Cantilever crane torsion test device

A torsion test and jib technology, applied in the direction of applying repeated force/pulsation force to test the strength of materials, cranes, etc., can solve problems affecting the performance and service life of cranes, safety issues, etc., and achieve simple structure, convenient operation, and effective testing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further explained in detail below in conjunction with the accompanying drawings.

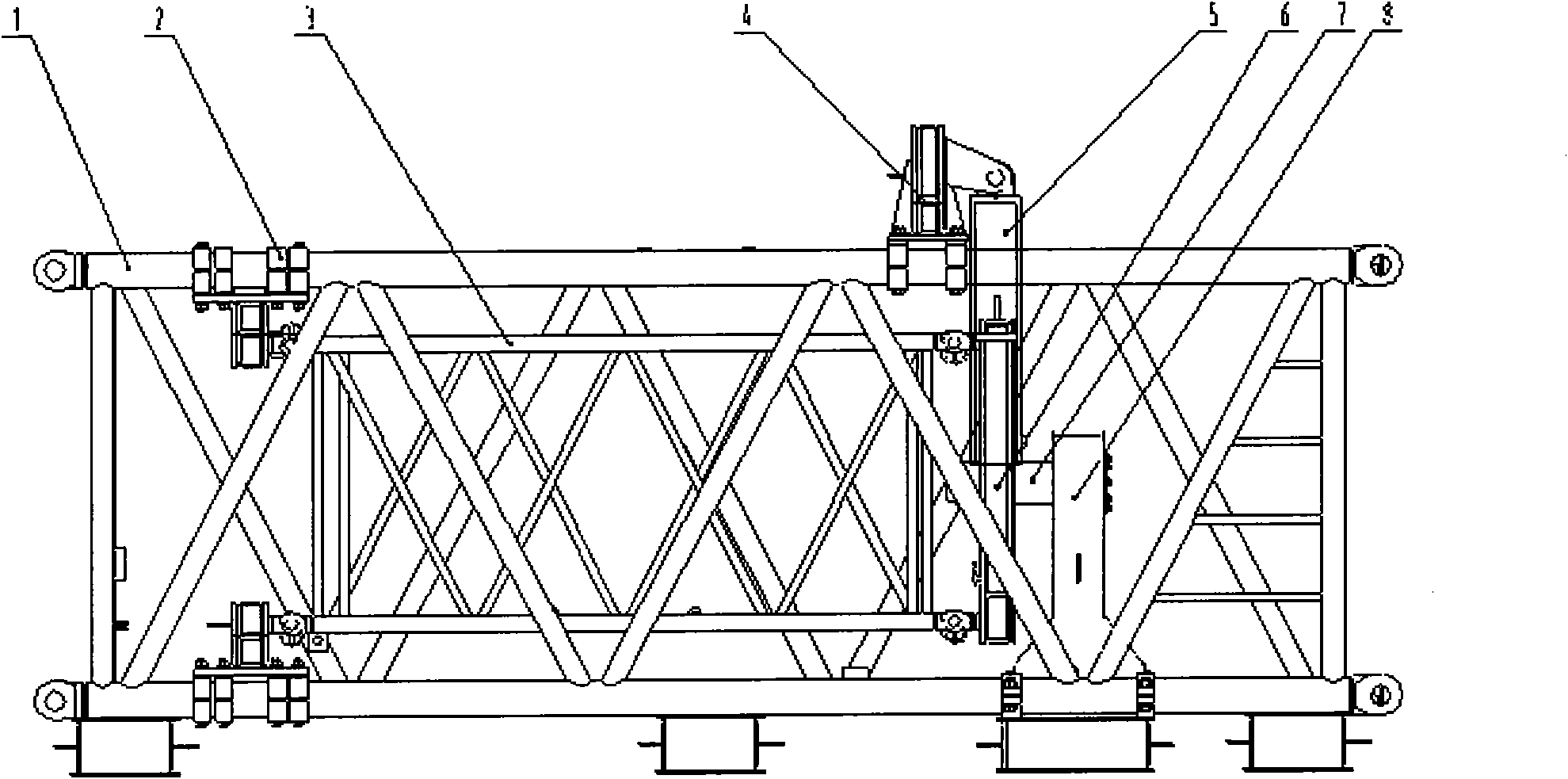

