Patents

Literature

126results about How to "To achieve the effect of environmental protection and energy saving" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Rubber product one-step injection, hollowing and vulcanization forming production method

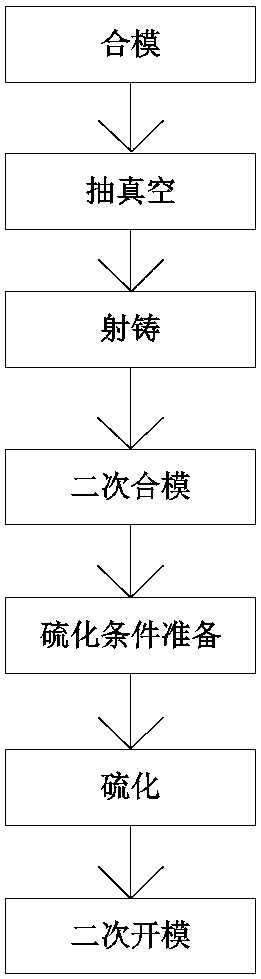

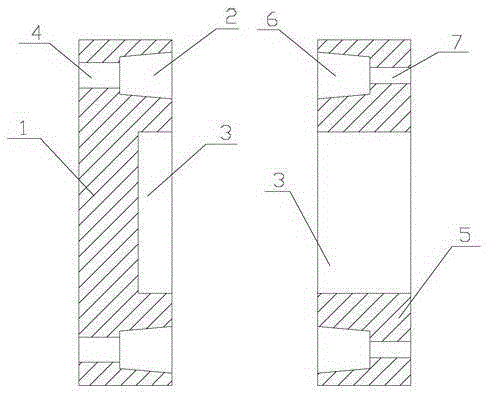

The invention discloses a rubber product one-step injection, hollowing and vulcanization forming production method, which belongs to the technical field of rubber product processes. By adopting the rubber product one-step injection, hollow and vulcanization forming production method, the injection, hollowing and vulcanization procedures can be completed in a same mold cavity, the mold cavity comprises an upper half mold, a lower half mold and a mold core, the mold core sets a foundation for the hollowing of the mold cavity, after the hollowing, the condition for introducing the high-temperature high-pressure gas for the vulcanization can be satisfied, the injection molding, hollowing and vulcanization apparatus can be integrated, the heat loss caused by the procedure circulation and the procedure circulation cost in the prior art can be avoided, and the traditional defects of the traditional rubber product production process such as re-pressurizing, heating, energy consumption, time consumption and high cost can be solved.

Owner:东营睿港招商服务有限责任公司

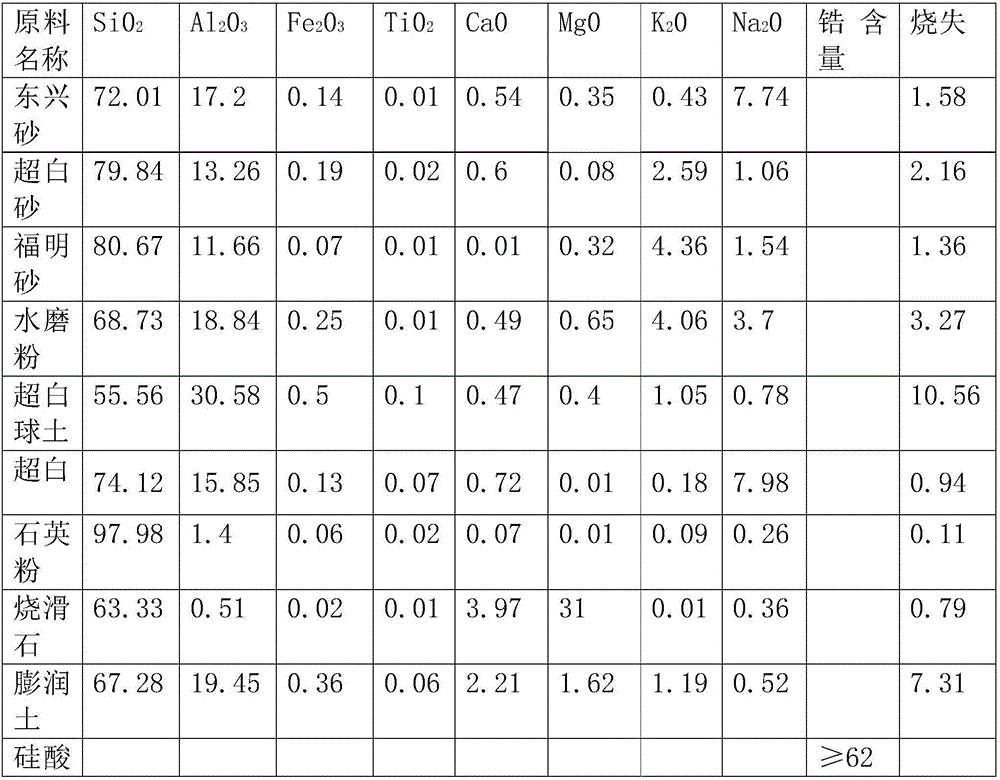

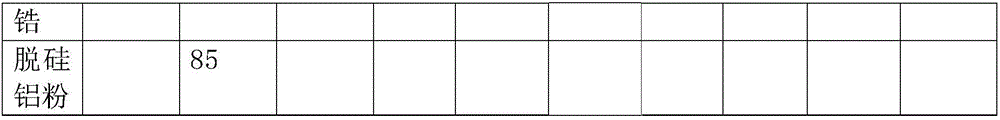

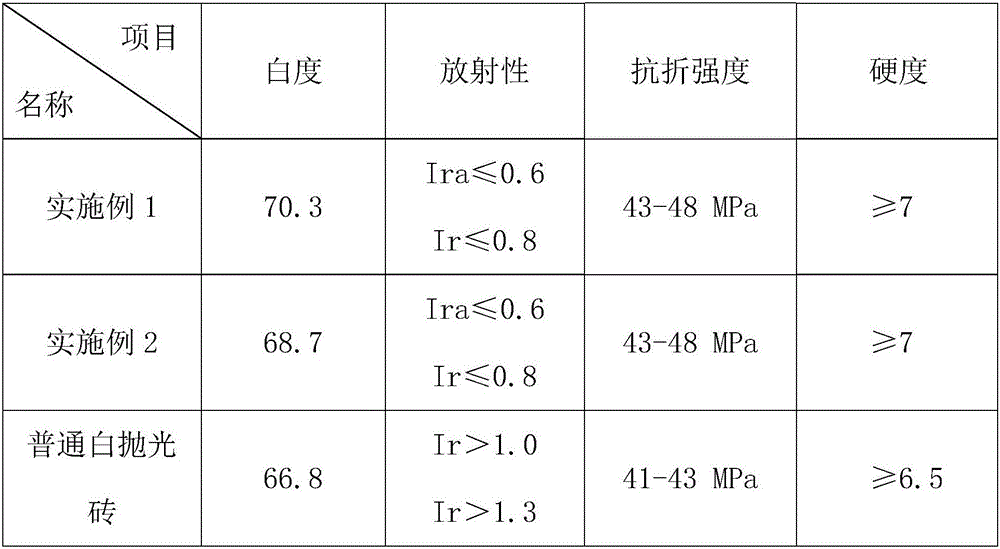

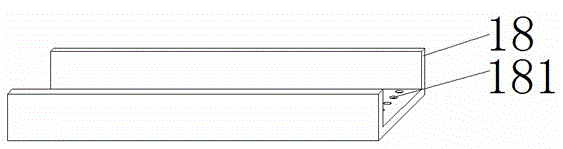

Ultrawhite polished tile and preparation method thereof

The invention discloses an ultrawhite polished tile and a preparation method thereof. The ultrawhite polished tile is prepared from chemical components of raw materials in percentage by mass as follows: 65%-74% of SiO2, 16%-23% of Al2O3, 5%-8% of alkali metal oxide and / or alkaline earth metal oxide, smaller than or equal to 0.2% of Fe2O3, smaller than or equal to 0.1% of TiO2 and 3%-5% of loss on ignition. Desiliconized aluminum powder is sufficiently utilized to replace conventional zirconium silicate and other zirconium-containing materials, the polished tile is whitened by directly using the raw materials instead of adding the zirconium-containing materials, accordingly, the whiteness of the polished tile is greatly improved through the desiliconized aluminum powder, the process requirement for whiteness is met, and the problem that the radioactivity of conventional polished tiles is beyond the standard is solved; the whiteness of the prepared polished tile is 70%-72%, and the prepared polished tile meets the market demands of the ceramic industry. The preparation method is simple to operate, raw materials are easy to obtain, the cost is low, the process controllability is high, and the ultrawhite polished tile with the whiteness of 70% can be prepared.

Owner:FOSHAN SHI WAN YING BRAND CERAMICS CO LTD

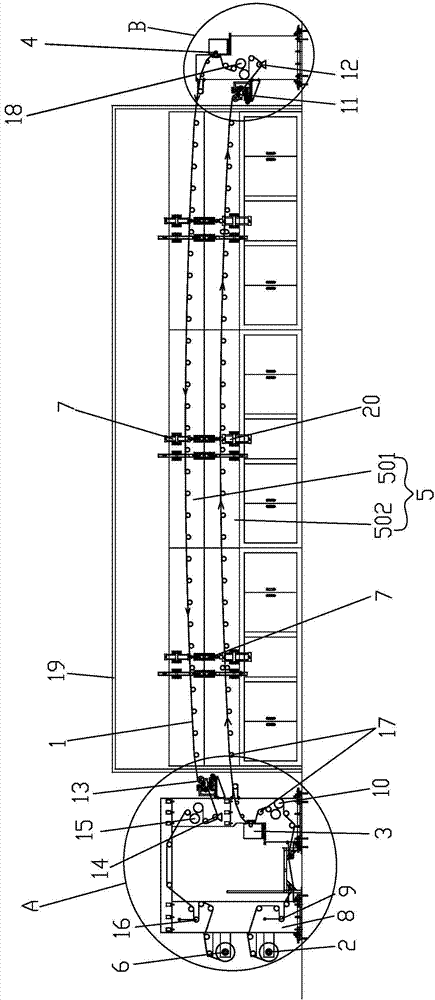

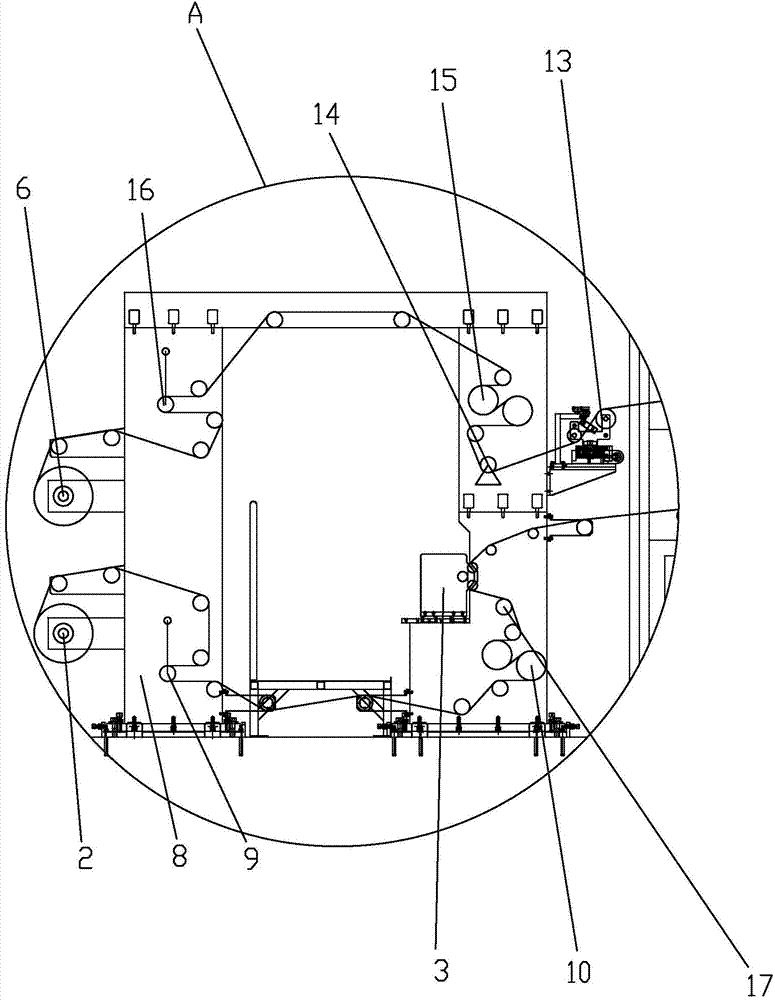

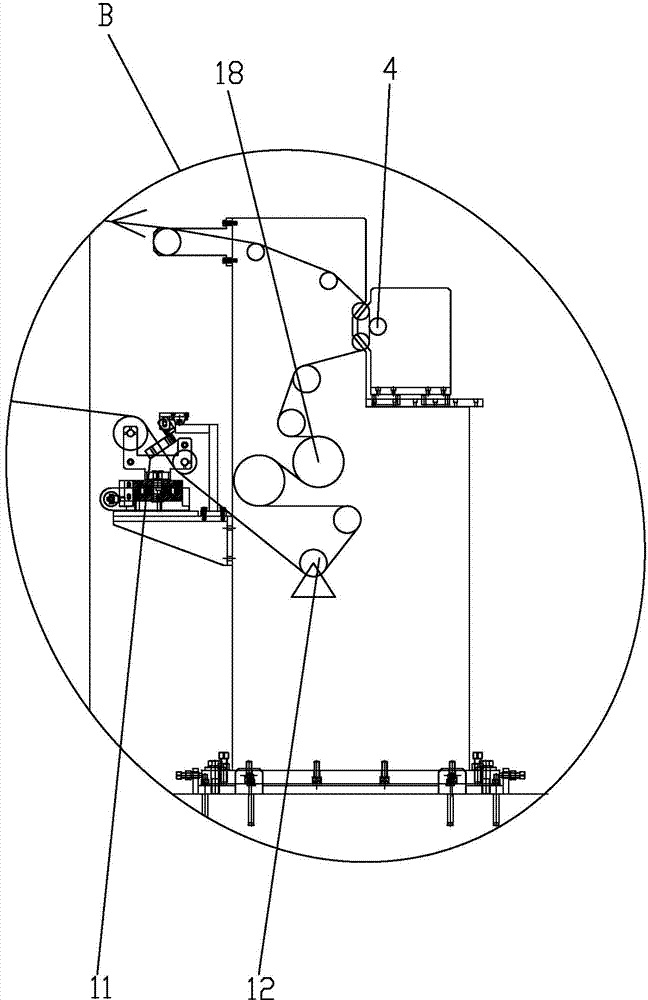

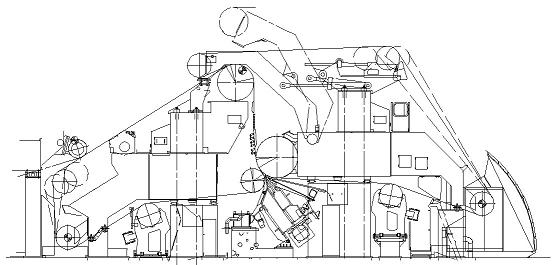

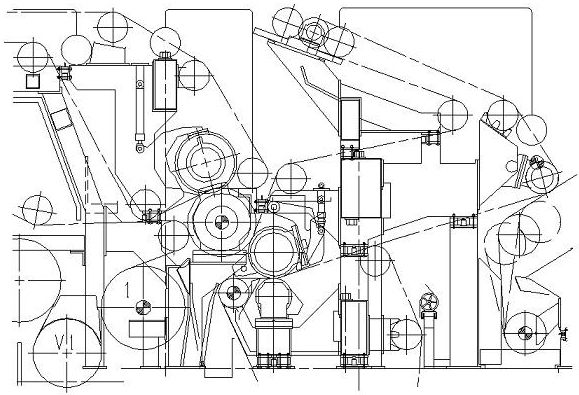

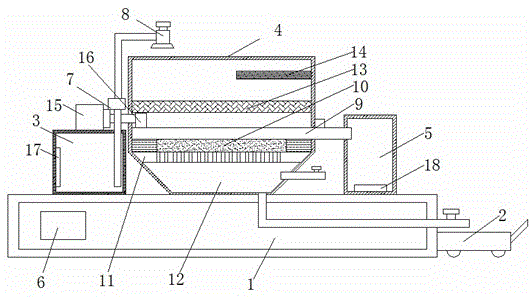

Double-faced coating all-in-one machine and coating method thereof

InactiveCN104492660AReduce length dimensionReduce labor costsLiquid surface applicatorsCoatingsEngineeringTension control

The invention discloses a double-faced coating all-in-one machine and a coating method thereof. The technical scheme has the key points that the double-faced coating all-in-one machine comprises a rack, a discharging roll with a base material, a first coating head for coating the front surface of the base material, a second coating head for coating the back surface of the base material, a drying box for drying the base material, a collecting roll for containing the base material, and a plurality of tension control devices for providing tension for the operation of the base material; the discharging roll, the first coating head, the second coating head, the collecting roll and the tension control devices are arranged on the rack; the collecting roll is arranged above the discharging roll; the base material is pulled out from the discharging roll; after the front surface of the base material is coated by the first coating head, the base material penetrates through the drying box and the back surface of the base material is coated by the second coating head; and then the base material returns to penetrate through the drying box and then is finally collected by the collecting roll. The coating method comprises the following steps: discharging, coating the front surface, drying the front surface, coating the back surface, drying the back surface, collecting and the like. The collection and discharging of the coating machine can be operated by one person so that the manual cost is reduced and a coating method is simple and convenient.

