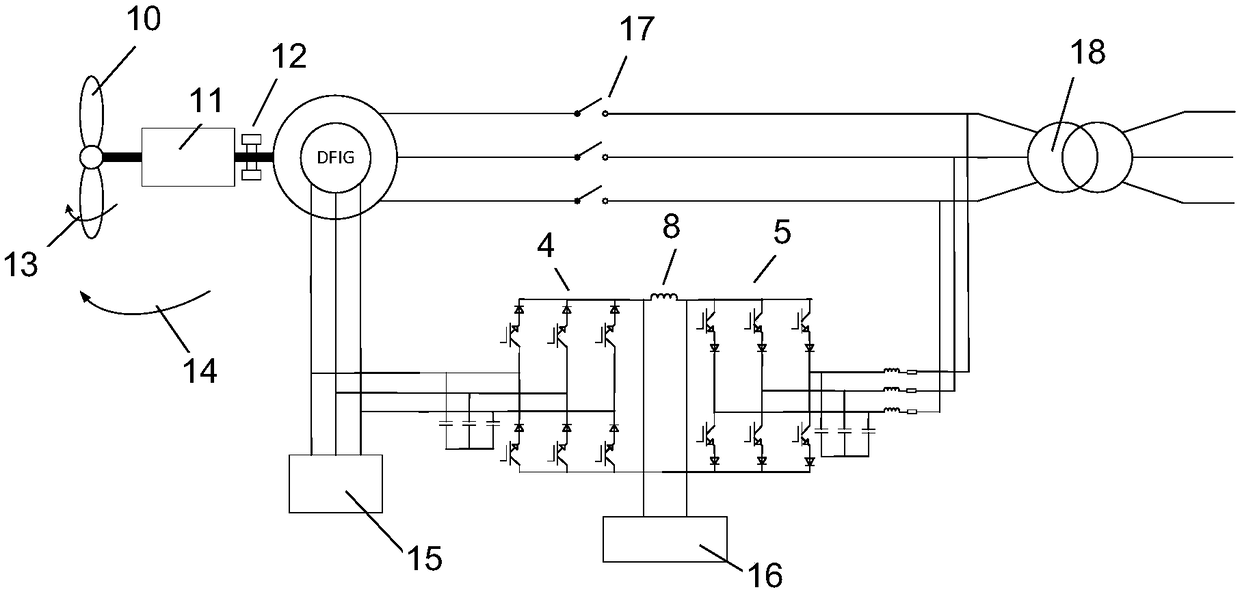

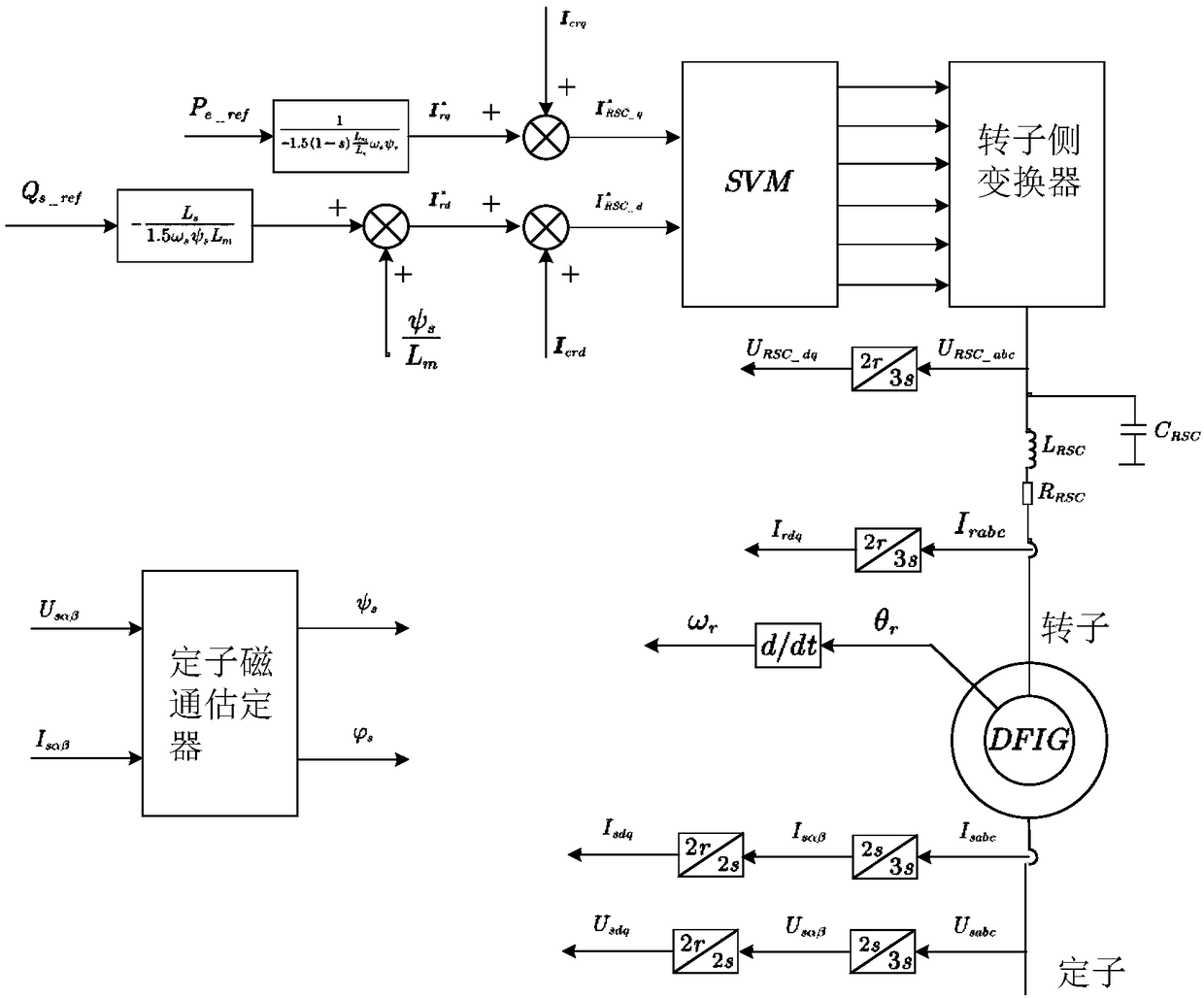

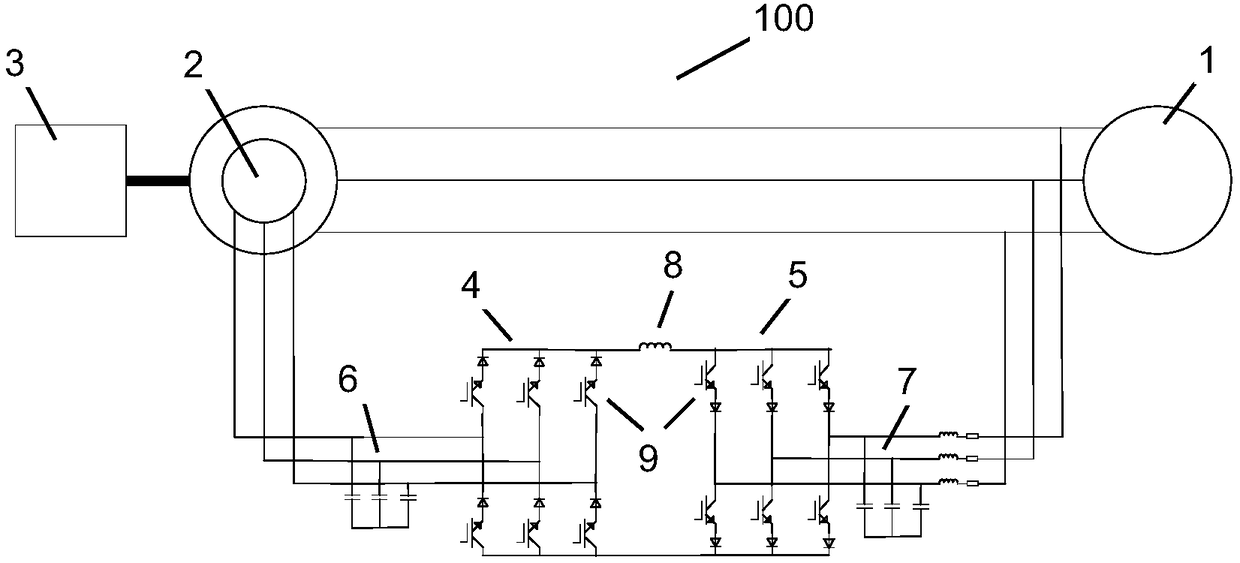

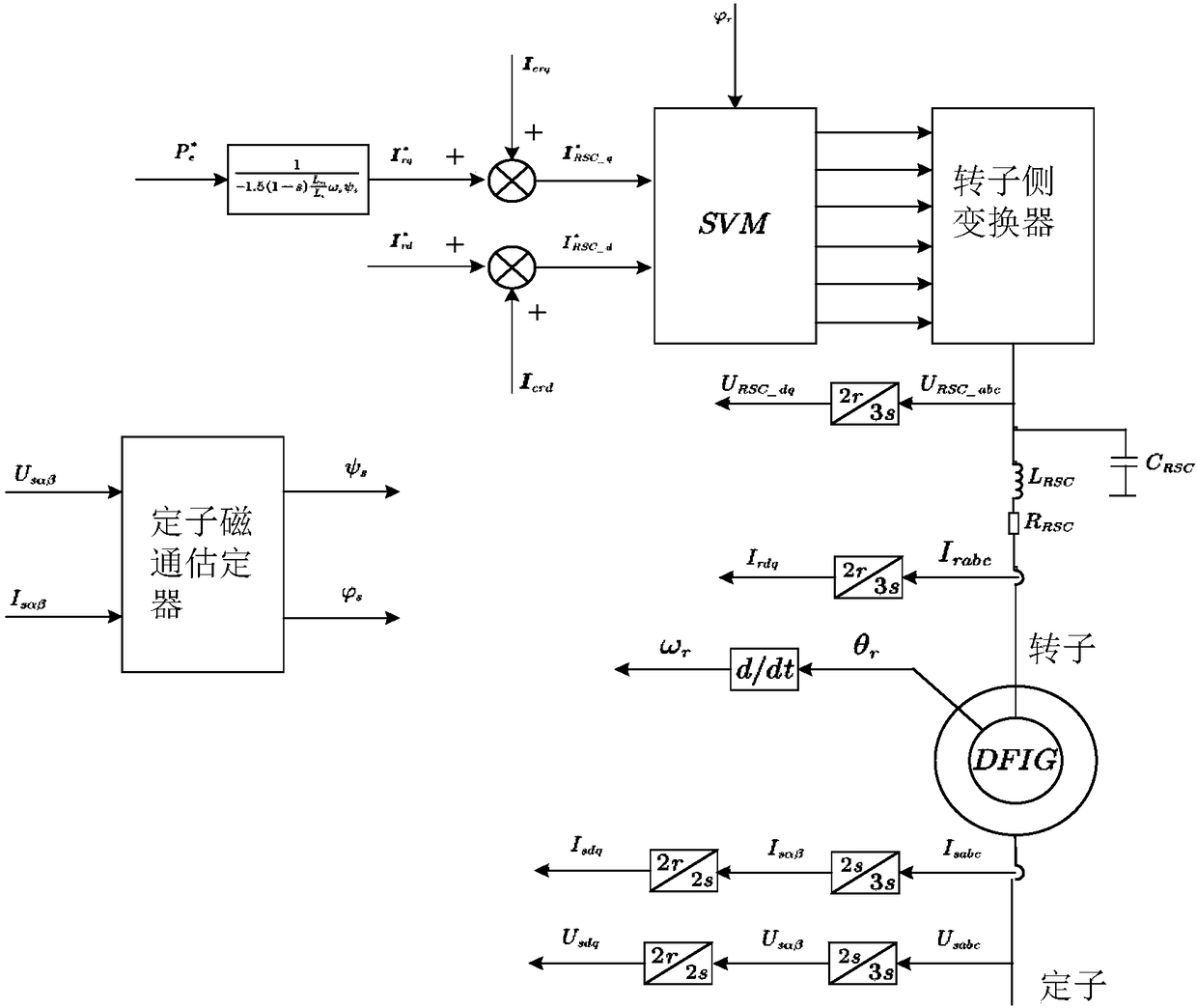

DC bus current control system of a doubly-fed motor variable-frequency speed regulating system

PendingCN109120206AShort transition timeSteady state transition timeAC motor controlVector control systemsPower factorDc current

The invention discloses a DC bus current control system of a doubly-fed motor variable-frequency speed regulating system. The DC bus current control system has high steady-state performance, and reduces the DC current of the speed regulating system without changing the power factor of the power grid, so as to increase the service life of the speed regulating system. The DC bus current control system comprises a motor-side converter, a grid-side converter, a motor-side filter, a grid-side filter and a DC inductor. The motor-side filter is connected between the control winding of a doubly-fed motor and the motor-side converter. The grid-side filter is connected between a three-phase AC power supply and the grid-side converter. The motor-side converter and the grid-side converter are connected with each other, and the DC inductor is connected between the motor-side emitter of the motor-side converter and the grid-side collector of the grid-side converter. The power winding of the doubly-fed motor is connected to the three-phase AC power supply. The method includes the following steps: the control winding of the doubly-fed motor provides excitation to reduce the motor-side current andincrease the grid-side current; and a controller makes the motor-side current equal to the grid-side current.

