Patents

Literature

20175results about "Refractors" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-density illumination system

ActiveUS6871982B2Valid conversionIncrease Lumen DensityPrismsMechanical apparatusHigh densityLed array

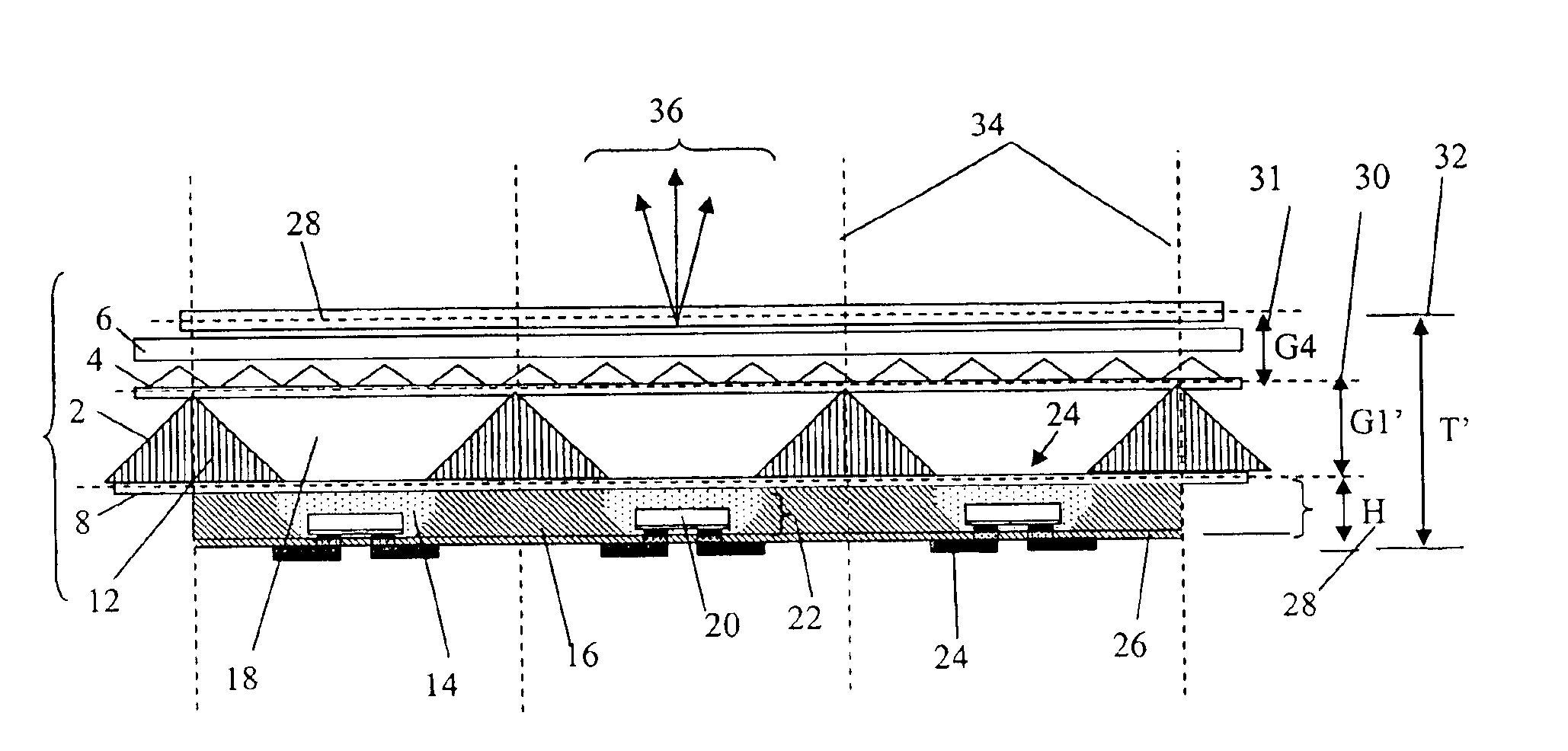

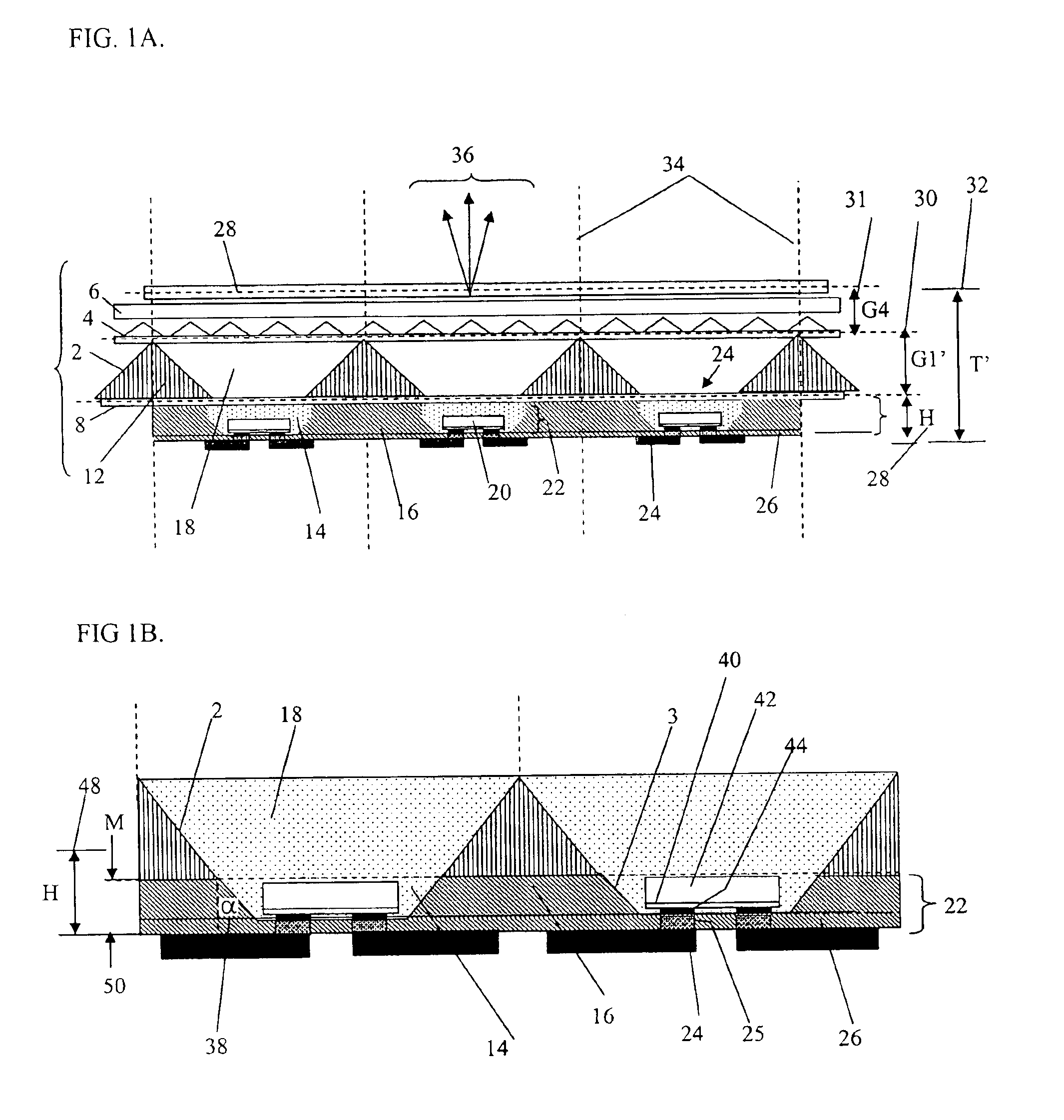

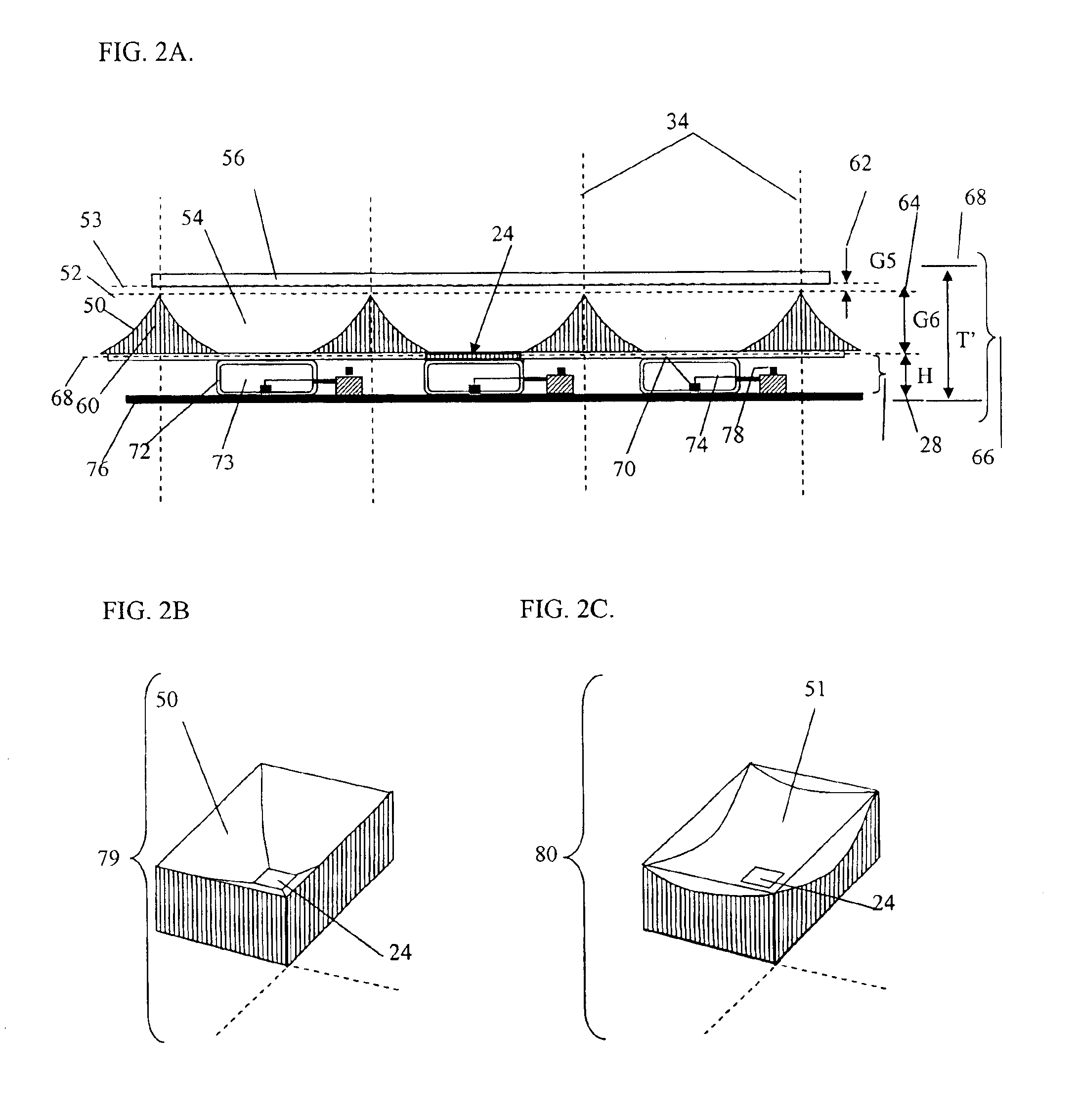

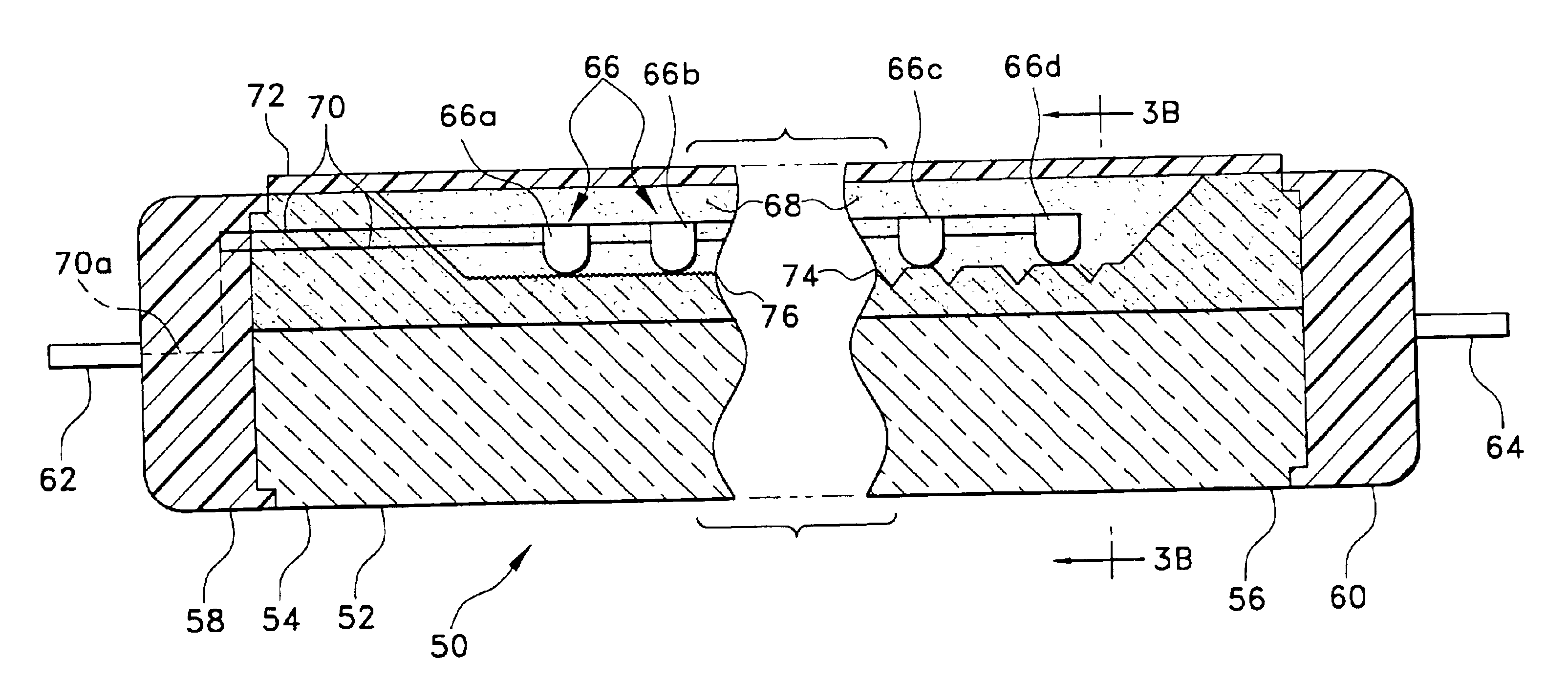

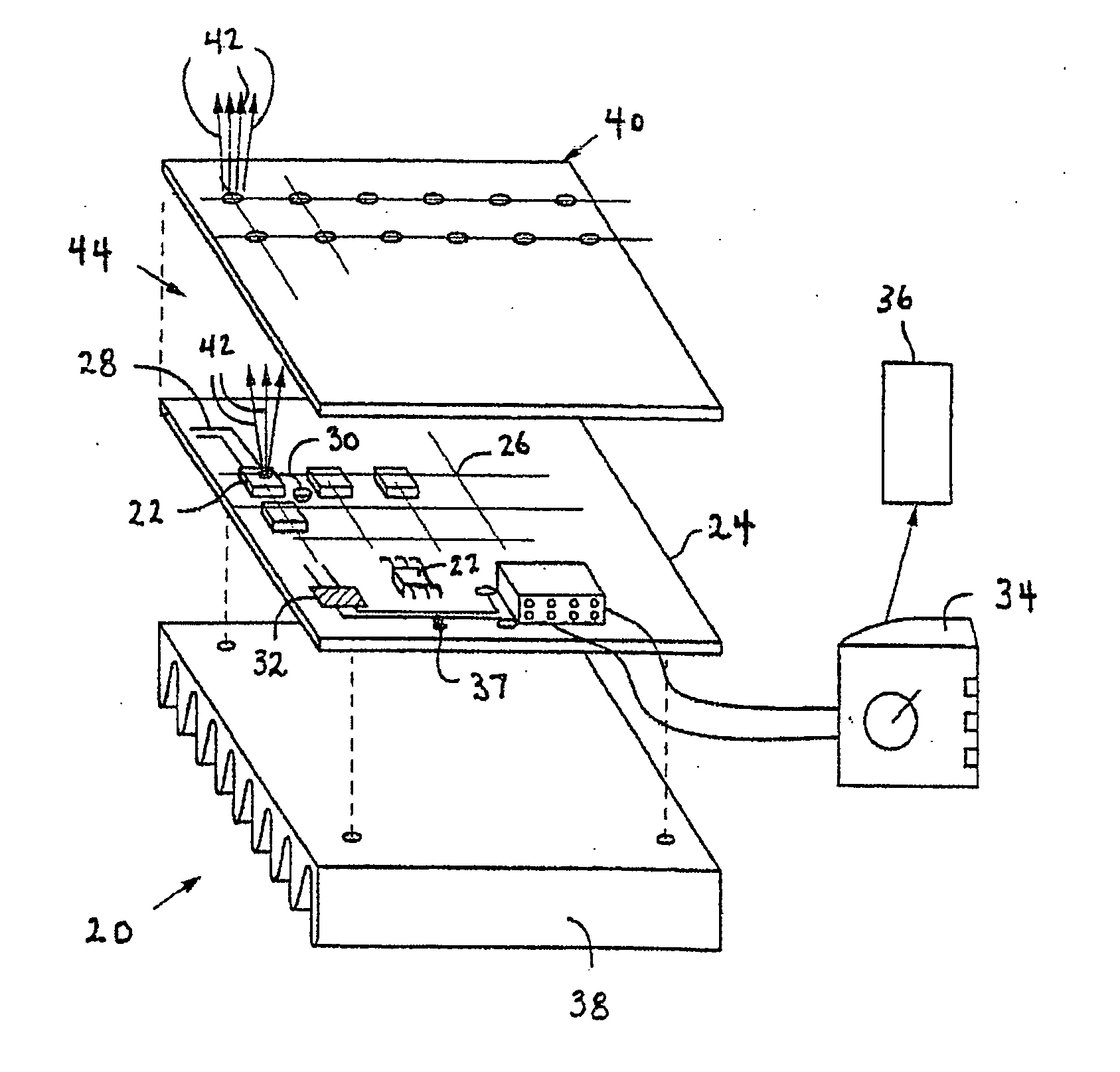

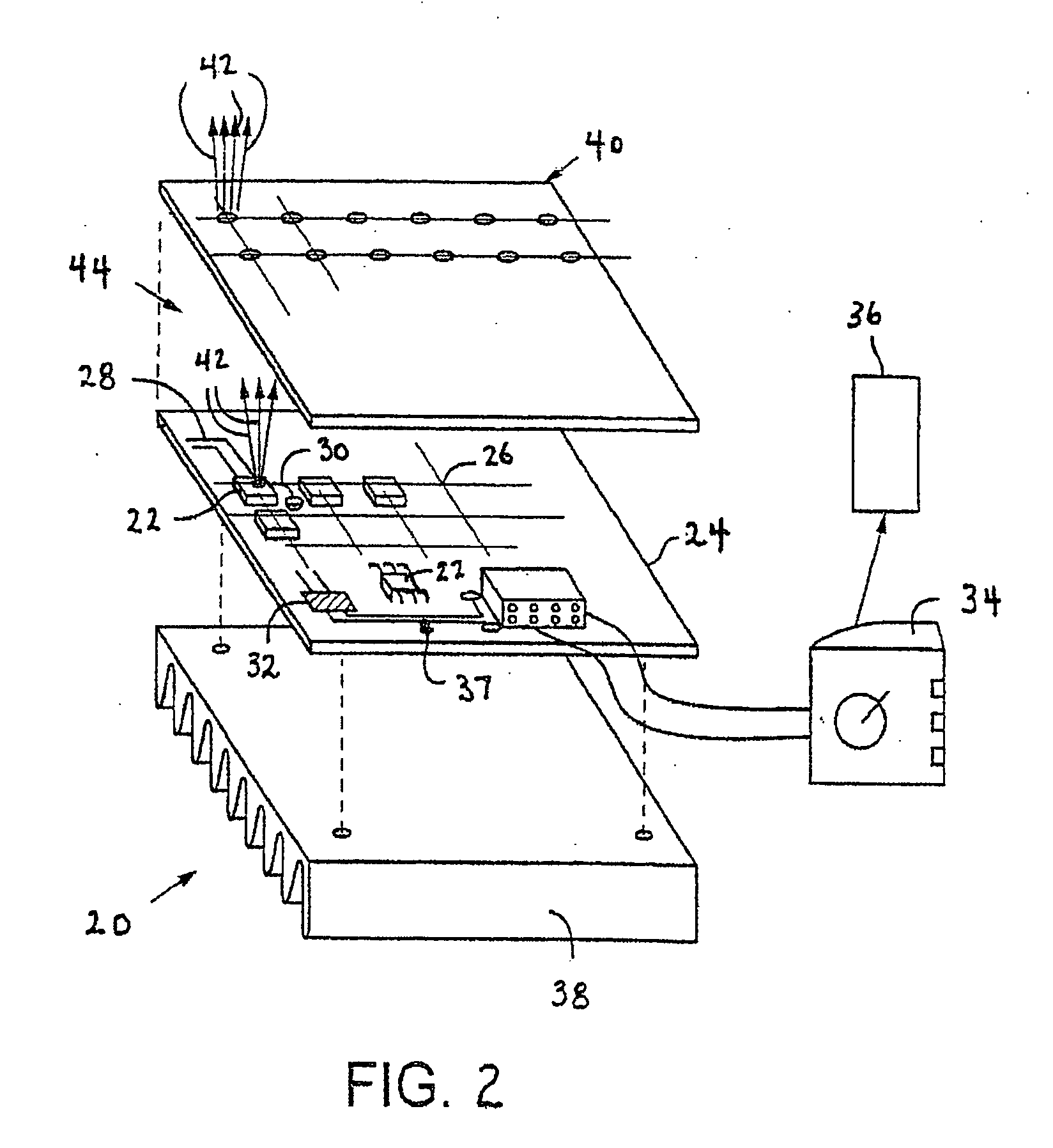

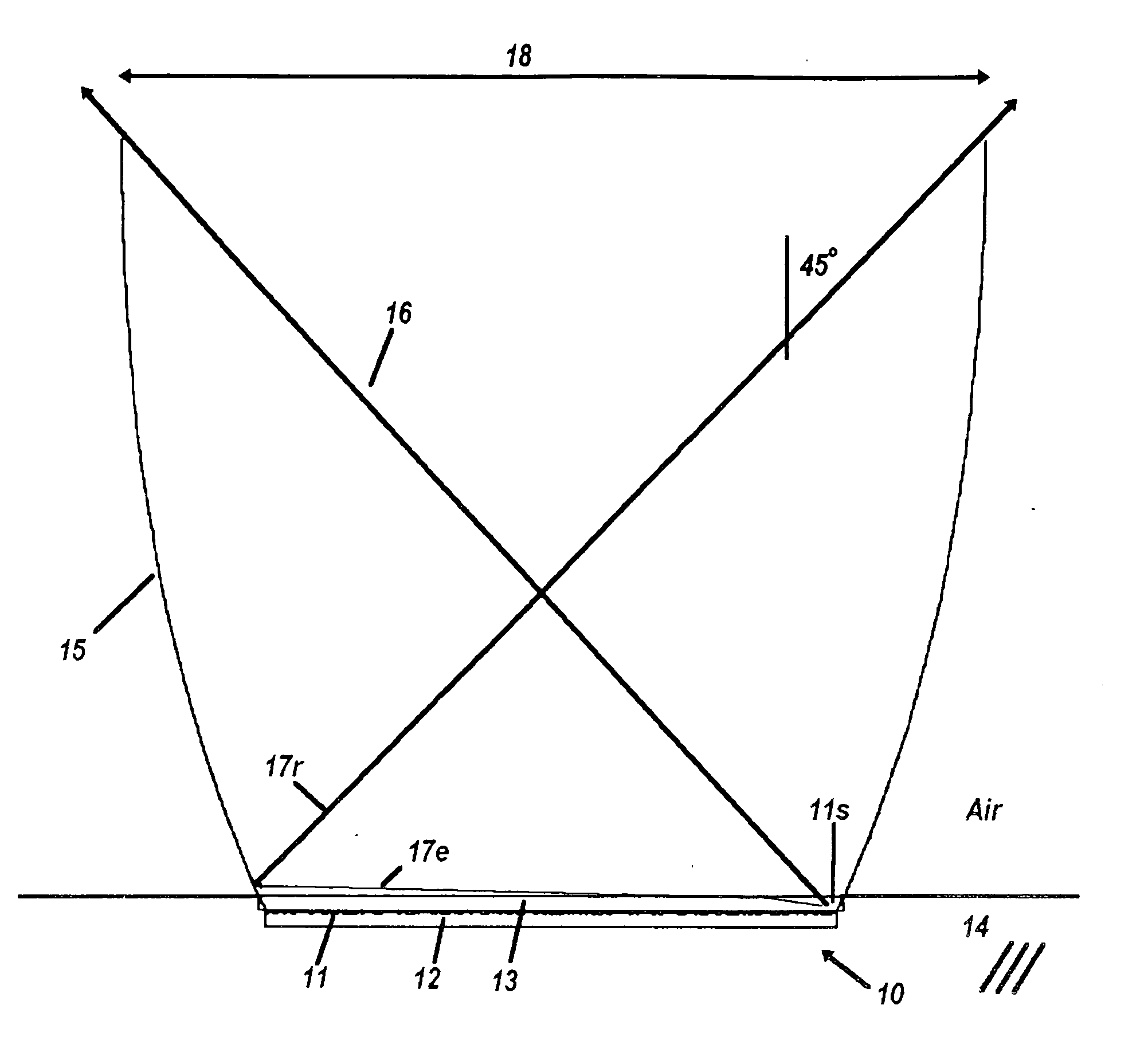

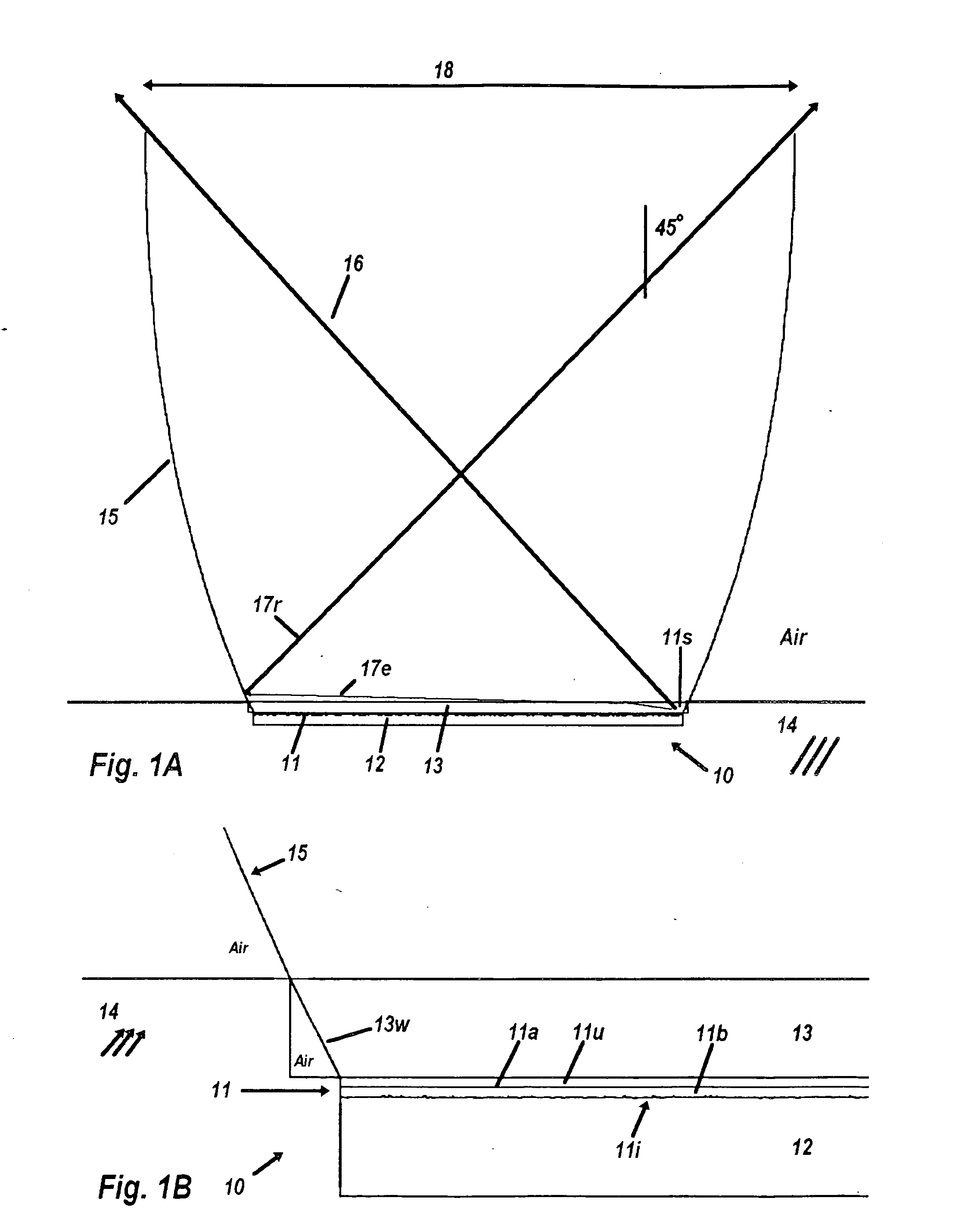

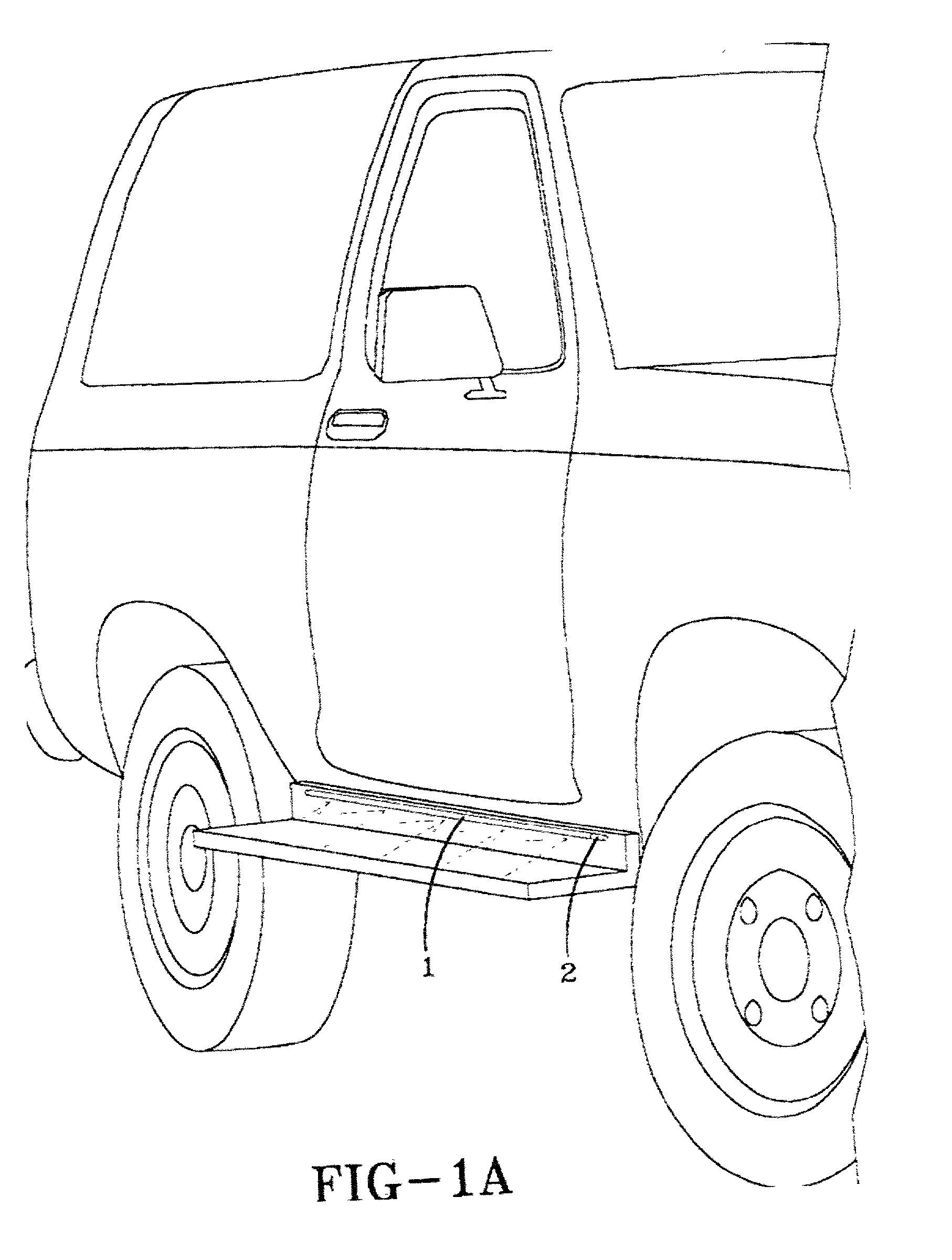

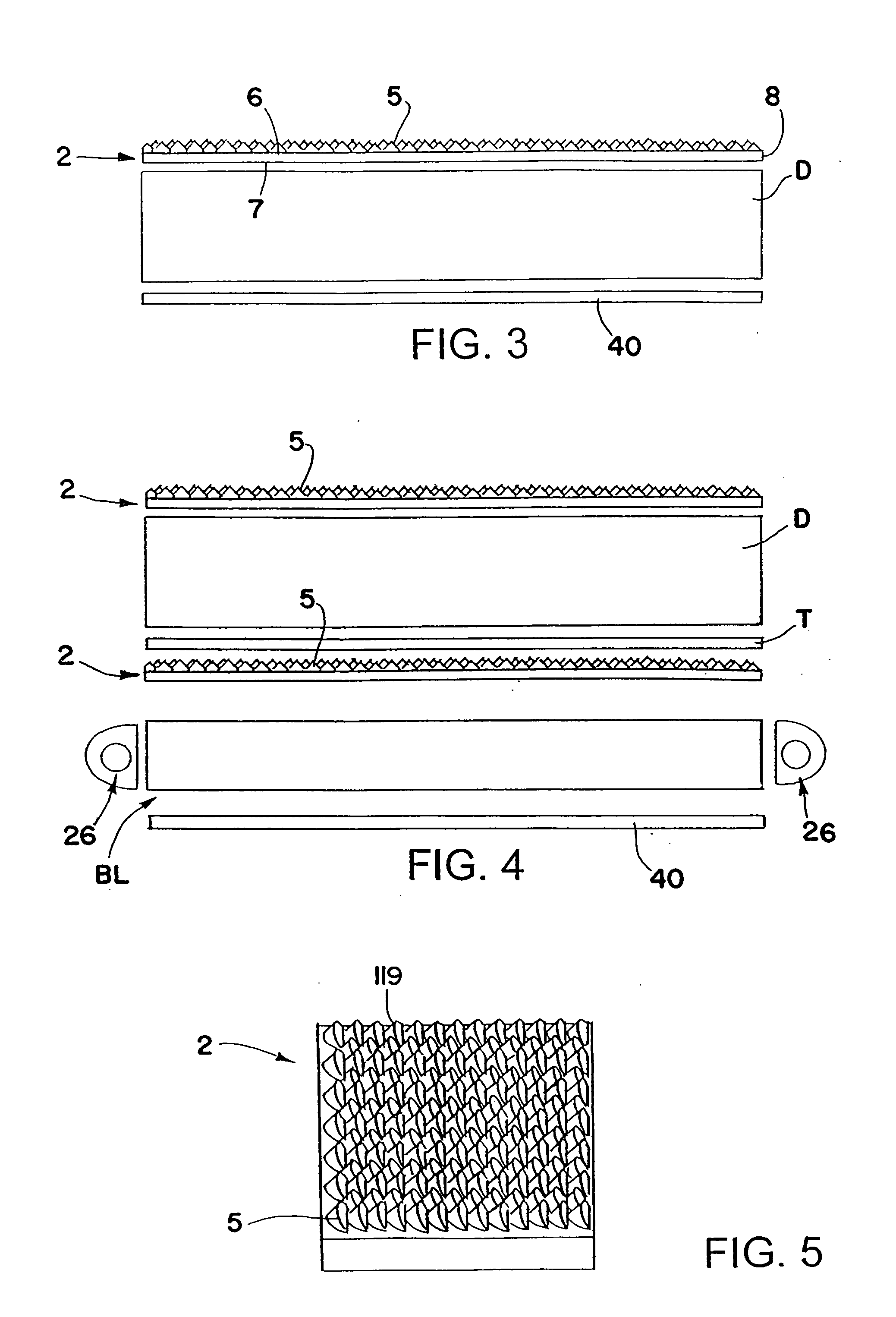

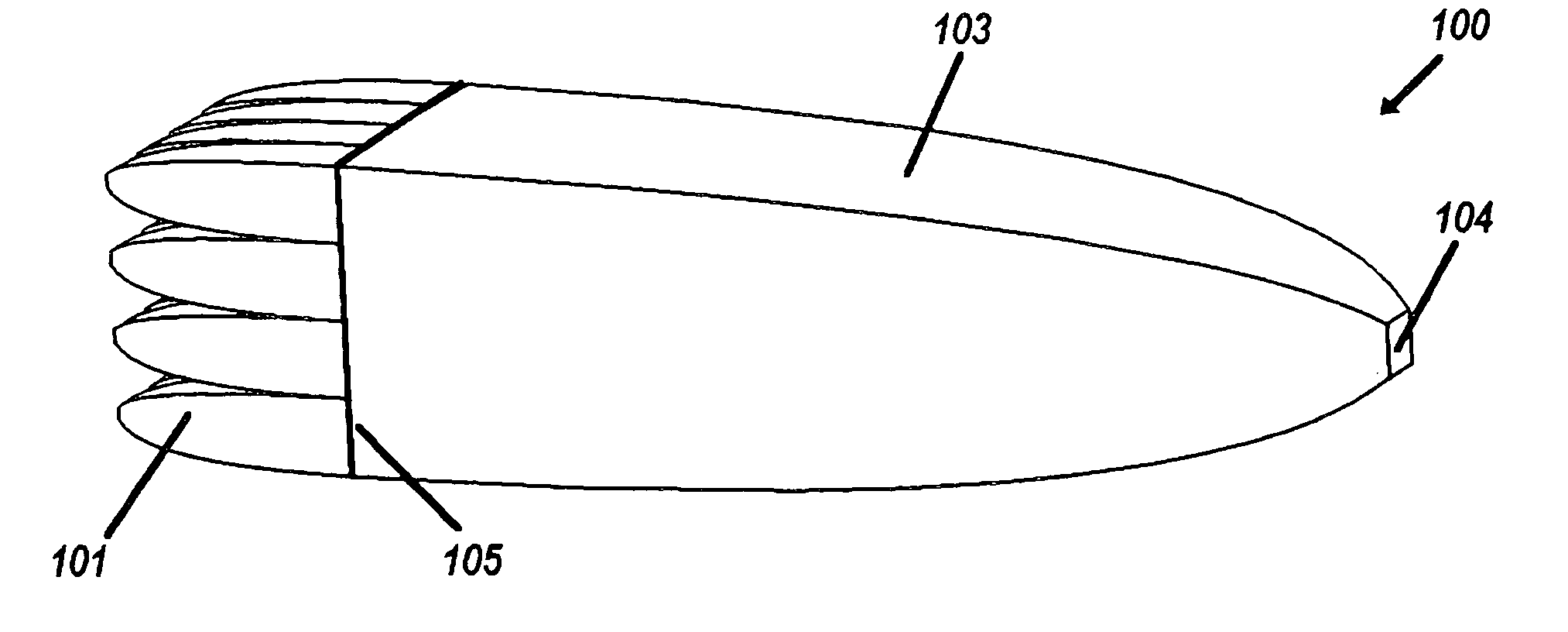

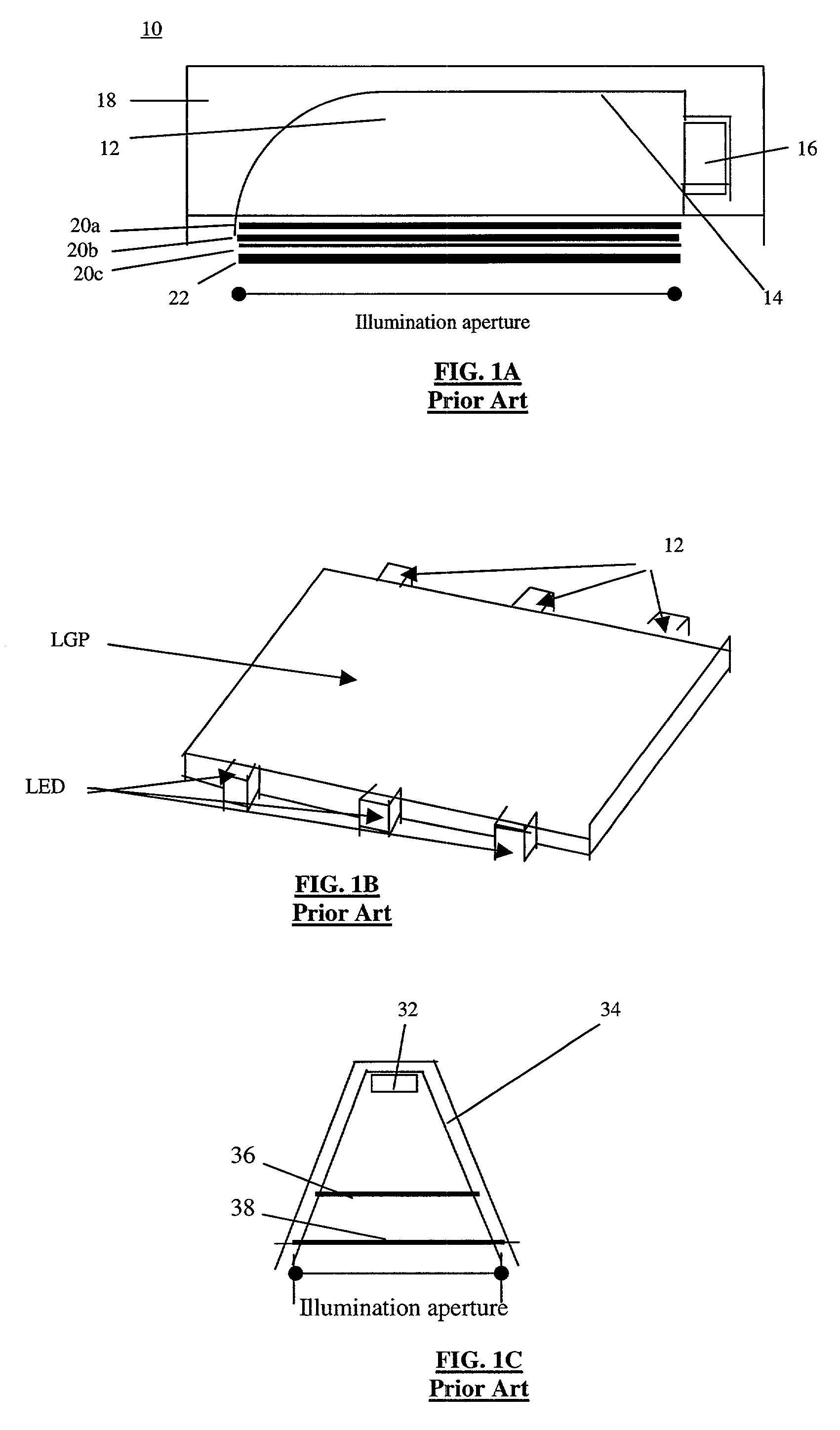

A compact and efficient optical illumination system featuring planar multi-layered LED light source arrays concentrating their polarized or un-polarized output within a limited angular range. The optical system manipulates light emitted by a planar array of electrically-interconnected LED chips positioned within the input apertures of a corresponding array of shaped metallic reflecting bins using at least one of elevated prismatic films, polarization converting films, micro-lens arrays and external hemispherical or ellipsoidal reflecting elements. Practical applications of the LED array illumination systems include compact LCD or DMD video image projectors, as well as general lighting, automotive lighting, and LCD backlighting.

