Patents

Literature

105results about How to "Increase the screening area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

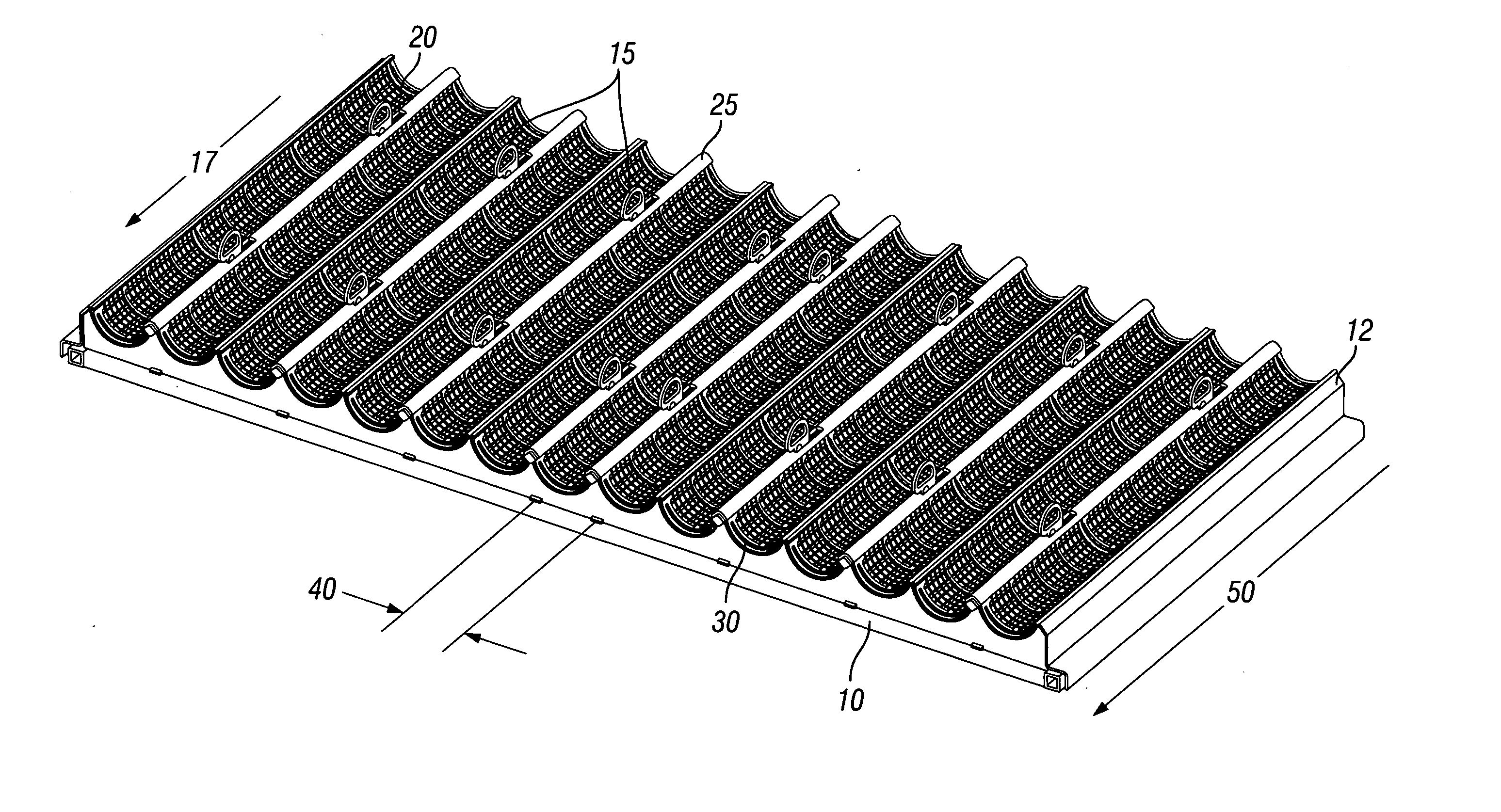

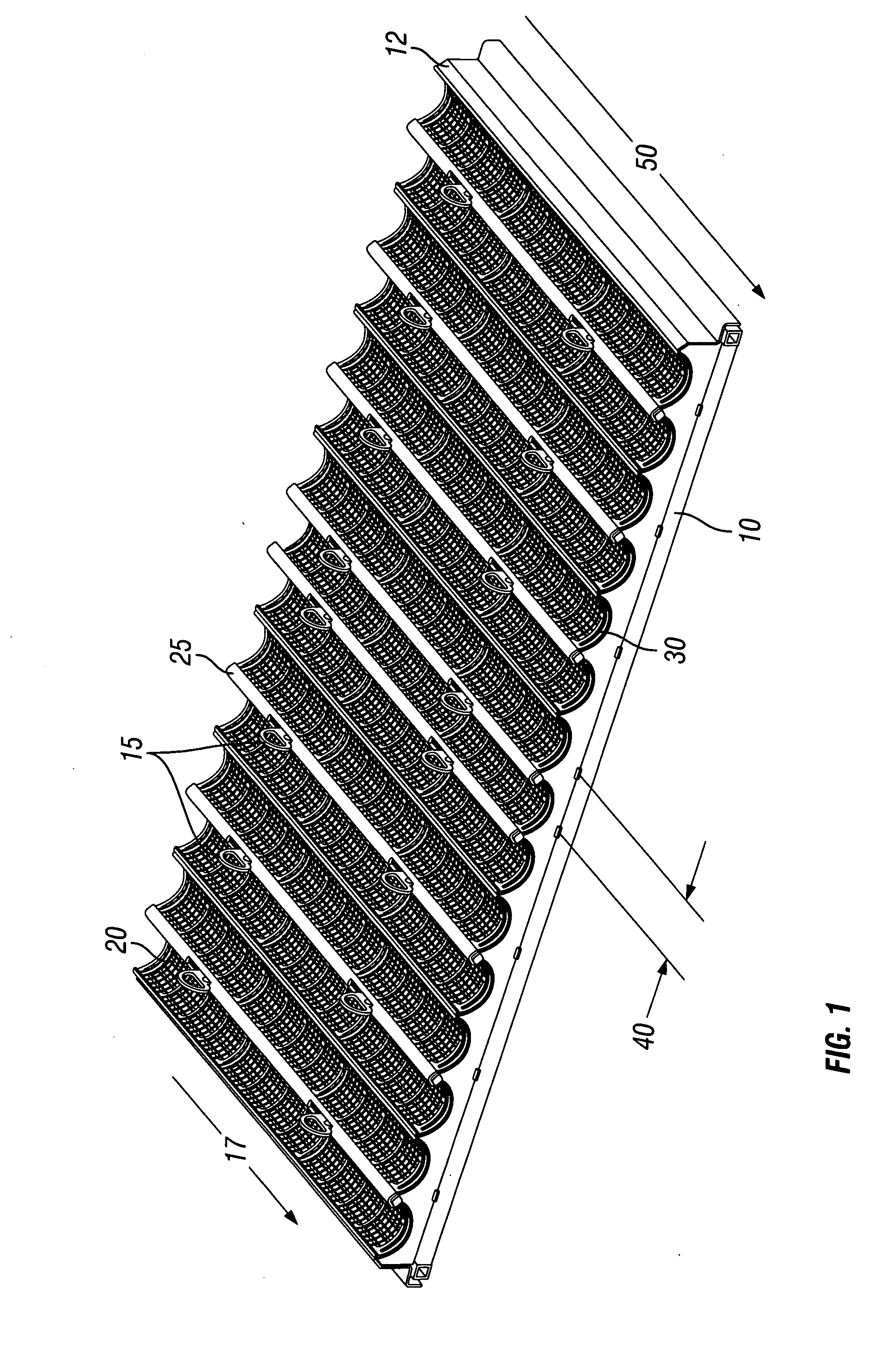

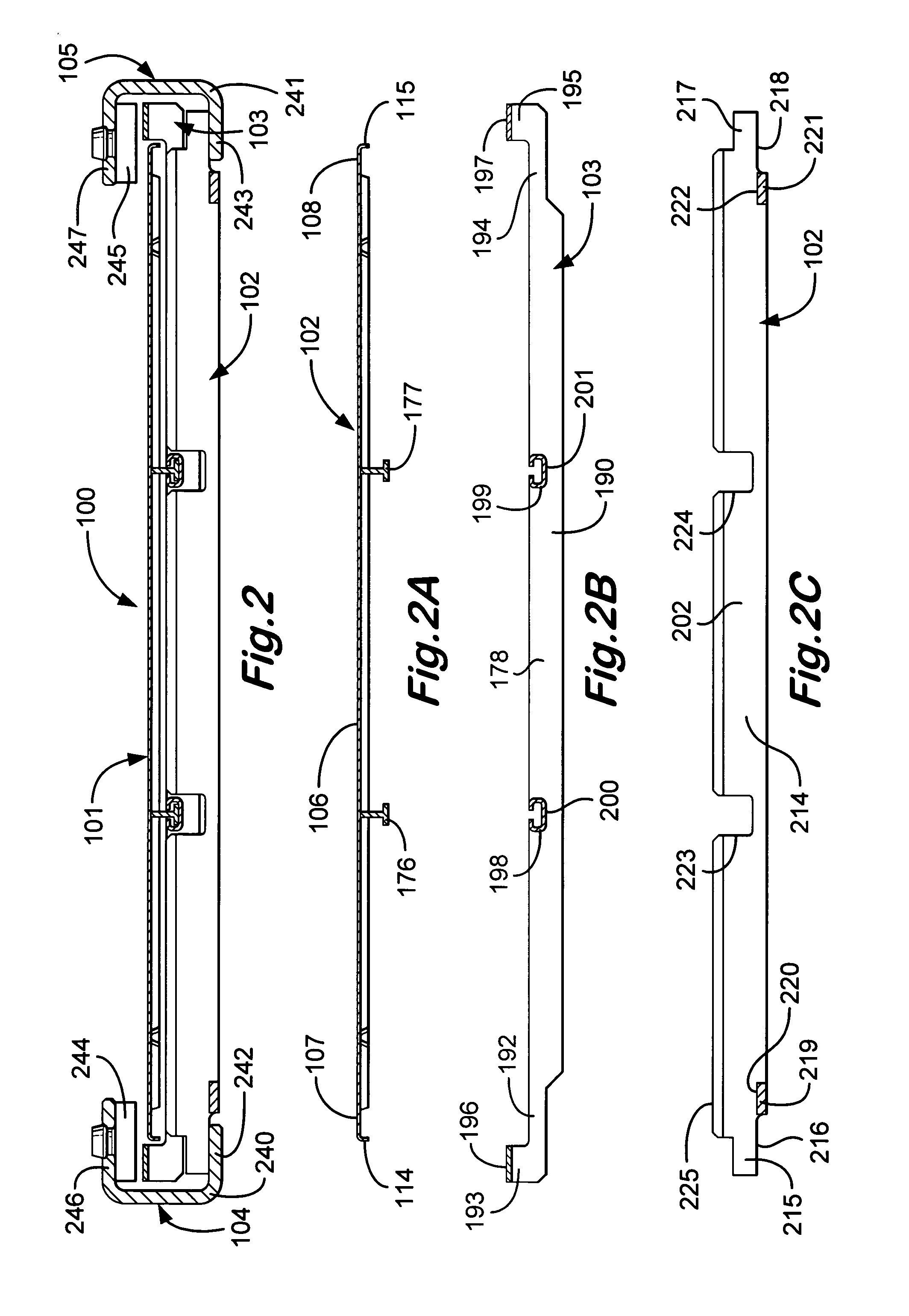

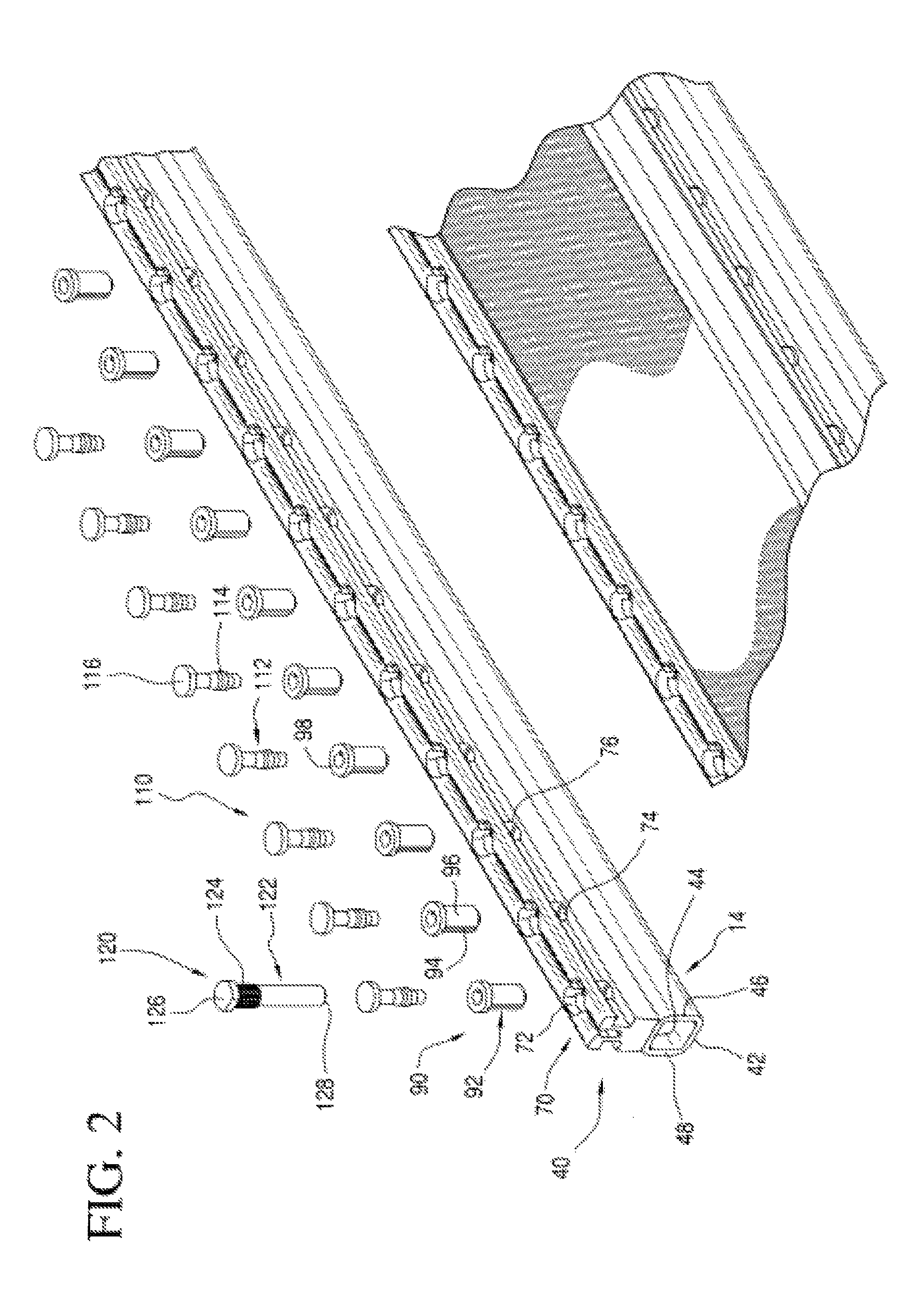

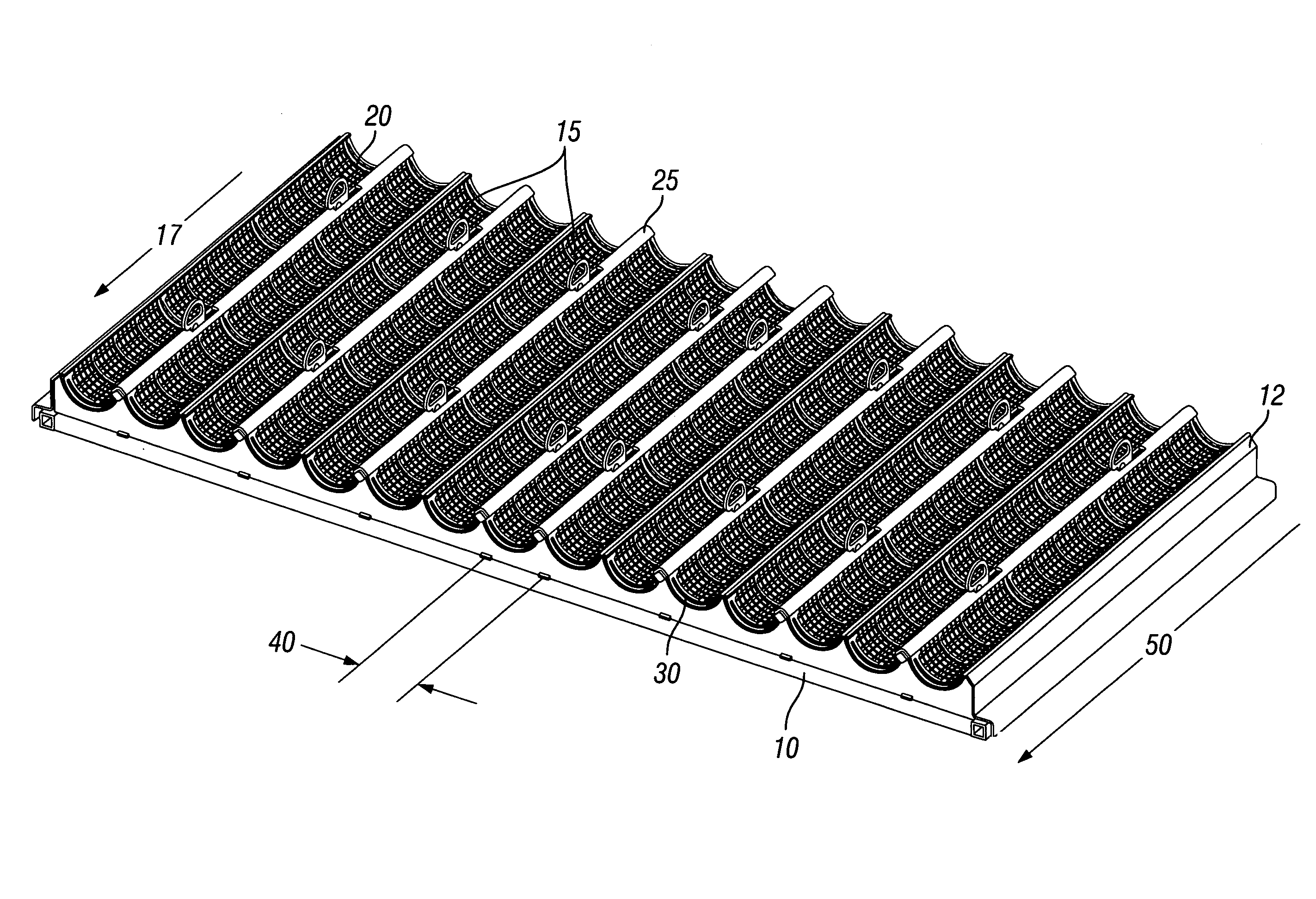

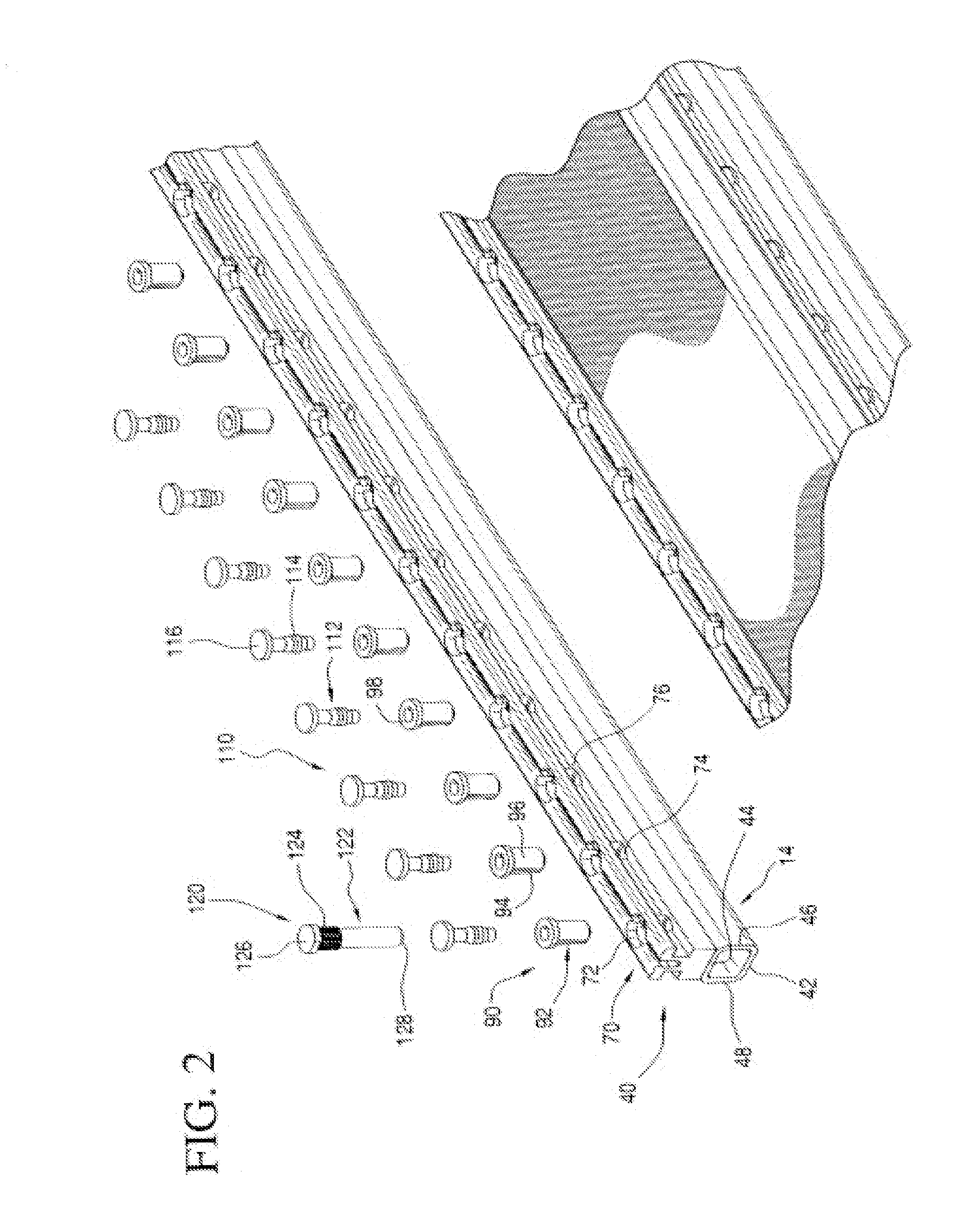

Screen assemblies utilizing screen elements retained in perforated supports

InactiveUS20080093268A1Minimize impactPrevent movementSievingScreeningEngineeringMechanical engineering

Owner:HUKKI ARI M +1

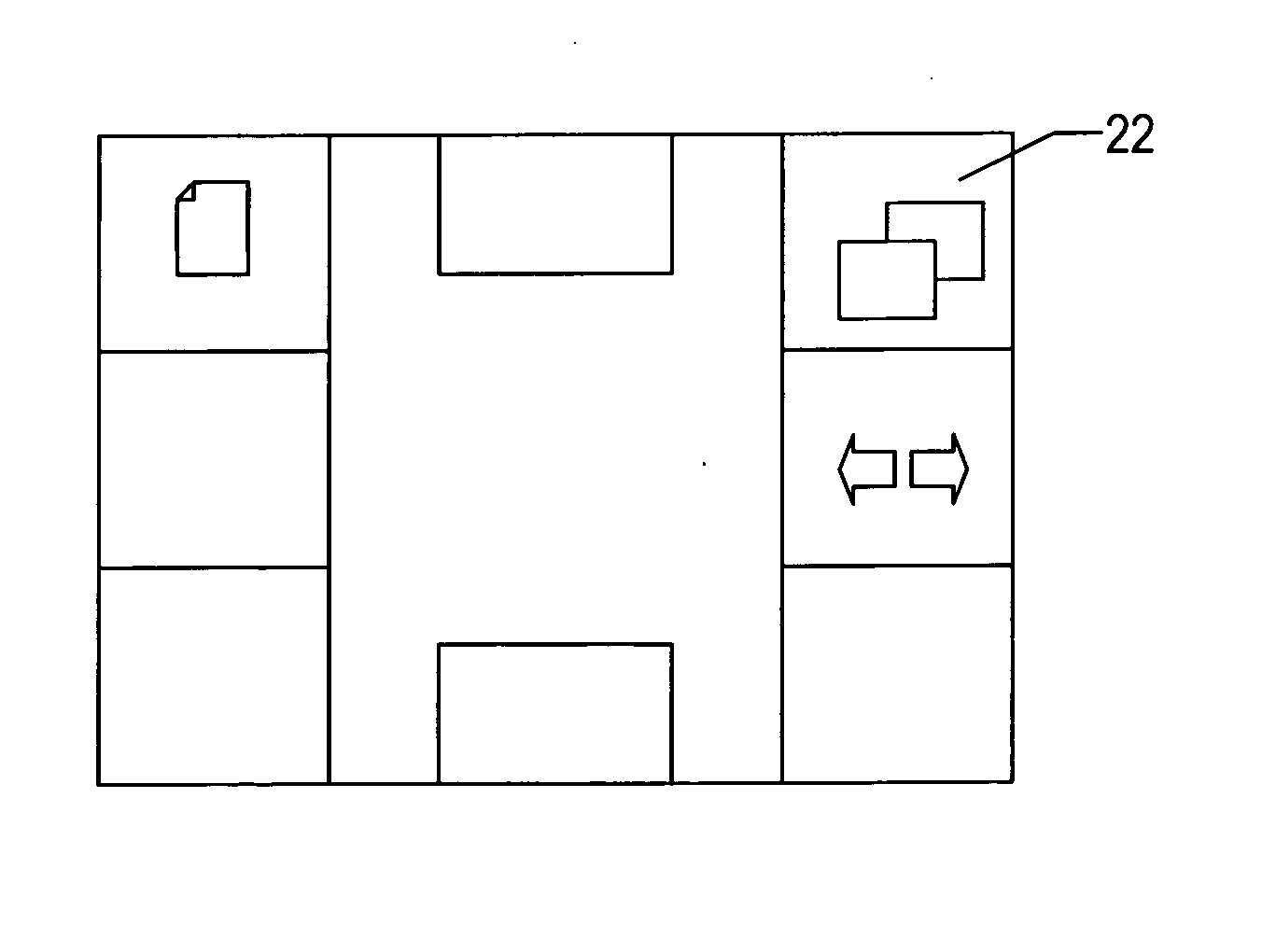

Semi-transparency in size-constrained user interface

InactiveUS20050166158A1Miniaturization exerciseIncrease the screening areaCathode-ray tube indicatorsInput/output processes for data processingInterface designUsability

The present invention provides a method that increases screen space of a computing device by using semi-transparent functional areas that overlap non-functional content areas on the screen. This method allows for relatively large functional targets on the screen—thus mitigating the usability problems associated with tiny buttons and other images—while also allowing the underlying content on the screen to be clearly visible. A main design feature of this invention is that two functional areas are never allowed to overlap. An overlap condition would cause user confusion as to which layer is active. Instead, the interface is designed to foreground functionality in all instances.

