Patents

Literature

206results about How to "Save sanding time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

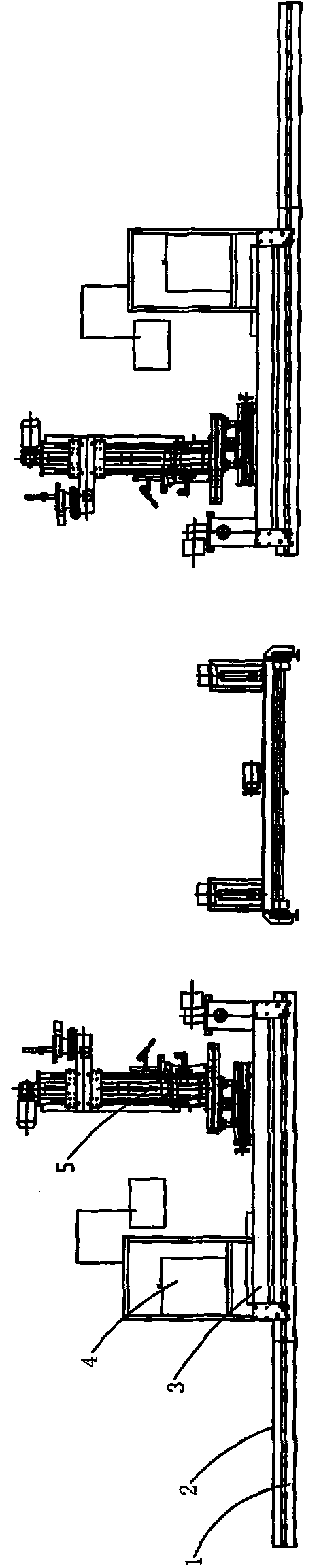

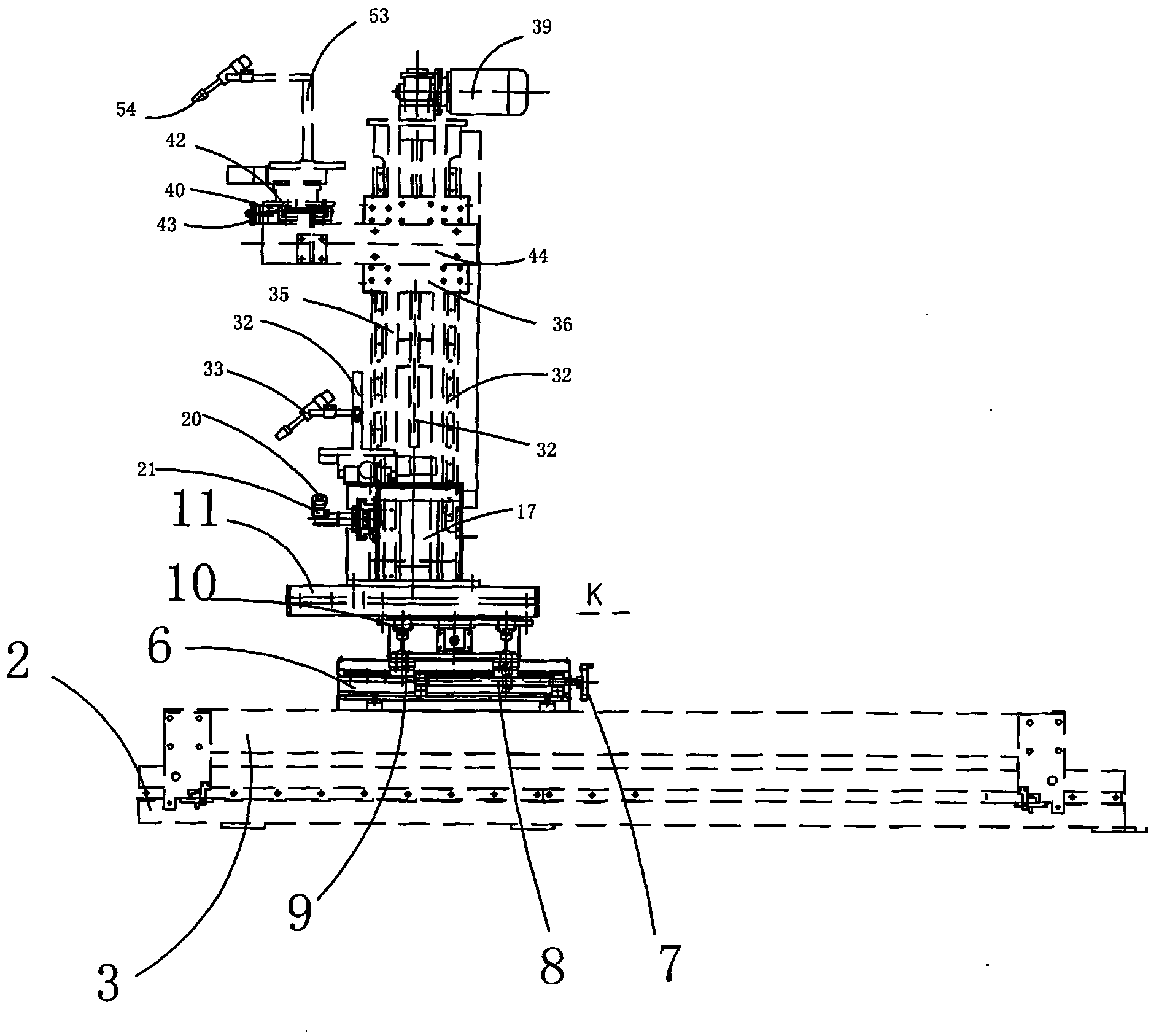

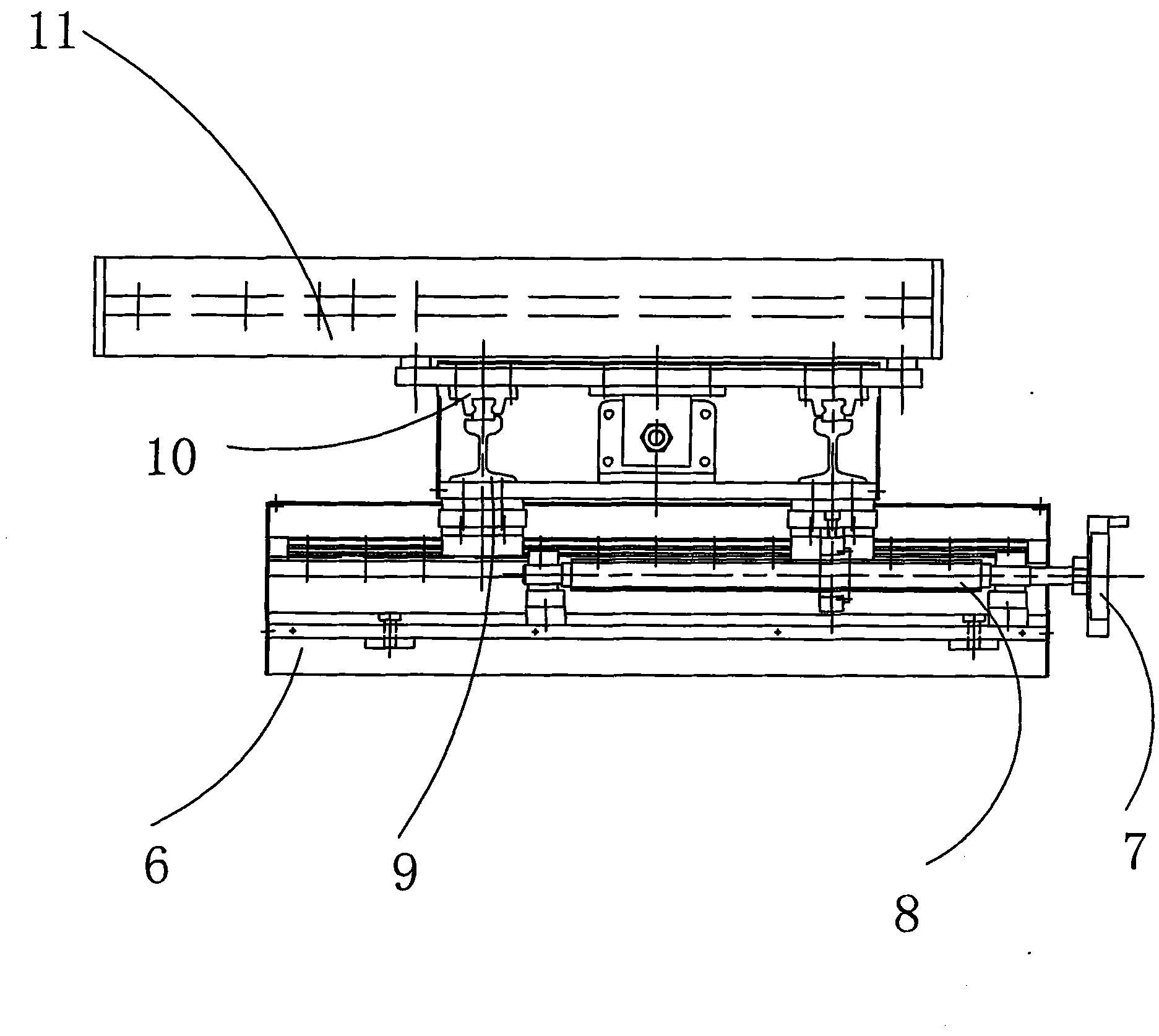

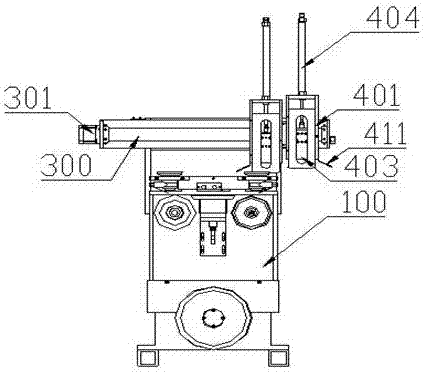

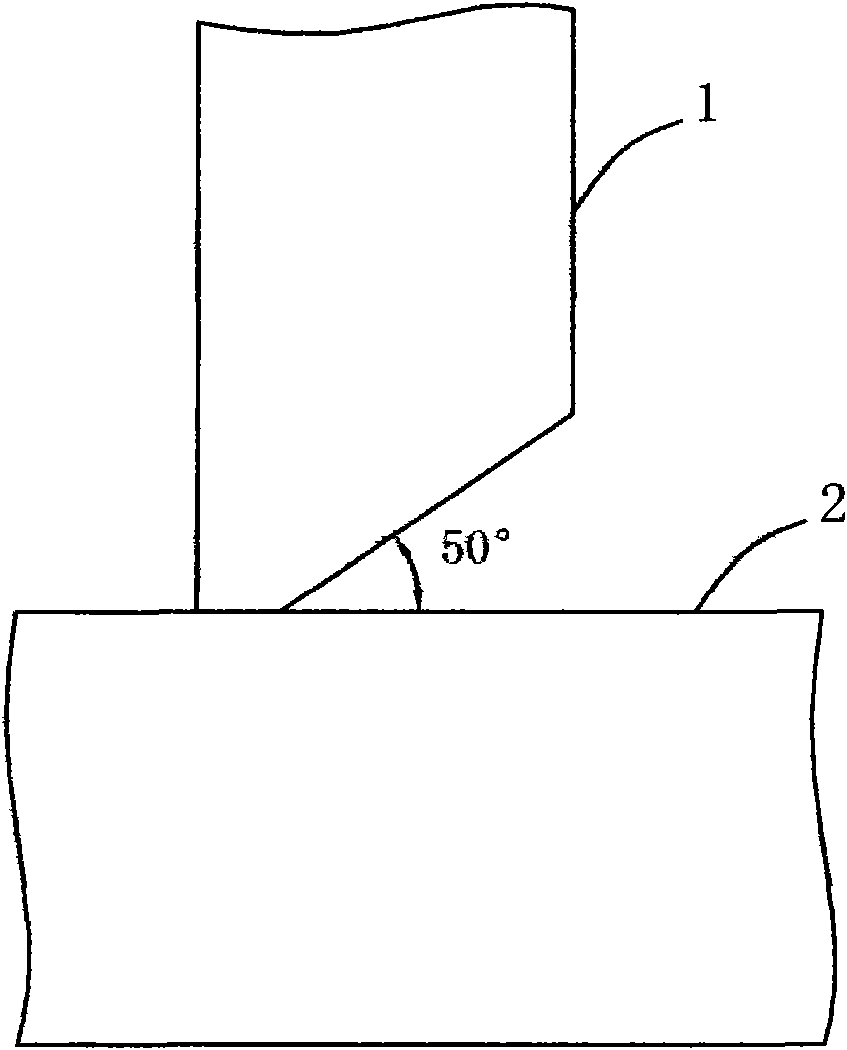

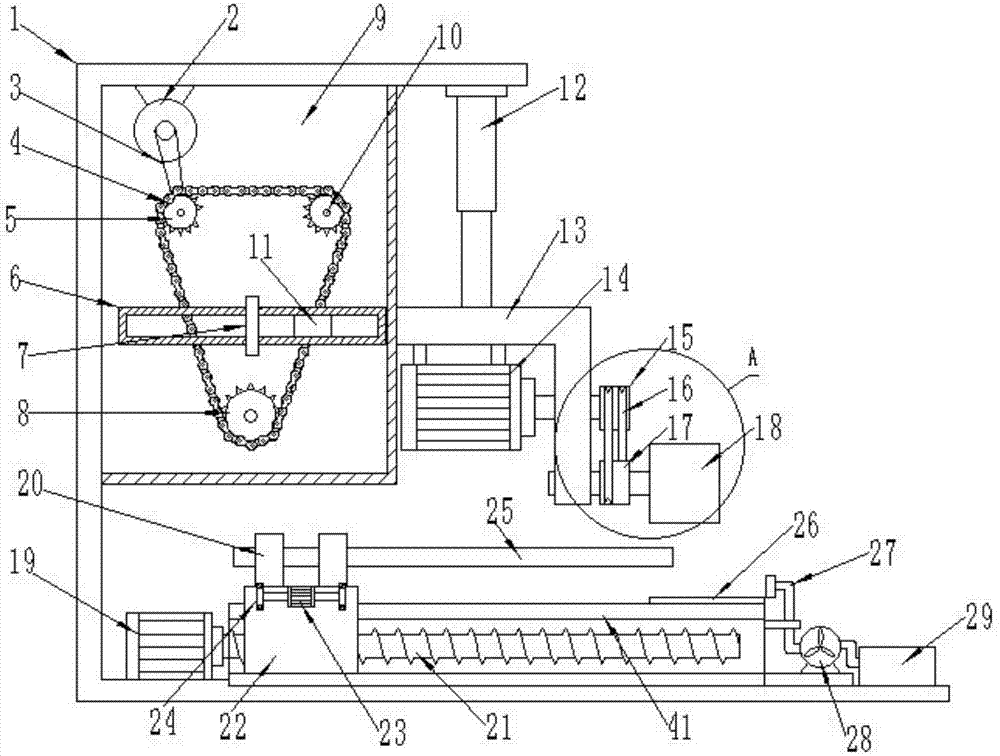

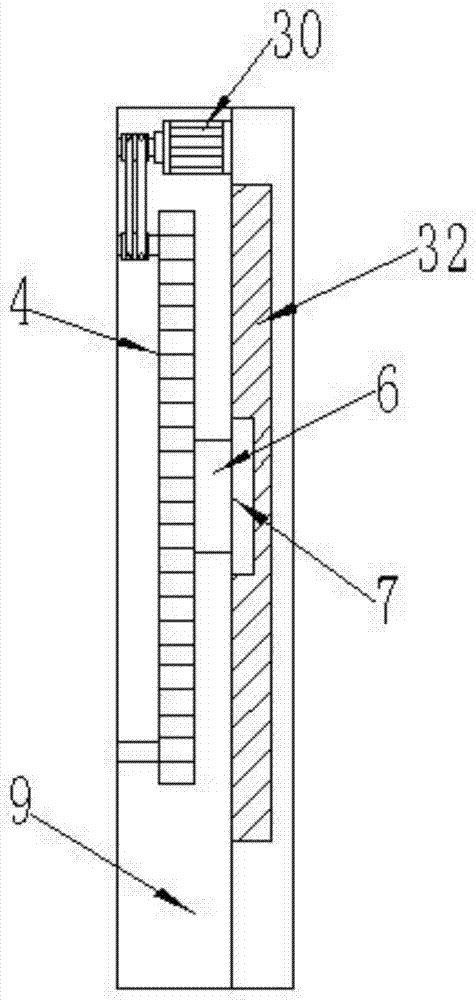

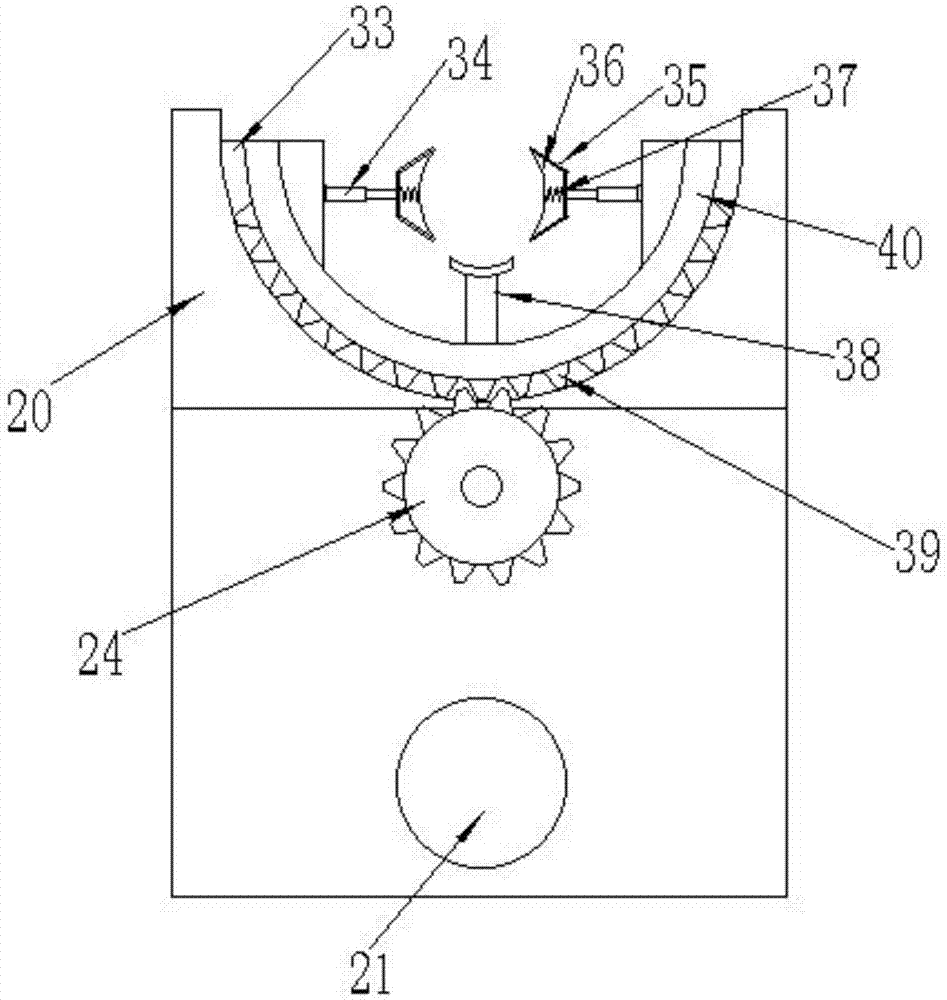

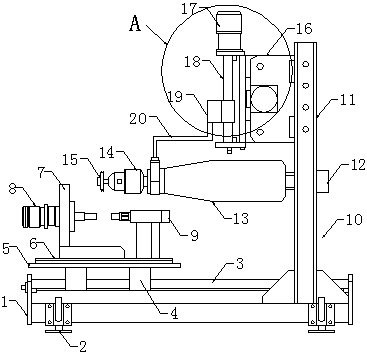

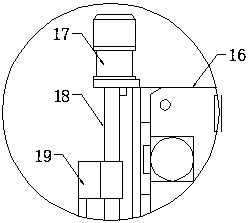

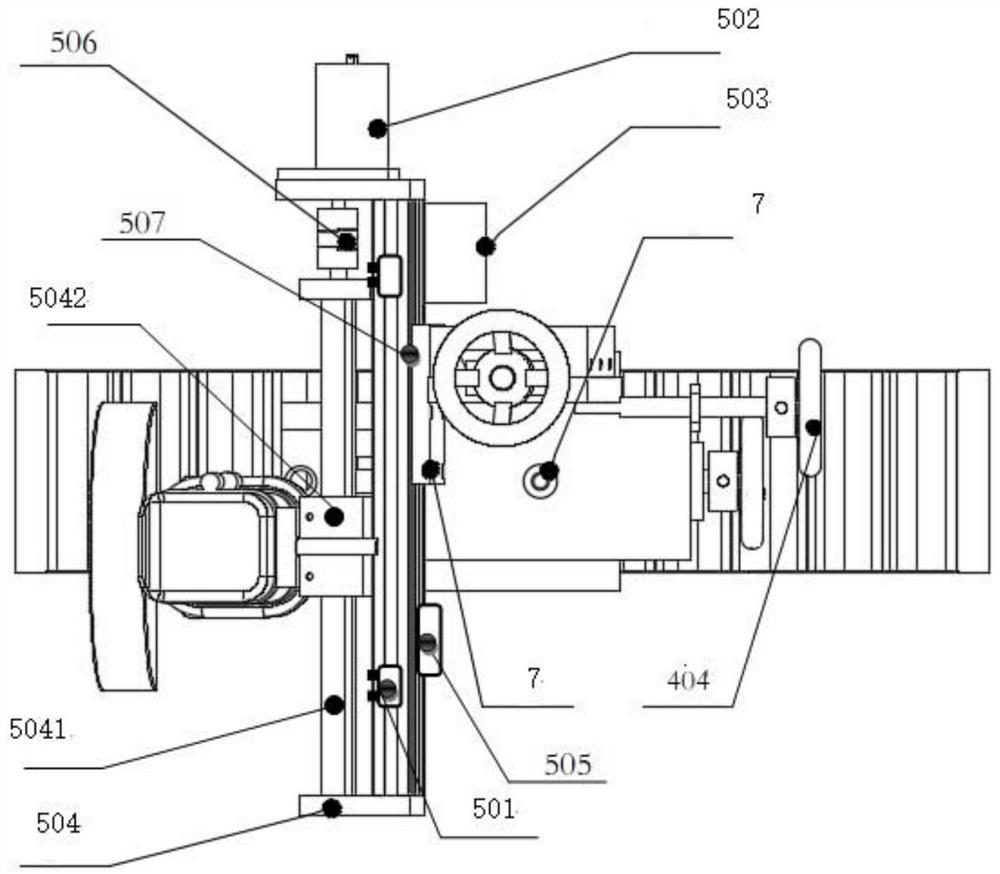

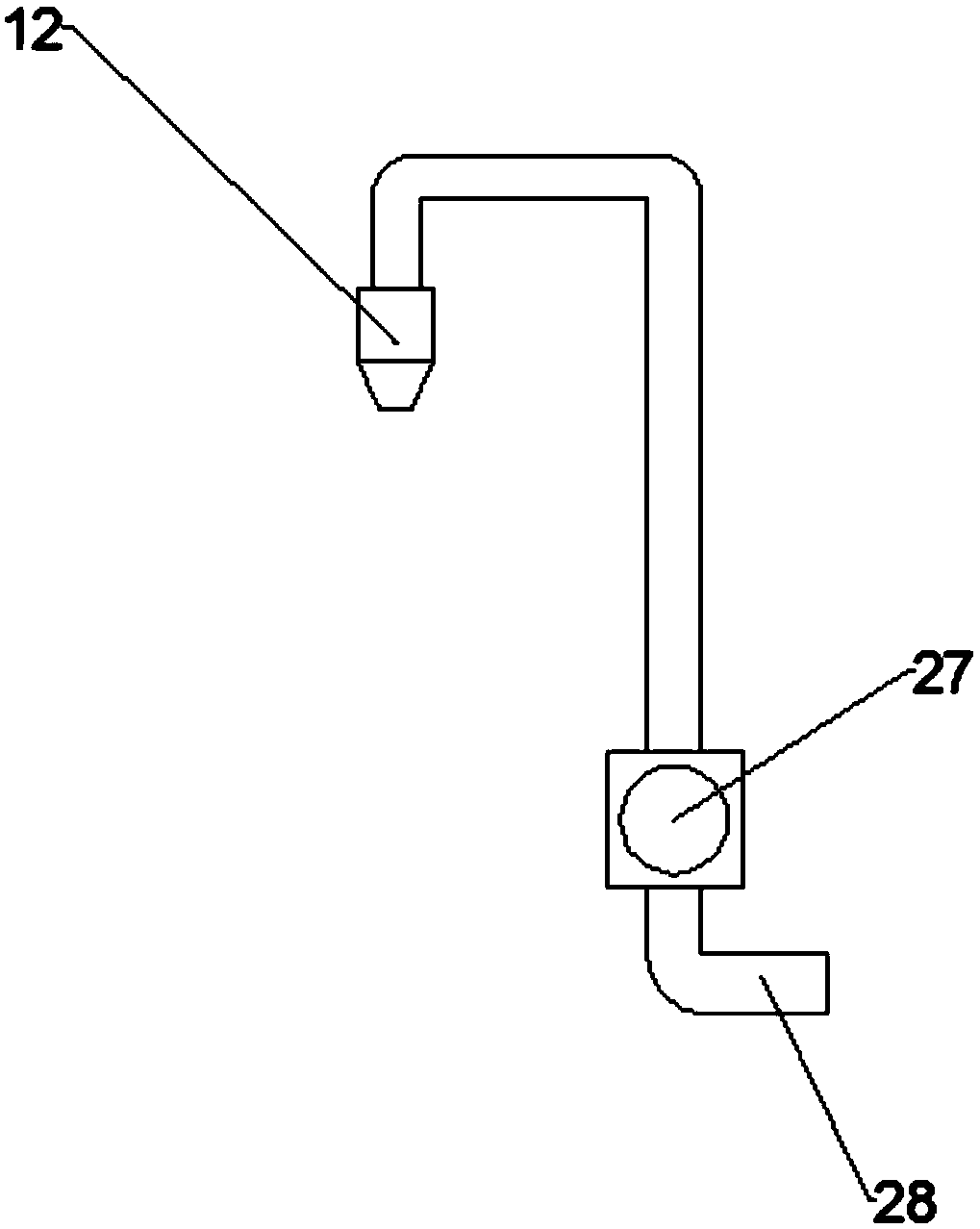

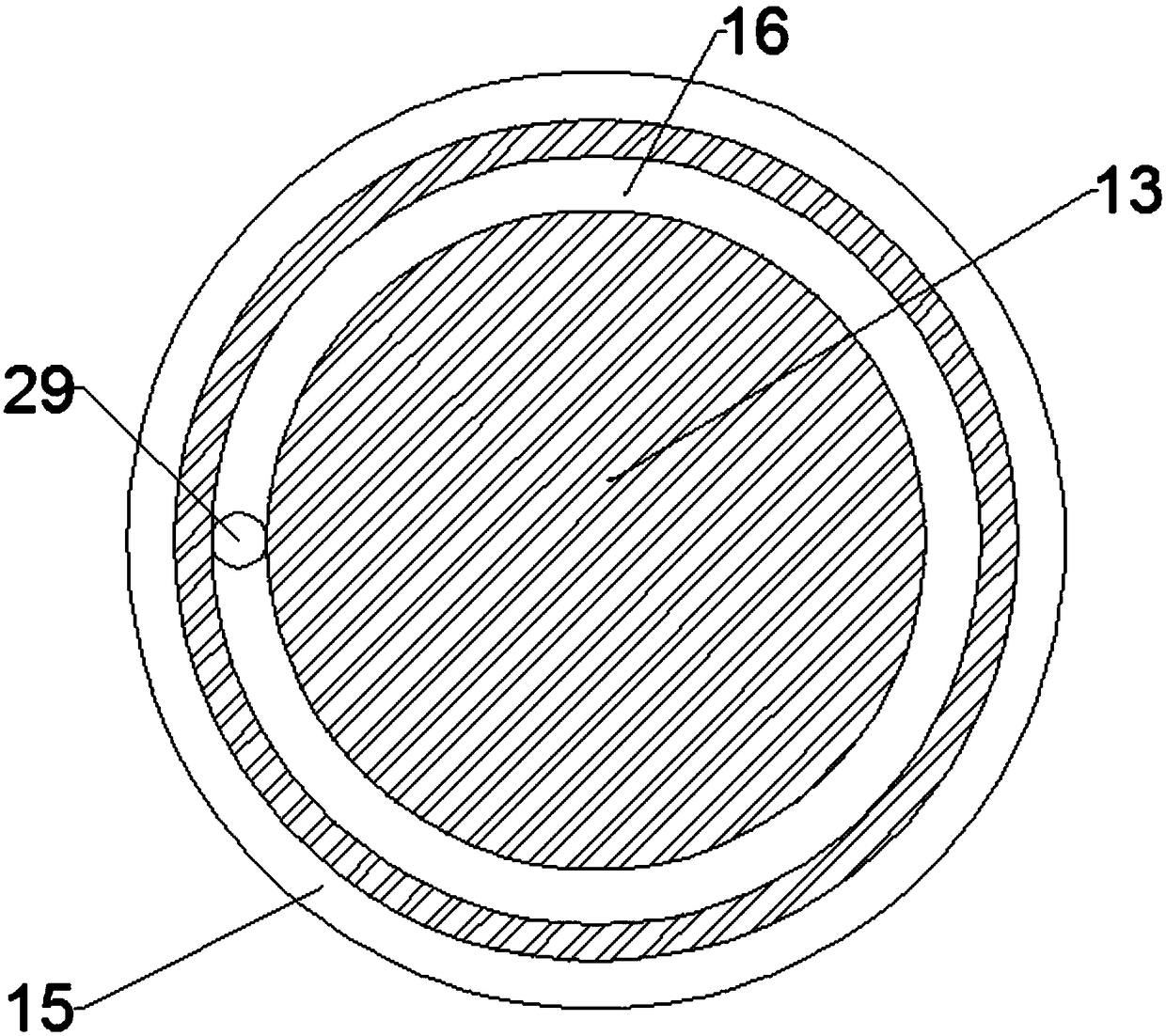

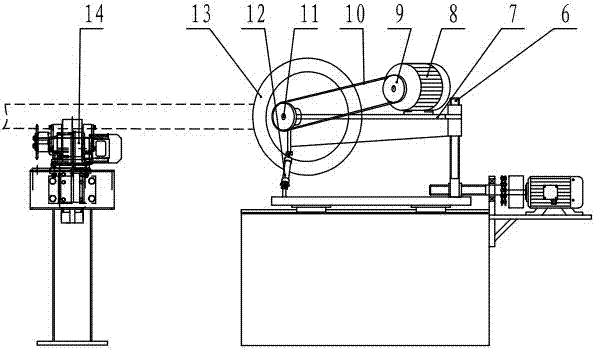

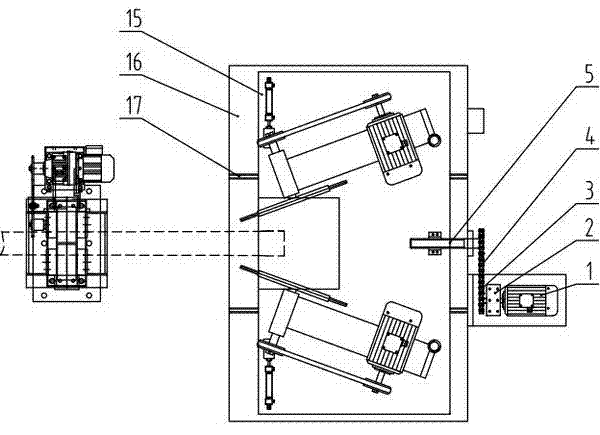

Automatic straight pipe flange welding machine

InactiveCN102009254AReduce playKeep the relative position unchangedElectrode supporting devicesWelding accessoriesWeld seamEngineering

The invention relates to a welding machine, particularly to an automatic straight pipe flange welding machine which is suitable for both plug-in type flange assembly type welding and butt-joint type flange assembly welding. The automatic straight pipe flange welding machine comprises a base, wherein base guide rails are arranged on the base, a trolley base is arranged on the base guide rails, a control system is arranged on one side of the trolley base, a welding torch machine is arranged on the trolley base and comprises a longitudinal adjusting mechanism, a lateral adjusting mechanism, an inner welding torch mechanism, an outer welding torch mechanism and a roller adjusting mechanism, wherein the inner welding torch mechanism consists of an inner welding torch upright post device and aninner welding torch device, and the outer welding torch mechanism includes an outer welding torch upright post device and an outer welding torch device. The automatic straight pipe flange welding machine has high automatic degree, improves welding efficiency, reduces grinding time and waste of welding materials, guarantees welding quality, and attractive formation of weld seams, is convenient to operate, saves labor, and lightens labor intensity.

