Patents

Literature

493 results about "Motor testing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Brushless servo motor tester

InactiveUS20070229018A1Accurate operationSimplified determinationMotor/generator/converter stoppersSynchronous motors startersMotor testingControl theory

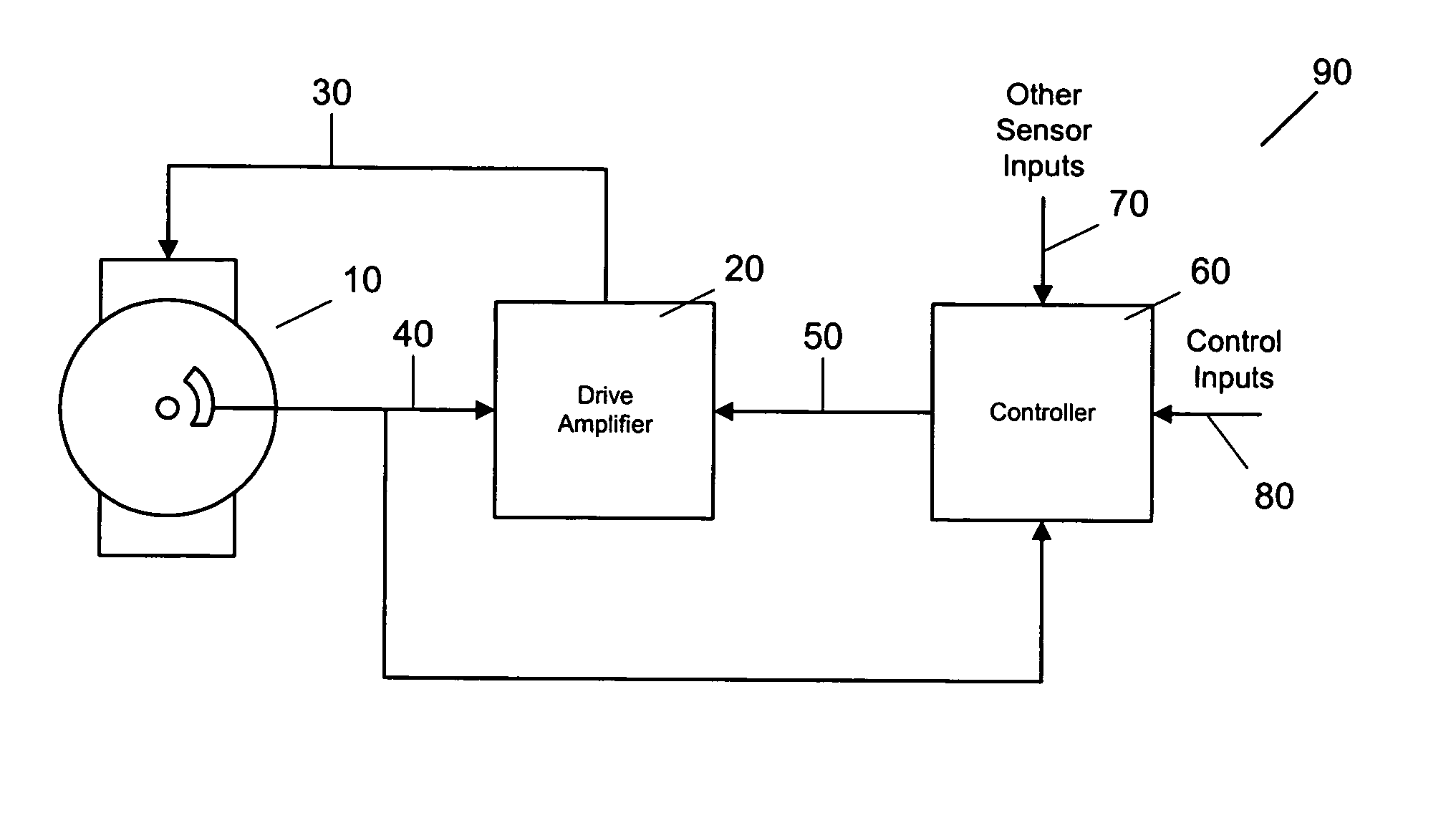

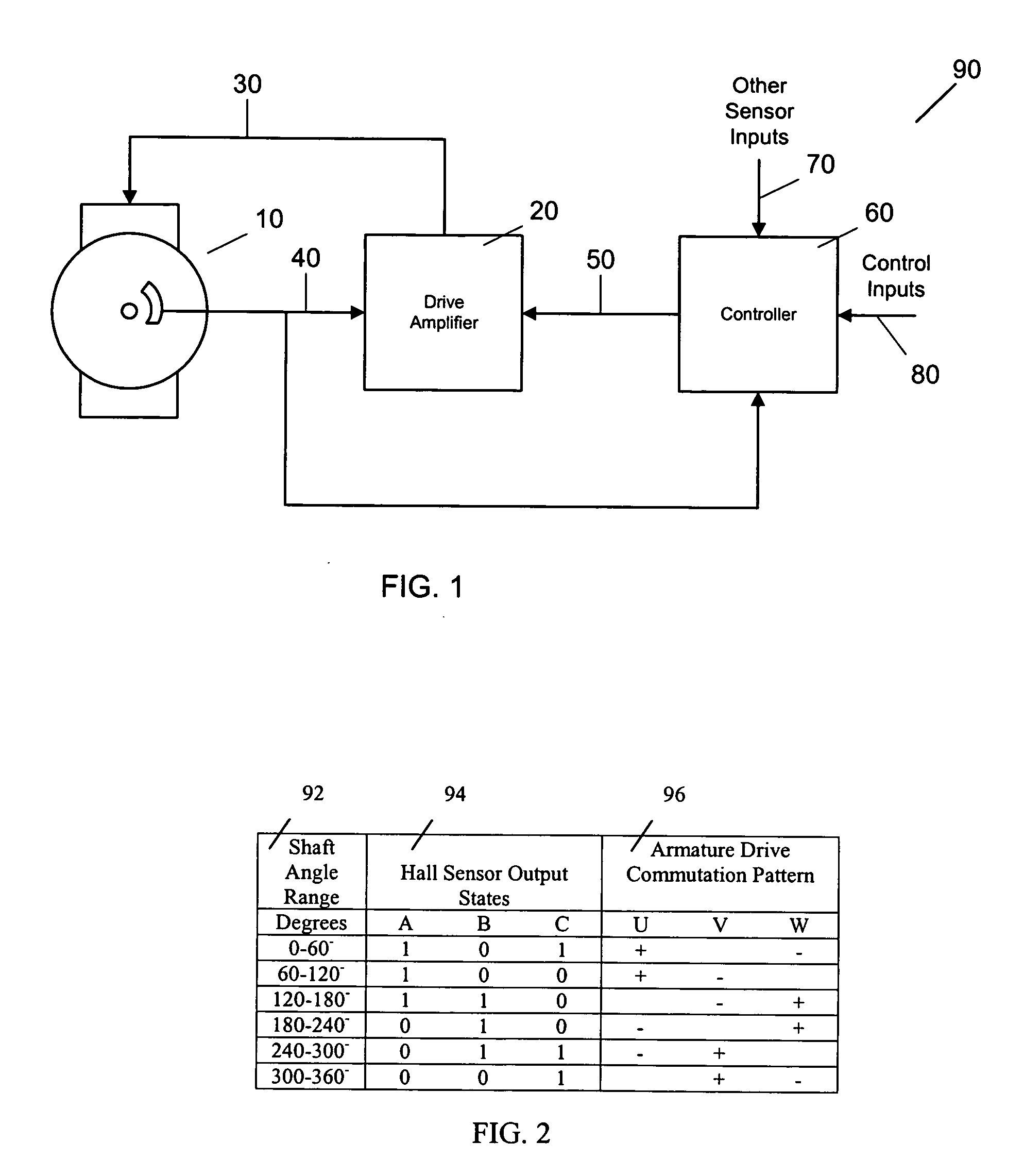

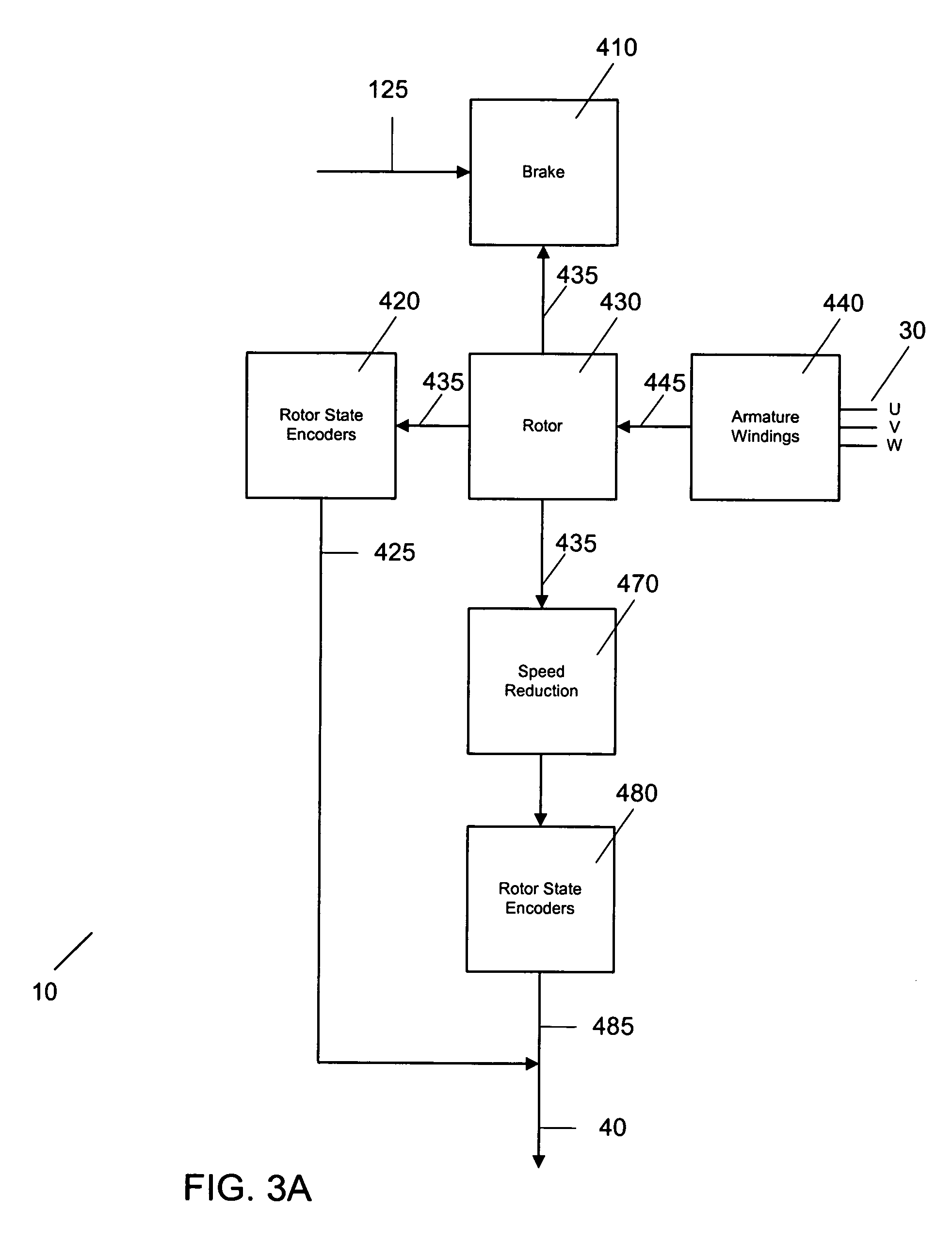

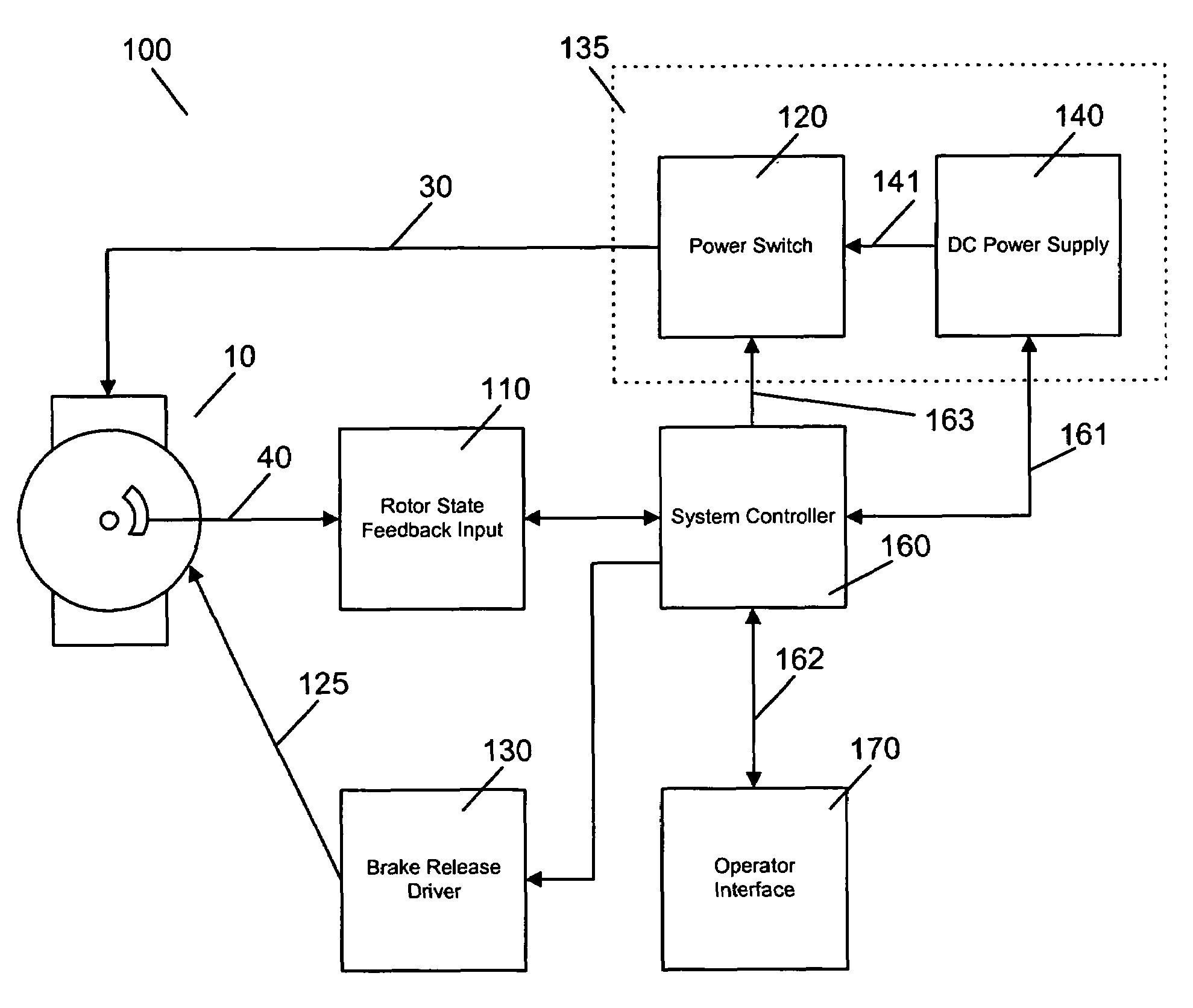

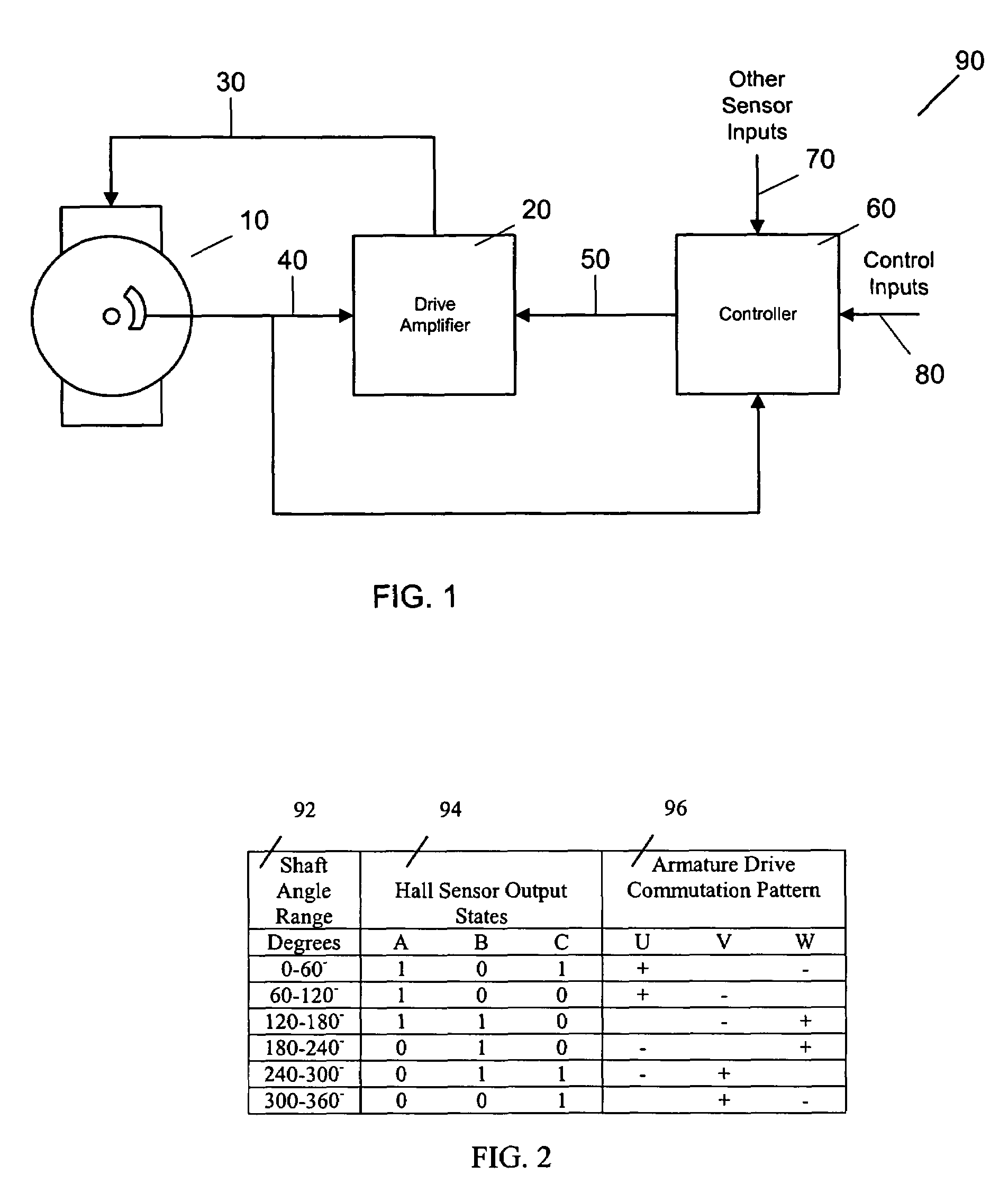

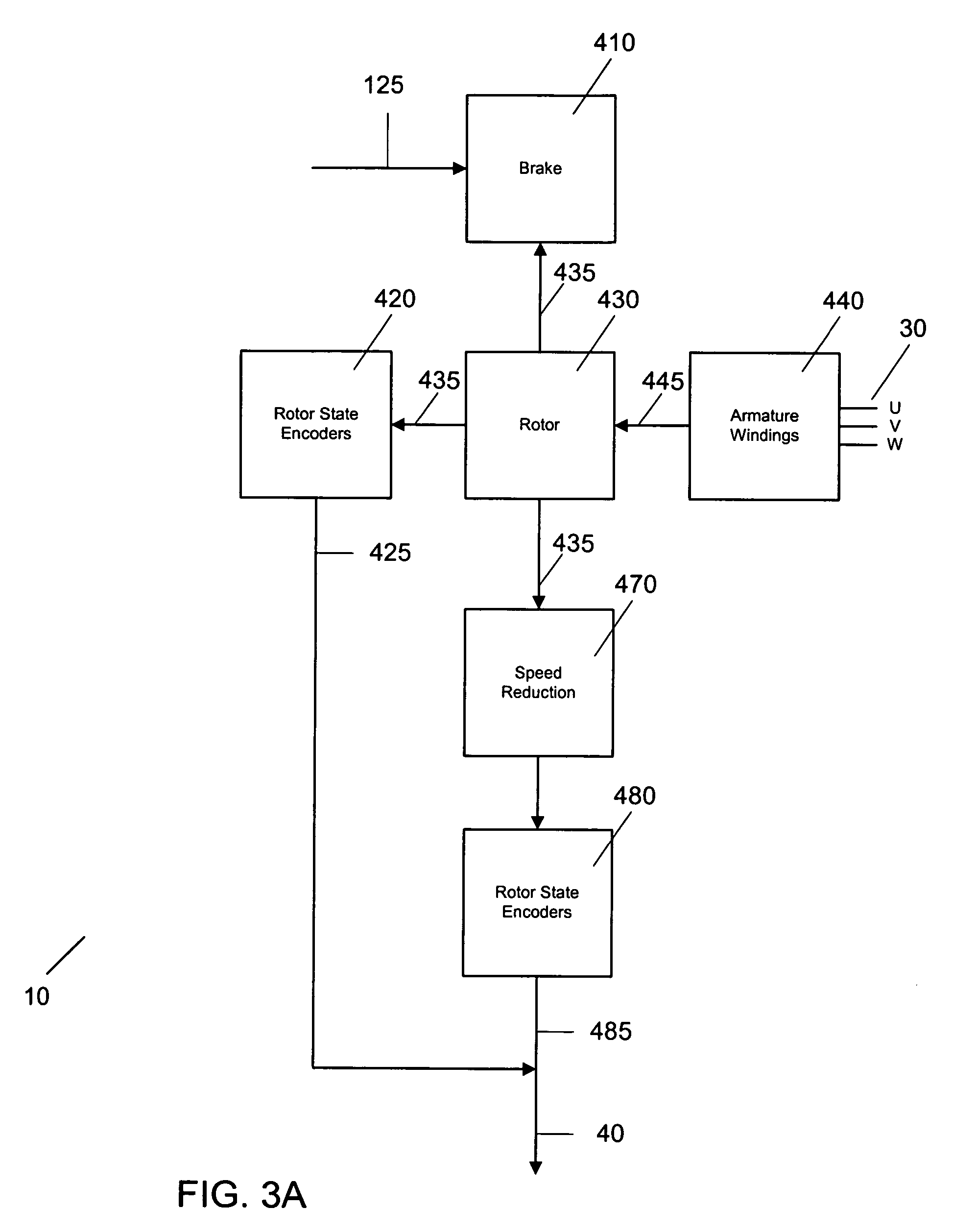

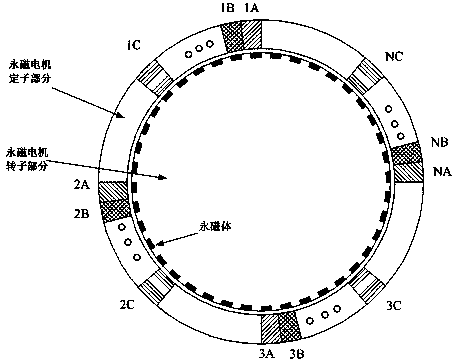

A permanent magnet brushless (PMBL) servo motor test apparatus and method allow testing of a motor in place. A set of static and dynamic tests is performed to determine proper motor operation of armature windings and rotor feedback devices. The test system of the present invention displaces the motor drive system. The test system comprises an armature driver, a feedback device input, and a system controller. The armature windings of the motor-under-test are driven in a polarity sequence according to a test sequence, whereby the rotor is driven in a series of rotations. Angle feedback is tested at a plurality of said rotations. Rotor velocity outputs are tested during said rotations. Armature current and voltage are determined at a plurality of said rotations and winding balance is tested. Said power switch is also operative to apply a voltage between the armature windings and the motor case to test for fault current flow. In another embodiment of the invention, motor identification is decoded by the system into motor configuration and motor operation parameters, necessary to test the motor. Motor identification may be entered by an operator or captured from machine readable tags such as a barcode tag or an RFID tag.

