Patents

Literature

32results about How to "Good dynamic balance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

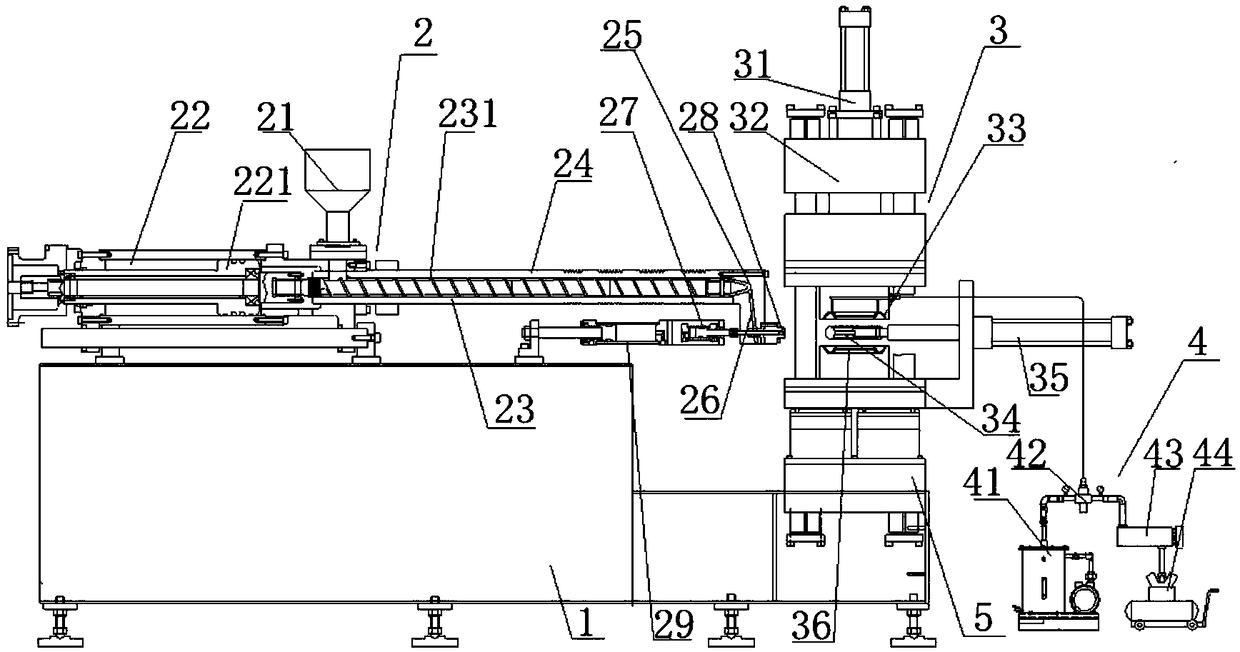

Rubber product one-step injection, hollowing and vulcanization forming production method

The invention discloses a rubber product one-step injection, hollowing and vulcanization forming production method, which belongs to the technical field of rubber product processes. By adopting the rubber product one-step injection, hollow and vulcanization forming production method, the injection, hollowing and vulcanization procedures can be completed in a same mold cavity, the mold cavity comprises an upper half mold, a lower half mold and a mold core, the mold core sets a foundation for the hollowing of the mold cavity, after the hollowing, the condition for introducing the high-temperature high-pressure gas for the vulcanization can be satisfied, the injection molding, hollowing and vulcanization apparatus can be integrated, the heat loss caused by the procedure circulation and the procedure circulation cost in the prior art can be avoided, and the traditional defects of the traditional rubber product production process such as re-pressurizing, heating, energy consumption, time consumption and high cost can be solved.

Owner:东营睿港招商服务有限责任公司

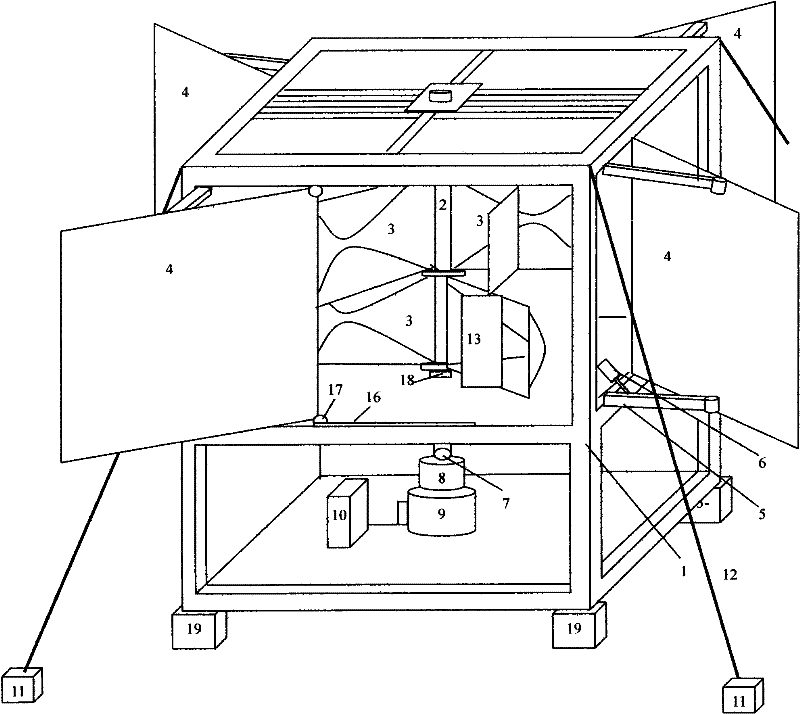

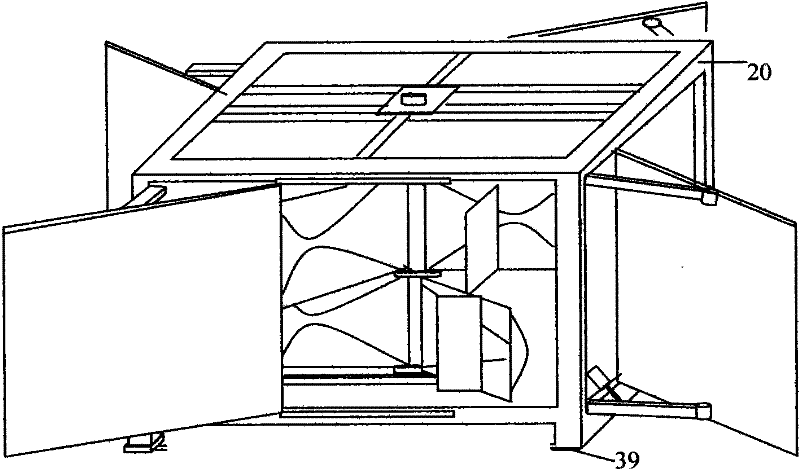

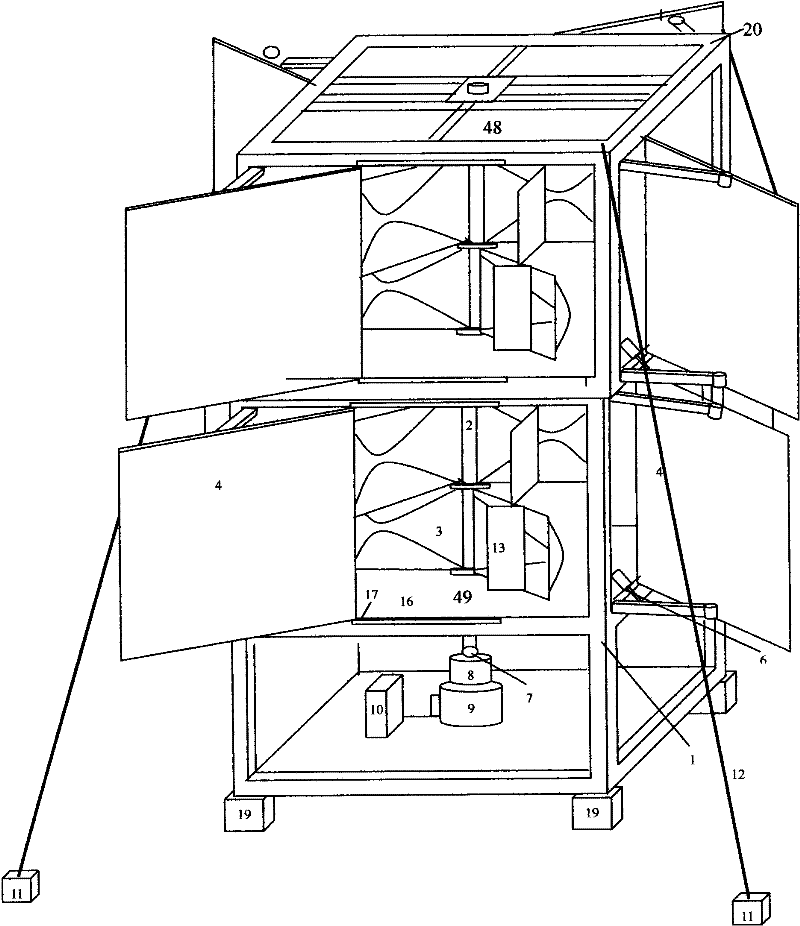

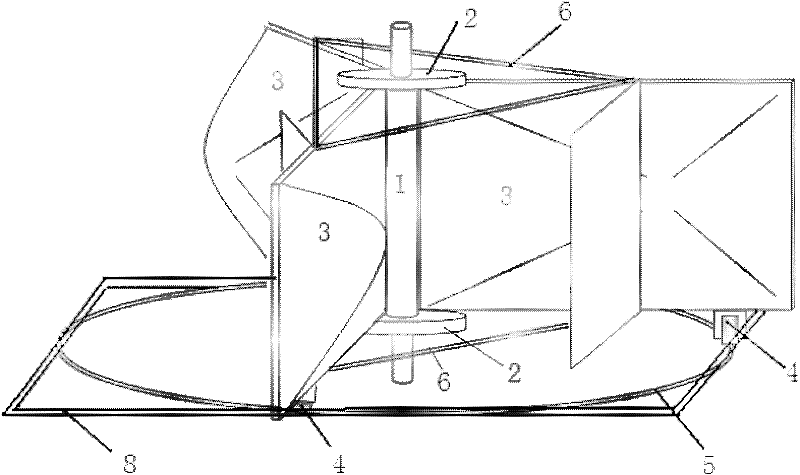

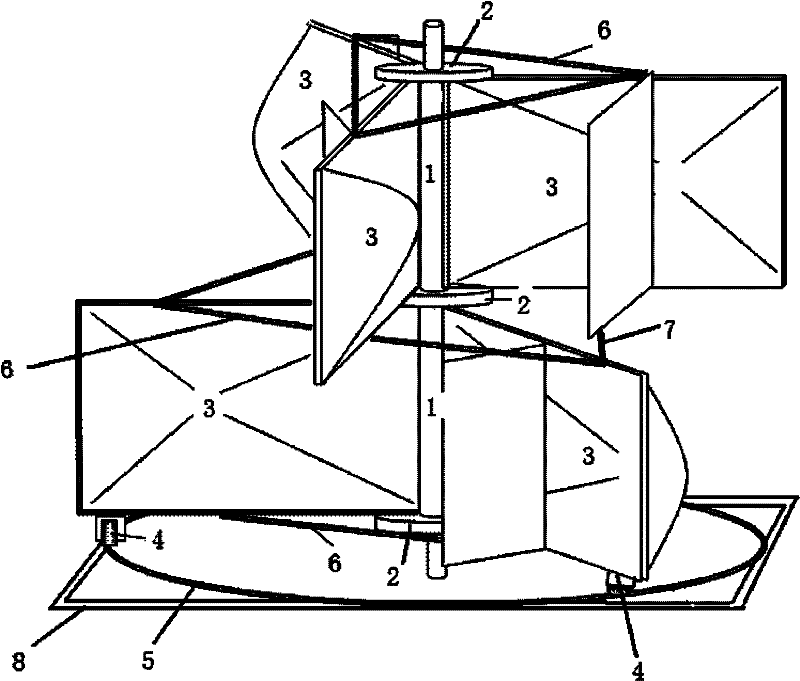

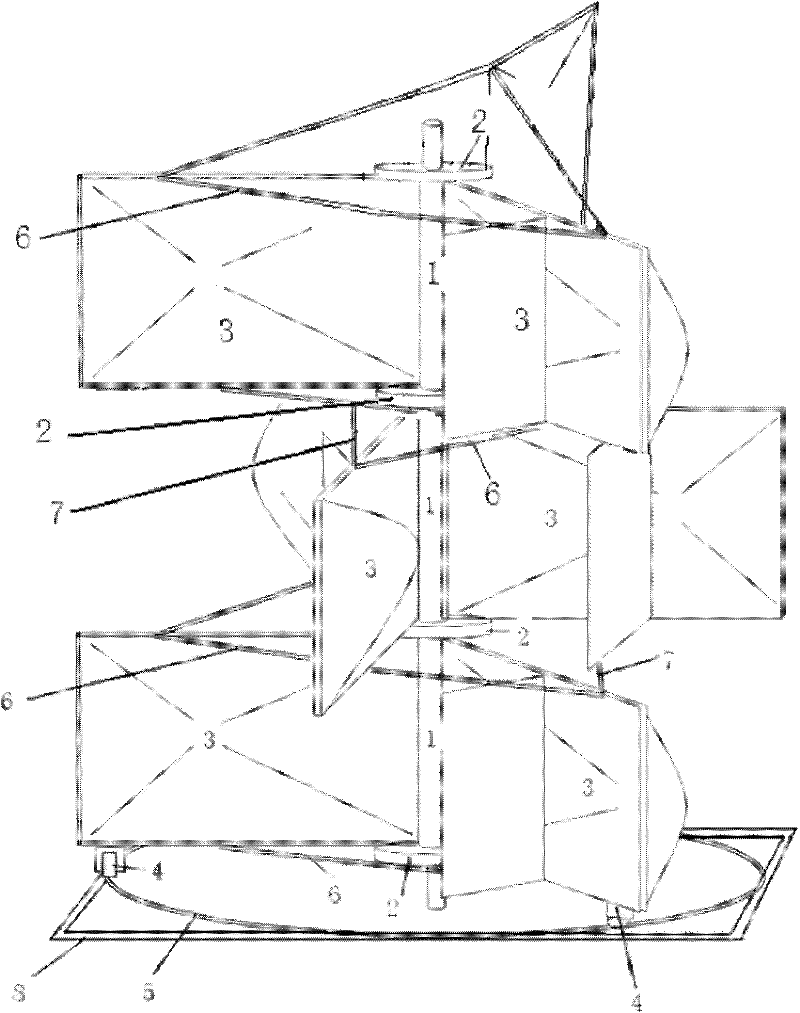

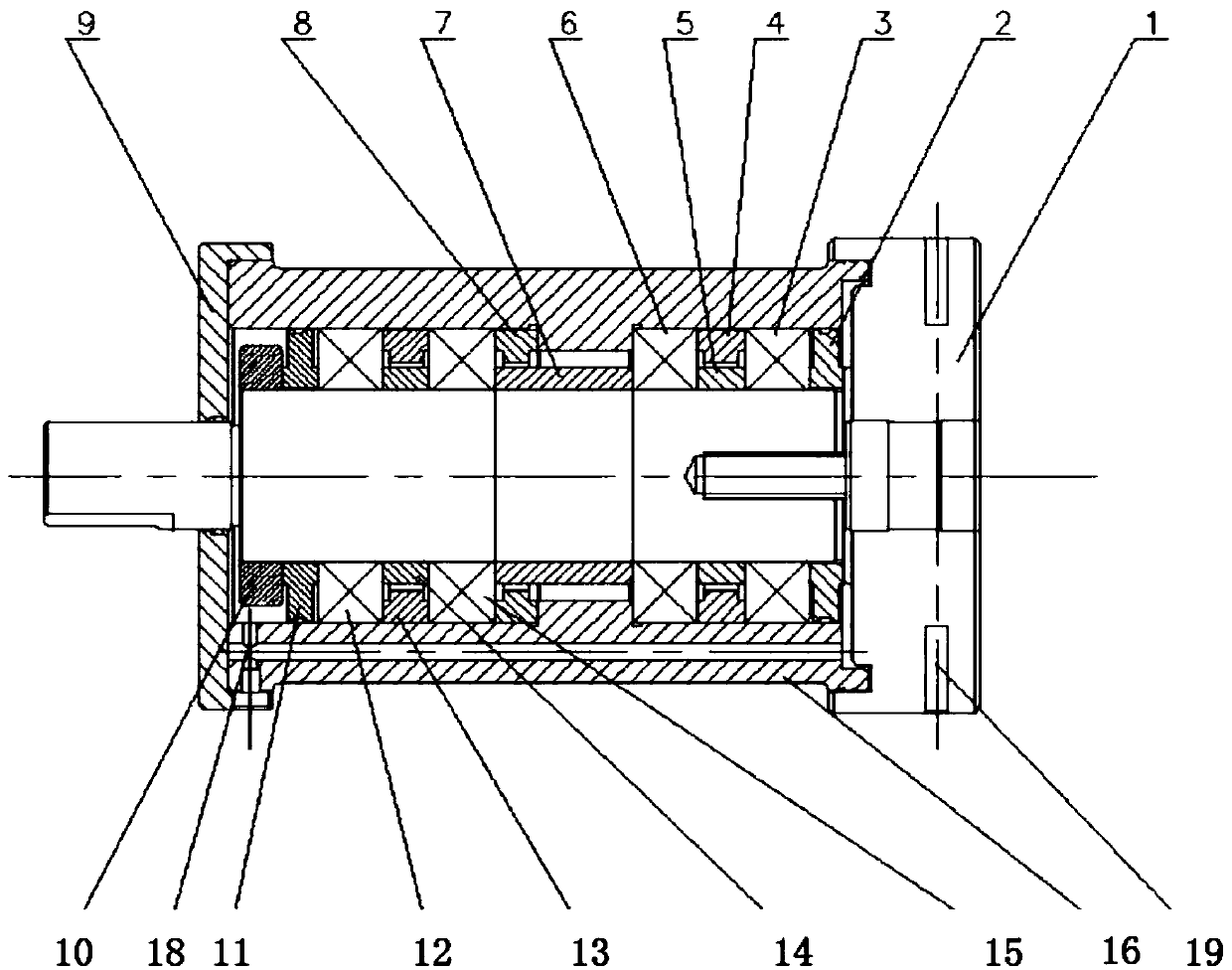

Multilayer stacking combined vertical type wind power generation system

InactiveCN102128138AReduce deformationReduce vibrationYielding couplingEngine fuctionsCouplingFan blade

The invention discloses a multilayer stacking combined vertical type wind power generation system, which comprises multi-section combined crankshafts, multilayer stacking combined vertical type wind power systems and a multilayer stacking combined type frame, wherein each layer of wind power system has a box frame structure and comprises a fan blade system, a wind collection and protection system, a double-speed increasing device and a multi-winding electrode variation generator system; each layer of wind power system individually forms an independent wind power system for operation or all layers of wind power systems are fixed together by vertical posts at all corners; a detachable combined coupling is used for connecting all layers of fan blade crankshafts into a whole, so that synchronous turning moment can be generated by each layer of fan blades; and the lower shaft end of a fan blade crankshaft on the lowermost layer of the multilayer wind power system is connected with the double-speed increasing device and the multi-winding electrode variation generator system together through the detachable combined coupling. In the invention, the wind power generation system is decomposed into a plurality of layers of combined structures, is convenient to manufacture, transport, mount, assemble and maintain, has a small volume and high performance and can form a high-capacity power generation system.

Owner:HARBIN POWER VERTICAL WIND POWER EQUIP ENG TECH RES CENT

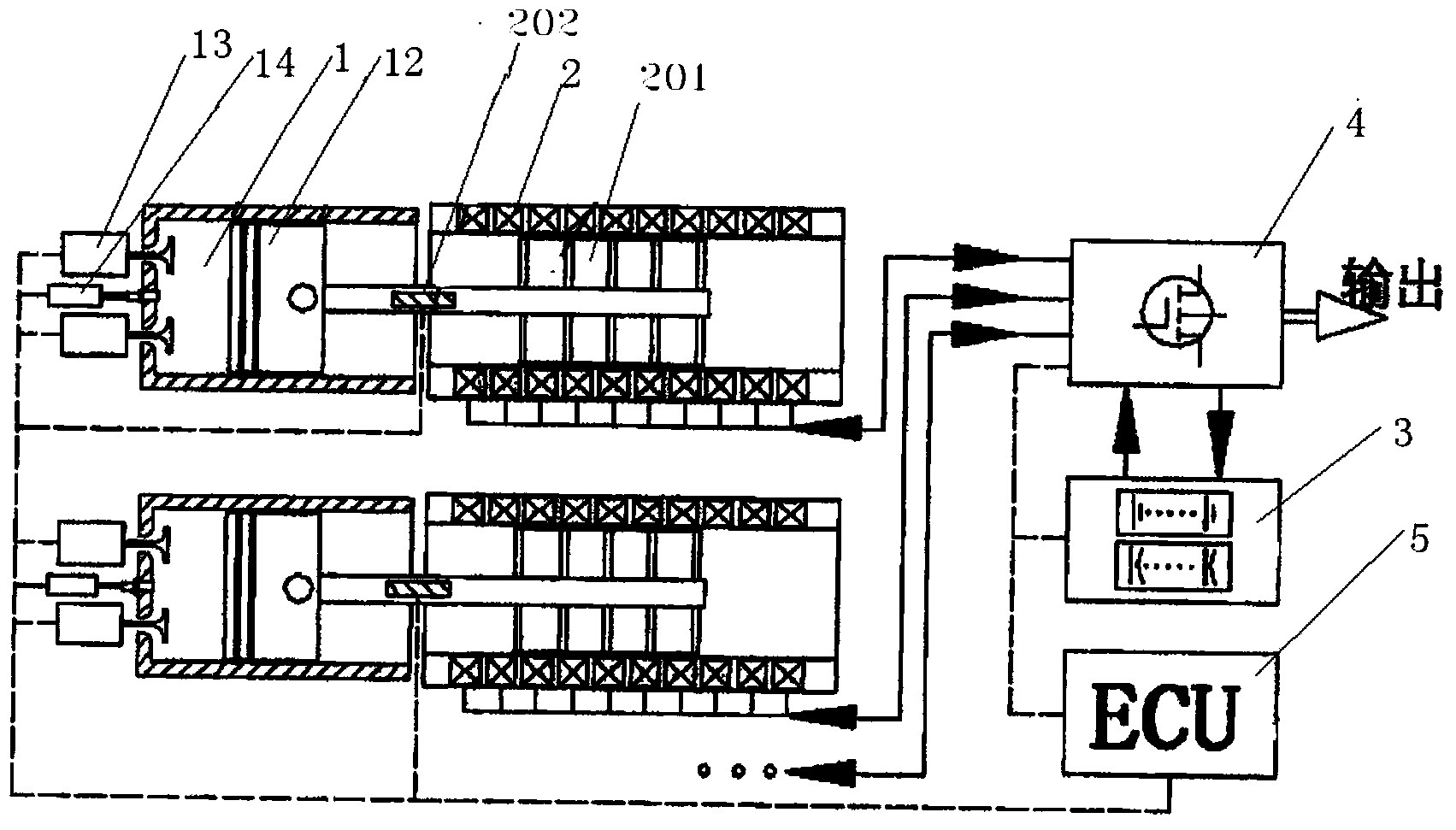

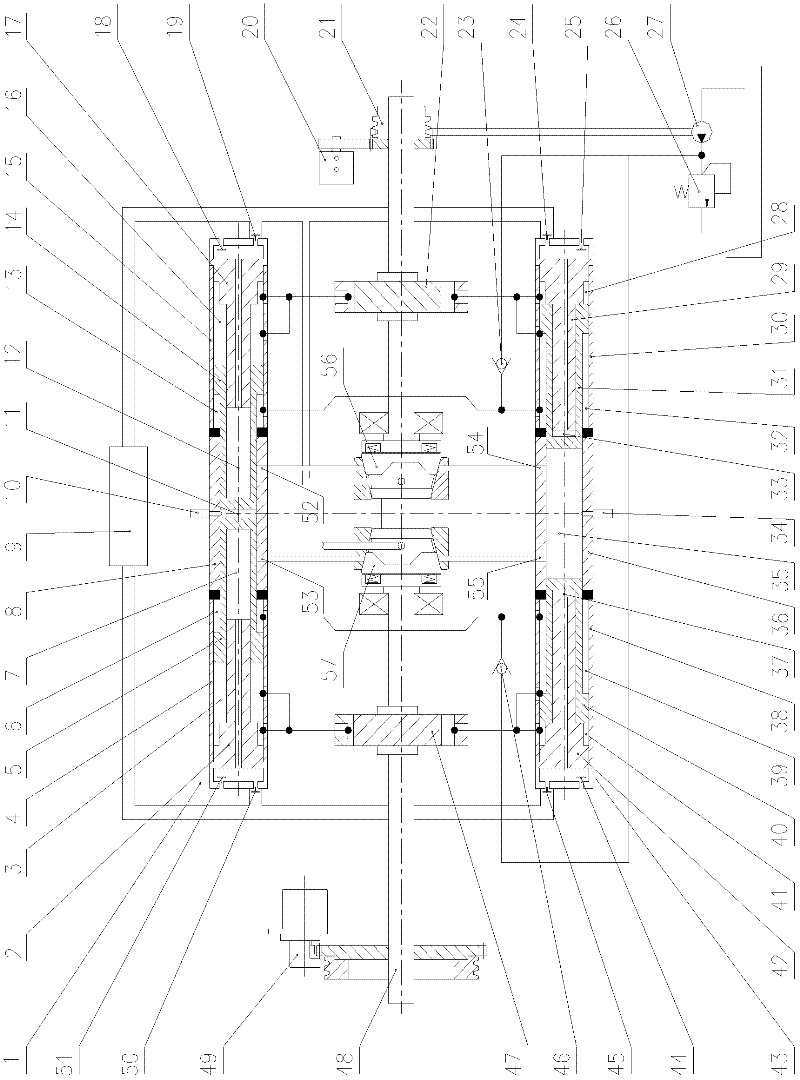

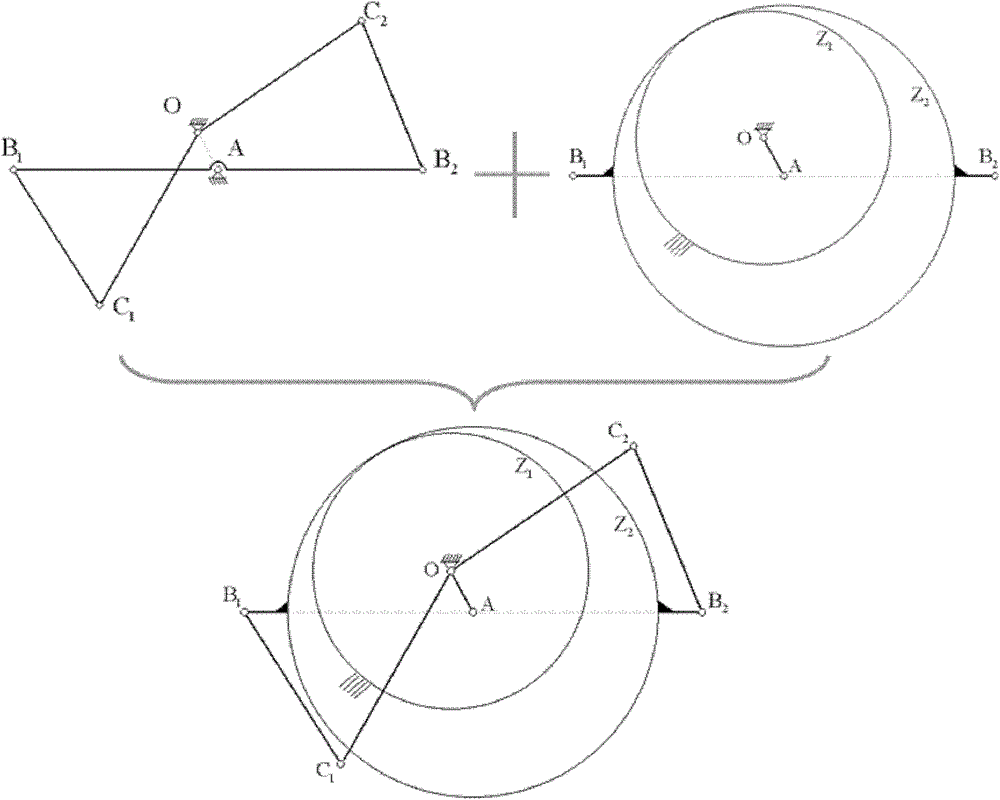

Oppositely-arranged four stroke free piston internal combustion-linear electricity generating integrated device

InactiveCN103590899AGood dynamic balanceMaintain dynamic balanceFree piston enginesExternal combustion engineActive cell

The invention discloses an oppositely-arranged four stroke free piston internal combustion-linear electricity generating integrated device. The oppositely-arranged four stroke free piston internal combustion-linear electricity generating integrated device comprises a four-stroke internal combustion engine, two linear motors, a reversible electric energy storing device, an electric power unit and an electronic control unit, wherein each linear motor has an electricity generating working mode and an electric working mode, the electric power unit is used for connecting the linear motors and the reversible electric energy storing device, the electronic control unit is respectively connected with a valve timing mechanism, an ignition device and the electric power unit of the four-stroke internal combustion engine, active cells of the linear motors are fixedly connected with two pistons of the internal combustion engine, the active cell of each linear motor is provided with a position detecting component which is connected with the electronic control unit, the two ends of a combustor cylinder of the four-stroke internal combustion engine are open, the two pistons are symmetrically arranged inside the combustor cylinder, and the two linear motors are symmetrically arranged inside the combustor cylinder. The oppositely-arranged four stroke free piston internal combustion-linear electricity generating integrated device is good in operation dynamic balanced performance and high in scavenging efficiency.

