Motor performance detection device

A testing equipment and performance technology, applied in the field of motor performance testing equipment, can solve the problems of long waiting time, low testing efficiency, long testing time, etc., and achieve the effect of reducing work intensity, short time, and high testing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

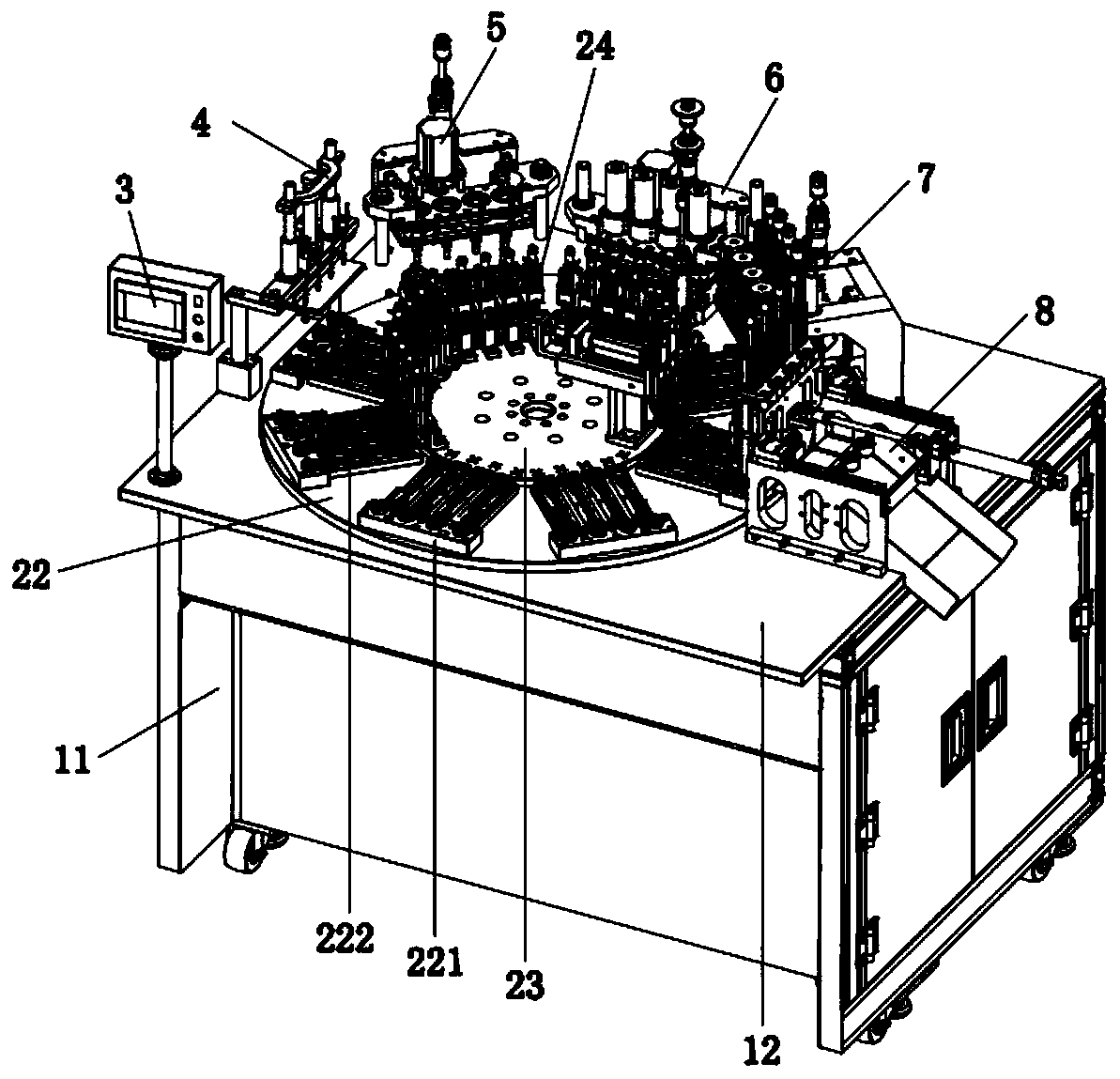

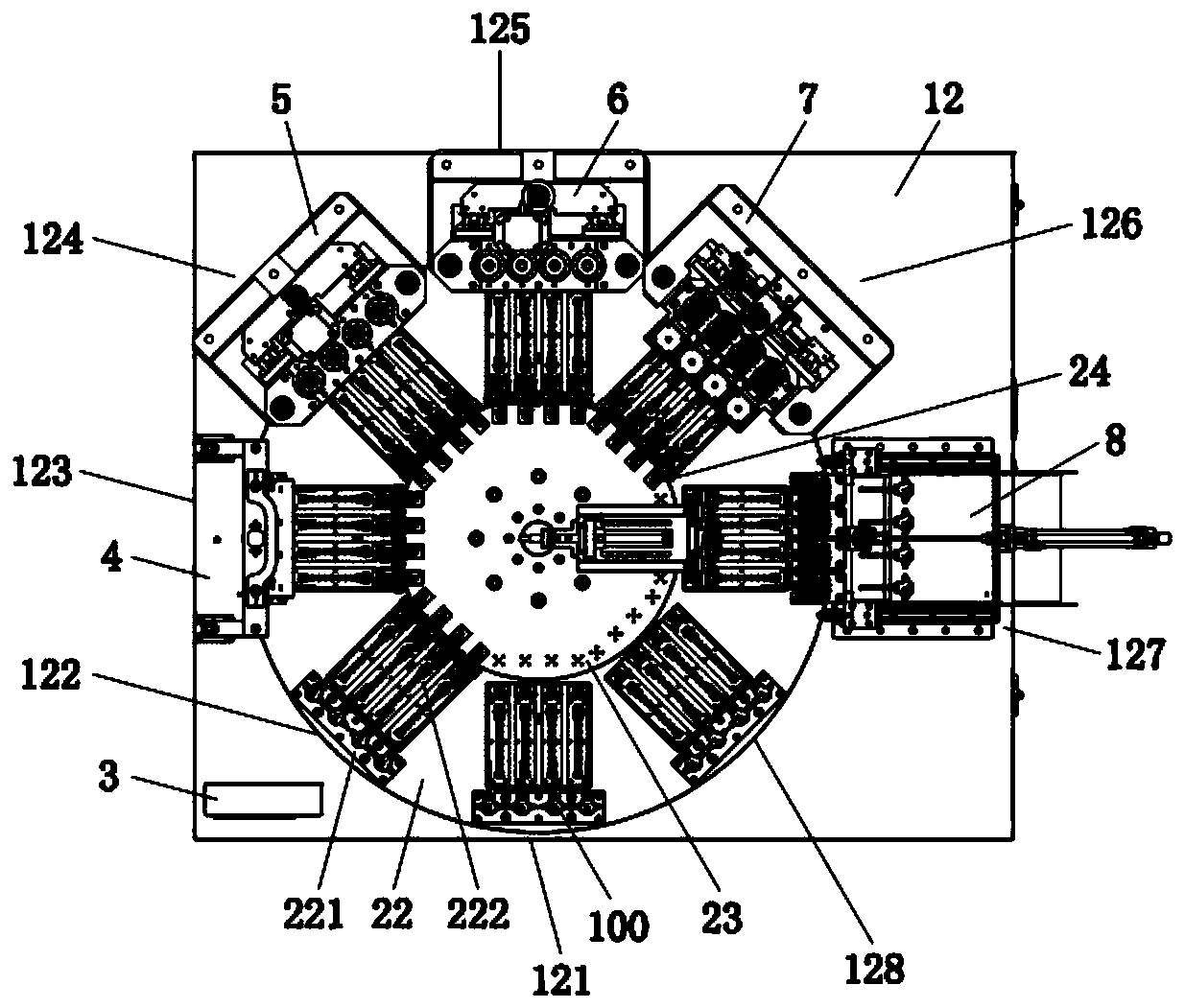

[0072] Cooperate figure 1 and figure 2 As shown, the invention discloses a motor performance testing device, which includes a cabinet and a turning device. The cabinet includes a cabinet body 11 and a workbench 12 arranged on the cabinet body 11. The workbench 12 is sequentially distributed with a feeding area 121, an impedance test area 122, a withstand voltage test area 123, a spindle positioning area 124, a torque test area 125, Lifting force test area 126, good product discharge area 127 and defective product discharge area 128, impedance test area 122, withstand voltage test area 123, spindle positioning area 124, torque test area 125, lifting force test area 126 and good product discharge area 127 is provided with an impedance test device 3 , a withstand voltage test device 4 , a spindle positioning device 5 , a torque test device 6 , a lifting force test device 7 and an unloading device 8 .

[0073] The impedance testing device 3 detects whether the motor to be teste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com