Owner:IBM CORP

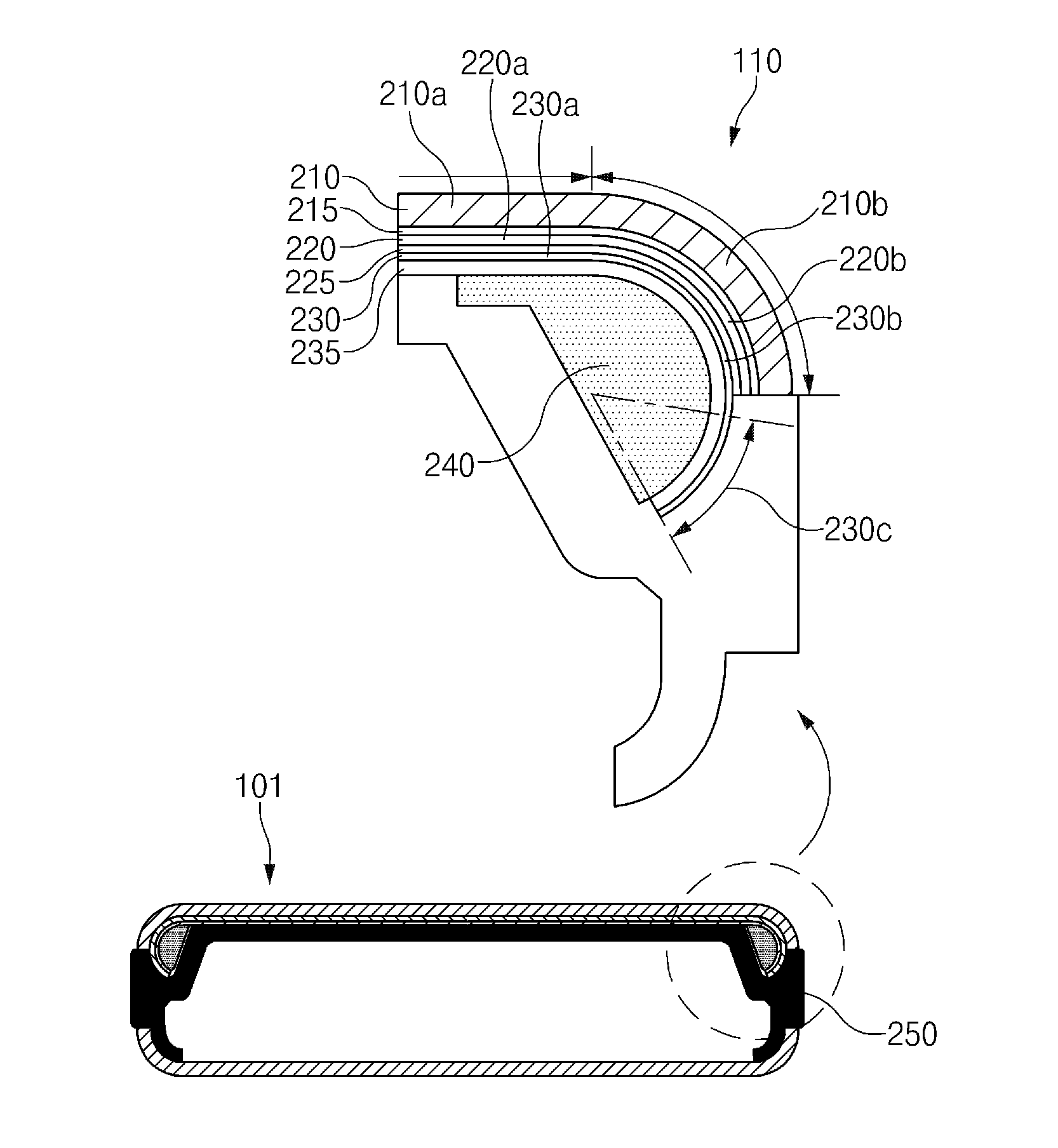

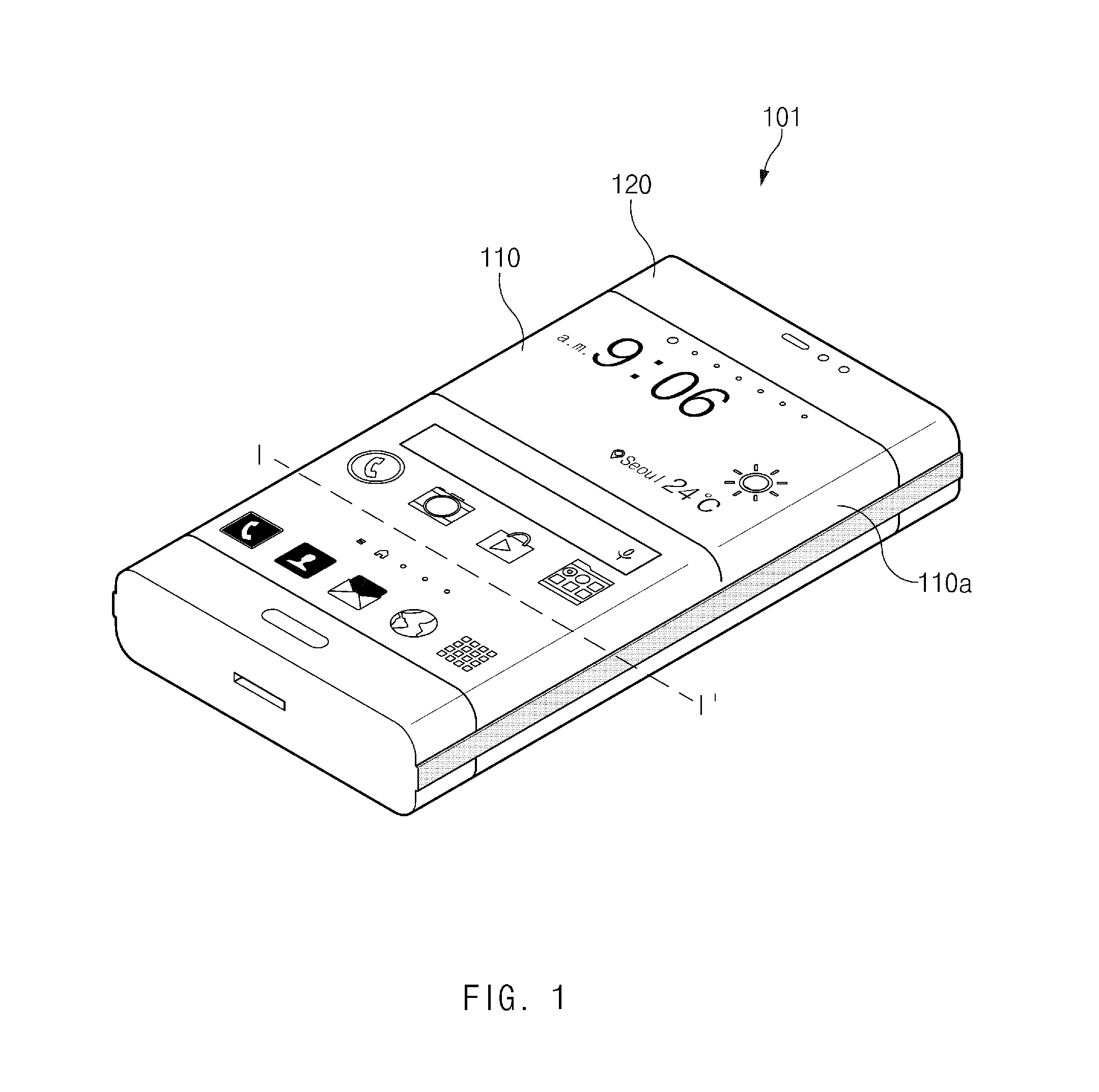

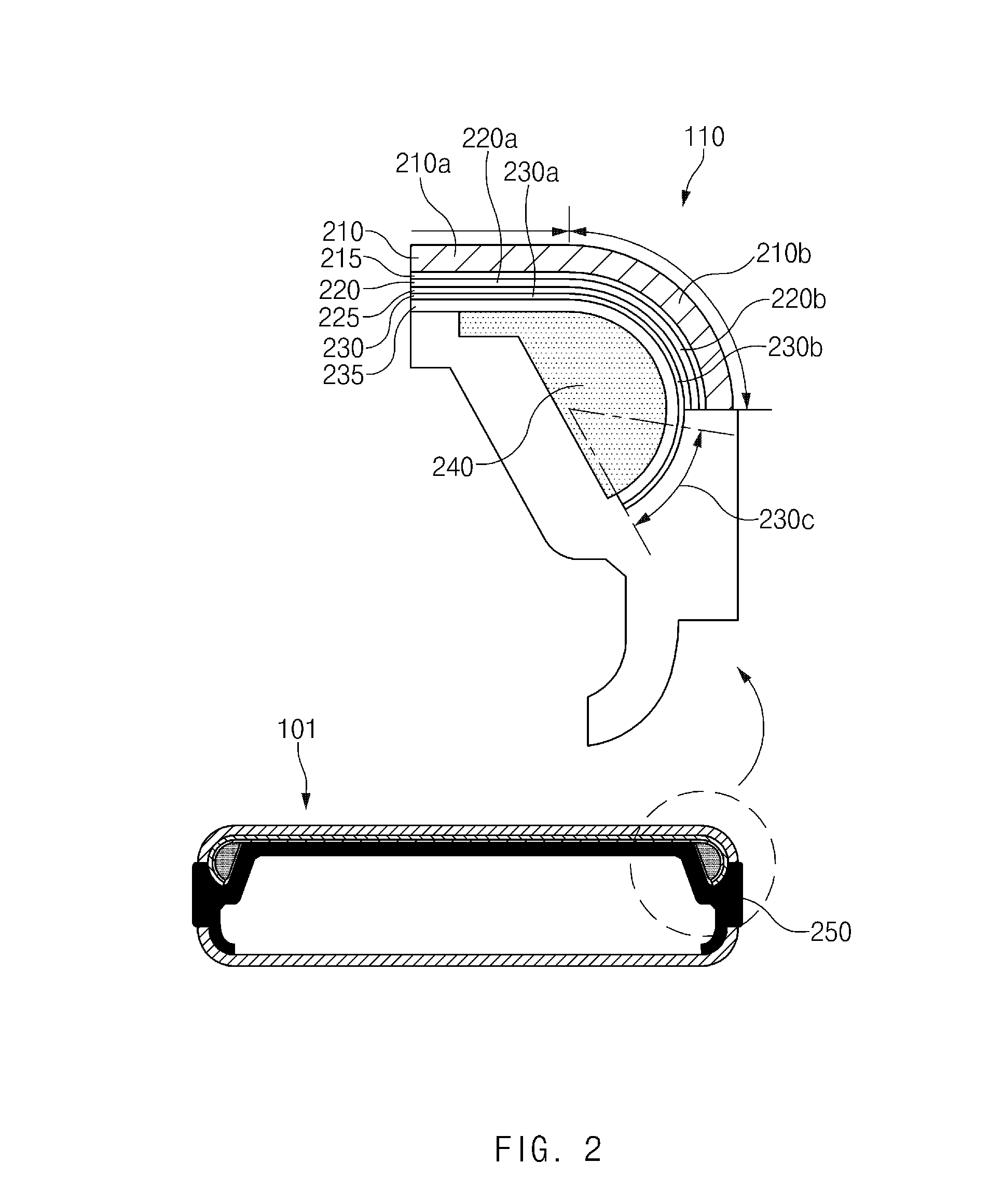

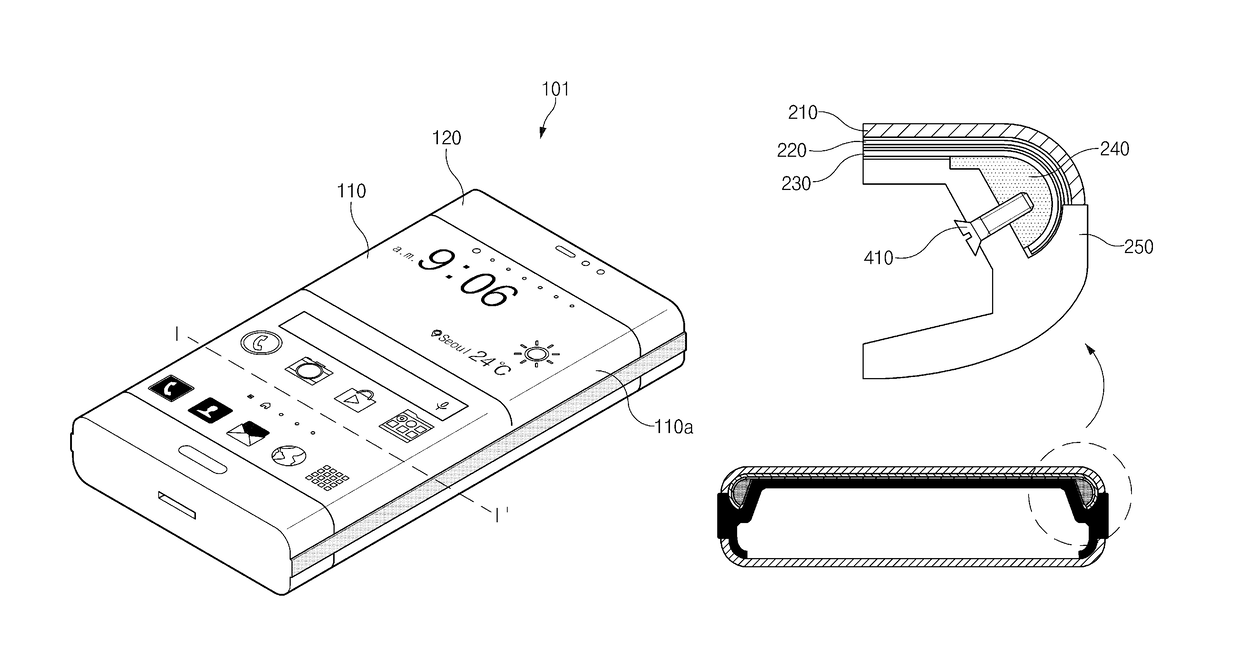

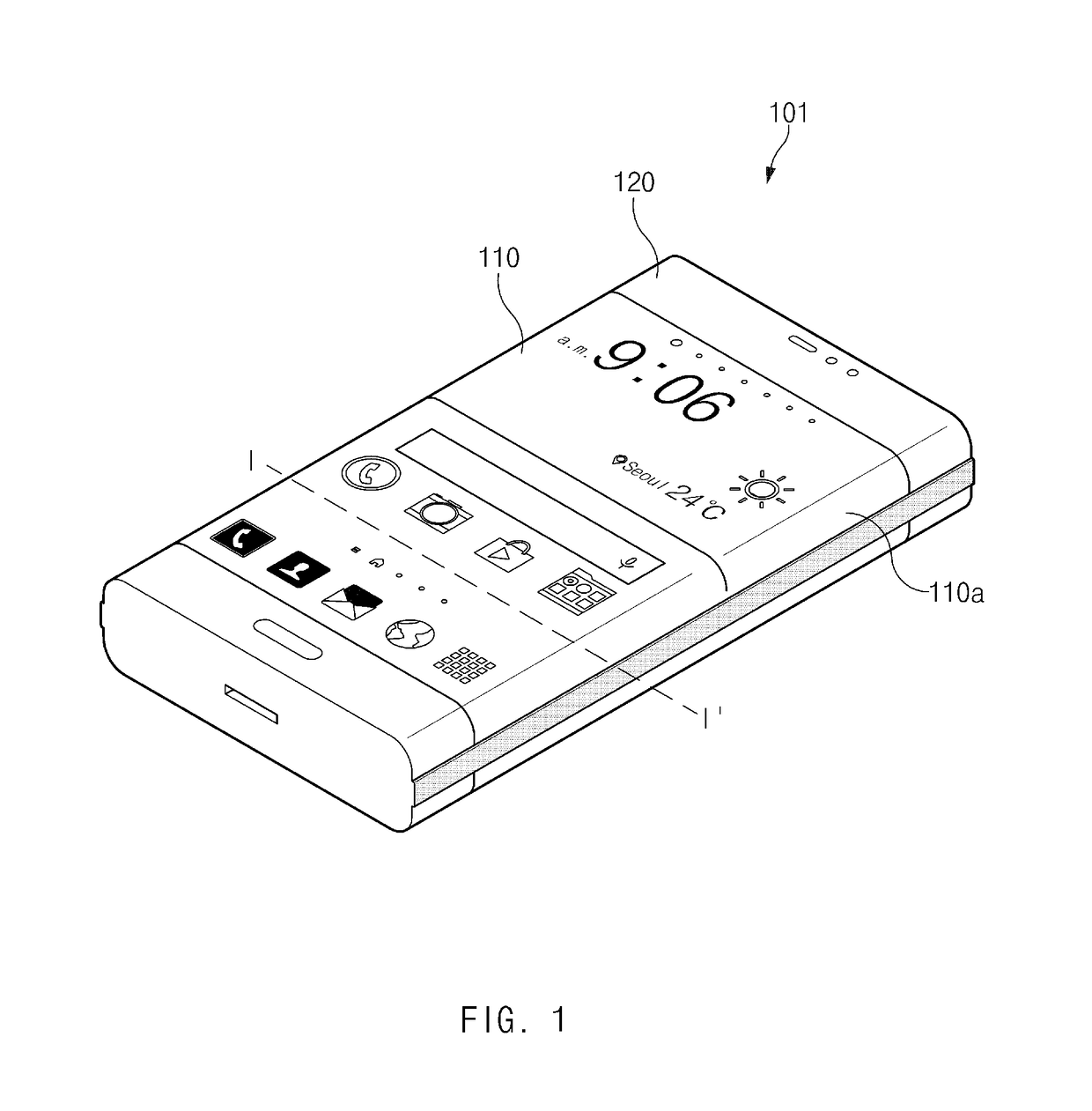

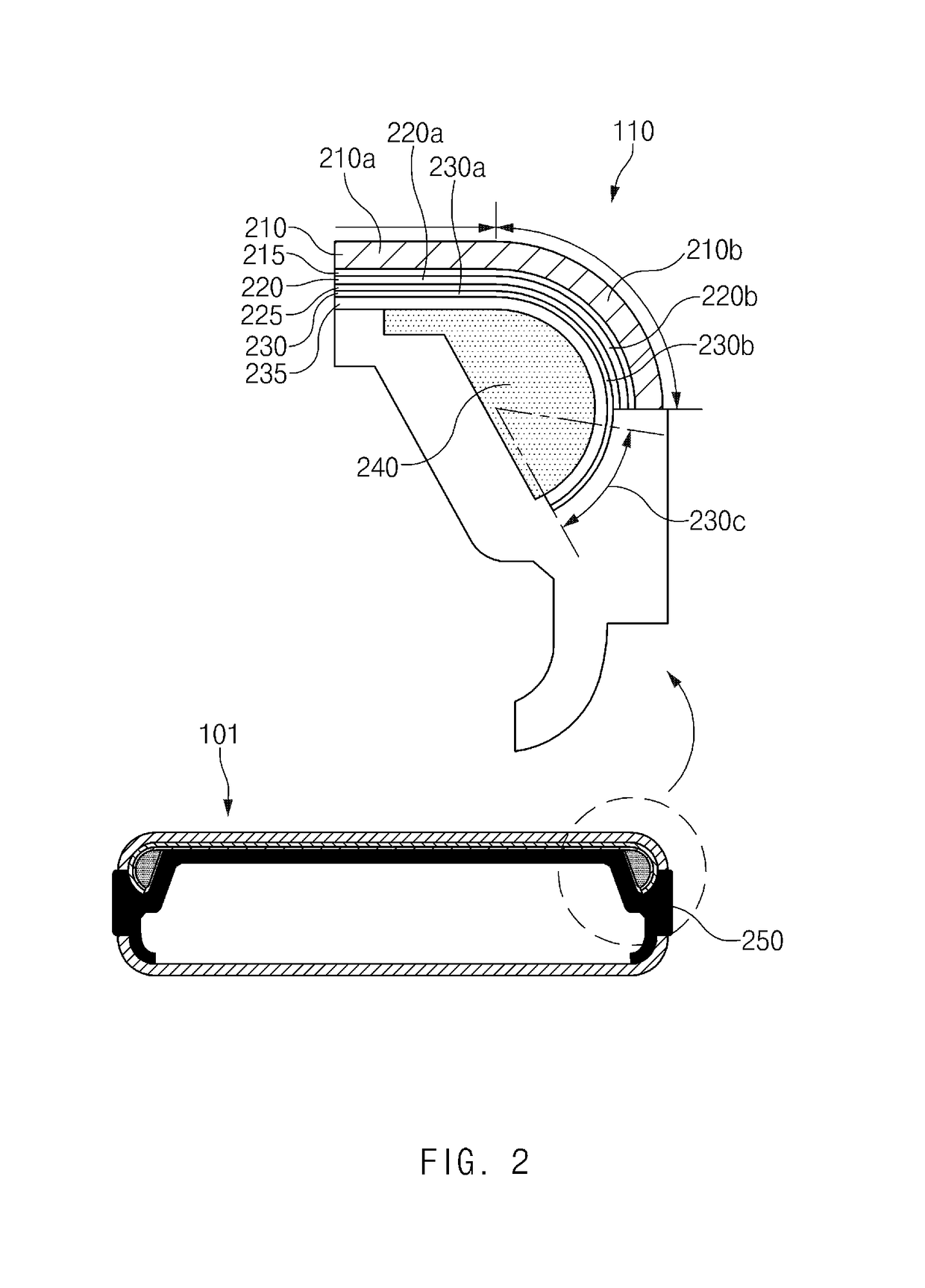

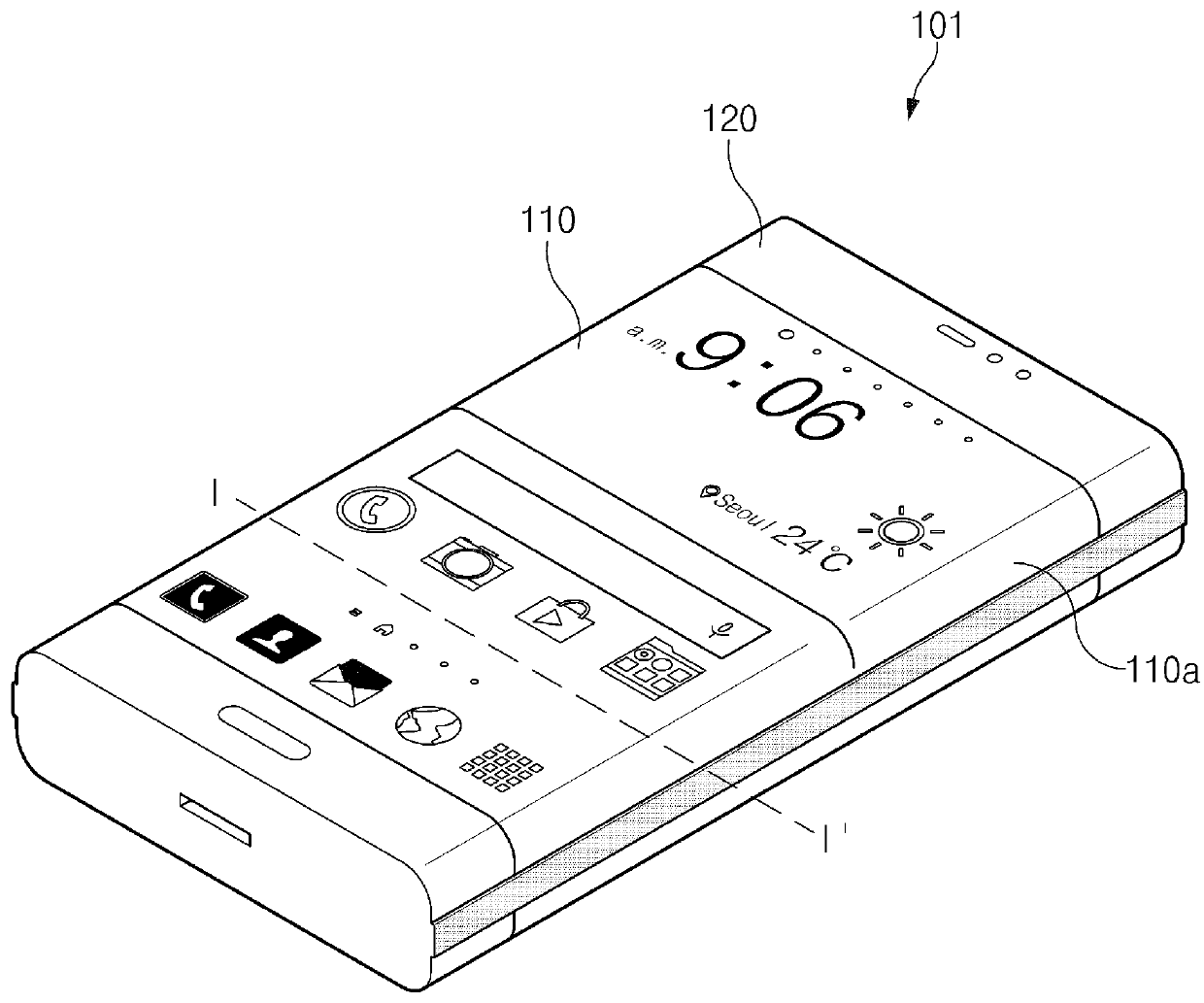

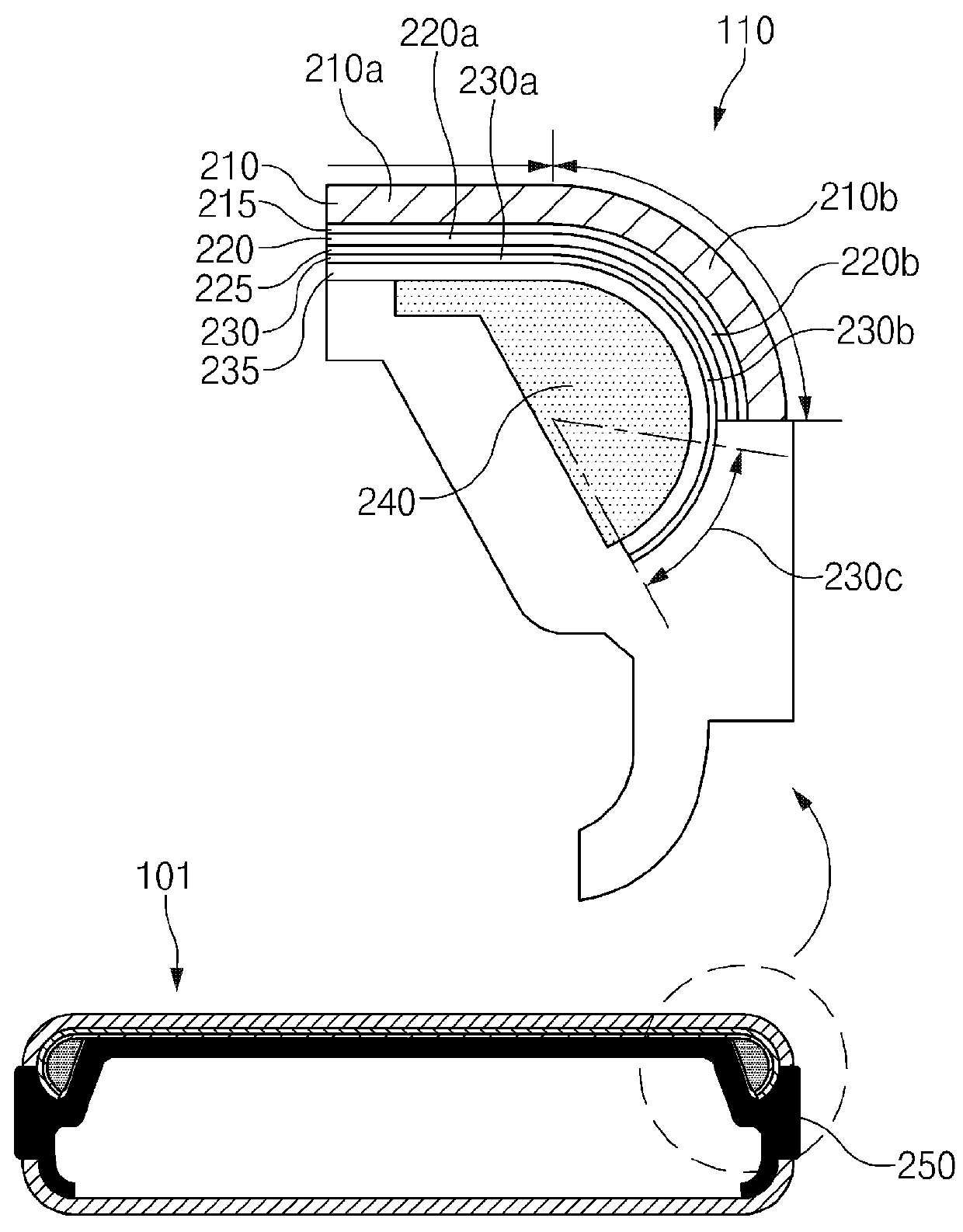

Electronic device with screen

ActiveUS20160299527A1Expand screen areaReduce bezel areaDigital data processing detailsSubstation equipmentElectrical and Electronics engineeringElectronic equipment

