Rubber bushing torsion test apparatus

A technology of rubber bushing and torsion test, which is used in measuring devices, testing of mechanical parts, testing of machine/structural parts, etc., can solve the problems of high cost, complex structure, difficult installation, etc., and achieves low cost and long service life. , the effect of easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further elaborated below according to the drawings and specific embodiments.

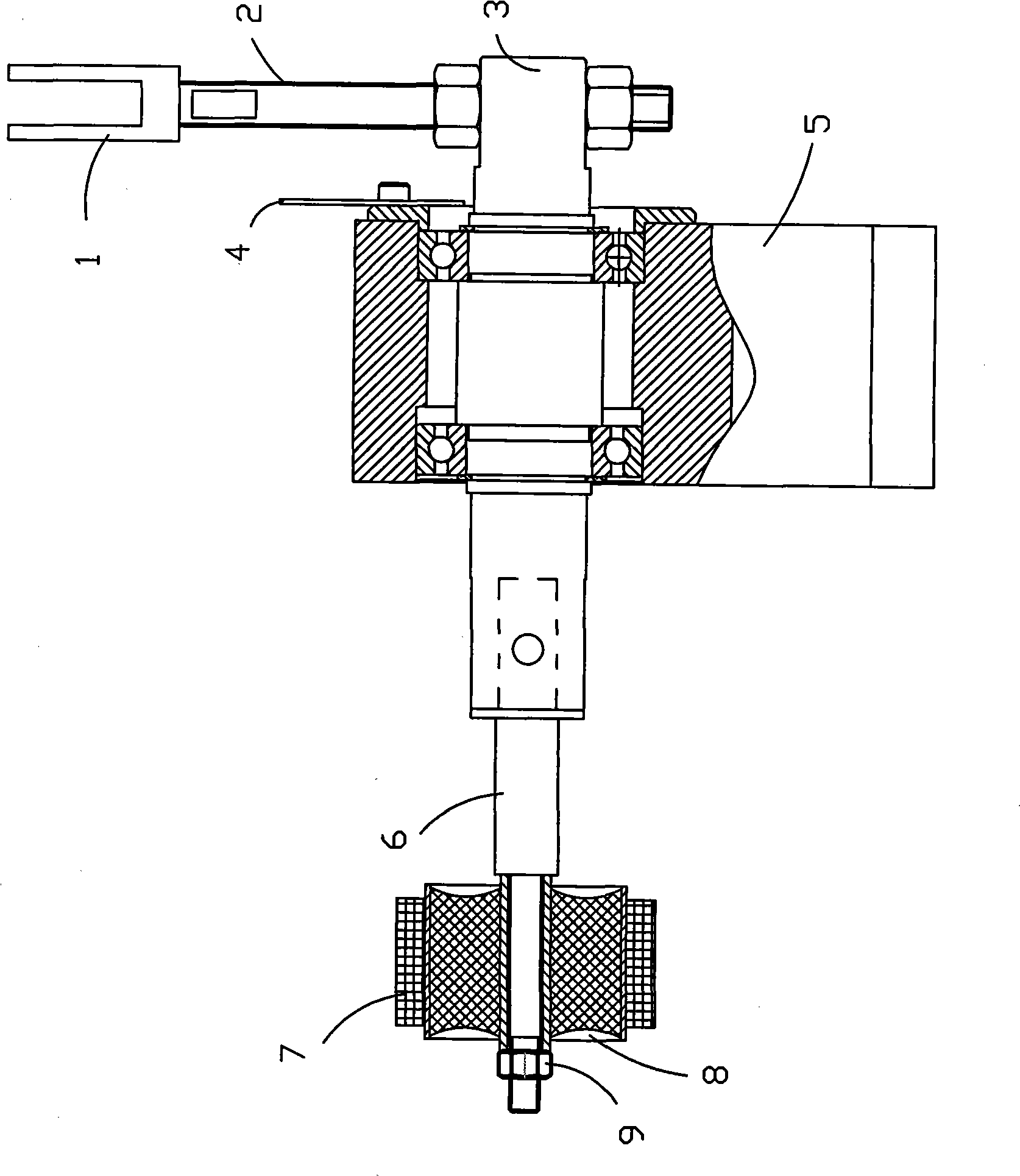

[0012] Such as figure 1 As shown, the rubber bush torsion test device provided by the present invention is used to test the durability test of the rubber bush 8, which includes a base 5, a torsion shaft that is arranged on the base 5 and rotates on the base 5 3, and the clamp 7 for fixing the rubber bushing 8, one end of the torsion shaft 3 is fixedly connected with the swing rod 2, and the other end of the torsion shaft 3 is fixedly connected with the torsion bar 6 passing through the rubber bushing 8, the clamp 7 is used In order to fix the rubber bushing 8 , the torsion bar 6 can apply a torsional force to the rubber bushing 8 . The connecting head 1 connected with the controllable linear motion device is movably connected with the swing rod 2 and drives the swing rod 2 to swing. In this embodiment, the output controllable linear motion device is any device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com