Owner:MITCHELL ELECTRONICS

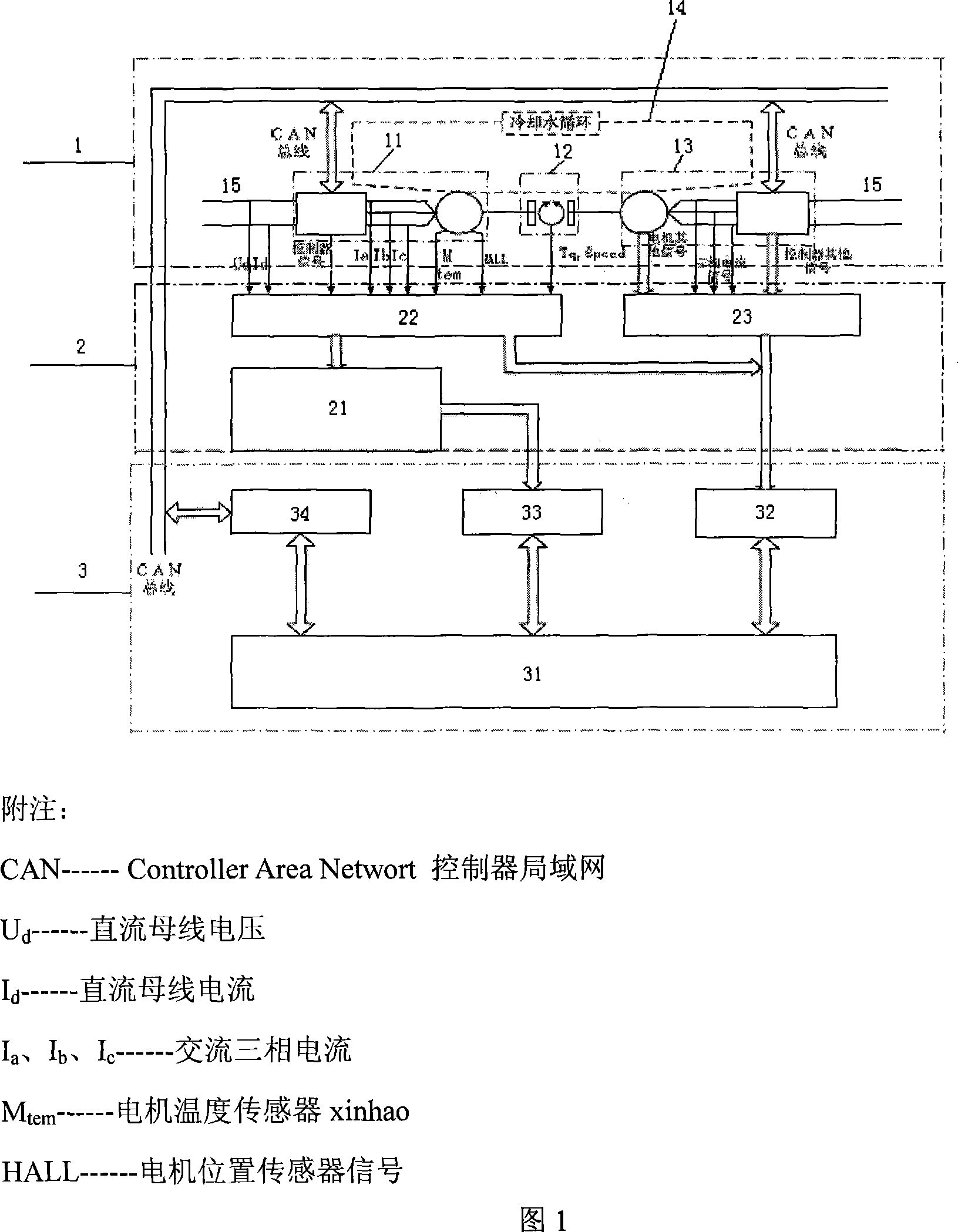

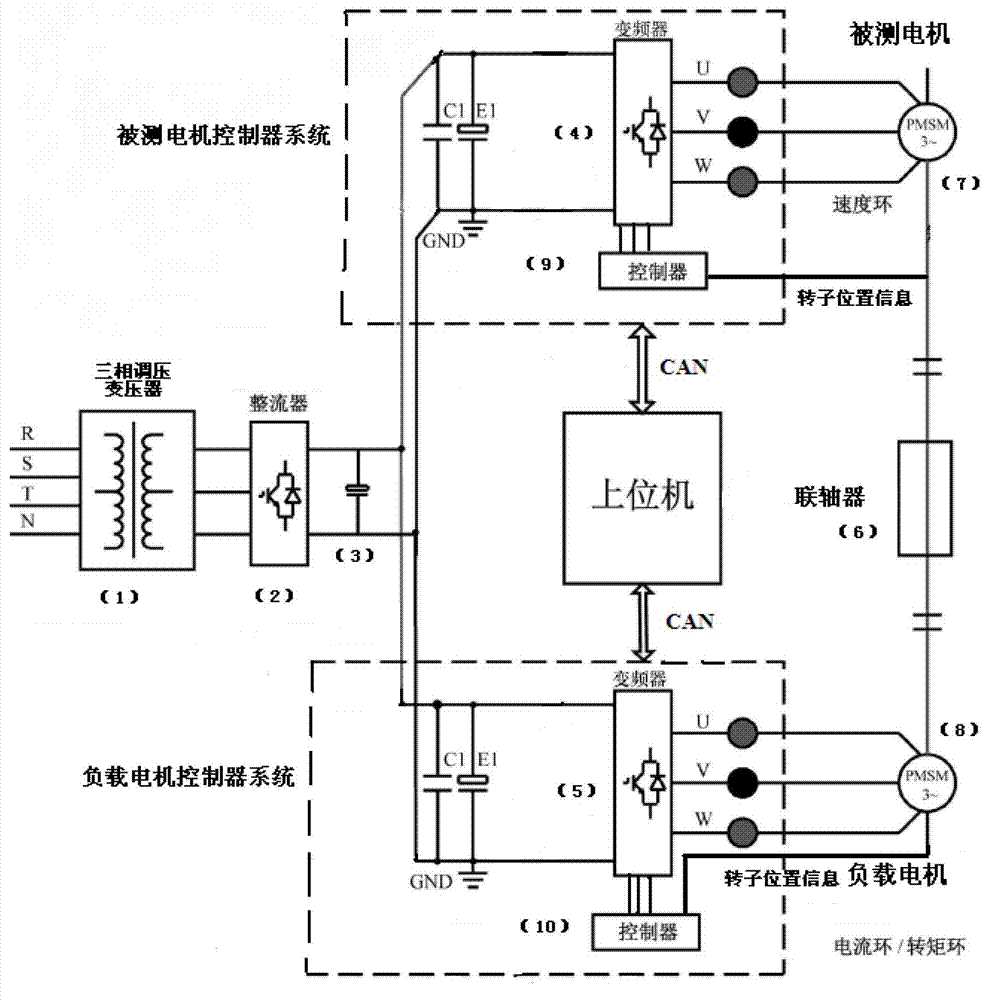

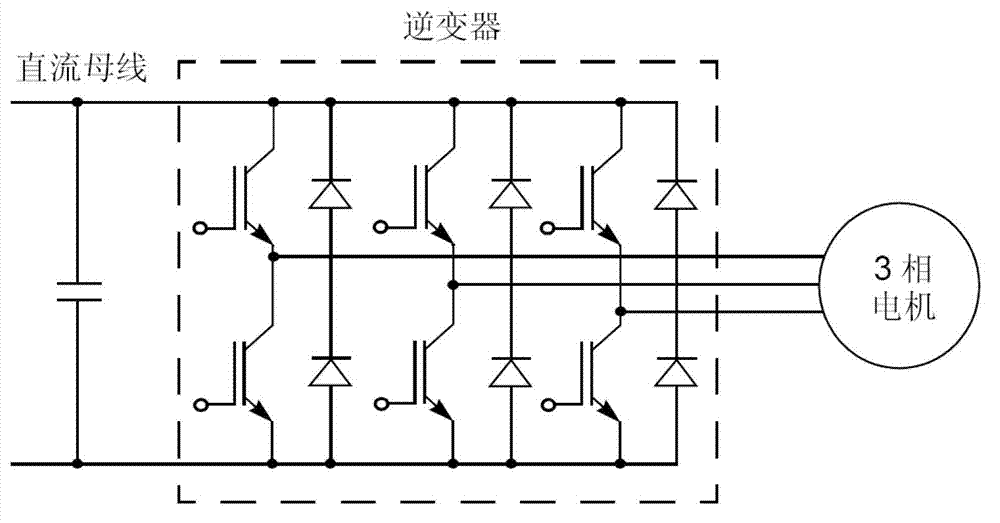

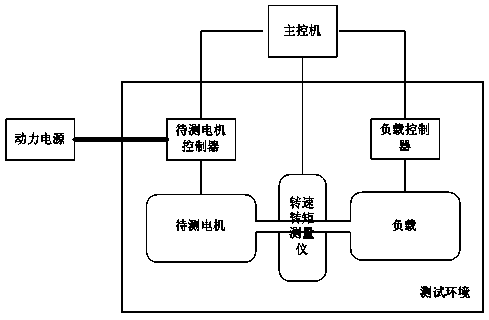

Hybrid power automobile drive electric motor test bench and test method

ActiveCN101241168AWide voltage rangeReduce lossVehicle testingDynamo-electric machine testingSkin complexionMotor testing

The present invention relates to test table for driving motor of hybrid electric vehicle to finish capability test of driving motor of hybrid electric vehicle and debugging function of control software. The table system has simple structure, convenient operation and maintains and high test precision. When the grades of motor and load voltage are identical, the system can work parallel with DC generatrix and feed back energy, the energy lose is less, the power supply need to provide system loss energy is about 10% to 20%, the cost is reduced greatly and the requirement of capacity of power supply is little. When the grades of motor and load voltage aren't identical, two complexions are happened, when motor is as driver, energy is applied to load resistance box by dynamometer system or power supply; when the motor is as generator, the energy is applied to load resistance box by power supply.

Owner:CHERY AUTOMOBILE CO LTD

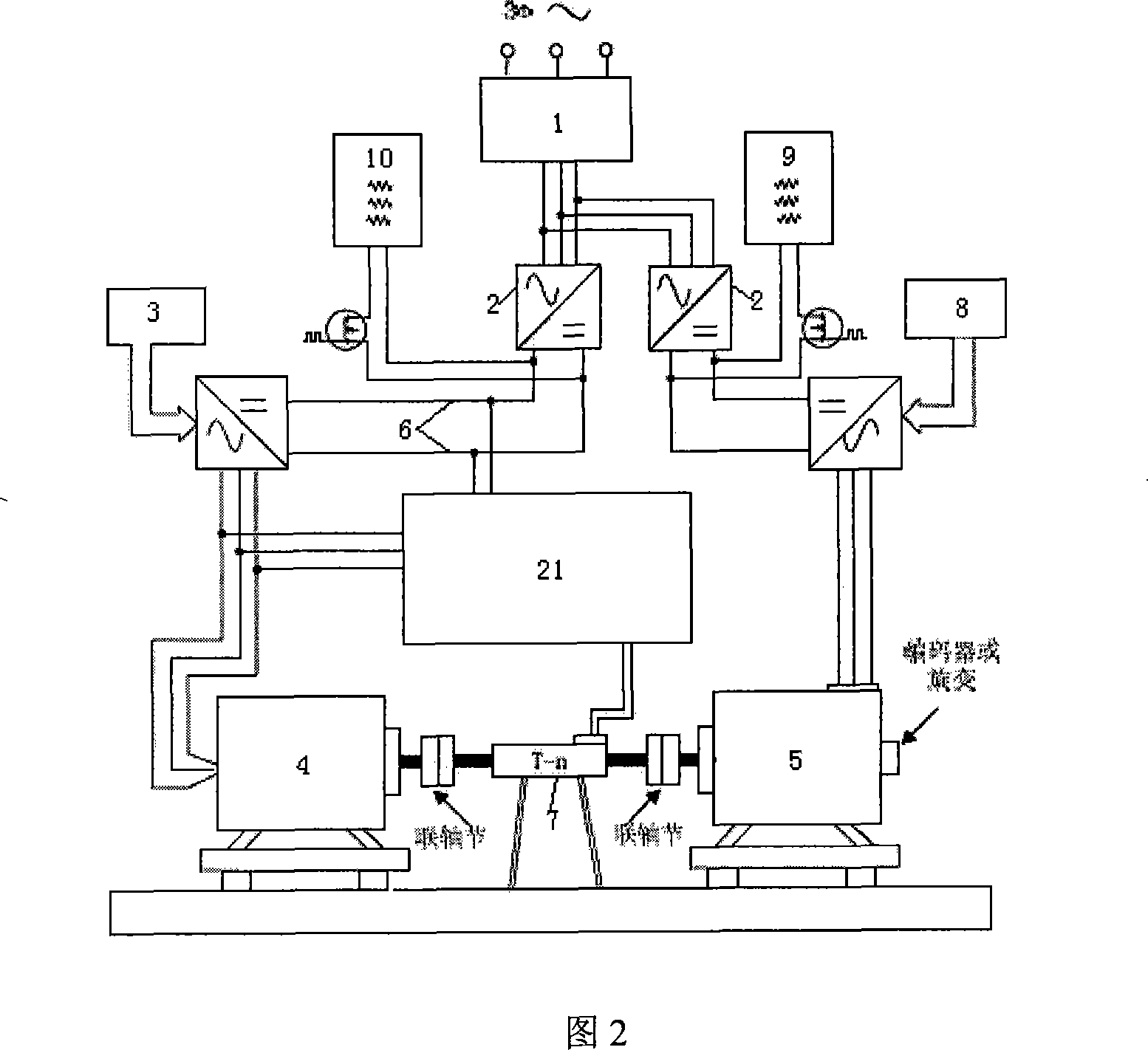

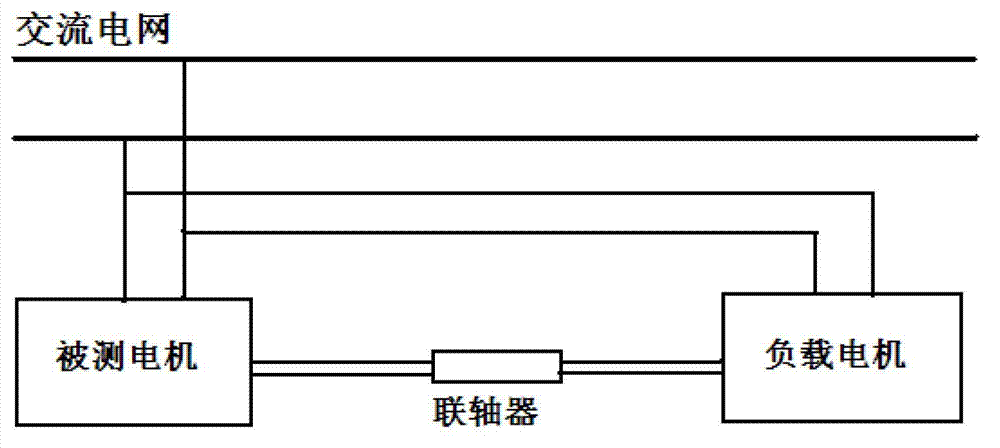

Motor twin trawling platform used for motor test

InactiveCN103163460AImprove efficiencyHigh moment of inertia ratioDynamo-electric machine testingMotor testingElectricity

The invention discloses a motor twin trawling platform used for a motor test. The motor twin trawling platform used for the motor test comprises a transformer, a rectifier, a filter, a tested motor, a master control system, a load motor, a coupler and two motor control systems. The rectifier is connected with the transformer, two ends of the filter are respectively connected with two output ends of the rectifier, a tested motor control system and a load motor control system are both connected with the filter, the load motor is connected with the load motor control system, a tested motor output shaft is connected with an output shaft of the load motor through the coupler, and the tested motor control system and the load motor control system are both connected with the master control system. The whole system of the motor twin trawling platform used for the motor test can be miniaturized, the motor can be output through random torque so as to enable the motor twin trawling test to be diversified, electricity is saved, and efficiency can be obviously improved.

Owner:ANHUI ZHONGJIA ZHIRUI TECH

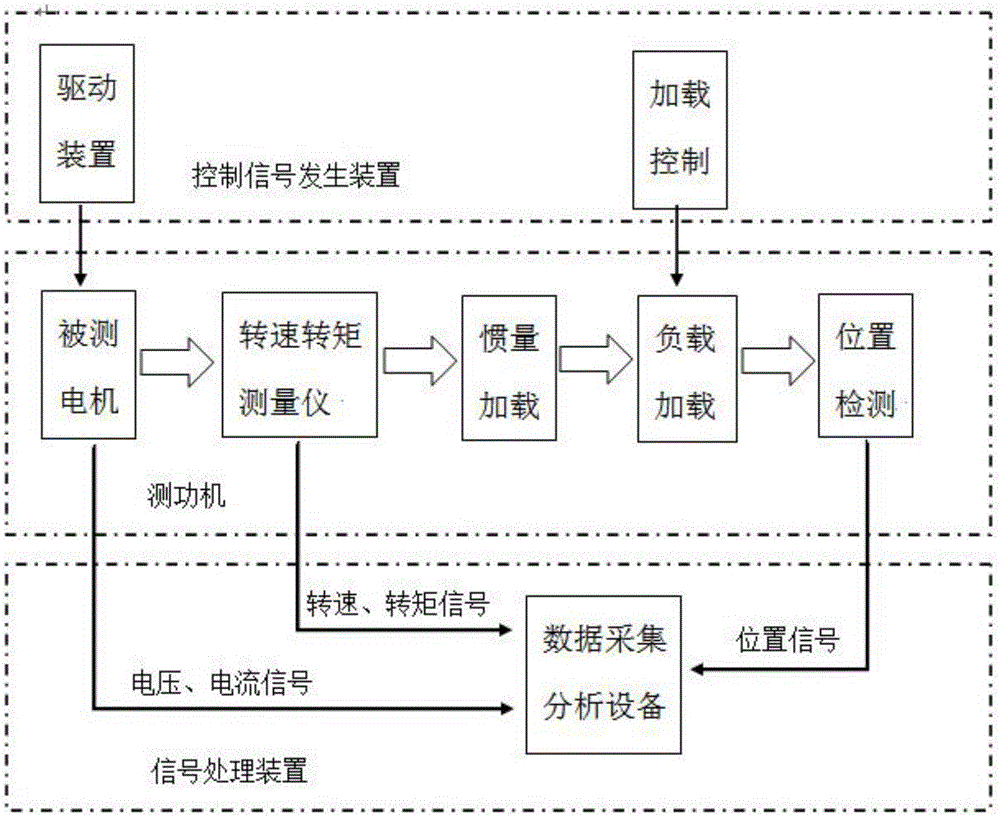

Test platform of drive system of electric vehicle motor

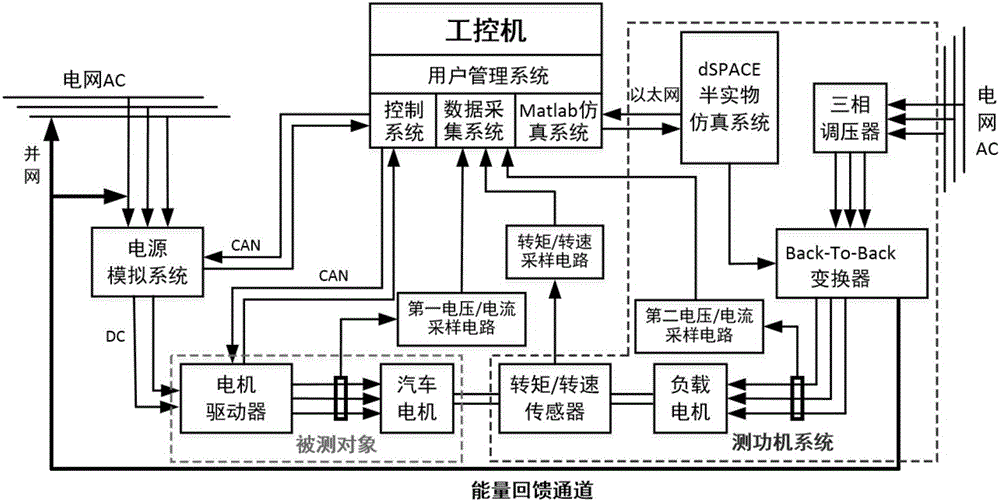

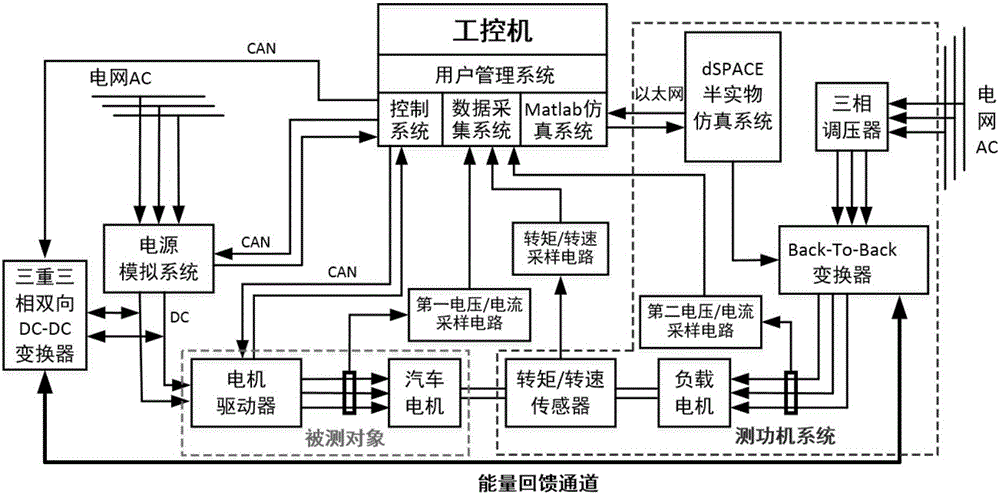

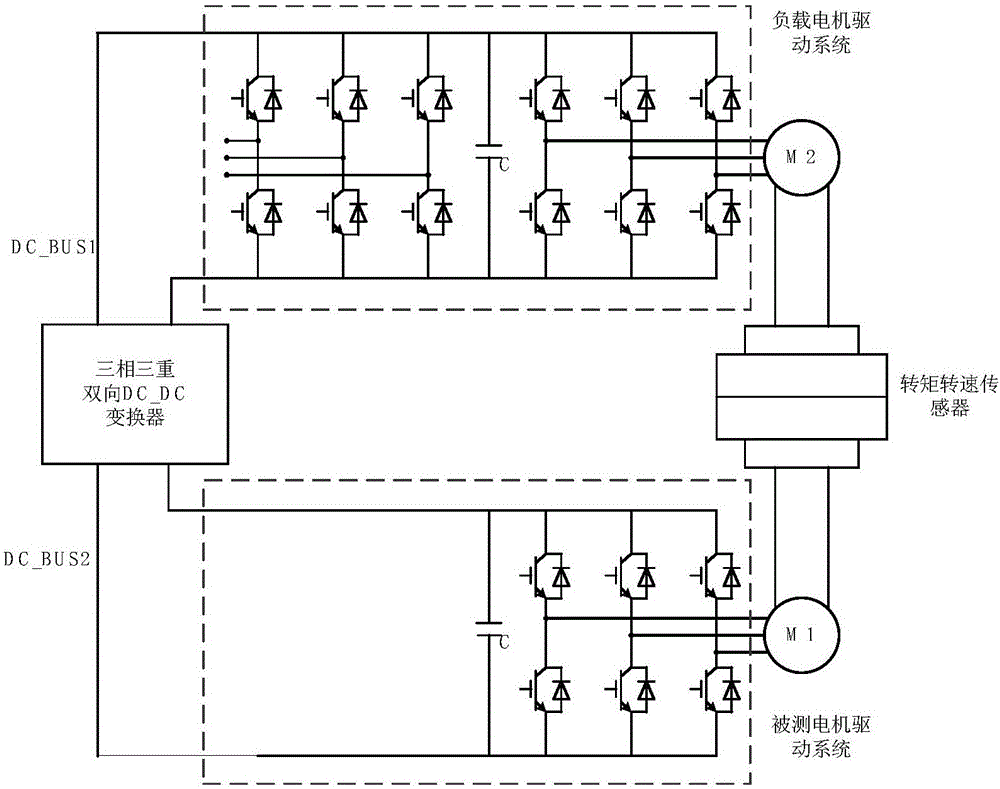

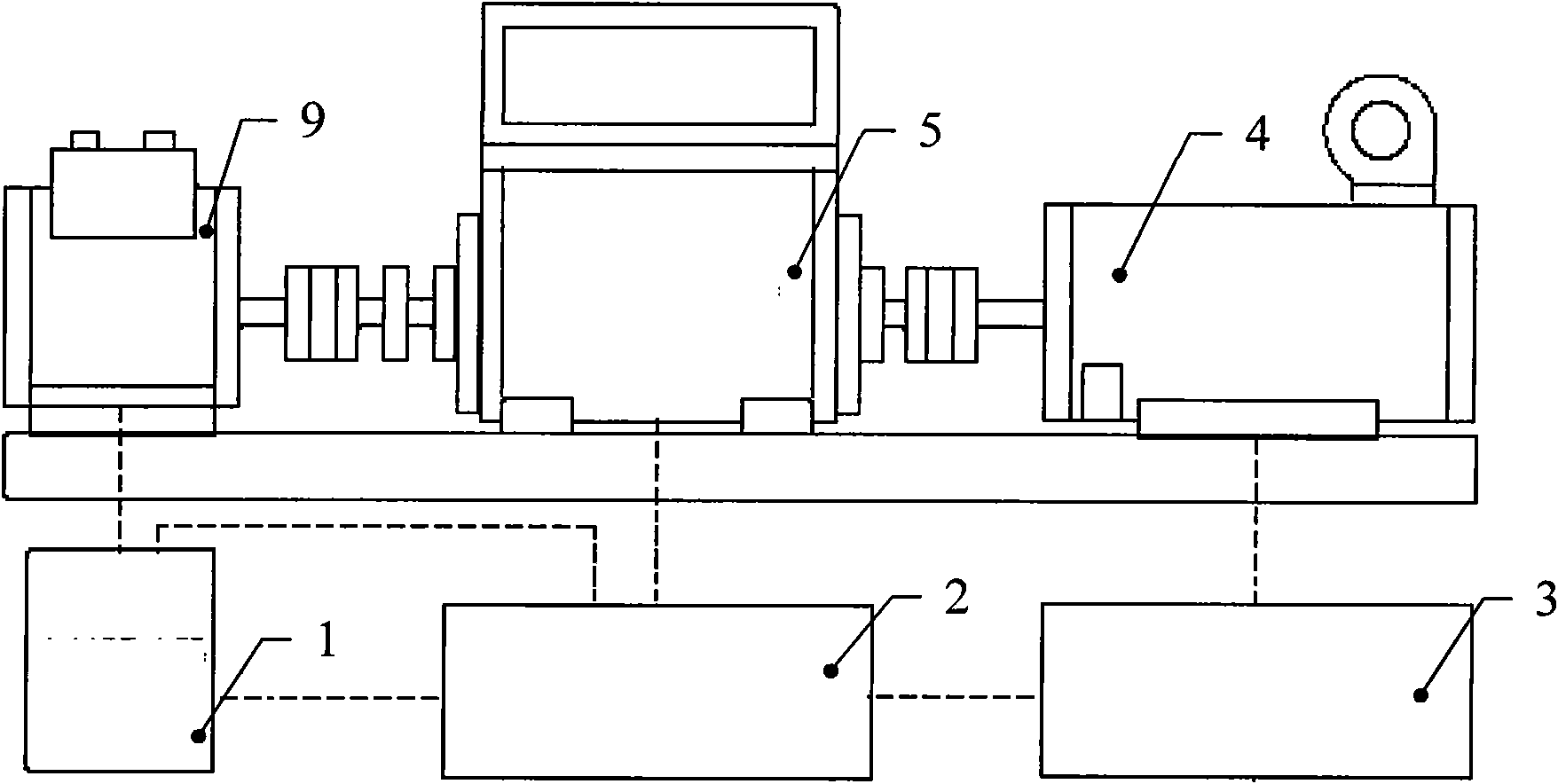

PendingCN106772029AImplement performance testingRealize analysisSimulator controlElectric testing/monitoringMotor testingDrive motor

The invention provides a test platform of a drive system of an electric vehicle motor. The test platform comprises an industrial personal computer, a dynamometer system, a voltage / current sampling circuit, a torque / rotating speed sampling circuit and a power supply simulation system. When the test platform works, a road situation simulation system is used for reproducing real acceleration and deceleration conditions of vehicle driving; a load simulation, tracking, and controlling system based on model prediction control is used for realizing rapid response and precise tracking and controlling on load simulation by the dynamometer system; and then a performance analysis system is used for realizing comprehensive performance testing and analysis of the motor drive system. The test platform provided by the invention is capable of detecting the motor performance in real time to obtain data needed by drive motor studying and developing timely and effectively, so that the research and development time of the drive motor can be shortened. Therefore, the test platform plays an important role in leading standardized and information development of motor testing.