Owner:NANJING UNIV OF SCI & TECH

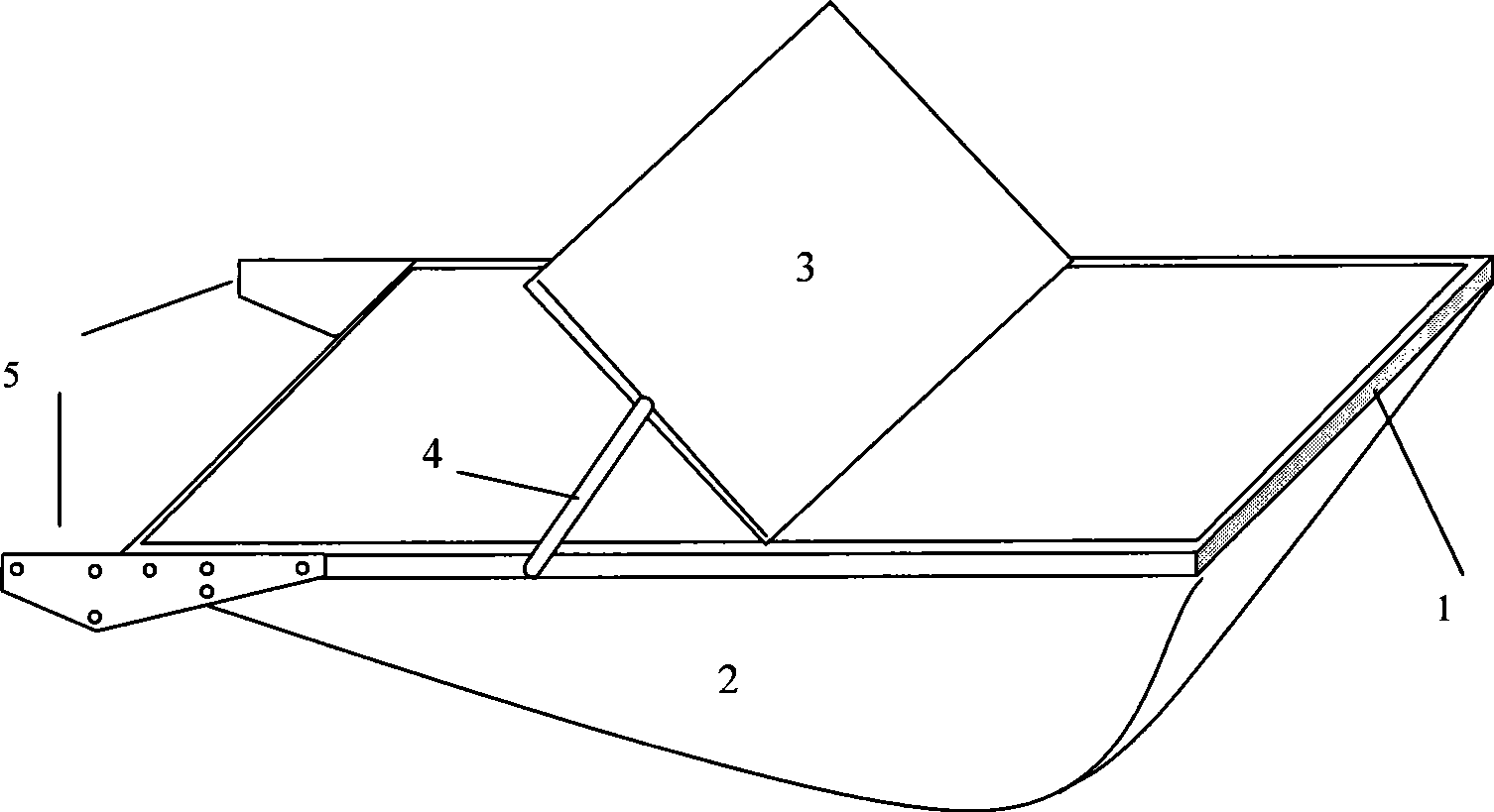

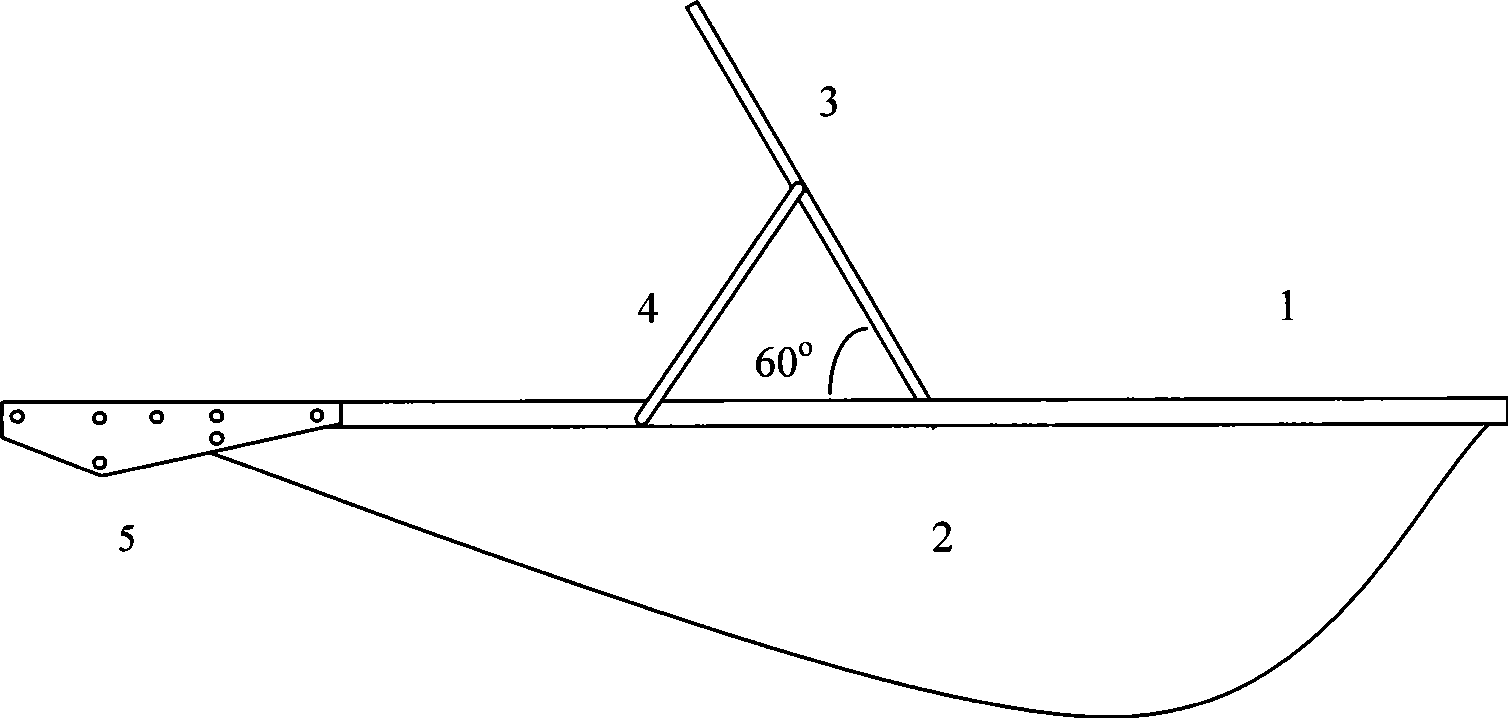

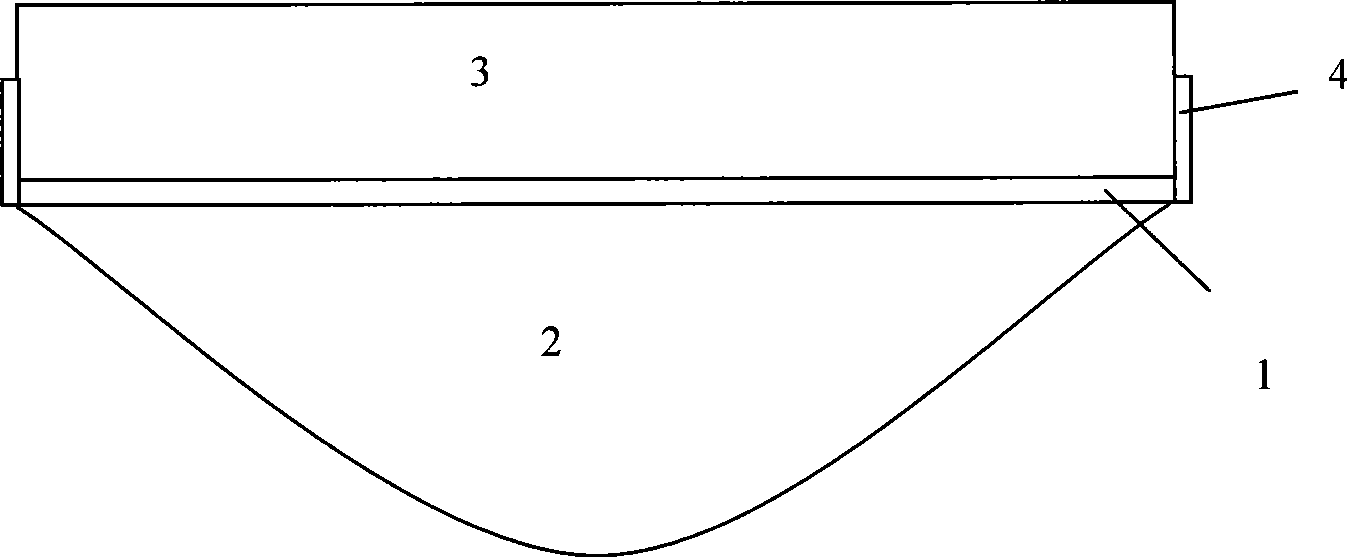

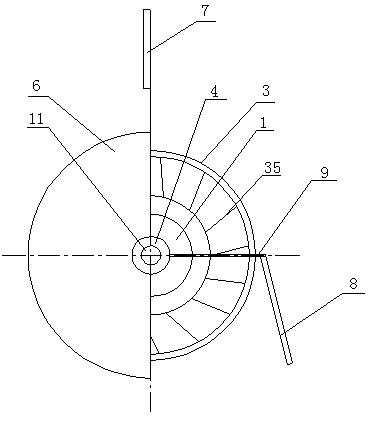

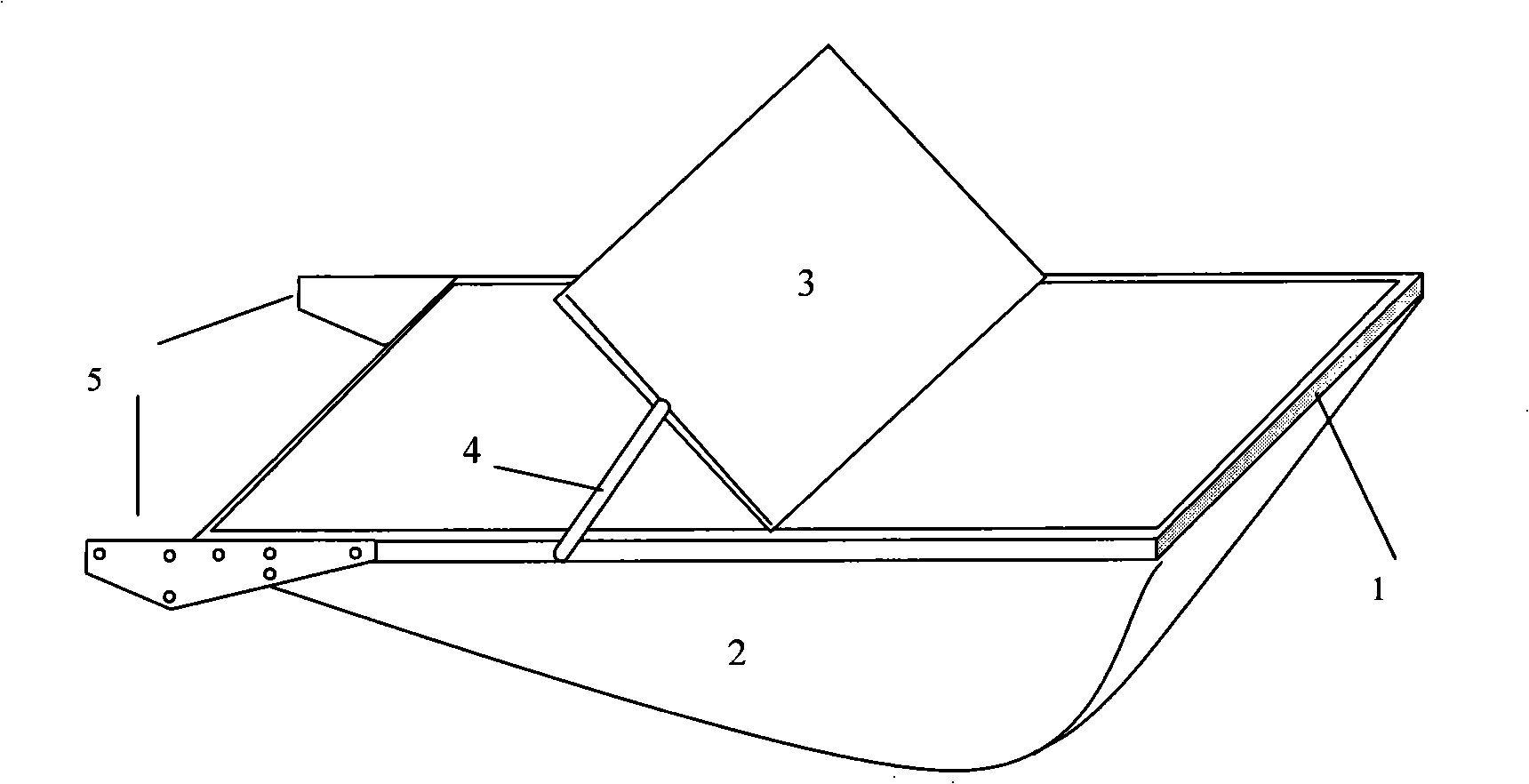

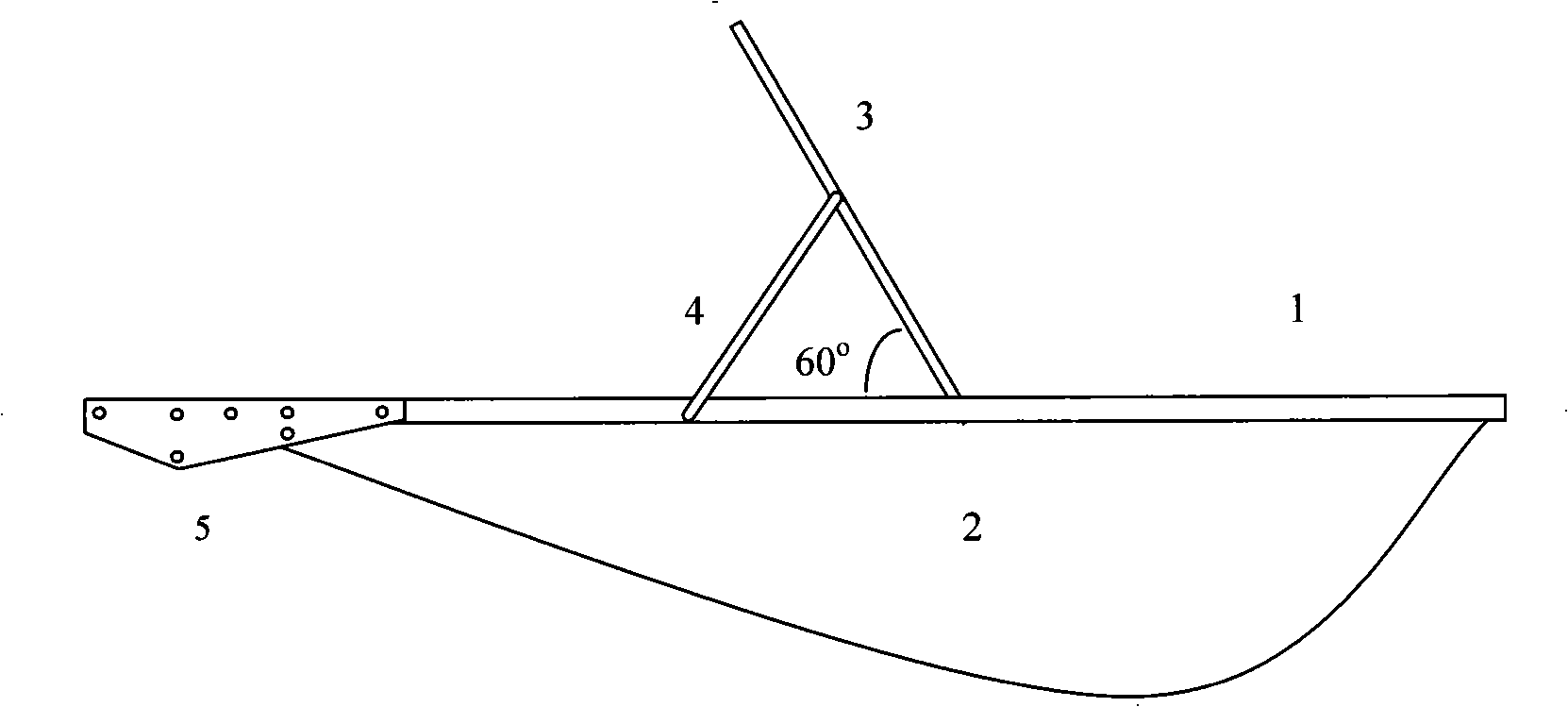

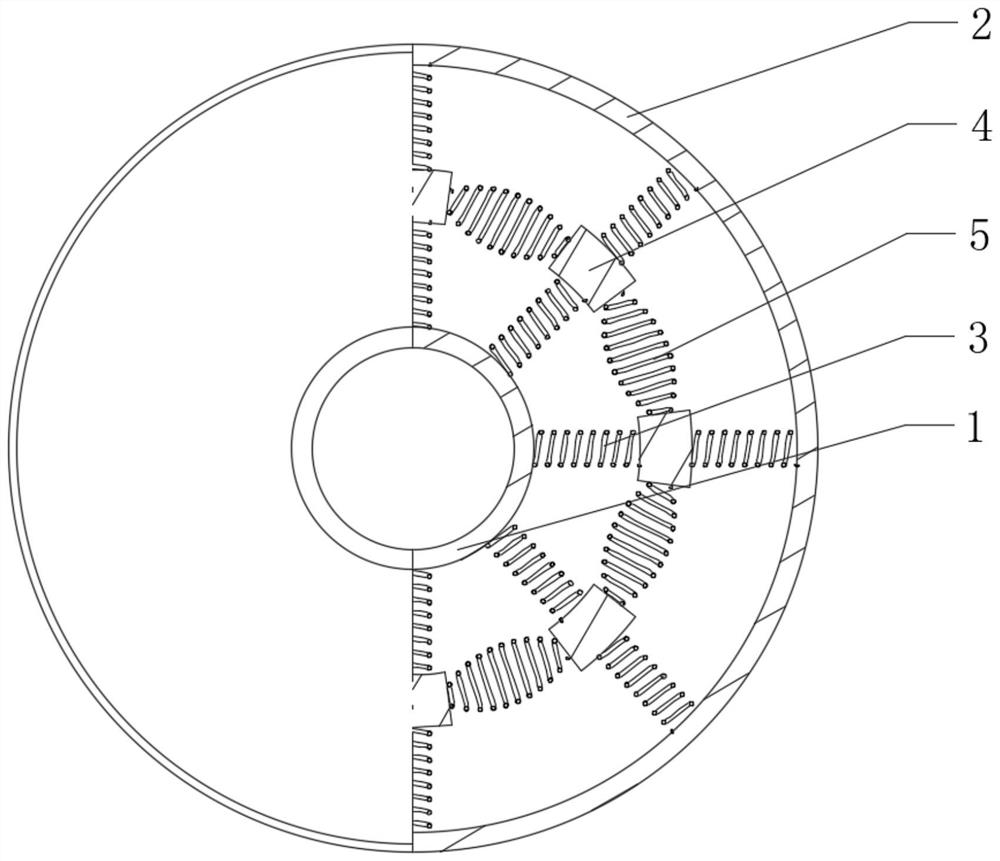

Refraction wind-guiding type fan blade system

InactiveCN101446265ASmall cross sectionImprove enduranceMachines/enginesWind energy generationDynamic balancePulp and paper industry

The invention relates to a refraction wind-guiding type fan blade system in the technical field of wind power generation. The refraction wind-guiding type fan blade system comprises a fan blade frame, a fan blade body, a fixed bracket, a fan blade-shaft connector and a refraction wind deflector. The fan blade frame and an internal steel mesh of the fan blade body are welded together to form an integral fan blade. The refraction wind deflector and the fan blade frame are fixed in 60 degrees. The lower end of the refraction air deflector is fixed on the fan blade frame. A fixing hole at the middle part of the refraction wind deflector is fixed with an end hole of the fixed bracket by a screw. The fan blade is connected with a connection flange fixed at a shaft by the fan blade-shaft connector. The refraction wind deflector and the fan blade are connected by the fixed bracket. The refraction wind-guiding type fan blade system ensures that no matter what position and what degree the fan blade rotates to, the fan blade always gets the largest wind area; wind power can refract to the largest rotation moment point to produce the largest push moment; the fan blade rotates along the horizontal direction; three fan blades complement one another to produce balanced rotation moment without starting the dead angle and the reversing dead angle; and the blade fan produces best dynamic balance characteristic and rotates stably.

Owner:HARBIN POWER VERTICAL WIND POWER EQUIP ENG TECH RES CENT

Double-cylinder four-piston opposed hydraulic control engine

InactiveCN102400784AGood dynamic balanceReduce parts countInternal combustion piston enginesMature technologySwing-piston engine

The invention discloses a double-cylinder four-piston opposed hydraulic control engine. Two groups of opposed piston components are respectively provided with a group of opposed moving pistons; and joints at oil-receiving ends of the pistons correspond to those of two groups of reciprocating volume pumps on a rotating main shaft respectively. The main shaft is rotated, then the volume pump is changed to be directly coupled on the piston, and the moving direction and the positions of the inner dead point and the outer dead point of the pistons are controlled accurately so as to respectively finish the working stroke of gas inlet, compression, working expansion and exhaust, and power output. In the double-cylinder four-piston opposed hydraulic control engine, the pistons are controlled by asimple mode so as to give consideration to the advantages of the conventional engine and the hydraulic free-piston engine, and also avoid the respective defects. Other systems such as a starting system, an oil supply system, a combustion system, a cooling system and a sealing system share the existing fully-mature technology so as to be convenient for implementation of the project. The double-cylinder four-piston opposed hydraulic control engine is applicable to promotion of the engine industry.

