Patents

Literature

103 results about "Strip tests" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

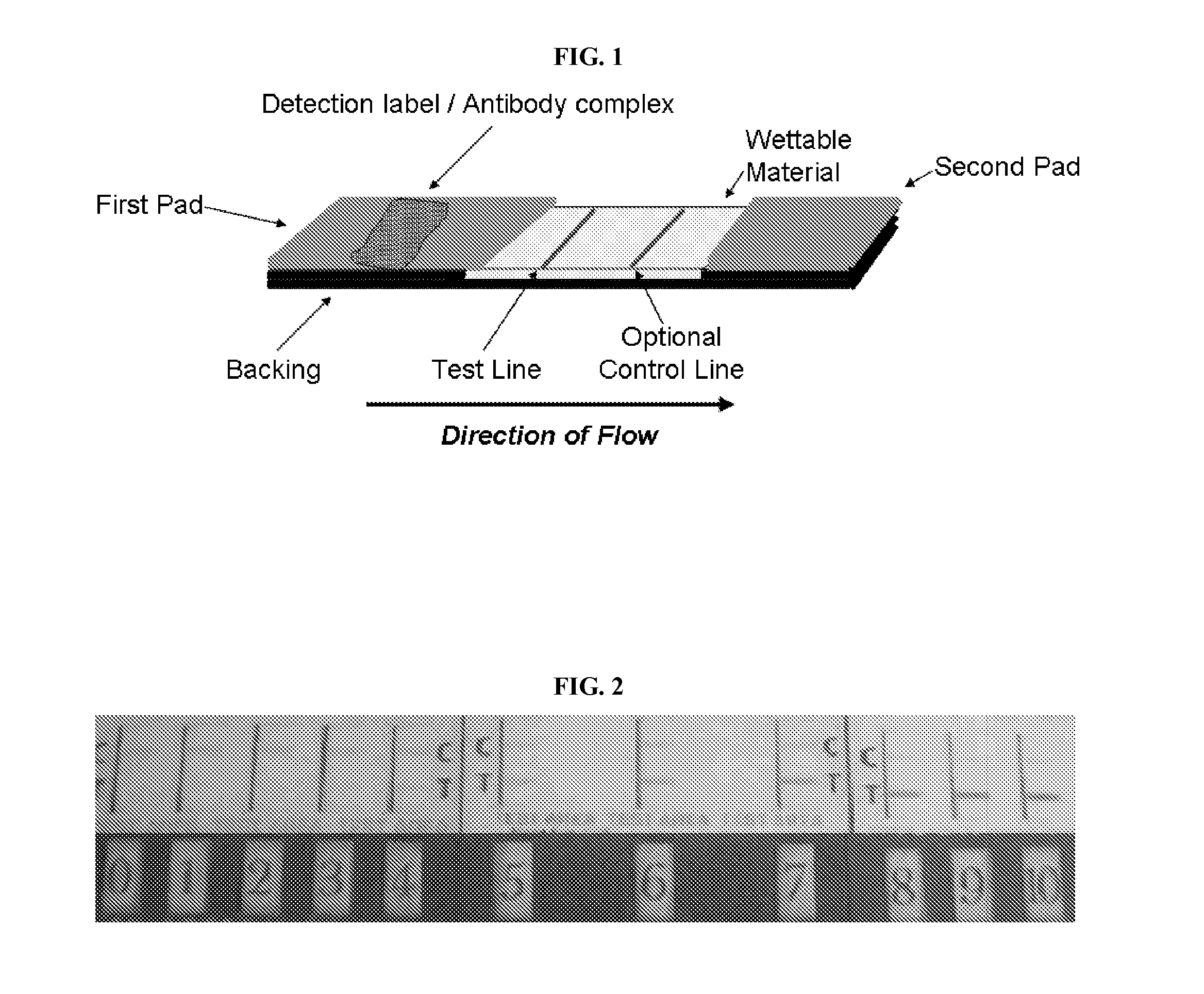

The most commonly used immuno- or antibody-based test for GMO detection is the strip test (also called a lateral flow device or dipstick). Strip tests are thin strips comprised of a nitrocellulose membrane covered by a sample pad on one end and a wicking pad on the other end.

