Patents

Literature

368 results about "Torsion test" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A torsion test measures the strength of any material against maximum twisting forces. It is an extremely common test used in material mechanics to measure how much of a twist a certain material can withstand before cracking or breaking.

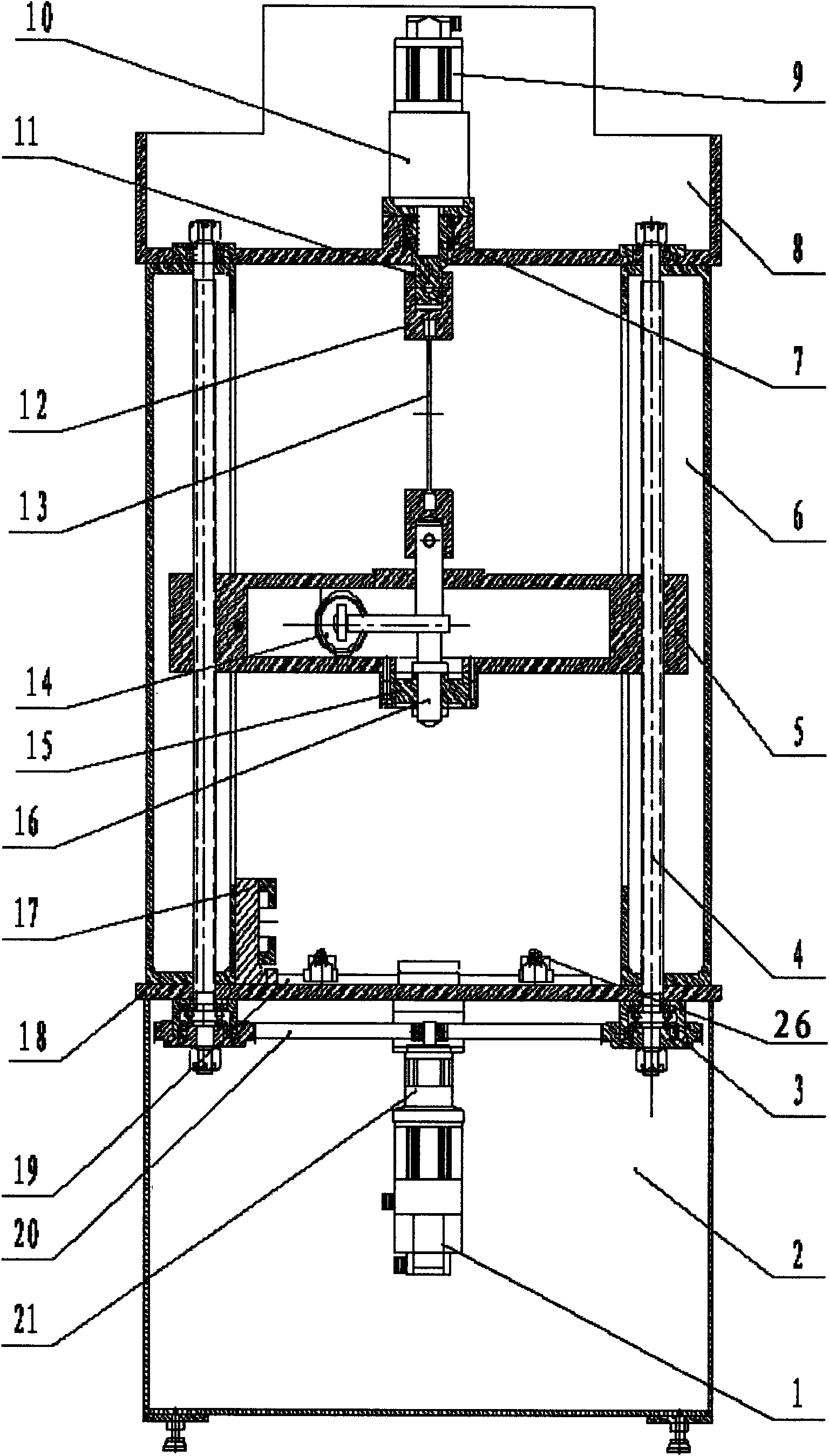

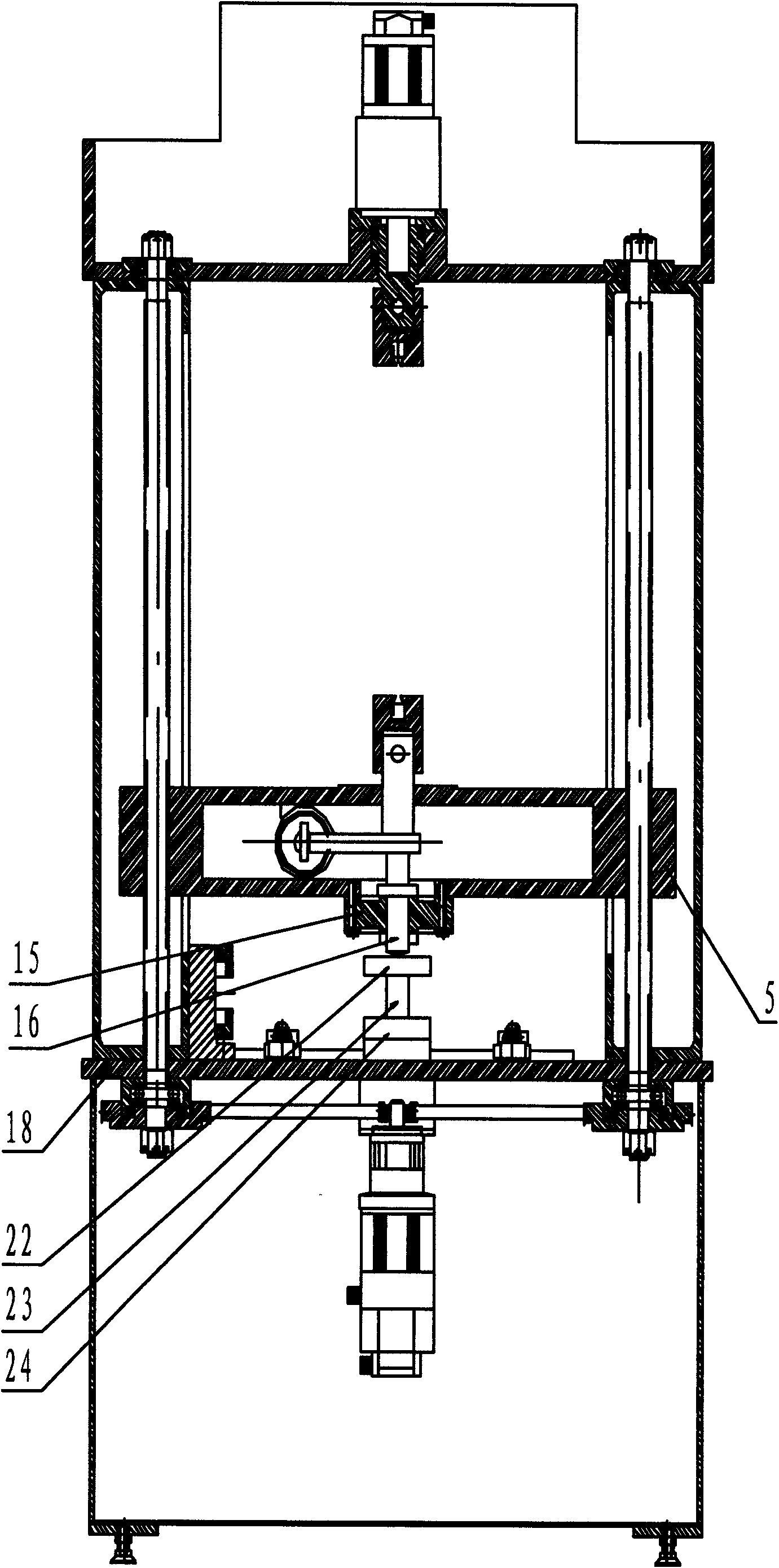

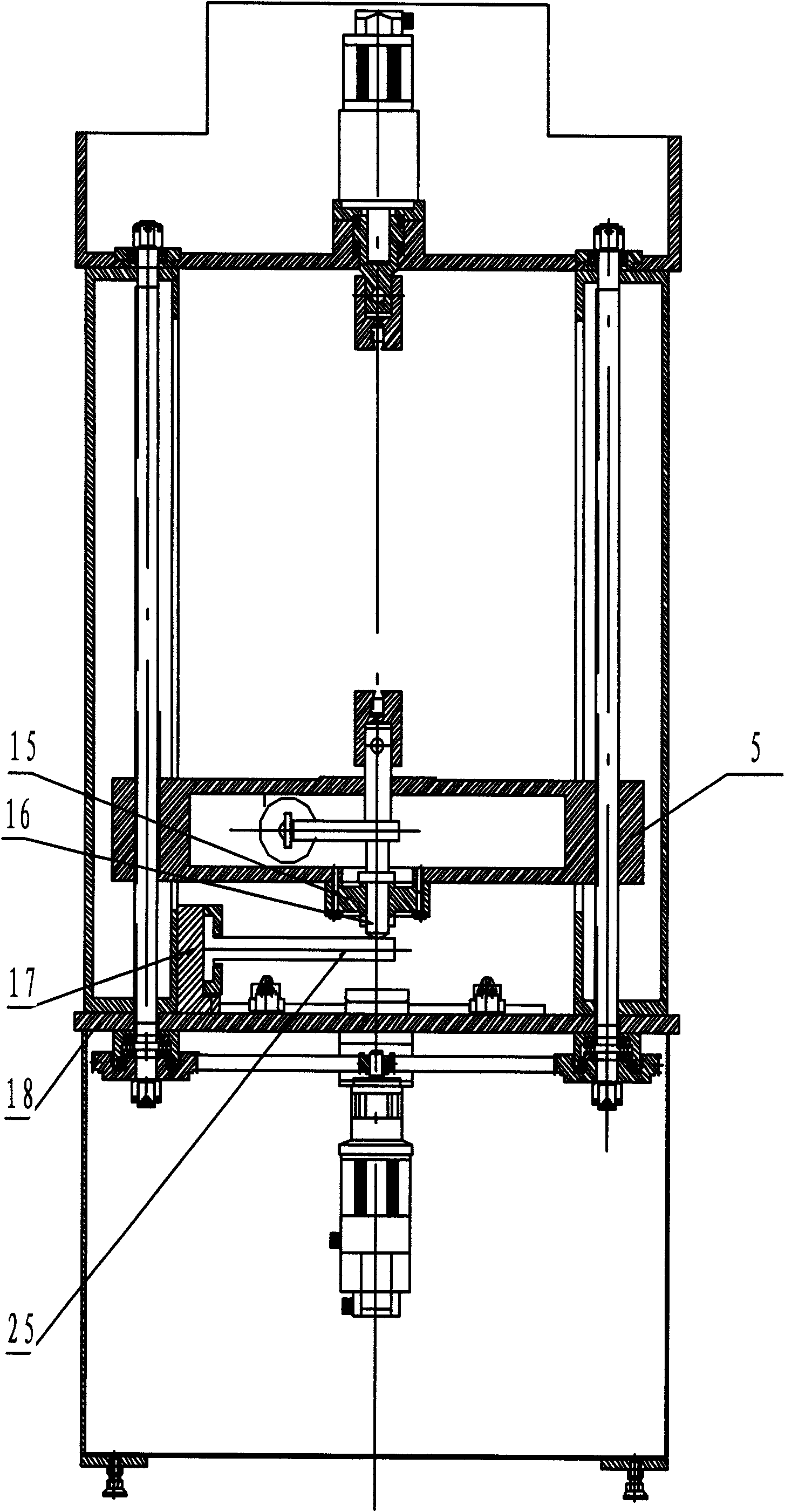

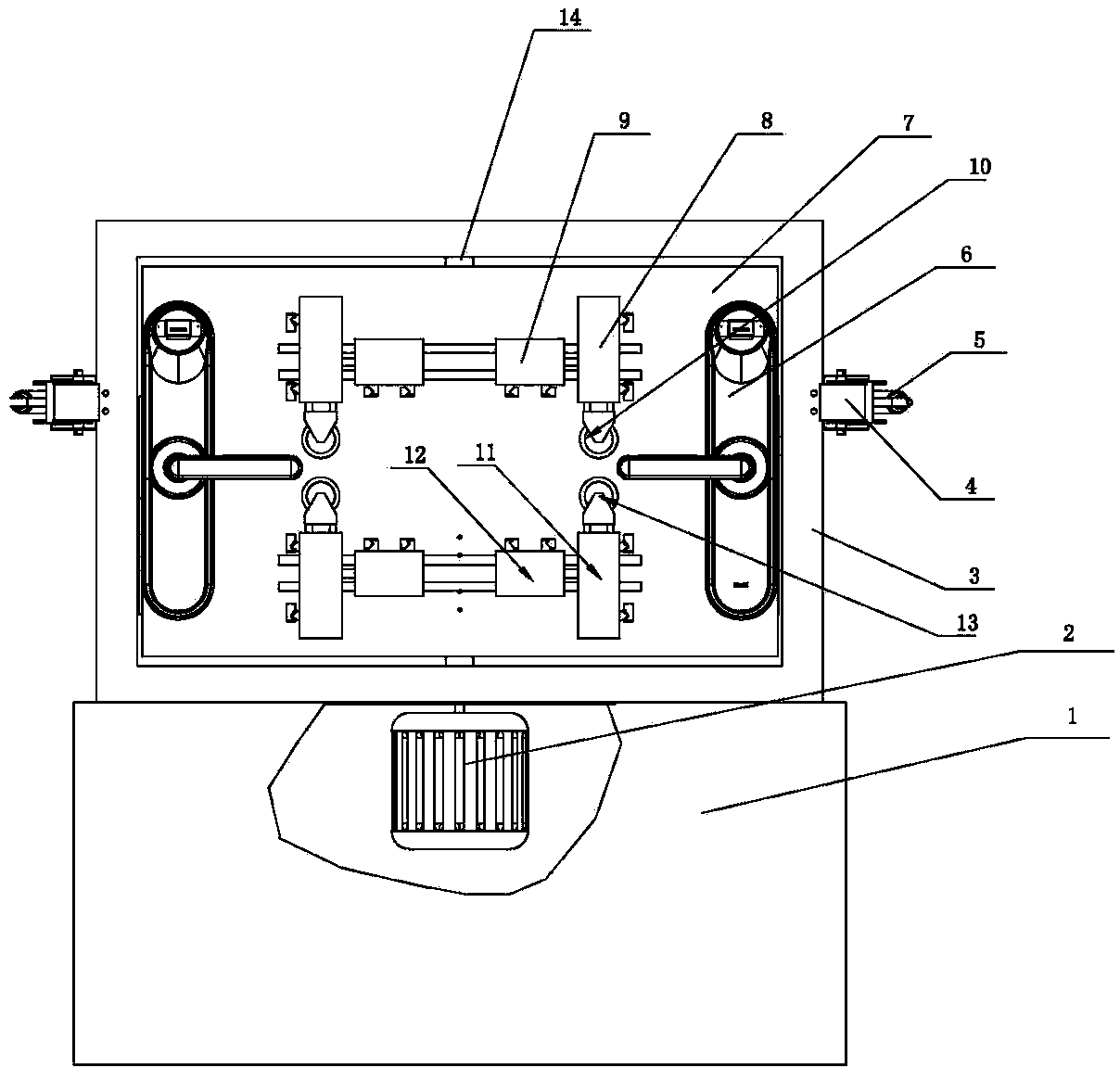

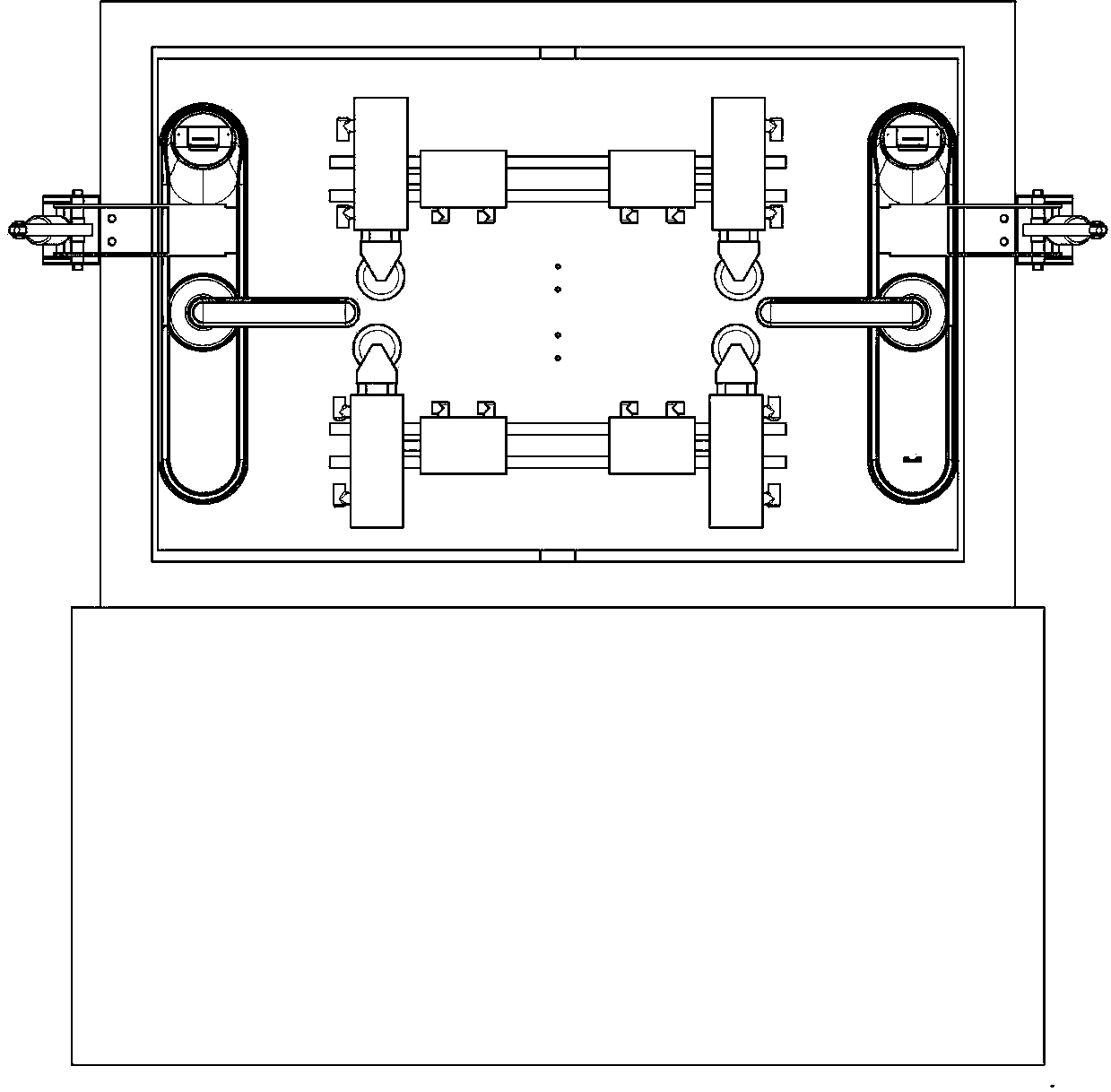

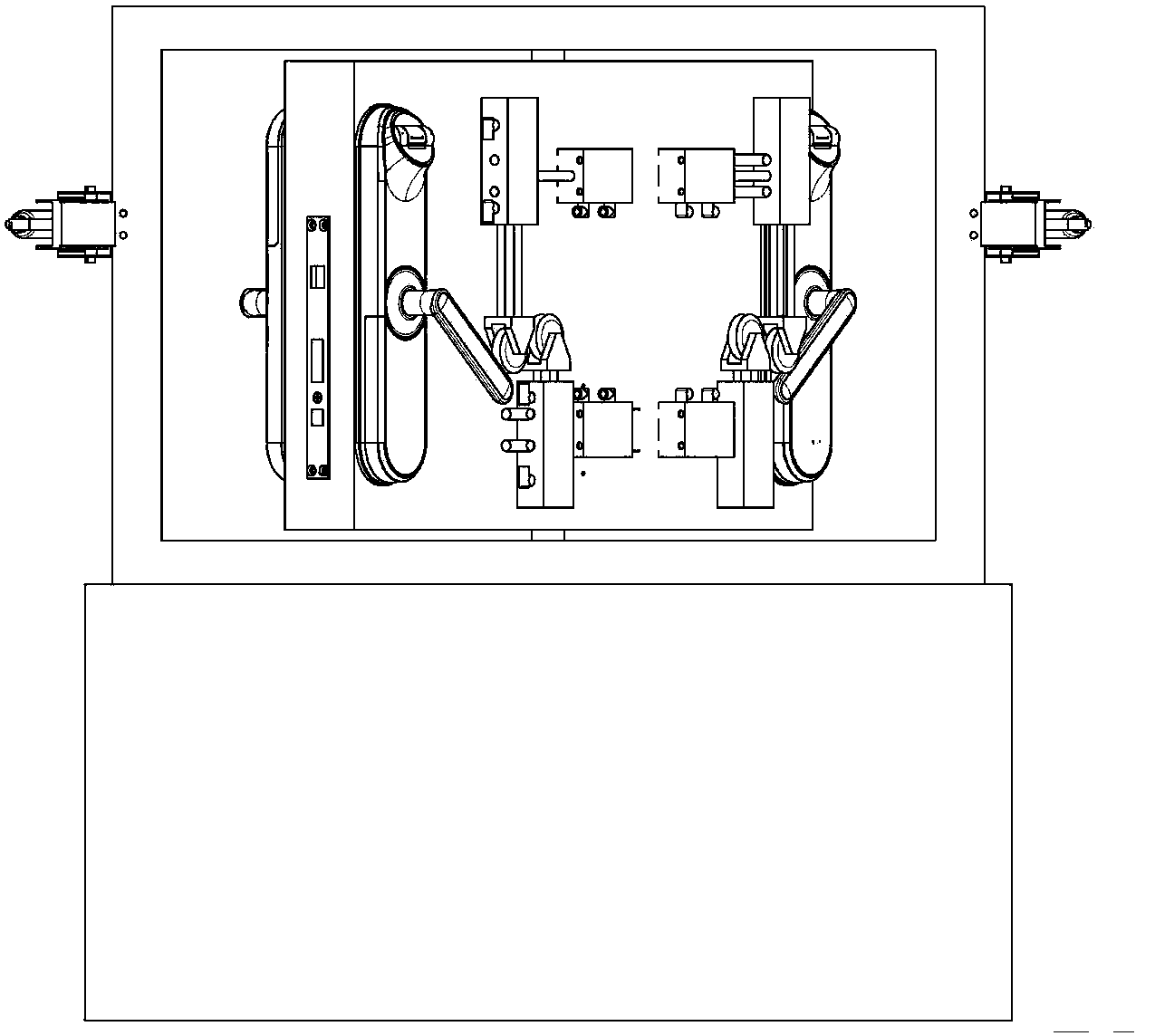

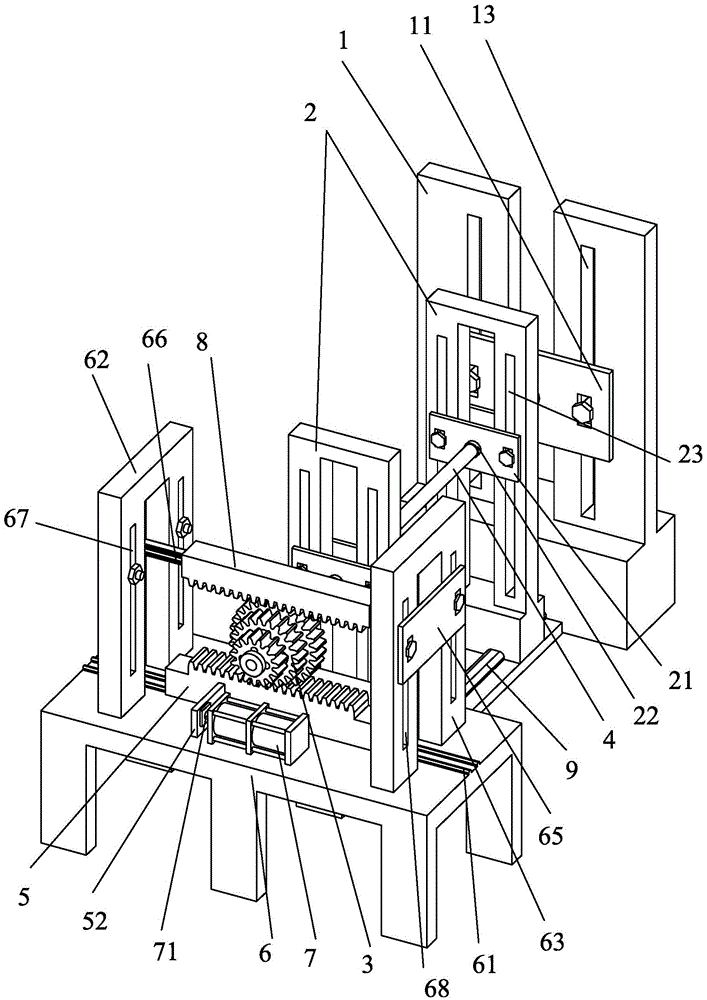

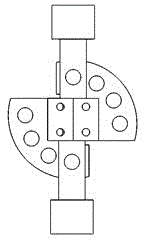

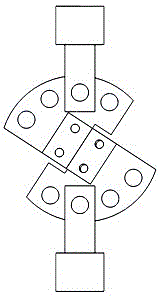

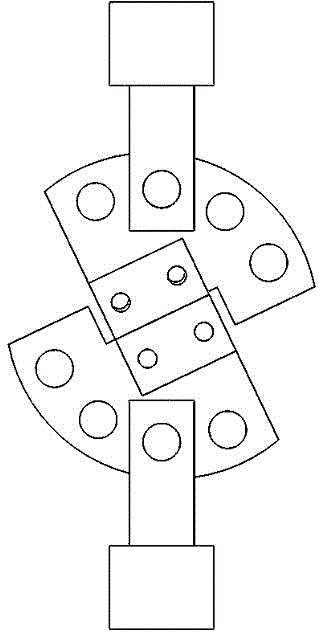

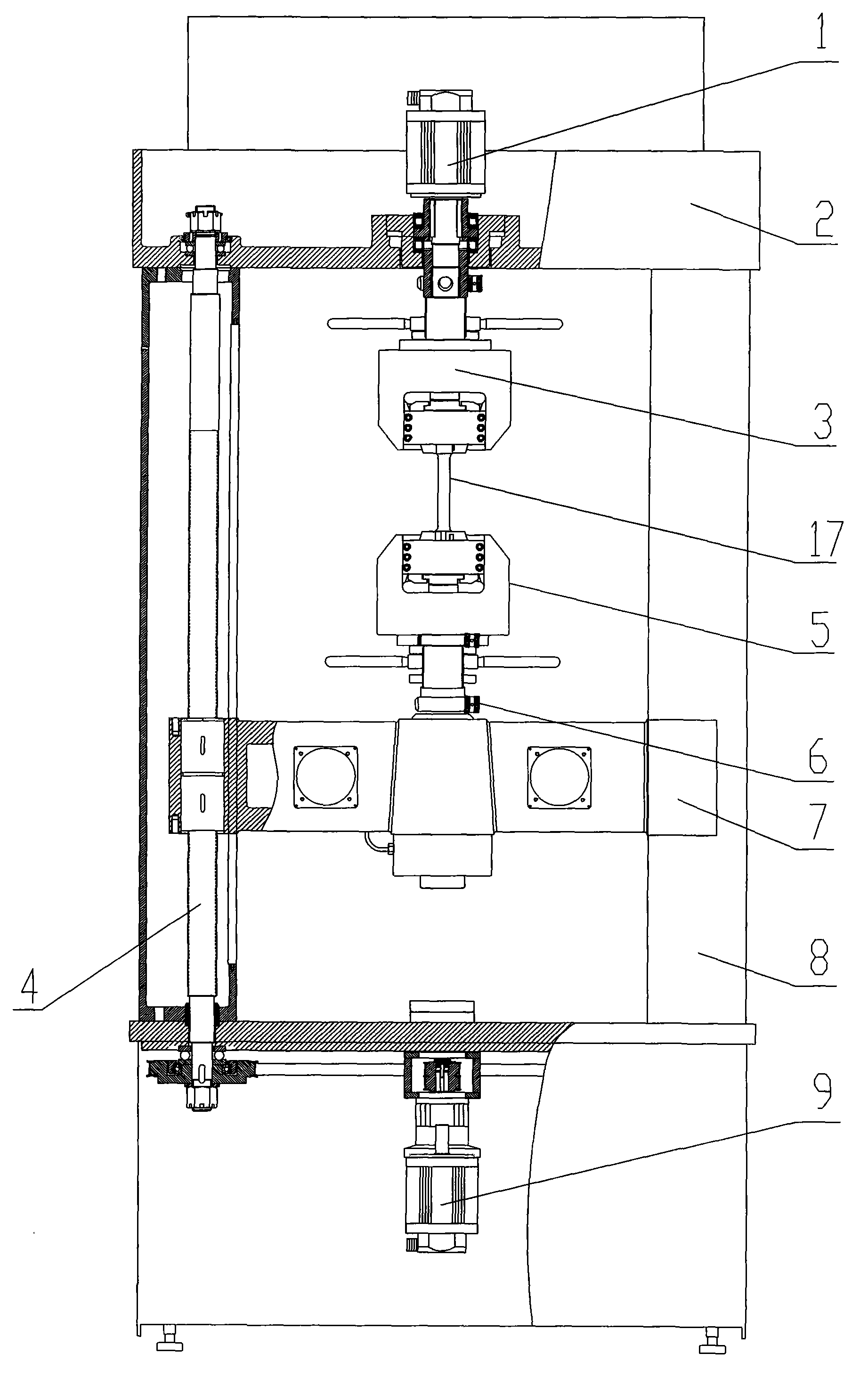

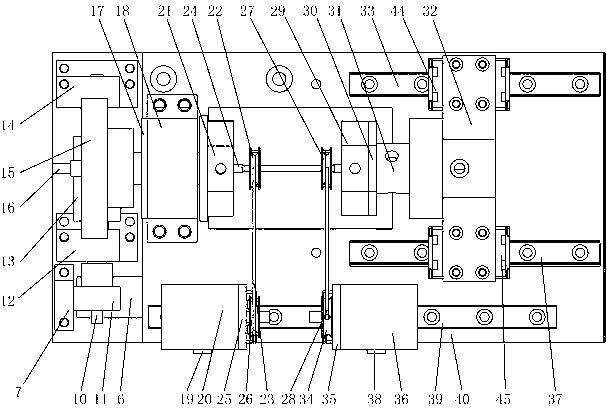

Multifunctional material mechanics testing machine with functions of tension torsion and pressure torsion

InactiveCN101625296ARealize pull torsionRealize functionMaterial strength using steady torsional forcesTorsion testTension compression

The invention relates to a material mechanics testing machine, belonging to the technical field of the material mechanics testing machine. The material mechanics testing machine is characterized in that the upper end and the lower end of the stander are provided with a lift motor and a torsion motor; the two motors form into one set of dynamic loading system and are controlled as well as coordinated to realize a tension torsion test and a pressure torsion test by an external electrical control system; a guide screw is arranged between the work table and an upper beam, wherein the upper end of the guide screw is fixed at the upper bean, and the lower end of the guide screw is driven by a synchronous belt wheel in a connection way; a middle beam is arranged between the work table and the upper beam; the middle beam is respectively provided with a tension compression rod and a tension compression sensor as well as a torsion sensor, wherein the tension compression sensor and the torsion sensor are communicated with a computer; the upper part of the wok table is provided with a slide way with a slide pillow; one side of the work table, near the vertical rod, is provided with a support seat; and the lower part of a torsion reduction machine is fixedly provided with a hanging rod, wherein the lower part of the hanging rod is provided with a clamp head. The two motors in the one set of dynamic loading system are simultaneously coordinated and controlled by the electrical control system to realize the functions of tension torsion and pressure torsion, and the rotate speeds of the two motors are adjusted by the electrical control system to meet the requirement of different experiments, digitally process the collection and the transmission of a parameter to be tested, and truly and exactly display the parameter on a screen.

Owner:孙仙山 +1

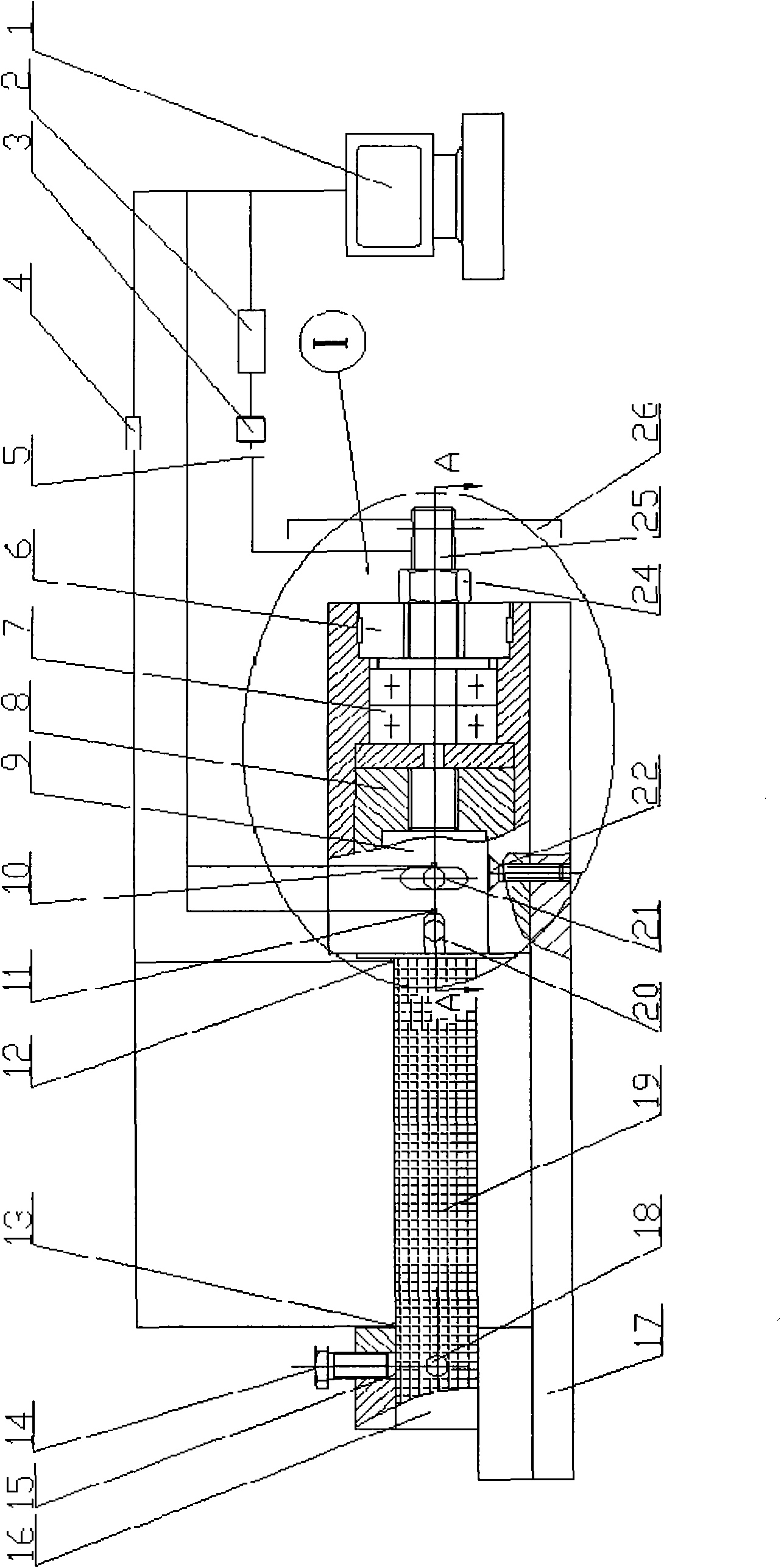

Location loading material testing machine

InactiveCN101881710ASimple structureCompact structureMaterial strength using tensile/compressive forcesTension compressionTorsion test

The invention relates to a location loading material testing machine which belongs to the technical field of material test. The location loading material testing machine is characterized in a location loading system; a support stand and a loading support part of the location loading system are respectively positioned at both ends of a fixing base; the loading support part comprises a location loading stand, a flange shaft, an overrunning clutch, a rolling bearing, a groove-shaped nut and two sliding blocks; three guide grooves are arranged on the location loading stand; the sliding blocks are respectively positioned in two keyways of the right external diameter of the groove-shaped nut; the