Owner:欧益忠 +2

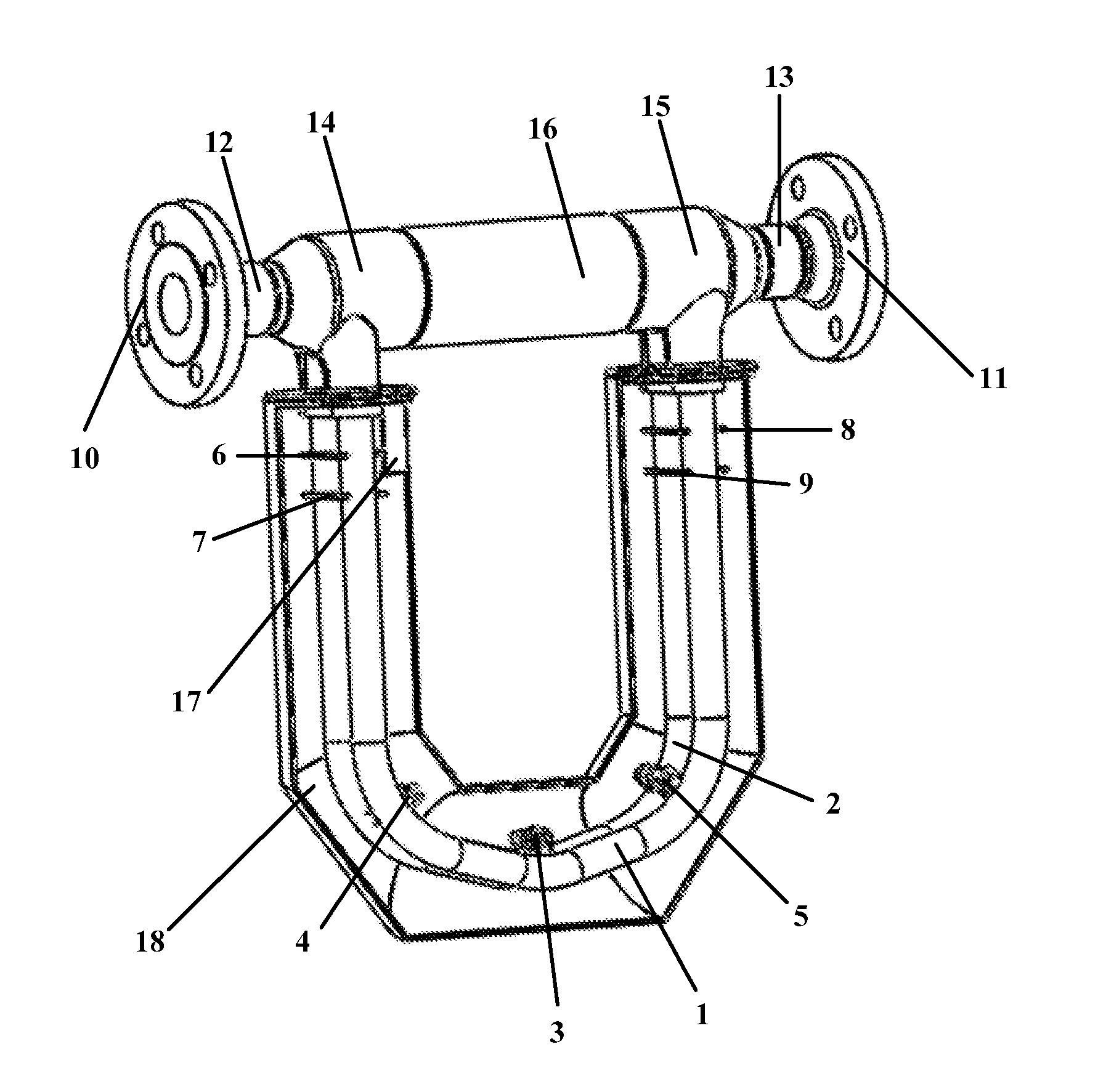

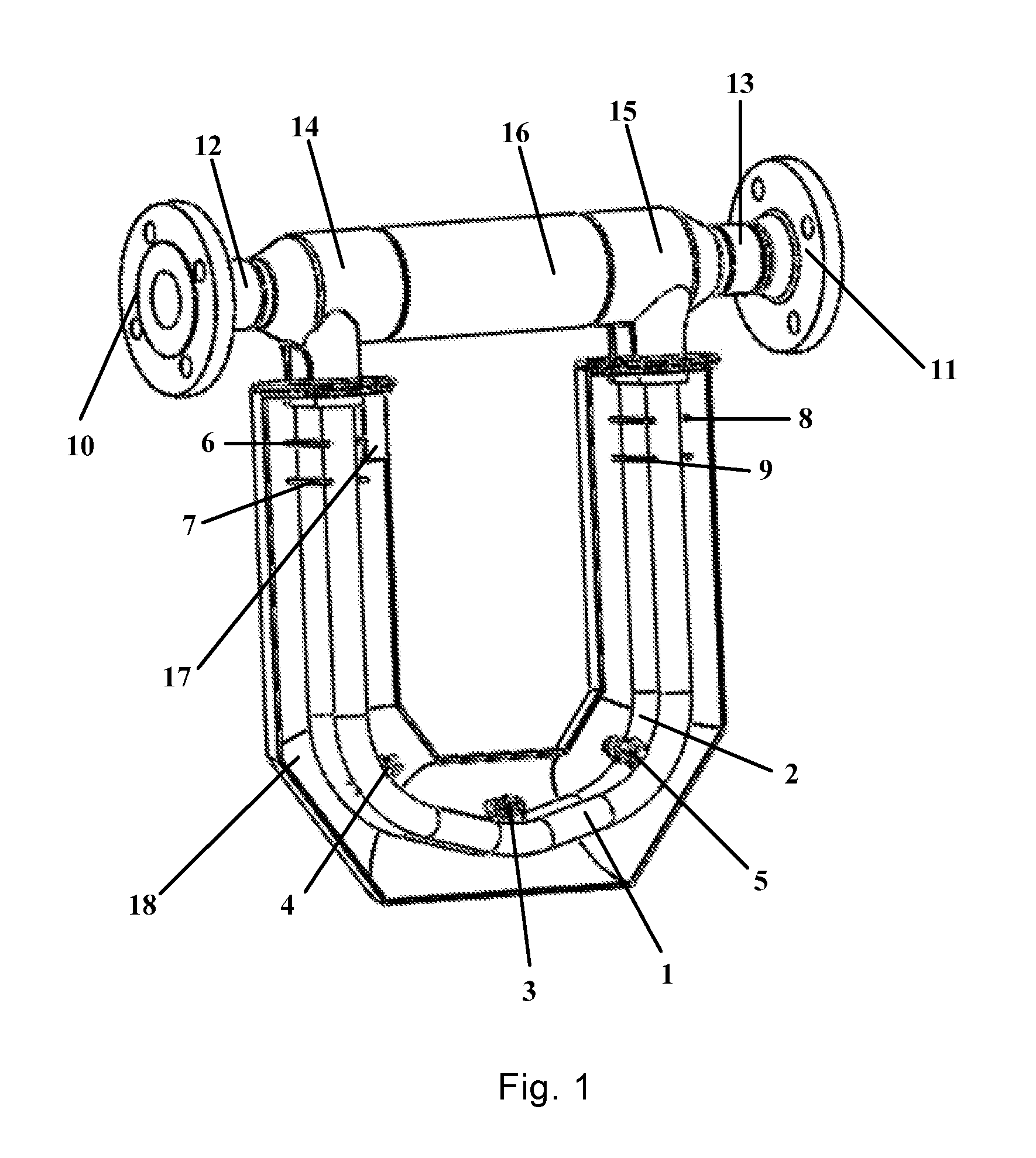

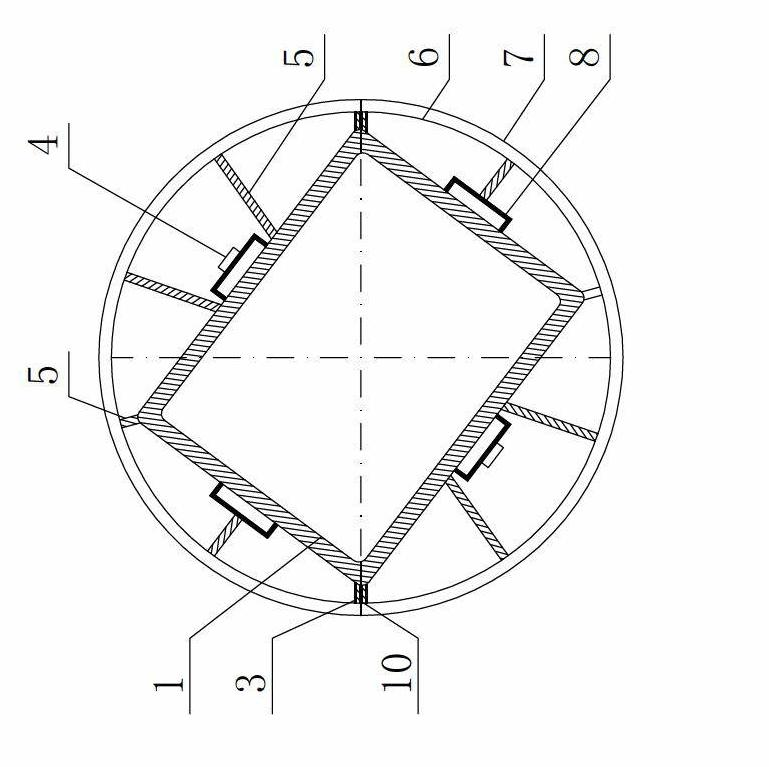

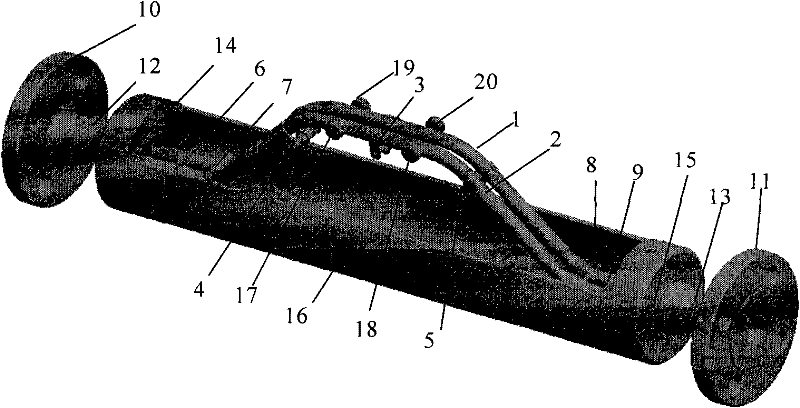

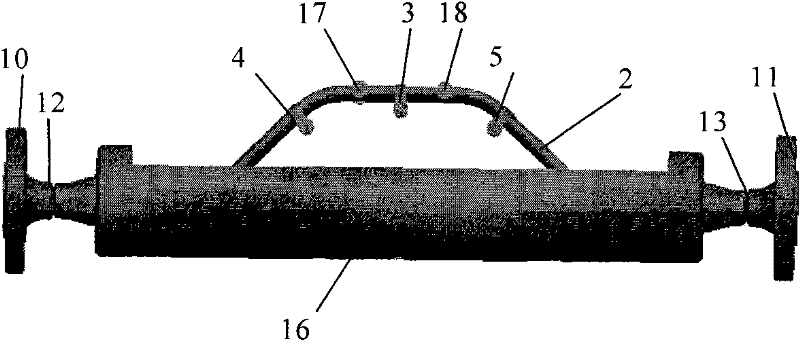

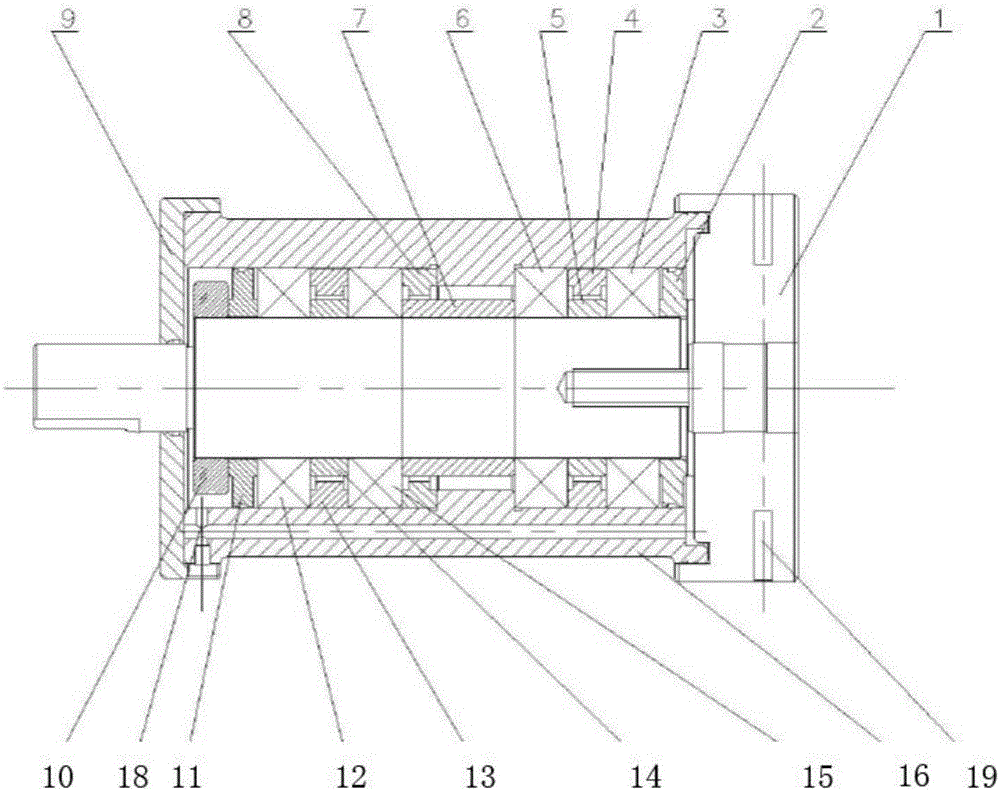

Mass flowmeter

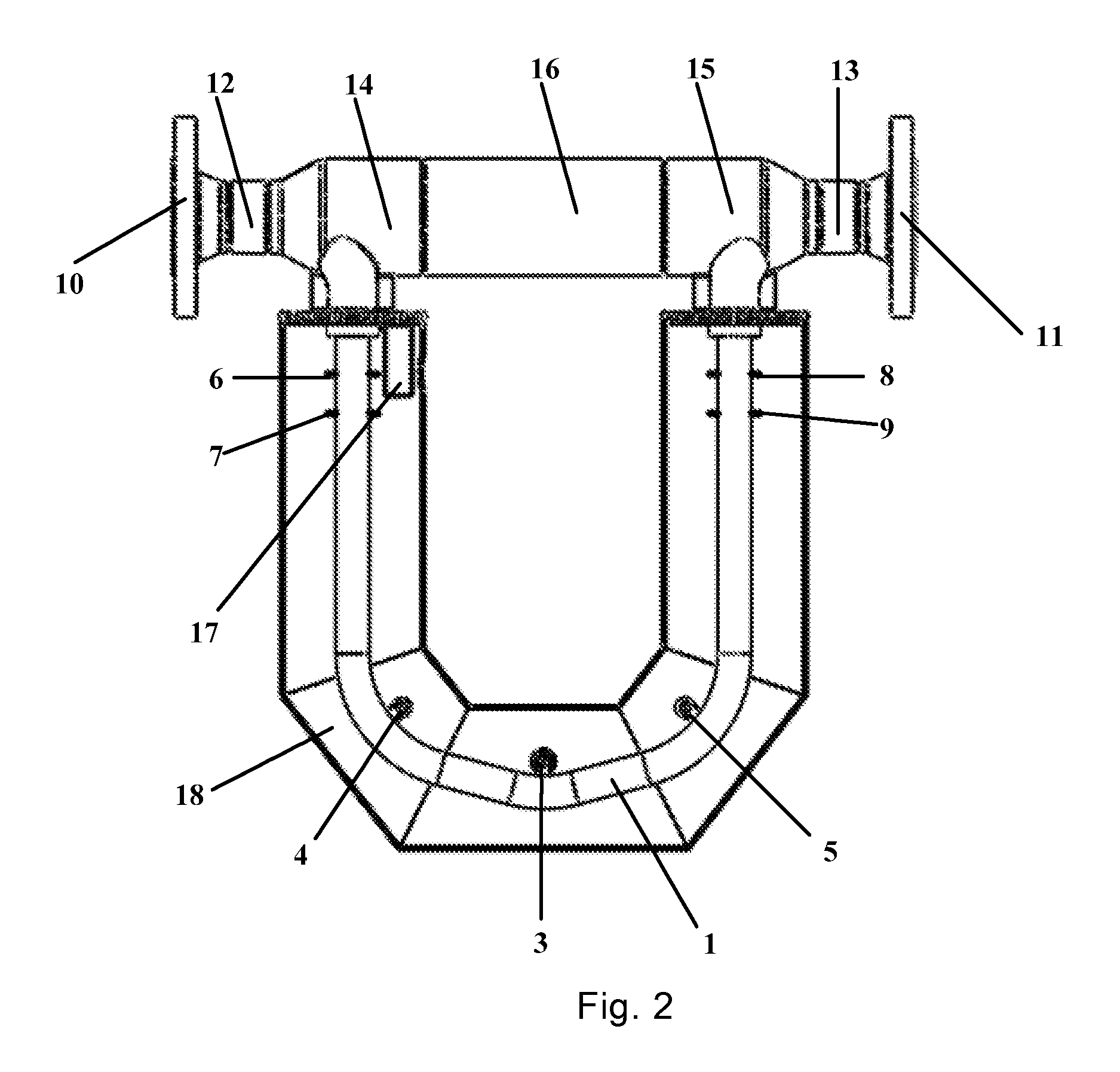

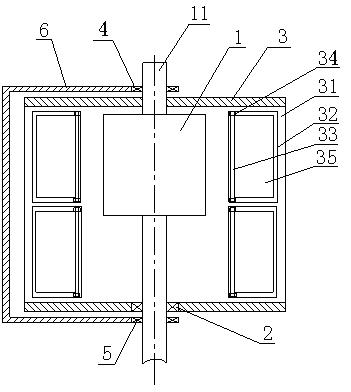

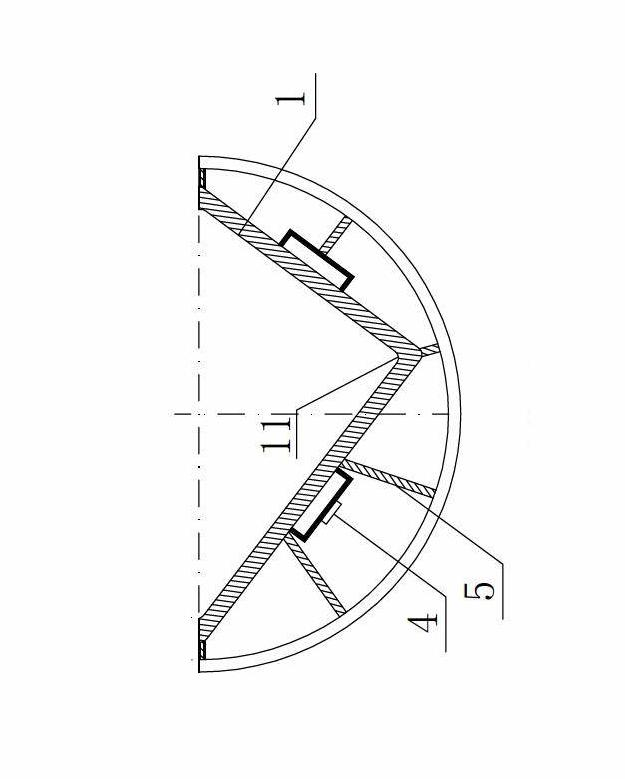

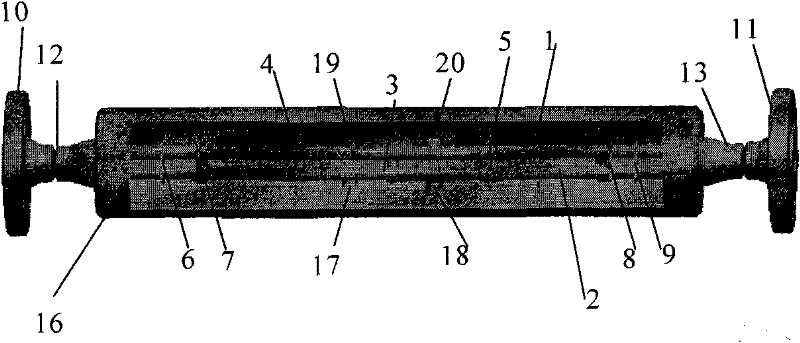

InactiveUS20150323362A1Improve mechanical performanceImproves of mechanical quality factorVolume meteringDirect mass flowmetersLeft halfStraight tube

A mass flowmeter includes: a casing (18), two U-shaped measurement tubes (1, 2) with identical structures within the casing (18), a vibration exciter (3) installed at a center axis line of the two U-shaped measurement tubes (1, 2), two detectors (4, 5) respectively located at centers of second circular arc segments (22, 23), four distance plates (6, 7, 8, 9), two flanges (10, 11) respectively arranged at two outermost ends of the mass flowmeter symmetrically, two end connecting tubes (12, 13) connected to the U-shaped measurement tubes (1, 2) through two flow dividers (14, 15) which are connected to each other through an intermediate connecting tube (16), and a lead wire connector (17); wherein the two U-shaped measurement tubes (1, 2) are arranged in parallel, each of the U-shaped measurement tubes (1, 2) includes a first circular arc segment (19), wherein both sides of the first circular arc segment (19) are each connected to sloped tube segments (20, 21), the second circular arc segments (22, 23), and straight tube segments (24, 25) in sequence, and left half parts and right half parts of the U-shaped measurement tubes (1, 2) constitute a symmetrical structure relative to a center line of the first circular arc segment (19).

Owner:WALSN ENTERPRISES LTD

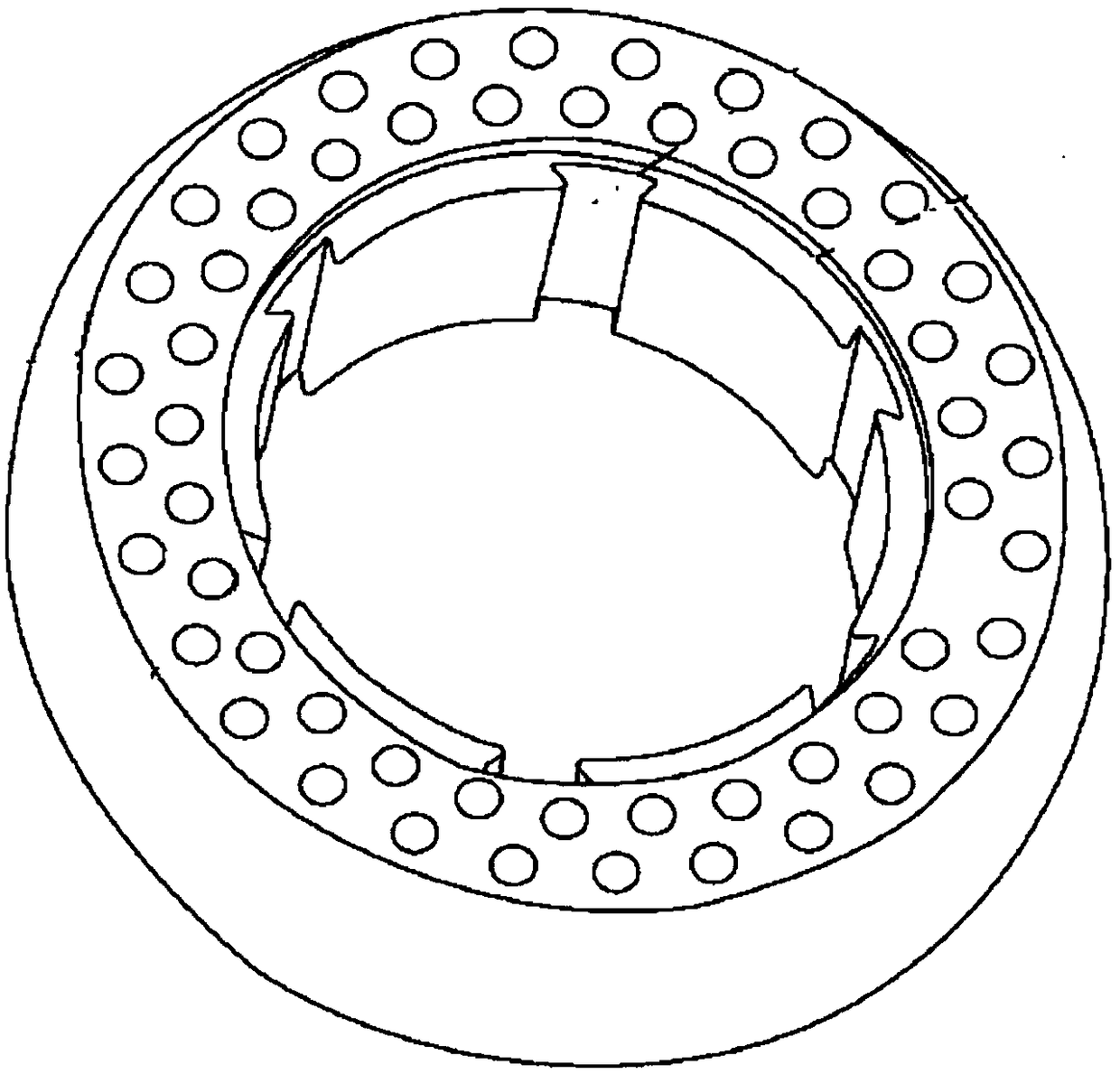

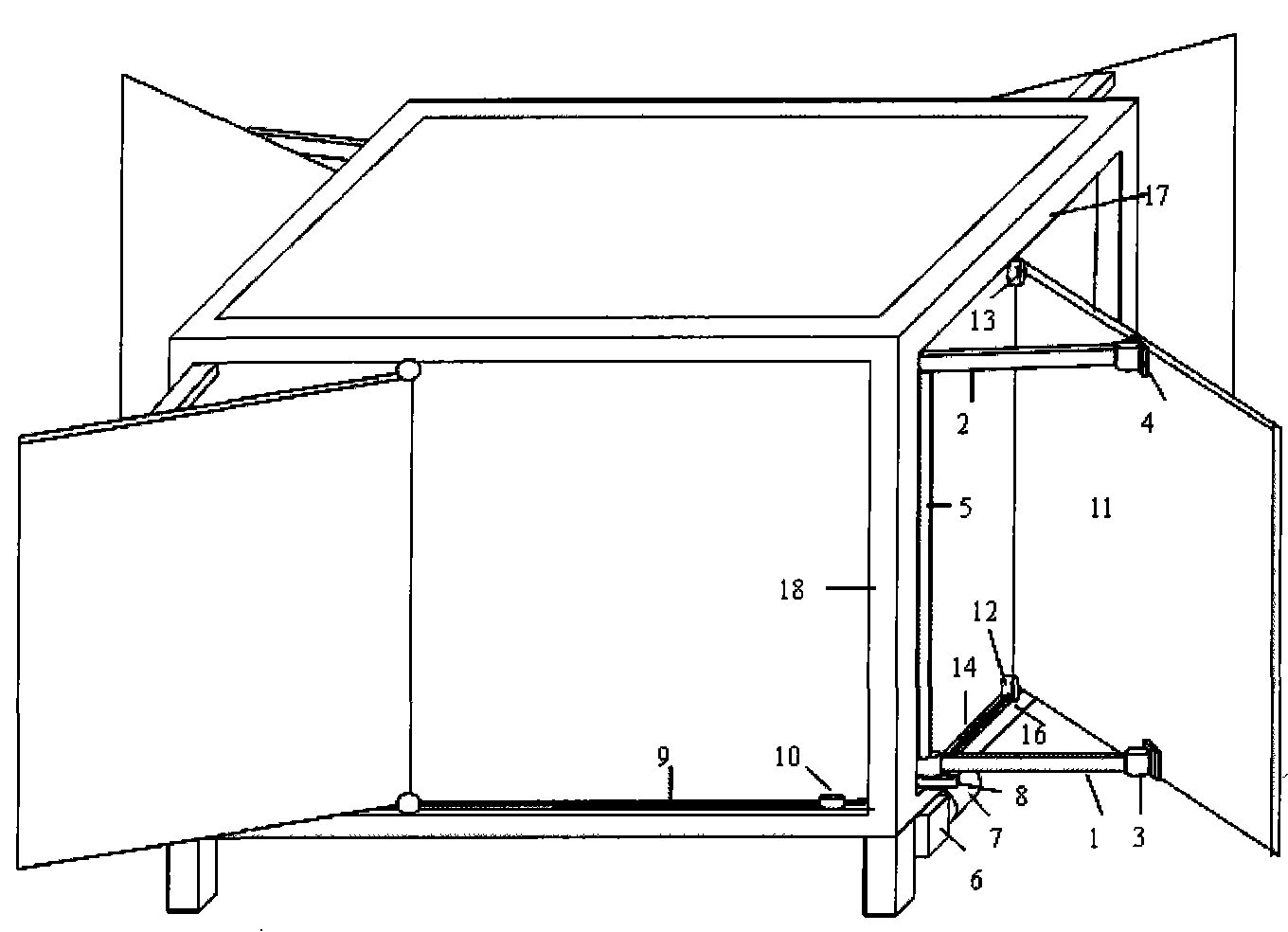

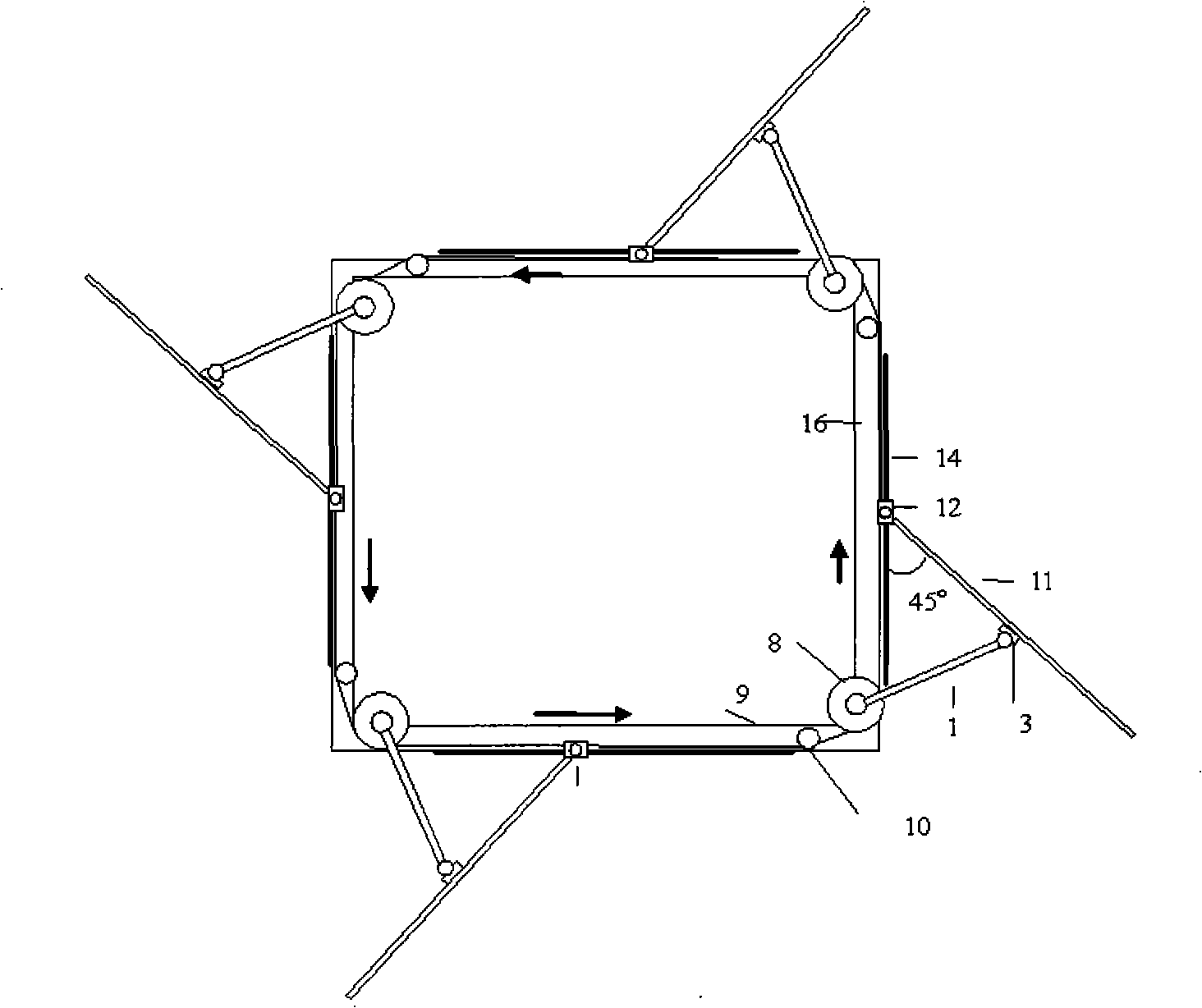

Slideway blade system for vertical wind turbines

InactiveCN102269122AIncrease wind areaImprove wind utilizationMachines/enginesRenewable energy generationEngineeringFan blade

The utility model relates to a slideway type wind blade system of a vertical wind power generator, which relates to a wind blade system of a vertical wind power generator. The present invention aims to solve the problem of large starting dead angle and large reversing dead angle in the starting and rotating motion of the existing fan blade, and the problem that the airfoil fan blade has a small wind-receiving area and is difficult to increase the capacity. Scheme 1 is a single-layer fan blade system. There are three single fan blades connected between the connecting flanges of the two shaft fan blades. The three single fan blades are ring-shaped around the compound shaft. The body blades are arranged at an angle of 120 degrees. The upper and lower ends of the three single blades are fixedly connected by a triangular blade fixing frame, and a blade pulley is installed at the lower end of each single blade. The blade annular slideway is fixedly installed on the frame beam, and the fan blade pulley slides on the slideway. The difference between Scheme 2 and Scheme 1 is that it is a double-layer fan blade system. The difference between Scheme 3 and Scheme 1 is that it is a multi-layer fan blade system. The invention is used in wind power generation.

