Patents

Literature

466results about How to "Clean enough" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

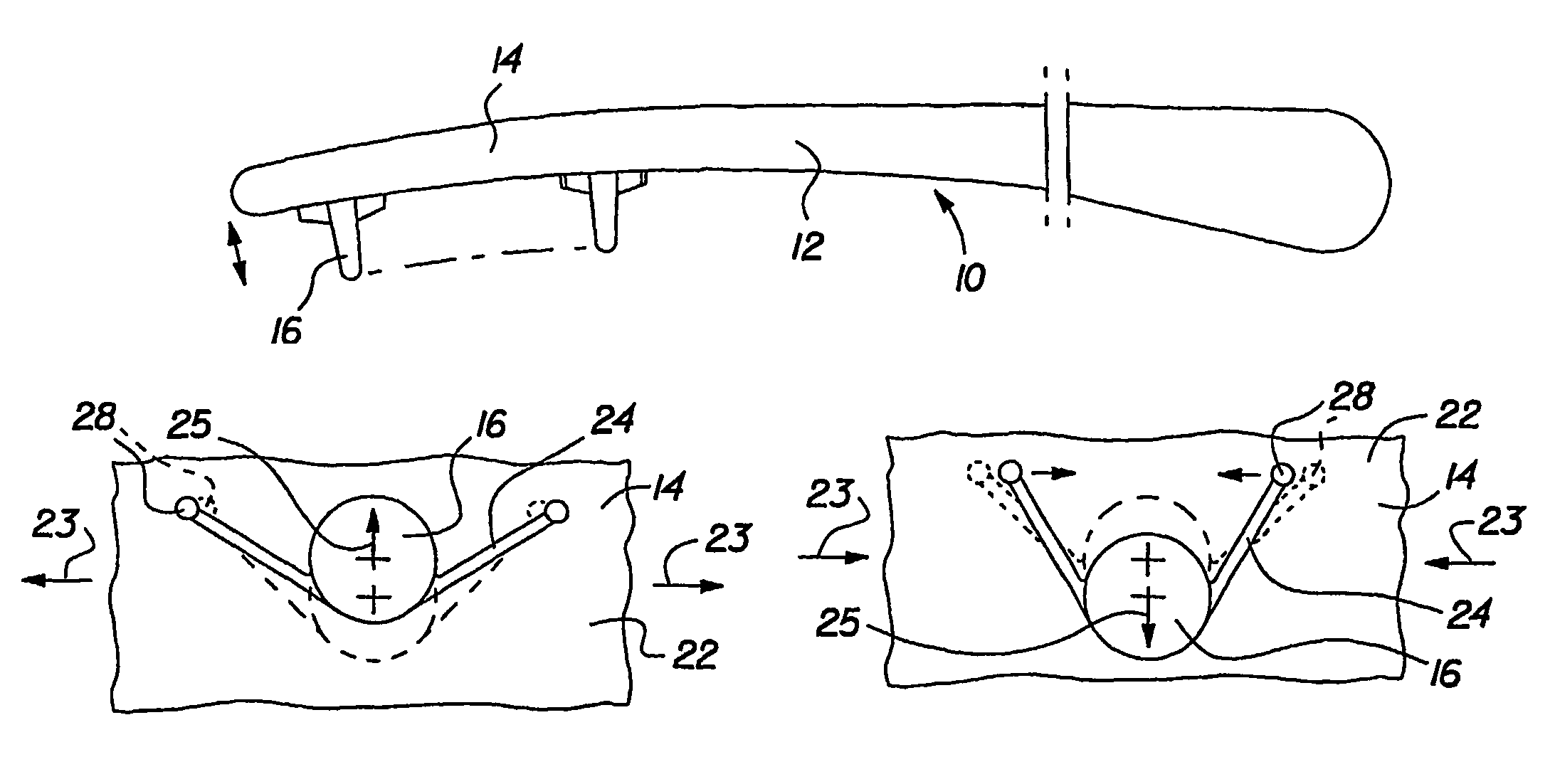

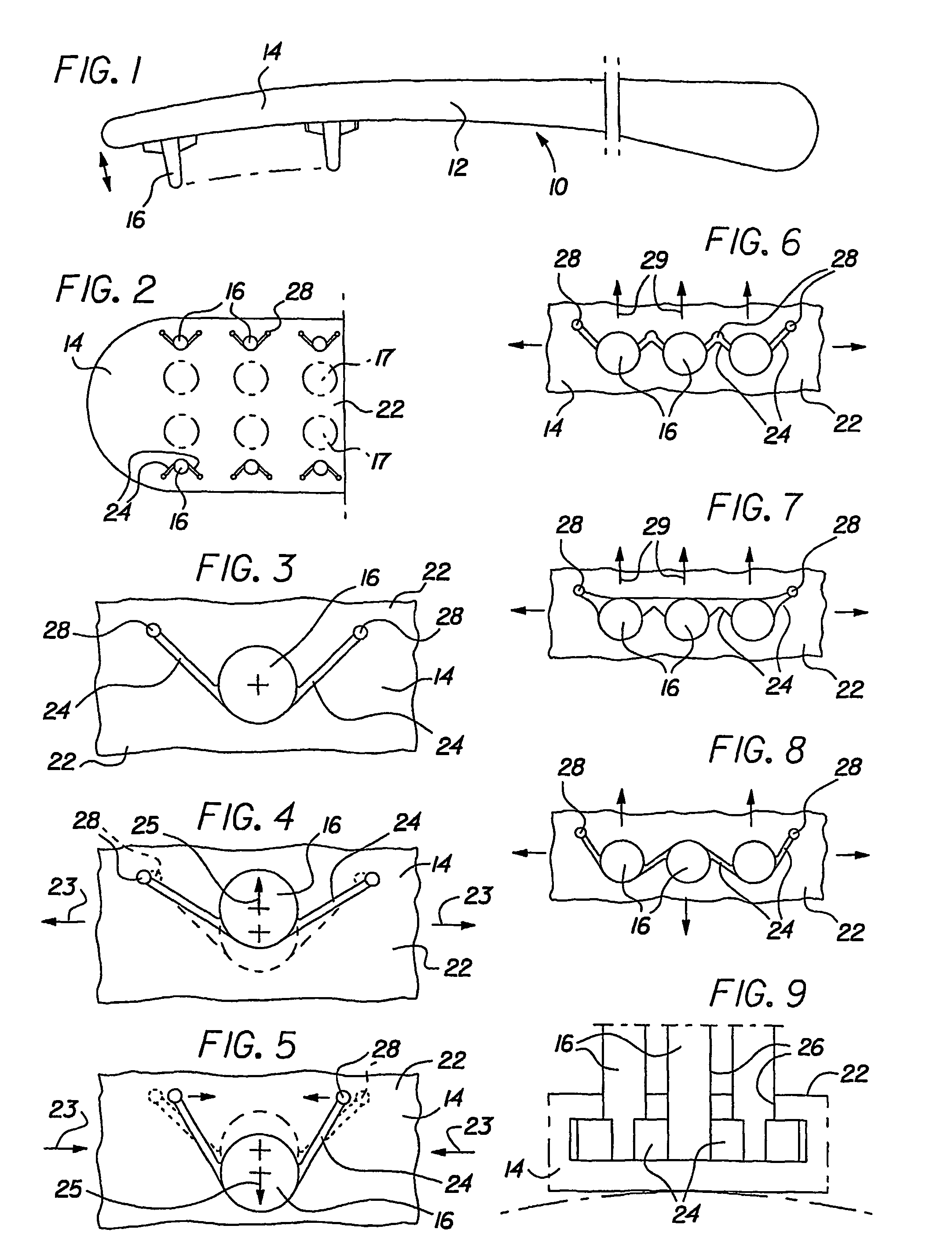

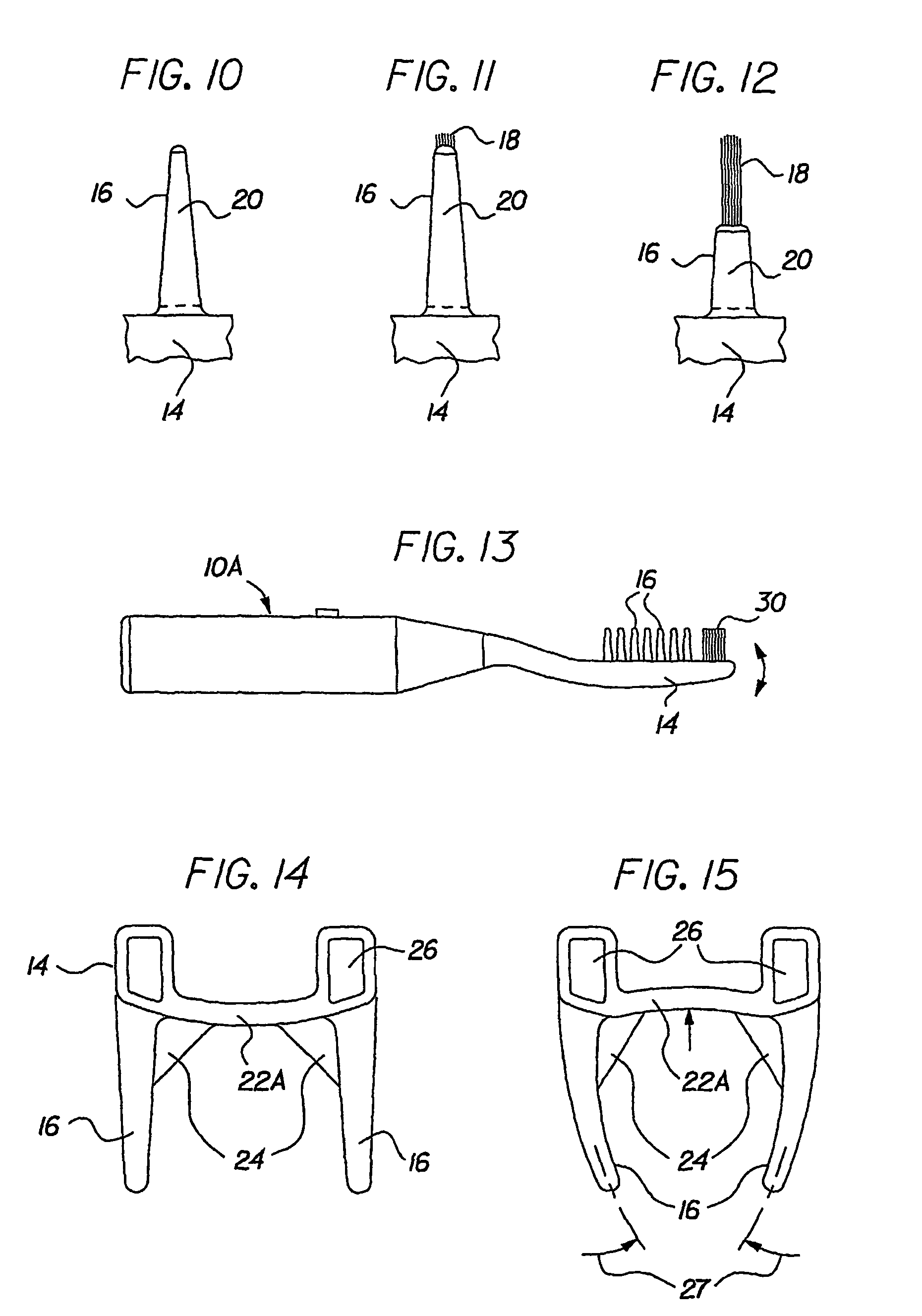

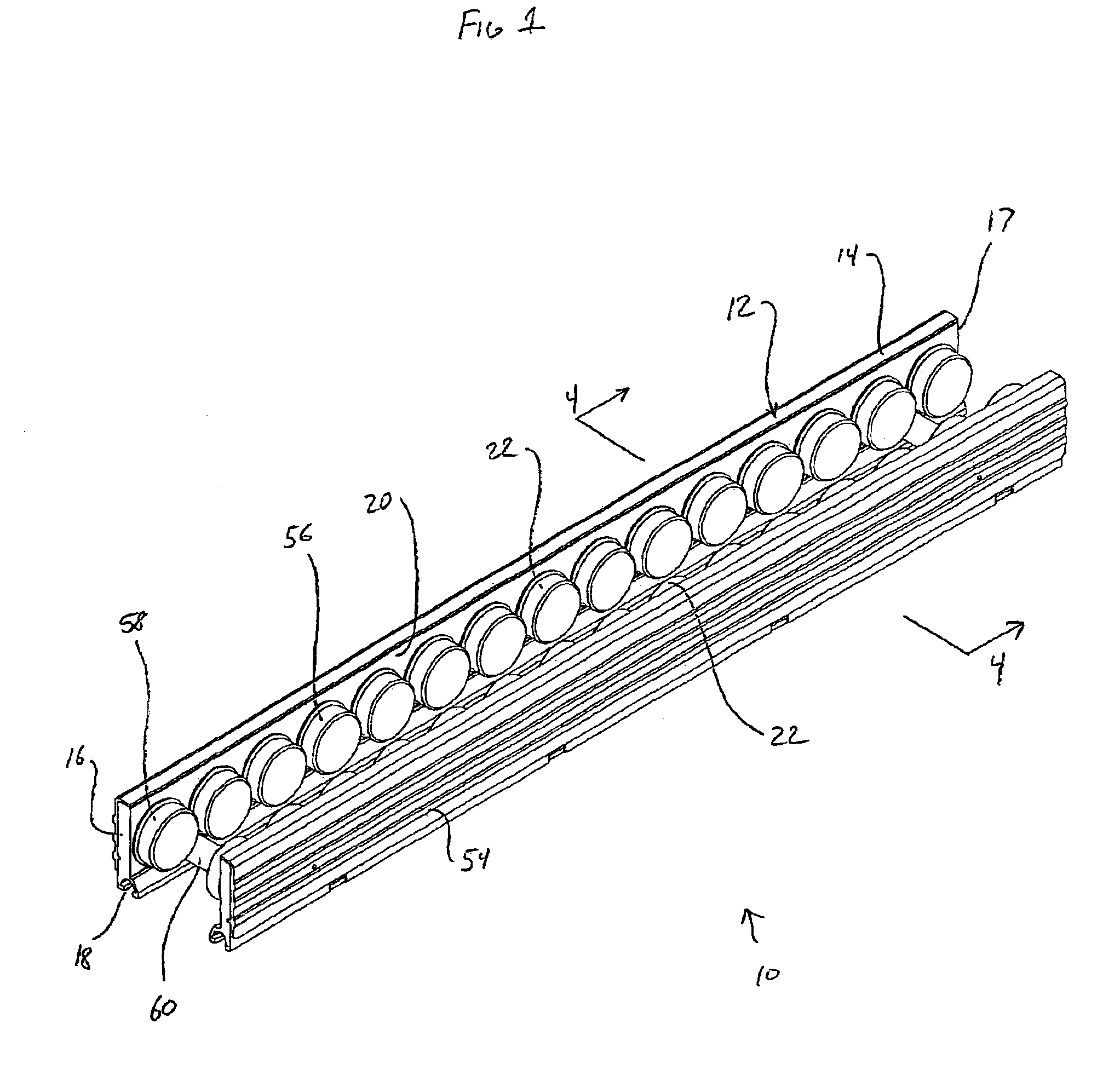

Toothbrush

A toothbrush (10) is disclosed with soft fingers (16) mounted on the toothbrush head (14). During use of the tooth-brush the fingers move laterally relative to the axis of the tooth-brush thereby improving the tooth cleaning and gum massaging performance of the toothbrush. The lateral movement of the fingers is accomplished by relatively stiff ribs (24) which physically interconnect the fingers to flexible portions of the toothbrush head. The ribs translate flexure of the head into the lateral movement of the fingers.

