Anticorrosion layer peeling testing device based on electrochemical impedance spectrum

A test device, electrochemical technology, applied in the direction of measuring devices, scientific instruments, material analysis through electromagnetic means, etc., can solve the problems of affecting the test area, affecting the test results, peeling failure, etc., to achieve good repeatability and reproducibility, The effect of fixed test area and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

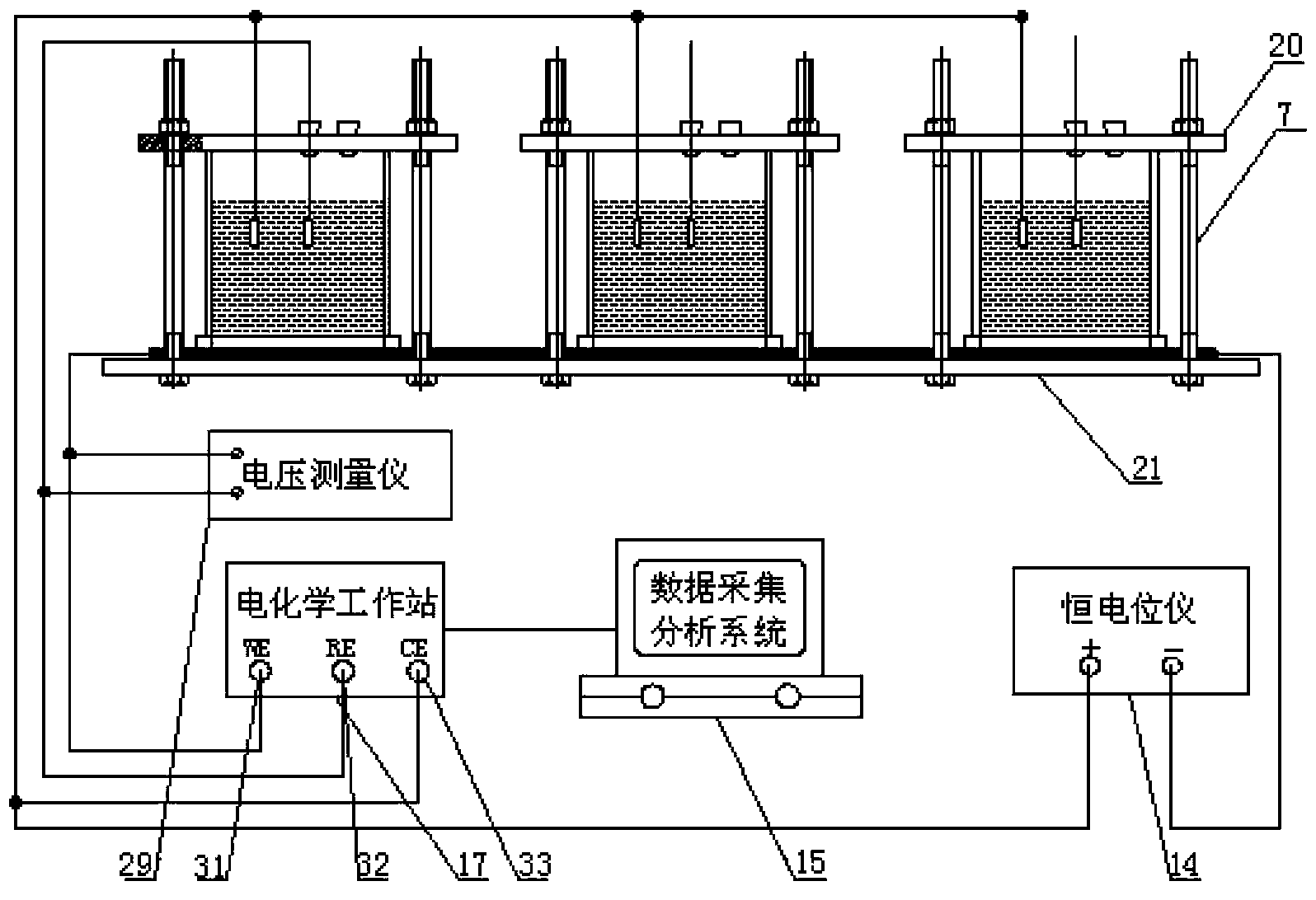

[0029] An anti-corrosion layer peeling test device based on electrochemical impedance spectroscopy, its specific structure schematic diagram, left view and top view are as follows figure 1 , 2 , 3, including: electrolytic cell group 7, potentiostat 14, data acquisition and analysis system 15, electrochemical workstation 17 and voltage measuring instrument 29.