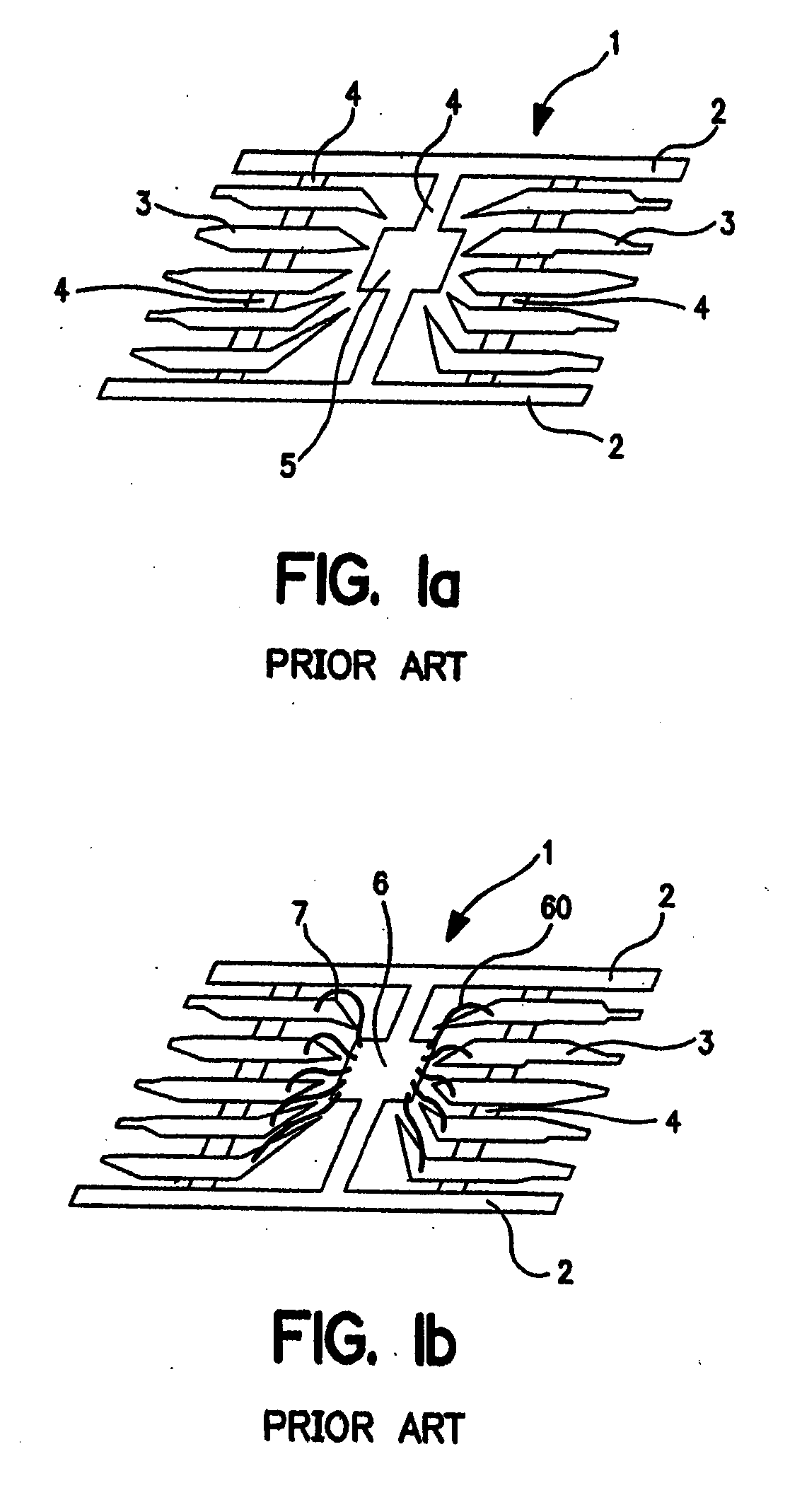

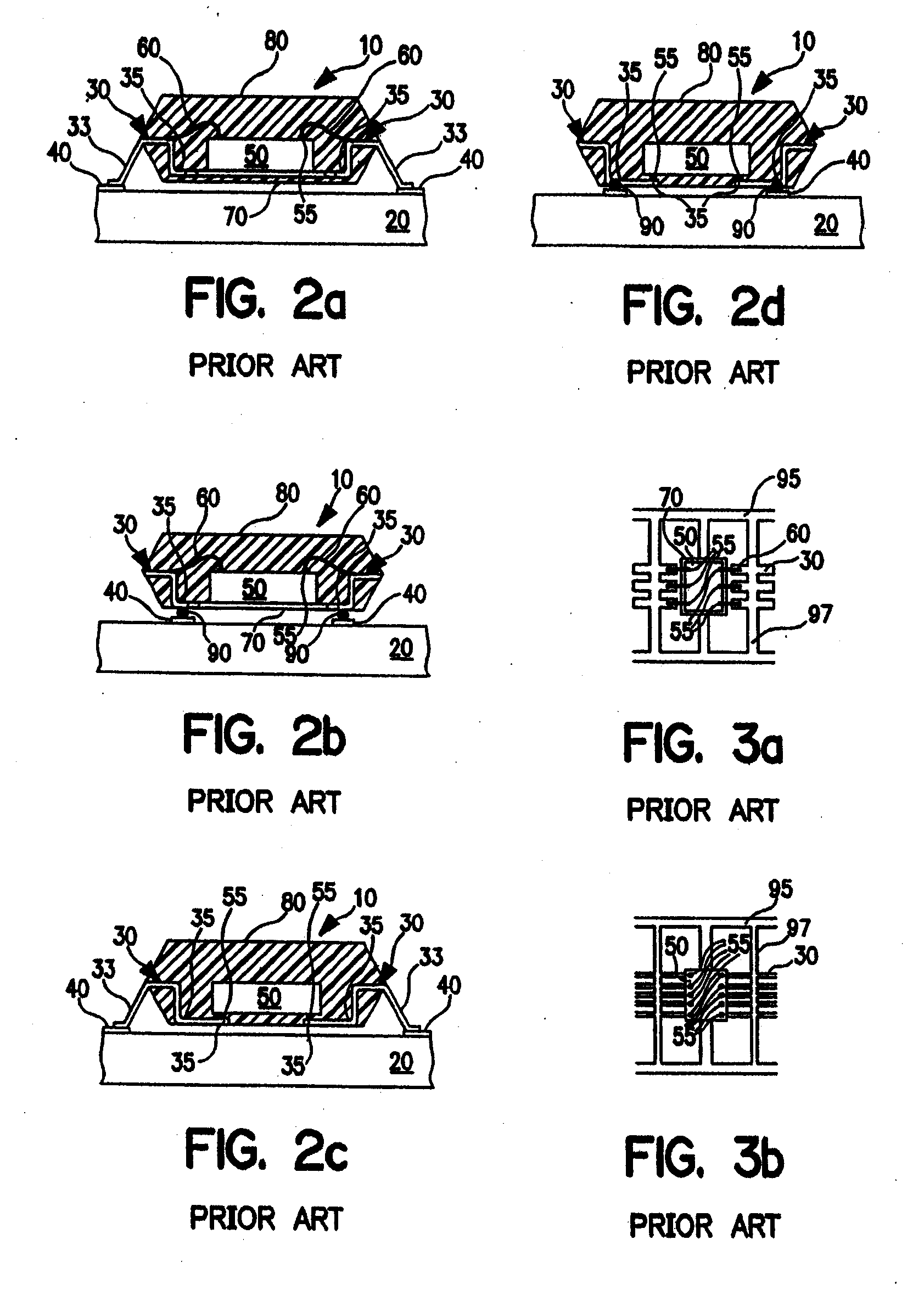

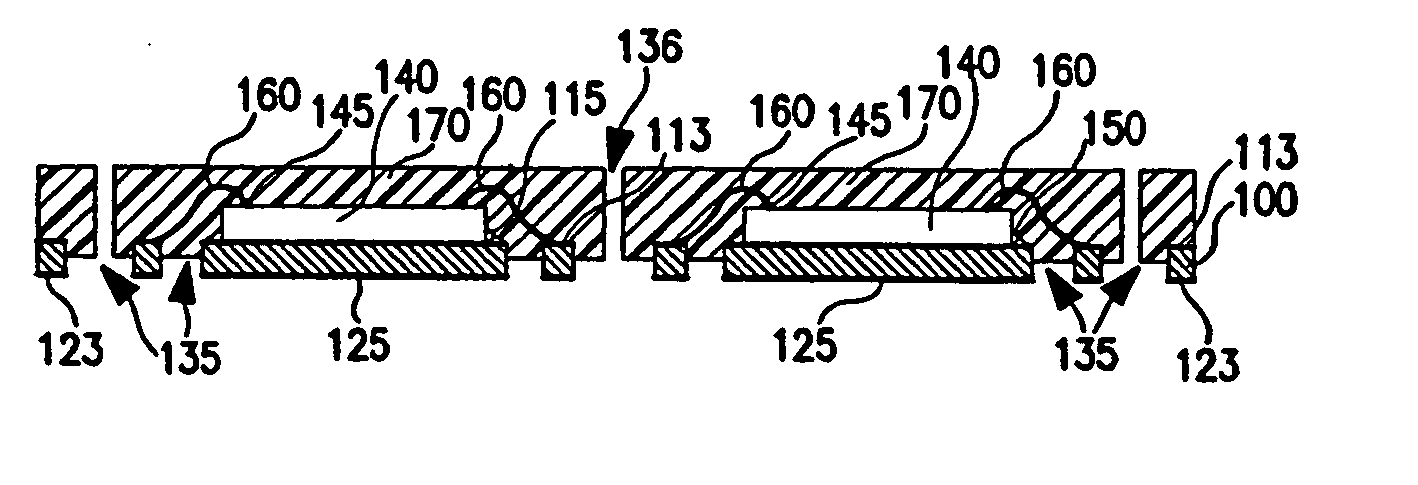

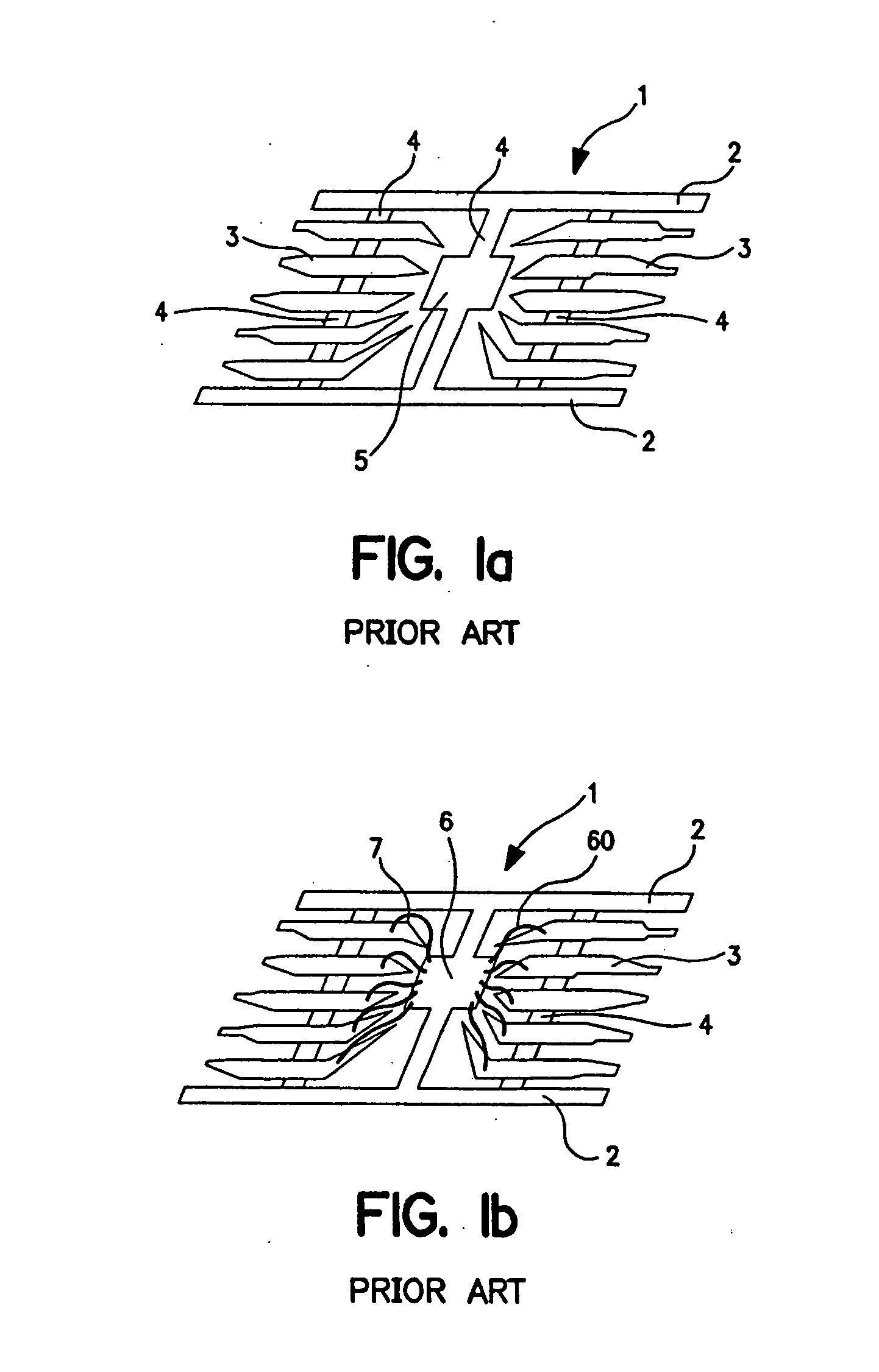

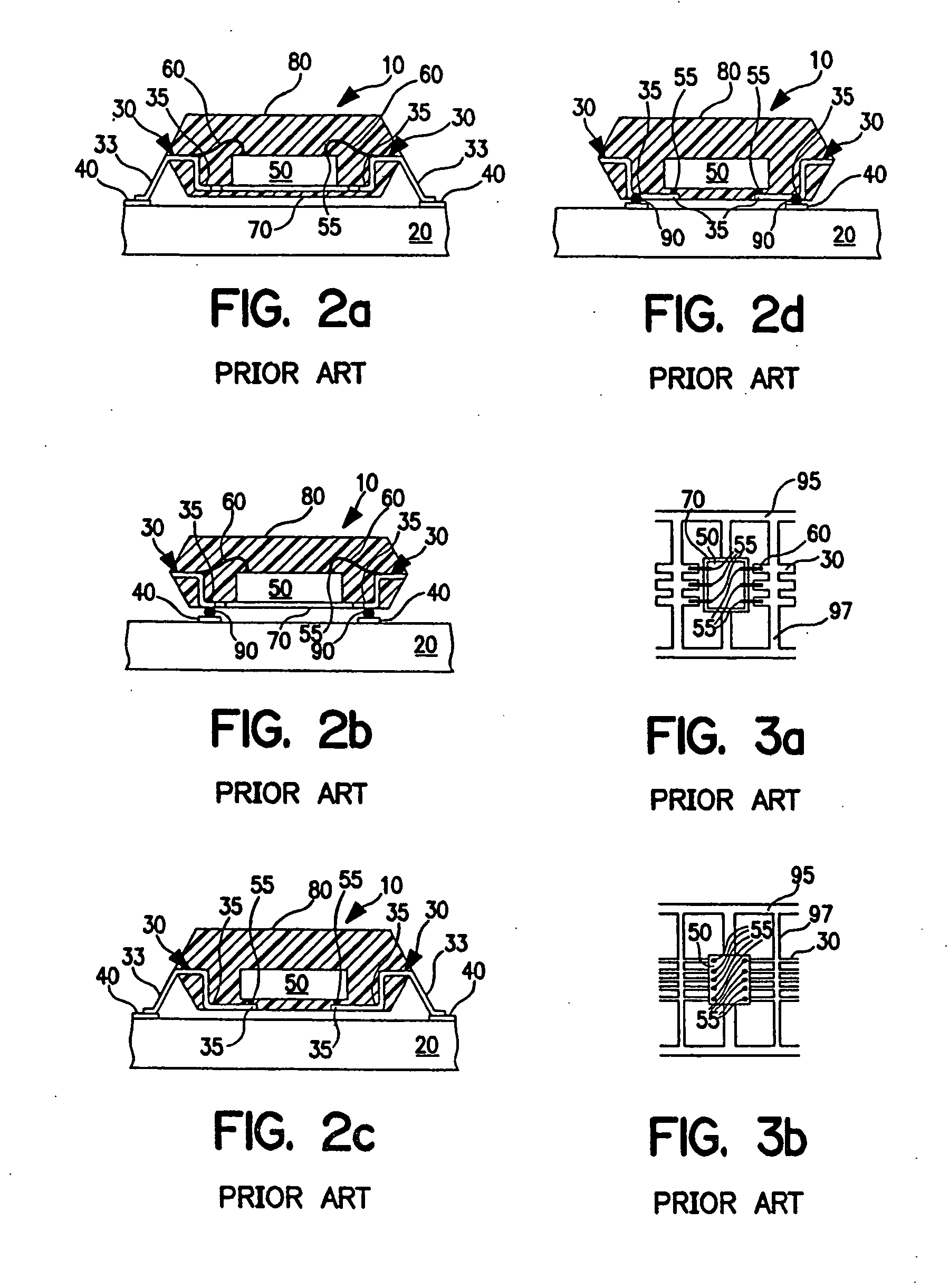

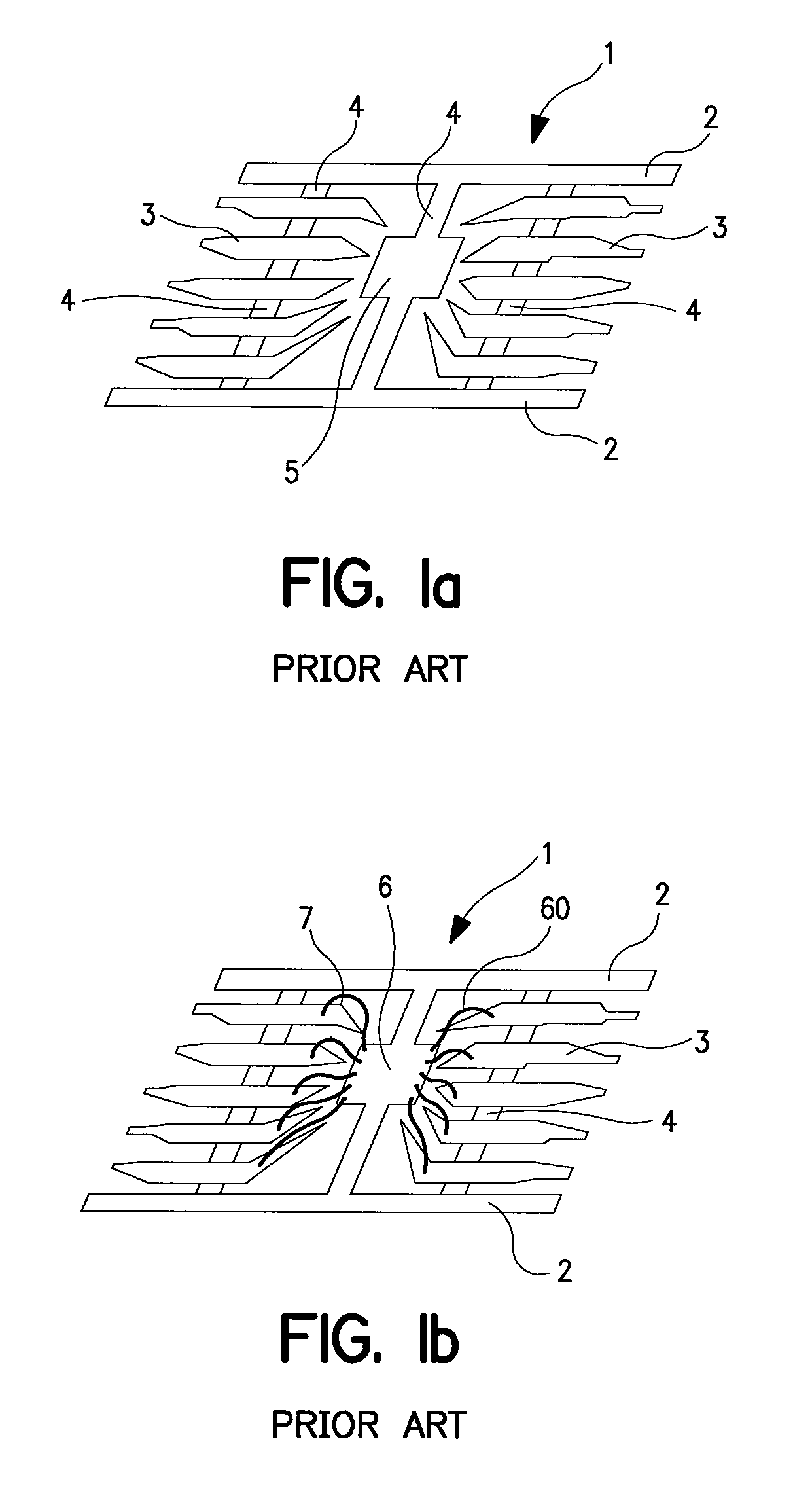

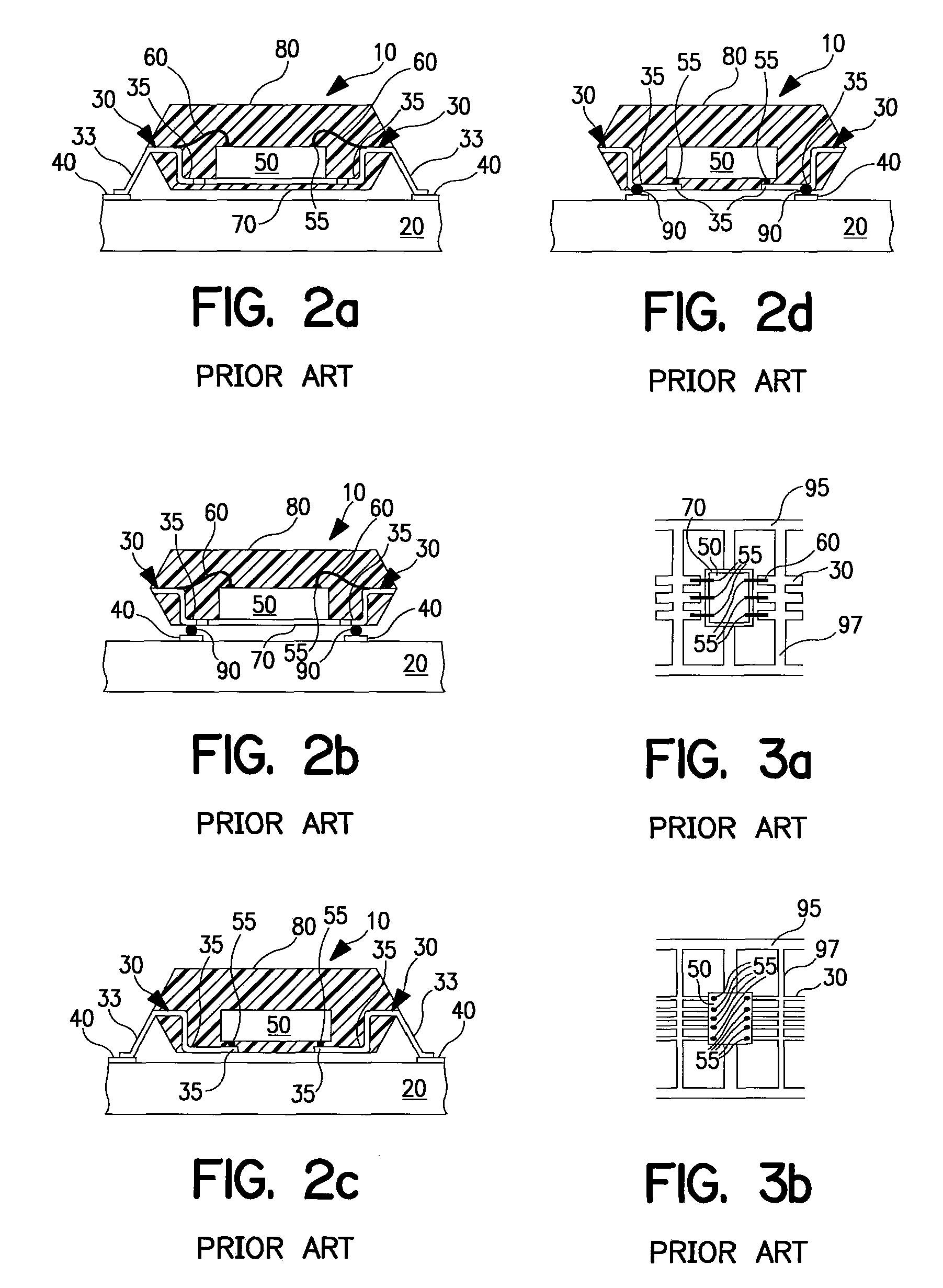

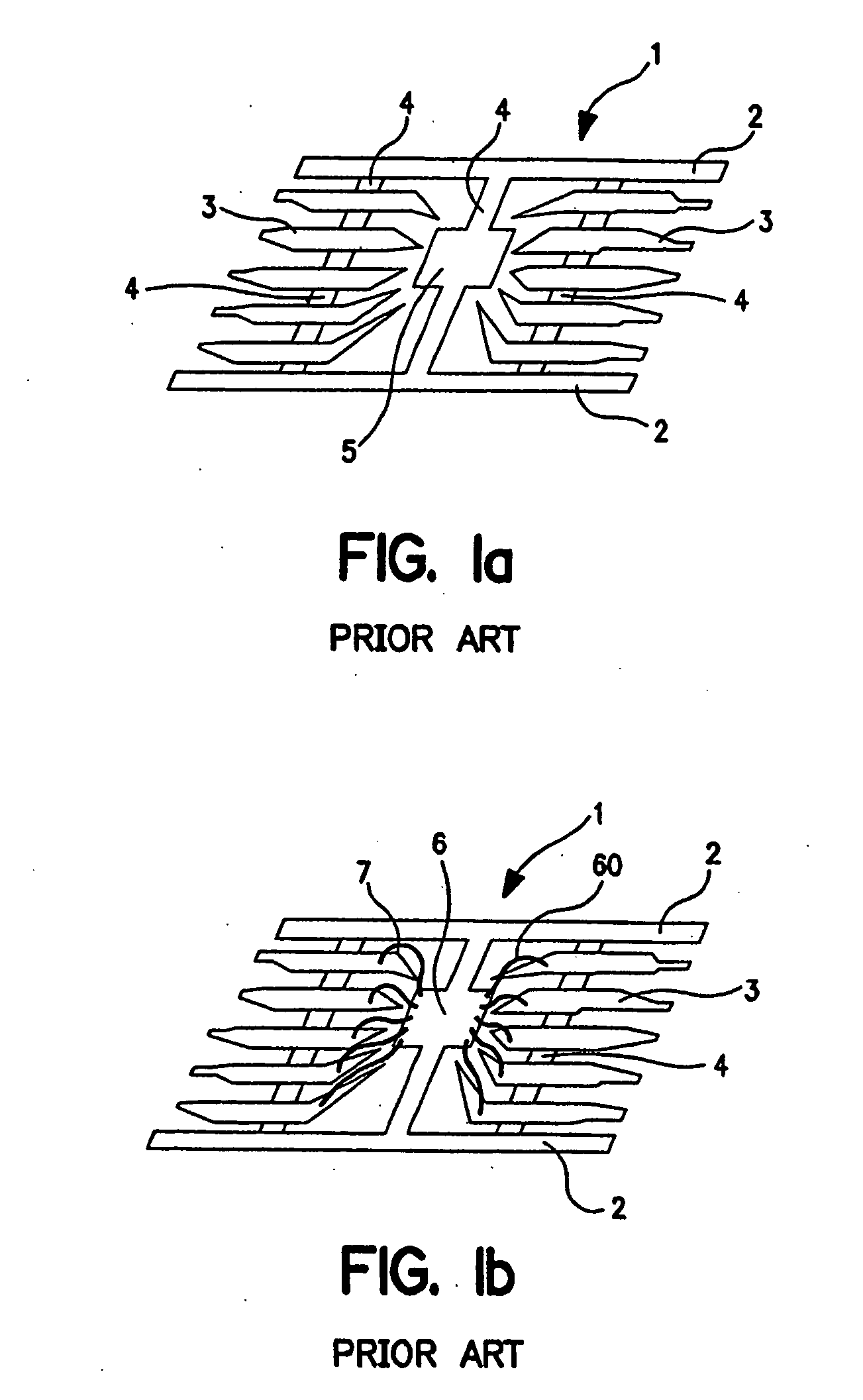

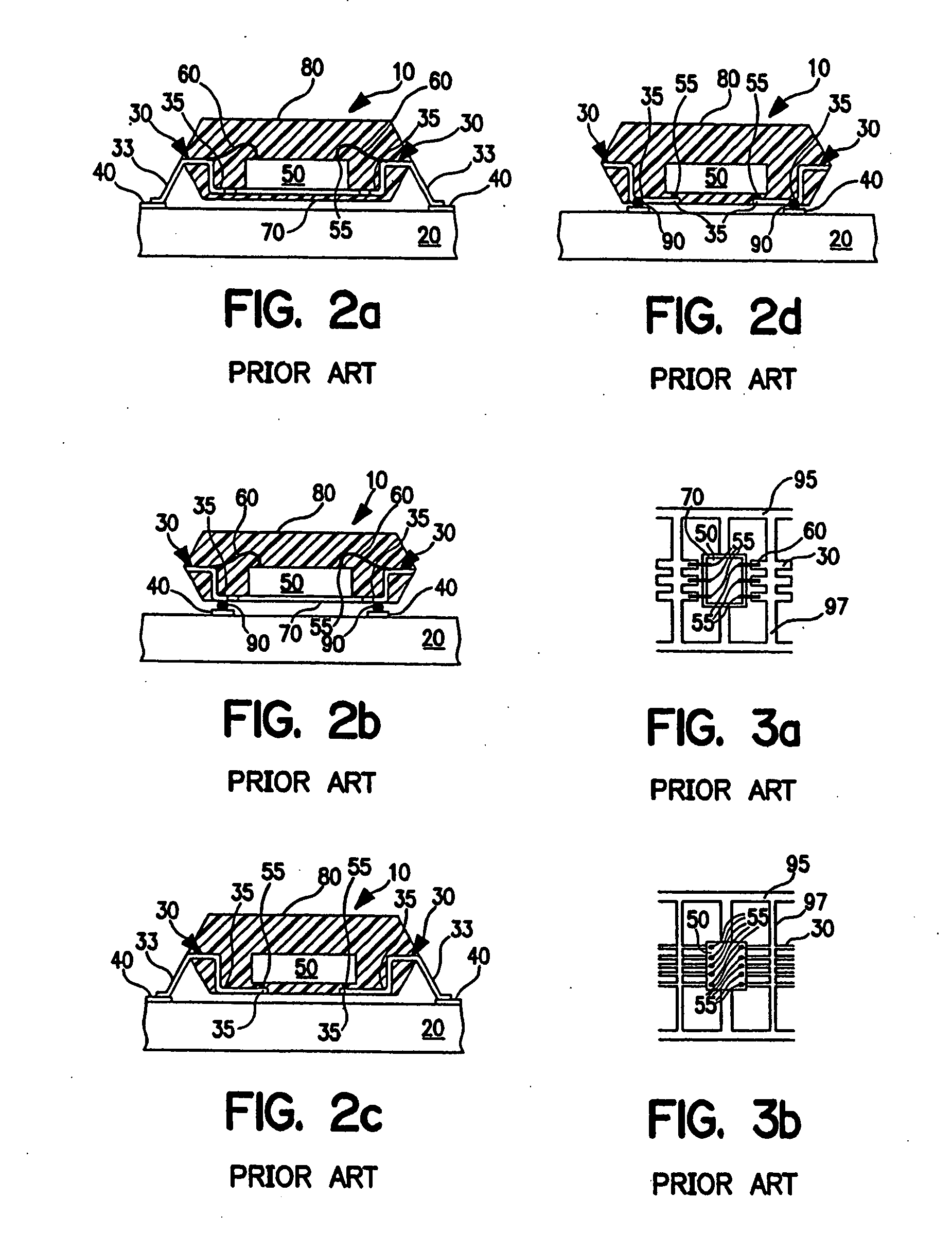

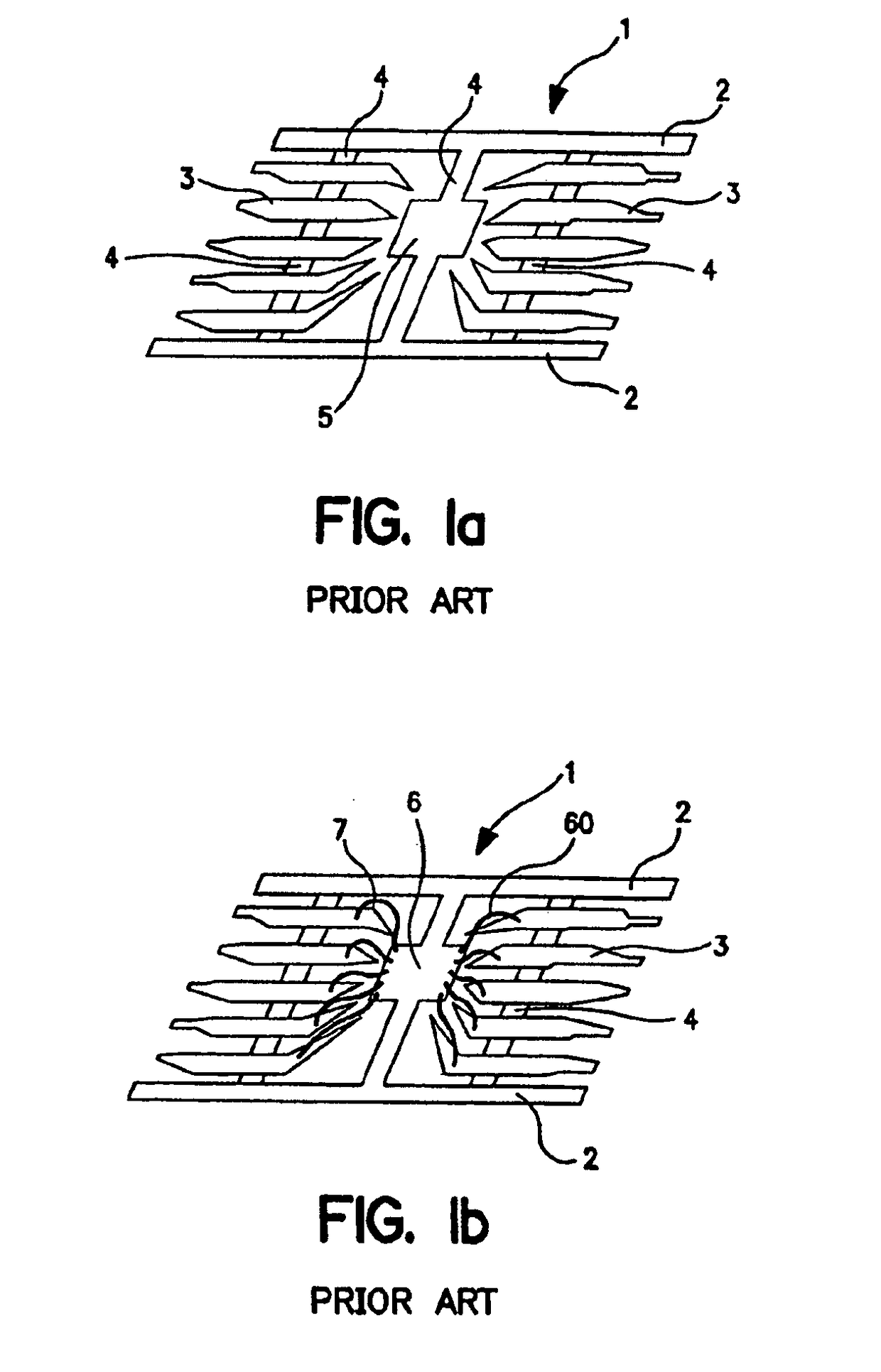

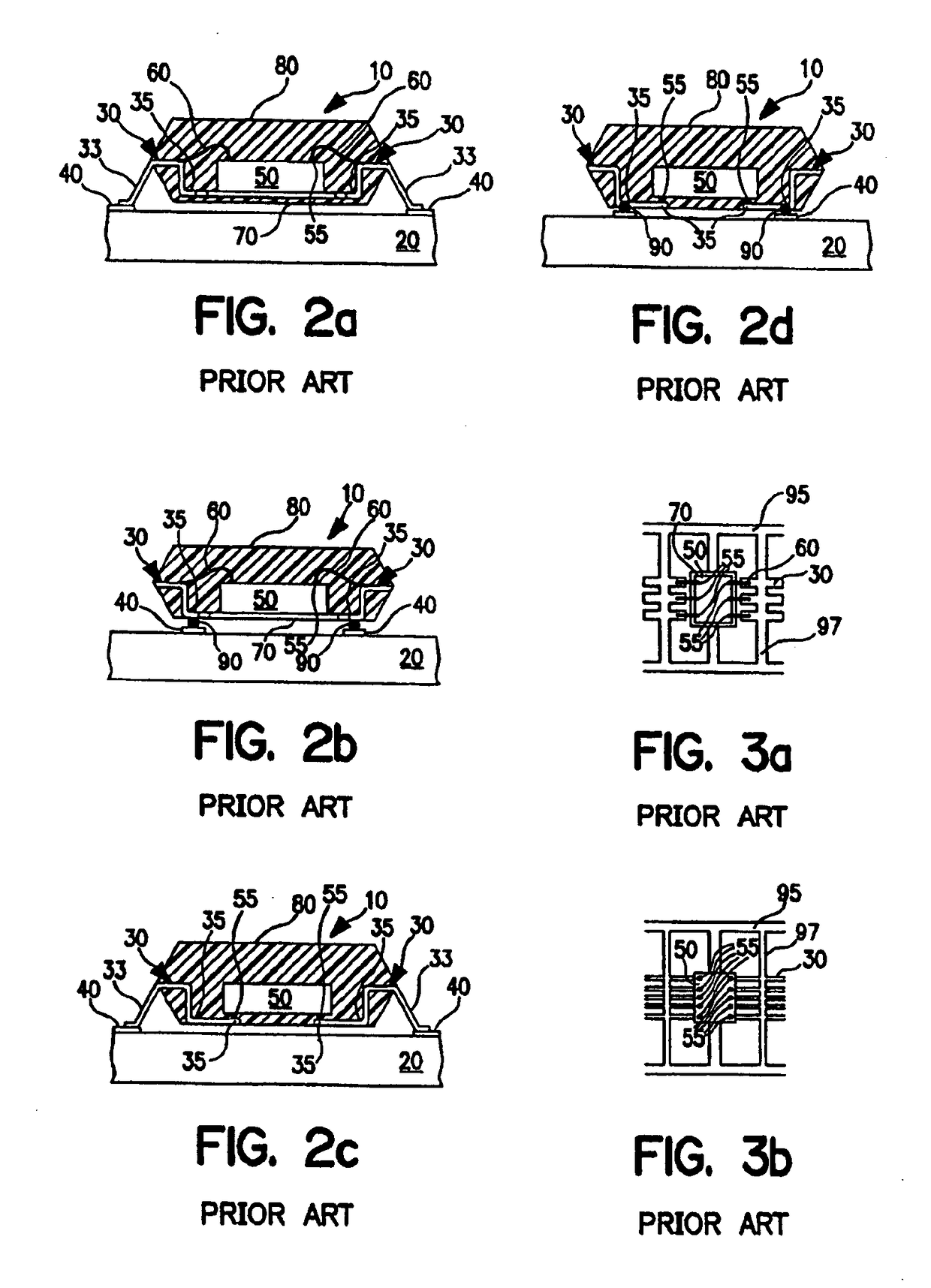

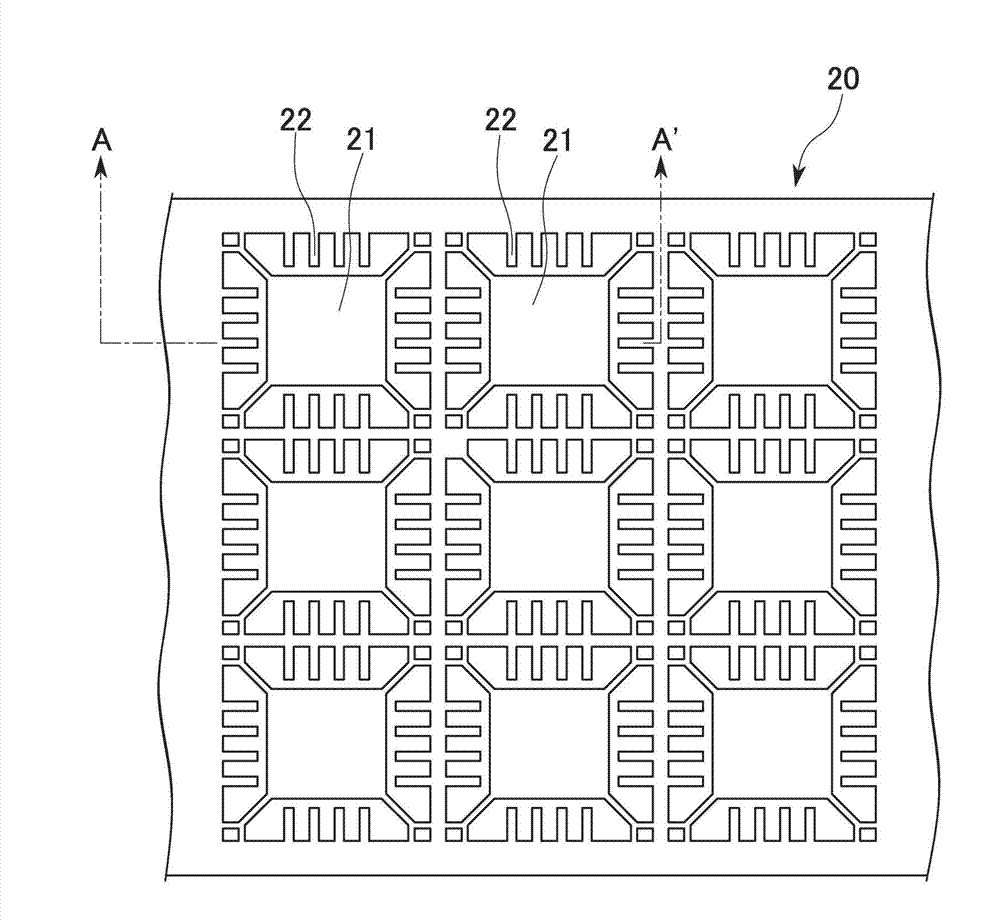

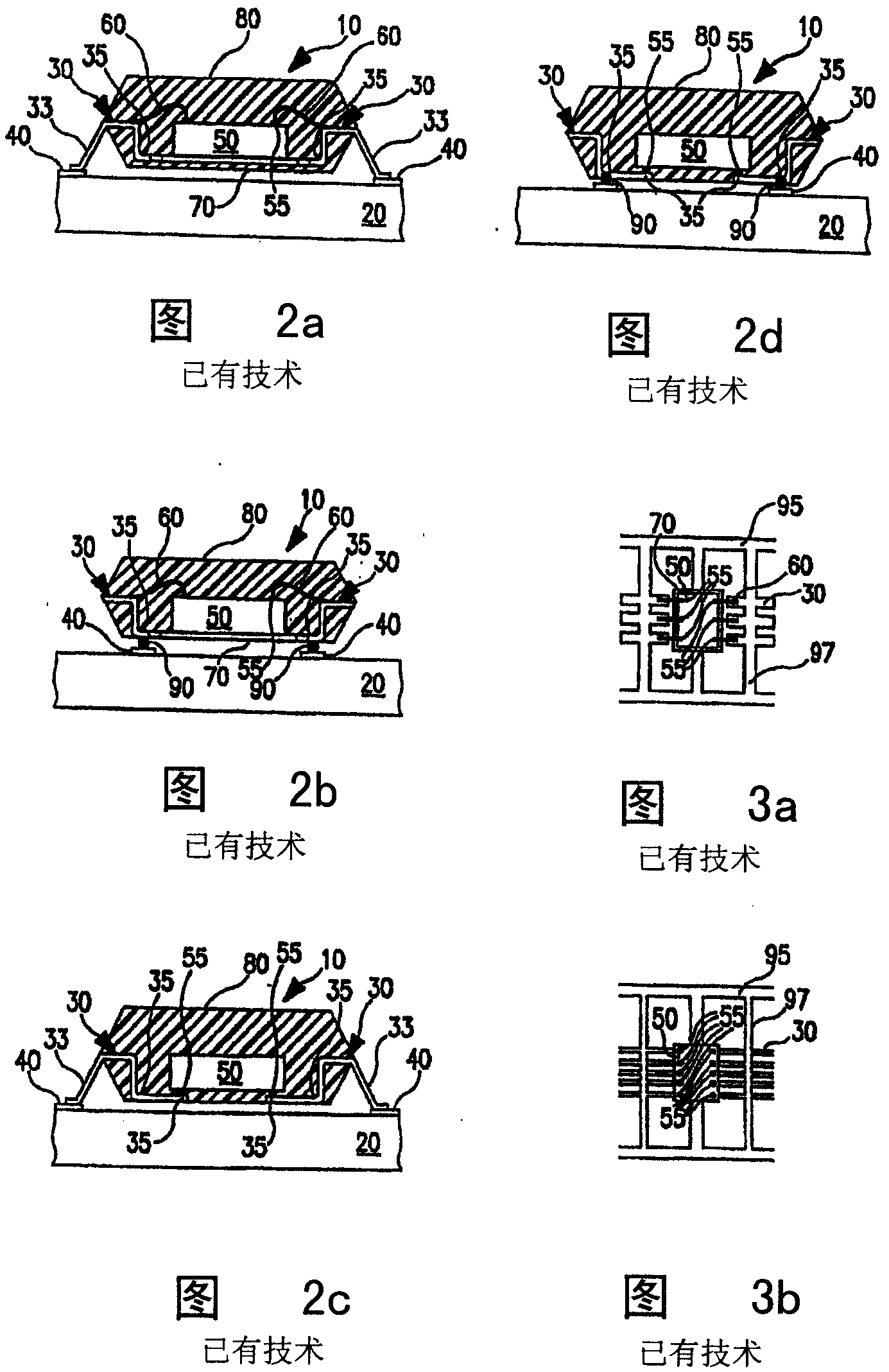

Partially patterned lead frames and methods of making and using the same in semiconductor packaging

InactiveUS20080258278A1Reduce thicknessImprove structural rigiditySemiconductor/solid-state device detailsSolid-state devicesLead bondingBonding process