Owner:COLGATE PALMOLIVE CO

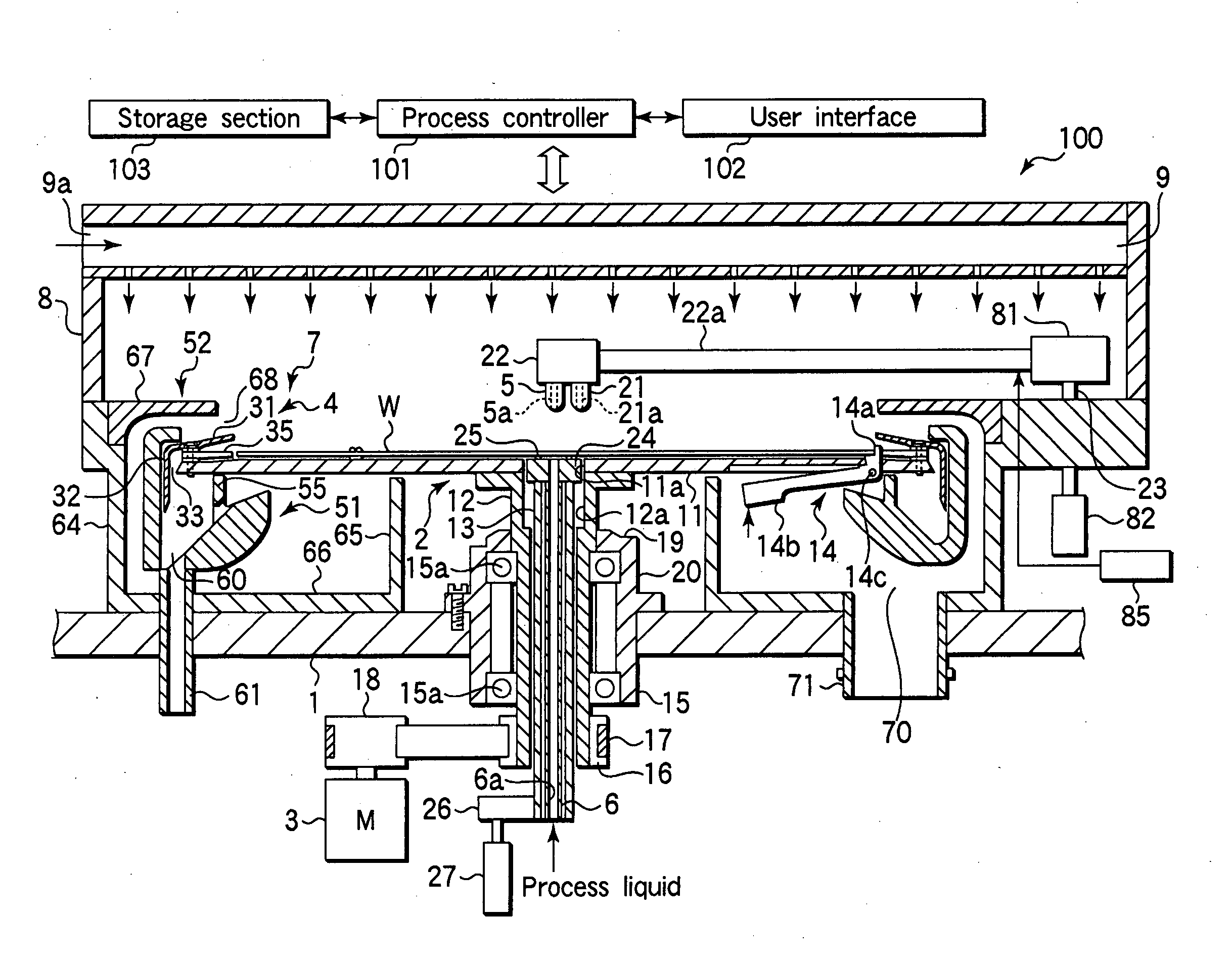

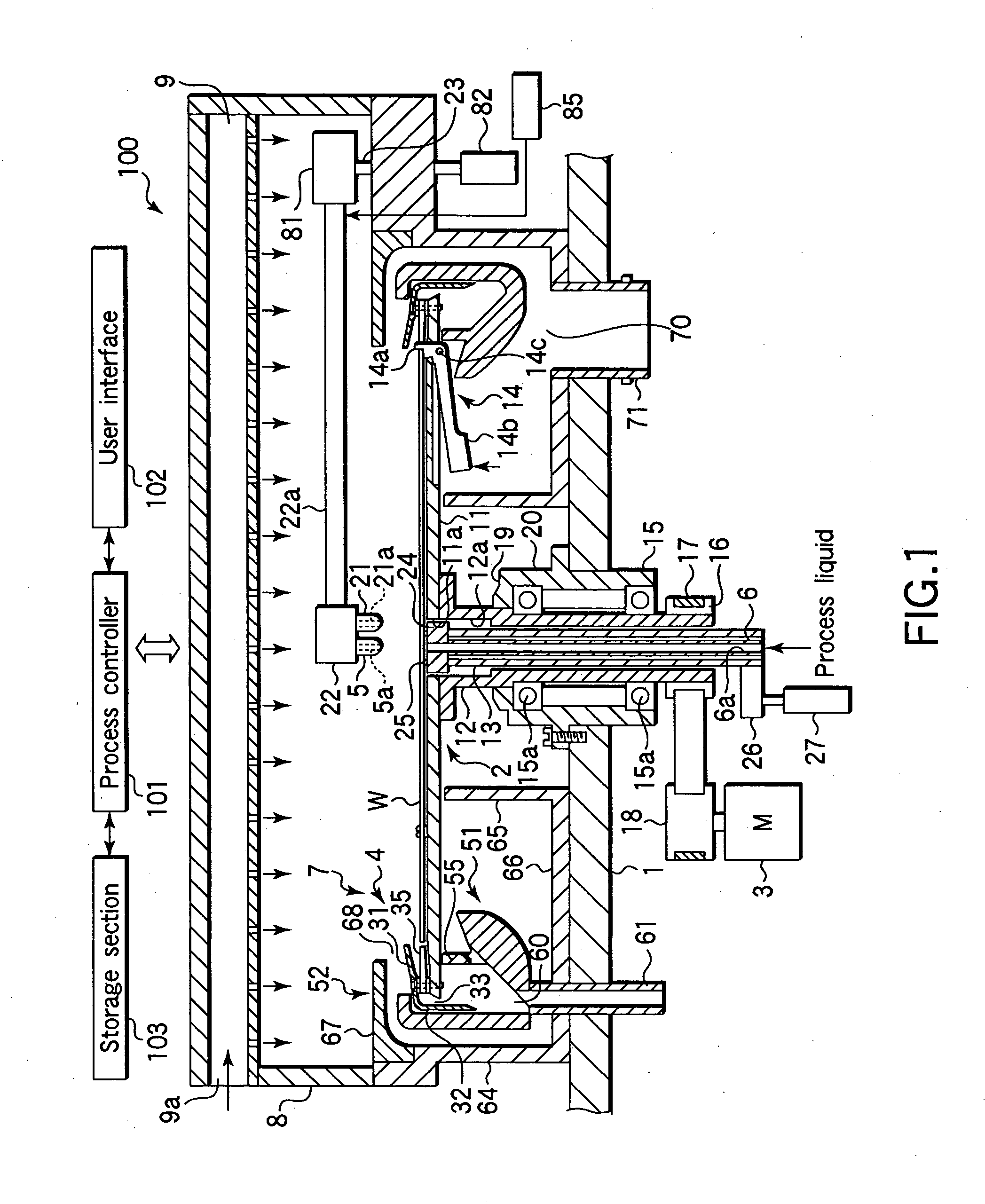

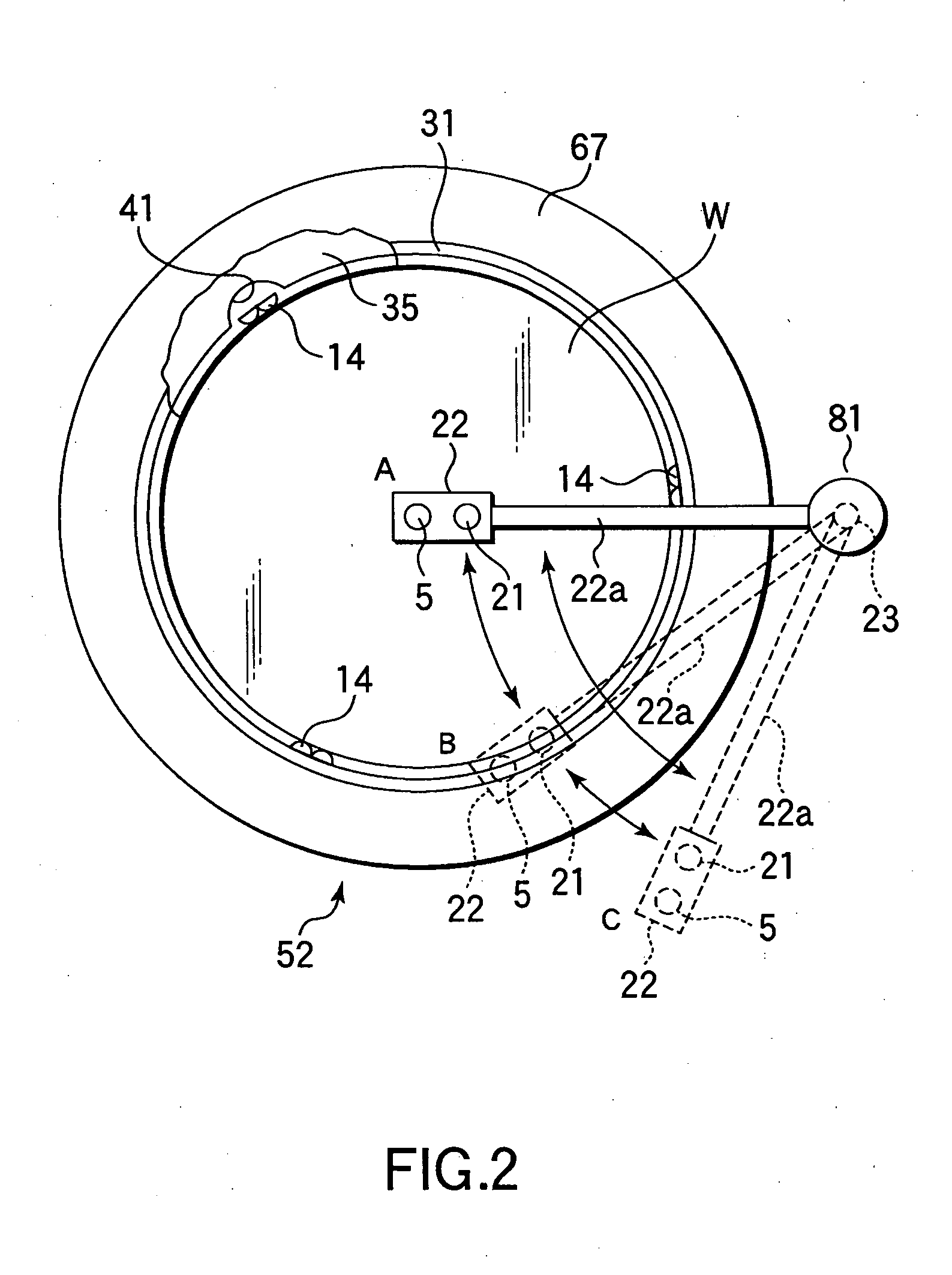

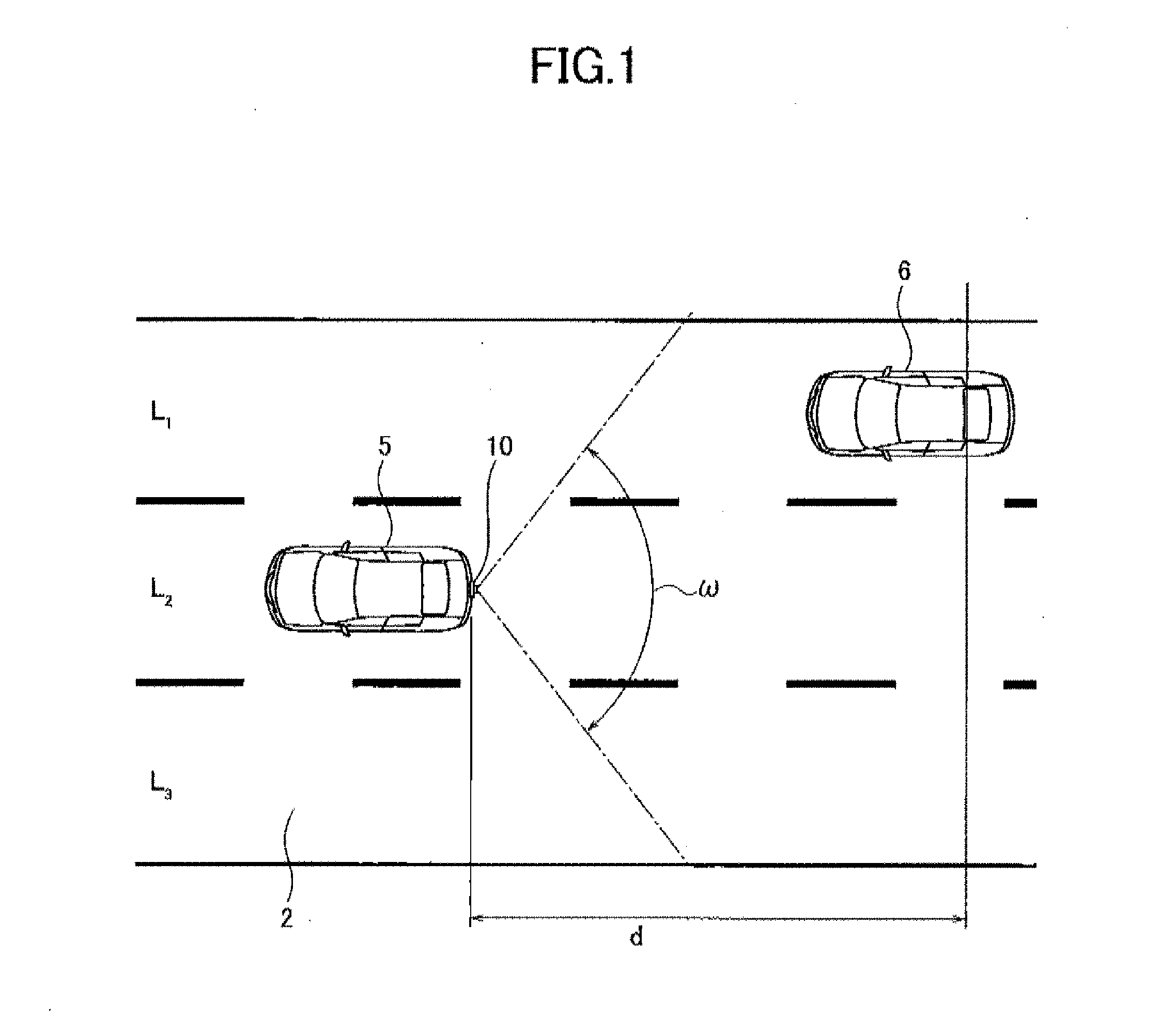

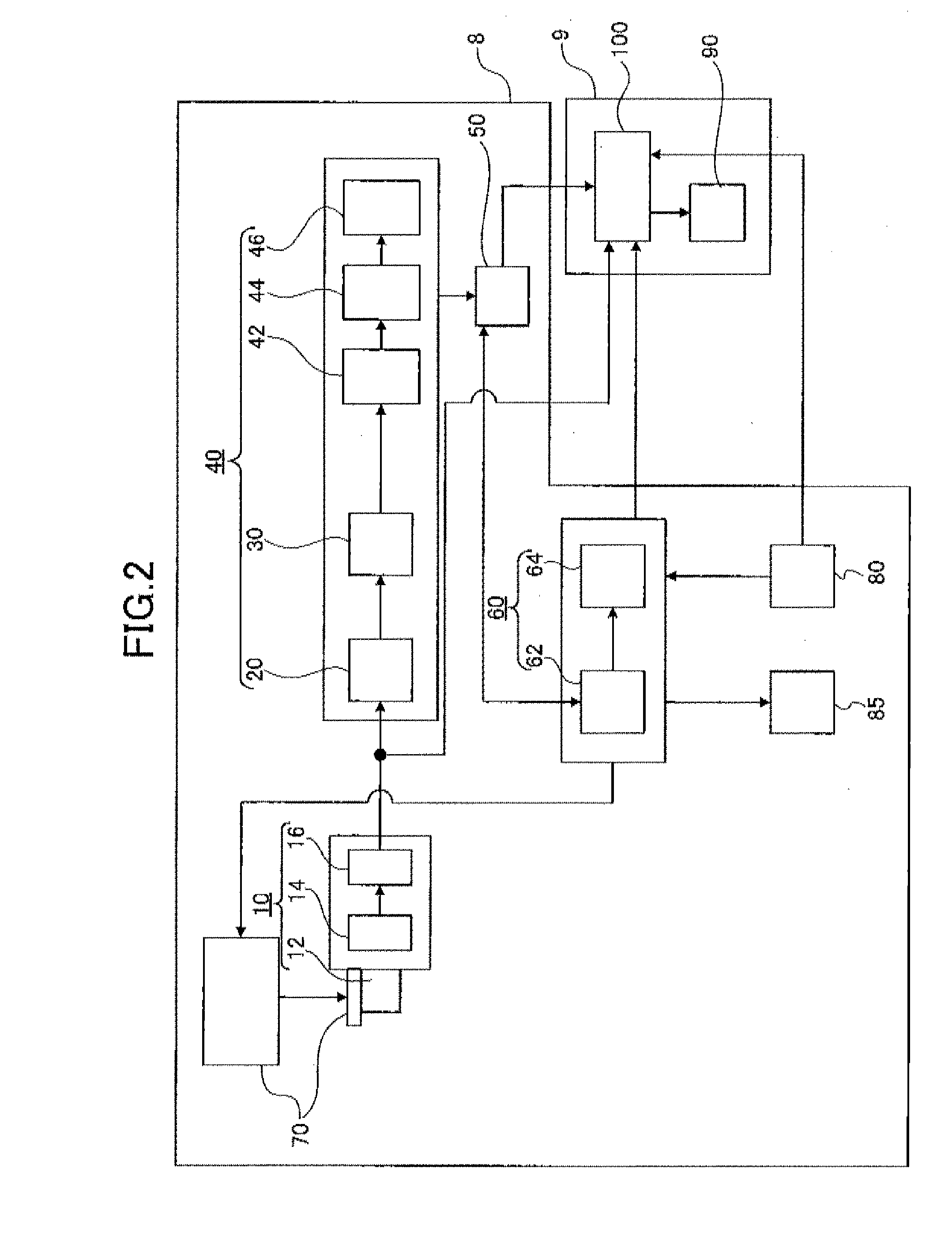

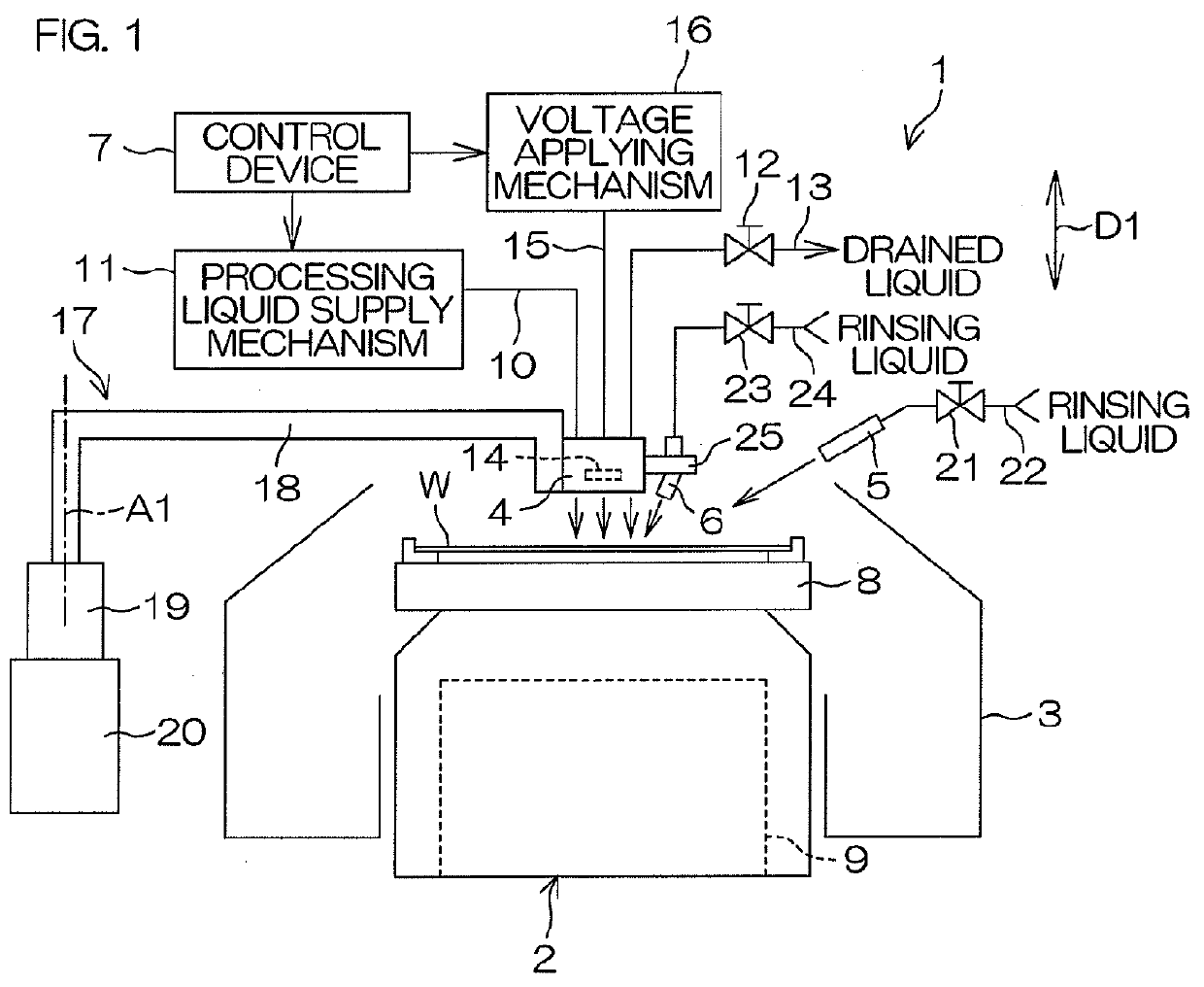

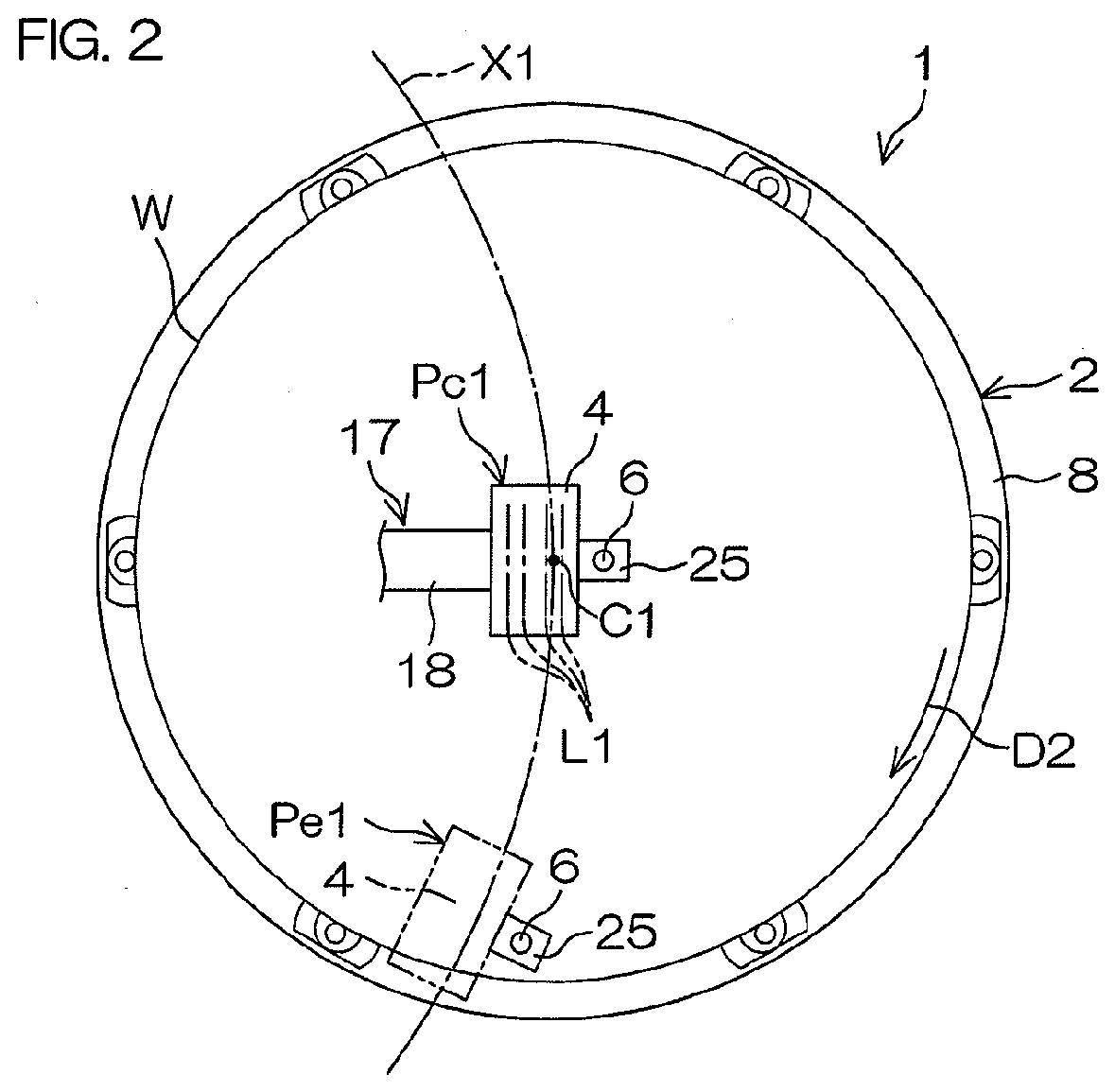

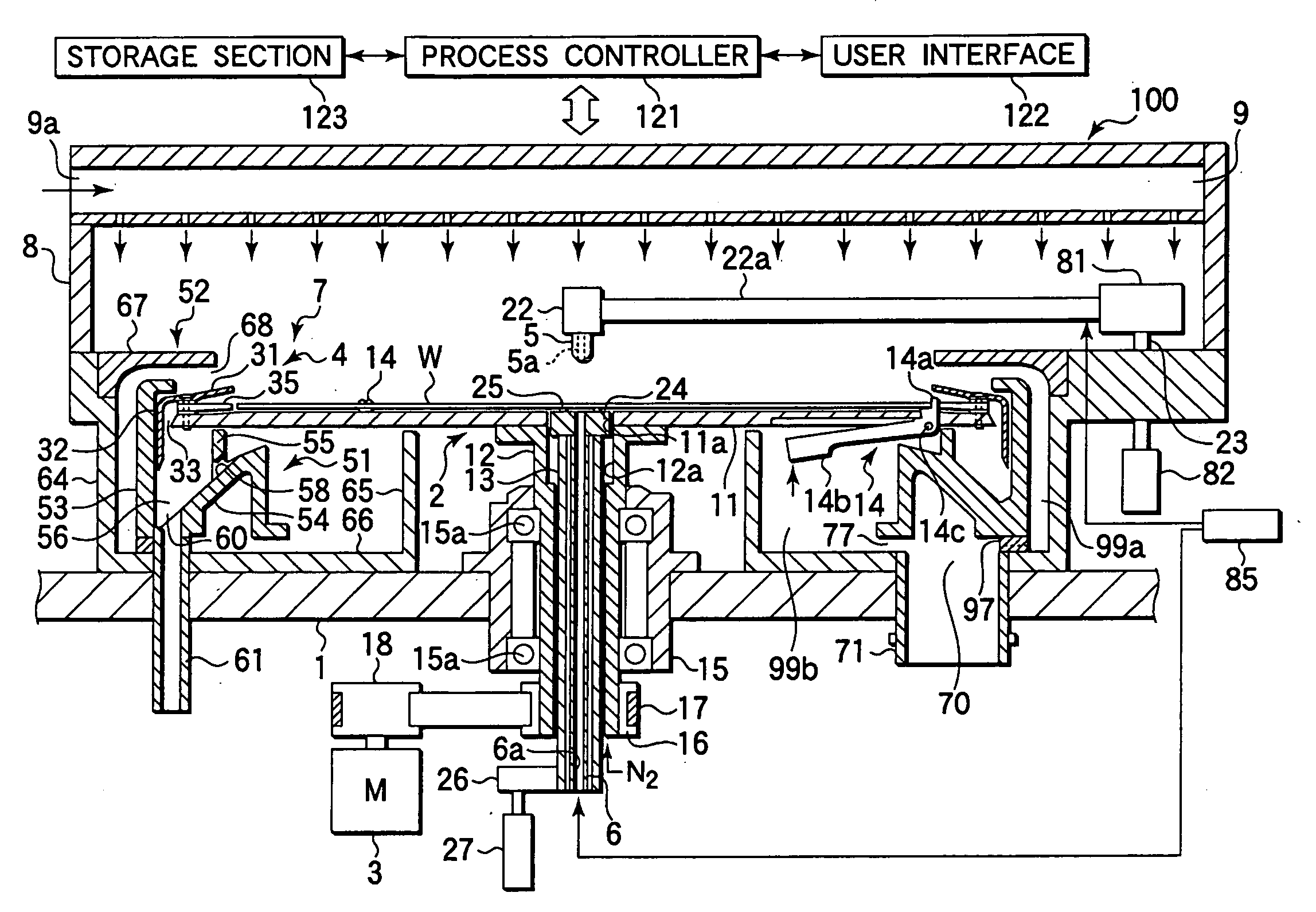

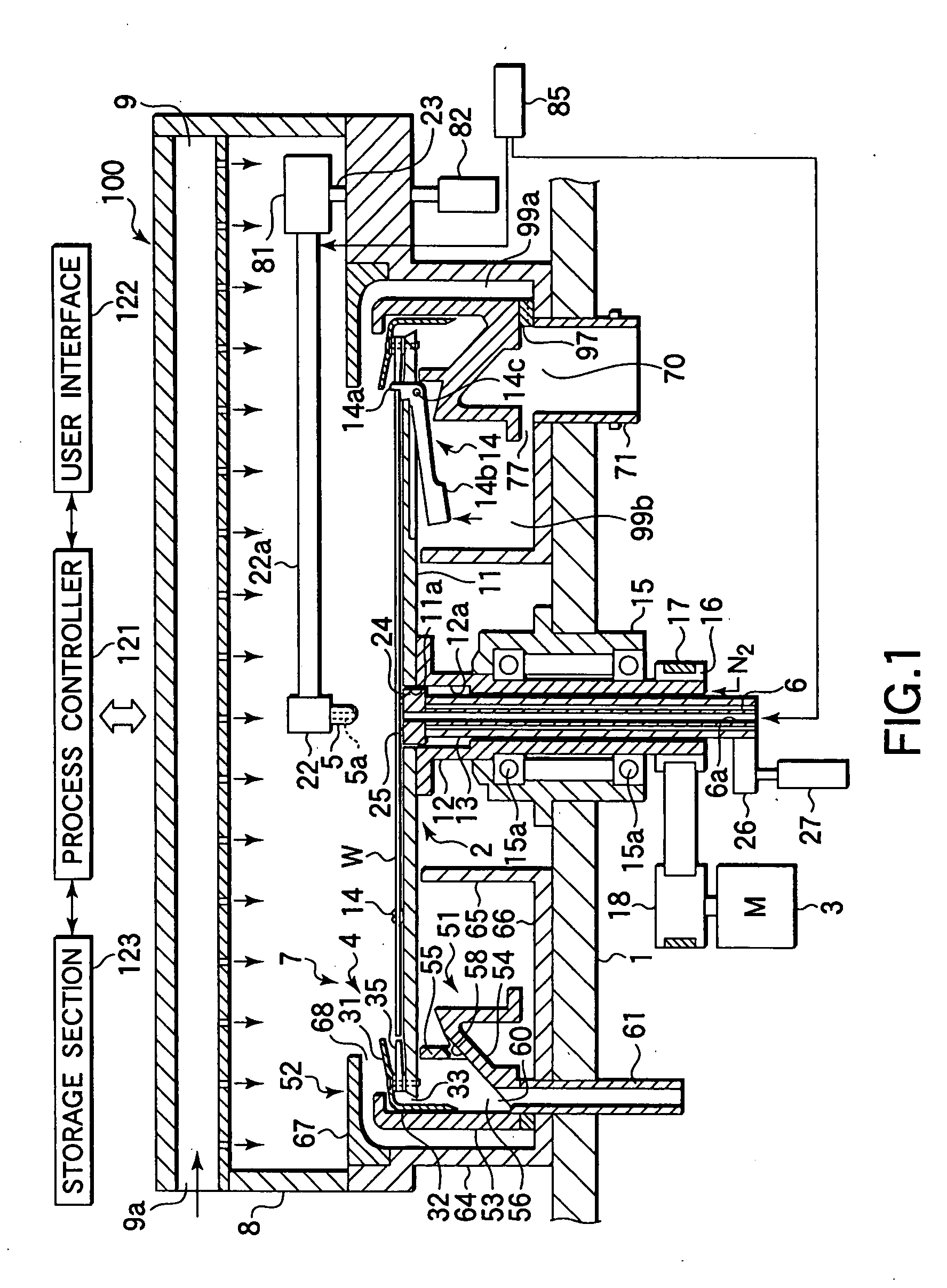

Liquid Processing Apparatus and liquid Processing Method

ActiveUS20100144158A1Clean enoughEffective preventionLiquid surface applicatorsSpraying apparatusEngineeringNozzle

A liquid treatment device having a substrate holding section (2) for horizontally holding a wafer (W) and capable of rotating with the wafer (W), a rotation cup (4) having an annular shape so as to surround the wafer (W) held by the substrate holding section (2) and capable of rotating with the wafer (W), a rotation mechanism (3) for integrally rotating the rotation cup (4) and the substrate holding section (2), a nozzle (5) for supplying a treatment liquid for the wafer (W) and a cleaning liquid for the rotation cup (4), a liquid supply section (85) for supplying the treatment liquid and cleaning liquid to the nozzle (5), and a nozzle movement mechanism for moving the nozzle (5) between a first position at which the liquid is discharged to the wafer (W) and a second position at which the liquid is discharged to an external portion of the rotation cup (4). The wafer (W) is treated with the liquid with the nozzle (5) positioned at the wafer treatment position, and the cleaning liquid is discharged to the external portion of the rotation cup with the nozzle (5) positioned at the rotation cup cleaning position.