Owner:CHINA POWER ENG CONSULTING GRP CORP EAST CHINA ELECTRIC POWER DESIGN INST +1

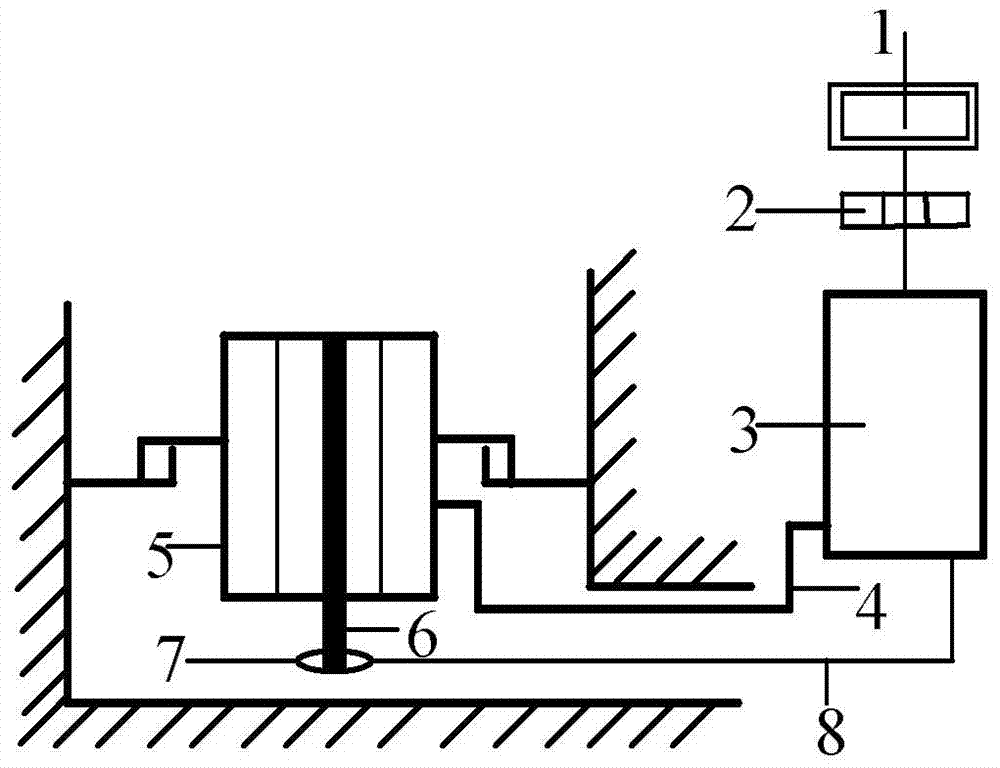

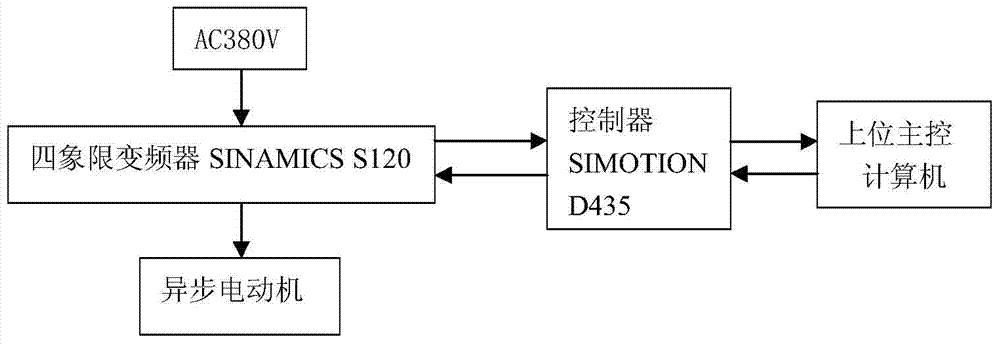

Pump storage group variable frequency starting load simulation system

InactiveCN104506087AShort development timeFriendly interfacePolyphase induction motor starterFour quadrantsInduction motor

The invention discloses a pump storage group variable frequency starting load simulation system with a controller, a four-quadrant frequency converter and an asynchronous motor serving as core devices and outputs a function relationship between the pump storage group generator motor variable frequency starting load resisting moment and the rotation speed. The four-quadrant frequency converter controls through torque when simulates the pump storage group generator motor variable frequency starting load and achieves a zero-speed-torque output function of the load simulation system at a starting stage of the variable frequency starting process of the group. During the group starting, speed rising and grid connection process, an SFC (Static Frequency Converter) adjusts the speed, the four-quadrant frequency converter outputs the torque according to the functional relationship of the load resisting moment and the rotation speed, and simulation of the pump storage group generator motor variable frequency starting load is achieved.

