Liquid crystal panel, display device and manufacturing method of liquid crystal panel

A liquid crystal panel and color film substrate technology, which is applied in the field of liquid crystal display, can solve the problem of insufficient friction between the sealant bonding color film substrate and array substrate, and achieve the effects of improving quality, wide application prospects, and enhancing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

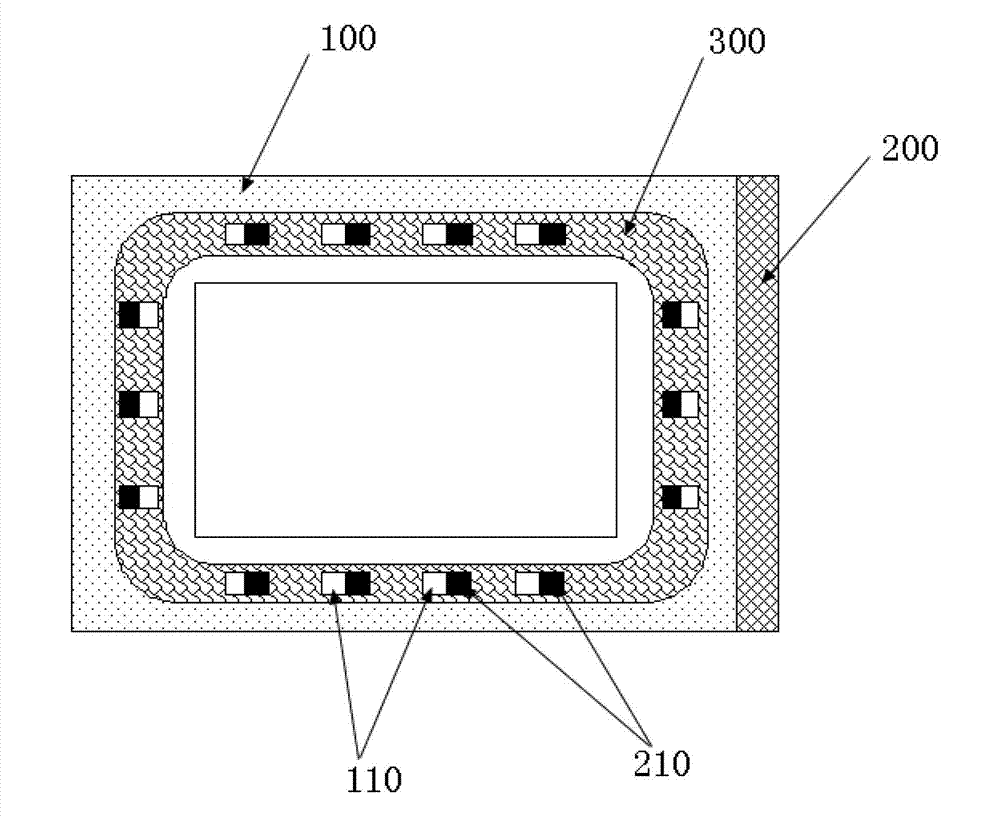

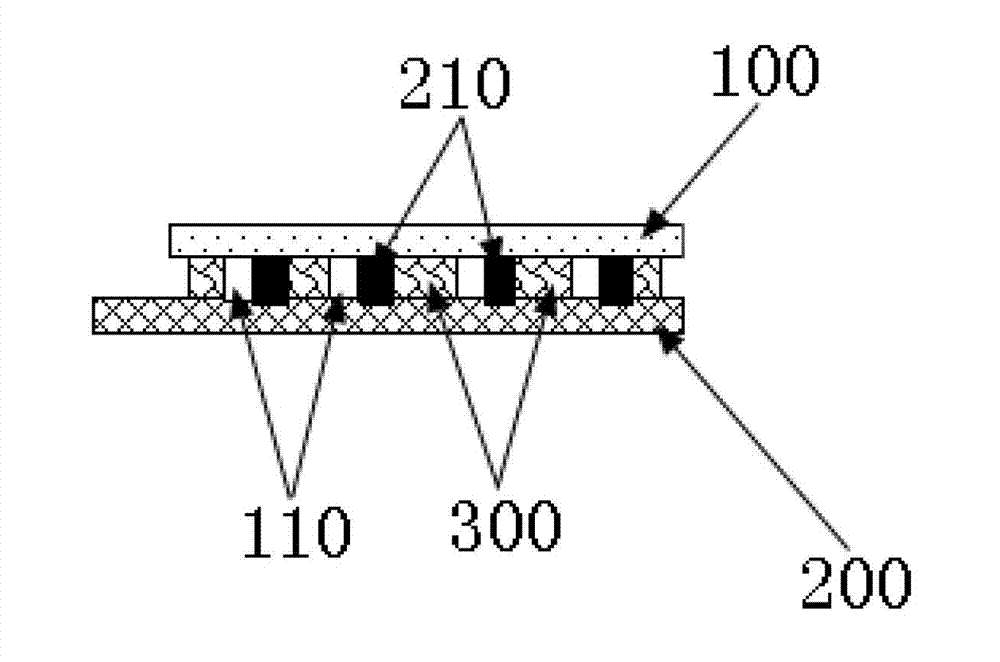

[0037] figure 1 It is a top view of the liquid crystal panel described in Embodiment 1 of the present invention, figure 2 It is a side sectional view of the liquid crystal panel described in Embodiment 1 of the present invention, as shown in figure 1 and figure 2 As shown, the liquid crystal panel includes: a color filter substrate 100 , an array substrate 200 , and a sealant 300 bonding the color filter substrate 100 and the array substrate 200 .

