LED strip light source and package method thereof

A technology of strip light source and packaging method, applied in the direction of light source, electric light source, point light source, etc., can solve the problems of unstable air pressure, individual and individual differences, affecting product consistency, etc., so as to reduce production costs and simplify production processes. , the effect of improving consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing and embodiment the present invention will be described in further detail:

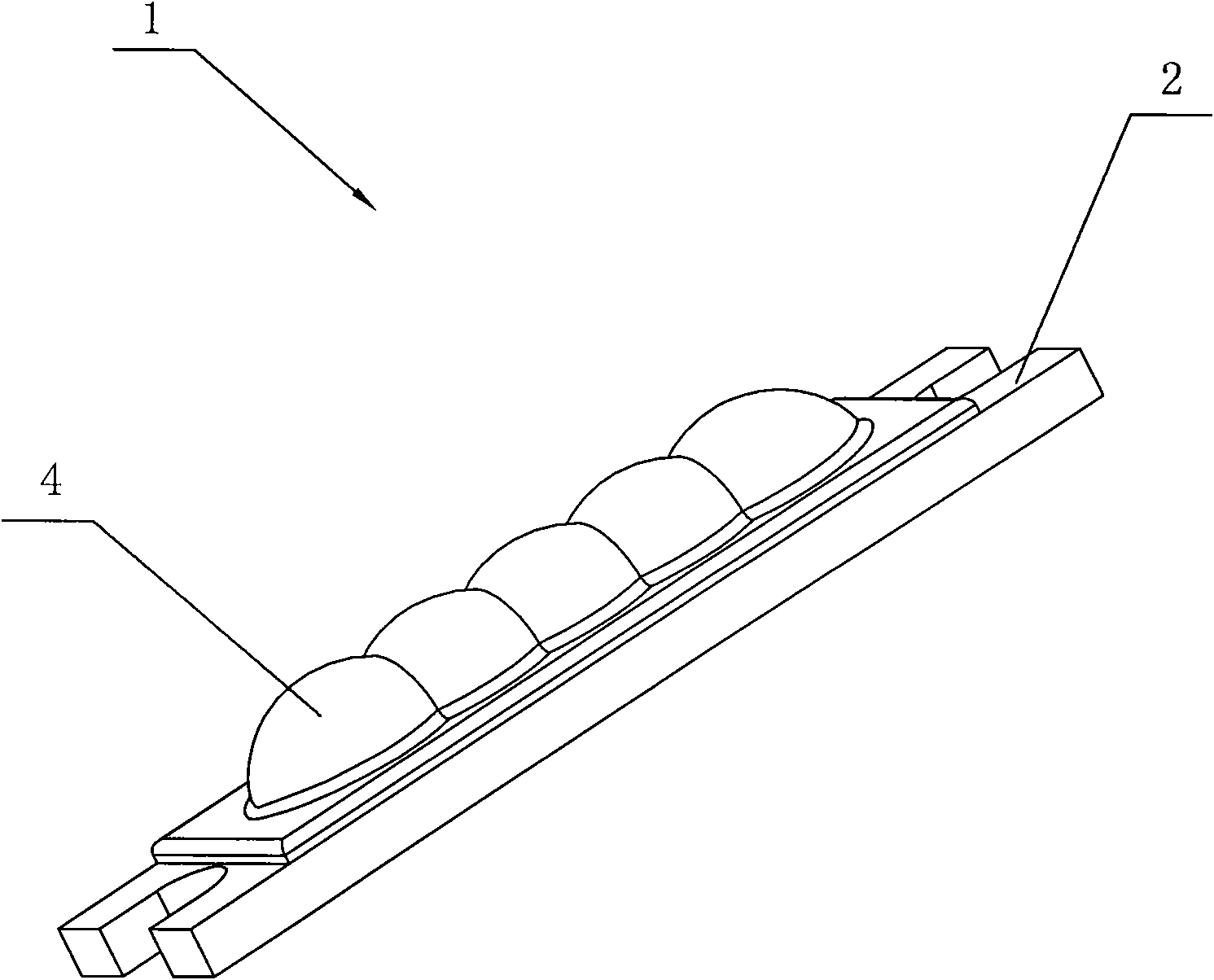

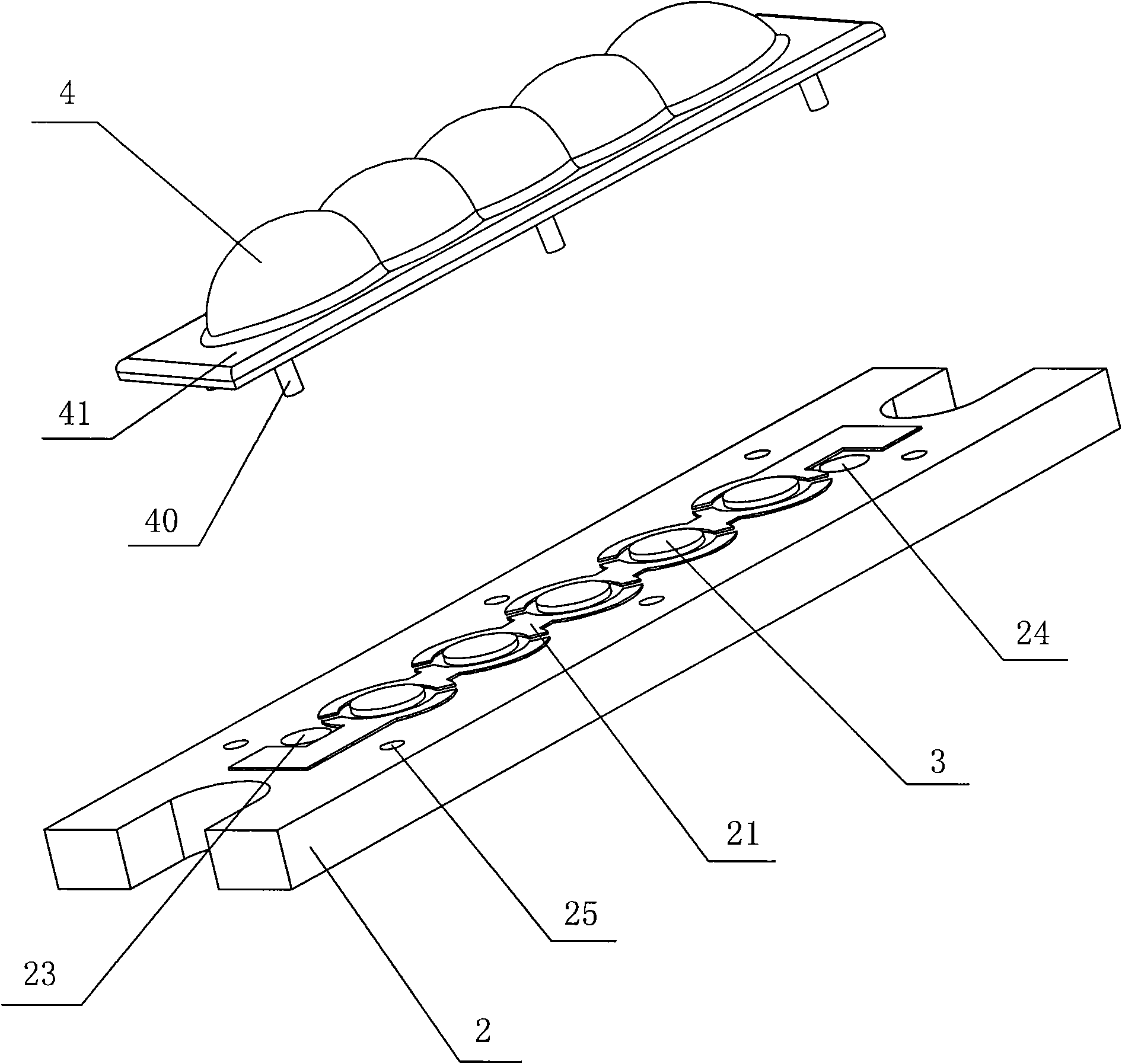

[0025] see figure 1 and figure 2 As shown, the LED bar-shaped light source 1 of the present invention includes a bar-shaped substrate 2, a plurality of chips 3, a bar-shaped lens 4 and a filling colloid (not shown).