Owner:HARBIN ELECTRIC MASCH CO LTD

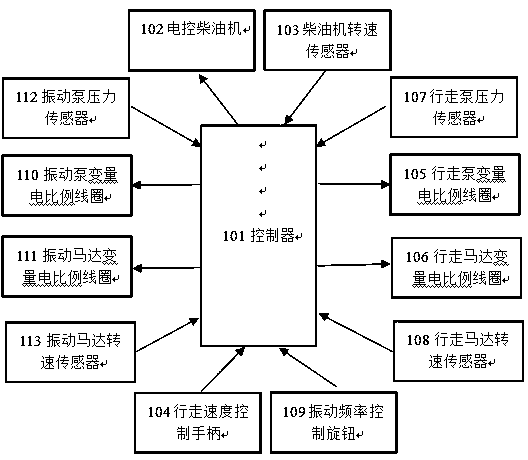

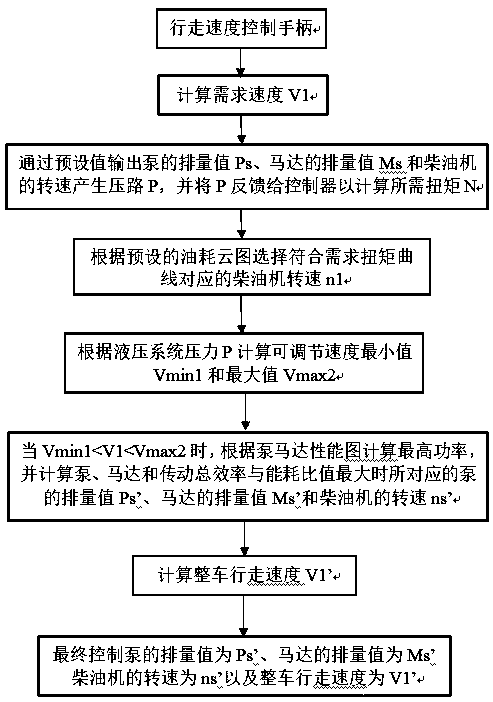

Novel power matching system of energy-saving road roller

ActiveCN109183568AAchieve energy savingAchieve noise reductionRoads maintainenceTotal efficiencyElectric control

The invention relates to a novel power matching system for an energy-saving road roller. The novel power matching system comprises a controller, an electric control diesel engine, a diesel engine rotary speed sensor, a travelling speed control handle, a travelling pump variable electric proportional coil, a travelling motor variable electric proportional coil, a travelling pump pressure sensor, atravelling motor rotary speed sensor, a vibration frequency control knob, a vibration pump variable electric proportional coil, a vibration motor variable electric proportional coil, a vibration pumppressure sensor and a vibration motor rotary speed sensor; and the speed of a whole machine can be automatically adjusted through monitoring operation states of the diesel engine, pumps and motors inthe road roller in real time, so that the total efficiency and energy consumption ratio of the diesel engine, the pumps and the motors are the highest. By adopting the power matching system provided by the invention, instant power generated in a travelling or vibration process of the road roller can be effectively inhibited; meanwhile, the power consumption and noise also can be effectively reduced and the utilization cost is saved.

