Patents

Literature

151 results about "Strip test" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A test strip is a material used to measure the concentration of a chemical or some characteristic of a liquid. Test strips are most often used to test a liquid's pH level, but some types of test strips serve other purposes, such as detecting the presence of a contaminant. A test strip is usually a piece of a paper that contains an indicator.

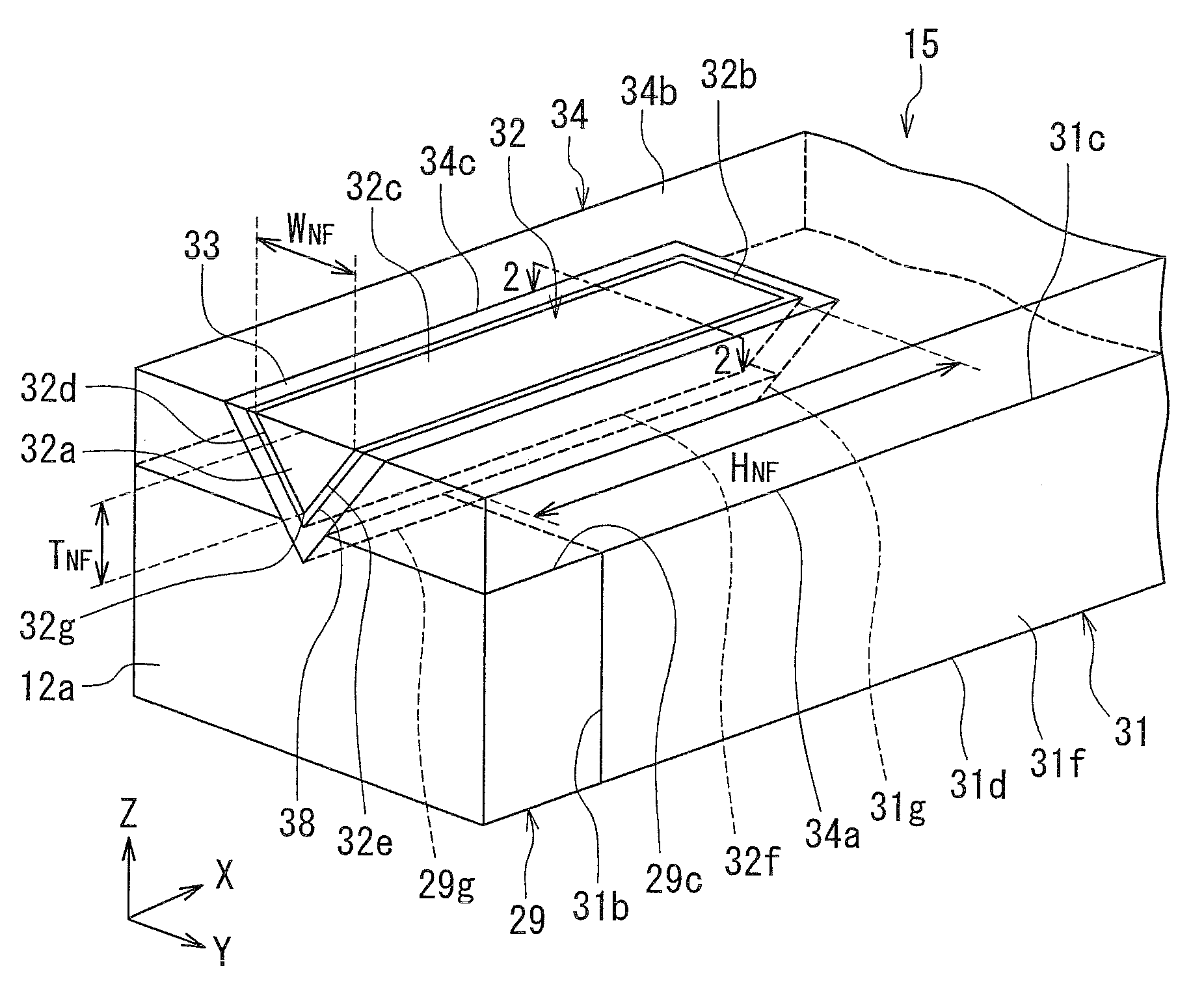

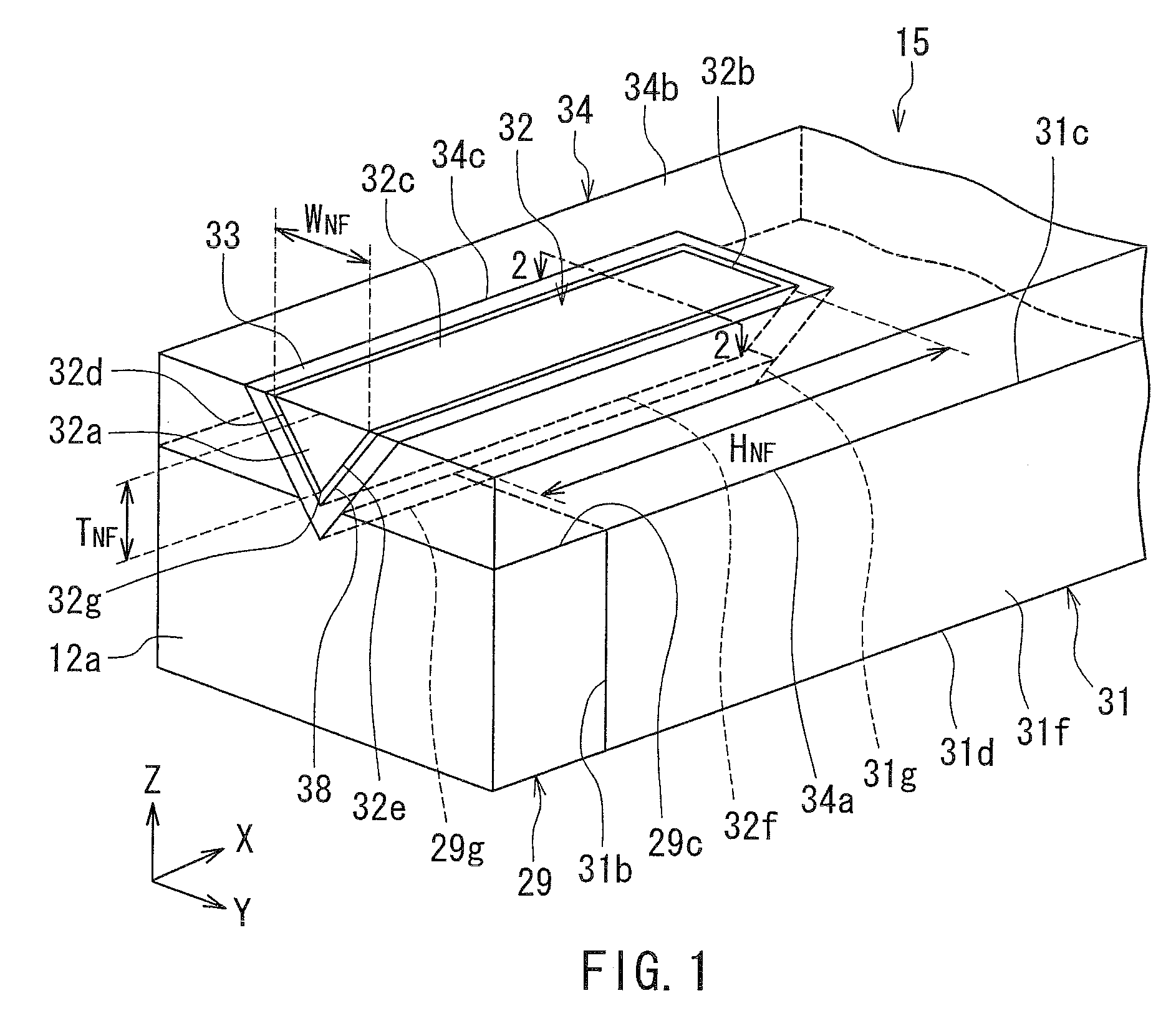

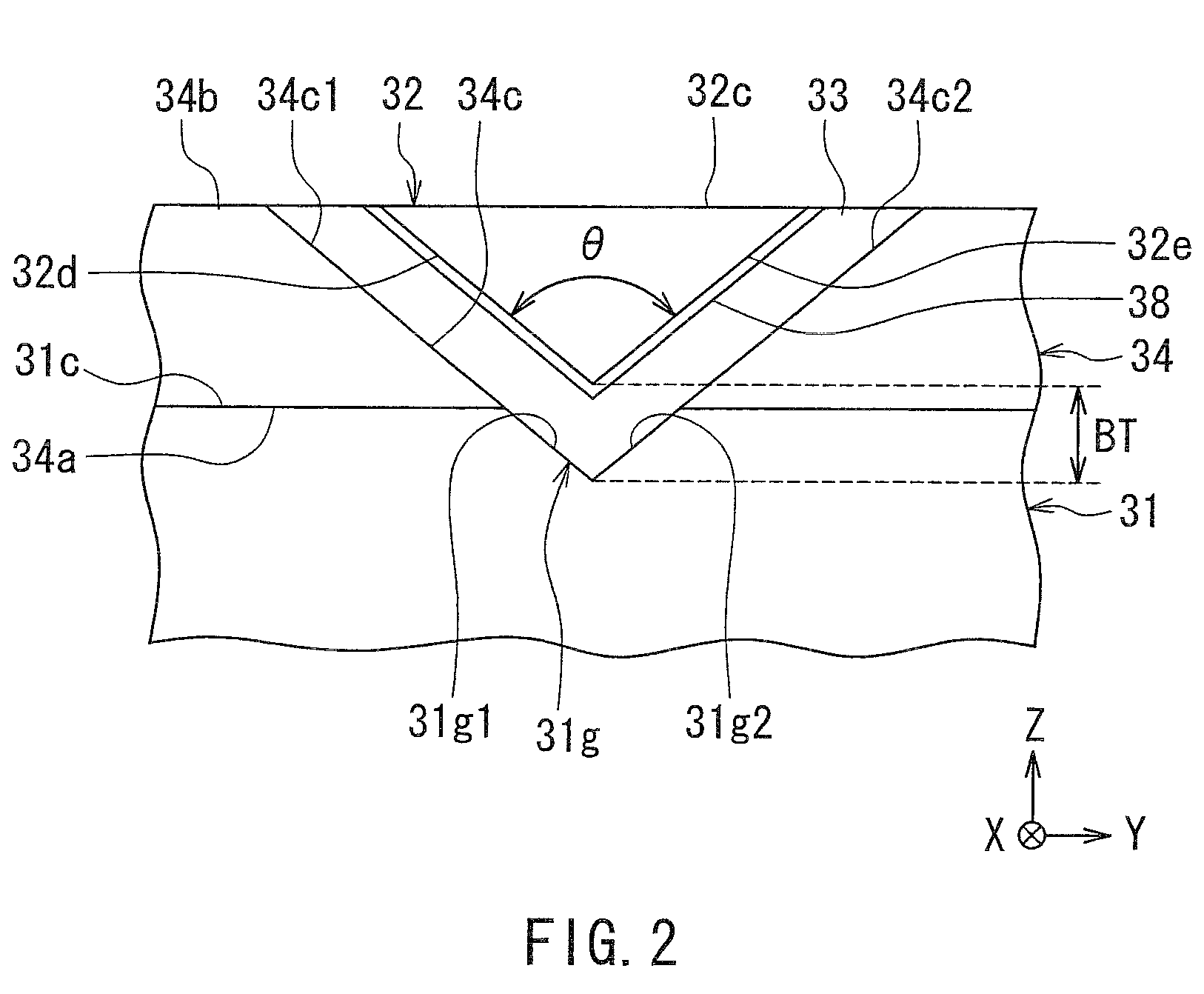

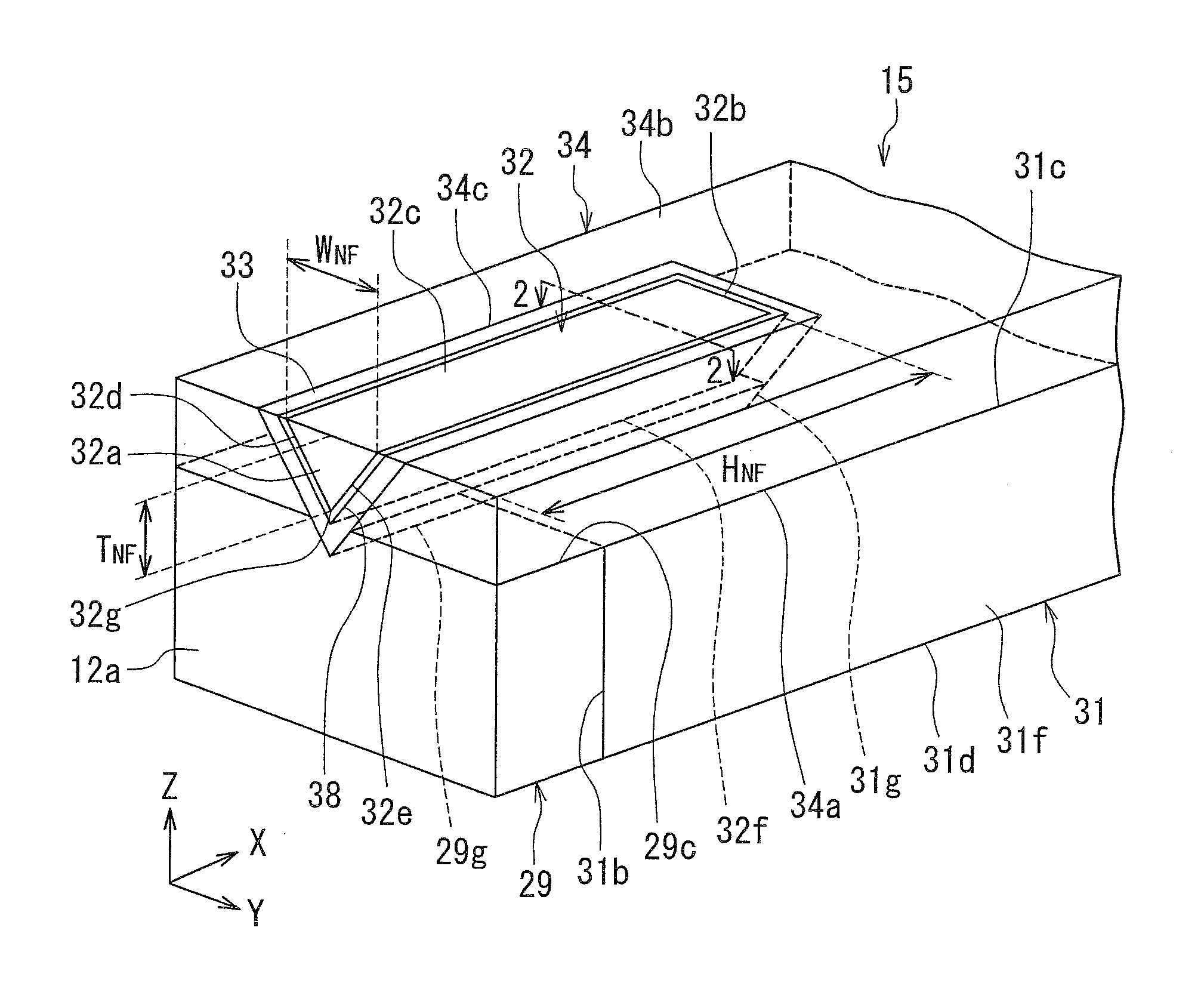

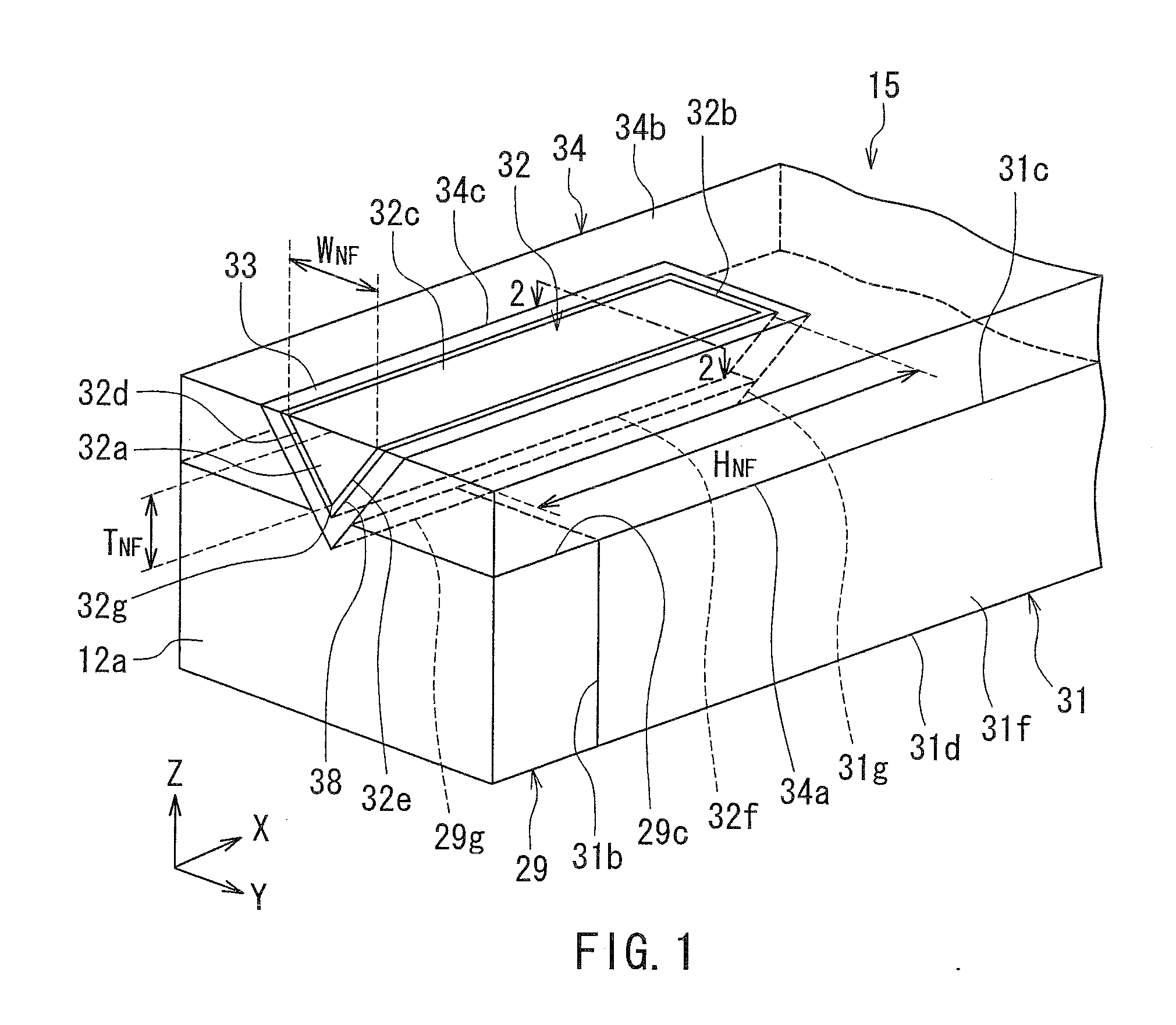

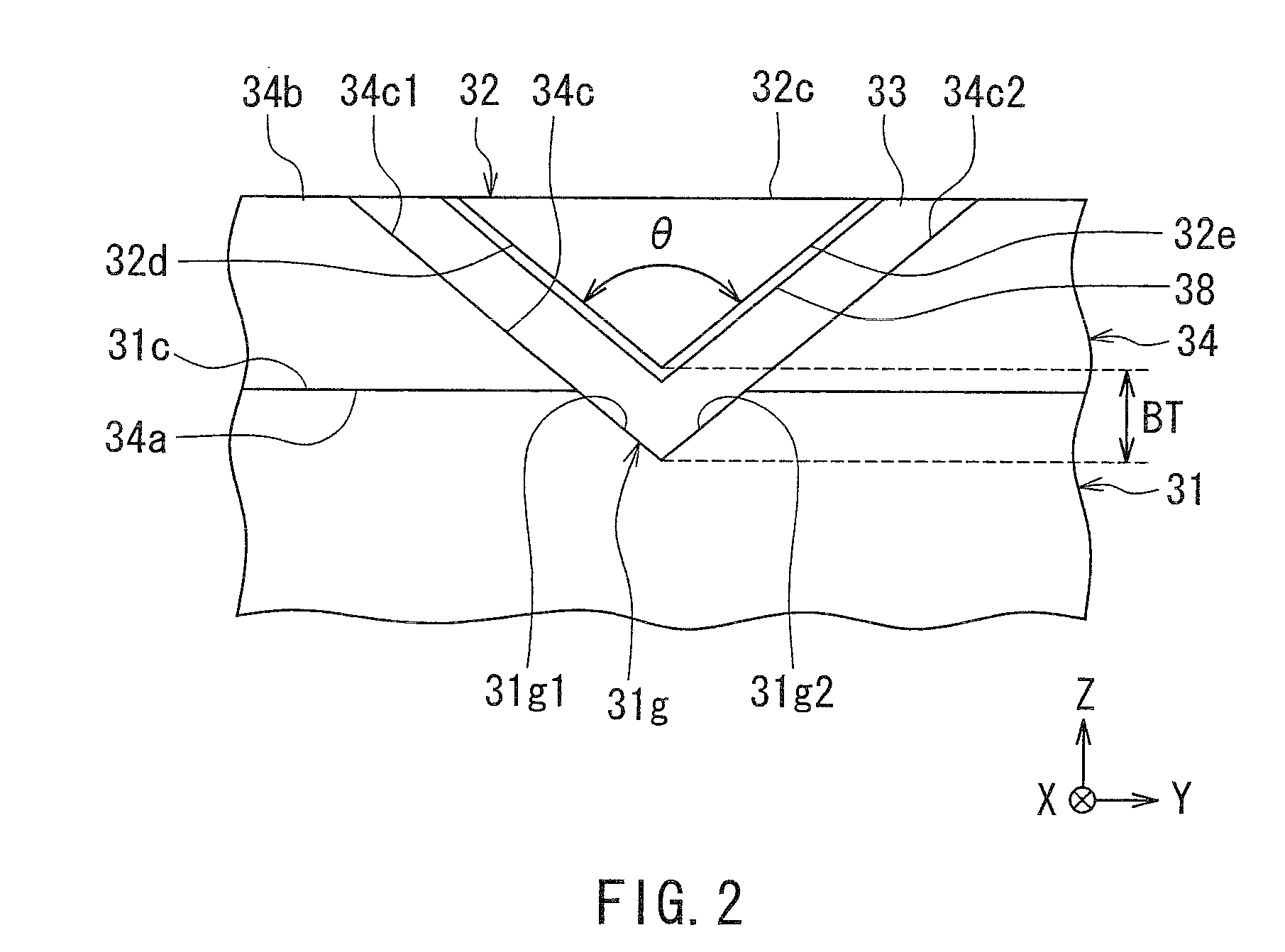

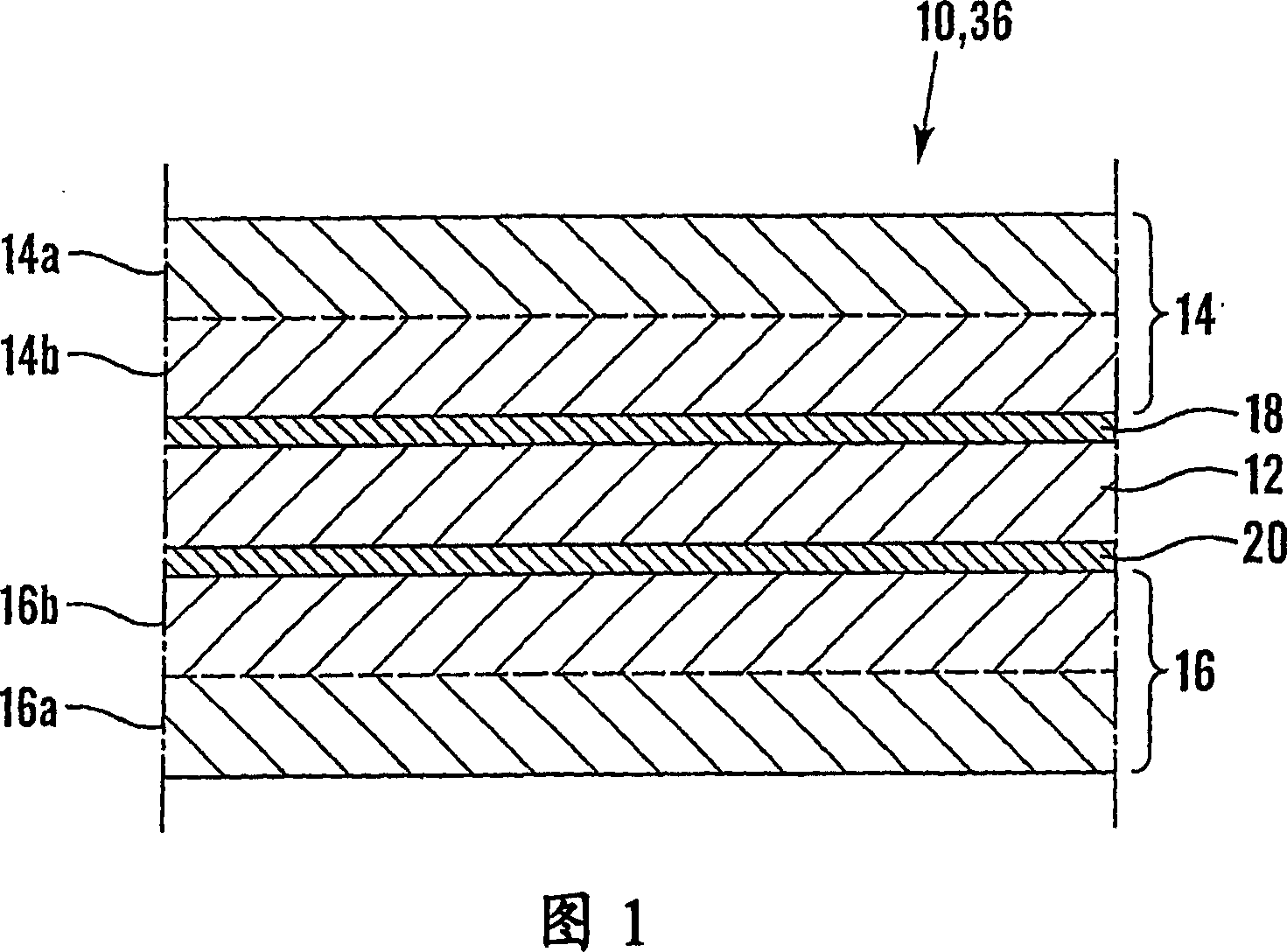

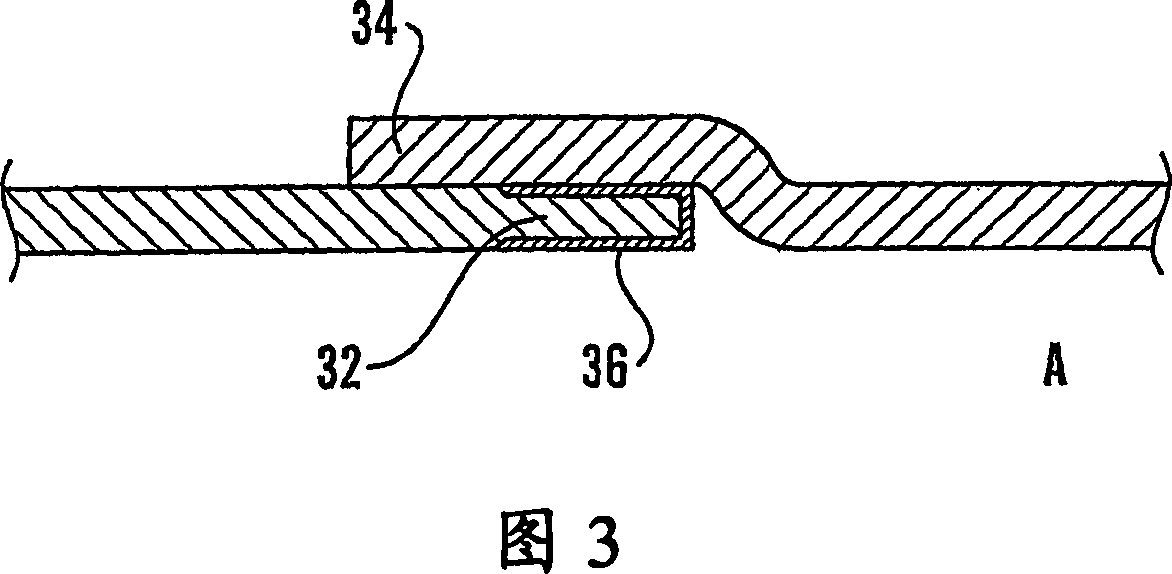

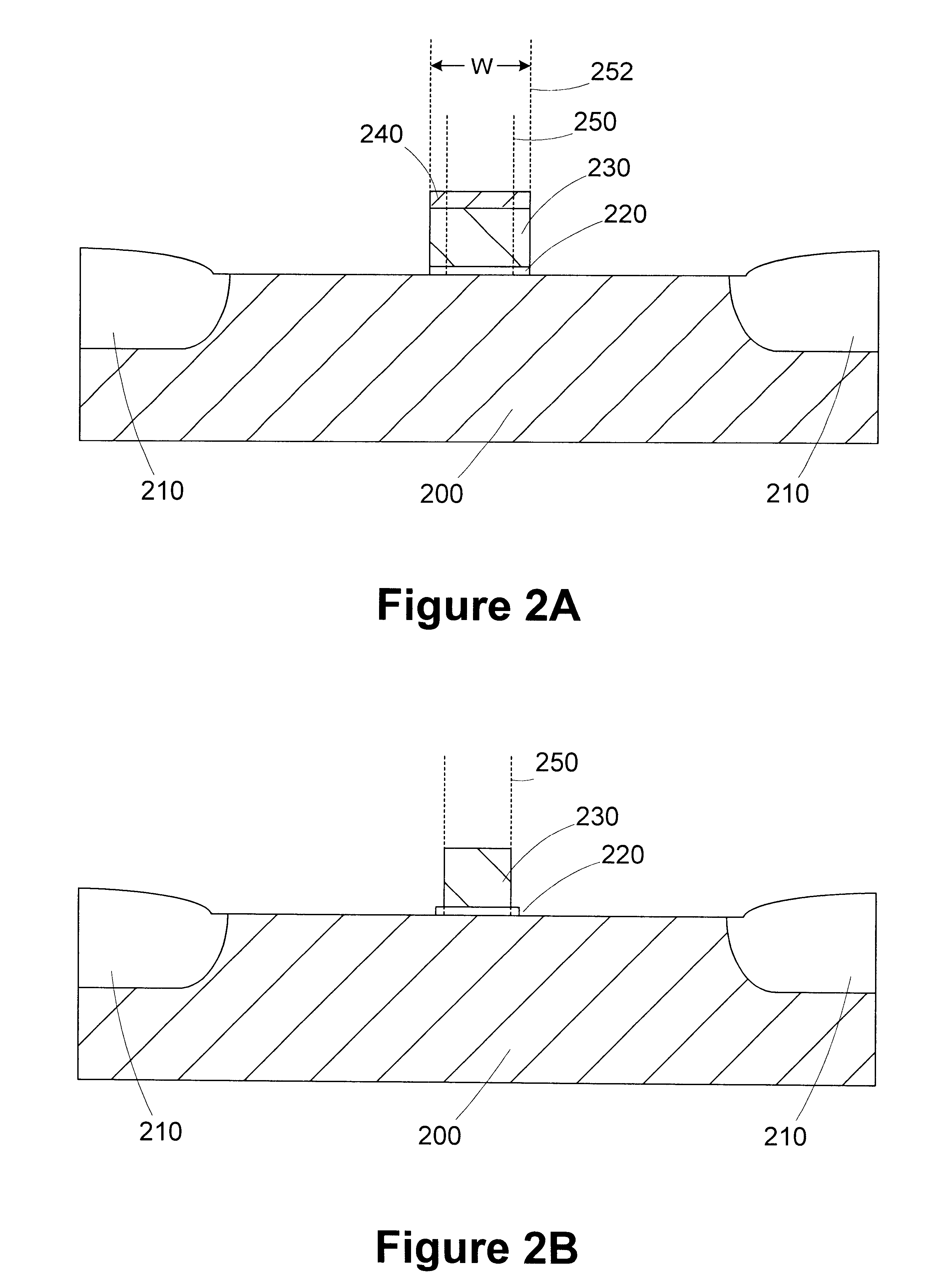

Near-field light generating device including near-field light generating element disposed over waveguide with buffer layer and adhesion layer therebetween

ActiveUS8040761B2Prevent peelingSuppressing drop use efficiencyCombination recordingRecord information storageElectrical resistance and conductanceAdhesive

Owner:TDK CORPARATION

Near-field light generating device including near-field light generating element disposed over waveguide with buffer layer and adhesion layer therebetween

ActiveUS20100329085A1Prevent peelingSuppressing drop use efficiencyCombination recordingRecord information storageAdhesiveWaveguide

A near-field light generating device includes: a waveguide; a buffer layer disposed on the top surface of the waveguide; an adhesion layer that is formed by incompletely oxidizing a metal layer and disposed on the buffer layer; and a near-field light generating element disposed on the adhesion layer. The adhesion layer has a resistance-area product higher than that of the metal layer unoxidized and lower than that of a layer that is formed by completely oxidizing the metal layer. A layered structure consisting of the buffer layer, the adhesion layer and the near-field light generating element has a peel-test adhesive strength higher than that of a layered structure consisting of the buffer layer and the near-field light generating element.

