Method for judging failures of spot-welded joint under recombination action

A composite effect and welding head technology, applied in welding equipment, resistance welding equipment, manufacturing tools, etc., can solve problems such as reservation, not deep enough, and no clear methods and steps, and achieve the effect of improving simulation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

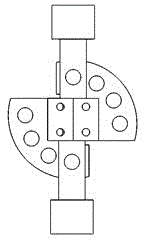

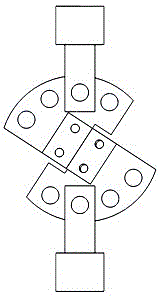

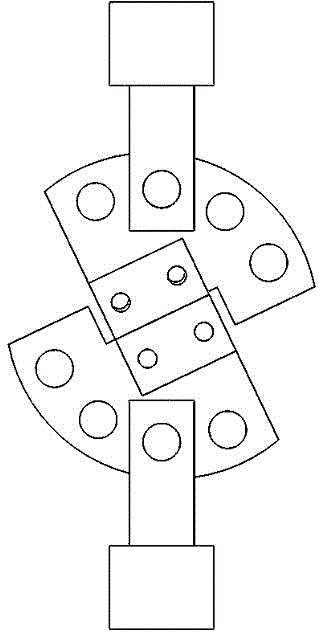

Image

Examples

Embodiment Construction

[0040] The method for judging the failure of the spot welded joint under the composite action of the present invention comprises the following steps:

[0041] Step 1. Prepare the sample, the specific steps are as follows:

[0042] Step 101, welding the double U-shaped spot welding sample, the flanging peeling sample, the torsion sample and the test nugget diameter sample, the welding parameters and the size and standard of the electrode tip used for welding should be consistent with the welding process on the actual production line Similarly, strive to make the solder joints on the sample the same as the solder joints on the actual component, and reduce the error as much as possible.

[0043] Step 2, carry out double U-shaped spot welding sample test, the specific steps are as follows:

[0044] Step 201, the double U-shaped spot welding sample test can be started after the sample is welded, and the double U-shaped spot welding sample is fixed on the fixture of the double U-sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com