Owner:HANGZHOU XINCHENGXIANG ELECTROMECHANICAL TECH

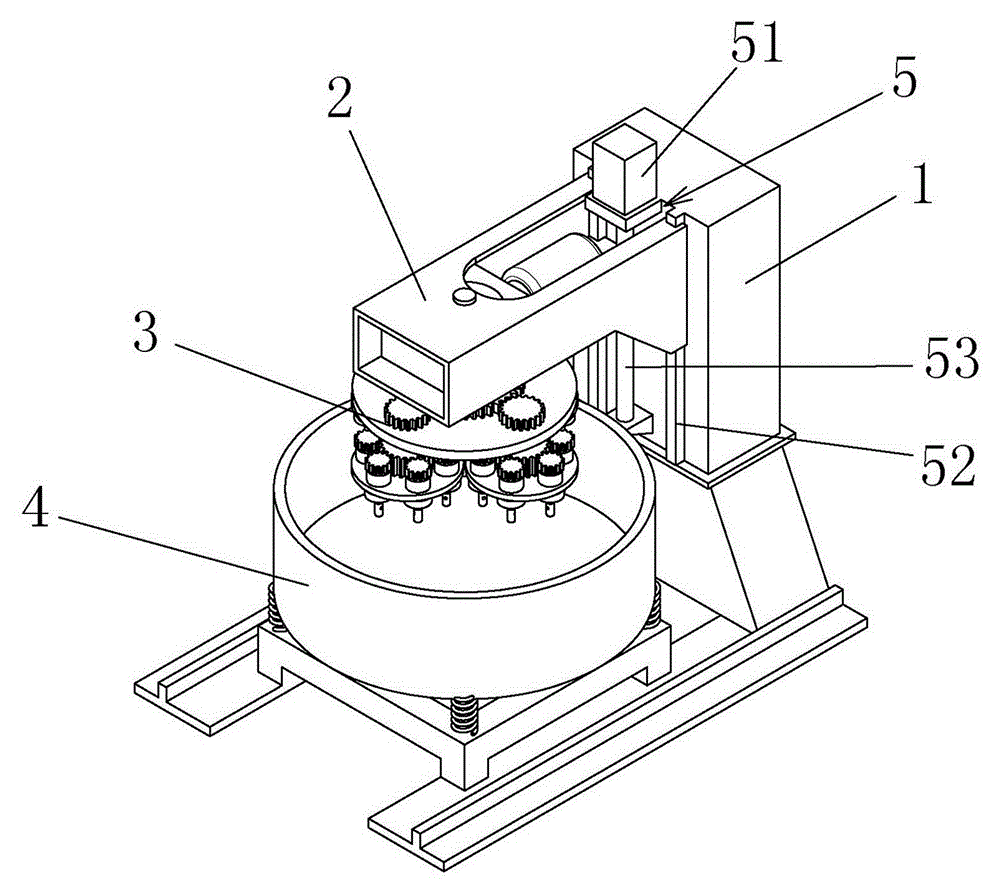

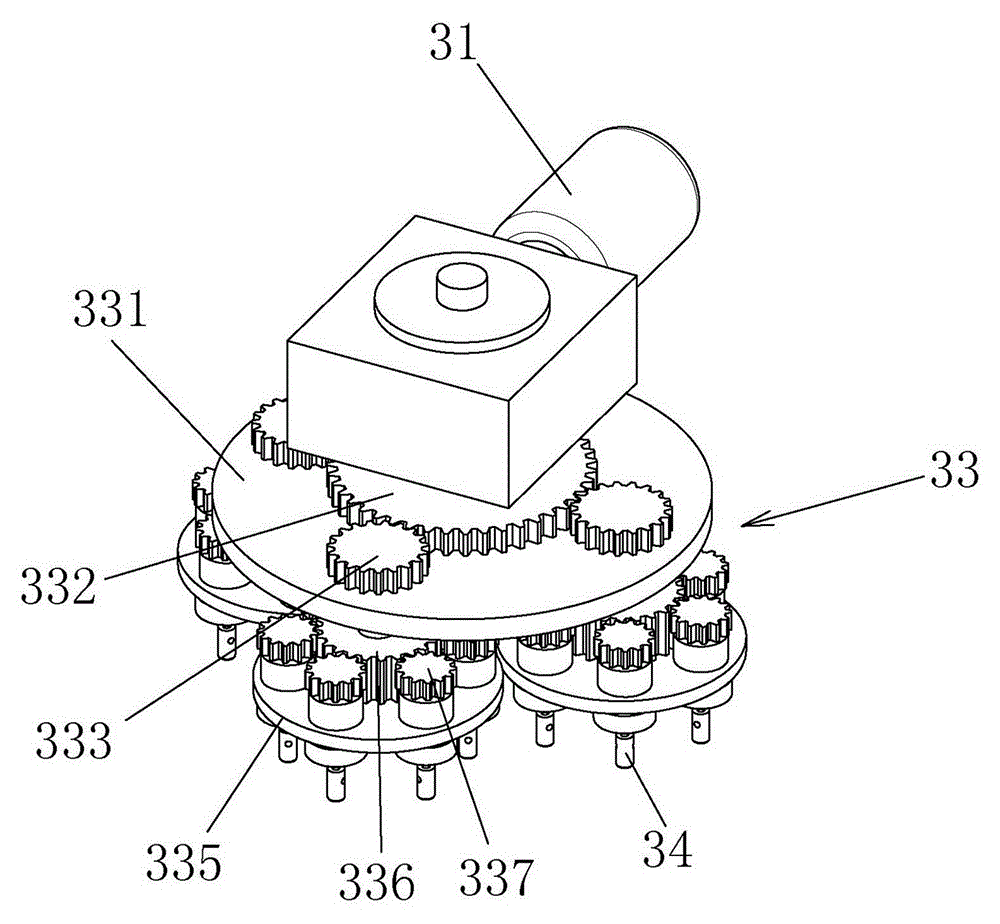

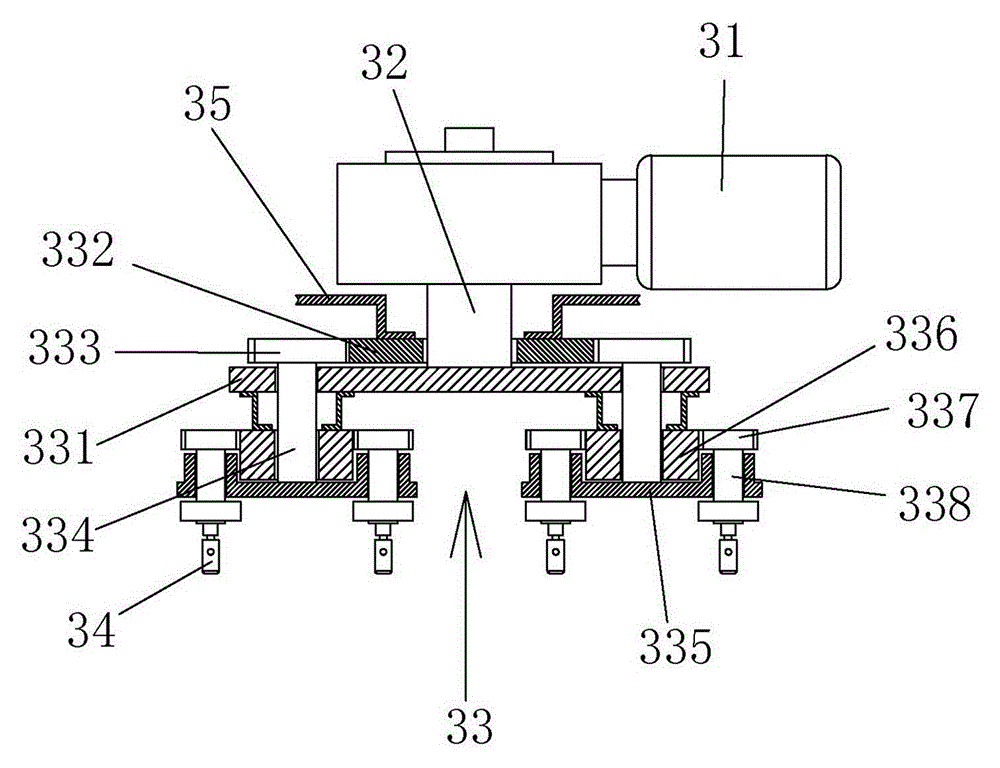

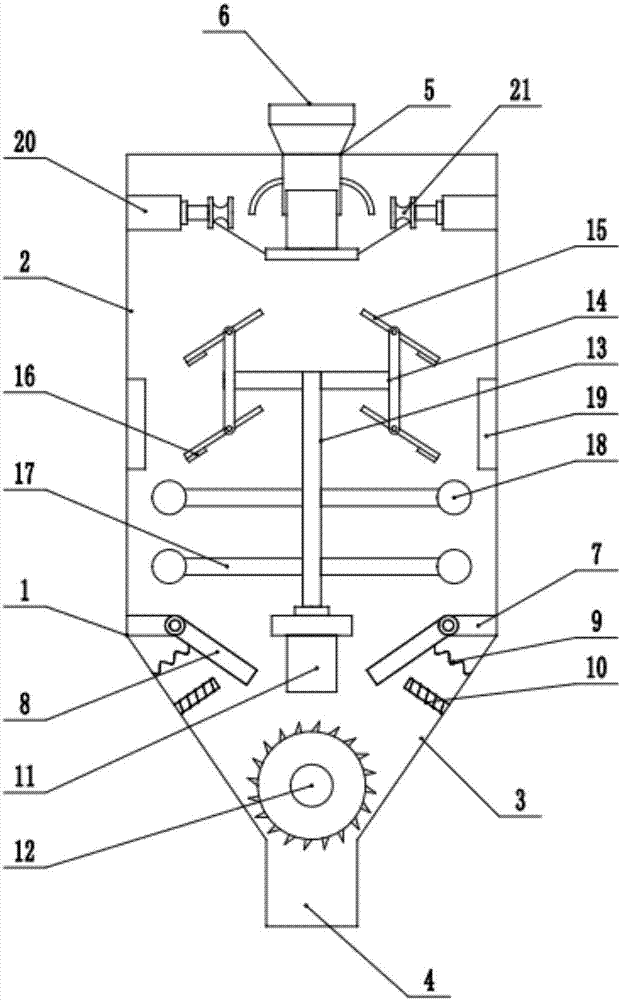

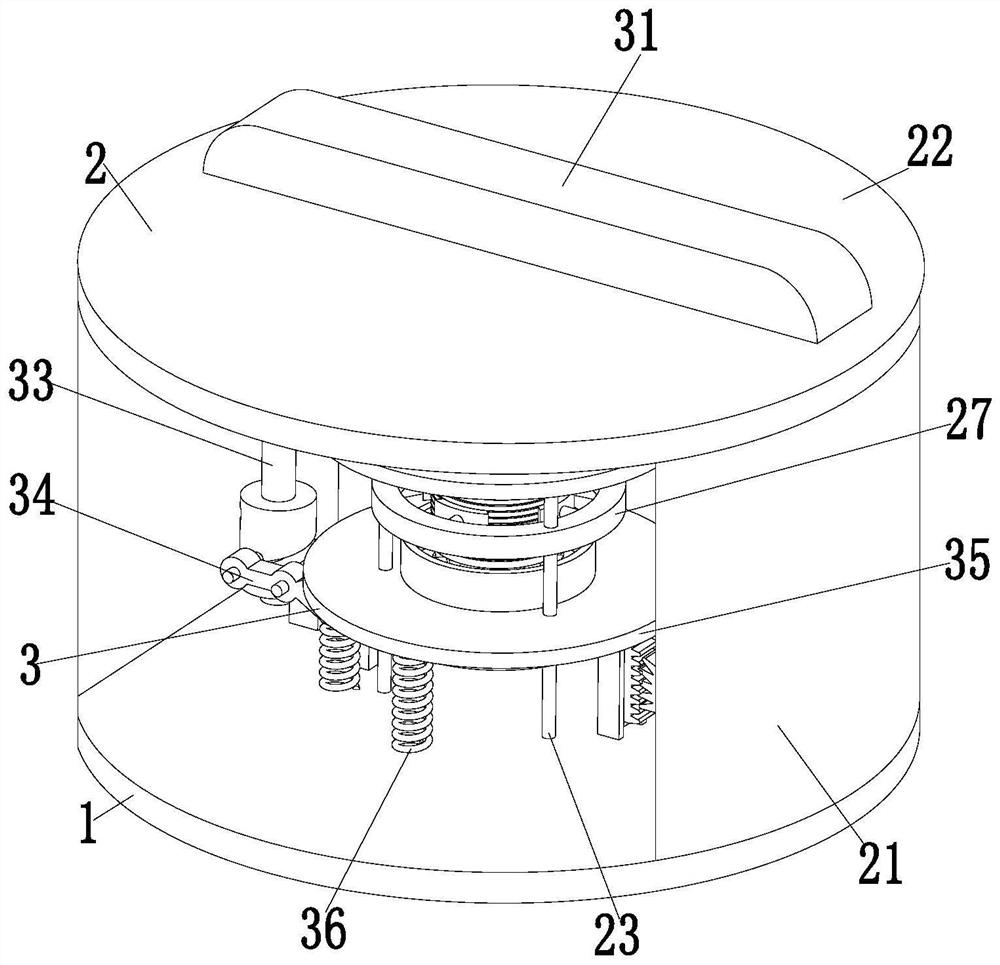

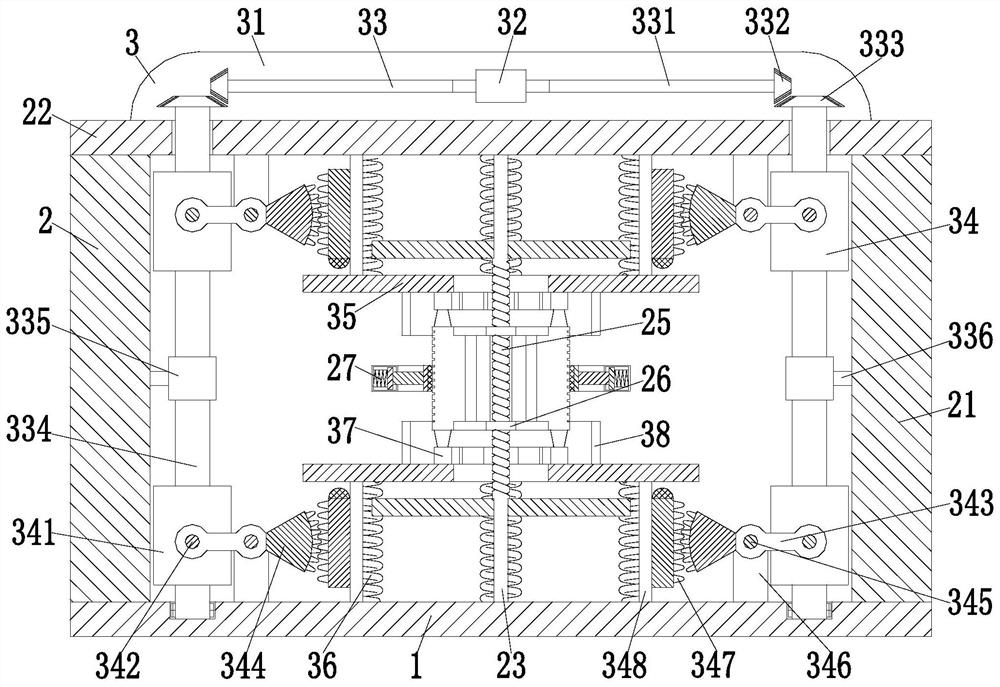

Multi-stage transmission type polisher

InactiveCN105058216AIncrease the amount of sandingSave sanding timeEdge grinding machinesPolishing machinesSurface finishDrive motor

The invention relates to a polishing and grinding device for workpieces, and in particular to a multi-stage transmission type polisher. The multi-stage transmission type polisher comprises a vertical column, a cross arm and a grinding barrel. The cross arm is connected with a lifting system. A grinding device connected to the cross arm is arranged over the grinding barrel. The grinding device comprises a drive motor, a main shaft, a rotating system and a grapping disc. The rotating system comprises a primary planet wheel rotating system and a secondary planet wheel rotating system. The drive motor drives the primary planet wheel rotating system to rotate through the main shaft. The primary planet wheel rotating system drives the secondary planet wheel rotating system to rotate. The secondary planet wheel rotating system drives the grapping disc to rotate. The polishing and grinding device has the following beneficial effects that 1, the machining number of the workpieces is large, the machining speed is high, and production efficiency is high; and 2, grinding is complete, the grinding effect is good, and the surface finish degree is high.