Owner:SAMSUNG ELECTRONICS CO LTD

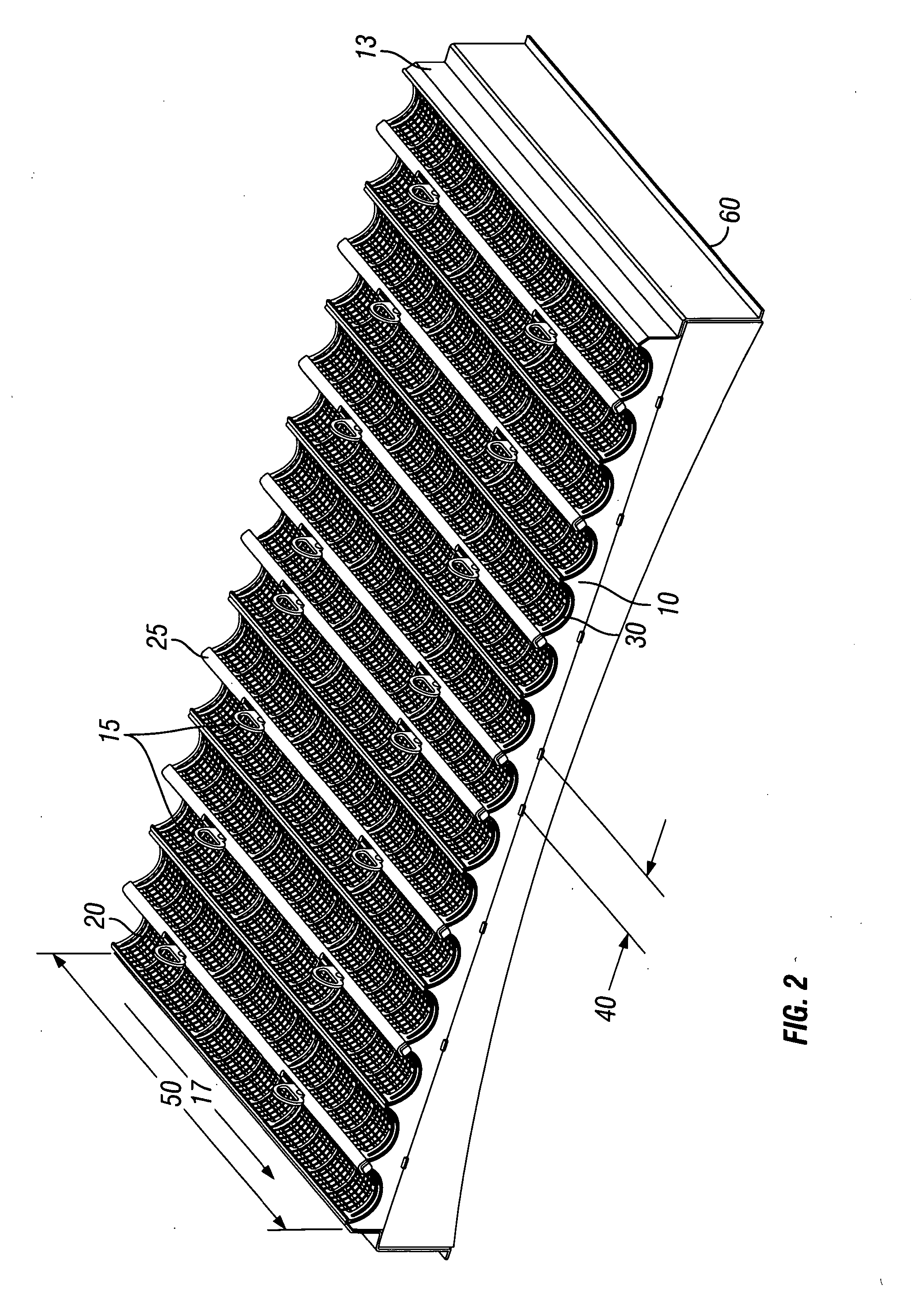

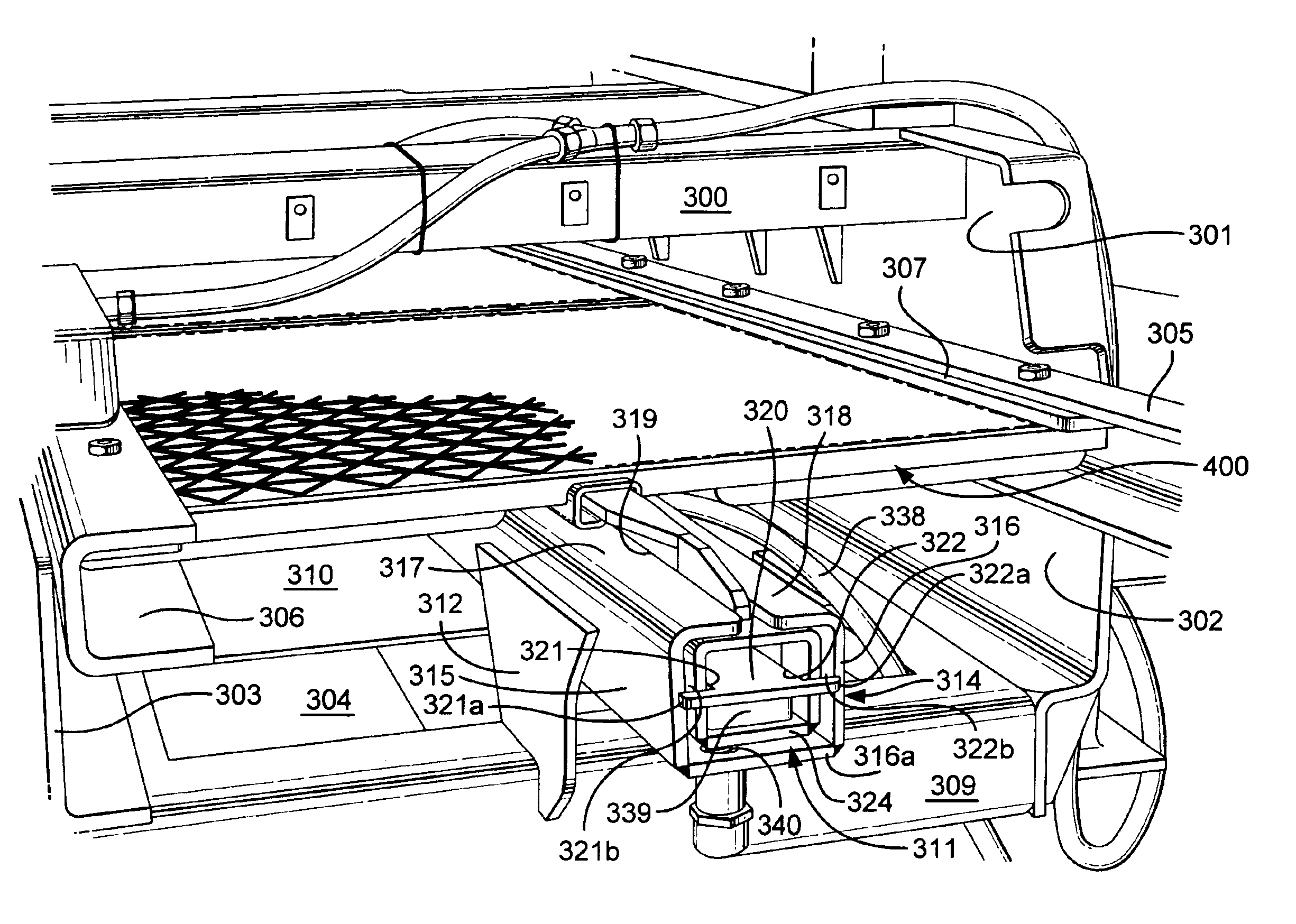

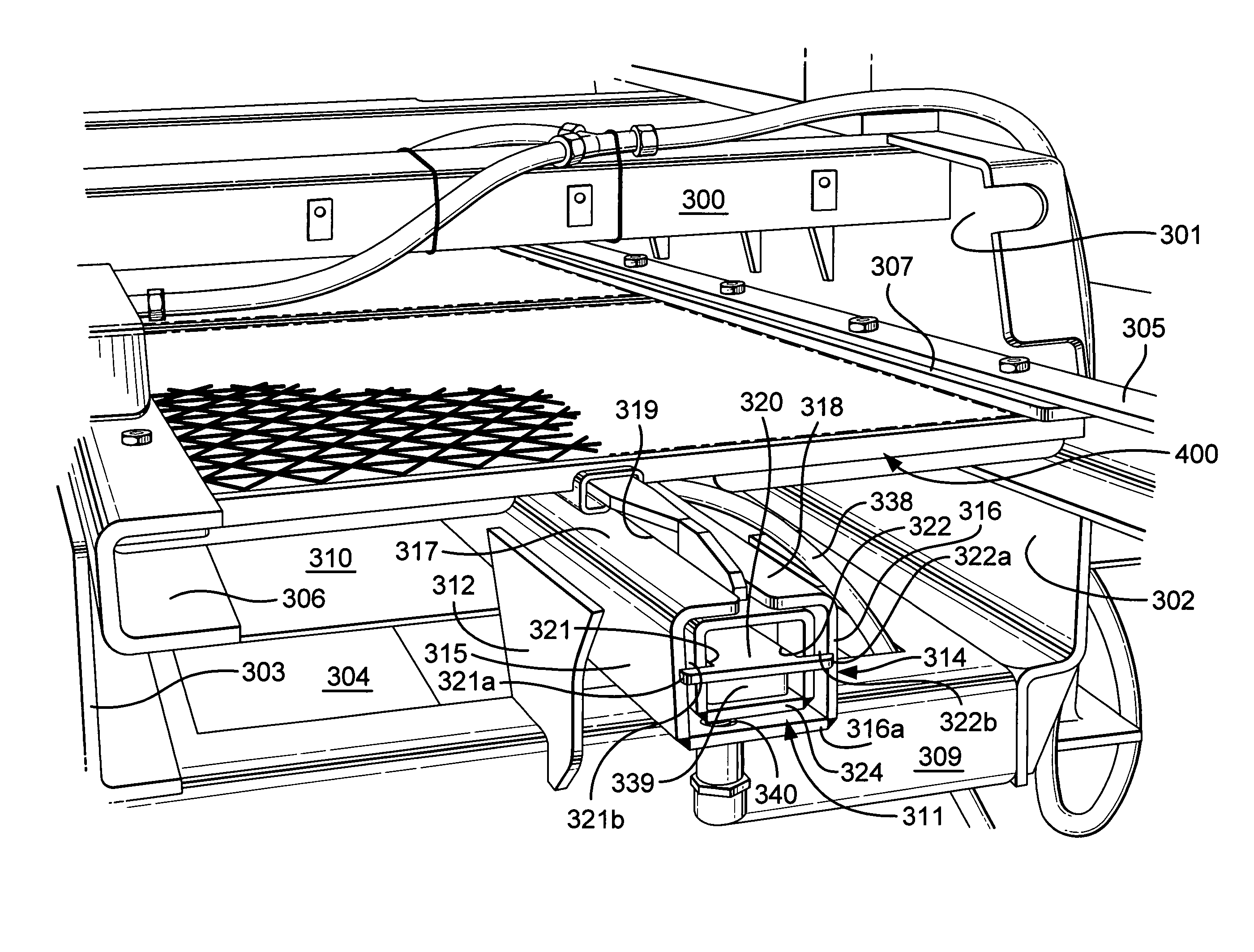

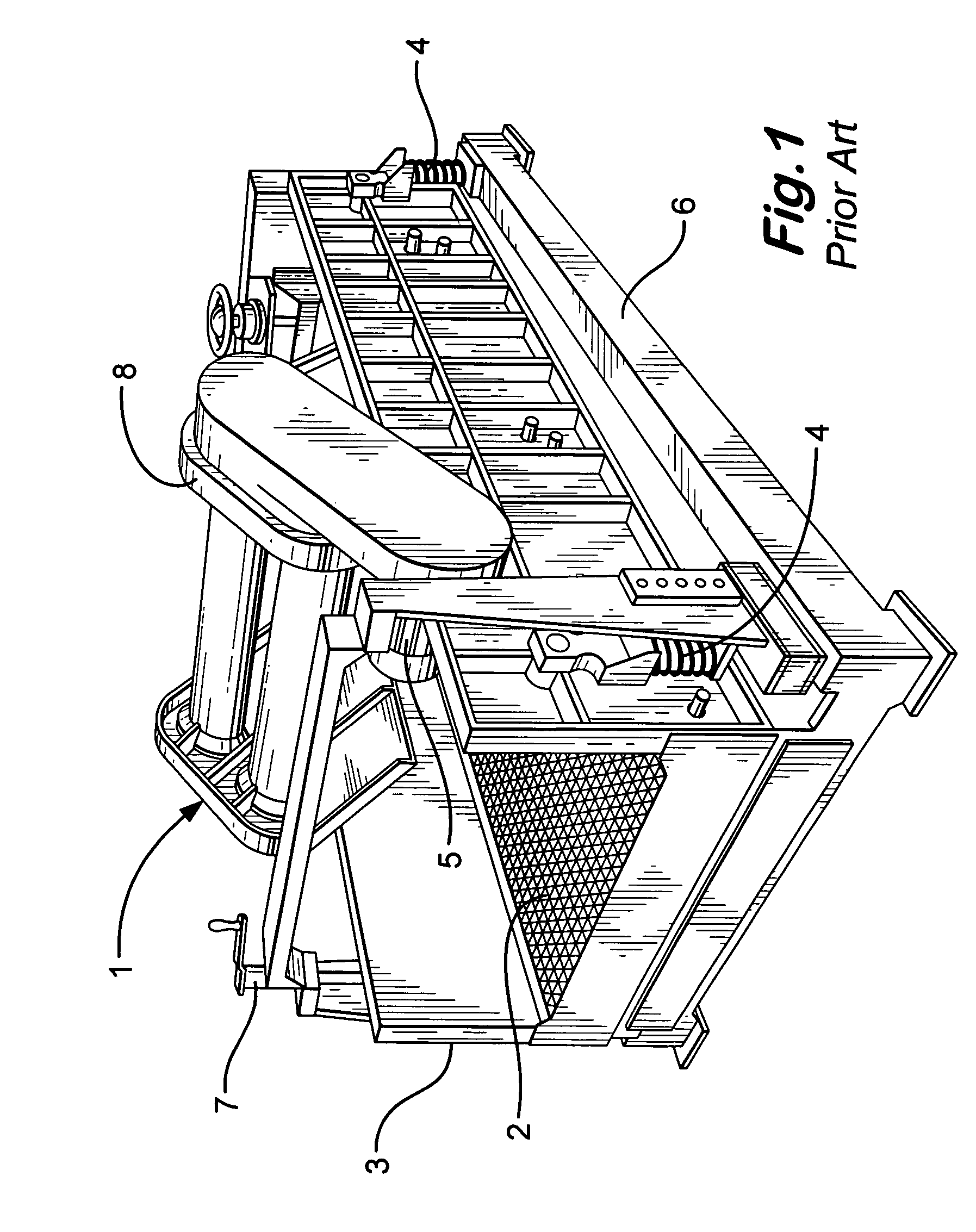

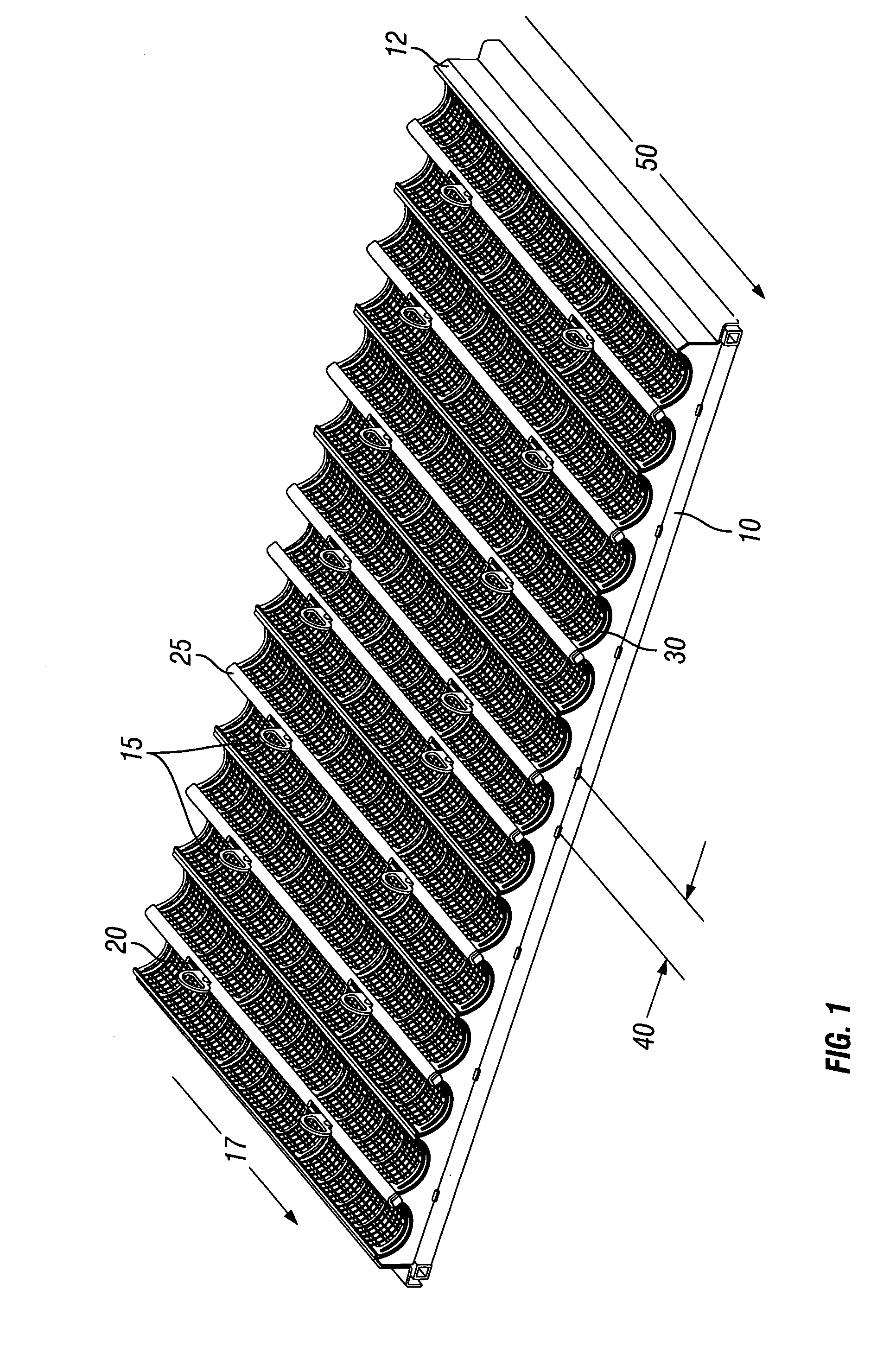

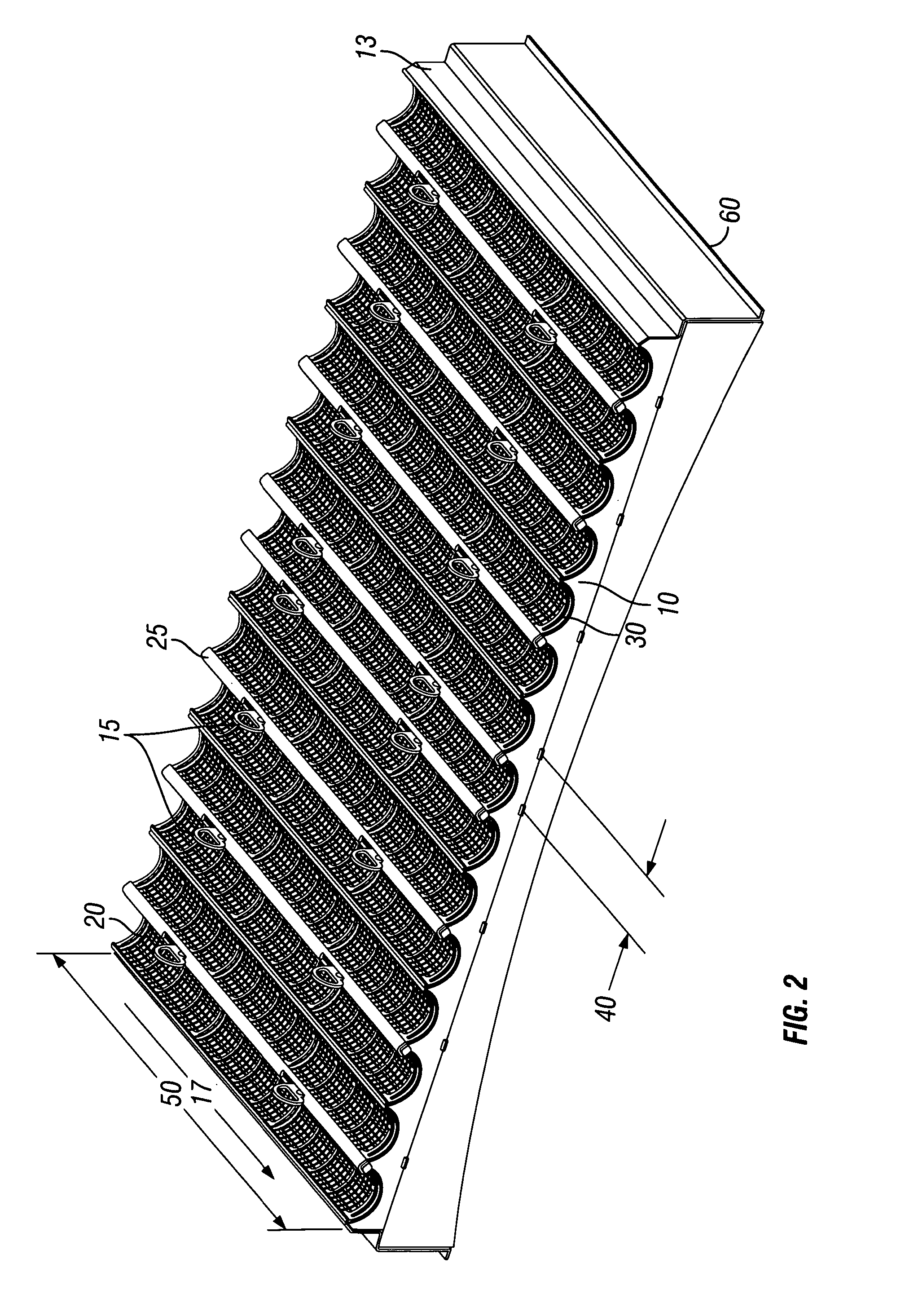

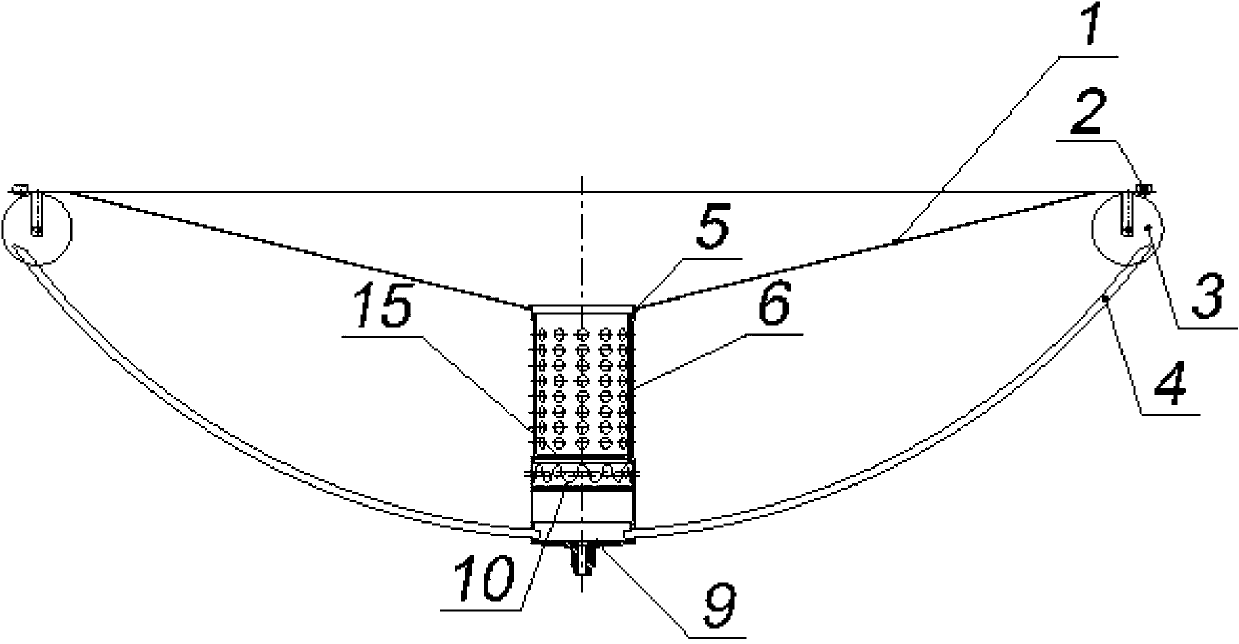

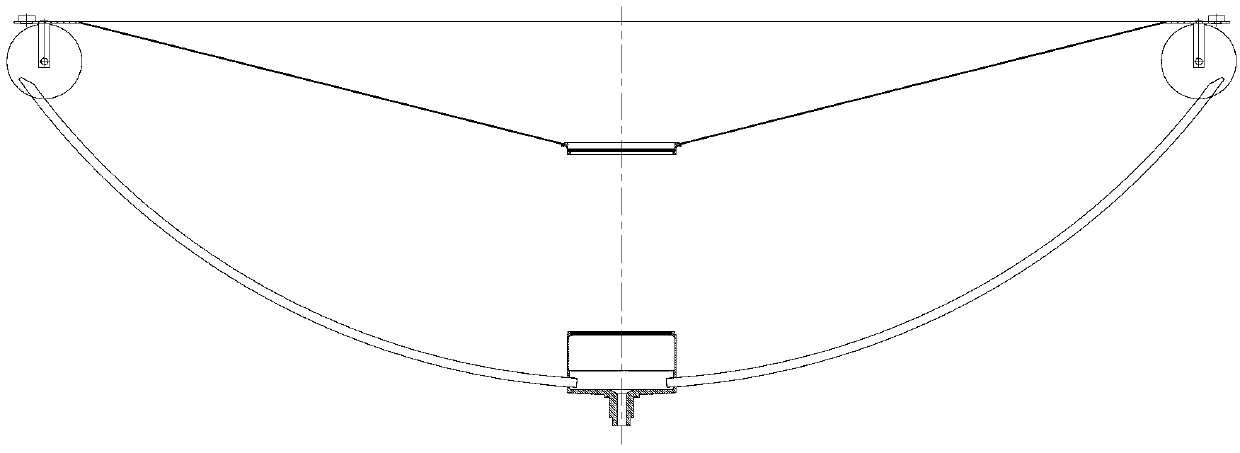

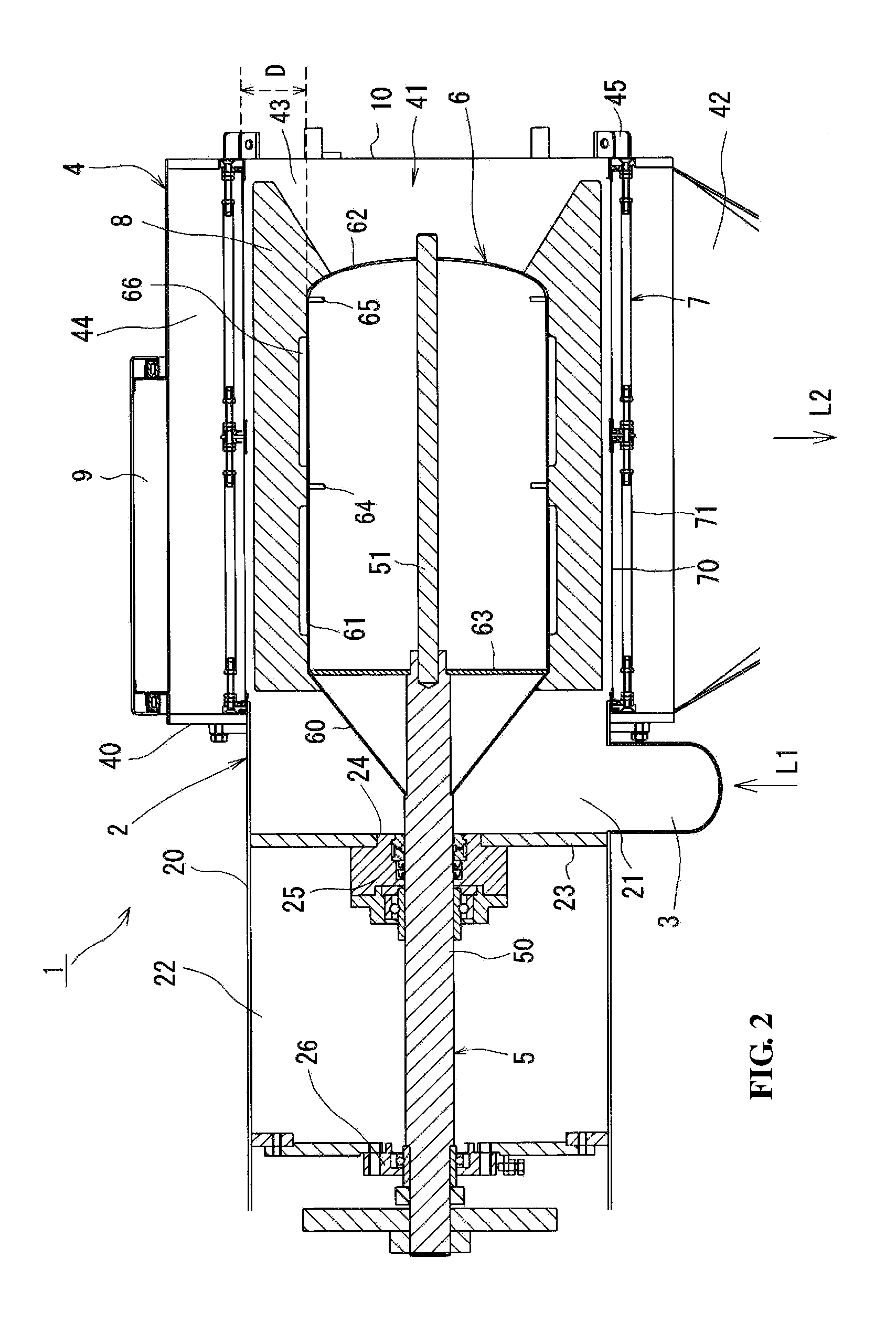

Centrally supported screen assembly

A vibratory separator having a basket with a first side spaced-apart from a second side, screen assembly apparatus mounted in the basket, the screen assembly apparatus having a central portion, a first screen side and a second screen side, central support apparatus connected to the basket and positioned beneath and in contact with the central portion of the screen assembly apparatus, and pressing apparatus on the first side and second side of the basket for pressing down on the first screen side and on the second screen side of the screen assembly apparatus so that the central portion of the screen assembly apparatus is higher than the first screen side and the second screen side.