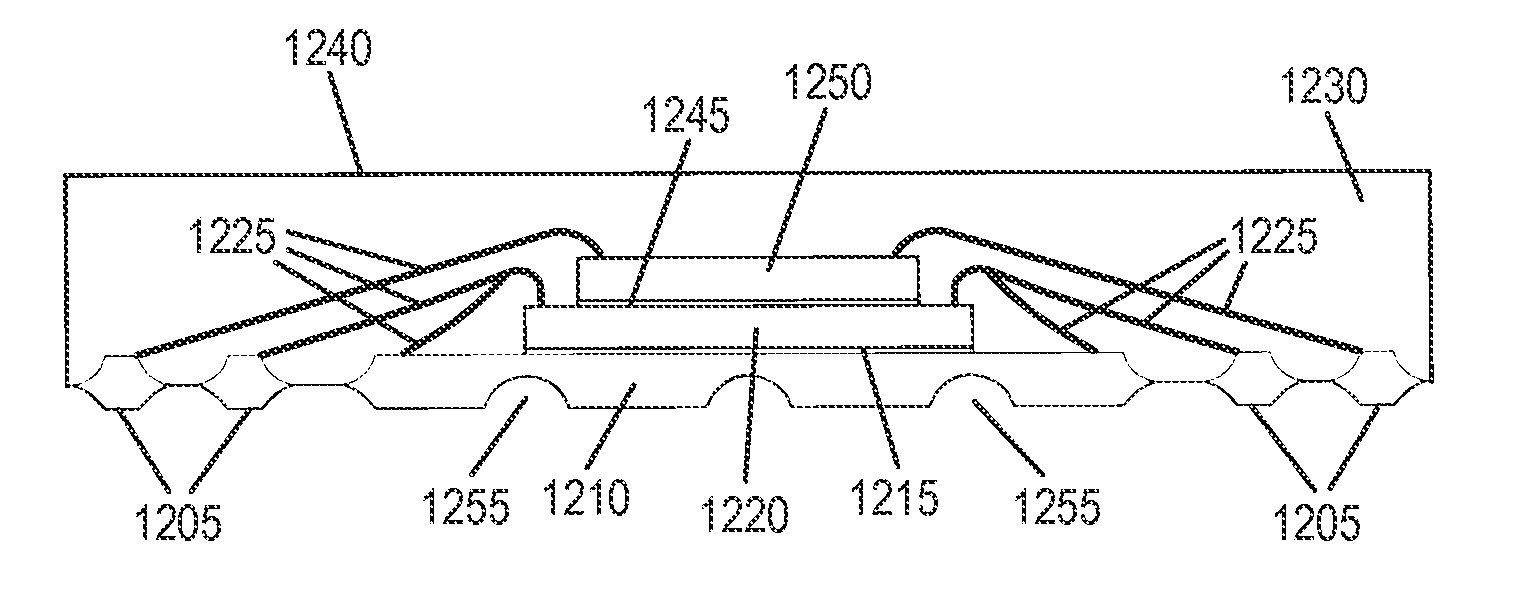

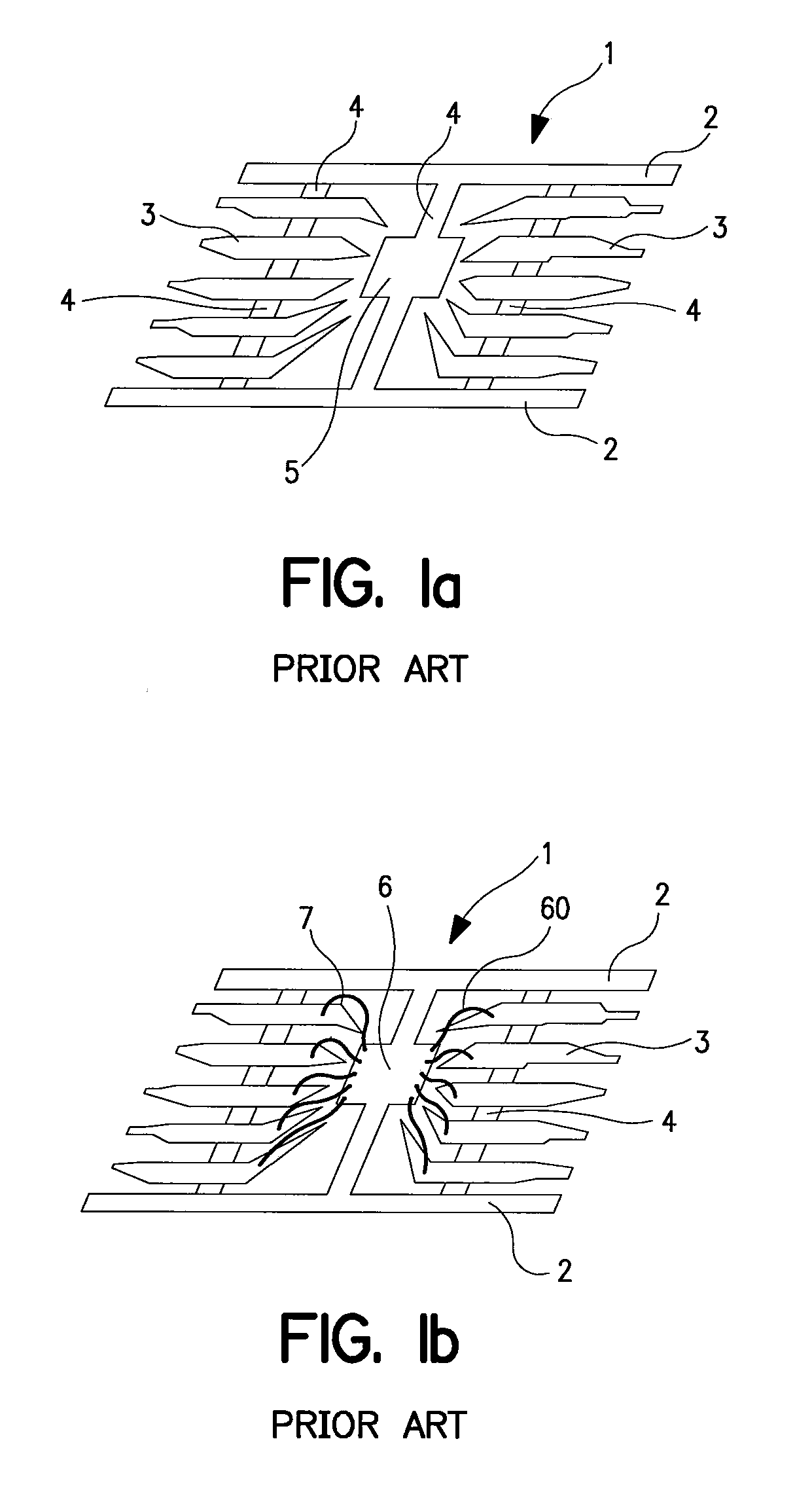

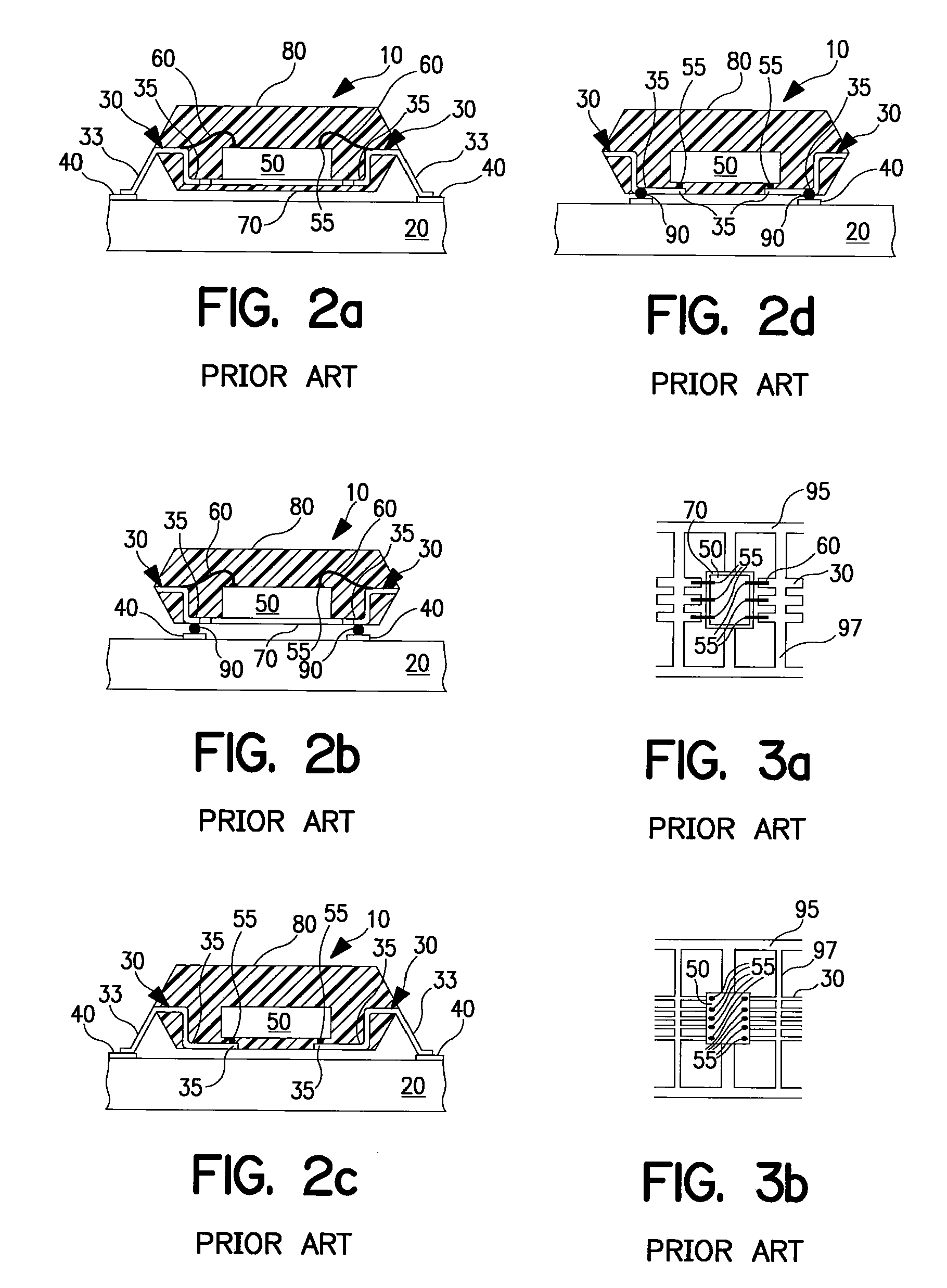

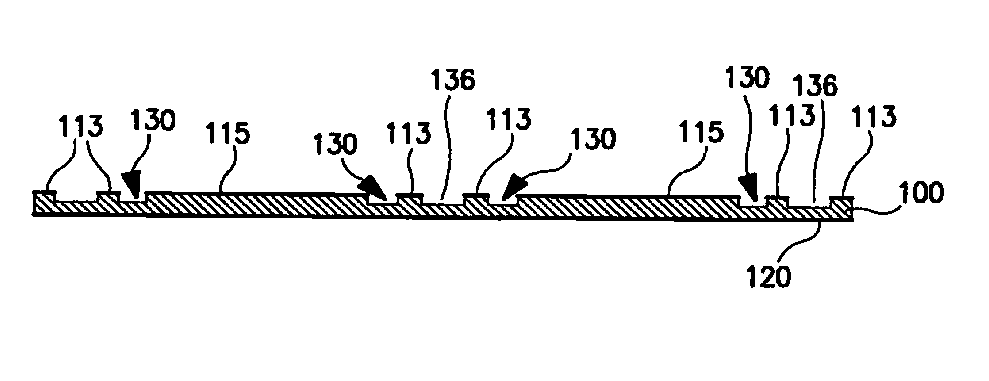

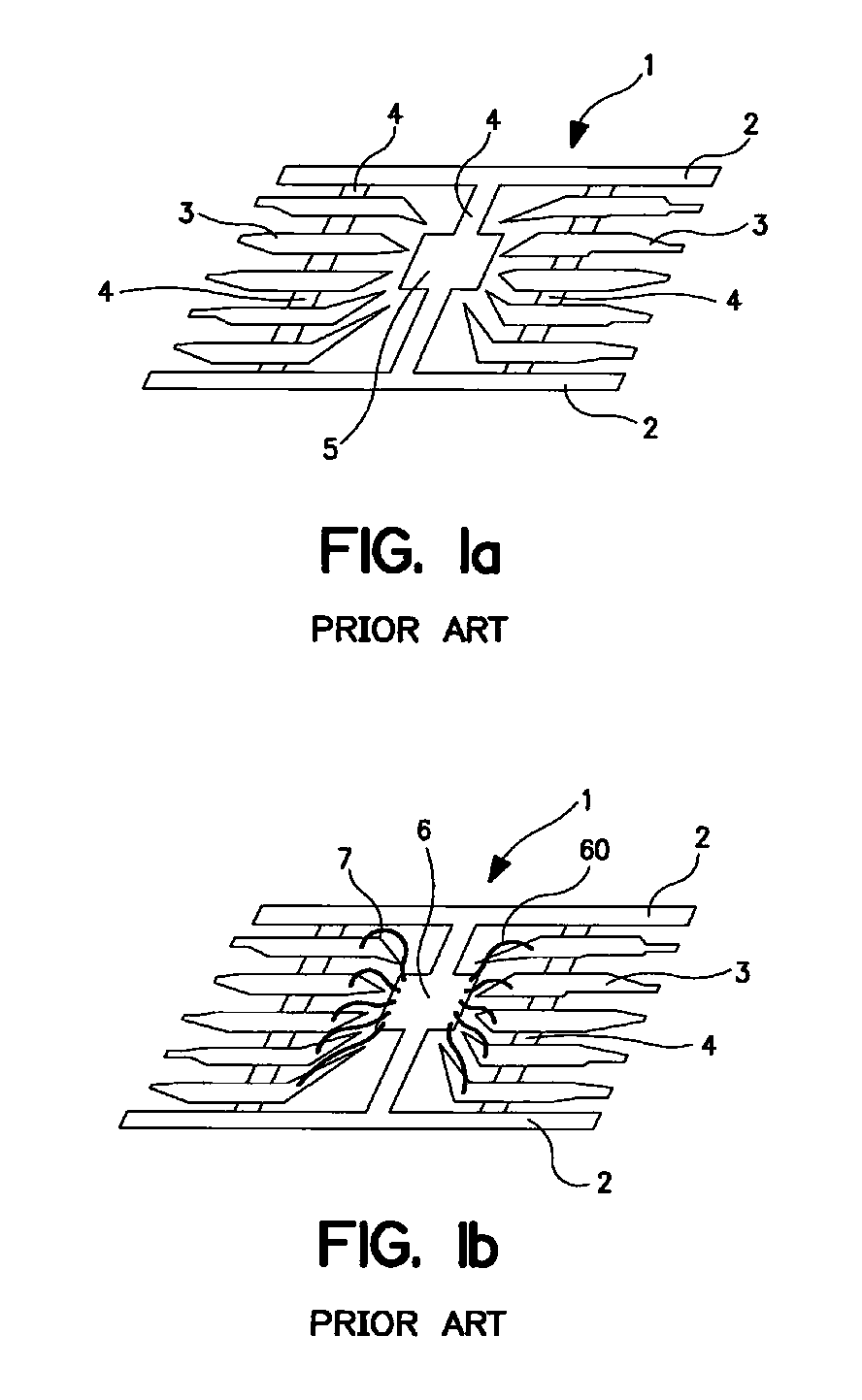

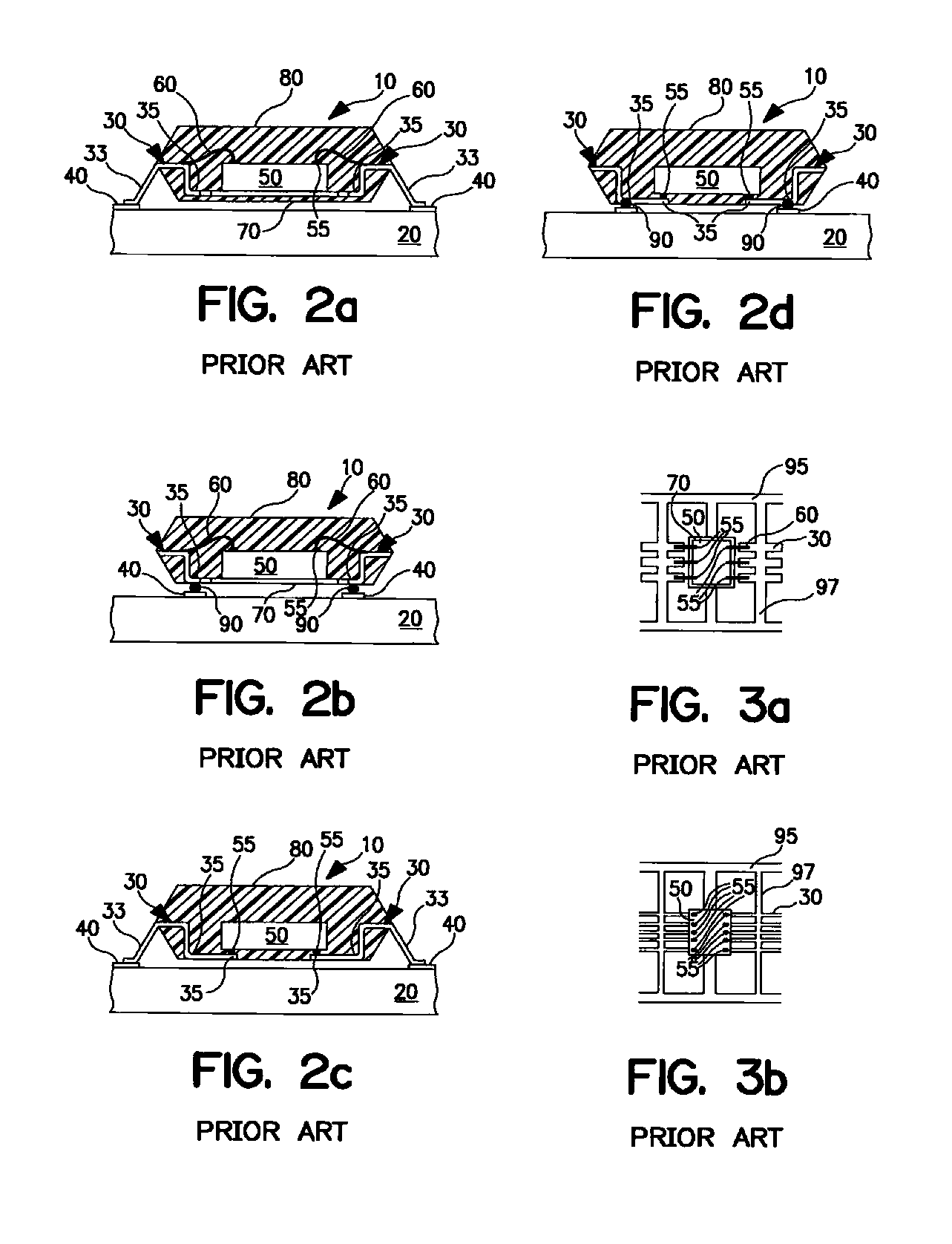

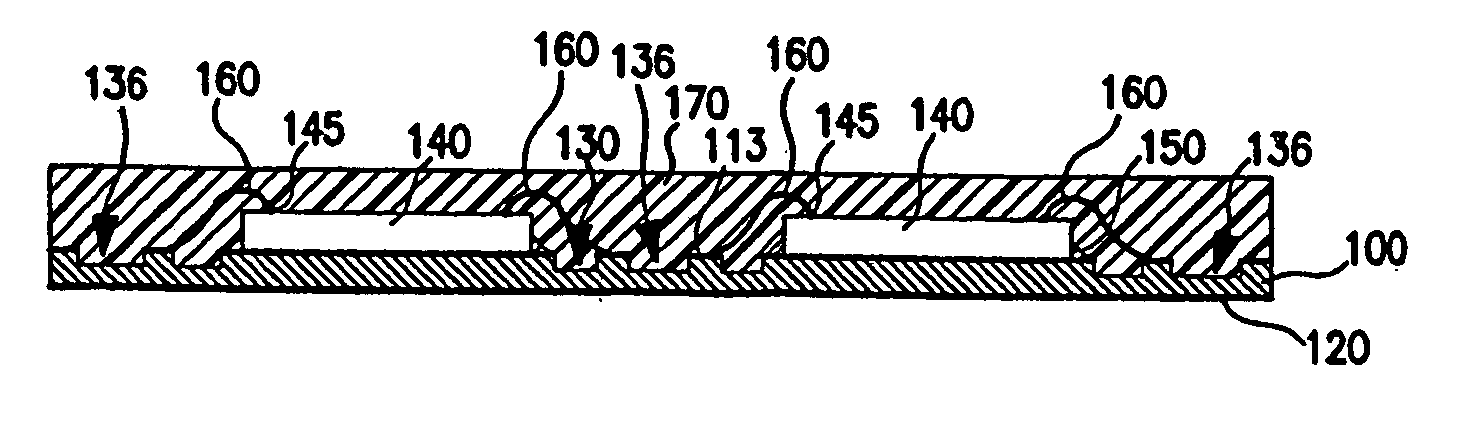

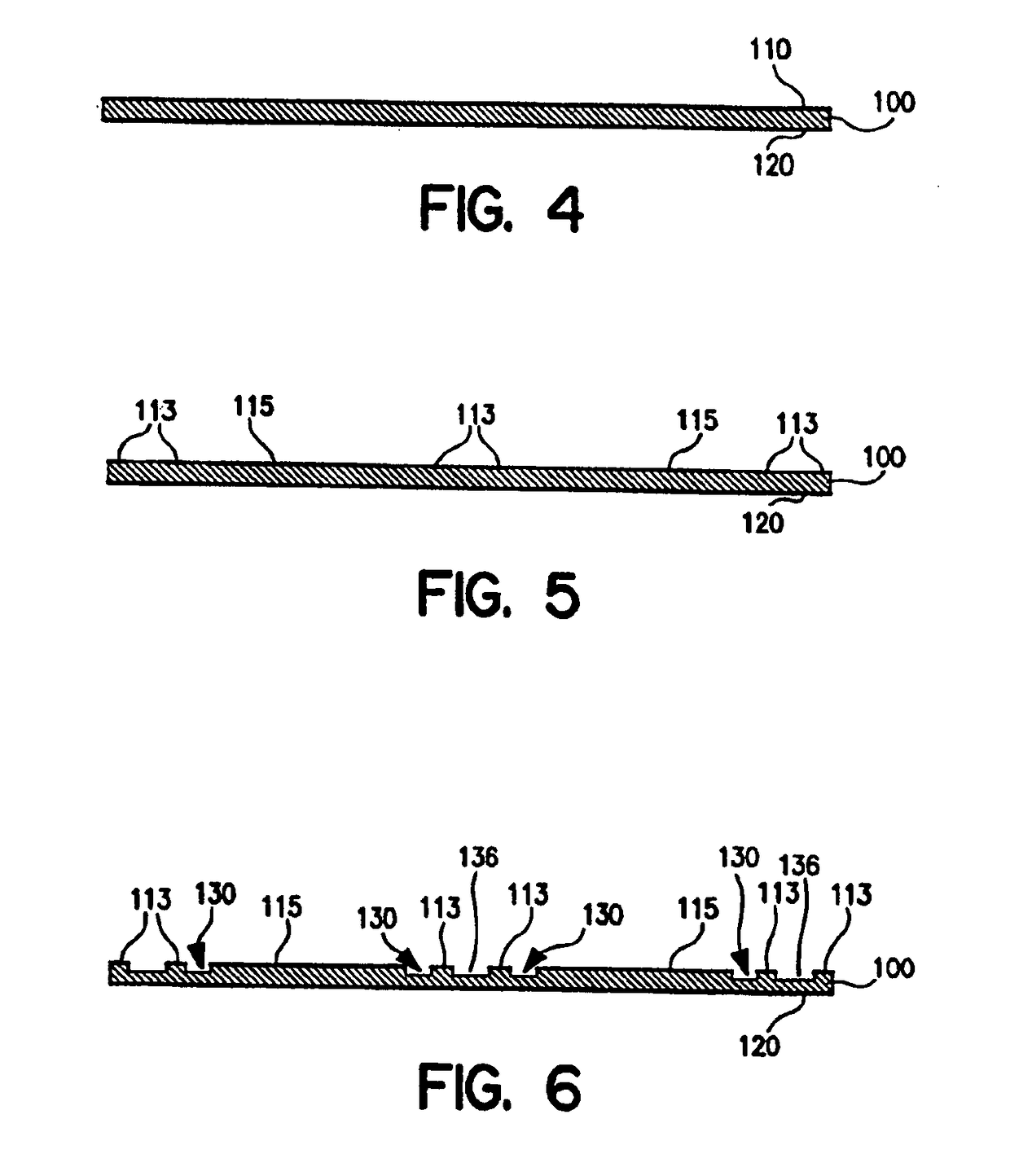

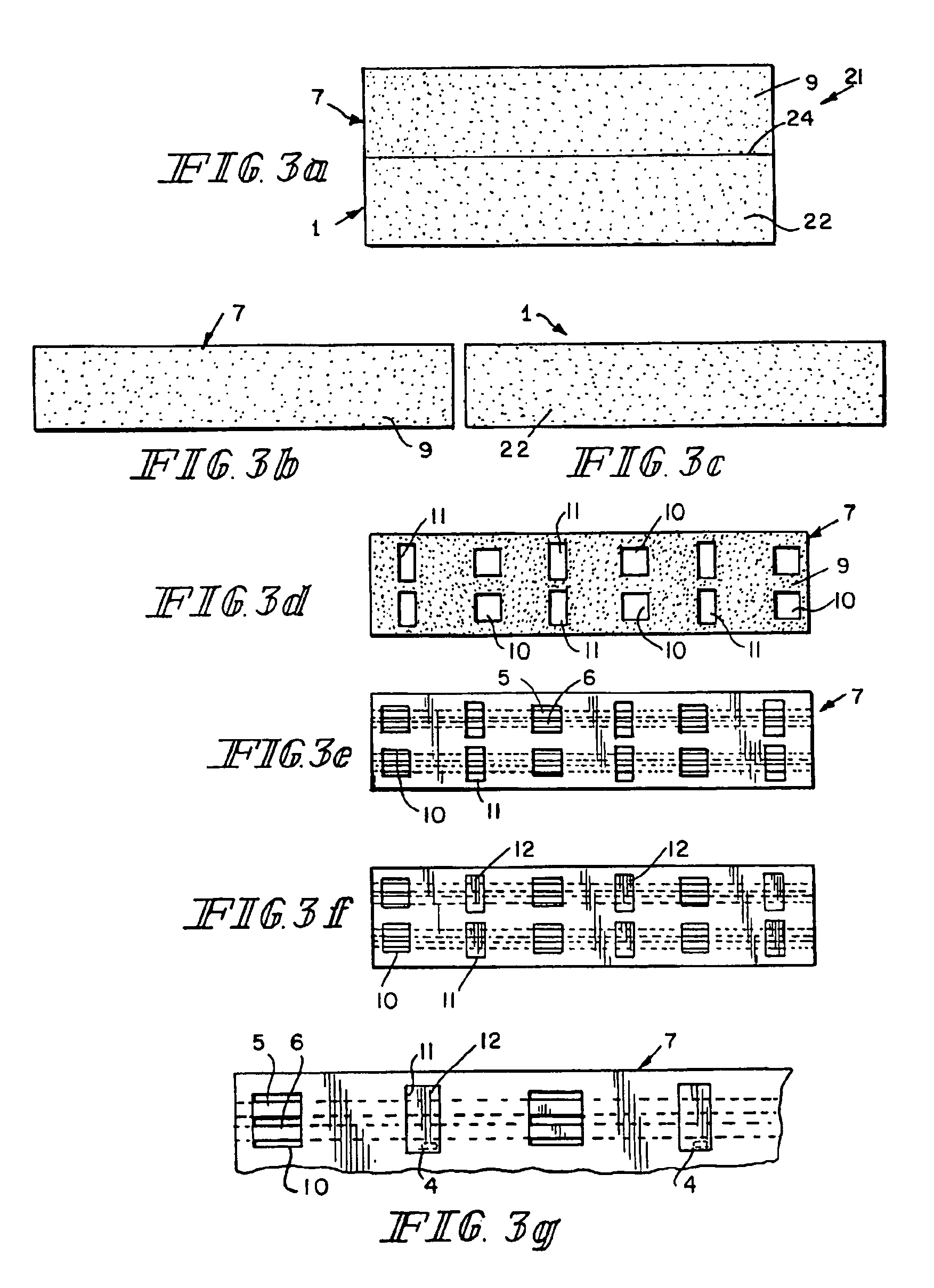

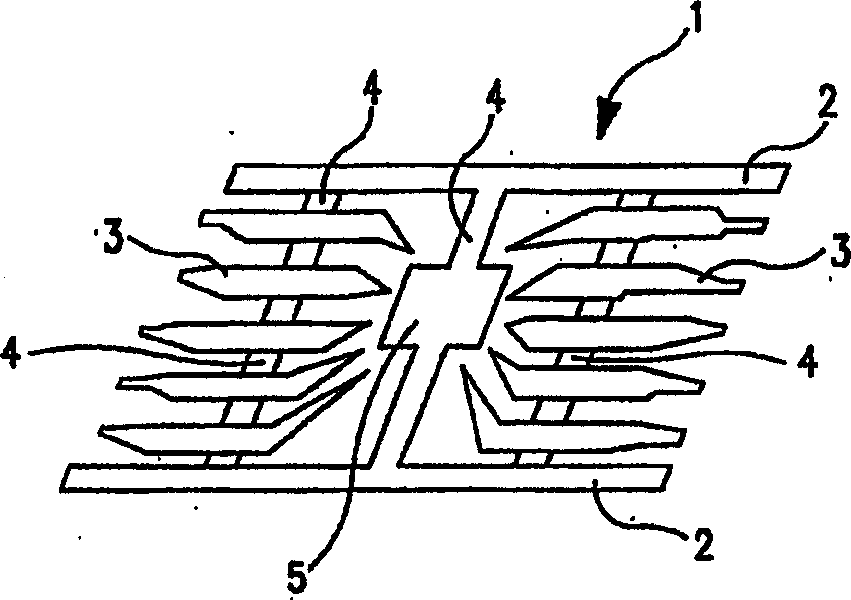

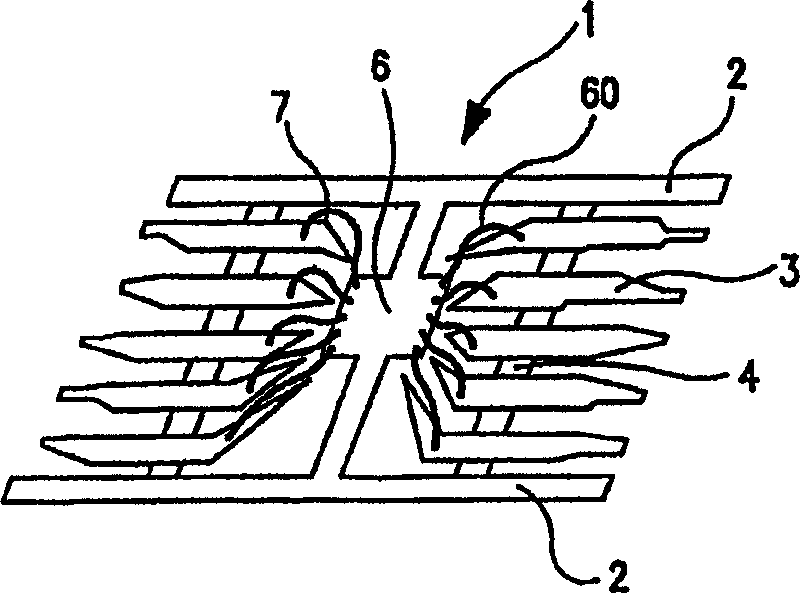

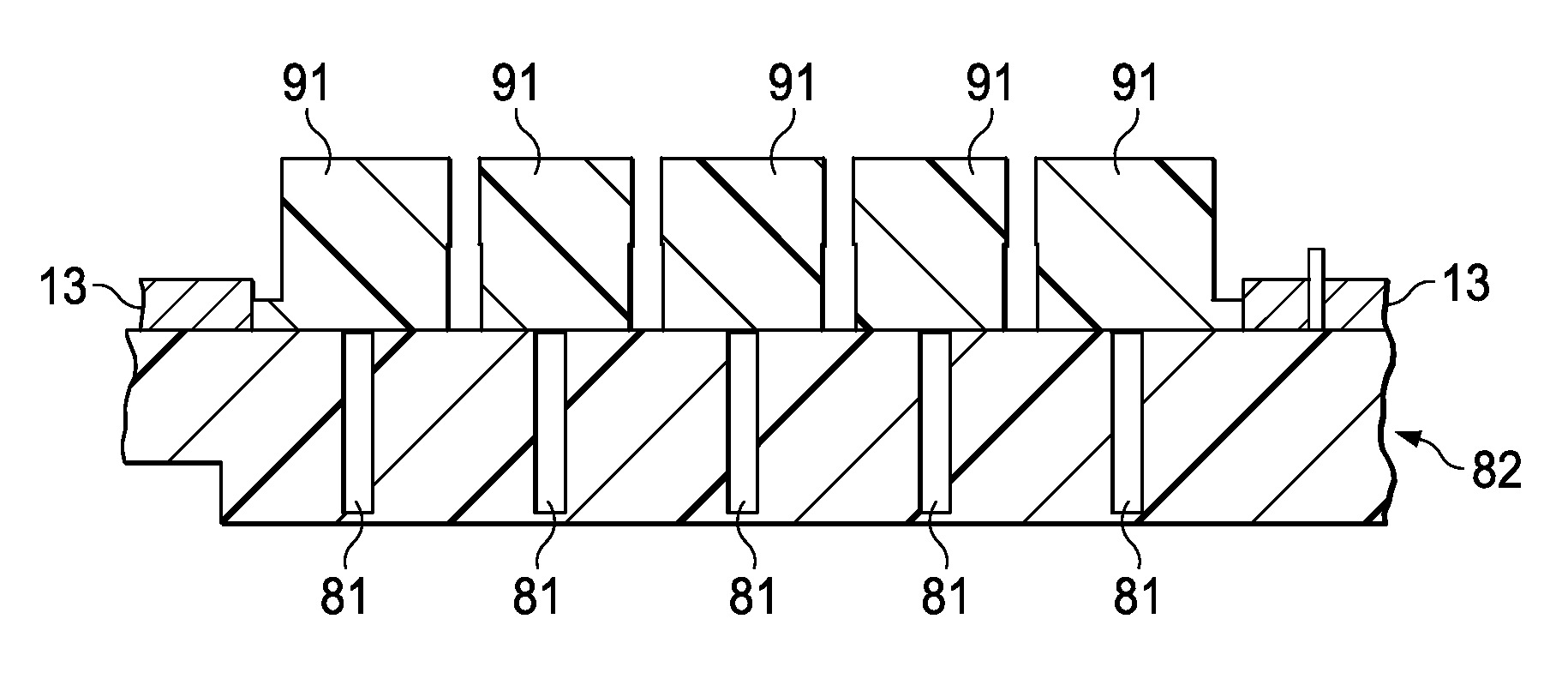

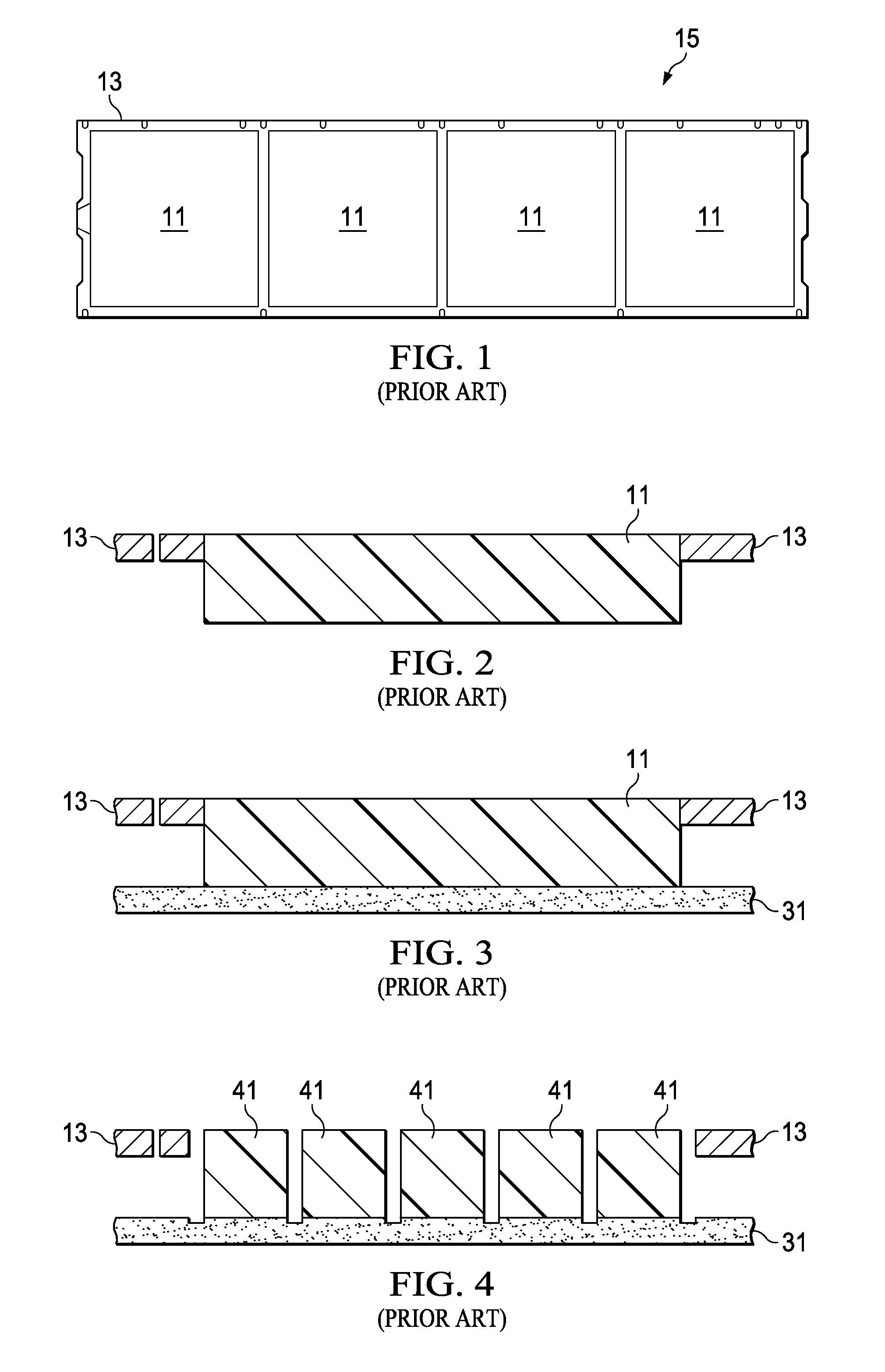

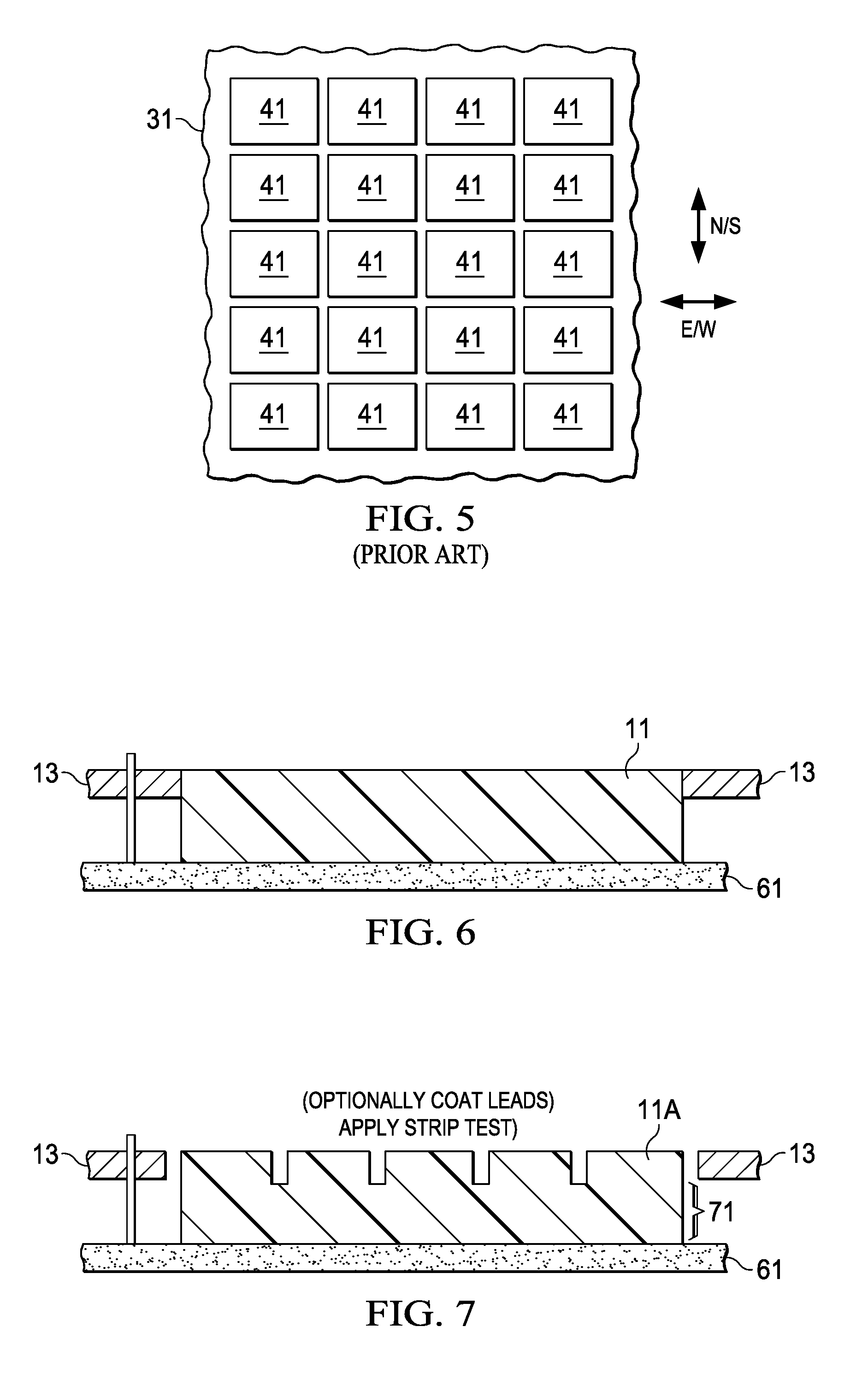

A method of making a lead frame and a partially patterned lead frame package with near-chip scale packaging lead-count, wherein the method lends itself to better automation of the manufacturing line and improved quality and reliability of the packages produced therefrom. A major portion of the manufacturing process steps is performed with a partially patterned strip of metal formed into a web-like lead frame on one side so that the web-like lead frame is also rigid mechanically and robust thermally to perform without distortion or deformation during the chip-attach and wire bond processes, both at the chip level and the package level. The bottom side of the metal lead frame is patterned to isolate the chip-pad and the wire bond contacts only after the front side, including the chip and wires, is hermetically sealed with an encapsulant. The resultant package being electrically isolated enables strip testing and reliable singulation.

Owner:UNISEM M BERHAD

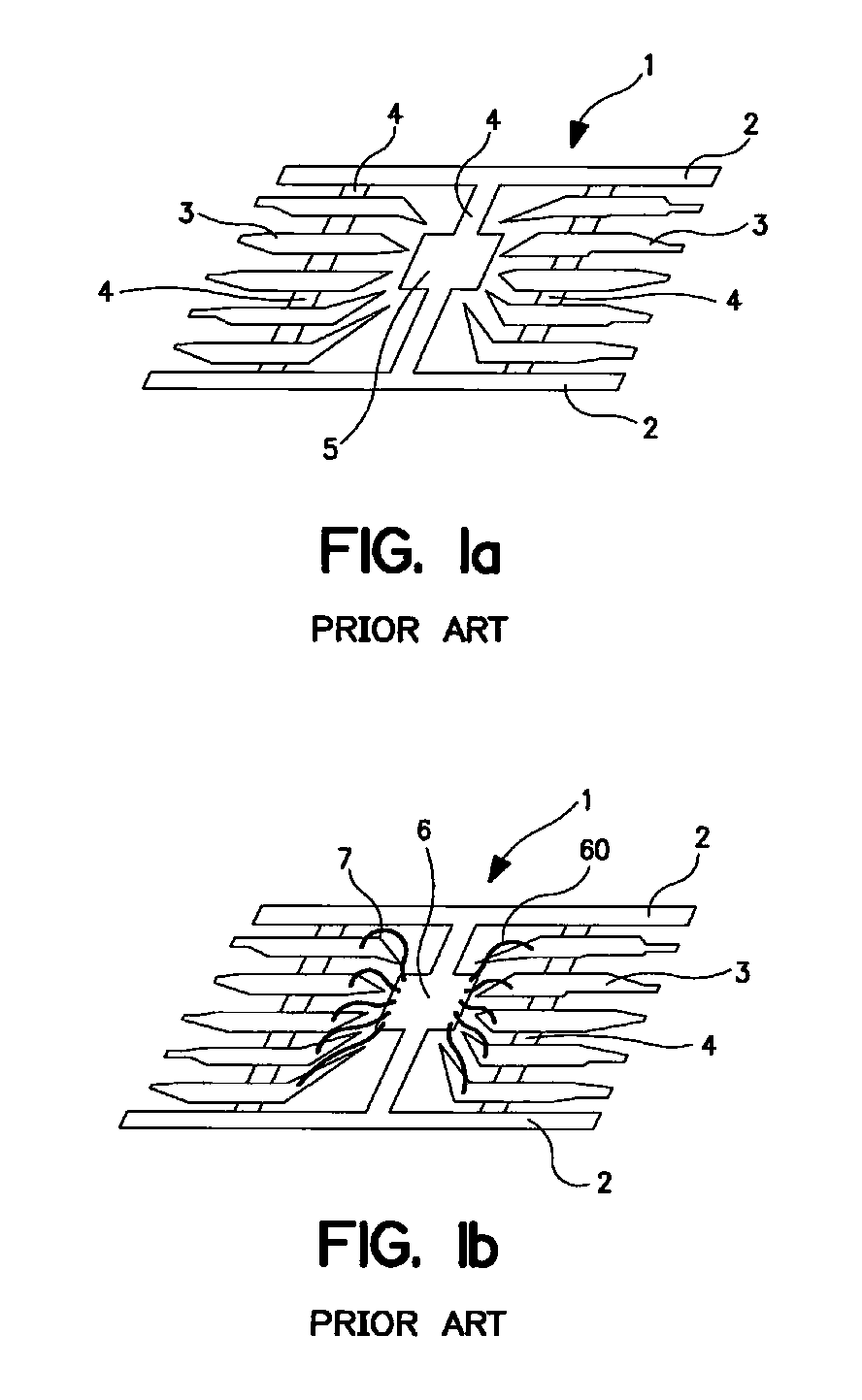

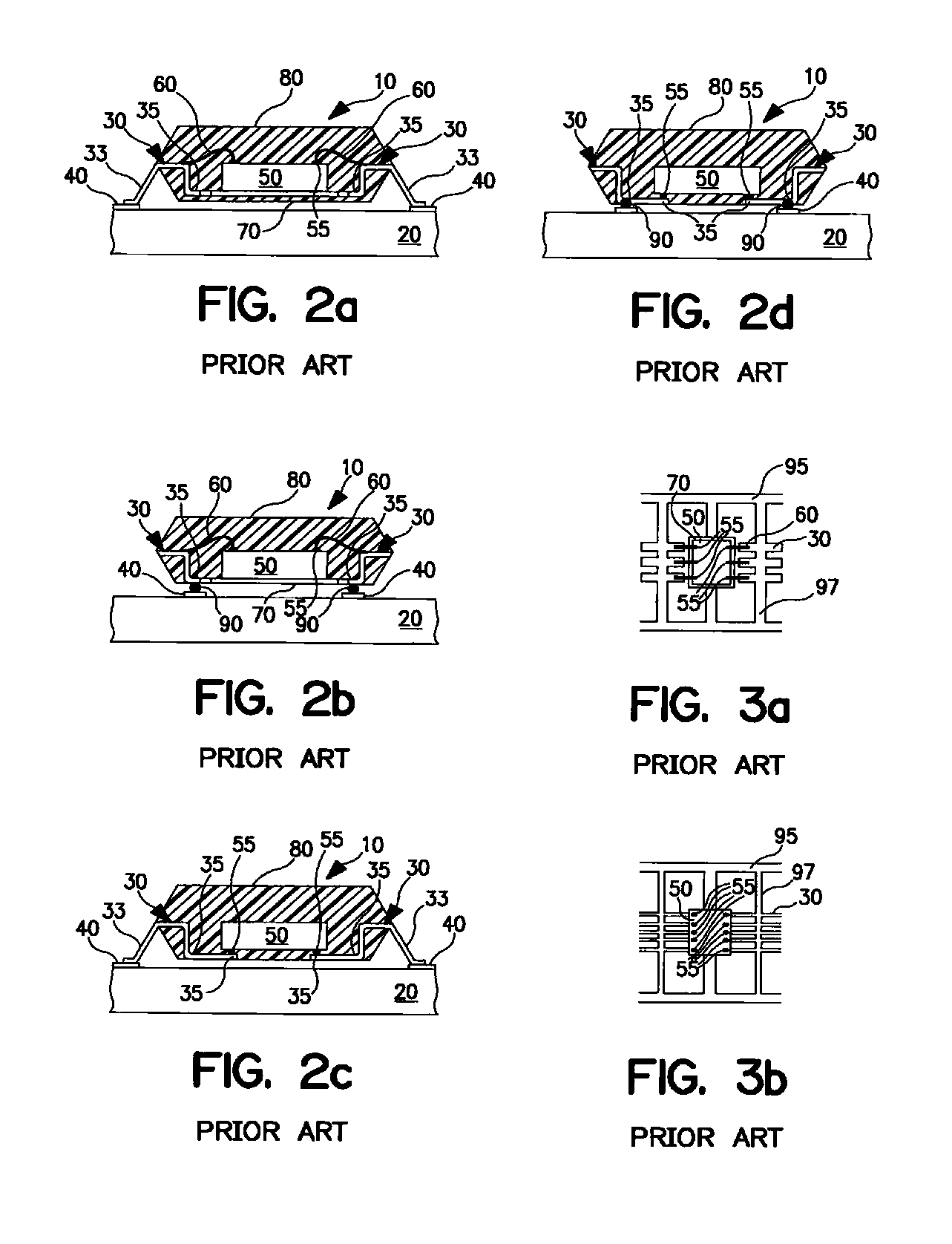

Partially Patterned Lead Frames and Methods of Making and Using the Same in Semiconductor Packaging

ActiveUS20070052076A1Increase surface areaImprove adhesionSemiconductor/solid-state device detailsSolid-state devicesManufacturing technologyLead bonding

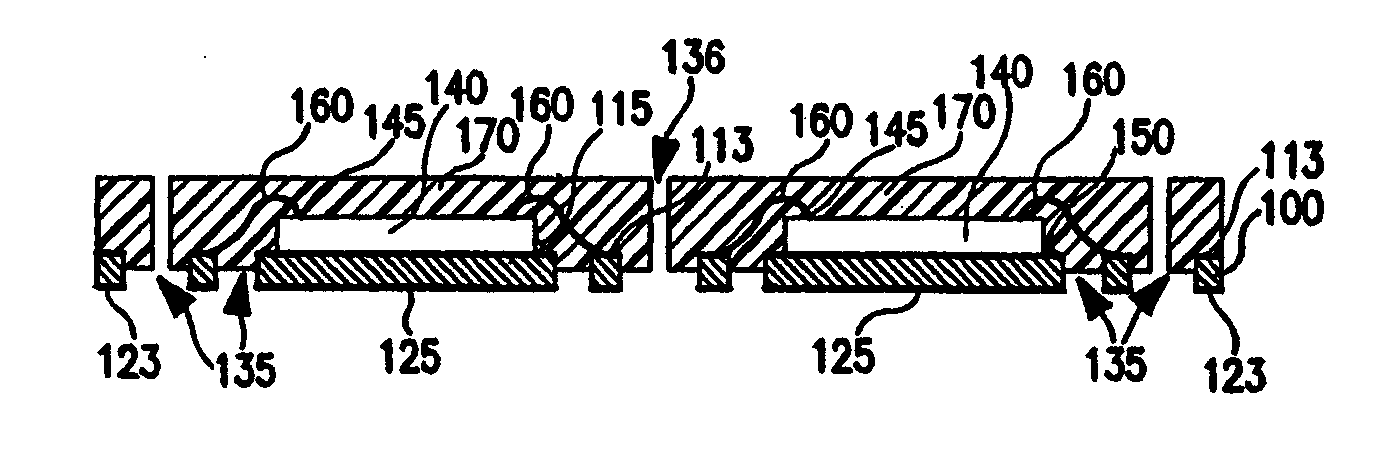

A method of making a lead frame and a partially patterned lead frame package with near-chip scale packaging (CSP) lead-counts is disclosed, wherein the method lends itself to better automation of the manufacturing line as well as to improving the quality and reliability of the packages produced therefrom. This is accomplished by performing a major portion of the manufacturing process steps with a partially patterned strip of metal formed into a web-like lead frame on one side, in contrast with the conventional fully etched stencil-like lead frames, so that the web-like lead frame, which is solid and flat on the other side is also rigid mechanically and robust thermally to perform without distortion or deformation during the chip-attach and wire bond processes, both at the chip level and the package level. The bottom side of the metal lead frame is patterned to isolate the chip-pad and the wire bond contacts only after the front side, including the chip and wires, is hermetically sealed with an encapsulant. The resultant package being electrically isolated enables strip testing and reliable singulation without having to cut into any additional metal. The use of the instant partially patterned lead frame in making ELP, ELPF and ELGA-type CSPs is also disclosed.

