A strip tape, a packaging container having such a strip tape, and a method of producing such a strip tape

A technology for packaging containers and strips, which is applied in the fields of strips, packaging containers with the strips, and the manufacture of the strips, and can solve problems such as damage to the strip structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

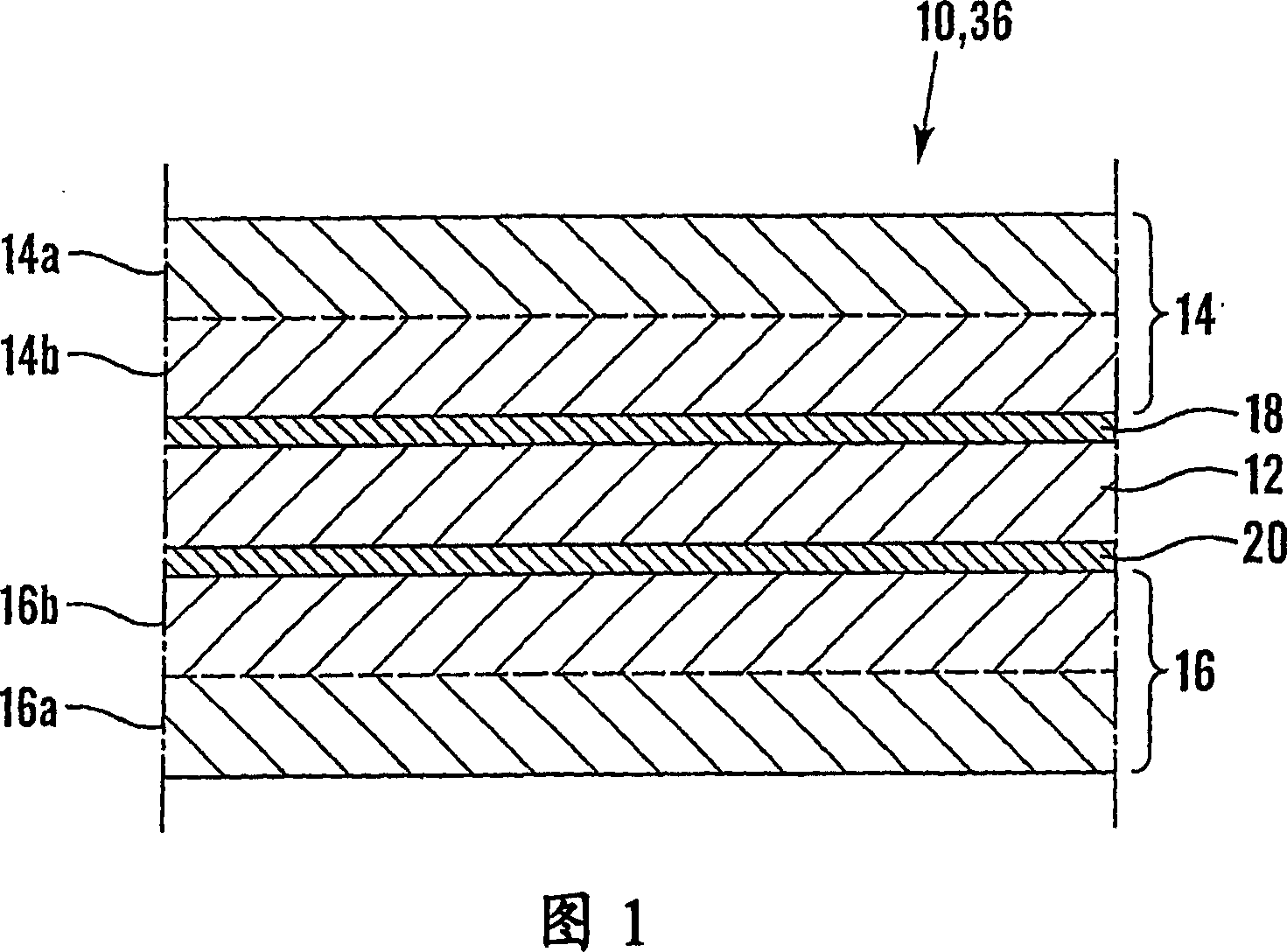

[0050] The preferred strip 36 according to the invention and as shown in FIG. 1 is of symmetrical construction 10 and is made by adhesive lamination of three prefabricated films 12 , 14 , 16 . The prefabricated core layer 12 has a thickness of 12 μm and is made of a biaxially oriented PET film.

[0051] The outwardly facing surface of the strip 10 consists of PP partial layers 14a and 16a which have been co-extruded and blown together with grafted PP partial layers 14b and 16b respectively to form 25 μm pre-films 14 and 16 respectively. The grafted PP partial layers 14b and 16b each directly face an adhesive layer 18, 20 and are suitable for proper adhesion to these adhesive layers due to the grafted character of the PP partial layers 14b, 16b. Examples of properly functioning PP grades are: Inspire 112 from Dow, Inspire 114 from Dow, Borclear RB707CF from Borealis, RB501BF from Borealis, BA110CF from Borealis, Daploy from Borealis SF203HMS, PP4352F1 from Exxon Mobil or PPH30...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com