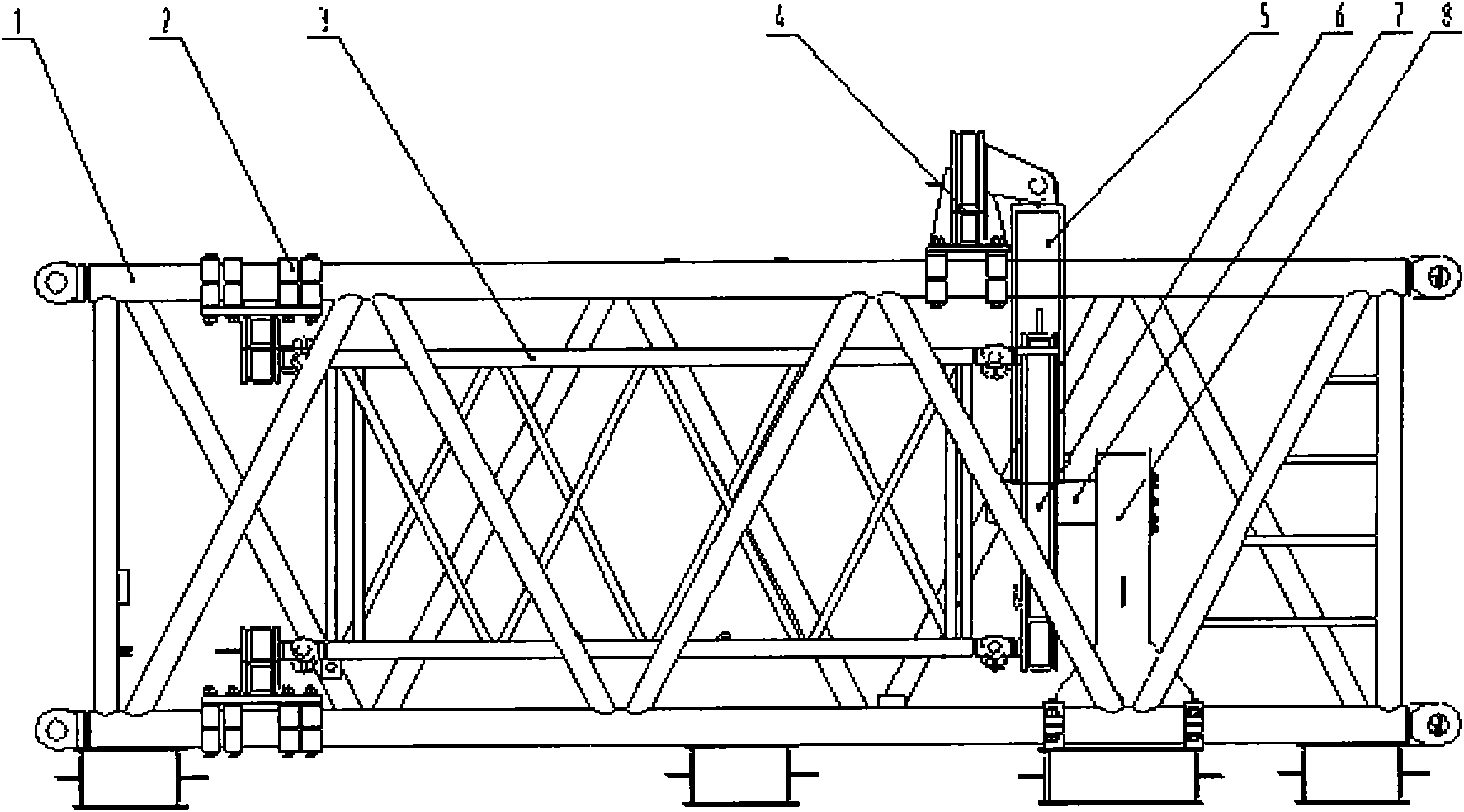

[0016] In order to provide accurate basic data of crane jib torsion, provide original reference data for crane jib design, and ensure safe operation of the crane, the invention provides a jib torsion test device. The jib torsion test device of the present invention uses a large-tonnage jib as a force carrier, a small-tonnage jib as a test jib, and generates torsional torque through symmetrically installed loading cylinders, thereby realizing multiple tests of jib torsion.