overrunning clutch and the rolling bearing are fixed in the location loading stand in parallel; one end of the flange shaft is fixed by a hexagon nut through threads, and the other end is connected with the groove-shaped nut by threads; the left side of the groove-shaped nut is provided with a groove-shaped cavity; two through holes which are distributed left and right are radially arranged in the groove-shaped cavity; and the positions of the two through holes correspond to the first guide groove and the second guide groove on a loading support stand. The invention can realize a series of tension and compression tests and torsion tests by applying the guide grooves in the horizontal direction and the vertical direction of a location tension-compression-torsion loading stand.

Owner:JIANGSU UNIV

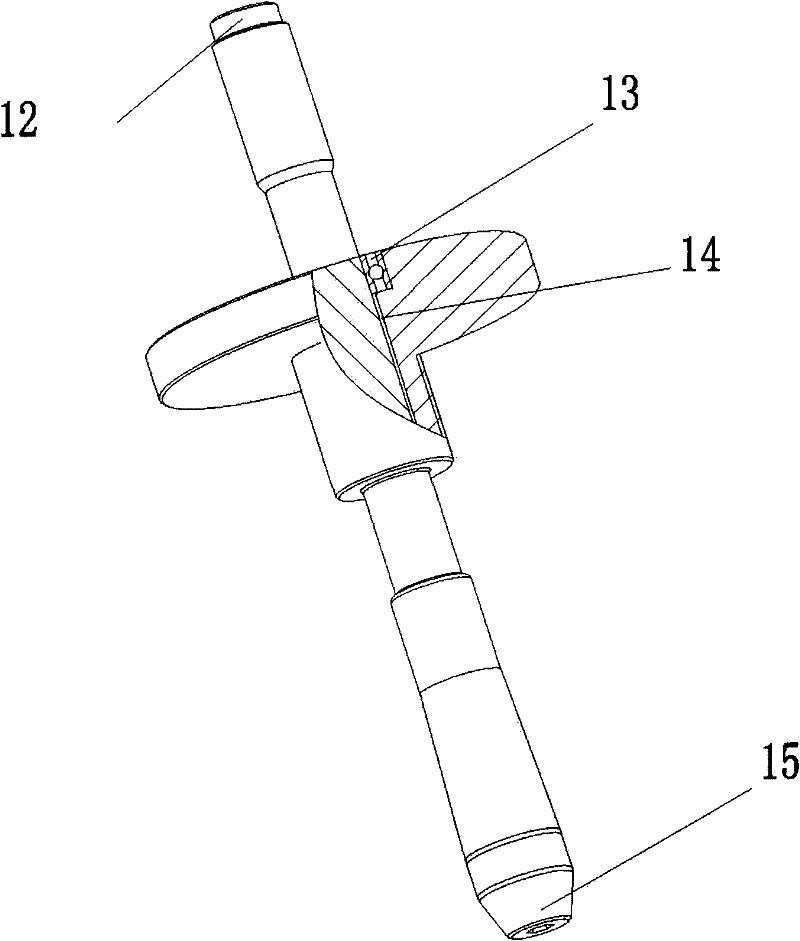

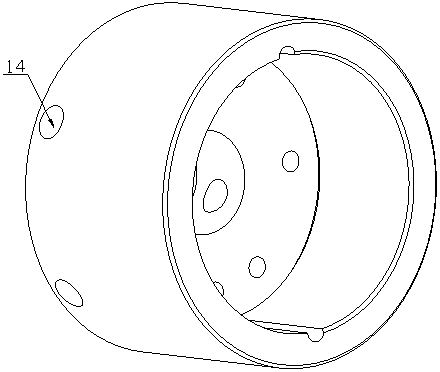

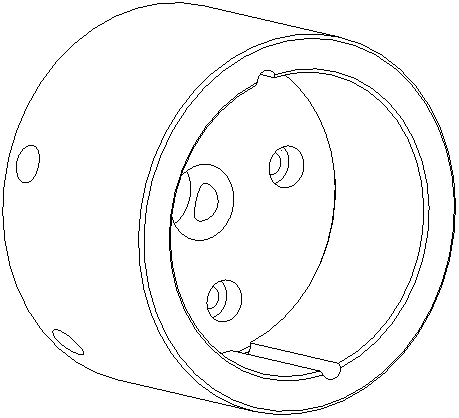

Rubber bushing torsion test apparatus

InactiveCN101482447ASimple appearanceReduce manufacturing difficultyMachine part testingTorsion testMechanical engineering

The invention relates to a rubber lining torsion test device used in rubber lining endurance test, which comprises a pedestal, a torsion shaft disposed on the pedestal and capable of rotating thereon, and a jig for fixing the rubber lining; one end of the torsion shaft is fixedly connected with a swing rod; the other end of the torsion shaft is fixedly connected with a torsion bar which passes through the rubber lining; the swinging of the swing rod drives the torsion bar to rotate to apply a torsional force onto the rubber lining. the rubber lining torsion test device in the invention realizes the multiple output modes needed in test, and achieves the advantages of simple appearance, low manufacturing difficulty, low cost, convenient installation and long service life.

Owner:CHERY AUTOMOBILE CO LTD

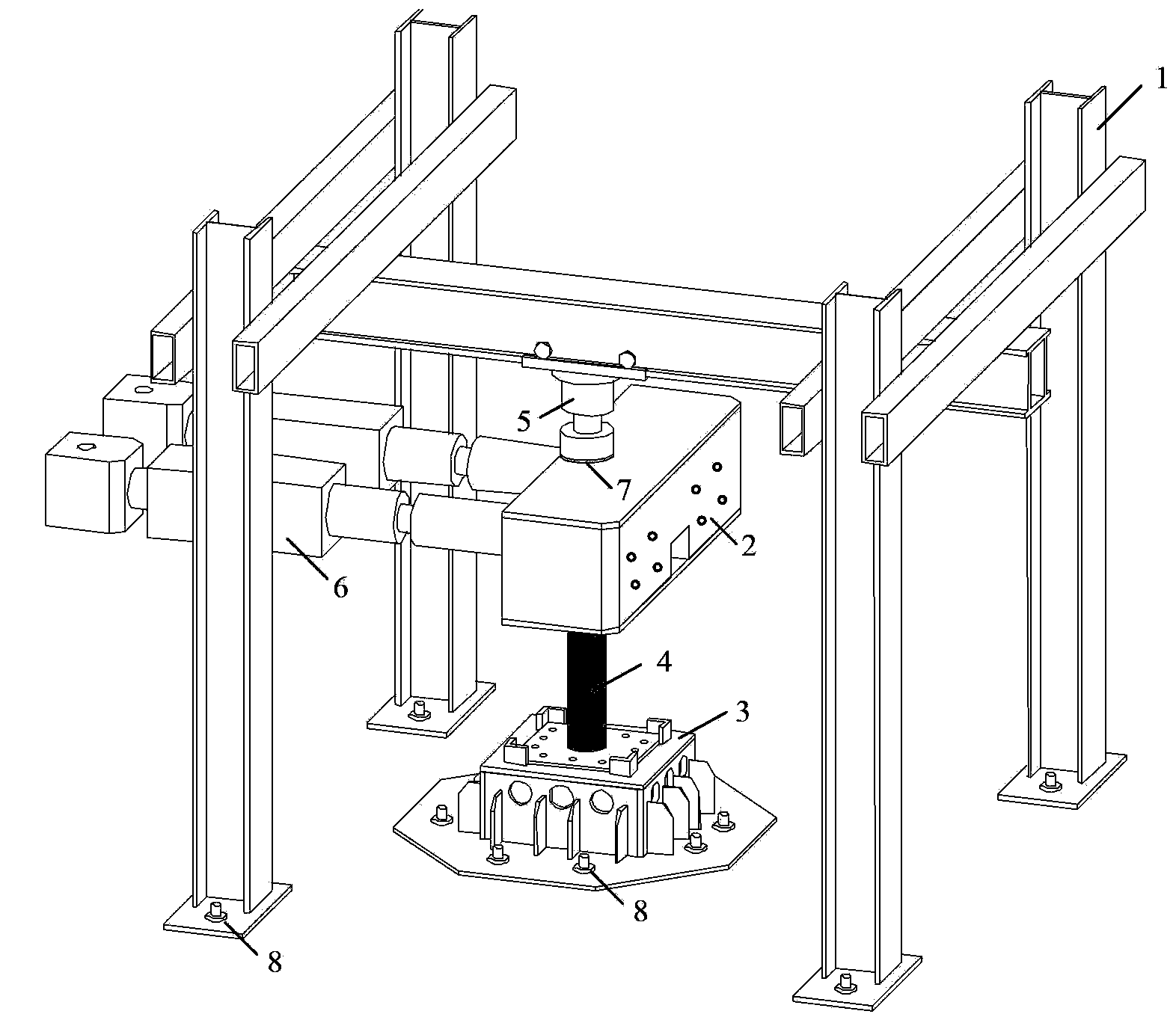

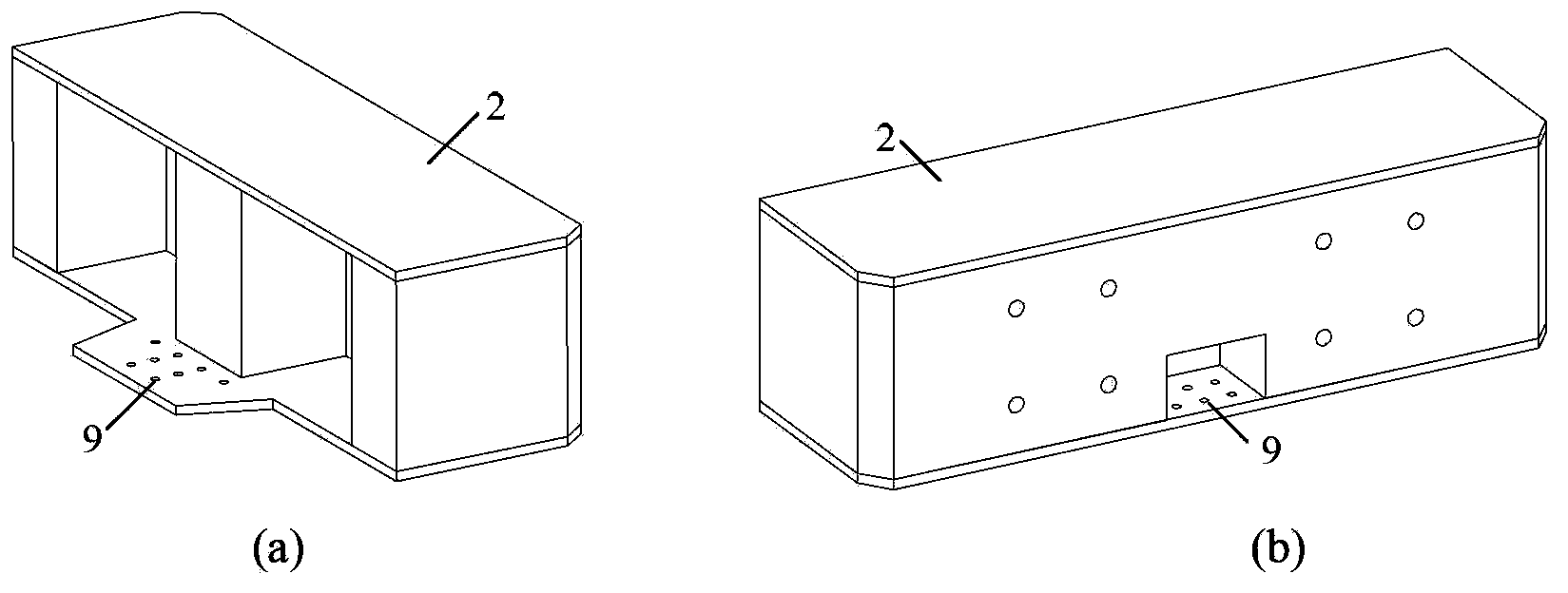

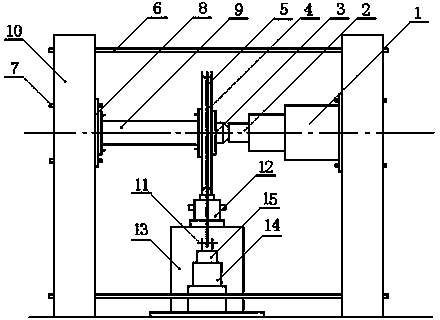

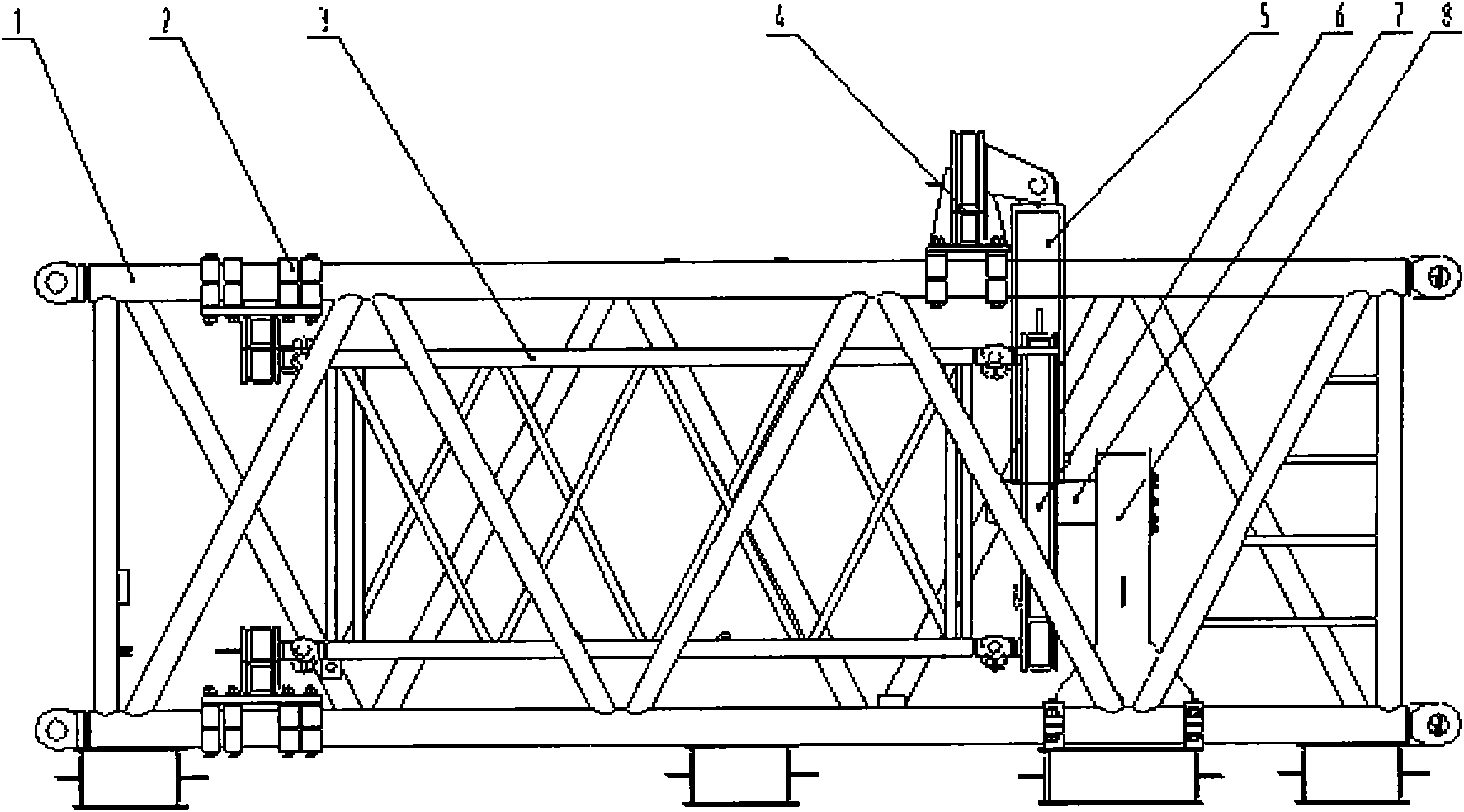

Steel-concrete composite column anti-seismic anti-torsion test loading device and manufacturing method thereof

InactiveCN103398908AGuaranteed to twist freelyFor quick replacementMaterial strength using steady bending forcesServo actuatorTorsion test

The invention relates to a steel-concrete composite column anti-seismic anti-torsion test loading device and a manufacturing method thereof, and belongs to the technical field of structure engineering. The steel-concrete composite column anti-seismic anti-torsion test loading device comprises a loading frame, a top beam, a base, an antifriction plate, a thrust jack, and two electro-hydraulic servo actuators. The loading frame is obtained by welding steel plates. All column bases of the loading frame are provided with bolt holes and are fixedly connected to the ground by ground anchor bolts. The top beam is obtained by welding steel plates. The bottom of the top beam is provided with bolt holes and is fixedly connected to a top steel plate of a test piece by bolts. The base is obtained by welding steel plates. The top of the base is provided with bolt holes and is connected to a bottom steel plate of the test piece by bolts. An upper end of the thrust jack is connected to the loading frame by a rolling bearing. The antifriction plate is horizontally arranged in the center of the top of the top beam. The electro-hydraulic servo actuators are arranged horizontally and are fixedly connected to the top beam. The steel-concrete composite column anti-seismic anti-torsion test loading device solves the problem of the prior art, has a simple structure, is convenient for use, has strong universality, can be used for anti-seismic anti-torsion tests on various steel-concrete composite columns, and has wide application prospects.