Owner:ZHEJIANG HUMO POLISHING GRINDER MFG

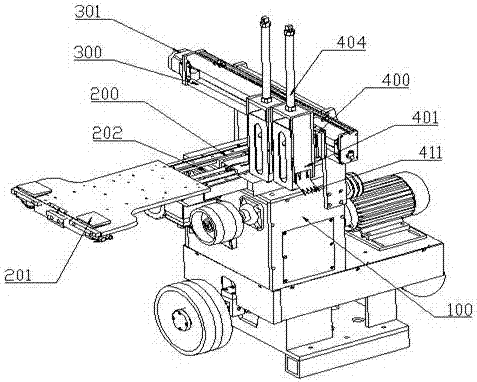

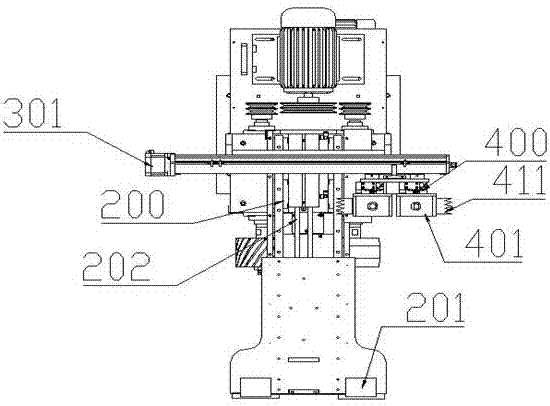

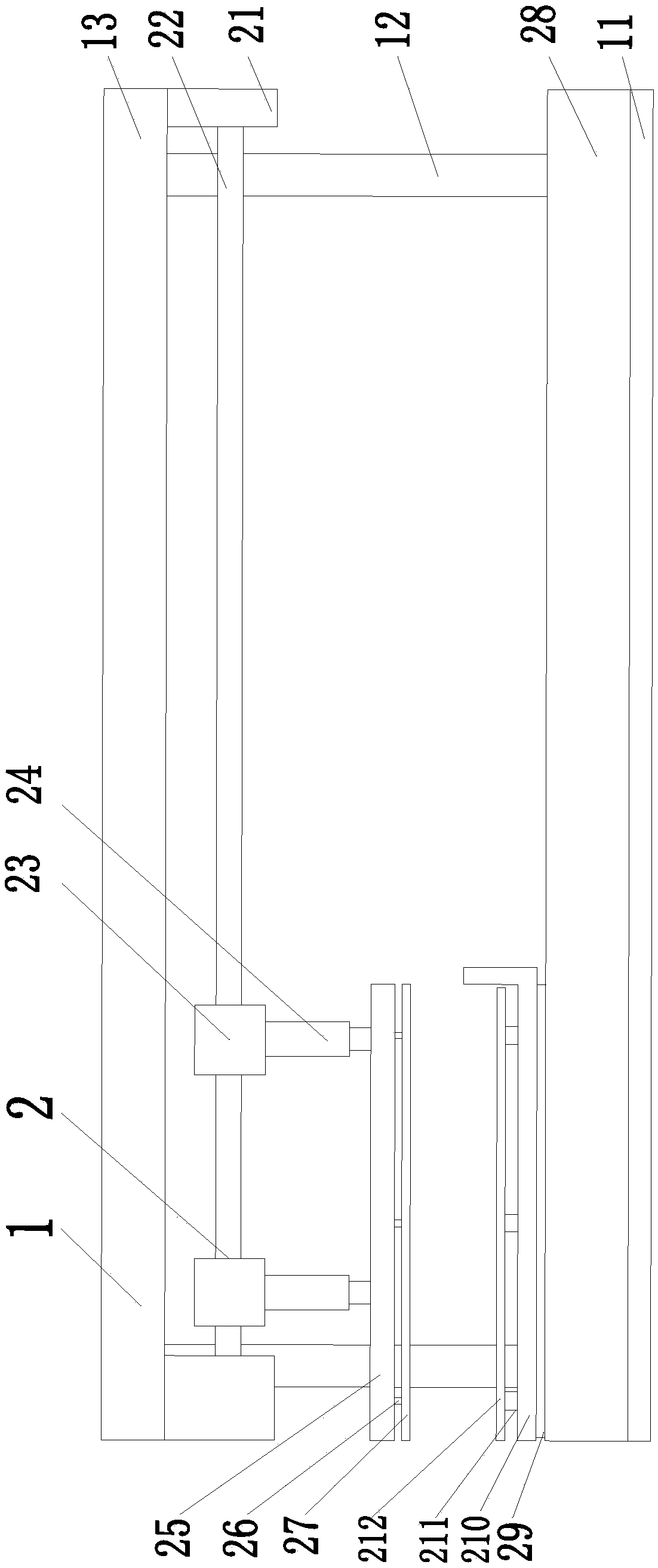

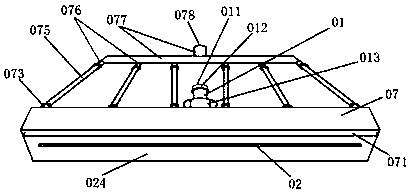

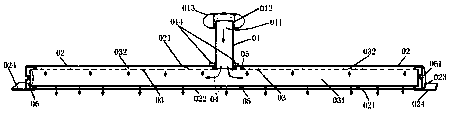

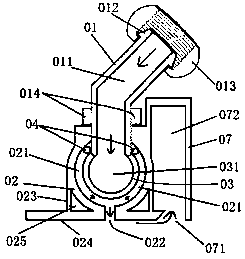

Automatic abrasive paper replacing device and method

ActiveCN107199510AReduce vibrationReduce loadGrinding wheel securing apparatusGrinding drivesEmery paperIndustrial engineering

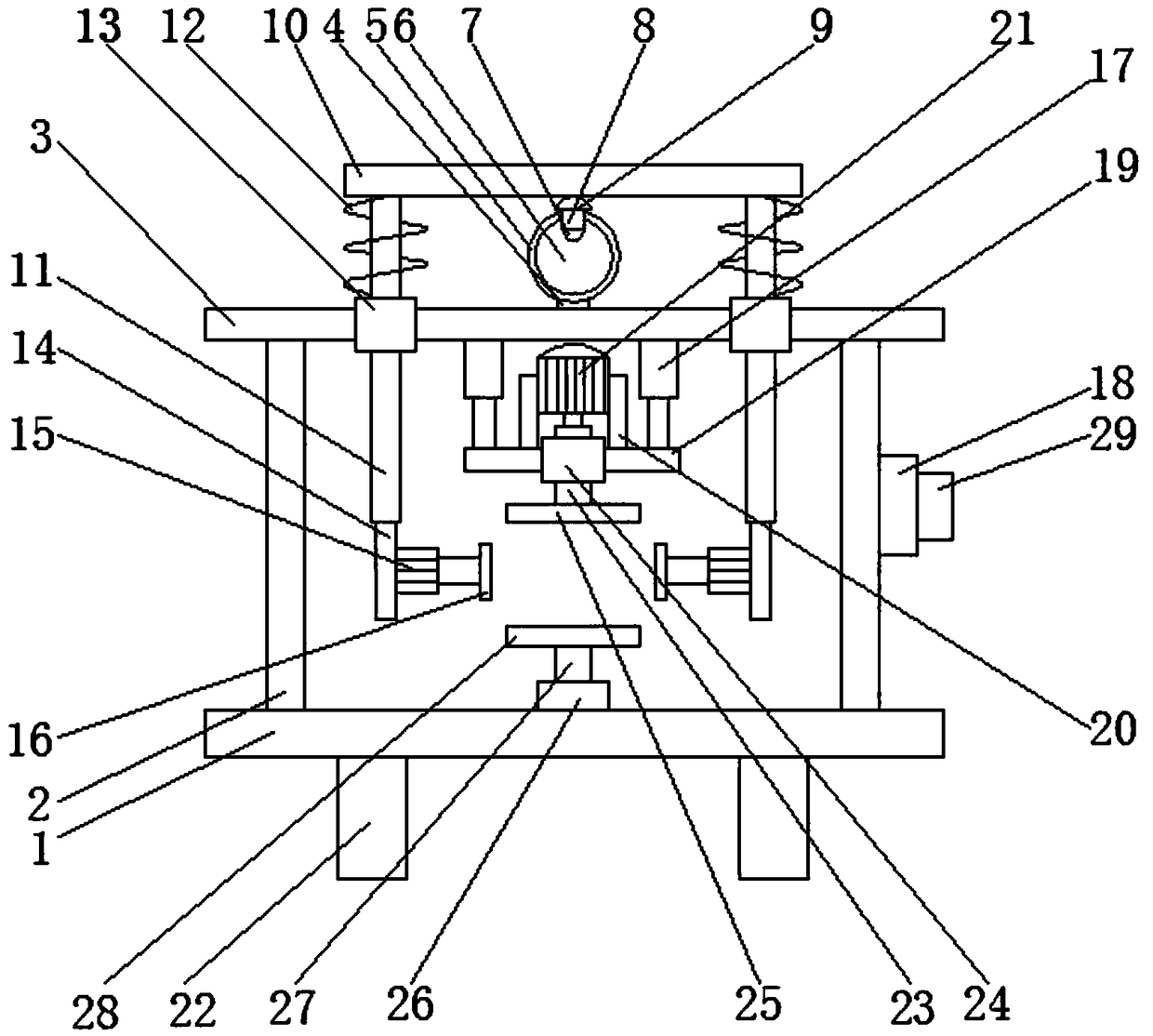

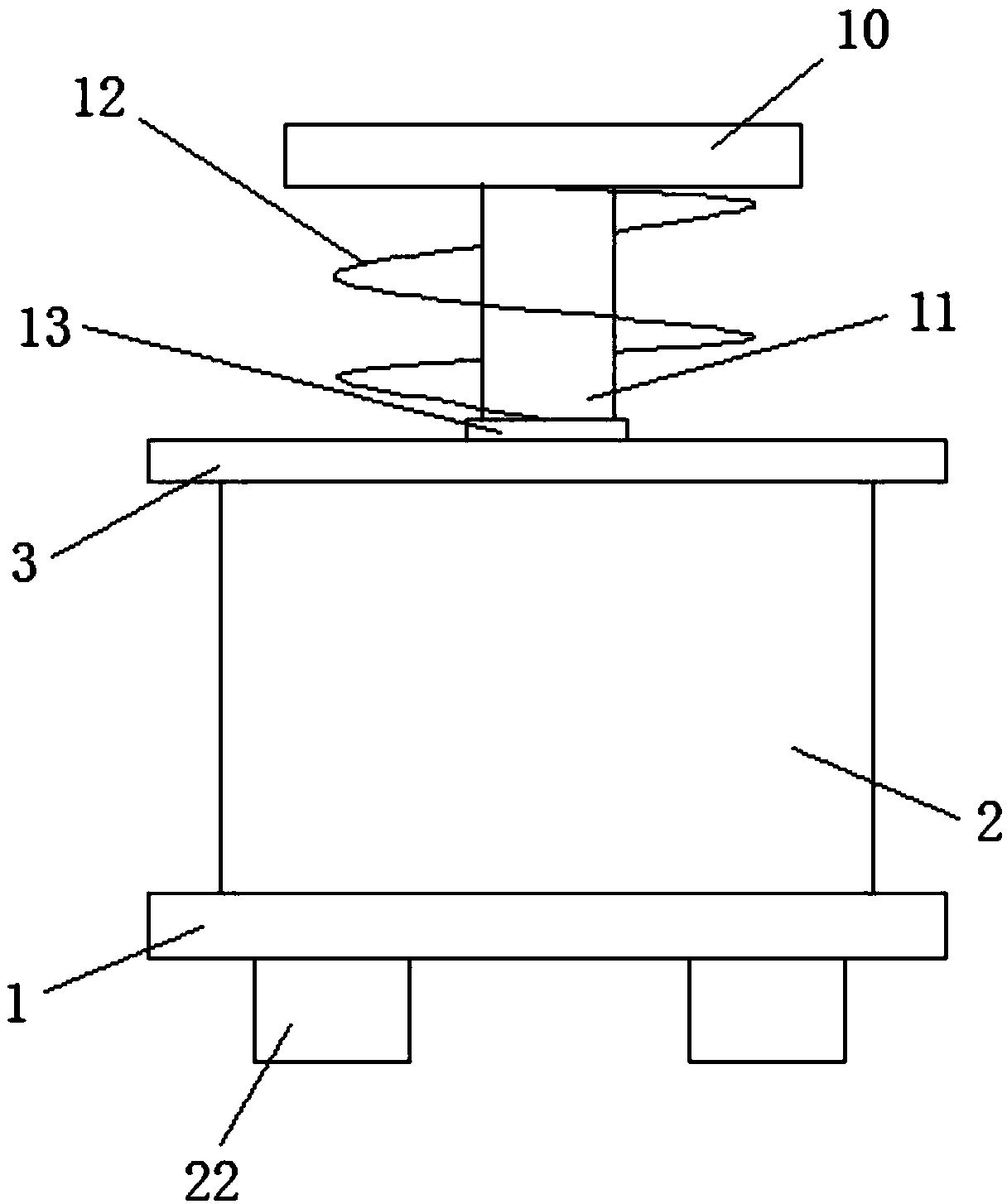

The invention discloses an automatic abrasive paper replacing device and method. The automatic abrasive paper replacing device comprises a base and an X-axis guide rail arranged on the base; a Y-axis guide rail is arranged above the X-axis guide rail, and the Y-axis guide rail is provided with Z-axis guide rails; the X-axis guide rail is connected with polishing heads, and the polishing heads are connected with first air cylinders for driving the polishing heads to move forwards and backwards along the X-axis guide rail; the Y-axis guide rail is connected with a motor for driving the Z-axis guide rails to move leftwards and rightwards along the Y-axis guide rail; the Z-axis guide rails are connected with material storage boxes, and the material storage boxes are connected with second air cylinders for driving the material storage boxes to move up and down along the Z-axis guide rails; the material storage boxes contain abrasive paper, and third air cylinders for driving the abrasive paper to move downwards are connected over the material storage boxes; and the bottoms of the side plates of the material storage boxes are connected with abrasive disc shovels for shoveling the abrasive paper. According to the automatic abrasive paper replacing device, the abrasive paper is pasted and torn off automatically, polishing time is saved, and polishing efficiency is improved.

Owner:东莞市尚弘博实业有限公司

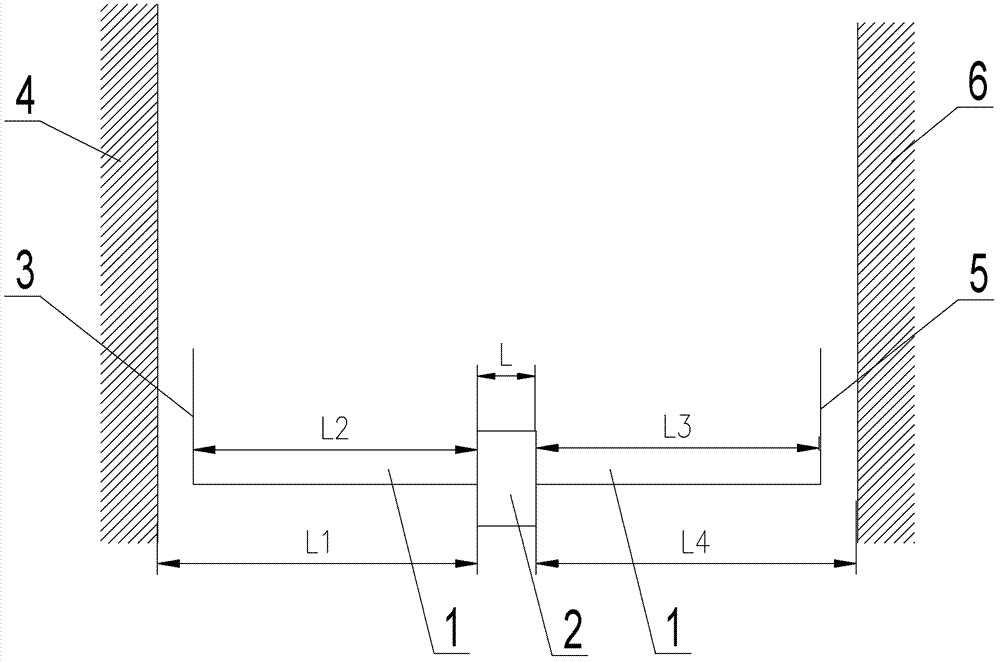

Method for calibrating center line of guide ruler

ActiveCN103191924AAvoid wear and tearReduce defective productsRolling equipment maintainenceGuiding/positioning/aligning arrangementsWaxEngineering

The invention relates to the field of hot rolled strip guide ruler centering, in particular to a method for calibrating the center line of a guide ruler. The method is characterized in that after maintenance is finished every time or strip steel with the thickness of 18 mm is rolled every time, the deviation of a transmission side and an operation side of the guide ruler is corrected in time to ensure the centering of the guide ruler. The method comprises the following specific operation steps: (1) measuring the width L of an extension strip at the middle part of the guide ruler, the distance L2 between the edge of the transmission side to a guiding plate on the transmission side of the extension strip, the distance L1 between the edge of the transmission side of the extension strip and an archway on the transmission side, the distance L3 between the edge of the operation side of the extension strip and the guiding plate on the operation side, and the distance L4 between the edge of the operation side of the extension strip and the archway on the operation side; (2) determining the deviation of the center of the extension strip; and (3) calibrating the center of the guide rule. Compared with the prior art, the method has the benefits that through in time correction of the deviation of the transmission side and the operation side of the guide rule after maintenance is finished every time or strip steel with the thickness of 18 mm is rolled every time, the wear and wax hanging phenomena of one side of the guide ruler, which is resulted from deviation of the guide ruler, are avoided.

Owner:ANGANG STEEL CO LTD

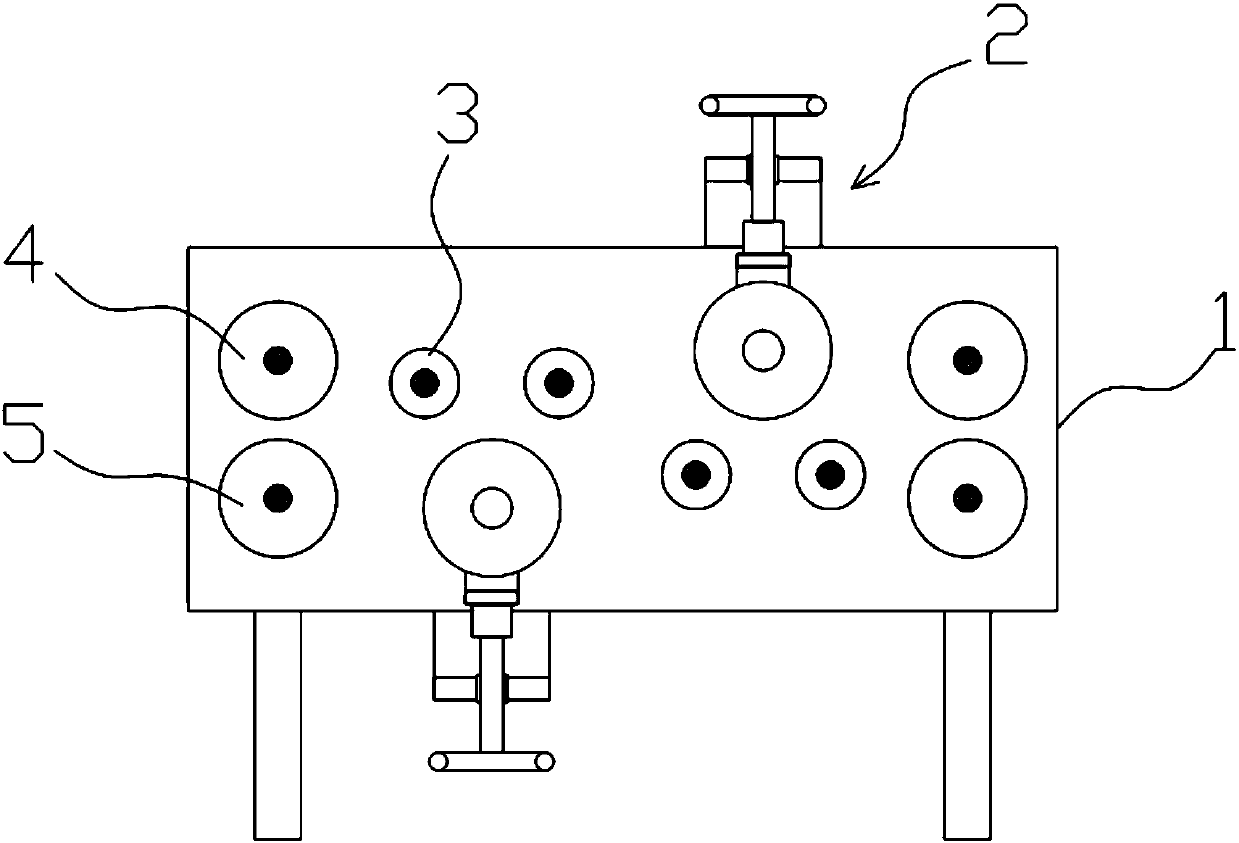

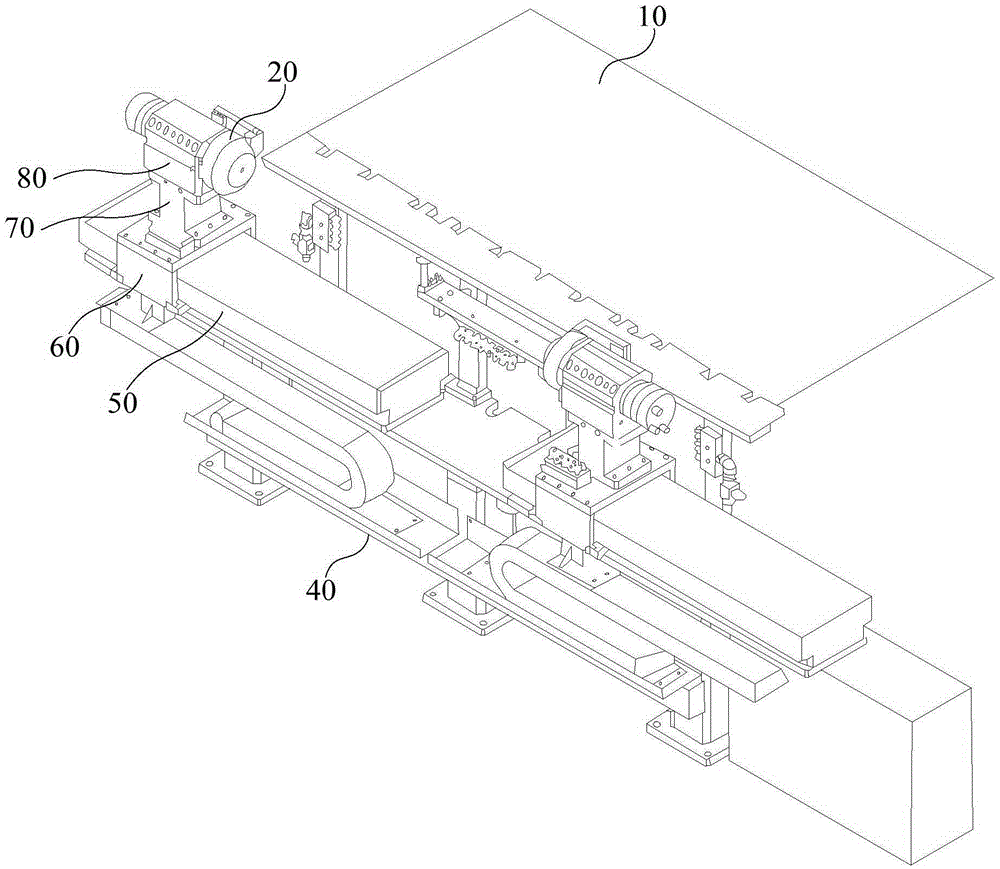

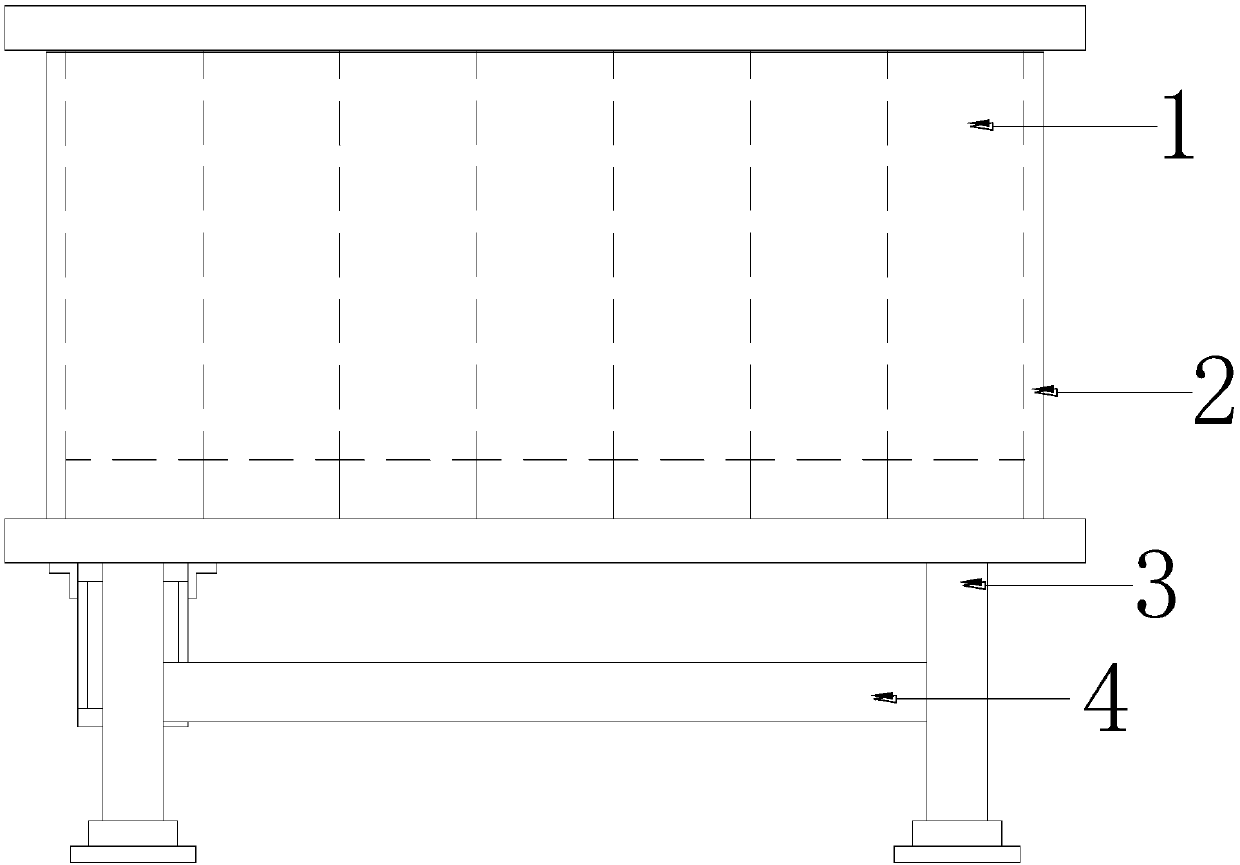

Quick polishing device for planks for machining

InactiveCN107584394AImprove grinding efficiencySave sanding timeGrinding carriagesGrinding feed controlPulp and paper industryMachining

The invention discloses a quick polishing device for planks for machining. The quick polishing device comprises a frame and two polishing components, wherein a driven roller and a driving roller are respectively mounted at the two ends of the frame; a support roller is arranged on the middle part of the frame; each polishing component comprises a portal gantry fixed on the frame; a screw rod is inthreaded connection with the portal gantry; the bottom end of the screw rod is moveably connected with the interior of a fixing sleeve; the bottom of the fixing sleeve is fixed on a bracket through abolt; a polishing roller is arranged on the bracket through a rotating shaft. According to the invention, the two sets of polishing components are used for respectively polishing the two surfaces ofthe plank at the same time, so that the polishing efficiency is greatly increased and the polishing time is reduced; a spring is utilized to drive the polishing roller to automatically adjust the acting force on the plank surface, the control on the polishing pressure of the polishing roller is benefited and the polishing quality is guaranteed; the polishing wire on the polishing roller is conveniently replaced and the use cost of the whole polishing roller is lowered.