Owner:VARCO I P INC

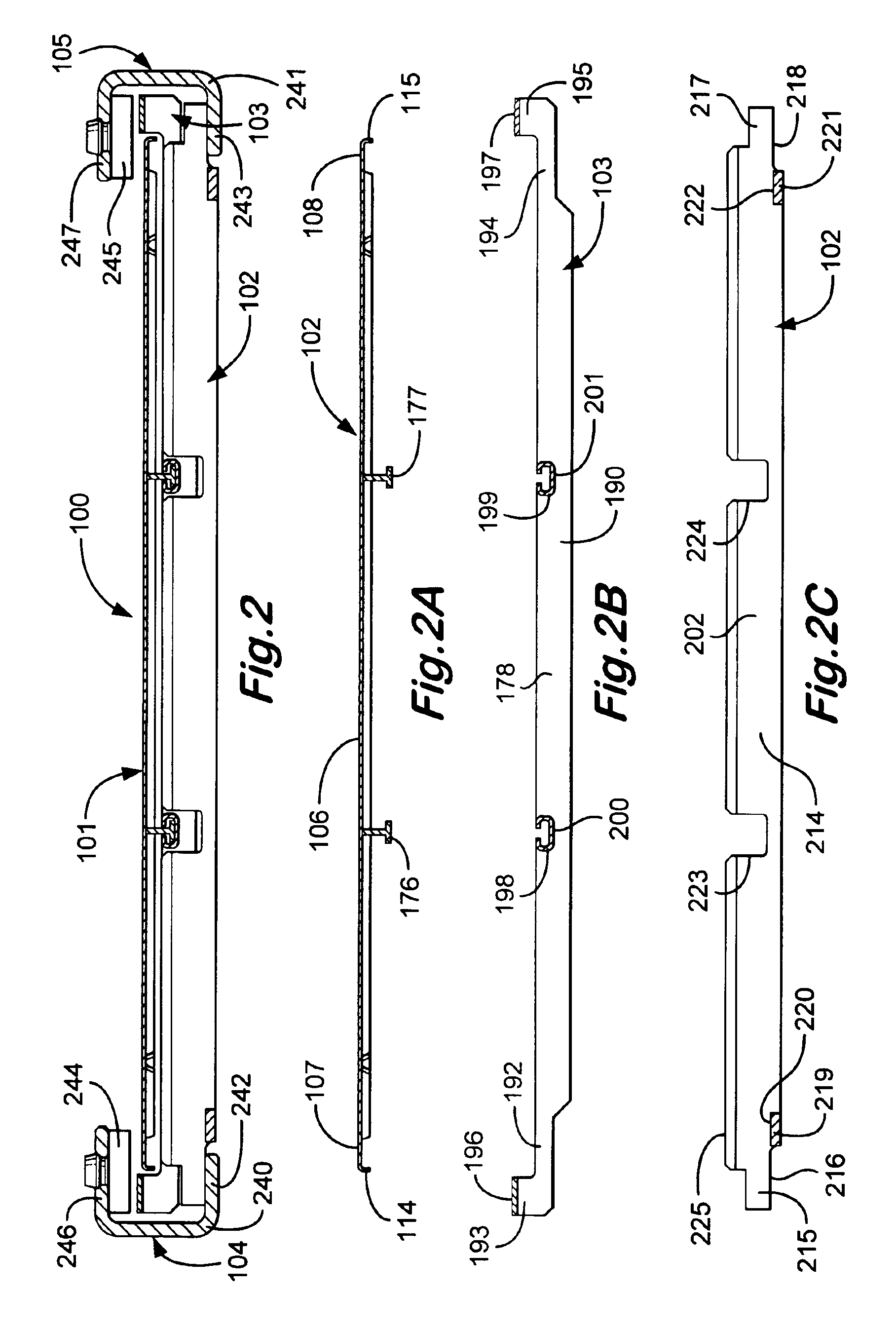

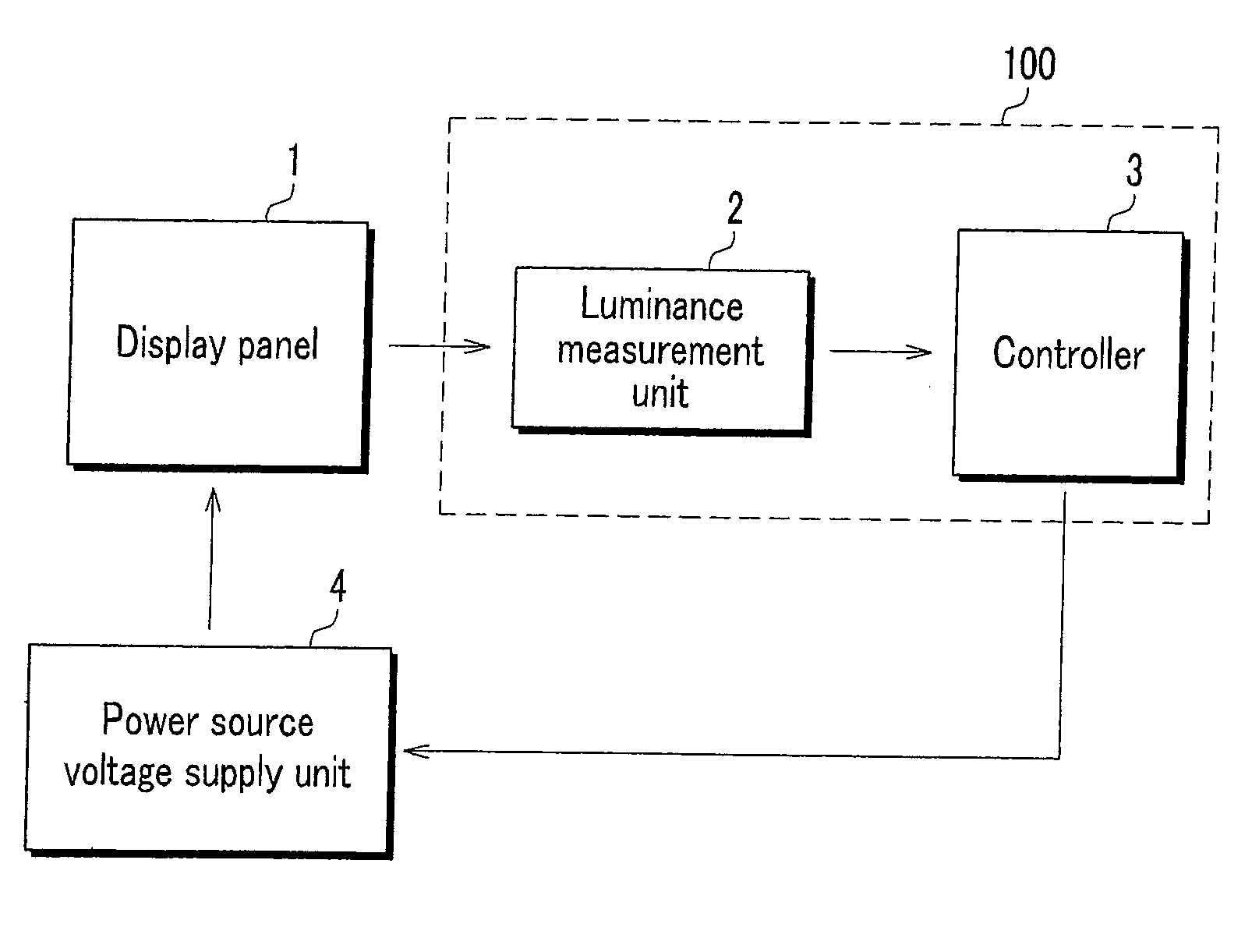

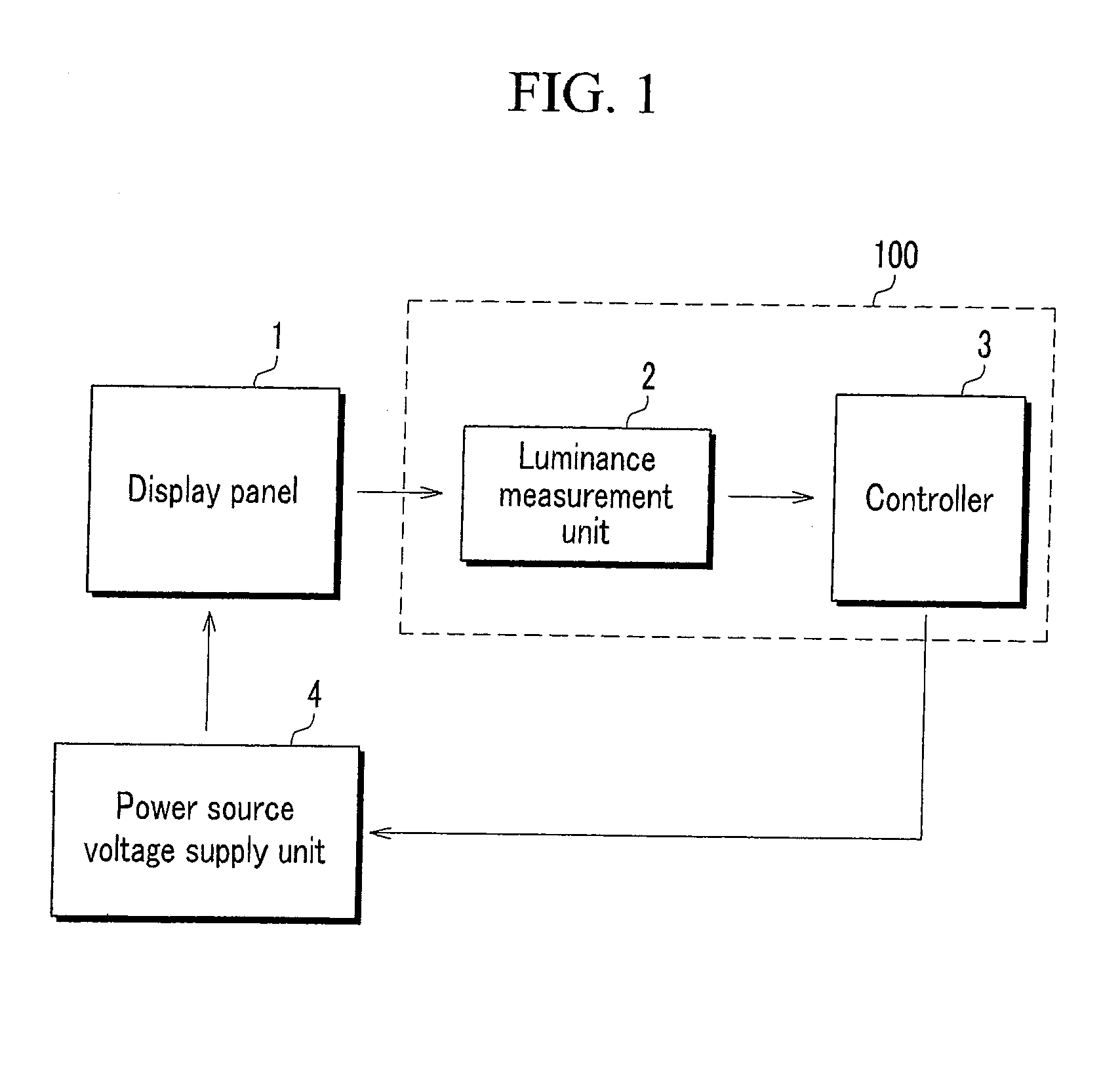

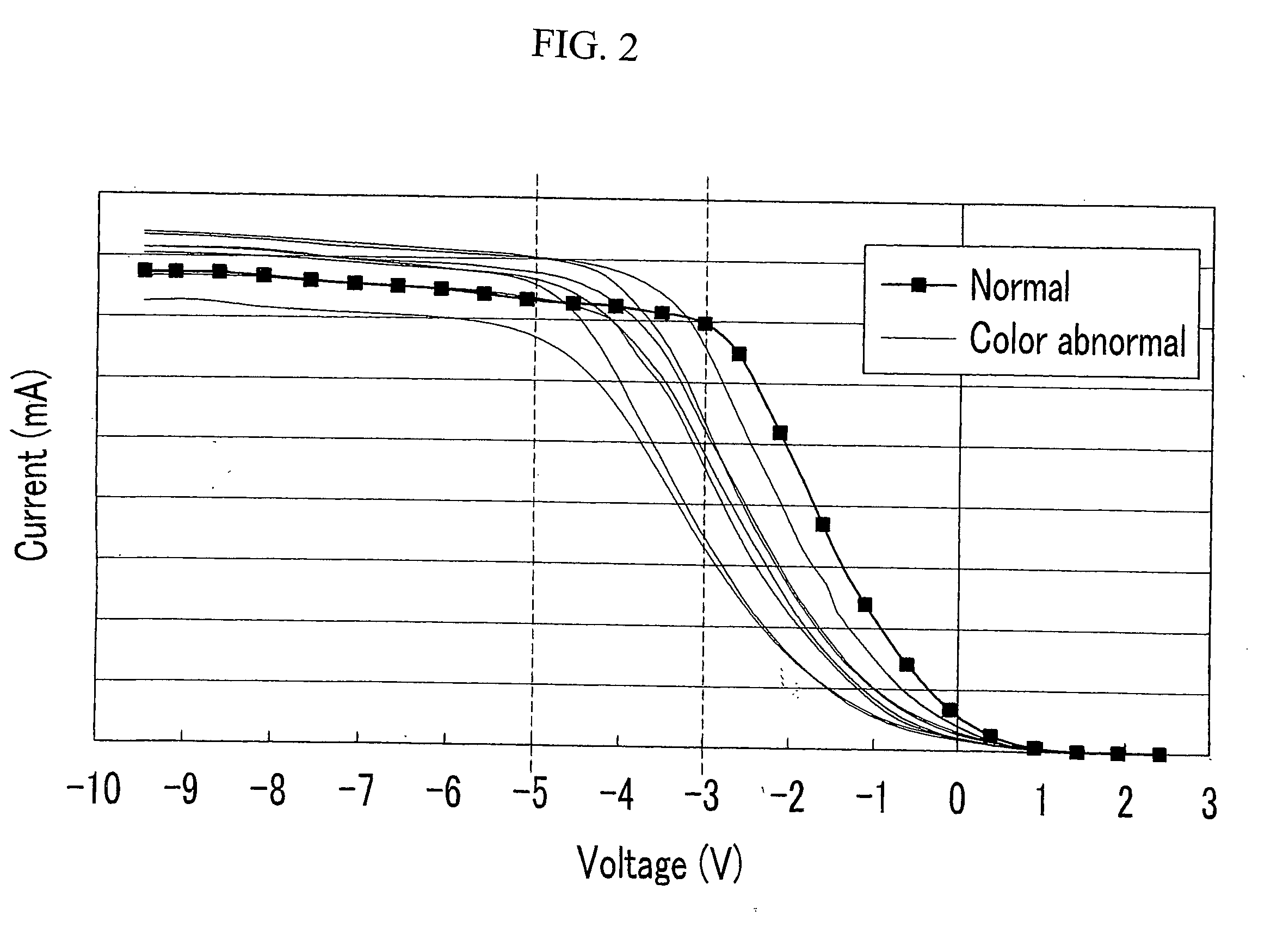

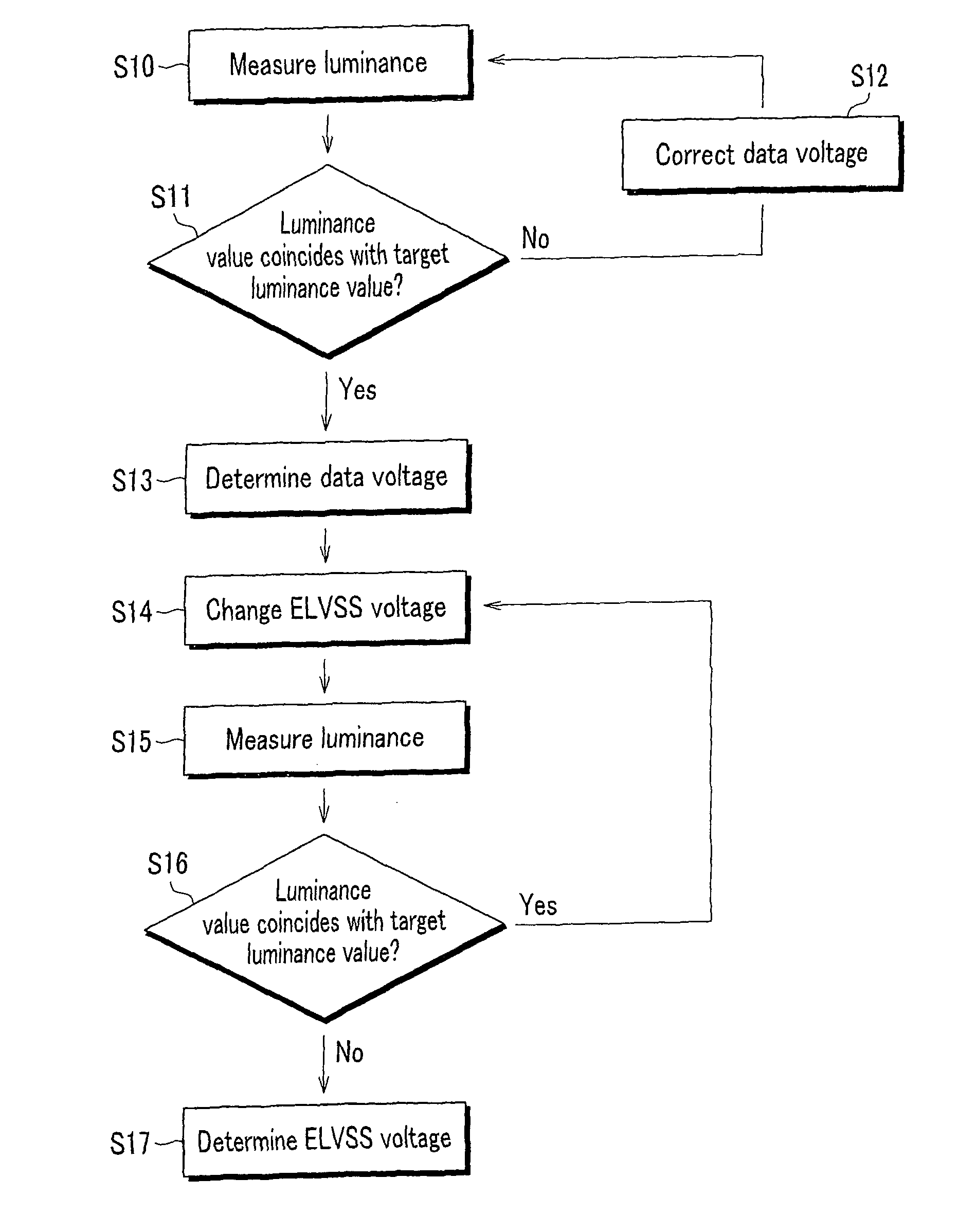

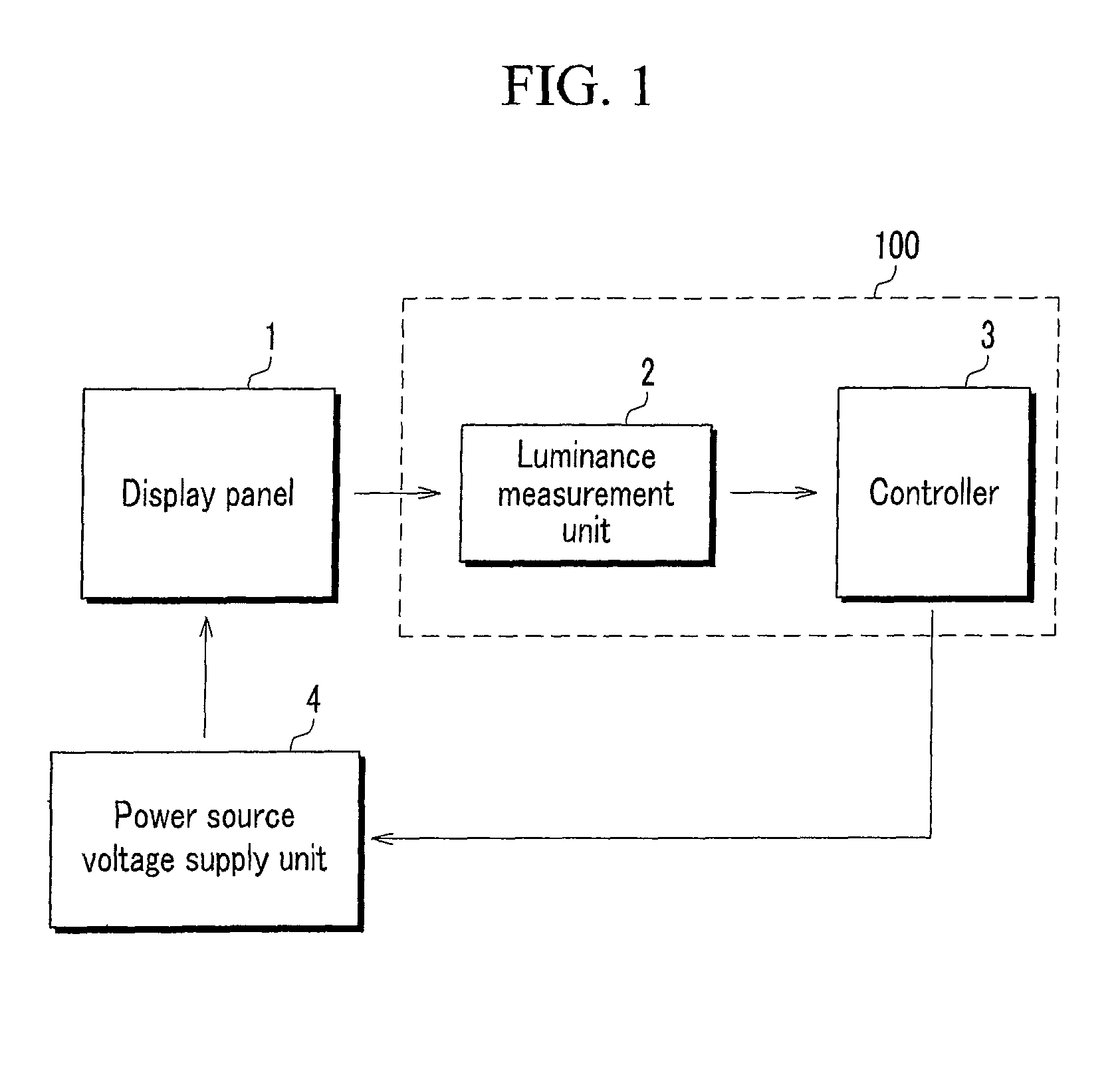

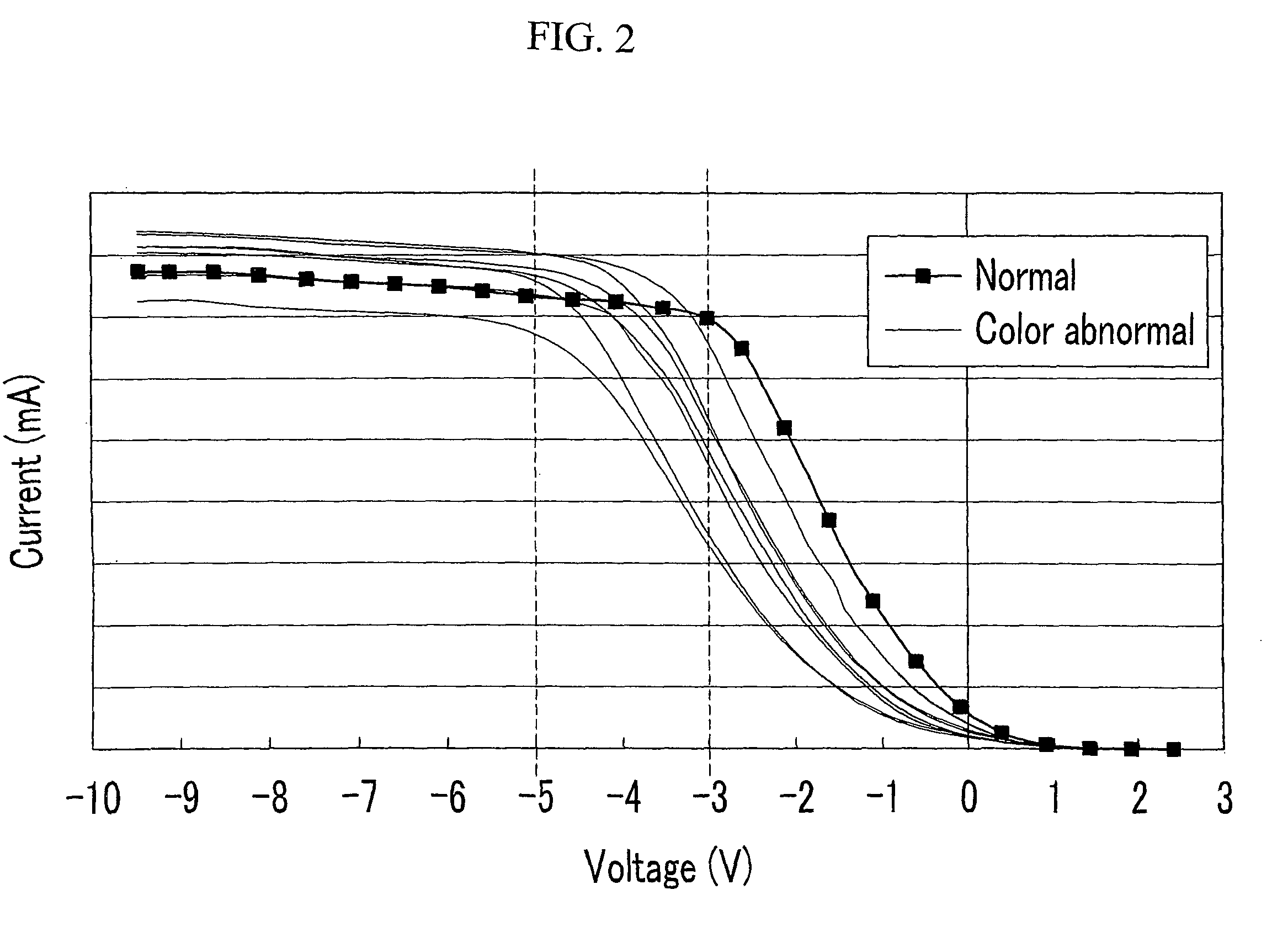

Test device for display panel and method of testing the same

ActiveUS20110221784A1Improve image qualityReduce power consumptionCathode-ray tube indicatorsInput/output processes for data processingControl signalData signal

A test device for a display panel and a method of testing the same are provided. The test device for a display panel includes a luminance measurement unit that measures a luminance value of a display panel including a plurality of pixels, and a controller that determines a voltage value of a data signal corresponding to a target luminance value, receives a measured luminance value of a pixel to which the data signal is supplied from the luminance measurement unit from among the plurality of pixels, compares the measured luminance value and the target luminance value, and outputs a control signal that changes a first power source voltage value supplied from a power source voltage supply unit to the pixel until the measured luminance value does not coincide with the target luminance value.

Owner:SAMSUNG DISPLAY CO LTD

Centrally supported screen assembly

InactiveUS20040074816A1Easy to replaceLess materialSievingScreeningEngineeringMechanical engineering

A vibratory separator having a basket with a first side spaced-apart from a second side, screen assembly apparatus mounted in the basket, the screen assembly apparatus having a central portion, a first screen side and a second screen side, central support apparatus connected to the basket and positioned beneath and in contact with the central portion of the screen assembly apparatus, and pressing apparatus on the first side and second side of the basket for pressing down on the first screen side and on the second screen side of the screen assembly apparatus so that the central portion of the screen assembly apparatus is higher than the first screen side and the second screen side.

Owner:VARCO I P INC

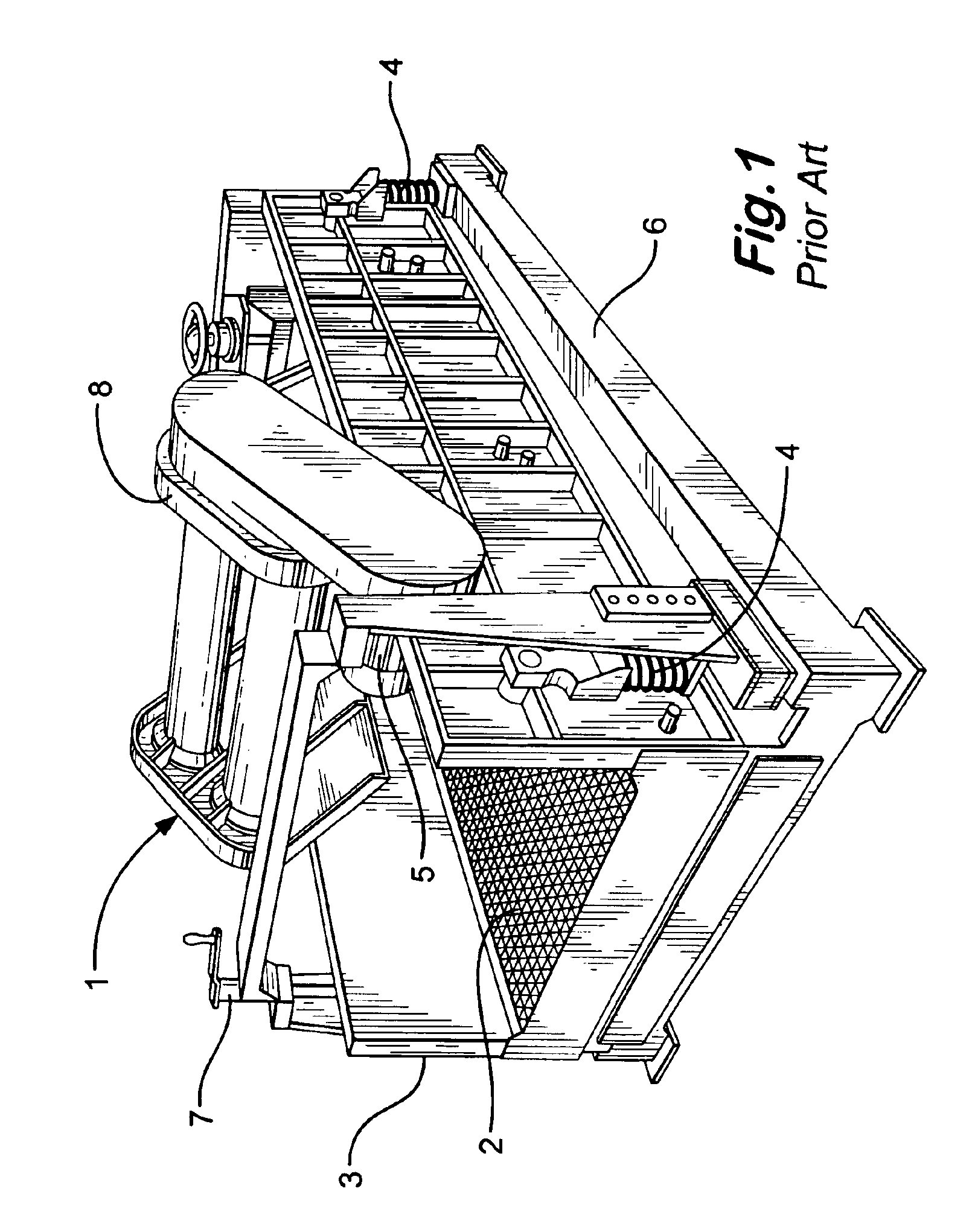

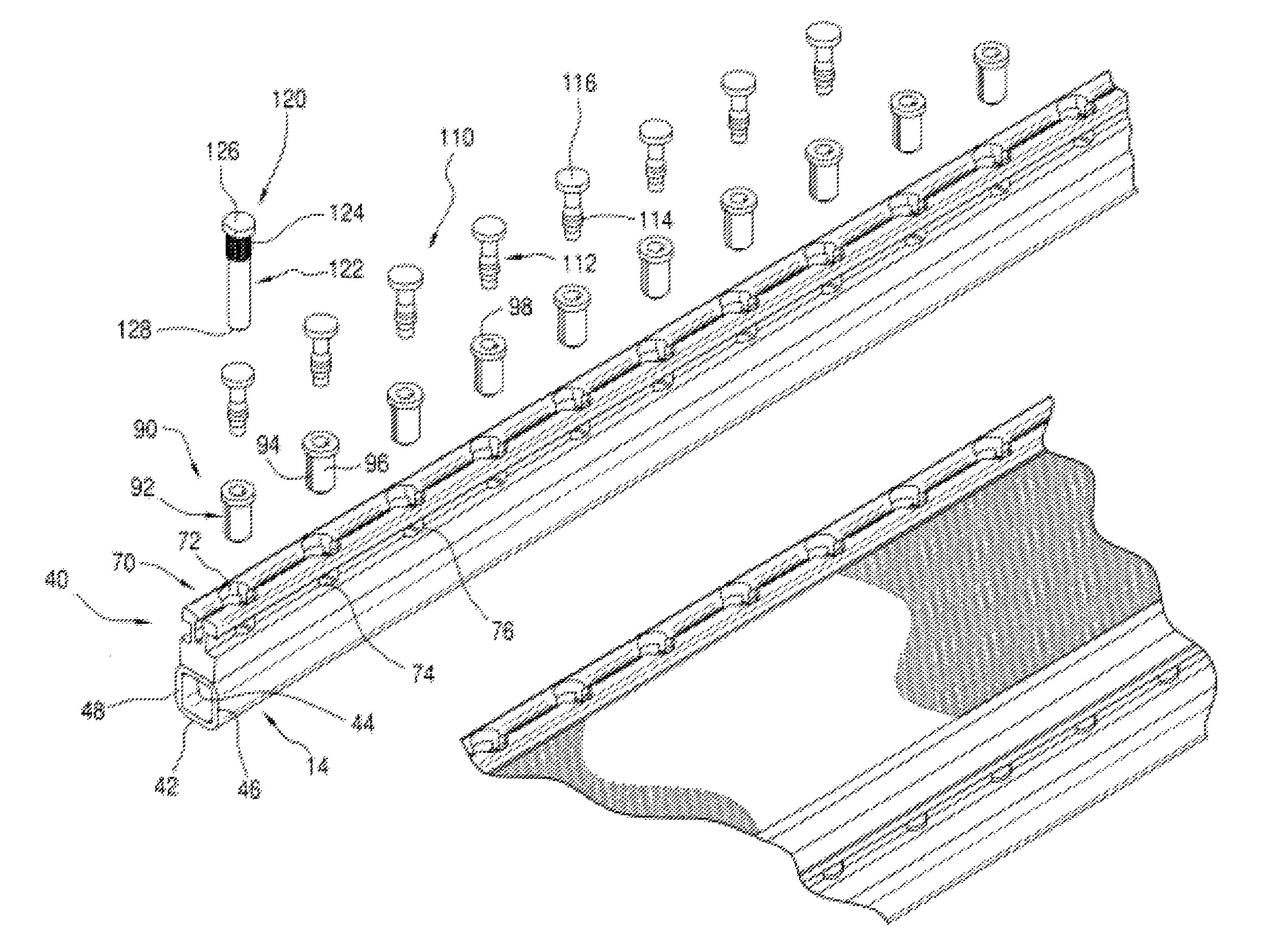

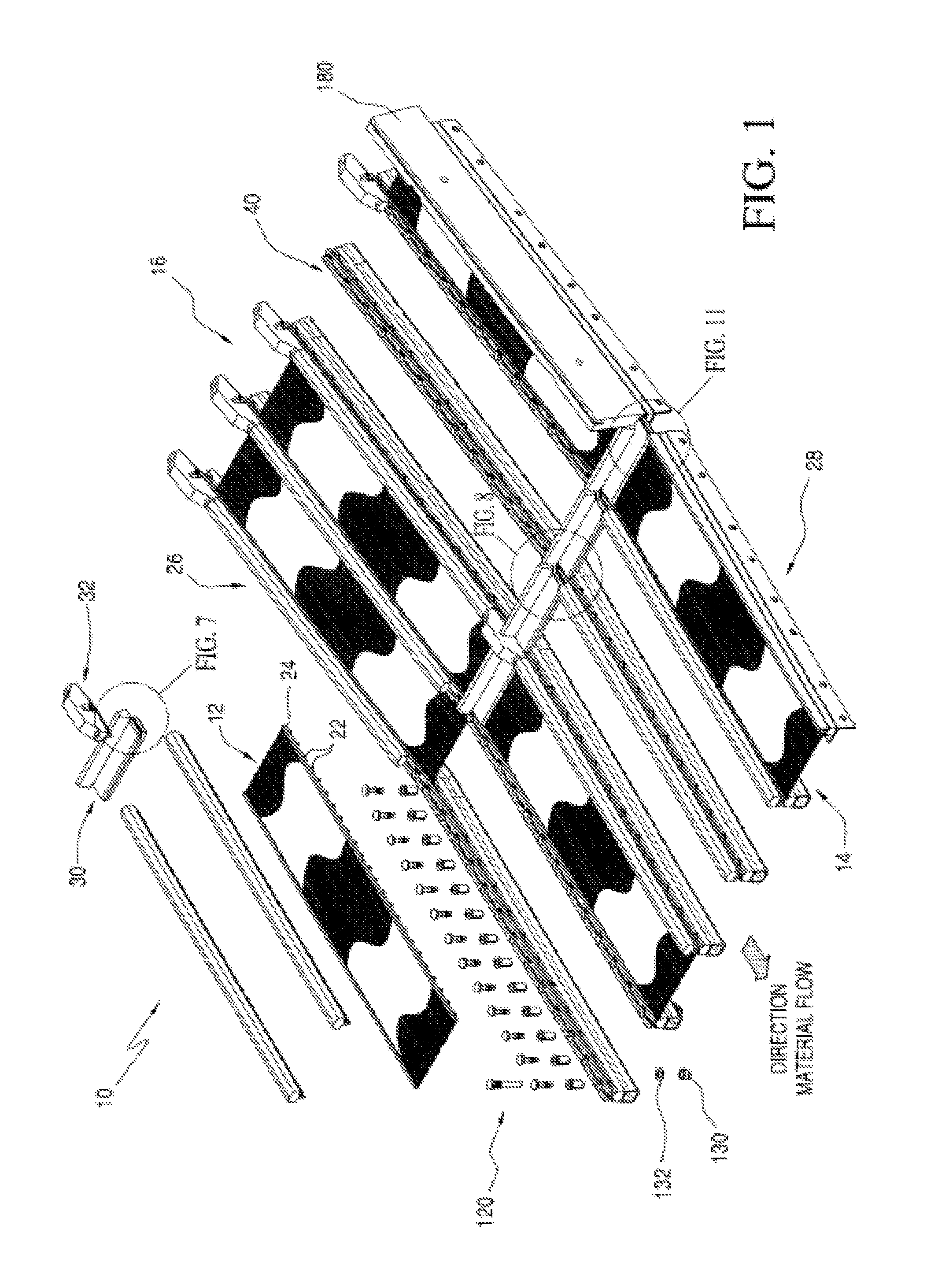

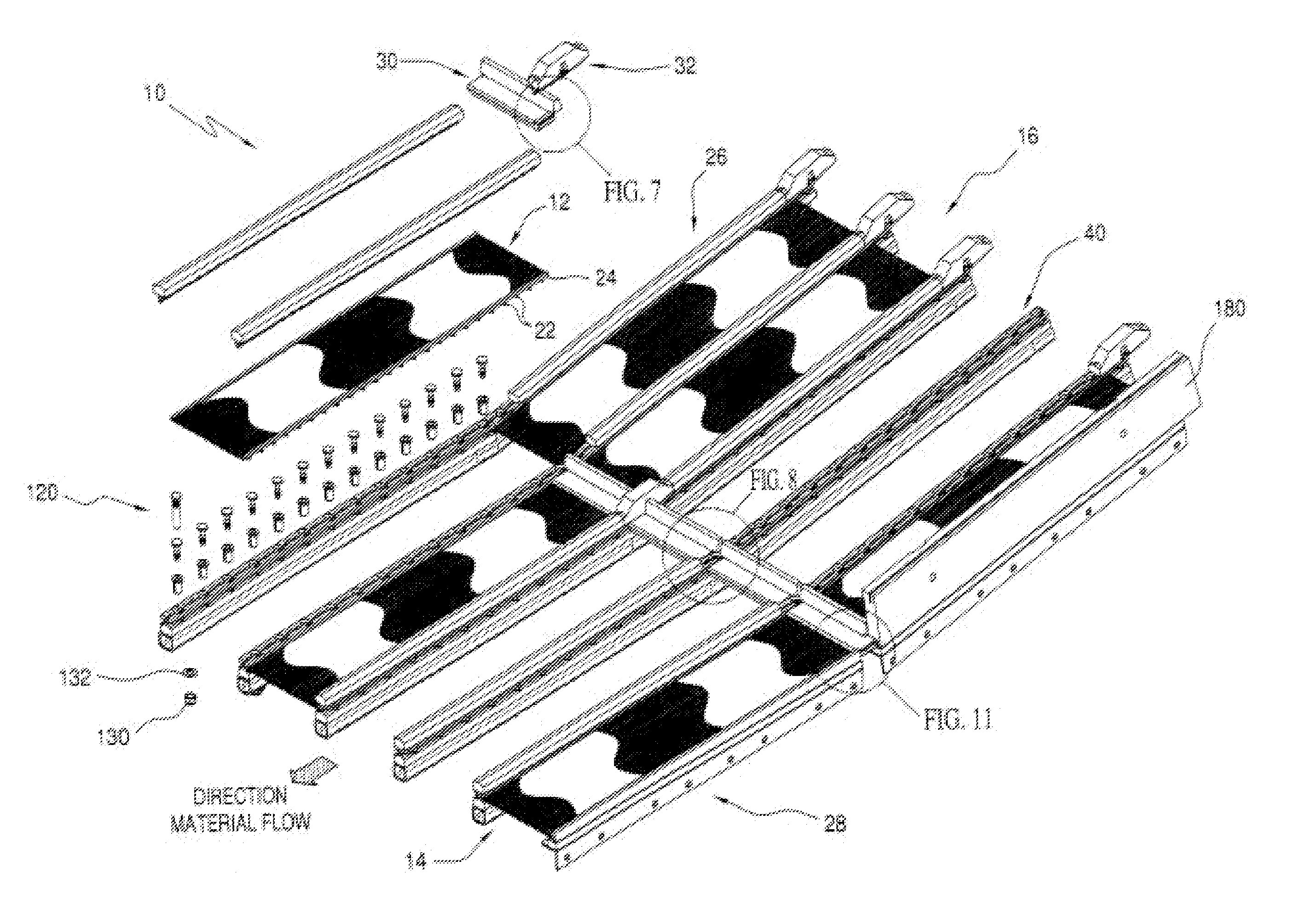

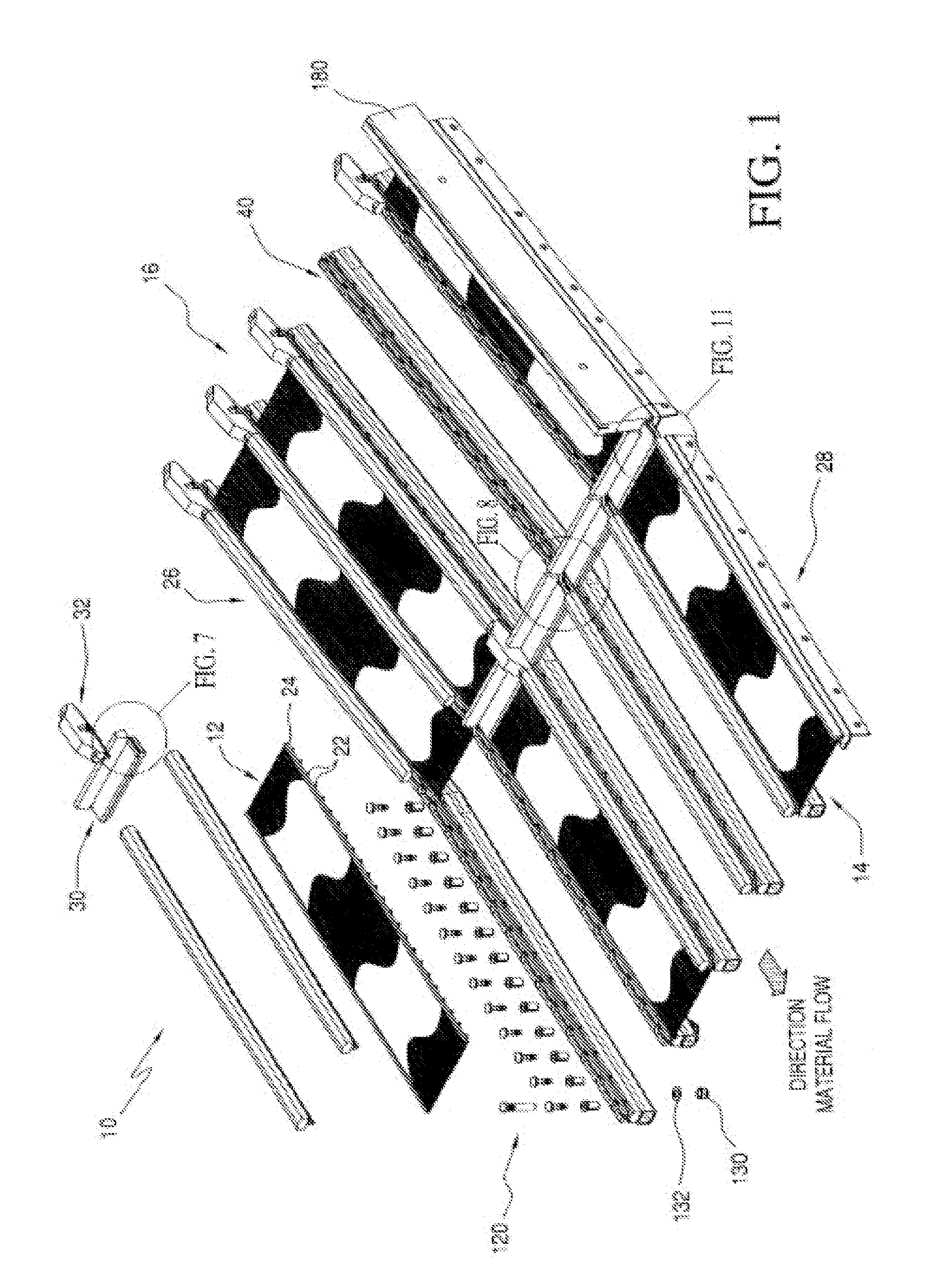

Screen panel center retainer system

A screen panel center retainer system utilizes a center retainer that is provided with a retainer base which is adapted to be secured to screen stringer rails of a vibrating separatory machine. A pair of retainer channel legs form an upper portion of the center retainer and have screen panel edge receiving slots. A locking strip, having a wedging tongue, is used in conjunction with the center retainer. The wedging tongue is insertable into the channel on the center retainer which is defined by the two retainer channel legs. Flow control dams and cross dam retainers are used in conjunction with, and in addition to the center retainers and locking strips, to provide the complete installation of screen panels on the vibrating separating machine.

Owner:CONN WELD IND

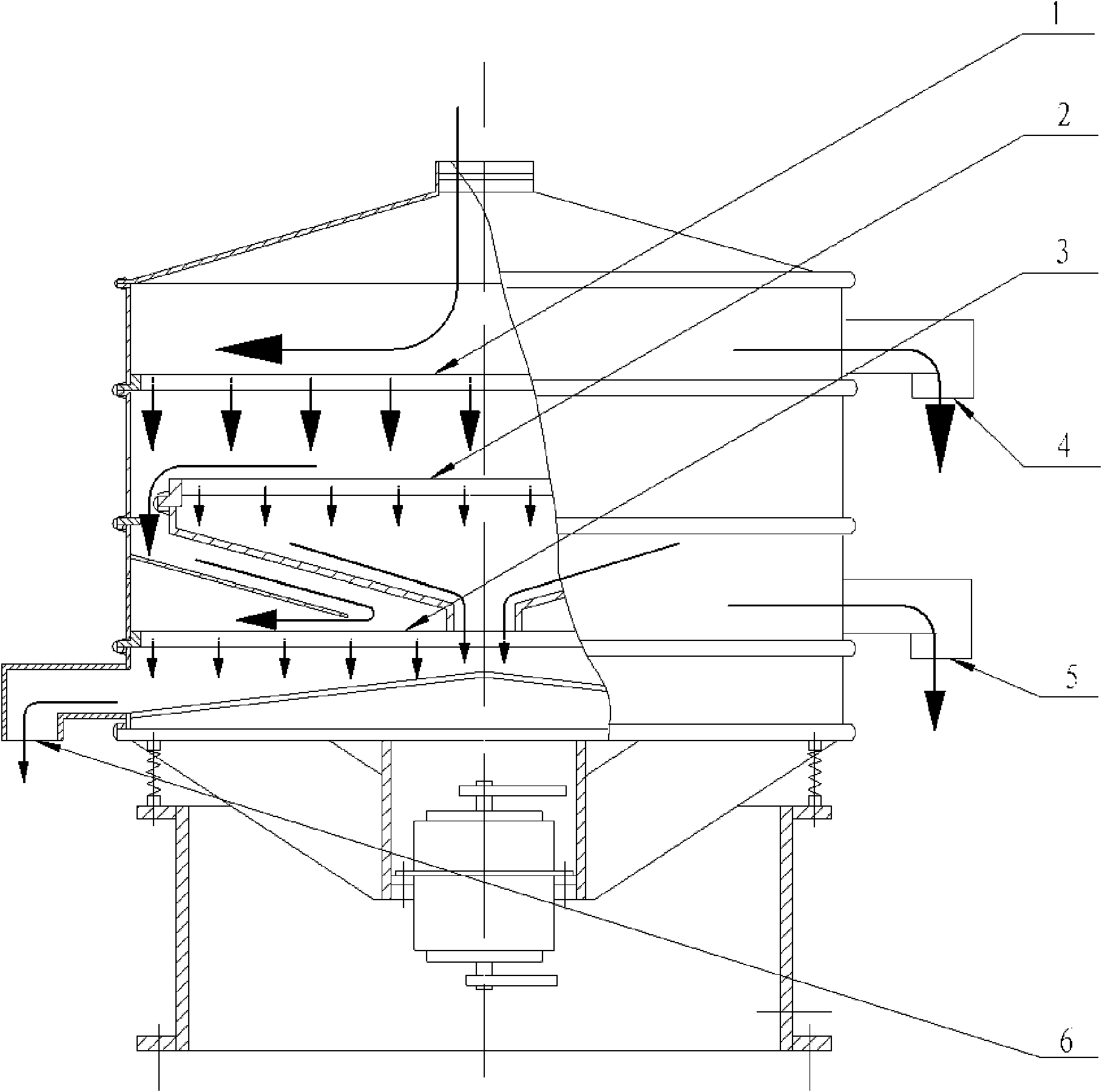

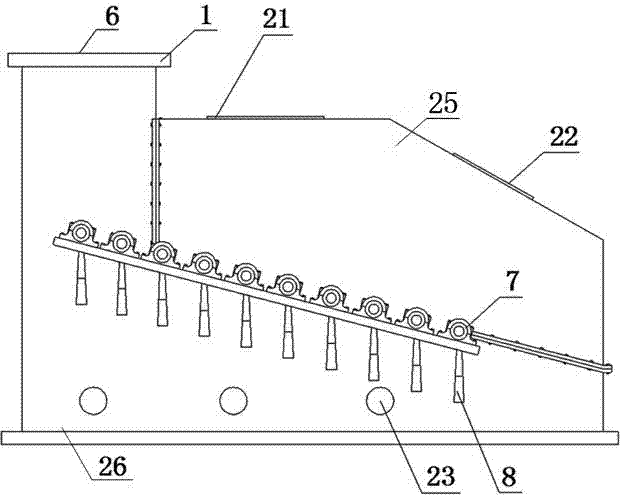

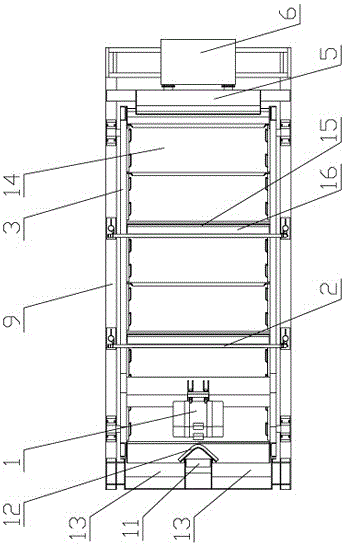

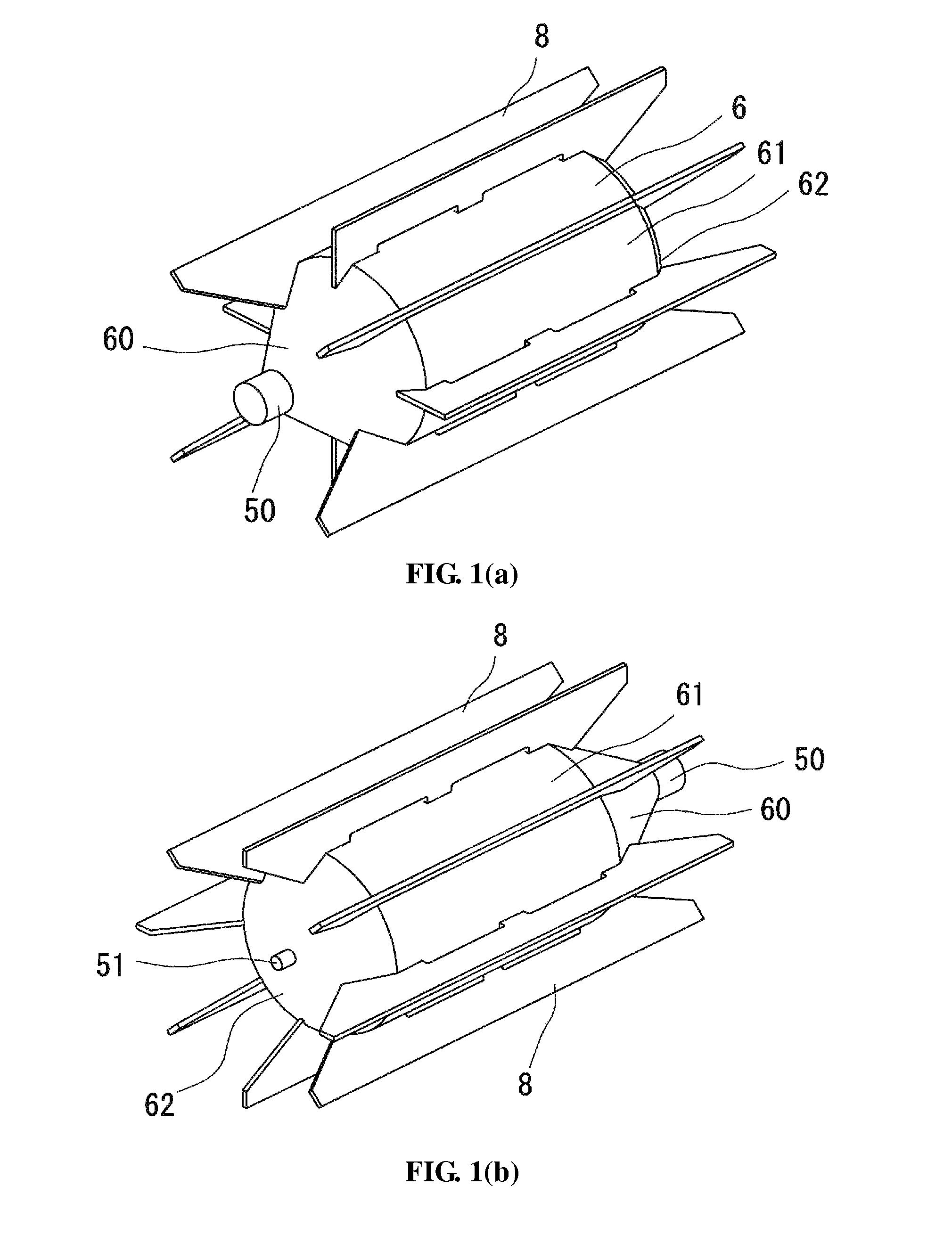

Vertical spiral vibrating screen

InactiveCN102371246AImproved resistance to fatigue vibrationIncrease the range of motionSievingScreeningEngineeringFine powder

The invention discloses a vertical spiral vibrating screen capable of greatly increasing the area of a screen and lengthening the movement stroke of powder. The vertical spiral vibrating screen comprises a base, a screen arranged on the base through a plurality of supporting springs, a vibrating device connected with the lower end of the screen and positioned in the base, a bin arranged at the upper end of the screen and a feeding valve arranged in the bin. The screen comprises a shell, a middle upright post and a screen net. The shell is a cylinder provided with a cover plate and a bottom plate, and the lower part of the shell is provided with a fine powder feeding hole and a coarse powder feeding hole; the middle upright post is vertical to the center of the shell; and the screen net comprises a bottom screen net, a lateral screen net and a top plate, wherein the inner edge of the bottom screen net is fixed on the middle upright post and is downwards spiral around the middle upright post, the lateral screen net is arranged coaxial with the middle upright post and is downwards spiral around the middle upright post, the lower end of the lateral screen net is connected with the outer edge of the bottom screen net, and the inner edge of the top plate is fixed on the middle upright post and is downwards spiral around the middle upright post.