Owner:SOTECH SMARTER EQUIP CO LTD

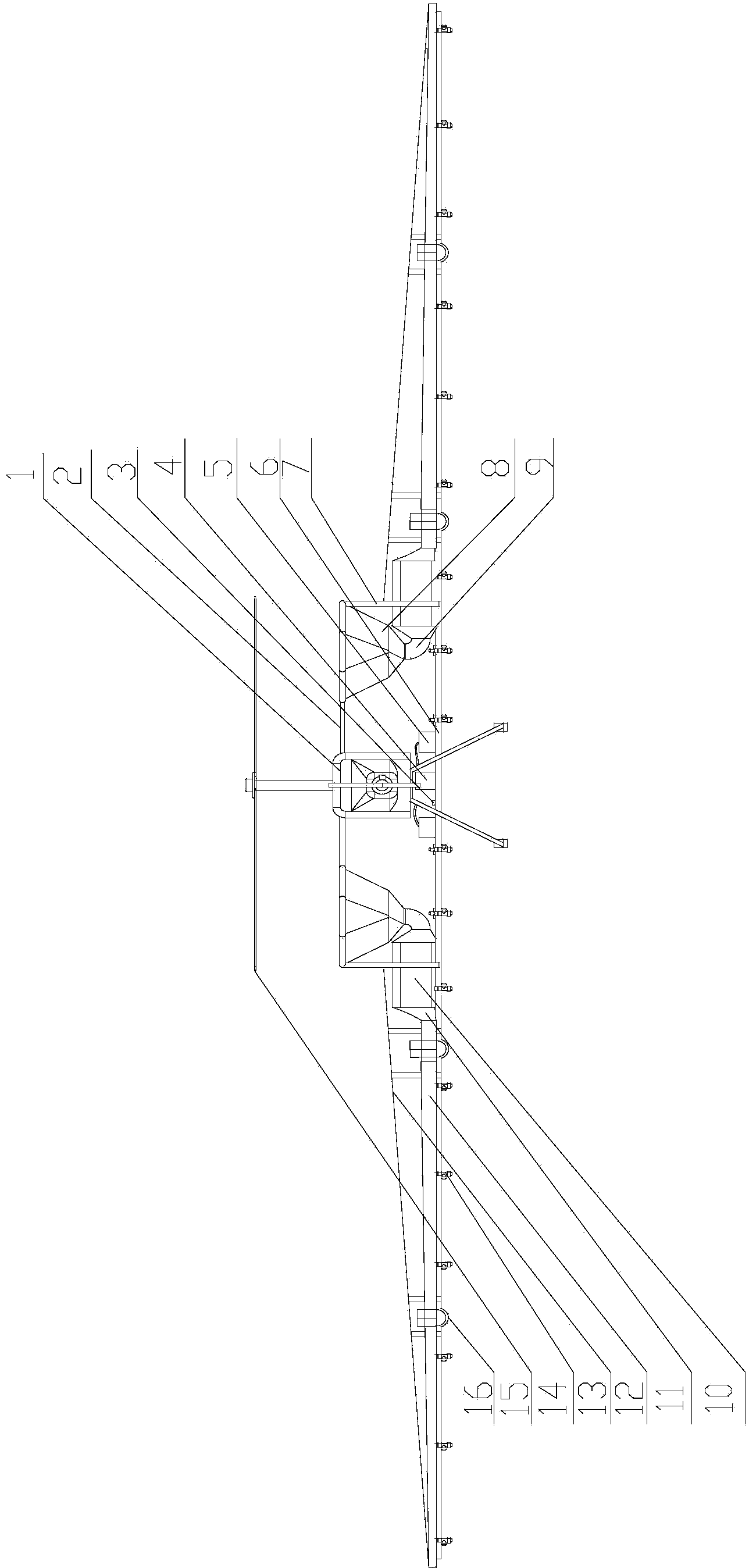

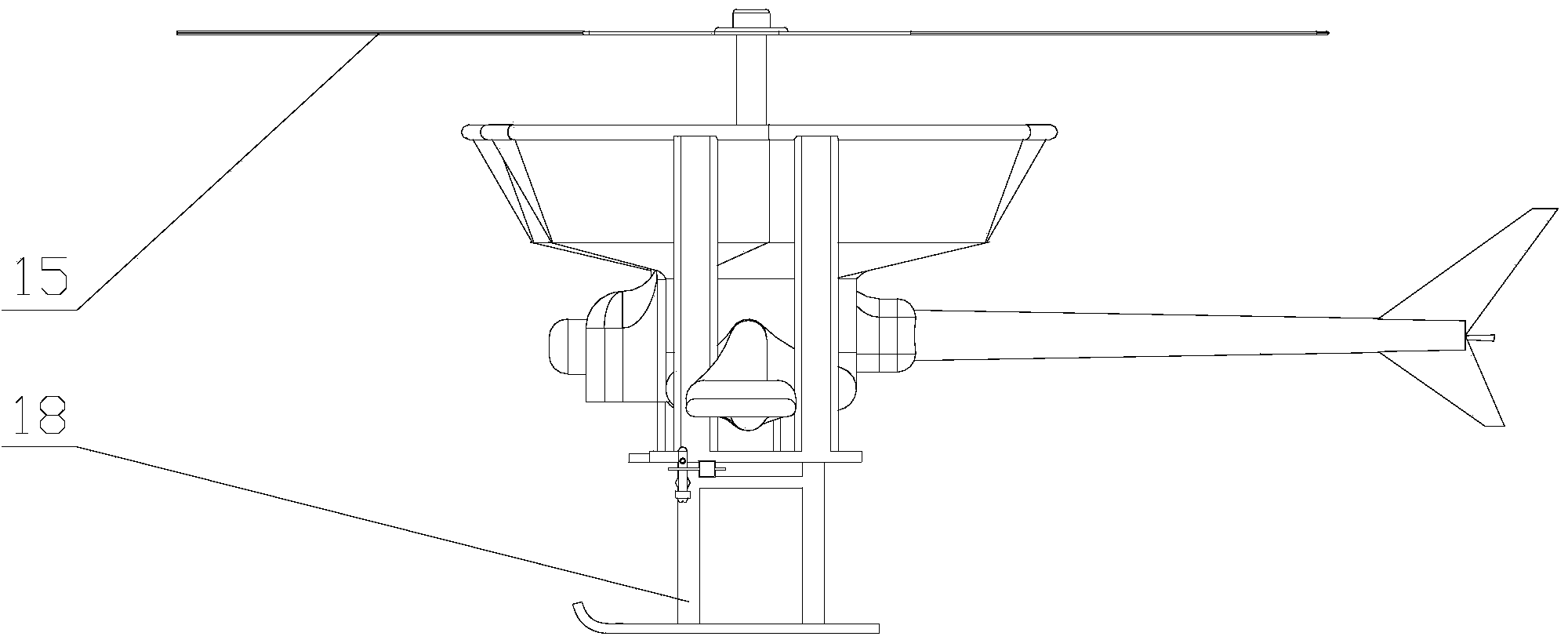

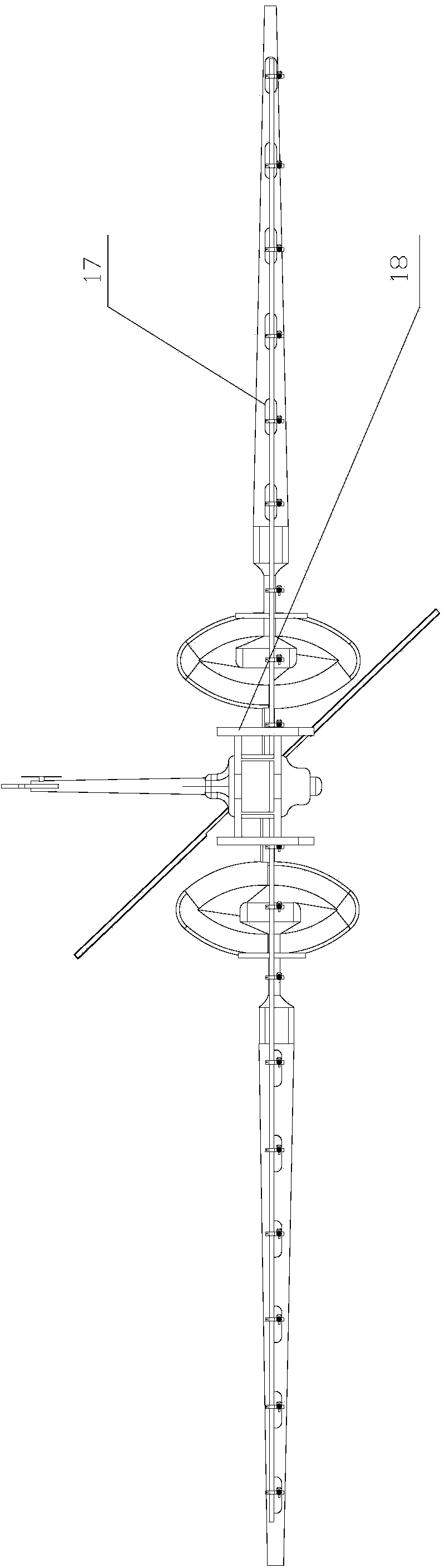

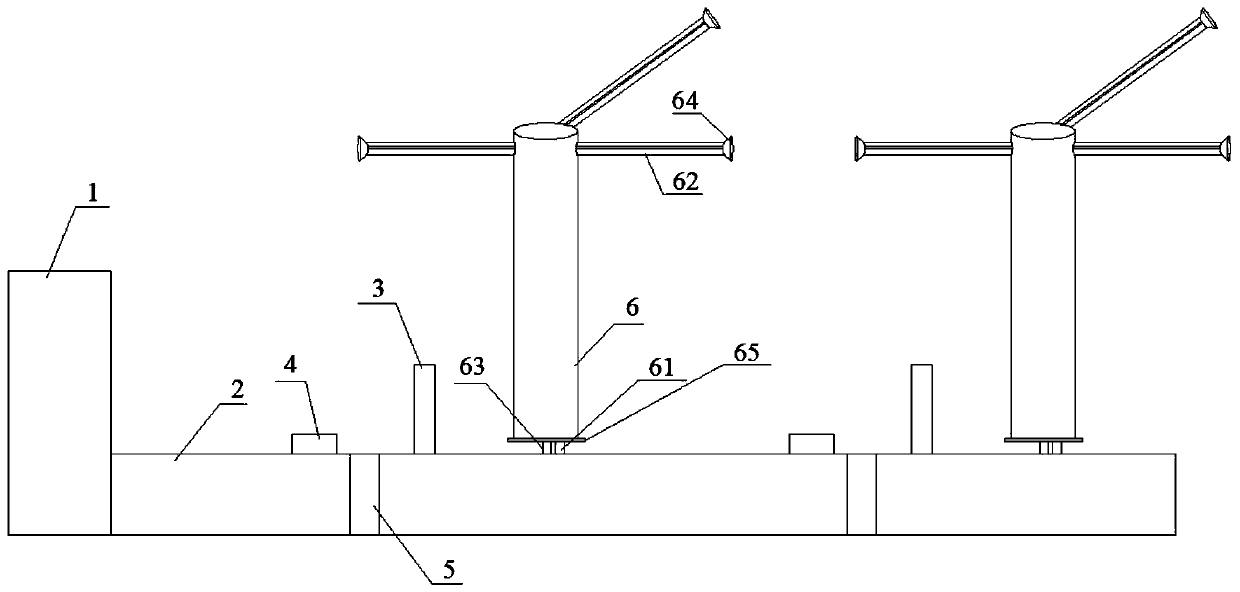

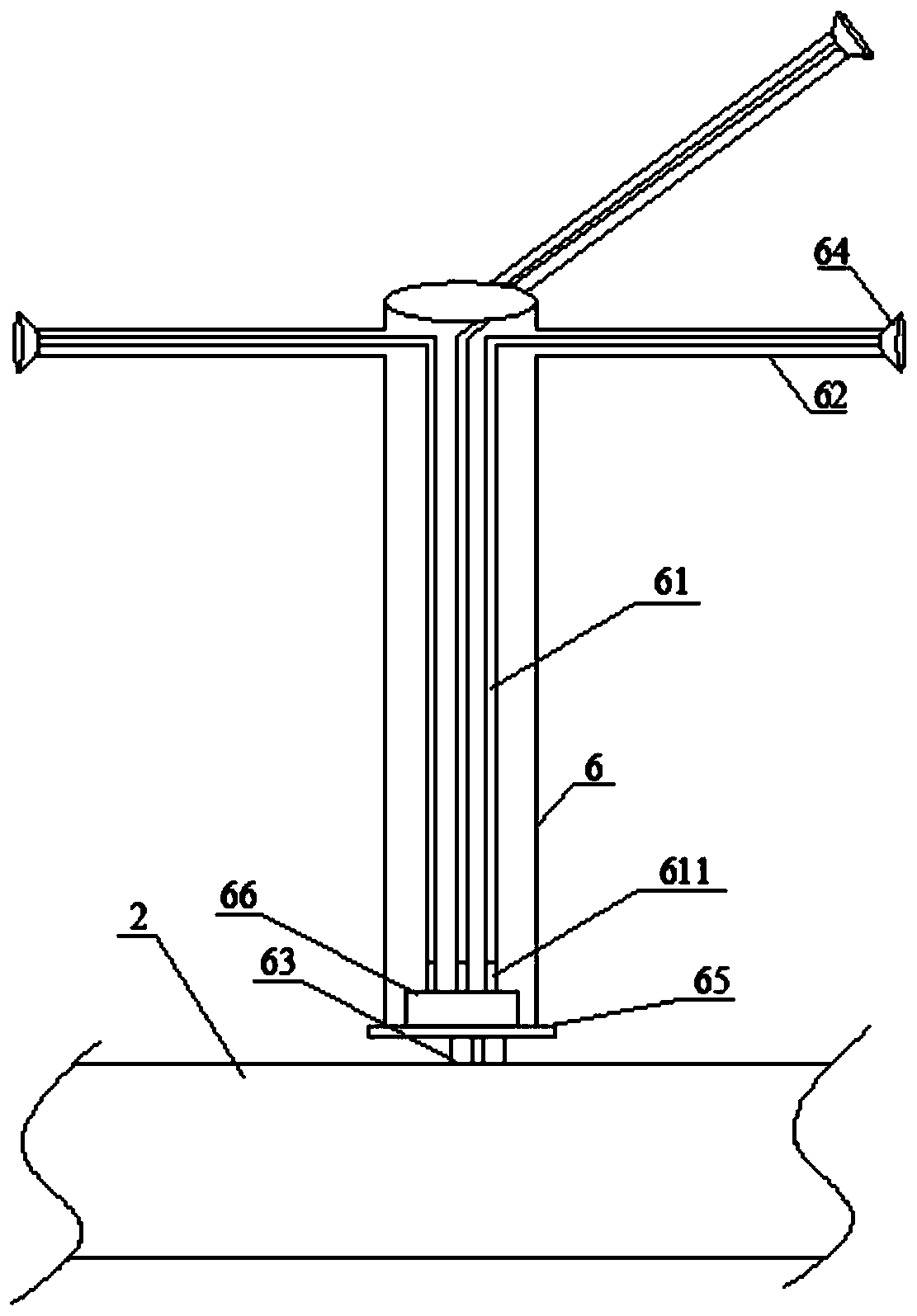

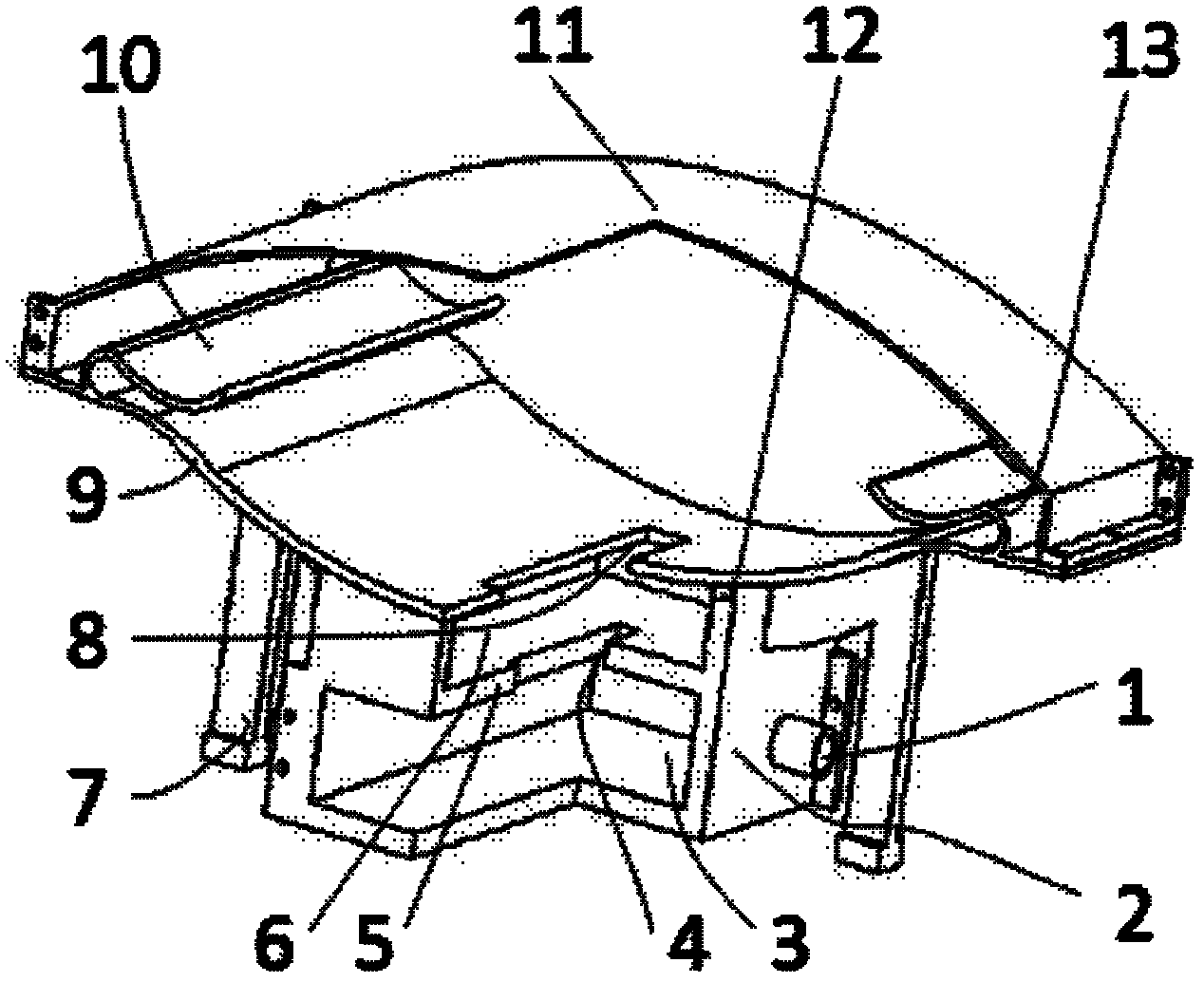

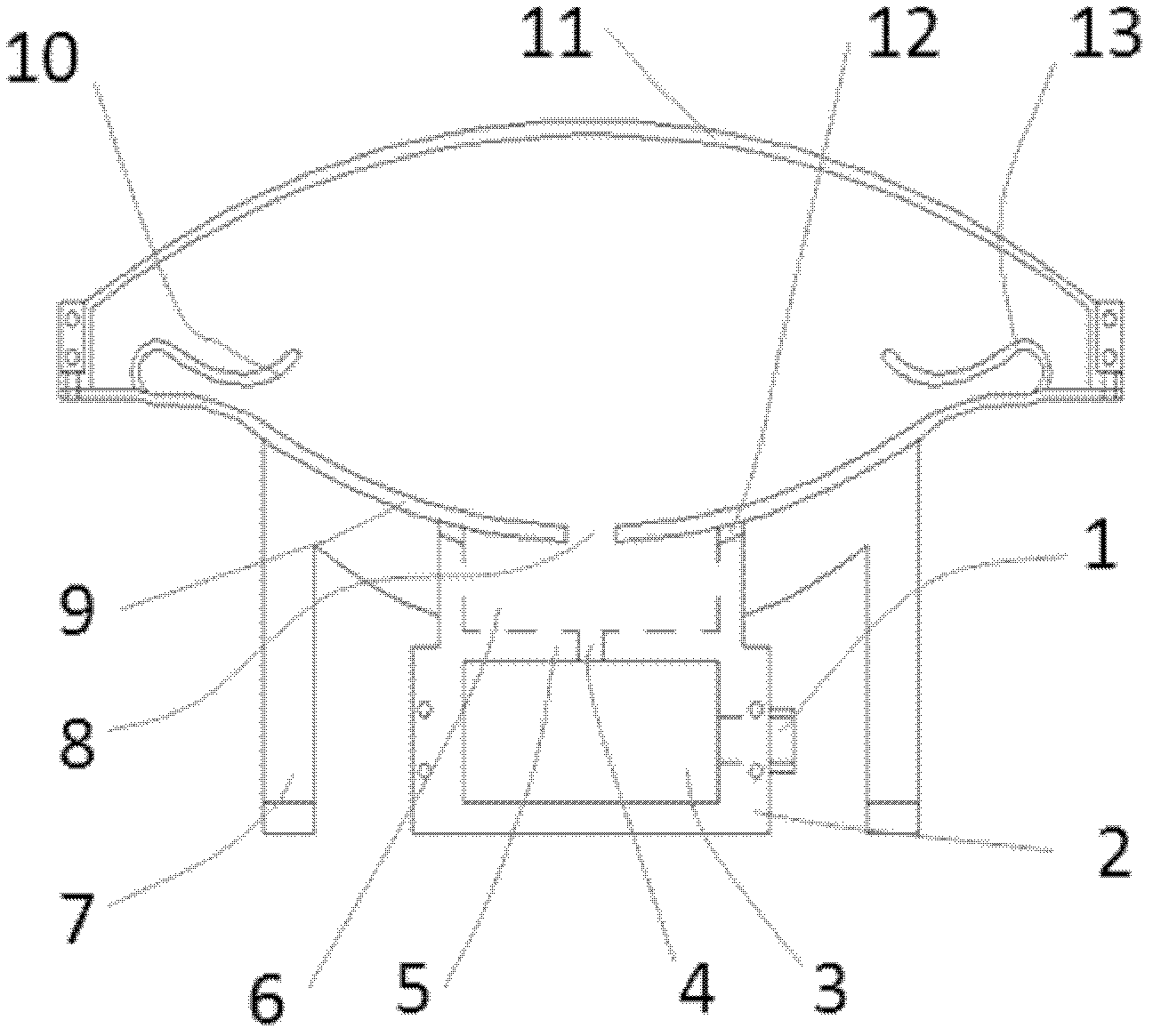

Air-assisted wide plant protection unmanned helicopter and operation method implemented by same

InactiveCN103910061AWide working widthIncrease the application rateAircraft componentsLaunching weaponsSpray nozzleAirflow

The invention relates to an air-assisted wide plant protection unmanned helicopter and an operation method implemented by the same. The air-assisted wide plant protection unmanned helicopter comprises an air-assisted air duct device, a support frame, a storage battery, an electric diaphragm pump, a chemical tank and a foldable spray rod. The air-assisted air duct device, the support frame, the storage battery, the electric diaphragm pump, the chemical tank and the foldable spray rod are mounted on an unmanned helicopter, spray nozzles are distributed on the foldable spray rod, the foldable spray rod is divided into a middle main spray rod, first spray rods and second spray rods, and the first spray rods and the second spray rods are arranged on the two sides of the foldable spray rod. Downwash airflow formed by the unmanned helicopter is accelerated by the aid of conical pipeline structures, and high-speed airflow flows through vertical flat columnar air pipes and then flows into horizontal flat tapered air pipes; an air curtain is formed on the spray rods in the width direction of the spray rods by the high-speed airflow, the air speed of the air curtain is downwardly uniformly distributed, accelerating, carrying and secondary atomizing effects can be realized for fog-drops by the air curtain, and the fog-drops are atomized by the spray nozzles. The air-assisted wide plant protection unmanned helicopter and the operation method have the advantages that the working widths of the spray rods are increased, so that the chemical application rate can be increased under the condition that the chemical liquid carrying amount of the unmanned helicopter is unchanged, the operation time can be shortened, the chemical application efficiency can be improved, and power consumption of the unmanned helicopter can be reduced.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

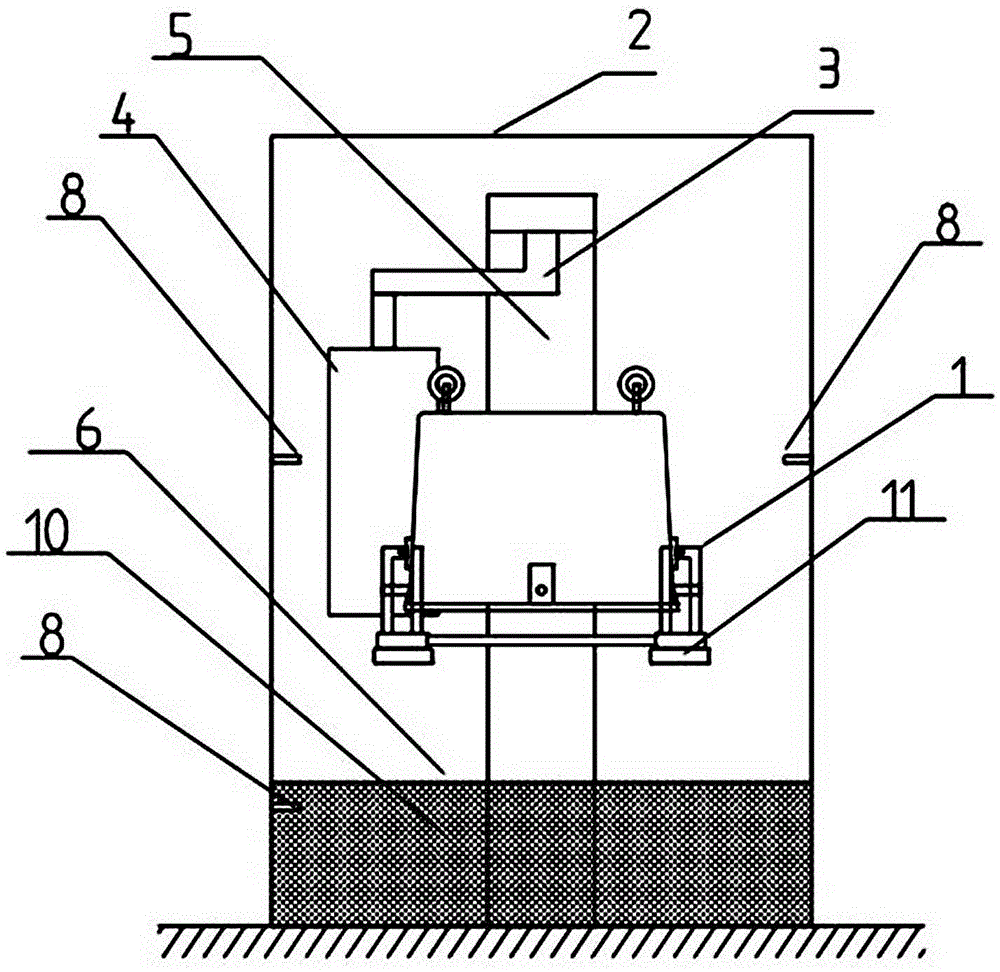

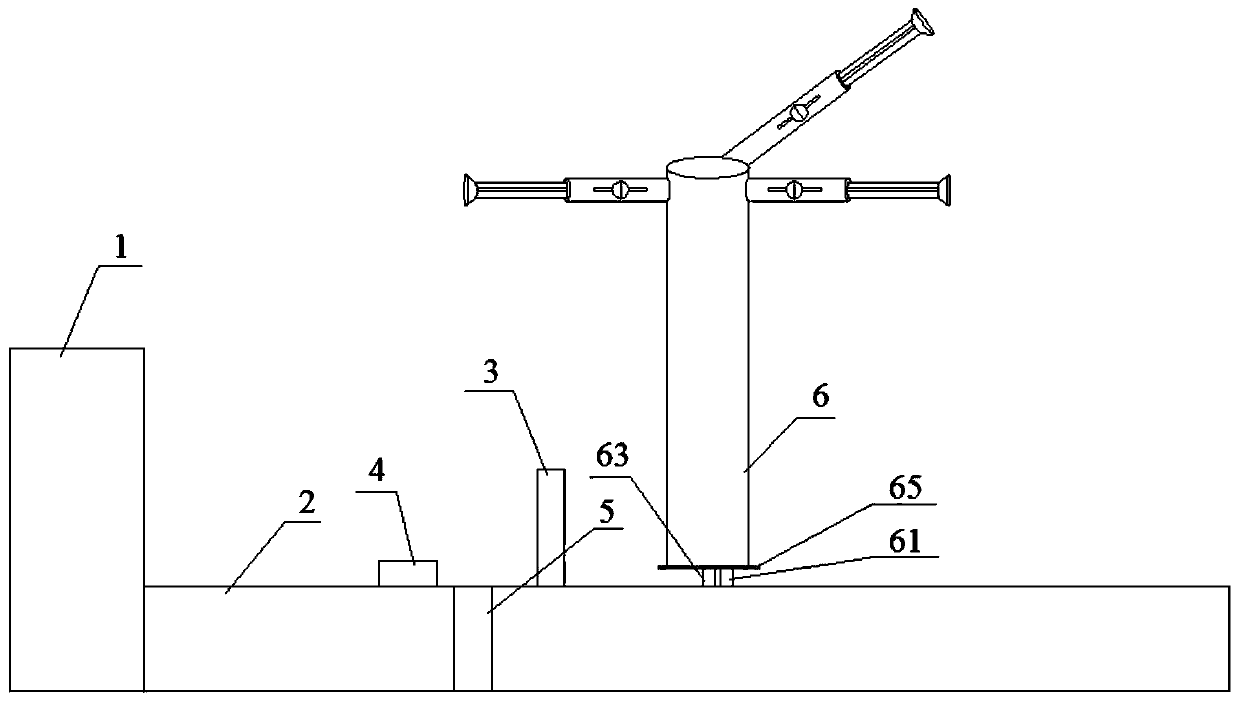

Garbage can cleaning machine

InactiveCN105382003AImprove cleaning qualityImprove cleaning efficiencyHollow article cleaningWater useIntegrated design

The invention discloses a garbage can cleaning machine. The garbage can cleaning machine comprises a shell and a bracket, wherein the top of the bracket is rotationally connected with a brush rotating arm; the brush rotating arm is provided with a brush wheel; the brush wheel drives the cleaning of garbage cans through a power device; a cleaning platform is mounted on a bracket, and is provided with a manipulator; the manipulator is hinged with the cleaning platform, tightly holds the garbage cans under the effect of the power device, and overturns the garbage cans on the cleaning platform; and multiple nozzles are arranged on the inner wall of the shell. The cleaning machine can synchronously clean the internals and the externals of the garbage cans to improve the universality, adopts an integrated design, is simple in appearance, can be fixedly used or can be used on a vehicle-mounted platform, is full-automatic in operation circulation, needs no manual auxiliary operation, is simple in structure, is easy to operate and maintain, improves the cleaning quality and efficiency of the garbage cans through mechanical operation, can reduce the water use level through recycling of cleaning water, and achieves the effects of environmental protection and energy conservation.

Owner:升禾城市环保科技股份有限公司

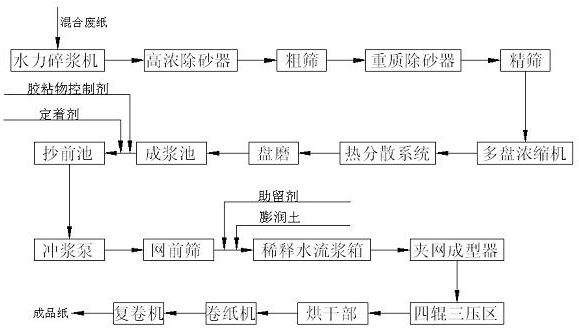

Production method for ultra-low quantitative corrugated core paper and product produced thereby

InactiveCN102433791AImprove box rateReduce manufacturing costMachine wet endPress sectionHigh concentrationWinding machine

The invention discloses a production method for making regeneration corrugated core paper of a micro-corrugated cardboard and a product produced thereby. The production method comprises the following steps of: 1) proportioning raw materials; 2) processing waste paper, namely sending mixed waste paper to a hydraulic pulp kneader, and then sequentially subjecting to a high-concentration desander, a coarse screen, a heavy-quality desander, a fine screen, a multi-disc thickener, a heat dispersion system, a disc mill and a pulp pool; and 3) making paper sheets, namely subjecting pulp to fore pool, a pulp washing pump, a net front screen, a dilution water pulp box, a clamping net forming device, a four-roller three-press area provided with shoe press, a drying part, a paper winding machine and a rewinder, and storing finished products in a cabin. The physics index of the ultra-low quantitative corrugated core paper produced by the method can meet the quality standard of body paper for making the micro-corrugated cardboard; as the ultra-low quantitative corrugated core paper is ultra-low quantitative, the micro-corrugated cardboard below G-corrugation can be made; meanwhile, the yield rate of cartons can be greatly improved, the production cost of the cartons is reduced, and an effect of environment protection and energy saving is further achieved.

Owner:SHANYING INT HLDG CO LTD

Heat-insulating plastering gypsum for building interior wall and preparation method thereof

The invention discloses heat-insulating plastering gypsum for a building interior wall and a preparation method thereof and relates to the technical field of plastering gypsum. The heat-insulating plastering gypsum comprises 55-75 parts of desulfurized gypsum, 20-30 parts of natural gypsum, 15-20 parts of cement, 15-20 parts of heat-insulating filler, 10-15 parts of modified heavy calcium carbonate, 10-15 parts of plant source additive, 5-10 parts of rubber powder, 5-10 parts of modified expandable graphite and 7-12 parts of auxiliary. The preparation method includes: pretreating the natural gypsum. The heat-insulating plastering gypsum is used for being brushed on the building interior wall, is excellent in heat-insulating performance and has high adhesiveness, and a coating is free of shrinking and cracking and less prone to shedding.

Owner:HEFEI FENGTENG ENERGY SAVING TECH CO LTD

Automatic farmland water-saving irrigation system capable of responding to wind changes

ActiveCN110692496AReduce driftIrrigate evenlyBatteries circuit arrangementsWatering devicesWater sourceStream flow

The invention belongs to the field of agricultural automatic irrigation systems, and particularly relates to an automatic farmland water-saving irrigation system capable of responding to wind changes,which comprises a water pump and a pipeline, wherein the water pump is connected to a water source, the pipeline for delivering water is provided with a wind power tester, a controller and a flow valve, the pipeline is provided with a plurality of water outlets, and each water outlet is correspondingly fitted with a spraying assembly capable of responding to wind changes; the spraying assembly comprises a fixing frame, a water pipe, a telescopic rod, a rotating motor, a main nozzle and a rotating ring. The spraying assembly capable of responding to wind changes is provided, so that response can be achieved to changes in wind power and speed, uneven spraying is alleviated, water is saved, and the environment is protected.