Owner:UNISEM M BERHAD

Partially patterned lead frames and methods of making and using the same in semiconductor packaging

InactiveUS20050263864A1Improve structural rigidityProcess stabilityLine/current collector detailsSemiconductor/solid-state device detailsLead bondingBonding process

A method of making a lead frame and a partially patterned lead frame package with near-chip scale packaging (CSP) lead-counts is disclosed, wherein the method lends itself to better automation of the manufacturing line as well as to improving the quality and reliability of the packages produced therefrom. This is accomplished by performing a major portion of the manufacturing process steps with a partially patterned strip of metal formed into a web-like lead frame on one side, in contrast with the conventional fully etched stencil-like lead frames, so that the web-like lead frame, which is solid and flat on the other side is also rigid mechanically and robust thermally to perform without distortion or deformation during the chip-attach and wire bond processes. The bottom side of the metal lead frame is patterned to isolate the chip-pad and the wire bond contacts only after the front side, including the chip and wires, is hermetically sealed with an encapsulant. The resultant package being electrically isolated enables strip testing and reliable singulation without having to cut into any additional metal. The use of the instant partially patterned lead frame in making ELP, ELPF and ELGA-type CSPs is also disclosed.

Owner:UNISEM M BERHAD

Partially patterned lead frames and methods of making and using the same in semiconductor packaging

InactiveUS7790500B2Improve structural rigiditySemiconductor/solid-state device detailsSolid-state devicesLead bondingBonding process

A method of making a lead frame and a partially patterned lead frame package with near-chip scale packaging lead-count, wherein the method lends itself to better automation of the manufacturing line and improved quality and reliability of the packages produced therefrom. A major portion of the manufacturing process steps is performed with a partially patterned strip of metal formed into a web-like lead frame on one side so that the web-like lead frame is also rigid mechanically and robust thermally to perform without distortion or deformation during the chip-attach and wire bond processes, both at the chip level and the package level. The bottom side of the metal lead frame is patterned to isolate the chip-pad and the wire bond contacts only after the front side, including the chip and wires, is hermetically sealed with an encapsulant. The resultant package being electrically isolated enables strip testing and reliable singulation.

Owner:UNISEM M BERHAD

Partially Patterned Lead Frames and Methods of Making and Using the Same in Semiconductor Packaging

InactiveUS20110111562A1Improve structural rigiditySemiconductor/solid-state device detailsSolid-state devicesLead bondingBonding process

A method of making a lead frame and a partially patterned lead frame package with near-chip scale packaging lead-count, wherein the method lends itself to better automation of the manufacturing line and improved quality and reliability of the packages produced therefrom. A major portion of the manufacturing process steps is performed with a partially patterned strip of metal formed into a web-like lead frame on one side so that the web-like lead frame is also rigid mechanically and robust thermally to perform without distortion or deformation during the chip-attach and wire bond processes, both at the chip level and the package level. The bottom side of the metal lead frame is patterned to isolate the chip-pad and the wire bond contacts only after the front side, including the chip and wires, is hermetically sealed with an encapsulant. The resultant package being electrically isolated enables strip testing and reliable singulation.

Owner:UNISEM M BERHAD

Partially patterned lead frames and methods of making and using the same in semiconductor packaging

InactiveUS20050006737A1Avoid layeringEliminate forceSemiconductor/solid-state device detailsSolid-state devicesLead bondingBonding process

A method of making a lead frame and a partially patterned lead frame package with near-chip scale packaging (CSP) lead-counts is disclosed, wherein the method lends itself to better automation of the manufacturing line as well as to improving the quality and reliability of the packages produced therefrom. This is accomplished by performing a major portion of the manufacturing process steps with a partially patterned strip of metal formed into a web-like lead frame on one side, in contrast with the conventional fully etched stencil-like lead frames, so that the web-like lead frame, which is solid and flat on the other side is also rigid mechanically and robust thermally to perform without distortion or deformation during the chip-attach and wire bond processes. The bottom side of the metal lead frame is patterned to isolate the chip-pad and the wire bond contacts only after the front side, including the chip and wires, is hermetically sealed with an encapsulant. The resultant package being electrically isolated enables strip testing and reliable singulation without having to cut into any additional metal. The use of the instant partially patterned lead frame in making ELP, ELPF and ELGA-type CSPs is also disclosed.

Owner:UNISEM M BERHAD

Partially patterned lead frames and methods of making and using the same in semiconductor packaging

InactiveUS7129116B2Improve structural rigidityProcess stabilitySemiconductor/solid-state device detailsSolid-state devicesBonding processSemiconductor package

A method of making a lead frame and a partially patterned lead frame package with near-chip scale packaging (CSP) lead-counts is accomplished by performing a major portion of the manufacturing process steps with a partially patterned strip of metal formed into a web-like lead frame on one side, so that the web-like lead frame, which is solid and flat on the other side is also rigid mechanically and robust thermally to perform without distortion or deformation during the chip-attach and wire bond processes, both the chip level and the package level. The bottom side of the metal lead frame is patterned to isolate the chip-pad and the wire bond contacts only after the front side, including the chip and wires, is encapsulated. The resultant package being electrically isolated enables strip testing and reliable singulation without having to cut into any additional metal.

Owner:UNISEM M BERHAD

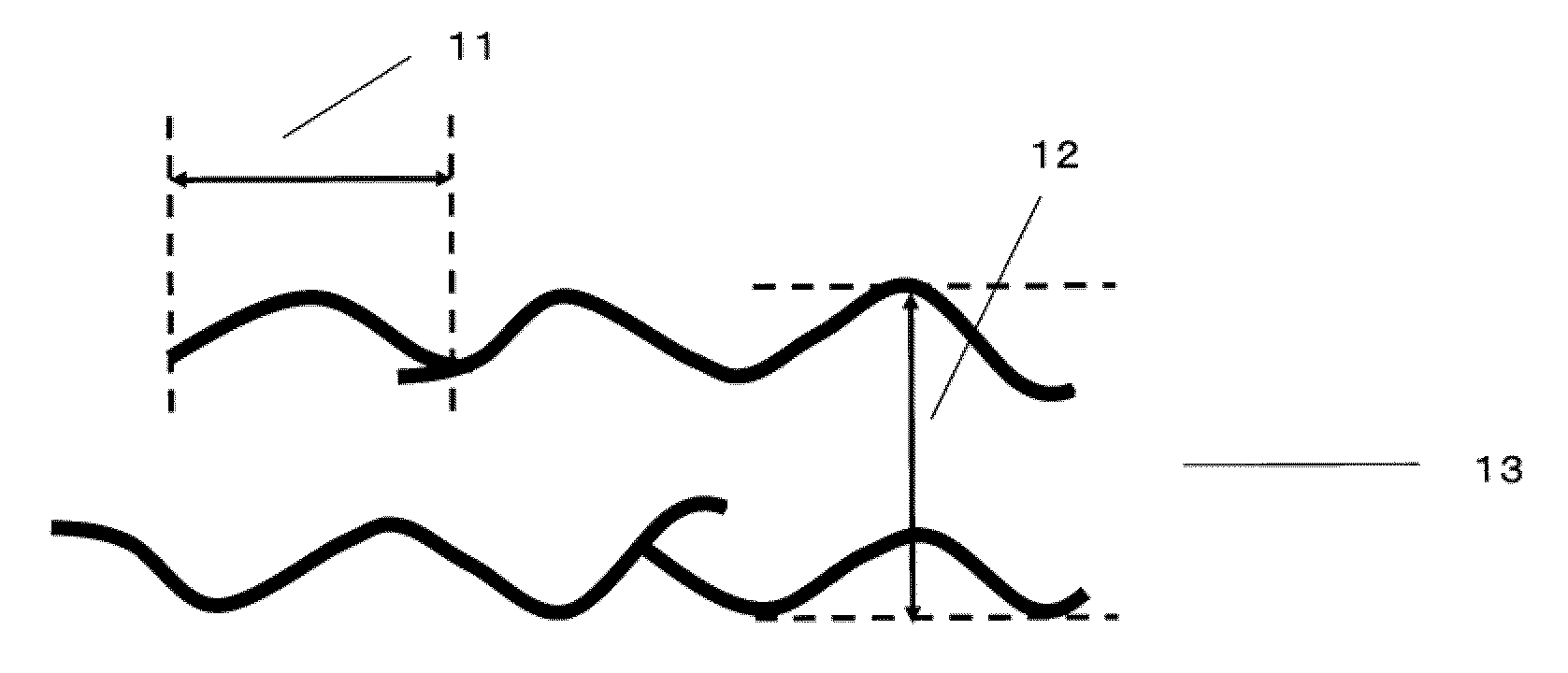

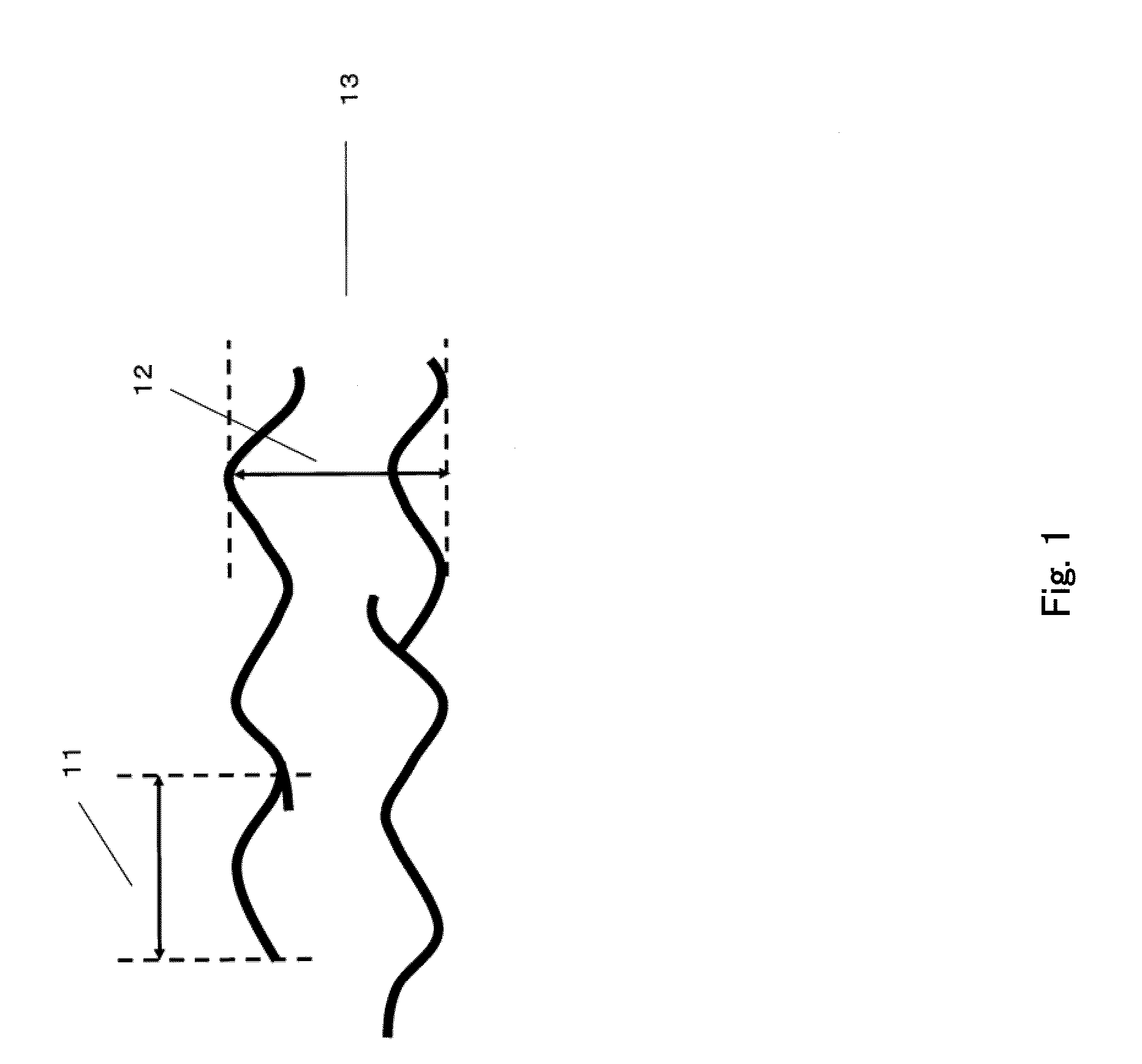

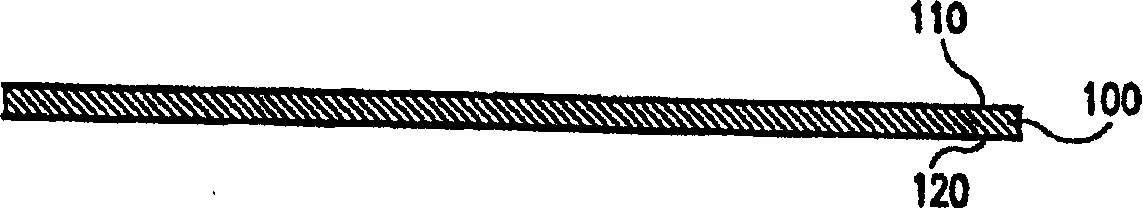

Graphite Film and Graphite Composite Film

ActiveUS20100196716A1Improve flex resistanceExcellent thermal diffusivityGraphiteSemiconductor/solid-state device detailsFolding enduranceElectronic instrument

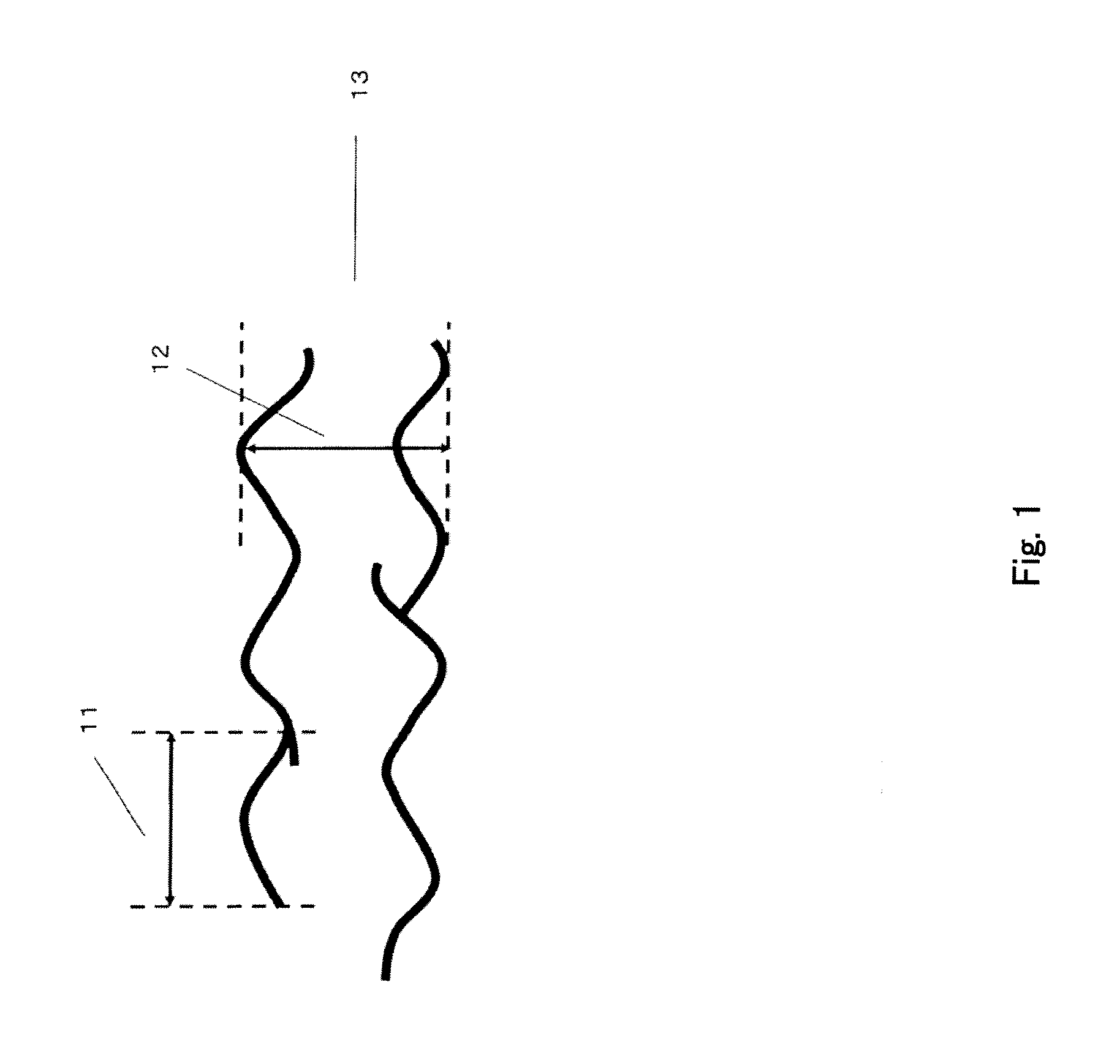

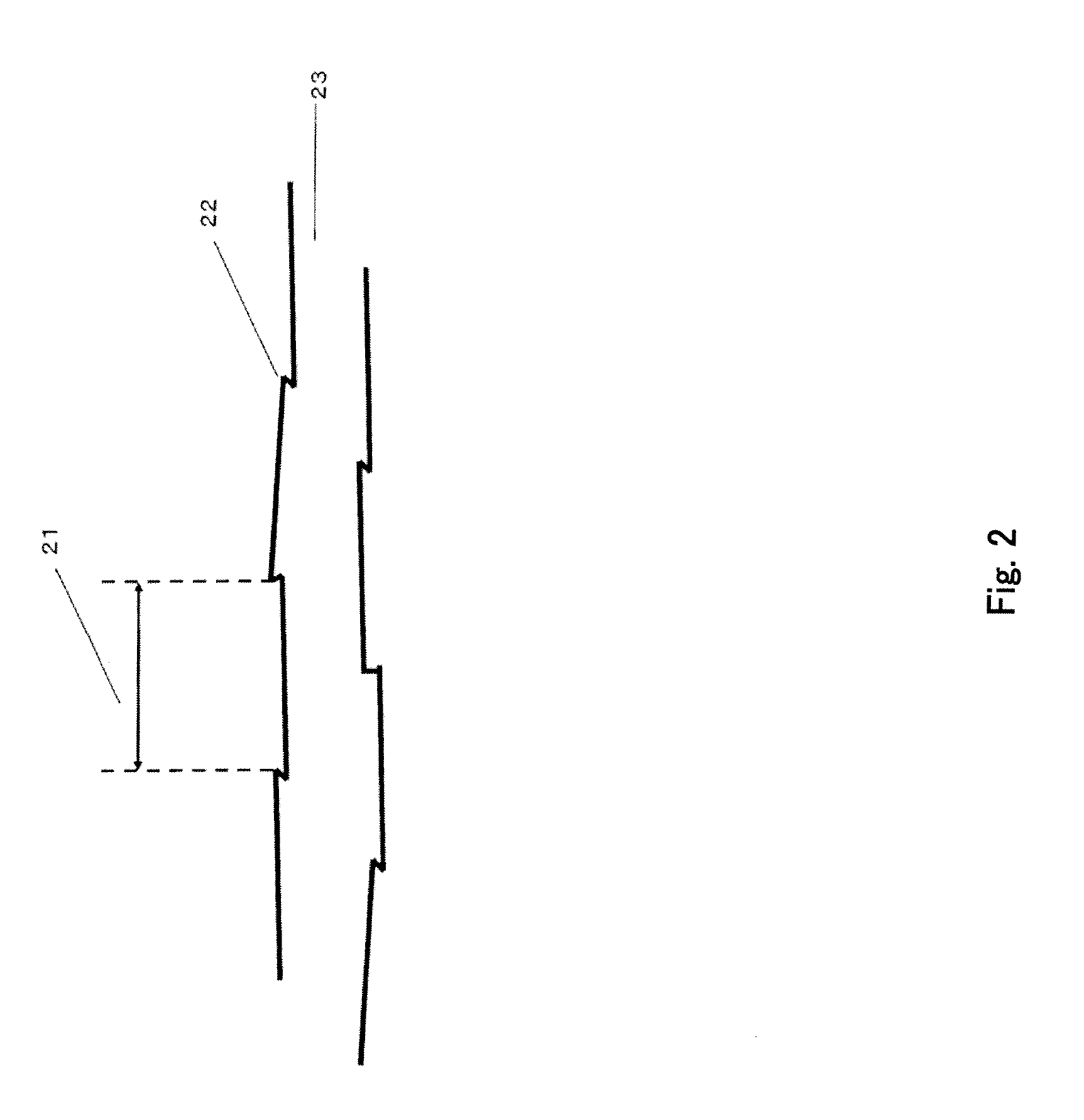

An object of the present invention is to provide a graphite film, and a graphite composite film both having an excellent thermal diffusivity which can sufficiently manage heat dissipation of electronic instruments, precision instruments and the like, along with an excellent flex resistance which can withstand application to bent portions.Means for Resolution of the present invention is a graphite film exhibiting the number of reciprocal foldings being 10,000 times or more as measured using a rectangular strip test piece having a width of 15 mm until the test piece breaks in a MIT folding endurance test under conditions of: a curvature radius R of the bending clamp being 2 mm; a left-and-right bending angle being 135°; a bending rate being 90 times / min; and a load being 0.98 N.

