Low-corrosion and high-cleanness chemical cleaning method for condenser

A chemical cleaning and condenser technology, applied in the field of low-corrosion and high-purity chemical cleaning of condensers, can solve the problems of high labor intensity, long cleaning time, copper pipe corrosion, etc., achieve thorough pipeline purification, improve service life, The effect of short cleaning time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

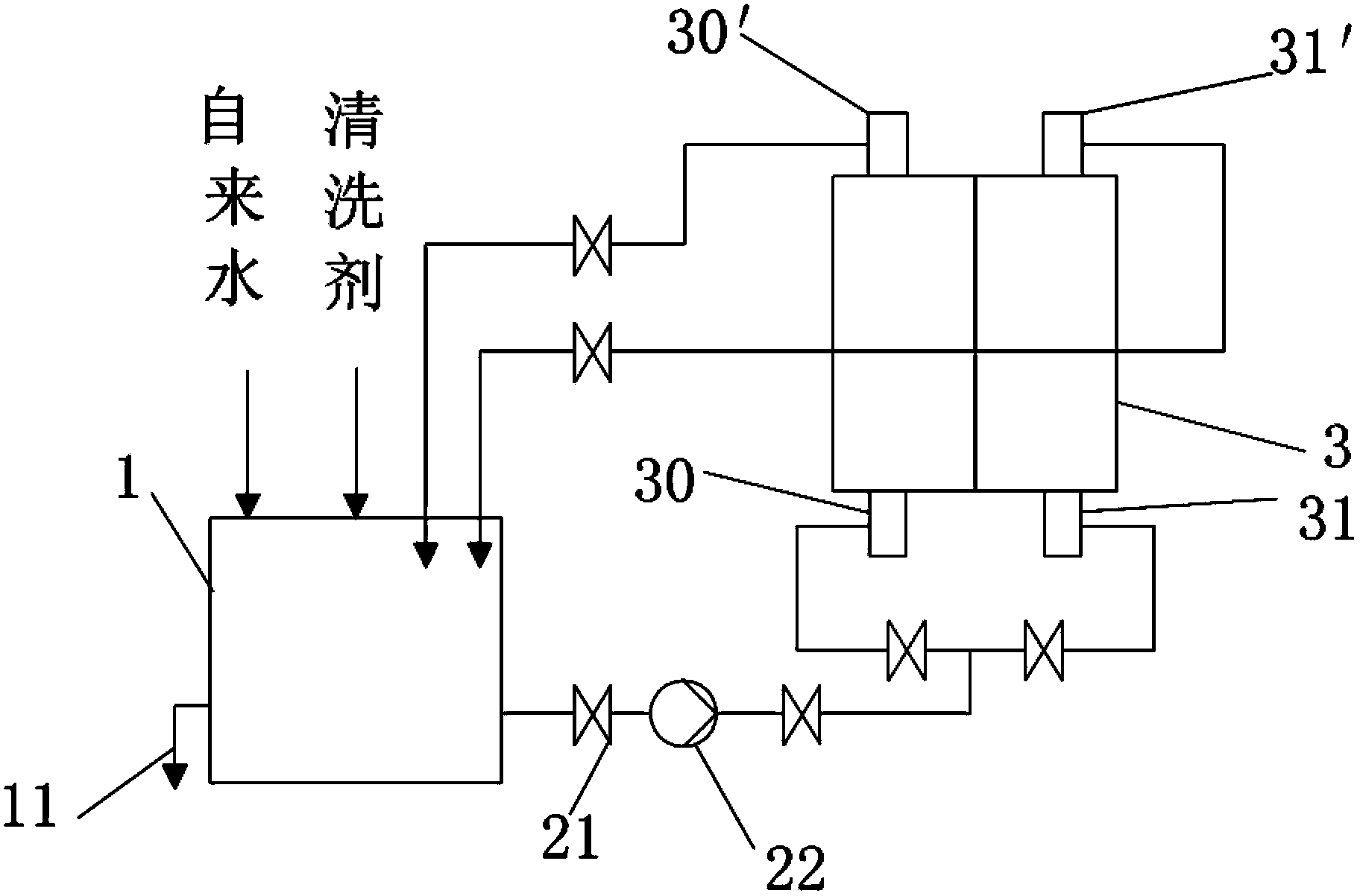

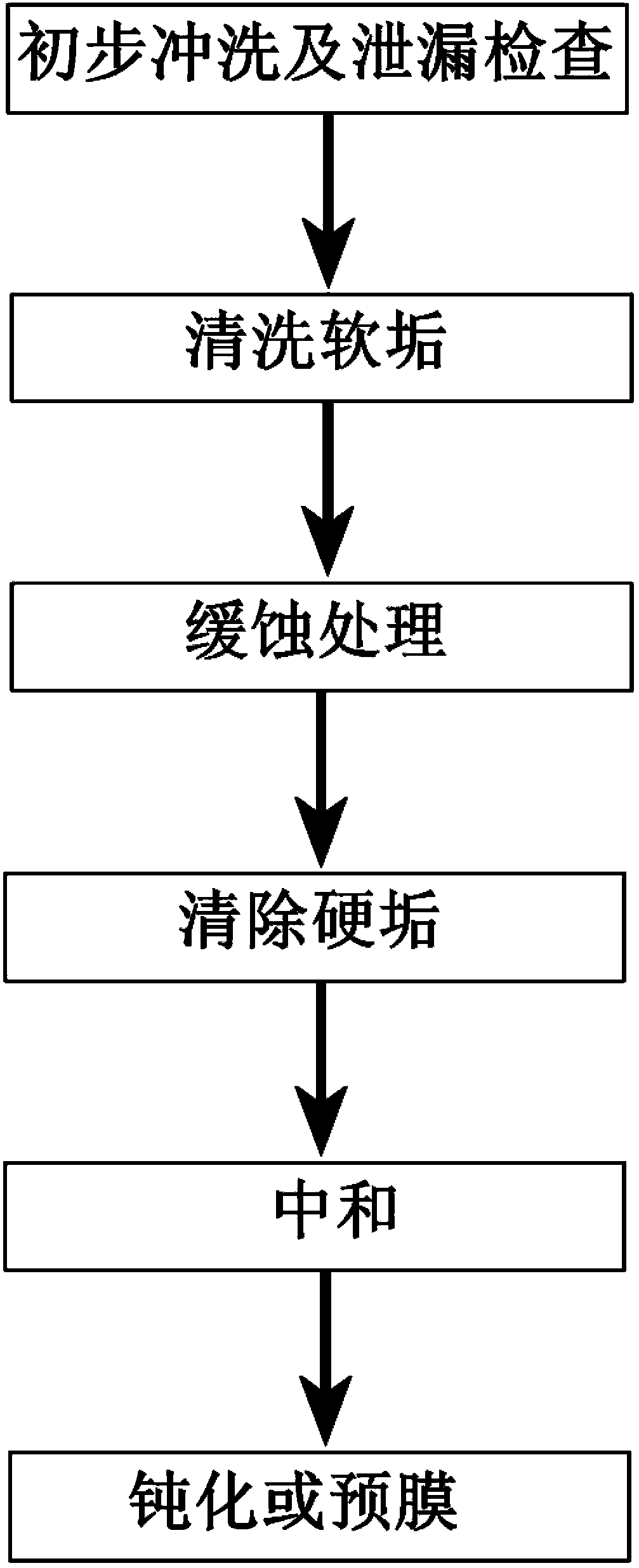

[0035] Such as figure 1 As shown, a low-corrosion and high-purity chemical cleaning method for condensers is especially suitable for low-corrosion and high-purity chemical cleaning methods for condensers whose pipe materials are stainless steel, carbon steel, and copper. The condenser must be cleaned before cleaning Stop the machine, close the inlet and outlet valves of circulating water, install blind plates and inlet and outlet flanges, and install exhaust pipes with a diameter of 50 mm on the uppermost part of the condenser water chambers on both sides to remove a large amount of gas generated during cleaning. Then, To establish a temporary cleaning system, the inlet pipes 30, 31 and outlet pipes 30', 31' of the condenser 3 are connected to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com