Owner:QUANZHOU INST OF EQUIP MFG

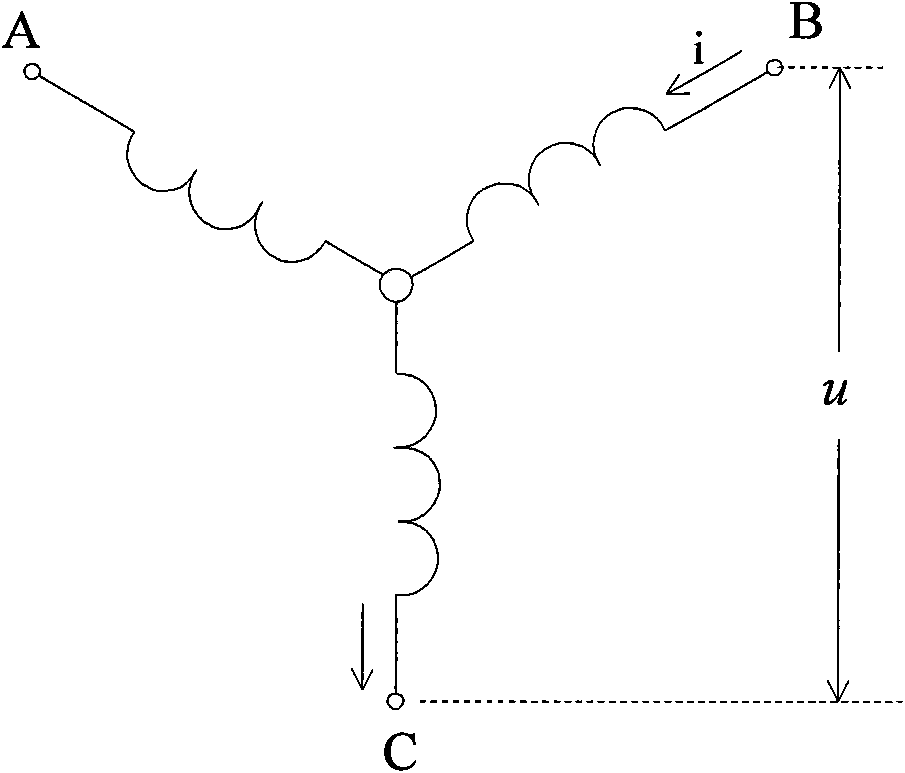

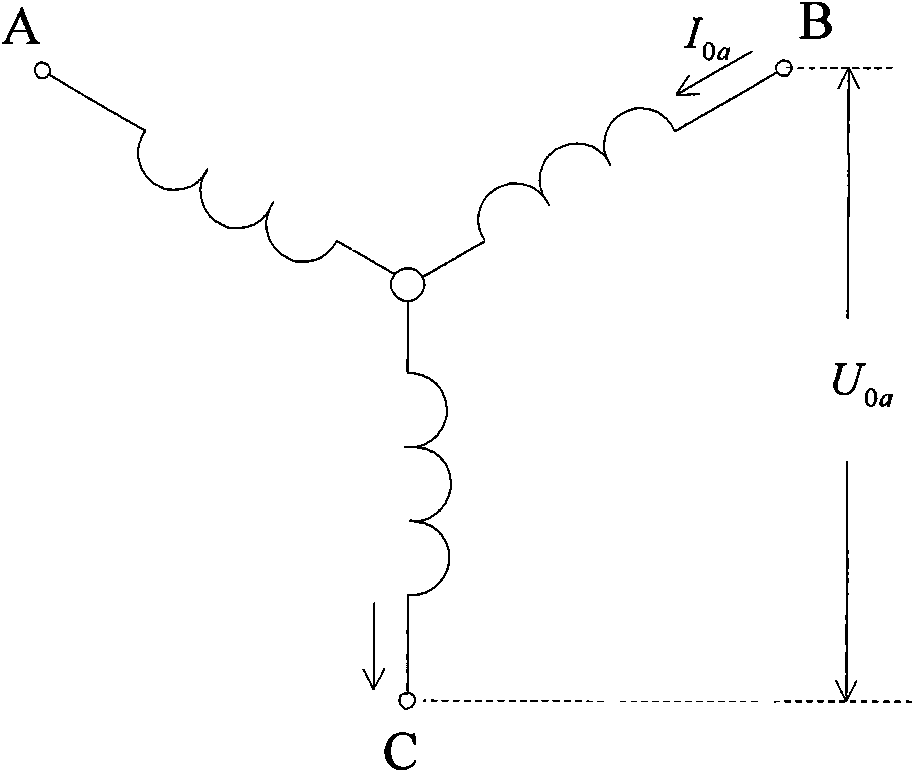

Method for testing parameters of synchronous motor and device for achieving same

ActiveCN101603997AAvoid influenceSimple structureCurrent/voltage measurementWork measurementSynchronous motorElectric machine

The invention provides a method for testing parameters of a synchronous motor and a device for achieving the same, which relate to the field of motor tests. The method and the device solve the problems of low testing accuracy of quadrature and direct axis inductance parameters, complex method for testing moment coefficient, and strong dependency on driver performance in the prior method. The method comprises the following steps: energizing any two phases in three phases of windings of a tested synchronous motor with single-phase alternating current (square root 2I sin omega t), driving a rotor of the tested synchronous motor with an external force to rotate at a uniform speed for at least one revolution, testing voltage signals at two ends of the energized windings, and obtaining the quadrature axis and direct axis inductances of Lq and Ld respectively of the tested synchronous motor according to the voltage signals; and energizing any two phases of the three phases of the windings of the tested synchronous motor with direct current I1, driving the motor of the tested synchronous motor with the external force to rotate at a uniform speed for at least one revolution, and calculating the moment coefficient KT of the tested synchronous motor according to the tested maximum moment value Tmax1. The method and the device are applied to the field of testing the parameters of the synchronous motor.

Owner:HARBIN INST OF TECH

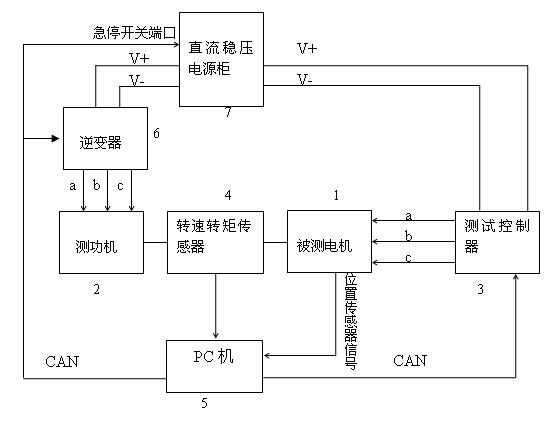

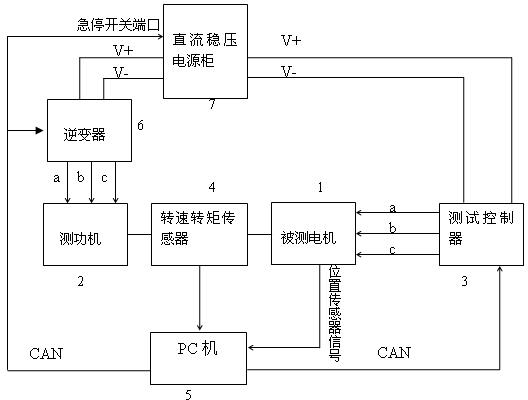

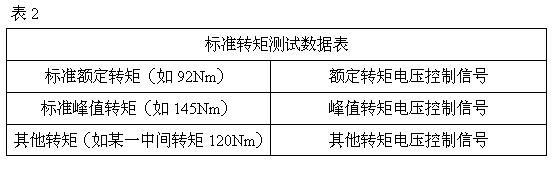

Delivery test system and method for motor for pure electric vehicle

ActiveCN102495367AGuarantee factory qualityMeet the testing requirementsDynamo-electric machine testingMotor testingArea network

The invention relates to a motor test system, which comprises a test controller, an inverter, a power tester, a rotating speed and torque sensor, a direct-current voltage stabilization power supply cabinet and a personal computer (PC). The invention also provides a method for testing a motor for an electric vehicle based on the test system. According to the test method, a whole rack test system is controlled through controller area network (CAN) communication; a rotating speed and torque measurement command is sent based on standard test data; rotating speed and torque data is fed back in real time by the rotating speed and torque sensor; and the feedback data is compared with standard data to judge whether the external characteristic of the motor is qualified. By the test system and the test method, the external characteristic of the tested motor can be detected accurately and efficiently, so that the delivery quality of the motor can be guaranteed; furthermore, the test process is high in automation degree and precise in test; and the method is easy to operate and low in cost, and has very wide application prospect.

Owner:奇瑞新能源汽车股份有限公司

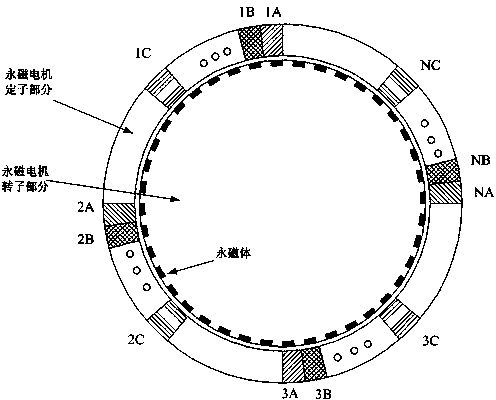

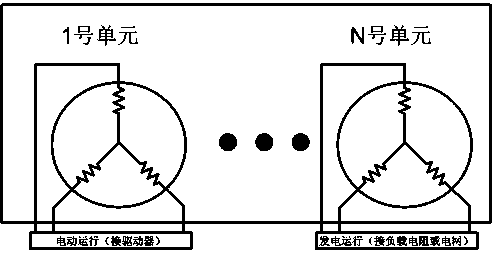

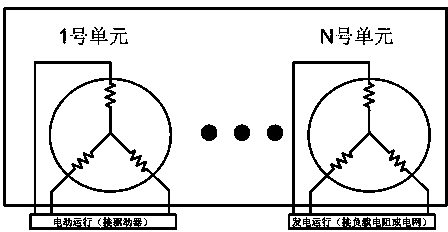

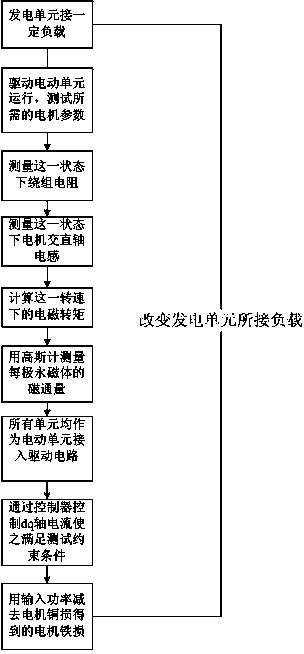

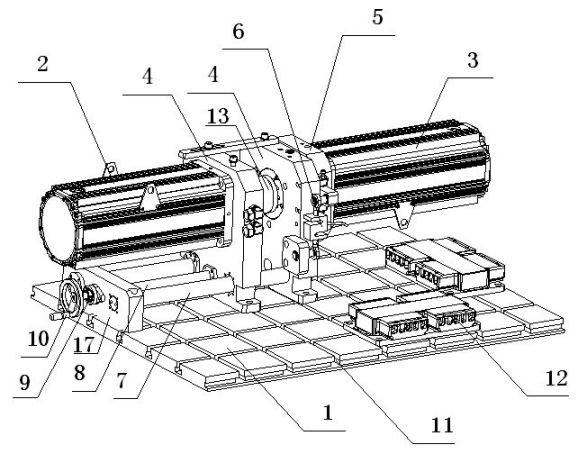

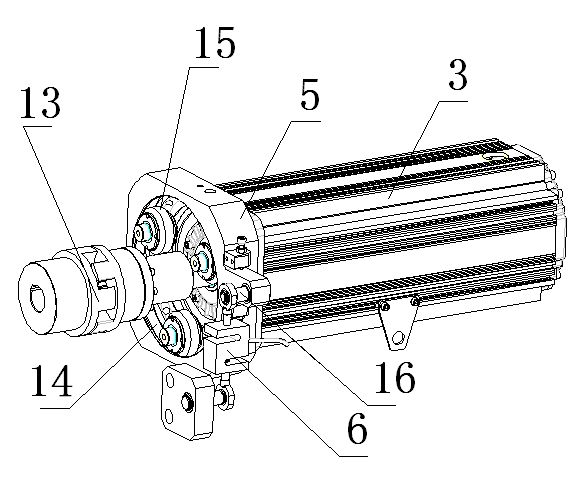

Testing method for mechanical characteristics of alternating-current permanent magnet motors

ActiveCN103472394AMeet the needs of mechanical property testingPredict mechanical propertiesWork measurementTorque measurementMotor testingElectric machine

The invention relates to a testing method for mechanical characteristics of alternating-current permanent magnet motors, and belongs to the technical field of motor testing. According to the method, the winding structure characteristics of multiple units of the multi-phase multi-unit permanent magnet synchronous motors are used when the mechanical characteristics of the motor is predicted, the mechanical characteristics of one unit motor can be predicted by testing related motor parameters under the operation condition that one unit motor operates electrically, and one unit motor operates in an electricity generating mode, and then the mechanical characteristics of the whole motor are obtained through the relation between one unit output torque and whole motor output torque, and therefore not only is the mechanical characteristics of the motor predicted, but also an extra loading device is omitted. In the testing process of the mechanical characteristics of the multi-phase multi-unit motors by the adoption of the method, a motor shell and shaft extension of the motors do not need special fixture, an external device is not needed, the motors have the advantages of being simple in structure and stable in property, and the testing method has the advantages of being reliable in data and the like and can meet testing requirements for testing the mechanical characteristics of the common permanent magnet synchronous motor.

Owner:HARBIN INST OF TECH

Brushless servo motor tester

A permanent magnet brushless (PMBL) servo motor test apparatus and method allow testing of a motor in place. A set of static and dynamic tests is performed to determine proper motor operation of armature windings and rotor feedback devices. The test system of the present invention displaces the motor drive system. The test system comprises an armature driver, a feedback device input, and a system controller. The armature windings of the motor-under-test are driven in a polarity sequence according to a test sequence, whereby the rotor is driven in a series of rotations. Angle feedback is tested at a plurality of said rotations. Rotor velocity outputs are tested during said rotations. Armature current and voltage are determined at a plurality of said rotations and winding balance is tested. Said power switch is also operative to apply a voltage between the armature windings and the motor case to test for fault current flow.In another embodiment of the invention, motor identification is decoded by the system into motor configuration and motor operation parameters, necessary to test the motor. Motor identification may be entered by an operator or captured from machine readable tags such as a barcode tag or an RFID tag.

Owner:MITCHELL ELECTRONICS

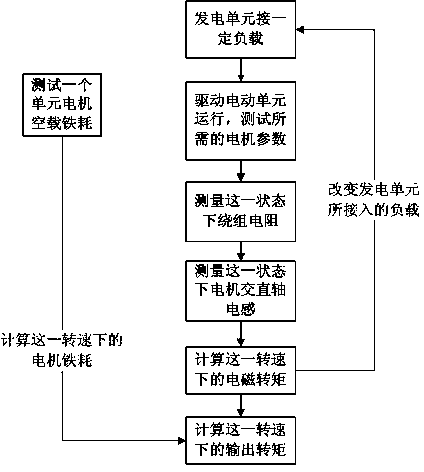

Testing method for iron core loss of alternating-current permanent magnet motors

ActiveCN103472312AMeet the needs of iron loss testingAvoid calculationResistance/reactance/impedenceMotor testingElectricity

The invention relates to testing method for iron core loss of alternating-current permanent magnet motors, and belongs to the technical field of motor testing. According to the method, the winding structure characteristics of multiple units of the multi-phase multi-unit permanent magnet motors are used, one unit motor is made to run electromechanically, and one unit motor is made to run in an electricity generating mode, so that motor parameters of the multi units of motors in a loading state are obtained without an extra mechanical loading device. All the units are made to run electrically, and the current of a dq shaft is adjusted appropriately by controlling a driver to simulate the iron core loss in the motor loading state, so that the problems that an existing testing method and instrument for the iron core loss are difficult to adjust and can not take influence of a rolling technology on the iron core loss testing into consideration are solved. In the testing process of the mechanical characteristics of the multi-phase multi-unit motors by the adoption of the method, a motor shell and shaft extension of the motors do not need to be fixed specially, an external device is not needed, the motors have the advantages of being simple in structure and stable in property, the testing method has the advantages of being reliable in data and the like and can meet testing requirements for testing the iron core loss of the common permanent magnet synchronous motor.

Owner:HARBIN INST OF TECH

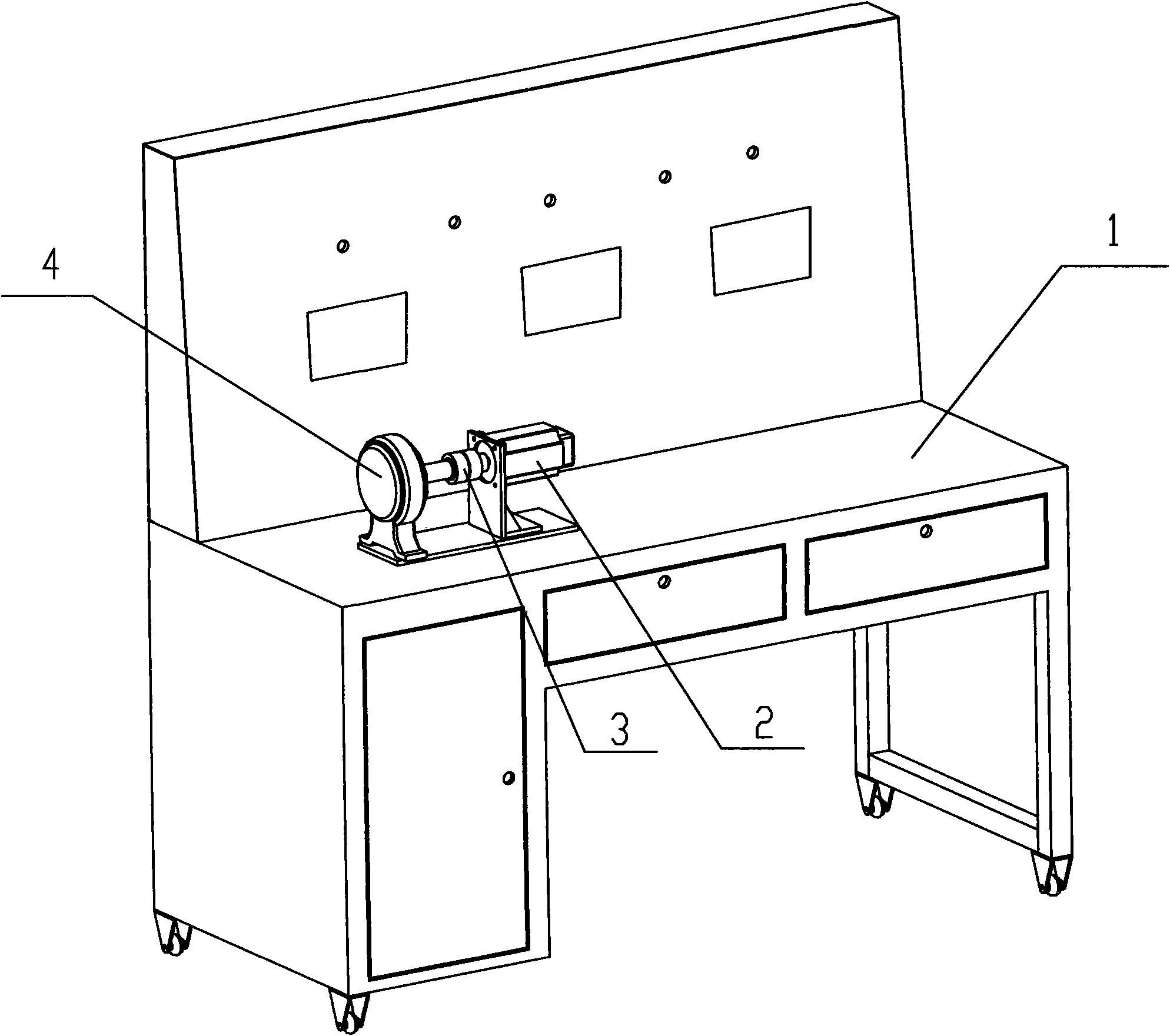

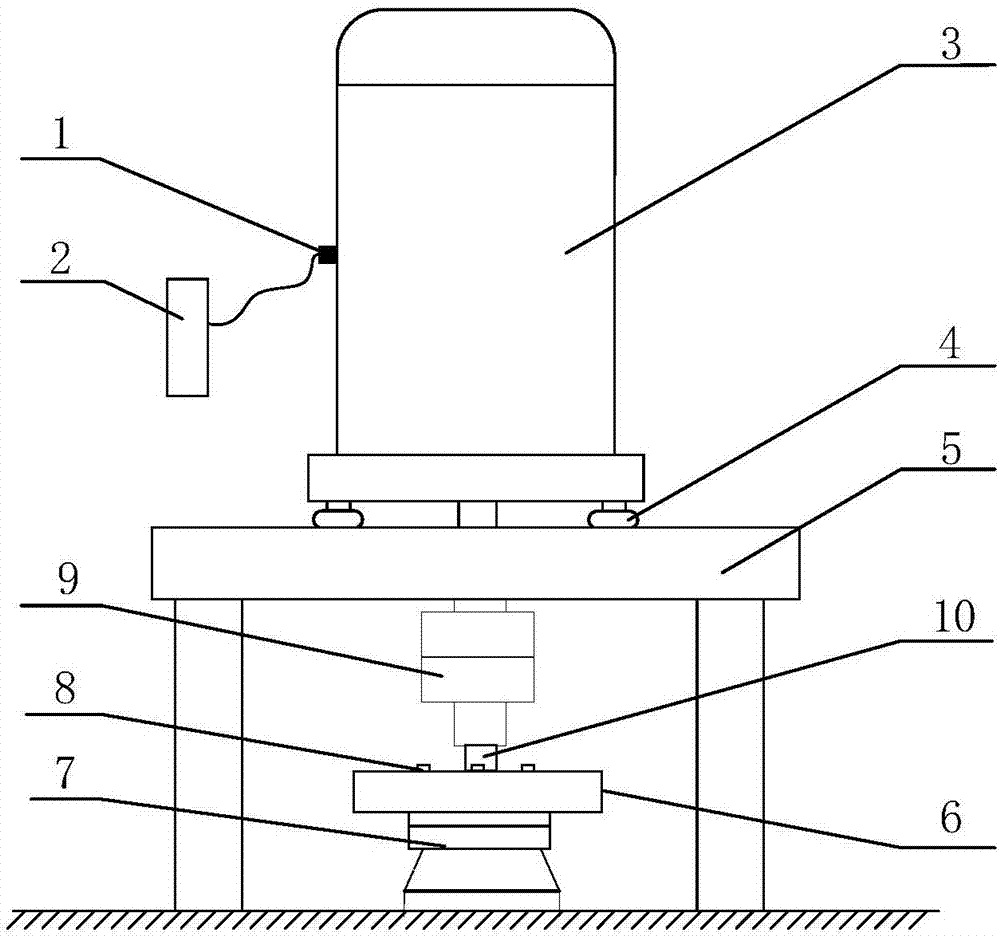

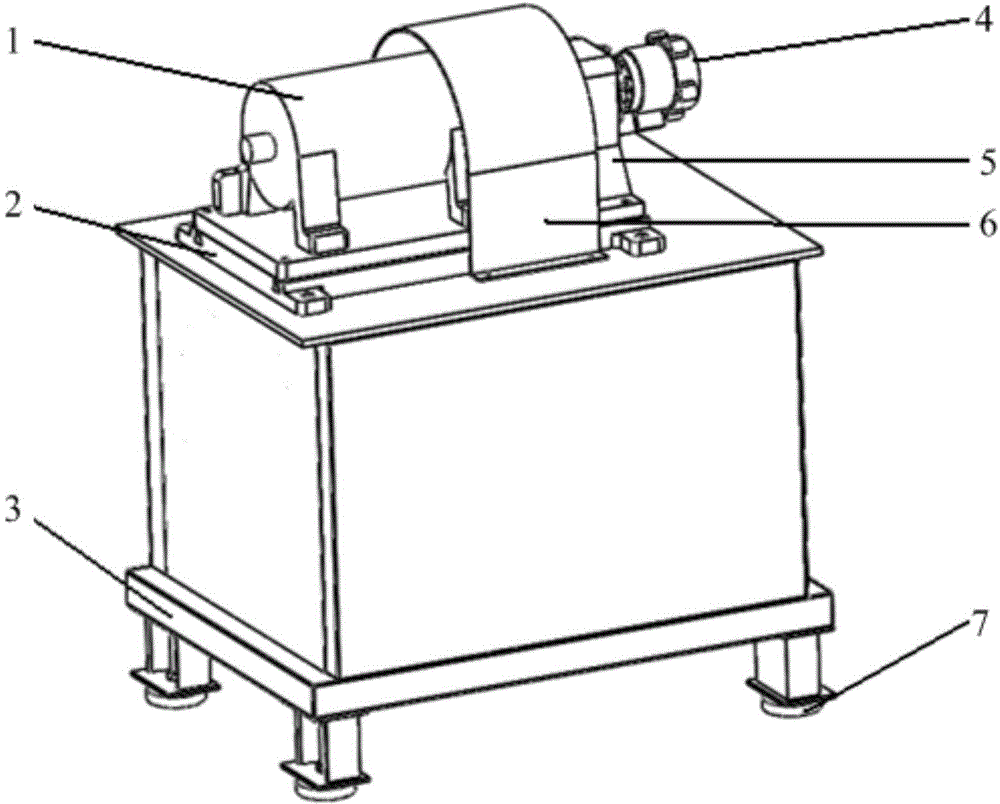

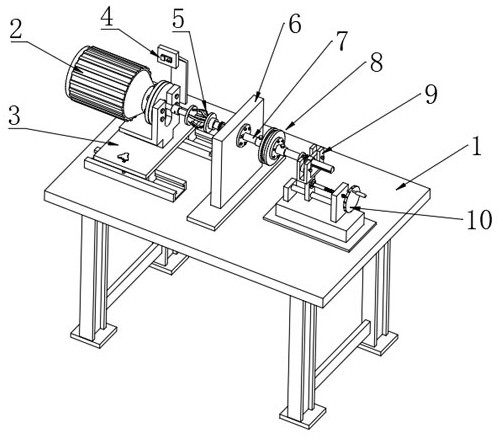

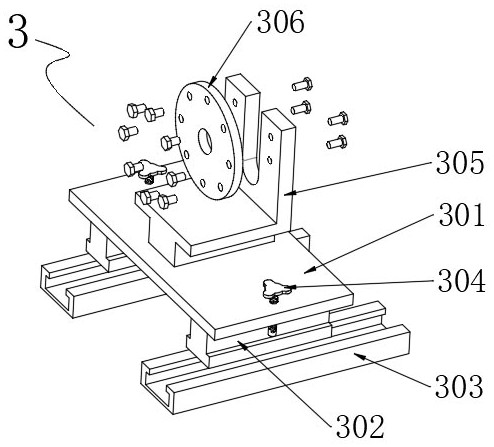

Servo motor test bench and test method

ActiveCN102109399AIntuitive test resultsThe test result is simpleWork measurementTorque measurementMotor testingControl theory

The invention relates to a servo motor test bench and a test method. The invention aims to provide a servo motor test bench which has high detection precision and is not related to the rotating speed of a motor, and a test method. The servo motor test bench comprises a test bench and a load motor mounted on the test bench; a rotor of the load motor is connected with a rotor of a to-be-tested servo motor; a stator of the to-be-tested servo motor is fixedly connected with the test bench; a stator of the load motor is movably connected with the test bench; and the test bench is also provided with a pressure sensor for detecting the rotation moment of the stator of the load motor. The servo motor test bench has the advantages that the torque change process of the to-be-tested servo motor can be detected when the to-be-tested servo motor is subjected to load change, the detection precision is not affected by the given velocity value, the requirement for the torque detection of the large-range speed value of the servo motor can be met, and the detection results are visual and brief.