Owner:SNAPTRACK

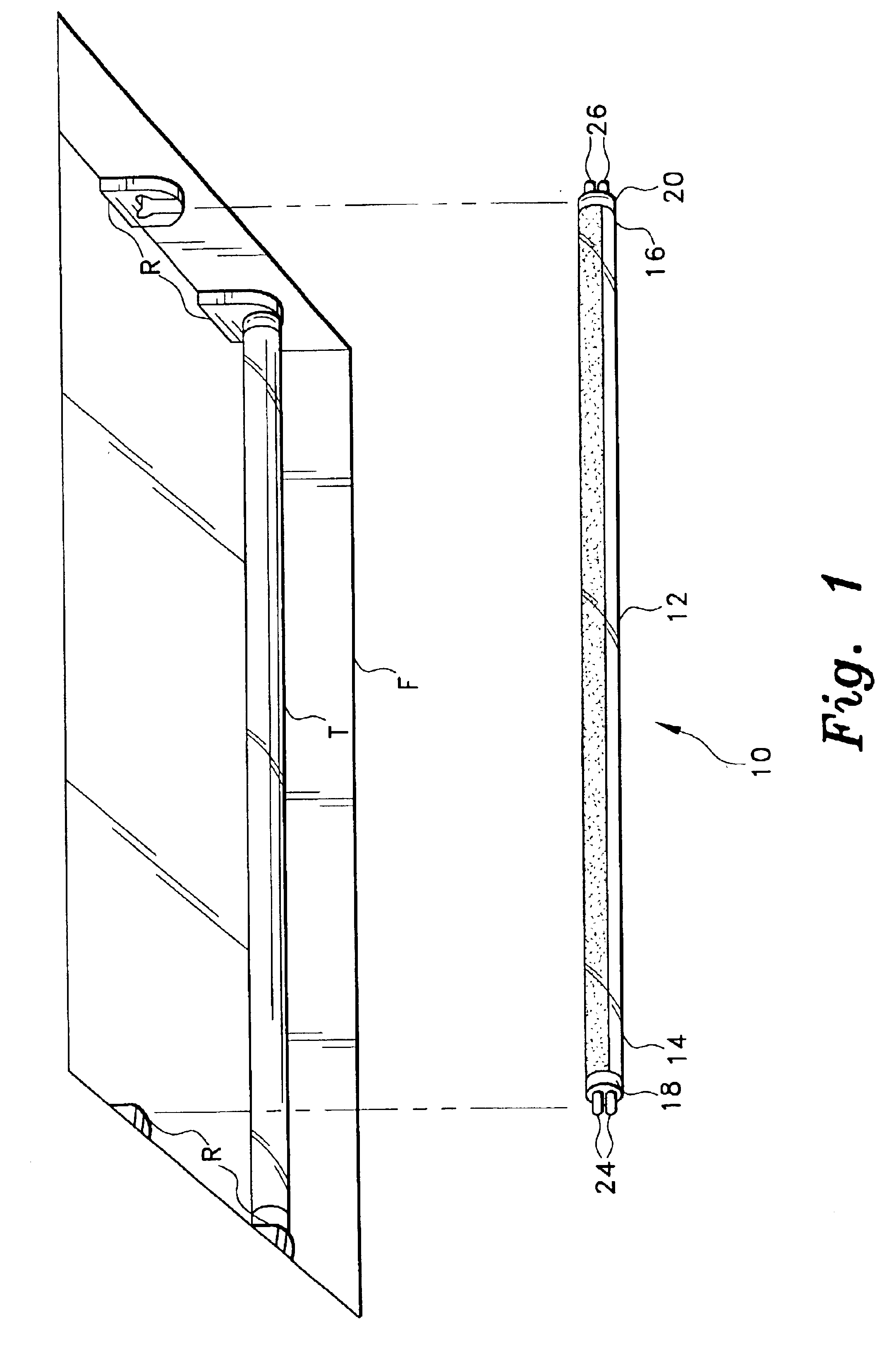

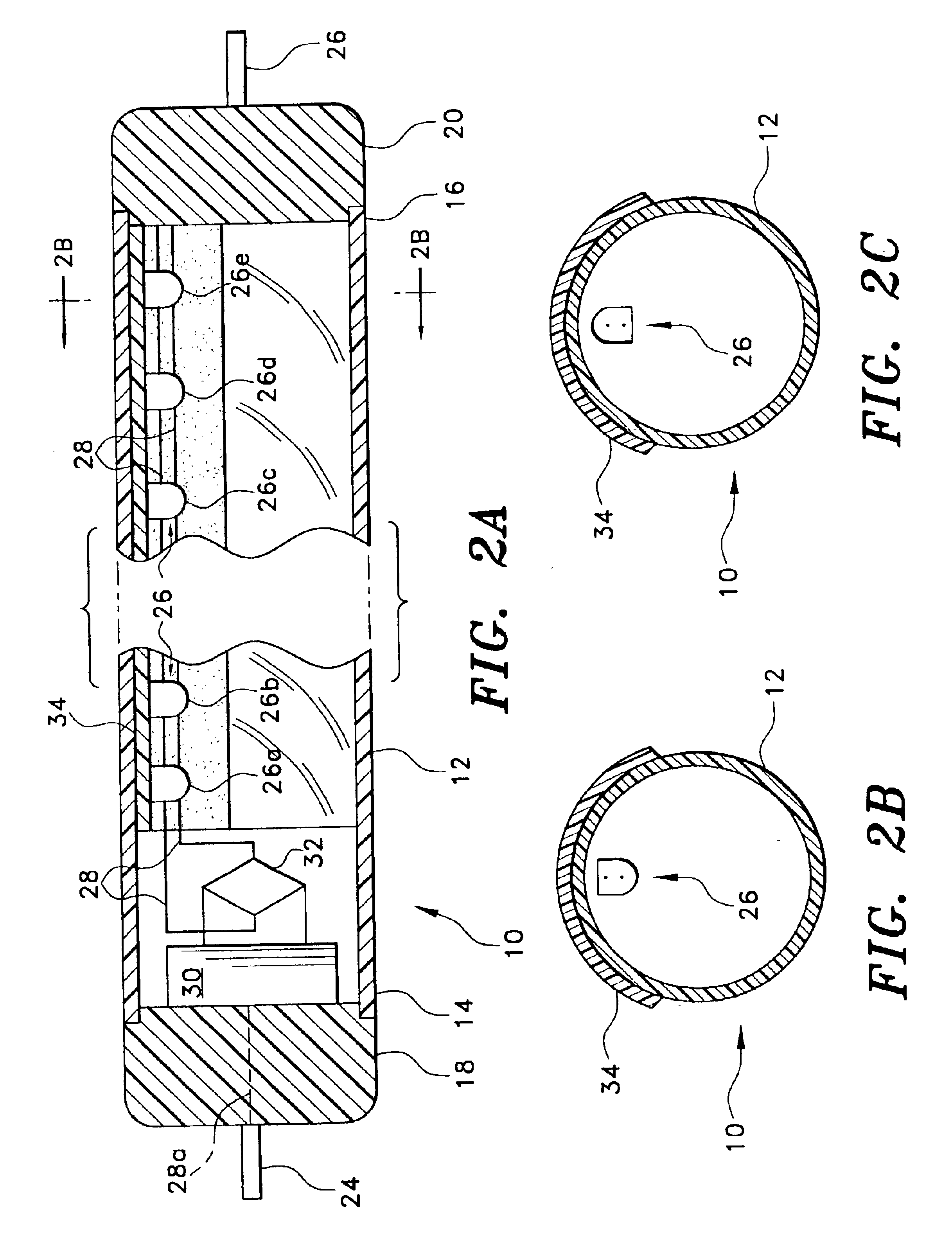

LED replacement for fluorescent lighting

InactiveUS6860628B2Reduce eliminateReducing or eliminating any additional electrical componentryCoupling device connectionsLight source combinationsTransformerFluorescence

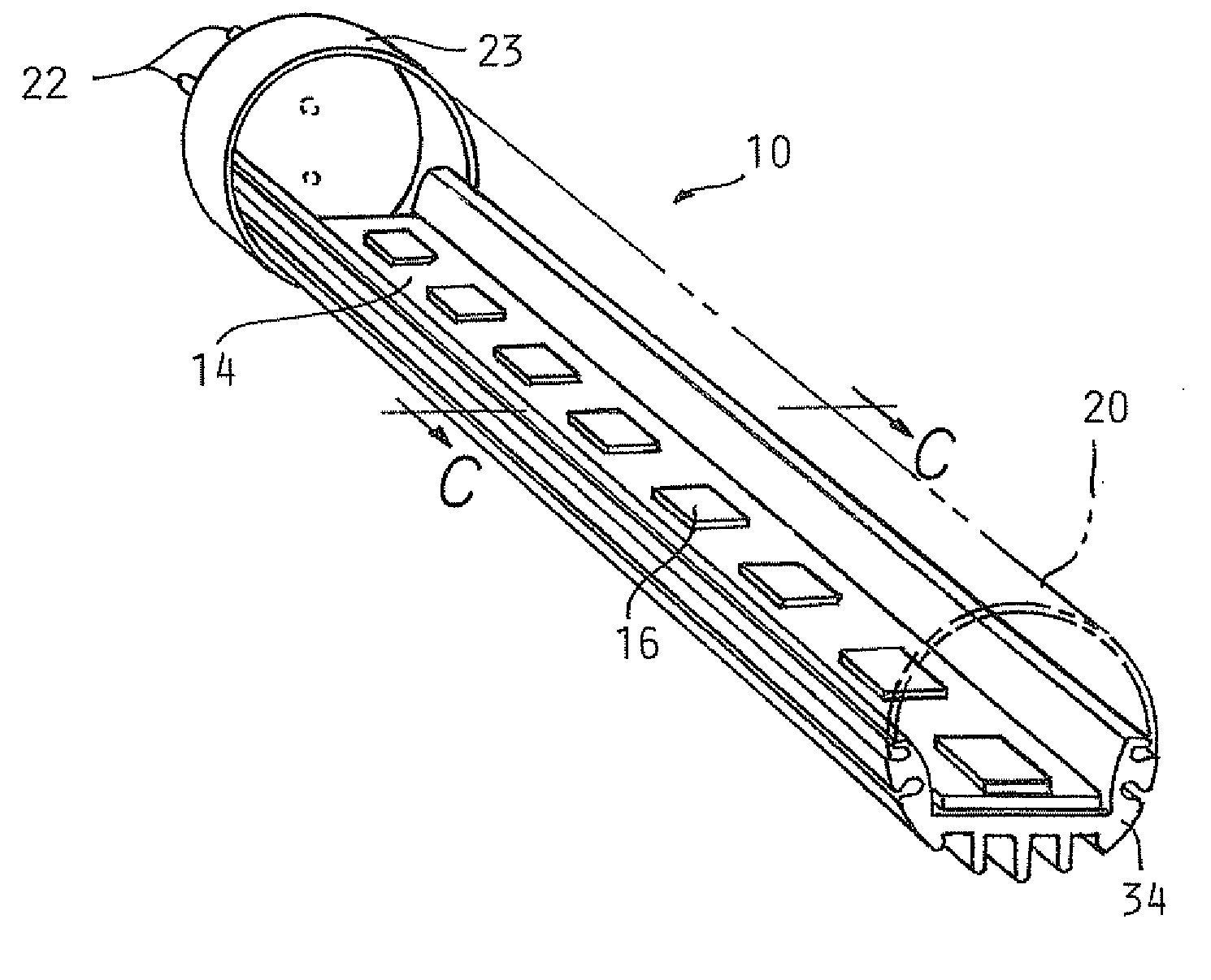

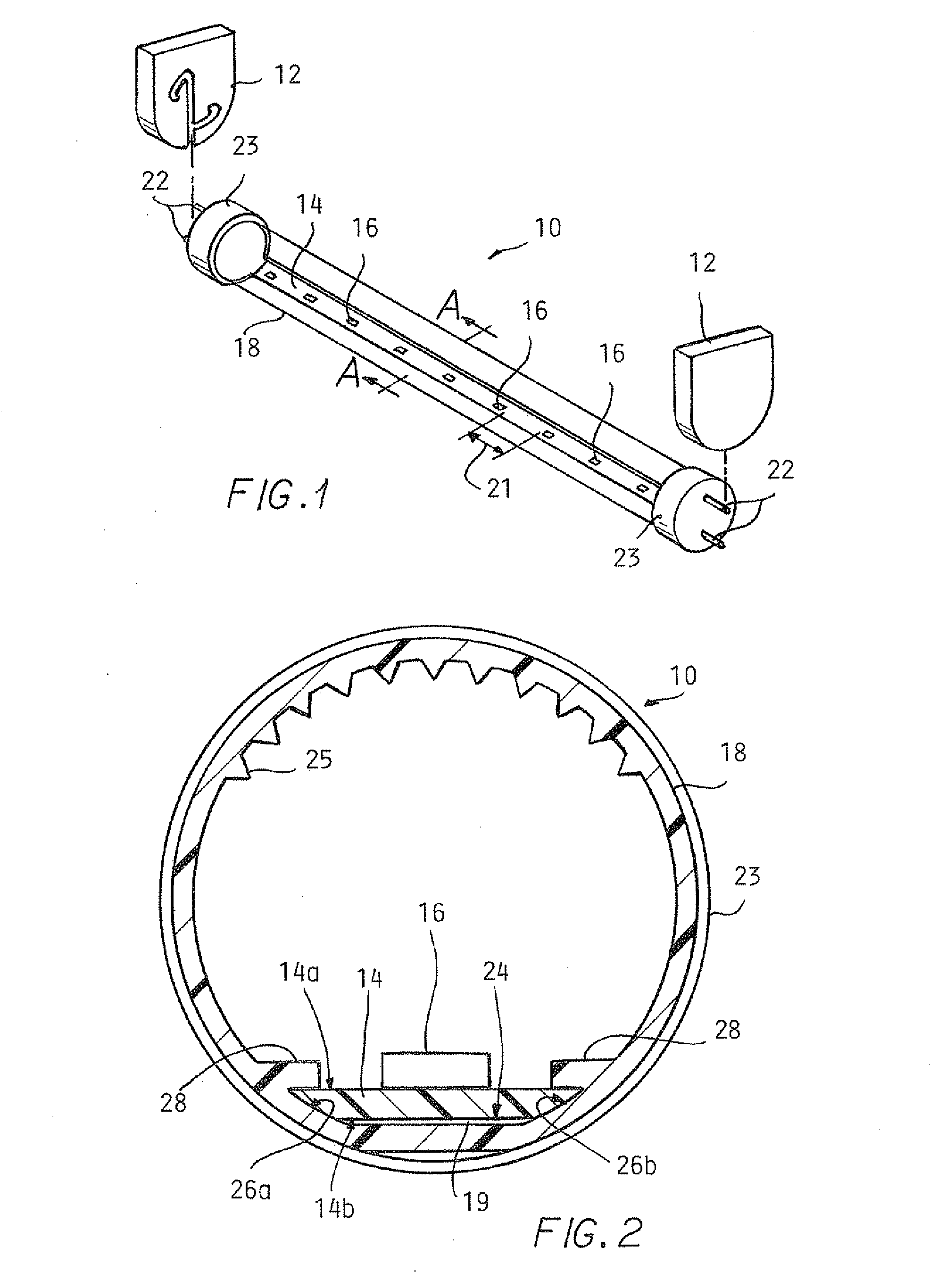

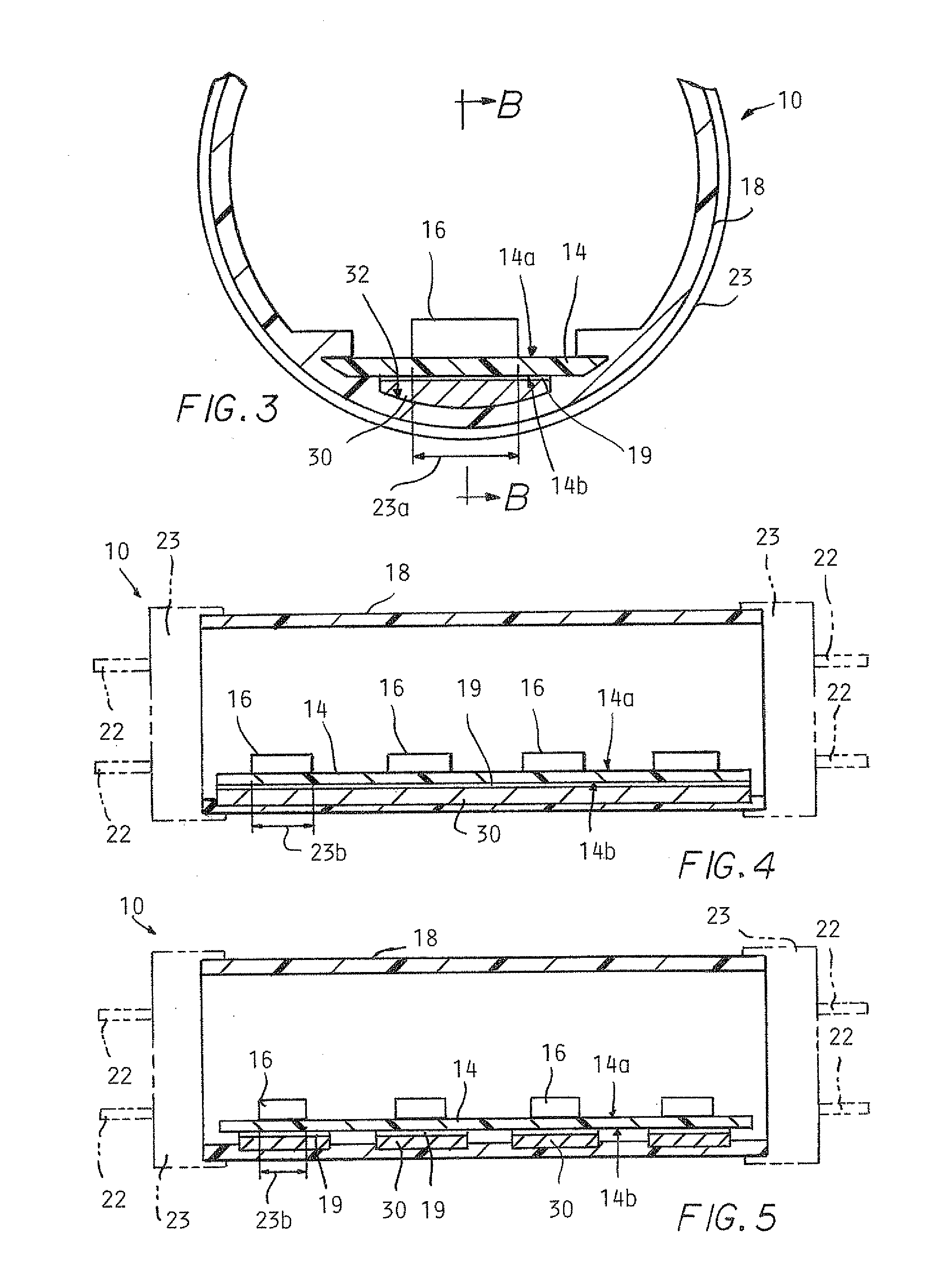

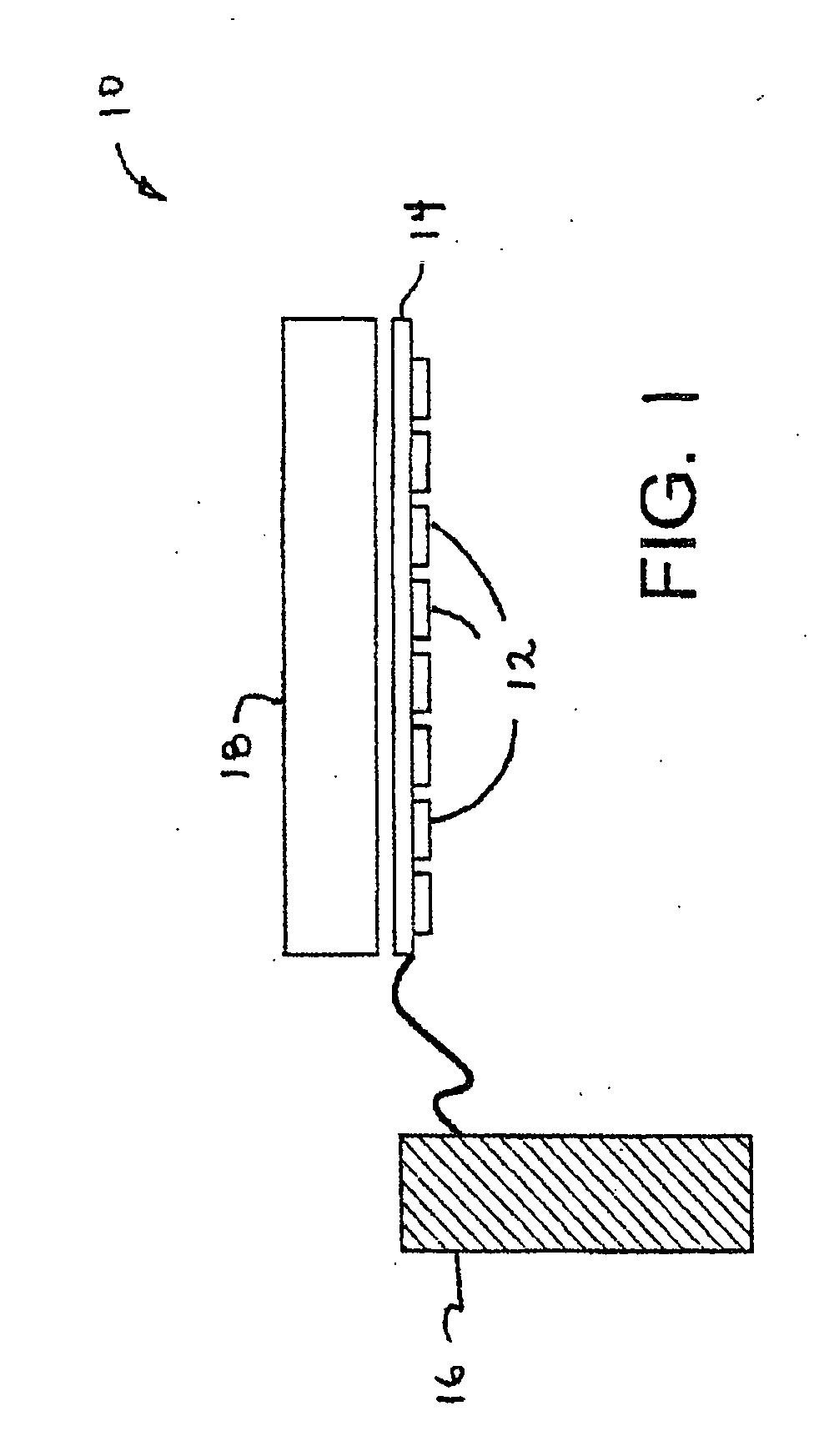

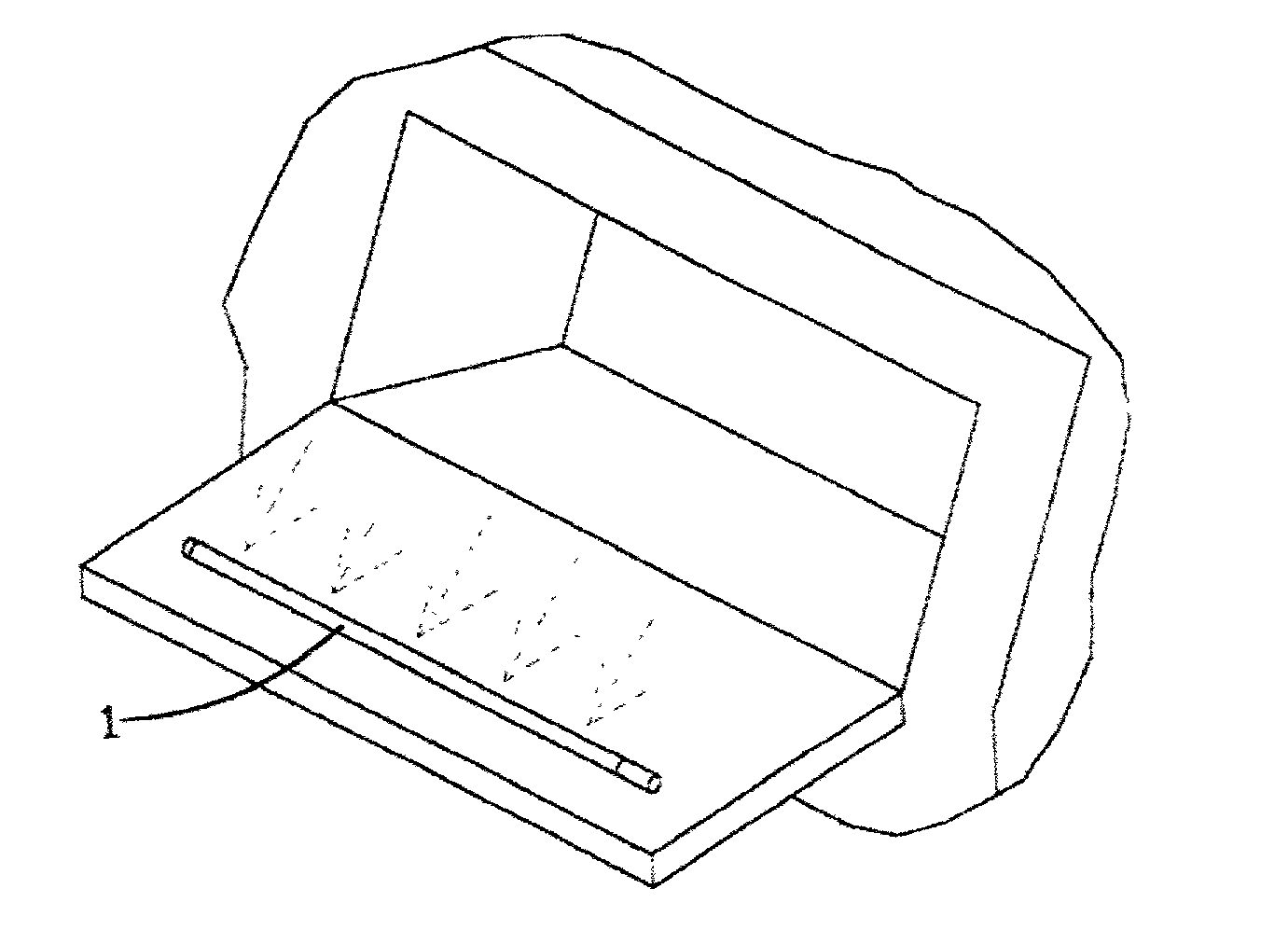

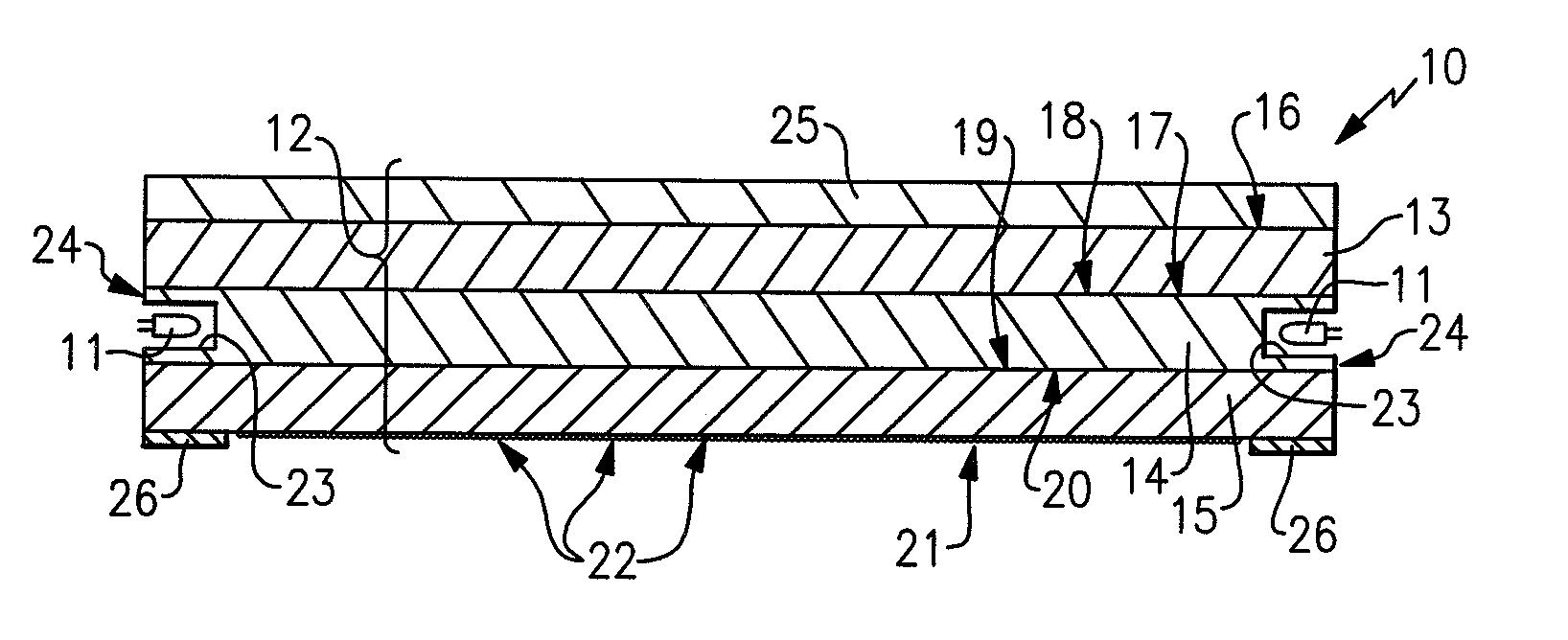

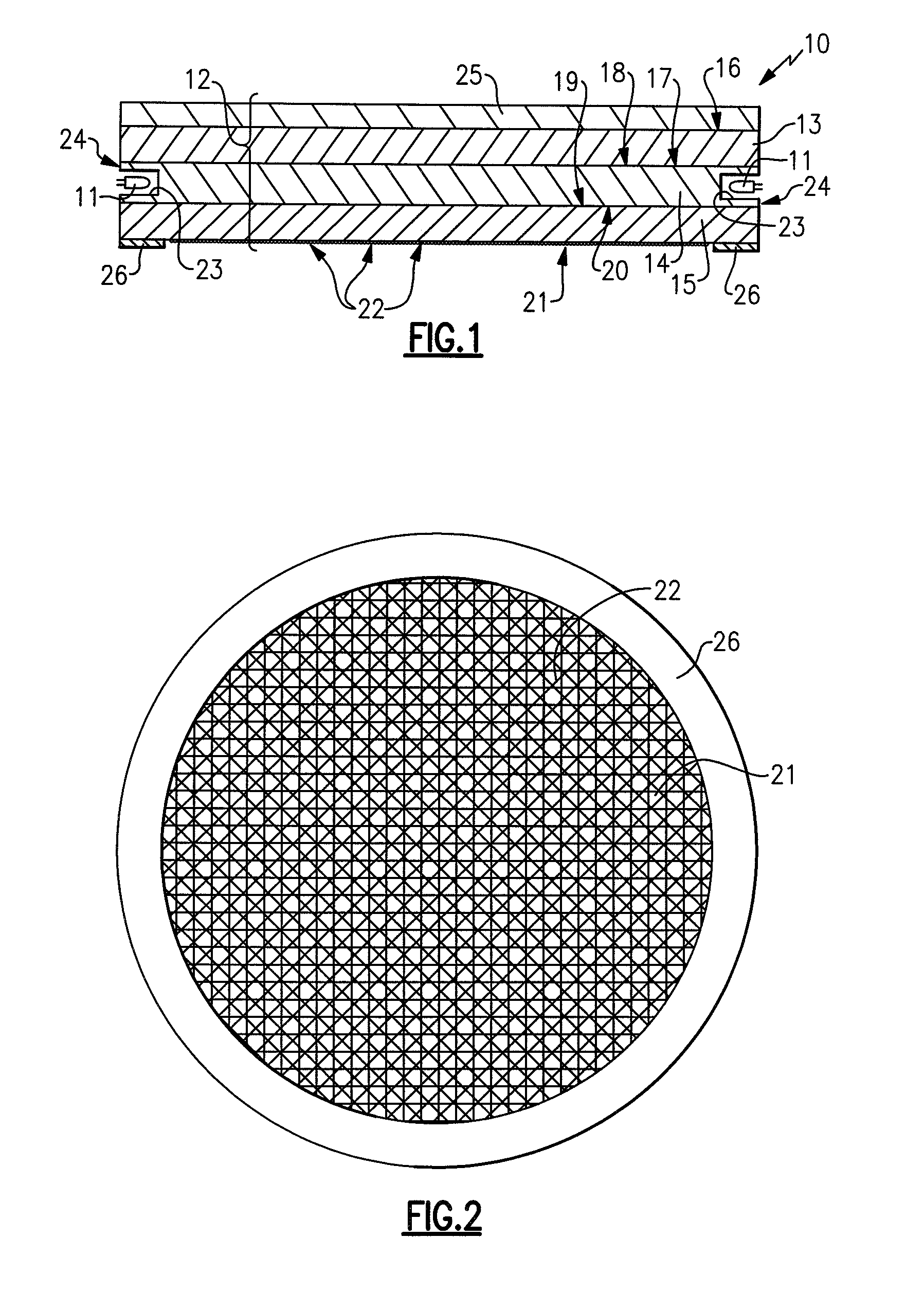

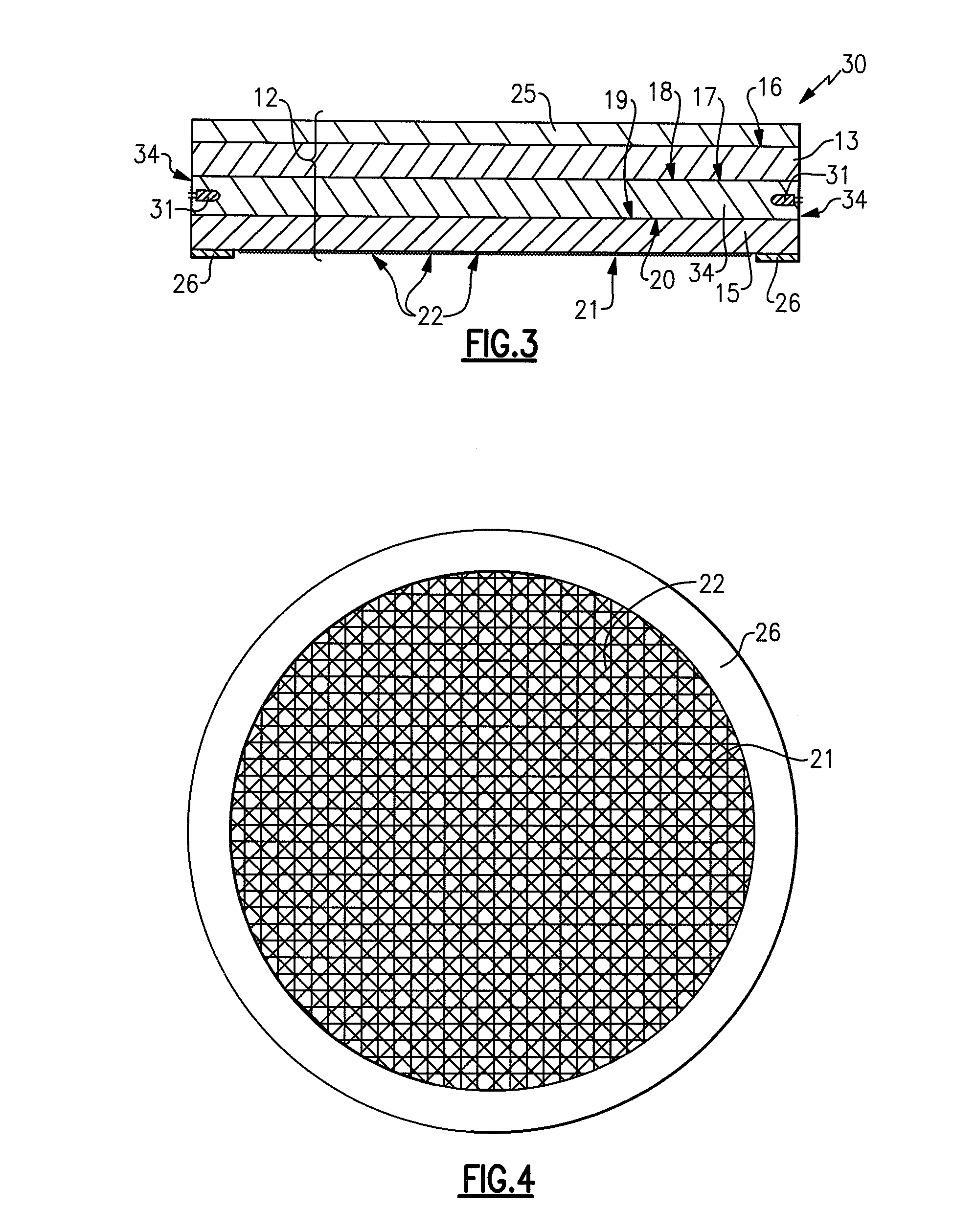

The present invention provides several embodiments of an elongate hollow tubular or solid rod lighting device including a plurality of LEDs therewith and appropriate electrical componentry, and serving as a direct replacement for a conventional fluorescent light tube in a conventional fluorescent lighting fixture. The present lighting device includes appropriate connector pins extending from each end thereof, enabling the device to be installed in a conventional fluorescent lighting fixture with no modification to the fixture. The light may include appropriate electrical componentry such as a step-down transformer to provide the required voltage for the LEDs, either integrally within the light, incorporated in an end cap thereof, or installed separately therefrom in the fixture, as desired. The light may be colored or tinted as desired by the use of LEDs providing the desired color output, and / or by installing a tinted sleeve over the tube or rod as desired.