Owner:柳工无锡路面机械有限公司

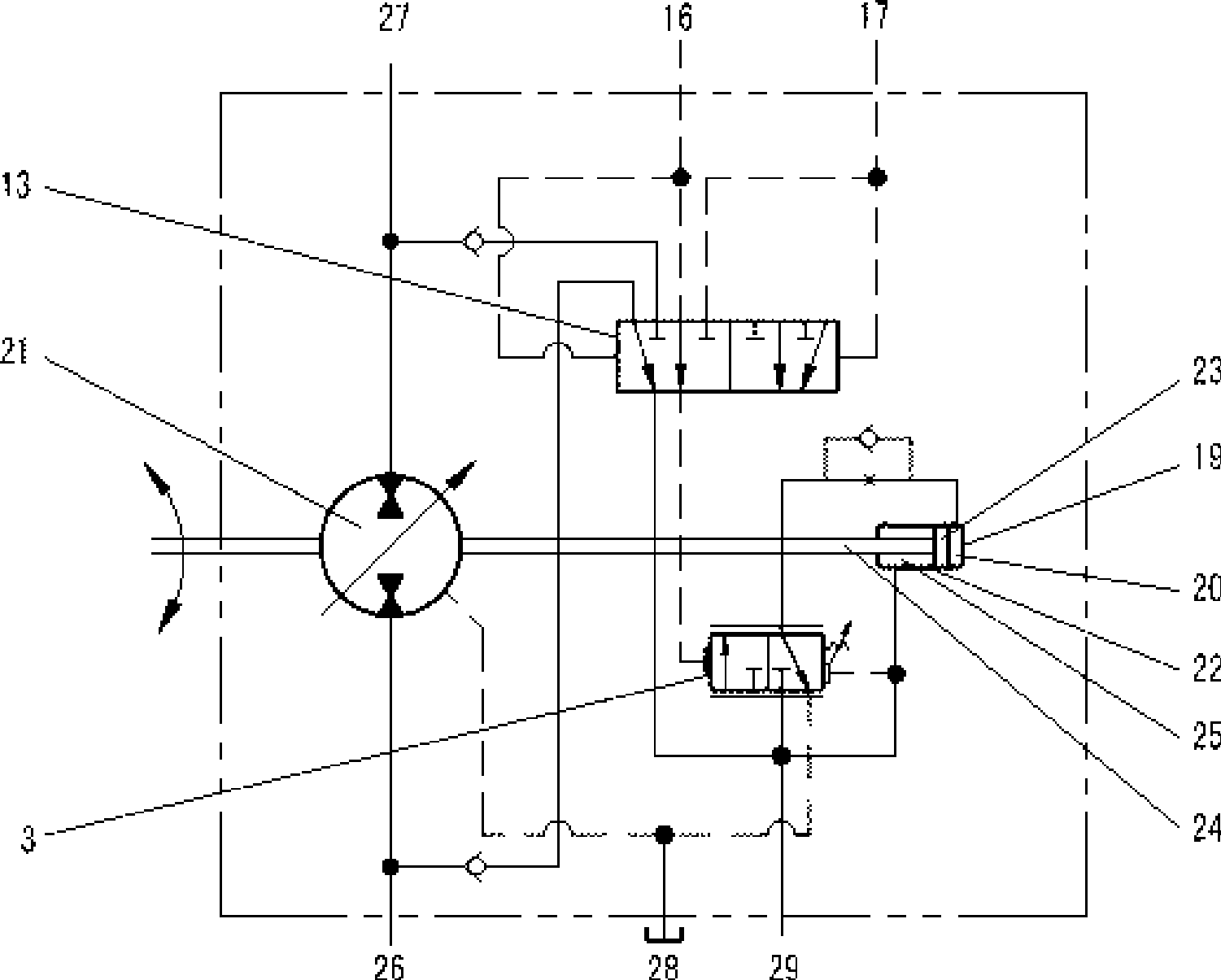

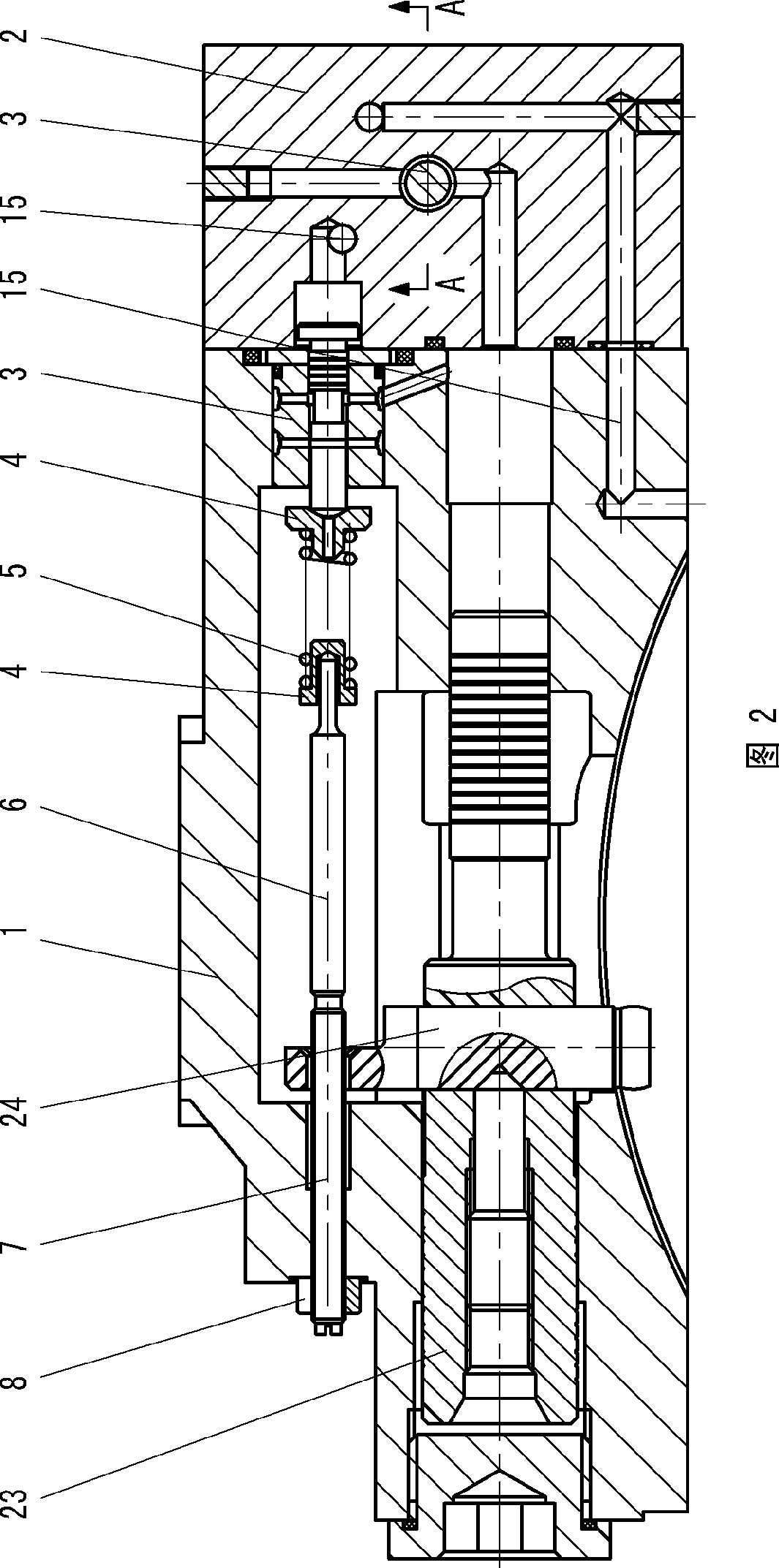

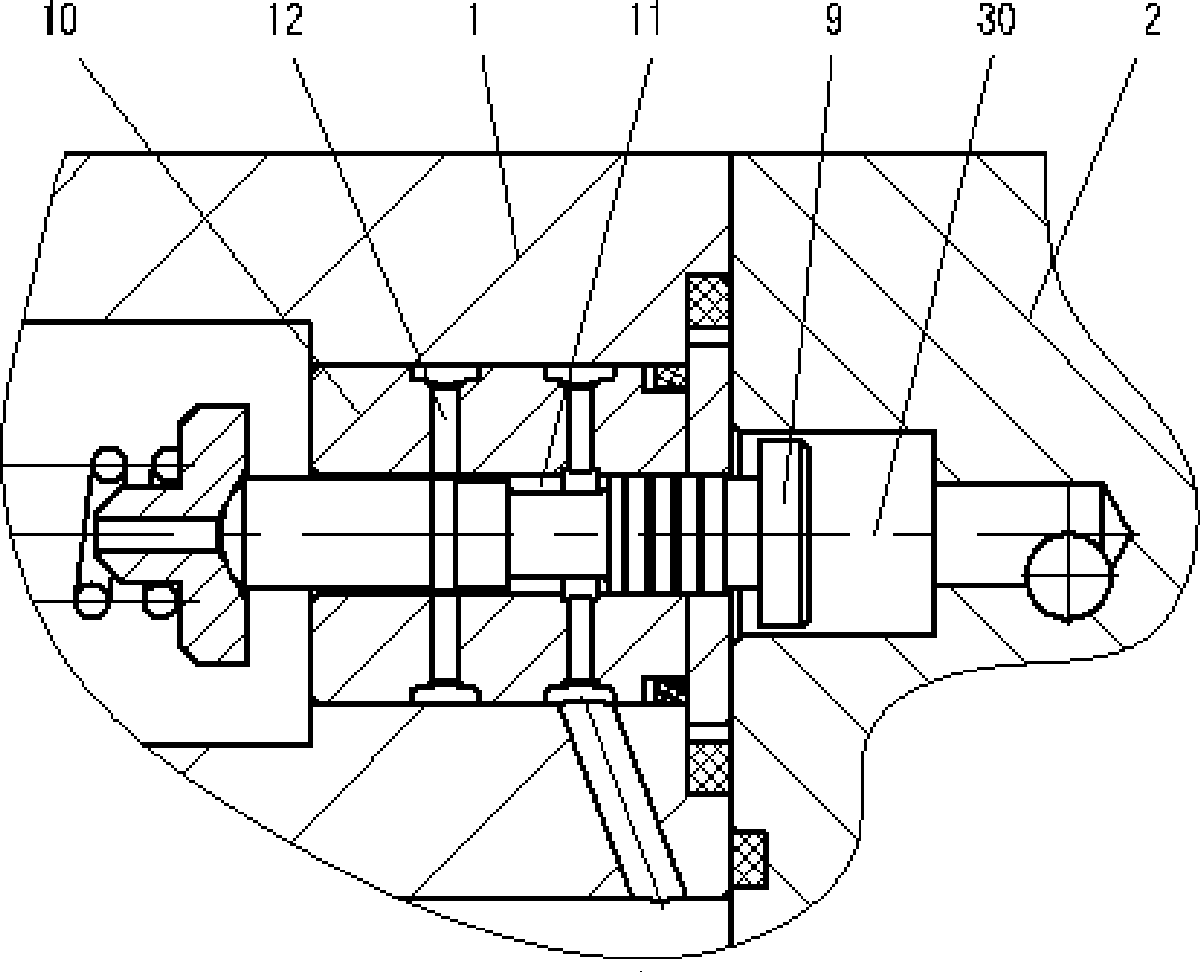

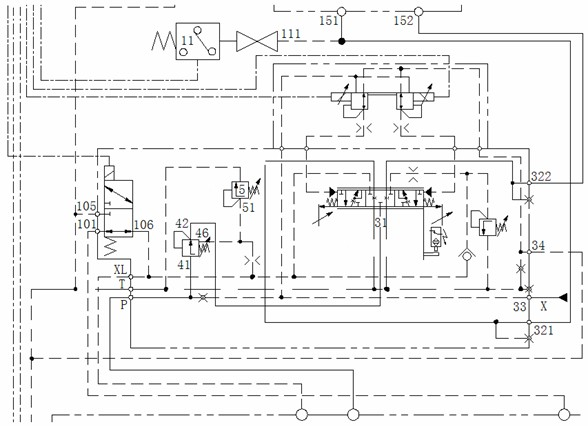

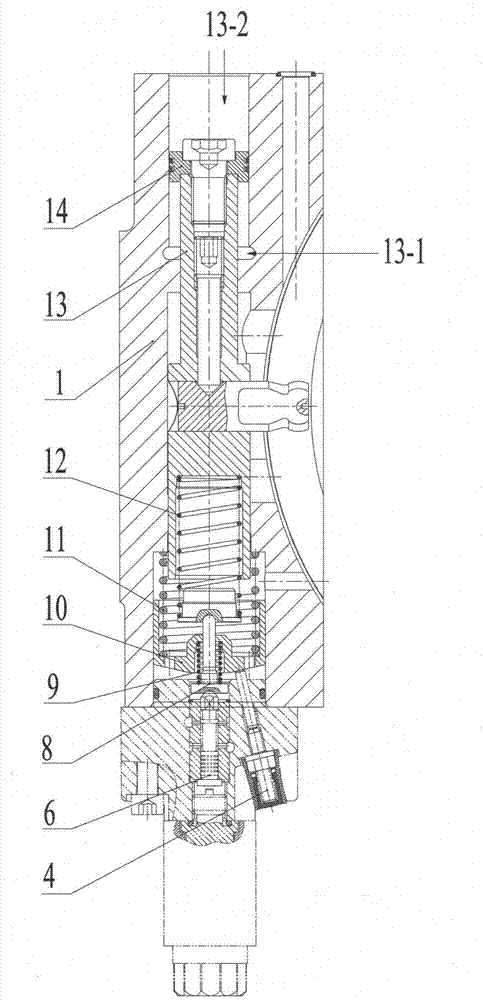

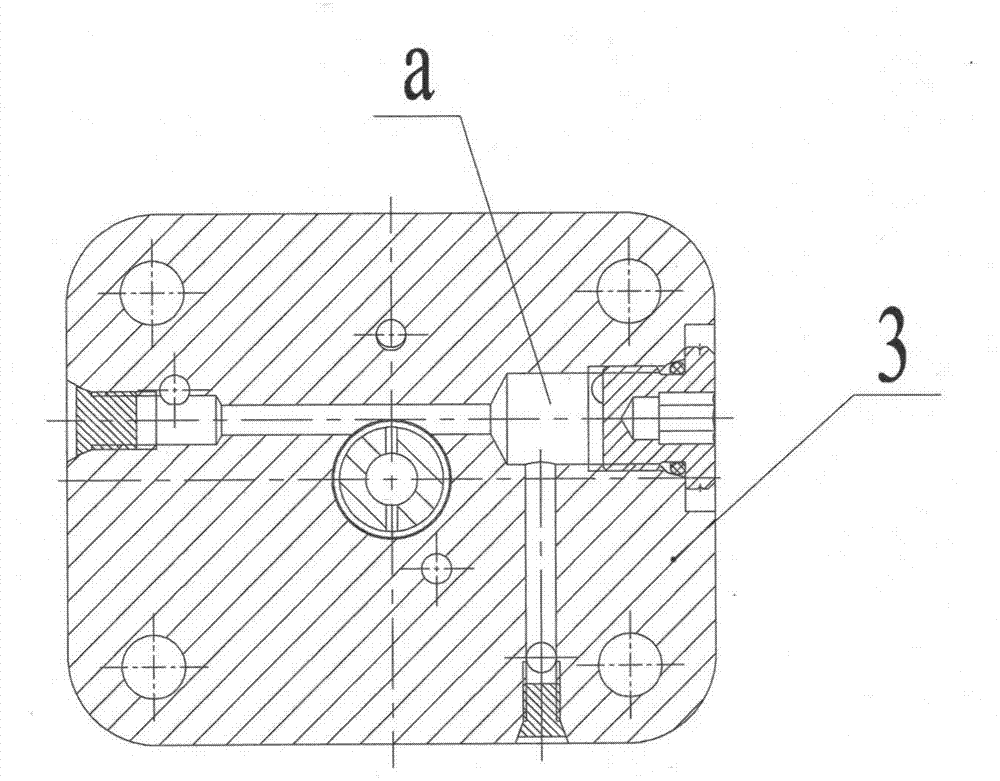

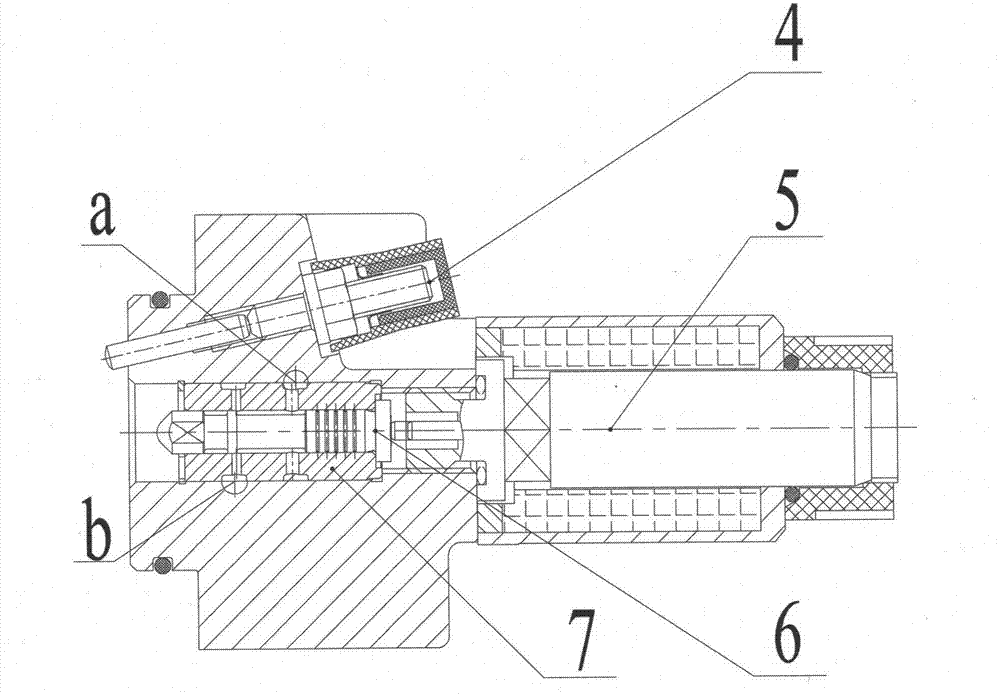

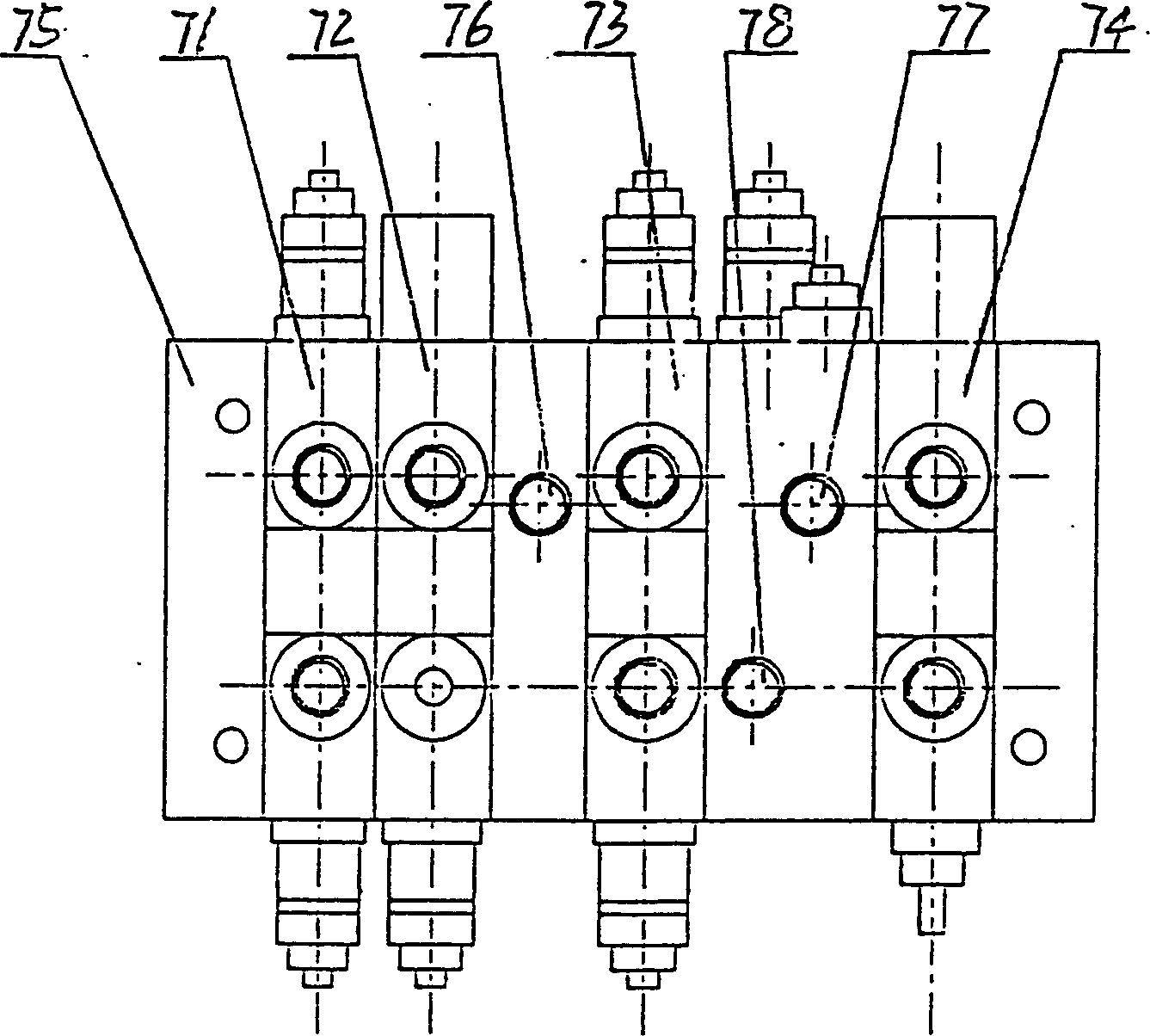

Hydraulic tilting-axis motor variable control mechanism

ActiveCN103671330AStable jobImprove work efficiencyServomotor componentsServomotorsMechanical engineeringElectromagnetic valve

The invention discloses a hydraulic tilting-axis motor variable control mechanism which is characterized by comprising a motor cover. A sliding rod is arranged inside the motor cover. One end of the sliding rod is connected with a piston. The other end of the sliding rod is connected with one end of a first spring base through a third spring. The other end of the first spring base is arranged inside an electromagnetic valve block to be connected with one end of a valve core. The valve core is arranged inside a valve sleeve. The valve sleeve is arranged inside the electromagnetic valve block. An adjusting screw rod is arranged on the side face of the electromagnetic valve block. The electromagnetic valve block is connected with an electromagnetic valve. The motor cover is internally connected with one end of a second spring base through a second spring. The other end of the second spring base is connected with a base of the first spring base through a first spring. The hydraulic tilting-axis motor variable control mechanism has the advantages of being flexible in reaction, steady in control, capable of achieving displacement stepless changes and the like.