Owner:TDK CORPARATION

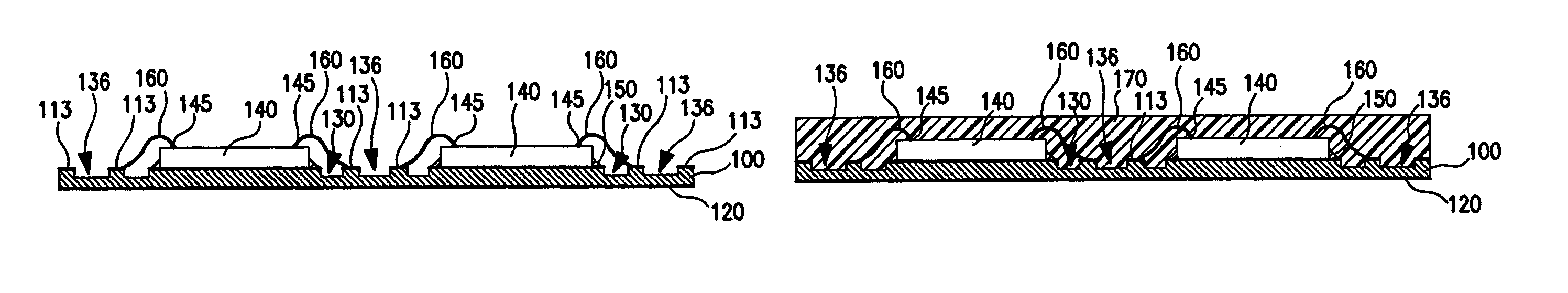

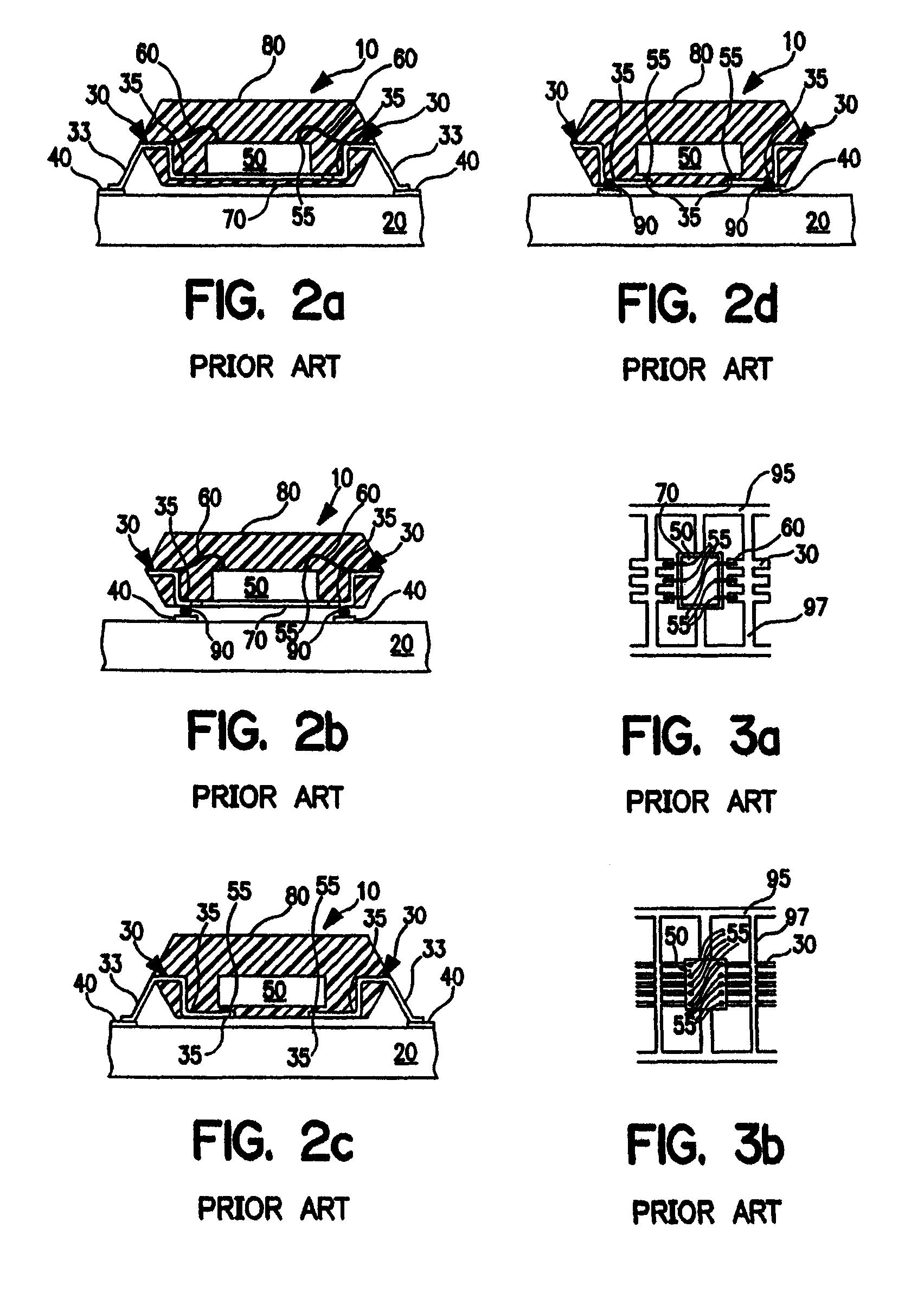

Partially patterned lead frames and methods of making and using the same in semiconductor packaging

ActiveUS7799611B2Improve stabilityImprove connectivitySemiconductor/solid-state device detailsSolid-state devicesBonding processSemiconductor package

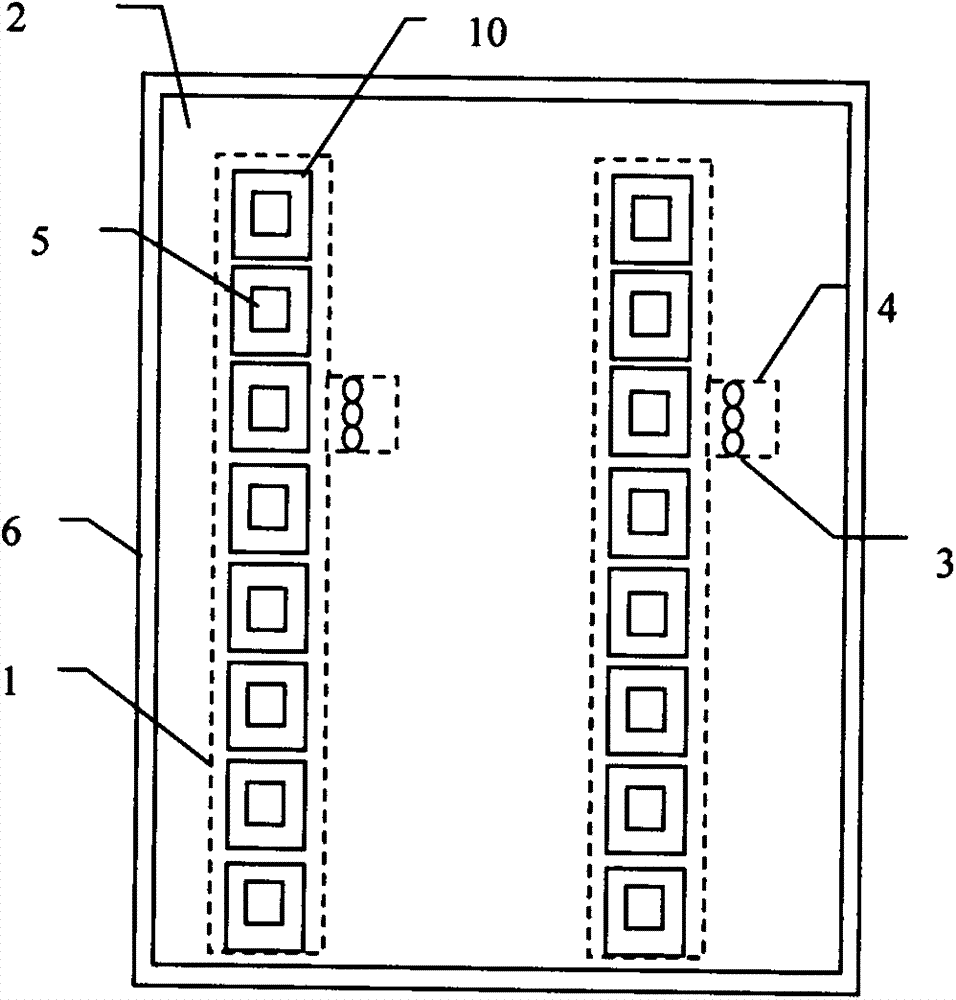

A method of making a lead frame and a partially patterned lead frame package with near-chip scale packaging (CSP) lead-counts is disclosed, wherein the method lends itself to better automation of the manufacturing line as well as to improving the quality and reliability of the packages produced therefrom. This is accomplished by performing a major portion of the manufacturing process steps with a partially patterned strip of metal formed into a web-like lead frame on one side, in contrast with the conventional fully etched stencil-like lead frames, so that the web-like lead frame, which is solid and flat on the other side is also rigid mechanically and robust thermally to perform without distortion or deformation during the chip-attach and wire bond processes, both at the chip level and the package level. The bottom side of the metal lead frame is patterned to isolate the chip-pad and the wire bond contacts only after the front side, including the chip and wires, is hermetically sealed with an encapsulant. The resultant package being electrically isolated enables strip testing and reliable singulation without having to cut into any additional metal. The use of the instant partially patterned lead frame in making ELP, ELPF and ELGA-type CSPs is also disclosed.

Owner:UNISEM M BERHAD

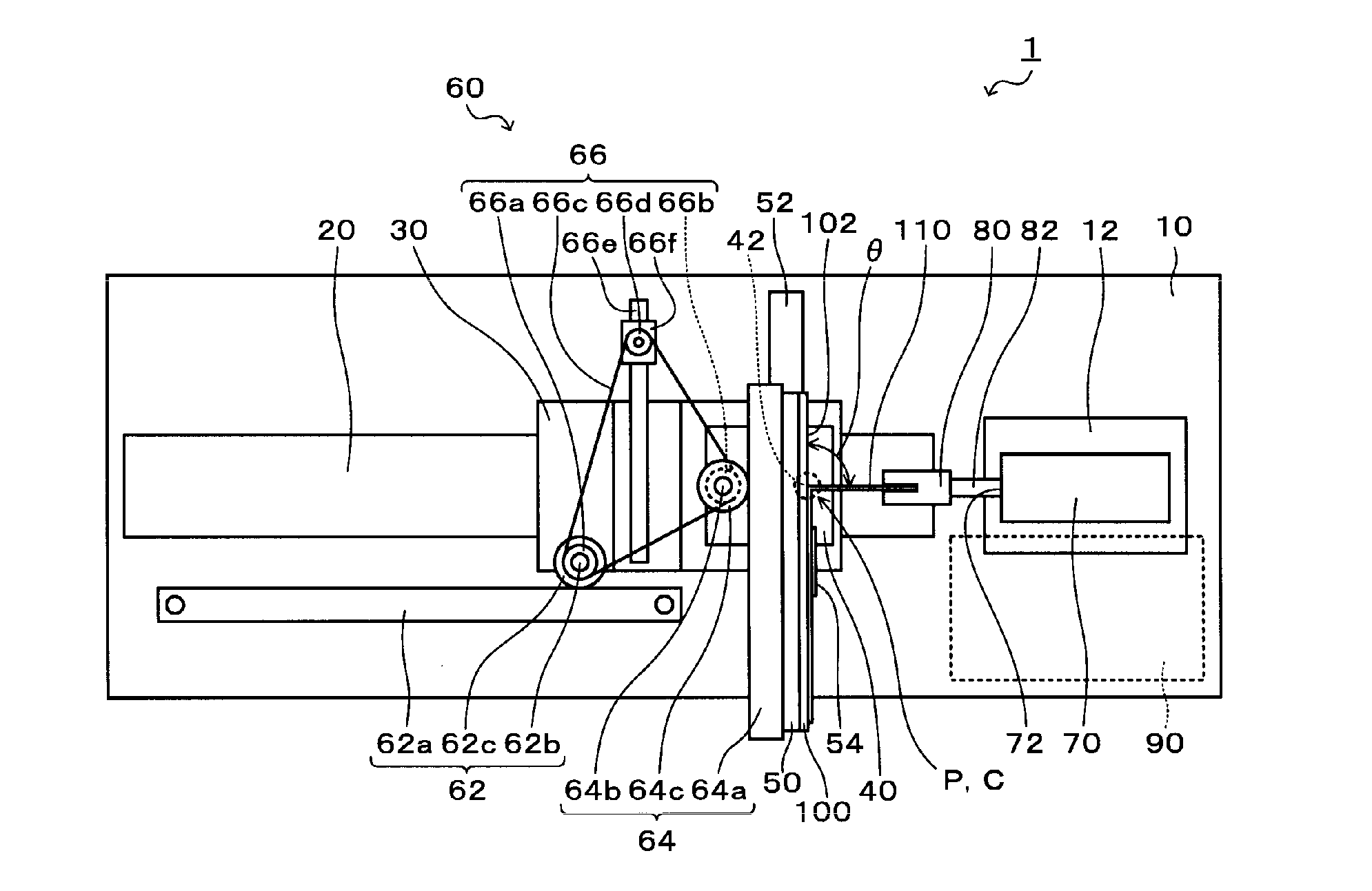

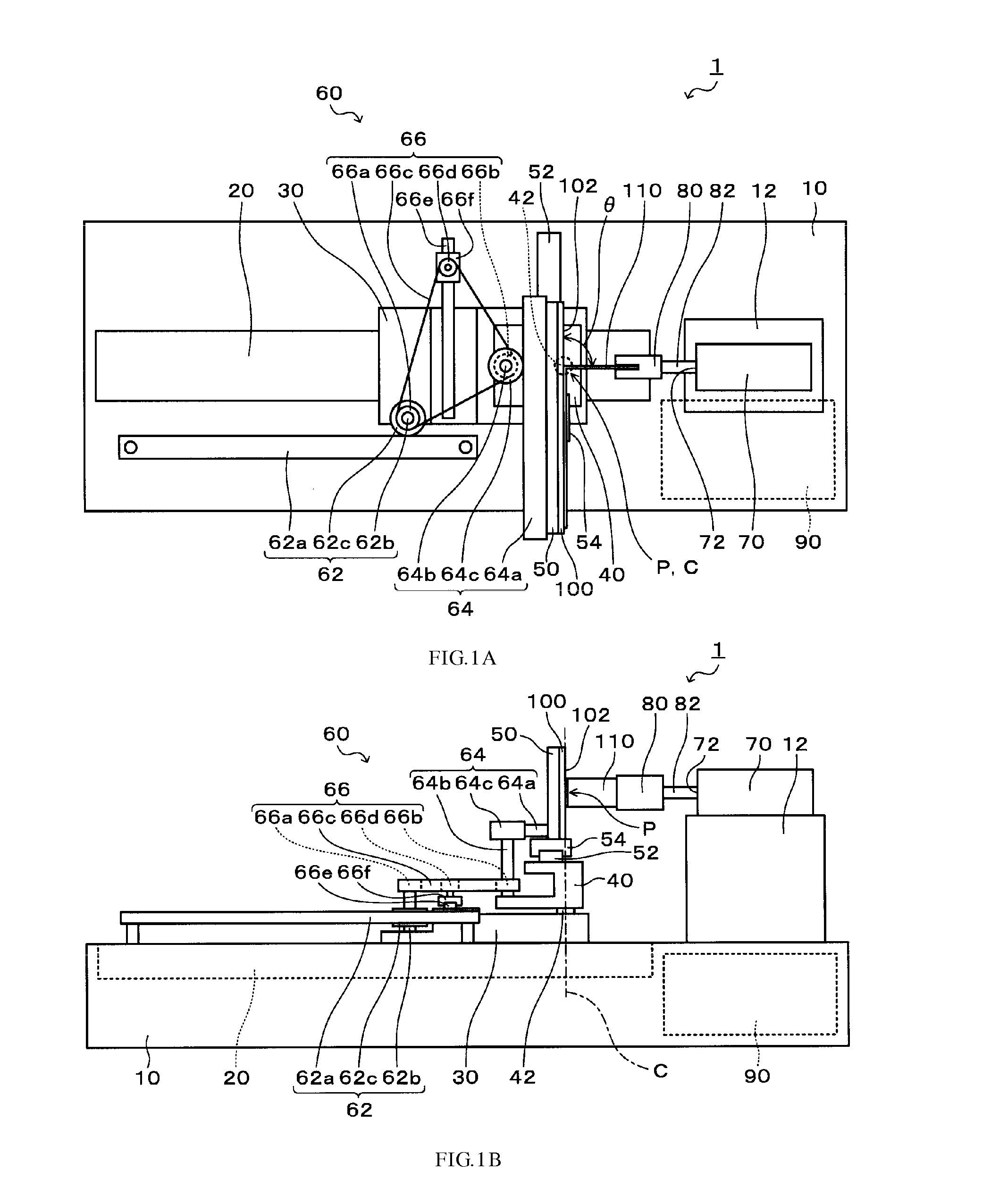

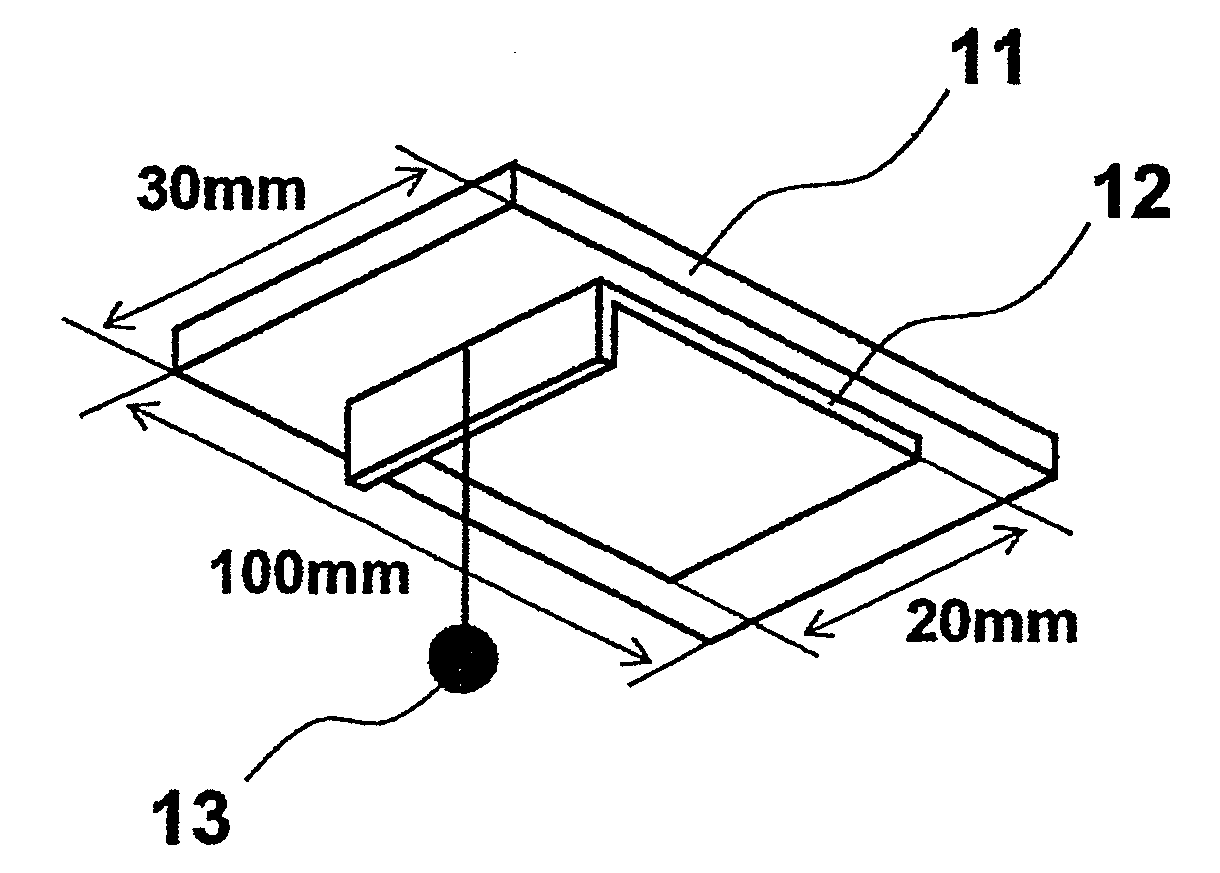

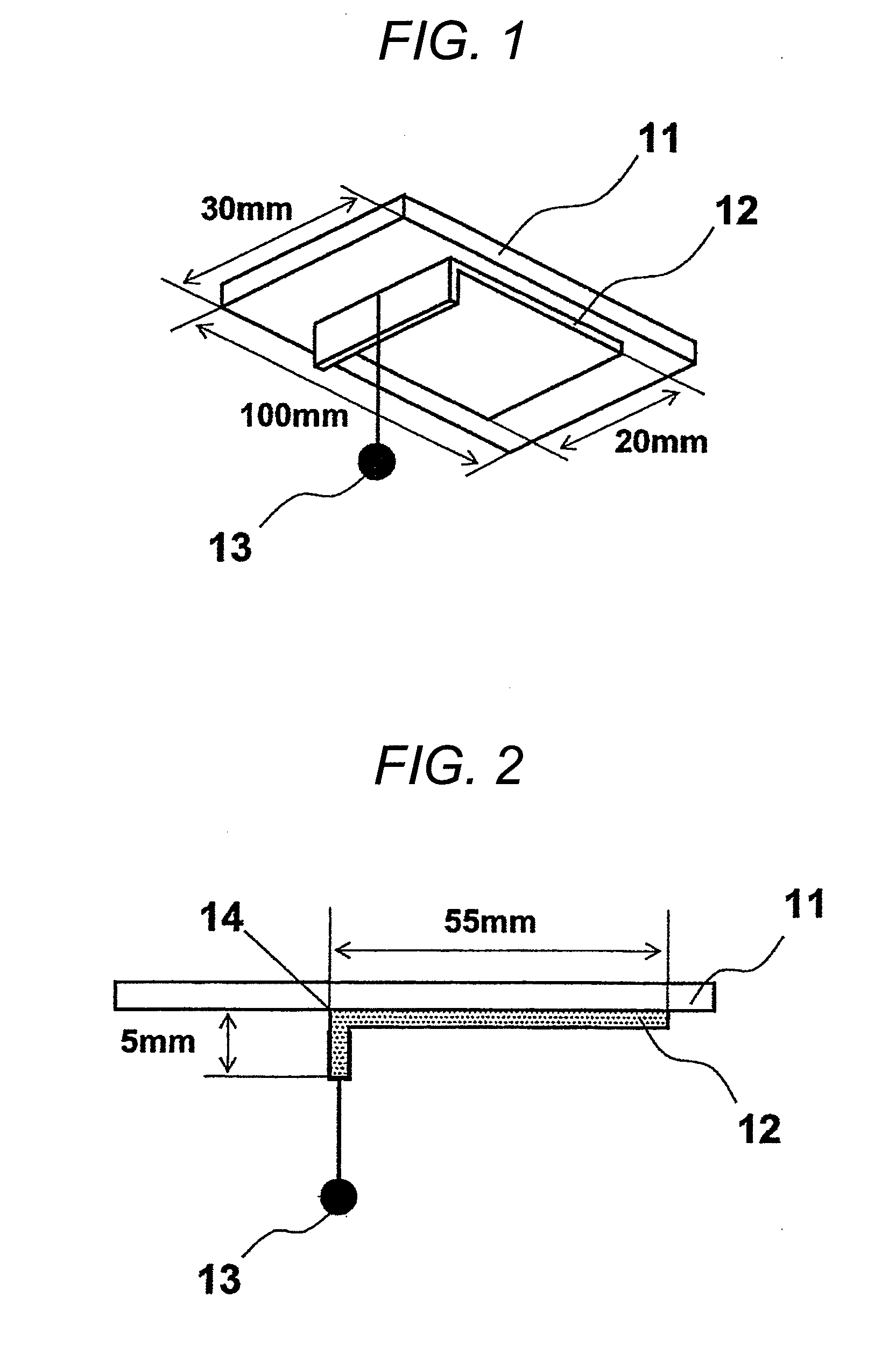

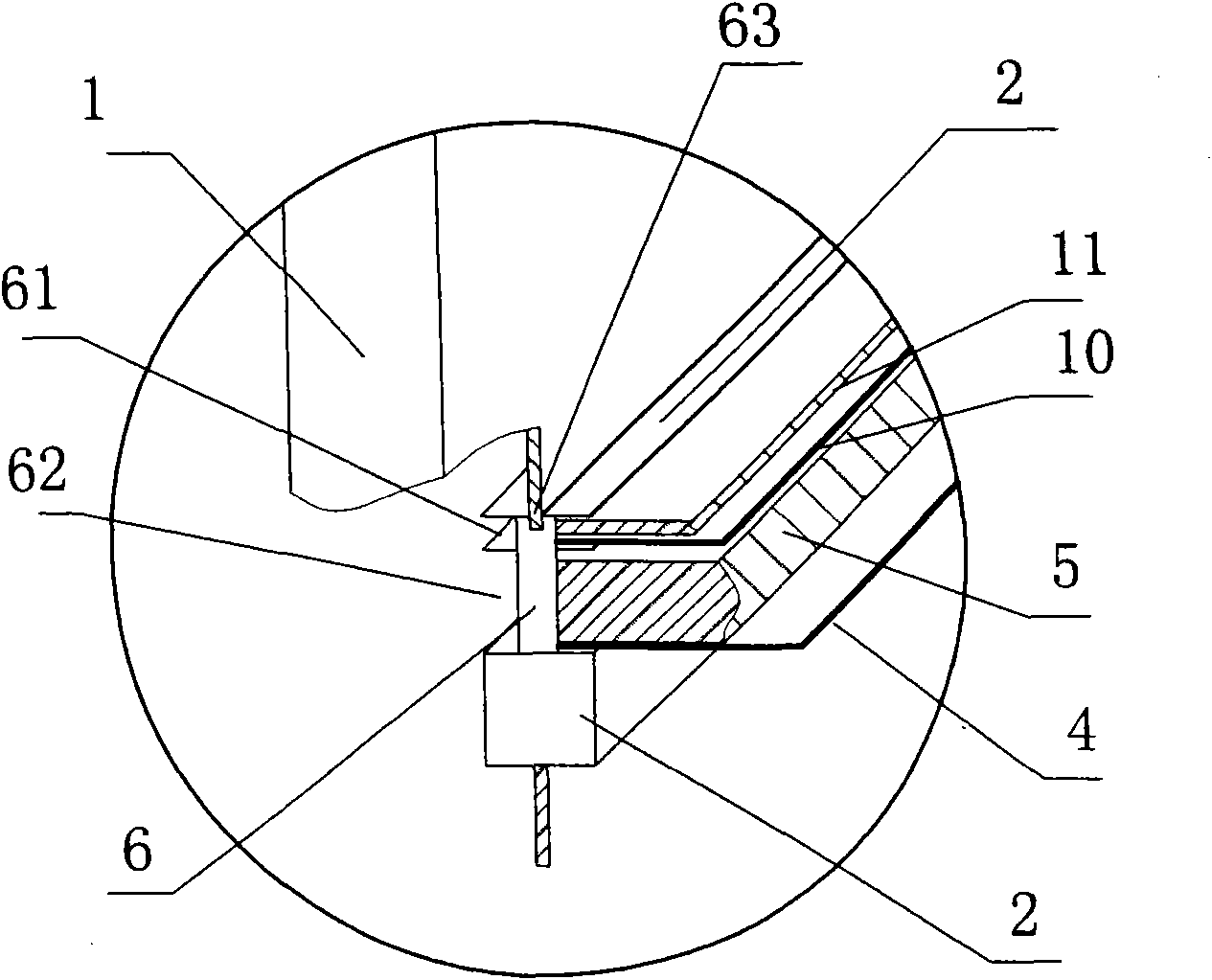

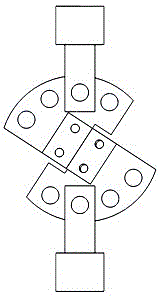

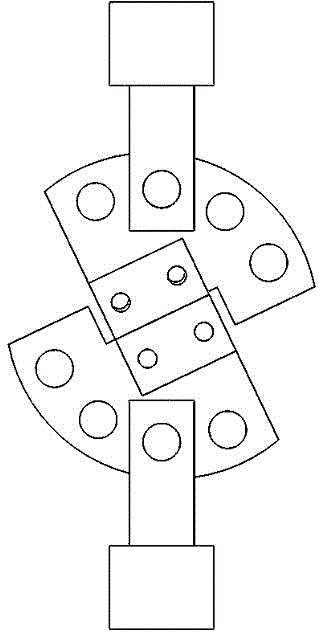

Device for peel test

ActiveUS20120103081A1Good effectTest accurateUsing mechanical meansStrength propertiesLinear motionEngineering

A device for a peel test. The device includes: a gripping member to grip an end of a test film to be peeled off a test object; a movable member linearly moving in a direction to or away from the gripping member; a holding member for the movable member capable of linearly moving in a direction along a peel surface of the test object while holding the test object; a moving mechanism configured to move the movable member linearly; a load measuring unit configured to measure a load applied to the gripping member; a first conversion mechanism to convert the linear motion of the movable member to rotational power, and output the rotational power; and a second conversion mechanism to convert the rotational power output from the first conversion mechanism to the linear motion of the holding member relative to the movable member.

Owner:KYOWA INTERFACE SCI

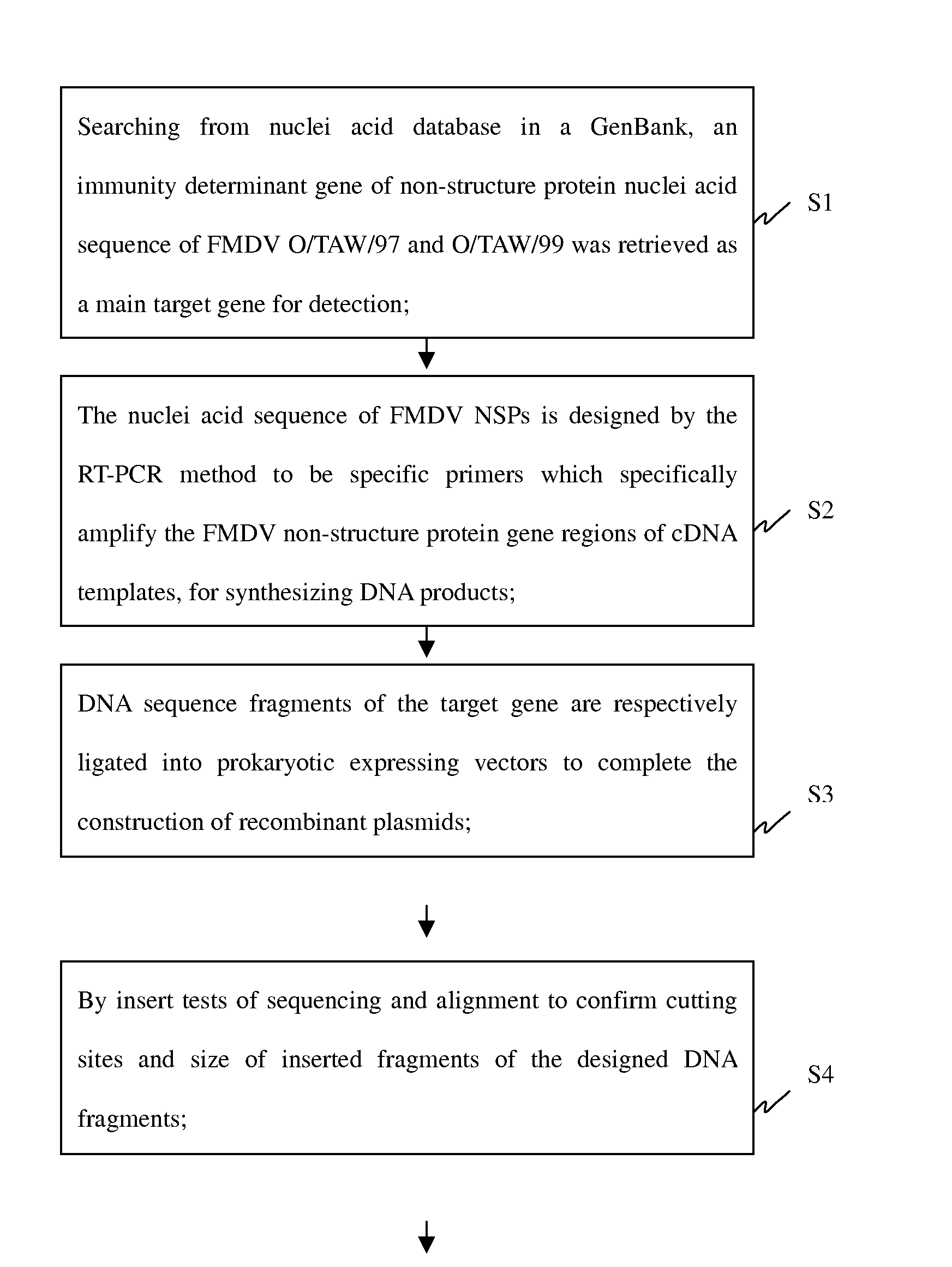

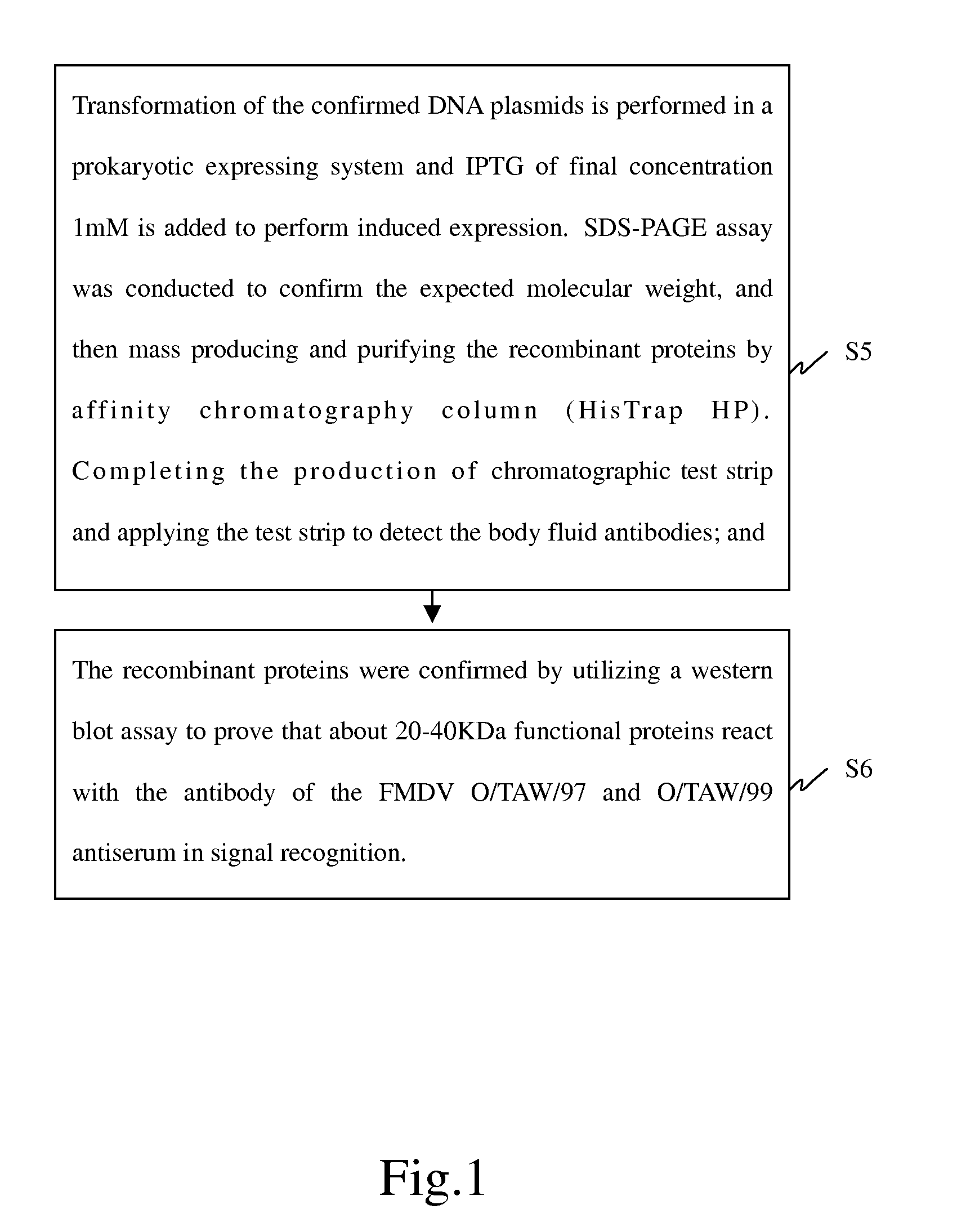

Method for detection of foot-and-mouth disease virus with chromatographic strip test

InactiveUS20080280296A1Improve detection efficiencyQuick stepsMicrobiological testing/measurementReverse transcriptasePoint-of-care testing

The present invention discloses a method for detection of foot-and-mouth disease virus with chromatographic strip test. Firstly, the nucleic acid sequence of FMDV NSPs is set up, the nucleic acid sequence is amplified by the reverse transcriptase polymerase chain reaction (RT-PCR) method, the recombinant vector is constructed and performed through a prokaryotic system to transform and express the recombinant protein, and the purified recombinant protein is mass produced. Design principles of the method are based on immunoassay and chromatographic analysis. The advantages are easy and simple to handle, no need of elaborate equipment, only one drop of body fluid is required to quickly complete the qualitative test in 10-20 minutes, and operating with a portable POCT (Point of care testing) instrument to complete the quantitative detection within 40-50 minutes.