Owner:TOKYO ELECTRON LTD

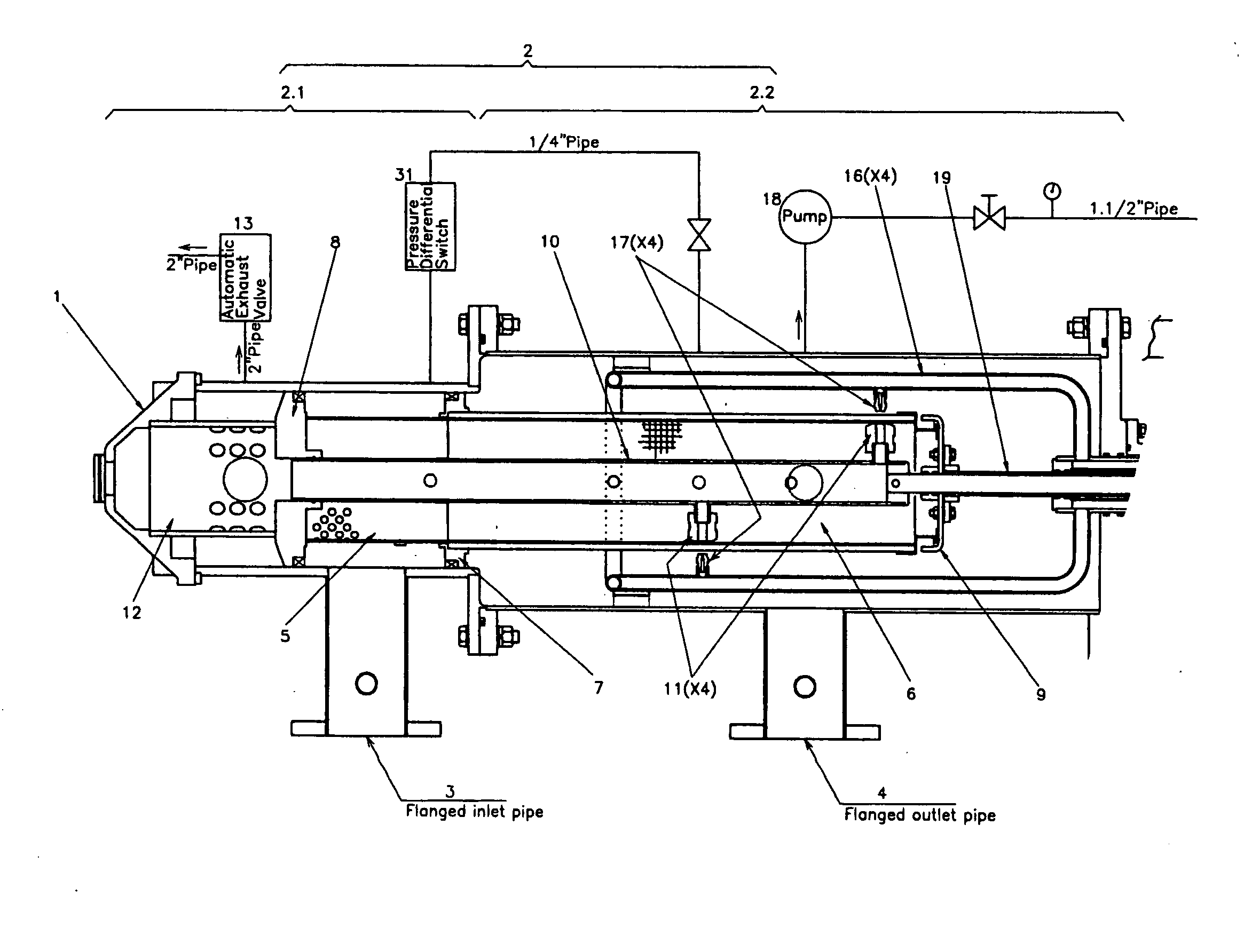

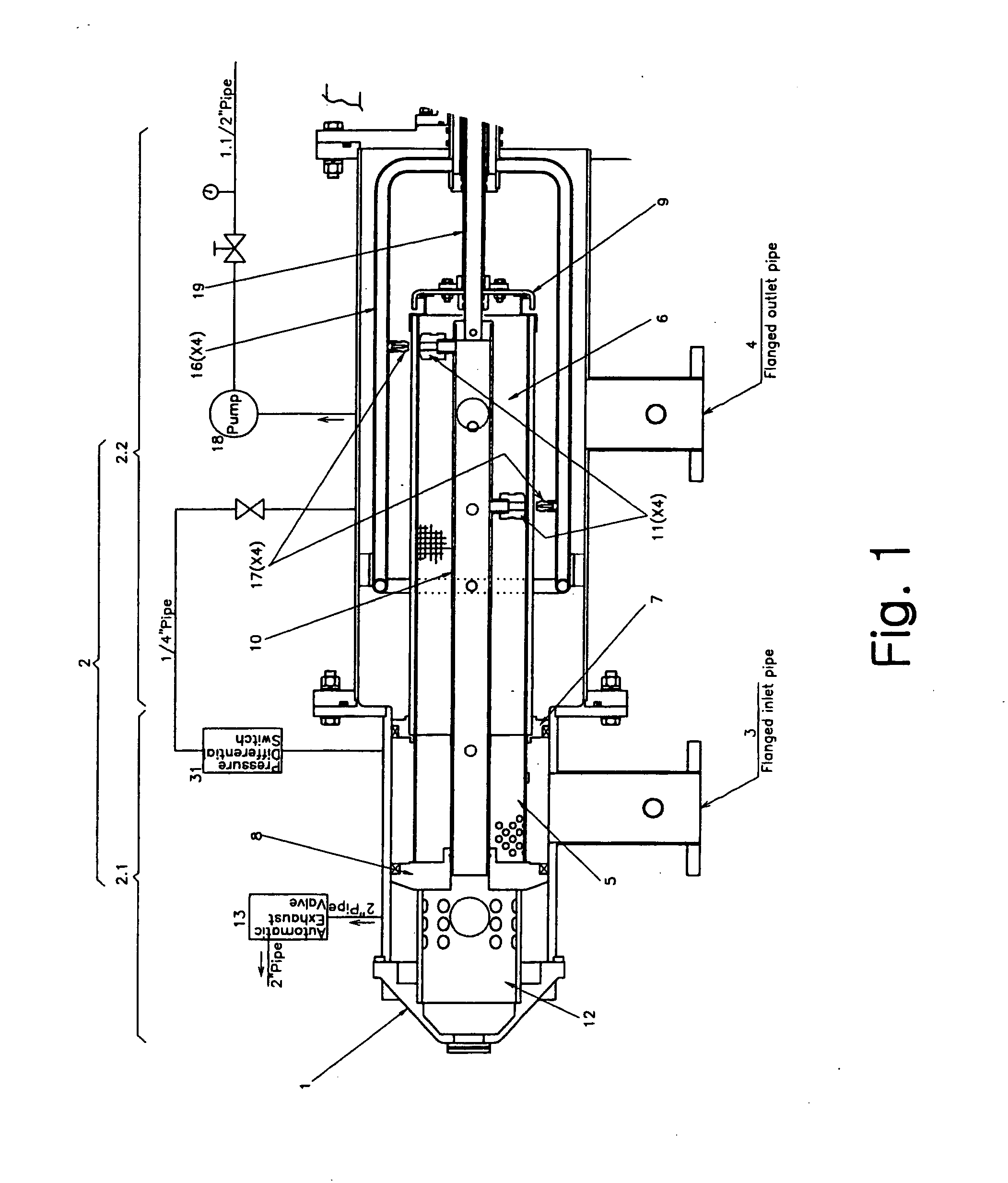

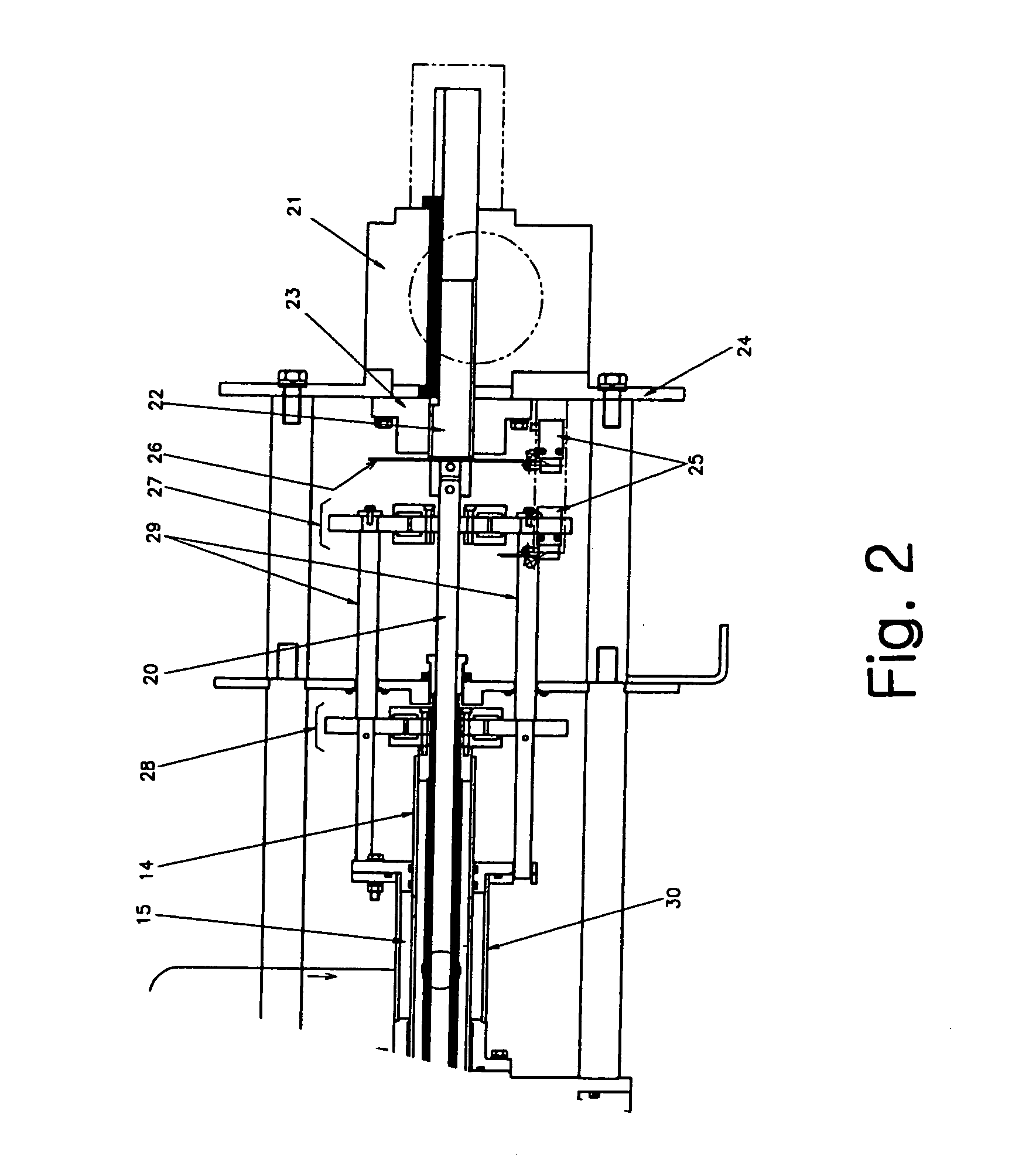

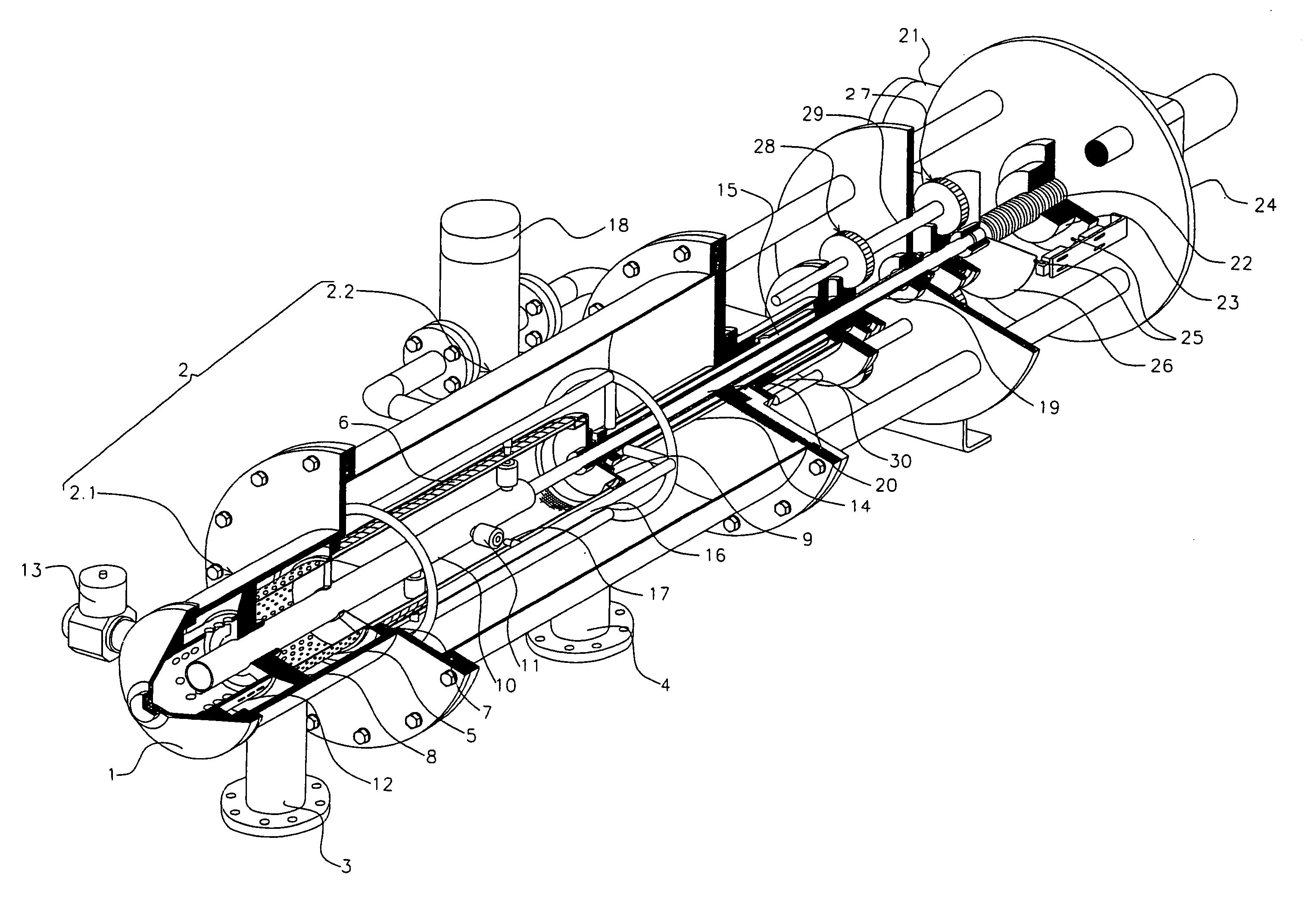

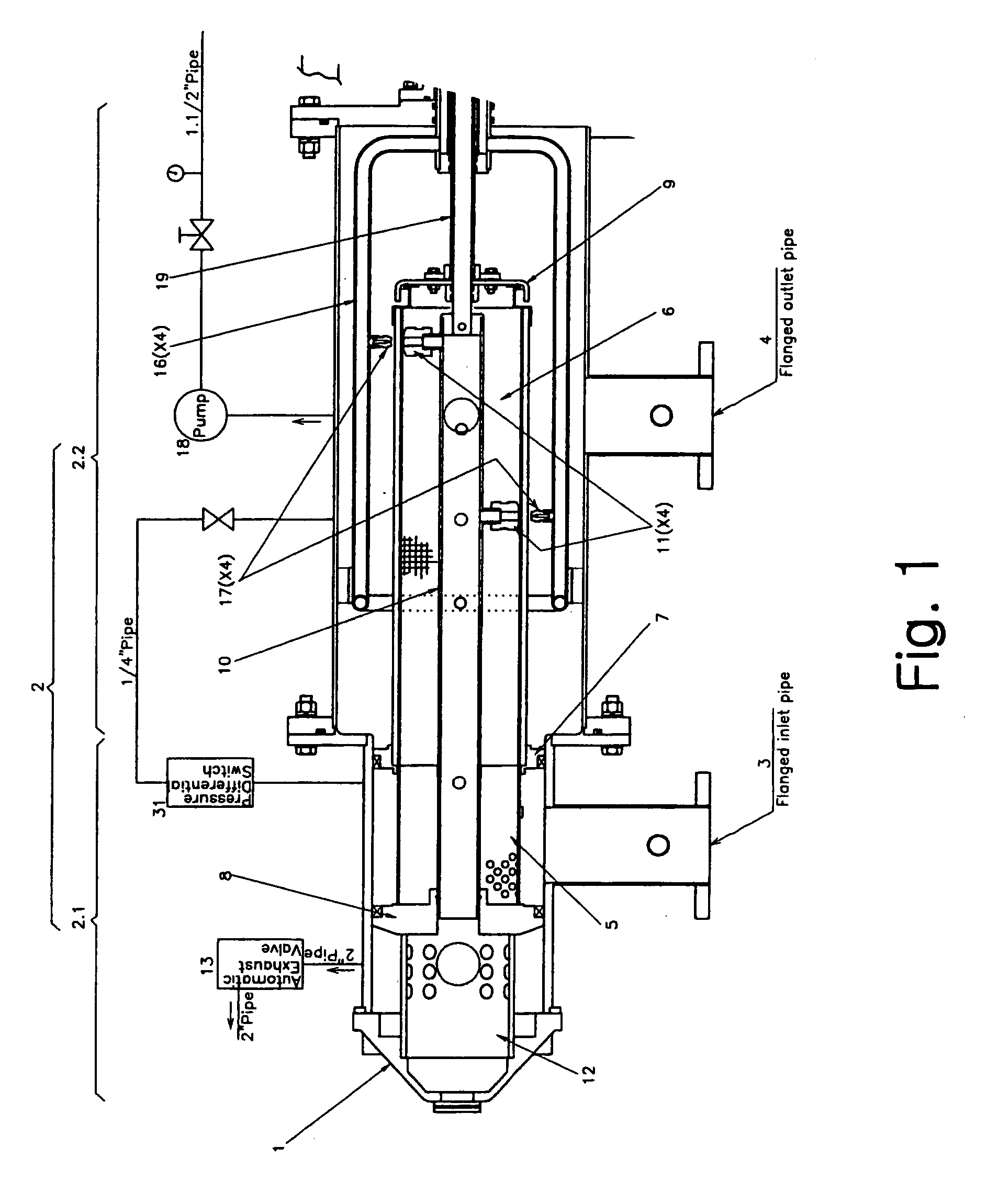

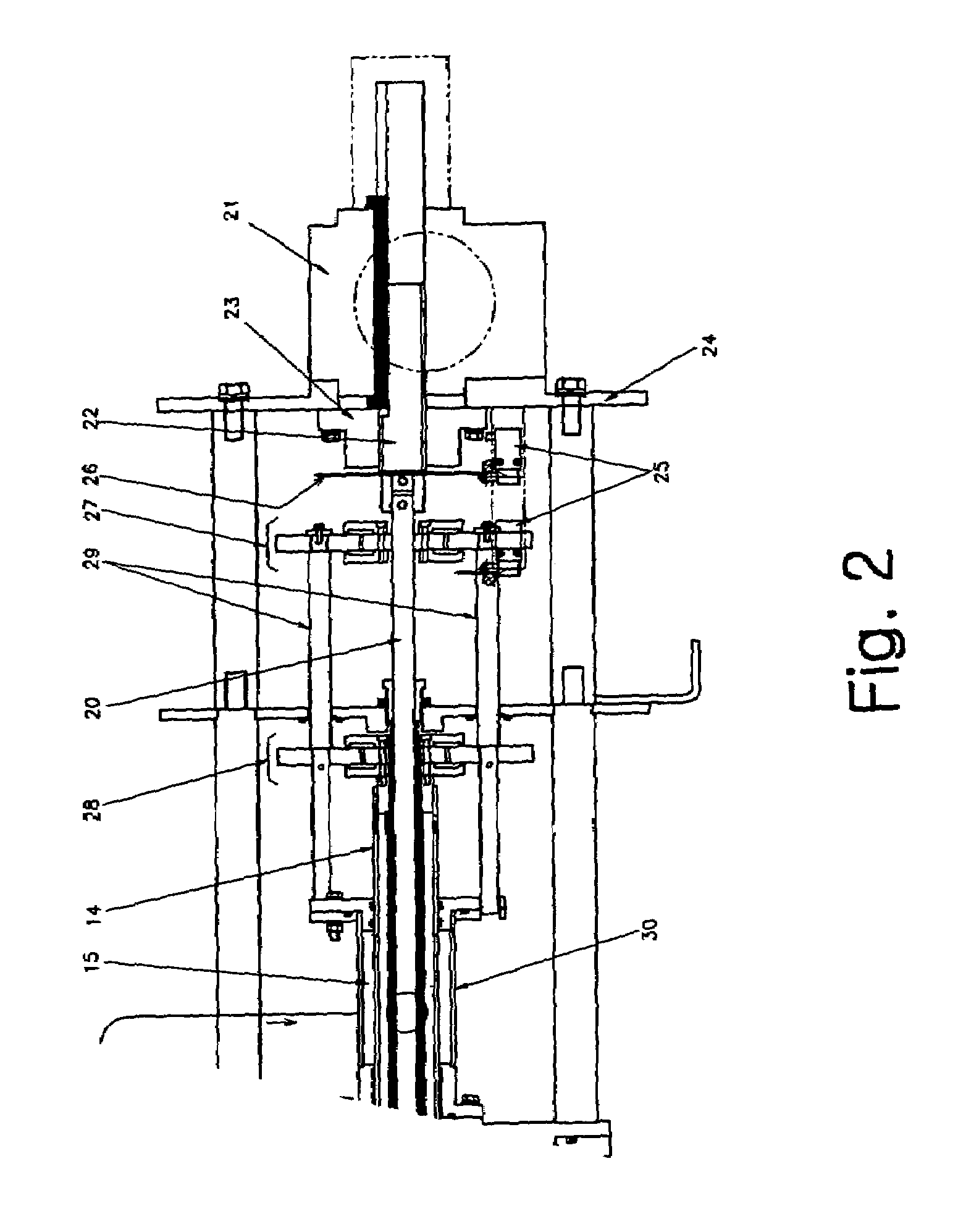

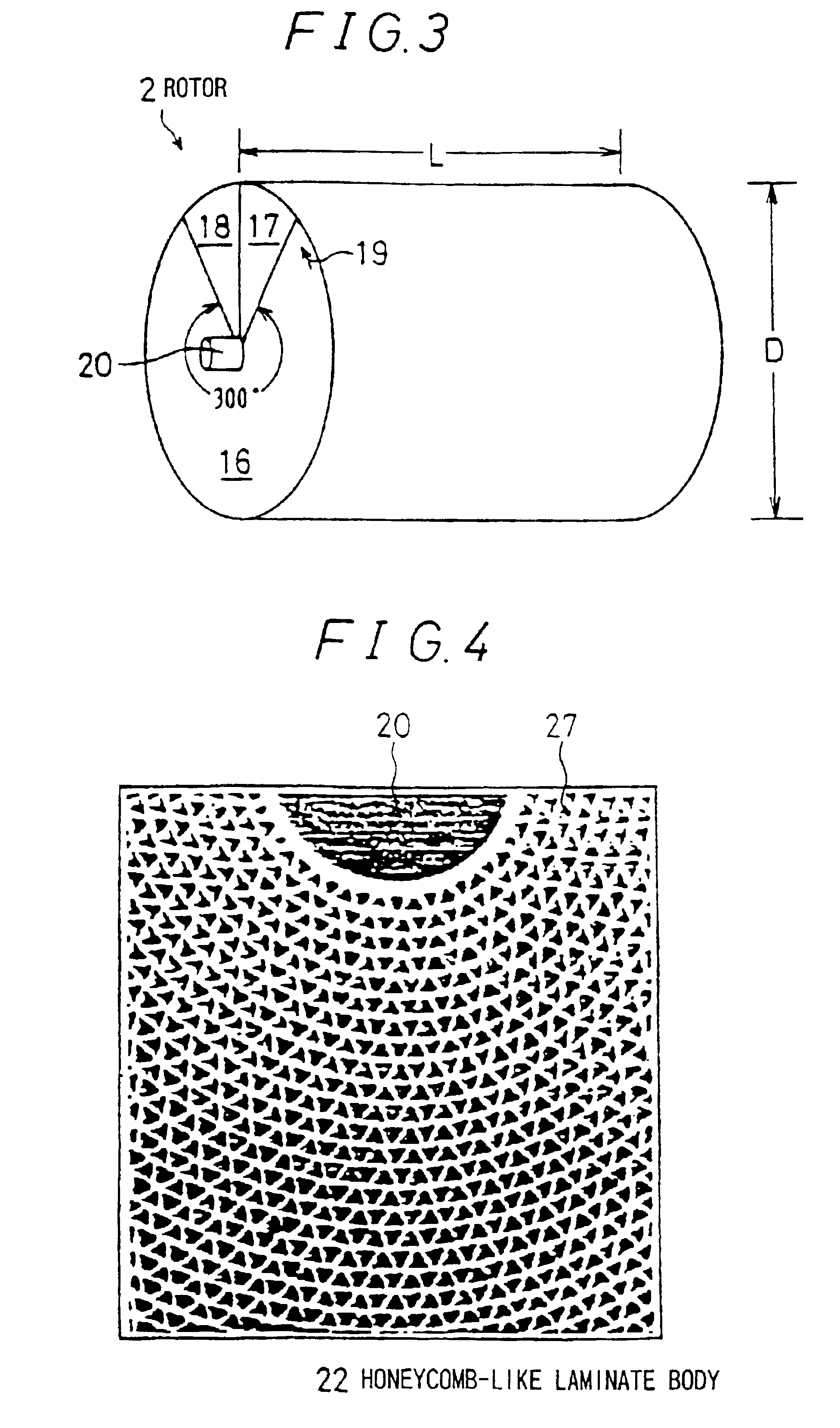

Self-cleaning mechanical filter

ActiveUS20060043014A1Long operationClean enoughMembrane filtersLoose filtering material filtersEngineeringMechanical filter

A self-cleaning mechanical filter comprises a mechanism for simultaneously cleaning the internal surface and the external surface of a filter element. The filter is provided with structure for performing suction scanning of solid materials accumulated on the internal surface of the filter element, and structure which can be operated in synchronization with the suction scanning structure for backwashing the external surface of the filter element during a self-cleaning process.

Owner:AJ BASSTECH

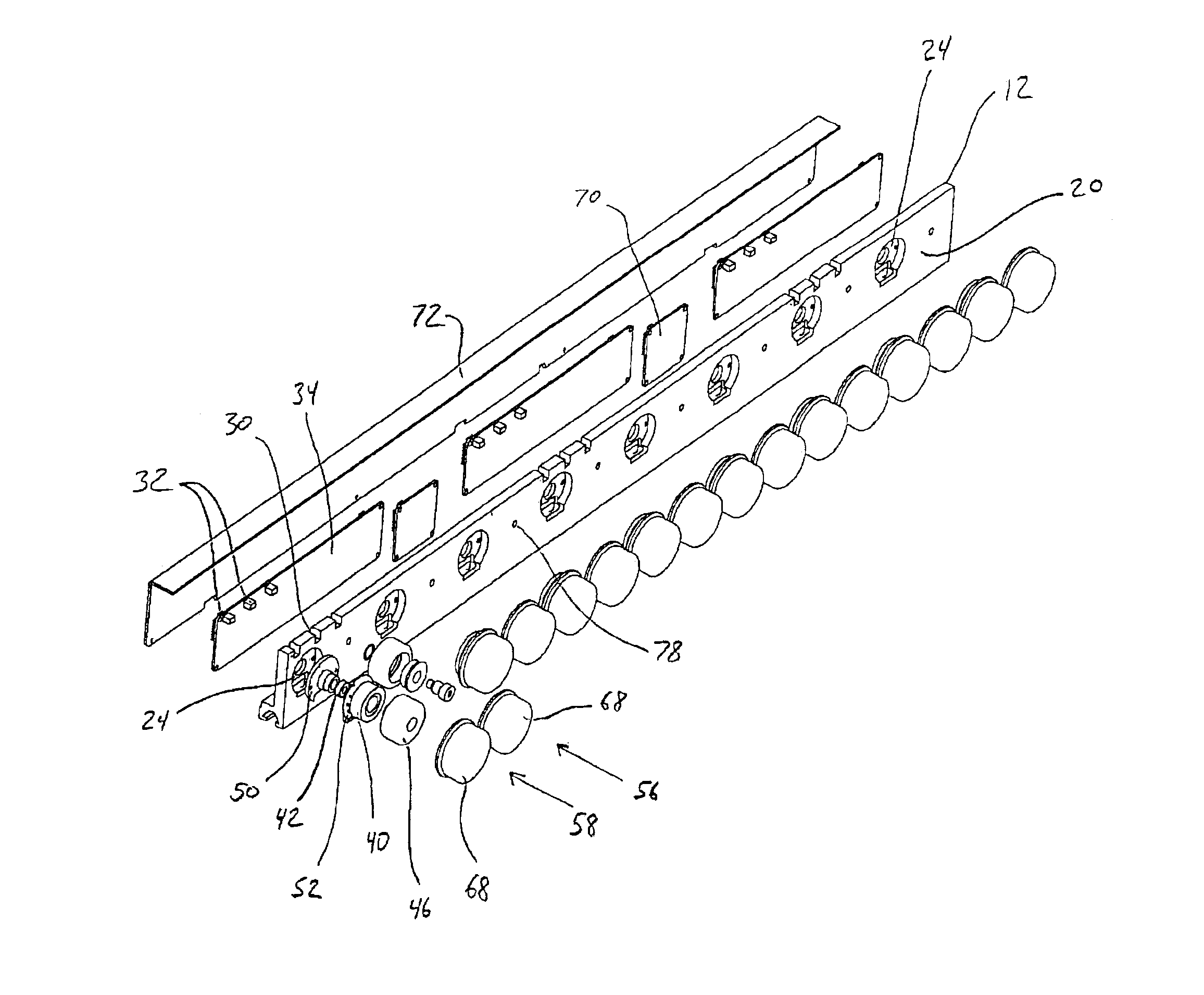

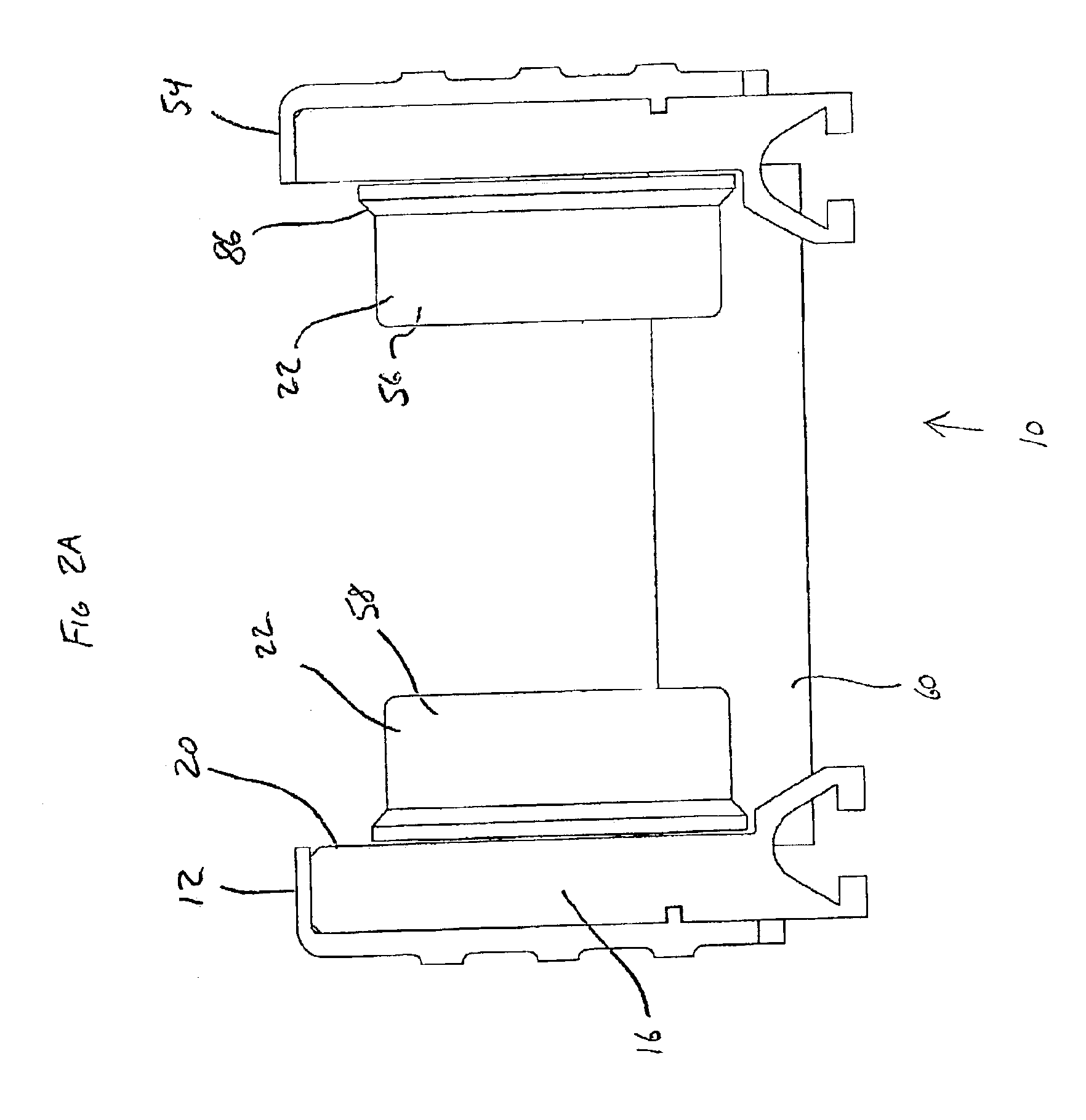

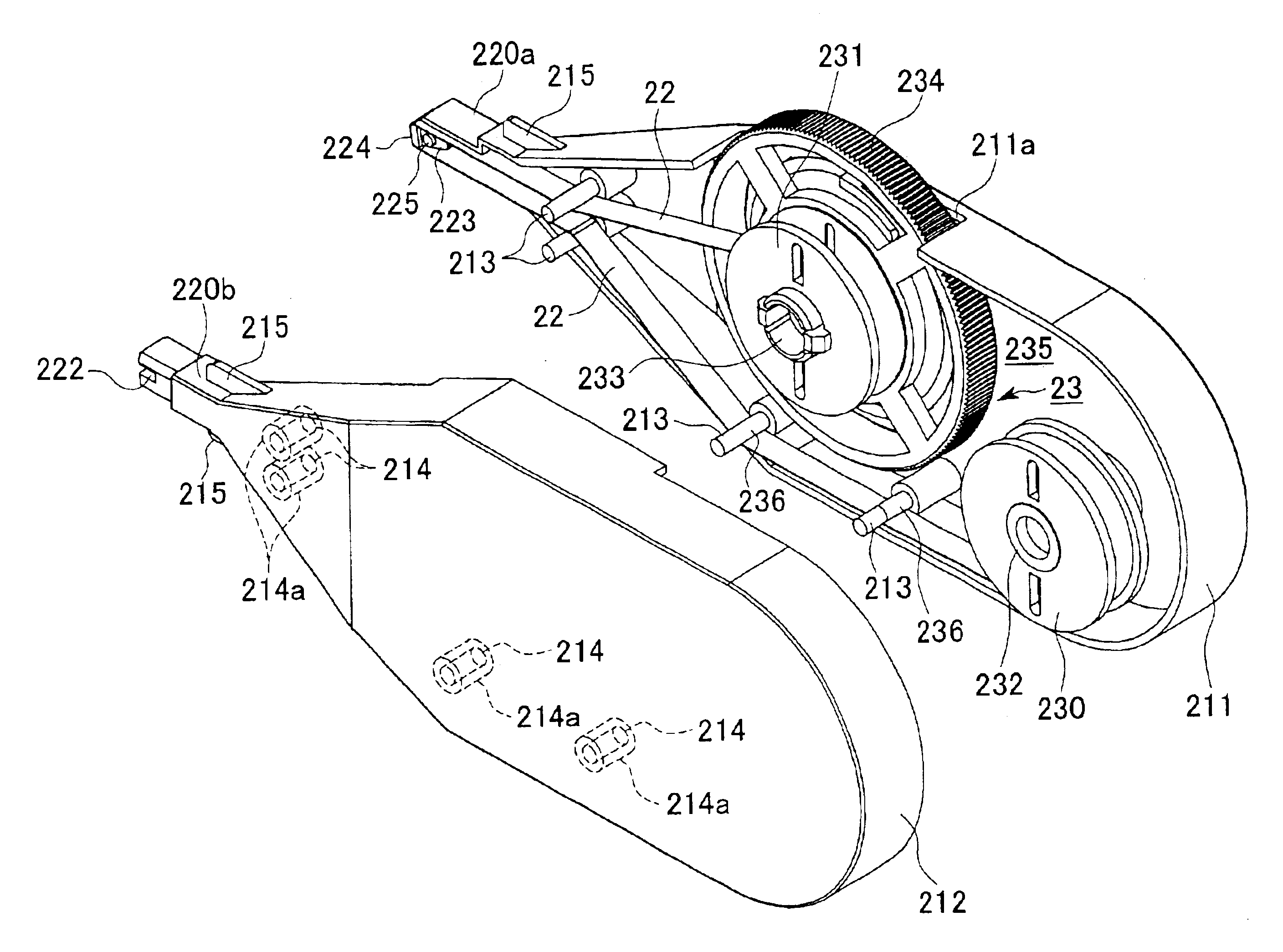

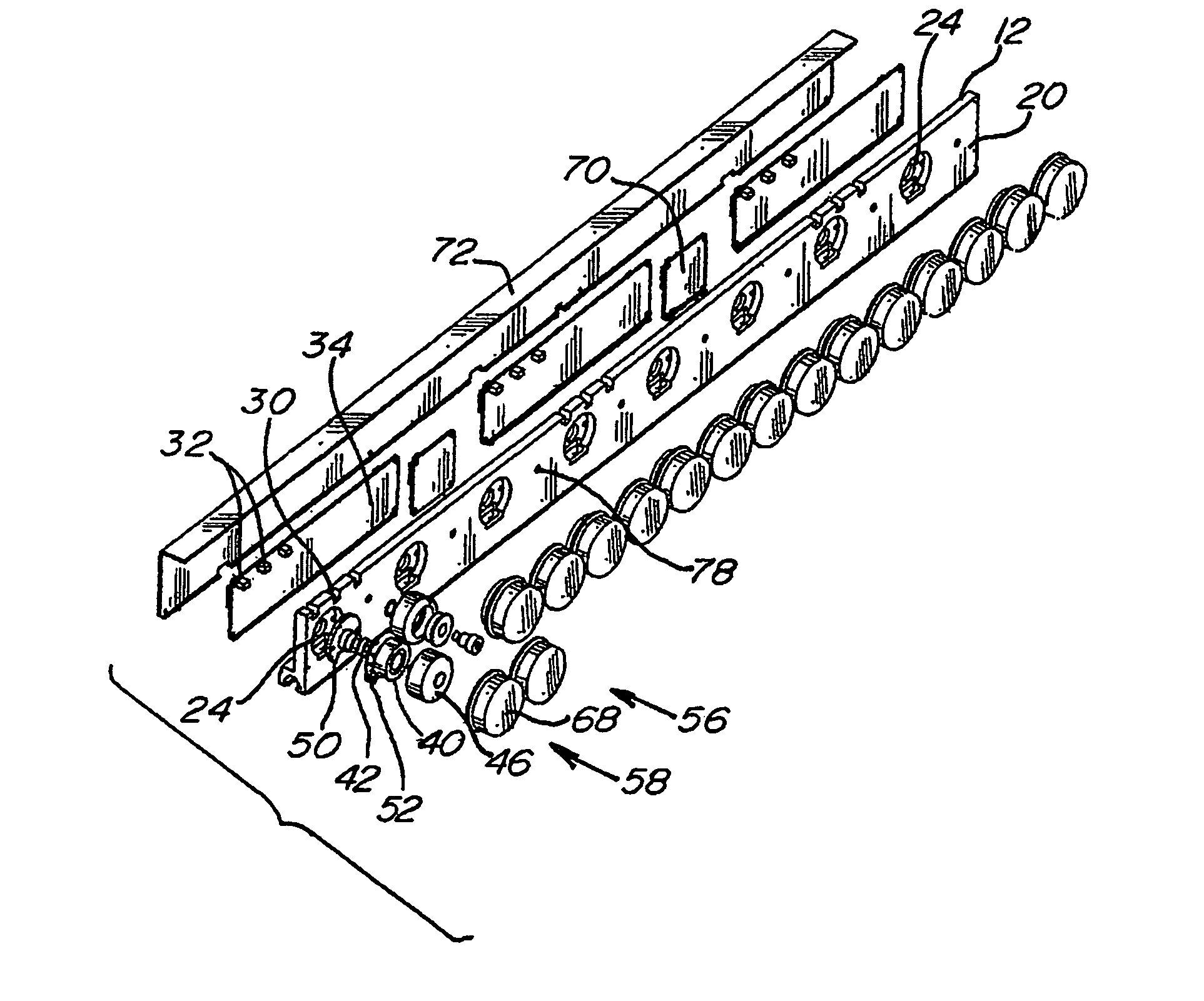

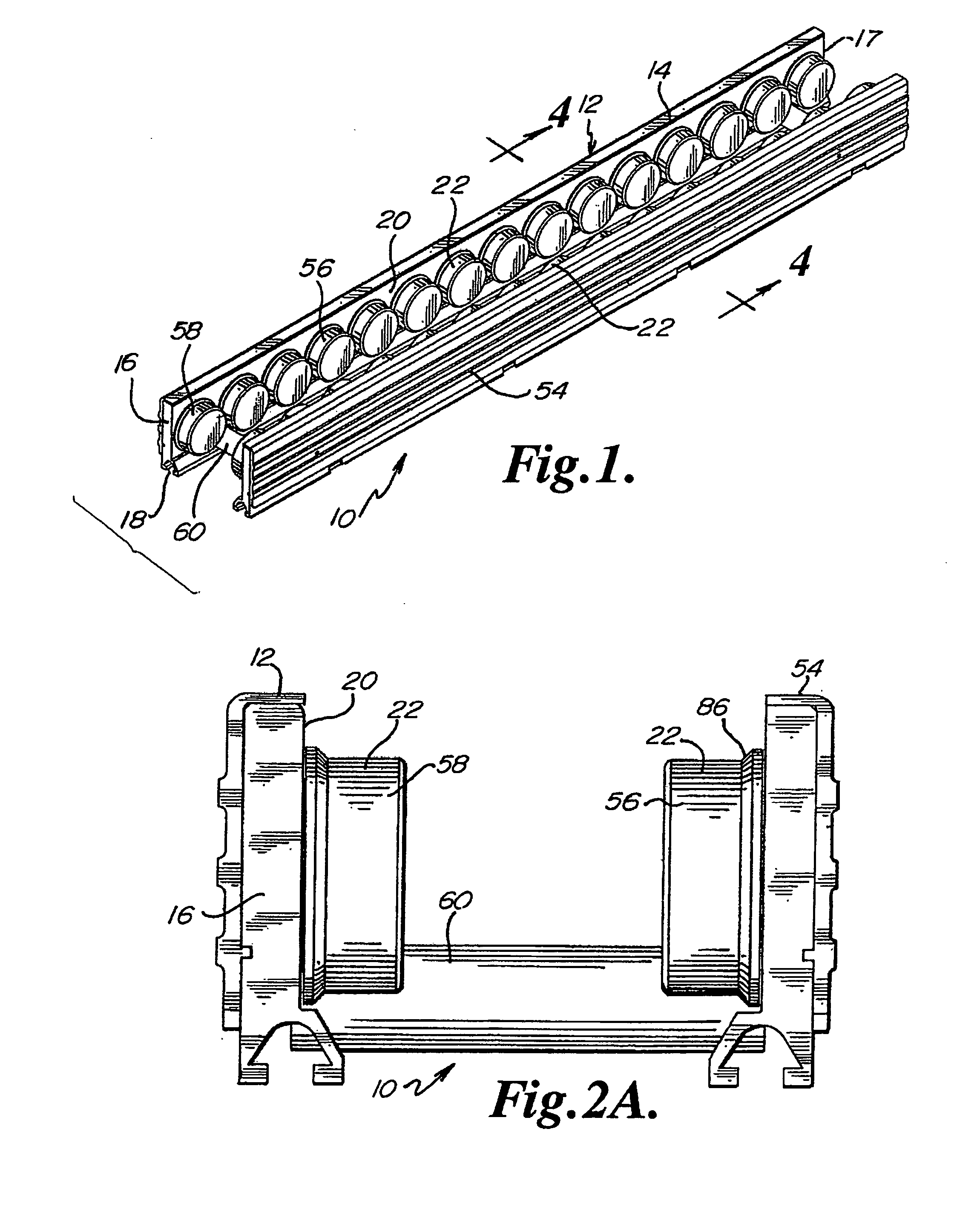

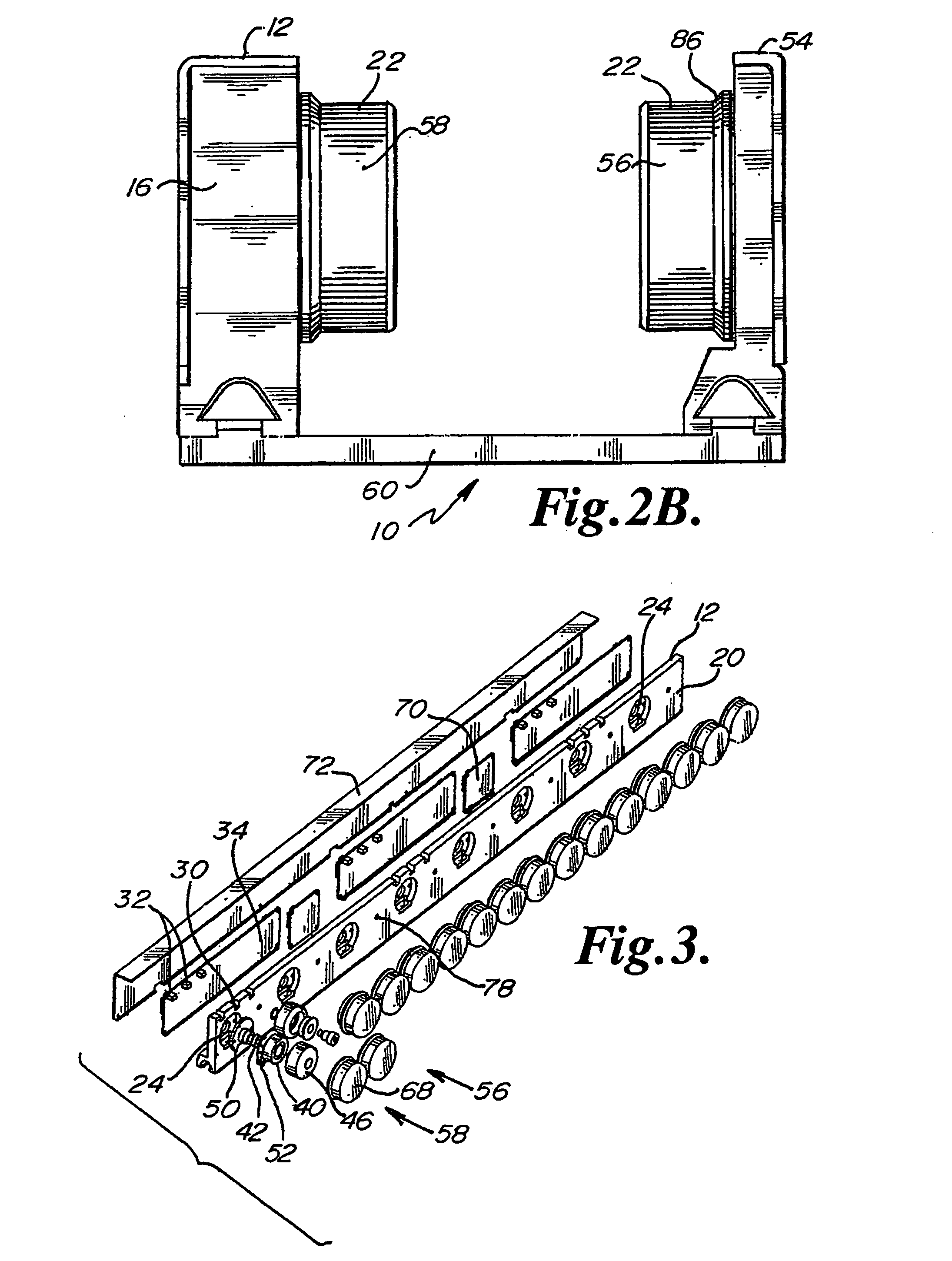

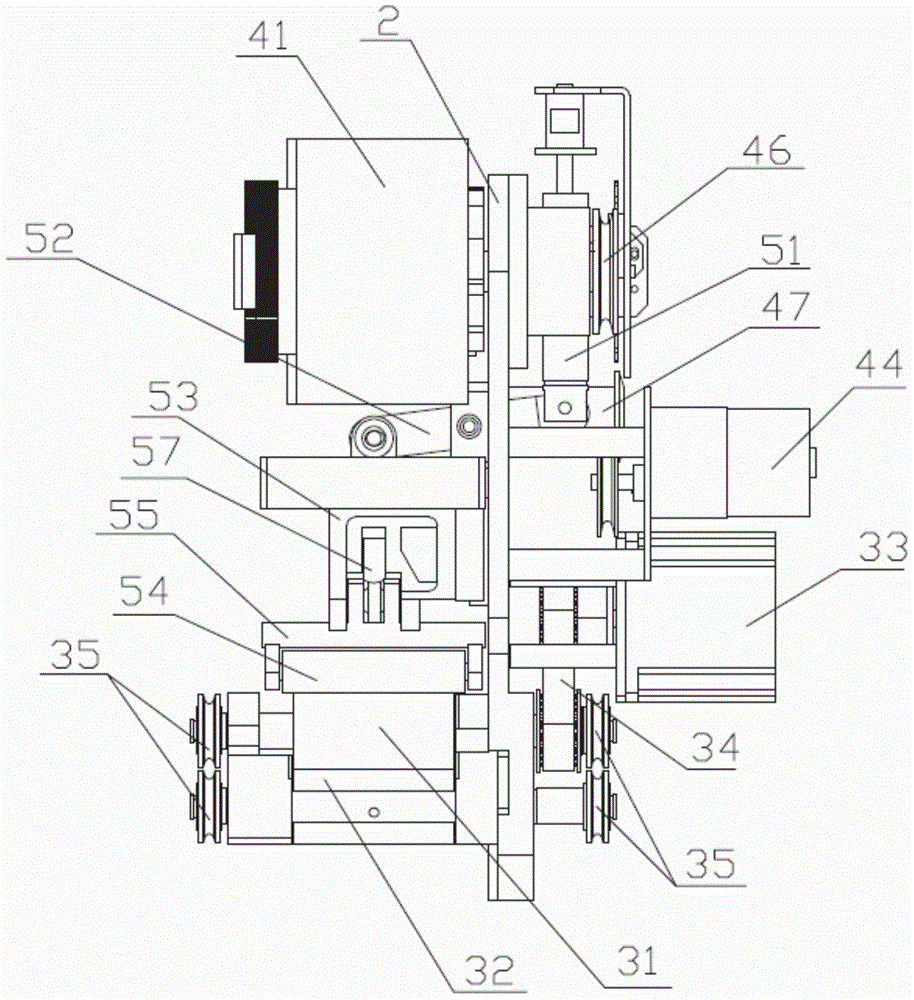

Conveyor assembly

InactiveUS6959804B2Simple and inexpensive componentMinimize the risk of damageConveyorsRollersEngineeringElectric motor

The conveyor apparatus disclosed herein is generally formed of a first rail and a second rail, each rail having a plurality of rollers. A portion of the rollers are desirably drive rollers, receiving power from an integral motor assembly. The motor generally comprises a stator that is coupled to the rail and an outer roller assembly rotatably coupled to the rail. The roller assembly includes an outer circumferential magnetized portion positioned in surrounding engagement to the motor stator and functions both as the motor rotor and the conveying surface of the roller. Non-slip roller covering material may be attached to the exterior of the roller assembly. A circuit board having logic controls is preferably in communication with at least one sensor and the motor rotor to regulate rotation of the motor rotor during use of the conveyor.