Owner:YELLOW RIVER CONSERVANCY TECHN INST

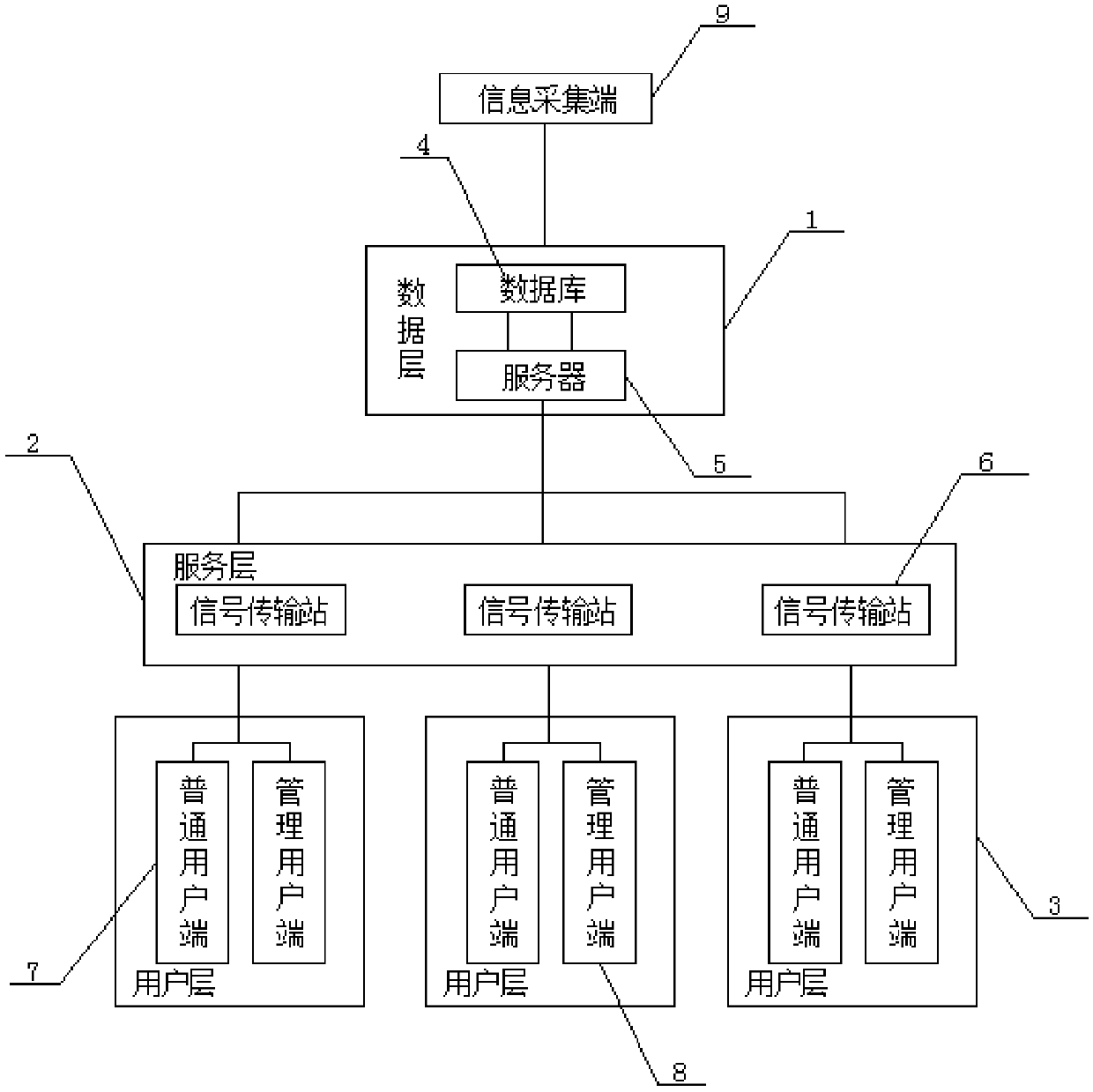

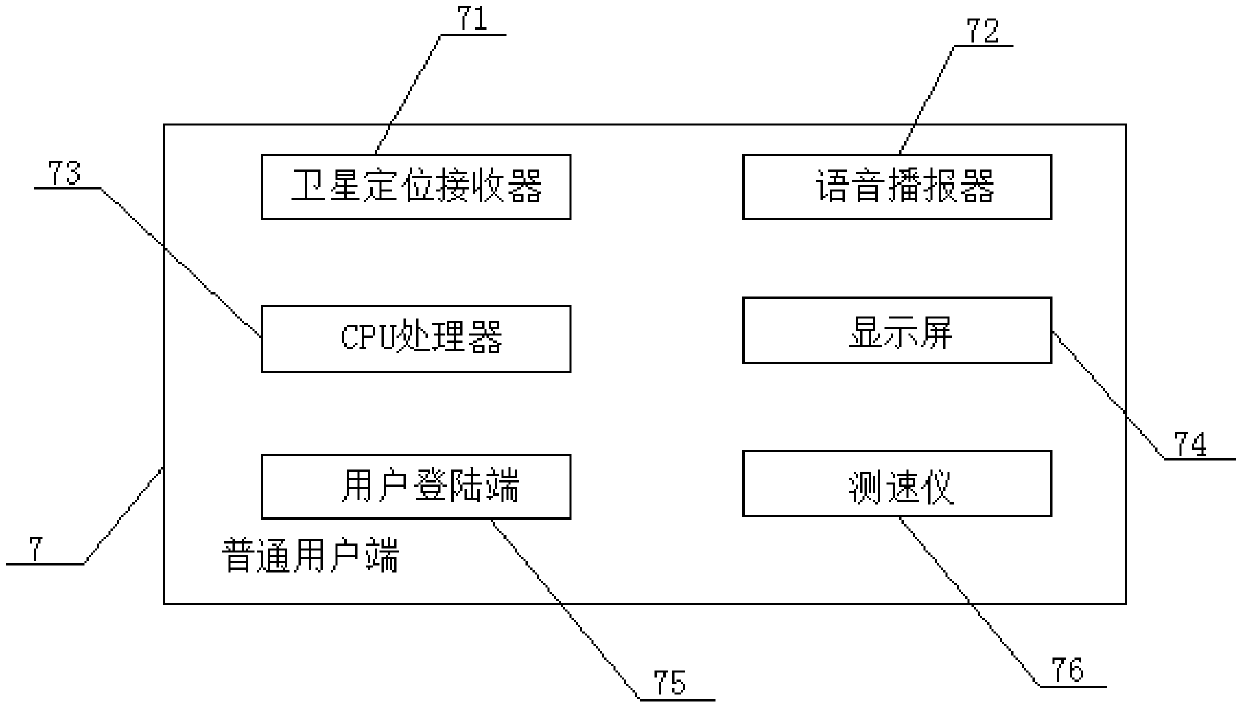

Smart city intelligent traffic guiding system

InactiveCN107895502AEasy to driveTo achieve the effect of environmental protection and energy savingRoad vehicles traffic controlGuidance systemParking space

The invention discloses an intelligent traffic guidance system for a smart city, which includes a data layer, a service layer and a user layer. The output end of the data layer is provided with a service layer, and the output end of the service layer is provided with a user layer. The layer includes a database and a server, the service layer includes a plurality of signal transmission stations, the user layer includes a common user layer and a management user layer, and the connection end of the data layer is provided with an information collection end. The present invention is provided with an information collection terminal, and the information collection terminal collects dynamic traffic information through the monitoring video of the traffic control department, the weather forecast system and the real-time parking information of the city parking lot, and collects various sudden accidents in the city and the parking information of the destination parking lot. Timely collection and transmission to the database provides convenience for users during driving, enabling users to avoid road sections where traffic accidents and traffic jams occur, and can directly guide users to the nearest parking lot with parking spaces when parking is required.

Owner:ANHUI HUITENG INTELLIGENT TRANSPORTATION TECH CO LTD

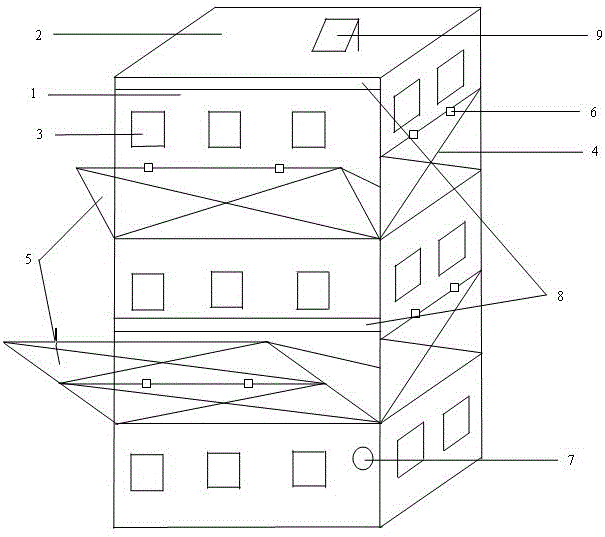

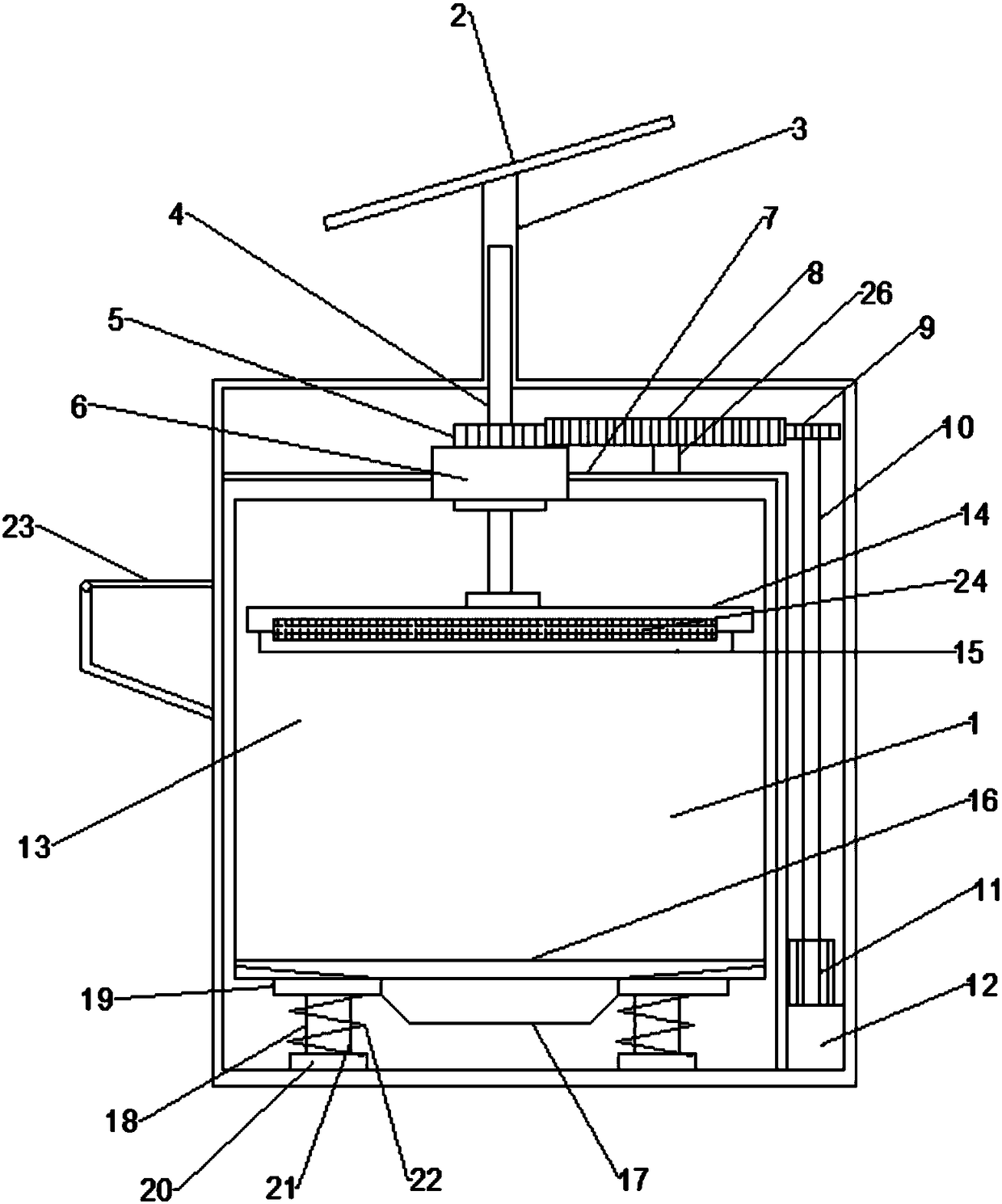

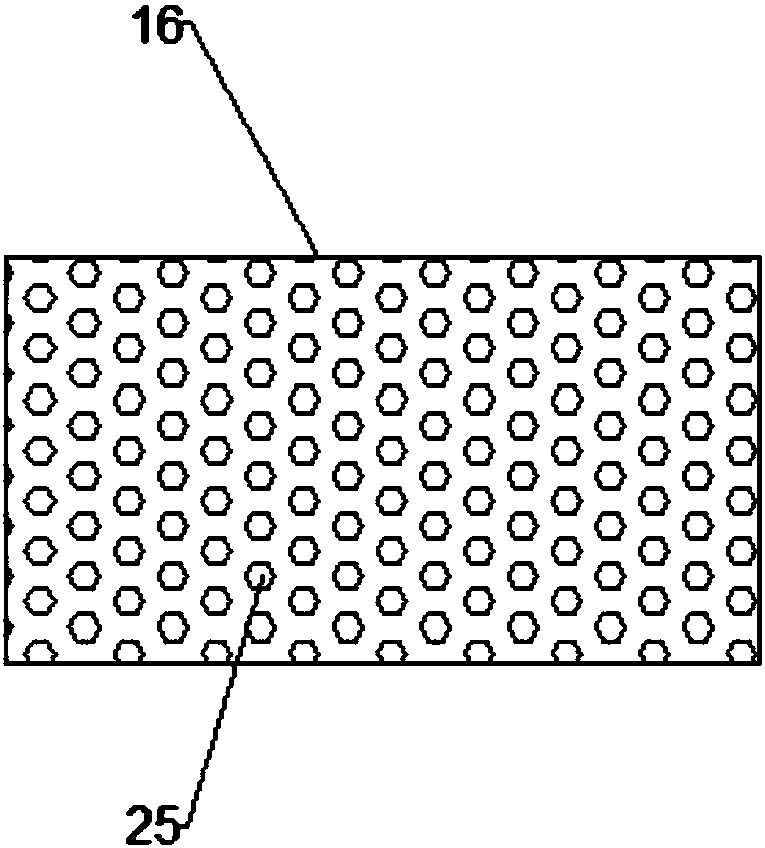

Intelligent device system for jumping protection and high-altitude falling catch

InactiveCN105920750ATo achieve the effect of environmental protection and energy savingBuilding rescueFloor levelEngineering

The non-patent invention discloses an intelligent device system for jumping protection and high-altitude falling catch. The intelligent device system comprises barrier nets, detection sensors, a solar panel, a single chip master, adsorption type electromagnetic relay switches, and alarm devices, all of which are mounted on a roof and at floors below the roof. The solar panel mounted on the roof supplies power to the devices. The sensors mounted at the periphery of the roof and between the floors to detect jumping of a person or falling of objects and to immediately trigger the barrier nets between the floors for reaction. Buzzers mounted at the root of a building alarm passing pedestrians. The intelligent device system for jumping protection and high-altitude falling catch is capable of flexibly coping with various emergencies, low in energy consumption and low in manufacture cost, and conforms to the economic and environmental protection advocacy.

Owner:王天伟

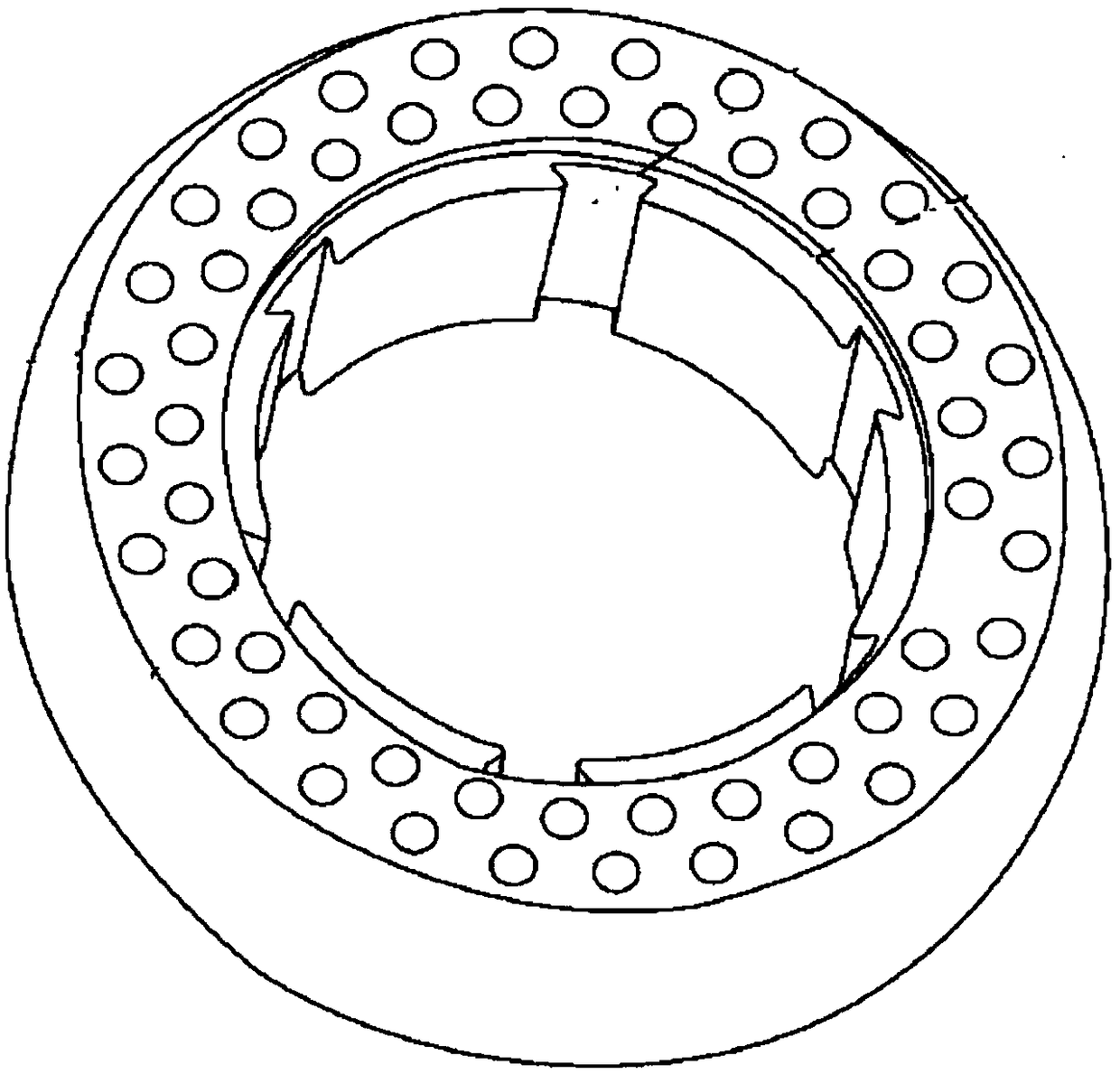

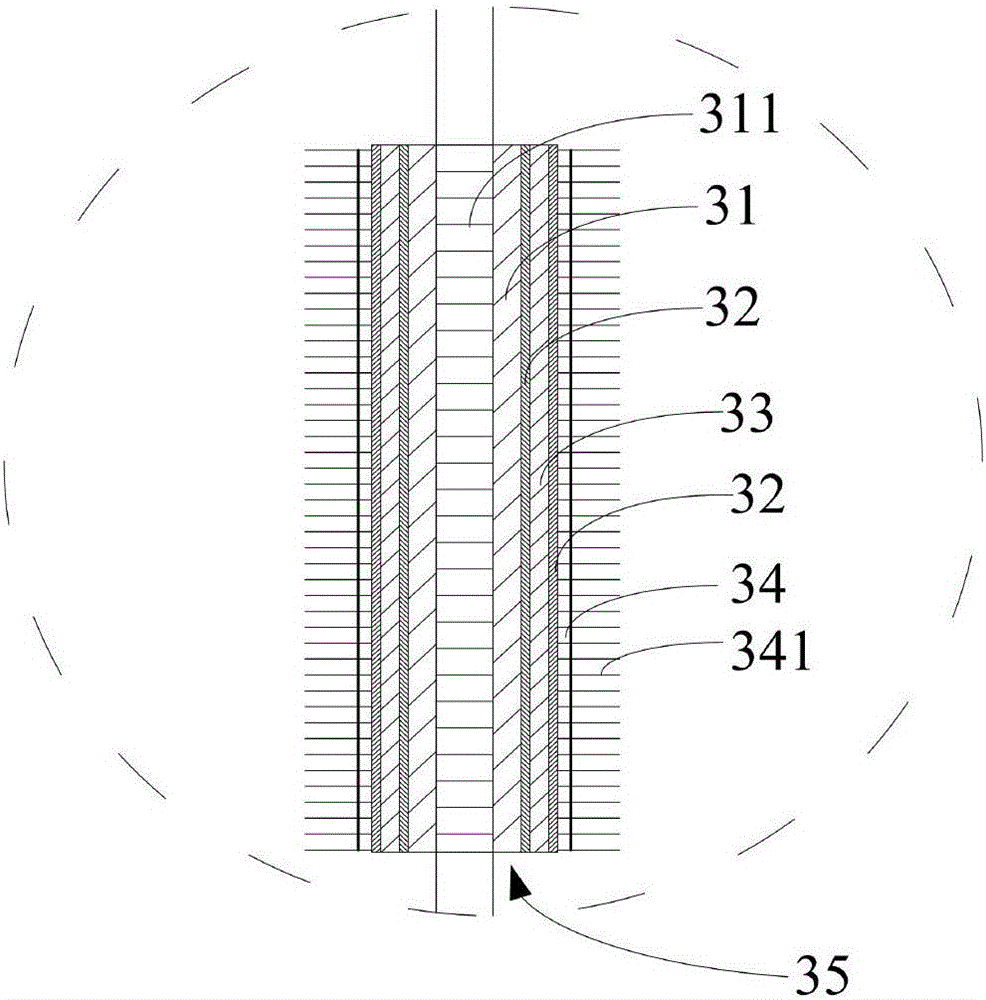

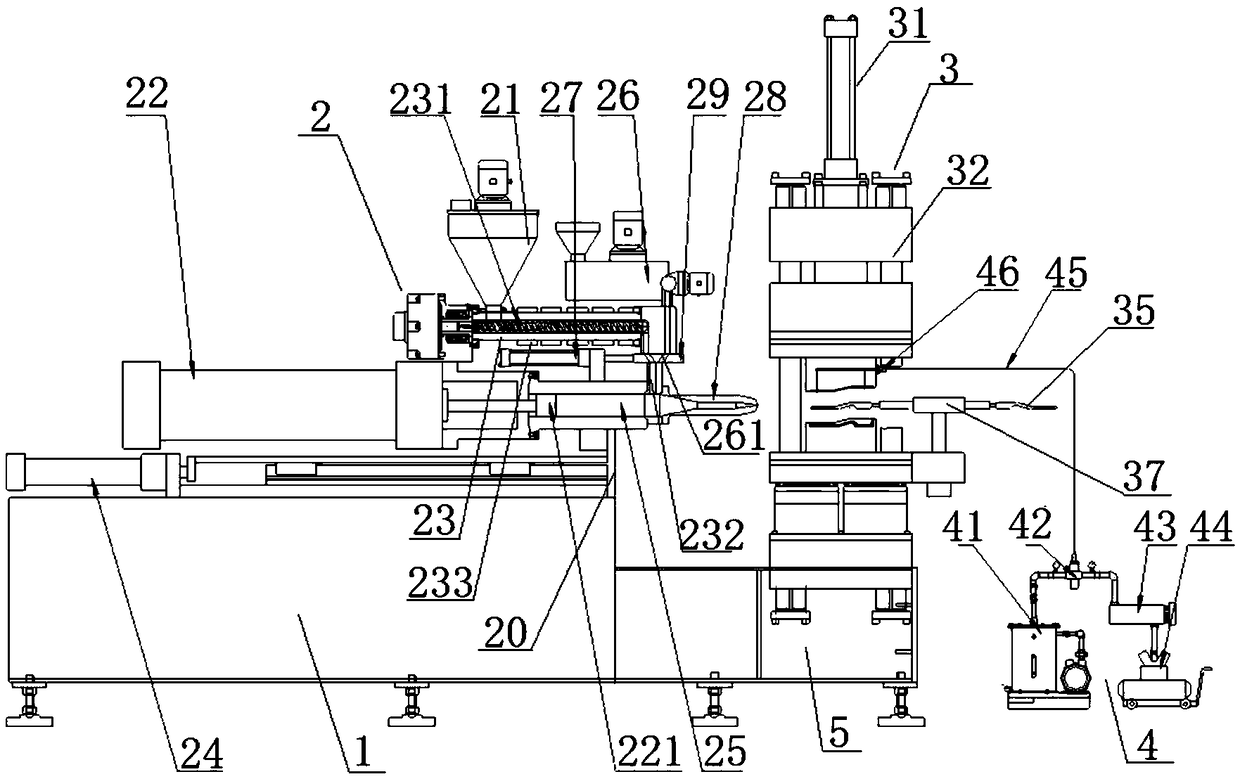

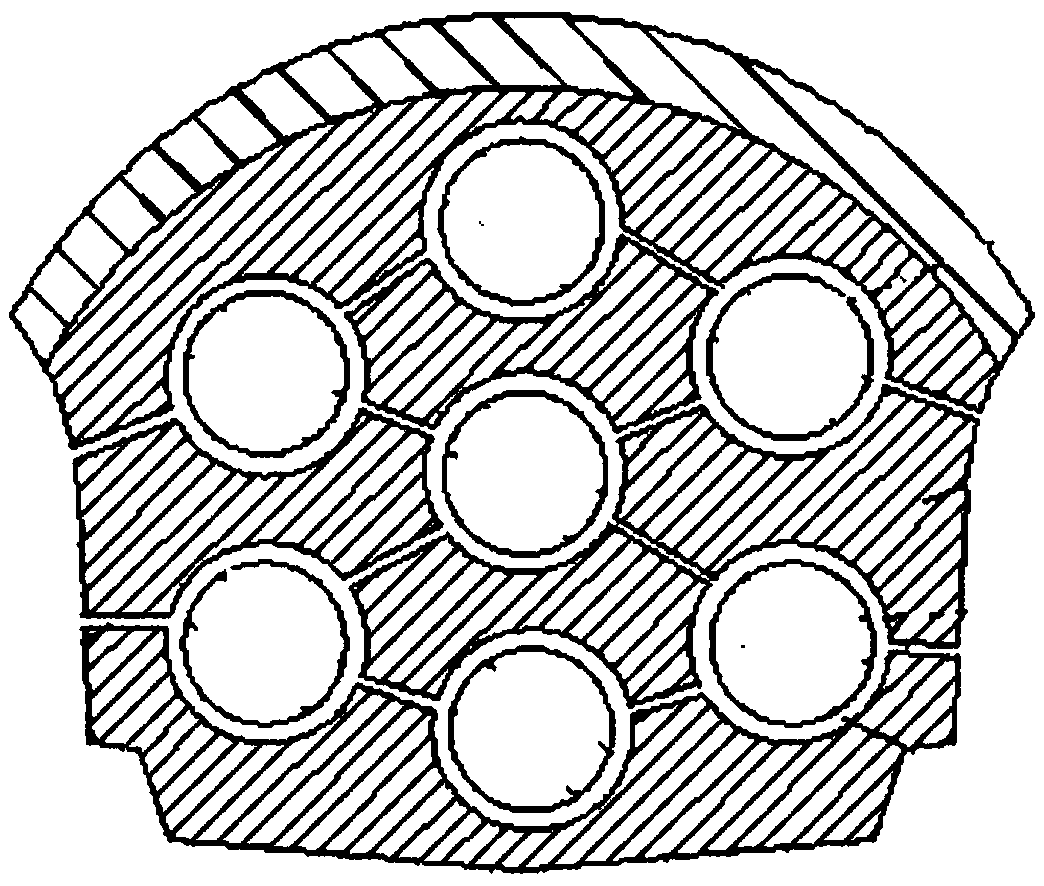

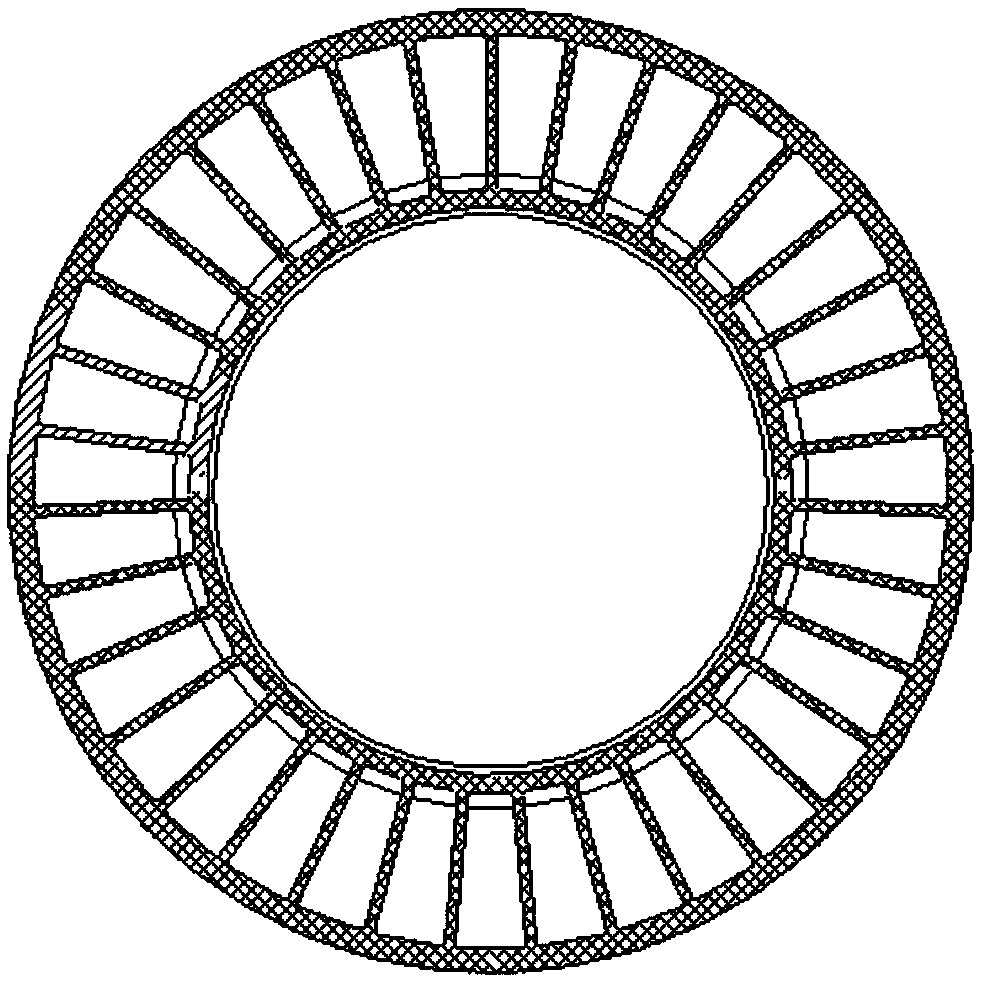

High-elasticity wear-resistant dual-density in-mold foaming rubber tire and manufacturing process thereof

ActiveCN109318445AIncrease elasticitySlow down elastic fatigue decayWith separate inflatable insertsWith multiple inflatable chambersRubber materialHigh density

The invention discloses a high-elasticity wear-resistant dual-density in-mold foaming rubber tire and a manufacturing process of the high-elasticity wear-resistant dual-density in-mold foaming rubbertire, and belongs to the technical field of rubber product processes. The high-elasticity wear-resistant dual-density in-mold foaming rubber tire comprises a high-density outer layer and a low-densityinner layer, and is of an integrated structure with the same mold for discharging. The high-density outer layer and the low-density inner layer are made of high-density rubber materials and low-density rubber materials correspondingly. Spring supports in a radial state are uniformly embedded in the low-density inner layer so as to play the role of framework support, and the elasticity of springscan be selected to be consistent with the elasticity of low-density rubber so as to enhance the supporting strength of the low-density inner layer. In addition, a dual-density bi-directional injectionin-mold forming-vulcanizing tire production system is applied to complete dual-density glue bi-directional injection, foaming and vulcanizing processes in one mold and obtain the manufactured tire. The problems of the insufficient elasticity of a rubber tire, the separate operation of injection, foaming and vulcanizing of a dual-density tire, energy consumption, time consumption and the high costare solved.