Owner:菲仕绿能科技(北京)有限公司

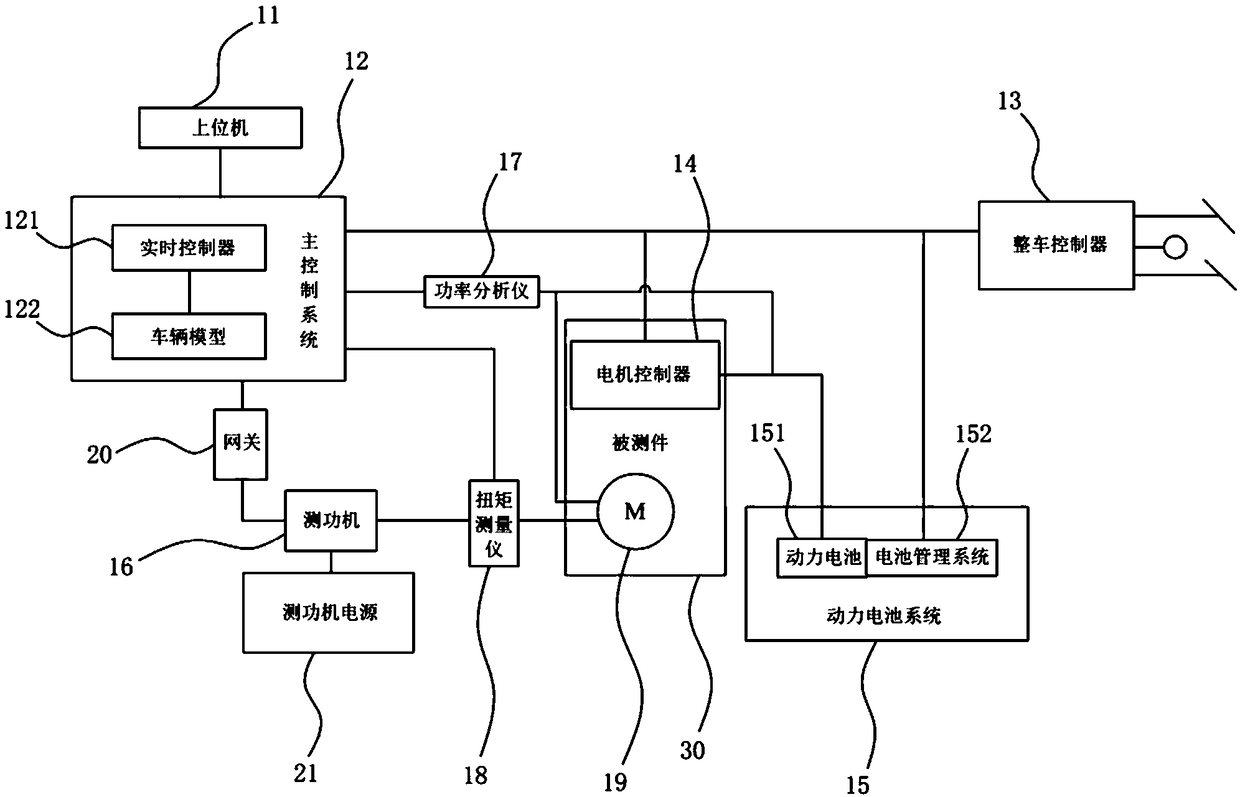

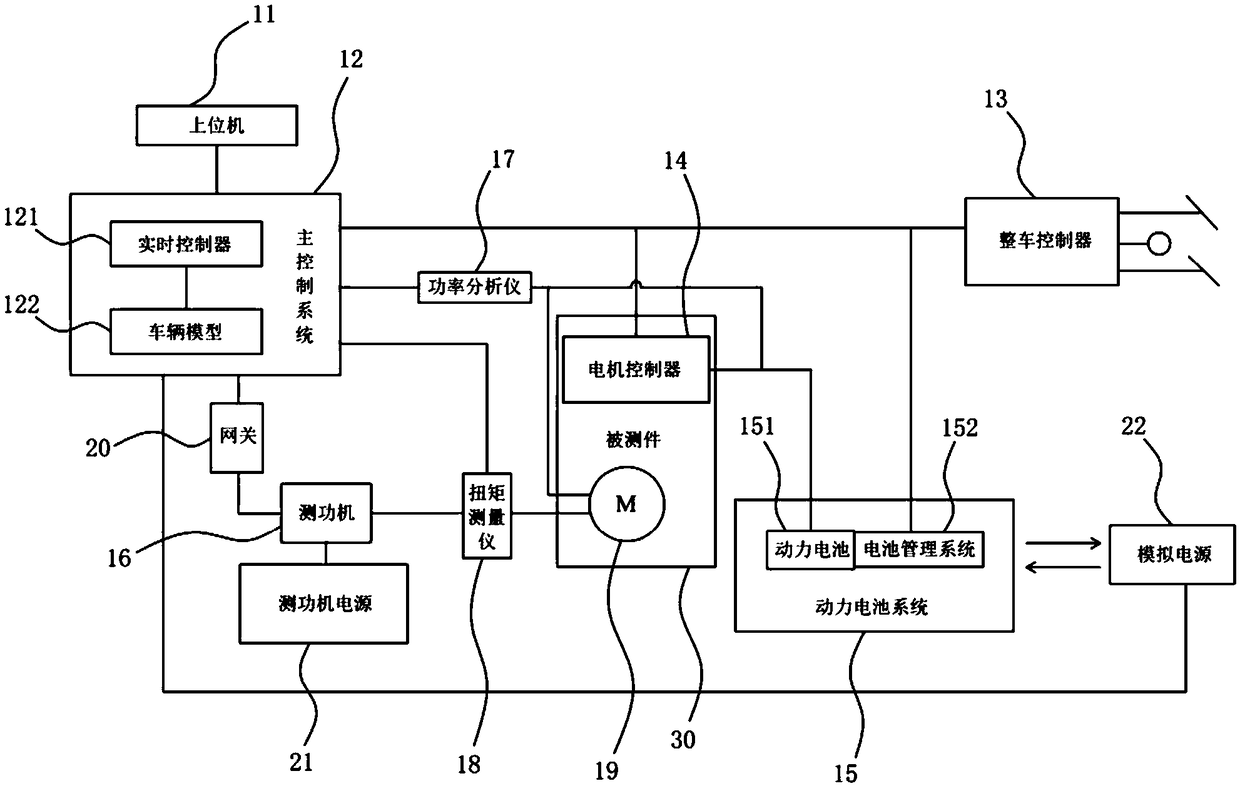

System for testing motor

InactiveCN108717163AEasy to deployFull grasp of dynamicsDynamo-electric machine testingPower batteryMotor testing

The invention discloses a system for testing a motor. The system comprises an upper computer, a main control system, a vehicle control unit, a motor controller, a power battery system, a dynamometer,a power analyzer and a torque measurement instrument. The main control system, the upper computer, the vehicle control unit, the motor controller and the power battery system are connected through a CAN bus, the motor controller is connected with the driving motor to be tested, the vehicle control unit is connected with an accelerator pedal, a braking pedal and gears, and used for sending a control instruction to the motor controller, the motor controller is used for controlling the rotating direction, rotating speed and torque of the driving motor after receiving the control instruction, thevoltage, current, temperature and other parameters of the driving motor are fed back to the upper computer in real time through the power analyzer, and the torque measurement instrument is used for measuring and feeding back the actual output torque and rotating speed of the driving motor to the main control system for calculation. With the system, the problems that a testing environment is difficult to deploy, and testing data is largely different from actual vehicle data can be solved.

Owner:JIANGXI JIANGLING GRP NEW ENERGY AUTOMOBILE CO LTD

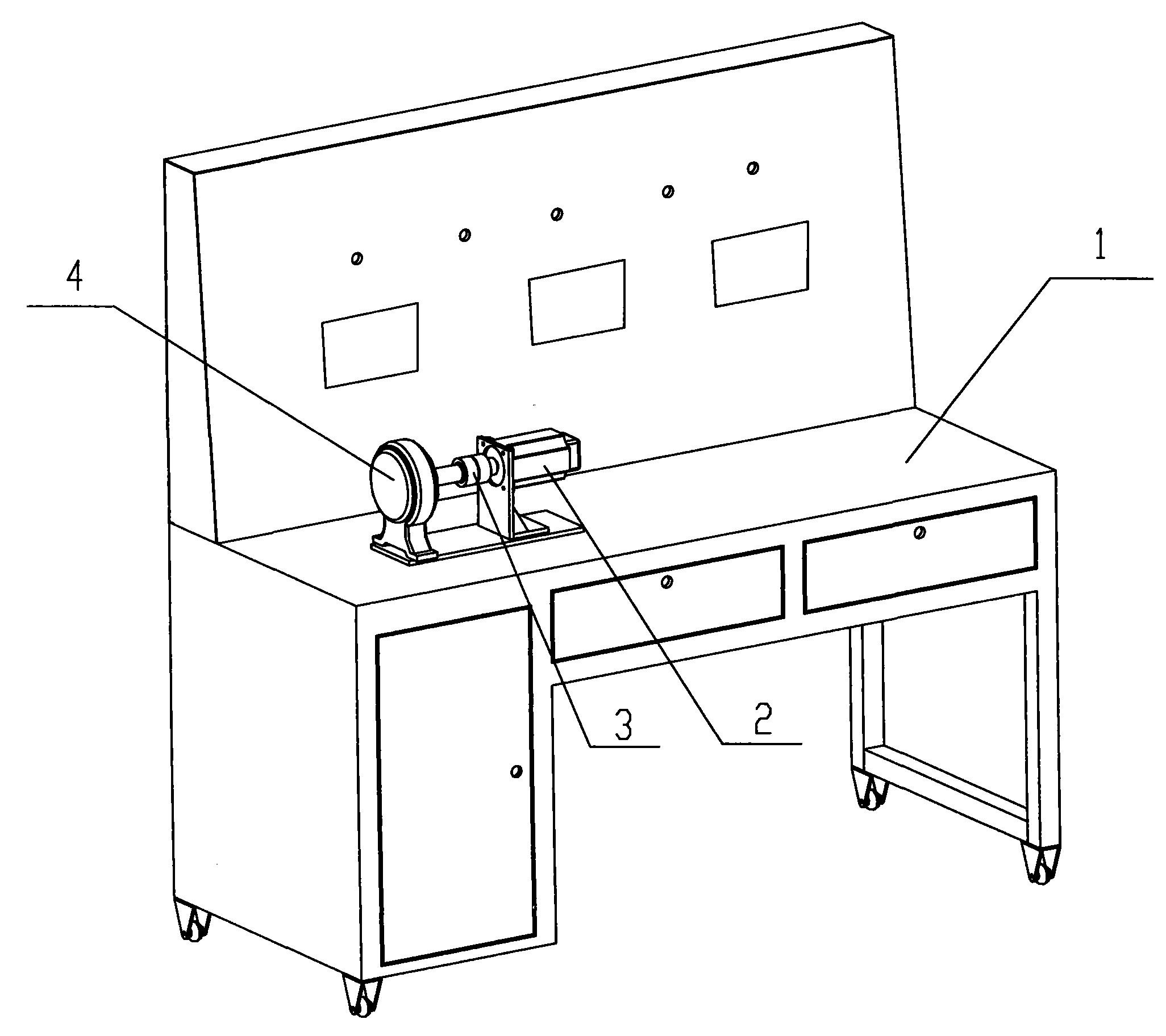

Novel motor test platform

InactiveCN101975924ARealize intelligenceMiniaturizationDynamo-electric machine testingMotor testingCoupling

The invention relates to a novel motor test platform, which comprises a stand, wherein a load is arranged on the stand; the load is connected with a tested motor through a coupler; the load is an eddy current loader; and torque, speed and power meters, torque and speed sensors and the automatic controller of the eddy current loader are arranged in the stand. The motor test platform overcomes the drawback that the common motor test platform can only test the parameters such as voltage and current of the tested motor and has difficulty in regulating the torque of the load and a large volume, and is intelligent and small and can be widely used.

Owner:JIANGSU HUIBO ROBOTICS TECH CO LTD

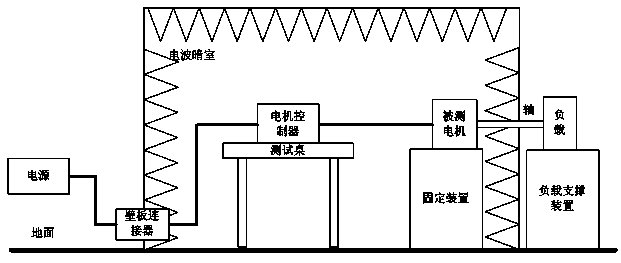

Hub motor on-load EMC performance test system

ActiveCN103728558AReduce testing costsReduce loadDynamo-electric machine testingMotor testingPower cable

The invention relates to the technical field of electromagnetic compatibility tests, in particular to a hub motor on-load EMC performance test system. The system comprises a power source, a linear impedance stabilization network, a hub motor controller, a load exertion mechanism and a fixed device, wherein the power source controls a hub motor to rotate. A vehicle wheel where the hub motor is installed is connected with the fixed device through a shaft. The load exertion mechanism exerts loads on the contact surface of the vehicle wheel making contact with the load exertion mechanism, then hub motor on-load is achieved, meanwhile the fixed device is adjusted to control vertical loads of the vehicle wheel, and it is guaranteed that the vehicle wheel reliably makes contact with the load exertion mechanism. EMC performance of one signal hub motor and a hub motor system comprising the hub motor, the hub motor controller and a power cable can be tested, and the test result is not affected by the motor loads and is accurate and credible; in a general electromagnetic compatibility test environment which is already constructed and provided with a drum, a test environment which is expensive and special for motor electromagnetic compatibility does not need to be constructed, and therefore the cost for testing the hub motor is reduced.

Owner:CHINA AUTOMOTIVE ENG RES INST

Non-sine periodic signal real time high precision detection method

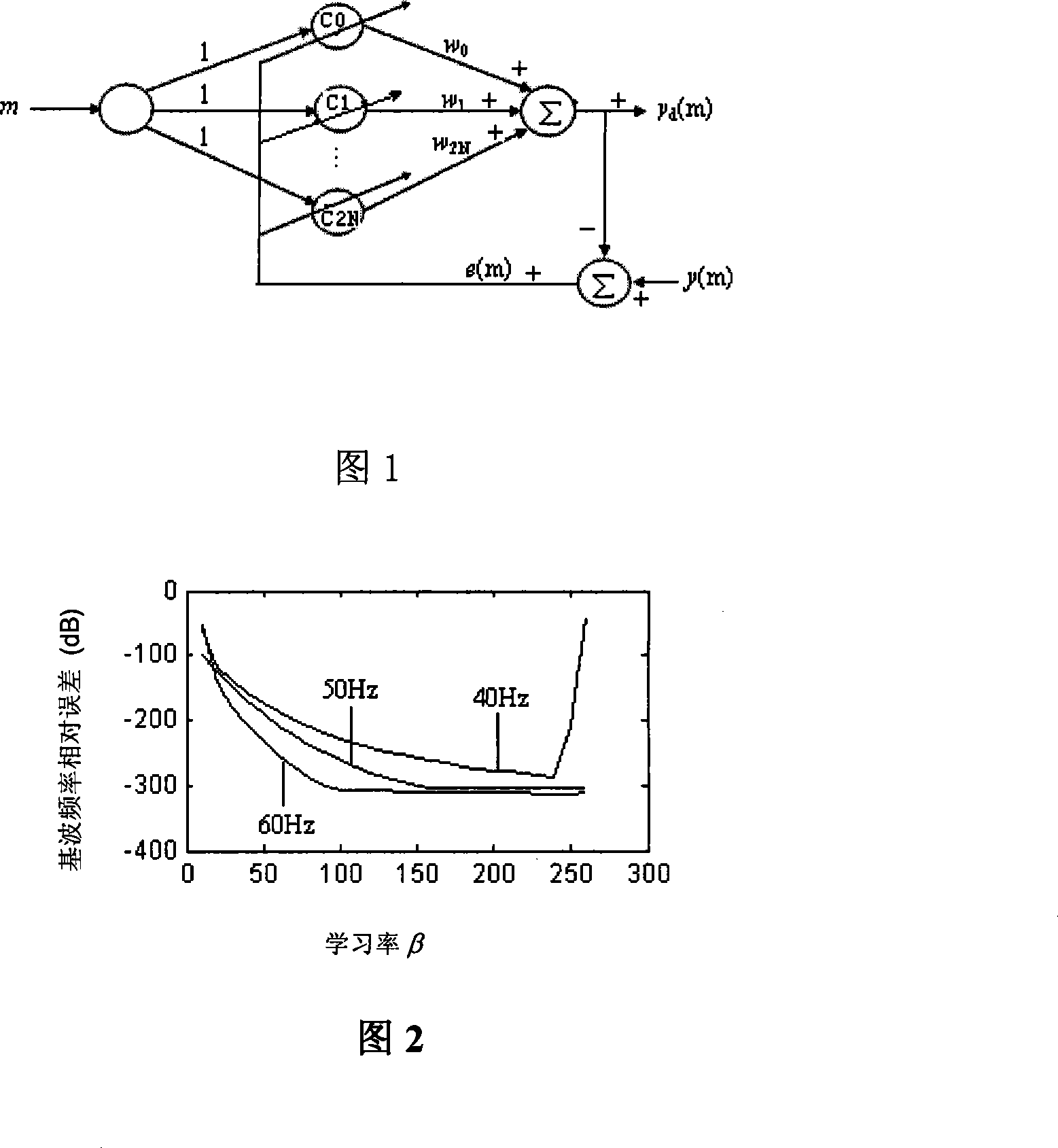

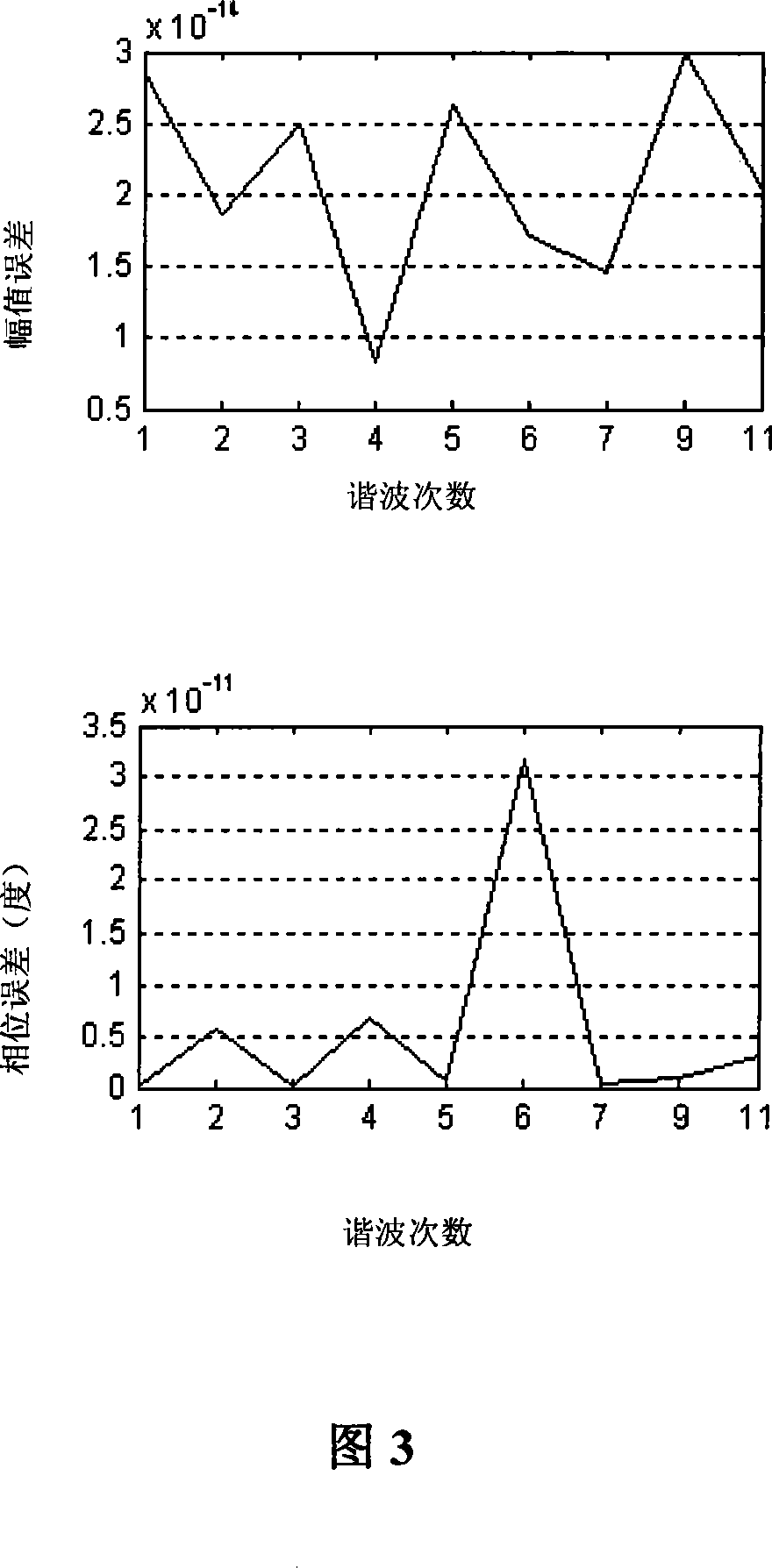

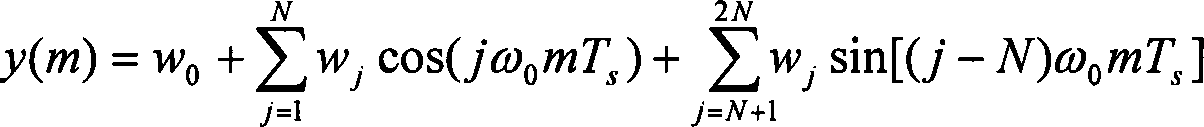

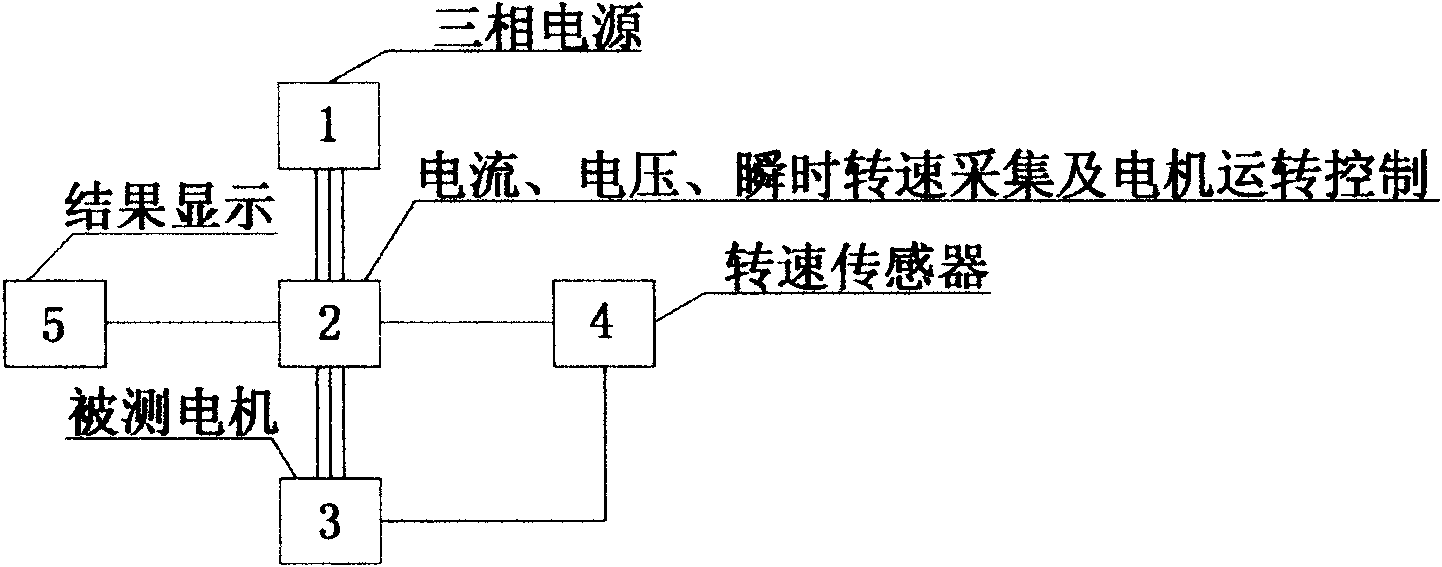

InactiveCN101216512AHigh precisionSpectral/fourier analysisPhysical realisationMotor testingHarmonic analysis

The invention discloses a realtime high-accuracy non-sinusoidal periodic signal detection method, which comprises the following steps of: sampling non-sinusoidal periodic signals to be detected; calculating frequency, amplitude and phase of fundamental wave and harmonic of each order by using neural network based on triangular base function; and correcting the frequency of the fundamental wave of the non-sinusoidal periodic signal calculated by the neutral network by using windowed interpolation algorithm. By improving the neural network algorithm, the invention can execute high-accuracy analysis of frequency of the fundamental wave and amplitudes and phases of the fundamental wave and the harmonic of each order for asynchronous sampling and non-integer-period truncation, and high-accuracy harmonic analysis result of non-sinusoidal periodical signal can be obtained when the neutral network is convergent. The invention has the advantages of high speed, realtime operation, high accuracy, etc., and has wide application prospect in fields of mechanical engineering, motor testing, electric system stability analysis, signal processing, instrument and apparatus, industrial control, etc.

Owner:HUNAN UNIV

Method for testing partial performances of three-phase asynchronous motors

InactiveCN101629860ALow costReduce consumptionStatic/dynamic balance measurementWork measurementElectric machineThree phase asynchronous motor

The invention provides a method for testing partial performances of three-phase asynchronous motors, which is mainly applied to the factory test and after-maintenance test on three-phase asynchronous motors, and can also be used for the quick verification of newly designed technical schemes for motors. The method comprises the steps of utilizing the inherent no-load operation characteristic of a three-phase asynchronous motor to measure the rotation inertia of a tested motor rotor and measuring the torque, output power, efficiency and other partial parameter indexes of the motor according to the change of the corresponding instantaneous speed of the rotor in different states and the operation parameters of the motor, thereby leaving out the part of applying analog load in the prior motor test method.