Owner:SAMSUNG ELECTRONICS CO LTD

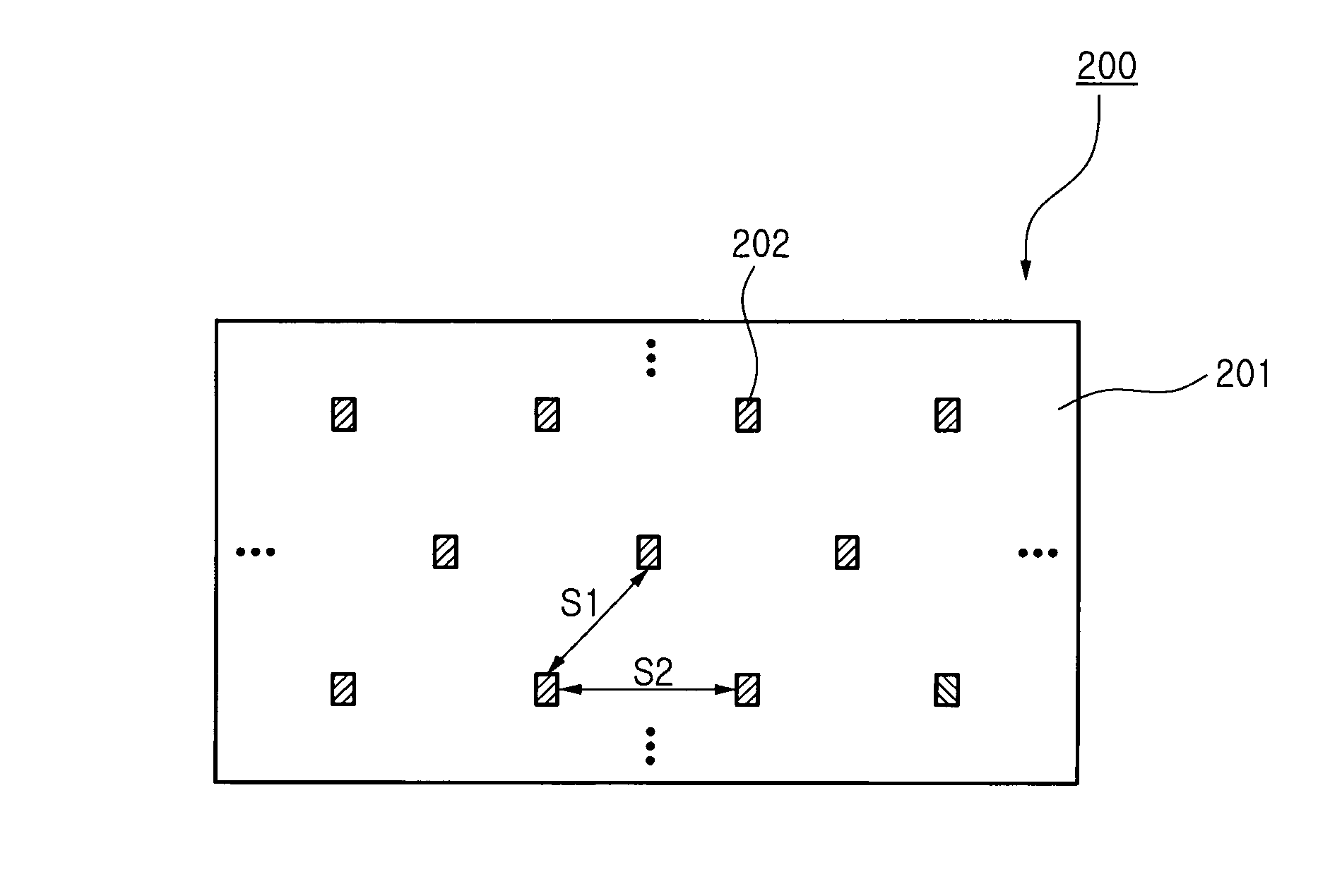

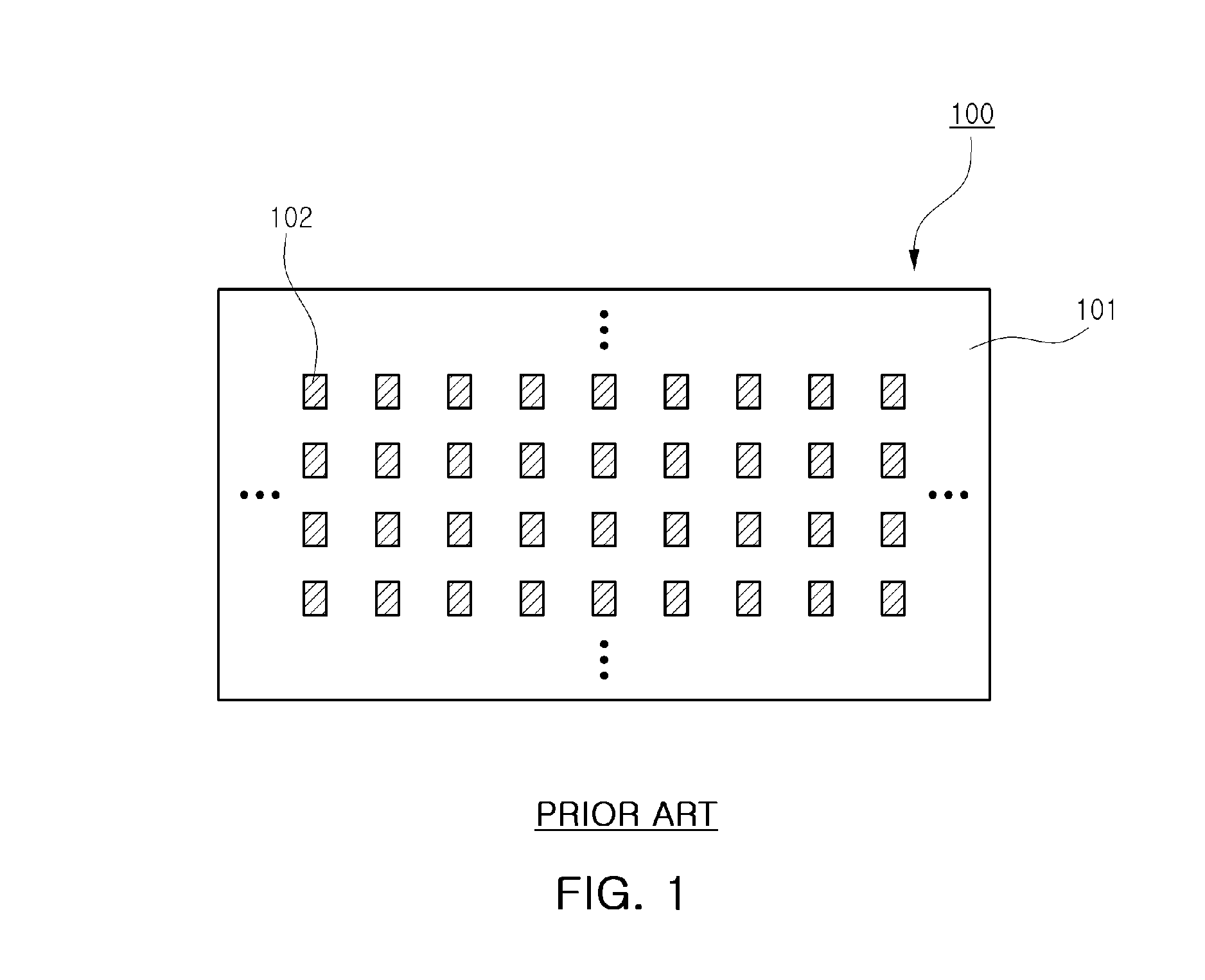

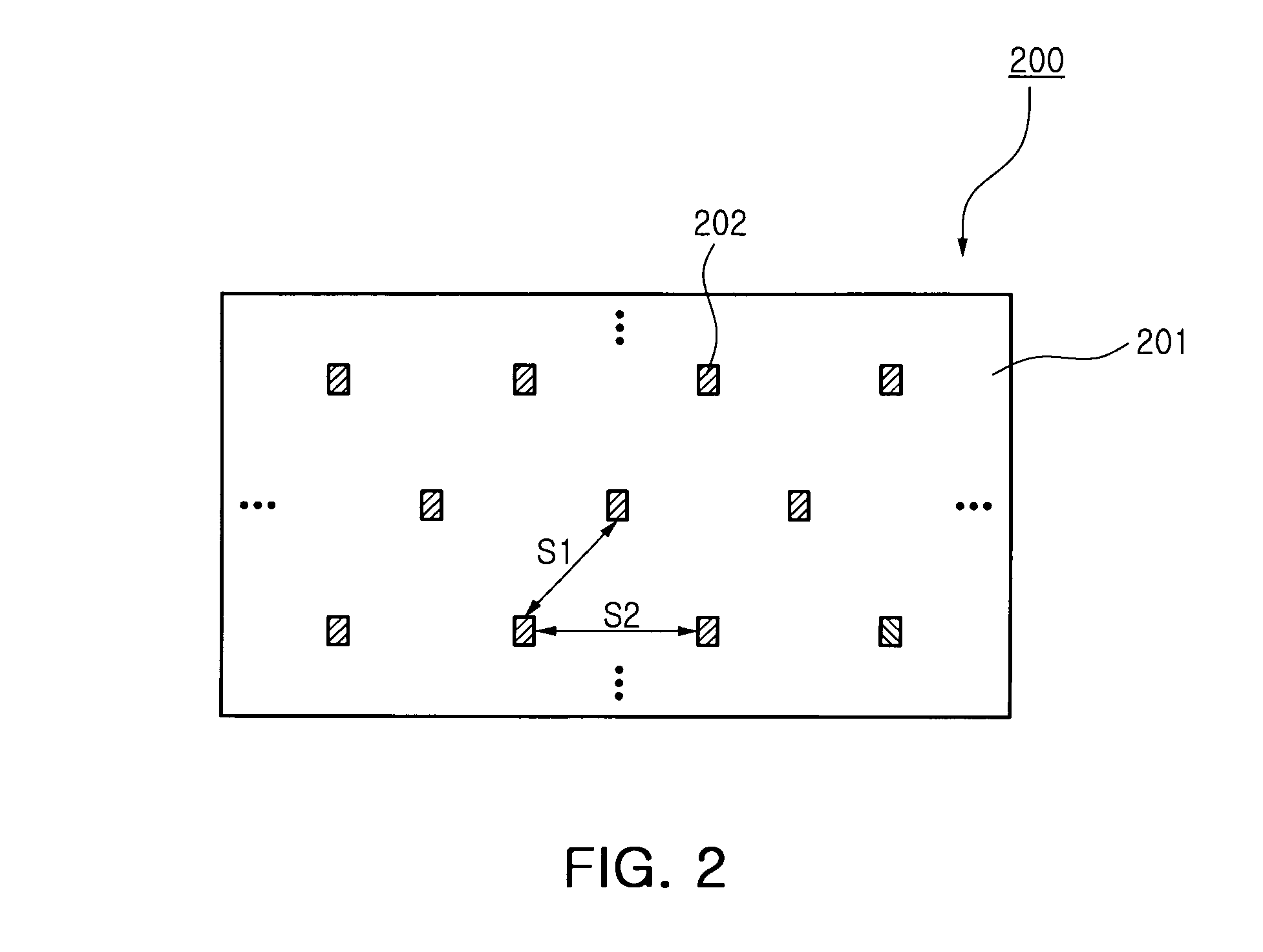

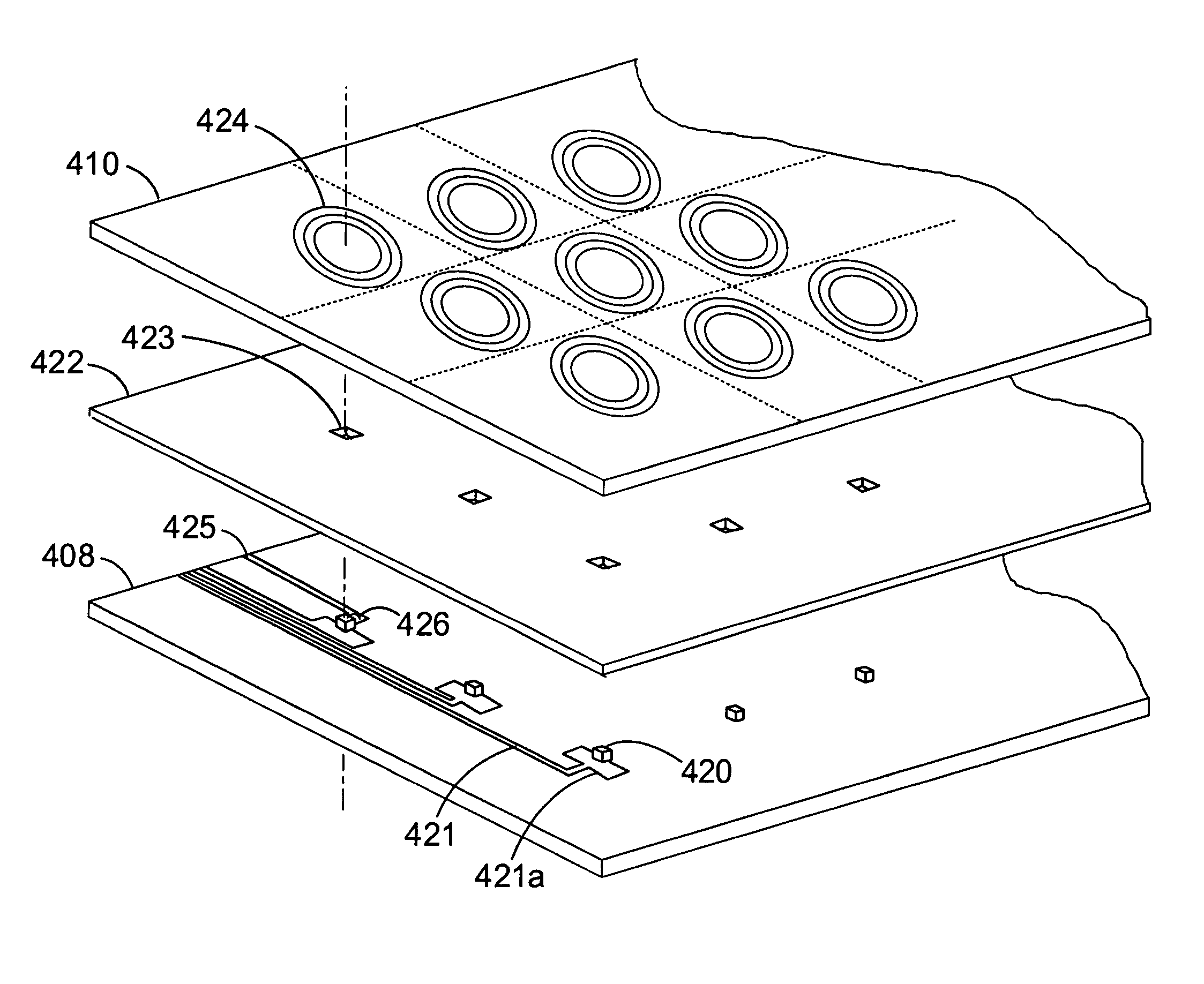

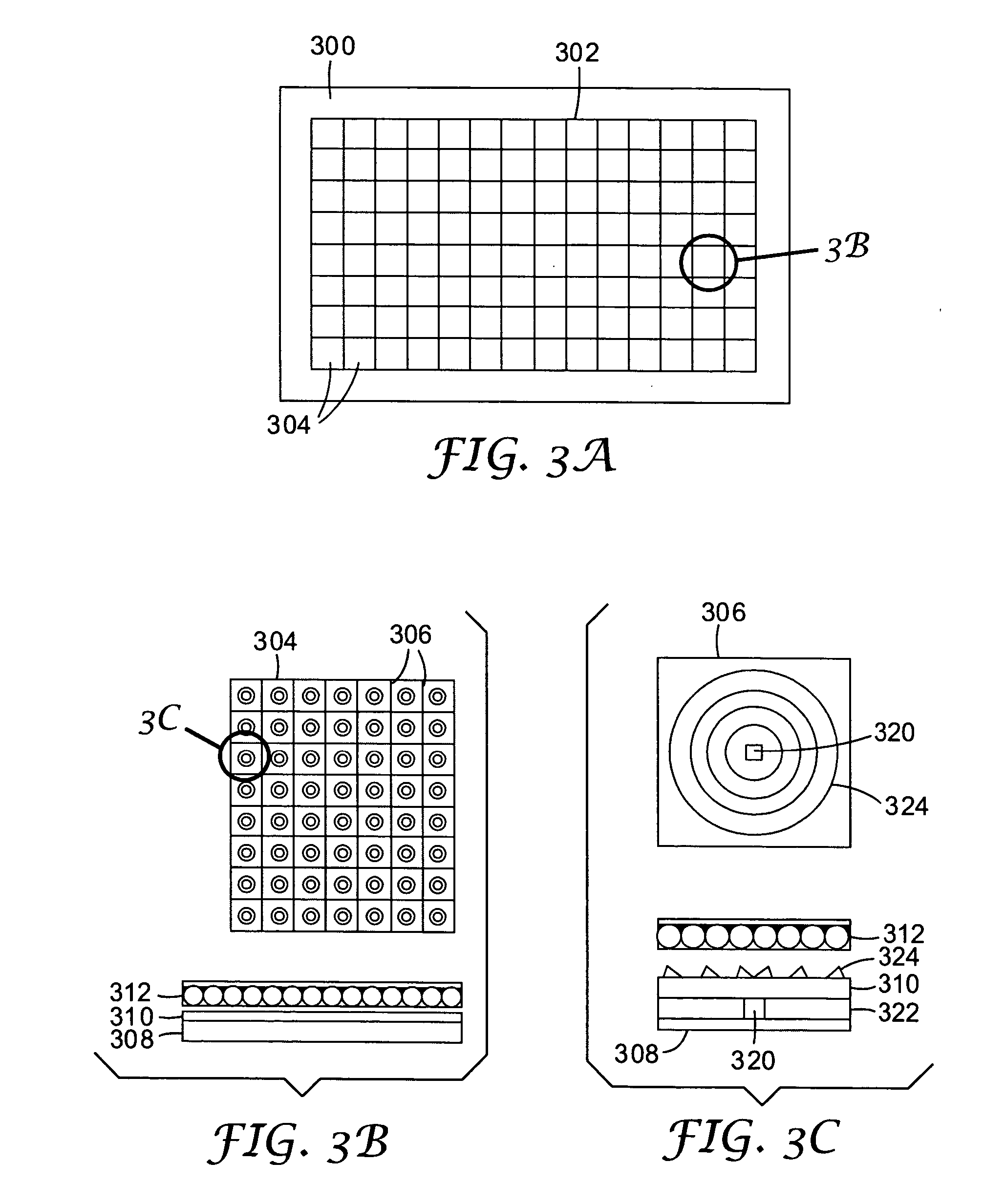

Plane light source and LCD backlight unit having the same

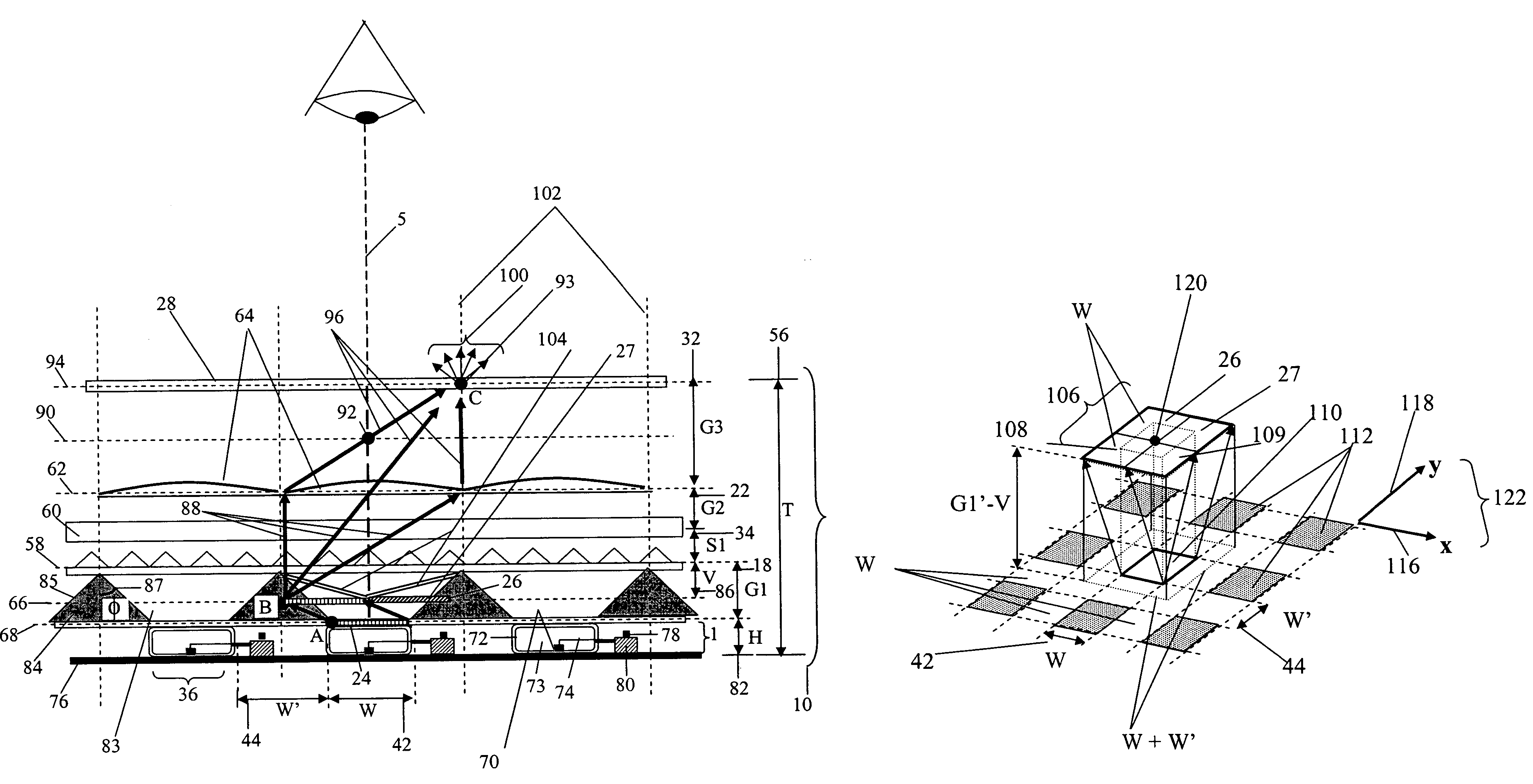

ActiveUS7940350B2Reduce in quantityImprove efficiencyLighting support devicesNon-linear opticsLight emitting deviceLightness

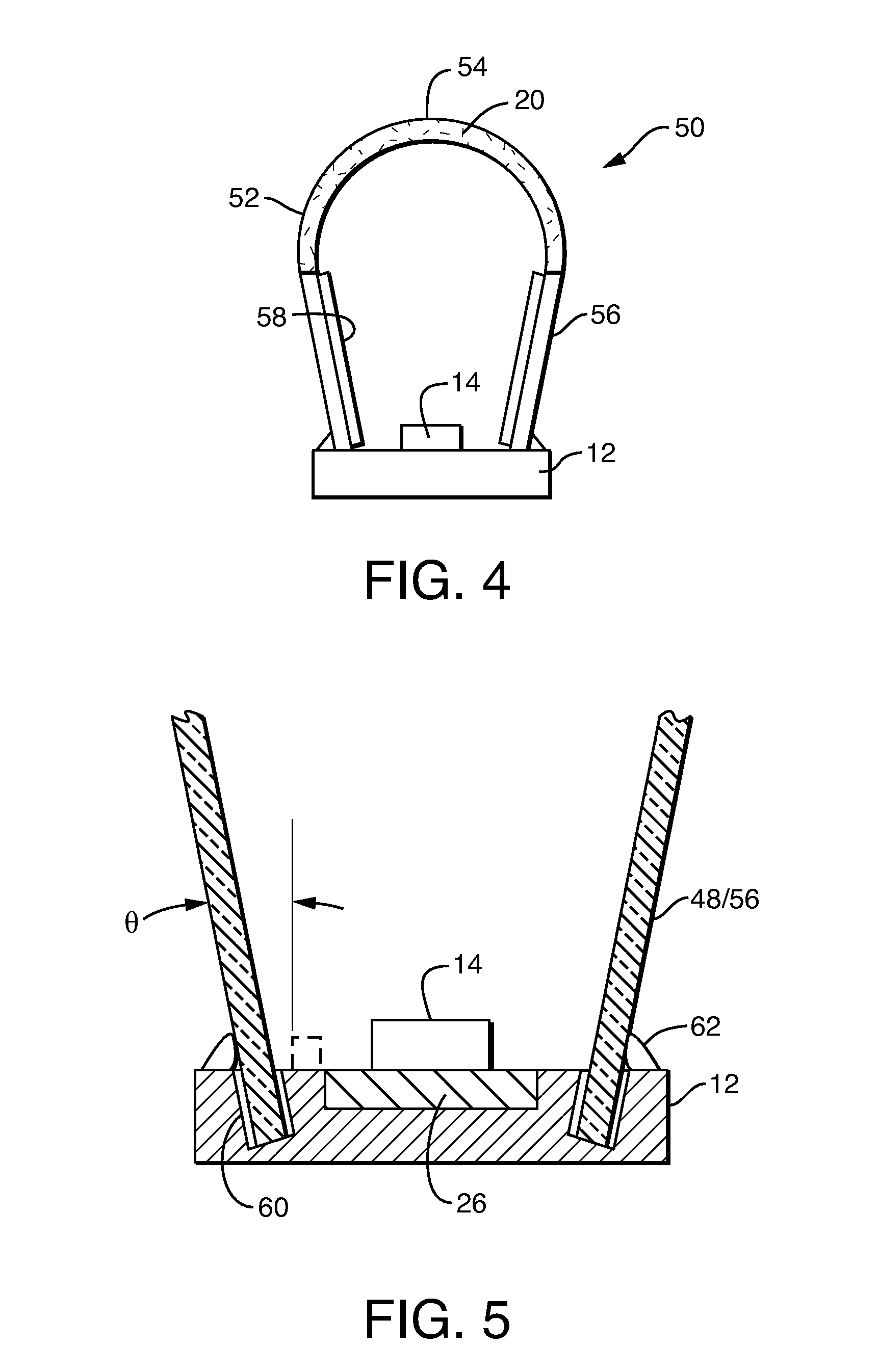

There are provided a plane light source and an LCD backlight unit having the same. A plane light source having a plurality of light emitting devices arranged in a light emitting device matrix having rows and columns at a substrate according to an aspect of the invention includes a first matrix having a plurality of light emitting devices arranged in rows and columns; and a second matrix having a plurality of light emitting devices arranged in rows and columns, each of the light emitting devices located within a quadrangle formed by four neighboring light emitting devices included in the first matrix, wherein a pitch S between one light emitting device included in the light emitting device matrix and another light emitting device most adjacent to the one light emitting device satisfies the following equation to obtain uniform luminance distribution at a position distant from a light emitting surface of the light emitting device by an optical length l,S≤l2×tan(θ2+α),Equationwhere −π / 18≦α≦π / 18 is satisfied, and θ is an orientation angle of the light emitting device.

Owner:SAMSUNG ELECTRONICS CO LTD

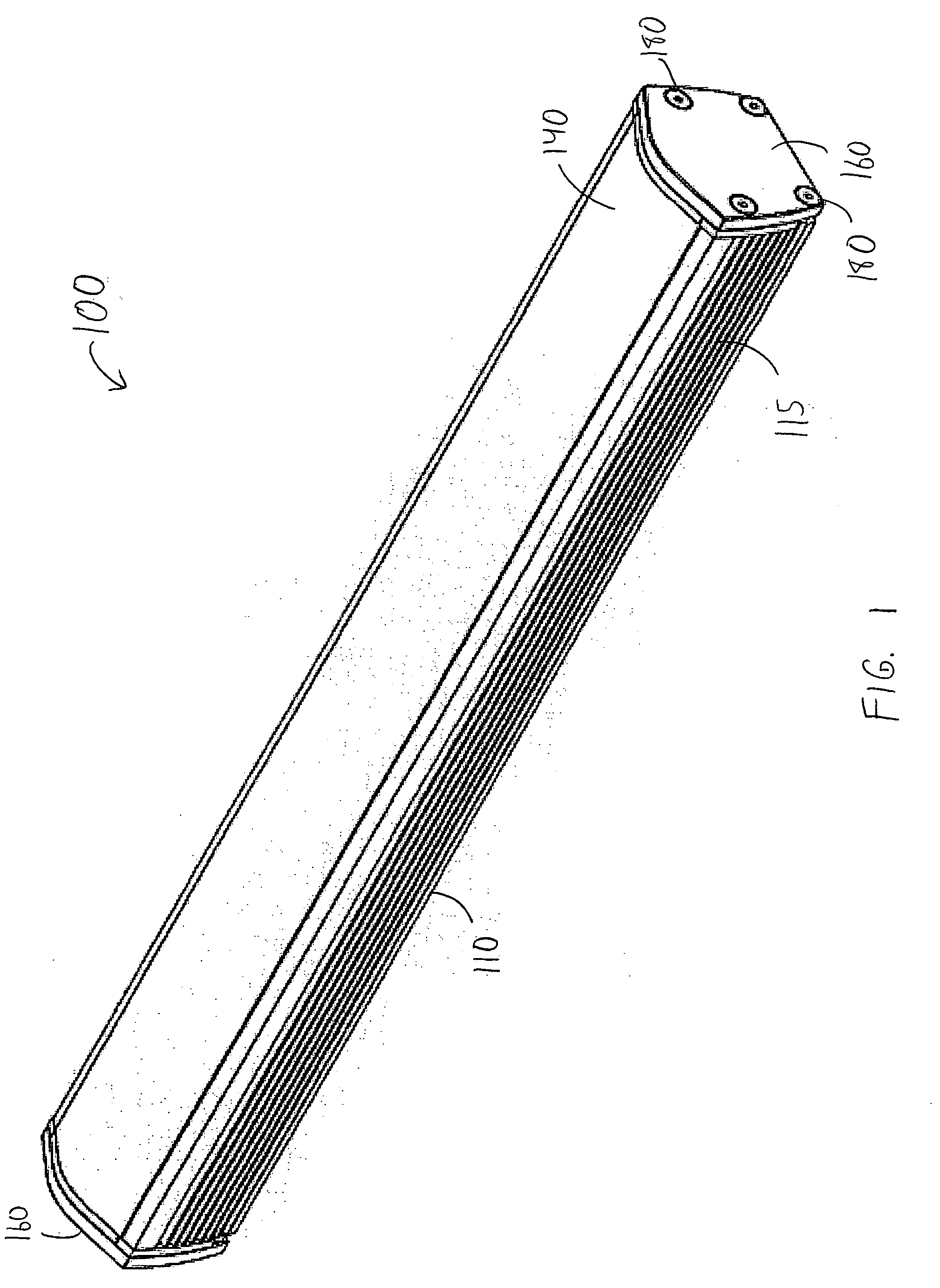

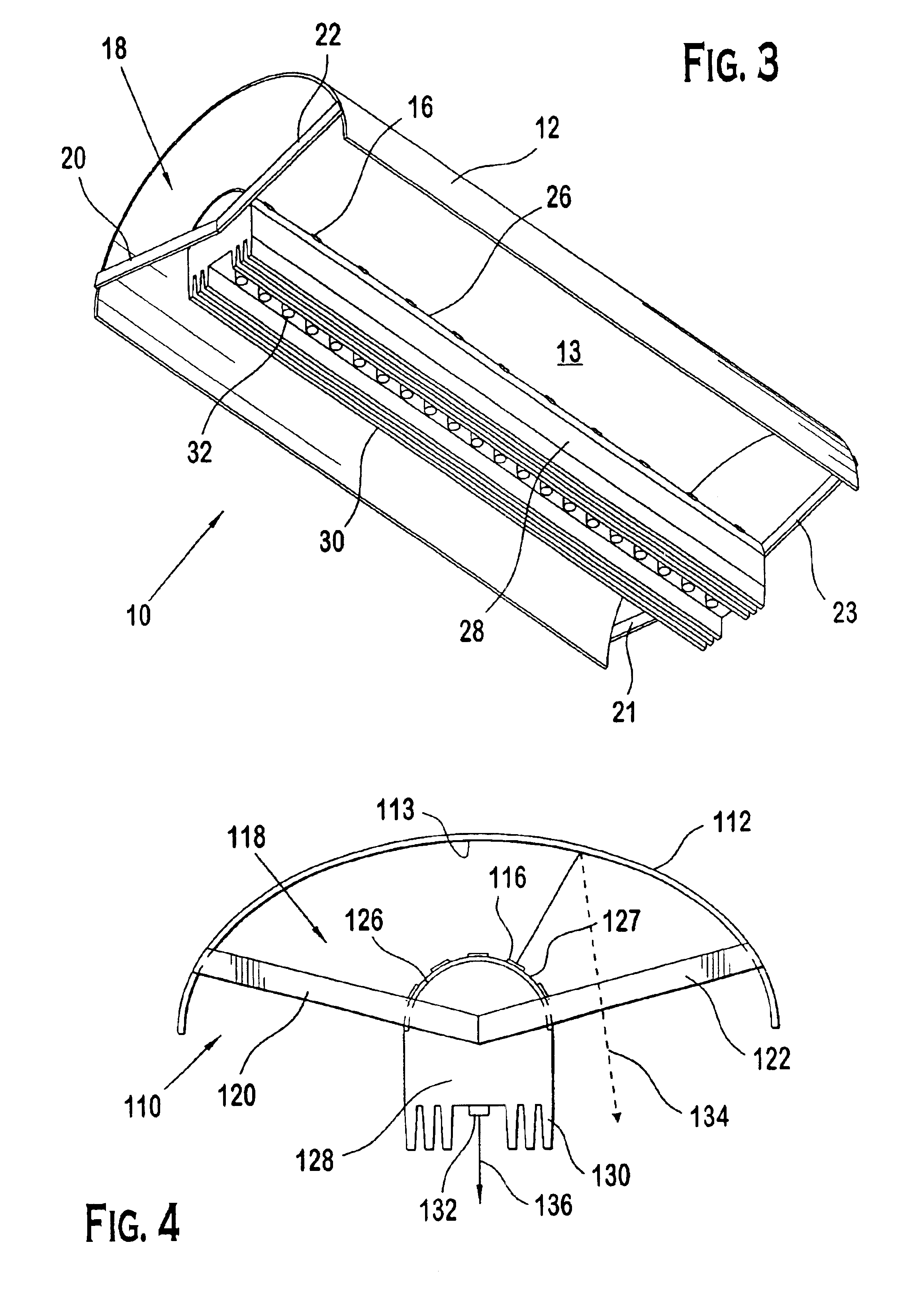

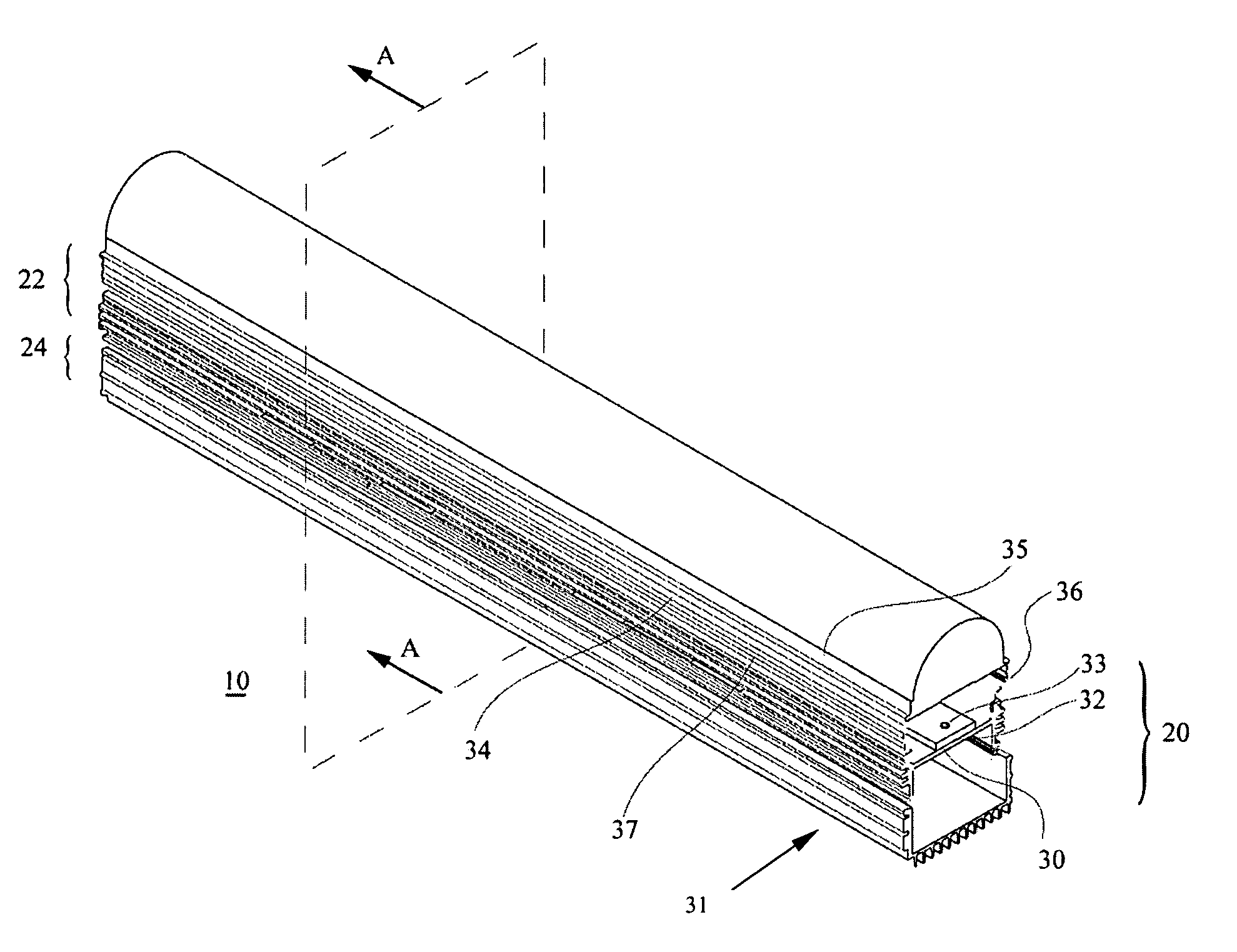

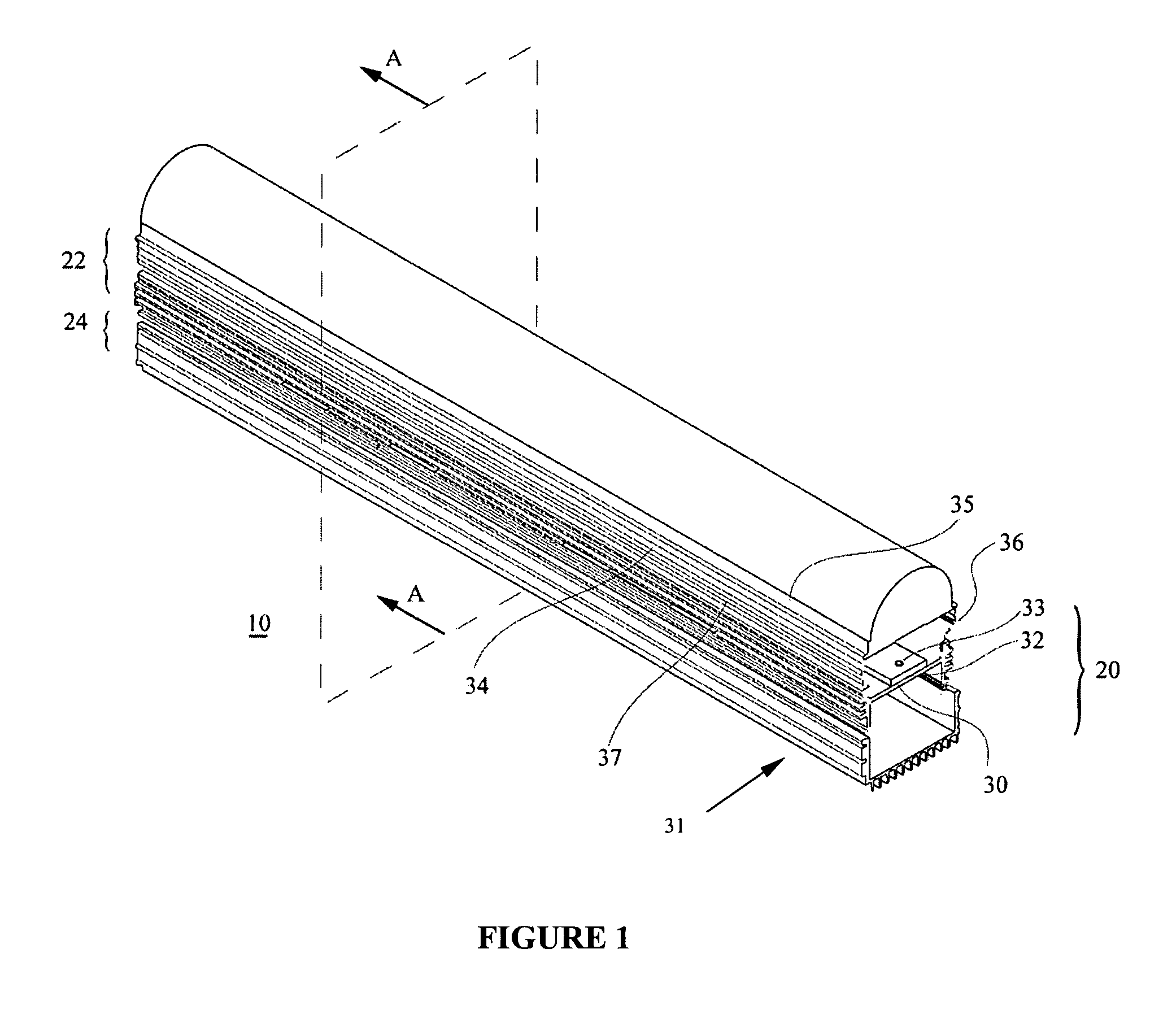

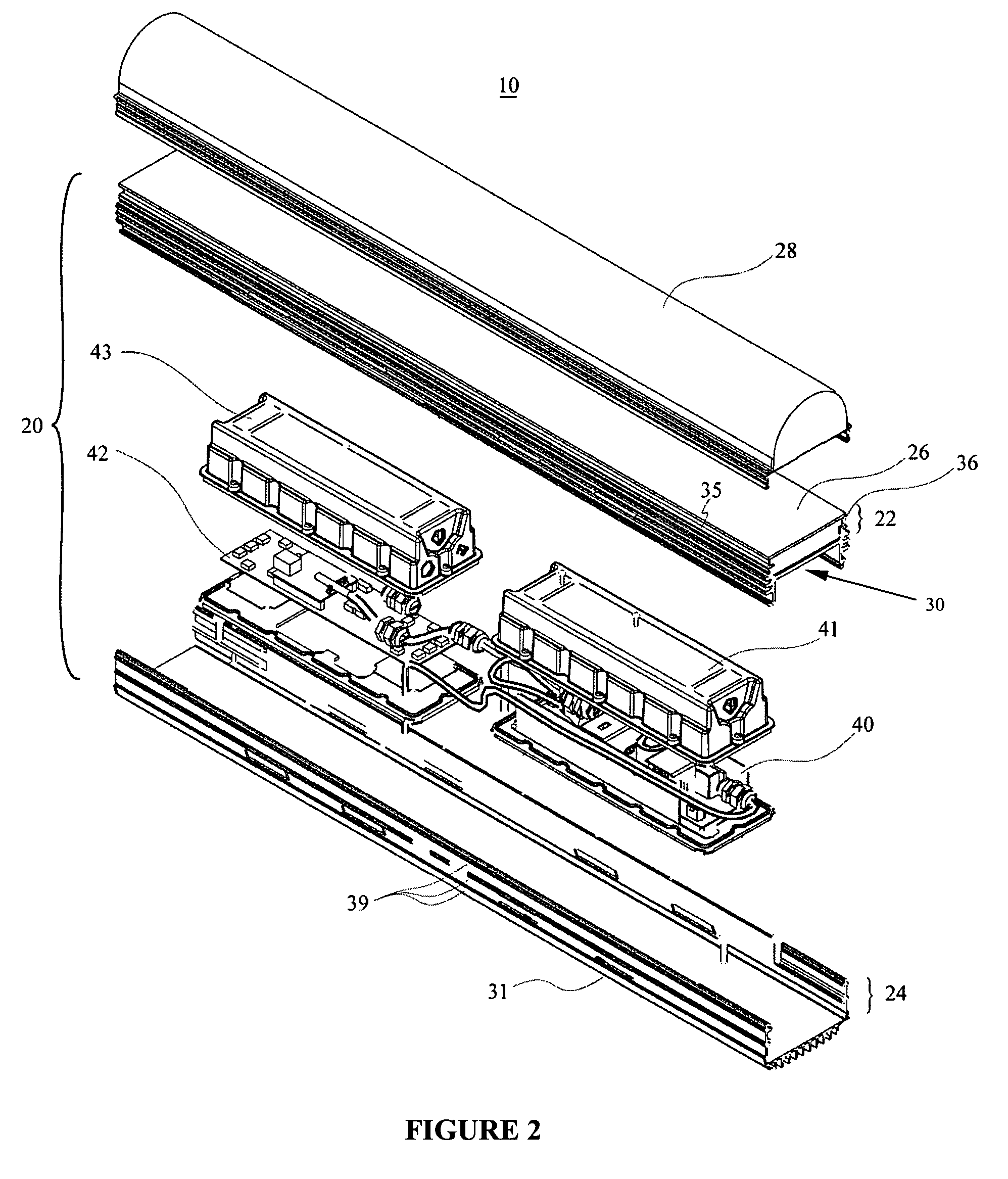

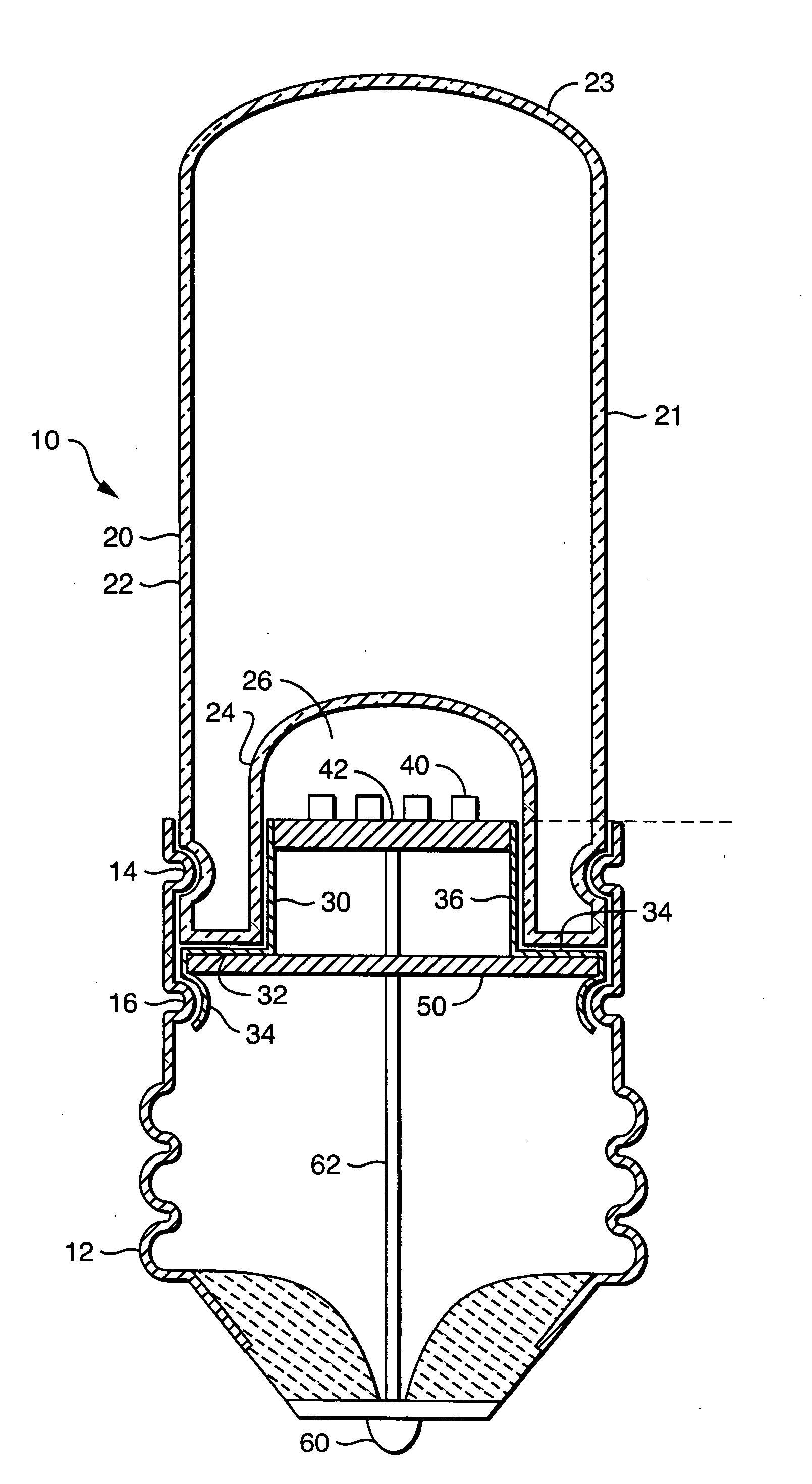

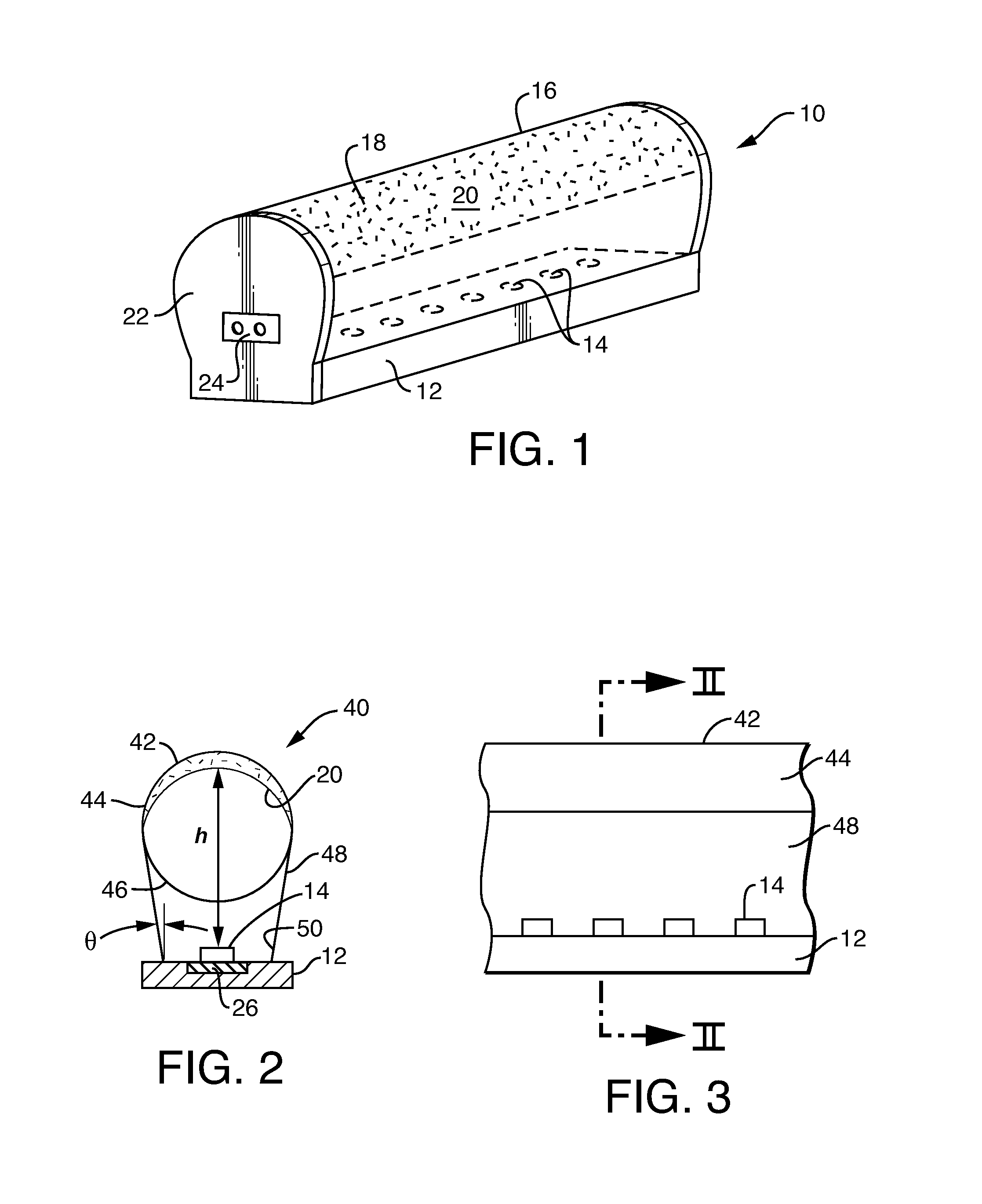

Linear lighting apparatus with improved heat dissipation

InactiveUS20060146531A1Improve cooling effectDissipate energyMechanical apparatusPoint-like light sourceThermal energyEffect light