Owner:KANEKA CORP

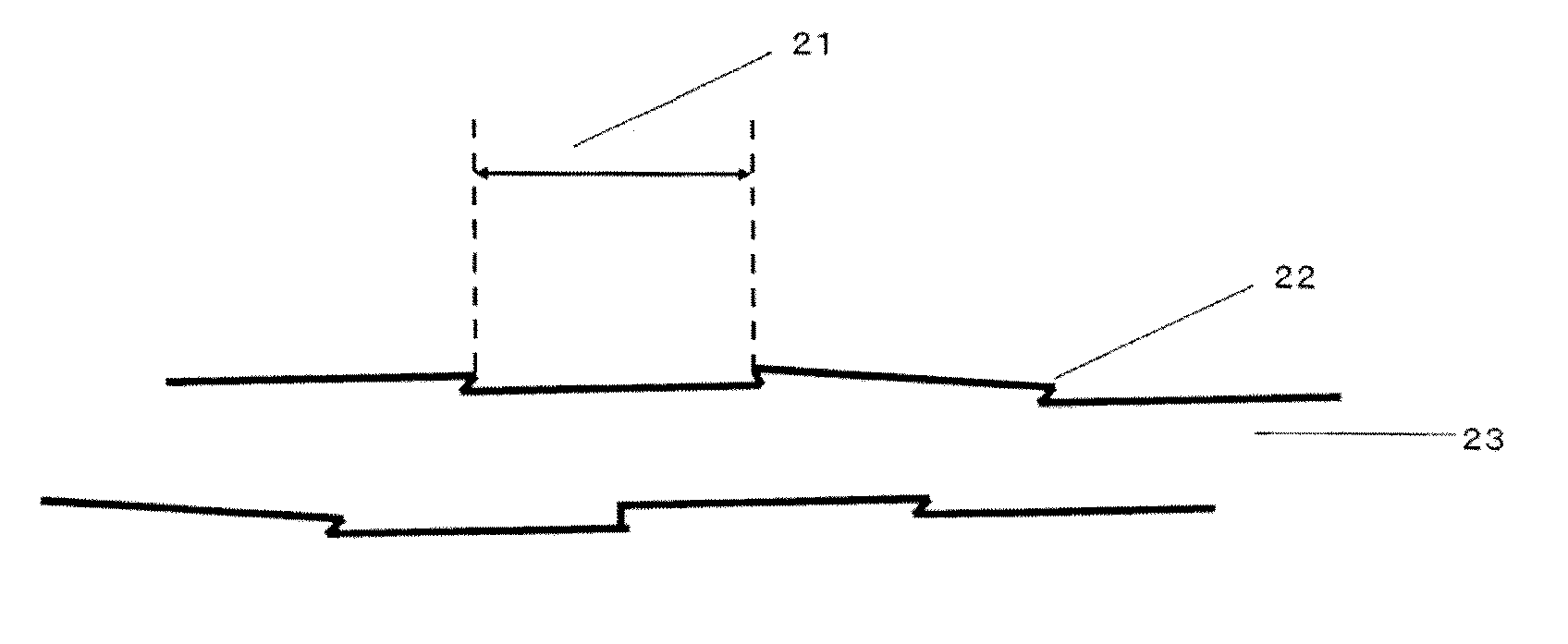

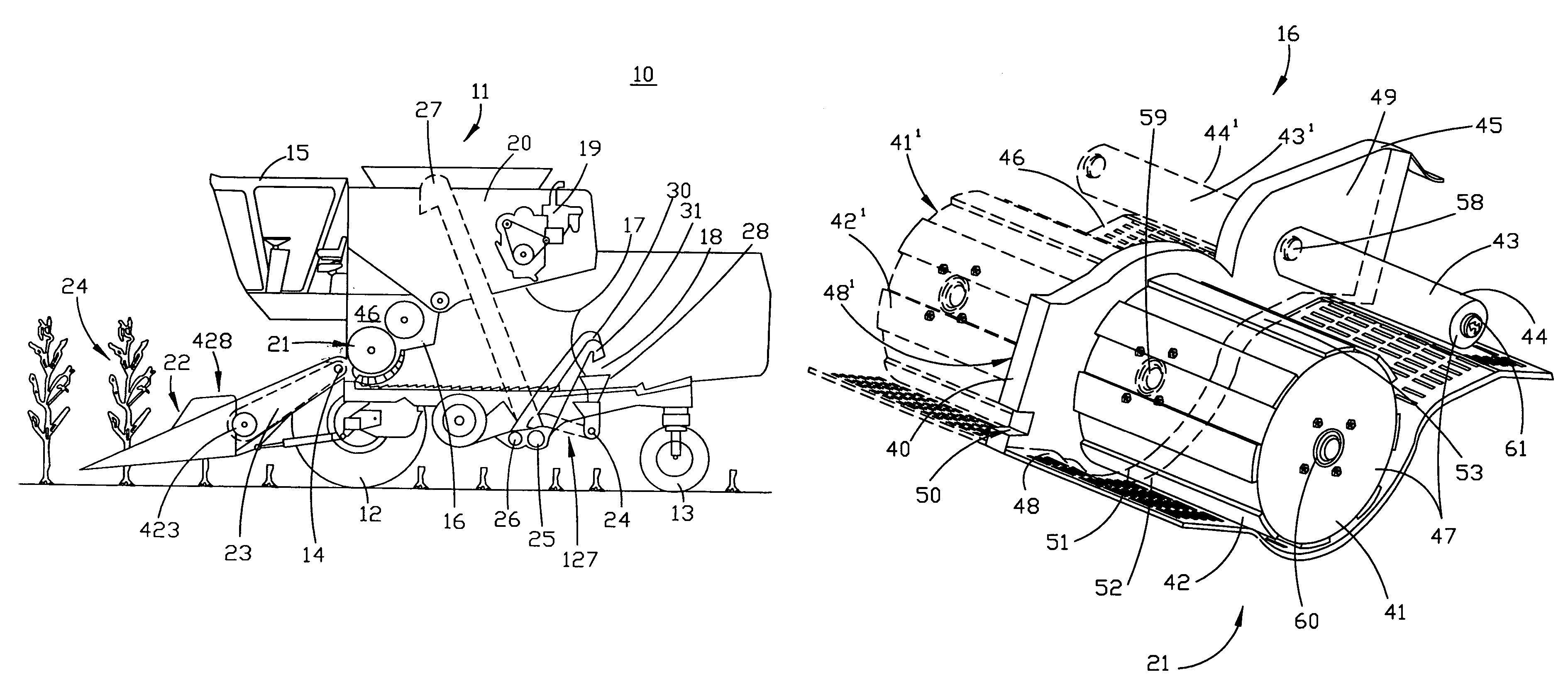

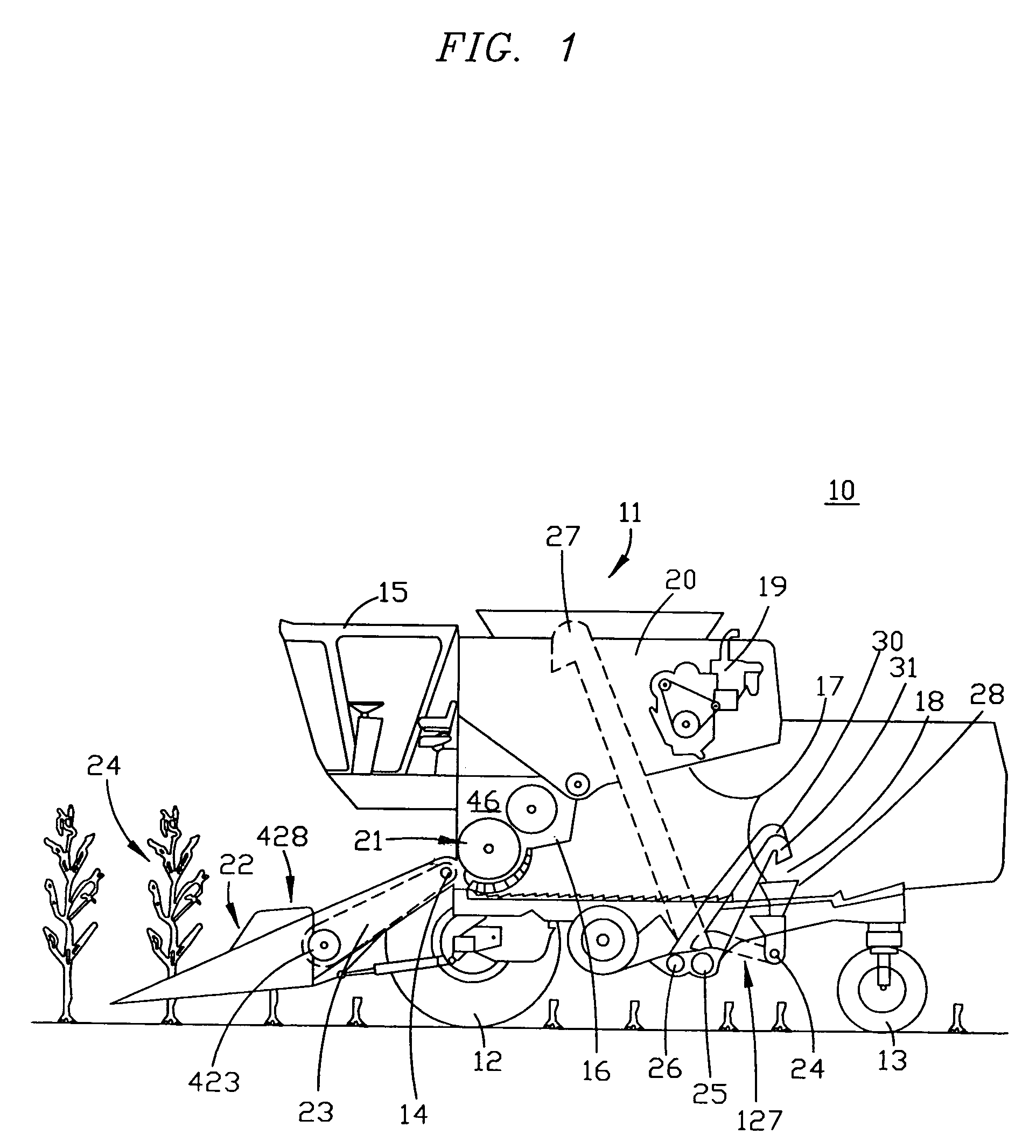

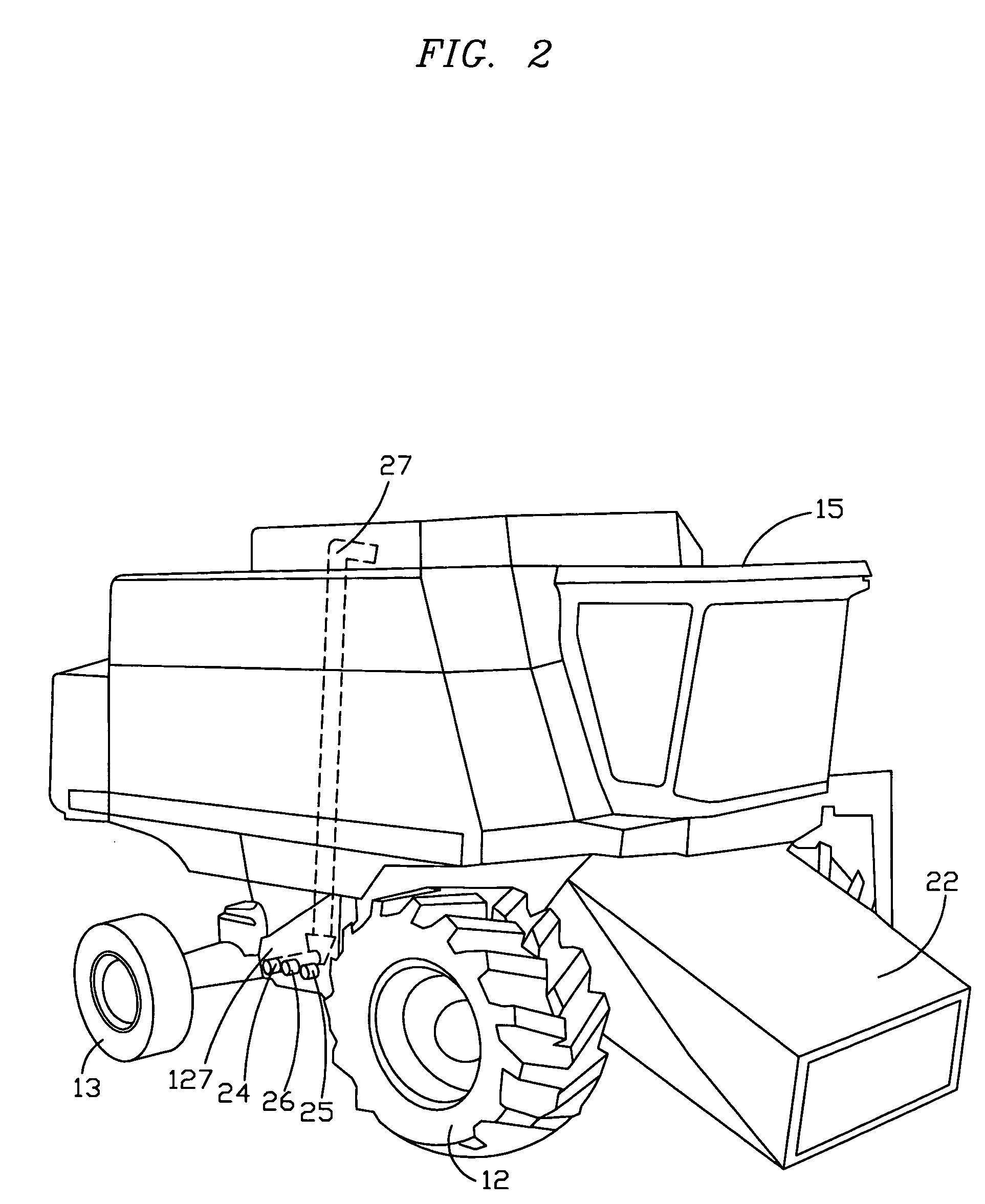

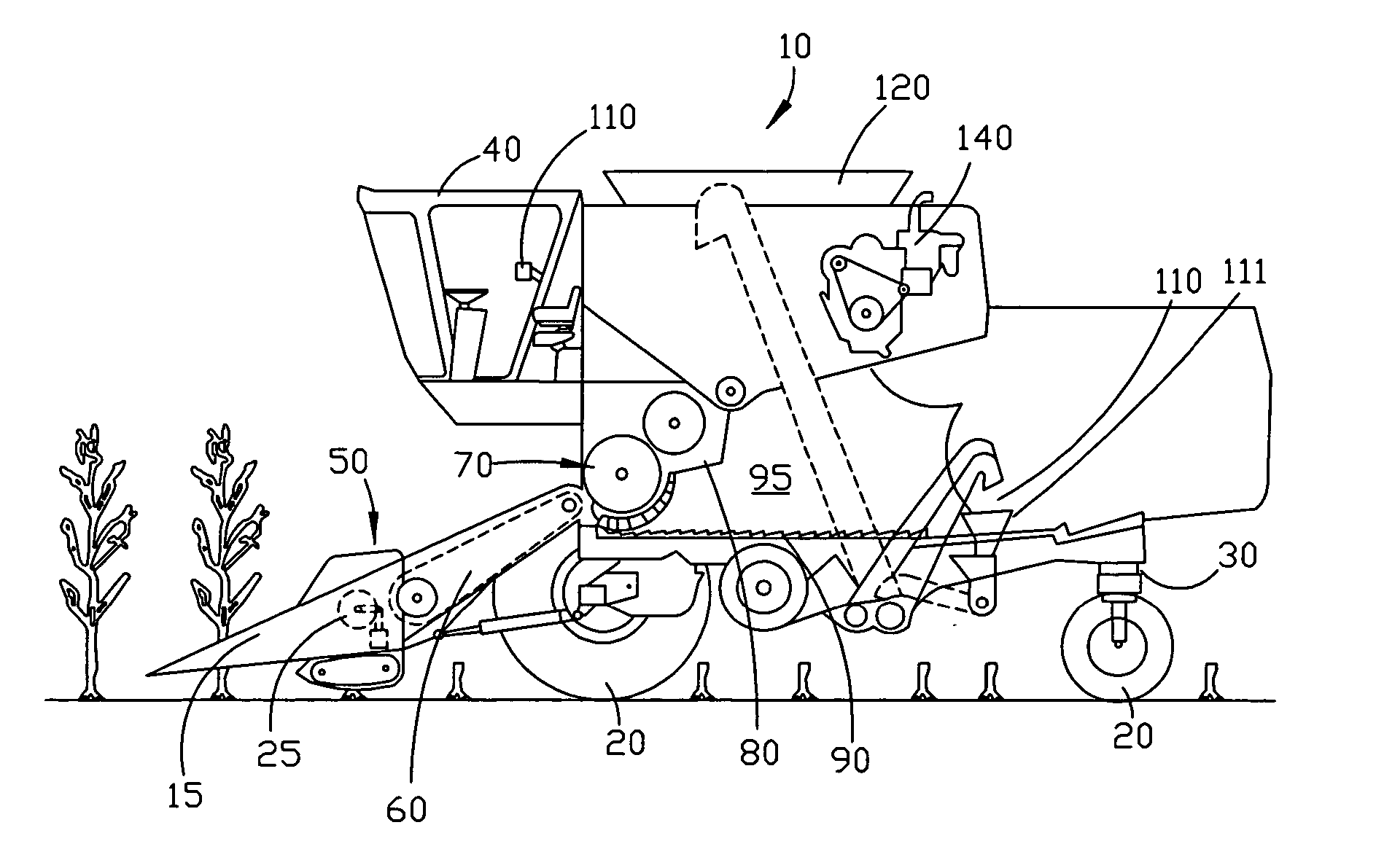

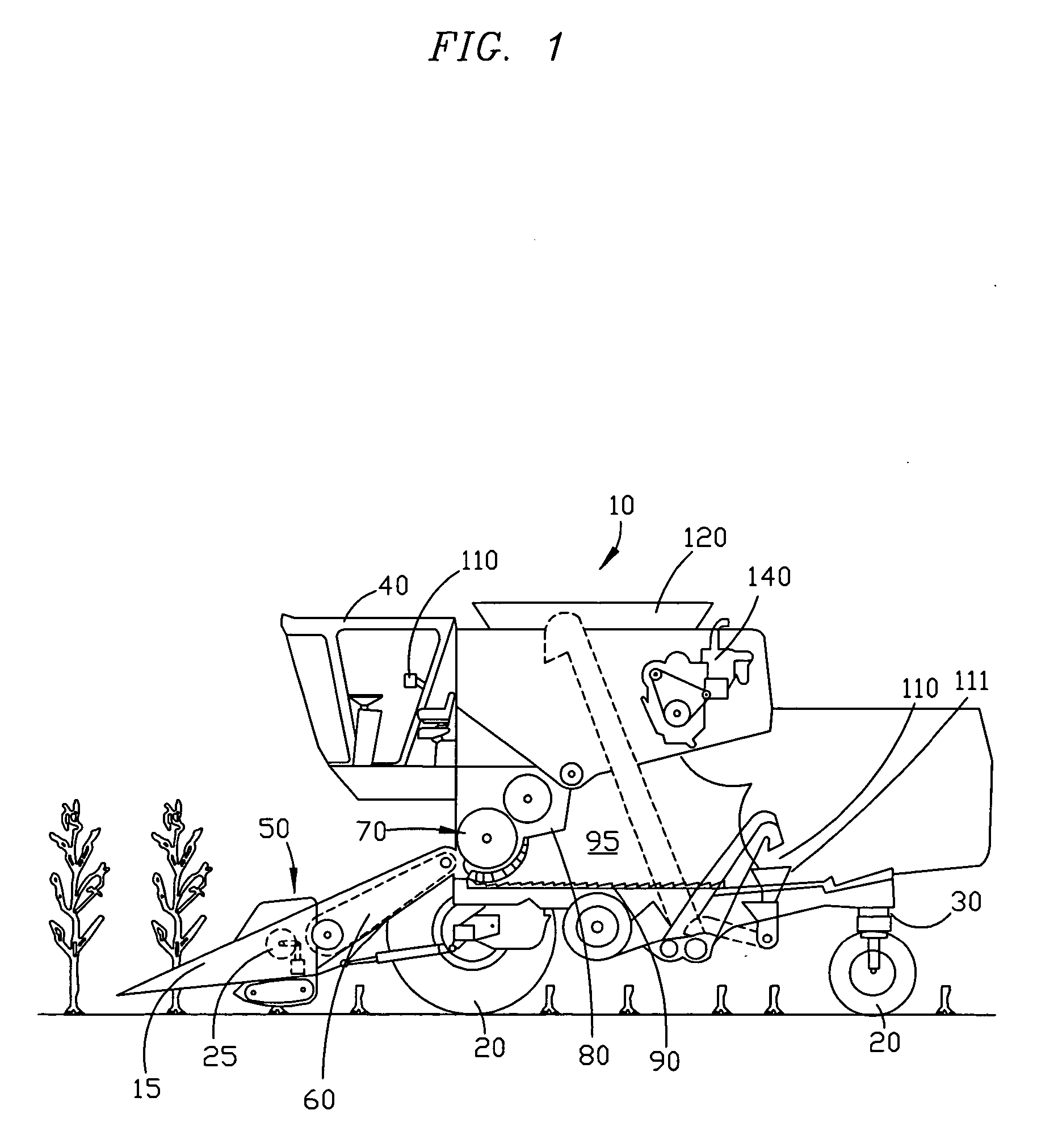

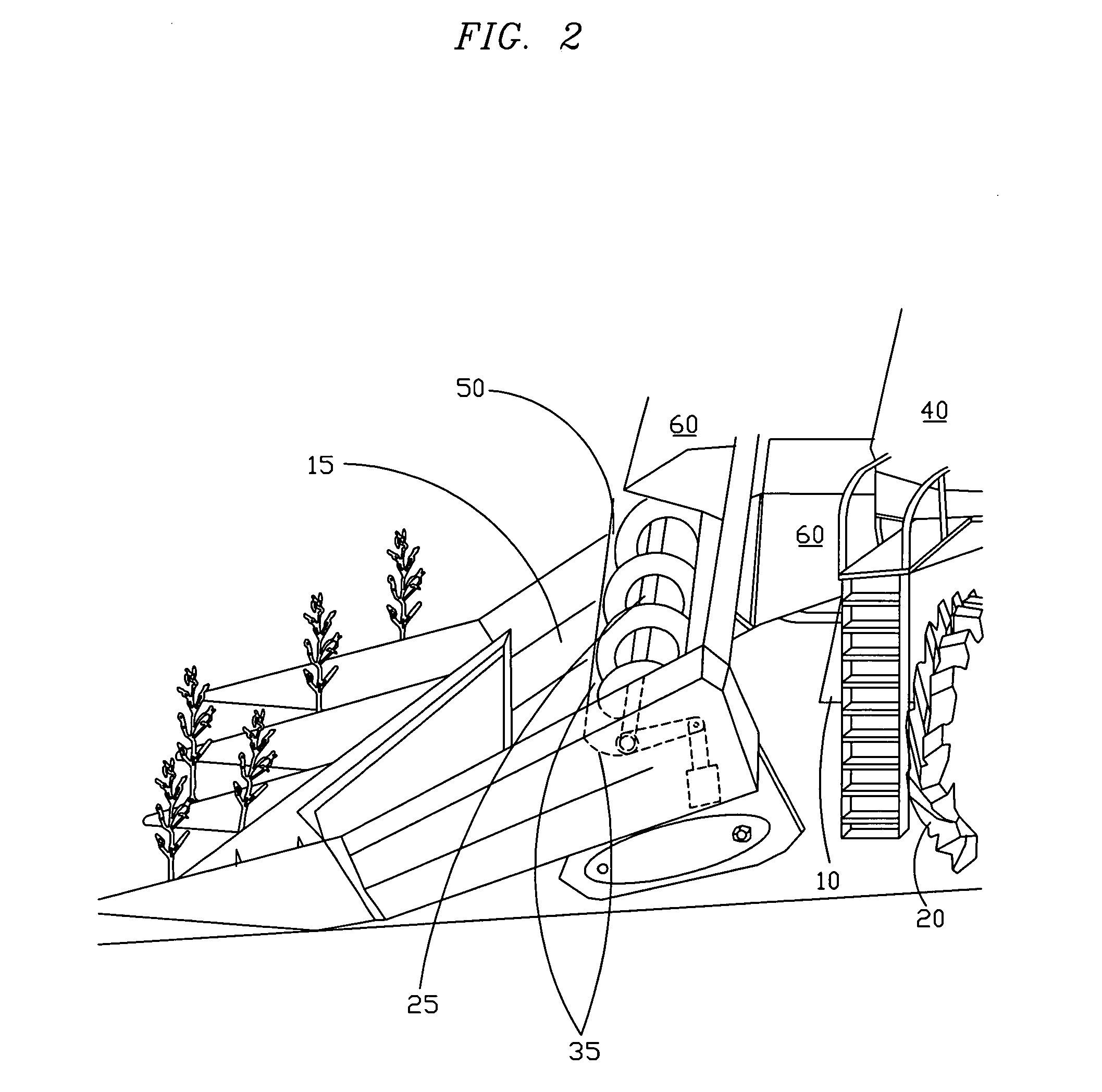

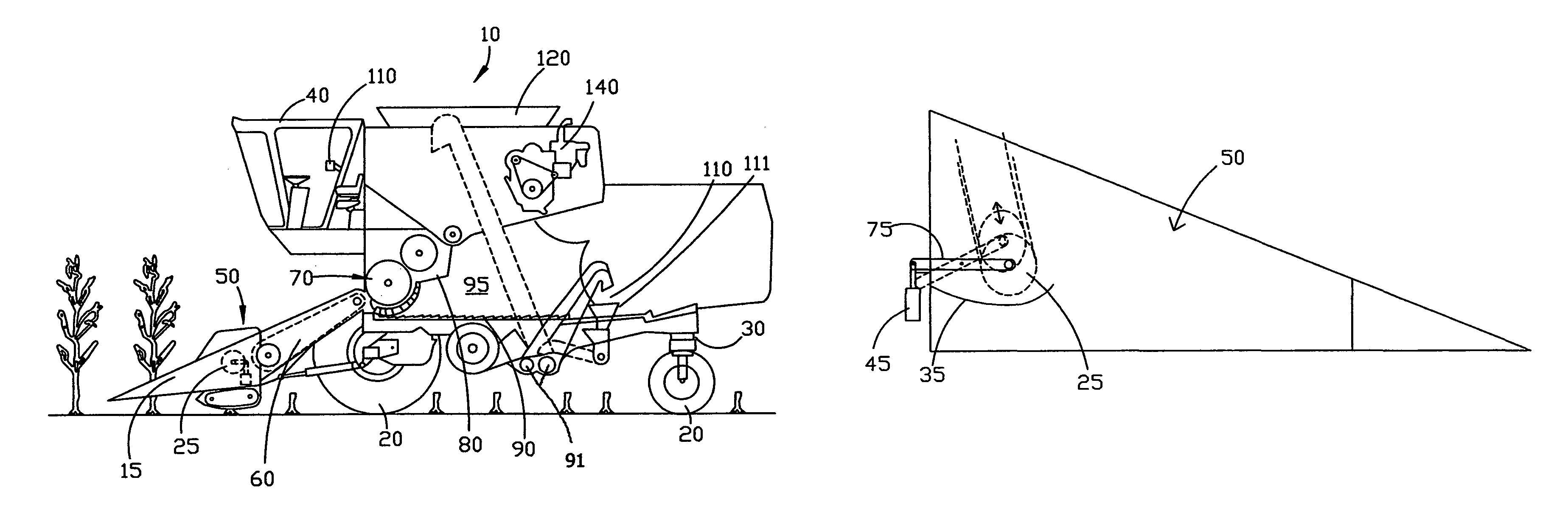

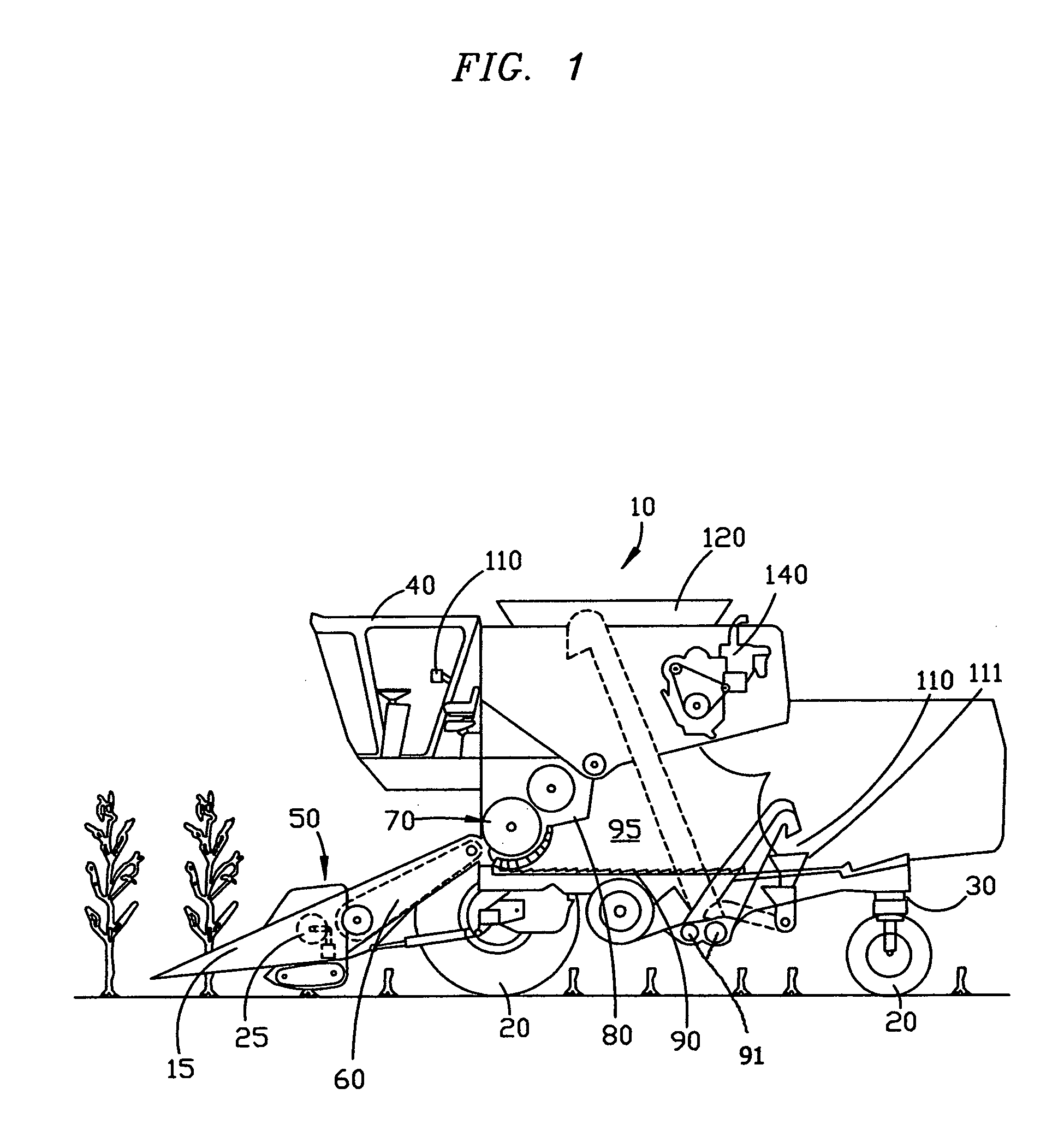

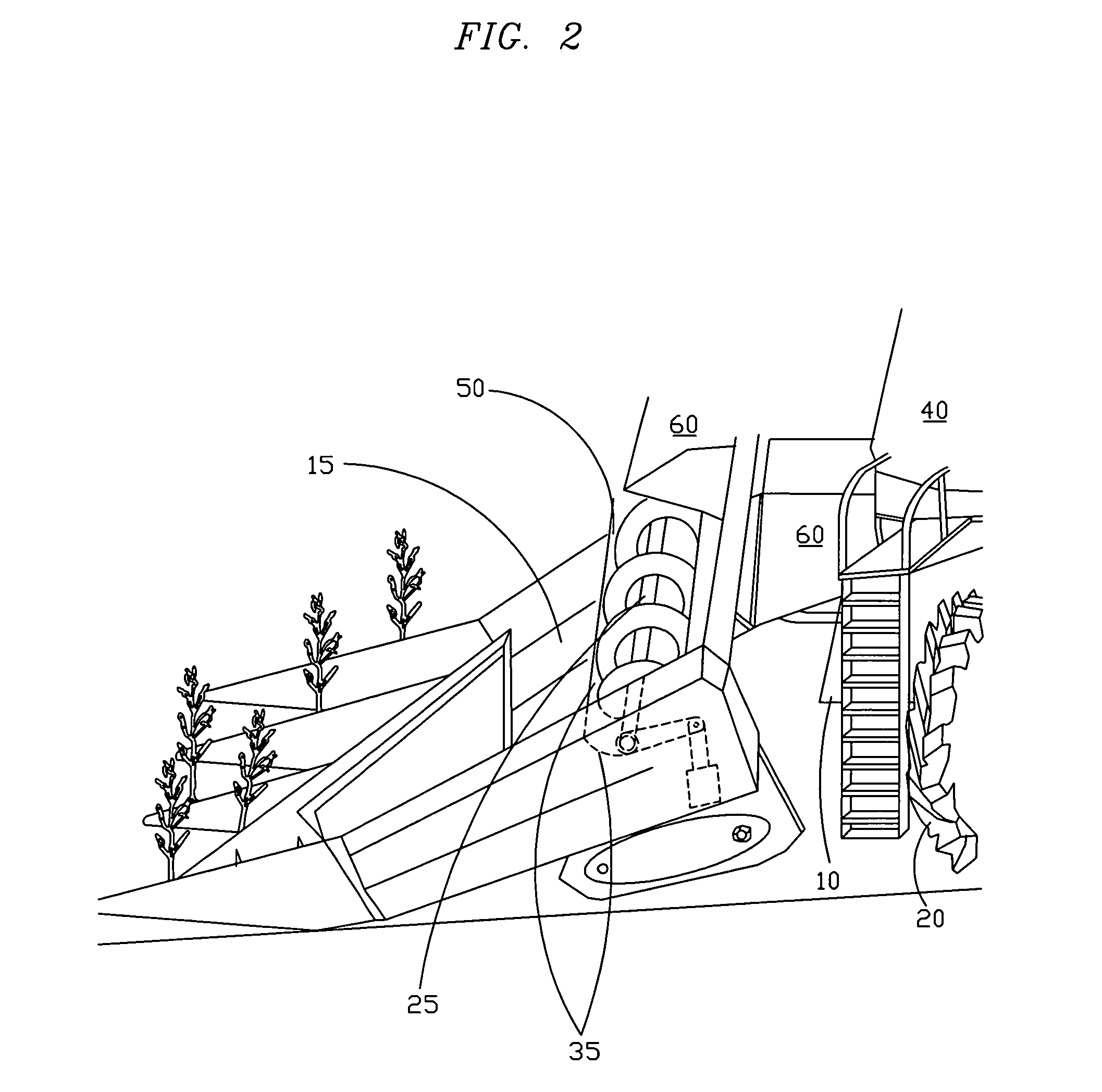

Dual research plot harvester with unconventional grain flow

The invention relates generally to harvesters and, more particularly, to a combine for harvesting rows crops, which has been modified, to collect and measure grain from two separate small strip test plots. The present invention is a dual plot combine with two separate and distinct internal sections of the combine. The combine's intake has two floatably mounted feeder house. This invention harvests two lots simultaneously while maintaining the integrity of each plots' harvest data. The dual plot combine has two separate unconventional grain paths for collecting and measuring the cleaned grain drums The divided clean grain bin and weigh bucket are positioned at a low position, inside the vertical confines of the combine, on a single side of the combine. The altered grain paths allow the data collection on the clean grain from each plot to be completed quickly. This in turn allows the combine to progress to the next set of two plots quickly.

Owner:SYNGENTA PARTICIPATIONS AG

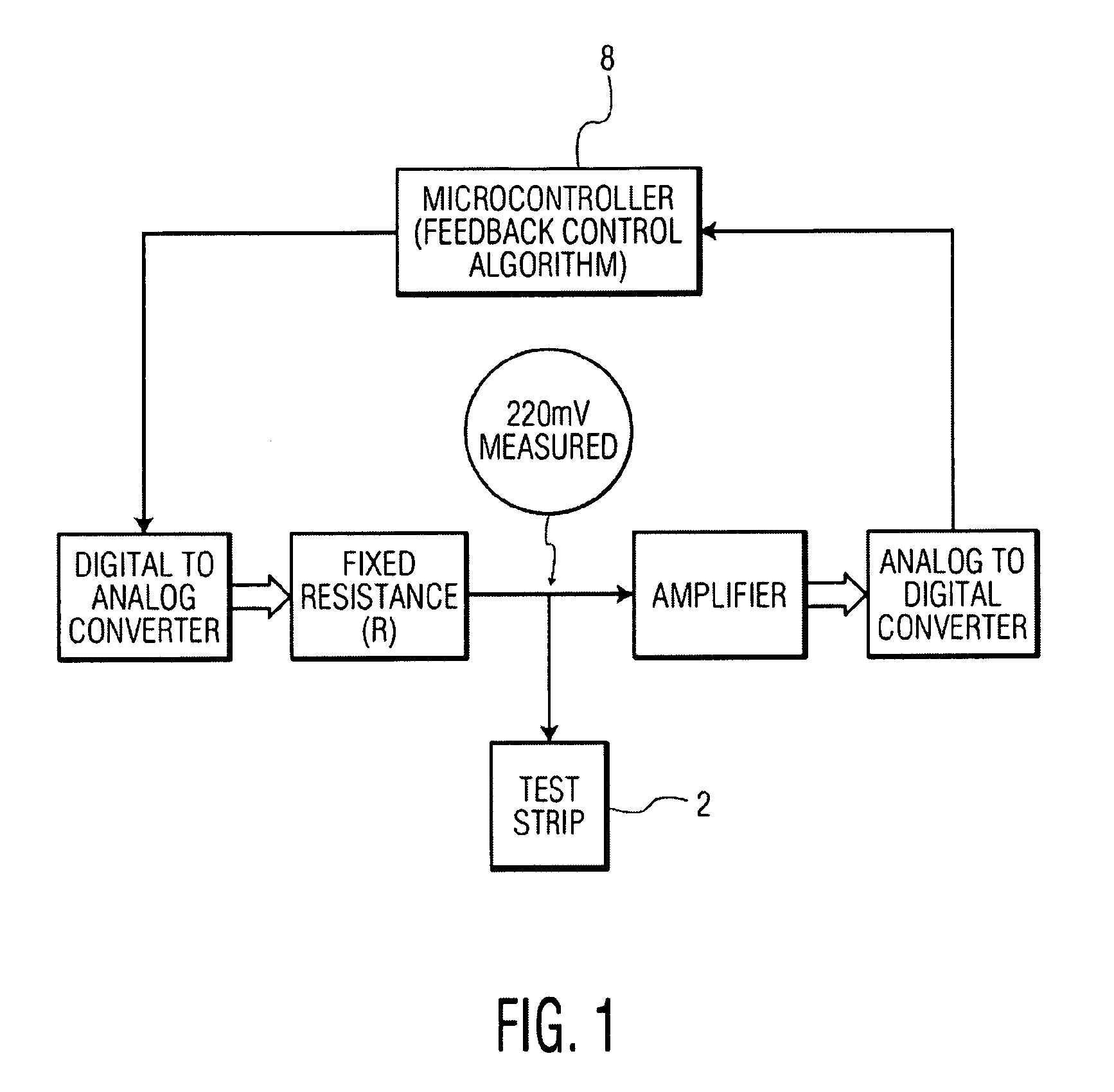

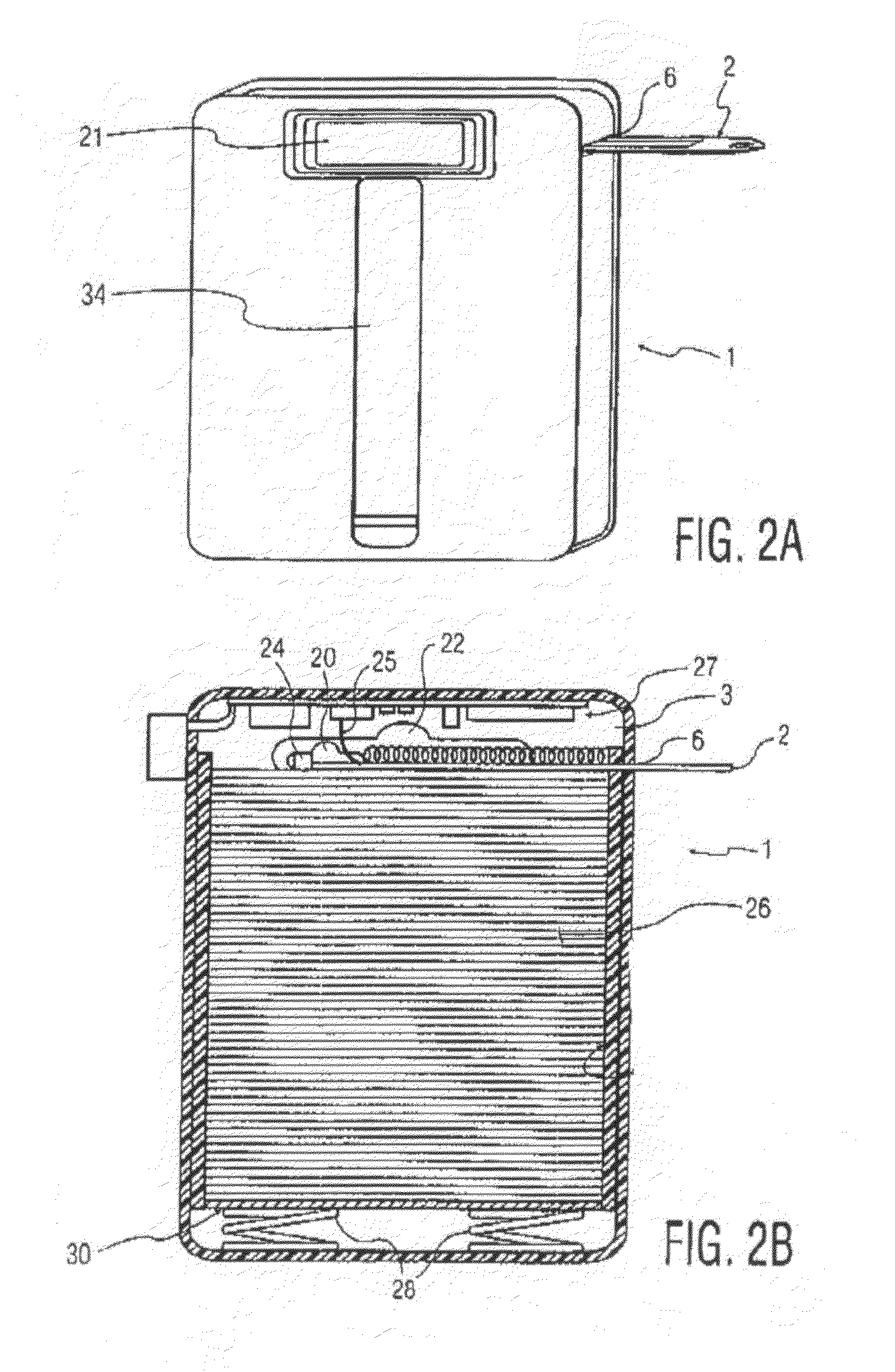

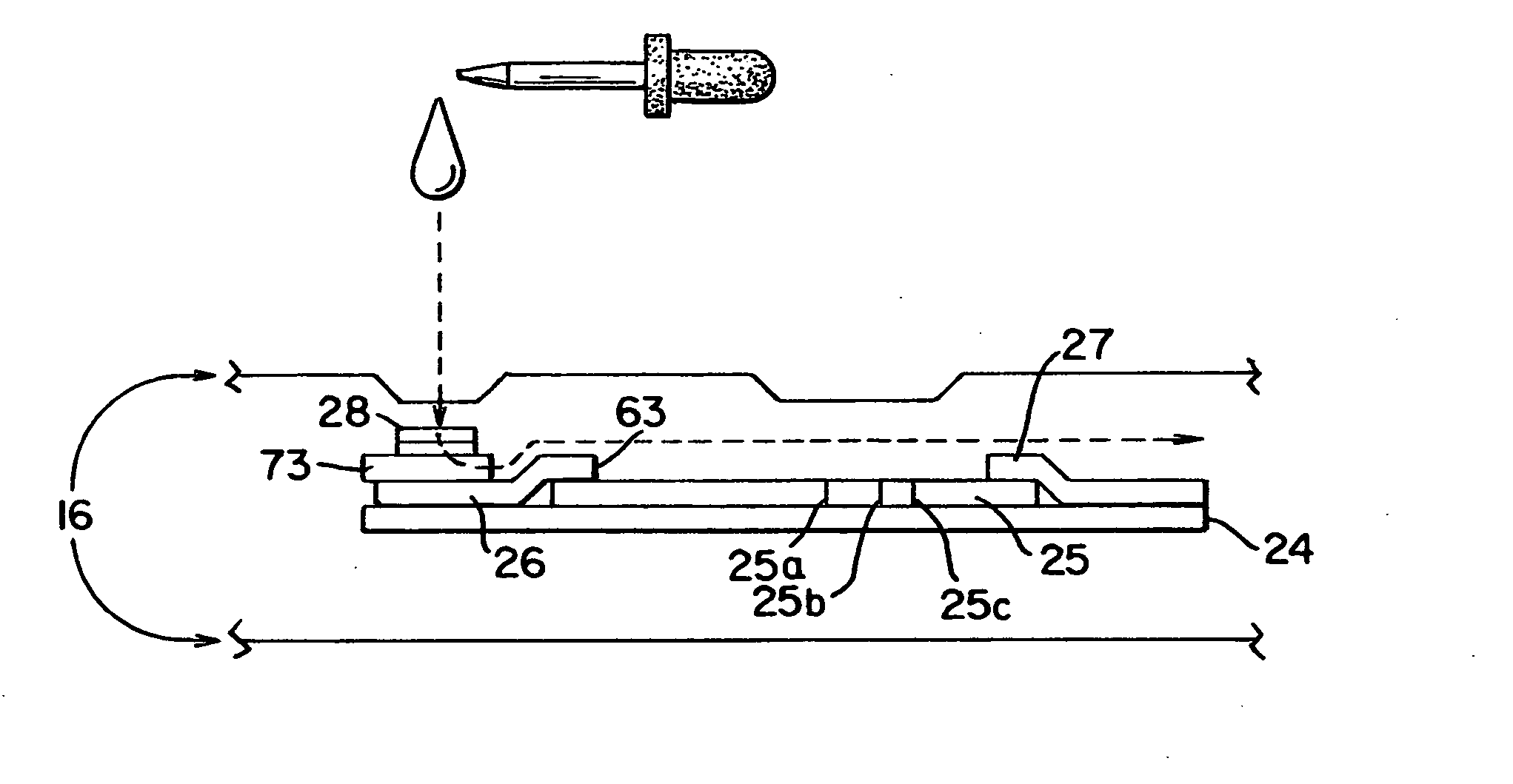

Disposable, refillable glucometer with cell phone interface for transmission of results

ActiveUS7935307B2Bioreactor/fermenter combinationsBiological substance pretreatmentsGlucose meter deviceEngineering

A disposable glucometer is disclosed which includes a testing region for receiving a test strip and electronic components to perform blood glucose monitoring, a cell phone interface for relaying test results to a monitoring station or server (which can be through a Bluetooth radio), and a multi-strip test strip holder. The glucometer includes a mechanism to automatically load test strips, one at a time, from the multi-strip test strip holder into the testing region, and a mechanism to eject the strip from the testing region after the test is complete. The test strip holder is preferably encased in a transparent material or otherwise includes a visual indicator so that the number of strips remaining strips and available for testing can be determined. In one embodiment, the entire unit is disposable, and is discarded when all of the strips have been used. In another embodiment, the test strip holder portion of the unit is removed and replaced with a new test strip holder which is loaded with test strips.