[0038] Within the region of the sealant 300 , a first limiting member 110 having a predetermined height is disposed on the color filter substrate 100 , and a second limiting member 210 is disposed on the array substrate. In this embodiment, the first limiting member 110 is a cylindrical body with a rectangular cross section, the second limiting member 210 is a cylindrical body with a rectangular cross section, and when the color filter substrate 100 and the array substrate When 200 are bonded to each other, the first limiting ...

Embodiment 2

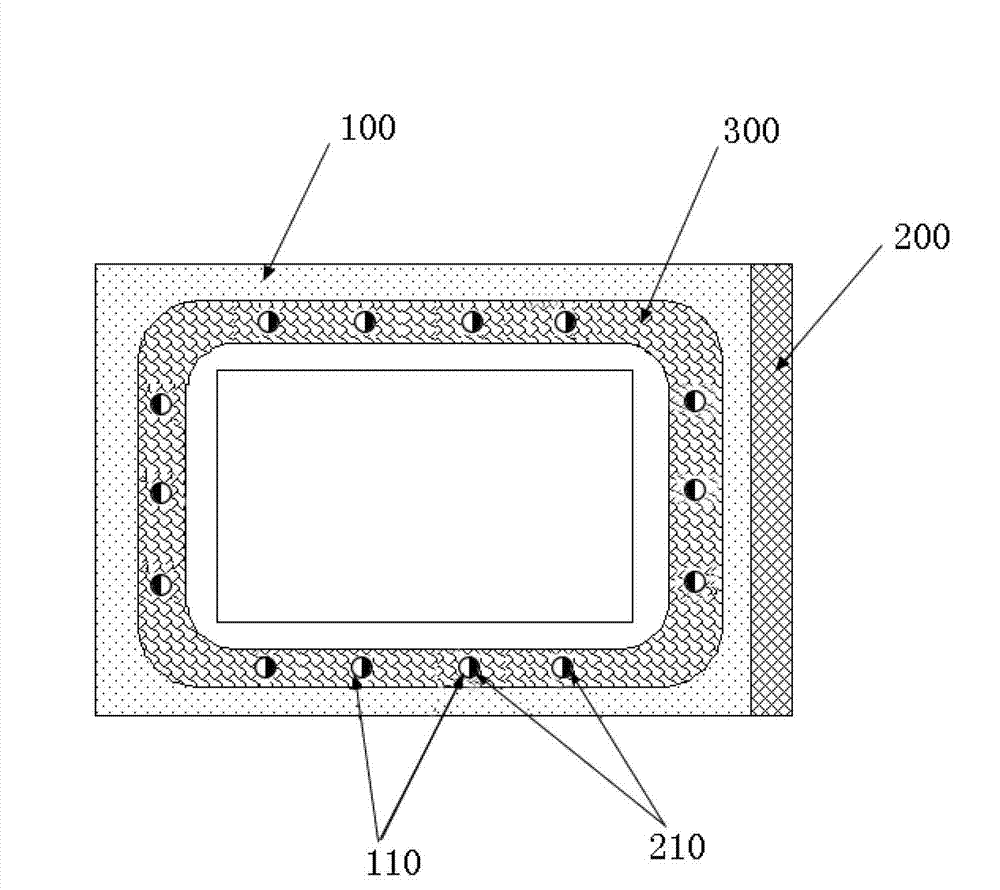

[0043] image 3 It is a top view of the liquid crystal panel described in Embodiment 2 of the present invention, as image 3 As shown, the liquid crystal panel described in this embodiment is basically the same as the liquid crystal panel described in Embodiment 1, the only difference is that the first limiting member 110 is a columnar body with a semicircular cross section, and the second limiting member 110 is a semicircular columnar body. The positioning member 210 is a cylindrical body with a semicircular cross section, and when the color filter substrate 100 and the array substrate 200 are bonded to each other, the first limiting member 110 and the second limiting member 210 are engaged with each other to form a cylindrical structure . With this structural arrangement, the frictional force between the color filter substrate 100 and the array substrate 200 can be significantly enhanced.

Embodiment 3

[0045] Figure 4 It is a side sectional view of the liquid crystal panel described in Embodiment 3 of the present invention, as Figure 4 As shown, the liquid crystal panel described in this embodiment is basically the same as the liquid crystal panel described in Embodiment 1, the only difference is that a groove is provided on the first limiting member 110, and when the color filter substrate 100 When bonding with the array substrate 200 , a part of the second limiting member 210 extends into the groove and engages with the first limiting member 110 .

[0046] In this embodiment, the second limiting member 210 is provided with a protrusion matching the groove, and the protrusion protrudes into the groove, so as to realize that the first limiting member 110 is aligned with the groove. The engagement of the second limiting member 210 . In practical applications, the second limiting member 210 can also be designed as a whole to match the shape of the groove, so that the secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com