Owner:东营睿港招商服务有限责任公司

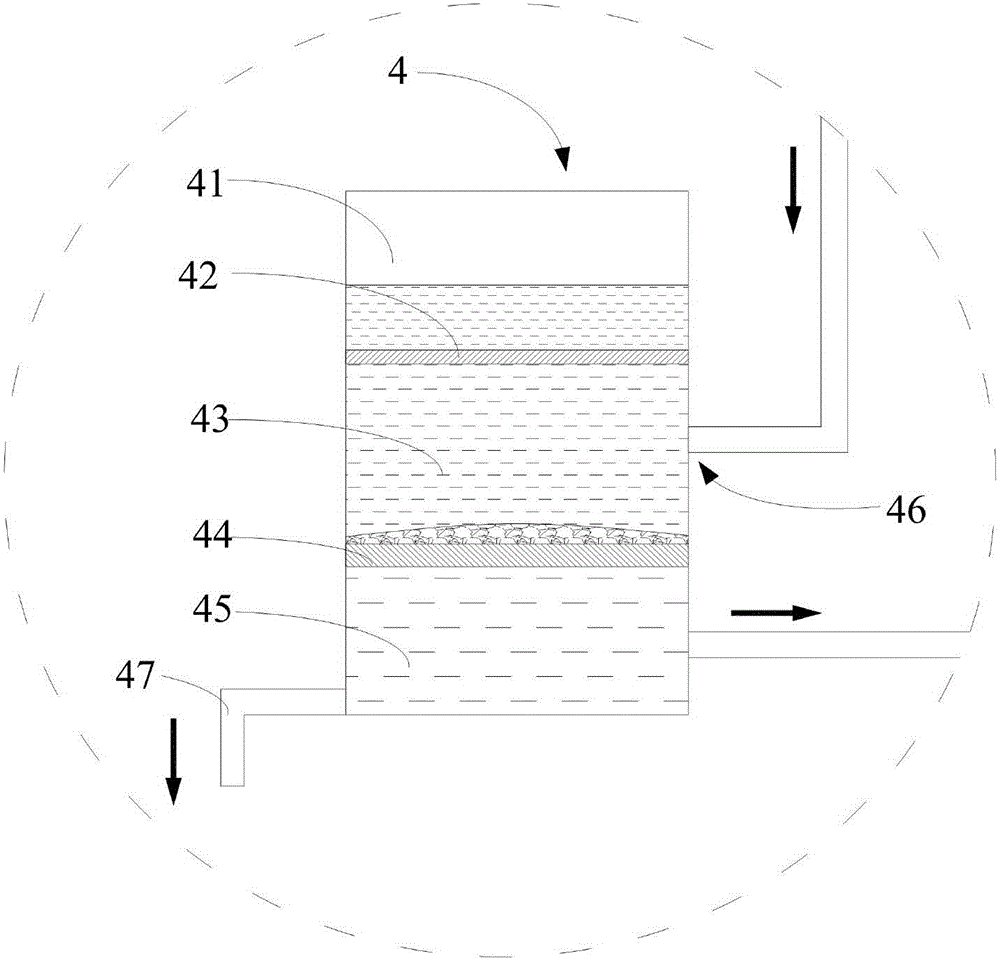

Double-air-chamber box body for transmitting suspended materials

The invention discloses a double-air-chamber box body for transmitting suspended materials, and relates to a transmission system for long-distance materials transmission. The problem of low running stability of a material transmission system is solved. According to the double-air-chamber box body, a first cambered body (10) and a second cambered body (13) are welded on two sides of a concave cambered surface of a disk slot (9) to form a combined body of the disk slot and the cambered bodies; a disk slot air gap (8) is formed in the middle of the disk slot (9); a rubber seal belt (2) is paved on the end face of an upper opening of an air chamber box (2); the combined body of the cambered bodies is arranged on the rubber seal belt (2); an air flow partition plate (5) is welded in the air chamber body, and divides the air chamber box into an upper small air chamber (6) and a lower large air chamber (3) which have different volumes; an air inlet (1) is formed in a side wall of the air chamber box; reinforcement ribs (7) are uniformly distributed on two side walls of the air chamber box; and an air flow partition plate air gap (4) is formed in the middle of the air flow partition plate (5). A plurality of double-air-chamber box bodies are connected in series with one another; and the conveyer belts are paved on the upper surface of the combined body of the disk slot and the cambered bodies, so that the material transmission system is formed.

Owner:BEIJING JIAOTONG UNIV

Strip mop with mechanical wiping device

InactiveCN101779941AEasy squeezeSqueeze thoroughlyCarpet cleanersFloor cleanersReciprocating motionEngineering

The invention relates to a strip mop with a mechanical wiping device, which is characterized in that the mechanical wiping device is additionally arranged on the common cloth strip or wire mop; the mechanical wiping device is driven by utilizing up-and-down movement of slide blocks of a connecting rod mechanism on a mop rod. The pressing modes comprise a roll mode, a pressure plate mode and a pressure claw mode, wherein the roll mode transforms linear movement of the slide blocks to rotation of a roll through a rack, a gear and a synchronous belt transmission mechanism, a mop head is towed by the rack and is pressed by the roll at the same time, the speed of pressing a mop head transfer strip belt by the roll is the same as the speed of towing the mop head strip belt by the rack, both of the speeds keep synchronous, and the mop head is wiped and reset by the reciprocating movement of the slide blocks; and the pressure plate mode and the pressure claw mode are both characterized in that driving force of the slide blocks acts on a power arm of a lever through a top block and a pressure wheel so as to drive a pressure plate or a pressure claw on a resistance arm of the lever to extrude the mop head; the slide blocks tow the mop head to move up and down through drive rods at the same time; and the mop head is wiped in a framework and is reset when leaving the framework.

Owner:周现华

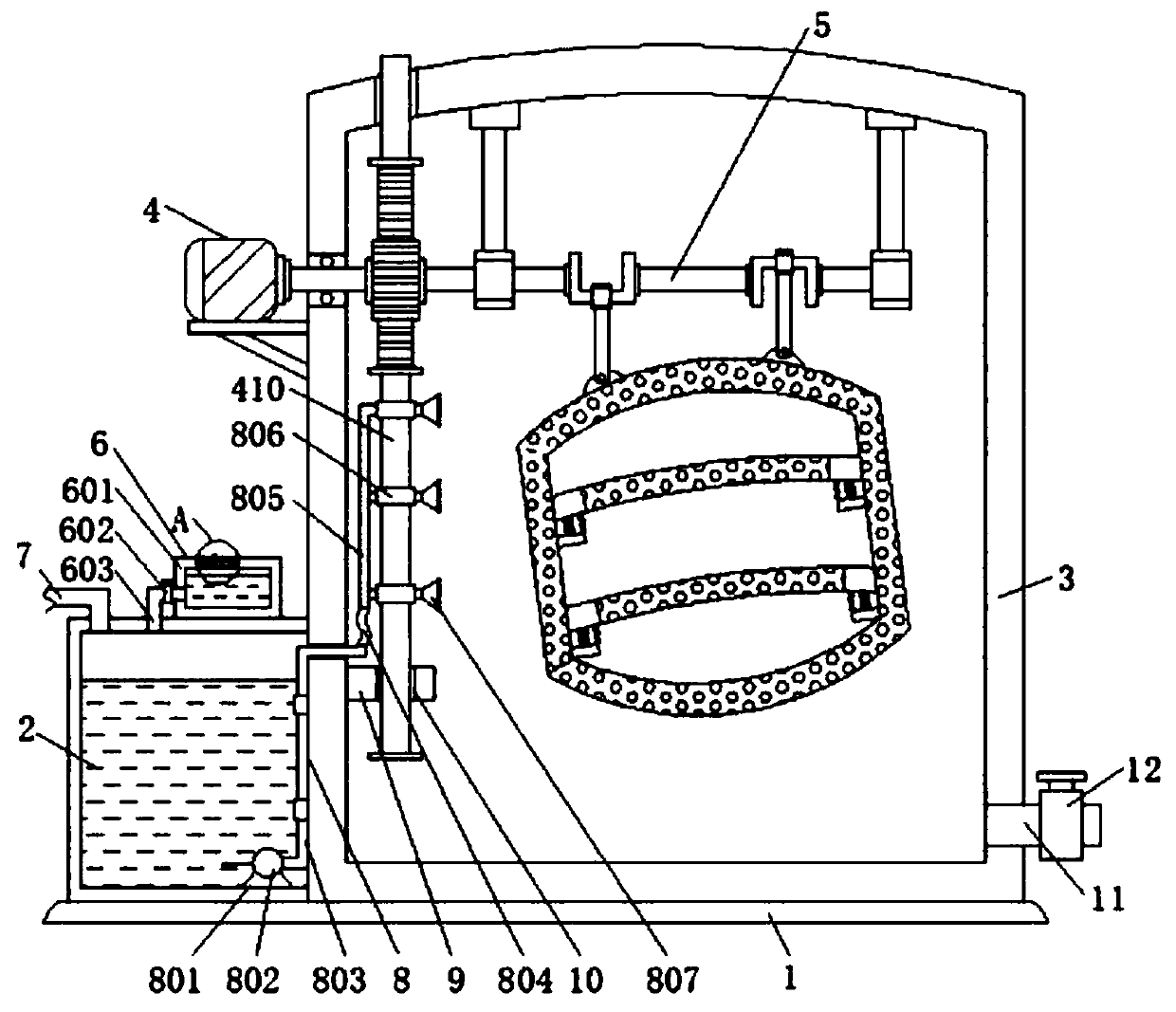

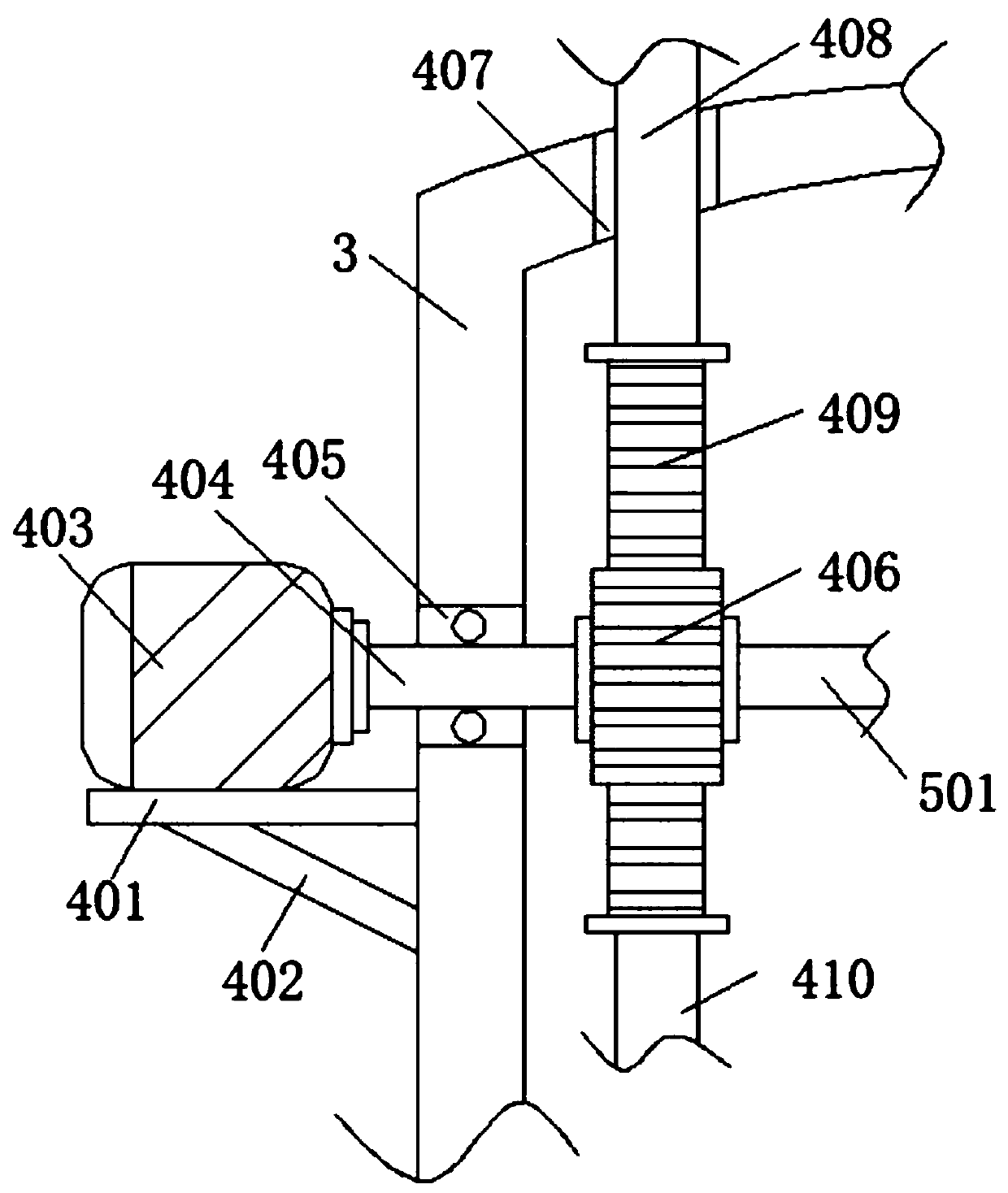

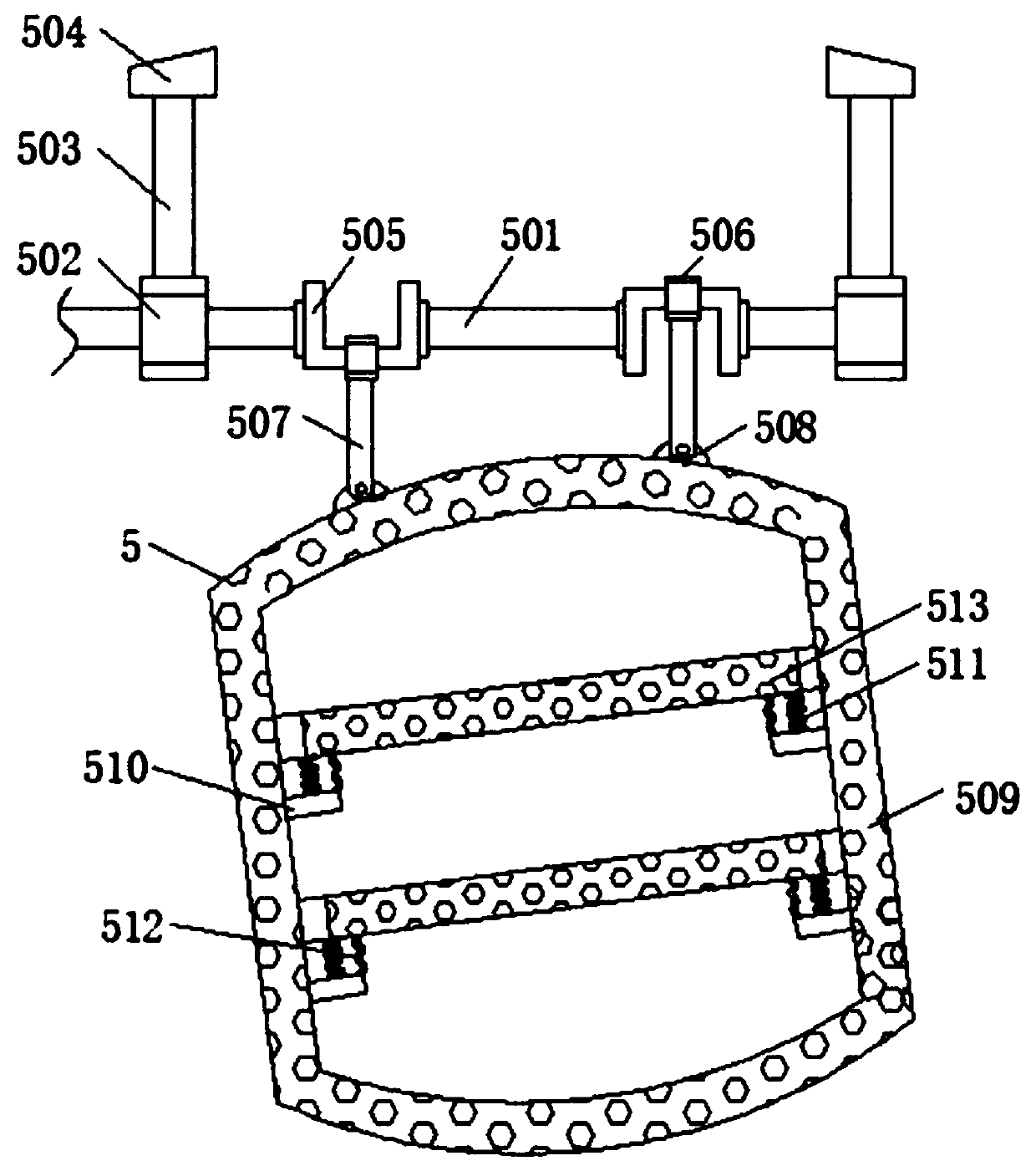

Free swinging device for removing hard yellow mud on surface of codonopsis pilosula and using method

InactiveCN111299263AGood for fallingEffectively eroded and brokenCleaning using liquidsCodonopsis pilosulaMechanical engineering

The invention relates to the technical field of traditional Chinese medicine, in particular to a free swinging device for removing hard yellow mud on the surface of codonopsis pilosula and a using method, and aims to solve the technical problem that after yellow soil is sun-dried, hard blocks are formed and attached to the surface of codonopsis pilosula as well as difficult to simply wash out. Inorder to solve the above technical problem, the free swinging device for removing the hard yellow mud on the surface of codonopsis pilosula is provided. The free swinging device comprises a base, wherein a water tank and a cleaning box are fixedly connected with the top of the base from left to right; a power actuator is fixedly connected with the top of one side of the cleaning box; and the output end of the power actuator penetrates through and extends into the cleaning box. By the adoption of the free swinging device, the hard yellow soil blocks can be effectively eroded and broken; the removal of the hard yellow soil blocks from the surface of codonopsis pilosula can be facilitated; and the problem that after the yellow soil is sun-dried, the hard blocks are formed and attached to thesurface of codonopsis pilosula as well as difficult to simply wash out can be solved.

Owner:杨喜兰

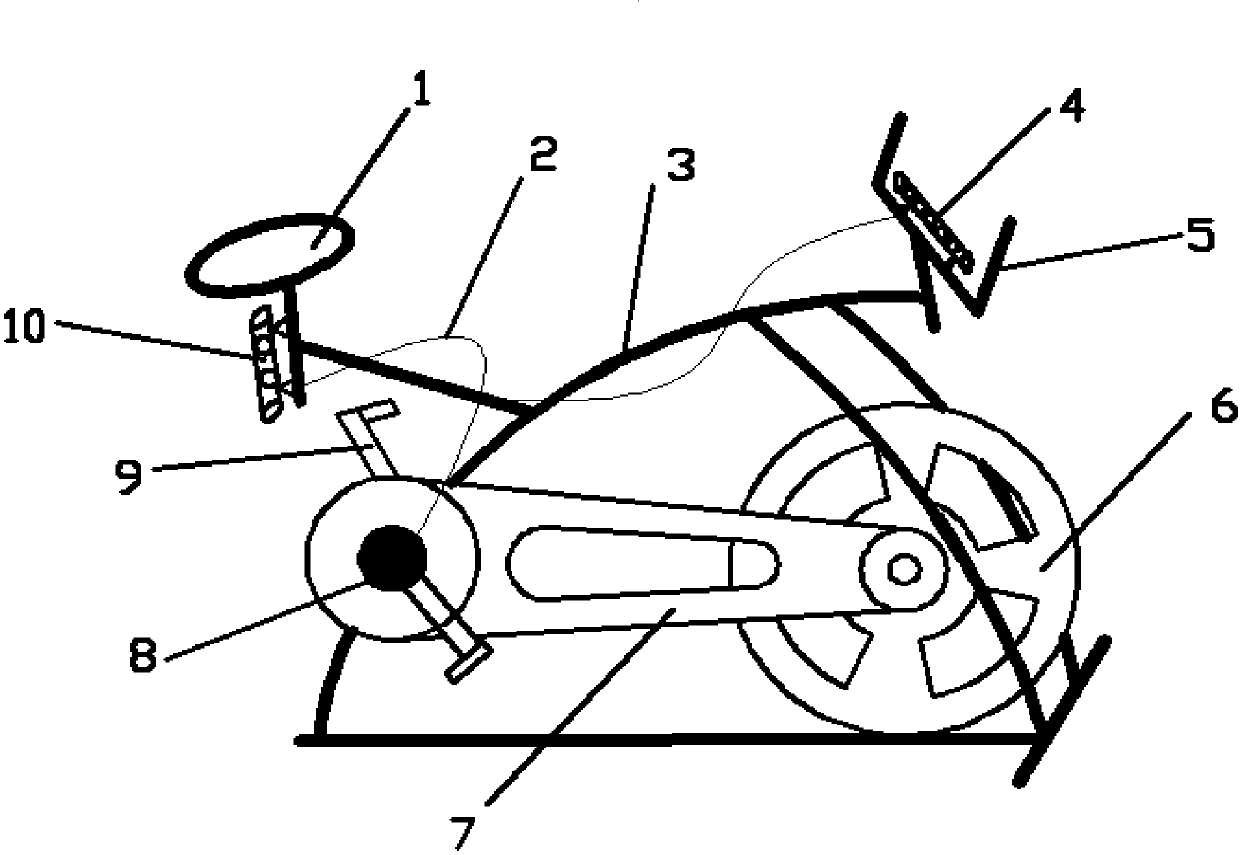

Colorful motivation bodybuilding energy-saving spinning

InactiveCN108016561AIncrease Fitness Fun and MotivationImprove performanceVehicle cranksFrom muscle energyFlywheelSprocket

A colorful motivation bodybuilding energy-saving spinning comprises a handlebar, a spinning frame, a saddle, a sprocket wheel crank, an inertial flywheel and a chain transmission assembly. Colorful lamps are installed at the position of the handlebar and the position below the saddle, a small electric generator is arranged in a center shaft of the sprocket wheel crank, the center shaft of the sprocket wheel crank is connected with a rotary shaft of the small electric generator through a gear, the sprocket wheel crank is driven to rotate through pedals so as to drive the electric generator to generate power, and power supply is conducted on the colorful lamps. Power generated by force of a person stepping on the pedals is transmitted to the colorful lamps to enable the colorful lamps to shine, but the rotating speeds of the pedals are different, the shining degrees of the colorful lamps are different, in this way, sensory stimuli is provided for bodybuilding personnel according to the different colorful brightness, the bodybuilding pleasure and the enthusiasm of the bodybuilding personnel are enhanced, and the effects of environmental protection and energy conservation can further be achieved.