Owner:TELADOC HEALTH INC

Research plot harvester for continuous plot to plot grain evaluation

The invention relates generally to harvesters and, more particularly, to a combine for harvesting row crops, which has been modified, to collect and measure grain from continuously from a plurality of strip test plots.

Owner:SYNGENTA PARTICIPATIONS AG

Research plot harvester for continuous plot to plot grain evaluation

Owner:SYNGENTA PARTICIPATIONS AG

Partially patterned lead frames and methods of making and using the same in semiconductor packaging

InactiveUS8236612B2Improve structural rigiditySemiconductor/solid-state device detailsSolid-state devicesLead bondingBonding process

A method of making a lead frame and a partially patterned lead frame package with near-chip scale packaging lead-count, wherein the method lends itself to better automation of the manufacturing line and improved quality and reliability of the packages produced therefrom. A major portion of the manufacturing process steps is performed with a partially patterned strip of metal formed into a web-like lead frame on one side so that the web-like lead frame is also rigid mechanically and robust thermally to perform without distortion or deformation during the chip-attach and wire bond processes, both at the chip level and the package level. The bottom side of the metal lead frame is patterned to isolate the chip-pad and the wire bond contacts only after the front side, including the chip and wires, is hermetically sealed with an encapsulant. The resultant package being electrically isolated enables strip testing and reliable singulation.

Owner:UNISEM M BERHAD

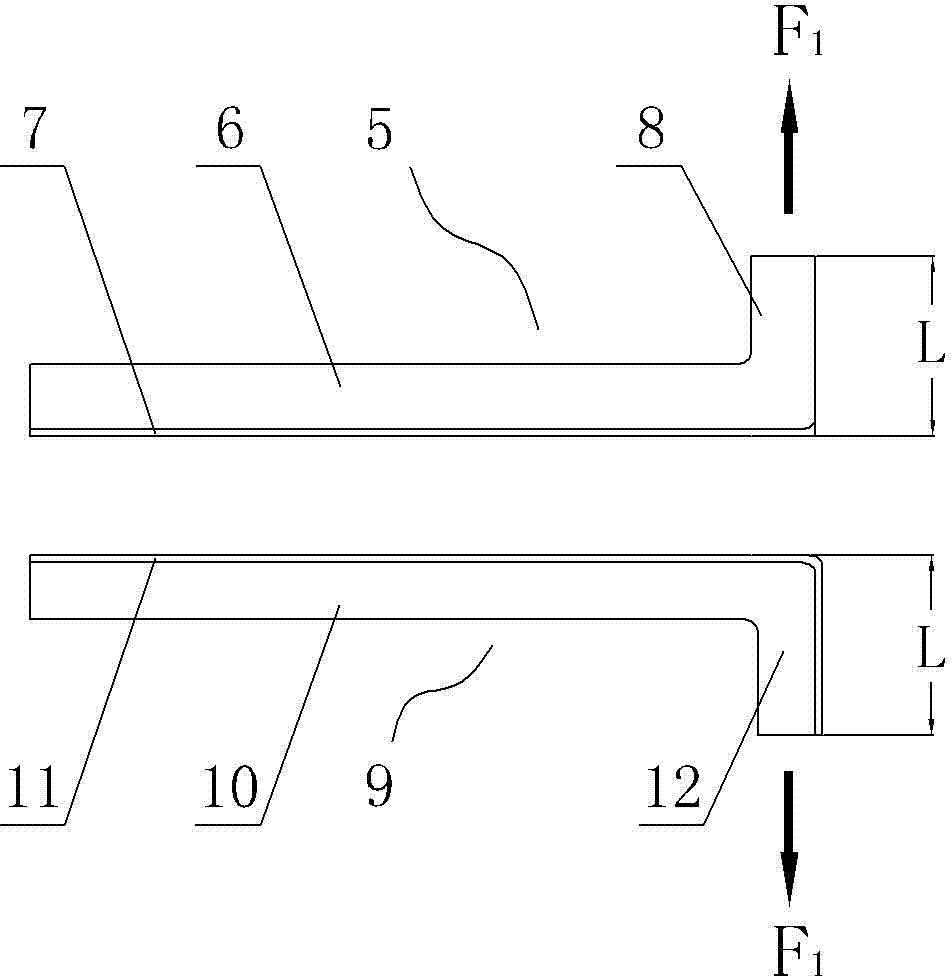

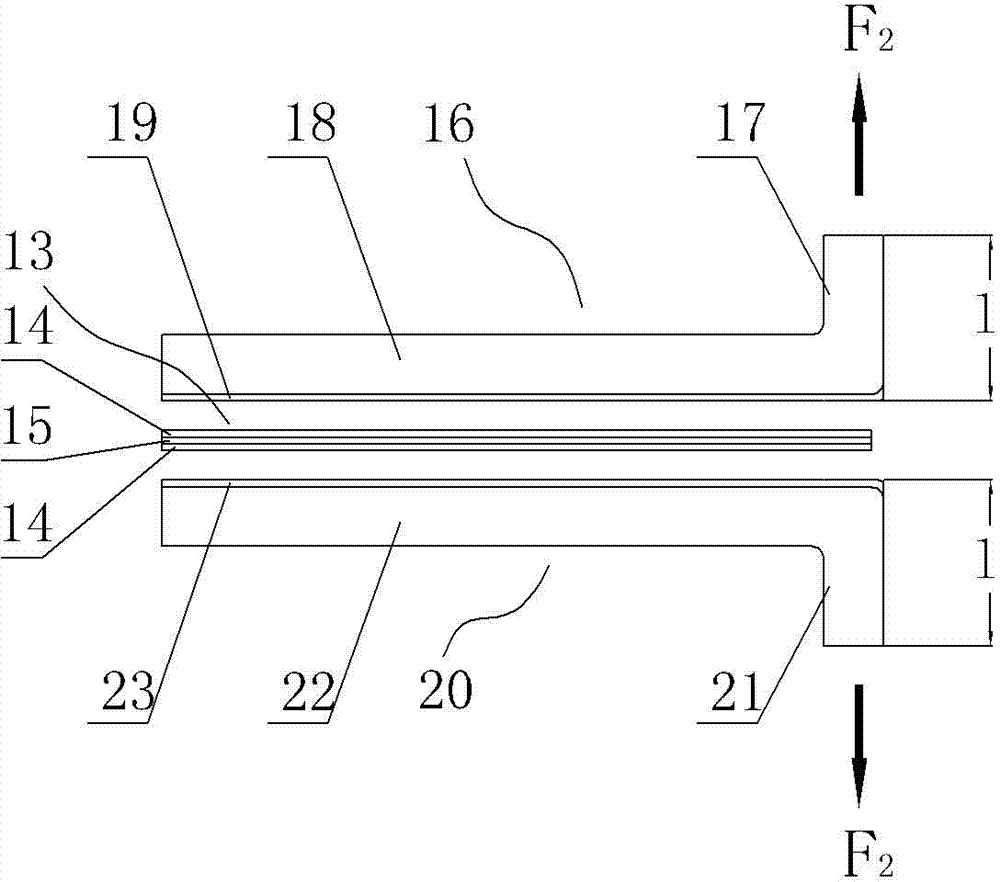

Method for detecting interface binding strength of aluminum-steel composite material for soldering

ActiveCN103776762AMake sure to peel off properlySmooth peelingUsing mechanical meansMaterial analysisTest sampleSoldering

The invention provides a method for detecting the interface binding strength of an aluminum-steel composite material for soldering. The method can be used for accurately detecting the aluminum-steel interface binding strength and quantifying the interface binding effect of the aluminum-steel composite material for the soldering. The method comprises the following steps: firstly, preparing a test sample of the aluminum-steel composite material and carrying out a stripping test on the test sample; and calculating according to a test result to obtain a binding strength value of an aluminum-steel interface. The method is characterized in that the preparation of the test sample comprises the following steps: soldering and connecting a metal reinforced layer on the surface of an aluminum layer of the sample and forming a compound layer by the metal reinforced layer and the aluminum layer of the sample. The binding strength of the metal reinforced layer in the compound layer and the aluminum layer of the sample is greater than the binding strength of the aluminum-steel interface; in the stripping test, the compound layer and a steel layer in the sample are stripped by a tension tester.

Owner:银邦(安徽)新能源材料科技有限公司

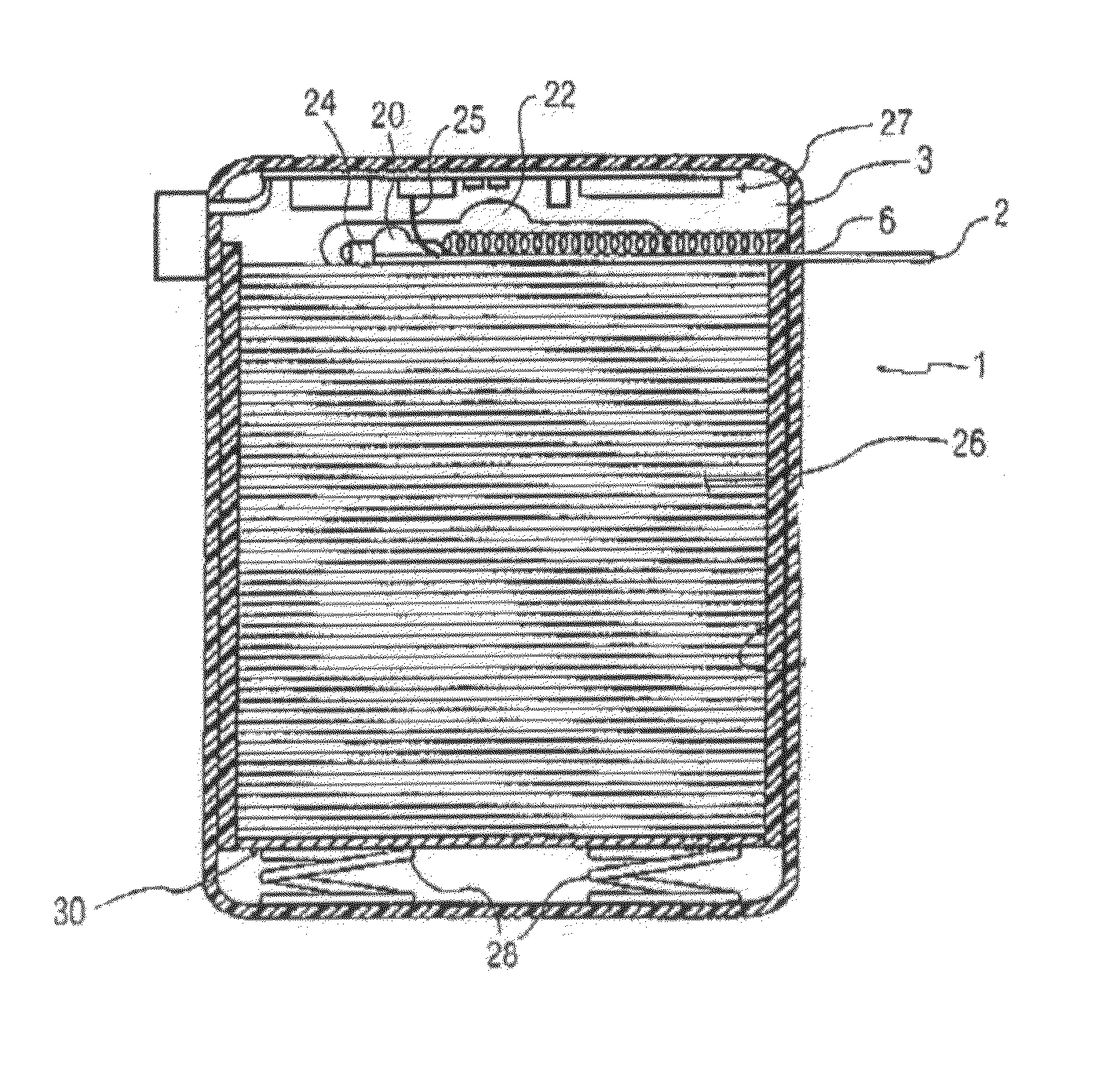

Electrochemical biosensor test strip

InactiveUSRE42924E1Easy to identifyEnsure correct executionImmobilised enzymesBioreactor/fermenter combinationsElectrochemical biosensorPolyethylene oxide

An electrochemical biosensor test strip with four new features. The test strip includes an indentation for tactile feel as to the location of the strips sample application port. The sample application port leads to a capillary test chamber, which includes a test reagent. The wet reagent includes from about 0.2% by weight to about 2% by weight polyethylene oxide from about 100 kilodaltons to about 900 kilodaltons mean molecular weight, which makes the dried reagent more hydrophilic and sturdier to strip processing steps, such as mechanical punching, and to mechanical manipulation by the test strip user. The roof of the capillary test chamber includes a transparent or translucent window which operates as a “fill to here” line, thereby identifying when enough test sample (a liquid sample, such as blood) has been added to the test chamber to accurately perform a test. The test strip may further include a notch located at the sample application port. The notch reduces a phenomenon called “dose hesitation”.

Owner:ROCHE OPERATIONS +1

Semiconductor packaging with partially patterned lead frames and its making methods

InactiveCN1735963AAdhesive treatment is stableEliminate hard-to-stuck problemsSemiconductor/solid-state device detailsSolid-state devicesLead bondingBonding process

A method of making a lead frame and a partially patterned lead frame package with near-chip scale packaging (CSP) lead-counts is accomplished by performing a major portion of the manufacturing process steps with a partially patterned strip of metal formed into a web-like lead frame on one side, so that the web-like lead frame, which is solid and flat on the other side is also rigid mechanically and robust thermally to perform without distortion or deformation during the chip-attach and wire bond processes, both at the chip level and the package level. The bottom side of the metal lead frame is patterned to isolate the chip-pad and the wire bond contacts only after the front side, including the chip and wires, is hermetically sealed with an encapsulant. The resultant package being electrically isolated enables strip testing and reliable singulation without having to cut into any additional metal.

Owner:UNISEM MAURITIUS HLDG

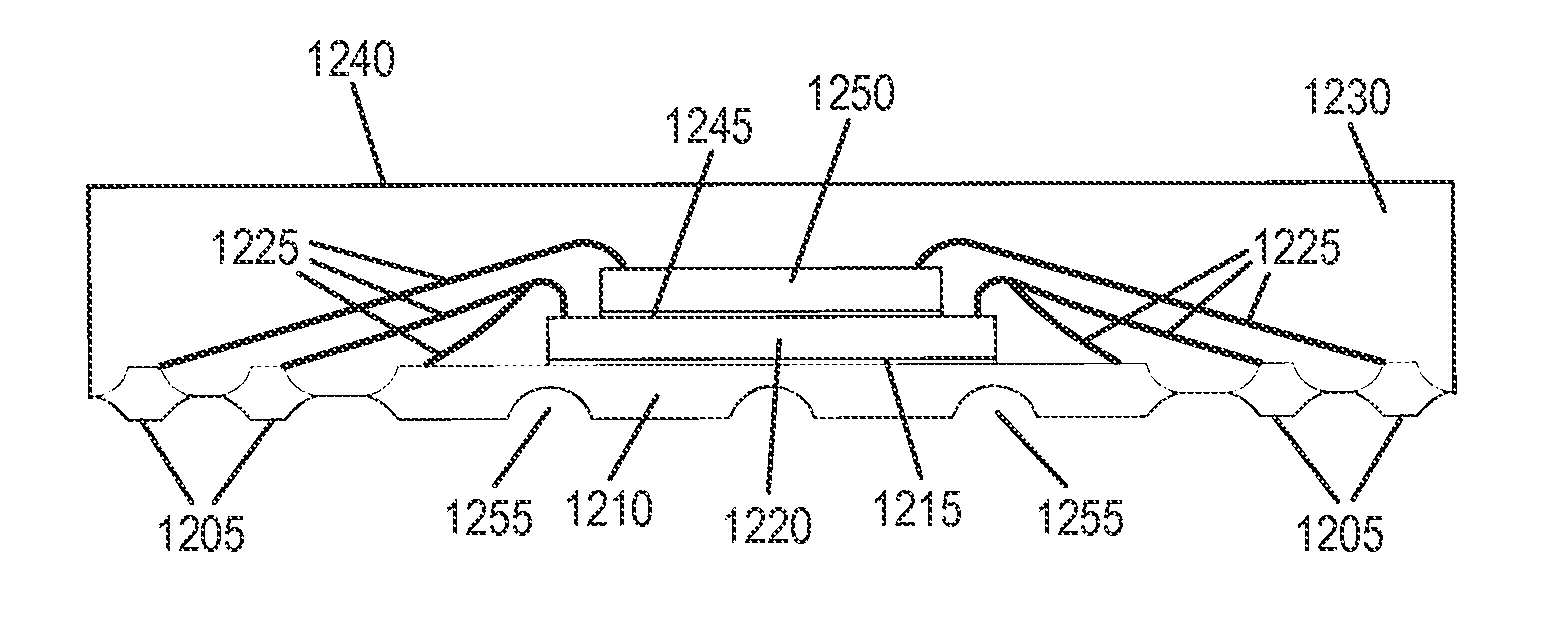

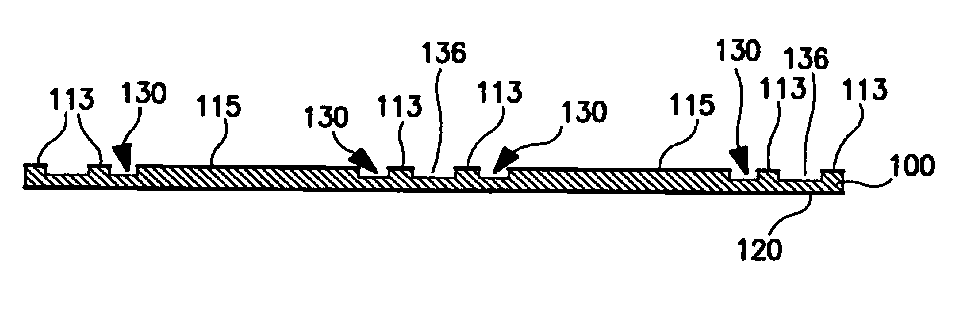

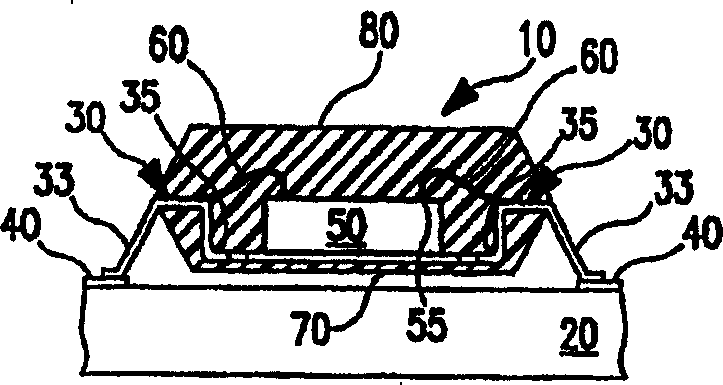

Singulation and Strip Testing of No-Lead Integrated Circuit Packages Without Tape Frame

ActiveUS20120252142A1Semiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsMagnetic tapeEngineering

Strip testing is applied to a plurality of integrated circuit dies that are each encapsulated in an encapsulant, that each have a set of externally accessible leads connected thereto, and that are electrically isolated from one another. Provision is made for the strip testing to be performed without mounting the encapsulated integrated circuit dies on a support tape.

Owner:TEXAS INSTR INC

Detection of amniotic fluid in vaginal secretions of pregnant women due to premature rupture of fetal membranes

ActiveUS20120052595A1Time stableStrong specificityAnalysis using chemical indicatorsLaboratory glasswaresAntigenObstetrics

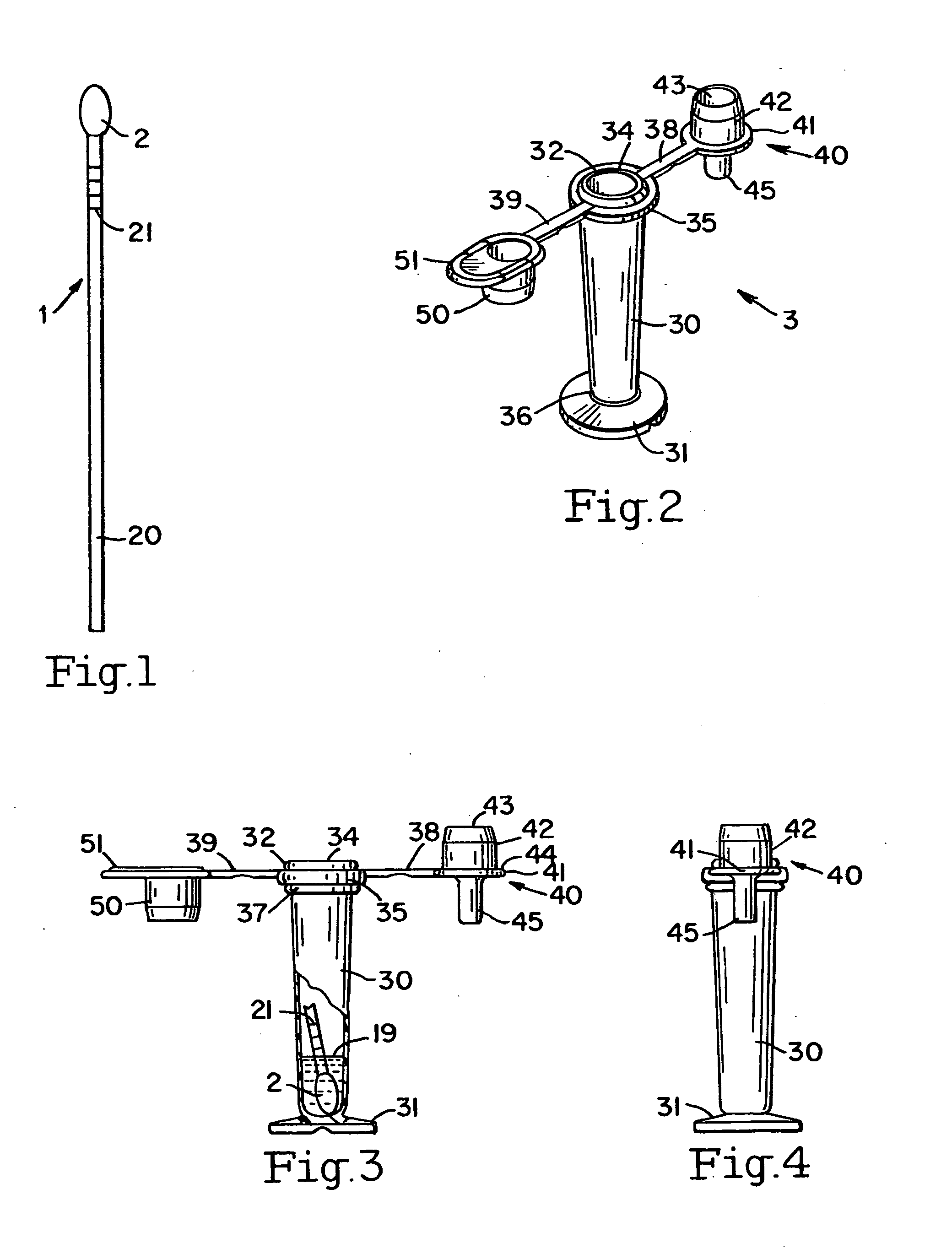

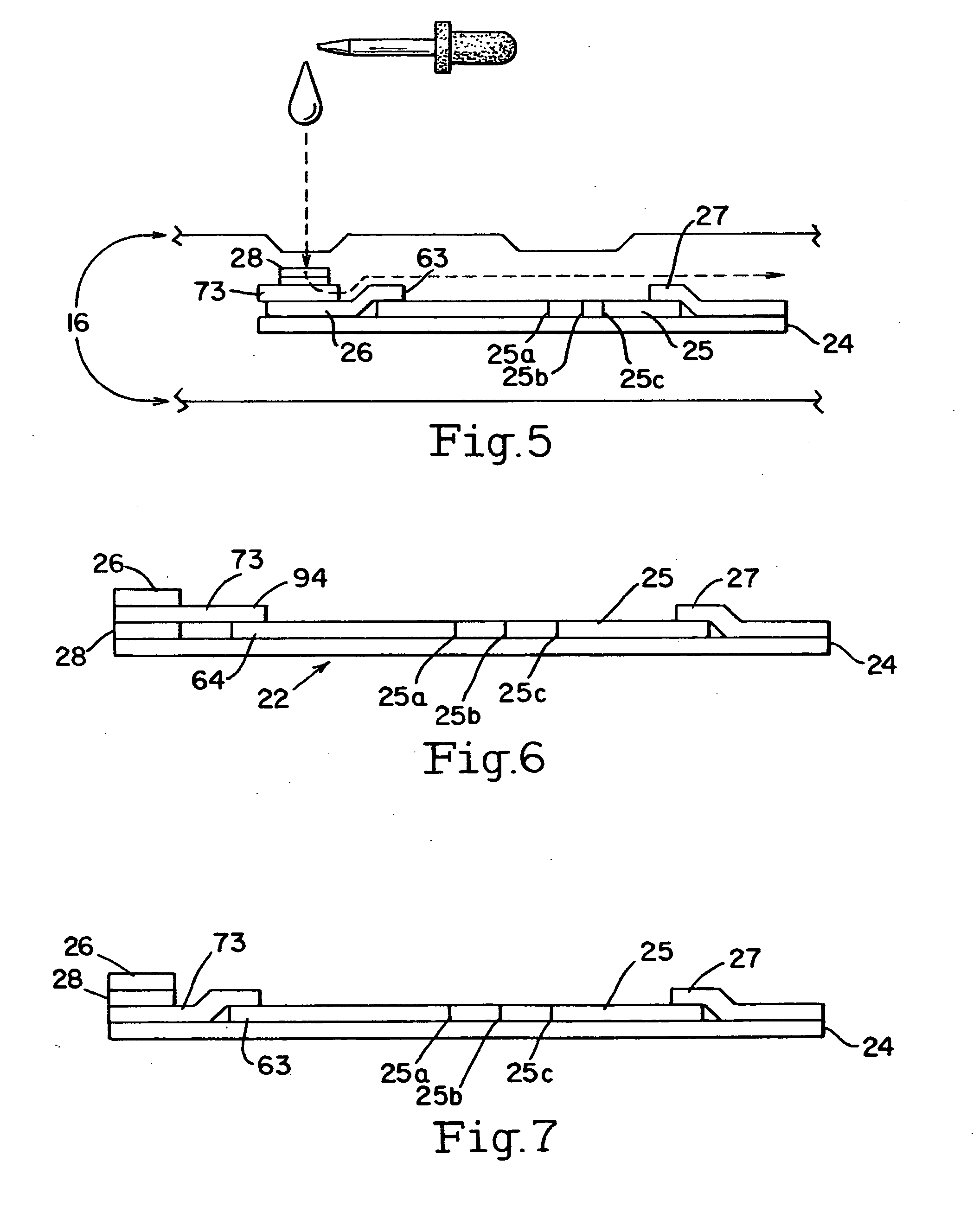

A method is taught for the accurate determination of the premature rupture of membranes (PROM), defined as spontaneous rupture of membranes before the onset of uterine contractions. More specifically, a lateral flow assay strip tests for at least two antigens to greatly limit or eliminate the possibility of false negatives. A built in timer in the cassette holding the lateral flow assay further increases the accuracy of the test. A collection buffer vial with self-contained shipping and dropper caps and built in stand is also taught.