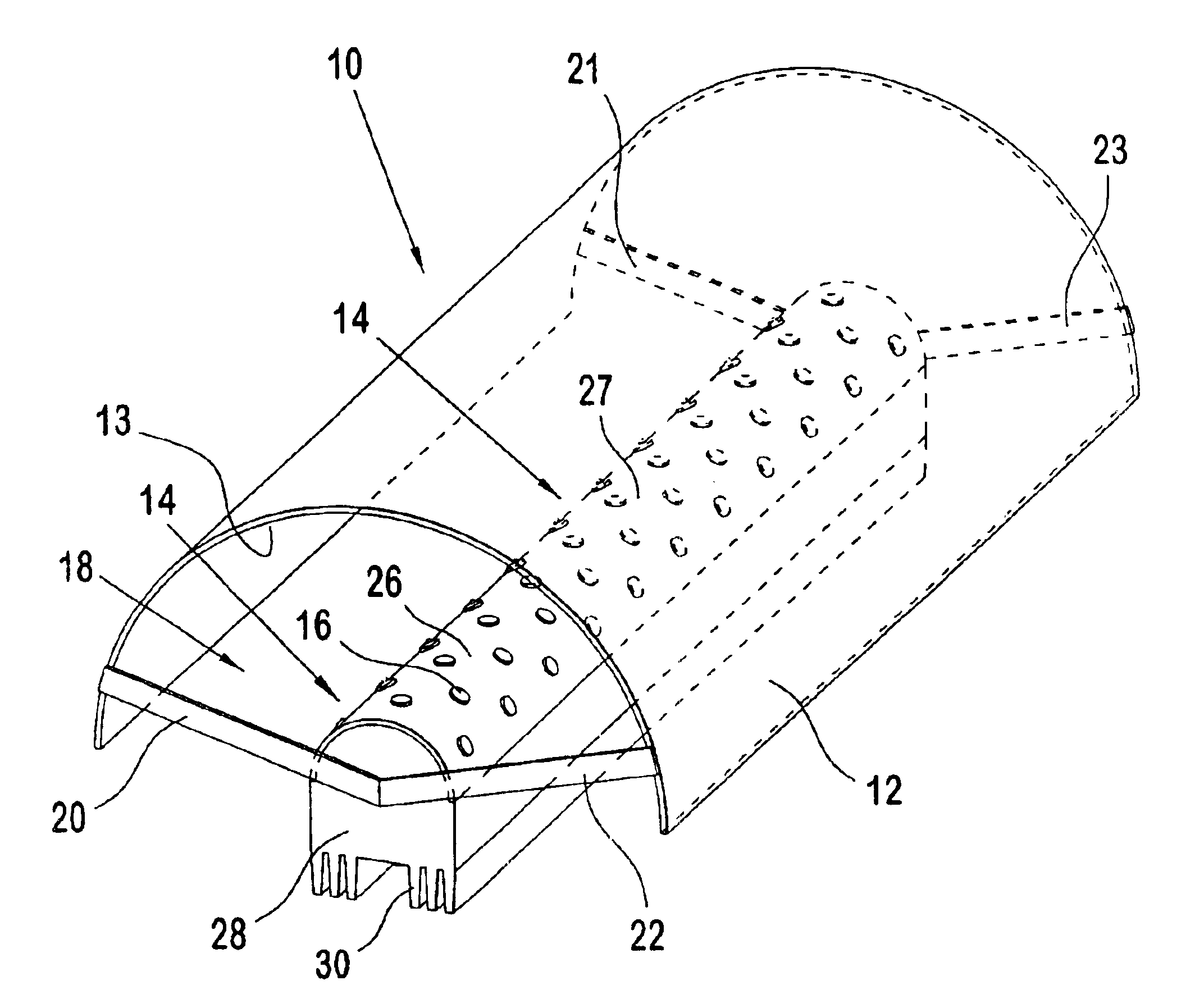

The present invention provides a linear lighting apparatus with improved heat dissipation and a method for improving the heat dissipation in a linear lighting apparatus. The apparatus includes a plurality of light emitting diodes, a plurality of primary optical assemblies and an apparatus housing. The primary optical assemblies are each in contact with one of the plurality of light emitting diodes. The primary optical assemblies and a second optical assembly are configured to refract the light so as to create a linear light source emanating from the apparatus. The apparatus housing is configured to dissipate thermal energy from the light emitting diodes.

Owner:IO LIGHTING

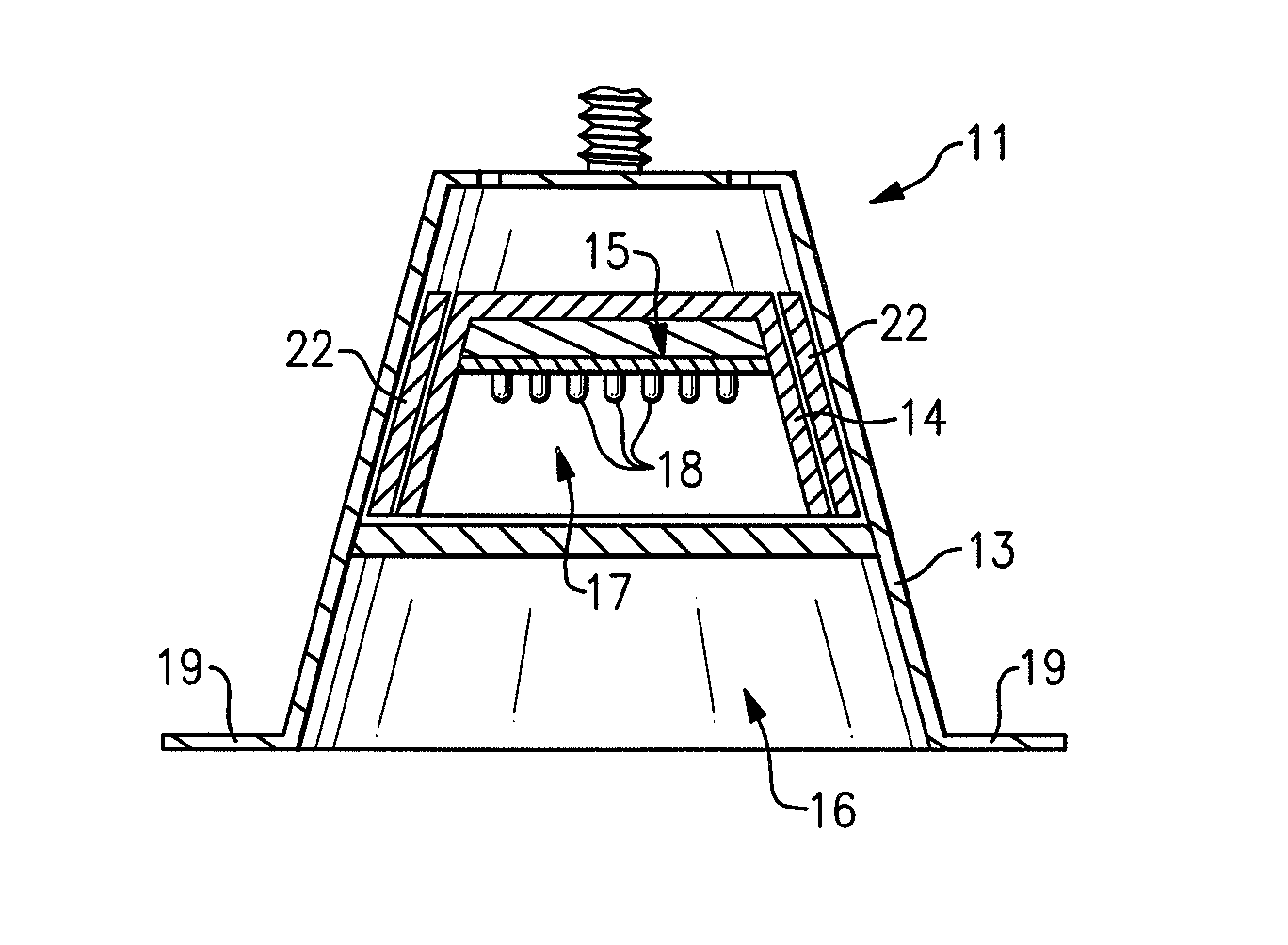

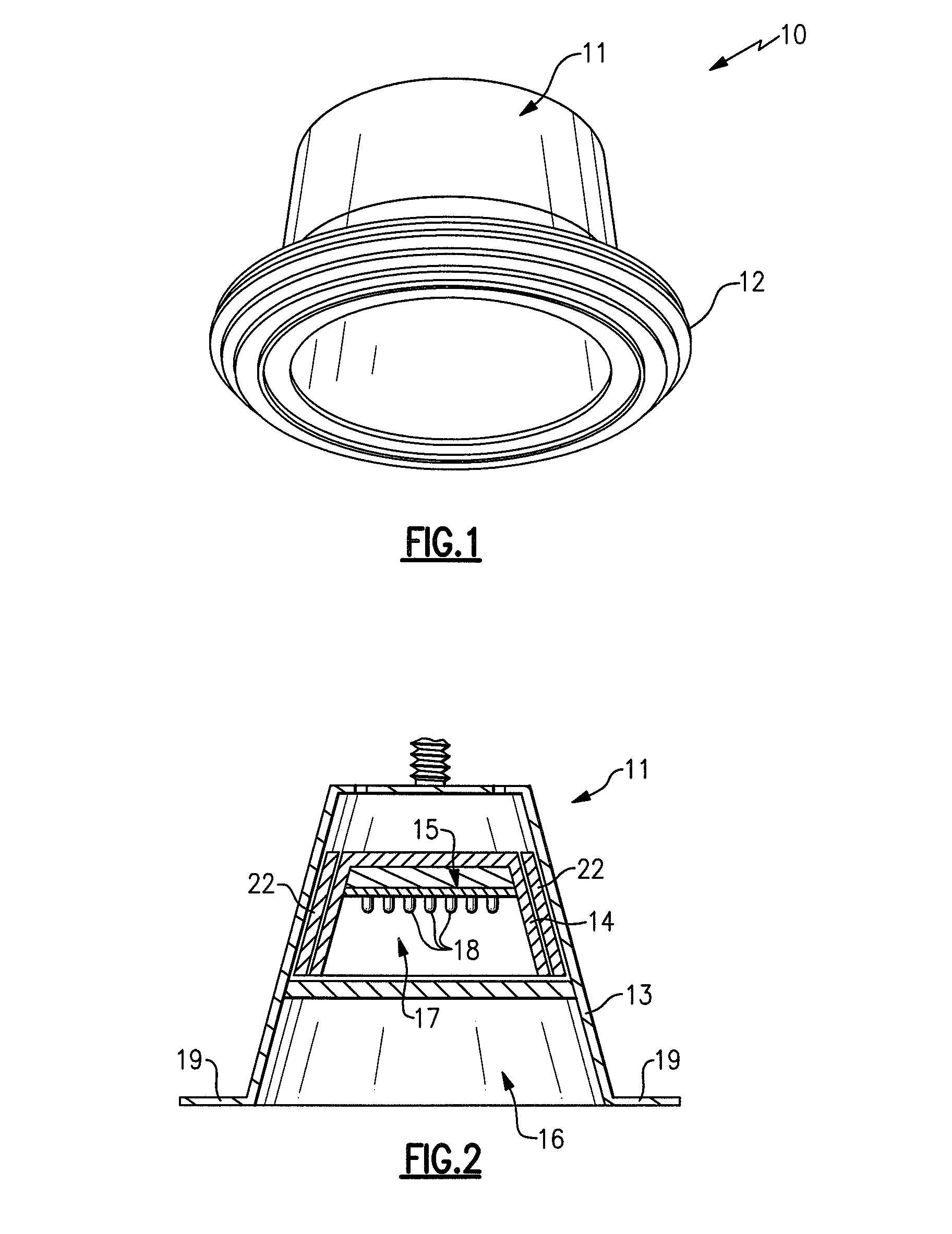

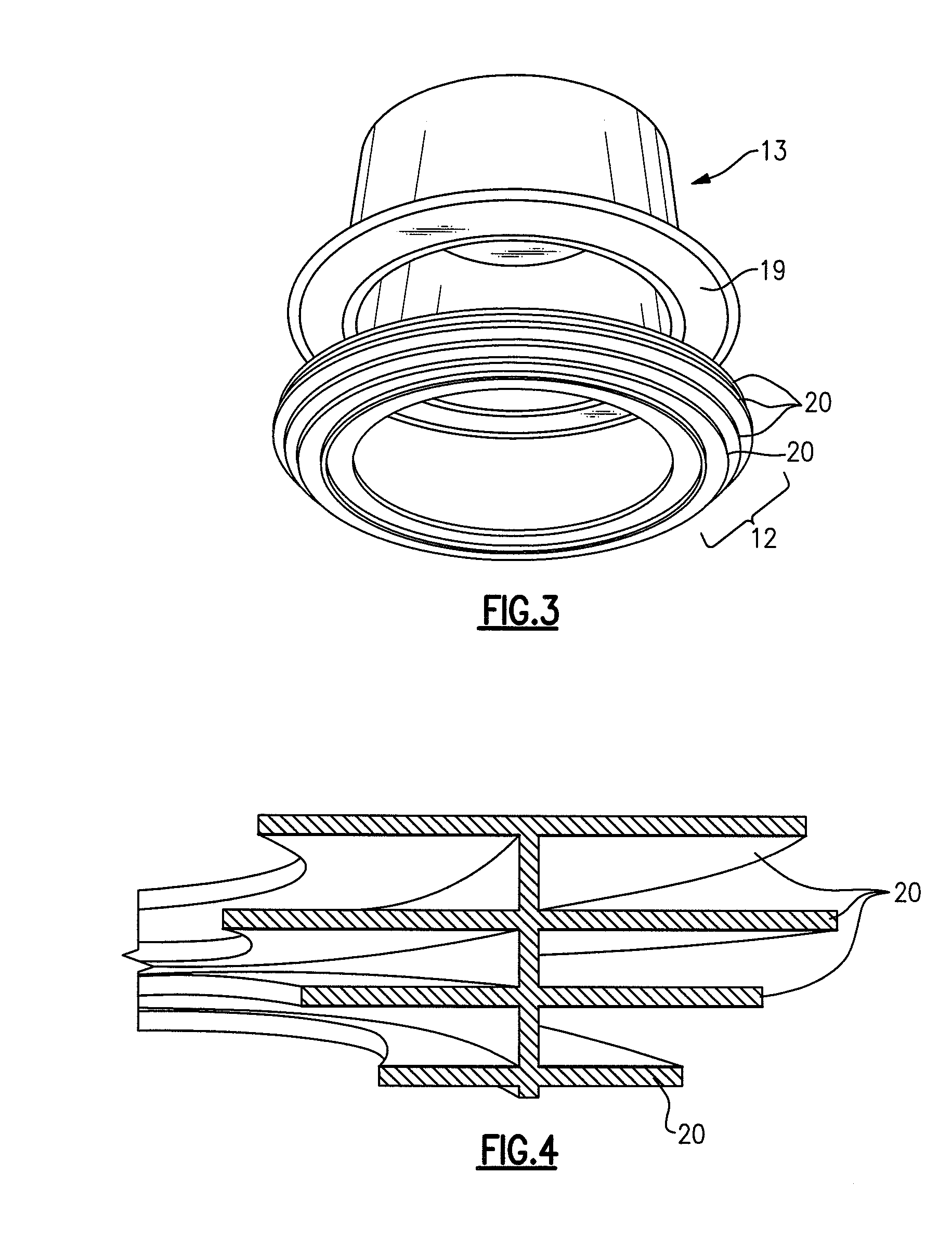

Lighting assemblies and components for lighting assemblies

ActiveUS20080112170A1Add additional massIncrease surface areaPlanar light sourcesMechanical apparatusInterior spaceEffect light

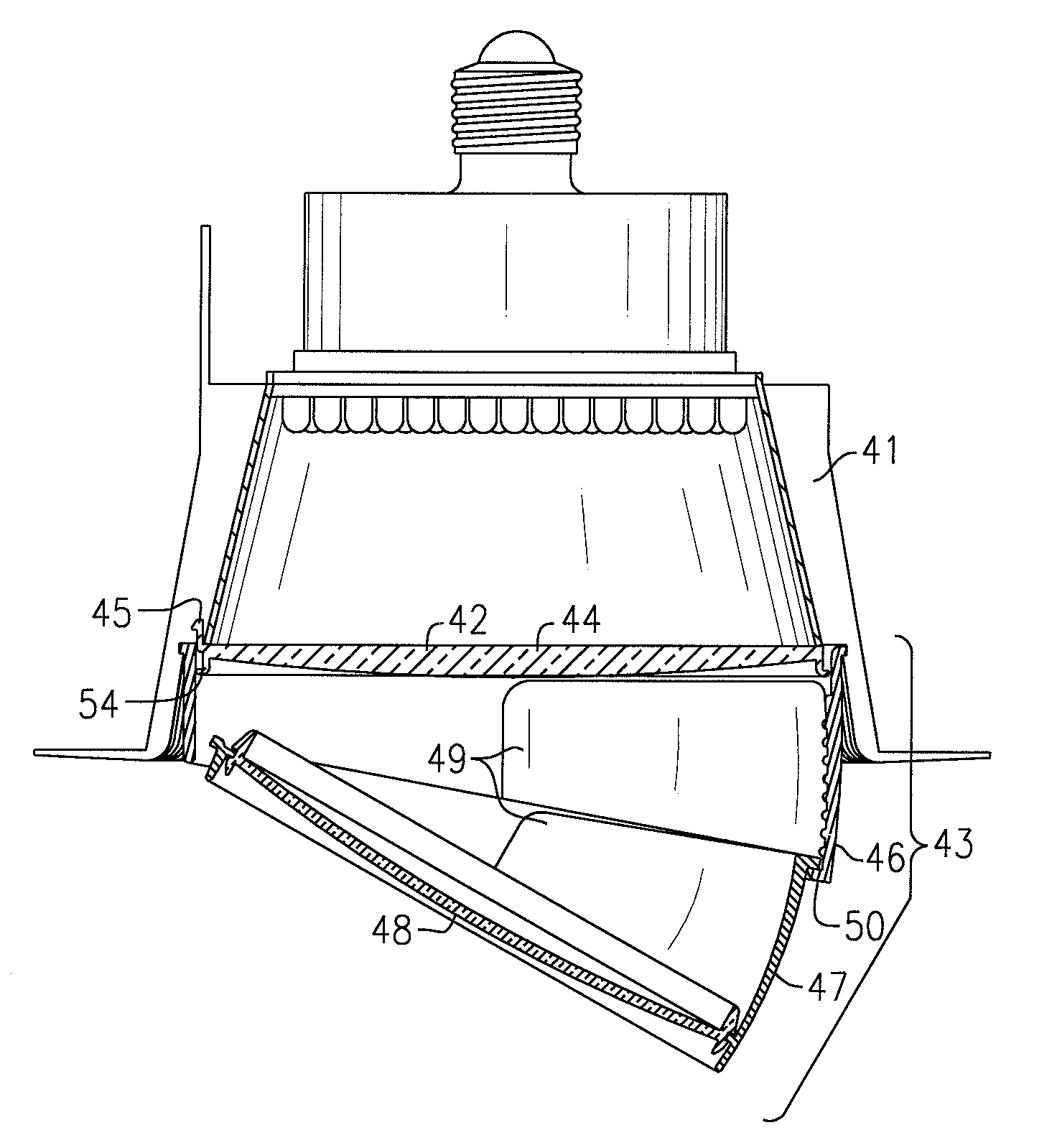

A lighting assembly, comprising a light engine assembly and a room-side element. The room-side element is in contact with the light engine assembly. The light engine assembly comprises at least one trim element and a light engine. The trim element defines a trim element internal space. The light engine comprises at least one solid state light emitter, and is positioned within the trim element internal space. Also, a lighting assembly, comprising a light engine assembly and means for dissipating heat from the light engine assembly.

