Vertical spiral vibrating screen

A vibrating screen and screw technology, applied in the field of high-precision fine powder screening machinery, can solve the problems of not being able to adapt to the increasing demand of production capacity in the powder industry, difficult to withstand long-term fatigue vibration, and increasing the number of screen contacts, etc. Achieve the effect of reducing the area of a single screen, reducing screen consumption, and increasing the screen area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to better understand the technical solution of the present invention, a detailed description will be given below through specific embodiments and in conjunction with the accompanying drawings.

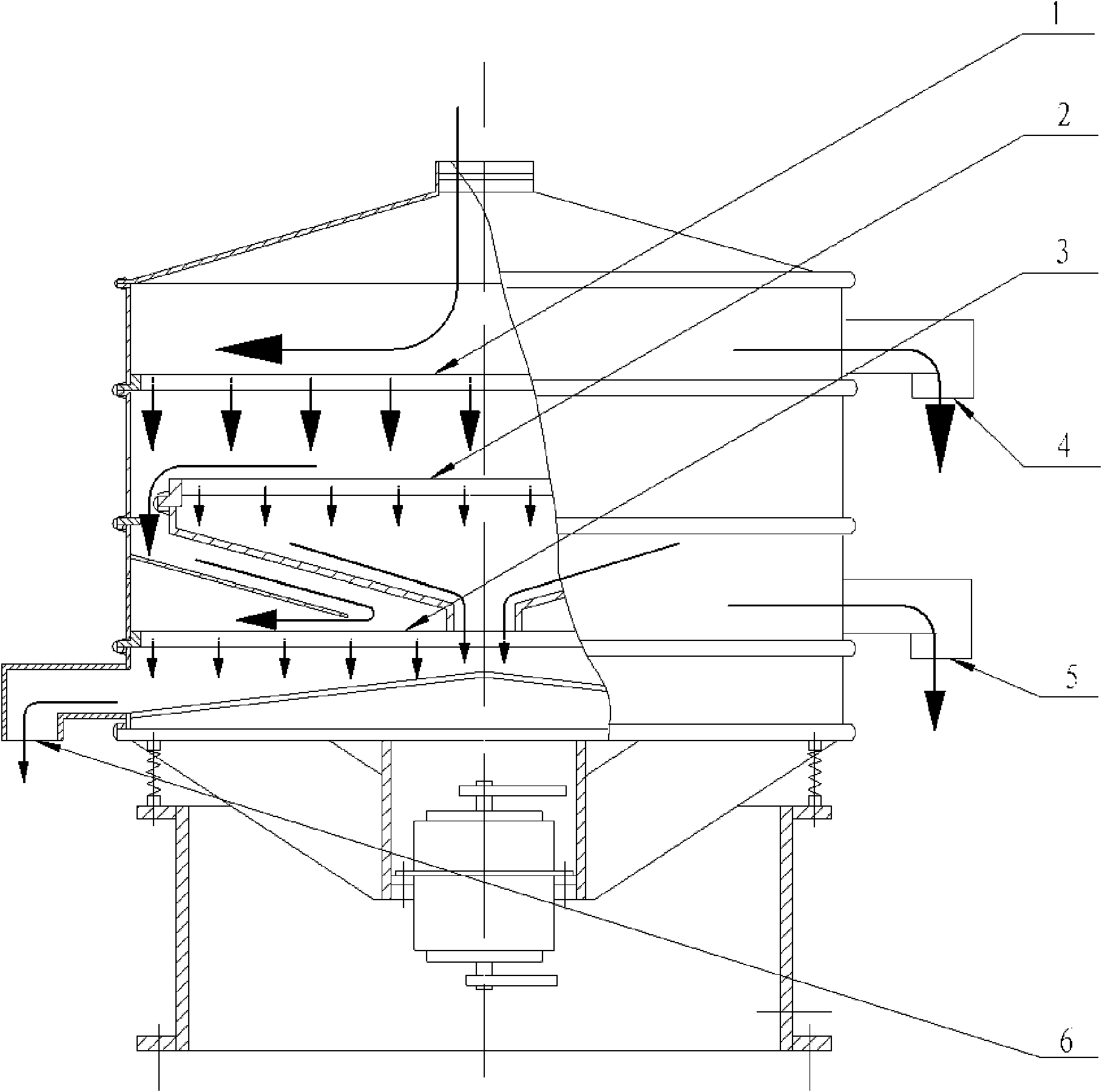

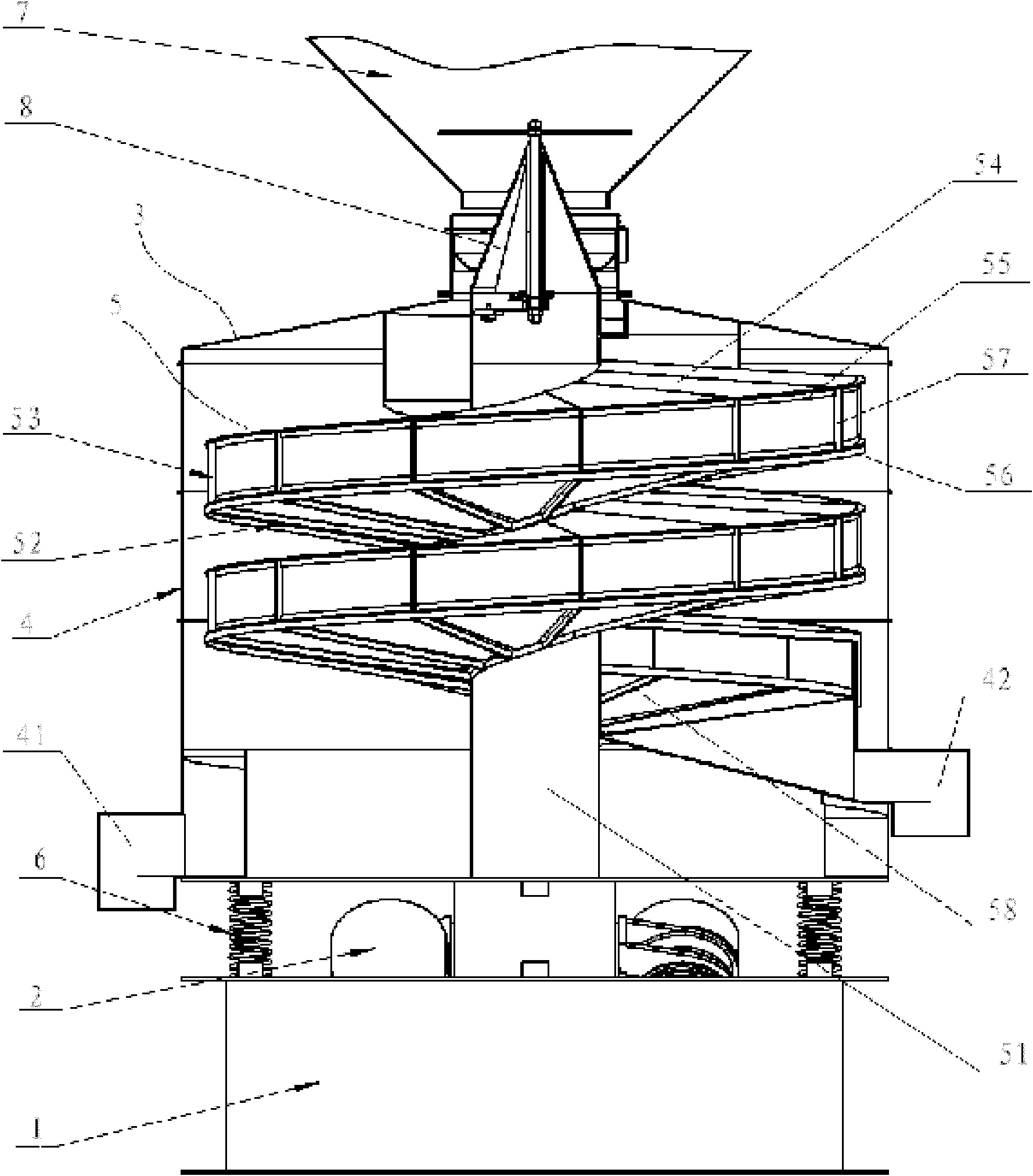

[0036] see figure 2, the vertical spiral vibrating screen of the present invention comprises a base 1, a sieve 3 installed on the base 1 through several supporting springs 6, a vibrating device 2 connected to the lower end of the sieve 3 and located in the base 1, a vibrating device 2 installed on the base 1 A feed bin 7 at the upper end of the sieve 3 and a feeding valve 8 installed in the feed bin 7 .