Owner:TSINGHUA UNIV

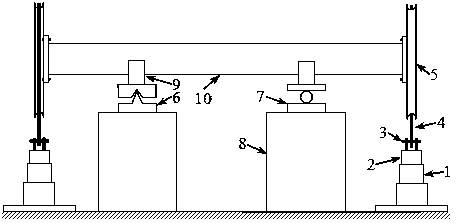

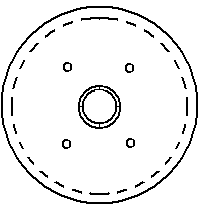

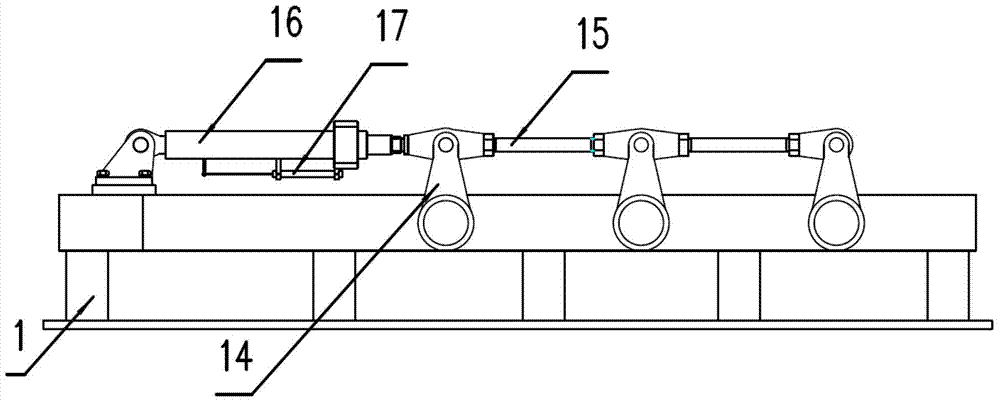

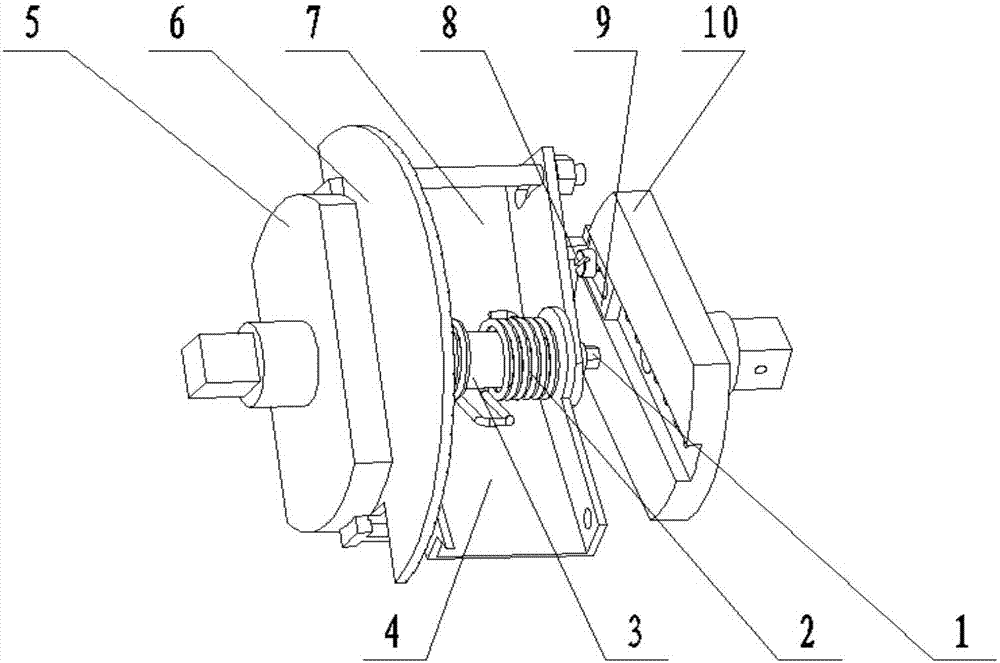

Bending torsion test loading device for steel tube concrete pile

InactiveCN103558099ASolution conditionsSolve the two major problems of non-ideal rotation of CFST columns when torque is appliedMachine part testingStrength propertiesCircular discPull force

The invention discloses a bending torsion test loading device for a steel tube concrete pile. According to the bending torsion test loading device for the steel tube concrete pile, two problems that the bending moment condition is not ideal and simple, and the rotation of the steel tube concrete pile is not ideal when the torque is applied in a previous bending torsion test are solved. The bending torsion test loading device comprises two tension jacks, tension sensors, a connection joint, steel wire ropes, round groove discs, a fixed hinge support, a sliding hinge support, two counterforce pillars and rotation supports, wherein the rotation supports are mounted on the fixed hinge support and the sliding hinge support respectively; the two tension jacks are mounted on the outer sides of the two counterforce pillars respectively and located on different sides of the round groove discs on two ends of the steel tube concrete pile; the top ends of the tension jacks are provided with the tension sensors; the tension sensors are connected with the steel wire ropes which are wound on the round groove discs through connection joints. Due to the adoption of the bending torsion test loading device for the steel tube concrete pile, bending torsion test results of the steel tube concrete pile fit with finite element analysis results well. Meanwhile, the bending torsion test loading device for the steel tube concrete pile also has the characteristics of convenience in assembly and recyclability.

Owner:SHENYANG JIANZHU UNIVERSITY

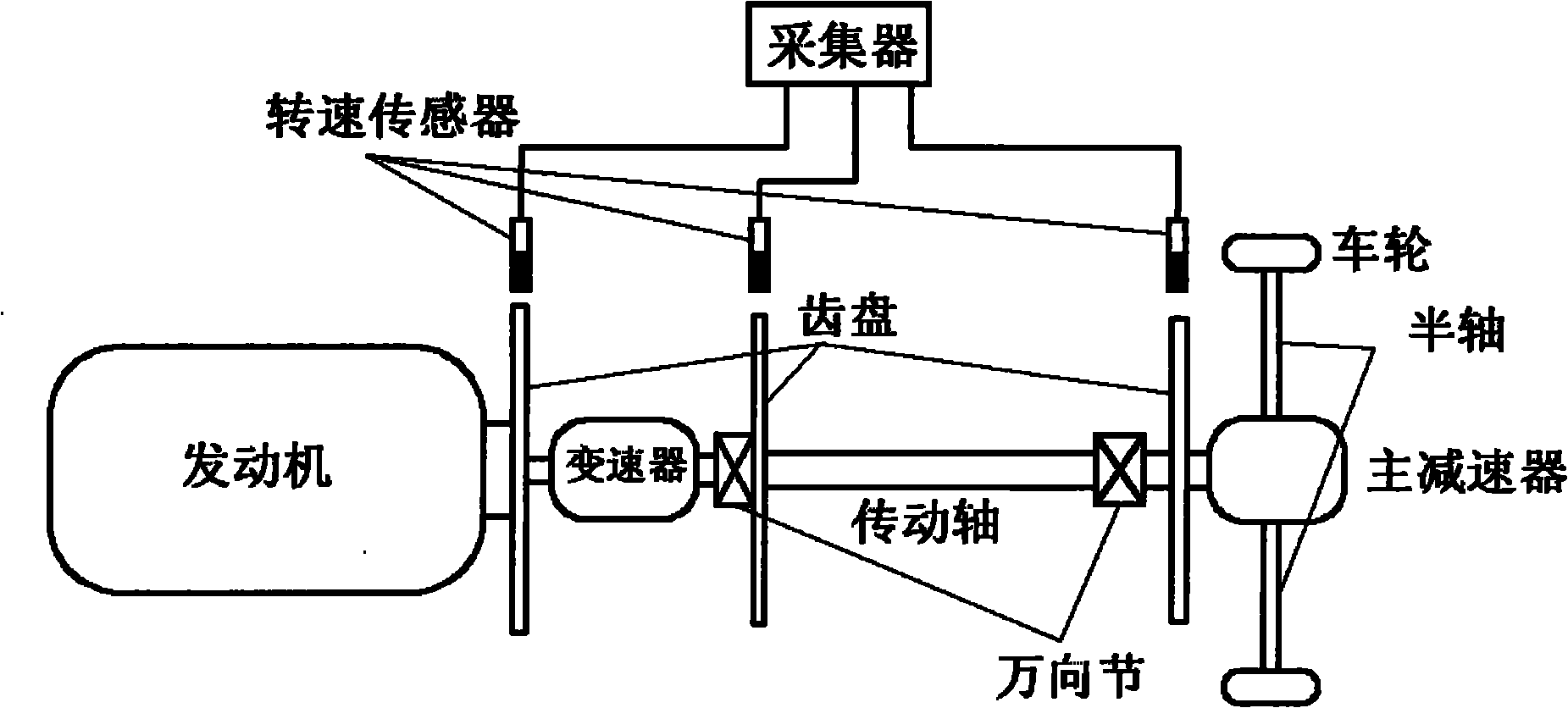

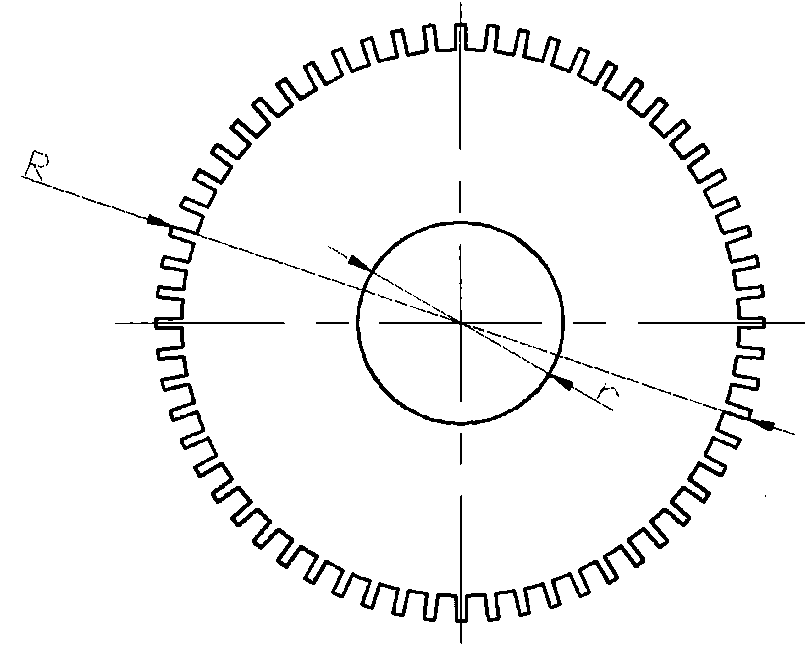

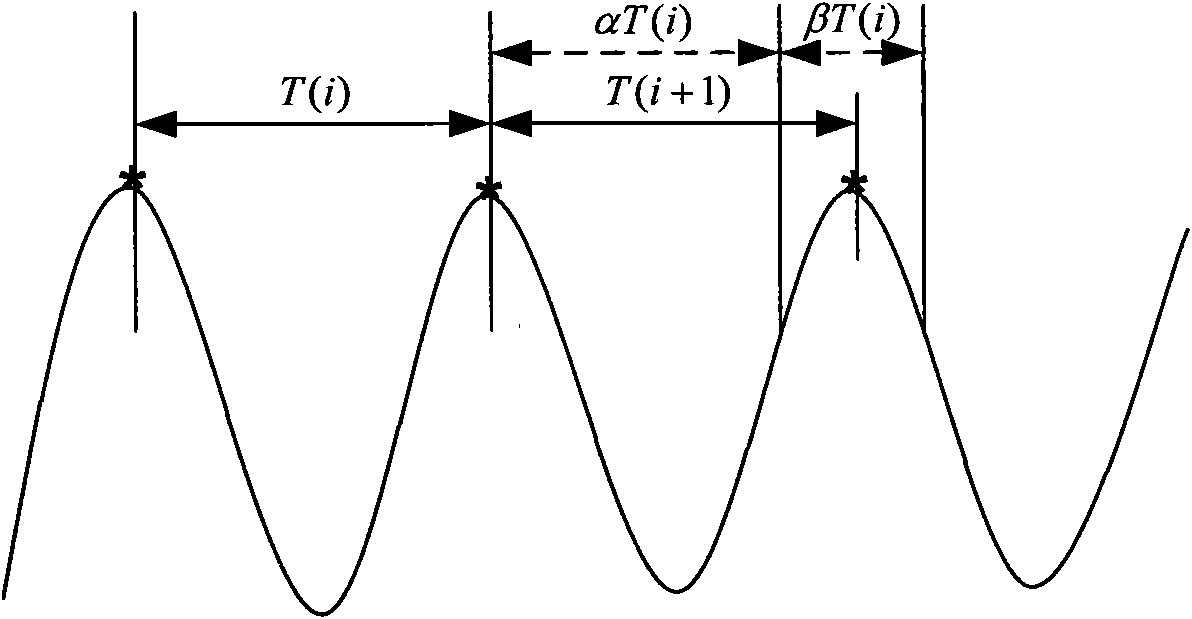

Online detection method for torsion vibration signal of automotive power transmission system

InactiveCN101871846AAccurate torsional vibration frequencyAccurate calculation of torsional vibration frequencyVibration measurement in solidsVehicle testingElectric power transmissionVibration control

Owner:TSINGHUA UNIV

Intelligent lock comprehensive performance tester and testing method thereof

InactiveCN103411768AImprove efficiencyGood effectMachine part testingProgramme control in sequence/logic controllersTorsion testControl system

The invention relates to a detection device, in particular to an intelligent lock comprehensive performance tester. The intelligent lock comprehensive performance tester comprises a device body, a door hinge capable of rotating around the device body, a central control system, a sound and light alarm and a plurality of detecting units arranged on the door hinge, wherein the a lock mounting area is arranged at the edge of the door hinge, and the detecting units correspond to the lock mounting area in position; each detecting unit comprises an outer dock detecting unit installed on the front face of the door hinge and an inner lock detecting unit installed on the back face of the door hinge. According to the tester, the testing range of performance of a lock is wide, and the tester is capable of performing a service life test on a lock body, a stretching in-place test on a spring bolt, a torsion test on a lever handle, a continuous card swiping test, a service life test on the lever handle, a service life test on a battery and a service life test on the whole lock, meanwhile reduces labor intensity of operators and improves the efficiency and the effect of testing of the performance of the lock, and therefore the testing period is shortened.

Owner:ZHEJIANG BADA HARDWARE

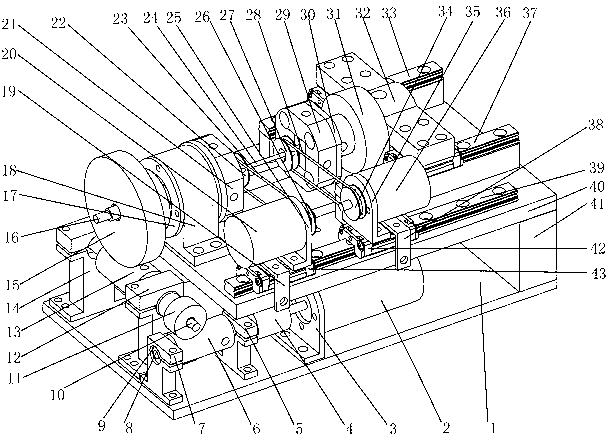

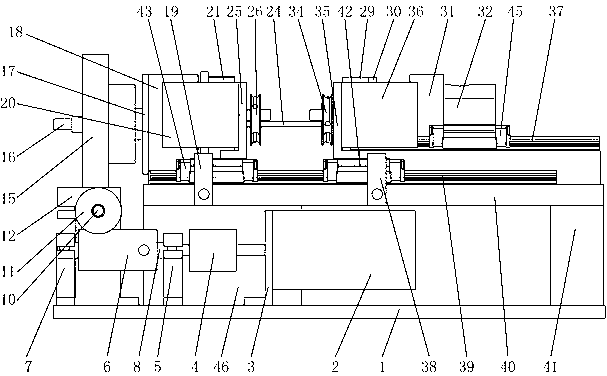

High-speed torsion testing machine

ActiveCN102183420ATrue detection of torsional performanceReal detection of fatigue lifeStrength propertiesTorsion testDrive shaft

The invention discloses a high-speed torsion testing machine which comprises a driving shaft driven by a motor and a driven shaft coaxially arranged with the driving shaft, wherein a driving gear is arranged on the driving shaft, a driven gear is arranged on the driven shaft, the driving gear and the driven gear are in transmission connection through a transmission shaft provided with a transmission gear, the transmission shaft is provided with a servo system for controlling the transmission shaft to axially move, and the driving gear and / or the driven gear are / is a bevel gear. When the driving gear performs axial reciprocating movement, the acting force to the driving shaft and the driven gear is formed, and the rotating phase angle of the driven gear is forced to be changed, thus the stated twisting vibration is formed. The high-speed torsion testing machine can ensure that a test workpiece can bear a torsion test under the high-speed running condition and accords with actual working conditions, thereby really detecting the torsion performance and the fatigue life of the workpiece. In addition, the driving shaft can be driven to rotate in a non-load way by utilizing the motor with lower power so as to be beneficial to decrease of test energy consumption.

Owner:JILIN DAHUA MACHINERY MANUFACTURING CO LTD

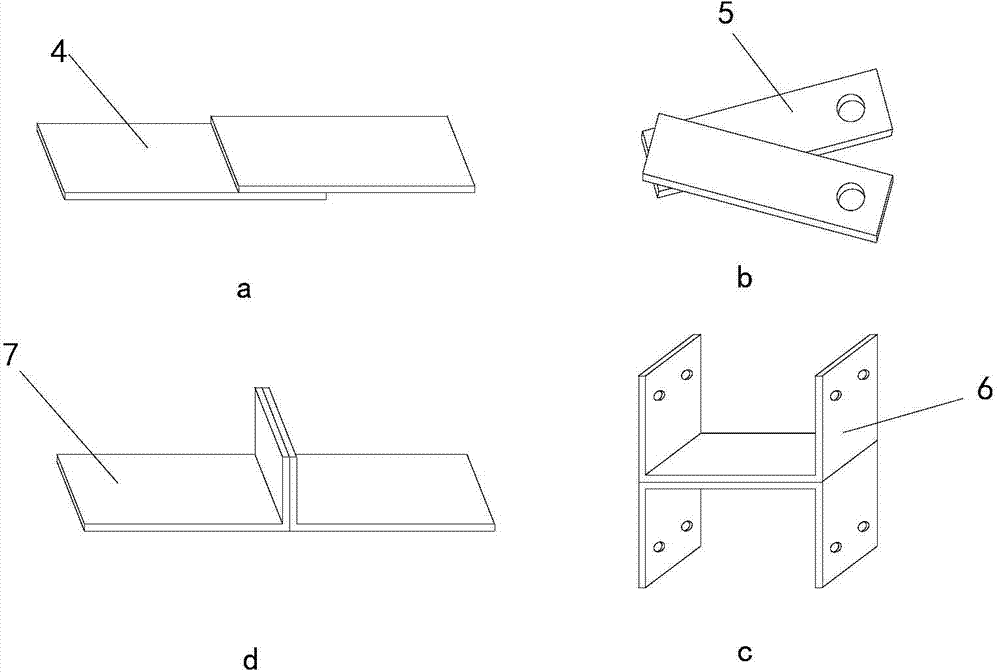

Test device and test method for measuring mechanical properties of lap joint samples

InactiveCN104764661AEasy to fixLow costMaterial strength using tensile/compressive forcesMaterial strength using steady bending forcesConnection typeTorsion test

The invention relates to a test device and a test method for measuring mechanical properties of lap joint samples. The test device comprises two clamps used for clamping the lap joint samples, two cover plates used for fixing the lap joint samples on the clamps, two loading heads used for connecting the test device and experimental equipment, four kinds of lap joint samples and a set of connecting bolt and pin. The test method comprises the following steps: clamping to-be-measured lap joint samples by virtue of the two clamps in a matching manner, connecting the clamps with the test equipment by virtue of the loading heads, loading, and testing the shear resistance, bending resistance, torsion resistance or tensile mechanical properties of the samples. With the adoption of the general design idea, the tensile properties, shear resistance, bending resistance and four-angle KSII of the lap joint samples can be tested, the device is applied to the lap joint samples of three different connection types and has extremely high universality, and the cost of the clamps is reduced.

Owner:SHANGHAI JIAO TONG UNIV

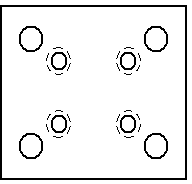

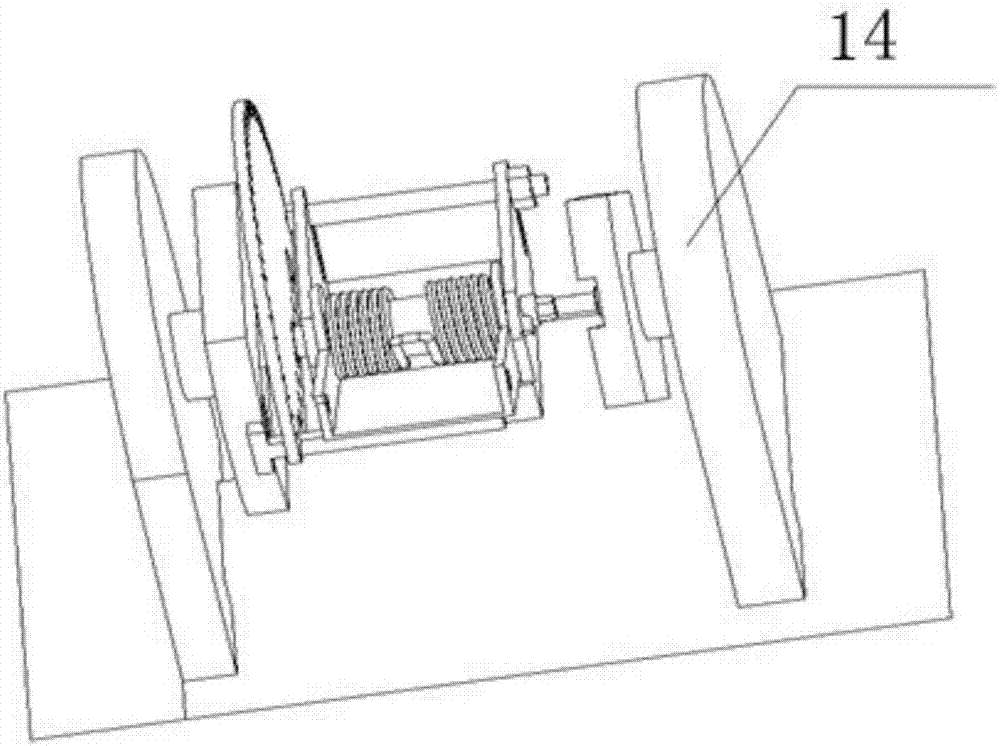

Pressure torsion test loading device for steel tube concrete pile

InactiveCN103558098AFit closelySolve the two major problems that the law of torque variation is not constantMachine part testingStrength propertiesCircular discTorsion test

The invention discloses a pressure torsion test loading device for a steel tube concrete pile. Through the pressure torsion test loading device for the steel tube concrete pile, two problems that the rotation of the steel tube concrete pile is affected when the pressure is applied in a previous pressure torsion test and the torque change rule in the test process is not constant are solved. The pressure torsion test loading device for the steel tube concrete pile comprises a pressure jack, a pressure sensor, a pressure bearing, a round groove disc, a rolling shaft support, a tension jack and a tension sensor, wherein counterforce pillars are mounted on the ground; the pressure jack is mounted on the counterforce pillar at one side; the front end of the pressure jack is provided with the pressure sensor and the pressure bearing; the top end of the tension jack is provided with the tension sensor which is connected with a steel wire rope wound on the round groove disc; the rolling shaft support and a pedestal are mounted under the round groove disc. In test, the steel tube concrete pile is mounted on the counterforce pillars; the other end of the steel tube concrete pile is mounted on the round groove disc; a torque is provided by the tension jack; an axial pressure is provided by the pressure jack; load values are collected by the two sensors. The pressure torsion test loading device for the steel tube concrete pile also has the characteristics of simple overall structure, convenience in assembly and recyclability, and the like.