Owner:IDEAL IND LIGHTING LLC

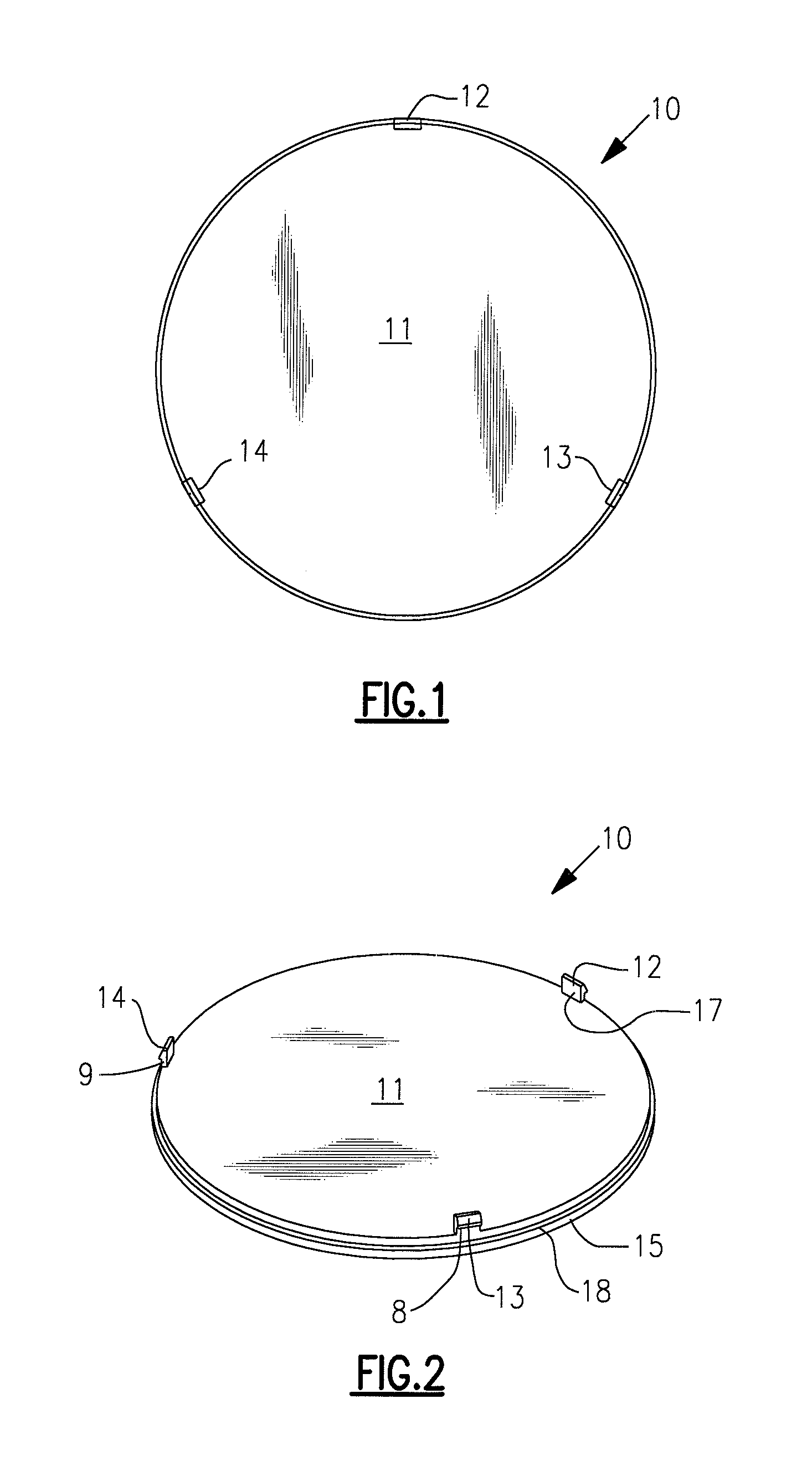

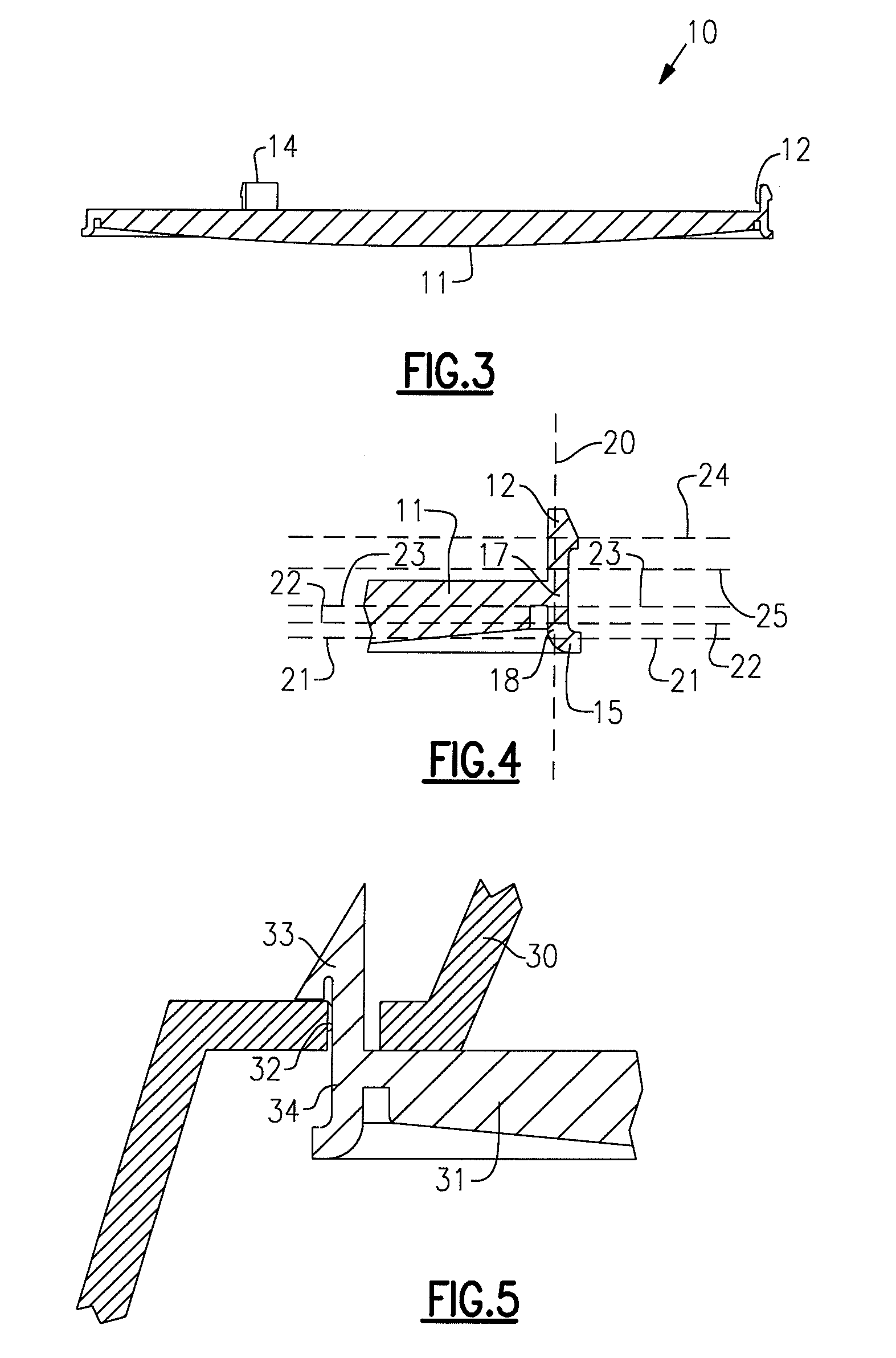

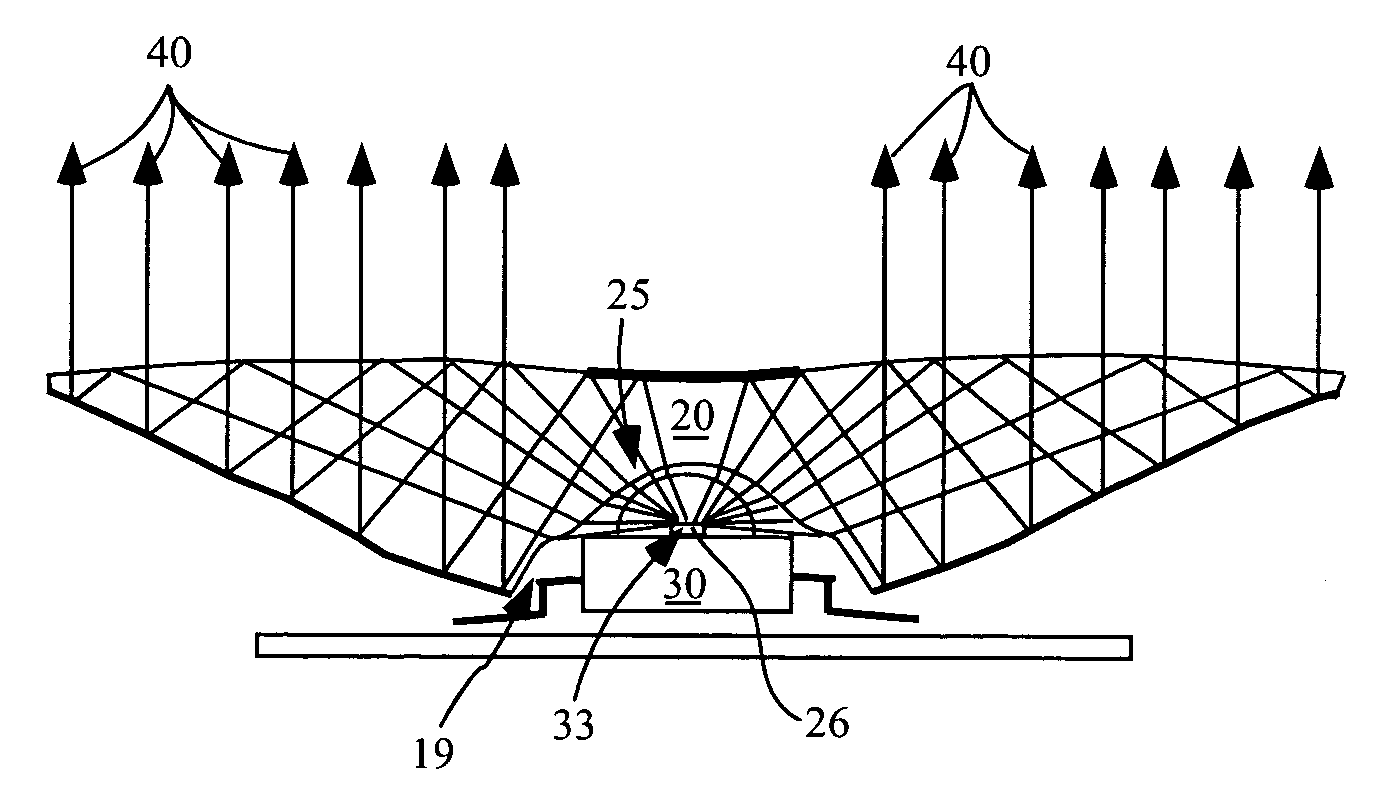

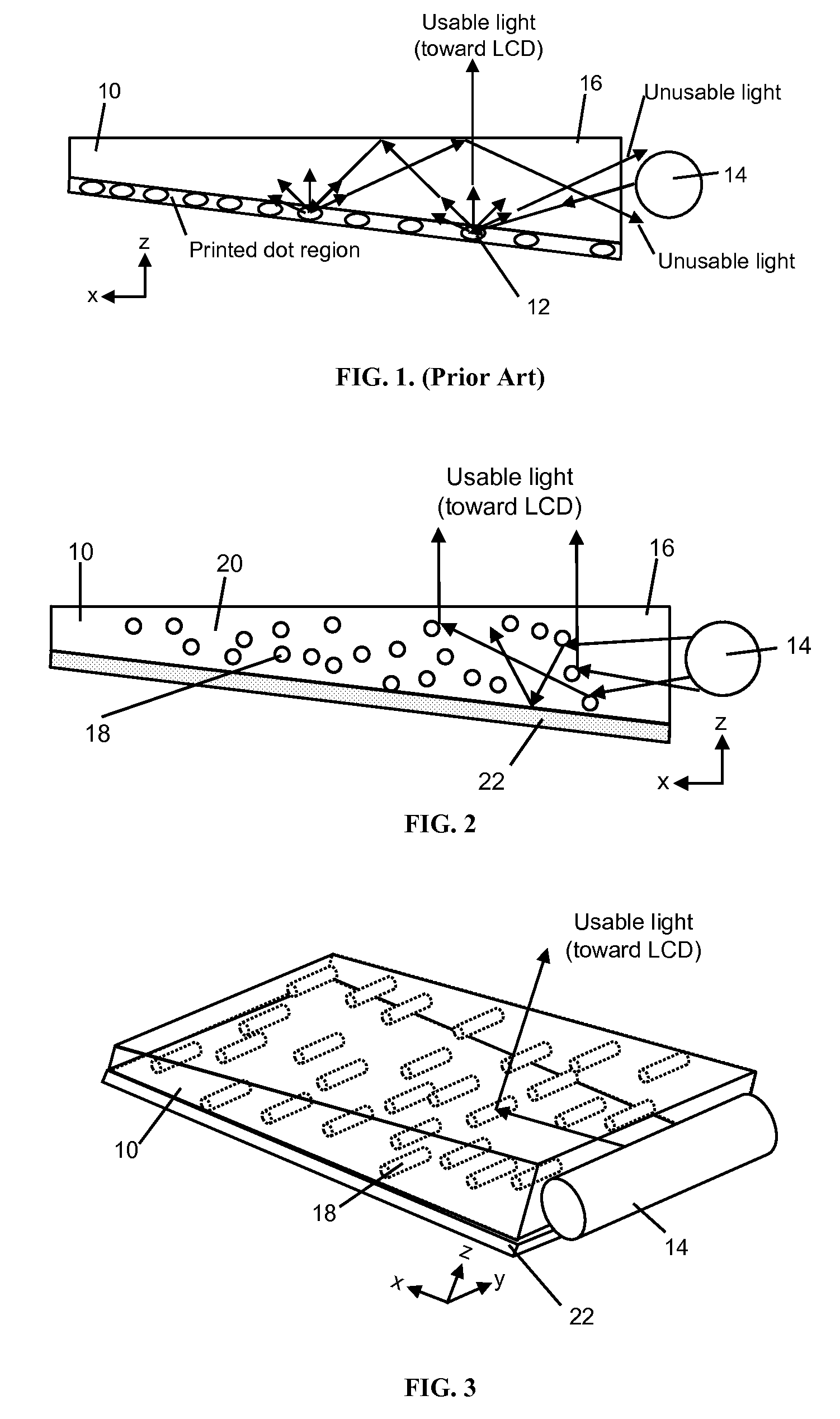

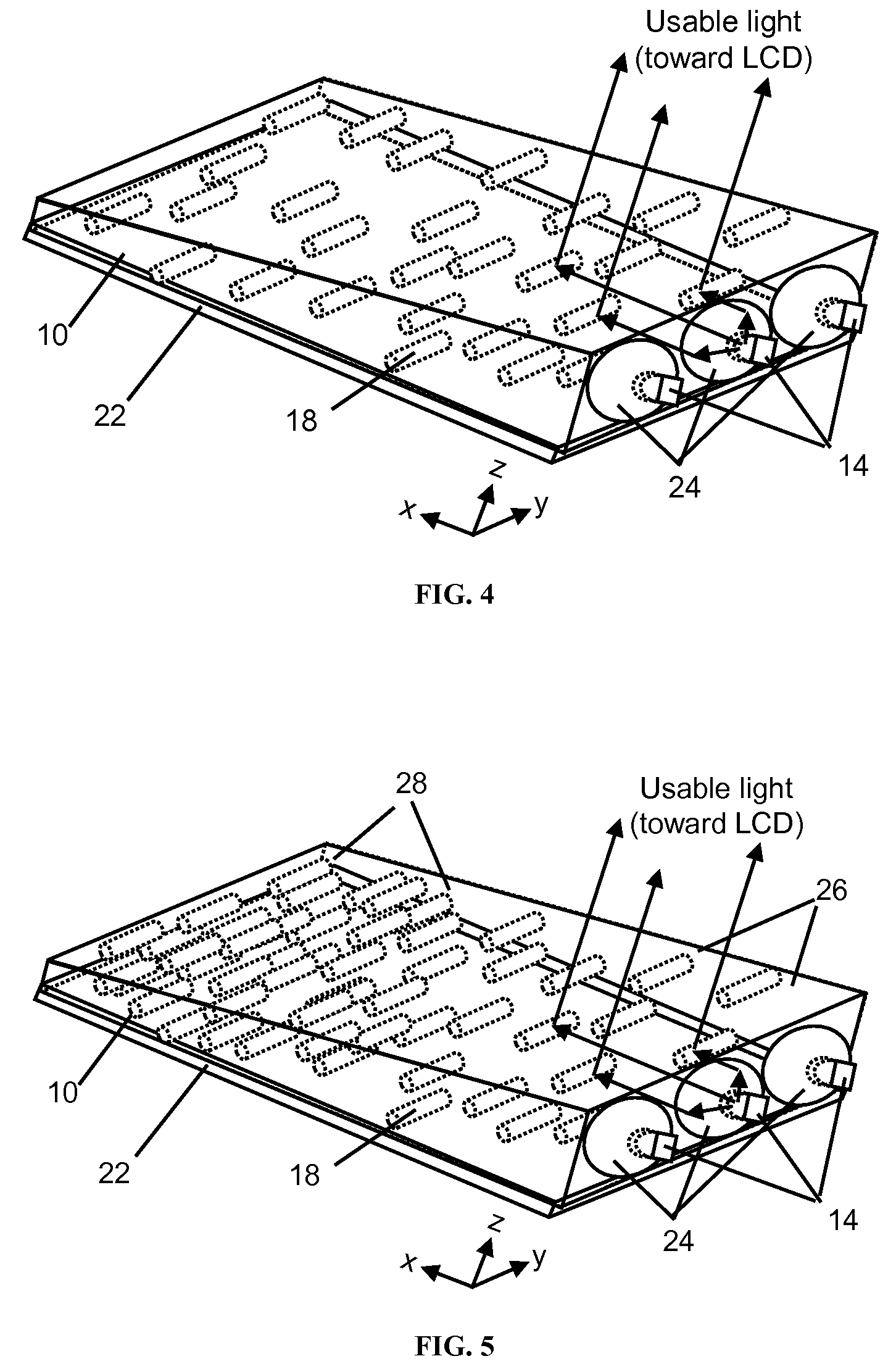

Led array systems

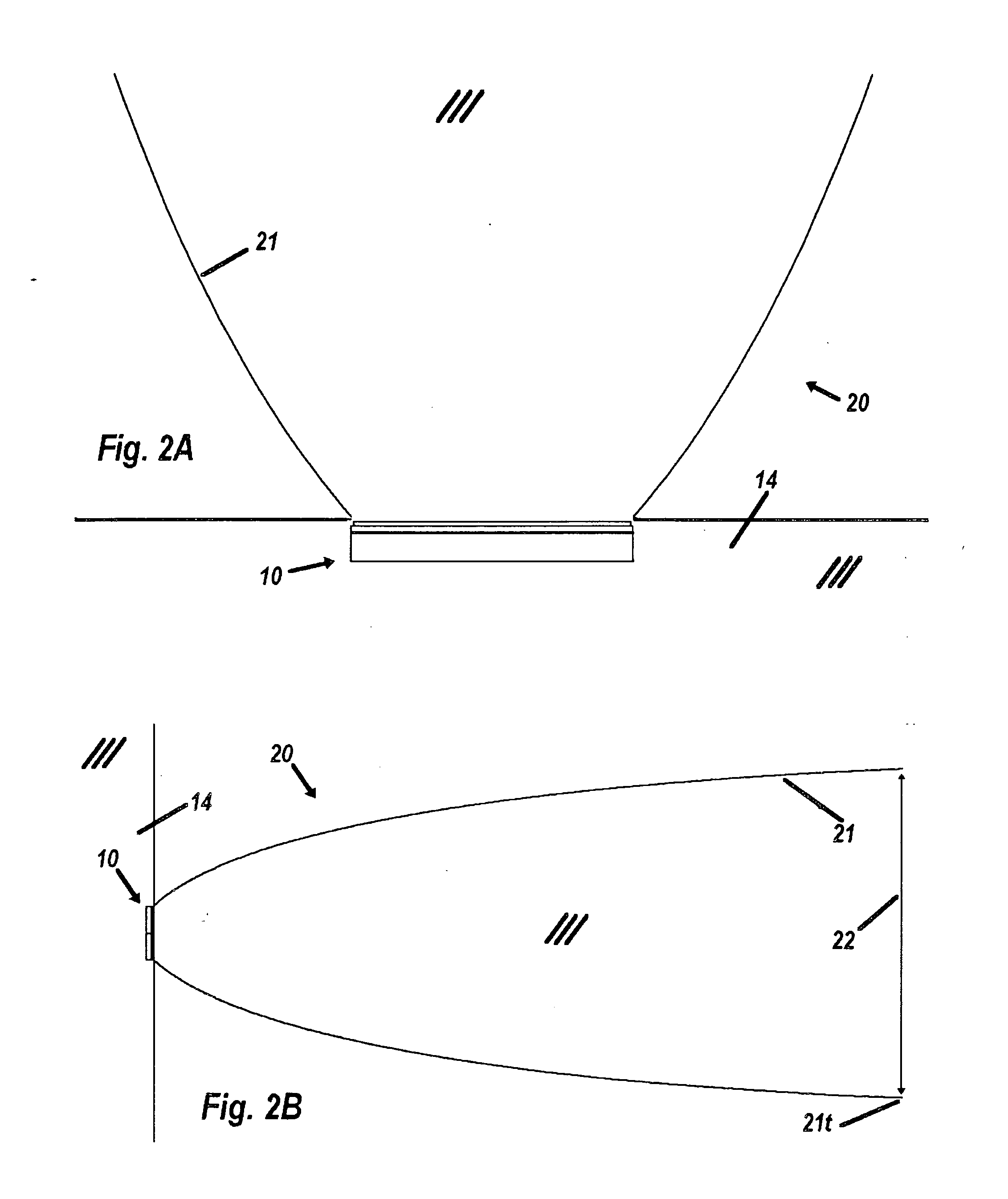

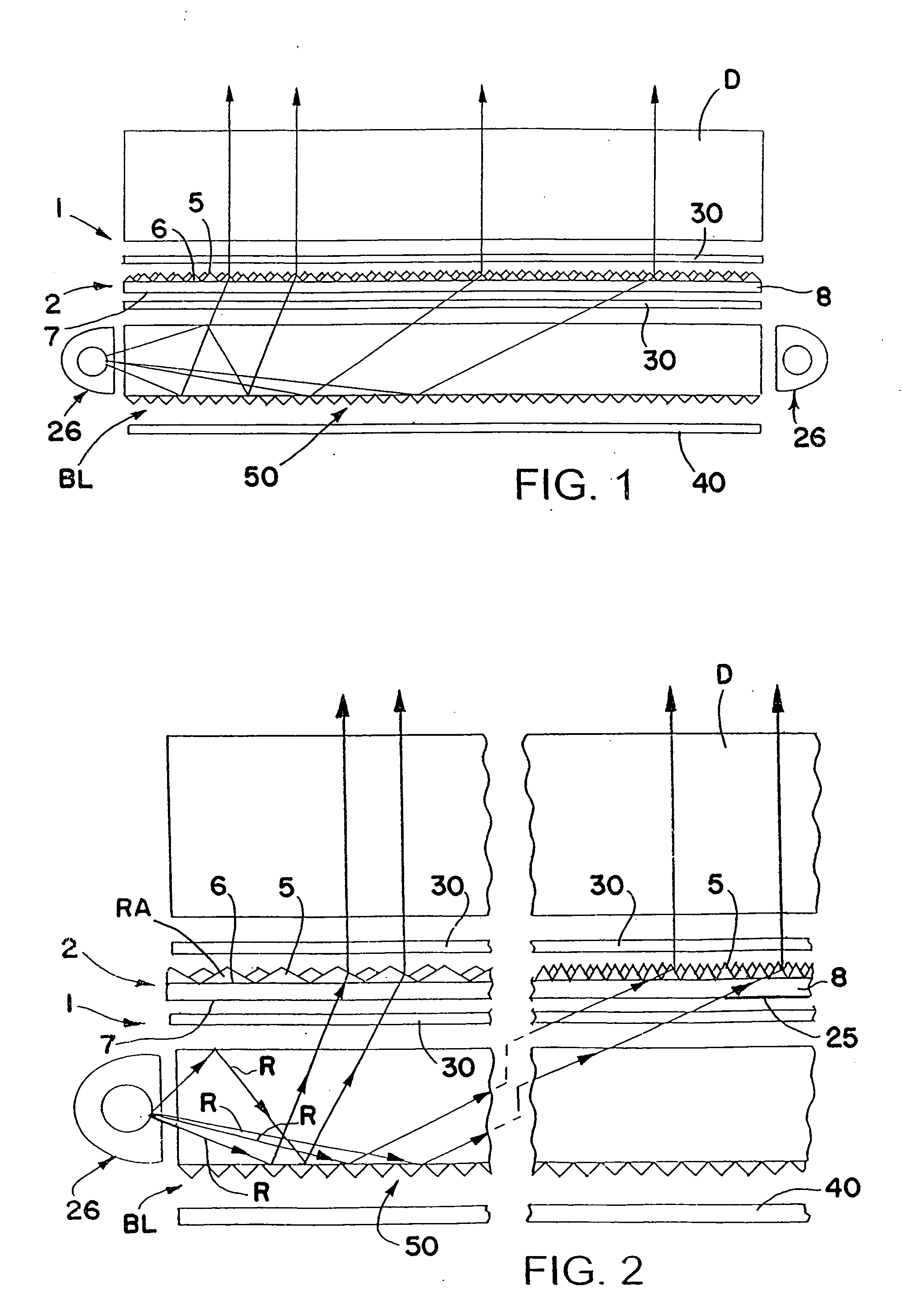

A light emitting diode (LED) array comprises an array of LEDs mounted to a substrate. The LEDs emit light in a direction generally perpendicular to the substrate. An optical sheet is disposed over the LEDs. At least a portion of light entering one side of the optical sheet from the LEDs is guided within the optical sheet in a direction generally parallel to the substrate. Light extraction features direct light from the optical sheet in a generally forward direction. Such an array is useful for several applications, including space lighting, direct information display and backlighting of liquid crystal displays. The light spreading effect of the optical sheet reduces the amount of black space between LED pixels.

Owner:3M INNOVATIVE PROPERTIES CO

D-shaped cross section l.e.d. based light

InactiveUS20100220469A1Launch evenlyNon-electric lightingLighting support devicesElectrical connectorBoard structure

A LED-based replacement light for a fluorescent socket is constructed such that a tubular housing has a D-shaped cross section with a flat base with opposing longitudinal edges, opposing sides extending generally perpendicular to the flat base from the opposing longitudinal edges, and a curved surface spanning the opposing sides opposite the flat base. A circuit board structure defines a LED-mounting side with multiple LEDs mounted on the LED-mounting side at predetermined intervals along a length of the circuit board, with at least areas of a primary heat transferring side directly underlying the respective LEDs in thermally conductive relation with the tubular housing for highly electrically insulated thermal transmission of heat generated by the multiple LEDs from the circuit board to an ambient environment surrounding an exterior of the tubular housing. At least one electrical connector is at a longitudinal end of the housing in electrical communication with the circuit board.

Owner:ILUMISYS

High efficiency solid-state light source and methods of use and manufacture

ActiveUS20050152146A1Eliminate needImprove light outputOptical radiation measurementPoint-like light sourceDevice materialFluorescence

A high-intensity light source is formed by a micro array of a semiconductor light source such as a LEDs, laser diodes, or VCSEL placed densely on a liquid or gas cooled thermally conductive substrate. The semiconductor devices are typically attached by a joining process to electrically conductive patterns on the substrate, and driven by a microprocessor controlled power supply. An optic element is placed over the micro array to achieve improved directionality, intensity, and / or spectral purity of the output beam. The light module may be used for such processes as, for example, fluorescence, inspection and measurement, photopolymerzation, ionization, sterilization, debris removal, and other photochemical processes.

Owner:SILICON VALLEY BANK

Light fixtures, lighting devices, and components for the same

ActiveUS20080137347A1Easy to removeGood adhesionPoint-like light sourceProtective devices for lightingLight equipmentEffect light

A diffuser for a lighting device comprises a diffuser region, a hook element and a nose element. A light fixture comprises a housing with an opening and a diffuser as described above, in which the nose element extends through the opening, optionally further comprising an accessory including at least one spring element engaging the hook element. A light fixture structure comprises a housing defining an opening and an first attachment element comprising a nose element, a hook element and a connection region, and optionally further comprising a diffuser engaging a first portion of the hook element, and / or an accessory which engages a second portion of the hook element. An eyeball accessory comprises first and second housing elements pivotably attached to each other. An accessory for a light fixture comprises a housing member and a spring element engageable with a fixture.

Owner:IDEAL IND LIGHTING LLC

Compact folded-optics illumination lens

The present embodiments provide for apparatuses, and methods for manufacturing apparatuses to convert a first distribution of an input radiation to a second distribution of output radiation. The apparatus can be defined in some embodiments by generating a two-dimensional representation of three active optical surfaces including calculating a segment of first, entry and second surfaces based on first second, and third generalized Cartesian ovals, respectively, and successively repeating the calculating of the segments of the first and second surfaces, and rotationally sweeping the two-dimensional representation about a central axis providing a three-dimensional representation. In some embodiments, portion of the first and / or second surfaces can be totally internally reflective.

Owner:LIGHT ENGINE

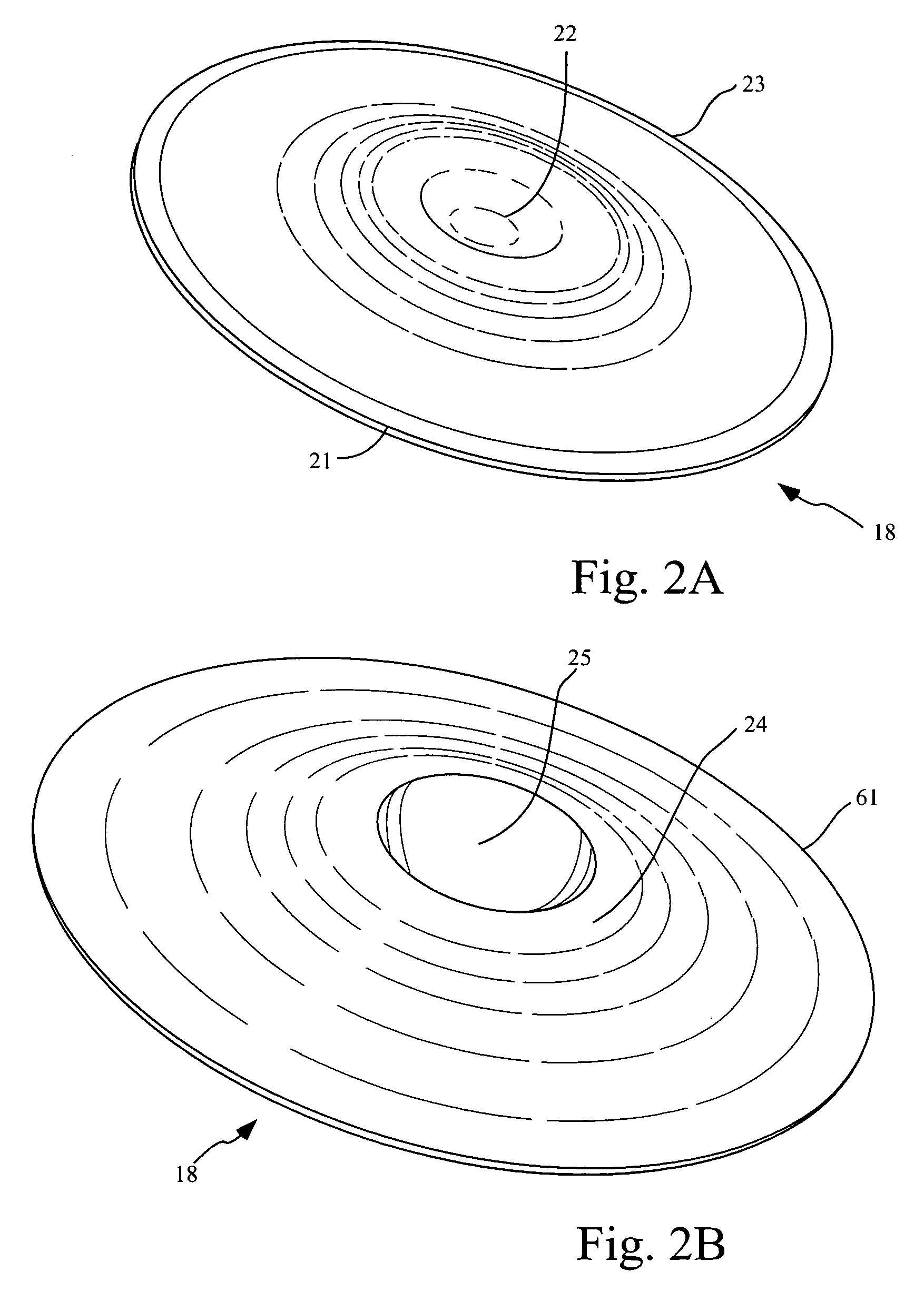

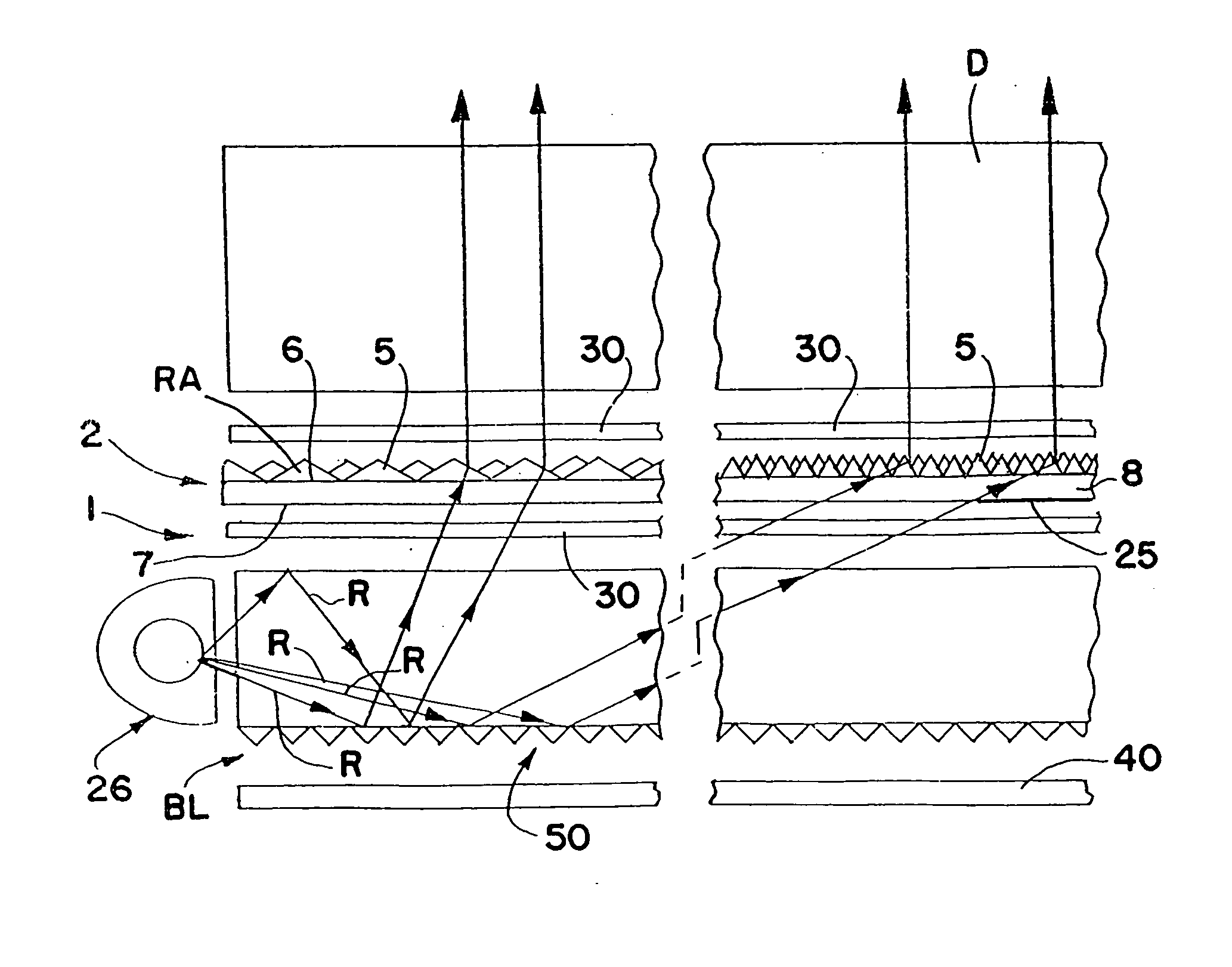

Lightguide comprising a low refractive index region

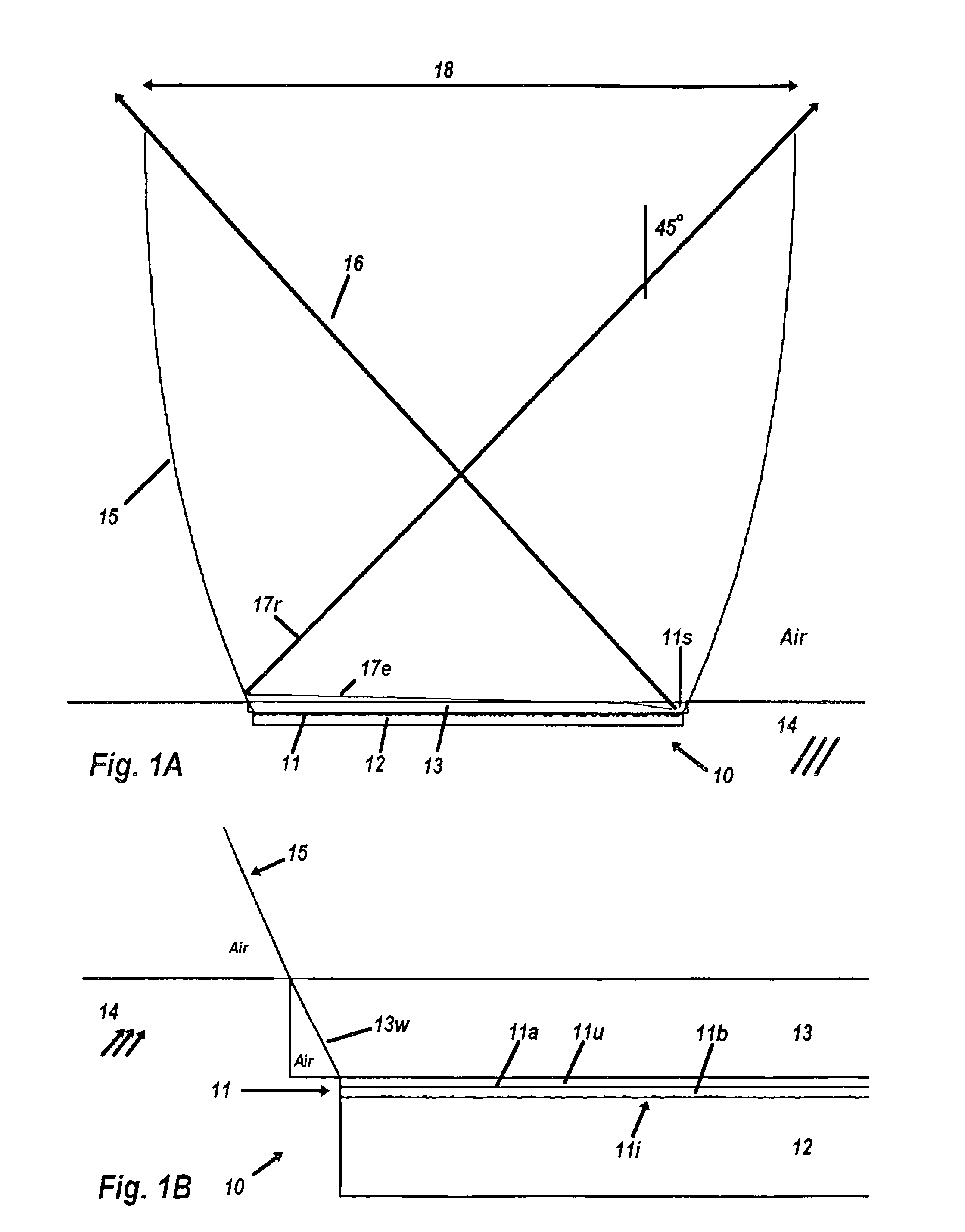

InactiveUS8033706B1Improve angular luminous intensityLight guides detailsOptical light guidesDirect illuminationLuminous intensity

In one embodiment of this invention, a lightguide comprises a low refractive index region disposed between light extracting region and a non-scattering region. In further embodiment of this invention, volumetric scattering lightguide comprises a low refractive index region disposed between a volumetric scattering region and a non-scattering region. In some embodiments, a light emitting device comprising a volumetric scattering lightguide can angularly filter light input into the edge of a volumetric scattering lightguide by controlling the refractive index of the low refractive index region relative to the refractive index of the non-scattering region to prevent direct illumination of the volumetric scattering region, provide a luminance uniformity greater than 70%, or improve the angular luminous intensity of the light emitting device. The volumetric scattering lightguide may be curved, tapered, and a light emitting device comprising the same may further comprise at least one light source and a light redirecting element.

Owner:MASSACHUSETTS DEV FINANCE AGENCY +1

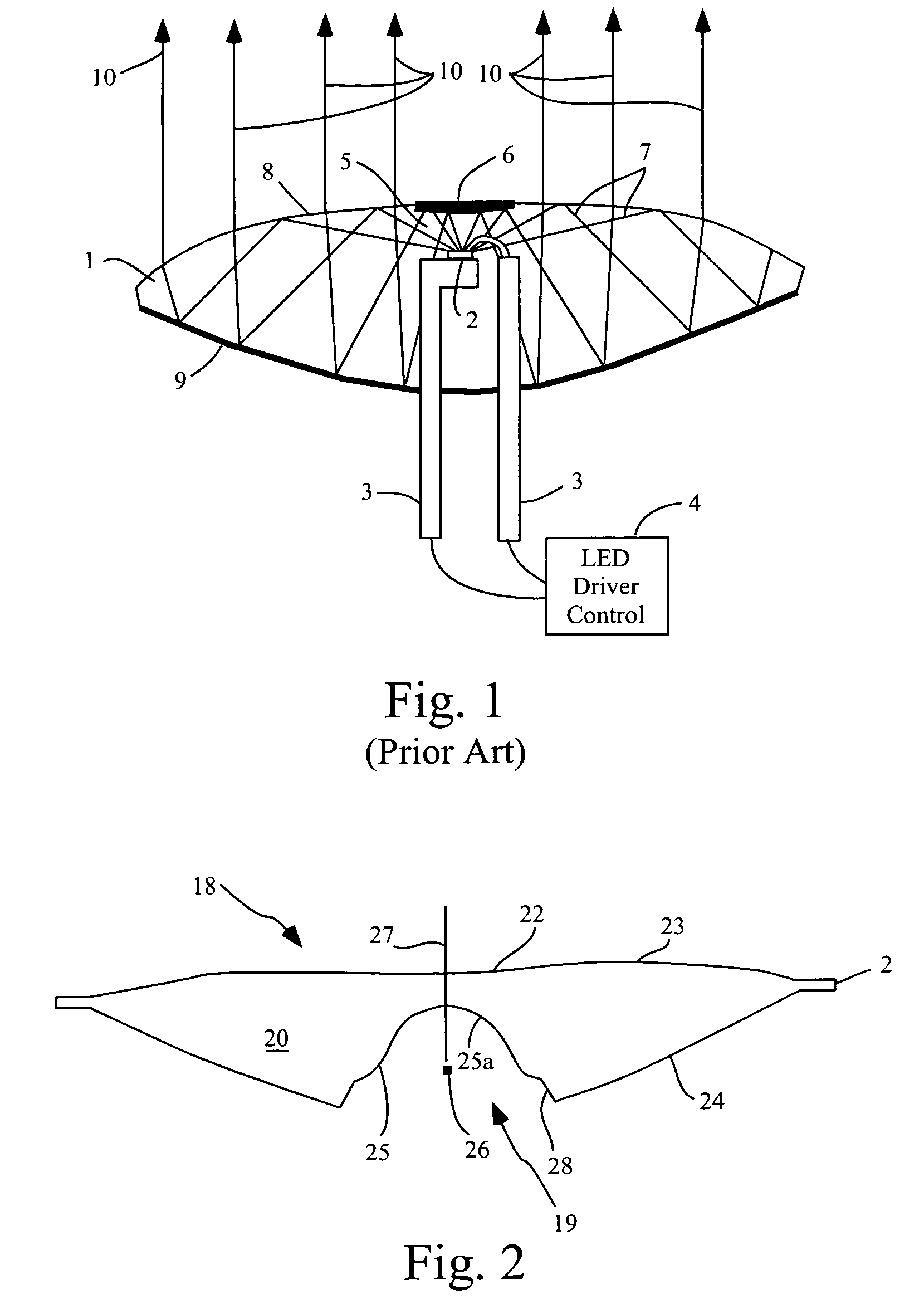

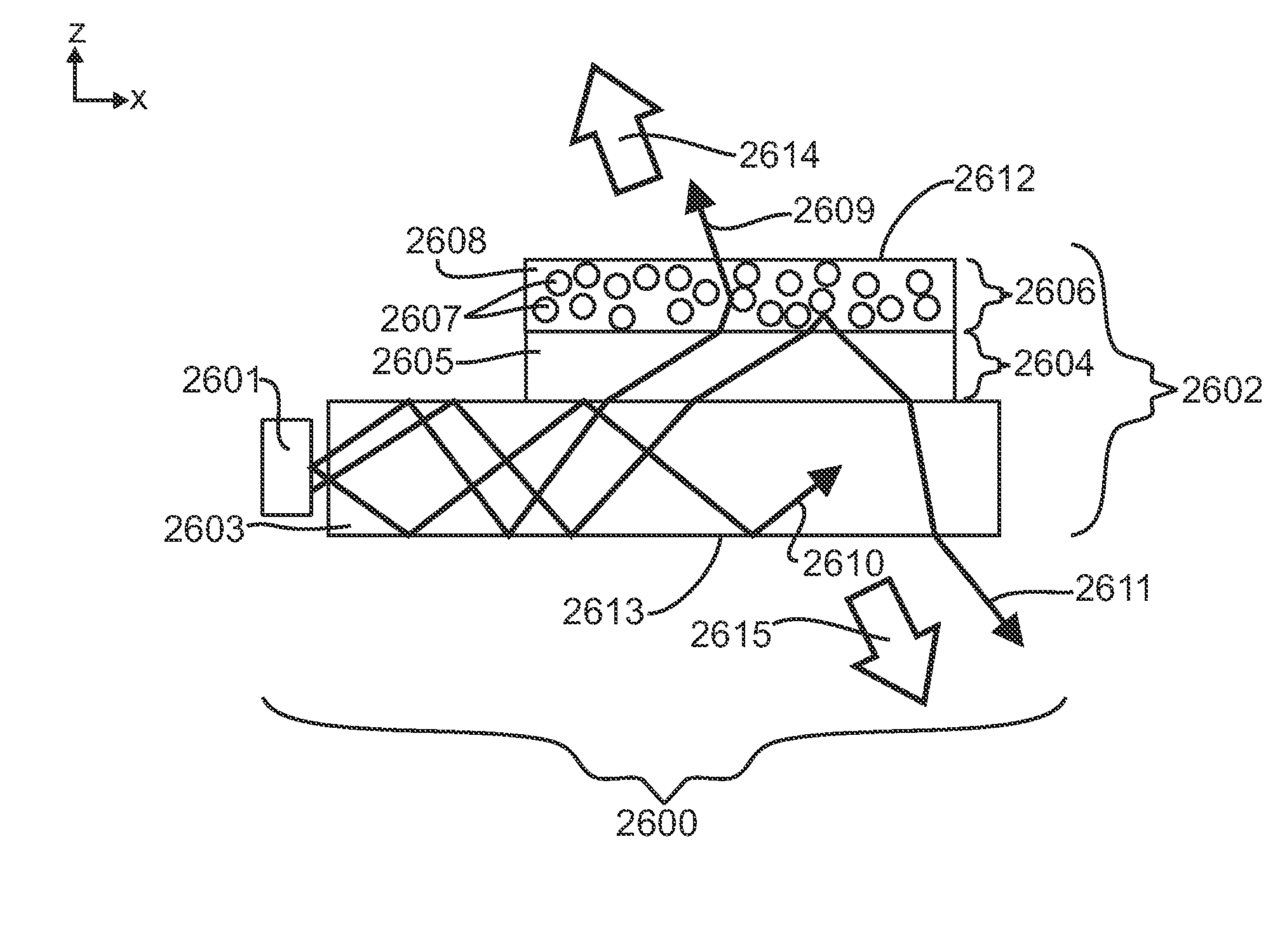

Optical manifold for light-emitting diodes

ActiveUS20050243570A1Cost-effectiveImprove throughputMechanical apparatusPoint-like light sourcePhotoluminescencePhosphor

An optical manifold for efficiently combining a plurality of LED outputs into a single, substantially homogeneous output, in a small, cost-effective package. The optical manifolds can be used to combine multiple LEDs of the same color and provide a high intensity output aperture with very high uniformity and sharp borders, or they can be used to generate a multiwavelength output, such as red, green, and blue LEDs that are combined to generate white light. Embodiments are also disclosed that use a single or multiple LEDs and a remote phosphor and an intermediate wavelength-selective filter arranged so that backscattered photoluminescence is recycled to boost the luminance and flux of the output aperture. The optical manifolds are designed to alleviate substantial luminance inhomogeneities inherent to LEDs. The optical manifold utilizes principles of non-imaging optics to transform light and provide directed, substantially uniform light sources.

Owner:SEOUL SEMICONDUCTOR

Optical transmission tube and applications thereof

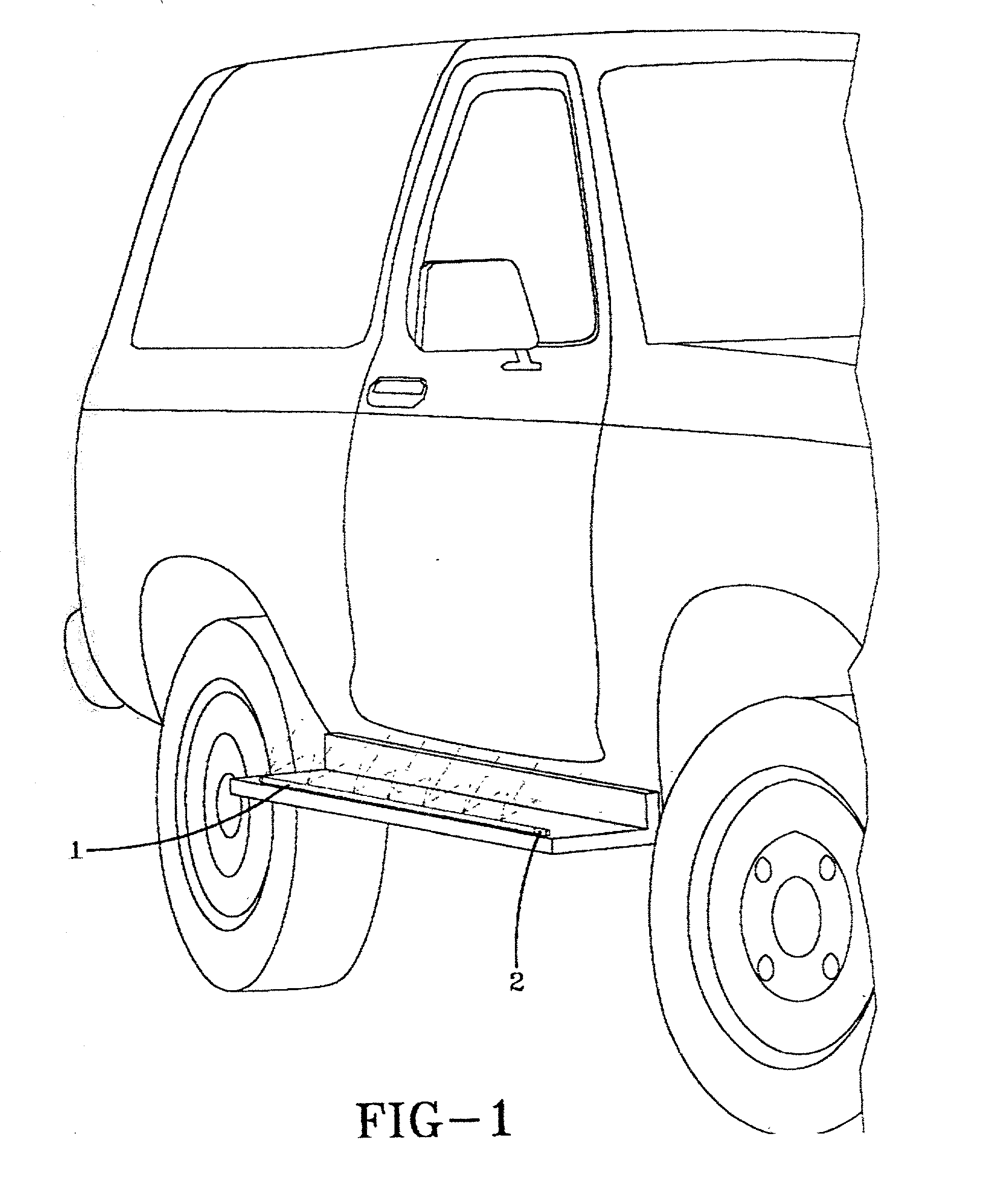

InactiveUS20020159741A1Minimize energyUse minimizedMechanical apparatusPoint-like light sourceEngineeringFlashlight

An optical transmission tube for illumination is uniquely incorporated into any one of a variety of automotive, commercial, retail, structural, architectural, safety, or other products including running boards, vehicle interior compartments such as a glove box, approximate the license plate attachment area on a vehicle, a trunk, a vehicle hood, on a vehicle door, a vehicle bumper, a vehicle luggage rack, a picture frame, a flashlight, a building, a guard rail, a construction barrier, a bicycle, a sign, an appliance interior compartment such as a refrigerator, a part bin, a retail display shelf, a clipboard, a step, a tractor trailer, a desk, a walkway, a room or storage chamber, a runway, an instrument panel, a railroad crossing gate, an emergency sign, an elevator doorway, a swimming pool, a dog collar, a fish tank, a baby crib a hand rail, an inline skate an island in a parking lot or on a street, affixed to a curb, or on safety clothing.

Owner:BRIDGESTONE CORP

Uniform illumination system

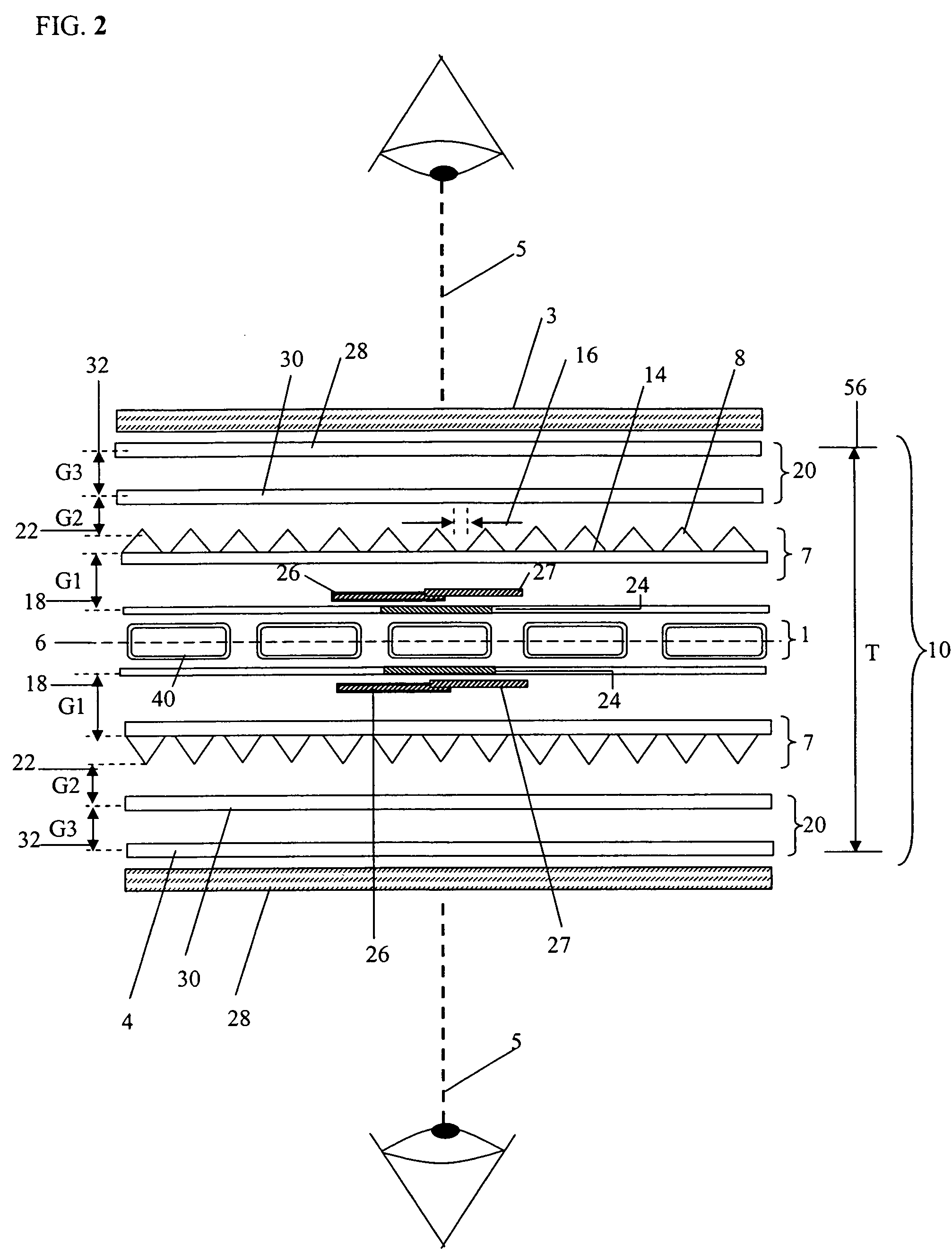

A compact and efficient optical illumination system featuring planar multi-layered LED light source arrays concentrating their polarized or un-polarized output within a limited angular range. The optical system manipulates light emitted by a planar light emitters such as electrically-interconnected LED chips. Each light emitting region in the array is surrounded by reflecting sidewalls whose output is processed by elevated prismatic films, polarization converting films, or both. The optical interaction between light emitters, reflecting sidewalls, and the elevated prismatic films create overlapping virtual images between emitting regions that contribute to the greater optical uniformity. Practical illumination applications of such uniform light source arrays include compact LCD or DMD video image projectors, as well as general lighting, automotive lighting, and LCD backlighting.

