Automatic grinding device for inspection of band steel

A grinding device and automatic technology, applied in grinding/polishing safety devices, machine tools suitable for grinding workpiece planes, grinding machines, etc., can solve the problems of manual grinding safety hazards, unstable grinding quality, and many people, and eliminate the problems of artificial grinding. Unsafe hidden danger, improve labor productivity, optimize the effect of inspection process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

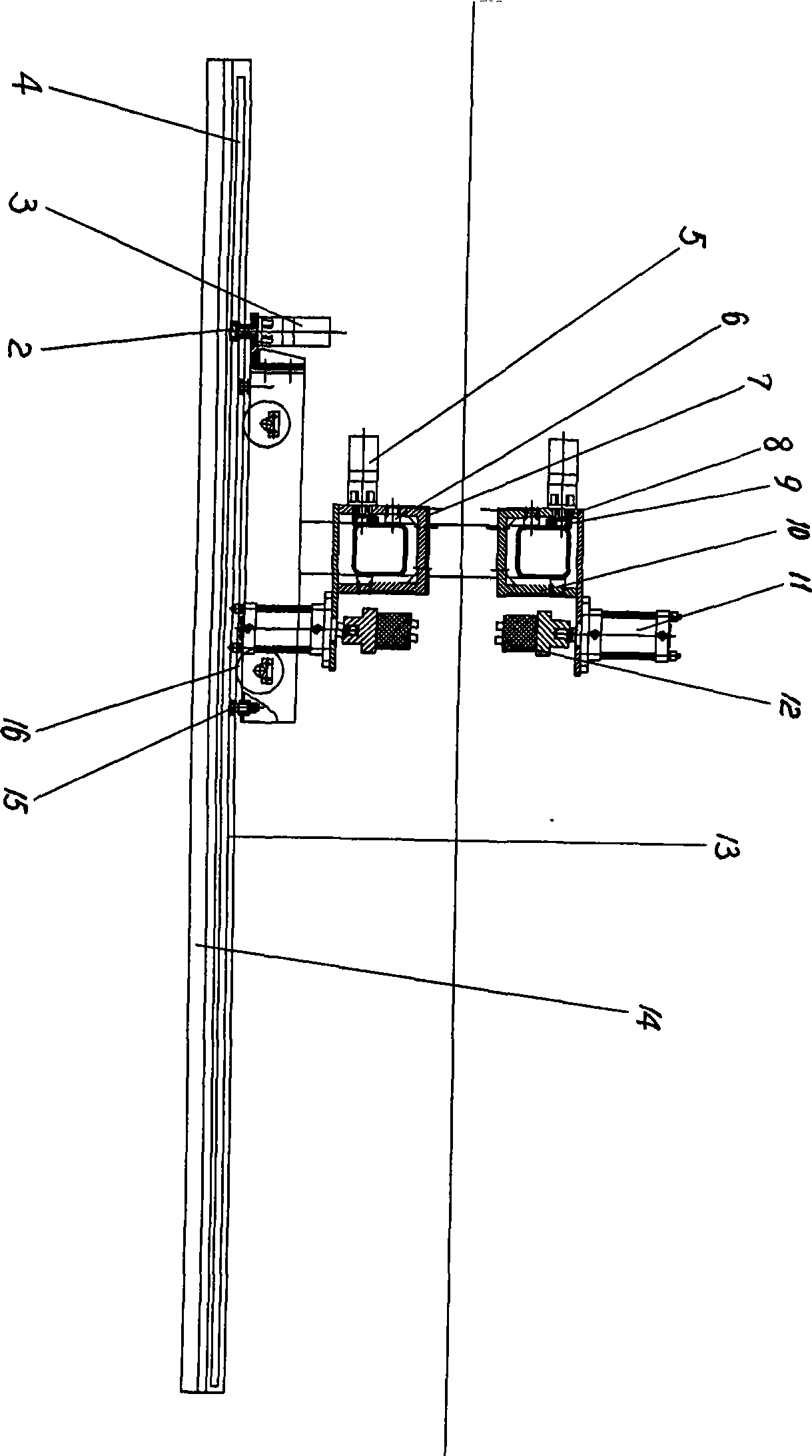