Owner:NAT INST FOR ANIMAL HEALTH COUNCIL AGRI EXECUTIVE YUAN

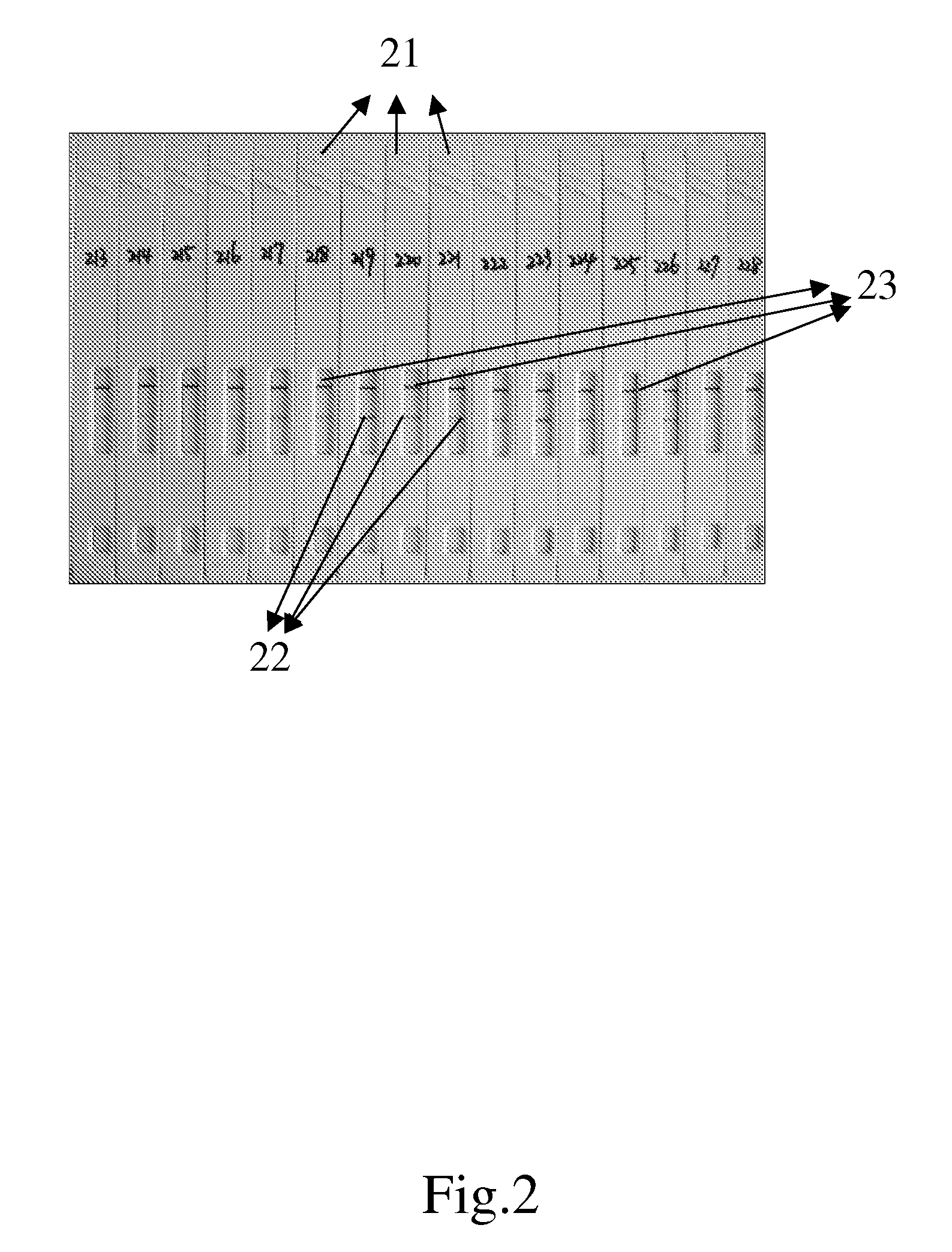

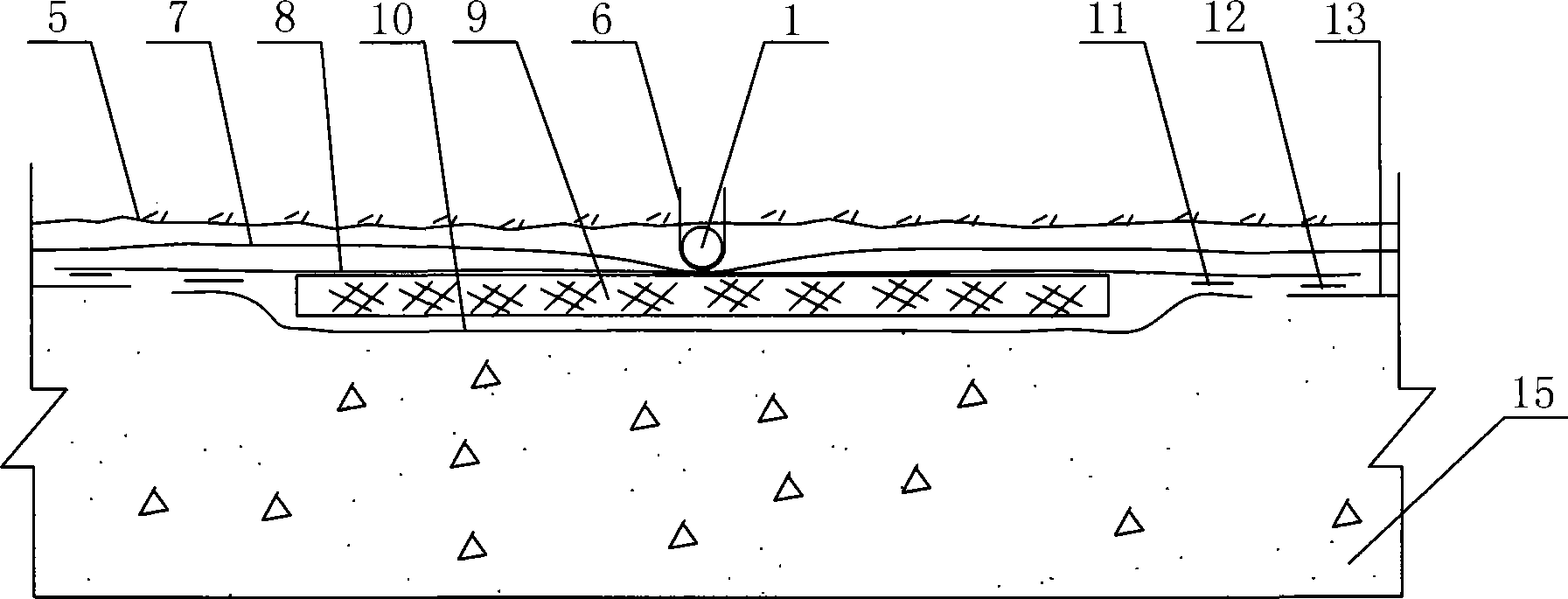

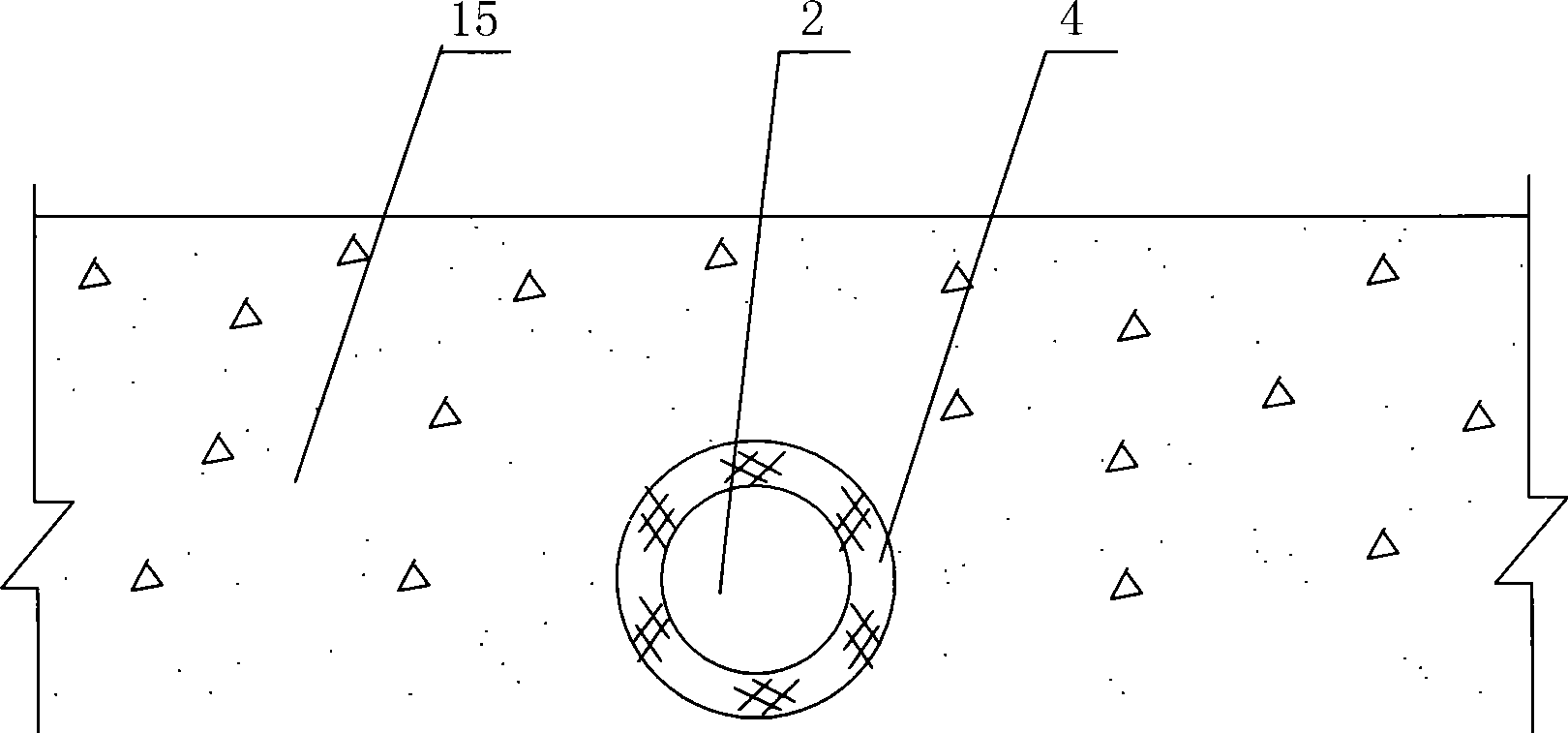

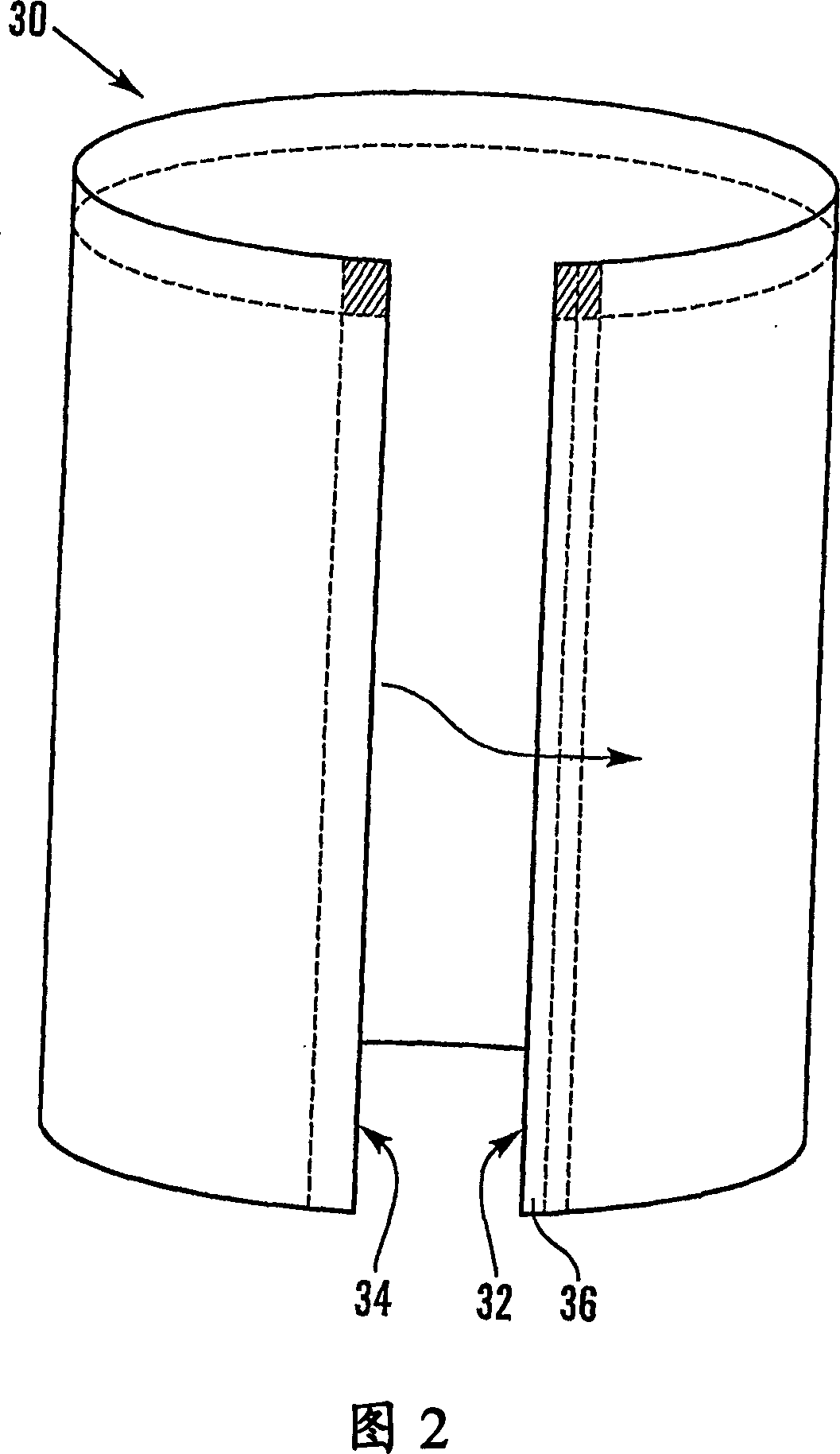

Tunnel ring direction drainpipe equipped with strip heat-insulating layer

The invention discloses a tunnel circumferential drainage pipe provided with a band insulation layer. The tunnel circumferential drainage pipe comprises a circumferential drainage pipe behind the liner wall, and two circumferential drainage pipe which are arranged below the road surface and are connected with two ends of the circumferential drainage pipe behind the liner wall., wherein the circumferential drainage pipes behind the liner wall is a water permeable pipe, the two circumferential drainage pipe arranged below the road surface are arranged transversely and are communicated with the circumferential drainage pipe behind the lining wall and a central drainage pipe at the center of the tunnel. The band insulation layer arranged at one side of the circumferential drainage pipe behind the liner wall close to a concrete lined wall comprises two layers of waterproof boards and a heat insulation material layer between the two layers of the waterproof boards. The tunnel circumferential drainage pipe has a simple structure, low cost, and short flow distance of drainage. In addition, the heat insulation material is not soaked by stratum seeped water, and the pipe is not blocked due to icing, so the stratum seeped water behind the tunnel liner wall can be effectively and rapidly drained.

Owner:CHANGAN UNIV

A strip tape, a packaging container having such a strip tape, and a method of producing such a strip tape

Owner:TETRA LAVAL HLDG & FINANCE SA

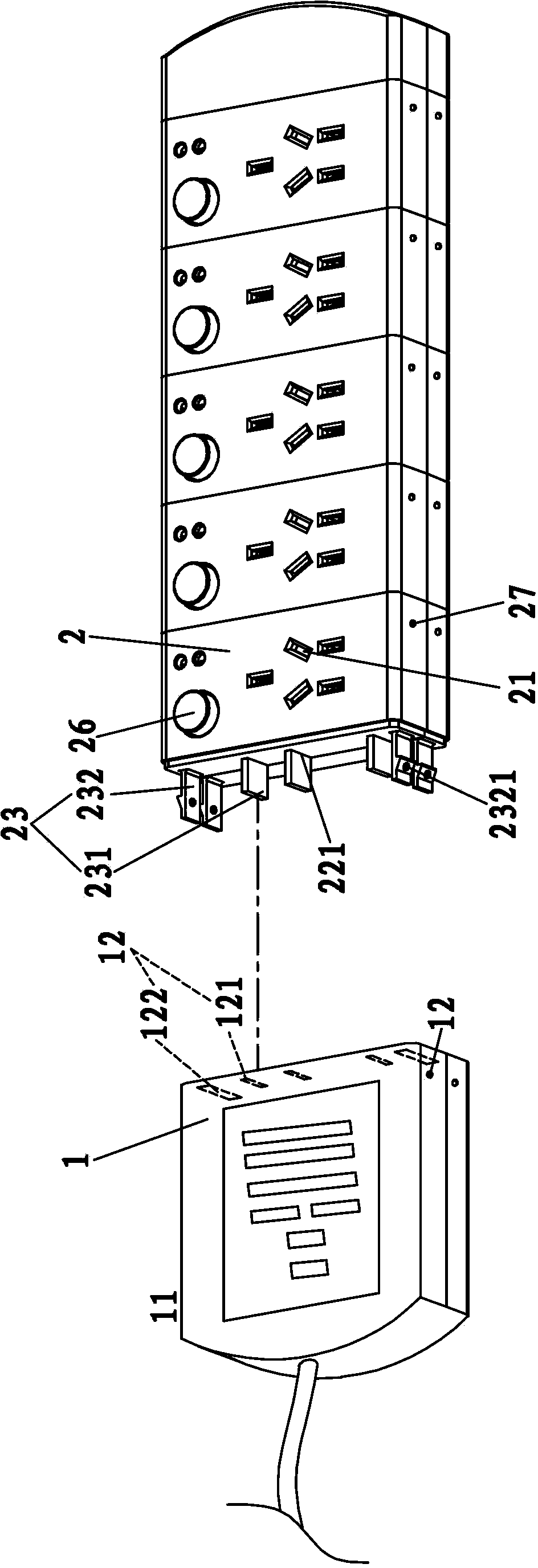

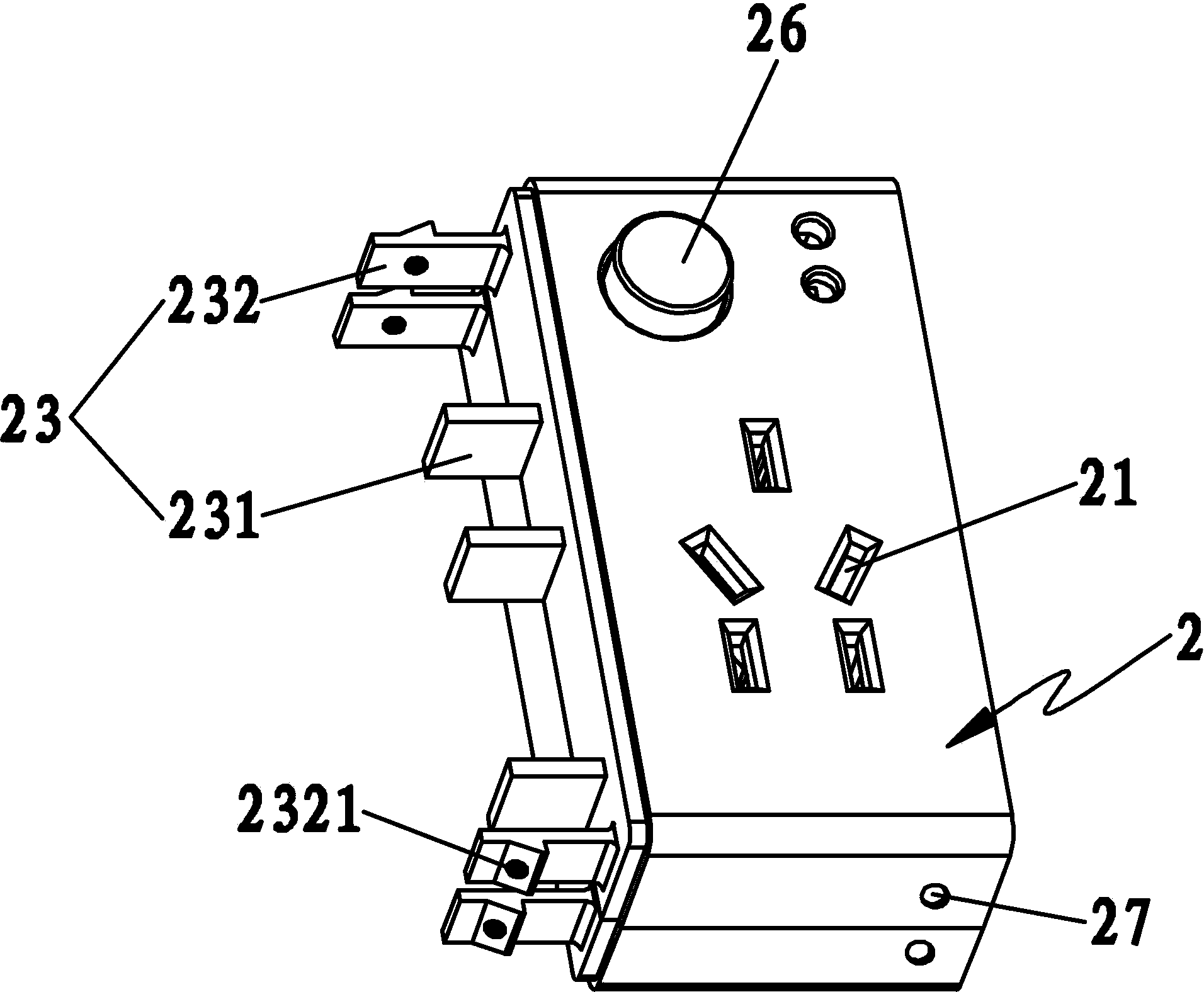

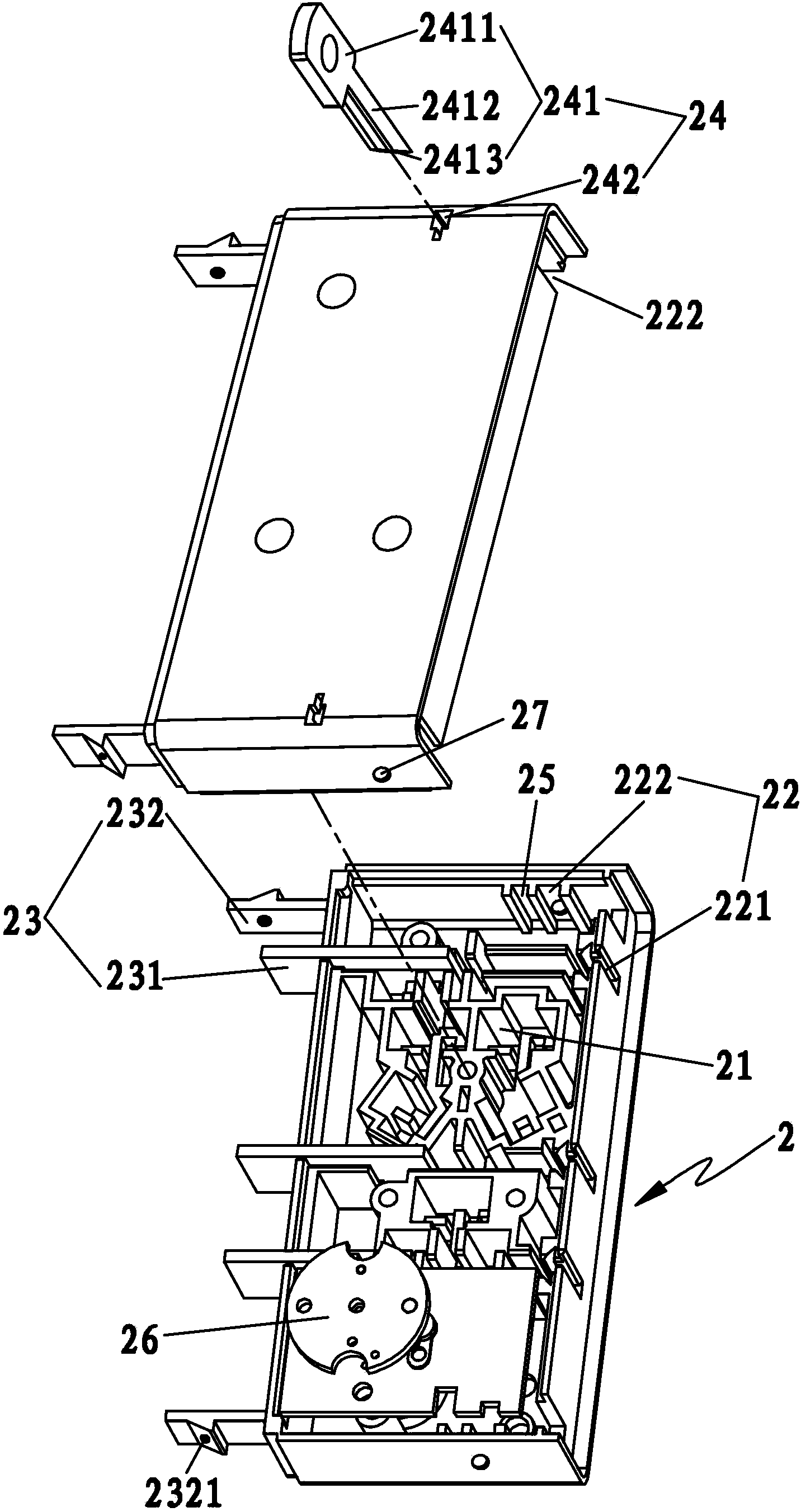

Combination type power strip

ActiveCN103531948AReasonable structural designEasy to useCoupling device detailsElectricityPublic place

The invention discloses a combination type power strip. The combination type power strip comprises a socket head and one or more socket bodies, wherein the socket head is provided with a power line connected with a mains supply and a slot group, the slot group comprises a clamping groove and a conducting strip slot, each socket body is provided with a socket aperture, a slot group and a clamping pin group, each clamping pin group comprises a conducting strip and a clamping hook, each conducting strip is matched with the conducting strip slot, and each clamping hook is matched with the clamping groove. According to the combination type power strip, jacks of the power strip can be combined in number according to specific requirements, the power strip is flexible in application and can meet different requirements for electric equipment numbers, and the space occupation caused by surplus socket apertures or access of another power strip due to insufficient socket apertures can be avoided. The combination type power strip is reasonable in structural design, safe, reliable, convenient to use, attractive in appearance and widely applicable to families, factories, public places and the like.

Owner:FUYIKAI ELECTRICAL

Optical pressure-sensitive adhesive sheet, optical film and display device

ActiveUS20120100359A1Increased durabilityObscures visibilitySynthetic resin layered productsAmide/imide polymer adhesivesDynamic viscoelasticitySheet film

The present invention provides an optical pressure-sensitive adhesive sheet in which white turbidity is not caused by humidification and durability is excellent as well. The present invention provides an optical pressure-sensitive adhesive sheet, comprising: a pressure-sensitive adhesive layer in which a moisture ratio after storage under an environment of 60° C. and 95% RH for 120 hours is 0.65 wt % or more, and a shear storage elastic modulus at 85° C. which is measured by a dynamic viscoelastic measurement is 5.0×104 to 5.0×105 Pa, wherein a peeling distance measured by the constant-load peel test is 30 mm or less when an adherend is a polyethylene terephthalate plate, and the peeling distance measured by the following constant-load peel test is 30 mm or less when the adherend is an acrylic plate.