Owner:GUANGXI UNIV

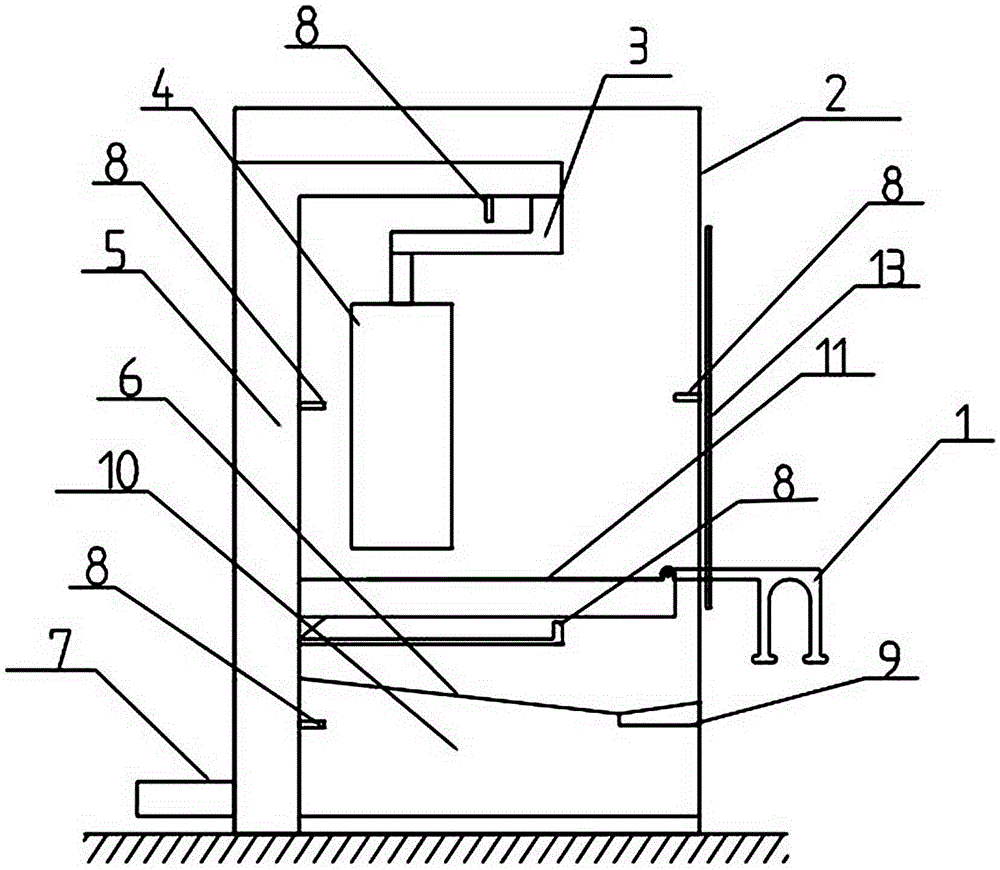

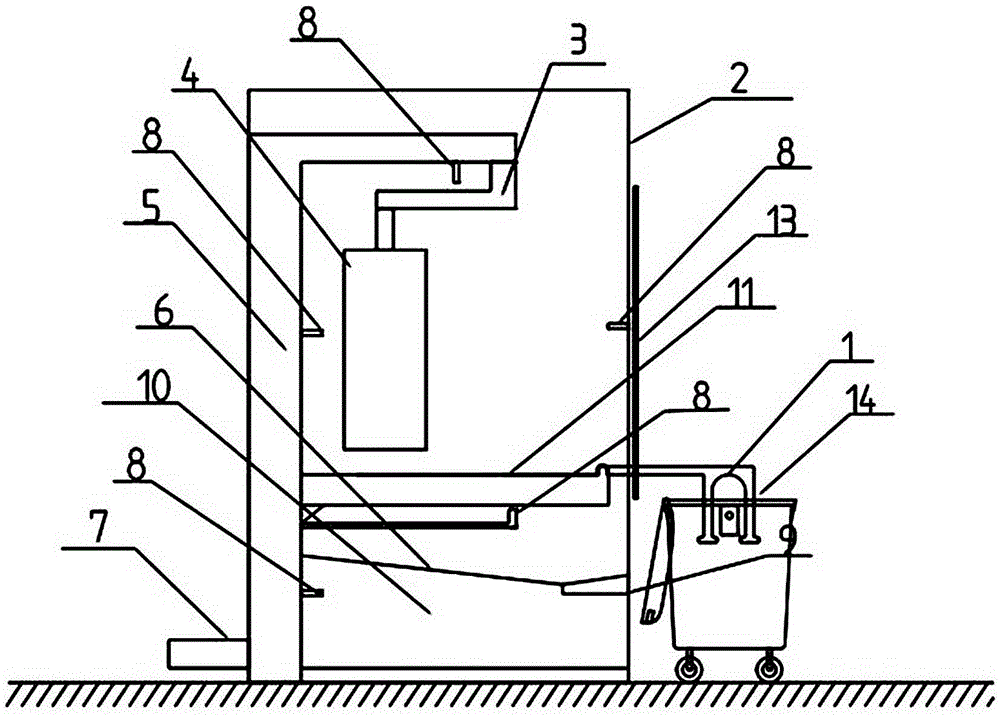

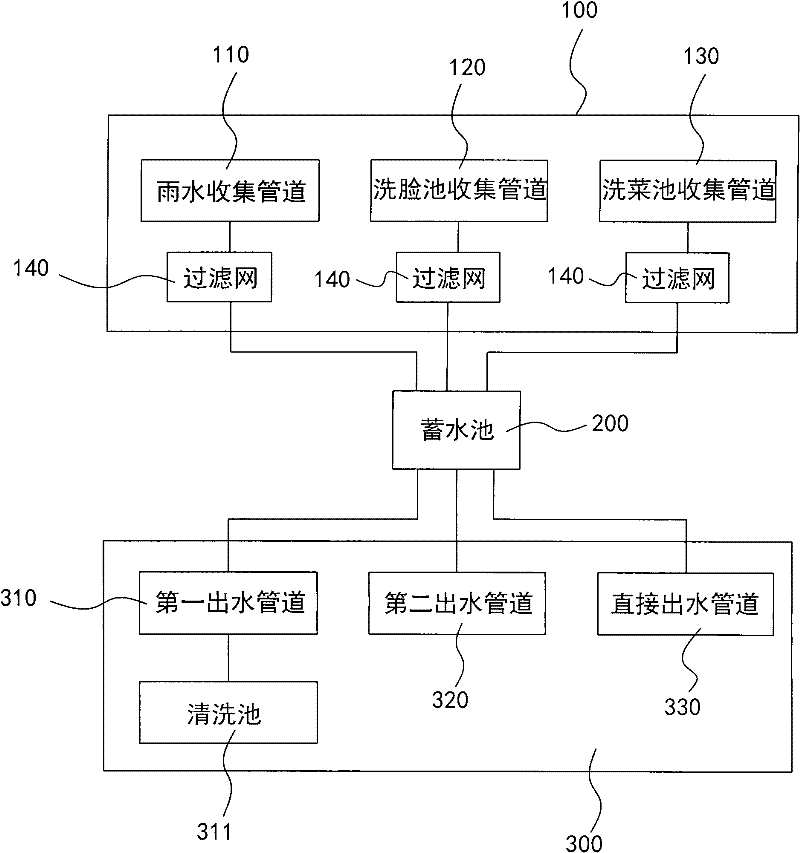

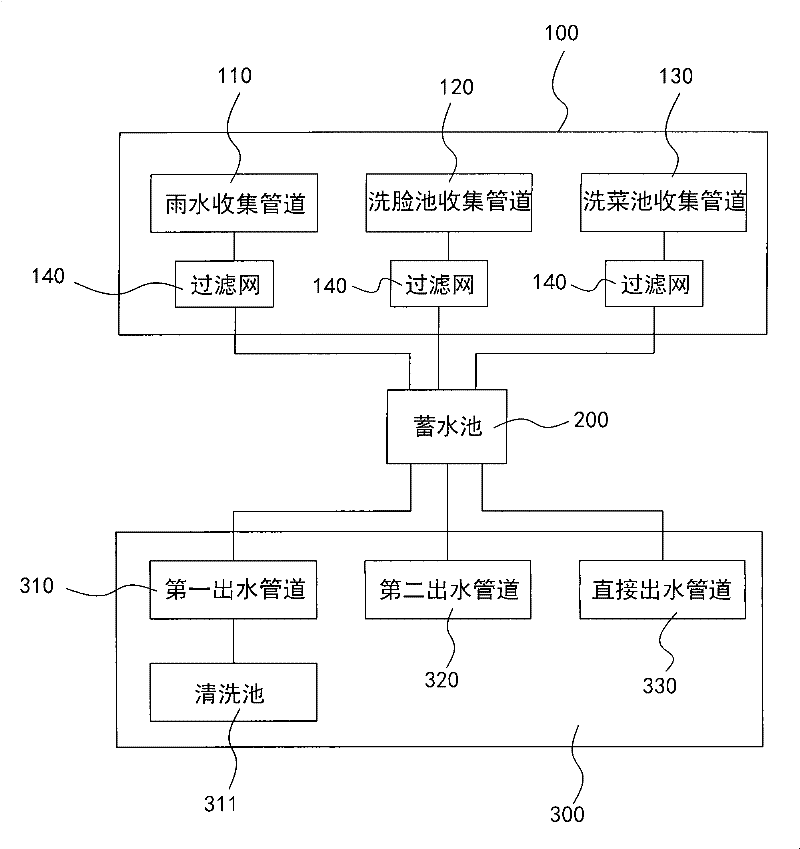

Kitchen washing tank with energy saving and environment protection functions

InactiveCN105617760AWith energy saving and environmental protection functionTo achieve the effect of environmental protection and energy savingKitchen equipmentFiltration circuitsWater useConservation energy

The invention discloses a kitchen washing tank with energy saving and environment protection functions. The kitchen washing tank comprises a base. A sewage treatment vehicle is arranged at the right end of the base, a water tank, a washing bin and a sundry collecting box are sequentially arranged on the top of the base from left to right, and a blow-off pipe is arranged on the right side of the bottom of the washing bin, sequentially penetrates through the upper portion and right side face of the base and stretches out of the base; a controller is arranged on the left side in the base, a water outflow pipe is arranged in the water tank, penetrates through the bottom of the water tank and stretches out of the water tank, and a water pump is connected to the upper portion of the water outflow pipe and connected with a sprayer through the water outflow pipe. The kitchen washing tank with the energy saving and environment protection functions achieves the energy saving and environment protection effects during use, the problem that water used for vegetable washing, hand washing and the like is drained randomly is solved, a fine filtering device is improved in the washing bin, the sewage purification effect is achieved, it is guaranteed that water is recycled, and energy is saved.

Owner:林丽芳

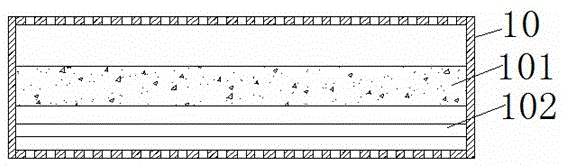

System for recycling and reuse of steam

The invention discloses a system for recycling and reuse of steam. The system for the recycling and the reuse of the steam comprises a heating device, a piezoelectric conversion device, a thermoelectric conversion device, an oil-water separation device and a water supply device, wherein the heating device, the piezoelectric conversion device, the thermoelectric conversion device, the oil-water separation device and the water supply device are connected successively by pipelines to form a steam loop. According to the invention, the piezoelectric conversion device and the thermoelectric conversion device are disposed, and the steam with pressure and heat is reused, so that pollution brought by the steam which contains grease to a kitchen can be prevented; and an actual utilization rate of the steam is increased, and environment-protection and energy-saving effects can be achieved.

Owner:北京涵智博雅能源科技有限公司

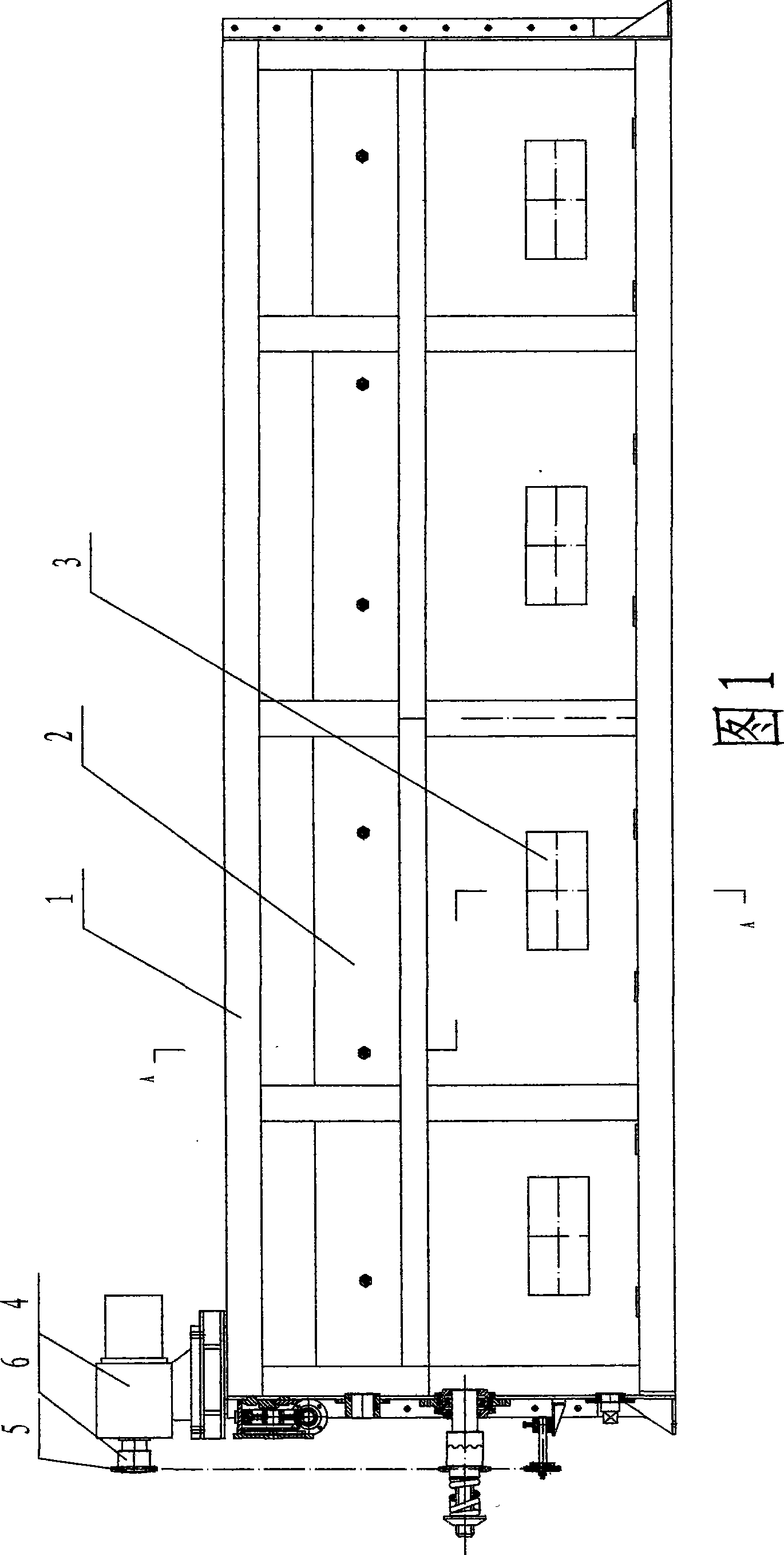

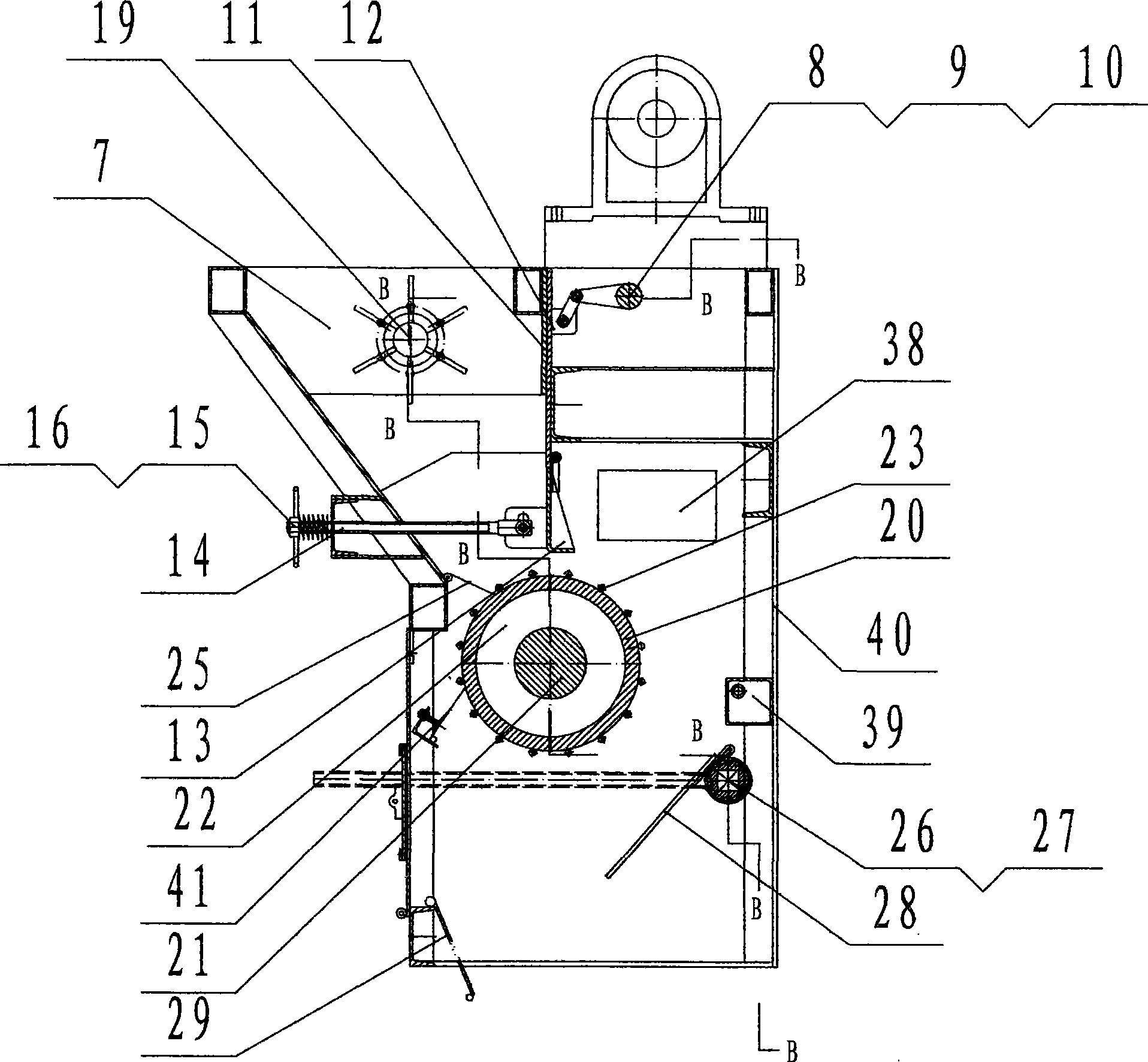

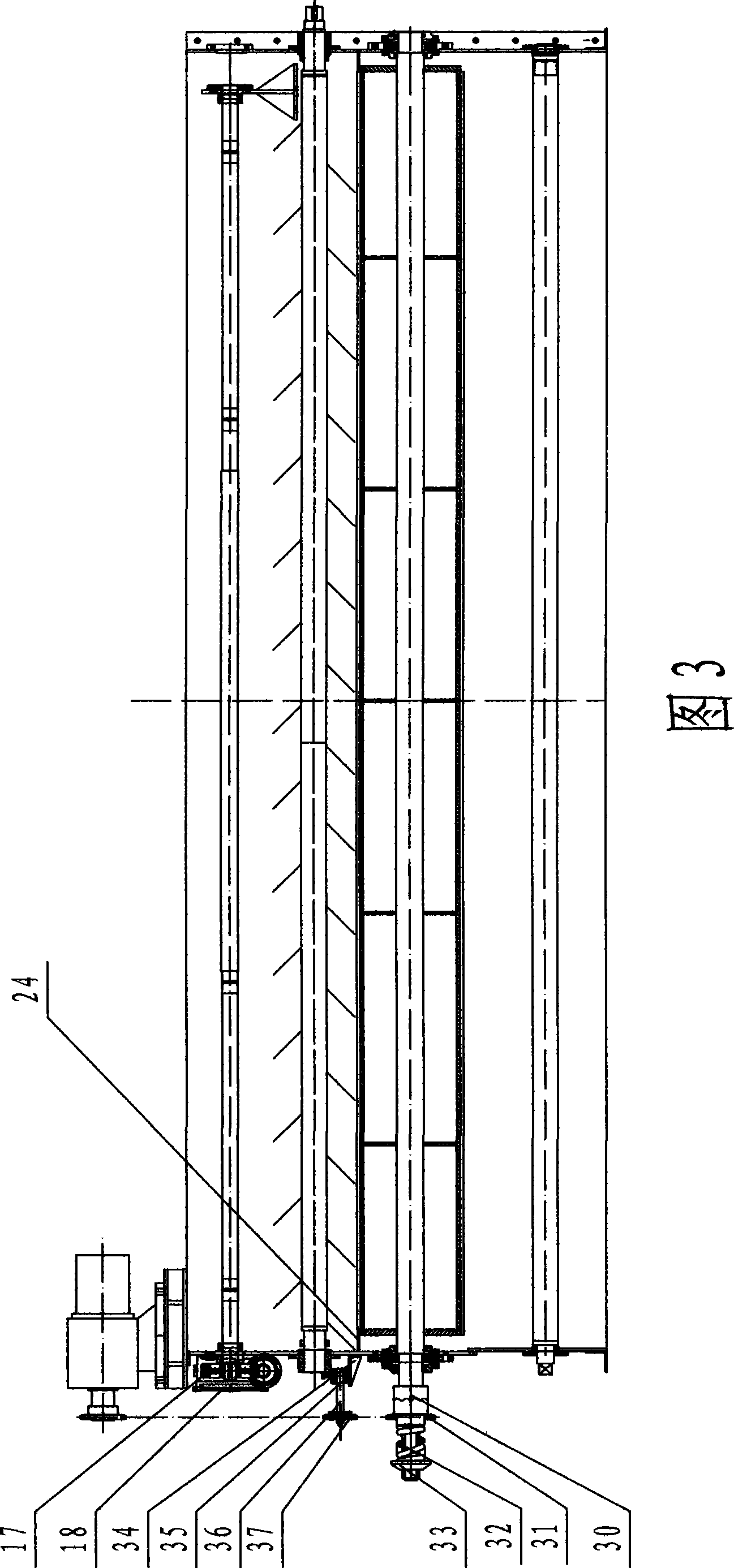

Novel heavy duty frame stressing layering coal supply apparatus

InactiveCN101387405ASolve coal congestionHigh outputLump/pulverulent fuel feeder/distributionApplied mechanicsEngineering

The invention discloses a novel heavy type frame stress type layered coal feeding device. According to the principles of engineering mechanics and granular media mechanics of fuel coal , the invention solves the problems that in the prior layered coal feeding device of an industrial chain grate boiler for integrated heat supply at home, the working condition of combustion in the boiler is directly influenced; the strength of structural design is deformed; a coal poking roller is deformed; a coal flashboard is heated and deformed; the transverse thickness of a coal burning layer is out of control; and the adjustment of synchronous combustion is out of control. A frame stress structure, an automatic coal scraping and roller cleaning device for an externally and internally-built two-level segmented independent coal poking roller, an automatic adjusting device for the thickness of a fuel coal layer, a device for sectionally and independently adjusting and controlling the thickness of the coal layer, a combined frame structure of a single coal poking roller, a coal roller for breaking frozen coal blocks and transporting coal in a cold region, a sub-caging and layering device and other technologies are adopted to form the novel heavy type frame stress type layered coal feeding device.

Owner:大连瓦房店市永宁排炉制造有限公司 +2

Wastewater recycling system

The invention relates to a wastewater reclamation system, particularly to a wastewater recycling system, which comprises a reclamation device, a water storage tank and a use device, wherein the reclamation device is connected with the water storage tank, and the water storage tank is connected with the use device. The wastewater recycling system provided by the invention has the following beneficial effects: the system reclaims the wastewater that is not reclaimed in life in the prior art, and effectively utilizes the wastewater, thereby achieving the effects of environmental protection and energy conservation; and the system is simple in structure and convenient in use, and easy for generalization.

Owner:李雅璇

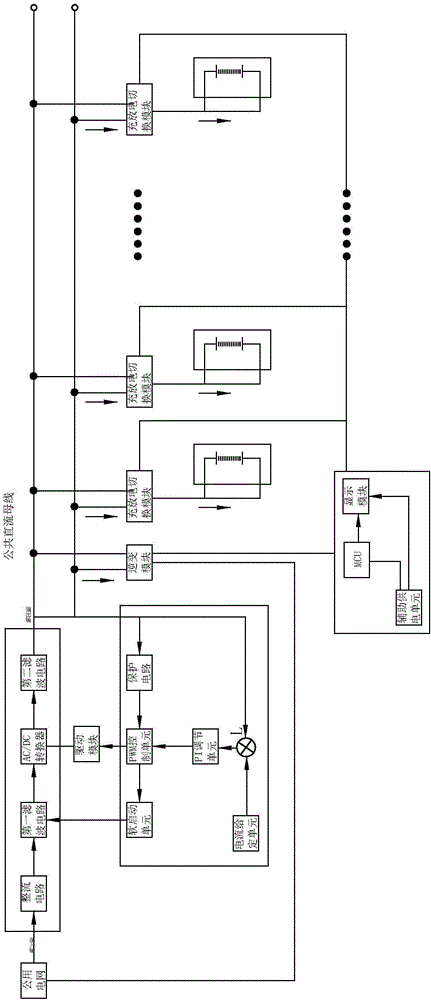

Energy-saving capacity grading device for power batteries

InactiveCN106208123AImprove charge and discharge conversion rateReduce power consumptionDifferent batteries chargingSingle network parallel feeding arrangementsElectrical batteryEngineering

The invention relates to an energy-saving capacity grading device for power batteries. The energy-saving capacity grading device comprises a plurality of terminal charge and discharge modules, an inverter module and an upper computer module, wherein the upper computer module simultaneously monitors and controls a plurality of capacity grading channels; the capacity grading channels charge single power batteries with the same voltage source; a constant-voltage and constant-current source of each terminal charge and discharge module is independently controlled; and during discharging, an MCU boosts the single power batteries through charge and discharge switching modules in series and a power module converts AC voltage into DC high voltage to connect to two ends of a common DC bus, so that energy is fed back to an AC power grid for grid connection or graded capacities are formed to be recycled in the single power batteries. Therefore, the charge and discharge conversion rate is effectively improved, the power consumption is low, the volume is small and the effects of environmental protection and energy conservation are achieved.