Owner:SHANGHAI JIANSHE LUQIAO MASCH CO LTD

Screen assemblies utilizing screen elements retained in perforated supports

InactiveUS8020705B2Increase the usable areaFacilitates storage and shippingSievingScreeningEngineeringMechanical engineering

Owner:HUKKI ARI M +1

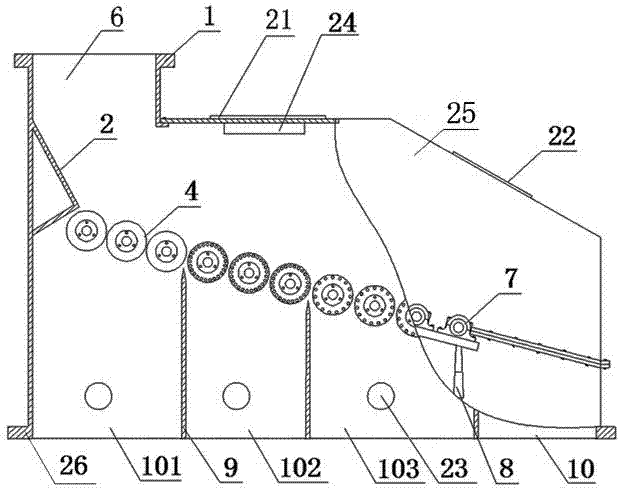

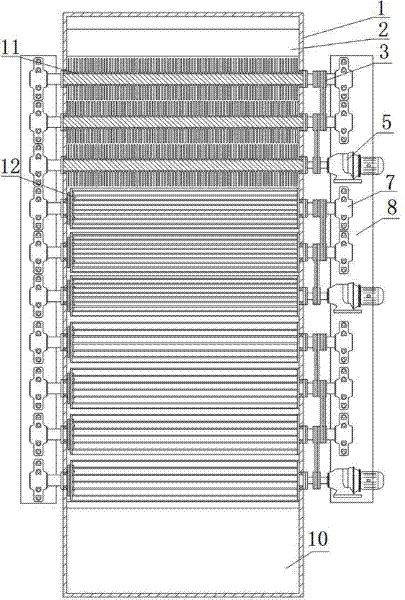

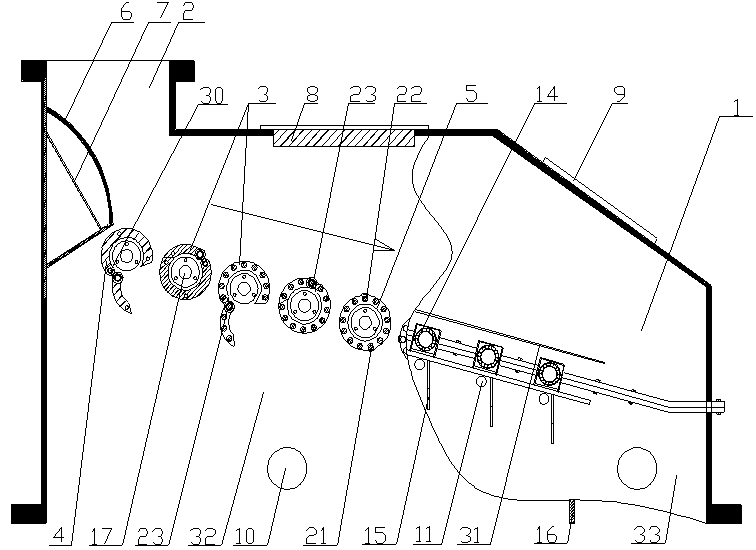

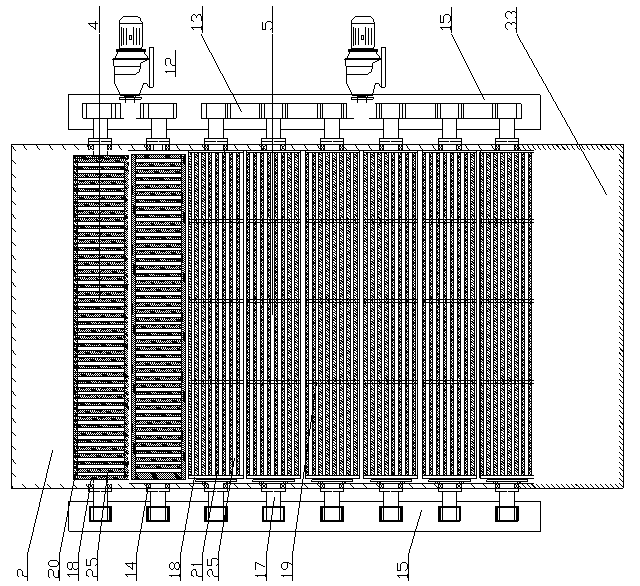

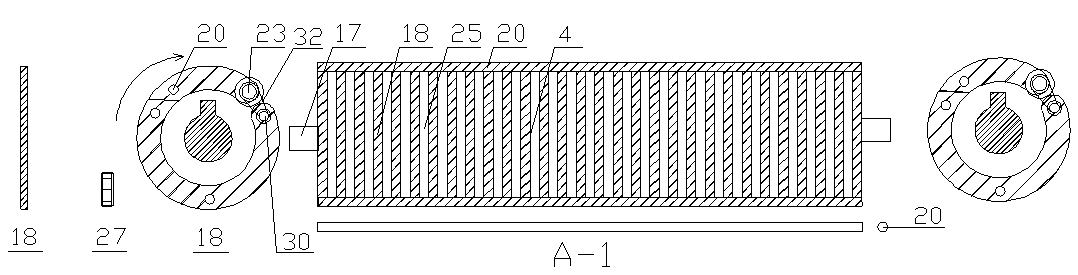

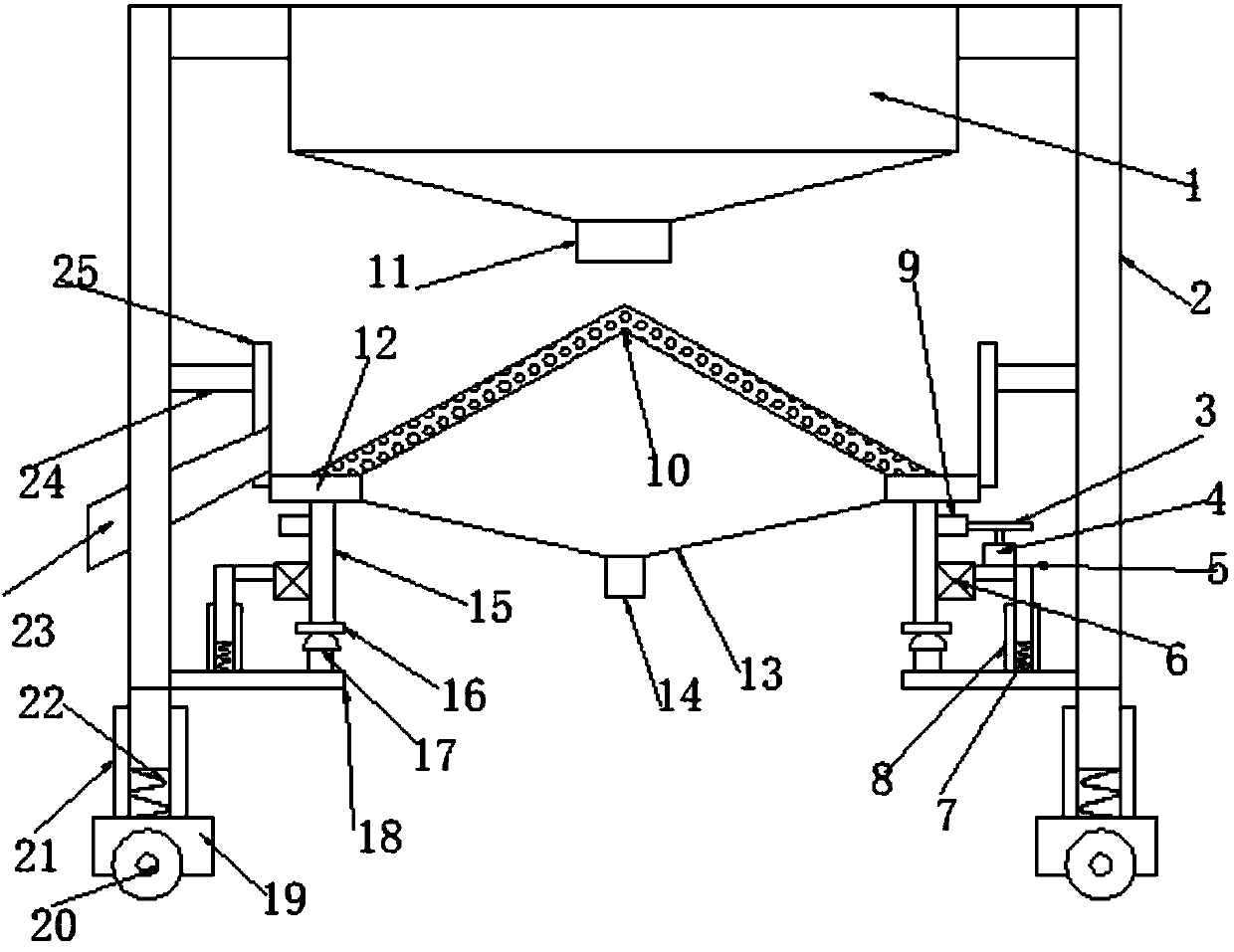

Material distributing screening machine

The invention discloses a material distributing screening machine, comprising a machine case (1), a forced fabric plate (2), a driving device (3), a filtering roller (4), a reducer motor (5) and an iron removing device (24), wherein the machine case (1) is provided with a feeding hole (6) and a plurality of discharging holes (10), the filtering roller (4) comprises a flange disk type roller (11) and a filtering rope type roller (12), the filtering roller (4) is provided with the driving device (3), the reducer motor (5) drives the filtering roller (4) to rotate by virtue of the driving device (3), and material enters from the feeding hole (6), is screened by the filtering roller (4) and is discharged by the discharging hole (10). The invention has the beneficial effects that: more than two materials in different grain sizes can be screened by setting different interstitial screen cuts, the working condition requirement for screening more than two materials can be met, screening efficiency is high, bulk material impact resistance is high, material is distributed more uniformly, no blockage is caused, and an iron piece contained in the material can be removed.

Owner:SICHUAN ZHONGMENG ELECTRIC POWER EQUIP MFG CO LTD

Electronic device with screen

ActiveUS9989995B2Increase the screening areaReduce border areaMagnetic/electric field screeningDigital data processing detailsEngineeringElectrical and Electronics engineering

Owner:SAMSUNG ELECTRONICS CO LTD

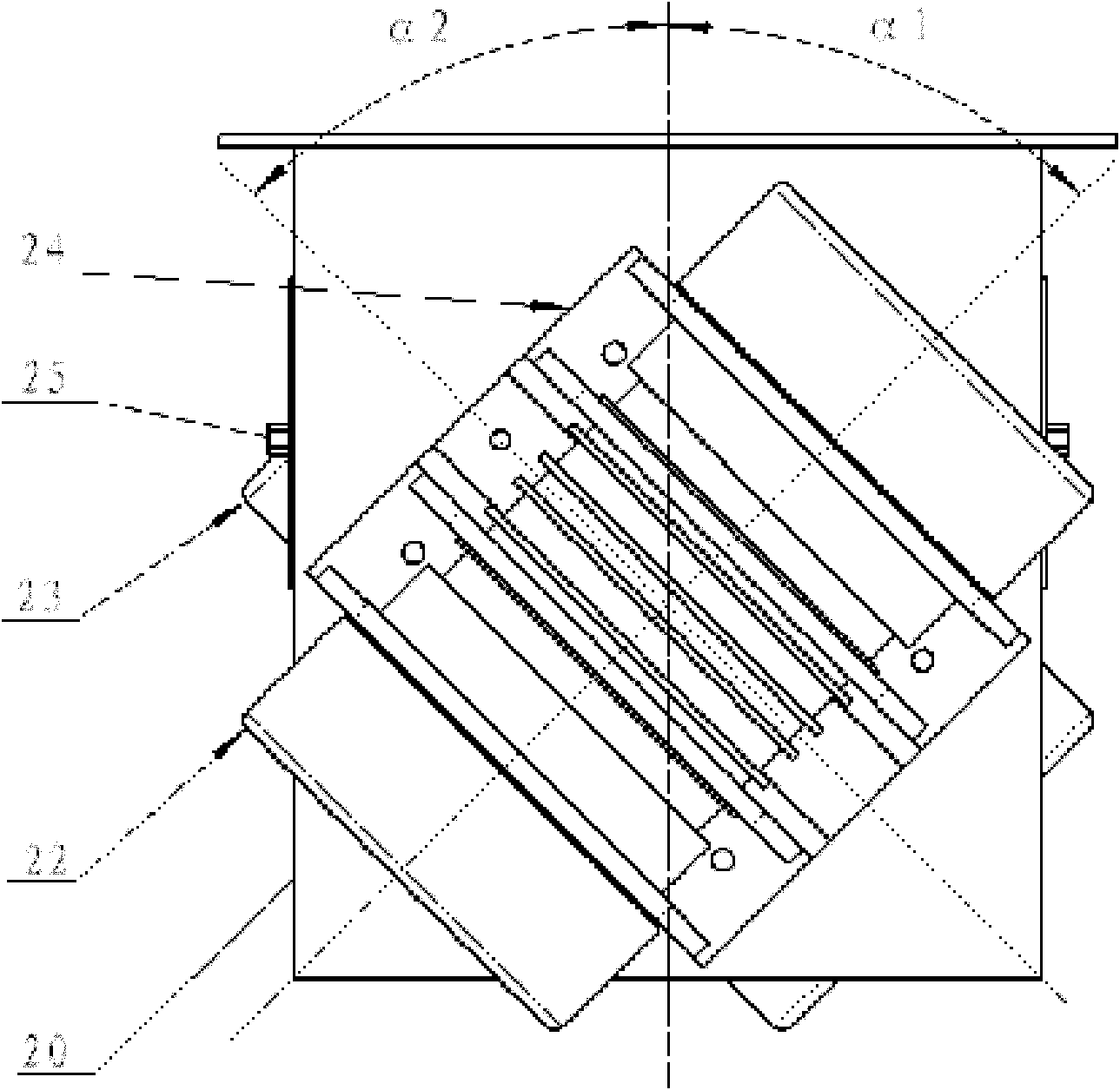

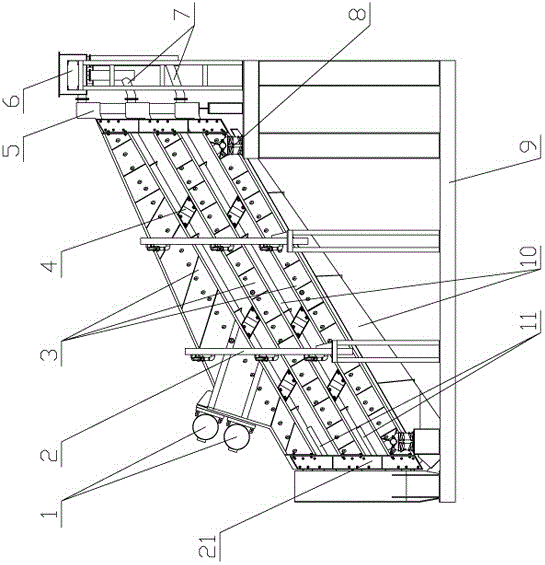

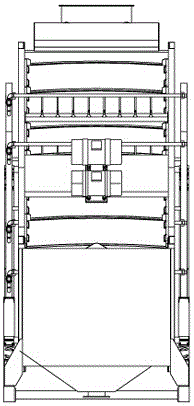

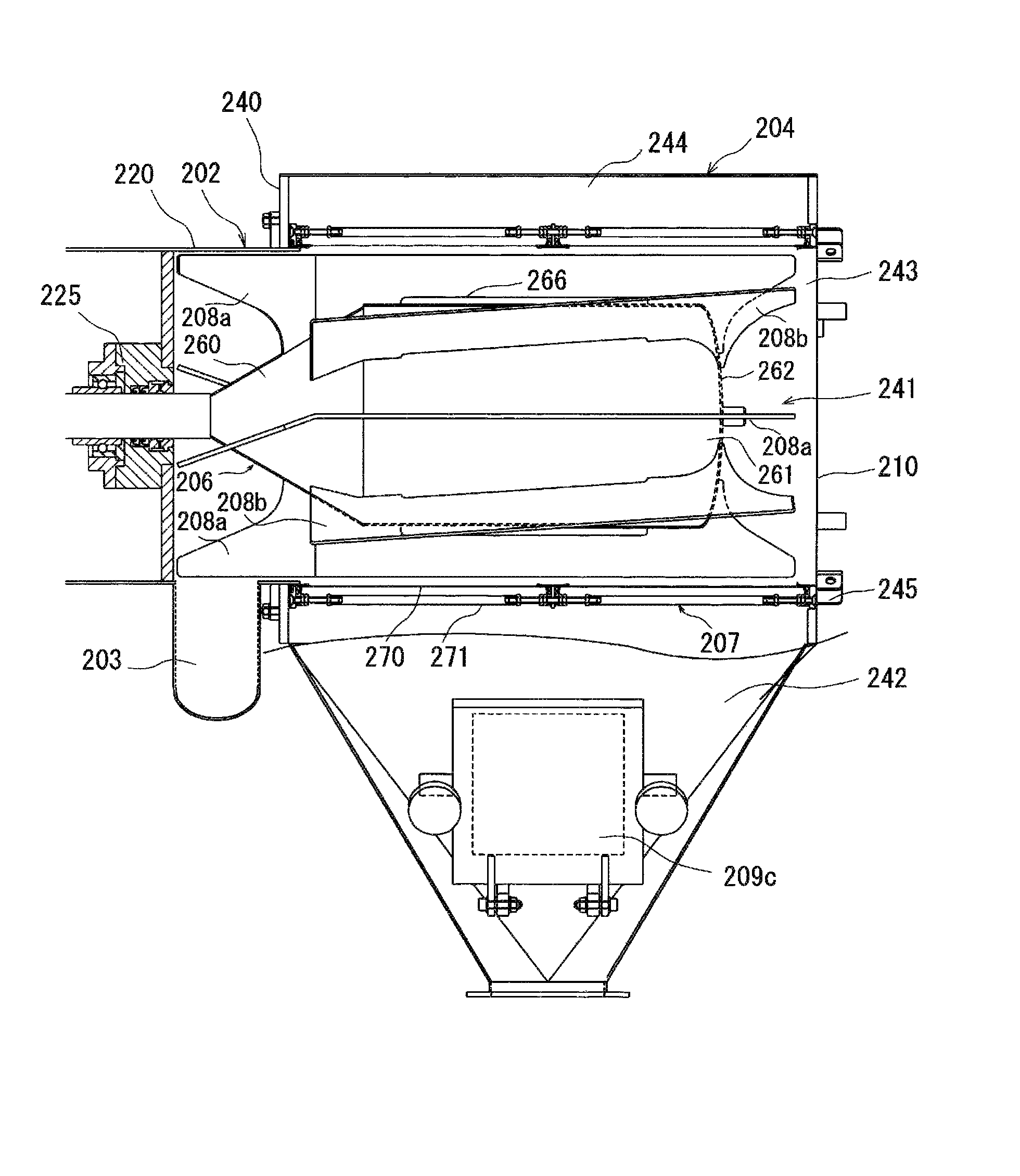

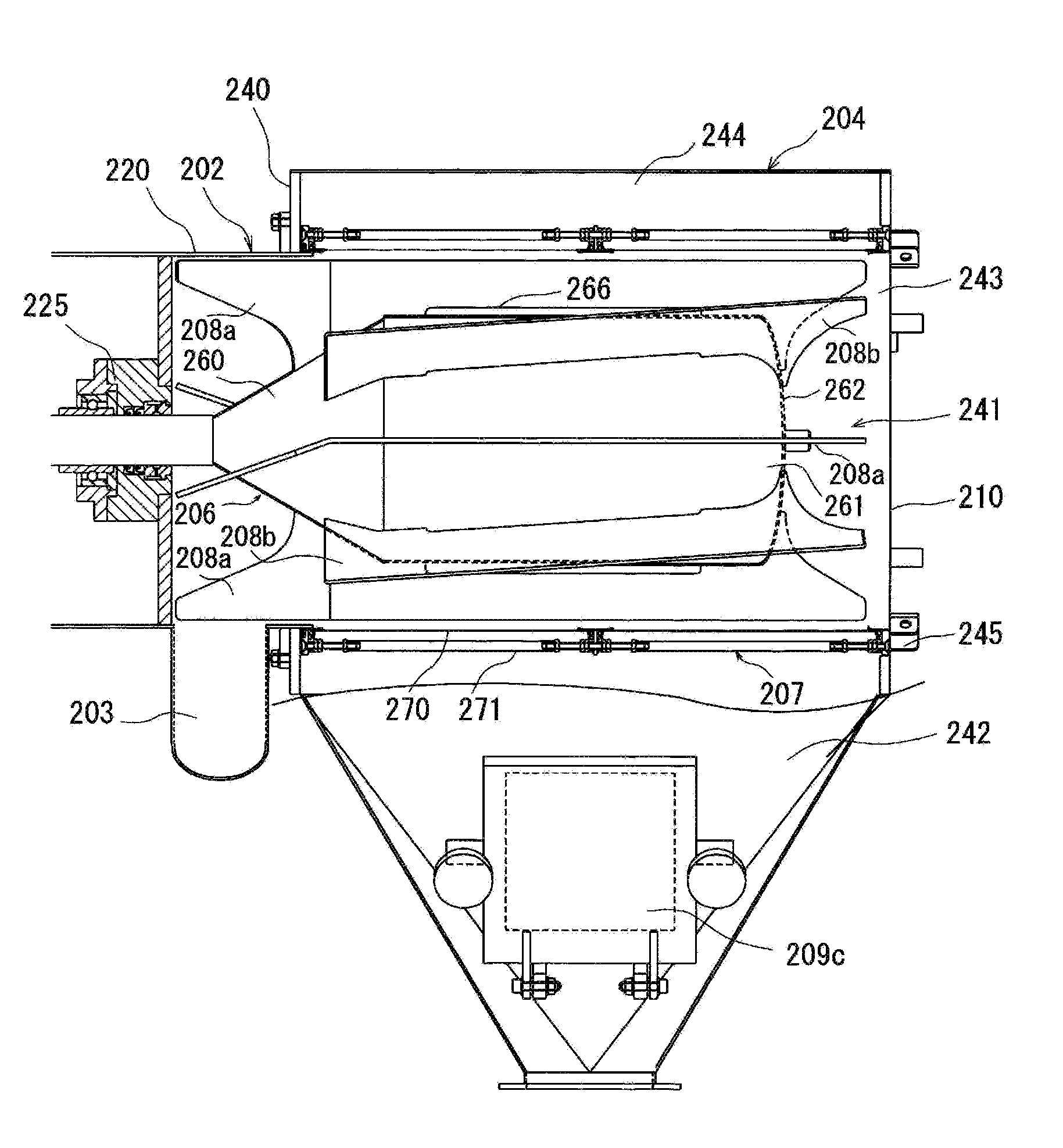

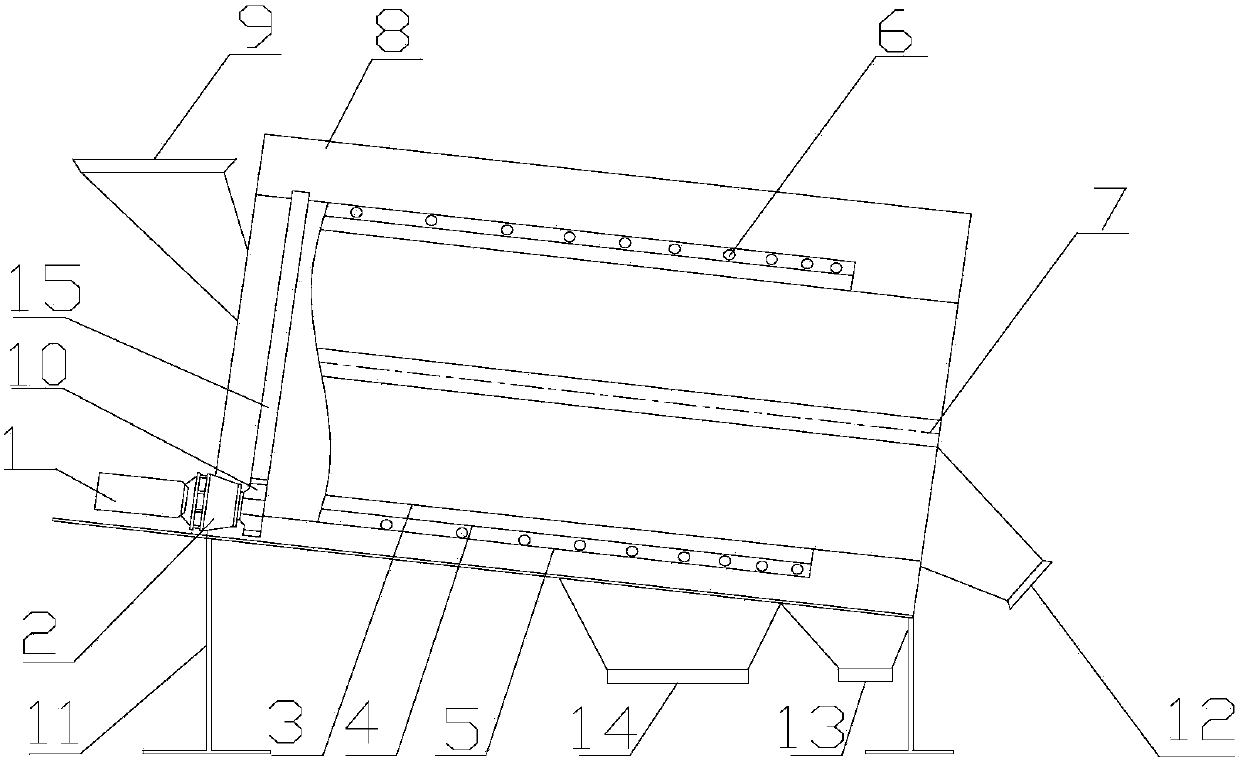

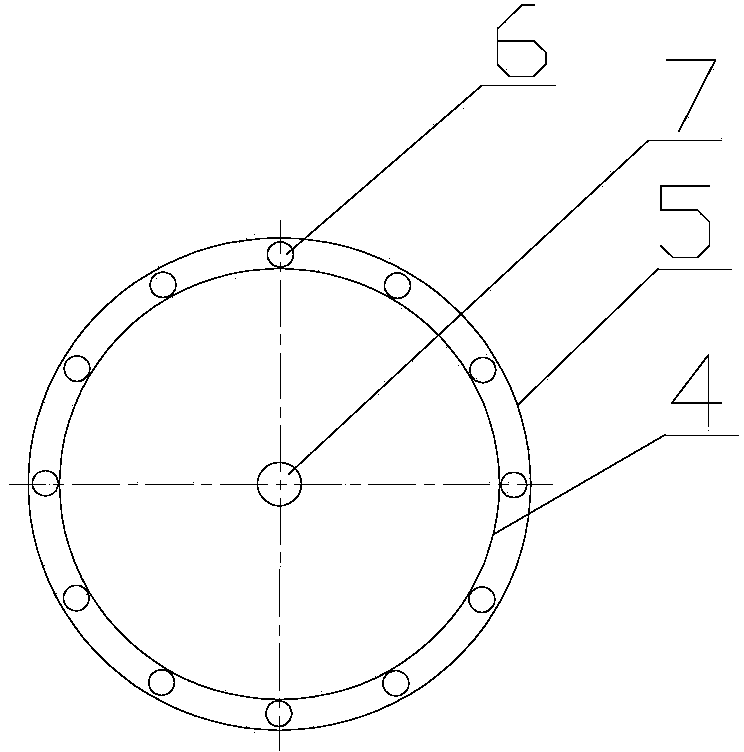

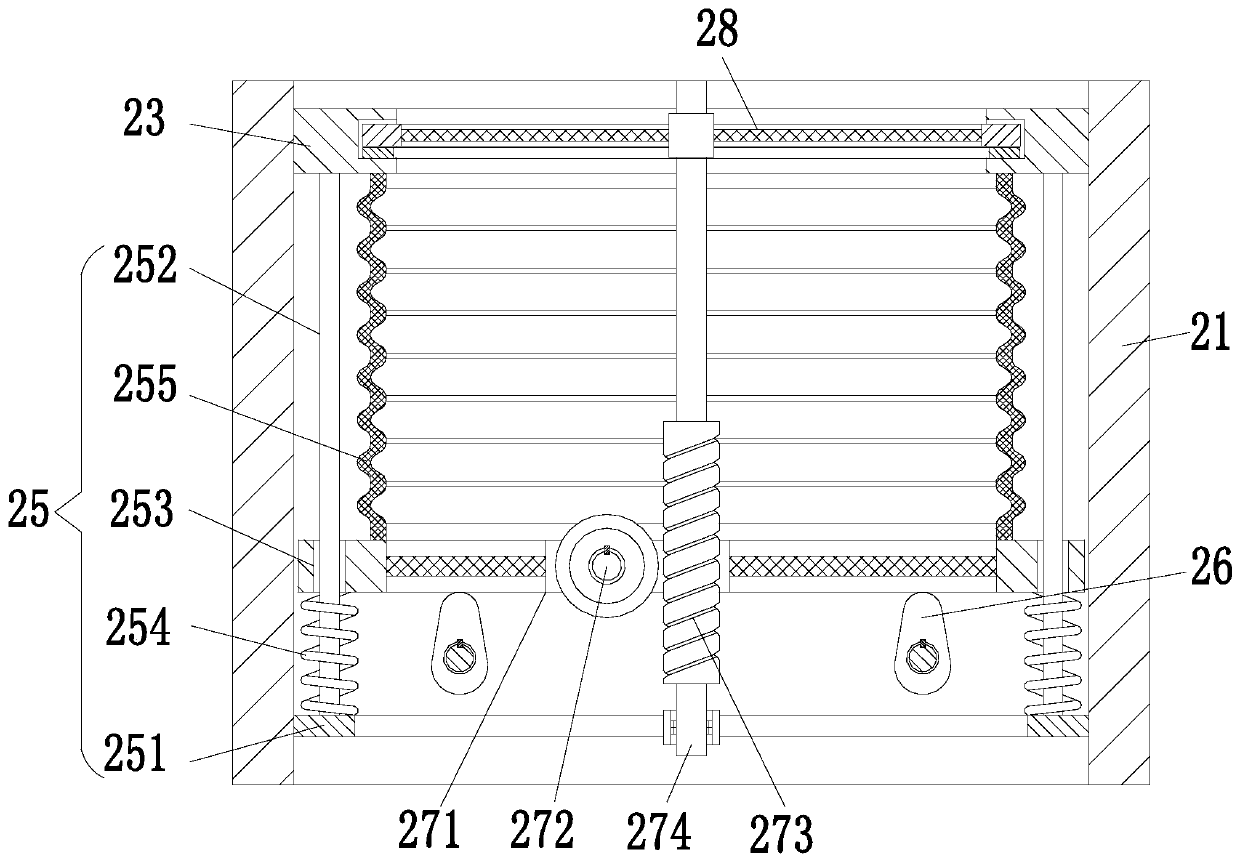

Overlapping high-frequency fine screen

The invention relates to an overlapping high-frequency fine screen, which is provided with a framework, a plurality of inclined screening units are arranged from the top down on the framework, a distributor is arranged at one end of the upper part of each screening unit, each distributor is connected to a divider, a vibration exciter is mounted on the framework over the uppermost screening unit, shock-absorbing springs are mounted on the bottom of the lowermost screening unit, screen frames of all the screening units are arranged in parallel from the top down, and moreover, the inclination angle of each screen frame inclined downward from the horizon is 20 to 35 degrees; an oversize discharge plate is provided with at least one longitudinal V-shaped separation baffle; undersize-receiving buckets are mounted just under corresponding screen surfaces, and the section of each undersize-receiving bucket is shaped like a circular arc or a trapezium. The overlapping high-frequency fine screen has a simple and compact structure, and does not occupy an extra space, the manufacturing cost is greatly reduced, the overall dimensions are small, the occupied area and the occupied space are small, moreover, the installation cost is little, the length of each layer of screen frame is not limited, and large scale can be easily achieved.