Owner:SNAPTRACK

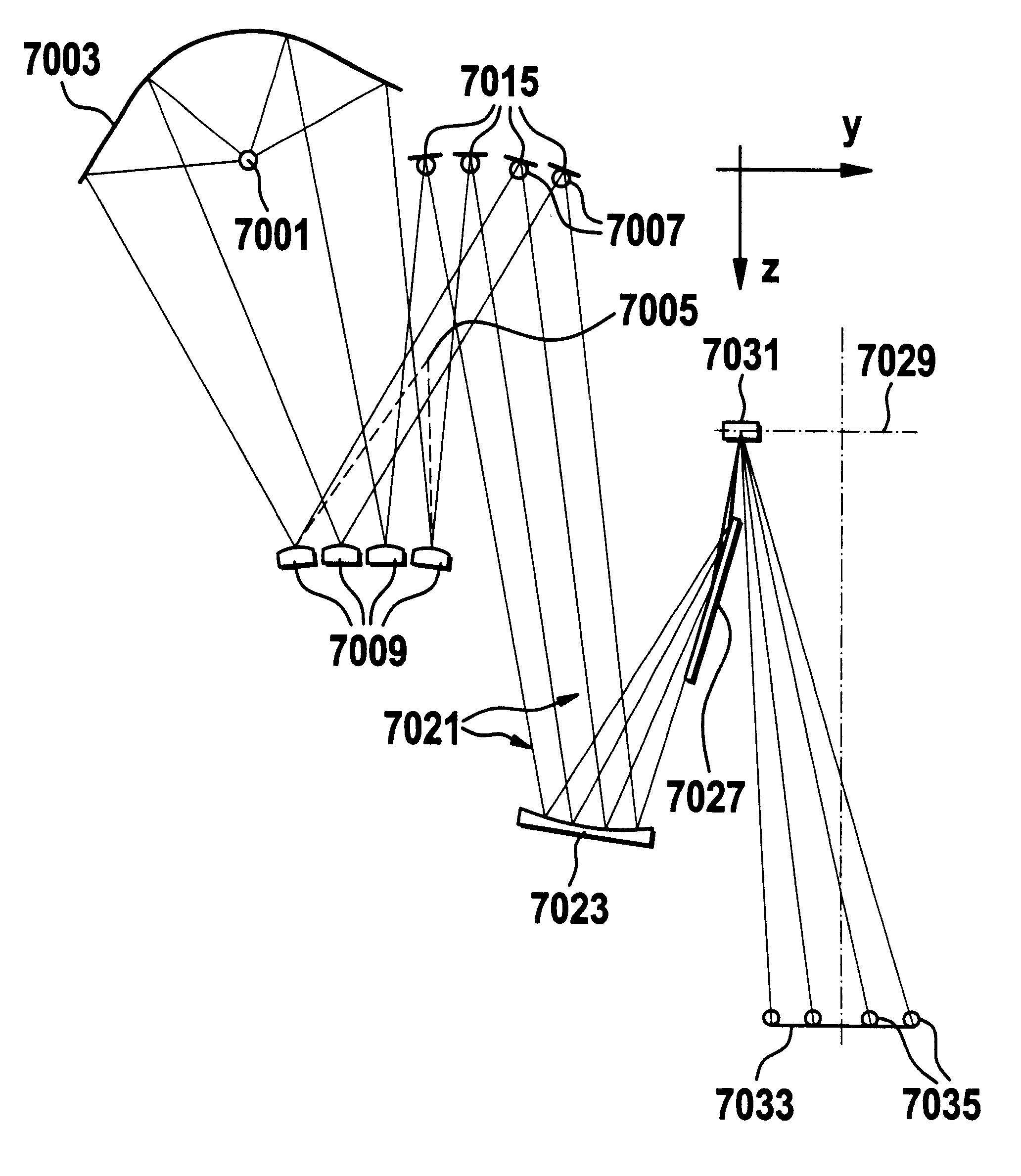

Illumination system particularly for EUV lithography

InactiveUS6198793B1Etendu can be effectively increasedAvoid blurringsNanoinformaticsHandling using diffraction/refraction/reflectionCamera lensGrating

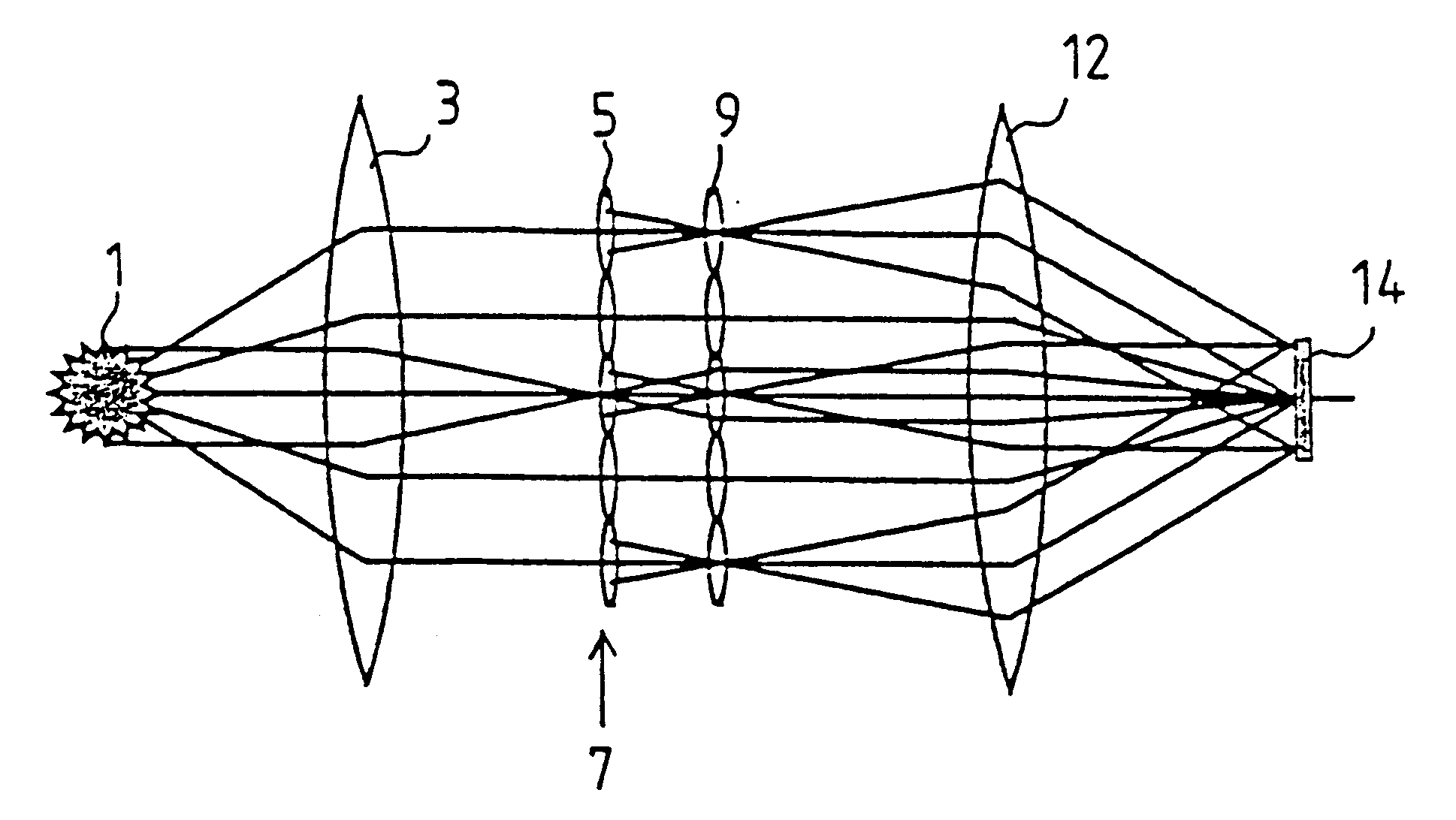

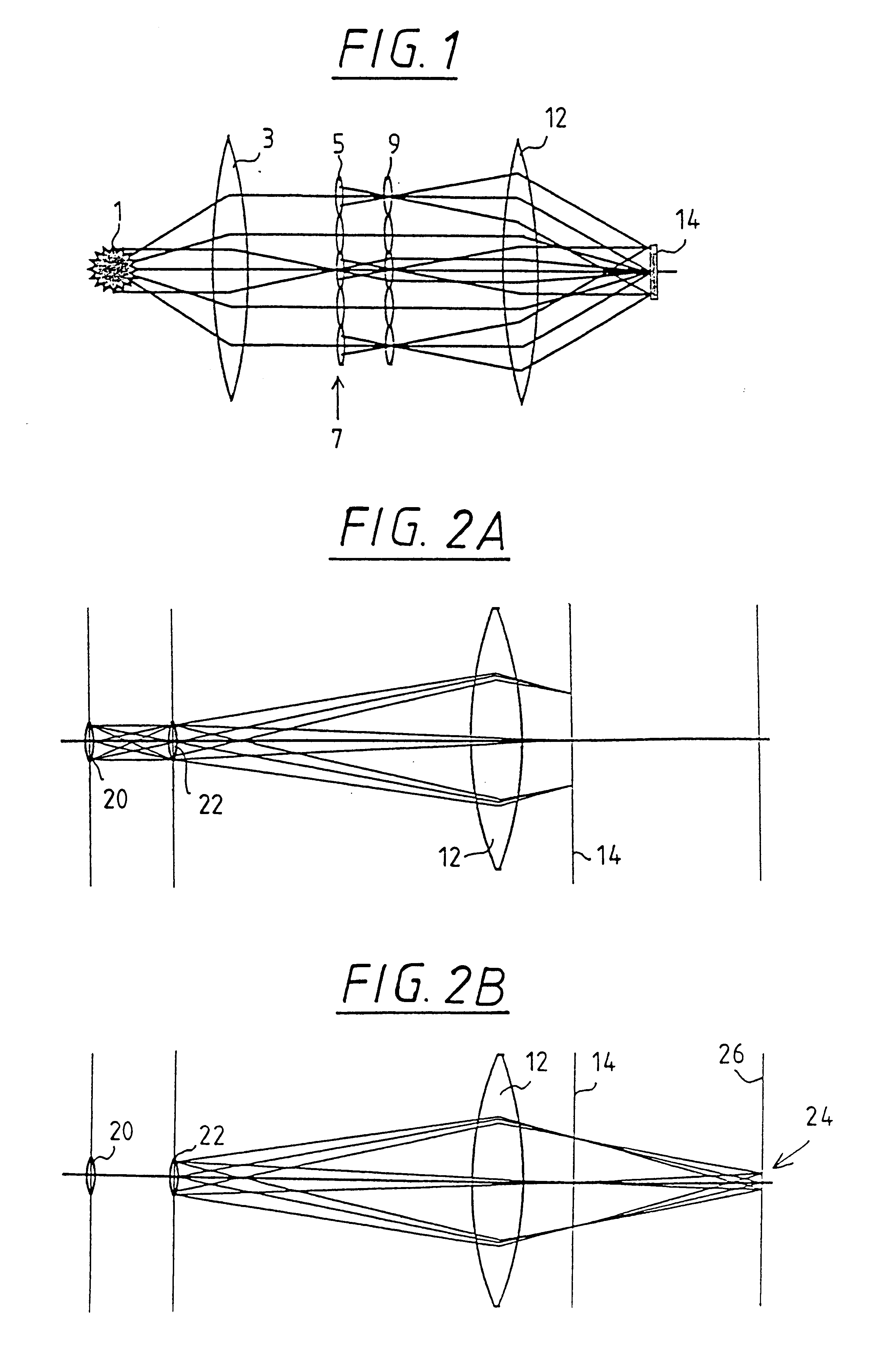

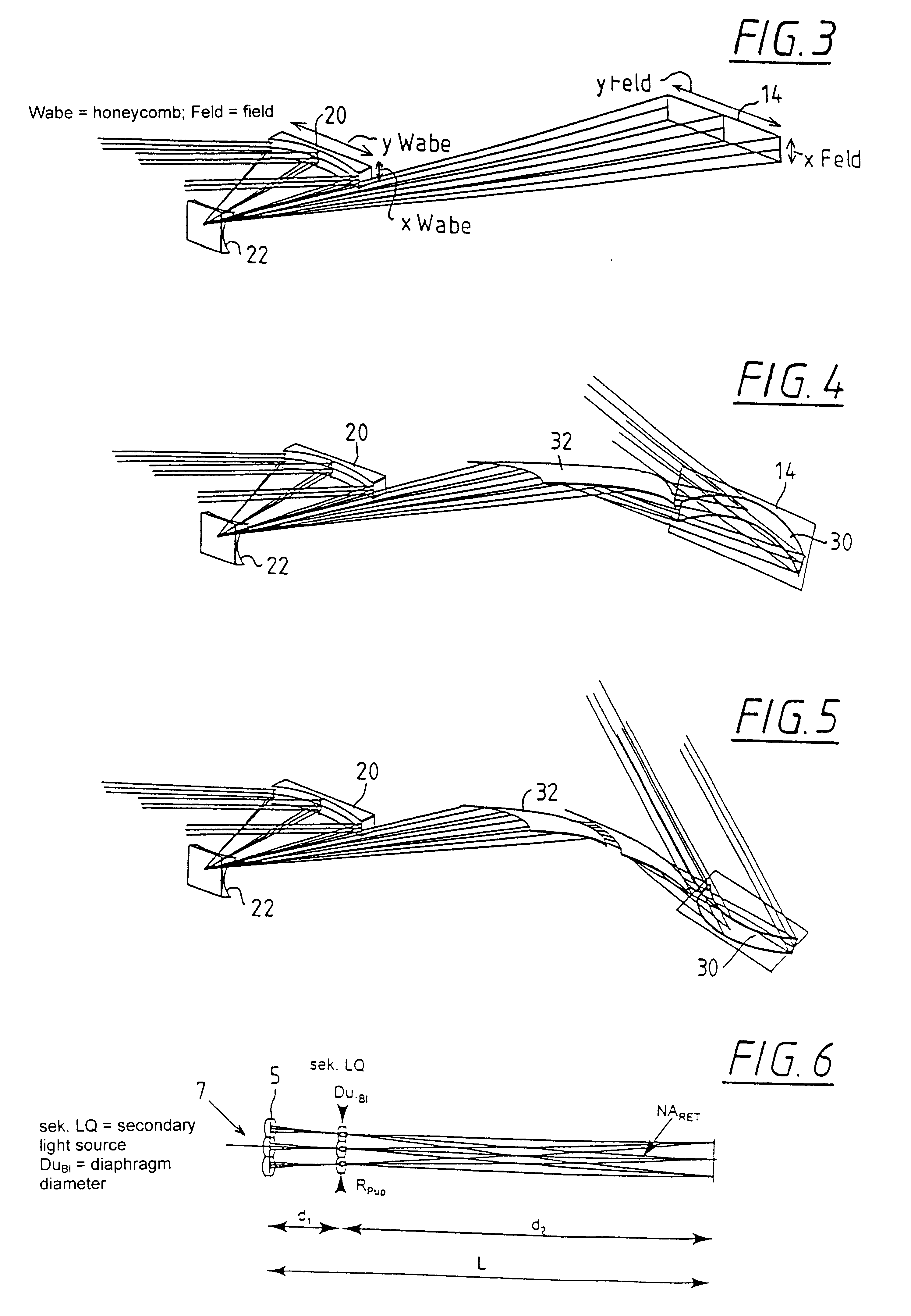

The invention concerns an illumination system for wavelengths <=193 nm, particularly for EUV lithography, with at least one light source, which has an illumination A in a predetermined surface; at least one device for producing secondary light sources; at least one mirror or lens device comprising at least one mirror or one lens, which is or are organized into raster elements; one or more optical elements, which are arranged between the mirror or lens device comprising at least one mirror or one lens, which is or are organized into raster elements and the reticle plane, whereby the optical elements image the secondary light sources in the exit pupil of the illumination system.The illumination system is characterized by the fact that the raster elements of the one or more mirror or lenses are shaped and arranged in such a way that the images of the raster elements cover by means of the optical elements the major portion of the reticle plane and that the exit pupil defined by aperture and filling degree is illuminated.

Owner:CARL ZEISS SMT GMBH

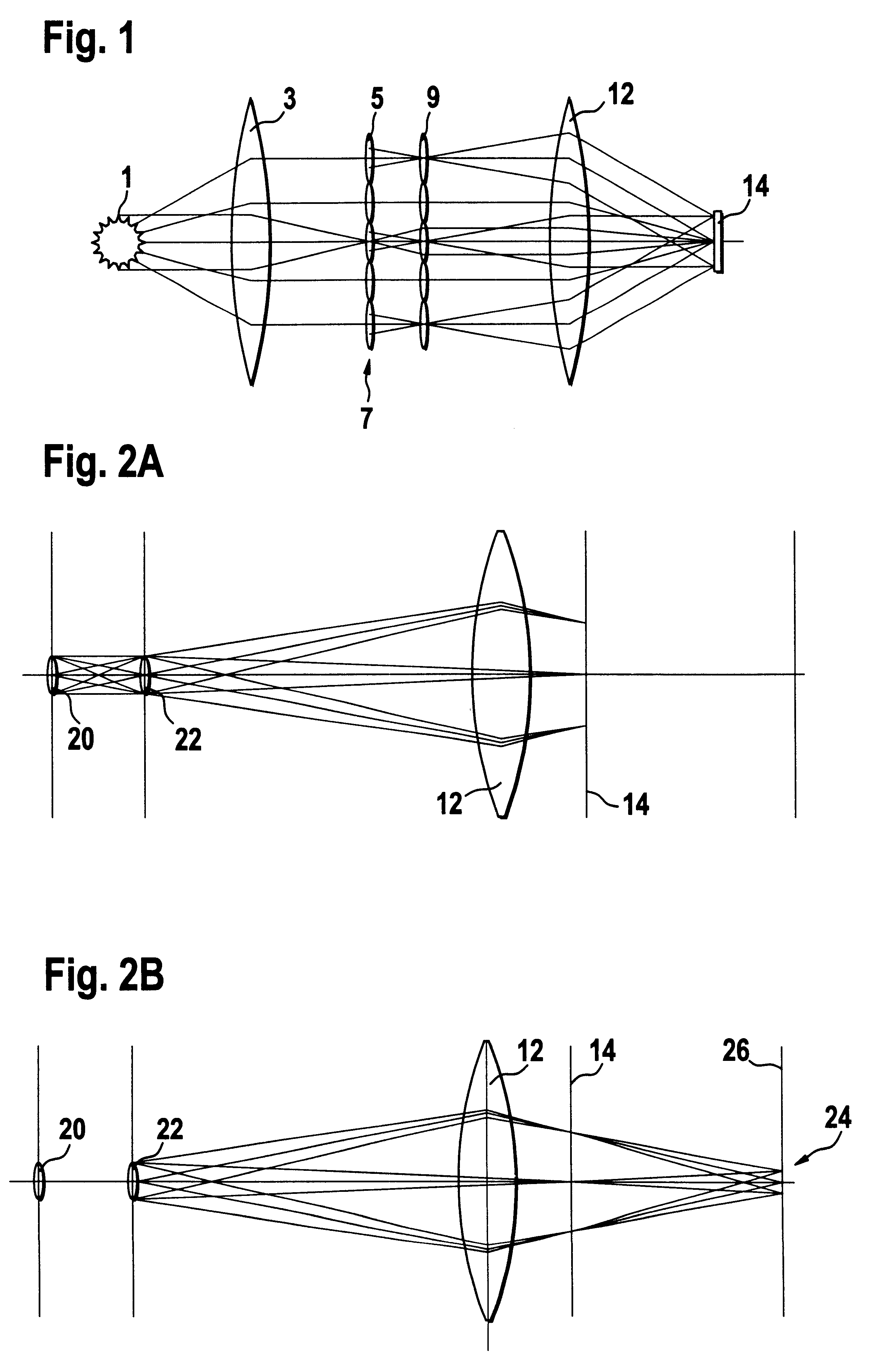

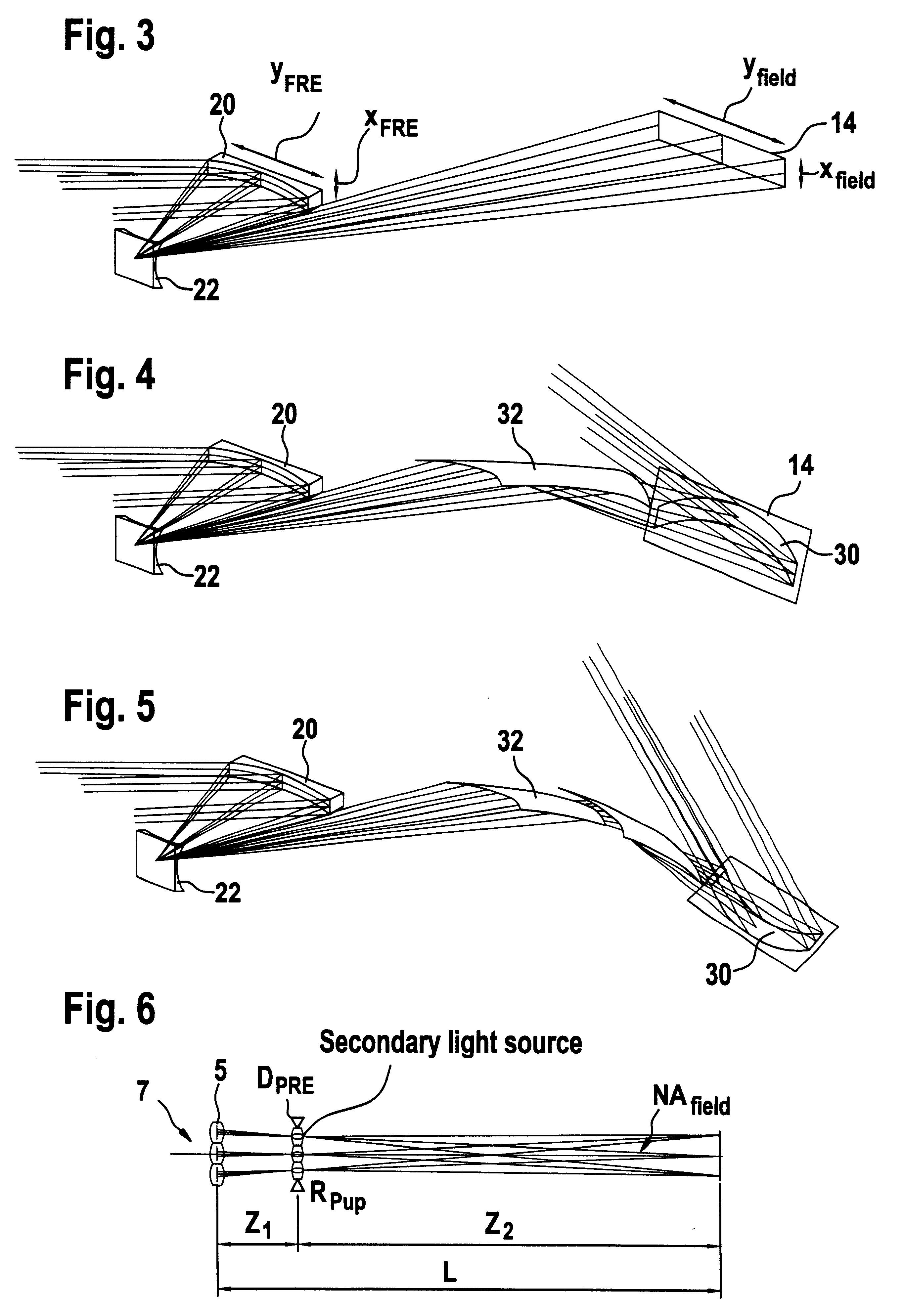

Illumination system particularly for microlithography

InactiveUS6438199B1Reduced beam diameterReduce the overall diameterNanoinformaticsHandling using diffraction/refraction/reflectionExit pupilGrating

The invention concerns an illumination system, particularly for microlithography with wavelengths <=193 nm, comprising a light source, a first optical component, a second optical component, an image plane and an exit pupil. The first optical component transforms the light source into a plurality of secondary light sources being imaged by the second optical component in said exit pupil. The first optical component comprises a first optical element having a plurality of first raster elements, which are imaged into said image plane producing a plurality of images being superimposed at least partially on a field in said image plane. The first raster elements deflect incoming ray bundles with first deflection angles, wherein at least two of the first deflection angles are different. The first raster elements are preferably rectangular, wherein the field is a segment of an annulus. To transform the rectangular images of the first raster elements into the segment of the annulus, the second optical component comprises a first field mirror for shaping the field to the segment of the annulus.

Owner:CARL-ZEISS-STIFTUNG TRADING AS CARL ZEISS

Methods of cutting or forming cavities in a substrate for use in making optical films, components or wave guides

InactiveUS20050024849A1Small in in lengthSmall in widthMechanical apparatusFlat articlesEngineeringRidge

The methods involve using a tool to cut or form multiple optical element shaped cavities in a surface of a substrate without rotating the tool or substrate during the cutting or forming process. At least some of the cavities are cut or formed to have at least two surfaces that come together to form a ridge and that are quite small relative to the length and width of the substrate. Thereafter the substrate is used to form optical films, components or wave guides having multiple optical elements on at least one surface corresponding to the cavities in the substrate.

Owner:SOLID STATE OPTO

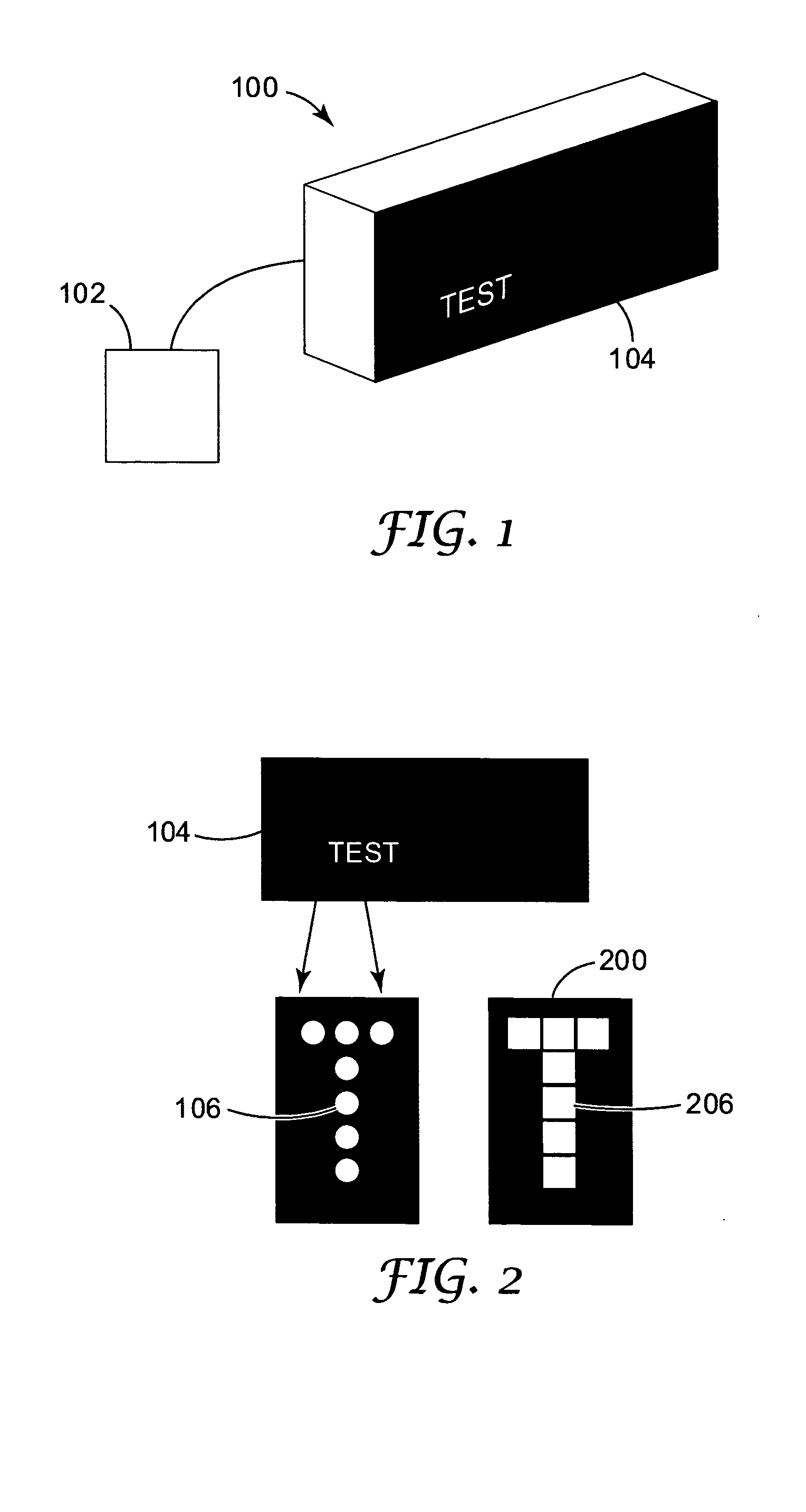

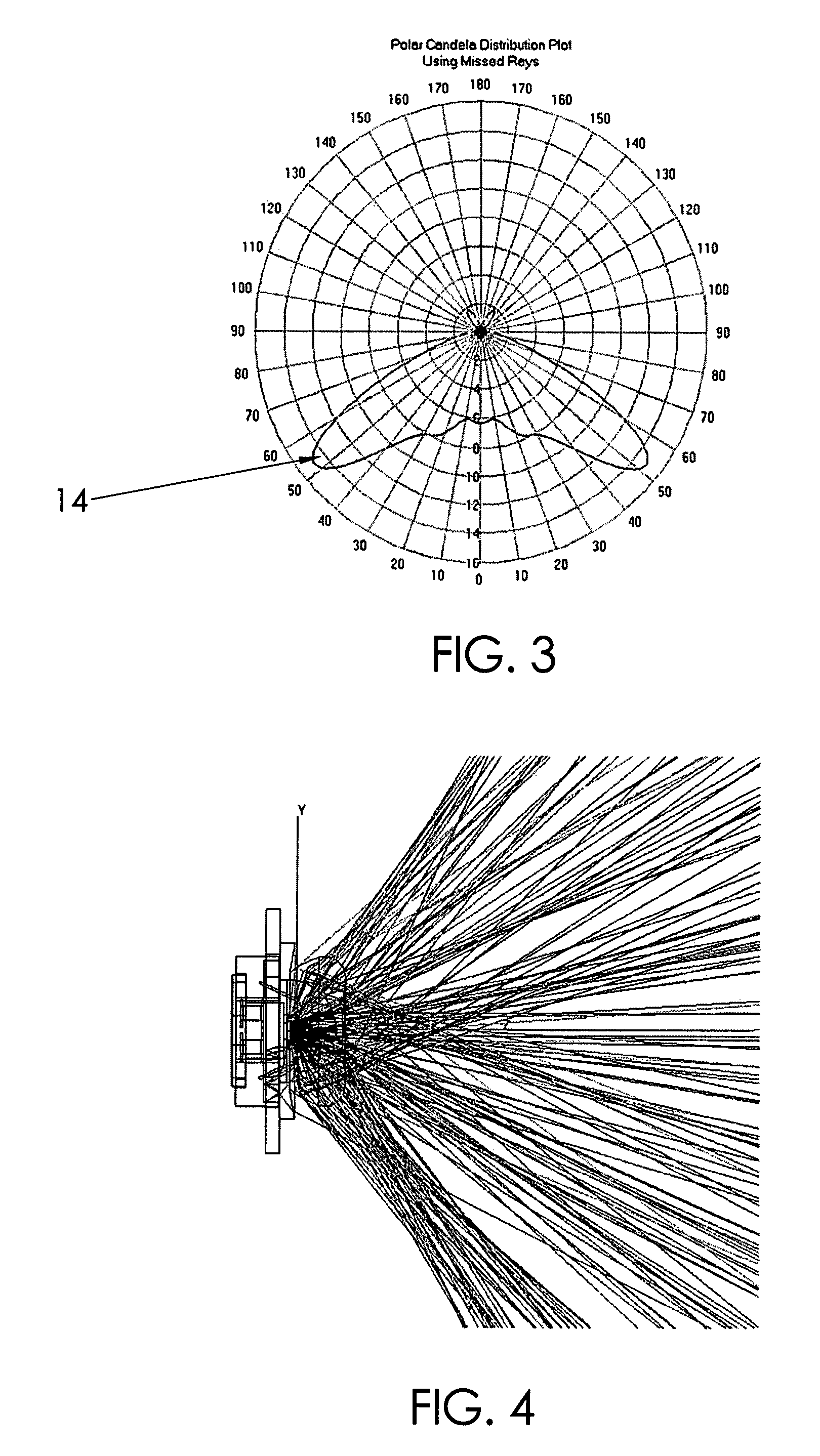

Integrating LED illumination system for machine vision systems

InactiveUS6871993B2Efficiently focusPoint-like light sourcePortable electric lightingLed arrayOptoelectronics

A system for focusing light on an illumination area. The system includes a reflector having a focusing reflective surface and a focal region and an LED array having a plurality of LEDs located within the focal region. Each of the plurality of LEDs in the LED array is positioned to emit light toward the focusing reflective surface. The focusing reflective surface reflects light from each of the plurality of LEDs of the LED array toward the illumination area.

Owner:DATALOGIC AUTOMATION

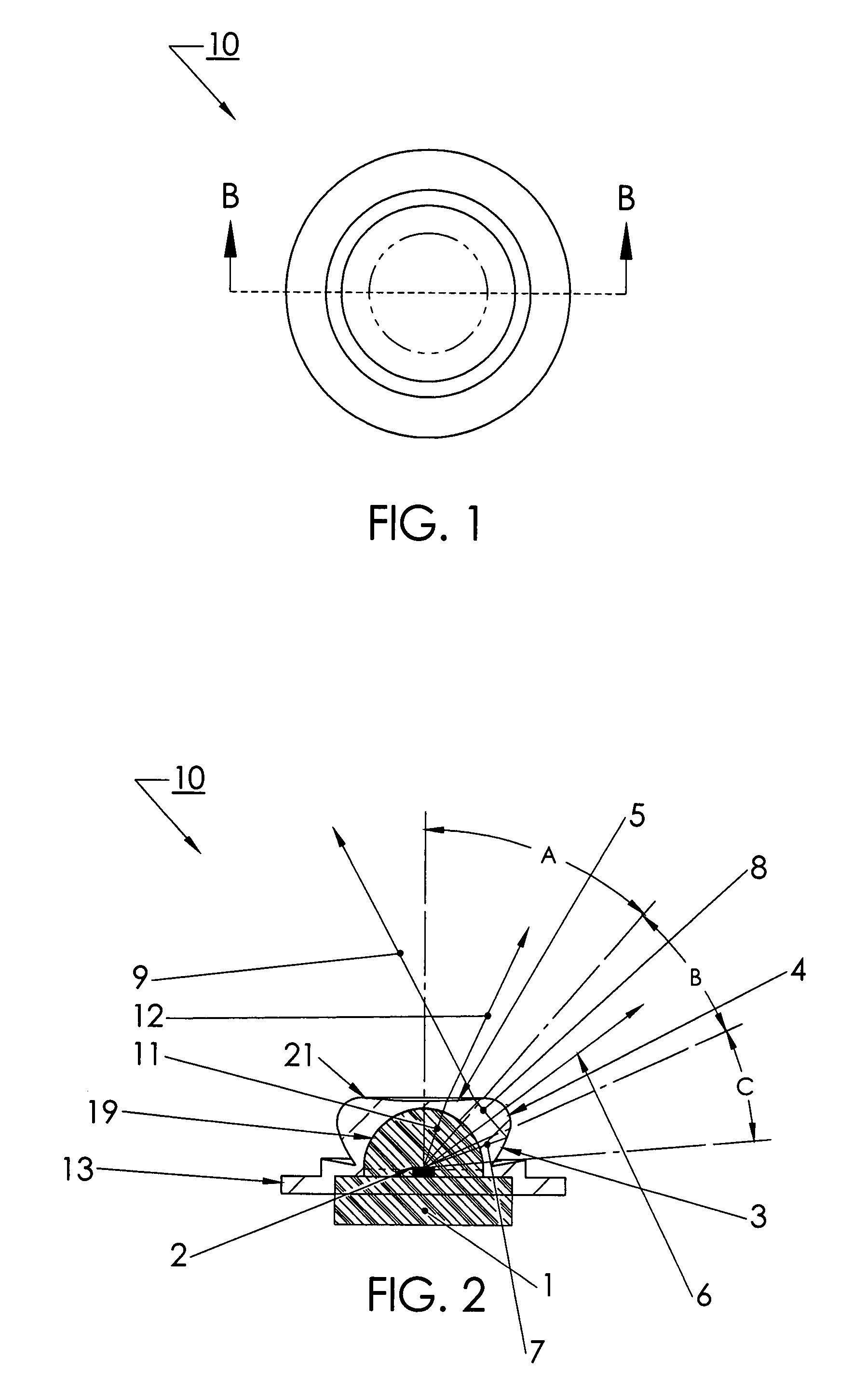

Optical device for repositioning and redistributing an LED's light

InactiveUS7021797B2Aircraft componentsMeasurement apparatus componentsTotal internal reflectionLight beam

An optical device is for spatially displacing the output of a light-emitting diode (LED) and coupling the output to a predominantly spherical emission pattern produced at a useftul height above the LED. The device is made of a transparent dielectric material, such as an injection-molded plastic. It comprises a lower transfer section that receives the LED's light from below and an upper ejector section that receives the transferred light and spreads it spherically. One or more LEDs. are optically coupled to the bottom of the transfer section, which operates by total internal reflection upon their entire hemispherical emission. One embodiment operates as a flashlight-bulb substitute with the ejector section radiating onto a parabolic reflector, which forms the beam. Thus hemisphencally emitting LEDs can be used in parabolic-mirror flashlights wherein these LEDs by themselves may be unsuitable for that role.

Owner:LIGHT ENGINE

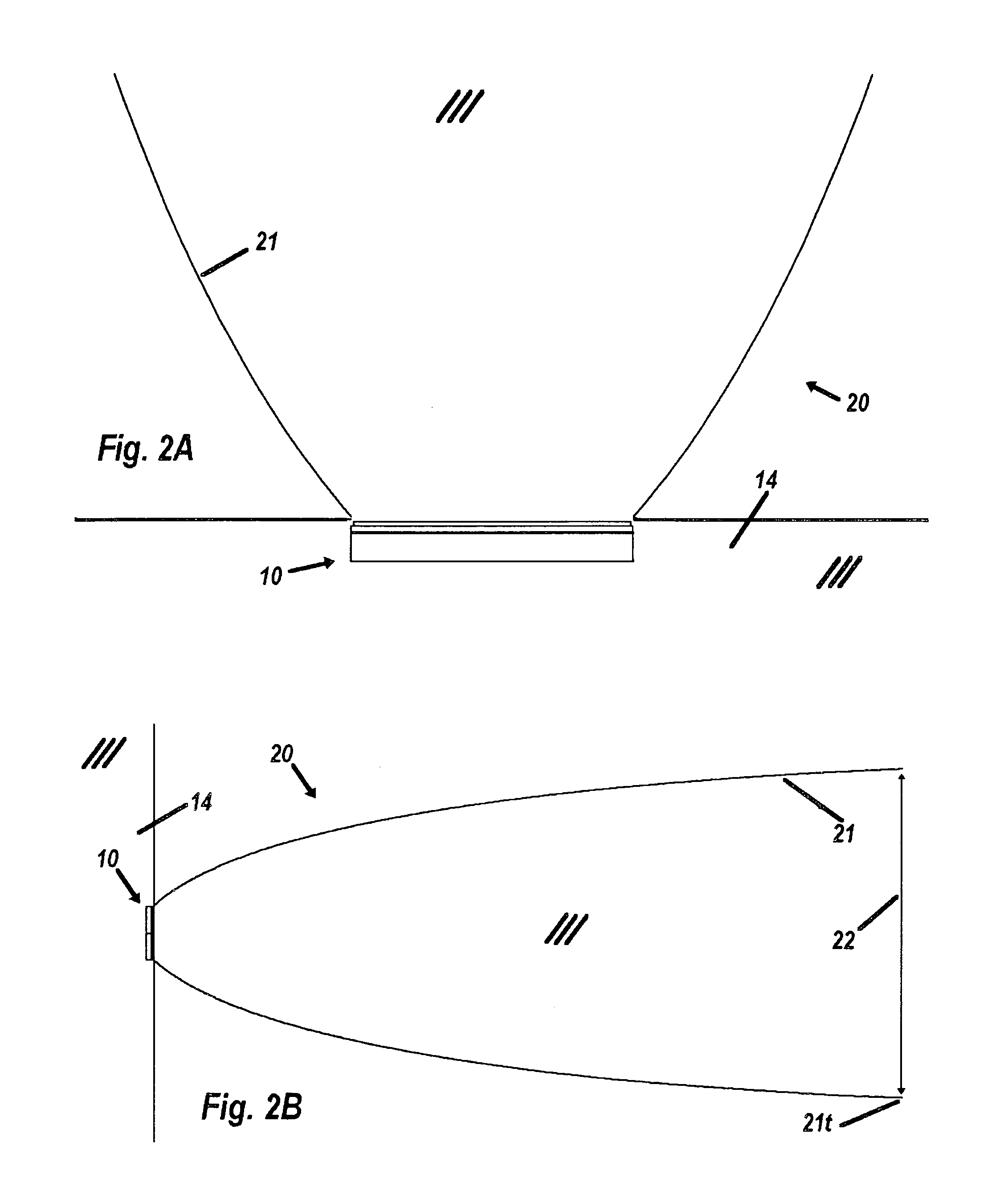

Optical manifold for light-emitting diodes

ActiveUS7286296B2Cost-effectiveImprove throughputMechanical apparatusPoint-like light sourcePhotoluminescencePhosphor

An optical manifold for efficiently combining a plurality of LED outputs into a single, substantially homogeneous output, in a small, cost-effective package. The optical manifolds can be used to combine multiple LEDs of the same color and provide a high intensity output aperture with very high uniformity and sharp borders, or they can be used to generate a multiwavelength output, such as red, green, and blue LEDs that are combined to generate white light. Embodiments are also disclosed that use a single or multiple LEDs and a remote phosphor and an intermediate wavelength-selective filter arranged so that backscattered photoluminescence is recycled to boost the luminance and flux of the output aperture. The optical manifolds are designed to alleviate substantial luminance inhomogeneities inherent to LEDs. The optical manifold utilizes principles of non-imaging optics to transform light and provide directed, substantially uniform light sources.

Owner:SEOUL SEMICONDUCTOR

Ultra-thin backlight

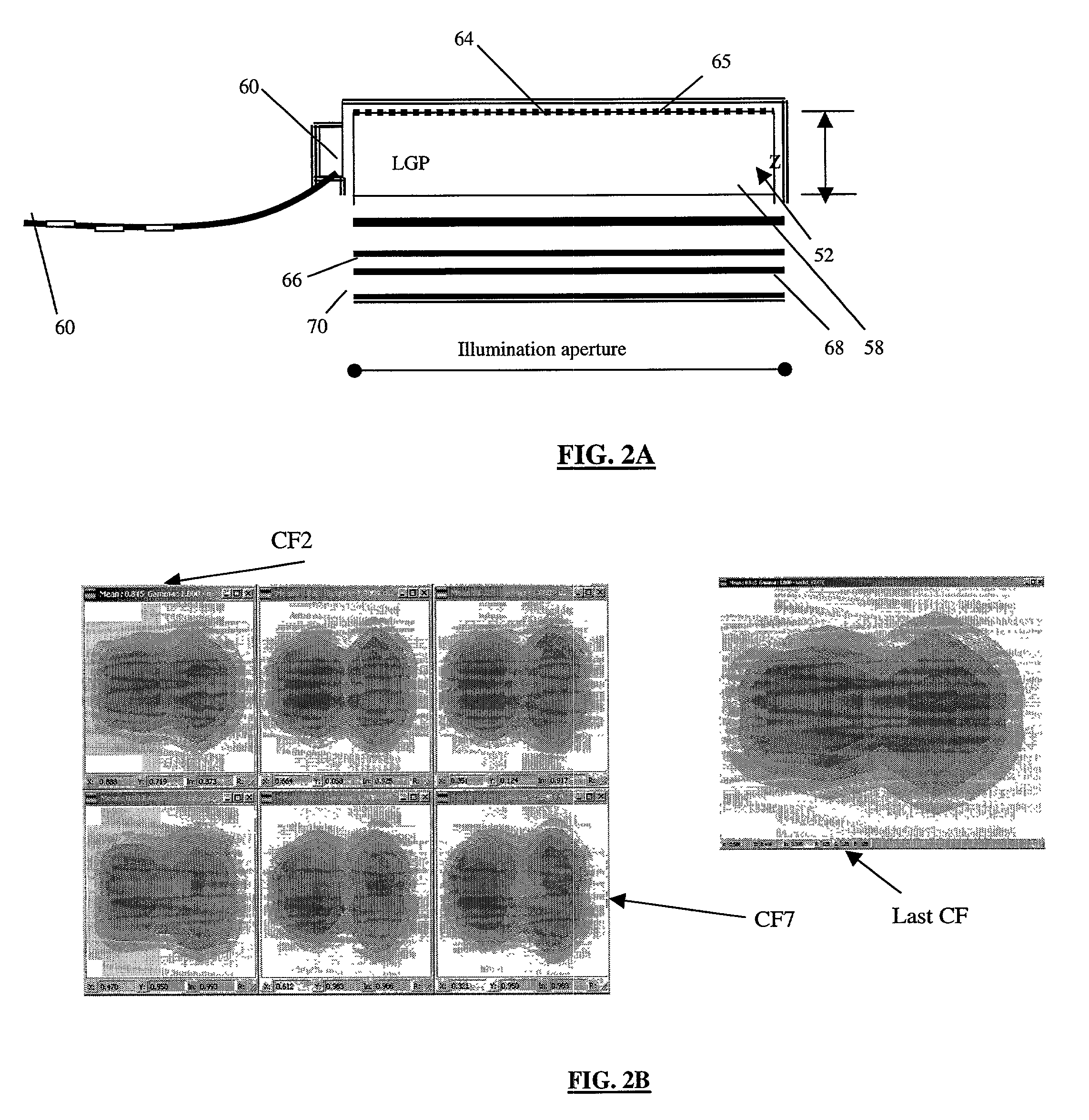

InactiveUS7001058B2Mechanical apparatusMeasurement apparatus componentsLiquid-crystal displayCoupling

A backlight for a display device, such as a liquid crystal display device, includes a light guiding plate having a front and a rear surface. The front and rear surfaces may be parallel to one another, or may instead be non-parallel. To the extent that such surfaces are non-parallel, one surface may be included at a single, or multiple angles with respect to the other surface. The backlight further includes a light source that is coupled to an edge of the light guiding plate by means of an energy conserving coupling section, and which provides light that is conditioned and transmitted through the light guiding plate. Light extractors are disposed on at least one side of the light guiding plate to assist in the transmission and conditioning of the light that is provided to the light guiding plate by the light source.