Owner:ACTIVAR TECHN PRODS GROUP

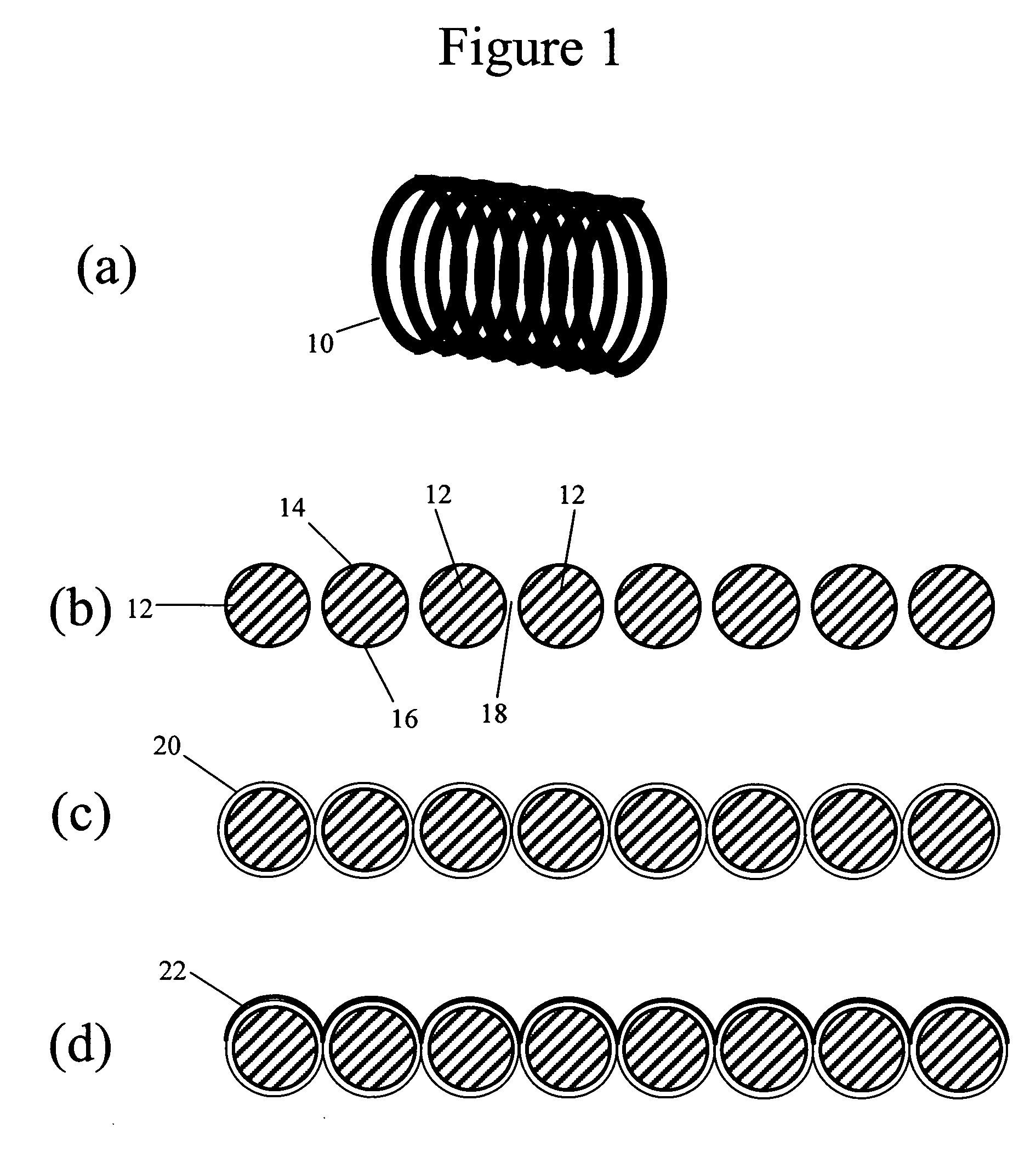

Compliant polymeric coatings for insertable medical articles

ActiveUS20060210816A1Simple coating processIncrease costMedical devicesPretreated surfacesPolymer scienceFunctional features

Compliant coatings for insertable medical articles are provided. In some aspects, the coating includes a diene polymer-containing layer, and a second coated layer that includes another polymer. The coating can be formed by coupling the polymer of the second coated layer to the first coated layer via latent reactive groups, such as photoreactive groups. In other aspects, the insertable medical article has a coating that provides different functional features to different surfaces of the article. The medical article can have a cylindrical shape with an interior surface having a first coating, and an exterior surface with a second coating, wherein the article also includes a plurality of openings.

Owner:SURMODICS INC

Lens cleaning apparatus

A turbidity degree calculating unit calculates a degree of the white turbidity U on a surface of the lens based on a brightness gradient g of an image I (x, y), and a lens cleaning control unit sets a lens cleaning mode for spraying at least one of the cleaning fluid and the compressed air, which is performed by the lens cleaning unit, based on the calculated turbidity degree U.

Owner:CLARION CO LTD

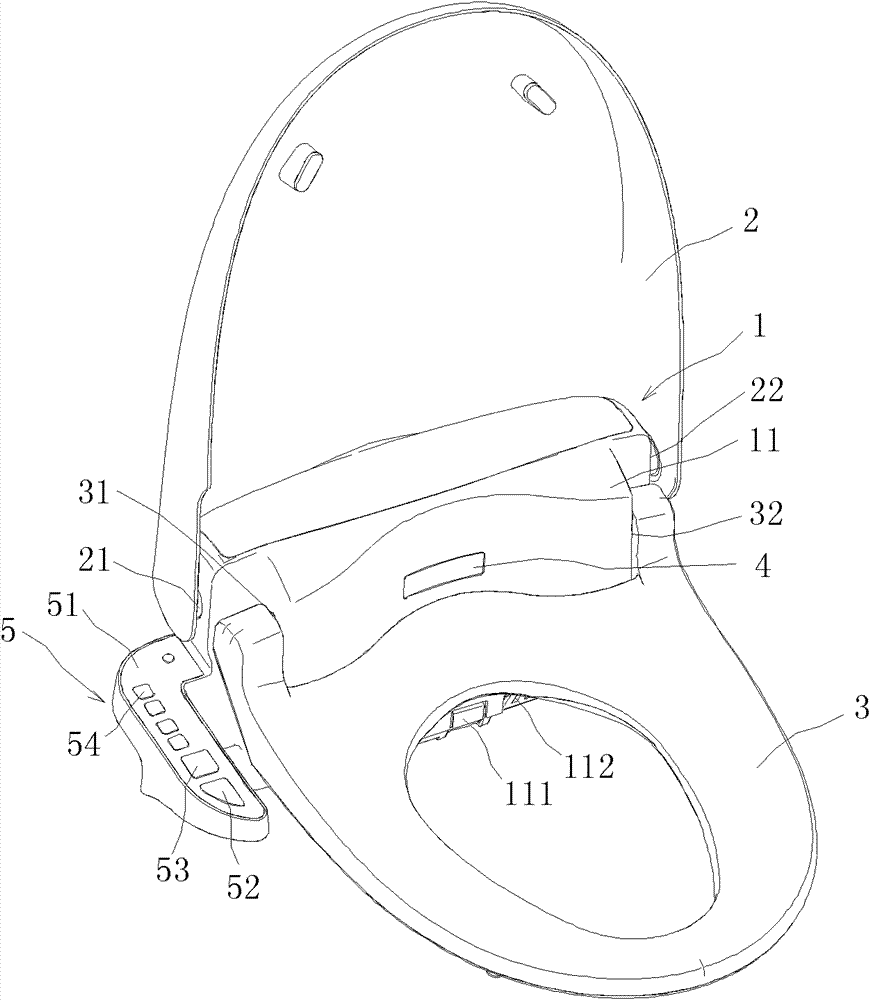

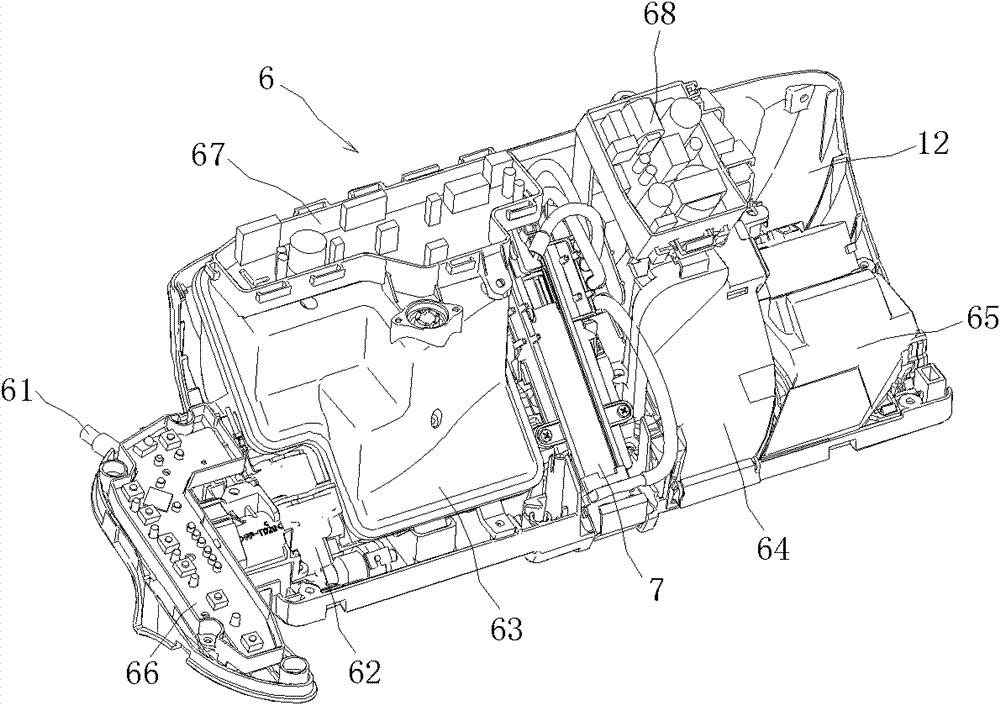

Spray nozzle cleaning method and warm water washlet device

The invention discloses a spray nozzle cleaning method which is used for cleaning a spray nozzle body of a spray nozzle assembly of a warm water washlet device. The method includes a fixed point cleaning step which includes that a baffle board of the spray nozzle assembly is located at a preset position relative to the spray nozzle body, a human body cleaning port arranged on the spray nozzle body sprays first water flow which is reflected to be along a preset direction by a reflection portion on the inner side of the baffle board, and the reflected first water flow is used for cleaning the spray nozzle body. The invention further discloses the warm water washlet device for implementing the spray nozzle cleaning method. The warm water washlet device comprises the spray nozzle assembly which comprises a bracket and the spray nozzle body installed on the bracket, and the baffle board with the reflection portion on the inner side is arranged on the bracket; and according to the reflection portion, under the condition that the relative position between the spray nozzle body and the baffle board is changed, the reflection direction of the first water flow sprayed by the human body cleaning port arranged on the spray nozzle body is changed.

Owner:PANASONIC APPLIANCES CHINA CO LTD +1

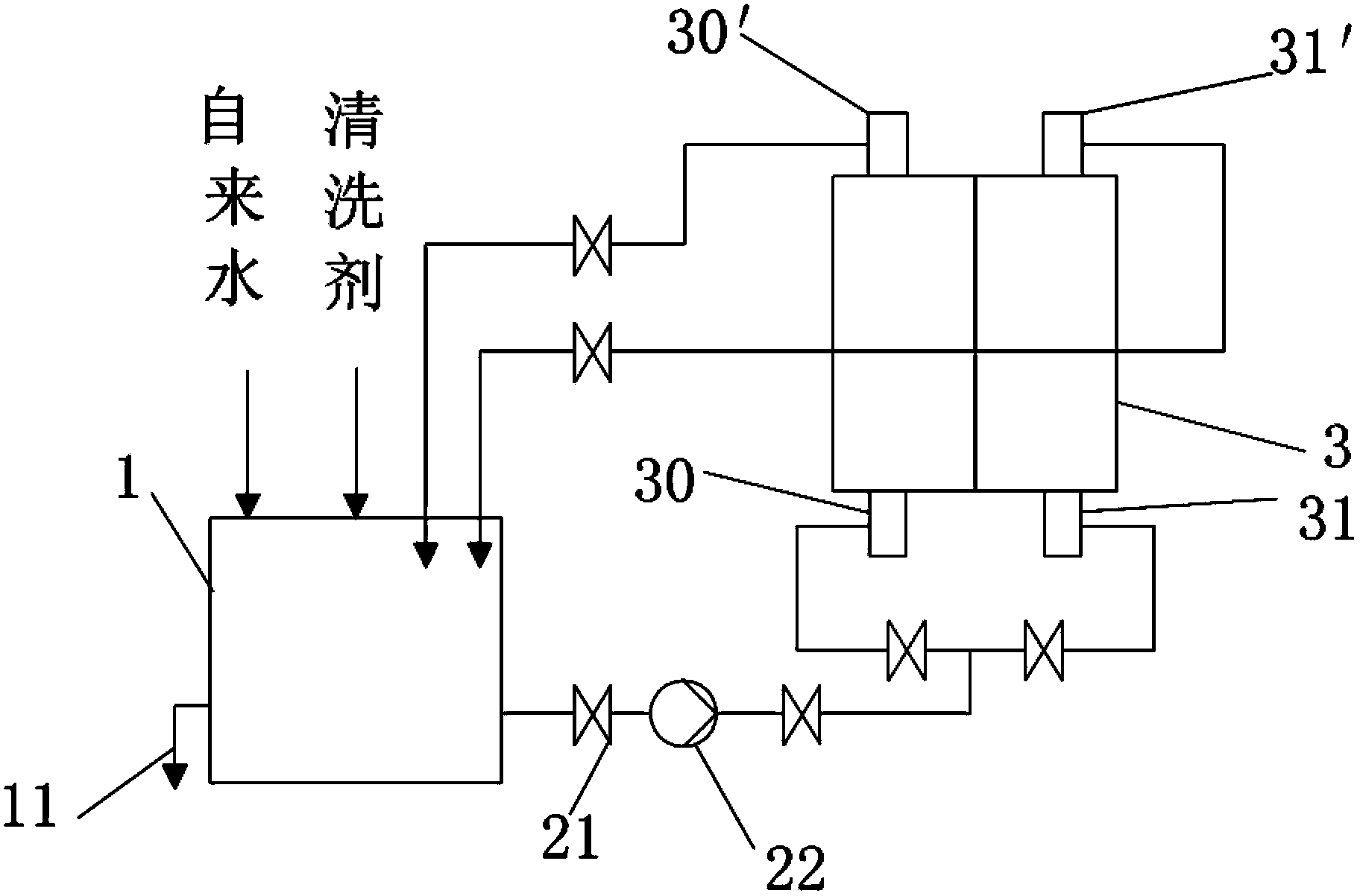

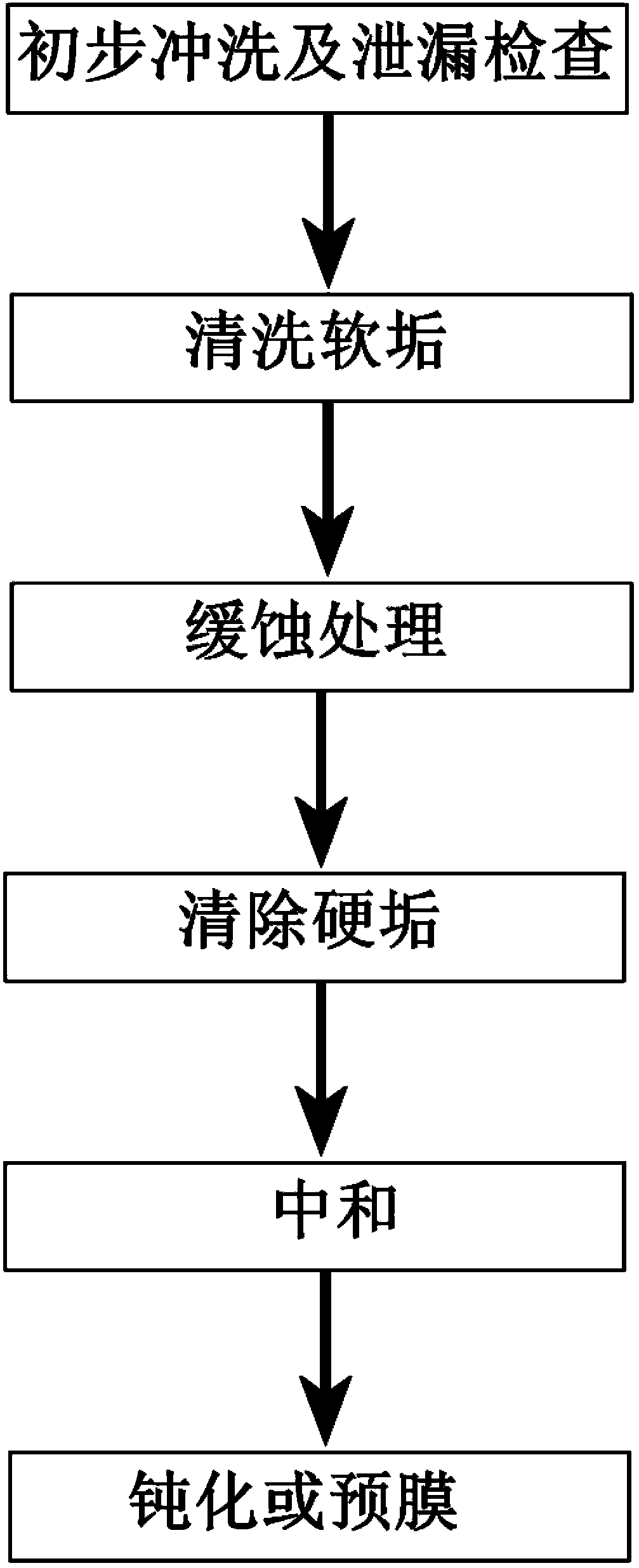

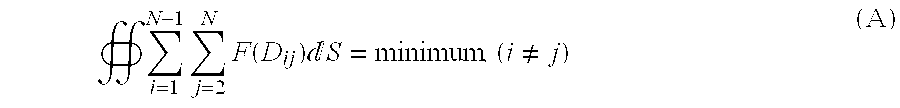

Low-corrosion and high-cleanness chemical cleaning method for condenser

The invention discloses a low-corrosion and high-cleanness chemical cleaning method for condenser. The cleaning process of the method is shown as follows: performing primary washing and leakage detection, adding a disinfectant slime remover for cleaning soft deposits, adding a Lan-826 multipurpose pickling inhibitor and a reducing agent to perform corrosion inhibition treatment, adding aGJ-2E rust removal and descaling agent and a Lan-826 multipurpose pickling inhibitor for removing hard scale, neutralizing with an alkaline cleaning neutralizer, and passivating or pre-filming. The method has the beneficial effects that the biological slime of the condenser is fully cleaned; the used corrosion inhibition method can be used for reducing the corrosion of the pickling cleaning agent to the pipeline of the condenser, and improving the service life of the pipeline of the condenser; meanwhile, the used pickling cleaning agent can be used for fully cleaning the pipeline hard scale, and the pipeline is cleaned more drastically; the cleaning time is short, the descaling efficiency is high, the labor intensity is low, the technology is simple, and the operation parameter of the cleaned set mainly achieves the plate rating.

Owner:HANGZHOU GUANJIE IND CLEANING WATER TREATMENT TECH

Self-cleaning mechanical filter

ActiveUS7055699B2Long operationClean enoughMembrane filtersLoose filtering material filtersEngineeringMechanical filter

A self-cleaning mechanical filter comprises a mechanism for simultaneously cleaning the internal surface and the external surface of a filter element. The filter is provided with structure for performing suction scanning of solid materials accumulated on the internal surface of the filter element, and structure which can be operated in synchronization with the suction scanning structure for backwashing the external surface of the filter element during a self-cleaning process.

Owner:AJ BASSTECH

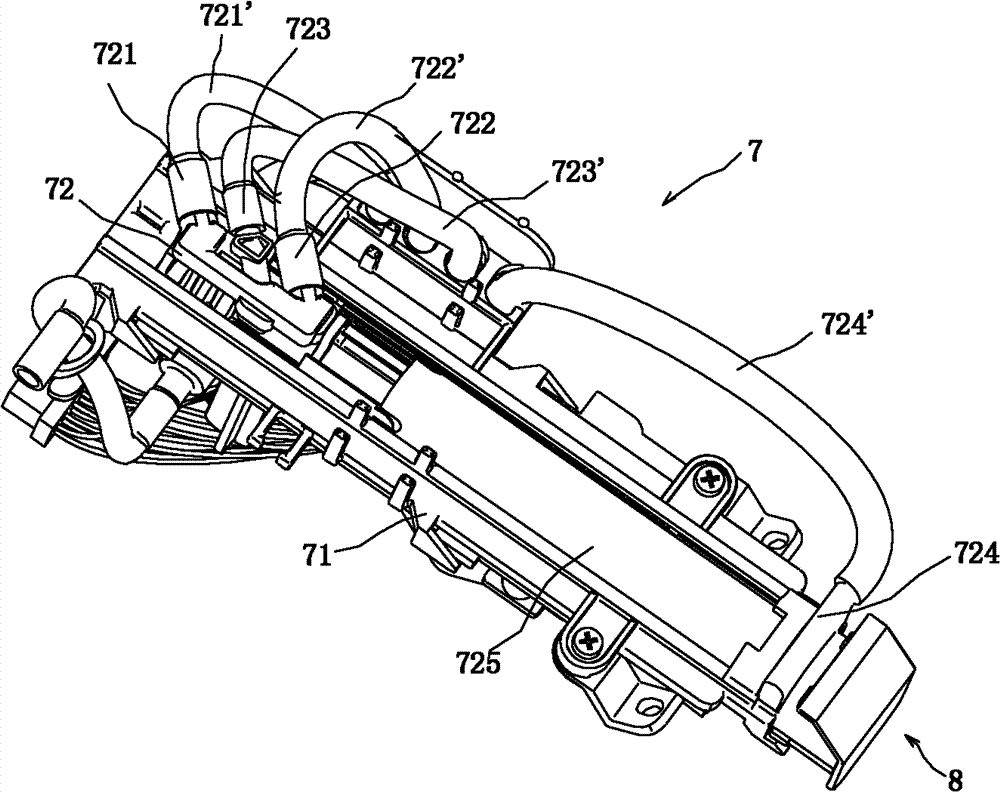

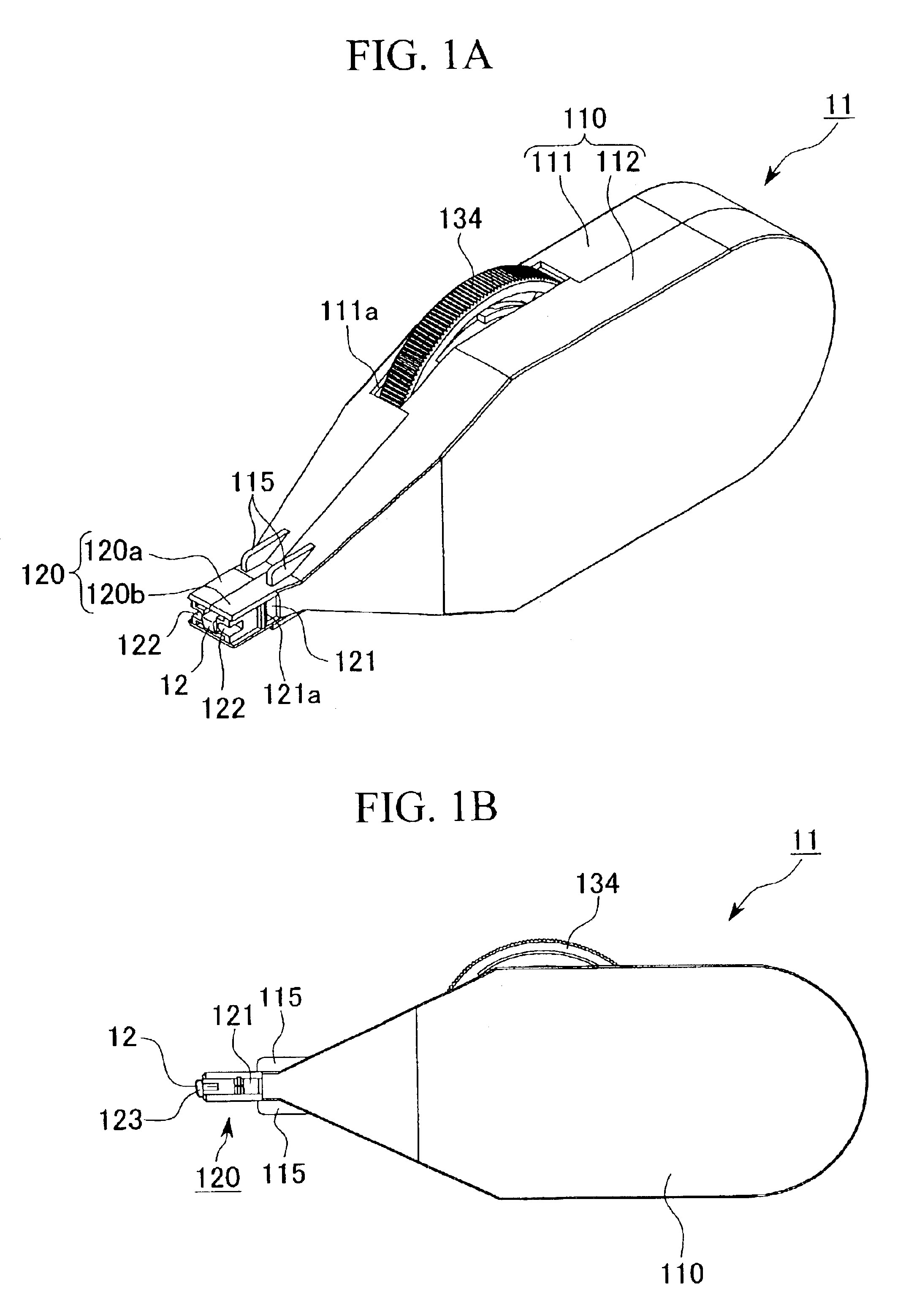

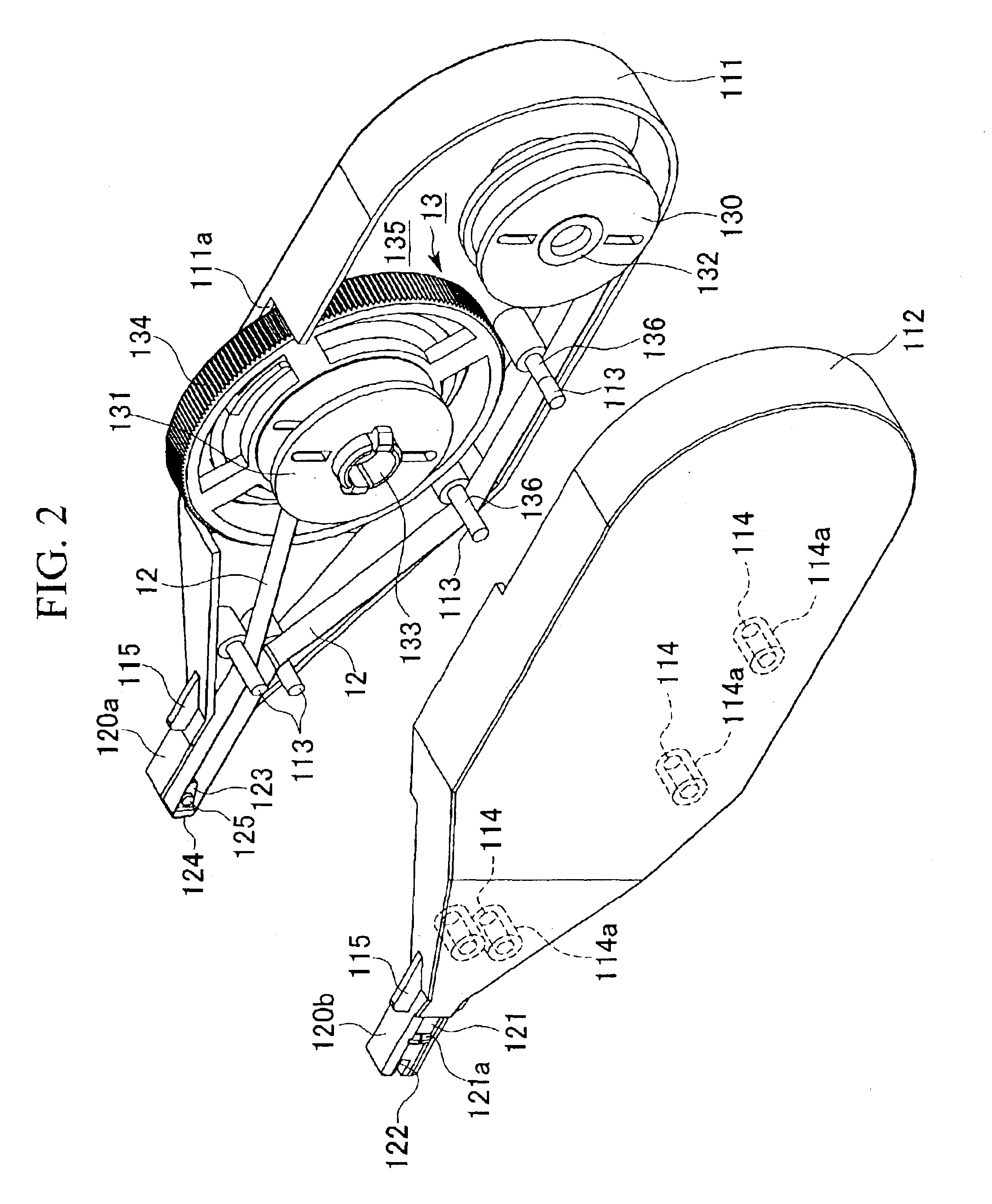

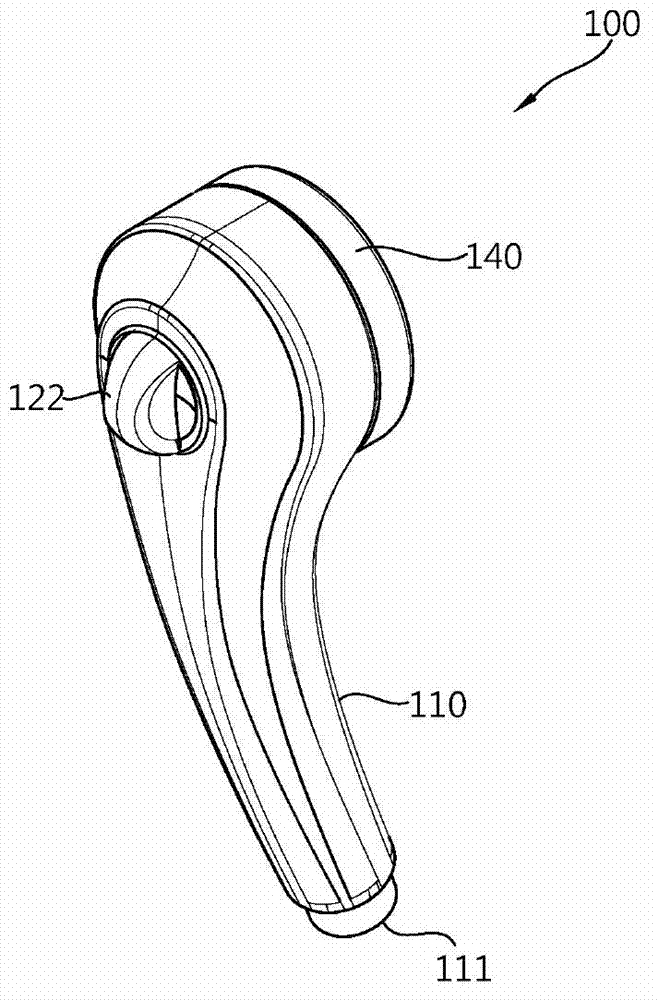

Optical connector cleaning tool

InactiveUS6905251B2Easy to disassemble and operateEasy to cleanLiquid processingCarpet cleanersEngineeringMechanical engineering

An optical connector cleaning tool, which can easily and reliably clean a connecting end face of an optical connector while the optical connector is disposed in a connector housing, is disclosed. The optical connector cleaning tool comprises a tool body, and an insertion portion which is provided so as to project from the tool body, and which is adapted to be inserted into the connector housing, and the optical connector cleaning tool is adapted such that the cleaning element disposed at an end of the insertion portion projecting from the tool body is positioned and abutted against the connecting end face when the insertion portion is inserted into the connector housing. It is easy to insert the cleaning element into the connector housing and to abut the cleaning element against the connecting end face. Furthermore, it is easy to maintain the cleaning element in position abutting against the connecting end face when the cleaning element is moved for wiping the connecting end face.