Owner:CLINICAL INNOVATIONS LTD

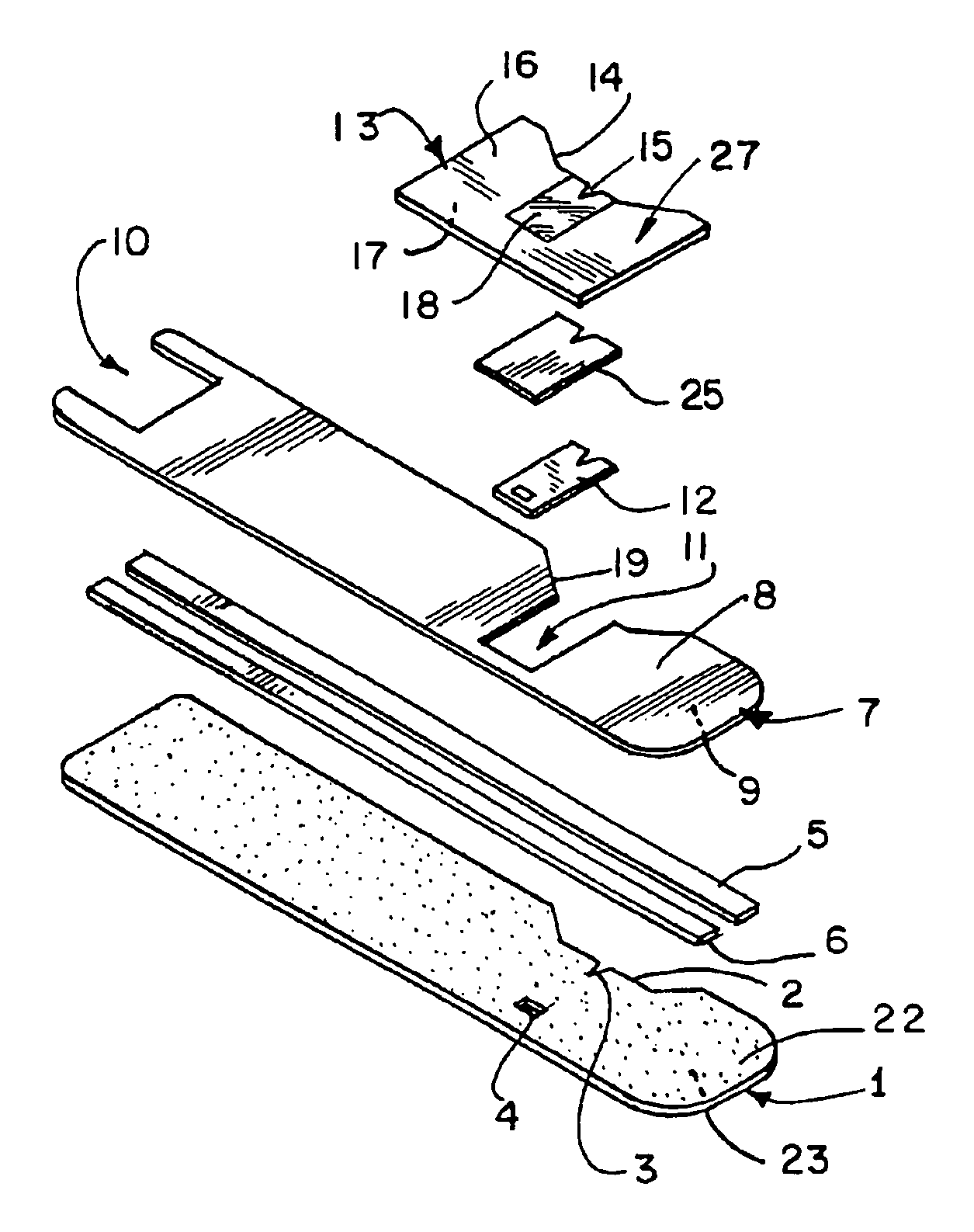

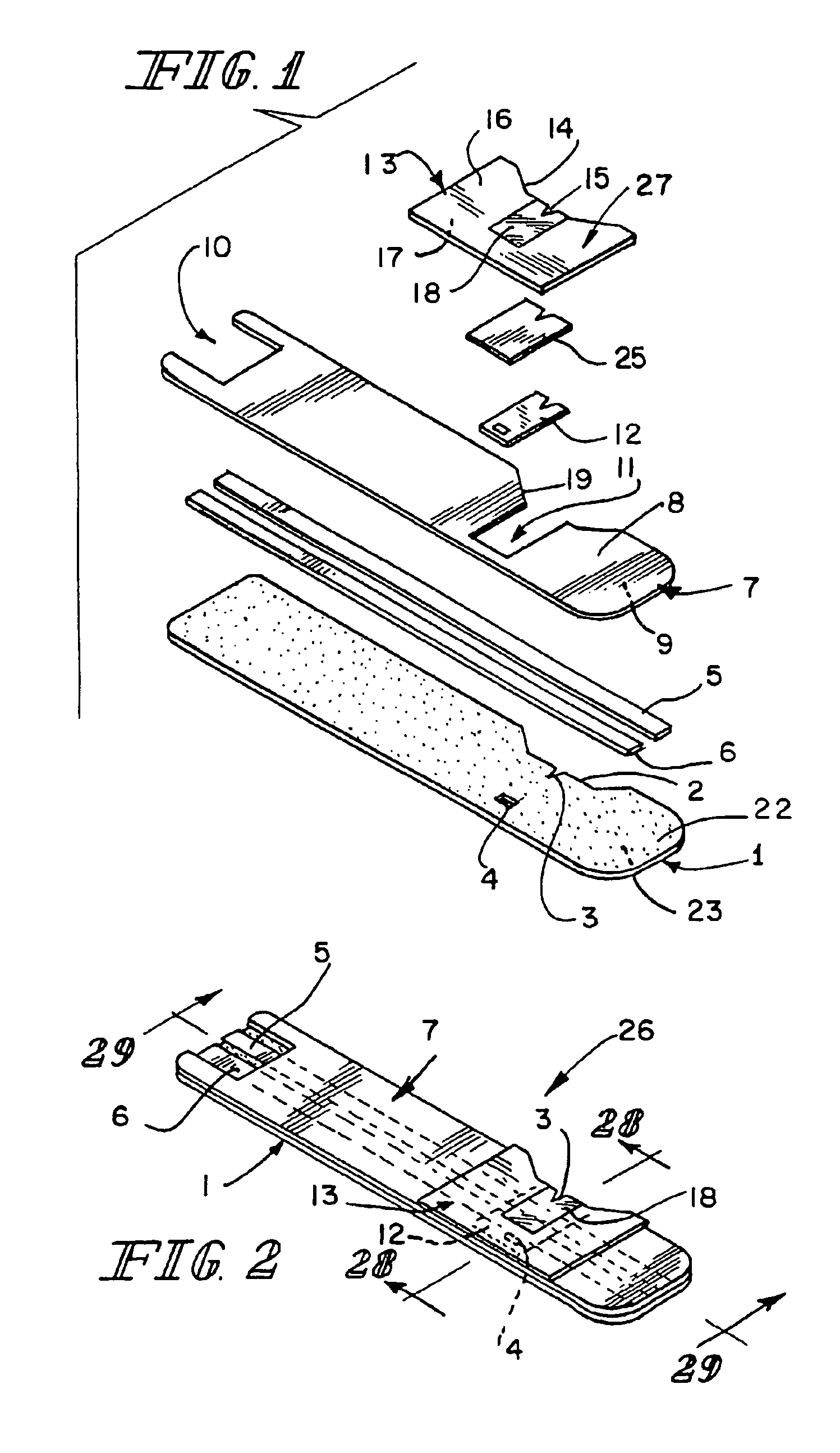

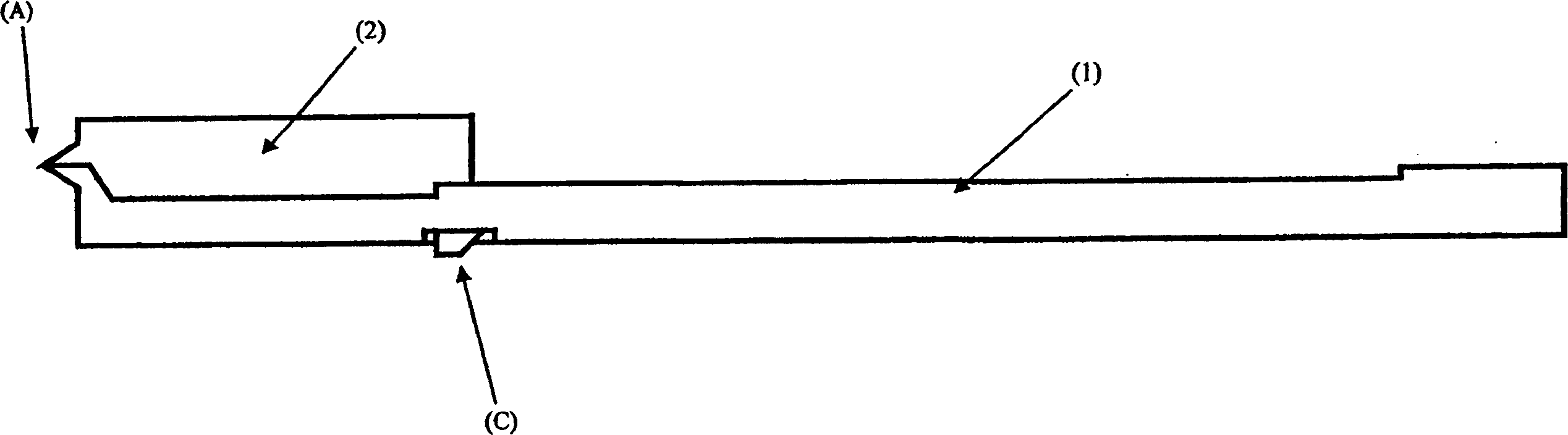

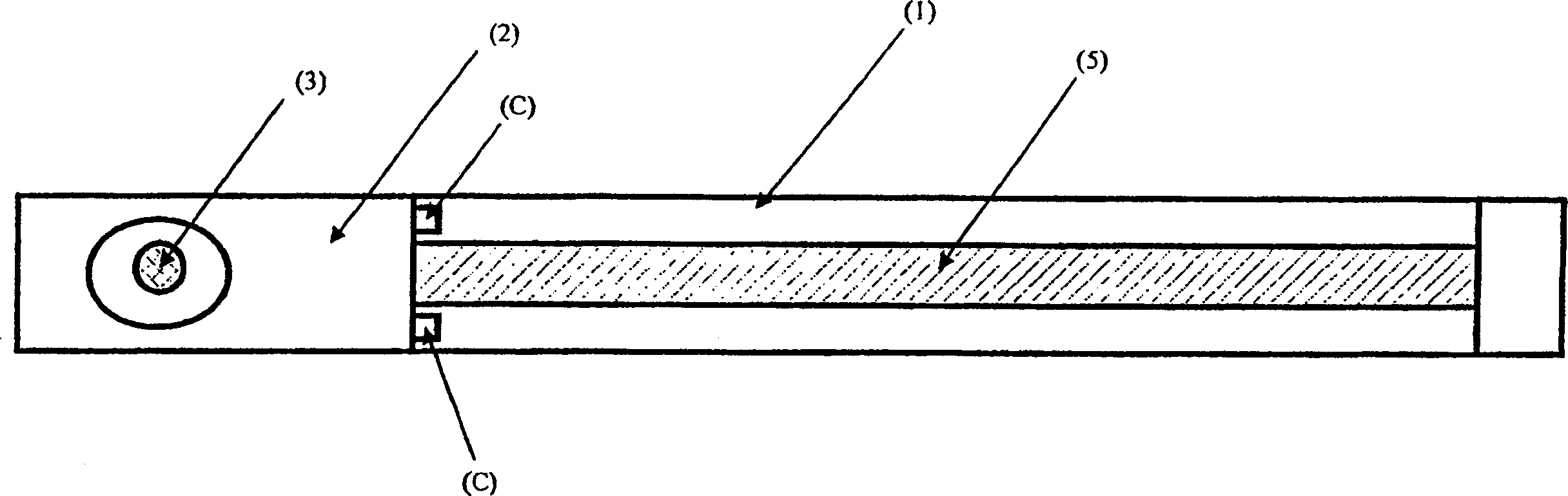

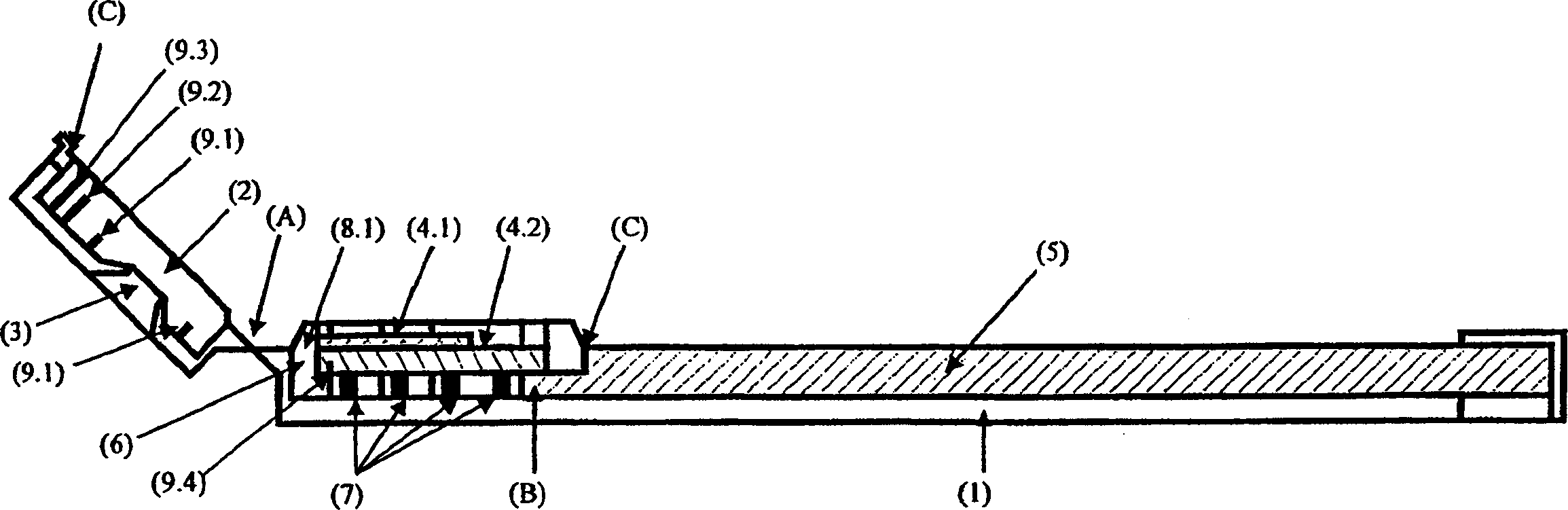

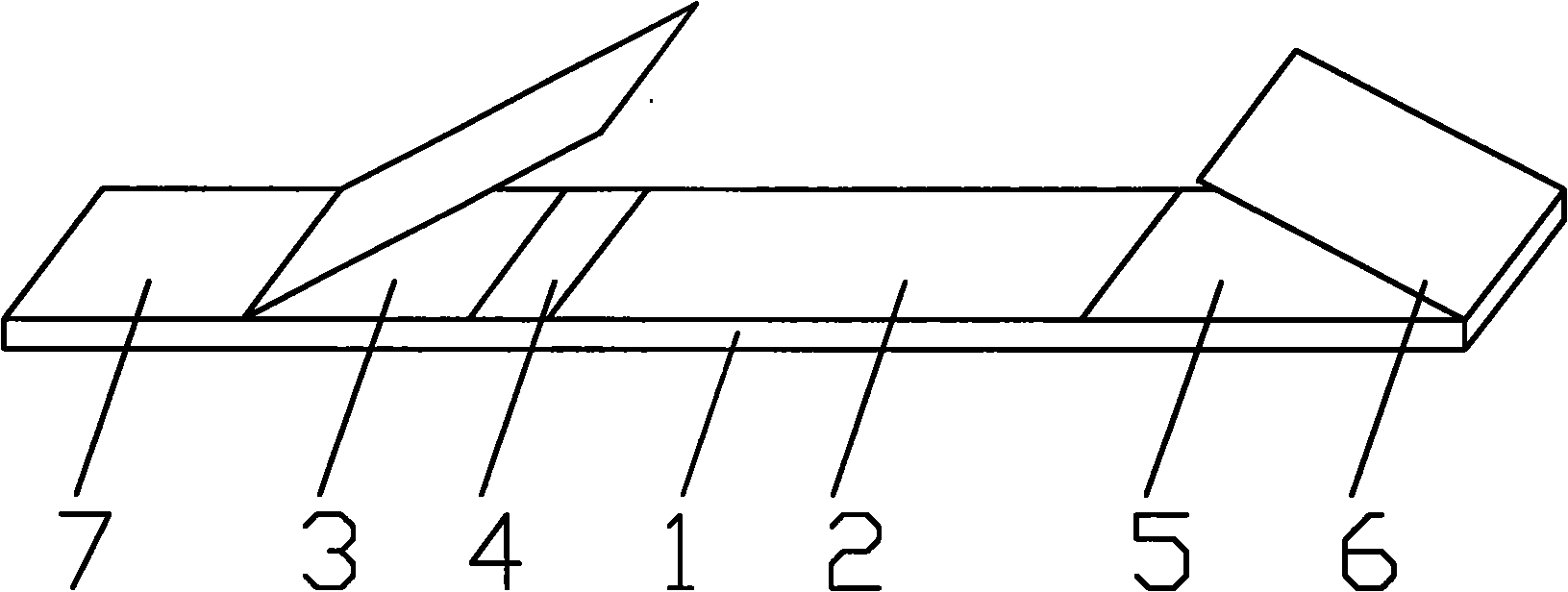

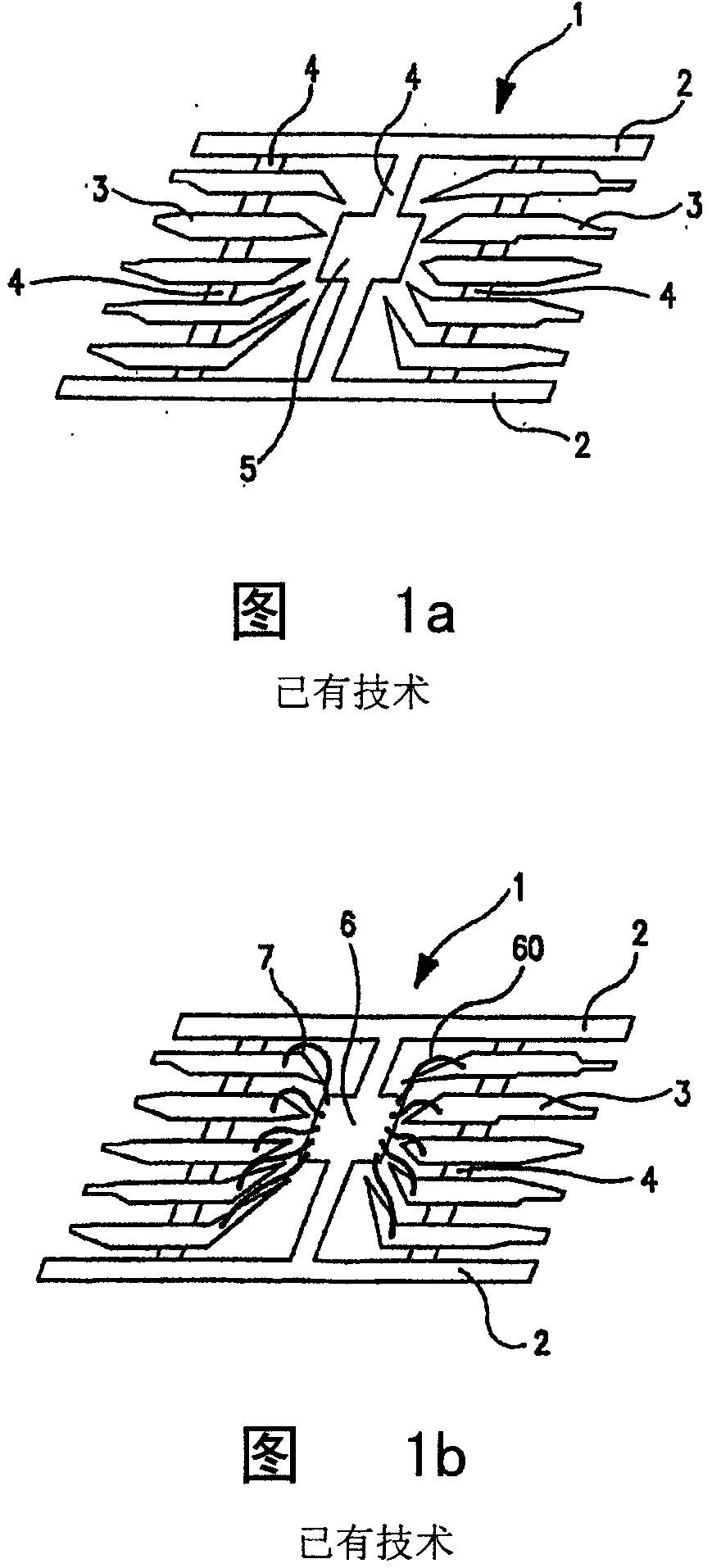

Test strip device with lid-provided pretreatment portion

The invention relates to a test device, which has a pretreatment part covered by a cover (2) having a hole (3) and connected by a hinge (A). The pretreatment part is mounted on the same base (1) as a test strip (not shown). In the lid (2) and the lid of the base are devices (7, 8 and 9) for supporting, fastening and fixing the pretreatment layers, forming excess liquid collection chambers (6), and controlling the flow of sample solutions and diluents. The test device is used in field tests and clinical methods, especially in emergency situations where fast results are required (Fig. 8).

Owner:MEDIX BIOCHEMICA

Graphite Film and Graphite Composite Film

ActiveUS20110165379A1Improve diffusivityIncrease resistanceGraphiteSemiconductor/solid-state device detailsFolding enduranceThermal diffusivity

An object of the present invention is to provide a graphite film, and a graphite composite film both having an excellent thermal diffusivity which can sufficiently manage heat dissipation of electronic instruments, precision instruments and the like, along with an excellent flex resistance which can withstand application to bent portions.Means for Resolution of the present invention is a graphite film exhibiting the number of reciprocal foldings being 10,000 times or more as measured using a rectangular strip test piece having a width of 15 mm until the test piece breaks in a MIT folding endurance test under conditions of: a curvature radius R of the bending clamp being 2 mm; a left-and-right bending angle being 135°; a bending rate being 90 times / min; and a load being 0.98 N.

Owner:KANEKA CORP

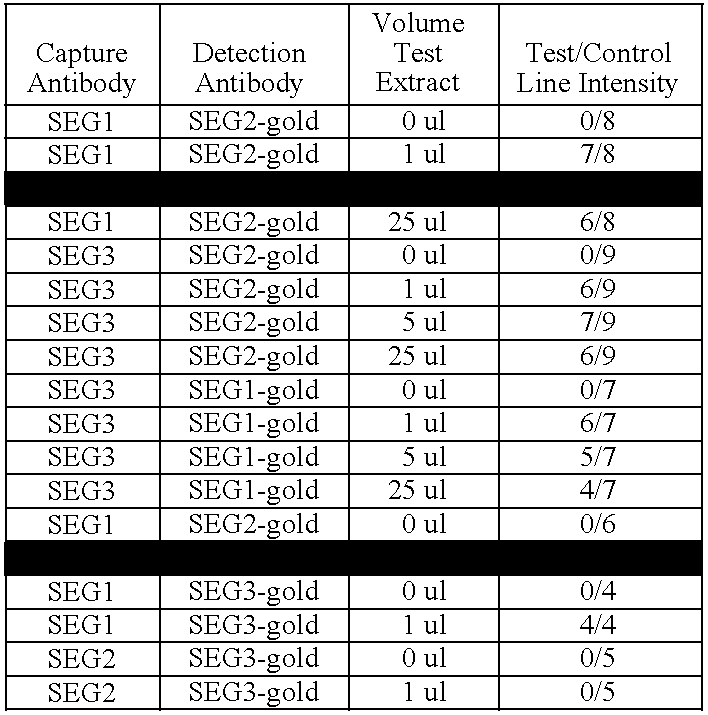

Forensic Test for Human Semen

Lateral flow immunochromatographic strip tests for the detection of human semen, method of detecting human semen, and methods of manufacturing ICS tests for the detection of human semen are described

Owner:INDEPENDENT FORENSICS

Binary detection test strip of beta-exhilarant ractopamine and salbutamol and preparation method thereof

InactiveCN101915842ASimple methodThe result is accurateColor/spectral properties measurementsBiological testingGlass fiberSalbutamol

The invention relates to a binary detection test strip of beta-exhilarant ractopamine and salbutamol and a preparation method thereof, which can effectively solve the problem that the beta-exhilarant ractopamine and salbutamol can not be detected quickly, easily and simultaneously. The preparation method comprises the following steps of: arranging diversion glass fiber, carrier glass fiber, a nitrocellulose membrane and an absorbent cotton pulp board a on a substrate PVC (Polyvinyl Chloride) board from back to front in order; covering a coating comprising a front coating and a rear coating onthe diversion glass fiber, the carrier glass fiber and the absorbent cotton pulp board, wherein a monoclonal antibody for resisting ractopamine protein conjugates and a monoclonal antibody colloid gold marker for resisting salbutamol protein conjugates are adsorbed in the carrier glass fiber; and coating the nitrocellulose membrane with a quality control line and two test lines, wherein the quality control line is coated with rabbit antimouse multi-resistant, and the test lines are coated with ractopamine protein conjugates and salbutamol protein conjugates. The invention can be used for detecting the beta-exhilarant ractopamine and the salbutamol simultaneously, effectively, conveniently and quickly and has accurate result.

Owner:HENAN ACAD OF SCI INST OF BIOLOGY LIABILITY

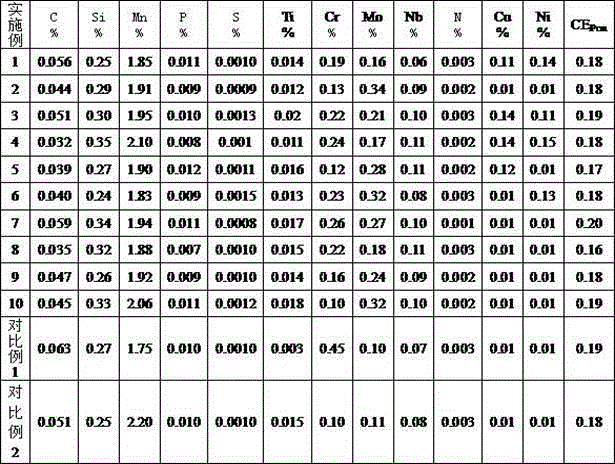

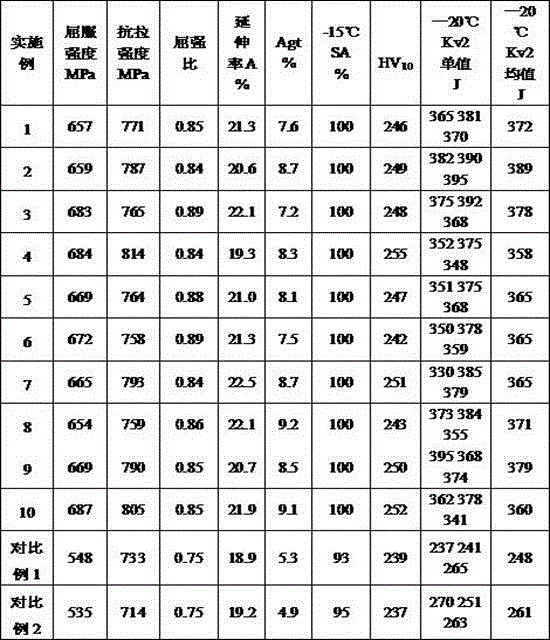

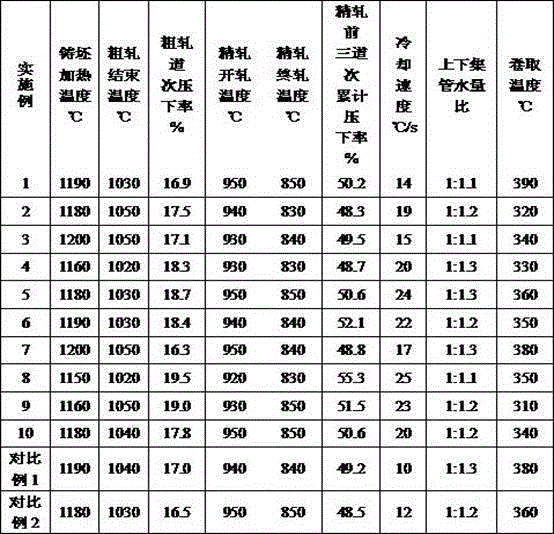

High-strength/toughness X90 hot-rolled steel strip for spiral submerged arc welded pipes and production method thereof

The invention relates to a high-strength / toughness X90 hot-rolled steel strip for spiral submerged arc welded pipes, which is composed of the following components in percentage by weight: 0.03-0.06% of C, 0.25-0.35% of Si, 1.80-2.10% of Mn, at most 0.012% of P, at most 0.002% of S, 0.10-0.25% of Cr, 0.15-0.35% of Mo, 0.06-0.11% of Nb, 0.009-0.02% of Ti and at most 0.003% of N. CEpcm(%)=C+Si / 30+(Cr+Mn+Cu) / 20+Mo / 15+V / 10+Ni / 60+5B<=0.2%. The production method comprises the following steps: smelting, and carrying out continuous casting to obtain a blank; heating the casting blank; carrying out hot rolling; carrying out laminar cooling; and coiling. When the included angle between the steel strip test sample direction and the rolling direction is 30 degrees, Rp0.2 is 630-720 MPa, Rm is greater than or equal to 730 MPa, Rp0.2 / Rm is less than or equal to 0.90, the elongation percentage A is greater than or equal to 18%, Agt is greater than or equal to 6%, the -15 DEG C DWTT cross-section shearing rate SA is greater than or equal to 95%, HV10 is less than or equal to 265, the ballistic work single value at -20 DEG C is greater than or equal to 285J, and the ballistic work average value at -20 DEG C is greater than or equal to 355J, thereby completely satisfying the requirements of long distance and high efficacy for the spiral submerged arc welded pipe.

Owner:武钢集团有限公司

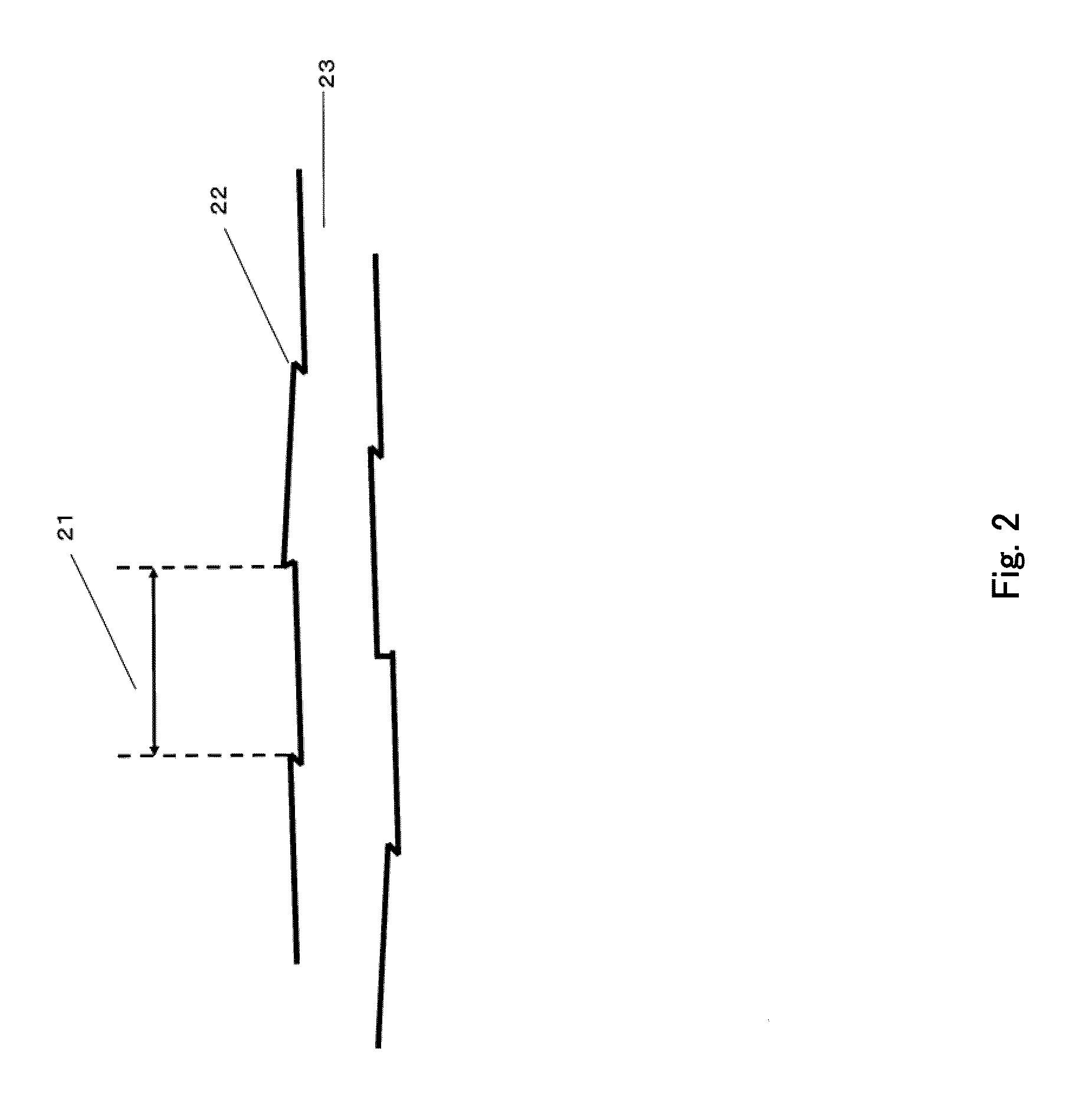

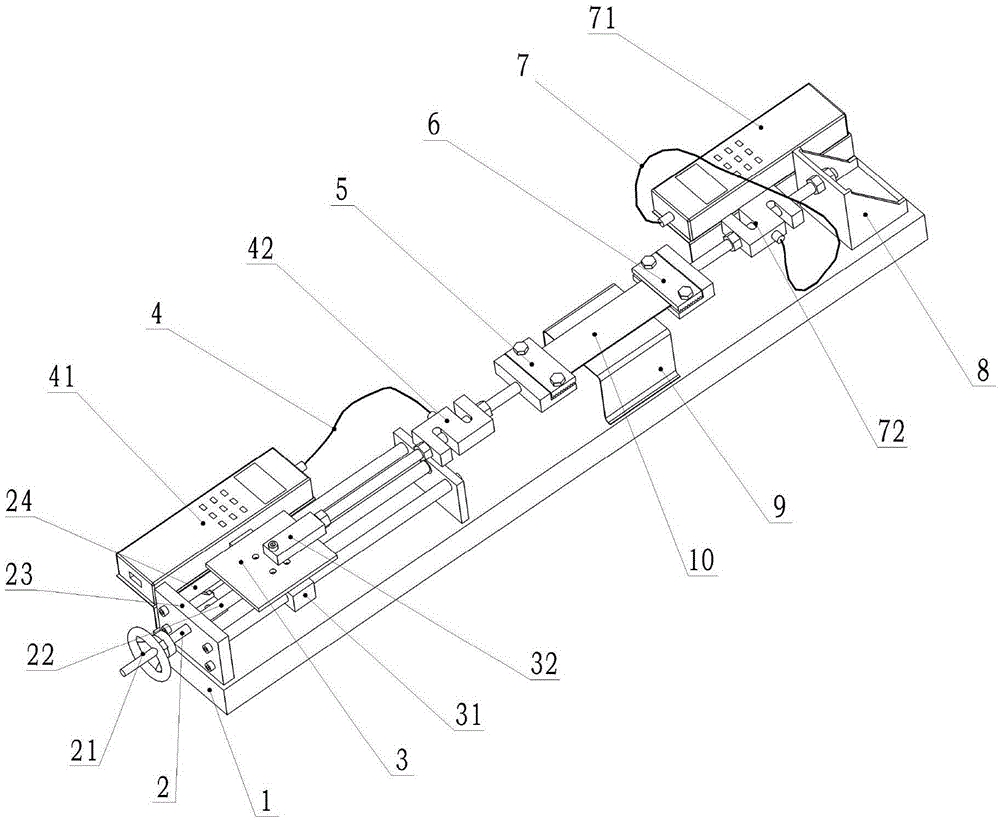

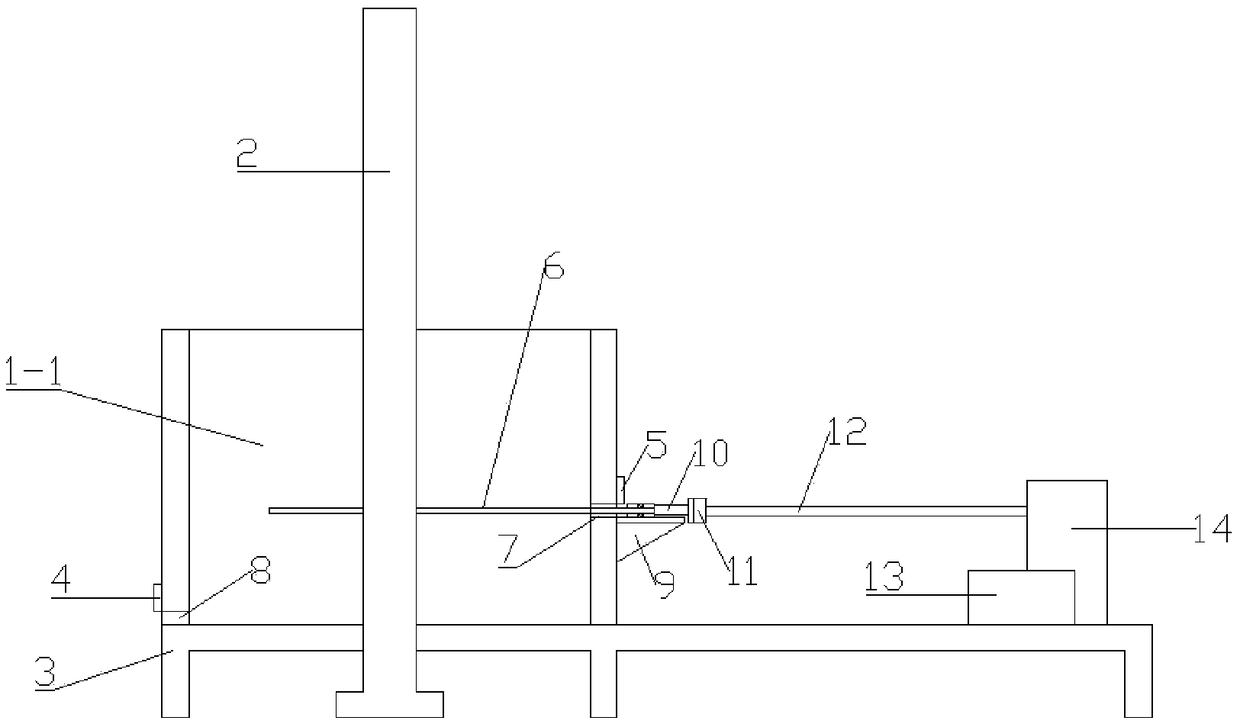

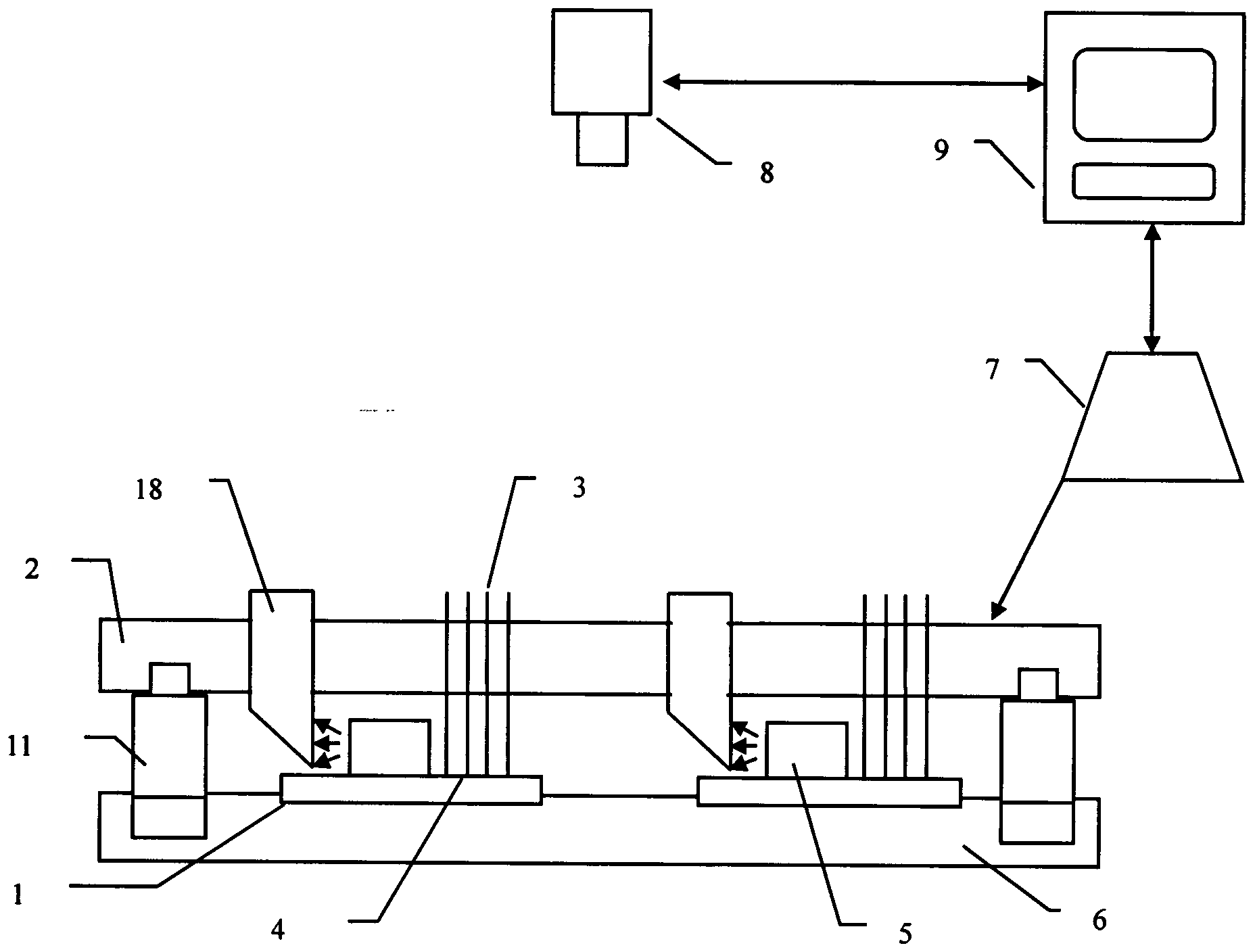

Portable coiled material tester and coiled material test method

InactiveCN105675404AImprove detection efficiencySimple structureMaterial strength using tensile/compressive forcesDisplay deviceTester device

The invention relates to the technical field of waterproof coiled material, and especially relates to a portable coiled material tester and a coiled material test method; the tester includes a driving device, a force measuring and display device, a mobile clamping device, a fixed clamping device and an instrument base; the driving device is arranged at one end of the instrument base and is connected with the mobile clamping device through the force measuring and display device, and the fixed clamping device is fixedly connected at the other end of the instrument base; the mobile clamping device and the fixed clamping device are used for fixing a coiled material specimen; the driving device is used for pulling the mobile clamping device to move toward the direction away from the fixed clamping device; the force measuring and display device is used for measuring and displaying a stripping force value of the coiled material specimen. The portable coiled material tester provided by the invention can detect the problem whether overlapping edges are reliable and are insufficiently welded, greatly improves the detection efficiency after construction site welding, also has the advantages of simple structure, small size, light weight, and convenience for carrying, and can be used for doing overlapping edge seams stripping tests at any time.