Owner:SHENYANG JIANZHU UNIVERSITY

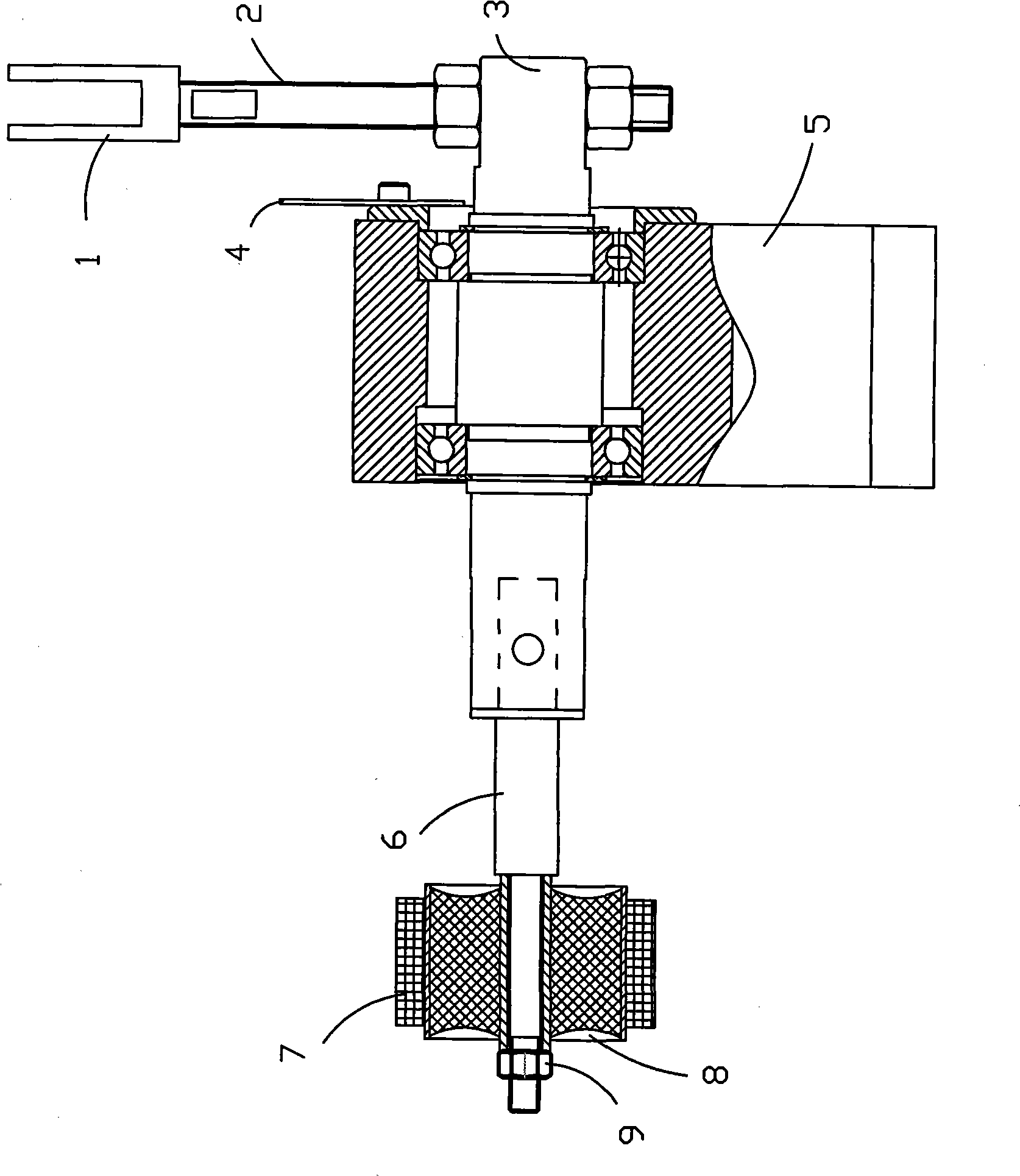

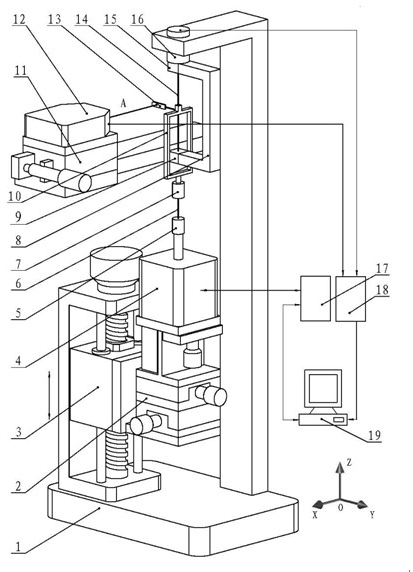

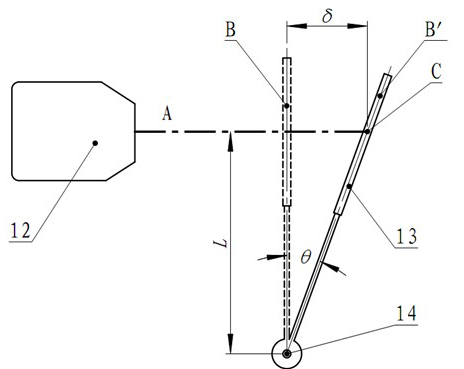

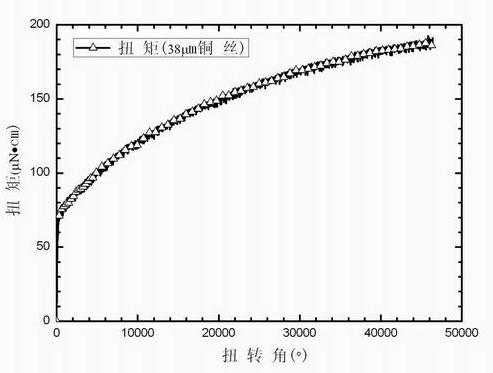

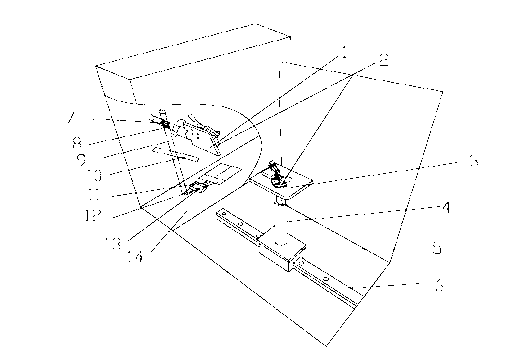

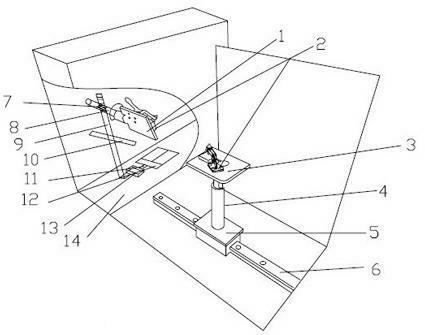

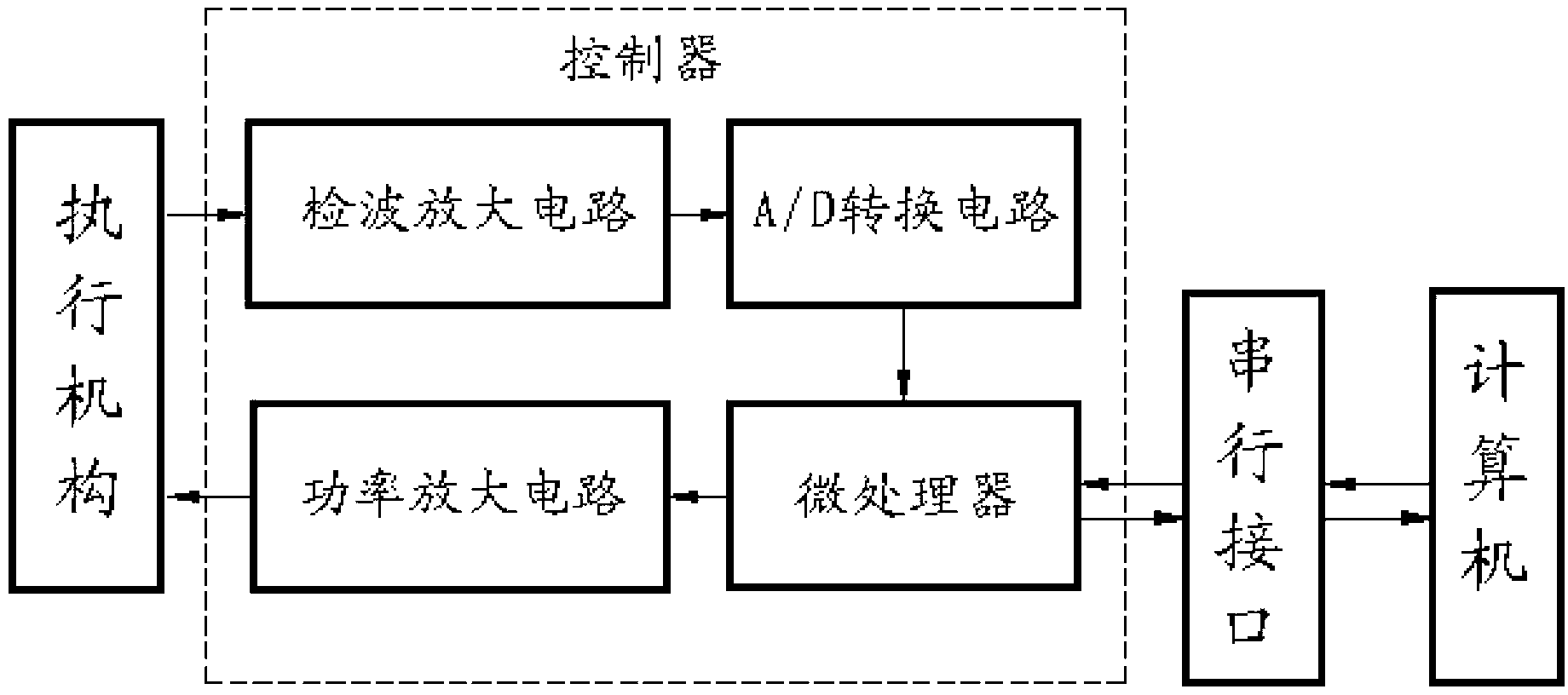

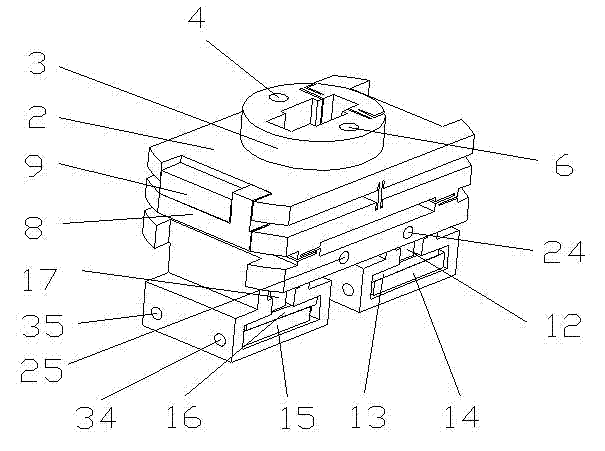

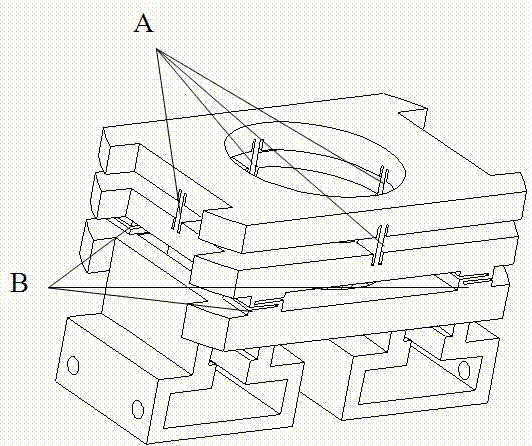

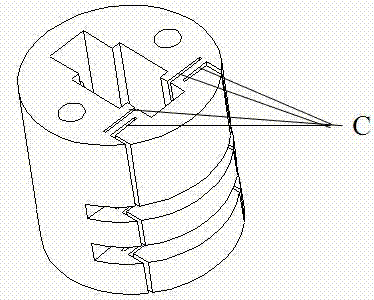

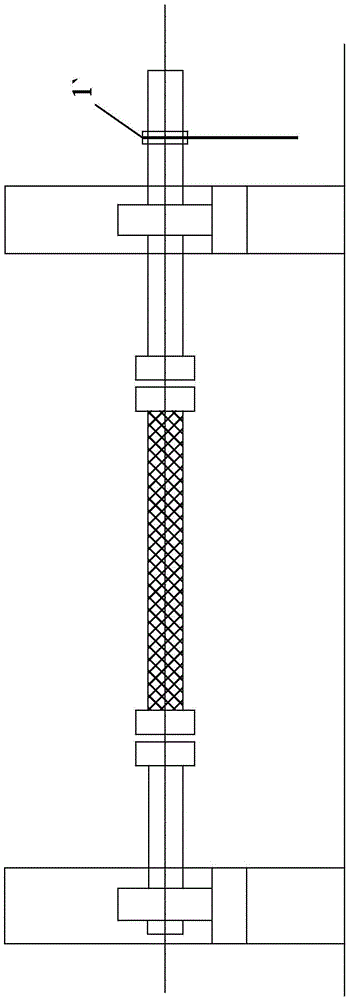

Device for testing micro-torsion mechanical property of low-dimension material

InactiveCN102183418AEasy clampingClamping real-time detectionMaterial strength using steady torsional forcesTorsion testEngineering

The invention provides a device for testing the micro-torsion mechanical property of a low-dimension material. The device comprises a stander, a force sensor, a micro-torsion sensor, a torsion wire rotation angle measurement component, an upper chuck, a lower chuck, a stepping motor, a three-dimensional translation table, a screw and nut component, a servo controller, an analog-to-digital collection card and a computer system, wherein both ends of a tension wire of the micro-torsion sensor are tensioned and fixed on a bracket and have high rigidity and stability; by replacement of the torsion wire, a measurement range can be adjusted; moreover, the force sensor is arranged at the upper end of the micro-torsion sensor, so that an axial force during torsion test can be detected in real time. In the device, a rotation angle of the torsion wire is measured in a manner of combining a light target and a photoelectric displacement sensor; and compared with a conventional light lever method, the device has a compact structure, high automation degree and high stability. By regulation of the three-dimensional translation table, an upper chucking point and a lower chucking point can be aligned. The computer system can obtain a torque-rotation-angle curve of a test sample in real time. The device is applicable to micro-torsion mechanical property of the low-dimension material.