Owner:赵健身

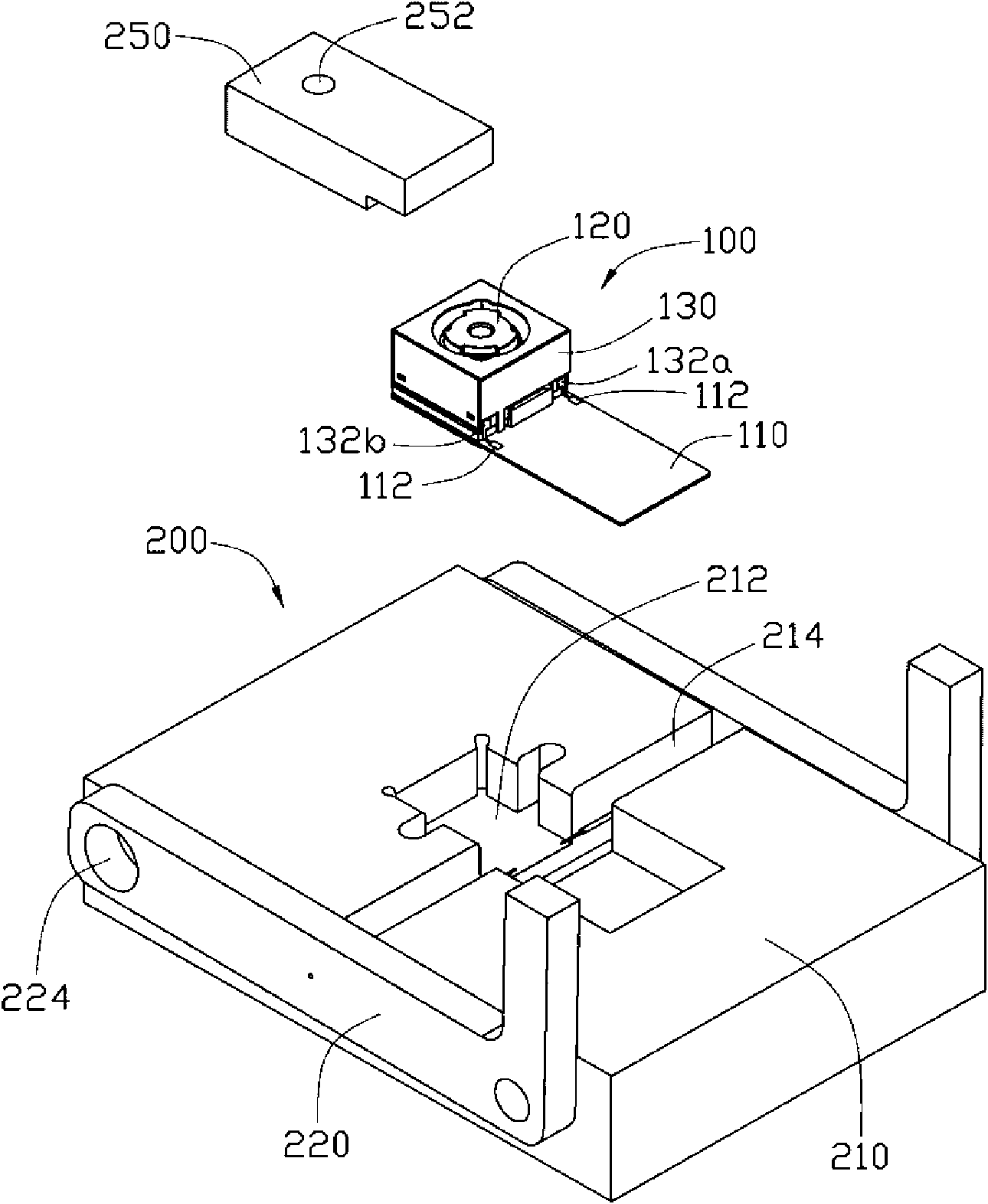

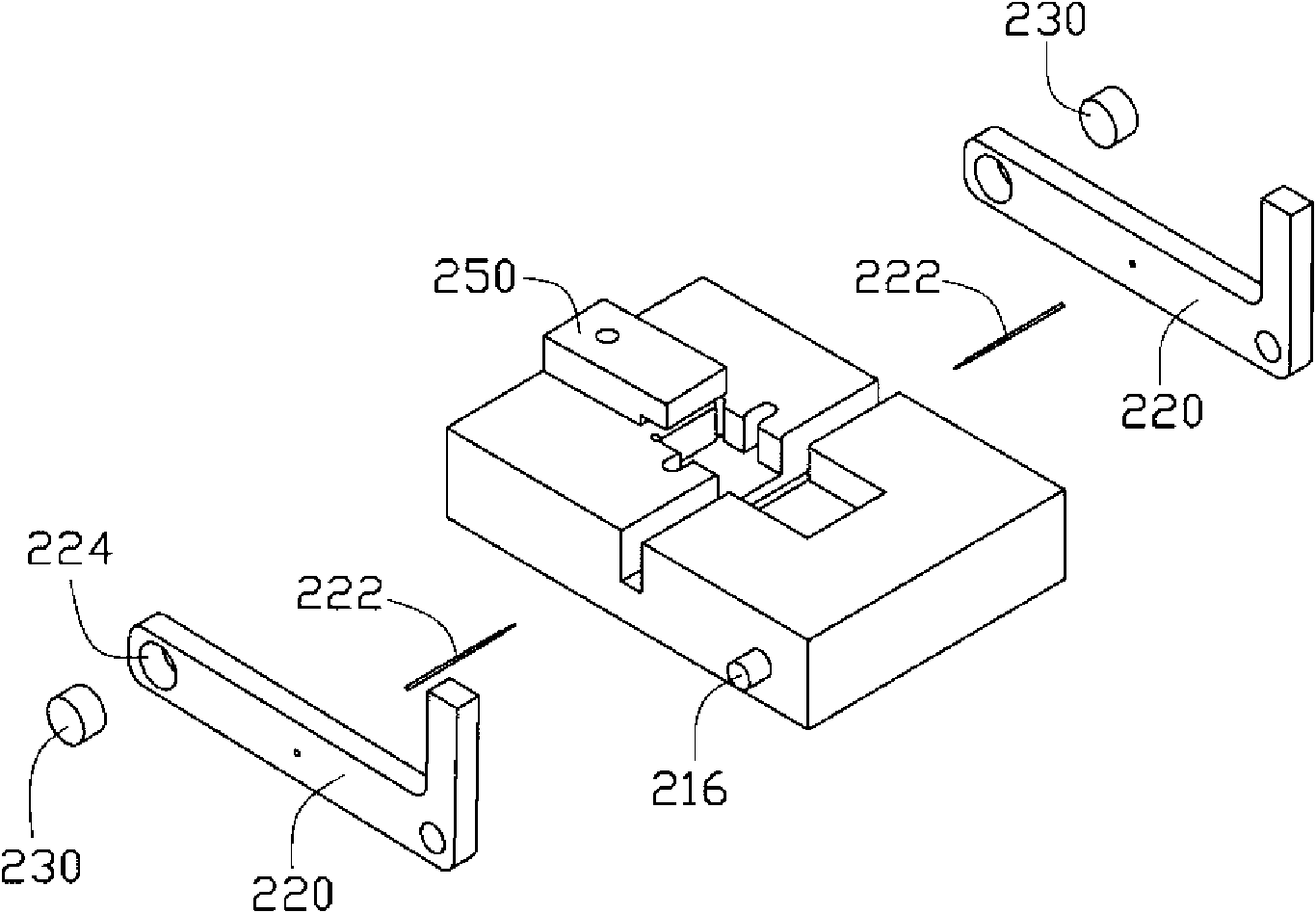

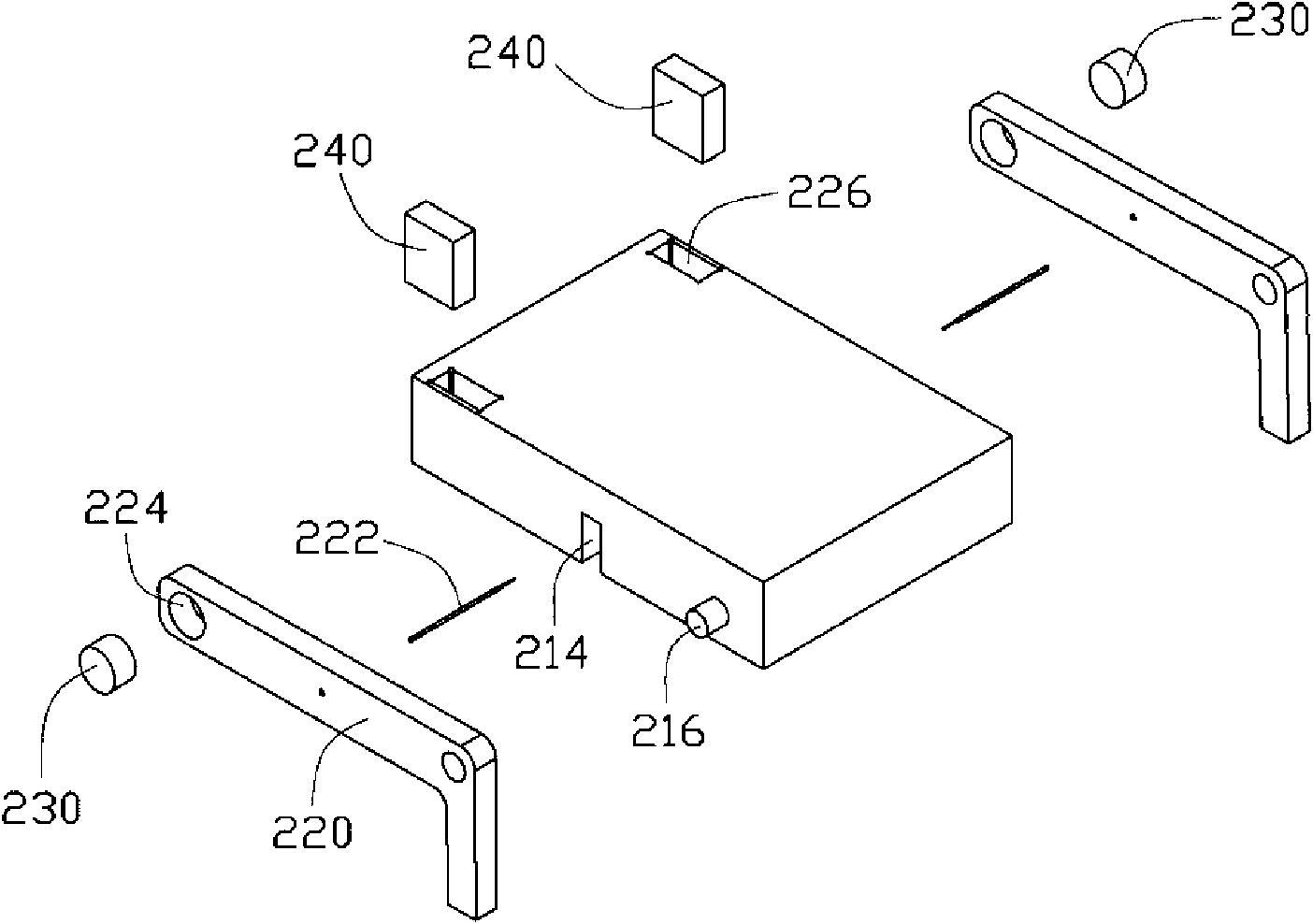

Voice coil motor testing device and auxiliary device thereof

The invention provides a voice coil motor testing device comprising a pedestal and two probe seats, wherein the pedestal is provided with a first containing slot used for containing a voice coil motor and a groove communicated with the first containing slot; the groove extends towards two sides of the pedestal from the first containing slot; the two probe seats are respectively pivoted to two sides of the pedestal, where the groove is arranged; and each probe seat is provided with a probe which can be embedded or be far away from the groove relative to the rotation of a pivot along with the probe seat, thereby respectively contacting or being far away from the current input end and the current output end of the voice coil motor to be tested and realizing power-on or power-off control on the voice coil motor. The voice coil motor testing device also comprises a range finder used for measuring the moving distance of the electrified voice coil motor and comparing the distance with a standard value.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

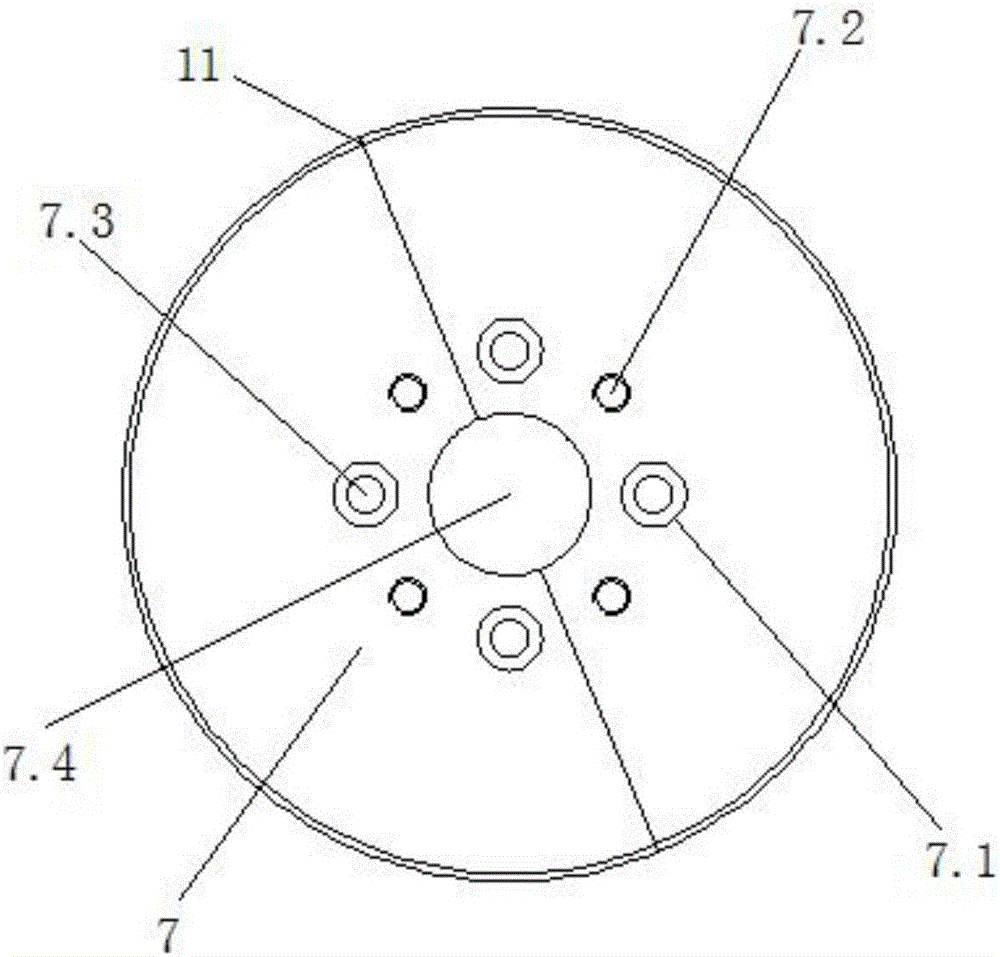

Motor vibration characteristic frequency detection device and method

ActiveCN107246948ASmall impact of test vibrationEliminate the problem of inaccurate judgment caused by excessive frequency offsetVibration testingMotor testingControl theory

The invention provides a motor vibration characteristic frequency detection device. The device comprises a mounting base, a flywheel disk, counterweight mass blocks, an air flotation bearing, a flexible coupling, a carrying shaft, an acceleration sensor, a vibration test analyzer and a vibration isolator; a motor is mounted on the mounting base through the vibration isolator; the shaft of the motor is connected with the carrying shaft through the elastic coupling; the carrying shaft is supported by the air flotation bearing; the carrying shaft is provided with the flywheel disk; inertia adjustment holes are evenly distributed in the flywheel disk along a radial direction; the counterweight mass blocks are installed in the inertia adjustment holes; and the acceleration sensor is mounted on the outer surface of the motor and is connected with the vibration test analyzer through a wire. The motor vibration characteristic frequency detection device of the invention has the advantages of convenient installation and adjustment, low test cost, long sampling time, fast separation, adjustable load inertia and high repeatability. The influence of external vibration on motor test vibration is small; and an electromagnetic excitation frequency and a natural frequency can be detected and separated out with only one-time signal continuous acquisition required.

Owner:HARBIN ENG UNIV

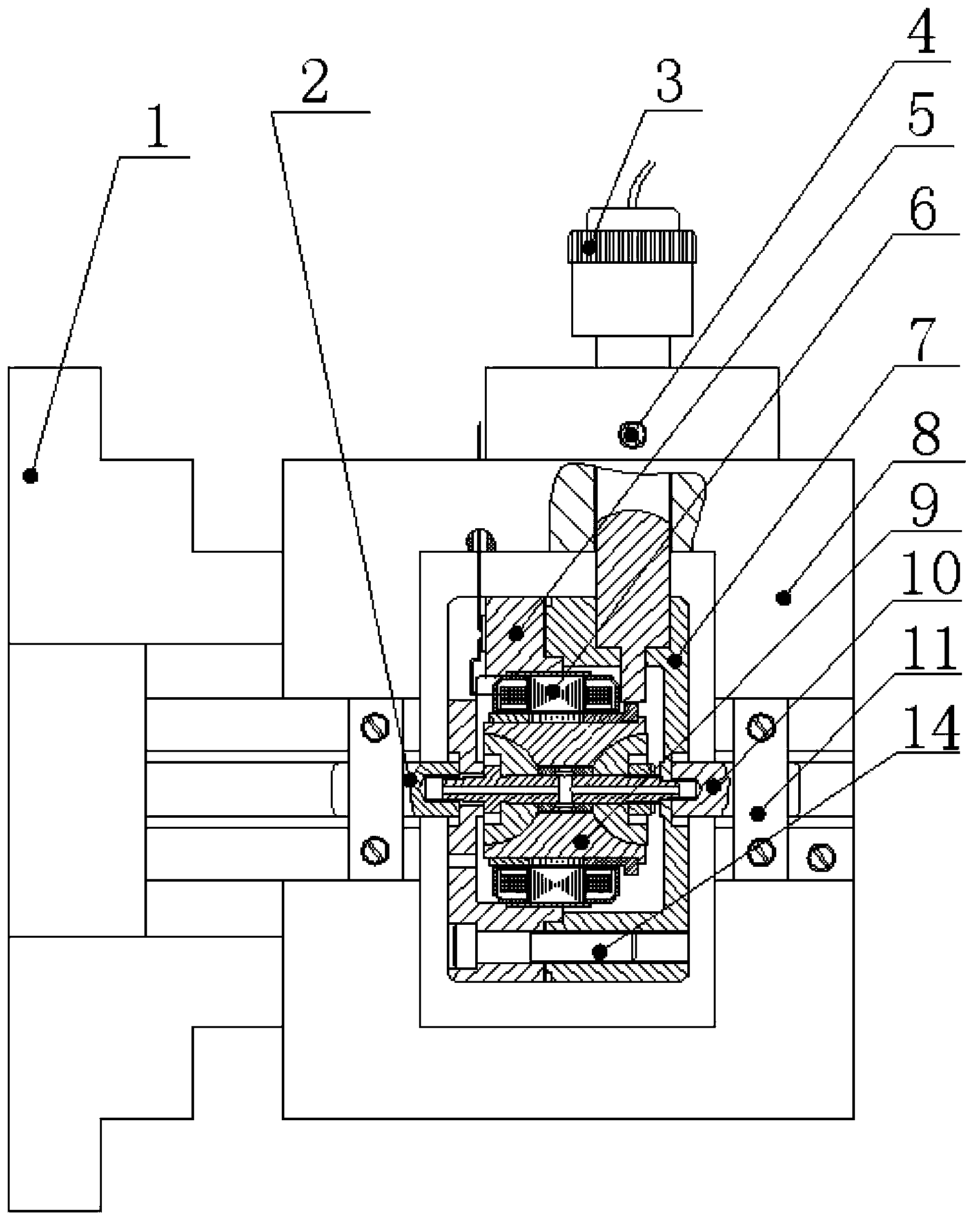

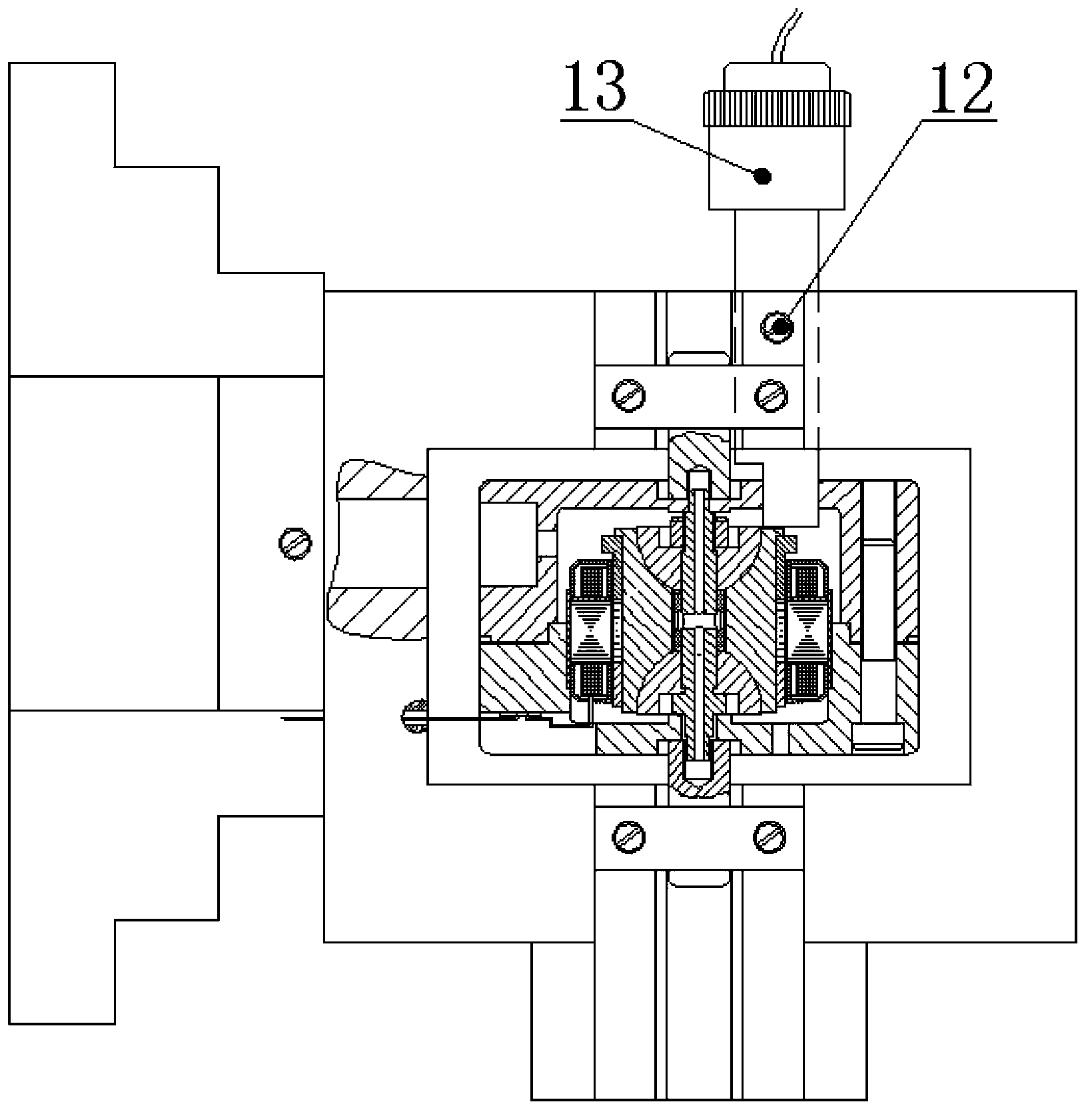

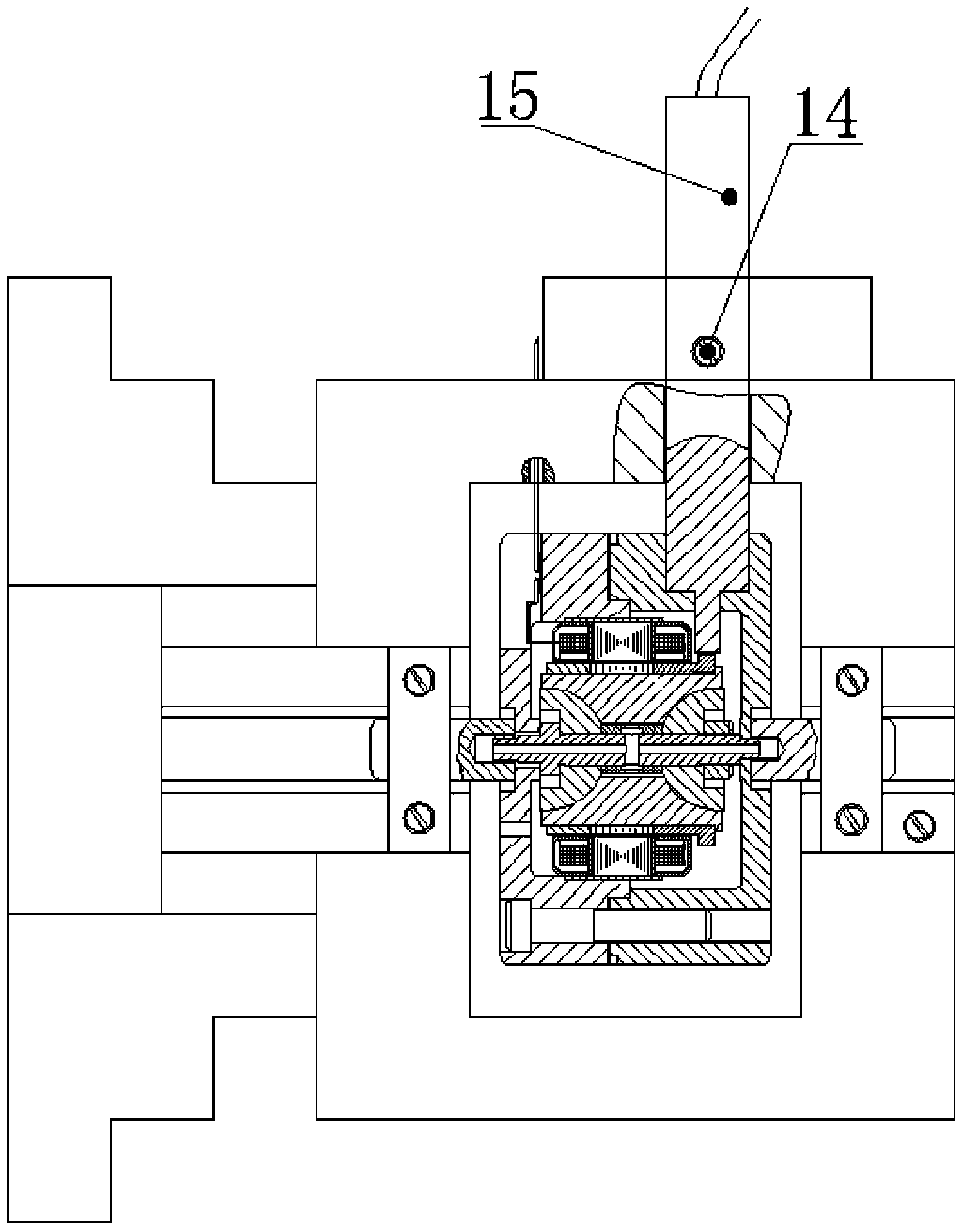

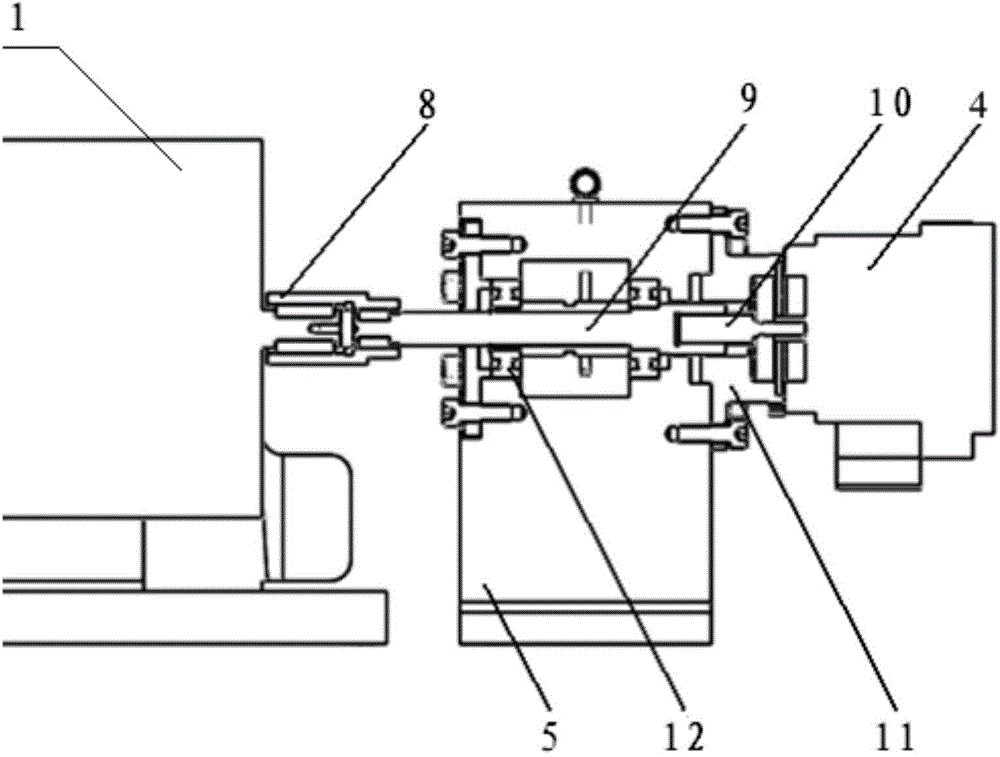

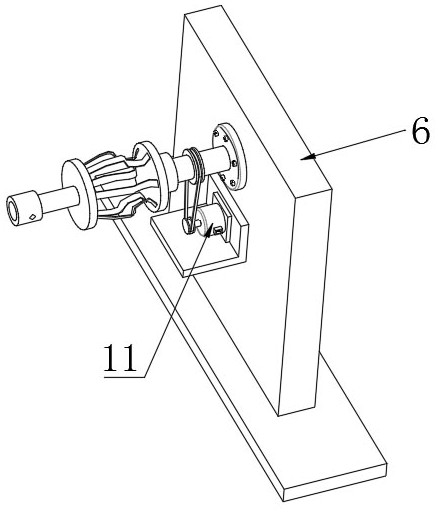

Inner rotor type gyro motor testing device

ActiveCN103411764ASolve the problem that cannot be installedSolve space problemsMachine part testingMotor testingVibration acceleration

The invention discloses an inner rotor type gyro motor testing device. A locknut (2) and a locknut (10) are in threaded connection with the big shaft end and the small shaft end of a gyro motor rotor (9). A testing support (8) and nut lock blocks (11) are matched to form a cylindrical cavity used for accommodating the locknuts. The locknuts are fixed to the testing support (8) through the two nut lock blocks (11). A gyro motor stator (6) is installed inside an upper stator installation seat (5). The gyro motor rotor (9) is installed inside the gyro motor stator (6), and the end face of the big shaft end of the gyro motor rotor (9) is matched with the bottom surface of the upper stator installation seat (5) for positioning. The end face of the small shaft end of the gyro motor rotor (9) is matched with the bottom surface of a lower stator installation seat (7) for positioning. The lower stator installation seat (7) and the upper stator installation seat (5) are locked through a connecting bolt (14). The inner rotor type gyro motor testing device can test the vibration acceleration and the bearing stiffness, and a testing method is simple and accurate.