Owner:李树广 +1

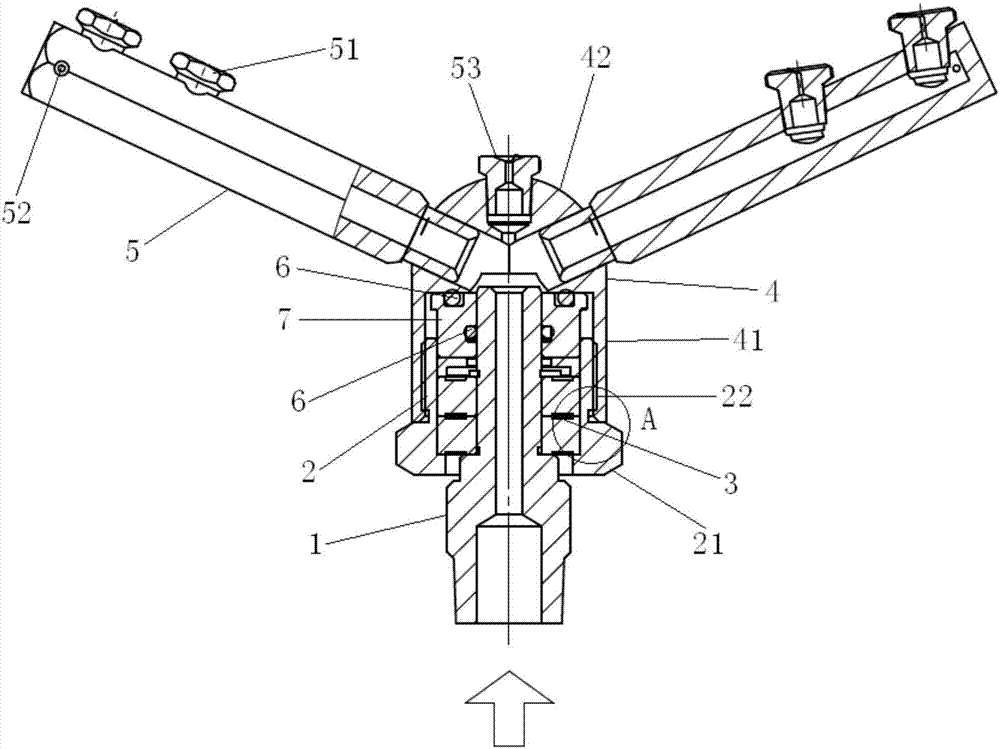

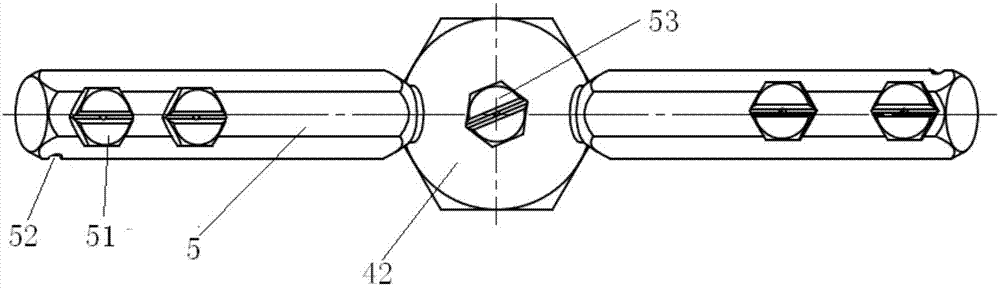

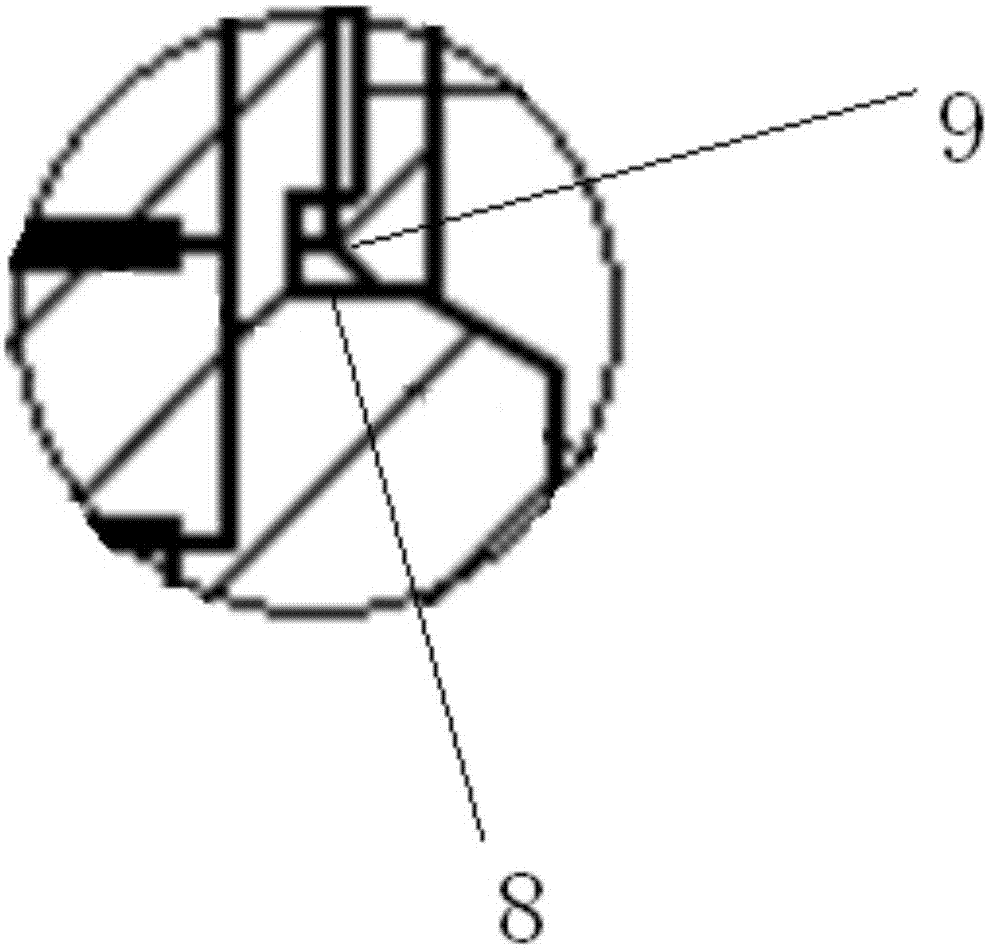

Y-shaped high-speed automatic rotating nozzle

The invention discloses a Y-shaped high-speed automatic rotating nozzle comprising a centering shaft, a shaft sleeve, a connecting frame and two supports. The shaft sleeve comprises a large diameter part and a small diameter part which are integrally formed, the outer side, close to the large diameter part, of the small diameter part is provided with a groove in a surrounding mode; the shaft sleeve is at least provided with two bearings, and the outer side of the centering shaft is sleeved with the shaft sleeve and the two bearings; the connecting frame comprises a cylinder and a hemisphere which are integrally formed, the inner side of one end of the cylinder is provided with a clamping block in a surrounding mode, and the clamping block is matched with the groove; the two supports are each of a structure with one open end and the through interior, the open ends of the two supports are symmetrically connected with the hemisphere, and the two supports, the connecting frame and the centering shaft form a Y-shaped structure; each support is provided with two nozzle bodies and an air hole, and air and a cleaning solution enter from the lower end of the centering shaft 1 and are sprayed from the air holes; and the supports rotate towards the direction opposite to the air spray-out direction, and the cleaning solution is sprayed out from the nozzle bodies and the air holes to clean a rotary cup omni-directionally.

Owner:SHANGHAI FANUC ROBOTICS

Driving sleeve for reducing running noise of electromagnetic disc brake and manufacturing method thereof

InactiveCN102022462AGood dynamic balanceAchieving wear resistanceBrake actuating mechanismsDisc brakeNylon 66

The invention discloses a driving sleeve for reducing the running noise of an electromagnetic disc brake. The driving sleeve comprises a shaft sleeve body of which the peripheral surface is provided with engaged teeth; and a noise reduction coating is coated on the engaged teeth and is a nylon 66, nylon T6 or nylon T1010 coating. The invention also discloses a manufacturing method for the driving sleeve. The manufacturing method comprises the following steps of: 1) performing sand blasting on the shaft sleeve body; 2) performing electrostatic coating on the shaft sleeve body subjected to sand blasting, and forming the noise reduction coating on the surface, wherein a paint is any of nylon 66, nylon T6 or nylon T1010 powder; 3) hanging the driving sleeve with the noise reduction coating into an oven, and heating and molding the driving sleeve; 4) taking the driving sleeve out of the oven, and naturally cooling the driving sleeve; and 5) reshaping the engaged teeth provided with the noise reduction coating on a press machine by using a push broach. The driving sleeve has the functions of damping and reducing noise to fulfill the aim of quiet operation of the brake, also can improve the wear resistance of a rotor of a friction plate, and prolongs the service life of the brake.

Owner:天津永恒泰科技有限公司

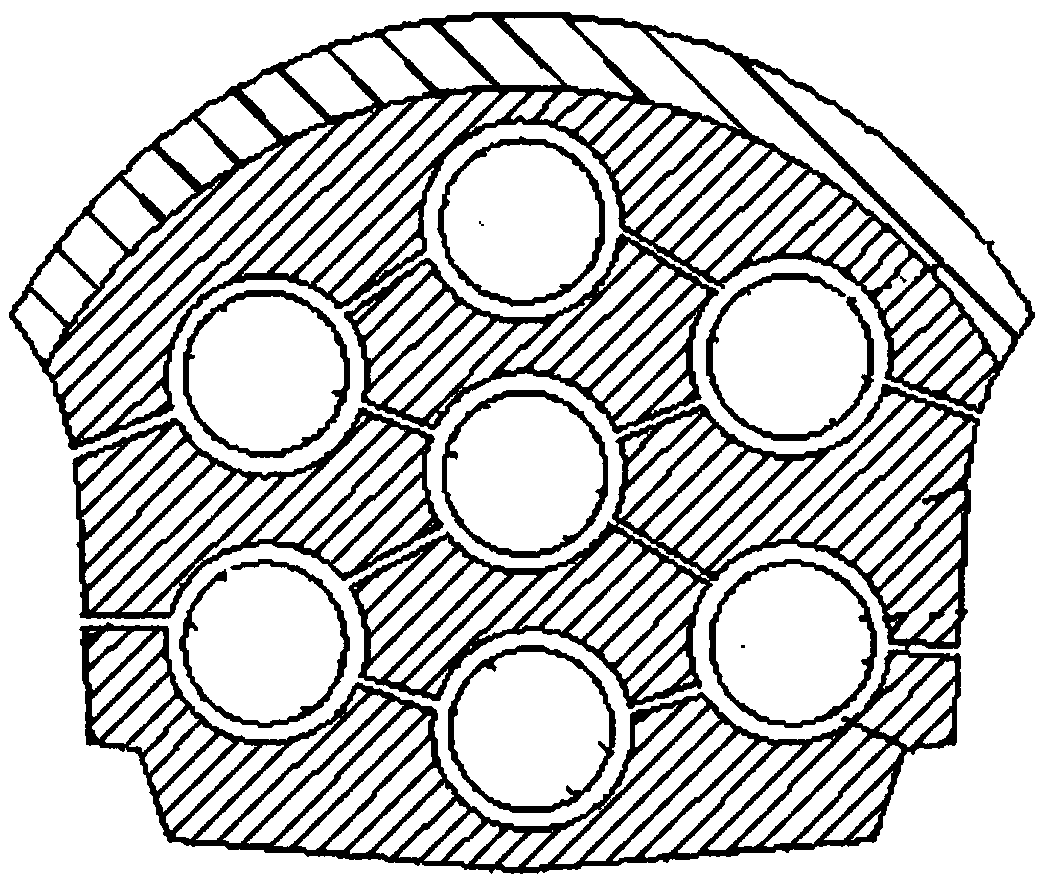

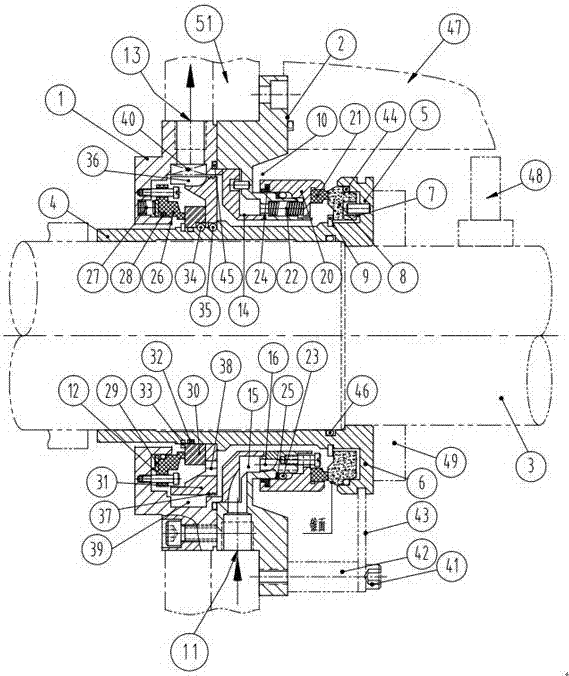

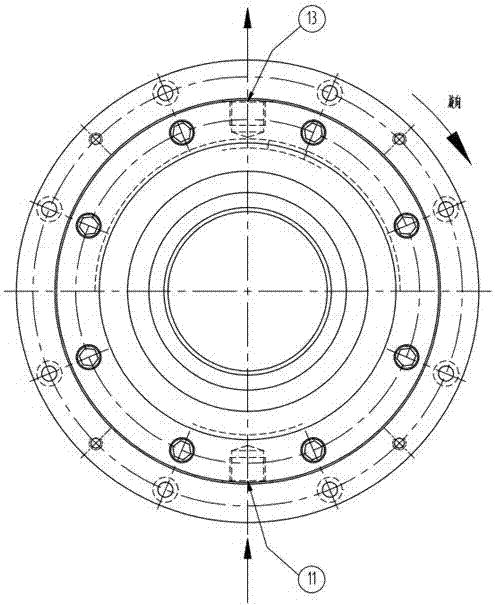

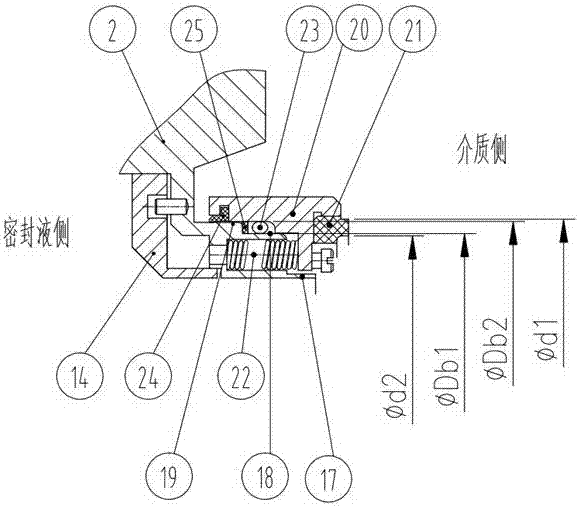

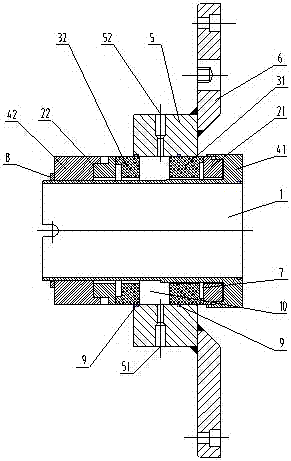

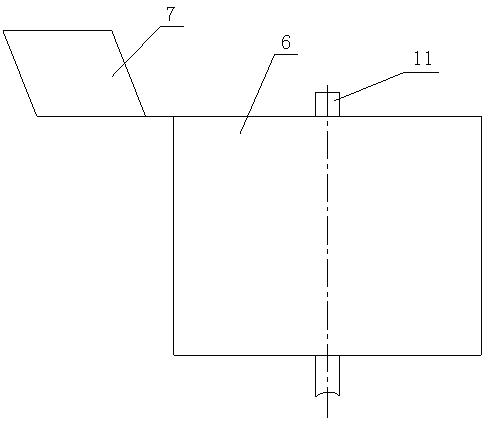

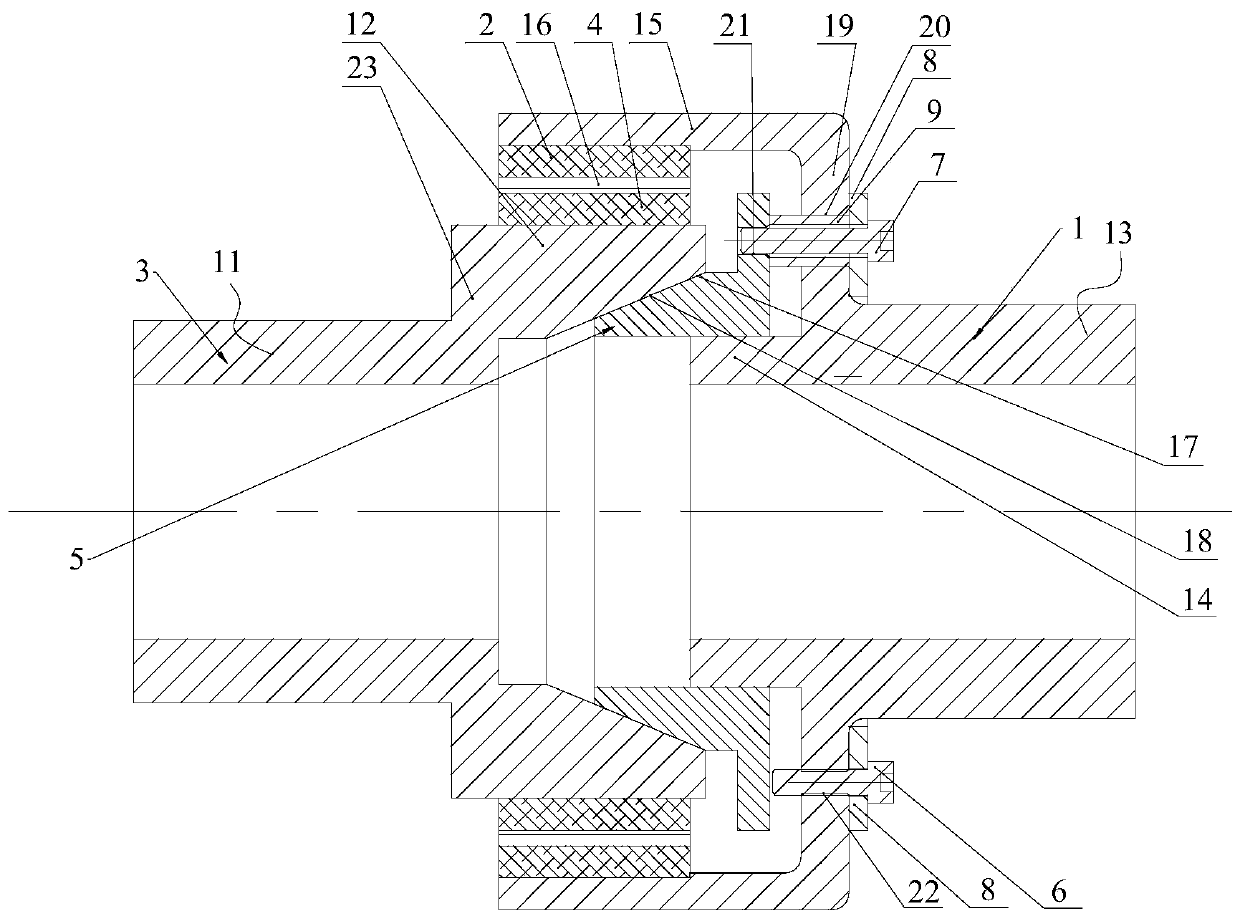

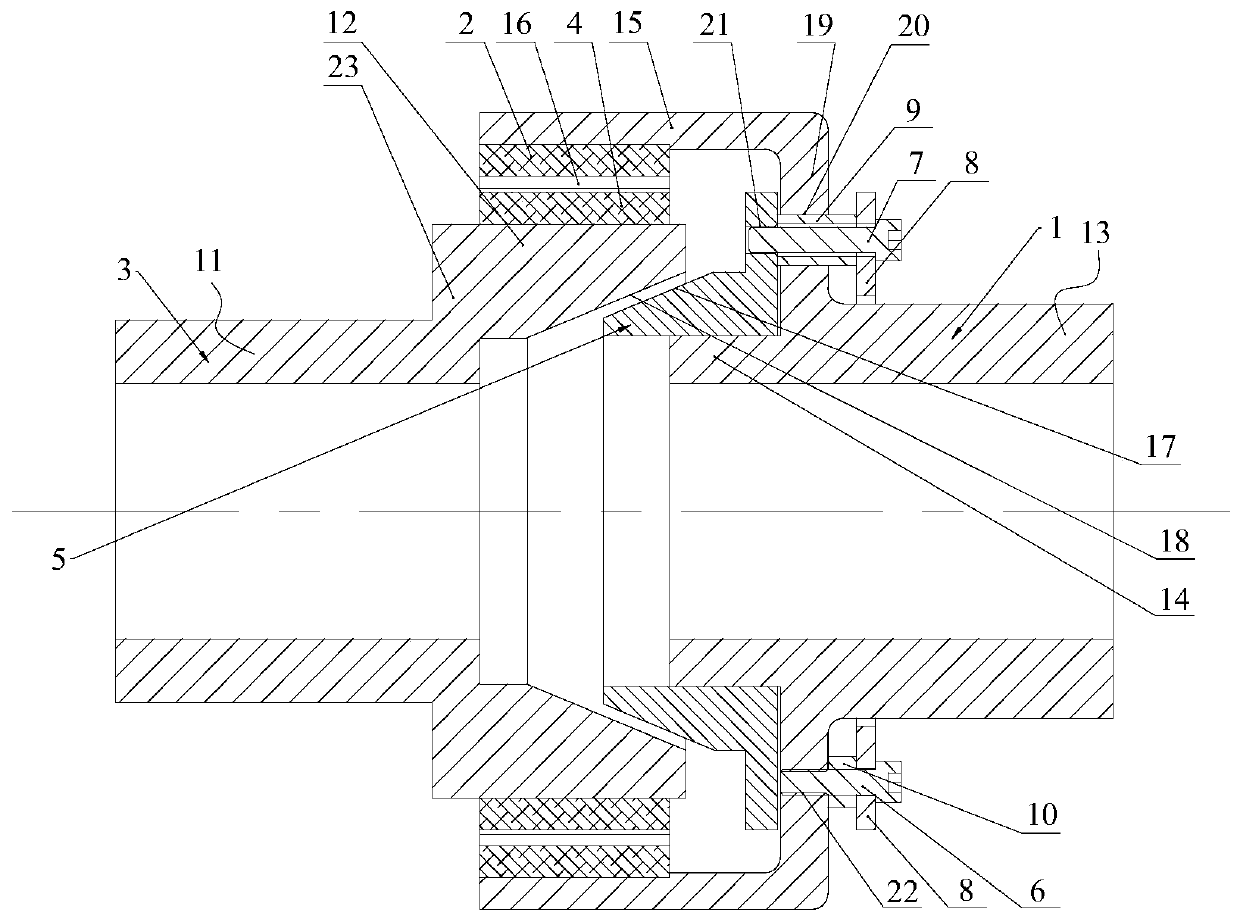

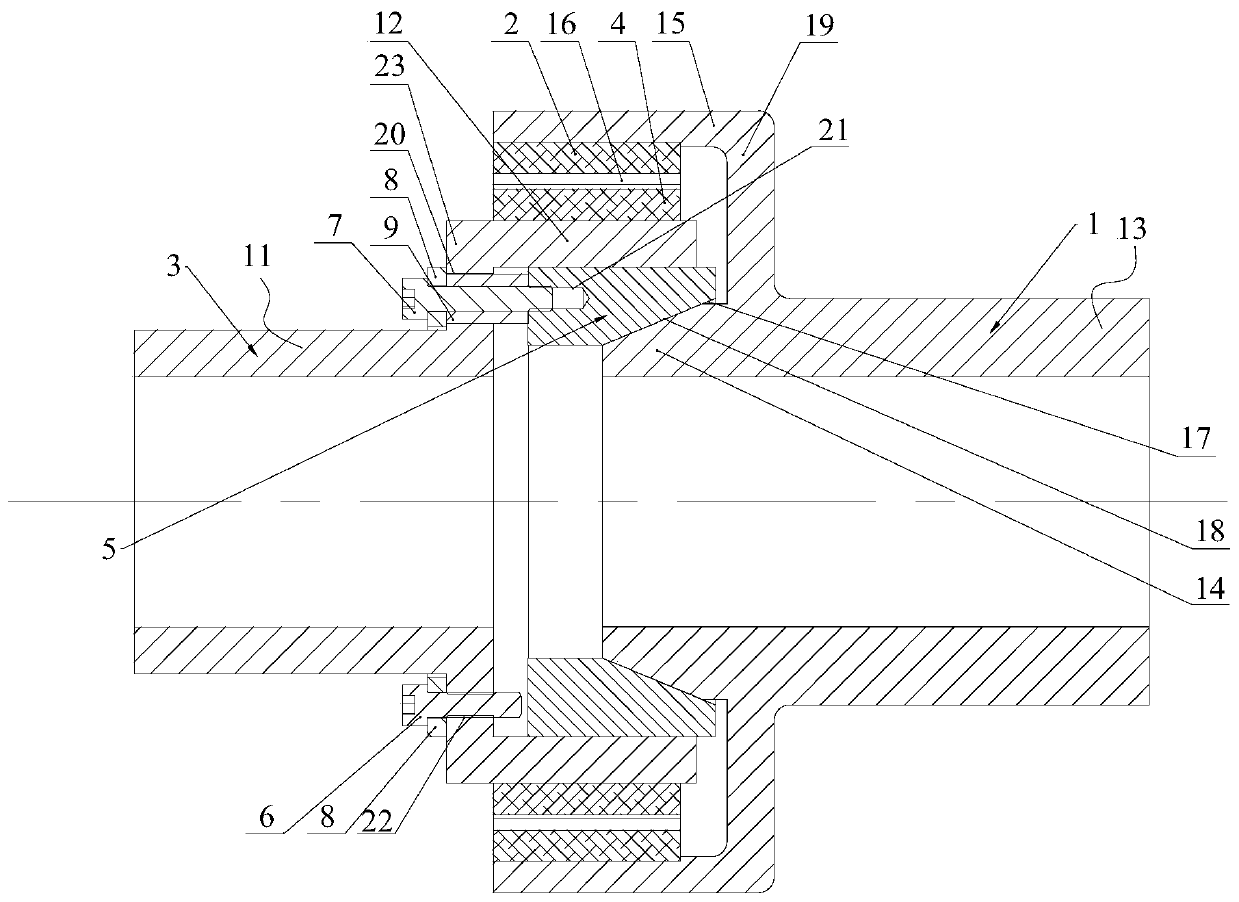

Mechanical sealing device for high-speed sand mill

PendingCN107355542AStrong sealing adaptabilityLiquid film stabilizationEngine sealsEngineeringMechanical engineering

The invention relates to a mechanical sealing device for a high-speed sand mill. The mechanical sealing device comprises an outer gland, an inner gland and a shaft sleeve. The shaft sleeve is sleeved with the outer gland and the inner gland. The outer gland and the inner gland are connected through a screw. An inner movable ring is arranged at the right end of the shaft sleeve. The right end of the inner gland is sleeved with an inner static ring assembly. The right end face of the inner static ring assembly is in fit with the left end face of the inner movable ring, and a main seal is formed. An inner movable ring assembly with which the shaft sleeve is sleeved is arranged in the gap between the shaft sleeve and the outer gland. The outer gland is provided with an outer static ring assembly. The left end face of the outer movable ring assembly is in fit with the right end face of the outer static ring assembly, and therefore a safe seal is formed. An isolation sleeve is arranged in the gap among the inner gland, the outer gland and the shaft sleeve. A sealing cavity is formed between the isolation sleeve and the inner gland and communicates with a liquid feeding hole, the sealing cavity communicates with an overflowing hole inside the inner gland, and therefore a liquid loop is formed. The mechanical sealing device is used for a device which is rotated at a high speed, a sealing end face is not likely to be damaged, and the service life is longer.

