Novel heavy duty frame stressing layering coal supply apparatus

A kind of coal feeding device and frame technology, which is applied in the field of new heavy-duty frame-loaded layered coal feeding device, can solve the problems of thermal deformation of coal ram, out-of-control of lateral thickness of coal-fired seam, and out-of-control adjustment, so as to solve the problem of coal blocking Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

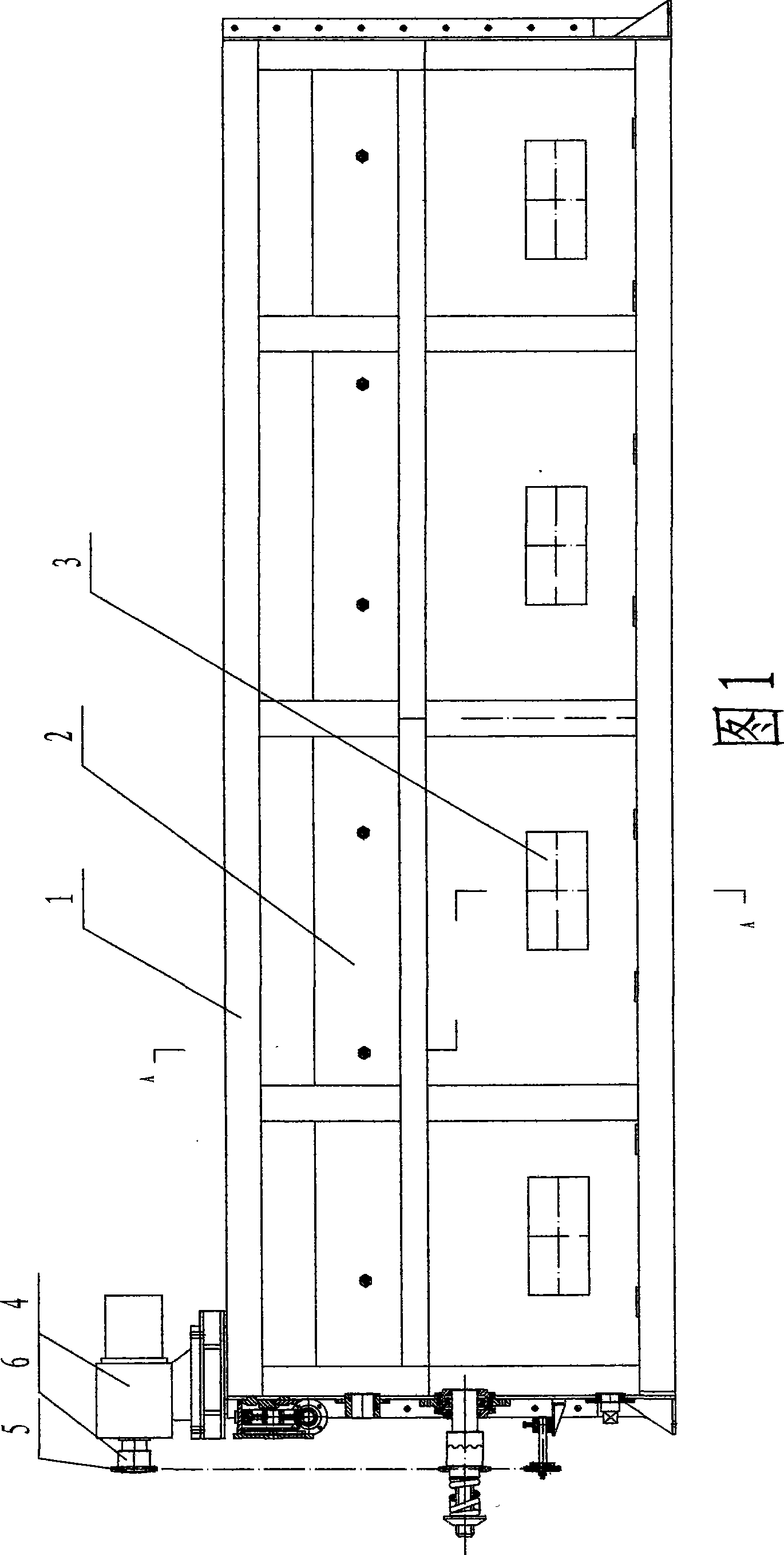

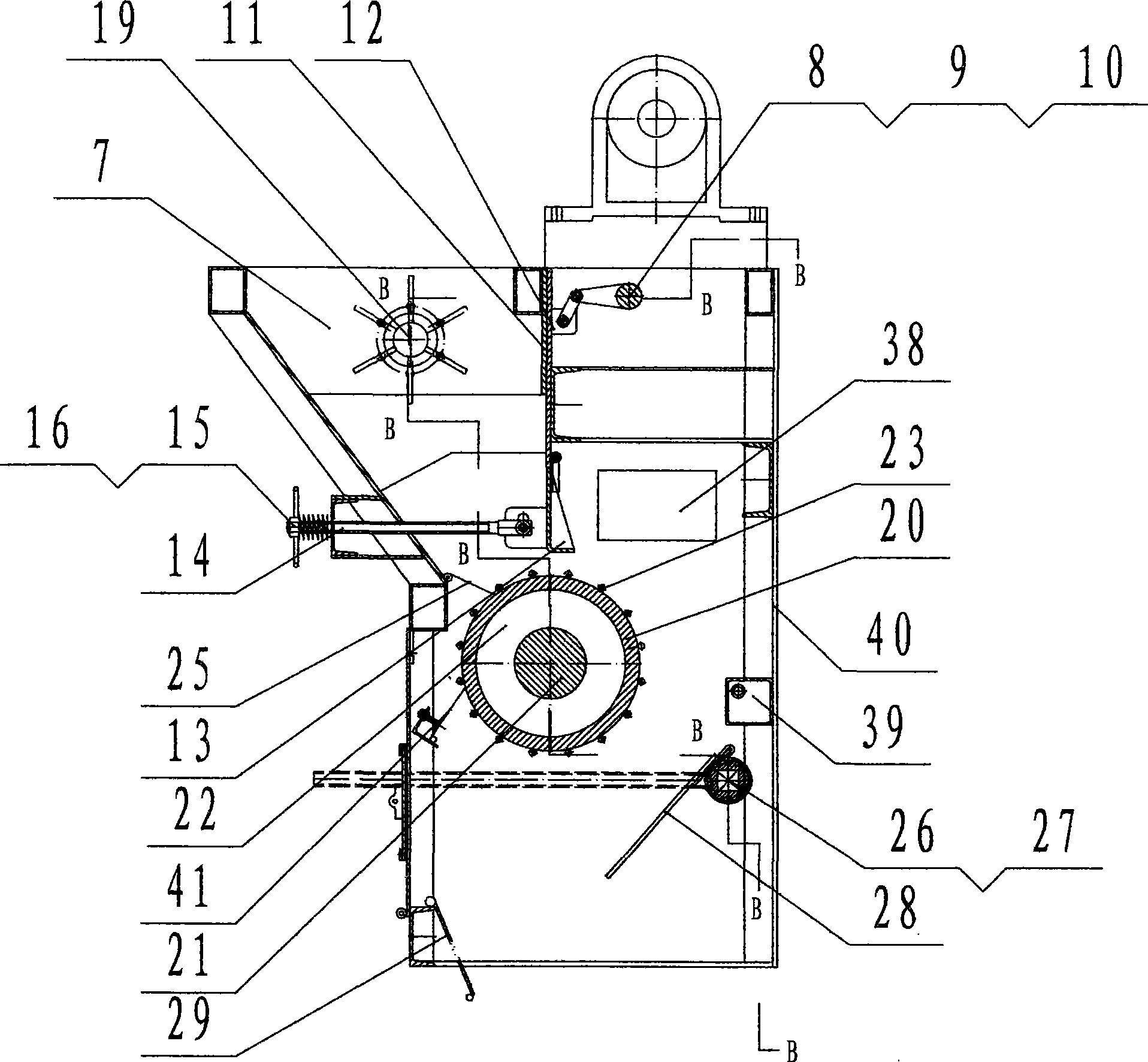