Owner:THE FUJIKURA CABLE WORKS LTD

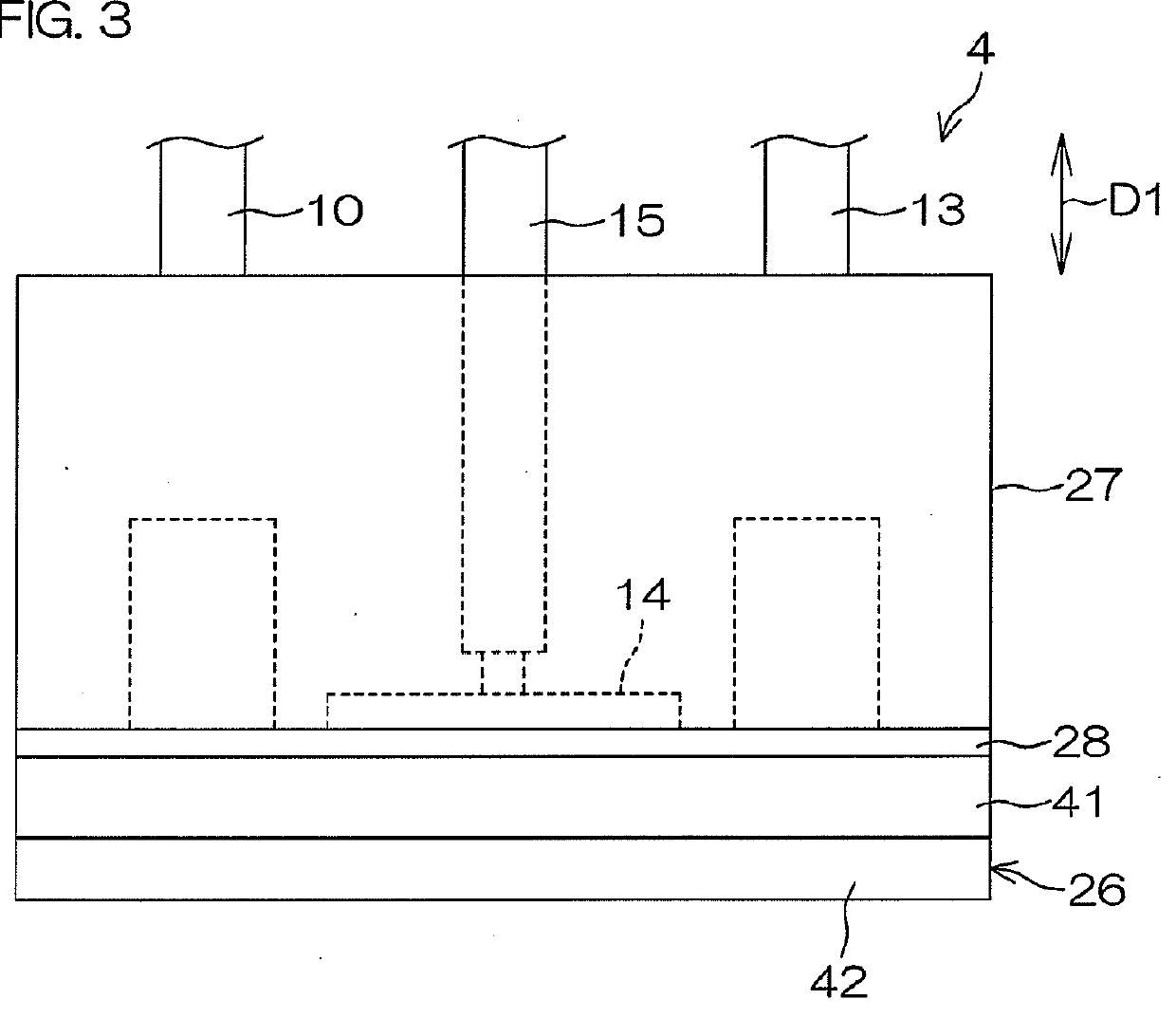

Nozzle, substrate processing apparatus, and substrate processing method

ActiveUS20120222707A1Variation in sizeVariation in speedMovable spraying apparatusSpray nozzlesWaste management

A nozzle for discharging droplets of a processing liquid for processing a substrate has a main body including a supply port, a drain port, a processing liquid flow passageway connecting the supply port and the drain port, and a plurality of discharge ports from which the processing liquid is discharged. The processing liquid flow passageway includes a plurality of branch flow channels, which branch out between the supply port and the drain port and collect together between the supply port and the drain port. The plurality of discharge ports form a plurality of columns respectively corresponding to the plurality of branch flow channels; and are aligned along and connected to the corresponding branch flow channels. A piezo element applies vibration to the processing liquid flowing through the plurality of branch flow channels.

Owner:DAINIPPON SCREEN MTG CO LTD

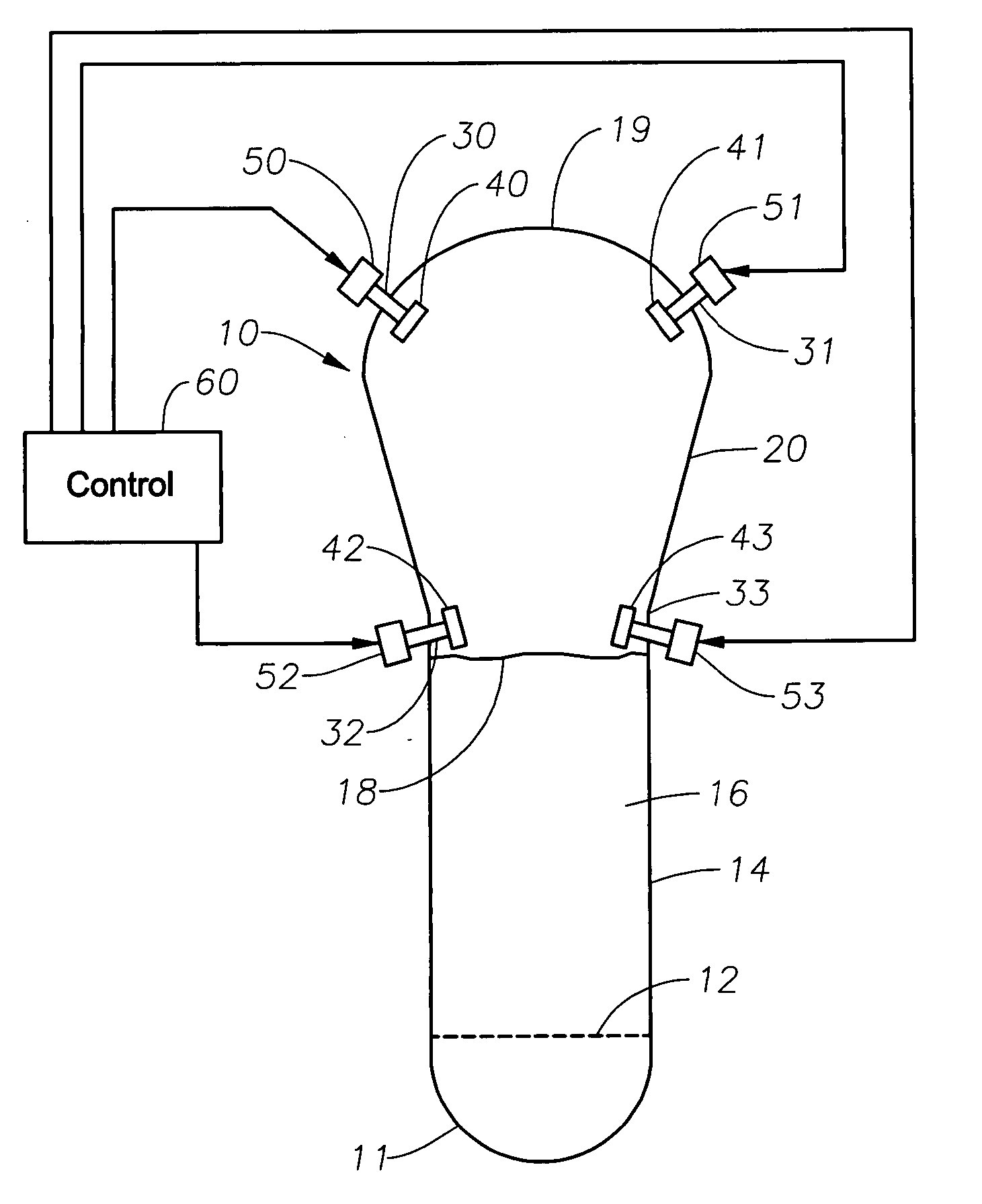

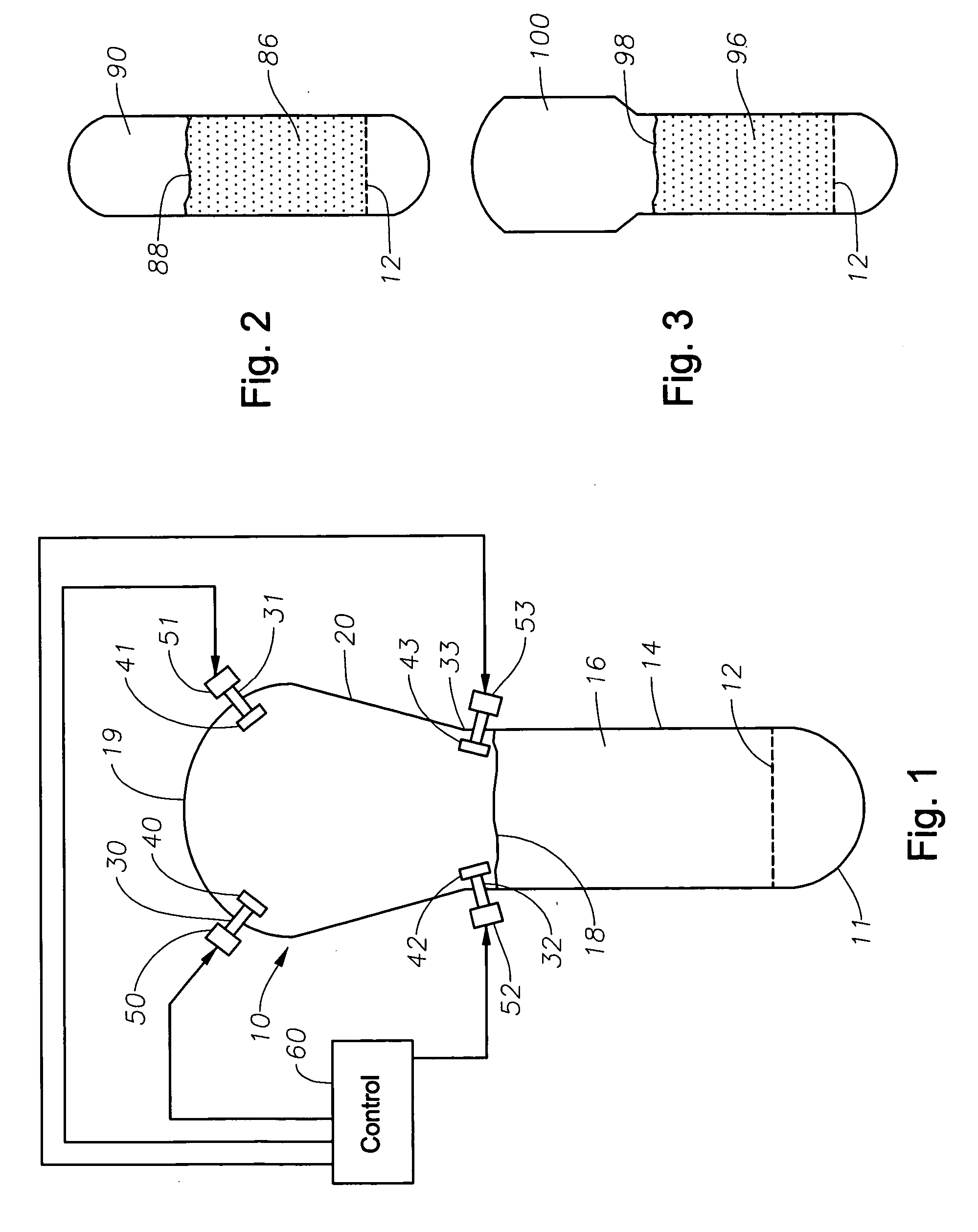

Method of bowel cleansing

InactiveUS7291324B2Lower the volumeSafe and effectiveDigestive systemPharmaceutical delivery mechanismIntestinal structureBowel cleansing

Stimulant laxative in combination with an osmotic laxative produces safe and effective bowel and colon cleansing with a reduced volume of liquid input. Administering to a patient an oral stimulant laxative, such as bisacodyl, followed, after a biologically determined interval, by a reduced volume of a PEG in water solution cleanses the bowels and colon in preparation for diagnostic colonoscopy, without the profuse uncontrollable diarrhea that typically follows either ingestion of large volume isotonic ravages, or smaller volume hypertonic lavages.

Owner:BRAINTREE LAB

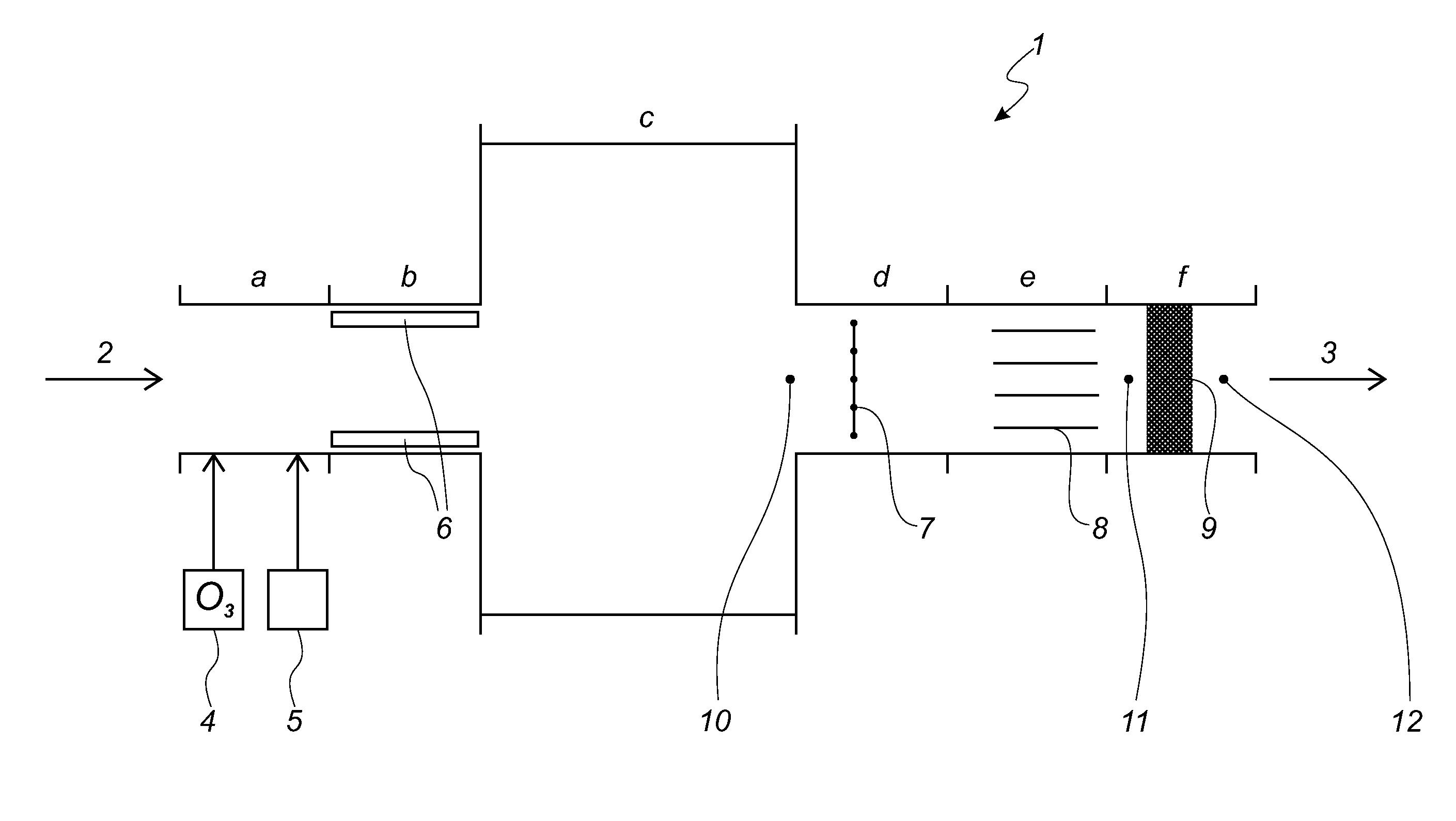

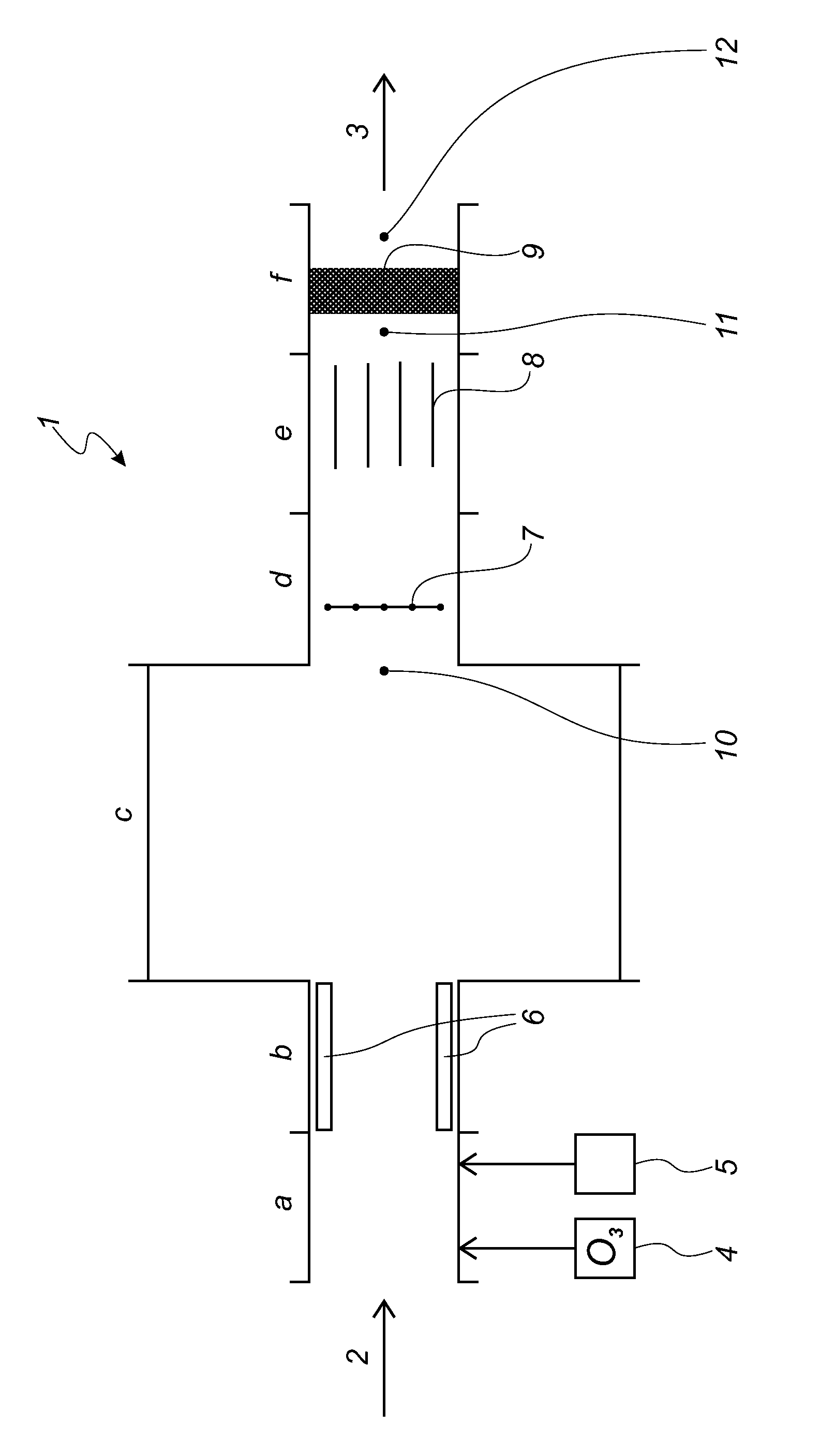

Method and device for cleaning air

ActiveUS8318084B2Health hazardSmall pressure dropMechanical apparatusLighting and heating apparatusSufficient timeUltraviolet lights

A method and device for cleaning air. The air to be cleaned is directed as a continuous flow in succession through a) a first zone wherein the air is treated with ozone and possibly also water, ammonia or other aerosol growth promoters; b) a second zone wherein the air is subjected to ultraviolet light; c) a third zone wherein the air is maintained for a sufficient time to allow aerosol growth; d) a fourth zone where particles in the air are given an electrical charge; e) a fifth zone wherein the air is passed through an electrostatic filter; and f) a sixth zone wherein the air flows over a catalyst to break down residual ozone.

Owner:UNIVERSITY OF COPENHAGEN

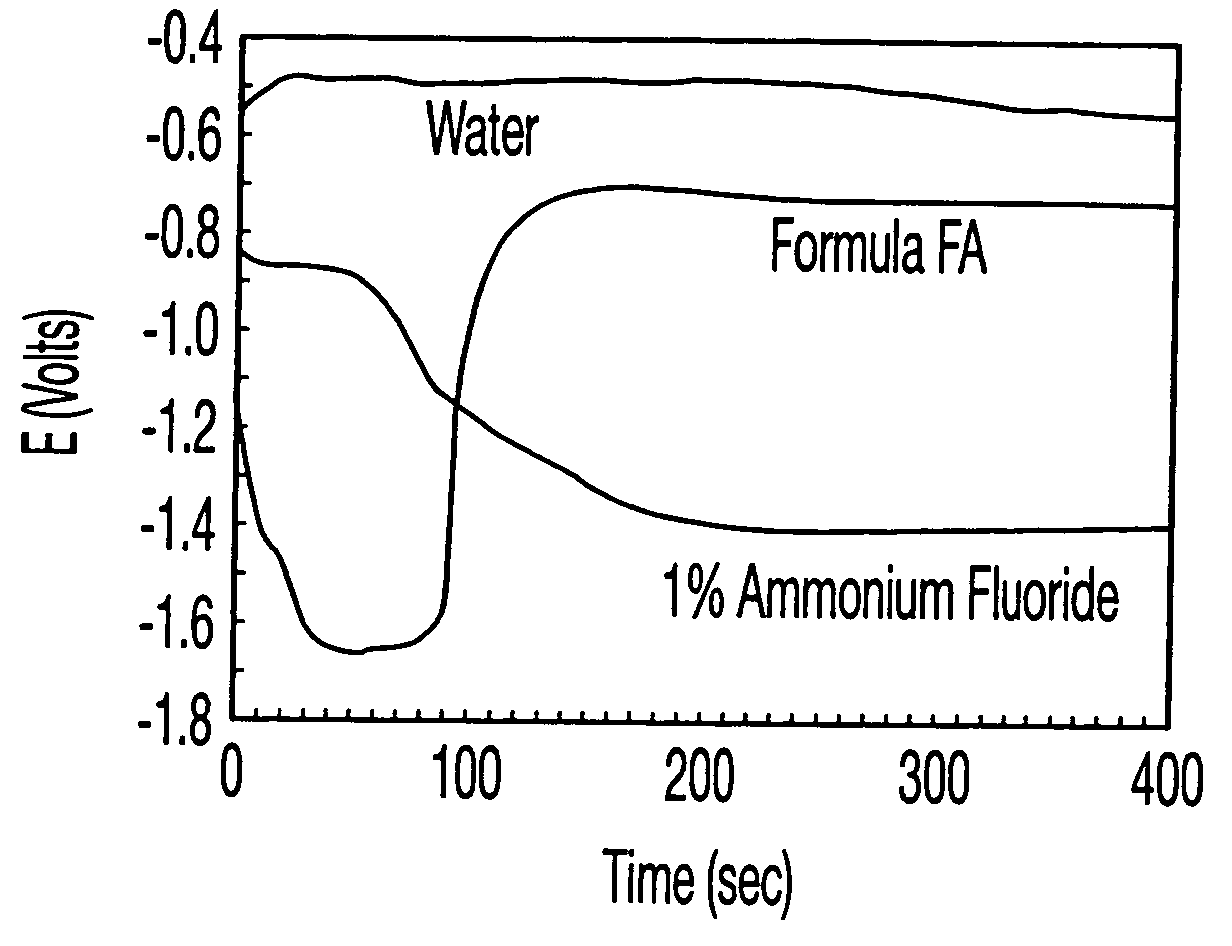

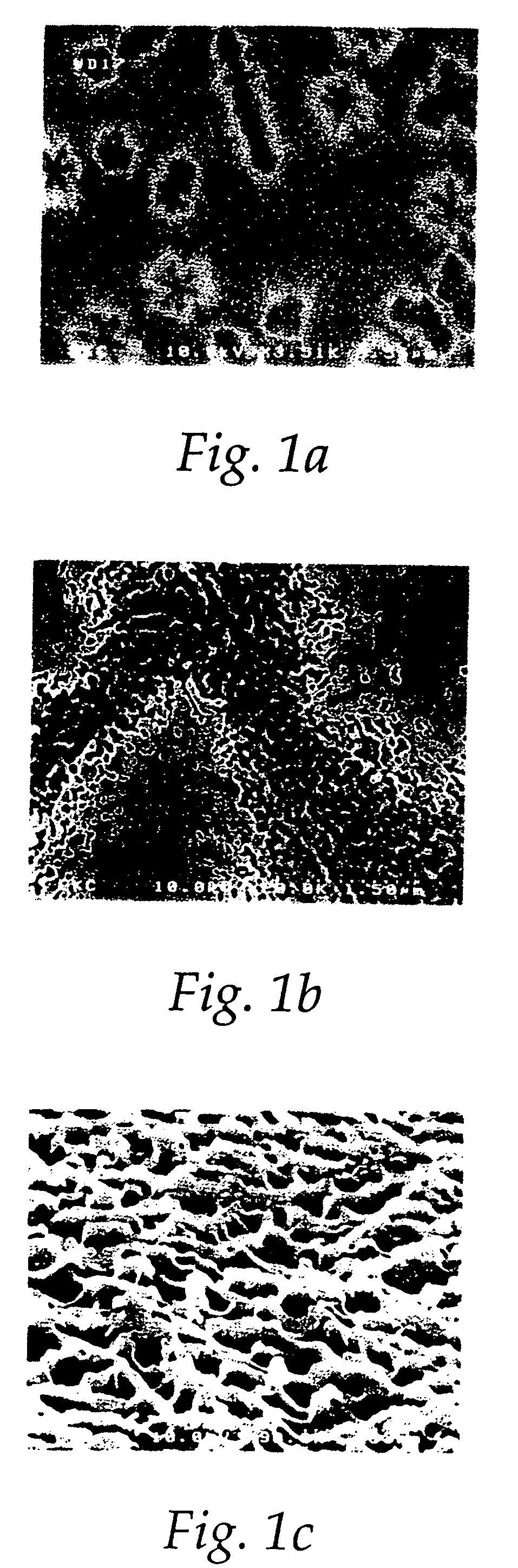

Forming a passivating aluminum fluoride layer and removing same for use in semiconductor manufacture

InactiveUS20060000492A1Enhance clean action and cleaning capabilityEffective temperatureDetergent mixture composition preparationSemiconductor/solid-state device manufacturingSolventFluoride salt

A composition for the cleaning of residues from substrates can contain from about 0.01 percent by weight to about 5 percent by weight of one or more fluoride compounds, from about 20 percent by weight to about 50 percent by weight water, from about 20 percent by weight to about 80 percent by weight of an organic amide solvent and from 0 to about 50 weight percent of an organic sulfoxide solvent. The composition can have a pH between about 7 and about 10, alternately from greater than 8 to about 10. Additionally, the composition optionally can contain corrosion inhibitors, chelating agents, surfactants, acids, and / or bases. In use of the composition, a substrate can advantageously be contacted with the composition for a time and at a temperature that permits cleaning of the substrate.