Owner:HUAZHONG UNIV OF SCI & TECH

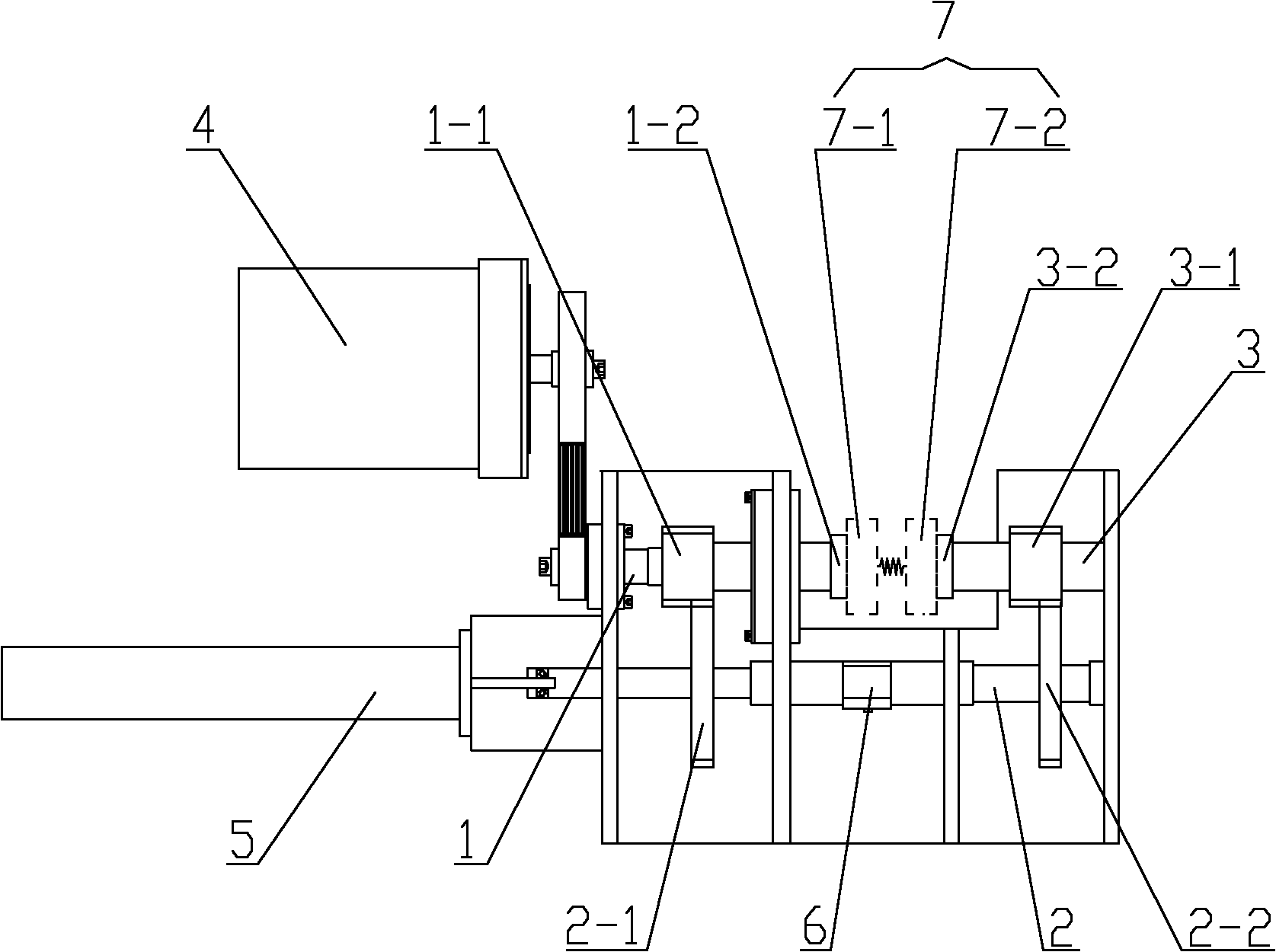

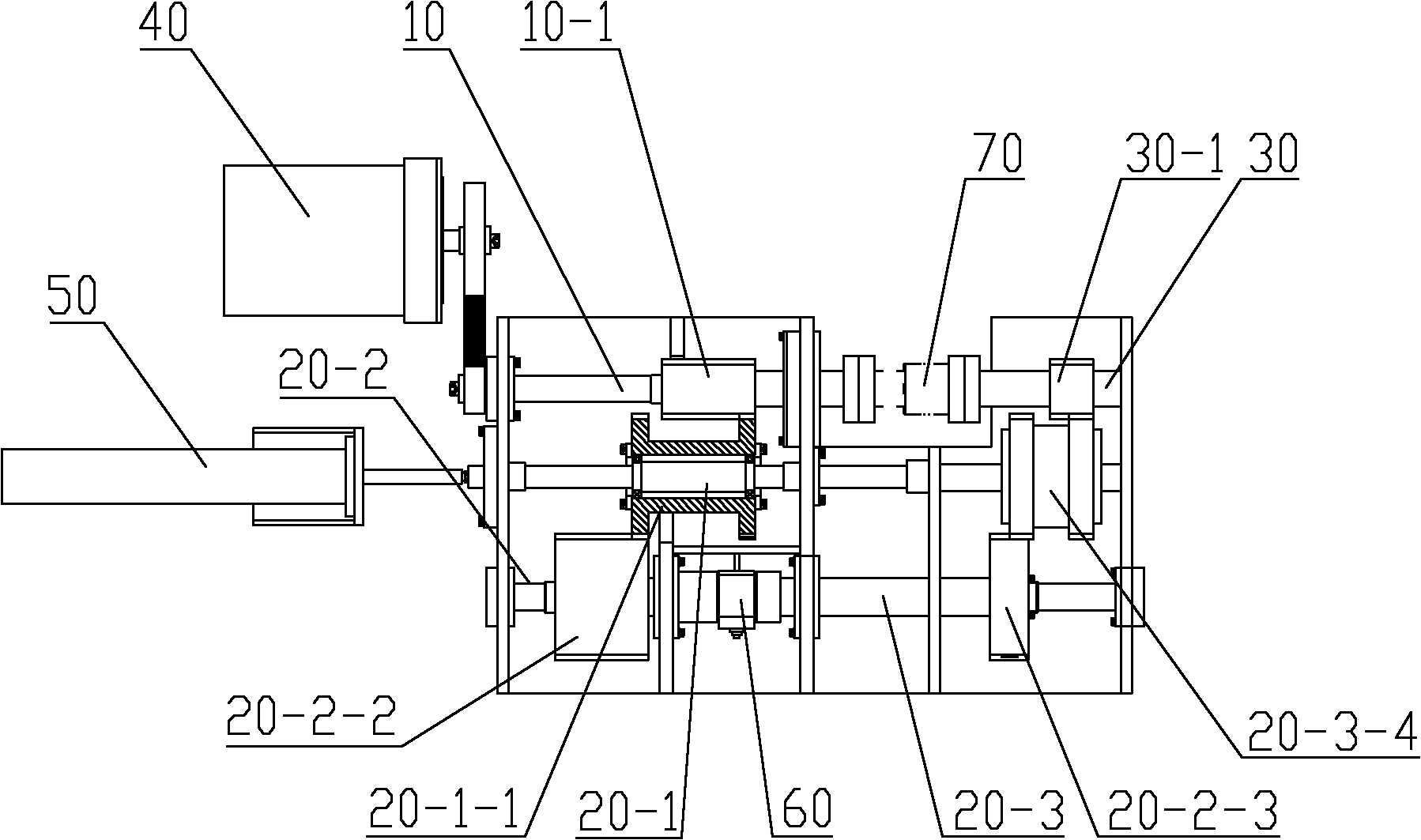

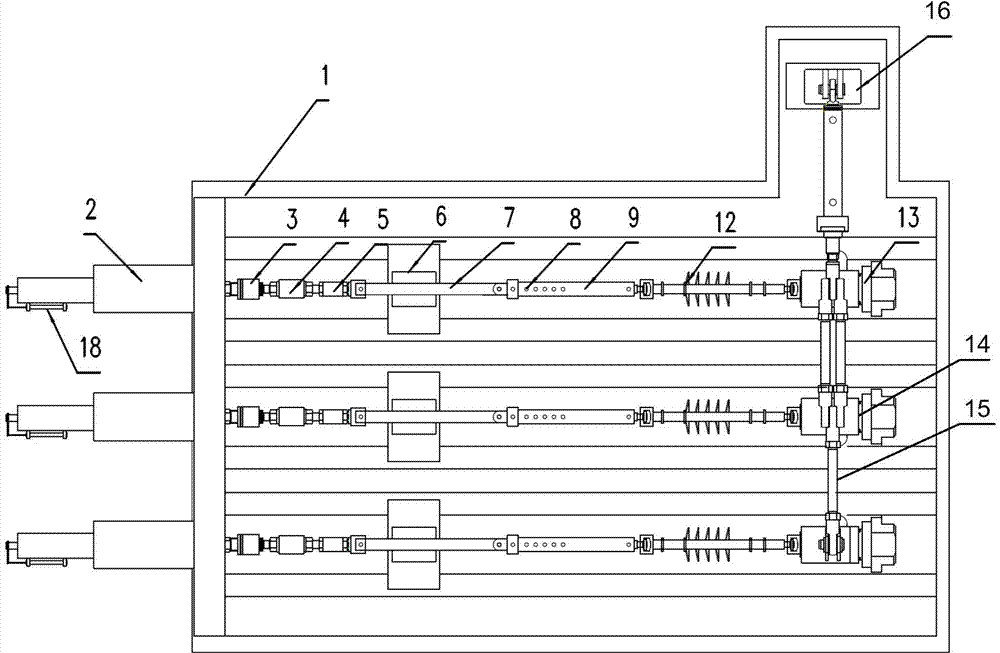

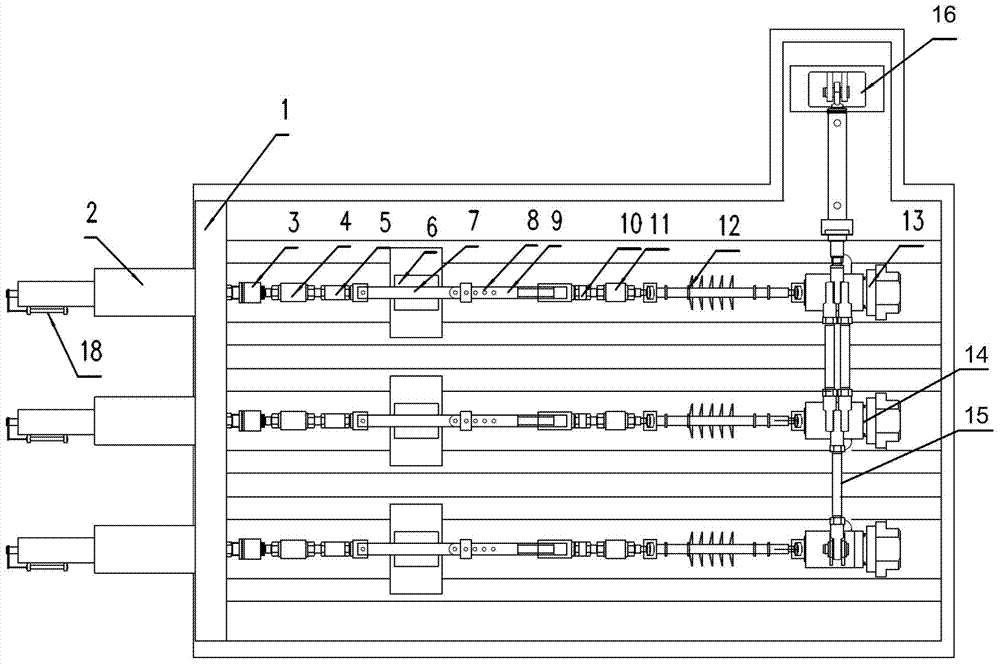

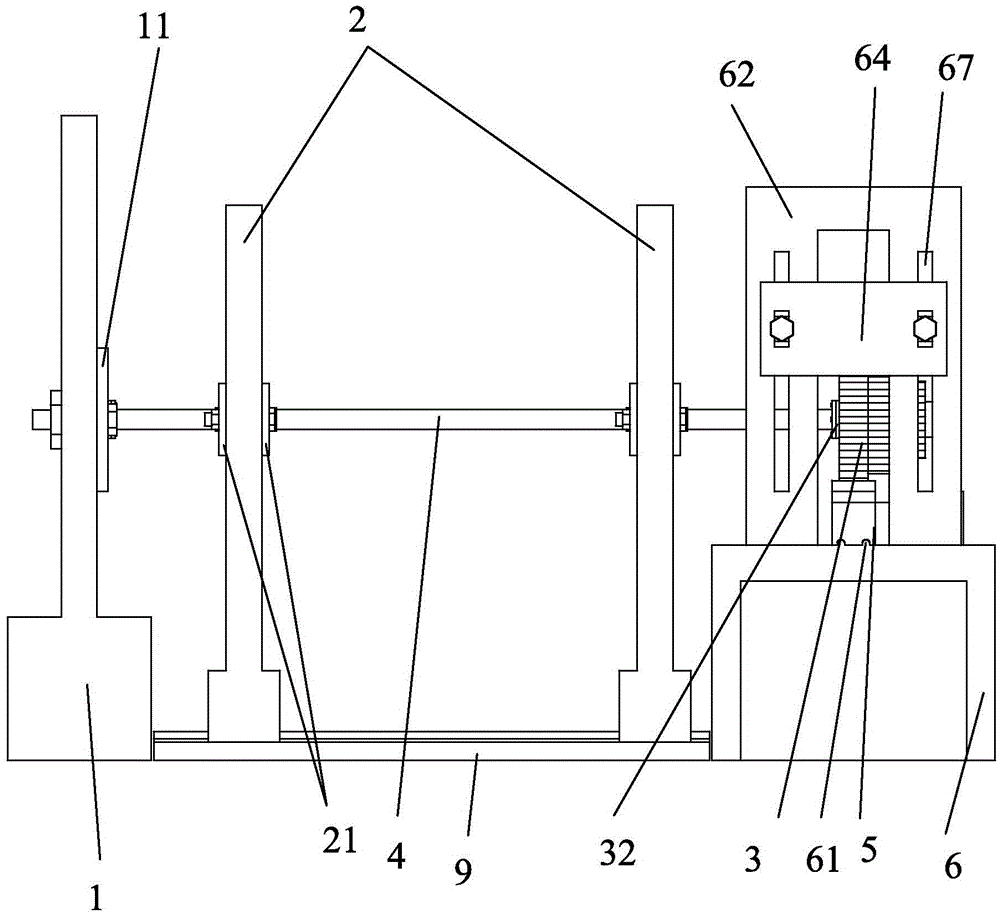

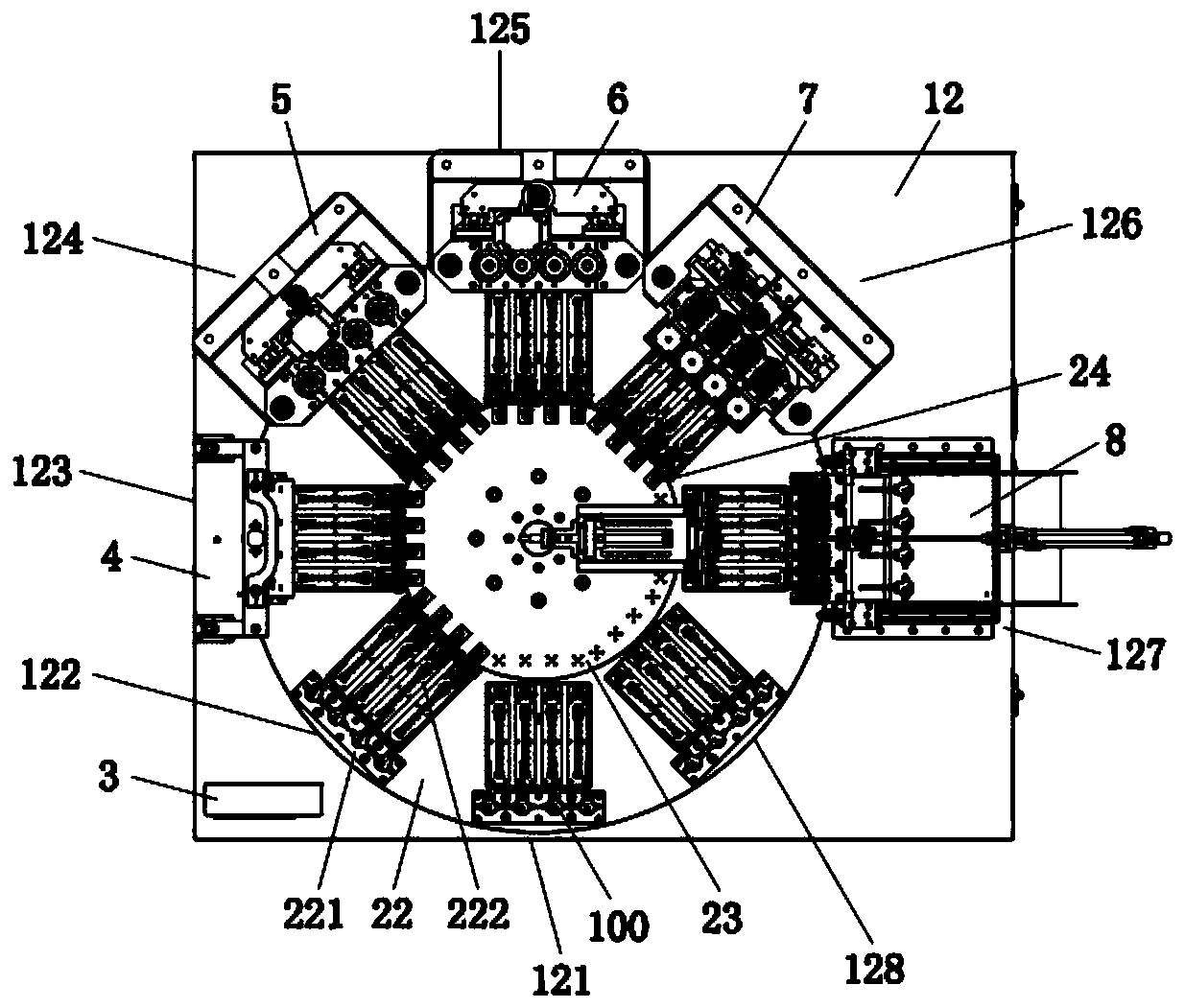

Tension-compression and torsion vibration fatigue test device

ActiveCN103616303AShorten test timeImprove test efficiencyMaterial strength using repeated/pulsating forcesTorsion fatigueTorsion test

The invention discloses a tension-compression and torsion vibration fatigue test device capable of simultaneously accomplishing tension-compression and torsion fatigue tests. The test device comprises a test device rack, a torsion test mechanism and a plurality of tension-compression test mechanisms. In each tension-compression test mechanism, a tension-compression actuating cylinder piston rod, a force sensor, a guide rod, an adjusting rod and a tested workpiece are sequentially connected end to end, wherein the adjusting rod is provided with a plurality of adjusting positions; according to the size of the tested workpiece, the guide rod is connected to the corresponding adjusting position of the adjusting rod; the guide rod does rectilinear movement under the limitation of a guide mechanism. In the torsion test mechanism, a rotating end of each bearing slewing mechanism is connected with the other end of the tested workpiece; oscillating rods of all the bearing slewing mechanisms are connected in series by a link mechanism, and the oscillating rod at one end is connected with the piston rod of a torsion actuating cylinder through a link mechanism. Tension-compression actuating cylinders, the bearing slewing mechanisms and the torsion actuating cylinder are all fixed on the test device rack.

Owner:北京乐冶液压气动设备技术有限公司 +1

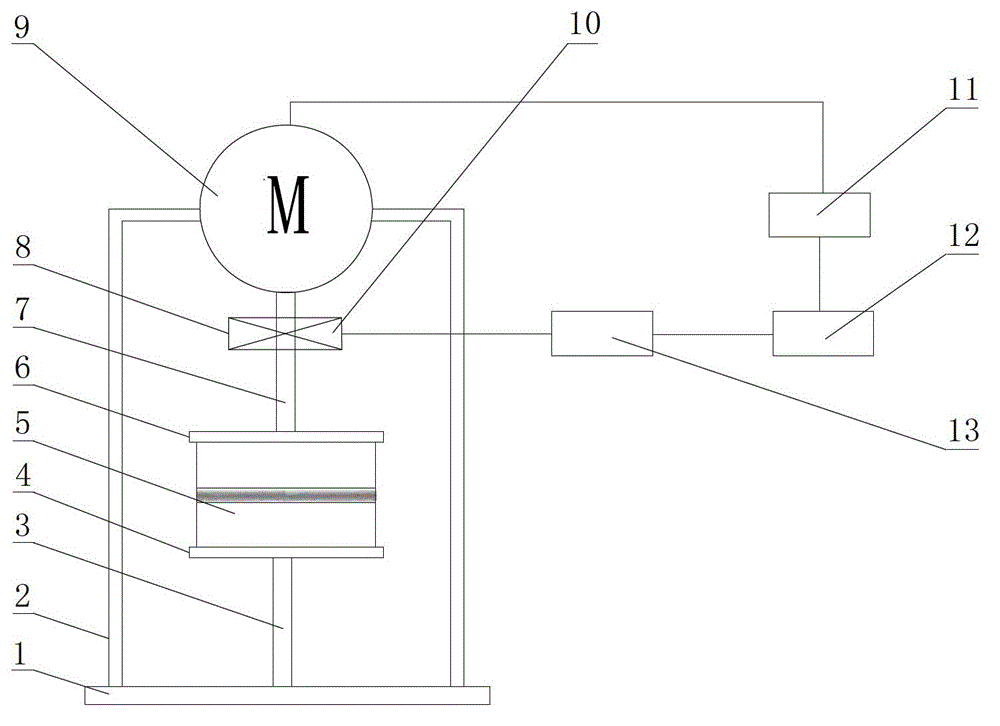

Device and method for estimating influence of surface lines on adhesion between asphalt and aggregates

ActiveCN102879327AReflect adhesionSimple structureUsing mechanical meansMaterial analysisTorsion testSurface roughness

The invention relates to a device and method for estimating influence of surface lines on adhesion between asphalt and aggregates. A torsion test is carried out on aggregate asphalt interlayer test pieces of the same aggregate with different surface lines, so as to detect torsions corresponding to the different lines. Therefore, the shearing damage to the asphalt mixture can be actually simulated, so as to reflect the adhesion between the asphalt and the aggregates; the influence on the adhesion between the asphalt and the aggregates, caused by the surface roughness of the surfaces of the aggregates, can be actually simulated; and the reliable proof can be provided for the research on the adhesion between the asphalt and the aggregates. Furthermore, the device provided by the invention has the advantages of simple structure and convenience in operation.

Owner:CHANGAN UNIV

Torsional testing machine for cable

InactiveCN102706755AEasy to operateGuarantee continuous and stable operationStrength propertiesTorsion testElectric machine

The invention discloses a torsional testing machine for a cable for detecting the torsion coefficient of the cable. The torsional testing machine comprises a drive motor, a bracket and a bottom plate; wherein the bracket is fixedly connected with the bottom plate; the drive motor is arranged on the bottom plate; a rotation shaft is arranged on the bracket; a rotating plate is arranged on the rotation shaft; a cable fixing mechanism is arranged on the rotating plate; the motor output shaft of the drive motor is connected with a transmission arm through a converter; the transmission arm is meshed with a gear fixedly connected with the rotation shaft; the bottom plate is fixedly connected with a supporting rod; a fixing plate is fixedly arranged at the upper part of the supporting rod, and a cable fixing mechanism is arranged on the fixing plate. The torsional testing machine has the advantages of according with test requirements, convenience in operation, continuous and stable operation, reliable use and automatic counting; scientific detecting means is provided for the efficient detection of the cable, and data foundation is provided for evaluation of the quality of the cable.

Owner:ZHEJIANG ZHAOLONG CABLE

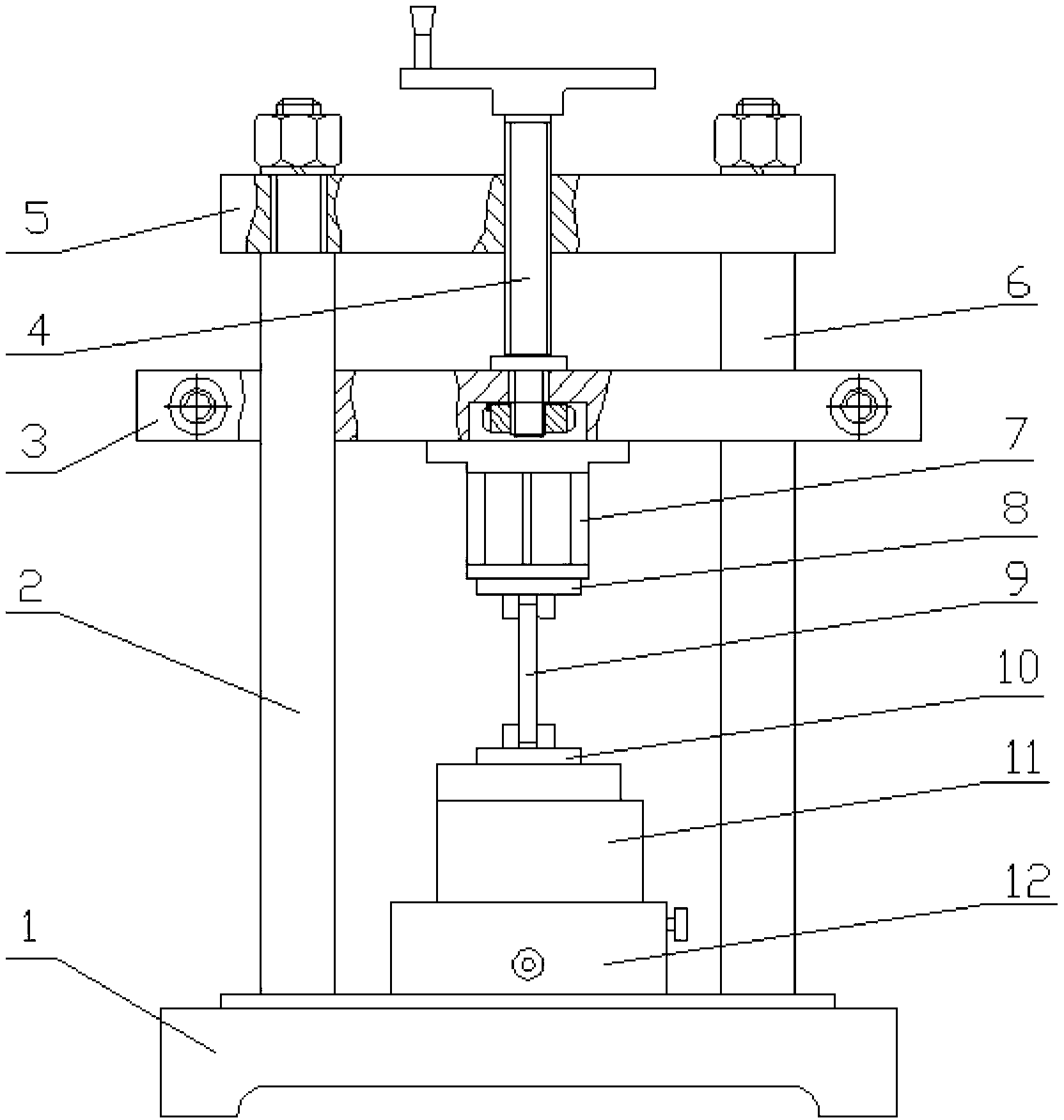

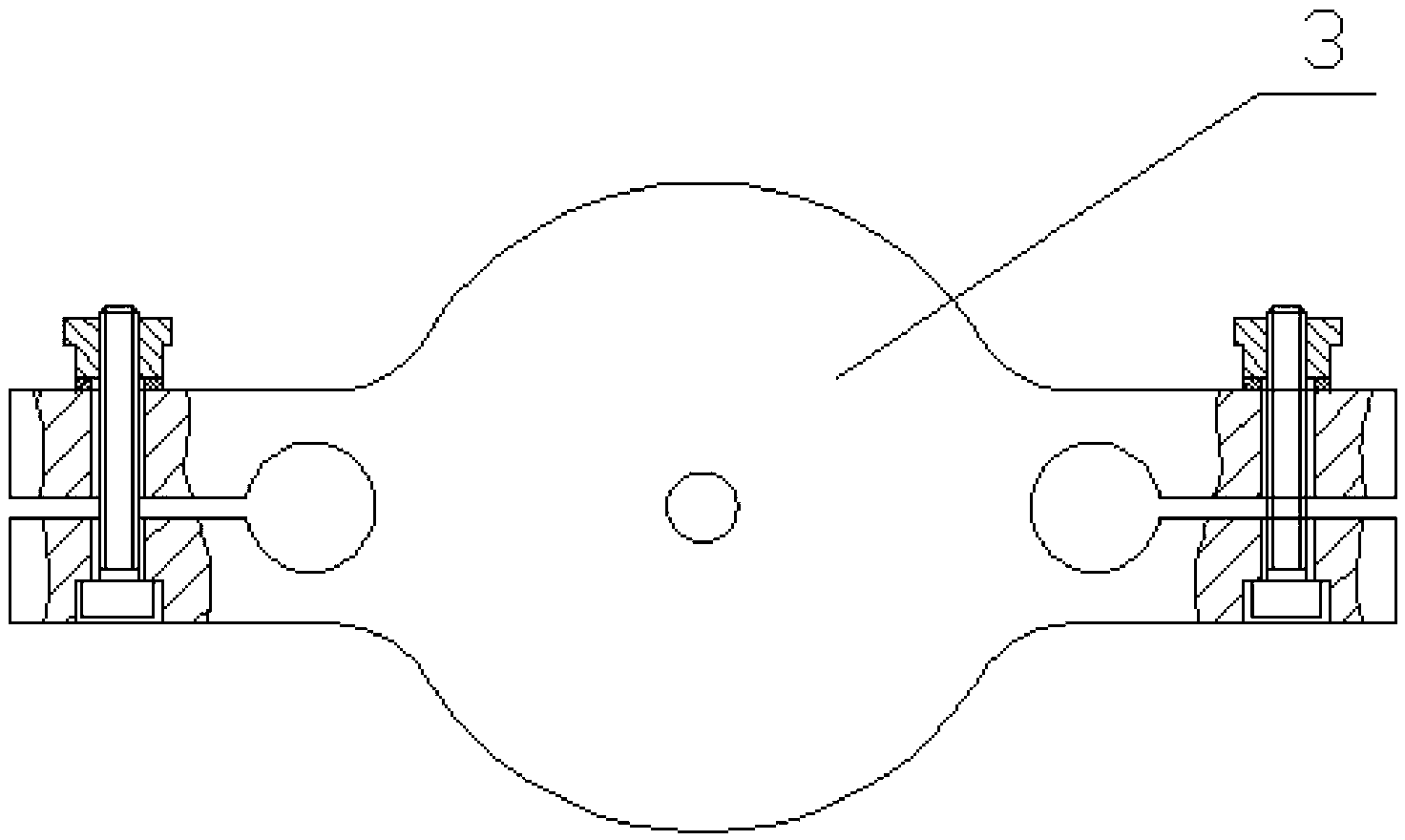

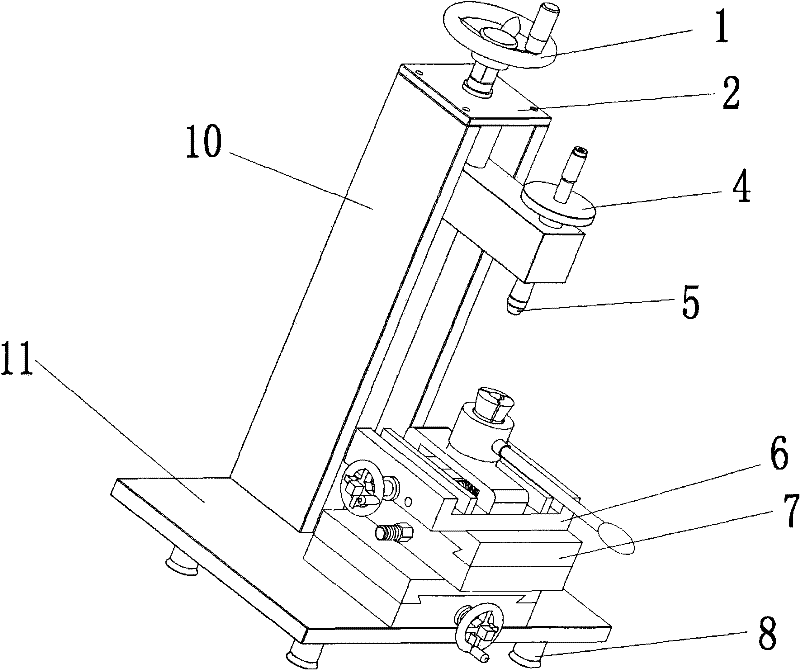

Micro-torsion testing platform

InactiveCN103217342AEasy to operateReduce mistakesMaterial strength using steady torsional forcesGratingTorsion test

The invention discloses a micro-torsion testing platform which is aimed at overcoming the problems of low testing precision and small test object range of a current torsion testing machine in a mechanical property test of torsion under a micro-torsion / deformation service condition. The micro-torsion testing platform comprises a precise adjusting unit, a precise electric control turn table, a torque / angular displacement signal detecting unit and a clamping unit, wherein the precise adjusting unit comprises a base, a movable cross beam, an adjusting screw, a left upright post, a right upright post, a top beam and an XY two-dimensional precise displacement platform; the precise electric control turn table is installed on a table top of the XY two-dimensional precise displacement platform; the torque / angular displacement signal detecting unit comprises a micro-torque sensor and a high-precision circular grating, the micro-torque sensor is installed on the bottom surface of the movable cross beam, and the high-precision circular grating is installed on a loading platform of the precise electric control turn table; and the clamping unit comprises a fixed clamp holder and a movable clamp holder, the fixed clamp holder is installed on the bottom end face of the micro-torque sensor, and the movable clamp holder is installed on the table top of the precise electric control turn table.

Owner:JILIN UNIV

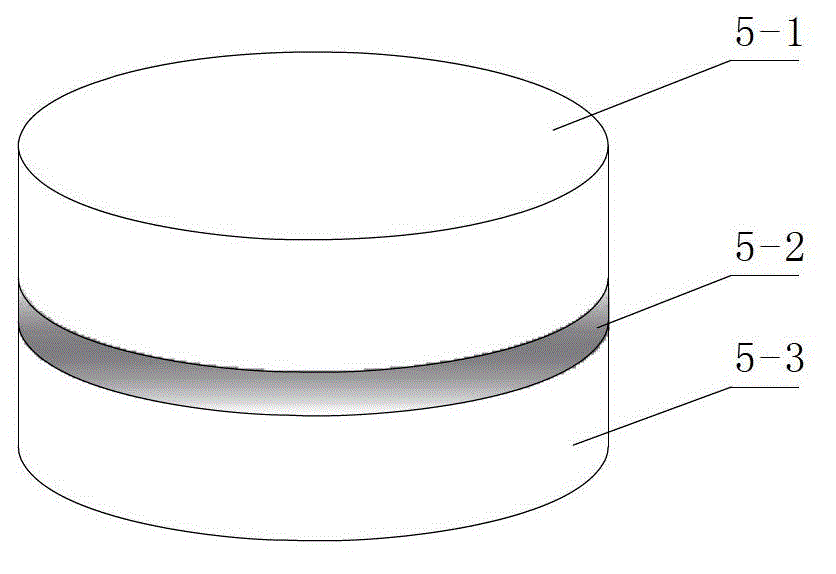

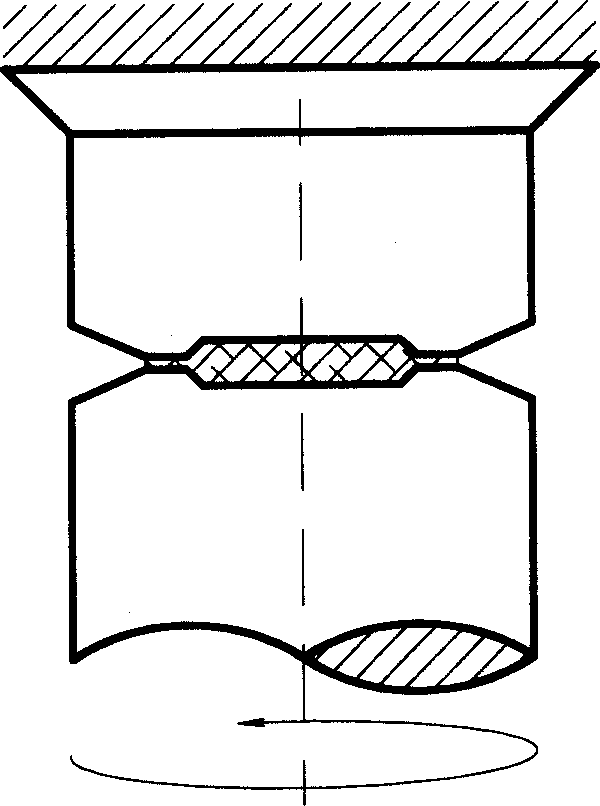

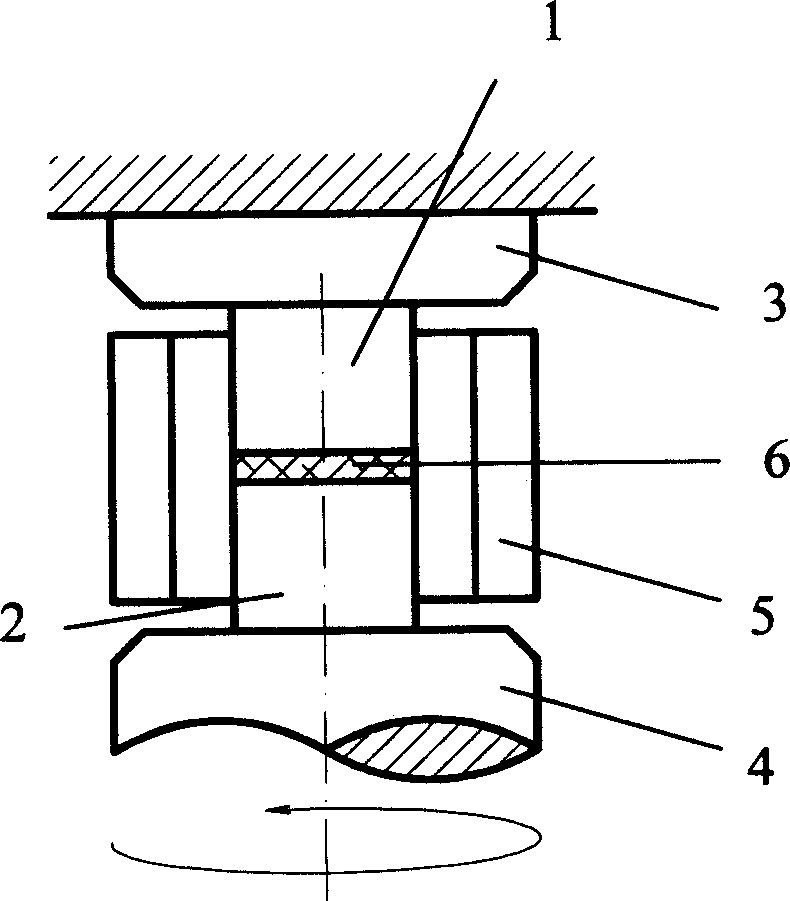

High pressure torsion test method capable of fining sample grain

InactiveCN1731131AImprove carrying capacityNo change in thicknessPreparing sample for investigationInterference fitTorsion test

The invention discloses a high pressure deflection experimental method which can lead the sample grain refined. It comprises the following steps: 1) fixing cylinder-type up-and-down peg bars on the up-and-down rams of the presser, wherein one of the up-and-down peg bars can rotate and the end part of the rams is after fur handle; 2) cover-fixing a flank ring on the up-and-down peg bars with zero gap matching; 3) depositing the sample inside the flank ring and between the up-and-down peg bars, wherein the sample and the flank ring have the same internal diameter; 4) pressing 1-9GPa vertical pressure to the sample by presser and then keeping it and rotating the ram 0.1-10 loops.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

Multi-degree-of-freedom bionic piezoelectric drive device

ActiveCN102291039AImprove rigidityImprove dynamic characteristicsPiezoelectric/electrostriction/magnetostriction machinesTorsion testMicroelectromechanical systems

The invention relates to a multi-degree-of-freedom bionic piezoelectric driver, which belongs to the field of precision machining. The multi-degree-of-freedom bionic piezoelectric driver comprises a case, a stator and a rotor, and is based on a stepping operation mode, the stator does not have embedded elements, and by utilizing the combined action of the forward thrust of piezoelectric stacks and the backward resilient force of flexible hinges, the multi-degree-of-freedom bionic piezoelectric driver realizes the forward and backward motion and axial linear motion of the rotor of the driver. In addition, in terms of the tests of micro-characteristics of materials, the driver can simultaneously carry out the nano-level elongation and torsion tests of fine materials. Based on inchworm type piezoelectric drive, the multi-degree-of-freedom bionic piezoelectric driver has high-precision positioning and repetitive positioning capability, and can be applied in the fields of ultraprecision machining machine tools, the testing of nano mechanical properties of material test specimens, microelectromechanical systems, precision optics, aeronautics and astronautics, robots and the like. The driving precision of ordinary drivers can be greatly increased, and the multi-degree-of-freedom bionic piezoelectric driver has the advantages of high displacement control precision, quick response, high driving force, low driving power, wide operating frequency, low cost, little investment, quick return, high benefit and the like.