Owner:西安普力流体科技有限公司

Integral packaging type mechanical seal device

The invention discloses an integral packaging type mechanical seal device. The integral packaging type mechanical seal device comprises a mechanical shaft, movable rings and fixed rings; the movable rings comprise the first movable ring and the second movable ring, the fixed rings comprise the first fixed ring and the second fixed ring, the device further comprises movable ring shaft casing pipes,a gland and a mechanical seal fixing flange, the movable ring shaft casing pipes comprise the first movable ring shaft casing pipe and the second movable ring shaft casing pipe, the first movable ring shaft casing pipe is arranged on the mechanical shaft and between the movable rings and the fixed rings, the two movable rings are arranged at the two ends, the fixed rings are arranged between thetwo movable rings, the second movable ring shaft casing pipe is adjacent to the second movable ring, and the second movable ring shaft casing pipe is arranged outside the first movable ring shaft casing pipe; the first fixed ring and the second fixed ring are sleeved with the gland with a water inlet and a water outlet, and the gland is connected with the mechanical seal fixing flange; and a sealcavity is formed among the gland, the movable rings, the fixed rings and the movable ring shaft casing pipes. The integral packaging type mechanical seal device is compact in structure, easy to mount,convenient to use, good in dynamic balance, durable, capable of being used for sealing of the solid and liquid particle mixture working condition and high in belt pressing seal durability.

Owner:上海易勒机电设备有限公司

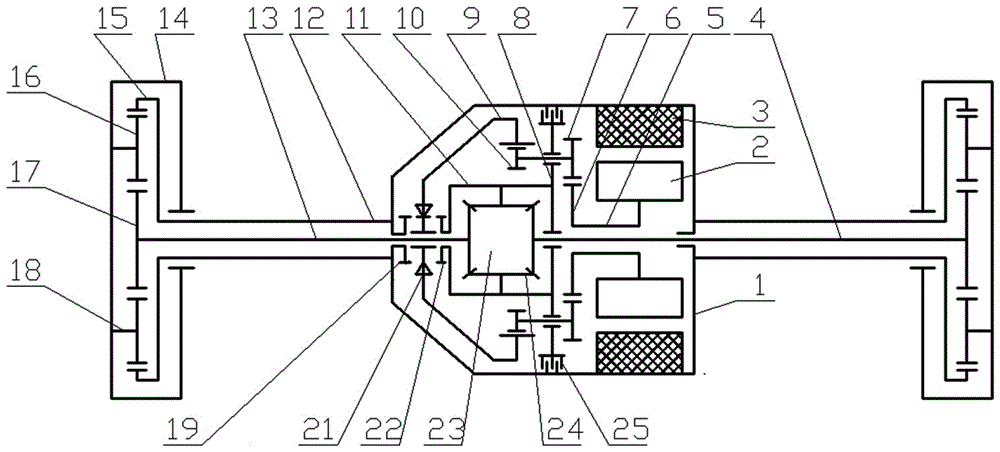

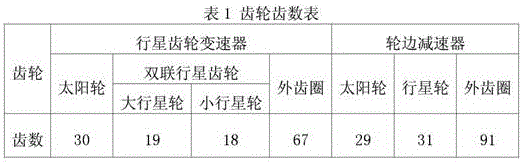

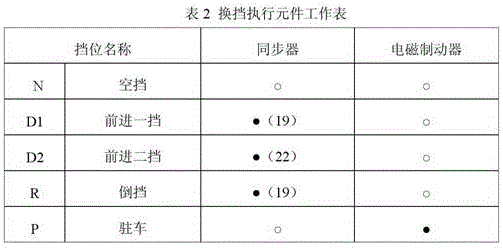

A power system for two-speed transmission of an electric vehicle

The invention relates to a two-gear speed changing power system of an electric automobile. The two-gear speed changing power system comprises a driving motor, a differential mechanism, a right half shaft and a left half shaft, and further comprises a planetary gear speed reducing mechanism, a synchronizer and two sets of wheel rim speed reducing mechanisms, wherein the planetary gear speed reducing mechanism and the synchronizer are located in a shell of the driving motor to form an integrated structure. The two-gear speed changing power system has extremely high integration degree; the wheel rim speed reducing mechanisms are used as the final stage of a transmission chain of a main speed reducing mechanism so that the load of the front-stage part of the transmission chain is greatly reduced and the part size of the front-grade part of the transmission chain is reduced, and a miniaturization and light-weight principle is met; a rotor rotary shaft of the driving motor is directly connected with a speed changer gear so that coaxial tolerance caused by matched installation is avoided; the quantities of duplex planetary gears and differential mechanism driving gears are the same and the duplex planetary gears and the differential mechanism driving gears are arranged around the central line at equal angles; the whole structure is centrally symmetrical, the weight distribution is uniform, the dynamic balance property is good, the transmission efficiency is higher, and the vibration noise condition is better.

Owner:HEFEI UNIV OF TECH

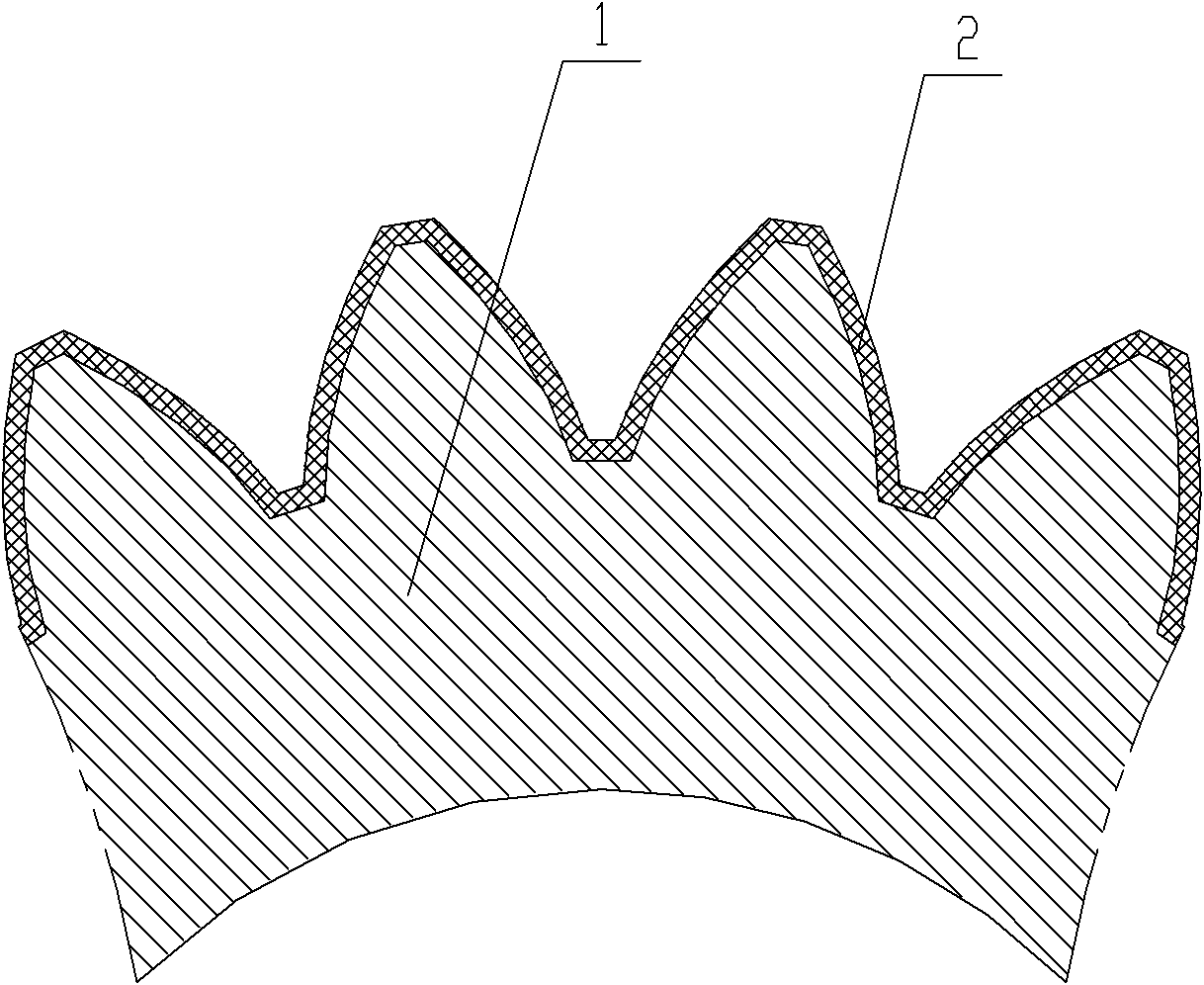

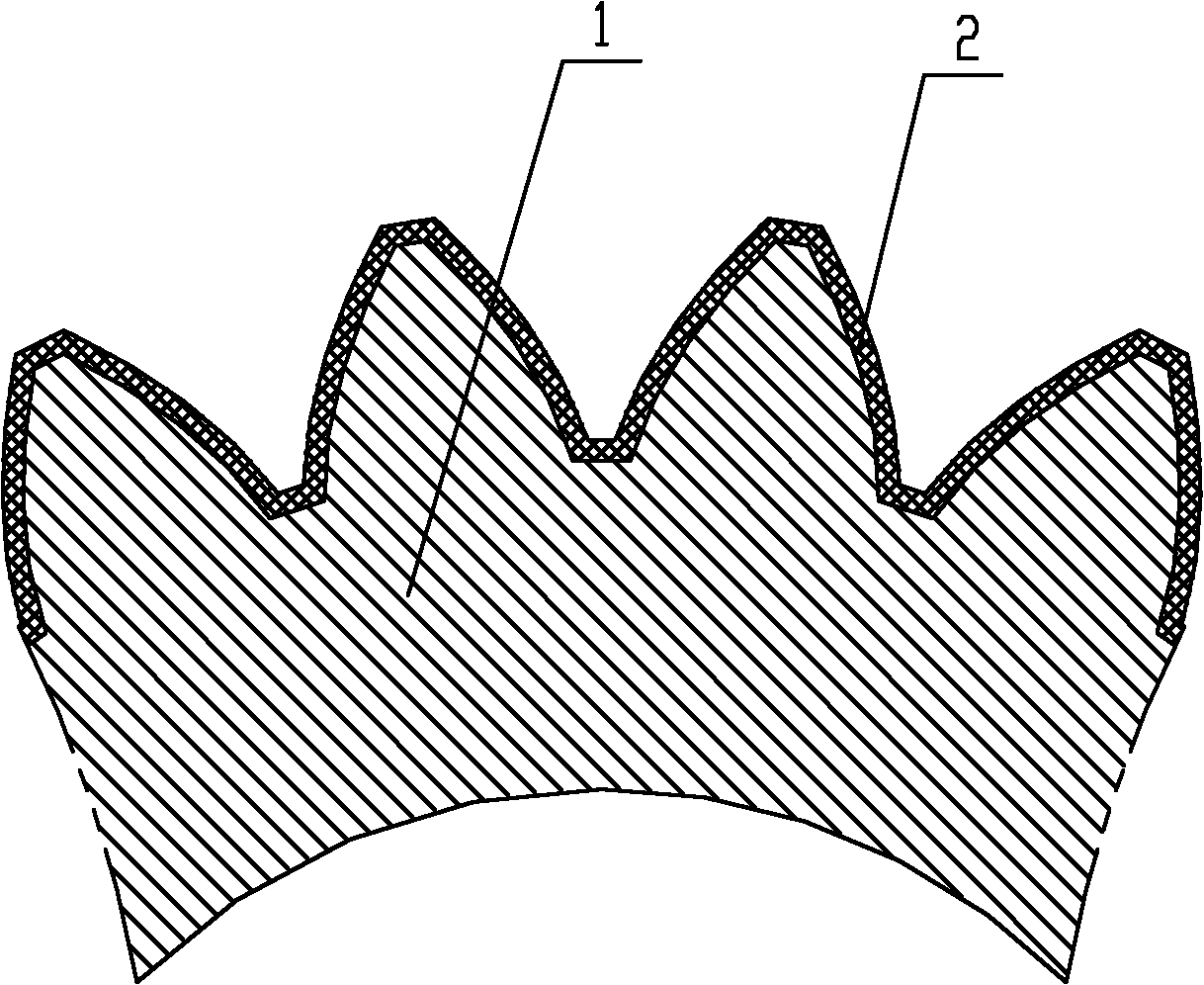

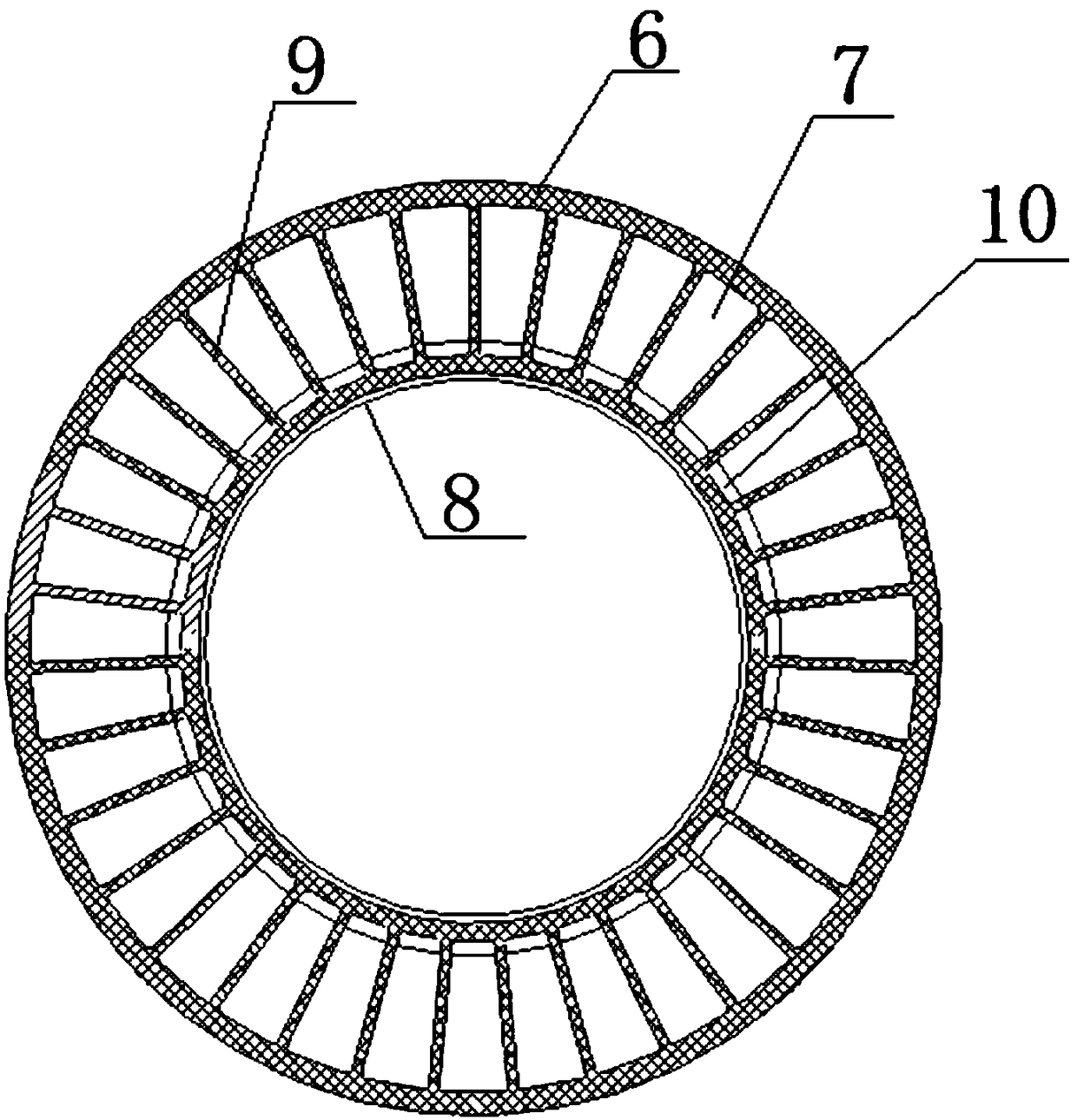

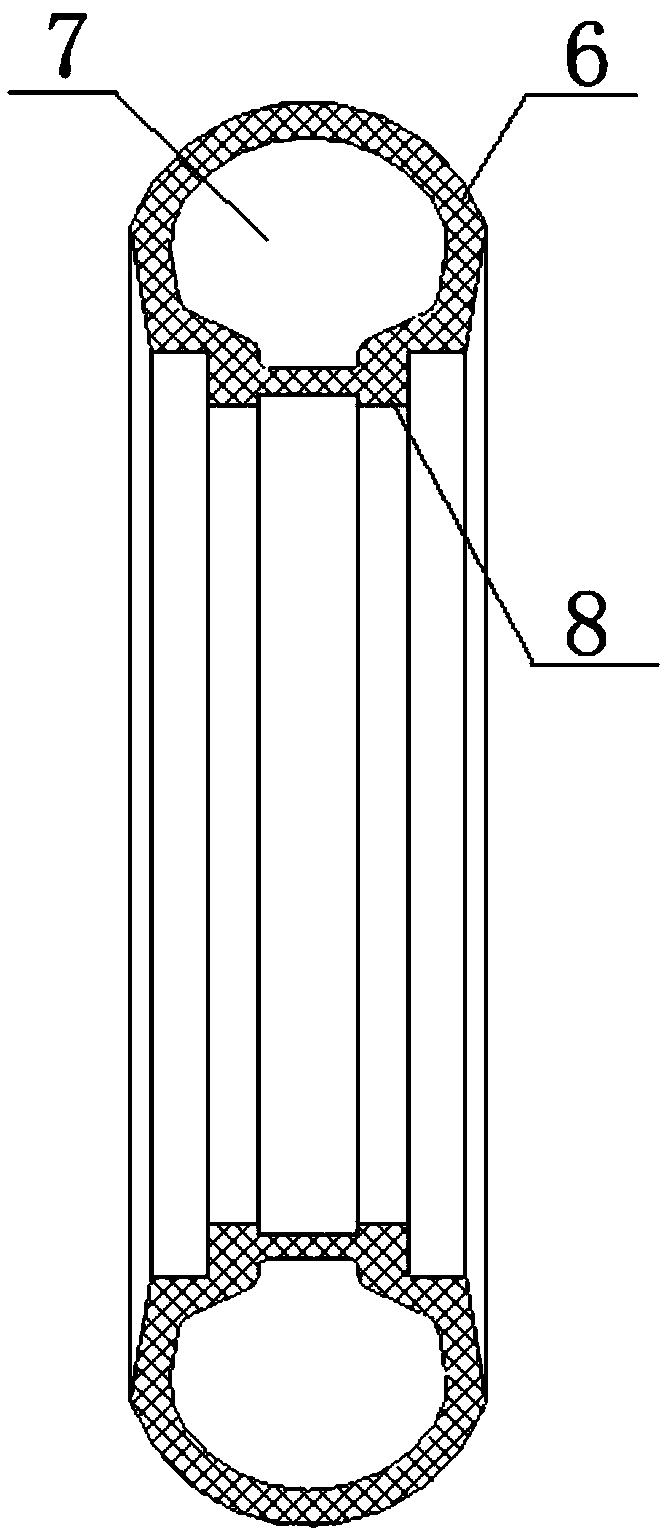

Highly-elastic hollow molded rubber tire and making process thereof

InactiveCN109159628ALow costShorten molding timeWith multiple inflatable chambersTyresVulcanizationTubeless tire

The invention discloses a highly-elastic hollow molded rubber tire and a making process thereof and belongs to the technical field of a rubber tire product. The highly-elastic hollow molded rubber tire comprises a tire body; the interior of the tire body is a hollow molded sealing cavity; the hollow molded sealing cavity is uniformly separated into a plurality of tire sub-cavities by separation plates, so that no additional inflation is required; when a certain cavity is penetrated, the use of the tire is not affected; an inner ring of the tire body is a tire clamping edge matched with a wheelhub; the shape of the tire clamping edge is matched with the shape of the wheel hub and presents a continuous concave and convex step shape to be convenient for stable and tight fit with the wheel hub. The highly-elastic hollow molded rubber tire is prepared by one-step injection, and hollowing and vulcanization processes in a one-time molding production system; the injection, the hollowing and the vulcanization of the highly-elastic hollow molded rubber tire are completed in a mold, so that the circulation of a product in all the processes is avoided, and the production cost is reduced. Theproblems of low production efficiency of a manual de-molding core of the tubeless tire and high labor intensity and great labor intensity of workers are solved.

Owner:安徽世界村智能装备有限公司

Crosswind type all-weather wind power generator

InactiveCN101968035AGood dynamic balanceReduce vibrationFinal product manufactureRenewable energy generationWind forceImpeller

The invention discloses a crosswind type all-weather wind power generator and relates to the technical field of wind power generation equipment. A main shaft of the generator is vertically arranged and externally connected with an impeller; a plurality of windward boards are evenly distributed on the impeller and each windward board is provided with a window; one side of each window is connected with a vane through a torsion spring and a rotation shaft parallel to the main shaft of the generator; the main shaft of the generator is externally connected with a wind shield through a bearing and the wind shield covers outside a part of the impeller; and a guiding empennage is fixedly connected with the outer side of the wind shield. The invention has the advantages of good dynamic balance, small vibration, stable and reliable running and large output power, and can greatly reduce the basic production cost and normally work under the condition of heavy wind and even storm wind.

Owner:扬州市金正机电制造有限公司

Centrifugal molding mold of concrete rectangular pile

The invention relates to a centrifugal molding mold of concrete rectangular piles. The centrifugal molding mold consists of two symmetrical groove-shaped mold structures, wherein each groove-shaped mold consists of a rectangular groove, a match board, a centrifugal balancer, a reinforcing longitudinal plate, reinforcing annular plates, semicircular running wheels and end plates, wherein the cross section of the groove is in a nonisosceles right-angled triangle shape, or the length of the groove is 1.5 times greater than the width of the groove, the match board is fixedly connected with the groove, and the end plates are installed at two axial ends of the groove. In addition, completely identical n-shaped box beams are also respectively and symmetrically connected onto the outer wall of a tube-shaped body, the n-shaped box beams can directly adopt channel steel, the opening ends of the n-shaped box beams are welded on each outer wall of the tube-shaped body, and meanwhile, the channel steel, the running wheels and the reinforcing annular plates are welded into a whole. The centrifugal molding mold has the beneficial effects that through the structure, the molding mold favorably realizes good dynamic balance performance, the intensity is better, and the tube wall of the mold is not easy to deform. The rigidity and the stability of the molding mold are improved, meanwhile, the economy is realized, and the structure is simple and reasonable.