Owner:EKC TECH

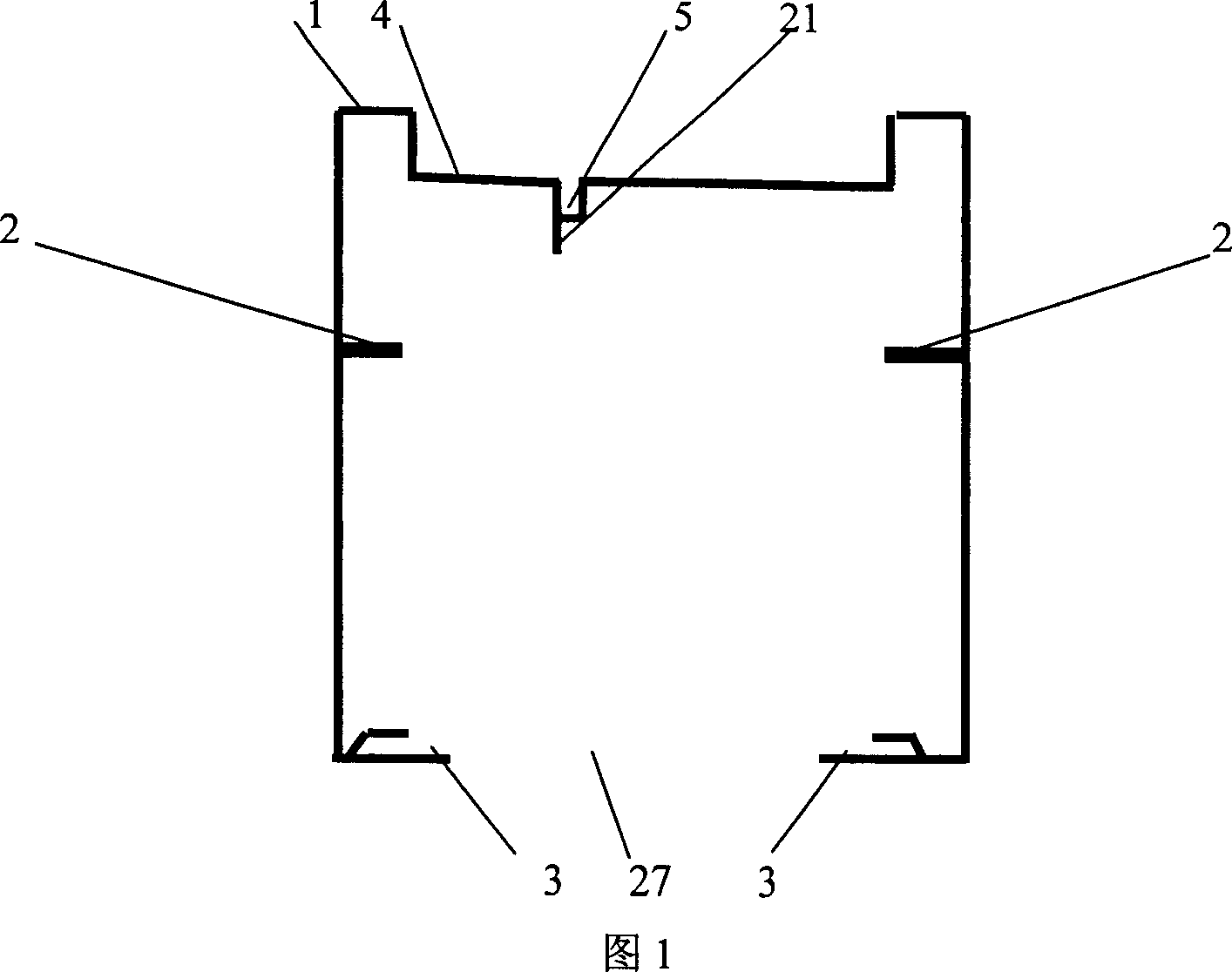

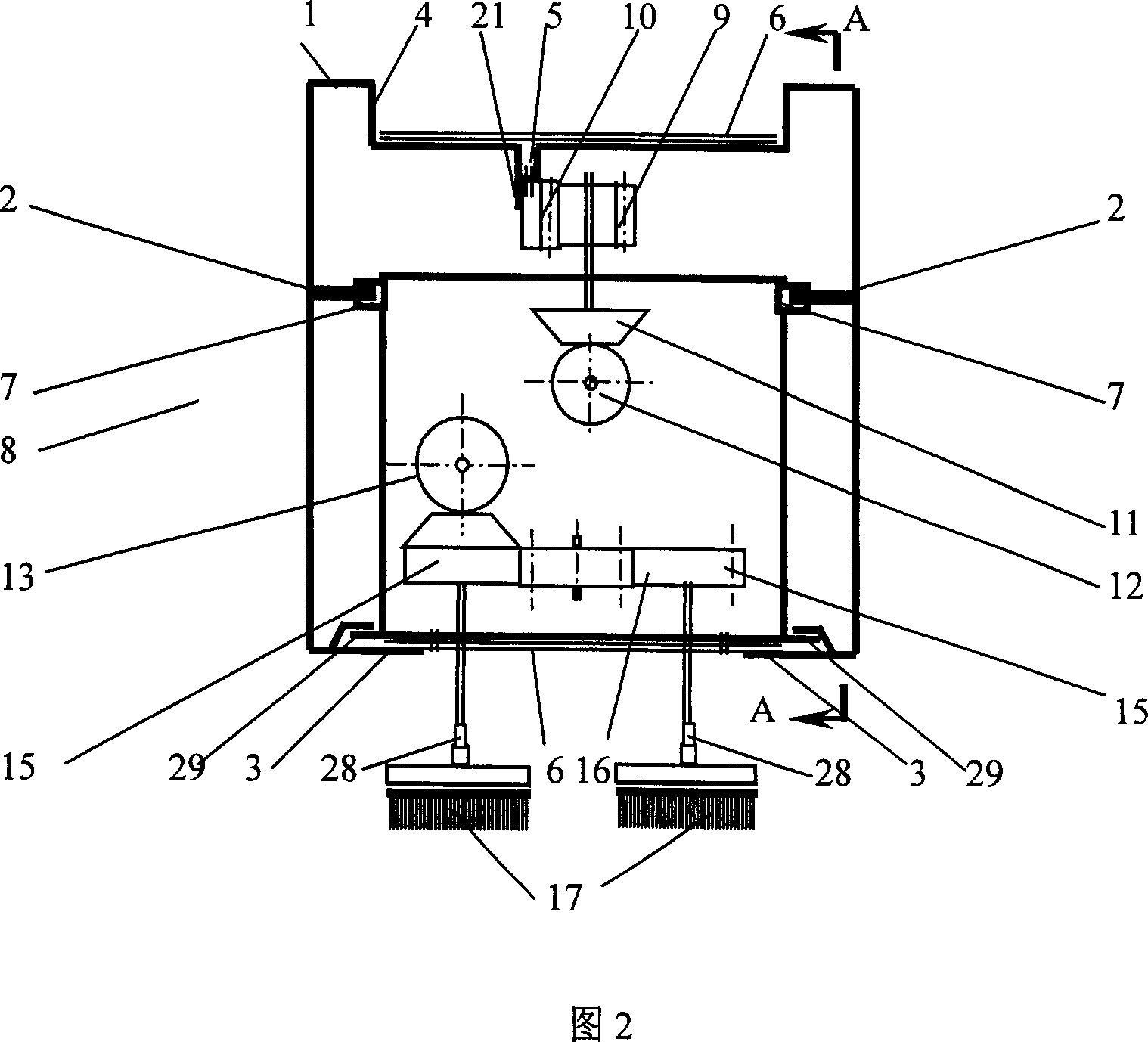

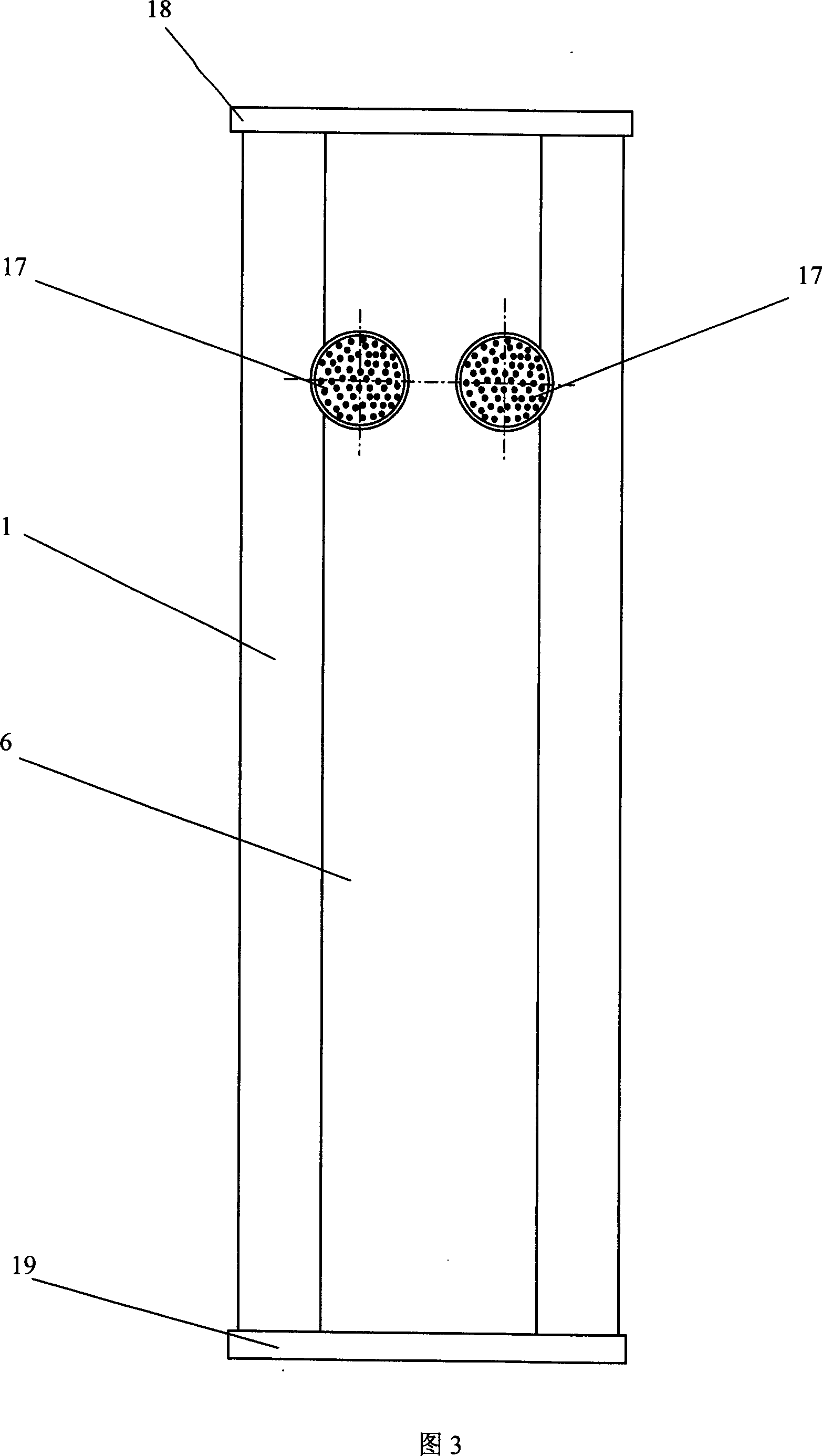

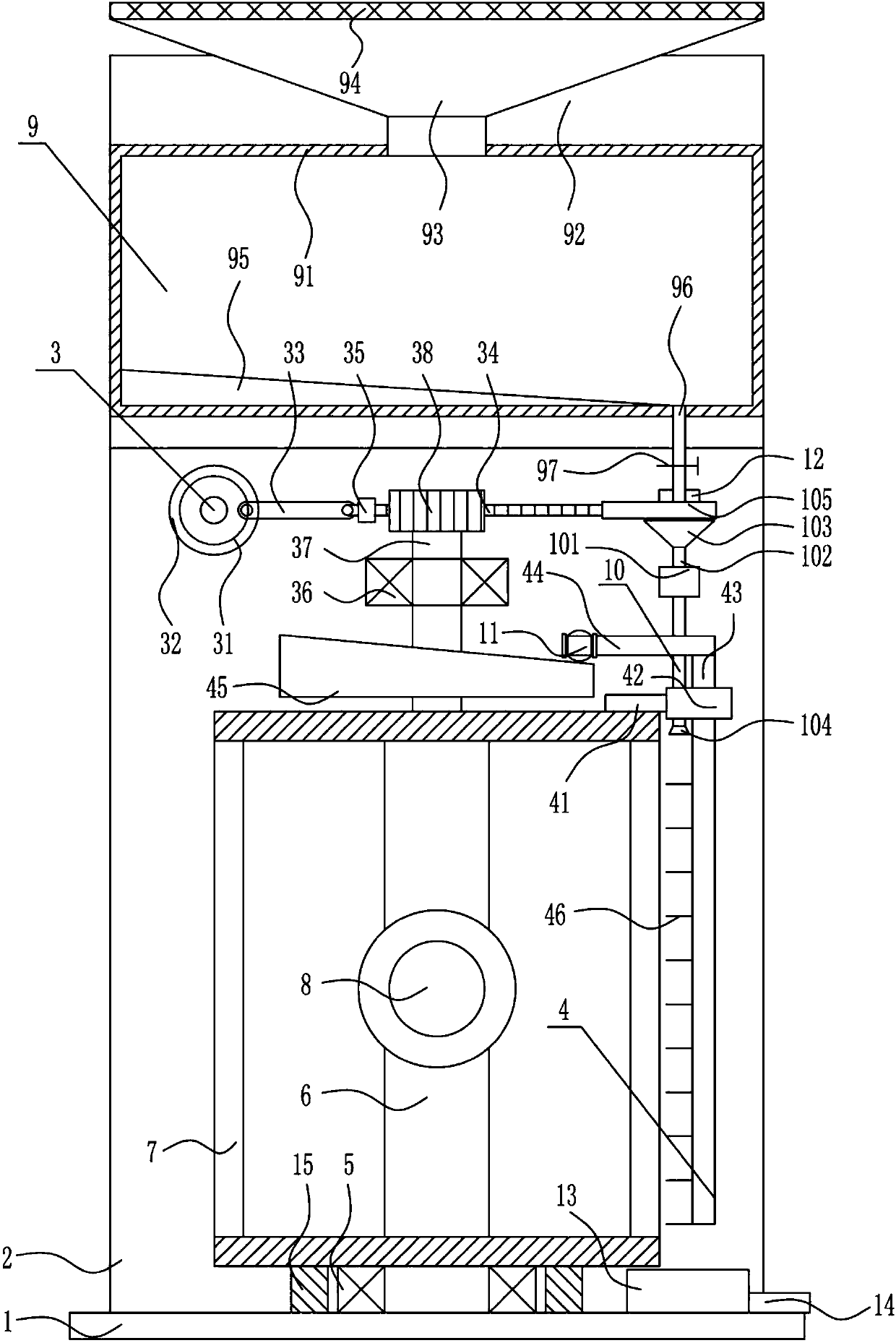

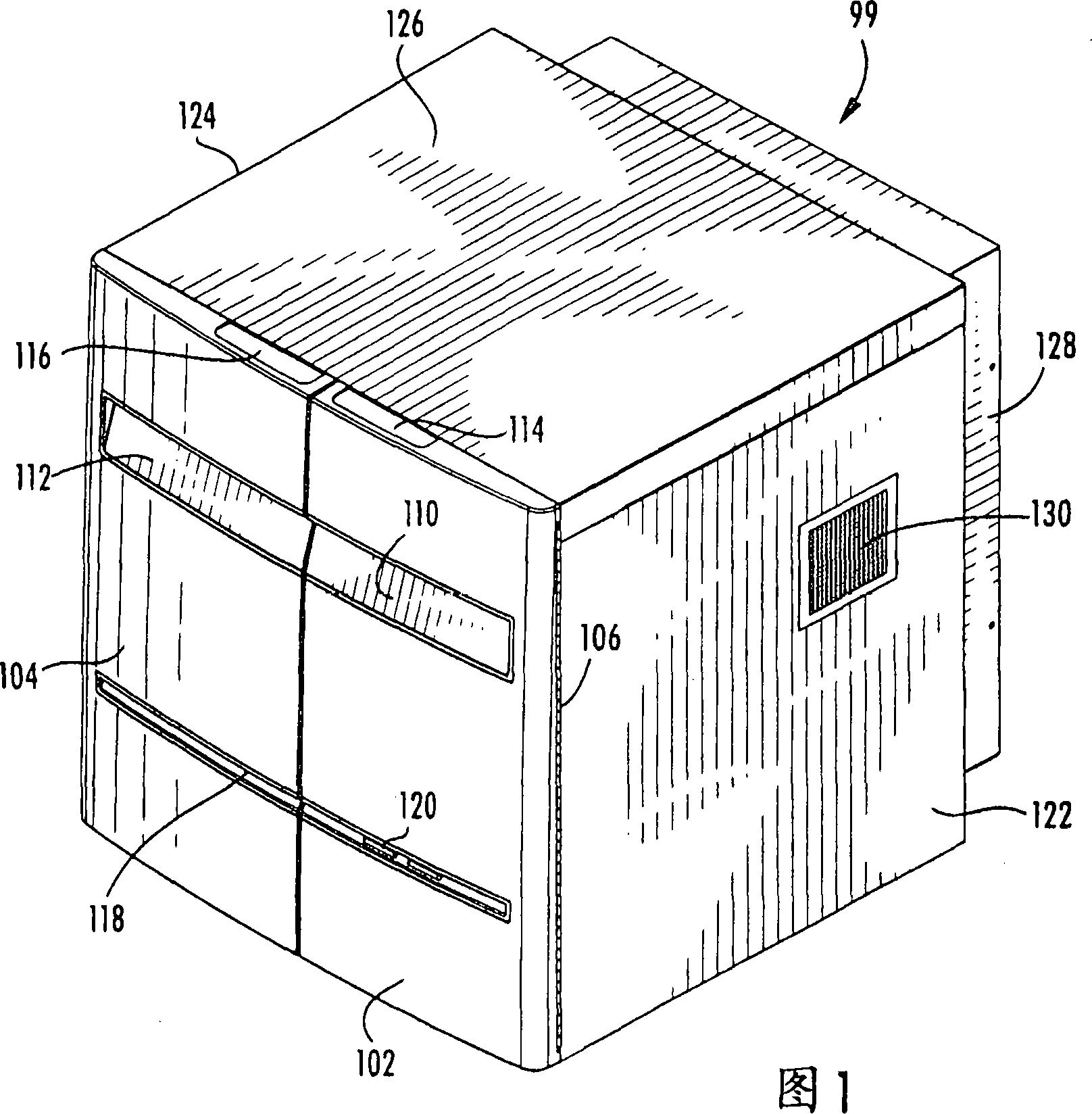

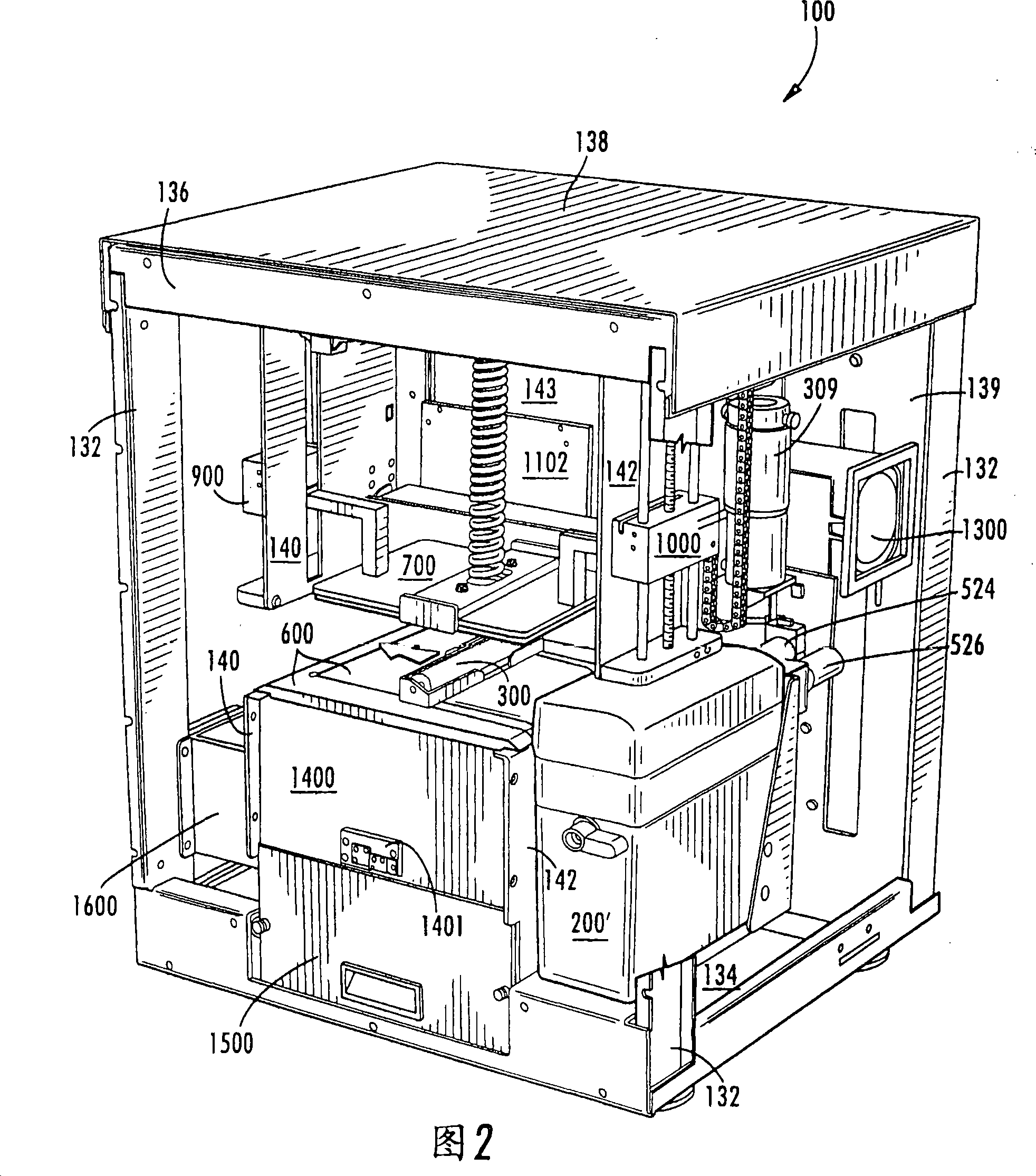

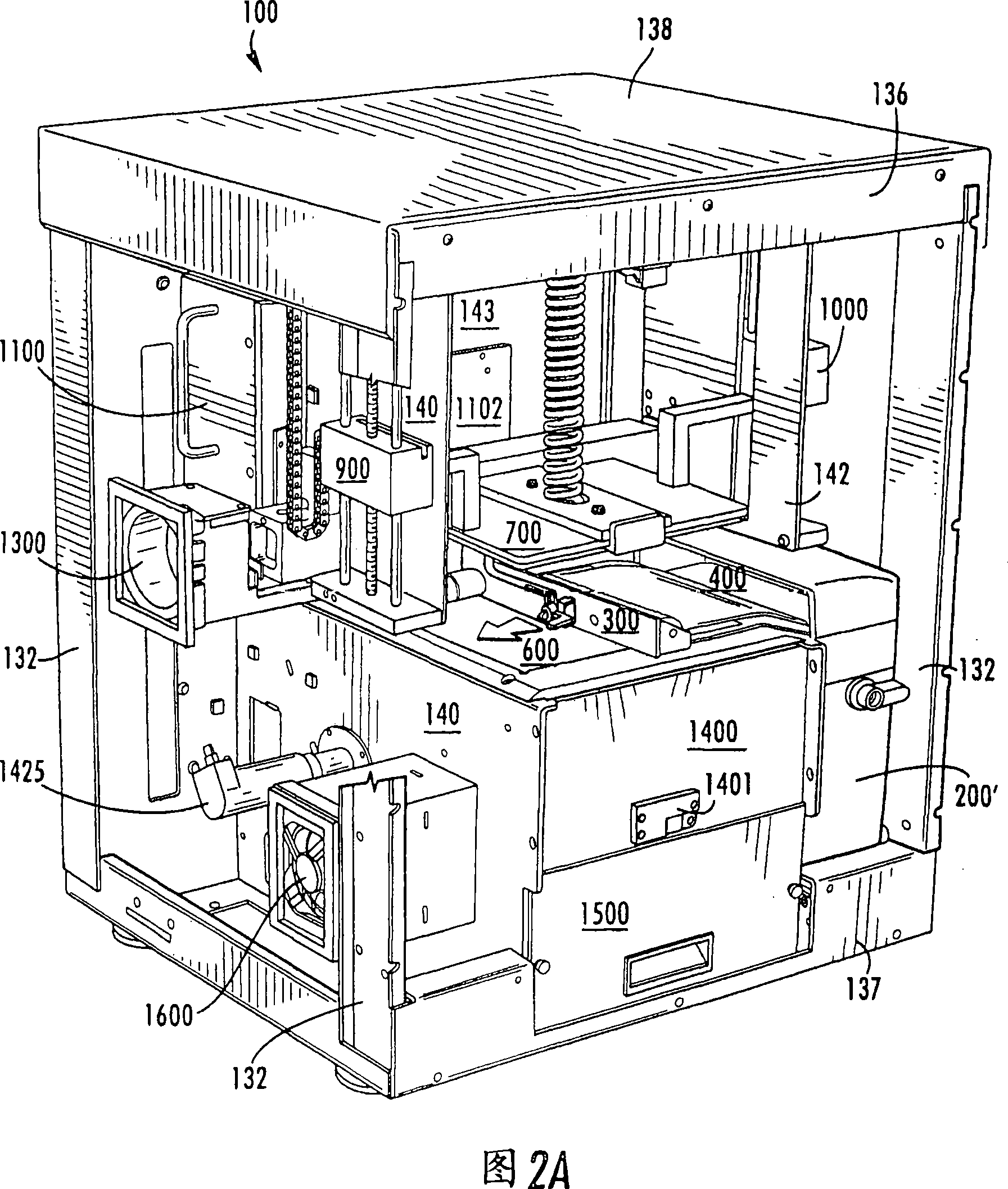

Automatic bathing machine

The automatic bathing machine capable of scrubbing different parts of human body automatically consists of one outer casing, one transmission mechanism and one scrubbing brush. The outer casing is manufactured with shapes and through stretching. The transmission mechanism includes one gear box inside the outer casing, one elevating motor, one rotating motor, one gear-rack driving mechanism connected to the elevating motor, and one gear mechanism connected to the rotating motor. The scrubbing brush is connected to the output shaft of the gear mechanism. The outer casing has opening with movable shielding belt connected to the gear box.

Owner:吕朝东

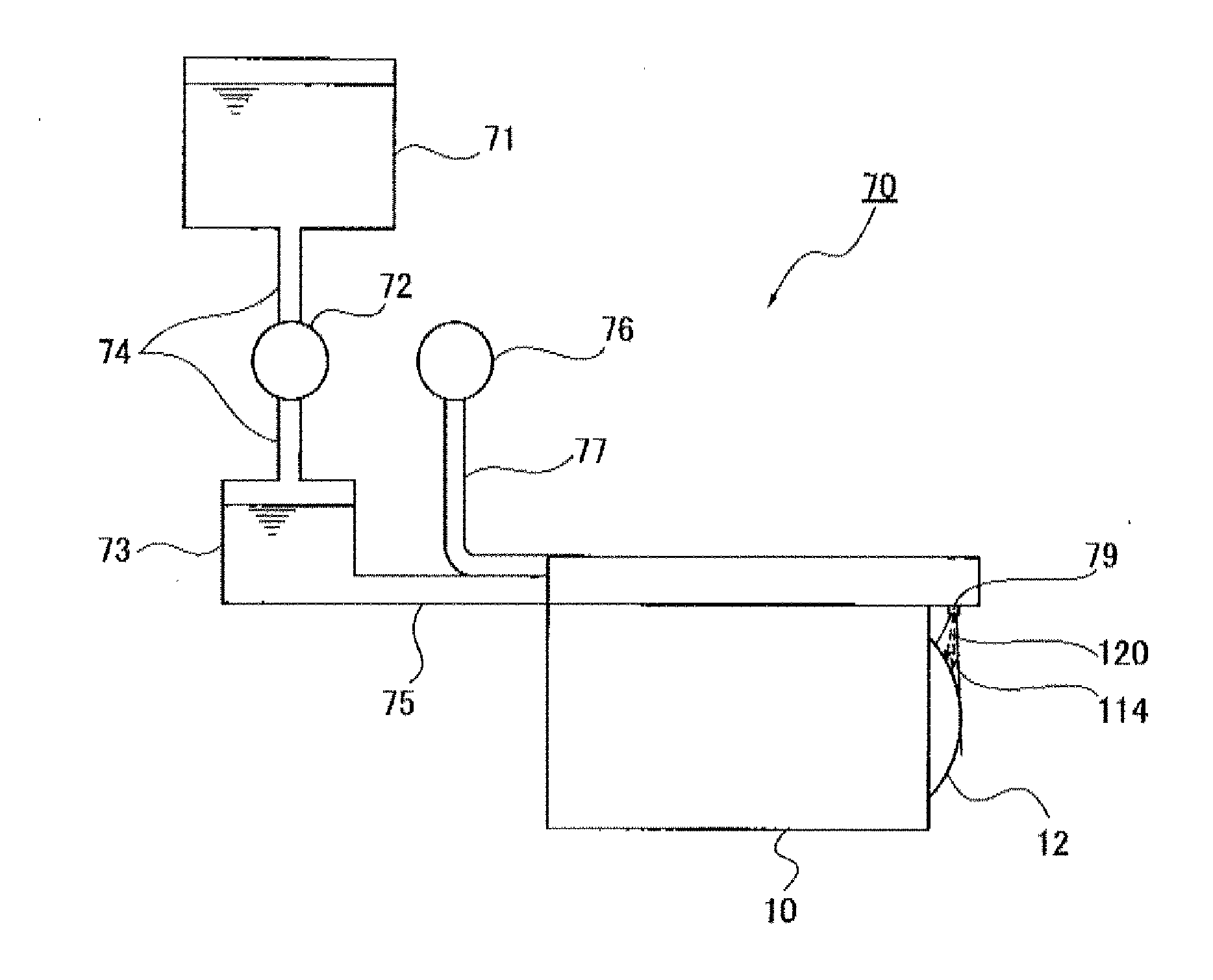

Cleaning apparatus and method and computer readable medium

ActiveUS20080173333A1Clean enoughSemiconductor/solid-state device manufacturingCleaning using gasesEngineeringNozzle

A control mechanism of a cleaning apparatus is preset to control the apparatus for a cleaning process or a rinsing process to include delivering a process liquid, which is corresponding one of a cleaning liquid and a rinsing liquid, from a back surface liquid supply nozzle through a liquid delivery port, thereby forming a liquid film on the back surface of a substrate, and then once stopping and then re-starting delivery of the process liquid from the back surface liquid supply nozzle, thereby forming a liquid film also on a portion around the liquid delivery port, so as to process the portion around the liquid delivery port as well as the substrate.