Owner:吉林大学重庆研究院

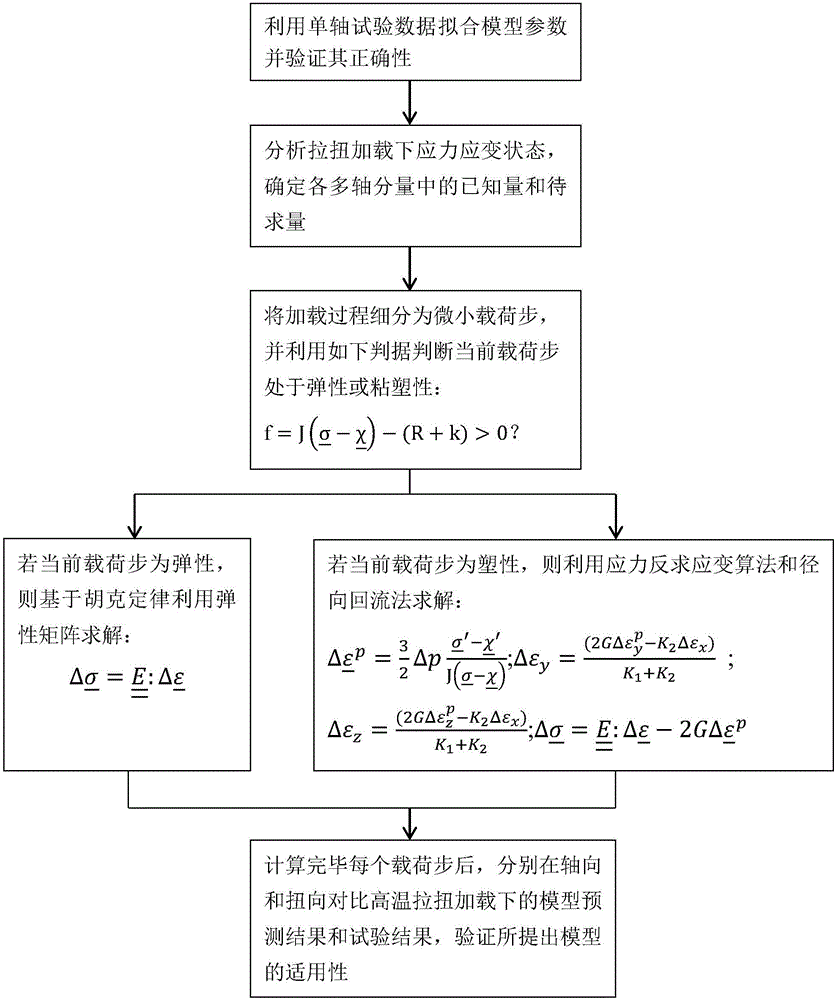

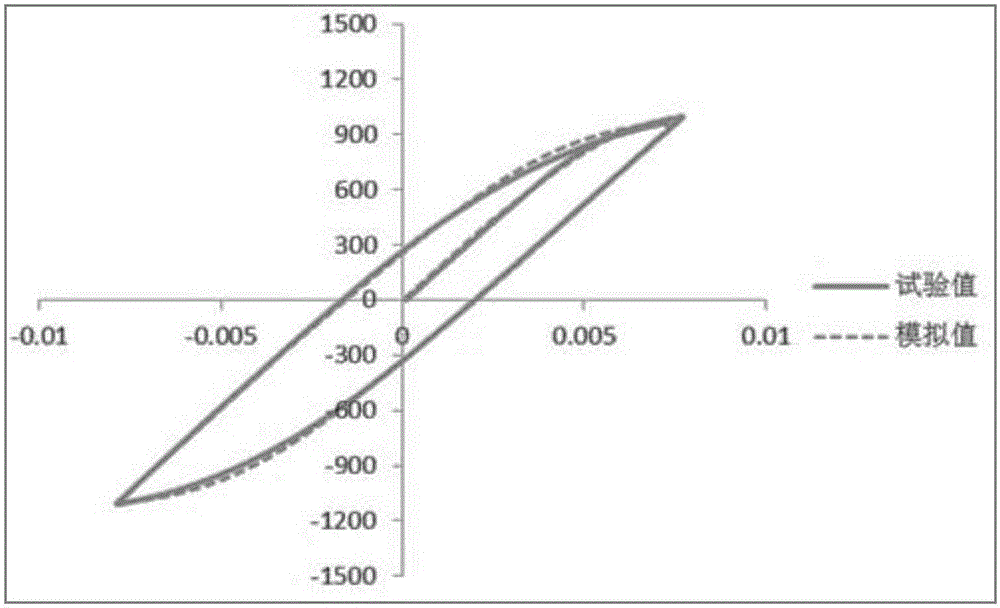

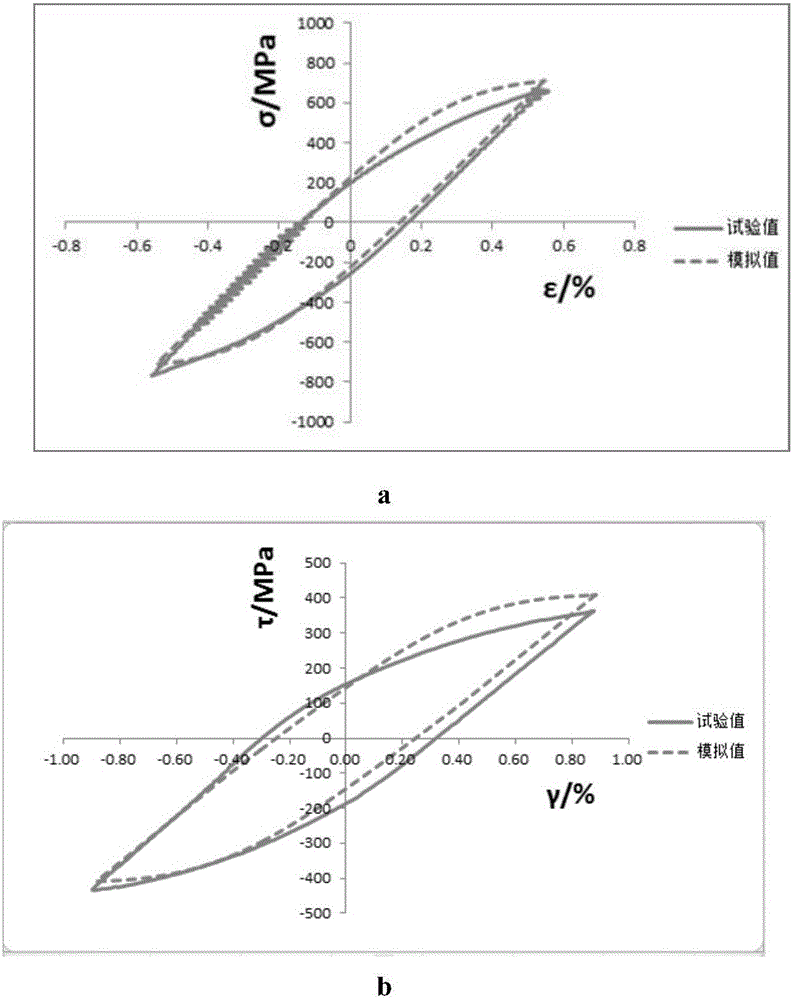

Method for modeling high-temperature multi-axis stress and strain relationship under tension and torsion loads

ActiveCN106769555AGood effectMaterial strength using repeated/pulsating forcesElastic matrixHysteresis

The invention discloses a method for modeling high-temperature multi-axis stress and strain relationship under tension and torsion loads. The method comprises the following steps of utilizing single-axis test data to fitting model parameters, and utilizing a single-axis stress and strain hysteresis loop to verify; analyzing the stress and strain states of each multi-axis component under the tension and tension loads; refining the loading process into enough load steps, and utilizing a yield criterion to judge whether each load step is elastic loading or non-elastic loading; for elastic loading step, utilizing an elastic matrix and a Hooke's law multi-axis type to solve the multi-axis stress states; for plastic loading step, utilizing a stress return algorithm to calculate the multi-axis strain increment, and utilizing a radial backflow method to solve the multi-axis stress state; according to the model predicting result and the stress and strain hysteresis loop drawn by the high-temperature tension and torsion test results, finding that the plastic strain and stress peak and valley values are close to the loop shape. After proofing by predicting results, the method can well calculate the high-temperature multi-axis stress and strain relationship under tension and torsion loads.

Owner:BEIJING UNIV OF TECH

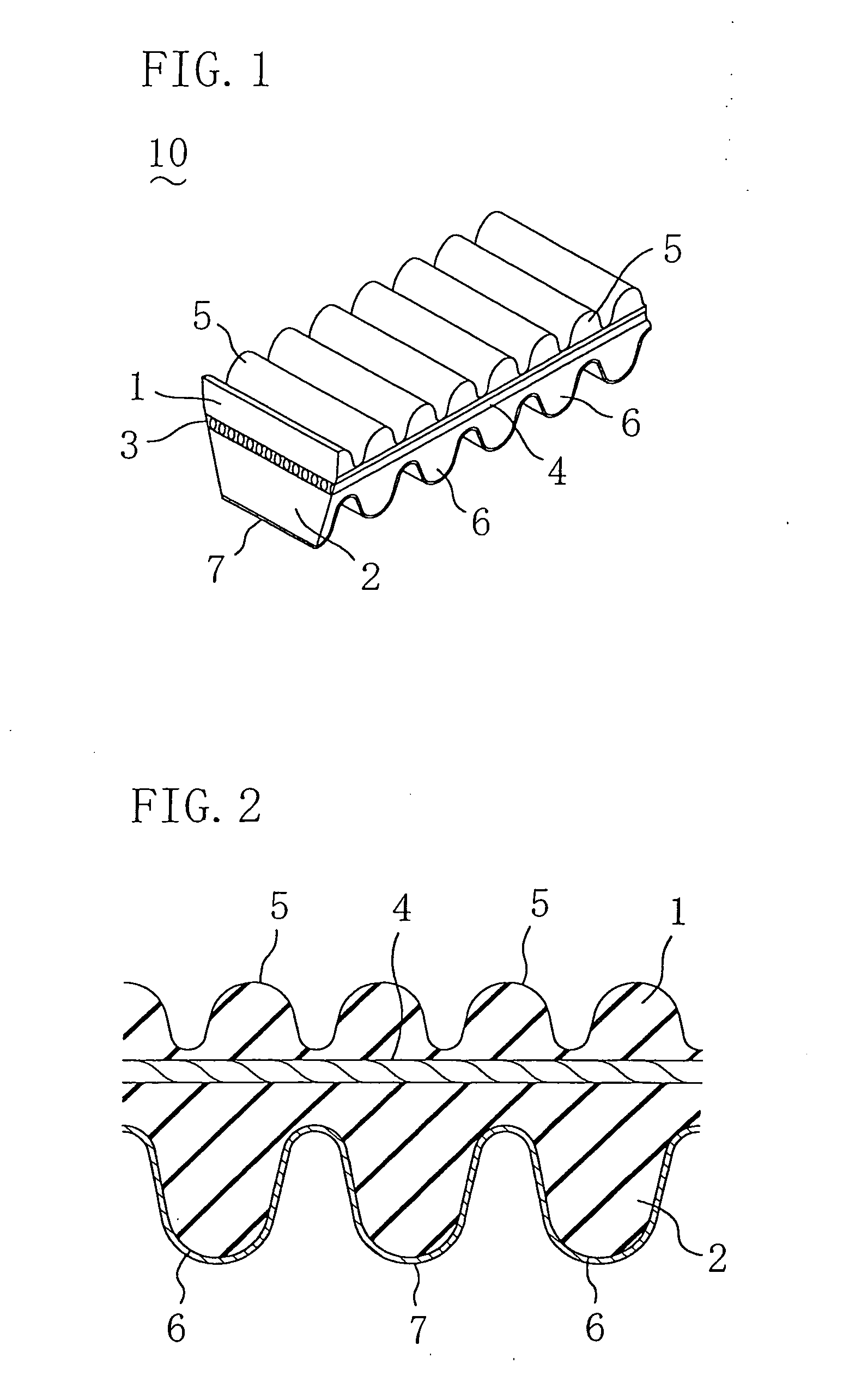

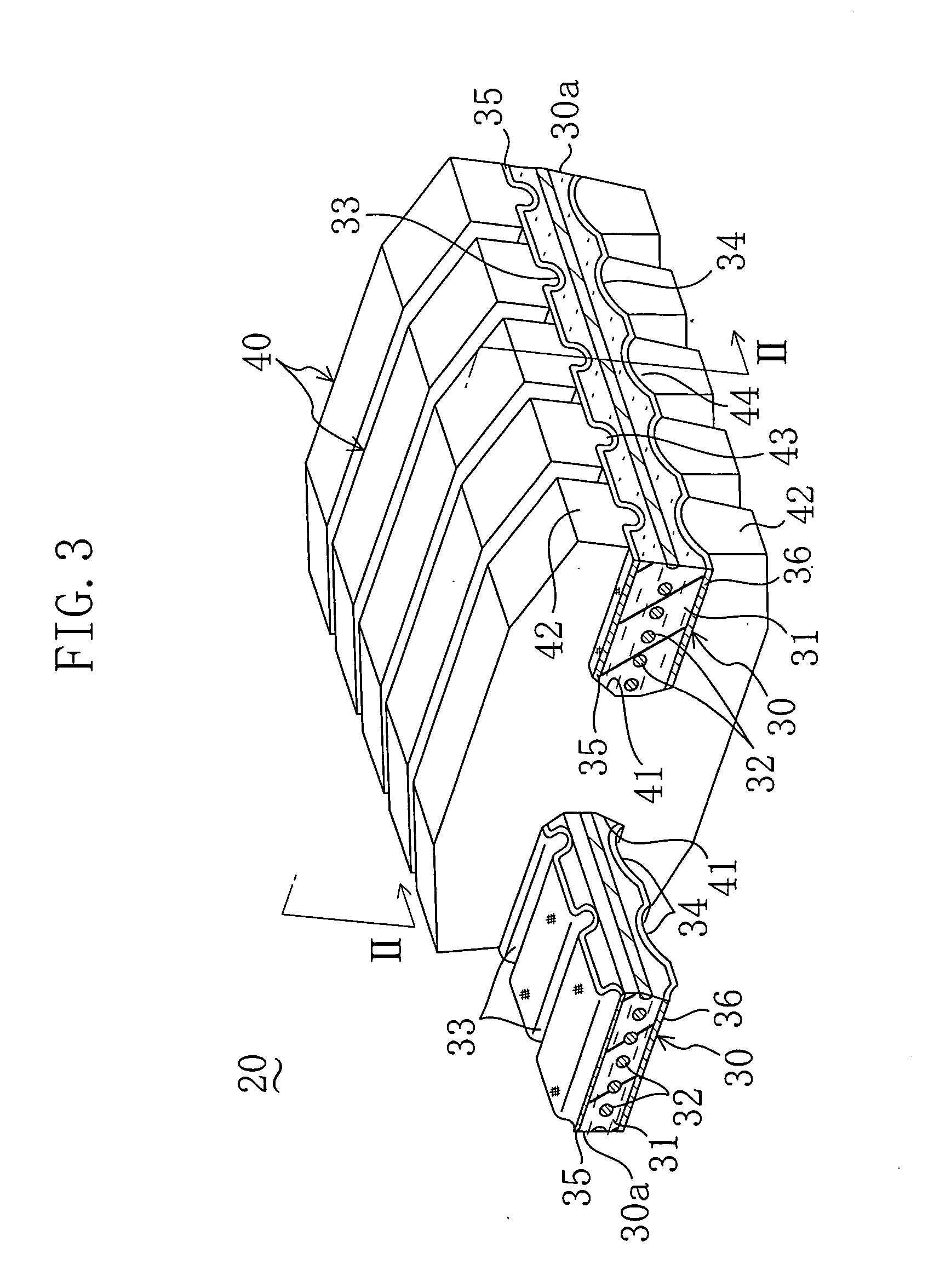

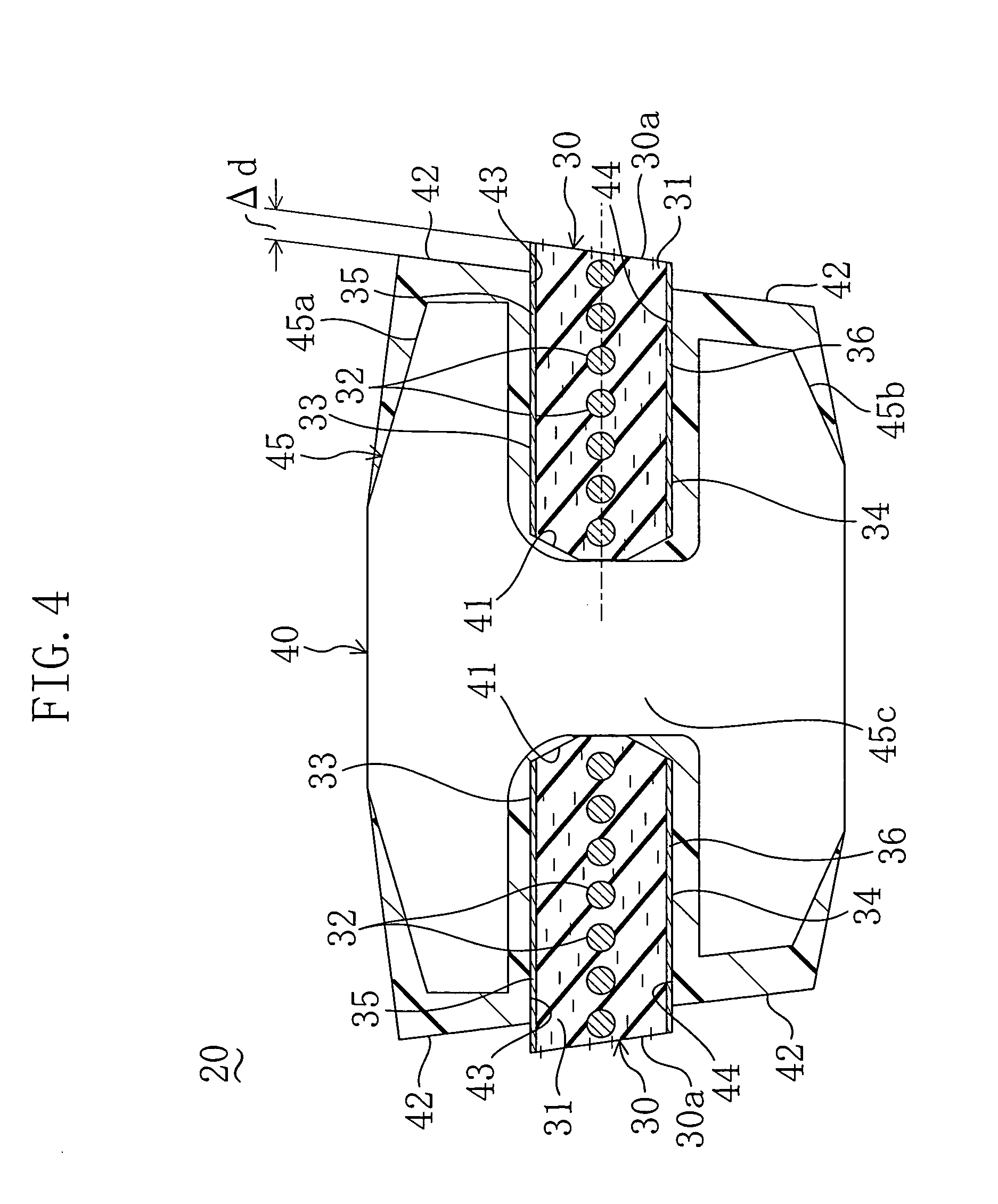

Rubber composition for high-load transmission belt and high-load transmission belt from the rubber composition

ActiveUS20050043486A1Improve balanceImprove cold resistanceV-beltsRopes and cables for vehicles/pulleyFiberTorsion test

This invention has an object of enhancing the cold resistance of a heavy duty power transmission V-belt without impairing its durability at high temperatures, ensuring its sufficient power transmission capability and concurrently enhancing its permanent set resistance. To attain the object, the invention employs, for a rubber element of the belt, a rubber composition in which 20 to 40 parts by weight of a metal salt monomer of an organic acid and 5 to 35 parts by weight of short fibers are mixed into 100 parts by weight of a rubber component composed of EPDM and HNBR in their ratio of 55 / 45 to 75 / 25, the rubber hardness measured with a durometer Type D is 40 to 60, the value of t5 given by a Gehman torsion test is −50° C. to −35° C., and the amount of acetone extract from the rubber component is 9% or less.

Owner:BANDO CHEM IND LTD

Movable ocean engineering flexible pipe cable torsion test device

ActiveCN105466792AOptimal control methodEffortless controlStrength propertiesTorsion testEngineering

The invention discloses a movable ocean engineering flexible pipe cable torsion test device. The movable ocean engineering flexible pipe cable torsion test device comprises a fixing end support, two fixing supports and a multi-stage gear, wherein the fixing end support, the two fixing supports and the multi-stage gear are sequentially and linearly arranged. The multi-stage gear is connected with a supporting table through a rack I. The supporting table is provided with an actuator and is further provided with a rack support I and a rack support II. The rack support I comprises a rack fixing plate I. The rack support II comprises a rack fixing plate II. Guide rails II parallel with guide rails I are arranged between the rack fixing plate I and the rack fixing plate II and are provided with a rack II pressing the multi-stage gear on the rack I. The lower ends of the fixing supports are provided with guide rails III perpendicular to the guide rails I. According to the movable ocean engineering flexible pipe cable torsion test device, the actuator drives the racks to complete rotation of the gear, operation is more convenient, labor is saved, operation is precise, torque loading is more flexible, and the movable ocean engineering flexible pipe cable torsion test device can be used for torsion testing of various pipe cables.

Owner:DALIAN UNIV OF TECH

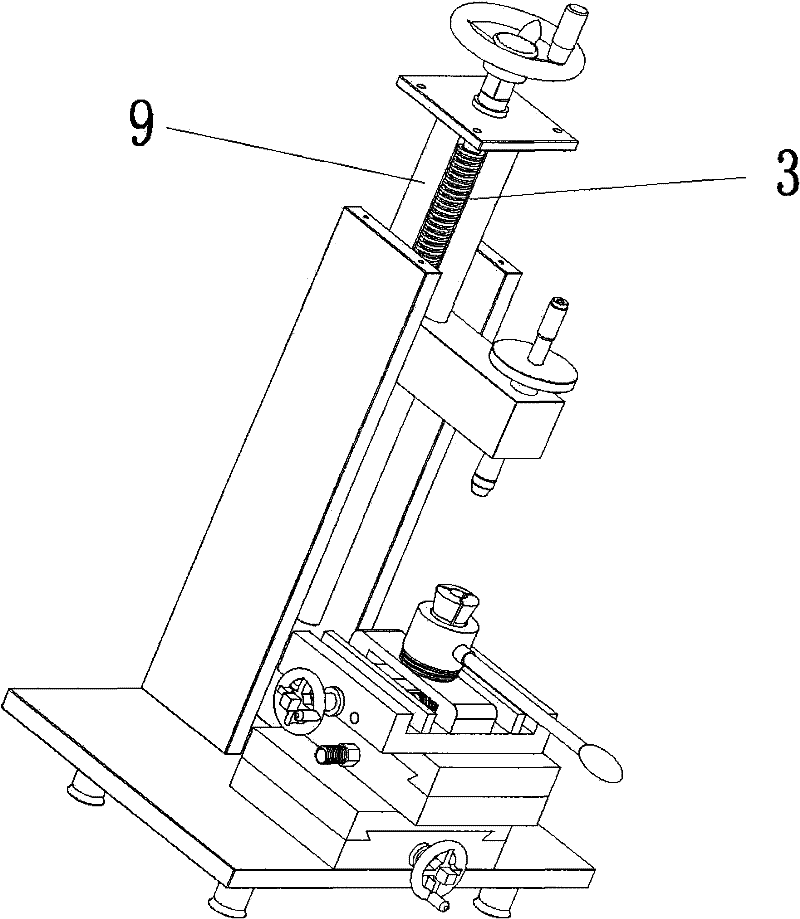

Torque test device

InactiveCN102288344AImprove fitImprove accuracyApparatus for force/torque/work measurementTorsion testEngineering

The invention discloses a torsion test device, which comprises a base, an XY regulating unit, a Z regulating unit, a clamping device and a torsion measuring unit, wherein the clamping device is arranged on the XY regulating unit and can move in the horizontal direction along the XY regulating unit, and the torsion measuring unit is arranged on the Z regulating unit and can move in the vertical direction along with the Z regulating unit. The torsion test device has the advantages that the three-dimensional regulation is adopted, so an object to be measured is preferably matched with the measuring unit, the fault and the danger caused by manual operation are avoided, and the accuracy of measurement results is improved. In addition, because the clamping device has high flexibility, and various measurement requirements can be met.