Owner:VISUS LTD

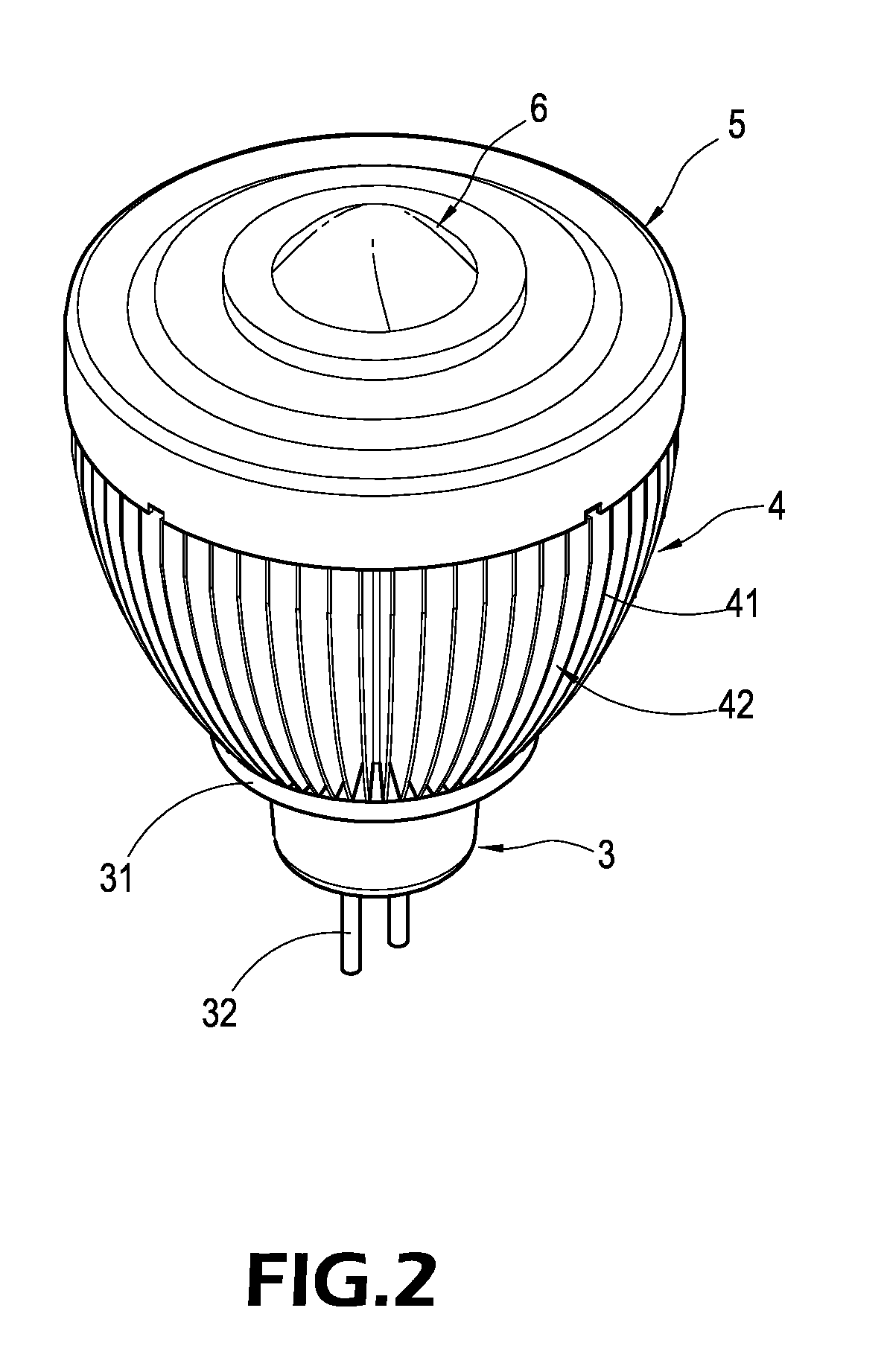

Heat dissipating LED signal lamp source structure

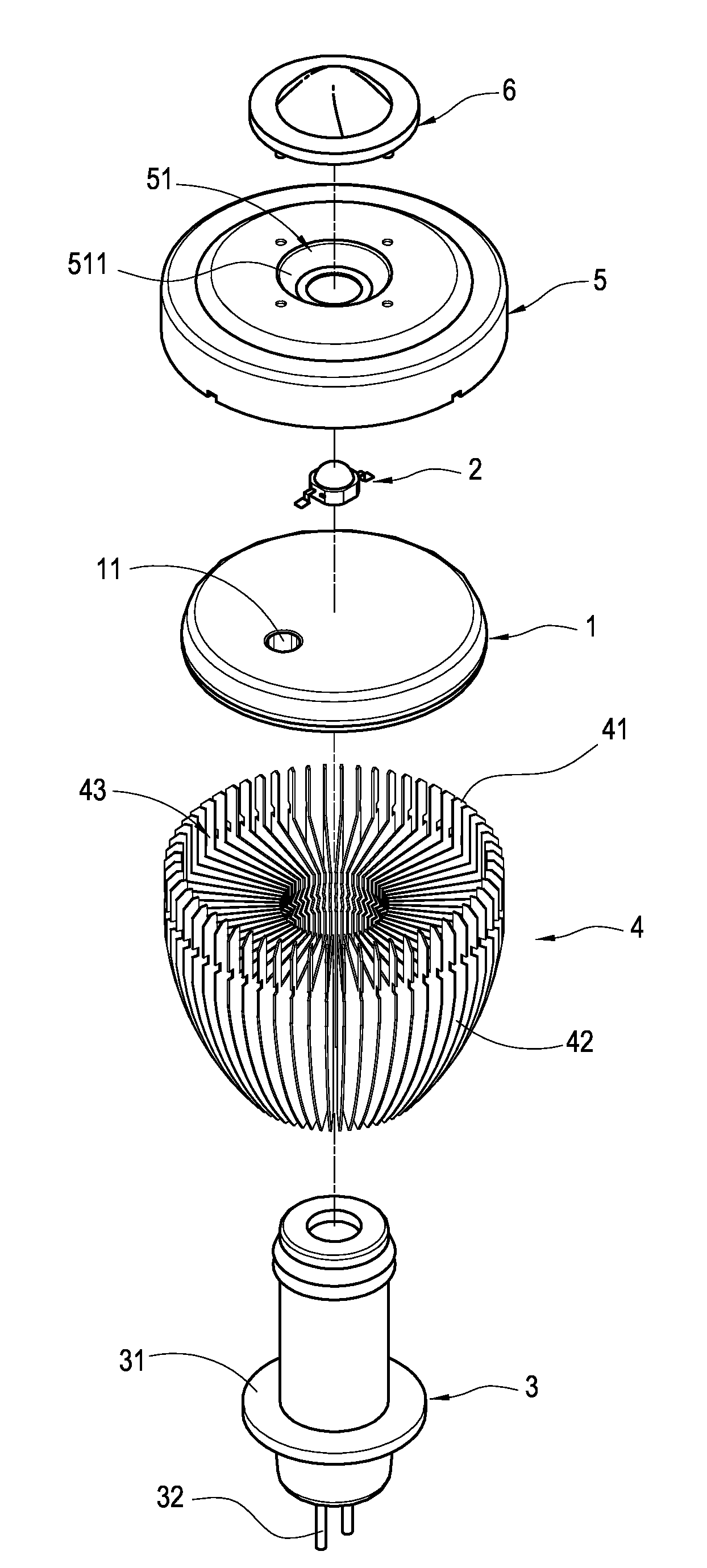

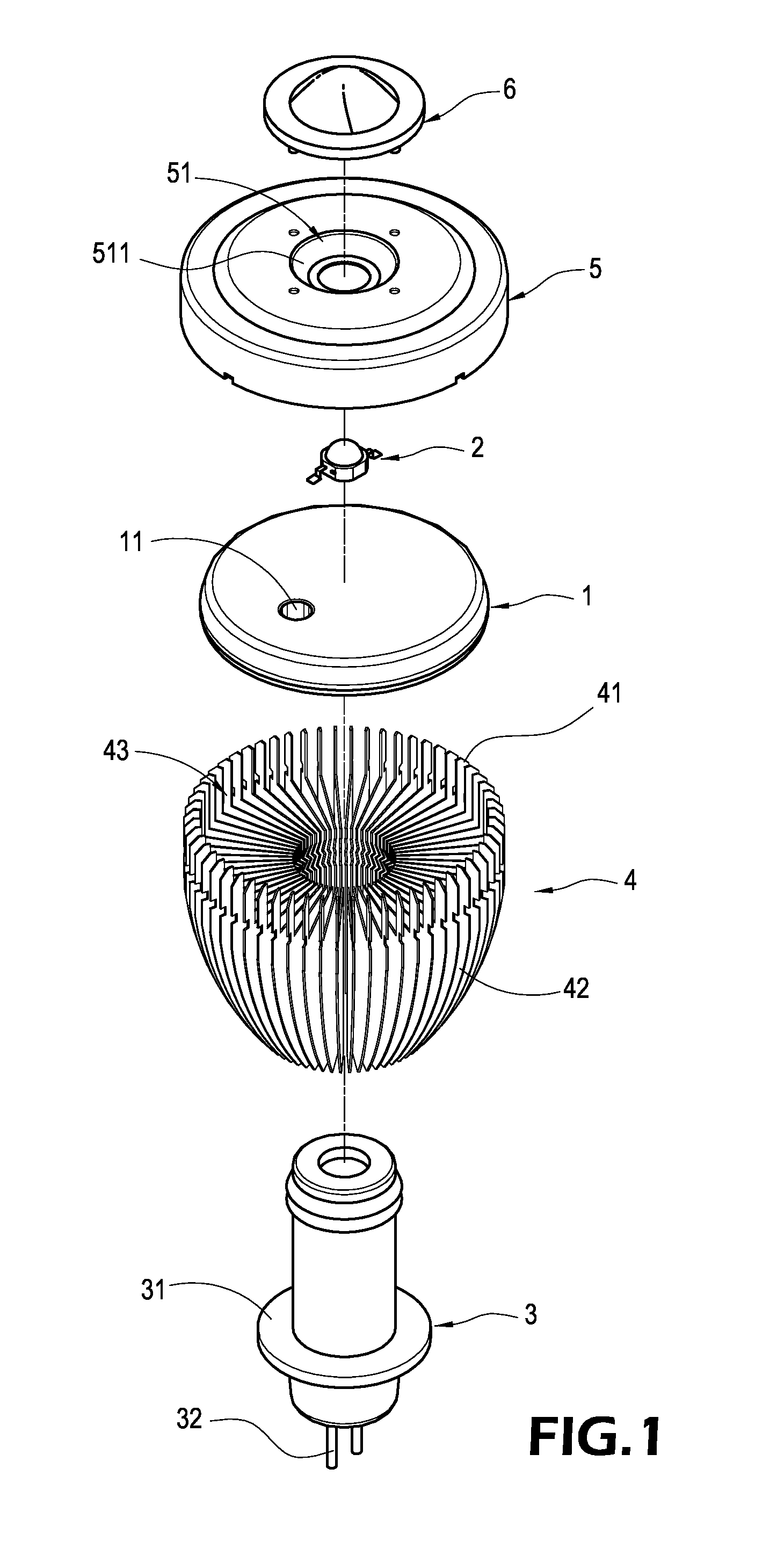

InactiveUS7396146B2Heat dissipationEnhances light emitting efficiency and life expectancy of light emittingPoint-like light sourceElectric circuit arrangementsHeat conductingEngineering

A heat dissipating LED signal lamp emitting structure includes an isothermal board, a light emitting unit on the isothermal board, a heat conducting cylinder connected to the bottom of the isothermal board, a heat dissipating body around the periphery of the heat conducting cylinder and comprised of heat sinks, a circular cover body above the isothermal board for covering the isothermal board, a reflecting groove at the center of the cover body for passing through the light emitting unit, and a transparent lid on the cover body for covering the light emitting unit. With the heat dissipating effect of the heat dissipating body, the operating heat produced by the light emitting unit can be dissipated to the outside. The invention not only uses a single light emitting unit as a signal lamp emitting source, but also enhances the light emitting efficiency and the life expectancy of the light emitting unit.

Owner:PYROSWIFT HOLDING CO LIMITED

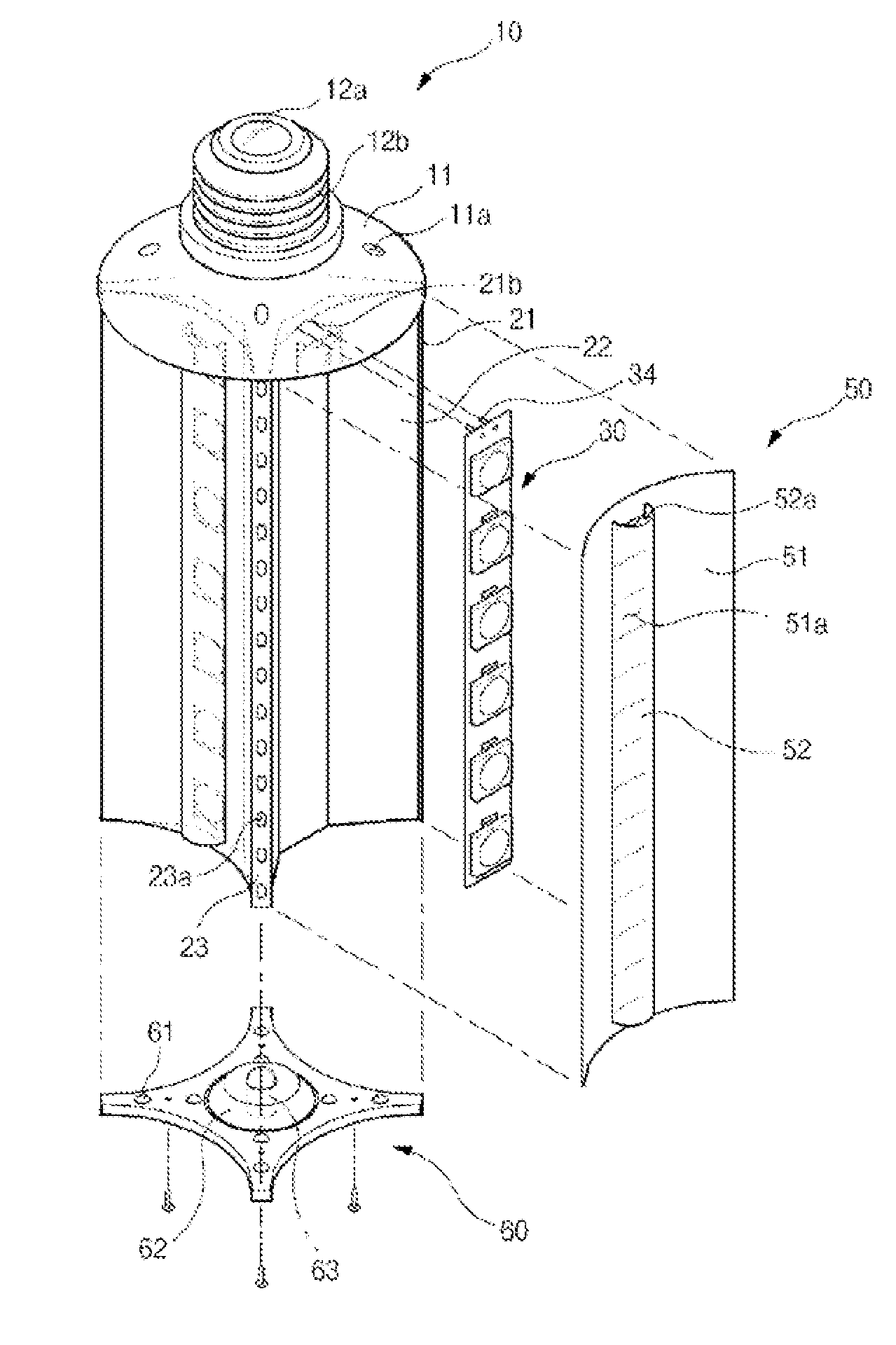

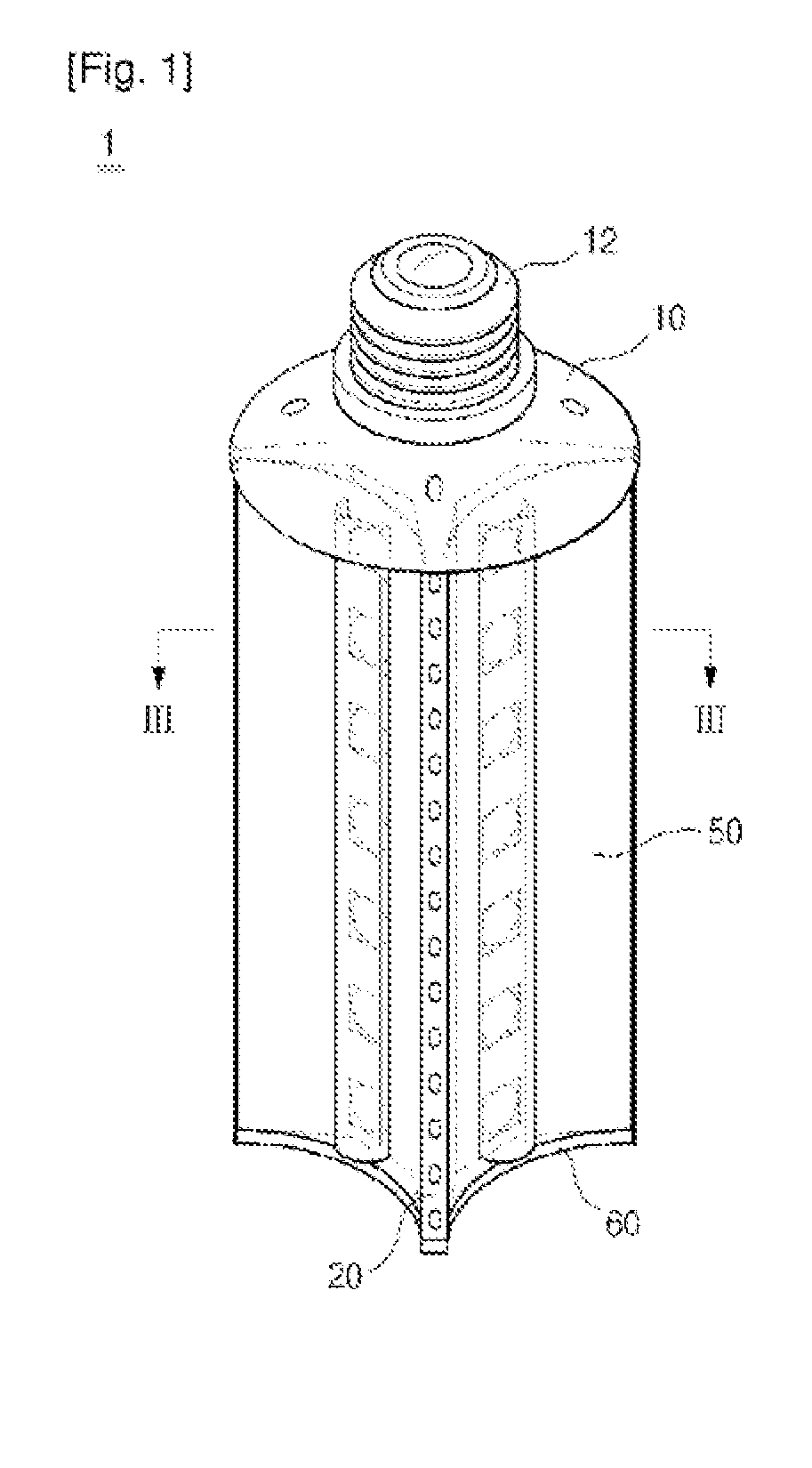

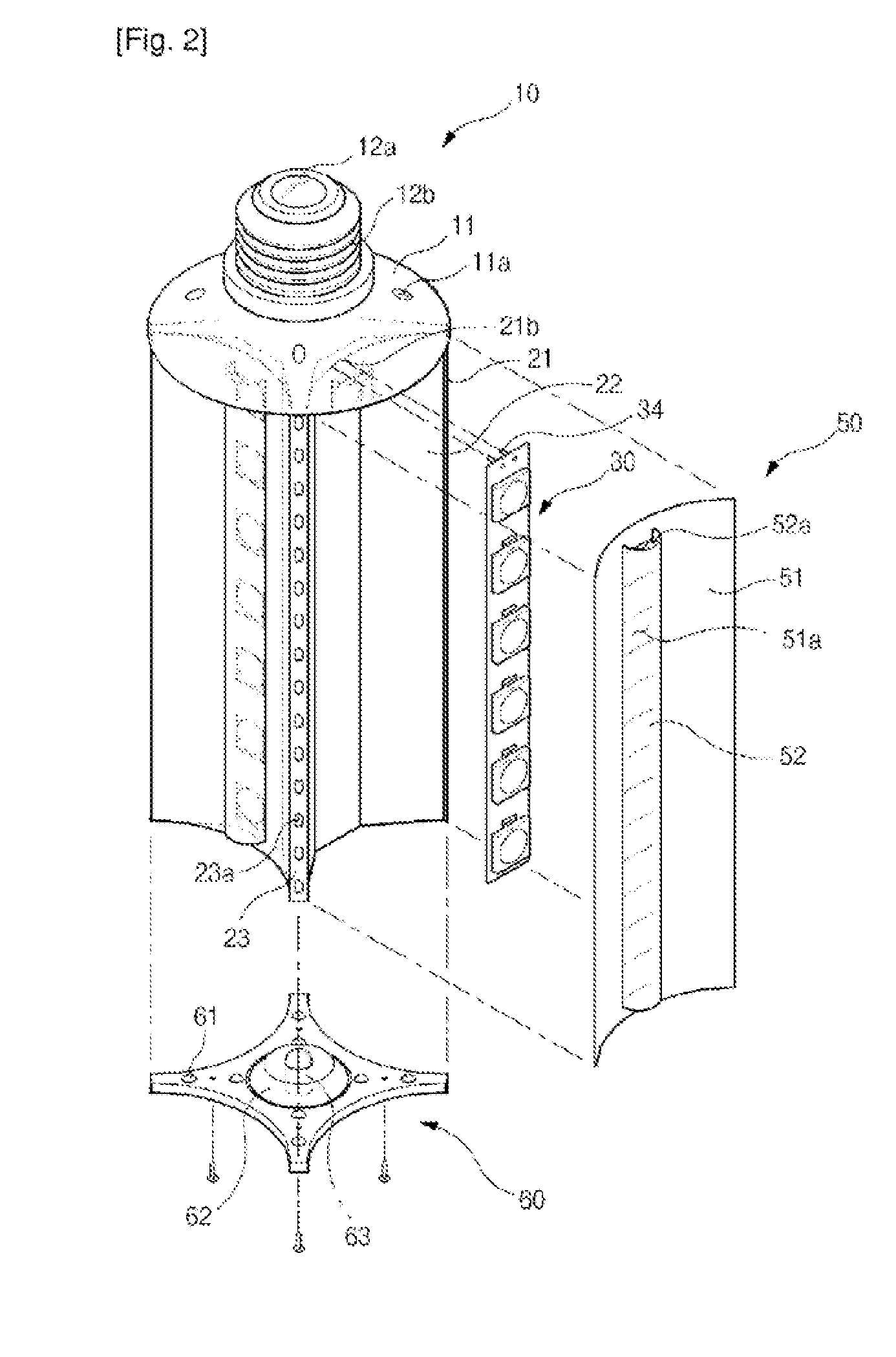

LED lighting device

InactiveUS20110156584A1Prevent glareSpread widelyPlanar light sourcesPoint-like light sourceAir cycleUltrasound attenuation

The present invention relates to a lighting device using an LED. One embodiment of the invention provides a lamp-shaped LED lighting device that can replace a known lighting device. The lamp-shaped LED lighting device promptly emits the heat generated by an LED element, which influences the optical output and the lifespan of the LED lighting device, through a lamp-shaped frame with a heat-ventilation structure that facilitates air circulation. In addition, the lamp-shaped LED lighting device prevents glare from an LED light source by using a lateral reflecting member, a diffusion lens and a diffusion cover and diffuses the light from the light source widely without optical attenuation. Another embodiment of the invention provides a tube and panel-shaped LED lighting devices that can be replaced with a previous tube-shaped fluorescent light and a panel-shaped lighting device. The tube and panel-shaped LED lighting devices rapidly emit the heat generated by an LED element, which influences the optical output and the life span of the LED lighting device, through a tube and panel-shaped frame with a heat-sink structure. In addition, the tube and panel-shaped LED lighting devices prevent glare from the LED light source by optically arranging a curved reflecting plate, a diffusion plate and a diffusion window which include a diffusion lens at the upper portion of the LED element. Furthermore the tube and panel-shaped LED lighting devices diffuse the light from the LED light source widely without optical attenuation.

Owner:SOLARKOR

Directly viewable luminaire

ActiveUS7267461B2Constant brightnessPlanar light sourcesMechanical apparatusThermal isolationPoint light