Owner:BEIJING PULIMEN ELECTRO MECHANICAL HIGH TECHN CO

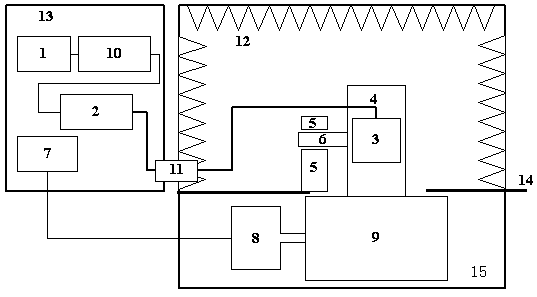

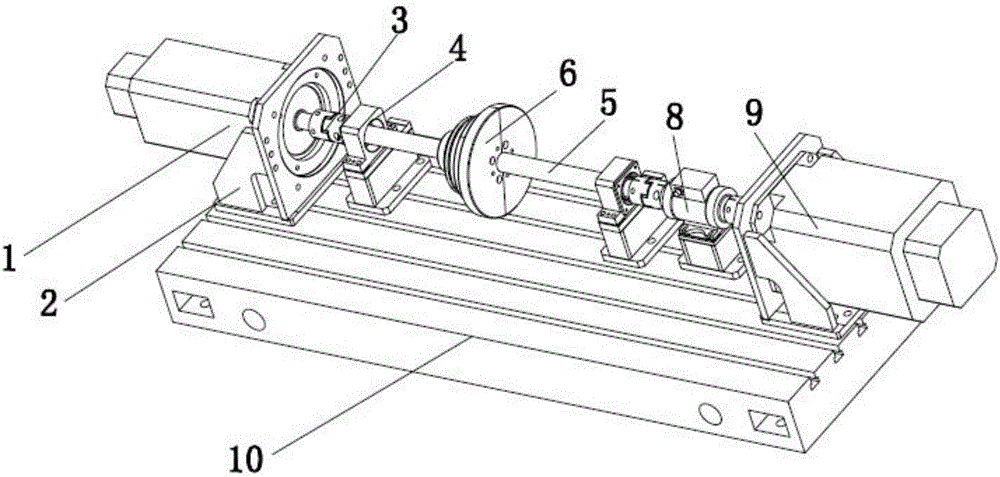

Motor performance testing system

The invention discloses a motor performance testing system which comprises a driving device, a motor to be tested, a loading control device, loading equipment, and data acquisition and analysis equipment. The driving device is electrically connected to the motor to be tested. The output shaft of the motor to be tested is axially connected to one end of a transmission shaft through a coupler. The other end of the transmission shaft is connected to the loading equipment through a transmission gear set. The loading equipment is electrically connected to the loading control device. The coupler is equipped with a torque rotation speed sensor. The transmission shaft is equipped with a combined inertia plate group for adjusting an inertia load. A position sensor is arranged between the transmission gear set and the loading equipment. The data acquisition and analysis equipment is connected to the motor to be tested, the torque rotation speed sensor and the position sensor. According to the motor performance testing system, the high precision position detection can be provided, at the same time the inertia load can be adjusted, the simulation of various working conditions is facilitated, and the system is especially suitable for the motor tests of all working conditions.

Owner:WUHAN HUAZHONG NUMERICAL CONTROL

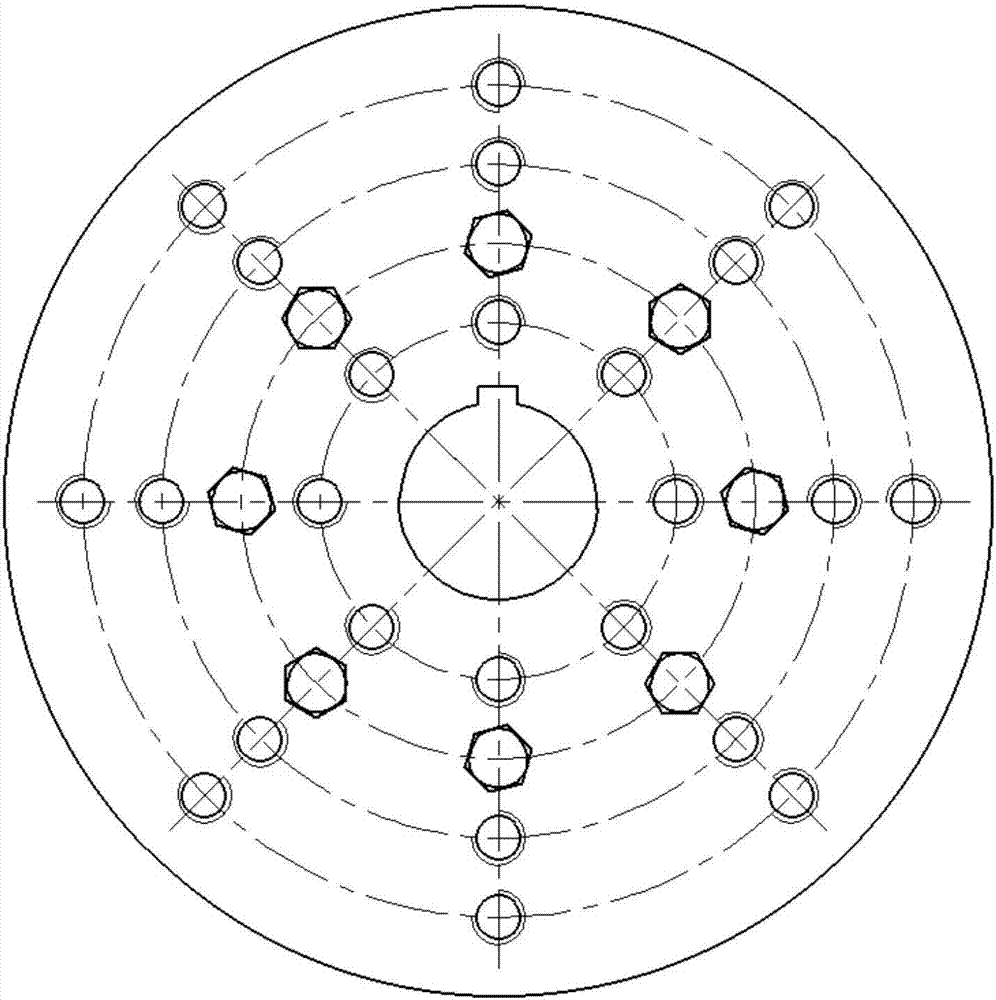

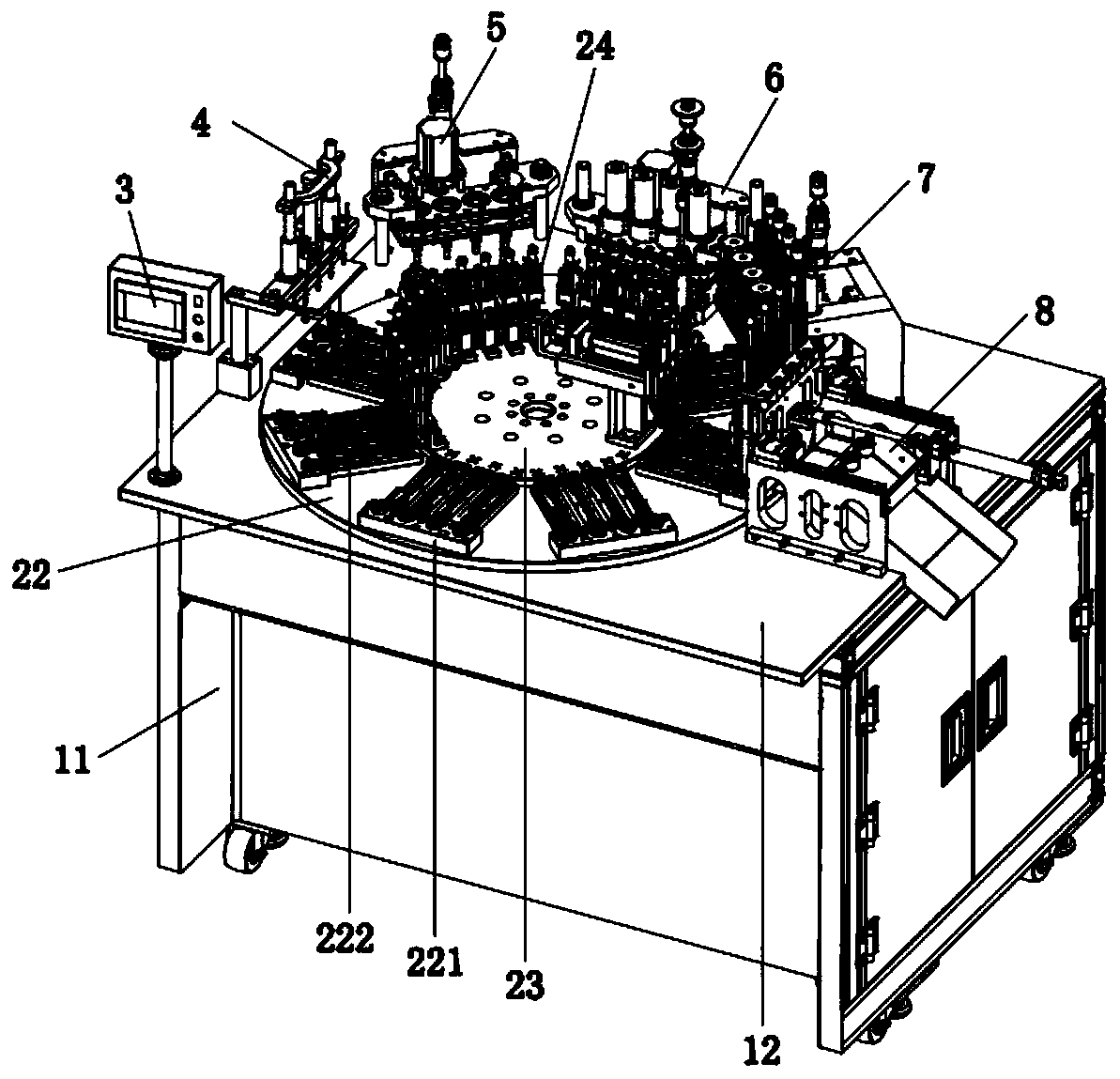

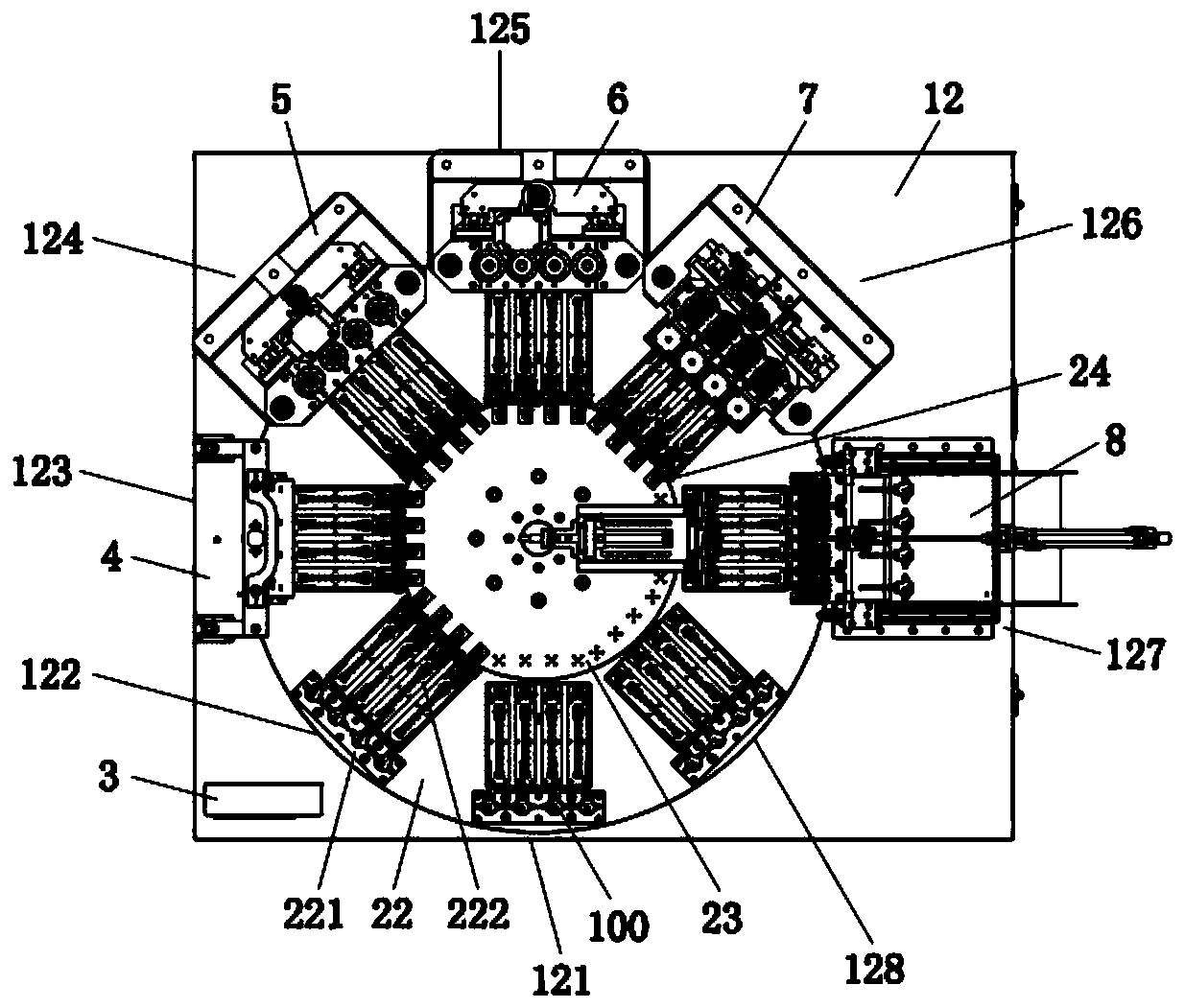

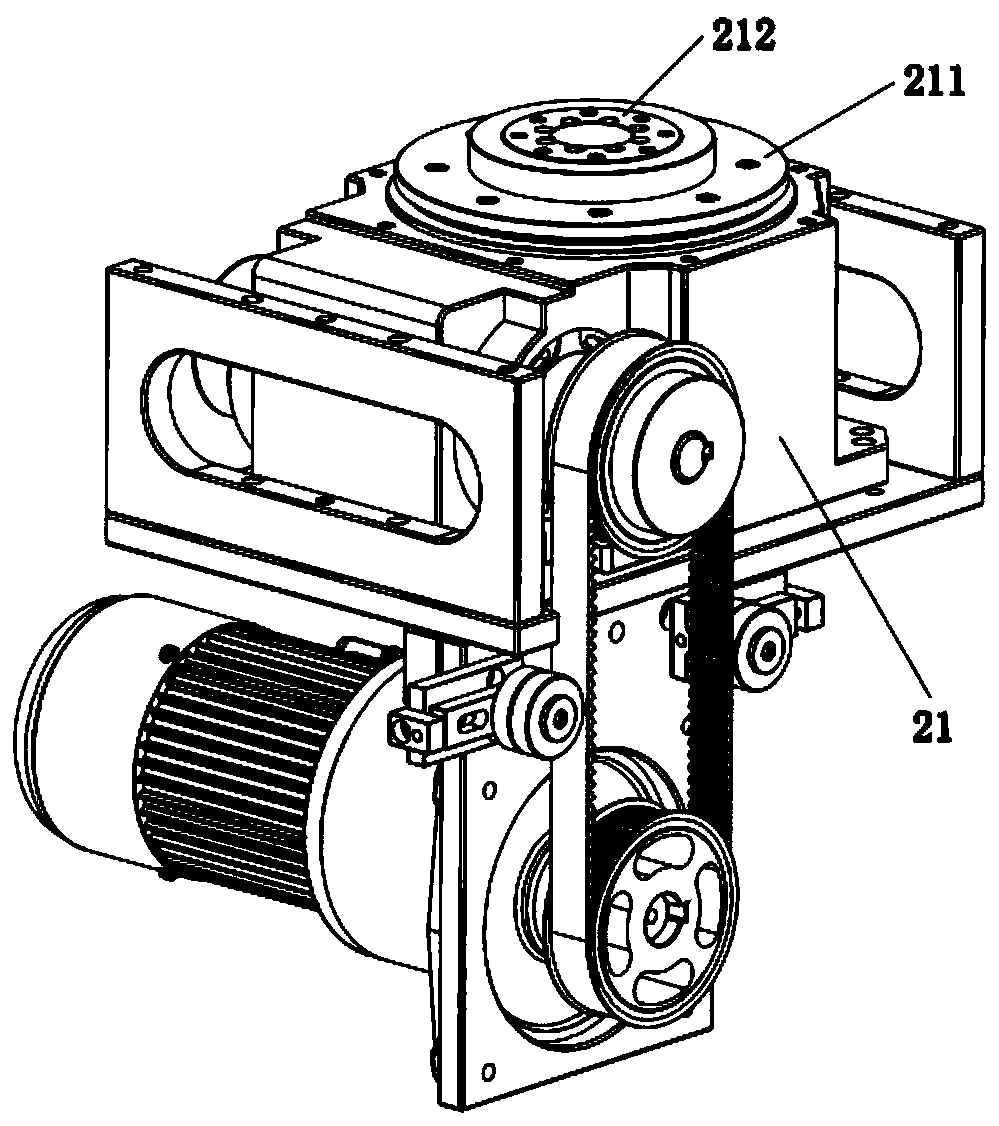

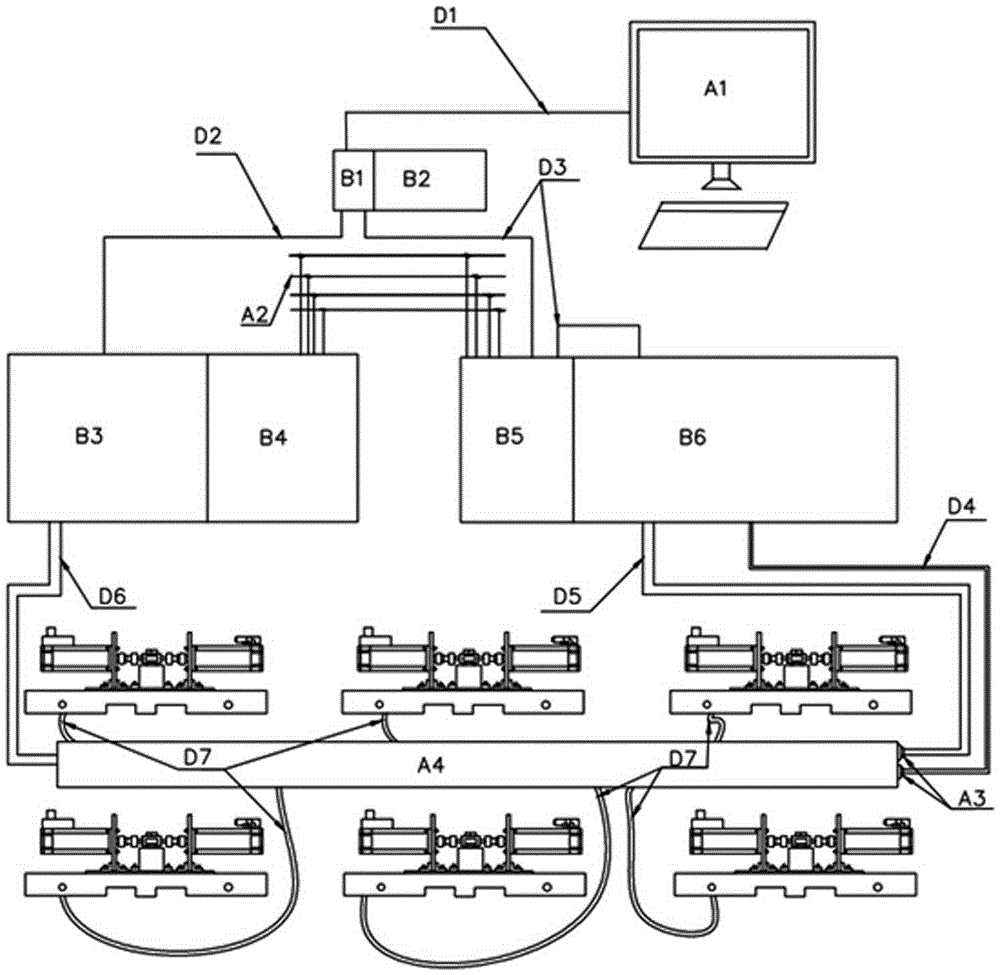

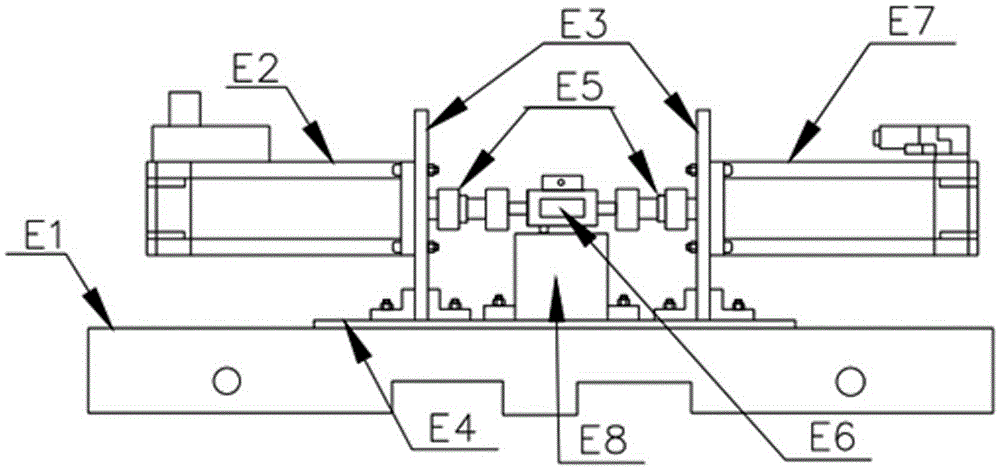

Motor performance detection device

PendingCN110261775ALow production costAdapt to production needsTesting dielectric strengthStructural/machines measurementMotor testingTorsion test

The invention discloses a motor performance detection device. The motor performance detection device comprises a cabinet and a rotating device, the cabinet comprises a cabinet body and a workbench; a feeding area, an impedance test area, a pressure-resistant test area, a main shaft positioning area, a torsion test area, a lifting force test area, a good product unloading area and a defective product unloading area are sequentially distributed on the workbench; the rotating device comprises a driving mechanism and a test disc; the test disc is driven to rotate by the driving mechanism; a plurality of jigs for placing a motor to be detected are arranged on the test disc; and each jig sequentially enters the impedance test area, the pressure-resistant test area, the main shaft positioning area, the torsion test area, the lifting force test area, the good product unloading area and the defective product unloading area from the feeding area along with the rotation of the test disc. The motor testing device can automatically perform impedance testing, pressure resistance testing, torsion performance testing, lifting force performance testing and unloading after the testing is finished in sequence, the time required for finishing various performance tests is short, the testing efficiency is high, and the working strength of testing personnel and the production cost of the motor are reduced.