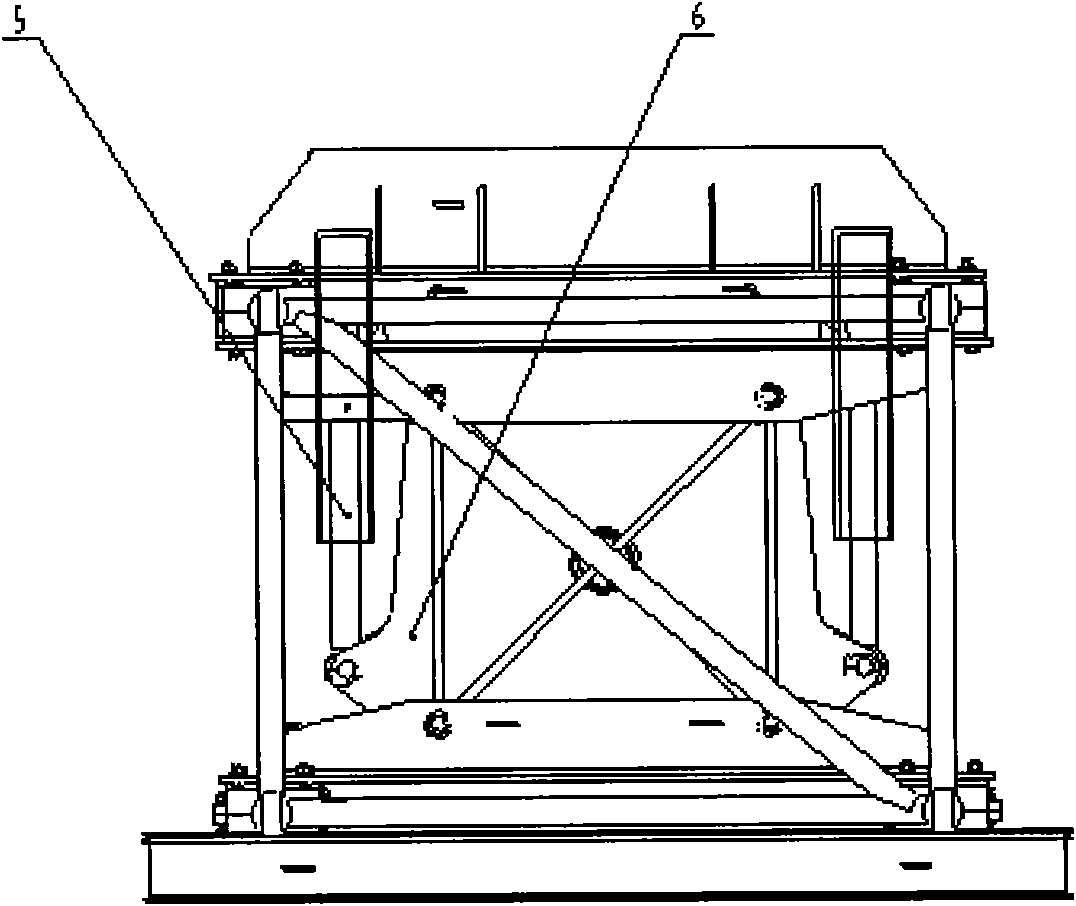

[0017] figure 1 , figure 2 They are respectively a structural schematic diagram and a partially enlarged schematic diagram of the boom torsion test device of the present invention. As shown in the figure, the boom torsion test device of the present invention includes a boom 1, a first fixed tool 2, a test boom 3, a second fixed tool 4, a loading cylinder 5, a loading plate 6, a rotating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com