Owner:TIANJIN JIANCHENGJIYE GRP

Refraction wind-guiding type fan blade system

InactiveCN101446265BSmall cross sectionImprove enduranceMachines/enginesWind energy generationDynamic balancePulp and paper industry

Owner:HARBIN POWER VERTICAL WIND POWER EQUIP ENG TECH RES CENT

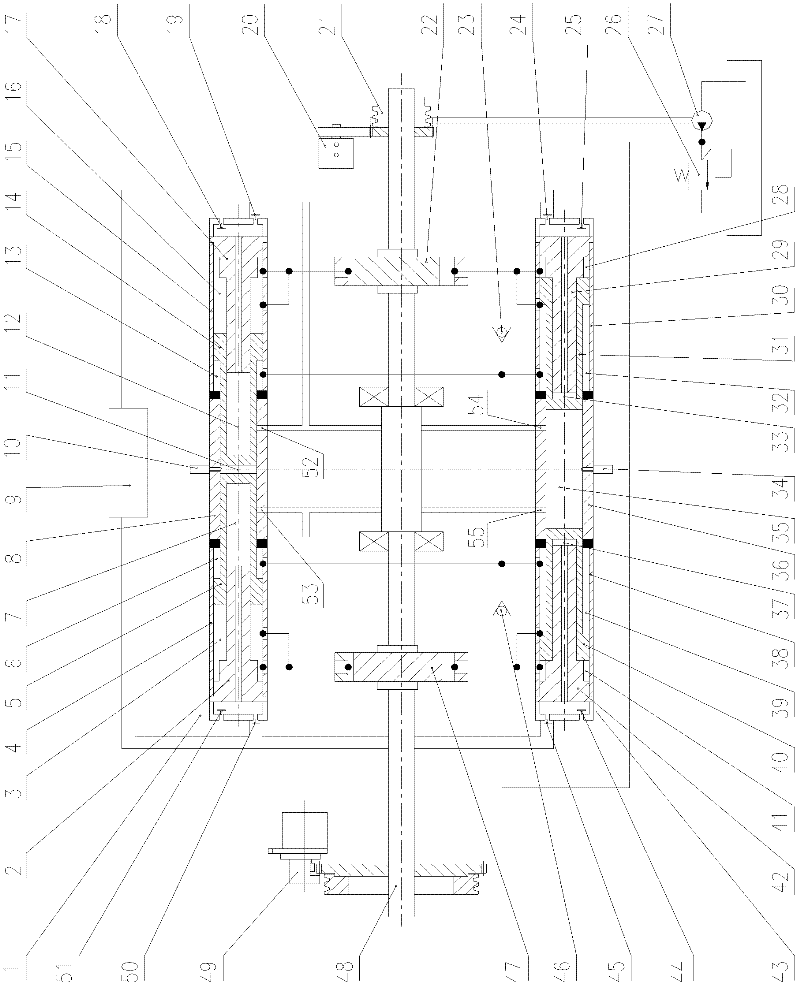

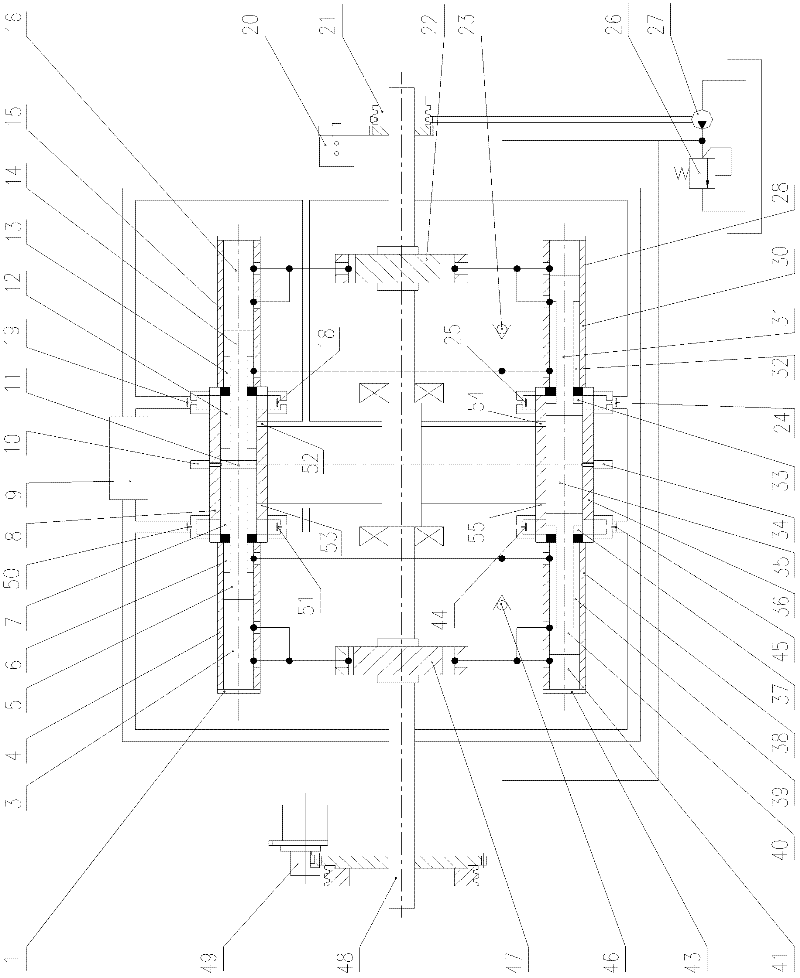

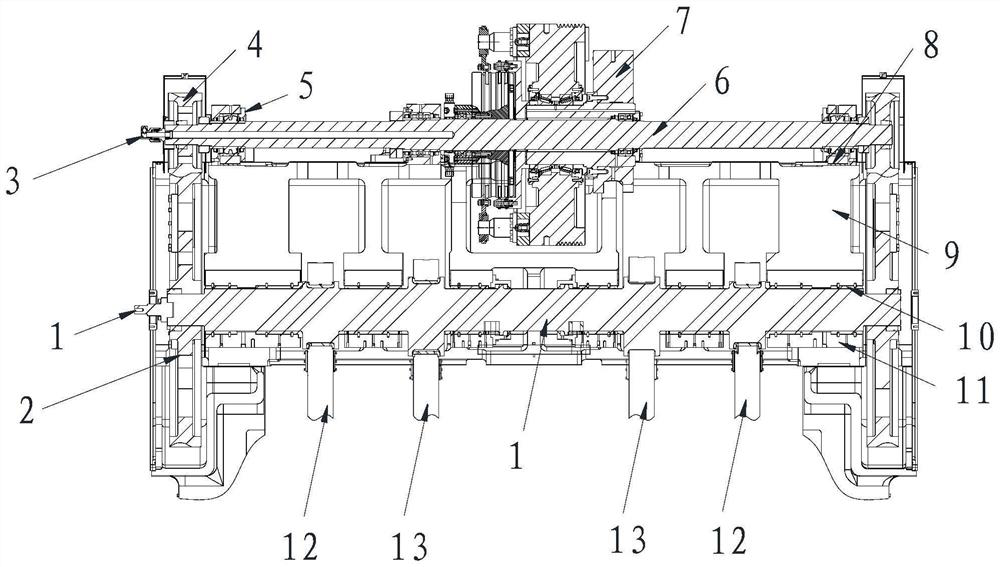

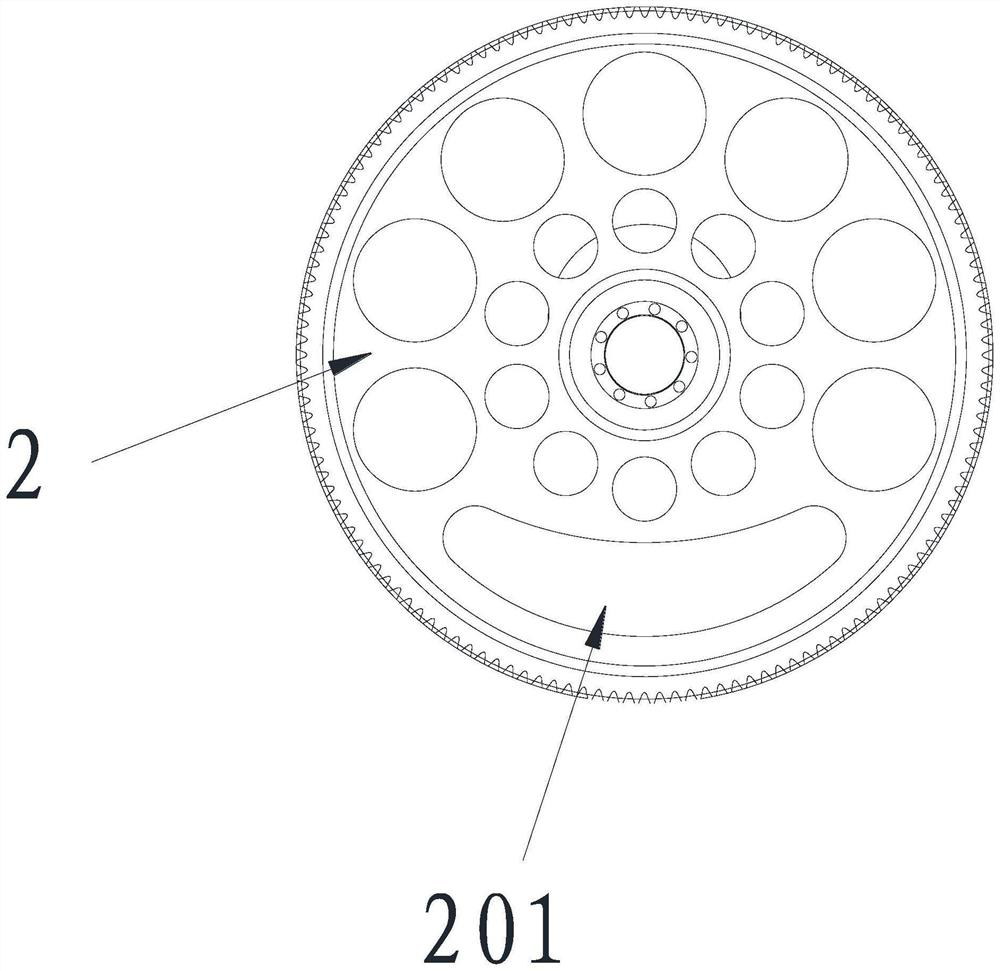

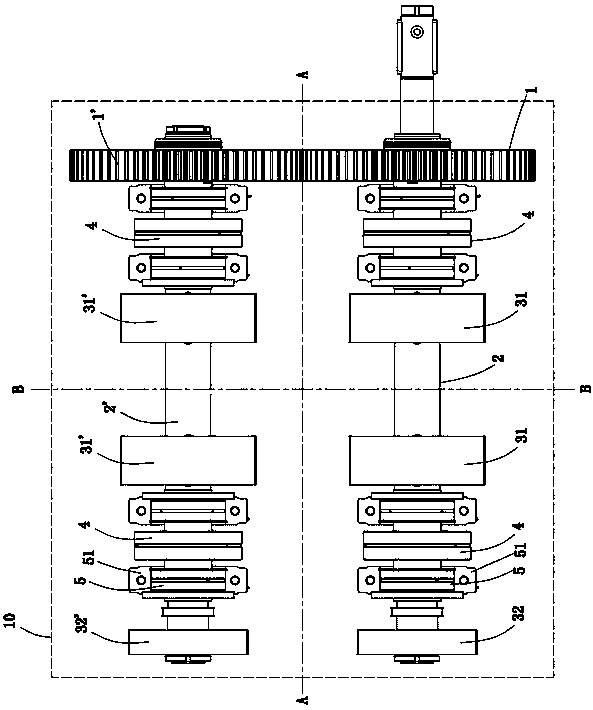

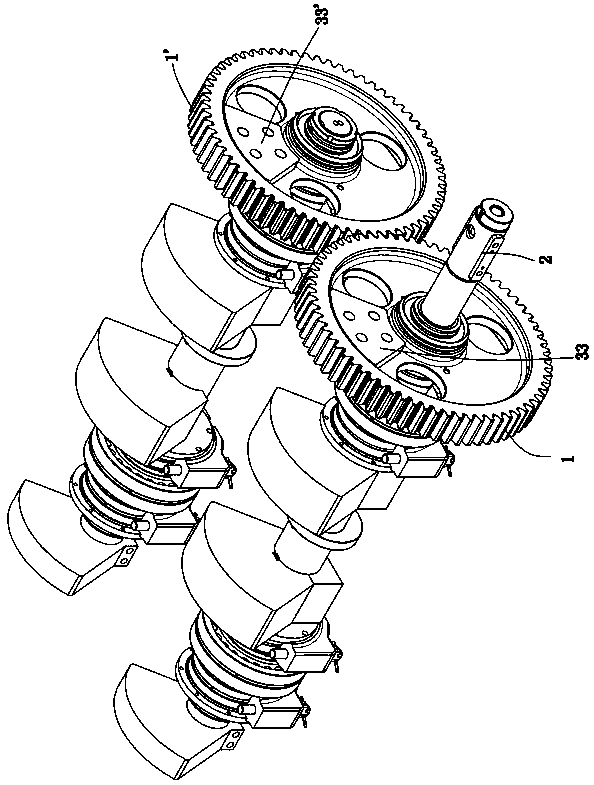

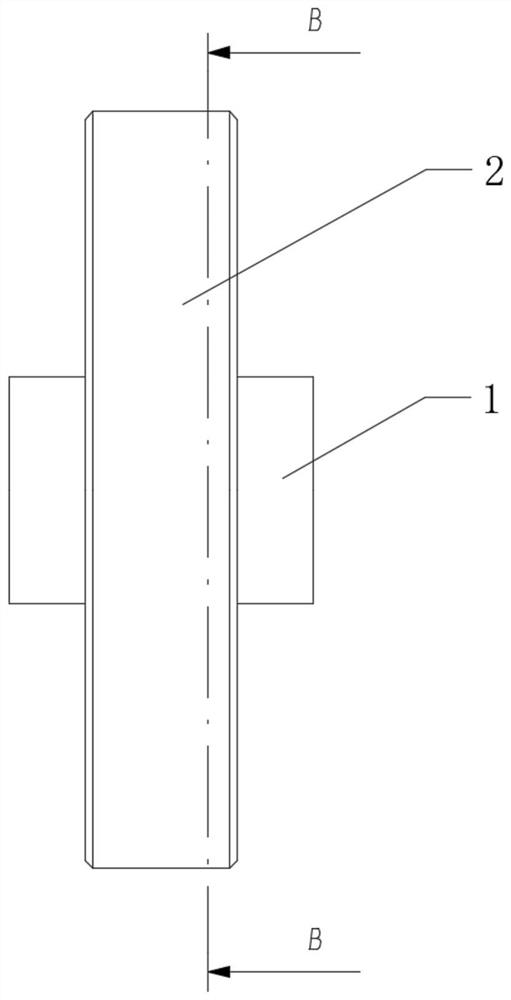

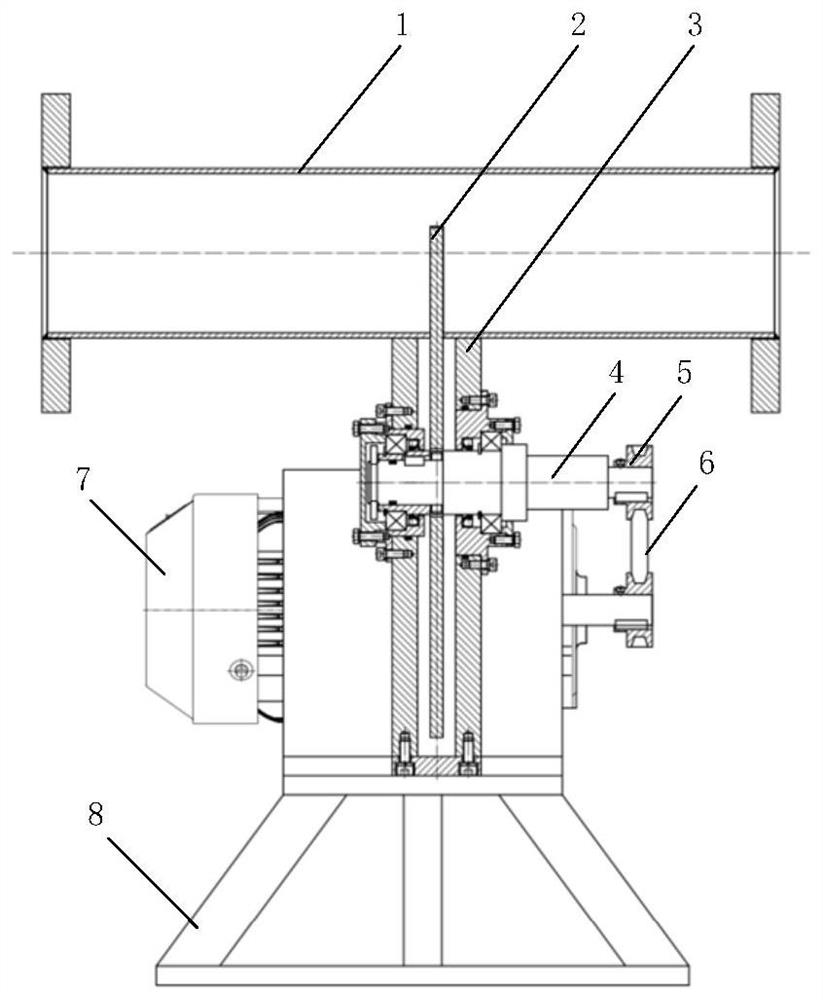

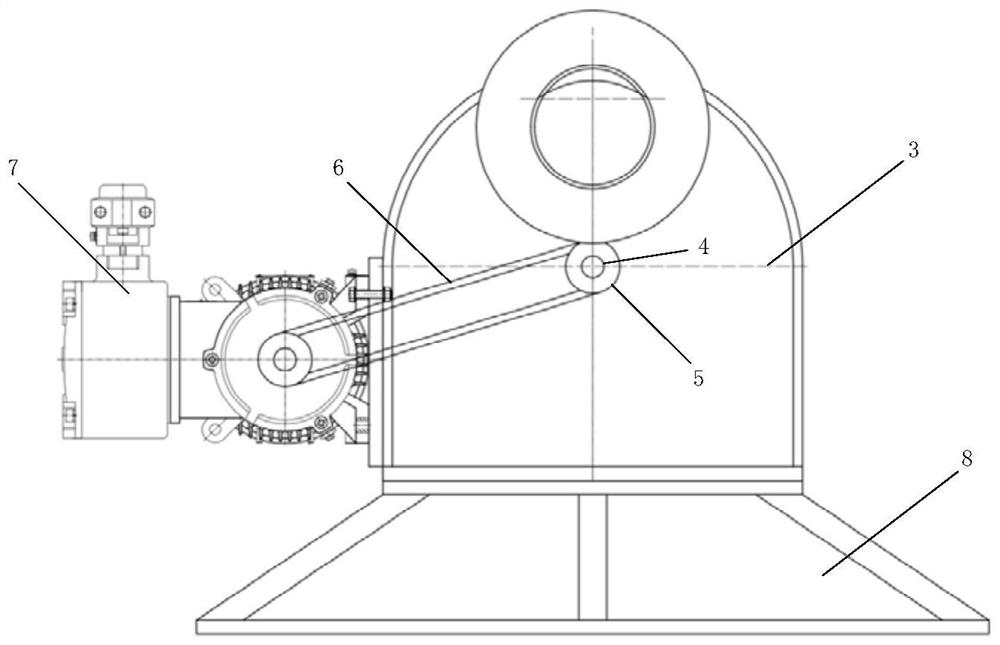

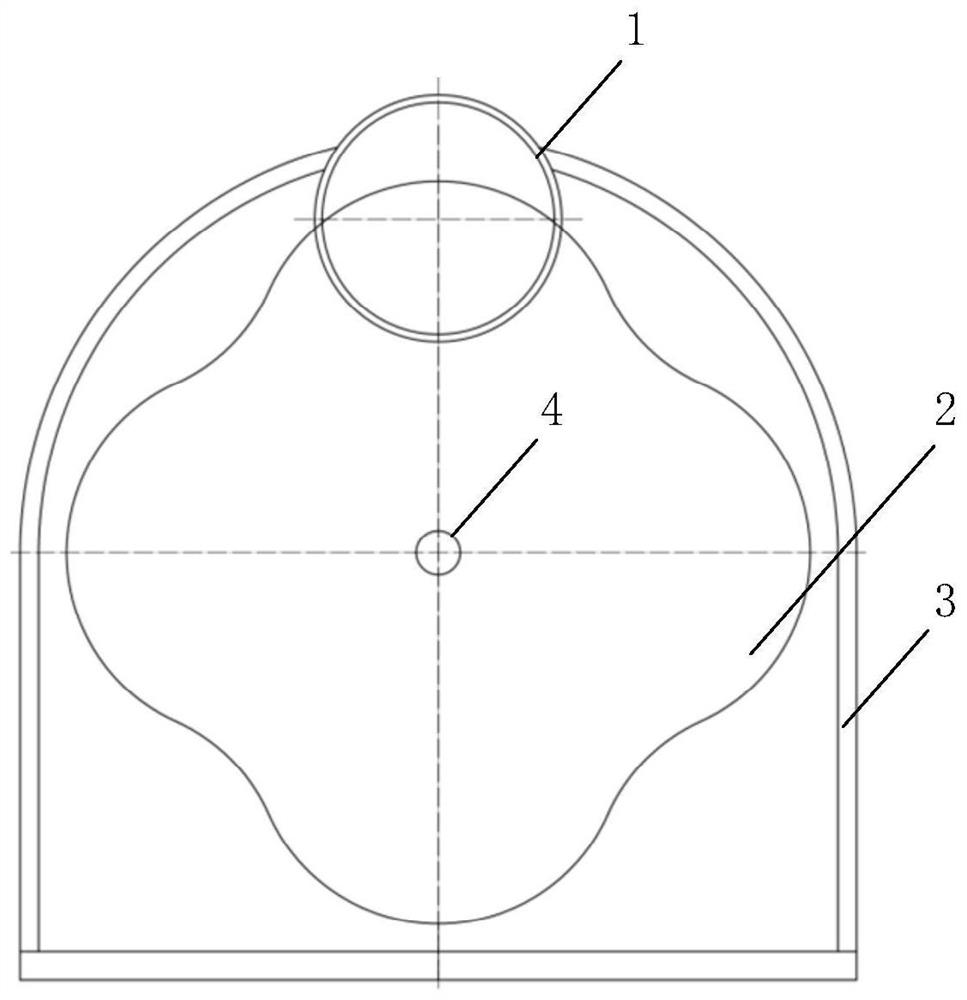

Main transmission structure of double-acting high-speed precision punching machine

The invention relates to the technical field of double-acting punching machines, in particular to a double-acting high-speed precision punching machine main transmission structure which comprises a crankshaft (1), large gears (2), small gears (4), a transmission shaft (6) and a flywheel clutch brake (7) assembly, the crankshaft (1) is of a four-crank-throw structure, and the large gears (2) are installed at the two ends of the crankshaft (1) respectively; the pinions (4) are mounted at the two ends of the transmission shaft (6); the lower end of the small gear (4) is meshed with the upper end of the large gear (2); the flywheel clutch brake (7) assembly is arranged in the middle of the transmission shaft (6) and connected with the transmission shaft (6), through the scheme, the dynamic balance balancing problem of the double-acting high-speed precision punching machine is solved, dynamic balance of components is kept in the working process, the precision of the punching machine and a die is effectively improved, the service life of the punching machine and the die is effectively prolonged, and the service life of the punching machine and the die is prolonged. And the abrasion of the shaft sleeve is reduced.

Owner:CHONGQING JIANGDONG MACHINERY

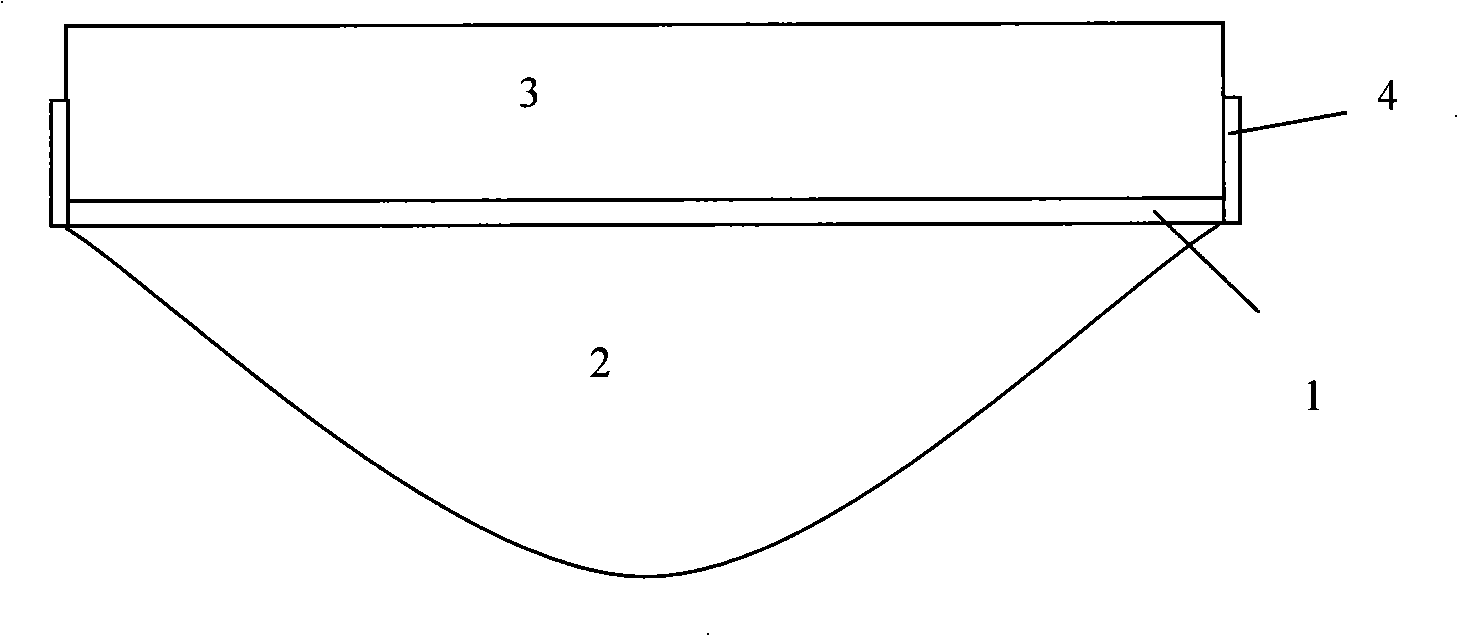

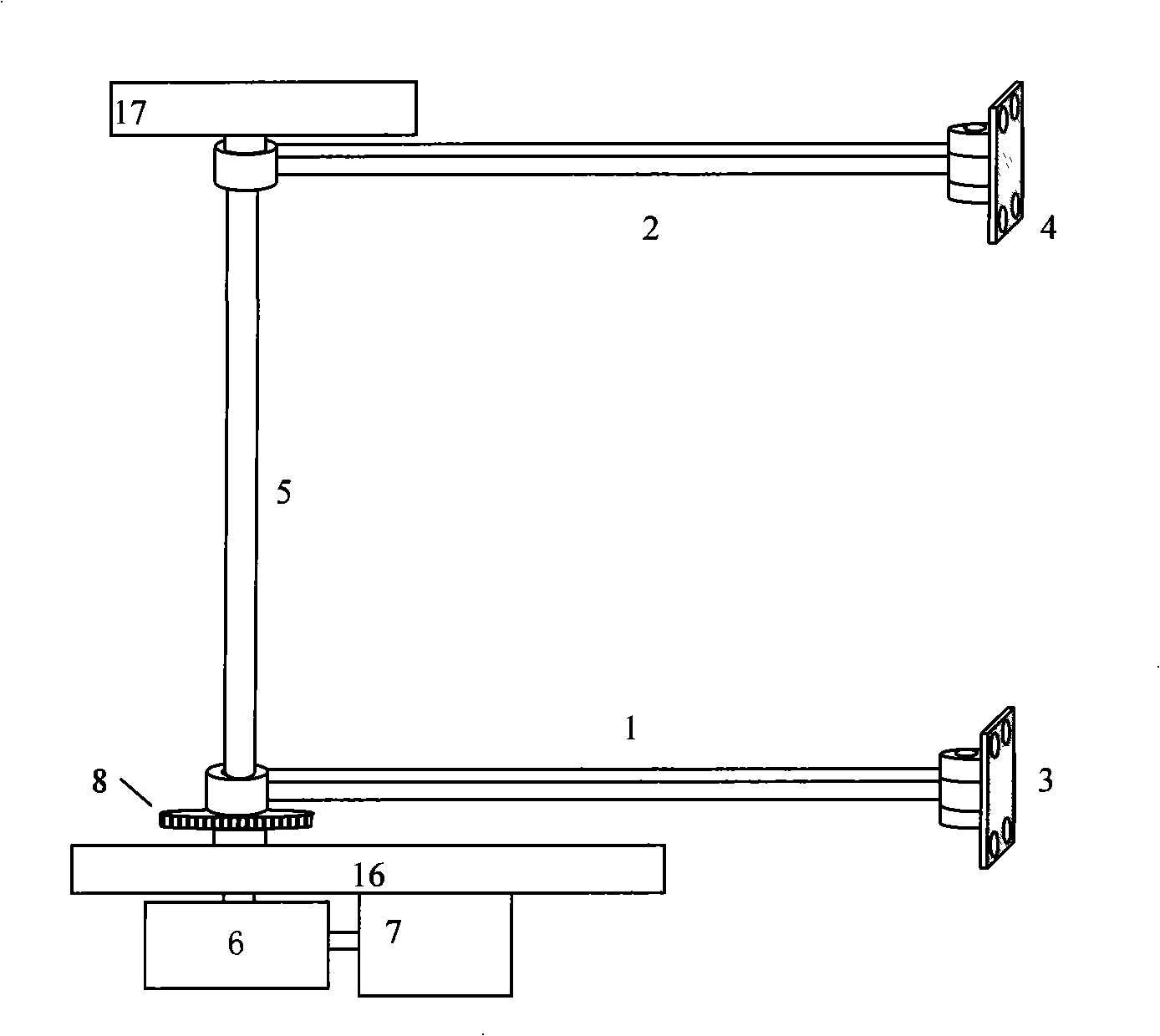

Wind collecting and protecting system of aerogenerator

InactiveCN101514686BGood dynamic balanceSmooth rotationWind motor controlMachines/enginesDrive wheelAir volume

The invention relates to a wind collecting and protecting system of an aerogenerator, belonging to the technical field of wind power generation. The wind collecting and protecting system comprises a wind collecting plate driving system, a drive traction system, a wind collecting plate system and a framework part; wherein, the wind collecting plate driving system comprises a lower driving bracket,an upper driving bracket, a lower connecting support and an upper connecting support of the wind collecting plate, a driving support shaft, a speed reducer and an electric motor; the drive traction system includes a drive sprocket, a traction chain and a driving wheel; the wind collecting plate system comprises a wind collecting plate, a lower sheave of the wind collecting plate, a top sheave of the wind collecting plate, a lower slideway and an upper slideway; and the framework part comprises a lower framework, an upper framework and a vertical framework. The angle between the wind collecting plate and the framework of the aerogenerator is within the range of 0-45 degrees, and is driven, regulated and controlled by the electric motor and a speed changer, so that the wind collecting plateis driven and pulled to slide on the slideways, thus adjusting and changing the size of a wind inlet and the wind collecting quantity of the wind collecting plate; when the wind speed is too high or storm wind, the wind collecting plate and the wind inlet are closed to play the role of protecting the system.