Owner:XIAMEN DAZHEN MOTOR

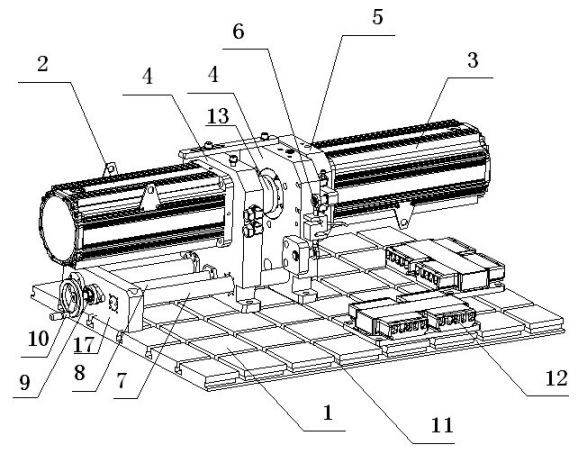

Dynamic testing system for permanent-magnetic synchronous linear motor

InactiveCN104198938AReduce the impactAdjust the air gapDynamo-electric machine testingMotor testingGrating

The invention discloses a dynamic testing system for a permanent-magnetic synchronous linear motor and belongs to the technical field of motor testing. The dynamic testing system is main composed of an operating platform, a control cabinet and a motor testing platform, and the motor testing platform further comprises a U-shaped marble base, a primary linear motor, linear guide rails, sliders, a tested primary linear motor, a testing-accompanied primary linear motor, working tables, an elastic connector, a push-pull force sensor, limiting switches, anticollision devices, a grating ruler, a reading head and a drag chain. Due to a marble tabletop, influence, of vibration of the testing platform, on testing result can be reduced effectively; the sliders in a linear guide rail component are in rolling friction, friction coefficient of rolling friction is 1 / 50 that of sliding friction only, and friction force is small. Performance parameters line push force, current, speed, temperature rise and the like of the permanent-magnetic synchronous linear motor are tested by adopting two linear motors by means of opposite dragging, the dynamic testing system is simple and convenient to operate, can be used for testing motor performance when air gaps are different and can complete performance testing of linear motors different in specification.

Owner:JILIN HENGLONG HLDG GRP

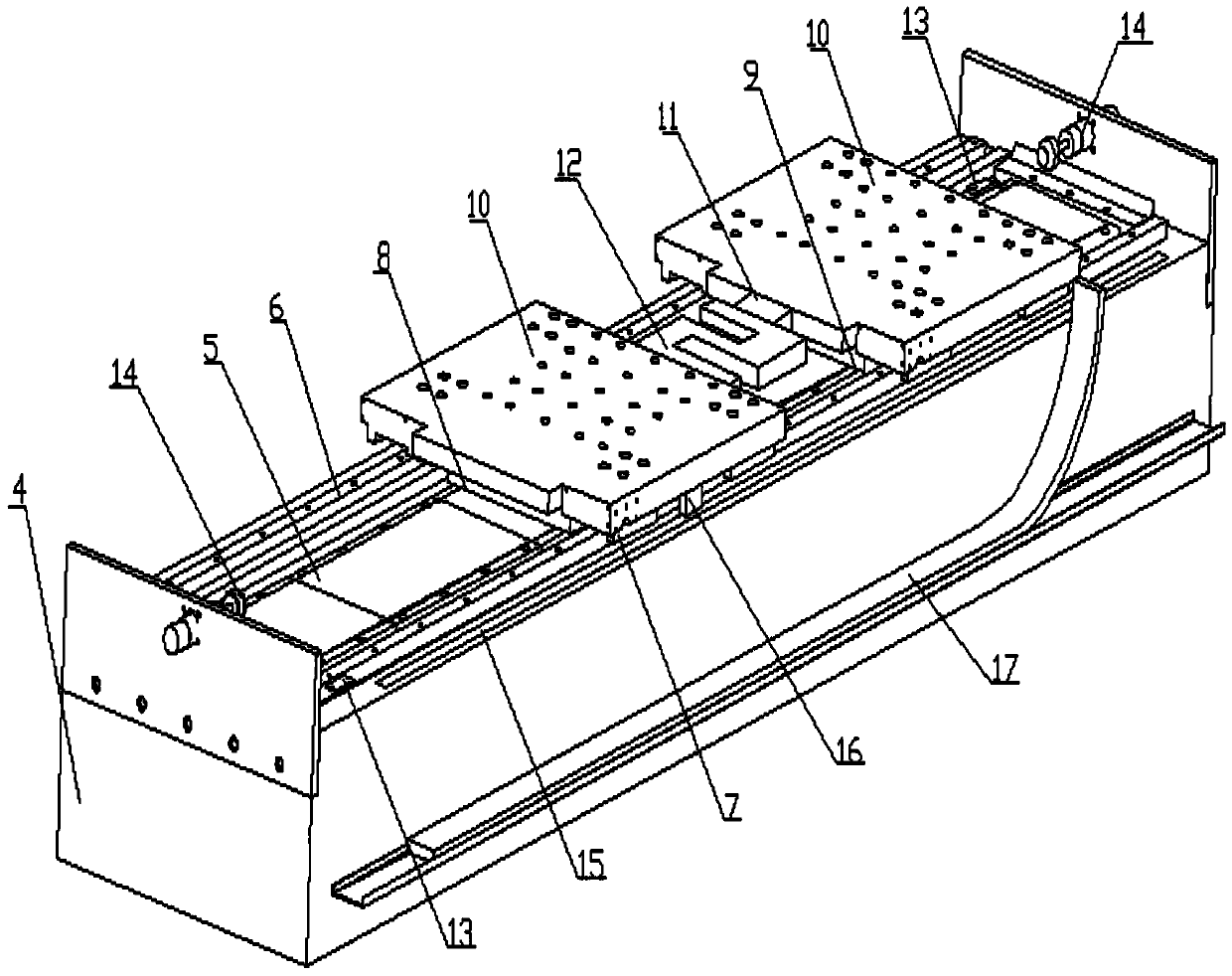

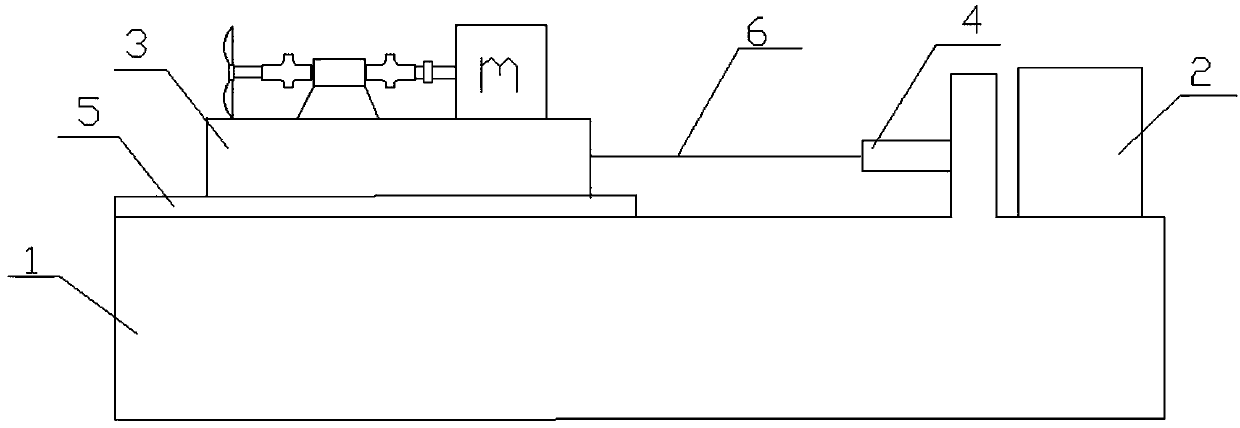

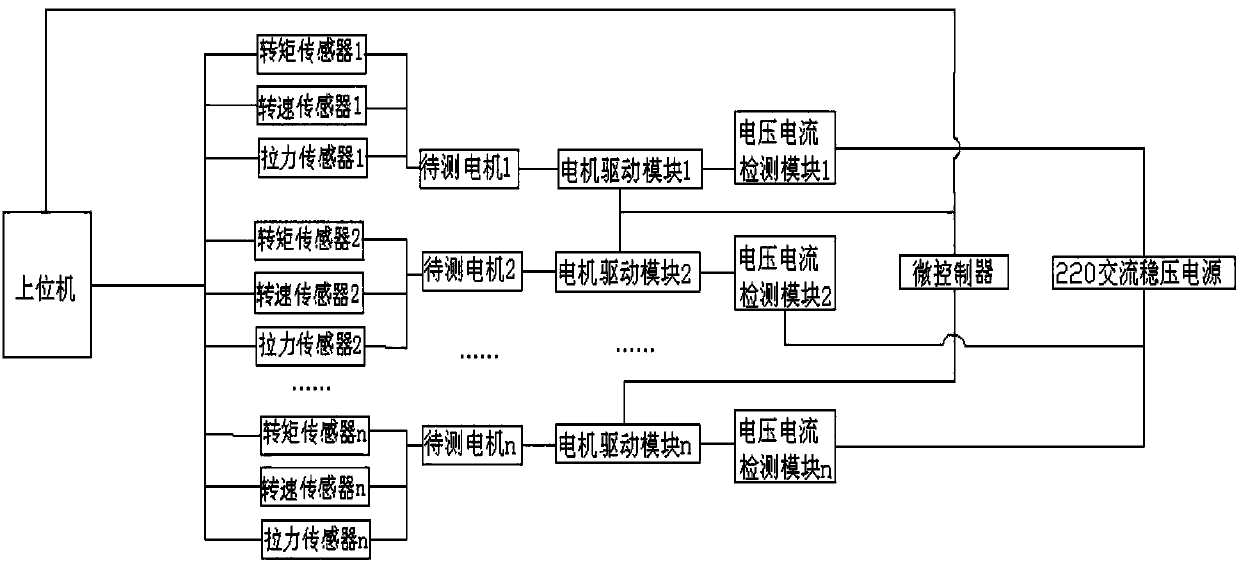

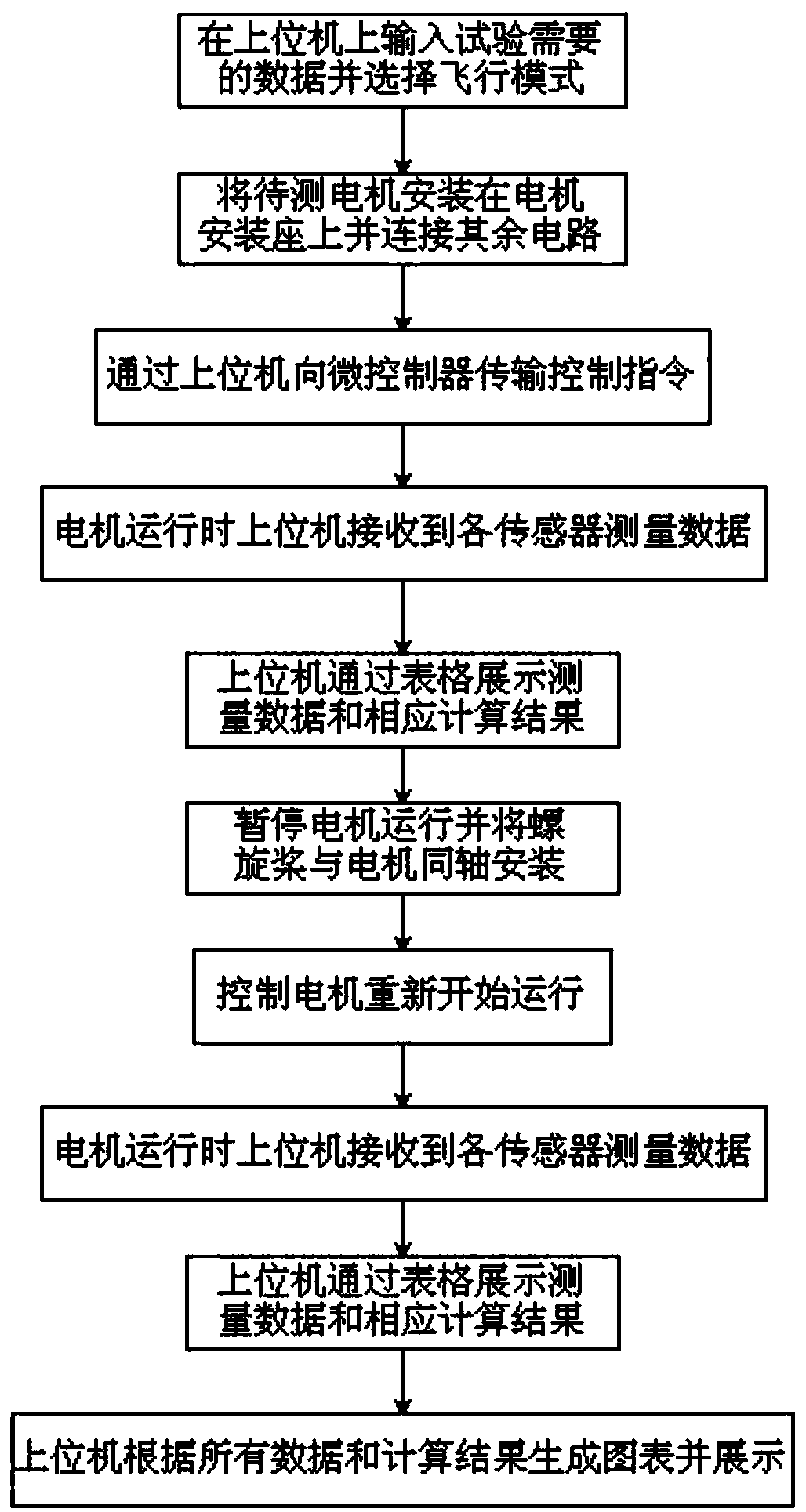

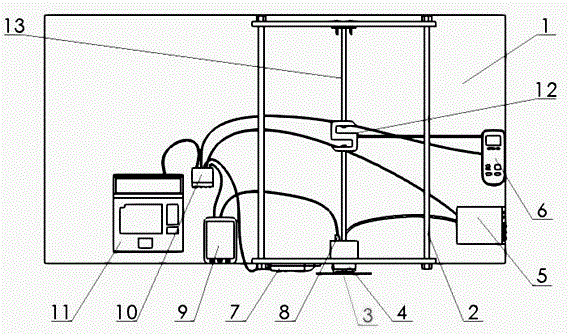

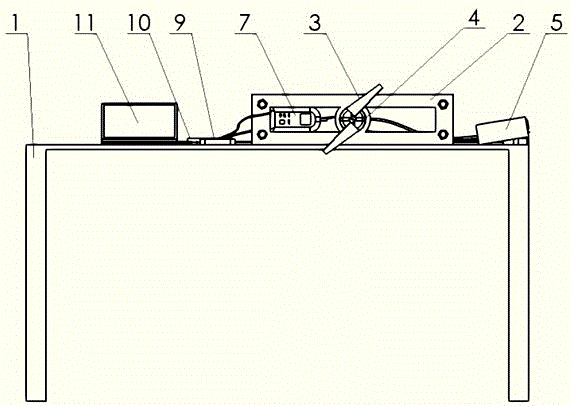

Integrated test stand for unmanned aerial vehicle induction motor and test method

InactiveCN107677959ATest output characteristicsEasy to operateDynamo-electric machine testingMotor testingMicrocontroller

The invention relates to the technical field of motor testing, and discloses an integrated test stand for an unmanned aerial vehicle induction motor and a test method. The integrated test stand for the unmanned aerial vehicle induction motor comprises an experiment platform, voltage and current detection modules, torque sensors, speed sensors, a microcontroller, motor driving modules, tension sensors and an upper computer, and is characterized in that the microcontroller is controlled to output PWM signals to each motor driving module; the sensors and the measurement modules detect physical variables and transmit detected values to the upper computer; and the upper computer calculates according to the data and displays a result in the form of a diagram. In order to reduce the interferenceimposed on the measurement process of the tension sensors, the integrated test stand adopts a sliding rail design to reduce the pulling friction. According to the invention, an external circuit and internal control signals of the unmanned aerial vehicle motor are simulated, the experiment can be conducted by being close to characteristics of the unmanned aerial vehicle motor, the application rangeof the experiment data is wide, the accuracy is high, and the upper computer autonomously completes the calculation process, thereby being more time-saving, and being more reliable in experiment result.

Owner:HANGZHOU WEIHENG TECH

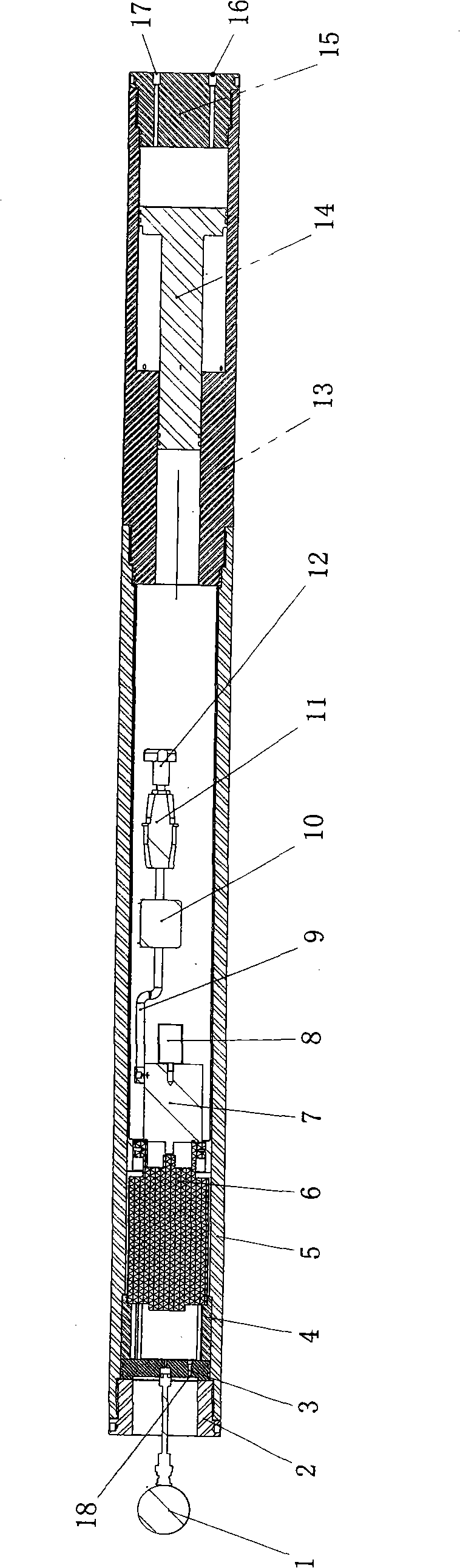

High temperature high voltage electric machine testing device

ActiveCN101281235AReal-time detection of working environment conditionsCalculate output powerDynamo-electric machine testingMotor testingElectric machine

The invention discloses a high temperature high-voltage motor testing device, which includes a cylindrical seal cavity shell, a pressure cylinder and a pressure piston thereof are provided in the cylindrical seal cavity shell, the pressure cylinder, the pressure piston and a bearing joint at the end of the seal cavity shell forms a high pressure seal cavity in the seal cavity shell, the inner of the high pressure seal cavity is filled with hydraulic oil, and a motor fixing sleeve for fixing the motor is mounted in the high pressure seal cavity. The apparatus can test operation situation and operating performance of the motor under and high voltage surroundings.

Owner:CHINA NAT OFFSHORE OIL CORP +1

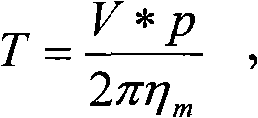

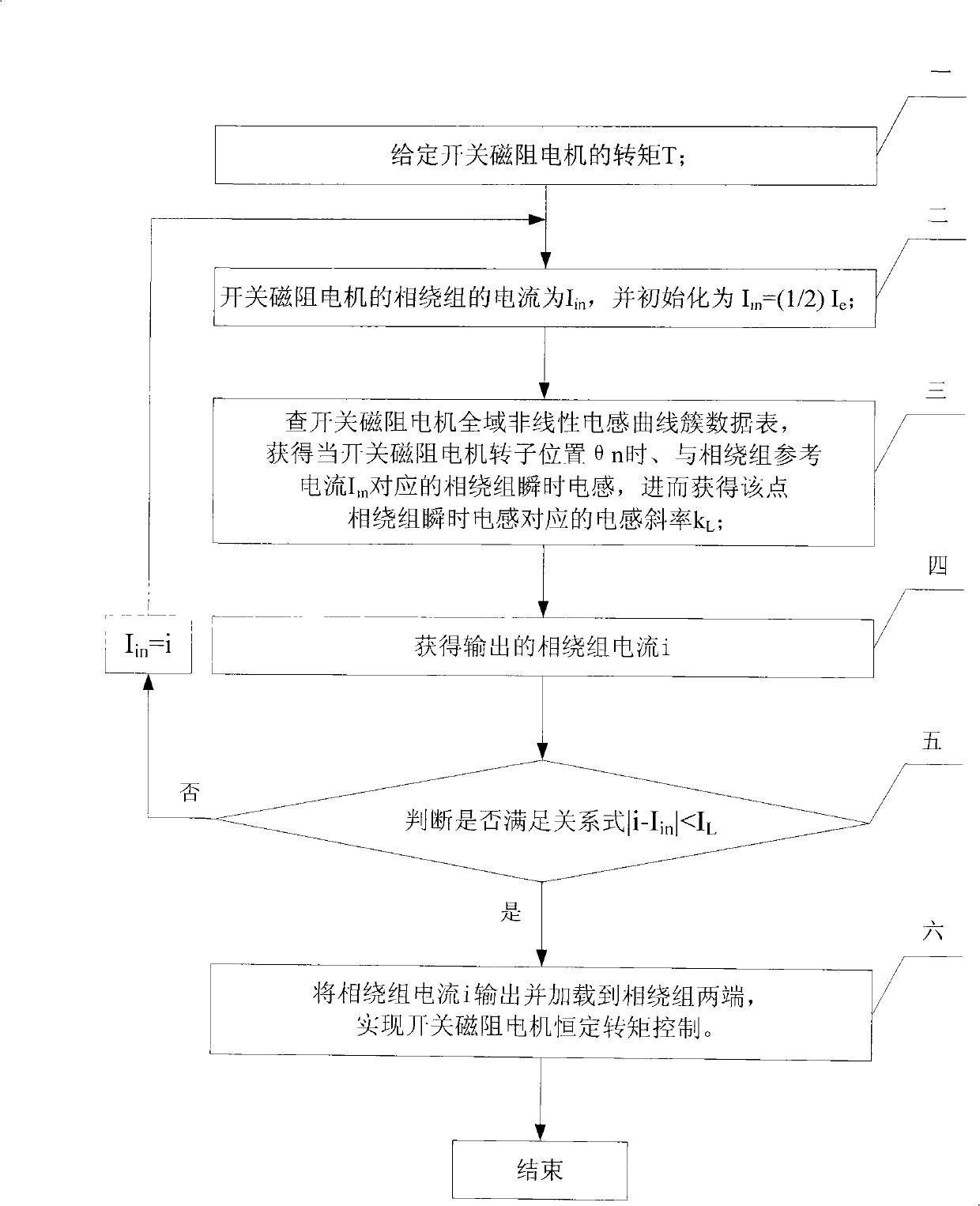

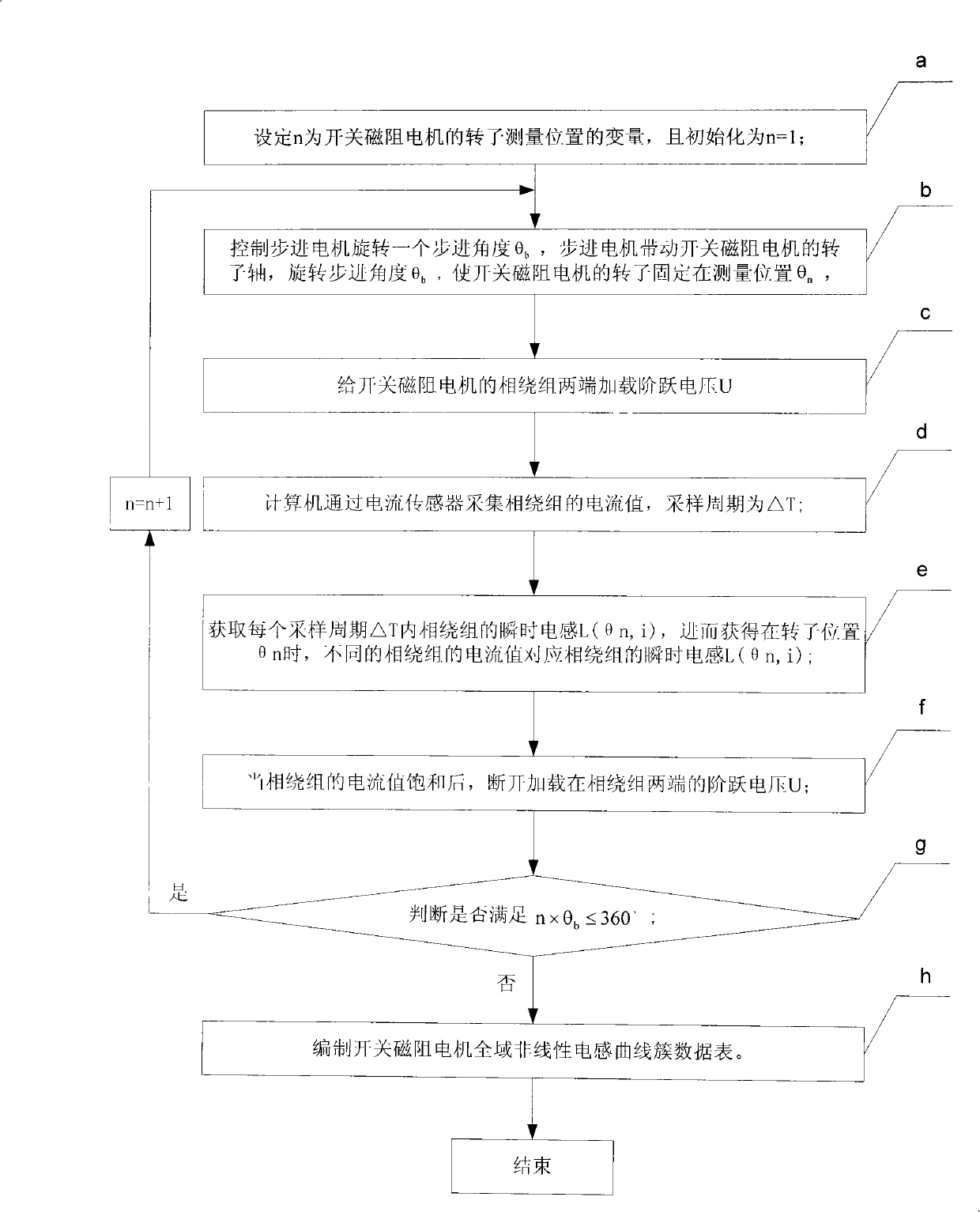

Control method of constant torque of switched reluctance motor

InactiveCN101526823AGood constant torque effectReduce torque rippleMechanical power/torque controlProgramme control in sequence/logic controllersMotor testingControl manner

A control method for constant torque of a switched reluctance motor is disclosed, belonging to the field of motor test. The inventive aims at solving the problem that torque pulsation is large when a conventional speed and current double closed-loop control manner is used to control the torque of the switched reluctance motor. The inventive method comprises the steps that: in order to ensure that the switched reluctance motor outputs constantly in accordance with the set torque, a reference current is given at first, a transient inductance corresponding to the reference current is then obtained by inquiring an universe nonlinear inductance curve family data sheet of the switched reluctance motor, an inductance slope corresponding to the transient inductance is further obtained, an output phase winding current is calculated in accordance with the formula i=square root (2T / K<L>), and whether the difference value between the phase winding current and the reference current is in a permissible error range is judged, if not, the phase winding current, which is calculated, is assigned to the reference current and is recalculated in accordance with the method, multiple circulations are implemented until the condition is satisfied, and the output phase winding current is loaded at two ends of the phase winding of the switched reluctance motor to realize control of the constant torque of the switched reluctance motor.