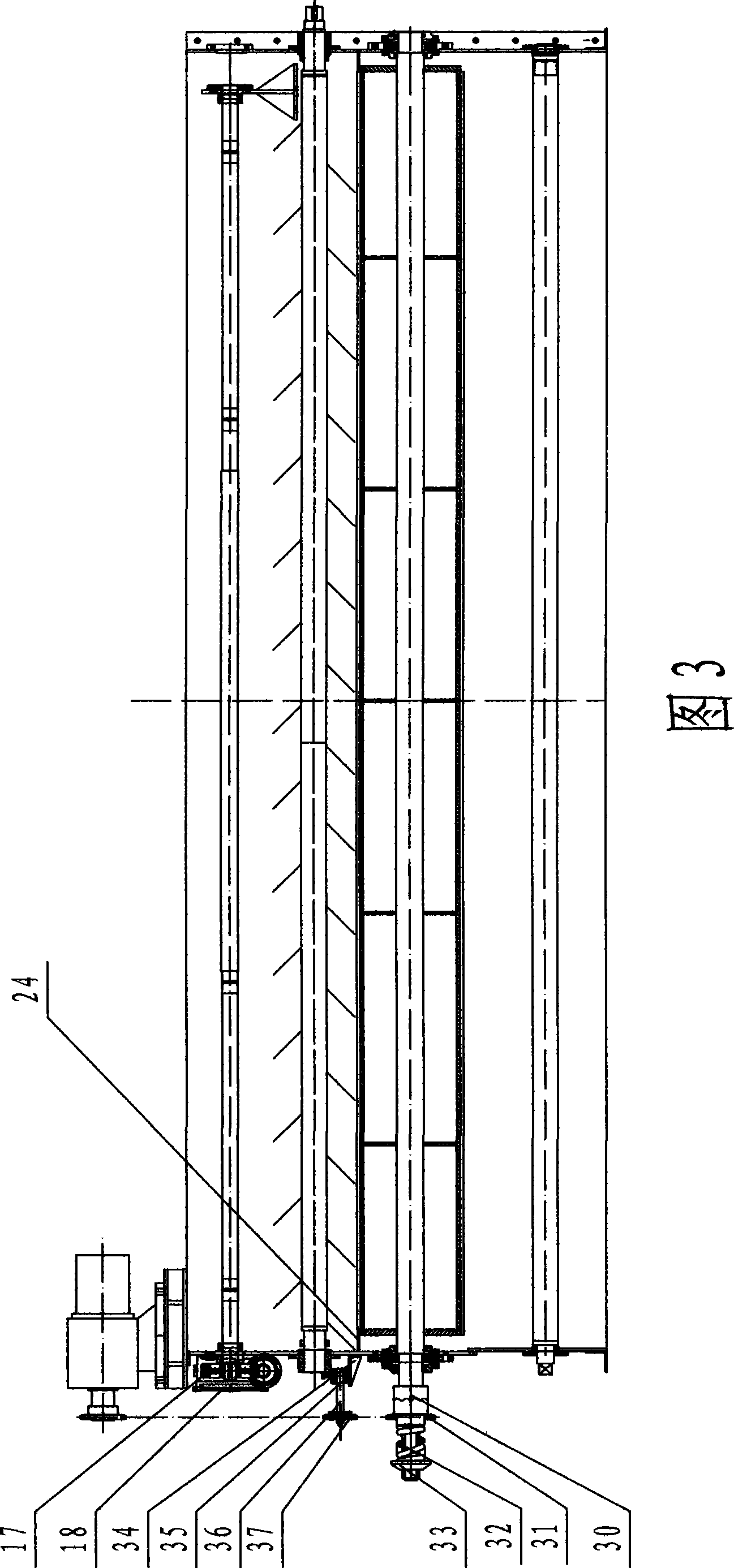

[0022]The novel heavy-duty frame stress-type layered coal feeding device of the present invention, the frame 1 is a stress-bearing structure, welded with the front web 2, and a plurality of inspection doors 3 are arranged on the front web. An independent power device 4 is installed on the upper part of the frame 1, a transmission power sprocket 5 is installed, and a fixing device 6 is connected. Side plates 7 are welded on both sides of the frame 1. The rear upper part of the side plate is equipped with a coal gate adjusting shaft 8, a fixed adjusting arm 9, and a movable connecting plate 10. The middle and upper part of the side plate is welded with a coal gate limit puller 11, a coal gate The plate 12 is connected to the movable connecting plate 10 , the lower part of the coal gate 12 is welded with the movable automatic fuel coal seam thickness adjusting device 13 , the connecting sliding screw 14 , the adjusting spring 15 , and the adjusting nut 16 . Both ends of the coal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com