Owner:NITTO DENKO CORP

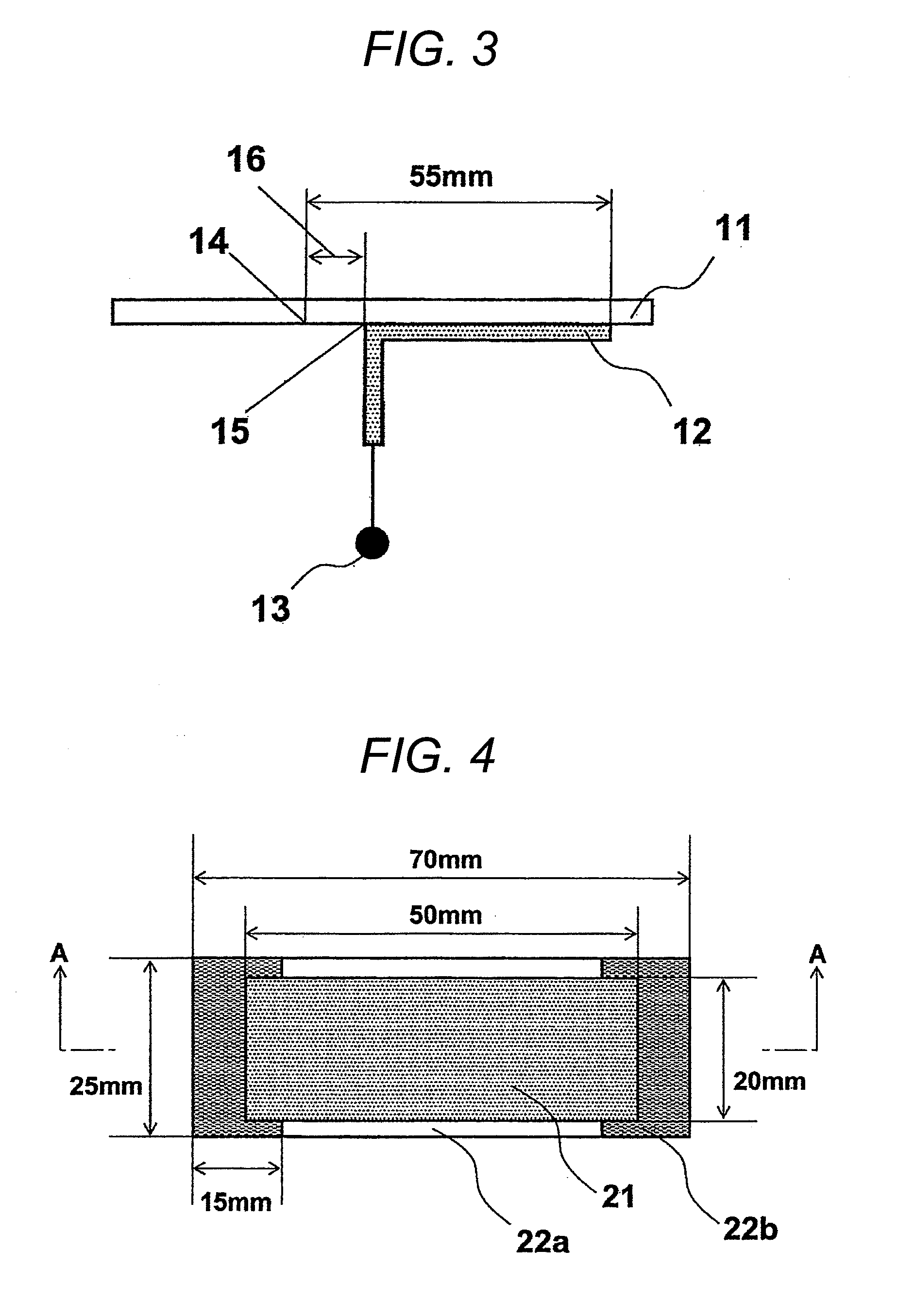

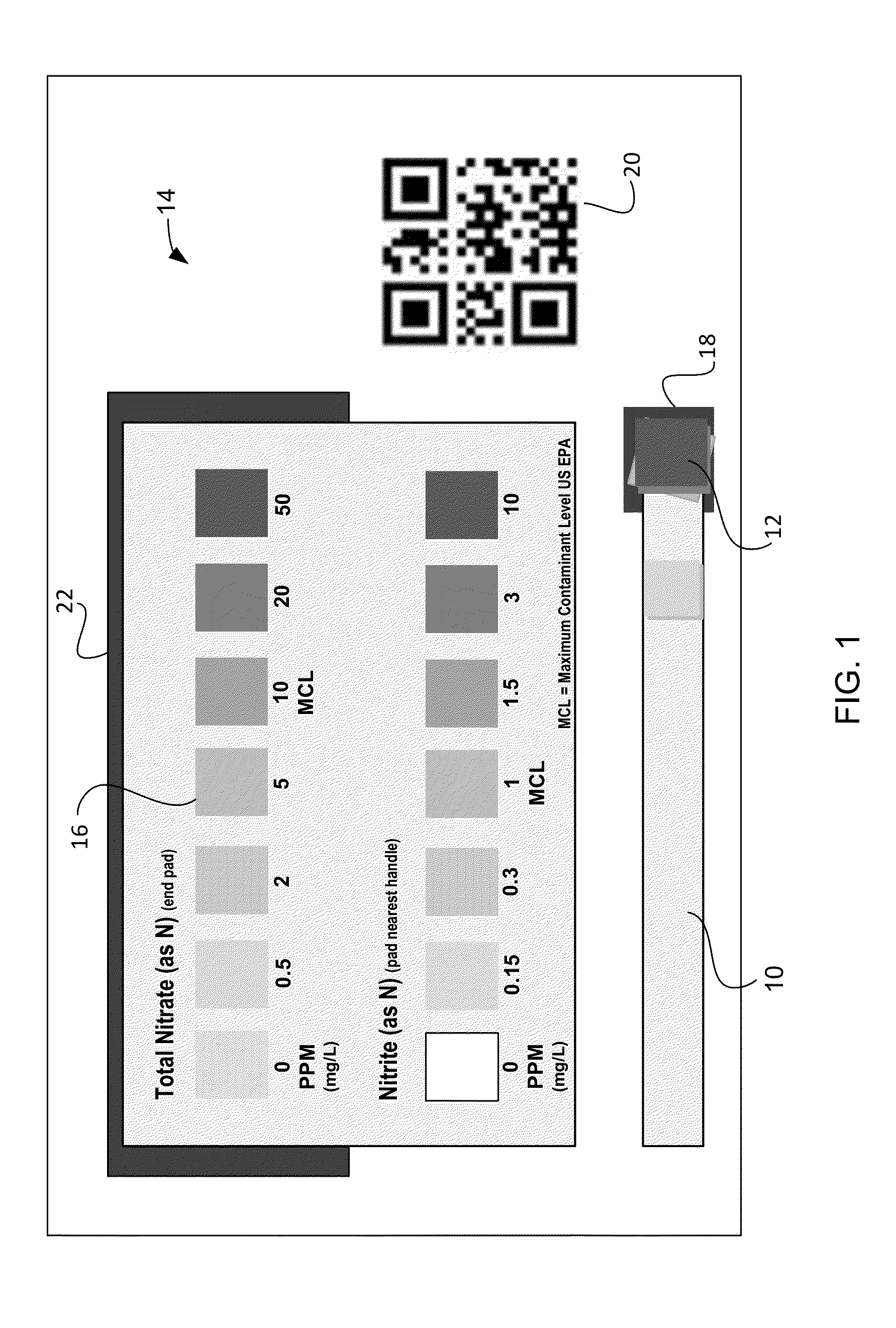

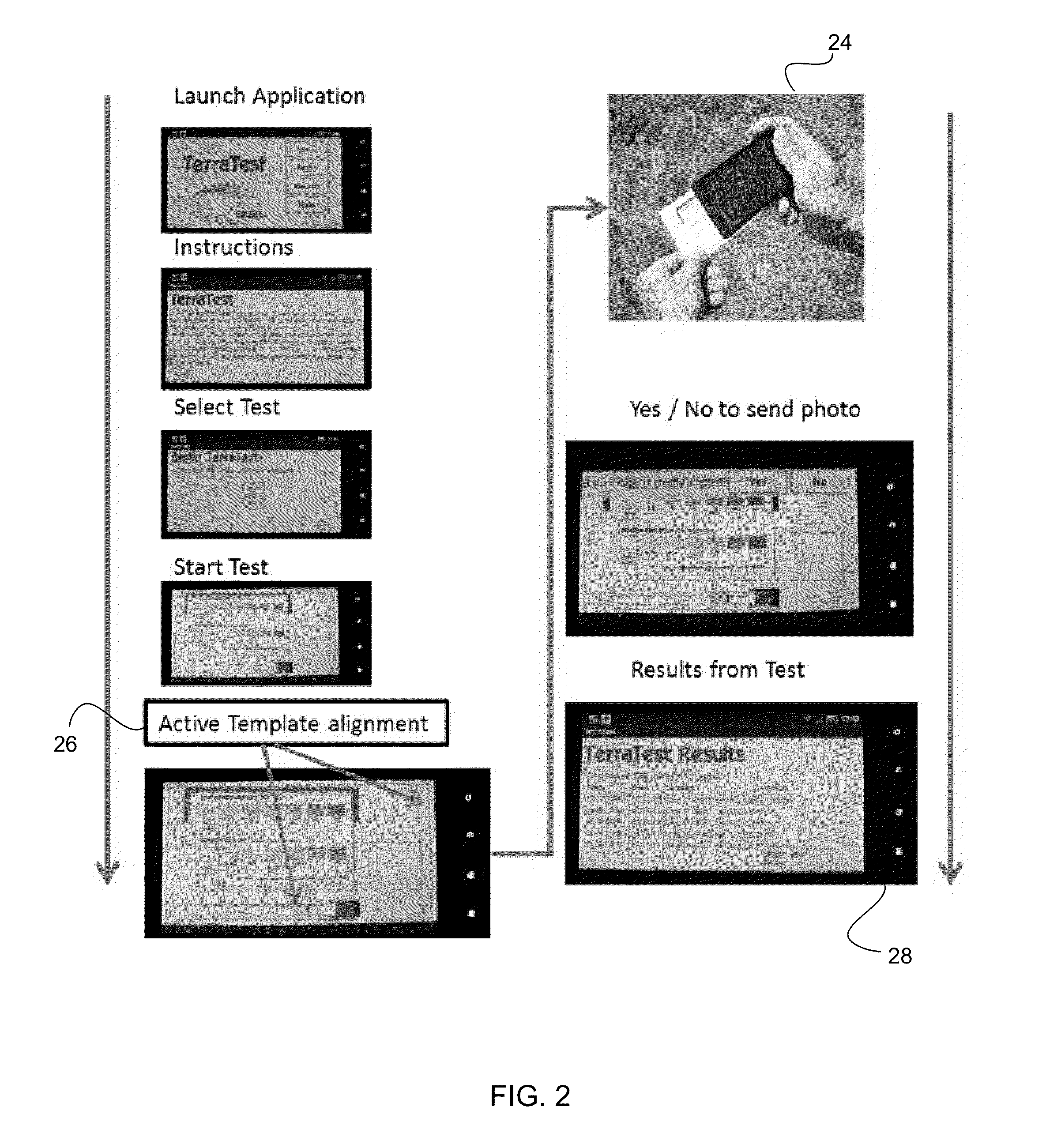

System for water and food safety testing

InactiveUS20130330831A1Material analysis by observing effect on chemical indicatorBiological testingData setFood safety

A system for testing for environmental contaminants using strip tests, obtaining and uploading images of strip tests into a processor, associating a test data set including location, time, and date of test with each image, determining a test result through computational analysis of each image, and storing and reporting test results and data sets.

Owner:MORROW DANNY +1

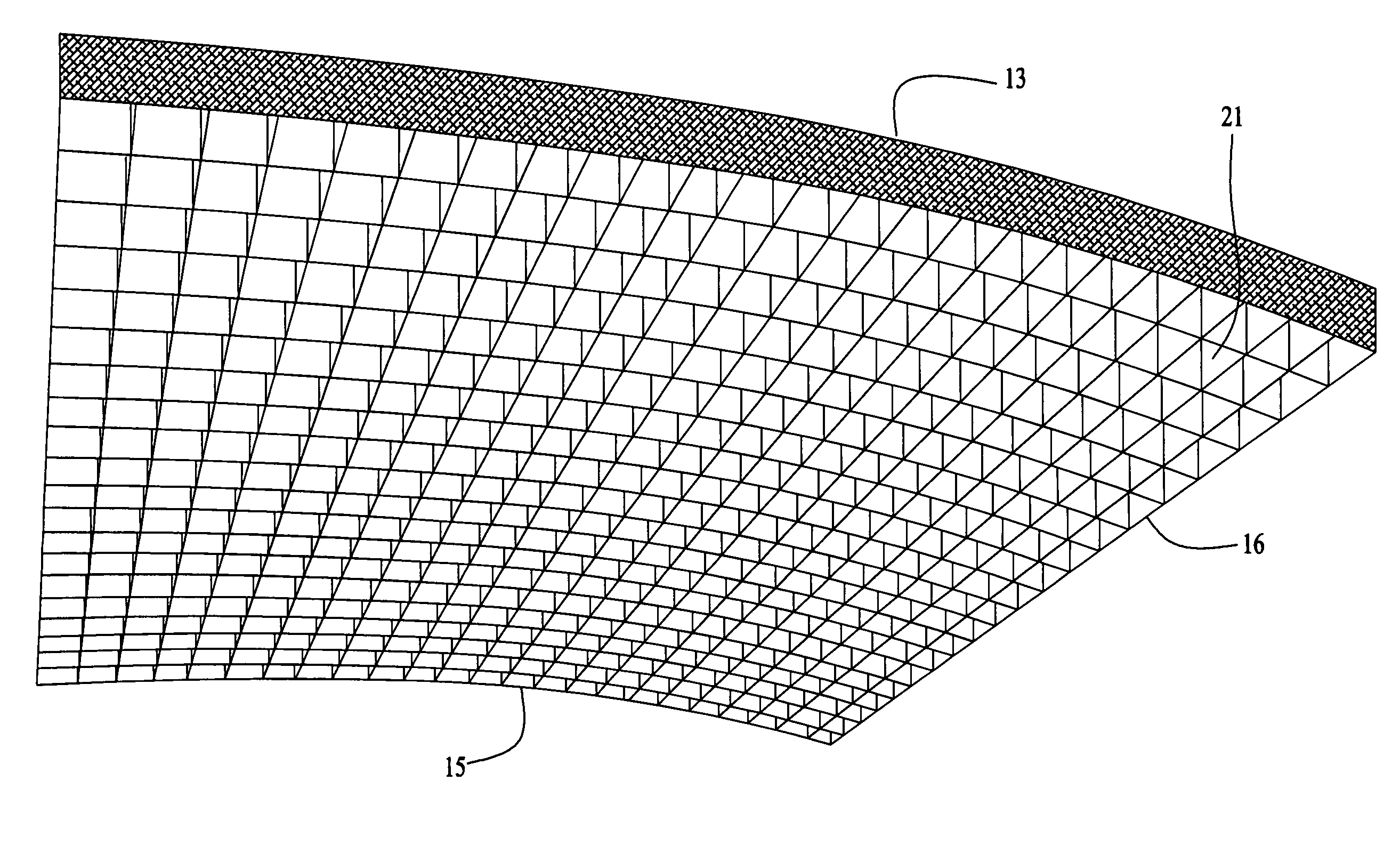

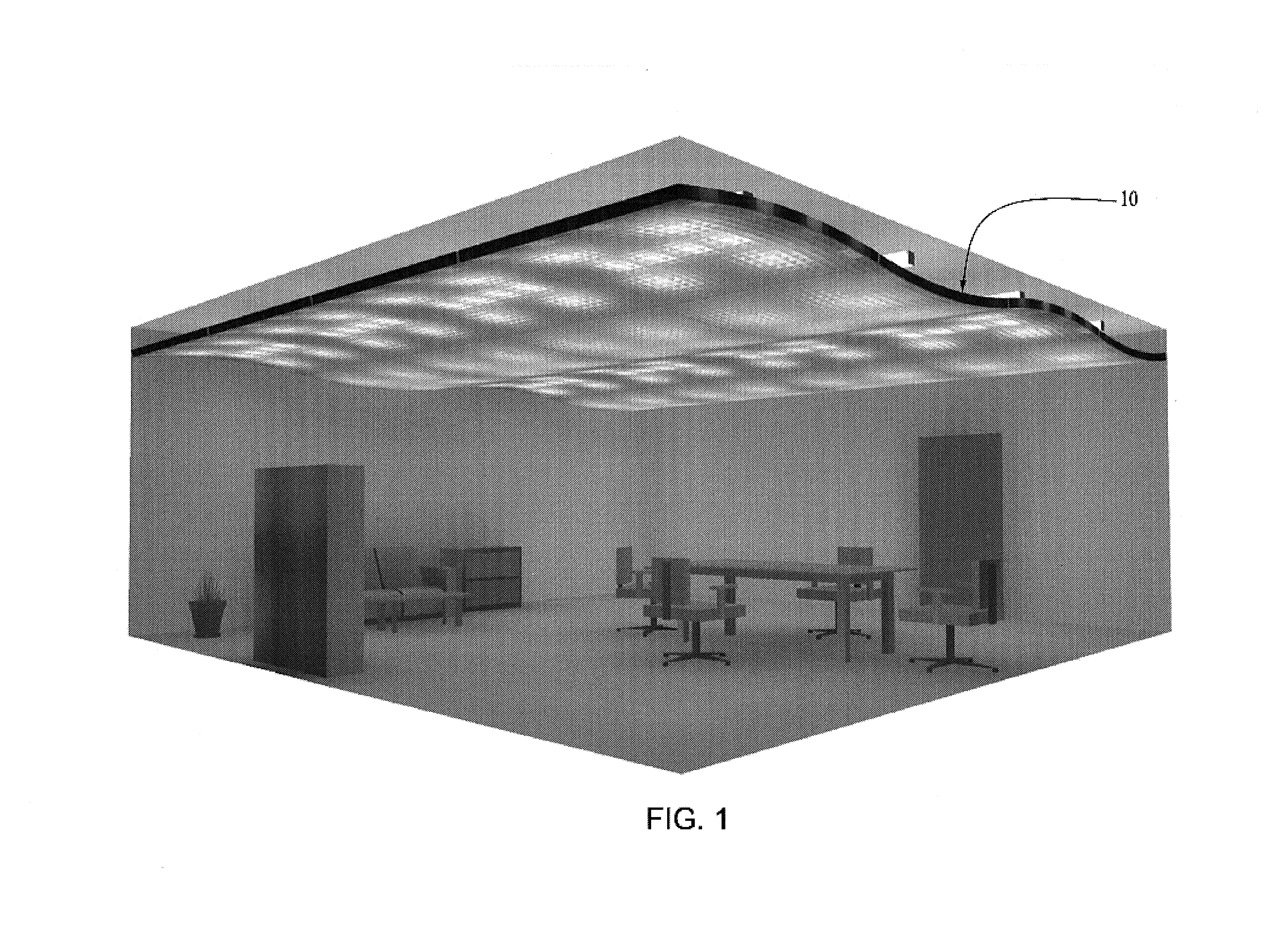

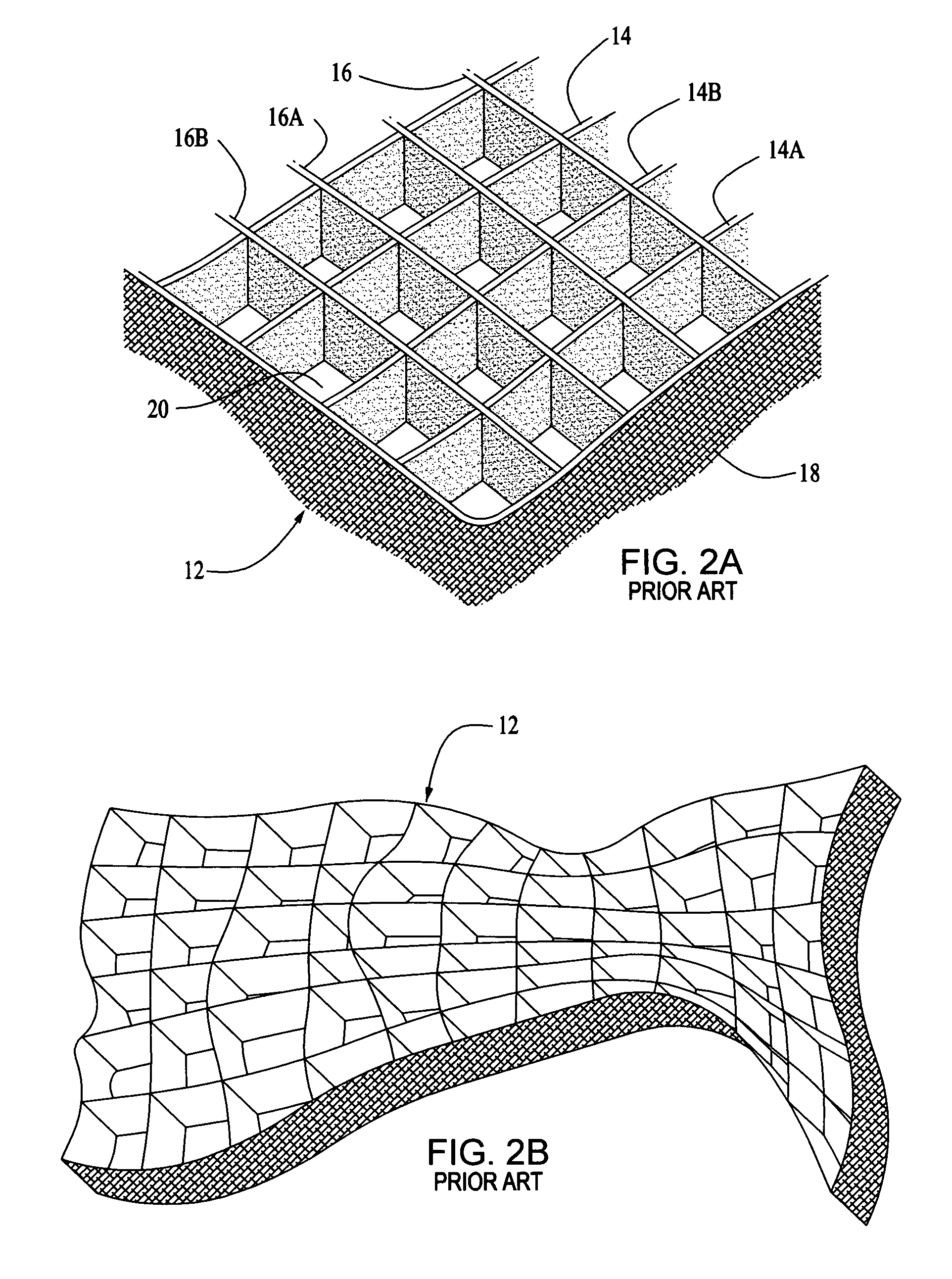

Curved flexible light control grids with rigid framework

Light control grids in curved ceilings or walls include an assembly of flexible, spaced-apart sets of fabric strips that intersect and interlock, one of the sets of strips being substantially curved along its length and / or of varying length. The grids are supported by a modular rigid framework that maintains the strips taut, the frames being substantially curved corresponding to the curved strips and / or strips of varying length. A number of connectors hold the frames together and are used to attach the assembly to the building, and a number of releasable fasteners moveably retained by the frames attach the grids to the frames.

Owner:PILBY STEPHEN E

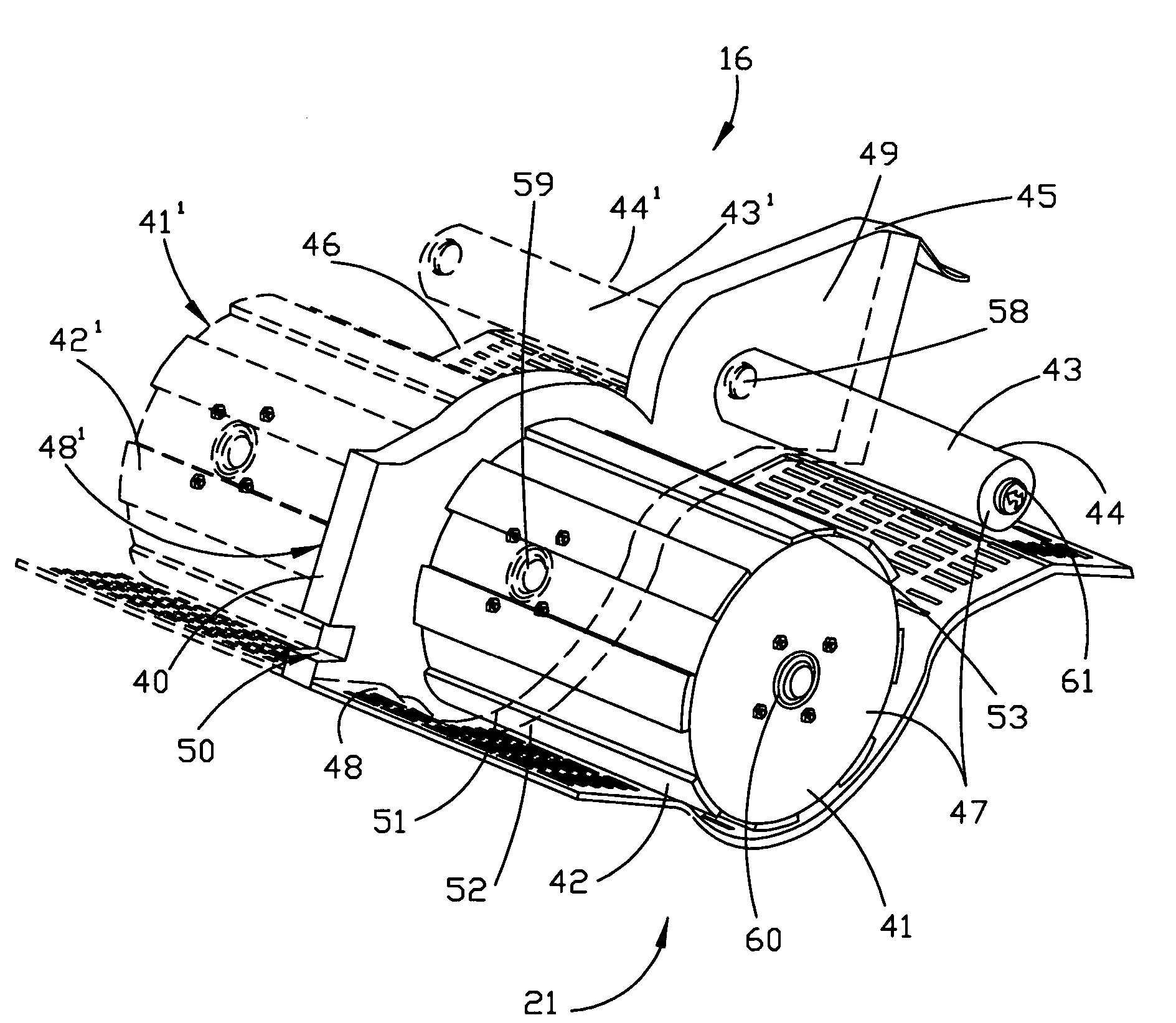

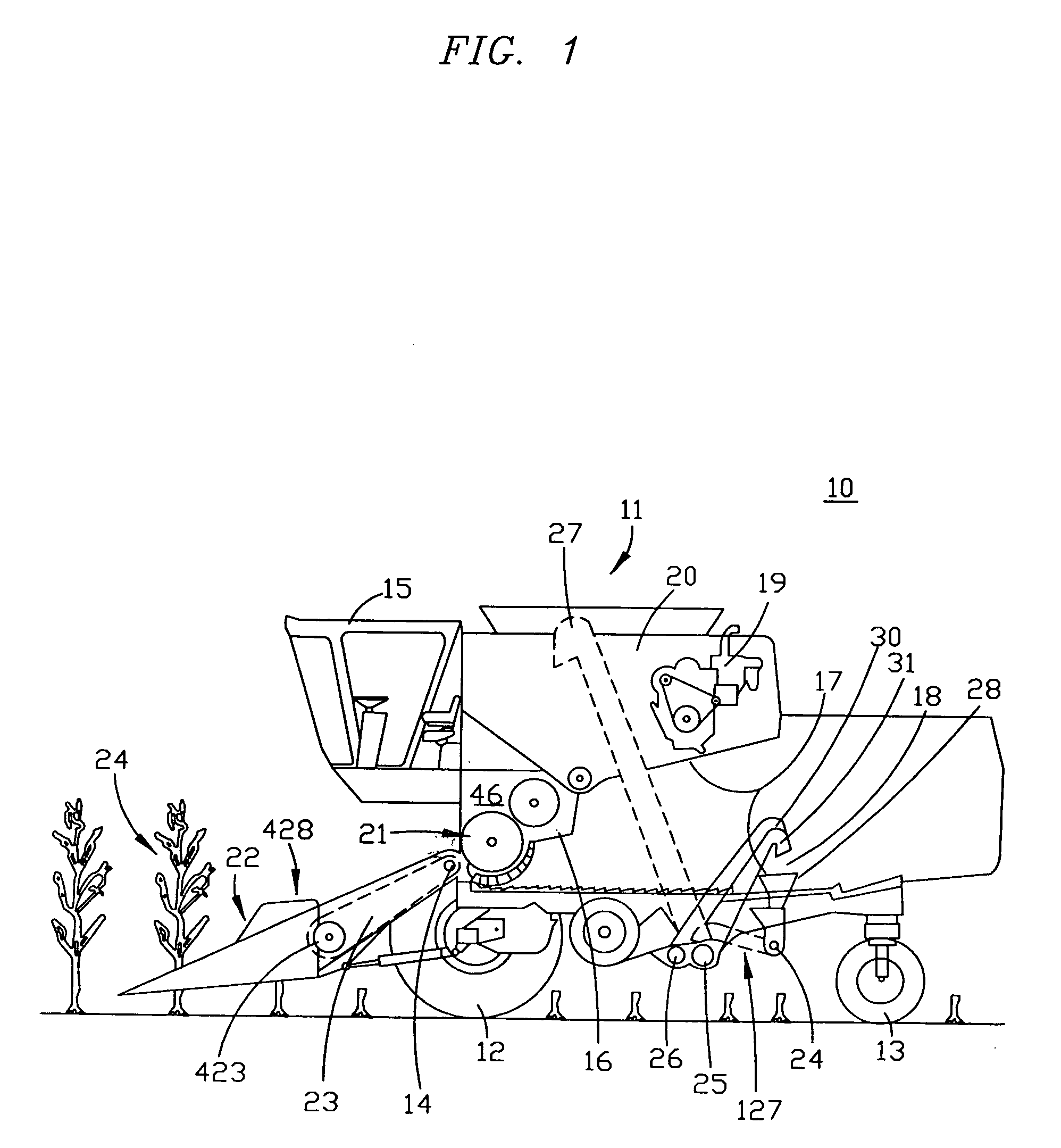

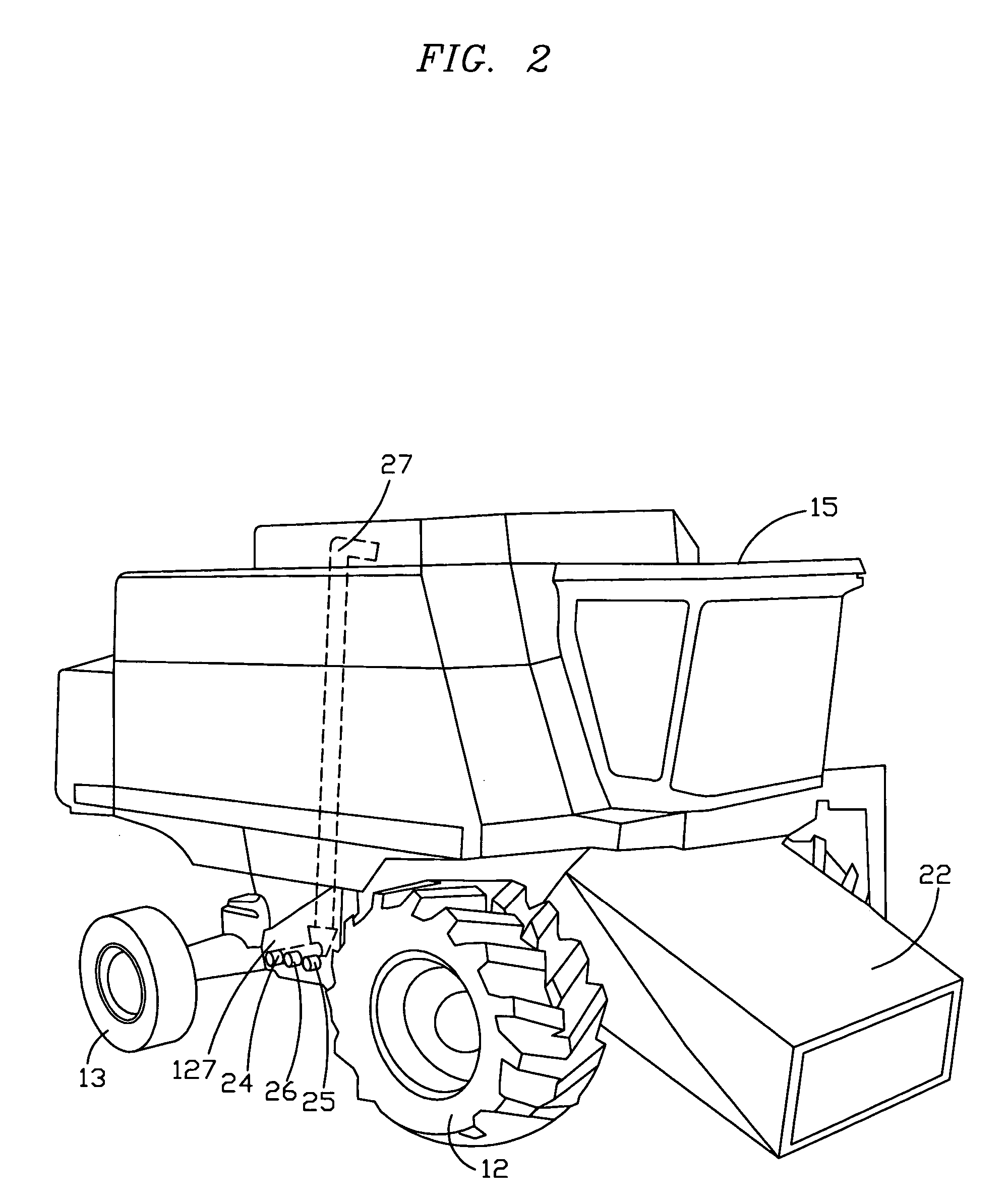

Dual research plot harvester with unconventional grain flow

ActiveUS20060046801A1Reduce the amount requiredSimplify installation workMowersThreshersEngineeringCombine harvester

The invention relates generally to harvesters and, more particularly, to a combine for harvesting row crops, which has been modified, to collect and measure grain from two separate small strip test plots.