Owner:WUXI ZHIGURUITUO TECH SERVICE CO LTD

Polishing device for plastic particle production and processing

InactiveCN107234539AImprove stirring efficiencyStir wellEdge grinding machinesPolishing machinesDrive motorEngineering

The invention discloses a polishing device for plastic particle production and processing. The polishing device comprises a device body. The device body is mainly composed of a polishing barrel and a discharging hopper. A bottom plate is arranged on the inner bottom of the polishing barrel and provided with an opening, and a rotating plate is hinged to the bottom plate. The lower surface of the rotating plate is fixedly connected with a spring, and the tail end of the spring is fixedly connected with the inner wall of the discharging hopper. The bottom plate is fixedly connected with a drive motor, the top of the drive motor is connected with a rotating shaft, and the top of the rotating shaft is fixedly connected with a supporting frame. The upper end and the lower end of the supporting frame are connected with stirring rods in a hinged manner correspondingly. The top of the polishing barrel is provided with a feeding port, the polishing barrel is internally provided with a distributing cylinder, and the feeding port communicates with the interior of the distributing cylinder. By means of the polishing device, the stirring efficiency of plastic particles is improved, polishing is facilitated, and the polishing load of the plastic particles is reduced by controlling the feeding amount of the plastic particles; and according to the polishing device, through cooperation of the rotating plate and a discharging wheel, the situation that the plastic particles block a discharging port is avoided, discharging is facilitated, and convenience is brought to people for use.

Owner:GUANGDONG DEXIN TECH INCUBATOR CO LTD

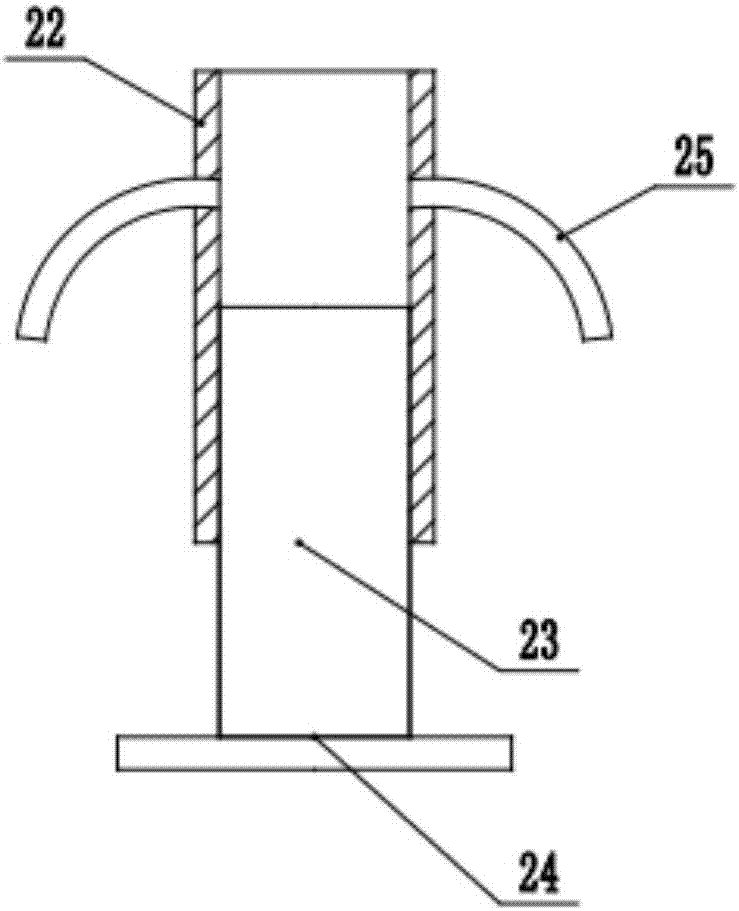

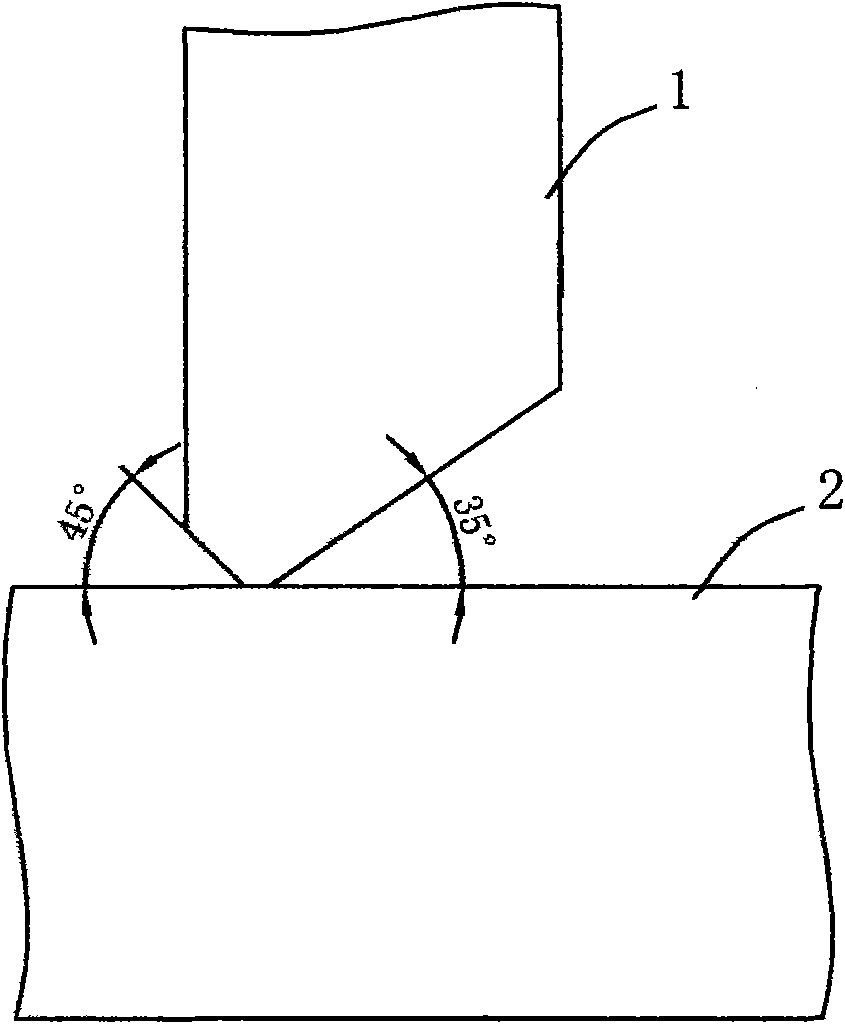

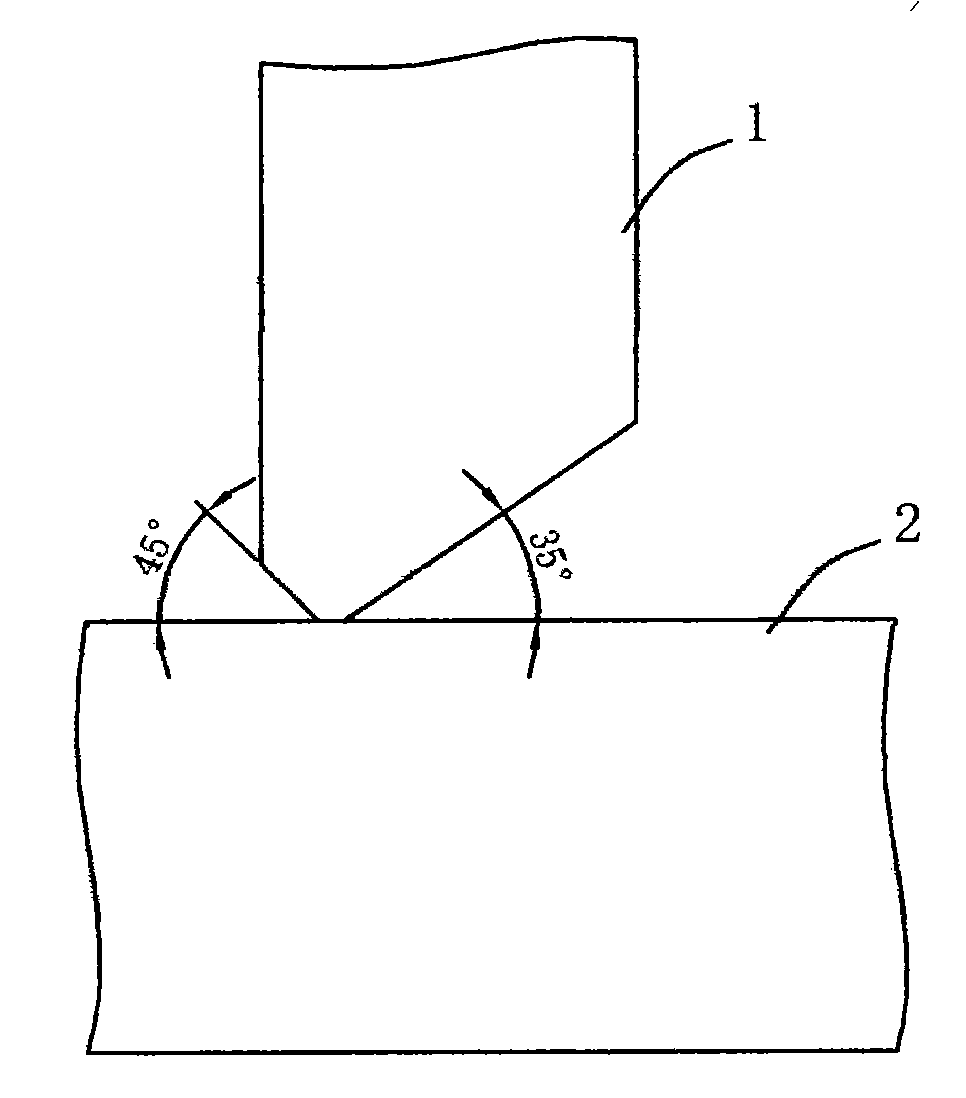

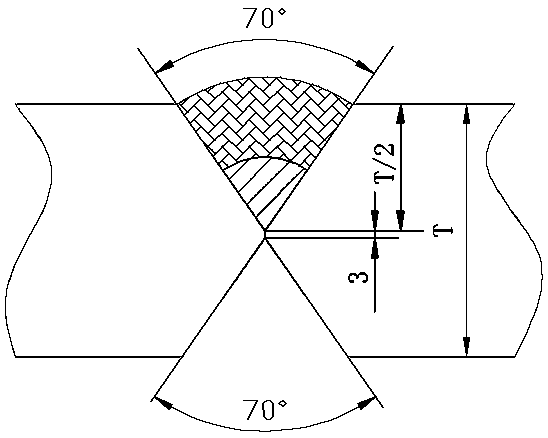

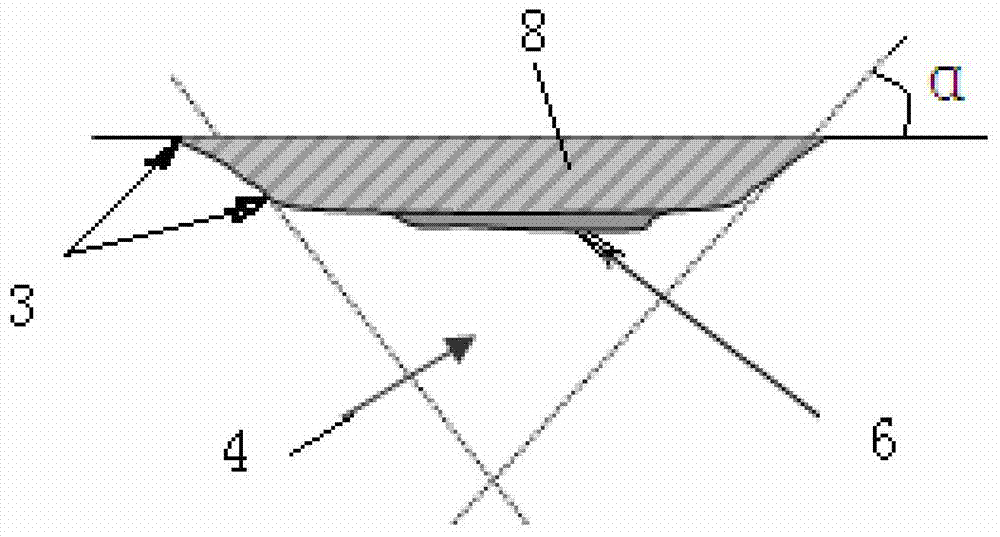

Welding process applying submerged automatic arc welding to wind power generation tower foundation seat

InactiveCN101885099AWeld firmlyExtended service lifeArc welding apparatusWorkpiece edge portionsMaterial consumptionCarbon dioxide

The invention discloses a welding process applying submerged automatic arc welding to a wind power generation tower foundation seat, belonging to the technical field of a wind power generation tower processing technique, comprising the following implementing steps: a, opening a K-shaped groove on the cylindrical section of a wind power generation tower, the groove angle outside the cylindrical section is 40-50 degrees, and the groove angle inside the cylindrical section is 30-40 degrees; b, assembling a flange of the cylindrical section and the wind power generation tower, forming an external circular seam at the groove between the external side of the cylindrical section and the flange, forming an internal circular seam at the groove between the internal side of the cylindrical section and the flange, and pointing welding the external circular seam; c, back welding the internal side circular seam for one time by utilizing carbon dioxide solid welding wire; d, welding the external circular seam by submerged automatic arc welding; and e, welding the internal circular seam by submerged automatic arc welding. The welding process of the invention solves the technical problems of large material consumption and low production efficiency when the wind power generation tower foundation seat is welded, and can be widely applied to the machining process of the wind power generation tower.

Owner:WEIFANG WUZHOU WIND POWER EQUIP

Autoclaved aerated concrete plate repairing agent

InactiveCN104926258AIncrease late strengthRealize comprehensive utilizationSolid waste managementFiberBuilding product

The invention discloses an autoclaved aerated concrete plate repairing agent and belongs to the technical field of building materials. The autoclaved aerated concrete plate repairing agent is composed of, by mass, 40-60% of coal ash, 10-30% of gypsum, 5-15% of cement, 10-30% of sand, 0.01-2.0% of fiber, 0.01-1.05 of water retaining agent and 0.01-1.5% of setting retarder. The coal ash is coal ash for silicate building products meeting JC / T, the gypsum is semi-hydrated gypsum, and the cement is universal silicate cement meeting GB. By the autoclaved aerated concrete plate repairing agent, the problem that an existing repairing agent and an autoclaved aerated concrete plate have chromatic aberration and are low in binding strength and long in setting time.

Owner:SHANDONG TIANYU WALL MATERIAL

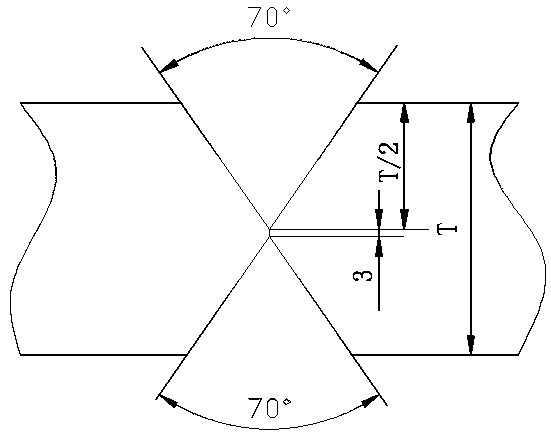

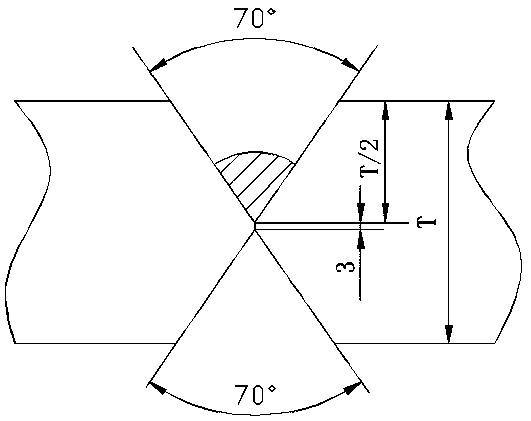

Back-chipping-free double-wire submerged arc welding method of pipe-shaped structure

InactiveCN108672901AQuality improvementReduce processArc welding apparatusManufacturing technologyEngineering

The invention relates to the technical field of manufacturing of wind power generation tower frames, in particular to a back-chipping-free double-wire submerged arc welding method of a pipe-shaped structure. The welding method is aimed at the longitudinal seam and circular seam welding of a thin plate with the thickness smaller than or equal to 30 mm, and comprises the steps of carrying out beveling, rolling a barrel body, carrying out preheating, carrying out backing weld, filling a cover surface at welding joints and carrying out welding joint quality inspection. According to the back-chipping-free double-wire submerged arc welding method, the double-arc double-wire submerged arc welding is adopted, so that the welding efficiency is improved by one time; and the backing-chipping-free technology is adopted, so that the gouging process is omitted compared with a traditional carbon arc air gouging technology, the time and the cost are saved, the labor intensity and the environmental pollution are reduced, the welding surface after forming is attractive in appearance, and the welding internal quality is improved; and mixed gas of Ar and CO2 is adopted for consumable electrode gas shielded welding, so that the weld joints are smooth in molding, the grinding time is shortened, the welding quality is improved, and the qualified rate of the weld joints is high.

Owner:蓬莱大金海洋重工有限公司

Efficient steel pipe polishing device

InactiveCN107378719AAvoid wear and tearReduce pollutionGrinding carriagesGrinding drivesDual axisMechanical engineering

The invention discloses an efficient steel pipe polishing device which comprises a support, a feeding mechanism, a polishing mechanism, a dust removing mechanism and a transmission chamber. The feeding mechanism comprises a forward and backward rotation motor, a feeding table, a second sliding block, a double-axis motor, a rotating gear and a clamping device. The clamping device comprises a clamping frame, a semicircular-ring-shaped rotating plate A, a semicircular-ring-shaped rotating plate B, an electric telescopic rod, a clamping rod and a supporting table. The dust removing mechanism is arranged on the right side of the feeding mechanism and comprises a suction fan, an electromagnet, a chip feeding pipe and a collecting groove. The polishing mechanism is arranged above the feeding mechanism and comprises a rotating motor B, a rotating wheel A, a second belt, a rotating wheel B, a polishing wheel A and a polishing wheel B. The transmission chamber is arranged on the left side of the polishing mechanism. The efficient steel pipe polishing device is simple in structure and convenient to operate, the polishing efficiency of the steel pipe polishing device is improved, meanwhile, labor force is greatly lowered, and the environment pollution is effectively reduced due to the arranged dust removing device.