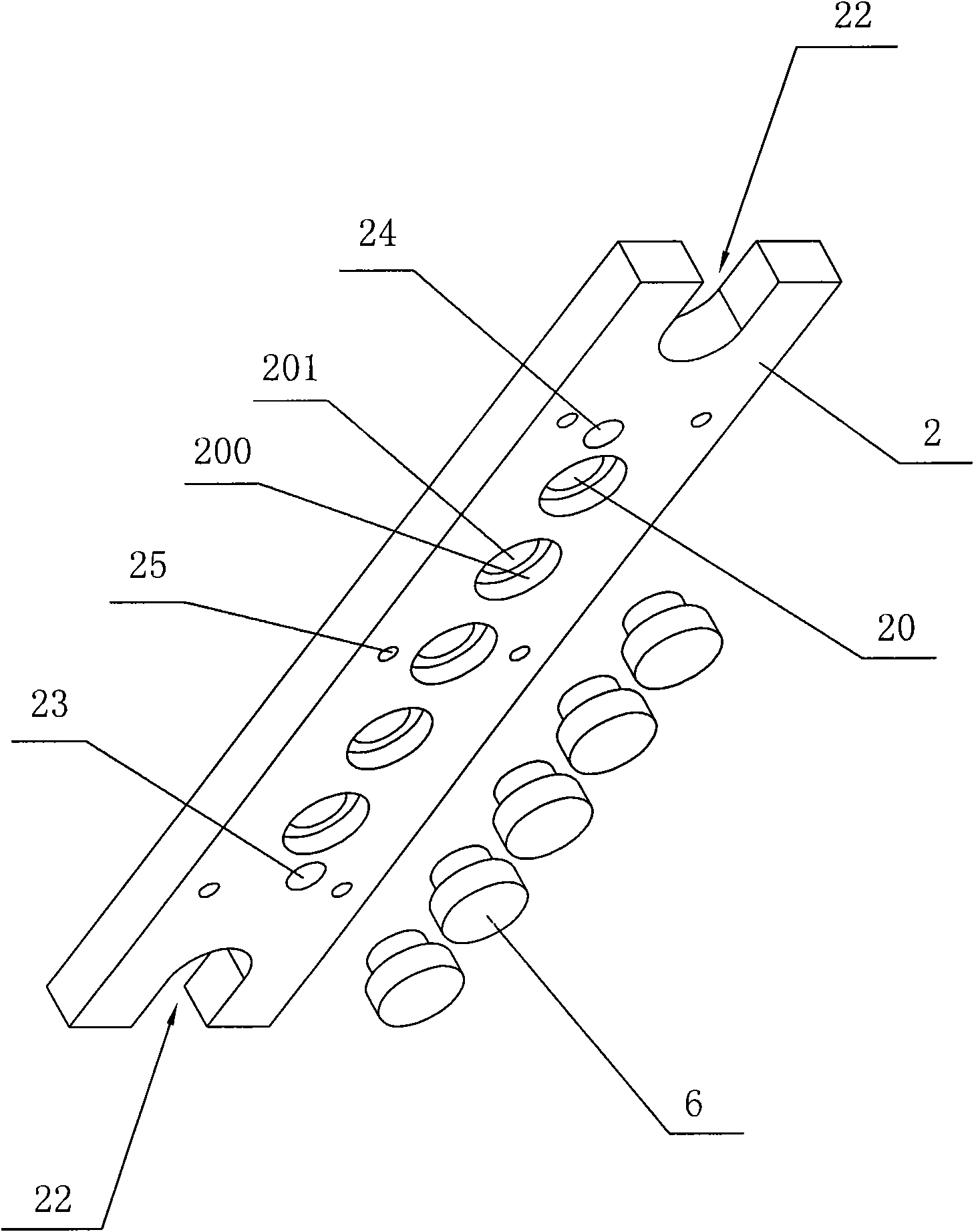

[0026] Please combine figure 2 and image 3 As shown, the substrate 2 can be a metal circuit board or a common circuit board equipped with a heat sink. In this embodiment, a common circuit board is used to embed the strip-shaped light source substrate 2 into the heat sink 6. The strip-shaped substrate 2 is provided with a sink hole 20 for mounting the chip 3. The diameter of the lower hole 200 of the sink hole 20 is larger than that of the upper hole. Hole 201 diameter. A heat sink 6 for heat dissipation is fixed in each sink hole 20 , the heat sink 6 is stepped, and its shape matches the structure of the sink hole 20 . The upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com