Owner:SYNGENTA PARTICIPATIONS AG

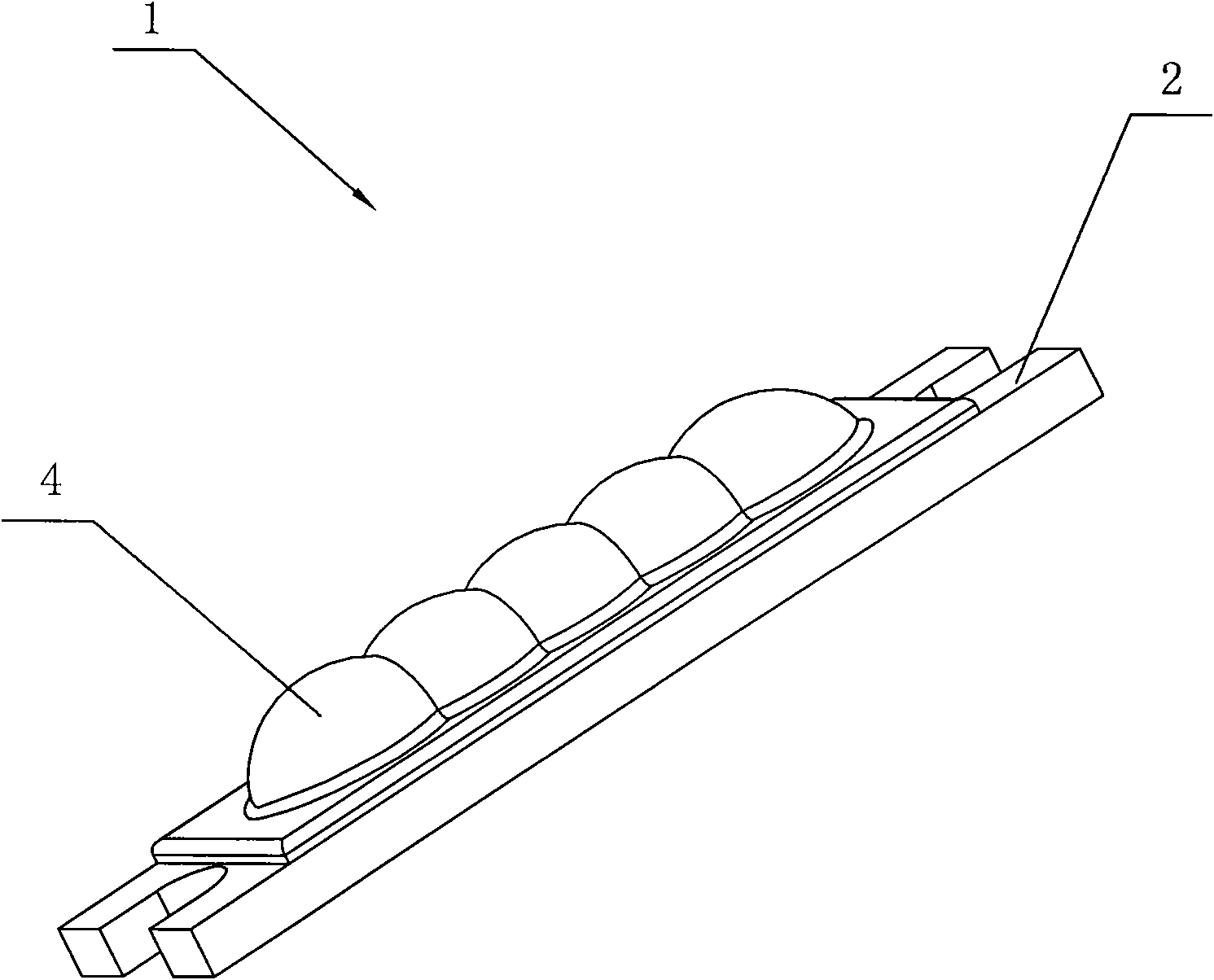

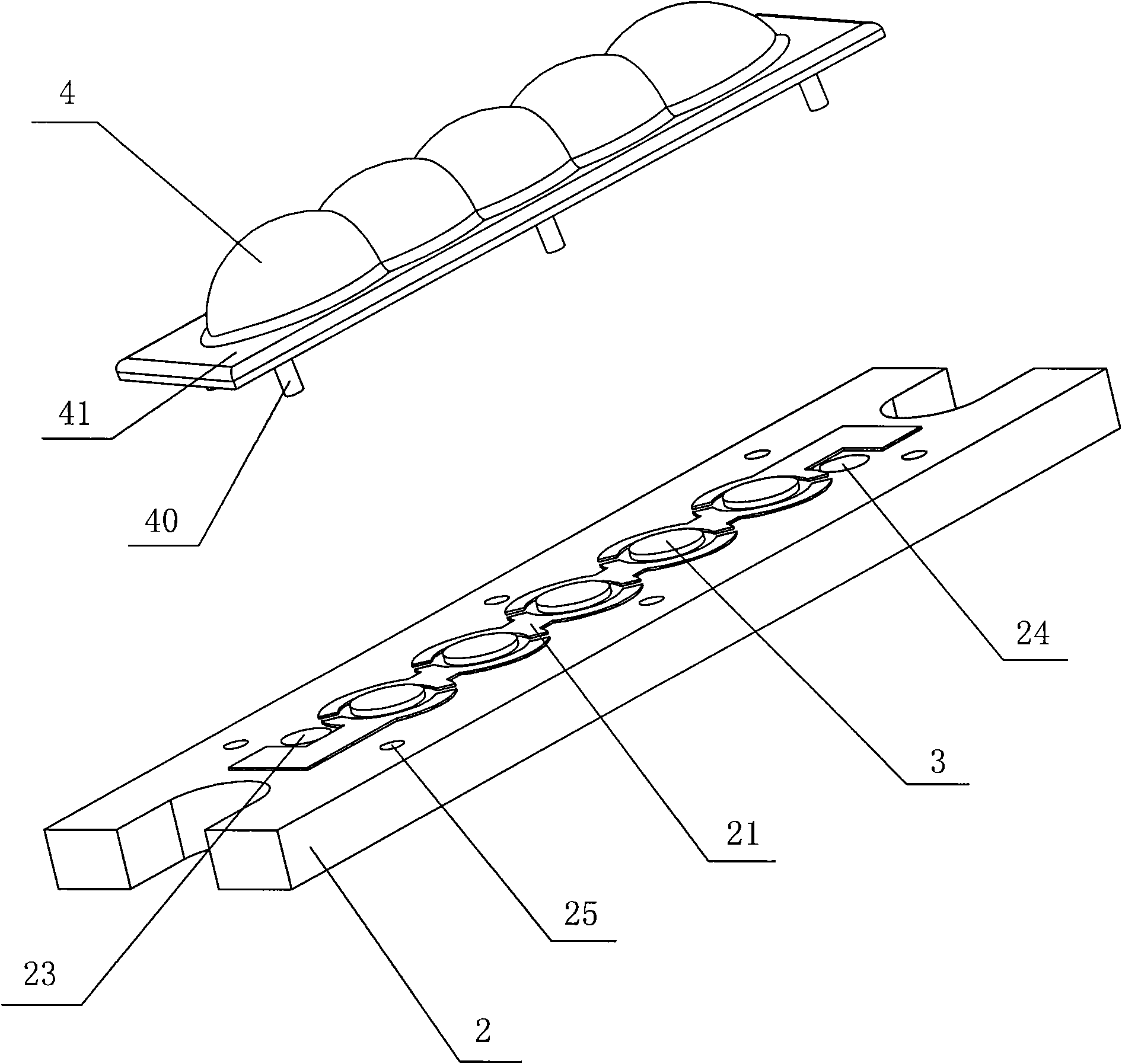

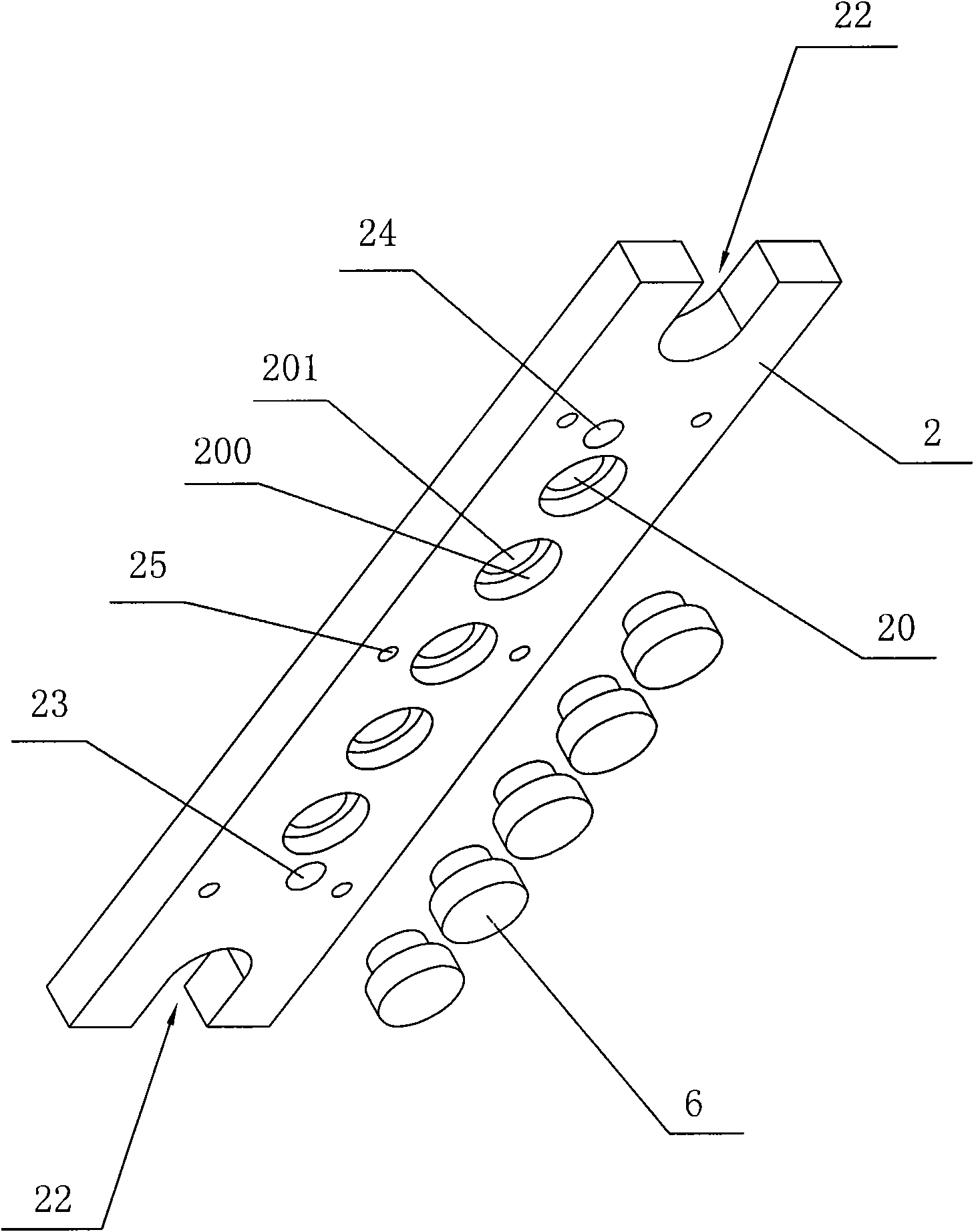

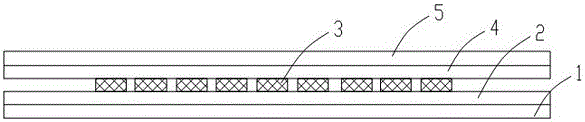

LED strip light source and package method thereof

ActiveCN101576212AImprove consistencySimple production processPoint-like light sourceElongate light sourcesColloidEngineering

The invention relates to an LED strip light source, which comprises a strip substrate with a circuit, at least one LED chip, a filling colloid and a strip lens, wherein the at least one LED chip is arranged on the strip substrate and is electrically connected with the circuit of the strip substrate; the filling colloid is used for packing the LED chip; and the strip lens and the strip substrate are mutually matched and form a cavity structure. The strip substrate is provided with a glue injecting hole and an exhaust hole; and the filling colloid is packed into the cavity structure through the glue injecting hole and the exhaust hole. The LED strip light source realizes the package structure by matching the lens with a cavity and adopting a mode of injection glue in the bottom of the substrate; the structure can not only simplify the production process and reduce the production cost, but also can improve the consistency of LED strip light source products and achieve the uniform chromaticity. In addition, the invention also provides a package method for manufacturing the LED strip light source.

Owner:FOSHAN NATIONSTAR OPTOELECTRONICS CO LTD

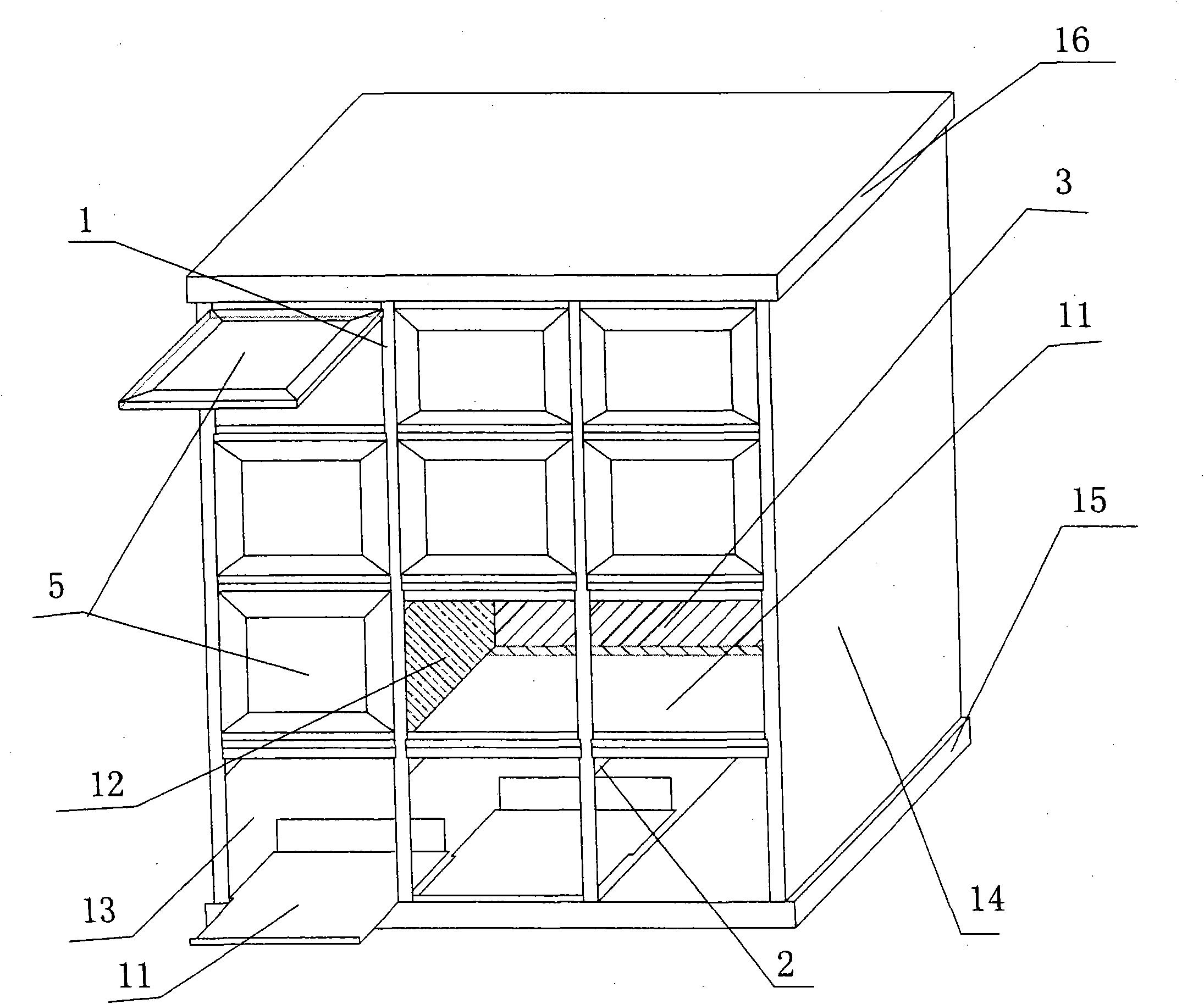

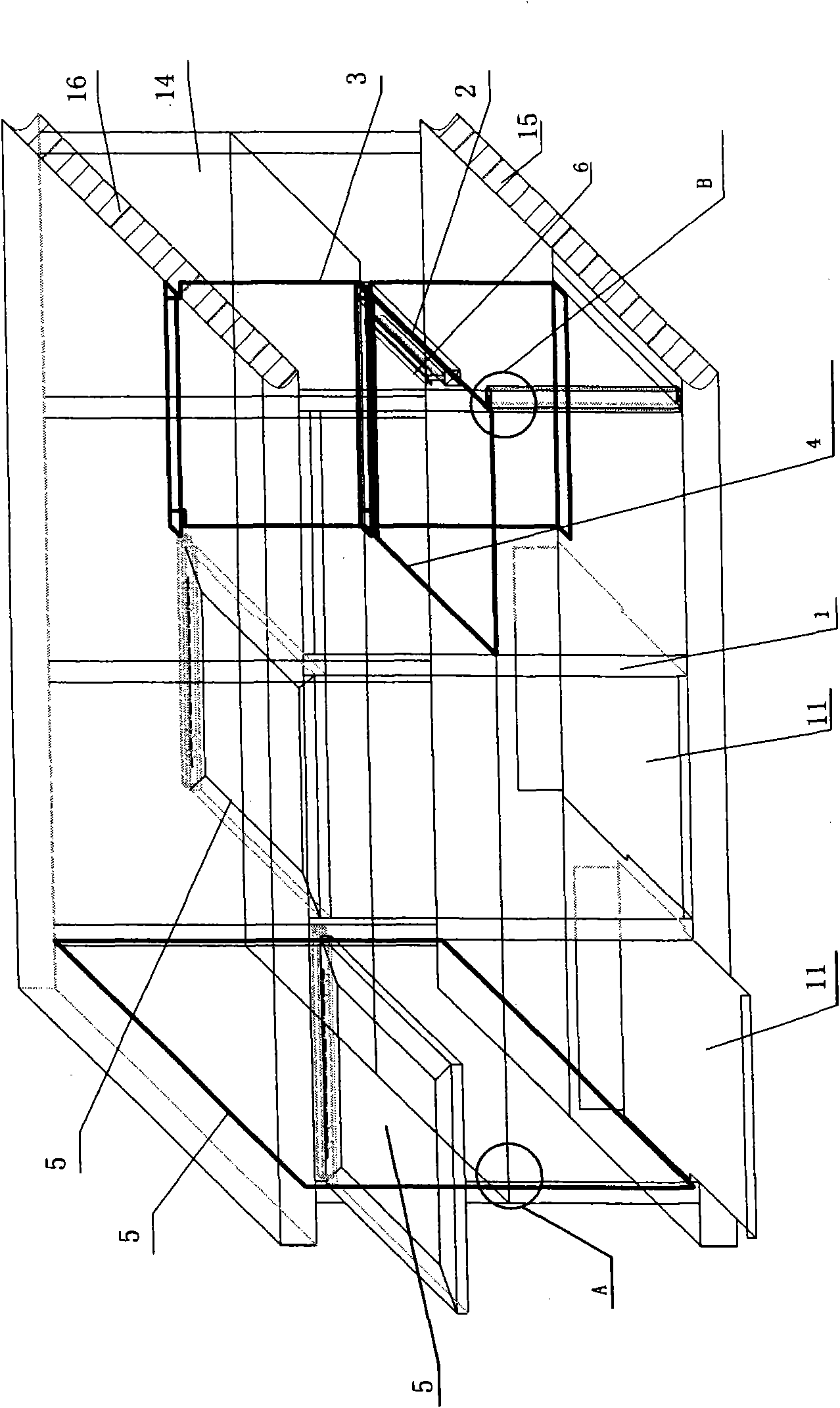

Combined cinerary casket storage rack

ActiveCN101886489AEasy to combineCombined transportation is convenientBurial vaultsMonumentsEngineeringRivet

The invention discloses a combined cinerary casket storage rack, which consists of more than two layers and two rows of storage units, and particularly consists of upright posts, rails, fixed bottom plates, sliding doors, double-strip slots, sliding tools, a door top rail, sandwich plates, movable bottom plates, inner clapboards, outer side plates, an underframe and an upper frame. The upright posts are fastened with corresponding rails together through rail post internal fasteners; a middle clapboard is vertically arranged in the middle to separate the storage rack into two parts symmetrical front and back; each layer is provided with the fixed bottom plates; the two sides of the fixed plates are provided with the double-strip slots; two sides of the sliding doors are respectively embedded into two double-strip slots; and the two sides of the movable bottom plates and the sandwich plates are simultaneously put into caulking grooves of two left-and-right opposite double-strip slots. The combined cinerary casket storage rack has the advantages of convenient combined transportation, delicate structure, flexibility, practicability, attractive appearance, invisible screws, rivets, interfaces and seams, and convenient assembly, disassembly, transportation and combination.

Owner:汪金苟

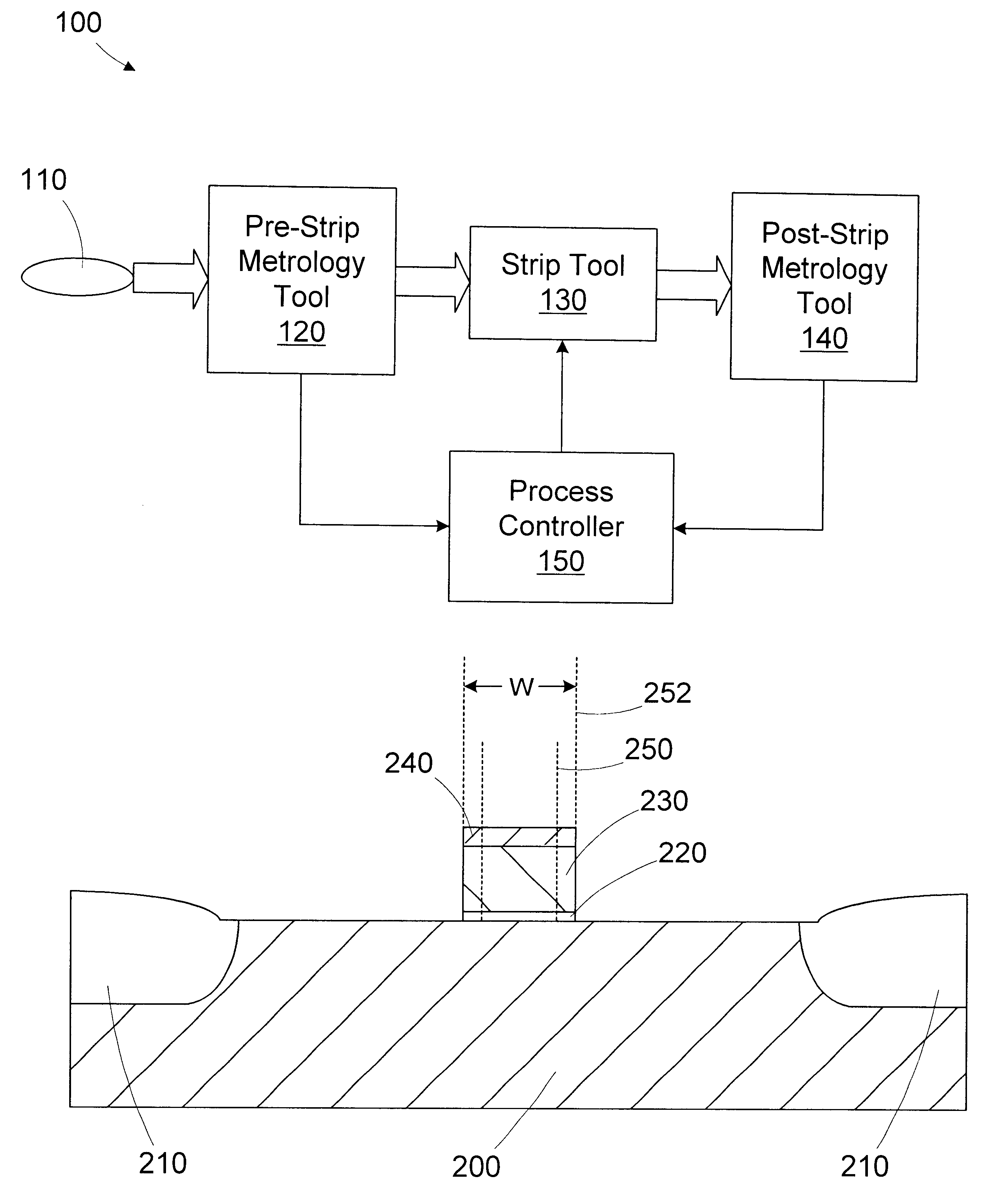

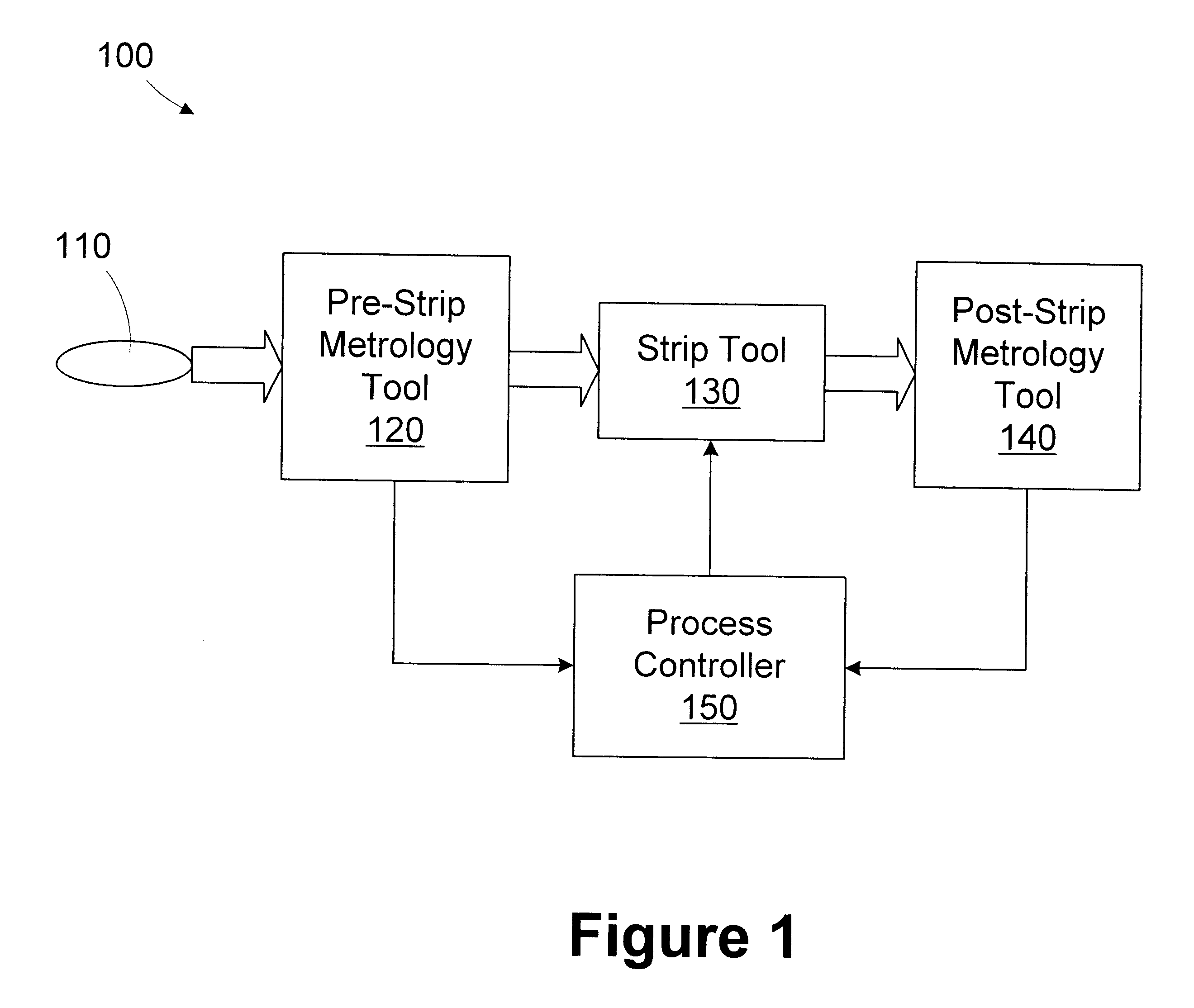

Feedback control of strip time to reduce post strip critical dimension variation in a transistor gate electrode

InactiveUS6461878B1Semiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingAnti-reflective coatingMetrology

A method for decreasing variations in gate electrode widths is provided. The method includes providing a wafer having a gate electrode formed thereon and an anti-reflective coating layer formed over at least a portion of the gate electrode. The gate electrode has a width. The width of the gate electrode is measured. A strip rate for a strip tool adapted to remove the anti-reflective coating is determined. The measured width of the gate electrode is compared to a target gate electrode critical dimension to determine an overetch time based on the strip rate. The operating recipe of the strip tool is modified based on the overetch time. A processing line includes a first metrology tool, a strip tool, and a process controller. The first metrology tool is adapted to measure the width of a gate electrode formed on a wafer. The gate electrode has an anti-reflective coating layer formed over at least a portion of the gate electrode. The strip tool is adapted to remove the anti-reflective coating. The process controller is adapted to determine a strip rate for the strip tool, compare the width of the gate electrode to a target gate electrode critical dimension to determine an overetch time based on the strip rate, and modify the operating recipe of the strip tool layer based on the overetch time.