Owner:HARBIN POWER VERTICAL WIND POWER EQUIP ENG TECH RES CENT +2

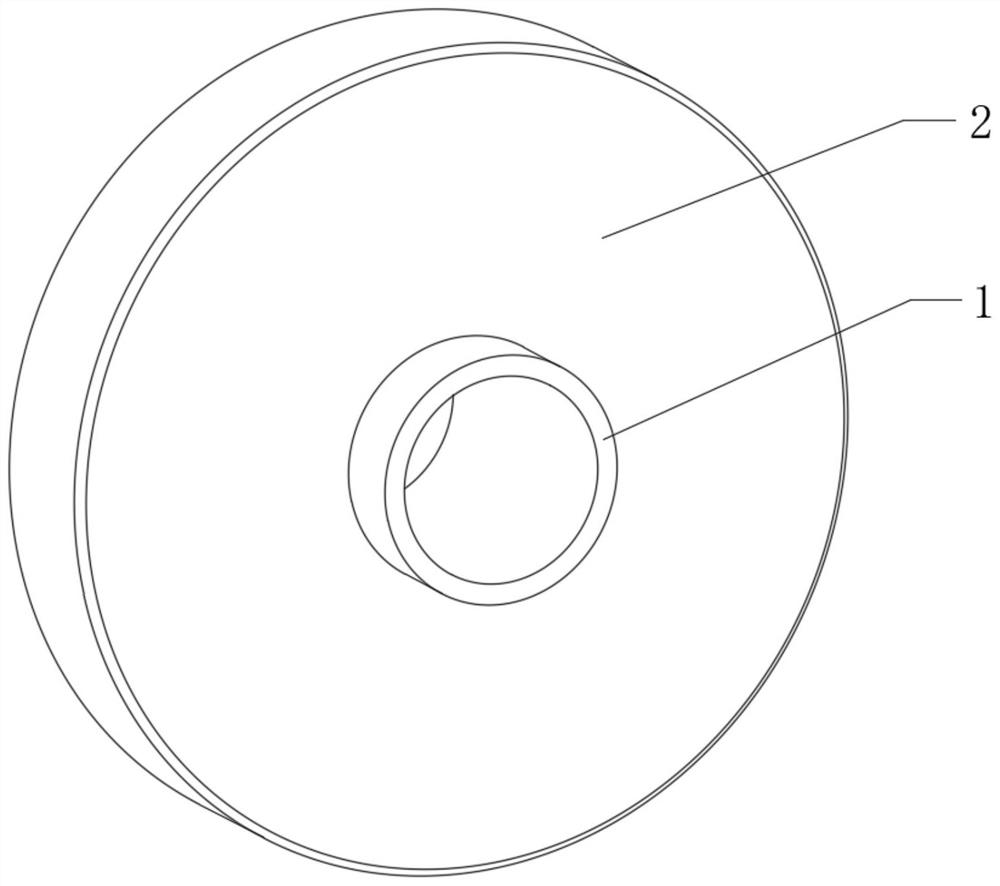

Built-in conical surface pre-positioned permanent magnet synchronous coupler

The invention discloses a built-in conical surface pre-positioning permanent magnet synchronous coupler. The built-in conical surface pre-positioning permanent magnet synchronous coupler comprises aninner rotor and an outer rotor, wherein the inner rotor is provided with a first annular part, and the outer rotor comprises a second annular part and a third annular part which are coaxially arranged. The end surface of the second annular part is located in the third annular part. The first annular part is sleeved with the third annular part. The built-in conical surface pre-positioning permanentmagnet synchronous coupler further comprises a conical positioning sleeve mounted at the inner side wall of the first annular part or the outer side wall of the second annular part in a sliding manner; the conical positioning sleeve is provided with a first conical surface; the rotor without the conical positioning sleeve is provided with a second conical surface; and the first conical surface and the second conical surface are matched with each other to position the two rotors. According to the built-in conical surface pre-positioning permanent magnet synchronous coupler of the invention, the second annular part and the third annular part which have height difference are designed, so that the conical positioning sleeve can be reliably arranged in the inner rotor or the outer rotor; and the two conical surfaces are positioned at the inner side of an inner permanent magnet and are close to the axes of the rotors; and therefore, the conical positioning sleeve is small in size, light inweight and good in operation stability compared with the prior art.

Owner:诸暨和创电机科技有限公司

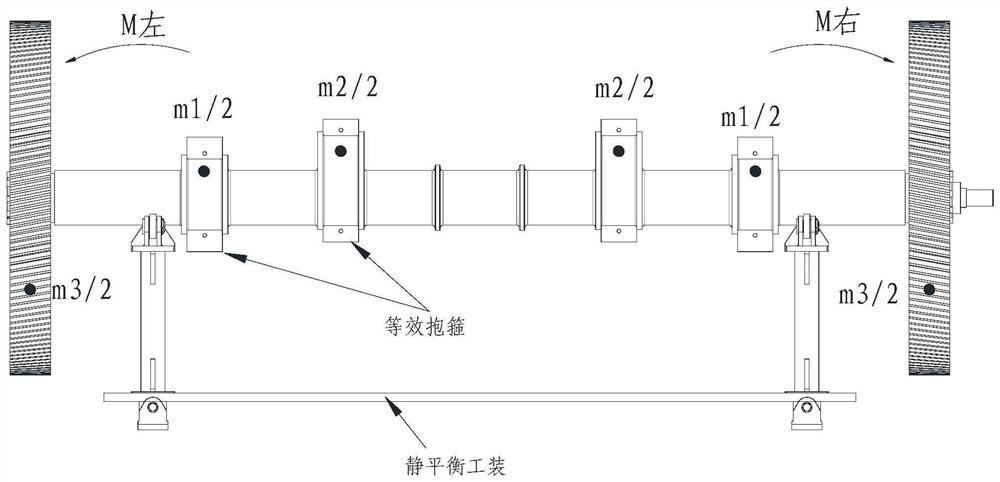

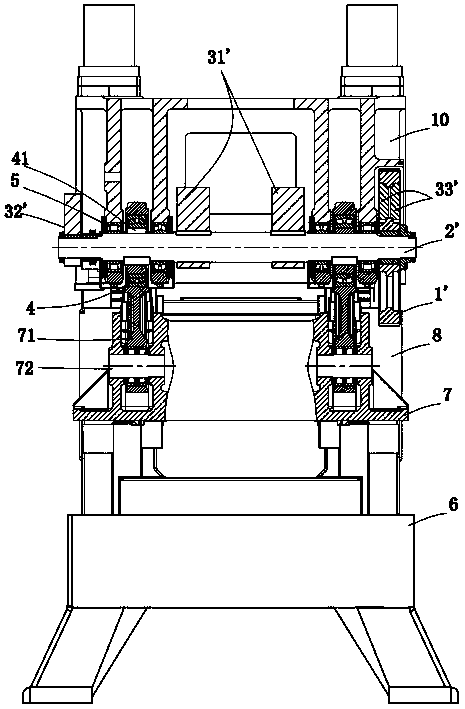

Pressure machine capable of driving balance mechanism

The invention discloses a pressure machine capable of driving a balance mechanism. The pressure machine comprises sliding blocks, upper beams, dynamic balance mechanisms; one ends of first transmission shafts of the dynamic balance mechanisms are connected with driving gears, one ends of second transmission shafts are connected with driven gears, the driving gears mesh with the driven gears, the first transmission shafts and the second transmission shafts are symmetrically arranged according to the horizontal center of the sliding blocks, the vertical center of each sliding block is taken as the center, force application bearings are symmetrically arranged on the two sides of the first transmission shafts and the second transmission shafts respectively, the force application bearings are eccentrically arranged, the two sides of each force application bearing are symmetrically provided with support bearings, and the support bearings support the first transmission shafts and the second transmission shafts. First balance blocks take the vertical center of the sliding blocks as the center, the two sides of the first balance blocks are arranged on the first transmission shafts and the second transmission shafts correspondingly, second balance blocks are arranged on the other sides of the first transmission shafts and the second transmission shafts; second balance blocks take the horizontal center of the sliding blocks as the center and are symmetrically arranged, third balance blocks are arranged on the two sides of the driving gears and driven gears as the symmetric center according to the gear thickness, and the first balance blocks, the second balance blocks and the third balance blocks are opposite to the eccentric direction of the force application bearings.

Owner:JDM JINGDA MASCH (NINGBO) CO LTD

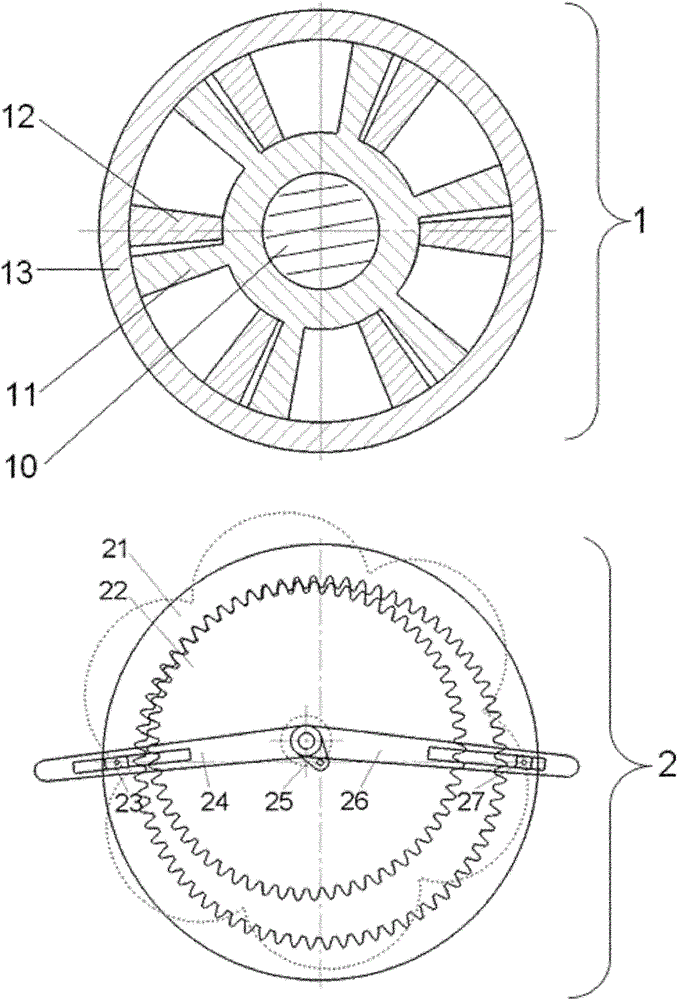

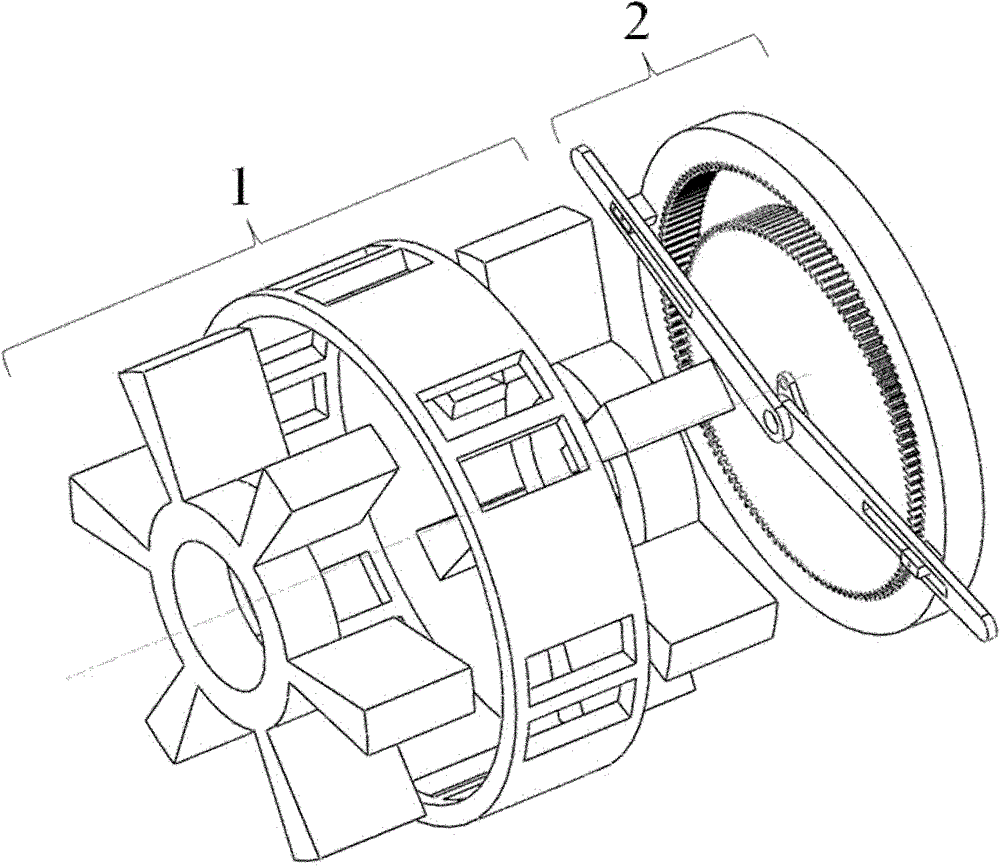

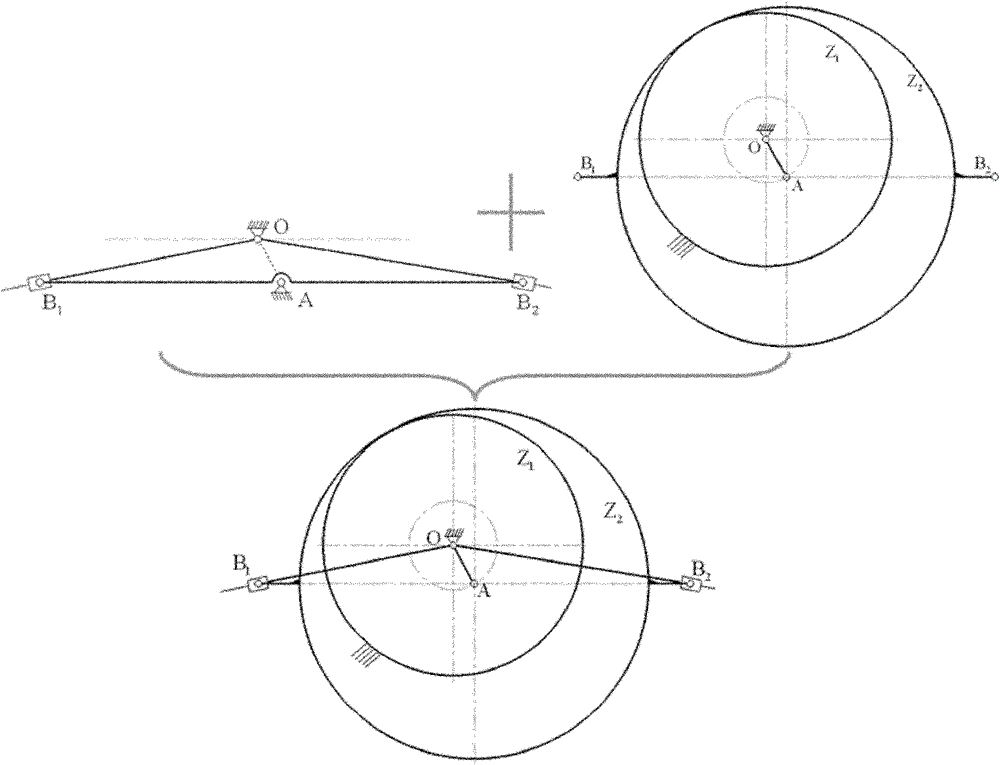

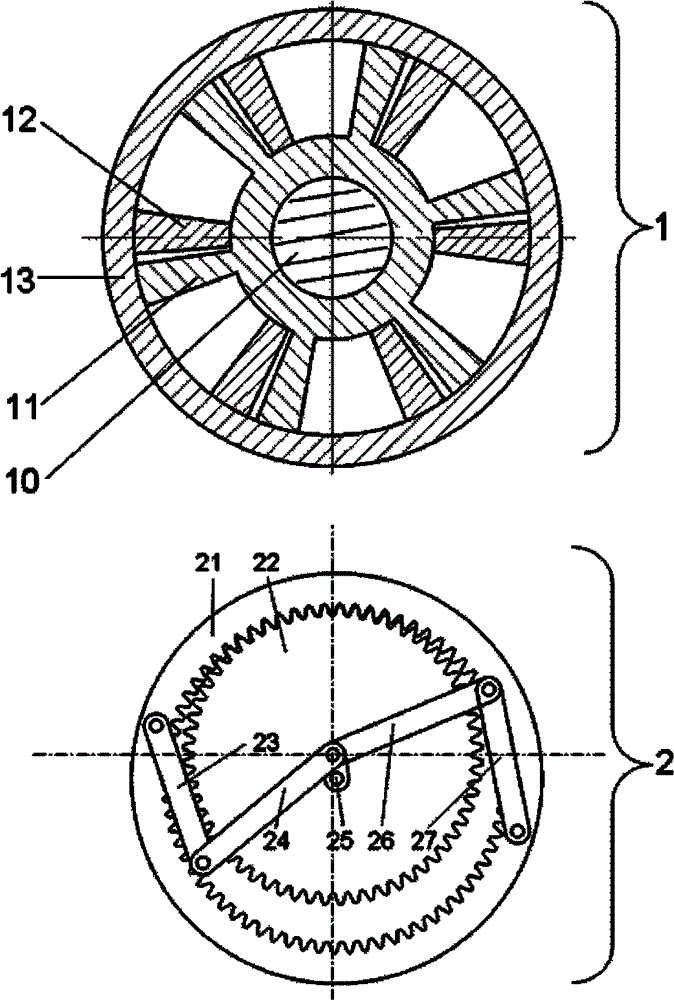

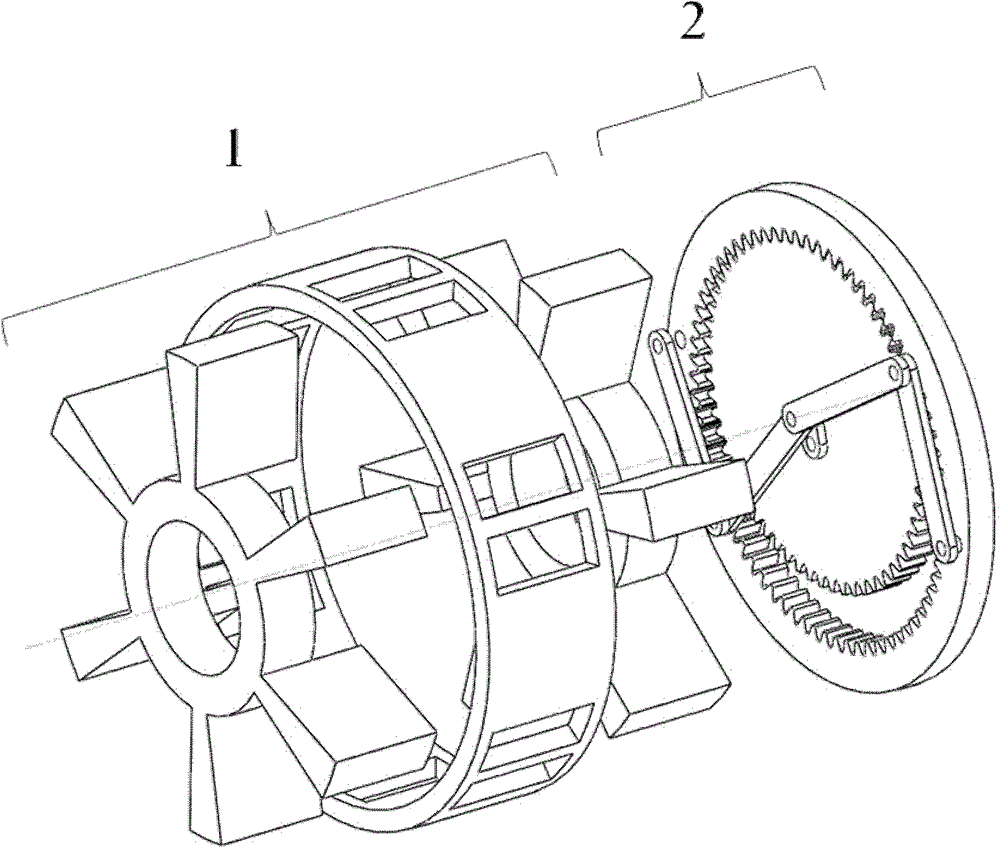

Power transmission device formed by combining pericycloid mechanism and guide rod mechanism

InactiveCN102182549BMore explosive workImprove power densityInternal combustion piston enginesDevice formEngineering

The invention discloses a power transmission device formed by combining a pericycloid mechanism and guide rod mechanisms, which comprises a power cylinder assembly and a differential drive assembly, wherein the differential drive assembly is connected with the power cylinder assembly; the power cylinder assembly comprises a rotor I, a rotor II, a power shaft and a cylinder body; the rotor I and the rotor II are coaxial, are alternately installed in the cylinder body and rotate around a rotating axis of the power shaft; and the differential drive assembly is a drive mechanism which is formed by combining one set of pericycloid mechanism and two sets of guide rod mechanisms and has the freedom degree of 1. The invention has the advantages of simple structure, stability, reliability and highefficiency in drive, and the like, and an efficient and high-power density double-rotor piston engine can be obtained by applying the device on an engine.

Owner:NAT UNIV OF DEFENSE TECH

Adaptive order tracking vibration reduction metamaterial shaft structure

ActiveCN113864399AGood vibration and noise reductionGood dynamic balanceRotating vibration suppressionPhysicsFrequency band

The invention discloses an adaptive order tracking vibration reduction metamaterial shaft structure, comprising a shaft base body, a shell and a unit cell unit. The unit cell unit comprises a constant-stiffness spring, mass blocks and variable-stiffness springs; the mass blocks are connected with the shaft base body and the shell through the constant-stiffness springs; and the adjacent mass blocks are connected through the variable-stiffness springs. The number of the mass blocks is eight; the mass blocks are annularly distributed on the periphery of the shaft base body; the number of the constant-stiffness springs is sixteen; and the number of the variable-stiffness springs is eight. The adaptive order tracking vibration reduction metamaterial shaft structure has the low-frequency vibration isolation capacity, the mass blocks with different thicknesses are designed in the circumferential direction of the shaft structure, a plurality of different band gaps are generated, and a wide low-frequency band gap is formed through combination. Adaptive order tracking can be achieved, the formed low-frequency forbidden band changes along with the change of the rotating speed, and the vibration and noise reduction effect is better.