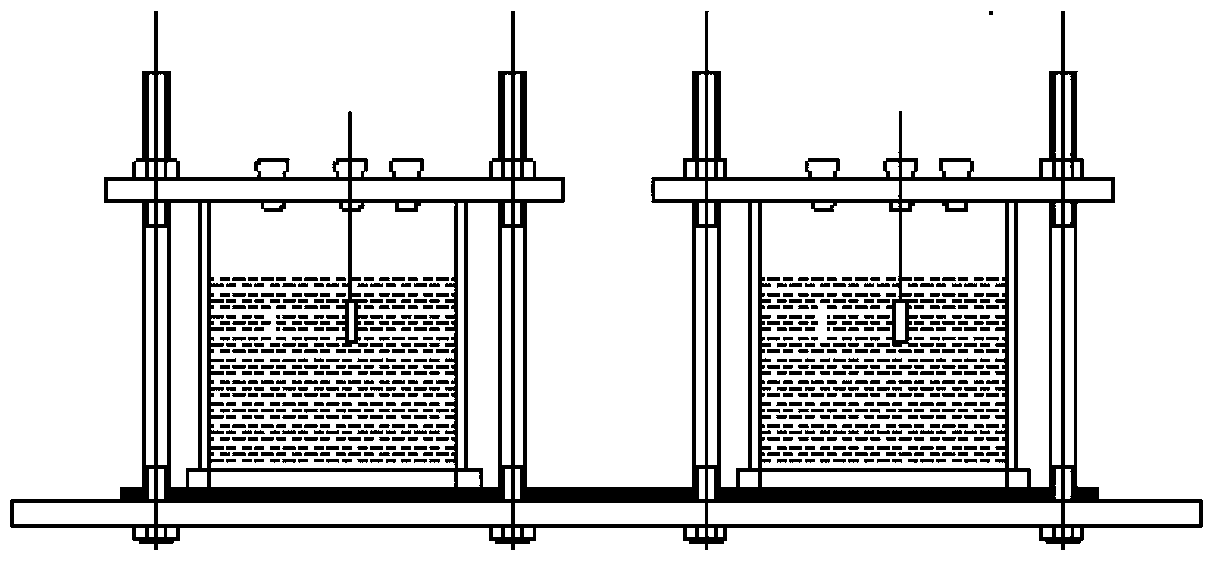

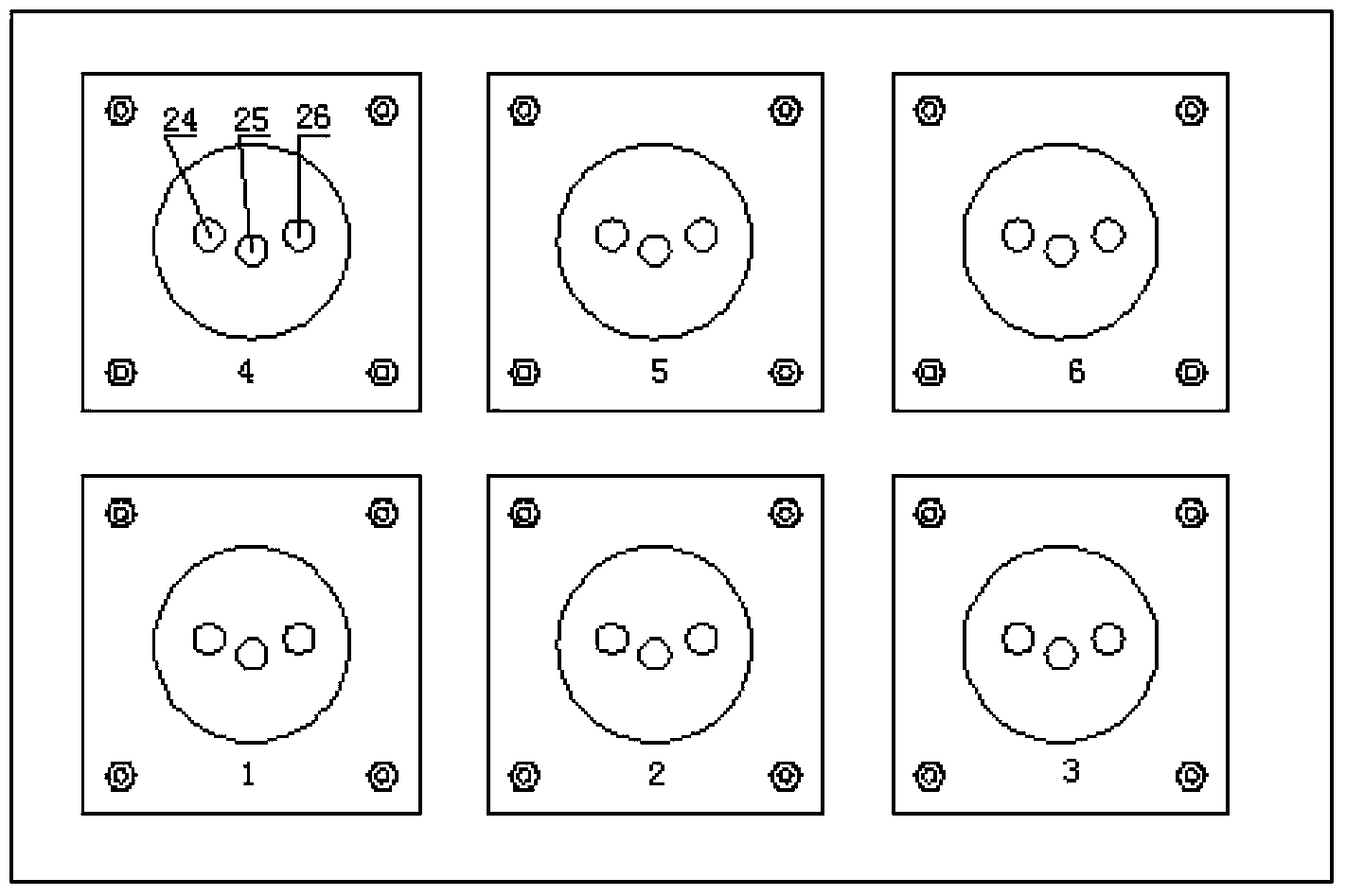

[0030] Electrolytic cell group 7 comprises six identical electrolytic cells, and the specific structure of each small electrolytic cell is as follows: Figure 4 shown. Each electrolytic cell contains simulated soil solution 8, the lower end surface 9 of each electrolytic cell is in direct contact with the upper end surface 11 of the rubber gasket 10, and the lower end surface 12 of the rubber gasket 10 is in direct contact with the test piece 13 with an anti-corrosion layer. The top v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com