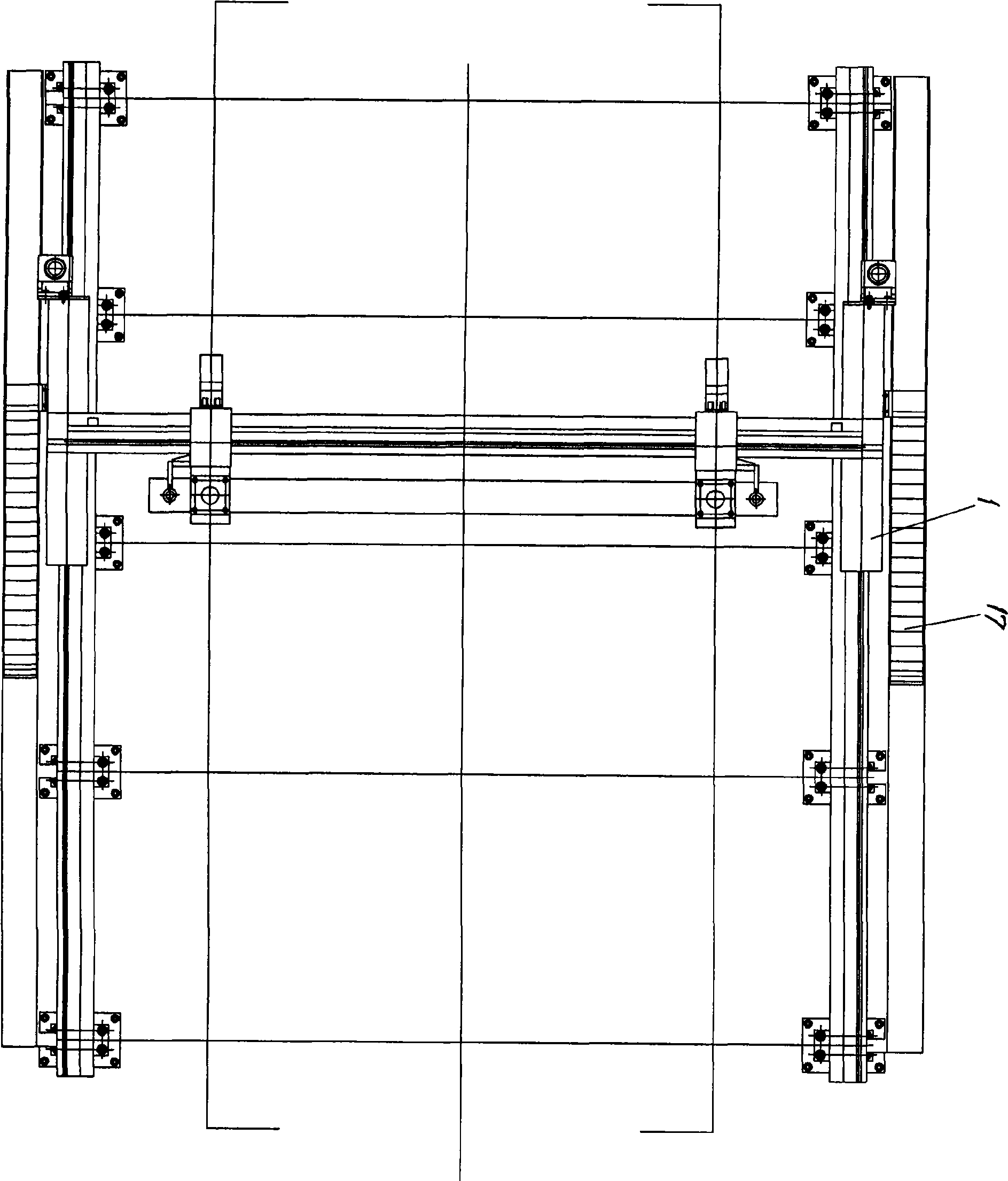

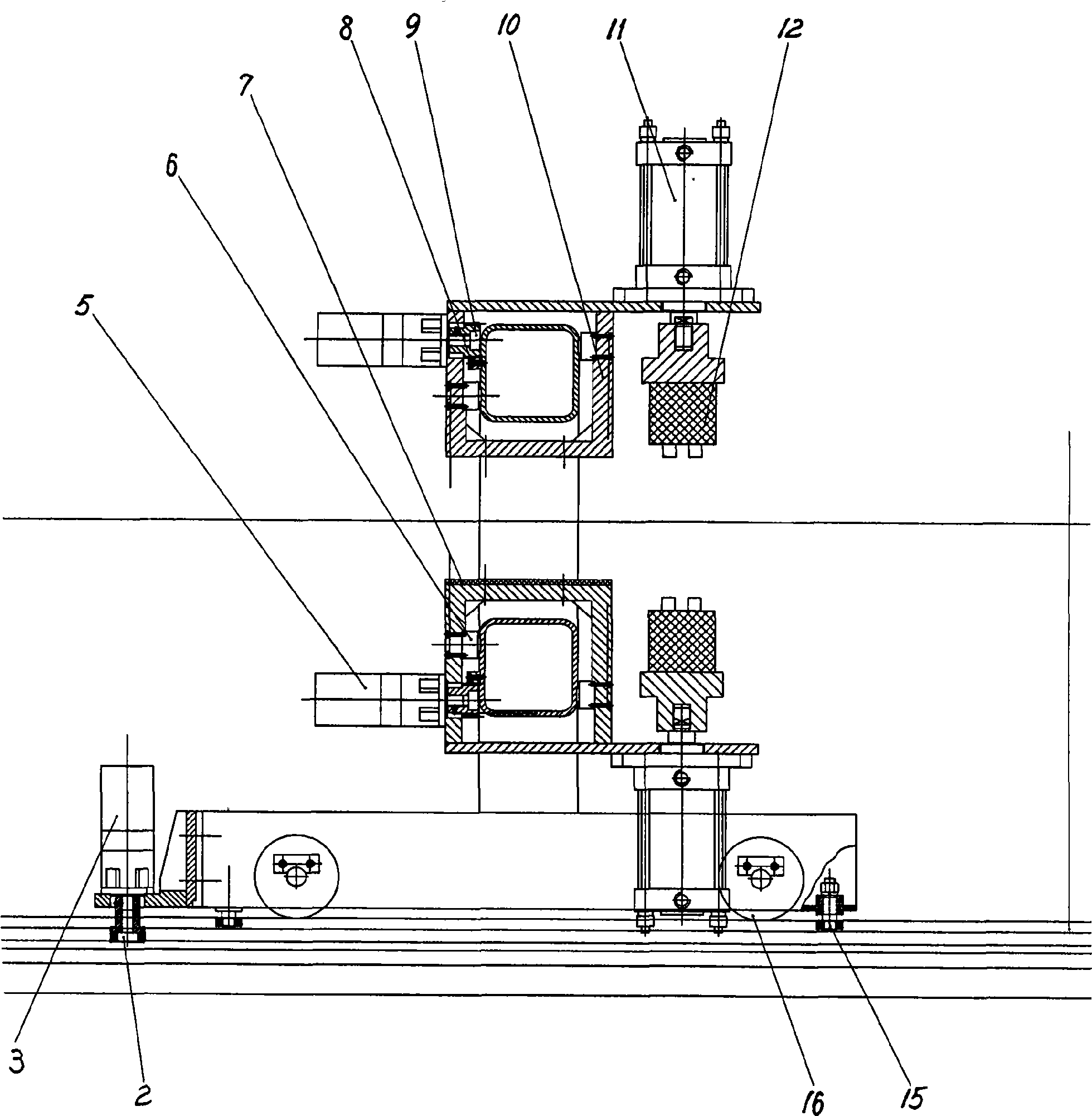

[0040] see Figure 1 to Figure 3 , the present invention is an automatic grinding device for strip inspection, which mainly consists of a frame 1, a first gear 2, a longitudinal servo motor 3, a longitudinal rack 4, a transverse servo motor 5, a linear transverse guide rail 6, and a flexible backing plate 7. Horizontal rack 8, second gear 9, horizontal moving trolley 10, cylinder 11, grinding head assembly 12, longitudinal guide rail 13, guide rail seat 14, rib wheel 15, roller 16, drag chain 17 and electrical control box 18, etc. components.

[0041] Two longitudinal guide rails 13 and guide rail seat 14 are added on the ground to provide guidance and support for the longitudinal movement of the grinding device. The connection at the bottom of the guide rail seat 14 adopts a pre-embedded steel plate welding and fixing method.

[0042] The frame 1 is arranged on the longitudinal guide rail 13 , the frame 1 is driven by the longitudinal servo motor 3 and moves on the longitud...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com