Back-chipping-free double-wire submerged arc welding method of pipe-shaped structure

A tubular structure, submerged arc welding technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of large labor consumption, large flux consumption, irregular grooves, etc., to reduce labor intensity and environmental pollution , The effect of improving the internal quality of welding, saving time and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

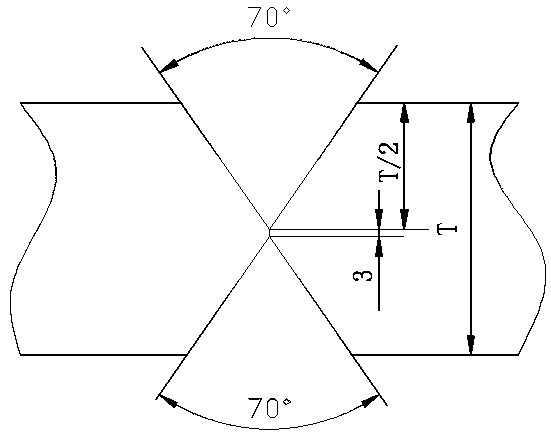

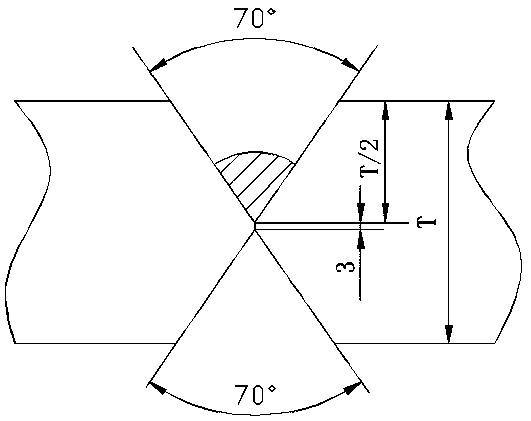

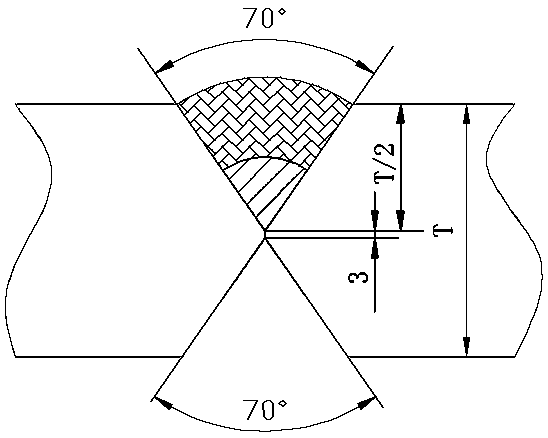

[0017] Embodiment 1: Referring to the accompanying drawings, a double-wire submerged arc welding method without root cleaning for a tubular structure is used to weld the longitudinal seam and the circumferential seam of a thin plate with a thickness of 25 mm, including beveling, rolling the cylinder, preheating, and root welding , weld filling cover and weld quality inspection, including:

[0018] a. Beveling: grooves are made on the inner and outer sides of the welds at both ends of the steel plate, the inner and outer grooves are 35° one-way grooves, and the blunt edge between the inner groove and the outer groove is 3mm. The depth of the inner groove is 12.5mm, and the depth of the outer groove is 9.5mm;

[0019] b. Coiled cylinder: roll the steel plate that has been beveled according to the diameter of the cylinder. After rolling, the butt joints of the cylinder formed are seamless and tight, and a V-shape with an angle of 70° is formed at the inner and outer grooves. wel...

Embodiment 2

[0024] Embodiment 2: Referring to the accompanying drawings, a double-wire submerged arc welding method without root cleaning for a tubular structure is used to weld the longitudinal seam and the circumferential seam of a thin plate with a thickness of 25mm, including beveling, rolling the cylinder, preheating, and root welding , weld filling cover and weld quality inspection, including:

[0025] a. Beveling: grooves are made on the inner and outer sides of the welds at both ends of the steel plate, the inner and outer grooves are 35° one-way grooves, and the blunt edge between the inner groove and the outer groove is 3mm. The depth of the outer groove is 12.5mm, and the depth of the inner groove is 9.5mm;

[0026] b. Coiled cylinder: roll the steel plate that has been beveled according to the diameter of the cylinder. After rolling, the butt joints of the cylinder formed are seamless and tight, and a V-shape with an angle of 70° is formed at the inner and outer grooves. weld...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com