Owner:TOKYO ELECTRON LTD

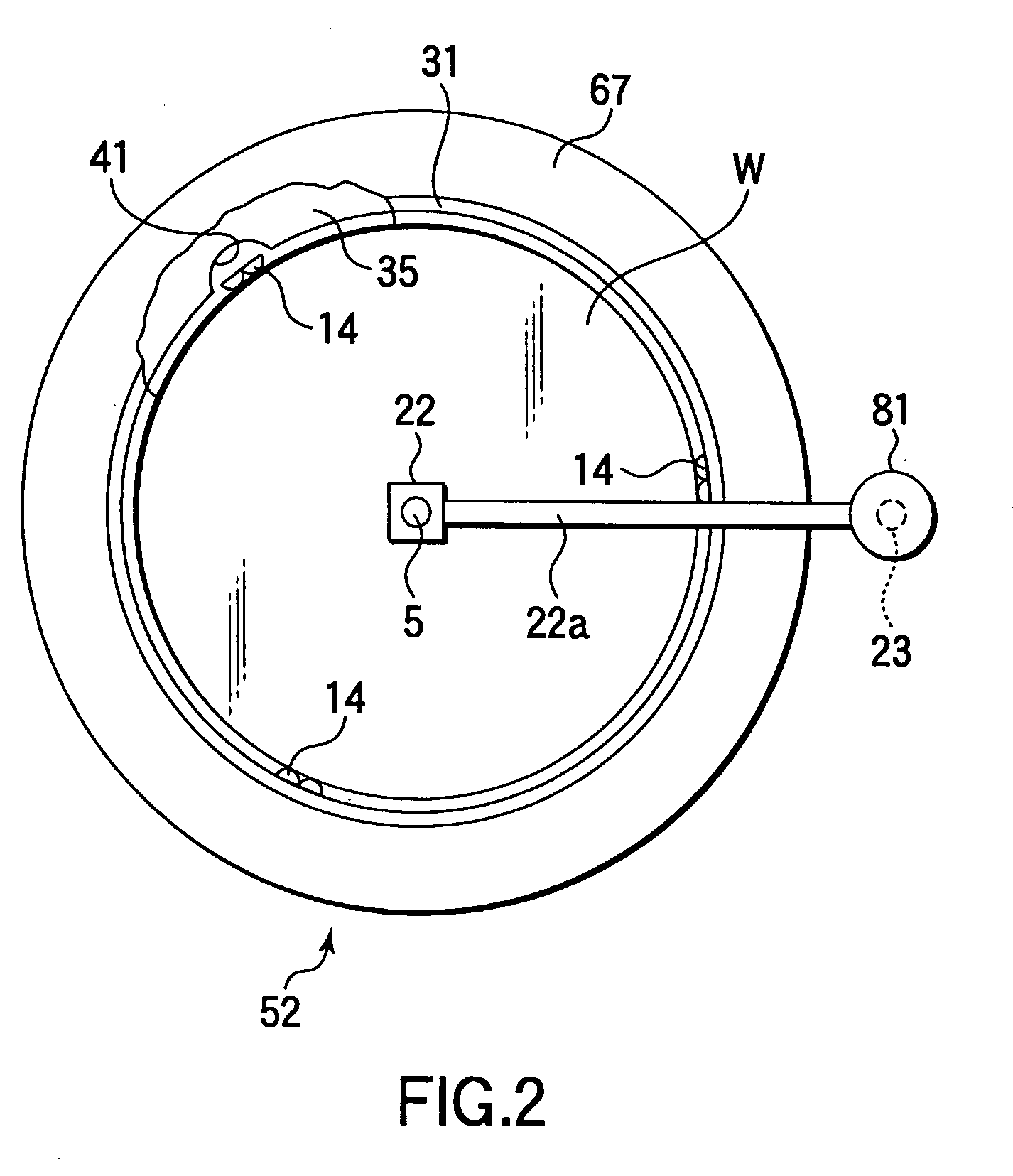

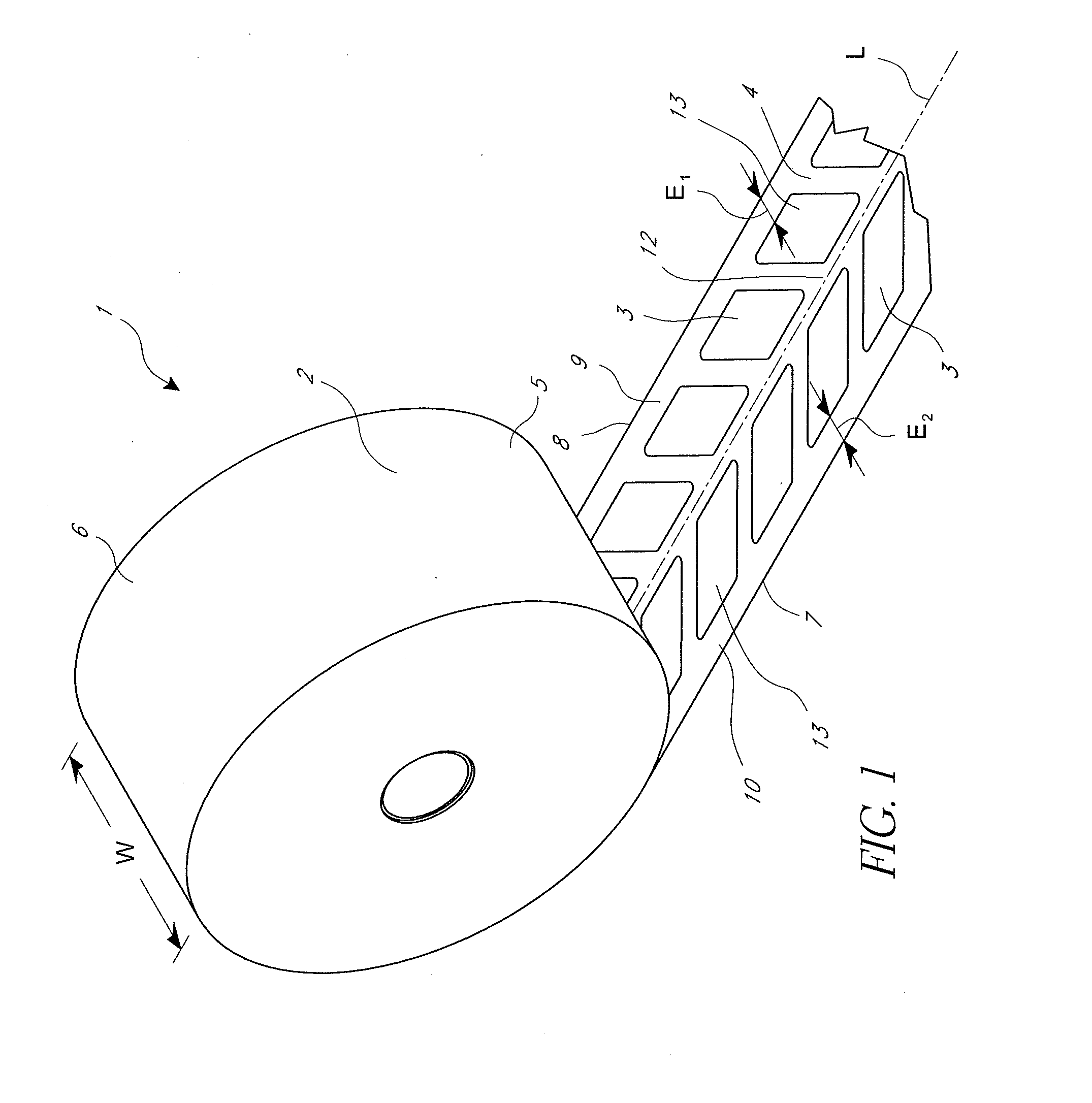

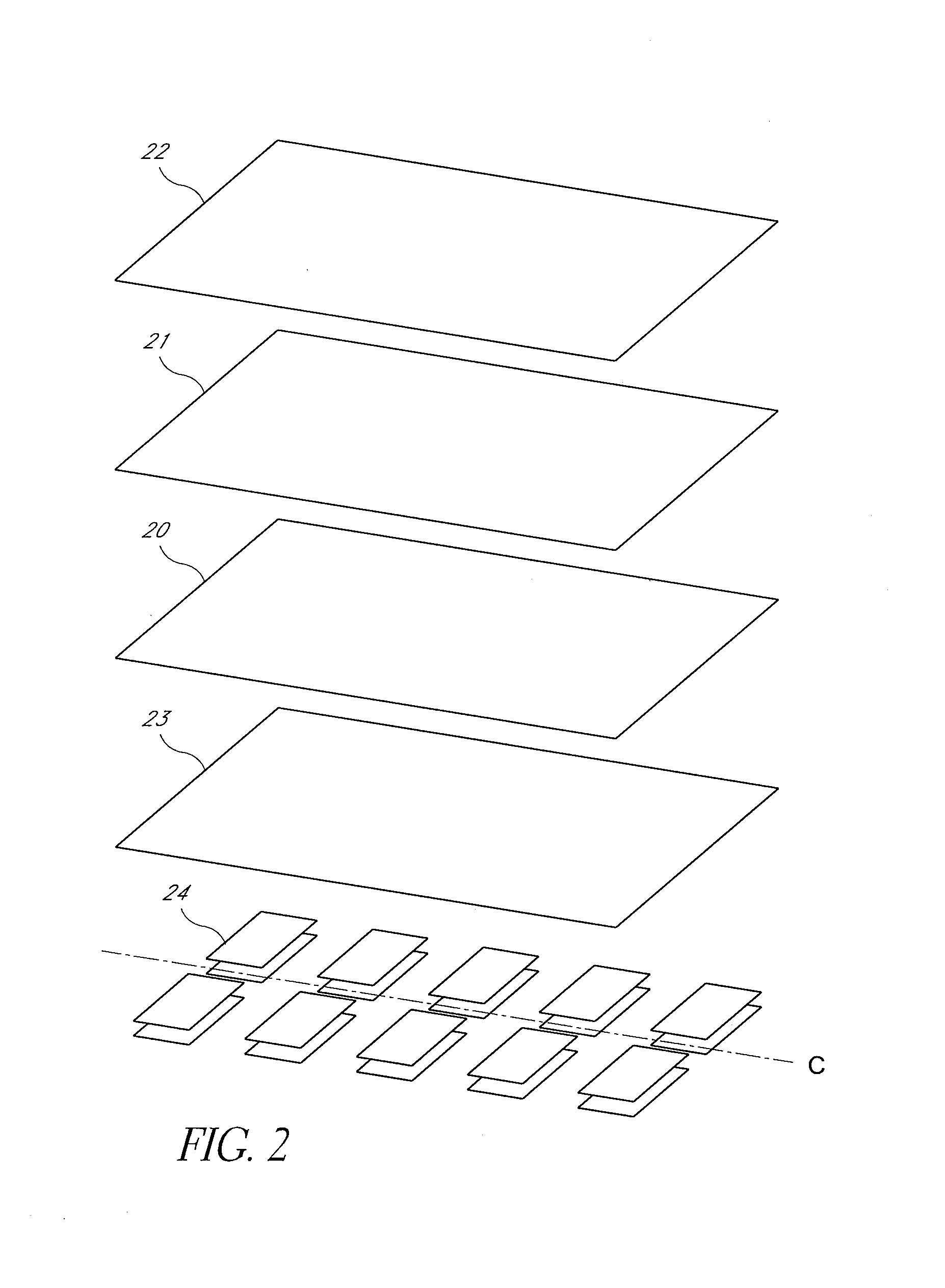

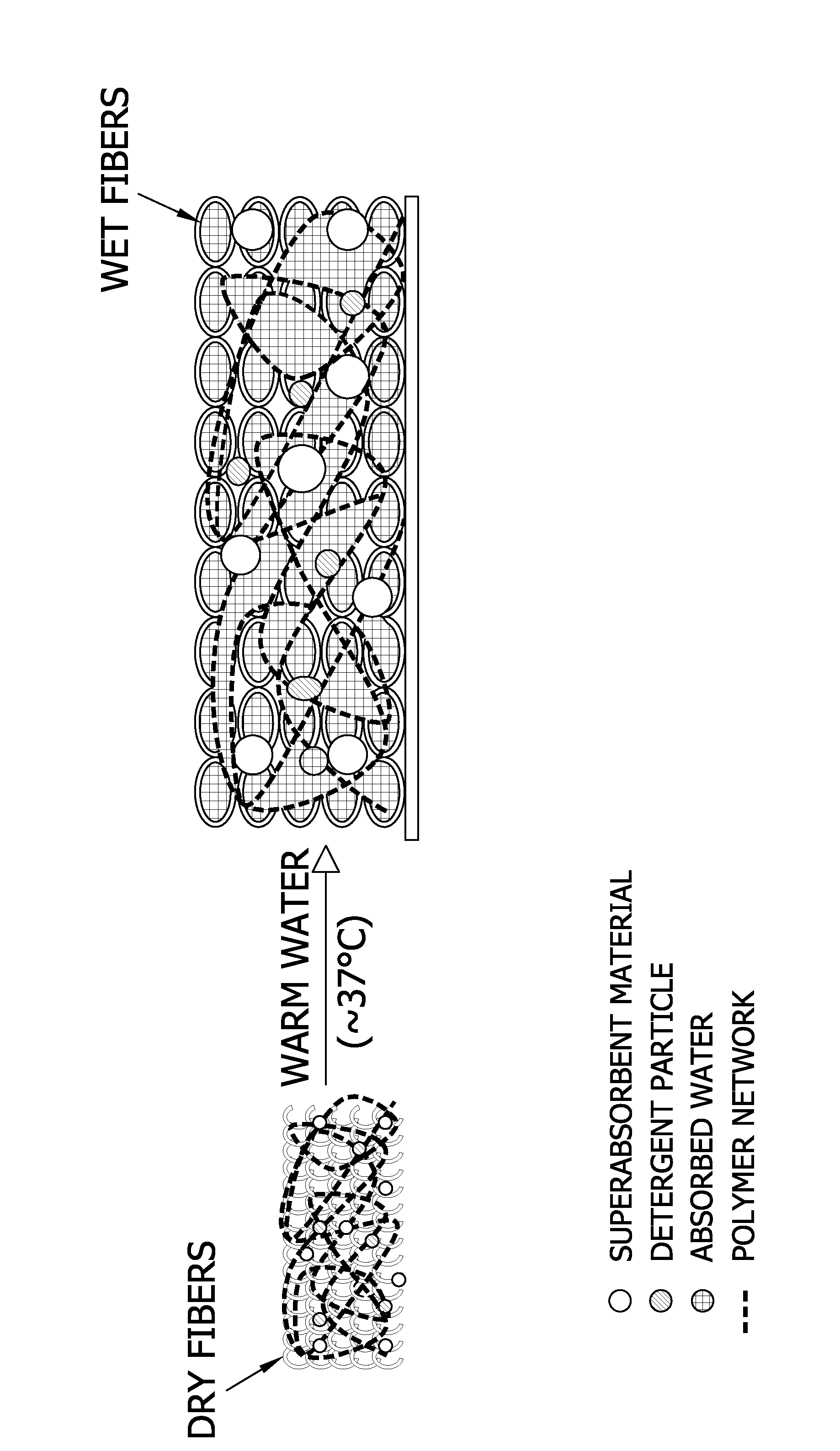

Paper, labels made therefrom and methods of making paper and labels

ActiveUS20130260991A1Clean enoughIncrease the amount of glueStampsPaper/cardboard articlesAdhesivePulp and paper industry

Paper is disclosed for use in making repositionable or removable adhesive labels. The adhesive can be applied in patches or discrete areas to the paper or to a layer of material that cleans rollers in the manufacturing line and / or in printers. The adhesive can be applied in single or multiple layers. The paper is light weight paper and preferably thermal paper for use in POS printers.

Owner:DOCUMOTION RES

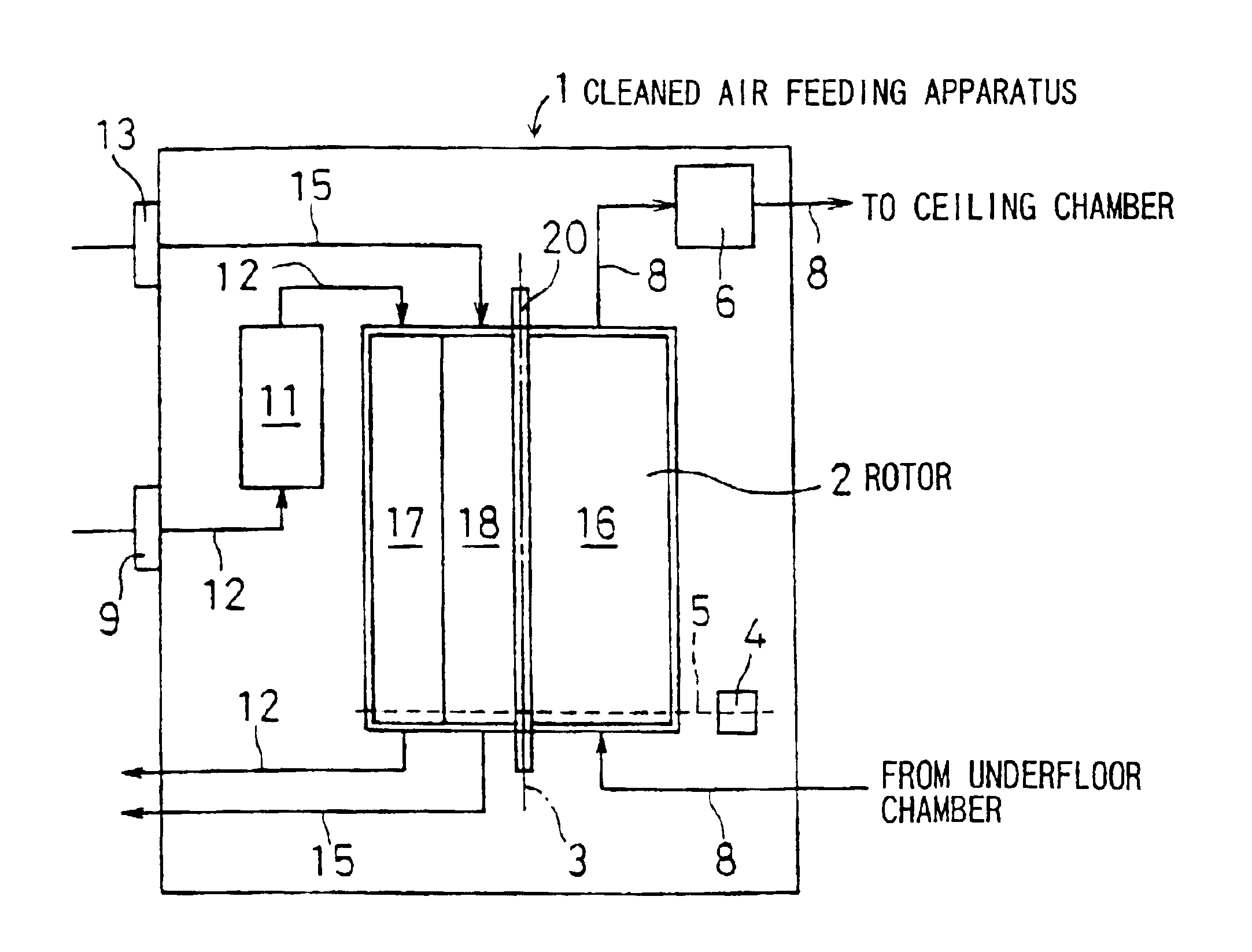

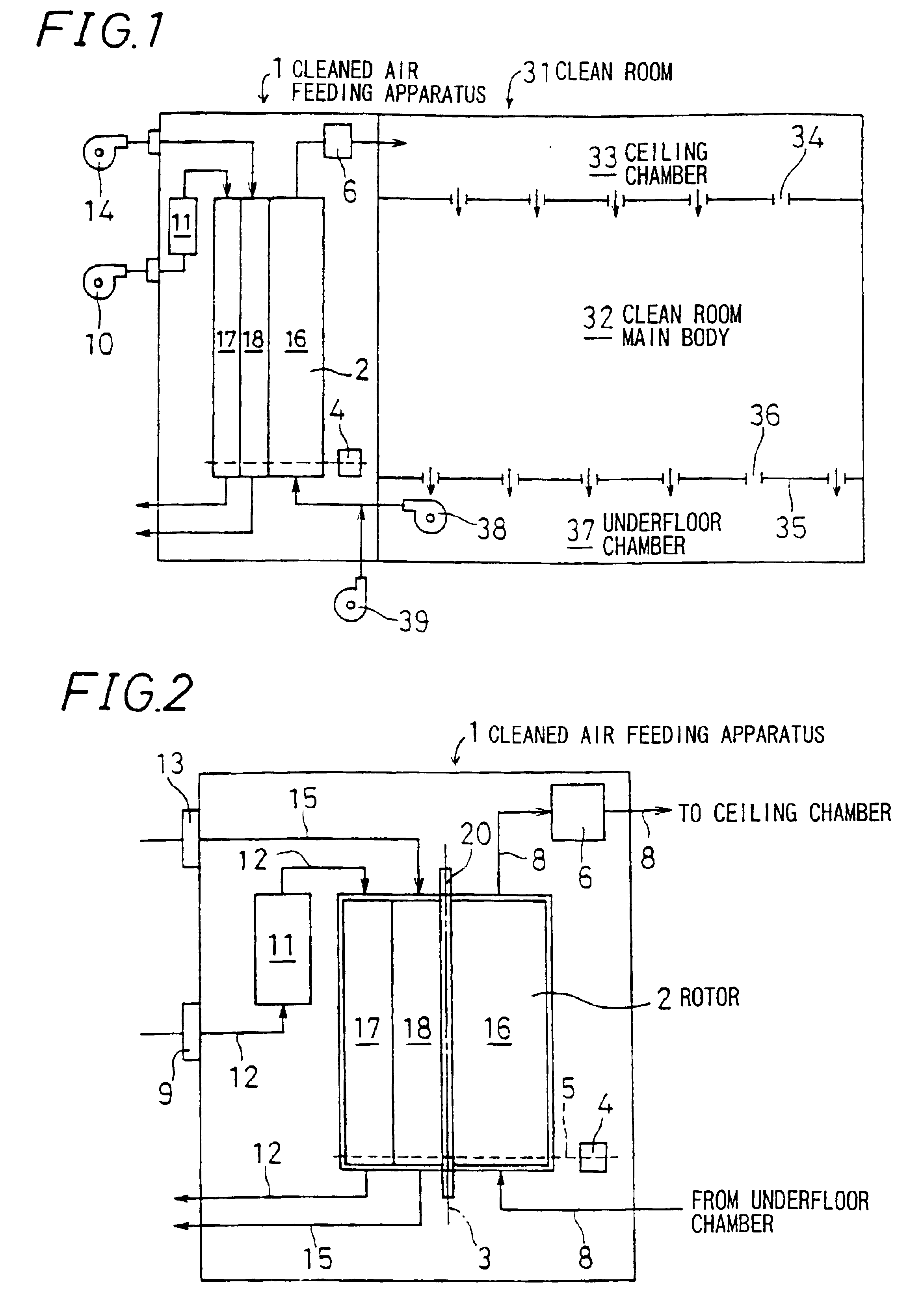

Clean room

InactiveUS6960236B1Clean enoughFully adsorbedCombination devicesNitrogen compoundsEnvironmental engineering

Owner:DAIKIN IND LTD

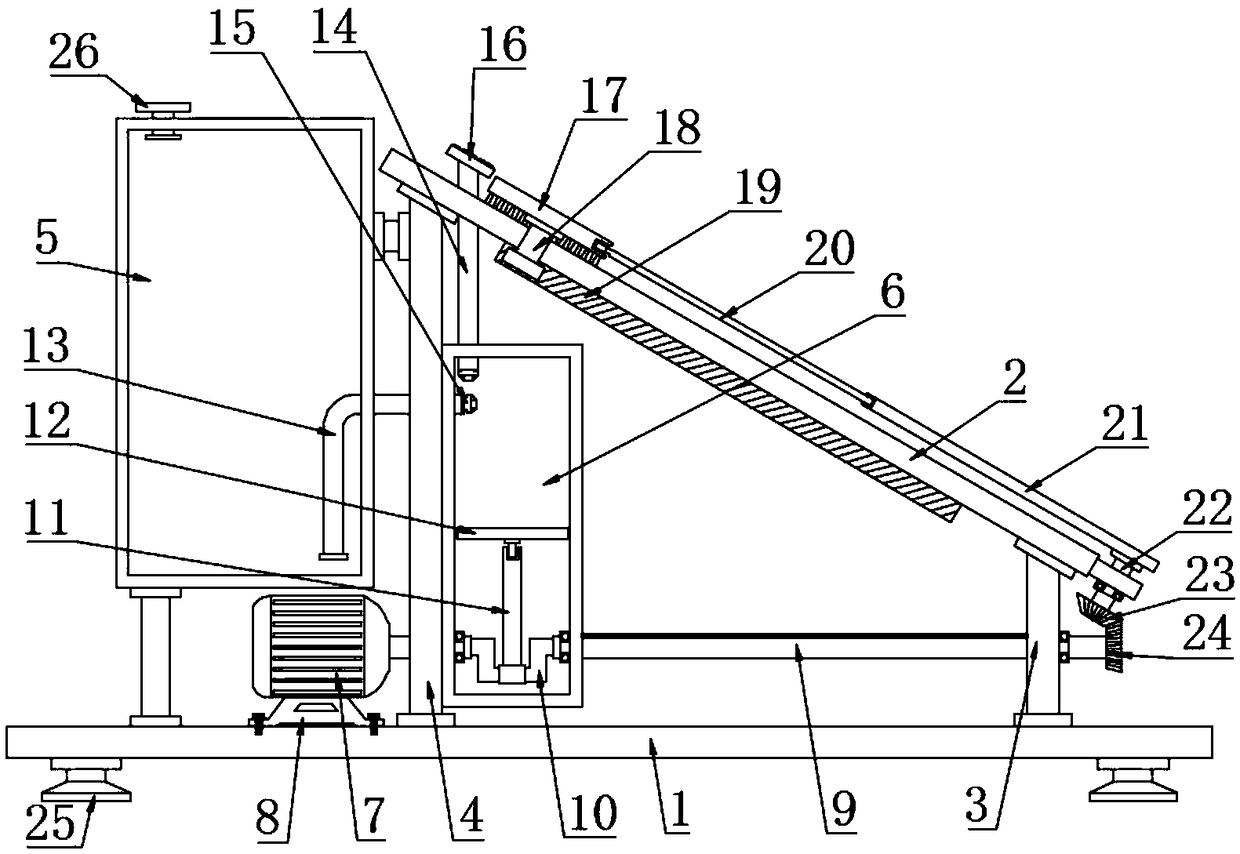

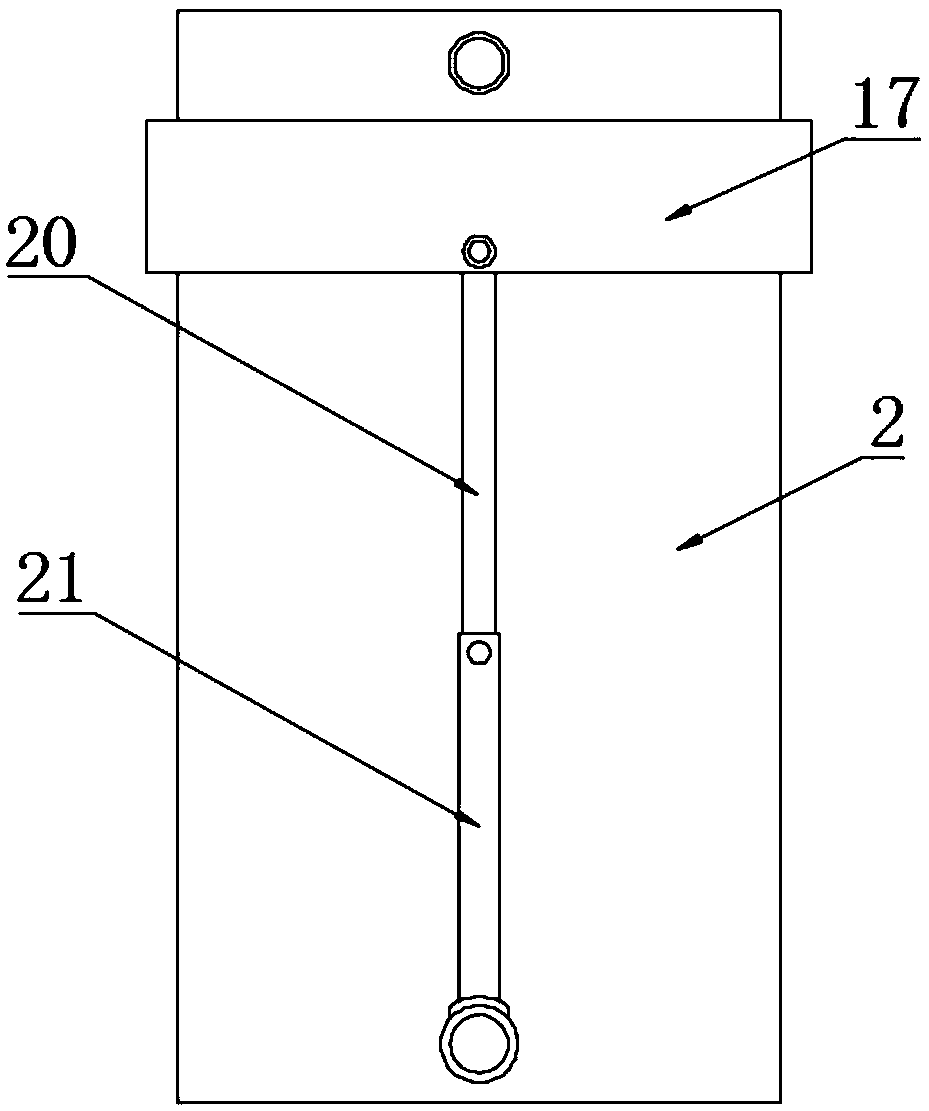

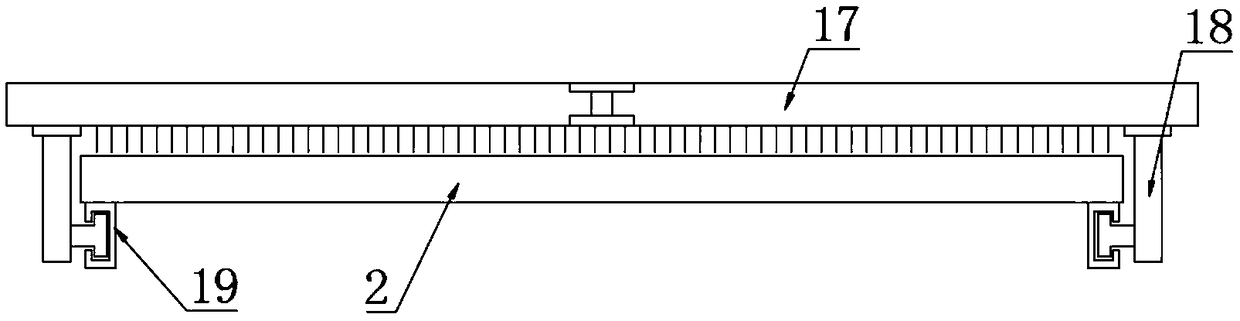

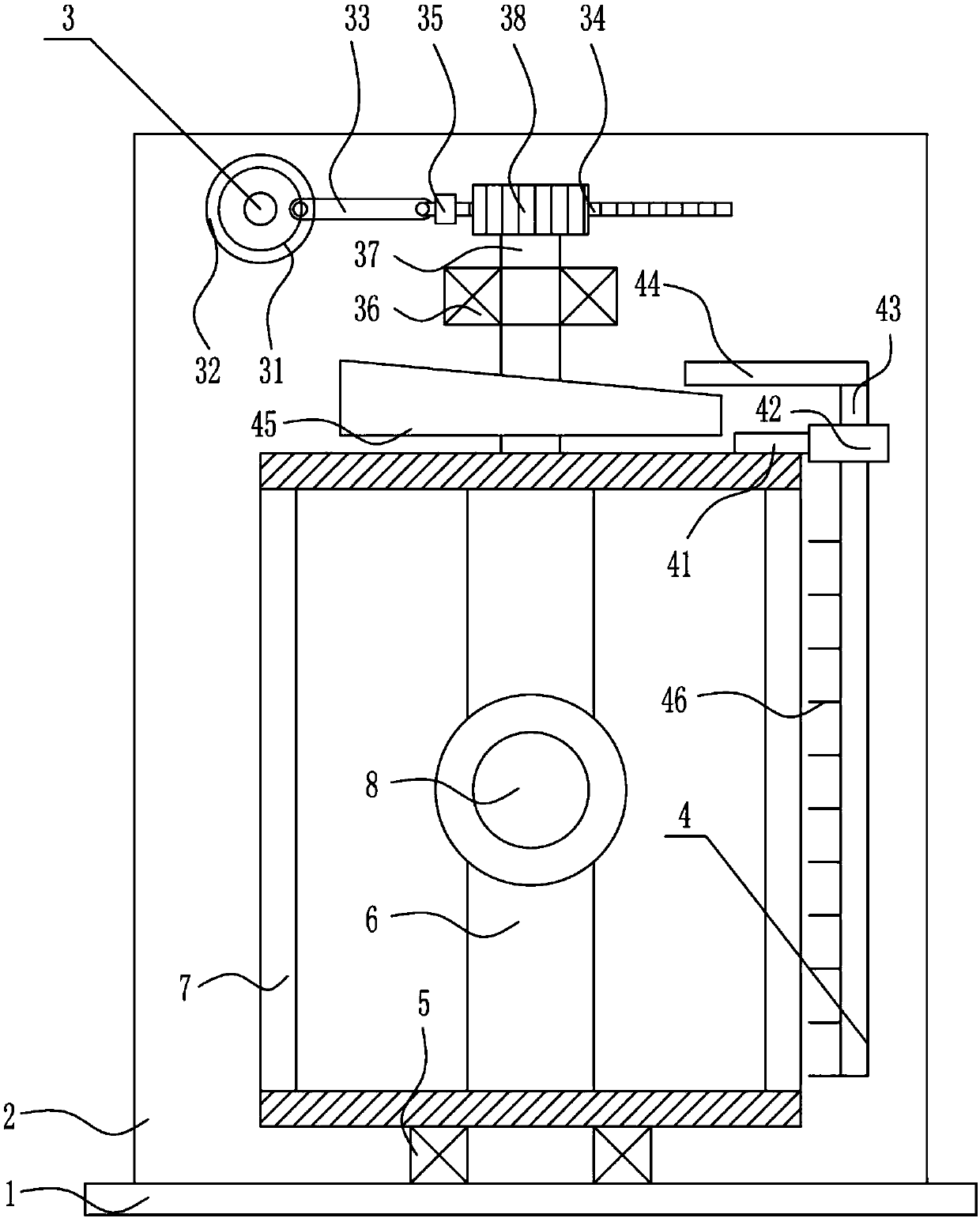

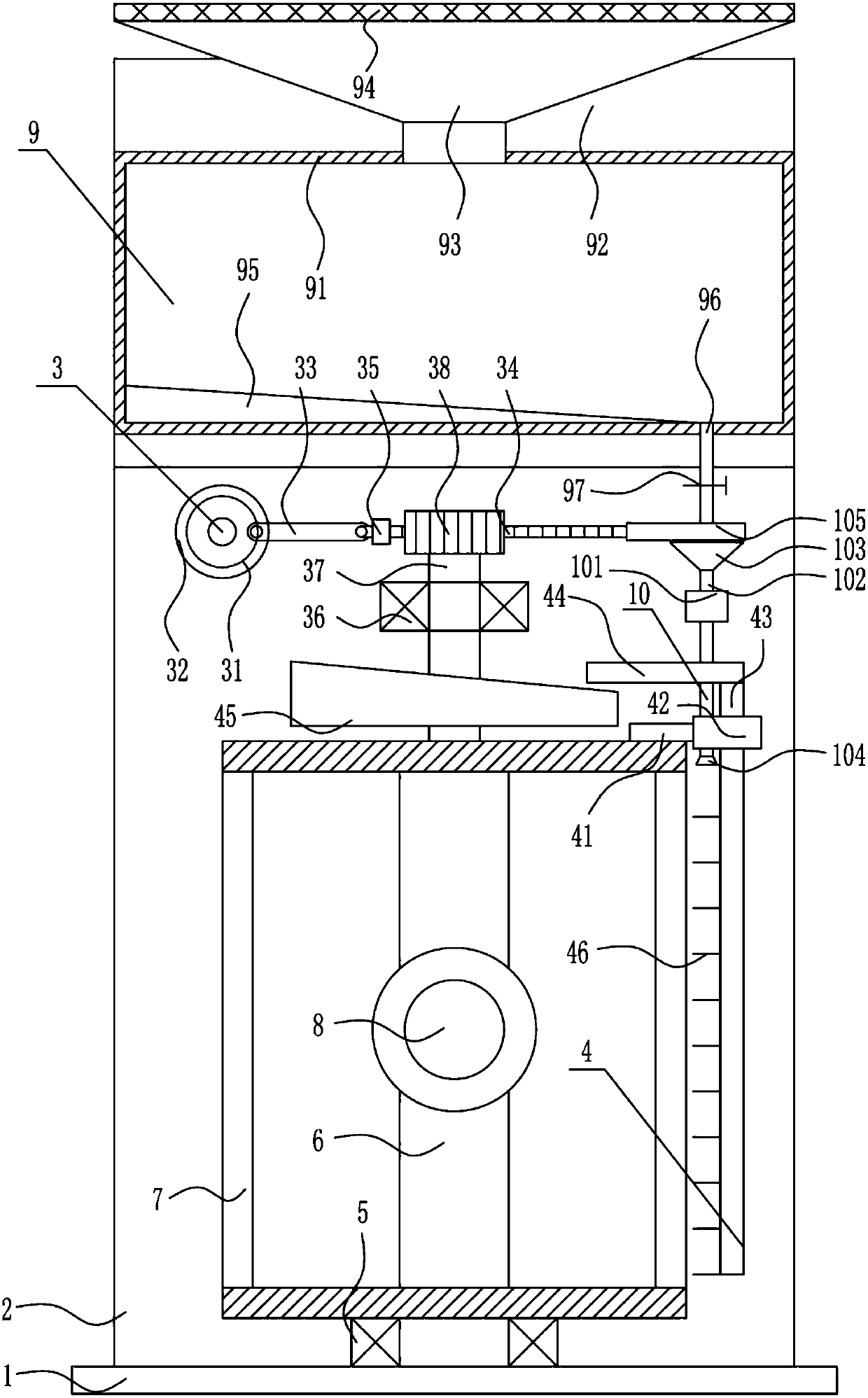

Solar power generation device with cleaning function

InactiveCN109120224AClean enoughExtended service lifePhotovoltaicsCleaning using toolsDrive shaftPump chamber

The invention discloses a solar power generation device with a cleaning function. The solar power generation device with a cleaning function is characterized in that the right side of a drive motor isrotatably connected to a driving shaft; the driving shaft passes through a first bracket and a second bracket and is rotatably connected with bearings of the first bracket and the second bracket; a water tank is arranged at the upper part of the driving motor; the water tank is fixedly connected to a bottom plate and the second bracket; the right side of the second bracket is fixedly connected toa pumping chamber; the left part of the driving shaft is fixedly connected with a crankshaft; the crankshaft is located at the lower part of the pumping chamber and passes through the side wall of the pumping chamber; the middle part of the crankshaft sleeves the lower part of a connecting rod; the upper end of the connecting rod is rotatably connected with a piston plate; the edge of the pistonplate is in sliding connection to the inner wall of the pumping chamber in a sealed manner; the left wall of the upper part of the pumping chamber is provided with a water inlet pipe; the water inletpipe is communicated with the bottom of the water tank; and the upper part of the pumping chamber is connected with a water outlet pipe. For the solar power generation device with a cleaning function,the piston plate is driven by the rotating crankshaft to reciprocate up and down so as to pump the water liquid in the water tank to spray to the upper surface of a photovoltaic panel, and in the water spraying process, a swinging rod is driven by a driving rod to drive a clean brush to reciprocate up and down along a guide groove, thus achieving the effect of cleaning and brushing.

Owner:河南东润电子有限公司

Conveyor assembly

InactiveUS20060016668A1Simple and inexpensive componentMinimize damageConveyorsRollersEngineeringMechanical engineering

The conveyor apparatus disclosed herein is generally formed of a first rail and a second rail, each rail having a plurality of rollers. A portion of the rollers are desirably drive rollers, receiving power from an integral motor assembly. The motor generally comprises a stator that is coupled to the rail and an outer roller assembly rotatably coupled to the rail. The roller assembly includes an outer circumferential magnetized portion positioned in surrounding engagement to the motor stator and functions both as the motor rotor and the conveying surface of the roller. Non-slip roller covering material may be attached to the exterior of the roller assembly. A circuit board having logic controls is preferably in communication with at least one sensor and the motor rotor to regulate rotation of the motor rotor during use of the conveyor.