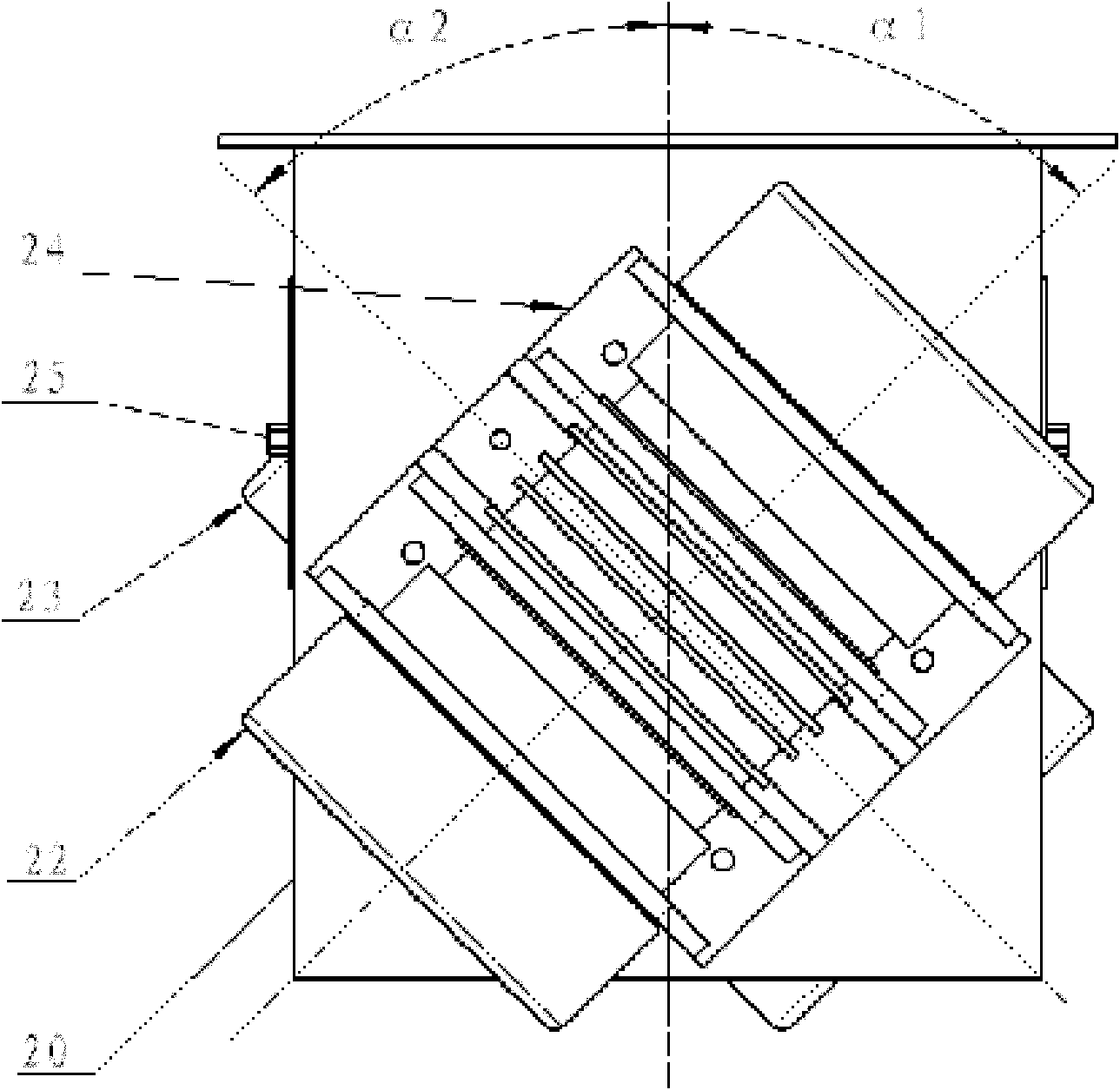

[0037] Sieve 1 comprises shell 4, middle column 51 and screen cloth 5, wherein:

[0038] The shell 4 is a cylinder with a cover plate 40 and a bottom plate, and a fine powder discharge port 41 and a coarse powder discharge port 42 are opened in its lower part;

[0039] The middle column 51 stands vertically in the center of the casing 4; the upper end of the middle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com