Owner:SIGNIFY HLDG BV

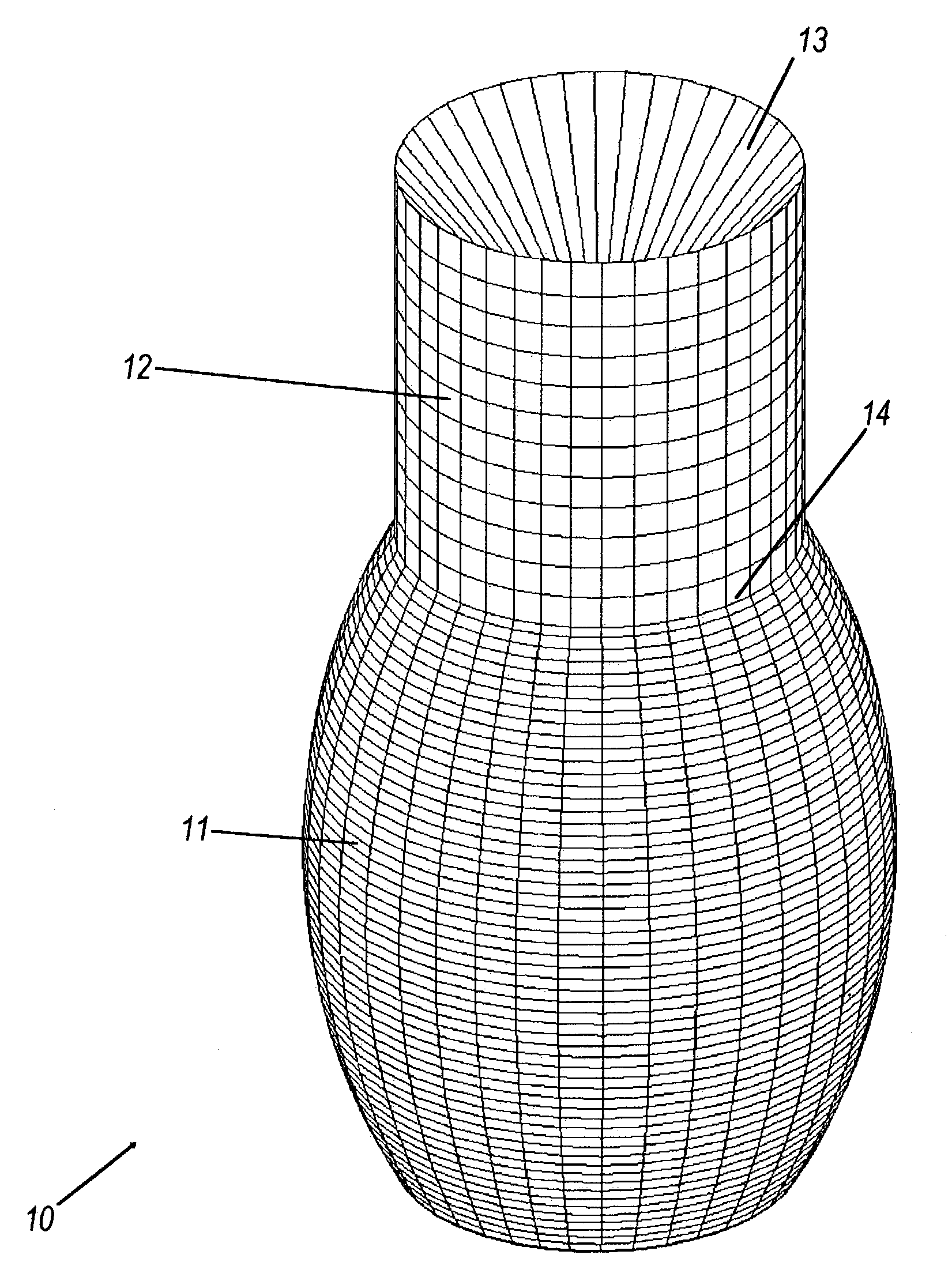

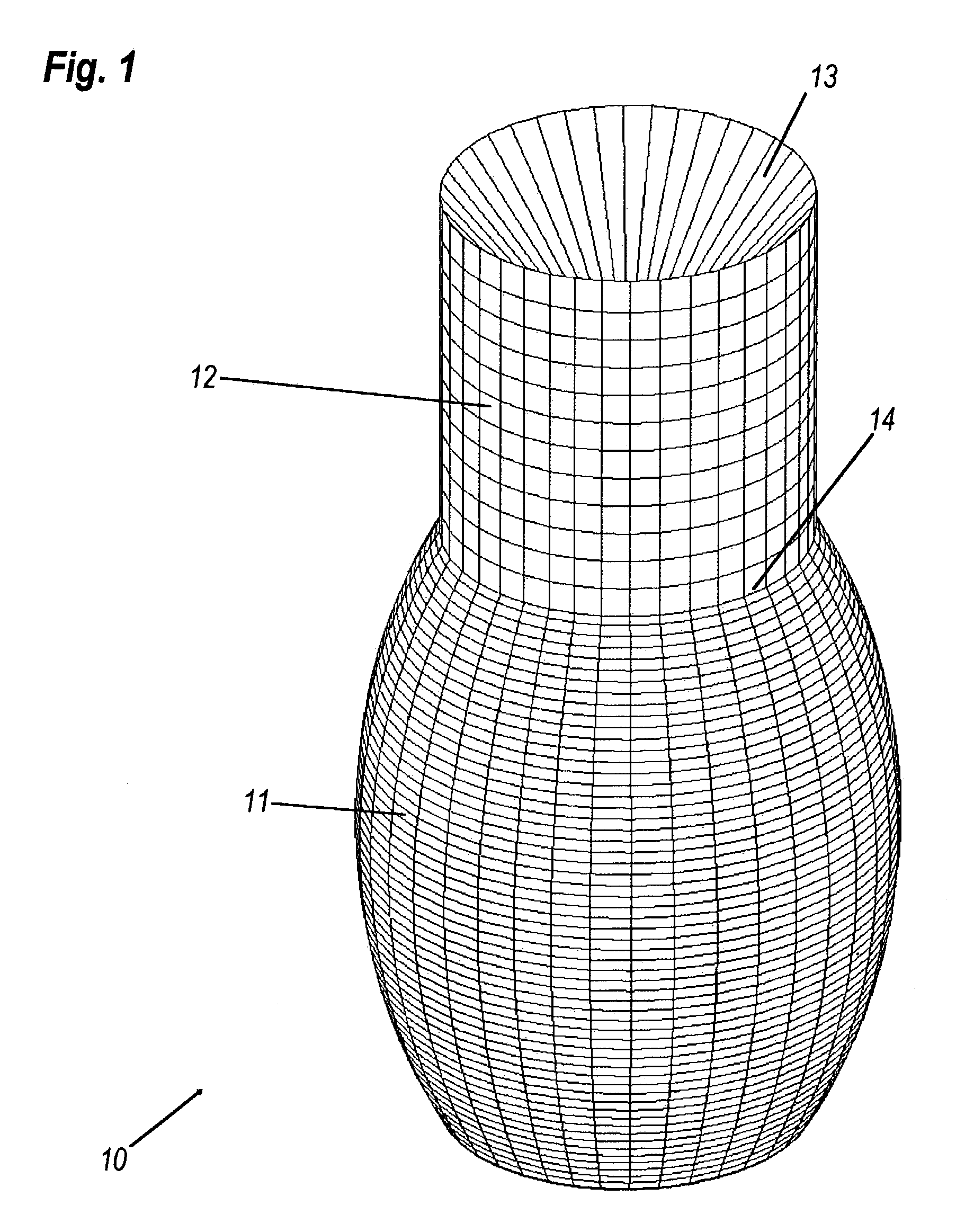

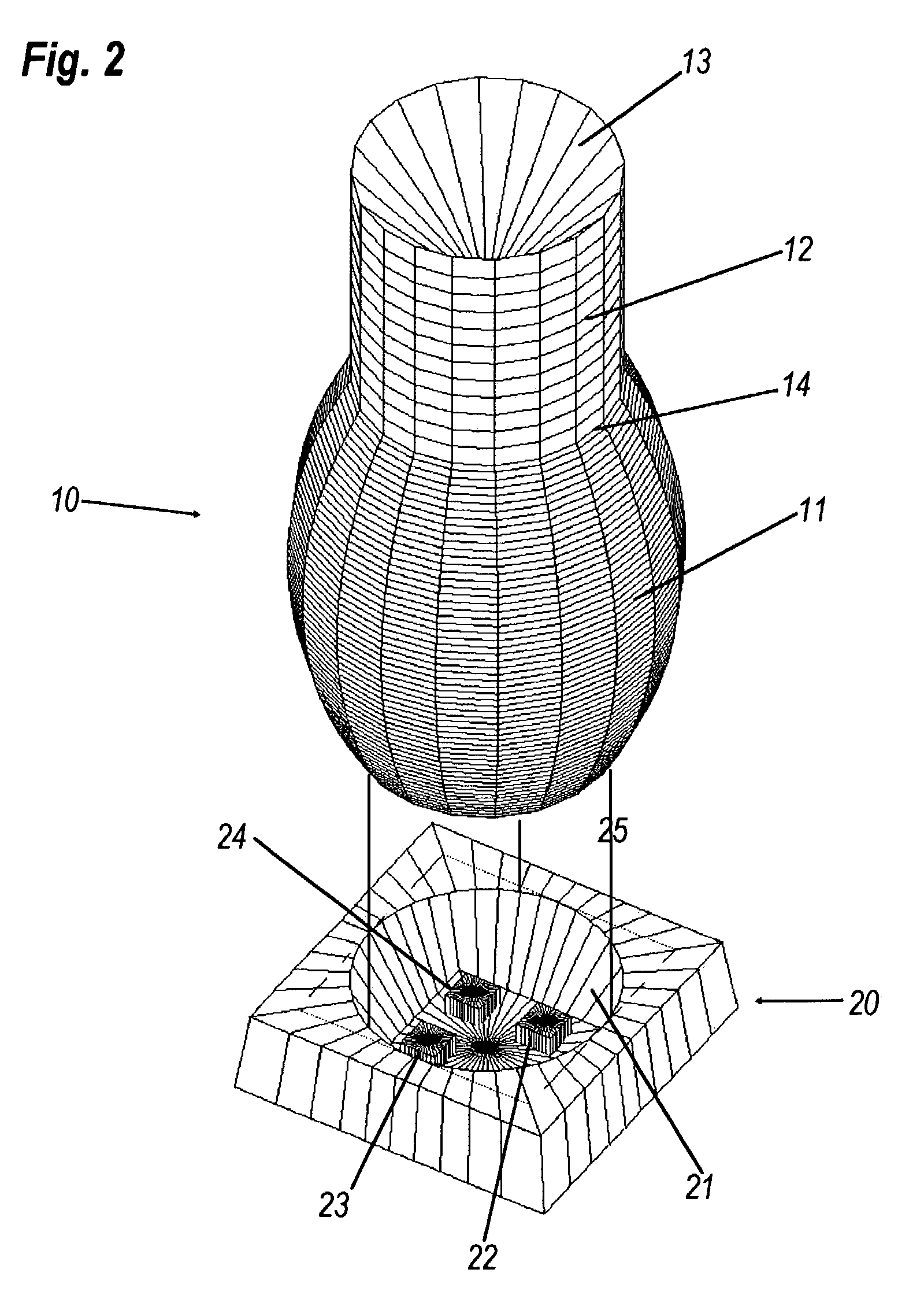

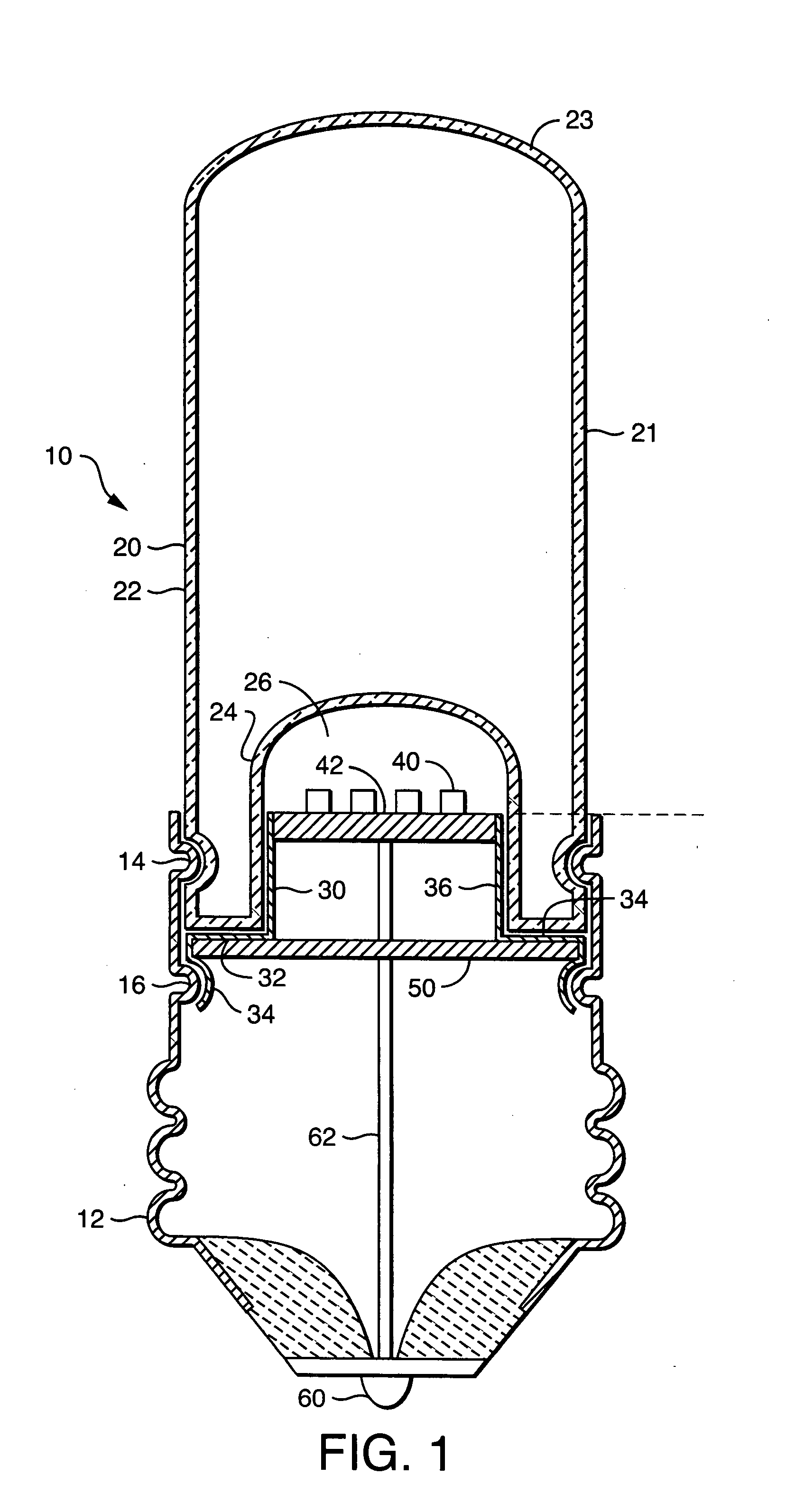

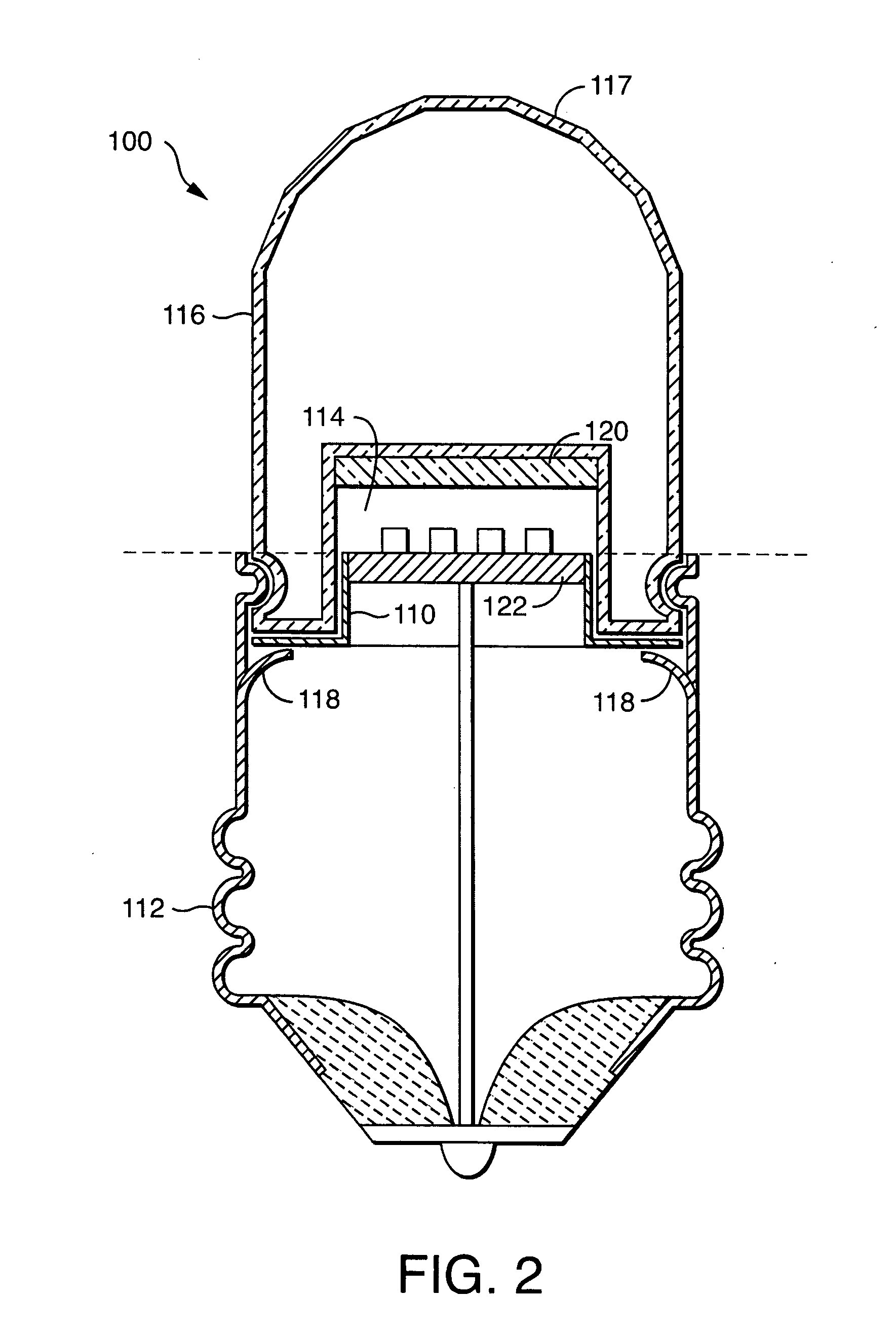

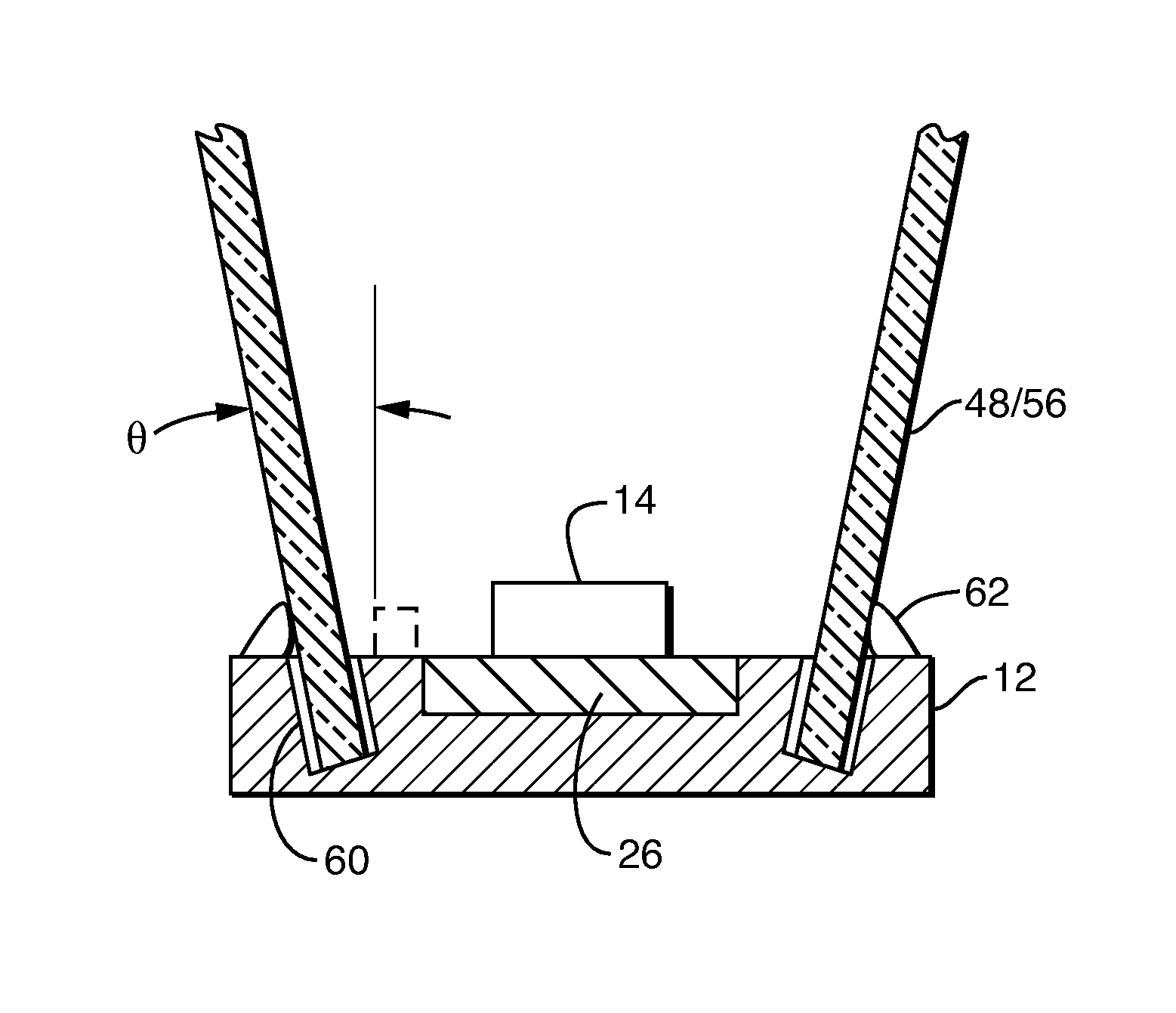

LED lamp with heat sink optic

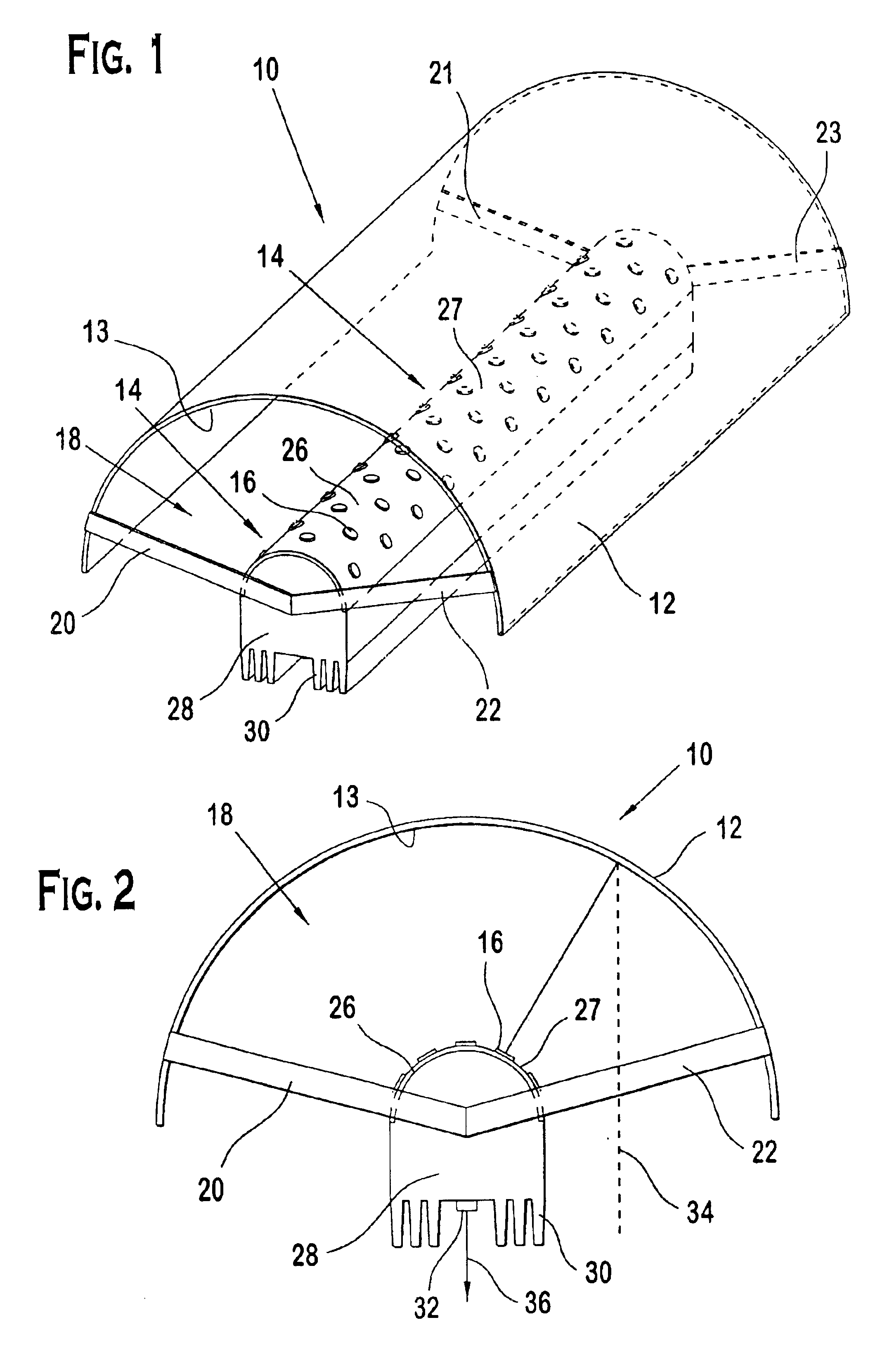

An LED lamp may be made with a heat sink optic. The lamp has a base having a first electrical contact and a second electrical contact for receiving current. At least one LED is mounted on a thermally conductive support; that supports electrical connections for the LED and provides thermal conduction of heat from the LED to the optic. The LED support mounted in the base and electrically coupled through the first electrical contact to electrical current. The light transmissive, and heat diffusing optic has an external an internal wall defining a cavity with the LED positioned in the cavity. The optic is in thermal contact with the LED support and mechanically coupled to the base. The snap together structure enables rapid manufacture while allowing numerous variations.

Owner:OSRAM SYLVANIA INC

Tubular blue LED lamp with remote phosphor

ActiveUS7618157B1Easy to manufactureEasily assembled partPoint-like light sourceElongate light sourcesPhosphorElectrical connection

A lamp includes a linearly extending heat sink, blue-light-emitting LEDs mounted on the heat sink, and a light emitting cover mounted on the heat sink in line with the LEDs, a first portion of the cover opposite the LEDs including a phosphor that is excited by the LEDs to emit white light. The cover may be a tube with the LEDs outside the tube, a portion of the tube nearest the LEDs being transparent and receiving light from the LEDs. The tube may include reflectors that are attached to an exterior surface of the tube to hold the tube on the heat sink. Alternatively, the cover may enclose the LEDs on the heat sink, where a portion of the cover has an interior surface that reflects light from the LEDs to the first portion. The lamp may include electrical connections that allow for multiple lamps to be connected in series.

Owner:ABL IP HLDG

Lighting device, illuminated enclosure and lighting methods

A lighting device, comprising at least one solid state light emitter and one (or more) optical device(s) which (each) comprises at least first, second and third optical structures, first and second surfaces of the second structure being in contact with a surface of the first structure and a surface of the third structure, respectively. The third structure has at least one optical feature. The light emitter is positioned, the optical feature is positioned, and the regions of the structures have indices of refraction, such that if the light emitter is illuminated, at least a portion of the emitted light will enter into the second optical device structure and exit from the optical feature on the third structure. Also, a method of lighting comprising illuminating a light emitter in such a device.

Owner:IDEAL IND LIGHTING LLC

LED work light

ActiveUS20050265035A1Preserve useful working lifeIncrease powerElectric lighting for hand-held useLighting support devicesLow voltageLight beam

Work light has LEDs that require heatsink. Desired radiation pattern achieved by using optical components designed to produce beam or LEDs may have beams in different directions. Radiation pattern of LEDs may be changed by refractive-reflective optics or by convex lenses. Convex lenses may be hemispheres, other planoconvex shapes, concavo-convex shapes, or other shapes. Curved surfaces on any lenses may be spherical or aspheric. Ballast to operate the LEDs from line voltage AC or low voltage DC. Work light may contain batteries. The work light may be mounted on a stand. May have accessory mount. May have charging station. May have a paging transmitter to activate a paging receiver in work light. May have openings for heat transfer from heatsink to ambient air external to light.

Owner:ALLTEMP PROD CO LTD

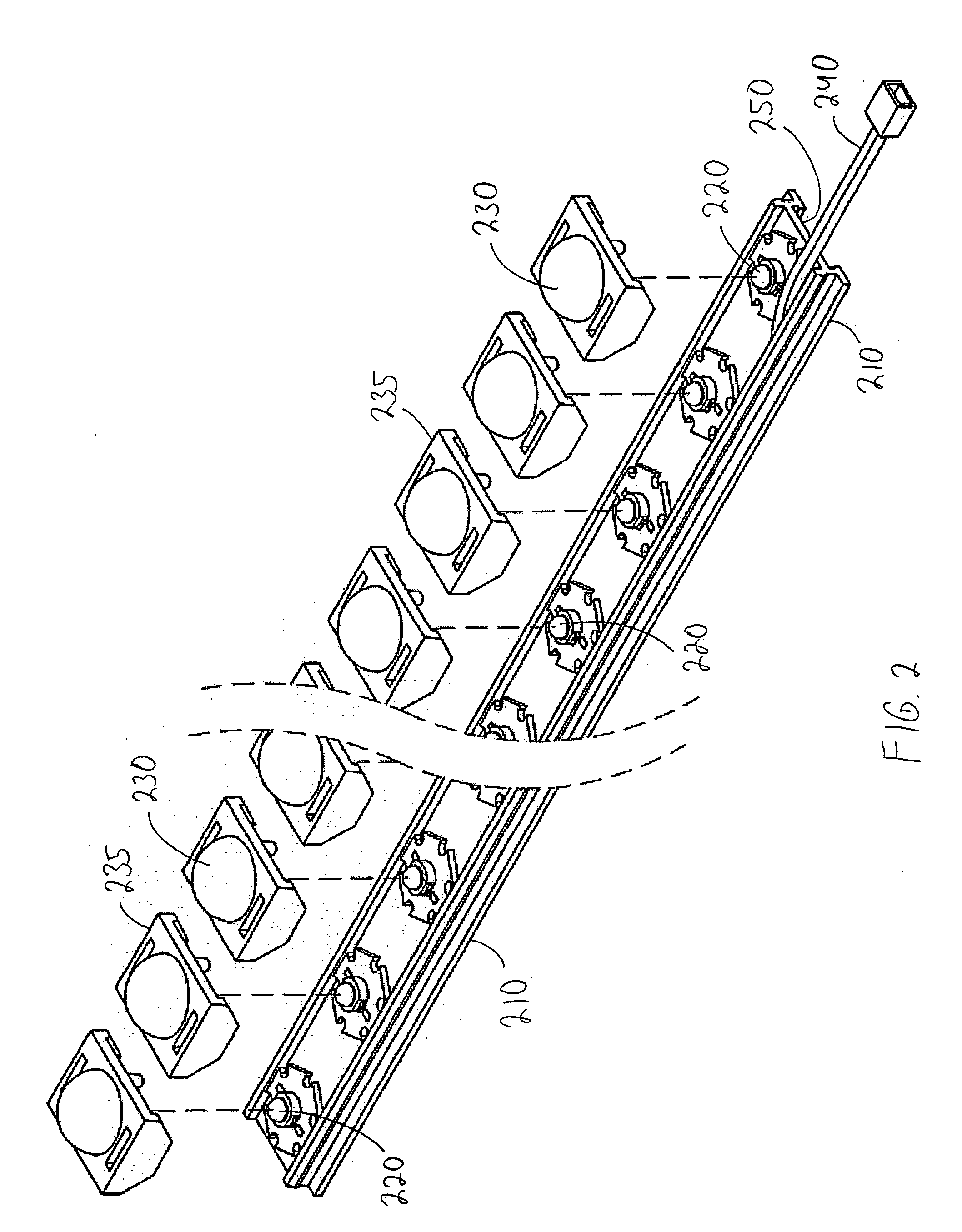

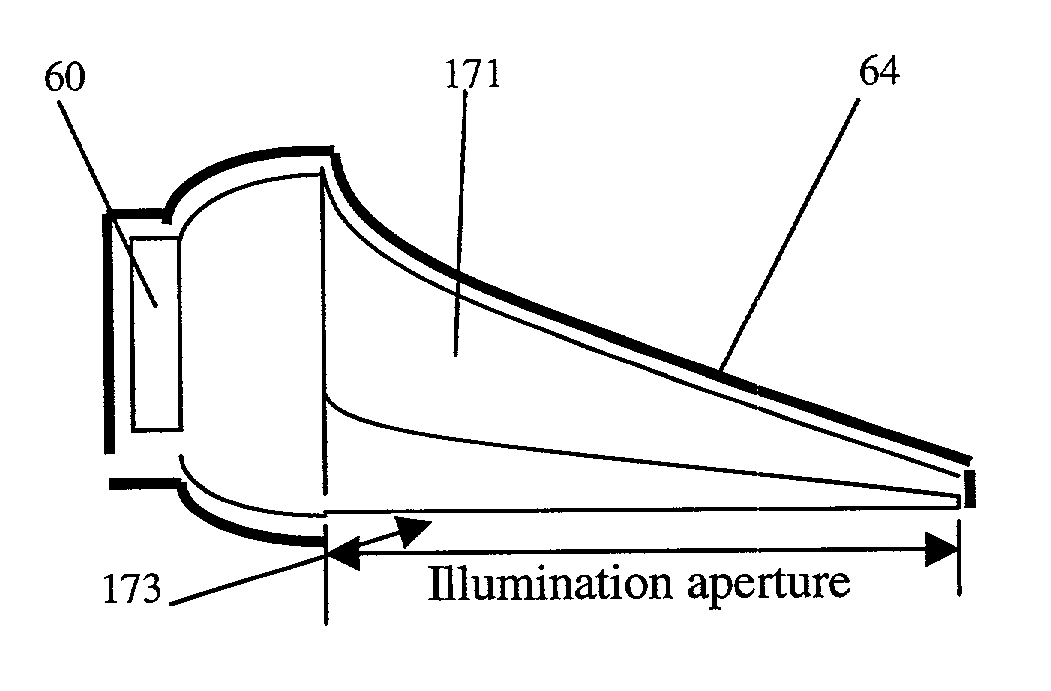

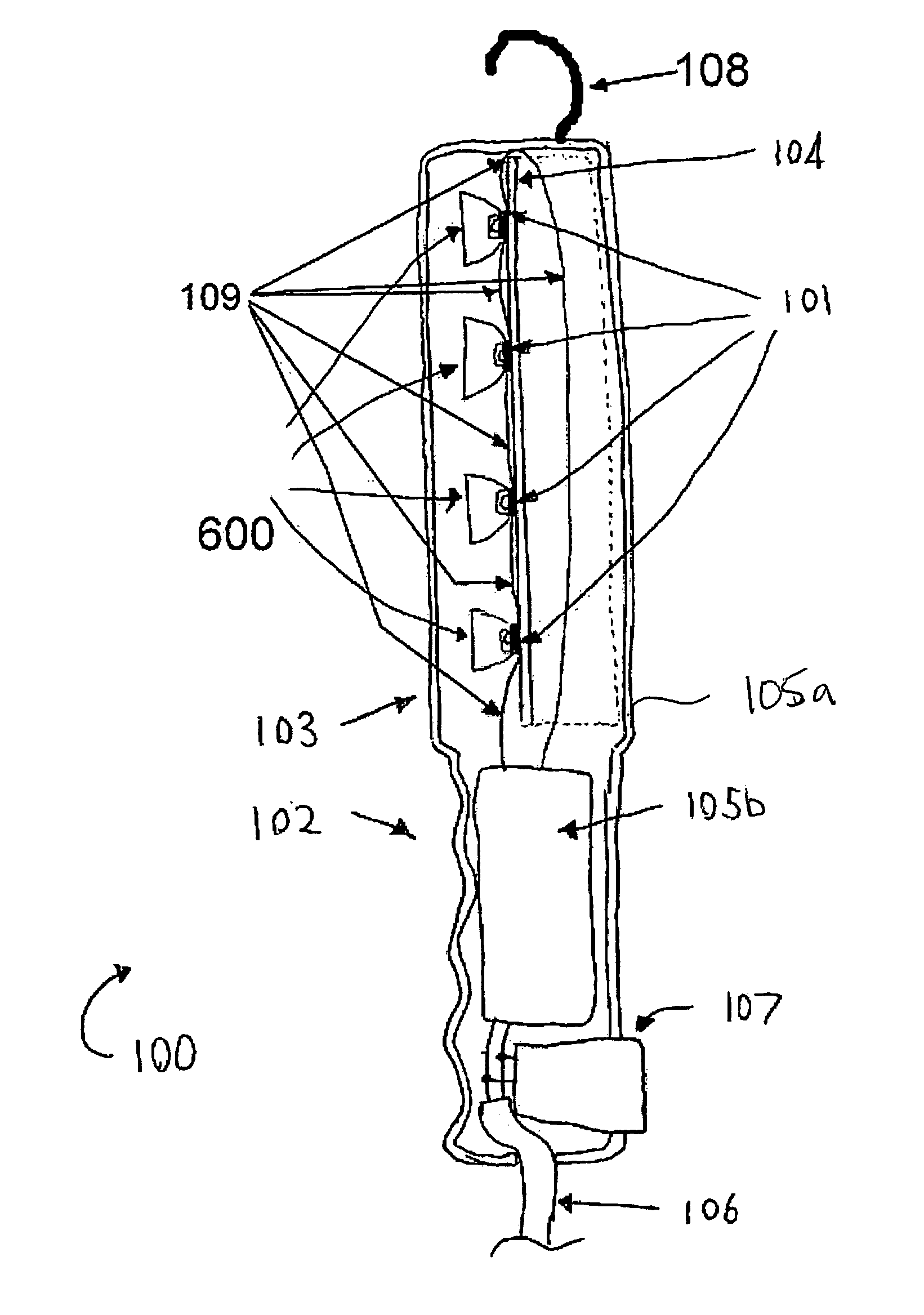

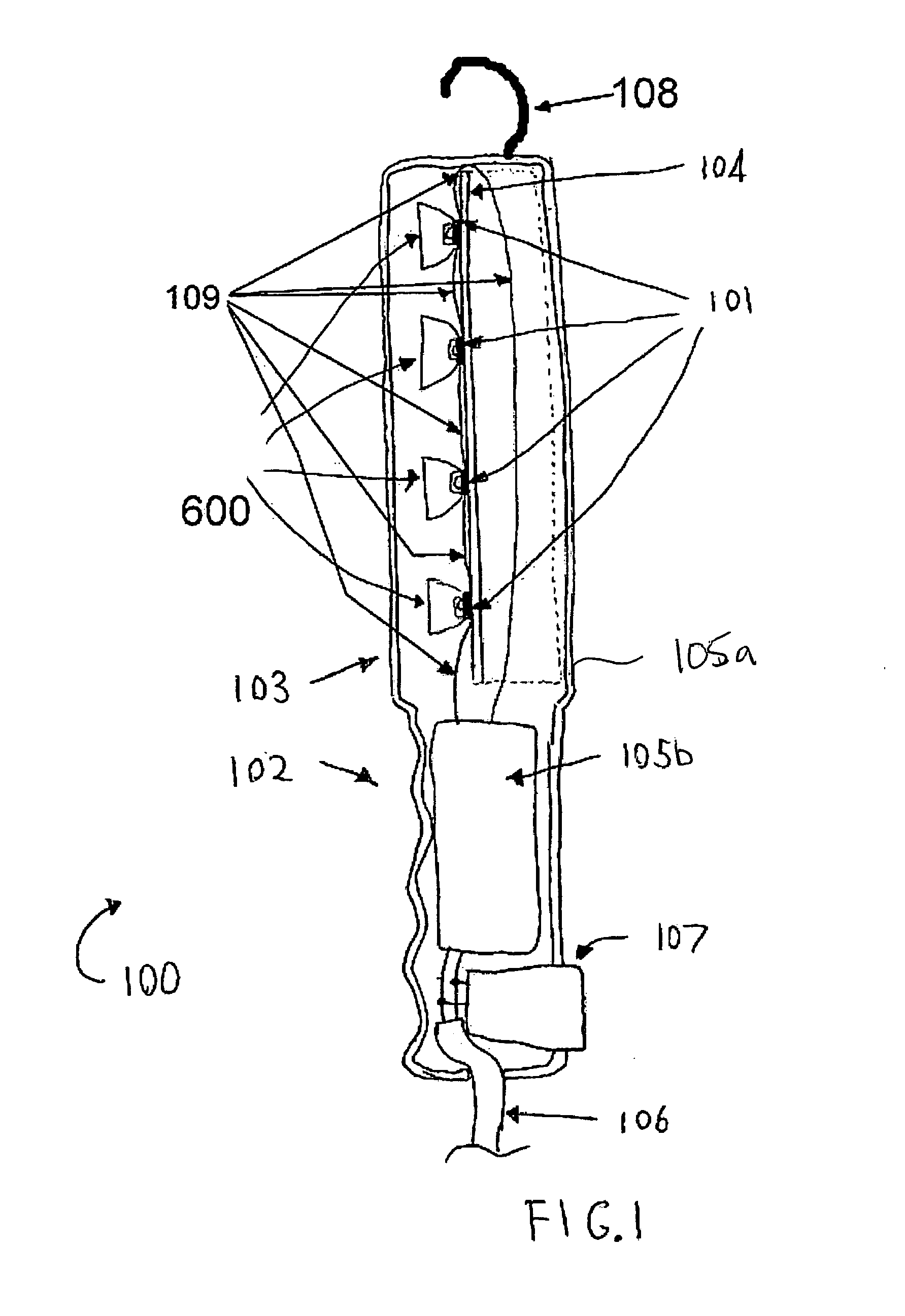

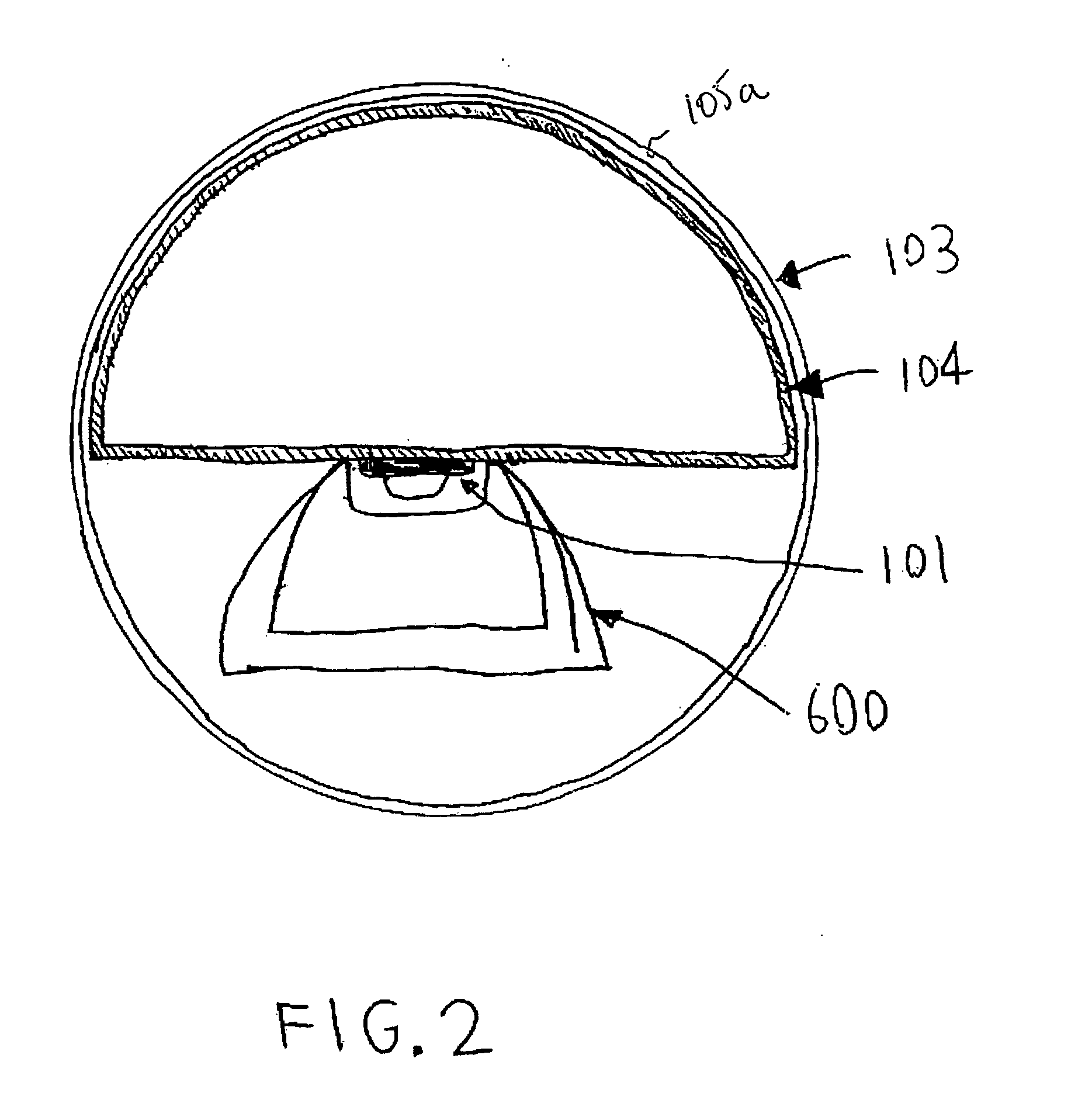

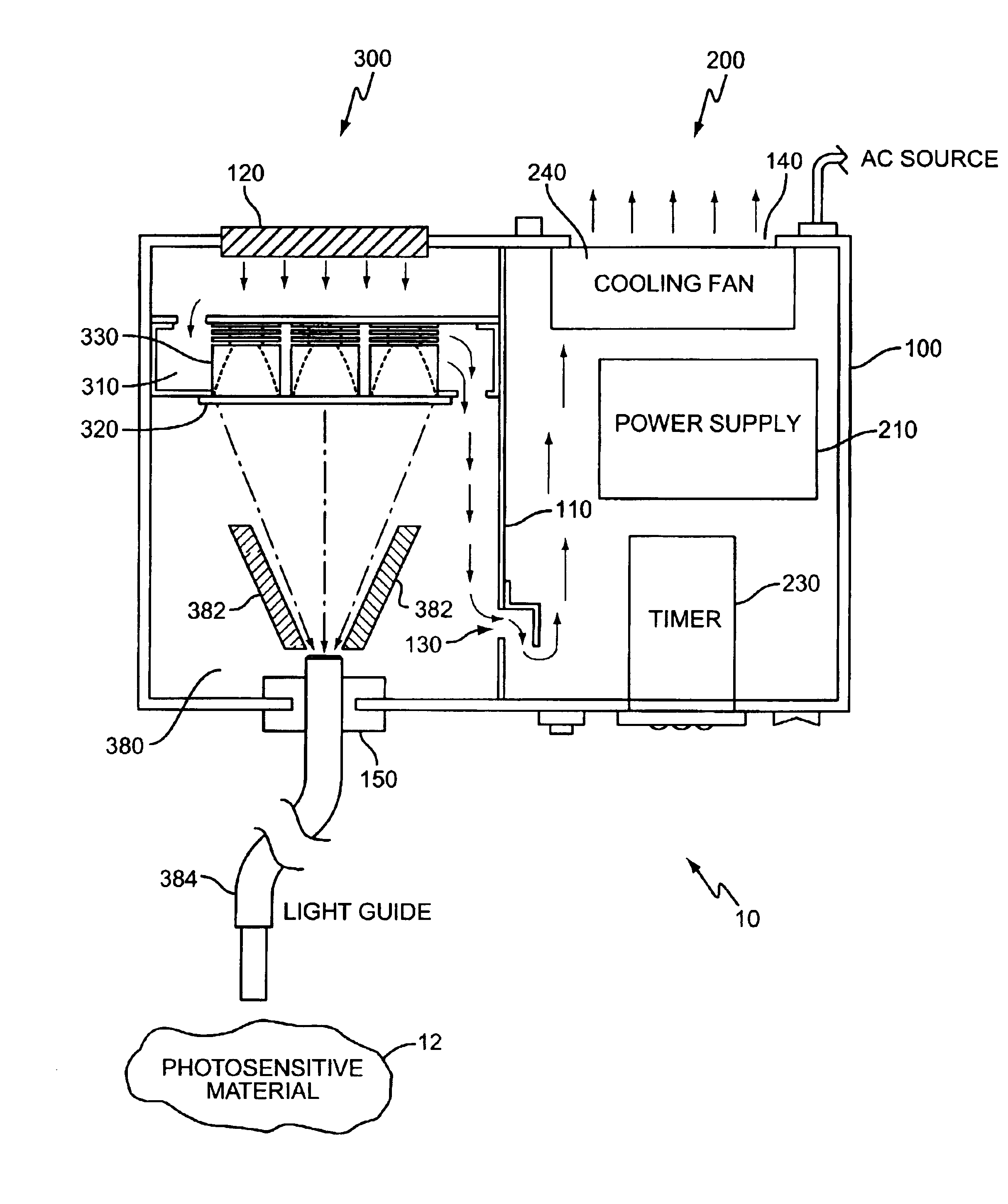

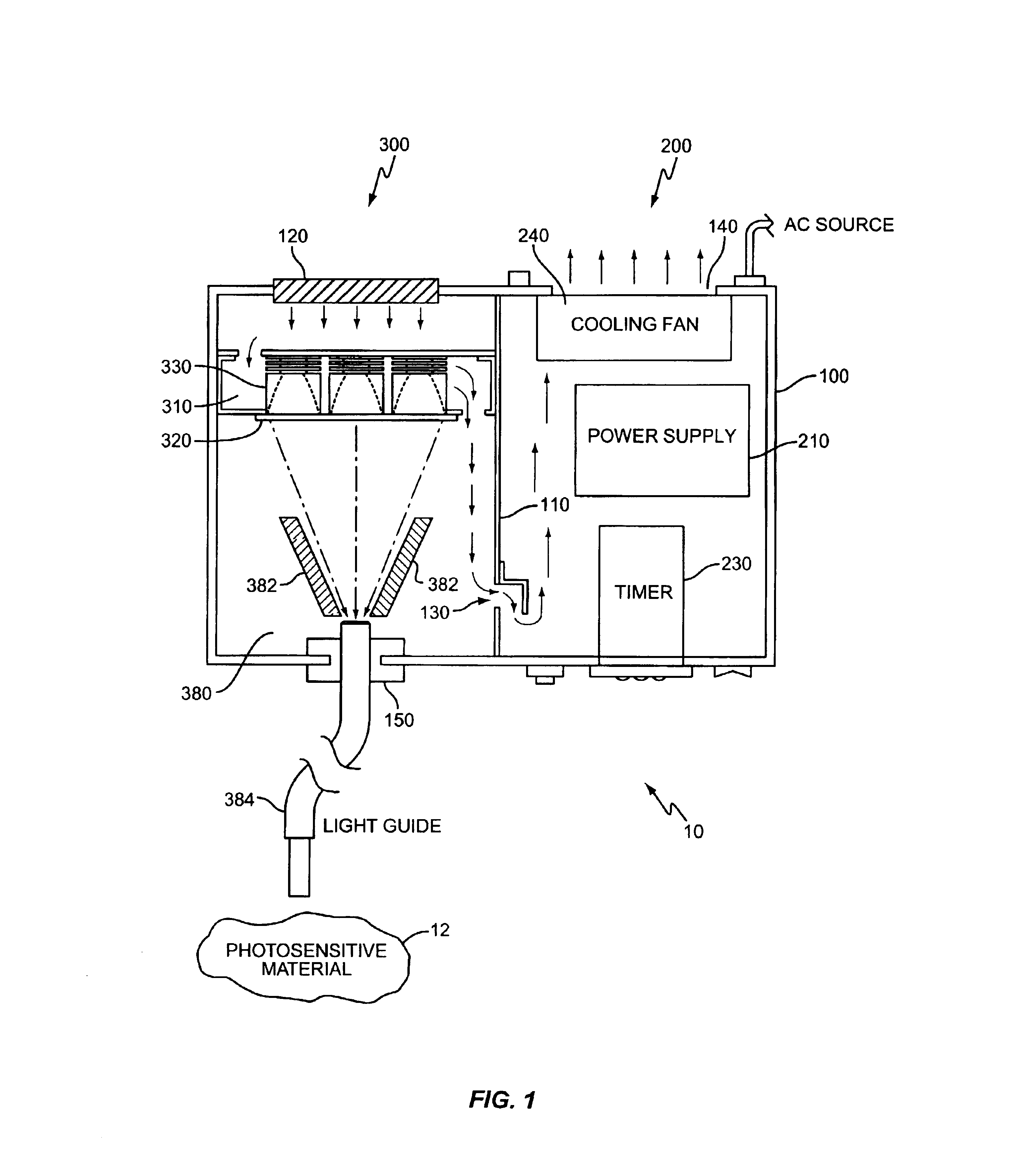

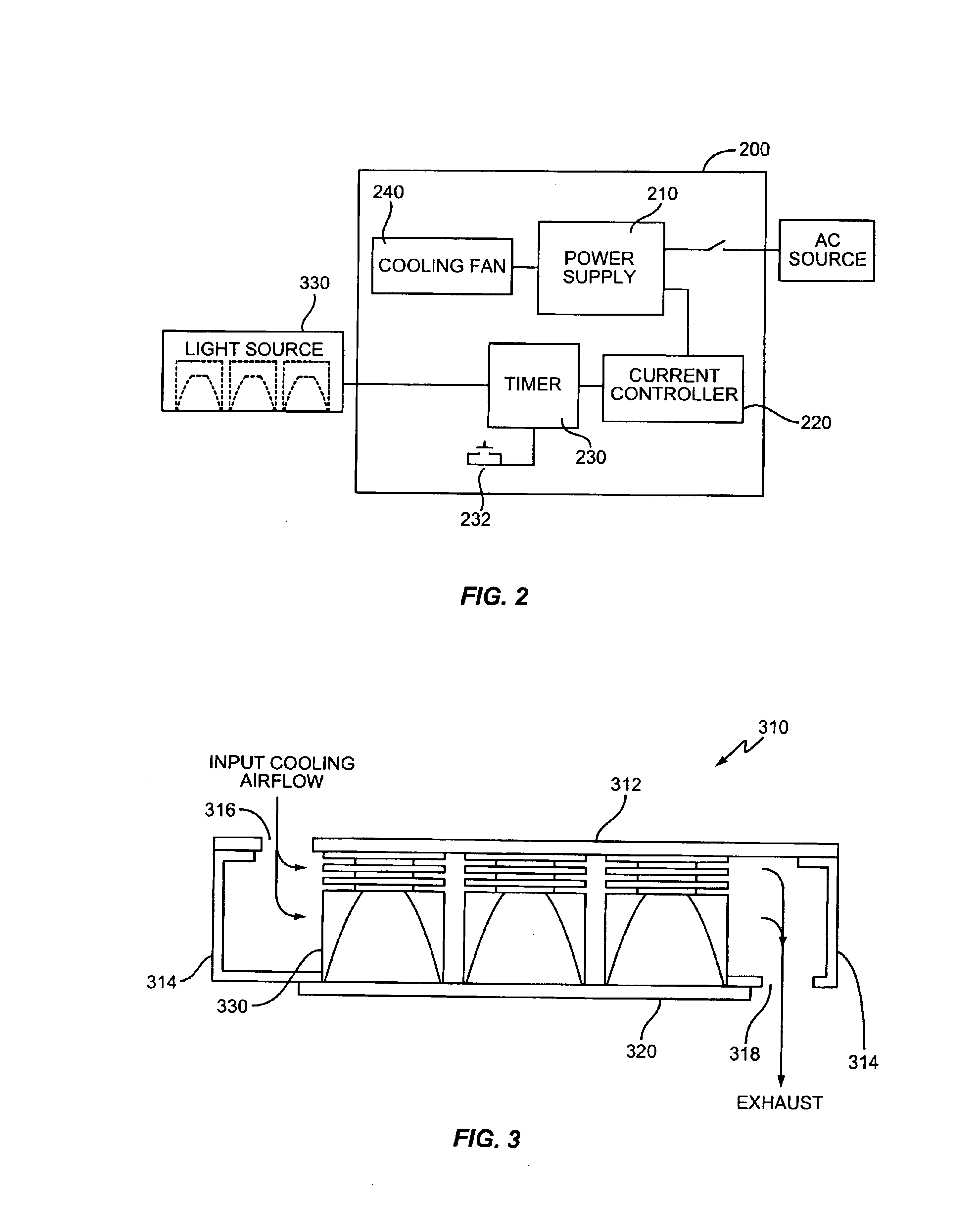

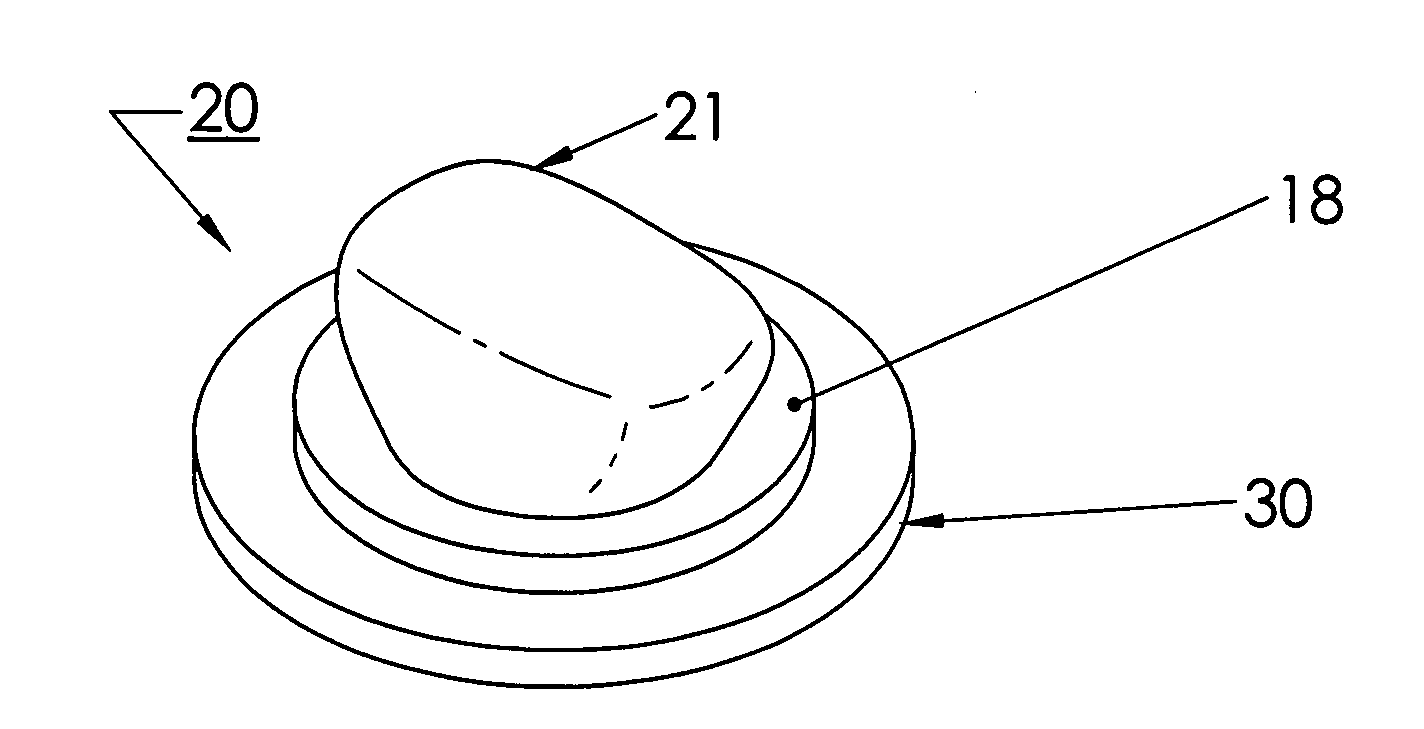

High intensity photocuring system

A method and apparatus for curing photosensitive materials uses LEDs and an optical concentrator to generate high optical power intensities. An LED array, comprising a plurality of LED assemblies, generates collimated light. A collection lens functions as an optical concentrator and focuses the collimated light to a desired spot size at a desired location. The LED assemblies may be at least partially disposed in a cooling plenum, where the cooling plenum is at least partially defined by the collection lens. Each LED assembly within the LED array may be detachably coupled to a mounting surface, enabling easy replacement of individual LED assemblies within the LED array. The photocuring assembly may also include a redirecting assembly disposed between the collection lens and the desired location that may further concentrate the light at the desired location. The photocuring assembly may include more than one of the above features.

Owner:SMD SOFTWARE

LED device for wide beam generation

ActiveUS7674018B2Easy to combineReduce discontinuityPlanar light sourcesMechanical apparatusSurface patternWide beam

An apparatus and method is characterized by providing an optical transfer function between a predetermined illuminated surface pattern, such as a street light pattern, and a predetermined energy distribution pattern of a light source, such as that from an LED. A lens is formed having a shape defined by the optical transfer function. The optical transfer function is derived by generating an energy distribution pattern using the predetermined energy distribution pattern of the light source. Then the projection of the energy distribution pattern onto the illuminated surface is generated. The projection is then compared to the predetermined illuminated surface pattern to determine if it acceptably matches. The process continues reiteratively until an acceptable match is achieved. Alternatively, the lens shape is numerically or analytically determined by a functional relationship between the shape and the predetermined illuminated surface pattern and predetermined energy distribution pattern of a light source as inputs.

Owner:SIGNIFY HLDG BV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com