Owner:周万龙

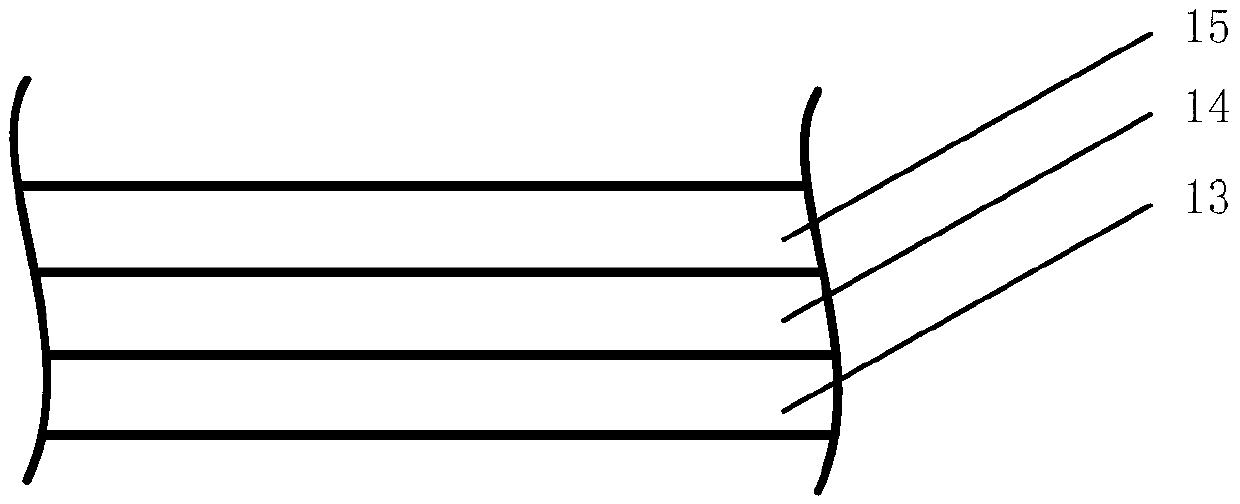

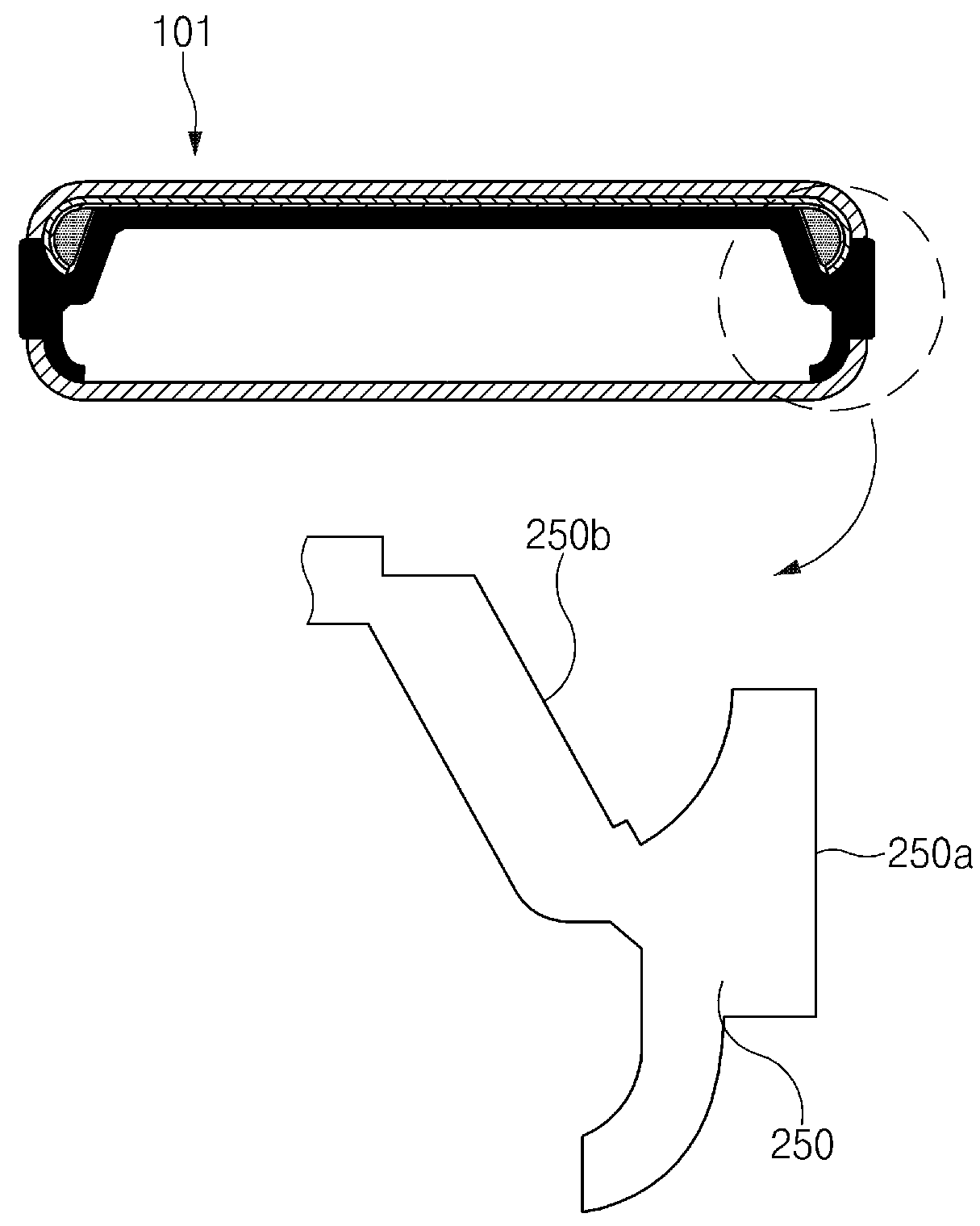

Vibration-proof liquid management inner core

InactiveCN103121515AIncrease the screening areaSimplify the core structureCosmonautic propulsion system apparatusEngineeringCoarse particle

The invention discloses a vibration-proof liquid management inner core. The vibration-proof liquid management inner core comprises a clapboard 1, an angle coarse particle collector 2, a coarse particle collector, a corner collector 3, and a bottom collector, wherein the coarse collector is connected between the clapboard 1 and the bottom collector, the angle coarse particle collector 2, the corner collector 3 are connected with the clapboard 1, the coarse particle collector comprises a force bearing barrel, a first thick mesh 7, a third supporting and pressing board 13, a second thick mesh 14, and a fourth supporting and pressing board 15, wherein the force bearing barrel comprises an adapter ring 5, an outer barrel 6, and an inner barrel 8, the bottom collector comprises a third collecting shell 9, a first supporting and pressing board 10, a thin mesh 11, and a second supporting and pressing board 12, wherein the bottom collecting shell is provided with a liquid outlet, and a thick collecting mesh structure is assembled by the third supporting and pressing board 13, the second thick mesh 14, and the fourth supporting and pressing board 15 from top to bottom. The vibration-proof liquid management inner core has the advantages of being simple in structure, and capable of effectively improving mechanical environmental adaptation of a storage tank, enhancing reliability of a system, and meanwhile meeting a mass flow requirement of the system.

Owner:SHANGHAI INST OF SPACE PROPULSION

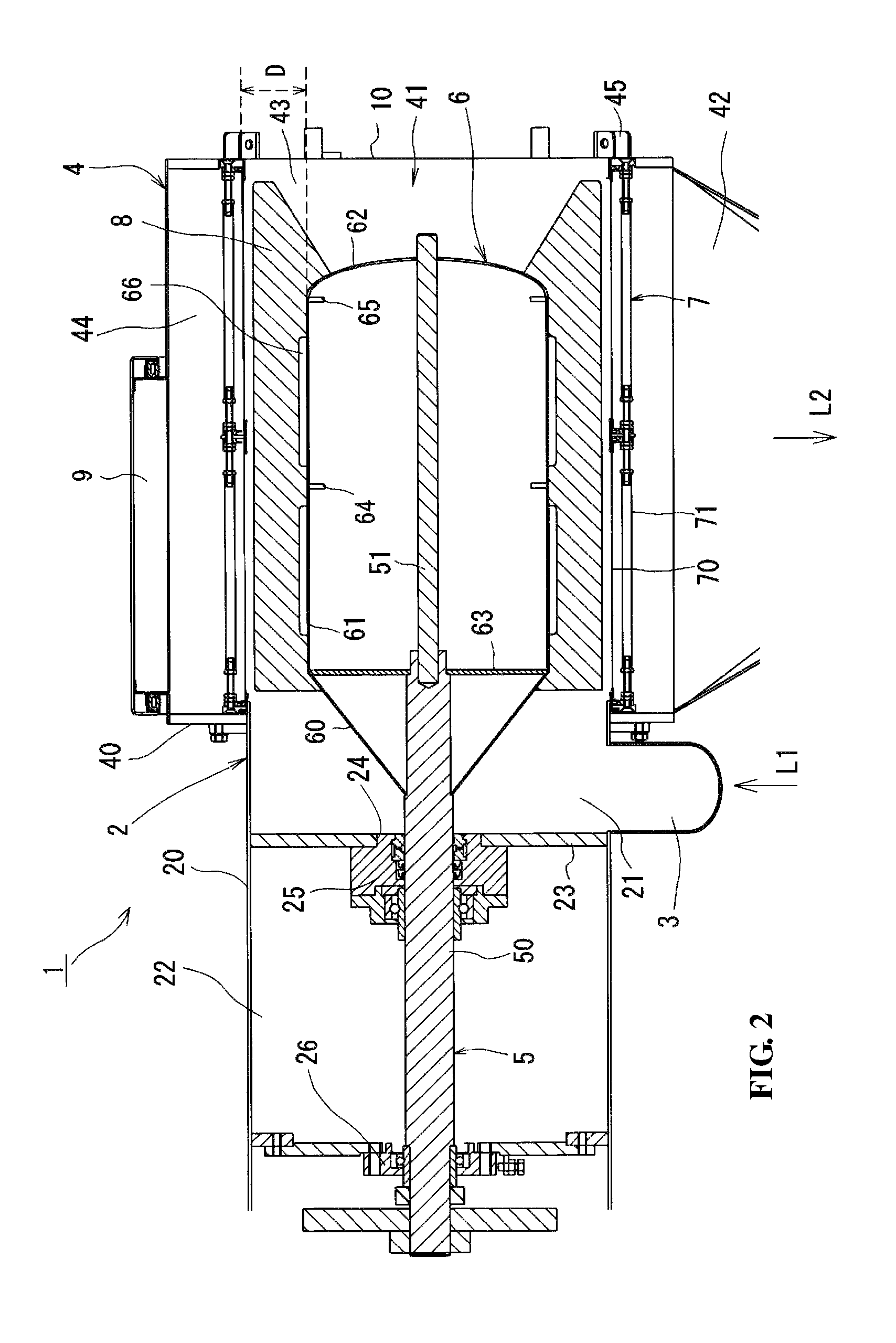

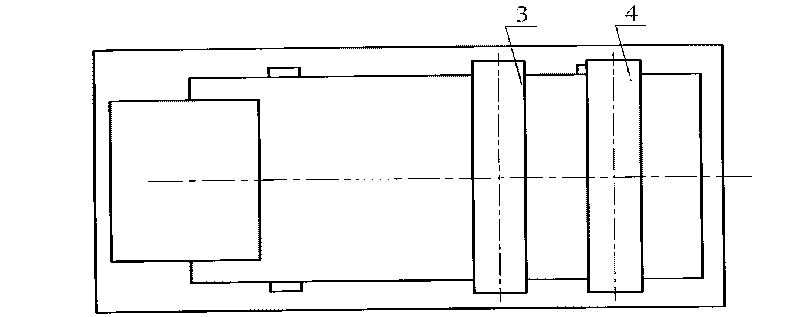

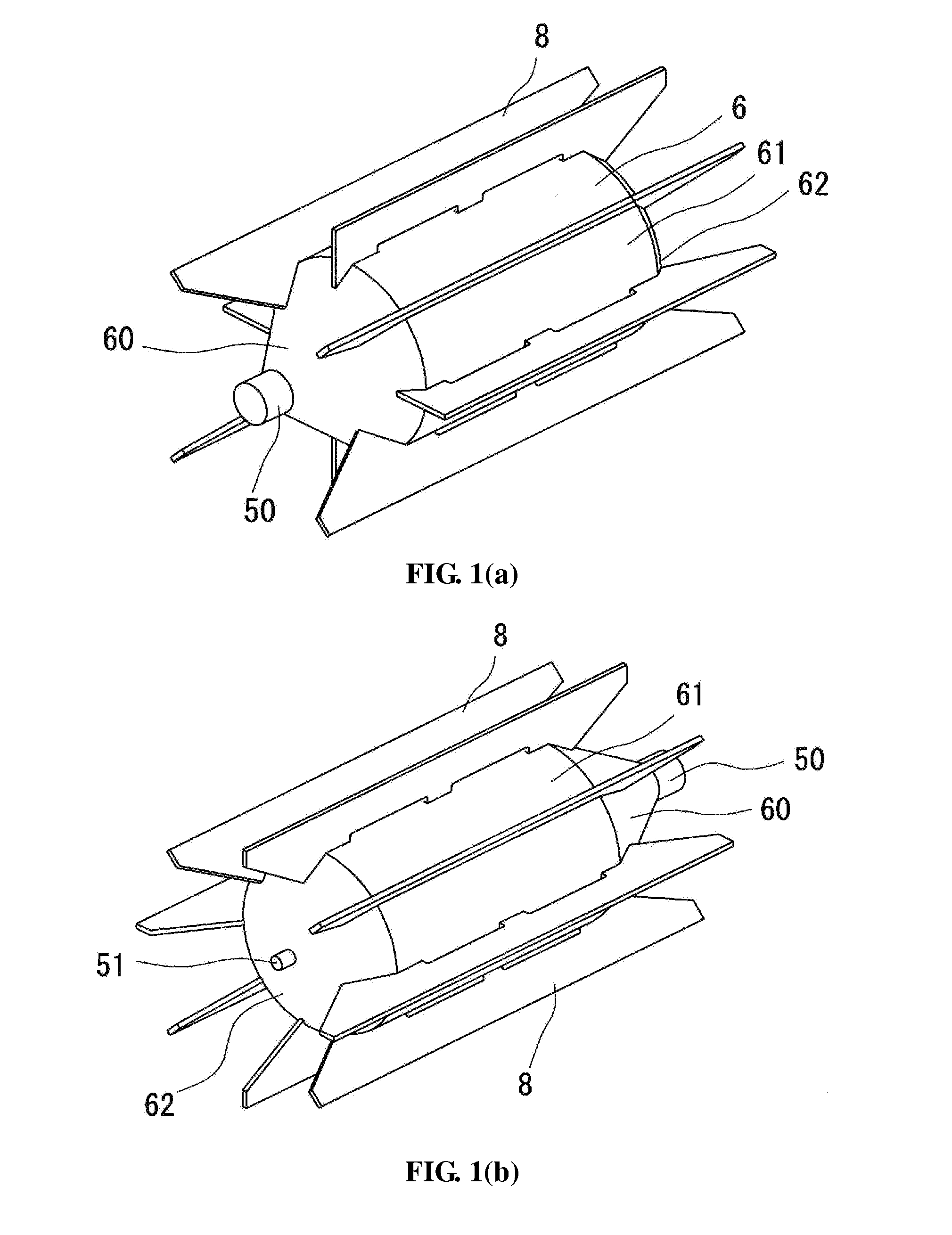

Sifter

ActiveUS7896163B2Reduce the amount requiredIncrease the screening areaSievingGas current separationEngineeringMechanical engineering

A sifter comprising: a receiver having a supply chamber; a sieve assembly having a sieving chamber coupled to the supply chamber; a rotator having a rotating shaft laterally arranged to pass through the supply chamber and the sieving chamber; a drum having a circular cross-section and having a larger diameter than the diameter of the rotating shaft, the drum being extended in at least space of the sieving chamber and arranged coaxially with the sieve; a cylindrical sieve located inside the sieving chamber and arranged coaxially with the rotating shaft; a stirring rotor located in an inner area of the sieving chamber inside the sieve comprising a rotating blade attached to the rotating shaft; an extraction member; and an outlet for discharging powder passing through the sieve from the inner area to the outer area.

Owner:TSUKASA

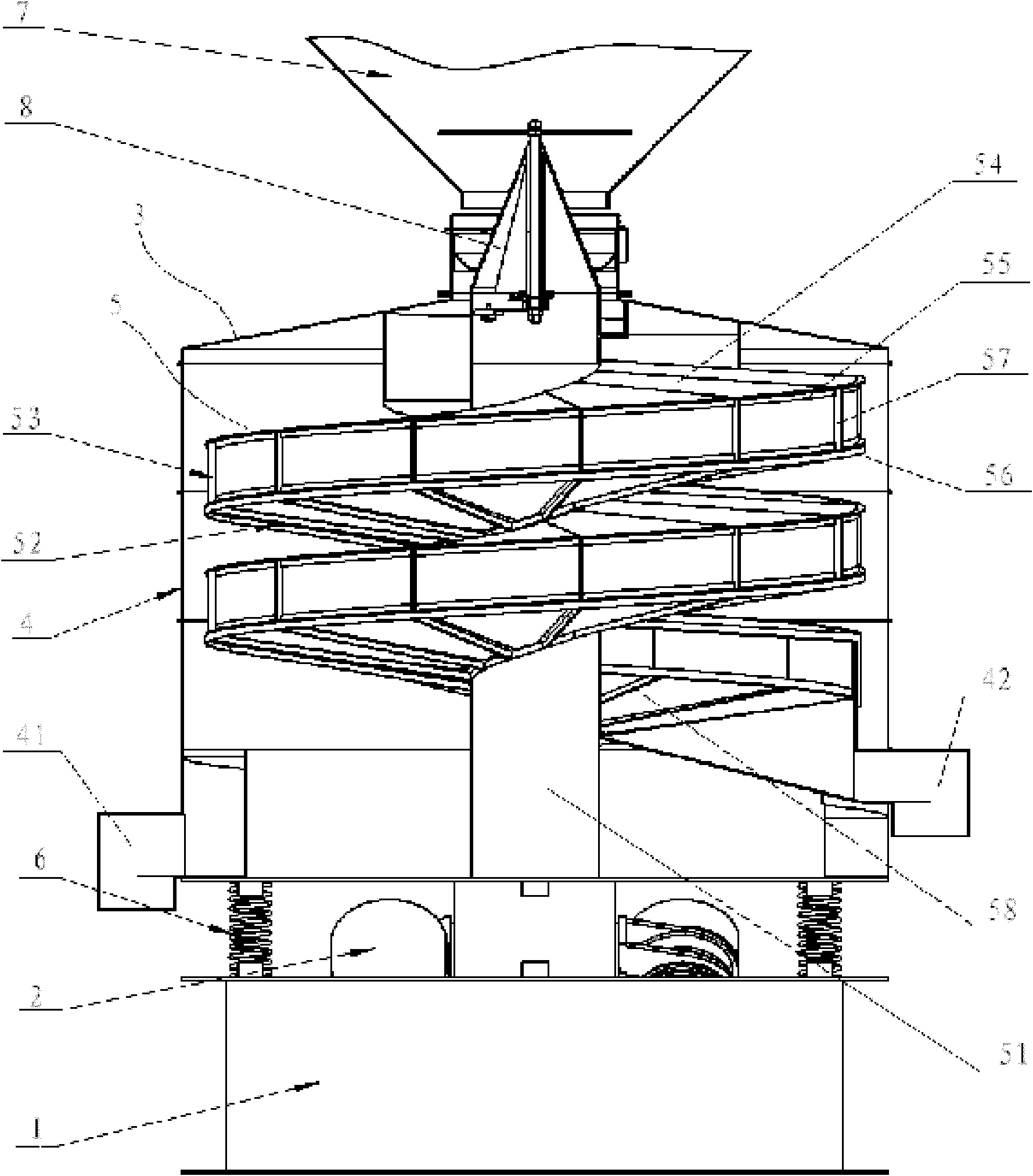

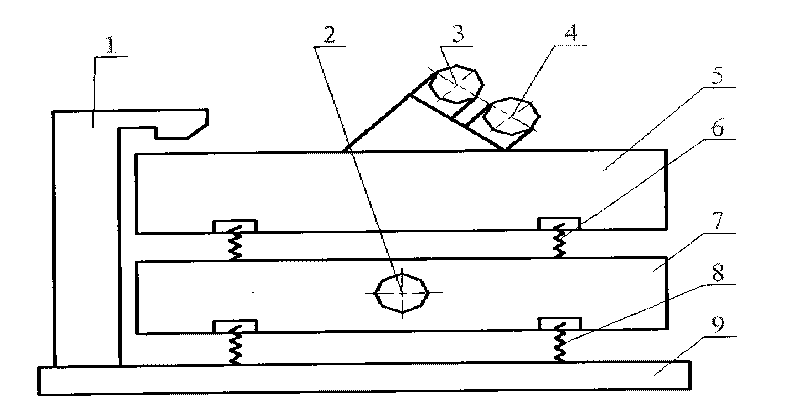

Double-mass self-synchronization elliptical vibrating screen based on motion synthesis

InactiveCN101693237AIncrease the screening areaSmall footprintSievingScreeningCounter rotationLow Mass

The invention relates to a double-mass self-synchronization elliptical vibrating screen based on motion synthesis, mainly comprising a feeding hopper, exciting motors, an upper mass, an upper mass-supporting spring, a lower mass, a lower mass-supporting spring and a base, wherein the two exciting motors with the same mass moment are mounted at the top of the upper mass in such a way that the axes of the two exciting motors are parallel and do uniform-speed reverse rotation to generate linear vibrating motion; an exciting motor which is bridged and mounted on the lower mass also does uniform-speed rotation to generate uniform-frequency circular vibrating motion; the linear vibrating motion and the circular vibrating motion are transferred by the upper mass-supporting spring and synthesized on the upper mass and the lower mass to form the elliptical motion of the upper mass and the lower mass; and the two exciting motors on the upper mass can be bridged and mounted at the top of the upper mass or on two lateral plates of the upper mass in such a way that the axes of the two exciting motors are parallel. The invention has the advantages of great screening area, great processing capability and high screening efficiency and can satisfy the production requirements of petroleum, chemical, coal, metallurgy, and the like.

Owner:SOUTHWEST PETROLEUM UNIV

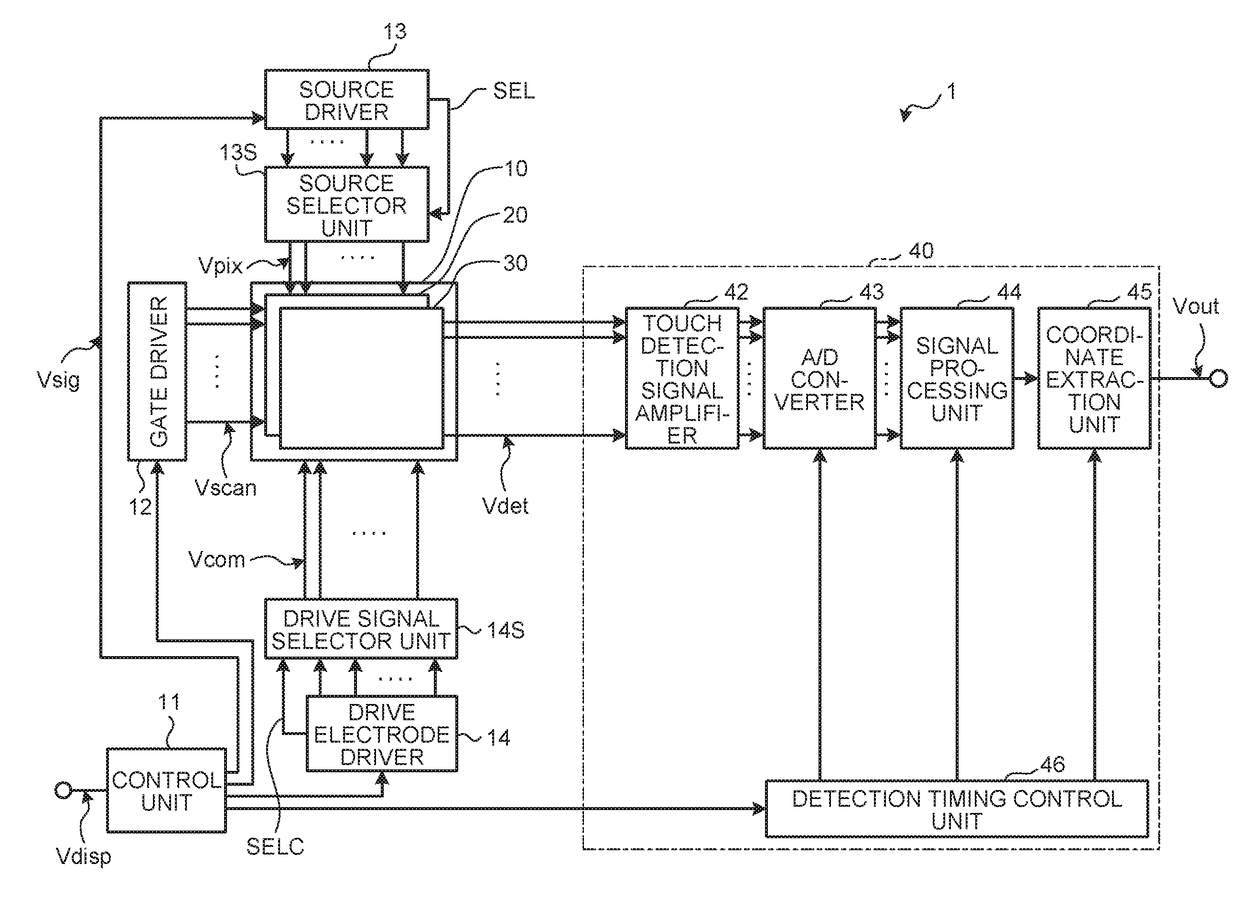

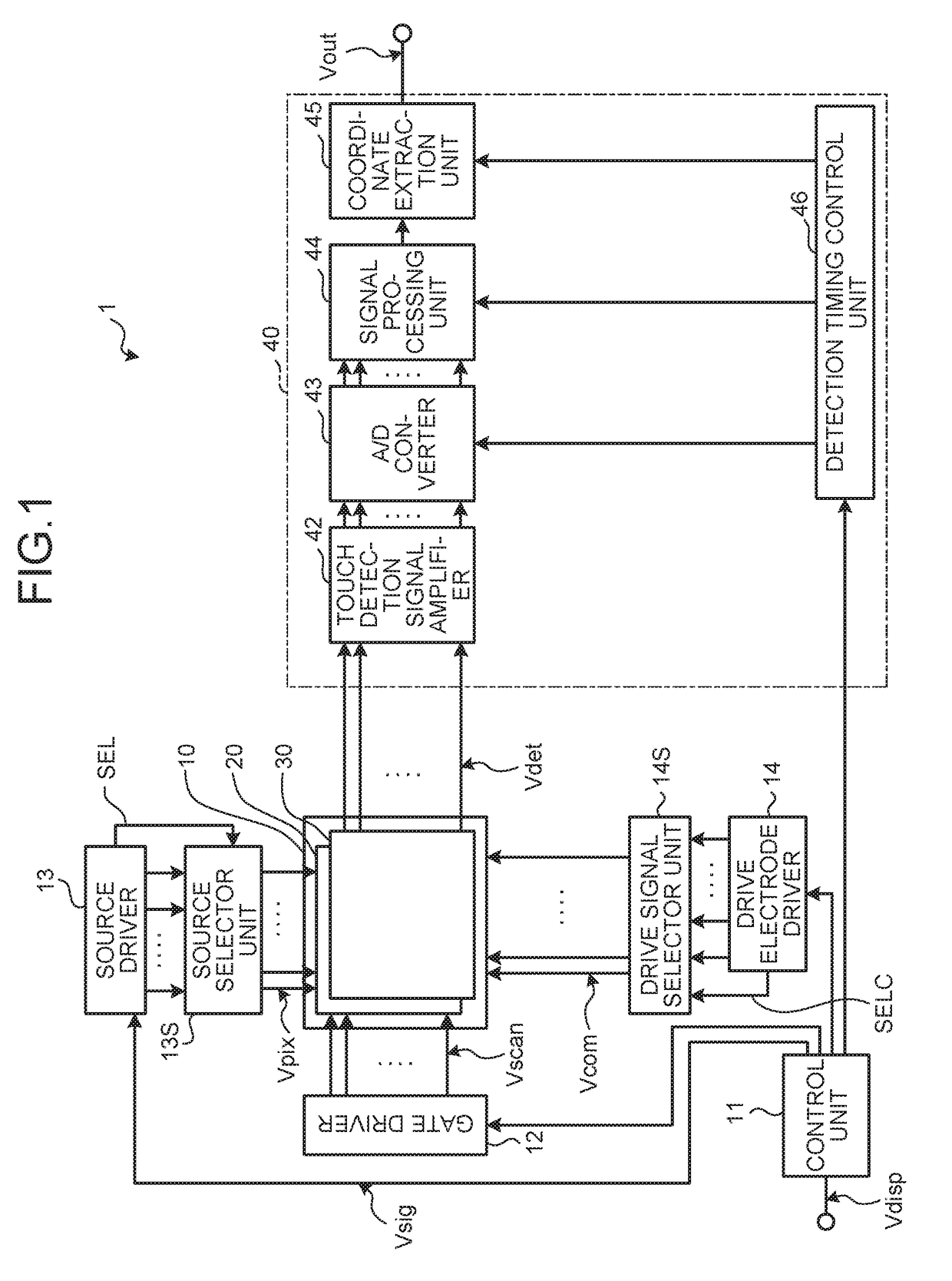

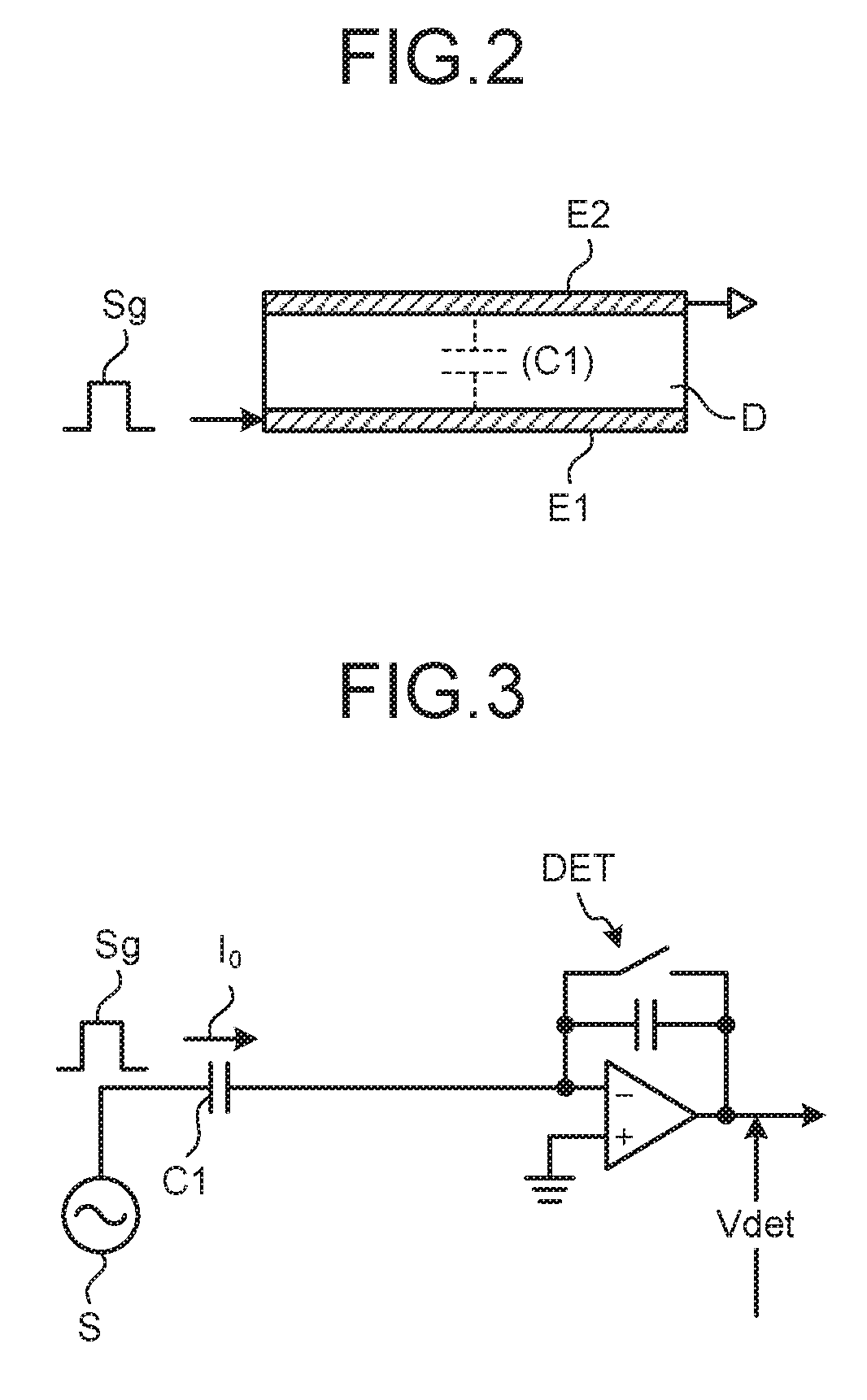

Display device with touch detection function and electronic apparatus

ActiveUS20170315639A1Suppress parasitic capacitanceSmall sizeInput/output processes for data processingDisplay deviceEngineering

According to an aspect, a display device with a touch detection function includes a plurality of drive electrodes that face a plurality of pixel electrodes in an orthogonal direction to the surface of the substrate, and extend in a direction parallel to the direction in which a plurality of signal lines extend. The display device with a touch detection function also includes a scan driving unit that applies a touch drive signal to a signal line that faces, in an overlapping manner in the orthogonal direction, a drive electrode to which the touch drive signal is applied.

Owner:JAPAN DISPLAY INC

Sifter

ActiveUS20080308469A1Lower potentialReduce pressure lossSievingGas current separationRotational axisEngineering

A sifter comprising: a receiver having a supply chamber; a sieve assembly having a sieving chamber coupled to the supply chamber; a rotator having a rotating shaft laterally arranged to pass through the supply chamber and the sieving chamber; a drum having a circular cross-section and having a larger diameter than the diameter of the rotating shaft, the drum being extended in at least space of the sieving chamber and arranged coaxially with the sieve; a cylindrical sieve located inside the sieving chamber and arranged coaxially with the rotating shaft; a stirring rotor located in an inner area of the sieving chamber inside the sieve comprising a rotating blade attached to the rotating shaft; an extraction member; and an outlet for discharging powder passing through the sieve from the inner area to the outer area.

Owner:TSUKASA

Filtering sieve shaft of sieving machine

ActiveCN102989657ATo achieve the function of forced deliveryRealization without material blockingSievingScreeningEngineeringMaterial distribution

The invention discloses a filtering sieve shaft of a sieving machine. The filtering sieve shaft comprises a sieving face composed of a movable flange plate type sieve shaft (4), a movable sieving strip type sieve shaft (5) and a spring type sieve shaft (24). The filtering sieve shaft has the advantages of guaranteeing sieving granular size and solving the problem that materials are not blocked in the hollow filtering sieve shaft. The filtering sieve shaft has the advantages of being good in anti-impact capacity, efficient in sieving, capable of guaranteeing granular size, free of material blocking, capable of removing iron, even in material distribution, capable of meeting requirements of more than two discharging granular sizes, convenient to overhaul, favorable for replacing parts and the like and is major breakthrough in the field of the sieving machine.