Owner:龙工(上海)精工液压有限公司

Current source converter based doubly-fed motor variable frequency speed control system

PendingCN109120197AExcellent steady state performanceImprove dynamic performanceElectronic commutation motor controlAC motor controlSpeed control systemThree-phase

The invention discloses a current source converter based doubly-fed motor variable frequency speed control system. The system has high steady state performance, and has faster dynamic response when the rotating speed or torque of a doubly-fed motor changes. The system includes a three-phase alternating-current power supply, the doubly-fed motor and a mechanical load connected to the rotating shaftof the doubly-fed motor; and the system is characterized in that the system also includes a motor side converter, a grid-side converter, a motor side filter, a grid-side filter and a direct current inductor. the motor side filter is connected between the control winding of the doubly-fed motor and the motor side converter; the grid-side filter is connected between the three-phase alternating-current power supply and the grid-side converter; the motor side converter is connected to the grid-side converter, and the direct current inductor is connected between the motor side emitter electrode ofthe motor side converter and the grid-side collector electrode of the grid-side converter; and the power winding of the doubly-fed motor is connected to the three-phase alternating-current power supply.

Owner:CHINA POWER ENG CONSULTING GRP CORP EAST CHINA ELECTRIC POWER DESIGN INST +1

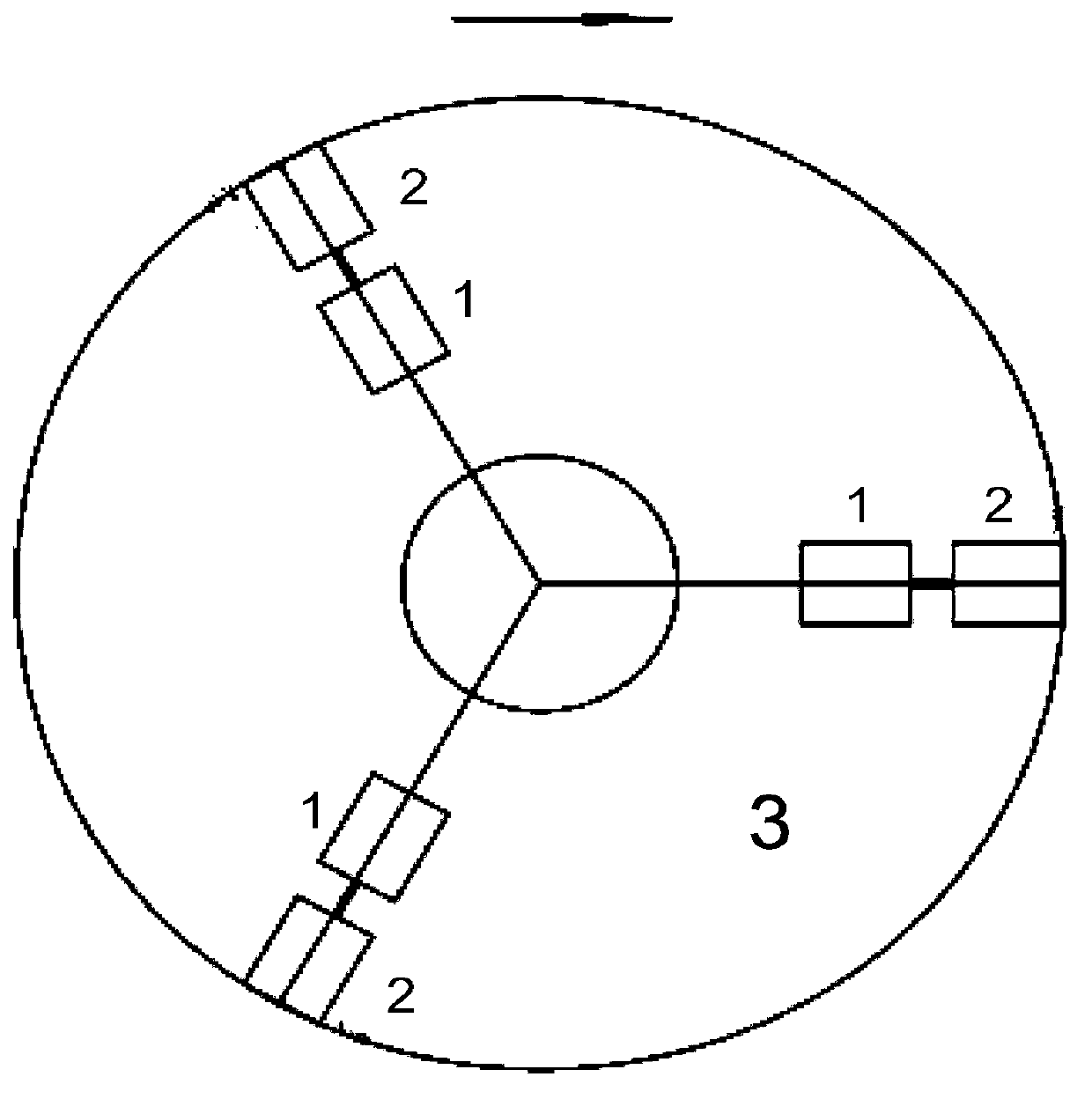

Rotation variable pitch test stand

InactiveCN104181464ASolve power problemsReflect the real way of operationDynamo-electric machine testingElectricityOperation mode

The invention discloses a rotation variable pitch test stand comprising a variable pitch motor, a load motor and a rotation mechanism. The rotation mechanism comprises a rotatable rotation platform. The variable pitch motor and the load motor are arranged on the rotation platform. According to the rotation variable pitch test stand, the variable pitch motor and the load motor are arranged on the rotatable rotation platform, a motor power supply problem is solved by adopting a slip ring electrification mode, the state of influence of pitch blade load change on a motor variable pitch system in wind speed disturbance is simulated, and the real operation mode of a variable pitch mechanism is reflected.

Owner:SIEMENS FACTORY AUTOMATION ENG

Variable frequency speed governor electric energy quality characteristic test cabinet, test system and test method thereof

PendingCN106338669AMeet testing needsImprove controllabilityElectrical testingPower qualityDigital collections

The invention provides a variable frequency speed governor electric energy quality characteristic test cabinet, a test system and a test method thereof. The system comprises an electric energy quality disturbance source which is connected to the input end of a tested Variable frequency speed governor, a drive motor which is connected to the output end of the tested variable frequency speed governor, a load motor whose input end is connected to a load motor variable frequency speed governor and whose output end is connected to the drive motor, and a digital collection device which is used for collecting and calculating the electric energy quality emission and tolerance characteristic indexes of the tested variable frequency speed governor. Compared with the prior art, the invention provides the frequency conversion speed governor electric energy quality characteristic test cabinet, the test system and the test method thereof, through controlling the electric energy quality disturbance source to output the test voltage comprising multiple types of electric energy quality disturbance, the electric energy quality tolerance of the tested variable frequency speed governor can be tested, the electric energy quality disturbance source is controlled to output standard voltage, and the various types of electric energy quality emission characteristics of the tested frequency conversion speed governor in various operation conditions can be tested.