Owner:HEFEI TOTEM LONG MACHINERY DESIGN CO LTD

Device for processing makrolon plastic boards and cutting and polishing processing method for boards

ActiveCN109262694AImprove stabilityEasy to fixEdge grinding machinesGrinding drivesPolycarbonate plasticMechanical engineering

Owner:岳阳经源塑胶制品有限公司

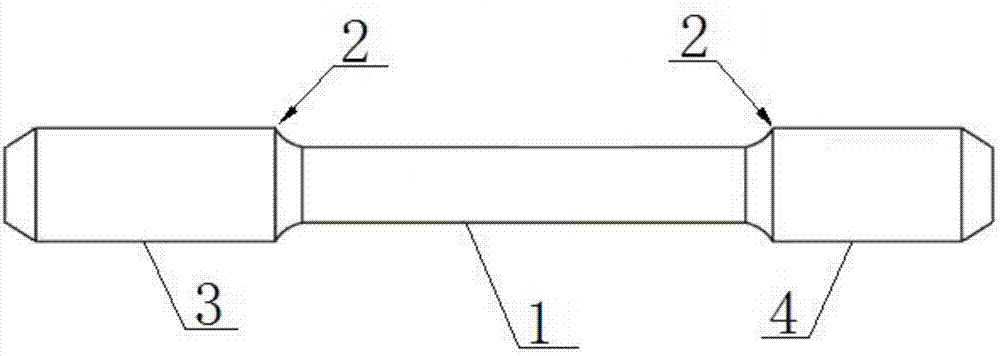

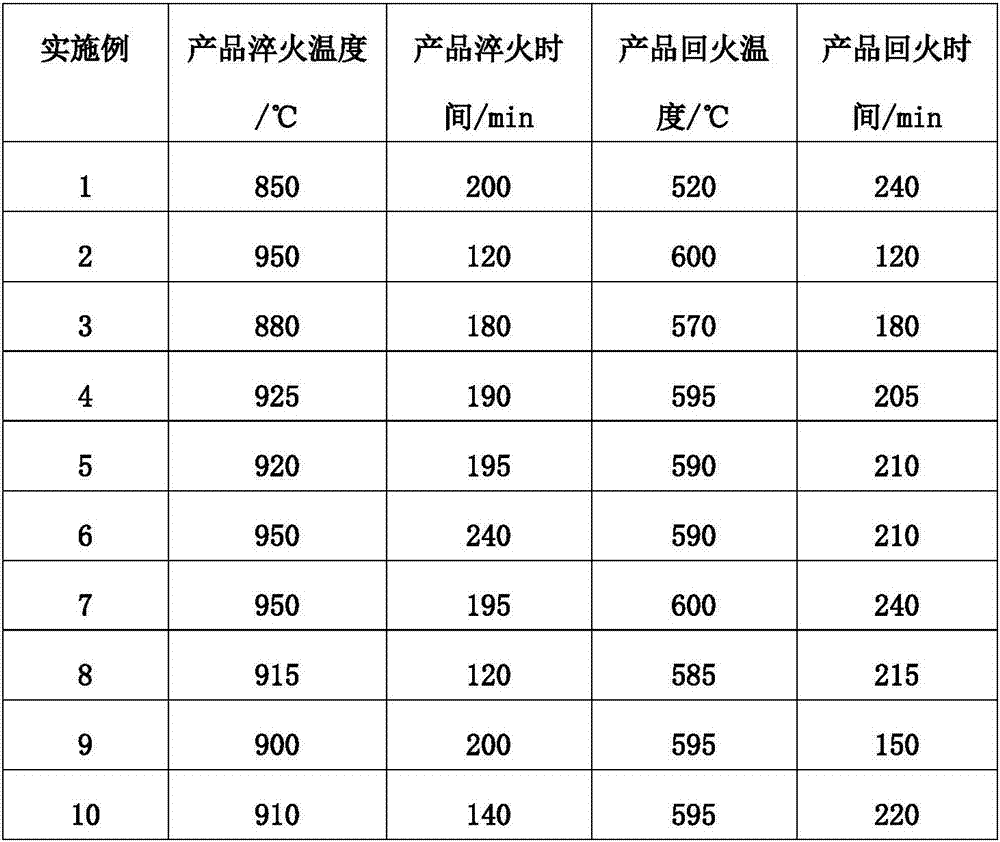

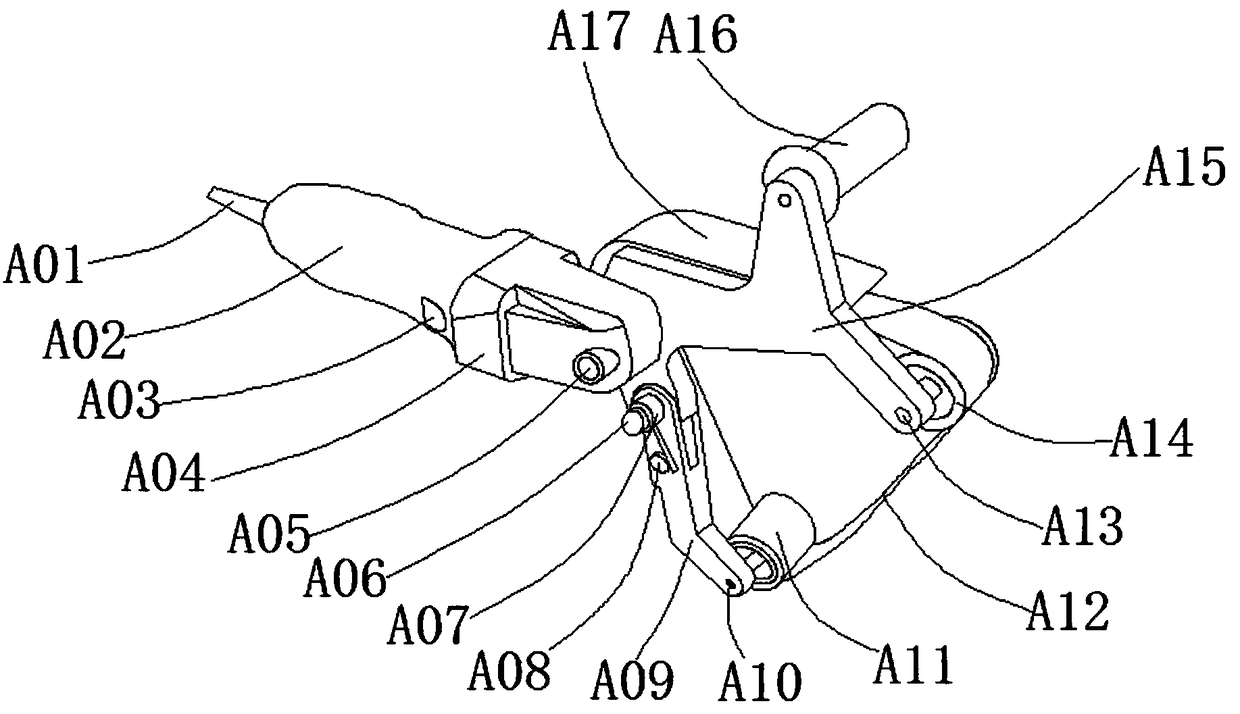

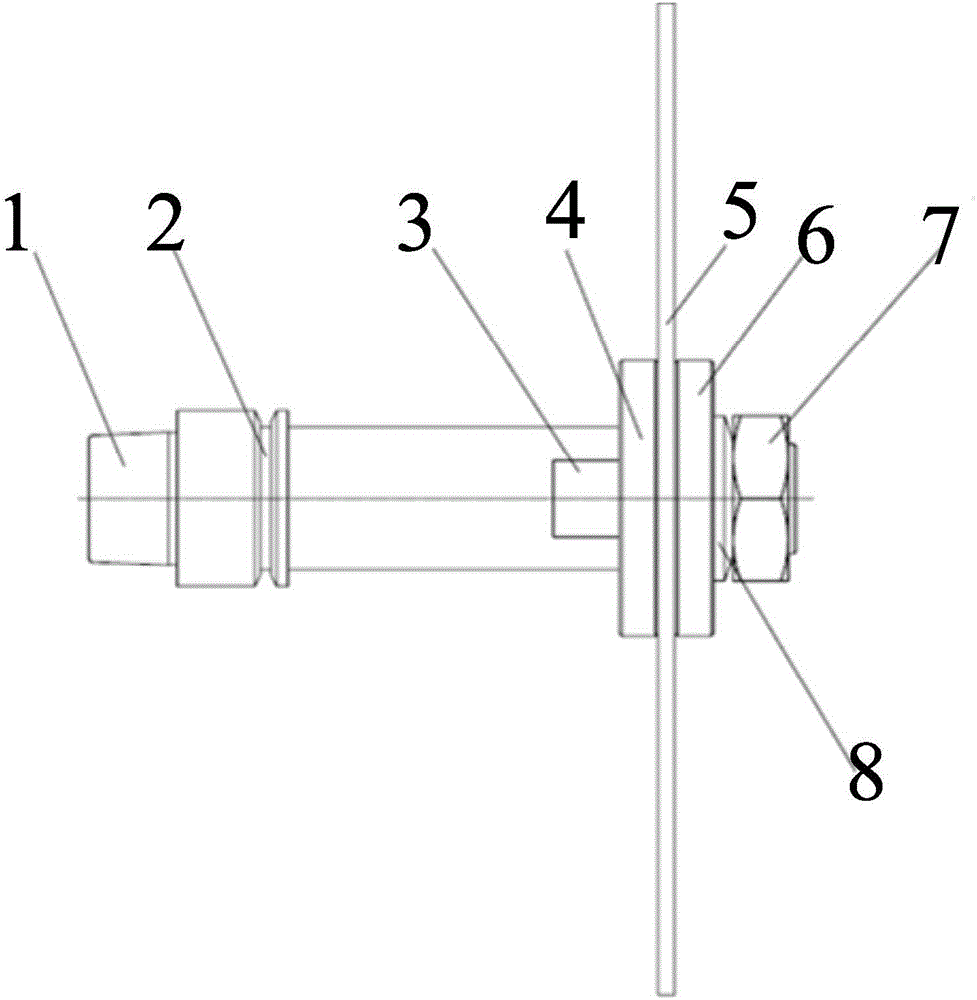

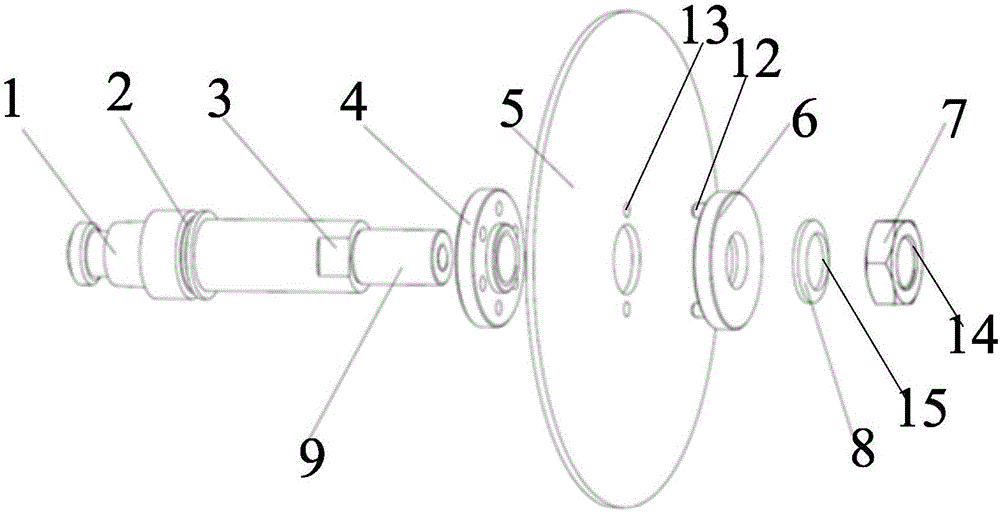

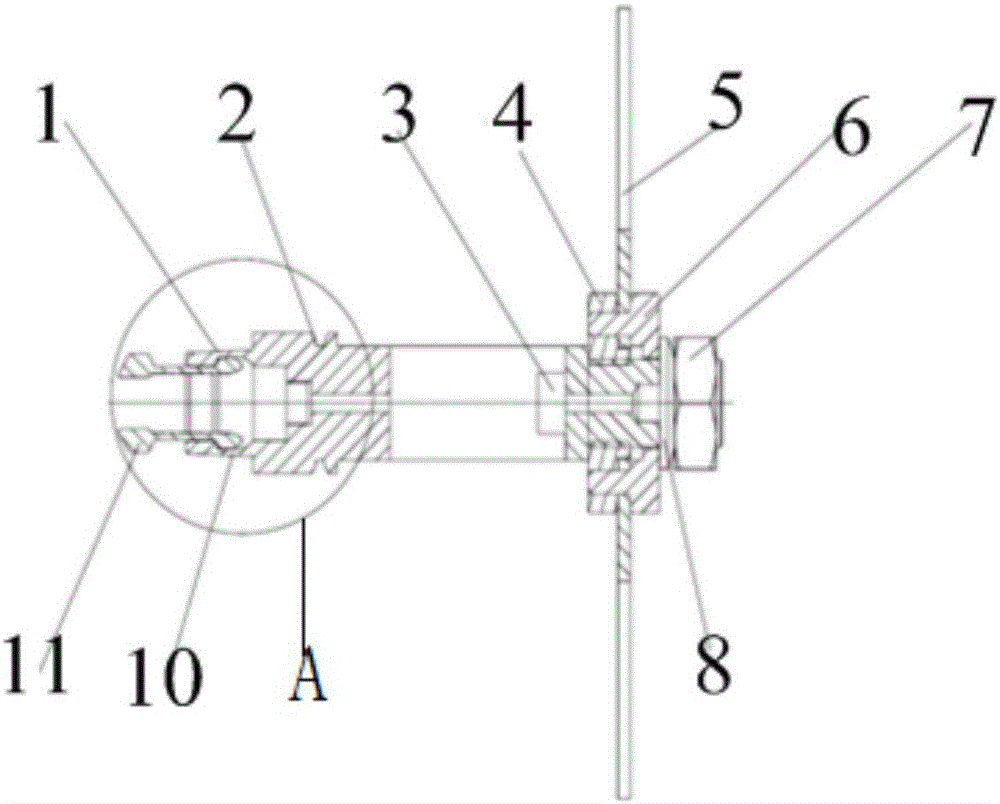

Double-end toothed stud and manufacturing method thereof

PendingCN107023554AImprove hardenabilityImprove toughnessScrewsTooth lengthArchitectural engineering

The invention discloses a double-end toothed stud. The double-end toothed stud comprises a stud body and threaded sections, the threaded sections comprise the first threaded section and the second threaded section, and the stud body is located between the first threaded section and the second threaded section; an included angle formed between a tooth arranged at the initial end of the first threaded section and the vertical line of the stud body is 20 degrees, an included angle formed between a tooth arranged at the tail end of the first threaded section and the vertical line of the stud body is 20 degrees, an included angle formed between a tooth arranged at the initial end of the second threaded section and the vertical line of the stud body is 20 degrees, and an included angle formed between a tooth arranged at the tail end of the second threaded section and the vertical line of the stud body is 20 degrees; the tooth length of the first threaded section is 180 mm, the tooth pitch between the two ends of the first threaded section is 10 mm, the tooth length of the second threaded section is 140 mm, and the tooth pitch between the two ends of the second threaded section is 10 mm; the stud body is in a cylindrical shape; the total length of the stud body and the threaded sections is 470+ / -0.8 mm. The double-end toothed stud has the advantages of being good in smooth finish, free of burrs and high in constant-temperature impact absorbing energy. The invention further discloses a method for manufacturing the double-end toothed stud.

Owner:湖北玖天机车部件有限公司

Stainless steel tube weld joint polishing device and use method thereof

InactiveCN108581699AReduce volumeSave spaceEdge grinding machinesBelt grinding machinesIntegrated designSteel tube

The invention provides a stainless steel tube weld joint polishing device and a use method of the stainless steel tube weld joint polishing device. The stainless steel tube weld joint polishing devicecomprises a gearbox, a supporting plate and a tensioning rod. A motor is arranged at one end of the gearbox. The end, far away from the gearbox, of the motor is provided with a power line. One side of the motor is provided with a power switch. The end, far away from the motor, of the gearbox is provided with a rotating shaft. The end, far away from the gearbox, of the rotating shaft is provided with a third roller. One side of the gearbox is provided with the supporting plate. The side, far away from the gearbox, of the supporting plate is provided with a protective cover. The upper portion of the supporting plate is provided with a handle. According to the stainless steel tube weld joint polishing device, small-sized integrated design is adopted, a user can hold the handle and the motorby hands and turns on the power switch to enable the motor to be electrified and operate, abrasive paper is driven to rotate, and then a weld joint can be polished; and the stainless steel tube weld joint polishing device is small in size, light in weight and suitable for conducting the weld joint polishing operation small in machining amount in a small-space machining place.

Owner:海宁鼎合工程技术开发有限公司

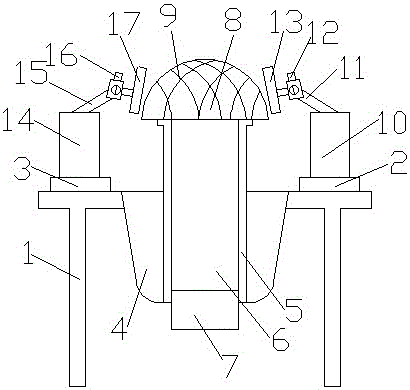

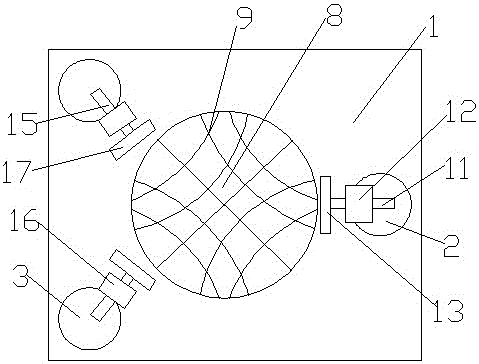

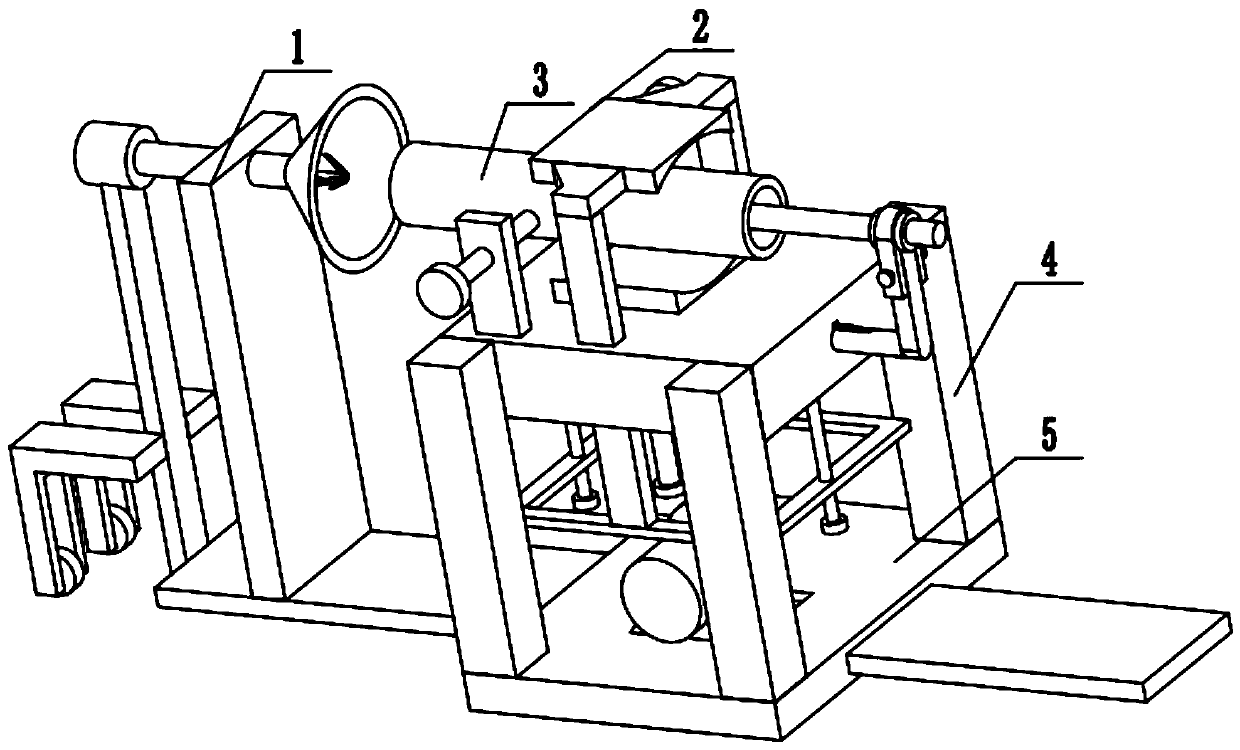

Spherical surface ring polishing machine

ActiveCN105773344AEasy to moveHigh precisionOptical surface grinding machinesAbrasive surface conditioning devicesDrive shaftEngineering

The invention discloses a spherical surface ring polishing machine. The spherical surface ring polishing machine comprises a work platform, a correcting machine base and a grinding machine base. A spherical surface grinding head is arranged in the middle of the work platform. The correcting machine base is provided with a first rotation movable support, a first rotating shaft is arranged at the front end of the correcting machine base, and a correcting machine head is arranged at the tail end of the first rotating shaft. The grinding machine base is provided with a second rotation movable support, a second rotating shaft is arranged at the front end of the grinding machine base, and a grinding machine head is arranged at the tail end of the second rotating shaft. According to the spherical surface ring polishing machine, the height and the angle of the correcting machine head and the grinding machine head are made to meet the grinding requirement by adjusting the first rotation movable support and the first rotating shaft on the correcting machine base and the second rotation movable support and the second rotation shaft on the grinding machine base. Materials are fixed to the grinding machine head, the spherical surface grinding head on a transmission shaft is driven by a transmission machine to rotate to grind the materials, the spherical surface grinding head, the correcting machine head and the grinding machine head can be replaced, different grinding requirements can be met, and different grinding effects are achieved; and the grinding speed is increased, the grinding time is saved, the applicability is high, and precision is high.

Owner:淮安艾利光电仪器有限公司

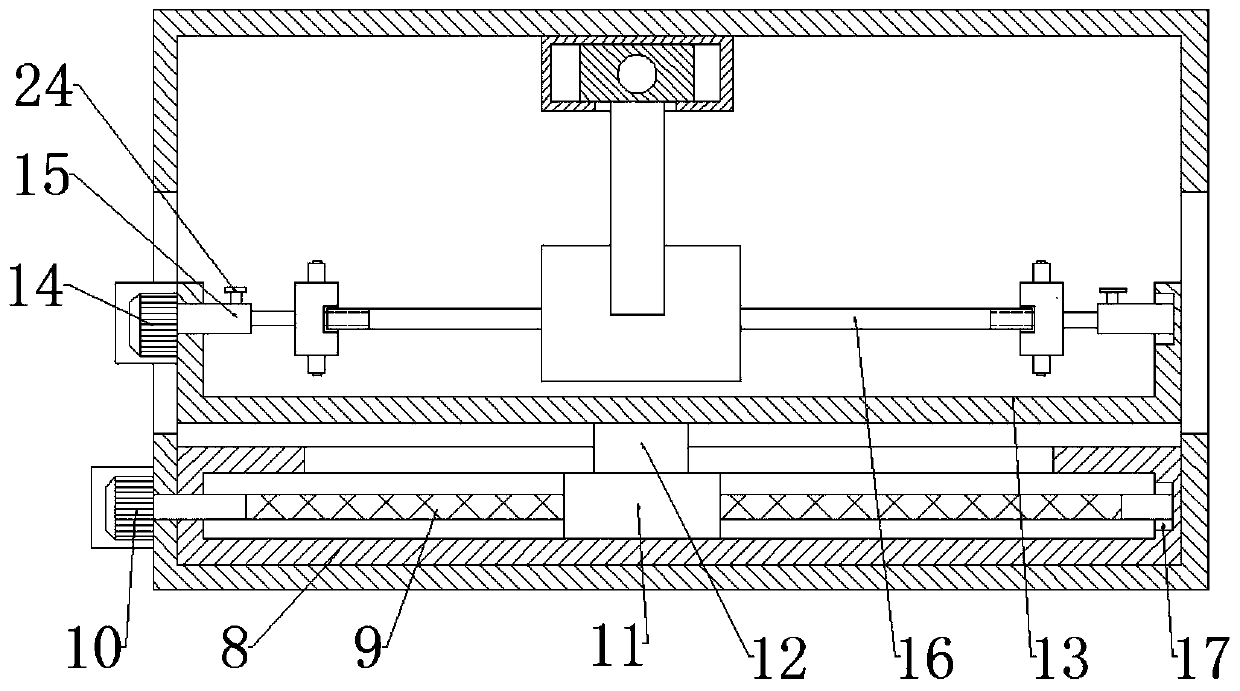

Outer circle polishing device for epoxy ceramic tube production

PendingCN110587399AEasy to polishSave sanding timeGrinding carriagesRevolution surface grinding machinesTransverse planeEngineering

The invention relates to the technical field of outer circle polishing, and discloses an outer circle polishing device for epoxy ceramic tube production. The outer circle polishing device comprises abox body, a first transverse plate and a second transverse plate, wherein the first transverse plate and the second transverse plate are both of hollow structures and are provided with sliding grooves; the first transverse plate is positioned at the inner top of the box body, and a bidirectional screw rod is transversely arranged in the first transverse plate; the left end of the bidirectional screw rod penetrates through the first transverse plate and the front side wall of the box body to be fixedly connected with a knob; two first sliding blocks are in threaded connection with the rod wallof the bidirectional screw rod, an L-shaped connecting rod is fixedly connected to the bottom of each first sliding block, and an arc polishing sheet is fixedly connected to the other end of each L-shaped connecting rod; the second transverse plate is positioned at the bottom end inside the box body; and a reciprocating screw rod is transversely arranged in the second transverse plate, and the left side of the reciprocating screw rod penetrates through the second transverse plate and the left side wall of the box body to be fixedly connected with a first motor. According to the outer circle polishing device, a ceramic tube can be polished in all directions, the polishing efficiency is increased, and the waste of human resources is reduced.