Owner:BEIJING ORIENTAL YUHONG WATERPROOF ENG

Method for testing grade of adhesive residue of pressure-sensitive adhesive product

ActiveCN106290150ATest Method SpecificationTest method can be replicatedUsing mechanical meansMaterial analysisEngineeringThermostat

The invention discloses a method for testing the grade of adhesive residue of a pressure-sensitive adhesive product. The test method comprises the following steps: (1) selecting a test board, namely utilizing one of a metal plate, a metal sheet, a plastic board and a plastic plate as the test board; (2) setting parameters of the test board, wherein the surface tension of the test board is 32-50mN / m, the size of the test board is greater than or equal to 150mm*35mm, and the thickness of the test board is greater than or equal to 50 microns; (3) manufacturing an assembly, namely adhering a to-be-tested pressure-sensitive adhesive test piece onto the test board so as to form the assembly; (4) processing the assembly, namely respectively placing the assembly in a thermo-hygrostat which has temperature higher than 30 DEG C and humidity higher than 60% or a thermostat at a temperature lower than 30 DEG C; and (5) performing a stripping test, namely stripping the test piece in the assembly treated in the step (4) from the test board. The test method disclosed by the invention can be used for determining the grade of adhesive residues of the pressure-sensitive adhesive, thus determining the viscous force of the pressure-sensitive adhesive product and the adhesion quality of the pressure-sensitive adhesive product and an adhered object.

Owner:GUANGZHOU JINWANZHENG PRINTING MATERIAL CO LTD

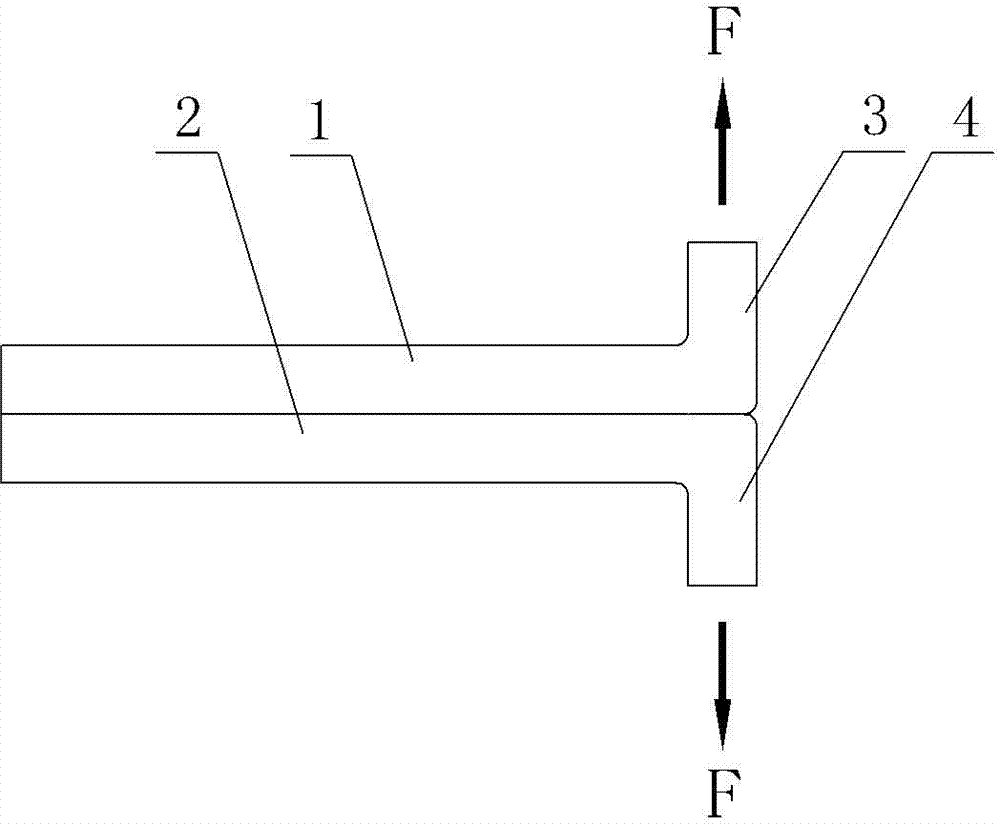

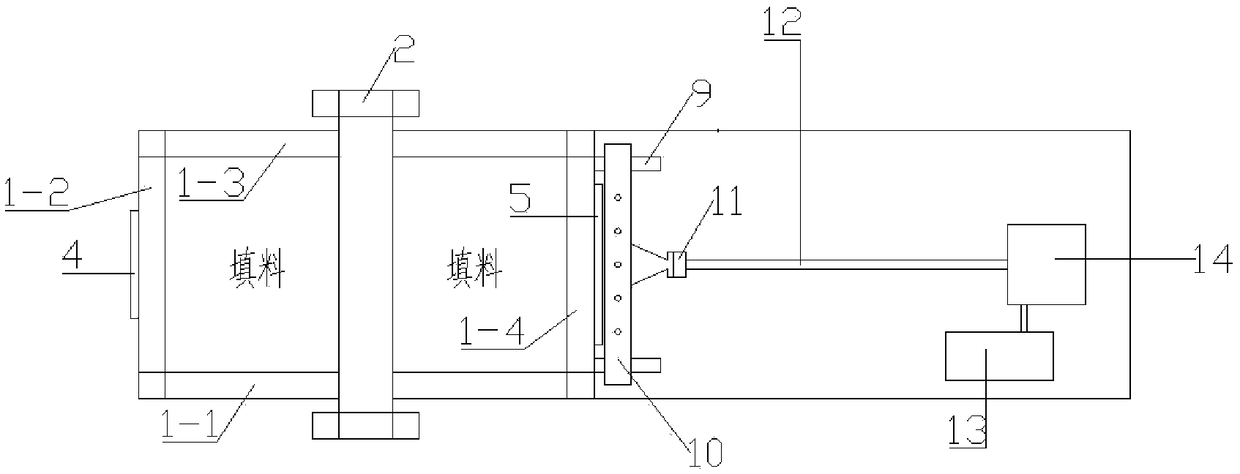

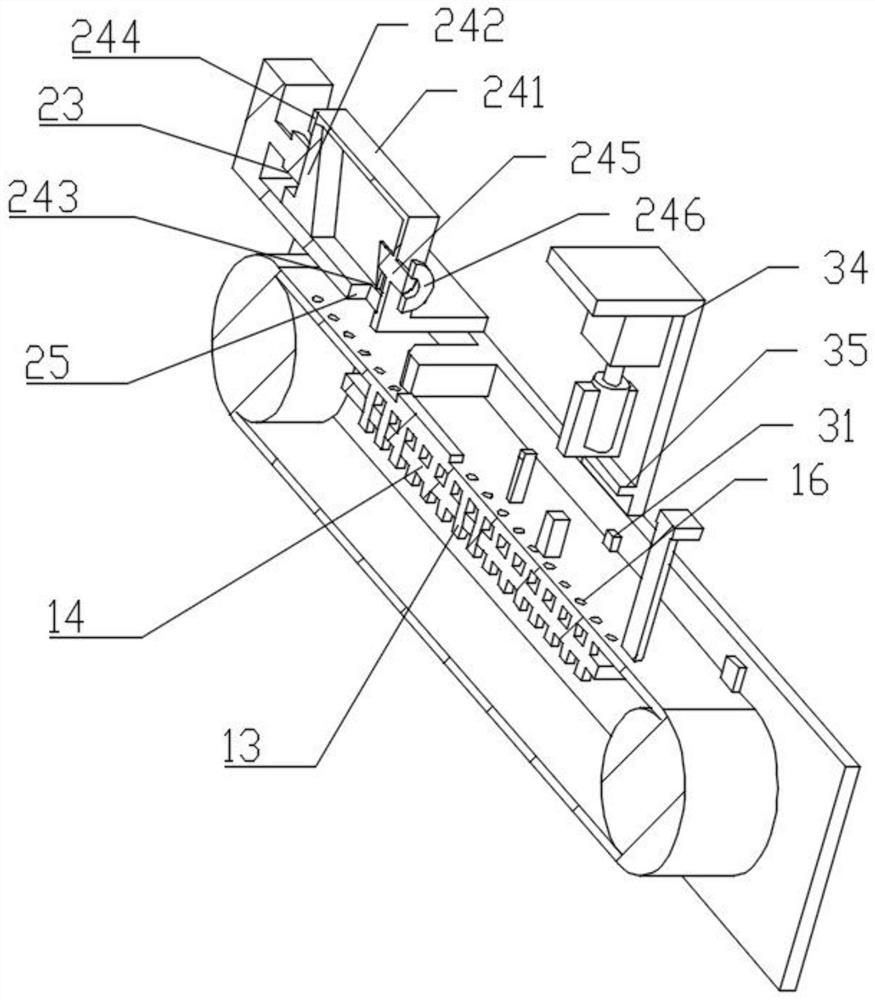

Test device and method for tire strip pull-out test

InactiveCN109163915AControl load levelSimple structure setupMaterial strength using tensile/compressive forcesVehicle tyre testingTension compressionStrip tests

The invention discloses a test device and method for a tire strip pull-out test, which solves the problem that in the prior art, a pull-out test device is complex in structure, and has the beneficialeffects of being convenient to observe, and capable of effectively obtaining data required by the pull-out test. The scheme is as follows: the test device for the tire strip pull-out test comprises atest box, and geotechnical packing is arranged inside the test box; a plurality of tire strip test pieces are arranged in the geotechnical packing of the test box, wherein the tire strip test pieces are connected with a drawing mechanism, so that the tire strip test pieces are pulled out from the geotechnical packing of the test box through the drawing mechanism; and a reaction frame, wherein a lifting component is arranged between the top of the geotechnical packing of the test box and the reaction frame, and a first tension-compression sensor connected with a controller is installed betweenthe lifting component and the reaction frame.

Owner:SHANDONG UNIV

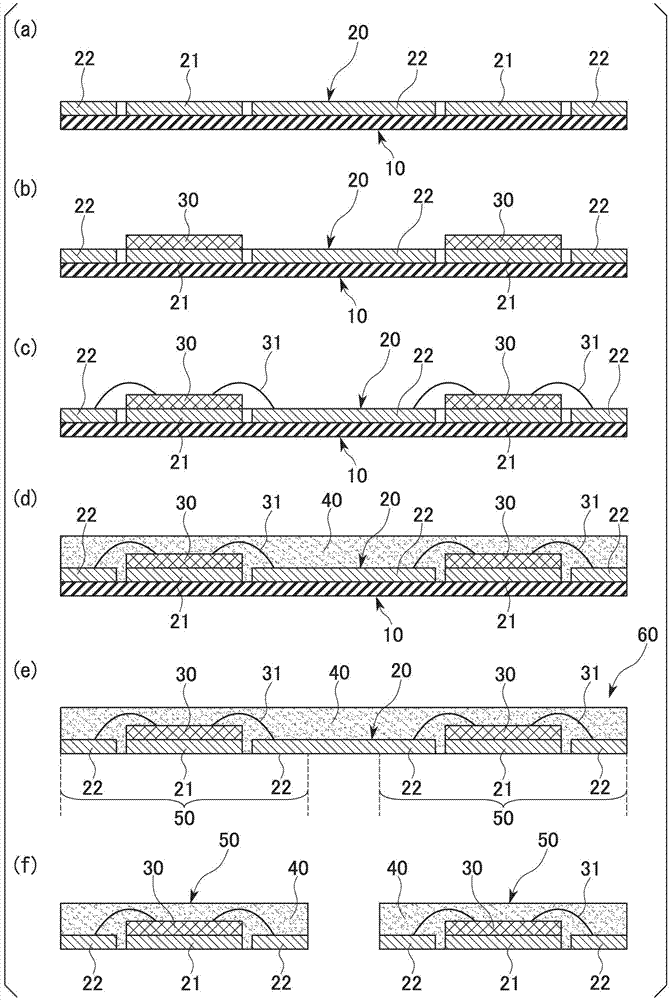

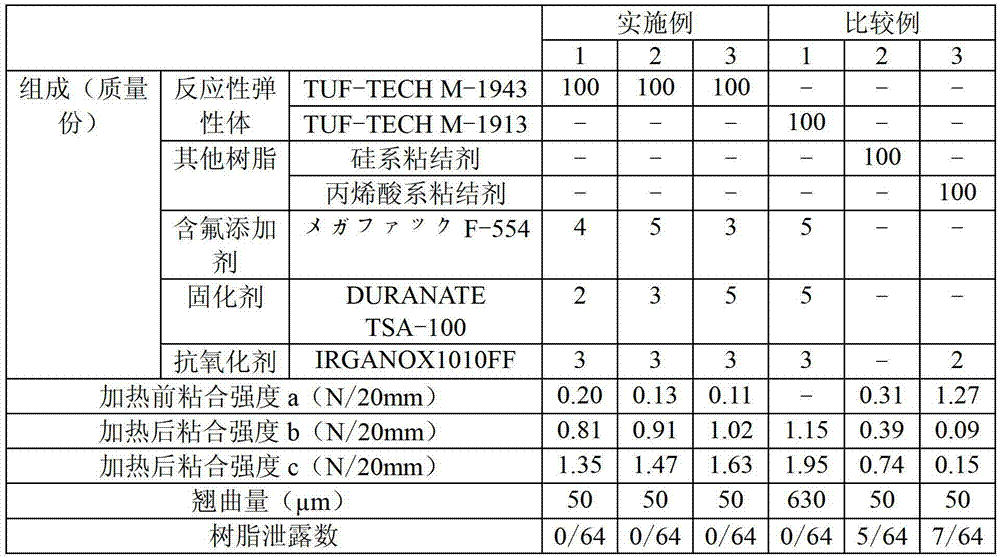

Bonding sheet for manufacturing semiconductor device, semiconductor device and manufacturing method thereof

ActiveCN103360969AImprove productivityInhibit flashingNon-macromolecular adhesive additivesSolid-state devicesLead frameUltimate tensile strength

The invention relates to a bonding sheet for manufacturing a semiconductor device, a semiconductor device and a manufacturing method thereof. The bonding sheet for manufacturing the semiconductor device comprises a base material and a thermosetting binder layer arranged on one surface of the base material, and can be pasted on a lead frame (20) or a wiring substrate of a semiconductor device in a strippable manner, the bonding strength a of the binder layer before heating measured in a specific stripping test A is above 0.07N / 20mm, the bonding strength b after heating measured in a specific stripping test B is above 0.58N / 20mm, and the bonding strength c after heating measured in a specific stripping test C is above 1.17N / 20mm.

Owner:TOMOEGAWA PAPER CO LTD

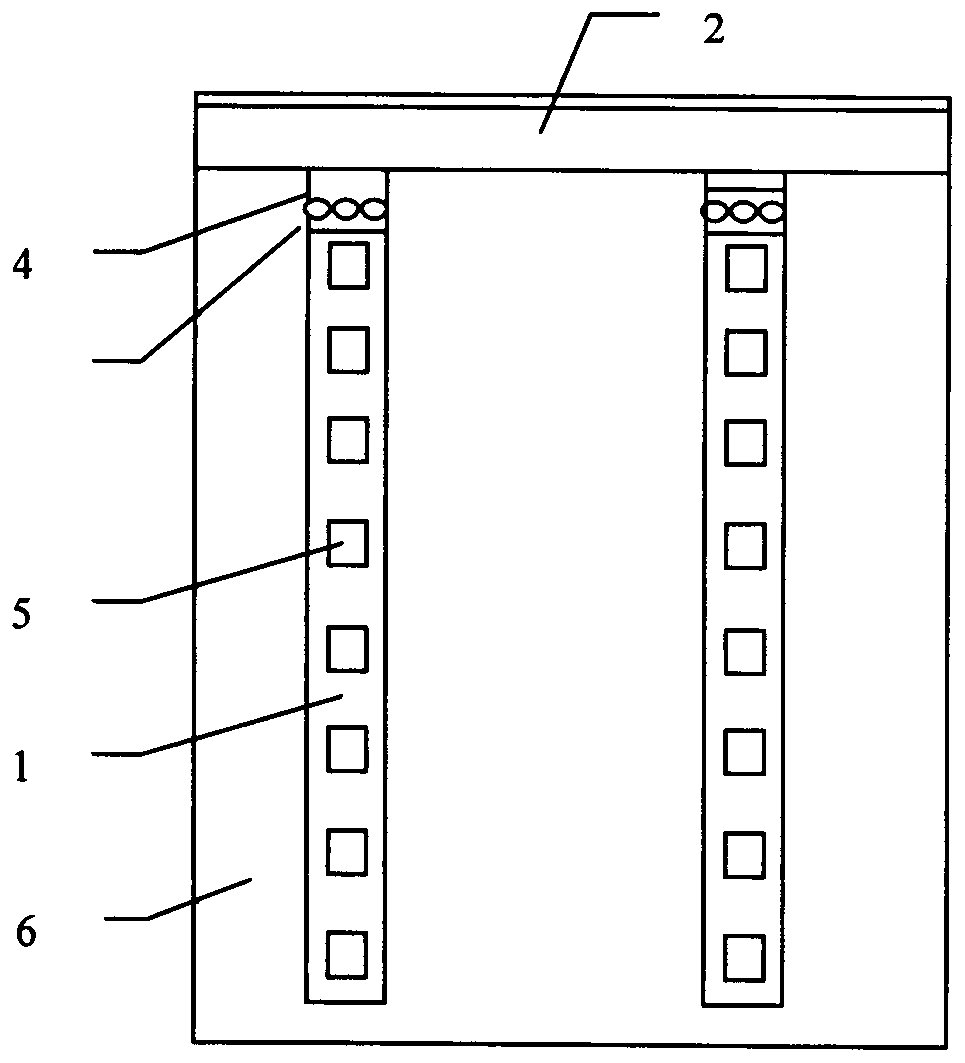

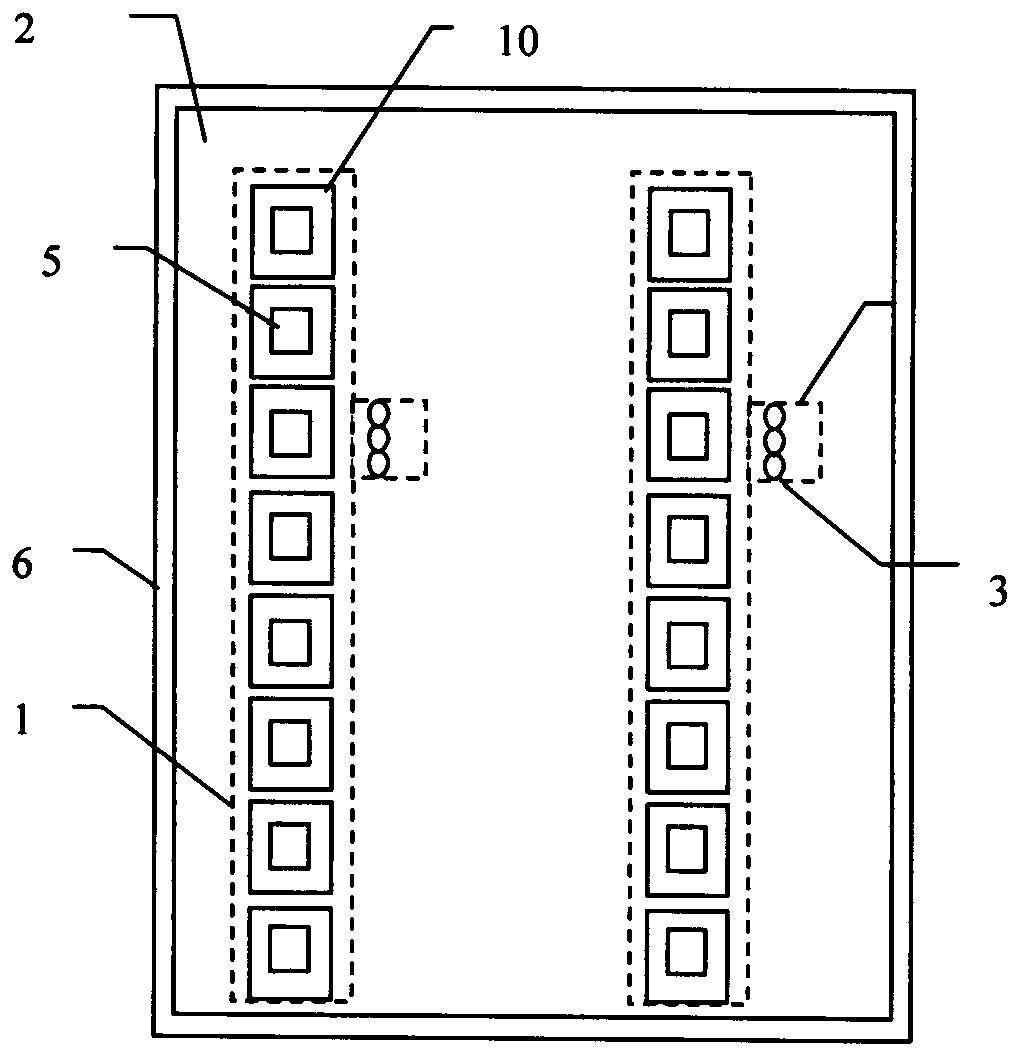

Testing device and method for LED light strips with side luminance

InactiveCN104062099AMeet online testing requirementsHigh speedTesting optical propertiesComputer moduleOptoelectronics

The invention relates to a testing device for LED light strips with side luminance. The testing device comprises the light strips, a light strip carrier, a light strip power module, a light strip testing board, a digital camera and a computing control unit. The light strips are provided with a plurality of LED lights and fixed on the light strip carrier. A plurality of light strips are arranged. The light strip power module supplies power to the LED light strips. The light strip testing board is provided with a light-transmitting device and located above the light strip carrier through a locating device. The digital camera is fixed on the portion above the light strip testing board. The light of the LED lights on the light strips illuminates the digital camera through the light strip testing board. The digital camera is connected with the computing control unit. According to the method, ten to sixty light strips can be tested at the same time, and the speed is increased by 10 times-60 times compared with that of manual work; moreover, uncertainty influence of human factors is avoided, the testing specification takes the numerical value as the standard, the stability and precision are ensured, and the online testing requirement of the LED light strips can be met completely; the cost is saved, the efficiency is improved, and the quality is ensured.

Owner:苏州威盛视信息科技有限公司

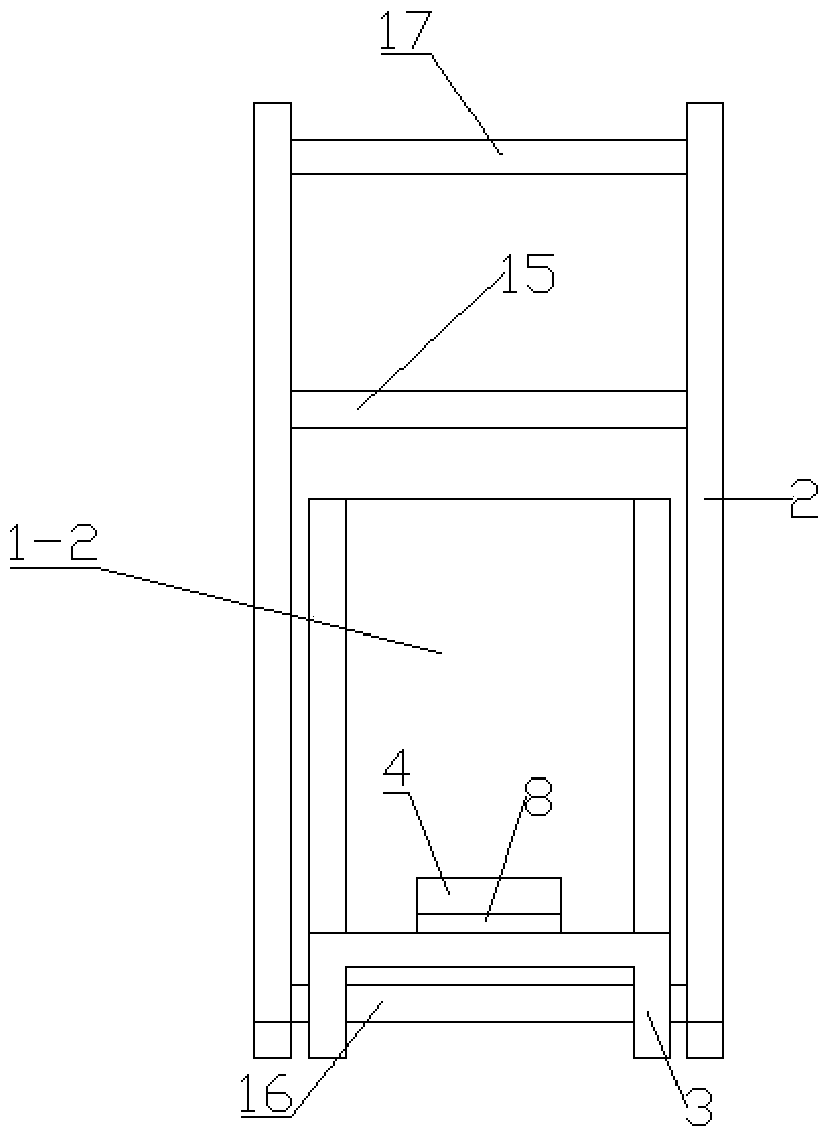

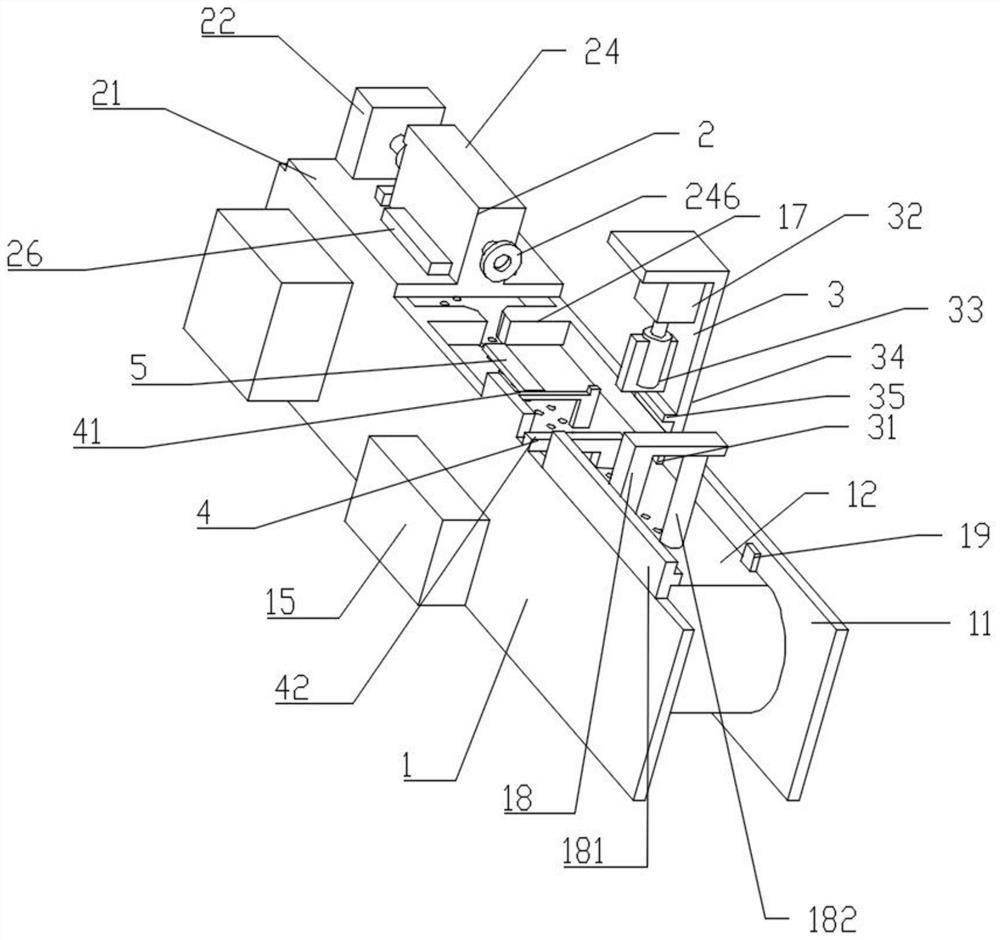

Laser Bar strip testing equipment feeding auxiliary device

PendingCN111924424AEasy and accurate feedingConveyorsElectrical testingTest efficiencyElectric machinery

The invention discloses a laser Bar strip testing equipment feeding auxiliary device. The laser Bar strip testing equipment feeding auxiliary device comprises a conveying assembly, a feeding assembly,a power-up assembly and a testing assembly; a conveying belt of the conveying assembly is installed on two side plates, a negative pressure pipe is installed between the two side plates through a supporting plate, a supporting table of the feeding assembly is installed on the two side plates, a screw of a first screw motor is in threaded connection with a push rod and is installed on the supporting table, a material box is installed on one side of the push rod, and a screw of a second screw motor of the power-up assembly is in threaded connection with a probe head and is installed on one sideof the supporting table. Bar strips are stacked in a box body of the material box, the first screw motor is started, so that the push rod pushes a triangular sliding block in the box body to move, the bar strips slide to the conveying belt through a first through hole in the box body and are fixed through the negative pressure pipe, then a first optocoupler is positioned, and the probe head is powered on for testing; therefore, feeding and testing can be conveniently and accurately carried out, and the testing efficiency is improved.

Owner:桂林芯隆科技有限公司

Semiconductor packaging with partially patterned lead frames and its making methods

InactiveCN100385641CImprove reliabilityEasy to useSemiconductor/solid-state device detailsSolid-state devicesLead bondingBonding process

A method of making a lead frame and a partially patterned lead frame package with near-chip scale packaging (CSP) lead-counts is accomplished by performing a major portion of the manufacturing process steps with a partially patterned strip of metal formed into a web-like lead frame on one side, so that the web-like lead frame, which is solid and flat on the other side is also rigid mechanically and robust thermally to perform without distortion or deformation during the chip-attach and wire bond processes, both at the chip level and the package level. The bottom side of the metal lead frame is patterned to isolate the chip-pad and the wire bond contacts only after the front side, including the chip and wires, is hermetically sealed with an encapsulant. The resultant package being electrically isolated enables strip testing and reliable singulation without having to cut into any additional metal.

Owner:UNISEM MAURITIUS HLDG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com