Owner:HARBIN INST OF TECH

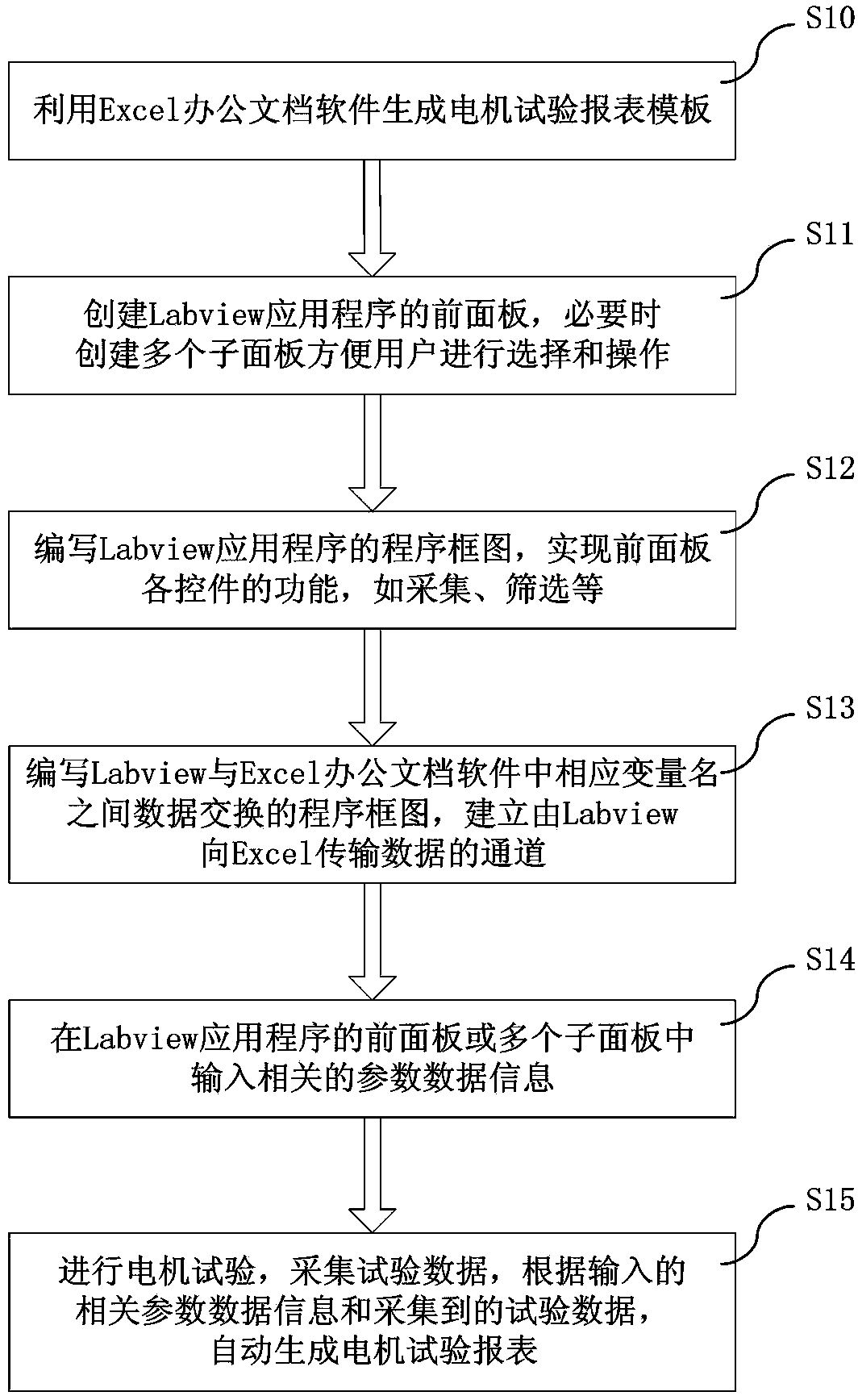

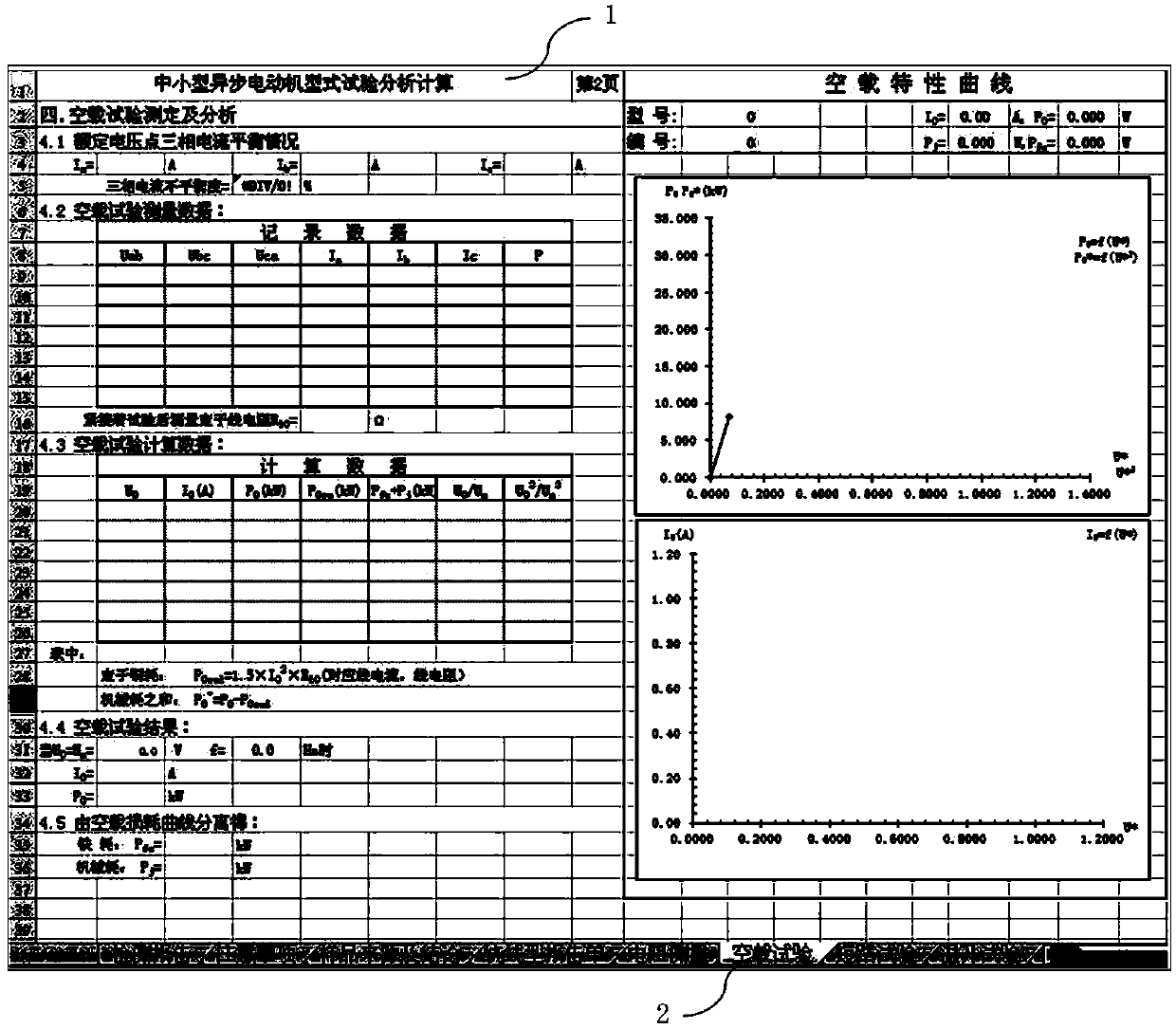

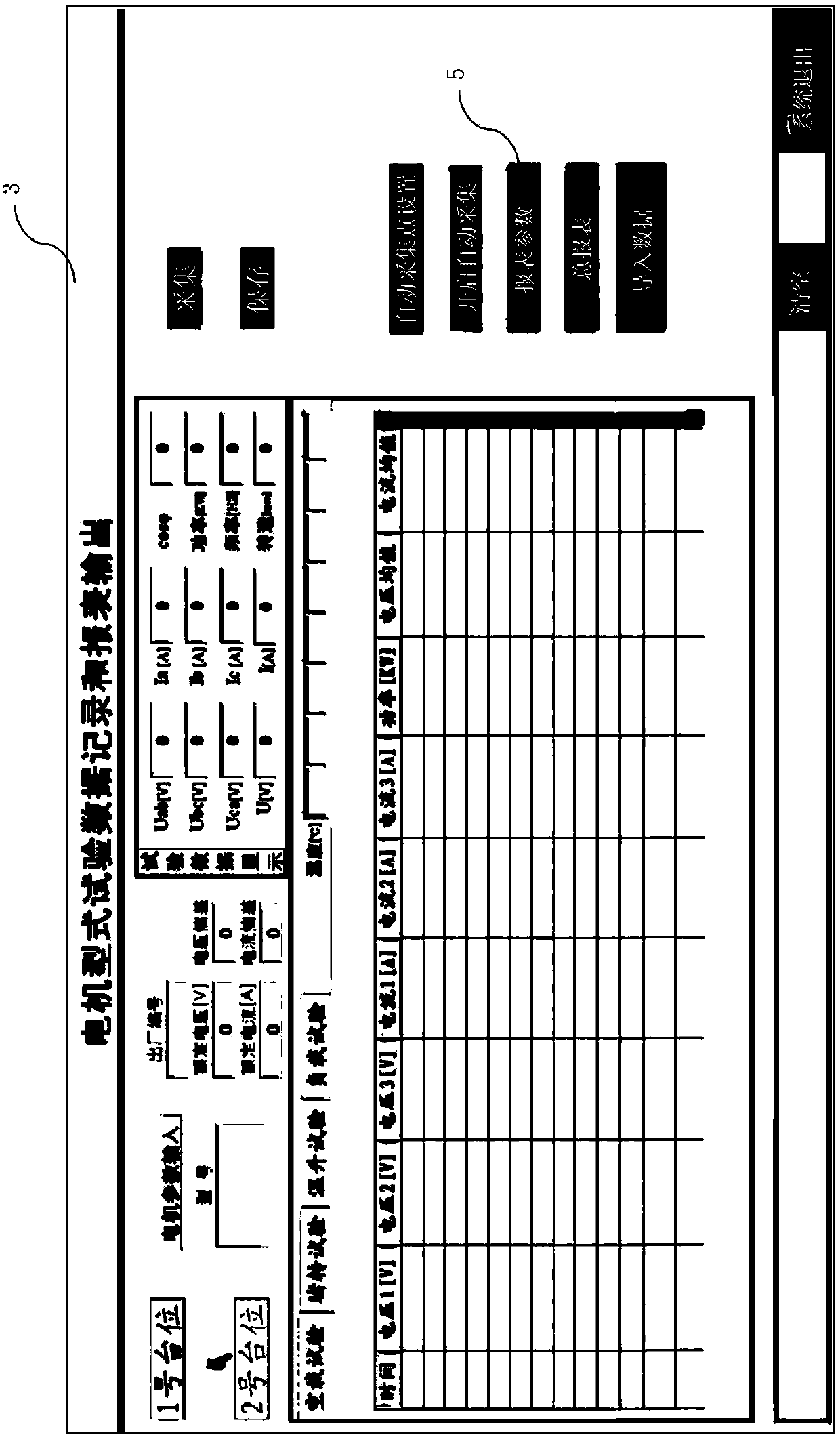

Motor testing port automatic generating method

InactiveCN103440135AEasy programmingSupport automation technologySpecific program execution arrangementsMotor testingData information

The invention discloses a motor testing port automatic generating method comprising the following steps of generating a motor testing report template through Excel office document software; establishing a front panel of a Labview application program, or establishing a plurality of sub-panels as required; compiling a Labview application program chart, to realize functions of various controls of the front panel; compiling a program chart for data exchange between corresponding variable names in Labview and Excel, and establishing a channel for data transmission from Labview to Excel; inputting related parameter data information in the Labview front panel or multiple sub-panels; and clicking a corresponding input control button of the Labview front panel to acquire motor testing data, and automatically generating a motor testing report according to the input and acquired data. The method can greatly shorten a cycle of generating the motor testing report, and improve efficiency and accuracy of generating the motor testing report.

Owner:ZHUZHOU NAT ENG RES CENT OF CONVERTERS

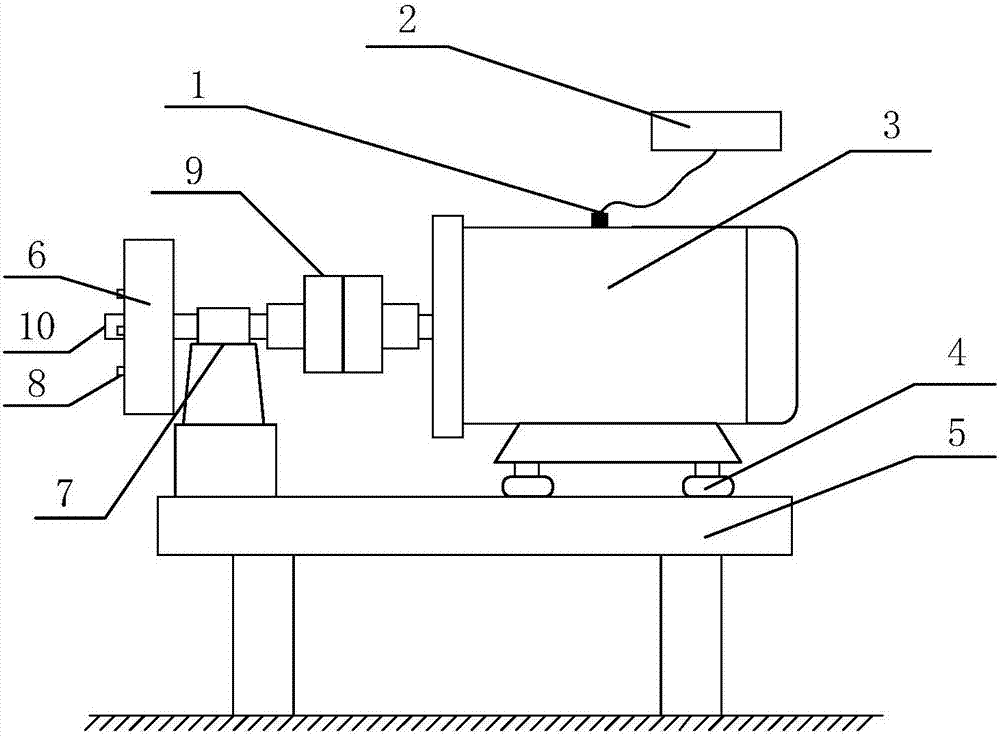

Load testing system for high-speed motor

InactiveCN104569810AHigh speed running stabilityGuaranteed uptimeDynamo-electric machine testingMotor testingElectric machine

The invention belongs to a motor testing system, and particularly discloses a load testing system for a high-speed motor. The load testing system comprises a dynamometer, a platform, a testing frame, a motor to be tested, a bearing seat, connecting shafts and high-speed bearings, wherein the platform is arranged on the testing frame; the dynamometer and the bearing seat are arranged on the platform; the high-speed bearings are arranged in the bearing seat; the dynamometer is connected with the motor to be tested through the connecting shafts; the middle parts of the connecting shafts are positioned in the high-speed bearings; the motor to be tested is fixed on the side wall of the bearing seat. The load testing system disclosed by the invention has the motor testing capacities under the conditions of rated power of 12 kW, rated torque of 20 Nm and maximum revolving speed of 30000 rpm, so that researching and testing capacities are greatly improved, the loading test requirement of the high-speed motor of which the rotational speed is as high as 12000 rpm is met, and the reliability of high-speed running of the testing system can be ensured.

Owner:BEIJING RES INST OF PRECISE MECHATRONICS CONTROLS +1

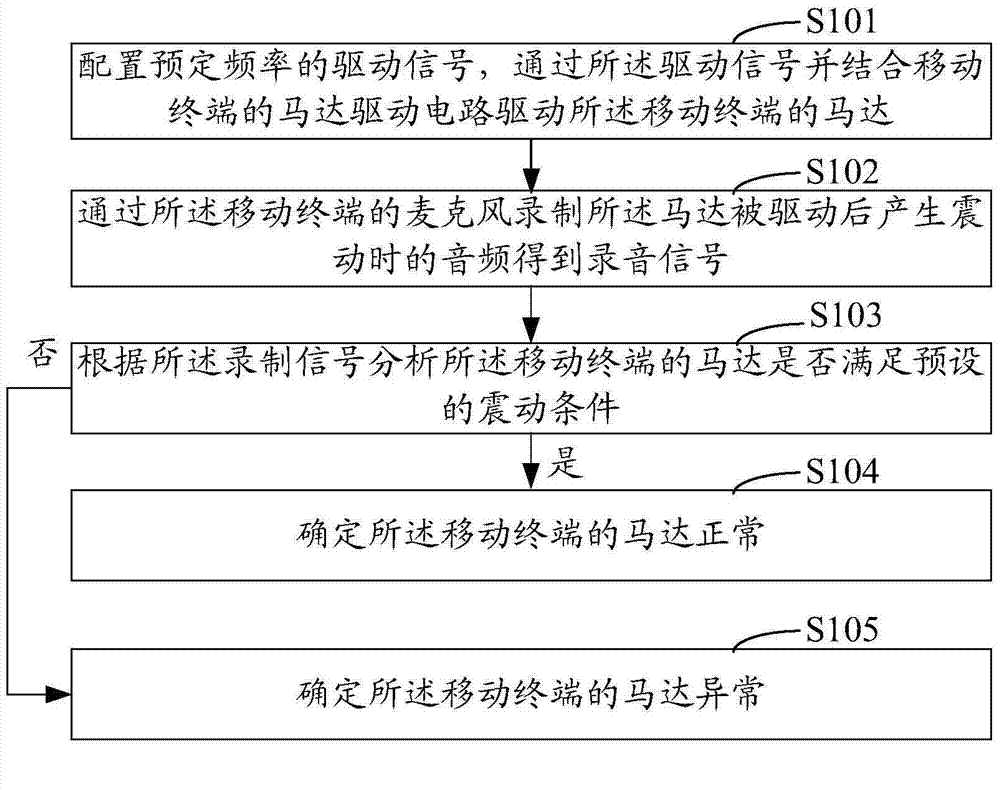

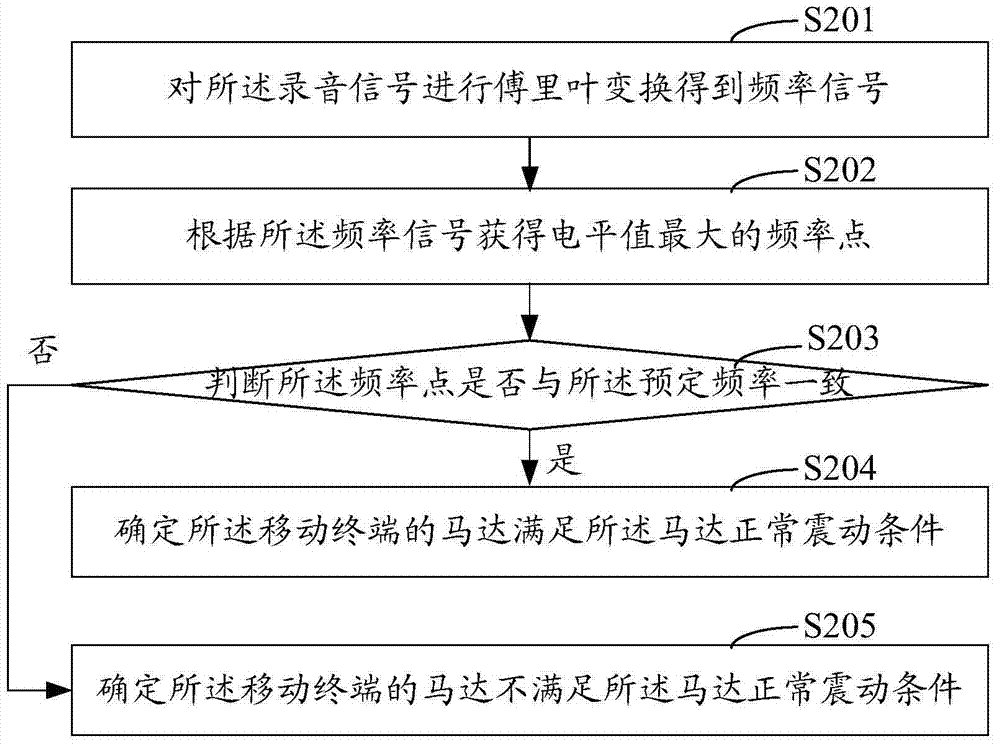

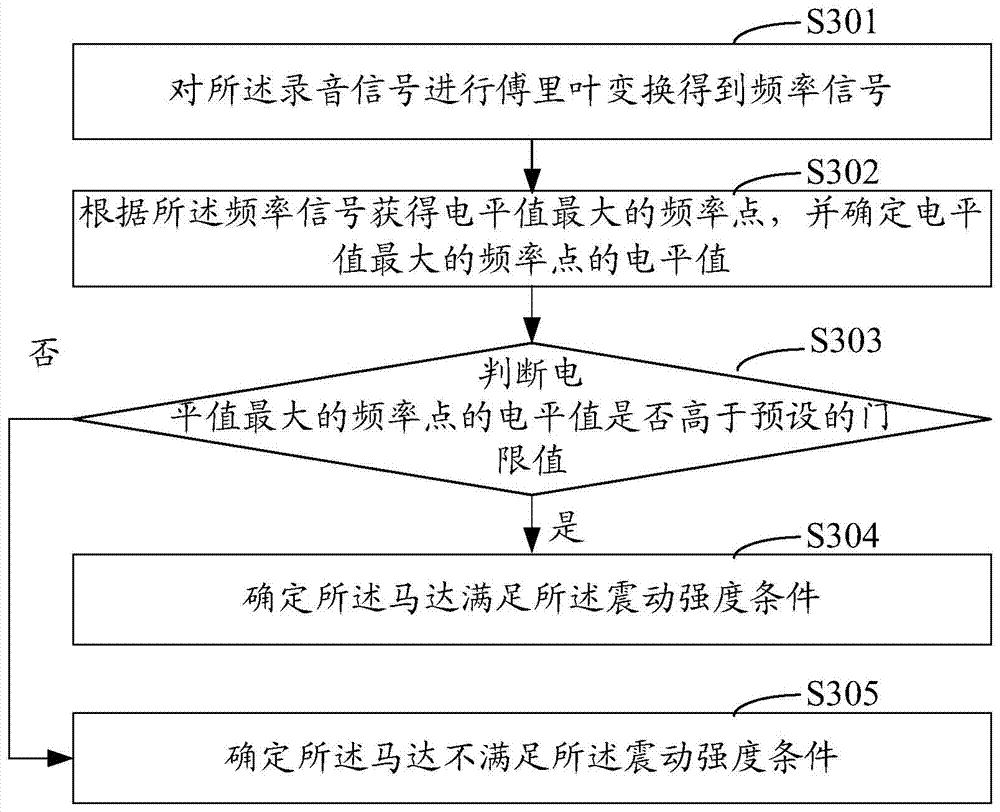

Mobile terminal motor testing method and system

ActiveCN104754094AImplement automated testingNo human intervention requiredSubstation equipmentMotor testingMotor drive

The invention provides a mobile terminal motor testing method and system. The method comprises the following steps: configuring a driving signal with a pre-set frequency; driving a motor of a mobile terminal through a driving signal by combining the driving of a motor driving circuit of the mobile terminal; recording a voice frequency caused by the fact the motor is driven to generate vibration through the mobile terminal to obtain a recording signal; analyzing whether the motor of the mobile terminal meets a pre-set vibration condition or not according to the recording signal; if so, determining that the motor of the mobile terminal is normal; and if not, determining that the motor of the mobile terminal is abnormal. By the aid of the mobile terminal motor testing method, an automatic test of the motor of the mobile terminal can be realized and the vibration strength can be quantified; manual intervention is not needed and the testing cost can be reduced.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Servo motor testing system for industrial robot

The invention discloses a servo motor testing system for an industrial robot, and relates to the technical field of robot control systems. X20PLC is connected with an inversion module through RS485 communication and is also connected with an AcoposMulti power module and an AcoposMulti inversion module respectively through POWELINK communication; the inversion module is connected with a mechanical test platform by virtue of a dynamometer machine power cable, a cable wire slot and a cable bus; the AcoposMulti inversion module is connected with the mechanical test platform by virtue of a servo motor power cable, a robot heavy-load plug, the cable wire slot and the cable bus in sequence; and the mechanical test platform is connected with the AcoposMulti inversion module by virtue of the cable bus, the cable wire slot, the robot heavy-load plug and a servo motor signal cable in sequence. The servo motor testing system disclosed by the invention is good in testing effect, can effectively reflect the motion state of a servo motor on a robot body, and is low in cost and wide in adaptability.

Owner:SHANGHAI FINEPOWER TECH

Small electric unmanned aerial vehicle motor testing device

InactiveCN103605076AThe test result is accurateThe test results are simple and clearInternal-combustion engine testingDynamo-electric machine testingMotor testingDisplay device

The invention relates to a small electric unmanned aerial vehicle motor testing device and belongs to testing equipment. A power supply voltage controller, a tension tester, a frame, a temperature displayer, an integrated processing box and a computer are assembled on a rack, a motor which is to be tested and provided with blades, a non-contact velometer and an infrared temperature measurement sensor are assembled on the frame, a tension test rod coaxially connected with the motor to be tested is arranged on the frame, an optical reflector plate matched with the non-contact velometer is attached to the outer side of the motor to be tested, a tension and pressure sensor is assembled on the tension test rod, the integrated processing box is respectively connected with the computer, the tension tester, the power supply voltage controller and the temperature displayer through wires, the temperature displayer is connected with the infrared temperature measurement sensor, the motor to be tested is connected with the power supply voltage controller, and the tension and pressure sensor is connected with the tension tester. The small electric unmanned aerial vehicle motor testing device is reliable in performance, high in automation degree and accurate in detection result and provides technological support for scientific selection of small unmanned aerial vehicle motors.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

New energy motor load test system

ActiveCN113777489ALarge adjustment rangeWide range of loading thresholdsDynamo-electric machine testingMotor testingNew energy

The invention discloses a new energy motor load test system in the technical field of motor testing. The new energy motor load test system comprises a test platform, an adjusting base, a test frame and a load adjusting assembly; a test motor is mounted on the adjusting base, and the adjusting base can be adjusted in a front-back sliding manner to adaptively mount different types of motors; and the load adjusting assembly is arranged between the transmission rods, real-time pressure regulation and control are performed on the extrusion part through the pressure regulation and control part, load pressure buffer application is performed on one end of each transmission rod by the extrusion part, and loading force loading is performed on the test motor by the load adjusting assembly through friction force. The new energy motor load test system is suitable for carrying out load test on the new energy motor; Through the test system, data such as temperature rise, noise and rotating speed of the new energy motor under different loads can be obtained, the load adjusting assembly adjusts and controls friction force through oppositely arranged friction plates, linear adjustment of load force is implemented, and load modification can be carried out without shutdown.

Owner:SUZHOU YINGTEMO AUTOMOBILE TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com