Owner:荆门正源光华管业有限公司

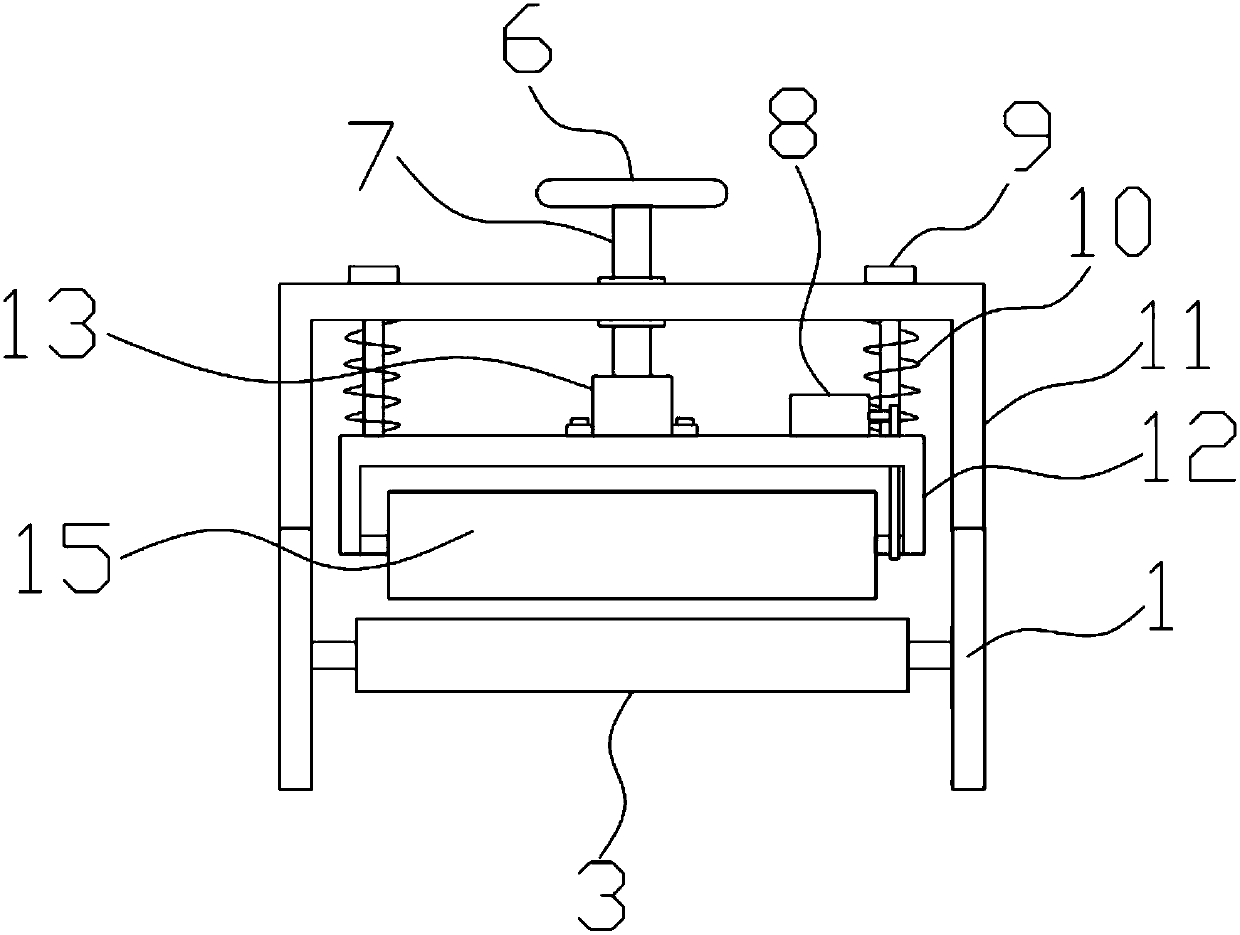

Grinding process for flange surface

InactiveCN106181262ASave sanding timeLow costMaintainance and safety accessoriesGrinding/polishing safety devicesEngineeringMachine tool

The invention discloses a grinding process for a flange surface. The grinding process comprises the following steps: firstly, fixing a flange on a base of a cutting machine tool, adjusting a cutting head for cutting to a proper height, and then transversely and horizontally cutting a front side and a back side of the flange; secondly, performing water spraying treatment on the cut flange surface; thirdly, taking out the flange on which water is sprayed and grinding, stopping until dust appears on the flange, and repeating the second step and the third step according to conditions until grinding is qualified; and fourthly, cleaning the polished flange, and then performing drying treatment on the cleaned flange. According to the grinding process disclosed by the invention, the flange surface is cut by a cutting machine tool first, so that a large amount of grinding time can be saved; in addition, the cost for grinding an abrasion wheel is reduced; and besides, dust can be prevented from being generated during grinding, so that danger caused by production and operation is avoided, and hazards to health of an operator are eliminated.

Owner:ZHANGJIAGANG HUARI FLANGE

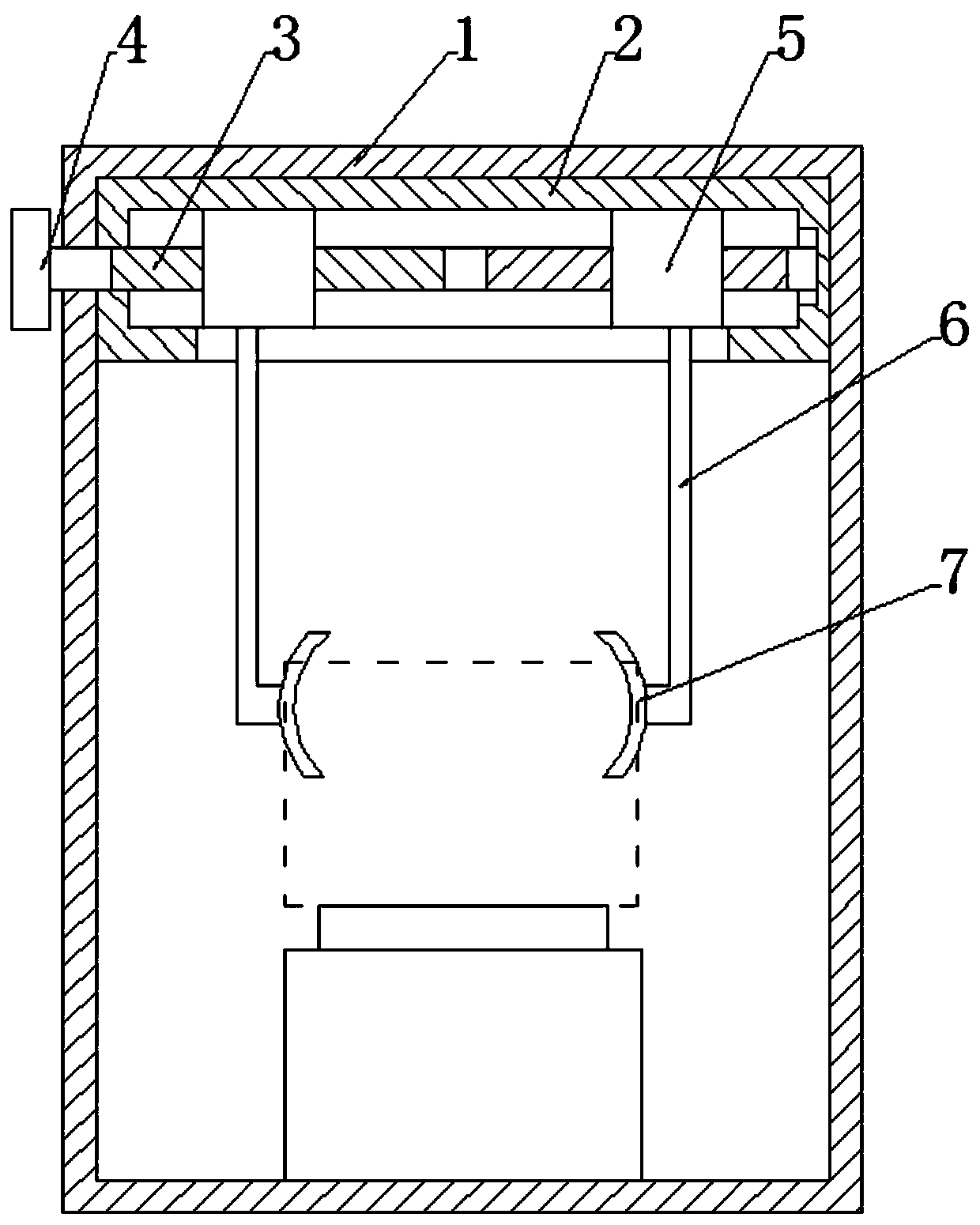

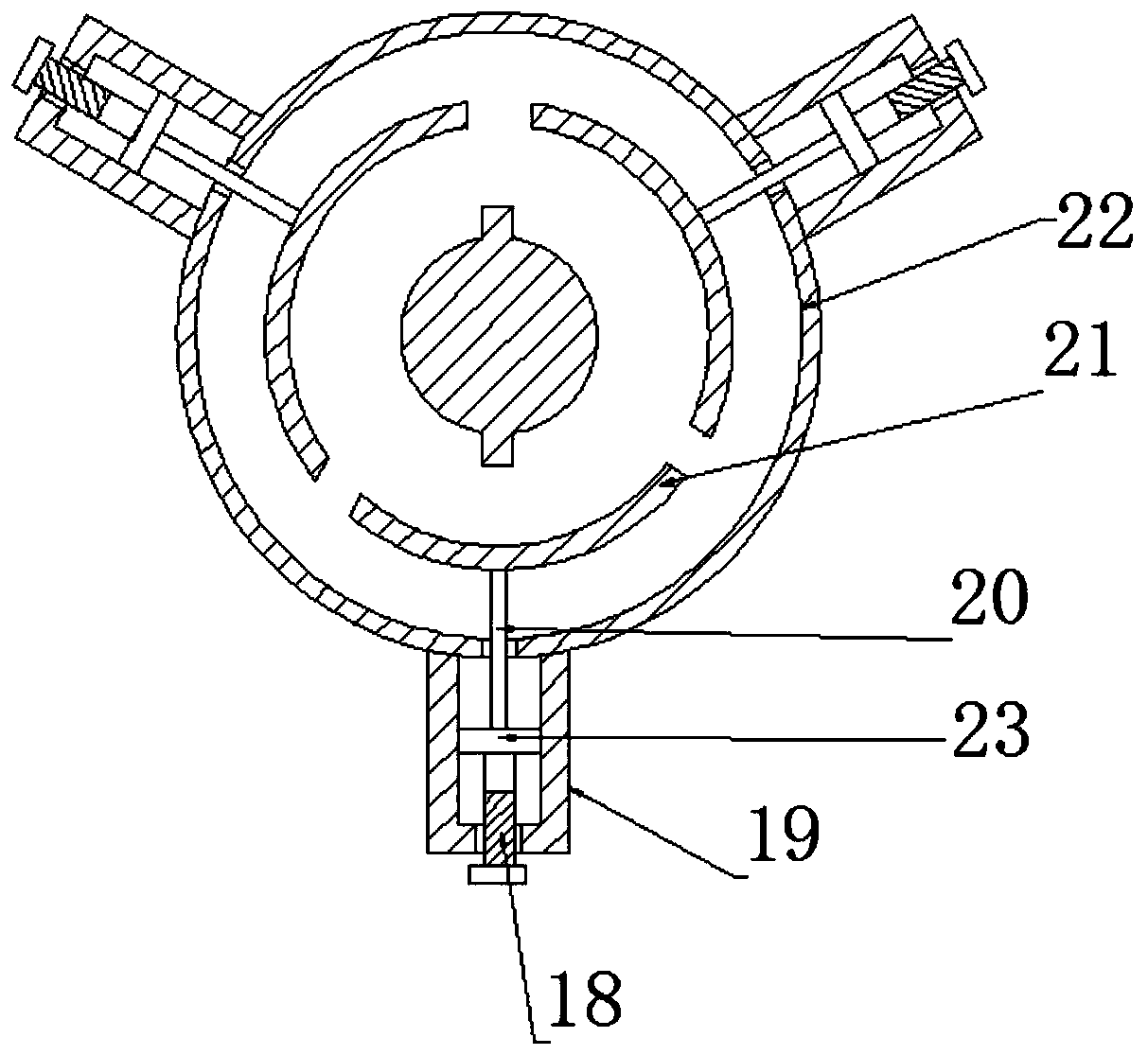

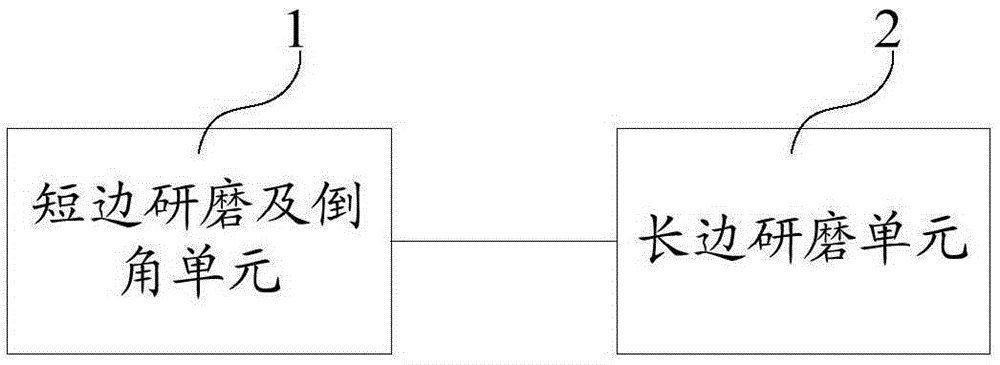

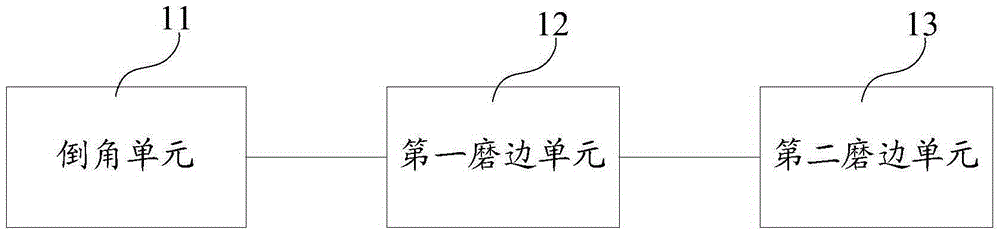

Liquid crystal display panel edge grinding machine and method for grinding liquid crystal display panel

InactiveCN105382655AImprove grinding efficiencySave sanding timeEdge grinding machinesLiquid-crystal displayEngineering

The invention provides a liquid crystal display panel edge grinding machine and a method for grinding a liquid crystal display panel. The liquid crystal display panel edge grinding machine is used for grinding the liquid crystal display panel and comprises a chamfer unit, a first edge grinding unit, a second edge grinding unit and a conveying mechanism; the liquid crystal display panel is sequentially transmitted along the chamfer unit, the first edge grinding unit and the second edge grinding unit; the chamfer unit comprises chamber rubstone which is used for carrying out chamfering and grinding on four corners of the liquid crystal display panel; and the first edge grinding unit comprises first edge grinding rubstone which is used for carrying out edge grinding on a first pair of edges of the liquid crystal display panel, and the second edge grinding unit comprises second edge grinding rubstone which is used for carrying out edge grinding on a second pair of edges of the liquid crystal display panel. According to the liquid crystal display panel edge grinding machine and the method for grinding the liquid crystal display panel, three independent grinding mechanisms are adopted, the grinding efficiency of the liquid crystal display panel can be greatly improved, and the grinding time of the liquid crystal display panel can be reduced.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

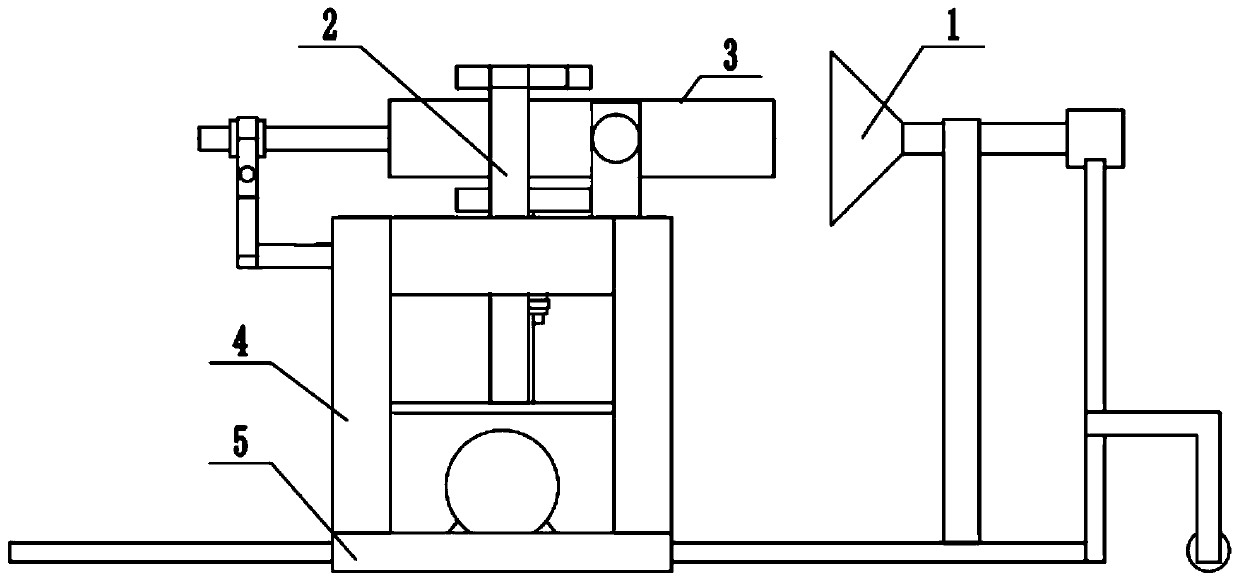

Steel pipe cutting surface polishing processing device

ActiveCN110788692APrevent slippingImprove work efficiencyEdge grinding machinesGrinding drivesElectric machineryEngineering

The invention relates to a steel pipe polishing processing device, in particular to a steel pipe cutting surface polishing processing device. The steel pipe cutting surface polishing processing devicecomprises a steel pipe polishing device, a steel pipe clamping device, a steel pipe body, a support fixing frame and a feeding device, wherein the steel pipe polishing device is fixedly installed onthe feeding device, the steel pipe body is placed on the steel pipe clamping device, the steel pipe clamping device is fixedly installed on the support fixing frame, and the support fixing frame is fixedly installed on the feeding device. According to the device, the steel pipe clamping device is arranged, and the steel pipe clamping device is fixed at multiple points, so that a steel pipe is morestable and is prevented from slipping; the device is used for automatically polishing, people only need to control a motor, and the device polishes an inner hole and an outer circle of the steel pipeat the same time, so that the working efficiency is greatly improved and the polishing time is saved; and the steel pipe clamping device is provided with a circle center aligning device, and burrs are polished in a circumferential polishing mode, so that the burrs are polished more thoroughly and uniformly.

Owner:CHANGZHOU TENGFEI STAINLESS STEEL

Rapid grinding device for hardware parts

ActiveCN107717672AQuick sandingSave sanding timeGrinding carriagesGrinding drivesEngineeringDrive motor

The invention discloses a rapid grinding device for hardware parts. The rapid grinding device comprises a supporting base, brackets, a first transverse sliding rail, a sliding block, a worktable, a second transverse sliding rail, a clamping frame, a rotating motor, a positioning frame, a stand column, a longitudinal sliding rail, a lifting sliding seat, a driving motor, a spindle box, a grinding joint, a fixed piece, a screw stepper motor, a screw, a sleeve and a connecting part. The rapid grinding device is compact in structure and convenient to use, and the screw is driven to move through the screw stepper motor, so that the sleeve is lifted, and thus the grinding joint is driven to move vertically to facilitate grinding operation; and meanwhile, workpieces are fixed and clamped throughthe clamping frame and the positioning frame, and then the workpieces are rotated through the rotating motor, so that the rotating directions of the workpieces and the rotating directions of the grinding joint are opposite, the grinding time is further reduced, the operational efficiency is improved, the high practicality is achieved, the operation effect is ensured, various different working modes are adapted, the high stability and high accuracy are achieved, and the use of manpower is effectively reduced.

Owner:卓培琨

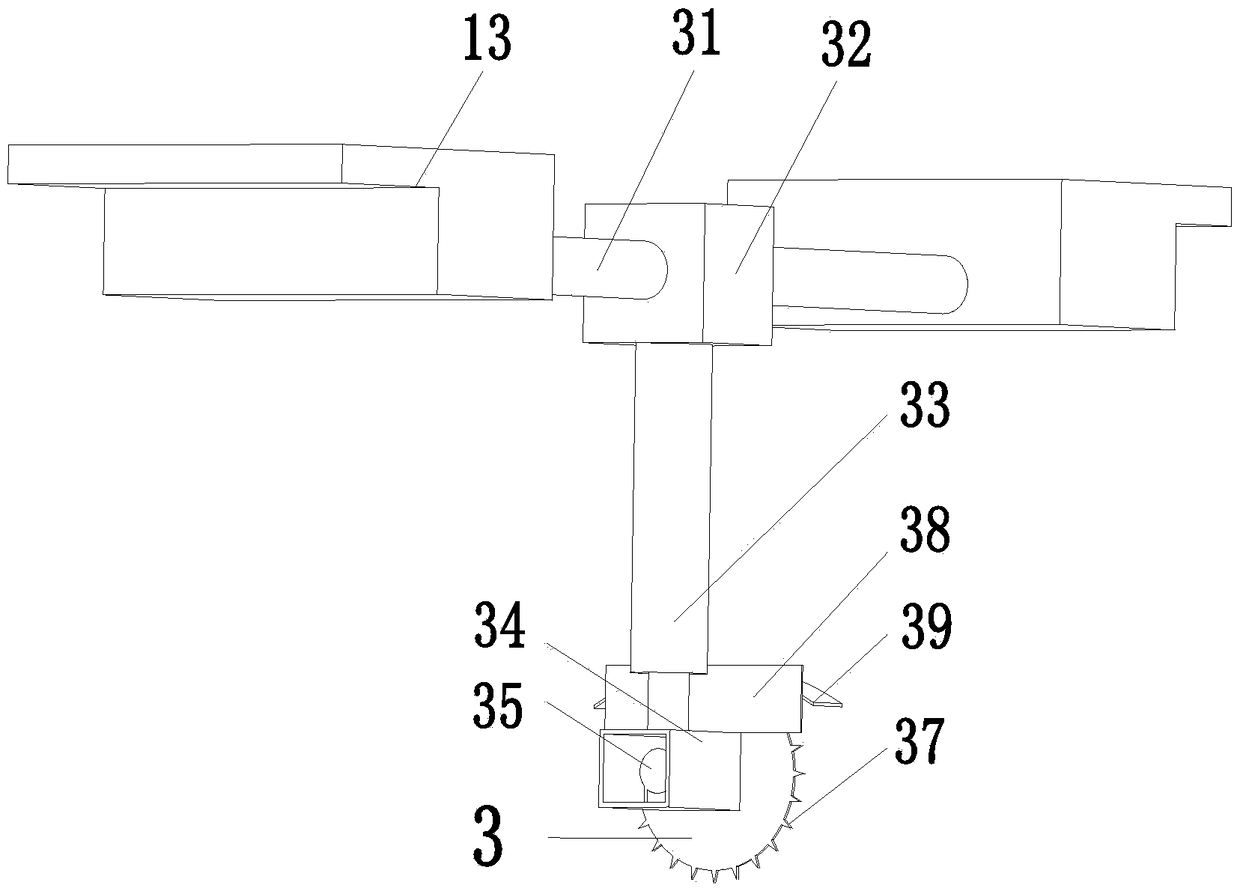

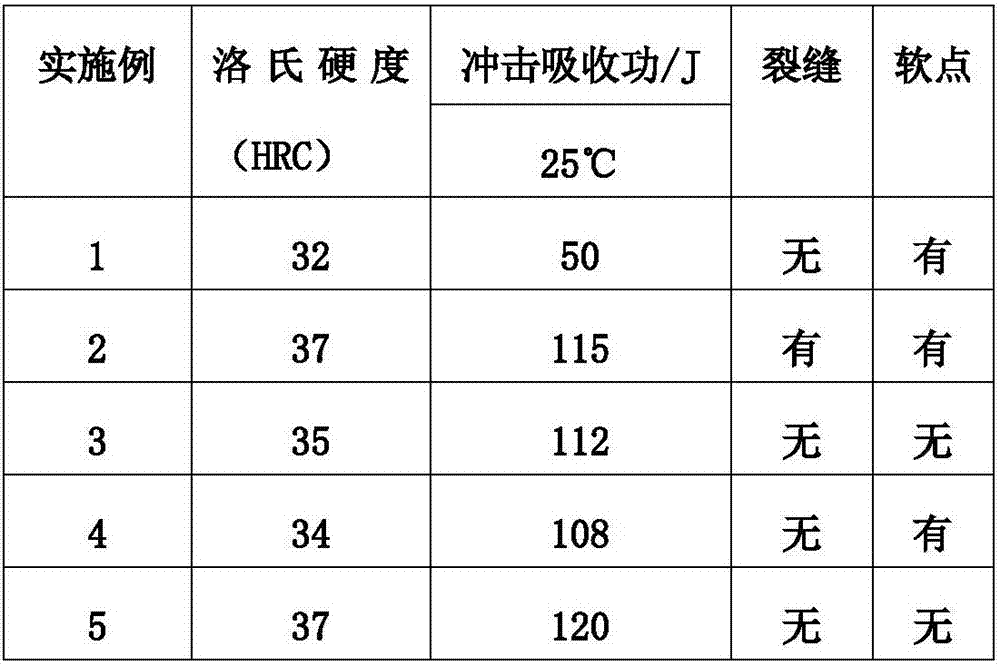

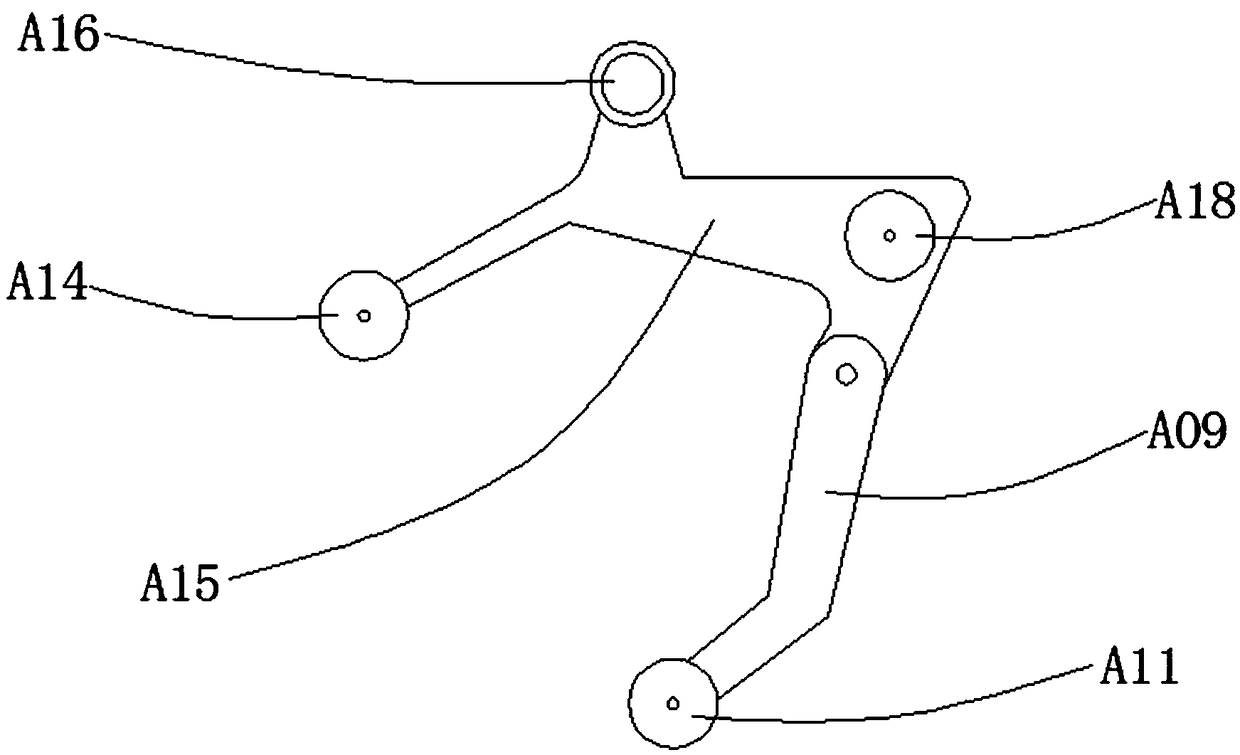

Quick-replacement grinding tool for automatic grinding by robot

ActiveCN106826546AIncrease the level of automationSave sanding timeGrinding wheel securing apparatusEngineeringDynamic balance