Owner:GLOBALFOUNDRIES INC

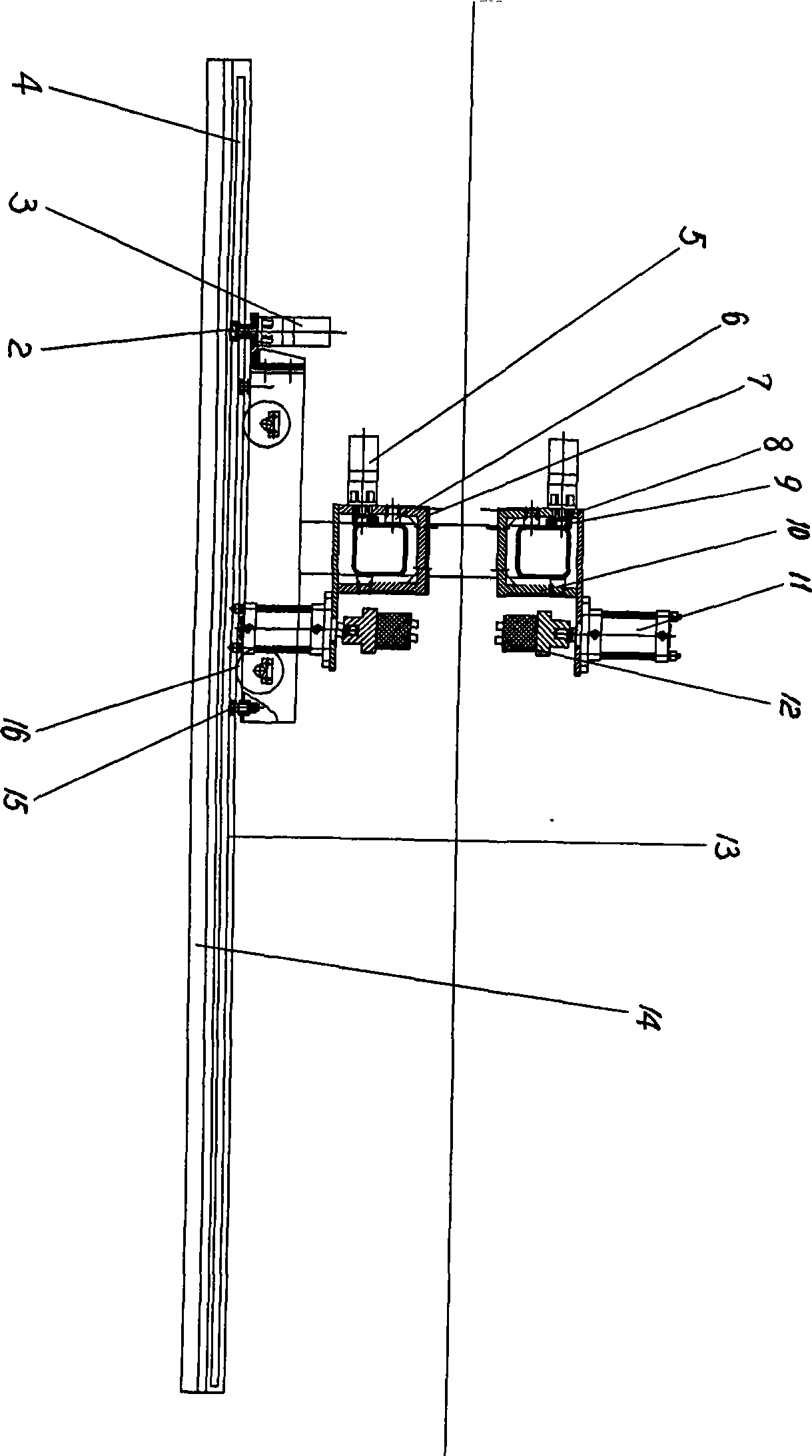

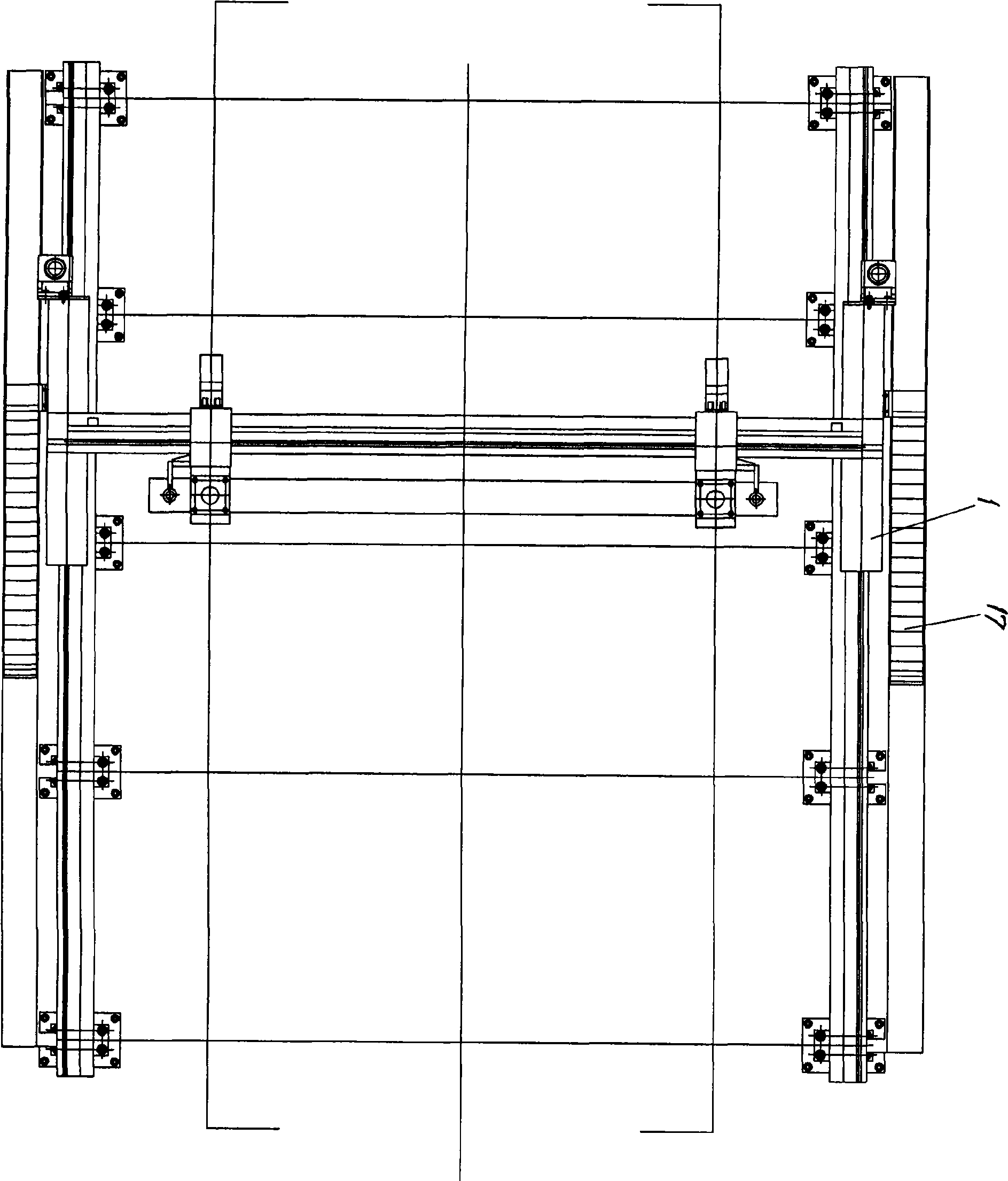

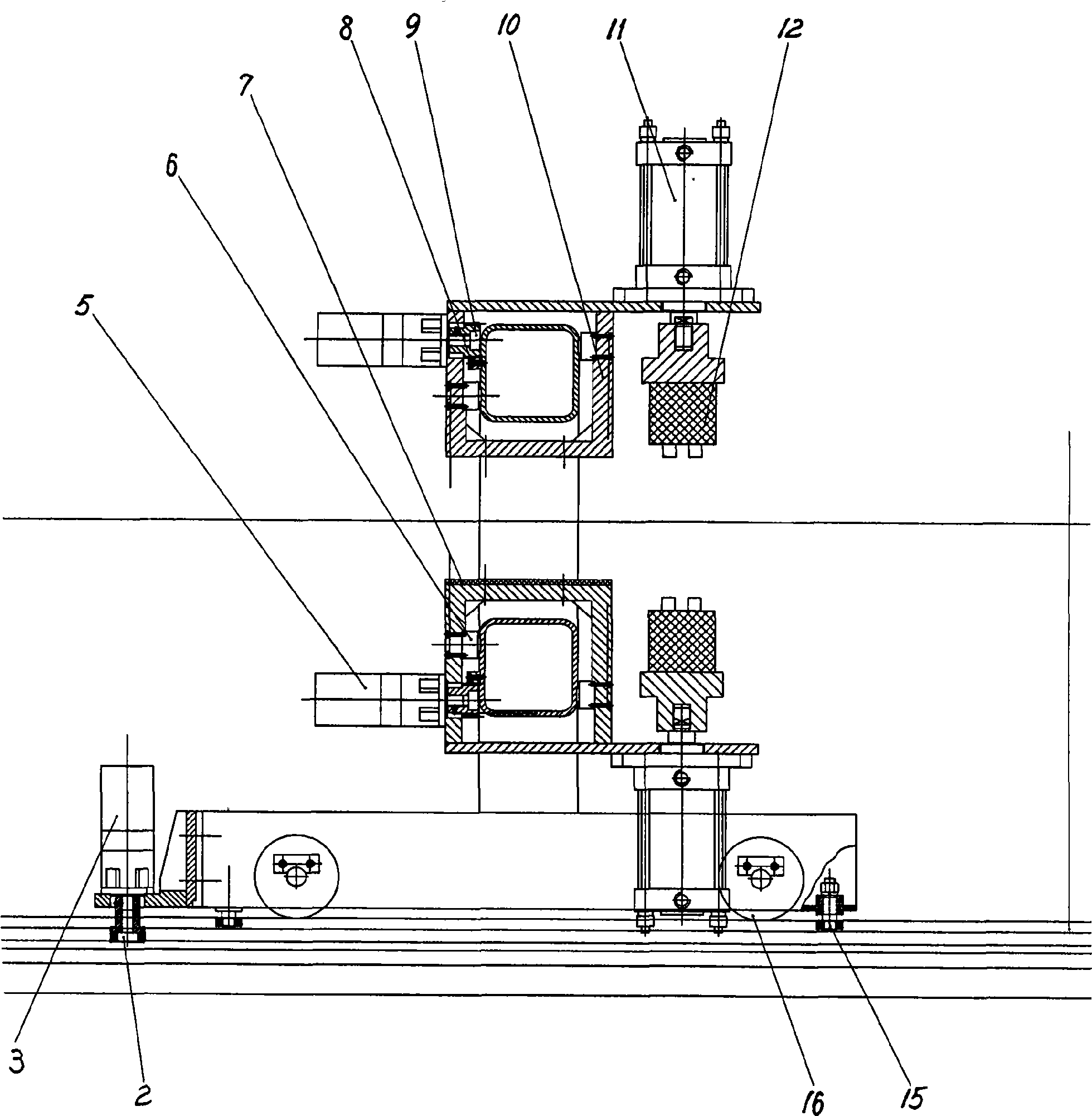

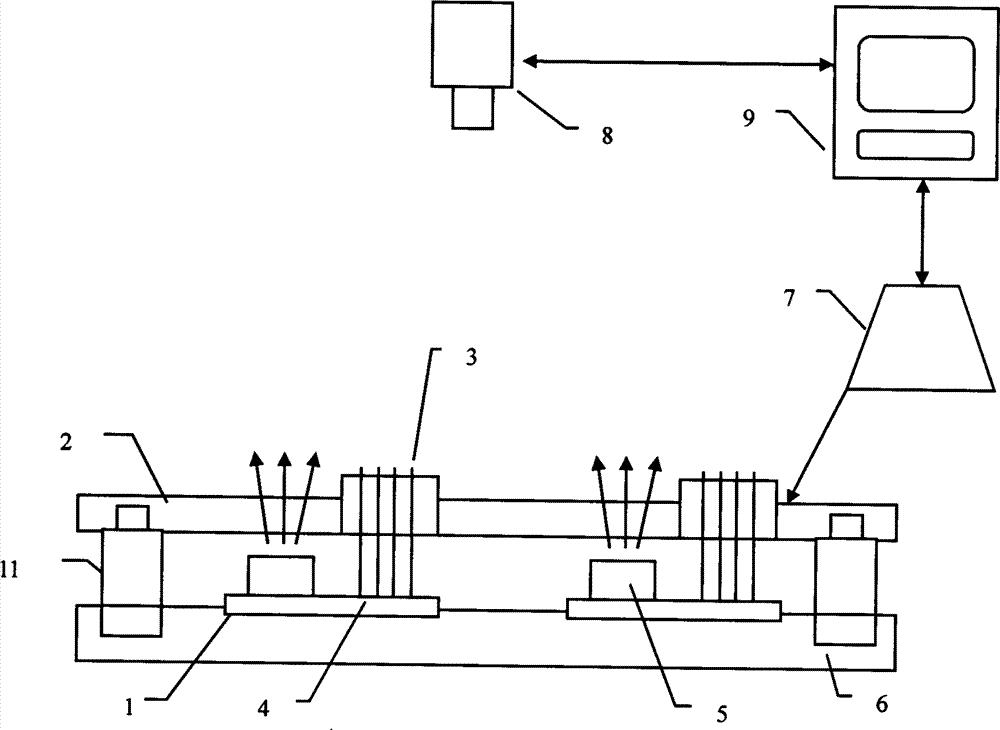

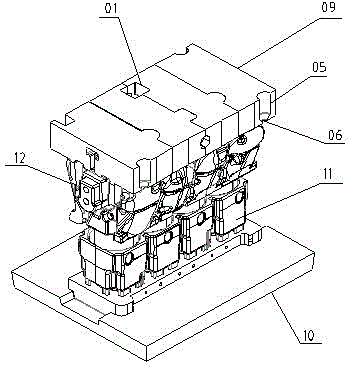

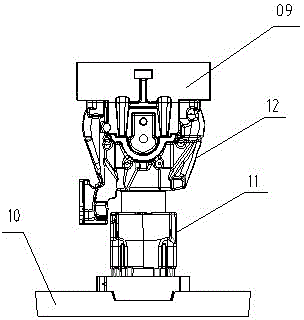

Automatic grinding device for inspection of band steel

InactiveCN101502940ARealize automatic grindingMonitor imprintGrinding carriagesGrinding headsMaterial consumptionStrip steel

The invention relates to an automatic grinding device used for strip test. A vertical guide and a guide base are arranged on the ground. A frame is arranged on the vertical guide. The frame is driven by a vertical servo motor and moves on the vertical guide. An upper transverse guide and a lower transverse guide are arranged on the frame. Two transverse mobile cars are respectively arranged on the upper transverse guide and the lower transverse guide. The transverse mobile cars are connected with the guides in a meshing way by gears and racks and are driven by a transverse servo motor to synchronously drag the grinding device to move transversely. A grinding head combination is combined with the upper transverse mobile car and the lower transverse mobile car by the linkage with a cylinder. An upper grinding head and a lower grinding head simultaneously pressurize on the upper side and the lower side of a steel strip and grind synchronously. By changing the prior artificial grinding mode into an automatic mode, the invention improves the effectiveness, the safety and the reliability of the strip surface quality test process, and eliminates the phenomena of quality error, grinding omission and test omission of artificial grinding, thereby saving manpower, time and material consumption and initial investment.

Owner:BAOSTEEL ENG & TECH GRP

Stereoscopic stripe glass cover plate and production method thereof

InactiveCN107935402AColorful cool color effectRaise the gradePlane surface grinding machinesGlass coverMetallurgy

The invention discloses a stereoscopic stripe glass cover plate and a production method thereof. The production method comprises the following steps: (S1) providing a glass substrate, wherein the glass substrate is provided with a first surface and a second surface which are opposite to each other; (S2) forming a grain layer on the first surface of the glass substrate, wherein the grain layer comprises a plurality of strip slots, the strip slots are combined to form a strip pattern, bulges are arranged among the strip slots, and the upper end surfaces of the bulges are polished to form smootharc surfaces; (S3) forming a coating film layer on the second surface of the glass substrate; and (S4) covering the coating film layer with an ink layer. The stereoscopic stripe glass cover plate presents a five-color fascinating luster effect and is capable of making light reflected to human eyes not dazzling when the external reflected light is too strong; and the stereoscopic stripe glass coverplate is high in grade and added value, and the appearance attractiveness and competitiveness of the stereoscopic stripe glass cover plate are greatly improved.

Owner:TRULY OPTO ELECTRONICS

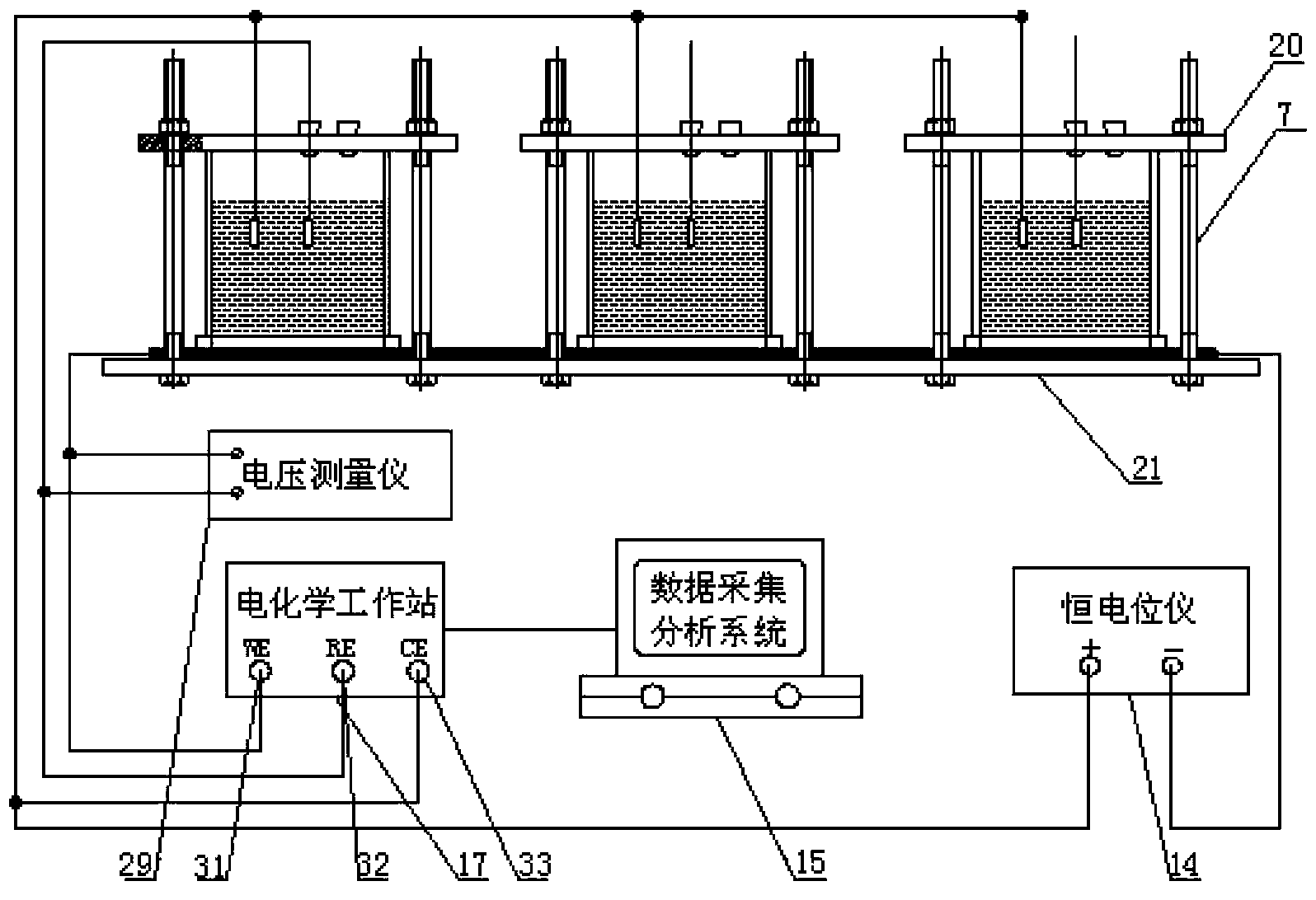

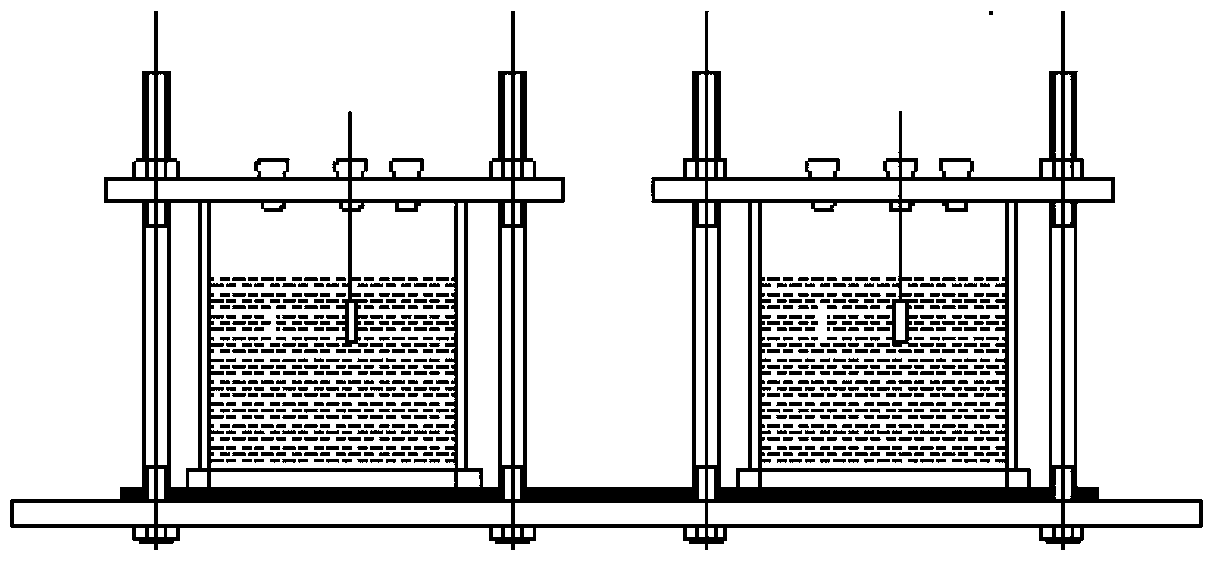

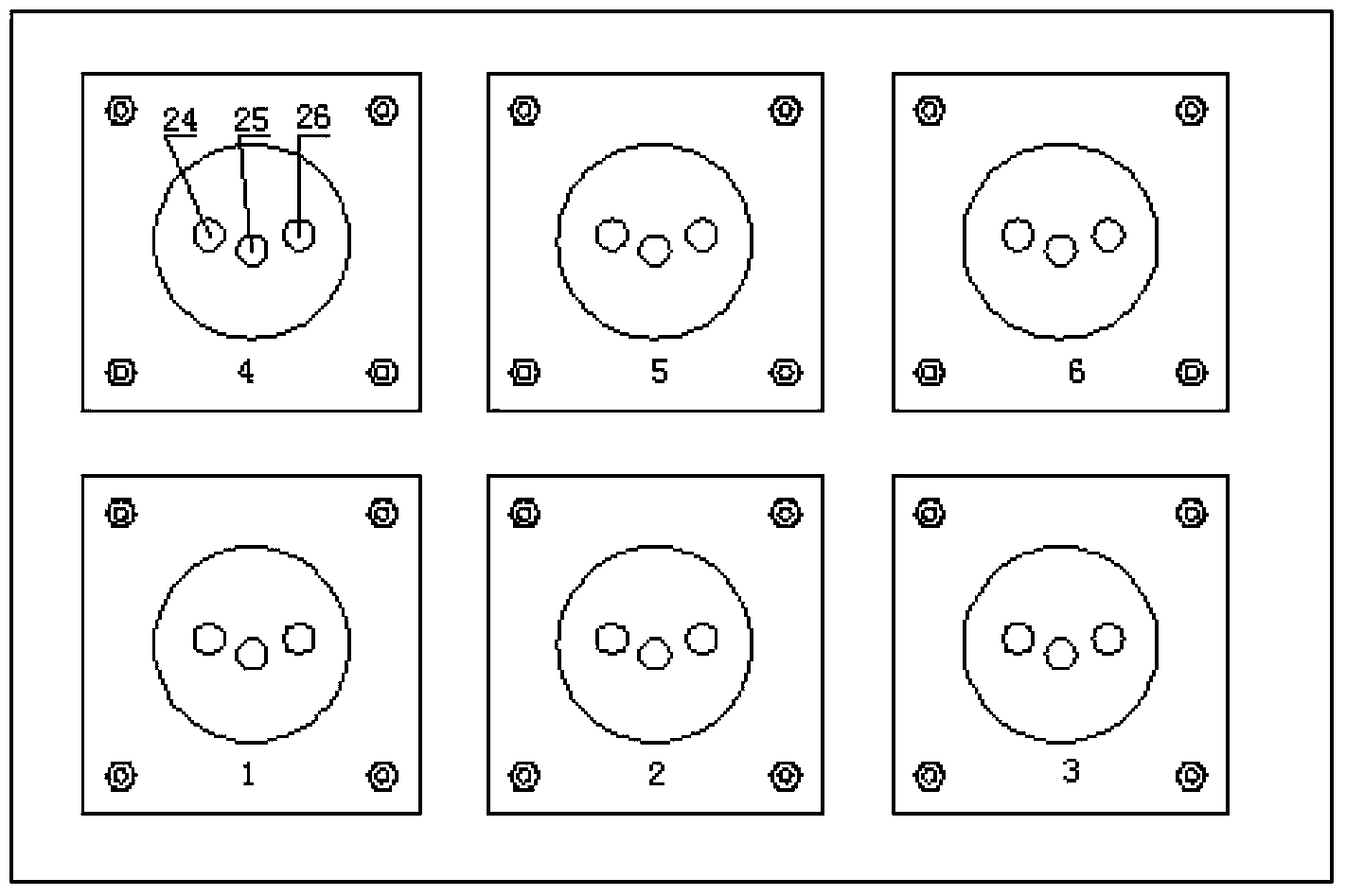

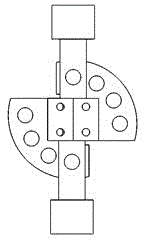

Anticorrosion layer peeling testing device based on electrochemical impedance spectrum

InactiveCN103364472AEfficiently simulate the actual conditions of strippingReal-time monitoring of peeling statusMaterial analysis by electric/magnetic meansMeasuring instrumentData acquisition

The invention belongs to the field of a testing device of a pipeline anticorrosion technology and discloses an anticorrosion layer peeling testing device based on an electrochemical impedance spectrum. The anticorrosion layer peeling testing device comprises an electrolytic tank group, a constant potential rectifier, a data collection and analysis system, an electrochemical work station and a voltage measuring instrument. A simulated soil solution is contained in the electrolytic tank group and is used for simulating an actual condition of peeling an anticorrosion layer of a buried steel pipeline. The data collection and analysis system is connected with the electrochemical work station to measure the electrochemical impedance spectrum in real time and carry out data processing and analysis; the performance of the anticorrosion layer is quantitatively evaluated to monitor the peeling condition of a defect hole part of the anticorrosion layer in real time. The device disclosed by the invention can effectively simulate the actual condition of peeling the anticorrosion layer of the buried steel pipeline and can monitor the cathode peeling process in real time; a test result has very good repeatability and reproducibility; the anticorrosion layer peeling testing device is simple and convenient to operate and is suitable for the cathode peeling tests and the test evaluation of the anticorrosion layers of various buried steel pipelines.

Owner:BEIJING UNIV OF TECH

Method for judging failures of spot-welded joint under recombination action

InactiveCN104785947AImprove simulation accuracyAccurately predict solder joint failuresResistance welding apparatusTorsion testReliability engineering

The invention provides a method for judging failures of a spot-welded joint under the recombination action. The method includes the following steps that firstly, a sample is prepared; secondly, a double-U-type spot-welded sample test is carried out; thirdly, an edgefold stripping test is carried out; fourthly, a torsion test is carried out; fifthly, a welding spot nugget diameter test is carried out; sixthly, failure criteria parameter processing based on resultant force is carried out; seventhly, failure criteria parameter processing based on stress is carried out. By means of the method for judging failures of the spot-welded joint under the recombination action, the failure conditions of the welding spot can be accurately predicted, and the simulation precision of car collision is improved.

Owner:SHANGHAI UNIV

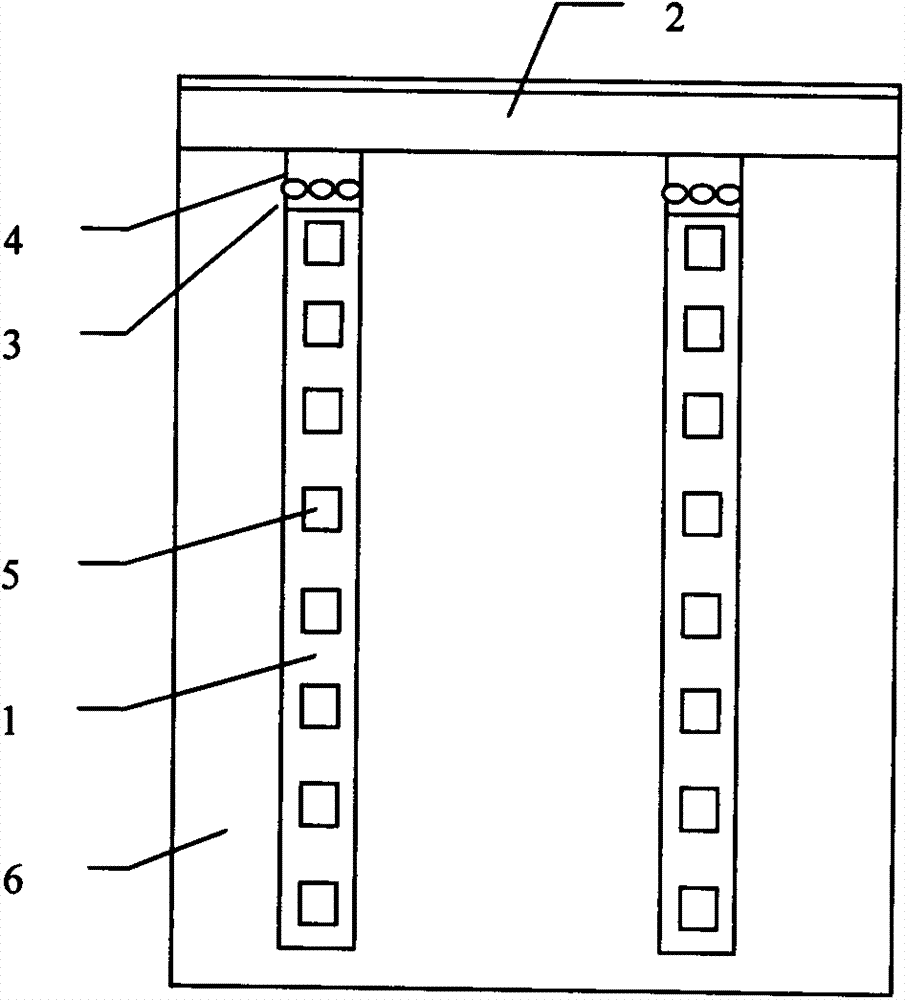

Front-side-illuminating LED light strip test device and method

ActiveCN104330749AMeet online testing requirementsHigh speedLamps testingTesting optical propertiesTest specificationOnline test

The invention relates to a front-side-illuminating LED light strip test device which comprises light strips, a light strip carrier, a light strip power module, a light strip test board, a digital camera and a computing control unit. The light strips are provided with a plurality of LED lights and fixed to the light strip carrier. A plurality of light strips are arranged. The light strip power module supplies power to the LED light strips. The light strip test board is provided with a light-transmitting device and is located above the light strip carrier through a locating device. The digital camera is fixedly arranged above the light strip test board. The light rays of the LED lights on the light strips illuminate the digital camera through the light strip test board. The digital camera is connected with the computing control unit. According to the method, multiple light strips (ten to sixty light strips) can be tested at the same time, and the test speed is increased by 10-60 times compared with that of manual work; and moreover, uncertainty influence of human factors is avoided, and the test specification takes the numerical value as the standard, so that the stability and precision are ensured, and the online test requirement of the LED light strips can be met completely, the cost is saved, the efficiency is improved, and the quality is ensured.

Owner:苏州威盛视信息科技有限公司

Method of fabricating flash memory device having self-aligned floating gate

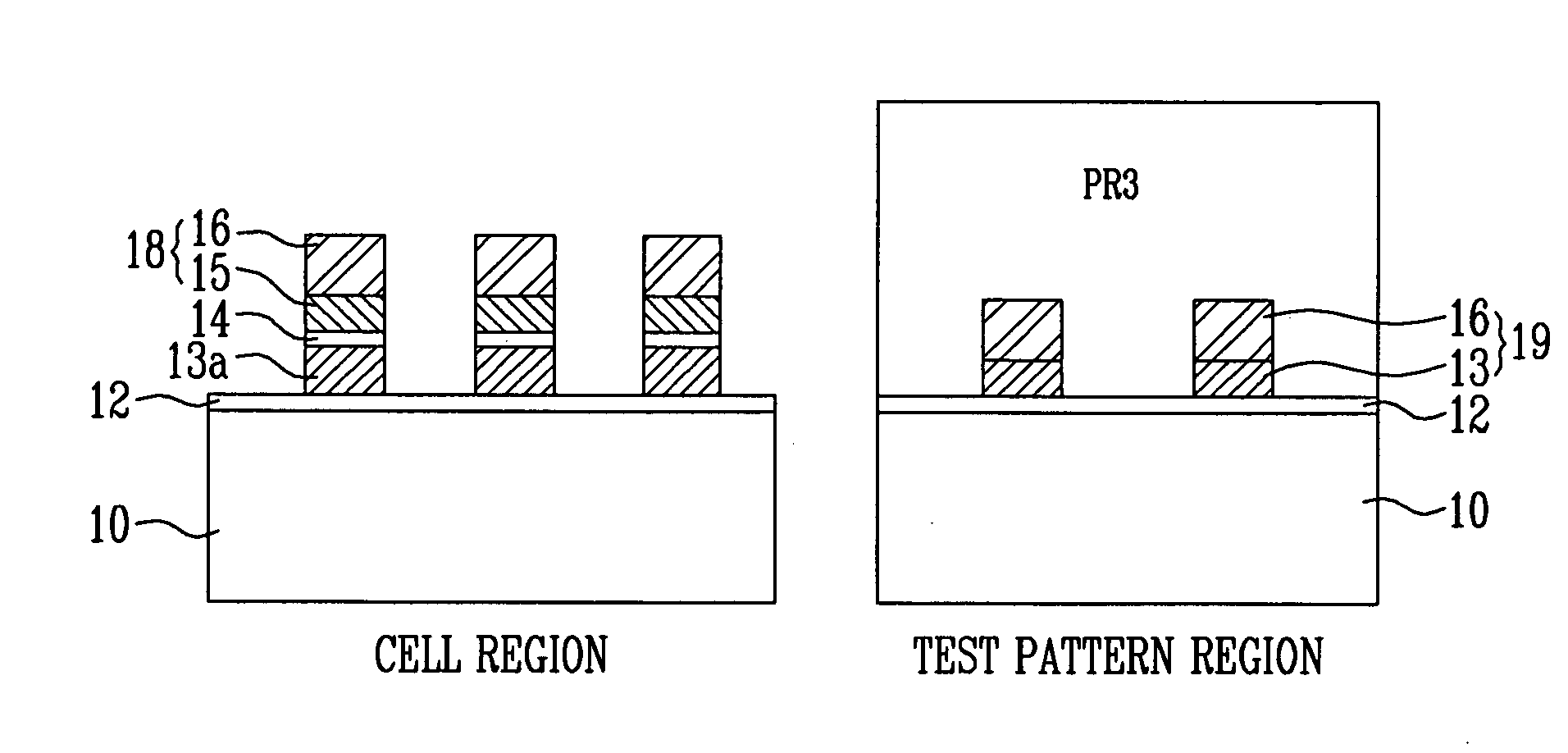

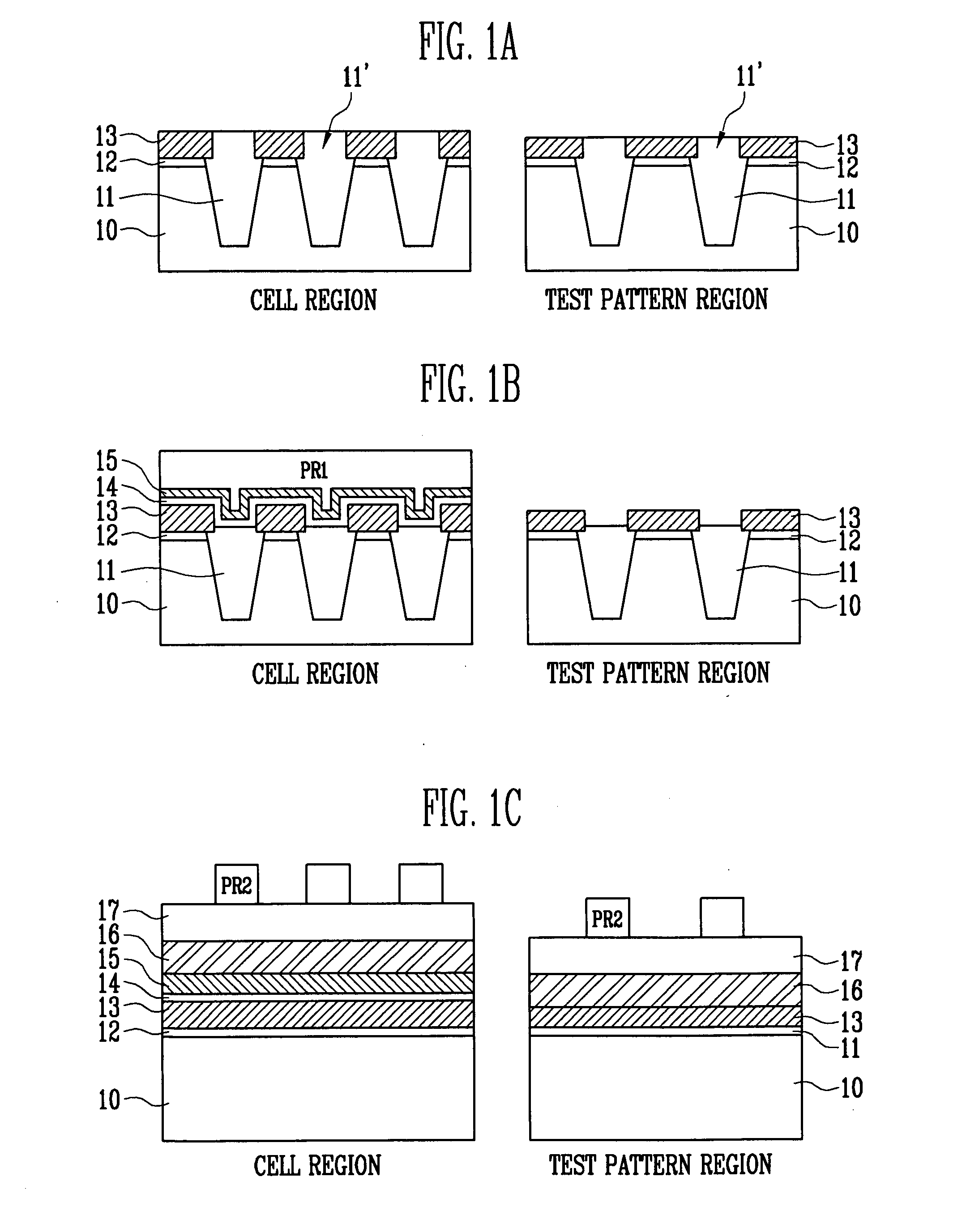

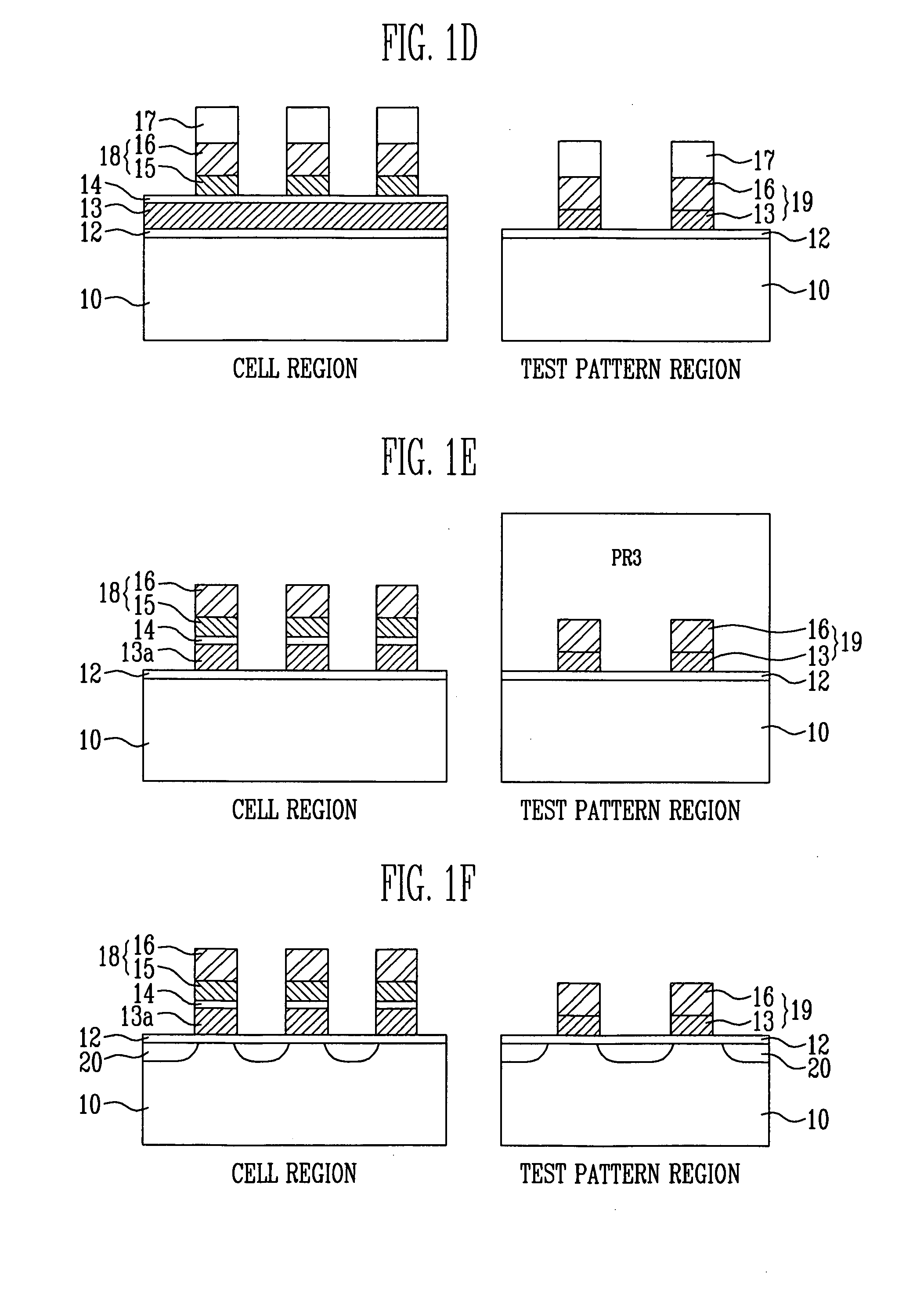

InactiveUS20070026612A1Solid-state devicesSemiconductor/solid-state device manufacturingEngineeringDielectric layer

A method of fabricating a flash memory device having a self-aligned floating gate (SAFG) wherein a floating gate is formed by a SAFG process. After a dielectric layer is formed, the dielectric layer of a test pattern region is stripped and a control gate is formed so that the control gate and the floating gate are interconnected. Therefore, a test transistor can be formed even in the SAFG scheme.