Owner:SICHUAN ZHONGMENG ELECTRIC POWER EQUIP MFG CO LTD

Elastic-ball self-cleaning rotary screen machine

An elastic-ball self-cleaning rotary screen machine comprises a motor, a reducer, a rotary screen device, a frame, a seal cover and feed and discharge holes. The motor is connected to the rotary screen through a coupling via the reducer, and drives the rotary screen device to rotate around a screen spindle. The rotary screen device comprises an inner rotary screen, an elastic-ball self-cleaning device and a transmission gear. The elastic-ball self-cleaning device comprises an outer rotary screen and elastic balls, the outer rotary screen comprises two layers of screens, and the elastic balls are tied to the outer rotary screen and are evenly distributed between the two layers of screens. The rotary screen device is mounted on the frame in an inclined manner. According to the elastic-ball self-cleaning rotary screen machine, the rotary screen can be vibrated through the elastic balls, the rotary screen can be automatically cleaned online in real time, smoothness of the screen is guaranteed, intensity of labor is reduced, and screening effect and operating efficiency are improved.

Owner:GUANGXI UNIV

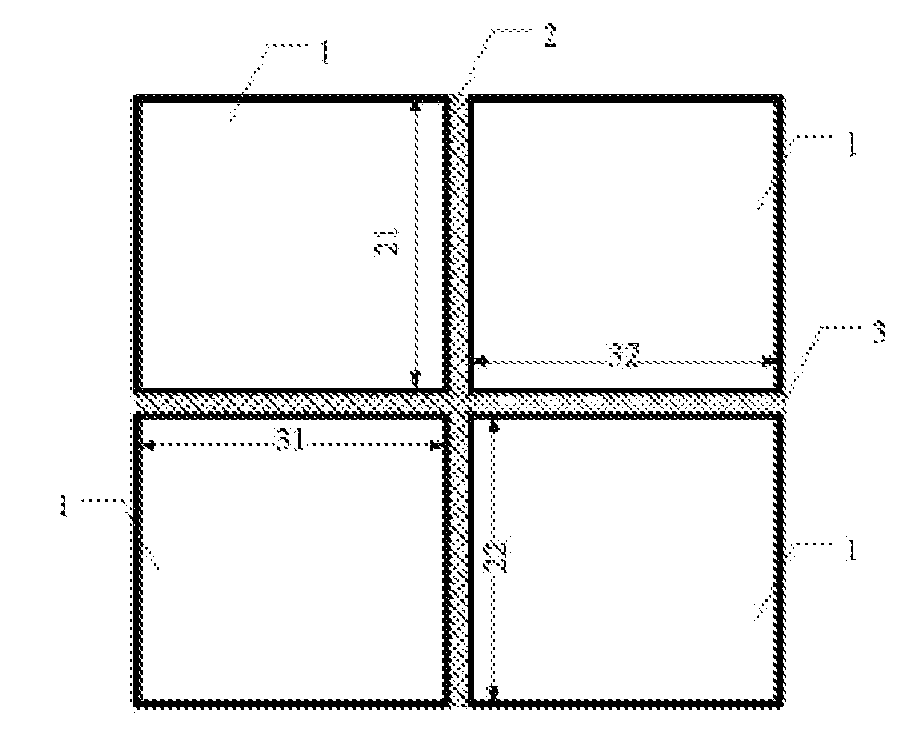

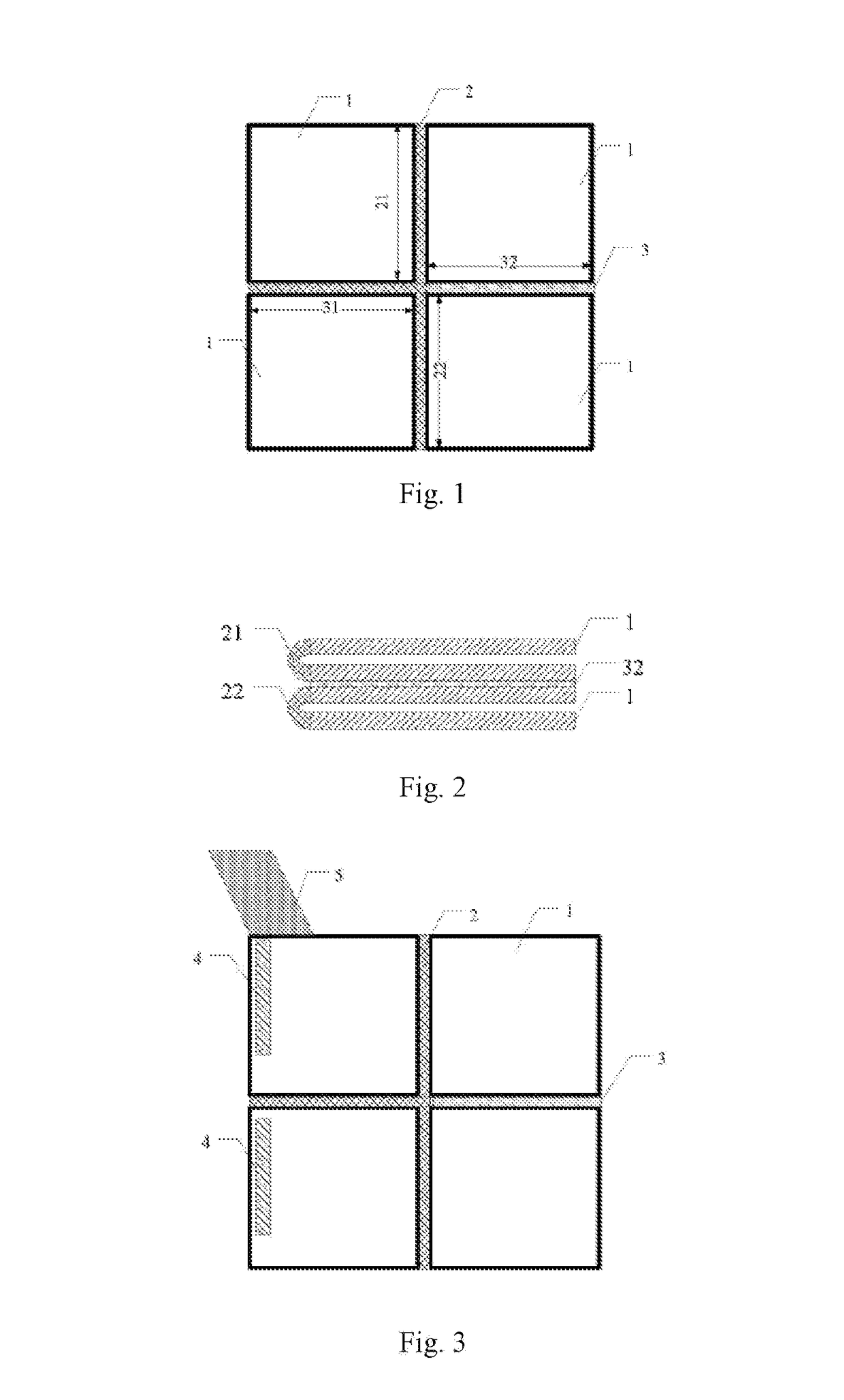

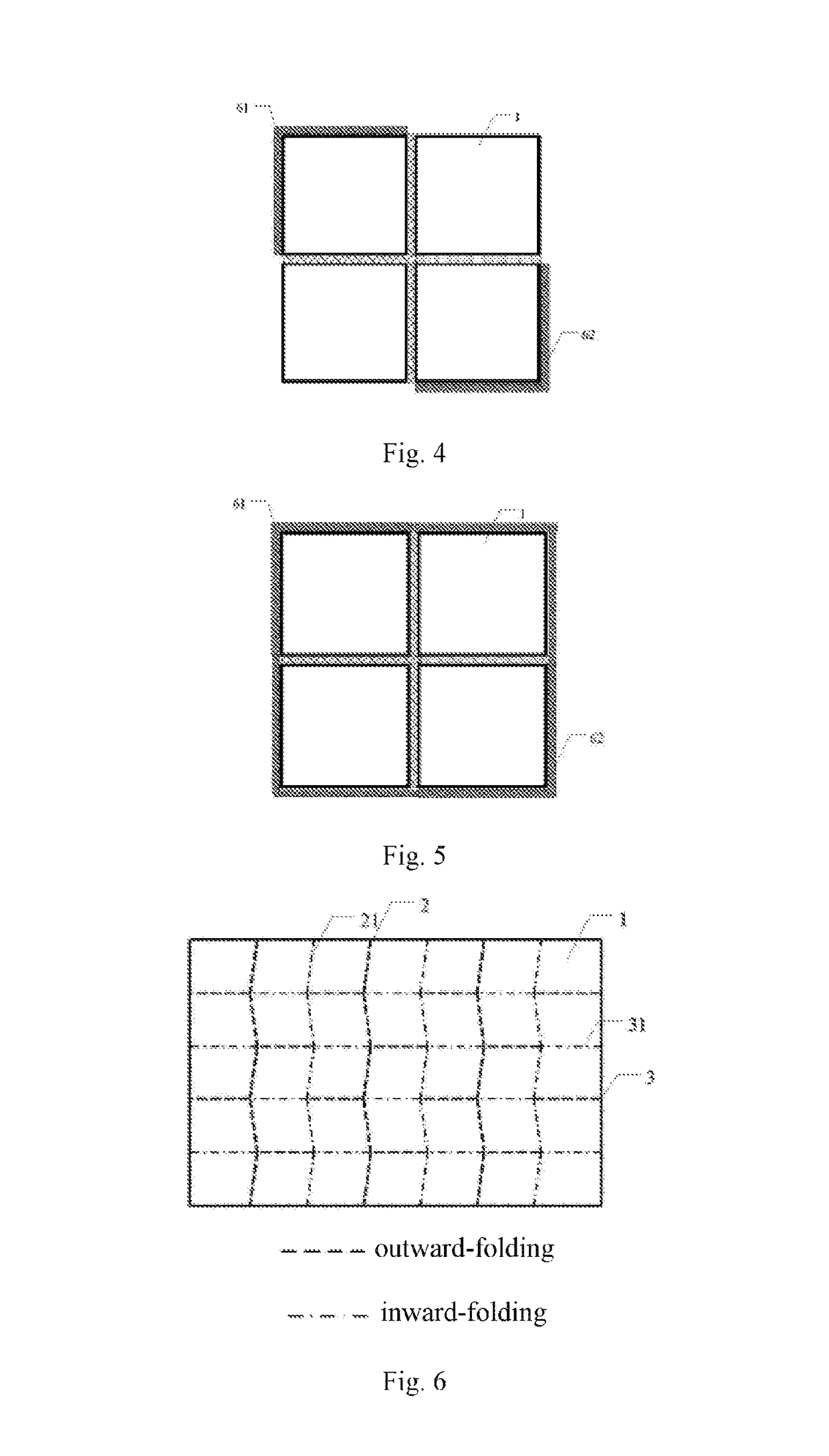

Flexible panel, display apparatus and wearable device

A flexible panel, a display apparatus and a wearable device are disclosed.The flexible panel comprises a first crease extending in a first direction, a second crease extending in a second direction and intersecting with the first crease, and a plurality of display units divided by the first crease and the second crease, the plurality of display units are folded and / or unfolded by the first crease and the second crease. When the flexible panel is in use, the plurality of display units may be completely unfolded by means of the creases, so that a usable area of the screen may be increased, the user experience can be improved; when the user does not use the flexible panel, the display units may be overlapped by means of the crease, which may change the shape of the panel, and thus the flexible panel is convenient to carry.

Owner:BOE TECH GRP CO LTD

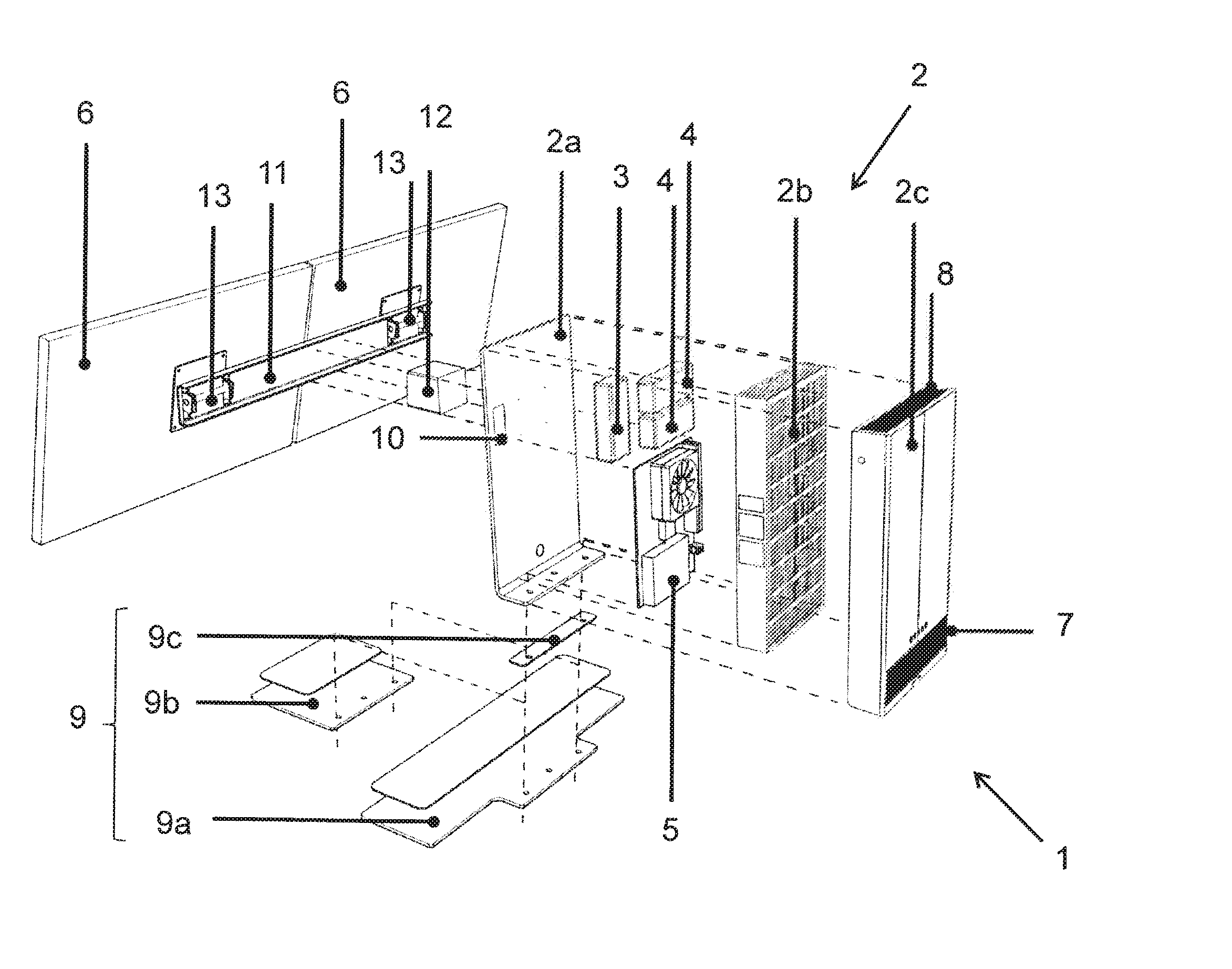

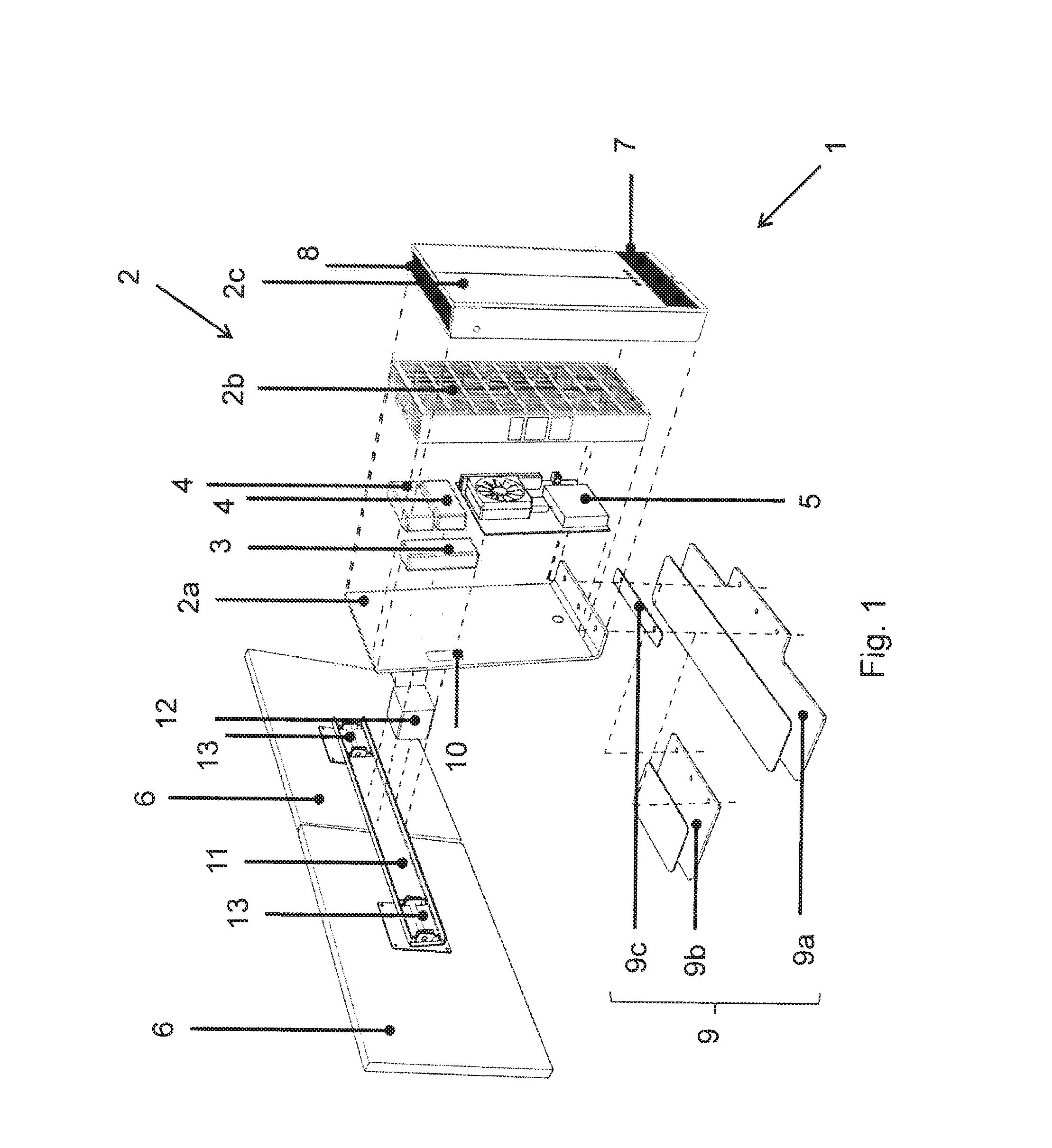

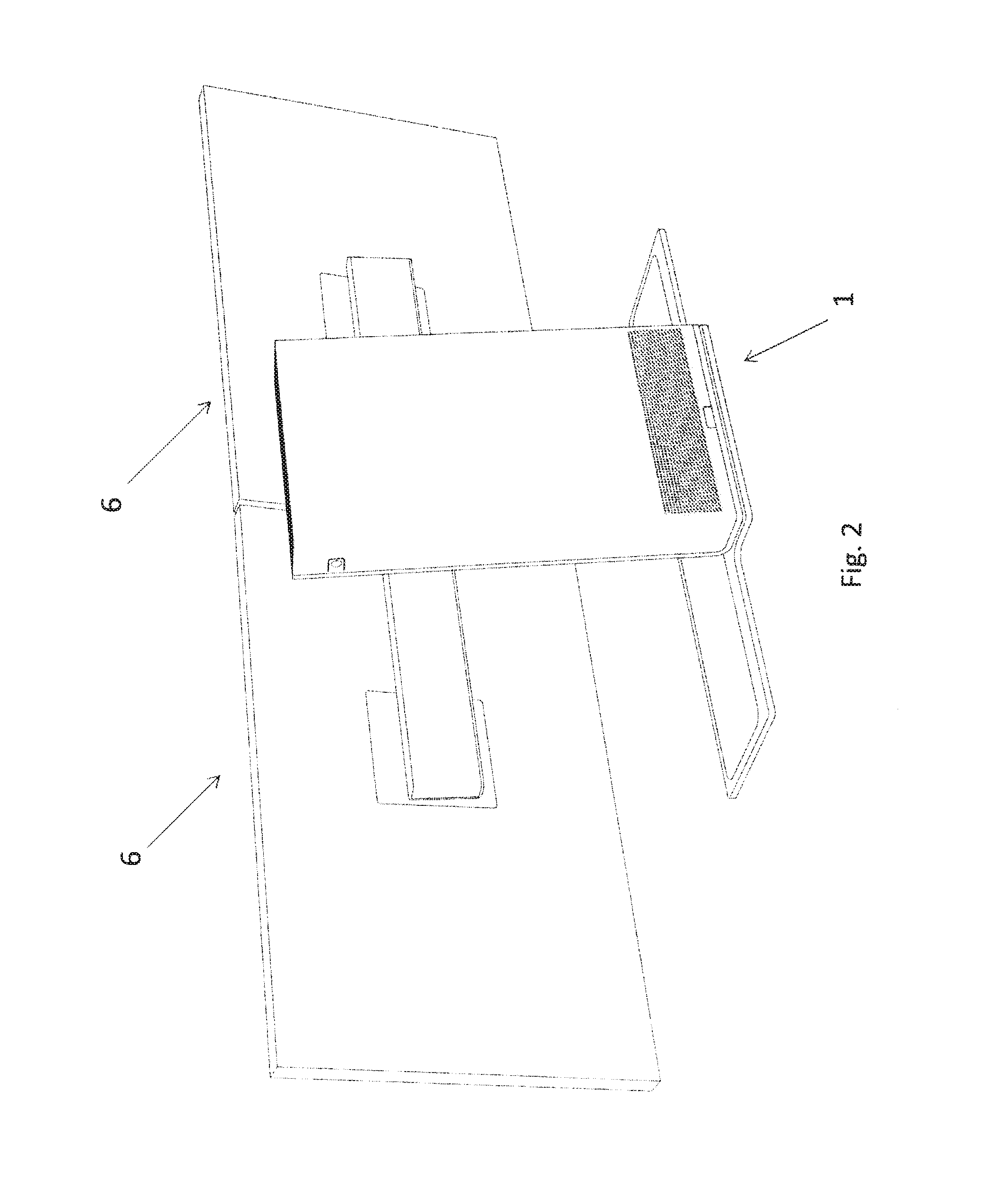

Screen rack for two screens with a case for electric components

InactiveUS20170018952A1Increased functional reliabilityIncrease the screening areaBatteries circuit arrangementsFurniture partsEngineeringElectrical element

Owner:MODINICE GMBH

Electronic device with screen

ActiveUS20180275719A1Increase the screening areaReduce border areaDigital data processing detailsTelephone set constructionsElectrical and Electronics engineeringElectronic equipment

Owner:SAMSUNG ELECTRONICS CO LTD

Screen panel center retainer system

A screen panel center retainer system for a vibrating separatory machine utilizes a center retainer that is provided with a retainer base which is adapted to be secured to screen stringer rails of a vibrating separatory machine. A pair of retainer channel legs form an upper portion of the center retainer and have screen panel edge receiving slots. A locking strip, having a wedging tongue, is used in conjunction with the center retainer. The wedging tongue is insertable into the channel on the center retainer which is defined by the two retainer channel legs. Flow control dams and cross dam retainers are used in conjunction with, and in addition to the center retainers and locking strips. The cross dam retainers are provided with locking strip end receiving pockets, to compensate for changes in the length of the locking strips. The screen panel center retainer system is configured to provide a functional, universal installation of screen panels on vibrating separating machines.

Owner:CONN WELD IND

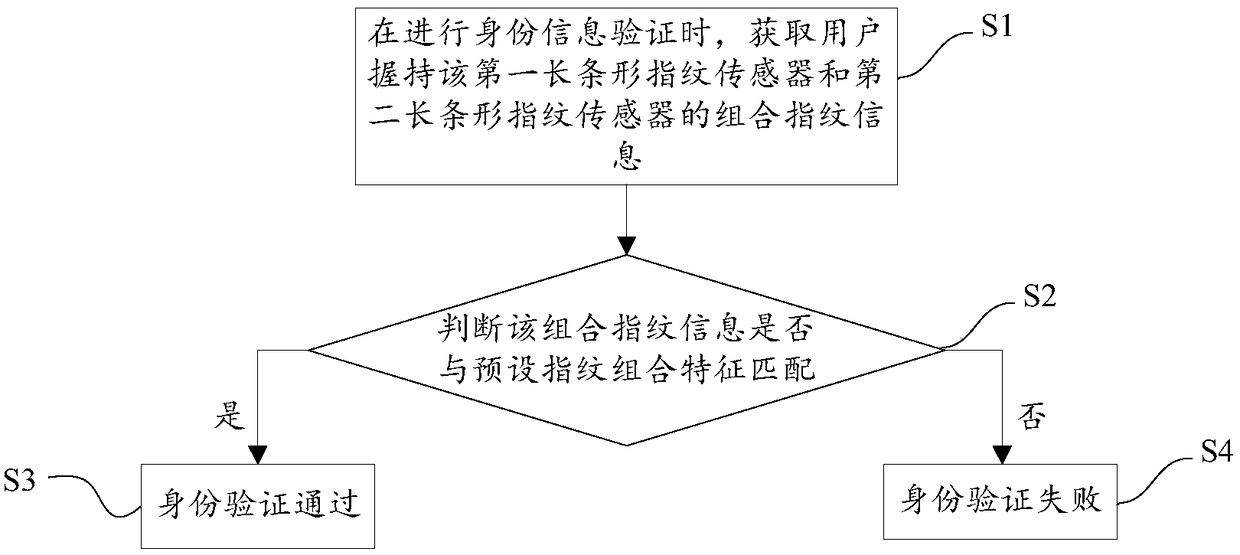

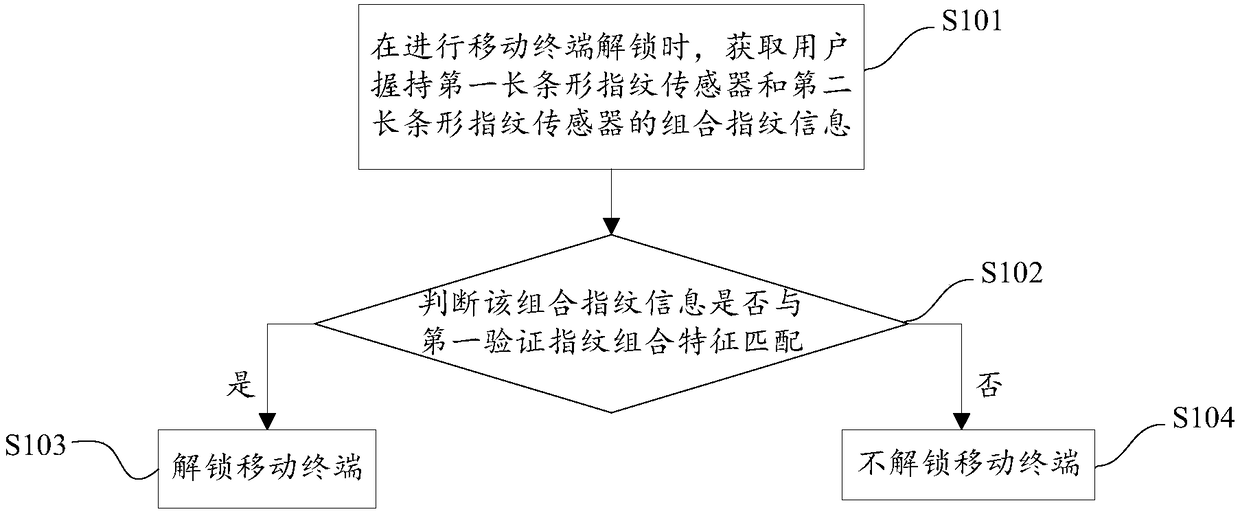

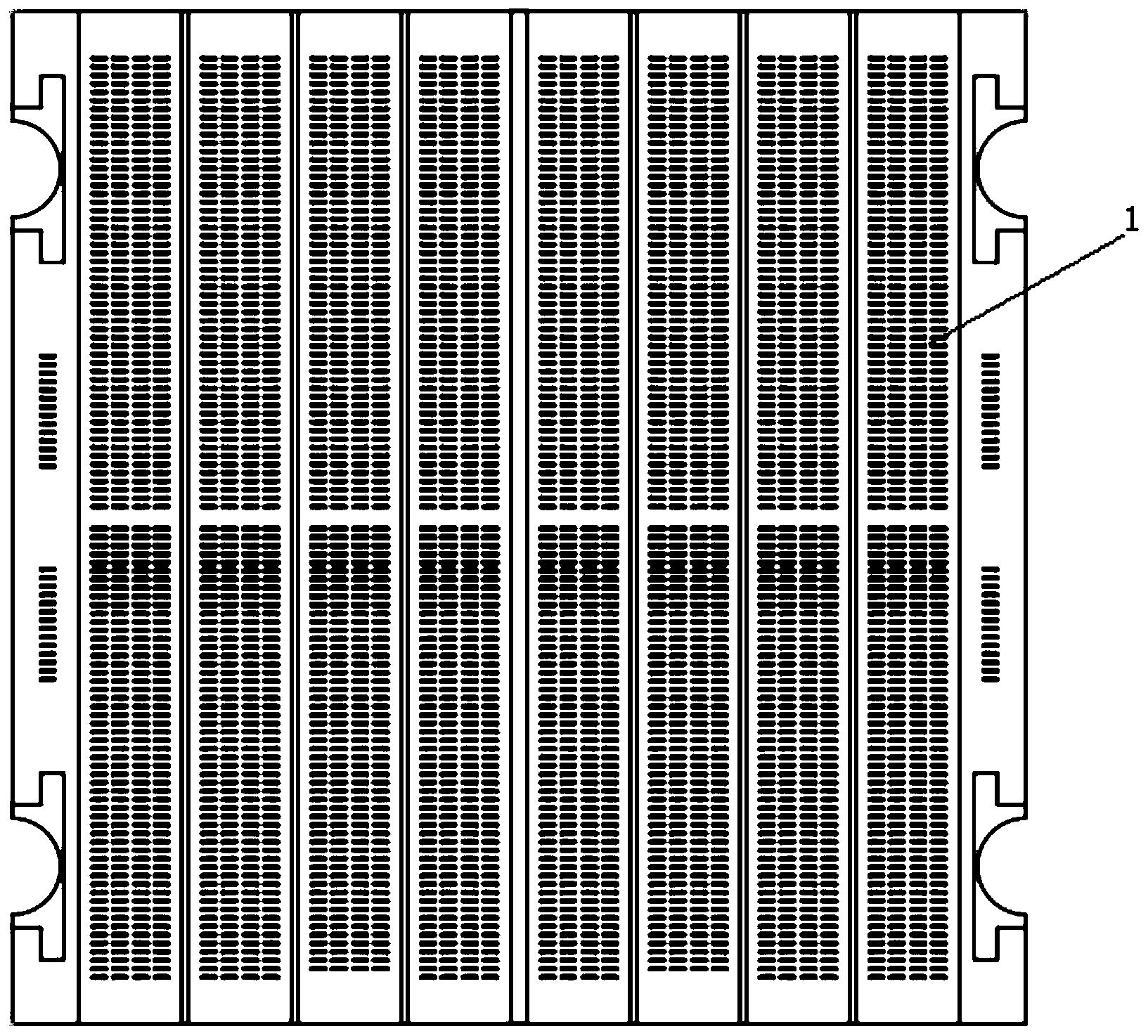

Mobile terminal control method, mobile terminal and storage medium

InactiveCN108171031AIncrease screen areaIncrease the screen ratioDigital data authenticationSound input/outputFingerprintAuthentication

The invention discloses a mobile terminal control method, a mobile terminal and a storage medium. The mobile terminal comprises a first long strip-shaped fingerprint sensor and a second long strip-shaped fingerprint sensor, wherein the first long strip-shaped fingerprint sensor is arranged at a first side of a mobile terminal body and the second long strip-shaped fingerprint sensor is arranged ata second side of the mobile terminal body. The control method comprises the following steps of: when identity information verification is carried out, obtaining combined fingerprint information of a user holding the first long strip-shaped fingerprint sensor and the second long strip-shaped fingerprint sensor; judging whether the combined fingerprint information is matched with a preset fingerprint combined feature or not; if the combined fingerprint information is matched with the preset fingerprint combined feature, considering that the identity verification succeeds; and if the combined fingerprint information is not matched with the preset fingerprint combined feature, considering that the identity verification fails.

Owner:BEIJING ZHUMU LANGMA MOBILE COMM CO LTD

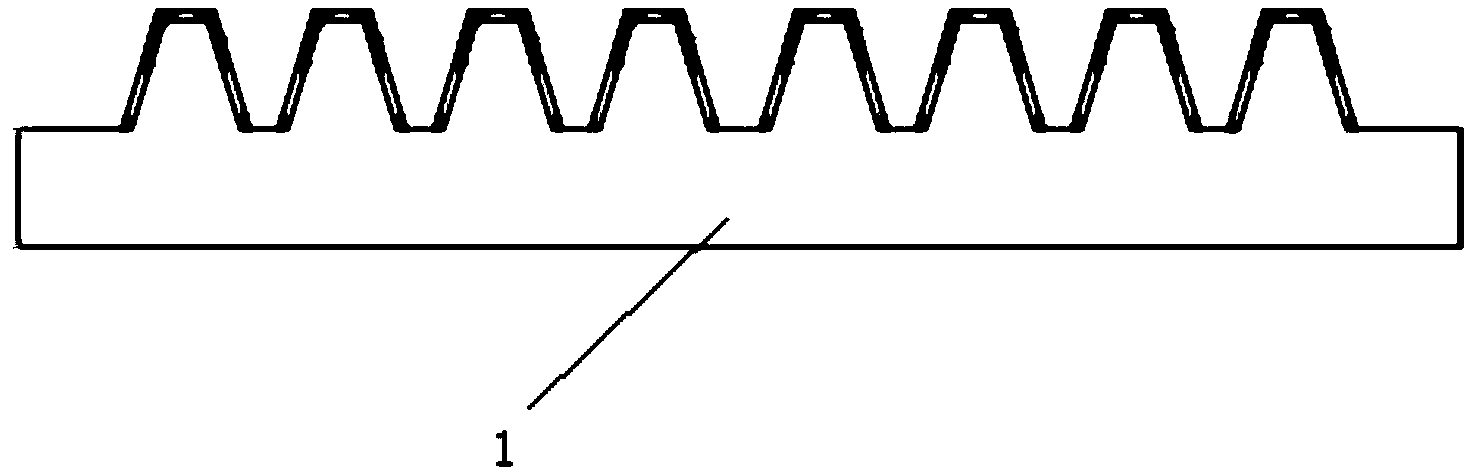

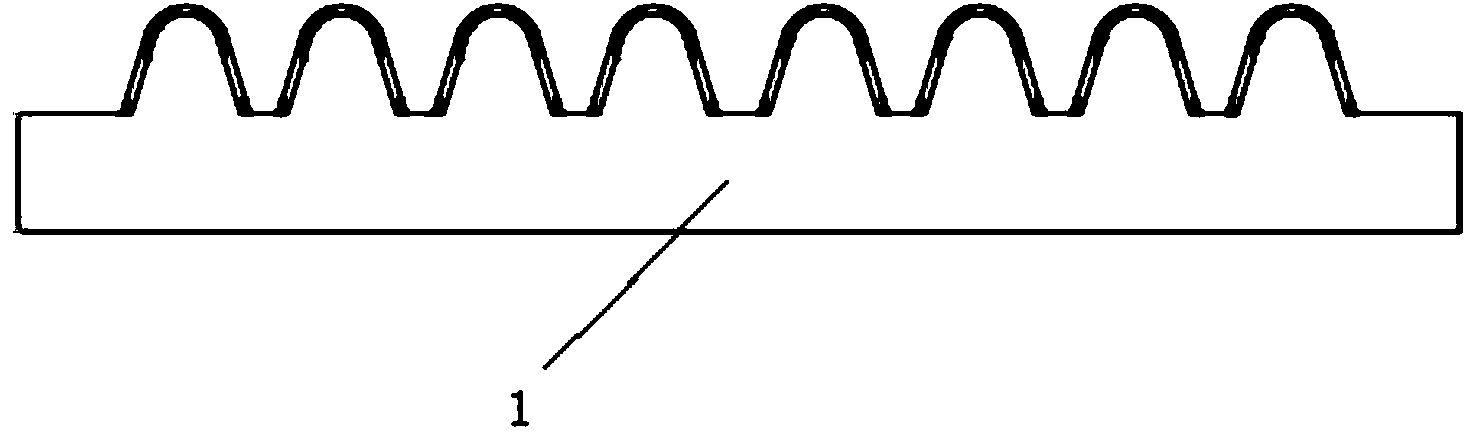

Forming method of non-planar polyurethane screen meshes

InactiveCN103770268AHigh porosityIncrease the screening areaDomestic articlesCoatingsChemistryRaw material

The invention discloses a forming method of non-planar polyurethane screen meshes. The forming method of non-planar polyurethane screen meshes comprises the operation steps of a, selecting high-tenacity polyurethane material, heating the high-tenacity polyurethane material to 140 DEG C, removing humidity, drying raw material and feeding the raw material into a material fixer, adding nanometer materials, gas-phase silicon dioxide and ultrafine ink powder to commonly mix and form a synthetic material. According to the forming method of the non-planar polyurethane screen meshes, the aperture ratio is increased by 50% on the original basis; an isosceles triangle is arranged; holes are formed in two oblique sides; compared with a normal plane screen, the aperture ratio is increased by 50%; apertures are formed in two oblique sides; due to the principle that the water flows through screen holes from top to bottom, high screening efficiency is achieved; good dewatering effect is achieved, so that the holes are not blocked.