The invention discloses a quick-replacement grinding tool for automatic grinding by a robot. The quick-replacement grinding tool comprises a connection cone matched with an electric spindle tool clamping jaw and the like, wherein a clamping slot connected with a tool frame is located on one side of the connection cone matched with the electric spindle tool clamping jaw; a manual quick-disassembly wedge slot is located between the clamping slot connected with the tool frame as well as a rear backing plate; the connection cone matched with the electric spindle tool clamping jaw, the clamping slot connected with the tool frame and the manual quick-disassembly wedge slot are all located on a front and rear backing plate threaded rod; one end of the front and rear backing plate threaded rod penetrates through a grinding wheel to be in threaded connection with a flat nut; the rear backing plate and a front backing plate are located on two sides of the grinding wheel; an anti-loose washer is located between the front backing plate and the flat nut. With the adoption of the quick-replacement grinding tool, the grinding tool can be replaced quickly, accurately and automatically, the automation level of robot grinding is further improved, the overall structure is light in mass and small in size, the center of gravity is in the axis, the dynamic balance is good, and accordingly, the grinding tool cannot shake during high-speed rotation.

Owner:YUYI INTELLIGENT TECH SHANGHAI CO LTD

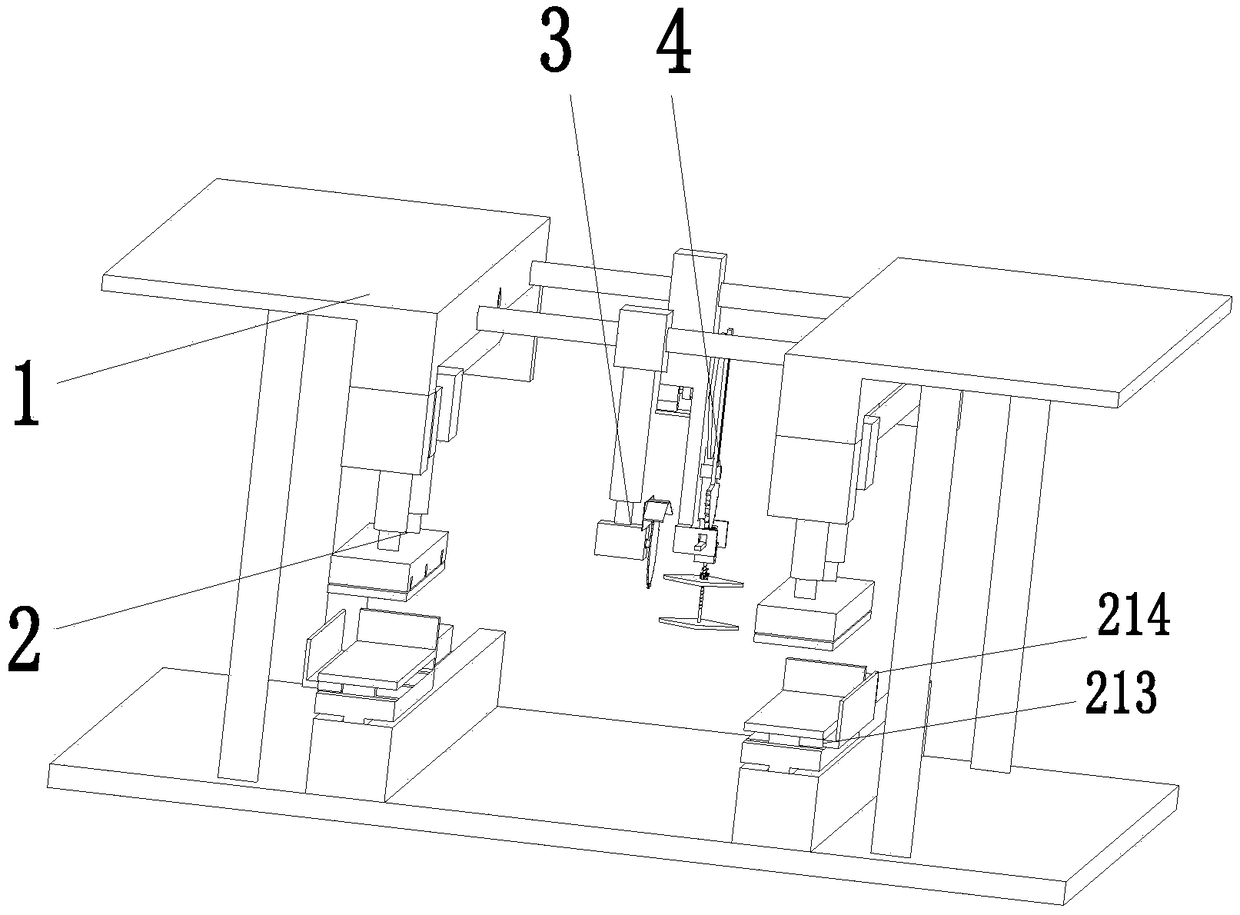

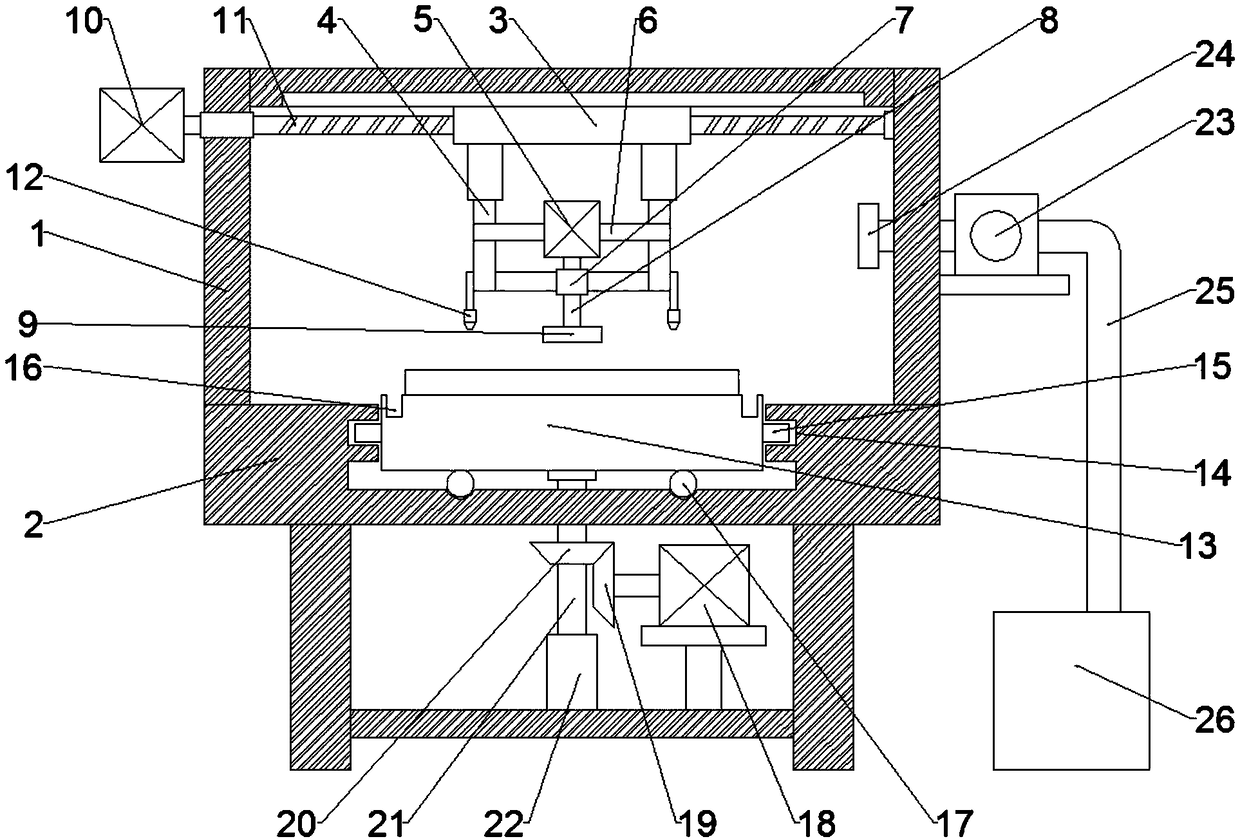

Intelligent grinding device for casting parts

InactiveCN106965064ARealize three-coordinate motionFully automatedEdge grinding machinesGrinding work supportsMechanical engineeringEngineering

The invention discloses an intelligent grinding device for casting parts. A first linear module arranged in the Z direction is mounted on a base, a second linear module arranged in the X direction is mounted on a sliding table of the first linear module, a stand column arranged in the Y direction is arranged on a sliding table of the second linear module, a third liner module arranged in the Y direction is arranged on one side of the stand column, a connecting plate is mounted on a sliding table of the third linear module, an offset swing head is arranged on the connecting plate, a grinding spindle is arranged on a swing head body of the offset swing head, and a feeding and discharging assembly is arranged on the side in the X direction of the base. Compared with the prior art, the grinding device has the beneficial effects of being high in grinding efficiency, short in grinding time, capable of ensuring product machining precision and the like.

Owner:KINHANYAN TECH DALIAN HLDG CO LTD

Concrete repairation and protection method and concrete repairation and protection structure based on asphalt materials

The invention provides a concrete repairation and protection method and a concrete repairation and protection structure based on asphalt materials. The method includes the following steps of (1) polishing damaged or pulverized portions of concrete surface until undamaged concrete is exposed; (2) evenly spraying or smearing modified emulsified asphalt emulsions onto the concrete surface according to the consumption of 0.2-0.6kg / m<2> to form a concrete surface permeation and solidification waterproof layer; (3) evenly smearing emulsified asphalt mortar with the initial extension reaching 260mm onto the concrete surface permeation and solidification waterproof layer, and controlling the thickness at 2-5mm to form an emulsified asphalt mortar protection waterproof leveling layer; (4) forming an asphalt concrete heat-insulating protection layer 2-6m in thickness on the surface of the non-solidified emulsified asphalt mortar protection waterproof leveling layer; (5) evenly spraying asphalt cement onto the surface of the asphalt concrete heat-insulating protection layer according to the consumption of 0.2-0.6kg / m<2> to form an asphalt cement waterproof anti-aging layer.

Owner:JIANGSU SOBUTE NEW MATERIALS +1

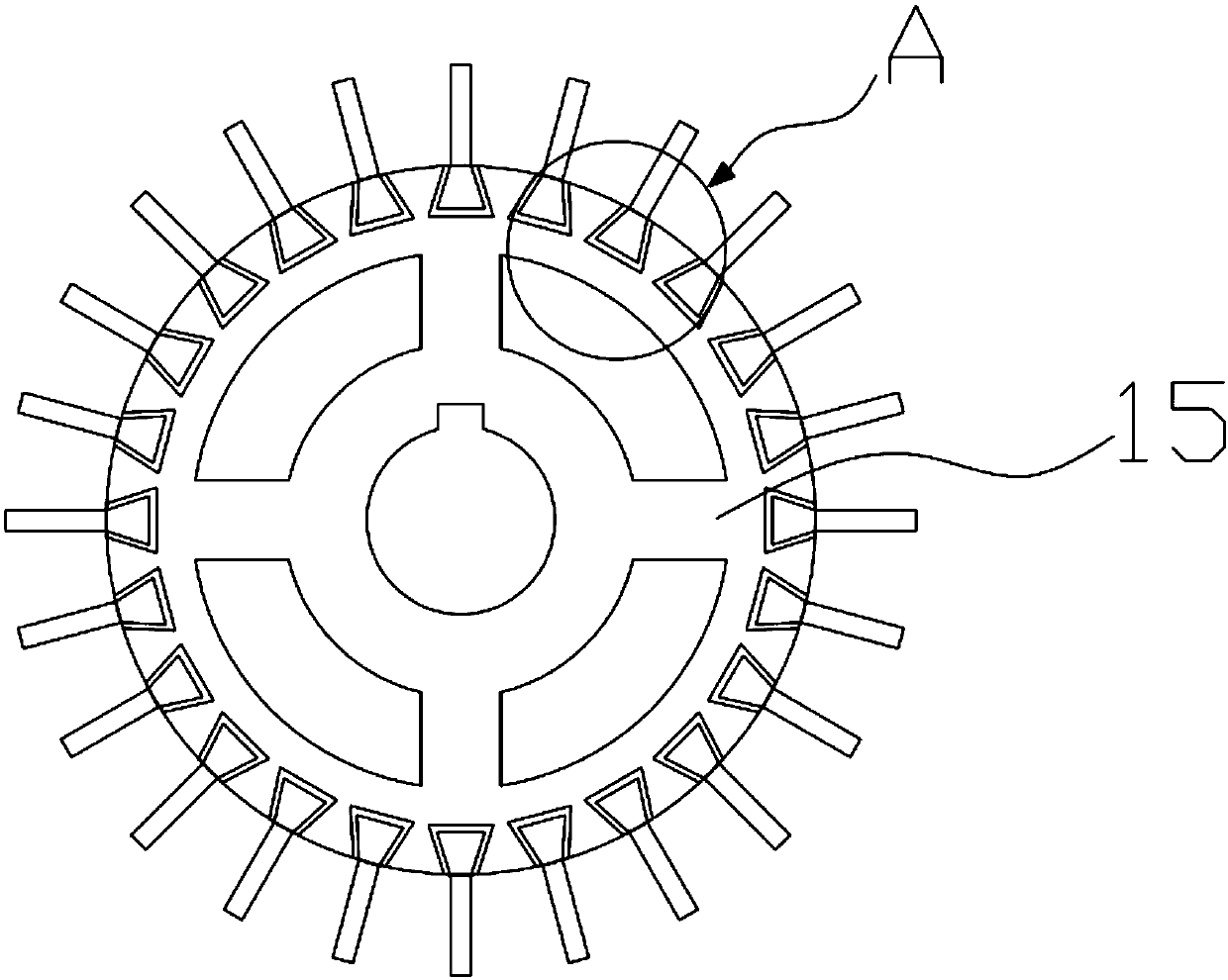

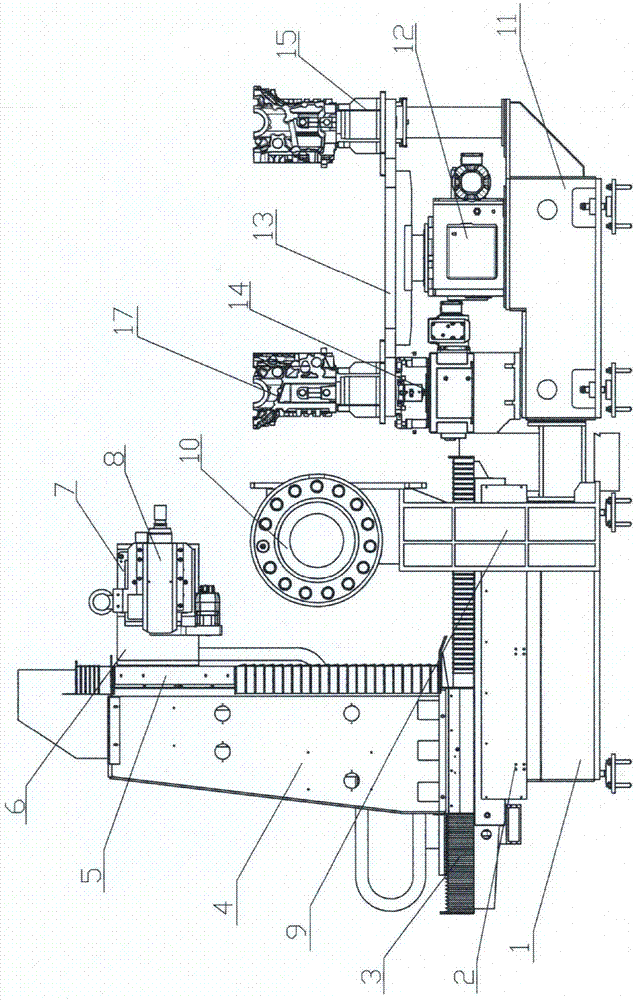

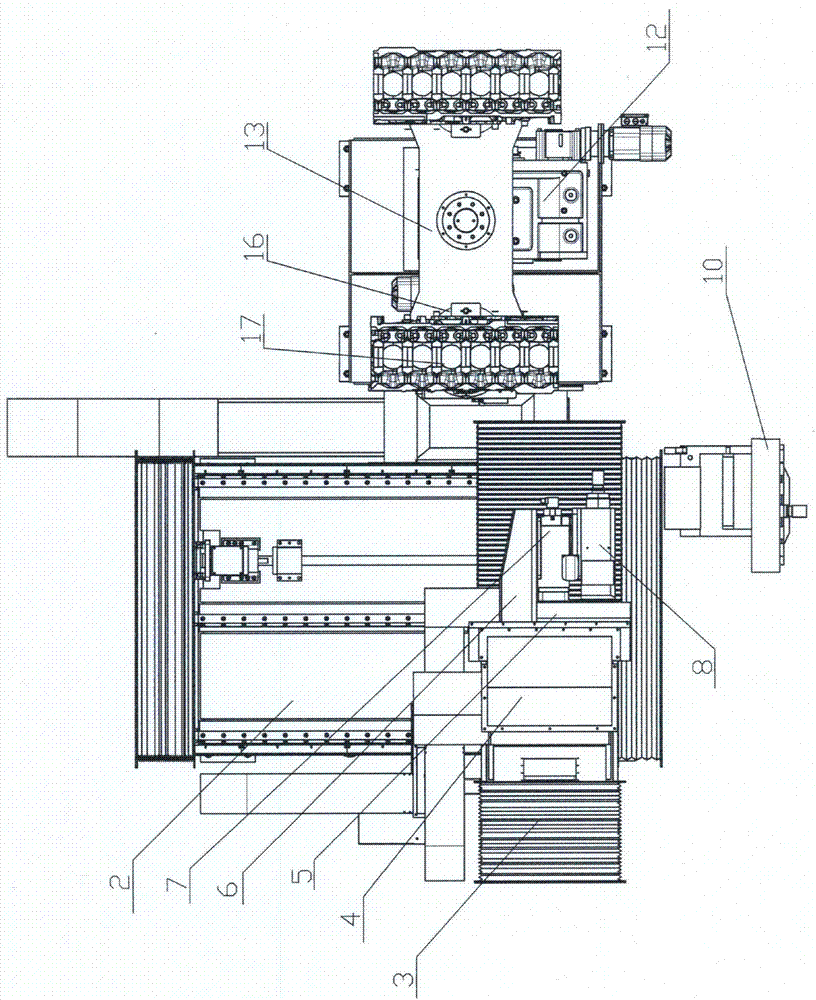

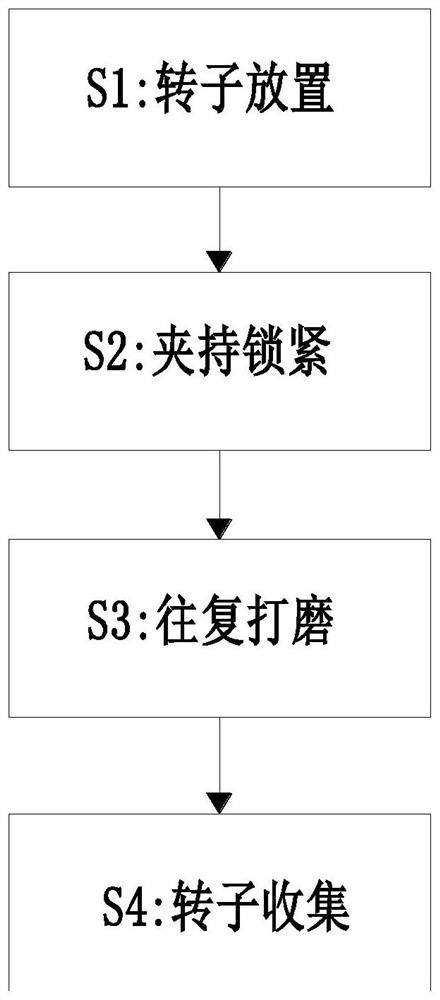

Manufacturing and processing technology for cast-aluminum rotor of three-phase asynchronous motor

InactiveCN112821689AReduce frictionReduce noise pollutionGrinding carriagesGrinding drivesCircular discThree phase asynchronous motor

The invention relates to a manufacturing and processing technology for a cast-aluminum rotor of a three-phase asynchronous motor, a manufacturing and processing device for the cast-aluminum rotor of the three-phase asynchronous motor is used, the manufacturing and processing device for the cast-aluminum rotor of the three-phase asynchronous motor comprises a bottom plate, supporting mechanisms and polishing mechanisms; the bottom plate has a circular disc structure; supporting mechanisms are symmetrically installed on the upper end face of the bottom plate, and the polishing mechanisms are installed on the supporting mechanisms. Problems that an existing cast-aluminum rotor machining device cannot stably lock and fix a cast-aluminum rotor, so that the cast-aluminum rotor is prone to shaking when end teeth are polished, and the polishing precision and the smoothness of the surface of the polished cast-aluminum rotor are affected are solved. And the problems that an existing cast-aluminum rotor machining device cannot conduct reciprocating polishing on end teeth at the two ends of the cast-aluminum rotor formed through pouring at the same time, the polishing efficiency is low, and time is wasted can be solved.

