Quick-replacement grinding tool for automatic grinding by robot

A robotic and automatic technology used in grinding machine parts, manufacturing tools, devices for fixing grinding wheels, etc., to achieve the effect of small size, saving grinding time and good dynamic balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

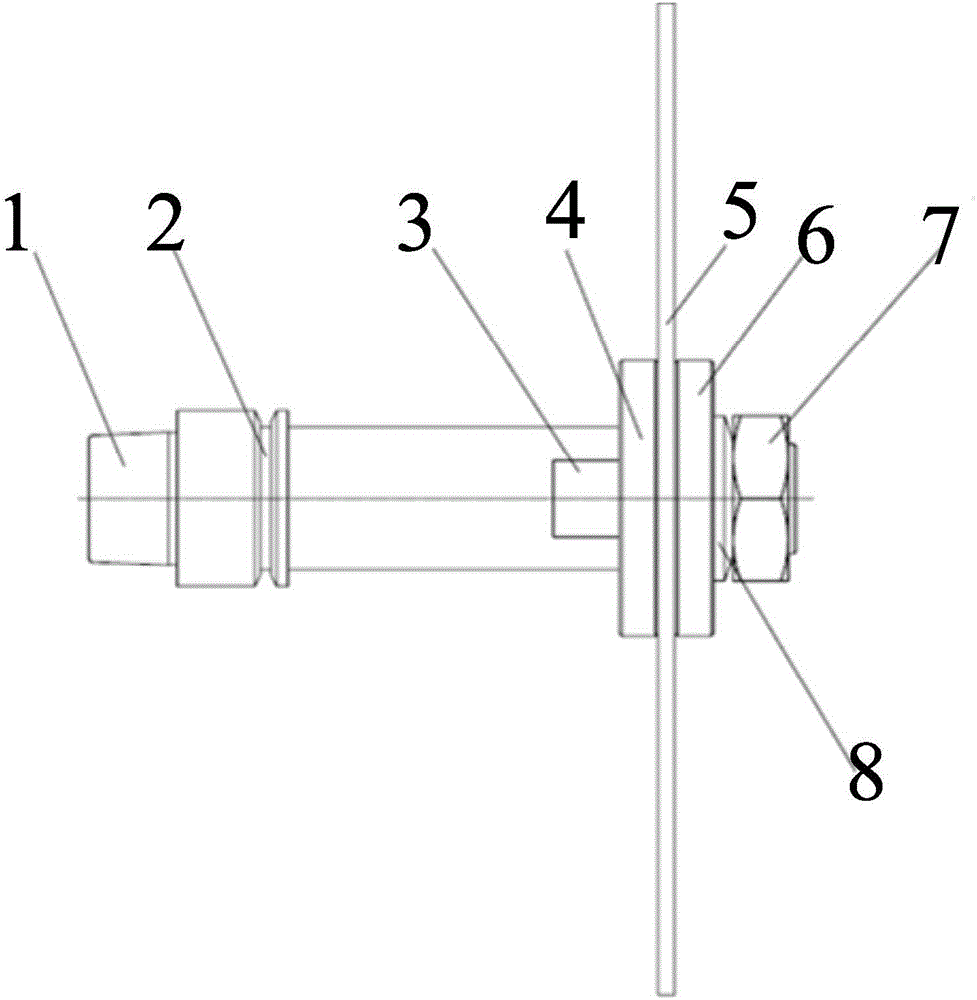

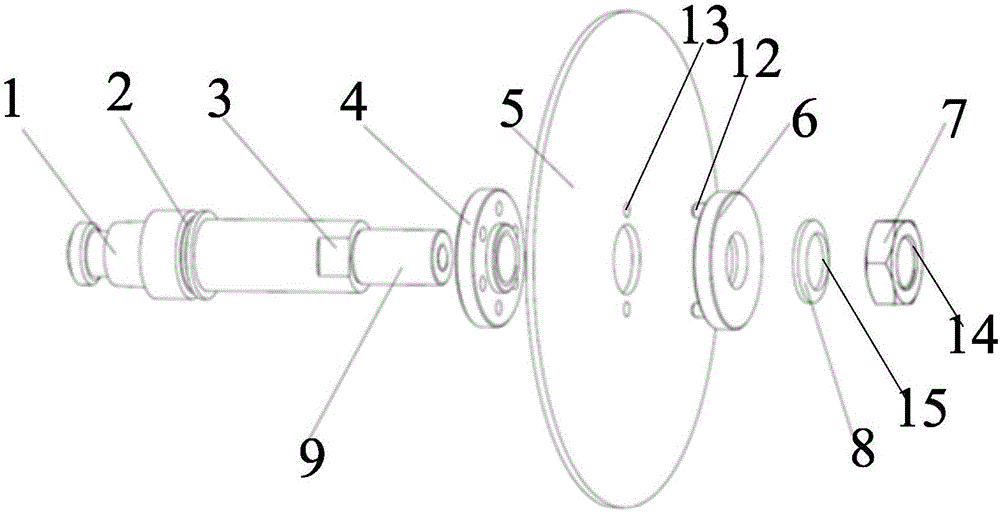

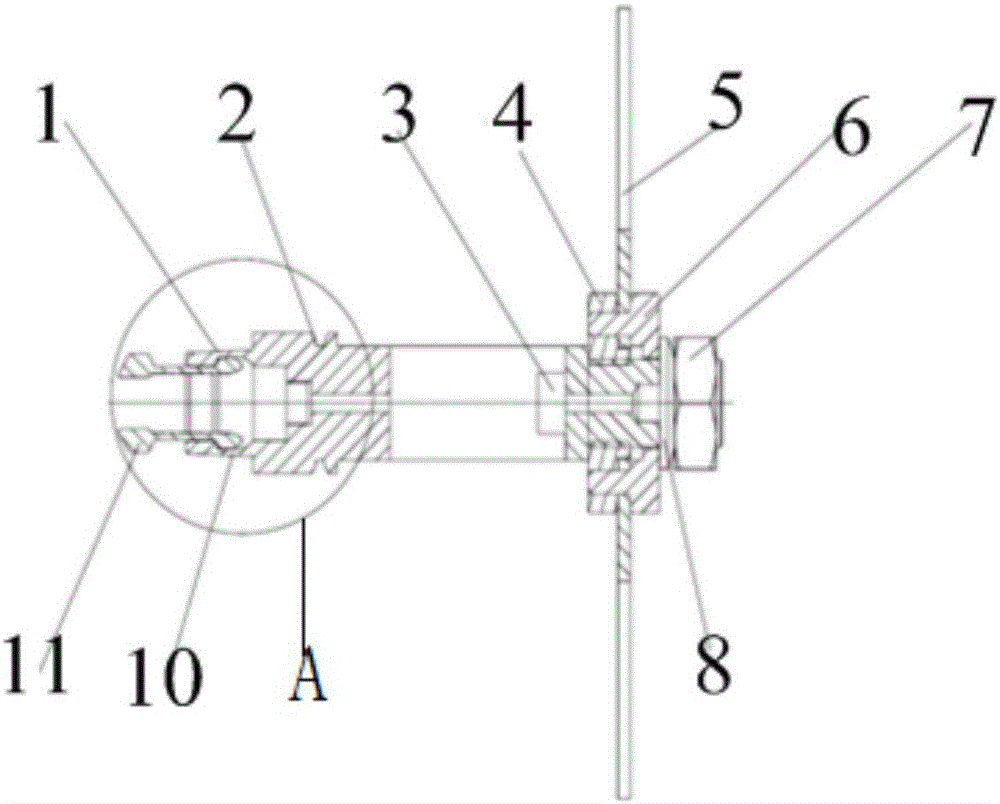

[0020] Such as Figure 1 to Figure 4 As shown, the quick-change abrasive tool for robot automatic grinding of the present invention includes a connecting taper surface 1 that cooperates with the claw of the electric spindle, a card slot 2 connected with the tool holder, a manual quick-release wedge groove 3, and a back plate 4 , grinding wheel sheet 5, front back plate 6, thin nut 7, lock washer 8, front and rear back plate threaded rod 9, the card slot 2 connected with the tool holder is located on one side of the connecting taper surface 1 matched with the claw of the electric spindle On the side, the manual quick release wedge groove 3 is located between the card slot 2 connected with the tool holder and the back plate 4, the connecting taper surface 1 matched with the claw of the ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com