Owner:GLOBAL ENERGY INTERCONNECTION RES INST CO LTD +1

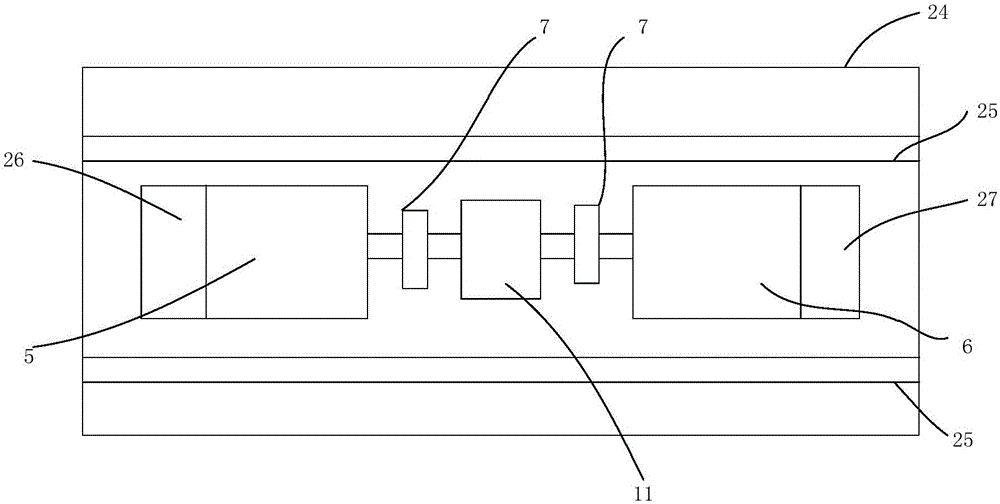

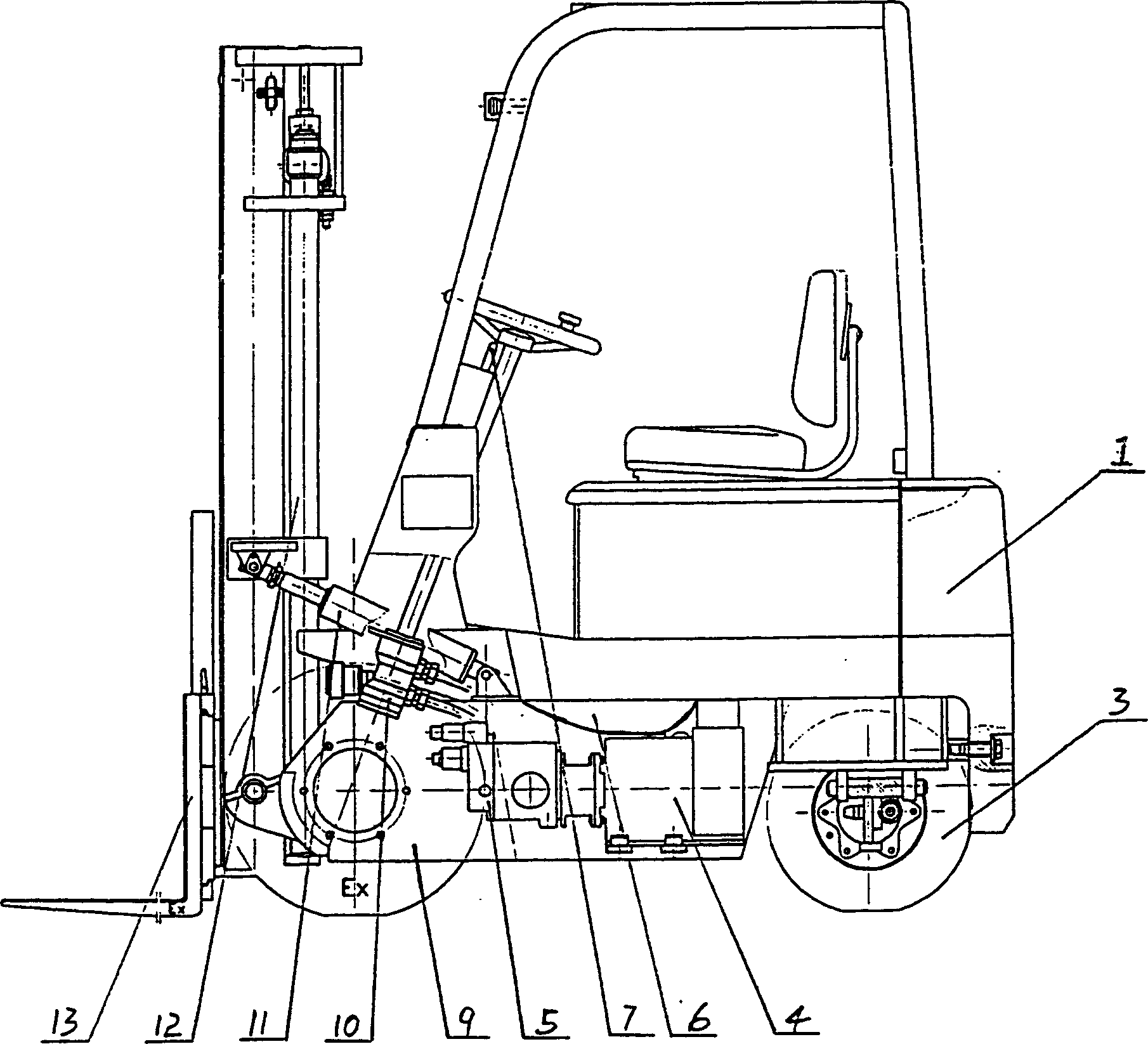

Fully-hydraulic electric fork truck

InactiveCN1142085CImprove reliabilityExtended service lifeLifting devicesFuel tankElectric machinery