Owner:南京淘略新能源科技有限公司

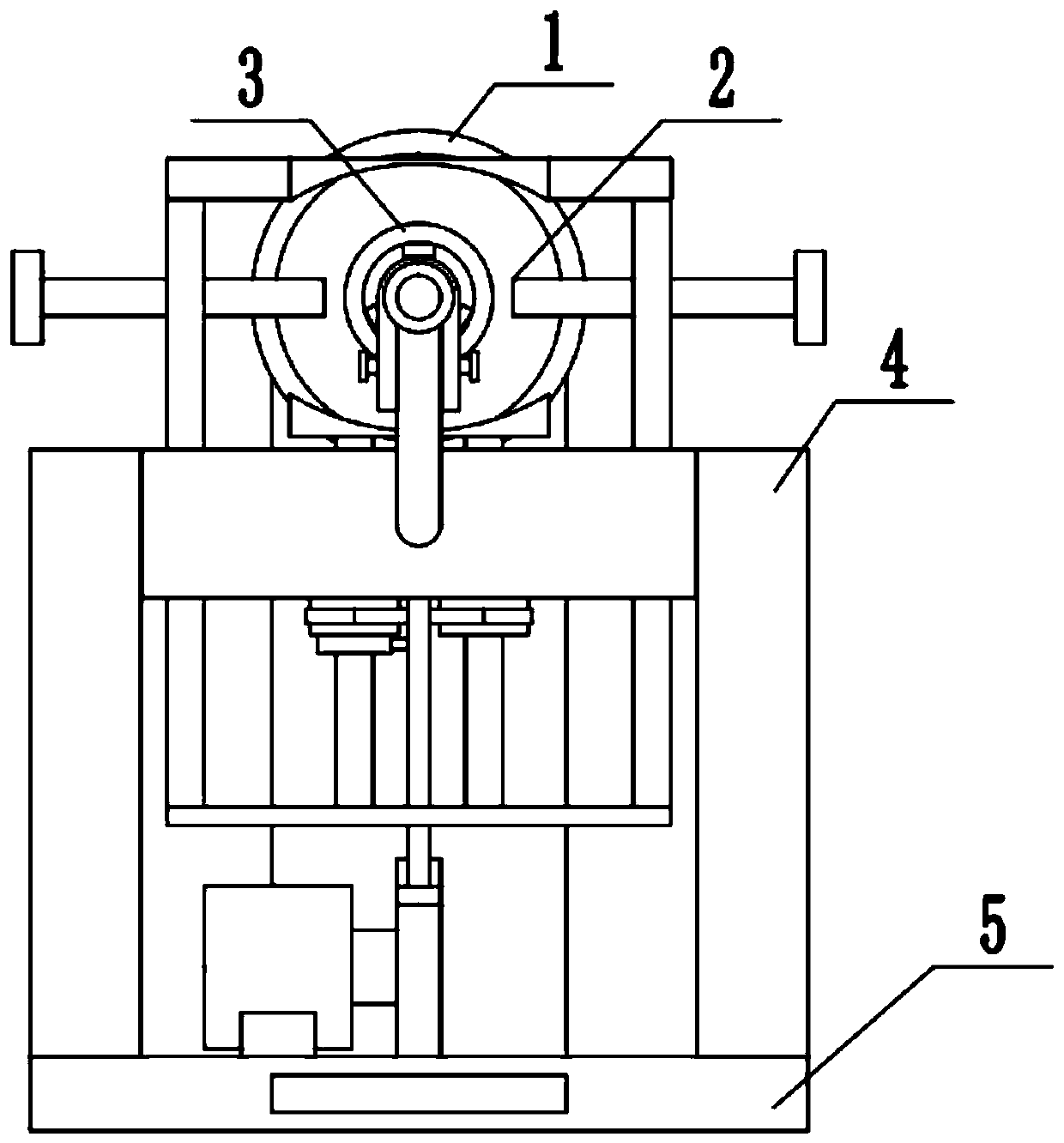

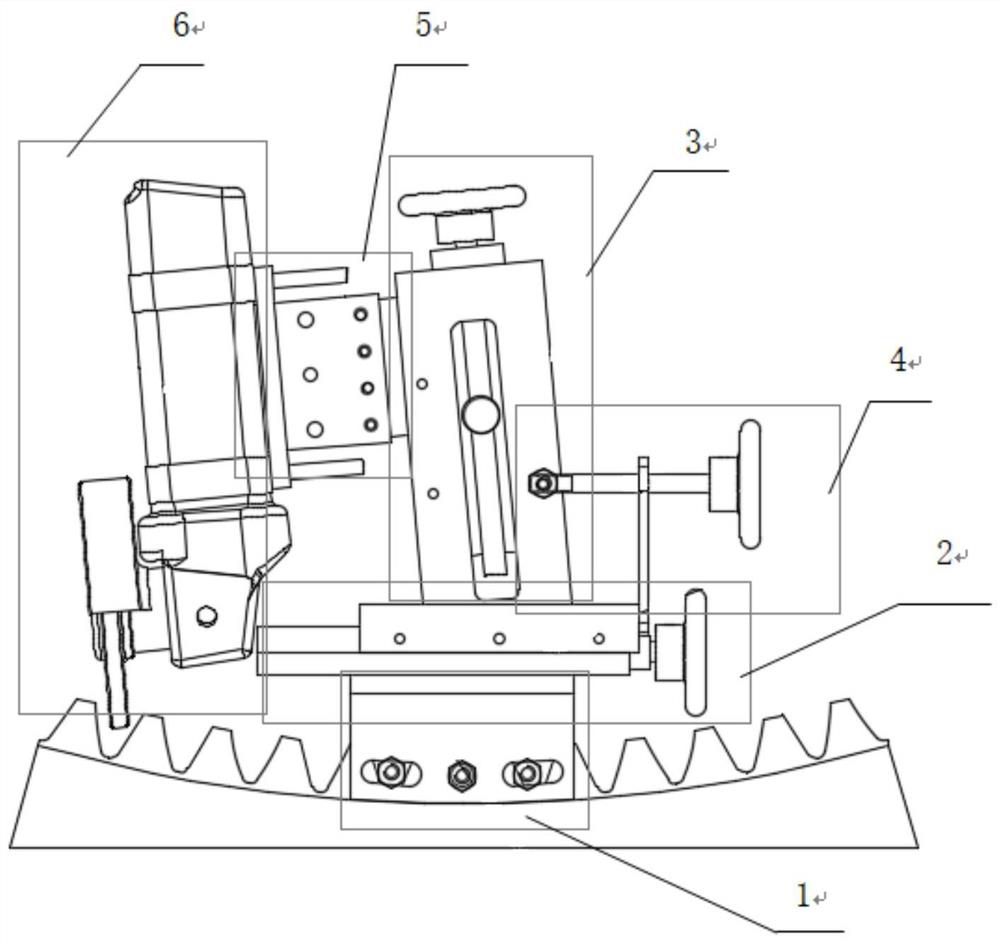

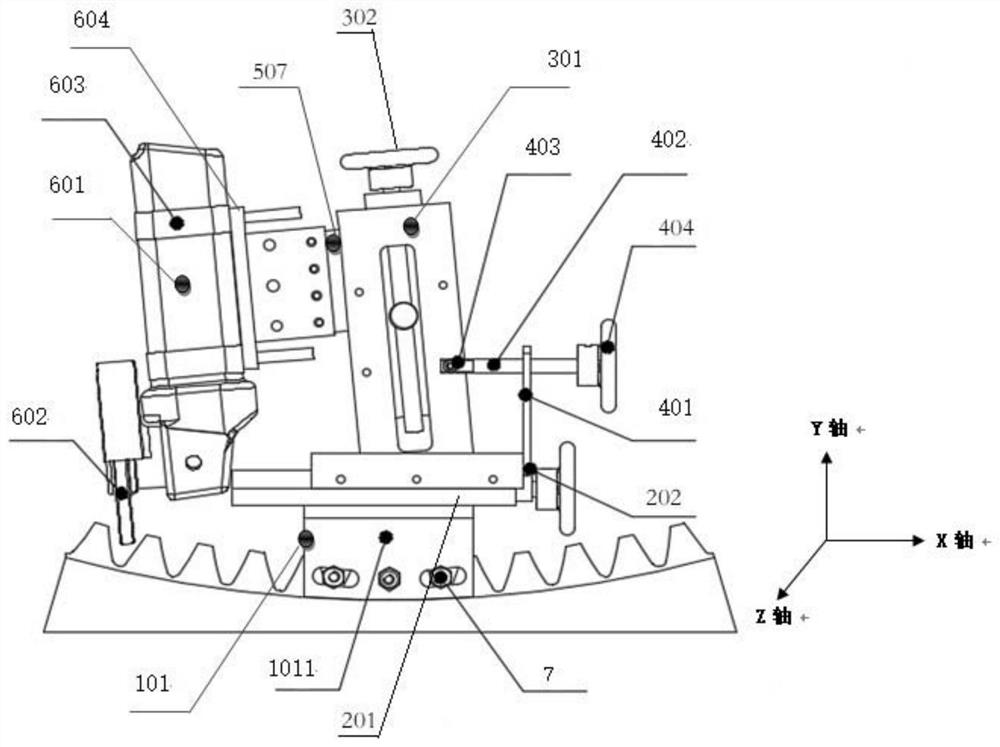

Portable three-dimensional adjustable grinding device for gear modification

PendingCN111922444ARealize real-time three-dimensional adjustmentReduce labor costsGear-cutting machinesGear teethGear wheelControl engineering

The invention provides a portable three-dimensional adjustable grinding device for gear modification. The grinding device comprises a fixing mechanism, a horizontal adjusting mechanism, an angle adjusting mechanism, a vertical adjusting mechanism, a stroke adjusting mechanism and a grinding mechanism, wherein the X-axis direction is parallel to the length direction of the horizontal adjusting mechanism; the Y-axis direction is parallel to the height direction of the vertical adjusting mechanism; and the Z-axis direction is parallel to the length direction of the stroke adjusting mechanism. According to the portable three-dimensional adjustable grinding device for gear modification, through the combination of the grinding mechanism, the stroke adjusting mechanism, the vertical adjusting mechanism, the horizontal adjusting mechanism, the angle adjusting mechanism and the fixing mechanism, the three-dimensional adjustment in the grinding process of a gear is achieved, the grinding deviceis suitable for gear tooth grinding in various working environments, the labor cost is saved, and the grinding time is reduced.

Owner:清研先进制造产业研究院(洛阳)有限公司 +2

Ceiling face and wall face putty scraping device with automatic supplying and residual slurry automatic recovery functions

InactiveCN108797959AWith automatic uniform feeding functionNo pollution in the processBuilding constructionsRubber ringSlurry

The invention discloses a ceiling face and wall face putty scraping device with automatic supplying and residual slurry automatic recovery functions. The ceiling face and wall face putty scraping device is constituted by a feeding pipe connector, a movable nut, locking nuts, an outer cavity slurry distributing pipe, supporting plate ribs, a scraping plate, an inner cavity slurry guiding pipe, sealing rubber rings, a fixing ring, a plugging head, a recovery pipe connector, a steel wire hose, a branch pipe and a hard pipe. The ceiling face and wall face putty scraping device mainly can be used for ceiling face putty scraping decoration construction, and can also be used for inner and outer wall face construction, the scraping face is wide, the speed is high, residual slurry generated duringscraping can be automatically recovered, flatness and straightness of the construction work surface process can be achieved, the ground is not polluted, the grinding time is reduced, the area of 120-250 square meters or above of the ceiling face can be scraped per hour, and construction through the ceiling face and wall face putty scraping device can be equivalent to construction through manpowerof 4-6 or more workers; and the ceiling face and wall face putty scraping device can overcome the defects and fill the blank of an existing putty scraping decorative technology and tool, manpower is saved, and the efficiency and quality are improved.

Owner:应鸽龙

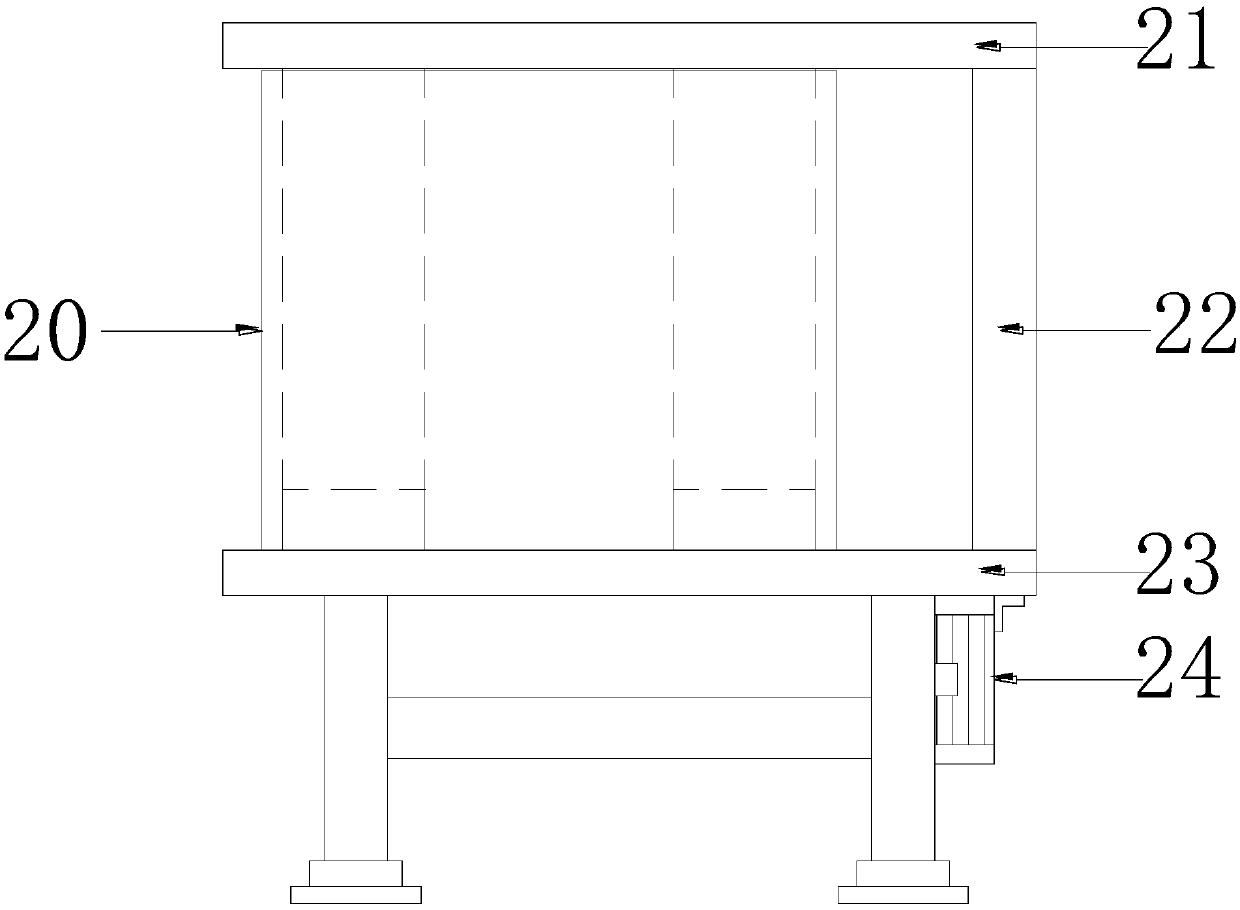

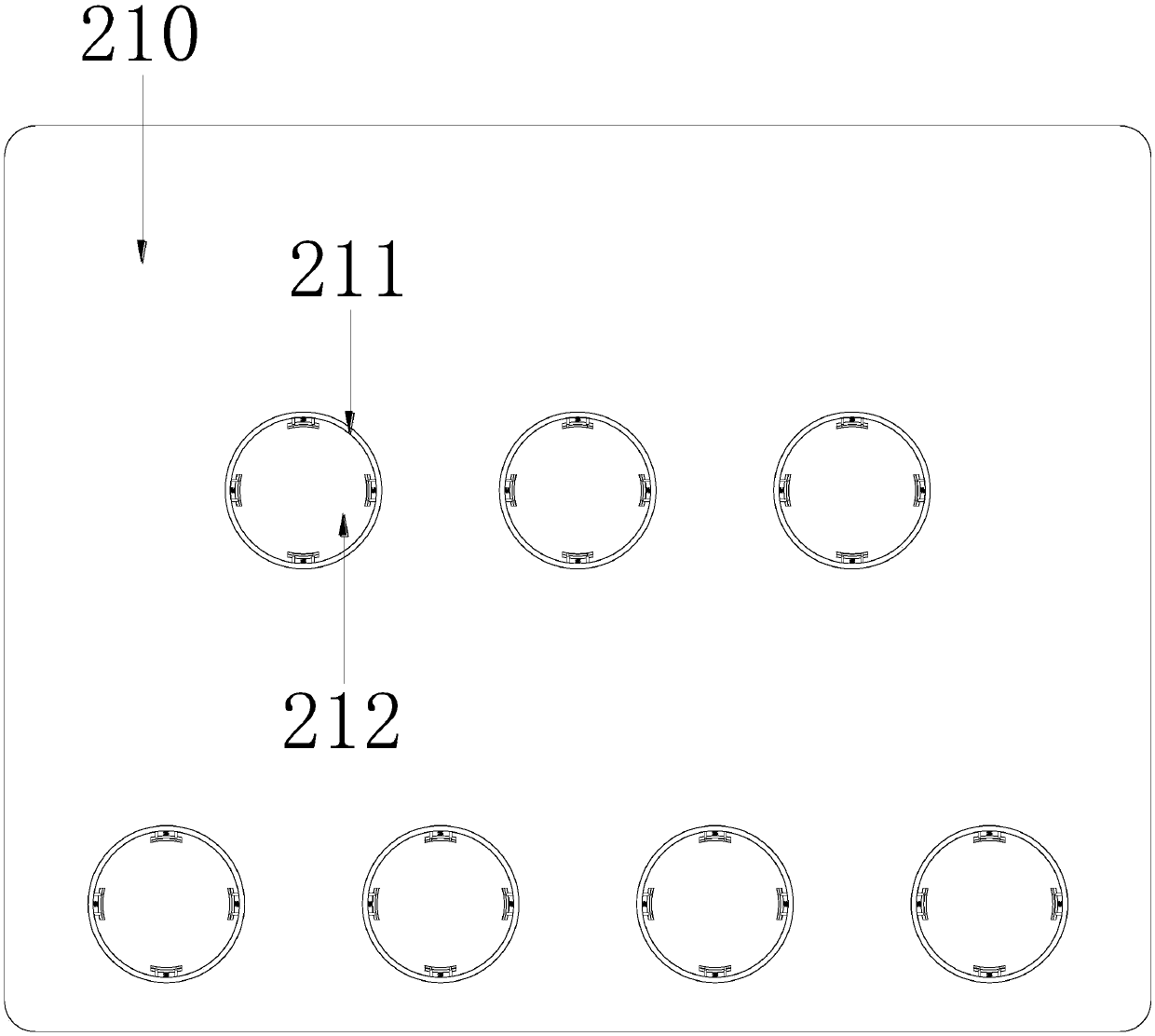

Efficient polishing machine applicable to cylindrical vacuum cup for rapid polishing

ActiveCN109514404APlay the role of guide limitAvoid misalignmentGrinding drivesBelt grinding machinesEngineeringMechanical engineering

The invention discloses an efficient polishing machine applicable to a cylindrical vacuum cup for rapid polishing. The efficient polishing machine structurally comprises the vacuum cup, a polishing machine body, supporting feet and a fastening connection plate. The four corners of the polishing machine body are perpendicularly connected with the supporting feet, the supporting feet are connected together through the fastening connection plate, and the vacuum cup is placed on the polishing machine body. Compared with the prior art, the efficient polishing machine has the beneficial effects thatby means of combined arrangement of a grinding abrasive belt, a top plate, a telescopic dustproof plate, a base and an efficient energy saving motor, by means of ingenious layout of a rotary clampingring and a rotary cup placing tray, the grinding abrasive belt makes contact with multiple guide wheels 232c to be of an S-shaped structure, the grinding abrasive belt can make large-area contact with the outer wall of the vacuum cup, the polishing contact face is increased, polishing time is reduced, the polishing efficiency can be improved, multiple vacuum cups can be polished at a time, and working efficiency is further improved.

Owner:莆田市城厢区诺林贸易有限公司

High-efficiency marble polishing equipment

InactiveCN109079630ASave sanding timeImprove grinding efficiencyGrinding carriagesGrinding work supportsWorking environmentEngineering

The invention discloses high-efficiency marble polishing equipment. The high-efficiency marble polishing equipment comprises a support, a workbench and a sliding sleeve, wherein the workbench is arranged at a lower end of the support, a sliding sleeve is arranged on the workbench, a lead screw sleeves the sliding sleeve, a left end of the lead screw is connected with a servo motor, and hydraulic rods are symmetrically arranged at a lower end of the sliding sleeve. When the equipment is used, marble to be polished is placed at an upper end of a rotation base, a speed reduction motor is started,a driving bevel gear is rotated, a driven bevel gear is driven to rotate, so that a support rod is rotated, the rotation base is rotated, the marble and a polishing head move relative to each other,the polishing time is reduced by a such design, and the polishing efficiency is improved; when the rotation base is rotated, a ball rotates and is used for supporting the rotation base, so that the rotation base is stably rotated, surface smoothness of the marble is maintained, and the phenomenon that a polishing surface is uneven is prevented; and an exhaust fan is started, floating dust generated by polishing is pumped to a dust collection groove, the floating dust pervaded into the air is reduced, so that the pollution of a working environment is reduced.

Owner:胡以宽

External transition belt grinding device for end upsetting of steel pipe

InactiveCN102962750ASave sanding timeImprove stabilityGrinding machinesGrinding/polishing safety devicesHigh volume manufacturingEngineering

The invention discloses an external transition belt grinding device for end upsetting of a steel pipe, belonging to the field of drilling equipment. The external transition belt grinding device comprises a lifting rotation roll, a grinding device, an adjusting device, guiderails and a dust collection box, wherein the dust collection box is an open box body, the adjusting device is fixedly arranged on the side surface of the dust collection box, the lifting rotation roll which is isolated from the dust collection box is arranged on the other side of the dust collection box opposite to the adjusting device, the guiderails are arranged on the upper surfaces of another two side walls of the dust collection box and provided with the grinding device. In use, the external transition belt grinding device is fast in grinding speed, high in production efficiency, simple and effect in structure, convenient to operate, safe and reliable to use, stable to run, excellent in performance, convenient to maintain, suitable for large-batch production and grinding, and long in service life.

Owner:CNPC BOHAI EQUIP MFG +1

Multi-direction component grinding device

InactiveCN108356634ASave sanding timeImprove grinding efficiencyEdge grinding machinesGrinding carriagesEngineeringGrinding wheel

The invention discloses a multi-direction component grinding device. The multi-direction component grinding device comprises a base. A first bearing is clamped and connected to the upper surface of the base. A first rotation shaft is in cup joint to the inner surface of the first bearing. The top end of the first rotation shaft and the lower surface of a carrying plate are fixedly connected. The upper surface of the base is fixedly connected with the lower surfaces of first supporting plates. The two first supporting plates are arranged, and the upper surfaces of the two first supporting plates and the lower surface of a transverse plate are fixedly connected. According to the multi-direction metal component grinding device, through mutual cooperation of second motors, grinding wheels, second fixing plates, sliding rods, sliding sleeves, springs, a top plate, an extrusion block, a first supporting rod, a second supporting rod, a rotation disc, a first motor, electric push rods, a second supporting plate, third fixing plates, a third motor, a second rotation shaft, an extrusion plate, the first rotation shaft and the carrying plate, a metal component is ground in an all-direction manner, accordingly, the grinding time is shortened, and the grinding efficiency is improved.

Owner:JIANSHI CHUYU PRECISION CASTING

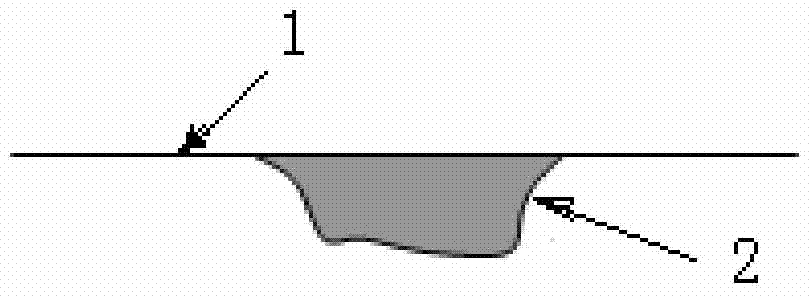

Repairing method for supporting roller of plate and strip rolling mill

The invention discloses a dish-shaped pit repairing method for a supporting roller of a rolling mill. The method includes the following steps that (1) an ultrasonic flaw detection mode is used for confirming the roller body crack range and depth, or the contact fatigue flaking range and depth or the collision flaw range and depth of the supporting roller of the rolling mill; (2) according to the roller body flaw position of the supporting roller of the rolling mill, a grinding machine and a polishing machine are used for conducting manual polishing treatment, a polished pit in a treated face is repaired to be in a bowl shape or in a dish shape, and due to the depth of the bowl-shaped pit or the depth of the dish-shaped pit, the purpose that flaws are eliminated or the flaws are controlled in an unstressed safe area can be achieved; (3) dye penetrant inspection is further matched in the polishing process, and it is guaranteed that the flaws can be completely polished or controlled in the unstressed safe area; (4) the position between the treated face and an adjacent plane or an adjacent curved surface is polished into a smooth transition circular arc; (5) grinding machining is conducted on a grinding machine; (6) the transition circular arc arranged between the treated face and the adjacent plane or the adjacent curved surface is treated again. The grinding amount of the supporting roller is reduced, the repairing efficiency is improved, grinding wheel consumption is reduced, and the use and maintenance cost of the supporting roller is lowered.

Owner:JIGANG GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com