Owner:SOUTHWEST JIAOTONG UNIV

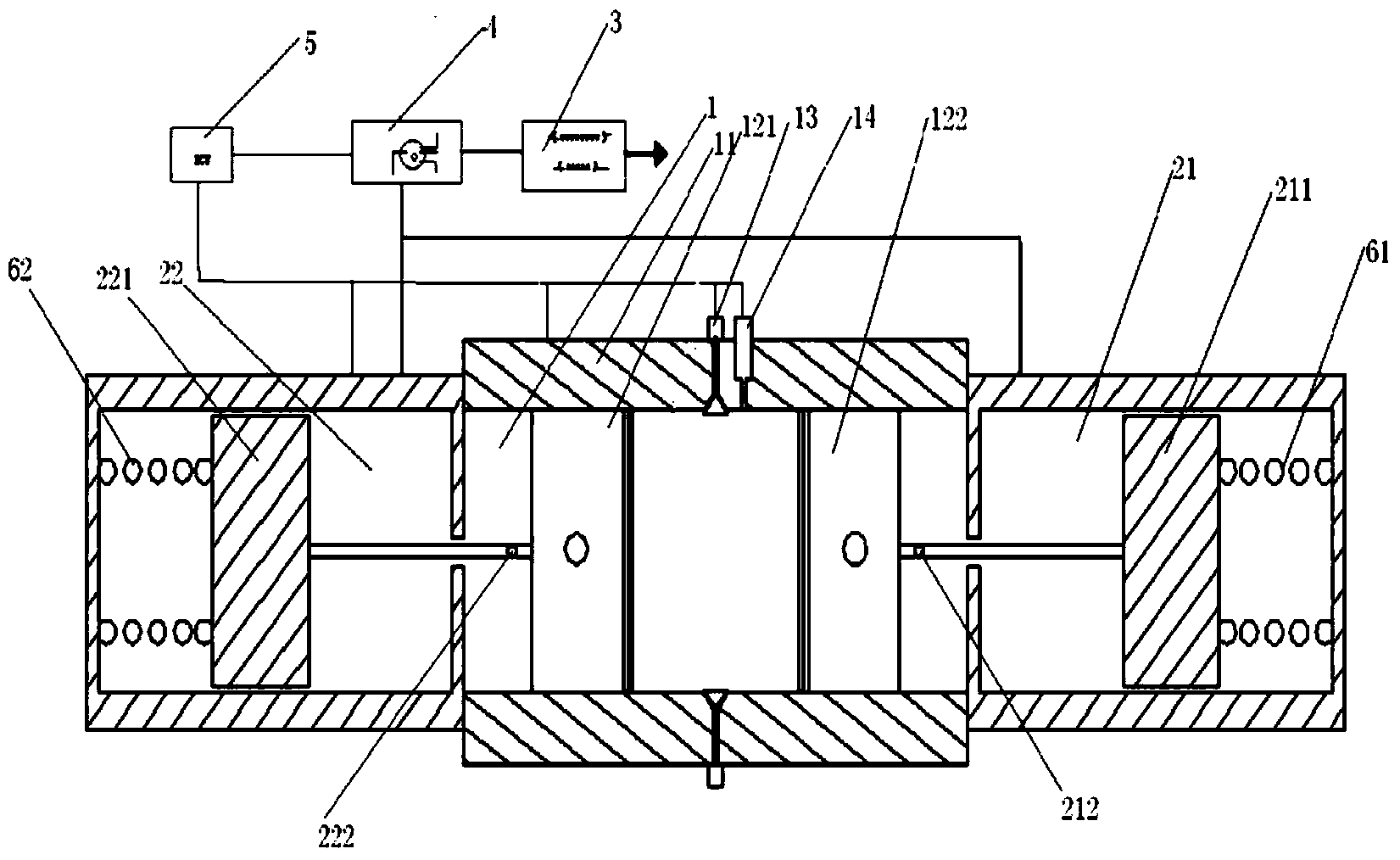

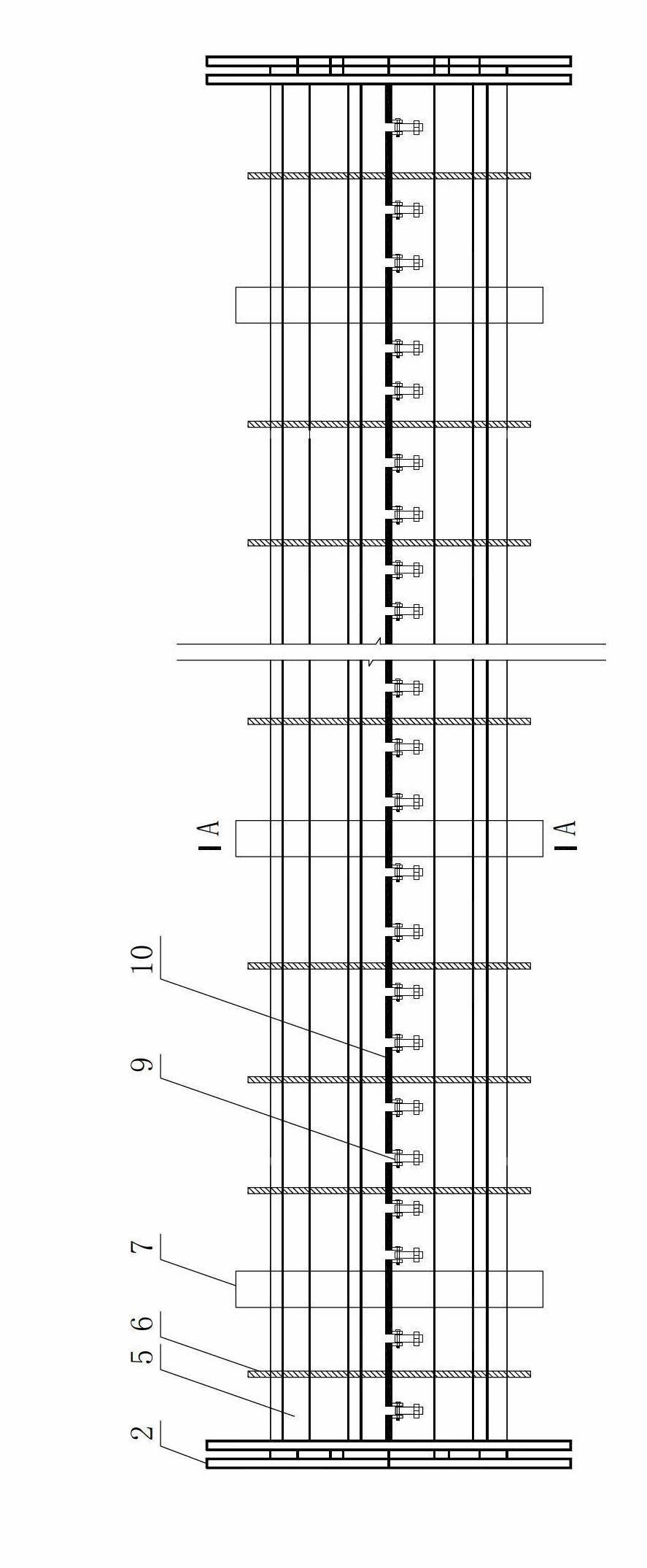

Quasi-linear tube Coriolis mass flowmeter

The invention provides for a quasi-linear tube Coriolis mass flowmeter (CMF), which is used for direct high-accuracy measure for mass flow and comprises two quasi-linear tube measuring tubes with the same structure in parallel, a vibration exciter, two detectors, four distance plates, two flanges, two end connecting tubes, two shunts and four matching blocks. The quasi-linear tube Coriolis mass flowmeter (CMF) can effectively improve the properties and quality factors of a resonance sensor, greatly reduces volume of a flowmeter, lowers flow field influence, and has small flow resistance, low pressure loss and simple installation and processing; the measuring tube has favorable dynamic equilibrium, can measure the liquid mass flow with high viscosity and high impurity content, further expands the application range of the CMF and satisfies the industrial development requirements on accuracy and range of flow measurement; and the invention plays a greater role in saving raw materials, lowering production cost, reducing environment pollution, improving profit margin and promoting product quality.

Owner:BEIHANG UNIV

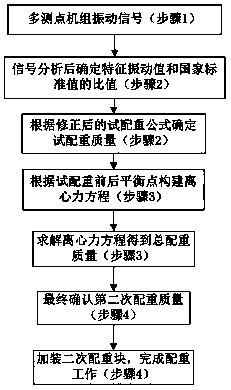

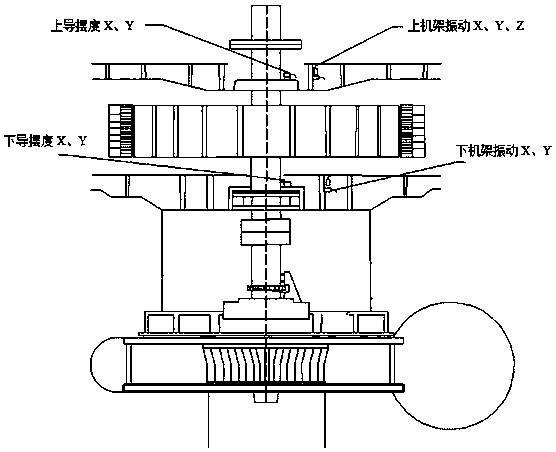

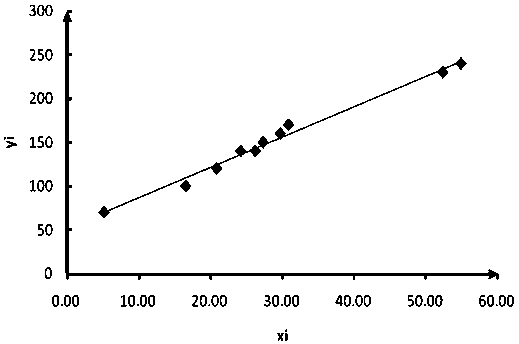

A dynamic balance test method for large hydroelectric units based on centrifugal force equation

ActiveCN109115408BImprove accuracy and reliabilityGood dynamic balanceStatic/dynamic balance measurementRotary machineField tests

Owner:大唐水电科学技术研究院有限公司

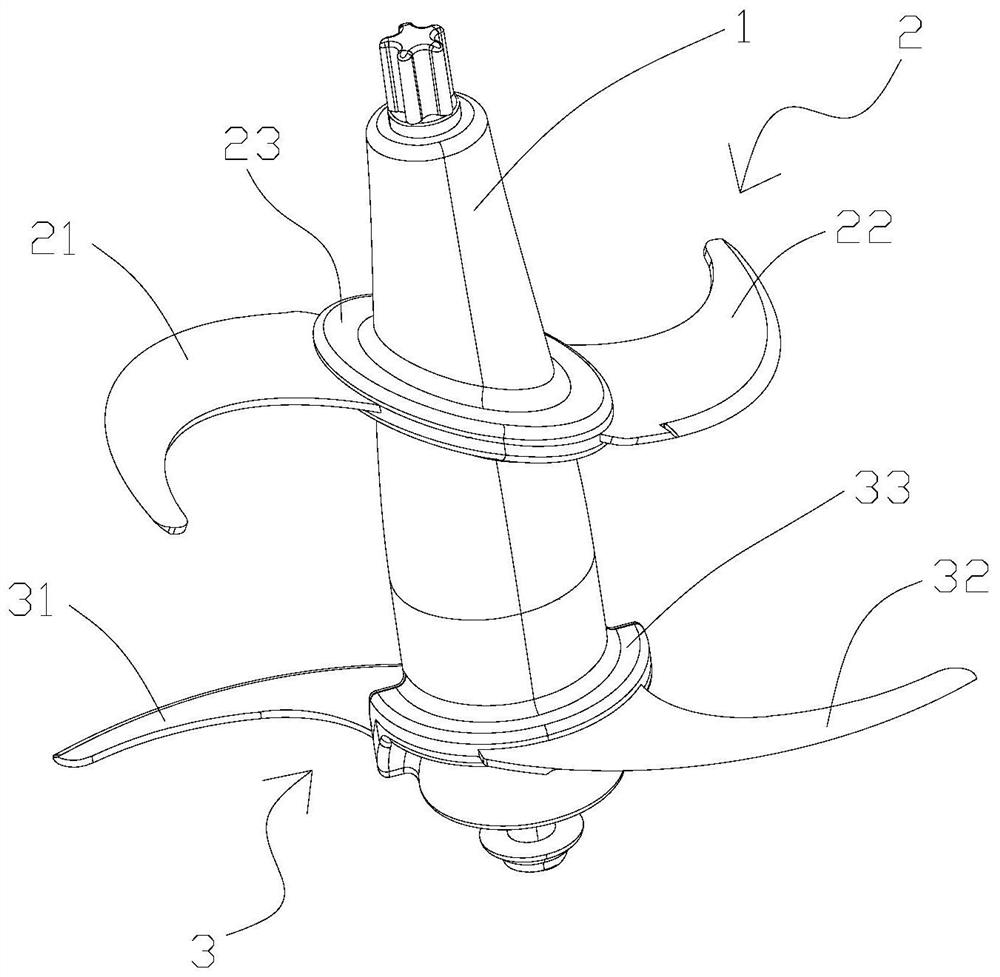

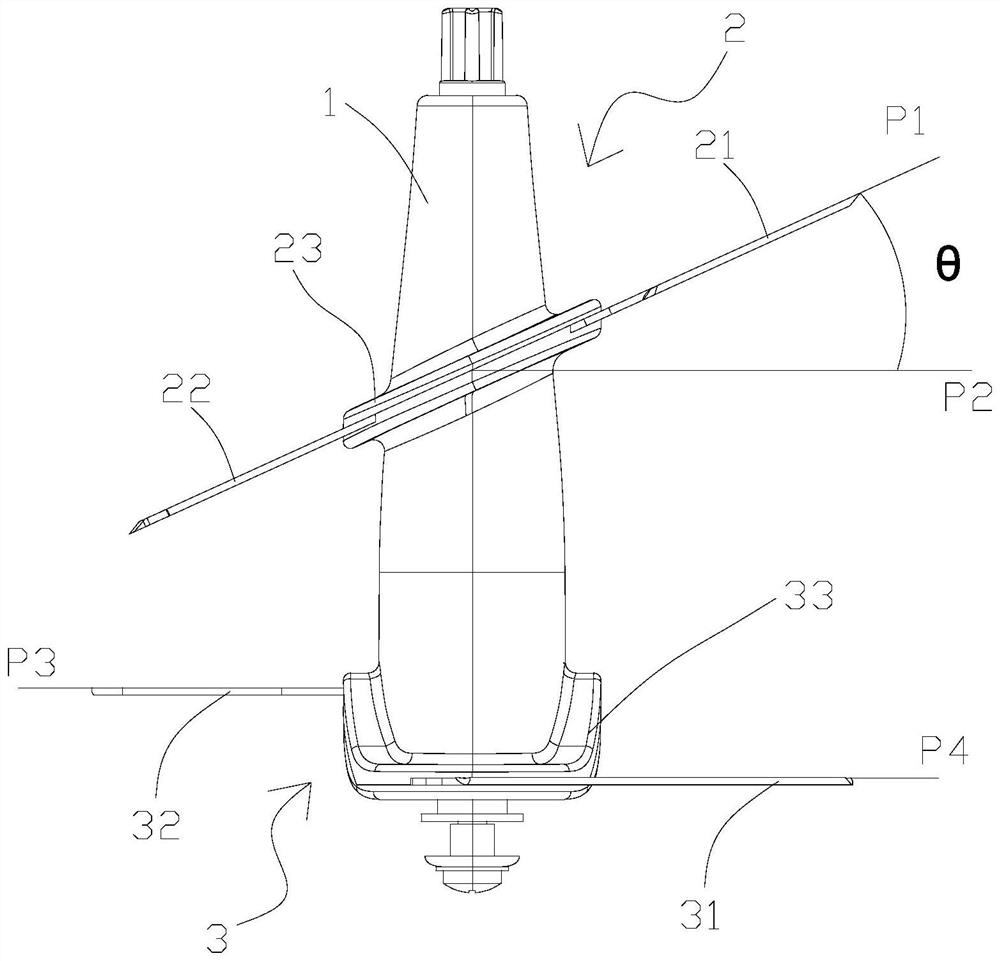

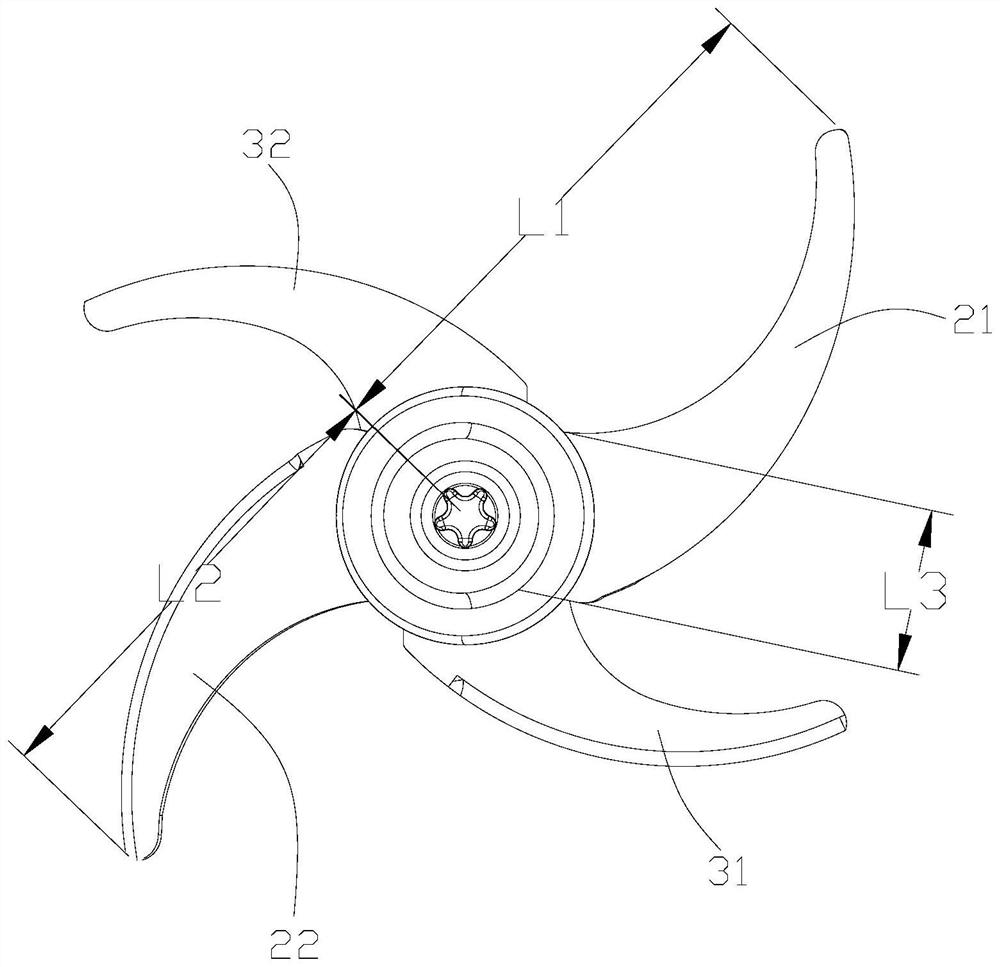

Cutter for food processor

PendingCN112971554ASame moment of inertiaGood dynamic balanceKitchen equipmentKnife bladesStructural engineering

The invention discloses a cutter for a food processor, which is characterized in that the cutter comprises a rotating shaft (1), an upper cutter assembly (2) arranged on the upper portion of a rod body of the rotating shaft (1) and a lower cutter assembly (3) arranged on the lower portion of the rod body of the rotating shaft (1), and the upper cutter assembly (2) comprises a left upper blade (21) arranged on one side of the rotating shaft (1) and a right upper blade (22) arranged on the other side of the rotating shaft (1), the lower cutter assembly (3) comprises a left lower blade (31) arranged on one side of the rotating shaft (1) and a right lower blade (32) arranged on the other side of the rotating shaft (1), the left upper blade (21) and the right upper blade (22) are located on the same inclined plane P1, and the included angle theta between the inclined plane P1 and the horizontal plane P2 is larger than or equal to 5 degrees and smaller than or equal to 60 degrees.The cutter for the food processor is consistent in rotation inertia, good in dynamic balance, small in vibration during working and low in noise, in the working process, a ground object rolls up and down, stirring is more uniform, grinding is finer, the particle size is more consistent, the structure is simple, and use is safe.

Owner:ZHONGSHAN JUNGUO ELECTRICAL APPLIANCES CO LTD

A high-speed precision rotating shaft with high air pressure seal

The invention provides a high-speed precision rotating shaft being sealed by high-pressure gas. The high-speed precision rotating shaft comprises a shaft core which is installed on an angular contact ball bearing. The angular contact ball bearing is fixed in a rotating shaft outer cover. A concave ring is arranged on the inner surface of the outer circumference of the large end of the shaft core. One end of the rotating shaft outer cover is connected with the concave ring. A wedge-shaped structure is arranged on the outer surface of the joint of the rotating shaft outer cover and the concave ring. The other end of the rotating shaft outer cover is fixedly connected with an end cover, a through hole which is parallel to a rotating shaft body is formed in the wall of the rotating shaft outer cover, one end of the through hole is located on the inner side of the concave ring, and an air inlet is formed in the rotating shaft outer cover, penetrates through the rotating shaft outer cover, and is connected with a channel. A wedge-shaped structure is arranged at the joint of the end cover and the shaft core. The rotating shaft is sealed by being filled with high-pressure gas, and an air path is simple; the special wedge-shaped structure is designed, so that high-pressure gas can be smoothly exhausted, and foreign materials can be prevented from entering the rotating shaft.

Owner:KUNSHAN YUNCO PRECISION IND TECH

Rotary flow pulsation generating device

InactiveCN113027875AGood dynamic balanceReduce axial forceCircuit elementsElectric machineDrive shaft

The invention aims to provide a rotary flow pulsation generating device. The device comprises a pipe section, an overflowing baffle, a motor and a shell, a transmission shaft is connected with a first belt pulley, a motor shaft of the motor is connected with a second belt pulley, the first belt pulley and the second belt pulley are connected through a belt, and the overflowing baffle is installed outside the transmission shaft and fixed to the transmission shaft. The shell is installed at the outer side of the overflowing baffle and fixed to the pipe section, a radial opening is formed in the pipe section in the radial direction of the pipe section, the overflowing baffle extends into the radial opening, the shell is fixed to the base, and the base is fixed to the ground. The overflowing baffle does not completely block the overflowing area of a pipeline in the rotating process, continuous flow pulsation can be generated, and the function of adjusting the flow fluctuation frequency and amplitude can be achieved by adjusting the rotating speed of the motor, the size of the overflowing baffle and the opening degree of a flow adjusting valve. The flow pulsation device has the advantages of being excellent in dynamic balance characteristic, small in axial force and compact in structure, and a pipeline connector is convenient to install.

Owner:HARBIN ENG UNIV

Power transmission device with combined pericycloid mechanism and double-crank mechanisms

InactiveCN102140959BImprove power densityIncrease powerInternal combustion piston enginesEngineeringPiston

The invention discloses a power transmission device with a combined pericycloid mechanism and double-crank mechanisms, which comprises a power cylinder assembly and a differential driving assembly connected with the power cylinder assembly, wherein the power cylinder assembly comprises a rotor I, a rotor II, a power shaft and a cylinder body, and the rotor I and the rotor II are coaxially installed in the cylinder body in a staggered shape and rotate around a rotating axis of the power shaft; and the differential driving assembly is a combined mechanism formed by combining a set of pericycloid mechanism together with two sets of double-crank mechanisms, wherein the combined mechanism has the freedom of 1. The power transmission device has the advantages of simple and compact structure, stable, reliable and high-efficiency transmission, wide application range and the like, and when the power transmission device is used on an engine, a double-rotor piston engine with high efficiency andlarge power density can be obtained.

Owner:NAT UNIV OF DEFENSE TECH

High-speed precision rotating shaft being sealed by high-pressure gas

The invention provides a high-speed precision rotating shaft being sealed by high-pressure gas. The high-speed precision rotating shaft comprises a shaft core which is installed on an angular contact ball bearing. The angular contact ball bearing is fixed in a rotating shaft outer cover. A concave ring is arranged on the inner surface of the outer circumference of the large end of the shaft core. One end of the rotating shaft outer cover is connected with the concave ring. A wedge-shaped structure is arranged on the outer surface of the joint of the rotating shaft outer cover and the concave ring. The other end of the rotating shaft outer cover is fixedly connected with an end cover, a through hole which is parallel to a rotating shaft body is formed in the wall of the rotating shaft outer cover, one end of the through hole is located on the inner side of the concave ring, and an air inlet is formed in the rotating shaft outer cover, penetrates through the rotating shaft outer cover, and is connected with a channel. A wedge-shaped structure is arranged at the joint of the end cover and the shaft core. The rotating shaft is sealed by being filled with high-pressure gas, and an air path is simple; the special wedge-shaped structure is designed, so that high-pressure gas can be smoothly exhausted, and foreign materials can be prevented from entering the rotating shaft.

Owner:KUNSHAN YUNCO PRECISION IND TECH

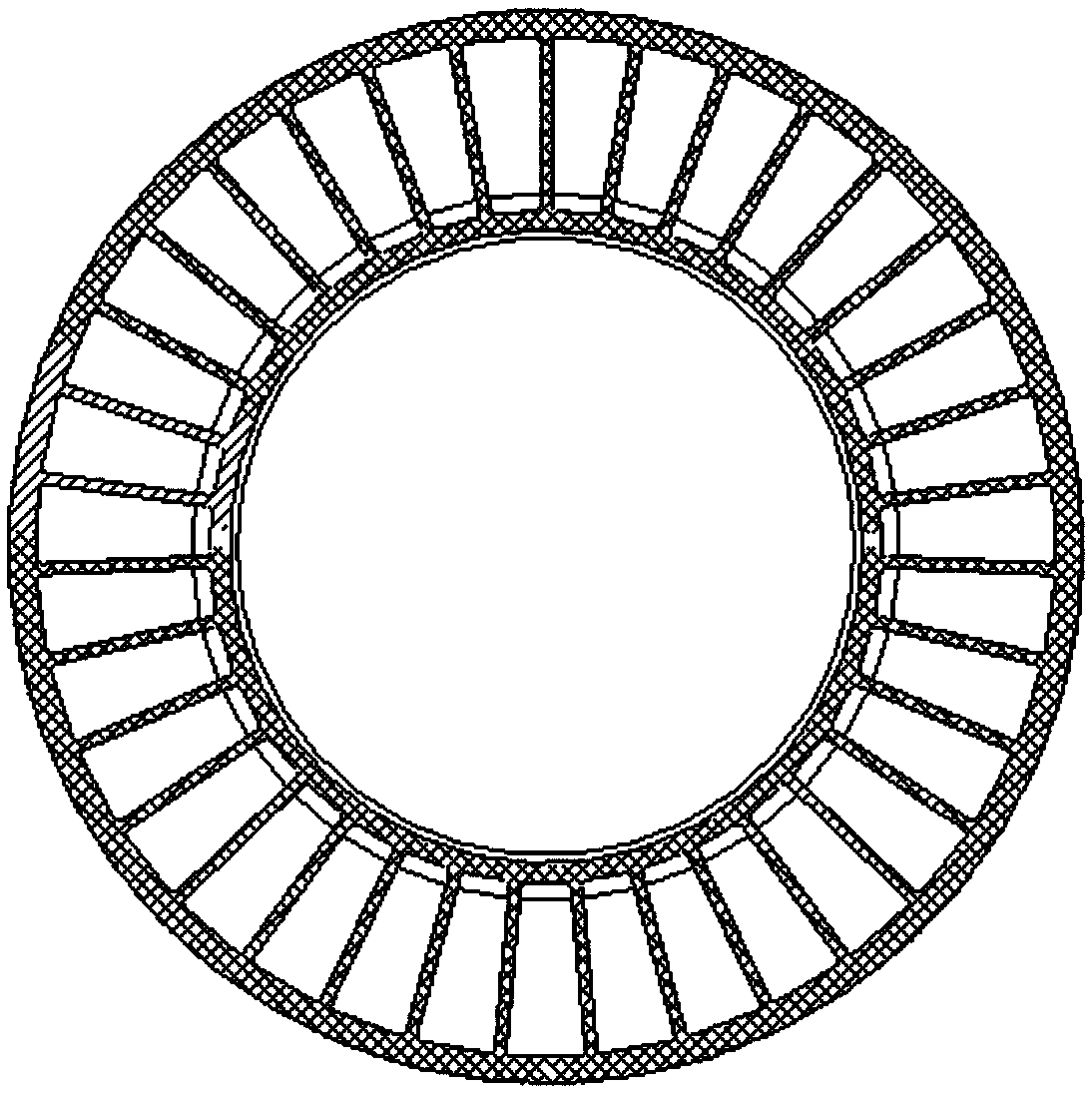

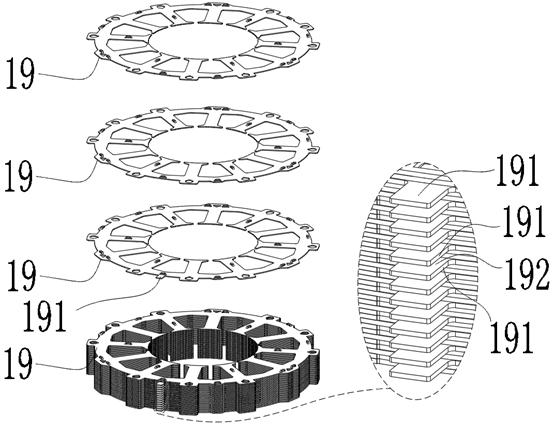

Iron core manufacturing process of motor for new energy automobile

ActiveCN114189114AGood concentricityGood dynamic balanceManufacturing stator/rotor bodiesStatorEngineering

According to the manufacturing process of the iron core of the motor for the new energy automobile, the material strip is continuously blanked between the upper die and the lower die of the continuous blanking die to form the motor rotor iron core and the motor stator iron core with the positioning groove, so that the blanking forming efficiency is high, and the motor iron core with the positioning groove and a special-shaped structure is not prone to deformation. According to the motor iron core, the iron core sheets are rotated after being formed, so that the concentricity between the iron core sheets of the formed motor iron core is good, the dynamic balance during working is good, and meanwhile, the formed motor iron core is small in size, light in weight and capable of meeting the performance requirement of the motor stator iron core.

Owner:岳阳范斯特机械科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com