Owner:SK HYNIX INC

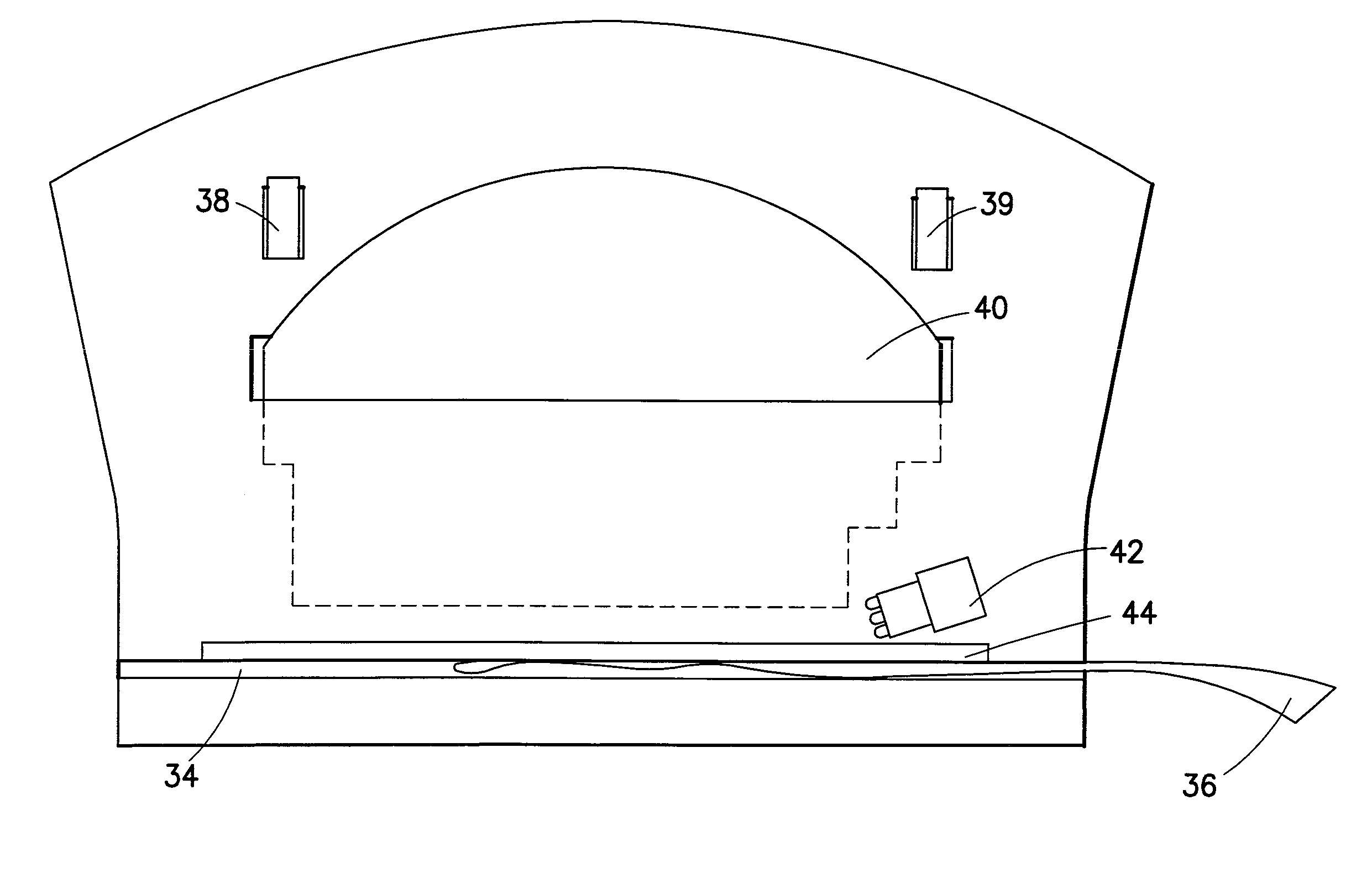

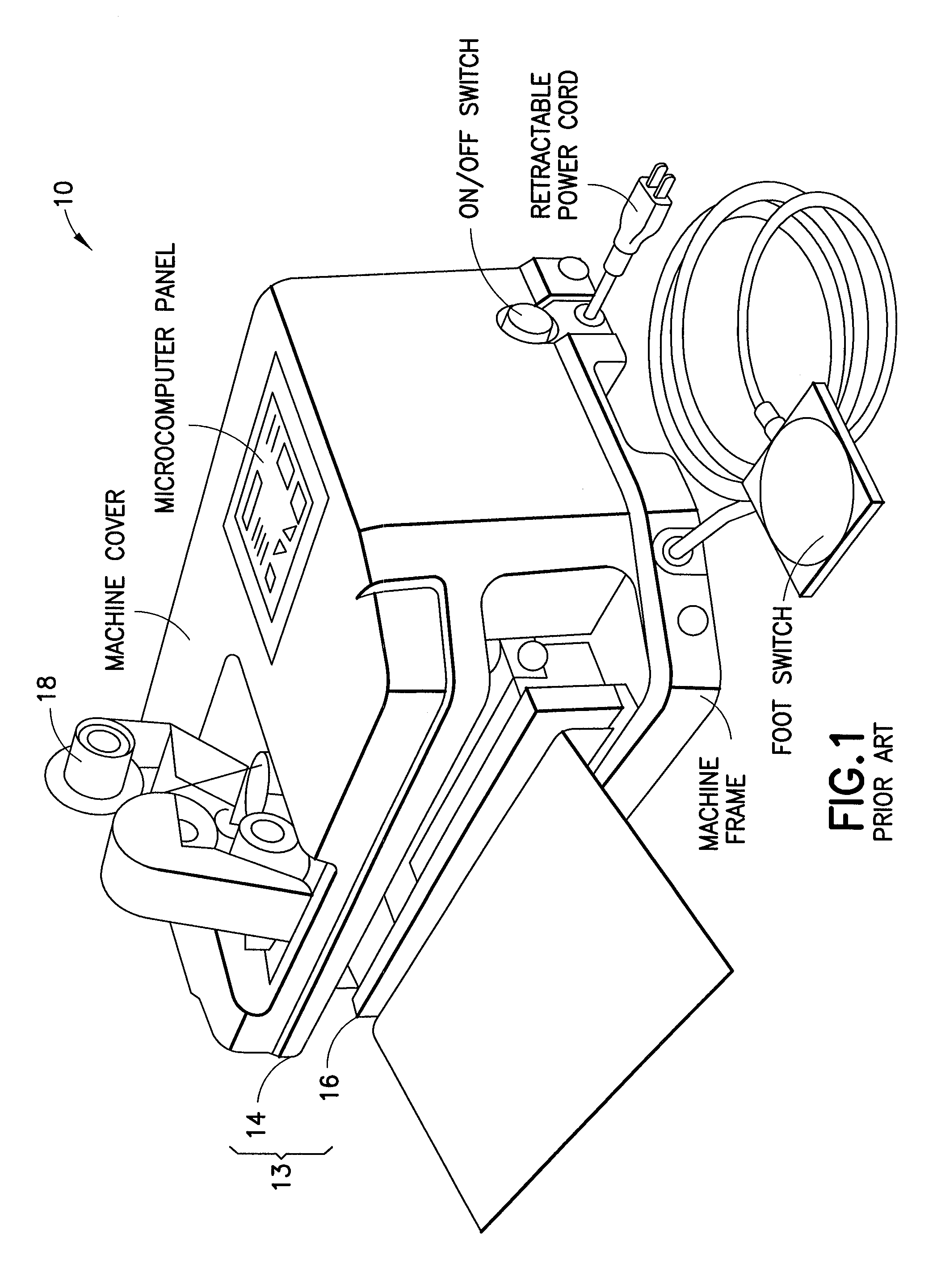

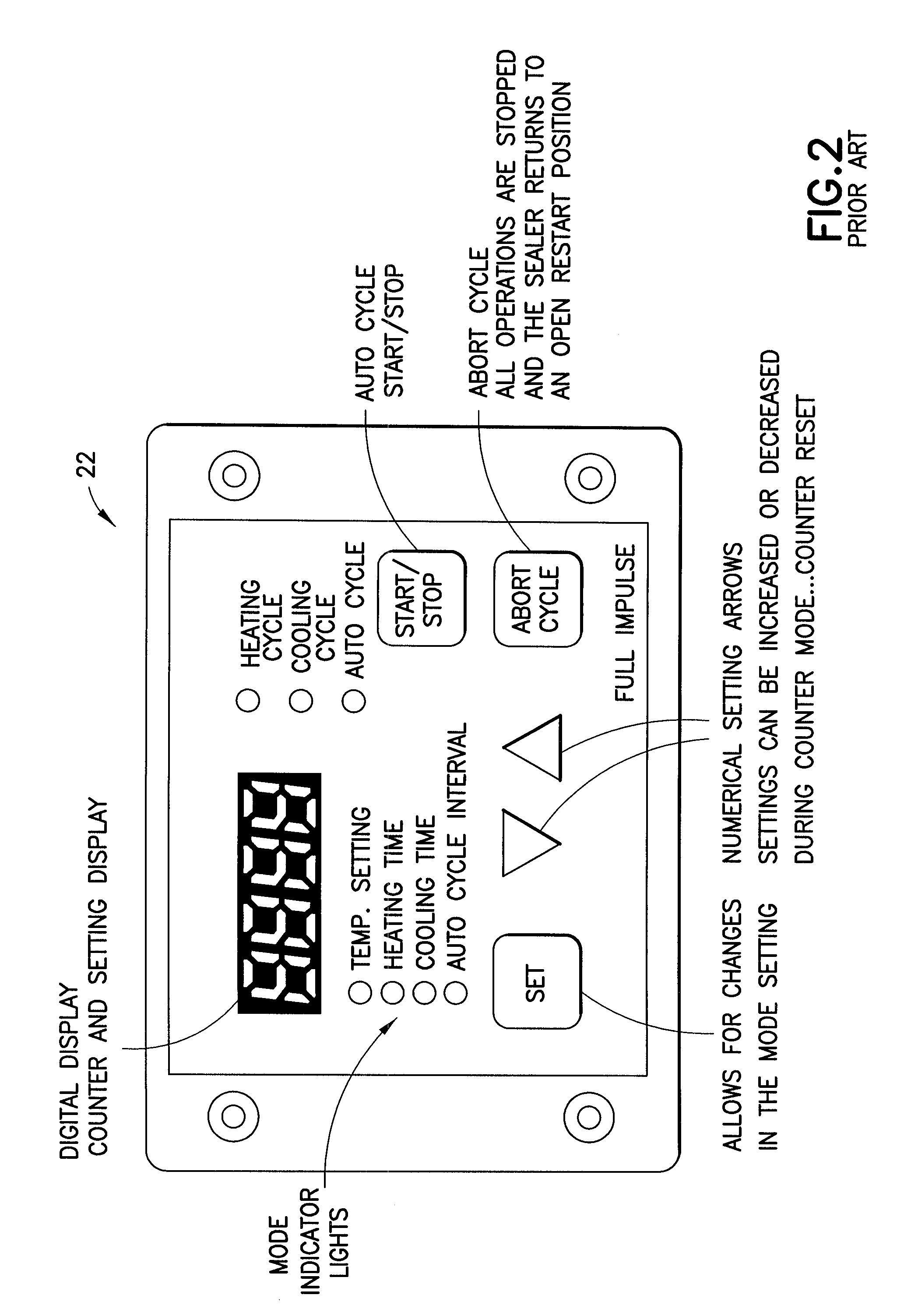

Method and device for inspecting and monitoring the seal integrity of sterile packages

InactiveUS7272916B2Optically investigating flaws/contaminationPackaging automatic controlVisual inspectionEngineering

A system for inspecting seal integrity of a sealed package including a visual inspection system and a medical packaging system having an integral peel testing device.

Owner:VAN DER STAHL SCI

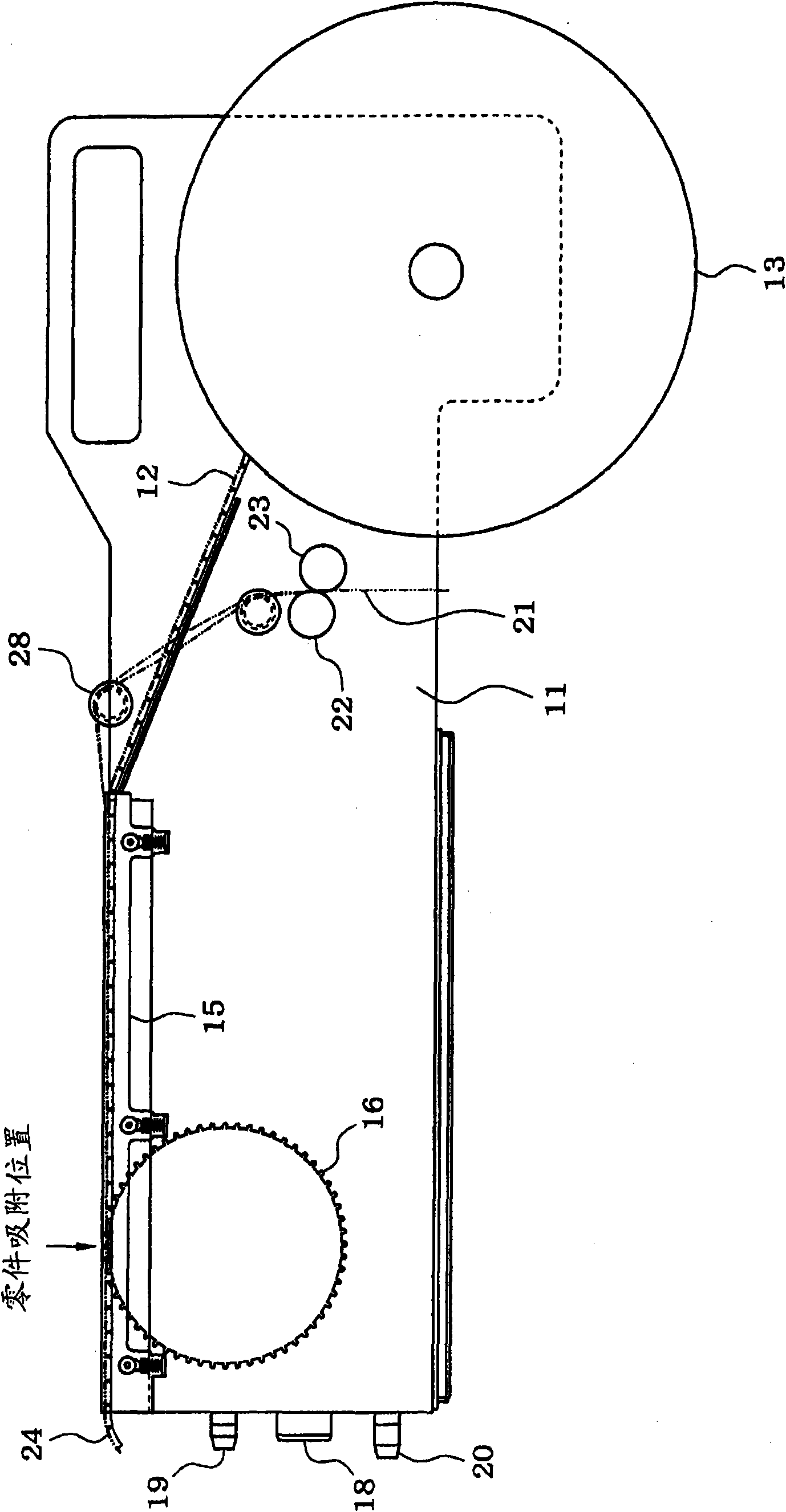

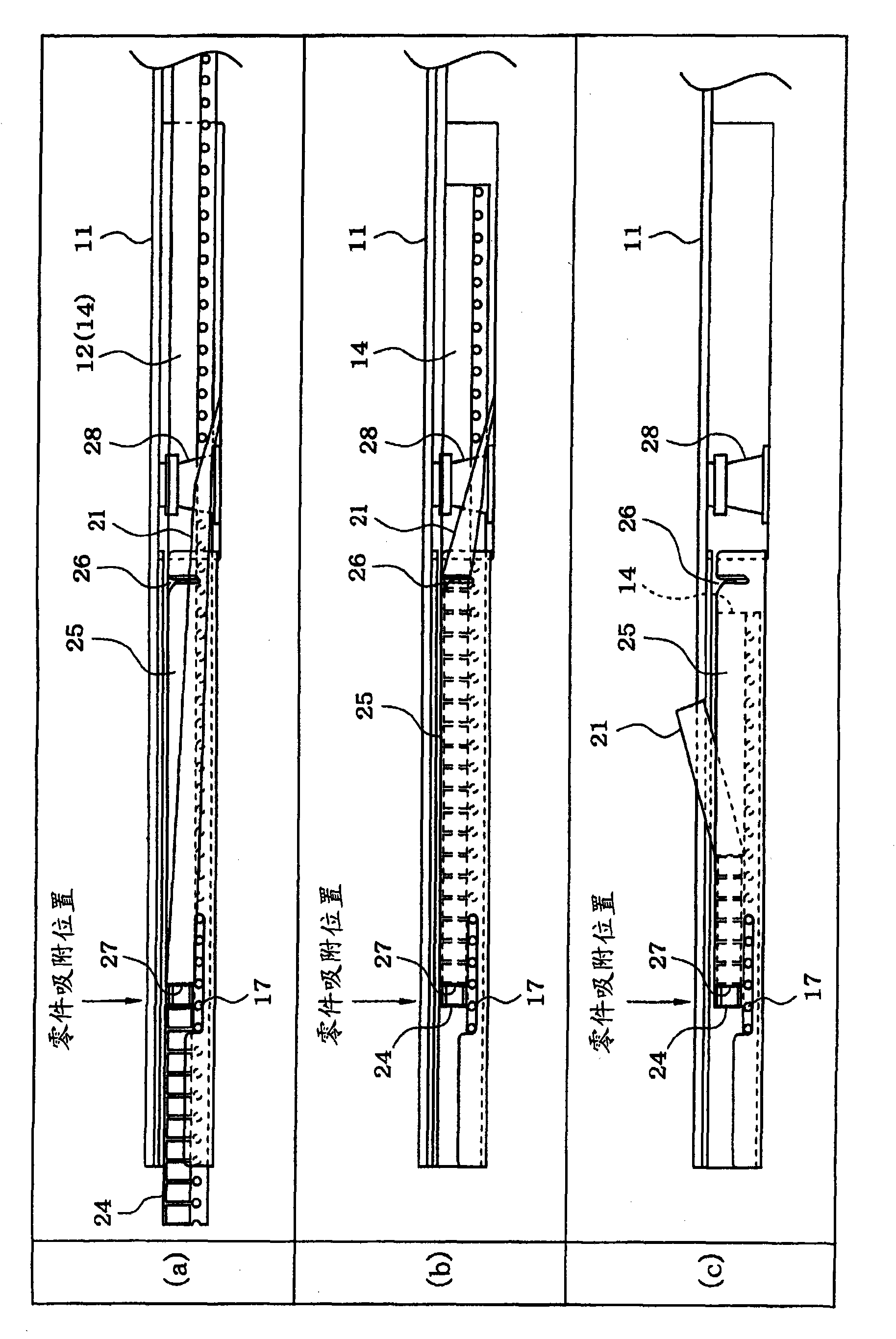

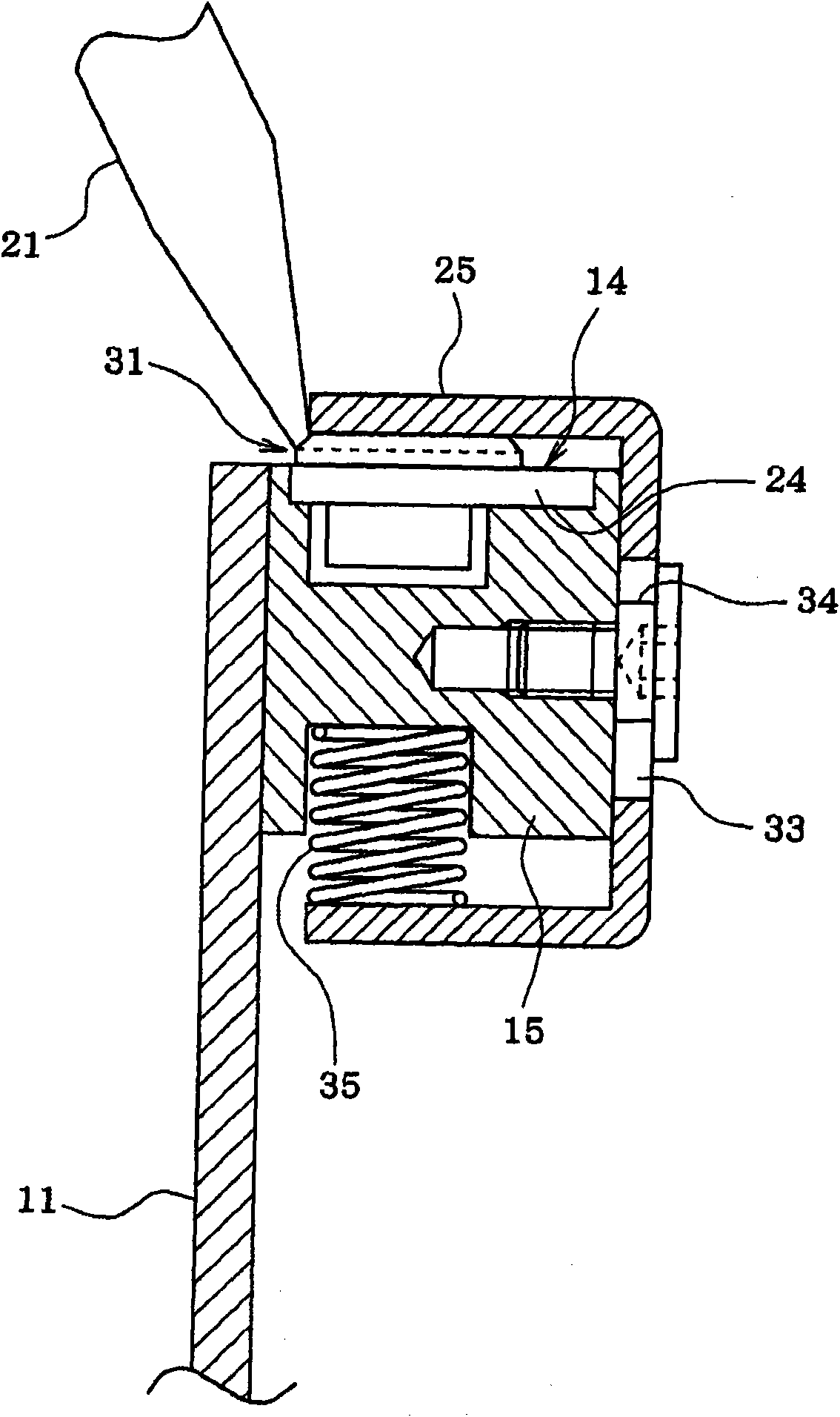

Tape feeder

ActiveCN101803491APrevent flying outStable stepping conveying actionElectrical componentsEngineeringElectrical and Electronics engineering

Owner:FUJI MASCH MFG CO LTD

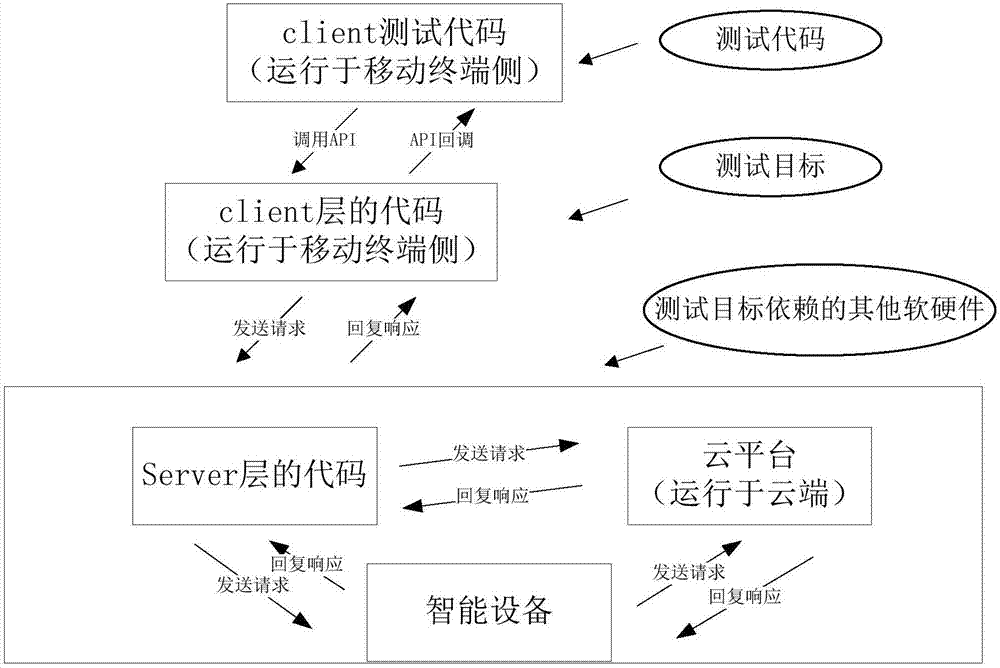

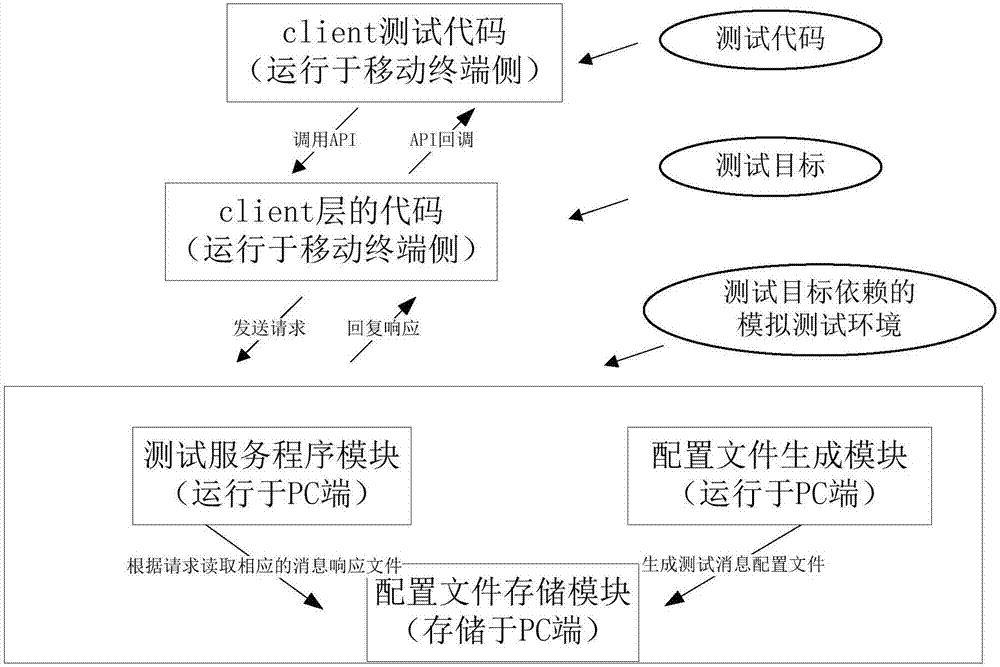

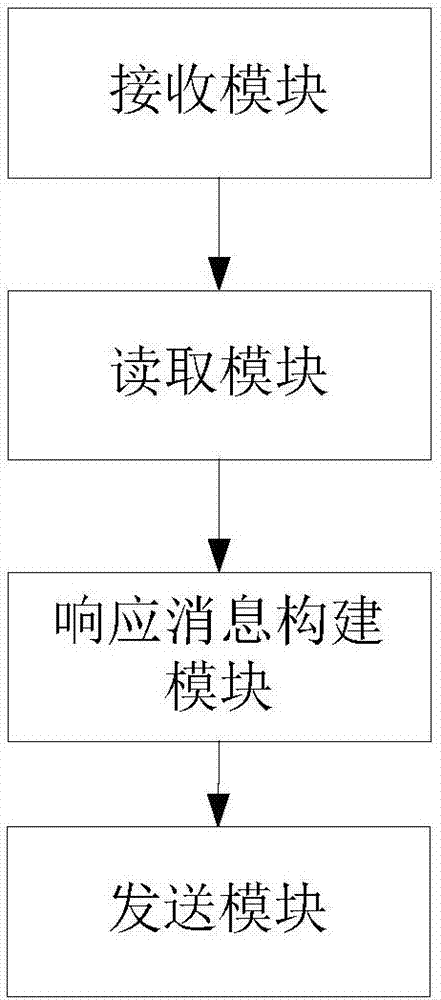

Test request processing method and device

ActiveCN107145439ALift restrictionsAutomated testing is fast and targetedSoftware testing/debuggingTransmissionSoftware systemComputer module

The invention discloses a test request processing method and device. The method comprises the following steps of: receiving a first test request message sent by application software on a mobile terminal from the mobile terminal by test equipment, wherein the first test request message is remote operation request information sent to a server by the mobile terminal; reading a first test response file corresponding to the test request message by the test equipment, wherein the test response file is a processing strategy for processing the remote operation request information by the server; and generating a first test response message according with a preset format by the test equipment according to the first test response file, and sending the first test response message to the mobile terminal. According to the method and device disclosed by the invention, aiming at the automatic test of codes of SDK development client layers in layered complicated software systems, upper-layer codes in the complicated software systems are decoupled, so that the overall dependency of each component during the test of the complicated software systems is dispensed, and other software and hardware environments on which the test of target software modules depends are stripped.