Owner:ACTIVAR TECHN PRODS GROUP

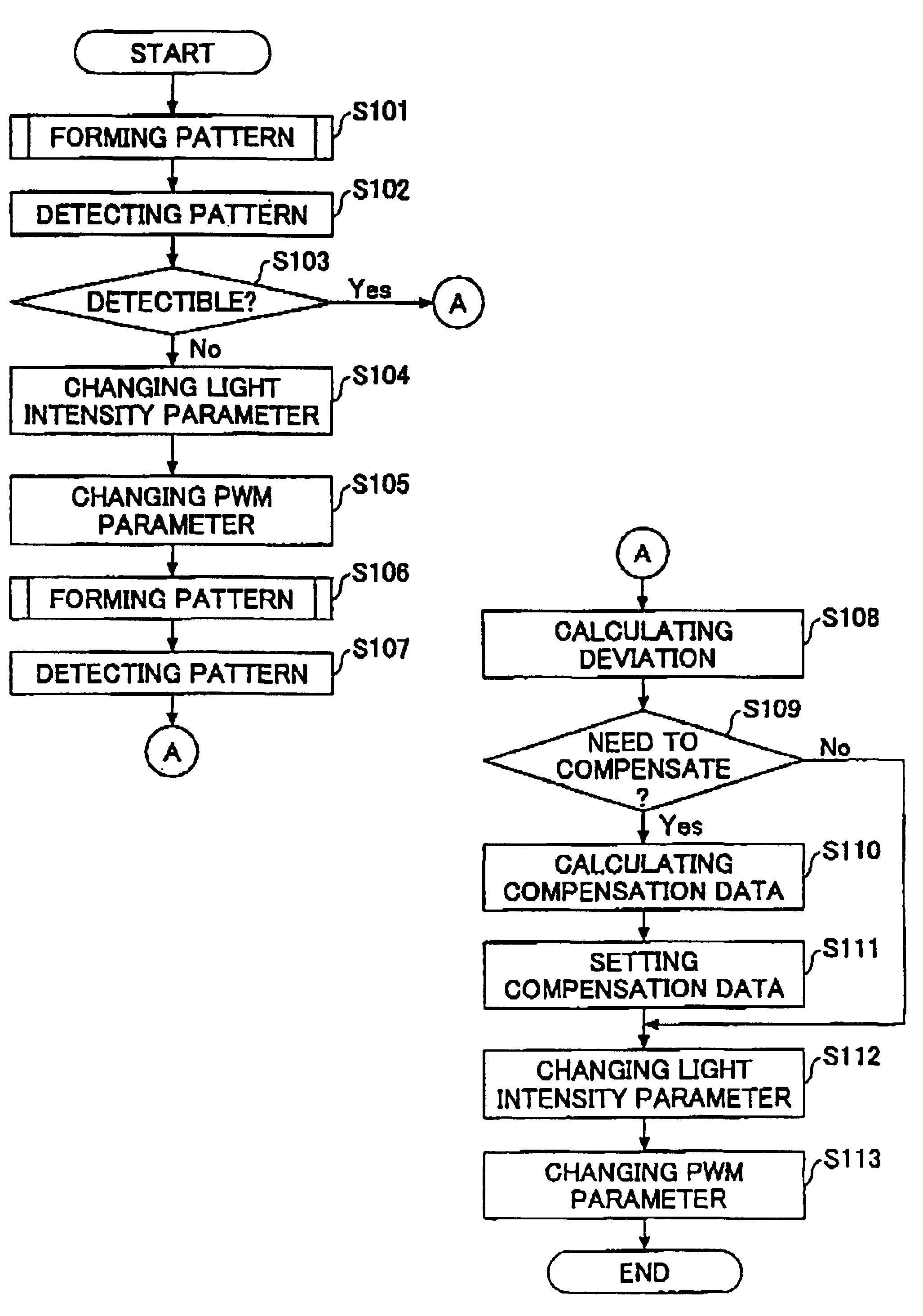

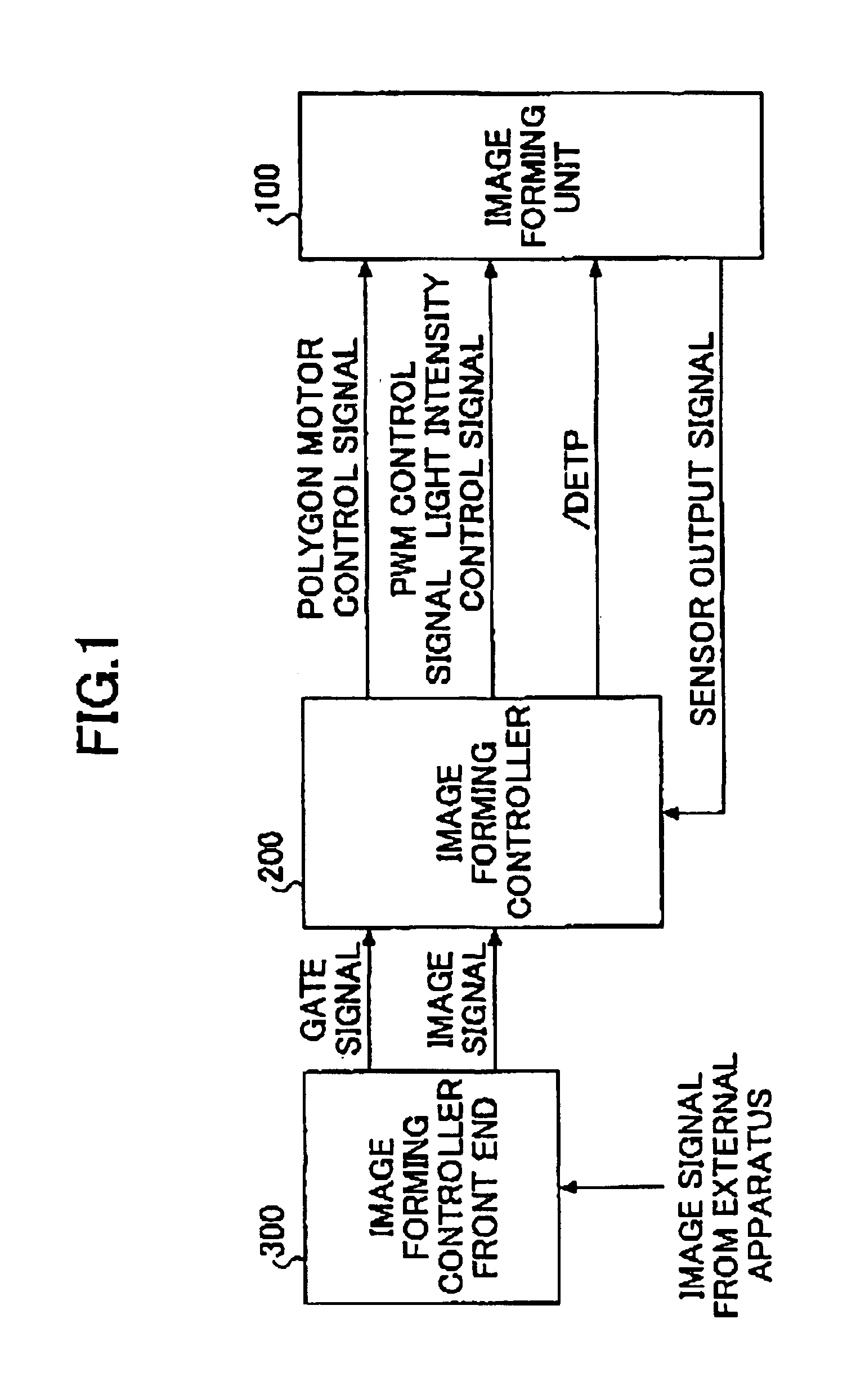

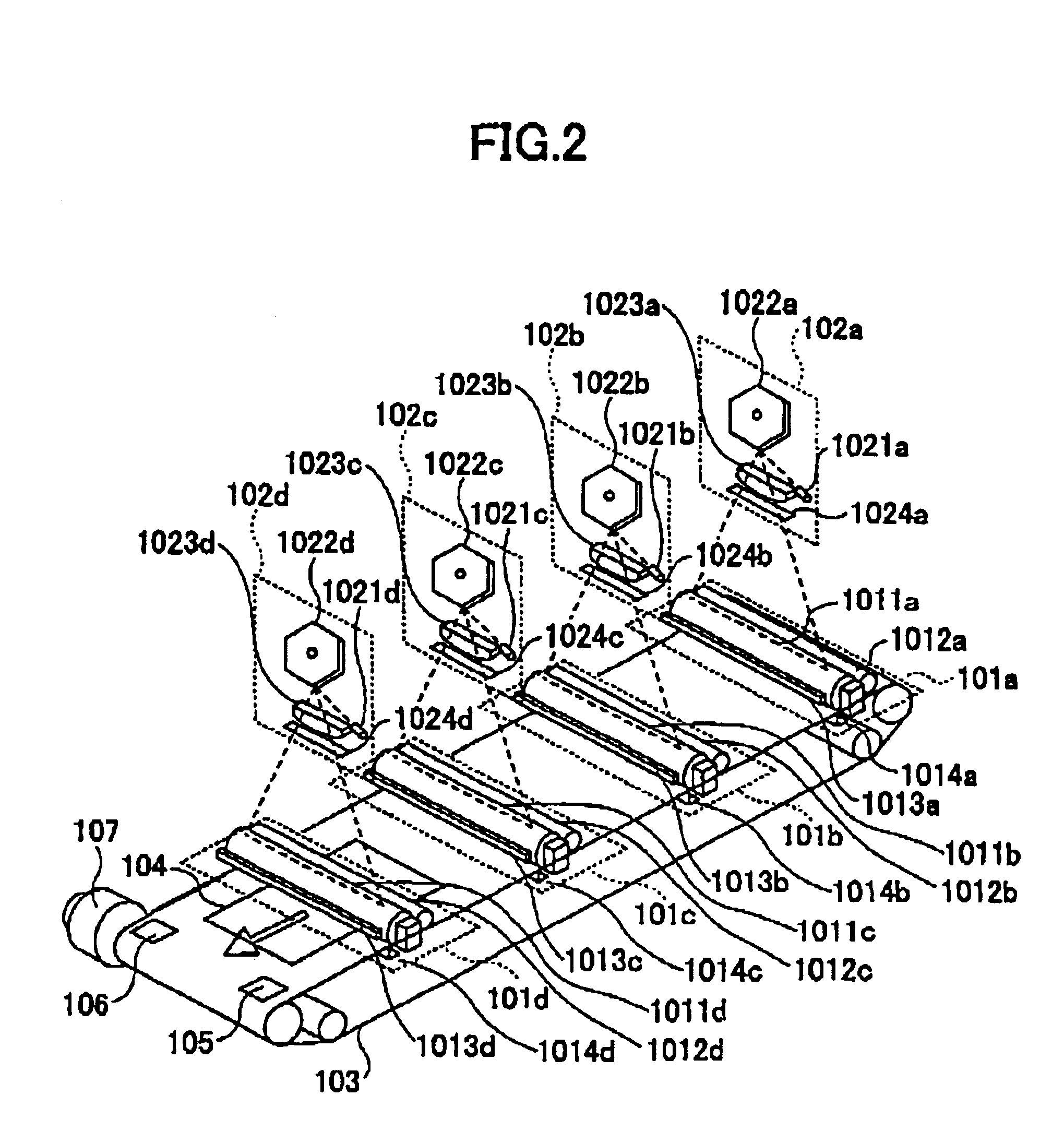

Image forming apparatus that adjusts image positional deviation without fail

InactiveUS6853392B2Quality improvementClean enoughRecording apparatusElectrographic process apparatusImage formationMonochrome Image

An image forming apparatus that forms a multi-color image by superposing a plurality of monochrome images is provided. The image forming apparatus includes, for each color, an image forming unit that forms the monochrome image; a pattern forming unit that forms a predetermined compensation pattern; a pattern position detecting unit that detects the position of the compensation pattern formed by the pattern forming unit; and an image position adjusting unit that adjusts the position of the monochrome image to be formed by the image forming unit based on the position of the compensation pattern detected by the pattern position detecting unit. Since the compensation pattern is formed under an image forming condition adjustable independently from another image forming condition with which the monochrome images are formed, the image forming apparatus can adjust positional deviation of monochrome images.

Owner:RICOH KK

Method of bowel cleansing

InactiveUS20070298008A1Lower the volumeSafe and effectiveDigestive systemSynthetic polymeric active ingredientsIntestinal structureBowel cleansing

Stimulant laxative in combination with an osmotic laxative produces safe and effective bowel and colon cleansing with a reduced volume of liquid input. Administering to a patient an oral stimulant laxative, such as bisacodyl, followed, after a biologically determined interval, by a reduced volume of a PEG in water solution cleanses the bowels and colon in preparation for diagnostic colonoscopy, without the profuse uncontrollable diarrhea that typically follows either ingestion of large volume isotonic lavages, or smaller volume hypertonic lavages.

Owner:BRAINTREE LAB

Automatic cleaning camera device for security protection

ActiveCN107682609AImplement the rotation operationClean enoughTelevision system detailsColor television detailsEngineering

Owner:南京南北通控制系统有限公司

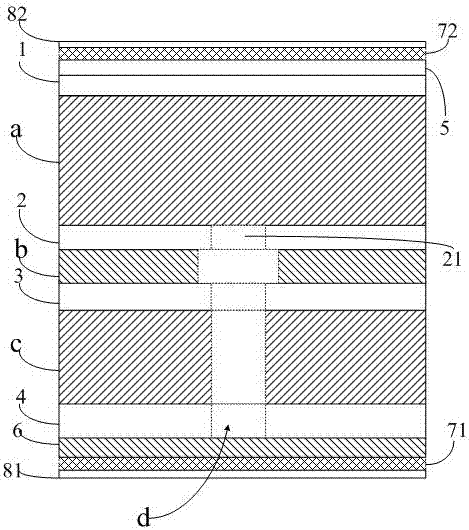

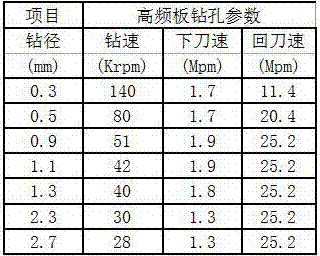

Hybrid different board material high-frequency board manufacturing method

ActiveCN107278062AAvoid bendingSolve the problem of overflow glueMultilayer circuit manufactureEpoxyProcess quality

The invention provides a hybrid different board material high-frequency board manufacturing method. A double-face copper-plated high-frequency board material and an epoxy resin board are employed for manufacturing, a non-flowing glue PP plate is utilized as a stitching medium of the high-frequency board material and the epoxy resin board, dimensions of a groove hole on the non-flowing glue PP plate are specially designed to solve a groove hole glue spilling problem, processing quality of products is improved, moreover, the overlapping process for drilling is further specially designed for the high-frequency board material, for a board material sinking problem of the high-frequency board material during stitching after grooving, a stitching overlapped structure is especially designed, a three-in-one buffer pad is employed to solve the grooving-side board material sinking problem, a hot pressing program is designed according to the stitching overlapped structure, the cold press time is further prolonged to further reduce a board bending problem caused by different expansion coefficients of different board materials, the high-frequency board material contains fillers which are not easily removed in a chemical glue removal mode, before electroplating, plasma glue removal is firstly carried out, chemical glue removal is then carried out, and complete cleaning is carried out to effectively improve electroplating quality.

Owner:VICTORY GIANT TECH HUIZHOU CO LTD

Foaming hand sponge with color change indicator

ActiveUS8343908B2Surface cleaningAllowing more fun for childrenInorganic/elemental detergent compounding agentsOther chemical processesColor changesCleaning product

Owner:KIMBERLY-CLARK WORLDWIDE INC

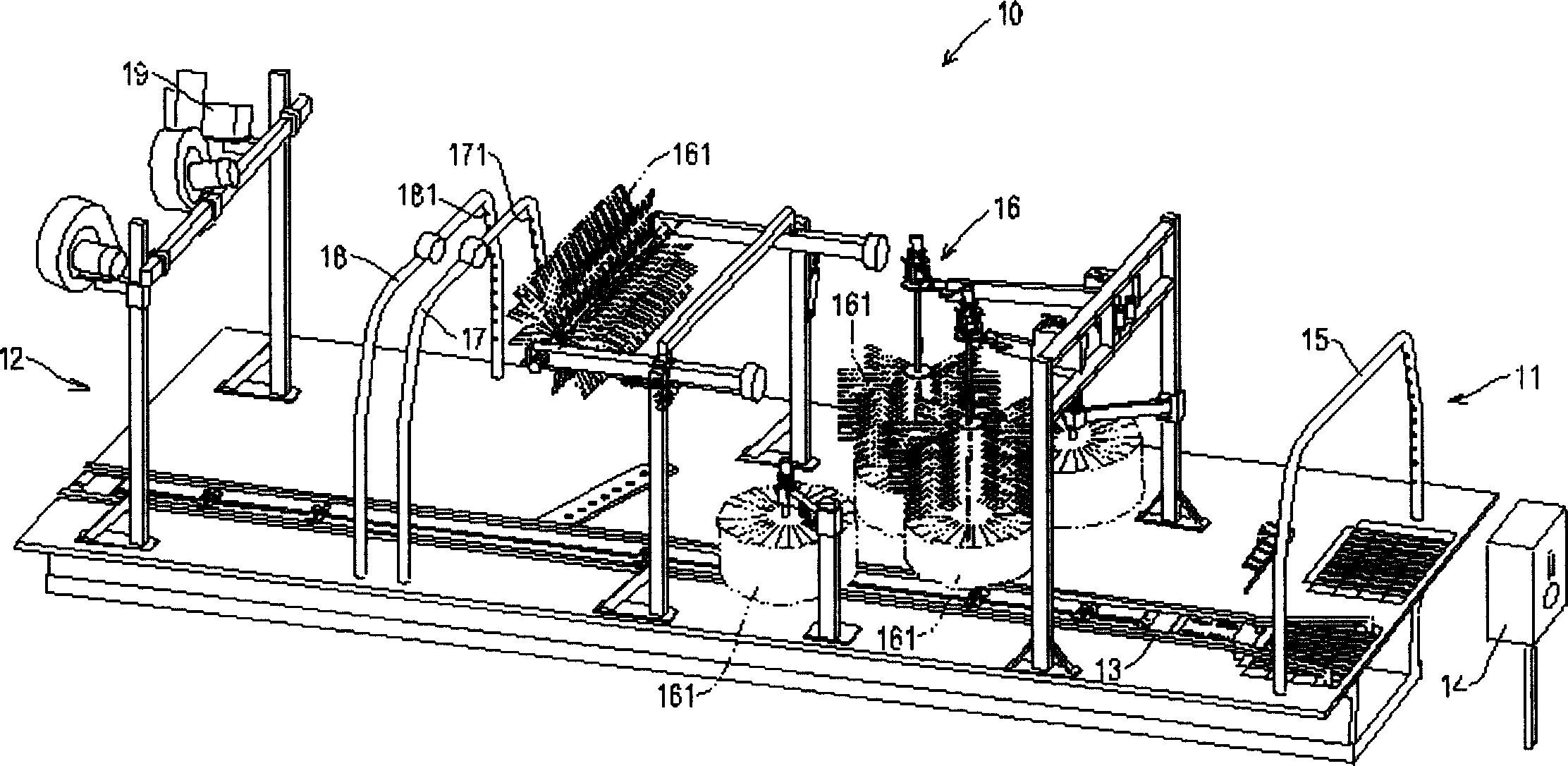

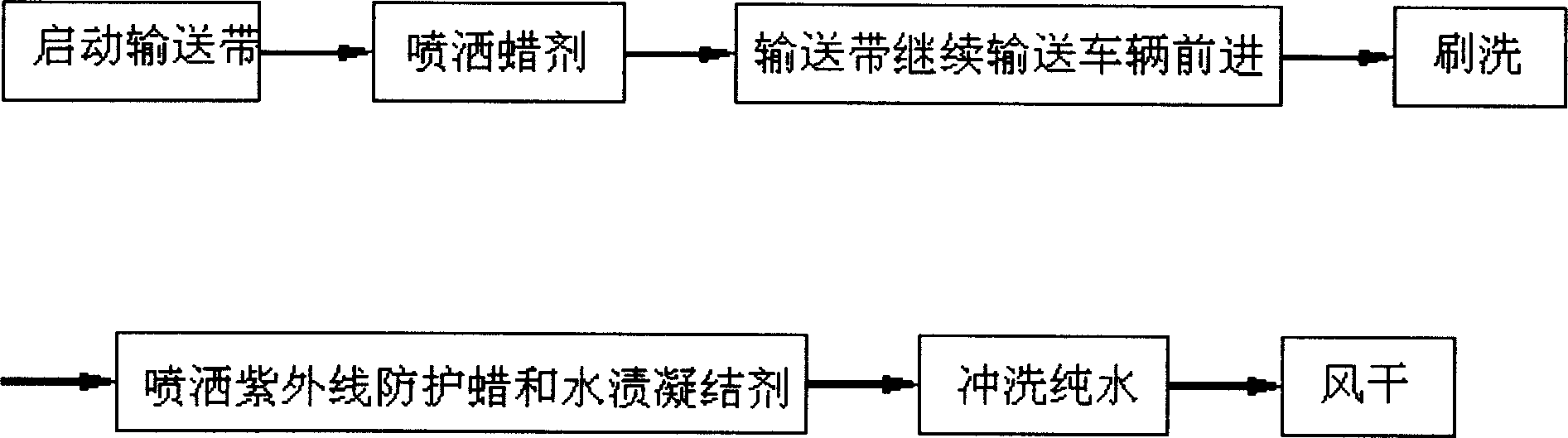

Unmanned fully-automatic car-washing method and fully-automatic car-washing machine

InactiveCN1850530AClean enoughExempt from workCleaning apparatus for vehicle exteriorsCleansers skinWax

An unmanned full automatic car washer and the method can decrease the cost and improve the efficient. The process is: 1. starting the conveyer apron; 2. spraying the cleanser and the cerate; 3.setting some time for cleanser and the cerate; 4. washing; 5. spraying the violet ray guar wax and the water stain coagulant; 6. washing by water; 7. drying by the wind. So the process can improve the cleaning quality.

Owner:FORMOSA TAFFETA CO LTD

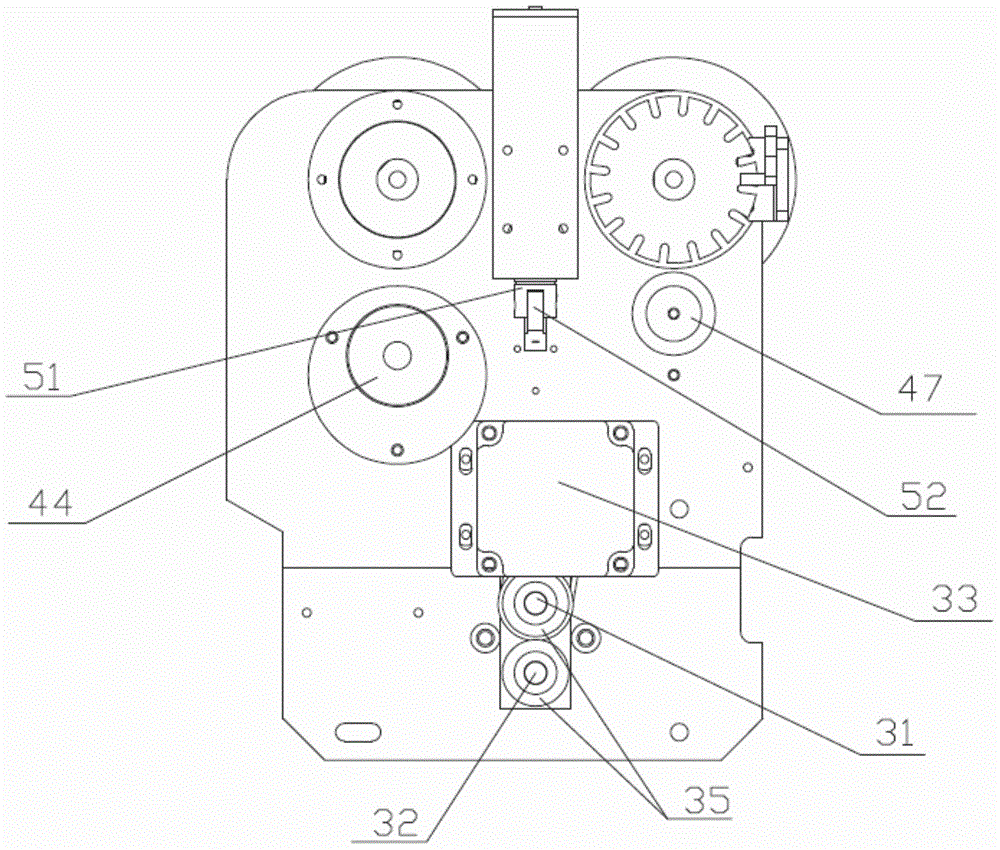

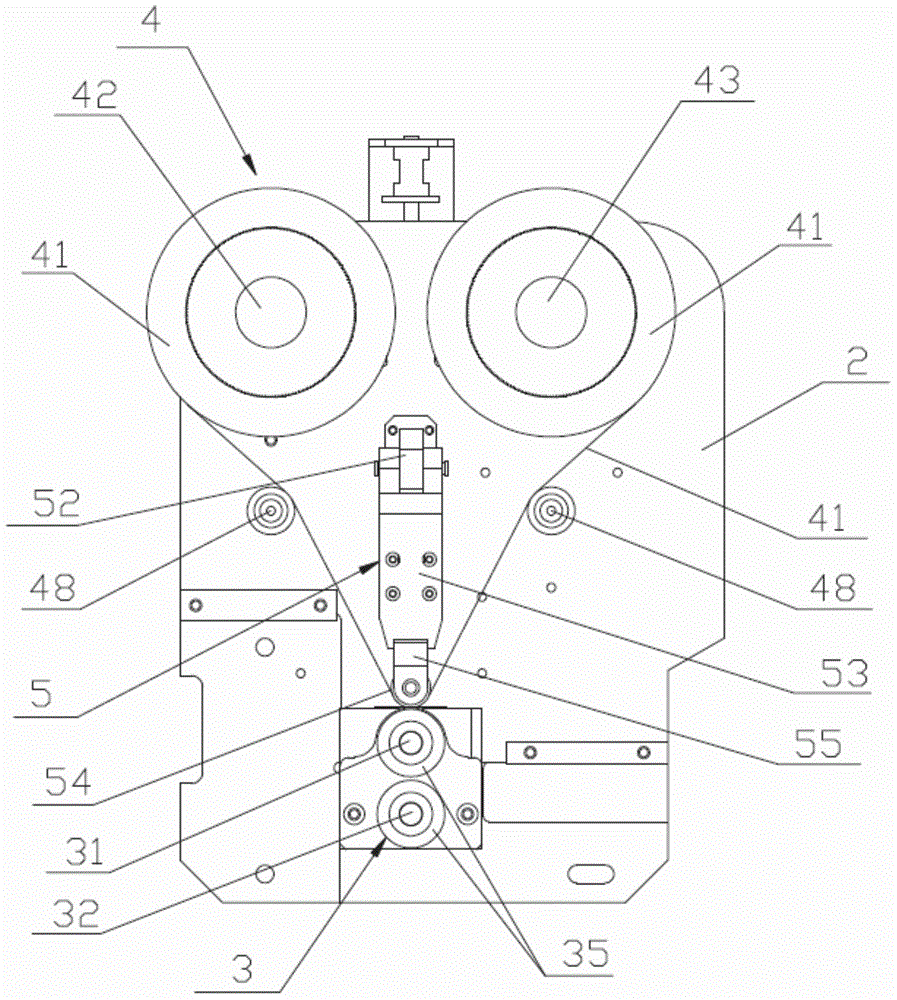

Smart card cleaning device

The invention discloses a smart card cleaning device, which comprises a rack, a card face dust removing mechanism, a cleaning tape delivery mechanism and a cleaning tape tension mechanism, wherein the card face dust removing mechanism, the cleaning tape delivery mechanism and the cleaning tape tension mechanism are arranged on the rack; the card face dust removing mechanism comprises a pair of upper and lower dust removing rollers and a dust removing roller driving mechanism for driving the dust removing rollers to rotate; elastic adhesive layers are arranged on the surfaces of the dust removing rollers; the cleaning tape delivery mechanism comprises an unused cleaning tape winding wheel, a used cleaning tape winding wheel, a winding power mechanism and a cleaning tape; the winding power mechanism is connected with the used cleaning tape winding wheel; the winding tape is wound on the unused cleaning tape winding wheel and the used cleaning tape winding wheel; the cleaning tape tension mechanism comprises a tension wheel and a tension power mechanism for driving the tension wheel to move up and down; the tension wheel is arranged above the dust removing rollers; the cleaning tape winds the bottom of the tension wheel. The cleaning device has the advantages of good cleaning effects, no dust accumulation and the like.

Owner:GUANGZHOU MINGSEN TECH CO LTD

Method for sonic cleaning of reactor with reduced acoustic wave cancellation

InactiveUS20060130870A1Reduce the time-averaged effect of weak spotsReduce and eliminate effectHollow article cleaningElectrostatic cleaningPolyolefinSound sources

In some embodiments, a method for sonically cleaning a reactor (for example, a fluidized bed reactor useful for the production of polyolefins) using a set of sonic sources, including by varying the operating mode of the set of sources to reduce or prevent cleaning problems that would otherwise result from weak spots if the operating mode were not so varied. Other embodiments are methods for determining positions and operating parameters (e.g., duty cycle and output acoustic wave frequency) of each source of a set of sonic sources to be used for sonically cleaning a reactor, and methods including the steps of determining a position (relative to a reactor) of each source of a set of sonic sources, positioning each said source in the determined position, and then sonically cleaning a surface of the reactor including by varying the operating mode of the set of sources to reduce or prevent cleaning problems that would otherwise result from weak spots if the operating mode were not so varied.

Owner:CAI PING +1

Solid imaging apparatus and method

A solid imaging device is provided that includes a replaceable cartridge containing a source of build material and an extendable and retractable flexible transfer membrane for layered transfer of build material from the cartridge to a surface of a construct in an image plane. Operators using the device can continue solid imaging with essentially no interruption simply by removing spent cartridges and replacing them with new ones. The device also includes the ability to withdraw and insert the imager without requiring a separate alignment step by the operator. Brushes attached to the transfer film and forming part of the cartridge are able to remove excess uncured build material intra-laminarly. If desired, the device can produce fully reacted constructs. A high intensity UV source cures the build between layers. Injection molded build pads are designed to hold the build in an inverted position for improved builds. The present invention also proposes tilting the structure elevator to reduce air entrapment and release the structure from the image plane.

Owner:3D SYST INC

Removal pressure sensitive adhesive of aqueous emulsion and method for preparing the same

ActiveCN103079441AEasy to cleanEfficient removalFlow mixersMixing methodsEmulsionMechanical engineering

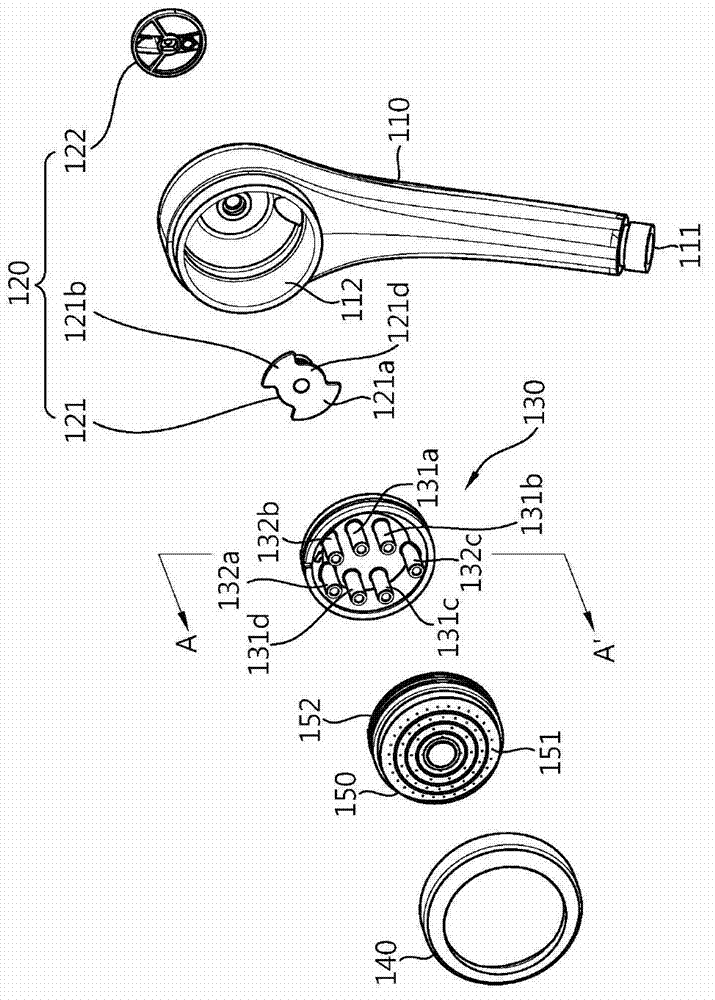

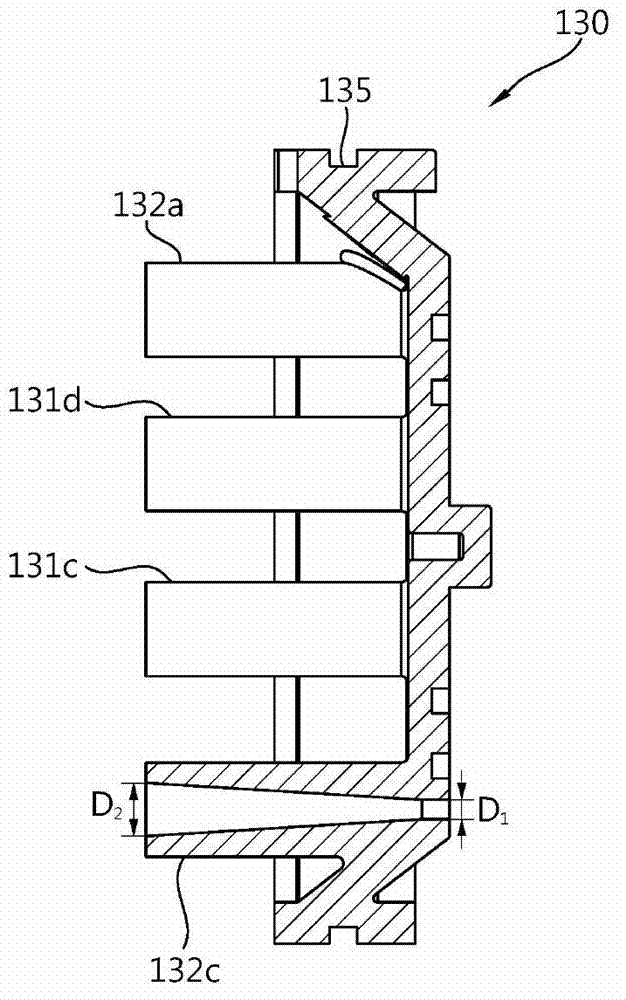

According to the present invention, a showerhead for generating micro air bubbles includes: a body including an inflow part disposed at one end thereof for supplying shower water, and a discharge part disposed at the other end thereof for discharging the shower water supplied through the inflow part; a bubble-generating part coupled to the discharge part, and including bubble-generating tubes which expand in the discharge direction of the shower water; a fluid regulator part for opening / closing a portion of the bubble-generating tubes; and a shower part disposed in front of the bubble-generating part, and including shower holes for discharging shower water. Since the bubble-generating part for generating micro air bubbles is disposed within the showerhead, shower water including micro air bubbles can be used by simply replacing a typical showerhead with the above-described showerhead.

Owner:ROBOTOUS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com