Owner:QINGDAO CENT TESTING INT CO LTD

Method for judging failures of spot-welded joint under recombination action

InactiveCN104785947AImprove simulation accuracyAccurately predict solder joint failuresResistance welding apparatusTorsion testReliability engineering

The invention provides a method for judging failures of a spot-welded joint under the recombination action. The method includes the following steps that firstly, a sample is prepared; secondly, a double-U-type spot-welded sample test is carried out; thirdly, an edgefold stripping test is carried out; fourthly, a torsion test is carried out; fifthly, a welding spot nugget diameter test is carried out; sixthly, failure criteria parameter processing based on resultant force is carried out; seventhly, failure criteria parameter processing based on stress is carried out. By means of the method for judging failures of the spot-welded joint under the recombination action, the failure conditions of the welding spot can be accurately predicted, and the simulation precision of car collision is improved.

Owner:SHANGHAI UNIV

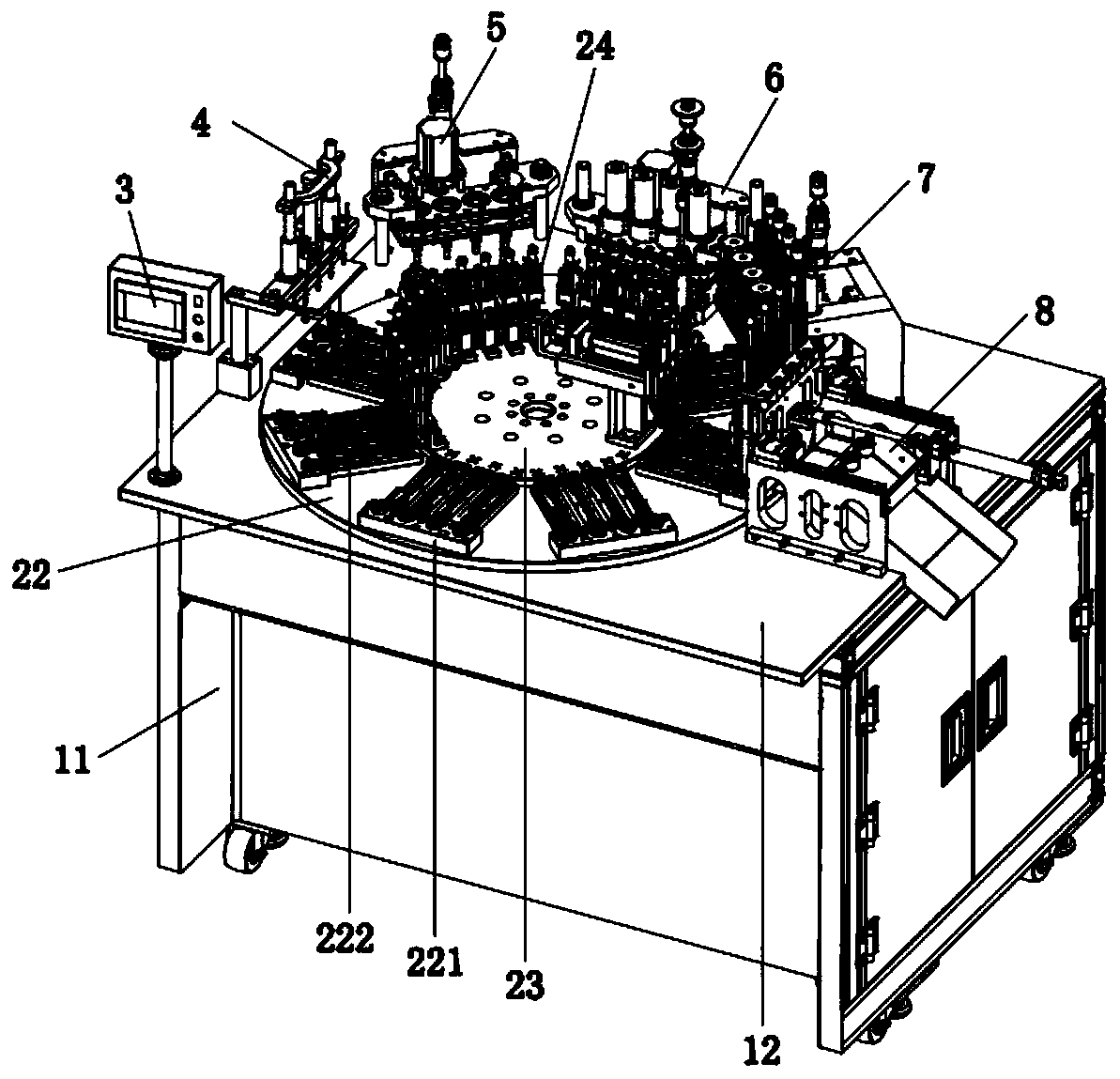

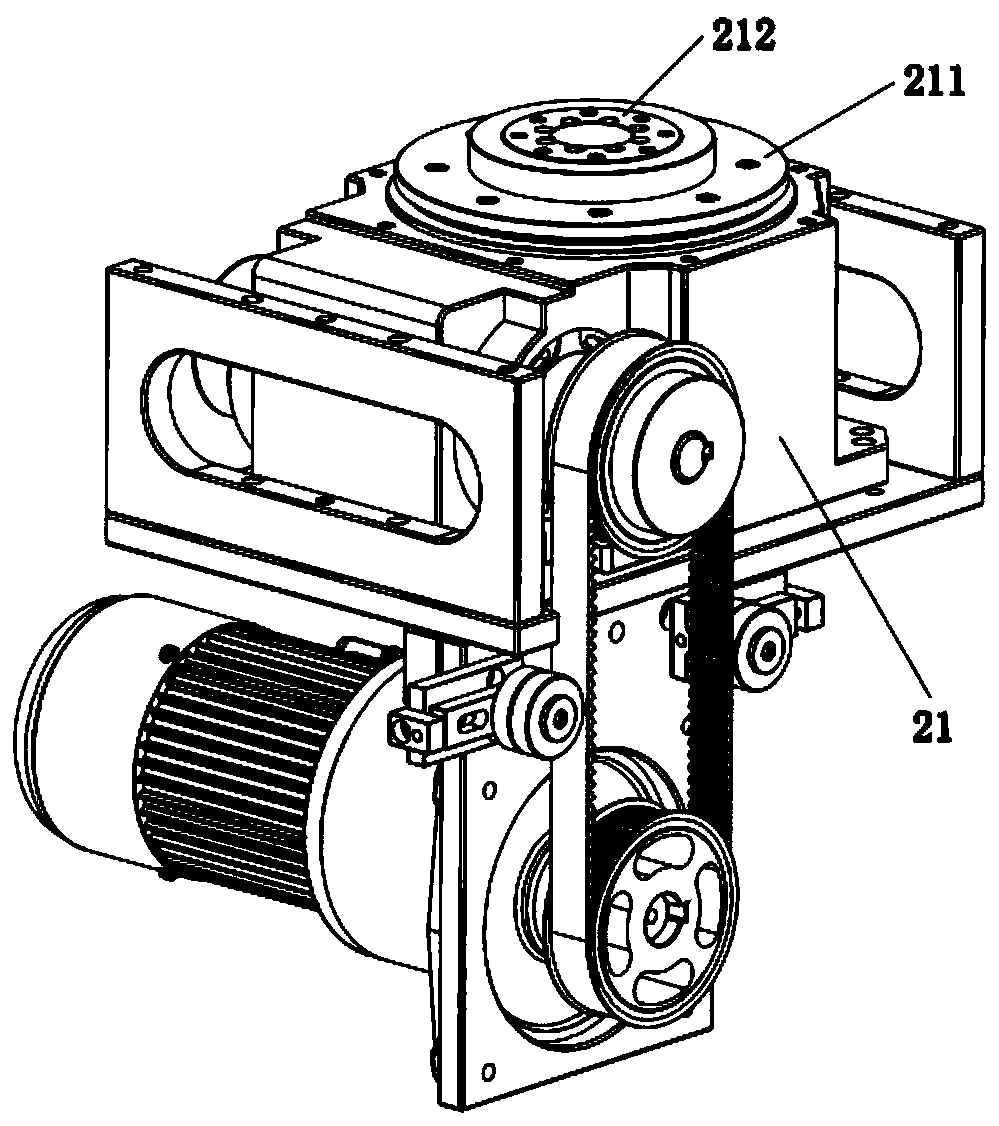

Motor performance detection device

PendingCN110261775ALow production costAdapt to production needsTesting dielectric strengthStructural/machines measurementMotor testingTorsion test

The invention discloses a motor performance detection device. The motor performance detection device comprises a cabinet and a rotating device, the cabinet comprises a cabinet body and a workbench; a feeding area, an impedance test area, a pressure-resistant test area, a main shaft positioning area, a torsion test area, a lifting force test area, a good product unloading area and a defective product unloading area are sequentially distributed on the workbench; the rotating device comprises a driving mechanism and a test disc; the test disc is driven to rotate by the driving mechanism; a plurality of jigs for placing a motor to be detected are arranged on the test disc; and each jig sequentially enters the impedance test area, the pressure-resistant test area, the main shaft positioning area, the torsion test area, the lifting force test area, the good product unloading area and the defective product unloading area from the feeding area along with the rotation of the test disc. The motor testing device can automatically perform impedance testing, pressure resistance testing, torsion performance testing, lifting force performance testing and unloading after the testing is finished in sequence, the time required for finishing various performance tests is short, the testing efficiency is high, and the working strength of testing personnel and the production cost of the motor are reduced.

Owner:XIAMEN DAZHEN MOTOR

Cantilever crane torsion test device

InactiveCN101881717ASimple structureEasy to operateMaterial strength using repeated/pulsating forcesCranesTorsion testCantilever

The invention provides a cantilever crane torsion test device, which comprises a large cantilever crane, a test cantilever crane, a first fixing tool, a second fixing tool, two loading oil cylinders, a loading plate, a rotation shaft and a rotary supporting bracket, wherein the test cantilever crane is smaller than the large cantilever crane, one end of the test cantilever crane is fixed on the large cantilever crane through the first fixing tool, and the other end is fixedly connected with the loading plate; one end of the rotation shaft passes through a central through hole of the loading plate, and the other end is connected on the rotation supporting bracket; the rotation bracket is fixed on the lower part of the large cantilever crane; and the two loading oil cylinders are symmetrically connected on two ends of the loading plate, and the loading oil cylinder is fixed on the upper part of the large cantilever crane through the second fixing tool. The cantilever crane torsion test device has simple structure and convenient operation, and can effectively perform the torsion deformation test of the cantilever crane.

Owner:ZHEJIANG SANY EQUIP

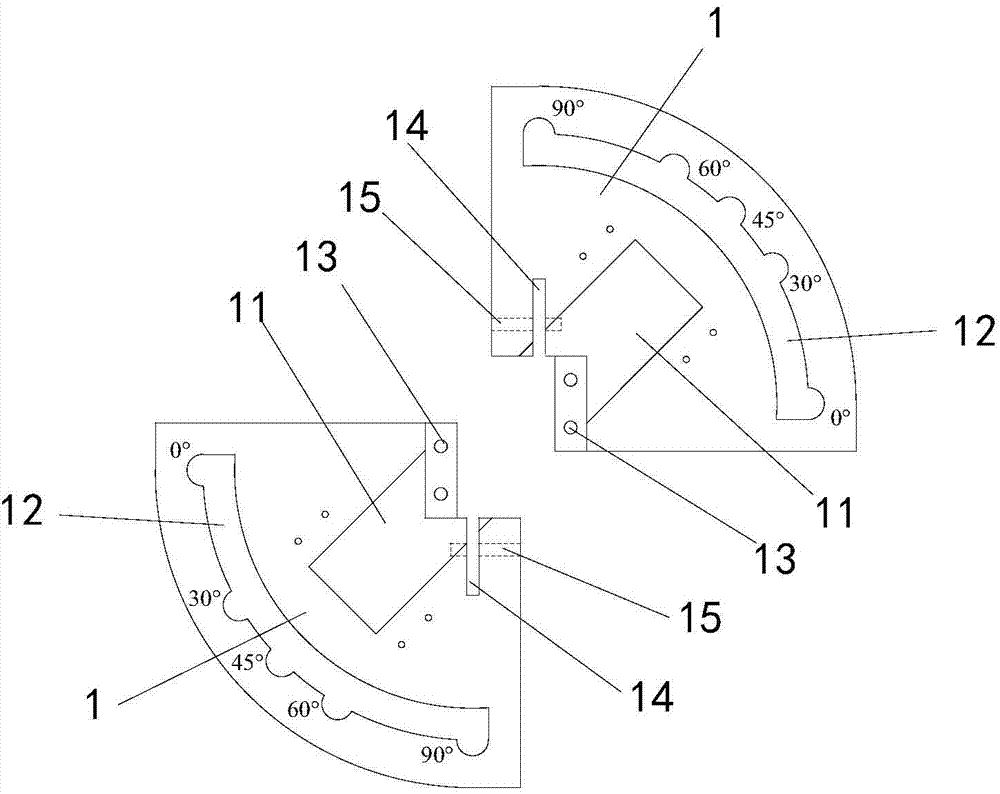

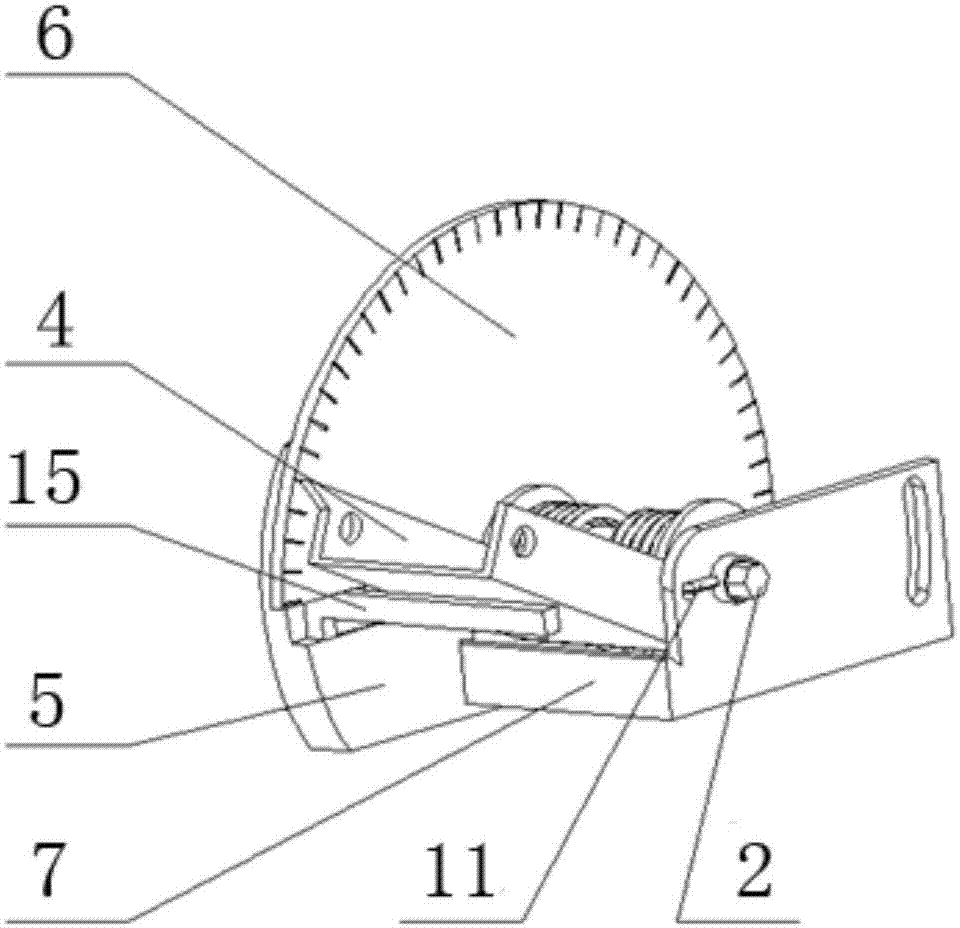

Torsion spring angle and torque testing system

ActiveCN107966286AIntuitive reading angle sizeThe value can be adjustedMachine part testingAngles/taper measurementsTorsion testControl theory

Owner:HUBEI SANJIANG AEROSPACE HONGFENG CONTROL

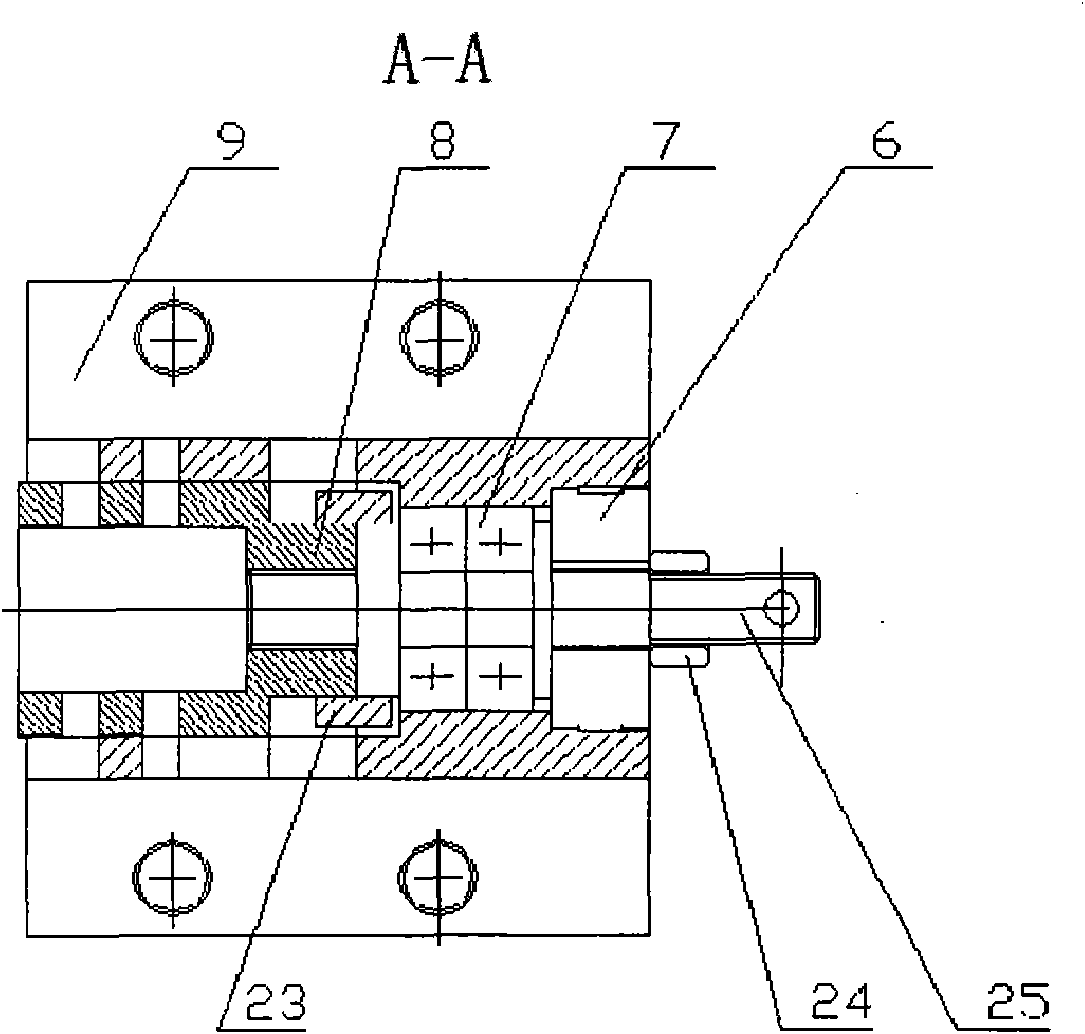

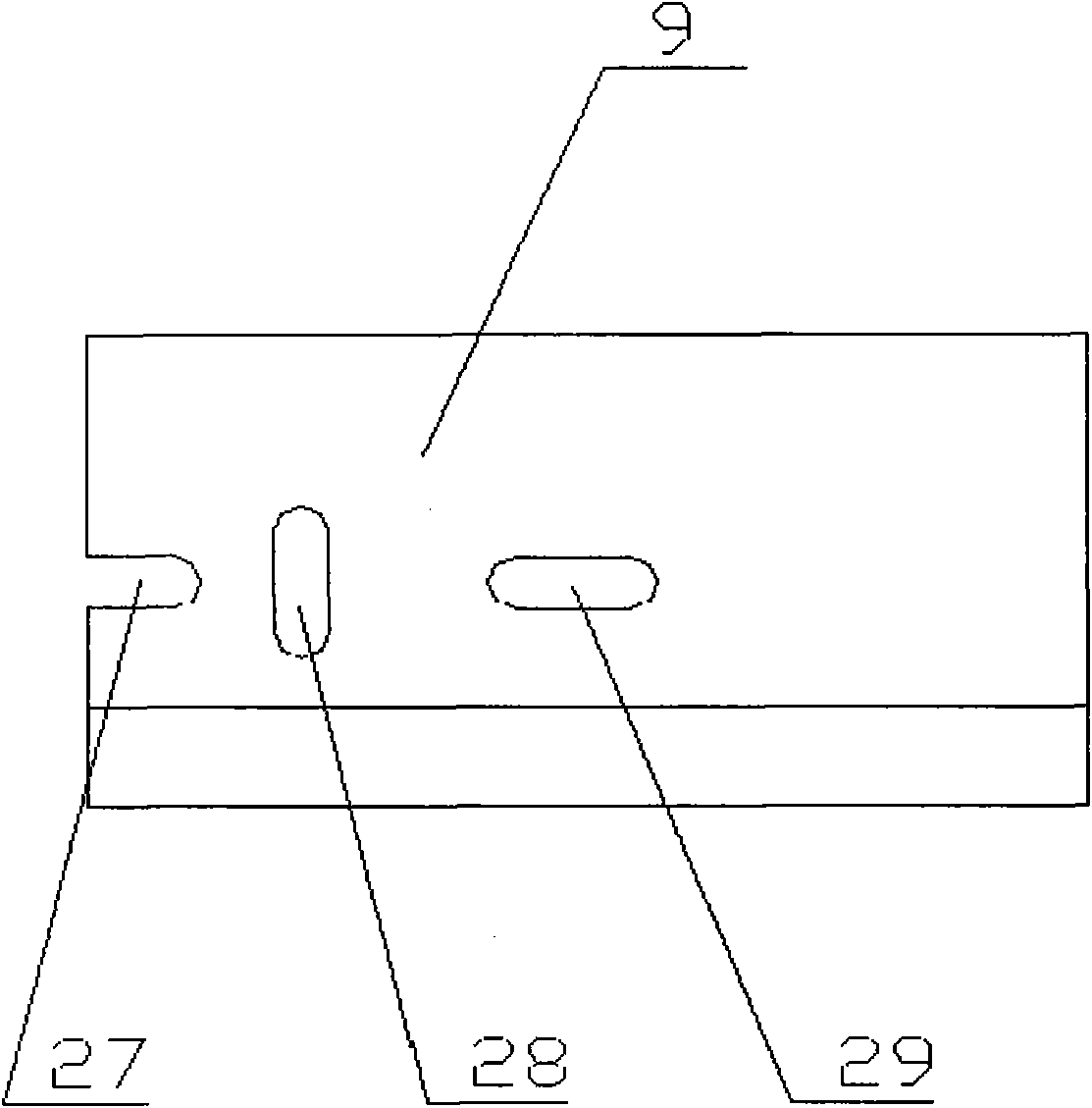

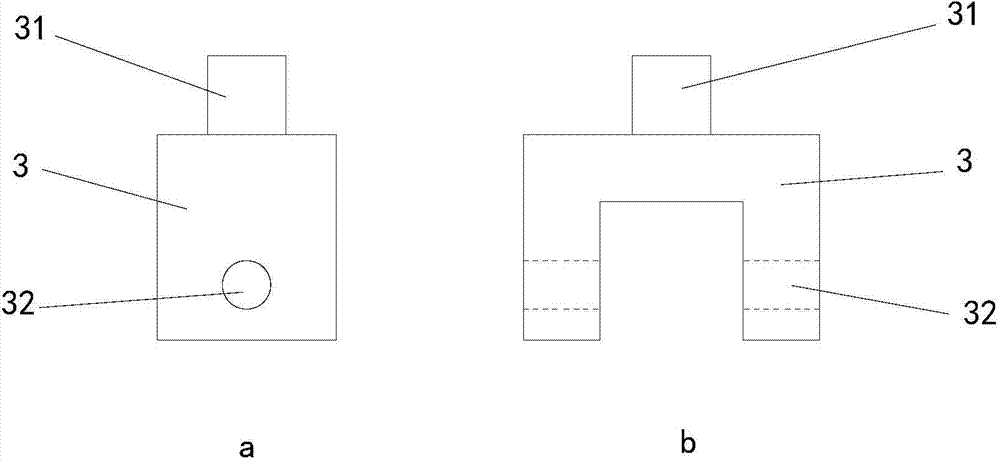

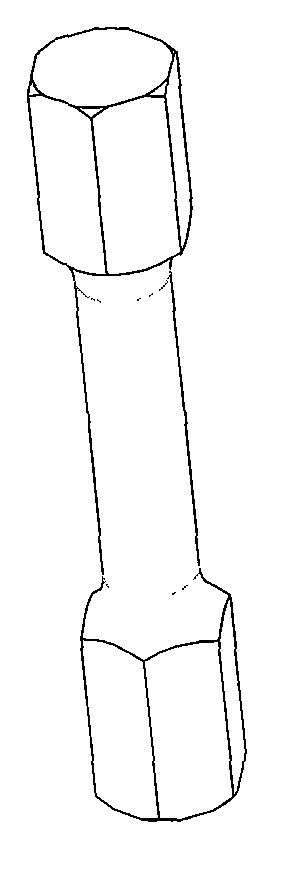

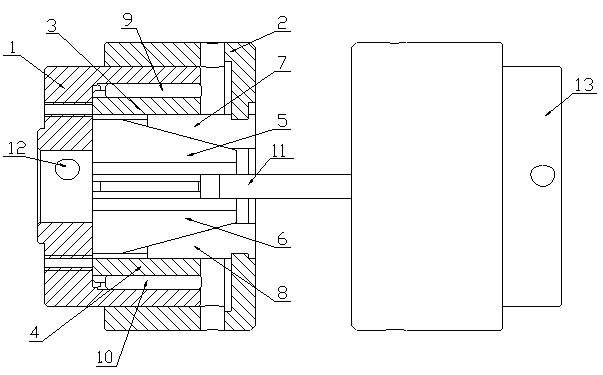

Tension-torsion test specimen fixture

The invention discloses a tension-torsion test specimen fixture, which comprises an upper chuck, a lower chuck and a tension-torsion test specimen, the upper chuck and the lower chuck are respectively provided with upper jaws and lower jaws, an upper clamped section of the tension-torsion test specimen is fixed by the upper jaws of the upper chuck, a lower clamped section of the tension-torsion test specimen is fixed by the lower jaws of the lower chuck, the upper clamped section of the tension-torsion test specimen is provided with upper test specimen key slots, the lower clamped section of the tension-torsion test specimen is provided with lower test specimen key slots, the upper jaws of the upper chuck are provided with upper jaw key slots corresponding to the upper test specimen key slots, the lower jaws of the lower chuck are provided with lower jaw key slots corresponding to the lower test specimen key slots, keys are mounted between the upper test specimen key slots and the upper jaw key slots, and keys are mounted between the lower test specimen key slots and the corresponding lower jaw key slots. The tension-torsion test specimen-clamping effect of the jaws of the tension-torsion test specimen fixture is good, the shapes of the clamped sections of the test specimen are not limited, the structure is simple, clamping does not need mechanical power, mechanical operation noise does not exist, the environment cannot be affected, and both the purchase cost and the use cost are low.