Owner:广州皖力实业有限公司

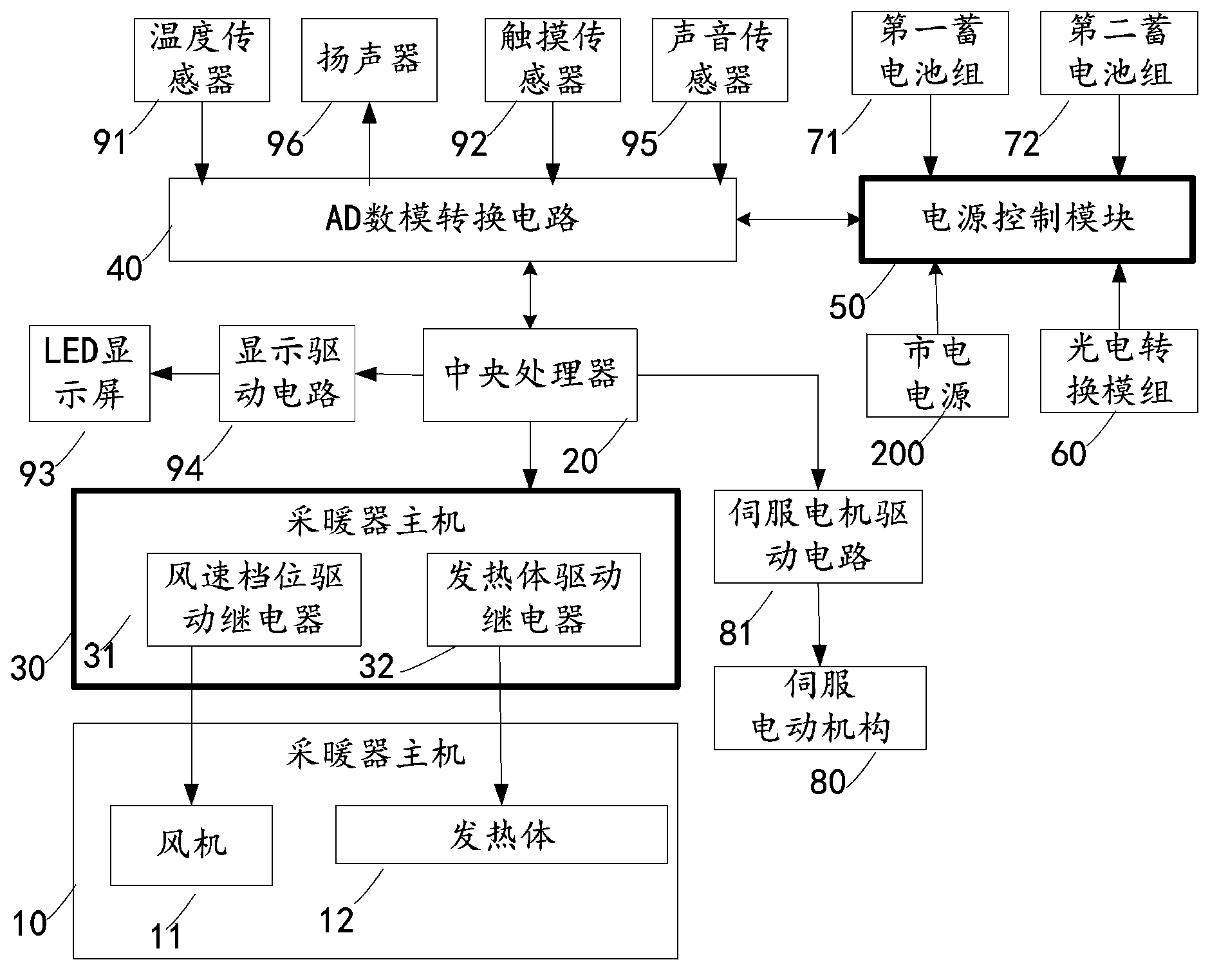

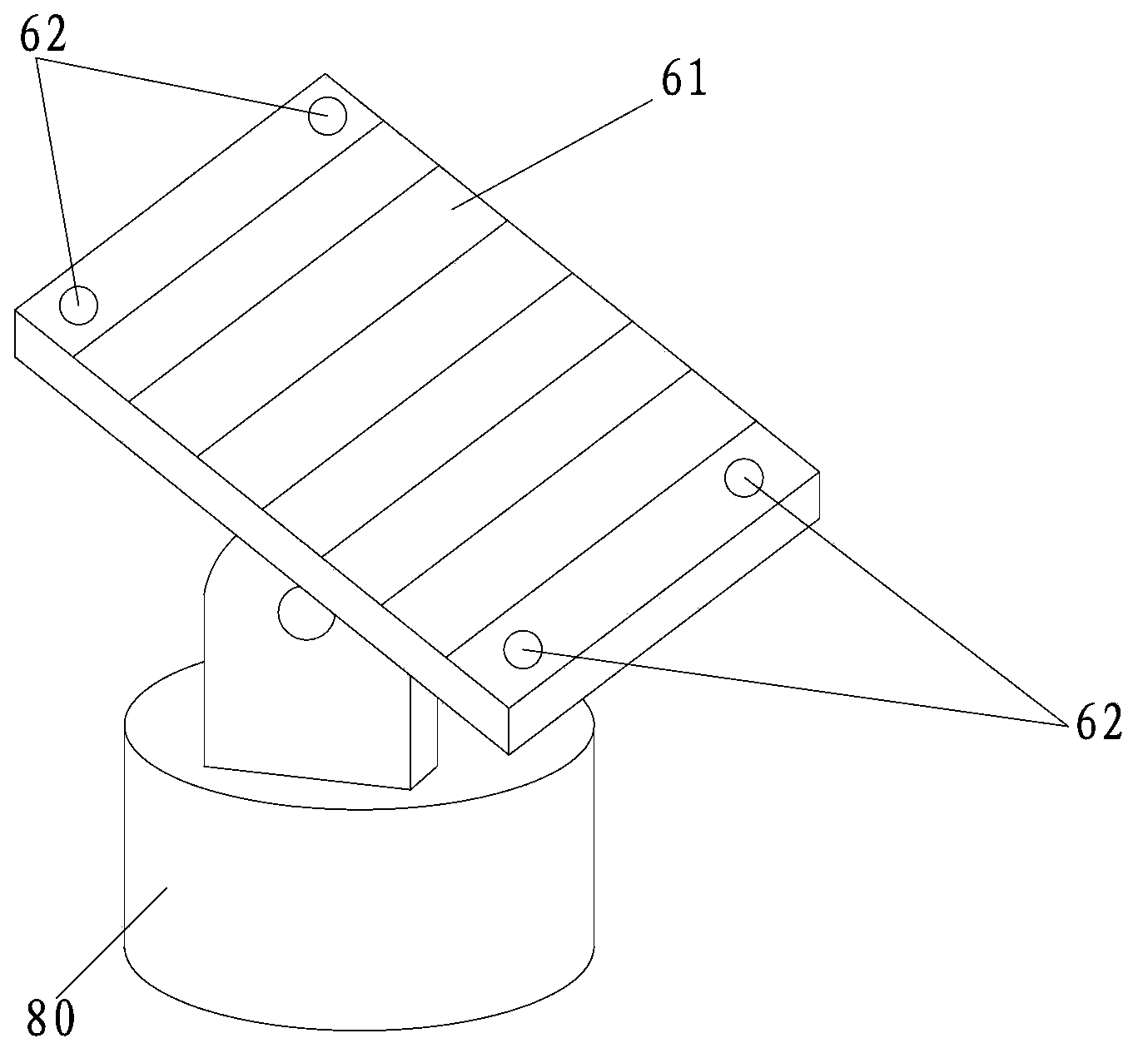

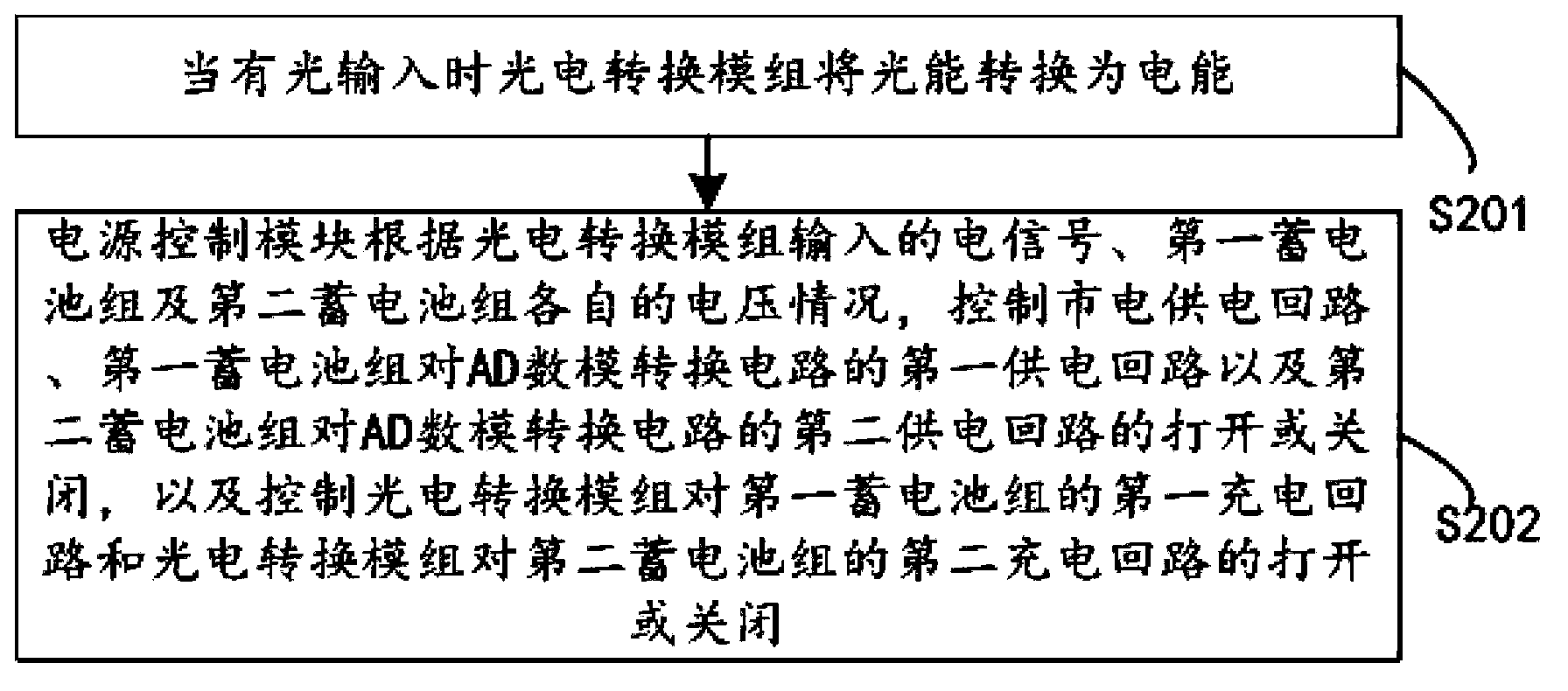

Solar heater and electric power storage and supply control method for same

ActiveCN104110720AIncrease profitAvoid working with high currentBatteries circuit arrangementsLighting and heating apparatusElectricityLight energy

The invention discloses an electric power storage and supply control method for a solar heater. The electric power storage and supply control method is applied to the solar heater which meets one of first-eighth claims, and includes S1, converting light energy into electric energy by the aid of a photoelectric conversion module when light is inputted; S2, enabling a power control module to control a mains supply circuit and a first storage battery set to open or close a first power supply circuit of an AD (analog-digital) conversion circuit, control a second storage battery set to open or close a second power supply circuit of the AD conversion circuit and control the photoelectric conversion module to open or close a first charging circuit of the first storage battery set and a second charging circuit of the second storage battery set according to electric signals inputted by the photoelectric conversion module and respective voltage conditions of the first storage battery set and the second storage battery set. The invention further discloses the solar heater.

Owner:徐州市通途装配式建筑科技有限公司

Environment-friendly energy-saving garbage can capable of increasing space utilization rate

InactiveCN108557337AImprove space utilizationAchieve energy saving effectWaste collection and transferRefuse receptaclesEngineeringUtilization rate

The invention discloses an environment-friendly energy-saving garbage can capable of increasing space utilization rate. The garbage can comprises a garbage can body, a solar panel is arranged at the top end of the garbage can body, a sleeving rod is supported at the lower end of the solar panel, a screw rod and a screw shaft are arranged at the inner upper end of the garbage can body, connecting plates are arranged on two sides of a fixing sleeve, a rotating gear and a driving gear are arranged at one end of a rotating shaft, a rotating rod is arranged at the lower end of the driving gear, a motor and a storage battery are arranged at the lower end of the rotating rod, a garbage recycling bin is arranged at the lower ends of the connecting plates, a fixed plate is arranged in the garbage recycling bin, a squeezing plate is arranged at the lower end of the fixed plate, a water accumulation box is arranged at the lower end of the middle, far away from the squeezing plate, of a filteringplate, a first fixing block and a second fixing block are arranged on one side, close to the filtering plate, of the upper end of an elastic device, and a telescopic rod and a spring are arranged between the first fixing block and the second fixing block. The garbage can has the advantages that the internal space utilization rate of the garbage can is increased, and environmental protection and energy saving effects are effectively achieved.

Owner:安徽目然信信息科技有限公司

Energy-saving and environment-friendly air purification furniture coating

InactiveCN105017924AImproves corrosion resistance and drynessSafe to useAnti-corrosive paintsEpoxy resin coatingsWaxChemistry

The invention discloses an energy-saving and environment-friendly air purification furniture coating. The energy-saving and environment-friendly air purification furniture coating is composed of, by weight, 60-70 parts of E-42 epoxy resin, 3-5 parts of di-butyl phthalate, 3-4 parts of methylsiloxane, 5-7 parts of water soluble silicone oil, 4-5 parts of triethanolamine, 7-8 parts of acetone, 4-6 parts of di-butyl phthalate, 2-4 parts of TDI, 5-8 parts of pure natural wax, 3-5 parts of epoxidized soybean oil, 2-4 parts of epoxy fatty acid polyol ester, 4-5 parts of antioxygen 1010, 5-8 parts of N-methyl pyrrolidone and 3-5 parts of isopropyl alcohol. According to the energy-saving and environment-friendly air purification furniture coating, E-42 epoxy resin and epoxidized soybean oil are used as raw materials, the effects of environmental protection and energy saving are achieved, and the manufactured coating wonderfully improves the corrosion resistant performance and the dryness of the coating; due to the fact that arene solvent and pungent odors are not contained, using is safe and convenient, the environmental protection advantage is achieved, the coating is suitable for various construction methods, painting is not limited by seasons, plenty of painting costs can be saved, and the service life is prolonged.

Owner:HEFEI LANTIAN FURNITURE MAKING CO LTD

Spray castable single-color double-density rubber tire and molding process thereof

InactiveCN110861334AAvoid circulationResolve multiple pressurizationTyresVulcanizationComposite material

The invention relates to the field of rubber tires, in particular to a spray castable single-color double-density rubber tire and a molding process thereof. The molding process comprises the followingsteps of 1, closing a mold and carrying out double-density spray casting; 2, opening the mold and automatically removing a mold core; 3, carrying out secondary mold closing; 4, putting the preformedlight high-elasticity rubber foaming tire into the mold, and closing the mold to enable the tire to have vulcanization conditions; 5, vulcanizing; and 6, carrying out secondary mold opening: opening amold cavity, and taking out the single-color double-density once-molded rubber tire. The one-time spray casting molding process is adopted, so that the production process is simple, the production efficiency is high, the energy consumption is low, the production cost is low, and the produced tire is good in comfort, shock absorption and anti-skid effects.

Owner:东莞同成塑胶五金制品有限公司

Energy-conservation eco-friendly intelligent monitoring device for indoor environment

InactiveCN107037180AConvenient queryEasy to monitorTelemetry/telecontrol selection arrangementsMessaging/mailboxes/announcementsElectronic marketsEnvironmental monitoring

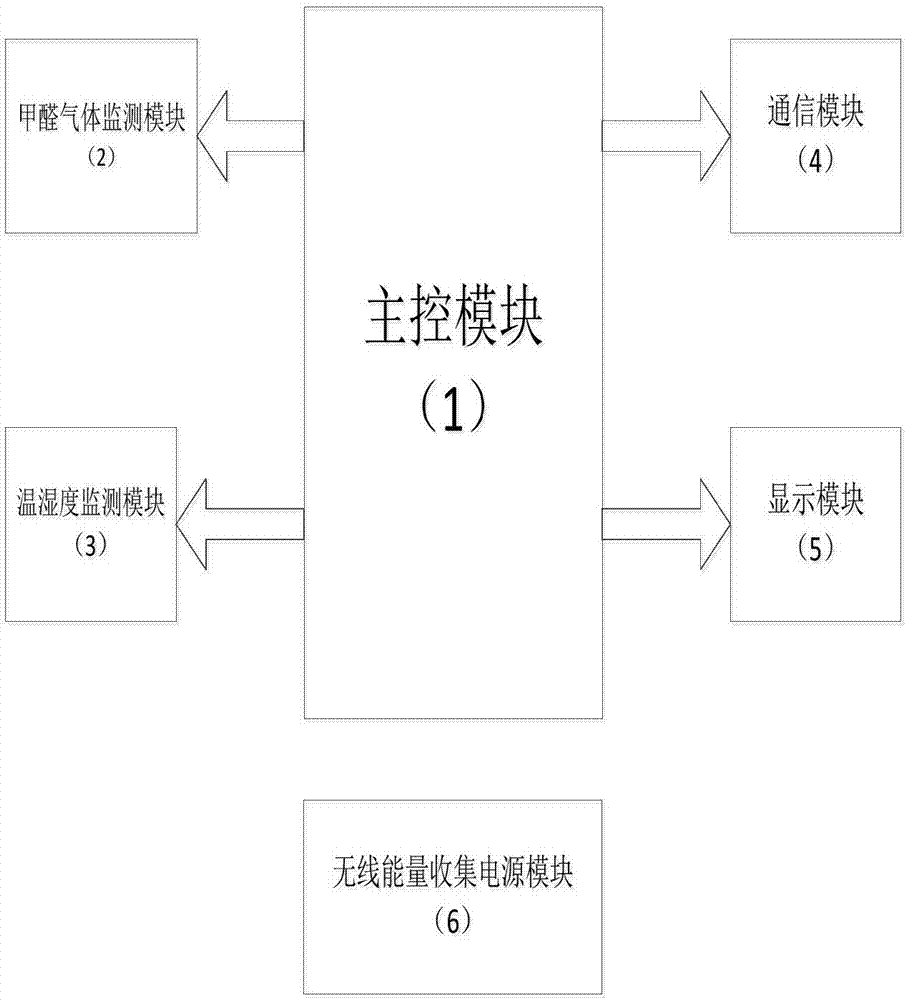

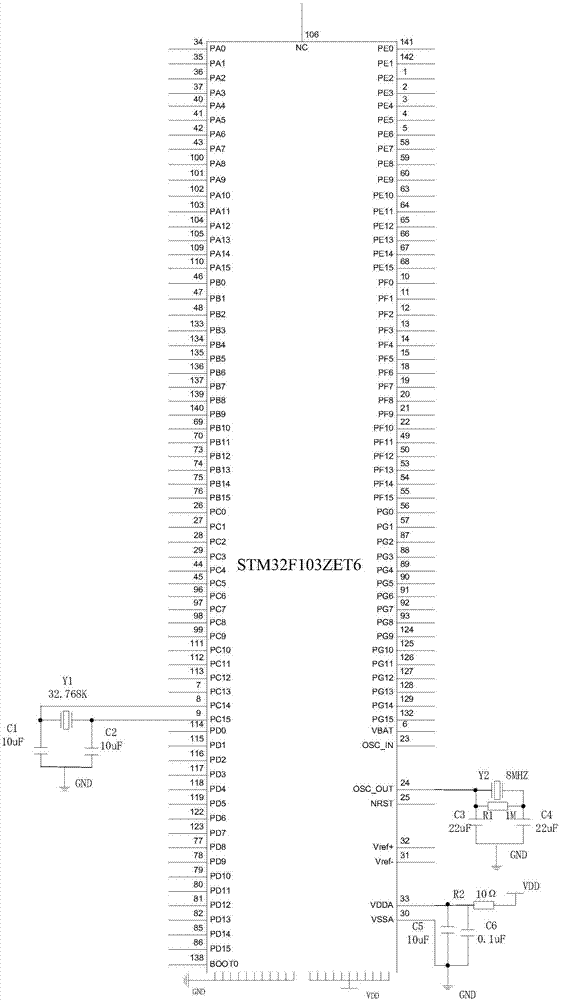

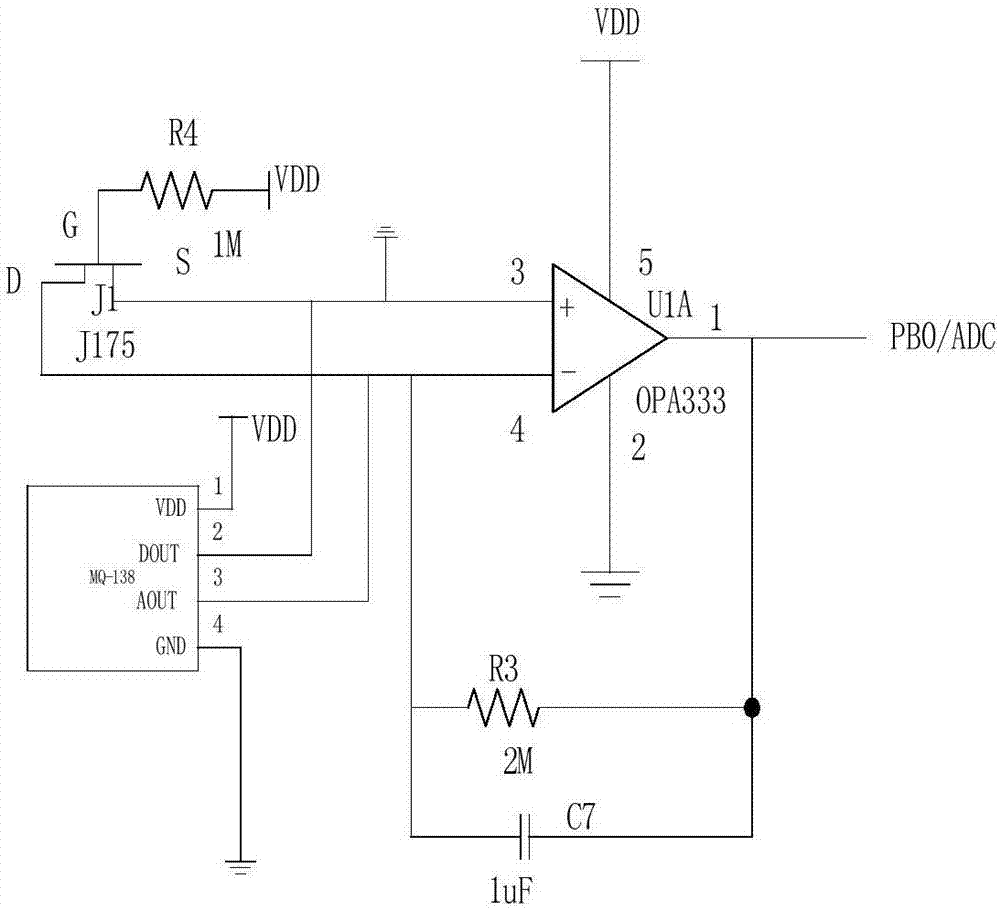

The invention discloses an energy-conservation eco-friendly intelligent monitoring device for indoor environment, and belongs to the field of communication technology. The device comprises a master control module (1), a formaldehyde gas monitoring module (2), a temperature and humidity measuring module (3), a communication module (4), a display module (5) and a power module for wireless energy harvesting (6). The device is capable of effectively measuring present indoor environment and timely reminding users as the quality of the present indoor environment dose not reach the standard. The energy-conservation eco-friendly intelligent monitoring device for indoor environment has the advantage of promoting the advance of measurement technique of indoor environment, thereby directly having a positive influence on development of an industry of environmental monitoring, and boosting development of the industry in an electronic market.

Owner:JILIN UNIV

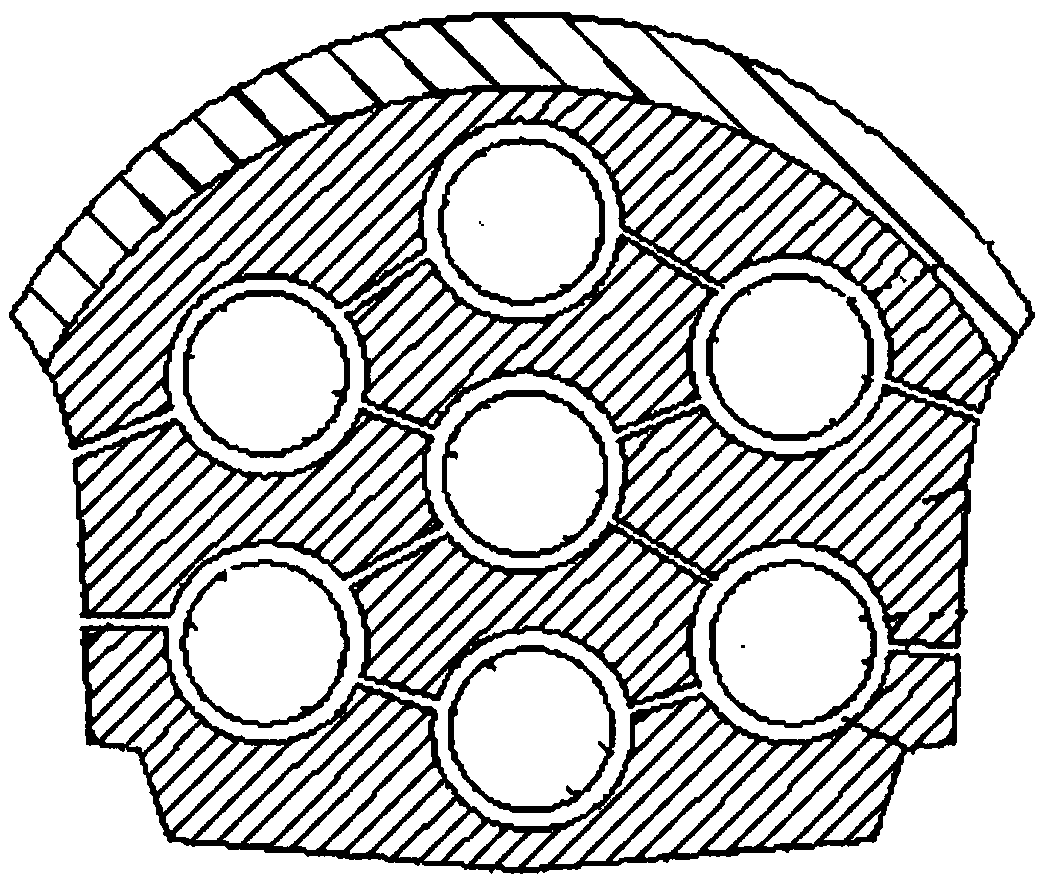

Production process of large-power submersible motor cast-aluminum rotor

InactiveCN105322735AReduce weightImprove efficiencyManufacturing stator/rotor bodiesSlagMaterials science

The invention relates to a production process of a large-power submersible motor cast-aluminum rotor, and is characterized by including the steps of: a. die pressing: placing a mandrel on which a rotor silicon steel sheet is superposed and fixed on a bottom die, then placing an upper die, and using a piston cylinder pusher to compress the upper die and the bottom die; b. melting aluminum and removing slag: using a high-frequency melting furnace to melt an aluminium ingot, clearing away slag in molten aluminum, and introducing high-purity aluminum liquid into an aluminum holding barrel after reducing the temperature to 700 to 750 DEG C; c. casting cage bars: putting the aluminum holding barrel which holds molten aluminum in a piston cylinder barrel in the piston cylinder pusher, and rapidly pushing a piston cylinder switch; and d. assembling machining: cutting an aluminum cake, taking the upper die and the bottom die, pushing out the mandrel, installing a rotor shaft to be machined, and performing anticorrosion treatment. Short circuit rings and the cage bars are formed in one step, welding and secondary machining are not needed, physical mass is uniform in distribution, and a balance error is greatly reduced. The weight of the rotor itself is reduced, the motor efficiency and rotating speed are improved, the energy consumption is reduced, and the cost is low.