Owner:安徽鑫诺矿业装备制造有限公司

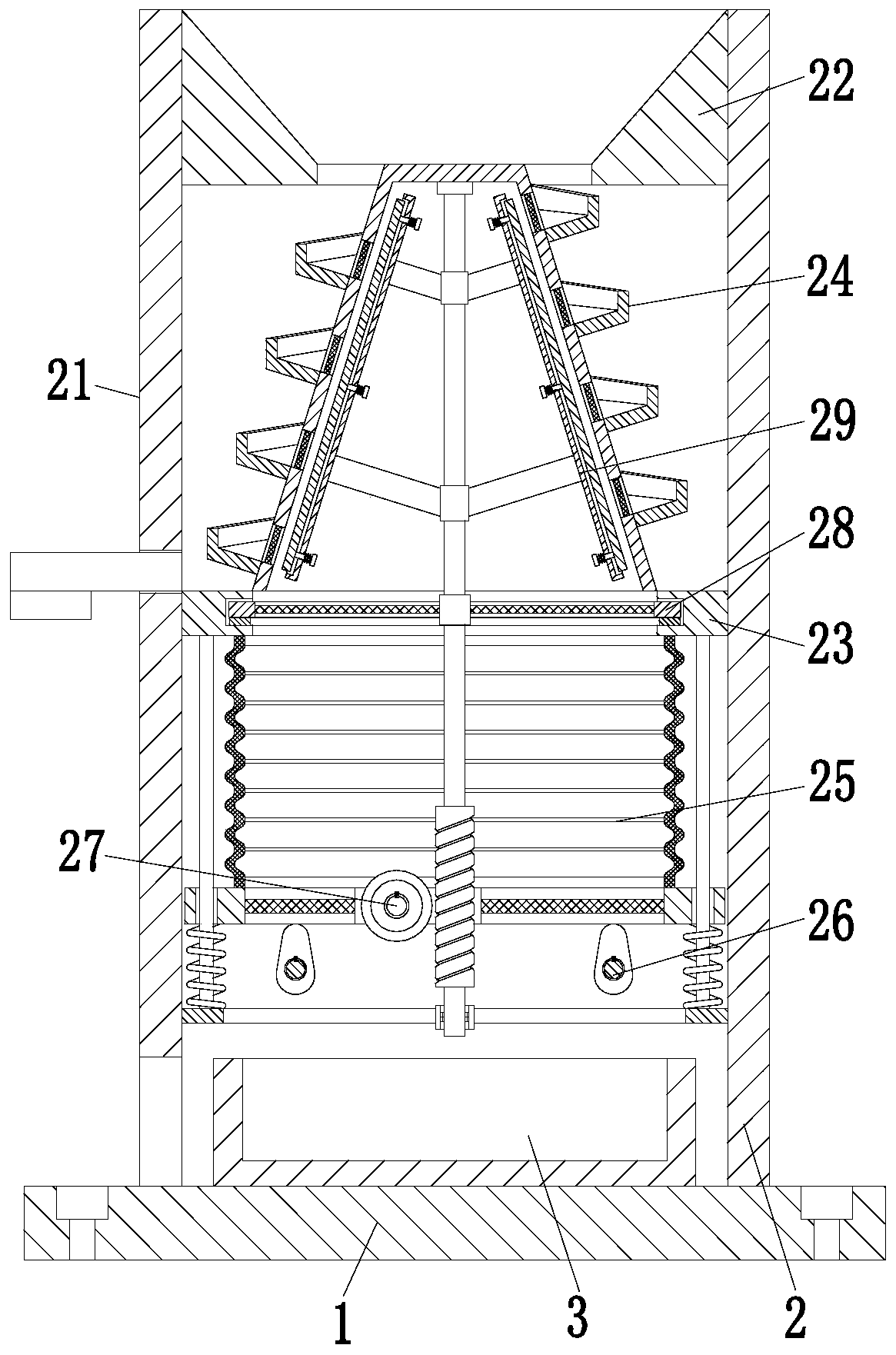

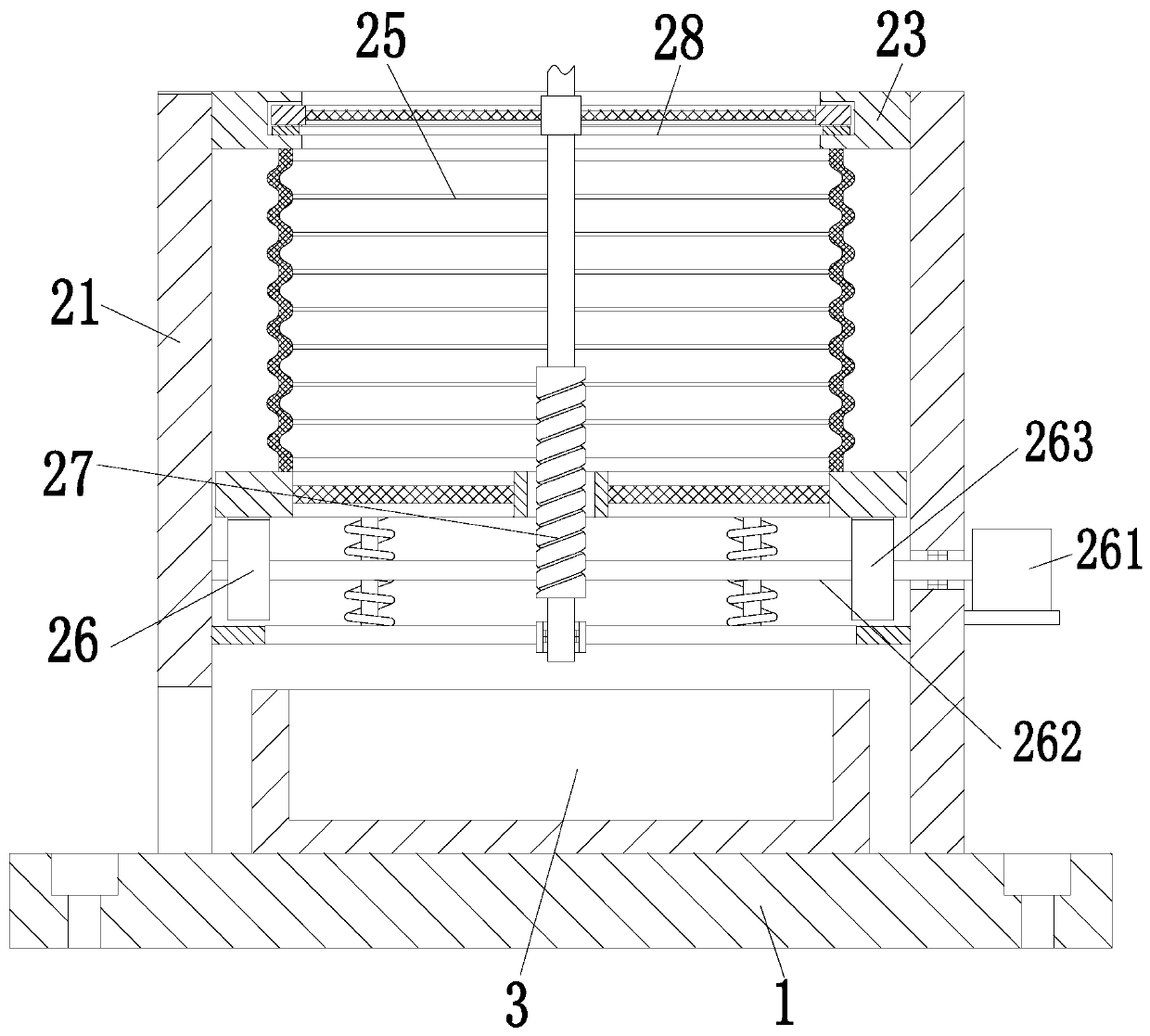

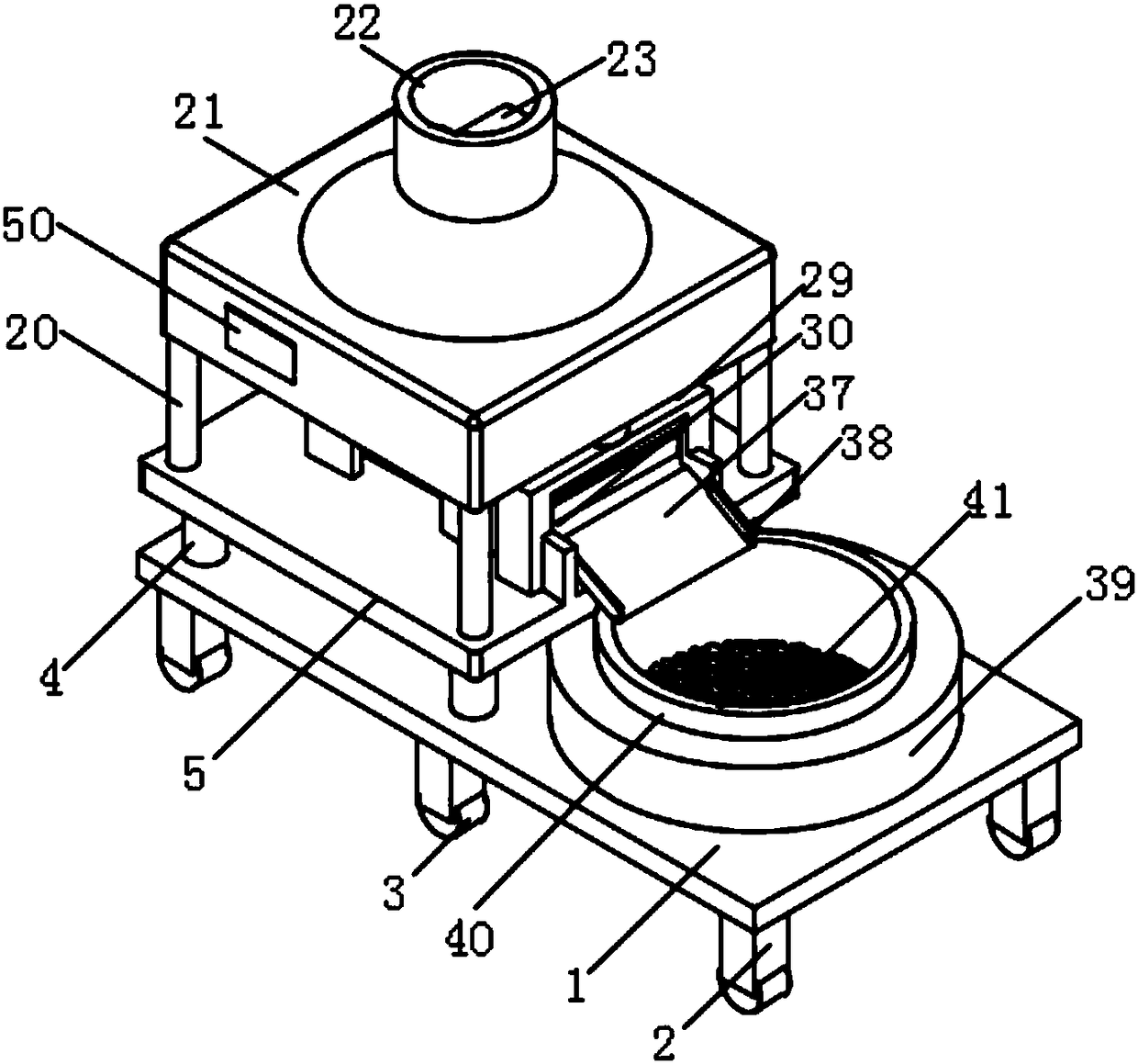

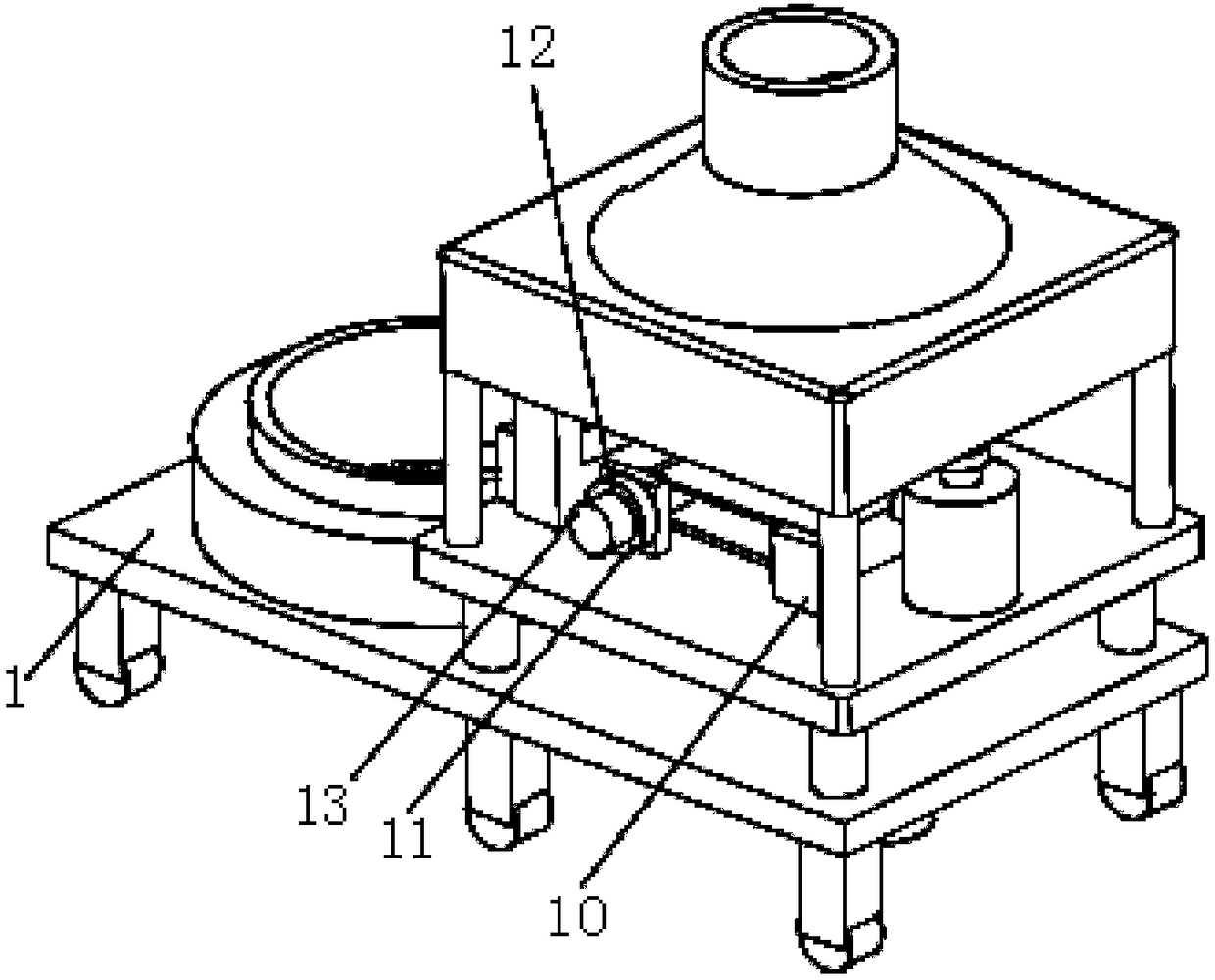

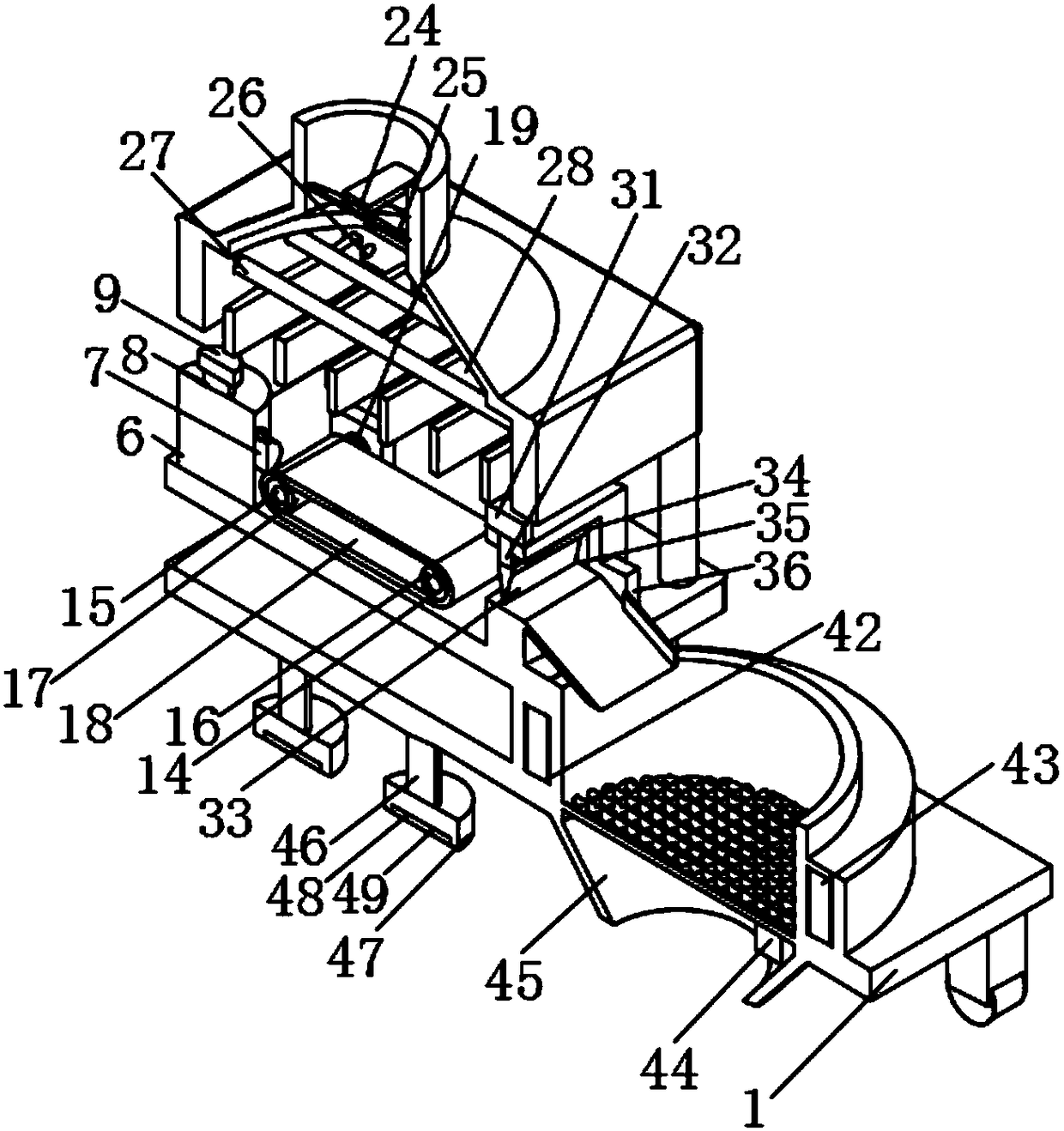

Printing ink manufacturing raw material pigment pretreatment system

ActiveCN111495751AGuaranteed preparation effectImprove processing efficiencySievingScreeningEngineeringProcess engineering

The invention relates to a printing ink manufacturing raw material pigment pretreatment system. The system comprises a bottom plate, a filtering device and a collecting box, mounting holes are evenlyformed in the bottom plate, the filtering device is mounted at the upper end of the bottom plate, a through groove is formed in the lower end of the filtering device, and the collecting box is arranged in the through groove and located in the middle of the upper end of the bottom plate. The system can solve the following problems that when existing equipment is used for filtering printing ink manufacturing raw material, the filtering effect is poor, filtering is incomplete, large-particle impurities in a raw material cannot be effectively removed, filter screen holes are easily blocked by theimpurities, and the impurities cannot be rapidly removed; when existing equipment is used for screening and processing the printing ink manufacturing raw material, the raw material cannot be vibratedto be screened, the raw material is likely to be accumulated at the upper end of a screen, the screening efficiency of the raw material is low, and subsequent processing of printing ink is affected.

Owner:英德市捷成化工有限公司

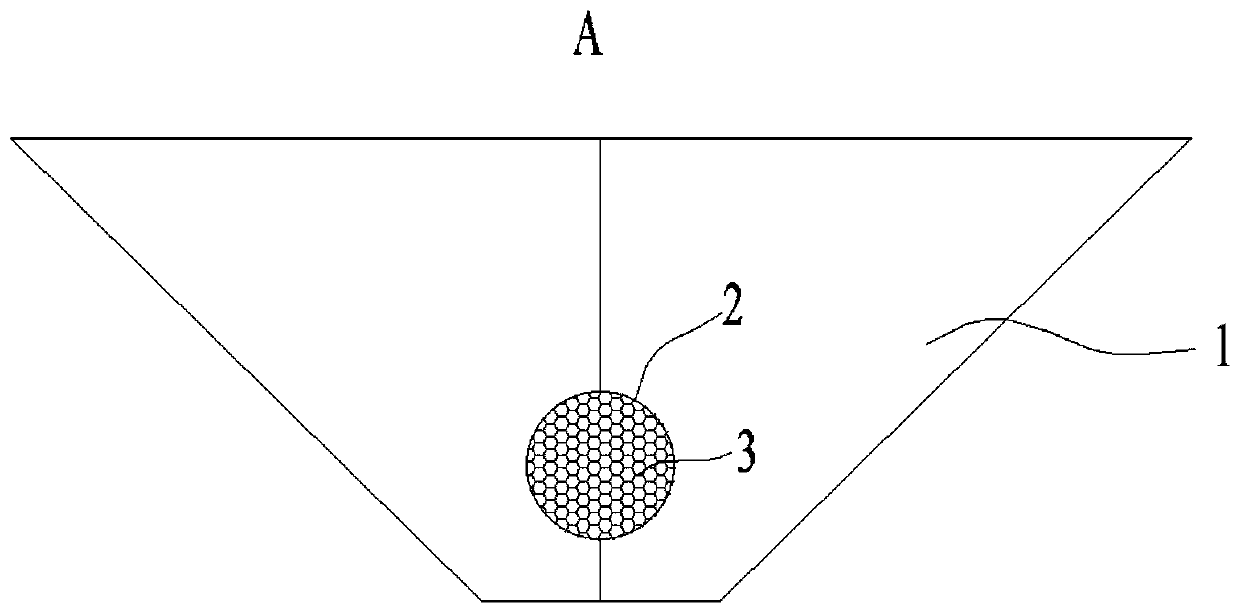

Efficient building sandstone screening device

The invention discloses an efficient building sandstone screening device which comprises a feeding hopper. A feeding pipe is arranged at the lower end of the feeding hopper; supporting columns are symmetrically arranged on the left side and the right side of the feeding hopper; supporting sleeves are arranged at the lower ends of the supporting columns in a sliding and sleeving manner; supportingblocks are arranged at the lower ends of the supporting sleeves; rollers facilitating device transportation are arranged on the supporting blocks; buffer springs are arranged inside the supporting sleeves, and connect and fix the supporting sleeves and the supporting columns; a buffer mechanism is arranged to effectively improve the vibration resistance of the device; a connecting ring is arrangedbelow the feeding hopper; a screening plate is arranged at the upper end of the connecting ring, and is cone-shaped; the cone-shaped tip is corresponding to the discharging pipe in position; a collecting hopper is arranged at the lower end of the connecting ring; and a discharging pipe is arranged at the lower end of the connecting hopper. The efficient building sandstone screening device is simple and reasonable in structure, convenient to carry, high in vibration resistance, and high in practicability, and eliminates defects in an existing device.

Owner:张佳宁

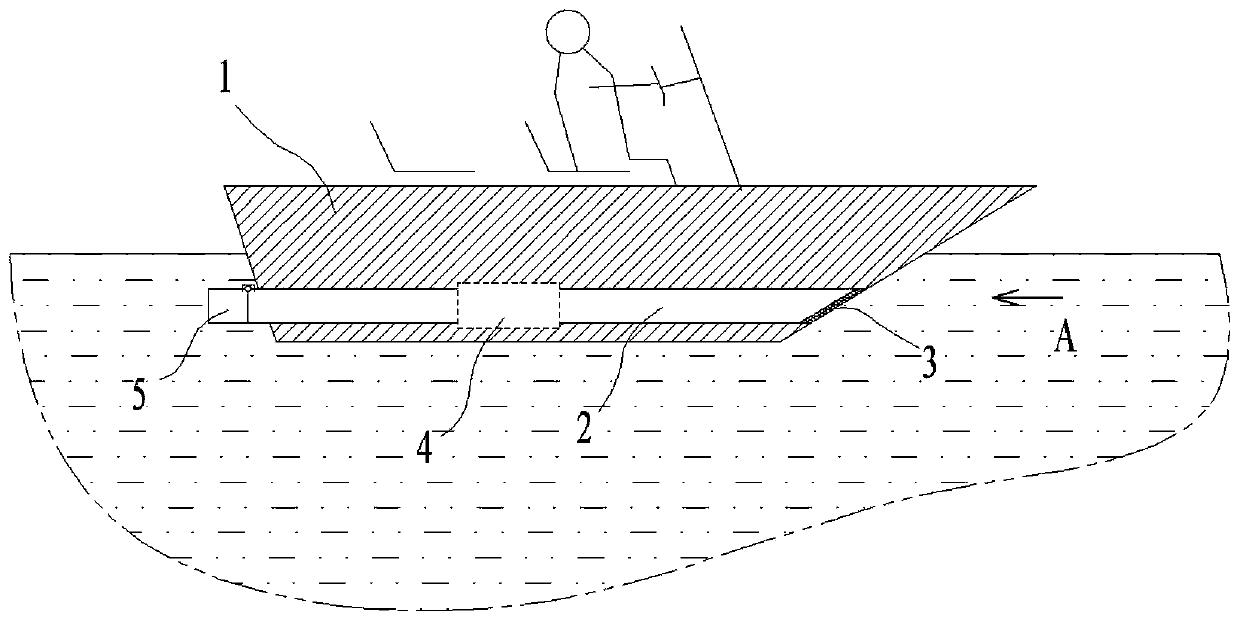

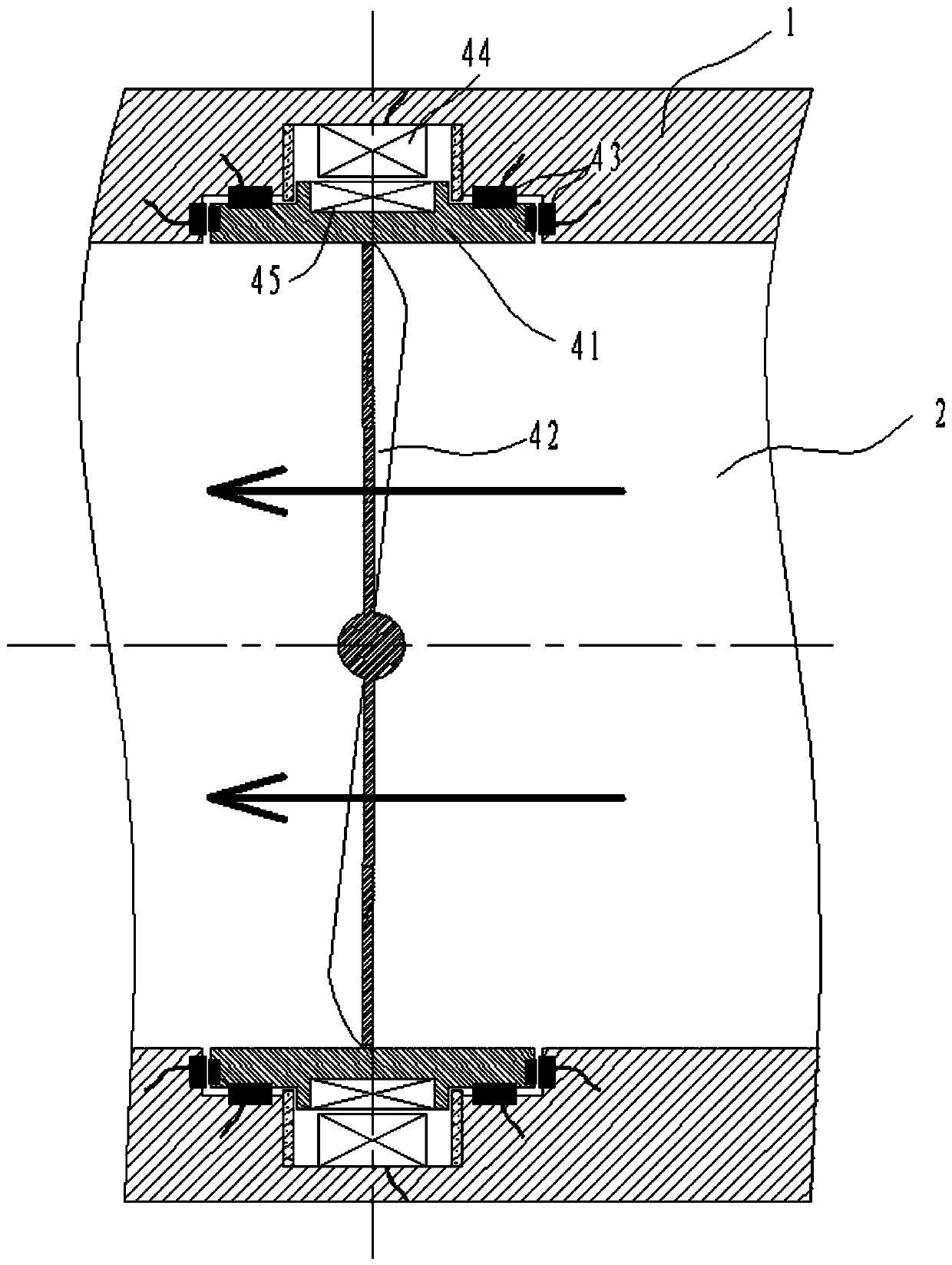

Water attack angle forward-inclined ultra-high-speed cruise rescue speedboat

ActiveCN111268064AImprove working conditionsEasy to solveWatercraft hull designLife-savingMagnetic bearingWater channel

The invention discloses a water attack angle forward-inclined ultra-high-speed cruise rescue speedboat. The speedboat comprises a speedboat body, a water channel and a propelling pump, the water channel parallel to the axis of the speedboat body is arranged at the bottom of the speedboat body, and the propelling pump is arranged on an internal path of the water channel. The propelling pump comprises a seat ring, axial flow blades, a magnetic bearing, a stator and a rotor. An annular groove is formed in the water channel, the seat ring is arranged in the groove through the magnetic bearing, theaxis of the seat ring coincides with that of the water channel, a plurality of axial flow blades which are circumferentially and uniformly distributed are mounted on the inner ring of the seat ring,the axial flow blades are fan-shaped about the axis of the seat ring and extend towards the axis direction of the seat ring, all the axial flow blades extend to the axis of the seat ring and then arespot-welded together, the rotor is fixedly installed on the outer ring of the seat ring, the stator is fixed to the inner wall of the water channel and faces the rotor, the magnetic bearings are installed on the seat ring and the inner wall of the water channel in pairs, and the magnetic bearings are arranged in the axial direction and the radial direction of the axis of the water channel.

Owner:济宁三泰和游艇制造有限公司

Air drying equipment for plastic extruded strips

InactiveCN108247980AEasy to moveAchieve fixationDrying gas arrangementsMetal working apparatusEngineeringAdverse effect

The invention discloses air drying equipment for plastic extruded strips. The air drying equipment comprises a bottom plate, wherein supporting feet are arranged on the edge of the lower end surface of the bottom plate; the number of the supporting feet is not smaller than 6; the supporting feet are uniformly distributed on the edge of the lower end surface of the bottom plate. According to the invention, through rollers, movement of the equipment can be achieved, so that a special production requirement of a user on the movement of the equipment in the production process can be met; meanwhile, through cooperative use of electric telescopic rods and counterweights, fixing of the equipment is achieved; furthermore, through vibration-proof gaskets on the bottom end surfaces of the counterweights, adverse effects of vibration generated by the equipment in the production process on other production processes are effectively reduced; through adjustment of rotating shafts 3, the inclinationangles of wind deflectors can be controlled so as to control the wind direction in the air drying process, and the air drying uniformity of plastic is guaranteed; moreover, air entering a main body isheated by heating tubes 1, so that the air drying efficiency of the plastic is greatly improved.

Owner:王诗韵

Test device for display panel and method of testing the same

ActiveUS8896636B2Reduce power consumptionIncrease the screening areaCathode-ray tube indicatorsNatural mineral layered productsControl signalData signal

A test device for a display panel and a method of testing the same are provided. The test device for a display panel includes a luminance measurement unit that measures a luminance value of a display panel including a plurality of pixels, and a controller that determines a voltage value of a data signal corresponding to a target luminance value, receives a measured luminance value of a pixel to which the data signal is supplied from the luminance measurement unit from among the plurality of pixels, compares the measured luminance value and the target luminance value, and outputs a control signal that changes a first power source voltage value supplied from a power source voltage supply unit to the pixel until the measured luminance value does not coincide with the target luminance value.

Owner:SAMSUNG DISPLAY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com