Owner:烟台力尔自动化设备有限公司

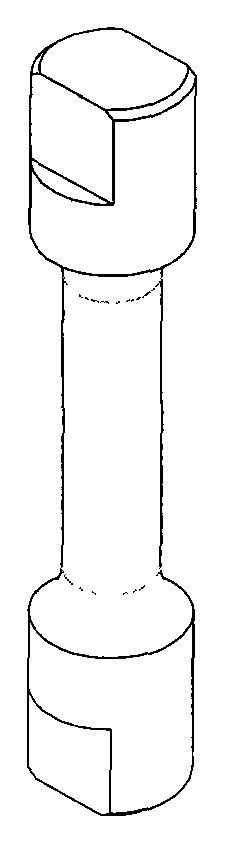

Clamp used for test piece sample in function material microscopic performance in-situ testing

ActiveCN104089815ARealize the loadRealize dynamic real-time detectionStrength propertiesTorsion testFatigue loading

The invention relates to a clamp used for a test piece sample in function material microscopic performance in-situ testing, and belongs to the technical field of material microscopic performance testing and the technical field of mechanical and electronic integration. The clamp comprises clamp bodies, screwing sleeves, linings, pins, compacting wedge blocks, clamping wedge blocks, and other components. The screwing sleeves are connected to the clamp bodies and the compacting wedge blocks. The linings are in the clamp cavities and are connected to the internal circular surfaces of the clamp bodies. The linings are connected to the compacting wedge blocks and the clamping wedge blocks. The clamp is advantageous in that: clamping of the test piece sample in stretching tests, compression tests, torsion tests, and other single-load tests is achieved, clamping of the test piece sample in stretching-torsion tests, compression-torsion tests, stretching / compression-torsion tests, and other composite-load tests and corresponding fatigue loading tests is achieved; and the clamp is compatible with thermal field loading units, electric field loading units, magnetic field loading units, and other physical field loading units and therefore loading and testing of multiple physical fields and multiple loading modes for a test piece sample to be tested can be achieved. The clamp is compact in structure, convenient in operation and high in compatibility.

Owner:JILIN UNIV

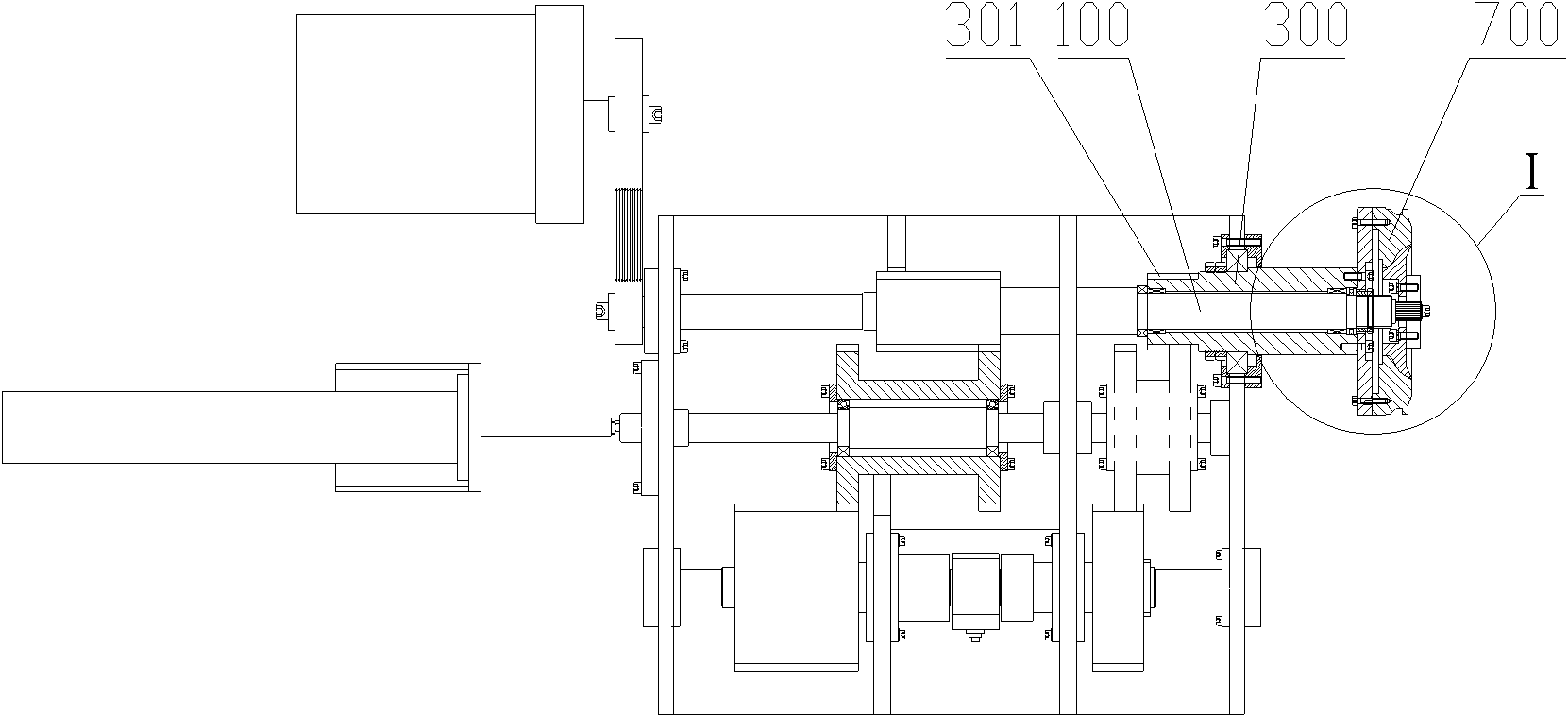

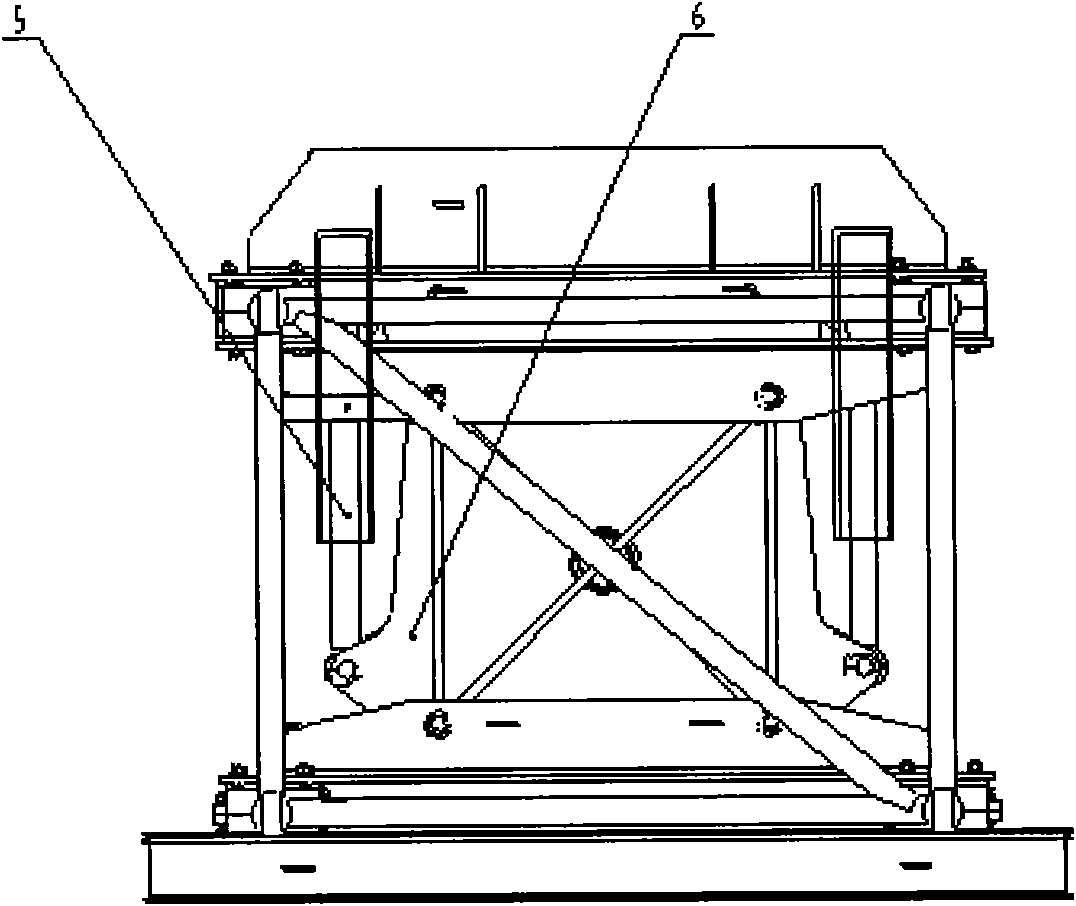

Precision material micro mechanical property in-situ torsion testing platform

ActiveCN103293066AReduce volumeSmall angle measurement errorStrength propertiesTorsion testEngineering

The invention relates to a precision material micro mechanical property in-situ torsion testing platform and belongs to the field of machinery. According to a torsion loading mechanism, a torque is loaded at one end of a driving clamp and is loaded to a testing workpiece; one end of a driven clamp is arranged on a precision guide rail slide block and has a degree of freedom in the axis direction of the testing workpiece; a precision torque sensor is arranged at one end of the driven clamp; two belt wheels are arranged on the testing workpiece; the corners on two sides of the workpiece are respectively transmitted to two precision angular displacement sensors through belts; an angular displacement signal is fed back to a detection system; the absolute corner on the nominal dimension of the workpiece is calculated, the detection precision of the angular displacement in a torsion test is obviously improved, and adverse impact on the testing precision is greatly reduced. The electromagnetic compatibility and vacuum compatibility of a testing device and an electron microscope operating cavity are realized, the material in-situ micro-nano torsion mechanical testing is realized, and a good method is provided for testing the torsional mechanical properties of the material under the micro-nano scale.

Owner:长春因赛图精密仪器设备有限公司

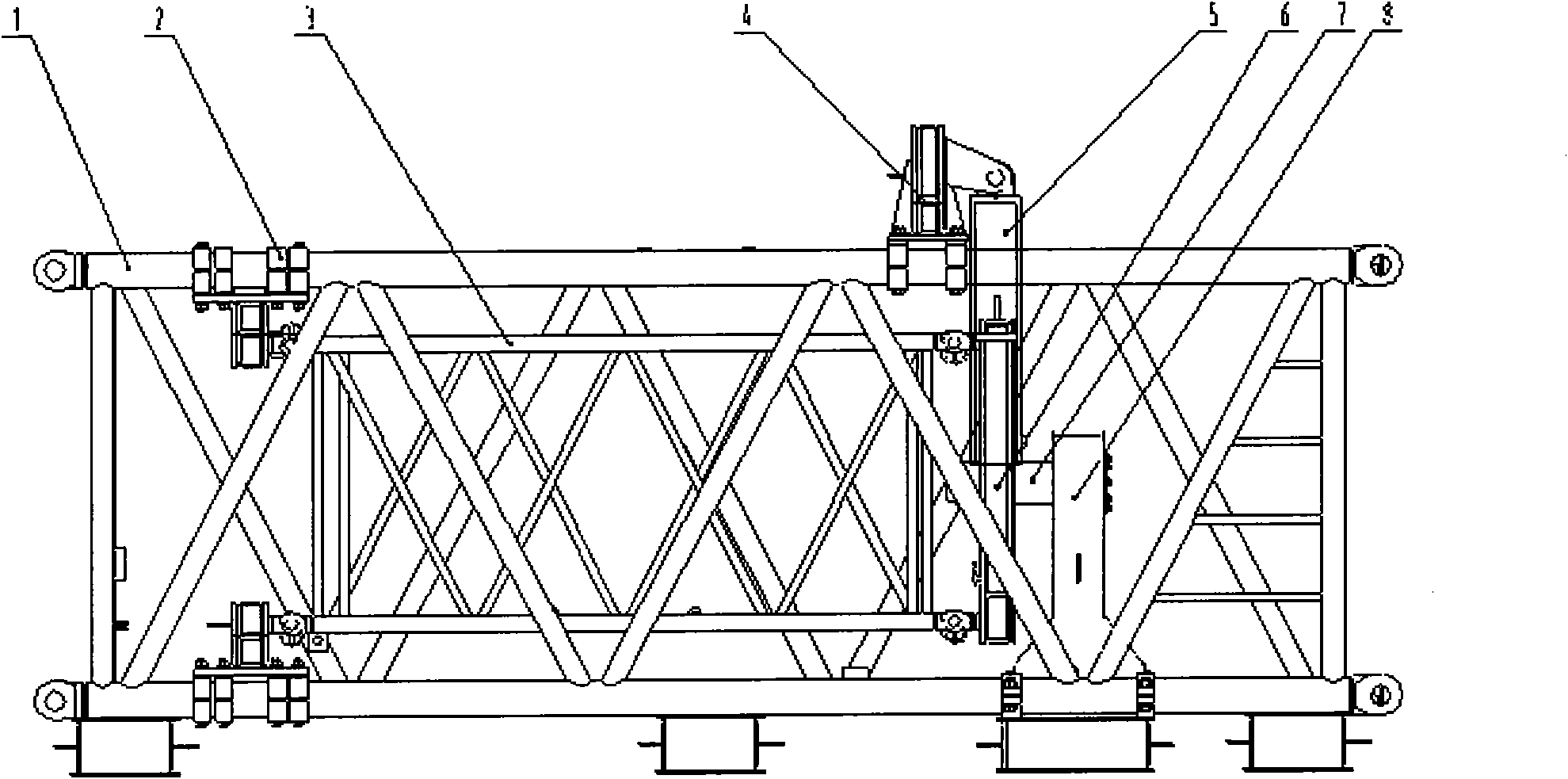

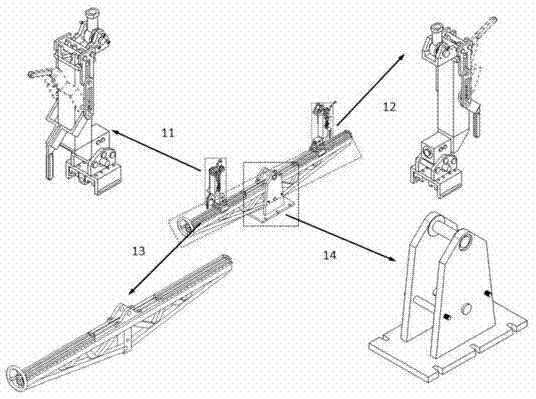

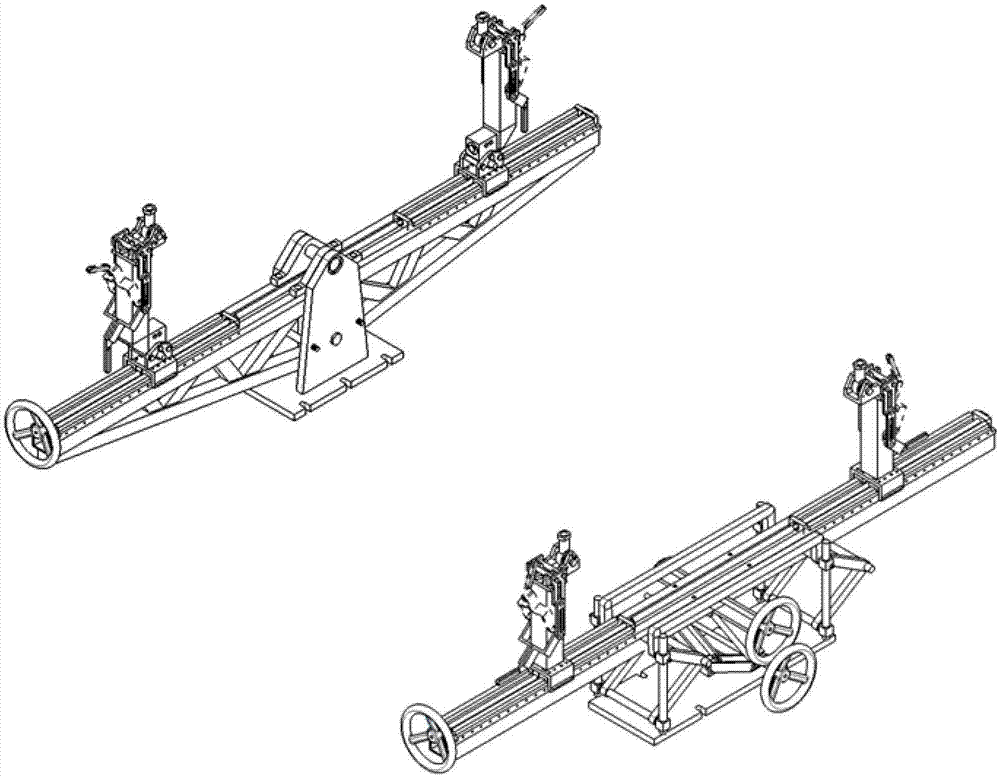

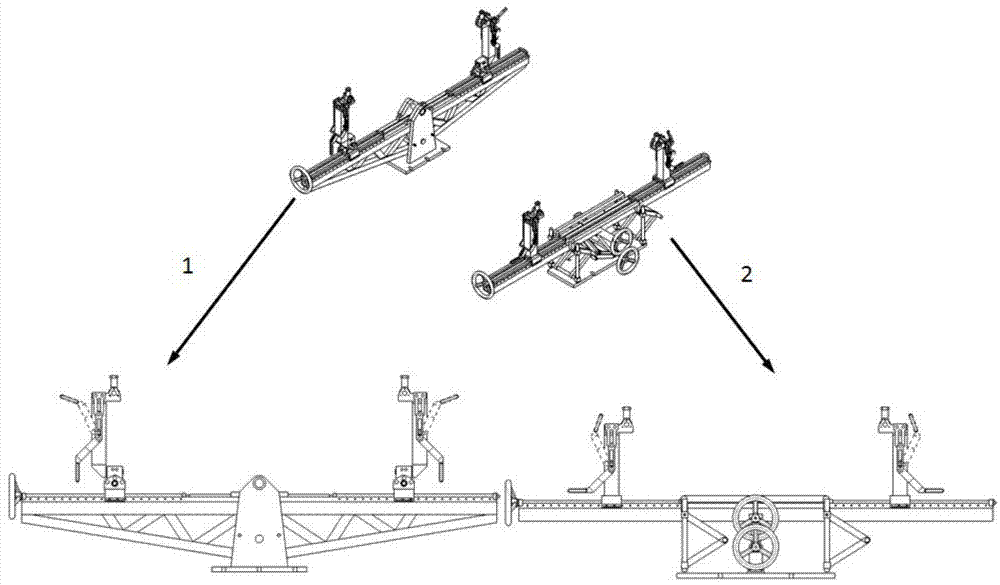

Finished automobile rigidity experiment bench and clamping method of experiment bench

ActiveCN103162969AReduce labor intensityEasily locate symmetrical positionsVehicle testingTorsion testEngineering

The invention discloses a finished automobile rigidity experiment bench. The finished automobile rigidity experiment bench comprises a front overhang bench (1) and a back overhang bench (2). The finished automobile rigidity experiment bench is characterized in that the front overhang bench (1) comprises a front left bracket assembly (11), a front right bracket assembly (12), a front overhang bench cantilever assembly and a regulating mechanism (13) and a front overhang bench support base assembly (14). The back overhang bench (2) comprises a back left bracket assembly (21), a back right bracket assembly (22), and a back overhang bench overall beam and a regulating mechanism (23), wherein the back left bracket assembly (21) and the back right bracket assembly (22) are respectively arranged on the left side and the right side of the back overhang bench overall beam and a regulating mechanism (23). Compared with the prior experiment bench, the finished automobile rigidity experiment bench does not need to clamp repeatedly in the process of conversion of a torsion test and a bending test, and only needs to regulate 3 corresponding control pins to finish the conversion. The clamping method of the experiment bench is simple, convenient and small in labor intensity.

Owner:HUNAN UNIV AISHENG AUTO TECH DEV

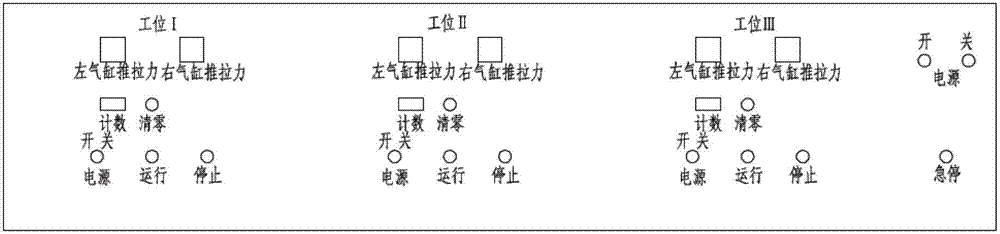

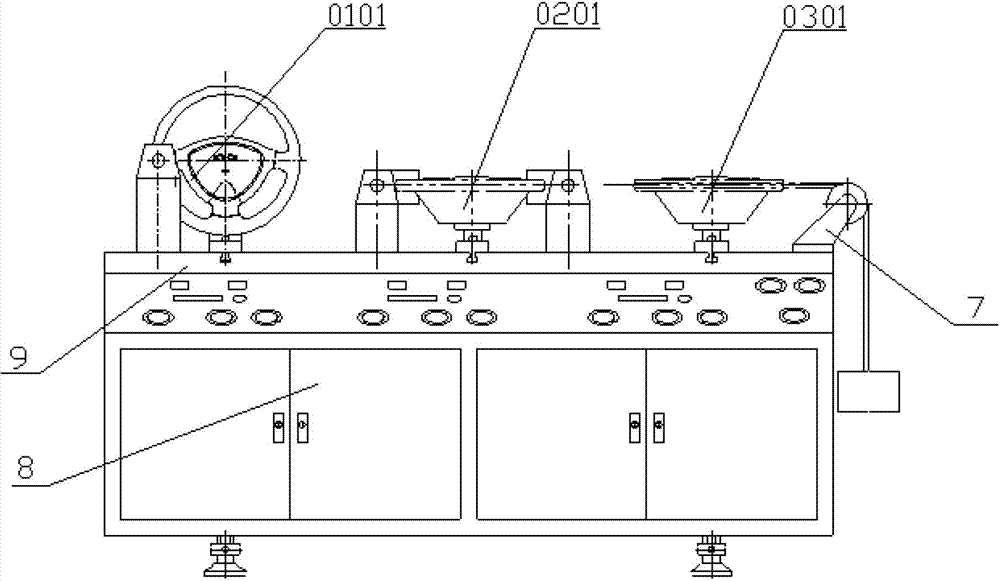

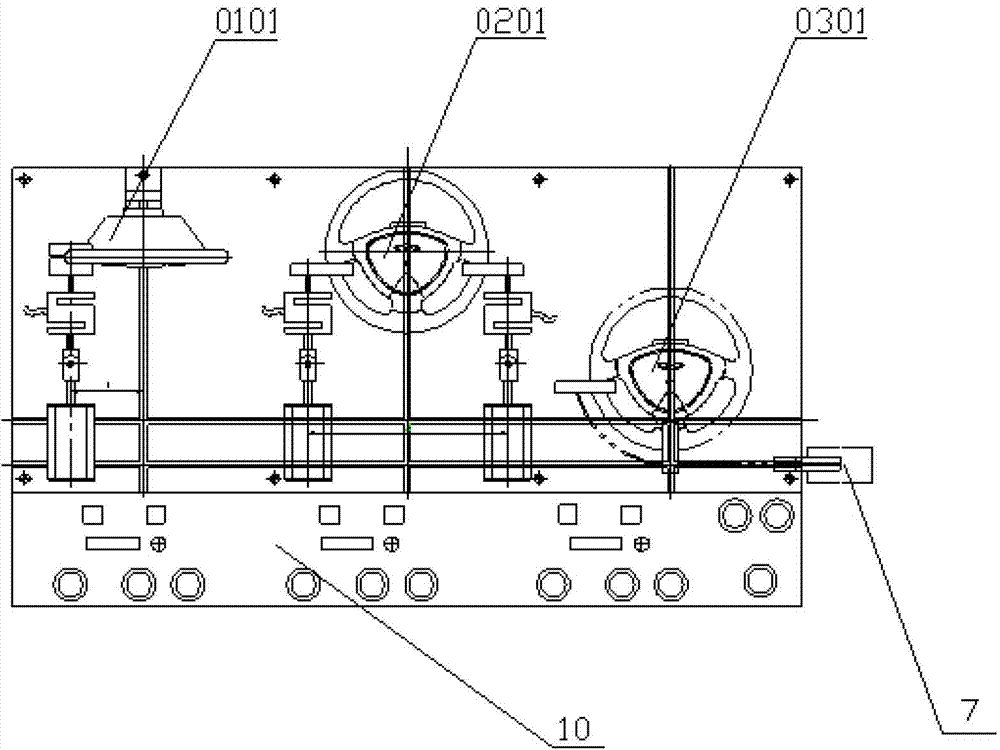

Comprehensive testing table of steering wheel

ActiveCN102788703ASpecification Performance TestReduce labor intensityVehicle testingMachine part testingTension compressionTorsion test

The invention relates to a comprehensive testing table of a steering wheel. The comprehensive testing table comprises a first working position, a second working position and a third working position which are mutually and independently arranged from left to right in sequence and respectively used for a torsional fatigue strength test of the steering wheel and / or a sinusoidal waveform load test and / or a contact switch endurance test and / or a static torsion test. The first working position comprises a cylinder, a digital readout instrument, a knuckle bearing, a tension-compression sensor and a steering wheel support, the steering wheel support is used for enabling the steering wheel to be vertically supported on the testing table, the cylinder is arranged on the testing table and used for moving so as to exert force on the steering wheel, the cylinder is connected with the tension-compression sensor through the knuckle bearing, and the tension-compression sensor is connected with one of the left side or the right side of the steering wheel.

Owner:CHERY AUTOMOBILE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com