Owner:白银海佳电泵制造有限公司

New process for synthesis of musk ketone by microchannel reactor

InactiveCN109293515AAvoid heavy useReduce generationOrganic-compounds/hydrides/coordination-complexes catalystsNitro compound preparationAcetic anhydrideMusk ketone

The invention discloses a new process for synthesis of musk ketone by a microchannel reactor. The process includes the steps of: S1. preparing an auxiliary catalyst; S2. mixing the auxiliary catalystwith a sulfuric acid solution to prepare a composite catalyst, mixing dichloroethane with acetic anhydride to prepare a mixed solvent, mixing the mixed solvent with 2, 6-dimethyl-4-tert-butylacetophenone evenly to obtain a material A, preheating the composite catalyst, a nitric acid solution and the material A respectively, and then conducting mixing; S3. carrying out mixing reaction, and drainingthe reaction liquid at the end of the reaction; and S4. quenching the reaction liquid by a quenching module to obtain musk ketone. The process provided by the invention employs a continuous microchannel reactor to synthesize musk ketone, and has the advantages of short reaction time, low reaction temperature, convenient operation, and high yield and output. The process thoroughly eliminates the danger of nitration reaction explosion in traditional intermittent kettle type reaction, achieves high yield continuous production of musk ketone, also the process produces little waste acid, and reduces the pressure of later sewage treatment.

Owner:濮阳市欧亚化工科技有限公司

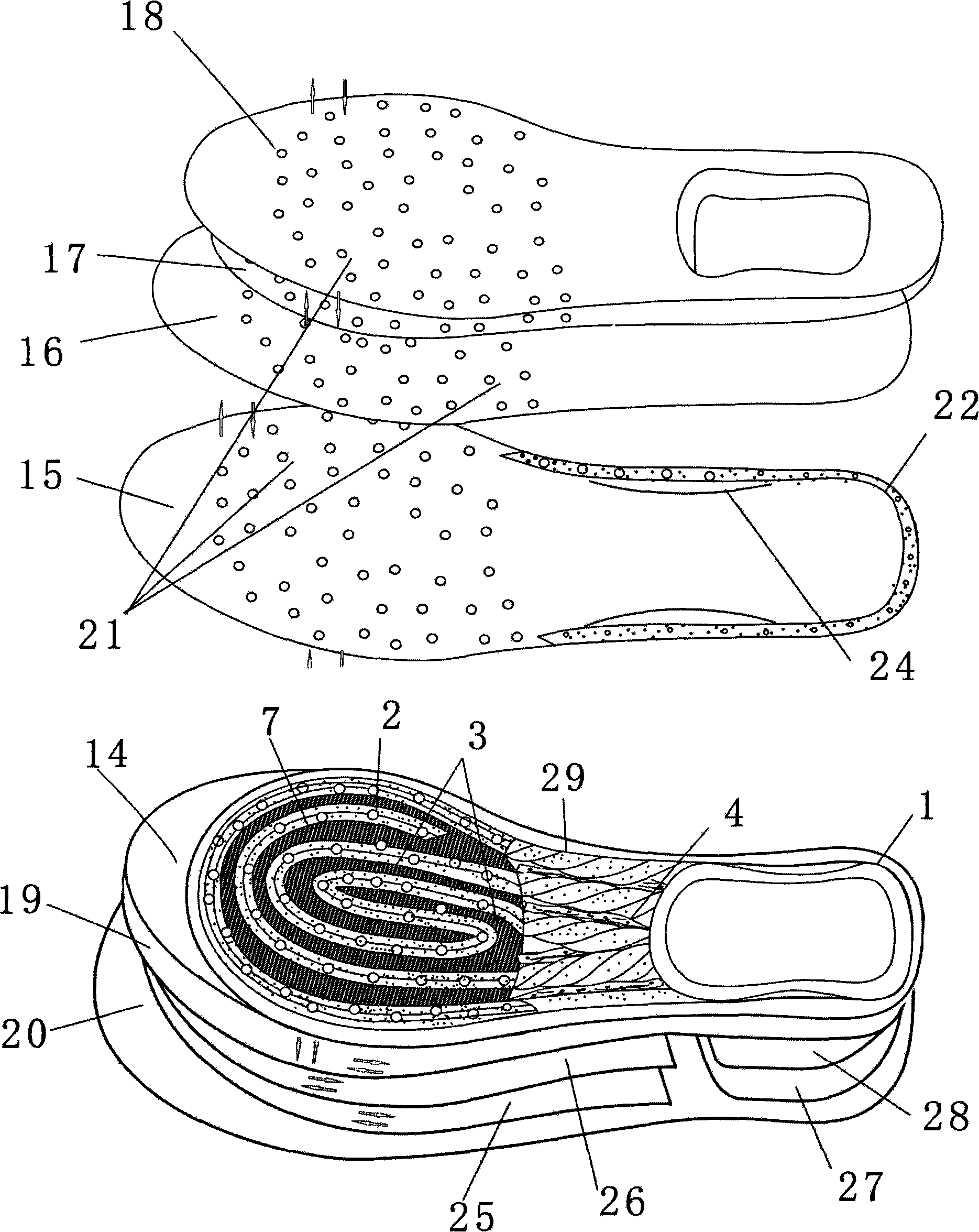

Insole

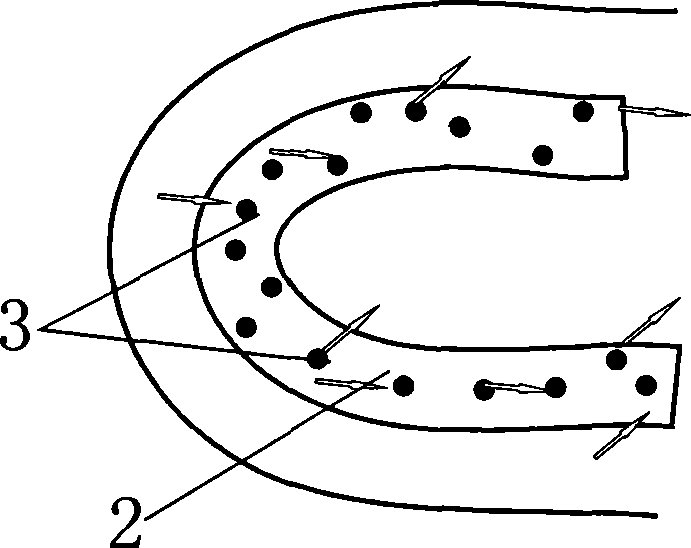

The invention discloses an insole, which comprises an insole body and is characterized in that the part, corresponding to the heel part of a human body, of the inside of the insole body is provided with an elastic air cushion; the part, corresponding to the sole of the human body, of the inside of the insole body is provided with annular air ducts at intervals in which rubber strings are arranged; air holes are distributed on the walls of the air ducts; the part, corresponding to the foot arch of the human body, of the inside of the insole is provided with connecting pipes; the walls of the connecting pipes are distributed with air holes; the openings of the air ducts are correspondingly connected with the openings at one end of the connecting pipes one by one; and the openings at the other end of the connecting pipes are connected with the elastic air cushion. The inside of the elastic air cushion is provided with an annular plastic horse and a rubber ring on which rubber string rings are distributed. The insole has the advantages of having the functions of heat absorption, heat dissipation, shock absorption, moisture absorption, odor prevention, purification of the inside of shoes, heat insulation and preservation and health care.

Owner:康胜前

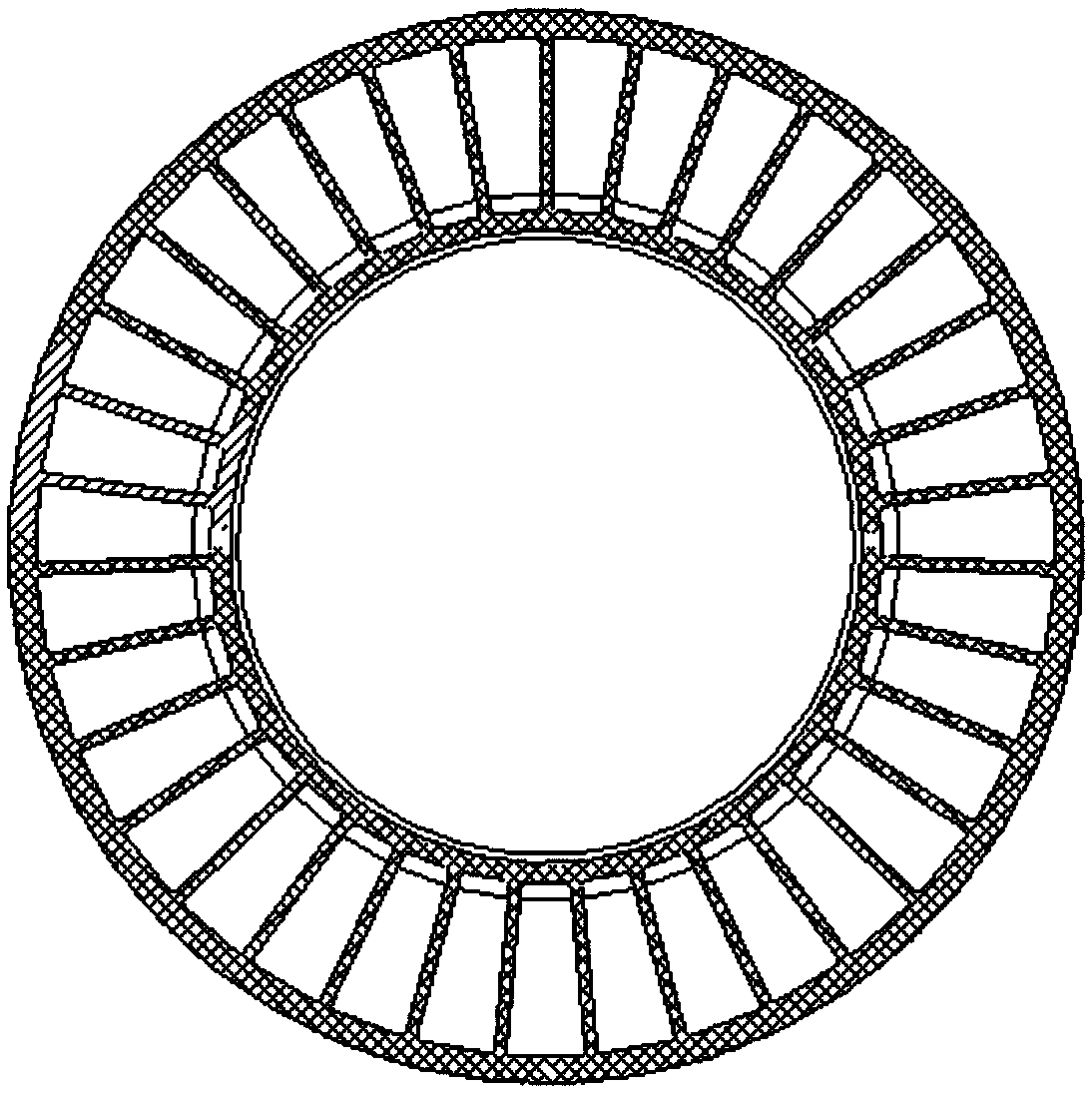

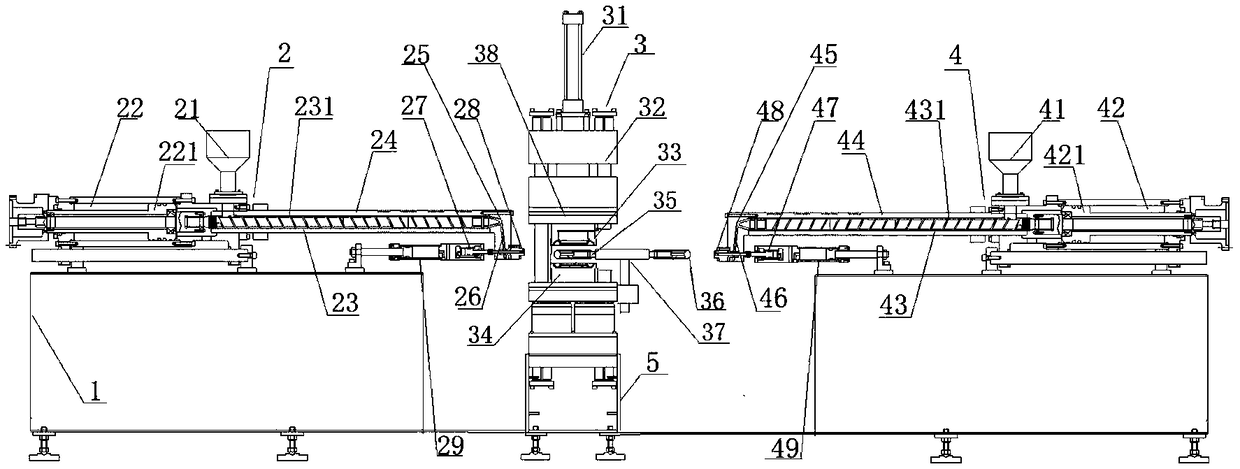

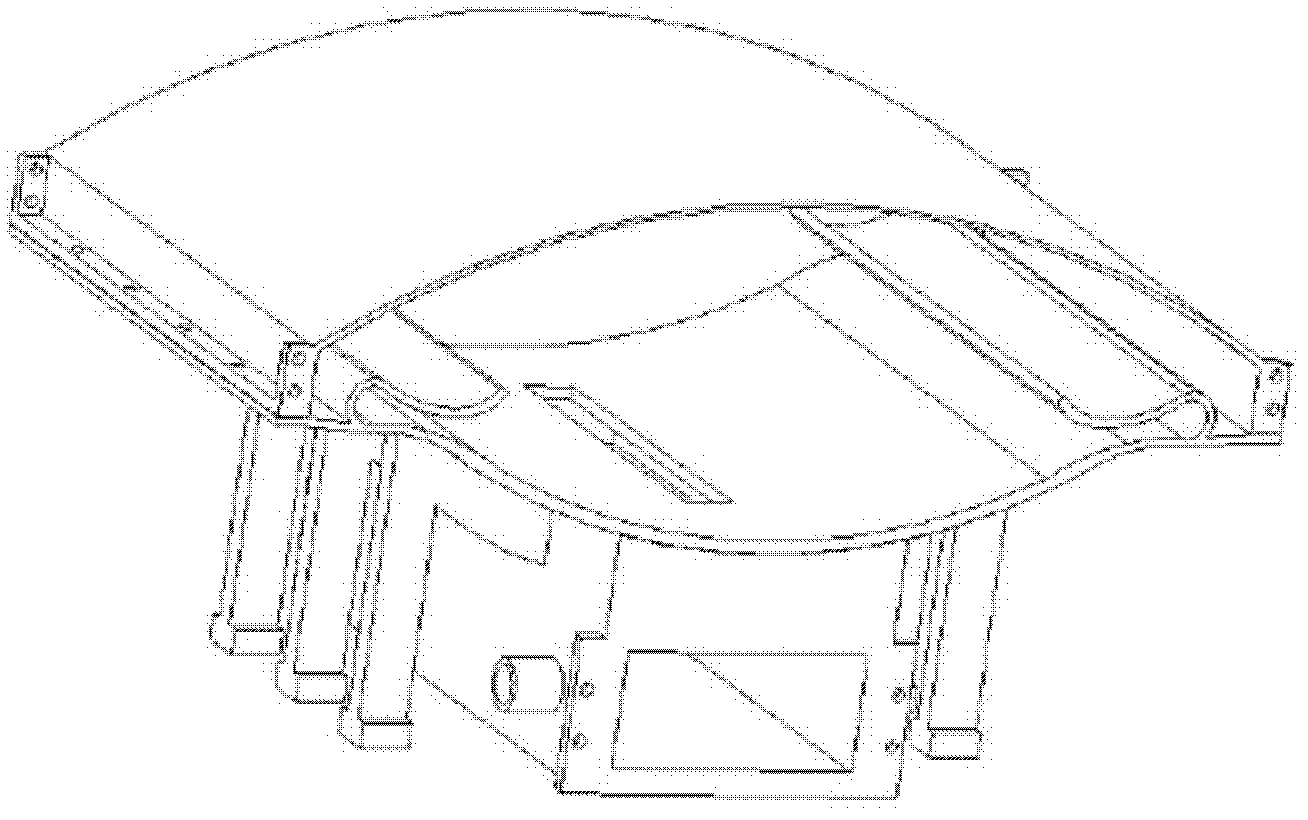

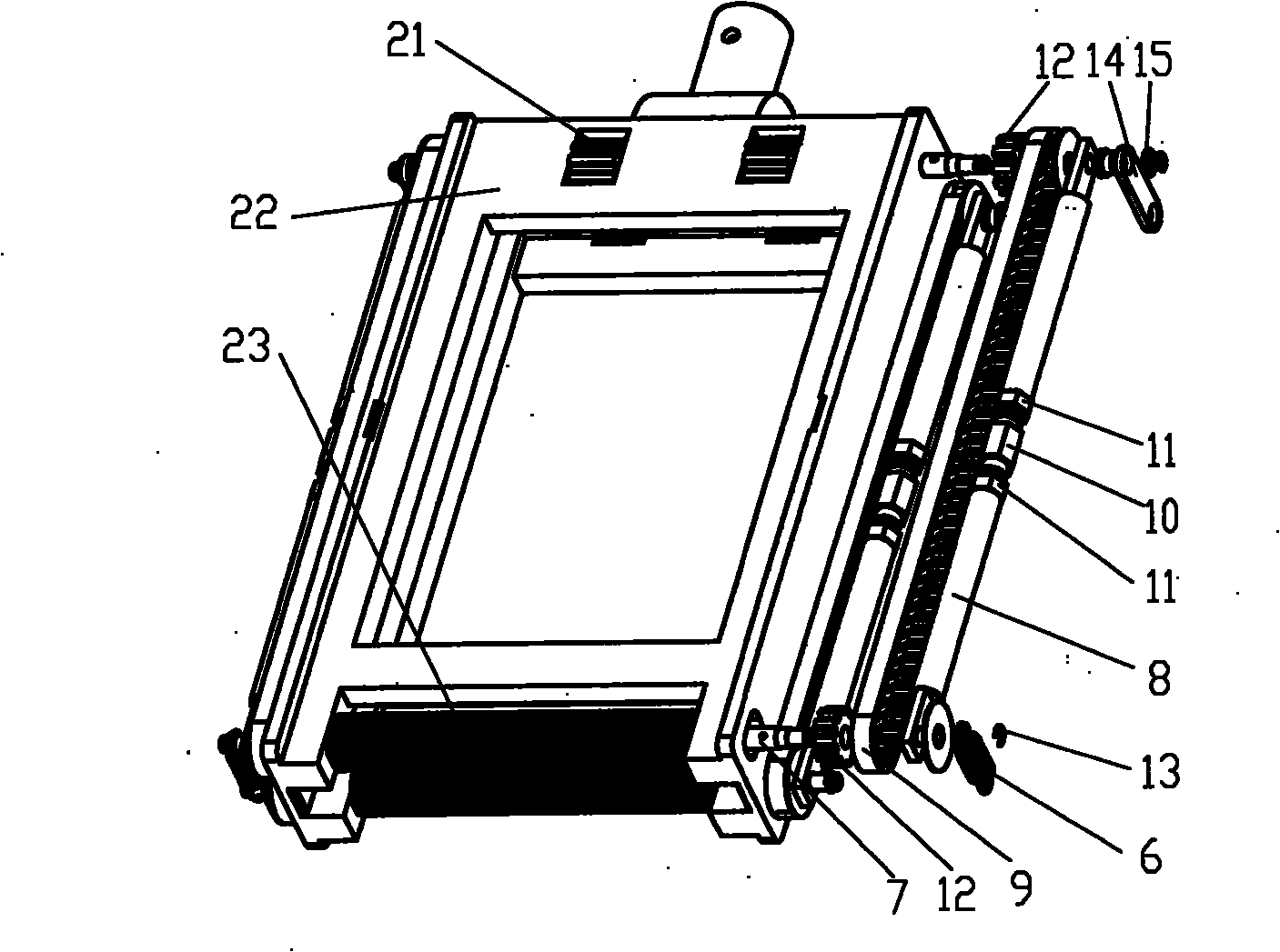

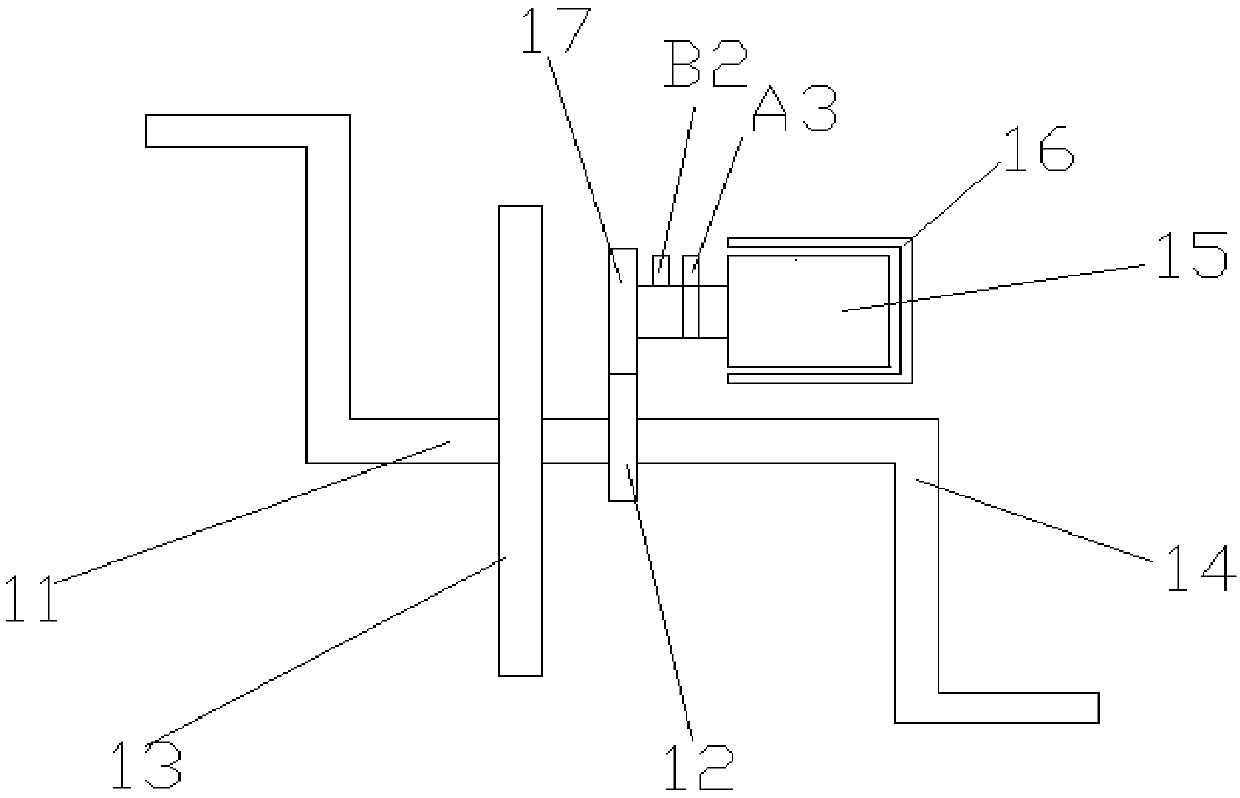

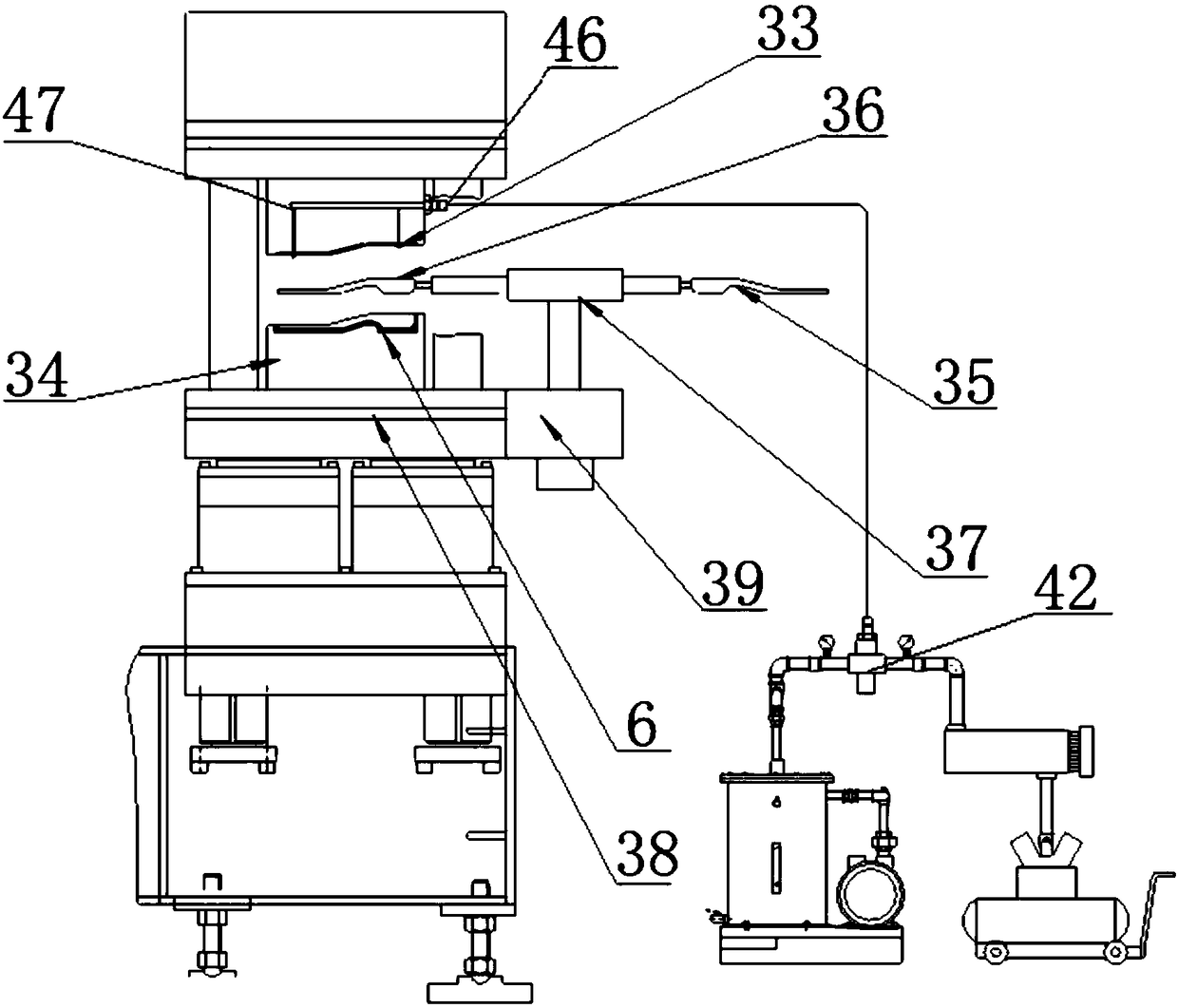

Rubber product double-density one-off injection molding production system and production process thereof

InactiveCN109318441AGuaranteed stabilityIncrease productivityTyresHollow articlesRubber materialEngineering

The invention discloses a rubber product double-density one-off injection molding production system and a production process for the rubber product double-density one-off injection molding productionsystem and belongs to the technical field of rubber product processes. The molding production system comprises an injection machine base, a mold-pressing vulcanizing platform seat, an injection deviceand a mold-pressing vulcanizing device and further comprises a hollowing device beside the mold-pressing vulcanizing platform seat, wherein the injection device and the mold-pressing vulcanizing device are fixed to the injection machine base and the mold-pressing vulcanizing platform seat correspondingly, and the mold-pressing vulcanizing device comprises two mold inner cores of the same shape and different specifications. According to the rubber product double-density one-off injection molding production system and the production process for the rubber product double-density one-off injection molding production system, the injection device injects two plasticized rubber materials with different densities into a mold of the mold-pressing vulcanizing device in sequence corresponding to thedifferent mold inner cores, the hollowing device introduces high-pressure gases in the plasticized rubber materials inside the mold of the mold-pressing vulcanizing device to form the high-pressure gases, the uniform vulcanizing effect inside and outside can be guaranteed, the mold-pressing vulcanizing device performs mold-pressing and vulcanizing on the plasticized rubber materials inside the mold, injecting, hollowing and vulcanizing of double-density rubber products can be finished inside one mold, and transfer of the products between all working procedures is avoided, so that the production cost is lowered.