Owner:ZHEJIANG JIALI TECH +1

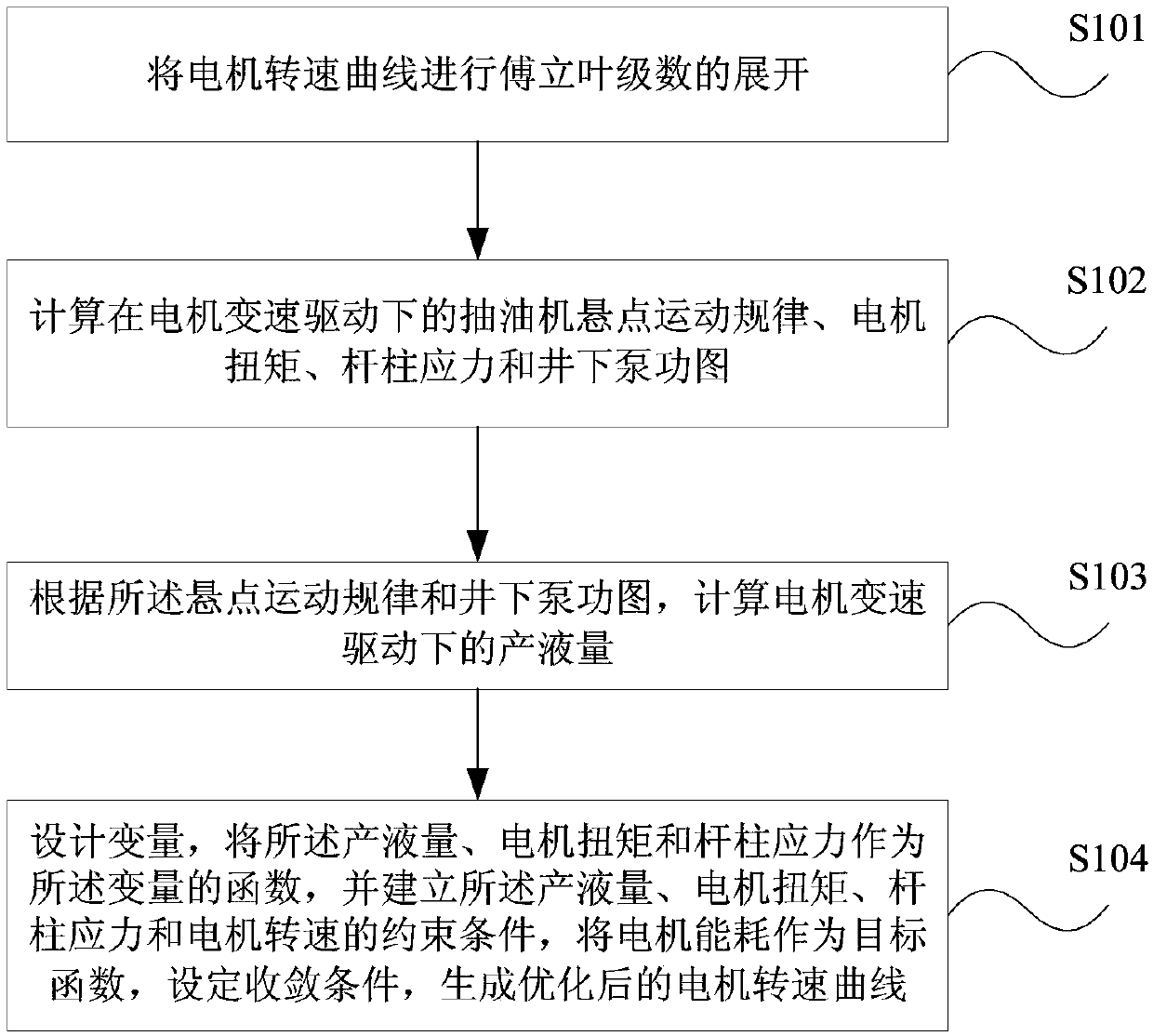

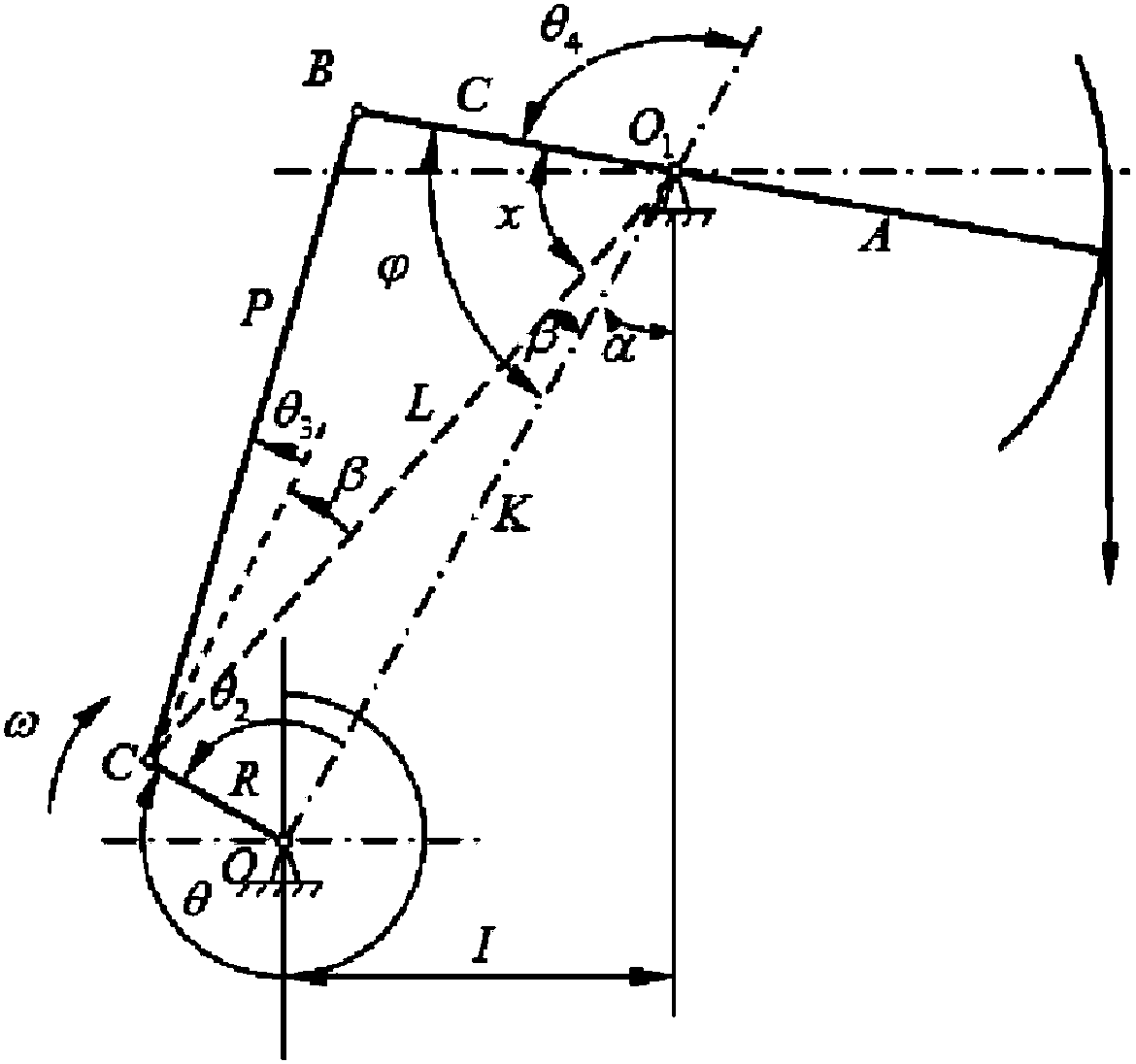

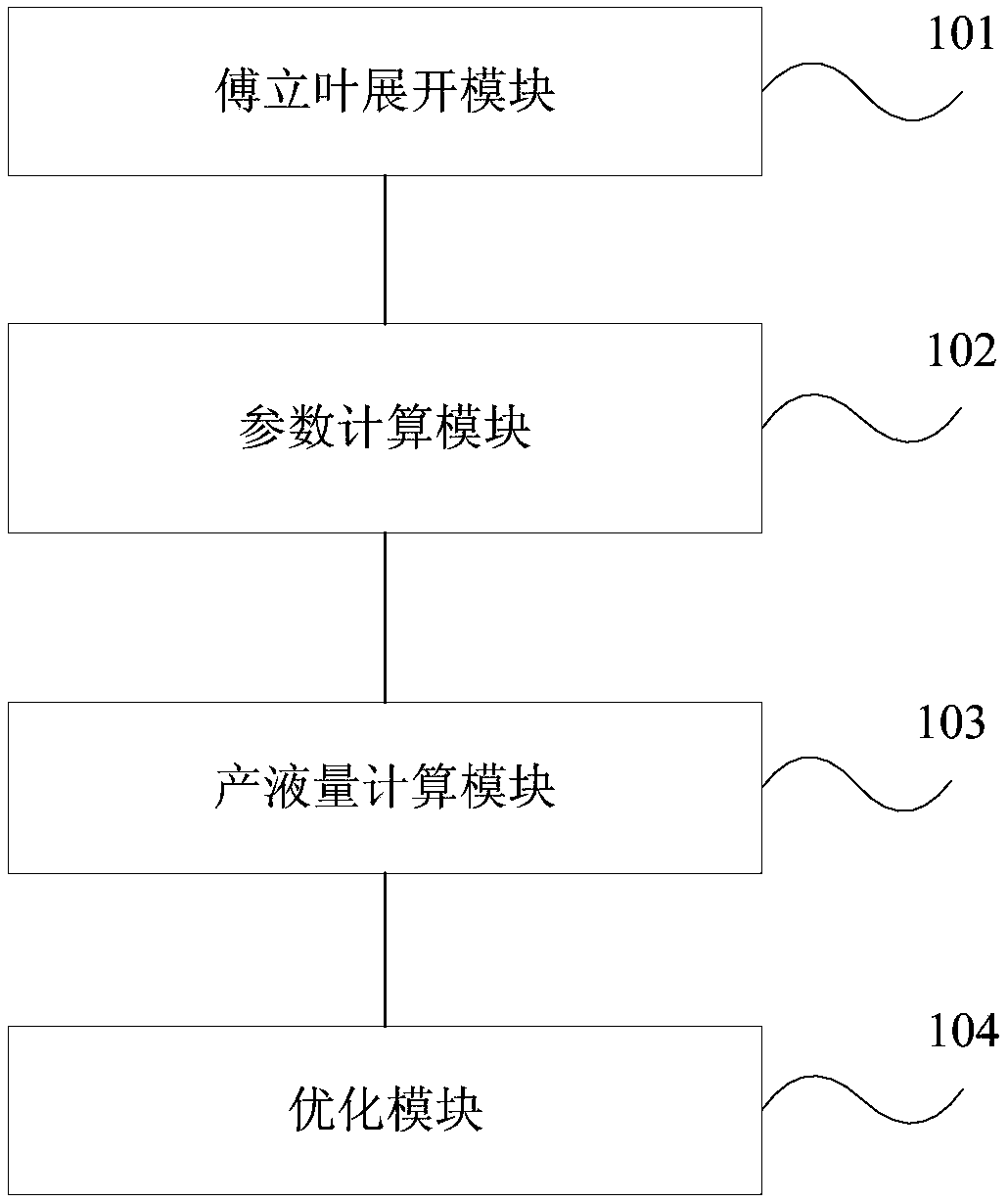

Method and device for optimizing motor rotation speed curve based on variable-speed driving

ActiveCN108661899AGuaranteed energy consumptionReduce energy consumptionPump controlPositive-displacement liquid enginesIndicator diagramMotor torque

The embodiment of the invention provides a method and a device for optimizing a motor rotation speed curve based on variable-speed driving. The method comprises the following steps: carrying out expansion of Fourier series on the motor rotation speed curve; calculating a suspension point movement rule of an oil pumping unit, a motor torque, rod string stress and a downhole pump indicator diagram under motor variable-speed driving; calculating liquid production capacity under the motor variable-speed driving according to the suspension point movement rule and the downhole pump indicator diagram; designing variable, taking the liquid production capacity, the motor torque and the rod string stress as functions of the variable, building constraint conditions of the liquid production capacity,the motor torque, the rod string stress and the motor rotation speed, taking motor energy consumption as a target function, and setting a convergence condition to generate the optimized motor rotationspeed curve. According to the method and the device for optimizing the motor rotation speed curve based on variable-speed driving, the real-time speed change of one stroke cycle is achieved by building a flexible control strategy; the inherent defects of the oil pumping unit four-rod structure can be overcome, so that the overall comprehensive performance of the system can be improved; the well yield of the oil pumping unit can be ensured; meanwhile, the motor energy consumption can be reduced, and the stress environment of the rod string can be improved.

Owner:CHINA UNIV OF PETROLEUM (BEIJING) +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com