Owner:HAIER YOUJIA INTELLIGENT TECH BEIJING CO LTD +1

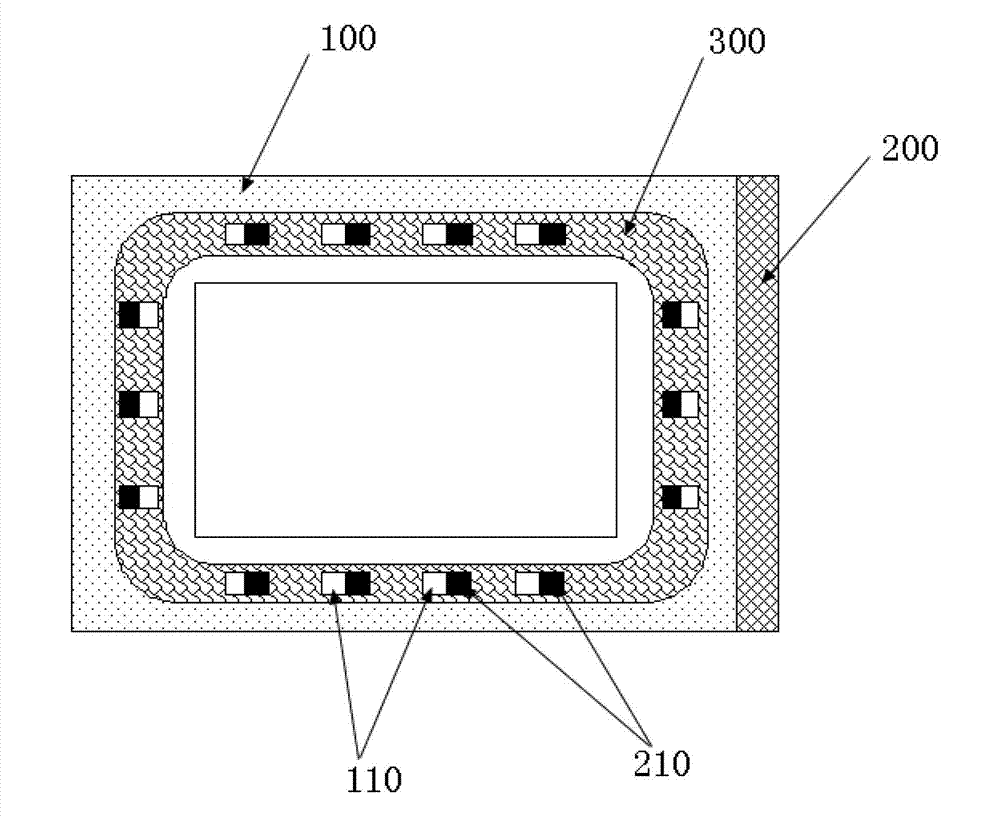

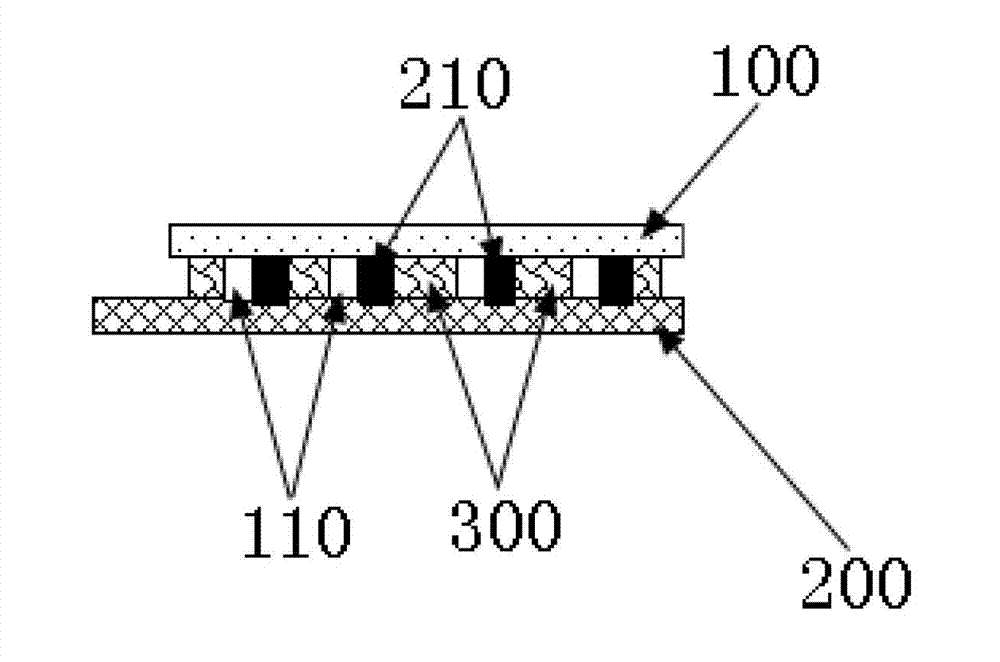

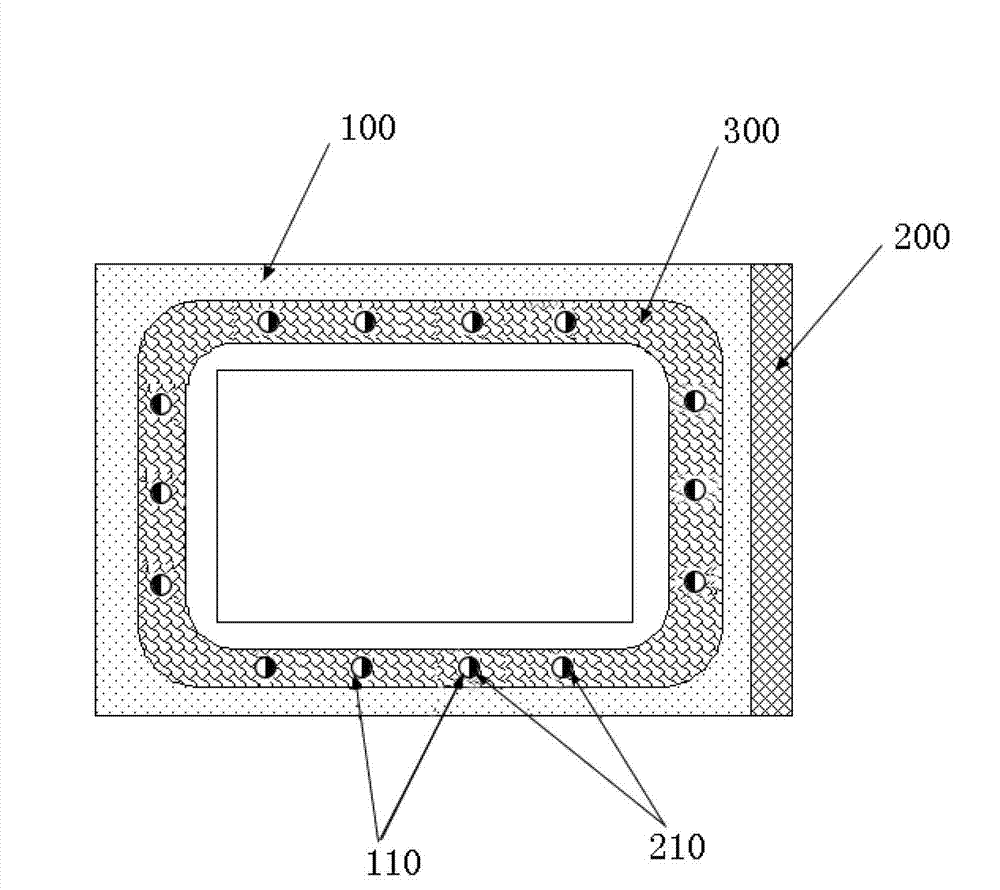

Liquid crystal panel, display device and manufacturing method of liquid crystal panel

ActiveCN102830519AQuality improvementIncrease frictionNon-linear opticsLiquid-crystal displayAdhesive

The invention discloses a liquid crystal panel, a display device and a manufacturing method of the liquid crystal panel. The invention relates to the field of liquid crystal display. The liquid crystal panel comprises a color film substrate, an array substrate and adhesive for adhering the color film substrate and the array substrate, wherein in the region range of the adhesive, a first limit part with preset height is arranged on the color film substrate, and a second limit part is arranged on the array substrate; when the color film substrate and the array substrate are adhered to each other, the first limit part is mutually matched with the second limit part. According to the liquid crystal panel, the display device and the manufacturing method of the liquid crystal panel, the first limit part is arranged on the color film substrate, the second limit part is arranged on the array substrate, and the first limit part is mutually matched with the second limit part, so that the frictional force between the color film substrate and the array substrate is remarkably enhanced, the liquid crystal panel is guaranteed to smoothly pass a peeling test, and the quality of the display device is improved.

Owner:BOE TECH GRP CO LTD

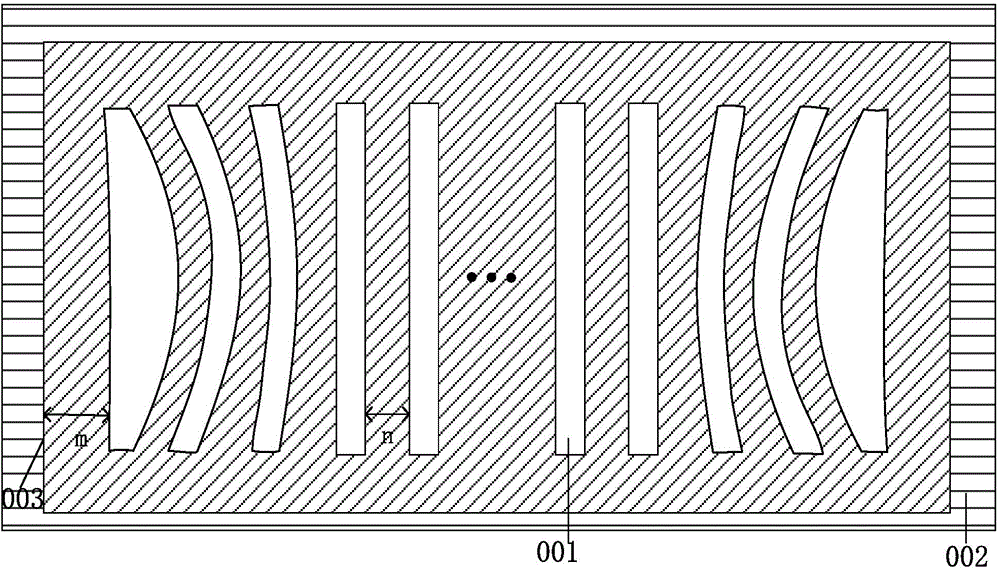

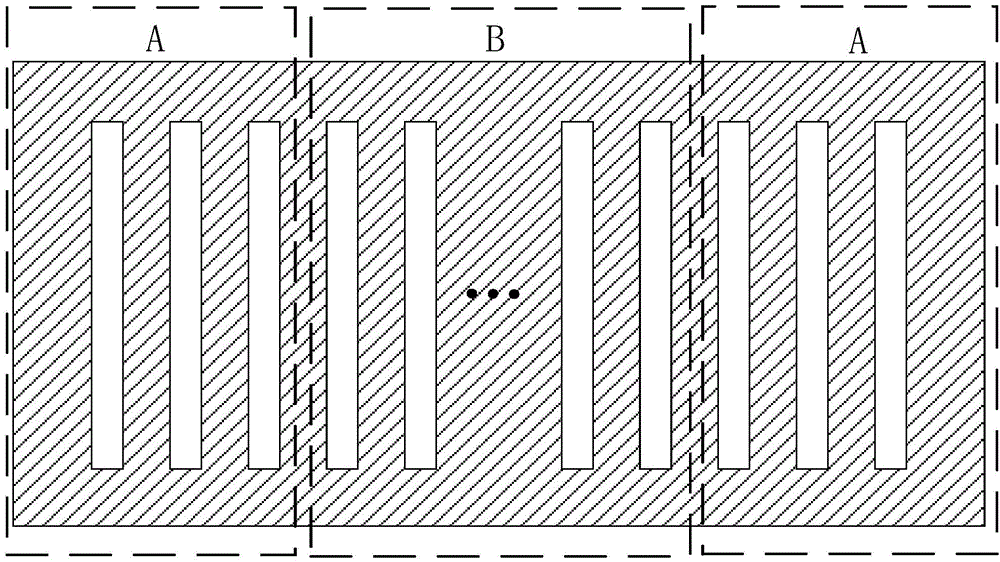

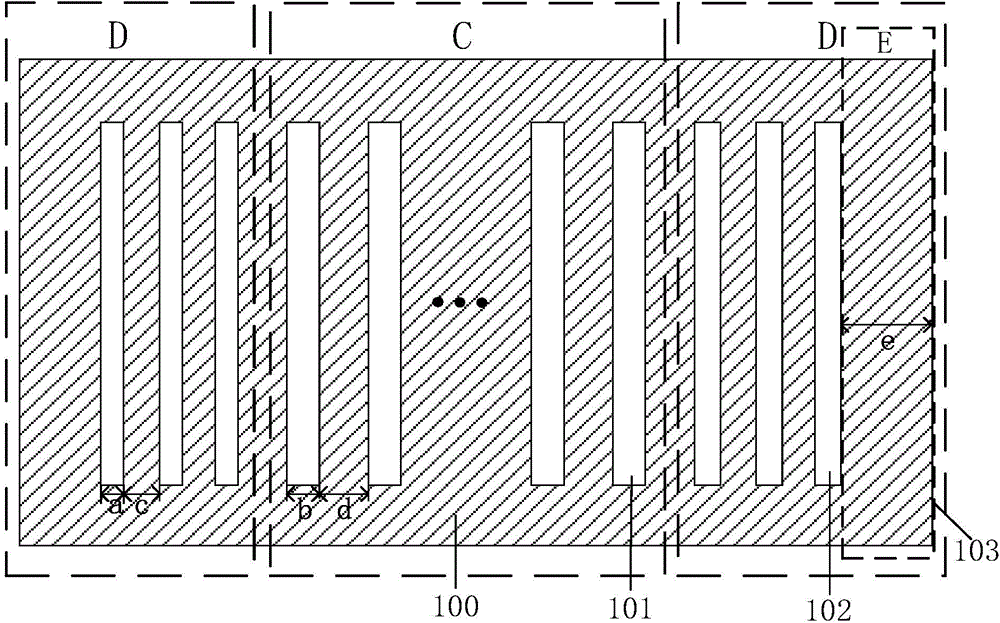

Metal mask plate and organic electroluminescent display device manufactured by metal mask plate

ActiveCN104651778AReduce occupancyLiquid surface applicatorsSolid-state devicesEngineeringOrganic electroluminescence

The invention discloses a metal mask plate and an organic electroluminescent display device manufactured by the metal mask plate. The metal mask plate comprises a substrate, a first region arranged on the substrate and second regions arranged at the left and right sides of the first region respectively, wherein a plurality of parallel first strip slits which extend along the column direction and are mutually parallel are arranged in the first region, and at least three second strip slits which are mutually parallel to the first strip slits are arranged in each second region; at least two of the three conditions needs to be met: the width of each second strip slit is smaller than that of each first strip slit, a distance between two adjacent second strip slits in the same second region is smaller than that between two adjacent first strip slits, the width of each region at the side becomes narrow. According to the metal mask plate and the organic electroluminescent display device disclosed by the invention, when at least two conditions are met, the influence of a magnetic field on the second strip slits can be relieved, the second regions occupy little area, and narrow frame is realized in space.

Owner:BOE TECH GRP CO LTD +1

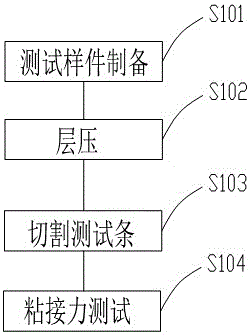

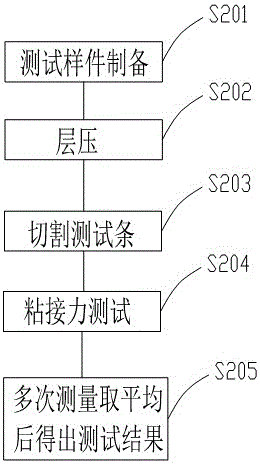

Double glass component EVA and glass adhesive property detection method

ActiveCN106340468AReduce the risk of useGuarantee product qualitySemiconductor/solid-state device testing/measurementFinal product manufactureTest sampleHot Temperature

The present invention discloses a double glass component EVA and glass adhesion property detection method, which relate to the technical field of adhesive property testing. The method comprises the following steps: preparing a test sample in which a piece of lower glass is placed on the plane, the four corners of the lower glass are provided with four pieces of Teflon high temperature cloth and one more piece of Teflon high temperature cloth is arranged between the two corners at the longer edge of the lower glass; sending the test sample to a laminator for lamination; using a cutting tool to cut the backboard at the upper side of each piece of Teflon high temperature cloth into long strips; fixing the test sample on the test bench of a ensile testing machine; and using a clamp to clamp the already cut backboard and one end of an adhesive tape composed of the upper EVA and the lower EVA to perform a 180-degree peel test between the EVA at the corresponding position and the glass. In the method, it is possible to obtain the real values of the EVA and the glass adhesive property inside a component, provide reliable detection data for the production process, guarantee the product quality of the double glass component and reduce the use risk of the component.

Owner:YINGLI ENERGY CHINA

Composite casting system of crank shaft box

InactiveCN102873278AEasy to manufactureImprove production efficiencyFoundry mouldsFoundry coresSlagCrankshaft

The invention discloses a composite casting system of a crank shaft box. The composite casting system comprises a base plate core, a jacket core, a main core, an end face core, an outer cast core and a pouring system. The base plate core, the jacket core, the main core and the pouring system are sequentially overlapped from the bottom layer to the high layer to form a crank shaft box sand mould structure. The pouring system comprises two rows of pouring openings evenly arranged and gates located outside the two rows of pouring openings. The two rows of pouring openings are communicated with a pouring opening cup through a flow division pouring gate and a pouring gate cup. The gates comprise hole-shaped gates located at four corners and strip gates located between the hole-shaped gates and outside the two rows of pouring gates. The composite casting system adopts a rain type pouring system in the middle of a cast piece to conduct liquid feeding pouring from a plurality of positions of a shaft seat and reduces impact of pouring to casts, floating impurities cannot be easily adhered to the cast wall or the cast core, and the pouring system is good in slag blocking effect. The main core is arranged on the upper portion of a sand mould and on the shaft seat, and the two strip gates and the four hole-shaped gates are utilized to discharge air completely. The composite casting system does not require core drying and is stable in cast piece pouring.

Owner:SICHUAN XIANGYE MASCH CASTING CO LTD

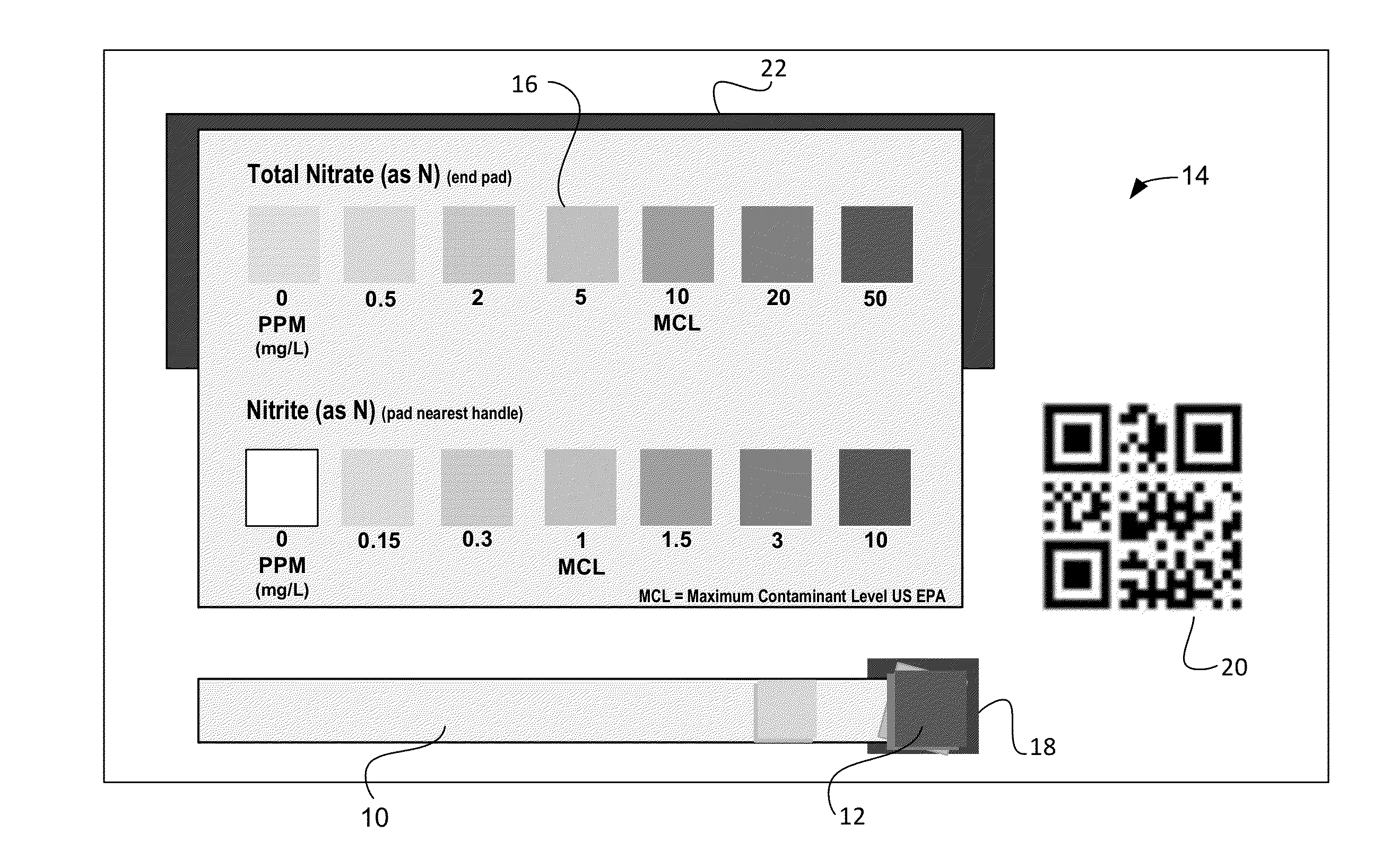

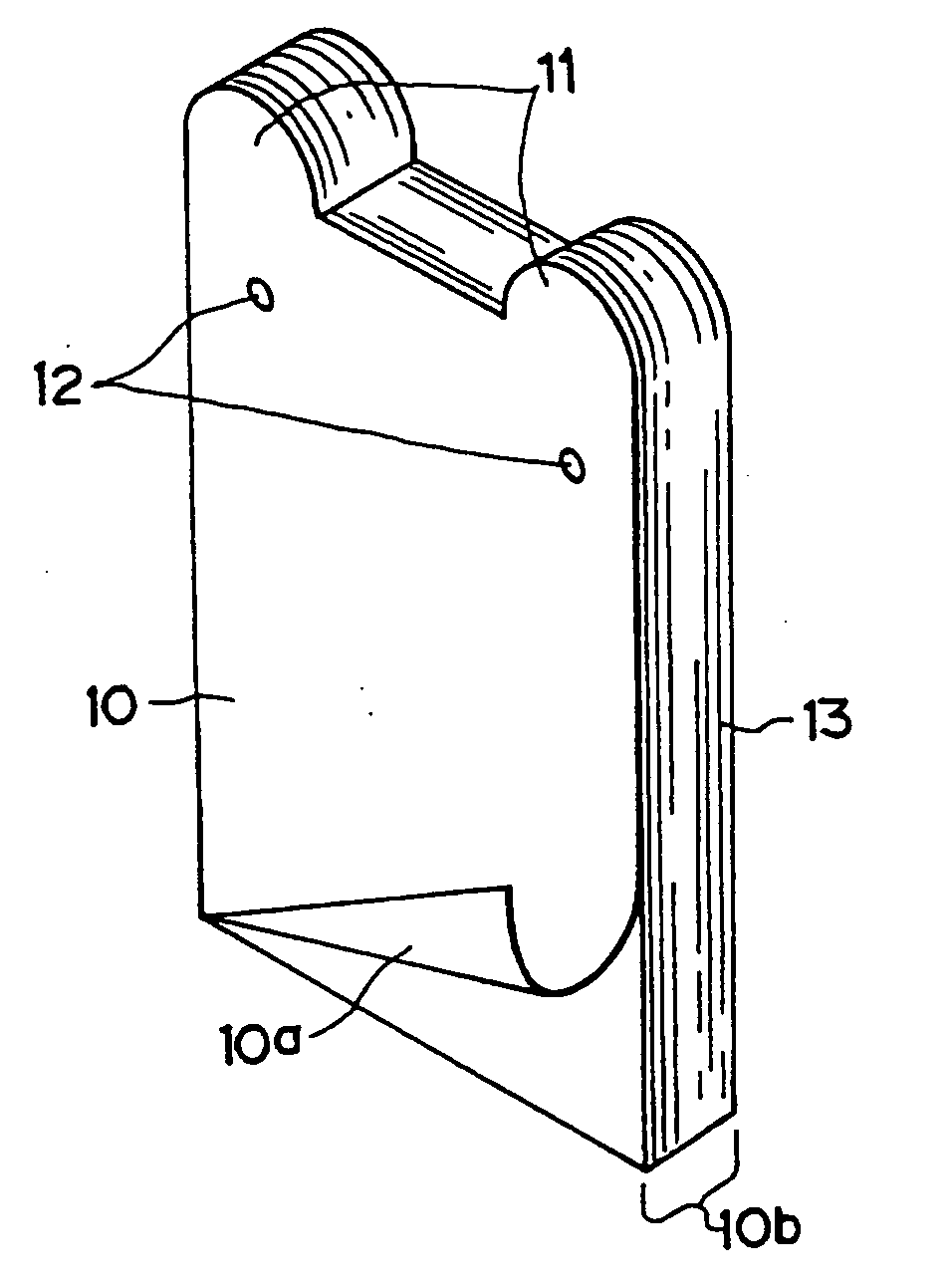

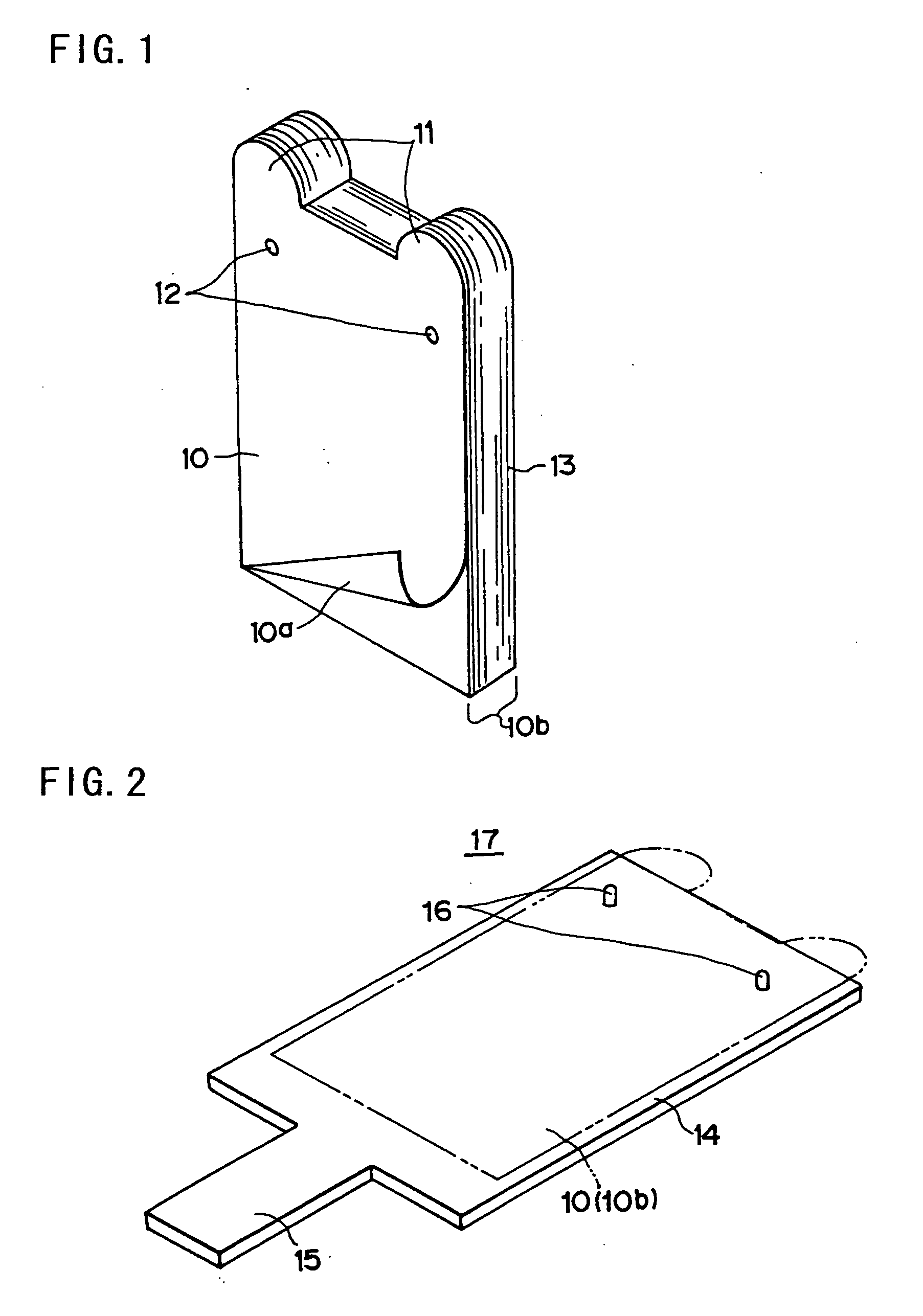

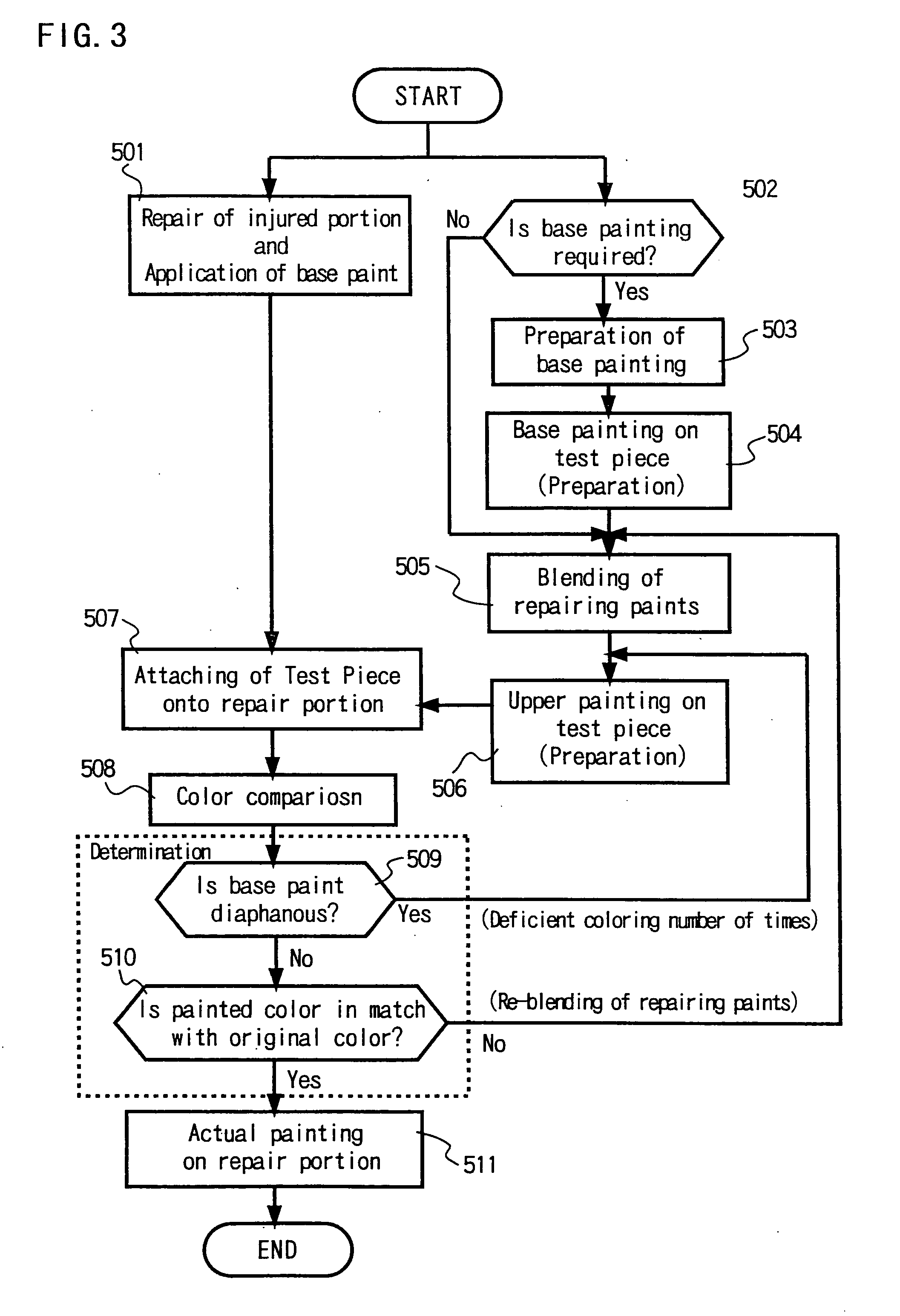

Color Matching Test Piece and repair painting method

InactiveUS20100239752A1Work lessEnsure correct executionLayered productsLaminationPattern recognitionColor matching

This invention provides a color matching test piece capable of freely changing a combination of a base color and an upper color to be overpainted one on another with less work.The color matching test piece 10 is formed of a clear-colorless film base 10a. A plurality of the color matching test pieces 10 painted with individual colors with respect to each color to be overpainted are prepared, and the test pieces 10 are stuck to a car body or the like with a defatting agent to reproduce the state of the overpainted color in order for color comparison relative to the original color of the car body. The color matching test piece 10 has peeling tabs 11 and jig holes 12 and is superposed on the other test pieces according to need. The superposed test pieces have peripheral surfaces other than the peeling tabs secured with one another by using adhesive 13 to form a lamination layer member 10b, so that the test pieces can be peeled off one by one from the uppermost test pieces by pinching and lifting the tabs 11 with fingers.

Owner:AIOI INSURANCE CO LTD

Release force detection method for glassine silicone oil paper

InactiveCN108956450AImprove accuracyIncreased complexityUsing mechanical meansMaterial analysisAdhesiveSilicone oil

The invention relates to a release force detection method for glassine silicone oil paper. The method includes the steps of: (1) pasting a detection adhesive tape on a silicone oil film layer of glassine silicone oil paper; and (2) performing peeling test on the glassine silicone oil paper and the detection adhesive tape pasted on the surface of the silicone oil film layer, thus obtaining the magnitude of release force between the silicone oil film layer and the detection adhesive tape. The method provided by the invention can improve the detection accuracy without increasing the operation complexity.

Owner:云南名博实业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com