Owner:ANHUI GVG NEW MATERIAL CO LTD

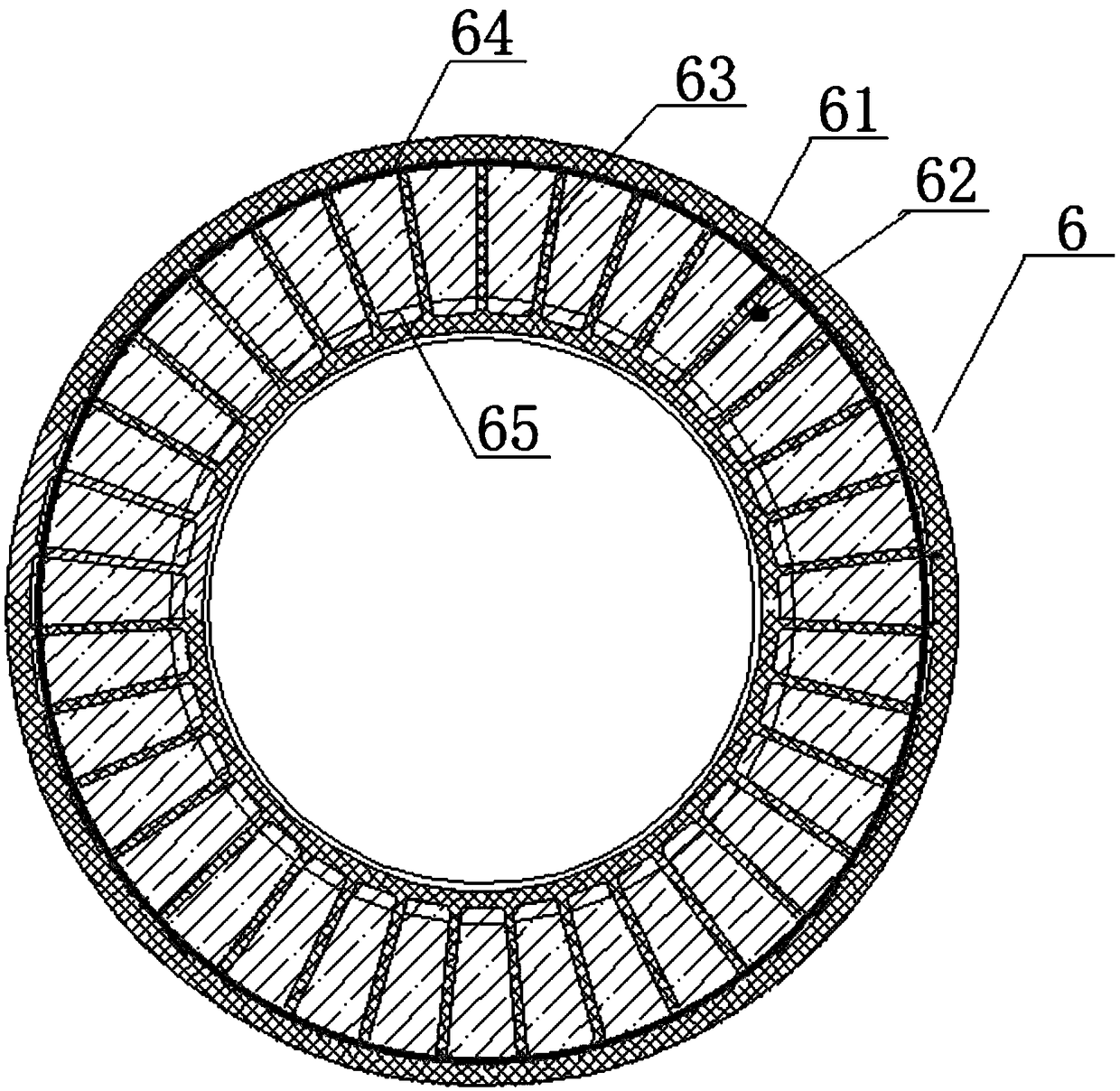

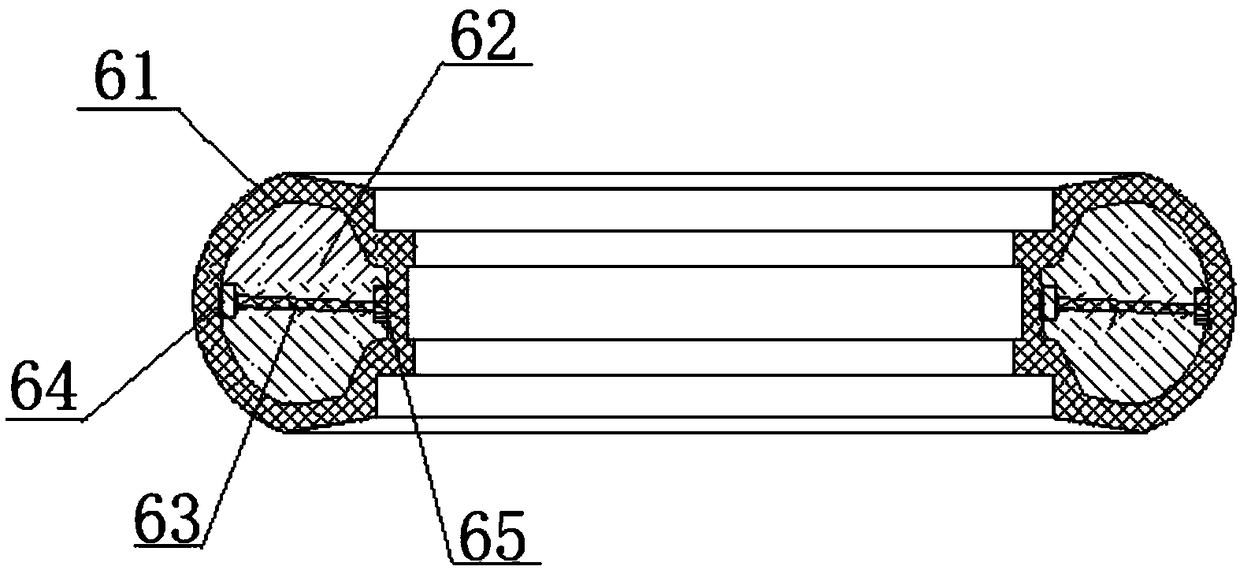

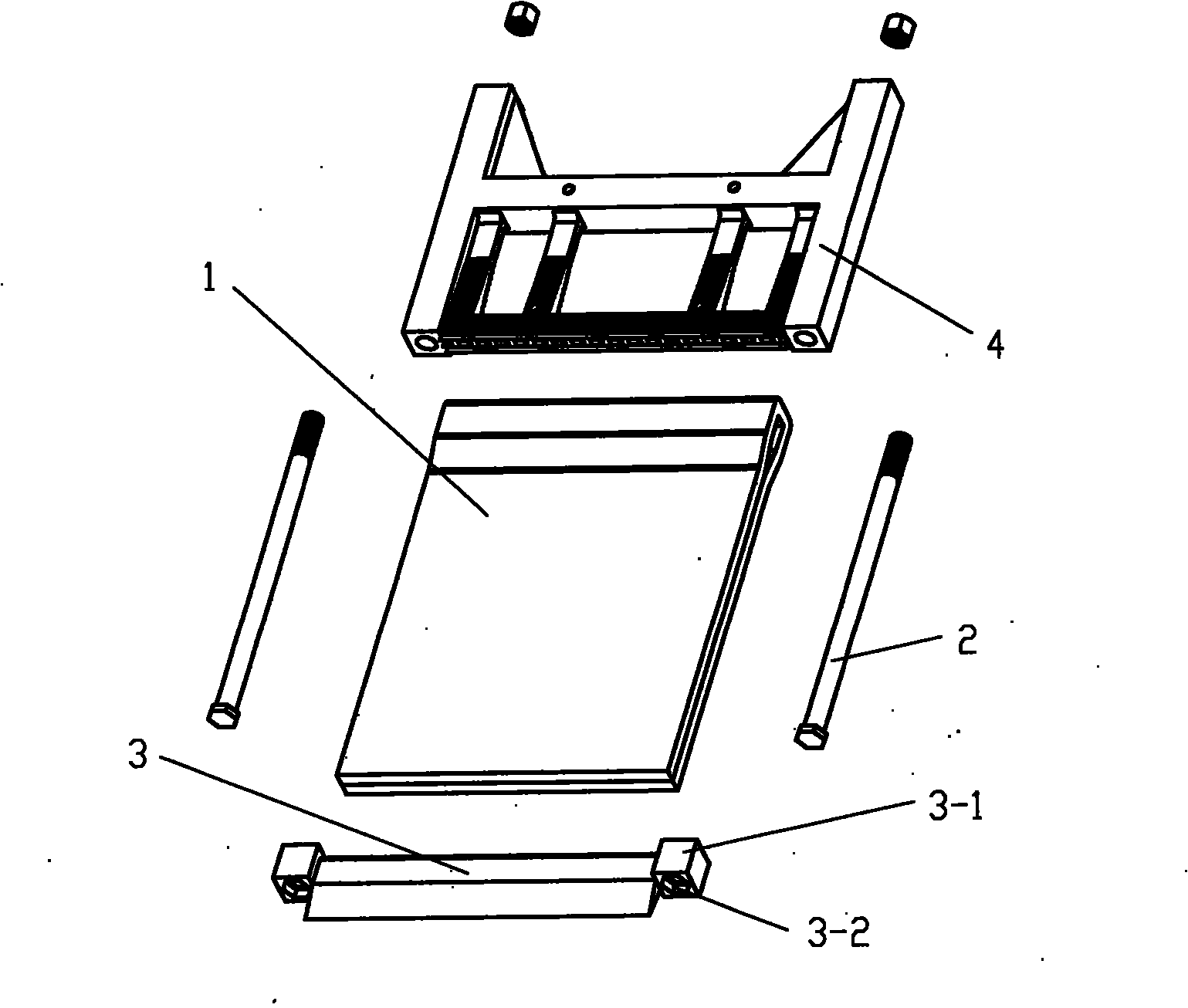

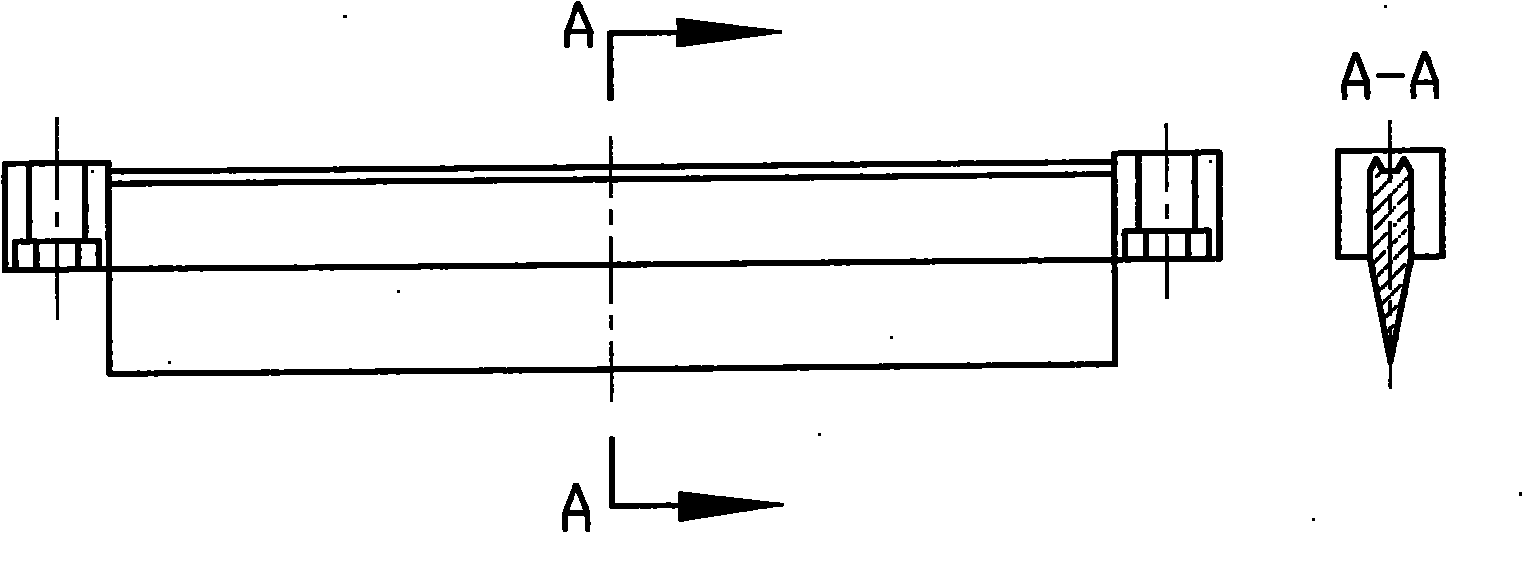

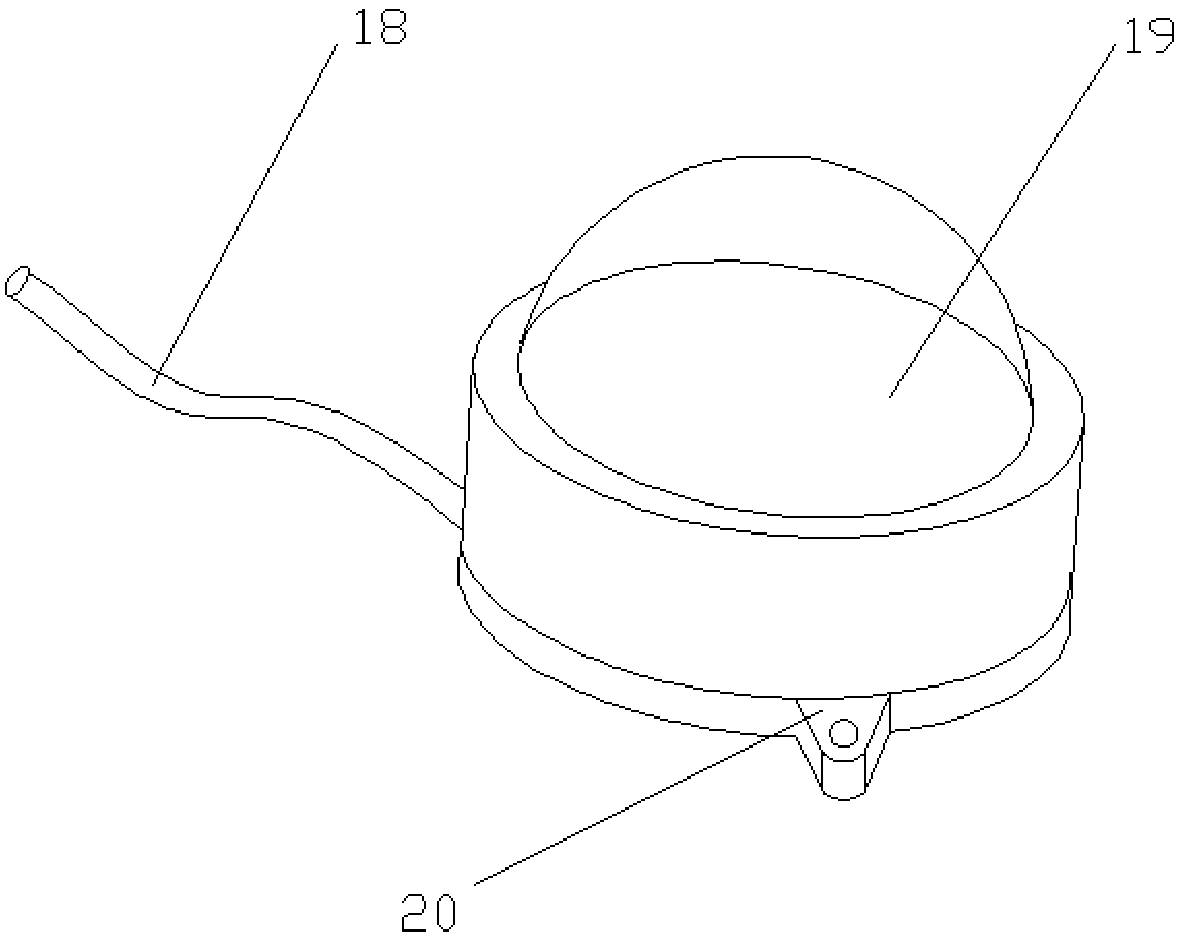

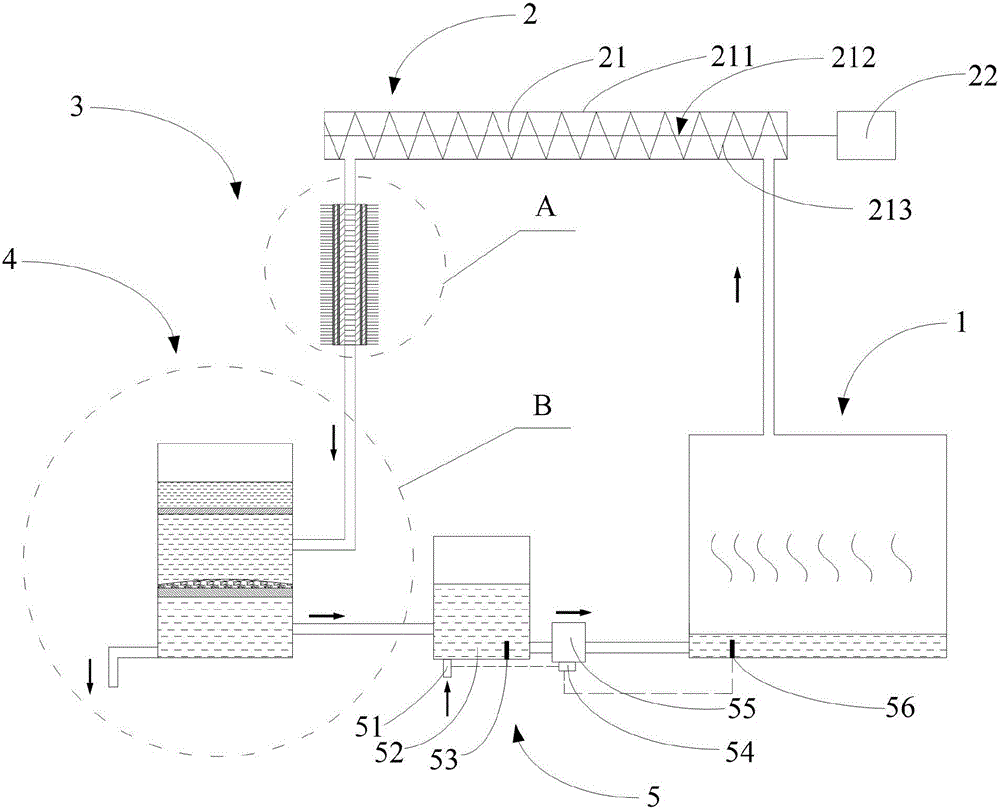

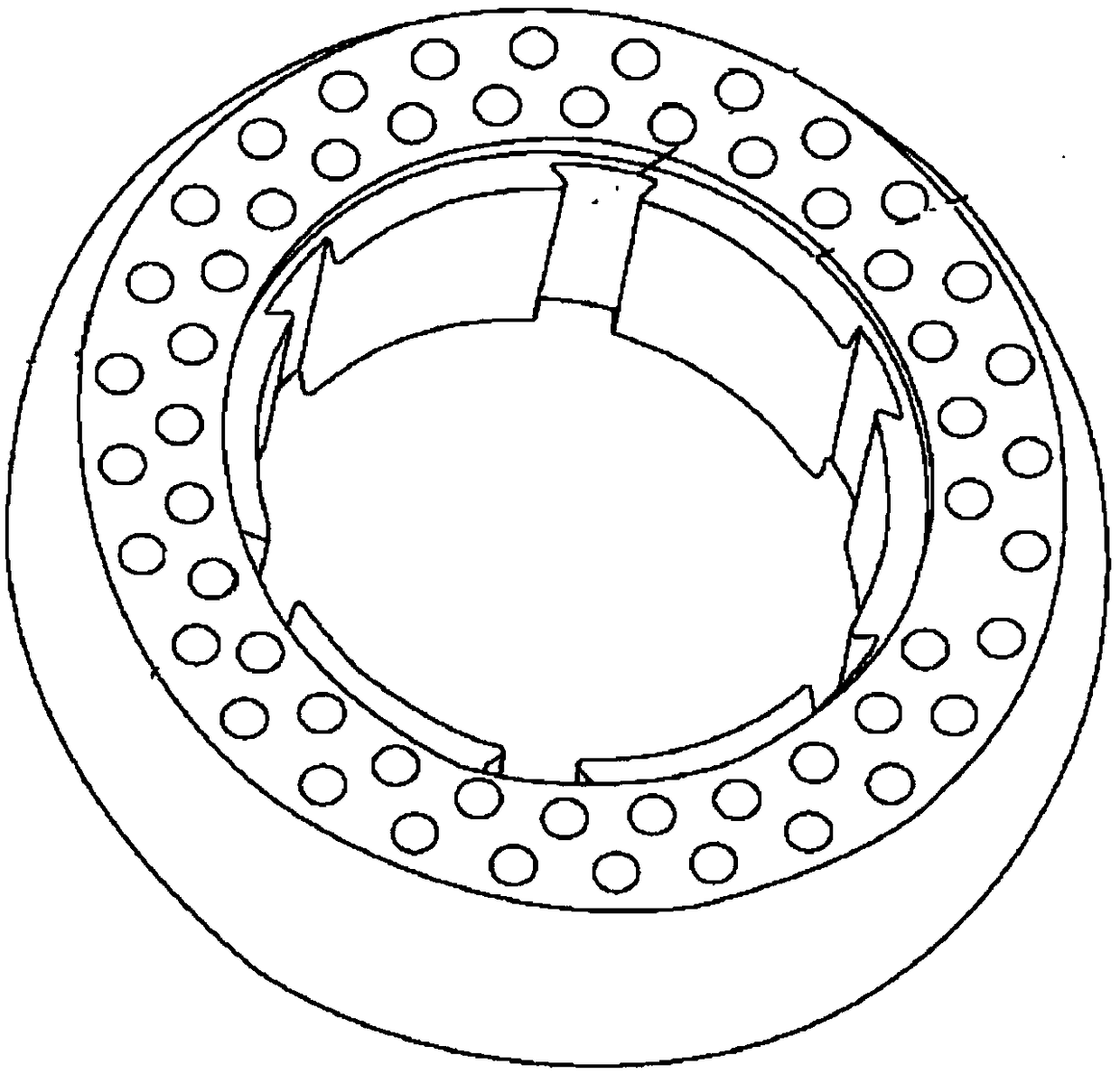

Hollow tire mold core, hollow tire based on mold core and tire manufacturing method

PendingCN109318438ALow costShorten molding timeWith separate inflatable insertsWith multiple inflatable chambersAerodynamic dragEar shaping

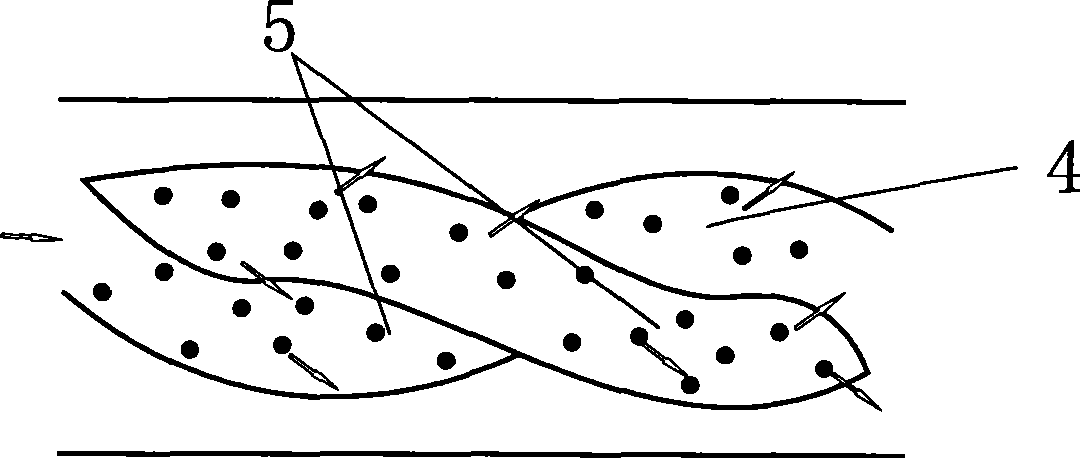

The invention discloses a hollow tire mold core, a hollow tire based on the mold core and a tire manufacturing method and belongs to the technical field of hollow tire technologies. The hollow tire mold core comprises a mold core plate, an upper mold core body and a lower mold core body, wherein the upper mold core body and the lower mold core body are symmetrically arranged on the upper end faceand the lower end face of the mold core plate. The shape and the size of the combination of the upper mold core body and the lower mold core body are consistent with those of an inner cavity of the hollow tire. The hollow tire comprises a round tire body and a hollow inner cavity. A tire skeleton is arranged in the ring direction of the inner cavity. The tire skeleton is in a barrel arch shape, ora wheat ear shape, or a propeller shape or an intersecting grid shape. The sealing manner is adopted in the periphery of the tire skeleton, on one hand, the situation that large air resistance is generated easily in the driving process of the tire can be avoided, and on the other hand, the situations that impurities such as various stones and sludge accumulate easily and cannot be washed easily,in the high-speed driving process, parts of the impurities are thrown out easily, and danger is caused can be effectively avoided. Injection forming, hollowing and vulcanizing devices of the hollow tire are integrated, and the cost expense of production of the hollow tire is reduced.

Owner:ANHUI GVG NEW MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com